Page 1

Smart Sensor

Multi-Controller

ZS-MDC (Ver 2.0)

User's Manual

Multi-Controller

Cat. No. Z209-E1-01

Page 2

Introduction

This manual provides information regarding functions, performance and operating

methods that are required for using the ZS-MDC.

When using the ZS-MDC, be sure to observe the following:

• The ZS-MDC must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding

of the product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

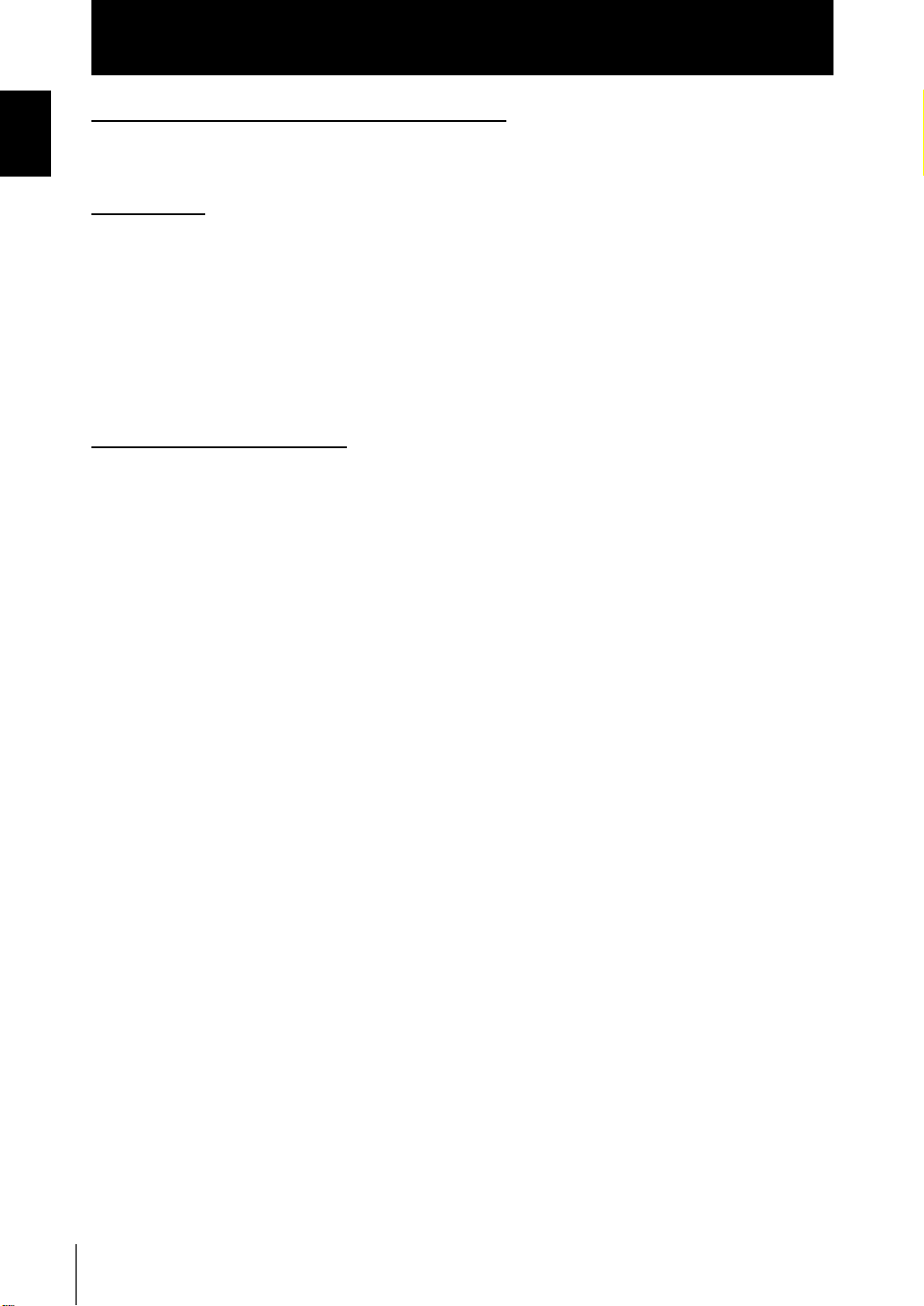

How to Switch the Display Language to English

Turn the power ON with the MENU key held down. This displays the display language

selection screen.

Select Language

1

If you change and save the setting, the Controller will start up with messages displayed in

English when it is next started up.

2Japanese English

Page 3

Introduction

‚Í‚¶‚ß‚É ‘æ 1 Í‘æ 2 Í‘æ 3 Í‘æ 4 Í

INTRODUCTION

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

APPLICATION CONSIDERATIONS (Please Read)

Section 1 Section 2 Section 3 Section 4 Section 5

FEATURES

INSTALLATION & CONNECTION

SETUP

APPLICATION SETTING EXAMPLES

APPENDIX

ection

User's Manual

Smart Sensors

Multi-Controller ZS-MDC

Page 4

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

ZS-MDC

User’s Manual

Page 5

Introduction

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Introduction

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

ZS-MDC

User’s Manual

3

Page 6

Introduction

Introduction

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

4

ZS-MDC

User’s Manual

Page 7

Precautions for Safe Use

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

(1) Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

(2) Power Supply and Wiring

• The supply voltage must be within the rated range (DC24V±10%).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing them in the same duct may cause induction, resulting in malfunction or damage.

Introduction

Introduction

(3) Others

• Do not attempt to dismantle, repair, or modify the product.

• Dispose of this product as industrial waste.

ZS-MDC

User’s Manual

5

Page 8

Introduction

Precautions for Correct Use

Introduction

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

(1) Installation Site

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding

machines)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray

• Strong magnetic or electric field

(2) Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit)

and the load current is appropriate. Incorrect wiring may result in breakdown of the

product.

• Before connecting/disconnecting the Peripheral device, make sure that the Multi-Controller is turned OFF. The Multi-Controller may break down if the Peripheral device is

connected or disconnected while the power is ON.

• Use only combinations with Sensor Controllers specified in this manual.

6

ZS-MDC

User’s Manual

Page 9

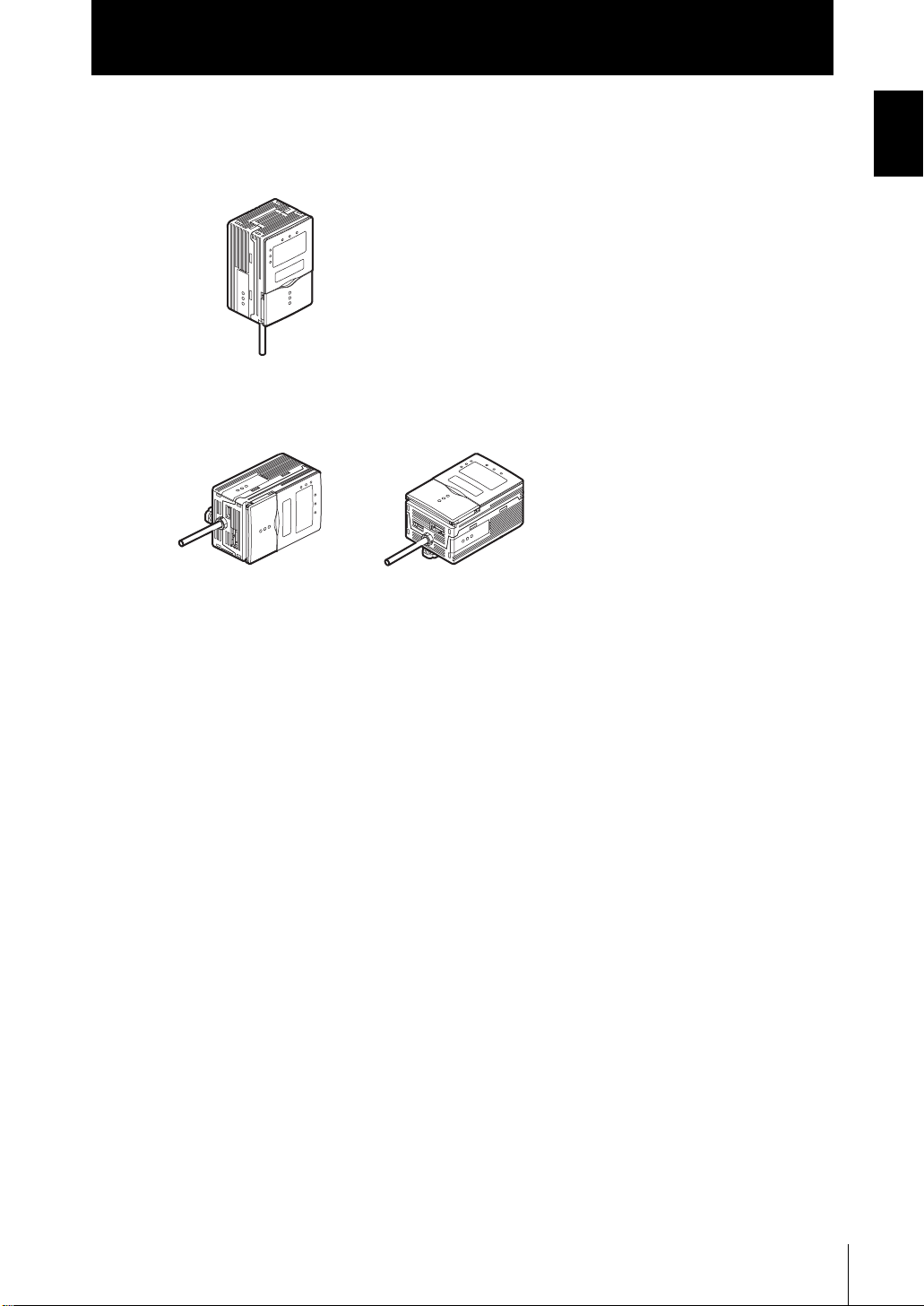

(3) Orientation when Installing the Multi-Controller

To improve heat radiation, install the Multi-Controller only in the

orientation shown below.

Right

Do not install the Multi-Controller in the following orientations.

Wrong Wrong

Introduction

Precautions for Correct Use

Introduction

(4) Warming Up

After turning ON the power supply, allow the product to stand for at least 30 minutes

before use. The circuits are still unstable immediately after the power supply is turned

ON, so measured values may fluctuate gradually.

(5) Maintenance and Inspection

Do not use thinner, benzene, acetone or kerosene to clean the Multi-Controller.

