Cat. No. W436-E1-02

SYSMAC

WS02-MNTC1

CX-Motion-NCF Ver. 1.2

WS02-MNTC1 CX-Motion-NCF Ver. 1.2

Operation Manual

Revised February 2005

iv

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

SECTION 1

CX-Motion-NCF Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 What is CX-Motion-NCF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Operation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1 Installing and Uninstalling the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Connecting to PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 3

Basic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-1 Screen Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-3 Operations Listed by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 4

Creating Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-1 Creating a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2 Adding and Deleting Position Control Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-3 Adding and Deleting Servo Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SECTION 5

Editing Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-1 Editing Unit Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5-2 Editing Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

vii

TABLE OF CONTENTS

SECTION 6

Saving and Reading Projects . . . . . . . . . . . . . . . . . . . . . . . . . 51

6-1 Saving Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6-2 Reading Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6-3 Import . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6-4 Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6-5 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

SECTION 7

Transferring and Comparing Data . . . . . . . . . . . . . . . . . . . . 57

7-1 Initial Setting for Connecting Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7-2 Setting/Changing Communications Specific. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7-3 Downloading Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7-4 Uploading Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7-5 Comparing Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7-6 Writing to Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

SECTION 8

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8-1 Unit Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8-2 Axis Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

SECTION 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9-1 Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

SECTION 10

Error Log and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 93

10-1 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10-2 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10-3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

viii

About this Manual:

This manual describes the installation, and operation of the WS02-MNTC1 CX-Motion-NCF software

package and includes the sections described below. The CX-Motion-NCF runs on Windows 98, Me,

NT4.0, 2000, and XP and is used to set and transfer data used by CJ1W-NCF71 Position Control Units

(also referred to as PCUs or NC Units), save and print the PCU data, and monitor the PCU’s operating

status.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the CX-Motion-NCF. Be sure to read the precautions provided in the following section. Please read the following manuals carefully and be sure you understand the informa-

tion provided before setting up or using an application for a Position Control Unit.

Name Contents Cat. No.

SYSMAC WS02-MNTC1

CX-Motion-NCF

Operation Manual

SYSMAC CJ1W-NCF71

Position Control Units

Operation Manual

SYSMAC CXONE-AL@@-E

CX-Integrator

Operation Manual

(suffixes omitted)

Describes the operating procedures for the CX-Motion-NCF W436 (this manual)

Describes the basic operation of the Position Control Unit. W426

Describes the operating procedures for the CX-integrator. W445

For details on procedures for installing the CX-Motion-NCF from the CX-One FA Integrated Tool Package, refer to the CX-One Setup Manual provided with CX-One.

Cat. No. Model Name Contents

W444 CXONE-AL@@-E CX-One Setup Manual Installation and overview of CX-One FA

Integrated Tool Package.

ix

Precautions provides general precautions for using the CX-Motion-NCF, Programmable Controller,

and related devices.

Section 1 provides an overview of the CX-Motion-NCF, and describes the functions and system configuration required to operate the CX-Motion-NCF.

Section 2 provides information on installing CX-Motion-NCF and CX-Server, and connecting to the

PLC.

Section 3 describes each of the screens and basic operations.

Section 4 provides information on creating projects and adding/deleting Position Control Units and

Servo Drivers.

Section 5 describes the operations used to edit Unit Parameters and Servo Parameters.

Section 6 describes the operations used to save and read newly created projects. Information is also

provided on importing, exporting, and printing procedures.

Section 7 describes the operations used to transfer or compare data between the personal computer

and Position Control Unit/Servo Driver, and to write data transferred to the Position Control Unit to the

Position Control Unit's flash memory.

Section 8 provides information on the Monitor Windows that are used to display the Position Control

Unit's communications status, error status, and axis's present position and status.

Section 9 describes the jogging operations for each axis.

Section 10 provides information on troubleshooting errors that may occur, meanings of error codes,

and the procedures required to reset errors in the Unit or axes.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

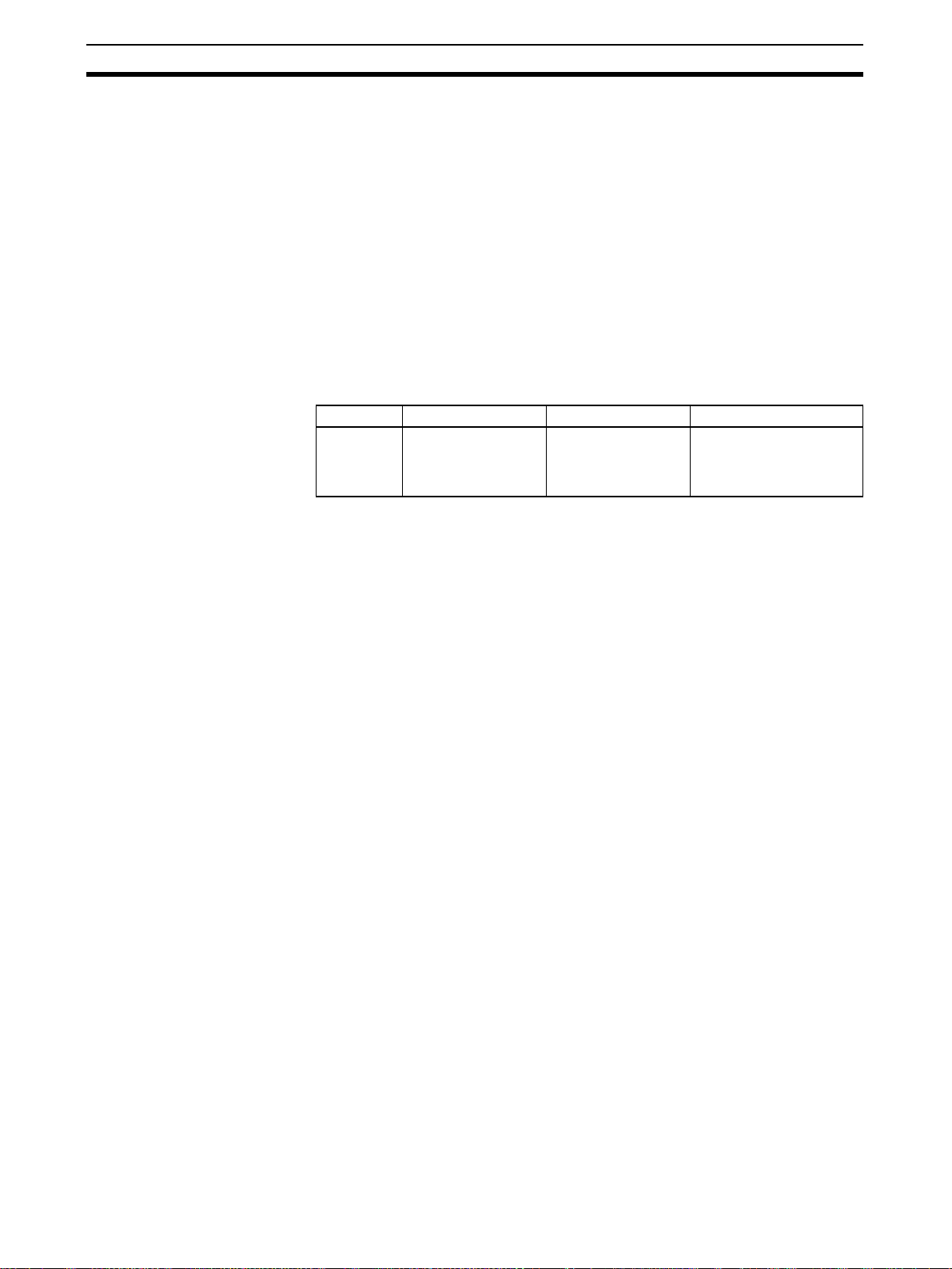

Version Upgrade Information

Improvements from Version 1.0 to Version 1.1

Supporting New Models of W-series Servo Driver

Item Ver. 1.0 Ver. 1.1

Applicable Servo Drivers W-series Servo Drivers W-series Servo Drivers

W-series Servo Drivers with Built-in MECHATROLINK Communications

Improvements from Version 1.1 to Version 1.2

Installing the CX-Motion-NCF from the CX-One FA Integrated Tool Package

Ver. 1.1 Ver. 1.2

The CX-Motion-NCF could be installed

only independently.

CX-Motion-NCF Startup Method

Ver. 1.1 Ver. 1.2

The CX-Motion-NCF could be started

only from the Windows Start Menu.

The CX-Motion-NCF can be installed as one of the functions of the CX-One

Integrated Tool Package.

The CX-Motion-NCF can also be started by right-clicking the following Position

Control Unit in the I/O Table Window opened from the CX-Programmer that

was installed from the CX-One and selecting Start Special Application from

the pop-up menu.

• CJ1W-NC71

Note When Start with Settings Inherited is selected, a new project will be

created and a Position Control Unit will be automatically added.

xiv

PRECAUTIONS

This section provides general precautions for using the CX-Motion-NCF software package.

The information contained in this section is important for the safe and reliable application of the CX-Motion-NCF.

You must read this section and understand the information contained before attempting to set up or operate the CXMotion-NCF.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

xv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that the CX-Motion-NCF and related devices be used

for the specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying Position Control Units and

related devices to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electric shock.

!WARNING Always back up parameter data or other data to the flash memory after it has

been transferred to the Position Control Unit. If transferred data is not backed

up in flash memory, the previous settings may be used the next time the

power is turned ON, resulting in a malfunction.

!Caution Confirm safety at the destination node before transferring parameters or other

data to another node. Doing either of these without confirming safety may

result in injury.

xvi

!Caution Check that the axis number is correct before operating an axis from the CX-

Motion-NCF.

Operating Environment Precautions 4

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the CX-Motion-NCF.

• Confirm that the correct unit number is specified for the destination node

before transferring parameters or other data to the Position Control Unit.

• Confirm that set parameters and data operate properly before using them

in actual applications.

• Always turn ON the power to the Unit again or restart the CPU Bus Unit

after transferring changed parameter settings, and writing them to flash

memory. Otherwise, the changed parameter settings will not be enabled.

• Do not turn OFF the power to the Unit while writing to flash memory.

Doing so may result in damage to the flash memory.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including changing the Startup Mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not turn OFF the power to the personal computer while installing or

uninstalling CX-Motion-NCF. Doing so may result in corrupted data in the

personal computer.

xvii

Application Precautions 5

xviii

SECTION 1

CX-Motion-NCF Overview

This section provides an overview of the CX-Motion-NCF, and describes the functions and system configuration required

to operate the CX-Motion-NCF.

1-1 What is CX-Motion-NCF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Operation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1

What is CX-Motion-NCF? Section 1-1

1-1 What is CX-Motion-NCF?

What is CX-MotionNCF?

