Page 1

Cat. No. W446-E1-10

SYSMAC

WS02-CXPC_-V9

CX-Programmer Ver. 9

OPERATION MANUAL

Page 2

Page 3

SYSMAC

WS02-CXPC@-V9

CX-Programmer Ver. 9.@

Operation Manual

Revised December 2009

Page 4

Page 5

OMRON CX-Programmer – Operation Manual

About this Manual (W446):

This manual describes the operation of the CX-Programmer and consists of the following three parts.

• Part 1: CX-Programmer

This part describes the CX-Programmer software that is a PLC

Programming Device, and also provides the overall precautions and the

version upgrades information.

• Part 2: CX-Server PLC Tools

This part describes the CX-Server PLC Tools software, which is a

collection of the following components:

PLC Memory, IO Table, PLC Setup, Data Trace/Time Chart Monitor, PLC

Error, Memory Card, PLC-Clock, and CX-Net Network Configuration

(including Data Link Editor and Routing Table).

• Part 3: CX-Server Runtime

This part describes the CX-Server software that is a communications

middleware.

Note: References within each part are references to the pages or chapters within that part.

Related Manual

For details on the function block functions and ST programming, refer to the CX-Programmer Operation

Manual Function Blocks and Structured Text (Cat. No. W447).

For details on the SFC programming functions, refer to the CX-Programmer Operation Manual SFC (Cat.

No. W469).

For details on procedures for installing the CX-Programmer from the CX-One FA Integrated Tool Package,

refer to the CX-One Setup Manual provided with CX-One.

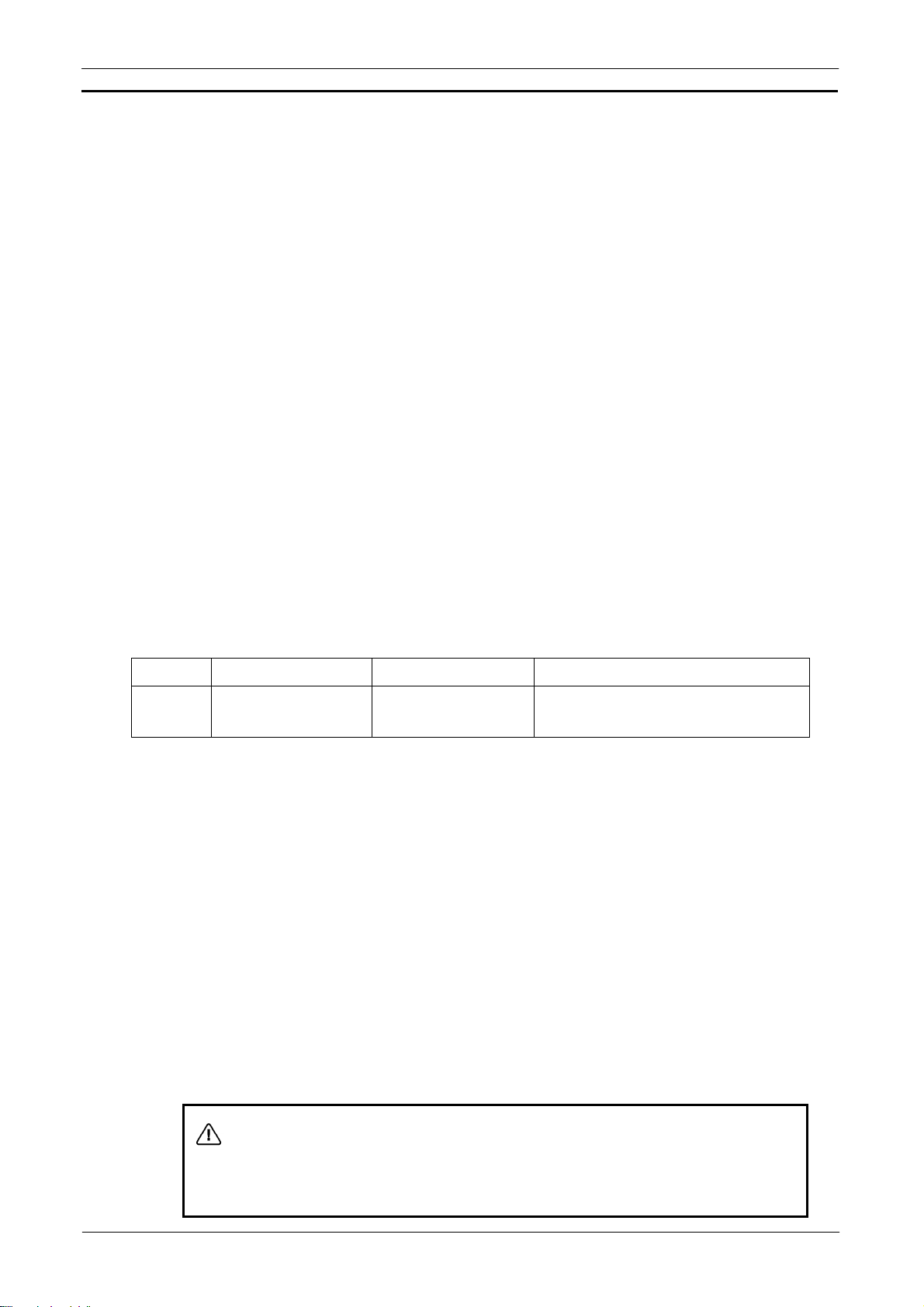

Cat. No. Model Manual name Contents

W463

CXONE-AL@@C-V4/

AL@@D-V4

CX-One Setup Manual Installation and overview of CX-One FA

Integrated Tool Package.

WARNING: Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each chapter in its entirety and be sure you understand the

information provided in the chapter and related chapters before attempting

any of the procedures or operations given.

CX-Programmer_Page (ii)

Page 6

Page 7

OMRON CX-Programmer – Operation Manual

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

(1) The warranty period for the Software is one year from either the date of purchase or the date on which

the Software is delivered to the specified location.

(2) If the User discovers a defect in the Software (i.e., substantial non-conformity with the manual), and

returns it to OMRON within the above warranty period, OMRON will replace the Software without

charge by offering media or downloading services from the Internet. And if the User discovers a defect

in the media which is attributable to OMRON and returns the Software to OMRON within the above

warranty period, OMRON will replace the defective media without charge. If OMRON is unable to

replace the defective media or correct the Software, the liability of OMRON and the User’s remedy shall

be limited to a refund of the license fee paid to OMRON for the Software.

LIMITATIONS OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER’S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT WILL OMRON BE LIABLE FOR ANY LOST PROFITS OR

OTHER INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

USE OF THE SOFTWARE.

(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE BASED ON

MODIFICATION OR ALTERATION OF THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

CX-Programmer_Page (iv)

Page 8

OMRON CX-Programmer – Operation Manual

Application Considerations

SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT DESCRIBED IN THE

ATTACHED USER MANUAL.

CX-Programmer_Page (v)

Page 9

OMRON CX-Programmer – Operation Manual

Disclaimers

CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at any time based on improvements or for

other reasons.

EXTENT OF SERVICE

The license fee of the Software does not include service costs, such as dispatching technical staff.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

CX-Programmer_Page (vi)

Page 10

OMRON CX-Programmer – Operation Manual

Precautions

Intended Audience

General Precautions

WARNING

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

The user must operate the product according to the performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad

systems, aviation systems, vehicles, combustion systems, medical

equipment, amusement machines, safety equipment, and other systems,

machines, and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product

are sufficient for the systems, machines, and equipment, and be sure to

provide the systems, machines, and equipment with double safety

mechanisms.

This manual provides information for programming and operating the Unit.

Be sure to read this manual before attempting to use the Unit and keep this

manual close at hand for reference during operation.

It is extremely important that a PLC and all PLC Units be used for the

specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must

consult with your OMRON representative before applying a PLC System to

the above-mentioned applications.

Safety Precautions

WARNING

Confirm safety sufficiently before transferring I/O memory area status from

the CX-Programmer to the PLC. The devices connected to Output Units

may malfunction, regardless of the operating mode of the CPU Unit.

Caution is required in respect to the following functions.

• Transferring from the CX-Programmer to real I/O (CIO Area) in the CPU

Unit using the PLC Memory window.

• Transferring from file memory to real I/O (CIO Area) in the CPU Unit

using the Memory Card window.

CX-Programmer_Page (vii)

Page 11

OMRON CX-Programmer – Operation Manual

WARNING

Observe the following precautions when using the PLC Backup Tool.

• Sufficiently check the data that is selected for restoring before performing

the next step. If the correct data is not restored, unexpected operation

may occur in the controlled system after the data is restored.

• Some Special I/O Units and CPU Bus Units operate with parameters that

are stored in the CPU Unit. If one of these Units is selected for backup,

restrictions will be displayed in the Comments Area of the Backup from

PLC Dialog Box. Confirm the restrictions, and always select the Special

I/O Unit or CPU Bus Unit together with the CPU Unit when backing up or

restoring data. If the data from both Units is not backed up or restored

together, unexpected operation may occur in the controlled system.

• If there are any backup restrictions for the Units to which data is being

restored, the restrictions will be displayed in the Comments Area of the

Backup from PLC Dialog Box. Confirm the restrictions, and always take

the required measures. If required measures are not taken, unexpected

operation may occur in the controlled system after the data is restored.

• Forced status can be backed up, but it cannot be restored. If you

restored data that contained forced status, use the CX-Programmer after

restoring the data to force-set or force-reset bits as required. If required

bits are not force-set or force-reset, differences in the forced status in

memory may cause unexpected operation of the controlled system.

• Confirm that stopping PLC operation will not create any problems before

restoring data during PLC operation. If the PLC stops at an unanticipated

time, unexpected operation may occur in the controlled system.

• Always turn the power supply to the PLC OFF and then ON after

restoring data. If the power supply is not turned OFF and then ON,

memory in the PLC may not be updated to the restored data, which may

cause unexpected operation of the controlled system.

Caution

Observe the following precaution when specifying a symbol or word

address for an array variable index in a ladder program or when specifying

a symbol for an array variable index in an ST program.

When using a symbol or address to indirectly specify the element number

of an array variable, be sure that the resulting address is not outside the

memory area that contains the first word in the array. For example, use a

symbol comparison instruction or an IF statement to ensure that processing

is performed only when the memory area is not exceeded. If an element

number that exceeds the memory area is specified, data in another

memory area will be read or written, possibly resulting in unexpected

operation.

Caution

Observe the following precaution when specifying a symbol or word

address for an offset in a ladder program.

When using a symbol or address to indirectly specify an offset for a

memory address, be sure that the resulting address is not outside the

memory area that contains original address. For example, use a symbol

comparison instruction to ensure that processing is performed only when

the memory area is not exceeded. If the final address (i.e., the original

address plus the specified offset) exceeds the memory area, data in

another memory area will be read or written, possibly resulting in

unexpected operation.

CX-Programmer_Page (viii)

Page 12

OMRON CX-Programmer – Operation Manual

Caution

Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

Caution

Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not

be readable.

Caution

If synchronous unit operation is being used, perform online editing only

after confirming that an increased synchronous processing time will not

affect the operation of the main and slave axes.

Caution

Confirm safety sufficiently before monitoring power flow and present value

status in the Ladder Section window or when monitoring present values in

the Watch window. If force-set/reset or set/reset operations are

inadvertently performed by pressing short-cut keys, the devices connected

to Output Units may malfunction, regardless of the operating mode of the

CPU Unit.

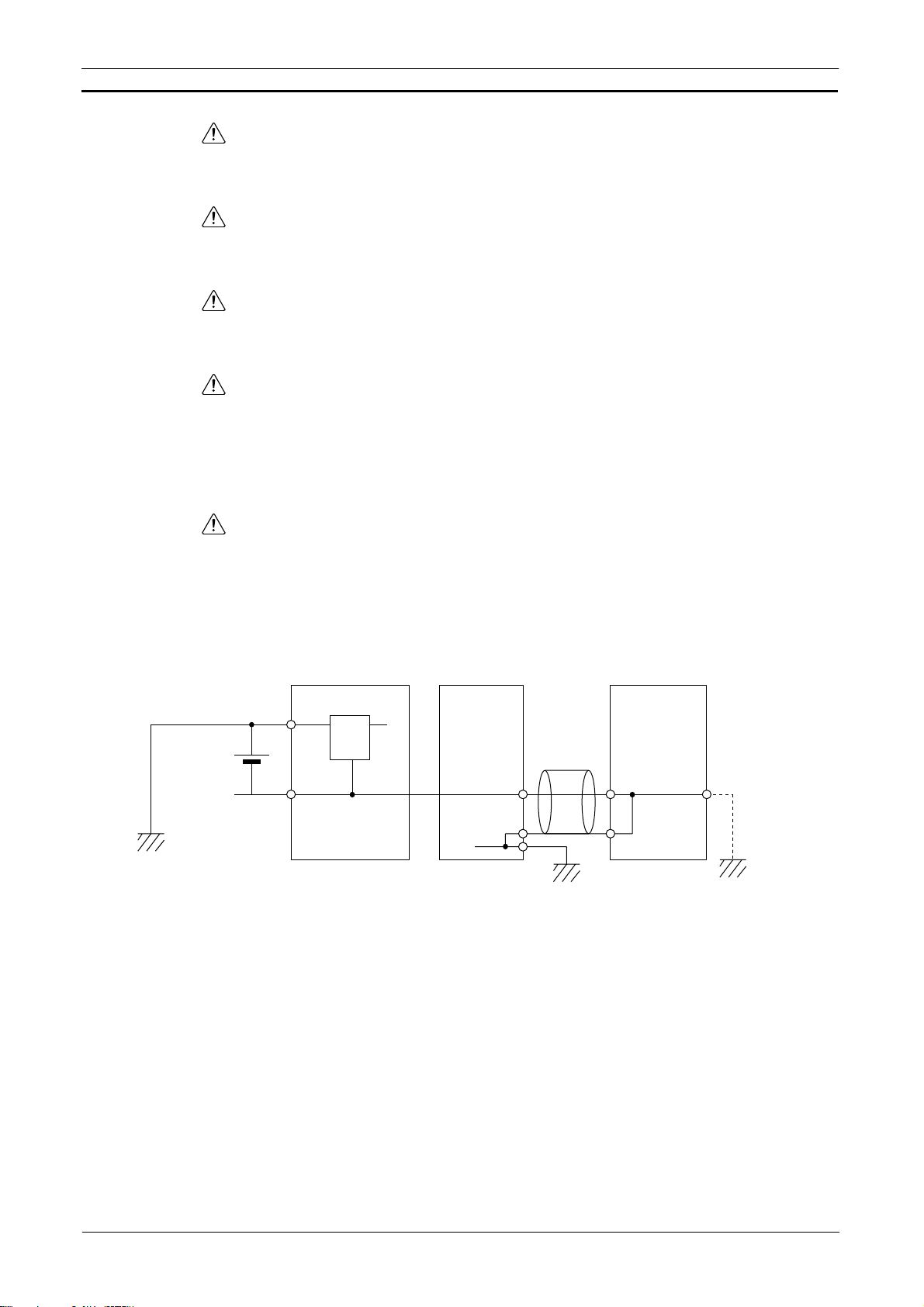

Caution

Caution is required when connecting peripheral devices, such as a

personal computer, to the PLC when Units with non-isolated power

supplies, such as the CS1W-CLK12/CLK52(-V1), that are connected to an

external power supply are mounted to the PLC. If the 24-V side is grounded

on the external power supply, a short will be created if the 0-V side of the

peripheral device is grounded. When connecting peripheral devices, either

ground the 0-V side of the external power supply or do not ground the

external power supply at all.

