Page 1

Two-circuit Limit Switch

WL

Wide Selection of Two-circuit Limit Switches

• A wide selection of models are available, including the overtravel models with greater OT, lamp-equipped models for checking

operation, low-temperature and heat-resistant models, and microload models.

• Microload models are added to the product lineup.

• Meets EN/IEC standards (only Switches with ground terminals).

• Switches with ground terminals have the CE marking.

Model Number Structure

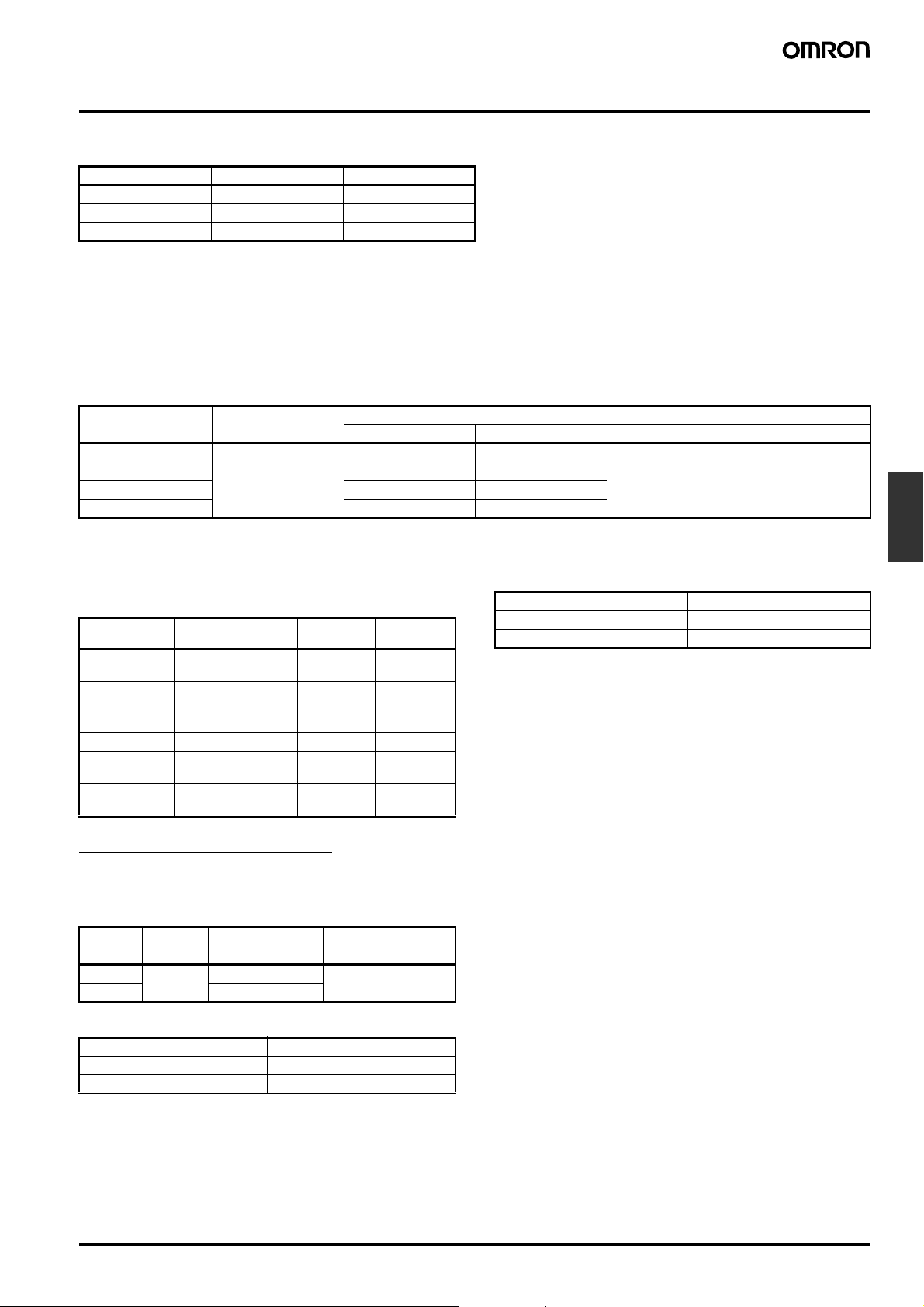

■ Model Number Legend

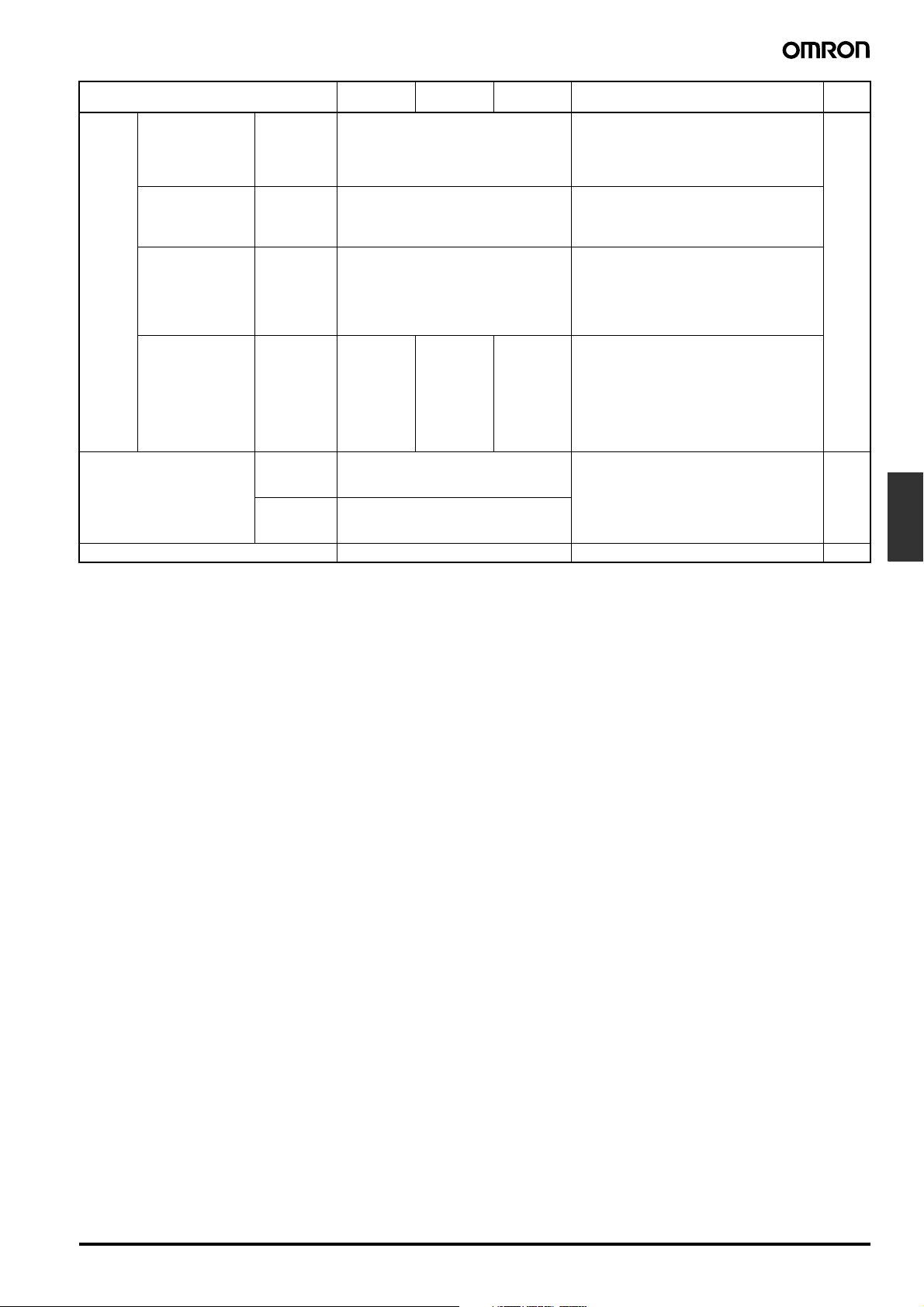

General-purpose Models/Environment-resistant Models

WL@@-@@@@@@@@

1 2 3 4 5 6 7 8 9 10

1. Electrical Rating

Blank: Standard

01: Micro

2. Actuator and Head Specifications

Symbol Actuator type Switches without levers

CA2 Roller lever: Standard model (R38) WLRCA2

CA2-7 Roller lever: Standard, standard model (R50) WLRCA2

CA2-8 Roller lever: Standard, standard model (R63) WLRCA2

H2 Roller lever: Overtravel, general-purpose model, 80° WLRH2

G2 Roller lever: Overtravel, high-sensitivity, 80° WLRG2

CA2-2N Roller lever: Overtravel, 90° WLRCA2-2N

GCA2 Roller lever: High-precision WLRGCA2

CA12 Adjustable roller lever: Standard WLRCA2

H12 Adjustable roller lever: Overtravel, general-purpose model, 80° WLRH2

G12 Adjustable roller lever: Overtravel, high-sensitivity, 80° WLRG2

CA12-2N Adjustable roller lever: Overtravel, 90° WLRCA2-2N

CL Adjustable rod lever: Standard WLRCL

HL Adjustable rod lever: Overtravel, general-purpose model, 80°, 25 to 140 mm WLRH2

HLAL4 Adjustable rod lever: Overtravel, general-purpose model, 80°, 350 to 380 mm WLRH2

GL Adjustable rod lever: Overtravel, high-sensitivity, 80°, 25 to 140 mm WLRG2

CL-2N Adjustable rod lever: Overtravel, 90°, 25 to 140 mm WLRCA2-2N

HAL5 Rod spring lever: Protective, Overtravel, general-purpose model, 80° WLRH2

CA32-41 Fork lever lock: Protective, WL-5A100 WLRCA32

CA32-42 Fork lever lock: Protective, WL-5A102 WLRCA32

CA32-43 Fork lever lock: Protective, WL-5A104 WLRCA32

D Plunger: Top plunger --D2 Plunger: Top-roller plunger --D28 Plunger: Sealed top-roller plunger --D3 Plunger: Top-ball plunger --SD Plunger: Horizontal plunger ---

Limit

Switches

Two-circuit Limit Switch WL F-57

Page 2

Symbol Actuator type Switches without levers

SD2 Plunger: Horizontal-roller plunger --SD3 Plunger: Horizontal-ball plunger --NJ Flexible rod: Coil spring --NJ-30 Flexible rod: Coil spring, multi-wire --NJ-2 Flexible rod: Coil spring, resin rod --NJ-S2 Flexible rod: Steel wire ---

