Cat. No. Z232-E1-02

Smart Sensors

ZS Series

Non-procedual Communication

Command Reference

Introduction

Thank you for purchasing the ZS Series.

This manual provides reference information on non-procedural communication commands

for ZS Series.

This manual provides information for the following models and versions.

Model Firmware Version

ZS-LDC v2.000 or later

ZS-HLDC v1.000 or later

ZS-MDC v2.000 or later

ZS-DSU v2.000 or later

Different firmware versions may cause communication errors, unintended setting

overwrite, and damages on the controller. Please make sure to use the controller with the

correct software version.

If your software version is not listed in the table above, please update the software using

the SmartMonitorZS firmware update software, such as WarpEngineZS, to match the

software version.

When using the ZS Series, be sure to observe the following:

• The ZS Series must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Contents

Contents

Setting the Communication Specifications ................................................... 2

Format.......................................................................................................... 3

List of Non-procedural Commands .............................................................. 4

List of Parameters (ZS-LDC) ........................................................................ 7

List of Parameters (ZS-HLDC) ................................................................... 12

List of Parameters (ZS-MDC) ..................................................................... 20

List of Parameters (ZS-DSU) ..................................................................... 25

FLOWDATA Reference .............................................................................. 30

Capturing Image Data ................................................................................ 36

Example of Usage ...................................................................................... 38

Revision History ......................................................................................... 42

Non-procedural Communication Command Reference

ZS-Series

1

Setting the Communication Specifications

Setting the Communication Specifications

Change the settings of the controller communication specifications for non-procedural

communication with the external device.

Use USB cable or RS-232C cable to connect ZS Series controllers to external devices. For USB cable

connection, install Smart Monitor ZS and USB driver beforehand. After installing Smart Monitor ZS, USB

ports are recognized as standard COM ports, and communication is achieved as with the RS-232C.

(Setting the communication specifications including baud rate is not necessary.) For details on how to

connect cable, refer to the User's Manual for each controller.

1.Set the mode switch to "FUN".

2.Select [System] - [Communication] - [Mode] menu.

3.Select [non-procedural].

4.For RS-232C cable connection, select [System] - [Communication] - [RS-232C]

menu to set the appropriate communication specifications for the external

device.

5.Save the settings.

If you are connecting multiple controllers, set all controllers other than ZS-HLDC to [non-procedural].

Note that the communication with SmartMonitor ZS is not available in [non-procedural] mode. If you

want to communicate with SmartMonitor ZS, reset to [CompoWay/F] communication.

ZS-Series

2

Non-procedural Communication Command Reference

Format

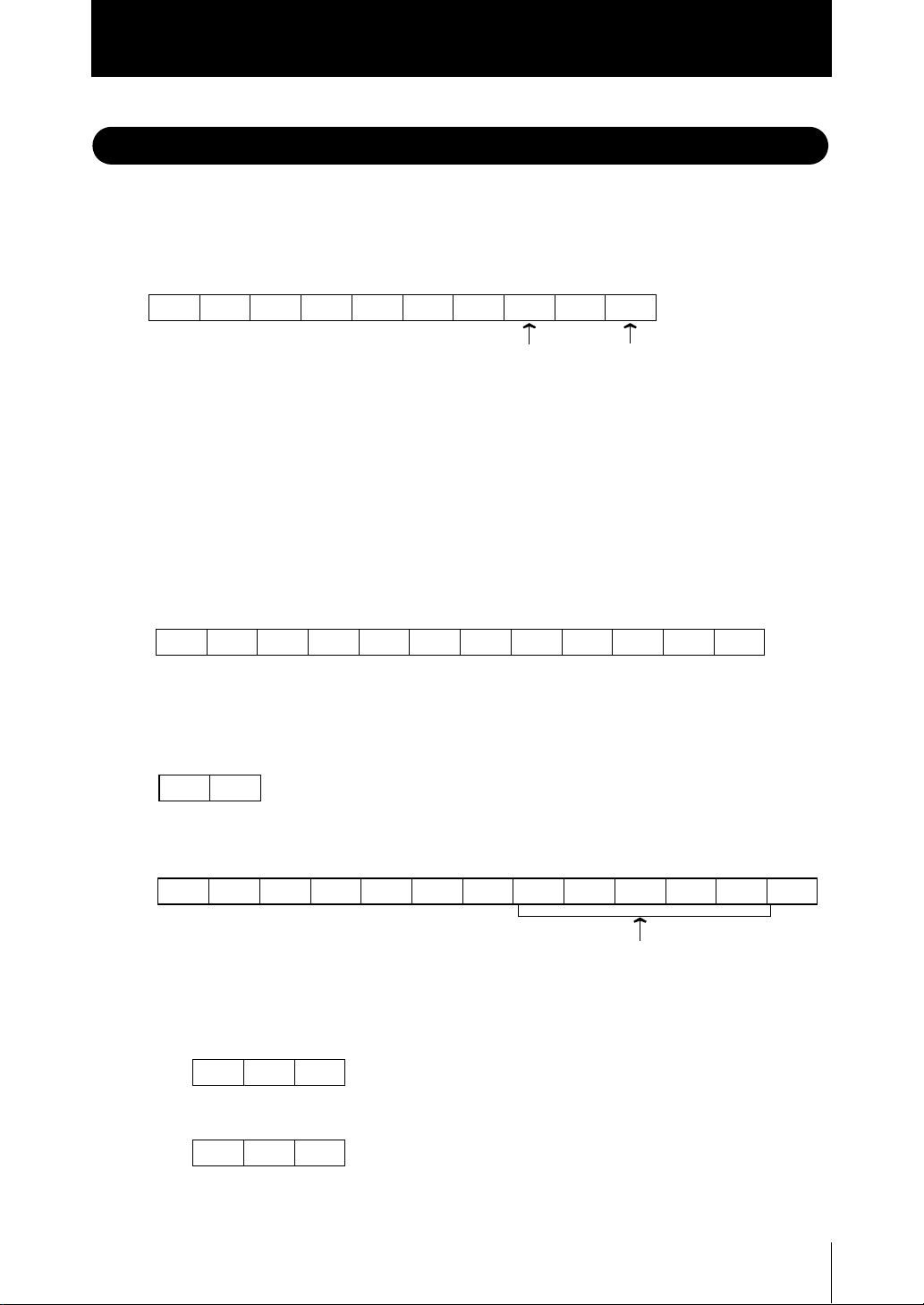

The format of non-procedural commands are as follows:

Example: A command to acquire a measured value MEASURE command

* Each character is output as an ASCII code (except for FLOWDATA response).

MEASURE OCR

Format

Space

Delimiter

The format of returned values changes depending on the command.

For the description of each command, refer to "List of Non-procedural Commands"

section.

•MEASURE / M / DATAGET

The returned value consists of right aligned 11 characters and a delimiter. The unit is

nm for a displacement value. Shortfalls of the characters are filled with spaces from

the left.

Example: The returned value is -30.719923 mm.

-30719923CR

•BANKGET command

The returned value is output as 1 character bank No.

Example: The bank No. is 2.

1CR

•VERGET command

The returned value is output in the following format:

ZS - LDC 2 . 0 0 0CR

Version

•Other commands

Either OK or ER is returned according to the result of the command. The command

was executed properly:

OKCR

The command was not executed properly or the setting was NG:

ERCR

The delimiter can be selected from the following three types.