Features

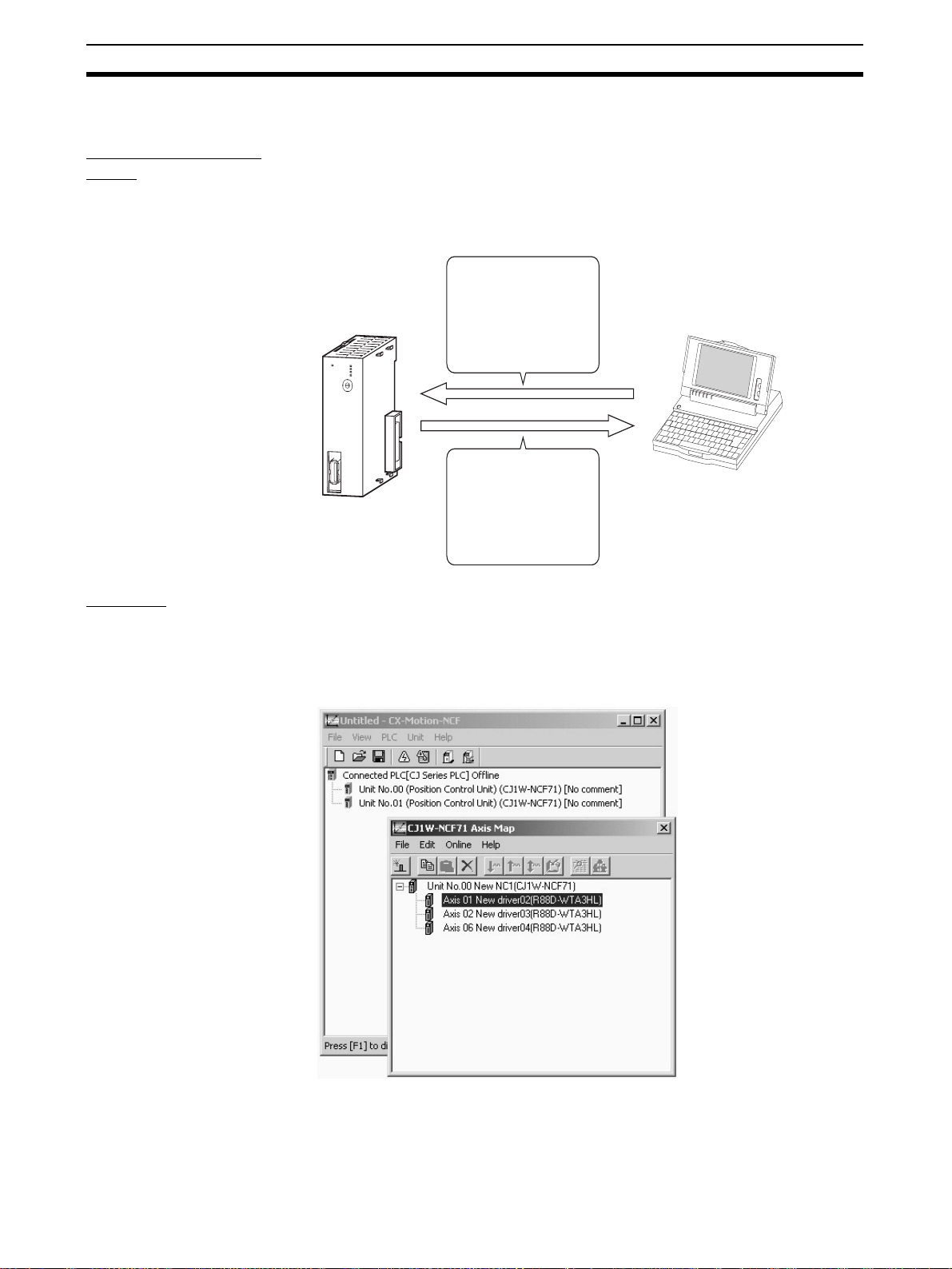

CX-Motion-NCF is a software package that helps to set, transfer, save, and

print various data used for the CJ1W-NCF71 Position Control Unit (also

referred to as PCU or NC Unit) and to monitor the operation status of the Position Control Unit.

CX-Motion-NCF runs on Windows98, Me, NT 4.0, 2000, or XP.

Computer with

Windows

operating system

CJ1W-NCF71

NCF71

MLK

R

UN

ERC

ER

H

ERM

D

C

E

B

U

N

IT

F

A

0

9

1

8

N

o

.

2

7

3

6

4

5

M

L

K

Parameters used with

the NC Unit are set and

transferred.

The NC Unit's operating

status (e.g., present

position, I/O status, and

error display) is

monitored.

Data Management and

Editing in Project Units

The CX-Motion-NCF manages data for several Position Control Units as one

project. Position Control Units are displayed under a PLC and several Servo

Drivers (up to 16 axes) are displayed under a Position Control Unit, both in

tree format.

Communications with

Position Control Units via

Networks

2

CX-Motion-NCF communicates with Position Control Units using CX-Server.

Host Link (SYSMAC WAY) or peripheral bus (Toolbus) can be used to perform

online operations (transferring, comparing, and monitoring parameter data)

with the Position Control Unit on the PLC.

What is CX-Motion-NCF? Section 1-1

Editing Servo Parameters Parameters of Servo Drivers connected to a Position Control Unit can be

edited using CX-Motion-NCF.

Displaying Error

Information

Applicable

Computers

Information on the error that is currently occurring on a Position Control Unit

or the error log can be displayed.

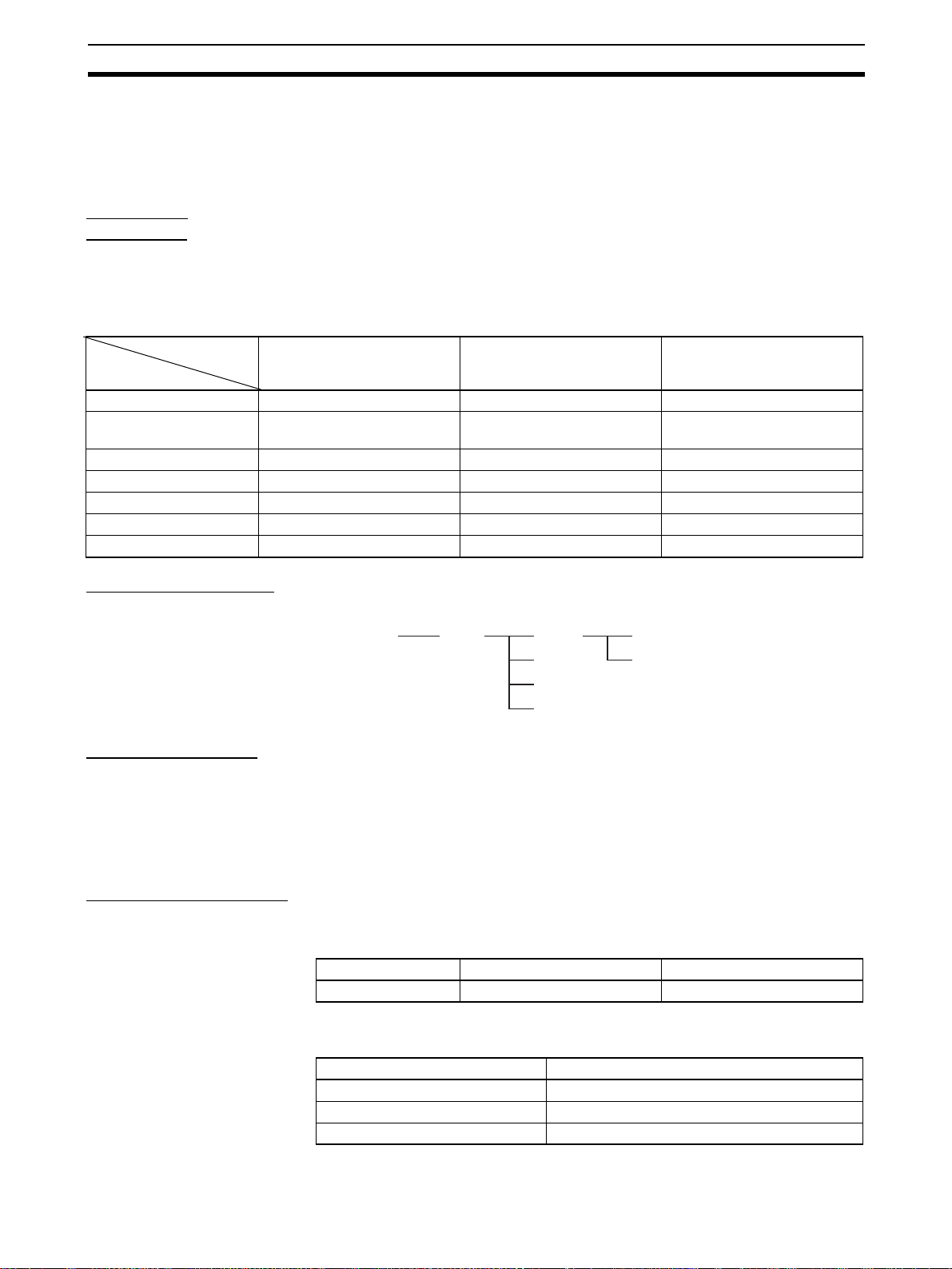

CX-Motion-NCF can be used on computers that satisfy the following conditions.

The following conditions apply when installing the CX-Motion-NCF as an individual application. Different conditions will apply when installing the CXMotion-NCF as one of the features of the CX-One FA Integrated Tool Package. Refer to the CX-One Setup Manual (W444) for the specific conditions.

OS

Windows 98 or Windows

Item

Computer IBM PC/AT or compatible IBM PC/AT or compatible IBM PC/AT or compatible

CPU Pentium Class 133 MHz or

RAM memory 64 Mb min. 96 Mb min. 128 Mb min.

Hard disk drive 100 Mb min. of free space 100 Mb min. of free space 100 Mb min. of free space

Monitor 800 × 600 SVGA or higher 800 × 600 SVGA or higher 800 × 600 SVGA or higher

CD-ROM drive 1 min. 1 min. 1 min.

Communications port 1 RS-232C port min. 1 RS-232C port min. 1 RS-232C port min.

NT4.0 Service Pack 6

higher

Windows Me or Windows

2000 Service Pack 3 or

higher

Pentium Class 150 MHz or

higher

Windows XP

Pentium Class 300 MHz or

higher

CX-Motion-NCF Data CX-Motion-NCF is used to create project files with the configuration shown

below. The file extension for project files is .mnf.

Project File

(

*.mnf)

PLC

NC

NC

NC

NC

Unit Parameter

Servo Parameter

Software Structure CX-Motion-NCF exchanges data (online communications) with Position Con-

trol Units via CX-Server. In order to execute functions online, CX-Server must

be installed on the same computer that has CX-Motion-NCF installed.

CX-Server is bundled on the setup disk of CX-Motion-NCF.

Either the Toolbus or SYSMAC WAY (Host Link) can be selected for the network type.

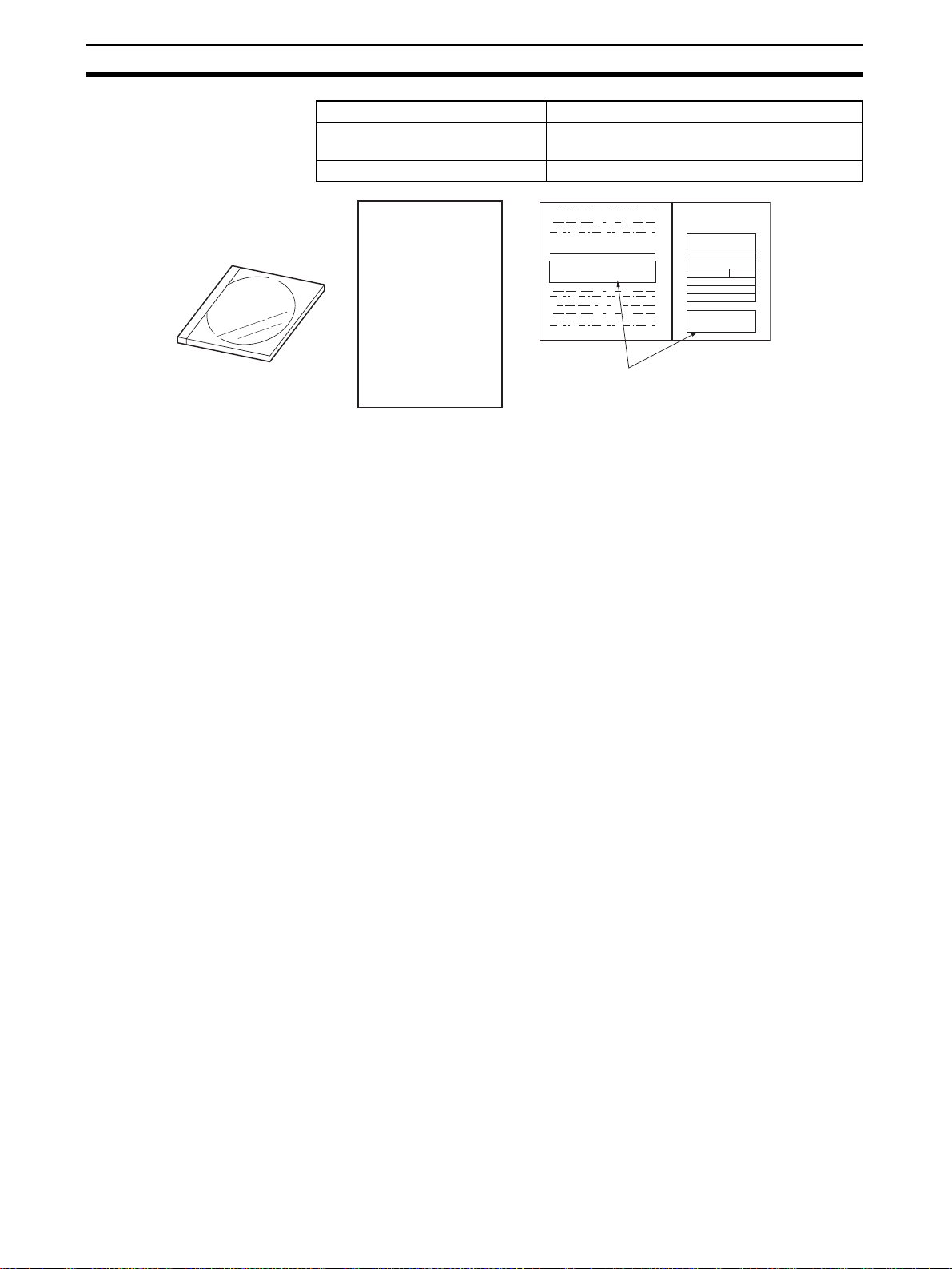

Checking the Package After purchase, confirm that the contents of the package are as described

below.

