Page 1

Cat. No. W372-E1-13

SYSMAC CS/CJ Series

WS02-LCTC1-EV5

CX-Process Tool Ver. 5.2

OPERATION MANUAL

Page 2

Page 3

WS02-LCTC1-EV5 CX-Process Tool Ver. 5.2

Operation Manual

Revised December 2009

Page 4

iv

Page 5

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Copyrights and Trademarks

Windows is a registered trademark of the Microsoft Corporation.

Other system and product names that appear in this manual are the trademarks or registered trademarks of the respective company.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

v

Page 6

About Loop Controllers

oop

p

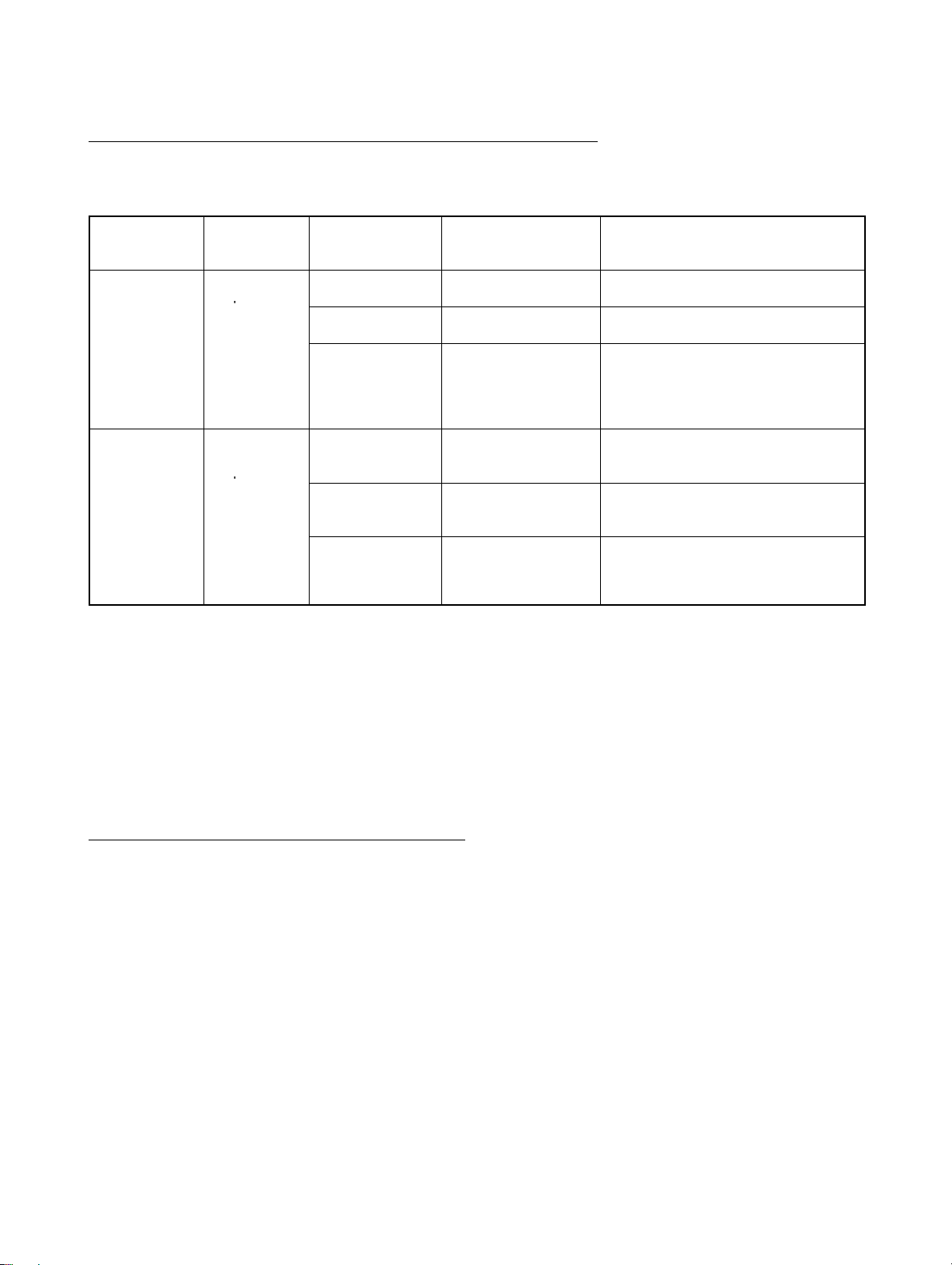

Loop Control Types, Functional Elements, and Versions

Loop Controller Types

There are two types of CS/CJ-series Loop Controller: Separate Loop Controllers and Loop Controllers Pre-installed in CPU Units

Loop

Controller

type

Separate Separate

Pre-installed in

CPU Unit

Type name Product name Model PLC series and Unit type

Loop

Controller

CPU Unit with

Pre-installed

Loop

Controller

Loop Control Unit CS1W-LC001 CS-series CPU Bus Unit Loop

Loop Control

Board

Loop Control

Board with

Gradient

Temperature

Controller

Process-control

CPU Unit

Loop-control CPU

Unit

Loop-control CPU

Unit with Gradient

Temperature

Controller

Loop Controller Functional Elements

• Separate Loop Controllers consist of only the Loop Controller functional element (i.e., the Loop Controller element).

• CPU Units with Pre-installed Loop Controller consists of a CPU Unit functional

element (i.e., the CPU Unit element) and the Loop Controller functional element (i.e., the Loop Controller element).

Controller

CS1W-LCB01/05 CS-series Inner Board Loop Controller

CS1W-LCB05-GTC CS-series Inner Board Loop Controller

CS1D-CPUP

CJ1G-CPUP

CJ1G-CPUP-GTC

A one-Unit Loop Controller consisting

of an Inner Board pre-installed in a

CS-series CS1D-H CPU Unit

An Inner Board Loop Controller

integrated into a CS-series CJ1-H CPU

Unit

An Inner Board Loop Controller

integrated into a CJ-series CJ1-H CPU

Unit

Versions

The functional elements (i.e., the CPU Unit element and Loop Controller element) have versions.

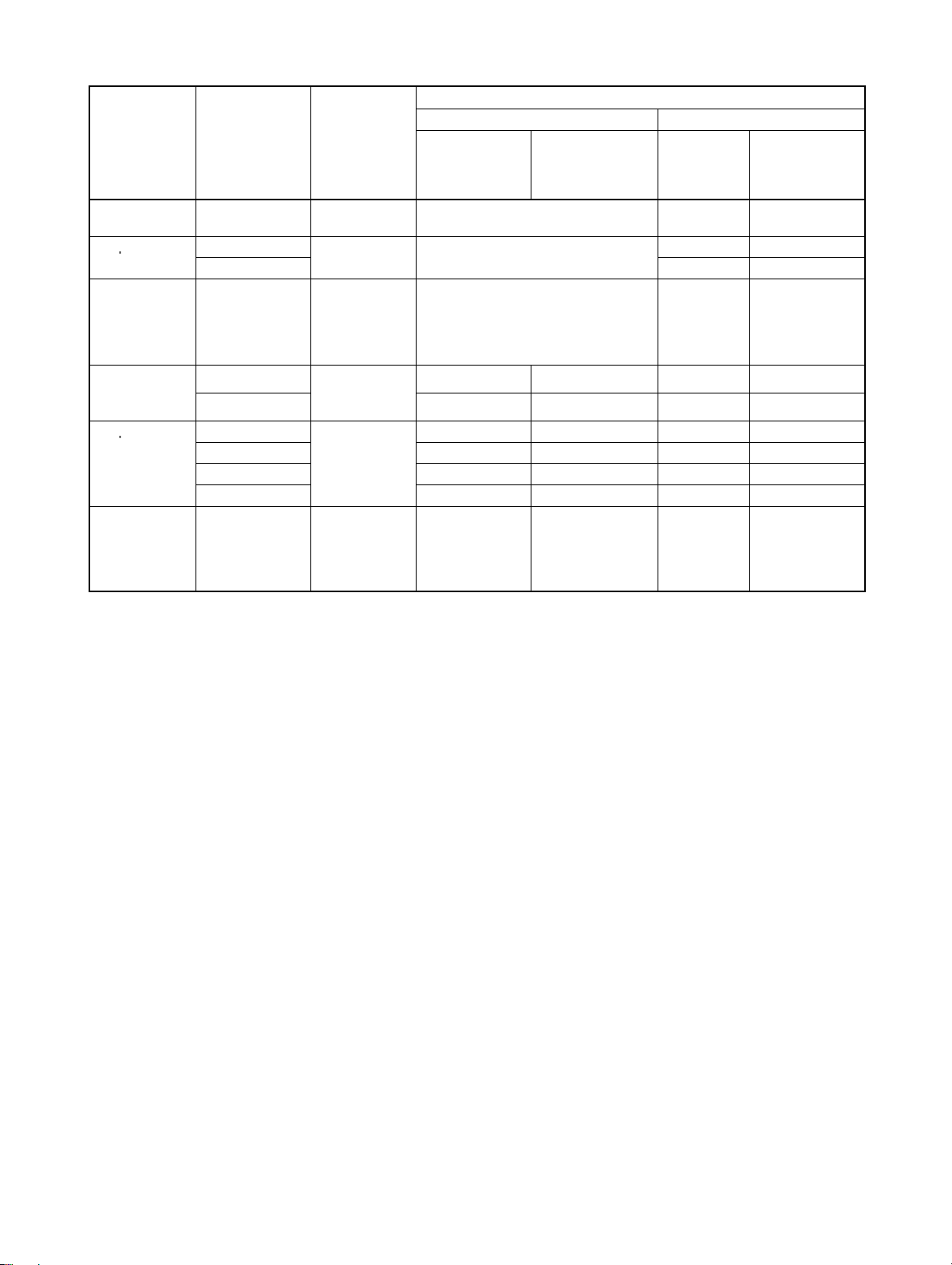

Model Numbers and Functional Elements

The following table lists the Loop Controller product model numbers, the functional element names for the CPU Unit elements and Loop Controller elements,

and the versions of the functional elements.