CR/LF/CR+LF

ZS-Series

Non-procedural Communication Command Reference

3

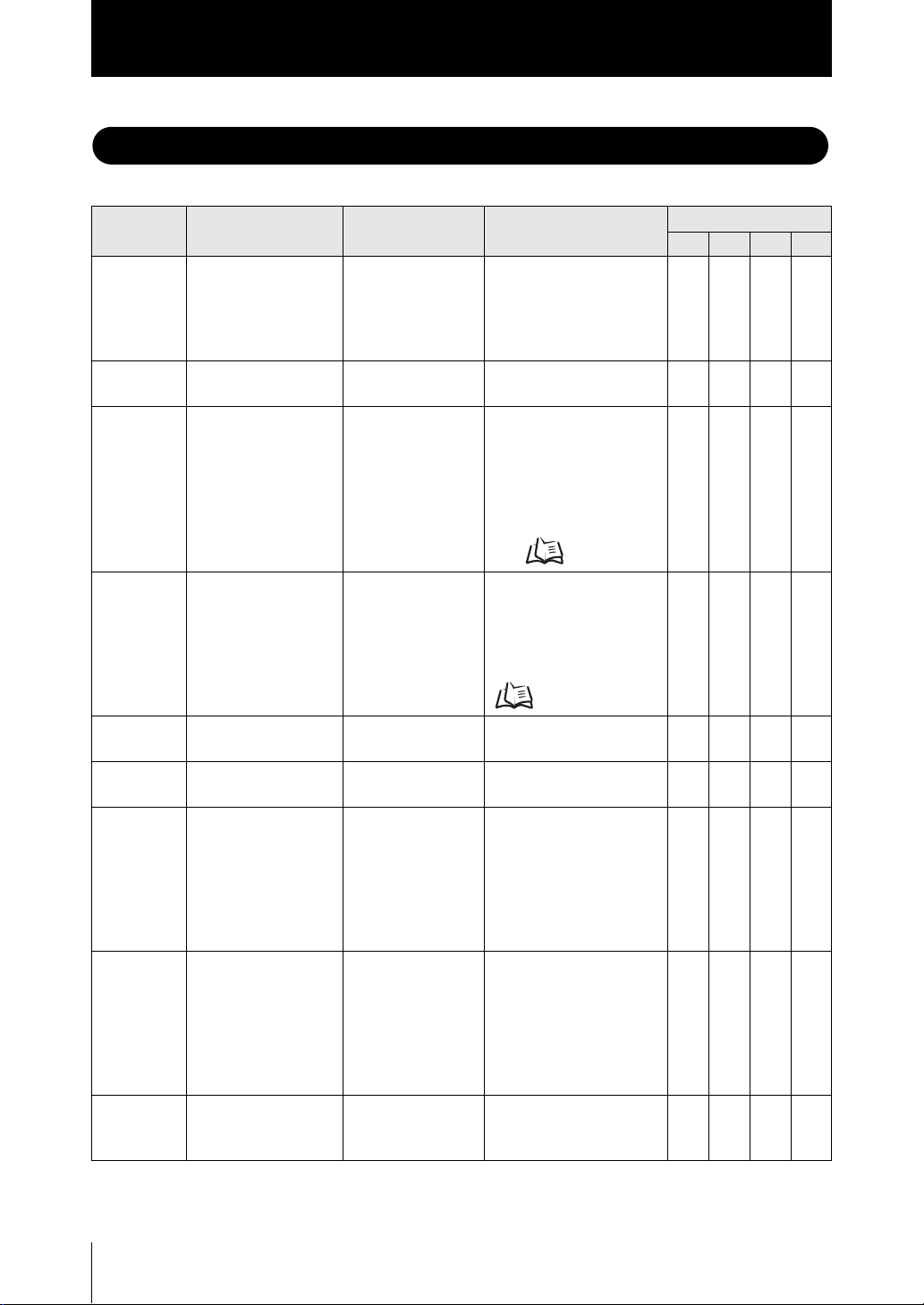

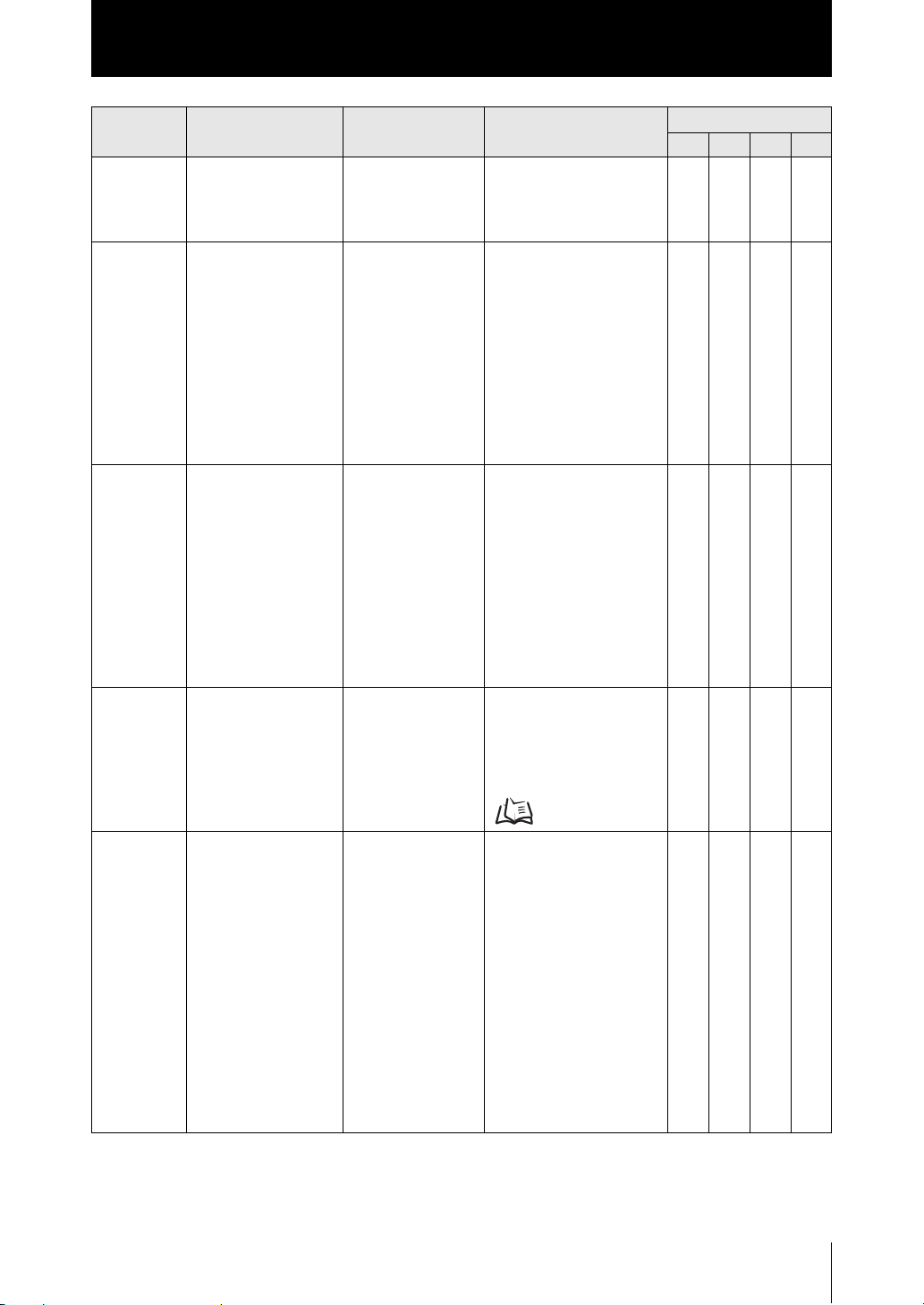

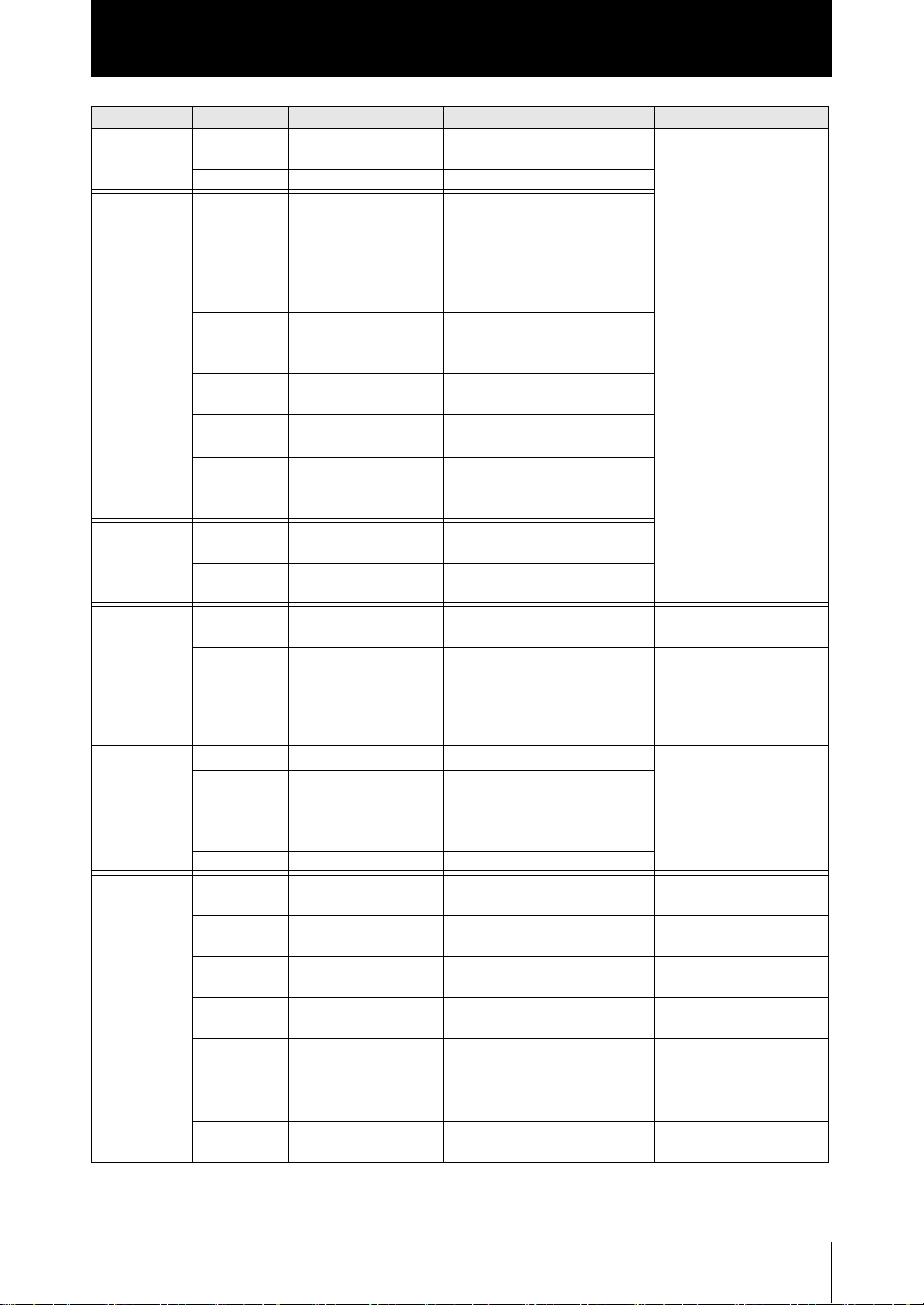

List of Non-procedural Commands

List of Non-procedural Commands

Command

name

MEASURE MEASURE

M M <Task No.>

DATAGET DATAGET <Unit No.>

DATASET DATAGET <Unit No.>

BANKGET BANKGET<delimiter> <Bank No.>

BANKSET BANKSET<Bank No.>

ZERORST ZERORST

ZEROCLR ZEROCLR

DATASAVE DATASAVE

Format Returned value Description

<measured value>

<Task No.>

<delimiter>

<delimiter>

<Data No.>

<delimiter>

<Data No.>

<Setting value>

<delimiter>

<delimiter>

<Task No.>

<delimiter>

<Task No.>

<delimiter>

<delimiter>

<delimiter>

<measured value>

<delimiter>

<Data>

<delimiter>

OK <delimiter>

ER <delimiter>

<delimiter>

OK <delimiter>

ER <delimiter>

OK <delimiter>

ER <delimiter>

OK <delimiter>

ER <delimiter>

OK <delimiter>

ER <delimiter>

Acquires a measured

value.

If <Task No.> is omitted, it

aqcuires the displayed

measured value.

Same as MEASURE

command.

Acquires measurement

data or setting data of the

processing unit.

* For details of numbers,

refer to "List of

Parameters."

p.7

Changes setting data of

the processing unit.

* For details of numbers,

refer to "List of

Parameters."

p.7

Acquires the current bank

No.

Switches to the designated

bank No.

Executes a zero-reset. If

<Task No.> is omitted, it

executes on the task

currently displayed as a

result. If <Task No.> is set

to 4, it executes on all the

tasks.

Cancels a zero-reset. If

<Task No.> is omitted, it

executes on the task

currently displayed as a

result. If <Task No.> is set

to 4, it executes on all the

tasks.

Saves all the bank data on

the flash memory of the

controller.