ZS-MDC

User’s Manual

7

Page 10

Introduction

Editor's Note

Introduction

Editor's Note

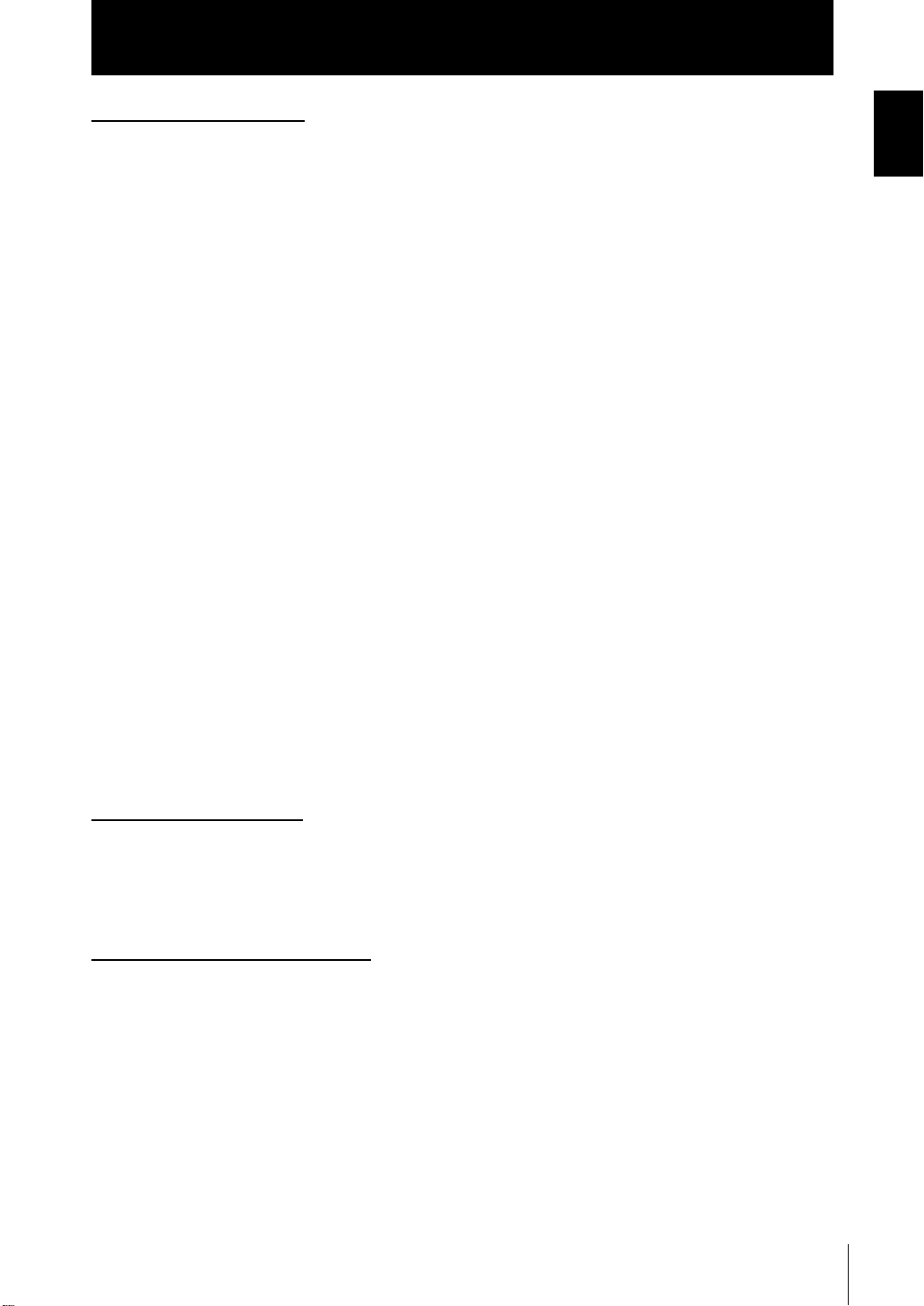

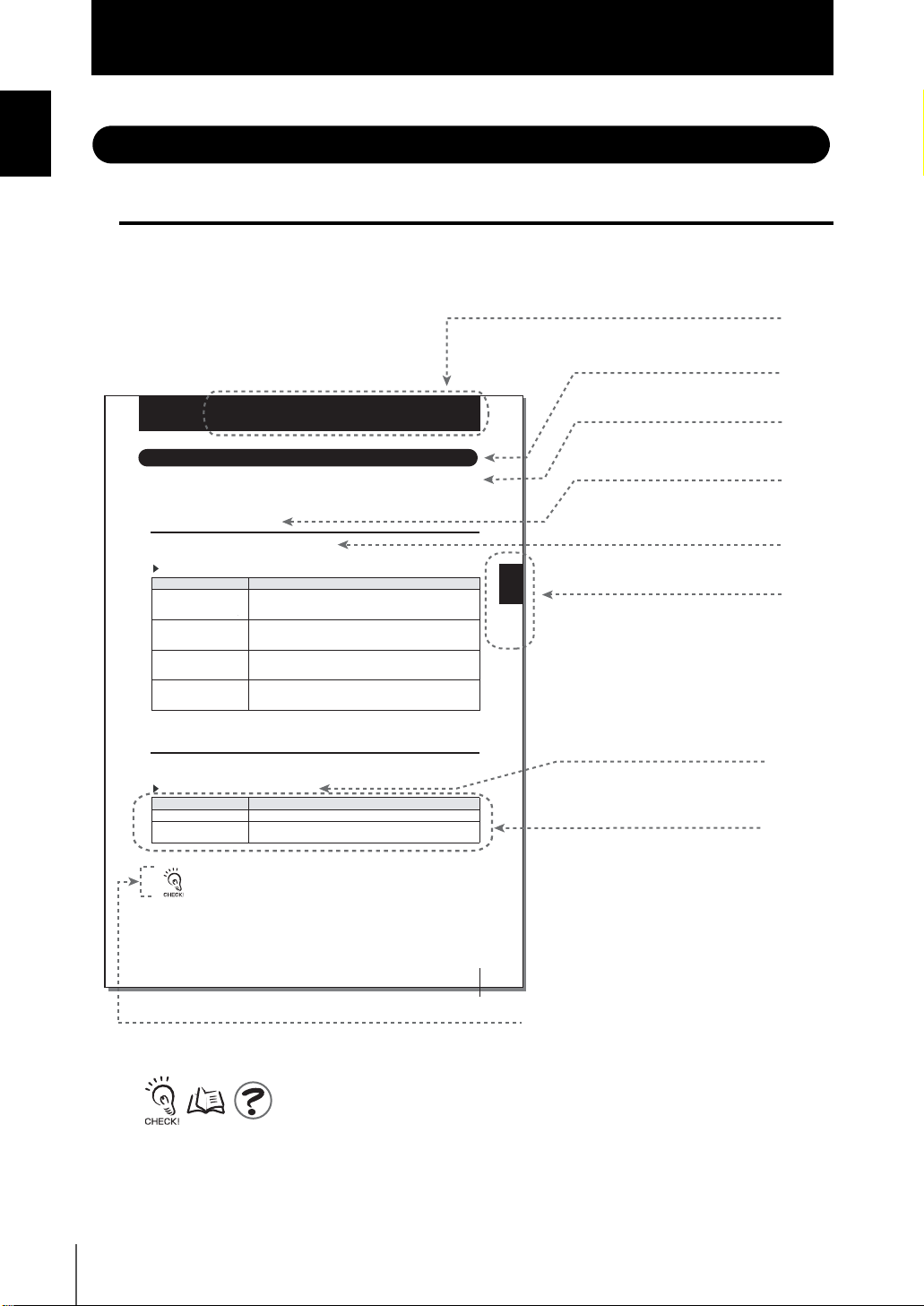

Page Format

Title of each section

Header

Setting the Sensor Controller to Obtain Sensing Information from

Section 3

Setting the Sensor Controller to Obtain Sensing Information from

Set which gang-mounted Sensor Controller to obtain information from, and which logic

operations are to be performed on that information.

Setting Assignments

Assign the channel to perform logic operation on.

FUNMode-[SENSIN SEL CHG]-[ ]

Setting Description

INPUT A (input A) Assigns the target Sensor Controller to input A.

INPUT B (input B) Assigns the target Sensor Controller to input B.

INPUT C (input C) Assigns the target Sensor Controller to input C.

INPUT D (input D) Assigns the target Sensor Controller to input D.

Setting Logic Operation Methods

Set how logic operations are to be performed on the tasks and CH specified by the

assignment settings.

FUNMODE-[SENSING]-[CALC]

Setting Description

OFF Expressions are not set.

CH Logic operations are not performed, and the measured value of a specific CH

Inputs do not undergo logical operation when “None” is set. Example: The operation “-B” is per-

formed when “None” is set to input A, “3CH” is assigned to input B and A-B is selected.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 1CH. Note that range becomes “None” if 1CH does not exist.)

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 2CH. Note that range becomes “None” if 2CH does not exist.)

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 3CH. Note that range becomes“None” if 3CH does not exist.)

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 4CH. Note that range becomes “None” if 4CH does not exist.)

is input as it is.Select the targ

et CH.

Section 3 SETUP

Overview

Cross-header

Overview of the

cross-header

Index label

Indicates the section

number and title.

Movement

through menus up

to setting items

Explanation of

options

8

Supplementary Explanation

Helpful information regarding operation and reference

pages are introduced here using symbols.

*This page has been made purely for explanatory purposes and does not exist.

ZS-MDC

User’s Manual

ZS-MDC

User’s Manual

3-15

Page 11

Introduction

Editor's Note

■ Meaning of Symbols

Menu items that are displayed on the Multi-Controller LCD screen, and windows, dialog

boxes and other GUI elements displayed on the PC are indicated enclosed by brackets

[aa].

■ Visual Aids

Indicates points that are important to ensure full product performance, such as operational

precautions and application procedures.

Indicates pages where related information can be found.

Indicates information helpful in operation.

Introduction

ZS-MDC

User’s Manual

9

Page 12

Introduction

Editor's Note

Introduction

MEMO

10

ZS-MDC

User’s Manual

Page 13

Contents

Introduction

Contents

Introduction

Precautions for Safe Use 5

Precautions for Correct Use 6

Editor's Note 8

Page Format 8

Contents 11

Section 1 FEATURES 1-1

Multi-Controller Features 1-2

Multi-Controller Applications 1-4

Basic Configuration 1-7

Part Names and Functions 1-8

Section 2 INSTALLATION & CONNECTION 2-1

About Installation and Connection 2-2

Multi-Controller 2-3

Attaching the ferrite core 2-3

Installing the Multi-Controller 2-4

Section 1 Section 2 Section 3 Section 4 Section 5

About the I/O cable 2-10

Section 3 SETUP 3-1

Setting Flow 3-2

About Setup 3-4

Basic Knowledge for Operation 3-4

List of Setting Items 3-9

Selecting Tasks 3-13

Setting the Sensor Controller to Obtain Sensing Information from 3-14

Setting Assignments 3-14

Setting Logic Operation Methods 3-15

Setting I/O Assignments 3-16

Switching banks by external signal input 3-16

Changing Output Assignments 3-17

Changing Linear Output Assignments 3-17

About Digital Output 3-17

ZS-MDC

User’s Manual

11

Page 14

Introduction

Introduction

Contents

Section 4 APPLICATION SETTING EXAMPLES 4-1

Measuring the Thickness of Multiple Points (sandwiched thickness) 4-2

Measuring the Relative Difference between Steps 4-5

Measuring the Reference Difference between Steps 4-8

Measuring Flatness 4-10

Measuring the Average Height 4-12

Measuring the Twist of a Workpiece 4-14

Measuring the Warp of a Workpiece 4-17

Section 5 APPENDIX 5-1

Troubleshooting 5-2

Error Messages and Countermeasures 5-3

Q&A 5-4

Glossary 5-5

Specifications and External Dimensions 5-6

Multi-Controller 5-6

Panel Mount Adapters 5-9

RS-232C Cable for Connecting to a Personal Computer 5-10

Controller Link Unit 5-11

Version Up Information 5-12

Index 5-13

Revision History 5-16

12

ZS-MDC

User’s Manual

Page 15

Section 1

FEATURES

Multi-Controller Features 1-2

Multi-Controller Applications 1-4

Basic Configuration 1-7

Part Names and Functions 1-8

Section 1 FEATURES

ZS-MDC

User’s Manual

1-1

Page 16

Section 1

p

r

Multi-Controller Features

Multi-Controller Features

Section 1 FEATURES

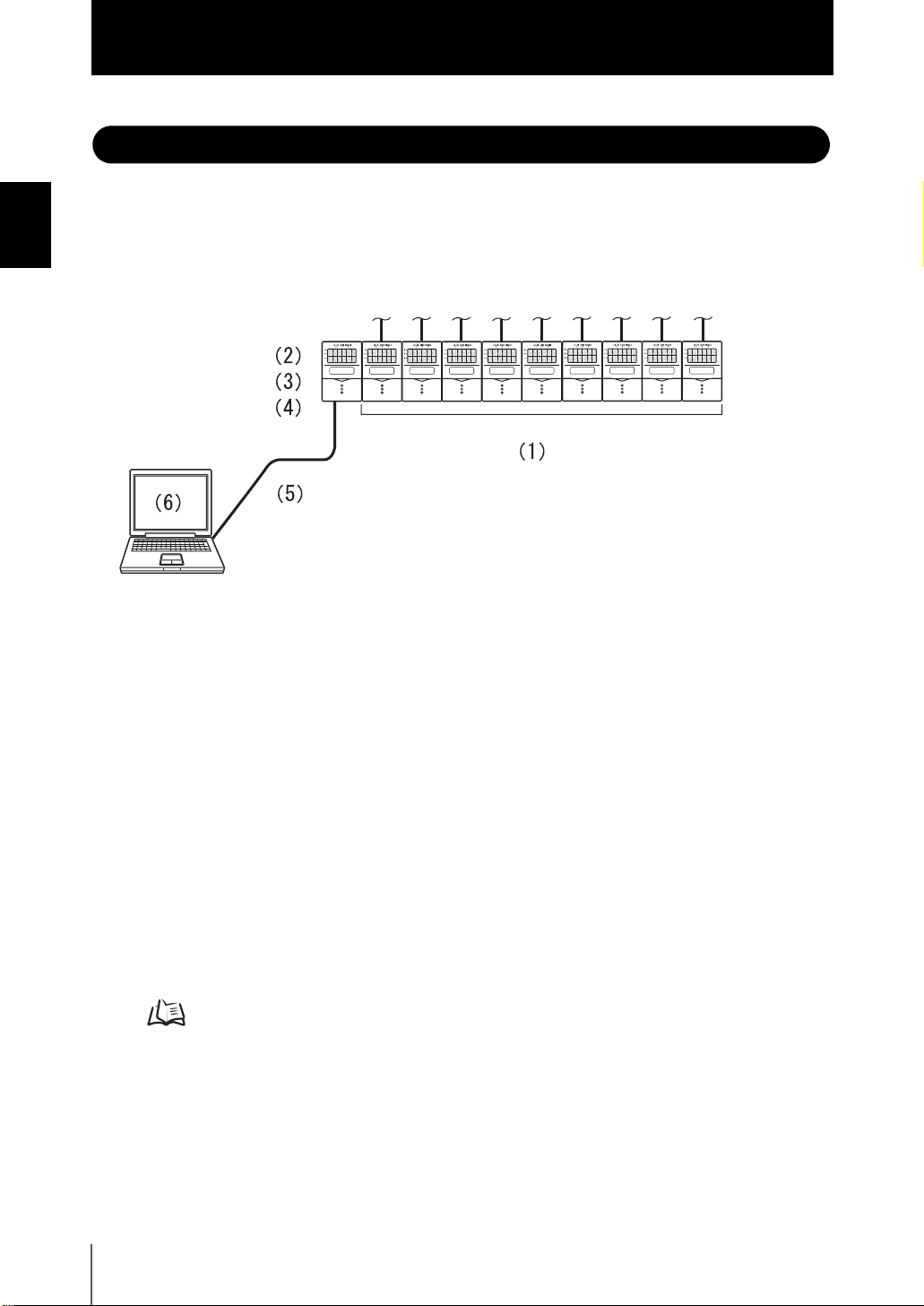

The Multi-Controller is a dedicated controller that gets and performs logical operations on

data obtained from multiple Sensor Controllers. This Multi-Controller features completely

digital-based, data corruption-free logic operation capabilities, and outstanding operability

and convenience.