vi

Page 7

Product Product model

t

p

l CPU

p

name number of the

Loop Control

Unit

Loop Control

Board

Loop Control

Board with

Gradient

Temperature

Controller

Processcontro

Unit

Loop-control

CPU Unit

Loop-control

CPU Unit with

Gradient

Temperature

Controller

CS1W-LC001 Pre-Ver. 2.0 --- LC001 Ver. 2.5

CS1W-LCB01

CS1W-LCB05

CS1W-LCB05GTC

CS1D-CPU65P

CS1D-CPU67P CS1D-CPU67H Ver. 1.0 or later LCB05D Ver. 1.0

CJ1G-CPU42P

CJ1G-CPU43P CJ1G-CPU43H Ver. 3.0 or later LCB03 Ver. 2.0 or later

CJ1G-CPU44P CJ1G-CPU44H Ver. 3.0 or later LCB03 Ver. 2.0 or later

CJ1G-CPU45P CJ1G-CPU45H Ver. 3.0 or later LCB03 Ver. 2.0 or later

CJ1G-CPU45PGTC

Unit version

produc

model

(See note.)

Ver. 2.0 or

later

Ver. 3.0 or

later

---

---

Ver. 3.0 or

later

Configuration

CPU unit element Loop Controller element

CPU Unit

model with

same

functionality

---

--- LCB05-GTC Ver. 3.0 or later

CS1D-CPU65H Ver. 1.0 or later LCB05D Ver. 1.0

CJ1G-CPU42H Ver. 3.0 or later LCB01 Ver. 2.0 or later

CJ1G-CPU45H Ver. 3.0 or later LCB05-GTC Ver. 3.0 or later

Functional

element unit

version

Functional

element

name

LCB01 Ver. 2.0 or later

LCB05 Ver. 2.0 or later

Functional

element

Note Only Separate Loop Controllers have a unit version for the product model. CPU

Units with Pre-installed Loop Controllers do not have a unit version for the product model.

Notation in this Manual

This manual uses the following notation.

• “Loop Controller” is used as a generic term to refer to the Loop Controllers in

general.

• “LCB” is used to refer to specific Loop Controller functional elements. For

example, the Loop Controller function element in a CS1W-LCB05 Loop Control Board is the LCB05, so “LCB05” is used to refer to the Loop Controller functional element. The Loop Controller function element in a CJ1G-CPU44P

Loop-control CPU Unit is the LCB03, so “LCB03” is used to refer to the Loop

Controller functional element.

• Model numbers are used to refer to specific Loop Controller models.

In the CX-Process Tool Operation Manual for version 3.2 or earlier, functional

element names (LCB) are given as “Loop Control Board.” In the CX-Process

Tool Operation Manual for version 4.0 or higher, simply “LCB” is used.

vii

Page 8

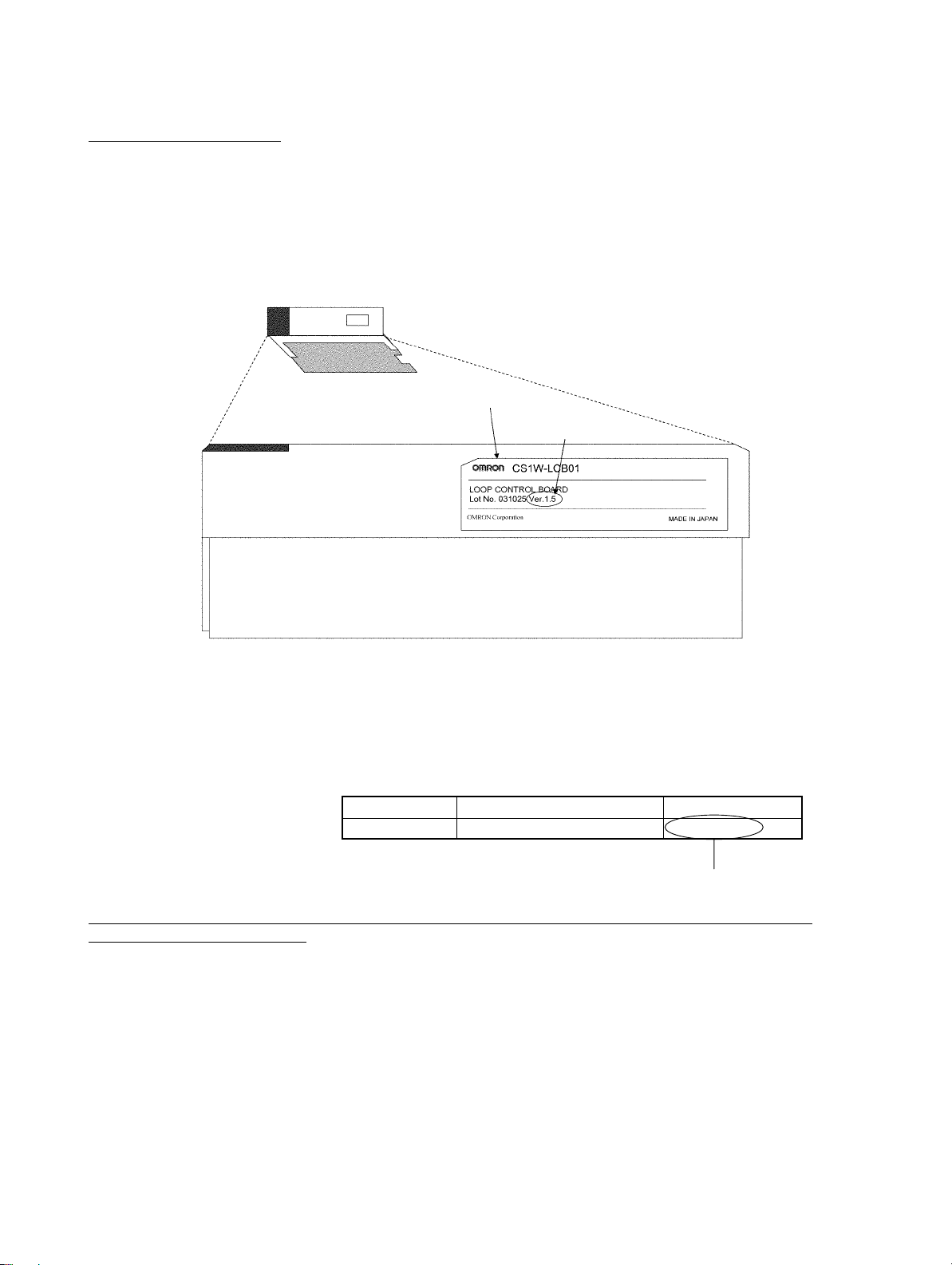

Unit Version Notation on Products

Loop Control Boards

A “unit version” has been introduced to manage CPU Units, Special I/O Units,

and Inner Boards in the CS/CJ Series according to differences in functionality

accompanying upgrades. This system applies to Units manufactured since October 1, 2003. The unit version code is provided on the nameplate of the product

for which unit versions are being managed, as shown below for the Loop Control

Board.

Loop Control Board

Product nameplate

Unit version

Example for unit version 1.5

The CX-Process Tool can be used to confirm the unit versions of Loop Control

Boards in the Monitor Run Status Window. After connecting the CX-Process

Tool online, select Operation – Monitor Run Status from the Execute Menu.

Confirm the unit version in ITEM099 (MPU/FROM version display) under from

the System Common Block (Block Model 000) in the Monitor Run Status Window.

ITEM Data name Data

099 MPU/FROM version indication V1.50

Version V1.50 and onwards must be indicated.

Functional Element Name and Version Code for Process-control CPU Units and

Loop-control CPU Units

The functional element name and functional element version code for Processcontrol CPU Units and Loop-control CPU Units are provided on the nameplate

as shown in the following diagrams.

viii

Page 9

Process-control CPU Units

Note CPU Unit elements for which no version code is provided are pre-Ver. 2.0 CPU

Units.

Nameplate on

left side of Unit

Loop-control CPU Units

Product model and functional

element name

Process-control CPU Unit

Functional element name for

Loop Controller element

Functional element version code for

Loop Controller element

Loop-control CPU Unit

Product nameplate

Product nameplate

Functional element name for

CPU Unit element

Functional element

version code for the

CPU Unit element

Unit model number

Functional element

version code for

Loop Controller element

Functional element

version code for

CPU unit element

Recommended location for

attaching version label

Lot No.