External power

supply

FG

24-VDC

0-VDC

Non-isolated

power supplies

Cable

0-VDC

FG

Controller Link unit Peripheral devices

CPU unit

FG

0-VDC

FG

CX-Programmer_Page (ix)

Page 13

OMRON CX-Programmer – Operation Manual

Application Precaution

Observe the following precautions when using the CX-Programmer.

• Observe the following precautions before starting the CX-Programmer.

• Exit all applications not directly related to the CX-Programmer.

Particularly exit any software such as screen savers, virus checkers,

email or other communications software, and schedulers or other

applications that start up periodically or automatically.

• Disable sharing hard disks, printers, or other devices with other

computers on any network.

• With some notebook computers, the RS-232C port is allocated to a

modem or an infrared port by default. Follow the instructions in

documentation for your computer and enable using the RS-232C port

as a normal serial port.

• With some notebook computers, the default settings for saving

energy do not supply the rated power to the RS-232C port. There

may be both Windows settings for saving energy, as well as setting

for specific computer utilities and BIOS. Following the instructions in

documentation for your computer, disable all energy saving settings.

• Do not turn OFF the power supply to the PLC or disconnect the

connecting cable while the CX-Programmer is online with the PLC. The

computer may malfunction.

• With the CS/CJ-series PLCs, when creating an AUTOEXEC.IOM file

from the CX-Programmer to automatically transfer data at startup, set the

first write address to D20000 and be sure that the size of data written

does not exceed the size of the DM Area. When the data file is read from

the Memory Card at startup, data will be written in the CPU Unit starting

at D20000 even if another address was set when the AUTOEXEC.IOM

file was created. Also, if the DM Area is exceeded (which is possible

when the CX-Programmer is used), the remaining data will be written to

the EM Area. Refer to information on file operations in the CS/CJ-series

Programming Manual for details.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Check the user program for proper execution before actually running it

on the Unit. Not checking the program may result in an unexpected

operation.

• Precaution on Using Indirect DM and EM Addresses in Comparison

Instructions:

When indirect DM or EM addresses are used as operands in comparison

instructions, the top portion of the comparison instruction will be displayed

in yellow when it is being monitored. At that time the power flow will not be

monitored to the right of such comparison instructions. The contact and

coil status, and present values of operands in special instructions will be

displayed normally.

CX-Programmer_Page (x)

Page 14

OMRON CX-Programmer – Operation Manual

• The user program and parameter area data in CS1-H CPU Units is

backed up in the built-in flash memory. The BKUP indicator will light on

the front of the CPU Unit when the backup operation is in progress. Do

not turn OFF the power supply to the CPU Unit when the BKUP indicator

is lit. The data will not be backed up if power is turned OFF.

To display the status of writing to flash memory on the CX-Programmer,

place a checkmark by Display dialog to show PLC Memory Backup

Status on the PLC properties and then select Windows | PLC Memory

Backup Status from the Windows menu.

• Precaution in Changing the PLC Type

On the CX-Programmer, you can change the PLC (device) type or CPU

type. When these are changed, however, only the data for the ladder

program and the symbol tables are changed. The following data will be

initialized and must be reset.

• PLC Setup

• Expansion instructions

• I/O tables

• PLC memory

Particularly the PLC Setup has a large impact on PLC system operation.

Be careful to reset all require settings after changing the PLC type.

If expansion instruction allocations are not reset, program errors could

occur, preventing the PLC from running. Always restore the expansion

instruction allocates to the previous settings after changing the PLC

type.

CX-Programmer_Page (xi)

Page 15

OMRON CX-Programmer – Operation Manual

Observe the following precautions when using the CX-Net.

• Do not change the operating mode of the CPU Unit without first

confirming that operation of the controlled system will not be affect.

• Do not run the user program on the PLC until its operation has been

checked sufficiently.

• The data link mode (manual setting or automatic setting) and data link

method are determined according to the data link setting in the startup

node. In the startup node, set a data link table in the case of manual

setting and data link automatic setting parameters in the case of

automatic setting. If the settings are incorrect, the data link will not start.

• Check the following items before starting data links. If incorrect data link

tables or parameters are set, injury may result due to unexpected

operation of the system. Even if the correct data link tables and

parameters have been set, do not start or stop data links before verifying

that there will be no adverse influence on the system.

(1) Manually Set Data Links

Check the data link tables in each node participating in the data link to

see that they are correct.

Be sure that data link tables are deleted from nodes that are not

participating in the data links.

(2) Automatically Set Data Links

Be sure that the correct DM parameters have been set in the data link

startup node.

• CPU Bus Units will be automatically restarted when routing tables are

transferred from a Programming Device to the CPU Unit. Resetting is

required to use the new tables. Confirm that restarting the CPU Bus

Units will not adversely affect system operation before transferring

routing tables.

• When Special I/O Unit or CPU Unit settings are performed in the I/O

Table Window and then transferred from the PLC Memory Window, the

following warning will be displayed if the allocated DM Area/CIO Area

addresses set for Special I/O Units or CPU Bus Units in the I/O Table

Window on the computer overlap with the PLC data table addresses.

Unless the CPU Bus Unit or Special I/O Unit settings have been

previously transferred to the CPU Unit and the allocated DM Area/CIO

Area data in the PLC data table for Special I/O Units or CPU Bus Units is

to be overwritten, always click the No Button, shift the address, and

repeat the transfer procedure.

• CPU Bus Unit and Special I/O Unit settings are not checked for logical

consistency. Be very careful of the logical consisting of the overall

settings when making any setting that affects other settings, e.g., settings

that enable or disable other settings. Transfer the Special I/O Unit or

CPU Bus Unit settings to the PLC and then start operation, being aware

that any logical inconsistencies may produce unexpected operation.

• For example, if one setting selects either user settings or default settings

and is set to use the default settings, it will not automatically change to

enable user settings even if the related user settings are made. To use

the user settings, they will have to be enabled manually and specifically

in the setting that selects either user settings or default settings.

CX-Programmer_Page (xii)

Page 16

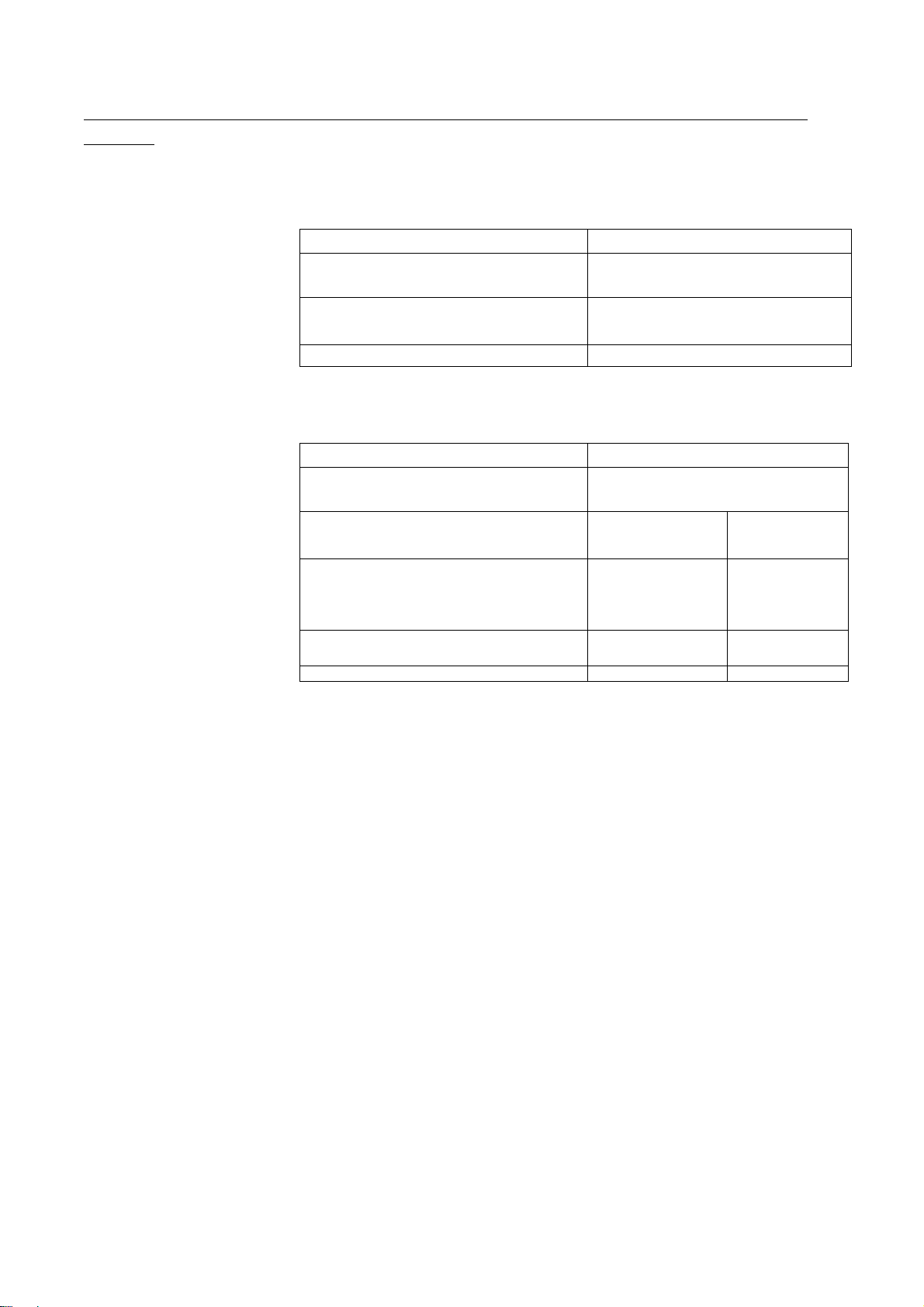

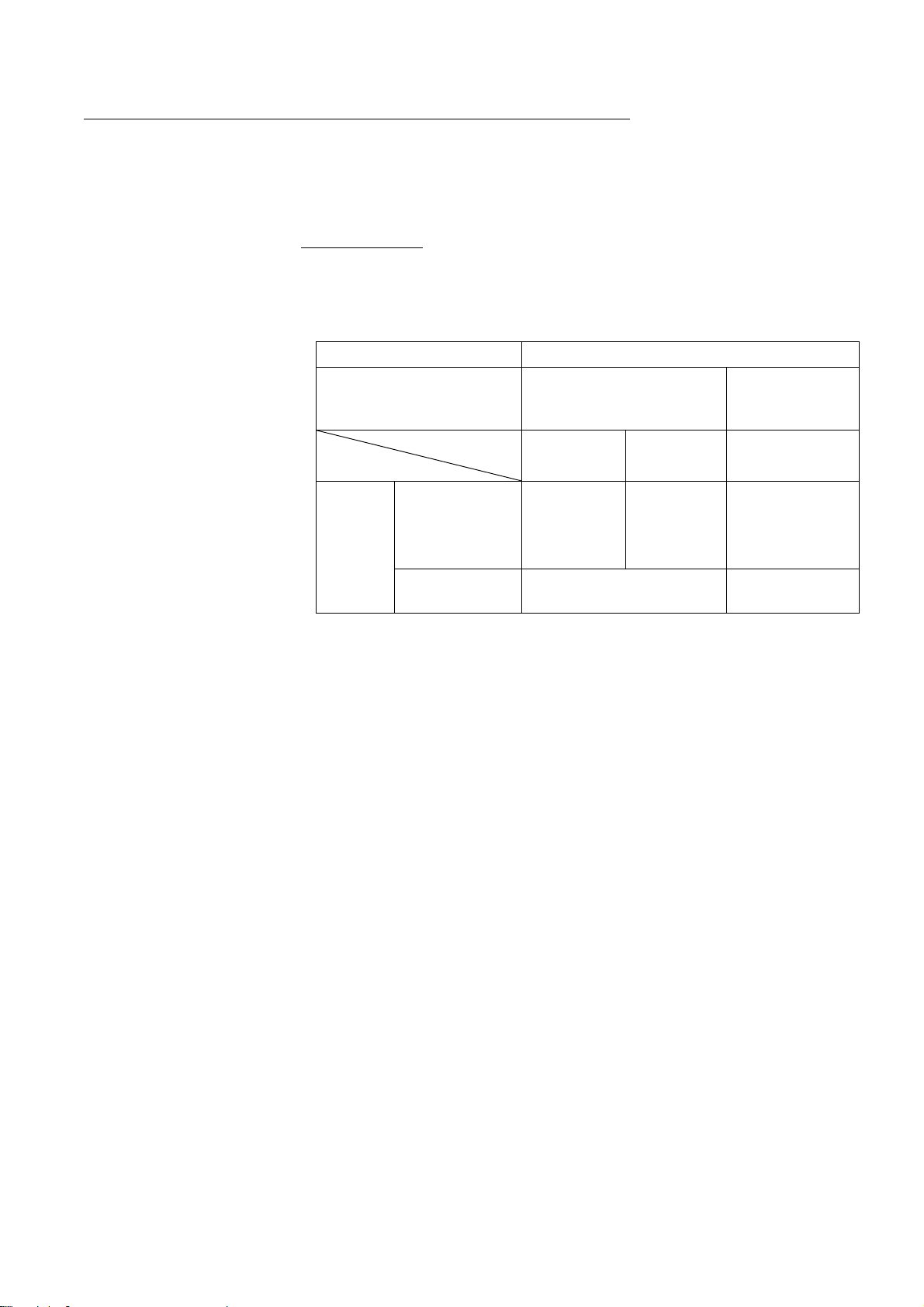

Unit Versions of CS/CJ/CP-series CPU Units

Unit Versions

A “unit version” has been introduced to manage CPU Units in the CS/CJ/CP

Series according to differences in functionality accompanying Unit upgrades.