Multi-Controller

Sensor Controllers

Personal Com

ute

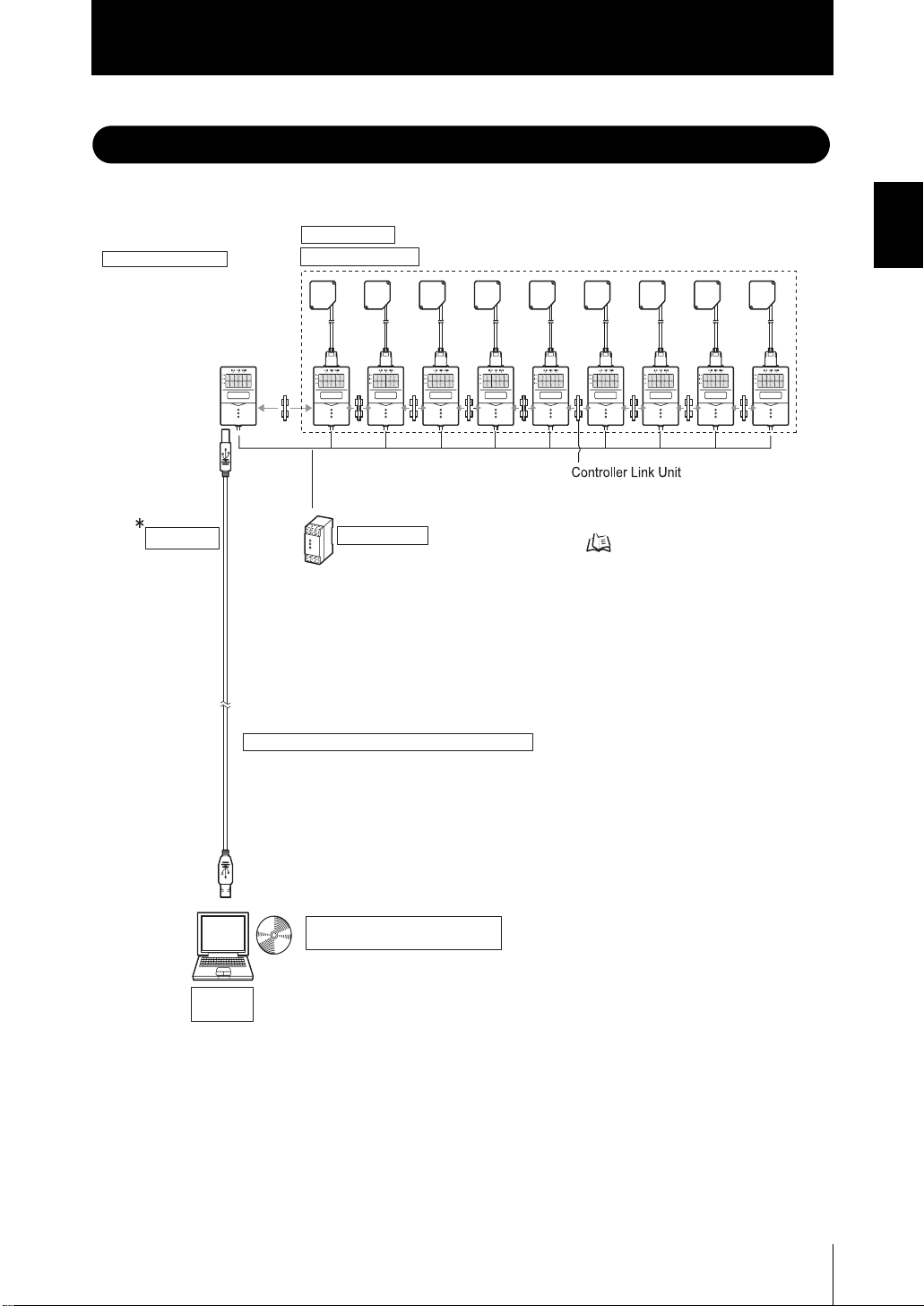

(1) Supports Connection to Up to 9 Sensor Controllers

Logic operations can be performed on gang-mounted controllers. Information can be

collected and logic operations performed on information from up to nine Sensor

Controllers, which makes the Multi-Controller ideal for multi-point measurement

applications.

1-2

(2) Wide Range of Logic Operation Functions

Dedicated expressions such as sandwiched thickness, step and average are

provided in the setup menu. Up to four types of expressions can be stored to memory

as “tasks,” which allows you to easily achieve multi-point measurement applications

for performing advanced operations such as measurement of workpiece waviness,

flexure, twist, and warp.

List of Setup Items p.3-9

(3) Completely Digitally Based Logic Operation Processing

Logic operations are batch-executed digitally on controller information. Even in multi-

point measurement applications, corruption-free measurement results can be output.

ZS-MDC

User’s Manual

Page 17

Section 1

Multi-Controller Features

(4) Same Compact Size as Sensor Controller

• The Multi-Controller is the same compact size as the Sensor Controller, which

means that it can be installed at a wide range of sites.

External Dimensions p.5-6

• A wide range of processing functions (e.g. filter and hold) the same as those on a

Sensor Controller are incorporated on the Multi-Controller, enabling processing of

logic operations matched to specific applications.

List of Setup Items p.3-9

(5) USB Connection

A USB port (Full-Speed USB2.0 specification-compliant) is provided as standard on

the Multi-Controller. This enables the results of operations between Sensor

Controllers to be easily loaded to a personal computer.

(6) Dedicated Software “SmartMonitor Zero”

The “SmartMonitor Zero” software for setting up and monitoring multi-window

displays and logging is provided (Sold separately). This software also supports the

display and setup of data such as monitoring of waveforms and designation of area

that is not possible on the Sensor Controller alone.

Section 1 FEATURES

ZS-MDC

User’s Manual

1-3

Page 18

Section 1

Multi-Controller Applications

Multi-Controller Applications

Section 1 FEATURES

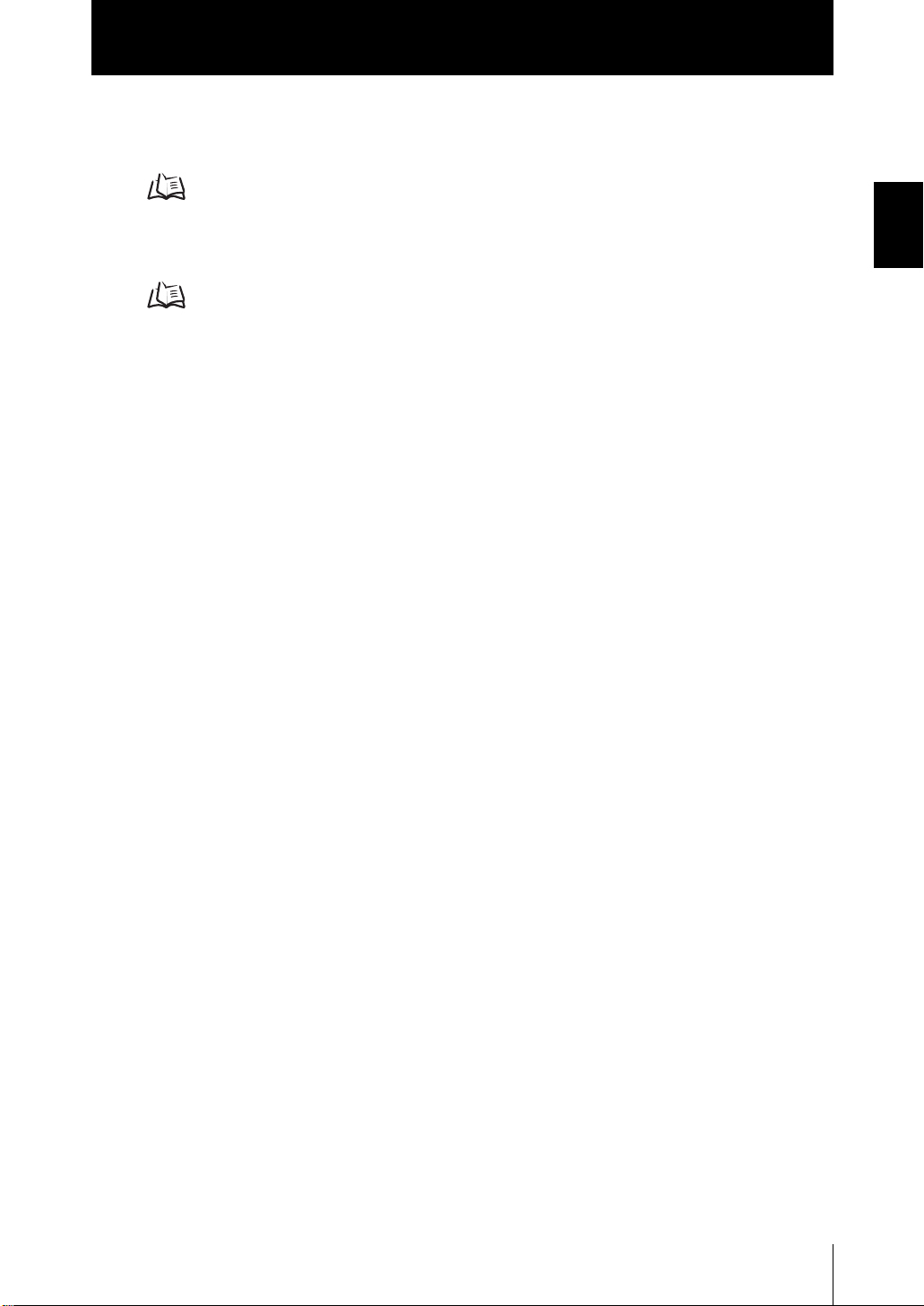

● Measurement of Workpiece Thickness at Multiple Locations

Sensor Heads can be placed so as to sandwich the workpiece and measure its thickness. Logic operations can be performed not only on one location but on multiple locations to calculate the difference in the measurement result.

● Measurement of Stepped Workpieces

Logic operations can be performed on measured values obtained from multiple Sensor

Controllers to measure steps in stepped workpieces.

1-4

● Measurement of Average Workpiece Height

Logic operations can be performed on measured values obtained from multiple Sensor

Controllers to measure the average height of workpieces.

ZS-MDC

User’s Manual

Page 19

Section 1

S

o

(

y)

Multi-Controller Applications

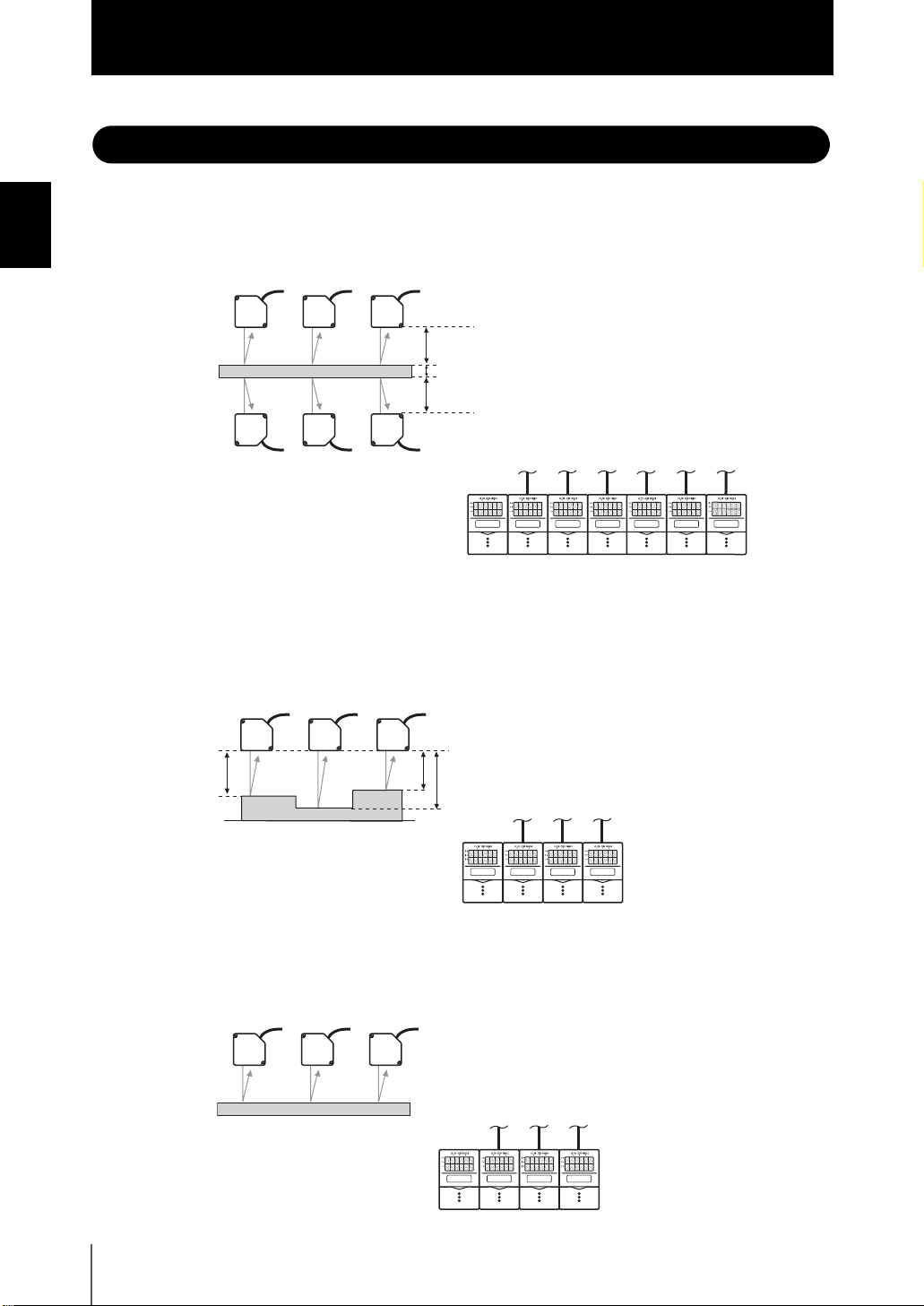

● Measurement of Workpiece Flatness

Logic operations can be performed on measured values obtained from multiple Sensor

Controllers to measure the flatness of workpieces.

● Measurement of Workpiece Strain

Logic operations can be performed on measured values obtained from multiple Sensor

Controllers to measure the waviness, flexure, twist, and warp of steel plate and other

workpieces.