Confirming CPU Unit Element Versions with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using either

of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can also be used for

Special I/O Units and CPU Bus Units.)

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit versions.

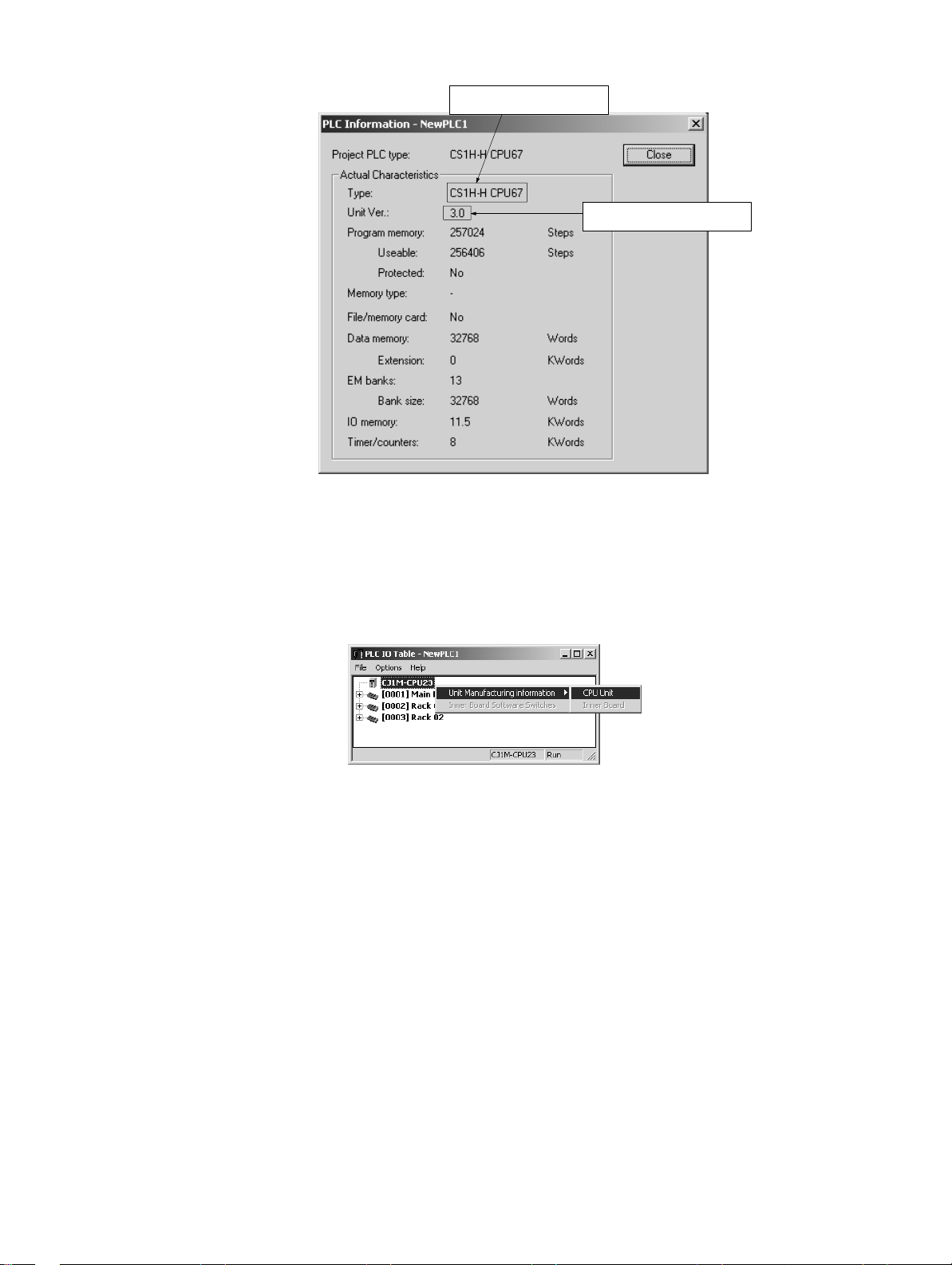

PLC Information

1, 2, 3... 1. If you know the device type and CPU type, select them in the Change PLC

dialog box, go online, and select PLC – Edit – Information from the menus.

If you do not know the device type and CPU type, but are connected directly

to the CPU Unit on a serial line, select PLC – Auto Online to go online, and

then select PLC – Edit – Information from the menus.

2. In either case, the following PLC Information Dialog Box will be displayed.

Functional element

version code for

Loop Controller

element

ix

Page 10

Functional element name

for CPU Unit element

Functional element version

code for CPU Unit element

Use the above display to confirm the unit version of the CPU Unit that is connected online.

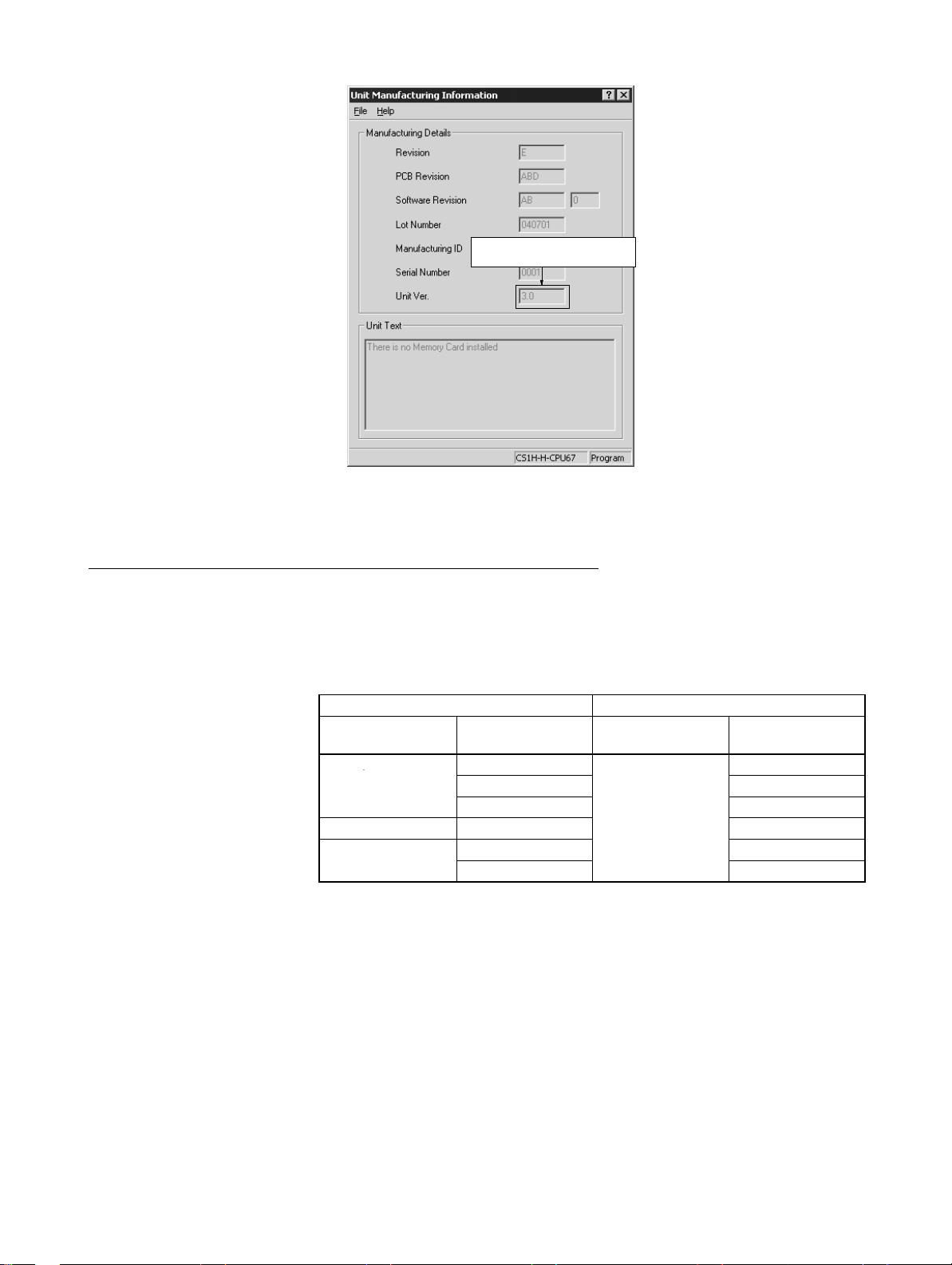

Unit Manufacturing Information

1, 2, 3... 1. In the I/O Table Window, right-click and select Unit Manufacturing In-

formation – CPU Unit.

2. The following Unit Manufacturing Information Dialog Box will be displayed.

x

Page 11

Functional element version

/

code for CPU Unit element

Use the above display to confirm the unit version of the CPU Unit connected

online.

