Cat. No. Z236-E1-02A

ZS-HL Series

Smart Sensor

2D CMOS Laser Type

USER’S MANUAL

Introduction

This manual provides information regarding functions, performance and operating

methods that are required for using the ZS-HL Series.

When using the ZS-HL Smart Sensor, be sure to observe the following:

• The ZS-HL Smart Sensor must be operated by personnel knowledgeable in electrical

•

engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding

•

of the product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

•

How to Switch the Display Language to English

Turn the power ON with the MENU key held down. This displays the display language

selection screen.

Select Language

1

The Controller will start up with the messages displayed in English when it is next started up.

2Japanese English

Introduction

INTRODUCTION

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

APPLICATION CONSIDERATIONS (Please Read)

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9

FEATURES

INSTALLATION & CONNECTION

APPLICATION and SETTING EXAMPLES

FUNCTIONS AND OPERATIONS USED DURING OPERATION

SETTINGS FOR FUNCTIONS

SECTION 6

SECTION 7

SECTION 8

SECTION 9

I/O

USB/RS-232C COMMUNICATION

SPECIFICATIONS AND EXTERNAL DIMENSIONS

APPENDIX

User’s Manual

Smart Sensor

2D CMOS Laser Type

ZS-HL Series

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

ZS-HL

User’s Manual

Introduction

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Introduction

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

ZS-HL

User’s Manual

3

Introduction

Introduction

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

4

ZS-HL

User’s Manual

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates general prohibitions for which there is no specific symbol.

Introduction

Meanings of Signal Words

Introduction

Indicates the possibility of laser radiation.

Indicates prohibition when there is a risk of minor injury from electrical shock

or other source if the product is disassembled.

Alert statements in this Manual

The following alert statements apply to the products in this manual. Each alert statement also

appears at the locations needed in this manual to attract your attention.

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

Never look into the laser beam. Doing so continuously will result in visual

impairment.

Do not disassemble the product. Doing so may cause the laser beam to

leak, resulting in the danger of visual impairment.

ZS-HL

User’s Manual

5

Introduction

Introduction

Precautions for Safe Use

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

(1) Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

(2) Power Supply and Wiring

• The supply voltage must be within the rated range (DC24 V ± 10 %).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing them in the same duct may cause induction, resulting in malfunction or damage.

(3) Others

• Do not attempt to dismantle, repair, or modify the product.

• Dispose of this product as industrial waste.

6

ZS-HL

User’s Manual

Introduction

Precautions for Correct Use

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

(1) Installation Site

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85 %

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding

machines)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray

• Strong magnetic or electric field

Introduction

(2) Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit)

and the load current is appropriate. Incorrect wiring may result in breakdown of the

product.

• Before connecting/disconnecting the Sensor Head, make sure that the Smart Sensor

is turned OFF. The Smart Sensor may break down if the Sensor Head is connected or

disconnected while the power is ON.

• Use the Extension Cable (provided) for extending the cable between the Sensor Head

and Sensor Controller. The total length varies according to the type of Extension Cable.

- Extension Cable: ZS-XC_A: within 10 m (including Sensor Head cable. Extension

Cable cannot be daisy-chained.)

- Extension Cable: ZS-XC_B(R): within 22 m (including Sensor Head. Up to two

Extension Cables can be daisy-chained.)

- Extension cable for a long distance ZS-XC_ _CR: within 27 m (including Sensor

Head. Digital equalizer ZS-XEQ and the Digital equalizer connection cable ZSXC02D are necessary. The extension cable cannot be daisy-chained.)

• The cable may break at locations when it is made to bend. So, use the robot cable

type Extension Cable (ZS-XC5BR, ZS-XC_ _CR).

• Use only combinations of Sensor Heads and Sensor Controllers specified in this manual.

ZS-HL

User’s Manual

7

Introduction

Introduction

Precautions for Correct Use

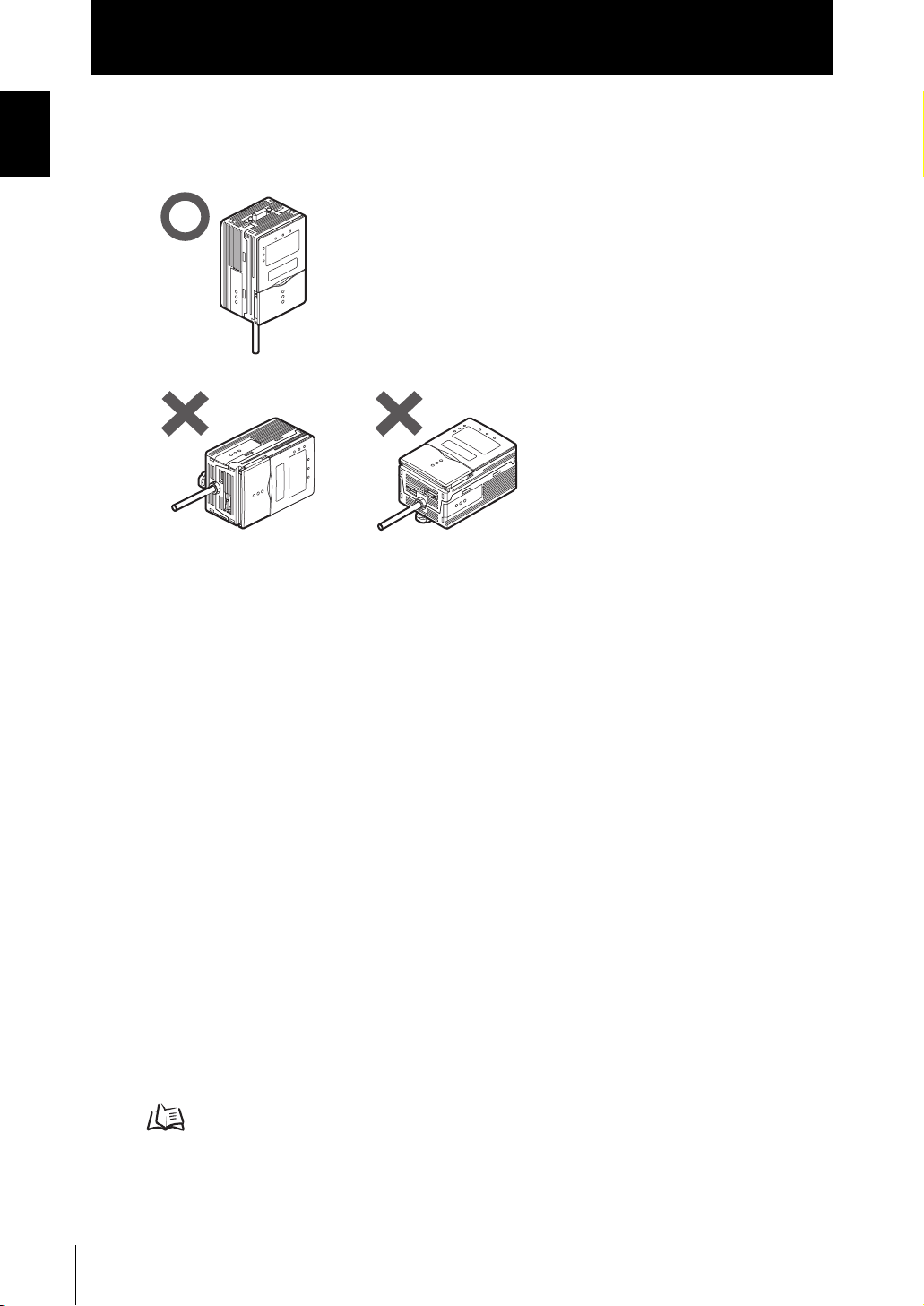

(3) Orientation when Installing the Sensor Controller

To improve heat radiation, install the Sensor Controller only in

the orientation shown below.

Do not install the Sensor Controller in the following orientations.

(4) Warming Up

After turning ON the power supply, allow the product to stand for at least 30 minutes

before use. The circuits are still unstable immediately after the power supply is turned

ON, so measured values may fluctuate gradually.

(5) Maintenance and Inspection

Do not use thinner, benzene, acetone or kerosene to clean the Sensor Head and Sensor Controller. If large dust particles adhere to the front filter of the Sensor Head, use a

blower brush (used to clean camera lenses) to blow them off. Do not blow the dust particles with your mouth. To remove smaller dust particles, wipe gently with a soft cloth

(for cleaning lenses) moistened with a small amount of alcohol. Do not use excessive

force to wipe off dust particles. Scratches on the filter may cause errors.

(6) Sensing Objects

The product sometimes cannot accurately measure the following types of objects:

Transparent objects, objects with an extremely low reflection factor, objects smaller

than the spot diameter, objects with a large curvature, excessively inclined objects, etc.

(7) Effect caused by peripheral lights

Do not install the Sensor Head in a place where strong light hits the laser emitter/

receiver section of the Sensor Head. Also, if a workpiece has a shiny surface, the light

from the lighting will be reflected and a malfunction may occur. In such a case, prevent

reflection by, for example, covering the light to stop reflection.

p.2-4

8

ZS-HL

User’s Manual

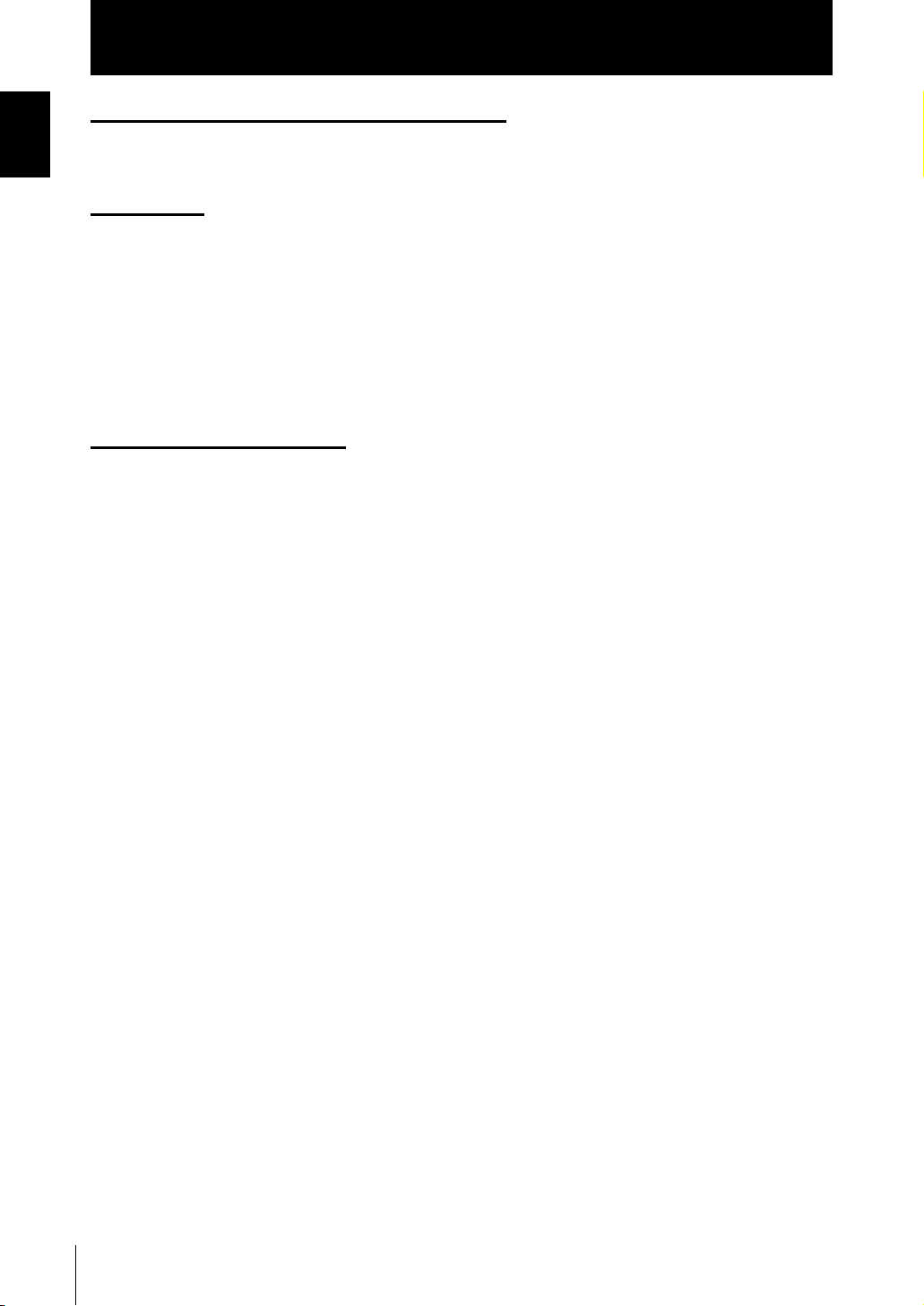

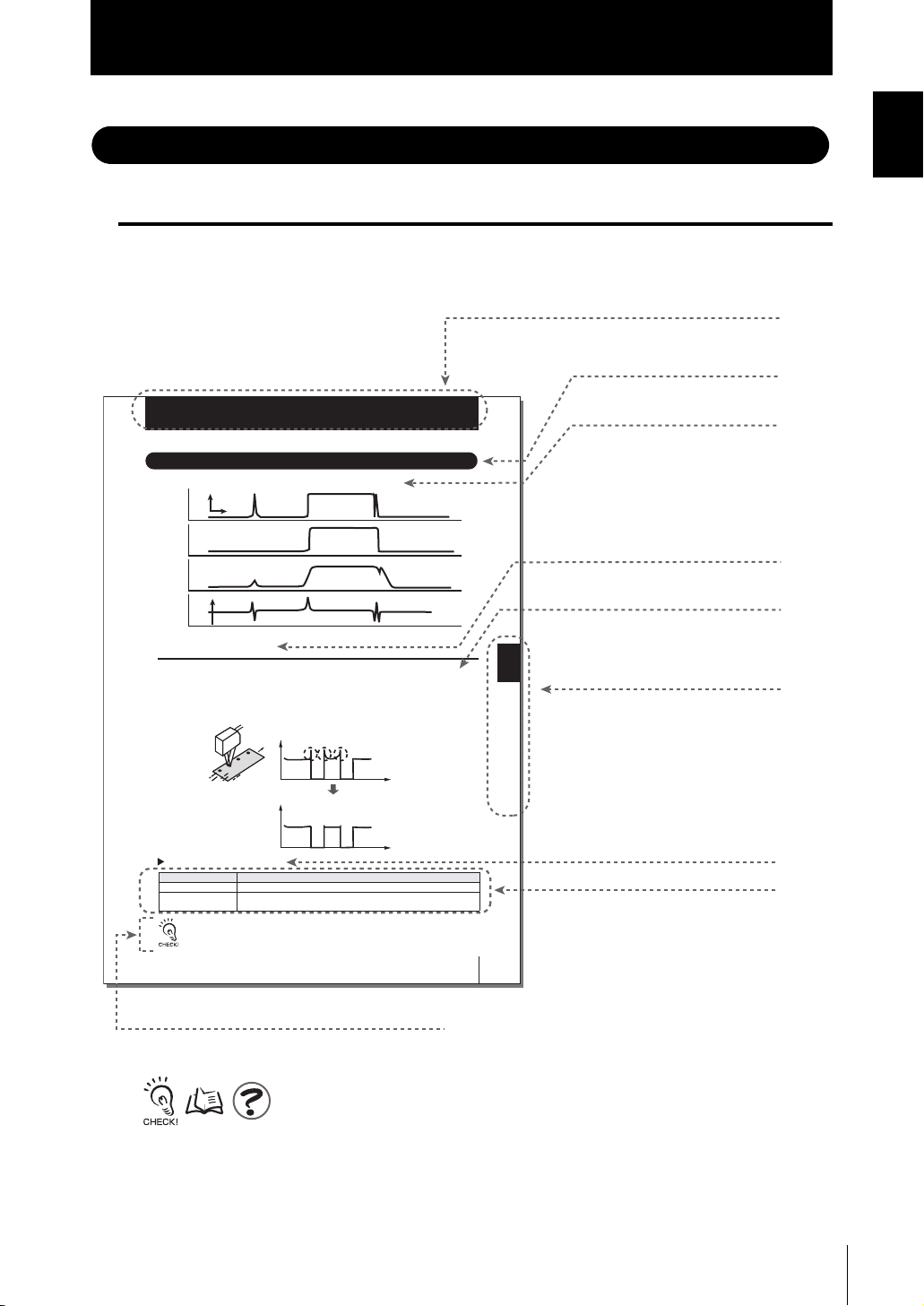

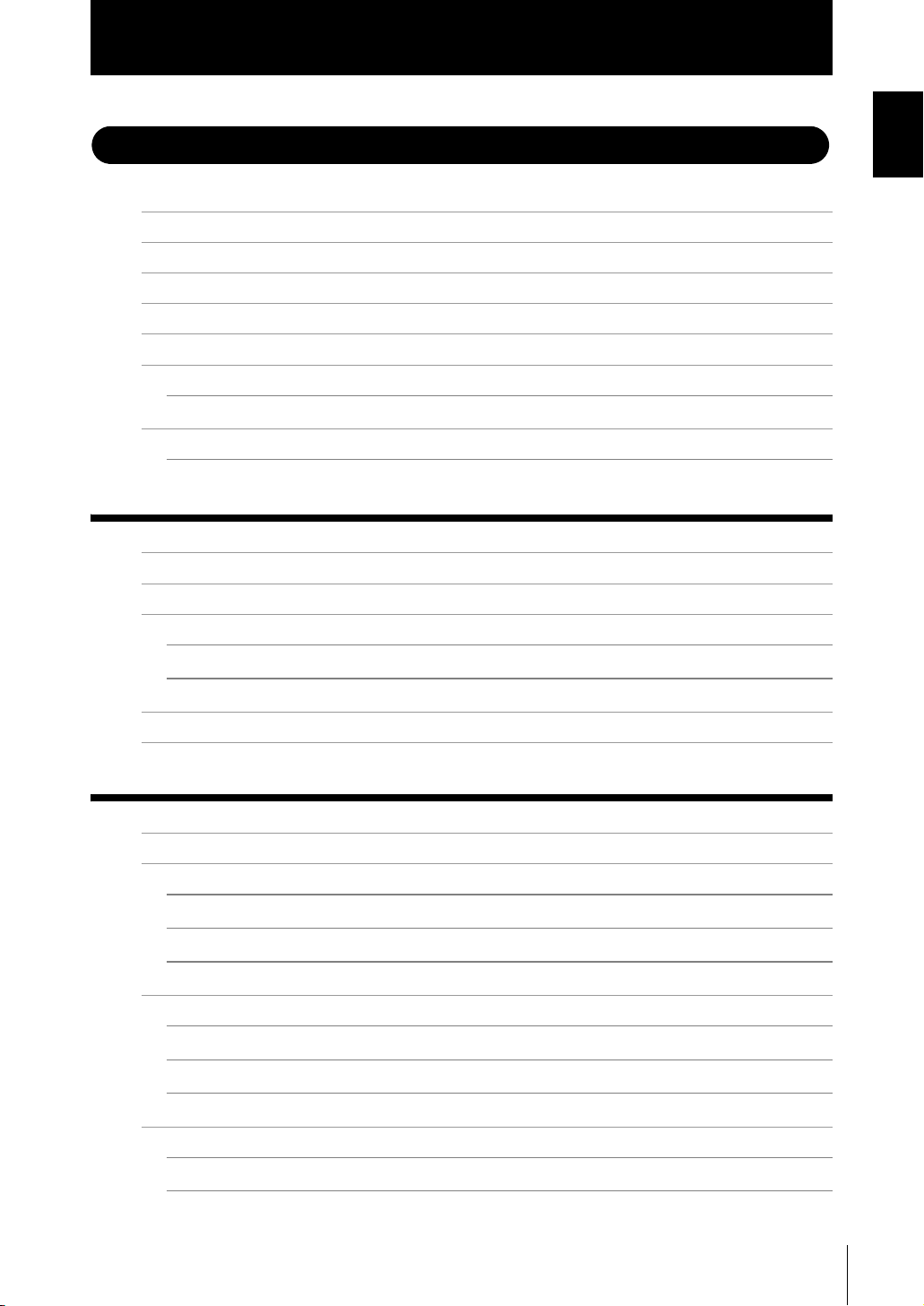

Editor's Note

Page Format

Introduction

Precautions for Correct Use

Introduction

Title of each section

Header

Setting the Filter Function

Section5

Setting the Filter Function

Set the conditions for filtering information obtained from the sensor.