Support

HLDC

LDC

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes N o

Yes Yes Yes N o

Yes Yes Yes Yes

MDC DSU

ZS-Series

4

Non-procedural Communication Command Reference

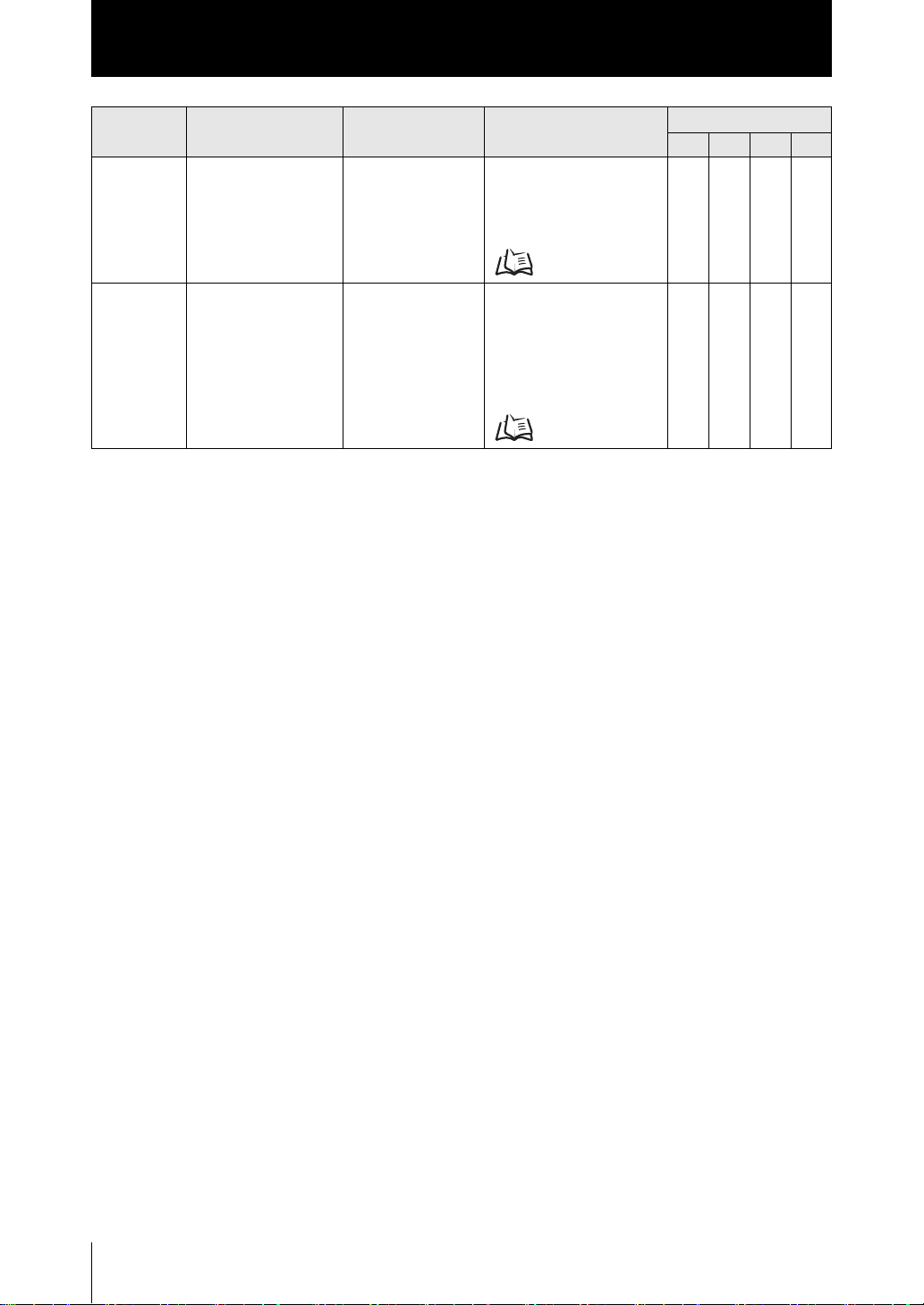

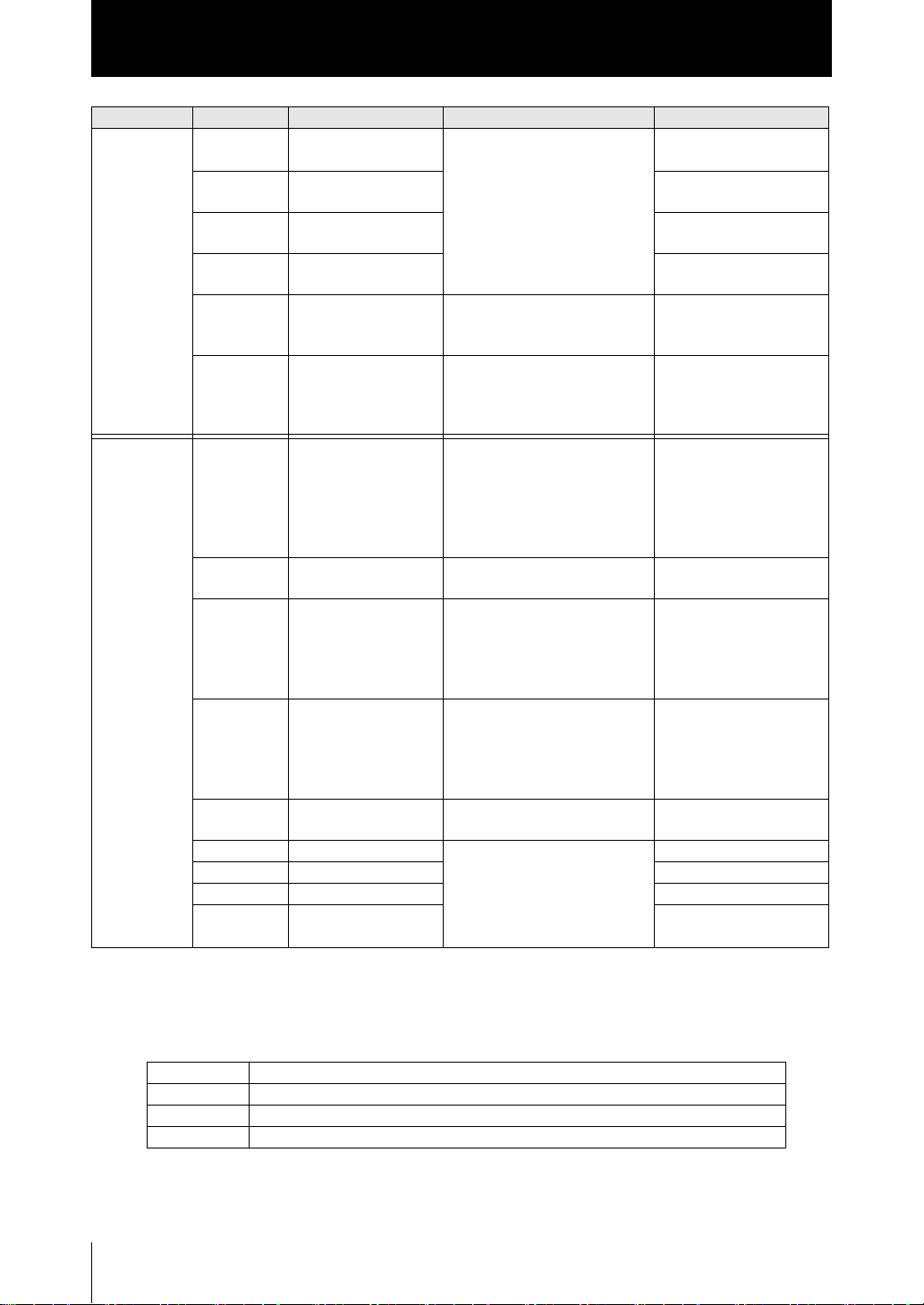

List of Non-procedural Commands

Command

name

Format Returned value Description

VERGET VERGET<delimiter> <Type/Version>

<delimiter>

BKMC2CTR

BKMC2CTR

<Bank file No.>

OK <delimiter>

ER <delimiter>

<Target controller CH>

<delimiter>

BKCTR2MC

BKCTR2MC

<Bank file No.>

OK <delimiter>

ER <delimiter>

<Target controller CH>

<Target Bank>

<delimiter>

FLOWDATA FLOWDATA

<delimiter>

OK <delimiter>

ER <delimiter>

Acquires version

information of the system.

Example: ZS-LDC

1.100<delimiter>

Sends bank files stored on

a memory card to the

specified bank of the

specified controller.

Example: To transfer the

bank data of the bank file

No. 2 on the memory card

to the controller of 1CH,

enter the following

command.

BKMC2CTR 2 1<delimiter>

Sends the specified bank

of the controller of the

specified CH to the

memory card.

Example: To transfer the

bank data on the Bank 3 of

2CH to the Bank file No. 10

on the memory card, enter

the following command.

BKCTR2MC 10 2

3<delimiter>

Used to acquire

measurement data at the

shortest intervals possible.

For details, refer to

"FLOWDATA Reference."

Support

HLDC

LDC

Yes Yes Yes Yes

No No No Yes

No No No Yes

Yes

(*1)

Yes

(*1)

MDC DSU

Yes

(*1)

No

CFLOGGET CFLOGGET

<Logging No.>

<delimiter>

<measurement value>

<delimiter>

:

<measurement value>

<delimiter>

Or, if the file with the

specified logging

No. does not exist,

the return value is

as follows:

NO FILE <delimiter>

If memory card is

not inserted, the

return value is as

follows:

p.30

Obtains the measurement

value from the logging file

with the specified No.

Enter 3-digits number to

the logging No.

Examples:

For the Logging No. 1

⇒ 001

No No No

For the Logging No. 11

⇒ 011

ZS-Series

Non-procedural Communication Command Reference

Yes

(*2)

5

List of Non-procedural Commands

Command

name

CFIMGGET CFIMGGET

Format Returned value Description

(Omitted) Capture the specified

<Group No.>

<Logging No.>

<delimiter>

image data.

For details, refer to

"Capturing Image Data."

HLDC

LDC

No No No

p.36

CFDATGET CFDATGET

<Group No.>

<delimiter>

<measurement value>

<delimiter>

:

<measurement value>

<delimiter>

Obtains the measurement

value from the logging file

for the image data in the

specified group.

For details, refer to

"Capturing Image Data."

No No No

p.36

*1 It is available when USB cable connection is used.

*2 For ZS-DSU Ver 2.00 or later. It is available when USB cable connection is used.

* Specifying CH

In case other than ZS-HLDC

Specify <CH No.> before <delimiter>. If <CH No.> is omitted, the command operates on the CH that received

it.

Example: To acquire the result for TASK2 of the controller of 2CH,

M 1 2 <delimiter>

Support

MDC DSU

Yes

(*2)

Yes

(*2)

In case of ZS-HLDC

Specify #XX at the beginning of the command.

If the CH No. is 1, specify #01. (Be sure to note double digits.)

If <CH No.> is omitted, the command operates on the CH that received it.

Example: To acquire the result for TASK2 of the controller of 2CH,

#02 M 1 <delimiter>

* Specifying the node

Specify @xx at the beginning of the command.

If the node No. is 1, specify @01. (Be sure to note double digits.)

If the node No. is omitted, the command operates on the node that received it.

To specify, the node and CH together in case of ZS-HLDC, specify @XX # △△ at the head of the

command.

* Format of a returned value

A returned value for MEASURE,M,DATAGET,CFLOGGET,CFDATGET is the right aligned 11 characters.

* Upper case and lower case characters

For alphabetic, only upper case characters are accepted.

* Task No.

Omit <Task No.> when issuing a command for ZS-LDC.

Task Nos are assigned as follows: 0: TASK1 1: TASK2 2: TASK3 3: TASK4.

ZS-Series

6

Non-procedural Communication Command Reference

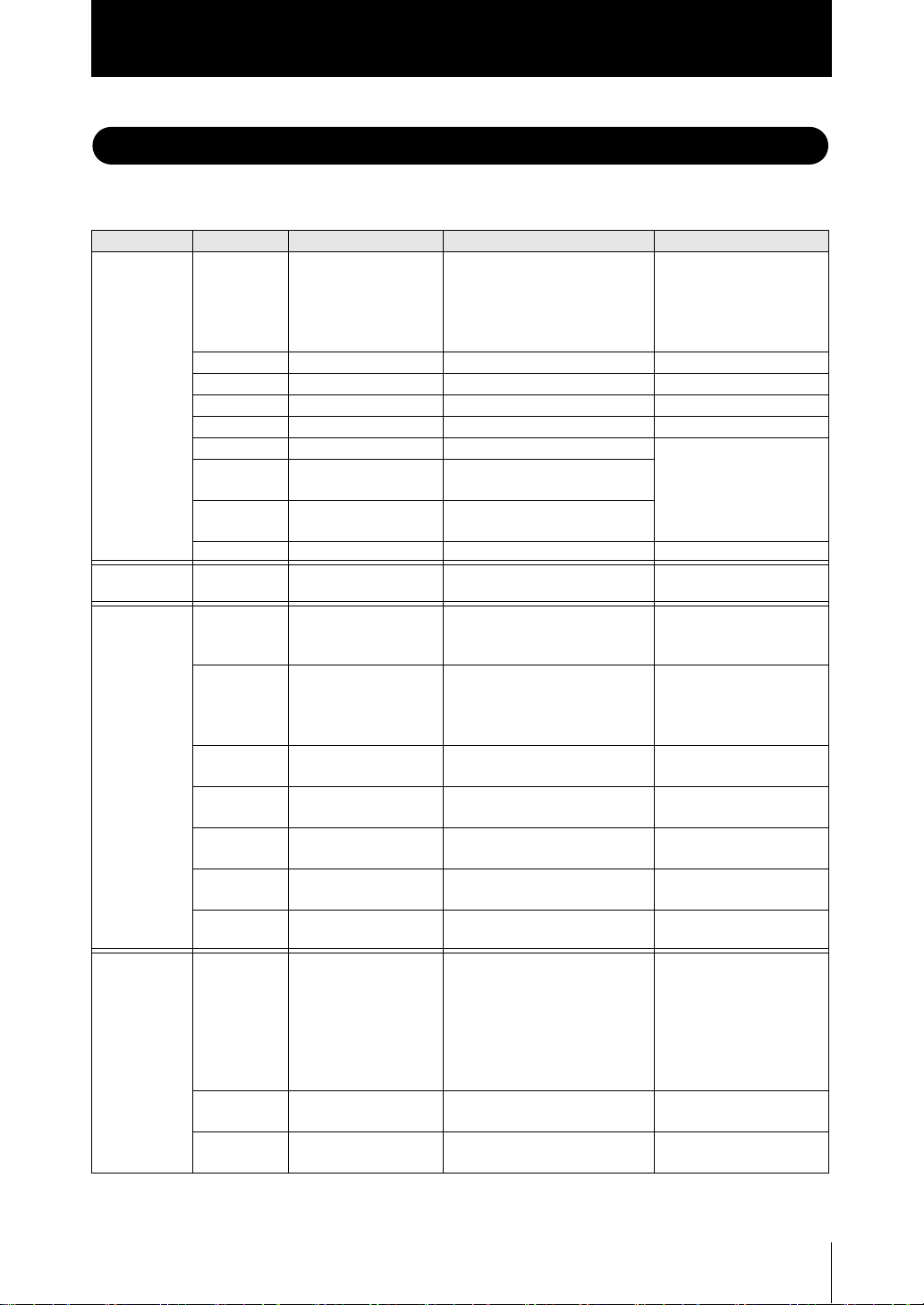

List of Parameters (ZS-LDC)

