Page 1

Cat. No. W447-E1-08

SYSMAC

CX-Programmer

Ver. 8.1

WS02-CXPC1-V8

OPERATION MANUAL

Function Blocks/

Structured Text

Page 2

CX-Programmer

Ver. 8.1

WS02-CXPC1-V8

Operation Manual

Function Blocks/Structured Text

Revised February 2009

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

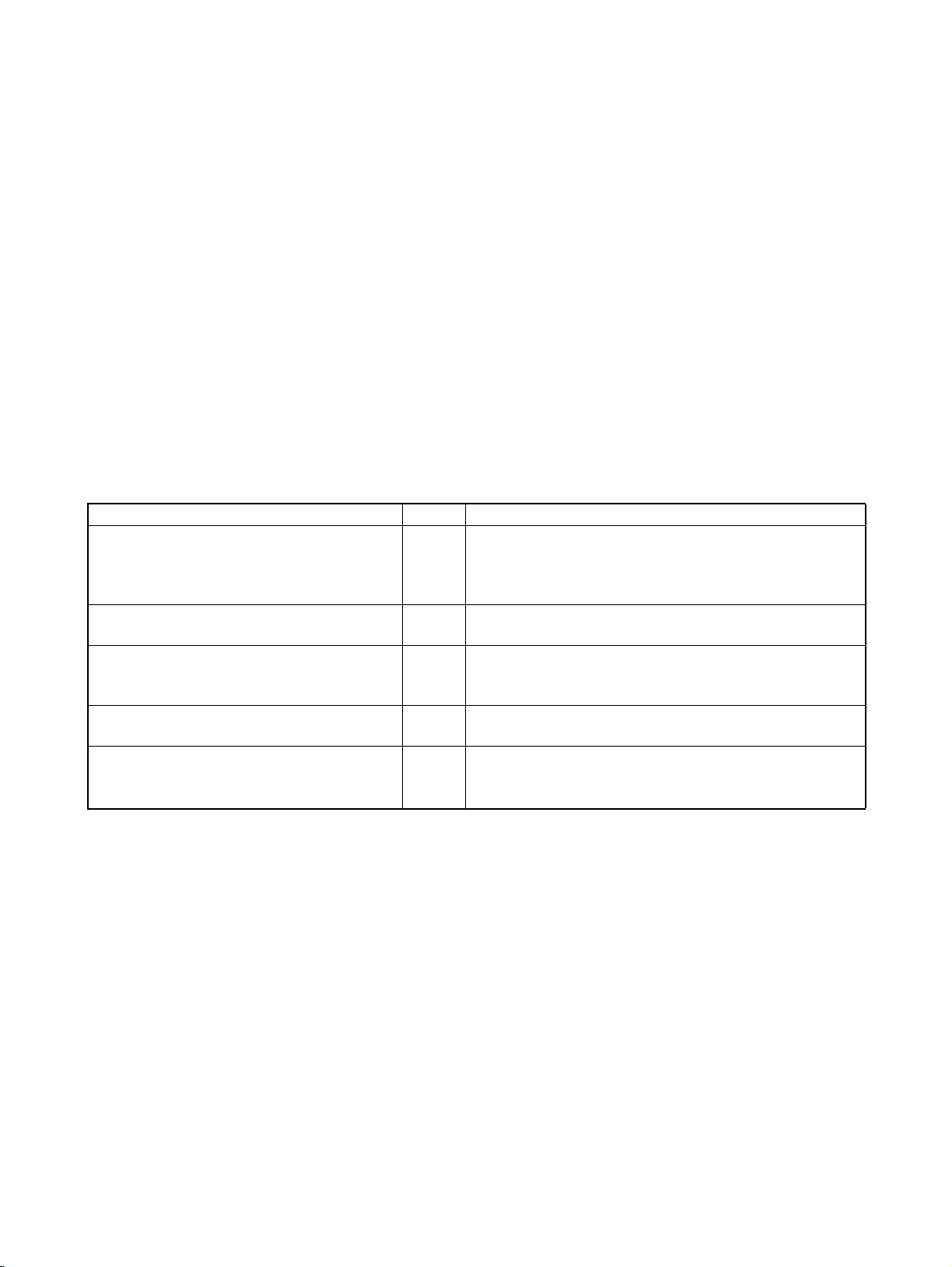

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2008

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

Part 1: Function Block

SECTION 1 Introduction to Function Blocks

SECTION 2 Function Block Specifications

SECTION 3 Creating Function Blocks

Part 2: Structured Text

SECTION 4 Introduction to Structured Text

SECTION 5 Structured Text (ST) Language Specifica-

tions

SECTION 6 Creating ST Programs

Appendices

Page 7

Page 8

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Part 1:

Function Blocks

SECTION 1

Introduction to Function Blocks . . . . . . . . . . . . . . . . . . . . . . 3

1-1 Introducing the Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4 Converting Function Block Definitions to Library Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5 Usage Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-6 Version Upgrade Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SECTION 2

Function Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . 29

2-1 Function Block Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2 Data Types Supported in Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-3 Instance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-4 Programming Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2-5 Function Block Applications Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2-6 Precautions for Instructions with Operands Specifying the First or Last of Multiple Words 65

2-7 Instruction Support and Operand Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2-8 CPU Unit Function Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2-9 Number of Function Block Program Steps and Instance Execution Time . . . . . . . . . . . . . . 76

SECTION 3

Creating Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3-1 Procedural Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3-2 Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

ix

Page 9

TABLE OF CONTENTS

Part 2:

Structured Text (ST)

SECTION 4

Introduction to Structured Text . . . . . . . . . . . . . . . . . . . . . . 131

4-1 ST Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4-2 CX-Programmer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

SECTION 5

Structured Text (ST) Language Specifications . . . . . . . . . . 135

5-1 Structured Text Language Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

5-2 Data Types Used in ST Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5-3 Inputting ST Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

5-4 ST Language Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

5-5 Statement Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5-6 ST-language Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

5-7 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

SECTION 6

Creating ST Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

6-1 Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Appendices

A System-defined external variables supported in function blocks . . . . . . . . . . . . . . . . . . . . . 181

B Structured Text Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

C Function Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

x

Page 10

About this Manual:

This manual describes the CX-Programmer operations that are related to the function block functions

and Structured Text (ST) functions. The function block and structure text functionality of CX-Programmer Ver. 8.1 is supported by CJ2H CPU Units, by CS1-H, CJ1-H, and CJ1M CPU Units with unit version 3.0 or later, by CP-series CPU Units, and by NSJ-series and FQM1-series Controllers.

Some function block and structure text functionality, however, is supported only by CJ2H CPU Units, by

CS1-H, CJ1-H, and CJ1M CPU Units with unit version 4.0 or later.

For details, refer to 1-6 Version Upgrade Information.

For information on functionality other than function blocks and structure text, refer to the following manuals.

• CX-Programmer

: CX-Programmer Operation Manual (W446) and CX-Programmer Operation Manual: SFC (W469)

• CPU Unit

: The operation manuals for the CS-series, CJ-series, CP-series, and NSJ-series Controllers

