Page 1

General-purpose Basic Switch X F-149

Limit

Switches

General-purpose Basic Switch

X

Direct Current Switch with Built-in Magnetic

Blowout

• Incorporates a small permanent magnet in the contact mechanism to deflect the arc to effectively extinguish it.

• Same shape and mounting procedures as the Z Basic Switches.

Model Number Structure

■ Model Number Legend

1. Ratings

10: 10 A (125 VDC)

2. Contact Gap

G: 0.9 mm

3. Actuator

None: Pin plunger

D: Short spring plunger

S: Slim spring plunger

Q: Panel mount plunger

Q21: Panel mount cross roller plunger

Q22: Panel mount roller plunger

L: Leaf spring

W: Hinge lever

W2: Hinge roller lever

W21: Short hinge lever

W22: Short hinge roller lever

W4: Low-force hinge lever

M: Reverse hinge lever

M2: Reverse hinge roller lever

M22: Reverse short hinge roller lever

4. Terminals

None: Solder terminal

B: Screw terminal (with toothed washer)

1 2 3 4

X-10G@-@

Page 2

F-150 General-purpose Basic Switch X

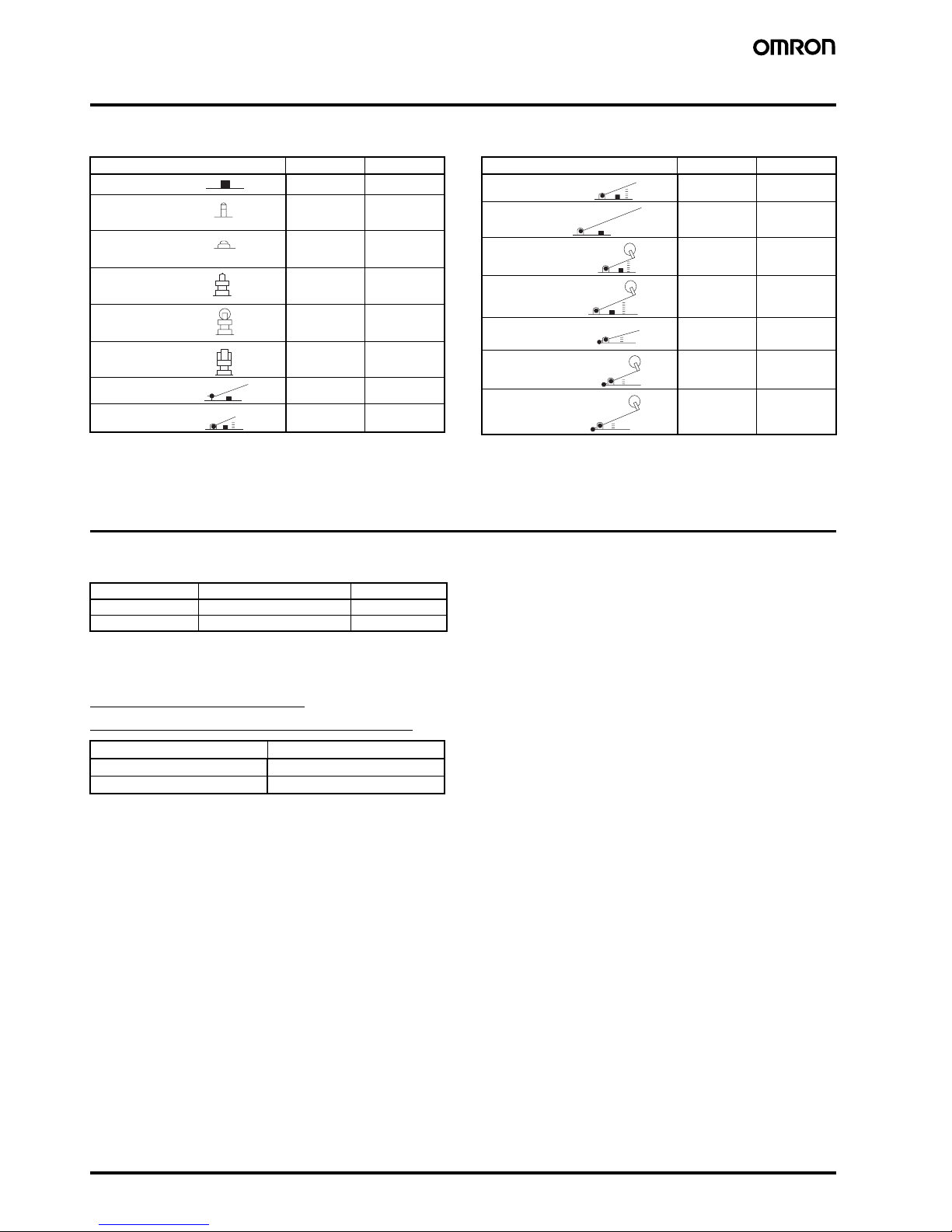

Ordering Information

■ List of Models

Note: The plungers of reverse-type models are continuously pressed by the compression coil springs and the plungers are freed by operating the

levers.

Specifications

■ Approved Standards

■ Approved Standard Ratings

UL508 (File No. E41515)

CSA C22.2 No.55 (File No. LR21642)

Actuator Solder Screw

X-10G X-10G-B

X-10GS X-10GS-B

X-10GD X-10GD-B

X-10GQ X-10GQ-B

X-10GQ22 X-10GQ22-B

X-10GQ21 X-10GQ21-B

X-10GL X-10GL-B

X-10GW21 X-10GW21-B

Pin plunger

Slim spring

plunger

Short spring

plunger

Panel mount

plunger

Panel mount

roller plunger

Panel mount cross

roller plunger

Leaf spring

Short hinge lever

Actuator Solder Screw

X-10GW X-10GW-B

X-10GW4 X-10GW4-B

X-10GW22 X-10GW22-B

X-10GW2 X-10GW2-B

X-10GM X-10GM-B

X-10GM22 X-10GM22-B

X-10GM2 X-10GM2-B

Hinge lever

Low-force hinge

lever

Short hinge roller