CX-Motion-NCF Model

Number

CX-Motion-NCF Package The CX-Motion-NCF software package consists of the following items. Con-

Product name Model number Setup disk

CX-Motion-NCF Model WS02-MNTC1 CD-ROM

firm that accessories are provided.

Item No. of items

Setup Disk (CD-ROM) 1

CX-Motion-NCF Operation Manual PDF manual on CD-ROM

Product Guide 1

3

What is CX-Motion-NCF? Section 1-1

Item No. of items

Software Licence Agreement/User

Registration Card

Address label 1

Product Guide

Note Software Licence Agreement/User Registration Card has the licence number

that is required to install CX-Motion-NCF. Please keep it in a safe place and

do not lose it.

2

The model, version, and license

No. is shown in the Software

License Agreement.

4

System Configuration Section 1-2

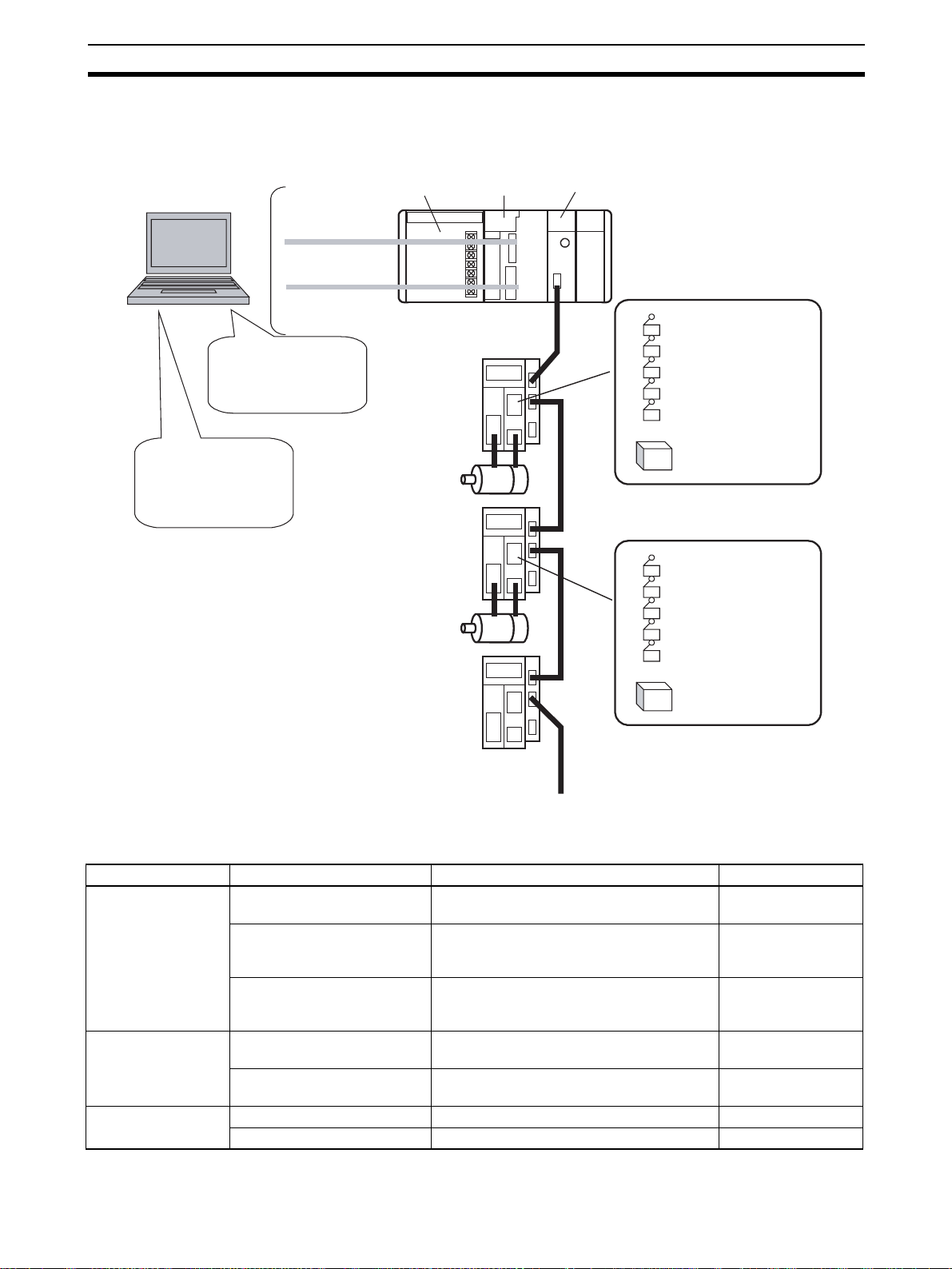

1-2 System Configuration

The system configuration for Position Control Units is shown below.

CX-Motion-NCF

Editing/Transferring

parameters

Monitor

File management, etc.

CX-Programmer

Creating/Transferring

ladder program

Monitor

File management, etc.

Toolbus/

Host Link

Power

Supply Unit

Servo Driver

Servomotor

Servo Driver

Servomotor

Servo Driver

CJ Series

CPU Unit

NC Unit

(CJ1W-NCF71)

External input

Forward rotation limit input signal

Reverse rotation limit input signal

Origin input signal

Origin proximity input signal

Interrupt input signal

:

24-V DC power supply for

interface

External input

Forward rotation limit input signal

Reverse rotation limit input signal

Origin input signal

Origin proximity input signal

Interrupt input signal

24-V DC power supply for

interface

MECHATROLINK-II

(16 axes max.)

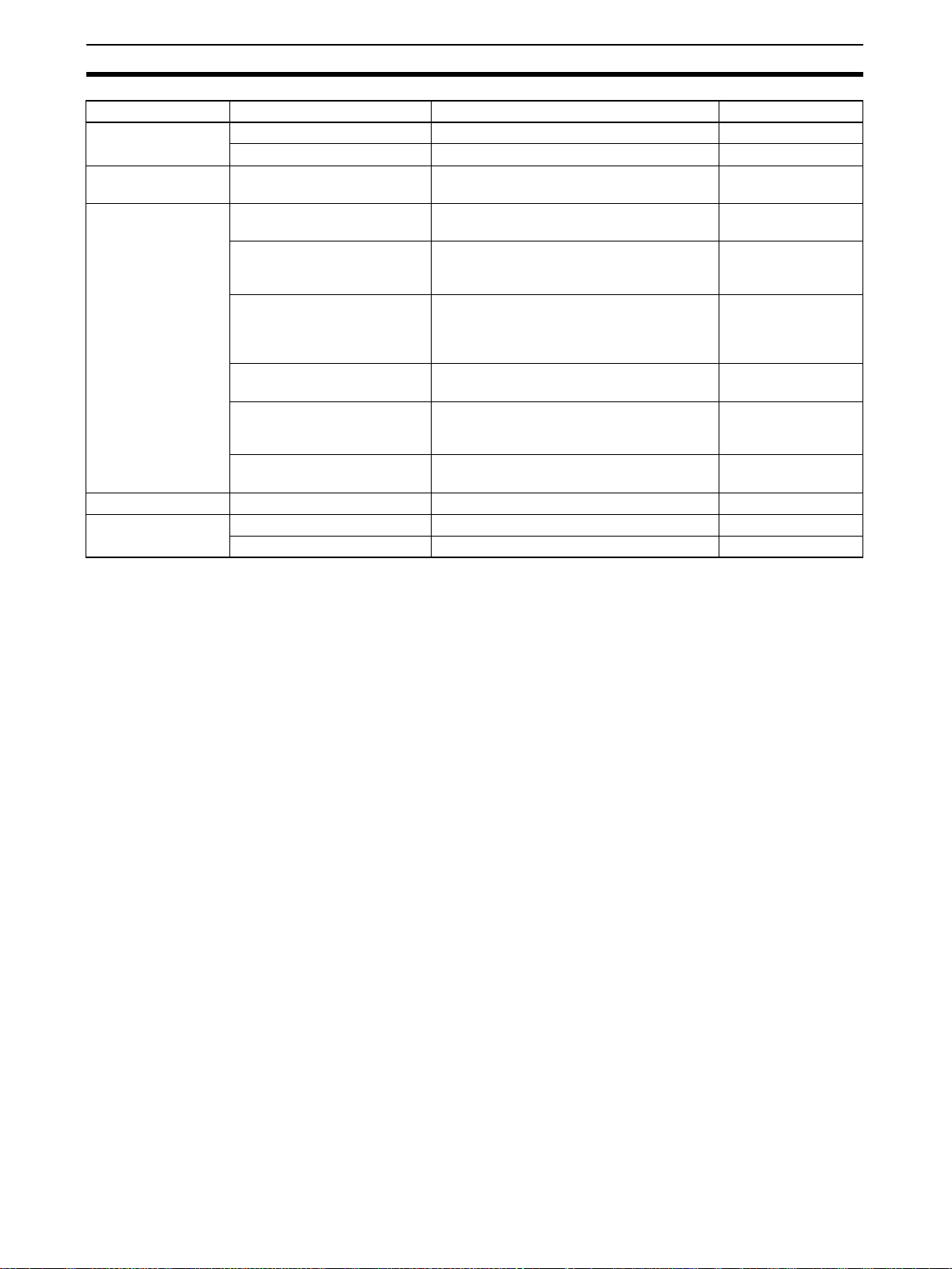

1-3 Function List

Group Function Details Reference

Editing projects Create project Used to create project files (*.mnf) 4-1 Creating a New

Project

Create Position Control Unit Used to add Position Control Unit data to a

project.

Create Servo Driver Used to add Servo Driver data to a project. 4-3 Adding and

Editing data Edit Unit Parameters Used to edit Unit Parameters. 5-1 Editing Unit

Edit Servo Parameters Used to edit Servo Parameters. 5-2 Editing Servo

Saving and reading

project files

Save project Used to save data as a project file (*.mnf). 6-1 Saving Project

Read project Used to read a project file (*.mnf). 6-2 Reading Project

4-2 Adding and

Deleting Position

Control Units

Deleting Servo Drivers

Parameters

Parameters

5

Function List Section 1-3

Group Function Details Reference

Importing and

exporting data

Printing Print Used to print the data displayed on the

Online Initial setting Used to setup CPU Unit or Position Control

JOG JOG Used to execute JOG operation. 9-1 Test Run

Error Error log Used to display the error log. 10-1 Error Log

Import Used to import Unit/Servo Parameters. 6-3 Import

Export Used to export Unit/Servo Parameters. 6-4 Export

screen.

Unit.

Communications setting Used to make communications settings. 7-2 Setting/Chang-

Download

Upload

Compare

Write to flash memory Used to save the downloaded Unit Parame-

Monitor Used to display the Unit's status, axis

Device information Used to read the Unit’s model, system soft-

Error information Used to display error code, error name. 10-2 Error Code

Used to download, compare, or upload Unit

or Servo Parameters.

ters.

present position, axis status, and error information.

ware version, and attached information.