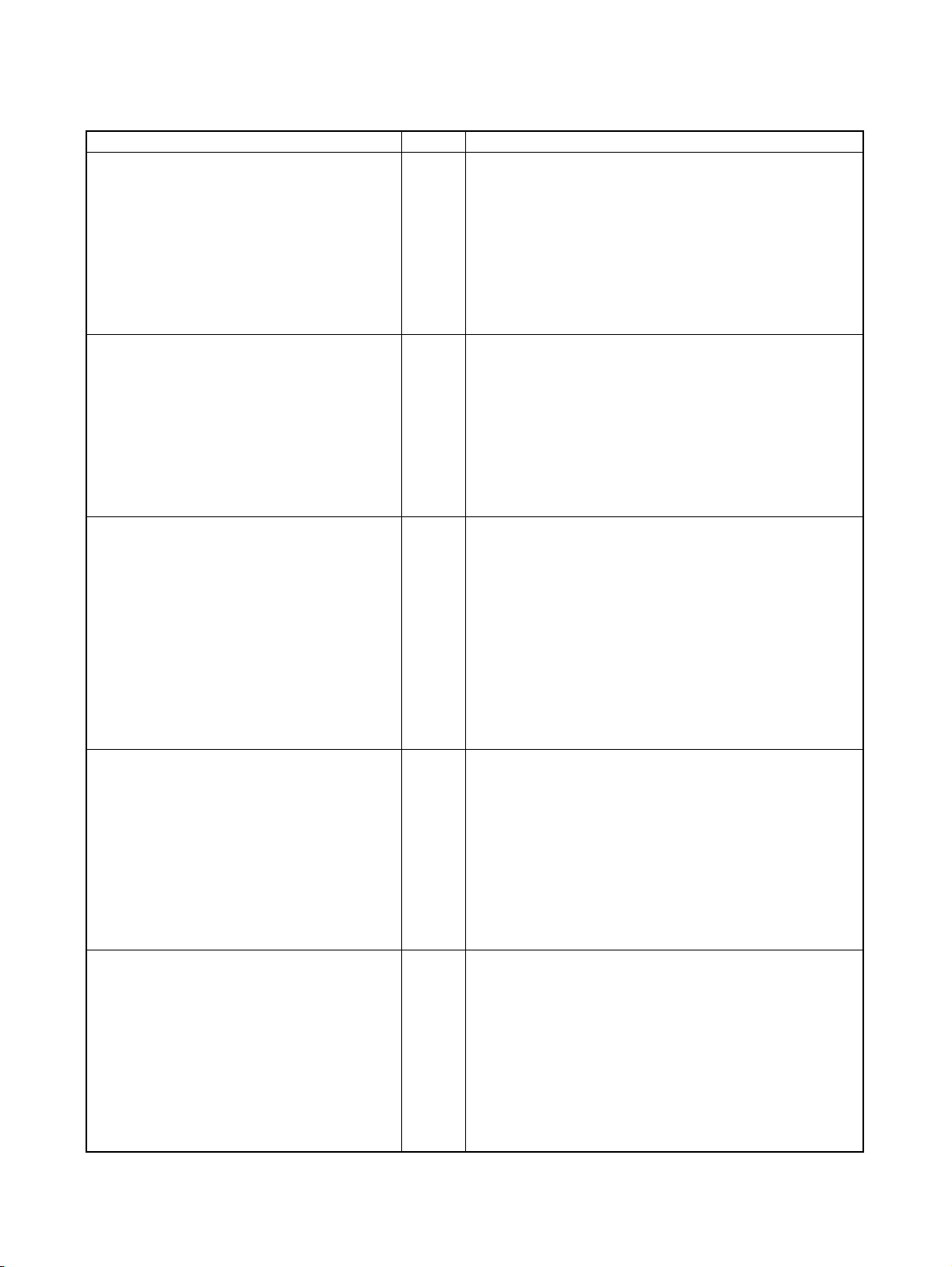

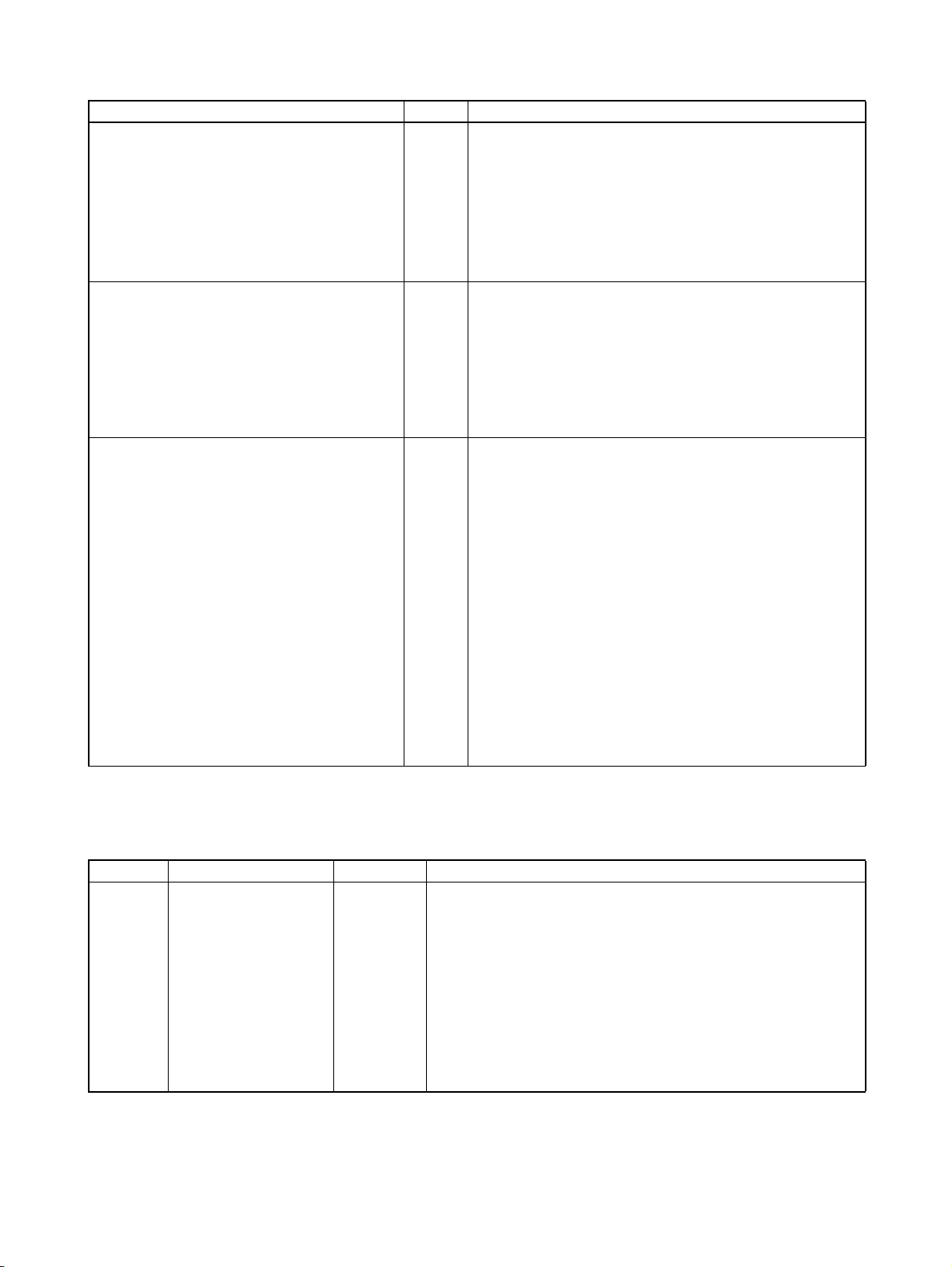

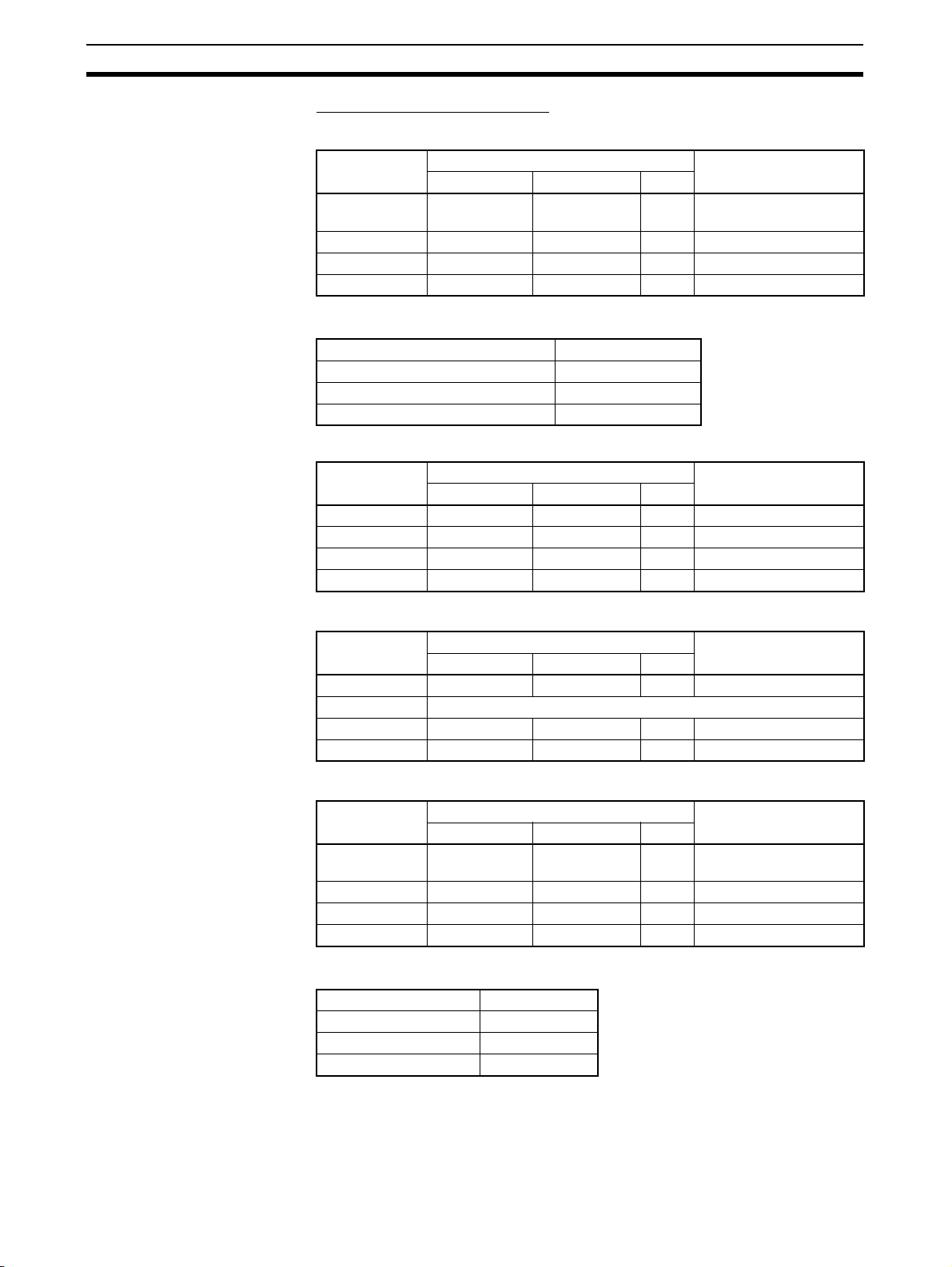

CX-Programmer Ver. 8.1 Manuals

Name Cat. No. Contents

SYSMAC WS02-CXPC1-V8

CX-Programmer Ver. 8.1 Operation Manual

Function Blocks/Structured Text

SYSMAC WS02-CXPC1-V8

CX-Programmer Operation Manual

SYSMAC WS02-CXPC1-V8

CX-Programmer Operation Manual: SFC

CX-Net Operation Manual W362 Information on setting up networks, such as setting data links,

SYSMAC CXONE-AL

SYSMAC CXONE-AL

CX-Integrator Operation Manual

@@C-V3

@@D-V3

W447

(this

manual)

W446 Provides information on how to use the CX-Programmer for

W469 Explains how to use the SFC programming functions. For

W445 Describes the operating procedures for the CX-Integrator.

