Cat. No. W344-E1-09

SYSMAC

WS02-PSTC1-E

CX-Protocol Ver. 1.8

OPERATION MANUAL

SYSMAC WS02-PSTC1-E CX-Protocol Ver. 1.8

Operation Manual

Revised February 2009

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

!DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

Additionally, there may be severe property damage.

!WARNING Indicates information that, if not heeded, could possibly result in loss of life or serious

injury. Additionally, there may be severe property damage.

!Caution Indicates information that, if not heeded, could result in relatively serious or minor injury,

damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller and the abbreviation “PC” means personal

computer and are not used as abbreviations for anything else.

The abbreviation “PMSU” means Protocol Macro Support Unit and refers to the Communications

Board for the C200HX/HG/HE, Serial Communications Board for the CS, and Serial Communications

Units for the CS/CJ.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2008

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form,

or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission

of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained

in this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

6 Software Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Supported PLC Models and Personal Computers . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-5 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6 Protocol Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-7 Protocol Macro Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-8 Data Created by the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-9 Main Screens of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-10 Overview of Project Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-11 Incorporated Standard System Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-12 Basic Procedure of the Protocol Macro Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-13 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-14 Differences between Protocol Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SECTION 2

Installing/Uninstalling/Starting/Ending . . . . . . . . . . . . . 39

2-1 Connecting to a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2-2 Installing and Uninstalling the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-3 Uninstalling Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-4 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2-5 Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2-6 Outline of User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

SECTION 3

Protocol Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3-1 Protocol Macro Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-2 Sequence Attributes (Common to All Steps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3-3 Step Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3-4 Communication Message Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3-5 Creating Matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3-6 Examples of Standard System Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3-7 Example of Communications Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3-8 Executing a Created Communications Sequence (CS/CJ) . . . . . . . . . . . . . . . . . . . 129

3-9 Executing a Created Communications Sequence (C200HX/HG/HE) . . . . . . . . . . 136

3-10 Auxiliary Area and Allocated Data Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

vii

TABLE OF CONTENTS

SECTION 4

Using the Protocol Macro Function. . . . . . . . . . . . . . . . . 159

4-1 Applicable Range of the Protocol Macro Function . . . . . . . . . . . . . . . . . . . . . . . . 160

4-2 Protocol Creation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

4-3 Transmission Control Mode Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

4-4 Ladder Programming Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

4-5 Calculation Method of Monitoring Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

4-6 Operation Confirmation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

4-7 Errors at the Protocol Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4-8 Communications Response Time Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4-9 Cycle Time Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

SECTION 5

Object Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

5-1 Creating Projects and Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

5-2 Creating Sequences and Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

5-3 Creating Messages and Matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

5-4 System Protocol Display and Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

SECTION 6

Project and Protocol Editing . . . . . . . . . . . . . . . . . . . . . . 221

6-1 Editing Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

6-2 Editing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

SECTION 7

Sequence Setting and Editing. . . . . . . . . . . . . . . . . . . . . . 227

7-1 Setting Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

7-2 Editing Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

SECTION 8

Step Setting and Editing . . . . . . . . . . . . . . . . . . . . . . . . . . 237

8-1 Step Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

8-2 Step Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

SECTION 9

Setting and Editing Messages and Matrix Lists . . . . . . . 247

9-1 Creating Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

9-2 Matrix Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

9-3 Message and Matrix Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

SECTION 10

Communications PLC Setup and Online Connections . 267

10-1 PLC System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

10-2 Communications Settings between Personal Computer and PLC . . . . . . . . . . . . . 269

10-3 Online Connections and Mode Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

10-4 Modem Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

10-5 I/O Table Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

10-6 PMSU Communications Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

10-7 Transfer of Communications Port Setting Data to PLC . . . . . . . . . . . . . . . . . . . . 290

viii

TABLE OF CONTENTS

SECTION 11

Protocol Data Transferring and Printing . . . . . . . . . . . . 293

11-1 Transferring and Reading Protocol Data between the Computer and PMSU . . . . 294

11-2 Printing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

11-3 Importing Protocol Data from PST/PSS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

11-4 CS/CJ Protocol and C200HX/HG/HE Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

SECTION 12

Tracing and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . 305

12-1 Tracing Transmission Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

12-2 Outline of PLC Memory Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

12-3 I/O Memory Display and Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

12-4 I/O Memory Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

12-5 I/O Memory Transfer and Comparison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

SECTION 13

Error and Error Log Display. . . . . . . . . . . . . . . . . . . . . . 329

SECTION 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

SECTION 15

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Appendices

A Creating the Protocol Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

B PLC Setup and PMSU Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

C Wiring RS-232C Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

ix

TABLE OF CONTENTS

x

About this Manual:

The CX-Protocol is Support Software for the protocol macro functionality of Windows 95, Windows 98,

Windows 98SE, Windows Me, Windows NT (SP6a), Windows 2000 (SP2 or higher), Windows XP, and

Windows Vista. This manual describes the installation and operation of the CX-Protocol and includes

the sections described below.

This manual is intended for the following personnel:

Personnel in charge of installing FA devices

Personnel designing FA systems

Personnel managing FA facilities

Name Cat. No. Contents

SYSMAC WS02-PSTC1-E

CX-Protocol

Operation Manual

CX-One Setup Manual

CXONE-AL@@C-V3/AL@@D-V3

SYSMAC CS/CJ Series

CS1W-SCB@@-V1, CS1W-SCU@@-V1

CJ1W-SCU@@-V1

Serial Communications Boards and Serial

Communications Unit Operation Manual

SYSMAC CS/CJ/CP/NSJ Series

CS1G/H-CPU@@H

CS1G/H-CPU@@-EV1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCU@@-V1

CS1W-SCB@@-V1

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ1H-CPU@@H-R

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1M-CPU@@

CJ1W-SCU@@-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Communications Commands Reference

Manual

SYSMAC CJ Series

CJ2H-CPU6@-EIP

CJ2H-CPU6@

Programmable Controllers

Hardware User's Manual

SYSMAC CJ Series

CJ2H-CPU6@-EIP

CJ2H-CPU6@

Programmable Controllers

Software User's Manual

SYSMAC CS Series

CS1G/H-CPU@@H

CS1G/H-CPU@@-EV1

Programmable Controllers

Operation Manual

W344

(this manual)

W463 Installation and overview of CX-One FA Integrated Tool Pack-

W336 Describes the use of Serial Communications Unit and Boards to

W342 Describes the C-series (Host Link) and FINS communications

W472 Provides an outline of and describes the design, installation,

W473 Describes programming and other methods to use the functions

W339 Describes the installation and operation of the CS-series PLCs.

Describes the use of the CX-Protocol to create protocol macros

as communications sequences to communicate with external

devices. (This manual)

age.

perform serial communications with external devices, including

the usage of standard system protocols for OMRON products.

commands used with CS/CJ/CP-series PLCs and NSJ-series

Controllers.

maintenance, and other basic operations for the CJ-series CJ2

CPU Units.

The following information is included:

Overview and features

System configuration

Installation and wiring

Troubleshooting

Use this manual together with the W473.

of the CJ2 CPU Units.