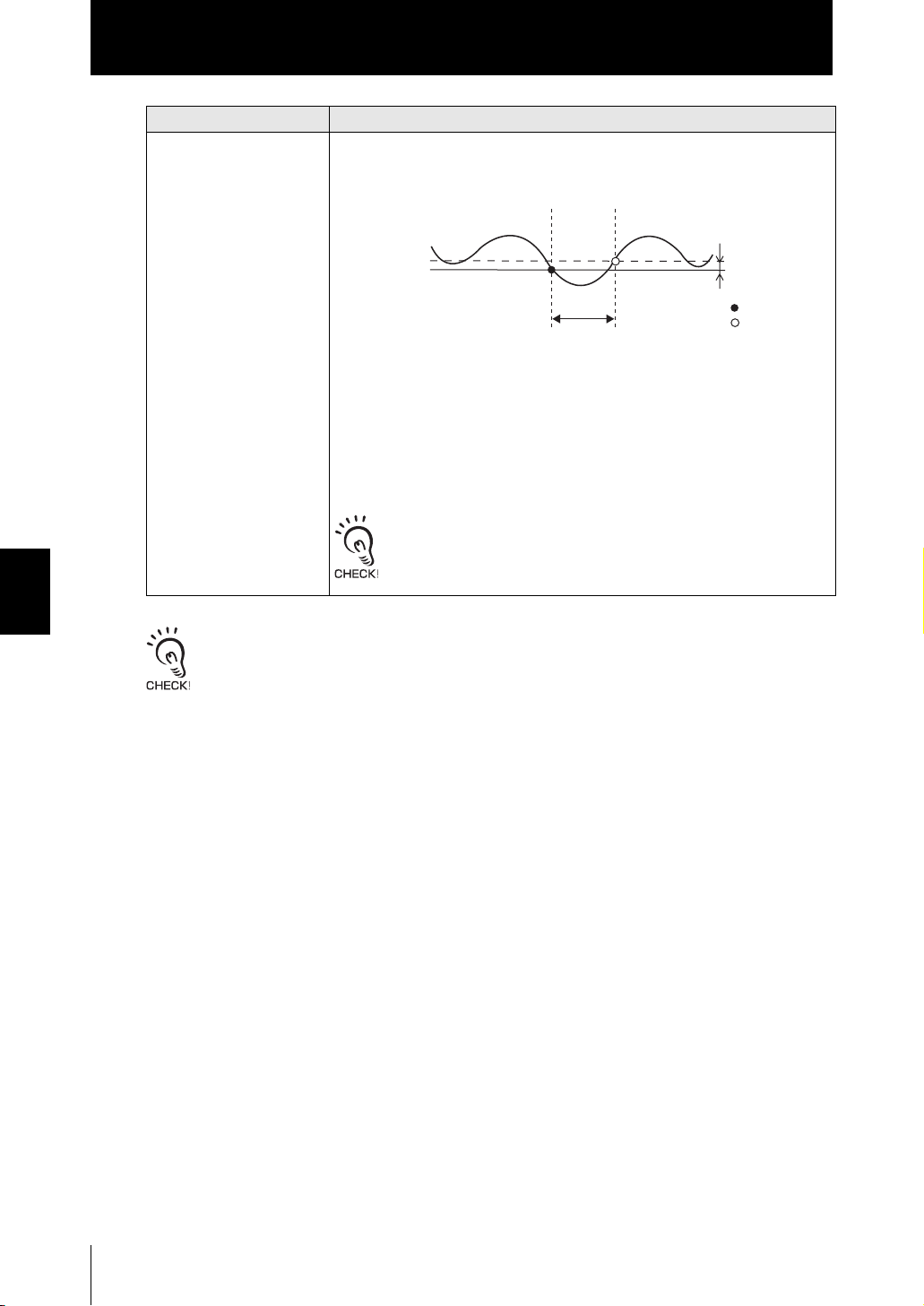

Wavefor m

when filter

function is not

set

SMOOTH

Average

value

Differentiation

Displacement

Smooth

Spike-like changes are

removed.

Changes are smoothed out.

Displacement

0

Changes are extracted to

eliminate displacement value.

Setting SMOOTH

The intermediate value of multiple sets of data can be output as the measurement result.

This function removes any abnormal values such as spiking that occur when the shape of

the workpiece suddenly changes during measurement.

Example: To remove spiking

FUN Mode-[FILTER]-[SMOOTH]

Setting Description

OFF The smooth function is not used.

ON The intermediate value of the past 15 measured values is set as the measurement

When "HI-SPEED" is set in the measurement mode, [OFF] is set.

Abnormal values such as spiking that occur when the shape

of the workpiece suddenly changes during measurement.

Measured valueMeasured value

The smoothing function can remove spikes

result at each sampling cycle.(default value)

Time

Time

Overview

Cross-header

Overview of the

cross-header

Section5 SETTINGS FOR FUNCTIONS

Index label

Indicates the section

number and title.

Movement through menus

up to setting items

Explanation of options

User’s Manual

Supplementary Explanation

Helpful information regarding operation and reference

pages are introduced here using symbols.

*This page has been made purely for explanatory purposes and does not exist.

ZS-HL

5-11

ZS-HL

User’s Manual

9

Introduction

Introduction

Precautions for Correct Use

■ Meaning of Symbols

Menu items that are displayed on the Sensor Controller’s LCD screen, and windows,

dialog boxes and other GUI elements displayed on the PC are indicated enclosed by

brackets [aa].

■ Visual Aids

Indicates points that are important to ensure full product performance, such as operational

precautions and application procedures.

Indicates pages where related information can be found.

Indicates information helpful in operation.