3. Environment-resistant Model Specifications

Blank: Standard

RP: Corrosion-proof (See note 1.)

P1: Weather-resistant (See note 1.)

4. Built-in Switch Specifications

Blank: General-purpose built-in switch

55: Hermetically-sealed built-in switch (See note 1.)

5. Temperature Specifications

Blank: Standard: –10°C to 80°C

TH: Heat-resistive: 5°C to 120°C (See note 1.)

TC: Low temperature: –40°C to 40°C (See note 1.)

6. Special Hermetic Model Specifications

Blank: No cables or molding

139: General-purpose built-in switch with cables attached and molded conduit opening and cover (cover cannot be removed).

(See note 1.)

140: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed).

(See note 1.)

141: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed).

The Head opening is created to protect it from cutting powder. (See note 1.)

145: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed, Head

can be mounted in any of 4 directions).

The Head opening is created to protect it from cutting powder. (See note 1.)

RP40: Airtight built-in switch with cables attached, SC Connector can be used, molded conduit opening, cover, and case cover

(cover cannot be removed, Head direction can be changed). (See note 1.)

RP60: Airtight built-in switch with cables attached, fluorine rubber-molded conduit opening, cover, and case cover

(cover cannot be removed, Head direction cannot be changed). (See note 1.)

7. Conduit Size, Ground Terminal Specifications (See note 2.)

Blank: G

G1: G

1

/

2

1

/

2

Without ground terminal

With ground terminal

G: Pg13.5 With ground terminal

Y: M20 With ground terminal

TS:

1

/2-14NPT With ground terminal

8. Indicator Type

Element Voltage Leakage Current

LE: Neon lamp 125 VAC Approx. 0.6 mA

250 VAC Approx. 1.9 mA

LD: LED 10 to 115 VAC/VDC Approx. 0.5 mA

9. Lamp Wiring

2: NC connection: Light-ON when operating

3: NO connection: Light-ON when not operating

10.Lever Type

Blank: Standard lever

A: Double nut lever

Note: 1. For information on applicable models, see page 60.

2. Switches with ground terminals meet EN/IEC standards (and have the CE marking).

Ground Terminal Models

WL -

12

F-58 Two-circuit Limit Switch WL

1: Type of actuator

2: Conduit opening size

The models differ depending on the size of the case’s conduit thread.

