Long-life Two-circuit Limit Switch

WLM@

New Long-life Limit Switches Added to the

Wide Variety of WL Models

• Improved resistance to abrasion and smoother movement in the

head section means that a mechanical life of 30,000,000 operations minimum is now a reality.

• Wiring and replacement for maintenance purposes are easy

done.

• Fluorescent indicators improve visibility when setting stroke

zones.

Model Number Structure

■ Model Number Legend

WLM@-LD@

1 2

1. Actuators

CA2: Roller lever: Standard

GCA2: Roller lever: High-precision

H2: Roller lever: Overtravel, general-purpose

G2: Roller lever: Overtravel, high-sensitivity

2. Wiring Specifications

Blank: Screw terminal: G1/2 conduit

K13A: Direct-wired connector: 2-core, AC

K13: Direct-wired connector: 2-core, DC

K43A: Direct-wired connector: 4-core, AC

K43: Direct-wired connector: 4-core, DC

-M1J: Pre-wired connector: 2-core, DC (See note.)

-AGJ03: Pre-wired connector: 4-core, AC (See note.)

-DGJ03: Pre-wired connector: 4-core, DC (See note.)

Note: With 0.3-m cable attached.

Limit

Switches

Long-life Two-circuit Limit Switch WLM@ F-99

Ordering Information

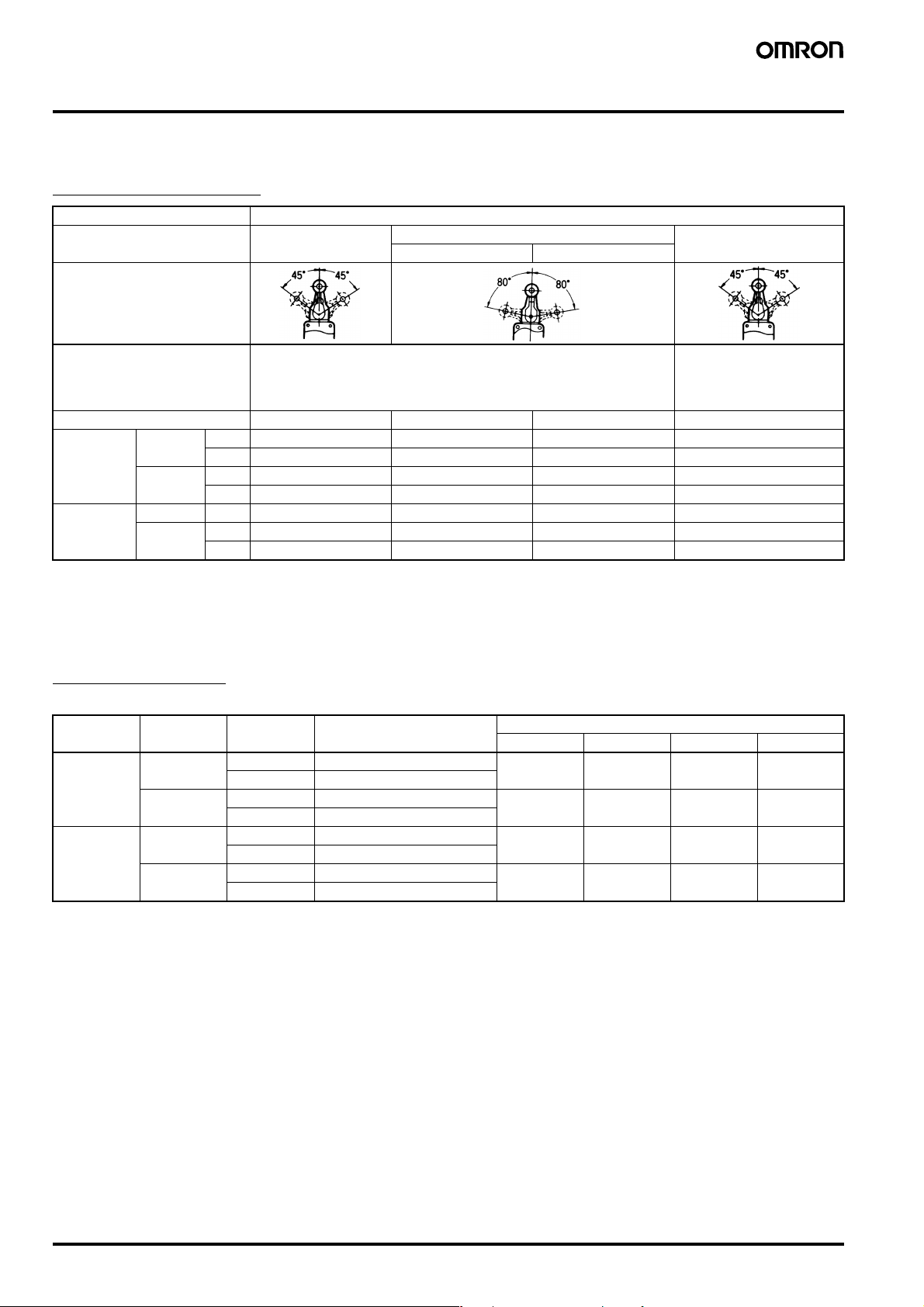

■ List of Models

Roller Lever with LED

Item Model

Type Standard Overtravel High-precision

General-purpose High-sensitivity

Overall movement