Explains how to use the CX-Programmer Ver. 8.1 software’s

function block and structured text functions. For explanations

of other shared CX-Programmer functions, refer to the CX-

Programmer Operation Manual (W446).

all functionality except for function blocks.

explanations of other shared CX-Programmer functions, refer

to the CX-Programmer Operation Manual (W446).

routing tables, and unit settings.

xi

Page 11

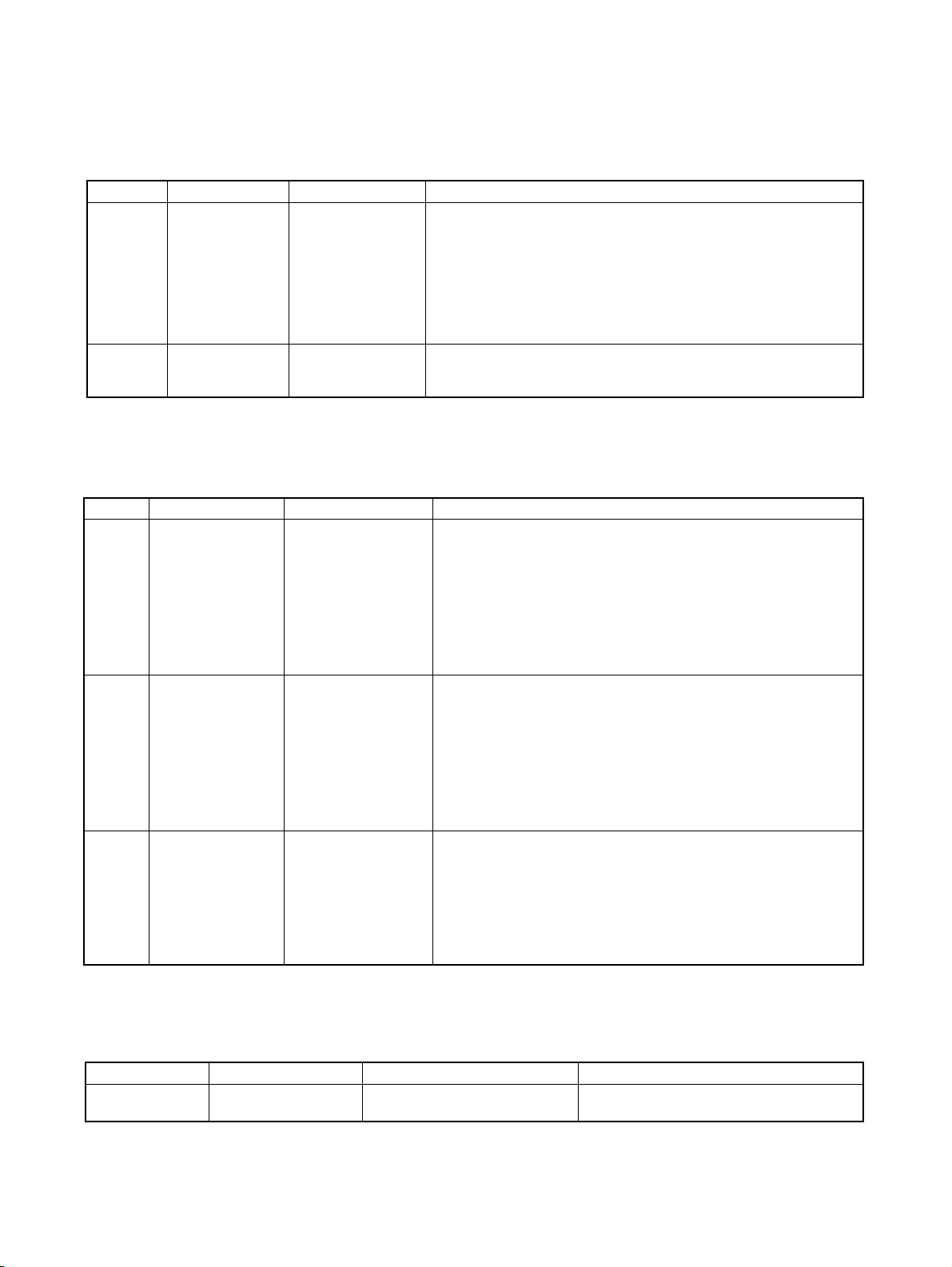

CS1-H, CJ1-H, and CJ1M CPU Unit Manuals

Name Cat. No. Contents

SYSMAC CJ Series

CJ2H-CPU6@-EIP, CJ2H-CPU6@

Programmable Controllers

Hardware User's Manual

SYSMAC CJ Series

CJ2H-CPU6@-EIP, CJ2H-CPU6@

Programmable Controllers

Software User's Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@ -EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S,

CJ2H-CPU6@-EIP, CJ2H-CPU6@,

CJ1H-CPU@@H-R

CJ1G-CPU@@, CJ1G/H-CPU@@H,

CJ1G-CPU@@P, C J 1 M - C P U @@

SYSMAC One NSJ Series

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Programmable Controllers

Instructions Reference Manual

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers

Operation Manual

SYSMAC CJ Series

CJ1G-CPU@@, CJ1G/H-CPU@@H,

CJ1H-CPU@@H-R, CJ1G-CPU@@P,

CJ1M-CPU@@

Programmable Controllers

Operation Manual

W472 Provides an outline of and describes the design, installation,

maintenance, and other basic operations for the CJ-series

CJ2 CPU Units.

The following information is included:

Overview and features

System configuration

Installation and wiring

Troubleshooting

Use this manual together with the W473.

W473 Describes programming and other methods to use the func-

tions of the CJ2 CPU Units.

The following information is included:

CPU Unit operation

Internal memory areas

Programming

Tasks

CPU Unit built-in functions

Use this manual together with the W472.

W474 Describes the ladder diagram programming instructions sup-

ported by CS/CJ-series or NSJ-series PLCs.

When programming, use this manual together with the Oper-

ation Manual or Hardware User's Manual (CS1: W339, CJ1:

W393,or CJ2:W472) and Programming Manual or Software

User's Manual (CS1/CJ1:W394 or CJ2:W473).

W339 Provides an outline of and describes the design, installation,

maintenance, and other basic operations for the CS-series

PLCs.

The following information is included:

An overview and features

The system configuration

Installation and wiring

I/O memory allocation

Troubleshooting

Use this manual together with the W394.

W393 Provides an outline of and describes the design, installation,

maintenance, and other basic operations for the CJ-series

PLCs.

The following information is included:

An overview and features

The system configuration

Installation and wiring

I/O memory allocation

Troubleshooting

Use this manual together with the W394.

xii

Page 12

Name Cat. No. Contents

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CJ1G-CPU@@, CJ1G/H-CPU@@H,

CJ1H-CPU@@H-R, CJ1G-CPU@@P,

CJ1M-CPU@@, NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Programmable Controllers

Programming Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CJ1G-CPU@@, CJ1G/H-CPU@@H,

CJ1H-CPU@@H-R, CJ1G-CPU@@P,

CJ1M-CPU@@, NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Programmable Controllers

Instructions Reference Manual

CS1G/H-CPU@@-EV1

CS1G/H-CPU@@H

CS1W-SCB21-V1/41-V1

CS1W-SCU21/41

CJ2H-CPU6@-EIP, CJ2H-CPU6@

CJ1G-CPU@@

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

CJ1W-SCU21-V1/41-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

SYSMAC CS/CJ Series Communications

Commands Reference Manual

W394 Describes programming and other methods to use the func-

tions of the CS/CJ-series and NSJ-series PLCs.

The following information is included:

Programming

Tasks

File memory

Other functions

Use this manual together with the W339 or W393.

W340 Describes the ladder diagram programming instructions sup-

ported by CS/CJ-series and NSJ-series PLCs.

When programming, use this manual together with the Oper-

ation Manual (CS1: W339 or CJ1: W393) and Programming

Manual (W394).

W342 Describes the communications commands that can be

addressed to CS/CJ-series CPU Units.

The following information is included:

C-series (Host Link) commands

FINS commands

Note: This manual describes commands that can be sent to

the CPU Unit without regard for the communications path,

which can be through a serial communications port on the

CPU Unit, a communications port on a Serial Communications Unit/Board, or a port on any other Communications

Unit.

NSJ-series NSJ Controller Manual

Refer to the following manual for NSJ-series NSJ Controller specifications and handling methods not

given in this manual.

Cat. No. Models Name Description

W452 NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ Series

Operation

Manual

Provides the following information about the NSJ-series NSJ Controllers:

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Use this manual in combination with the following manuals: SYS-

MAC CS Series Operation Manual (W339), SYSMAC CJ Series

Operation Manual (W393), SYSMAC CS/CJ Series Programming

Manual (W394), and NS-V1/-V2 Series Setup Manual (V083)

xiii

Page 13

FQM1 Series Manuals (Unit Version 3.0 or Later)

Refer to the following manuals for specifications and handling methods not given in this manual for

FQM1 Series unit version 3.0 (FQM1-CM002/MMP22/MMA22).

Cat. No. Models Name Description

O012 FQM1-CM002

FQM1-MMP22

FQM1-MMA22

O013 FQM1-CM002

FQM1-MMP22

FQM1-MMA22

FQM1 Series

Operation Manual

FQM1 Series

Instructions

Reference Manual

Provides the following information about the FQM1-series Modules

(unit version 3.0):

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Individually describes the instructions used to program the FQM1.

Use this manual in combination with the FQM1 Series

Operation Manual (O012) when programming.

CP-series PLC Unit Manuals

Refer to the following manuals for specifications and handling methods not given in this manual for CPseries CPU Units.

Cat. No. Models Name Description

W450 CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

W462 CP1L-M@@@@-@

CP1L-L@@@@-@

W451 CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CP1L-M@@@@-@

CP1L-L@@@@-@

SYSMAC CP Series

CP1H CPU Unit

Operation Manual

SYSMAC CP Series

CP1L CPU Unit Operation Manual

SYSMAC CP Series

CP1H/CP1L CPU

Unit Programming

Manual

Provides the following information on the CP-series CP1H PLCs:

• Overview/Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H/CP1L Programmable

Controllers Programming Manual (W451).

Provides the following information on the CP-series CP1L PLCs:

• Overview/Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Programmable Control-

lers Programming Manual (W451).

Provides the following information on the CP-series CP1H and

CP1L PLCs:

• Programming instructions

• Programming methods

• Tasks

Use this manual together with the CP1H/CP1L Programmable

Controllers Operation Manual (W450).

Installation from CX-One

For details on procedures for installing the CX-Programmer from CX-One FA Integrated Tool Package,

refer to the CX-One Ver. 3.0 Setup Manual provided with CX-One.

Cat. No. Model Manual name Contents

W463 CXONE-AL@@C-V3/

AL@@D-V3

xiv

CX-One Setup Manual Installation and overview of CX-One FA

Integrated Tool Package.

Page 14

Overview of Contents

Precautions provides general precautions for using the CX-Programmer Ver. 8.1.

Part 1

Part 1 contains the following sections.

Section 1 introduces the function block functionality of the CX-Programmer and explains the features

that are not contained in the non-function block version of CX-Programmer.

Section 2 provides specifications for reference when using function blocks, including specifications on

function blocks, instances, and compatible PLCs, as well as usage precautions and guidelines.

Section 3 describes the procedures for creating function blocks on the CX-Programmer.

Part 2

Part 2 contains the following sections.

Section 4 introduces the structure text programming functionality of the CX-Programmer and explains

the features that are not contained in the non-structured text version of CX-Programmer.

Section 5 provides specifications for reference when using structured text programming, as well as

programming examples and restrictions.