lever

Hinge roller lever

Reverse hinge

lever

Reverse short

hinge roller lever

Reverse hinge

roller lever

Agency Standard File No.

UL UL508 E41515

CSA CSA C22.2 No. 55 LR21642

Rated voltage X-10G

125 VDC 10 A

250 VDC 3 A

Page 3

General-purpose Basic Switch X F-151

Limit

Switches

■ Ratings

Note: 1. The above values are for the steady-state current.

2. Inductive load has a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The above electrical ratings also apply to the AC voltage.

6. With the reverse-type models (X-10GM@), the normally closed circuits and normally open circuits are reversed.

7. The ratings values apply under the following test conditions:

Ambient temperature: 20±2°C

Ambient humidity: 65±5%

Operating frequency: 20 operations/min

■ Characteristics

Note: 1. The values are for the pin plunger models. (Contact your OMRON representative for other models.)

2. Malfunction: 1 ms max.

■ Contact Specification ■ Contact Form (SPDT)

Note: With the reverse-type models (X-10GM@), the NC and NO ter-

minal arrangements are reversed.

Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO

8 VDC

14 VDC

30 VDC

125 VDC

250 VDC

10 A

10 A

10 A

10 A

3 A

3 A

3 A

3 A

3 A

1.5 A

1.5 A

1.5 A

1.5 A

1.5 A

0.75 A

10 A

10 A

10 A

7.5 A

2 A

10 A

10 A

10 A

6 A

1.5 A

5 A

5 A

5 A

5 A

2 A

2.5 A

2.5 A

2.5 A

2.5 A

1.5 A

Operating speed 0.1 mm to 1 m/s (see note 1)

Operating frequency Mechanical: 240 operations/min

Electrical: 20 operations/min

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Dielectric strength 1,500 VAC, 50/60 Hz for 1 min between terminals of the same polarity, between current-carrying metal parts and

the ground, and between each terminal and non-current-carrying metal parts

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note 2)

Shock resistance

Destruction: 1,000 m/s

2

{approx. 100G} max.