10

ZS-HL

User’s Manual

Introduction

CONTENTS

Meanings of Signal Words 5

Meanings of Alert Symbols 5

Alert statements in this Manual 5

Precautions for Safe Use 6

Precautions for Correct Use 7

Editor's Note 9

Page Format 9

CONTENTS 11

Search from Menu Tree 16

Section 1 FEATURES 1-1

Introduction of the ZS-HL Series 1-2

CONTENTS

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9

System Configuration 1-3

Part Names and Functions 1-4

Sensor Head 1-4

Sensor Controller 1-5

Operation Modes 1-7

Setting Flow 1-8

Section 2 INSTALLATION & CONNECTION 2-1

About Installation and Connection 2-2

Sensor Head 2-2

Measuring Range 2-3

Basic Precautions for Installation 2-4

Connecting the Sensor Head 2-5

Sensor Controller 2-7

Installation of Sensor Controller 2-7

Wiring the I/O cable 2-10

I/O Circuit Diagrams 2-12

SmartMonitor ZS 2-14

Operating Environment 2-14

Installation/Uninstallation Method 2-15

ZS-HL

User’s Manual

11

Introduction

CONTENTS

Section 3 APPLICATION and SETTING EXAMPLES 3-1

Section 4 FUNCTIONS AND OPERATIONS USED DURING OPERATION 4-1

Starting and Exiting SmartMonitor ZS 2-19

Measuring Height (basic) 3-2

Measuring the Thickness of Transparent Objects 3-4

Measuring the Vertex 2 (peak) in the Line Beam 3-6

Measuring Multiple Items Simultaneously (Multi-Task) 3-8

Switching the Display of the Measured Value 4-2

List of Key Operations in RUN Mode 4-4

Zero Reset Operation 4-5

Threshold Setting 4-7

Bank Switching (change of device setup) 4-10

Section 5 SETTINGS FOR FUNCTIONS 5-1

Basic Operations of Sensor Controller 5-2

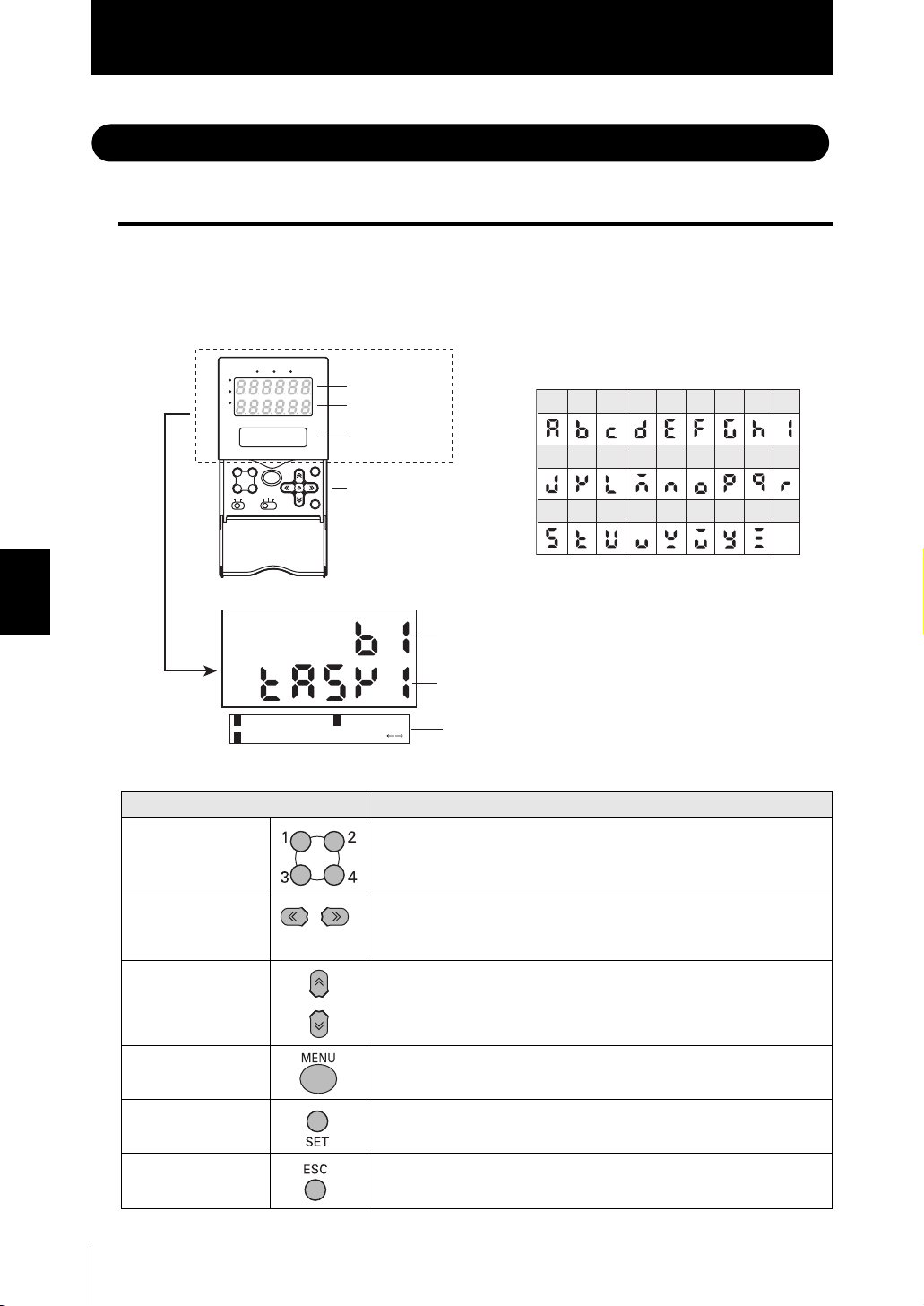

Displays and Key Operations 5-2

Using the Multi-Task Function 5-4

Switching to Multi-Task Mode 5-5

Selecting Tasks 5-5

Setting for Sensing Conditions 5-6

Setting Measurement Mode 5-6

Setting GAIN 5-7

Setting Head Installation 5-8

Setting the Emitted Light Amount 5-8

Setting Measurement Object 5-9

Setting Mutual Interference Prevention 5-11

Setting the Filter Function 5-12

Setting SMOOTH 5-12

Setting AVERAGE 5-13

12

Setting Differentiation 5-13

Setting Output Processing of Sensing Information 5-14

Setting the Scaling 5-14

Setting HOLD Functions 5-18

ZS-HL

User’s Manual

Introduction

Setting the Zero Reset Function 5-22

Setting for Measurement of Characteristic Points 5-24

CONTENTS

Setting Display Method 5-25

Setting the Digital Display 5-25

Displaying HELP 5-25

Setting the LCD Screen 5-26

Setting the System Environment 5-27

Checking Information 5-27

Setting the Key Lock 5-27

Setting the Sensor Load Method 5-28

Setting the Display Language 5-28

Changing the Way of Obtaining Banks 5-28

Saving the Settings Data 5-29

Clearing the Settings 5-29

Initializing All Settings 5-29

Clearing Banks 5-29

Section 6 I/O 6-1

Overview 6-2

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9

I/O Cable 6-2

Terminal Block Output 6-2

Settings for Linear Output 6-3

Assignment of Linear Output 6-3

Setting Focus 6-4

Correcting Linear Output Values 6-5

Settings for Judgment Output 6-7

Operation Settings at Judgment Output 6-7

Assignment of Judgment Output (For Multi-Task) 6-8

Settings for Terminal Block Output 6-9

Real-Time Parallel Output Unit 6-9

Assignment of Terminal Block Output 6-10

Output Format 6-11

Setting Focus 6-13

Setting the Update Cycle 6-14

ZS-HL

User’s Manual

13

Introduction

CONTENTS

Section 7 USB/RS-232C COMMUNICATION 7-1

Settings for Processing when Measurement Cannot be Performed 6-15

When Connecting ZS-MDC and ZS-DSU 6-16

Settings for Input Signal 6-17

Settings for the Active Direction of an Input Signal 6-17

Changing the Assignment of Input Signals 6-17

Timing Charts 6-18

Overview 7-2

USB 7-2

RS-232C 7-3

Connecting Using a USB Cable 7-4

Connection Method 7-4

Setting the Communication Specifications 7-4

Connecting Using a RS-232C Cable 7-5

Connection Method 7-5

Setting the Communication Specifications 7-6

Settings for High-Speed Digital Output 7-7

Timing Charts 7-8

Section 8 SPECIFICATIONS AND EXTERNAL DIMENSIONS 8-1

Sensor Head 8-2

Specifications 8-2

External Dimensions 8-7

Adjusting Mutual Interference 8-15

Spot Diameter 8-19

Usage Width of Line Beam 8-20

Linearity Characteristic by Materials 8-21

Sensor Controller 8-38

Specifications 8-38

External Dimensions 8-40

14

Accessory 8-41

Panel Mount Adapter 8-41

Extension Cable 8-42

ZS-HL

User’s Manual

Introduction

Extension Cable (Long-Distance, Flexible Type) 8-43

RS-232C Cable 8-45

Control Link Unit 8-46

Real-Time Parallel Output Unit 8-47

Section 9 APPENDIX 9-1

Troubleshooting 9-2

Error Messages and Countermeasures 9-3

Safety Precautions for Using Laser Equipment 9-4

Requirements from Regulations and Standards 9-6

Summary of Requirements to Manufactures 9-6

Summary of Requirements to User 9-10

Definitions of Laser Classification 9-13

Updating Firmware 9-15

CONTENTS

Flow of Updating Firmware 9-15

Index 9-21

Revision History 9-25

ZS-HL

User’s Manual

15

Introduction

CONTENTS

CONTENTS

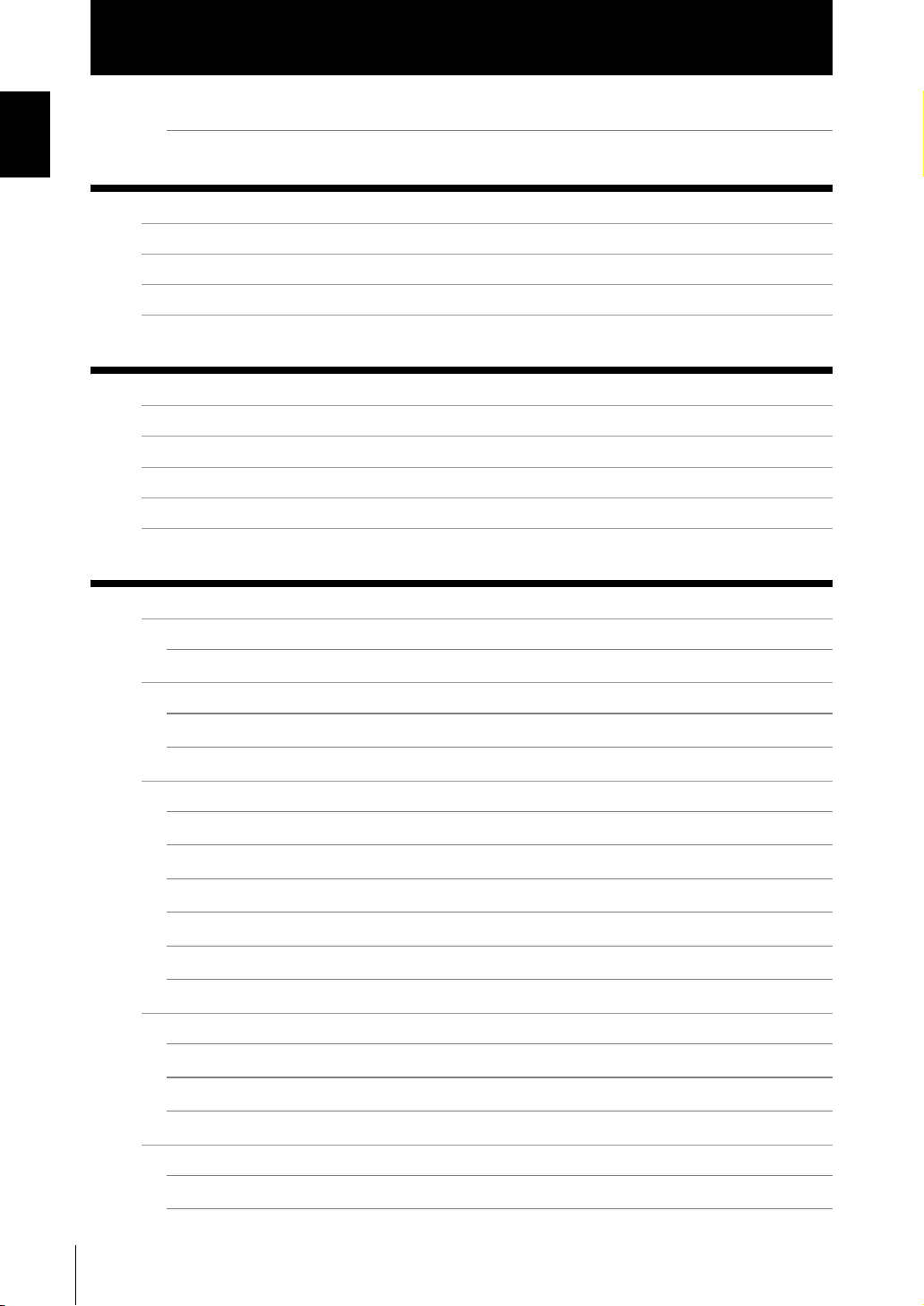

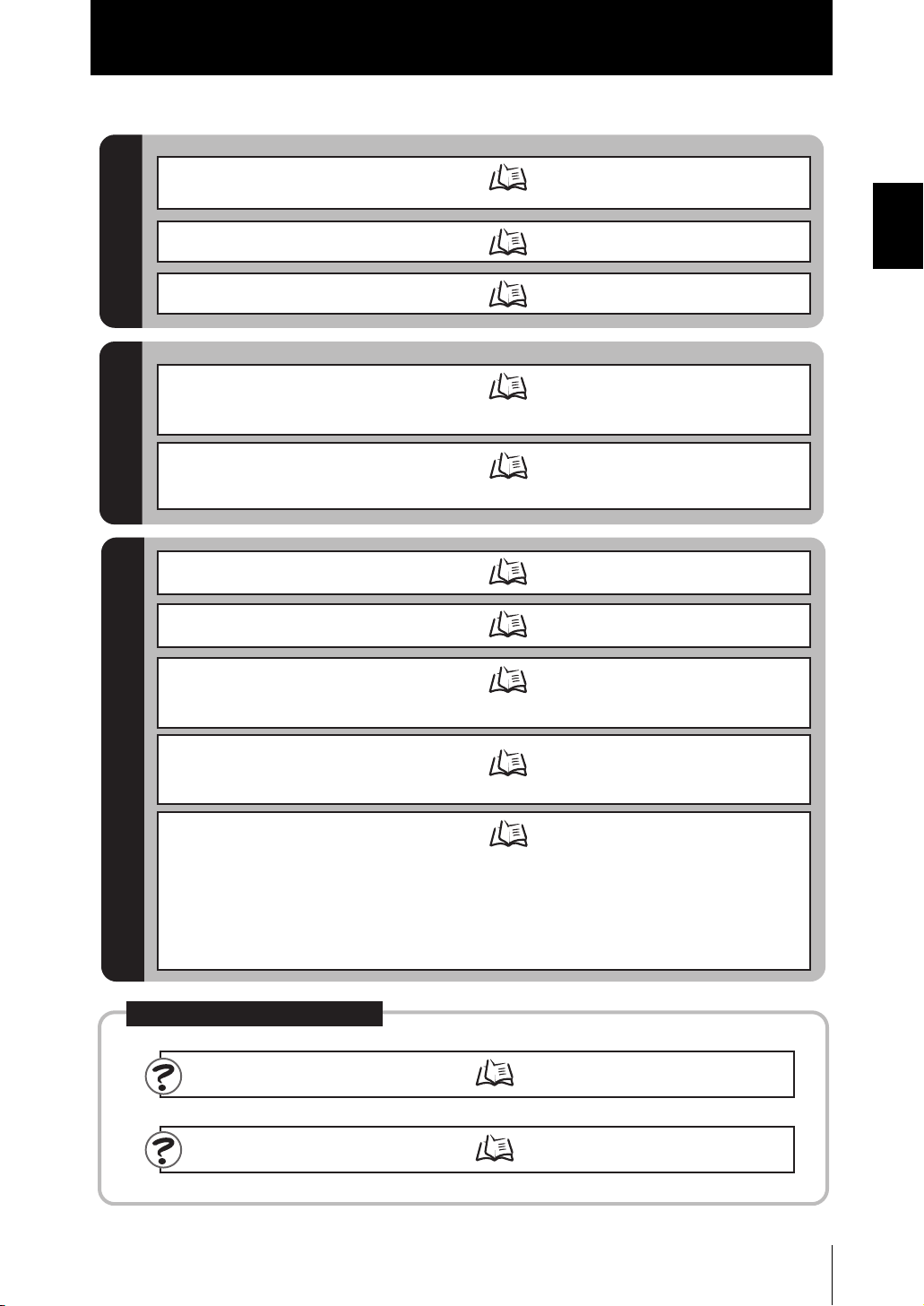

Search from Menu Tree

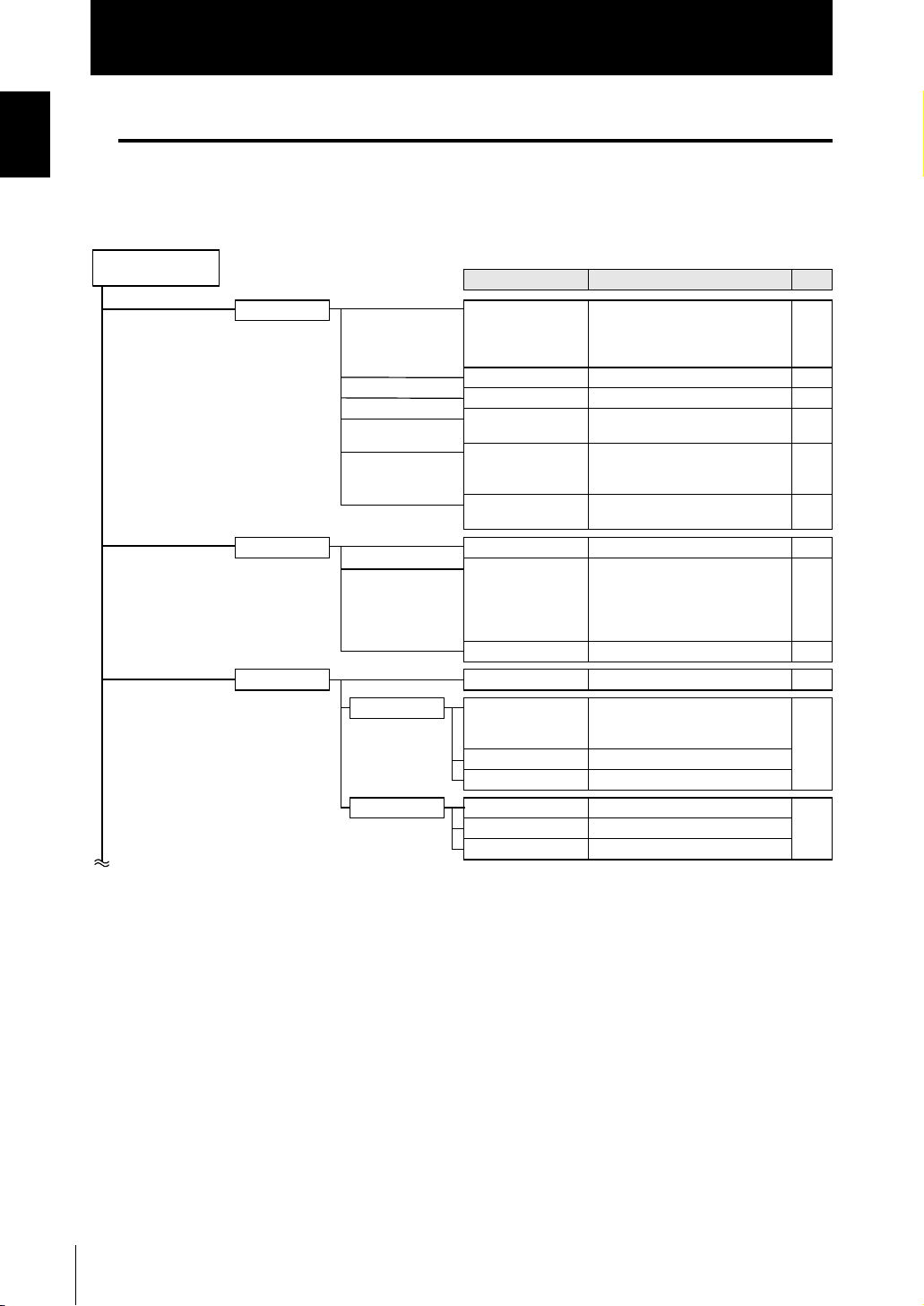

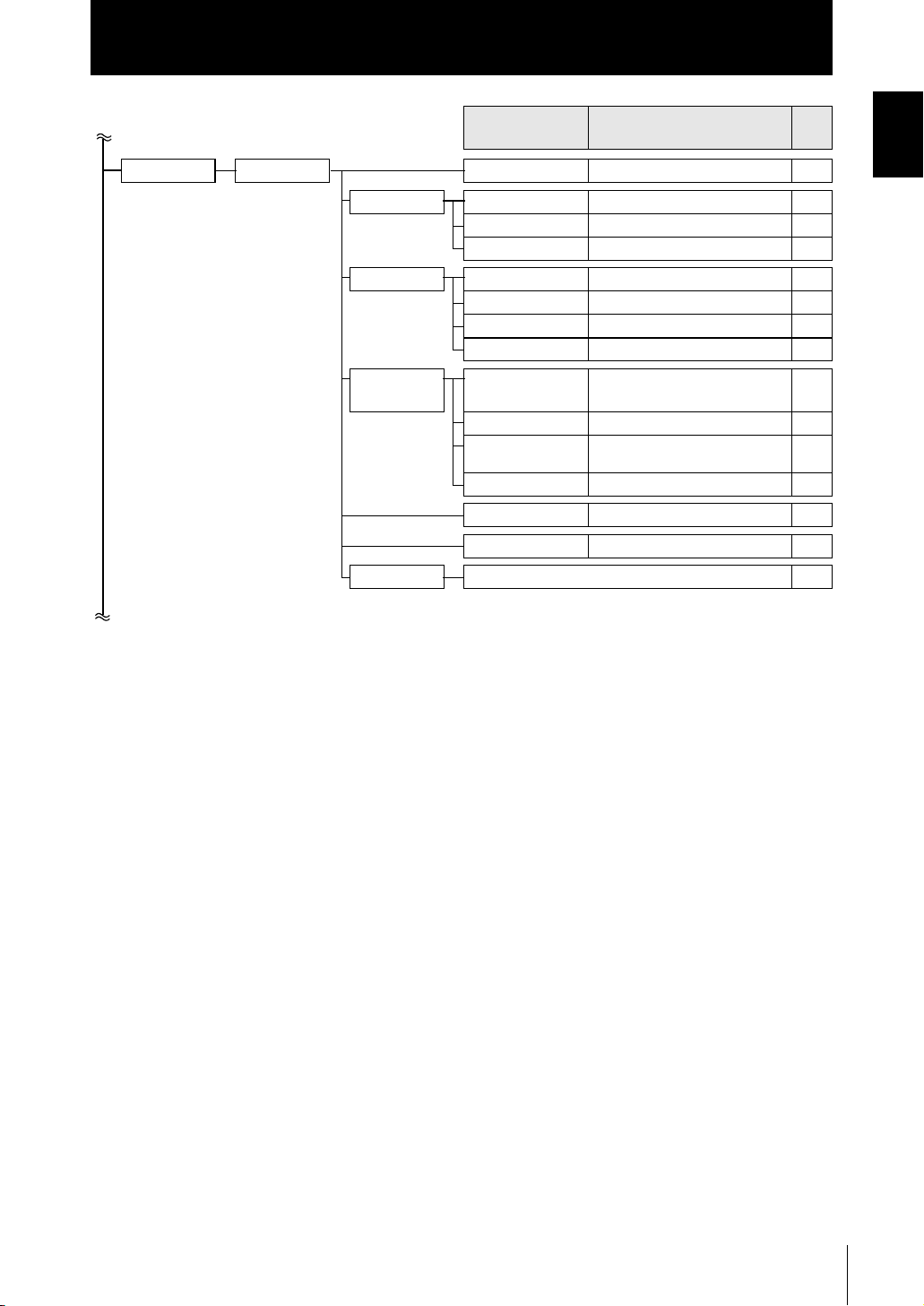

■ FUN Mode

● For the Single-Task mode

FUN Mode

Settings Option/Range

SENSING MODE

GAIN

SETTING

LASER

OBJECT

SYNC

FILTER SMOOTH

AVERAGE

DIFF

OUTPUT SCALING

HOLD TYPE

TRIGGER

DELAY

Zero reset TYPE

OFFSET

STATUS

*Default Value

Pages

STAND, HI-RESO*, HI-SPEED, HISENS

CUSTOM (EXPOSE, SKIP,

LINE)

1*, 2, 3, 4, 5 p.5-7

DIFFUSE, REGULAR p.5-8

AUTO*, RANGE, FIXED

(upper limit 0.1 to 80 %)

NORMAL*, PCB, MIRROR,

GLASS (MODE 1, MODE2),

THICK (MODE 1, MODE2)

OFF*,

ON (timing A, timing B)

*

OFF, ON

1, 2, 4, 8, 16, 32, 64, 128*, 256, 512,

1024, 2048, 4096

(When the mode is set to HIGHSPEED mode, the value is from 1 to

256.)

OFF*, ON p.5-13

OFF*, ON (AUTO, MAN) p.5-14

OFF*, PEAK, BOTTOM,

P-P, AVERAGE,

SAMPLE

EXT*, SELF-UP, SELF-DN

OFF*, ON

(T-DELAY, T-TIME)

REAL*, HOLD p.5-22

-999.999 to 999.999 (default value:0)

*

OFF, ON

p.5-6

p.5-8

p.5-9

p.5-11

p.5-12

p.5-13

p.5-18

16

ZS-HL

User’s Manual

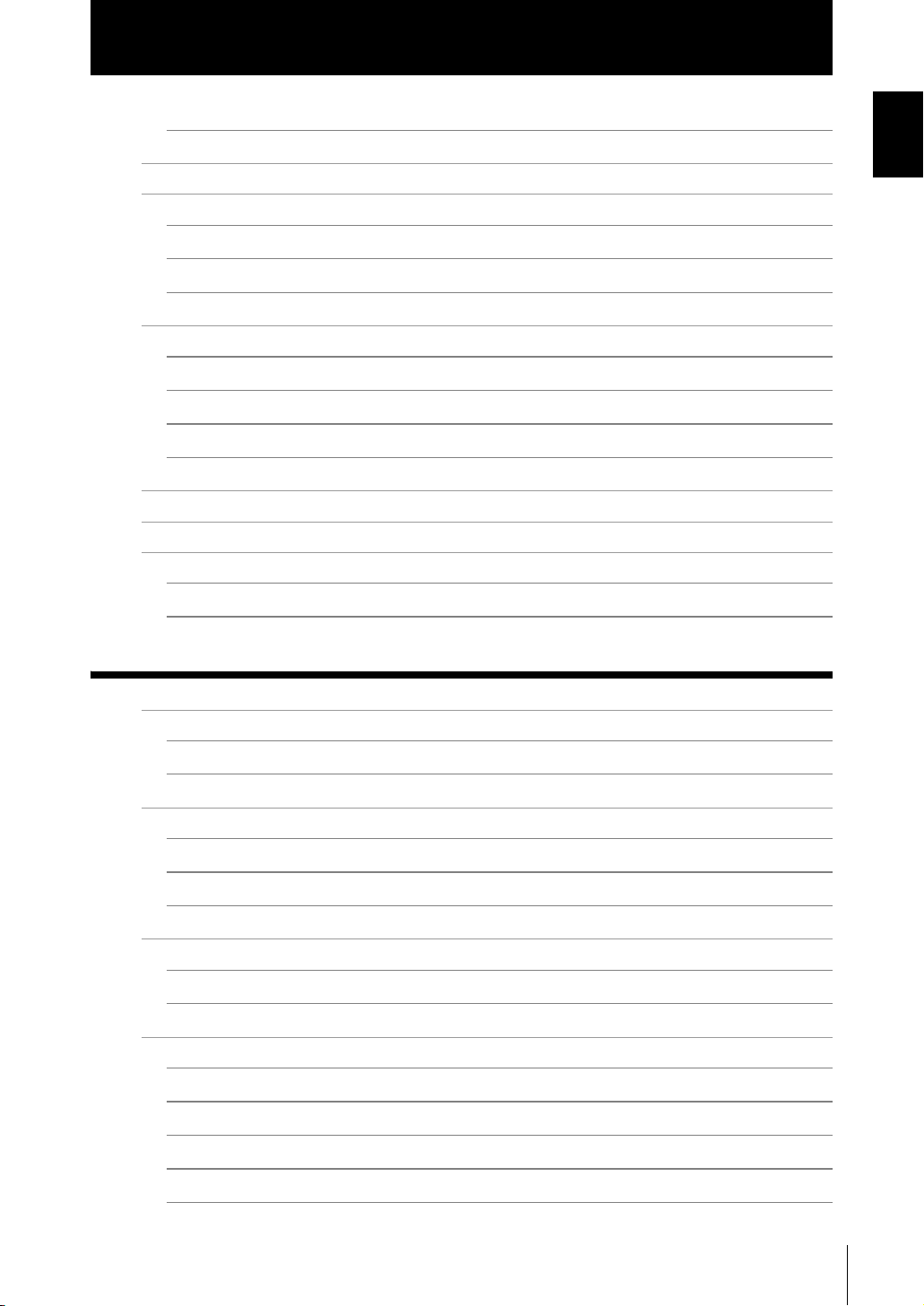

Settings Option/Range

I/O SET NO MEAS

JUDGE

HYS

TIMER

ANALOG FOCUS

ADJUST

OUT

CLAMP

TERMINAL FOCUS

CYCLE

OUT

CLAMP

DIGITAL

CONNECT

INPUT ACTIVE

MODE

CHANGE

BANK

MODE

CLEAR

SYSTEM SAVE

INIT

INFO

CYCLE

VERSION

COM

(RS-232C)

LENGTH

PAR ITY

STOP

BAUDRAT

DELIMIT

COM NODE

KEYLOCK

SenINFO

ZERORST

MUITI

LANGUAG

Introduction

CONTENTS

Pages

KEEP, CLAMP

0 to 999.999 (default value: 0.05 %

of Sensor Head measuring range)

OFF*, OFF-DLY (1 to 5,000 ms),

ON-DLY (1 to 5,000 ms),

1SHOT (1 to 5,000 ms)

OFF*, ON p.6-3

OFF*, ON (-999 to 999)

OFF, ON

(for current output)

4`20 mA (every1 mA), MAX

(for voltage output)

-10 V to 10 V (every1 V), MAX

MIN

OFF*, ON p.6-9

1 to 100 (default value: 1)

NONE*, MEASURE, JUDGE

0 to 65535 (default value: 65535)

OFF, ON

OFF, ON

IN0 to IN3 (OFF, ON

NORMAL*, BANK

BANK1*, BANK2, BANK3, BANK4

(if you change the mode to

[THRESH], you can select up to

BANK32.)

NORMAL*, THRESH p.5-28

(Initializes bank settings.) p.5-29

(Saves Sensor Controller settings.)

(Initializes Sensor Controller settings.)

(Displays the current sampling

cycle.)

(Displays the Sensor Controller version.)