Model Conduit opening size

G1

G

1

/

2

G Pg 13.5

YM20

TS

1

/2-14NPT

Page 3

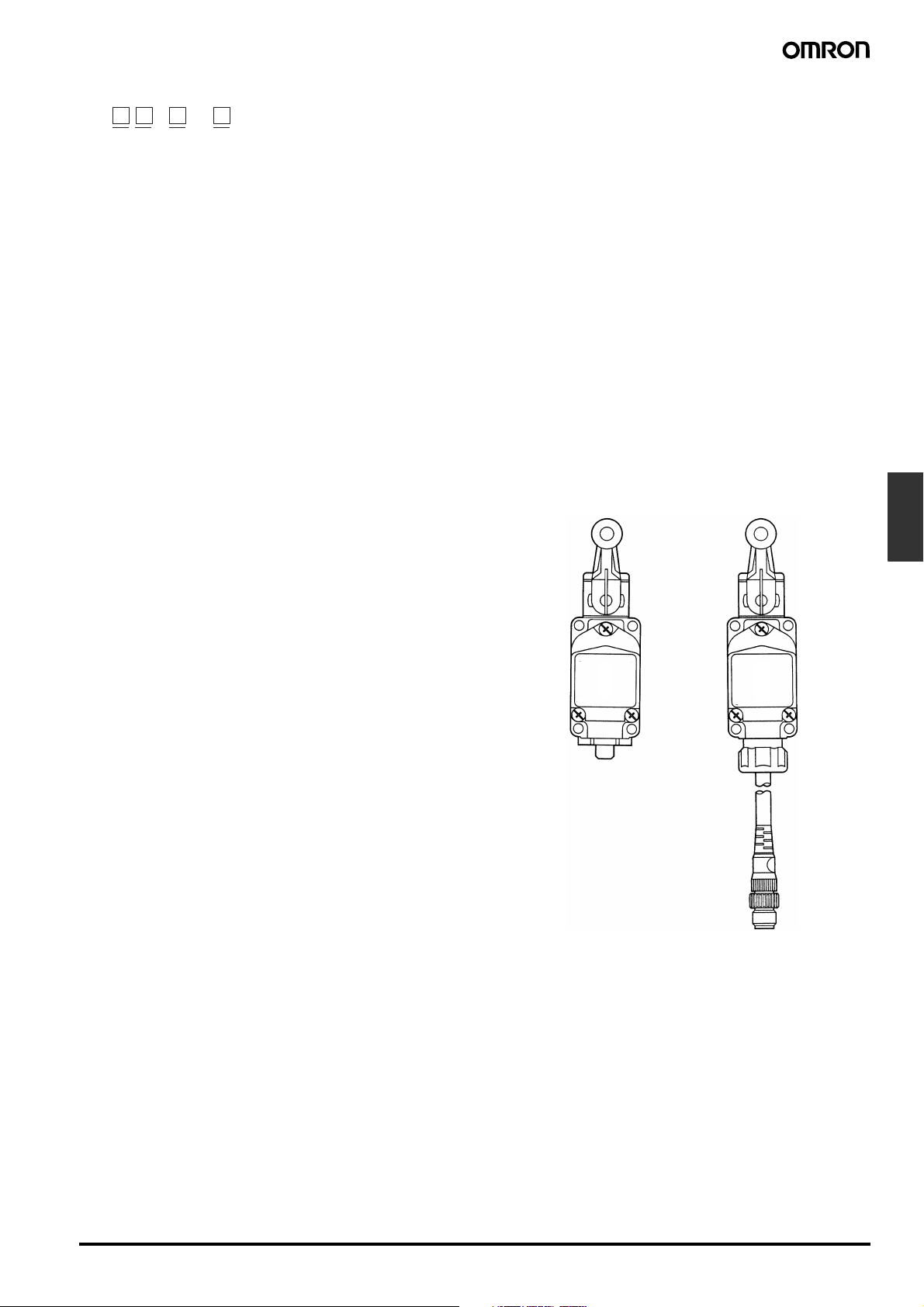

Sensor I/O Connector Models

WL - LD

12 34

1. Electrical Rating

Blank: Standard

01: Microload

2. Actuator Type

CA2: Roller lever: Standard

GCA2: Roller lever: High-precision

H2: Roller lever: Overtravel, general-purpose

G2: Roller lever: Overtravel, high-sensitivity

D2: Plunger: Top-roller plunger

D28: Plunger: Sealed top-roller plunger

3. Built-in Switch Type

Blank: Standard

55: Hermetically sealed

4. Wiring Specifications

K13A: Direct-wired Connector

K13: Direct-wired Connector

K43A: Direct-wired Connector (4-core: AC)

K43: Direct-wired Connector (4-core: DC)

-M1J: Pre-wired Connector (See note 2.)

-M1GJ: Pre-wired Connector (See note 2.)

(See note 1.) (2-core: DC, NO wiring, connector pins No. 1, 4)

-M1JB: Pre-wired Connector (See note 2.)

(See note 1.) (2-core: DC, NC wiring, connector pins No. 3, 2)

-AGJ03: Pre-wired Connector (See note 2.) (4-core, AC)

-DGJ03: Pre-wired Connector (See note 2.) (4-core, DC)

(See note 1.)

-DK1EJ03: Pre-wired Connector (See note 2.)

(See note 1.) (3-core: DC, NO wiring, connector pins No. 2, 3, 4)

Note: 1. Models with pre-wired connectors and DC specifications

2. With 0.3-m cable attached.

Direct-wired Connector

(2-core: AC, NO wiring, connector pins No. 3, 4)

(2-core: DC, NO wiring, connector pins No. 3, 4)

(2-core: DC, NO wiring, connector pins No. 3, 4)

have EN/IEC approval.