6-5 Print

7-1 Initial Setting for

Connecting Online

ing Communications

Specific

7-3 Downloading

Data

7-4 Uploading Data

7-5 Comparing Data

7-6 Writing to Flash

Memory

8-1 Unit Monitor

8-2 Axis Monitor

---

6

Operation Procedure Section 1-4

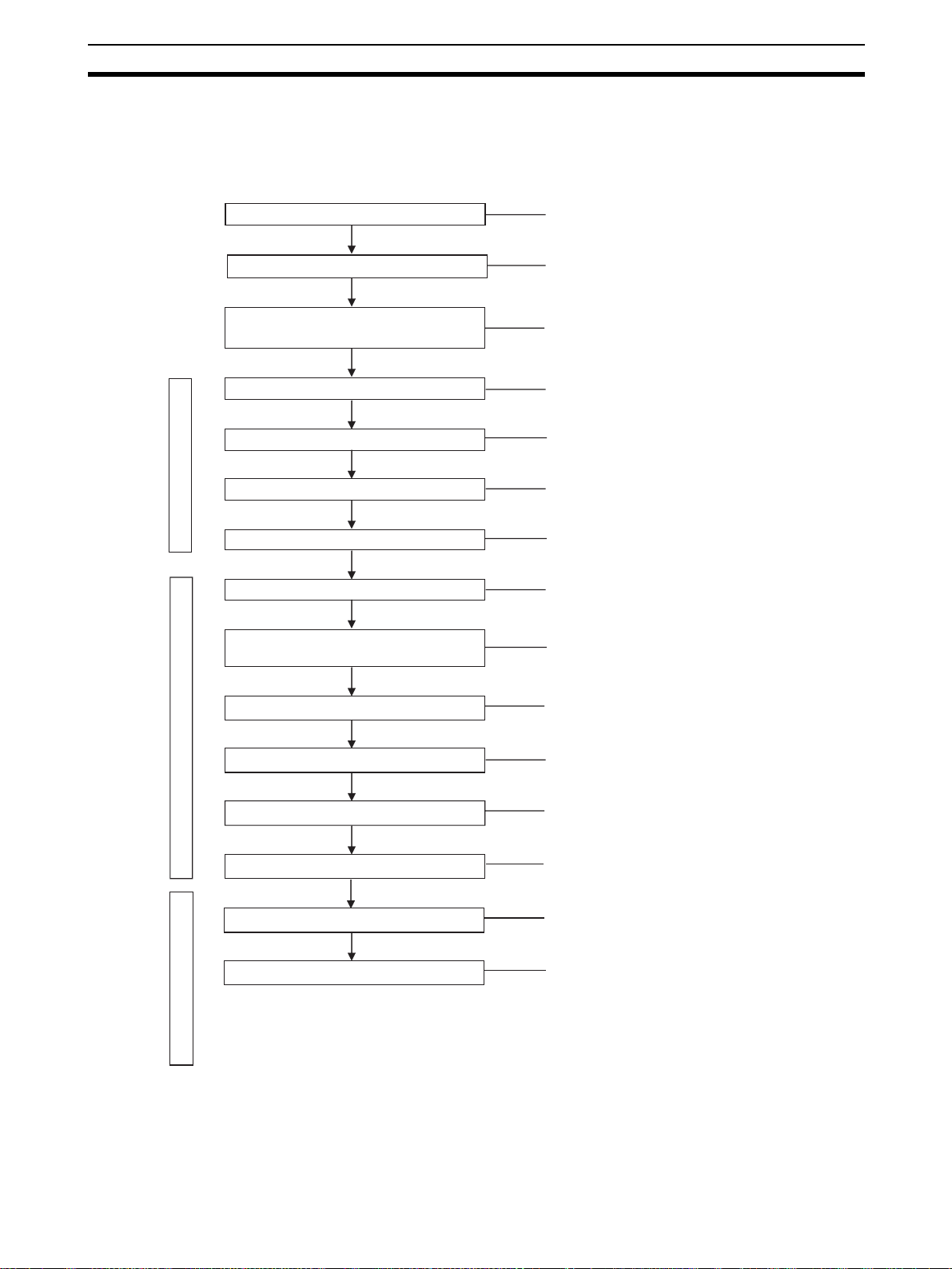

1-4 Operation Procedure

The outline of the procedures required to install CX-Motion-NCF and CXServer, create various data, transfer it to Position Control Units, and use in

actual operations is shown below.

Installing CX-Server

Installing CX-Motion-NCF

Connecting to Built-in RS-232C port on

CPU Unit

CX-Motion-MCF Basic Window

Axis Map Setting Window

Starting CX-Motion-NCF

Creating a New Project

Adding NC Unit to Project

Starting Axis Map Setting Window

Adding Servo Driver to NC Unit

Editing/Transferring Unit

Parameters/Servo Parameters

Refer to SECTION 2-1

Refer to SECTION 2-1

Refer to SECTION 2-2

Refer to SECTION 3-2

Refer to SECTION 4-1

Refer to SECTION 4-2

Refer to SECTION 3-2

Refer to SECTION 4-3

Refer to SECTION 5-1, 5-2, 7-3, and 7-4

Writing to Flash Memory

NC Unit Positioning Operation

Monitoring

Quitting Axis Map Setting Window

CX-Motion-NCF Basic Window

Saving Project

Quitting CX-Motion-NCF

Refer to SECTION 7-6

Refer to the Position Control

Unit's operation manual.

Refer to SECTION 8

Refer to SECTION 3-2

Refer to SECTION 6-1

Refer to SECTION 3-2

7

Operation Procedure Section 1-4

8

SECTION 2

This section provides information on installing CX-Motion-NCF and CX-Server, and connecting to the PLC.

2-1 Installing and Uninstalling the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-1 Software That Must Be Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-2 Preparations for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-3 Precautions for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1-4 Installing the CX-Motion-NCF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-5 Uninstalling the CX-Motion-NCF . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-6 Uninstalling the CX-Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2 Connecting to PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setup

9

Installing and Uninstalling the Software Section 2-1

2-1 Installing and Uninstalling the Software

2-1-1 Software That Must Be Installed

The following software must be installed on the same computer to use the CXMotion-NCF.

1,2,3... 1. CX-Motion-NCF

2. CX-Server (the communications driver)

Types of CX-Motion-NCF The CX-Motion-NCF is available both on an independent CD-ROM and on the

CX-One FA Integrated Tool Package. The contents of the CX-Motion-NCF are

the same in either case.

The installation procedure for the independent CD-ROM is provided here.

Refer to the CX-One Setup Manual (W444, provided with the CX-One) for the

installation procedure for the CX-One.

Cat. No. Model Manual name Contents

W444 CXONE-AL@@-E CX-One Setup Man-

ual

2-1-2 Preparations for Installation

An overview of the CXOne FA Integrated Tool

Package and the CX-One

installation procedure

Note If the CX-Motion-NCF was previously installed from the CX-One and it's nec-

essary to install it from the individual CX-Motion-NCF CD-ROM, always uninstall the CX-Motion-NCF using the following procedure before installing it from

its individual CD-ROM. The CX-Motion-NCF will not operate properly if it is

installed without first uninstalling it.

a) Insert the CX-One installation disk 1 into the CD-ROM drive.

b) Select the Modify Option to enable modifying the Support Software

that is installed.

c) In the Select Features Dialog Box, clear the selection of only the CX-

Motion-NCF. Do not change any other selections.

d) Continue by following the instructions in the dialog boxes to modify the

installation and uninstall CX-Motion-NCF.

e) Once the CX-Motion-NCF uninstallation process has been completed,

place the individual CD-ROM disk for the CX-Motion-NCF into the CDROM drive and install the CX-Motion-NCF. (See note.)

Note If the version of the CX-Server bundled on the individual CX-Motion-

NCF CD-ROM is lower than the version of the CX-Server bundled

with the CX-One, install only the CX-Motion-NCF and NOT the CXServer. (A message will be displayed if the version is lower.) If a version of CX-Server that is lower than the version with the CX-One is

installed, the CX-One will not operate properly.

10

Installing and Uninstalling the Software Section 2-1

Uninstalling the Previous

Version of CX-Motion-NCF

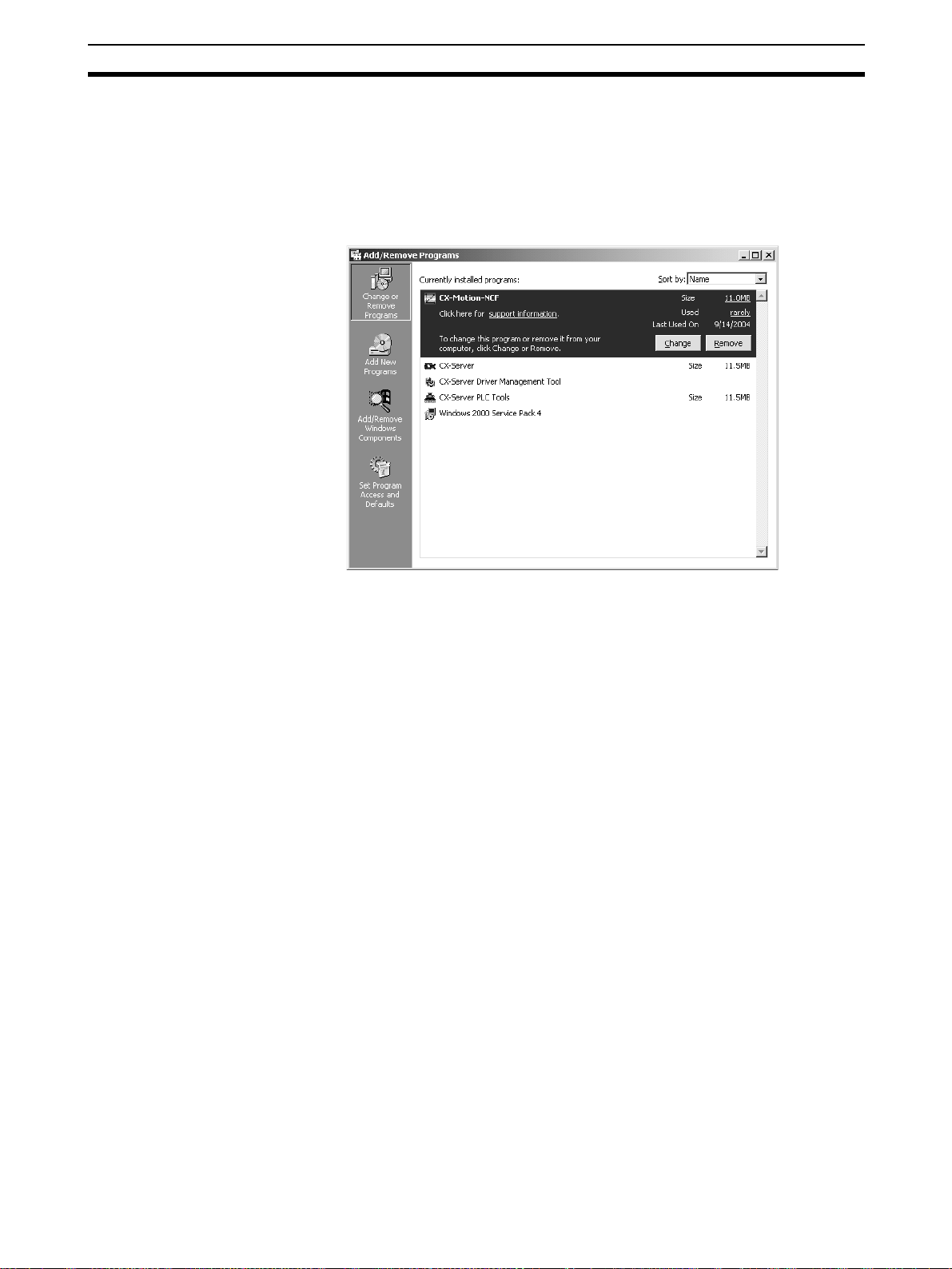

1,2,3... 1. Start Add/Remove Programs from the control panel.

Always uninstall the previous version of the CX-Motion-NCF before installing

the new version.

2. Select CX-Motion-NCF from the dialog box.

3. Click the Change/Remove Button. The CX-Motion-NCF will be uninstalled.

Note The Installer manages the version and driver for the CX-Server. If the CX-

Server installed on the computer is old, the Installer will automatically update

the CX-Server. If the CX-Server Driver Management Tool or the CX-Server is

uninstalled from the control panel, it may no longer be possible to use certain

Units. Do not uninstall the CX-Server Driver Management Tool or the CXServer from the control panel.

2-1-3 Precautions for Installation

This section describes the procedures involved in the installation of CXMotion-NCF on a standard workstation running Microsoft Windows 98, Me,

NT4.0, 2000, or XP.

• Close all programs running on Windows before starting the installation

procedure.

• Do not stop the setup process in the middle. Copied files may remain in

the installation directory.

• Do not turn OFF or reset the computer in the middle of the installation

process. Computer data may become corrupted.

• On Windows NT 4.0, 2000, or XP, the administrator or a user with administrator rights must perform the installation. Other users will not have sufficient write permissions and access errors will occur.

• With Windows 2000, always use service pack 3 or later. With Windows

NT 4.0, always use service pack 6a. The service pack can be confirmed

by selecting Start - Settings - Control Panel - System. The service pack

will be displayed under System on the General Tab Page of the System

Properties Dialog Box. If a service pack is not displayed, no service pack

has been installed. Refer to Microsoft’s website for service pack installation methods.

11

Installing and Uninstalling the Software Section 2-1

• It may be necessary to restart Windows after finishing the installation. If

required, restart Windows according to the messages displayed by the

Installer.

Note Internet Explorer version 5.0 or higher must be installed in advance to use the

CX-Server Installer. Install Internet Explorer version 5.0 in advance if it is not

already installed.