8 BIT*, 7 BIT p.7-6

NONE*, ODD, EVEN

1 BIT*, 2 BIT

9600, 19200, 38400*, 57600, 115200

CR*, LF, CR+LF

0 to 16 (default value: 0) p.7-6

OFF*, ON p.5-27

LOAD*, SAVE p.5-28

OFF*, ON p.5-23

OFF*, ON p.5-5

Japanese*, English p.5-28

*

*

*

*

*)

*

, MIN

p.6-15

p.6-7

*

,

p.7-7

p.6-16

p.6-17

p.4-10

p.5-29

p.5-29

p.5-27

CONTENTS

ZS-HL

User’s Manual

17

Introduction

CONTENTS

CONTENTS

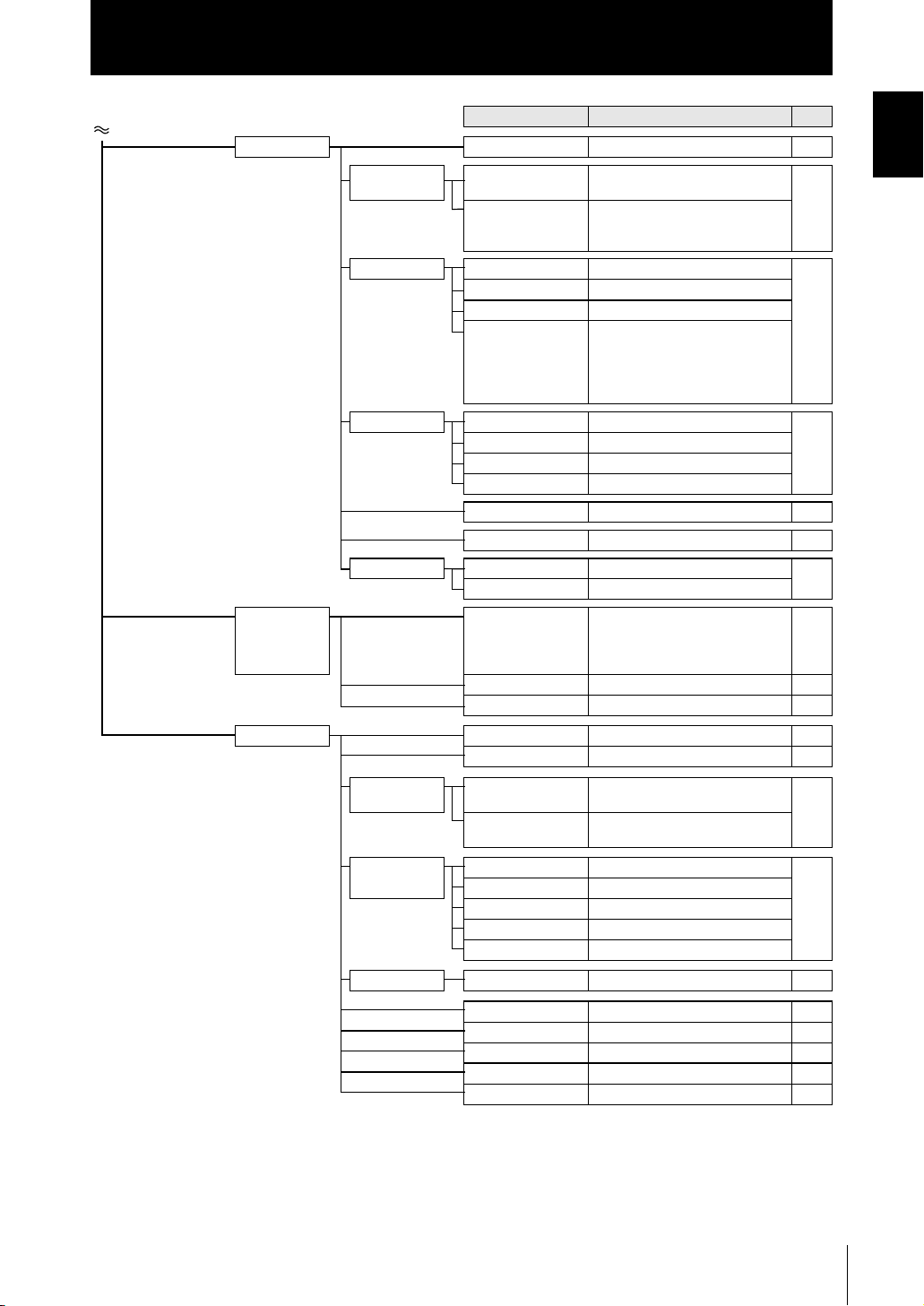

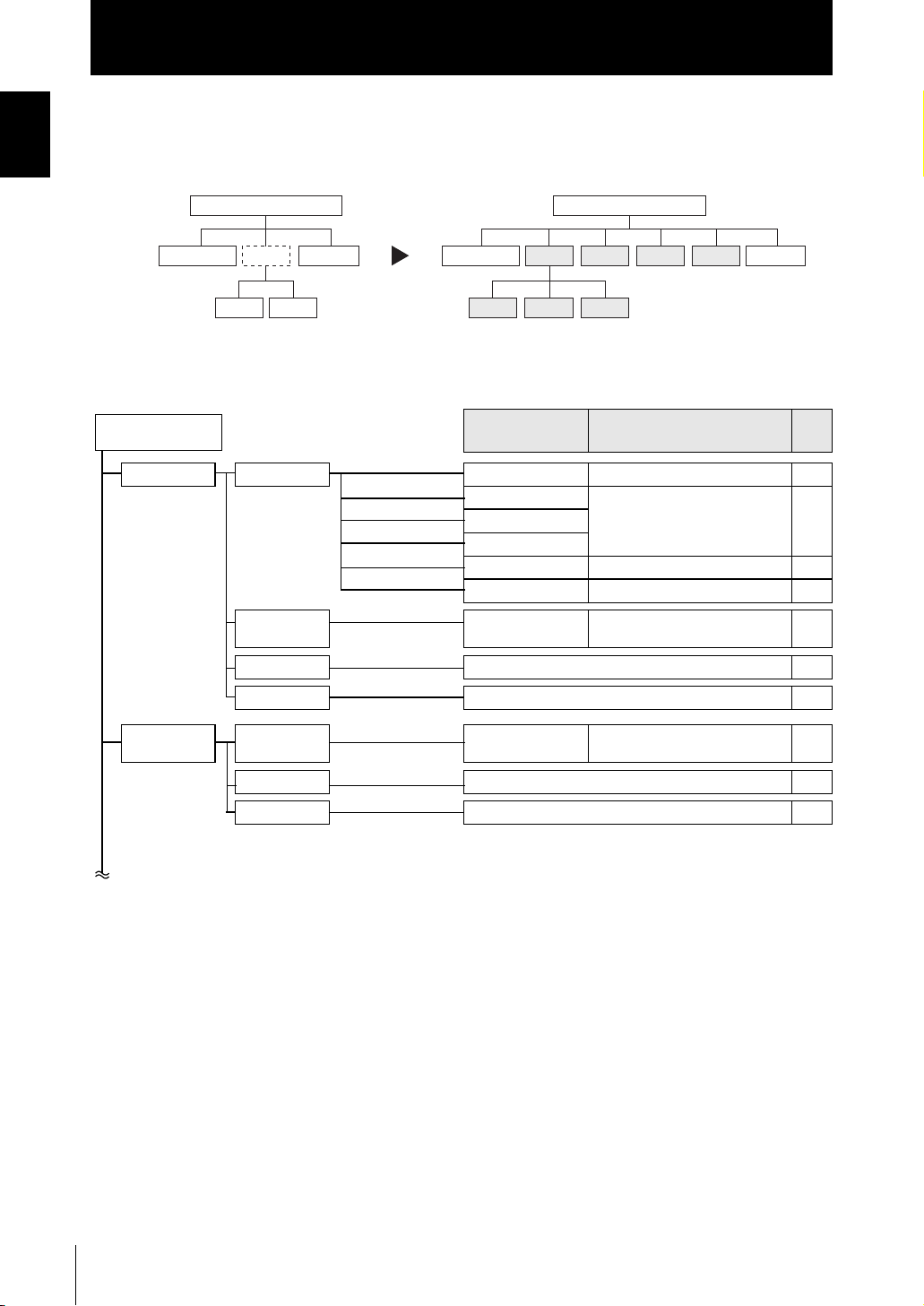

● For Multi-Task mode

The menu configuration is changed to one in which multiple characteristic points can

be measured and output simultaneously (up to four characteristic points).

Single-Task mode

SENSING I/O SETTASK1

FILTER

OUTPUT

SENSING I/O SETTAS K1

MEASURE

FILTER

Multi-Task mode

TAS K2 TA SK3 TA SK4

OUTPUT

This section describes only the parts that are different from those in Single-Task mode.

FUN Mode

TASK1 SENSING MODE

MEASURE

FILTER (Same as Single-Task mode)

OUTPUT (Same as Single-Task mode)

Settings

GAIN

SETTING

LASER

OBJECT

SYNC

TASKSET

(Difference with Single-Task mode)

([HIGH SPEED] is not displayed.) –

(Same as Single-Task mode) –

([THICK] is not displayed.) –

(Same as Single-Task mode) –

NONE*, AVERAGE, PEAK, BOTTOM, THICK, STEP, K+mX+nY

Option/Range

*Default Value

Pages

p.5-24

–

–

18

TASK2 to 4 MEASURE

ZS-HL

User’s Manual

TASKSET

FILTER (Same as Single-Task mode)

OUTPUT (Same as Single-Task mode)

NONE*, AVERAGE, PEAK, BOTTOM, THICK, STEP, K+mX+nY

p.5-24

–

–

Settings

Introduction

CONTENTS

Option/Range

(Difference with Single-Task mode)

CONTENTS

Pages

TASK1 I/O SET NON-MEAS

Select TASK you

want to output.

JUDGE HYS

TIMER

OUT

ANALOG FOCUS

ADJUST

OUT

CLAMP LEVEL

TERMINAL

FOCUS

BLOCK

CYCLE

OUT

CLAMP

DIGITAL

CONNECT

INPUT (Same as Single-Task mode)

(Same as Single-Task mode) –

(Same as Single-Task mode) –

(Same as Single-Task mode) –

TASK1*, TASK2, TASK3, TASK4 p.6-8

(Same as Single-Task mode) –

(Same as Single-Task mode) –

TASK1*, TASK2, TASK3, TASK4, None

(Same as Single-Task mode) –

(Same as Single-Task mode) –

(Same as Single-Task mode) –

NONE*, Measured value

TASK4, REPEAT)

(Same as Single-Task mode) –

TASK1 to TASK4 (OFF, ON) p.7-7

TASK1*, TASK2, TASK3, TASK4 p.6-16

(TASK1 to

, JUDGE

p.6-3

p.6-10

–

ZS-HL

User’s Manual

19

Introduction

CONTENTS

CONTENTS

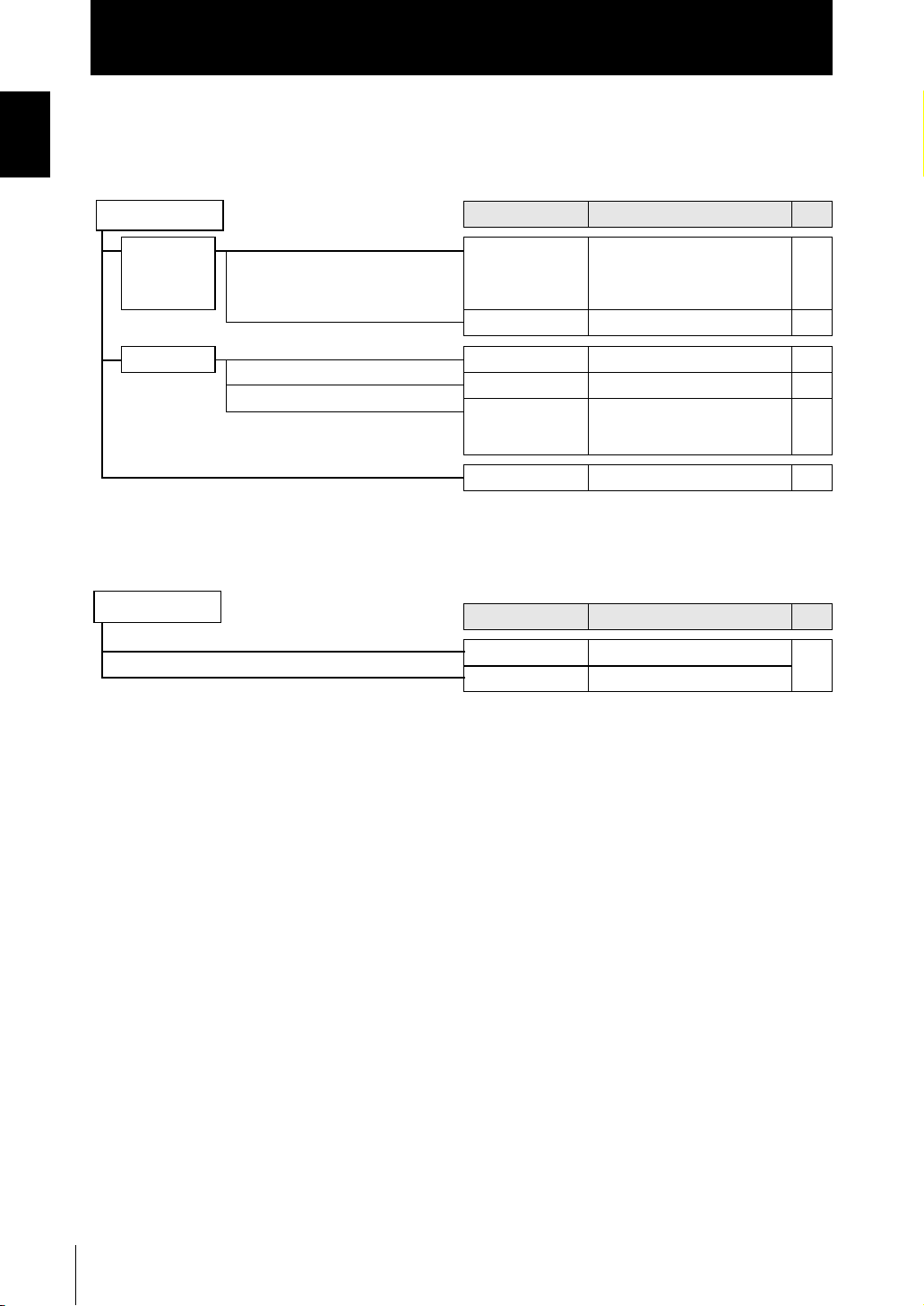

■ RUN mode

In RUN mode, you can customize the details that are displayed in the digital displays.

To call up the display customize menu, press the MENU key in RUN mode.

RUN Mode

DIGITAL

LCD ON/OFF

■ TEACH Mode

This is the mode for setting the threshold values.

TEACH Mode

Settings Option/Range

DOT

ECO

B.LIGHT

CUSTOM

HELP

Settings Option/Range

TEACHING

DIRECT IN

0 to 5th

(Item whose default value varies

according to the connected Sensor

Head)

NORMAL*, ECO, OFF p.5-25

ON*, AUTOOFF, OFF p.5-26

ON*, AUTOOFF, OFF p.5-26

U- ON/OFF, L- ON/OFF

U- CUSTM, L- CUSTM

(default value: U- OFF, L- OFF)

–p.5-25

–p.4-7

–

Pages

p.5-25

p.5-26

Pages

20

ZS-HL

User’s Manual

Section 1 FEATURES

Introduction of the ZS-HL Series 1-2

System Configuration 1-3

Part Names and Functions 1-4

Sensor Head 1-4

Sensor Controller 1-5

Operation Modes 1-7

Setting Flow 1-8

Section 1 FEATURES

ZS-HL

User’s Manual

1-1

Section 1

Introduction of the ZS-HL Series

Introduction of the ZS-HL Series

Section 1 FEATURES

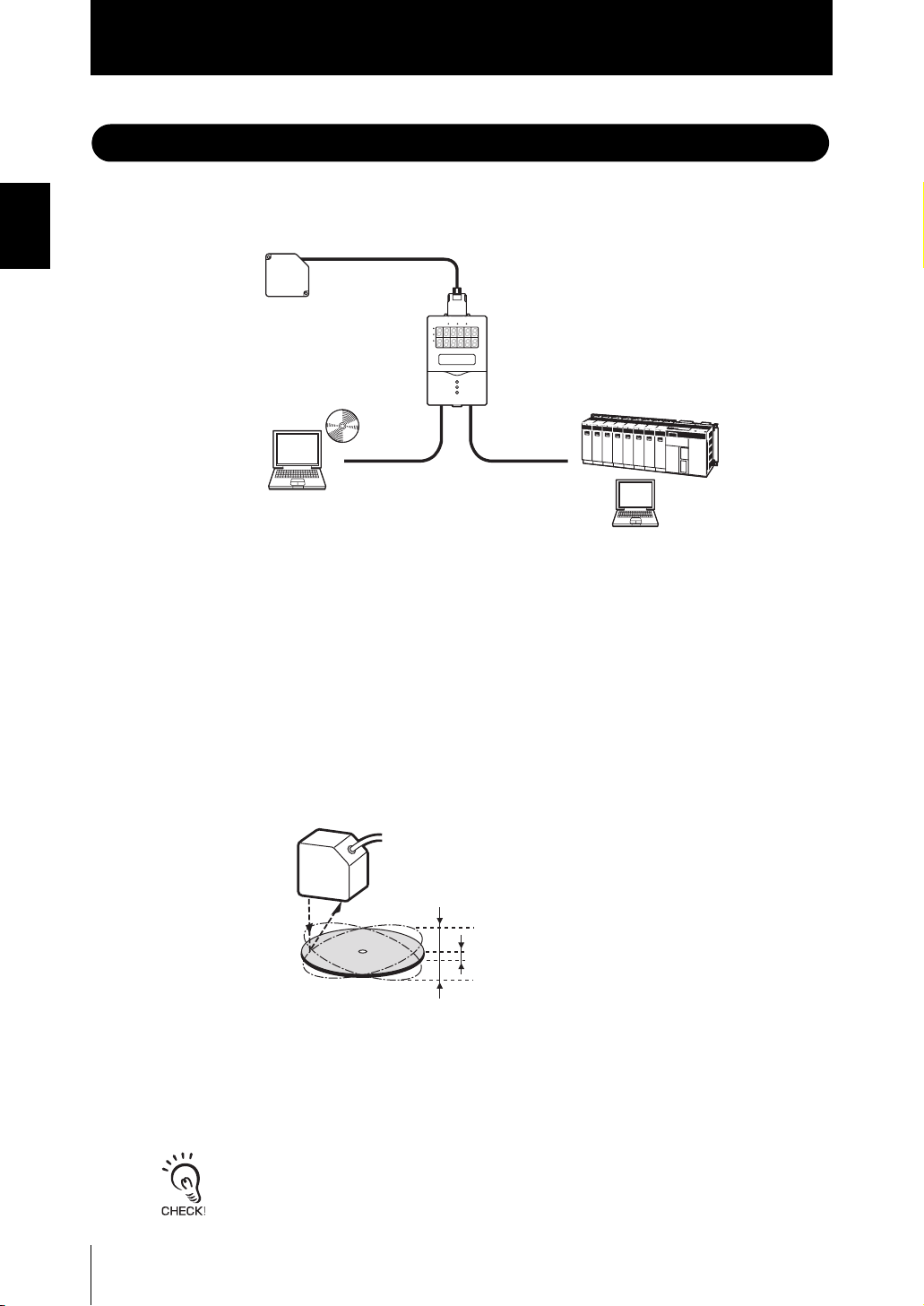

The ZS-HLDC Series is a 2D COMS laser type displacement sensor. In addition to ZS-L

full-digital processing, it maximizes sensing performance using a multi-task function.

Sensor Head

(1)

LD ON ZERO ENABLE

H

SmartMonitor ZS

Personal computer

(3)

P

L

Sensor Controller

(2)

(1) Enhanced Variation of Sensor Heads

Suitable as a high-end displacement sensor, it supports a wide range of Sensor Heads.

You can perform a stable measurement using a Sensor Head that is suitable for the

workpiece, from 0.001 µm ultra-high-resolution type to 1500-mm ultra-long-range type.

(2) Sensor Controller Incorporating Multiple Functions

For one sensing condition, it incorporates a multi-task function that holds up to a

maximum of four kinds of measurement processing as a “task.” Because you can

measure any characteristic point for each task, you can measure and judge multiple

characteristic points simultaneously.

1-2

Example: Measure the height and surface fluctuation simultaneously.

Surface fluctuation (TASK2)

Height (TASK1)

(3) Setting Support Software for Personal Computer “SmartMonitor ZS”

It displays data and specifies the settings for the controller that is connected via

“SmartMonitor ZS” bundled with the Sensor Controller (ZS-HLDC_1A). You can

easily check the sensing status and specify the settings in more detail, which cannot

be done using a controller.

If you use “SmartMonitor ZS Professional,” which is sold separately, you can do logging for a

measured value.