This applies to the CJ2, CS1-H, CJ1-H, CJ1M, CS1D, CP1H, CP1L, and

CP1E CPU Units.

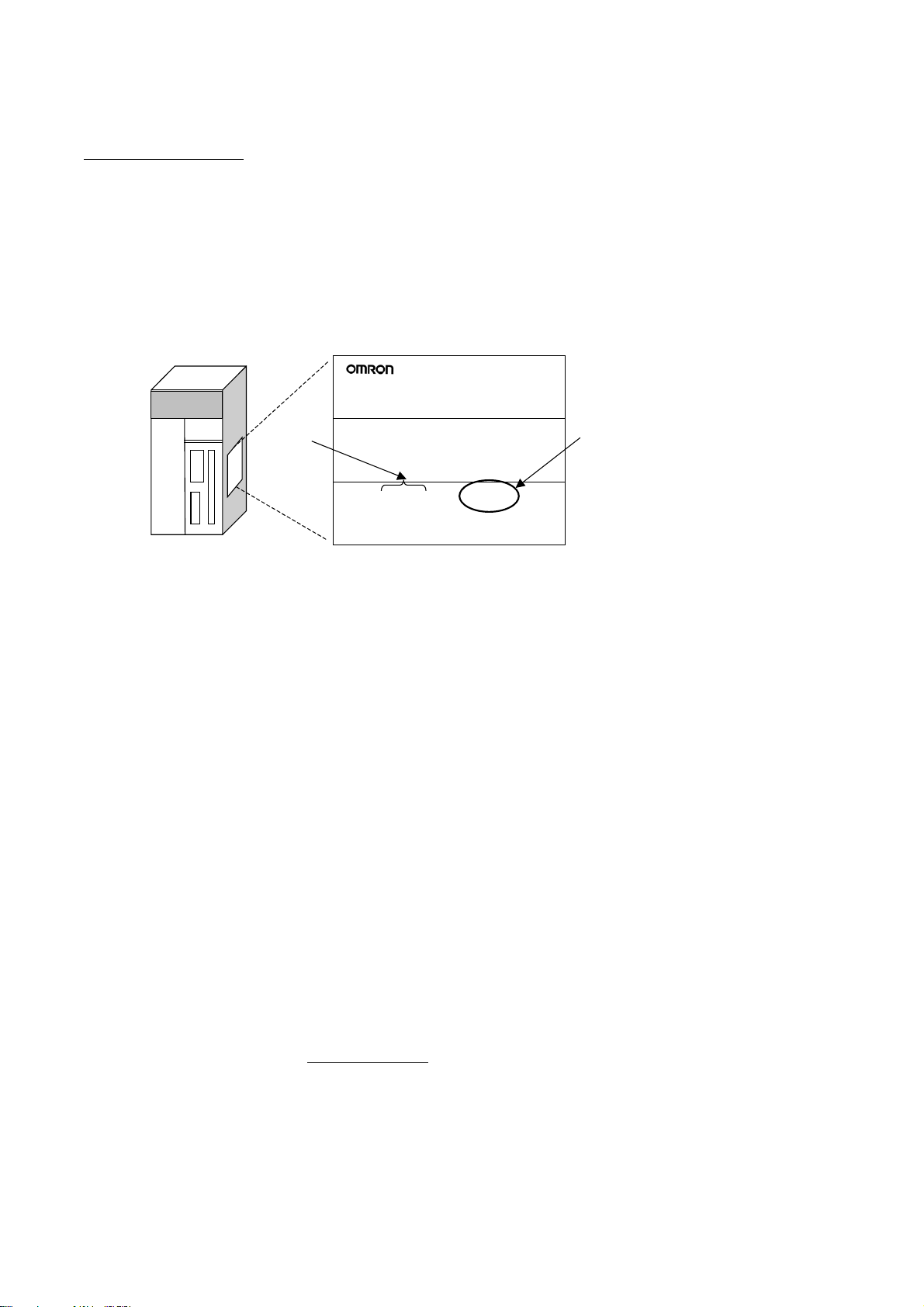

Notation of Unit Versions on Products

The unit version is given to the right of the lot number on the nameplate of

the products for which unit versions are being managed, as shown below.

Produce nameplateCS/CJ/CP-series CPU Unit

CS1H-CPU67H

CPU UNIT

Confirming Unit Versions

with Support Software

Lot No.

Lot No. 040715 0000 Ver.3.0

OMRON Corporation MADE IN JAPAN

Unit version

Example for unit version 3.0

• CS1-H, CJ1-H, and CJ1M CPU Units (except for low-end models)

manufactured on or before November 4, 2003 do not have a unit version

given on the CPU Unit (i.e., the location for the unit version shown above is

blank).

• The unit version of the CJ1-H-R CPU Units begins at version 4.0.

• The unit version of the CS1-H, CJ1-H, and CJ1M CPU Units, as well as the

CS1D CPU Units for Single-CPU Systems, begins at version 2.0.

• The unit version of the CS1D CPU Units for Duplex-CPU Systems begins

at version 1.1.

• The unit version of the CP1H/CP1L/CP1E CPU Units begins at version 1.0,

except for the CP1H-Y@@@@-@, for which the unit version begins at

version 1.1.

• CPU Units for which a unit version is not given are called Pre-Ver.

CPU Units, such as Pre-Ver. 2.0 CPU Units and Pre-Ver. 1.1 CPU Units.

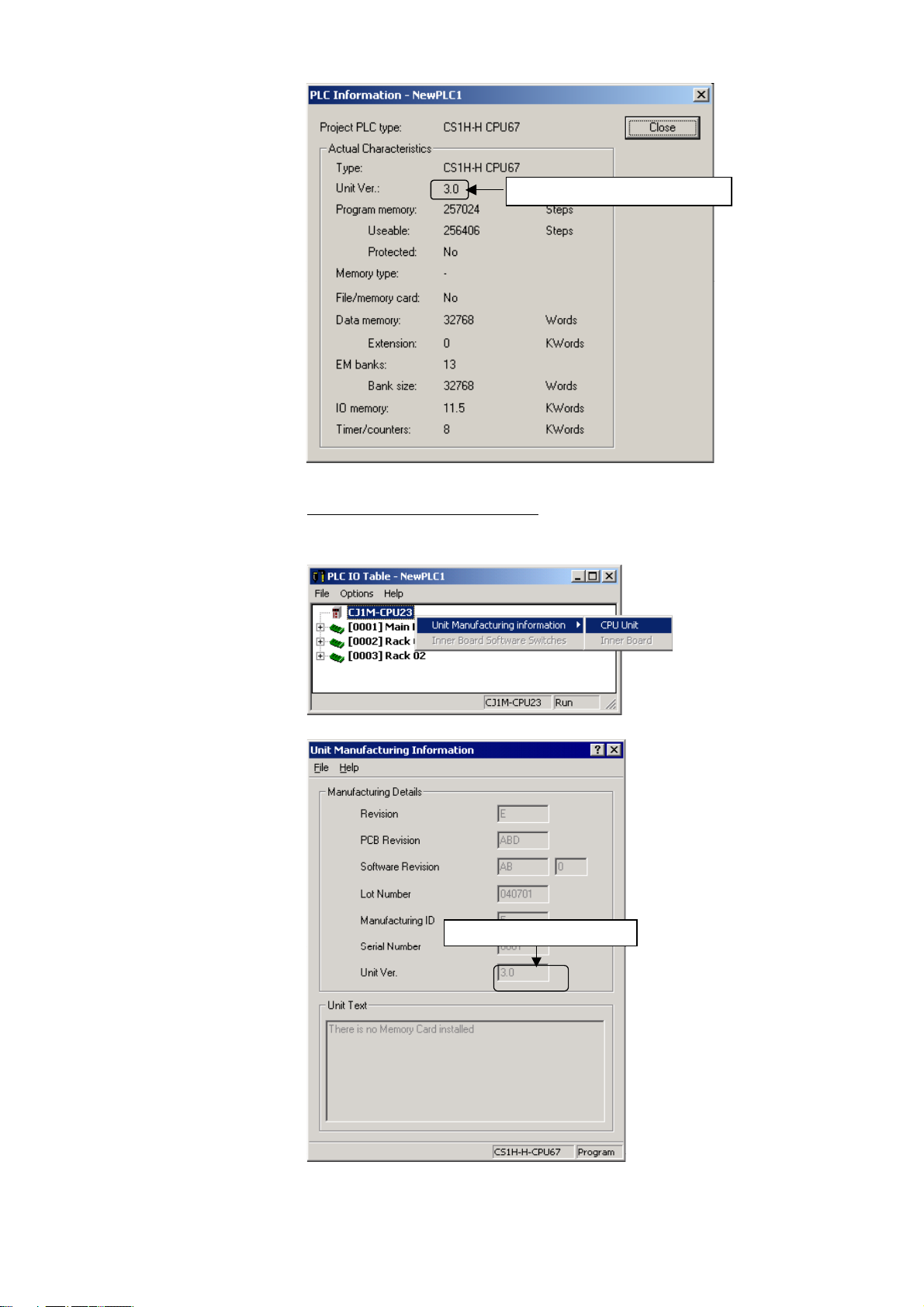

CX-Programmer version 4.0 can be used to confirm the unit version using

one of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can be used for

Special I/O Units and CPU Bus Units as well.)

@.@

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit versions.

PLC Information

• If you know the device type and CPU type, select them in the Change PLC

Dialog Box, go online, and select PLC - Edit - Information from the

menus.

• If you don’t know the device type and CPU type, but are connected directly

to the CPU Unit on a serial line, select PLC - Auto Online to go online, and

then select PLC - Edit - Information from the menus.

In either case, the following PLC Information Dialog Box will be displayed.

CX-Programmer_Page (xiii)

Page 17

Unit version

Use the above display to confirm the unit version of the CPU Unit.

Unit Manufacturing Information

In the IO Table Window, right-click and select Unit Manufacturing

information - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed

Unit version

Use the above display to confirm the unit version of the CPU Unit connected

online.

CX-Programmer_Page (xiv)

Page 18

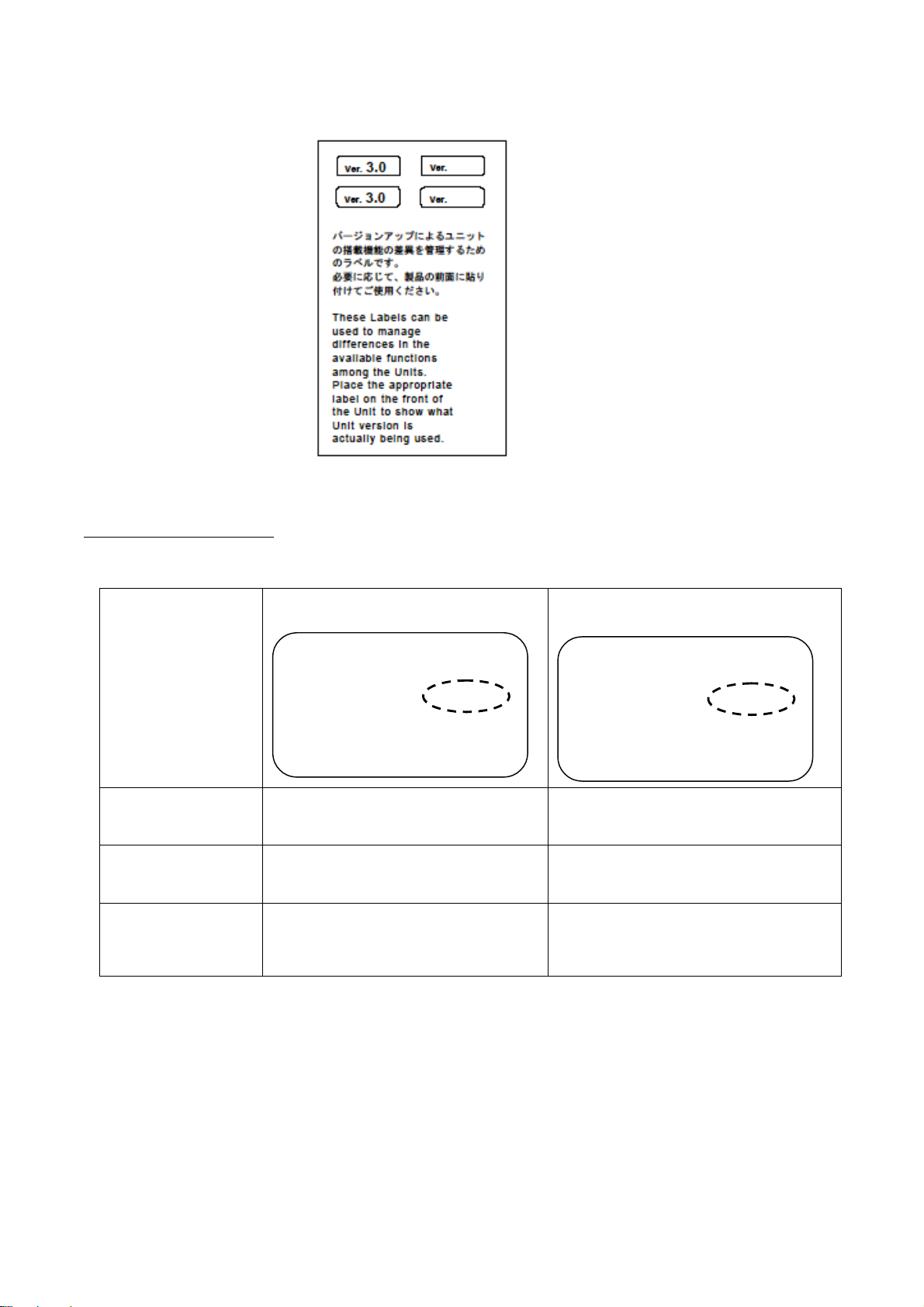

Using the Unit Version Labels

Unit Version Notation

The following unit version labels are provided with the CPU Unit.