Features One-side operation not possible.

Head can be mounted in any of the four directions.

(See note 3.)

Screw terminal WLMCA2-LD WLMH2-LD WLMG2-LD WLMGCA2-LD

Direct-wired

connector

Pre-wired

connector

(See note 2.)

Note: 1. The default setting is light-ON when not operating (NO connection). To switch to light-ON when operating, simply rotate the lamp holder

2. 0.3-m cable attached.

3. One-side operation possible means that, by changing the direction of the operational plunger, one of three operating directions can be

2-core AC WLMCA2-LDK13A WLMH2-LDK13A WLMG2-LDK13A WLMGCA2-LDK13A

DC WLMCA2-LDK13 WLMH2-LDK13 WLMG2-LDK13 WLMGCA2-LDK13

4-core AC WLMCA2-LDK43A WLMH2-LDK43A WLMG2-LDK43A WLMGCA2-LDK43A

DC WLMCA2-LDK43 WLMH2-LDK43 WLMG2-LDK43 WLMGCA2-LDK43

2-core DC WLMCA2-LD-M1J WLMH2-LD-M1J WLMG2-LD-M1J WLMGCA2-LD-M1J

4-core AC WLMCA2-LD-AGJ03 WLMH2-LD-AGJ03 WLMG2-LD-AGJ03 WLMGCA2-LD-AGJ03

DC WLMCA2-LD-DGJ03 WLMH2-LD-DGJ03 WLMG2-LD-DGJ03 WLMGCA2-LD-DGJ03

by 180°. Contact your OMRON representative for details on the 2-core models.

selected. One-side operation not possible means that only operation on both sides is possible. See page 106 for details.

One-side operation possible.

Head can be mounted in any

of the four directions.

(See note 3.)

Applicable Cables

Use the Cables listed below with the Limit Switch with Connector.