ZS-HL

User’s Manual

System Configuration

RUN

Section 1

System Configuration

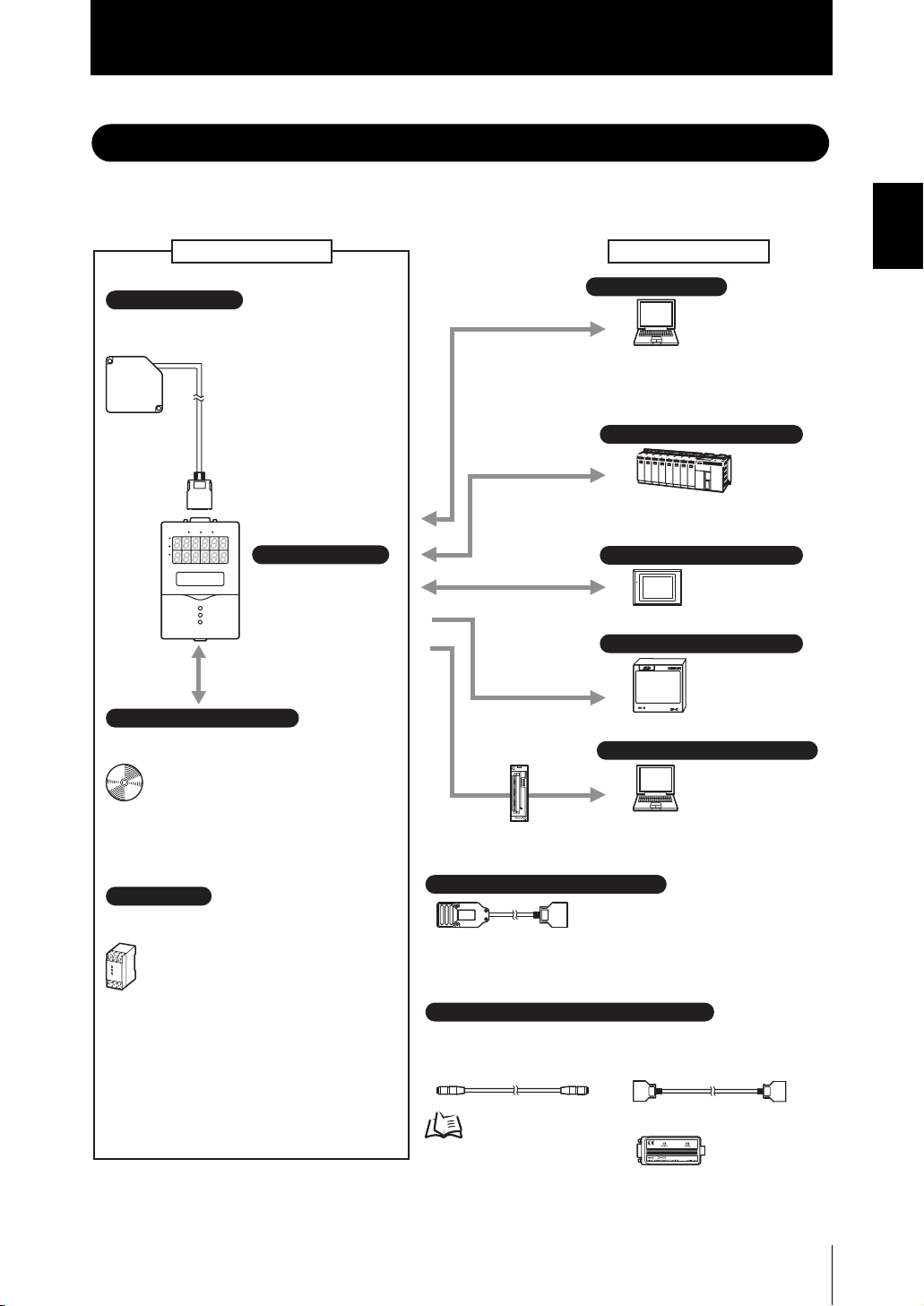

In addition to operations with the basic configuration, ZS-HLDC can support various

measurement applications when combined with numerous peripheral devices.

Basic configuration

Sensor Head

ZS-HLDS_ _ _/LD_ _

Detects a sensing object.

LD ON ZEROENABLE

H

P

L

(*1)

SmartMonitor ZS

(Setting support software for personal computers)

This setting support software sets

sensing conditions while monitoring

the receiving status, and allows a user

to check the measured value in a time

series graph.

*1: Accessory for the Sensor Controller ZS-HLDC_1A

Power supply

DC24 V (±10 %)

Recommended part

(1) If the number of connections is

1: S82K-01524 (DC24 V, 0.6 A)

(2) If the number of connections is

2 to 3: S82K-05024 (DC24 V, 2.1 A)

(3) If the number of connections is

4 to 10: Prepare as many of the

above power supplies of (1) and

(2) as you need.

Sensor Controller

ZS-HLDC_ _

Performs measurements

and outputs the results.

(*1)

USB

USB

RS-232C

ZS-XPT2

RS-232C

ZS-XPT2

Linear output

High-speed parallel

output

DATA

ZS-RPD

RS-232C

PARALLEL OUTPUT UNIT

Real-time parallel

Output unit

ZS-RPD_1

Extension cable for Sensor Head

ZS-XC_A (1 m, 4 m, 8 m)

ZS-XC_ _B(5 m, 10 m): Up to two cables can be connected.

ZS-XC5BR (5 m): Up to two cables can be connected.

Robot cable type.

Long Extend the cable of Sensor Head

• Extension cable for a long

distance (*2)

ZS-XC_ _CR (15 m, 25 m)

Peripheral devices

Personal computer

• Communication using commands

• Communication using SmartMonitor

ZS Professional

Programmable controller

• Communication using commands

Programmable terminal

RUN

•

C

ommunication using NS SmartMonitor

Digital panel meter

• Compare waveforms and make a judgment

High-speed input board (personal computer)

• Obtain measurement data quickly

• Digital equalizer

connection cable

ZS-XC02D (*2)

Section 1 FEATURES

Method of connecting

a cable

*2:

Only the ZS-HLDS@@@ Sensor Head can be connected to the ZS-XC@@CR,

ZS-XC02D, and ZS-XEQ.

p.2-6

• Digital equalizer ZS-XEQ (*2)

User’s Manual

ZS-HL

1-3

Section 1

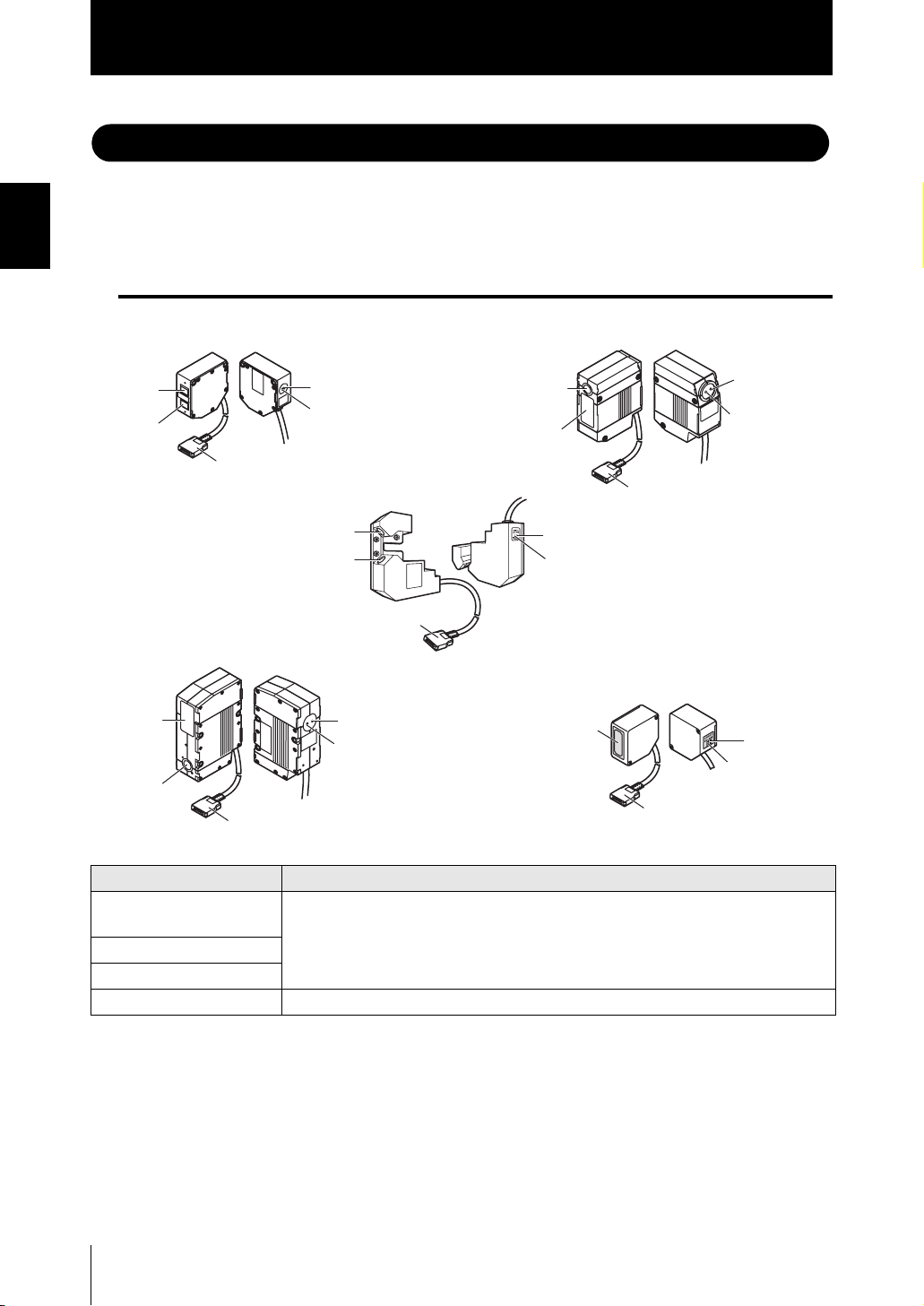

Part Names and Functions

Part Names and Functions

Section 1 FEATURES

[ZS-HLDS2T]

(3) Receiver

section

(2) Emitter

[ZS-HLDS60/HLDS150]

(3) Receiver

(2) Emitter

The following describes the names and functions of parts of the Sensor Head and Sensor

Controller.

Sensor Head

[ZS-HLDS5T/HLDS10]

(6) NEAR

indicator

(5) FAR

indicator

(5) FAR

indicator

(6) NEAR

indicator

section

section

section

(6) NEAR indicator

(5) FAR indicator

(4) Connector

[ZS-LD10GT/LD15GT]

(2) Emitter section

(3) Receiver section

(4) Connector

(2) Emitter section

(4) Connector

(6) NEAR indicator

(5) FAR indicator

(3) Receiver section

(4) Connector

(5) FAR indicator

(6) NEAR indicator

[ZS-LD_ _ _]

(1) Laser emitter/

receiver section

(4) Connector

1-4

Names Functions

(1) Laser Emitter/Receiver

Section

(2) Emitter section

(3) Receiver section

(4) Connector To be connected to the Sensor Controller

ZS-HL

User’s Manual

This is the section that emits the laser beam and receives reflected light.

Section 1

Part Names and Functions

Names Functions

(5) FAR Indicator These indicators light up as follows according to the distance between the front of the

(6) NEAR Indicator

Sensor Head and the workpiece.

Both NEAR/FAR indicators are lit up: Measuring center distance ± (measuring range

× 10 %)

NEAR indicator is lit up: Near side within measuring range

FAR indicator is lit up: Far side within measuring range

Both NEAR and FAR indicators are flashing: Outside measuring range

These indicators also double as laser alarm indicators.

- At least one of the indicators will either light up or flash after the Sensor

Head is turned ON.

- Both indicators go out for 15 to 25 seconds after the Sensor Head is turned

ON to indicate that the laser beam is OFF.

- Either of these indicators will light up or flash while the laser beam is being

emitted.

- Both indicators go off when the laser beam is OFF.

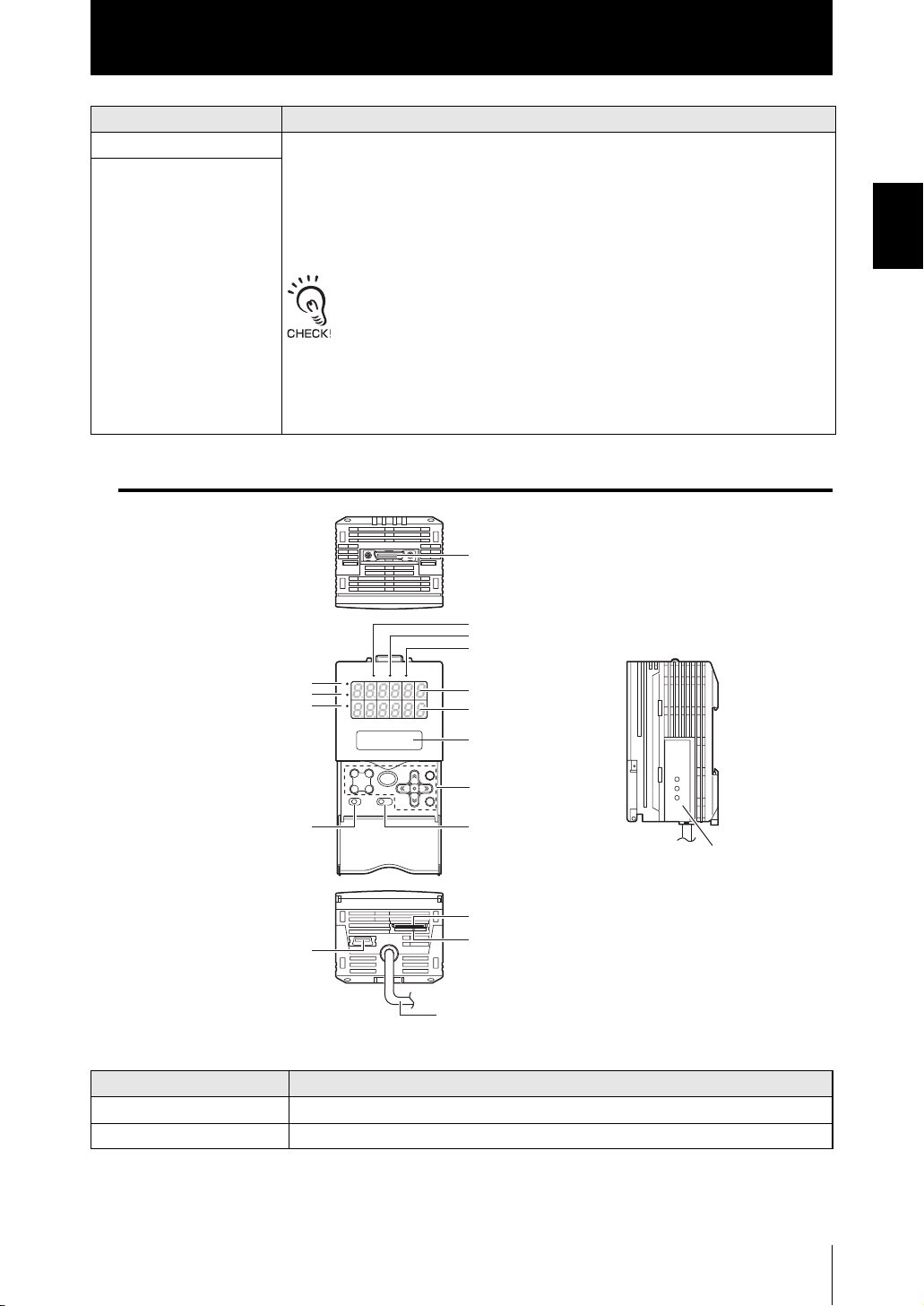

Sensor Controller

(13) Sensor Head connector

Section 1 FEATURES

(1) Laser indicator

(2) Zero Reset indicator

(3) ENABLE indicator

(12) HIGH indicator

(11) PASS indicator

(10) LOW indicator

H

P

L

LD ON ZERO ENABLE

(4) Main display

(5) Sub-display

(6) LCD screen

(7) Control keys

(9) Threshold switch

(8) Mode switch

(14) Coupler

(15) RS-232C connector

(18) USB port

(16) Voltage/Current switch

(17) I/O cable

Names Functions

(1) Laser indicator The Laser indicator is lit while the Sensor Head is emitting a laser beam.

(2) Zero Reset indicator The Zero Reset indicator is lit while the zero reset function is enabled.

ZS-HL

User’s Manual

1-5

Section 1

Part Names and Functions

(3) ENABLE indicator The ENABLE indicator lights when the Sensor is ready for measurement.

Section 1 FEATURES

(4) Main Display The Main Display shows measured values.

(5) Sub-display The sub-display shows thresholds and additional information during measurement.

(6) LCD screen RUN mode : Displays additional information for the main display and the setup

(7) Control keys The Control Keys are for setting measurement conditions and other information. The

(8) Mode switch The Mode Switch selects the operating mode.

(9) Threshold switch The Threshold Selector switch selects whether to set (or display) the HIGH or LOW

(10) LOW indicator The LOW indicator is lit while the condition “measured value < LOW threshold” is

(11) PASS indicator The PASS indicator is lit while the condition “LOW threshold ≤ measured value ≤

(12) HIGH indicator The HIGH indicator is lit while the condition “HIGH threshold < measured value” is

(13) Sensor Head connec-

(14) Coupler This connector is used to connect two or more Sensor Controllers. It is located on

(15) RS-232C connector Connect the RS-232C cable when you are connecting the Sensor Controller to a

(16) Voltage/Current switch The Voltage/Current switch selects between voltage output and current output.

Names Functions

It goes off when measurement is not possible (e.g. when the received light amount is

excessive or insufficient, when the measuring range is exceeded, when the Sensor

Head is not connected, or when measurement is not being performed in FUN mode).

menu for display related information.

TEACH mode: Displays the menu for setting up the thresholds.

FUN mode : Displays the measurement condition setup menu.

functions assigned to the Control Keys change according to the operating mode.

Key Operations p.4-4, p.5-2

RUN mode : Select this mode when performing regular measurement.

TEACH mode: Select this mode when setting the judgment thresholds.

FUN mode : Select this mode when setting measurement conditions.

threshold.

satisfied.

HIGH threshold” is satisfied.

satisfied.

This connector connects the Sensor Head.

tor

both sides of the Sensor Controller.

PLC or a programmable terminal. For the RS-232C cable, please use the following

exclusive products: If you use a cable not included in the exclusive products, a malfunction or breakdown may result.

- For connecting to a PLC or programmable terminal: ZS-XPT2

- For connecting to a personal computer: ZS-XRS2

If you connect the Sensor Controller to ZS-RPD and use it, connect a connector for

ZS-RPD.

1-6

Before operating this switch, make sure that the Sensor Controller is turned

OFF. Also, make sure that the load connected to “linear output wire (coaxial) - linear GND wire” satisfies the rating of the set state (voltage or current output) before turning the Sensor Controller ON. Otherwise, the Sensor

Controller may be damaged.

Rating of connected load (I/O Circuit Diagrams) p.2-12

(17) I/O Cable The I/O cable connects the Data Storage Unit to the power supply and external

devices, such as timing sensors or programmable controllers.

(18) USB port Connect the USB cable to the USB port to connect to a personal computer.

ZS-HL

User’s Manual

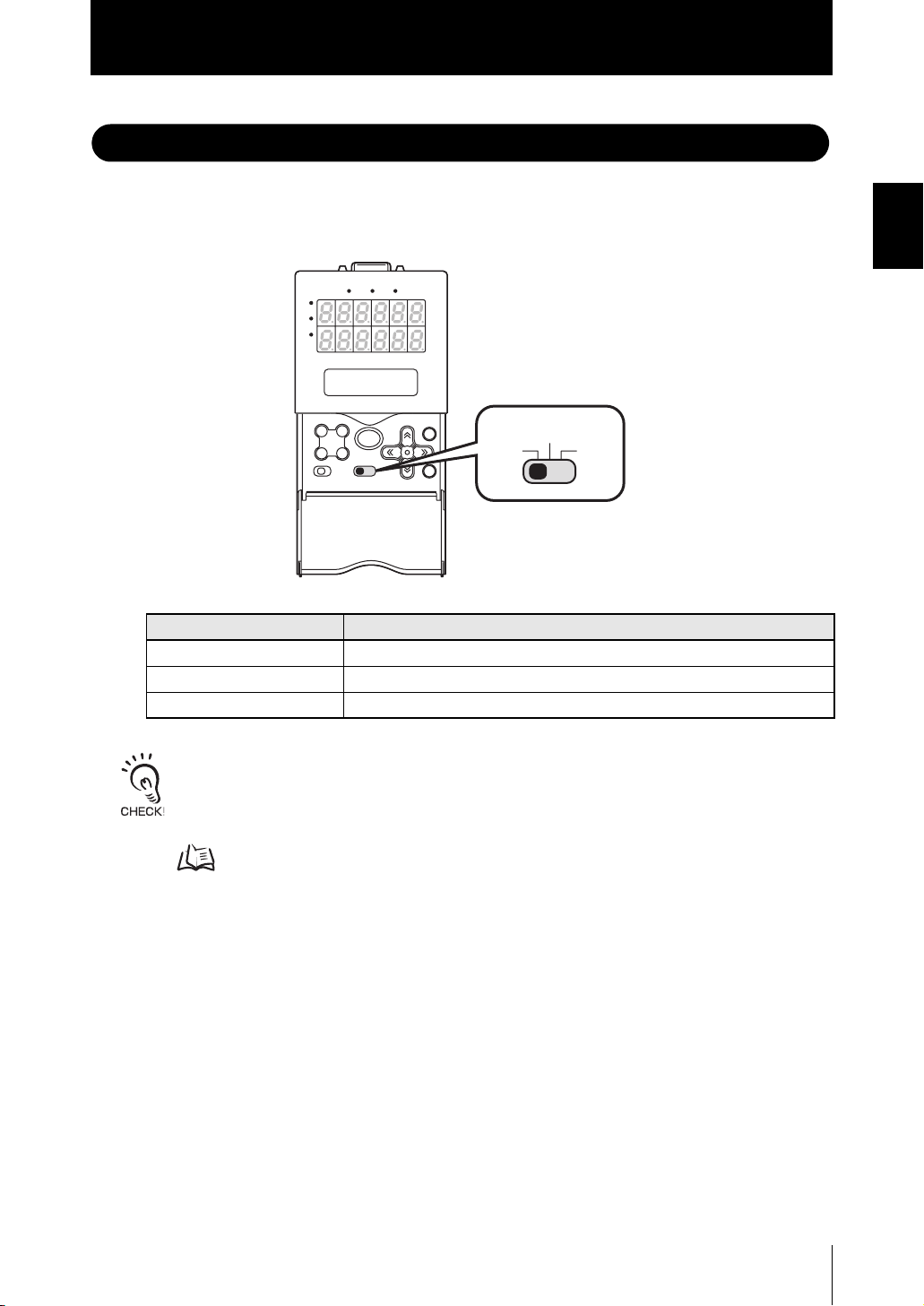

Operation Modes

Section 1

Operation Modes

The ZS-HL has the following 3 operating modes. Switch to the desired mode before you

start operation.