The following information is included:

CPU Unit operation

Internal memory areas

Programming

Ta s ks

CPU Unit built-in functions

Use this manual together with the W472.

xi

Name Cat. No. Contents

SYSMAC CJ Series

CJ1H-CPU@@H-R, CJ1G/H-CPU@@H,

CJ1G-CPU@@P,

CJ1G-CPU@@, CJ1M-CPU@@

Programmable Controllers

Operation Manual

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@H, CS1G/H-CPU@@EV1, CS1D-CPU@@H, CS1D-CPU@@S,

CJ1H-CPU@@H-R, CJ1G/H-CPU@@H,

CJ1G-CPU@@P, C J 1 G - CP U @@, CJ1MCPU@@, NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Programmable Controllers

Programming Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S,

CJ2H-CPU6@-EIP, CJ2H-CPU6@,

CJ1H-CPU@@H-R

CJ1G-CPU@@, CJ1G/H-CPU@@H,

CJ1G-CPU@@P, C J 1 M - CP U @@

SYSMAC One NSJ Series

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Programmable Controllers

Instructions Reference Manual

SYSMAC CP Series

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CP1H CPU Unit Operation Manual

NSJ Series

NSJ5-TQ@@(B)-G5D, NSJ5-SQ@@(B)-

G5D, NSJ8-TV@@(B)-G5D, NSJ10TV@@(B)-G5D, NSJ12-TS@@(B)-G5D,

NSJ5-TQ@@(B)-M3D, NSJ5-SQ@@(B)M3D, NSJ8-TV@@(B)-M3D, NSJWETN21, NSJW-CLK21-V1, NSJW-IC101

Operation Manual

SYSMAC WS02-CXPC1-V8

CX-Programmer

Operation Manual

SYSMAC CS/CJ Series

CQM1H-PRO-E1

C200H-PRO27-E, CQM1-PRO01-E

Programming Consoles

Operation Manual

W393 Describes the installation and operation of the CJ-series PLCs.

W394 Describes programming and other methods to use the functions

W474 Describes the ladder diagram programming instructions sup-

W450 Provides the following information on the CP Series:

W452 Provides the following information about the NSJ-series NSJ

W446 Provides information on how to use the CX-Programmer, a pro-

W341 Provides information on how to program and operate

of the CS/CJ/NSJ-series PLCs.

The following information is included:

• Programming

•Tasks

• File memory

• Other functions

Use this manual in combination with the SYSMAC CS Series

Operation Manual (W339) or SYSMAC CJ Series Operation

Manual (W393).

ported by CS/CJ-series or NSJ-series PLCs.

When programming, use this manual together with the Opera-

tion Manual or Hardware User's Manual (CS1: W339, CJ1:

W393,or CJ2:W472) and Programming Manual or Software

User's Manual (CS1/CJ1:W394 or CJ2:W473).

• Overview/Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Programmable Control-

lers Programming Manual (W451).

Controllers:

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Use this manual in combination with the following manuals:

SYSMAC CS Series Operation Manual (W339), SYSMAC CJ

Series Operation Manual (W393), SYSMAC CS/CJ Series Programming Manual (W394), and NS-V1/-V2 Series Setup Manual

(V083)

gramming device that supports the CS/CJ-series PLCs, and the

CX-Net contained within CX-Programmer.

CS/CJ-series PLCs using a Programming Console.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xii

Please read this manual carefully and be sure you understand the information provided before

attempting to install and/or operate the CX-Protocol. Be sure to read the precautions provided in

the following section.

Section 1 Introduction outlines the Protocol Macro function and the CX-Protocol.

Section 2 Environment/Installing/Uninstalling/Starting/Editing outlines the functions of CX-Proto-

col and describes the operating environment, installation procedure, and the setting of the usage environment.

Section 3 Protocol Macro describes details of the protocol macro functions.

Section 4 Using the Protocol Macro Function describes various precautions in using the protocol

macro function.

Section 5 Object Creation describes how to create objects, such as projects, protocols, sequences,

steps, messages, and matrices.

Section 6 Project and Protocol Editing describes details of the editing of projects and protocols.

Section 7 Sequence Setting and Editing describes details of the setting and editing of sequences.

Section 8 Step Setting and Editing describes details of the setting and editing of steps.

Section 9 Setting and Editing Messages and Matrix Lists describes details of the setting and edit-

ing of messages and matrix lists.

Section 10 Communications PLC Setup and Online Connections describes details of the communications settings and online connections.

Section 11 Protocol Data Transferring and Printing describes details of the transferring, converting,

and printing of protocol data.

Section 12 Tracing and Monitoring describes details of PLC memory area monitoring and the transmission line tracing.

Section 13 Error and Error Log Display describes details of the displaying of errors and the error

log.

Section 14 Troubleshooting lists the error messages and describes their causes and remedies.

Section 15 Help describes the online help services.

Appendix A Creating the Protocol Applications shows some examples of data transmission

between personal computers using the protocol macro function.

Appendix B PLC Setup and PMSU Settings provides the settings for the PLC Setup and PMSU.

Appendix C Wiring RS-232C Cable Connectors describes how to wire RS-232C connectors.

xiii

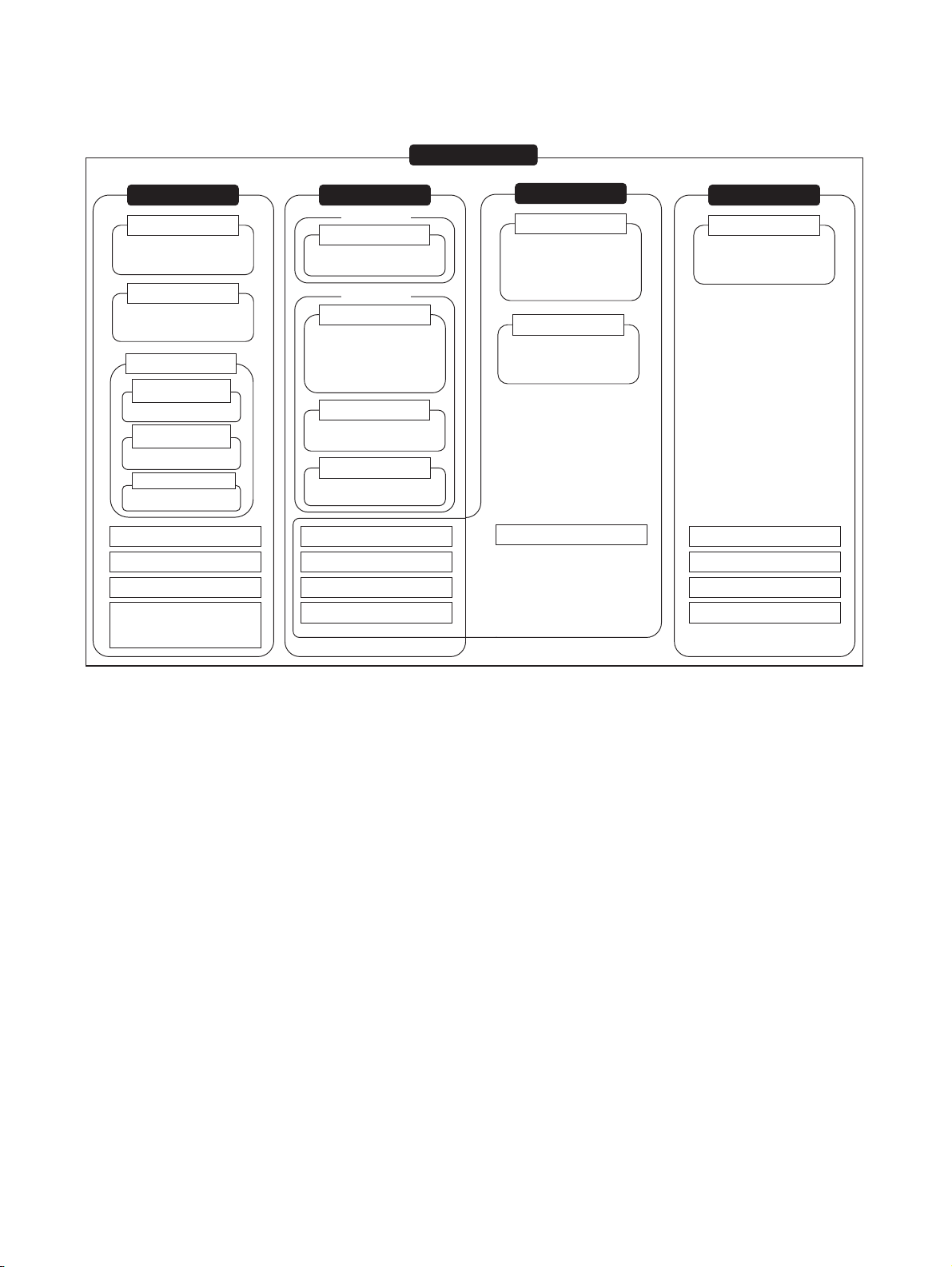

The CS Series, CJ Series, NSJ Series, and CP Series are subdivided as shown below.