Pre-wired Connector

Limit

Switches

Two-circuit Limit Switch WL F-59

Page 4

Spatter-prevention Models

WL - S

12 34 5

1. Electrical Rating

Blank: Standard

01: Microload

2. Actuator Type

CA2: Roller lever: Standard model

GCA2: Roller lever: High-precision model

H2: Roller lever: Overtravel, general-purpose model

G2: Roller lever: Overtravel, high-sensitivity model

D28: Plunger: Sealed top-roller plunger

3. Built-in Switch Type

Blank: Standard

55: Hermetically sealed

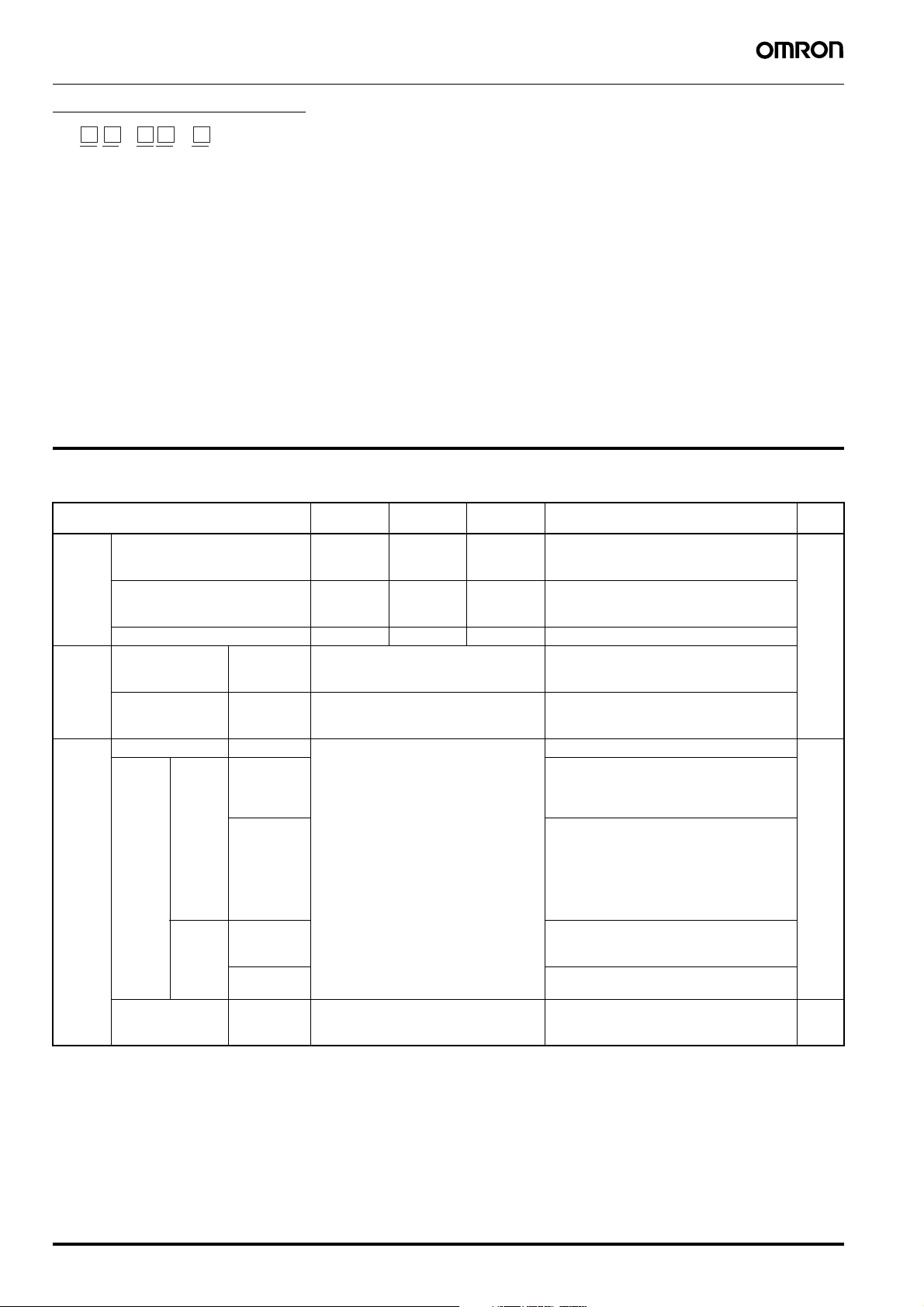

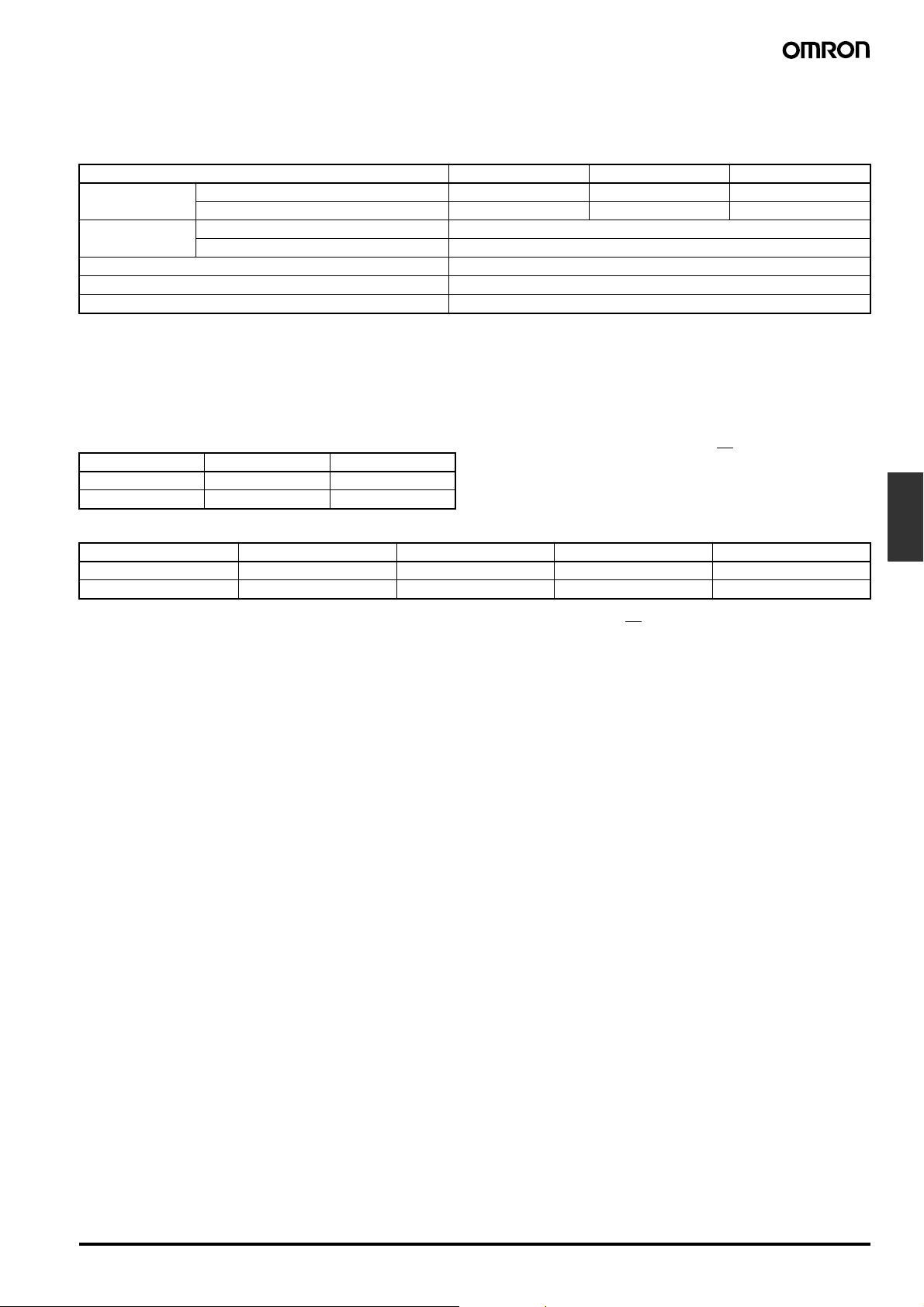

Ordering Information

■ Classification

4. Indicator Lamp

Blank: None

LD: LED indicator lamp (AC/DC common)

LE: Neon Lamp

5. Wiring Specifications

-M1J-1: Pre-wired Connector (See note.)

(2-core: DC, NO wiring, connector pins No. 3, 4)

-M1GJ-1: Pre-wired Connector (See note.)

(2-core: DC, NO wiring, connector pins No. 1, 4)

-DGJS03: Pre-wired Connector (See note.) (4 core, DC)

Note: With 0.3-m cable attached.

Specifications Standard Overtravel High-

Actuators Roller lever Yes Yes Yes Five models: Roller lever, adjustable roller le-

Plunger Yes --- --- Six models: Top plunger, top-roller plunger,

Flexible rod Yes --- --- Two models: coil spring and steel wire.

Load/

contact

Environment-resistant

models

(See

note 3.)

Standard load SPST-NO/

Microload SPST-NO/

Airtight-seal WL@-55 Yes (Cannot be used with heat-resistive

Hermet-

ic seal

Spatter-prevention WL@-S Yes To improve spatter prevention during welding,

Molded

terminals

Anti-coolant

SPST-NC

type

SPST-NC

type

WL@-139 Lead wires are attached.

WL@-140

WL@-141

WL@-145

WL@-RP40 The connector can be removed, so it is possi-

WL@-RP60 Rubber parts are made from fluorine rubber.