To switch the operating mode, use the mode switch.

LD ON ZERO ENABLE

H

P

L

TEACH

RUNFUN

Mode Description

RUN Mode Normal operating mode

TEACH Mode This mode is for setting the judgment threshold values.

FUN Mode Mode for setting the measurement conditions.

Section 1 FEATURES

When you switch the operating mode after changing the measurement conditions, you will be prompted

to save the settings. Save the settings as required. If you turn off the Sensor Controller without saving

these settings, the newly set measurement conditions will be cleared from memory. You can also save

all the settings later on.

Saving the Settings Data p.5-29

ZS-HL

User’s Manual

1-7

Section 1

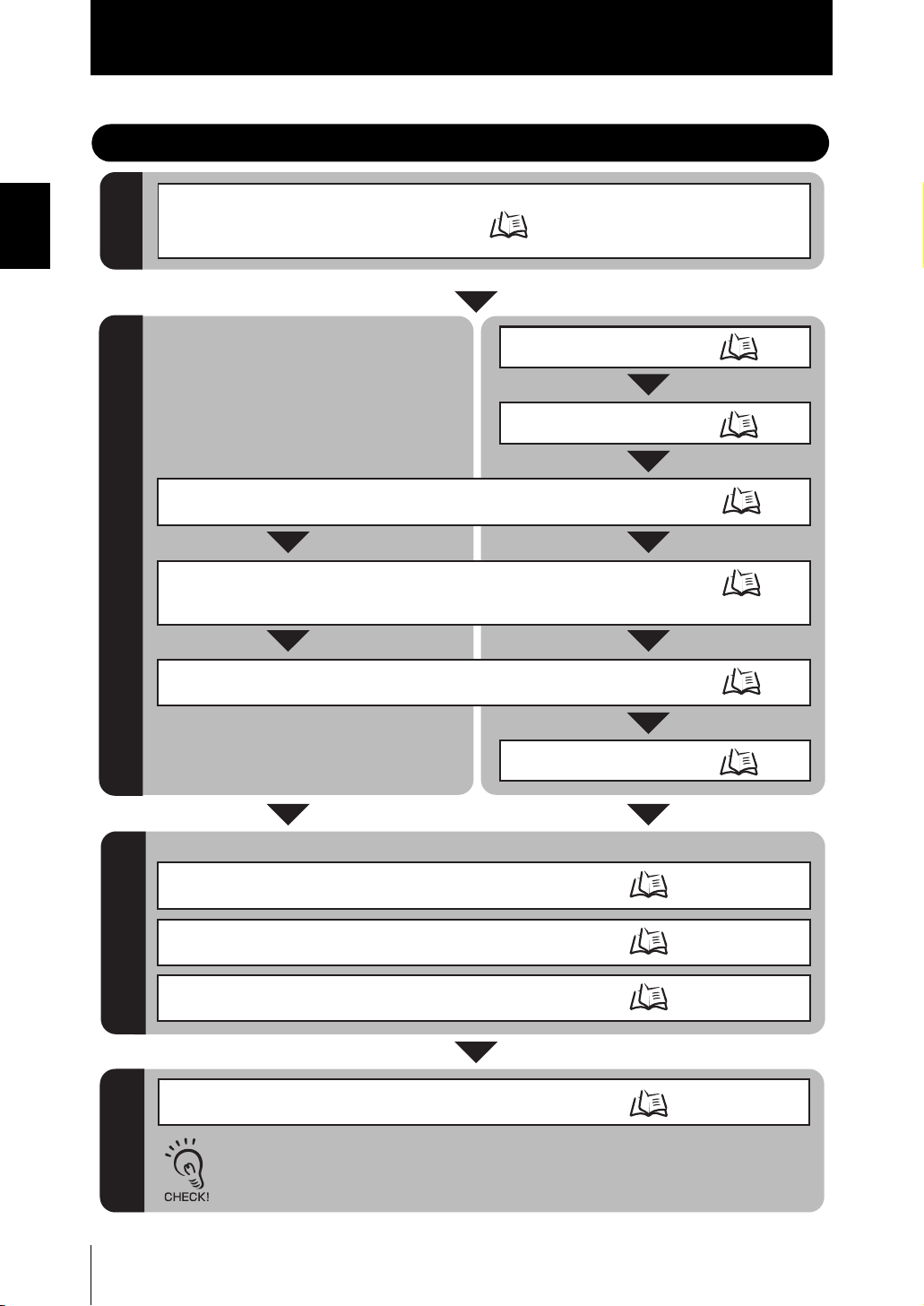

Setting Flow

Section 1 FEATURES

Setting Flow

Installation & Connection

Attach a Sensor Head according to the front side

Preparation for

material of the workpiece and the features of the Sensor.

measurement

Single-Task Multi-Task

Turn ON the power.

Section2

INSTALLATION & CONNECTION

p.2-2

Switching to Multi-Task Mode

Selecting Tasks

Selecting the Status of Head Installation

Select either regular reflection or diffuse reflection.

Selecting Measurement Mode

Change it when the received light amount is small or when you want to increase the

processing speed. (Usually, select [HI-RESO] of the default values.)

Setting for measurement conditions

Selecting the Measurement Object

Change it when you measure glass or mirrors. (Usually, select [NORMAL] of the default values.)

Setting for Measurement

of Characteristic Points

When you select Multi-Task mode, specify the setting for each task.

p.5-4

p.5-5

p.5-8

p.5-6

p.5-9

p.5-24

1-8

Setting the Scaling

You can correct the display value of the measured value as desired.

Setting HOLD

Set the hold conditions.

Setting the Zero Reset Function

Set zero reset.

Setting for output processingSaving the Settings

Save the Settings Data

Save the data you have set.

ZS-HL

User’s Manual

p.5-14

p.5-18

p.5-22

p.5-29

Make sure that you always save the data after you set it.

If you turn OFF the power without saving the data, all the settings data will be cleared.

Section 1

I/O (JUDGE, LINEAR, and OUTPUT

of TERMINAL BLOCK)

Setting Flow

Executing Zero Reset

Threshold Setting

Operation

Bank Switching

Functions Used During

Adjusting and Setting Sensing

Conditions

Setting the Filter Function

Measurement Smoothly

If You Cannot Perform a

I/O (JUDGE, LINEAR, and OUTPUT

of TERMINAL BLOCK)

USB/RS-232C communication

Setting Banks

Setting the Display Method

p.4-6

p.4-7

p.4-10

Setting the Emitted Light Amount

Setting Mutual Interference Prevention

Setting GAIN

Setting SMOOTH

Setting AVERAGE

Setting DIFF

Section6 I/O

Section7

USB/RS-232C COMMUNICATION

Changing the Way of

Obtaining Banks

Clearing Banks

Setting the Display

Setting the LCD display

HELP

Section 1 FEATURES

p.5-8

p.5-11

p.5-7

p.5-12

p.5-13

p.5-13

p.6-2

p.7-2

p.5-28

p.5-29

p.5-25

p.5-26

p.5-25

Setting the System Environment

Operations and Settings as Required

When a Problem Occurs...

When The Smart Sensor Does

Not Operate Correctly

When An Error Message Appears

Initializing Settings Data

Checking Information

Setting the Communication

Specifications

Setting Key Lock

Setting the Sensor Load Method

Setting the Display Language

Troubleshooting

Error Messages and

Countermeasures

p.9-2

p.9-3

p.5-29

p.5-27

p.7-6

p.5-27

p.5-28

p.5-28

ZS-HL

User’s Manual

1-9

Section 1

Setting Flow

Section 1 FEATURES

MEMO

1-10

ZS-HL

User’s Manual

Section2 INSTALLATION & CONNECTION

About Installation and Connection 2-2

Sensor Head 2-2

Measuring Range 2-3

Basic Precautions for Installation 2-4

Connecting the Sensor Head 2-5

Sensor Controller 2-7

Installation of Sensor Controller 2-7

Wiring the I/O cable 2-10

I/O Circuit Diagrams 2-12

SmartMonitor ZS 2-14

Operating Environment 2-14

Installation/Uninstallation Method 2-15

Starting and Exiting SmartMonitor ZS 2-19

Section2 INSTALLATION & CONNECTION

ZS-HL

User’s Manual

2-1

Section2

About Installation and Connection/Sensor Head

About Installation and Connection

■ Checking the installation environment

Section2 INSTALLATION & CONNECTION

■ Checking the installation site

■ About the power supply

Read “Important Points on Safety” at the beginning of this manual, and check the

installation environment.

Read “Notes on Use” at the beginning of this manual, and check the installation site.

Before installing and connecting the Sensor Controller, be sure to turn it OFF.

Also read “Important Points on Safety” and “Notes on Use” at the beginning of this

manual, and check the power supply and wiring.

Sensor Head

Never look into the laser beam. Doing so continuously will result in

visual impairment.

Never look into the laser beam.

Do not disassemble the product. Doing so may cause the laser beam

to leak, resulting in the danger of visual impairment. Do not disassemble the product.

2-2

ZS-HL

User’s Manual

Section2

Sensor Head

Measuring Range

The ZS-HL Series displays - (minus) for the NEAR side and + (plus) for the FAR side with

the measuring center distance set to 0 (zero).

Example: For the Sensor Head ZS-HLDS2T

Section2 INSTALLATION & CONNECTION

Measurement center

distance: 20 mm

Measuring range

NEAR side

Measuring center

FAR side

-1 mm

0 mm

+1 mm

• ZS-HLDS_ _ _ Series

Regular reflection Diffusive reflection

Measuring center

distance

ZS-HLDS2T 20 mm ±1 mm 5.2 mm ±1 mm

ZS-HLDS5T 44 mm ±4 mm 50 mm ±5 mm

ZS-HLDS10 94 mm ±16 mm 100 mm ±20 mm

ZS-HLDS60 – – 600 mm ±350 mm

ZS-HLDS150 – – 1,500 mm ±500 mm

Measuring range

Measuring center

distance

Measuring range

• ZS-LD_ _ _ Series

Regular reflection Diffusive reflection

Measuring center

distance

ZS-LD10GT 10 mm ±0.5 mm – –

ZS-LD15GT 15 mm ±0.75 mm – –

ZS-LD20T/20ST 20 mm ±1 mm 6.3 mm ±1 mm

ZS-LD40T 40 mm ±2.5 mm 30 mm ±2 mm

ZS-LD50/50S 47 mm ±4 mm 50 mm ±5 mm

ZS-LD80 78 mm ±14 mm 80 mm ±15 mm

ZS-LD130 130 mm ±12 mm 130 mm ±15 mm

ZS-LD200 200 mm ±48 mm 200 mm ±50 mm

ZS-LD350 – – 350 mm ±135 mm

Measuring range

Measuring center

distance

Measuring range

ZS-HL

User’s Manual

2-3

Section2

Sensor Head

Basic Precautions for Installation

Color/shiny surface boundary

Wrong Right

Section2 INSTALLATION & CONNECTION

Color/shiny

surface boundary

Measuring in narrow grooves

Emission axis

Wrong Right

Reception axis

Installing near walls

Measurement errors can be reduced by

installing the Sensor Head with the line

formed by the emission and reception axes

parallel to the wall, and painting the wall with

non-reflective black paint.

Wrong Right

Rotating objects

When measuring rotating workpieces, you can

minimize the influence caused by vibration of

the rotating object and positional shifts by

installing the Sensor Head with the line

formed by the emission and reception axes

parallel to the axis of rotation.

Wrong Right

Measuring stepped workpieces

Wrong Right

Effect caused by peripheral lights

Do not install the Sensor Head in a place

where strong light hits the laser

emitter/receiver section of the Sensor Head.

Also, if a workpiece has a shiny surface, the

light from the lighting will be reflected and a

malfunction may occur. In such a case,

prevent reflection by, for example, covering

the light to stop reflection.

Wrong Right

2-4

ZS-HL

User’s Manual

Sensor Head

Connecting the Sensor Head

This connector connects the Sensor Head and controller.

Before connecting/disconnecting the Sensor Head, make sure that the Smart Sensor is turned OFF. The

Sensor Controller may break down if it is connected or disconnected while the power is ON.

■ Connecting the Sensor Head

Insert the Sensor Head connector into the Sensor Controller until it locks in place.

Section2

Section2 INSTALLATION & CONNECTION

LD ON ZEROENABLE

H

P

L

Ferrite core

Insure lock

Ferrite core

Attach the ferrite core (provided with the Sensor Head) to both ends of the Sensor Head cable in

advance.

If the ferrite core comes loose from the cable, fasten the ferrite core in place with the Insure Lock

(supplied).

■ Disconnecting the Sensor Head

Pull out the Sensor Head while pressing in the hooks on both sides of the Sensor Head

connector.

LD ON ZEROENABLE

H

P

L

• Do not touch the terminals inside the connector.

• All settings on the Sensor Controller will be cleared if the Sensor Head is replaced with a different

type.

ZS-HL

User’s Manual

2-5

Section2

Sensor Head

■ Extension Cable

There are three ways to extend a cable.

• Entire length within 12 m

Section2 INSTALLATION & CONNECTION

LD ON ZEROENABLE

H

P

Cable for the Sensor Head

: 0.5 m, 2 m

Extension cable

ZS-XC_A_: 1 m, 4 m, 8 m

L

ZS-XC_B(R): 5 m, 10 m

• Entire length within 22 m (Connect extension cables)

Cable for the Sensor Head

: 0.5 m, 2 m

Extension cable

ZS-XC_B(R): 5 m, 10 m

ZS-XC_B(R): 5 m, 10 m

• Extended for a long distance (Use a repeater)

Digital equalizer

ZS-XEQ

Cable for the Sensor Head

: 0.5 m, 2 m

Extension cable

ZS-XC15CR: 15 m

ZS-XC25CR: 25 m

Digital equalizer

ZS-XEQ

Extension cable

Digital equalizer

connection cable

ZS-XC02D: 0.2 m

LD ON ZEROENABLE

H

P

L

LD ON ZERO ENABLE

H

P

L

2-6

ZS-HL

User’s Manual

• Only the ZS-XC_B(R) cable allows this extended connected. Note, however, that the connection

with the ZS-XC_A cannot be extended.

• The cable may break at locations where it is made to bend. So, use a robot cable type extension

cable (ZS-XC5BR, ZS-XC_ _CR).

• There are restrictions on the Sensor Head that can connect to ZS-XC_ _CR, ZS-XC02D, and ZS-

XEQ. For details, contact your OMRON representative.

Section2

Sensor Controller

Sensor Controller

This section describes installation of the Sensor Controller, and connection of the I/O

cable.

Before connecting/disconnecting peripheral devices, make sure that the Sensor Controller is turned

OFF. The Sensor Controller may break down if it is connected or disconnected while the power is ON.

Installation of Sensor Controller

■ Installing on the DIN track

The following describes how to attach the 35 mm wide DIN track very quickly and easily.

LD ON ZERO ENABLE

H

P

L

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

Ferrite core

End plate (sold separately)

PFP-M

Section2 INSTALLATION & CONNECTION

In advance, attach the ferrite core (provided with the Sensor Controller) to the input/output cable of

the Sensor Controller.

ZS-HL

User’s Manual

2-7

Section2

Sensor Controller

● Installation procedure

1. Hook the connector end of the Sensor

Controller onto the DIN track.

Hook on connector

Section2 INSTALLATION & CONNECTION

● Removal procedure

2. Push the Sensor Controller down onto

the DIN track until the hook on the I/O

cable side is locked.

Push down until you hear it snap into place.

Always hook the connector end of the Sensor Controller on the DIN track first. Hooking the I/

O cable end on the DIN track first may impair the mounting strength of the DIN track attach-

ment.

1. Pull the hook on the I/O cable end of the

Sensor Controller downwards.

2. Lift up the Sensor Controller from the I/O

cable end, and remove it from the DIN

track.

Hook on I/O cable

Hook on I/O cable

2-8

■ Mounting on a panel

The optional Panel Mount Adapters (ZS-XPM1) can be used to mount the Sensor Controller on a panel.

Panel cutout dimensions p.8-41

1. Push out the Sensor Controller from the

rear of the panel towards the front.

H

H

LD ON ZERO

LD ON ZERO

P

P

ENABLE

ENABLE

L

L

ZS-HL

User’s Manual

Panel

Section2

Sensor Controller

2. Install the small Mount Adapters on the

four holes of the Sensor Controller.

3. Install the long Mount Adapters on the

two holes of the small Mount Adapter.

Panel Mount

Adapter

H

H

LD ON ZERO

LD ON ZERO

P

P

ENABLE

ENABLE

L

L

Panel Mount

Adapter

H

H

LD ON ZERO

LD ON ZERO

P

P

ENABLE

ENABLE

L

L

Section2 INSTALLATION & CONNECTION

Panel Mount

Adapter

4. Install the Sensor Controller with Panel

Mount Adapters attached onto the panel

from the front.

Take care not to pinch the I/O cable.

5. Hook the hooks of the mounting fixture

onto the two holes of the smaller Mount

Adapters and tighten the screws.

Panel Mount

Adapter

Panel

H

H

L

L

D

D

O

O

N

N

Z

Z

E

E

P

P

R

R

O

O

E

E

N

N

A

A

B

B

L

L

L

L

E

E

Mounting

fixture

6. Make sure that the Sensor Controller is

firmly fixed on the panel.

ZS-HL

User’s Manual

2-9

Section2

Sensor Controller

Wiring the I/O cable

The following shows the leads that comprise the I/O cable.

Section2 INSTALLATION & CONNECTION

(1) Power supply

Brown

Blue

Red

Green

Black

Pink

Gray

Co-axial (black)

Shielded

Yellow

Light blue

Purple

White

Orange

(Cable length: 2 m)

(1) Power supply

(2) GND

(3) OUT0

(4) OUT1

(5) OUT2

(6) OUT3

(7) OUT4

(8) Linear output

(9) Linear GND

(10) IN0

(11) IN1

(12) IN2

(13) IN3

(14) Unused

This connects the 24 VDC (±10 %) power supply. When using a Sensor Controller

with a PNP output, the power supply terminal is also the common I/O terminal for all I/

O except for the linear output.

Supply power from a DC power supply unit that has a countermeasure (safety ultra-

low voltage circuit) built-in for preventing high voltages from occurring.

Recommended power supply unit p.1-3

Wire the power supply separately from other devices. Wiring them together or placing

them in the same duct may cause induction, resulting in malfunction or damage.

(2) GND

The GND terminal is the 0 V power supply terminal. When using a Sensor Controller

with an NPN output, the GND terminal is also the common I/O terminal for all I/O

except for the linear output.

(3) OUT0 (HIGH output)

This outputs judgment results (HIGH).

(4) OUT1 (PASS output)

This outputs judgment results (PASS).

(5) OUT2 (LOW output)

This outputs judgment results (LOW).

(6) OUT3 (ENABLE output)

This turns ON when the Sensor Controller is ready for measurement. This output is

interlocked with the ENABLE indicator.

2-10

ZS-HL

User’s Manual

Sensor Controller

(7) OUT4 (BUSY output)

This turns ON during sampling with the hold function enabled.