Section 1 FEATURES

● Batch-acquisition of Multi-point Measurement Data

Communications commands can be used to batch-acquire the measurement results of

gang-mounted Sensor Controllers.

About Digital Output p.3-17

You can also use the optional software “SmartMonitor Zero” to batch-display on the

digital displays and batch-log measurement results.

martMonitor Zer

sold separatel

ZS-MDC

User’s Manual

1-5

Page 20

Section 1 FEATURES

Section 1

Multi-Controller Applications

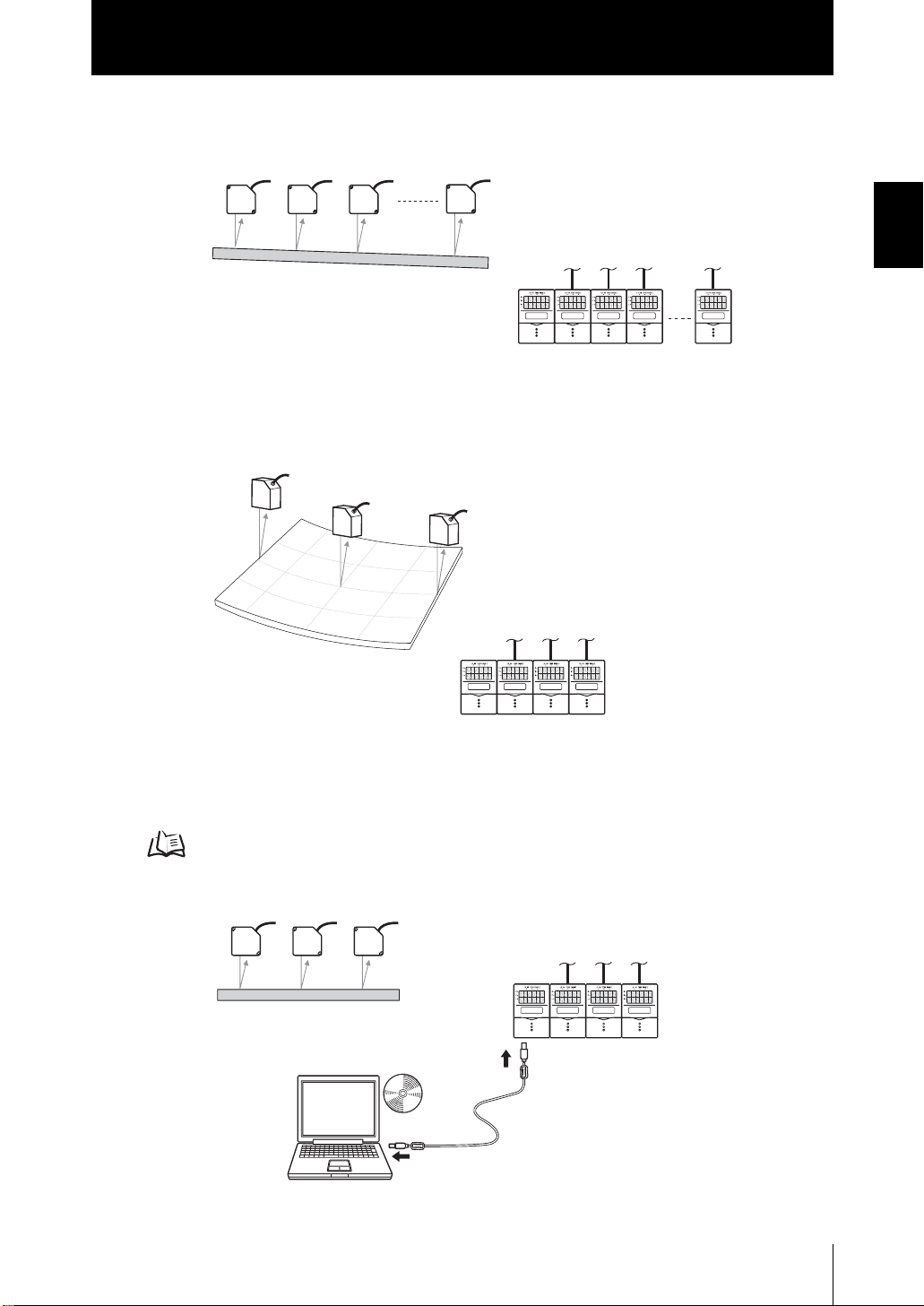

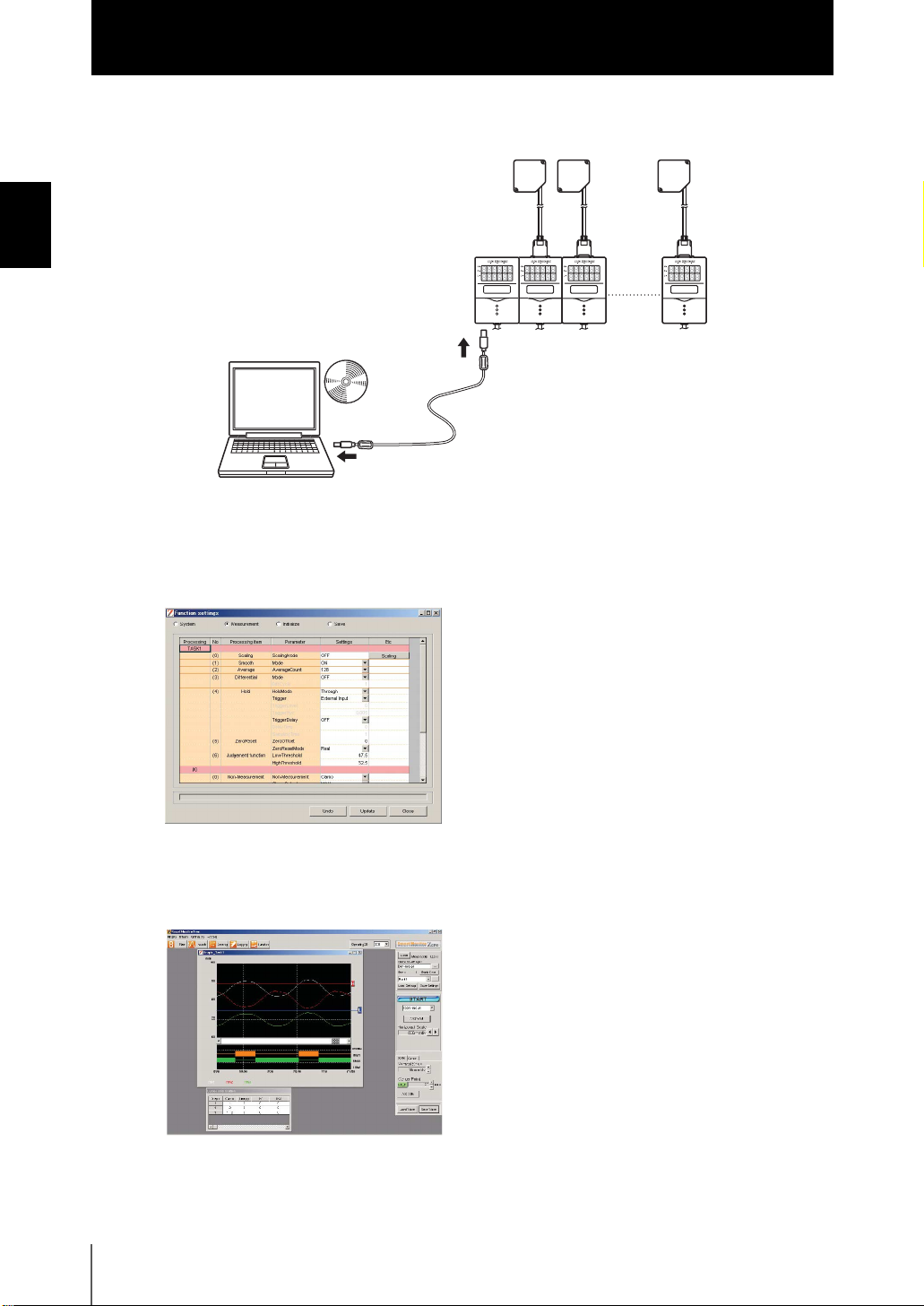

Moreover, connecting a personal computer pre-installed with SmartMonitor Zero to the

Multi-Controller allows you to perform the following.

● Gang-mounted Sensor Controllers can be set up.

The measurement conditions of each Sensor Controller can be set up, and settings

saved, read or copied.

1-6

* The screen shown here may differ from the actual screen.

● The state of gang-mounted Sensor Controllers can be monitored.

The operating state of each Sensor Controller can be batch-monitored. The waveforms

of each Sensor Controller can be displayed simultaneously.

* The screen shown here may differ from the actual screen.

ZS-MDC

User’s Manual

Page 21

Basic Configuration

Section 1

Basic Configuration

The figure below shows the Basic Configuration of the ZS Series.

This section detects the sensing object and processes measurement.

Up to 9 Sensor Controllers can be gang-mounted.

For details, refer to the User's Manual for the Sensor Controller.

ZS-XCN

This unit is for gang-mounting controllers.

+

-

Multi-Controller

ZS-MDC11/MDC41

The Multi-Controller calculates

the measurement information

of gang-mounted Sensor

Controllers, and outputs

the calculation results.

USB cable

(1m)

Sensor Heads

Sensor Controllers

Power Supply

DC24V ( 10%)

Recommended parts

(1) When 1 Sensor Controller is connected

S82K-01524 (DC24V, 0.6 A)

(2) When 2 to 3 Sensor Controllers are connected

S82K-05024 (DC24V, 2.1 A)

(3) When 4 to 10 Sensor Controllers are connected

Prepare the required number of (1) and (2)

power supplies above.

Section 1 FEATURES

p.2-5

RS-232C cable for personal computer connection

ZS-XRS2

This is used for communicating with a personal computer without a USB port.

(SmartMonitor Zero cannot be used on the RS-232C interface.

Communication using CompoWay/F or non-procedural protocol is possible.)

SmartMonitor Zero

(option software, sold separately)

ZS-SW11E

Personal

computer

allows you to operate the Multi-Controller and

connected Sensor Controller, monitor or log

measured values from a personal computer.

In this manual, the software is referred to as

"SmartMonitor Zero".

ZS-MDC

User’s Manual

1-7

Page 22

Section 1

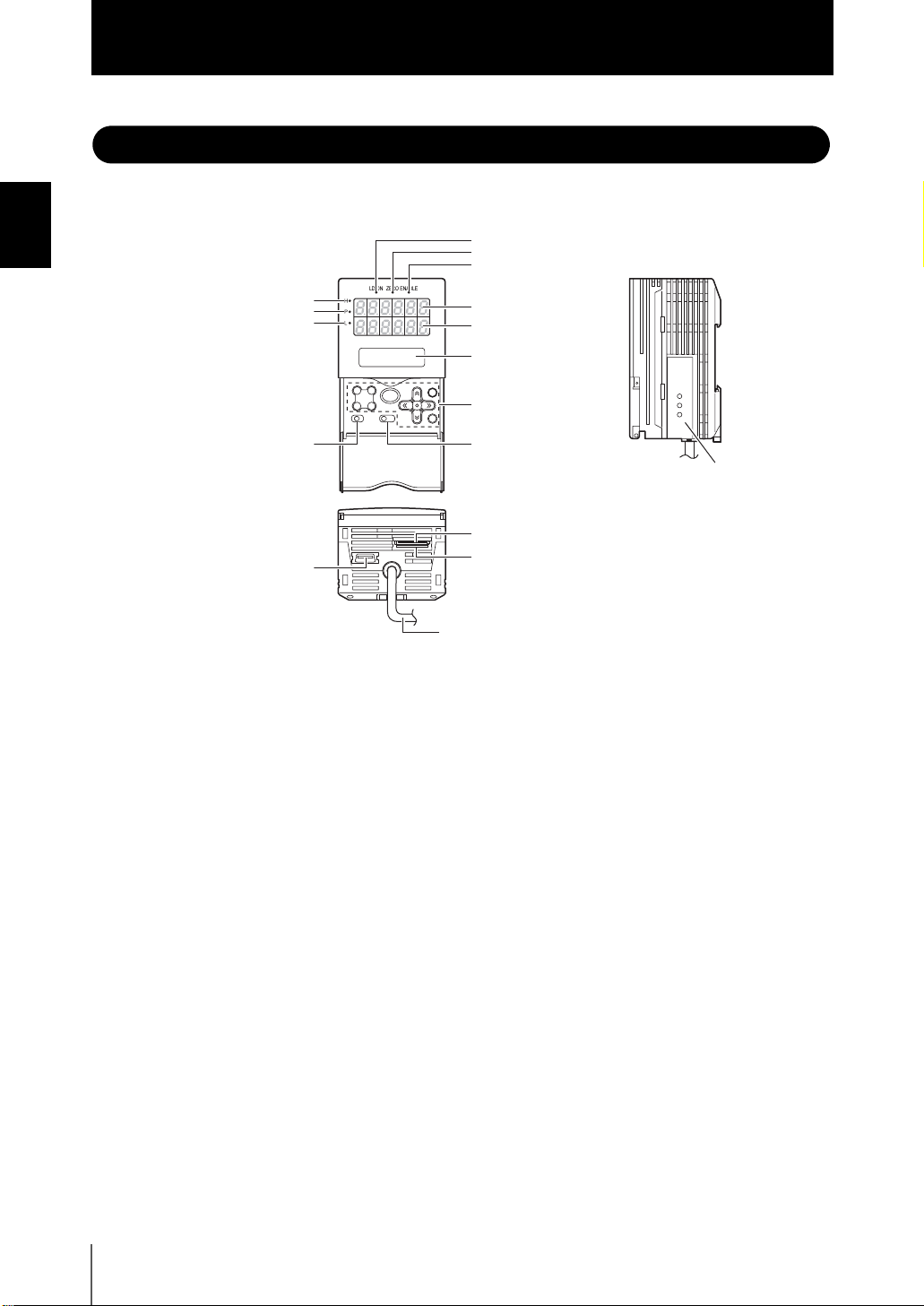

Part Names and Functions

Part Names and Functions

Section 1 FEATURES

The following describes the names and functions of parts on the Multi-Controller.