Yes Standard models use a two-circuit double-

Yes Specifications include gold-plated contacts.

and low-temperature models.)

precision

ver, adjustable rod lever, fork lever lock, rod

spring lever.

top-ball plunger, horizontal plunger, horizontal-roller plunger, horizontal-ball plunger.

break switch.

Uses an airtight-sealed built-in switch. 66, 76

The case cover and conduit section are molded from epoxy resin to improve sealing performance.

Lead wires are attached.

The case is filled with epoxy resin, to ensure

high sealing performance.

The Head opening is protected from cutting

powder. (WL@-141 and -145 models)

Only WLG2, WLCA2, and WLGCA2 can be

fabricated. (WL@-141 models.)

ble to use flexible wires in the cable. The

Head can be removed.

The Head cannot be removed.

a heat-resistant resin is used, and screws

and rollers are all made from stainless steel.

Features Page

77 to

94

62 to

64

69, 73

to 75

67, 69,

71, 73,

76, 89

F-60 Two-circuit Limit Switch WL

Page 5

Specifications Standard Overtravel High-

Environment-resistant

models

(See

note 3.)

Lamp-equipped WL@-LE Yes Operating status can be checked at a glance.

Relevant pages Pages 77 to 94 --- ---

Heat-resistive WL@-TH Yes (Cannot be used with airtight, hermet-

Low-temperature WL@-TC Yes (Cannot be used with airtight, hermet-

Corrosion-proof

(See note 4.)

Outdoor specifications

WL@-RP Yes (Cannot be used with lamp-equipped

WL@-P1 ---

WL@-LD Yes

ic, low-temperature, corrosion-proof, or

lamp-equipped models.)

ic, heat-resistive, corrosion-proof, or lampequipped models.)

models.)

(See note 5.)

Ye s

(See note 6.)

precision

To improve heat resistance, silicone rubber is

used for rubber parts and for the built-in

switch.

The operating temperature range is +5°C to

120°C.

To improve low temperature resistance, silicone rubber is used.

The operating temperature range is –40°C to

40°C.

Diecast parts such as the switch box are

made of corrosion-proof aluminum. Rubbersealing parts are made of fluorine rubber and

exposed nuts and screws are made of stainless steel. These all aid in resisting oil, chemicals and adverse weather conditions.

--- Rotary shafts are made of unquenched (i.e.,

untreated) stainless steel to improve corrosion resistance. Exposed nuts and screws

are made of stainless steel and rubber sealing parts of silicone rubber. These factors all

combine to create a product which is resistant

to temperature changes and adverse weather

conditions.

Lit when operating and not lit when not operating.

WL@-LE: 100 VAC/VDC min.

WL@-LD: 115 VAC/VDC min. (Refer to

page 71 for detailed ratings.)

Features Page

66

64, 72,

73, 75,

86

Limit

Switches

Note: 1. Do not expose to extreme changes in temperature.

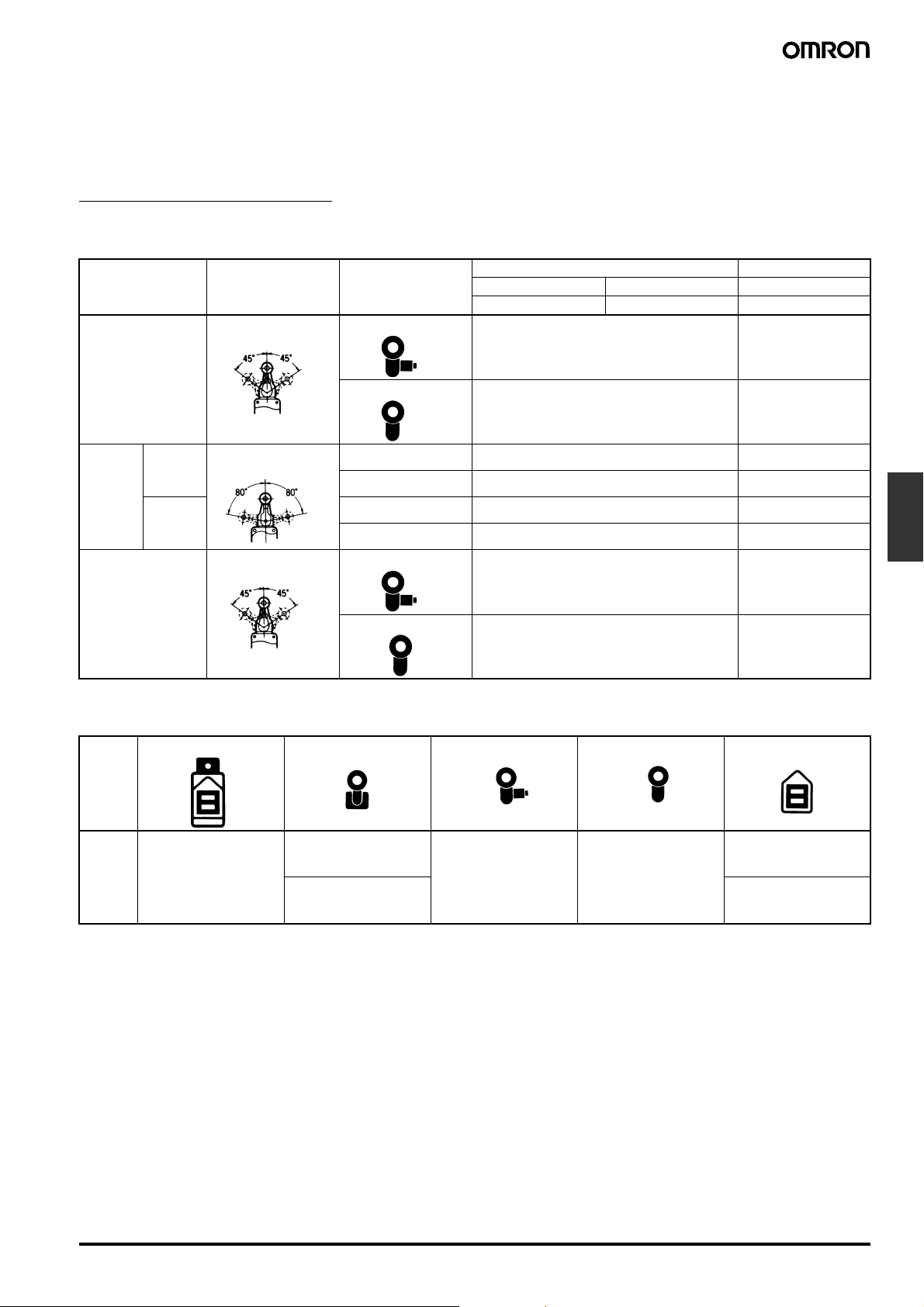

2. Standard Models: Operate on each side at an angle of 45°.

Overtravel Models: Standard and high-sensitivity models operate on each side at an angle of 80°.

High-precision Models: Operate on each side at an angle of 45°.

3. When ordering, add the suffix for the environment-resistant model or indicator specifications required according to the operating environ-

ment and purpose.