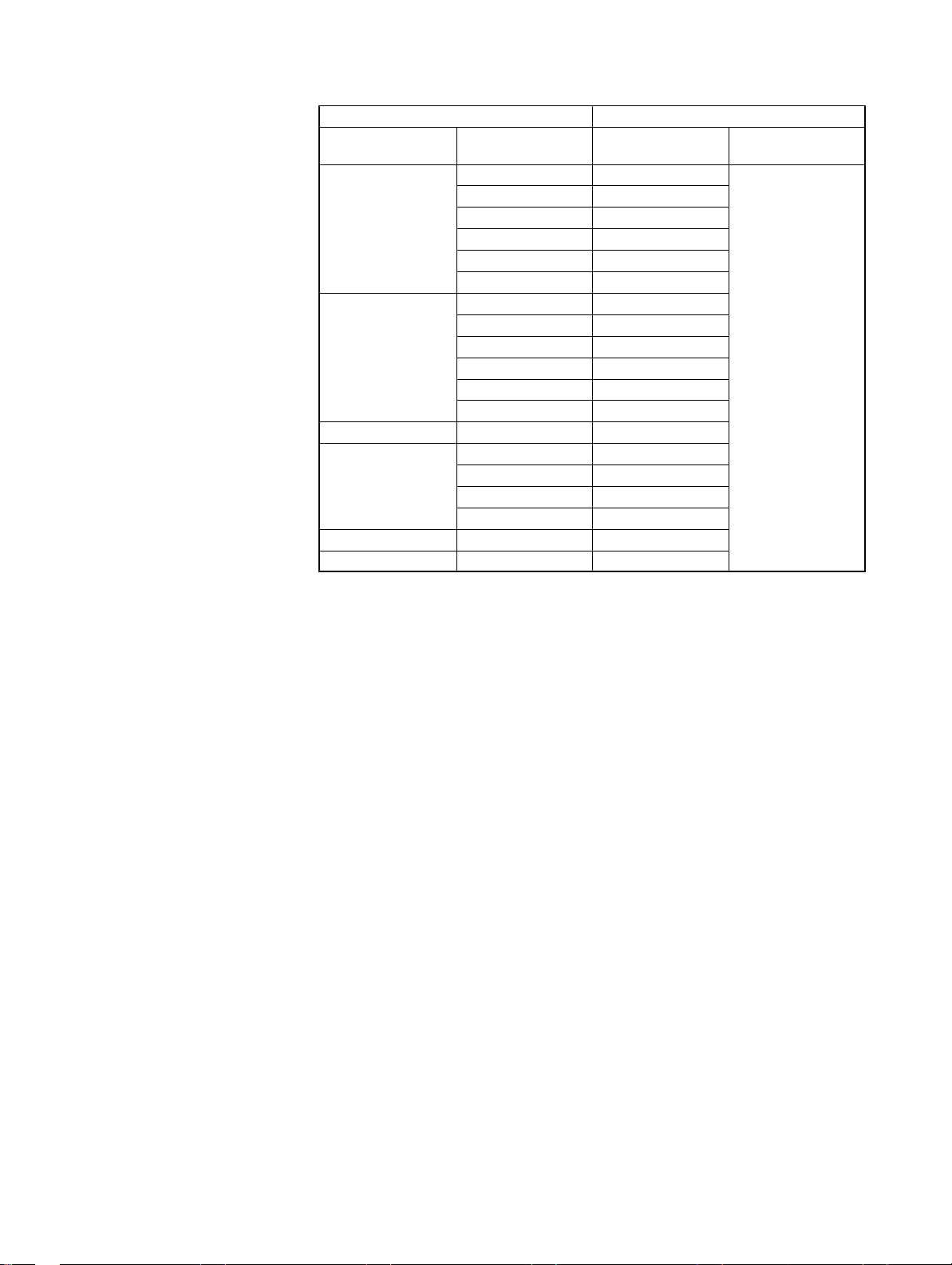

Functional Element Versions and Programming Devices

The Programming Device that supports the functional element version code

must be used to enable all the functions in the corresponding functional element.

Note Upgrading versions is not necessary if only the basic functions of the CPU Unit

element are required.

CPU Unit Element

Loop Controller Programming Device

Functional

element name

CS1G/H-CPUH

CS1D-CPUH

CJ1G-CPUH

Functional

element version

Pre-Ver. 2.0

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 1.1 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 4.0 Ver. 7.0 or higher

CX-Process Tool CX-Programmer

(See note.)

---

---

xi

Page 12

Loop Controller Element

Loop Controller Programming Device

Functional

element name

LCB01

LCB05

LCB05-GTC Ver. 3.0 Ver. 5.1 or higher

LCB03

LCB03-GTC Ver. 3.0 Ver. 5.1 or higher

LCB05D Ver. 1.0 Ver. 3.1 or higher

Functional

element version

Ver. 1.0 Ver. 3.0 or higher

Ver. 1.5 Ver. 3.2 or higher

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.23 or higher

Ver. 1.0 Ver. 3.0 or higher

Ver. 1.5 Ver. 3.2 or higher

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.23 or higher

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.23 or higher

CX-Process Tool CX-Programmer

(See note.)

---

xii

Page 13

TABLE OF CONTENTS

PRECAUTIONS xxiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application Precautions xxvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 CX-Process Tool 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Relationship with CX-Process Monitor 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 CX-Process Tool Specifications 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Version Improvements 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Function Blocks/ITEMs Incompatible with Earlier Versions 25. . . . . . . . . . . . . . . . . . . . . .

1-6 Connecting to the PLC 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Basic Operating Procedures 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 Operations 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Preparations to Create Function Blocks 49. . . . . . . . . . . . .

2-1 Installing and Uninstalling the Software 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Overview of User Interface 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Creating Function Blocks 97. . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Creating Function Block 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Using the CX-Process Monitor 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Using the CX-Process Monitor Plus 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Using SCADA Software 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 User Link Tables 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Creating User-defined Blocks 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Creating Step Ladder Program Instructions 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Creating Sequence Tables 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Displaying and Setting in Engineering Units 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Displaying Loop Controller Memory Maps 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 Printing 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-12 Setting Options 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Online Operation 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Overview of Online Functions 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Initial Settings for Online Connections 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Downloading, Uploading and Comparing Data 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Run/Stop Command 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Monitor Run Status 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Operation Check 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Tuning 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Backup and Recovery 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Transferring Tag and Comment Data 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Clear All 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Controlling the CPU Unit 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 Password Protection 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Troubleshooting 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Troubleshooting 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Error Codes 319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiii

Page 14

TABLE OF CONTENTS

Appendices

A Table of LC Type Changes 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B ITEM Notation in Block Diagrams 325. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Setting Segment Programs 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Sequence Table Design Sheet 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

Page 15

About this Manual:

This manual describes the installation and operation of the WS02-LCTC1-EV5 CX-Process Tool software

package and includes the sections described below. The CX-Process Tool is used to create and test function blocks for the CS1W-LC001 Loop Control Unit, the CS1W-LCB01, CS1W-LCB05, and

CS1W-LCB05-GTC Loop Control Boards, the CS1D-CPUP Process-control CPU Units, and the

CJ1G-CPUP and CJ1G-CPUP-GTC Loop-control CPU Units.

In this manual, the WS02-LCTC1-EV5 CX-Process Tool software package is generally referred to as simply the “CX-Process Tool.”

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the CX-Process Tool. Please read the following manuals carefully and be sure you

understand the information provided before setting up or using an application for a Loop Control Unit/

Board.

xv

Page 16

Product Manual name Cat. No. Contents

WS02-LCTC1-EV5

CX-Process Tool

CXONE-ALC-EV

4/ALD-EV4

CX-One FA

Integrated Tool

Package

WS02-LCTC1-E

CX-Process Monitor

WS02-LCMC1-E

CX-Process Monitor

Plus

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

Loop Control Boards,

CS1D-CPUP

Process-control CPU

Units, and

CJ1G-CPUP

Loop-control CPU

Units

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

Loop Control Boards,

CS1D-CPUP

Process-control CPU

Units, and

CJ1G-CPUP

Loop-control CPU

Units

CS1W-LCB05-GTC

Loop Control Board

with Gradient

Temperature

Controller

CJ1G-CPU45P-GTC

Loop-control CPU

Unit with Gradient

Temperature

Controller

CX-Process Tool

Operation Manual

CXONE-ALC-EV

4/ALD-EV4

CX-One FA

Integrated Tool

Package Setup

Manual

CX-Process Monitor

Operation Manual

CX-Process Monitor

Plus Operation

Manual

Loop Control Unit

Operation Manual

Loop Control Board

Operation Manual

Loop Control Unit

Function Block

Reference Manual

Loop Control Board

Function Block

Reference Manual

Loop Control Board

with Gradient

Temperature

Controller

User’s Manual

W372

(this manual)

W463 Provides an overview of the

W373 Installation and operation

W428 Installation and operation

W374 Installation and operation

W406 Installation and operation

W375 Detailed information on function

W407 Detailed information on function

W460 Provides information required

Installation and operation

procedures for the CX-Process

Tool.

CX-One and describes the

installation procedures for

CX-One software.

Refer to this manual when

installing the CX-Integrator from

the CX-One.

procedures for the CX-Process

Monitor.

procedures for the CX-Process

Monitor Plus.

procedures for the Loop Control

Unit (except for function blocks).

procedures for the Loop Control

Boards (except for function

blocks).

blocks for Loop Control Units.

blocks for Loop Control Boards

when using the gradient

temperature control functions. For

information not related to the

gradient temperature control

functions, please refer to the

Loop Control Board Operation

Manual (Cat. No. W406).

xvi

For details on procedures for installing the CX-Process Tool from the CX-One FA Integrated Tool Package, refer to the CX-One Setup Manual provided with CX-One.

