Page 1

NEW

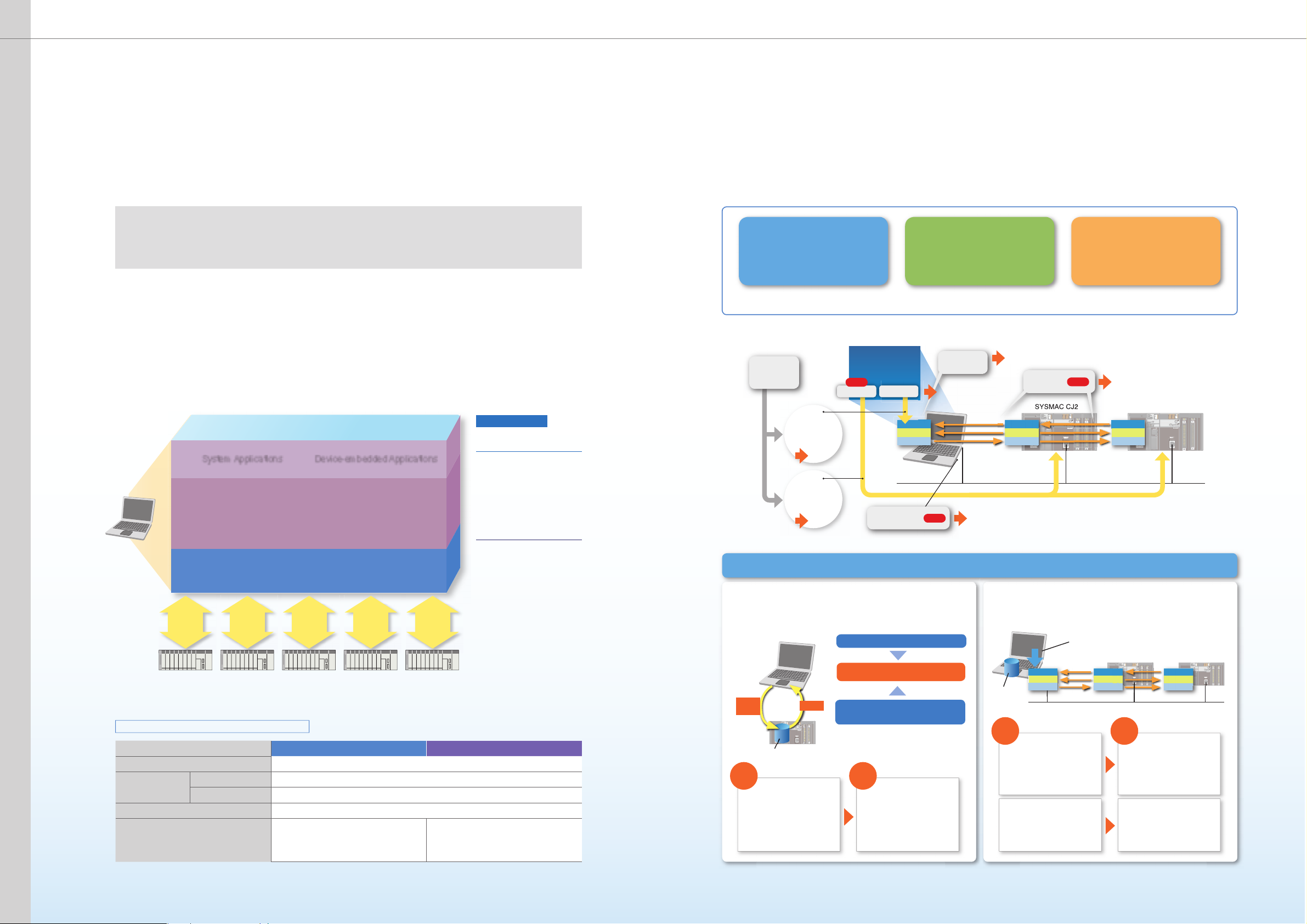

FA Communications

Software

SYSMAC Gateway

WS02-SGWC1

CX-Compolet

WS02-CPLC1

Page 2

Flexible, High-speed Software for Direct PLC Access

OMRON’s Upgraded FA Communications Software Lets You Create Applications with

Flexible, High-speed, and Direct Data Link Access to SYSMAC PLCs from Personal

Computers.