Section 6 explains how to create ST programs.

Appendices provide information on structured text errors and ST function descriptions.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xv

Page 15

xvi

Page 16

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

(1) The warranty period for the Software is one year from either the date of purchase or the date on which

the Software is delivered to the specified location.

(2) If the User discovers a defect in the Software (i.e., substantial non-conformity with the manual), and

returns it to OMRON within the above warranty period, OMRON will replace the Software without charge

by offering media or downloading services from the Internet. And if the User discovers a defect in the

media which is attributable to OMRON and returns the Software to OMRON within the above warranty

period, OMRON will replace the defective media without charge. If OMRON is unable to replace the

defective media or correct the Software, the liability of OMRON and the User's remedy shall be limited to

a refund of the license fee paid to OMRON for the Software.

LIMITATIONS OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER'S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT WILL OMRON BE LIABLE FOR ANY LOST PROFITS OR

OTHER INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

USE OF THE SOFTWARE.

(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE BASED ON

MODIFICATION OR ALTERATION OF THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

xvii

Page 17

Application Considerations

SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT DESCRIBED IN THE

ATTACHED USER MANUAL.

xviii

Page 18

Disclaimers

CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at any time based on improvements or for

other reasons.

EXTENT OF SERVICE

The license fee of the Software does not include service costs, such as dispatching technical staff.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xix

Page 19

xx

Page 20

PRECAUTIONS

This section provides general precautions for using the CX-Programmer and the Programmable Logic Controller.

The information contained in this section is important for the safe and reliable application of the CX-Programmer

and Programmable Controller. You must read this section and understand the information contained before

attempting to set up or operate the CX-Programmer and Programmable Controller.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

xxi

Page 21

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the product.

Be sure to read this manual before attempting to use the product and keep

this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Confirm safety sufficiently before transferring I/O memory area status from the

CX-Programmer to the actual CPU Unit. The devices connected to Output

Units may malfunction, regardless of the operating mode of the CPU Unit.

Caution is required in respect to the following functions.

• Transferring from the CX-Programmer to real I/O (CIO Area) in the CPU

Unit using the PLC Memory Window.

• Transferring from file memory to real I/O (CIO Area) in the CPU Unit using

the Memory Card Window.

!Caution Variables must be specified either with AT settings (or external variables), or

the variables must be the same size as the data size to be processed by the

instruction when specifying the first or last address of multiple words in the

instruction operand.

xxii

1. If a non-array variable with a different data size and without an AT setting

is specified, the CX-Programmer will output an error when compiling.

2. Array Variable Specifications

Page 22

Application Precautions 4

• When the size to be processed by the instruction operand is fixed:

The number of array elements must be the same as the number of elements to be processed by the instruction. Otherwise, the CX-Programmer

will output an error when compiling.

• When the size to be processed by the instruction operand is not fixed:

The number of array elements must be greater than or the same as the

size specified in the other operands.

• If the other operand specifying a size is a constant, the CX-Programmer will output an error when compiling.

• If the other operand specifying a size is a variable, the CX-Programmer

will not output an error when compiling, even if the size of the array

variable is not the same as that specified by the other operand (variable). A warning message, however, will be displayed. In particular, if

the number of array elements is less than the size specified by the other operand (e.g., the size of the instruction operand is 16, and the number of elements registered in the actual variable table is 10), the

instruction will execute read/write processing for the area that exceeds

the number of elements. For example, read/write processing will be executed for the 6 words following those for the number of elements registered in the actual variable table. If these words are used for other

instructions (including internal variable allocations), unexpected operation will occur, which may result in serious accidents.

Check that the system will not be adversely affected if the size of the

variable specified in the operand is less than the size in the operand

definition before starting PLC operations.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution If synchronous unit operation is being used, perform online editing only after

confirming that an increased synchronous processing time will not affect the

operation of the main and slave axes.

!Caution Confirm safety sufficiently before monitoring power flow and present value

status in the Ladder Section Window or when monitoring present values in the

Watch Window. If force-set/reset or set/reset operations are inadvertently performed by pressing short-cut keys, the devices connected to Output Units

may malfunction, regardless of the operating mode of the CPU Unit.

4 Application Precautions

Observe the following precautions when using the CX-Programmer.

• User programs cannot be uploaded to the CX-Programmer.

• Observe the following precautions before starting the CX-Programmer.

• Exit all applications not directly related to the CX-Programmer. Particularly exit any software such as screen savers, virus checkers, E-mail

or other communications software, and schedulers or other applications that start up periodically or automatically.

xxiii

Page 23

Application Precautions 4

• Disable sharing hard disks, printers, or other devices with other computers on any network.

• With some notebook computers, the RS-232C port is allocated to a

modem or an infrared line by default. Following the instructions in documentation for your computer and enable using the RS-232C port as

a normal serial port.

• With some notebook computers, the default settings for saving energy

do not supply the rated power to the RS-232C port. There may be both

Windows settings for saving energy, as well as setting for specific computer utilities and the BIOS. Following the instructions in documentation for your computer, disable all energy saving settings.

• Do not turn OFF the power supply to the PLC or disconnect the connecting cable while the CX-Programmer is online with the PLC. The computer

may malfunction.

• Confirm that no adverse effects will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• When online editing is performed, the user program and parameter area

data in CJ2, CS1-H, CJ1-H, CJ1M, and CP1H CPU Units is backed up in

the built-in flash memory. The BKUP indicator will light on the front of the

CPU Unit when the backup operation is in progress. Do not turn OFF the

power supply to the CPU Unit when the BKUP indicator is lit. The data will

not be backed up if power is turned OFF. To display the status of writing to

flash memory on the CX-Programmer, select Display dialog to show PLC

Memory Backup Status in the PLC properties and then select Windows -

PLC Memory Backup Status from the View Menu.

• Programs including function blocks (ladder programming language or

structured text (ST) language) can be downloaded or uploaded in the

same way as standard programs that do not contain function blocks.

Tasks including function blocks, however, cannot be downloaded in task

units (uploading is possible).

• If a user program containing function blocks created on the CX-Programmer Ver. 5.0 or later is downloaded to a CPU Unit that does not support

function blocks (CS/CJ-series CPU Units with unit version 2.0 or earlier),

all instances will be treated as illegal commands and it will not be possible

to edit or execute the user program.

• If the input variable data is not in boolean format, and numerical values

only (e.g., 20) are input in the parameters, the actual value in the CIO

Area address (e.g., 0020) will be passed. Therefore, be sure to include an

&, #, or +, - prefix before inputting the numerical value.

• Addresses can be set in input parameters, but an address itself cannot be

passed as an input variable. (Even if an address is set as an input parameter, the value passed to the function block will be that for the size of data

of the input variable.) Therefore, an input variable cannot be used as the

operand of an instruction in the function block when the operand specifies

the first or last of multiple words. With CX-Programmer version 7.0, use

xxiv

Page 24

Application Precautions 4

an input-output variable specified as an array variable (with the first

address set for the input parameter) and specify the first or last element of

the array variable, or, with any version of CX-Programmer, use an internal

variable with an AT setting. Alternatively, specify the first or last element in

an internal variable specified as an array variable.

• Values are passed in a batch from the input parameters to the input variables or input-output variables before algorithm execution (not at the

same time as the instructions in the algorithm are executed). Therefore, to

pass the value from a parameter to an input variable or input-output variable when an instruction in the function block algorithm is executed, use

an internal variable or external variable instead of an input variable or

input-output variable. The same applies to the timing for writing values to

the parameters from output variables.

• Always use internal variables with AT settings in the following cases.

• The addresses allocated to Basic I/O Units, Special I/O Units, and

CPU Bus Units cannot be registered to global symbols, and these variables cannot be specified as external variables (e.g., the data set for

global variables may not be stable).

• Use internal variables when Auxiliary Area bits other than those preregistered to external variables are registered to global symbols and

these variables are not specified as external variables.

• Use internal variables when specifying PLC addresses for another

node on the network: For example, the first destination word at the remote node for SEND(090) and the first source word at the remote node

for RECV(098).

• Use internal variables when the first or last of multiple words is specified by an instruction operand and the operand cannot be specified as

an array variable (e.g., the number of array elements cannot be specified).

xxv

Page 25

Application Precautions 4

xxvi

Page 26

Part 1:

Function Blocks

Page 27

Page 28

SECTION 1

Introduction to Function Blocks

This section introduces the function block functionality of the CX-Programmer and explains the features that are not

contained in the non-function block version of CX-Programmer.

1-1 Introducing the Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-1 Overview and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-2 Function Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1-3 Files Created with CX-Programmer Ver. 6.0 or Later . . . . . . . . . . . 8

1-1-4 Function Block Menus in CX-Programmer Ver. 5.0

(and later Versions). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2 Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-2 Advantages of Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-2-3 Function Block Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-3 Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-3-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-3-2 Variable Usage and Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-3-3 Variable Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-3-4 Variable Properties and Variable Usage . . . . . . . . . . . . . . . . . . . . . . 20

1-3-5 Internal Allocation of Variable Addresses . . . . . . . . . . . . . . . . . . . . 21

1-4 Converting Function Block Definitions to Library Files . . . . . . . . . . . . . . . . 23

1-5 Usage Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-1 Creating Function Blocks and Executing Instances . . . . . . . . . . . . . 23

1-5-2 Reusing Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-6 Version Upgrade Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3

Page 29

Introducing the Function Blocks Section 1-1

1-1 Introducing the Function Blocks

1-1-1 Overview and Features

The CX-Programmer Ver. 5.0 (and later versions) is a Programming Device

that can use standard IEC 61131-3 function blocks. The CX-Programmer

function block function is supported for CJ2H CPU Units, CP1H CPU Units,

NSJ-series NSJ Controllers, and FQM1 Flexible Motion Controllers as well as

CS/CJ-series CPU Units with unit version 3.0 or later and has the following

features.

• User-defined processes can be converted to block format by using function blocks.

• Function block algorithms can be written in the ladder programming language or in the structured text (ST) language. (See note.)

• When ladder programming is used, ladder programs created with nonCX-Programmer Ver. 4.0 or earlier can be reused by copying and pasting.

• When ST language is used, it is easy to program mathematical processes that would be difficult to enter with ladder programming.