Cat. No. Model Manual name Contents

W463

CXONE-ALC-EV

4/ALD-EV4

CX-One Setup

Manual

Installation and overview of

CX-One FA Integrated Tool

Package.

Page 17

Section 1 introduces the operations of the CX-Process Tool and connections to the PLC.

Section 2 describes installing the CX-Process Tool and provides an overview of the user interface.

Section 3 describes how to create and manipulate function blocks.

Section 4 describes online operations for uploading, downloading, and testing function block data.

Section 5 describes errors that can occur while using the CX-Process Tool.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

xvii

Page 18

xviii

Page 19

Read and Understand this Manual

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

БББББББББББББББББББББББББББББББ

a period of one year (or other period if specified) from date of sale by OMRON.

БББББББББББББББББББББББББББББББ

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

БББББББББББББББББББББББББББББББ

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

БББББББББББББББББББББББББББББББ

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

БББББББББББББББББББББББББББББББ

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

БББББББББББББББББББББББББББББББ

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

БББББББББББББББББББББББББББББББ

STRICT LIABILITY.

БББББББББББББББББББББББББББББББ

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

БББББББББББББББББББББББББББББББ

which liability is asserted.

БББББББББББББББББББББББББББББББ

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

БББББББББББББББББББББББББББББББ

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

БББББББББББББББББББББББББББББББ

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

БББББББББББББББББББББББББББББББ

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xix

Page 20

Application Considerations

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

БББББББББББББББББББББББББББББББ

the combination of products in the customer’s application or use of the products.

БББББББББББББББББББББББББББББББ

At the customer’s request, OMRON will provide applicable third party certification documents identifying

БББББББББББББББББББББББББББББББ

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

БББББББББББББББББББББББББББББББ

complete determination of the suitability of the products in combination with the end product, machine,

БББББББББББББББББББББББББББББББ

system, or other application or use.

БББББББББББББББББББББББББББББББ

The following are some examples of applications for which particular attention must be given. This is not

БББББББББББББББББББББББББББББББ

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

БББББББББББББББББББББББББББББББ

uses listed may be suitable for the products:

БББББББББББББББББББББББББББББББ

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

БББББББББББББББББББББББББББББББ

or uses not described in this manual.

БББББББББББББББББББББББББББББББ

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

БББББББББББББББББББББББББББББББ

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

БББББББББББББББББББББББББББББББ

industry or government regulations.

БББББББББББББББББББББББББББББББ

• Systems, machines, and equipment that could present a risk to life or property.

БББББББББББББББББББББББББББББББ

Please know and observe all prohibitions of use applicable to the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

БББББББББББББББББББББББББББББББ

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

БББББББББББББББББББББББББББББББ

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

БББББББББББББББББББББББББББББББ

consequence thereof.

xx

Page 21

Disclaimers

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

CHANGE IN SPECIFICATIONS

БББББББББББББББББББББББББББББББ

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

БББББББББББББББББББББББББББББББ

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

БББББББББББББББББББББББББББББББ

key specifications for your application on your request. Please consult with your OMRON representative

БББББББББББББББББББББББББББББББ

at any time to confirm actual specifications of purchased products.

БББББББББББББББББББББББББББББББ

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

БББББББББББББББББББББББББББББББ

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

БББББББББББББББББББББББББББББББ

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

БББББББББББББББББББББББББББББББ

must correlate it to actual application requirements. Actual performance is subject to the OMRON

БББББББББББББББББББББББББББББББ

Warranty and Limitations of Liability.

БББББББББББББББББББББББББББББББ

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

БББББББББББББББББББББББББББББББ

ERRORS AND OMISSIONS

xxi

Page 22

xxii

Page 23

PRECAUTIONS

This section provides general precautions for using the CX-Process Tool, CS/CJ-series Programmable Controllers (PLCs),

and related devices.

The information contained in this section is important for the safe and reliable application of Programmable Controllers. You must read this section and understand the information contained before attempting to set up or operate a

PLC system.

1 Intended Audience xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application Precautions xxvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xxiii

Page 24

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent) and instrumentation systems (a process engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, petrochemical plants, and other systems, machines,

and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Loop Controller. Be sure to read this manual before attempting to use the Loop Controller

and keep this manual close at hand for reference during operation.

3Safety Precautions

WARNING It is extremely important that a PLC and all PLC Units/Boards be used for the

!

specified purpose and under the specified conditions, especially in applications

that can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PLC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Check the following items before starting to run the LCB:

!

• Do not allow the bank of the EM Area with the number specified for allocation to

the HMI (human-machine interface) data to be used by the CPU Unit or other

Units for any other purpose. The block allocated for the HMI is specified in

ITEM 050 (EM Area Bank Allocated for HMI Memory = 0 to 12) of the System

Common block. If areas overlap, the system may operate in an unexpected

fashion, which may result in injury.

• Do not allow the area to which user link table data is written to be used by the

CPU Unit or other Units for any other purpose. If areas overlap, the system

may operate in an unexpected fashion, which may result in injury.

• Analog Input/Output Units used in combination with the LCB must be

mounted correctly, and the unit number set on the front panel of the Analog

Input/Output Unit must match the unit number set on the Field Terminal block.

If the unit numbers do not match, input/output (read/write) is performed on the

data of another Special I/O Unit (i.e., the one whose unit number is set on the

Field Terminal block).

• The defaults of the System Common block on the LCB must be set correct-

ly.

xxiv

Page 25

WARNING Check the following items before starting Loop Controller operation:

!

Do not allow the area to which user link table data is written to overlap with any

other area used by the CPU Unit or other Units. If areas overlap, the system may

operate in an unexpected manner, which may result in injury.

When using a user link table to write bit data to I/O memory in the CPU Unit.

Never allow ladder programming or communications processes in the CPU Unit

to write to any bits in the words in which bits are written from a user link table.

Depending on the timing, any attempts to write to these words from ladder programming or communications processes may be ignored. Example: If tag A in a

user link table writes to bit 00 of W000 and an OUT instruction in the ladder program in the CPU Unit write to bit 01 of W000, the write from the ladder program

may be ignored.

Analog I/O Units used in combination with the Loop Controller must be mounted

correctly.

The unit number set on the front panel of the Analog I/O Unit must be the same

as the unit number set on the Field Terminal Function Block. If the unit numbers

are not the same, I/O (read/write) will be performed on the data for another Special I/O Unit (i.e., the one whose unit number is set in the Field Terminal Function

Block).

The initial settings of the System Common Block in the Loop Controller must be

set correctly. In particular, make sure that words in the Data Memory used for the

Node Terminals in the CPU Unit controlling the Loop Controller are not used for

other applications on the PLC.

When writing data to the I/O memory in the CPU Unit with function blocks (e.g.,

using Send All Blocks, Expanded DO/AO Terminal to CPU Unit, or DO/AO Terminal to CPU Unit), be sure that the words written to in I/O memory are not being

used for any other purpose. If I/O memory words are allocated to more than one

purpose, the PLC system may act unexpectedly and cause injury.

3Safety Precautions

WARNING Always stop the operation of the LCB before converting any of the EM Area

!

to file memory. If any part of the EM Area that is being used by the LCB for

the HMI is converted to file memory during Board operation, the system may

operate in an unexpected fashion, which may result in injury.

WARNING Do not perform processing in such a way that the Loop Controller and CPU Unit

!

write to identical I/O memory words allocated to a contact output or analog

output of an external Unit. If the same words are written to, the externally

connected loads may act unexpectedly and cause injury.

WARNING When the calibration function is executed, the MV (manipulated variable) will

!

change due to changes in the PVs (present values) input to the control block.

Therefore, set pseudo-input values to confirm safety when the MW changes

before executing the calibration function. Devices may perform unexpected

operations, resulting in serious accidents.

Caution Before transferring function block data (initial setting data or operation data) to

!

the Loop Controller, confirm that the destination for the data is correct and also

confirm the overall safety of the system (including the Loop Controller). Not doing so may result in unexpected operation.

Caution Before performing Validate Action, be sure to perform Compare on currently

!

opened function files and the Loop Controller’s function block data. If there are

inconsistencies in the registered function blocks (block address vs. block model), it will not be possible to perform Validate Action correctly.

xxv

Page 26

Before forcing changes of analog signals or contact signals using Validate Action, confirm the safety of the instrumentation system as a whole. Not doing so

may result in unexpected operation.

Caution When downloading a sequence table for the LCB (unit ver. 1.5 or later) that

!

has been edited online with the CX-Process Tool version 3.2 or higher, confirm

that the system will operate normally with the edited sequence. If the sequence

is not suitable for operation, unexpected operation may result.

Caution Confirm in advance the conditions at any node for which the sequence table is

!

being edited over a Controller Link or Ethernet network. Not doing so may result

in unexpected operation.

Caution Confirm the status of connected devices before transferring the setting for the

!

MV tight shut function and MV analog output reverse function to the Loop Controller. Devices and equipment may perform unexpected operations if the data

destination is mistaken.