CS Series

CS1-H CPU Units

CS1H-CPU@@H

CS1G-CPU@@H

CS1 CPU Units

CS1H-CPU@@(-V1)

CS1G-CPU@@(-V1)

CS1D CPU Units

CS1D CPU Units for

Duplex Systems

CS1D-CPU@@H

CS1D CPU Units for

Simplex Systems

CS1D-CPU@@S

CS1D Process-control CPU Units

CS1D-CPU@@P

CS-series Basic I/O Units

CS-series Special I/O Units

CS-series CPU Bus Units

CS-series Power Supply Units

Note: A special Power Supply Unit must

be used for CS1D CPU Units.

CJ Series

CJ2 CPU Units

CJ2H CPU Units

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ1 CPU Units

CJ1-H CPU Units

CJ1H-CPU@@H-R

CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G -CPU@@P

(Loop-control CPU Units)

CJ1M CPU Units

CJ1M-CPU@@

CJ1 CPU Units

CJ1G-CPU@@

CJ-series Basic I/O Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

CJ-series Power Supply Units

CS/CJ/NSJ/CP Series

NSJ-series Expansion Units

NSJ Series

NSJ Controllers

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ Controllers

NSJ5-TQ@@(B)-M3D

NSJ5-SQ@@(B)-M3D

NSJ8-TV@@(B)-M3D

CP Series

CP1H CPU Units

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CPM1A-series Expansion I/O Units

CPM1A-series Expansion Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

xiv

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

(1) The warranty period for the Software is one year from either the date of purchase or the date on which

the Software is delivered to the specified location.

(2) If the User discovers a defect in the Software (i.e., substantial non-conformity with the manual), and

returns it to OMRON within the above warranty period, OMRON will replace the Software without charge

by offering media or downloading services from the Internet. And if the User discovers a defect in the

media which is attributable to OMRON and returns the Software to OMRON within the above warranty

period, OMRON will replace the defective media without charge. If OMRON is unable to replace the

defective media or correct the Software, the liability of OMRON and the User's remedy shall be limited to

a refund of the license fee paid to OMRON for the Software.

LIMITATIONS OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER'S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT WILL OMRON BE LIABLE FOR ANY LOST PROFITS OR

OTHER INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

USE OF THE SOFTWARE.

(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE BASED ON

MODIFICATION OR ALTERATION OF THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

xv

Application Considerations

SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT DESCRIBED IN THE

ATTACHED USER MANUAL.

xvi

Disclaimers

CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at any time based on improvements or for

other reasons.

EXTENT OF SERVICE

The license fee of the Software does not include service costs, such as dispatching technical staff.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xvii

Version Upgrades

Improvements from Version 1.8 to Version 1.81

The following functionality has been added in upgrading the CX-Protocol from version 1.8 to 1.81.

New Units Supported

The following CPU Units are now supported.

Series Models

CJ Series CJ2H-CPU68/67/66/65/64

Improvements from Version 1.71 to Version 1.8

The following functionality has been added in upgrading the CX-Protocol from version 1.71 to 1.8.

New Units Supported

The following CPU Units are now supported.

Series Models

CJ Series CJ2H-CPU68-EIP/67-EIP/66-EIP/65-EIP/64-EIP

Improvements from Version 1.70 to Version 1.71

The following functionality has been added in upgrading the CX-Protocol from version 1.70 to 1.71.

New Units Supported

The following CPU Units are now supported.

Series Models

CJ Series CJ1H-CPU67H-R/66H-R/65H-R/64H-R

Windows Vista Supported

Improvements from Version 1.6 to Version 1.7

The following functionality has been added in upgrading the CX-Protocol from version 1.6 to 1.7.

New Units Supported

The following Serial Communications Units are now supported.

Series Unit Model

CS Series Serial Communications Unit CS1W-SCU31-V1

CJ Series Serial Communications Unit CJ1W-SCU31-V1

The following PLCs are now supported.

Series CPU Units Models

CP Series CP1H-series CPU Units CP1H-XA, CP1H-X, and CP1H-Y

NSJ Series NSJ Controller NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Protocol Comparisons

• The CX-Protocol can now be used to compare the protocols in the project with those in the PLC.

Improvements from Version 1.5 to Version 1.6

Installing the CX-Protocol from the CX-One FA Integrated Tool Package

Ver. 1.5 Ver. 1.6

The CX-Protocol could be installed only independently.

The CX-Protocol can be installed as one of the functions of the CX-One Integrated Tool Package.

xviii

CX-Programmer Startup Method

Ver. 1.5 Ver. 1.6

The CX-Protocol could be started only from the Windows Start Menu.

The CX-Protocol can also be started by right-clicking

one of the following Serial Communications Boards/

Units in the I/O Table Window opened from the CXProgrammer that was installed from the CX-One and

selecting Start Special Application from the pop-up

menu.

• CS1W-SCU@@-V1

• CS1W-SCB@@-V1

• CJ1W-SCU@@-V1

Note When the Start with Settings Inherited Option

is selected, a new project will be created and

the device type setting will be automatically

performed.

Version 1.5 Upgrade Information

The changes that have been made from version 1.4 to version 1.5 of the CX-Protocol to support the

upgraded functionality of CS/CJ-series Serial Communications Boards/Units with unit version 1.2 are

explained here.

Version 1.5 Improved Functionality from Version 1.4

Compatible PLCs

Serial Communications Board/Unit Version Upgrade Compatibility

CX-Protocol version 1.5 supports the following CS/CJ-series Serial Communications Boards/Units with

unit version 1.2.

Series Unit Model

CS Series Serial Communications Board CS1W-SCB21-V1, CS1W-SCB41-V1

Serial Communications Unit CS1W-SCU21-V1

CJ Series Serial Communications Unit CJ1W-SCU21-V1, CS1W-SCU41-V1

CX-Protocol version 1.5 supports the following new CPU Units.