Note The ST language is an advanced language for industrial control

(primarily Programmable Logic Controllers) that is described in IEC

61131-3. The ST language supported by CX-Programmer conforms to the IEC 61131-3 standard.

• Function blocks can be created easily because variables do not have to

be declared in text. They are registered in variable tables.

A variable can be registered automatically when it is entered in a ladder or

ST program. Registered variables can also be entered in ladder programs

after they have been registered in the variable table.

• A single function block can be converted to a library function as a single

file, making it easy to reuse function blocks for standard processing.

• A program check can be performed on a single function block to easily

confirm the function block’s reliability as a library function.

• Programs containing function blocks (ladder programming language or

structured text (ST) language) can be downloaded or uploaded in the

same way as standard programs that do not contain function blocks.

Tasks containing function blocks, however, cannot be downloaded in task

units (uploading is possible).

• One-dimensional array variables are supported, so data handling is easier for many applications.

Note The IEC 61131 standard was defined by the International Electro-

technical Commission (IEC) as an international programmable logic controller (PLC) standard. The standard is divided into 7 parts.

Specifications related to PLC programming are defined in Part 3

Textual Languages (IEC 61131-3).

• A function block (ladder programming language or structured text (ST)

language) can be called from another function block (ladder programming

language or structured text (ST) language). Function blocks can be

nested up to 8 levels and ladder/ST language function blocks can be combined freely.

4

Page 30

Introducing the Function Blocks Section 1-1

1-1-2 Function Block Specifications

For specifications that are not listed in the following table, refer to the CX-Programmer Operation Manual (W446).

Item Specifications

Model number WS02-CXPC1-E-V7

Setup disk CD-ROM

Compatible CPU Units (PLC models)

Note The function block and structured

text functions supported by CS/

CJ-series CPU Units with unit version 4.0 or later can not be used

in CS/CJ-series CPU Units with

unit version 3.0 or earlier, CPseries PLCs, NSJ-series PLCs, or

FQM1-series PLCs.

For details, refer to 1-6 Version

Upgrade Information.

CS/CJ-series CS1-H, CJ1-H, and CJ1M CPU Units with unit version 3.0 or later

are compatible.

Device Type CPU Type

• CJ2H CJ2H-CPU68/67/66/65/64/68-EIP/67-EIP/66-EIP/65-EIP

/64-EIP

• CS1G-H CS1G-CPU42H/43H/44H/45H

• CS1H-H CS1H-CPU63H/64H/65H/66H/67H

• CJ1G-H CJ1G-CPU42H/43H/44H/45H

• CJ1H-H CJ1H-CPU65H/66H/67H/64H-R/65H-R/66H-R/67H-R

• CJ1M CJ1M-CPU11/12/13/21/22/23

The following CP-series CPU Units are compatible.

• CP1H CP1H-X/XA/Y

• CP1L CP1L-M/L

Note If a user program containing function blocks created on the CX-Program-

mer Ver. 5.0 or later is downloaded to a CPU Unit that does not support

function blocks (CS/CJ-series CPU Units with unit version 2.0 or earlier),

all instances will be treated as illegal commands and it will not be possible to edit or execute the user program.

• NSJ G5D (Used for the NSJ5-TQ0@-G5D, NSJ5-SQ0@-G5D, NSJ8

-TV0@-G5D, NSJ10-TV0@-G5D, and NSJ12-TS0@-G5D)

M3D (Used for the NSJ5-TQ0@-M3D, NSJ5-SQ0@-M3D, and

NSJ8-TV0@-M3D)

• FQM1-CM FQM1-CM002

• FQM1-MMA FQM1-MMA22

• FQM1-MMP FQM1-MMP22

CS/CJ/CP Series Function Restrictions

• Instructions Not Supported in Function Block Definitions

Block Program Instructions (BPRG and BEND), Subroutine Instructions (SBS,

GSBS, RET, MCRO, and SBN), Jump Instructions (JMP, CJP, and CJPN),

Step Ladder Instructions (STEP and SNXT), Immediate Refresh Instructions

(!), I/O REFRESH (IORF), ONE-MS TIMER (TMHH and TMHHX) (These timers can be used with CJ1-H-R CPU Units.)

Note For details and other restrictions, refer to 2-4 Programming Restrictions.

5

Page 31

Introducing the Function Blocks Section 1-1

Item Specifications

Functions not

supported by

CX-Programmer Ver. 4.0

or earlier.

Defining

and creating function blocks

Number of

function

block definitions

Function

block

names

CJ2H Units:

• CJ2H-CPU6@(-EIP): 2,048 max. per CPU Unit

CS1-H/CJ1-H CPU Units:

• Suffix -CPU44H/45H/64H/65H/66H/67H/64H-R/65H-R/66H-R/67H-R: 1,024

max. per CPU Unit

• Suffix -CPU42H/43H/63H: 128 max. per CPU Unit

CJ1M CPU Units:

• CJ1M-CPU11/12/13/21/22/23: 128 max. per CPU Unit

CP1H CPU Units:

• All models: 128 max. per CPU Unit

CP1L CPU Units:

• CP1L-M/L: 128 max. per CPU Unit

NSJ Controllers:

•NSJ@-@@@@-G5D: 1,024 max. per Controller;

NSJ@-@@@@-M3D: 128 max. per Controller

FQM1 Flexible Motion Controllers:

• FQM1-CM002/MMA22/MMP22: 128 max. per Controller

64 characters max.

6

Page 32

Introducing the Function Blocks Section 1-1

Item Specifications

Functions not

supported by

CX-Programmer Ver. 4.0

or earlier.

Defining

and creating function blocks

Creating

instances

Storing

function

blocks as

files

Variables Variable names 30,000 characters max.

Variable types Input variables (Inputs), output variables (Out-

Number of variables used in

a function block

(not including internal variables, external variables,

EN, and EN0)

Allocation of addresses

used by variables

Actual address specification Supported

Array specifications Supported (one-dimensional arrays only and only

Language Function blocks can be created in ladder programming language or structured

text (ST, see note).

Number of

instances

CJ2H Units:

• CJ2H-CPU6@(-EIP): 2,048 max. per CPU Unit

CS1-H/CJ1-H CPU Units:

puts), input-output variables (In Out), internal

variables (Internals), and external variables

(Externals)

Maximum number of variables per function block

definition

• Input-output variables: 16 max.

• Input variables + input-output variables: 64 max.

• Output variables + input-output variables: 64

max.

Automatic allocation (The allocation range can be

set by the user.)

for internal variables and input-output variables)

• Suffix -CPU44H/45H/64H/65H/66H/67H/64H-R/65H-R/66H-R/67H-R: 2,048

max. per CPU Unit

• Suffix -CPU42H/43H/63H: 256 max. per CPU Unit

CJ1M CPU Units:

• CJ1M-CPU11/12/13/21/22/23: 256 max. per CPU Unit

CP1H CPU Units:

• All models: 256 max. per CPU Unit

CP1L CPU Units:

• CP1L-M/L: 256 max. per CPU Unit

NSJ Controllers:

•SJ@-@@@@-G5D: 2,048 max. per Controller;

NSJ@-@@@@-M3D: 256 max. per Controller

FQM1 Flexible Motion Controllers:

• FQM1-CM002/MMA22/MMP22: 256 max. per Controller

Instance

names

Project files The project file (.cxp/cxt) Includes function block definitions and instances.

Program

files

Function

block library

files

15,000 characters max.

The file memory program file (*.obj) includes function block definitions and

instances.

Each function block definition can be stored as a single file (.cxf) for reuse in

other projects.

Note The structured text (ST language) conforms to the IEC 61131-3 standard, but

CX-Programmer Ver. 5.0 supports only assignment statements, selection

statements (CASE and IF statements), iteration statements (FOR, WHILE,

REPEAT, and EXIT statements), RETURN statements, arithmetic operators,

logical operators, comparison functions, numeric functions, standard string

functions, numeric string functions, OMRON expansion functions, and comments. For details, refer to SECTION 5 Structured Text (ST) Language Speci-

fications in Part 2: Structured Text (ST).

7

Page 33

Introducing the Function Blocks Section 1-1

1-1-3 Files Created with CX-Programmer Ver. 6.0 or Later

Project Files (*.cxp) and

File Memory Program

Files (*.obj)

Function Block Library

Files (*.cxf)

Projects created using CX-Programmer that contain function block definitions

and projects with instances are saved in the same standard project files

(*.cxp) and file memory program files (*.obj).

The following diagram shows the contents of a project. The function block definitions are created at the same directory level as the program within the relevant PLC directory.

Project file (.cxp)

PLC1

PLC2

Global symbol table

I/O table

PLC Setup

PLC memory table

Program (with rung comments)

Local symbol table

Section 1 (with instances)

Section 2 (with instances)

END section (with instances)

Function block definitions

FunctionBlock1

FunctionBlock2

Instances created

in program

sections.

Each function block can be

stored in a separate

definition file (.cxf).

A function block definition created in a project with CX-Programmer Ver. 6.0

can be saved as a file (1 definition = 1 file), enabling definitions to be loaded

into other programs and reused.

Note When function blocks are nested, all of the nested (destination) function block

definitions are included in this function block library file (.cxf).

Project Text Files

Containing Function

Data equivalent to that in project files created with CX-Programmer Ver. 6.0

(*.cxp) can be saved as CXT text files (*.cxt).

Blocks (*.cxt)

1-1-4 Function Block Menus in CX-Programmer Ver. 5.0 (and later

Versions)

The following tables list menus related to function blocks in CX-Programmer

Ver. 5.0 and later versions. For details on all menus, refer to the CX-Program-

mer Operation Manual (W446).

Main Menu

Main

menu

File Function Block Load Function

Submenu Shortcut Function

--- Reads the saved function block library files (*.cxf).

Block from File

Save Function

Block to File

--- Saves the created function block definitions to a file ([func-

tion block library file]*.cxf).

8

Page 34

Introducing the Function Blocks Section 1-1

Main

menu

Edit Update Function Block --- When a function block definition’s input variables, output

To Lower Layer --- Jumps to the function block definition for the selected

Function Block (ladder) generation --- Generates a ladder-programmed function block for the

View Monitor FB Instance --- When monitoring the program online, monitors ST variable

To Lower Layer --- Displays on the right side the contents of the function block

To Upper Layer --- Returns to the calling instance (ladder diagram or ST).