(1) Laser indicator

(2) Zero Reset indicator

(3) ENABLE indicator

(12) HIGH indicator

(11) PASS indicator

(10) LOW indicator

(17) USB port

(4) Main display

(5) Sub-display

(6) LCD screen

(7) Control keys

(8) Mode switch(9) Threshold switch

(13) Coupler

(14) RS-232C connector

(15) Voltage/current switch

(16) I/O cable

(1) Laser indicator

Does not lit.

1-8

(2) Zero Reset indicator

The Zero Reset indicator lits when the zero reset function is enabled on the MultiController.

(3) ENABLE indicator

The ENABLE indicator lits when the Multi-Controller is ready for measurement. It

goes off when measurement is not possible (e.g. when the light amount received by

the sensor on the operation target CH is excessive or insufficient, when the

measuring range is exceeded, when the Sensor Head is not connected, or when

measurement is not being performed in the FUN mode).

(4) Main Display

The Main Display shows measured values after operations have been performed.

(5) Sub-display

The sub-display shows thresholds and additional information during measurement.

(6) LCD screen

RUN mode : Displays additional information for the main display and the setup

menu for display related information.

TEACH mode : Displays the menu for setting up the thresholds.

FUN mode : Displays the measurement condition setup menu.

ZS-MDC

User’s Manual

Page 23

Section 1

Part Names and Functions

(7) Control keys

The Control Keys are for setting measurement conditions and other information. The

functions assigned to the Control Keys change according to the operating mode.

Displays and Key Operations p.3-5

(8) Mode Switch

The Mode Switch selects the operating mode.

RUN mode : Select this mode when performing regular measurement.

TEACH mode : Select this mode when setting the judgment thresholds.

FUN mode : Select this mode when setting measurement conditions.

(9) Threshold Selector Switch

The Threshold Selector switch selects whether to set (or display) the HIGH or LOW

threshold.

(10) LOW indicator

The LOW indicator lits when the condition “measured value < LOW threshold” is

satisfied.

(11) PASS indicator

The PASS indicator lits when the condition “LOW threshold ≤ measured value ≤

HIGH threshold” is satisfied.

Section 1 FEATURES

(12) HIGH indicator

The HIGH indicator lits when the condition “HIGH threshold < measured value” is

satisfied.

(13) Coupler

This connector is for connecting the Multi-Controller to the Sensor Controller.

(14) RS-232C connector

Connect the RS-232 cable when you are connecting the Multi-Controller to a

personal computer that does not have a USB port.

(15) Voltage/Current switch

The Voltage/Current switch selects between voltage output and current output.

Before operating this switch, make sure that the Multi-Controller is turned OFF. Also, make sure

that the load connected to “linear output wire (co-axial) — linear GND wire” satisfies the rating of

the set state (voltage or current output) before turning the Multi-Controller ON. Otherwise, the

Multi-Controller may be damaged.

Rating of connected load (I/O Circuit Diagrams) p.2-12

(16) I/O Cable

The I/O cable connects the Sensor Controller to the power supply and external

devices, such as timing sensors or programmable controllers.

(17) USB port

Connect the USB cable to the USB port to connect to a personal computer.

ZS-MDC

User’s Manual

1-9

Page 24

Section 1 FEATURES

Section 1

Part Names and Functions

MEMO

1-10

ZS-MDC

User’s Manual

Page 25

Section 2

INSTALLATION & CONNECTION

About Installation and Connection 2-2

Multi-Controller 2-3

Attaching the ferrite core 2-3

Installing the Multi-Controller 2-4

About the I/O cable 2-10

Section 2 INSTALLATION & CONNECTION

ZS-MDC

User’s Manual

2-1

Page 26

Section 2 INSTALLATION & CONNECTION

Section 2

About Installation and Connection

About Installation and Connection

■ Checking the installation environment

Read “Precautions for Safe Use” at the beginning of this manual, and check the installation environment.

■ Checking the installation site

Read “Precautions for Correct Use” at the beginning of this manual, and check the

installation site.

■ About the power supply

Before installing and connecting the Multi-Controller, be sure to turn it OFF.

Also read “Precautions for Safe Use” and “Precautions for Correct Use” at the beginning of this manual, and check the power supply and wiring.

2-2

ZS-MDC

User’s Manual

Page 27

Section 2

Multi-Controller

Multi-Controller

This section describes installation of the Multi-Controller and connection of the I/O cable.

Before connecting/disconnecting peripheral devices, make sure that the Multi-Controller is turned OFF.

The Multi-Controller may break down if the Multi-Controller is connected or disconnected while the

power is ON.

Attaching the ferrite core

Attach the ferrite core (provided with the Multi-Controller) to the I/O cable of the MultiController.

Section 2 INSTALLATION & CONNECTION

Ferrite core

ZS-MDC

User’s Manual

2-3

Page 28

Section 2 INSTALLATION & CONNECTION

Section 2

Multi-Controller

Installing the Multi-Controller

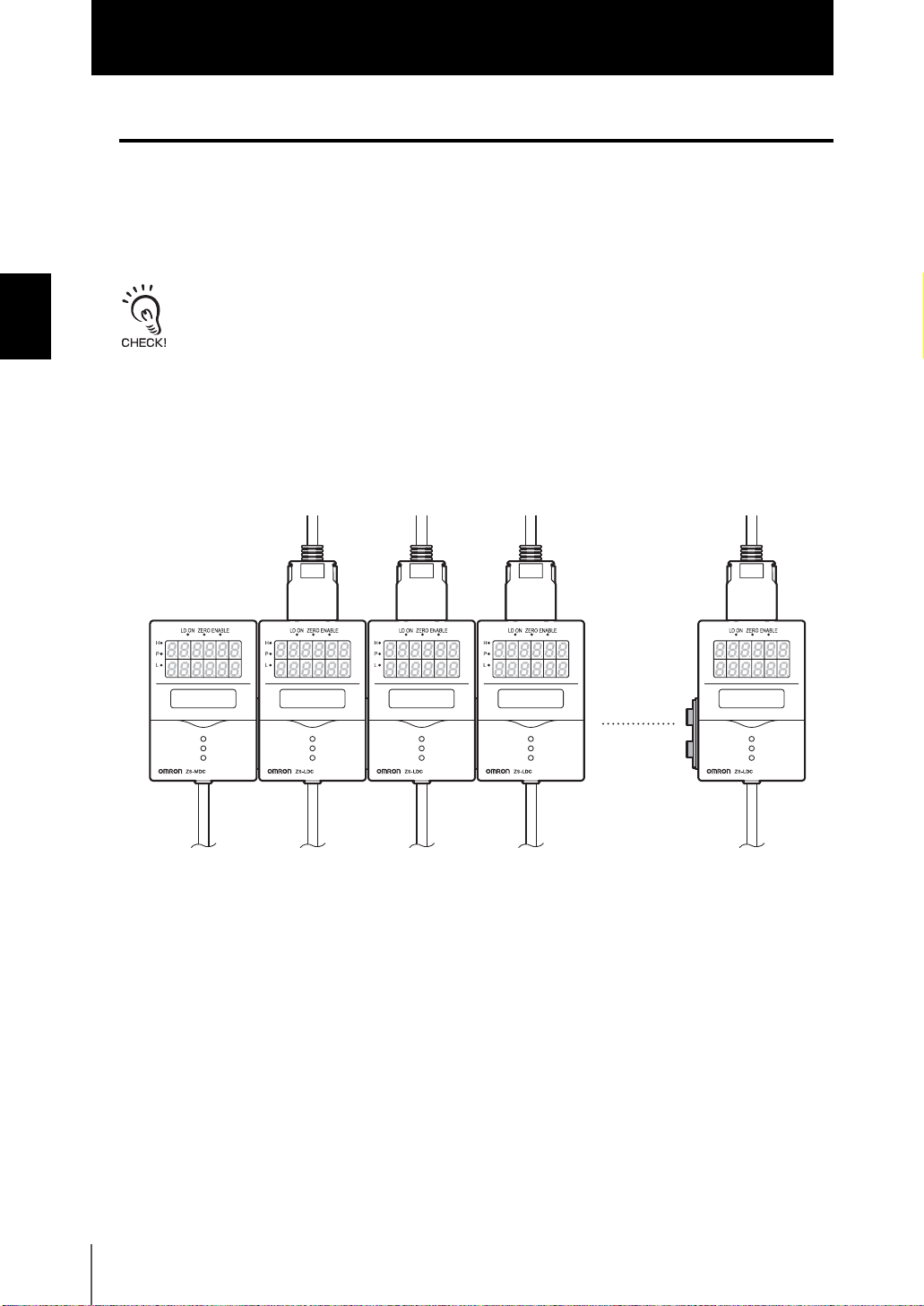

The Multi-Controller performs logical operations on the sensing information obtained from

multiple connected Sensor Controllers. Up to 9 Sensor Controllers can be gang-mounted.

For details on the Sensor Controller and Sensor Heads, refer to the User's Manual for the

Sensor Controller.

Provide power to all connected Sensor Controllers.

■ About channel No. when controllers are gang-mounted

When performing operation from SmartMonitor Zero or an external device, select the

controller to be set up by its channel No. The following shows how channel Nos. are

assigned when Sensor Controllers are gang-mounted.

2-4

Multi-Controller

CH0

ZS-MDC

User’s Manual

Sensor Controller

CH1

Sensor Controller

CH2

Sensor Controller

CH3

Sensor Controller

CH9

Page 29

Section 2

Multi-Controller

■ Installing on the DIN track

The following describes how to attach the 35 mm wide DIN track by quick, easy operation.

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

End plate (sold separately)

PFP-M

● Installation procedure

The following describes how to install the Multi-Controller and Sensor Controller on the

DIN track.

1. Hook the connector end of the Sensor

Controller onto the DIN track.

Hook on connector

Hook on I/O cable

2. Push the Multi-Controller down onto the

DIN track until the hook on the I/O cable

side is locked.

Push down until you hear it snap into

place.

Section 2 INSTALLATION & CONNECTION

Always hook the connector end of the Multi-Controller on the DIN track first. Hooking the I/O cable

end on the DIN track first may impair the mounting strength of the DIN track attachment.

ZS-MDC

User’s Manual

2-5

Page 30

Section 2

Multi-Controller

Section 2 INSTALLATION & CONNECTION

3. Open the connector cover on the con-

troller.

Slide the cover to remove.

H

H

LD ON ZERO

LD ON ZEROENABLE

P

P

ENABLE

L

L

Controller

Link Unit (sold

H

H

LD ON ZERO

LD ON ZEROENABLE

P

P

ENABLE

L

L

separately)

4. Insert the Controller Link Unit into the

connector on the Multi-Controller.

The connectors are designed to be connected in a

particular direction. Insert the connector in the direc-

tion so that the indented section of the Controller

Link Unit in the figure on the right matches the con-

nector protrusion on the Data Storage Unit.

Indented

section

5. Slide the Sensor Controller to insert to

the Controller Link Unit connector.

● Removal procedure

The following describes how to remove the Multi-Controller and Sensor Controller from

the DIN track.

1. Slide and remove the Sensor Controller

from the connector on the Controller

Link Unit.

2. Slide the Controller Link Unit and

remove from the connector on the MultiController.

3. Install the cover on the coupler of the controller.

Controller

H

H

LD ON

LD ON

ZER

ZER

P

P

O

OENABLE

ENABLE

L

L

Link Unit

(sold sepa-

rately)

H

H

LD ON

LD ON

ZERO

ZEROENABLE

P

P

ENABLE

L

L

2-6

ZS-MDC

User’s Manual

Page 31

4. Pull the hook on the I/O cable end

downwards.

Section 2

Multi-Controller

5. Lift up the Sensor Controller from the I/O

cable end, and remove it from the DIN

track.