These labels can be attached to the front of previous CPU Units to

differentiate between CPU Units of different unit versions.

Product nameplate

Meaning

Designating individual

CPU Units (e.g., the

CS1H-CPU67H)

Designating groups of

CPU Units (e.g., the

CS1-H CPU Units)

Designating an entire

series of CPU Units

(e.g., the CS-series

CPU Units)

In this manual, the unit version of a CPU Unit is given as shown in the

following table.

CPU Units on which no unit version is

given

Lot No. XXXXXX XXXX

OMRON Corporation MADE IN JAPAN

Units on which a version is given

@.@)

(Ver.

Lot No. XXXXXX XXXX

Ver.@.@

Pre-Ver. 2.0 CS1-H CPU Units CS1H-CPU67H CPU Unit Ver. @.@

Pre-Ver. 2.0 CS1-H CPU Units CS1-H CPU Units Ver. @.@

Pre-Ver. 2.0 CS-series CPU Units CS-series CPU Units Ver. @.@

CX-Programmer_Page (xv)

Page 19

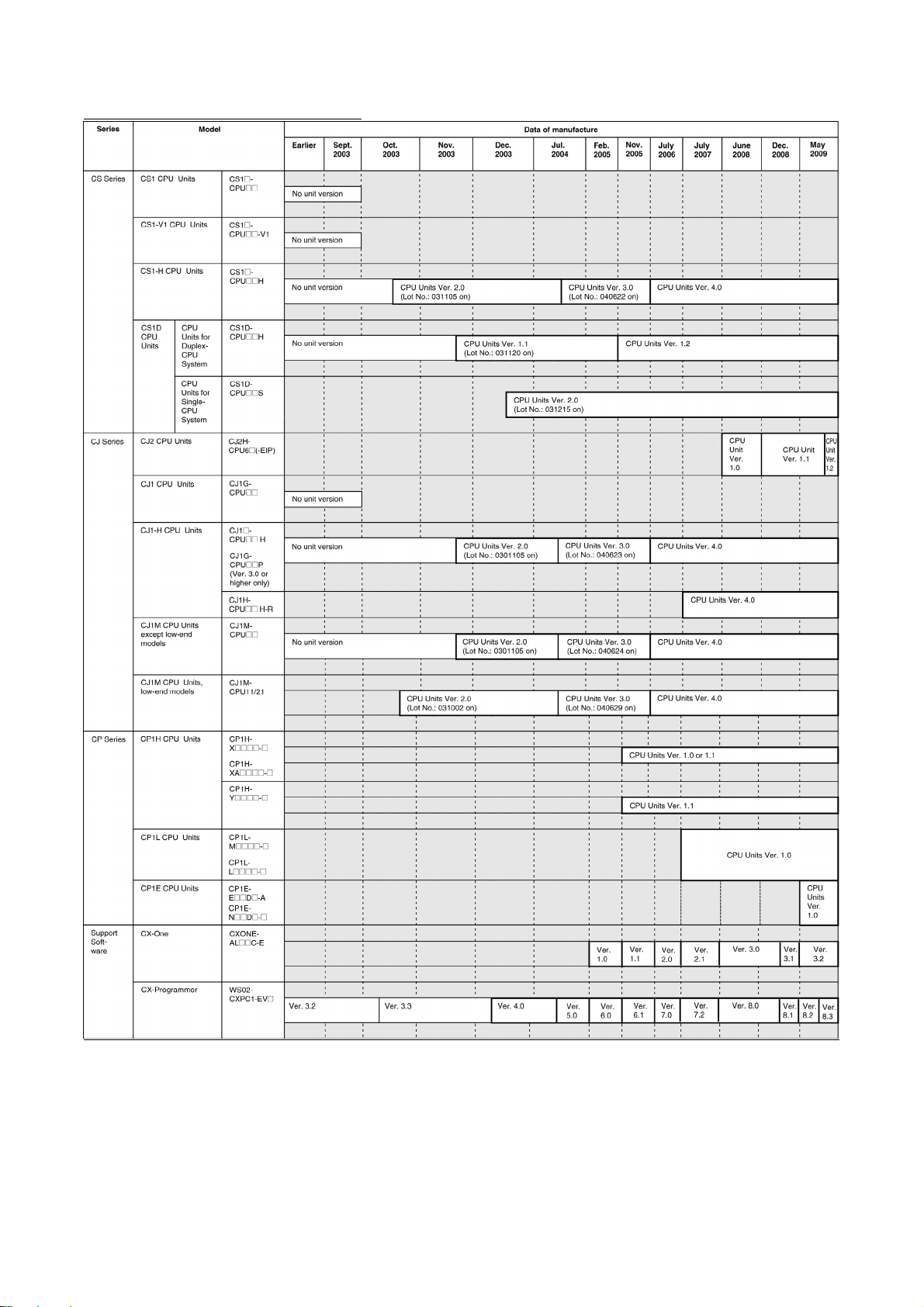

Unit Versions and Lot Numbers

CX-Programmer_Page (xvi)

Page 20

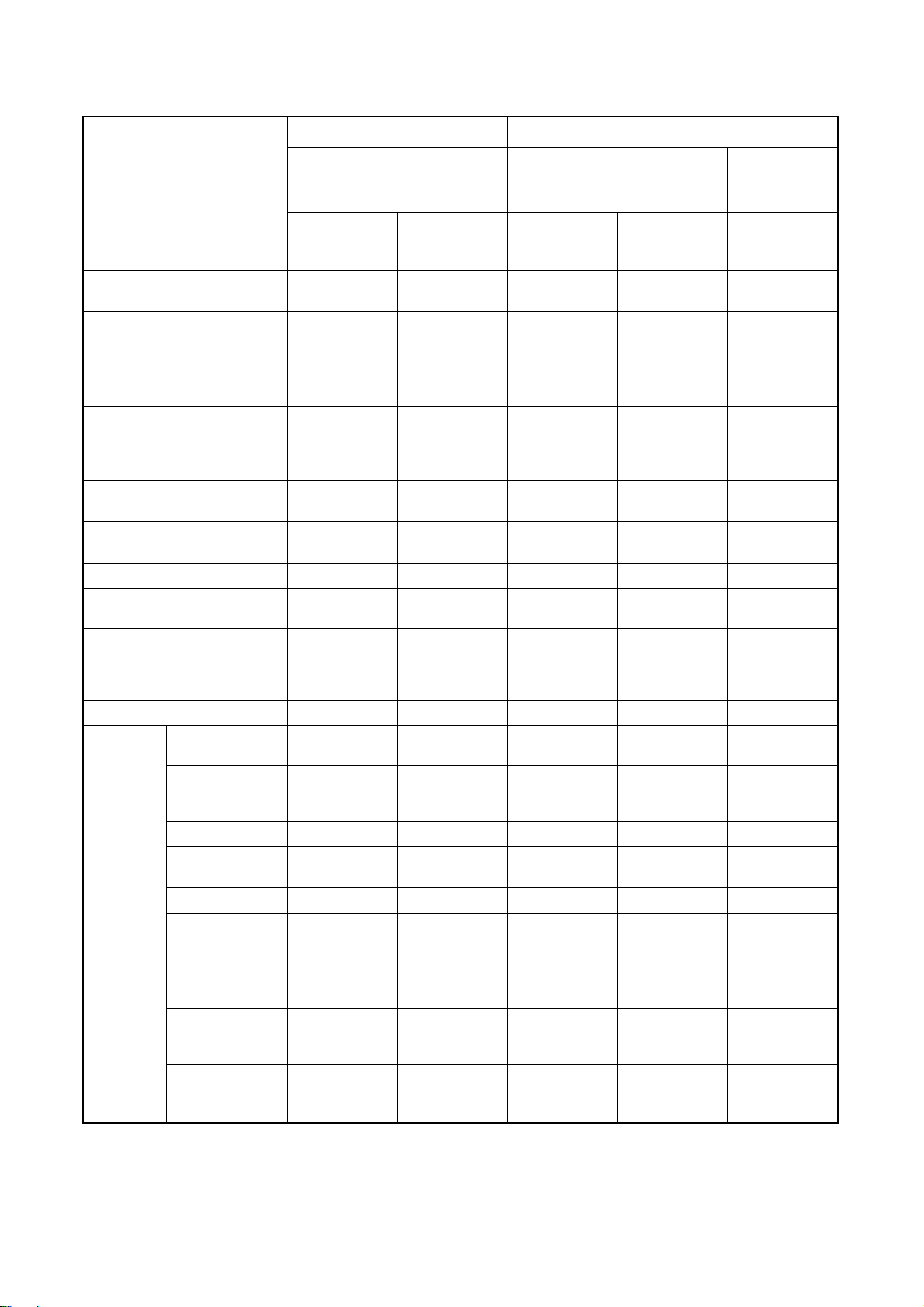

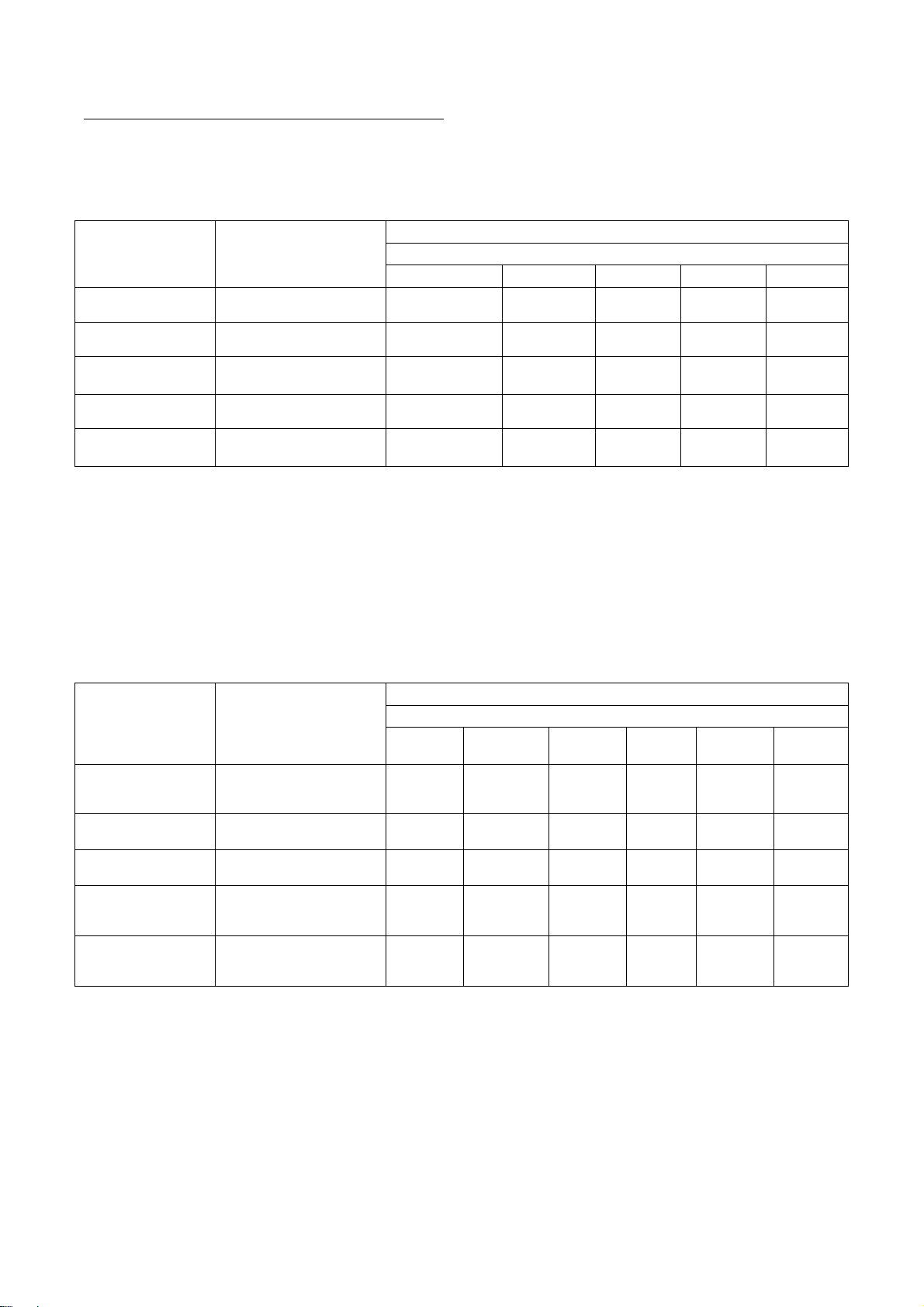

Function Support by Unit Version

CS1-H CPU Units (CS1@-CPU@@H)

Function

Downloading and Uploading Individual Tasks

Improved Read Protection Using Passwords

Write Protection from FINS Commands Sent to CPU Units via

Networks

Online Network Connections without I/O Tables

Communications through a Maximum of 8 Network Levels

Connecting Online to PLCs via NS-series PTs

Setting First Slot Words

Automatic Transfers at Power ON without a Parameter File

Automatic Detection of I/O Allocation Method for Automatic

Transfer at Power ON

Operation Start/End Times

New

Application

Instructions

MILH, MILR, MILC

=DT, <>DT, <DT, <=DT, >DT, >=DT

BCMP2

GRY

TPO

DSW, TKY, HKY, MTR, 7SEG

EXPLT, EGATR, ESATR, ECHRD, ECHWR

Reading/Writing CPU Bus Units with IORD/IOWR

PRV2

Unit version

Pre-Ver. 2.0 CPU

Units

--- OK

--- OK

--- OK

--- OK

--- OK

OK from lot number

030201

OK for up to 8 groups OK for up to 64 groups

--- OK

--- ---

--- OK

--- OK

--- OK

--- OK

OK from lot number

030201

--- OK

--- OK

--- OK

OK from lot number

030418

--- ---

CPU Units Ver. 2.0 or

later

OK

OK

OK

CX-Programmer_Page (xvii)