Voltage Core wires Cable length Model Connection wires

1234

AC 2 2 m XS2F-A421-DB0-A --- --- Brown Blue

5 m XS2F-A421-GB0-A

4 2 m XS2F-A421-D90-A Brown White Blue Black

5 m XS2F-A421-G90-A

DC 2 2 m XS2F-D421-DD0 --- --- Blue Brown

5 m XS2F-D421-GD0

4 2 m XS2F-D421-D80-A Brown White Blue Black

5 m XS2F-D421-G80-A

F-100 Long-life Two-circuit Limit Switch WLM@

Specifications

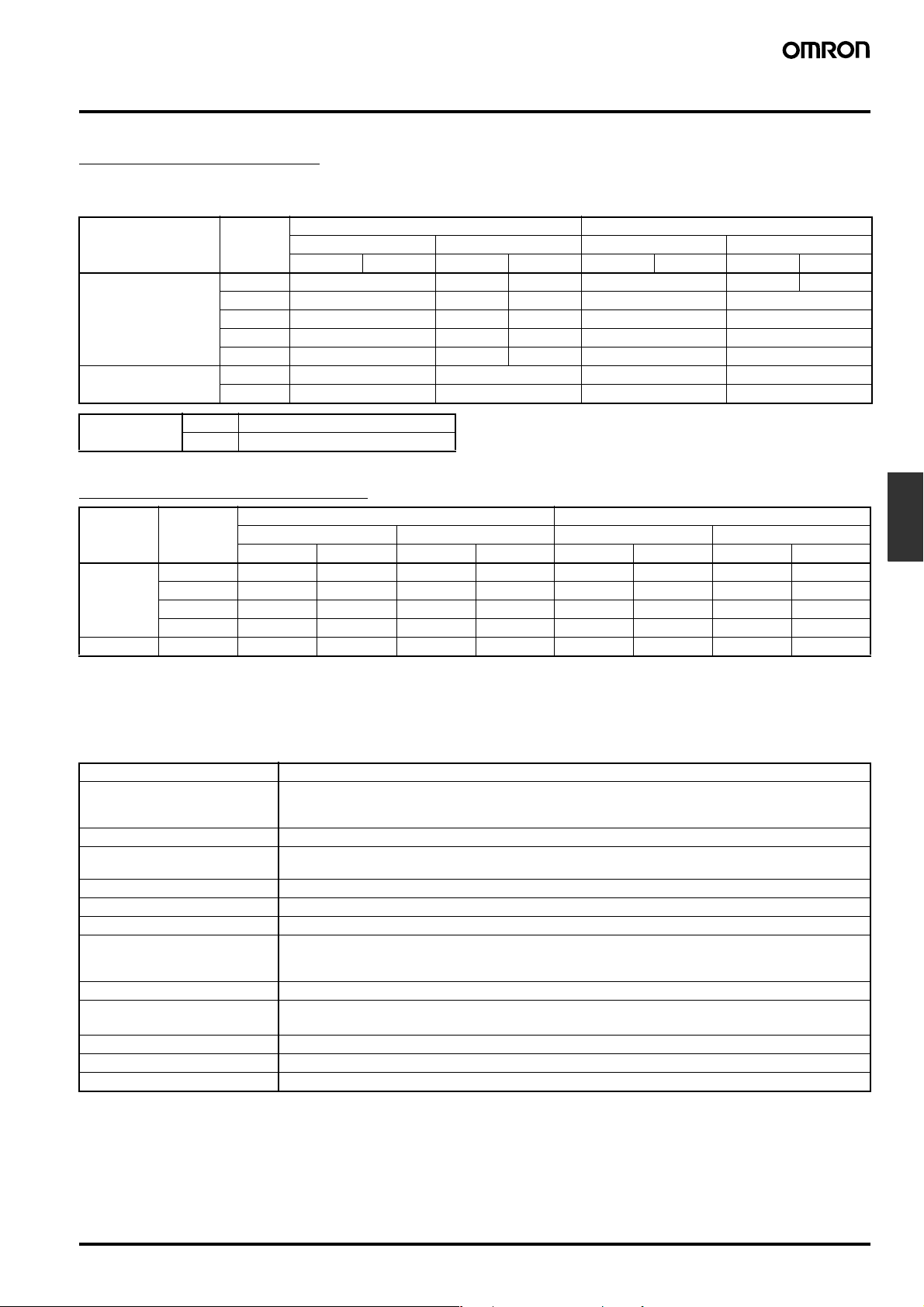

■ Ratings

General-purpose Ratings

Refer to these ratings before using the product.

Screw Terminal Models

Model Rated

Standard, overtravel

(except high-sensitivity),

and high-precision

Overtravel

(High-sensitivity)

Inrush current NC 30 A max. (15 A max. (See note))

NO 20 A max. (10 A max. (See note))

Note: Only for high-sensitivity overtravel models.