Hook on I/O cable

Section 2 INSTALLATION & CONNECTION

ZS-MDC

User’s Manual

2-7

Page 32

Section 2

Multi-Controller

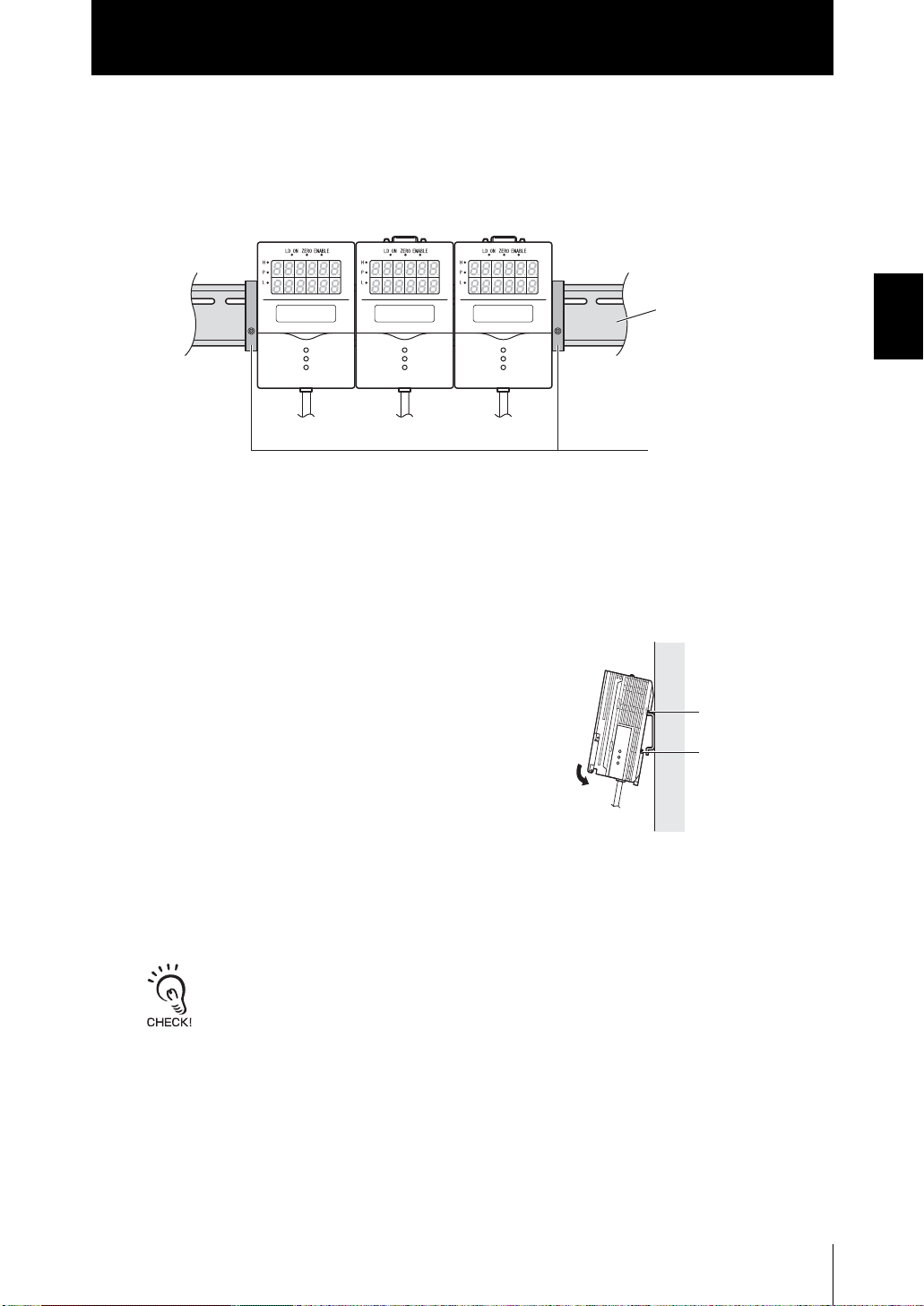

■ Mounting on a panel

The optional Panel Mount Adapters (ZS-XPM1/XPM2) can be used to mount the MultiController on a panel.

Panel Mount Adapters p.5-9

Section 2 INSTALLATION & CONNECTION

1. Install the Multi-Controller and Sensor Controller on the DIN track.

p.2-5

When mounting on a panel, be sure to install the DIN track on the rear side of the Multi-

Controller for support.

2. Push out the Multi-Controller and Sensor

Controller from the rear of the panel

towards the front.

H

H

LD ON

LD ON

ZER

ZER

P

P

O

OENABLE

ENABLE

L

L

H

H

LD ON

LD ON

ZER

ZER

P

P

O

OENABLE

ENABLE

L

L

Panel

H

H

LD ON

LD ON

ZERO

ZEROENABLE

P

P

ENABLE

L

L

3. Install the small Mount Adapters on the

four holes on the Multi-Controller and

Sensor Controller.

Install the small Mount Adapters on all gang-

mounted Multi-Controllers and Sensor

Controllers.

H

H

LD ON

LD ON

ZER

ZER

P

P

O

O

ENABLE

ENABLE

L

L

H

H

LD ON

LD ON

ZER

ZER

P

P

O

OENABLE

ENABLE

L

L

H

H

LD ON

LD ON

ZERO

ZEROENABLE

P

P

ENABLE

L

L

Panel

Mount

Adapter

2-8

Panel Mount

Adapter

ZS-MDC

User’s Manual

Page 33

Section 2

Multi-Controller

4. Install the long Mount Adapters on the

two holes on the small Mount Adapter.

Install the long Mount Adapters only on both

sides of gang-mounted controllers.

5. Install the Multi-Controller and Sensor

Controller with Panel Mount Adapters

attached onto the panel from the front.

Take care not to pinch the I/O cable.

Panel Mount Adapter

H

H

LD ON

LD ON

ZER

ZER

P

P

O

OENABLE

ENABLE

L

L

H

H

LD ON

LD ON

ZERO

ZEROENABLE

P

P

ENABLE

L

L

H

H

LD ON

LD ON

ZERO

ZEROENABLE

P

P

ENABLE

L

L

Panel Mount Adapter

Panel

H

H

LD ON ZERO

LD ON ZERO ENABLE

P

P

ENABLE

L

L

H

H

LD ON ZERO

LD ON ZERO ENABLE

P

P

ENABLE

L

L

H

H

LD ON ZERO

LD ON ZERO ENABLE

P

P

ENABLE

L

L

Section 2 INSTALLATION & CONNECTION

6. Hook the hooks of the mounting fixture

onto the two holes of the small Mount

Adapters and tighten the screws.

Attach two mounting fixtures each on all gang-

mounted Multi-Controllers and Sensor

Controllers.

7. Make sure that the Multi-Controller and

Sensor Controllers are firmly fixed on

the panel.

Mounting

fixture

ZS-MDC

User’s Manual

2-9

Page 34

Section 2 INSTALLATION & CONNECTION

Section 2

About the I/O cable

About the I/O cable

■ Wiring the I/O cable

The following shows the leads that comprise the I/O cable.

Brown

Blue

Red

Green

Black

Pink

Gray

Co-axial (black)

Shielded

Yellow

Light blue

Purple

White

Orange

(1) Power supply

(2) GND

(3) OUT0

(4) OUT1

(5) OUT2

(6) OUT3

(7) OUT4

(8) Linear output

(9) Linear GND

(10) IN0

(11) IN1

(12) IN2

(13) IN3

(14) Unused

(1) Power supply

This connects the 24 VDC (±10%) power supply. When using a Multi-Controller with

a PNP output, the power supply terminal is also the common I/O terminal for all I/O

except for the linear output.Supply power from a DC power supply unit that has a

countermeasure (safety ultra-low voltage circuit) built-in for preventing high voltages

from occurring.

Recommended power supply unit p.1-7

Wire the power supply separately from other devices. Wiring them together or placing

them in the same duct may cause induction, resulting in malfunction or damage.

Supply power simultaneously to all gang-mounted controllers to be used.

When power is turned ON individually, the channels will not be recognized normally.

(2) GND

The GND terminal is the 0V power supply terminal. When using a Multi-Controller

with an NPN output, the GND terminal is also the common I/O terminal for all I/O

except for the linear output.

(3) OUT0 (HIGH output)

This outputs judgment results (HIGH).

2-10

(4) OUT1 (PASS output)

This outputs judgment results (PASS).

(5) OUT2 (LOW output)

This outputs judgment results (LOW).

ZS-MDC

User’s Manual

Page 35

Section 2

About the I/O cable

(6) OUT3 (ENABLE output)

This turns ON when the Multi-Controller is ready for measurement. This output is

interlocked with the ENABLE indicator.

(7) OUT4 (BUSY output)

This turns ON during sampling with the hold function enabled. It allows you to check

whether or not the self-trigger is functioning correctly. It also turns ON during bank

switching.

(8) Linear output

The linear output outputs a current or voltage in accordance with the measured

value.

(9) Linear GND

The linear GND terminal is the 0V terminal for the linear output.

This ground wire must be grounded separately from the other ground wires.

Always ground the linear output terminal even when linear output is not used.

Section 2 INSTALLATION & CONNECTION

(10) to (13) IN0 to IN3

The following input signal assignments can be selected.

• Signal assignments

Signal

IN0 External trigger (timing) input Bank input A

IN1 Reset input Bank input B

IN2 Unused Unused

IN3 Zero reset input Zero reset input

Setting I/O Assignments p.3-16

When [Standard] is selected

(default)

When [Bank] is selected

• Signal functions

Signal Name Description

External trigger (timing) input This timing input is for signal input from external devices. Use it for hold

function timing.

Reset input This resets all executing measurements and outputs. While a reset is

being input, judgment output conforms to the non-measurement setting. If this reset input switches ON while the hold function is used, the

state in effect before the hold function was set will be restored.

Zero reset input This is used to execute and clear a zero reset.

Bank input A, B This is used for switching banks. Specify the bank No. in combinations

of A and B.

For details on the timing charts of external I/O, refer to User’s Manual for the Sensor Controller.

ZS-MDC

User’s Manual

2-11

Page 36

Section 2

About the I/O cable

■ I/O Circuit Diagrams

●

NPN type (ZS-MDC11)

Brown

DC24V

Section 2 INSTALLATION & CONNECTION

Internal circuits

Current voltage/

output selector switch

40 Ω

Current output

4 to 20 mA

Voltage output

10 V

Red

OUT0

Green

OUT1

Black

OUT2

Pink

OUT3

Gray

OUT4

Blue

GND(0V)

Yellow

Light blue

Purple

White

Orange

Co-axial (black)

Shielded

IN0

IN1

IN2

IN3

Load

Linear output

Linear GND

Load

Load

Load

Load

Load

DC24V

Current output: 300Ω or less

Voltage output: 10 kΩ or more

2-12

ZS-MDC

User’s Manual

Page 37

● PNP type (ZS-MDC41)

Internal circuits

Brown DC24V

Red

OUT0

Green

OUT1

Black

OUT2

Pink

OUT3

Gray

OUT4

Blue GND(0V)

Yellow

IN0

Light blue

IN1

Purple

IN2

White

IN3

Orange

Load

Load

Load

About the I/O cable

Load

Load

DC

24V

Section 2

Section 2 INSTALLATION & CONNECTION

Current voltage/

output selector switch

40Ω

Current output

4 to 20 mA

Voltage output

10 V

Co-axial (black)

Shielded

Linear output

Linear GND

Current output: 300 Ω or less

Load

Voltage output: 10 kΩ or more

ZS-MDC

User’s Manual

2-13

Page 38

Section 2 INSTALLATION & CONNECTION

Section 2

About the I/O cable

MEMO

2-14

ZS-MDC

User’s Manual

Page 39

Section 3

SETUP

Setting Flow 3-2

About Setup 3-4

Basic Knowledge for Operation 3-4

List of Setting Items 3-9

Selecting Tasks 3-13

Section 3 SETUP

Setting the Sensor Controller to Obtain Sensing Information from

Setting Assignments 3-14

Setting Logic Operation Methods 3-15

Setting I/O Assignments 3-16

Switching banks by external signal input 3-16

Changing Output Assignments 3-17

Changing Linear Output Assignments 3-17

About Digital Output 3-17

3-14

ZS-MDC

User’s Manual

3-1

Page 40

Section 3

Setting Flow

Setting Flow

Section 3 SETUP

Installation and Connection

Gang-mount Sensor Controller to Multicontroller.

Preparation for Measurement

Power ON

Section 2

Installation & Connection

Setting the Sensor Controller to obtain sensing information from

Set the Sensor Controller to obtain sensing

information from and operations to be

performed.

Setting Filter Function

Set the filter conditions for processing

measured information.

Setting of Measurement Conditions

Setting output processing

Set how measured information is to be

processed for outputting the required values.

p.3-14

Sensor Controller User's Manual,

Section 3 Setup

p.3-16

Sensor Controller User's Manual,

Section 3 Setup

p.2-2

3-2

Setting the Threshold

Set the threshold value for judging measured

values.

External I/O

Set how measured values are to be output.

Output Results

Save Setup Data

Save the data you have set.

Save Setup

ZS-MDC

User’s Manual

Sensor Controller

User's Manual,

Section 3 Setup

Sensor Controller User's Manual,

Section 3 Setup

Sensor Controller User's Manual,

Section 3 Setup

After you have made or changed settings,

be sure to save the setup data. All settings

will be deleted if you turn the power OFF

without saving the data.

Page 41

When a Problem Occurs...

Section 3

Setting Flow

The Multi-Controller does not operate correctly.

Troubleshooting

p.5-2

Want to know the meanings of terms

Glossary

p.5-5

Setting Banks

Set up the banks.

Set Up the System Environment

Set up the system environment.

Applied Use of Functions

An error message has appeared

When [Error] is Displayed on the

Main Display

Sensor Controller User's Manual,

Section 3 Setup

Sensor Controller User's Manual,

Section 3 Setup

p.5-3

Section 3 SETUP

Setting the Display Method

Set what is to be displayed on the MultiController during measurement in the RUN

mode.

Additional Functions

Sensor Controller User's Manual,

Section 3 Setup

ZS-MDC

User’s Manual

3-3

Page 42

Section 3

About Setup

About Setup

The ZS-MDC Series can be set up on the Multi-Controller or on the SmartMonitor Zero

software utility.

This manual describes setup on the Multi-Controller.

For details on how to set up the ZS-L Series on SmartMonitor Zero, refer to Help

contained on the SmartMonitor Zero CD-ROM.

Section 3 SETUP

Basic Knowledge for Operation

The following describes basic operation of the Multi-Controller before you set up the ZS-L

Series.

■ Switching Modes

The ZS-MDC has the following 3 operating modes.Switch to the desired mode before

you start operation.

To switch the operating mode, use the Mode Switch.

TEACH

FUN RUN

3-4

Mode Description

FUN Mode Mode for setting the measurement conditions

RUN mode Normal operating mode

TEACH Mode This mode is for setting the judgment threshold values.

When you switch the operating mode after changing the measurement conditions, you will be

prompted to save the settings. Save the settings as required. If you turn off the Multi-Controller with-

out saving these settings, the newly set measurement conditions will be cleared from memory. You

can also save all the settings later on.