Series CPU Unit model

CJ Series CJ1H-CPU67H

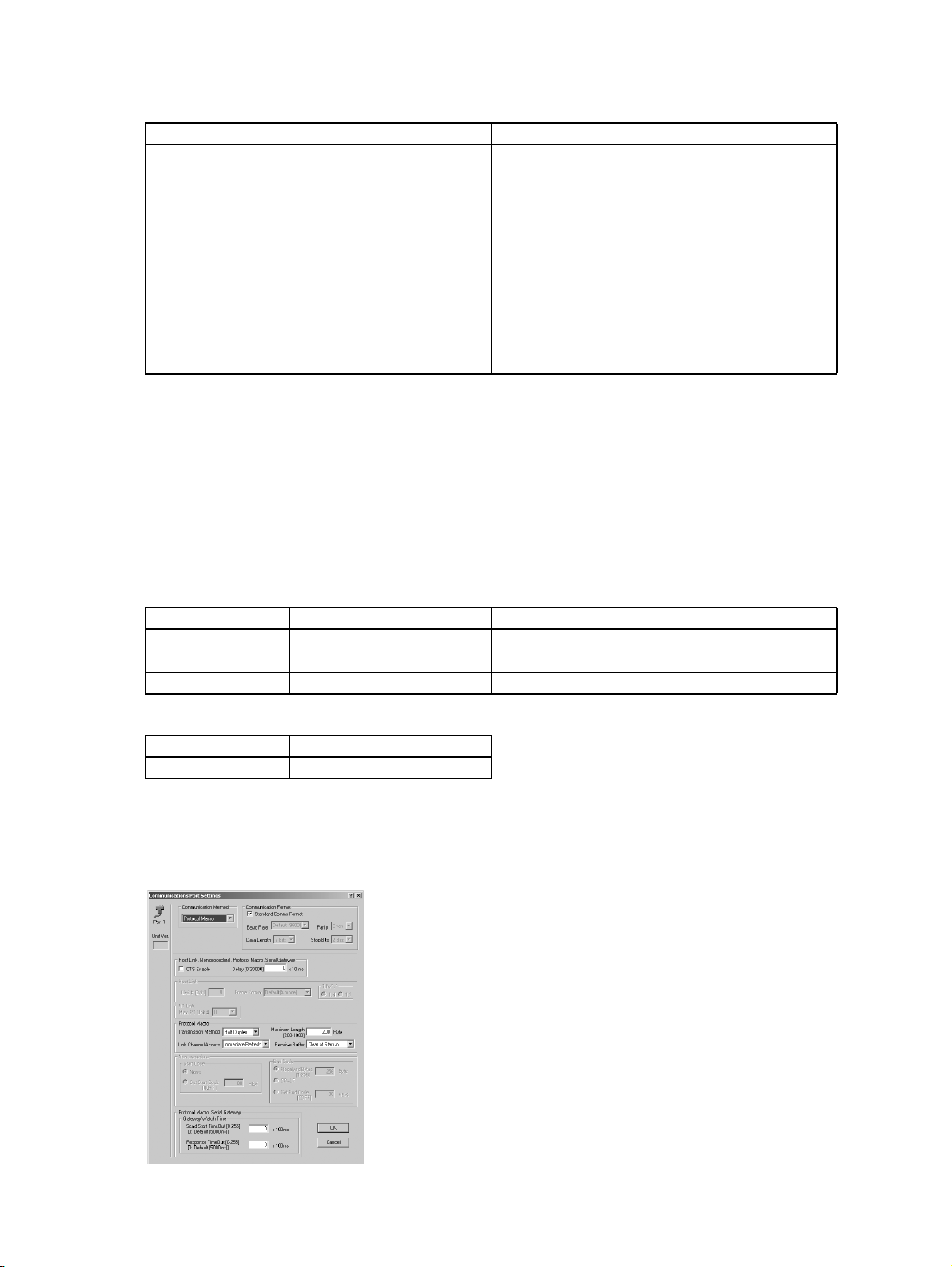

Communications Port Settings for Serial Communications Boards/Units

The communications port settings for CS/CJ-series Serial Communications Boards/Units with unit version 1.2 can be set using CX-Protocol version 1.5 in the Communications Port Settings for Boards/

Units. The following Communications Port Settings Dialog Box will be displayed.

xix

For details on each of the settings, refer to the CS/CJ Series Serial Communications Boards and Serial

Communications Units Operation Manual (W336-E1-06 or later).

CX-Protocol version 1.4 or earlier cannot read the CX-Protocol version 1.5 project files (.psw) that contain the communications port settings for the upgrade functions, such as no-protocol and Serial Gateway, in the Serial Communications Boards/Units with unit version 1.2. If an attempt to read these files

is made, the message “Unexpected file format.” will be displayed.

Standard System Protocol Additions

CX-Protocol version 1.5 includes the following additional standard system protocols that have been

added to Serial Communications Boards/Units with unit version 1.2.

• Host Link C-mode Command Master (Sequence numbers 700 to 721)

• Host Link FINS Command Master (Sequence numbers 750 to 767)

• Mitsubishi Computer Link Master (A-compatible, 1C frame, model 1) (Sequence numbers 802 to

817)

• Additional communications sequences for CompoWay/F Master (added Sequence numbers 606 to

621)

Operation Manual

The CX-Protocol Ver. 1.4 Operation Manual (W344) is included with CX-Protocol version 1.5. Apart

from the new functions and improvements in version 1.5 explained here, however, there are no other

changes in the upgrade that will affect operation or functionality.

Version 1.4

The following functions have been added to the CX-Protocol with the upgrade from Ver. 1.3 to Ver. 1.4.

New PLCs Supported

Simulation is newly supported for the following PLCs.

Series CPU Unit model numbers

CS CS1D-CPU67H/65H

CS1D-CPU67S/65S/44S/42S

CJ CJ1M-CPU11/21

Version 1.3

The following functions have been added to the CX-Protocol with the upgrade from Ver. 1.2 to Ver. 1.3.

CJ1M-CPU23/22/13/12 CPU Units Supported

Windows XP Supported

Version 1.2

The following functions have been added to the CX-Protocol with the upgrade from Ver. 1.1 to Ver. 1.2.

CS1-H, CJ1, and CJ1-H CPU Units Supported

xx

PRECAUTIONS

This section provides general precautions for using the CX-Protocol and related devices.

The information contained in this section is important for the safe and reliable application of the CX-Protocol. You

must read this section and understand the information contained before attempting to set up or operate the CXProtocol.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

6 Software Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

xxi

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

PLCs. Be sure to read this manual before attempting to use the software and

keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above mentioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing

so may result in serious electrical shock or electrocution.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Where the PLC is exposed to direct sunlight.

• Where the ambient temperature is below 0°C or over 55°C.

• Where the PLC may be affected by condensation due to radical temperature changes.

• Where the ambient humidity is below 10% or over 90%.

• Where there is any corrosive or inflammable gas.

• Where there is excessive dust, saline air, or metal powder.

• Where the PLC is affected by vibration or shock.

• Where water, oil, or chemical may splash onto the PLC.

xxii

Application Precautions 5

!Caution The operating environment of the PLC system can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

system. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the PLC.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to

protect against electrical shock.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Performing any of the following with the power supply turned

ON may lead to electrical shock:

• Mounting or removing any Units (e.g., I/O Units, CPU Unit, etc.) or

memory cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any cables or wiring.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or system or could damage the PLC or PLC Units. Always heed

these precautions.

• Use the Units only with the power supplies and voltages specified in the

operation manuals. Other power supplies and voltages may damage the

Units.

• Take measures to stabilize the power supply to conform to the rated supply if it is not stable.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Do not apply voltages exceeding the rated input voltage to Input Units.

The Input Units may be destroyed.

• Do not apply voltages exceeding the maximum switching capacity to Output Units. The Output Units may be destroyed.

• Always disconnect the LG terminal when performing withstand voltage

tests.

• Install all Units according to instructions in the operation manuals.

Improper installation may cause faulty operation.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

• Be sure to tighten Backplane screws, terminal screws, and cable connector screws securely.

xxiii

Software Operating Procedures 6

• Do not attempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

!Caution The following precautions are necessary to ensure the general safety of the

system. Always heed these precautions.

• Provide double safety mechanisms to handle incorrect signals that can be

generated by broken signal lines or momentary power interruptions.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PLC to ensure safety.

6 Software Operating Procedures

Observe the following precautions when using the CX-Protocol.

!WARNING Confirm safety before transferring the I/O memory area state to the CIO area

of the PLC using the PLC memory window function of the CX-Protocol. Not

doing so may cause malfunction in devices connected to the I/O Units regardless of the operating mode of the CPU Unit.

!Caution Confirm safety at the destination node before transferring a protocol to

another node or editing the I/O area. Doing either of these without confirming

safety may result in injury.

!Caution Confirm that no adverse effect will occur in the system before changing the

present value of any word in memory. Not doing so may result in an unexpected operation.