Caution When the calibration function is executed, the MV (manipulated variable) will

!

change due to changes in the PVs (present values) input to the control block.

Therefore, set pseudo-input values to confirm safety when the MW changes before executing the calibration function. Devices may perform unexpected operations, resulting in serious accidents.

4Application Precautions

4 Application Precautions

Observe the following precautions when using CX-Process Tool and Loop Controller.

Caution If the power supply is turned OFF while function block data is being backed up

!

from RAM to flash memory, the backup will not be completed normally. If the

power supply is turned back ON within 24 hours, however, the super capacitor

will have held the RAM data. The backup operation will restart when power is

turned ON and operation will start when the backup has been completed. If the

power supply is turned OFF for more than 24 hours, however, RAM data will be

lost and operation will be started with the data that was previously saved to flash

memory. If this happens, the Cold Start Auto-execution Flag (A35807) will turn

ON to show that the previous data has been used. Use this bit in programming to

take whatever steps are necessary, such as downloading the most recent function block data. (For LCB only)

Caution Loop Control Unit data is monitored and operated using CX-Process Monitor or

!

CX-Process Monitor Plus based on the monitor tag files created using CX-Process Tool. When creating monitor tag files using CX-Process Tool, CX-Process

Monitor must be installed on the same computer.

Caution Before using function block data in actual operation, confirm operation by moni-

!

toring run status (to check the load rate; select Execute/Operation/Monitor

Run Status) and validating actions (select Validate Action/Start) with CX-Pro-

cess Tool. In particular, be sure to confirm that the load rate will be less than 60%.

(For details on the load rate, refer to the Operation Manual for the Loop Controller.)

xxvi

Page 27

Caution When uploading the Loop Controller’s function block data, observe the following

!

precautions.

When performing Upload New for Loop Control Units of version 1.5 or earlier,

data on the Edit Block Diagram Screen (function block information) will be lost,

and the block diagram showing the connections between function blocks will not

be displayed.

When performing Upload Previous, if the data in the source file currently

opened using the CX-Process Tool and the Loop Controller’s function block data

does not match the registered function blocks or the data on the Edit Block Diagram Screen, the data currently opened may change to illegal data.

Caution The Loop Controller can read and write I/O memory in the CPU Unit using the

!

Field Terminal Function Blocks or CPU Terminal Blocks independent of the user

program (Step Ladder Program) in the CPU Unit. Do not write to the same I/O

memory words from both the Loop Controller and the CPU Unit.

Caution To hold an analog output or contact output at a specific value (for example, the

!

maximum value or minimum value) when the Loop Controller stops running,

create a Step Ladder Program in the CPU Unit so that the corresponding output

bit allocated to Analog Output Unit or Contact Output Unit is set to the desired

value using an NC condition of the Loop Controller Running Flag (bit 00 in allocated CIO word “n”) as an input condition.

4Application Precautions

Caution If a fatal error occurs in the CPU Unit (including fatal errors created by execution

!

of a FALS instruction), the Loop Controller will also stop running. To hold analog

outputs to the previous values before the stop occurred, and to set analog outputs to either the minimum value or maximum value, use the output hold function

of the Analog Output Unit or Analog I/O Unit.

Caution Before turning ON the power to the PLC, make sure that the facilities are safe.

!

The analog output values and contact outputs from the Loop Controller are updated when the power to the PLC is turned ON regardless of the operating mode

of the CPU Unit (including in the PROGRAM mode). (Internally, the analog output values and contact outputs are sent from the CPU Unit to Basic I/O Units and

Analog Output Units.)

Caution Fail-safe measures must be taken by the customer to ensure safety in the event

!

of incorrect, missing, or abnormal signals caused by broken signal lines, momentary power interruptions, or other causes.

Caution Confirm that no adverse effect will occur in the system before attempting any of

!

the following:

• Changing the operating mode of the PLC (including the setting of the startup

operating mode).

• Force-setting/force-resetting any bit in memory

• Changing the present value or any set value in memory

Caution Be sure that all mounting screws, terminal screws, and cable connector screws

!

are tightened to the torque specified in the user manuals. Incorrect tightening

torque may result in malfunction.

xxvii

Page 28

Caution In the event of system or power failure, CX-Process function files (extension

!

“.ist”) may not be saved. It is recommended that function files are saved regularly.

Caution Do not connect pin 6 (+5 V power supply line) of the RS-232C port on the CPU

!

Unit to any external device except the CJ1W-CIF11 RS-422A Adapter or NTAL001 RS-232C/RS-422A Adapter. Doing so may damage the external device

or CPU Unit.

4Application Precautions

xxviii

Page 29

This section introduces the operations of the CX-Process Tool and connections to the PLC.

1-1 CX-Process Tool 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Project Workspace 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 Files Created with CX-Process Tool 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-4 Relationships between Tag Files 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-5 Operating Conditions of CX-Process Tool 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Relationship with CX-Process Monitor 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Overview of the CX-Process Monitor and CX-Process Monitor Plus 9. . . . . . . . .

1-2-2 Settings Required on the CX-Process Tool 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 CX-Process Tool Specifications 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Version Improvements 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 Version 1.20 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 Version 1.50 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 Version 2.00 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-4 Version 2.50 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-5 Version 3.00 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-6 Version 3.1 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-7 Version 3.2 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-8 Version 4.0 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-9 Version 4.1 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-10 Version 5.0 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-11 Version 5.1 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-12 Version 5.2 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Function Blocks/ITEMs Incompatible with Earlier Versions 25. . . . . . . . . . . . . . . . . . . . . . .

1-5-1 Incompatibility with Versions Earlier than Version 1.20 25. . . . . . . . . . . . . . . . . . . .

1-5-2 Incompatibility with Versions Earlier than Version 1.50 25. . . . . . . . . . . . . . . . . . . .

1-5-3 Incompatibility with Versions Earlier than Version 2.00 26. . . . . . . . . . . . . . . . . . . .

1-5-4 Incompatibility with Versions Earlier than Version 2.50 28. . . . . . . . . . . . . . . . . . . .

1-5-5 Incompatibility with Versions Earlier than Version 3.2 29. . . . . . . . . . . . . . . . . . . . .

1-5-6 Incompatibility with Versions Earlier than Version 4.0 30. . . . . . . . . . . . . . . . . . . . .

1-5-7 Incompatibility with Versions Earlier than Version 5.0 30. . . . . . . . . . . . . . . . . . . . .

1-5-8 Incompatibility with Versions Earlier than Version 5.2 30. . . . . . . . . . . . . . . . . . . . .

1-6 Connecting to the PLC 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6-1 Features of FinsGateway and CX-Server 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6-2 Selecting the Communications Driver 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6-3 Using FinsGateway 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6-4 Connecting Cables 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Basic Operating Procedures 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 Operations 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-1 Creating Function Blocks 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8-2 Online Operations 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction

1

Page 30

1-1 CX-Process Tool

1-1-1 Overview

The CX-Process Tool supports the following functions for Loop Controllers.

In this manual, the WS02-LCTC1-EV5 CX-Process Tool software package is

generally referred to as simply the “CX-Process Tool.”

• Creating function blocks, including the following functions

1-1SectionCX-Process Tool

• Setting the Step Ladder Program Block (block 000), including the following: System common operation cycle, Loop Control Unit number (Loop

Control Unit only), start mode, first address of data memory of node terminal (Loop Control Unit only)

• Registering function blocks (allocating block addresses)

• Connecting function blocks with analog and accumulator signals

• Setting ITEMs in function blocks

• Editing sequence tables (Block 302) and the Step Ladder Program Block

(Block 302) (See note.)

Note Editing sequence tables is supported only by the CS1W-LCB05 Loop

Control Board (00-LCB05) and CS1D-LCB05D Loop Control Board

(00-LCB05D).

• Settings tags for CX-Process Monitor (Loop Control Unit only) or CX-Process Monitor Plus software or setting CSV tags for SCADA software (Tag

Names and Analog Signals) and creating monitor tag files (Loop Control

Unit only, CX-Process Monitor must be already installed), or CSV tag files.

• Downloading function block data to Loop Controllers

• Uploading data from Loop Controllers

• Comparing function block data with data in a Loop Controller or Function Block

File

• Sending Run/Stop Commands to Loop Controller

• Monitoring status (including System Common Block Settings, Load Rate per

Operation Cycle Group, and Execution Errors)

• Monitoring actions of Loop Controllers (including operation checks on function

block diagrams and ladder diagrams)

• Tuning parameters such as PID constants in function blocks (Control Blocks)

• Backing up function block data from the Loop Controller’s RAM to flash

memory and restoring that function block data from flash memory back to RAM

• Initializing function block data in Loop Controllers

Note To create monitor tag files using the CX-Process Tool with the CX-Process Moni-

tor or CX-Process Monitor Plus software, both the CX-Process Tool, and CXProcess Monitor or CX-Process Monitor Plus, must be installed on the same

computer.

2

Page 31

1-1-2 Project Workspace

Project Workspace can be used to access the data created in memory with the

CX-Process Tool. Data can be created for up to 32 CPU Units and 96 Loop Control Units (3 Loop Control Units each for 32 CPU Units) or 32 LCBs (1

LCB each for 32 CPU Units). The data has the following configuration.