List of Parameters (ZS-LDC)

The following parameters can be obtained or set by DATASET or DATAGET command:

Unit No. Data No. Parameter Setting range/Output range Others

0 0 Measurement mode 0: STANDARD

1: HI-RESO

2: HI-SPEED

3: HI-SENS

4: CUSTOM

12 Start position of area 1 0 to 639 (pix)

14 End position of area 1 0 to 639 (pix)

24 Start position of area 2 0 to 639 (pix)

26 End position of area 2 0 to 639 (pix)

18 Exposure time 2 to 200 (1 div: 0.1ms) Parameters for CUSTOM

19 Number of additional

lines

20 Line skipping 0: OFF

32 Meas. Cycle 112 to 20000 (us)

1 0 Head installation 0: DIFFUSE

2 0 LD power mode 0: Auto

2 Surface to be

controlled for light

amount

13 Lower limit of LD

power

14 Upper limit of LD

power

37 Incident level

(1st surface)

38 Incident level

(2nd surface)

39 Incident level

(3rd surface)

3 0 Measurement object 0: NORMAL

1 Glass thickness/Gap

mode

2 Glass thickness/Gap

mode

1 to 200

1: ON

1: REGULAR

1: Auto-scale

2: Fixed

0: Peak

1: 1st surface

2: 2nd surface

3: 3rd surface

0 to 800 (1 div: 0.1%)

0 to 800 (1 div: 0.1%)

0 to 4095 (tone)

0 to 4095 (tone)

0 to 4095 (tone)

1: PCB

2: MIRROR

3: GLASS

4: THICK

5: GAP

6: CUSTOM

0: Normal

1: Film/Else

0: STOP

1: MOVE

mode

Non-procedural Communication Command Reference

ZS-Series

7

List of Parameters (ZS-LDC)

Unit No. Data No. Parameter Setting range/Output range Others

3 3 Image smoothing level 0: None

1: Filter size 2

2: Filter size 4

3: Filter size 8

4: Filter size 16

4 Background removing

level before addition

5 Background removing

level after addition

6 Edge threshold 0: 0%

4 0 Mutual interference

prevention mode

1 Mutual interference

prevention timing

5 0 Gain 1 to 5

40 1 Measurement surface

of area 1

32 Measurement value of

area 1 (1st surface)

33 Measurement value of

area 1 (2nd surface)

34 Measurement value of

area 1 (3rd surface)

41 0 Scaling mode 0: OFF

1 Span value -20000 to 20000 (1 div: 0.0001)

2 Offset value

42 2 Smooth 0: OFF

43 2 Average 0: 1 time

0 to 255 (tone)

0 to 4095 (tone)

1: 12.5%

2: 25%

3: 37.5%

4: 50%

5: 62.5%

6: 75%

7: 87.5%

0: OFF

1: ON

0: Timing A

1: Timing B

0: 1st surface

1: 2nd surface

2: 3rd surface

- (nm)

- (nm)

- (nm)

1: ON

-999999999 to 999999999 (nm)

1: ON

1: 2 times

2: 4 times

3: 8 times

4: 16 times

5: 32 times

6: 64 times

7: 128 times

8: 256 times

9: 512 times

10: 1024 times

11: 2048 times

12: 4096 times

Parameters for area 1 at

Glass thickness/Gap

measurement by moving

the objects.

To refer to or set the

parameters for area 2,

add 20 to the unit No. (*)

ZS-Series

8

Non-procedural Communication Command Reference

List of Parameters (ZS-LDC)

Unit No. Data No. Parameter Setting range/Output range Others

44 2 Differential 0: OFF

1: ON

3 Differentiation cycles 1 to 5000 (ms)

45 2 Hold type 0: OFF

1: PEAK

2: BOTTOM

3: P-P

4: AVERAGE

5: SAMPLE

3 Trigger method 0: EXT

1: SELF-UP

2: SELF-DOWN

4 Trigger level -999999999 to 999999999

(nm)

5 Trigger hysteresis 0 to 999999999 (nm)

6 Trigger delay (ms) 0 to 5000 (ms)

7 Sampling period (ms) 1 to 5000 (ms)

8 Trigger delay mode 0: OFF

1: ON

46 5 Offset at zero reset -999999999 to 999999999

(nm)

6 Zero reset mode 0: REAL

1: HOLD

120 0 Non-measurement

settings

1 Output at CLAMP 0: MAX

121 0 Hysteresis width 0 to 999999999 (nm) Setting judgment process

1 Timer mode 0: OFF

2 Delay time 1 to 5000 (ms)

122 2 Monitor focus mode 0: OFF

3 Monitor focus distance

value 1

4 Monitor focus distance

value 2

5 Monitor focus current

value 1

6 Monitor focus current

value 2

7 Monitor focus voltage

value 1

8 Monitor focus voltage

value 2

0: KEEP

1: CLAMP

1: 20mA

2: 12mA

3: 4mA

4: MIN

1: OFF DELAY

2: ON DELAY

3: ONE SHOT

1: ON

-999999999 to 999999999

(nm)

-999999999 to 999999999

(nm)

4 to 20 (mA)

4 to 20 (mA)

-10 to 10 (V)

-10 to 10 (V)

Non-procedural Communication Command Reference

ZS-Series

9

List of Parameters (ZS-LDC)

Unit No. Data No. Parameter Setting range/Output range Others

126 4 External input 0

ActiveSelect

5 External input 1

ActiveSelect

6 External input 2

ActiveSelect

7 External input 3

ActiveSelect

8 External input mode 0: Standard mode

9 Control TASK setting 0: TASK1

127 0 External input (IN) task

mode

1 External input (IN)

function mode

2 External output (OUT)

task mode

4 Linear output task

mode

6 Digital output target 0: OFF

10 External input 0 mode 0: Not used

11 External input 1 mode

12 External input 2 mode

13 External input 3 mode

0: Low Active

1: High Active

1: Bank switching mode

2: Parallel IN off mode

1: TASK2

2: TASK3

3: TASK4

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

5: TASKALL

0: Standard

1: Bank

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

1: ON

1: Trigger

2: Hold reset

3: Laser off

4: Zero reset

10

(*)

When [Glass thickness/Gap-Film/Else-Move] is selected, task processes similar to those of ZS-MDC are

performed internally.

The following processes are assigned to respective tasks:

TASK 1 Calculates Area 1 displacement value.

TASK 2 Calculates Area 2 displacement value.

TASK 3 Calculates the difference value (=Thickness/Gap) between TASK1 and TASK2.

TASK 4 Unused

The measurement conditions can be set for each task in this mode.

ZS-Series

Non-procedural Communication Command Reference

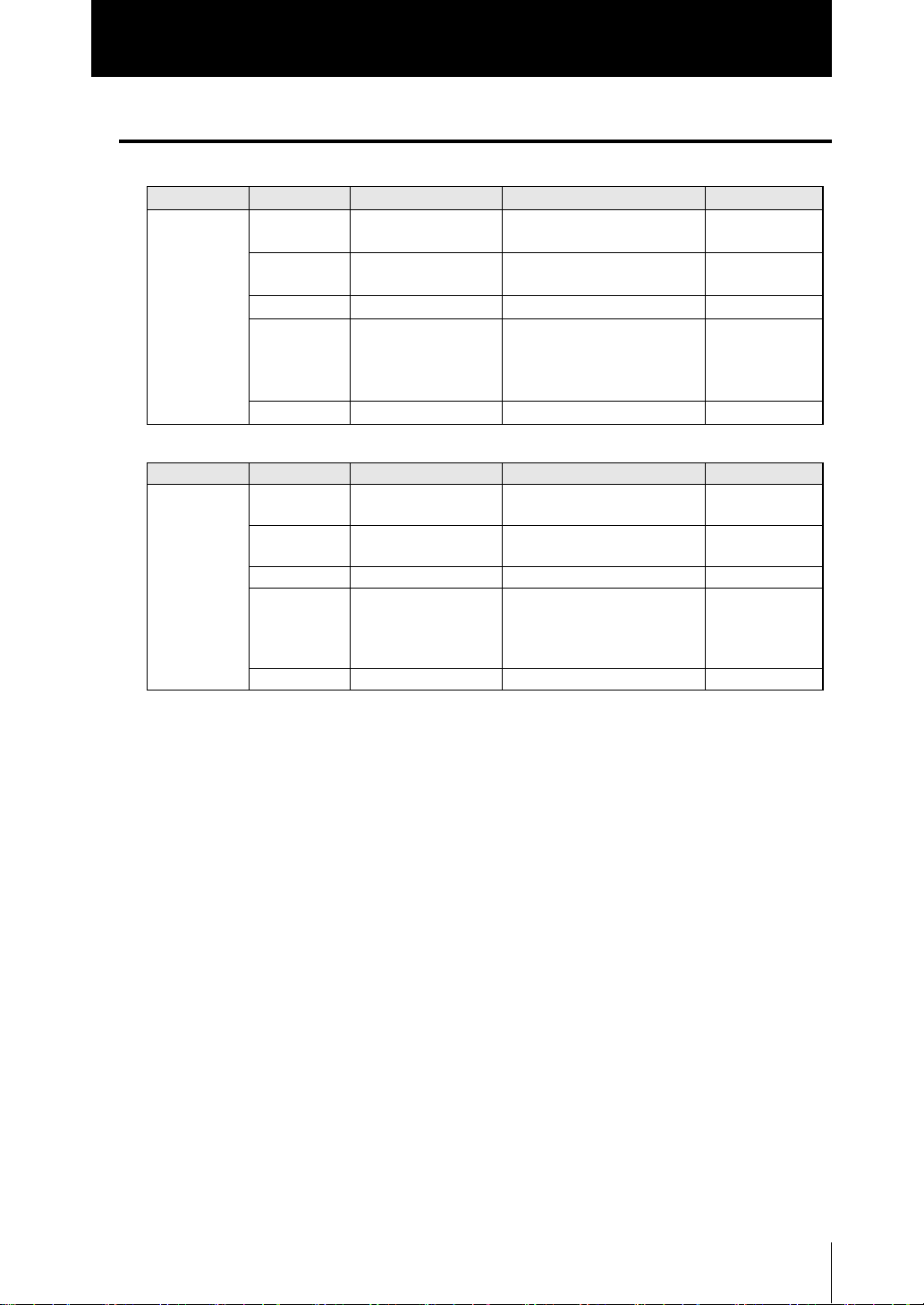

List of Parameters (ZS-LDC)

Setting Threshold Value

• A mode other than [Glass thickness/Gap-Film/Else-Move] is selected.