The need for faster transmission of more and more information between personal computers and

PLCs is coupled with the need for frequent changes to specifications, such as address allocations

in PLCs, a demand for software standardization to eliminate dependence on specific applications

and networks, and a demand for cost reductions.

In response to this demand, OMRON has completely renovated its FA Communications Software under new names. Data links are now possible using Ethernet. Data links can even be accessed via a LAN port on a notebook computer.

And FA Communications Software can be used to access PLC data by using

only tag names to enable more flexible and higher-speed access of PLC data

from personal computers, and that lowers costs by eliminating the need for a

special board for data links.

FA Communications Software

Product Positioning

SYSMAC Gateway

System Applications Device-embedded Applications

CX-Compolet

(formerly SYSMAC Compolet)

FINS/CIP Communications Middleware

SYSMAC Gateway

RS-232C USB

Easy PLC Data Reading

and Writing with VB.NET

and VC#.NET Control

Objects

EtherNet/IP

(formerly FinsGateway)

Ethernet

Controller Link

SYSMAC Gateway can be

used as the communications

driver on most networks. It is

the successor to FinsGateway and has inherited all

FinsGateway functionality.

CX-Compolet

CX-Compolet software

enables easily reading and

writing PLC data using Visual

Basic.NET and Visual

C#.NET. It is the successor to

SYSMAC Compolet.

High SpeedFlexibility

−Tag Access

−Two Types of Access

Simultaneous Upgrade for All OMRON FA Communications Software

Application

Two types of

access are

supported.

Access to

collected data

in personal

computers

High-speed

access

As-needed

access to

PLCs on

networks

Easy

CX-Compolet, etc.

NEW

Tag access

Tag access

Personal computer

No special

Board required.

Tag Access Data Links

Application data can be accessed using tag names

rather than addresses.

No changes are required at the application.

−Access to personal computers

via data links.

−Communicate using software

processing.

Virtual PLC

memory

Flexibility

You can easily handle

changes to specifications.

EtherNet/IP

NEW

Reduced costs and greater communications capacity.

Two New Features

Data links are possible between personal computers

and PLCs on Ethernet networks.

Personal computers become nodes on EtherNet/IP data links just like PLCs.

Data links

SYSMAC CJ2 SYSMAC CJ2

Direct Data Link Access

−Special Boards, such as

Controller Link and SYSMAC

LINK Support Boards, are not

required.

NEW

PLC data can be read and written across

EtherNet/IP networks by simply reading and

writing values in personal computer memory.

High-speed, large-capacity data links are possible.

∗1

You can easily handle changes to

SYSMAC PLC SYSMAC PLC SYSMAC PLC SYSMAC PLC SYSMAC PLC

Upgraded Functions for FA Communications Software

Item

Operating system Windows Vista

Network

PLCs CJ2 (with EtherNet/IP functionality)

Other functions Checking operation on EtherNet/IP

EtherNet/IP Yes (Tag access and data links enabled.)

USB Yes (CJ2, CP1)

SYSMAC Gateway CX-Compolet

Visual Studio.NET 2008

• Array variables are supported.

Tag

name

Name server

Data

FROM TO

PLC data was accessed

using addresses, so if an

address was changed in the

PLC it also had to be

changed in the application.

specifications.

The addresses in PLC assigned to tag

names can be changed without creating

additional work.

CJ2

With EtherNet/IP functionality

PLC data is accessed using

tag names, so there is no

need to change addresses in

the application even if

addresses are changed in the

PLC. This enables application

standardization.

Same name

server as for CJ2

FROM TO

A PCI Controller Link Support

Board was required to

establish data links.

There were strict limitations on

the capacity and speed of

Controller Link data links.

∗1

EtherNet/IP is required for data links on Ethernet networks.

− The LAN port at the personal

computer is used, so no special

board is required. Data links are

possible even for a notebook

computer.