!Caution Confirm that no adverse effect will occur in the system before changing the

operating mode of the CPU Unit. Not doing so may result in an unexpected

operation.

!Caution Confirm that no adverse effect will occur in the system before force-setting/

force-resetting any bit in memory. Not doing so may result in an unexpected

operation.

!Caution Confirm that no adverse effect will occur in the system before transferring the

communications port A/B settings to the Protocol Macro Support Unit

(PMSU). Not doing so may result in an unexpected operation.

!Caution Check the user protocol for proper execution before actually running it on the

Unit. Not checking the protocol may result in an unexpected operation.

xxiv

!Caution Online connection of the CX-Protocol cannot be made to a PLC which is con-

nected online to SYSMAC-CPT or SYSMAC-PST. Therefore, when SYSMACCPT or SYSMAC-PST is running and connected online to a PLC, it must be

offline before making online connection to the CX-Protocol. Similarly, when

the CX-Protocol is connected online to a PLC, it must be switched to offline

before making online connection to SYSMAC-CPT or SYSMAC-PST.

This section outlines the Protocol Macro function and the CX-Protocol.

1-1 Overview of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2-1 Features of the Protocol Macro Function . . . . . . . . . . . . . . . . . . . . . 2

1-2-2 Features of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Supported PLC Models and Personal Computers . . . . . . . . . . . . . . . . . . . . . . 5

1-4-1 Supported PLC Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4-2 Supported PMSUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4-3 Supported Personal Computers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5-1 Connecting the CX-Protocol and the PLC . . . . . . . . . . . . . . . . . . . . 9

1-5-2 Connecting the PLC to External Devices . . . . . . . . . . . . . . . . . . . . . 11

1-6 Protocol Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-1 Protocol Macro Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-2 Standard System Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-7 Protocol Macro Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-7-1 Step Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-8 Data Created by the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-9 Main Screens of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-10 Overview of Project Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-11 Incorporated Standard System Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-12 Basic Procedure of the Protocol Macro Usage . . . . . . . . . . . . . . . . . . . . . . . . 25

1-12-1 For the CS/CJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-12-2 For the C200HX/HG/HE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1-13 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-13-1 Protocol Macro Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-13-2 Specifications of the CX-Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1-14 Differences between Protocol Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SECTION 1

Introduction

1

Overview of the CX-Protocol Section 1-1

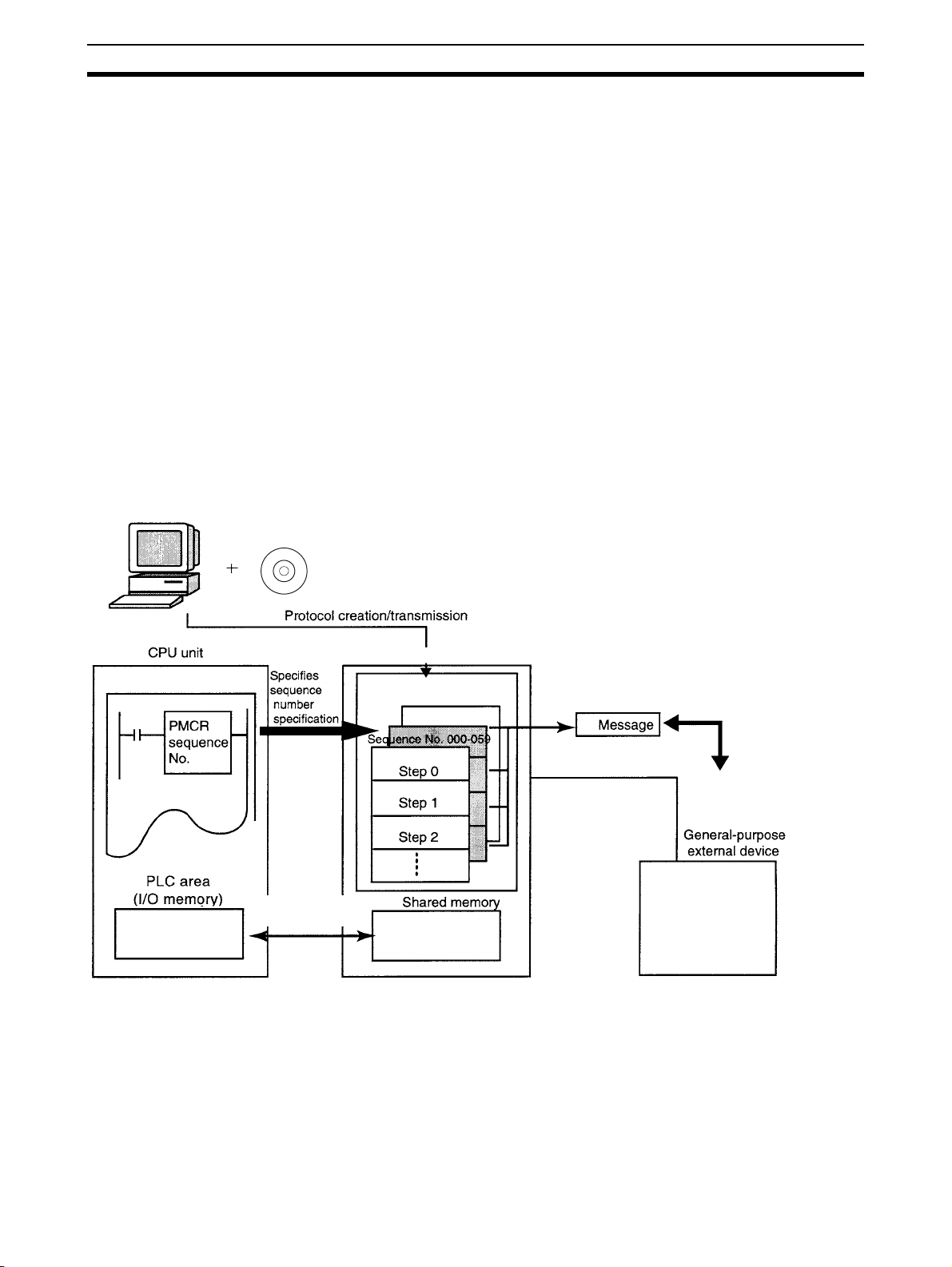

1-1 Overview of the CX-Protocol

The CX-Protocol is the software for creating a procedure (or protocol) for

sending or receiving data to or from general-purpose external devices connected to a Protocol Macro Support Unit (PMSU) through RS-232C or RS485A/422.

A protocol consists of a set of communications sequences. CX-Protocol transfers a protocol to the PMSU, specifies the sequence number of the protocol

using the PMCR instruction on the CPU Unit, and executes the communications sequence.

The communications sequence consists of several steps and allows the user

to iterate, branch, or end these steps according to the result of the process.

Note 1. In the following section, the Communications Board for the C200HX/HG/

HE, Serial Communications Board for the CS and CQM1H, and Serial

Communications Units for the CS/CJ are referred to as the “PMSU.”

2. The CJ-series protocol macro function of the CJ-series Serial Communications Unit is used even for the system configuration described below,

which uses a CP-series CPU Unit with a CJ-series Serial Communications

Unit. The CJ Series is thus specified in descriptions unless there is information unique to the CP Series.

1-2 Features

Programming

Device

servicing

CX-Protocol

Protocol

Sequence No. 060-099

PMSU

Command execution (Send, Receive, or Send&Receive)

RS-232C or

RS-422A/485

1-2-1 Features of the Protocol Macro Function

Support for a wide range of communications protocols

Supports communications with almost all external general-purpose devices

that have RS-232C or RS-422A/485 ports and support half-duplex or fullduplex mode (full-duplex is for CS/CJ only) and start-stop synchronization

2

Fe atu re s Section 1-2

mode (refer to 4-1 Applicable Range of the Protocol Macro Function for

restrictions).