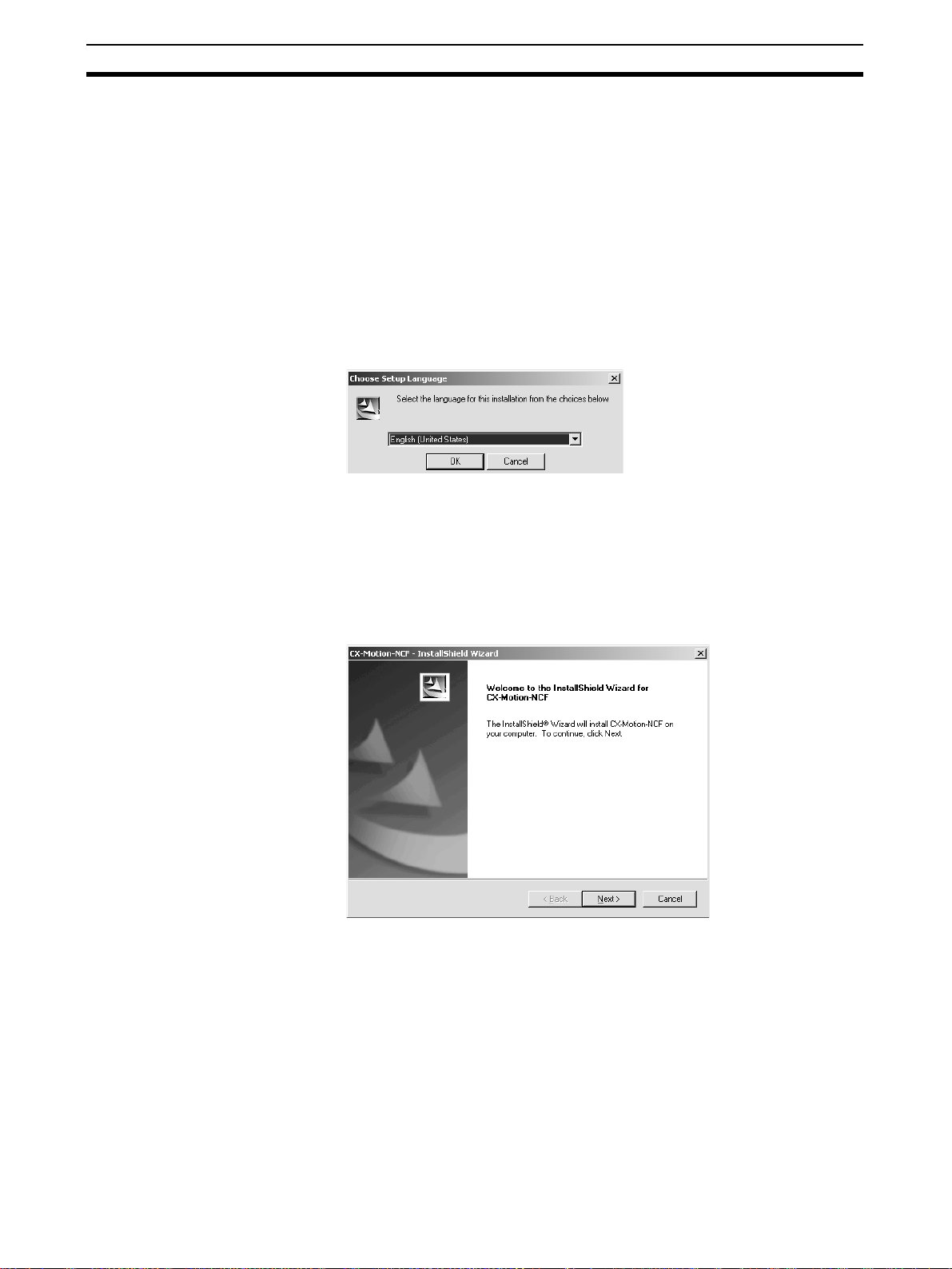

2-1-4 Installing the CX-Motion-NCF

1,2,3... 1. Insert the CX-Motion-NCF installation disk (CD-ROM) into the CD-ROM

drive.

2. The setup program will start automatically and the Choose Setup Lan-

guage Dialog Box will be displayed.

The language of the operating system running on the computer will be selected automatically.

If the above dialog box is not displayed, double-click the CD-ROM drive

from the Explorer to display it.

Select the language to be installed and click the OK button.

3. A splash window for the CX-Motion-NCF will be displayed, followed by the

Setup Wizard.

12

Click the Next Button.

Installing and Uninstalling the Software Section 2-1

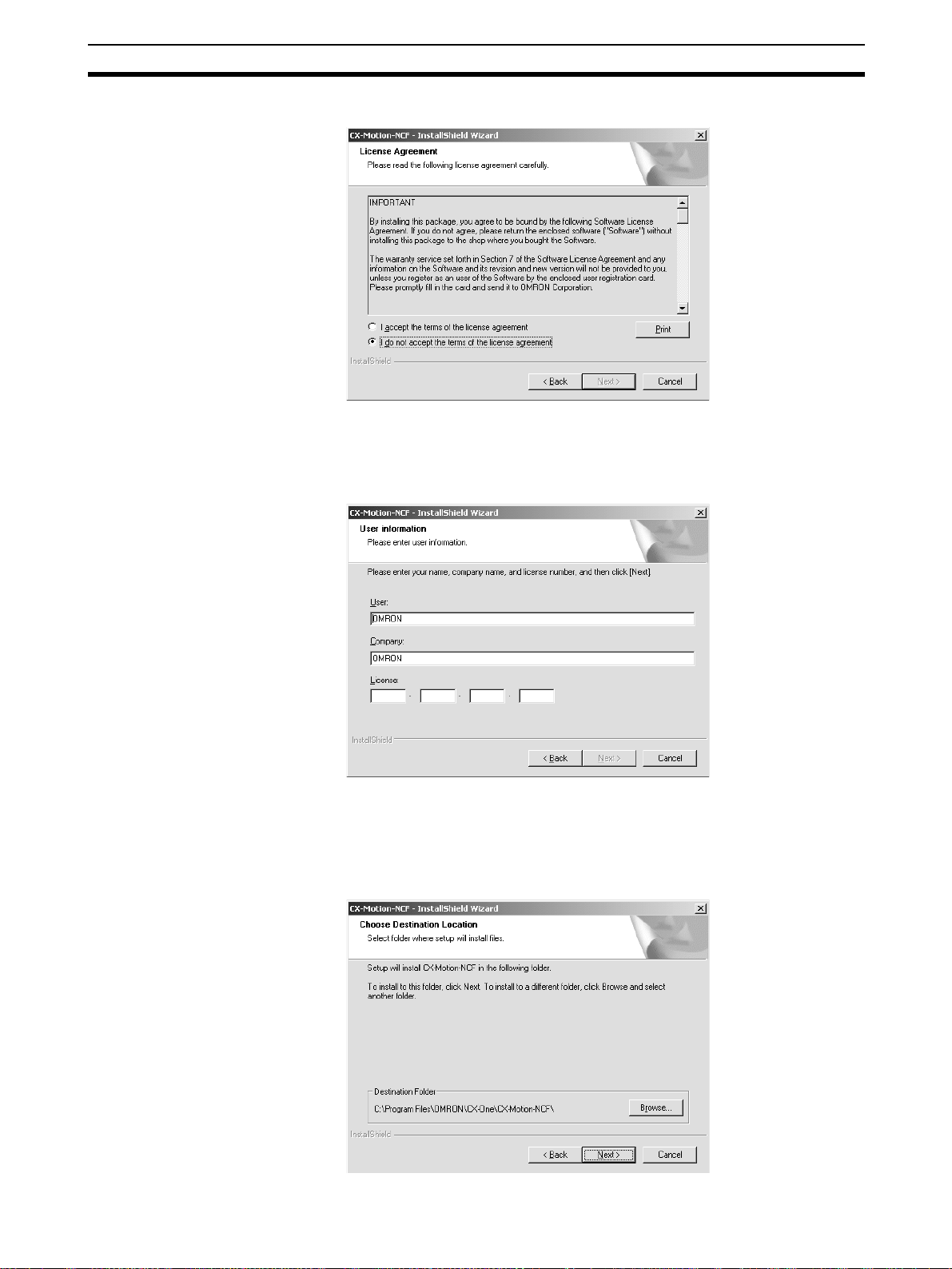

4. The License Agreement Dialog Box will be displayed.

Read the license agreement completely and if you accept all of the terms,

select the I accept the terms of the license agreement Option and click the

Next Button.

5. The User Information Dialog Box will be displayed.

The default names registered in the computer will be entered for the user

name and company name. Enter the license number and click the Next

Button. The license number is given on the Software License/Registration

Card provided with the product.

6. The Choose Destination Location Dialog Box will be displayed.

13

Installing and Uninstalling the Software Section 2-1

Select the destination location and click the Next Button. By default, the

CX-Motion-NCF will be installed in the following location: C:\Program

Files\OMRON\CX-One\CX-Motion-NCF\.

7. The Setup Type Dialog Box will be displayed.

Select the Complete option and click the Next Button.

8. The Select Program Folder Dialog Box will be displayed.

14

Specify the location to add a shortcut in the program folder of the Windows

Start Menu and click the Next Button.

9. The Ready to Install the Program Dialog Box will be displayed.

Installing and Uninstalling the Software Section 2-1

Click the Install Button.

The Installer will start the installation.

To check the installation settings, click the Back Button.

To cancel installation, click the Cancel Button.

10. If the CX-Server is already installed on the computer, the Installer will automatically check the CX-Server version and driver and update them as required. Depending on the version of CX-Server that was already installed,

a confirmation dialog box may be displayed.

11. The following dialog box will be displayed when the Installer completes the

installation. Click the Finish Button.

The following dialog box will be displayed if restarting the computer is required.

Select to restart the computer

immediately (default).

Select to restart the computer

manually sometime later.

Select the desired option and click the Finish Button. If the Yes, I want to

restart my computer now Option was selected, the computer will be restarted.

12. The Readme.txt file will be displayed after the computer is restarted.

Note Always read the Readme.txt file before using the CX-Motion-NCF.

15

Installing and Uninstalling the Software Section 2-1

13. The Online Registration Dialog Box will be displayed when the Readme.txt

file is closed.

A wizard will be started and will connect to the OMRON CX-One Web if the

Register Button is clicked. (See notes.)

Note (a) If the Exit Button is clicked to cancel registration, the Online Reg-

istration Dialog Box will be displayed every time the CX-One Configuration Tool is started.

(b) Online installation will not be possible if the computer is not con-

nected to the Internet. Enter the required information on the registration card and mail it in.

This completes installation of the CX-Motion-NCF.

2-1-5 Uninstalling the CX-Motion-NCF

Use the following procedure to delete the CX-Motion-NCF from the computer.

1,2,3... 1. Select Start - Settings - Control Panel - Add/Remove Programs.

The Add/Remove Programs Dialog box will be displayed.

2. Select CX-Motion-NCF from the dialog box.

3. Click the Change/Remove Button.

4. If deleting the CX-Motion-NCF completely is selected, the following dialog

box will be displayed. Click the Yes Button to start the Uninstaller that will

delete the CX-Motion-NCF.

16

Installing and Uninstalling the Software Section 2-1

5. When the uninstallation has been completed, the following dialog box will

be displayed.

2-1-6 Uninstalling the CX-Server

Note (1) The Installer manages the version and driver for the CX-Server. If the CX-

Server installed on the computer is old, the Installer will automatically update the CX-Server. If the CX-Server Driver Management Tool or the CXServer is uninstalled from the control panel, it may no longer be possible

to use certain Units. Do not uninstall the CX-Server Driver Management

Tool or the CX-Server from the control panel.

(2) Do not uninstall the CX-Server if there are other programs on the com-

puter that use it as the communications driver, e.g., the CX-Motion. If the

CX-Server is uninstalled, it will no longer be possible to use these other

programs.

(3) Do not uninstall the CX-Server while other programs that use it as the

communications driver are running on the computer, e.g., the CX-Motion.

The CX-Server may not uninstall properly if other programs are using it.

(4) Always uninstall the CX-Server Driver Management Tool before uninstall-

ing the CX-Server. If the CX-Server is uninstalled first, it may no longer

be possible to uninstall the CX-Server Driver Management Tool properly.

17

Installing and Uninstalling the Software Section 2-1

1,2,3... 1. Select Start - Settings - Control Panel - Add/Remove Programs.

The Add/Remove Programs Dialog box will be displayed.

2. Select CX-Server Driver Management Tool from the dialog box.

3. Click the Change/Remove Button.

4. A confirmation dialog box will be displayed. Click the Yes Button.

The CX-Server Driver Management Tool will be uninstalled.

5. When the uninstallation has been completed, the following dialog box will

be displayed. Click the Finish Button. The Add/Remove Programs Dialog

Box will be displayed again.