Sensor Controller User’s Manual, Section 3 Setup

ZS-MDC

User’s Manual

Page 43

Section 3

About Setup

■ Displays and Key Operations

The Multi-Controller has digital displays and an LCD screen.The details displayed on

these differ according to the operating mode.

Main Display

Sub-display

LCD screen

Control keys

Alphabet characters that appear on the

digital displays

(1) FUN Mode

The LCD screen displays the setup menus.

The No. at the top of each menu corresponds to a function key.

“← →“ displayed at the top right of the LCD screen indicates that the setup menu is

made up of two or more pages. Scroll pages by the LEFT or RIGHT key.

Top menu in FUN mode

The currently selected bank No. will be displayed on

the main display (upper section).

The currently selected bank No. will be displayed on

the main display (lower section).

Section 3 SETUP

1SENSING

3OUTPUT

2FILTER

Pressing the MENU key in the FUN mode returns to

the display.

Key Operations

Key FUN Mode

Function keys Directly sets the No. preceding the items displayed on the LCD

screen.

←

LEFT key

→ RIGHT key

The function changes depending on the settings.

• Scrolls pages in list menus.

• Selects the digit of numerical values.

ZS-MDC

User’s Manual

3-5

Page 44

Section 3 SETUP

Section 3

About Setup

Key FUN Mode

↑ UP key

↓ DOWN key

MENU key Displays the top menu of the FUN mode.

SET key Applies the item you are setting up.

ESC key Returns to the previous menu.

Changes numerical values during numerical value input.

The following example describes basic operations for changing the filter to [SMOOTH].

1. Press function key 2 representing

[FILTER].

2. Press function key 1 representing

[SMOOTH].

The currently selected No. is displayed

flashing.

3. Press function key 2 representing

[ON].

The “Complete!” message is displayed.

4. Press the MENU key to return to the

top menu.

Pressing the ESC key returns to the

previous menu.

1SENSING

3OUTPUT

1SMOOTH

3DIFF

1OFF

SMOOTH

Complete!

2FILTER

2AVERAGE

2ON

: ON

3-6

ZS-MDC

User’s Manual

Page 45

Section 3

About Setup

● RUN Mode

In this mode, measured values are displayed on the main display, and threshold values

and other information are displayed on the sub-display.

Pressing the MENU key displays the display customize menu.

Measured value display

MAIN : MESURE

SUB : THRESH

MAIN : MESURE

SUB : DISTANCE

MAIN : MESURE

SUB : VOLTAGE

MAIN : MESURE

SUB : RESOLU

Display customise menu

1DIGITAL

3HELP

2LCD

Details displayed on the sub-display

Display Details Description

THRESH Displays the HIGH/LOW threshold values according to the setting of the

threshold switch.

VOLTAGE (CURRENT) Displays the voltage (current) to be linearized. The display details change

according to the setting of the current/voltage switch. (Values displayed here

are reference values only. These values differ from actual linear output values.)

RESOLU Displays the fluctuation width (peak to peak) of the measured value over a

fixed amount of time.

DISTANCE Displays the measured value before it is processed by hold or other functions.

Section 3 SETUP

Key Operations

Key Measured Value Display Display Customize Menu

Function keys Not used Directly select functions.

LEFT key

←

→ RIGHT key

Changes sub-display content. The function changes depend-

ing on the settings.

• Scrolls pages in list menus.

• Selects digits.

User’s Manual

ZS-MDC

3-7

Page 46

Section 3

About Setup

Key Measured Value Display Display Customize Menu

↑ UP key

↓ DOWN key

MENU key Displays the display customize

SET key Executes a zero reset. Applies numerical value settings.

↑ UP key: Executes trigger input.

↓ DOWN key: Executes reset

input.

menu.

The function changes depending on the settings.

• Changes numerical values.

• Changes text.

Returns to the top of the display

customize menu.

Section 3 SETUP

ESC key Hold down for at least two sec-

onds to cancel a zero reset.

Returns to the previous menu.

When the top menu is displayed,

returns to the measured value

display.

● TEACH Mode

In this mode, the measured value is displayed at all times on the main display. The

threshold values are displayed on the sub-display. Which of the HIGH or LOW threshold

values is displayed changes according to the setting of the threshold selector switch.

TEACH MODE

MENU : TEACHING

Displayed alternately

Key Operations

Key TEACHING DIRECT IN

Function keys Not used Not used

TEACH MODE

: DIRECT IN

3-8

←

LEFT key

→ RIGHT key

↑ UP key

↓ DOWN key

MENU key Registers the measured value

SET key Not used Applies the newly set threshold

ESC key Not used Cancels the newly set threshold

Not used Selects the digit in the threshold

numerical value.

Not used Changes the threshold numerical

value.

Not used

when this key is pressed as the

threshold value.

value.

value.

ZS-MDC

User’s Manual

Page 47

Section 3

About Setup

List of Setting Items

This manual describes only “FUN Mode-[SENSING]” functions unique to the Multi-Controller. Details of

other functions are the same as those for the Sensor Controller. Refer to the Sensor Controller Userís

Manual.

■ FUN Mode

This is the mode for setting the measurement conditions. The items that can be set differ according to which task is selected. When TASK1 is selected, all items including

items common to all tasks can be set. When a task other than TASK1 is selected, only

items specific to that task can be set.

● When TASK1 is selected

Section 3 SETUP

FUN Mode

SENSING SEL CH

FILTER SMOOTH

OUTPUT SCALING

HOLD TYPE

0RESET TYPE

Settings Default Value Option/Range

- Input A to input I p.3-14

CALC

AVERAGE

DIFF

TRIGGER

DELAY

OFFSET

CH OFF, CH (input A to input I), CALC

ON OFF, ON -

1 1, 2, 4, 8, 16, 32, 64, 128, 256, 512,

OFF OFF, ON -

OFF OFF, ON (AUTO, MAN) -

OFF

EXT

OFF OFF, ON (T-DELAY, T-TIME) -

REAL REAL, HOLD -

0 -999.99 to 999.999 -

(THICK, STEP, K+mX+nY, AVE,

MAX-MIN)

1024, 2048, 4096

OFF, PEAK, BOTTOM, P-P, AVERAGE,

SAMPLE

EXT, SELF-UP, SELF-DN

Pages

p.3-15

-

-

-

ZS-MDC

User’s Manual

3-9

Page 48

Section 3

About Setup

Section 3 SETUP

Settings Default Value Option/Range

I/O SET NO-MEAS

JUDGE HYS

TIMER

ANALOG FOCUS

ADJUST

INPUT IN0

IN1

IN2

IN3

I/O SET

IN

OUT

ANALOG

DIGITAL

BANK CHANGE

CLEAR

CLAMP KEEP, CLAMP -

20 µm

OFF OFF, OFF DELAY (1 to 5000ms),

OFF OFF, ON -

OFF OFF, ON (-999 to 999) -

ON OFF, ON -

ON OFF, ON

ON OFF, ON

ON OFF, ON

TASK TASK (TASK1 to 4, ALL TASK,

TASK1 TASK1 to TASK4, NONE

TASK1 TASK1 to TASK4, NONE

- LOG1 to 9(NONE, INPUT A to

BANK1 BANK1, BANK2, BANK3, BANK4 -

- (Initializes bank settings.) -

0 to 999.999 -

ON DELAY (1 to 5000ms), ONE

SHOT (1 to 5000ms)

NONE), FUNC (NORMAL, BANK)

INPUT I, TASK1 to TASK4)

Pages

-

p.3-16

SYSTEM SAVE

INIT

INFO

CYCLE

VERSION

COM

(RS-232C)

LENGTH

PAR ITY

STOP

BAUDRAT

DELIMIT

COM MODE

NODE

KEYLOCK

ZERORST

LANGUAG

-

-

-

8BIT 8BIT, 7BIT -

NONE NONE, ODD, EVEN -

1BIT 1BIT, 2BIT -

38400 9600, 19200, 38400, 57600,

CR CR, LF, CR+LF -

COMPWAY COMPWAY, NORMAL -

0 0 to 16 -

OFF OFF, ON -

OFF OFF, ON -

Japanese Japanese, English -

(Saves Multi-Controller settings.)

(Initializes Multi-Controller settings.)

(Displays the current measurement

cycle.)

(Displays the Multi-Controller version.)

115200

-

-

-

-

-

3-10

ZS-MDC

User’s Manual

Page 49

● When other than TASK1 is selected

Section 3

About Setup

FUN Mode

SENSING CALC

FILTER SMOOTH

OUTPUT SCALING

HOLD TYPE

0RESET TYPE

BANK

SYSTEM

Settings Default Value Option/Range

AVERAGE

DIFF

TRIGGER

DELAY

OFFSET

CH OFF, CH(input A to input I), CALC

ON OFF, ON -

1 1, 2, 4, 8, 16, 32, 64, 128, 256, 512,

OFF OFF, ON -

OFF OFF, ON (AUTO, MAN) -

OFF

EXT

OFF OFF, ON (T-DELAY, T-TIME) -

REAL REAL, HOLD -

0 -999.99 to 999.999 -

(THICK, STEP, K+mX+nY, AVE,

MAX-MIN)

1024, 2048, 4096

OFF, PEAK, BOTTOM, P-P, AVERAGE,

SAMPLE

EXT, SELF-UP, SELF-DN

(same as when

TASK1 is selected)

(same as when

TASK1 is selected)

Page

s

p.3-15

-

Section 3 SETUP

-

-

ZS-MDC

User’s Manual

3-11

Page 50

Section 3

About Setup

■ RUN Mode

In the RUN mode, you can customize the details that are displayed in the digital displays.

To call the display customize menu, press the MENU key in the RUN mode.

Section 3 SETUP

RUN mode

DIGITAL DOT

LCD ON/OFF

Settings Default Value Option/Range

ECO

B.LIGHT

CUSTOM

HELP

■ TEACH Mode

This is the mode for setting the threshold values

TEACH Mode

Settings Default Value Option/Range

TEACHING

DIRECT IN

Page

s

3 0 to 5 -

NORMAL NORMAL, ECO, OFF -

ON ON, AUTOOFF, OFF -

ON ON, AUTOOFF, OFF -

U-OFF

D-OFF

-- -

-- -

--

U-ON/OFF, L-ON/OFF

Upper section customize, lower

section customize

-

Page

s

3-12

ZS-MDC

User’s Manual

Page 51

Section 3

Selecting Tasks

Selecting Tasks

By assigning expressions to “tasks,” you can process (multi-tasking) multiple logic

operations (max. 4). After selecting the task in the task selection menu, make the various

settings for the selected task in the respective setup menus. The currently selected task is

displayed on the sub-display.

Press the ESC key with the FUN Mode-TOP menu displayed.

Setting Description

TASK1 Selects TASK1 as the destination to store the expression to.

TASK2 Selects TASK2 as the destination to store the expression to.

TASK3 Selects TASK3 as the destination to store the expression to.

TASK4 Selects TASK4 as the destination to store the expression to.

• In the RUN and TEACH modes, the task to display can be selected.As function keys correspond to

a stored task, press the function key of the task No. you want to display. (The currently selected task

is displayed as “TKX” on the LCD display.)

• The items that can be set in the FUN mode change according to the currently selected task.When

TASK1 is selected, all items including items common to all tasks can be set. When a task other than

TASK1 is selected, only items specific to that task can be set.Items common to all tasks are as fol-

lows:

• SEL CH

• NO-MEAS

• JUDGE

• ANALOG

• IN

• I/O SET

BANK and SYSTEM can also be changed whichever task is selected.

Section 3 SETUP

ZS-MDC

User’s Manual

3-13

Page 52

Section 3

Setting the Sensor Controller to Obtain Sensing Information from

Setting the Sensor Controller to Obtain Sensing Information from

Set which gang-mounted Sensor Controller to obtain information from, and which logic

operations are to be performed on that information.

Setting Assignments

Assign the channel to perform logic operation on.

Section 3 SETUP

▲

FUNMode-[SENSING]-[SEL CH]

Setting Description

INPUT A (input A) Assigns the target Sensor Controller to input A.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 1CH. Note that range becomes “None” if 1CH does not exist.)

INPUT B (input B) Assigns the target Sensor Controller to input B.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 2CH. Note that range becomes “None” if 2CH does not exist.)

INPUT C (input C) Assigns the target Sensor Controller to input C.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 3CH. Note that range becomes“None” if 3CH does not exist.)

INPUT D (input D) Assigns the target Sensor Controller to input D.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 4CH. Note that range becomes “None” if 4CH does not exist.)

INPUT E (input E) Assigns the target Sensor Controller to input E.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 5CH. Note that range becomes “None” if 5CH does not exist.)

INPUT F (input F) Assigns the target Sensor Controller to input F.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 6CH. Note that range becomes “None” if 6CH does not exist.)

INPUT G (input G) Assigns the target Sensor Controller to input G.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 7CH. Note that range becomes “None” if 7CH does not exist.)

INPUT H (input H) Assigns the target Sensor Controller to input H.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 8CH. Note that range becomes “None” if 8CH does not exist.)

INPUT I (input I) Assigns the target Sensor Controller to input I.

Range: None, 1CH onwards (largest CH of gang-mounted Sensor Controllers)

(default: 9CH. Note that range becomes “None” if 9CH does not exist.)

3-14

ZS-MDC

User’s Manual

Page 53

Section 3

Setting the Sensor Controller to Obtain Sensing Information from

Setting Logic Operation Methods

Set how logic operations are to be performed on the tasks and CH specified by the

assignment settings.

▲

FUNMODE-[SENSING]-[CALC]

Setting Description

OFF Expressions are not set.

CH Logic operations are not performed, and the measured value of a specific CH

is input as it is.Select the target CH.

CALC THICK

K-(X+Y)

Select this item to set the sandwiched thickness. (sandwiched measurement)

• Xrange: input A to input I, TASK1 to TASK4

• Yrange: input A to input I, TASK1 to TASK4

• The thickness input is automatically set.