Malfunction: 300 m/s

2

{approx. 30G} max. (see note 1, 2)

Durability Mechanical: 1,000,000 operations min.

Electrical: 100,000 operations min.

Degree of protection IP00

Degree of protection against

electric shock

Class I

Proof tracking index (PTI) 175

Switch category D (IEC335-1)

Ambient temperature Operating: −25°C to 80°C (with no icing)

Ambient humidity Operating: 35% to 85% max.

Weight Approx. 27 to 63 g

Item X-10

Contacts Material Silver alloy

Gap (standard value) 0.9 mm

Inrush current NC 30 A max.

NO 15 A max.

COM NC NC

Page 4

F-152 General-purpose Basic Switch X

Engineering Data

■ Mechanical Durability

(Pin Plunger)

■ Electrical Durability

(Pin Plunger)

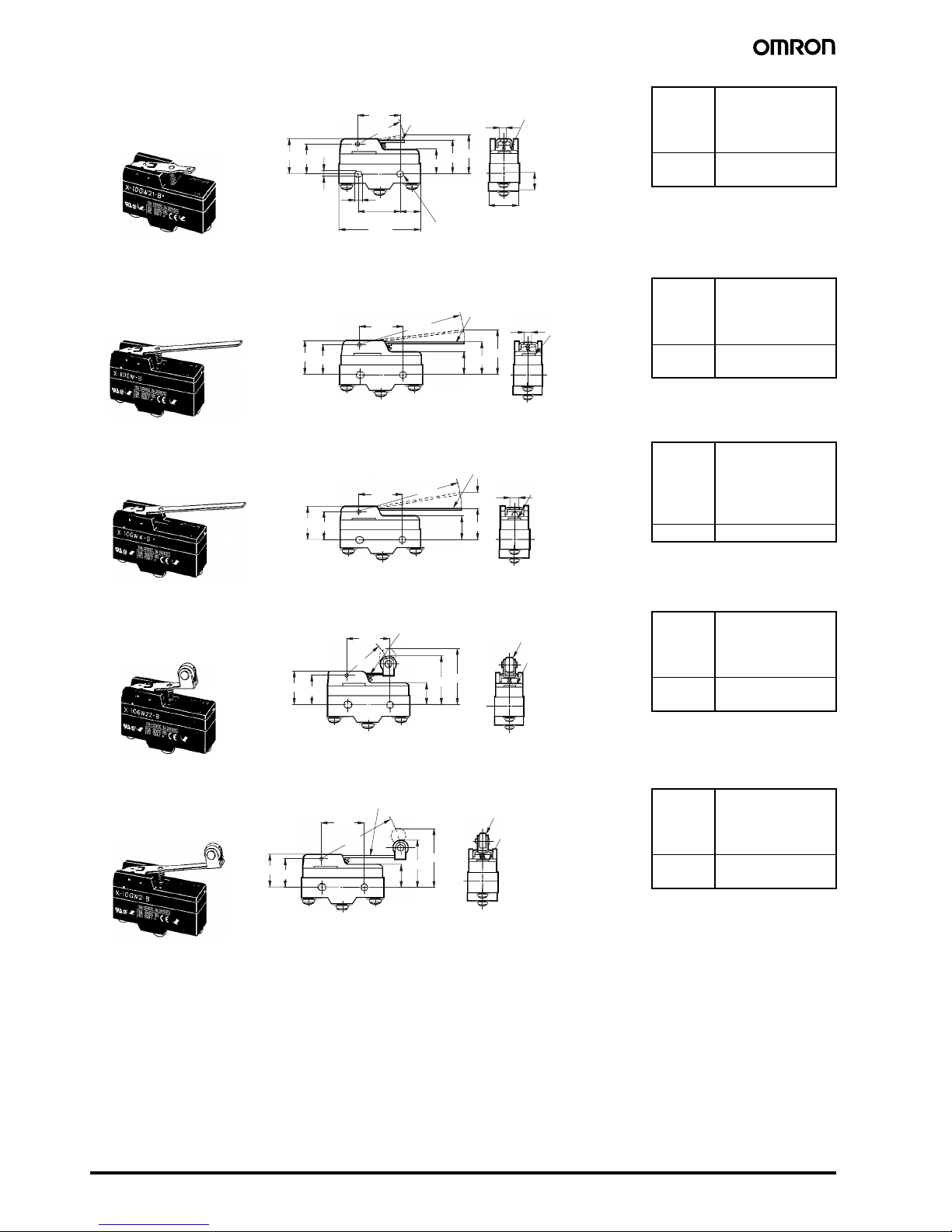

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

■ Dimensions and Operating Characteristics

The models, illustrations, and graphics are for screw-terminal models. (The dimensions for models that are omitted here are the same as for pinplunger models.)

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

0.13 mm

0.18 mm

OP 15.9±0.4 mm

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

1.6 mm

0.18 mm

OP 28.2±0.5 mm

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

1.6 mm

0.18 mm

OP 21.2±0.5 mm

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

50,000

30,000

10,000

7,000

5,000

3,000

2,000

1,000

700

500

300

200

100

02468

10 12 14

5,000

3,000

2,000

1,000

700

500

300

200

100

70

50

30

20

10

Overtravel (mm) Switching current (A)

Durability (x10

3

operations)

Durability (x10

3

operations)

125 VDC L/R = 0

Ambient temperature: 20±2°C

Ambient humidity: 65±5%

Without load

Operating frequency: 240 operations/min

Ambient temperature: 20±2°C