Page 21

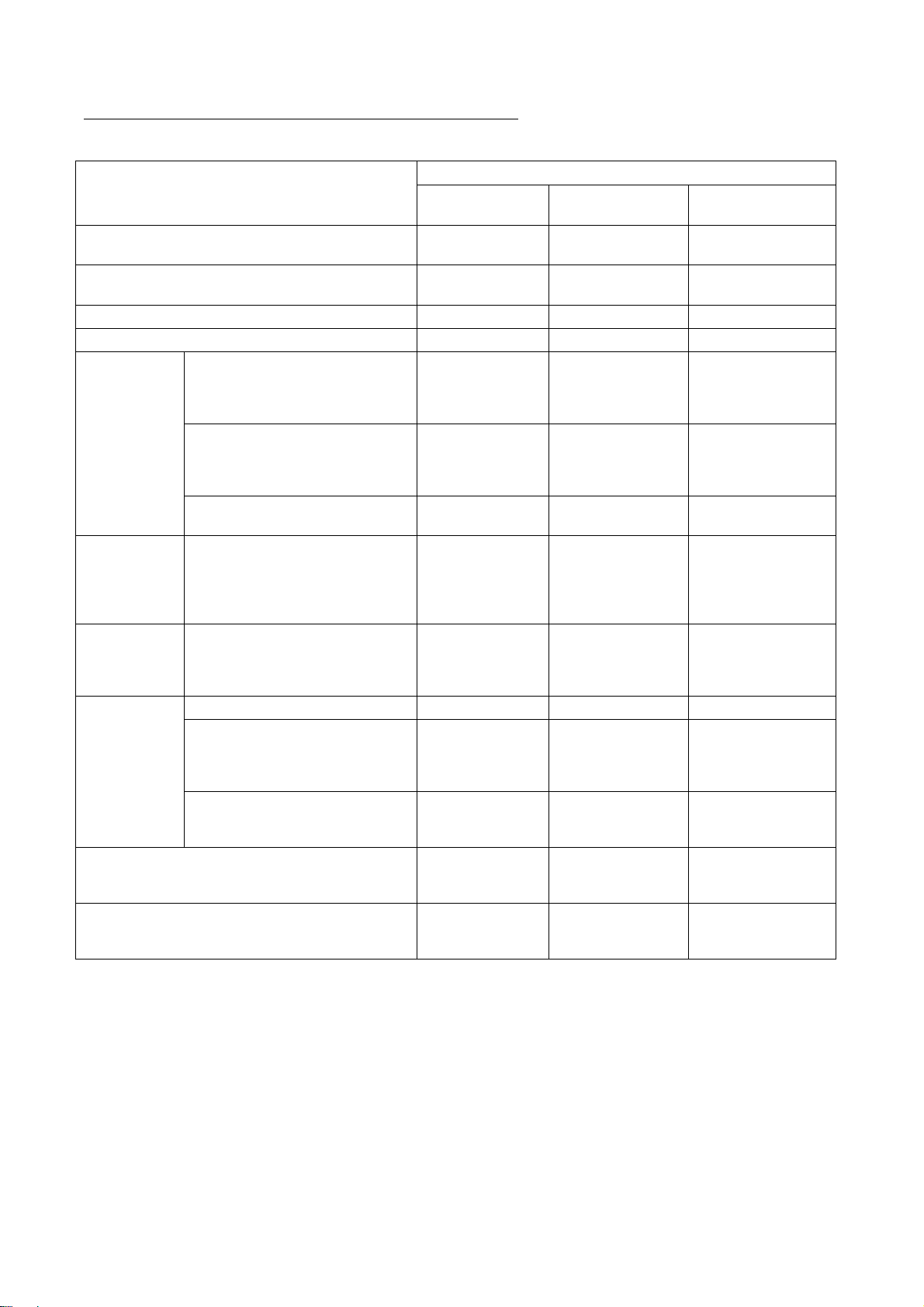

CS1D CPU Units

Function

Functions

unique to

CS1D CPU

Units

Downloading and Uploading Individual Tasks

Improved Read Protection Using Passwords

Write Protection from FINS Commands Sent

to CPU Units via Networks

Online Network Connections without I/O

Tables

Communications through a Maximum of 8

Network Levels

Connecting Online to PLCs via NS-series

PTs

Setting First Slot Words

Automatic Transfers at Power ON without a

Parameter File

Automatic Detection of I/O Allocation Method

for Automatic Transfer at Power ON

Operation Start/End Times

New

Application

Instructions

Duplex CPU Units OK OK ---

Online Unit Replacement OK OK OK

Duplex Power Supply Units OK OK OK

Duplex Controller Link Units OK OK OK

Duplex Ethernet Units --- OK OK

MILH, MILR, MILC

=DT, <>DT, <DT, <=DT, >DT,

>=DT

BCMP2

GRY

TPO

DSW, TKY, HKY, MTR, 7SEG

EXPLT, EGATR, ESATR,

ECHRD, ECHWR

Reading/Writing CPU Bus

Units with IORD/IOWR

PRV2

CS1D CPU Units for Duplex-CPU

Systems (CS1D-CPU@@H)

Pre-Ver. 1.1 CPU

Units

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK for up to 64

--- --- OK

--- --- ---

--- OK OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- OK

--- --- ---

CPU Unit Ver. 1.1 CPU Unit Ver. 2.0

CS1D CPU Units

for Single-CPU

Systems

(CS1D-CPU@@S)

or later

groups

CX-Programmer_Page (xviii)

Page 22

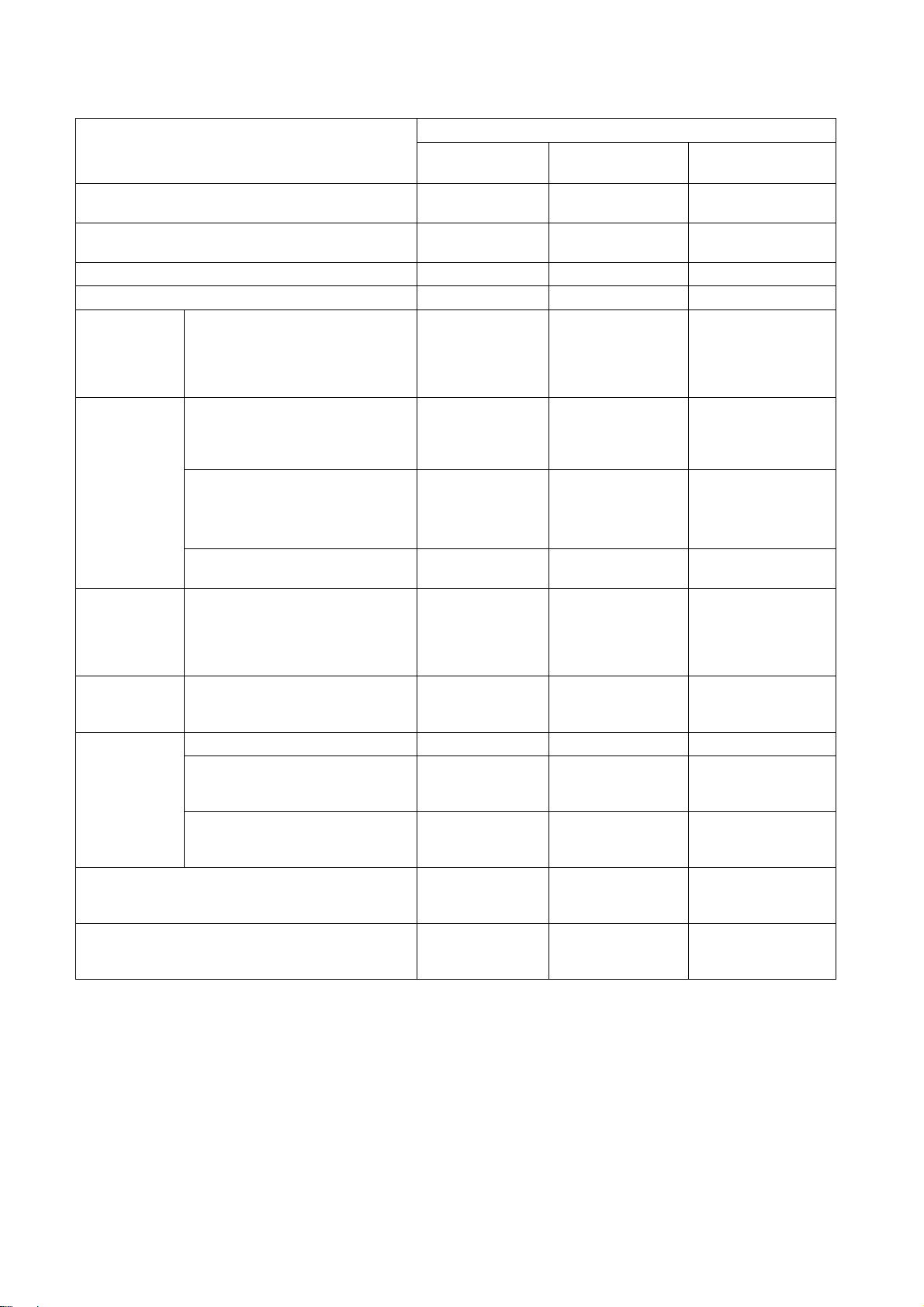

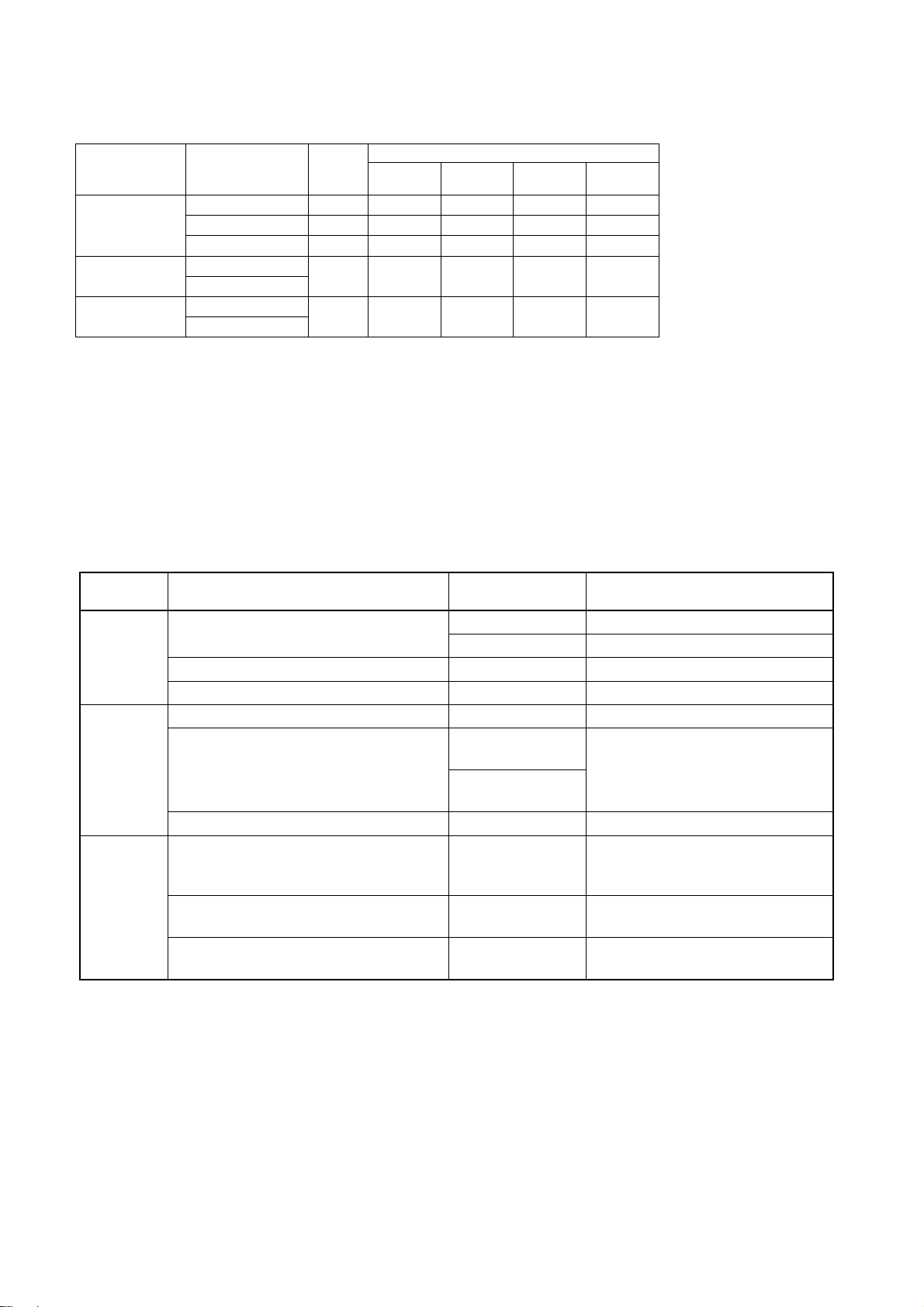

CJ1-H/CJ1M CPU Units

Function

Downloading and Uploading

Individual Tasks

Improved Read Protection

Using Passwords

Write Protection from FINS

Commands Sent to CPU Units

via Networks

Online Network Connections

without I/O Tables

Communications through a

Maximum of 8 Network Levels

Connecting Online to PLCs via

NS-series PTs

Setting First Slot Words

Automatic Transfers at Power

ON without a Parameter File

Automatic Detection of I/O

Allocation Method for

Automatic Transfer at Power

ON

Operation Start/End Times

New

Application

Instructions

MILH, MILR,

MILC

=DT, <>DT, <DT,

<=DT, >DT,

>=DT

BCMP2

GRY

TPO

DSW, TKY, HKY,

MTR, 7SEG

EXPLT, EGATR,

ESATR, ECHRD,

ECHWR

Reading/Writing

CPU Bus Units

with IORD/IOWR

PRV2

CJ1-H CPU Units CJ1M CPU Units

(CJ1H-CPU@@H-R)

(CJ1@-CPU@@H)

(CJ1G-CPU@@P)

Pre-Ver. 2.0

CPU Units

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

OK, but only if

I/O table

allocation at

power ON is set

OK for up to 8

groups

OK from lot

number 030201

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- OK OK OK OK

OK from lot

number 030201

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

--- --- --- OK, but only for

CPU Units

Ver. 2.0

OK OK, but only if

OK for up to 64

groups

OK OK from lot

OK OK from lot

CJ1M-CPU12/13/22/23 CJ1M-

Pre-Ver. 2.0

CPU Units

I/O table

allocation at

power ON is set

OK for up to 8

groups

number 030201

number 030201

CPU Units

Ver. 2.0

OK OK

OK for up to 64

groups

OK OK

OK OK

models with

built-in I/O

CPU11/21

CPU Units

Ver. 2.0 or

later

OK for up to 64

groups

OK, but only for

models with

built-in I/O

CX-Programmer_Page (xix)

Page 23

Functions Supported by Unit Version 3.0 or Later

CS1-H CPU Units (CS1@-CPU@@H)

Unit version Function

Pre-Ver. 2.0, Ver.