voltage

115 VAC 10 3 1.5 10 5 2.5

12 VDC 10 6 3 10 6

24 VDC 6 4 3 6 4

48 VDC 3 2 1.5 3 2

115 VDC 0.8 0.2 0.2 0.8 0.2

115 VAC 5 --- --- --115 VDC 0.4 --- --- ---

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

Direct-wired/Pre-wired Models

Model Rated

DC12 VDC33333333

AC 115 VAC 3 3 3 1.5 3 3 3 2.5

Note: 1. The above figures are for standard currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

voltage

24 VDC33333333

48 VDC33333333

115 VDC 0.8 0.8 0.2 0.2 0.8 0.8 0.2 0.2

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

■ Characteristics

Degree of protection IP67

Durability (See note 2.) Mechanical: 30,000,000 operations min. (10 mA at 24 VDC, resistive load)

Operating speed 1 mm to 1 m/s (for WLMCA2)

Operating frequency Mechanical: 120 operations/minute

Rated frequency 50/60 Hz

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 25 mΩ max. (initial value)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between non-continuous terminals. (Except connector models.)

Vibration resistance 10 to 55 Hz, 1.5-mm double amplitude

Shock resistance

Ambient temperature Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: 95% max.

Weight Approx. 275 g (for WLMCA2)

Note: 1. The figures in parentheses for dielectric strength, are those for overtravel (high-sensitivity) or connector models.

2. The values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your OMRON

sales representative for more detailed information on other operating environments.

Electrical: 750,000 operations min. (10 A at 115 VAC, resistive load),

Electrical: 30 operations/minute

2,200 VAC (1,500 V), 50/60 Hz for 1 min between non-current-carrying metal part and ground.

2,200 VAC (1,500 V), 50/60 Hz for 1 min between each terminal and non-current-carrying metal part.

Destruction: 1,000 m/s

Malfunction: 300 m/s

Non-inductive load Inductive load

Non-inductive load Inductive load

but for high-precision models: 500,000 operations min. (10 A at 115 VAC, resistive load)

2

min.

2

min.

Limit

Switches

Long-life Two-circuit Limit Switch WLM@ F-101

■ Operating Characteristics

Operating characteristics WLMCA2-LD@

OF max. 9.81 N 9.81 N 9.81 N 13.34 N

RF min. 0.98 N 0.98 N 0.98 N 1.47 N

PT

OT min. 30° 55° 65° 40°

MD max. 12° 12° 7° 3°

Standard models

15±5

°

WLMH2-LD@

Overtravel models

(general-purpose)

15±5

°

WLMG2-LD@

Overtravel models

(high-sensitivity)

+2°

10

−1°

WLMGCA2-LD@

High-precision models

+2°

5

−0°

■ Contact Form

Screw Terminal Models

WLM@-LD

Lamp-equipped: Light-ON when not operating

Internal circuit

Built-in switch

Direct-wired Connector/Pre-wired Connector Models

AC Models: WLM@-LD@@

Lamp-equipped: Light-ON when not operating (See note.)

AC model DC model

Internal circuit

Built-in switch

Pin No.

2-core

4-core

Note: Light-ON when not operating means that the lamp remains lit when the actuator is free, and goes out when the Limit Switch contacts (NO)

close when the actuator rotates or is pushed down.

Pin No.

2-core

4-core

Internal circuit

Built-in switch

F-102 Long-life Two-circuit Limit Switch WLM@

Engineering Data

■ Electrical Durability: cosφ = 1

Operating temperature: 5°C to 30°C

Operating humidity: 40% to 70%

Operating frequency: 30 operations/min

cosφ = 1

125 VAC

250 VAC

operations)

4

480 VAC

Durability (x 10

Switching current (mA)

■ Lamp-equipped Models

The operating status of the Switch can be checked using a neon

lamp of LED indictor.

Circuit checks and troubleshooting errors are easy done.

Light emitting diode (LED)

Lamp holder

Operation

indicator

window

The built-in switch’s terminal screws are used to connect the lamp

terminal (indicator cover). Since the connection spring (coil spring) is

used for this connection, it will not be necessary to connect to the

lamp terminal. When a ground terminal is provided however, lead

wire method must be used.

WL-LD has a built-in rectifier stack, so it will not be necessary to

change the polarity.

The indicator cover is molded from diecast aluminum and has outstanding sealing properties. Furthermore, regardless of whether the

power is connected or not, the operating status is shown (operating

or not operating), and indicators can be switched from light-ON when

operating and light-ON when not operating, by simply rotating the

lamp holder by 180°.