It allows you to check whether or not the self-trigger is functioning correctly.

It also turns ON during bank switching.

(8) Linear output

The linear output outputs a current or voltage in accordance with the measured

value.

(9) Linear GND

The linear GND terminal is the 0 V terminal for the linear output.

This ground wire must be grounded separately from the other ground wires.

Always ground the linear output terminal even when linear output is not used.

(10)-(13) IN0 to IN3

The following input signal assignments can be selected.

• Signal assignments

Signal

IN0 External trigger (timing) input Bank input A

IN1 Reset input Bank input B

IN2 LD-OFF input LD-OFF input

IN3 Zero reset input Zero reset input

When [NORMAL] is selected

(default)

When [BANK] is selected

Section2

Section2 INSTALLATION & CONNECTION

Setting the I/O assignments p.6-17

• Signal functions

Signal name Description

External trigger (timing) input This timing input is for signal input from external devices. Use it for hold

function timing.

Reset input This resets all executing measurements and outputs. While a reset is

being input, judgment output conforms to the non-measurement setting. If this reset input switches ON while the hold function is used, the

state in effect before the hold function was set will be restored.

Status indicators p.8-39

LD-OFF input If this LD-OFF signal is set to ON, the laser will stop emission, causing

a light amount error. While LD-OFF is being input, judgment output

conforms to the non-measurement setting.

Zero reset input This is used to execute and clear a zero reset.

Bank input A, B This is used for switching banks. Specify the bank No. in combinations

of A and B. However, if the bank mode is set to [THRESH], the bank

cannot be switched at the external signal input because the number of

banks increases to 32.

External I/O timing chart p.6-18

ZS-HL

User’s Manual

2-11

Section2

Sensor Controller

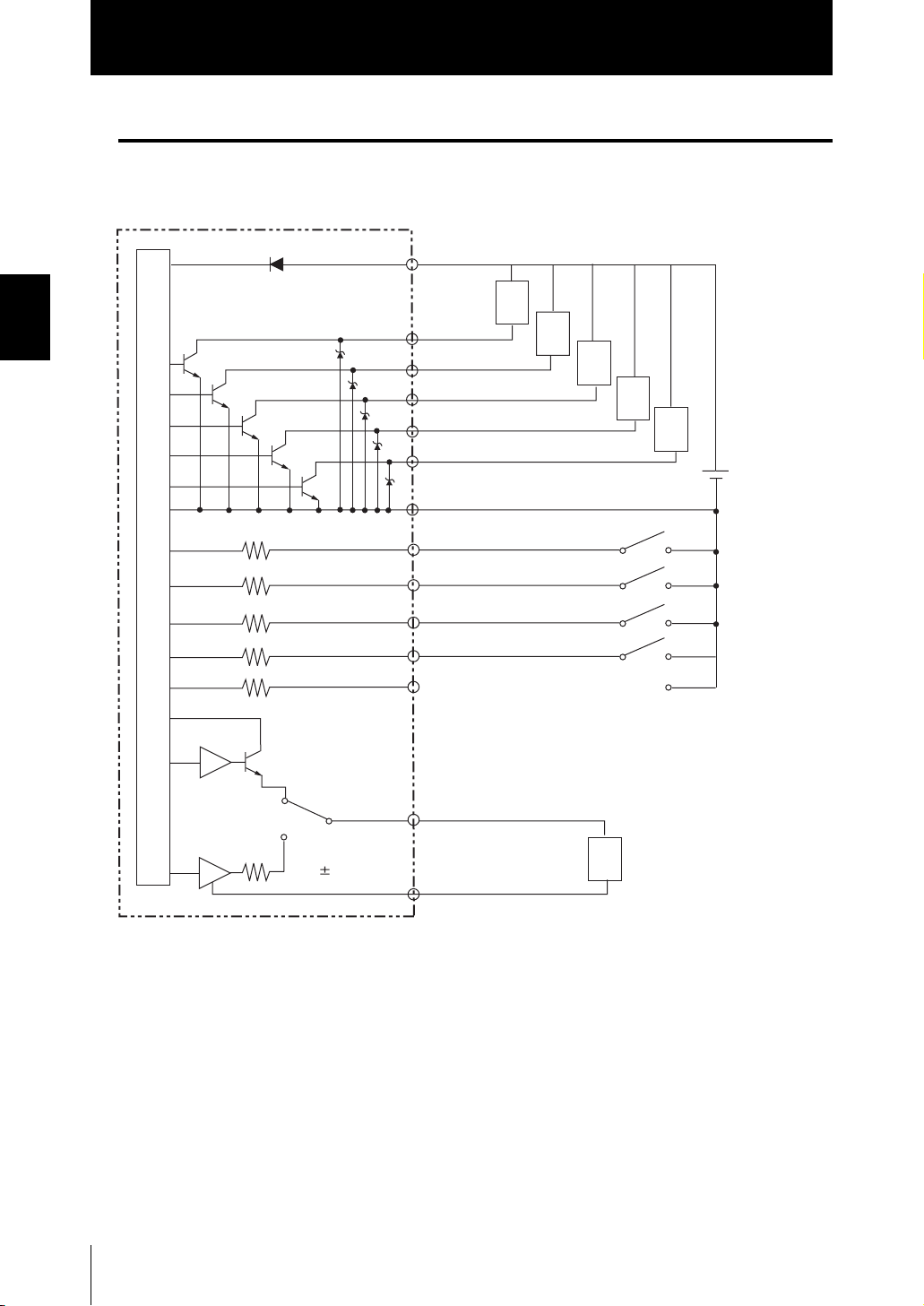

I/O Circuit Diagrams

● NPN type (ZS-HLDC11)

Section2 INSTALLATION & CONNECTION

Brown

Red

Green

Black

Pink

Gray

Blue

DC24 V

Load

OUT0

OUT1

OUT2

OUT3

OUT4

GND (0 V)

Load

Load

Load

Load

DC24 V

Internal circuits

Current voltage/

output selector switch

40 Ω

Current output

4 to 20 mA

Voltage output

10 V

Yellow

Light blue

Purple

White

Orange

Co-axial (black)

Shielded

IN0

IN1

IN2

IN3

Linear output

Linear GND

Current output: 300 Ω or less

Load

Voltage output: 10 kΩ or more

2-12

ZS-HL

User’s Manual

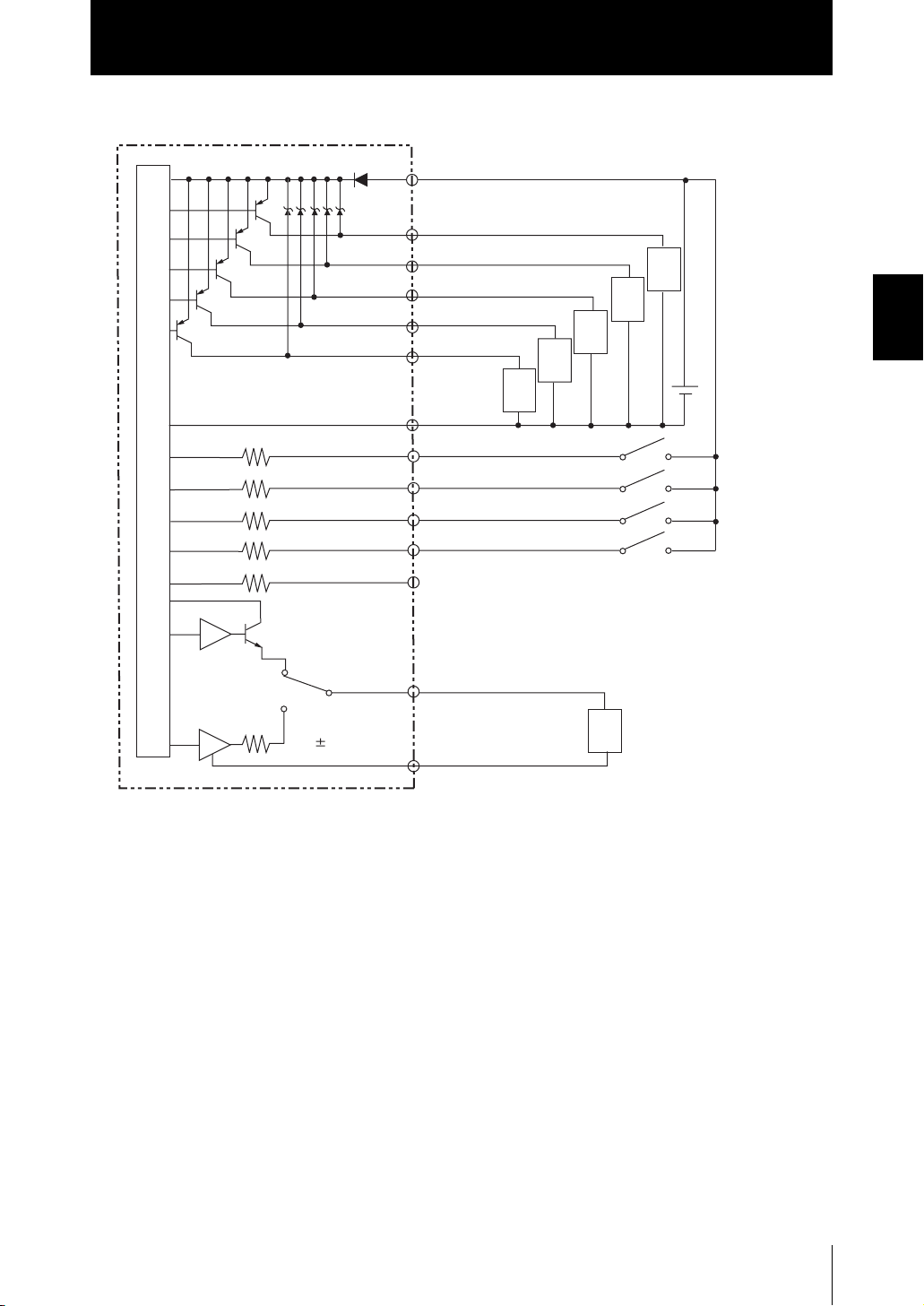

● PNP type (ZS-HLDC41)

Brown DC24 V

Red

OUT0

Green

OUT1

Black

OUT2

Pink

OUT3

Gray

OUT4

GND (0 V)

Blue

Yellow

IN0

Load

Load

Load

Sensor Controller

Load

Load

DC

24 V

Section2

Section2 INSTALLATION & CONNECTION

Internal circuits

Current voltage/

output selector switch

40 Ω

Current output

4 to 20 mA

Voltage output

10 V

Light blue

Purple

White

Orange

Co-axial (black)

Shielded

IN1

IN2

IN3

Linear output

Linear GND

Current output: 300 Ω or less

Load

Voltage output: 10 kΩ or more

ZS-HL

User’s Manual

2-13

Section2

SmartMonitor ZS

SmartMonitor ZS

ZS-HL is provided with the SmartMonitor ZS software utility. This utility allows you to set up

sensing functions and monitor the waveforms of measurement results on a personal computer.

Section2 INSTALLATION & CONNECTION

● Monitoring the measurement state

● Setting support for functions

SmartMonitor ZS

(accessory for ZS-HLDC_1A)

USB cable

Checks the measured value of the gang-mounted

controller in the list.

Sets the sensing conditions in detail while checking

the receiving status of the Sensor Head (sensitivity).

Receiving

status

Displays the change of the time series for the measured value in a graph.

Displays and sets the settings for the controller

in the list.

2-14

Line bright

If you use SmartMonitor ZS Professional, which is sold separately, you can also do the following:

• Display multiple CH waveforms using multiple controllers.

• Perform logging for the measured value.

Operating Environment

The following describes the operating environment for SmartMonitor ZS. Please check them.

Item Condition

OS Windows 98/2000/XP

CPU Celeron 500MHz or faster

Memory At least 128 MB

Display 1024 × 768 dots HighColor

• Windows is a trademark or registered trademark of Microsoft Corporation.

• Celeron is a trademark or registered trademark of Intel Corporation or its subsidiaries.

ZS-HL

User’s Manual

Section2

SmartMonitor ZS

Installation/Uninstallation Method

The following describes the preparations for using SmartMonitor ZS.

■ Installing SmartMonitor ZS

• Before you install SmartMonitor ZS, quit all other programs that are running. If virus detection soft-

ware is enabled, installation may take time to complete.

• Log on as an Administrator or a user with system access rights.

• Install SmartMonitor ZS before installing the USB driver.

1. Turn your PC ON and startup up Windows.

2. Insert your “SmartMonitor ZS” CD-ROM into the CD-DOM drive on your per-

sonal computer.

3. Auto-run automatically displays the installation screen. Follow the on-

screen instructions to install SmartMonitor ZS.

Section2 INSTALLATION & CONNECTION

■ Uninstalling SmartMonitor ZS

• Before you uninstall SmartMonitor ZS, quit all other programs that are running. If virus detection

software is enabled, uninstallation may take time to complete.

• Log on as an Administrator or a user with system access rights.

1. Turn your PC ON and startup up Windows.

2. Select [Settings]-[Control Panel] from the [Start] menu in the personal com-

puter.

3. Double-click [Add/Remove Programs].

4. Select [SmartMonitorZS] from the list and click the [Remove] button.

5. Click the [Yes] button.

ZS-HL

User’s Manual

2-15

Section2

SmartMonitor ZS

■ Installing the USB driver

Section2 INSTALLATION & CONNECTION

The USB driver must be installed on the personal computer to establish a connection

between the personal computer and the Sensor Controller by the USB interface.

• The exclusive USB driver must be installed only when the Sensor Controller is connected to the

personal computer for the first time. From the second startup onwards, the USB driver is automat-

ically recognized and does not need to be re-installed.

• To install the USB driver, log on as an Administrator or a user with system access rights.

• Install SmartMonitor ZS before installing the USB driver.

• The error message “Failed to pass the Windows logo test” is sometimes displayed at USBinstalla-

tion. Press the [Continue] button to continue with the installation.

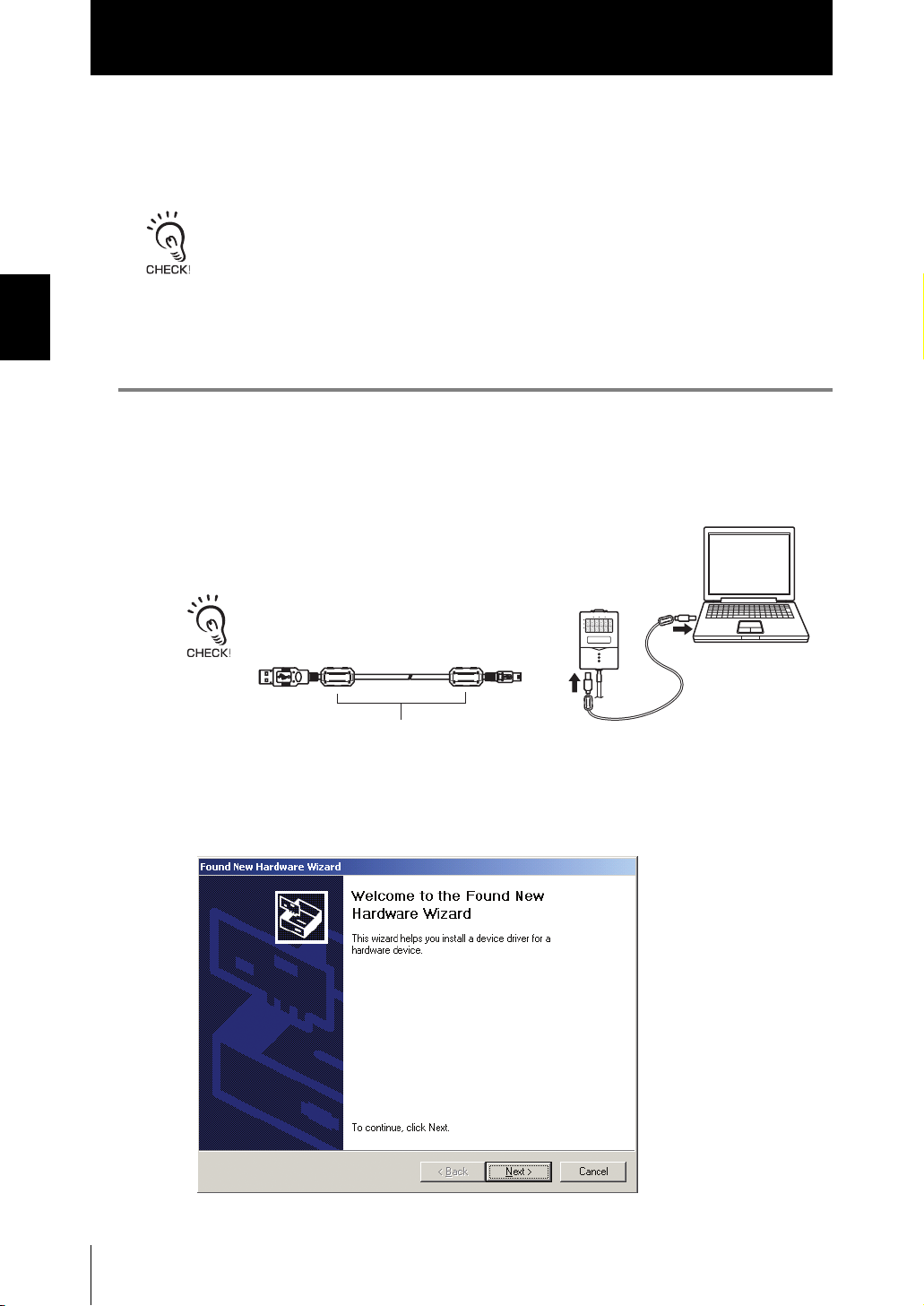

1. Turn your PC ON and startup up Windows.

2. Connect the Sensor Controller to the

personal computer by the USB cable.

Attach the ferrite core (provided with the Sen-

sor Controller) to the USB cable (provided with

the Sensor Controller).

Ferrite core

“Detected new hardware” will be displayed on the Windows tool bar,

and the [New Hardware Detection Wizard] dialog box will appear.

2-16

ZS-HL

User’s Manual

Section2

SmartMonitor ZS

3. Click the [Next>] button.

4. Select the [Search for a suitable driver for my disk (recommended)] radio

button, and click the [Next>] button.

Section2 INSTALLATION & CONNECTION

5. Mark the [CD-ROM drives] checkbox, and click the [Next>] button.

• When the Sensor Controller is not detected automatically

Click the [Browse] button and select [USB] folder on the CD-ROM.

• To install on a personal computer not equipped with a CD-ROM driveSelect

[Specify directory], and specify the [Program Files]-[OMRON]-[SmartMonitorZS]-[usb]

folder.

ZS-HL

User’s Manual

2-17

Section2

SmartMonitor ZS

Section2 INSTALLATION & CONNECTION

6. Make sure that the optimum driver has been detected, and click the [Next>]

button.

Installation begins.

When installation ends, the completion message is displayed.

7. Click the [Finish] button.

The same screen in step 2 is displayed. Repeat the above procedure.

This completes installation of the USB driver.

2-18

ZS-HL

User’s Manual

Section2

SmartMonitor ZS

Starting and Exiting SmartMonitor ZS

■ Start-up of SmartMonitor ZS

After installation is completed, start up SmartMonitor ZS by the following procedure.

1. Make sure that the Sensor Controller is connected to the personal com-

puter.

2. Turn the Sensor Controller ON and set it to the RUN mode.

3. Select [Programs]-[OMRON]-[SmartMonitorZS] from the Windows [Start]

menu.

■ When the connection between the personal computer and

Sensor Controller cannot be established

Check the COM port No. assigned on the personal computer in Device Manager.

Section2 INSTALLATION & CONNECTION

1. Right-click [My Computer] on the Windows desktop and click [Properties].

2. Click [Device Manager(D)] on the [Hardware] tab.

3. Open [Port (COM/LPT)], and check which number COM in [OMRON Smart

Sensor USB COM] is set to.

4. Set this COM port No. to the [Communication Settings] screen on Smart-

Monitor ZS.

If “OMRON Smart Sensor USB COM” is not recognized in Device Manager, re-install the USB driver

and reboot the personal computer.

■ Exiting SmartMonitor ZS

Exit SmartMonitor ZS by the following procedure.