4. The overtravel model (-2N Series), fork lever lock model (WLCA32-41 to 44), horizontal plunger (WLSD@) model, heat-resistive model,

low-temperature model, and lamp-equipped model cannot be used with the corrosion-proof model.

5. Outdoor specifications are available for some standard models. Consult your OMRON representative for details.

6. Outdoor specifications are only available for general models and high-sensitivity models.

Possible to set to one-side operation on either side.

Pretravel (PT) is 15°.

Not possible to set to one-side operation.

-2N Series operate on each side at an angle of 90°.

Possible to set to one-side operation on either side.

Possible to set to one-side operation on either side.

Pretravel (PT) is 5°.

Two-circuit Limit Switch WL F-61

Page 6

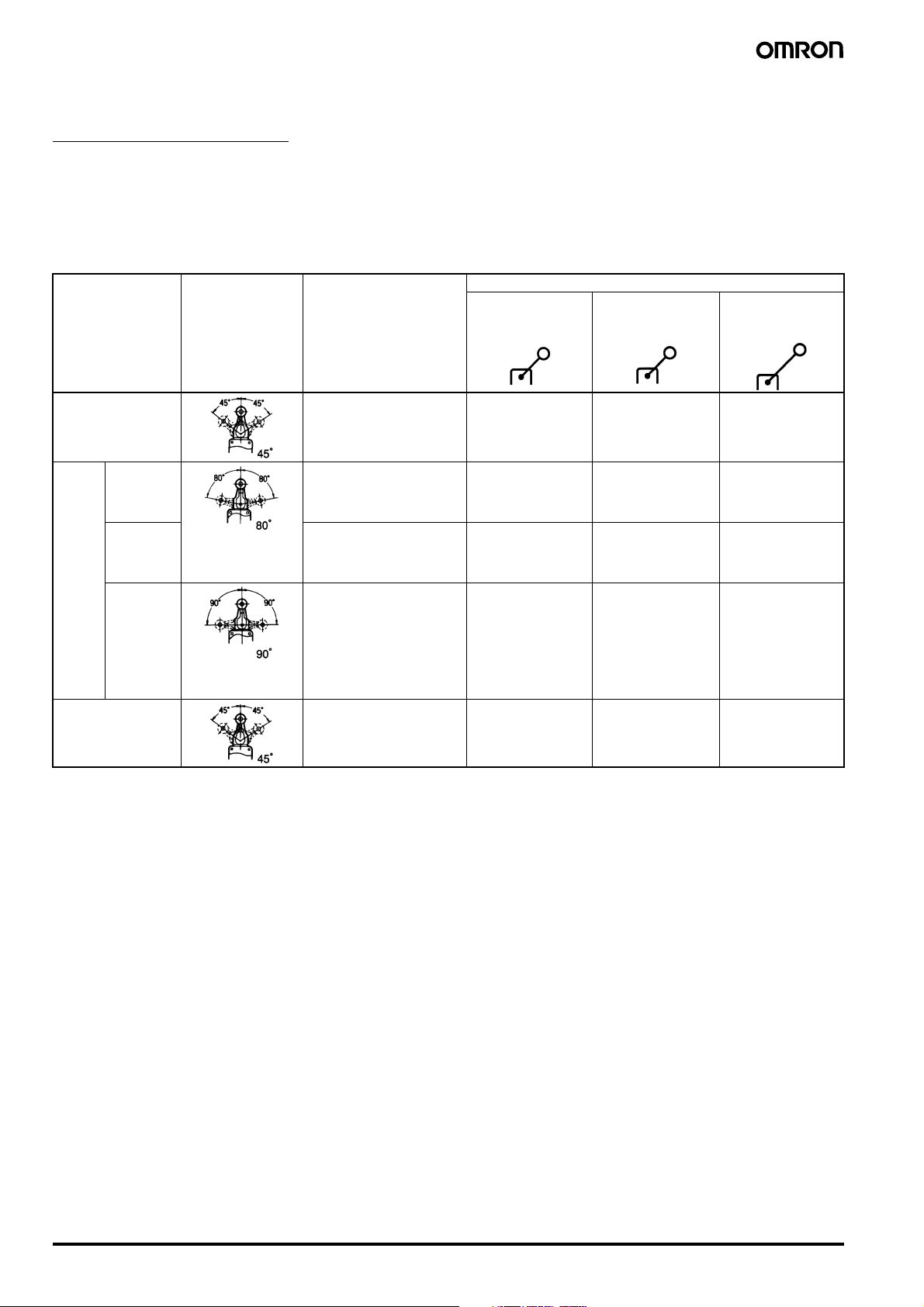

■ List of Models

General-purpose Models

These Limit Switches are two-circuit double-break switches housed in rugged diecast, thus making it an oil-tight, waterproof and dustproof construction (complies with IP67).

In addition to the standard models, microload models are also available.

A wide range of actuators with a range of functions are available; rotating lever, plunger, flexible rod etc.

The rubber material in the standard models is designed to be resistant to water and most oils.

Roller Lever Models: Short, Medium, and Long Lever Models

Type Total travel (TT) Features Actuator (See note 2.)

WL-1A100 Roller

Lever: Short

lever (R38)

WL-1A200 Roller

Lever: Medium

lever (R50)

WL-1A300 Roller

Lever: Long

lever (R63)

Standard One-side operation is possi-

Overtravel

High-precision One-side operation is possi-

Note: 1. For the approved standards file numbers, refer to page 69.

General One-side operation is impos-

High-sensitivity

Side-installation

2. For external dimensions and other information, refer to pages 77 to 94.

3. One-side operation means that three operational directions can be selected electrically, according to the change in direction of the oper-

ating plunger. Those models for which one-side operation is impossible can only operate on both sides. For details, see page 94.

ble. (See note 3.)

Head can be mounted in any

of the four directions.

sible. (See note 3.)

Head can be mounted in any

of the four directions.

One-side operation is possible. (See note 3.)

Head can be mounted in any

of the four directions.

One-side operation is possible. (See note 3.)

Head can be mounted in any

of the two directions. (When

the Head can be mounted

horizontally, the Head can be

mounted in any of the four directions.)

ble. (See note 3.)

Head can be mounted in any

of the four directions.

WLCA2 WLCA2-7 WLCA2-8

WLH2 --- ---

WLG2 --- ---

WLCA2-2N --- ---

WLGCA2 --- ---

F-62 Two-circuit Limit Switch WL

Page 7

Adjustable Roller Levers and Adjustable Rod Levers

Type Total Travel (TT) Features Actuator (See note 2.)

WL-2A100

Adjustable

Roller Lever

WL-4A100

Adjustable Rod

Lever (Adjustable

length: 25 to

140 mm)

WL-3A100

(Adjustable length:

350 to 380 mm)

Standard One-side operation possible. (See note 3.)

Overtrav-elGeneral One-side operation possible. (See note 3.)

High-sensitivity

Side-installation

p

Note: 1. For the approved standards file numbers, refer to page 69.

2. For external dimensions and other information, refer to pages 77 to 94.

3. One-side operation means that three operational directions can be selected electrically, according to the change in direction of the oper-

ating plunger. The operating plunger is set for operation on both sides before delivery. Those models for which one-side operation is impossible can only operate on both sides. For details, see page 94. The operational plunger is factory-set to both sides.