Window FB Instance

Insert Function Block Invocation F Creates an instance in the program (section) at the present

Function Block Parameter P When the cursor is located to the left of an input variable or

PLC Memory

Allocation

Program Online Edit Begin --- Starts online editing of a function block.

Submenu Shortcut Function

variables, or input-output variables have been changed

after the instance was created, an error will be indicated by

displaying the instance’s left bus bar in red. This command

updates the instance with the new information and clears

the error.

instance.

selected program section while automatically determining

address application conditions.

status as well as I/O bit and word status (I/O bit monitor) of

the ladder diagram in the instance.

(Supported by CX-Programmer Ver. 6.1 and later only).

definition of the selected instance. (Supported by CX-Programmer Ver. 6.0 and later only.)

(Supported by CX-Programmer Ver. 6.0 and later only.)

--- Displays the FB Instance Viewer. (When nesting, the display shows details such as the relationship between

instance nesting levels and allocated variable addresses in

the instances.)

cursor location.

the right of an output variable, sets the variable’s input or

output parameter.

--- Sets the range of addresses (function block instance areas)

internally allocated to the selected instance’s variables.

--- Checks the status of the addresses internally allocated to

the selected instance’s variables.

--- Checks the addresses internally allocated to each variable

in the selected instance.

--- Optimizes the allocation of addresses internally allocated to

variables.

block.

online.

--- Transfers only the function block source.

--- Forcefully releases the access rights for function block,

SFC, and ST online editing held by another user.

Function

Block/

SFC

Memory

Viewer

Function Block

/SFC Memory

Allocation

Function Block

/SFC Memory

Statistics

Function Block

Instance

Address

Optimize Function Block/SFC

Memory

Send Change --- Transfers changes made during online editing of a function

Cancel --- Cancels changes made to a function block being edited

Transfer FB

Source

Release FB

Online Edit

Access Rights

9

Page 35

Introducing the Function Blocks Section 1-1

Main

menu

Tools Simulation Break Point |

Submenu Shortcut Function

Set/Clear

Break Point

Break Point |

Clear All Break

Point

Mode | Run

(Monitor Mode)

Mode | Stop

(Program

Mode)

Mode | Pause --- Pauses simulator operation.

Step Run --- Executes just one step of the simulator’s program.

Step Run |

Step In

Step Run |

Step Out

Step Run |

Continuous

Step Run

Step Run |

Scan Run

Always Display

Current Execution Point

Break Point List --- Displays a list of the break points that have been set.

--- Sets or clears a break point.

--- Clears all break points.

--- Executes continuous scanning. (Sets the ladder execution

engine’s run mode to MONITOR mode.)

--- Sets the simulator’s operation mode to PROGRAM mode.

--- When there is a function block call instruction, this command moves to execution of the internal program step.

--- When a function block’s internal program step is being executed, this command returns to the next higher level (call

source) and pauses execution.

--- Executes steps continuously for a fixed length of time.

--- Executes for one cycle and pauses execution.

--- Used with the Step Run or Continuous Step Run commands to automatically scroll the display and always show

the pause point.

(Operation can be jumped to a specified point.)

Main Pop-up Menus

Pop-up Menu for Function Block Definitions

Pop-up menu Function

Insert Function Block Ladder Creates a function block definition with a ladder programming language algo-

rithm.

Structured Text Creates a function block definition with an ST language algorithm.

From file Reads a function block definition from a function block library file (*.cxf).

Pop-up Menu for Inserted Function Blocks

Pop-up menu Function

Open Displays the contents of the selected function block definition on the right side

Save Function Block File Saves the selected function block definition in a file.

Compile Compiles the selected function block definition.

FB online Edit Begin Starts online editing of a function block.

Send Change Transfers changes made during online editing of a function block.

Cancel Cancels changes made to a function block being edited online.

Transfer FB Source Transfers only the function block source.

Release FB Online

Edit Access Rights

of the window.

Forcefully releases the access rights for function block online editing held by

another user.

10

Page 36

Function Blocks Section 1-2

Pop-up Menu for Function Block Variable Tables

Pop-up menu Function

Edit Edits the variable.

Insert Variable Adds a variable to the last line.

Insert Variable Above Inserts the variable above the current cursor position.

Below Inserts the variable below the current cursor position.

Cut Cuts the variable.

Copy Copies the variable.

Paste Pastes the variable.

Find Searches for the variable. Variable names, variable comments, or all (text strings) can

be searched.

Replace Replaces the variable.

Delete Deletes the variable.

Rename Changes only the name of the variable.

Pop-up Menu for Instances

Pop-up menu Function

Edit Changes the instance name.

Update Invocation When a function block definition’s input variables, output variables, or input-output vari-

ables have been changed after the instance was created, an error will be indicated by

displaying the instance’s left bus bar in red. This command updates the instance with

the new information and clears the error.

Monitor FB Ladder Instance When monitoring the program online, monitors I/O bit and word status (I/O bit monitor)

of the ladder diagram in the instance.

(Supported by CX-Programmer Ver. 6.0 and later only).

Monitor FB Instance When monitoring the program online, monitors ST variable status as well as I/O bit and

word status (I/O bit monitor) of the ladder diagram in the instance.

(Supported by CX-Programmer Ver. 6.1 and later only).

Register in Watch Window Displays the FB variables registration Dialog Box in order to register a variable from the

selected instance to the Watch Window.

Function Block Definition Displays the selected instance’s function block definition on the right side of the window.

Shortcut Keys

F Key: Pasting Function

Block Definitions in

Program

Enter Key: Inputting

Parameters

Move the cursor to the position at which to create the copied function block

instance in the Ladder Section Window, and press the F Key. This operation is

the same as selecting Insert - Function Block Invocation.

Position the cursor at the left of the input variable or input-output variable, or

at the right of the output variable and press the Enter Key. This operation is

the same as selecting Insert - Function Block Parameter.

1-2 Function Blocks

1-2-1 Outline

A function block is a basic program element containing a standard processing

function that has been defined in advance. Once the function block has been

defined, the user just has to insert the function block in the program and set

the I/O in order to use the function.

As a standard processing function, a function block does not contain actual

addresses, but variables. The user sets addresses or constants in those variables. These address or constants are called parameters. The addresses

used by the variables themselves are allocated automatically by the CX-Programmer for each program.

11

Page 37

Function Blocks Section 1-2

With the CX-Programmer, a single function block can be saved as a single file

and reused in other PLC programs, so standard processing functions can be

made into libraries.

Program 2

Copy of function block A

Function block A

Standard

program section

written with

variables

Define in advance.

Insert in

program.

Save function

block as a file.

Convert to

library function.

Function

block A

Reuse.

1-2-2 Advantages of Function Blocks

Function blocks allow complex programming units to be reused easily. Once

standard programming is created in a function block and saved in a file, it can

be reused just by placing the function block in a program and setting the

parameters for the function block’s I/O. The ability to reuse existing function

blocks will save significant time when creating/debugging programs, reduce

coding errors, and make the program easier to understand.

Program 1

Copy of function block A

Input Output

Variable Variable

Set

Copy of function block A

Input Output

Variable Variable

To another PLC program

Set

Variable

Output

Structured

Programming

Easy-to-read “Black Box”

Design

Structured programs created with function blocks have better design quality

and require less development time.

The I/O operands are displayed as variable names in the program, so the program is like a “black box” when entering or reading the program and no extra

time is wasted trying to understand the internal algorithm.

Use One Function Block

for Multiple Processes

Many different processes can be created easily from a single function block by

using the parameters in the standard process as input variables (such as

timer SVs, control constants, speed settings, and travel distances).

Reduce Coding Errors Coding mistakes can be reduced because blocks that have already been

debugged can be reused.

Black-boxing Know-how Read-protection can be set for function blocks to prevent programming know-

how from being disclosed.

Data Protection The variables in the function block cannot be accessed directly from the out-

side, so the data can be protected. (Data cannot be changed unintentionally.)

Improved Reusability with

Variable Programming

The function block’s I/O is entered as variables, so it isn’t necessary to change

data addresses in a block when reusing it.

Creating Libraries Processes that are independent and reusable (such as processes for individ-

ual steps, machinery, equipment, or control systems) can be saved as function block definitions and converted to library functions.

12

Page 38

Function Blocks Section 1-2

The function blocks are created with variable names that are not tied to actual

addresses, so new programs can be developed easily just by reading the definitions from the file and placing them in a new program.