1. Select [File]-[Close] in the SmartMonitor ZS menu bar.

ZS-HL

User’s Manual

2-19

Section2

SmartMonitor ZS

MEMO

Section2 INSTALLATION & CONNECTION

2-20

ZS-HL

User’s Manual

Section3

APPLICATION and SETTING EXAMPLES

Measuring Height (basic) 3-2

Measuring the Thickness of Transparent Objects 3-4

Measuring the Vertex 2 (peak) in the Line Beam 3-6

Measuring Multiple Items Simultaneously (Multi-Task) 3-8

Section3 APPLICATION and SETTING EXAMPLES

ZS-HL

User’s Manual

3-1

Section3

t

Measuring Height (basic)

Measuring Height (basic)

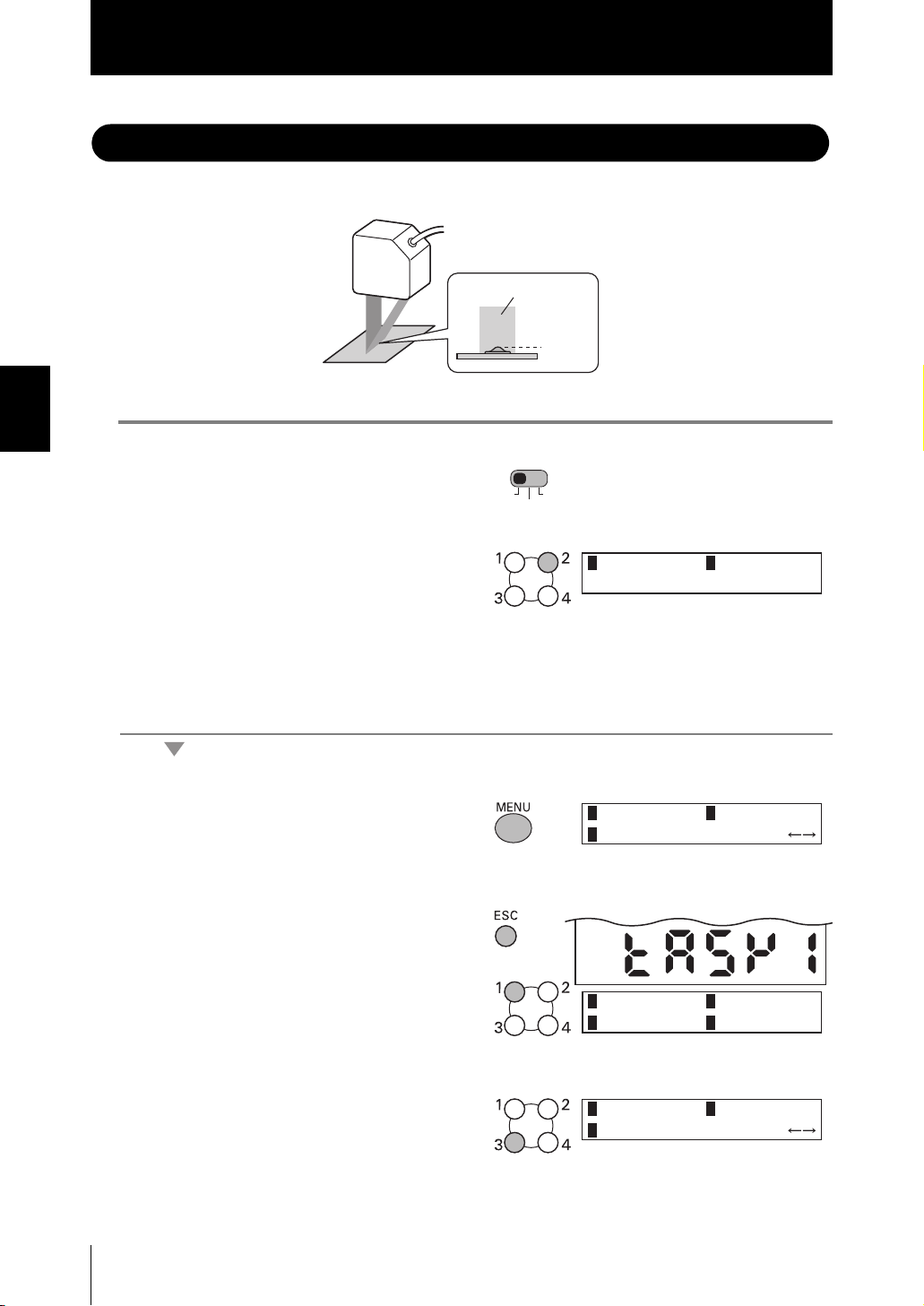

This section describes the basic setting procedures for measuring height.

Section3 APPLICATION and SETTING EXAMPLES

Setting for sensing conditions

Sensor head

heigh

Name of the Controller and Key Code

LD ON ZERO ENABLE

Main display

Sub-display

H

P

L

MENU

12

34

H L FUN RUN

TEACH

ESC

SET

1. Set the mode switch to FUN.

FUN RUN

TEACH

2. Select measurement mode in

[SENSING]-[MODE].

1 STAND

3 H-SPEED

[HI-RESO]:Usually select this menu. A stable measurement can be performed

while the effect of the front side of the workpiece is minimized.

[HI-SENS]: In addition to the effect of [HI-RESO], a measurement is stable even

when the received light amount is insufficient. (black rubber, PCB, etc.)

3. Select the mounting status of the

1 DIFFUSE

Head in [SENSING]-[SETTING].

4. Select the material of the work-

piece in [SENSING]-[OBJECT].

1 NORMAL

3 MIRROR

[NORMAL]: Usually select this menu.

[PCB] : When a laser beam passes through an object like PCB and there is a

diffused reflection effect.

[MIRROR] : For a mirror

[GLASS] : For glass

2 HI-RESO

2 REGULAR

2 PCB

3-2

ZS-HL

User’s Manual

Saving the Settings

5. Set the mode switch to RUN.

FUN RUN

TEACH

Section3

Measuring Height (basic)

6. Select [Yes] and save the settings.

Measurement

7. Check the measured value.

Is change saved?

1 YES 2 NO

Measurement center = 0

Measured

value

Section3 APPLICATION and SETTING EXAMPLES

(-)

(+)

ZS-HL

User’s Manual

3-3

Section3

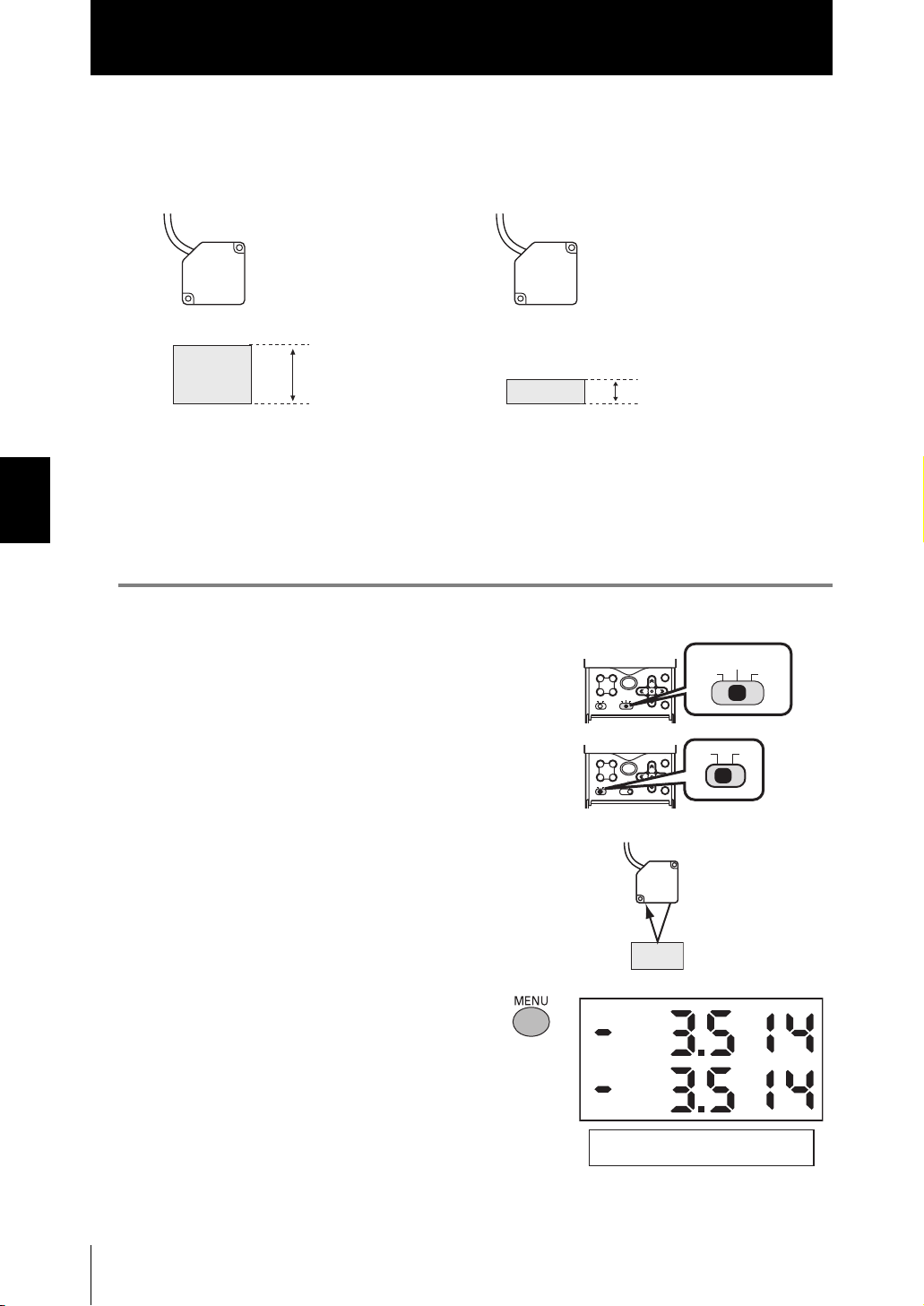

Measuring the Thickness of Transparent Objects

Measuring the Thickness of Transparent Objects

If you already know the glass thickness, you can adjust the scaling with reference to the

thickness, and easily measure the thickness of a transparent object.

Section3 APPLICATION and SETTING EXAMPLES

Sensor Head

[Points for installation]

•

For regular reflection heads (such as ZS-HLDS2T and ZS-LD20T)

By fixing the Sensor Head to a position such that it is kept in

parallel with the front side of the workpiece, you can perform

high-precision measurement. When you install the Sensor Head,

we recommend that you match the front side of the workpiece

with the reference surface of the Sensor Head, and then bring

up the Sensor Head horizontally and install it.

ront side

Backside

Raw glass

Thickness

Setting for sensing conditions

1. Set the mode switch to FUN.

2. Select [REGULAR] in [SENSING]-

[SETTING].

•

For diffuse reflection heads

Adjust the position of the Sensor Head while checking the

display of the emitted light amount and received light amount.

Adjust the position of the Sensor Head such that the emitted

light amount becomes the minimum compared to 1,000 for the

received light amount.

LD POWER: 1.0%

SUB : BRIGHT

Switching the Display of the Measured Value p.4-2

FUN RUN

TEACH

1 DIFFUSE

Received light amount

Emitted light amount

2 REGULAR

3-4

3. Select [THICK]-[MODE1] in [SENS-

ING]-[OBJECT].

ZS-HL

User’s Manual

1 GLASS

2 THICK

Measuring the Thickness of Transparent Objects

e

Setting Scaling

4. Set the actual workpiece within

the measuring range.

Section3

Measuring distance

Measuring rang

5. Select [OUTPUT]-[SCALING]-[ON]-

[AUTO].

When you want to execute [SCALING FOR GLASS THICKNESS], set the workpiece within

the measuring range. In the status in which a measurement cannot be performed, you cannot

set the scaling (automatic).

6. Enter the actual size of

the glass thickness.

Saving the Settings

7. Set the mode switch to RUN.

Value

Digit

FUN RUN

TEACH

1 AUTO

INPUT THICKNESS

DIG VAL SET:OK

2 MANUAL

Section3 APPLICATION and SETTING EXAMPLES

8. Select [Yes] and save the settings.

Is change saved?

1 YES 2 NO

Measurement

9. Check the measured value.

Measured

value

When a measurement is not stable

Select [THICK]-[MODE2] at the step 3. When you select [MODE2], the mode is switched to 2-area measurement mode that executes an adjustment for suitable received light amount for the front side and

back side of the glass respectively. When you use SmartMonitor ZS, you can adjust the area while

checking the received light amount.

Setting Measurement Object p.5-9

User’s Manual

ZS-HL

3-5

Section3

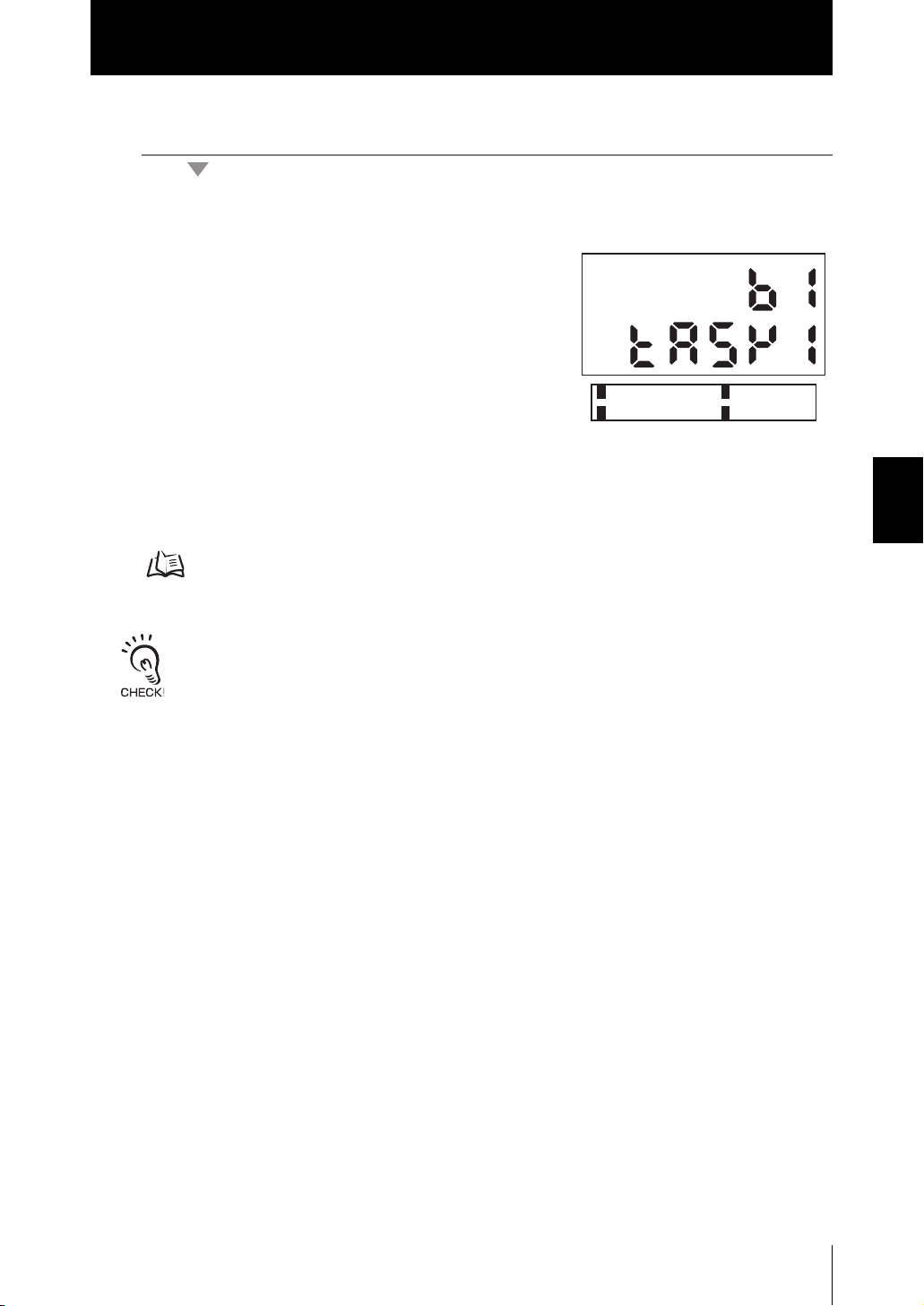

Measuring the Vertex 2 (peak) in the Line Beam

Measuring the Vertex 2

The following describes the setting procedure for measuring a small vertex.

Section3 APPLICATION and SETTING EXAMPLES

1. Set the mode switch to FUN.

2. Select [ON] in [SYSTEM]-[MULTI-

TASK].

The confirmation message is

displayed. Select [OK].

(peak)

Line beam

Peak

FUN RUN

TEACH

in the Line Beam

1 OFF

2 ON

Setting peak (TASK1)

3. Press the MENU key to display the

TOP menu.

4. Press the ESC key to display the

TASK switching menu, and select

[TASK1].

5. Select [PEAK] in [MEASURE]-

[TASKSET].

1 SENSING

3 FILTER

1 TASK1

3 TASK3 4 TASK4

1 OFF

3 PEAK

2 MEASURE

2 TASK2

2 AVERAGE

3-6

ZS-HL

User’s Manual

Measuring the Vertex 2 (peak) in the Line Beam

Saving the Settings

6. Set the mode switch to RUN.

FUN RUN

TEACH

Section3

7. Select [Yes] and save the settings.

Measurement

Is change saved?

1 YES 2 NO

8. Check the measured value.

Measured

value

You can measure the bottom or step using the same procedure. Select [BOTTOM] or [STEP] at step 5.

Bottom

Step

Section3 APPLICATION and SETTING EXAMPLES

ZS-HL

User’s Manual

3-7

Section3

Measuring Multiple Items Simultaneously (Multi-Task)

Measuring Multiple Items Simultaneously (Multi-Task)

If you use the multi-task function, you can measure the height and surface fluctuation

simultaneously. The following describes the procedure for setting “height” for TASK1 and

“surface fluctuation” for TASK2.

Section3 APPLICATION and SETTING EXAMPLES

1. Set the mode switch to FUN.

Surface fluctuation (TASK2)

Height (TASK1)

FUN RUN

TEACH

2. Select [ON] in [SYSTEM]-[MULTI-

TASK].

The confirmation message is

displayed. Select [OK].

Setting height (TASK1)

3. Press the MENU key to display the

TOP menu.

4. Press the ESC key to display the

TASK switching menu, and select

[TASK1].

1 OFF

1 SENSING

3 FILTER

1 TASK1

3 TASK3 4 TASK4

2 ON

2 MEASURE

2 TASK2

3-8

5. Select [AVERAGE] in [MEASURE]-

[TASKSET].

ZS-HL

User’s Manual

1 OFF

3 PEAK

2 AVERAGE

Section3

Measuring Multiple Items Simultaneously (Multi-Task)

6. Select [AVERAGE] in [OUTPUT]-

[HOLD]-[TYPE].

7. Set the mode switch to TEACH.

8. Select [Yes] and save the settings.

9. Set the threshold value.

Setting surface fluctuation (TASK2)

10. Set the mode switch to FUN.

FUN RUN

TEACH

H L

FUN RUN

TEACH

1 P – P

3 SAMPLE

Is change saved?

1 YES 2 NO

Value

Digit

2 AVERAGE

Section3 APPLICATION and SETTING EXAMPLES

11. Select [Yes] and save the settings.

12. Press the ESC key to display the

TASK switching menu, and select

[TASK2].

13. Select [AVERAGE] in [MEASURE]-

[TASKSET].

14. Select [P-P] in [OUTPUT]-[HOLD]-

[TYPE].

Is change saved?

1 YES 2 NO

1 TASK1

3 TASK3 4 TASK4

1 OFF

3 PEAK

1 P – P

3 SAMPLE

2 TASK2

2 AVERAGE

2 AVERAGE

ZS-HL

User’s Manual

3-9

Section3

Measuring Multiple Items Simultaneously (Multi-Task)

15. Set the threshold value using the

same steps from 7 to 9.

Measurement

16. Set the mode switch to RUN.

Section3 APPLICATION and SETTING EXAMPLES

17. Select [Yes] and save the settings.