Unit No. Data No. Parameter Setting range/Output range Others

48 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0:OFF

6 Delay time 1 to 5000 (ms)

• [Glass thickness/Gap-Film/Else-Move] is selected.

Unit No. Data No. Parameter Setting range/Output range Others

88 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0:OFF

6 Delay time 1 to 5000 (ms)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1:OFF DELAY

2:ON DELAY

3:ONE SHOT

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1:OFF DELAY

2:ON DELAY

3:ONE SHOT

Non-procedural Communication Command Reference

ZS-Series

11

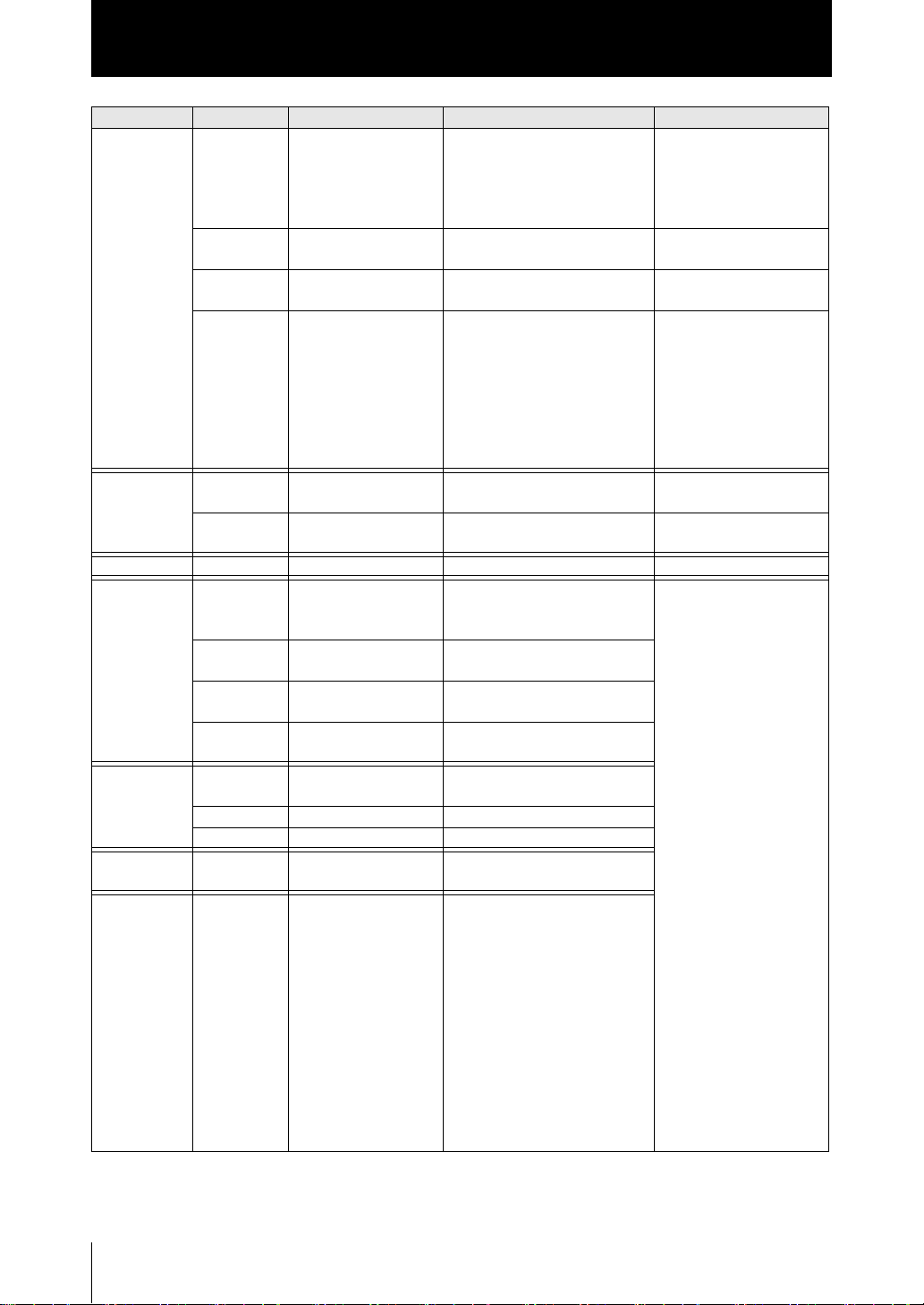

List of Parameters (ZS-HLDC)

List of Parameters (ZS-HLDC)

The following parameters can be obtained or set by DATASET or DATAGET command:

Unit No. Data No. Parameter Setting range/Output range Others

0 0 Measurement mode 0: STANDARD

1: HI-RESO

2: HI-SPEED

3: HI-SENS

4: CUSTOM

Measurement mode 1: STANDARD

2: HI-RESO

3: HI-SENS

4: CUSTOM

12 Start position of area 1 0 to 639 (pix)

14 End position of area 1 0 to 639 (pix)

13 Start line of area 1 0 to (No. of additional lines - 1)

15 End line of area 1 0 to (No. of additional lines - 1)

24 Start position of area 2 0 to 639 (pix)

26 End position of area 2 0 to 639 (pix)

25 Start line of area 2 0 to (No. of additional lines - 1)

27 End line of area 2 0 to (No. of additional lines - 1)

18 Exposure time 2 to 200 (1 div: 0.1ms)

When multi-task mode is OFF.

5 to 200 (1 div: 0.1ms)

When multi-task mode is ON.

19 Number of additional

lines

20 Line skipping 0: OFF

22 2-area mode 0: OFF

23 Compensation mode 0: OFF

32 Measurement cycle 112 to 20000 (us)

192 Reference point teach for

compensation mode

193 2-area teach 1: Execute teach

1 0 Head installation 0: Diffuse

2 0 LD power mode 0: Auto

2 Surface to be controlled

for light amount

1 to 200

When multi-task mode is OFF.

8 to 200

When multi-task mode is ON.

1: ON

1: ON

1: Start position compensation

2: End position compensation

3: Start/End position

compensation

1: Execute teach

1: Regular

1: Auto-scale

2: Fixed

0: Peak

1: First surface

2: Second surface

3: Third surface

When multi-task mode

is OFF.

When multi-task mode

is ON.

Parameters for

CUSTOM mode

12

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-HLDC)

Unit No. Data No. Parameter Setting range/Output range Others

2 6 LD power when fixed 0 to 800 (1 div: 0.1%)

13 Lower limit of LD power 0 to 800 (1 div: 0.1%)

14 Upper limit of LD power 0 to 800 (1 div: 0.1%)

32 Incident level 0 to 4095

36 LD power 0 to 800 (1 div: 0.1%)

37 Incident level

(First surface)

38 Incident level

(Second surface)

39 Incident level

(Third surface)

3 0 Measurement object 0: Normal

2 GLASS/GLASS

THICKNESS mode

3 Image smoothing level 0: No filter

4 Background removing

level before addition

6 Edge threshold 0: 0%

4 0 Mutual interference

prevention mode

1 Mutual interference

prevention timing

5 0 Gain setting 1 to 5

0 to 4095

0 to 4095

0 to 4095

1: PCB

2: Mirror

3: Glass

4: Glass thickness

0: Mode 1

1: Mode 2

1: Filter size 2

2: Filter size 4

3: Filter size 8

4: Filter size 16

0 to 255 (tone)

1: 12.5%

2: 25%

3: 37.5%

4: 50%

5: 62.5%

6: 75%

7: 87.5%

0: OFF

1: ON

0: Timing A

1: Timing B

When the

measurement object is

changed, the settings

are initialized

according to the

selected object.

Non-procedural Communication Command Reference

ZS-Series

13

List of Parameters (ZS-HLDC)

Unit No. Data No. Parameter Setting range/Output range Others

40 0 Measurement mode 0: OFF

1: Average

2: Peak

3: Bottom

4: Thickness

5: Gap

6: K+mX; +nY

3 Parameter X 0: None

1: TASK 1

2: TASK 2

3: TASK 3

4: TASK 4

4 Parameter Y 0: None

1: TASK 1

2: TASK 2

3: TASK 3

4: TASK 4

5 Parameter K -999999999 to 999999999 (nm)

8 Parameter M -100 to 100 (1div: 0.1)

9 Parameter N -100 to 100 (1div: 0.1)

1 Surface for

measurement (Area 1)

10 Surface for

measurement (Area 2)

11 Measurement position 1

(for thickness

measurement)

12 Measurement position 2

(for thickness

measurement)

13 Measurement area 0: Area 1

14 Width of peak bottom 0 to 255

32 Measurement value

(First surface)

33 Measurement value

(Second surface)

34 Measurement value

(Third surface)

41 0 Scaling mode 0: OFF

1 Span value -20000 to 20000 (1 div: 0.0001)

2 Offset value

42 2 Smooth 0: OFF

0: First surface

1: Second surface

2: Third surface

0: First surface

1: Second surface

2: Third surface

0: None

1: Average

2: Peak

3: Bottom

0: None

1: Average

2: Peak

3: Bottom

1: Area 2

- (nm)

- (nm)

- (nm)

1: ON

-999999999 to 999999999 (nm)

1: ON

TASK1 settings.

The settings in Unit

Number 40 are valid

only for multi-task

mode.

14

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-HLDC)

Unit No. Data No. Parameter Setting range/Output range Others

43 2 Average 0: 1 time

1: 2 times

2: 4 times

3: 8 times

4: 16 times

5: 32 times

6: 64 times

7: 128 times

8: 256 times

9: 512 times

10: 1024 times

11: 2048 times

12: 4096 times

44 2 Differential type 0: OFF

1: ON

3 Differentiation cycles 1 to 5000 (ms)

45 2 Hold type 0: Through

1: Peak

2: Bottom

3: Peak to peak

4: Average

5: Sampling

3 Trigger method 0: External input

1: Self up

2: Self down

4 Trigger level -999999999 to 999999999 (nm)

5 Trigger hysteresis 0 to 999999999 (nm)

6 Trigger delay (ms) 0 to 5000 (ms)

7 Sampling period (ms) 1 to 5000 (ms)

8 Trigger delay mode 0: OFF

1: ON

46 5 Offset at zero reset -999999999 to 999999999 (nm)

7 Zero reset mode 0: REAL

1: HOLD

64 Status 0: OFF

1: ON

TASK1 settings.

The settings in Unit

Number 40 are valid

only for multi-task

mode.

(*)

If GLASS/MODE 2 or GLASS THICKNESS/MODE 2 is selected, a process using multiple tasks will be

performed, as in the multi-task mode.

The following processes are assigned to the respective tasks:

TASK 1 Calculates Area 1 displacement value.

TASK 2 Calculates Area 2 displacement value.

TASK 3 GLASS: Calculates the result of the NEAR side of TASK 1 and TASK 2.

GLASS THICKNESS: Calculates the difference value between TASK1 and TASK2.

TASK 4 Unused

ZS-Series

Non-procedural Communication Command Reference

15

List of Parameters (ZS-HLDC)

The measurement conditions can be set for each task in this mode.