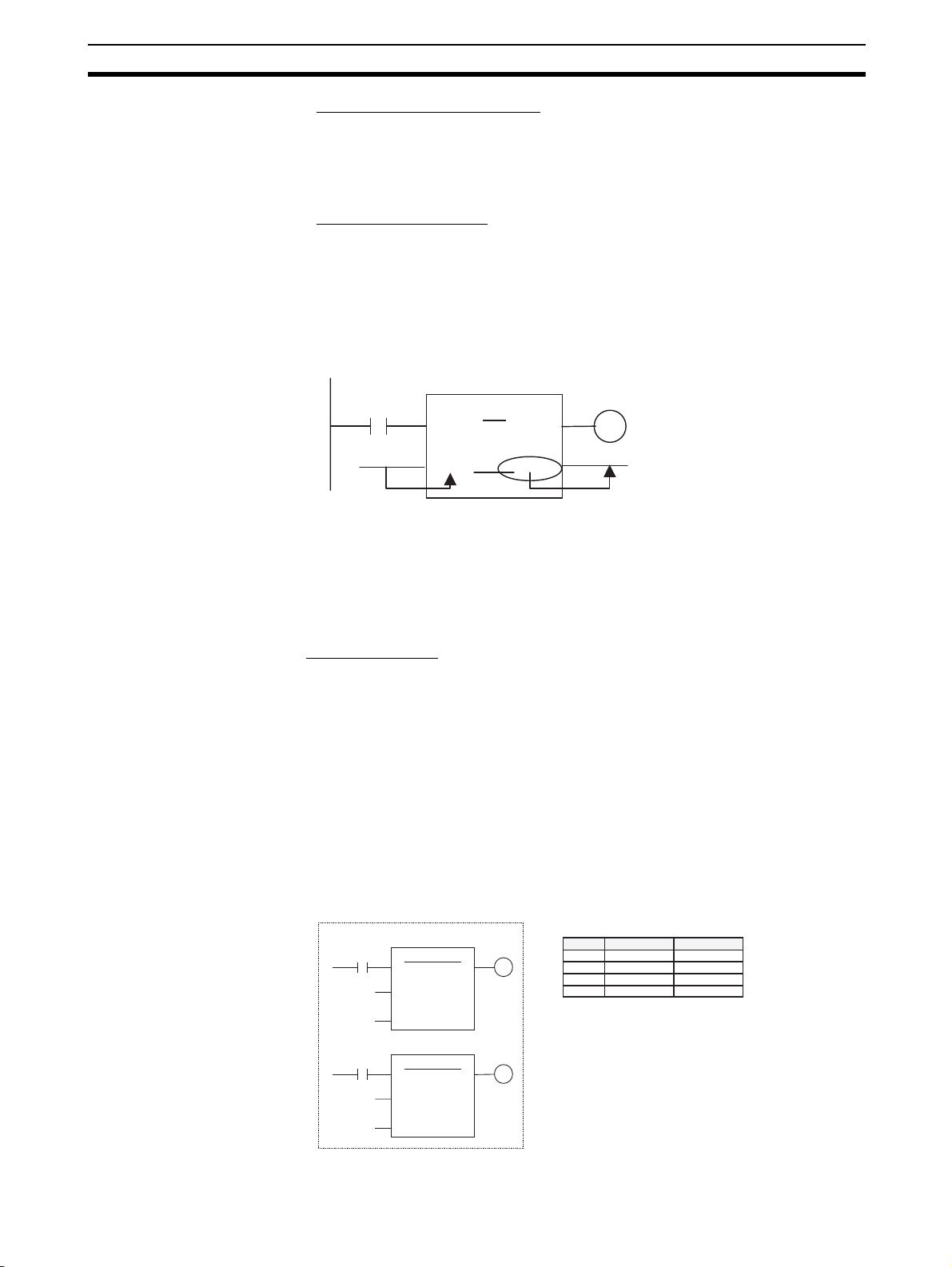

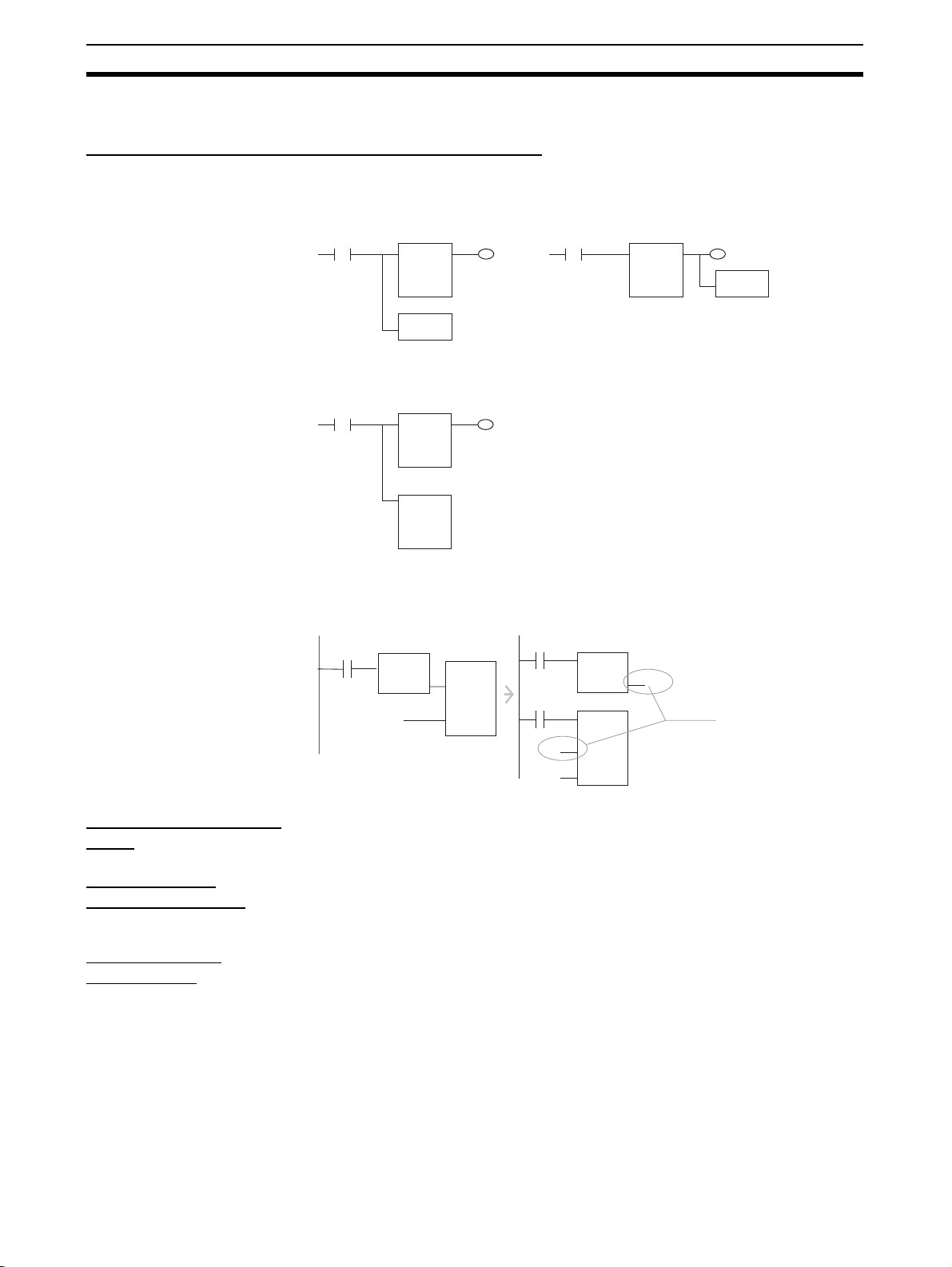

Supports Nesting and

Multiple Languages

Mathematical expressions can be entered in structured text (ST) language.

With CX-Programmer Ver. 6.0 and later versions, function blocks can be

nested. The function block nesting function allows just special processing to

be performed in a ST-language function block nested within a ladder-language function block.

Function block (ladder language)

1-2-3 Function Block Structure

Function blocks consist of function block definitions that are created in

advance and function block instances that are inserted in the program.

Function Block

Definitions

Function block definitions are the programs contained in function blocks. Each

function block definition contains the algorithm and variable definitions, as

shown in the following diagram.

Call (Nesting)

Function block (ST language)

Number of Function Block

Definitions

Function Block Definition

Example: CLOCK PULSE

Algorithm

Variable definitions

Example: CLOCK PULSE

1. Algorithm

tim_b

tim_a

2. Variable Definitions

Usage

Internal

Internal

Input

Input

TIMX tim_a OFF_TIME

TIMX tim_b ON_TIME

Name

tim_a TIMER

tim_b TIMER

ON_TIME INT

OFF_TIME INT

ENO

Type

1. Algorithm

Standardized programming is written with variable names rather than real I/O

memory addresses. In the CX-Programmer, algorithms can be written in

either ladder programming or structured text.

2. Variable Definitions

The variable table lists each variable’s usage (input, output, input-output, or

internal) and properties (data type, etc.). For details, refer to 1-3 Variables.

The maximum number of function block definitions that can be created for one

CPU Unit is either 128 or 1,024 depending on the CPU Unit model.

13

Page 39

Function Blocks Section 1-2

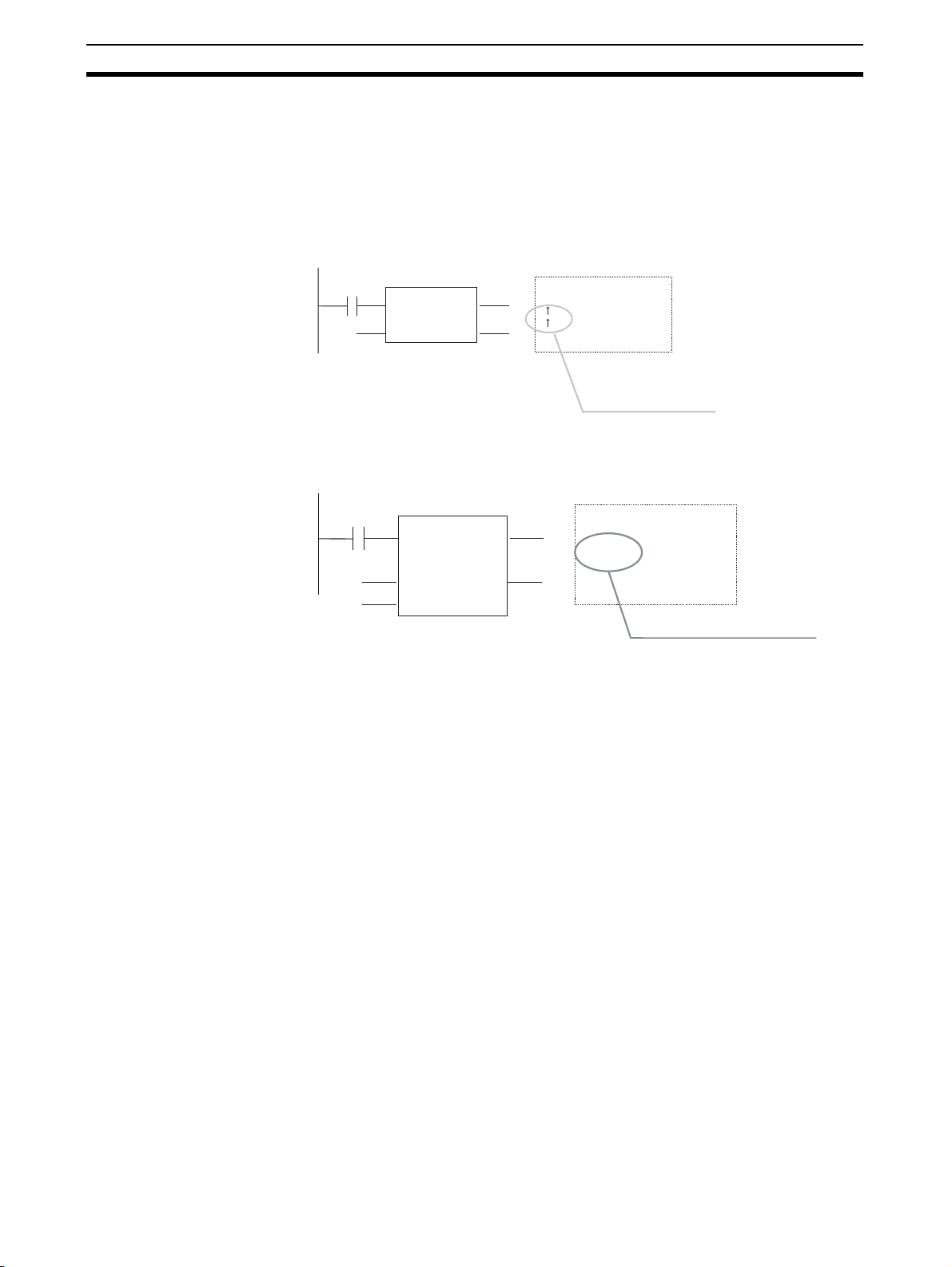

Instances To use an actual function block definition in a program, create a copy of the

function block diagram and insert it in the program. Each function block definition that is inserted in the program is called an “instance” or “function block

instance.” Each instance is assigned an identifier called an “instance name.”