Ambient humidity: 65±5%

Operating frequency: 20 operations/min

125 VDC

L/R = 7 ms

4.2

+0.075

−0.025

11.9

49.2

25.4±0.1

OP

PT

23.3±0.25

9.2

24.2

17.45±0.2

Pin Plunger

X-10G-B

4.36

+0.1

dia.

−0.05

2.3 dia.

2.3SR (see note 1)

(see note 2)

4.2

+0.075

dia.

−0.025

Note: 1. Stainless-steel pin plunger

2. Three vent holes

OP

PT

23.3±0.25

24.2

Slim Spring Plunger

X-10GS-B

5.2 dia.

9 dia.

4 dia.

(see note 2)

Note: 1. Stainless-steel pin plunger (flat, 1R chamfering)

2. Vent holes (3 places)

See

note 1

OP

PT

23.3±0.25

24.2

Short Spring Plunger

X-10GD-B

10 dia.

7.15 dia.

12.3 dia.

12SR (see note 1)

(see note 2)

Note: 1. Plated iron plunger

2. Three vent holes

Page 5

General-purpose Basic Switch X F-153

Limit

Switches

Note: 1. Stainless-steel pin plunger

2. Three vent holes

3. Imperfect screw part with a maximum length of 1.5 mm.

Note: 1. Stainless-steel roller

2. Three vent holes

3. Imperfect screw part with a maximum length of 1.5 mm.

Note: 1. Stainless-steel roller

2. Three vent holes

3. Imperfect screw part with a maximum length of 1.5 mm.

Note: 1. Reference value

2. Be sure to use the switch at the

rated OT value of 1.6 mm.

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

5.5 mm

0.18 mm

OP 21.8±0.8 mm

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

3.6 mm

0.18 mm

OP 33.4±1.2 mm

OF max.

RF min.

PT max.

OT min.

MD max.

5.00 N {510 gf}

1.12 N {114 gf}

0.9 mm

3.6 mm

0.18 mm

OP 33.4±1.2 mm

OF max.

RF min.

OT min.

MD max.

1.96 N {200 gf}

0.14 N {14 gf}

1.6 mm (see note)

2.3 mm

FP max.OP22.1 mm

17.4±0.8 mm

16.3

OP

PT

23.3±0.25

13.1

Panel Mount Plunger

X-10GQ-B

8.35 dia.

M12 × 1 mounting screw

16 dia.