2.0

Function blocks (supported for CX-Programmer Ver.

5.0 or higher)

Serial Gateway (converting FINS commands to

CompoWay/F commands at the built-in serial port)

Comment memory (in internal flash memory) --- OK OK

Expanded simple backup data --- OK OK

New

application

instructions

Additional

instruction

functions

New

application

instructions

Improved

function block

(FB) functions

Using ST language programming in tasks --- --- OK with CX-

Using SFC programming in tasks --- --- OK with CX-

TXDU(256), RXDU(255) (support

no-protocol communications with

Serial Communications Units with

unit version 1.2 or later)

Model conversion instructions:

XFERC(565), DISTC(566),

COLLC(567), MOVBC(568),

BCNTC(621)

Special function block instructions:

GETID(286)

TXD(235) and RXD(236)

instructions (support no-protocol

communications with Serial

Communications Boards with unit

version 1.2 or later)

ASCII conversion instructions

(NUMBER-TO-ASCII and ASCIITO- NUMBER)

Text File Write (TWRIT)

Online editing of function blocks --- --- OK

Input-output variables are

supported.

(Input-output variables can be

specified in arrays.)

The STRING data type and textstring processing functions are

supported in ST language.

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- --- OK

--- --- OK

--- --- OK

Note: CX-Programmer version 7.0 or higher is required to use functions added for unit version

4.0. Additional functions are supported if CX-Programmer version 7.2 or higher is used.

Ver. 3.0 Ver. 4.0

(See note.)

Programmer Ver. 7.2

or higher

Programmer Ver. 7.2

or higher

CS1D CPU Units

Unit version 3.0 (Ver. 3.0) is not supported.

CX-Programmer_Page (xx)

Page 24

CJ1-H/CJ1M CPU Units (CJ1@-CPU@@H, CJ1M-CPU@@)

Unit version Function

Pre-Ver. 2.0,

Ver. 2.0

Function blocks (supported for CX-Programmer Ver.

5.0 or higher)

Serial Gateway (converting FINS commands to

CompoWay/F commands at the built-in serial port)

Comment memory (in internal flash memory) --- OK OK

Expanded simple backup data --- OK OK

Additional

instruction

functions

New

application

instructions

Additional

instruction

functions

New

application

instructions

Improved

function block

(FB) functions

Using ST language programming in tasks --- --- OK with CX-

Using SFC programming in tasks --- --- OK with CX-

PRV(881) and PRV2(883)

instructions: Added high-frequency

calculation methods for calculating

pulse frequency. (CJ1M CPU Units

only)

TXDU(256), RXDU(255) (support

no-protocol communications with

Serial Communications Units with

unit version 1.2 or later)

Model conversion instructions:

XFERC(565), DISTC(566),

COLLC(567), MOVBC(568),

BCNTC(621)

Special function block instructions:

GETID(286)

TXD(235) and RXD(236)

instructions (support no-protocol

communications with Serial

Communications Boards with unit

version 1.2 or later)

ASCII conversion instructions

(NUMBER-To-ASCII and ASCIITO NUMBER)

Online editing of function blocks --- --- OK

Input-output variables are

supported. (Input-output variables

can be specified in arrays.)

The STRING data type and textstring processing functions are

supported in ST language.

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- OK OK

--- --- OK

--- --- OK

--- --- OK

Ver. 3.0 Ver. 4.0

(See note.)

Programmer Ver. 7.2

or higher

Programmer Ver. 7.2

or higher

Note: CX-Programmer version 7.0 or higher is required to use functions added for unit version

4.0. Additional functions are supported if CX-Programmer version 7.2 or higher is used.

CX-Programmer_Page (xxi)

Page 25

Functions Supported by Unit Version for CJ2 CPU Units (CJ2H-CPU6@-EIP, CJ2HCPU6@)

Unit Version 1.2 or Later

Unit Version 1.1 or Later

CX-Programmer version 8.3

functions added for unit version 1.2.

Unit CJ2H CPU Unit

Model

Item

EM Area force-setting/resetting Supported.

CX-Programmer version 8.1

functions added for unit version 1.1.

Unit CJ2H CPU Unit

Model

Item

High-speed interrupt function

Decreased overhead time for interrupt tasks

Minimum interval setting of 0.1 ms for Scheduled

Interrupt Task

Changing the minimum cycle time setting in

MONITOR mode

Synchronous unit operation Supported. Not supported.

or higher must be used to enable using the

CJ2H-CPU6@-EIP

CJ2H-CPU6@

Unit version

or higher must be used to enable using the

Unit version

Unit version 1.1 Unit version 1.0

Supported. Not supported.

Supported. Not supported.

Unit version 1.2

CJ2H-CPU6@-EIP

CJ2H-CPU6@

Unit Version 1.0

All functions that are supported by unit version 4.0 or later of the CJ1 CPU

Units are supported by unit version 1.0 of the CJ2 CPU Units.

CX-Programmer version 8.0 or higher must be used to enable using unit

version 1.0 of the CJ2 CPU Units.

CX-Programmer_Page (xxii)

Page 26

Functions Supported by Unit Version for CP-series CPU Units

Functions Supported by Unit Version 1.0 and 1.1

Functionality is the same as that for CS/CJ-series CPU Units with unit version

3.0. The functionality added for CS/CJ-series CPU Unit unit version 4.0 is not

supported.

CP1H CPU Units

• CX-Programmer version 6.11 or higher is required to use CP1H-X@@@@-

@/XA@@@@-@ with unit version 1.1 or 1.0.

• CX-Programmer version 6.20 or higher is required to use CP1H-Y@@@@-

@ with unit version 1.1.

CPU Unit CP1H CPU Unit

Model CP1H-@@@@-@

CP1H-XA@@@@-@

(See note 1.)

Function

Pulse

outputs

Unit version

Allocated built-in

I/O terminals

Special pulse

output terminals

Ver. 1.1 or

later

4 axes at

100 kHz

None 2 axes at 1 kHz

Ver. 1.0 Ver. 1.1

2 axes at

100 kHz

2 axes at

30 kHz

Note 1. The unit version for the CP1H-X@@@@-@/XA@@@@-@ begins at 1.0.

2. The unit version for the CP1H-X@@@@-@ begins at 1.1.

CP1H-Y@@@@-@

(See note 2.)

2 axes 100 kHz

3. CX-Programmer version 7.11 or higher is required to use CP1L CPU Units with unit

version 1.0.

CX-Programmer_Page (xxiii)

Page 27

Unit Versions and Programming Devices

CX-Programmer version 4.0 or higher must be used to enable using the

functions added for CPU Unit Ver. 2.0. The following tables show the

relationship between unit versions and CX-Programmer versions.

Unit Versions and Programming Devices for CJ2 CPU Units

CPU Unit Functions

Ver. 7.1 or lower Ver. 8.0 Ver. 8.1 Ver. 8.2 Ver. 8.3

CJ2H-CPU6@-EIP

Unit version 1.0

CJ2H-CPU6@-EIP

Unit version 1.1

CJ2H-CPU6@

Unit version 1.1

CJ2H-CPU6@-EIP

Unit version 1.2

CJ2H-CPU6@

Unit version 1.2

Functions for unit version

1.0

Functions added for unit

version 1.1

Functions added for unit

version 1.1

Functions added for unit

version 1.2

Functions added for unit

version 1.2

×

×

×

×

×

×: Cannot be used, ∆: Can be used except for new functions added for unit versions, ❍: Can be used

Note 1. It is not necessary to upgrade the version of the CX-Programmer if functionality that was

enhanced for the upgrade of the CPU Unit will not be used.

2. CX-Programmer version 8.1 or higher is required to use the functions added for unit

version 1.1. The high-speed interrupt function and changing the minimum cycle time

setting in MONITOR mode, however, are also supported by CX-Programmer version

8.02.

Required Programming Device

CX-Programmer

❍ ❍ ❍ ❍

∆

∆

∆ ∆ ∆

∆ ∆ ∆

❍ ❍ ❍

❍ ❍ ❍

❍

❍

3. A Programming Console cannot be used with a CJ2H CPU Unit.

Unit Versions and Programming Devices for CPU Units Other Than CJ2 CPU Units

CPU Unit Functions

CS/CJ Series CPU

Units, Unit Ver. 4.0

CS/CJ Series CPU

Units, Unit Ver. 3.0

CS/CJ Series CPU

Units, Unit Ver. 2.0

CS1D CPU Units for

Single-CPU Systems,

Unit Ver. 2.0

CS1D CPU Units for

Duplex-CPU Systems,

Unit Ver.1.1

Functions added for unit

version 4.0

Functions added for unit

version 3.0

Functions added for unit

version 2.0

Functions added for unit

version 2.0

Functions added for unit

version 1.1

Ver. 3.3 Ver. 4.0 Ver. 5.0

∆ ∆ ∆

∆ ∆

∆

❍ ❍ ❍ ❍ ❍

∆

❍ ❍ ❍ ❍ ❍

∆

❍ ❍ ❍ ❍ ❍

Required Programming Device

CX-Programmer

Ver. 7.0 Ver. 7.2 Ver. 8.0

Ver. 6.0

❍ ❍ ❍

❍ ❍ ❍ ❍

×: Cannot be used, ∆: Can be used except for new functions added for unit versions, ❍: Can be used

Note 1. As shown above, there is no need to upgrade to CX-Programmer version 4.0 as long as

the functions added for unit version 2.0 or unit version 1.1 are not used.

2. CX-Programmer version 7.0 or higher is required to use functions added for unit version

4.0. Additional functions are supported if CX-Programmer version 7.2 or higher is used.

or later

(See note

4.)

3. Unit version 4.2 of the CJ1H-CPU6@-R is supported only by CX-Programmer version 8.0

or higher.

4. CX-Programmer version 8.0 or higher is required to use unit version 4.2 of the CJ1H-

CPU6@-R.

CX-Programmer_Page (xxiv)

Page 28

Unit Versions of CP-series CPU Units and Programming Devices

CX-Programmer version CPU Unit Model Unit

or later

CP1H CPU Units

CP1L CPU Units

CP1E CPU Units

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CP1L-M@@@@-@

CP1L-L@@@@-@

CP1E-E@@D@-A

CP1E-N@@D@-@

version

Ver. 1.1 OK OK OK OK

Ver. 1.0 OK OK OK OK

Ver. 1.1 --- OK OK OK

Ver. 1.0 --- --- OK OK

Ver. 1.0 --- --- --- OK

Ver. 6.11 Ver. 6.20 Ver. 7.11 Ver. 8.2

Note 1. Functionality of CP1H CPU Units with unit version 1.0 or 1.0 and CP1L CPU Units with

unit version 1.0 is the same as that for CS/CJ-series CPU Units with unit version 3.0.

The functionality added for CS/CJ-series CPU Unit unit version 4.0 is not supported.

2. There is no need to upgrade to CX-Programmer as long as the upgraded functionality is

not used.

Device Type Setting

The unit version does not affect the setting made for the device type on the

CX-Programmer. Select the device type as shown in the following table

regardless of the unit version of the CPU Unit.

Series CPU Unit group CPU Unit model Device type setting on

CX-Programmer

CS Series

CJ Series

CS1D CPU Units for Duplex-CPU Systems

CS1D CPU Units for Single-CPU Systems

CJ2 CPU Units

CJ1-H CPU Units

CS1G-CPU@@H

CS1H-CPU@@H

CS1D-CPU@@H

CS1D-CPU@@S

CJ2H-CPU6@(-EIP)

CJ1G-CPU@@H

CS1G-H CS1-H CPU Units

CS1H-H

CS1D-H (or CS1H-H)

CS1D-S

CJ2H

CJ1G-H

CJ1G- CPU@@P

CJ1H-CPU@@H–R

CJ1H-CPU@@H

CP Series

CJ1M CPU Units

CP1H CPU Units

CJ1M-CPU@@

CP1H-X@@@@-@

CJ1M

CP1H

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CP1L CPU Units

CP1L-M@@@@-@

CP1L

CP1L-L@@@@-@

CP1E CPU Units

CP1E-E@@D@-A

CP1E

CP1E-N@@D@-@

Note Device types not supported by the CX-Programmer version that is being used will not be

displayed on the pull-down list of the Device type Field.