1-1SectionCX-Process Tool

LCU/LCB Elements

(one for each Loop

Function Block File

for Each Node (.ist)

Node01.ist

Node02.ist

Project Workspace

Node32.ist

Project file (.mul)

Controller)

00-LCB03

00-LCB01

00-LCB05

00-LCB05D

01-LC001

02-LC001

03-LC001

Project Workspace data is stored in one folder called the project folder. Project

folders are created for the following commands.

• File – New

When a new project is created, the project name will be used as the folder

name.

• File – Save As

When a project is saved under a new name, the new project name will be used

as the folder name.

1-1-3 Files Created with CX-Process Tool

Function Block Groups

System common

Field terminals

Block diagrams

Function Blocks

Basic PID

Project File (.mul)

The CX-Process Tool creates a folder with the project name in the data folder

under the default installation folder for the CX-Process Tool, and then creates

the following files inside the project folder.

The project file consists of administrative data for the Project Workspace.

Files File name

extension

Function block files .ist

Block diagram information files .mtbd

Mnemonics/Ladder diagram

information files

Comment files .cmt

CSV tag setting files project_name.csv

CX-Server configuration files .cdm Only when CX-Server is

Job information files .sjb

Loop Controller configuration

files

Data files of user link tables LnkTable.csv

Data files of sequence tables .stbl

.mtld

selected as the

communications driver

.lcb

Remarks

The project file (.mul) can be specified when opening files so that the above related files will be all read at the same time. The project file is created by selecting

New from the File Menu and specifying the project name. The file name will be

the same as the project name.

3

Page 32

1-1SectionCX-Process Tool

Function Block Files (.ist)

A function block file consists of the data for the function blocks of a single CPU

Unit (i.e., for up to three LCU elements and/or one LCB element). This file is

created by selecting Settings – Insert. The file will be automatically named

“Node XX,” where XX denotes the node number between 01 and 32.

The following data is contained in a function block file.

Item Data name Description

Function block data

for one Loop

Controller

Initial settings (S) Data on registered function blocks

(block address allocations),

analog/accumulator signal software

connections, and initial settings of

each function block.

Operation data (O) Operation data for each function block

The contents of the function block file (.ist) are used to compare download data

and upload data. Initial settings (S), operation data (O), or initial settings and operation data together can be set in the function block file.

Note 1. The function block file does not include mnemonic data for Step Ladder Pro-

gram Blocks. The mnemonic data is stored in the mnemonics/ladder diagram information file. Refer to Mnemonics/Ladder Diagram Information File

(.mtld) Created by System

below.

2. Function block files (.ist) created for the CX-Process Tool can be imported to

the Project Workspace data by selecting Add Function Block File from the

File Menu.

Block Diagram

Information Files (.mtbd)

Mnemonics/Ladder

Diagram Information

Files (.mtld)

The block diagram information file consists of graphic data that shows the software connections.

The system will automatically store this file with the function block file (.ist) in the

same folder whenever a block diagram is edited. The user does not normally

need to access the block diagram information file directly.

Note 1. When backing up or changing the storage location of this file, the file must be

backed up or moved together with the node function block files because

these files must always be in the same folder. The block diagram information

files are named as shown below.

File name and extension: Name of function block file .mtbd

Function block group

LCU/LCB number

(04 for LCB)

2. The block diagram information file (.mtbd) is not used for downloading,

uploading, or comparing data, but the block diagram information between

function blocks (i.e., ITEM data) is uploaded and downloaded if the Loop

Control Unit is version 2.00 or later or an LCB is used. Thus, newly

uploaded data will have connection diagrams displayed between function

blocks. (This is not actually the same as the connection diagram information

file, and even though connections themselves will be restored, complex

connections will be normalized for display.)

A mnemonics/ladder diagram information file consists of mnemonic data and

ladder diagram data for sequence instructions in step ladder programs.

The system will automatically store this file with the function block file (.ist) in the

same folder whenever a Step Ladder Program Block is registered. The user

does not normally need to access the mnemonics/ladder diagram information

file directly.

Note 1. When backing up or changing the storage location of this file, the file must be

backed up or moved together with the node function block files because

4

Page 33

CX-Process Monitor Tag

Files (with Fixed File

Name without Extension)

CX-Process Monitor Plus

Tag Files (monitor.csv)

(CX-Process Tool Ver. 3.2

or Higher)

CSV Setting File

(project_name.csv)

1-1SectionCX-Process Tool

these files must always be in the same folder. The mnemonics/ladder diagram information files are named as shown below.

File name and extension: Name of function block file .mtld

Block address

LCU/LCB number

(04 for LCB)

2. The mnemonic data in the mnemonics/ladder diagram information file

(.mtld) is used in downloading, uploading, or comparing data but the ladder

diagram data is not.

A CX-Process Monitor tag file consists of monitor tag data (binary data) for a

single CPU Unit (with a maximum of three Loop Control Units).

CX-Process Monitor tag data consists of tag names, tag comments, corresponding ITEM numbers or block addresses, and analog signal scaling data. By

reading the tag file with the CX-Process Monitor, the block address or ITEM

number in function block data corresponding to the CX-Process Monitor tag on

each screen can be specified.

The CX-Process Monitor tag file is created by selecting Create Tag File – Moni-

tor Tag from the Execution Menu.

Note 1. It is necessary to install the CX-Process Monitor on the same computer be-

fore creating monitor tag files.

2. Monitor tag files are stored by default in the following folder with fixed file

names.

Folder: Omron\CX-Process Monitor\

(The underlined part is the folder of CX-Process Monitor.)

File names: mtagmst and mtagsubmst

You can change the folder in which monitor tag files are stored using the

Monitor Software from the Setup Dialog Box.

3. CX-Process Monitor tag files are not used when comparing, downloading,

or uploading data.

A CX-Process Monitor Plus tag file contains the CX-Process Monitor Plus tag

data for a single CPU Unit (with a maximum of three Loop Control Units).

CX-Process Monitor Plus tag data consists of tag names, tag comments, corresponding ITEM numbers or block addresses, and analog signal scaling data. By

reading the tag file with the CX-Process Monitor Plus, the block address or ITEM

number in function block data corresponding to the CX-Process Monitor tag on

each screen can be specified.

The CX-Process Monitor tag file is created by selecting Create Tag File – Moni-

tor Plus Tag from the Execution Menu. If the CX-Process Monitor Plus is then

started and the Start Button is pressed, the monitor tag files mtagmst and mtag-

submst will be automatically generated. If the monitor tag files are read from the

CX-Process Monitor, the block addresses or ITEM numbers in the function block

data corresponding to the monitor tag names pasted on the screen can be selected.

Note 1. It is necessary to install the CX-Process Monitor Plus on the same computer

before creating monitor tag files.

2. CX-Process Monitor tag files are stored by default in the following folder with

fixed file names.

Folder: Omron\CX-Process Monitor Plus\

3. CX-Process Monitor Plus tag files are not used when comparing, downloading, or uploading data.

The CSV setting file contains the CSV tag settings required to output a CSV tag

file for SCADA software. This data is automatically generated in advance by the

system. It can be edited by the user using Excel or another editor.

db

db

5

Page 34

1-1SectionCX-Process Tool

The file contains the tag names, tag comments, scaling upper limits, scaling lower limits, scaling decimal point, units, and other settings for each function block.

The data is comma delimited.

Note This file does not contain the tags for individual ITEMs in function block or ad-

dress allocations for CPU Unit I/O memory. (These are stored in the CSV tag

files for SCADA software after the CSV tags have been compiled.)

This file is automatically generated after CSV tag settings have been made after

selecting Settings – Tag Setting – CSV Tag or (for CX-Process Tool software

version 3.1 or higher) when function blocks are saved in function block files after

selecting the automatic CSV tag registration option when registering function

blocks.

This file is saved in the data project folder under the CS-Process installation

folder as project_name.csv.

The CSV automatic tag registration function can be used with version 3.1 or

higher to automatically save CSV tag settings in this file when function blocks

are registered. The tag name will be Tag + block address, the scaling upper limit

will be 1,000, and the scaling lower limit will be 0.

If this file is edited with Excel or another editor and overwritten, the new settings

will be read when the project is opened.

CSV Tag Files for SCADA

Software (.csv, Default

File Name: TagList.csv)

Tag Files for RS View

(.csv, User-set File Name)

A CSV tag file can contain CSV tag data for up to 32 CPU Units (i.e., up to 96

Loop Control Units and 32 LCBs).

CSV tag data consists of comma-delimited test data containing tag names, numbers, tag comments, block addresses, tag ITEMs, and allocated I/O memory addresses (in CPU Unit).

The CSV tag file can be read from SCADA software via an OMRON OPC Server

to specify block addresses and ITEM numbers in the function block data of the

Loop Controller.

Settings – Tag Setting – CSV Tag is used to set CSV tags for each function

block, and Execute/Create Tag File/CSV Tag is used to allocate I/O memory ad-

dresses in the CPU Unit and compile a CSV tag file.

Note 1. CSV tag files are not downloaded, uploaded, or compared.

2. Basically speaking, CSV tag files are imported to SCADA software through

an OMRON OPC server.

An RS View tag file can contain CSV tag data for up to 32 CPU Units (i.e., up to 96

Loop Control Units and 32 LCBs) for direct importing into RS View 32. Any

file name can be specified.