Head can be mounted in any of the four directions.

Head can be mounted in any of the four directions.

One-side operation possible. (See note 3.)

Head can be mounted in any of the four directions.

One-side operation is possible. (See note 3.)

Head can be mounted in any of the two directions.

(When the Head can be mounted horizontally, the

Head can be mounted in any of the four directions.)

WLCA12 ---

--- WLCL (WL-4A100)

WLH12 WLHL (WL-4A100)

WLHAL4 (WL-3A100)

WLG12 WLGL (WL-4A100)

WLCA12-2N WLCL-2N (WL-4A100)

Rod Spring Levers and Fork Lever Locks

Type Total travel (TT) Features Actuator (See note 2.)

WL-3A200 Rod

Spring Lever

Fork Lever Locks:

WL-5A100,

WL-5A102,

WL-5A104

Limit

Switches

Protective Head can be mounted in any of the four directions. --- WLCA32-41

Overtrav-elGeneral One-side operation is possible. (See note 3.)

Head can be mounted in any of the four directions.

Note: 1. For the approved standard file numbers, refer to page 69.

2. For external dimensions and other information, refer to pages 77 to 94.

3. One-side operation means that three operational directions can be selected electrically, according to the change in direction of the oper-

ating plunger. The operating plunger is set for operation on both sides before delivery. Those models for which one-side operation is impossible can only operate on both sides. For details, see page 94. The operational plunger is factory-set to both sides.

4. The fork lever lock is configured so that the dog pushes the lever to reverse the output and this reversed state is maintained even after

the dog continues on. If the dog then pushes the lever from the opposite direction, the lever will return to its original position.

WLHAL5 ---

(WL-5A100)

WLCA32-42

(WL-5A102)

WLCA32-43

(WL-5A104)

Two-circuit Limit Switch WL F-63

Page 8

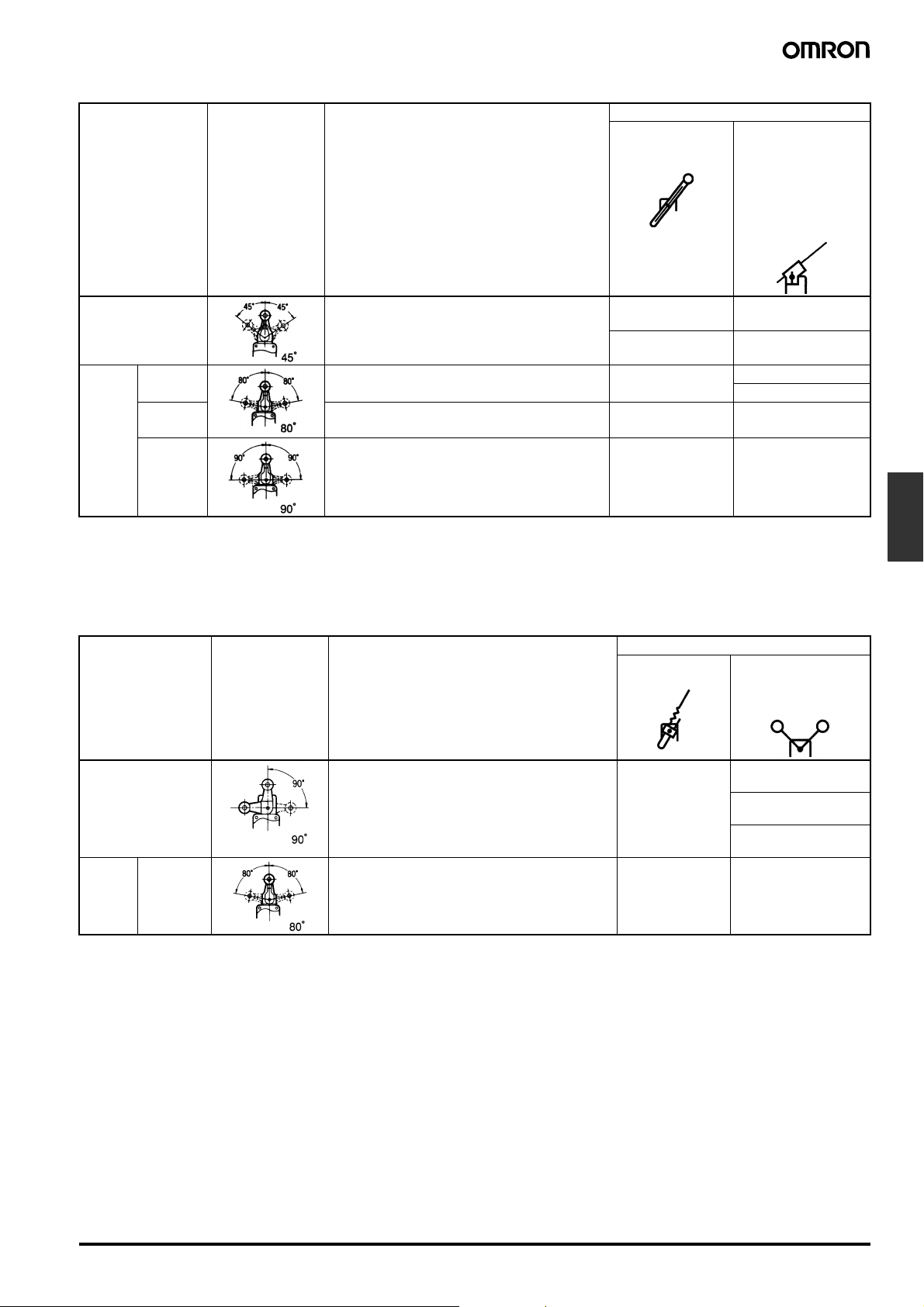

Standard Plungers

Type Actuators Model

To p W L D

Top Plunger

Top-roller Plunger

Top-ball Plunger

WLD2

WLD28 (See note.)

WLD3

Standard Flexible Rods

Actuators Model

Coil spring

Steel wire

Spring dia. 6.5 WLNJ

Spring dia. 4.8 WLNJ-30

Resin rod dia. 8.0 WLNJ-2

1.0-dia. wire WLNJ-S2

Horizontal WLSD

Horizontal Plunger

Microload Models

Horizontal-roller

Plunger

Horizontal-ball Plunger

Note: Sealed roller.

WLSD2

WLSD3

A series of microload models has also been developed for the configurations outlined on pages 62 to 64. The model numbers become

WL01@. For example, WLCA2 becomes WL01CA2.

Lamp-equipped Models

Operating

characteristics

Neon lamp 125 VAC Approx. 0.6 mA WL@-LE (See note 1.) WL-LE

LED 10 to 115 VAC/VDC Approx. 0.5 mA WL@-LD (See note 1.) WL-LD

Note: 1. In the model number, @ indicates the actuator number. For example, CA2, D, NJ, etc.

2. The default setting is “light-ON when not operating.” Turn the lamp holder by 180° to change the setting to “light-ON when operating.”

Ordering Information

When ordering general-purpose indicator-equipped models insert the specifications number at the end of the basic model number.