• Configuration of Task

The ZS-HLDC performs task processing.

The processing units for each task are grouped into 20 units.

To refer to the processing unit of TASK N, therefore, add 20×(N-1) to the above processing unit No.

Example: To change the averaging process of TASK2, refer to or set to a parameter with:

Process unit No.=43+20×(2-1)=63 and

Data No.=2

Unit No. Data No. Parameter Setting range/Output range Others

120 0 Hysteresis width 0 to 999999999 (nm) Setting judgment process

1

2

3 Judgment output

121 0 Non-measurement

122 2 Monitor focus mode 0: OFF

3 Monitor focus distance

4 Monitor focus distance

5 Monitor focus current

6 Monitor focus current

7 Monitor focus voltage

8 Monitor focus voltage

21 Output mode TASK When multi-task mode is OFF.

Timer mode 0: OFF

1: OFF-Delay

2: ON-Delay

3: One shot

Delay time 1 to 5000 (ms)

0: TASK 1

TASK

settings

value 1

value 2

value 1

value 2

value 1

value 2

1: TASK 2

2: TASK 3

3: TASK 4

0: Keep

1: Clamp

1: ON

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

4 to 20 (mA)

4 to 20 (mA)

-10 to 10 (V)

-10 to 10 (V)

0: OFF

1: ON

When multi-task mode is ON.

0: OFF

1: TASK 1

2: TASK 2

3: TASK 3

16

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-HLDC)

Unit No. Data No. Parameter Setting range/Output range Others

122 23 Output at CLAMP Voltage output

0: MAX

1: 10 V

2: 9 V

3: 8 V

4: 7 V

5: 6 V

6: 5 V

7: 4 V

8: 3 V

9: 2 V

10: 1 V

11: 0 V

12: -1 V

13: -2 V

14: -3 V

15: -4 V

16: -5 V

17: -6 V

18: -7 V

19: -8 V

20: -9 V

21: -10 V

22: MIN

Current output

0: MAX

1: 20 mA

2: 19 mA

3: 18 mA

4: 17 mA

5: 16 mA

6: 15 mA

7: 14 mA

8: 13 mA

9: 12 mA

10: 11 mA

11: 10 mA

12: 9 mA

13: 8 mA

14: 7 mA

15: 6 mA

16: 5 mA

17: 4 mA

123

Digital output

2 Monitor focus mode 0: OFF

1: ON

3

4

5

6

7 Clear monitor focus 1: Clear

Monitor focus distance

value 1

Monitor focus distance

value 2

Monitor focus current

value 1

Monitor focus current

value 2

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

0 to 65535

0 to 65535

Non-procedural Communication Command Reference

ZS-Series

17

List of Parameters (ZS-HLDC)

Unit No. Data No. Parameter Setting range/Output range Others

123 8 Output at CLAMP 0 to 65535

124

Logging

126

Link

240

Parallel input

10 Output TASK

(When the

measurement value is

output)

11 Output mode 0: OFF

12 Update cycle 0 to 100

2Mode 0: OFF

3 Buffering period 1 to 65535

4 Buffer size per item of

data

14 TASK 1 0: OFF

15 TASK 2 0: OFF

16 TASK 3 0: OFF

17 TASK 4 0: OFF

0 Output TASK 0: TASK 1

6Mode 0: OFF

4 Input 0 0: Low Active

5 Input 1

6 Input 2

7 Input 3

8 External input mode 0: Normal mode

9 Control TASK setting 0: TASK1

0: TASK 1

1: TASK 2

2: TASK 3

3: TASK 4

4: Consecutively

1: Measurement value

2: Judgment

1: ON

1 to 1000

1: ON

1: ON

1: ON

1: ON

1: TASK 2

2: TASK 3

3: TASK 4

1: ON

1: High Active

1: Bank switching mode

2: Parallel IN off mode

1: TASK2

2: TASK3

3: TASK4

When multi-task mode is

ON.

18

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-HLDC)

Setting Threshold Value

When multi-task mode is OFF

• When selecting a mode other than "GLASS/MODE 2" and "GLASS THICKNESS/

MODE 2".

Unit No. Data No. Parameter Setting range/Output range Others

48 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0:OFF

6 Delay time 1 to 5000 (ms)

• When selecting "GLASS/MODE 2" or "GLASS THICKNESS/MODE 2" mode.

Unit No. Data No. Parameter Setting range/Output range Others

88 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0:OFF

6 Delay time 1 to 5000 (ms)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1:OFF DELAY

2:ON DELAY

3:ONE SHOT

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1:OFF DELAY

2:ON DELAY

3:ONE SHOT

When multi-task mode is ON

• Can be set for each TASK.

Unit No. Data No. Parameter Setting range/Output range Others

48 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0:OFF

6 Delay time 1 to 5000 (ms)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1:OFF DELAY

2:ON DELAY

3:ONE SHOT

Non-procedural Communication Command Reference

TASK1 settings.

For TASK2 to

TASK4, the unit

numbers are as

follows:

TASK2: 68

TASK3: 88

TASK4: 108

ZS-Series

19

List of Parameters (ZS-MDC)

List of Parameters (ZS-MDC)

The following parameters can be acquired or set by DATASET or DATAGET command:

Unit No. Data No. Parameter Setting range/Output range Others

0 0 Destination CH to

input data A

1 Destination CH to

input data B

2 Destination CH to

input data C

3 Destination CH to

input data D

4 Destination CH to

input data E

5 Destination CH to

input data F

6 Destination CH to

input data G

7 Destination CH to

input data H

8 Destination CH to

input data I

9 Input mode of data A 0: OFF 1: ON

10 Input mode of data B 0: OFF 1: ON

11 Input mode of data C 0: OFF 1: ON

12 Input mode of data D 0: OFF 1: ON

13 Input mode of data E 0: OFF 1: ON

14 Input mode of data F 0: OFF 1: ON

15 Input mode of data G 0: OFF 1: ON

16 Input mode of data H 0: OFF 1: ON

17 Input mode of data I 0: OFF 1: ON

32 Acquisition result A

33 Acquisition result B

34 Acquisition result C

35 Acquisition result D

36 Acquisition result E

37 Acquisition result F

38 Acquisition result G

39 Acquisition result H

40 Acquisition result I

40 0 Data setting mode 0: OFF

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

0 to 11 (CH)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1: Individual

2: Calculation

20

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-MDC)

Unit No. Data No. Parameter Setting range/Output range Others

40 1 Individual setting

mode

2 Calculation setting

mode

3 Parameter X 0: Input A

4 Parameter Y

5 Parameter K

6 Parameter m -100 to 100 (×0.1)

7 Parameter n -100 to 100 (×0.1)

8 Input A setting

(AVE,MAX-MIN)

9 Input B setting

(AVE,MAX-MIN)

10 Input C setting

(AVE,MAX-MIN)

11 Input D setting

(AVE,MAX-MIN)

12 Input E setting

(AVE,MAX-MIN)

13 Input F setting

(AVE,MAX-MIN)

14 Input G setting

(AVE,MAX-MIN)

15 Input H setting

(AVE,MAX-MIN)

16 Input I setting

(AVE,MAX-MIN)

17 TASK1 setting

(AVE,MAX-MIN)

0: Input A

1: Input B

2: Input C

3: Input D

4: Input E

5: Input F

6: Input G

7: Input H

8: Input I

0: Thickness (K-(X+Y))

1: Step (X-Y)

2: K+mX+nY

3: AVE

4: MAX-MIN

1: Input B

2: Input C

3: Input D

4: Input E

5: Input F

6: Input G

7: Input H

8: Input I

9: TASK 1

10: TASK 2

11: TASK 3

12: TASK 4

-999999999 to 999999999 (nm)

0: OFF

1: ON

Non-procedural Communication Command Reference

ZS-Series

21

List of Parameters (ZS-MDC)

Unit No. Data No. Parameter Setting range/Output range Others

40 18 TASK2 setting

(AVE,MAX-MIN)

19 TASK3 setting

(AVE,MAX-MIN)

20 TASK4 setting

(AVE,MAX-MIN)

21 Thickness

41 0 Scaling mode 0: OFF

1 Span value -20000 to 20000 (×0.0001)

2 Offset value

42 2 Smooth 0: OFF

43 2 Average 0: 1 time

44 2 Differential 0: OFF

3 Differentiation cycles 1 to 5000 (ms)

45 2 Hold type 0: OFF

3 Trigger method 0: EXT

4 Trigger level

5 Trigger hysteresis 0 to 999999999 (nm)

6 Trigger delay (ms) 0 to 5000 (ms)

7 Sampling period (ms) 1 to 5000 (ms)

8 Trigger delay mode 0: OFF

46 5 Offset at zero reset

6 Zero reset mode 0: REAL

0: OFF

1: ON

-999999999 to 999999999 (nm)

1: ON

-999999999 to 999999999 (nm)

1: ON

1: 2 times

2: 4 times

3: 8 times

4: 16 times

5: 32 times

6: 64 times

7: 128 times

8: 256 times

9: 512 times

10: 1024 times

11: 2048 times

12: 4096 times

1: ON

1: PEAK

2: BOTTOM

3: P-P

4: AVERAGE

5: SAMPLE

1: SELF-UP

2: SELF-DOWN

-999999999 to 999999999 (nm)

1: ON

-999999999 to 999999999 (nm)

1: HOLD

22

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-MDC)

Unit No. Data No. Parameter Setting range/Output range Others

120 0 Non-measurement

settings

1 Output at CLAMP 0: MAX

121 0 Hysteresis width 0 to 999999999 (nm)

1 Timer mode 0: OFF

2 Delay time 1 to 5000 (ms)

122 2 Monitor focus mode 0: OFF

3 Monitor focus

distance value 1

4 Monitor focus

distance value 2

5 Monitor focus current

value 1

6 Monitor focus current

value 2

7 Monitor focus voltage

value 1

8 Monitor focus voltage

value 2

125 4 External input 0

ActiveSelect

5 External input 1

ActiveSelect

6 External input 2

ActiveSelect

7 External input 3

ActiveSelect

8 External input mode 0: Standard mode

9 Control TASK setting 0: TASK1

126 0 External input (IN)

task mode

1 External input (IN)

function mode

0: KEEP

1: CLAMP

1: OFF DELAY

2: ON DELAY

3: ONE SHOT

1: ON

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

4 to 20 (mA)

4 to 20 (mA)

-10 to 10 (V)

-10 to 10 (V)

0: Low Active

1: High Active

1: Bank switching mode

2: ParallelIN off mode

1: TASK2

2: TASK3

3: TASK4

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

5: TASKALL

0: Standard

1: Bank

Non-procedural Communication Command Reference

ZS-Series

23

List of Parameters (ZS-MDC)

Unit No. Data No. Parameter Setting range/Output range Others

126 2 External output (OUT)

task mode

4 Linear output task

mode

6 Digital output target 0: OFF

10 External input 0 mode 0: Not used

11 External input 1 mode

12 External input 2 mode

13 External input 3 mode

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

0: None

1: TASK1

2: TASK2

3: TASK3

4: TASK4

1: ON

1: Trigger

2: Hold reset

3: Laser off

4: Zero reset

• Configuration of Task

The ZS-MDC performs task processing. The processing units for each task are grouped

into 20 units. To refer to the processing unit of TASK N, therefore, add 20×(N-1) to the

above processing unit No.