CX-Programmer_Page (xxv)

Page 29

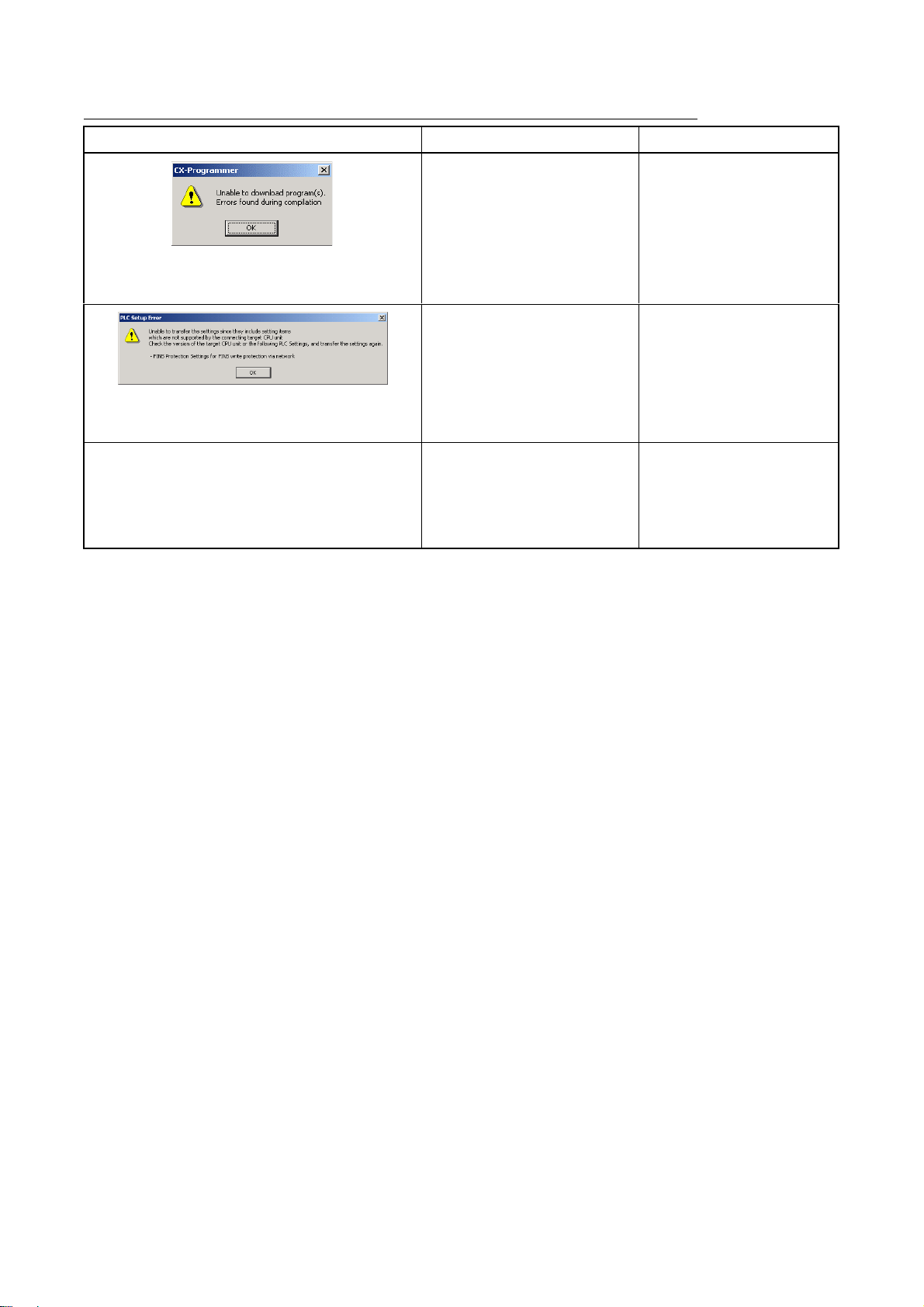

Troubleshooting Problems with Unit Versions on the CX-Programmer

Problem Cause Solution

After the above message is displayed, a compiling

error will be displayed on the Compile Tab Page in

the Output Window.

"????" is displayed in a program transferred from the

PLC to the CX-Programmer.

An attempt was made using CXProgrammer version 4.0 or

higher to download a program

containing instructions supported

only by CPU Units Ver. 2.0 or

later to a Pre-Ver. 2.0 CPU Units.

An attempt was made using CXProgrammer version 4.0 or

higher to download a PLC Setup

containing settings supported

only by CPU Units Ver. 2.0 or

later (i.e., not set to their default

values) to a Pre-Ver. 2.0 CPU

Units.

CX-Programmer version 3.3 or

lower was used to upload a

program containing instructions

supported only by CPU Units

Ver. 2.0 or later from a CPU Unit

Ver. 2.0 or later.

Check the program or change

the CPU Unit being

downloaded to a CPU Unit

Ver. 2.0 or later.

Check the settings in the PLC

Setup or change the CPU Unit

being downloaded to a CPU

Unit Ver. 2.0 or later.

The new instructions cannot

be uploaded using CXProgrammer version 3.3 or

lower. Use CX-Programmer

version 4.0 or higher.

CX-Programmer_Page (xxvi)

Page 30

Page 31

PART 1:

CX-Programmer

Page 32

Page 33

OMRON PART 1: CX-Programmer

Notice

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the

information provided in them. Failure to heed precautions can result in injury to people or damage to the

product.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “PLC” means Programmable Logic Controller and is not used as an abbreviation for

anything else.

CX-Programmer_Page (i)

Page 34

OMRON PART 1: CX-Programmer

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Indicates information of particular interest for efficient and convenient operation of the product.

1, 2, 3…

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of OMRON.

All copyright and trademarks acknowledged.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information contained in

this manual is subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained in this publication.

Indicates lists of one sort or another, such as procedures, checklists etc.

Represents a shortcut on the Toolbar to one of the options available on the menu of the same

window.

CX-Programmer_Page (ii)

Page 35

OMRON PART 1: CX-Programmer

About this Part

This part describes the CX-Programmer application and its ability to create and maintain programs for use

with OMRON SYSMAC CS/CJ/CP, CV and C PLCs. It does not provide detailed information concerning

the PLCs themselves, for this information the commercial manual for the device must be consulted.

This part contains the following chapters:

• Precautions. This portion describes general precautions for using the CX-Programmer (including

CX-Server PLC Tools).

• Version Upgrade Information. This portion describes the changes that have been made from version

3.0 to version 3.1 of the CX-Programmer.

• Chapter 1 Technical Specifications. This chapter describes the CX-Programmer software in general

terms and also provides details of the operating environment and minimum configuration necessary

for the satisfactory operation of CX-Programmer.

• Chapter 2 Quick Start Guide. This chapter describes the basic features of CX-Programmer together

with a simple tutorial for familiarization purposes.

• Chapter 3 Project Reference. This describes the features common to two or more parts of CX-

Programmer.

• Chapter 4 Reference. This chapter introduces the features contained in the Project workspace and

discusses their associated commands and features.

• Chapter 5 Advanced Topics. This chapter discusses the more advanced topics in relation to CX-

Programmer.

• Appendix A Toolbars and Keyboard Shortcuts. This appendix summarizes the toolbar and keyboard

shortcuts available from CX-Programmer.

A Glossary of Terms and Index are also provided.

CX-Programmer_Page (iii)

Page 36

OMRON PART 1: CX-Programmer

Functions Supported by the CXProgrammer Installed from the CX-One

• Starting Specialized Support Tools from the I/O Table Window

Previous version New version (CX-Programmer Installed from CX-One)

Each CPU Bus Unit or

Special I/O Unit’s

Programming Tool was

started individually.

Functionality Improved from Version 8.3 to 9.0

Compatible PLC Models

The CX-Programmer also supports CP1E-NA20 CPU Units (20-point CPU Units).

Supported Operating Systems

The CX-Programmer will run on Windows 7.

Data Structures Supported as Symbol Data Types

Data structures are not supported. CJ2 CPU Units now support data structures as

If the PLC model is set to the CS/CJ/CP-series, each Unit’s Programming Tool (e.g.,

CX-Integrator, CX-Protocol, CX-Position, or CX-Process Tool) can be started directly

from the Special I/O Unit or CPU Bus Unit in the I/O Table Window. When the

Specialized Support Tool is started, the CX-Programmer can pass information such as

the PLC model, Unit model, and online/offline status.

Previous version (version 8.3) New version (version 9.0)

symbol data types.

Enhanced Program Input Functions

Previous version (version 8.3) New version (version 9.0)

The input mode cannot be changed. A Smart Input Mode is supported that

automatically displays suggested instructions

and addresses.

The input mode can be changed from a menu or

a tool bar.

When copying circuits to create similar rungs

with different addresses, the addresses must be

input again.

The Address Incremental Copy function can be

used to easily create copies of similar circuit

structures with offset addresses.

Enhanced User Interface for Menu and Option Settings

Previous version (version 8.3) New version (version 9.0)

The display configuration for menus and options

cannot be changed.

Switching to Smart Style Mode is now possible

for the menu and option setting style.

Smart Style is the same type of menu and option

setting function as the one supported in CXProgrammer for CP1E.

Either the previous Classic Mode or the new

Smart Style Mode can be selected for the menus

and options by selecting Tools - Options and

then setting the Menu/Options Style on the

General Tab Page.

Changes to Search/Replace Dialog Boxes

Previous version (version 8.3) New version (version 9.0)

Searches can be performed only in the entire

PLC or in the data in the current view.

The setting for the item to be searched for was

very detailed and included bit addresses,

address, values (constants/numbers),

mnemonics, symbols, and I/O comments.

"Programs" has been added to the search range.

Searched objects have been grouped into

addresses, symbol names, and all (text strings).

CX-Programmer_Page (iv)

Page 37

OMRON PART 1: CX-Programmer

Previous version (version 8.3) New version (version 9.0)

Replacements can be performed only in the

entire PLC or in the data in the current view.

The setting for the item to be replaced was very

detailed and included bit addresses, address,

values (constants/numbers), mnemonics,

symbols, and I/O comments.

"Programs" has been added to the replacement

range.

Also, the selected circuits can be set as the

replacement range.

Searched objects have been grouped into

addresses, symbol names, mnemonics, and

comments.

Version 8.3 Upgrade Information

Functionality Improved from Version 8.2 to 8.3

Compatible PLC Models

The functionality improvements are supported for CJ2H CPU Units with unit version

1.2 or later.

TIMER and COUNTER Added as Symbol Data Types

Previous version (version 8.2) New version (version 8.3)

When defining timer numbers and counter

numbers as symbols, the following three different

symbols had to be registered in the symbols

table.

1. Timer numbers and counter numbers

specified in instruction operands had to

be defined as NUMBER symbols.

2. Timer and Counter Completion Flags

had to be defined as BOOL symbols.

3. Timer and counter present values had

to be defined as CHANNEL symbols.

Automatically assigning timer and counter

numbers in ladder programs was not possible.

TIMER and COUNTER symbols are supported

so that all of the previous three types of symbols

can be managed as one data type. (TIMER and

COUNTER are supported only by CJ2H CPU

Units with unit version 1.0 or later.)

TIMER: Can be used for 1) the timer number, 2)

the Timer Completion Flag, and 3) the timer

present value.

COUNTER: Can be used for 1) the counter

number, 2) the Counter Completion Flag, and 3)

the counter present value.

Automatic address assignment and layout are

supported for TIMER and COUNTER symbols.

(TIMER and COUNTER are supported only by

CJ2H CPU Units with unit version 1.0 or later.)

Force-setting/resetting Bits in EM Area

Previous version (version 8.2) New version (version 8.3)

Bits in the EM Area could be force-set/reset in

CJ2H CPU Units only for specific EM Area banks

for which automatic address assignment was

used.

With CJ2H CPU Units with unit version 1.2 or

later, PLC • Memory Allocate • EM Memory

Settings can be used to specify the EM Area

banks for which bits can be force-set/reset. (The

first bank is specified and force-setting/resetting

bits is possible in that bank and all banks

following it.) This is called the EM Area forcesetting/resetting function.

Searching for Symbol Names and Displaying Usage Locations from Cross-reference Pop-

ups

Previous version (version 8.2) New version (version 8.3)

Searching from cross-reference pop-ups was

possible only for address specifications. (To

search for symbols, you had to click the Browse

button and search for symbol names from the

Symbol Search Dialog Box.)

Symbol names can be specified directly in crossreference pop-ups to display a list of locations

that use the address of that symbol.

CX-Programmer_Page (v)

Page 38

OMRON PART 1: CX-Programmer

Version 8.2 Upgrade Information

Functionality Improved from Version 8.1 to 8.2

Connecting Online to the PLC through an NV-series PT*

Previous version (version 8.1) New version (version 8.2)

It was not possible to connect online from the

CX-Programmer through an NV-series PT to a

PLC connected to the NV-series PT.

*Functionality improved in version 8.21 over version 8.20.

CP1E CPU Unit Supported for Connecting Online to a PLC via an NS-series PT

Previous version (version 8.1) New version (version 8.2)

With a CP1E CPU Unit, it was not possible to

connect online from the CX-Programmer through

an NS-series PT to a PLC connected to the NSseries PT.

Compatible PLC Models

The functionality improvements are supported for CP-series CP1E CPU Units

with unit version 1.0.

It is now possible to connect online from the CXProgrammer through an NV-series PT to a PLC

connected to the NV-series PT.

With a CP1E-N@@D@-@ CPU Unit, it is now

possible to connect online from the CXProgrammer through an NS-series PT to a PLC

connected to the NS-series PT.

Online Connection to the PLC via an NS-series PT

Previous version (version 8.1) New version (version 8.2)

An online connection from the CX-Programmer

through an NS-series PT to a PLC connected to

the PT was not possible.

An online connection from the CX-Programmer

through an NS-series PT to a PLC connected to

the PT is possible when the PLC is connected to

the PT using a serial connection, Ethernet

connection, or Controller Link connection.

CX-Programmer_Page (vi)

Page 39

OMRON PART 1: CX-Programmer

Version 8.1 Upgrade Information

Functionality Improved from Version 8.0 to 8.1

Compatible PLC Models

The functionality improvements are supported for CJ-series CJ2 CPU Units

(CJ2H-CPU6@(-EIP)) with unit version 1.1.

Support for Synchronous Unit Operation

Support has been added for the synchronous unit operation function for a

combination of a CJ-series CJ2 CPU Unit (CJ2H-CPU6@ (-EIP)) with unit version

1.1 and CJ-series Position Control Units (CJ1W-NC@@4). Settings and

monitoring are now possible for synchronous unit operation.

Improved Special I/O Unit and CPU Bus Unit Setup Functionality

Multiple dialog boxes can now be opened simultaneously when setting CJ-series

Position Control Unit (CJ1W-NC@@4) parameters. In addition, the CAM Data

Creation Software (WS02-MOPC2) can be used to convert cam data in a CSV file

into data that can be used by a Position Control Unit, and the data can be

imported to the PLC memory component of the CX-Programmer.

Improved CS/CJ Data Tracing Function

• Improved

With support for the synchronous unit operation function of CJ2 CPU Units with unit

version 1.1, tracing can now be executed for each synchronous cycle.

• Improved Bit Graph Display

Bit graphs are displayed according to screen size, and addresses are displayed

beside the graphs.

Trace Settings

CX-Programmer_Page (vii)

Page 40

OMRON PART 1: CX-Programmer

Version 8.0 Upgrade Information

Functionality Improved from Version 7.2 to 8.0

Support has been added for the following PLC models as part of the version 7.2 to version 7.3

upgrade.

Compatible PLC Models

New CP-series CP1L CPU Units

The CP-series CP1L CPU Units (CP1L-L10D@-@ and CP1L-M60D@-@) are

supported.

The following functions have been added or improved as part of the upgrade from version 7.3 to

8.0.

Compatible PLC Models

CJ-series CJ2 CPU Units

The CJ-series CJ2 CPU Units (CJ2H-CPU6@-EIP) are supported.