See note 3

(see note 2)

11.9SR

(see

note 1)

Two hexagonal nuts

(2 t × 14 width across flats)

Two lock nuts

(2 t × 15.6 width across flats)

16.3

OP

PT

23.3±0.25

15.5

12.7 dia. × 4.8 (see note 1)

M12 × 1 mounting screw

16 dia.

See note 3

(see note 2)

Panel Mount Roller Plunger

X-10GQ22-B

Two hexagonal nuts

(3 t × 17 width across flats)

16.3

15.5

OP

PT

23.3±0.25

Panel Mount Cross Roller Plunger

X-10GQ21-B

16 dia.

See note 3

12.7 dia. × 4.8 (see note 1)

M12 × 1 mounting screw

(see note 2)

Two hexagonal nuts

(3 t × 17 width across flats)

4.8

FP

49.6±0.8

OP

Leaf Spring

X-10GL-B

t = 0.3 (see note 1)

(see note 2)

Note: 1. Stainless-steel spring lever

2. Three vent holes

Page 6

F-154 General-purpose Basic Switch X

OF max.

RF min.

OT min.

MD max.

2.45 N {250 gf}

0.31 N {32 gf}

2.1 mm

1.7 mm

FP max.OP25.5 mm

20.7±0.8 mm

OF max.

RF min.

OT min.

MD max.

1.08 N {110 gf}

0.14 N {14 gf}

4.8 mm

3.9 mm

FP max.OP34.6 mm

21.1±0.8 mm

OF max.

RF min.

PT max.

OT min.

MD max.

0.25 N {25 gf}

0.05 N {5 gf}

14.3 mm

4.8 mm

3.9 mm

OP 21.1±0.8 mm

OF max.

RF min.

OT min.

MD max.

2.16 N {220 gf}

0.34 N {35 gf}

2.4 mm

1.7 mm

FP max.OP37.1 mm

32.2±0.8 mm

OF max.

RF min.

OT min.

MD max.

1.42 N {145 gf}

0.21 N {21 gf}

4 mm

3 mm

FP max.OP40.5 mm

32.2±0.8 mm

t = 1 (see note 1)

4.2

+0.075

−0.025

20.2

25.4±0.1 11.9

49.2

26.2

28.2 R

14.4

OP

FP

4.9

9.2

17.45±0.2

17.4

Short Hinge Lever

X-10GW21-B

4.36

+0.1

dia.

−0.05

t = 1 (see note 1)

(see note 2)

4.2

+0.075

dia. holes

−0.025

Note: 1.

Stainless-steel lever

2.

Three vent holes

17.4

20.2

26.2

14.4

OP

FP

4.9

63.5R

t = 1 (see note 1)

(see note 2)

Note: 1.

Stainless-steel lever

2.

Three vent holes

Hinge Lever

X-10GW-B

20.2

26.2

14.4

OP

PT

4.9

63.5R

17.4

t= 1 (see note 1)

(see note 2)

Note: 1.

Stainless-steel lever

2.

Three vent holes

Low-force Hinge Lever

X-10GW4-B

17.4

20.2

26.2

26.6R

14.4

OP

FP

Short Hinge Roller Lever

X-10GW22-B

t = 1 (see note 3)

9.5 dia. × 4 (see note 1)

(see note 2)

Note: 1. Plastic roller

2. Three vent holes

3. Stainless-steel spring lever

20.2

26.2

48.5R

14.4

OP

FP

17.4

Hinge Roller Lever

X-10GW2-B

t = 1 (see note 3)

9.5 dia. × 4 (see note 1)

(see note 2)

Note: 1. Plastic roller

2. Three vent holes

3. Stainless-steel spring lever

Page 7

General-purpose Basic Switch X F-155

Limit

Switches

■ Terminals

Note: 1. Tighten the terminal screws to a torque of 0.78 to 1.18 N·m {8 to 12 kgf·cm}.

2. In case of DC voltage, set the COM to the positive terminal.

OF max.

RF min.

OT min.

MD max.

2.16 N {220 gf}

0.25 N {25 gf}

5.5 mm

2.1 mm

FP max.OP26.8 mm

21.1±0.8 mm

OF max.