Creation of send frames and receive (expected) frames according to the desired communications

frame specifications

Enables creation of almost all send frames (frames composed of commands,

data, and so on) and receive (expected) frames (frames composed of

responses and so on) according to the communications frame (message)

specifications of external devices.

Support for operation functions relating to communications

Supports error check code calculation, frame length calculation during transmission process, and numeral data conversion between ASCII and hexadecimal.

Support for the send and receive time monitoring function

Supports the receive wait monitoring, receive finish monitoring, and send finish monitoring functions. This function lets you designate whether to finish

send/receive process or to start retry process when those monitoring times

are exceeded.

Support for retry process Lets you designate, only by designating the number of retries, whether to

automatically execute send/receive retries when an error occurs.

Integration of variables for read/write process with PLC into send frames and receive (expected)

frames

Enables integration of variables for read process from PLC’s I/O memory into

send frames (messages) themselves. Data in the PLC that has been read

during transmission process can be used for addresses (destinations) or data.

This function also enables integration of variables for write process to PLC’s I/

O memory into receive frames (messages) themselves. Addresses (destinations) or data can be written into the PLC during the receive process.

Easy realization of rich functions including 1:N communications and switching data write destinations,

using repetition variables

Lets you designate repeat variables for send/receive process (repeat counter)

in variables. With this function, a wide variety of process can be easily realized: for example, sending the same data to multiple addresses (destinations)

by switching them during 1:N communications; switching write destination

addresses in PLC’s I/O memory during data receive process.

Execute interrupt program on the PLC while receiving data

Enables interrupt program execution on the PLC (CPU Unit) while receiving

data. The interrupt function is supported only by the Communications Board

for the C200HX/HG/HE and Serial Communications Board for the CS. It cannot be used with the Serial Communications Unit for the CS/CJ.

Switch the next process depending on the received data

The next process can be switched according to the data comparison with the

data registered to the maximum of 15 types.

The following functions have been added to the protocol macro for the CS/CJ.

Error check code (only for the CS/CJ protocol macro)

LRC2 (2’s complement of LRC) and SUM1 (1’s complement of SUM) have

been added to the error check codes.

3

Features Section 1-2

Wait command to keep the next process on standby until a synchronous signal is input from the PLC

(only for the CS/CJ protocol macro)

During the send/receive sequence step, the next process can be kept on

standby until a synchronous signal is input from the PLC (CPU Unit). This

enables computation processing such as data processing on the CPU Unit

during the send/receive sequence.

Supports half-duplex and full-duplex transmission mode (only for the CS/CJ protocol macro)

The conventional protocol macro provides only the half-duplex macro. With

the half-duplex macro, the receive buffer is cleared right after the send operation, thus the received data cannot be used. With the full-duplex mode, all the

data received within the sequence can be used and data can be sent and

received at the same time.

Note The full-duplex mode can be used with the RS-232C or four-wire setting. It

cannot be used with the 1:N or two-wire setting. (Only for models with the RS422A/485.)

Clear data using Flush command within the receive buffer at any time (only for the CS/CJ protocol

macro)

With the full-duplex mode, the receive buffer is cleared only right before executing the send/receive sequence. If any reception error occurs, the received

data can be cleared at any time using the Flush command (receive buffer

clear).

Turn the DTR control signal ON and OFF using the Open/Close command (only for the CS/CJ protocol

macro)

When connected to a modem device, DTR signal is used to indicate that the

Serial Communications Board or Unit (DTE) is ready to send or receive data.

Previously, the DTR signal could be turned ON only during the send/receive

sequence.

Now the DTR signal can be turned ON or OFF at any time within the send/

receive sequence. This allows connection or disconnection with a modem

using the protocol macro.

The DTR signal can be set to ON even after the send/receive sequence has

completed. The DTR signal can be retained even after changing to another

protocol mode (for example, host link).

With this function, remote programming or monitoring can be performed

through a remote Programming Device by changing to the host link mode

using the STUP instruction after connecting to a modem.

1-2-2 Features of the CX-Protocol

Simultaneous display of tree (hierarchical) view and list (table) view

The CX-Protocol displays data in the form of a tree in the left pane, which

gives you easier understanding of the hierarchical structure of data you are

setting/monitoring.

Object-oriented operation Double-clicking target data, instead of choosing from menus, opens its corre-

sponding pop-up dialog, which enables you to create protocols quickly without

a thorough understanding of operation menus.

Supplied standard system protocols

Data exchange protocols for OMRON’s components (Temperature Controllers, Panel Meters, Bar Code Readers, Modems, and so on) are included as

standard system protocols.

Notice that those standard system protocols are included also in the PMSU.

4

Checking the Contents of the Package Section 1-3

Possible to trace send/receive message

By executing the trace function from the CX-Protocol, the PMSU can trace

and save chronological data of send/receive messages up to 670 bytes for the

C200HX/HG/HE and up to 1,700 bytes for the CS/CJ. Each data item can be

displayed and printed for reading and saved as a trace file.

1-3 Checking the Contents of the Package

After purchase, first check the contents of your CX-Protocol package.

CX-Protocol Model

Product Name Model Setup disk Version

CX-Protocol WS02-PSTC1-E CD-ROM Ver. 1.81

CX-Protocol Components Check that all the following components of the CX-Protocol are included in

your package.

WS02-PSTC1-E

Item Quantity

Product Guide 1

Setup disk (CD-ROM) 1

Software license agreement and user

registration card for outside Japan

Software license agreement and user

registration card for within Japan

Seal 1

Notice sheet 1

1

1

1-4 Supported PLC Models and Personal Computers

1-4-1 Supported PLC Models

The CX-Protocol supports the following PLCs (Programmable Controllers).

Series CPU Unit

CS (See note 1.) CS1H-CPU67/66/65/64/63

CS1G-CPU45/44/43/42

CS1H-CPU67H/66H/65H/64H/63H

CS1G-CPU45H/44H/43H/42H

CS1D-CPU67H/65H

CS1D-CPU67S/65S/44S/42S

CJ CJ2H-CPU68/67/66/65/64/68-EIP/67-EIP/66-EIP/65-EIP/64-EIP

CP CP1H-XA@@@@-@

NSJ G5D (Same for the NSJ5-TQ@@-G5D, NSJ5-SQ@@-G5D, NSJ8-TV0@-G5D, NSJ10-TV0@-G5D,

C200HX/HG/HE

(See note 2.)

CQM1H

(See note 3.)

CJ1G-CPU45/44

CJ1G-CPU45H/44H/43H/42H

CJ1G-CPU45P/44P/43P/42P

CJ1H-CPU67H-R/66H-R/65H-R/64H-R/67H/66H/65H

CJ1M-CPU23/22/21/13/12/11

CP1H-X@@@@-@

CP1H-Y@@@@-@

and NSJ12-TS0@-G5D.)

M3D (Same for the NSJ5-TQ@@- M3D, NSJ5-SQ@@- M3D, and NSJ8-TV0@- M3D.)

C200HX-CPU34-E/44-E/54-E/64-E/34-ZE/44-ZE/54-ZE/64-ZE/65-ZE/85-ZE

C200HG-CPU33-E/43-E/53-E/63-E/33-ZE/43-ZE/53-ZE/63-ZE

C200HE-CPU-32-E/42-E/32-ZE/42-ZE

CQM1H-CPU51/61

5

Supported PLC Models and Personal Computers Section 1-4

Note 1. When using the CS1D-H, set the device type as follows:

CS1D-H with unit Ver. 1.1:CS1D-H

Pre-Ver. 1.1 CS1D-H: CS1H-H

2. CX-Protocol Version 1.0 does not support the C200HX/HG/HE.

3. When using CQM1H-series PLCs, use the C200HG-CPU43 from the

C200HX/HG/HE Series as the CPU Unit.