Example: To change the averaging process of TASK2, refer to or set to a parameter with:

Process unit No.=43+20×(2-1)=63 and

Data No.=2

Setting Threshold Value

• In case of TASK1

Unit No. Data No. Parameter Setting range/Output range Others

48 2 Lower limit of

threshold

3 Upper limit of

threshold

4 Hysteresis width 0 to 999999999 (nm)

5 Timer mode 0: OFF

6 Delay time 1 to 5000 (ms)

To change the threshold of TASKN, change the unit No. as follows:

Unit No.=48+20X(N-1)

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

1: OFF DELAY

2: ON DELAY

3: ONE SHOT

24

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-DSU)

List of Parameters (ZS-DSU)

The following parameters can be obtained or set by DATASET or DATAGET command:

Unit No. Data No. Parameter Setting range/Output range Others

0 0 Input CH to Source A 0: 1CH

1 Input CH to Source B

2 Input CH of Source C

3 Input CH to Source D

4 Input CH to Source E

5 Input CH to Source F

6 Input CH to Source G

7 Input CH to Source H

8 Input CH of Source I

9 Input CH of Source J

10 Input CH of Source K

11 Input CH of Source L

12 Input CH of Source M

13 Input CH of Source N

14 Selected TASK of Source A0: TASK1

15 Selected TASK of Source

B

16 Selected TASK of Source

C

17 Selected TASK of Source

D

18 Selected TASK of Source

E

19 Selected TASK of Source

F

20 Selected TASK of Source

G

21 Selected TASK of Source

H

22 Selected TASK of Source

I

23 Selected TASK of Source

J

24 Selected TASK of Source

K

25 Selected TASK of Source

L

26 Selected TASK of Source

M

27 Selected TASK of Source

N

1: 2CH

2: 3CH

3: 4CH

4: 5CH

5: 6CH

6: 7CH

7: 8CH

8: 9CH

9: 10CH

:

13: 14CH

1: TASK2

2: TASK3

3: TASK4

4: InputA

5: InputB

:

13: InputI

Valid when the

connected controller

is a ZS-MDC.

Non-procedural Communication Command Reference

ZS-Series

25

List of Parameters (ZS-DSU)

Unit No. Data No. Parameter Setting range/Output range Others

0 28 Save mode of Source A 0: OFF

29 Save mode of Source B

30 Save mode of Source C

31 Save mode of Source D

32 Save mode of Source E

33 Save mode of Source F

34 Save mode of Source G

35 Save mode of Source H

36 Save mode of Source I

37 Save mode of Source J

38 Save mode of Source K 0: OFF

39 Save mode of Source L

40 Save mode of Source M

41 Save mode of Source N

64 Acquisition result A

65 Acquisition result B

66 Acquisition result C

67 Acquisition result D

68 Acquisition result E

69 Acquisition result F

70 Acquisition result G

71 Acquisition result H

72 Acquisition result I

73 Acquisition result J

74 Acquisition result K

75 Acquisition result L

76 Acquisition result M

77 Acquisition result N

1 0 Start trigger mode 0: None

1 Start trigger

Trigger edge polarity

2 Start trigger

Data selection

3 Start trigger

Delay

4 Start trigger

Data threshold

1: ON

1: ON

-999999999 to 999999999 (nm)

1: External input

2: Data

3: Window

4: I/O

5: HOUR

0: Up trigger

1: Down trigger

0: Source A

1: Source B

:

13: Source N

-9999 to 9999 (ms) (*1)

-127 through 127 (Number of

images) (*2)

-999999999 to 999999999 (nm)

(*1) [Save image] is

set to OFF.

(*2) [Save image] is

set to ON.

26

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-DSU)

Unit No. Data No. Parameter Setting range/Output range Others

1 6 Start trigger

Window mode

7 Start trigger

Window upper limit

8 Start trigger

Window upper limit

10 Start trigger

Pattern of I/O

I/O selection

12 End trigger mode 0: BUTTON

13 End trigger

Trigger edge polarity

14 End trigger

Data selection

15 End trigger

Data threshold

17 End trigger

Window mode

18 End trigger

Window upper limit

19 End trigger

Window lower limit

21 End trigger

Pattern of I/O

I/O selection

24 End trigger

Logging data points

2 0 Save mode 0: OneShot

1 Repeat mode 0: New

2 Repeat end conditions 0: None

0: WindowIn

1: WindowOut

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

0: IN0

1: IN1

2: IN2

3: IN3

4: OUT0

5: OUT1

6: OUT2

7: OUT3

8: OUT4

1: EXT

2: DATA

3: WINDOW

4: I/O

5: HOUR

6: QUANT

7: TIME

Same as Start trigger

Same as Start trigger

1 through 999999 (*1)

1 through 128 (*2)

1: Repeat

1: ADD

2: OVER WR

1: Trigger times

2: Elapsed time (timeout)

When [Save image] is

set to ON, [TIME] is

not available.

(*1) [Save image] is

set to OFF.

(*2) [Save image] is

set to ON.

When [Save image] is

set to ON, [REPEAT]

is not available.

When [Save image] is

set to ON, [ADD] is

not available.

Non-procedural Communication Command Reference

ZS-Series

27

List of Parameters (ZS-DSU)

Unit No. Data No. Parameter Setting range/Output range Others

2 3 Repeat end conditions

Trigger times

6 Interval of saving image 0: All

7 NG save mode 0: OR

8 Save image mode 0: Standard

3 1 I/O data 0: No save

2 Save direction (Range) 0: COLUMN

3 New line input 0: Ignore

Label input and time settings can not be set or referenced.

1 to 100000 (pcs)

1: Save NG

1: AND

1: Latest

1: Save

1: ROW

1: Enable

It is available only if

[Save image] is set to

ON.

28

ZS-Series

Non-procedural Communication Command Reference

List of Parameters (ZS-DSU)

Judgment relation

Unit No. Data No. Parameter Setting range/Output range Others

40 0 Input source 0: Source A

1: Source B

2: Source C

3: Source D

4: Source E

5: Source F

6: Source G

7: Source H

8: Source I

9: Source J

10: Source K

11: Source L

12: Source M

13: Source N

1 Lower limit of

threshold

2 Upper limit of

threshold

-999999999 to 999999999 (nm)

-999999999 to 999999999 (nm)

For Image Logging

Unit No. Data No. Parameter Setting range/Output range Others

20 0 Align image 0: None

1: 1CH

2: 2CH

:

14: 14CH

1 Save image 0: OFF

1: ON

Non-procedural Communication Command Reference

ZS-Series

29

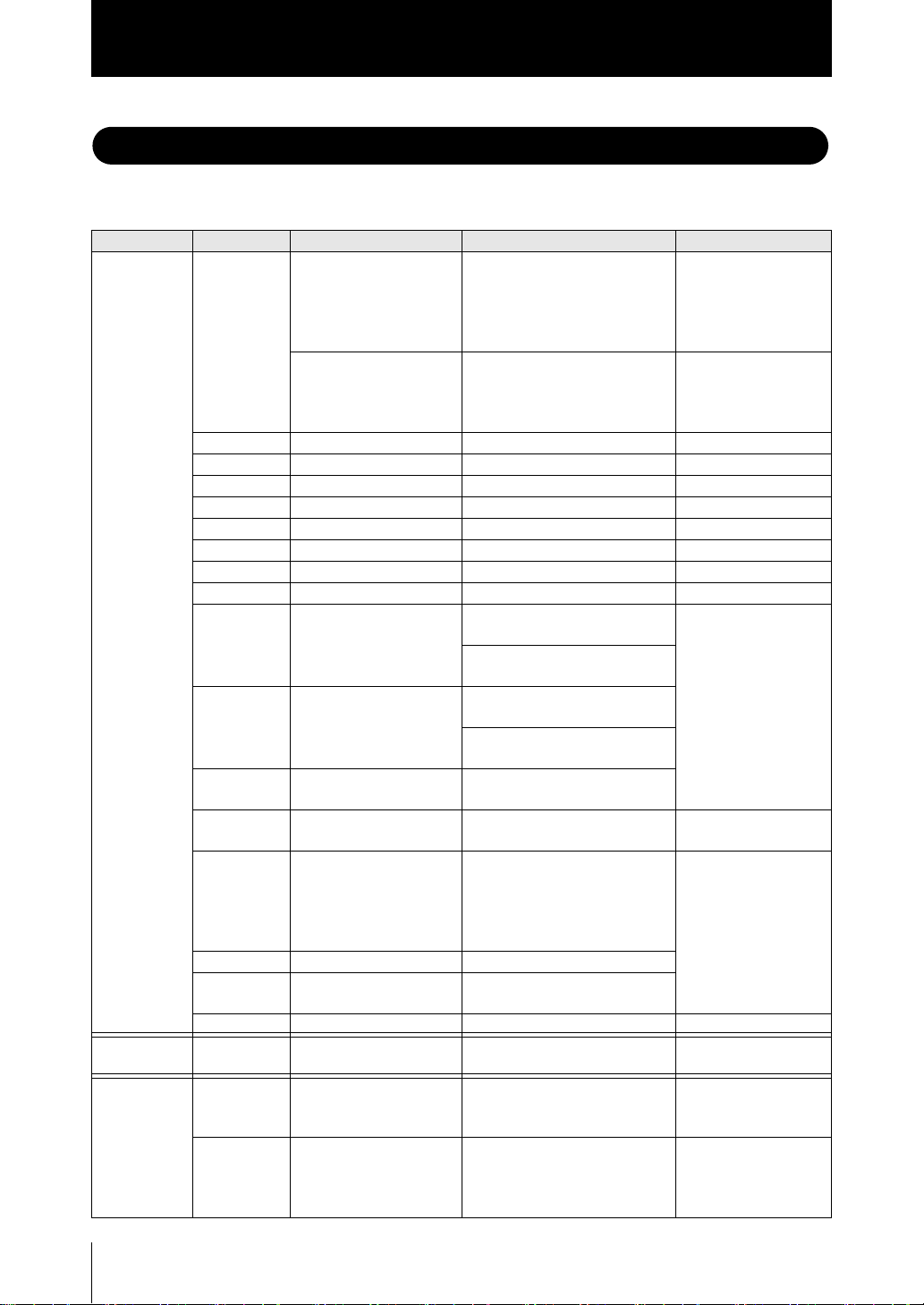

FLOWDATA Reference

C

FLOWDATA Reference

What is FLOWDATA?

The ZS series implements high speed sampling measurement up to 110us.

Handling these measurement data with an external device requires reading in a large

amount of data.

The ZS series are provided with a mechanism which enables to handle and acquire

measurement data by a given bundle.

This bundle of data is called a FLOWDATA.

■ How to acquire FLOWDATA

FLOWDATA is batch output if the controller has accepted the command for acquiring a

FLOWDATA when data is accumulated for the specified buffer size (max. 1000 data).

A device receiving data (such as PC) needs to issue the command before the ZS controller accumulates measurement data for the buffer size.

LD ONZEROENABLE

H

P

L

P

Issue command

Batch acquire data for the buffer size

Receive data

Issue command

Batch acquire data for the buffer size

Receive data

Issue command

Batch acquire data for the buffer size

Receive data

Issue command

If the controller has not received the command when measurement data for the buffer size is

accumulated in the controller, the past data is overwritten:

In this case, it raises an error flag for buffer overflow. A device receiving data (such as PC) needs

to check this flag to see if the commands have been issued in time.

Controller

Accumulating data

Output the result

Accumulating data

Output the result

Accumulating data

Output the result

Accumulating data

ZS-Series

30

Non-procedural Communication Command Reference

FLOWDATA Reference

Format

After outputting the command for acquiring FLOWDATA, the binary data is output in the

following format:

Header division (4bytes) Data division (4bytes)

Configuration of FLOWDATA p.34

Binary data is used for response data of FLOWDATA to give the highest priority to the speed. Therefore,

general purpose communication tools such as HyperTerminal may not be used to receive the data.