• EtherNet/IP

Connection is possible to the CJ2H-CPU6@-EIP and EtherNet/IP Units.

• New Ladder Programming Instructions

The new instructions for the CJ2 CPU Units can be used, including the Tracking

Instructions and Data Search/Sort Instructions.

Improved Data Trace Function

Overhaul of Data Tracing Function for CS/CJ-series PLCs

If a CJ2 CPU Unit is used, long-term continuous data tracing is possible.

Operations have been improved, including zooming in and out of trace results

graphs and adjusting offsets. Trace results can also be printed or saved as bit

maps.

PLC Backups

Data from the CPU Unit, Special I/O Units, and CPU Bus Units can be backed up

as a batch from a personal computer. The backup data can be compared or

restored as a batch, or the data for only selected Units can be restored.

CX-Programmer_Page (viii)

Page 41

OMRON PART 1: CX-Programmer

Improvements in Programming

• Symbols in Array Variable Subscripts.

Previous version (version 7.2) New version (version 8.0)

Symbols could be used for array variable

subscripts only inside function blocks.

With a CJ2 CPU Unit, symbols can be used for array variable

subscripts in ladder diagram programming in tasks.

• Address Offsets

Previous version (version 7.2) New version (version 8.0)

With a CJ2 CPU Unit, an offset value can be input to offset a

specific bit or word address in ladder diagram programming.

• DM/EM Bit Addresses

Previous version (version 7.2) New version (version 8.0)

Only word addresses could be used in the EM

and DM Areas.

With a CJ2 CPU Unit, bit addresses can be specified in the EM and

DM Areas.

Improvements to Online Functions

With a CJ2 CPU Unit, you can easily connect to a PLC on an EtherNet/IP network.

Improvements to Monitoring

When registering an array variable in the Watch Window, it is now possible to

register and monitor a selected range of array elements.

Improvements to Symbol Tables

It is now possible to edit data items (i.e., arrange or delete) when copying and

pasting variable table data via the clipboard from external applications. It is also

possible to set the contents of symbol table data to be copied to the external

application in advance using option settings.

Other Improvements

Previous version (version 7.2) New version (version 8.0)

The error log of the CPU Unit only displayed

the error code.

In the error log of the CPU Unit, a code which gives more detailed

information about the error is displayed in addition to the error code.

CX-Programmer_Page (ix)

Page 42

OMRON PART 1: CX-Programmer

Version 7.2 Upgrade Information

Functionality Improved from Version 7.0 to Version 7.2

Support has been added for the following PLC models as part of the version 7.0 to version 7.10

upgrade.

Compatible PLC Models

The high-speed CJ1-H-R CPU Units (CJ1-CPU@@H-R) are supported.

Support has been added for the following PLC models as part of the upgrade from version 7.10 to

7.11.

Compatible PLC Models

The CP-series CP1L CPU Units (CP1L-M and CP1L-L) are supported.

The following functions have been added or improved as part of the upgrade from version 7.11 to

7.2.

Improved IEC 61131-3 Language Support

Support has been strengthened for the ST and SFC languages, which are IEC

61131-3 languages.

Ladder, ST, and SFC programs can be combined freely, so the user program can

be written in the language most appropriate for the required processing. Using the

most appropriate language can reduce program development time and simplify

programming.

• Support for ST Language Programming in Tasks

Previous version (version 7.0) New version (version 7.2)

The ST language could be used only in function

blocks.

The ST language can be used in programs other than function

blocks. (ST programs can be allocated to tasks.)

Different languages can be used in a single user program, which

allows numerical processing and string processing to be written in

ST programs, while other processing is written in ladder or SFC

programs.

Note: The ST language is supported only in CS/CJ-series CPU

Units with unit version 4.0 or later. It is not supported in CPseries CPU Units.

• Support for SFC Language Programming in Tasks

Previous version (version 7.0) New version (version 7.2)

The SFC language could not be used. The SFC language can be used in programs. (SFC programs can

be allocated to tasks.)

Different languages can be used in a single user program, which

allows the overall system processing to be written in SFC programs,

while other processing is written in ladder or ST programs.

Note: The SFC language is supported only in CS/CJ-series CPU

Units with unit version 4.0 or later. It is not supported in CPseries CPU Units.

CX-Programmer_Page (x)

Page 43

OMRON PART 1: CX-Programmer

• Support for Array Variables in Ladder, ST, and SFC Programs

Previous version (version 7.0) New version (version 7.2)

Array variables could be used for internal

variables and input-output variables in a

function block’s algorithm, but array variables

could not be used in programs (tasks).

Array variables can be specified even in programs (tasks) written in

ladder, ST, or SFC language.

This feature allows multiple variables with the same data

characteristics to be managed as a group.

• Comparing Function Block Definitions

Previous version (version 7.0) New version (version 7.2)

Function block definitions could not be

compared.

Function block definitions can be compared in detail.

This feature makes it easy to check for differences between the

programs in function block definitions.

• Comparison of Function Block Definitions, ST Programs, and Action Programs/Transition

Programs/Subcharts in SFC Programs

Previous version (version 7.0) New version (version 7.2)

ST programs and SFC programs could not be

compared.

ST programs and SFC programs can be compared.

ST programs in an SFC program can also be compared in detail.

PLC-PT Integrated Simulation

The following improvements have been made to the simultaneous interactive

debugging function (integrated simulation), which debugs operation between the

CX-Programmer’s ladder program and NS-series PT touch panel test screens in

the CX-Designer

.

• Starting Integrated Simulator from the CX-Programmer

Previous version (version 7.0) New version (version 7.2)

The integrated simulator could be started from

the CX-Designer only; it could not be started

from the CX-Programmer.

The integrated simulator can be started from the CX-Programmer

(specifying a saved CX-Designer screen file).

With this feature, it is possible to easily confirm the interaction

between a ladder program being edited in the CX-Programmer and

NS-series PT touch panel test screens.

• Simulating the Occurrence of PLC Errors

Previous version (version 7.0) New version (version 7.2)

During simulation, it was not possible to

generate PLC system errors by manipulating

the corresponding Auxiliary Area flags. (The

system error flags were write-protected.)

It was necessary to create ladder programming

that generated errors using the FAL and FALS

instructions, and check operation in the

simulation.

PLC system errors can be generated during CX-Programmer ladder

program simulation by selecting Simulation - PLC Error Simulator

and writing the corresponding system error flags in the Auxiliary

Area.

With this feature, it is not necessary to create ladder programming

to generate errors. Also, it is easy to check the operation of the

ladder program and NS-series touch panel when PLC errors occur.

Improvements to Symbol Tables

• Improved Interaction of the CX-Designer with Symbol Table Data

Previous version (version 7.0) New version (version 7.2)

Symbol tables could be copied and pasted from

the CX-Programmer to the CX-Designer, but

not the opposite direction.

Consequently, when NS-series touch panel test

screens were being edited in the CX-Designer

and I/O comments were edited in the CXDesigner symbol table, it was necessary to

write the data in Excel and transfer it to the CXProgrammer’s symbol table.

Symbol tables can be copied in pasted in both directions between

the CX-Designer and CX-Programmer.

This feature makes it easy to reflect changes to the CX-Designer’s

symbol table, such as edited I/O comments, in the CXProgrammer’s symbol table.

CX-Programmer_Page (xi)

Page 44

OMRON PART 1: CX-Programmer

• Support for the STRING Data Type in Ladder Programs and ST Programs

Previous version (version 7.0) New version (version 7.2)

The STRING data type could be used only in

ST-language function blocks.

The STRING data type can be used in both ladder and ST

languages, in both task programs and function blocks.

The STRING data type supports ASCII characters between 1 and

255.

Improved Automatic Online Connection

• Added Automatic Detection of the Computer’s Serial Port

Previous version (version 7.0) New version (version 7.2)

When automatic online connection was

performed from the computer’s serial port, it

was not necessary for the user to set the PLC

model because it was recognized automatically,

but the serial port had to be set in advance.

It is not necessary for the user to select the computer’s serial port in

advance.

When automatic online connection is performed, the software

automatically searches for computer serial ports that can be used. If

the software finds a serial port that can be used for the online

connection, the software automatically connects online from the

detected port, and the serial port setting is also changed

automatically.

Improved Conversion of C500/C120/C**P Programs

Previous version (version 7.0) New version (version 7.2)

Programs stored in C500, C120, or C**P-series

PLCs could be uploaded and converted for use

in CS/CJ/CP-series PLCs or CVM1/CV-series

PLCs, but the DM and HR Area data could not

be converted to PLC memory.

A backup program and I/O memory (DM and

HR Area data) file (extension .c5b) could be

used to restore the program to a

C500/C120/C**P-series PLC, but it could not be

converted to a CX-Programmer project.

A program uploaded from a C500, C120, or

C**P-series PLC could not be saved to a file in

mnemonic-text format.

DM and HR Area data can also be converted to PLC memory.

After conversion, it is now possible to select the CP1L as the PLC

model.

A backup program and I/O memory (DM and HR Area data) file

(extension .c5b) can be converted to a CX-Programmer project for

a CS/CJ/CP-series PLC or CVM1/CV-series PLC.

A program uploaded from a C500, C120, or C**P-series PLC can

be saved to a file in mnemonic-text format. The saved file can be

pasted as text in the CX-Programmer’s Statement List (mnemonic

window), and displayed or printed in ladder format.

This feature allows the program to be checked in the CXProgrammer before converting it to a CS/CJ/CP-series PLC or

CVM1/CV-series PLC program.

Other Improvements

Previous version (version 7.0) New version (version 7.2)

The CPU Unit’s production information could be

displayed from the I/O table only.

When a CS1D Duplex System CPU Unit was

being used, the CPU Unit’s Active/Standby

status could not be displayed in the project

directory tree.

The CPU Unit’s production information can be displayed from the

Main Menu’s PLC Information Dialog Box.

When a CS1D Duplex System CPU Unit (CS1D-H) is being used,

the CPU Unit’s Active/Standby status is displayed in the project

directory tree.

CX-Programmer_Page (xii)

Page 45

OMRON PART 1: CX-Programmer

Version 7.0 Upgrade Information

Functionality Improved from Version 6.1 to Version 7.0

Compatible PLC Models

The following PLC models have been added as compatible PLCs as part of the

version 6.1 to version 7.0 upgrade.

CS/CJ Series CPU Units with unit version Ver. 4.0 and higher

Ver. 4.0 and higher CS/CJ Series CPU Units are supported.

CP Series CPU Units

The CP Series CPU Units (CP1H-Y) are supported.

Support for NSJ-M3D Controllers

The NSJ@-@@@@(B)-M3D Controllers are supported.

Ladder Program to Function Block Conversion Function

Previous version (Ver. 6.1) New version (Ver. 7.0)

To convert existing ladder programming to a

function block, the ladder programming was

copied and pasted into a function block

definition. At that point, it was necessary to

check the variables and addresses used in

the program and manually register those

variables and addresses while organizing the

input variables, internal variables, and output

variables.

Existing ladder program sections can be easily converted to function

blocks by selecting the program circuits to be converted and selecting

Function Block (ladder) generation. The function block definition is

created automatically and the variables are allocated automatically

based on the usage of the variables and addresses in the program.

Online Editing of Function Blocks

Previous version (Ver. 6.1) New version (Ver. 7.0)

A function block definition (algorithm and

variable table) could not be edited while the

PLC program was being executed. (The

instance I/O parameters could be changed.)

A function block definition (algorithm and variable table) can be edited

while the PLC program is being executed. (Instances cannot be added.)

With this capability, it is possible to debug and edit the function block

definitions themselves even if the PLC must operate 24 hours/day

because there are devices that cannot be stopped. To edit a function

block, select the function block definition in the Workspace and select

FB Online Edit – Begin from the popup menu.

Note: Function block instances cannot be added.

Note: This function cannot be used for simulations on the CX-

Simulator.

STRING Data and Text-processing Functions Supported in ST-language Function Blocks

Previous version (Ver. 6.1) New version (Ver. 7.0)

The STRING data type could not be used in

the ST language. (See note.)

The STRING data type can be used as a data type in the ST language.

With this capability, it is easy to set a variable containing text (ASCII) in

another variable with a substitution operation (such as: a := ‘@READ’;).

In this case, it is not necessary to know the length of the ASCII text

string.

CX-Programmer_Page (xiii)

Page 46

OMRON PART 1: CX-Programmer

Previous version (Ver. 6.1) New version (Ver. 7.0)

There were no text-processing functions for

the ST language.

To process text for message displays and

no-protocol communications in the ladder

language, the user had to know the length of

the ASCII string and execute instructions

such as text-processing instructions, data

conversion instructions, and serial

communications instructions.

Note: The user can input text strings can in

I/O memory using the CXProgrammer’s PLC memory function,

but it is necessary to know the data

size in I/O memory.

Text-processing functions (extracting text, merging, searching, etc.) are

supported for the ST language. With these functions, it is easy to create

text strings and process displayed messages using ST language in a

function block without knowing the actual ASCII codes.

Support for Input-Output Variables

Previous version (Ver. 6.1) New version (Ver. 7.0)

Input-output variables were not supported in

function blocks. (Only input variables, internal

variables, and output variables could be used.)

Input variables could not be specified as arrays. Input-output variables can be specified as arrays.

Values are passed from input parameters to

input variables.

Input-output variables can be used in function blocks.

Addresses (not values) are passed from input parameters to input

variables. Consequently, array input-output variables can be used in

the function blocks and large amounts of data can be passed easily

to the function blocks through input parameters.

Support for C500/C120/C**P Backup Function

Previous version (Ver. 6.1) New version (Ver. 7.0)

The programs in C500/C120/C**P PLCs could

not be managed online from the CXProgrammer.

A program stored in a C500/C120/C**P PLC can be uploaded and

converted to a CS/CJ/CP Series program or CVM1/CV Series PLC

program. If an instruction’s specifications are different, a comment is

displayed to alert the user of the differences when the program is

converted. To convert a program, select Tools – C500/C120/CxxP

Support – Online PLC Program Conversion.

Program and I/O memory data (DM and HR) stored in a

C500/C120/C**P PLC can be backed up. Later, the backed up

program and I/O memory data can be restored to a C500/C120/C**P

PLC. To backup or restore the data, select Tools – C500/C120/CxxP

Support – Backup from PLC or Tools – C500/C120/CxxP Support

– Restore to PLC.

Program and I/O memory data (DM and HR) stored in a specified file