By generating instances, a single function block definition can be used to process different I/O data with the same function.

Not yet in program

and memory not yet

allocated

(abstract).

Function Block Definition FB1

1. Algorithm

Standard

program unit

with variable

names a, b, c,

etc.

2. Parameters

Table defining usage

and properties of

variables a, b, c, etc.

Insert in

program.

Insert in

program.

Block instance in program with memory

allocated. (object)

Program

Instance FB1_1 of function block definition FB1

Input

data

Instance FB1_2 of function block definition FB1

Input

data

Instance

ab

ab

c

Output data

Output data

c

Output data

Output data

Automatic

allocation

Automatic

allocation

Memory

used

Memory

for FB1_1

Memory

for FB1_2

Different I/O data

can be processed

with the same

function.

Note Instances are managed by names. More than one instance with the same

name can also be inserted in the program. If two or more instances have the

same name, they will use the same internal variables. Instances with different

names will have different internal variables.

For example, consider multiple function blocks that use a timer as an internal

variable. In this case all instances will have to be given different names. If

more than one instance uses the same name, the same timer would be used

in multiple locations, resulting in duplicated use of the timer.

If, however, internal variables are not used or they are used only temporarily

and initialized the next time an instance is executed, the same instance name

can be used to save memory.

instance_A

Function Block Definition

TIMER_FB

Variable Definitions

Internal variable: WORK_NUM

TIMER_FB

Use same internal variables.

instance_A

TIMER_FB

Use different internal variables.

instance_B

TIMER_FB

Number of Instances Multiple instances can be created from a single function block definition. Up to

either 256 or 2,048 instances can be created for a single CPU Unit depending

on the CPU Unit model. The allowed number of instances is not related to the

number of function block definitions and the number of tasks in which the

instances are inserted.

14

Page 40

Function Blocks Section 1-2

Parameters Each time an instance is created, set the real I/O memory addresses or con-

stants for input variables, output variables, and input-output variables used to

pass input data values to instances and obtain output data values from

instances. These addresses and constants are called parameters.

Instance of Function Block Definition A

Input 0.00

Input 3.00

Set the constants or

input source addresses

from which to pass data.

ab

c

Output 2.00

Set the constant or

output destination

address to which to pass

data.

Using Input Variables and Output Variables

With input variables and output variables, it is not the input source address

itself, but the contents at the input address in the form and size specified by

the variable data type that is passed to the function block. In a similar fashion,

it is not the output destination address itself, but the contents for the output

address in the form and size specified by the variable data type that is passed

from the function block.

Even if an input source address (i.e., an input parameter) or an output destination address (i.e., an output parameter) is a word address, the data that is

passed will be the data in the form and size specified by the variable data type

starting from the specified word address.

Program

Instance of Function Block Definition A

Input D100

mk

Output D300

Input D200

Examples:

If m is type WORD, one word of data from D100 will be passed to the

variable.

If n is type DWORD, two words of data from D200 and D201 will be

passed to the variable.

If k is type LWORD, four words of data from the variable will be passed

to the D300 to D303.

n

Note (1) Only addresses in the following areas can be used as parameters: CIO

Area, Auxiliary Area, DM Area, EM Area (banks 0 to C), Holding Area,

and Work Area.

The following cannot be used: Index and Data Registers (both direct and

indirect specifications) and indirect addresses to the DM Area and EM

Area (both in binary and BCD mode).

(2) Local and global symbols in the user program can also be specified as

parameters. To do so, however, the data size of the local or global symbol

must be the same as the data size of the function block variable.

(3) When an instance is executed, input values are passed from parameters

to input variables before the algorithm is processed. Output values are

15

Page 41

Function Blocks Section 1-2

passed from output variables to parameters just after processing the algorithm. If it is necessary to read or write a value within the execution cycle of the algorithm, do not pass the value to or from a parameter. Assign

the value to an internal variable and use an AT setting (specified addresses).

!Caution If an address is specified in an input parameter, the values in the address are

passed to the input variable. The actual address data itself cannot be passed.

!Caution Parameters cannot be used to read or write values within the execution cycle

of the algorithm. Use an internal variable with an AT setting (specified

addresses). Alternatively, reference a global symbol as an external variable.

Using Input-Output Variables (In Out)

When using an input-output variable, set the address for the input parameter.

A constant cannot be set. The address set for the input parameter will be

passed to the function block. If processing is performed inside the function

block using the input-output variable, the results will be written to I/O starting

at the address set for the size of the variable.

Program

Instance of function block definition A

Automatically set.

Input

D200 D200 a a

Address passed.

D200

D201

Processing is performed inside the function block using variable

“a.” The resulting value is written to I/O memory for the size of

variable “a” starting at address D200.

Variable “a”

Output

Address passed.

“a” changed by function

block processing.

Note Input-output variables are specified in a CX-Programmer variable table by

selecting “In Out” for the variable usage.

16

Page 42

Function Blocks Section 1-2

■ Reference Information

A variety of processes can be created easily from a single function block by

using parameter-like elements (such as fixed values) as input variables and

changing the values passed to the input variables for each instance.

Example: Creating 3 Instances from 1 Function Block Definition

Cyclic task 0

Instance

CASCADE_01

Algorithm

Internal and I/O

Function Block Definition

Example: CONTROL

Algorithm

Variables

Example:

There are 3 FB

instances and each

has its own I/O and

internal variables.

variables

Instance

CASCADE_02

Algorithm

Internal and I/O

variables

Instance

CASCADE_03

Algorithm

Internal and I/O

variables

If internal variables are not used, if processing will not be affected, or if the

internal variables are used in other locations, the same instance name can be

used at multiple locations in the program.

Cyclic task 0

P_On

The same instance can be

Function block definition

Example: CONTROL

Algorithm

Variables

used at multiple locations.

Instance

CASCADE

Algorithm

Internal and I/O

variables

P_On

P_On

&20

&10

P_On

&15

&10

Cyclic task 1

P_On

&7

&8

CASCADE

CONTROL

EN ENO

&100

PARA_1

&130

PARA_2

CASCADE

CONTROL

EN ENO

&50

PARA_1

&150

PARA_2

CASCADE_01

CONTROL

EN ENO

ON_TIME

OFF_TIME

CASCADE_02

CONTROL

EN ENO

ON_TIME

OFF_TIME

CASCADE_03

CONTROL

EN ENO

ON_TIME

OFF_TIME

1.0

1.1

1.2

1.0

1.1

Cyclic task 1

P_On

&100

&200

CASCADE

EN ENO

PARA_1

PARA_2

CONTROL

1.2

Some precautions are required when using the same memory area. For

example, if the same instance containing a timer instruction is used in more

than one program location, the same timer number will be used causing coil

duplication, and the timer will not function properly if both instructions are executed.

17

Page 43

Variables Section 1-3

Registration of Instances Each instance name is registered in the global symbol table as a file name.

Program

Instance (sample) of function block definition A

ab

c

The instance is registered in the

global symbol table with the instance

name as the symbol name.

Name

sample FB [FunctionBlock1] N/A[Auto]

Instance name

Data type

Address/

value

The function block definition

name is registered after FB in

square parentheses [ ].

1-3 Variables

1-3-1 Introduction

In a function block, the addresses (see note) are not entered as real I/O memory addresses, they are all entered as variable names. Each time an instance

is created, the actual addresses used by the variable are allocated automatically in the specified I/O memory areas by the CX-Programmer. Consequently, it isn’t necessary for the user to know the real I/O memory addresses

used in the function block, just as it isn’t necessary to know the actual memory allocations in a computer. A function block differs from a subroutine in this

respect, i.e., the function block uses variables and the addresses are like

“black boxes.”

Example:

Insert in

program.

Program

Instance of function block definition A

Input 0.00

Input 3.00

ab

c

Output 2.00

Function block definition A

Standard program section with

variable names a, b, c, etc.

a

c

b

MOV

Specify inputs and outputs

at the same time.

18

Table indicating usage and

properties of variables a, b, c, etc.

Usage: Inputs

Properties:

Name Type AT Initial Value Retained

a BOOL

c BOOL

Usage: Outputs

Properties:

Name Type AT Initial Value Retained

BOOL

b

Status of 0.00 (1 or 0) is

passed to a.

0.00 a

1 1

Status of 3.00 (1 or 0) is

passed to c.

3.00 c

0 0

The system automatically allocates the

addresses used by variables a, b, and c. For

example, when W100 to W120 is set as the

system’s non-retained memory area, bit

Status of b (1 or 0) is

passed to 2.00.

2.00b

11

addresses such as a = W10000, b = W10001,

and c = W10002 will be allocated.

Note Constants are not registered as variables. Enter constants directly in instruc-

tion operands.

Page 44

Variables Section 1-3

• Ladder programming language: Enter hexadecimal numerical values

after the # and decimal values after the &.

• Structured text (ST language): Enter hexadecimal numerical values after 16# and enter decimal numerical values as is.

Exception: Enter directly or indirectly specified addresses for Index Registers

IR0 to IR15 and Data Registers DR0 to DR15 directly into the instruction

operand.

1-3-2 Variable Usage and Properties

Variable Usage The following variable types (usages) are supported.

Internals: Internal variables are used only within an instance. They cannot

be used pass data directly to or from I/O parameters.

Inputs: Input variables can input data from input parameters outside of