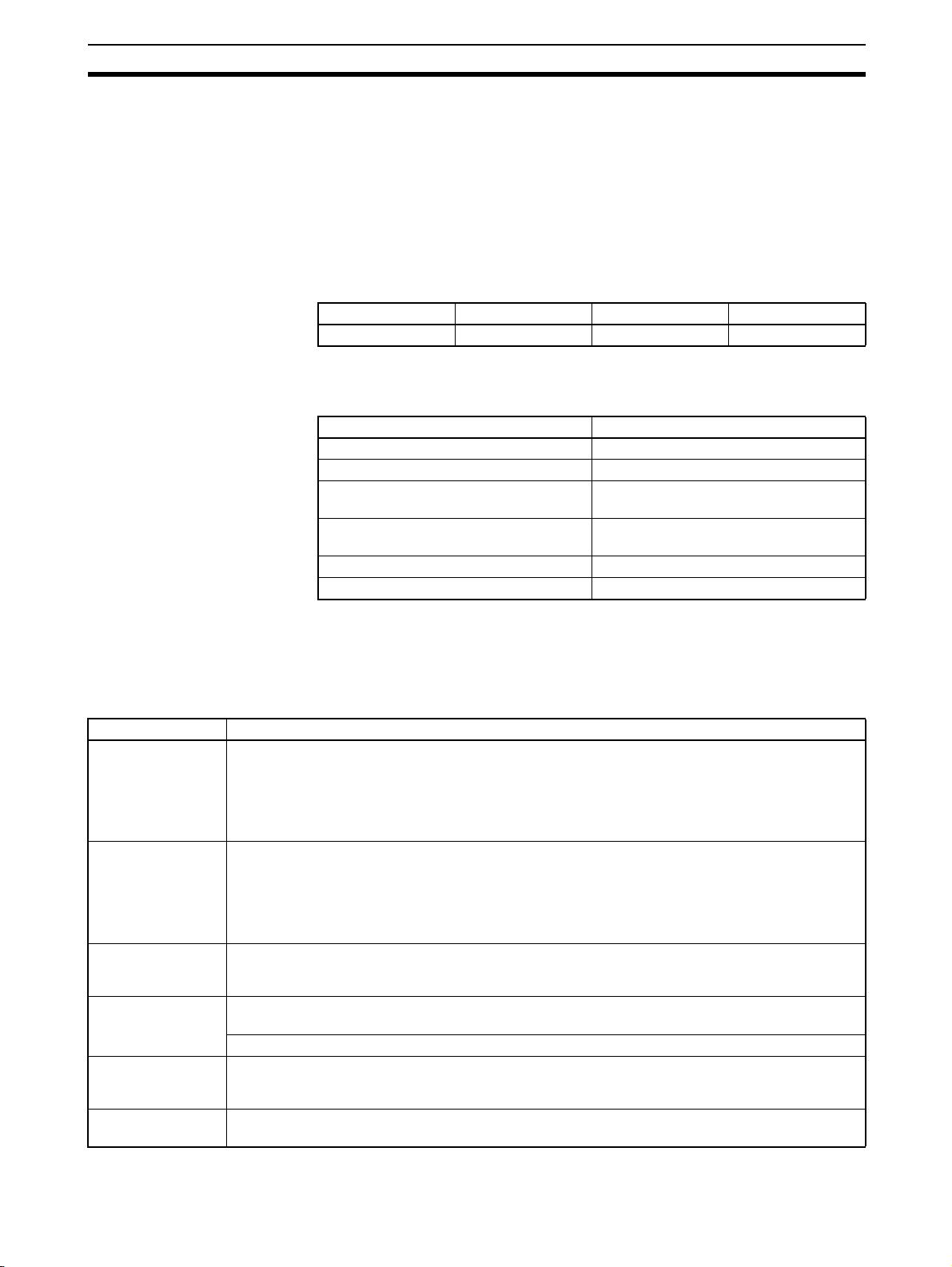

1-4-2 Supported PMSUs

CS-series PLCs

Product name Installation Model Serial communications ports

Serial Communications

Boards (Inner Board)

Serial Communications

Unit (CPU Bus Unit)