− Software operations are used,

improving personal computer and

communications performance.

EtherNet/IP provides greater capacity

and higher speed, and because data

link areas in personal computer

memory are accessed, data access is

faster than having to constantly

access EtherNet/IP nodes.

2 3

Page 3

An OMRON PLC Driver with Virtual PLC Memory Functionality

SYSMAC Gateway

SYSMAC Gateway

SYSMAC Gateway

■ Software Configuration ■ System Configuration Examples

SYSMAC Gateway can access the PLCs in all of the following configurations.

Communications Driver and Virtual PLC Memory

SYSMAC Gateway provides an OMRON PLC communications driver and virtual memory. OMRON’s FA

Communications Software uses the SYSMAC Gateway communications middleware as a common platform.

● In addition to FINS communications, operation of SYSMAC

Gateway has been verified on EtherNet/IP.

● SYSMAC Gateway absorbs the differences in the physical layers

of RS-232C, USB, Ethernet, EtherNet/IP, and Controller Link.

● Virtual PLC event memory is provided to enable a personal

computer to participate as a data link node.

● Changes to memory can be detected in applications at the

personal computer.

Situation

Developing or Modifying PLC Applications Is Too Much Work

SYSMAC Gateway

Serial

Real PLC

Note: USB and Ethernet can also be used for communications.

Applications

EtherNet/IP

Real PLC Real PLC

Controller Link

Application Software

CX-Compolet

Message Communications

SYSMAC Gateway

RS-232C

USB

SYSMAC PLC

Data Links

EtherNet/IP

Controller Link

SYSMAC Gateway

Note: The above configurations are only examples. Communications are also possible with

SYSMAC Gateway SYSMAC Gateway

USB

Commercially available

USB cable

CJ2/CP1 CJ2/CJ1/CS1

SYSMAC Gateway

USB

Data links

CJ2

EtherNet/IP

CJ2/

CJ1/

CS1

Ethernet

EtherNet/IP

PLCs other than those shown here. For details, refer to page 8.

RS-232C

Special Cable

CJ2/

CJ1/

CS1

CJ2/

CJ1/

CS1

■ Application Example

Using Events to Provide Notification of Changes in Data

• The application is notified using events only when preset conditions are met.

• Eliminating programming for checking cyclic data changes reduces the load on the personal computer processor.

• Notification of data changes is provided immediately, eliminating wasted communications time.

SYSMAC Gateway

RS-232C

CJ2/

CJ1/

CS1

SYSMAC Gateway

Controller Link

Support Board

Data links

Controller Link

CJ2/

CJ1/

CS1

Controller Link

CJ2/

CJ1/

CS1

CJ2/

CJ1/

CS1

Problem Solution with SYSMAC Gateway

Costumers who have

created their own

communications

programs

Modifying programs

for different networks

is a lot of work.

−Insufficient speed.

−Insufficient data link capacity.

Application

ABC

Networks

Time spent on programming

communications can be reduced

by absorbing the differences

between networks.

Using EtherNet/IP enables

Application

SYSMAC Gateway

ABC

Network differences are absorbed.

Application

CX-Compolet

SYSMAC Gateway

Cyclic data checking is not required.

EtherNet/IP

high-speed, large-capacity data

links with no need for a special

Customers who are

already using

FinsGateway

Insufficient

capacity

Programming communications

to send and receive messages

for each node or block of data

is too much work.

Insufficient speed

Programming is

required for each node

or block of data.

communications board.

Communications efficiency

can be optimized by using

EtherNet/IP data links.

Large capacity

Application

Notification of changes is sent.

Fast

Main SYSMAC Gateway Functions

Item Description

Supported protocols

Supported PLCs CJ2, CJ1, CS1, CP1, C, and CVM1/CV

SYSWAY, SYSWAY-CV, Peripheral Bus

(Toolbus), FINS, and CIP

Environment for SYSMAC Gateway

Item Description

Languages English or Japanese

Supported OS Windows 2000, XP, or Vista and 2003 Server

CIP Service Specifications

Customers who want

to standardize

personal computer

applications

Having to modify personal

computer applications

whenever the PLC memory

map is changed is too much

work.