The RS View tag file can be directly imported using the RS View import utility.

This file is created together with the SCADA CSV tag file when the RS View CSV

tags are compiled using Execute/Create Tag File/RS View Tag. When this file is

imported into the RS View 32 using the import utility, the ITEMs and tags specified with CSV tag settings are registered in the tag database in the RS View 32

project.

Comment Files (.cmt)

CX-Server Settings File

(.cdm)

6

Note 1. RS View tag files are not downloaded, uploaded, or compared.

2. The SYSMAC OPC Server Version 2.40 or higher is required to generate an

RS View tag file from the CX-Process Tool.

A comment file contains of the tag data attached to a function block connection

diagram or step ladder diagram.

The file name is automatically set to the same name as the project.

This file contains the communications settings for communications with the PLC

when CX-Server is being used as the communications driver.

The file name is automatically set to the same name as the project.

Page 35

1-1SectionCX-Process Tool

Job Information Files

(.sjb)

The job information file consists of data on the registration of jobs for Project

Workspace.

The file name is automatically set to the same name as the project.

Loop Controller

Configuration Files (.lcb)

Data Files of User Link

Tables (CSV Format)

(LnkTable.csv)

(LCB Only)

Data Files of Sequence

The Loop Controller configuration file is a system file that includes data on the

existence of Loop Controllers in the project.

The data file of user link table consists of user link table data that can be edited by

the user. If this file is edited using Excel, for example, the editing results will be

reflected in the user link table when the project is opened or when the active

node is switched.

The data file of sequence table consists of sequence table data.

Tables (.stbl)

1-1-4 Relationships between Tag Files

The relationships between the tag files created by the CX-Process Tool and the

HMI applications that use these files are shown below. The HMI applications that

use the tag files include NS-series PTs, SCADA software, the CX-Process Monitor, and the CX-Process Monitor Plus.

Imported Imported

NS Face Plate

Auto Builder

NS project

file (.ipp,

binary)

Outputs CSV tag file.

Execute/Create Tag

File/CSV Tag

CSV tag file

for SCADA

software

(Taglist.csv)

SYSMAC OPC

Server

RS View

tag file

(***.csv)

Manually

exported.

Automatically

generated.

OPC tag

settings

file (.sdb,

binary)

CX-Process Tool

Outputs RS View tag file.

Execute/Create Tag File/RS

View Tag

CSV tag file

for SCADA

software

(Taglist.csv)

SYSMAC

OPC Server

version 2.4 or

higher

RS View

tag file

(***.csv)

(CX-Process

Tool version

3.2 or higher)

Automatically

generated.

Automatically

generated.

Outputs CX-Process

Monitor tag file.

Execute/Create Tag

File/Monitor Tag

CX-Process

Monitor Plus

tag file

(monitor.csv)

CX-Process

Monitor Plus tag

file automatically

generated when

Start Button is

clicked.

(CX-Process

Tool version

3.2 or higher)

Outputs CX-Process

Monitor Plus tag file.

Execute/Create Tag

File/Monitor PlusTag

CX-Process

Monitor tag

file (mtagmst,

mtagsubmst)

NS-series PT

Imported using

import utility.

RS View

Imported using

import utility.

CS-Process

Monitor Plus

CS-Process Monitor

7

Page 36

1-1-5 Operating Conditions of CX-Process Tool

As shown below, the CX-Process Tool uses a FinsGateway (Embedded), Version 2003, or CX-Server communications driver to communicate with the PLC

(Programmable Controller) to which a Loop Controller is mounted. It is thus necessary to install the FinsGateway (Embedded), Version 2003, or CX-Server

software in the personal computer that will be used.

Note When the CX-Process Tool starts up, a dialog box is displayed to select whether

FinsGateway or CX-Server will be used as the communications driver.

1-1SectionCX-Process Tool

Using FinsGateway

The following FinsGateway (Embedded) communications drivers are available.

• Serial Unit Driver

• CLK (PCI) Driver

• Controller Link Driver

• ETN_UNIT Driver

The software configuration is shown below.

CX-Process Tool CX-Process Monitor

Software

FinsGateway (Embedded)

Hardware

RS-232C port

Controller Link Support Board

(PCI or ISA)

Ethernet Board

Note 1. If FinsGateway (Embedded) has not been installed, it will not be possible to

set FinsGateway as the communications driver and start the CX-Process

Tool. Likewise, if CX-Server has not been installed, it will not be possible to

set CX-Server as the communications driver and start the CX-Process Tool.

2. The CX-Process Tool cannot use FinsGateway version 1 as the communications driver. Use FinsGateway version 3 or later.

3. If any other Support Software (e.g., the CX-Programmer, CX-Protocol, or

CX-Motion) is connected over the CX-Server or an application using the

dedicated serial driver is connected, the same COM port cannot be initialized for online Host Link serial communications for the CX-Process Tool.

Disconnect the other Support Software or the application using the dedicated serial driver offline, and then go online with the CX-Process. (While

the CX-Process Tool is connected online, no other Support Software can

communicate via the CX-Server.)

4. The CX-Process Tool and FinsGateway Version 1 cannot be installed on the

same computer.

5. The CX-Process Tool runs on Windows NT 4.0 (with Service Pack 6a or

higher).

6. FinsGateway version 3 and FinsGateway 2003 (Embedded) are bundled together with the CX-Process Tool. If the FinsGateway Runtime version 3 has

been already installed, there is no need to install the FinsGateway embedded version.

Using CX-Server

8

The CX-Server is a communications driver shared by the following OMRON

Tools:

• CX-Programmer

• CX-Protocol

• CX-Motion

The CX-Server has the following advantages:

• If the CX-Server is being used, one of the three Tools listed above can be

started at the same time as the CX-Process Tool and simultaneous online connections can be established with the same PLC through the same COM port on

Page 37

1-2SectionRelationship with CX-Process Monitor

the personal computer. The simultaneous online connections make it unnecessary to switch between communications drivers or switch the Tools between

online/offline operation.

• If the CX-Server is being used, Peripheral Bus mode can be used as a serial

communications mode. The Peripheral Bus mode provides even faster communications than Host Link mode.

Note The CX-Process Monitor software is not compatible with the CX-Server; it is

compatible with the FinsGateway only. The following diagram shows the software configuration.

CX-Process Tool

Software

Hardware

CX-Programmer

RS-232C port

CX-Server

CX-Protocol

FinsGateway NSB Driver (See note.)

Controller Link, Ethernet

CX-Motion, etc.

Note The CX-Server can be connected to other networks, such as Controller Link and

Ethernet, through the FinsGateway NSB driver.

1-2 Relationship with CX-Process Monitor

1-2-1 Overview of the CX-Process Monitor and CX-Process Monitor Plus

The CX-Process Monitor is used to monitor function blocks in Loop Controllers.

The CX-Process Monitor does not support the LCBs. The CX-Process Monitor Plus is used to monitor function blocks in LCBs. A connection can be

made through Host Link, Controller Link, or Ethernet so that the data can be

monitored on the Control Screens (like on-site instruments), Trend Screens,

Graphic Screens, or Annunciator Screens. The CX-Process Monitor and CXProcess Monitor Plus are used in combination with the CX-Process Tool.

The CX-Process Monitor and CX-Process Monitor Plus have the following three

main functions.

Monitoring Status of Function Blocks in Loop Controllers

Control Block PVs, SPs, MVs, analog signals, and contact signals can be monitored.

Loop Controllers can be started and stopped.

The status of the CPU Unit, such as the operating mode, can be displayed.

Manipulating Function Blocks in Loop Controllers

In Control Blocks, settings can be changed, automatic or manual operation can

be selected, manual control is possible, and PID constants can be adjusted.

It is possible to stop the processing of specific Control Blocks on a Tuning

Screen.

Monitoring Alarms in Function Blocks in Loop Controllers

Alarms from Control and Alarm Blocks can be displayed and alarm logs can be

saved.

Note The CX-Process Monitor and CX-Process Monitor Plus use FinsGateway as the

communications driver for connections with the PLC. When using the CX-Process Monitor or CX-Process Monitor Plus, always set FinsGateway as the communications driver for the CX-Process Tool. If the CX-Server is set, the CX-Process Monitor or CX-Process Monitor Plus will not be able to go online with the

PLC.

1-2-2 Settings Required on the CX-Process Tool

The CX-Process Monitor and CX-Process Monitor Plus use tag names set on

the CX-Process Tool to read and write data in Loop Control Units through func-

9

Page 38

CX-Process Monitor

1-2SectionRelationship with CX-Process Monitor

tion blocks for data exchange with the monitor software. Before using the CXProcess Monitor or CX-Process Monitor Plus, the following settings must be

made with the CX-Process Tool.

Set Network Address,

Node Address, and Unit

Address.

Register Function Blocks

for Data Exchange.

Set Tag Names.

Create a Monitor Tag File

for CX-Process Monitor.

The CX-Process Monitor uses the network address, node address, and unit address set using the CX-Process Tool (Setting – Network Settings or Setting –

Change PLC) for communications with the PLC. The communications settings

for the CX-Process Monitor Plus are thus made from the CX-Process Tool.

Create a Send Terminal to Computer Function Block or certain other function