Mounting the Serial Communications

Board on the CPU Unit

Installed in the CPU Unit

Installed on the CPU Rack

or CS Expansion Rack

CS1W-SCB21-V1 RS-232C port x 1 + RS-232C port x 1

CS1W-SCB41-V1 RS-232C port x 1 + RS-422A/485 port x 1

CS1W-SCU21-V1 RS-232C port x 1 + RS-232C port x 1

CS1W-SCU31-V1 RS-422A/485 port x 1 +

RS422A/485 port x 1

Mounting the Serial Communications

Unit on the CPU Rack

CPU Rack CPU Unit

Power Supply Unit

Serial Communications

Units

CS1 Expansion Rack

Power Supply Unit

CJ-series and CP-series

PLCs

Product name Classification Installation Model Serial communications ports

Serial Communications Unit

CJ-series CPU

Bus Unit

CPU Rack or

CJ Expansion Rack

CJ1W-SCU21-V1 RS-232C port x 1 + RS-232C port x 1

CJ1W-SCU31-V1 RS-422A/485 port x 1 +

RS422A/485 port x 1

CJ1W-SCU41-V1 RS-232C port x 1 +

RS-422A/485 port x 1

6

Supported PLC Models and Personal Computers Section 1-4

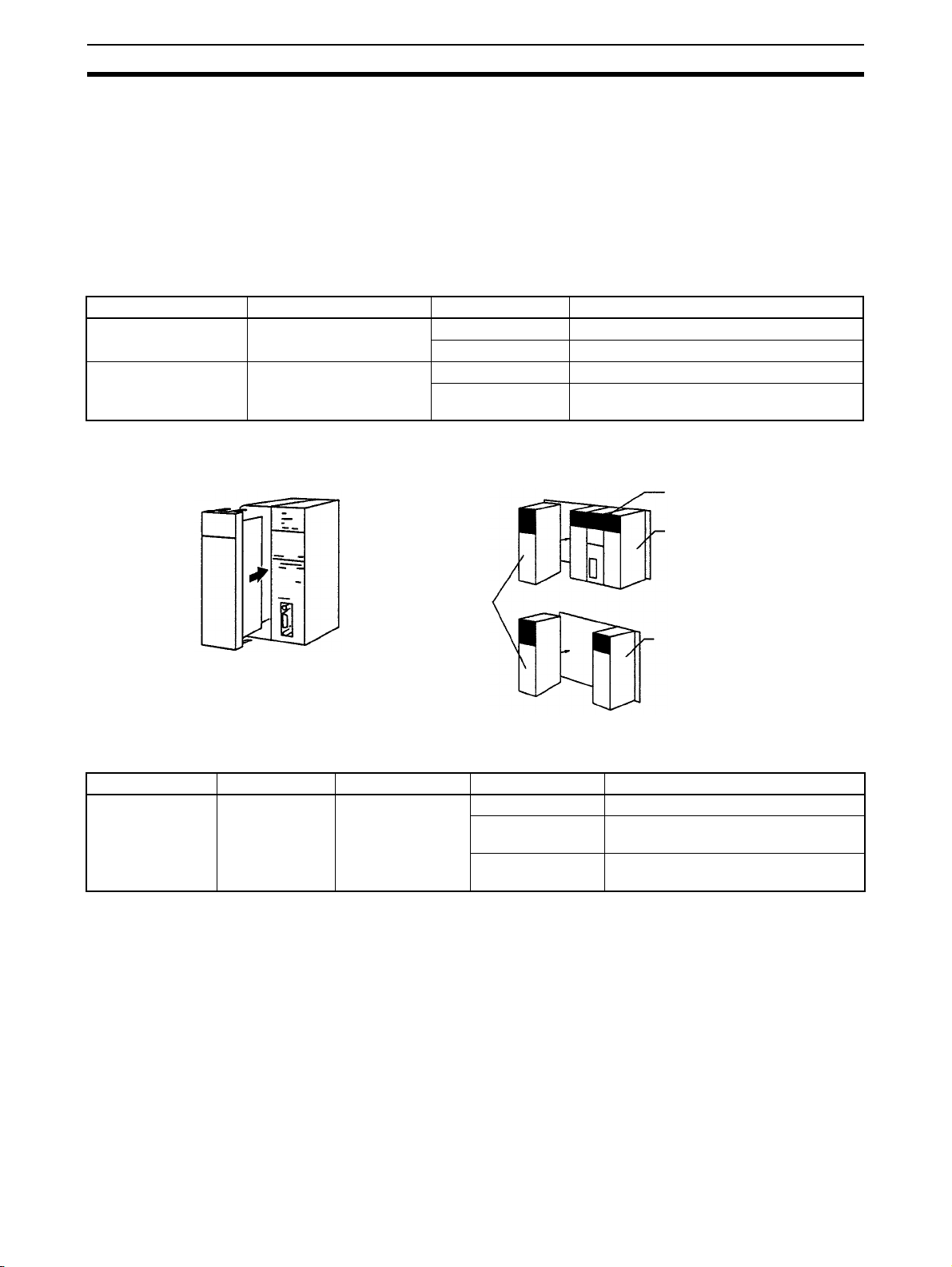

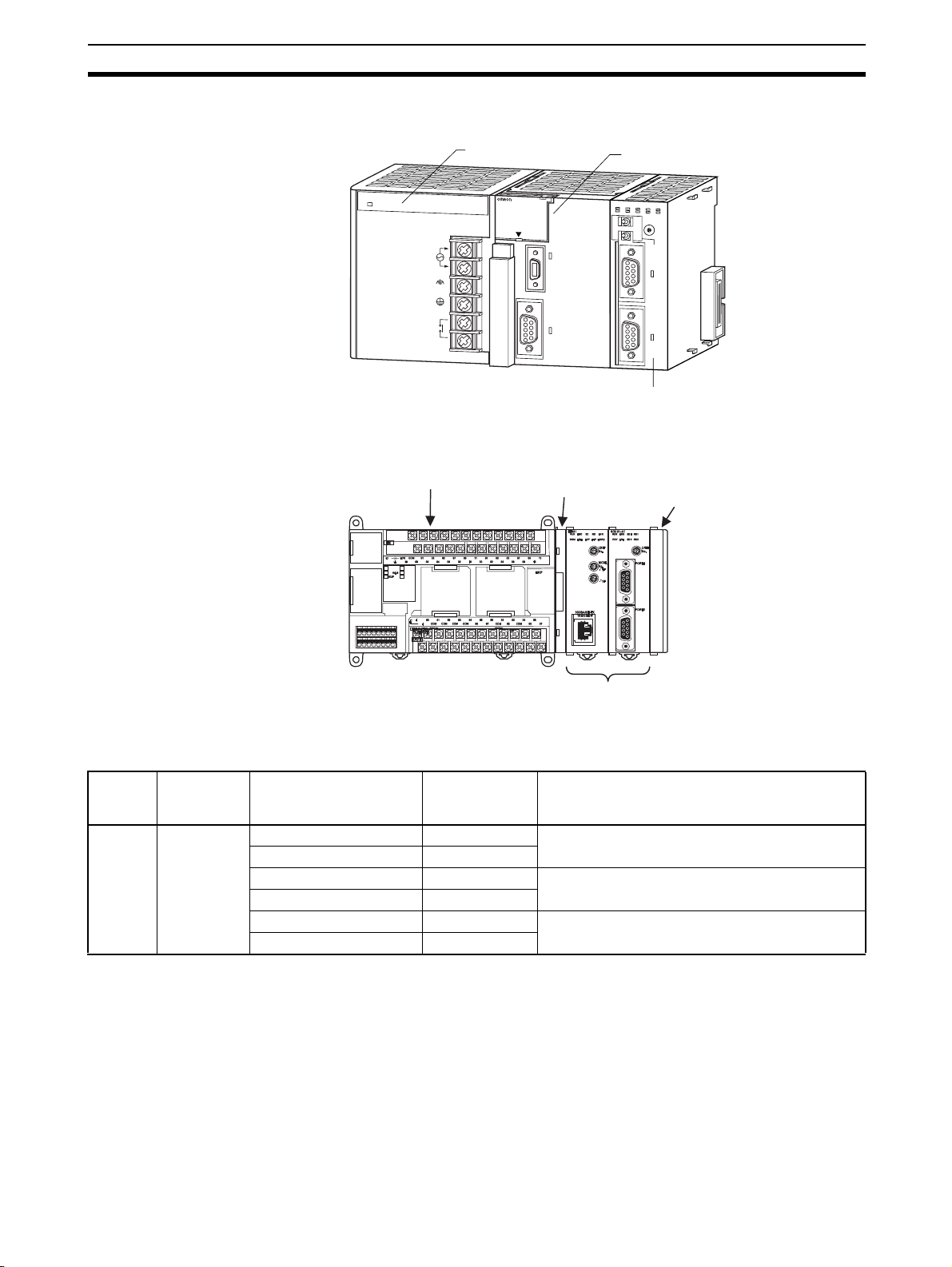

Connecting the Serial Communications Unit

• Mounting to a CJ-series CPU Unit

Power Supply Unit

CPU Unit

PA205R

POWER

AC100-240V

INPUT

OUTPUT

AC240V

DC24V

L1

L2/N

RUN

SYSMAC

CJ1G-CPU44

P

R

O

G

R

A

M

C

O

N

T

R

O

LL

M

A

B

L

E

R

OPEN

M

C

B

U

E

PW

R

S

Y

PERIPHERAL

PO

RUN

ERR/ALM

INH

PRPHL

COMM

R

T

Serial Communications Unit

• Mounting to a CP-series CPU Unit

CP1H CPU Unit

CP1W-EXT01

CJ-series Unit Adapter

SCU41

RUN

ERC

SD1

RD1

TER1

RDY

ERH

SD2

RD2

TERM

OFF

ON

UNIT

5

4

6

3

7

2

8

1

9

NO.

0

A

F

B

E

C

D

WIRE

2

4

PORT1

(RS422

/485)

PORT2

CJ1W-TER01

CJ-series End Cover

(Included with CJ-series

Unit Adapter)

C200HX/HG/HE PLCs

Product

name

PMSU

Installation Model Enhanced

Installed in

the CPU

Unit

Connect the Serial Communications

Unit to one of these.

Specifications

functions (see

note)

C200HW-COM04-E --- CPU bus interface + RS-232C port x 1

C200HW-COM04-EV1 ❍

With the protocol macro function

C200HW-COM05-E --- RS-232C port x 2

C200HW-COM05-EV1 ❍

With the protocol macro function

C200HW-COM06-E --- RS-232C port x 1 + RS-422A/485 port x 1

C200HW-COM06-EV1 ❍

With the protocol macro function

Note 1. The enhanced functions are as follows:

• SUM2 (2’s complement of SUM) and CRC-16 are added as error

check codes.

• Repeat counter N current value, Sequence End Finish Flag, and Sequence Abort Finish Flag are added to the auxiliary area.

• A check code can be located behind a terminator in messages.

• Swap between high byte and low byte can be designated for error

check codes.

7

Loading...

Loading...