RF min.

OT min.

MD max.

6.86 N {700 gf}

1.52 N {155 gf}

2 mm

0.75 mm

FP max.OP36.1 mm

32.2±0.8 mm

OF max.

RF min.

OT min.

MD max.

3.14 N {320 gf}

0.49 N {50 gf}

4 mm

1.5 mm

FP max.OP37.4 mm

32.2±0.8 mm

20.2

18.65

56R

14.4

OP

FP

4.9

17.4

Reverse Hinge Lever

X-10GM-B

t = 1 (see note 1)

(see note 2)

Note: 1.

Stainless-steel lever

2.

Three vent holes

17.4

20.2

18.65

14.4

OP

FP

18.5R

Reverse Short Hinge Lever

X-10GM22-B

t = 1 (see note 3)

9.5 dia. × 4 (see note 1)

(see note 2)

Note: 1.

Plastic roller

2.

Three vent holes

3.

Stainless-steel spring lever

20.2

18.65

40.6R

17.4

14.4

OP FP

Reverse Hinge Roller Lever

X-10GM2-B

t = 1 (see note 3)

9.5 dia. × 4 (see note 1)

(see note 2)

Note: 1.

Plastic roller

2.

Three vent holes

3. Stainless-steel spring lever

17.45±0.2

2020

9.2

49.2

17.45±0.2

25.4±0.1 11.9

6.4

49.2

Screw Terminals (-B)

Solder Terminal

Three, M4 × 5.5

Terminal screws

(with toothed

washer)

Appropriate terminal screw tightening torque:

0.78 to 1.18 N⋅m {8 to 12 kgf⋅cm}.

Page 8

F-156 General-purpose Basic Switch X

Precautions

Refer to the Technical Information for Basic Switches (Cat. No. C122) for common precautions.

■ Correct Use

Mounting

Use M4 mounting screws with plane washers or spring washers to

securely mount the Switch. Tighten the screws to a torque of 1.18 to

1.47 N·m {12 to 15 kgf·cm}

The Switch can be panel mounted, provided that the hexagonal nut

of the actuator is tightened to a torque of 2.94 to 4.9 N·m {30 to

50 kgf·cm}.

Mounting Holes

Handling

Set the common (COM) terminal to the positive terminal. If it is set to

the negative terminal, the Switch will not turn OFF.

When using the Switch under an inductive load, the arc suppression

capability varies depending on current. If the current becomes 0.6 to

1.2 A or of the time constant L/R exceeds 7 ms, be sure to provide an

arc suppressor.

Since the Switch incorporates a permanent magnet, attention must

be paid to the following points:

• Avoid mounting the Switch directly onto a magnetic substance.

• Do not subject the Switch to severe shocks.

• Avoid placing the Switch in a strong magnetic field.

• Be sure to prevent iron dust or iron chips from adhering to the

built-in magnet or the magnetic blowout function of the Switch

will be adversely affected.

• Do not apply thermal shock to the Switch, or the magnetic flux

will be diminished.

Since a ventilation hole is provided to avoid abnormal corrosion due

to operating conditions, provide a dustproofing device in locations

where the Switch is exposed to dust.

Do not change operating positions for the actuator. Changing the

position may cause malfunction.

Panel-mounted Model (X-10GQ@)

To side-mount the panel-mount Switch to the panel with screws,

remove the hexagonal nut from the actuator.

Too large a dog angle and too fast operating speed may damage the

Switch when the Switch is side-mounted on the panel.

Too fast operating speed and too long overtravel of the roller plunger

Switch may result in damage to the Switch.

■ Accessories (Order separately)

Refer to Z/A/X/DZ Common Accessories for details about Terminal

Covers, Separators, and Actuators.

25.4±0.1

Panel Mount Plunger Panel Mount Roller Plunger

12.5

+0.2

dia.

0

Two, 4.2-dia. mounting

holes or M4 screw holes

12.5

+0.2

dia.

0

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. B003-E1-08

Loading...

Loading...