During thickness input, the mode changes to the measurement

mode, and the current thickness value is displayed on the main dis-

play. For this reason, during thickness input enter in a measurement

ready state.

K

XY

Section 3 SETUP

STEP

X-Y

K+mX+nY Select this to perform logic operations on X and Y with the coefficient freely

AVE

(average height

measurement)

MAX-MIN

(flatness measurement)

Select this item to set step measurement. (step measurement)

• Xrange: input A to input I, TASK1 to TASK4

• Yrange: input A to input I, TASK1 to TASK4

Y

set.

• K range: -999999 to 999999

• m range: -10.0 to 10.0

• n range: -10.0 to 10.0

• Xrange: input A to input I, TASK1 to TASK4

• Yrange: input A to input I, TASK1 to TASK4

Select this item to average the values of input A to input I, and the values of

TASK1 to TASK4.

Set ON/OFF to each input and each TASK.The average of inputs set to ON

and TASK is calculated.

Select this item to subtract the maximum and minimum values by the values

of input A to input I.

Set ON/OFF to each input and each TASK.The average of inputs set to ON

and TASK is calculated.

X

Inputs do not undergo logical operation when “None” is set. Example: The operation “-B” is performed

when “None” is set to input A, “3CH” is assigned to input B and A-B is selected.

ZS-MDC

User’s Manual

3-15

Page 54

Section 3

Setting I/O Assignments

Setting I/O Assignments

Switching banks by external signal input

Set the task or function to the external input.

If you use SmartMonitor Zero, you can change the function assignments of IN2 and IN3 if [BANK] is

selected. For details, refer to the Help for SmartMonitor Zero.

Section 3 SETUP

▲

FUN mode-[I/O SET]-[I/O SET]-[IN]

Setting Description

TASK Select to task for enabling the external signal lead. Note, however, that reset input

and bank inputs affects tasks at all times.

Range: TASK1 to TASK4, TASK-ALL

FUNC NORMAL Select this to use external input function as in standard applications so far (default

value).

IN0 IN1 IN2 IN3

External trigger

(timing) input

BANK Select this to switch banks using external inputs.

IN0 IN1 IN2 IN3

Bank input A Bank input B Unused Zero reset input

Reset input Unused Zero reset input

For bank inputs A and B, the bank can be selected in the following combinations.

Bank to be Selected Bank input A Bank input B

BANK1 OFF OFF

BANK2 OFF ON

BANK3 ON OFF

BANK4 ON ON

3-16

• Bank switching is begun 0.5 seconds after the input state changes.

• At most it takes about 10 seconds to switch banks.

• During bank switching the BUSY output becomes ON.

ZS-MDC

User’s Manual

Page 55

Changing Output Assignments

▲▲ ▲

FUN mode-[I/O SET]-[I/O SET]-[OUT]

Setting Description

TASK1

TASK2

TASK3

TASK4

The measurement value of the task selected here is output as the judgment result

of the Multi-Controller.

Section 3

Setting I/O Assignments

Changing Linear Output Assignments

FUN Mode-[I/O SET]-[I/O SET]-[ANALOG]

Setting Description

TASK1

TASK2

TASK3

TASK4

The measurement value of the task selected here is linear-output from the MultiController.

About Digital Output

FUN Mode-[I/O SET]-[I/O SET]-[DIGITAL]-[LOG1 to 9]

Setting Description

NONE

Input A to input I

TASK1 to TASK4

Set this to batch-output multiple data to external devices using CompoWay/F or

non-procedural commands.

Assign to log 1 to 9 inputs A to I or TASK1 to 4 to be output. When a command is

input, the inputs or tasks are output continuously in order from log 1 to 9.

(The data of the nine channels can be batch-output when input A to I is set to log1

to 9 with all inputs assigned.)

For details on commands, refer to the “Communication Command Reference”

(provided separately).

When multi-channel waveforms are plotted or logging is performed on SmartMonitor Zero, the details set on SmartMonitor Zero are automatically reflected in this

setting.

Section 3 SETUP

ZS-MDC

User’s Manual

3-17

Page 56

Section 3 SETUP

Section 3

Setting I/O Assignments

MEMO

3-18

ZS-MDC

User’s Manual

Page 57

Section 4

APPLICATION SETTING EXAMPLES

Measuring the Thickness of Multiple Points (sandwiched thickness)

Measuring the Relative Difference between Steps 4-5

Measuring the Reference Difference between Steps 4-8

Measuring Flatness 4-10

Measuring the Average Height 4-12

Measuring the Twist of a Workpiece 4-14

Measuring the Warp of a Workpiece 4-17

4-2

Section 4 APPLICATION SETTING EXAMPLES

ZS-MDC

User’s Manual

4-1

Page 58

Section 4

Measuring the Thickness of Multiple Points (sandwiched thickness)

Measuring the Thickness of Multiple Points (sandwiched thickness)

This is an example of how to measure the sandwiched thickness at three places on a

workpiece, and calculate the difference (max. value - min. value) of each measured

thickness value. [THICK] and [MAX-MIN] are used as the operation modes.

Input A Input C

Section 4 APPLICATION SETTING EXAMPLES

Input B Input D

For details on how to connect and install the Sensor Heads and Sensor Controllers, refer to the “ZS-L

User’s Manual”.

Input E

Thickness

Input A Input B Input CInput D Input E Input F

Input F

CH0 CH1 CH2 CH3 CH4 CH5 CH6

The operation and/or measurement results are output

as judgement output or linear output.

▲

FUN Mode-[SENSING]-[SEL CH]

4-2

1. Assign the CH No. of the controller to inputs

A to F to be used for the expression.

INPUT A:1CH

INPUT B:2CH

INPUT C:3CH

INPUT D:4CH

INPUT E:5CH

INPUT F:6CH

ZS-MDC

User’s Manual

1INPUT A

3INPUT C

2INPUT B

Page 59

Measuring the Thickness of Multiple Points (sandwiched thickness)

▲

Press MENU key - ESC key.

2. Select [TASK1].

Section 4

▲

[SENSING]-[CALC]-[CALC]-[THICK]

3. Set the expression of TASK1.

INPUT X: INPUT A

INPUT Y: INPUT B

4. Place a workpiece of known thickness at the

rough sensor.

5. Select [THICK].

6. Enter the thickness of the workpiece.

The thickness of the workpiece you placed is

displayed on the LCD. Enter the thickness value

referring to the displayed value.

1TASK1

3TASK3

1INPUT X

3THICK

Input A

Input B

THICK : 0 1 0 . 0 0 0

DIG VAL

2TASK2

4TASK4

2INPUT Y

X

Y

SETOK

Section 4 APPLICATION SETTING EXAMPLES

7. Press the SET Key to apply the setting.

8. Following the same procedure as 2 to 7, set

up TASK2 and TASK3.

(TASK2) Enter C to input X and D to input Y.

(TASK3) Enter E to input X and F to input Y.

THICK : 0 1 0 . 0 0 0

Complete!

Input C

Input D

Input E

X

Y

Input F

ZS-MDC

User’s Manual

4-3

Page 60

Section 4

Measuring the Thickness of Multiple Points (sandwiched thickness)

▲

Press MENU key - ESC key.

9. To set the expression for calculating the dif-

ference in the thickness of the 3 locations

for TASK4, select [TASK4].

1TASK1

3TASK3

2TASK2

4TASK4

▲

[SENSING]-[CALC]-[CALC]-[MAX-MIN]

10. Set task 1 to task3 for calculating the differ-

Section 4 APPLICATION SETTING EXAMPLES

ence to ON, and other tasks to OFF.

• To output the judgment result of the operation

▲

1TASK1

3TASK3

2TASK2

[I/OSET]-[I/O SET]-[OUT]

11. Select [TASK4] so that the judgment on the

thickness difference can be output.

• To linear-output the operation result

▲

1TASK1

3TASK3

2TASK2

4TASK4

[I/O SET]-[I/O SET]-[ANALOG]

11. Select [TASK4] so that the thickness differ-

ence can be linear-output.

1TASK1

3TASK3

2TASK2

4TASK4

4-4

The calculation results of each CH can be batch-acquired if you use the communication command.

ZS-MDC

User’s Manual

Page 61

Section 4

Measuring the Relative Difference between Steps

Measuring the Relative Difference between Steps

This is an example of how to measure the height at three locations on a workpiece, and

calculate the difference (step difference) between each of the measured values. Use

[STEP] (X-Y) for the expression.

Input A

Step difference

Step difference

For details on how to connect and install the Sensor Heads and Sensor Controllers, refer to the “ZS-L

User’s Manual.”

Input B Input C

The operation and/or measurement results are output

as judgement output or linear output.

Step difference

Input A Input B Input C

CH0 CH1 CH2 CH3

▲

FUN Mode-[SENSING]-[SEL CH]

1. Assign the CH No. of the controller to inputs

A to C to be used for the expression.

1INPUT A

3INPUT C

2INPUT B

Section 4 APPLICATION SETTING EXAMPLES

INPUT A:1CH

INPUT B:2CH

INPUT C:3CH

▲

Press MENU key - ESC key.

2. Select [TASK1].

1TASK1

3TASK3

2TASK2

4TASK4

ZS-MDC

User’s Manual

4-5

Page 62

Section 4

Measuring the Relative Difference between Steps

▲

[SENSING]-[CALC]-[CALC]-[STEP]

3. Set the expression of TASK1.

INPUT X: INPUT A

1INPUT X 2INPUT Y

Input A Input B Input C

INPUT Y: INPUT B

Y X

4. Following the same procedure as 2 to 3, set

Input A Input B Input C

up TASK2.

Section 4 APPLICATION SETTING EXAMPLES

INPUT X: INPUT B

Y

X

INPUT Y: INPUT C

5. Following the same procedure as 2 to 3, set

Input A

Input B

Input C

up TASK3.

INPUT X: INPUT C

Y

X

INPUT Y: INPUT A

4-6

• To output the judgment result of the operation

▲

[I/O SET]-[I/O SET]-[OUT]

6. Select TASK1, TASK2, or TASK3 depending

on the details to be output.

To output judgment on the difference between

point A and point B: Set TASK1 to I/O SET

To output judgment on the difference between

point B and point C: Set TASK2 to I/O SET

To output judgment on the difference between

point C and point A: Set TASK3 to I/O SET

ZS-MDC

User’s Manual

1TASK1

3TASK3

2TASK2

4TASK4

Page 63

Measuring the Relative Difference between Steps

• To linear-output the operation result

▲

[I/O SET]-[I/O SET]-[ANALOG]

Section 4

6. Select TASK1, TASK2, or TASK3 depending

on the details to be output.

1TASK1

3TASK3

2TASK2

4TASK4

To output judgment on the difference between

point A and point B: Set TASK1 to I/O SET

To output judgment on the difference between

point B and point C: Set TASK2 to I/O SET

To output judgment on the difference between

point C and point A: Set TASK3 to I/O SET

The calculation results of each CH can be batch-acquired if you use the communication command.

Section 4 APPLICATION SETTING EXAMPLES

ZS-MDC

User’s Manual

4-7

Page 64

Section 4

Measuring the Reference Difference between Steps

Measuring the Reference Difference between Steps

This is an example of how to measure the height at three locations on a workpiece, and

calculate the difference (step difference) between the value of the reference height

(obtained by taking one of the locations to be the reference height) and the other two

locations. Use [STEP] (X-Y) for the expression.

Input A Input B Input C

Reference

difference

between steps

Reference

difference

between steps

Input A Input B Input C

Section 4 APPLICATION SETTING EXAMPLES

CH0 CH1 CH2 CH3

The operation and/or measurement results are output

as judgement output or linear output.

For details on how to connect and install the Sensor Heads and Sensor Controllers, refer to the “ZS-L

User’s Manual.”

▲

FUN Mode-[SENSING]-[SEL CH]

1. Assign the CH No. of the controller to inputs

A to C to be used for the expression.

1INPUT A

3INPUT C

2INPUT B

INPUT A:1CH

INPUT B:2CH

INPUT C:3CH

4-8

▲

Press MENU key - ESC key.

2. Select [TASK1].

ZS-MDC

User’s Manual

1TASK1

3TASK3

2TASK2

4TASK4

Page 65

Measuring the Reference Difference between Steps

▲

[SENSING]-[CALC]-[CALC]-[STEP]

Section 4

3. Set the expression of TASK1.

INPUT X: INPUT A

INPUT Y: INPUT B

4. Following the same procedure as 2 to 3, set

up TASK2.

INPUT X: INPUT A

INPUT Y: INPUT C

• To output the judgment result of the operation

▲

[I/O SET]-[I/O SET]-[OUT]

5. Select TASK1 or TASK2 depending on the

details to be output.

1INPUT X 2INPUT Y

Input A Input B Input C

Y X

Input A Input B Input C

X

1TASK1

3TASK3

2TASK2

4TASK4

Y

Section 4 APPLICATION SETTING EXAMPLES

To output judgment on the difference between point A (reference point) and point

B: Set TASK1 to I/O SET

To output judgment on the difference between point A (reference point) and point

C: Set TASK2 to I/O SET

• To linear-output the operation result

▲

[I/OSET]-[I/O SET]-[ANALOG]

5. Select TASK1 or TASK2 depending on the

details to be output.

1TASK1

3TASK3

2TASK2

4TASK4

To output the difference between point A (reference point) and point B: Set TASK1

to I/O SET

To output the difference between point A (reference point) and point C: Set TASK2

to I/O SET

The calculation results of each CH can be batch-acquired if you use the communication command.

ZS-MDC

User’s Manual

4-9

Page 66

Section 4

Measuring Flatness

Measuring Flatness

This is an example of how to measure the height at 9 locations on a workpiece, and