Personal computer

applications must

also be modified.

Changes to PLC

memory map

No special board is required.

For the CJ2 with EtherNet/IP

functionality, tag access and tag

data links (

∗1

) provide freedom

from PLC memory maps.

∗

1

Tag data links are not possible from a C

language library. They are possible only

with .NET.

High-speed,

large-capacity data links

Personal computer

applications do not

need to be modified.

Even when the PLC

memory map is changed.

Supported networks

Virtual event memory

Tag access

RS-232C (SYSWAY, SYSWAY-CV, Peripheral

Bus (Toolbus)) USB, EtherNet/IP

(FINS), Controller Link (FINS), and SYSMAC

LINK (FINS)

∗1

Data links are supported.

CIO, Auxiliary (A), Holding (H), Work (W), DM,

and EM1 to EM1F

For the CJ2 (with EtherNet/IP functionality),

access by tag name is enabled.

∗1

, Ethernet

Tag data links

Explicit

messages

Number of connections 256

Allowable communications bandwidth 5,000 pps

Refresh period (RPI) 1 to 10,000 ms (unit: 1 ms)

Link data capacity 184, 832 words max.

Data size per connection 722 words (1,444 bytes) max.

Message send function (client)

Message receive function (server)

Data size 502 bytes

CIP routing Not supported.

∗1

The RPIs that can be set depend on the number of connections.

CIP connectionless (UCMM) and CIP

connection (Class 3) communications

CIP connectionless (UCMM) and CIP

connection (Class 3) communications

∗1

4 5

Page 4

CX-Compolet

CX-Compolet

Easily Create Programming to Read and Write PLC Data using VB or VC#.

CX-Compolet

.NET Control Objects ∗ActiveX Control Objects are also included.

CX-Compolet is a package of software components that make it easy to program reading and writing OMRON PLC data.

● Read and write I/O memory in the PLC, change the

operating mode, read error logs, and perform other

operations.

● Supports Microsoft Visual Studio.NET 2008.

NEW

● Can be used from Visual Basic.NET and

Visual C#.NET.

● For the CJ2 with EtherNet/IP functionality, I/O

memory in the PLC can be accessed by using

tag names rather than addresses.

● Array variable access is possible.

Situation

Creating and Modifying VB/VC# Communications Programming Is Too Much Work

NEW

NEW

User-created Applications

VB.NET or VC#.NET

.NET Controls

Example:

Reading I/O Memory

SYSMAC Gateway

D0 12 34

SYSMAC PLC

CX-Compolet

Simply paste to the form and

specify the tags (addresses).

Example

Press the button to read the

value (D0 in this example).

■ Software Configuration ■ System Configuration Examples

CX-Compolet can access the PLCs in all of the following configurations.

CX-Compolet CX-Compolet

VB.NET/VC#.NET

USB

Commercially

available USB cable

CJ2/CP1

RS-232C

Special Cable

CJ2/CJ1/CS1

CX-Compolet

CX-Compolet

SYSMAC Gateway

SYSMAC PLC

USB

Data links

CJ2

EtherNet/IP

CJ2/

CX-Compolet

Ethernet

Note: The above configurations are only examples. Communications are also possible with PLCs

other than those shown here. For details, refer to page 8.

CJ1/

CS1

EtherNet/IP

CJ2/

CJ1/

CS1

CJ2/

CJ1/

CS1

■ Application Example

Easily Program Device Alarm Monitoring.

● Using the control components provided by CX-Compolet frees the application designers from having to program the communications portions of the

application.

● Data for device alarms and other data are sent to the applications using non-solicited EtherNet/IP communications events.

● Standardization is made easy by specifying data using tag names (such as “Alarm A” and “Alarm B”) in the applications.

CX-Compolet

RS-232C

CJ2/

CJ1/

CS1

CX-Compolet

Controller Link

Support Board

Data links

Controller Link

CJ2/

CJ1/

CS1

Controller Link

CJ2/

CJ1/

CS1

CJ2/

CJ1/

CS1

Problem Solution with CX-Compolet

Having to program communications

Customers who are

developing VB/VC# programs

including communications

with PLCs

frame assembly, reception response

interpretation, and monitoring is too

much work.