6. In the same way, select CX-Server from the Add/Remove Programs Dialog

Box, click the Change/Remove Button, and uninstall the CX-Server following the messages that appear on the screen.

7. Restart the computer when all programs have been uninstalled.

18

Connecting to PLC Section 2-2

t

2-2 Connecting to PLC

To transfer the project data that was created using CX-Motion-NCF to the

Position Control Unit, the personal computer and PLC (CPU Unit) have to be

physically connected with a cable and also connected online.

Connection Format Using either the Host Link (SYSMAC WAY) or Toolbus, connect the personal

computer to the peripheral port or RS-232C port on the PLC.

Personal

Connecting to Peripheral Port Connecting to RS-232C Port

computer

IBM PC/AT

or compatible

P

C

9

8

0

1

B

X

N

E

C

CS1W-CN118

CS1W-CN226

CS1W-CN626

9-pin

male

9-pin

female

Peripheral port

(10-pin female)

CS1W-CN118 (0.1 m) (See note.)

CS1W-CN226 (2.0 m)

CS1W-CN626 (6.0 m)

(See note.)

9-pin

10-pin

female

9-pin

male

PC

-980

1

B

X

NE

C

9-pin

female

XW2Z-200S-CV / 200S-V (2.0 m)

XW2Z-500S-CV / 500S-V (5.0 m)

XW2Z-200S-CV / -200S-V

XW2Z-500S-CV / -500S-V

9-pin

male

RS-232C port

(9-pin female)

9-pin

female

Note The cable model CS1W-CN118 is used as a relay cable to connect the per-

sonal computer to the CPU Unit's peripheral port using the RS-232C cable

(model XW2Z-@@@@-@@) as shown below.

Peripheral Por

P

C

-9

8

0

1

BX

N

EC

RS-232C Cable

CS1W-CN118

9-pin

male

Note Two network types (serial communications mode), SYSMAC WAY and Tool-

bus, are supported when connecting CX-Motion-NCF to the PLC. The characteristics of the network types are as shown below.

Network type Characteristics

Toolbus Faster communications. If possible, use this network type.

• For CS/CJ Series, the baud rate on the peripherals can be

detected automatically, and be connected.

• Only 1 on 1 connection possible.

• For CX-Motion-NCF, it can also be connected to a modem.

SYSMAC WAY

(Host Link)

Used for communications with general host computers.

• Slower than Toolbus.

• Not only 1 on 1 connection, but also 1-many connection possible.

• Connecting to a modem and optical adaptor possible.

19

Connecting to PLC Section 2-2

Connection Method Use one of the following method to connect the personal computer (CX-

Motion-NCF) and PLC (CPU Unit). It is also possible to connect the personal

computer to the port on the CJ Series Serial Communications Unit. In that

case, the only network type that can be used is Host Link.

Connecting to Peripheral Port Connecting to RS-232C Port

IBM PC/AT or compatible IBM PC/AT or compatible

9-pin connector

CS1W-CN118 (0.1 m)

CS1W-CN226 (2.0 m)

CS1W-CN626 (6.0 m)

Connection Cables

Unit Port on Unit Computer Port on

CPU Unit Built-in

peripheral

port

Built-in RS232C port

(D-SUB, 9pin, female)

Serial

Communications

RS-232C port

(D-SUB, 9pin, female)

Unit

IBM PC/AT

compatible

IBM PC/AT

compatible

IBM PC/AT

compatible

D-SUB, 9pin, male

D-SUB, 9pin, male

D-SUB, 9pin, male

computer

9-pin connector

Peripheral port

on CPU Unit

Network type

XW2Z-200S-CV (2.0 m)

9-pin connector

XW2Z-500S-CV (5.0 m)

Model number Length Remarks

Built-in RS-232C port

on CPU Unit or Serial

Communications Unit

(serial commu-

nications

mode)

SYSMAC WAY CS1W-CN226 2 m ---

CS1W-CN626 6 m

SYSMAC WAY XW2Z-200S-CV 2 m Uses anti-static

XW2Z-500S-CV 5 m

connector

SYSMAC WAY XW2Z-200S-CV 2 m Uses anti-static

XW2Z-500S-CV 5 m

connector

Note When connecting the connectors of the above cables to the PLC's RS-232C

port, discharge any static build-up (e.g., by touching a grounded metal object)

before touching the connectors. Although XW2Z-@@@S-CV Cables use the

anti-static XM2S-0911-E Connector Hood (thus reducing the possibility of

static build-up), be sure to discharge any static as a safety precaution.

20

This section describes each of the screens and basic operations.

3-1 Screen Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Basic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-2-1 CX-Motion-NCF Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-2-2 Axis Map Setting Window Basic Operation. . . . . . . . . . . . . . . . . . . 29

3-3 Operations Listed by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 3

Basic Operation

21

Screen Name Section 3-1

3-1 Screen Name

The window names for CX-Motion-NCF are shown here.

Basic Window

CX-Motion-NCF Basic Window

Axis Map Setting Window

22

Screen Name Section 3-1

Edit Parameter Window

23

Screen Name Section 3-1

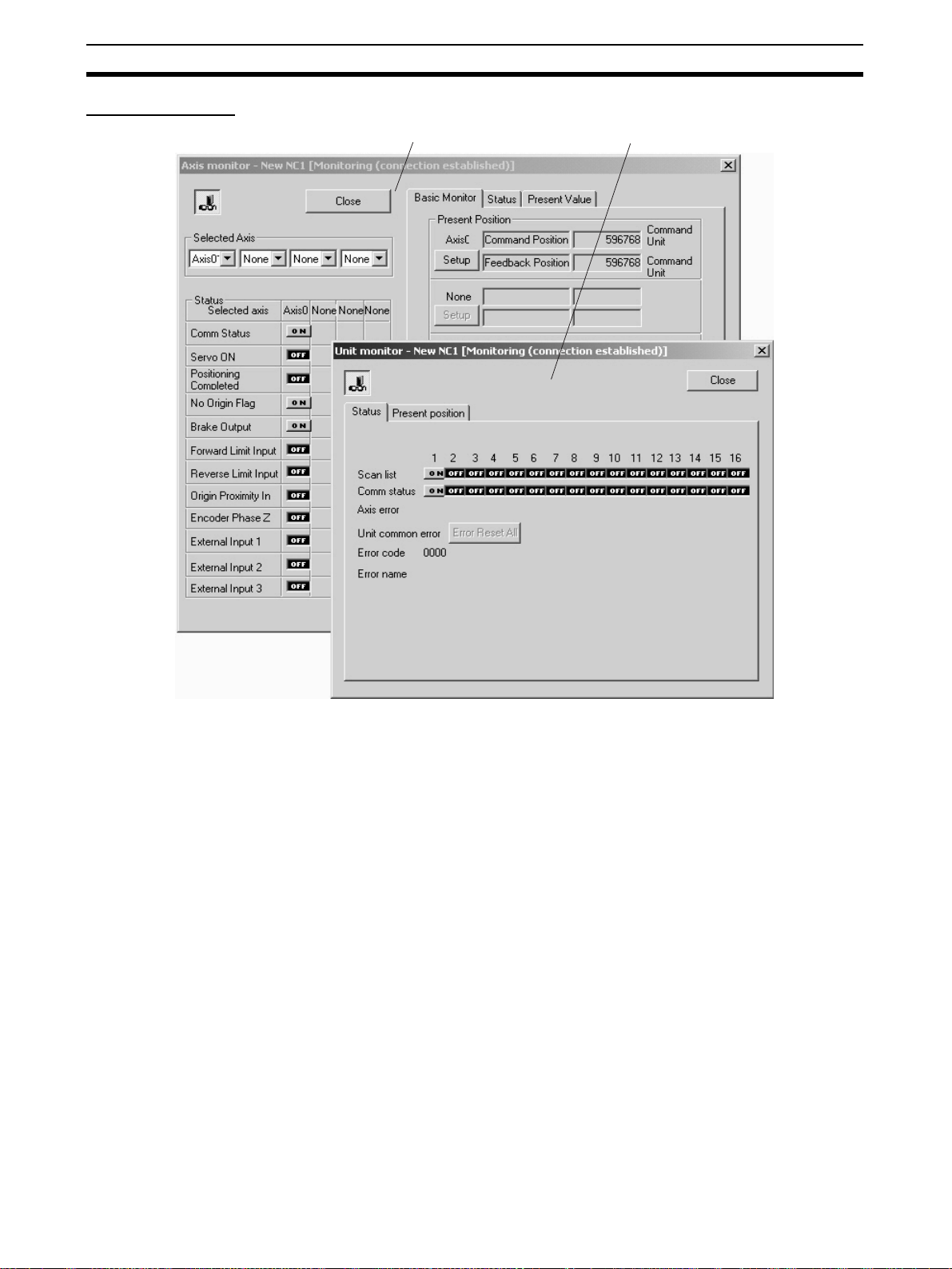

Monitor Window

Axis Monitor Window Unit Monitor Window

24

Basic Operation Section 3-2

3-2 Basic Operation

3-2-1 CX-Motion-NCF Basic Operation

The basic operations of CX-Motion-NCF are explained here.

Starting CX-Motion-NCF

Starting CX-Motion-NCF Using Start Special Application - Start with Settings Inherited from the I/O

Table Window Opened from the CX-Programmer That Was Installed from the CX-One

1,2,3... 1. Right-click a Position Control Unit in the I/O Table Window and select Start

Special Application - Start with Settings Inherited from the pop-up

menu.

2. The CX-Motion-NCF will be started, a new project will be created, and a

Position Control Unit will be added automatically. The Position Control Unit

model will be inherited as shown below

25

Basic Operation Section 3-2

Starting CX-Motion-NCF Using Start Special Application - Start Only from the I/O Table Window

Opened from the CX-Programmer That Was Installed from the CX-One

Right-click a Position Control Unit in the I/O Table Window and select Start

Special Application - Start Only from the pop-up menu. The following win-

dow will be displayed with a new project.

Starting CX-Motion-NCF

from Windows Start Menu

Quitting CX-Motion-NCF

1,2,3... 1. Select File/Exit or click at the top right corner of the window. After ed-

Select Start. Select Programs - OMRON - CX-One - CX-Motion-NCF - CX-

Motion-NCF. The same window as when selecting Start Only will be dis-

played with a new project.

iting a project, if the project has not been saved, the following dialog box

will be displayed.

2. Click the Yes Button to save the changes made. Click the No Button if it is

not necessary to save the changes. Click the Cancel Button to return to

the Basic Window without quitting CX-Motion-NCF.

26

Basic Operation Section 3-2

CX-Motion-NCF Basic

Window

Main Menus

The CX-Motion-NCF Basic Window is shown below.

Main Menu Contents Keyboard

File Used to create or save projects. Alt+F

View Used to display or hide Toolbar or Status Bar. Alt+V

PLC Used to connect to PLC. Alt+P

Unit Used to add or delete Position Control Unit, or to open

Axis Map Setting Window.

Help Used to display help and version information. Also used

to register online.

shortcut

Alt+U

Alt+H

Main Menu Items The names and functions for all of the menus are given in the table below.

When an item is selected, the dialog box for that function is displayed. follow

the instructions in the dialog box.

Main menu Item Contents Keyboard

shortcut

File New Creates a new project file. Ctrl+N

Open... Opens an existing project file. Ctrl+O

Save Saves the active project (over-

Save As Saves the active project with a

Exit Quits CX-Motion-NCF. ---

View Toolbar Displays/hides toolbar. ---

Status Bar Displays/hides status bar. ---

PLC Online Connects to PLC. ---

Communication Settings

writes the previous data).

new name.

Sets communications for online

connection.