■ Buffer size and buffer intervals

The buffer size of measurement data to be accumulated in the ZS controller and its

buffer intervals can be changed.

Change the following parameters:

* DATAGET and DATASET commands are used to change and refer to the parameters.

Unit No. Data No. Parameter Description

124 2 FLOWDATA accumulation

mode

3 Buffer intervals 1 to 65535 (pcs)

4 Buffer size 1 to 1000 (pcs)

0: OFF

1: ON

■ Logging data

Data to be accumulated in the ZS controller can be selected.

●In case of ZS-LDC

A maximum of 3 data can be accumulated.

Unit No. Data No. Parameter Description

124 5 Accumulated data 1 *

6 Accumulated data 2

7 Accumulated data 3

* A setting value changes in accordance with the measurement mode.

•[Glass thickness/Gap-Film/Else-Move] is selected.

Val ue Description

0 No accumulation

1 Result for area 1

2 Result for area 2

3 Thickness/Gap value

Non-procedural Communication Command Reference

ZS-Series

31

FLOWDATA Reference

•Glass thickness/Gap except for the above is selected.

Val ue Description

0 No accumulation

1 Thickness/Gap value

•A mode other than above is selected.

Val ue Description

0 No accumulation

1 Distance value (Measurement value)

●In case of ZS-HLDC

• When multi-task mode is OFF

• When GLASS/MODE 2 or GLASS THICKNESSS/MODE 2 is selected for the measurement object

Unit No. Data No. Value Description

124 5 0 No accumulation

1 Accumulation of result of area 1

2 Accumulation of result of area 2

3 Accumulation of result of glass surface or

glass thickness

• When a mode other than the above is selected for the measurement object

Unit No. Data No. Value Description

124 5 0 No accumulation

1 Accumulation

• When multi-task mode is ON

Unit No. Data No. Value Description

124 14 0 Does not accumulate the result of TASK 1

1 Accumulate the result of TASK 1

15 0 Does not accumulate the result of TASK 2

1 Accumulate the result of TASK 2

16 0 Does not accumulate the result of TASK 3

1 Accumulate the result of TASK 3

17 0 Does not accumulate the result of TASK 4

1 Accumulate the result of TASK 4

32

ZS-Series

Non-procedural Communication Command Reference

●In case of ZS-MDC

A maximum of 9 data can be accumulated.

Unit No. Data No. Parameter Description

124 5 Accumulated data 1 0: No accumulation

6 Accumulated data 2

7 Accumulated data 3

8 Accumulated data 4

9 Accumulated data 5

10 Accumulated data 6

11 Accumulated data 7

12 Accumulated data 8

13 Accumulated data 9

Increasing data to be accumulated extends the measurement cycle of the ZS controller. Confirm it

by selecting [SYSTEM]-[INFO]-[CYCLE] after setting.

1: Measurement result of TASK 1

2: Measurement result of TASK 2

3: Measurement result of TASK 3

4: Measurement result of TASK 4

5: Measurement result of Input A

6: Measurement result of Input B

7: Measurement result of Input C

8: Measurement result of Input D

9: Measurement result of Input E

10: Measurement result of Input F

11: Measurement result of Input G

12: Measurement result of Input H

13: Measurement result of Input I

FLOWDATA Reference

Non-procedural Communication Command Reference

ZS-Series

33

FLOWDATA Reference

Configuration of FLOWDATA Response

1 packet of FLAWDATA

Header division

1st byte 2nd byte 3rd byte 4th byte –

ABCDEFGHIJKLData

8 11245121115 32

Details of header division

Data Name Description

A Unused Reserved bit

B FLOWDATA overflow bit Normally set to 0.Set to 1 when there is an overflow in

FLOWDATA accumulation.

C Decimal information Normally set to 0.0: nm order, 1: µm order

D TASK No. TASK1 to TASK4 (*1)

E CH No. CH No. of data source

F Unit states (Input) Indicates ON/OFF states of various input lines. (*2)

G FLOWDATA stop bit • All data are set to 1 if FLOWDATA does not flow over subse-

quently. (Always set to 1 for one-shot requests)

• All data are set to 0 if FLOWDATA continues to flow over.

(Until FLOWDATA is stopped after requested (in succession)

H TASK judgment result bit

I Disabled Reserved bit

J

K

L Unit states (Output) Indicates output states (states of measurement results). (*4)

Data Measurement data Signed 32 bit data

Indicates the TASK judgment result of data source. (*3)

When the decimal info division is 0, the unit of the data is nm.

When the decimal info division is 1, the unit of the data is µm

Data

division

Meaning of

data

Number of

bits

=Total

64 bits

34

*1 TASK No.=bit data+1

Example: bit data=10B=2 (dec)

indicates TASK3 data.

*2 The input lines are, from the lower bit, assigned to:

In case of ZS

• Input terminal 4 (Unused. Always set to 0.)

• Input terminal 3

• Input terminal 2

• Input terminal 1

• Input terminal 0 (5 inputs in total.)

ZS-Series

Non-procedural Communication Command Reference

FLOWDATA Reference

*3 Data to be received and their states are as follows:

00b=Not executed

01b=LOW

10b=PASS

11b=HIGH

*4 The output states are, from the lower bit, assigned to:

In case of ZS

• Output terminal 4 (Busy output)

• Output terminal 3 (Enable output)

• Output terminal 2 (Low output)

• Output terminal 1 (Pass output)

• Output terminal 0 (High output)

(5 outputs in total). States in parenthesis indicate the standard states.

[FLOWDATA setting example]

DATASET 124 2 1

DATASET 124 3 1

DATASET 124 4 1

DATASET 0 0 1

DATASET 0 1 2

DATASET 0 2 3

DATASET 0 3 4

DATASET 124 5 5

DATASET 124 6 6

DATASET 124 7 7

DATASET 124 8 8

DATASAVE

FLOWDATA

FLOWDATA accumulation mode ON

1 buffer interval

1 buffer size

Input A is 1 CH.

Input B is 2 CH.

Input C is 3 CH.

Input D is 4 CH.

Accumulate data 1 is Input A.

Accumulate data 2 is Input B.

Accumulate data 3 is Input C.

Accumulate data 4 is Input D.

Data save

ABCDEFGHIJKL

FF81010642724D0A

1 㸢䇭172847682111111110000001000000010000011001000010011100100100110100001010

FF8201065A74F103

1 㸢䇭66155610111111110000010000000010000011001011010011101001111000100000011

FF830312FF837405

1 㸢䇭91522047111111110000011000000110001001011111111100000110111010000000101

FF84031240118B05

1 㸢䇭92000000111111110000100000000110001001001000000000100011000101100000101

Indicates the unit status (states of

measurement results).

From the lower bit

Output terminal 4 BUSY

Output terminal 3 ENABLE

Output terminal 2 LOW

Output terminal 1 PASS

Output terminal 0 HIGH

Disabled

TASK judgment result bit

00b= Not executed

01b= LOW

10b= PASS

11b= HIGH

FlowData stop bit

Unit status: Indicates ON/OFF states of

various input lines.

From lower bit

Input terminal 4 (Unused, Always 0)

Input terminal 3

Input terminal 2

Input terminal 1

Input terminal 0

CH No.

TASK No.

Decimal information

Normally set to 0: nm order, 1: µm order

FlowData overflow bit

Normally set to 0. Set to 1 when there is an

overflow in FLOWDATA accumulation.

Unused

Non-procedural Communication Command Reference

ZS-Series

35

Capturing Image Data

Capturing Image Data

For ZS-DSU (Ver 2.000 or later), image data logging from ZFV is available. Image data on

the memory card can be shown as image files (.bmp) by inserting the memory card into

the memory slot on the personal computer. Image data can also be imported from the

memory card inserted into the ZS-DSU by entering the command below.

Command name Format

CFIMGGET CFIMGGET <Group No.> <Logging No.> <delimiter>

* Group No. is the logging group number that is assigned for each logging trigger.

* Logging No. is the serial number (logging number) that is assigned during one logging process.

* Receiving of the image data is performed through the XMODEM communication. (Refer to the next topic.)

* For you reference: Folder tree in the memory card

Top OMRON LOG Date 1 Log000.log

Log001.log

Date 2 Log002.log

↓Group No.

IMG Date 000 Log.log

OK 000_***.bmp

Folder

NG 002_***.bmp

File

↓Logging No.

001_***.bmp

↓Group No.

001 Log.log

OK 000_***.bmp

NG 001_***.bmp

Example:

To read image data with (*) mark, enter the following command.

CFIMGGET 001 002<delimiter>

001 is Group No.

002 is Logging No.

* Numbers must be entered in the 3-digit format.

* Specifying OK/NG folders is not necessary.

Measurement result for the logged image data can also be obtained. Measurement result is stored in the log

file in the same group folder. To get the measurement result to the personal computer, enter the following

command.

Command name Format

CFDATGET CFDATGET <Group No.> <delimiter>

↓Logging No.

002_***.bmp (*)

36

ZS-Series

Non-procedural Communication Command Reference

Capturing Image Data

●Flow of XMODEM communication

When you capture image data by entering this command, image data are obtained

through XMODEM communication. Communication flow is as follows:

Host device (personal computer)

Switch XMODEM

Request to receiving

* 1 packet = 128 bytes

(Check by CRC)

Data are successfully received.

* Returns "NAK" if receiving error

has been occurred.

Data are successfully received.

Data are successfully received.

CFIMGGET command

"READY" reply

NAK (a)

128-byte data (BK No. 1)

ACK

128-byte data (BK No. 2)

ACK

128-byte data (BK No. *)

ACK

EOT

ZS-DSU

Switch XMODEM

Start the reply to the request

(Send BK No. 1)

* No reply when "C" is sending.

(Send BK No. 2)

(Send BK No. *)

All data has been completely sent

XMODEM abort ACK

OK

Completed.

ZS-Series

Non-procedural Communication Command Reference

37

Example of Usage

Example of Usage

To give an example, provided below is a procedure to communicate by non-procedural

commands using Windows standard tool HyperTerminal.

1. Start up HyperTerminal.

HyperTerminal is located under [Program]-[Accessory]-[Communication].

(1) Enter an appropriate project name.

(2) Select the COM port connected to the ZS in the Connection Method section.

(3) Set the communication conditions.

38

ZS-Series

Non-procedural Communication Command Reference

Example of Usage

(4) HyperTerminal is started up.

2. To make the interaction with commands easier, set echo and other

functions.

(1) Open [Property].

(2) Select the setting tag, and then ASCII settings.

Non-procedural Communication Command Reference

ZS-Series

39

Example of Usage

(3) Check the following items, and press OK to complete the setting.

3. Set the communication conditions for the ZS side.

(1) Set [System]-[Communication]-[RS-232C] as consistent with the above setting.

(2) Set [System]-[Communication]-[Protocol] as non-procedural.

4. Change ZS into "RUN" mode.

5. Perform non-procedural communication.

(1) Input a command, and then press the return key.

40

ZS-Series

Non-procedural Communication Command Reference

Example of Usage

(2) A returned value responding to the command is returned from the controller.

Non-procedural Communication Command Reference

ZS-Series

41

Revision History

Revision History

Revision

Symbol

A October 2004 First edition

B June 2005 • Commands and parameters compatible with ZS-DSU (v2.000) are added.

C October 2005 • Commands and parameters compatible with ZS-HLDC is added.

Revision Date Description

• Multiple controllers connection with ZFV is added.

42

ZS-Series

Non-procedural Communication Command Reference

Loading...

Loading...