The lamp-equipped models are ideal in locations using a conveyor

belt where items need to be checked, or locations that are difficult to

inspect for faults.

Contact spring

Light-ON when Operating

LED at top

Light-ON when Not Operating

LED at bottom

Indicator Lamp and Load Operation

When the indicator lamp is set to light-ON when operating, connect

the load on the NC side, and set so that the load turns ON when the

actuator is free.

When the indicator lamp is set to light-ON when not operating, connect the load on the NO side, and set so that the load turns ON when

the actuator is pushed down.

Light-ON when Operating

When the Switch’s contacts and the internal circuit of the lamp holder

are connected in parallel, there is large resistance from the internal

circuit, so the current will flow through the Switch’s contacts and the

load will turn ON.

When the contacts and the internal circuit are separated, only a

small voltage, enough to light the indicator lamp will flow to the lamp,

but the load will not turn ON.

Operation

LIght-ON

when

operating

(See note 1.)

Light-ON

when not

operating

(See note 2.)

WL-LD

WL-LD

Power supply

Built-in switch

Load

Internal circuit

Power supply

Internal circuit

Load

Limit

Switches

Built-in switch

Note: 1. Light-ON when operating means that the lamp lights when

the Limit Switch contacts (NC) release, or when the actuator

rotates or is pushed down.

2. Light-ON when not operating means the lamp remains lit

when the actuator is free, or when the Limit Switch contacts

(NO) close when the actuator rotates or is pushed down.

Long-life Two-circuit Limit Switch WLM@ F-103

Models/Ratings

Operating

characteristics

LED 10 to

Note: 1. In the model number, @ indicates the actuator number. For

2. The default setting is “light-ON when not operating.” Turn the

Maximum

rated voltage

115 VAC, DC

Leakage

current

Approx. 1 mA WL@-LD

Lamp-

equipped

Switch

(See note 1.)

Lamp-

equipped

cover only

WL-LD

example, MCA2, etc.

lamp holder by 180° to change the setting to “light-ON when

operating.”

Nomenclature

Internal Circuits

WL-LD

Contact spring

Zener

diode

Rectifier stack

Resistance

Constant current diode

Light-emitting diode (LED)

Release Plunger

Hardening method changed for greater abrasion resistance.

Standard Model Long-life Model

Sintered

alloy

Head

The Head can be mounted in any of the

four directions by removing the screws at

the four corners of the Head.

Shaft Section Seal

By fitting a double seal consisting of an oil seal

and an X-ring to the rotary shaft, even greater

sealing properties are achieved.

Standard Model Long-life Model

O-ring

Smoother Movement

A grease holder is provided on the shaft to

prevent the grease from running out.

Standard Model

Stainless steel

+

Hardening

Oil seal X-ring

Head

Mounting

Screws

Set Position Marker Plate

The set position is easy to view. The stroke is

indicated in fluorescent color that is visible from

the slit in the rubber cap.

Standard Model Long-life Model

Requires maintenance

(excessive overtravel)

Proper range

Requires maintenance (insufficient overtravel)

Proper range

Requires maintenance (excessive overtravel)

Roller

The roller is made of self-lubricating stainless sintered

and boasts high resistance to wear.

Lever

The lever forged of anti-corrosive aluminium alloy

features high corrosion resistance and outstanding

ruggedness. With roller lever models, the actuator

position can be set anywhere within 360°. (The lever

cannot be mounted in the opposite direction.)

Operational Plunger (See note.)

Fluorescent paint

Cover Seal

Long-life Model

Grease holder

Smooth movement is achieved using

olefin grease. (Standard models use

molybdenum disulfide grease.)

Bearing

The bearing smooths the plunger movement.

Built-in Switch

Built-in switch with SPST-NO+NC contact form.

Conduit Opening

In addition to level screws which use G 1/2 tube, directwired and pre-wired connectors have been added.

By using a packing seal as the cover seal, an

optimum squeeze can be obtained and high sealing

properties are assured as well.

Terminal Screws

Four, M4 screws

Cover

Separator

The separator has outstanding insulation

properties and prevents the generation of any

gases which may corrode the internal parts.