Ctrl+S

---

---

27

Basic Operation Section 3-2

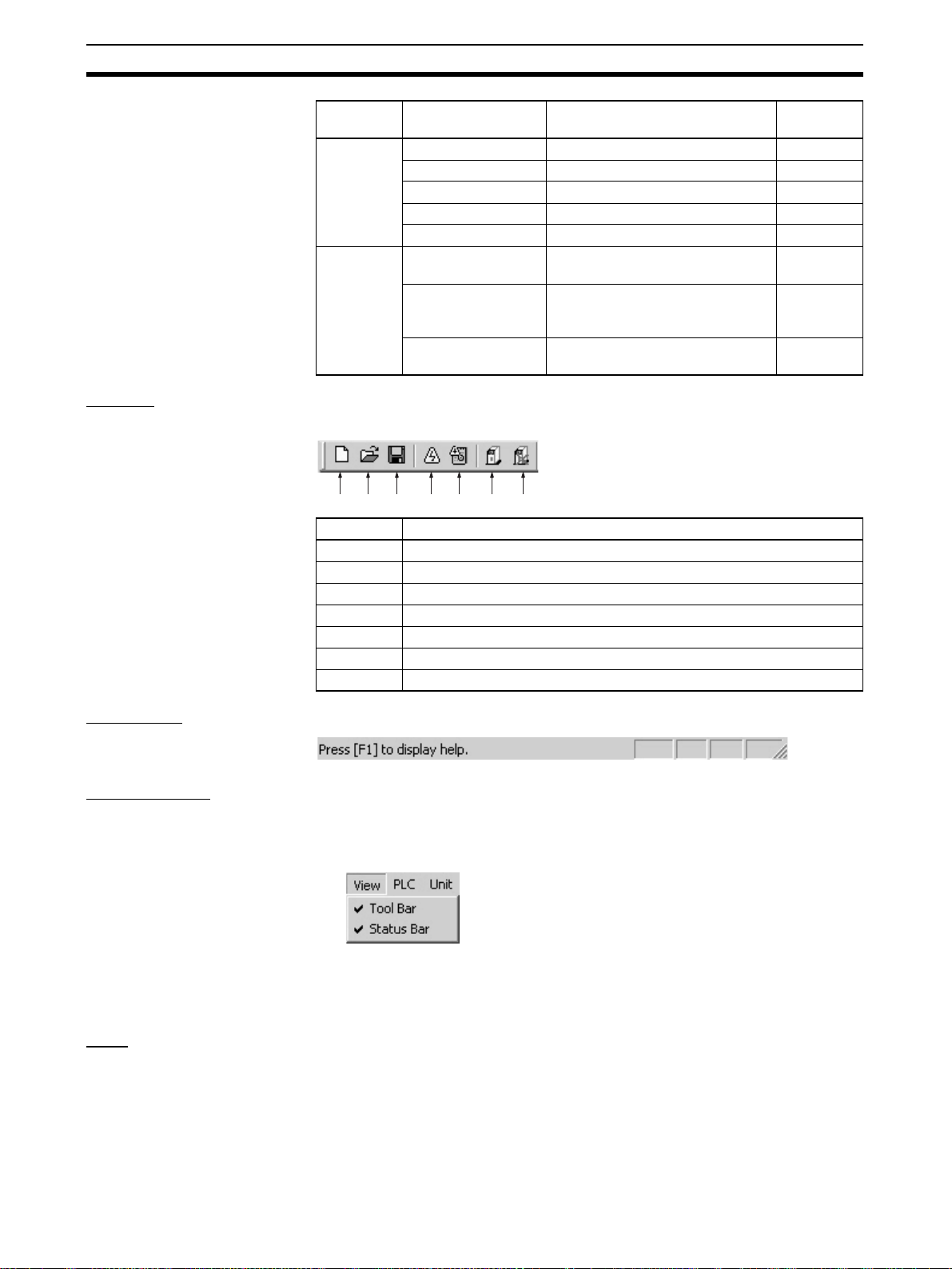

(1) (2) (3) (4) (5) (6) (7)

Main menu Item Contents Keyboard

Unit Edit Parameters Opens Axis Map Setting Window. ---

Change Unit No. Changes Unit No. of PCU. ---

Edit Comment Edits comment. ---

Add Adds PCU to a project. ---

Delete Deletes PCU from a project. ---

Help Help Index Displays the table of contents for

Online Registration Connects to the Omron CX-One

About CX-Motion

NCF...

help.

Website for online user registration.

Displays the version information

for CX-Motion-NCF.

shortcut

F1

---

---

Toolbar Functions can be executed directly by clicking on the appropriate icon on the

toolbar. The functions that can be executed from the toolbar are given below.

Number Function

(1) Creates a new project.

(2) Opens an existing project.

(3) Saves the active project.

(4) Connects online to PLC.

(5) Displays communications settings window to connect to PLC.

(6) Adds a new Position Control Unit.

(7) Deletes a Position Control Unit.

Status Bar The following information is displayed on the status bar.

View Settings The view settings can be used to display or hide the toolbar or status bar.

Display/Hide Settings

1,2,3... 1. Click View.

2. If a check appears next to Toolbar or Status Bar, the corresponding item is

displayed. To hide any of these, click Toolbar or Status Bar to remove the

check.

Help

Displaying the Help Contents

1,2,3... 1. Click Help/Help Index. The table of contents for help will be displayed.

2. Click an item to display information related to that item.

28

Basic Operation Section 3-2

Displaying CX-MotionNCF and CX-Server

Version Information

Click Help/About CX-Motion-NCF. The CX-Motion-NCF and CX-Server ver-

sion information will be displayed.

3-2-2 Axis Map Setting Window Basic Operation

The basic operations of the Axis Map Setting Window used to make the Position Control Unit settings are explained here.

Starting the Axis Map

Setting Window

Click Unit/Edit Parameters, or double-click on a Position Control Unit after

selecting one on the CX-Motion-NCF Basic Window.

Quitting Axis Map

Setting Window

Axis Map Setting

Window

Main Menus

Click File/Exit, or click at the right top corner of the Axis Map Setting Window.

The Axis Map Setting Window is shown below.

Main menu Contents Keyboard

File Used, for example, to import or export. Alt+F

Edit Used, for example, to add Servo Drivers or edit parame-

ters.

Online Used, for example, to transfer parameters or monitor

PCUs or axes.

Help Used to display help and version information. Alt+H

shortcut

Alt+E

Alt+L

29

Basic Operation Section 3-2

Main Menu Items The names and functions for all of the menus are given below. When an item

is selected, the dialog box for that function is displayed. Follow the instructions

in the dialog box.

Main menu Item Contents Keyboard

File Import Imports entire PCU project files

Export Exports entire PCU project files

Properties When a Servo Driver item has

Print Prints out Unit Parameters or

Close Closes Axis Map Setting Win-

Edit New Driver Displays the New Driver Dialog. ---

Edit Parameters

Copy Copies an axis. Ctrl+C

Paste Pastes an axis. Ctrl+V

Delete Deletes the selected Servo

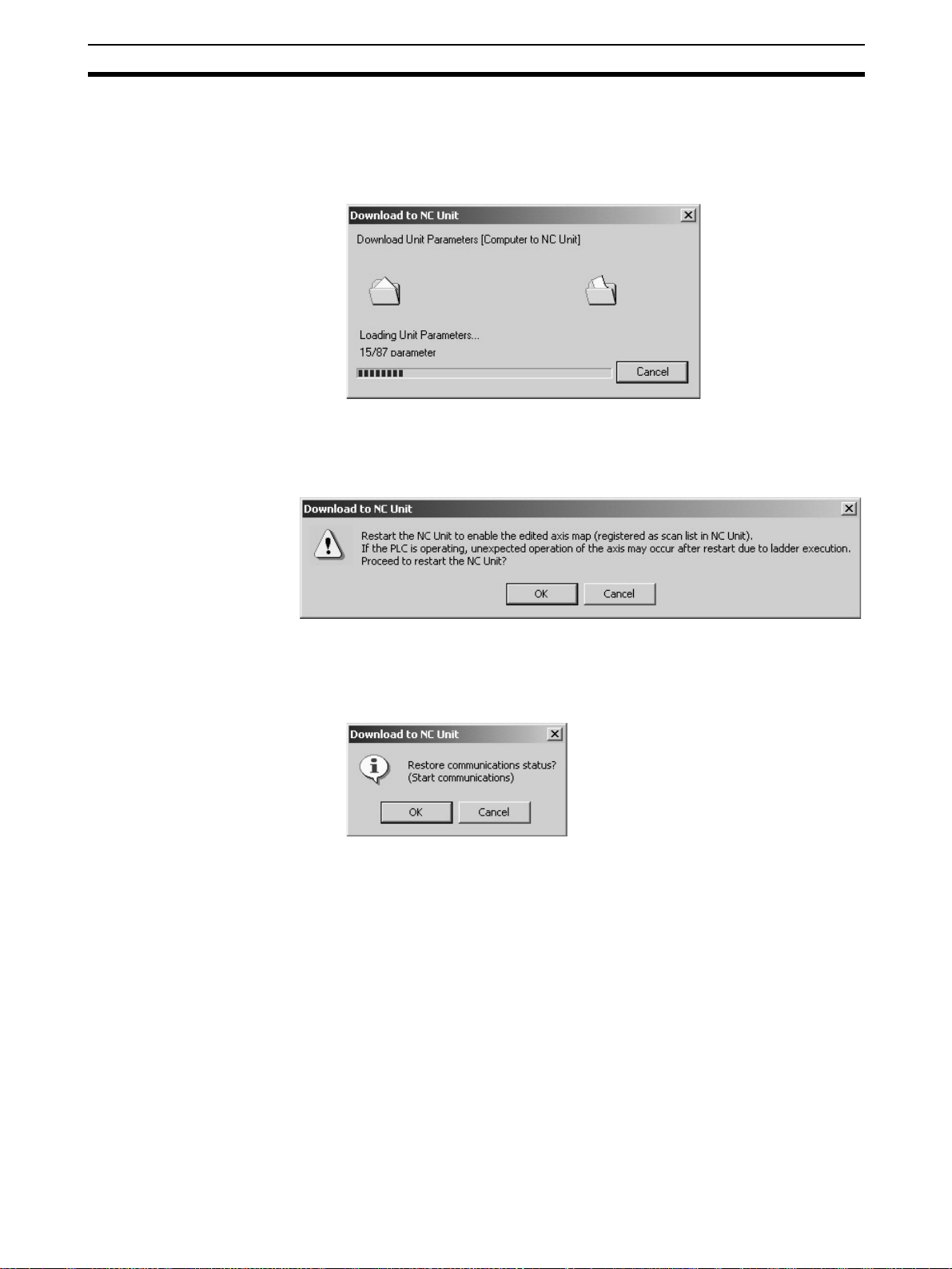

Online Download to NC Unit Executes batch download. Dis-

Upload from NC Unit Executes batch upload. Dis-

Compare Executes batch compare. Dis-

Write Flash Memory Writes data to flash memory. ---

Unit Monitor Starts Unit Monitor. ---

Axis Monitor Starts Axis Monitor. ---

Test Run Displays the Test Run Window.

Error Log Displays error log. ---

Device Information Displays device information. ---

Help Help Displays help. F1

About Displays the version information

NC Unit Edits Unit Parameters. ---

Axis Edits Servo Parameters. ---

or Servo Parameters. The file is

to be in CSV format.

or Servo Parameters. The file is

to be in CSV format

been selected, displays the

Servo Driver Properties Window. Invalid when no Servo

Driver item has been selected.

Servo Parameters.

dow.

Closes all the active Edit Parameters and Monitor Windows.

Driver.

plays the Batch Download Dialog.

plays the Batch Upload Dialog.

plays the Batch Compare Dialog.

Connection status, Servo Lock/

Unlock, JOG, etc. can be controlled.

for CX-Motion-NCF and Driver

database.

shortcut

---

---

---

Ctrl+P

---

DEL

---

---

---

---

---

Toolbar Functions can be executed directly by clicking on the appropriate icon on the

toolbar. The functions that can be executed from the toolbar are given below.

(1) (2) (3) (4) (5) (6) (7)

(8) (9) (10)

30

Basic Operation Section 3-2

Number Function

(1) Adds a new driver.

(2) Copy

(3) Paste

(4) Remove

(5) Download to Position Control Unit

(6) Upload from Position Control Unit

(7) Compare

(8) Writes data to flash memory.

(9) Unit Monitor

(10) Axis Monitor

Help

Displaying the Help Contents

1,2,3... 1. Click Help/Help. The table of contents for help will be displayed.

2. Click an item to display information related to that item.

Displaying CX-MotionNCF and Driver Database

Version Information

Click Help/About. The CX-Motion-NCF and Driver database version information will be displayed.

31

Operations Listed by Purpose Section 3-3

3-3 Operations Listed by Purpose

Operations Listed by Purpose

Function (Purpose) Operation Keyboard

Project

Starting CX-Motion-NCF Select Start/Programs/OMRON/CX-Motion-NCF

and click CX-Motion-NCF.

Creating a new project Select File/New on CX-Motion-NCF Basic Window. Ctrl+N 36

shortcut

--- --- 25

Toolbar

icon

Page

Opening a project Select File/Open on CX-Motion-NCF Basic Win-

dow.

Saving (overwriting) Select File/Save on CX-Motion-NCF Basic Win-

dow.