Having to change communications

processing, e.g., for Ethernet and serial

communications, is too much work.

Handling PLC address changes is

particularly time consuming.

For a block of data of the same data

type, it is too much work to have to

specify the addresses one by one rather

than being able to view them as one

group and access that data as an

element.

Processing such as communications frame assembly is prepared

in advance!

Data is accessed by using tag names rather than by using

addresses, so programming does not have to be changed even if

PLC addresses are changed.

Note: When combined with the CJ2 with EtherNet/IP functionality.

Array variables are supported, so data can be easily specified by

simply changing the element subscript with the same tag name.

■ Procedure

Simply Paste to a Form and Enter a Line of Code.

After installation, the

1

OMRON SYSMAC CJ2

Icon will be displayed in

the controls.

Position the SYSMAC

2

CJ2 Icon in the form.

3

Arrange the command buttons,

text boxes, etc., in the form.

Set the remote PLC in

4

the properties.

5

In the Command Button Code

Dialog Box, enter the PLC tag

name on one line. (The tag

name below is “PV.”)

Text1=SYSMAC CJ2.ReadVariable “PV”)

Main CX-Compolet Functions

Interface Function Description

Communications with SYSMAC PLCs Specifies the PLC to communicate with, and reads network information.

Read and writes data in memory areas, such as the DM Area or CIO

Reading and writing I/O memory

Properties

Methods

Events Scheduled events

Operating status

Area information

Error information

Other SYSMAC PLC information

Reading and writing I/O memory

Creating I/O tables

Force-setting, force-resetting and clearing bits

Communications with SYSMAC PLCs Specifies the PLC to communicate with.

FINS service execution

Area. For example, DM word 100 can be specified by using “D100”

or by using a tag name.

Reads and changes the operating mode.

Reads information such as the program area size and number of DM Area words.

Reads the value and error message when an error occurs.

Reads the model and reads and changes the clock.

Reads and writes memory, such as consecutive words in the DM

Area or CIO Area. For example, it is possible to specify the data type

(integer, single, etc.) or change the data type (BCD, BIN, SBIN).

Creates the I/O tables for the present configuration.

Force-sets, force-resets, and clears bits.

Sends FINS commands and gets the responses that are received.

Events occur at regular intervals.

Alarm A

EtherNet/IP

Alarm B

Environment for CX-Compolet

Item Description

Languages English or Japanese

Supported OS

Supported

execution

environment

Development

environment

Note: Only the components compatible with

SYSMAC Compolet version 2003 are

supported. A development environment of

.NET 2003 or higher is required for CIP

communications.

Windows 2000, XP, or Vista

and 2003 Server

.NET Framework

(1.1, 2.0, 3.0, or 3.5)

Microsoft Visual Studio

.NET (See note.), .NET

2003, .NET 2005, or

.NET2008

Development languages:

Visual Basic.NET and Visual

C#.NET

Visual Basic version 5 or 6

(Only the functions

compatible with Compolet

V2 can be used.)

6 7

Page 5

Ordering Information

SYSMAC Gateway (Communications Middleware)

Product name

SYSMAC Gateway

∗1

SYSMAC Gateway SDK

CX-Compolet

Product name

CX-Compolet

∗1

Communications middleware for personal computers running Windows. Supports CIP communications and tag data links (EtherNet/IP) in addition to FinsGateway functions.

Supported communications: RS-232C, USB, Controller Link, SYSMAC LINK, Ethernet, EtherNet/IP

10 additional licenses (This product provides only additional licenses.)

Software development kit for creating communications programs using SYSMAC Gateway.

Development languages: C, C++, Visual Basic.NET, Visual C#.NET

Software components that can make it easy to create programs for communications between a

computer and controllers. This packaged product bundles SYSMAC Gateway.

Development environment: Visual Studio.NET2003/.NET2005/.NET2008

Development languages: Visual Basic .NET, Visual C#.NET, Visual Basic Ver. 5/6

Supported communications: Equal to SYSMAC Gateway.