Cover Mounting Screw

A Phillips screw is used to ensure ease of use.

Note: By changing the direction of the operational plunger, any one of the three operational directions (both sides, left, or right) can be selected.

(Only applicable to the WLMGCA2-@.)

F-104 Long-life Two-circuit Limit Switch WLM@

Dimensions

Rotating Lever Models: Standard

Screw Terminals

WLM@-LD

17.5 dia. × 7 (See note)

38R

14.7

58.7±0.2

5

(15.1)

(4.9)

Pre-wired Connectors

WLM@-LD@

17.5 dia. × 7 (See note)

38R

14.7

58.7±0.2

30.2

40±0.7

±

0.2

Four, M3.5

(length: 26.5)

M5 × 12

Allen-head

bolt

+0.2

Four ,5.2

0

holes

Rubber cap

Three, M4 × 13

Lamp cover

JIS B0202 G1/2

Effective thread:

4 threads min.

Four, M3.5

(length: 26.5)

M5 × 12

Allen-head

bolt

+0.2

Four, 5.2

0

Rubber cap

Three, M4 × 13

dia.

dia.

holes

60 max.

53±1.5

41.5±1.5

40±1.5

42 max.

53.2±0.8

60 max.

53±1.5

41.5±1.5

25.4

21.6

29.2

35

40±1.5

25.4

13.1

12.7

Four, M6

Depth: 15 min.

±

1.2

13.1

12.7

25.4

68.7

25.4

68.7

Direct-wired Connectors

WLM@-LD@

14.7

58.7±0.2

5

(15.1)

(4.9)

Note: Stainless steel rollerNote: Stainless steel roller

17.5 dia. × 5 (See note)

38R

Four, M3.5

(length: 26.5)

Four ,5.2

Rubber cap

Three, M4 × 13

Lamp cover

12.5

30.2

40±0.7

±

0.2

SC-2FD

M12 × 1

JIS B0202 G1/2

Effective thread:

4 threads min.

M5 × 12

Allen-head

bolt

+0.2

dia.

0

holes

60 max.

53±1.5

41.5±1.5

40±1.5

29.2

42 max.

53.2±0.8

35

25.4

21.6

±

13.1

1.2

12.7

25.4

68.7

Four, M6

Depth: 15 min.

Limit

Switches

(25)

5

Four, M6

Depth: 15 min.

XS2H-D421

Lamp cover

300±50

52

(15.1)

(4.9)

30.2

40±0.7

±

0.2

53.2±0.8

29.2

35

42 max.

21.6

6 dia.

±

1.2

Note: Stainless steel roller

Note: Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Long-life Two-circuit Limit Switch WLM@ F-105

Accessories

Cable

Straight

5 dia.

5 dia.

6 dia.

14.9 dia.

DC

AC

Installation

Item Appropriate model/actuator Details

Changing the installation position of

the actuator

By loosening the Allen-head bolt on the

actuator lever, the position of the actuator can be set anywhere within 360°.

With Lamp-equipped Switches, the actuator lever comes in contact with the

top of the lamp cover, so use caution

when rotating and setting the lever.

Installing the roller on the inside

By installing the roller lever in the opposite direction, the roller can be installed

on the inside. (Set so that operation can

be completed within a 180° level

range.)

Changing the orientation of the head

By removing the screws in the four corners of the Head, the Head can be set

in any of the four directions. Be sure to

change the plunger for internal operations at the same time. (The operational

plunger does not need to be changed

on overtravel general-purpose and

overtravel high-sensitivity models.)

Roller Levers: WLMCA2@, WLMH2@,

WLMG2@, WLMGCA2@

Roller Levers: WLMCA2@, WLMH2@,

WLMG2@, WLMGCA2@

Roller Levers: WLMCA2@, WLMH2@,

WLMG2@, WLMGCA2@

Loosen the

Allen head bolt

Head

Loosen the M5 × 12 bolt, set the

actuator's position and then

tighten the bolt again.

Loosen the screws

Head

Loosen the

screws

Changing the operating direction

Roller Levers: WLMGCA2@

By removing the Head on models which

can operate on one-side, and then

changing the direction of the operational plunger, one of three operating directions can be selected.