Saving with a different

name

Quitting CX-Motion-NCF Select File/Exit on CX-Motion-NCF Basic Window. --- --- 26

Adding a Position Control Unit

Importing Parameters Select a Position Control Unit on Axis Map Setting

Exporting All the Parameters

Exporting Servo Parameters

Displaying Servo Driver

Properties

Opening Axis Map Setting Window

Closing Axis Map Setting

Window

Adding a Servo Driver On Axis Map Setting Window, click Edit/New

Deleting a Servo Driver Select a Servo Driver on Axis Map Setting Window.

Printing Select File/Print on Axis Map Setting Window. Ctrl+P --- 54

Editing data

Editing Unit Parameters Select Edit/Edit Parameters/NC Unit, or select

Editing Servo Parameters Select Edit/Edit Parameters/Axis**, or select and

Jumping between windows

Select File/Save As on CX-Motion-NCF Basic

Window.

Select Unit/Add on CX-Motion-NCF Basic Window.

Window. Click File/Import, or right-click and click

Import from the pop-up menu.

Select a Position Control Unit on Axis Map Setting

Window. Click File/Export, or right-click and click

Export from the pop-up menu.

Select File/Export, or right-click and select Export

from the pop-up menu after selecting a Servo

Driver on the Axis Map Setting Window.

Select File/Properties, or right-click and select

Properties from the pop-up menu after selecting a

Servo Driver on the Axis Map Setting Window.

Select a Position Control Unit on CX-Motion-NCF

Basic Window. Click Unit/Edit Parameters, or dou-

ble-click the Position Control Unit.

Select File/Close on Axis Map Setting Window. --- --- 29

Driver, or right-click and selecting a Position Control Unit and click New Driver from the pop-up

menu.

Click Edit/Delete, or right-click and click Delete

from the pop-up menu.

and right-click a Position Control Unit and click Edit

Unit Parameters from the pop-up menu on Axis

Map Setting Window.

right-click a Servo Driver and click Edit Servo

Parameters from the pop-up menu on Axis Map

Setting Window.

Jumps around over Axis Map Setting Window, Edit

Parameter Window, and Monitor Window by clicking the mouse.

Ctrl+O 52

Ctrl+S 52

--- --- 52

--- 36

--- --- 53

--- --- 53

--- --- 54

--- --- ---

--- --- 29

--- 37

DEL 39

--- --- 42

--- --- 45

Ctrl+Tab or

Ctrl+Shift+Tab

--- ---

32

Operations Listed by Purpose Section 3-3

Function (Purpose) Operation Keyboard

Online operations

Starting communications

with PLC

Communications setting Select PLC/Communication Settings on CX-

Batch download On Axis Map Setting Window, select Online/

Batch upload On Axis Map Setting Window, select Online/

Batch compare On Axis Map Setting Window, select Online/Com-

Writing to flash memory Select Online/Write Flash Memory on the Axis

Monitoring Position Control Unit

Monitoring axis On Axis Map Setting Window, click Online/Axis

Error log On Axis Map Setting Window, click Online/Error

JOG Select Online/Test Run on the Axis Map Setting

Displaying device information

Display settings

Displaying or hiding Toolbar

Displaying or hiding Status Bar

Displaying help

Displaying Position Control Unit model and version

Displaying help Select Help/Help Index on CX-Motion-NCF Basic

Online registration Select Help/Online Registration in the CX-

Displaying version information

Select PLC/Online on CX-Motion-NCF Basic Window.

Motion-NCF Basic Window.

Download to NC Unit, or select and right-click a

Position Control Unit and click Download to NC

Unit from the pop-up menu.

Upload from NC Unit, or select and right-click a

Position Control Unit and click Upload from NC

Unit from the pop-up menu

pare, or select and right-click a Position Control

Unit and click Compare from the pop-up menu.

Map Setting Window.

On Axis Map Setting Window, click Online/Unit

Monitor, or select and right-click a Position Control

Unit and click Unit Monitor from the pop-up menu.

Monitor, or select and right-click a Position Control

Unit or Servo Driver and click Axis Monitor from

the pop-up menu.

Log, or select and right-click a Position Control Unit

and click Error Log from the pop-up menu.

Window.

Select Online/Device Information from the Axis

Map Setting Window.

Select View/Toolbar on CX-Motion-NCF Basic

Window.

Select View/Status Bar on CX-Motion-NCF Basic

Window.

On Axis Map Setting Window, click Online/Device

Information, or select and right-click a Position

Control Unit and click Device Information from the

pop-up menu.

Window.

Select Help/Help on Axis Map Setting Window. F1 --- 27

Motion-NCF Basic Window.

Select Help/About. --- --- 27

--- 59

--- 58

--- 60

--- 65

--- 69

--- 73

--- 76

--- 79

--- --- 94

--- --- 88

--- --- ---

--- --- 27

--- --- 27

--- --- 27

F1 --- 27

--- --- ---

shortcut

Toolbar

icon

Page

33

Operations Listed by Purpose Section 3-3

34

SECTION 4

Creating Projects

This section provides information on creating projects and adding Position Control Units and Servo Drivers.

4-1 Creating a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2 Adding and Deleting Position Control Units . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-3 Adding and Deleting Servo Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

35

Creating a New Project Section 4-1

4-1 Creating a New Project

Follow the procedure below to create a new project on the CX-Motion-NCF

Basic Window.

On the CX-Motion-NCF Basic Window, click File/New, press the Ctrl+N keys,

or click in the toolbar.

No new project has to be created when CX-Motion-NCF has just been

started. Operate on the project already being displayed.

4-2 Adding and Deleting Position Control Units

Adding Position

Control Units to

Projects

1,2,3... 1. On the CX-Motion-NCF Basic Window, click Unit/Add, click in the

A Position Control Unit is added to the project.

toolbar, or right click and select Add NC from the pop-up menu.

2. Set the Unit No.

Select a Unit No. for the Position Control Unit as a CPU Bus Unit.

3. Enter comment.

This can be skipped.

36

Adding and Deleting Servo Drivers Section 4-3

4. Click the OK Button.

A Position Control Unit is added to the project.

Deleting Position Control Units

1,2,3... 1. On the CX-Motion-NCF Basic Window, click Unit/Delete, click , or

right-click and select Delete from the pop-up menu after selecting a Position Control Unit to be deleted.

2. The dialog box saying “Delete the selected Unit. Proceed?” will be displayed. Click the OK Button.

4-3 Adding and Deleting Servo Drivers

Adding Servo Driver

to Position Control

Unit

On the CX-Motion-NCF Basic Window, click Unit/Edit Parameters after

selecting a registered Position Control Unit, or double-click a Position Control

Unit to display the Axis Map Setting Window. On the Axis Map Setting Window, add a new Servo Driver.

37

Adding and Deleting Servo Drivers Section 4-3

1,2,3... 1. Click Edit/New Driver, Click in the toolbar, or right-click the Position

Control Unit and select New Driver from the pop-up menu.

2. Enter Driver Name.

Up to 32 one-byte characters can be entered.

3. Select Series.

Click on the drop-down list to select an appropriate series.

Note Select OMRON W Series when using an OMRON R88M-WT@ W-

series Servo Driver with a Yaskawa JUSP-NS115 MECHATROLINK-II Application Module. Select OMRON W Series (Built-in

Communications) when using an OMRON R88M-WN@-ML2 W-se-

ries Servo Driver with Built-in MECHATROLINK-II Communications.

4. Select Driver Model.

Click on the drop-down list to select an appropriate driver model. The driver

models in the list depends on the selected series.

5. Select Version.

Click on the drop-down list to select an appropriate version. The driver versions in the list depends on the selected driver model.

6. Set Axis No.

Click on the drop-down list to select an axis No. The axis Nos. that are already in use will not be displayed.

7. Enter Comment.

Up to 256 one-byte characters can be entered. This can be skipped.

8. Click the OK Button.

A new Servo Driver will be added to the Position Control Unit.

38

Adding and Deleting Servo Drivers Section 4-3

Copying Servo Driver

to Position Control

Unit

Deleting Servo Driver

from Position Control

Unit

On the Axis Map Setting Window, when a Servo Driver that has been registered under a Position Control Unit is copied and pasted on the same Position

Control Unit, a new Servo Driver will be added with the lowest axis number

that is not in use. When a Servo Driver that has been registered under a Position Control Unit is copied and pasted on another Servo Driver (that has to be

registered in advance), the parameters of the copied Servo Driver will be overwritten to the other Servo Driver.

A Servo Driver that has been registered under a Position Control Unit is

deleted.

1,2,3... 1. On the Axis Map Setting Window, after selecting a Servo Driver to be de-

leted, click Edit/Delete, Click in the toolbar, press the Delete key, or

right-click the Servo Driver and select Delete from the pop-up menu.

39

Adding and Deleting Servo Drivers Section 4-3

2. Click the OK Button.

The Servo Driver will be deleted from the Position Control Unit.

40

This section describes the operations used to edit data.

5-1 Editing Unit Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5-1-1 Editing Memory Area Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5-1-2 Editing Communications Parameters . . . . . . . . . . . . . . . . . . . . . . . . 44

5-1-3 Editing Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5-2 Editing Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 5

Editing Data

41

Editing Unit Parameters Section 5-1

5-1 Editing Unit Parameters

The methods used to edit data are described in this section. For details on the

setting contents, Unit parameters, and Servo Parameters, refer to the CJ1W-

NCF71 Position Control Units Operation Manual (W426).

1,2,3... 1. Click Edit/Edit Parameters/NC Unit on the Axis Map Setting Window,

double-click a Position Control Unit, or right-click and select Edit Unit Pa-

rameters from the pop-up menu. The Edit Unit Parameter Window will be

displayed.

Item Explanation

Download Downloads all the parameters that are set on the Edit Unit Param-

Upload Uploads all the parameters that are set on the Edit Unit Parameter

Compare Compares all the parameters that are set on the Edit Unit Parame-

Initialize Initializes all the parameters (see note 2) that are set on the Edit

OK Determines the parameters that are set on the Edit Unit Parameter

Cancel Cancels the parameters that are set on the Edit Unit Parameter

eter Window to a Position Control Unit. (See notes 1 and 2.)

Window from a Position Control Unit. (See notes 1 and 2.)

ter Window with the parameters saved in a Position Control Unit.

(See notes 1 and 2.)

Unit Parameter Window to their default settings.

Window.

Window.

Note (1) It can be executed only when the connection to the PLC has been estab-

lished on the CX-Motion-NCF Basic Window.

(2) “All the parameters that are set on the Edit Unit Parameter Window” indi-

cates the parameters that are set in Memory Area Setting, Communications Setting, and Axis Setting.

42

Editing Unit Parameters Section 5-1

5-1-1 Editing Memory Area Parameters

Edit Memory Area

Click Memory Area Setting from the tree.

Parameter Window

Editing Memory Area Parameters

1,2,3... 1. Set the Output Memory Area (PLC to Position Control Unit).

Click on the drop-down list of the Output Memory Area (PLC to Position

Control Unit) to select an appropriate area type from the list.

In the right box, set the beginning address of the specified area type. The

setting range varies depending on the selected area type and the largest

axis No. of the registered axes. When a value out of the range is entered,

the value will be displayed in red. Enter a value within the range.

2. Set the Input Memory Area (Position Control Unit to PLC)

Click on the drop-down list of the Input Memory Area (Position Control Unit

to PLC) to select an appropriate area type from the list.

In the right box, set the beginning address of the specified area type. The

setting range varies depending on the selected area type and the largest

axis No. of the registered axes. When a value out of the range is entered,

the value will be displayed in red. Enter a value within the range.

Note When selecting the same area type for the Output and Input Memory Areas,

make sure to set the appropriate beginning addresses so that the areas do

not overlap. Do not set EM banks that do not exist in the PLC being used as

the areas used for the Output and Input Memory Areas.

43

Editing Unit Parameters Section 5-1

5-1-2 Editing Communications Parameters

Edit Communications

Parameters Window

Editing

Communications

Parameters

Click Communications Setting from the tree.

For details of the communications settings, refer to SECTION 6 MECHATROLINK in the CJ1W-NCF71 Position Control Units Operation Manual

(W426).

1,2,3... 1. Set Transfer Cycle.

Click on the drop-down list of the Transfer Cycle to select an appropriate

Transfer Cycle.

2. Set Communications Cycle.

The setting range is between 1 and 32. The set value is used as the multiplier with which the Transfer Cycle is multiplied. When a value out of the

setting range is entered, the value will be displayed in red. Enter a value

within the range.

3. Set No. of Communications Retries.

The setting range is between 0 to 7. When a value out of the setting range

is entered, the value will be displayed in red. Enter a value within the range.

4. Set C2 Master Connection.

Click on the drop-down list of the C2 Master Connection to select whether

the C2 Master is connected or not.

Note (1) Set the Communications and Transfer Cycles so that the following ex-

pression is satisfied: Transfer Cycle