3 additional licenses (This product provides only additional licenses. The software must be purchased in advance.)

5 additional licenses (This product provides only additional licenses. The software must be purchased in advance.)

10 additional licenses (This product provides only additional licenses. The software must be purchased in advance.)

Software components only. This package doesn’t include SYSMAC Gateway as communications drivers.

Specification

Specification

Supported OS: Microsoft Windows Vista, XP, 2000, and 2003 Server

∗1

One license is required per computer.

Supported OS: Microsoft Windows Vista, XP, 2000, and 2003 Server

∗1

One license is required per computer.

∗2

Only functions provided by Compolet V2 as ActiveX controls are supported for Visual Basic version 5 or 6.

Correspondence between Main PLC Models and Connected Networks

Model

Standards

WS02-SGWC1

WS02-SGWC1-L10

WS02-SGWC1S

Model

∗2

WS02-CPLC1

Standards

WS02-CPLC1-L3

WS02-CPLC1-L5

WS02-CPLC1-L10

WS02-CPLC2

Personal computer

PLC

CJ2 with EtherNet/IP functionality

CJ1

CS1

CP1

C200HX/HG/HE, CQM1H

C

Series

CPM1/CPM2

CVM1/CV

CompoWay/F Slaves, such as Temperature Controllers

RS-232C

SYSWAY

(Host Link C

Mode)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

SYSWAY-

CV (Host

Link FINS)

Yes

Yes

Yes

Yes

No

No

Yes

No

CompoWay/F

(master at personal

computer)

No

No

No

No

No

No

No

Yes

∗1

A separate Communications Unit is required.

Peripheral Bus FINS FINSEtherNet/IP

Yes (Peripheral

Bus – CS/CJ)

Yes (Peripheral

Bus – CS/CJ)

Yes (Peripheral

Bus – CS/CJ)

Yes (Peripheral

Bus – CS/CJ)

Yes (Peripheral

Bus – C)

Yes (Peripheral

Bus – C)

Yes (Peripheral

Bus – CV)

No

USB Controller LinkEthernet (LAN)

∗2

Yes

No

No

Yes

No

No

No

No

Correspondence between FA Communications Software and Connected Networks

Personal Computer Boards

FA Communications Software

⋅ SYSMAC Gateway

⋅ CX-Compolet

This catalog mainly provides information that is necessary for selecting suitable models, and does

not contain precautions for correct use. Always read the precautions and other required information

provided in product operation manuals before using the product.

Communications

Message

communications

Data link

communications

Note: Do not use this document to operate the Unit.

Communications

method

FINS communications

FINS communications

SYSMAC

Board

Yes

Yes

CS1 Board

Yes

Yes

The application examples provided in this catalog are for reference only. Check functions and

safety of the equipment before use.

Never use the products for any application requiring special safety requirements, such as nuclear

energy control systems, railroad systems, aviation systems, medical equipment, amusement

machines, vehicles, safety equipment, or other application involving serious risk to life or property,

without ensuring that the system as a whole has been designed to address the risks, and that the

OMRON products are properly rated and installed for the intended use within the overall equipment

or system.

CS1 Bus

Interface

Board

Yes

Yes

Ethernet

(FINS)

Yes (Specification

∗1

∗1

using tag names is

possible.)

∗1, ∗2

Ye s

∗1, ∗2

Ye s

No

No

No

No

No

Yes

Yes (Communications Units

are not required for CJ1M

PLCs with Ethernet

functionality.)∗1

Yes

Ye s∗1 (CP1H only)

No

No

Yes

No

∗2

Specification using tag names is not possible.

∗1

Yes

∗1

Yes

∗1

Yes

Ye s∗1 (CP1H only)

∗1

Yes

No

∗1

Yes

No

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

PLC Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81) 75-344-7084/Fax: (81) 75-344-7149

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON Industrial Automation Global: www.ia.omron.com

Authorized Distributor:

© OMRON Corporation 2009 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Printed in Japan

Cat. No. V302-E1-02

0209 (0109)

Loading...

Loading...