The tightening torque for the screws on

the Head is 0.78 to 0.88 N·m.

F-106 Long-life Two-circuit Limit Switch WLM@

The output of the

Switch will be changed,

regardless of which

direction the lever is

pushed.

Operating

Operation in both

directions

Not operating Not operating

Operating Operating Operating

Clockwise operation Anti-clockwise

The output of the

Switch will only be

changed when the lever

is pushed in one

direction.

Operational

plunger

operation

Precautions

■ Correct Use

When wiring terminal screws, use M4 round crimp terminals and

tighten screws to the recommended torque. Wiring with broken

wires, or the incorrect crimp terminals, or not tightening screws to the

recommended torque can lead to short-circuits, leakage current, and

fire.

When performing internal wiring there is a chance of short-circuit,

leakage current, or fire, so be sure to protect the inside of the Switch

from splashes of oil or water, corrosive gases, and cutting powder.

Using an inappropriate connector or assembling Switches incorrectly

(assembly, tightening torque) can result in malfunction, leakage current, or fire, so be sure to read the instruction manual thoroughly

beforehand.

Even when the connector is assembled and set correctly, the end of

the cable and the inside of the Switch may come in contact. This can

lead to malfunction, leakage current, or fire, so be sure to protect the

end of the cable from splashes of oil or water and corrosive gases.

Environmental Precautions

When the Switch is used in locations subject to splashes of water or

oil, the material of the seal, which ensures the sealing properties of

the Switch, may undergo changes in shape and quality. This is due to

deterioration (including expansion and contraction), and may result in

reduced performance, ineffective return, and ineffective sealing

(leading to ineffective contact, insulation, leakage current, and fire).

Confirm the possible effects of the operating environment on the

Switch before use.

Tightening Torque

If screws are too loose they can lead to an early malfunction of the

Switch, so ensure that all screws are tightened using the correct

torque.

No. Type Torque

1 Head mounting screw 0.78 to 0.88 N·m

2 Cover mounting screw 1.18 to 1.37 N·m

3 Allen-head bolt

(for securing the lever)

4 Terminal screw 0.59 to 0.78 N·m

5 Connector 1.77 to 2.16 N·m

6 Main Unit screws 4.90 to 5.88 N·m

4.90 to 5.88 N·m

Limit

Switches

Built-in Switch

Do not replace the built-in switch. If the position of the insulation

sheet moves (separator), the insulation may become ineffective.

In particular, when changing the direction of the Head, make sure

that all screws are tightened again to the correct torque. Do not allow

foreign objects to fall into the Switch.

Installing the Switch

To install the Switch, make a mounting panel, as shown in the following diagram, and tighten screws using the correct torque.

+0.2

Four, 5.2

dia. mounting holes or M5 taps

0

Connectors

Either the easy-to-use Allen-head nut or the SC Connector can be

used as connectors. To ensure high-sealing properties, use the SC

Connector. (SC-1M to -5M and others.)

Long-life Two-circuit Limit Switch WLM@ F-107

Wiring

Use 1.25-mm lead wires and M4-insulation covered crimp terminals

for wiring.

Crimp Terminal External Dimensions

D dia.

dz dia. 4.3

D dia. 4.5

B: 8.5

L: 21.0

F: 7.8

l: 9.0 (mm)

Wiring Method

Switch Box Section

dz dia.

Operation Set Position

There is a set position marker slit on the rubber cap of the head.

After operation, set the slit on the rubber cap so that the fluorescent

color on the shaft section can be seen.

Terminal Plate

By using a short circuit plate, as shown in the following diagram, the

Switch can be fabricated into a single-polarity double-break model.

When ordering specify WL Terminal-Plate (IWPA01).

.

3R

9+0.2

16±0.15

2R

Ground terminal

NO terminal

NC terminal

Note: Ground terminals are not installed on the standard models.

2.1R

t = 0.6 Copper plate

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C112-E1-02

In the interest of product improvement, specifications are subject to change without notice.

F-108 Long-life Two-circuit Limit Switch WLM@

Loading...

Loading...