E.g.: When a neon lamp is installed in a General-purpose/Standard Roller Lever Switch (WLCA2).

WLCA2

↑↑

Standard Lamp

When ordering indicator-equipped molded terminal models, insert the specifications number at the end of the standard model number.

E.g.: When a Neon Lamp (WL-LE) is installed in a general-purpose molded terminal model (WLCA2-139).

WLCA2-139

↑↑↑

Standard Lamp Lamp 2: NC connection: Light-ON when operating

Note: The indicator cover cannot be replaced on the molded terminals. In all cases the indicator does not light when the load is ON.

Rated voltage Leakage current Lamp-equipped Switch Lamp-equipped cover only

250 VAC Approx. 1.9 mA

LE

specifications

LE 2

specifications wiring 3: NO connection: Light-ON when not operating

F-64 Two-circuit Limit Switch WL

Page 9

Sensor I/O Connector Models

A reduction in the amount of wiring and parts makes maintenance easy and reduced wiring mistakes, in addition it’s already compact size for fitting

into areas of limited space.

Ordering Information

Item Standard Overtravel High sensitivity

Actuators Rotating lever Yes Yes Yes

Plunger Yes --- ---

Load Standard load (SPST-NO/SPST-NC) Yes

Microload (SPST-NO/SPST-NC) Yes

High-precision models WL-@55 Yes

Spatter-prevention models (See note 3.) Yes

Lamp Yes

Note: 1. Standard Models: For standard models only one-side operation at an angle of 45° is possible.

Direct-wired Connectors

Lamp-equipped WL@-LDK13 WL@-LDK43

Double-seal WL@-55LDK13 WL@-55LDK43

Overtravel Models: Only one-side operation at an angle of 80° is possible. One-side operation only is not possible.

High-precision Models: Only one-side operation at an angle of 45° is possible, and pretravel (PT) is 5°, as opposed to 15° for standard

models.

2. For information other than that listed at the above, contact your OMRON representative.

3. The spatter-prevention models are only available as pre-wired connectors.

Note: 1. In the model number, @ indicates the actuator number. For

Type 2-core (NO) 4-core

example, Overtravel Model WLG2

2. The lamp is set to “light-ON when not operating” (NO con-

nection).

-LDK13.

Pre-wired Connectors

Type 2-core (NO) 2-core (NC) 4-core 3-core (NO)

Lamp-equipped WL@-LD-M1J WL@-LD-M1JB WL@-LD-DGJ03 WL@-LD-DK1EJ03

Double-seal WL@-55LD-M1J WL@-55LD-M1JB WL@-55LD-DGJ03 WL@-55LD-DK1EJ03

Note: 1. In the model number, @ indicates the actuator number. For example, Overtravel Model WLG2-LD-M1J.

2. The lamp is set to “light-ON when not operating” (NO connection).

Limit

Switches

Two-circuit Limit Switch WL F-65

Page 10

Environment-resistant Models

Airtight, Hermetic Seal, Low-temperature, Heat-resistive, Corrosion-proof, and Weatherresistant Models

Using the general-purpose model, six types of environment-resistant models can be created to meet a variety of difficult operating conditions. Select the model most appropriate to your operating environment.

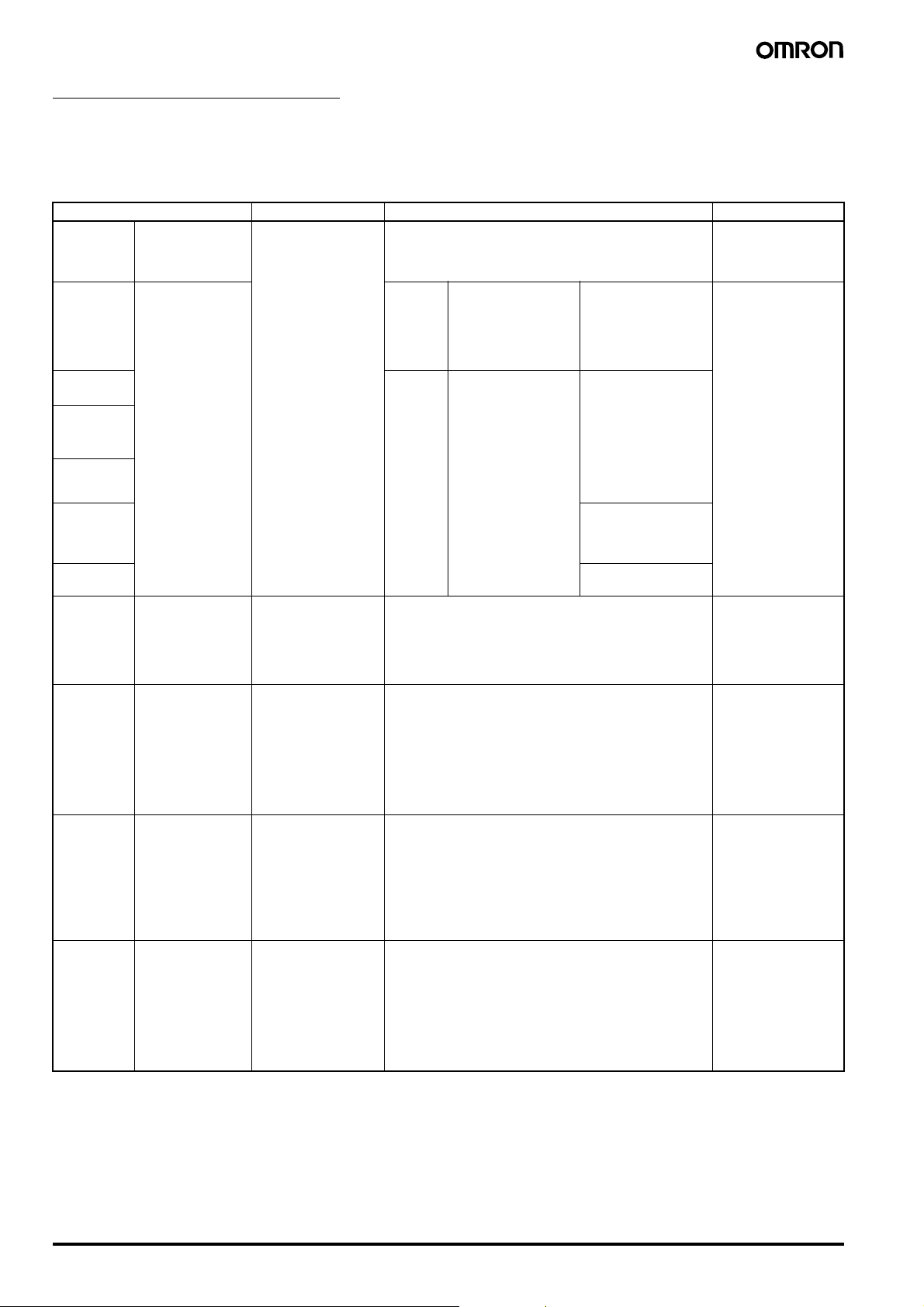

Type Usage Environment-resistant construction Appropriate models

WL@-55 Airtight seal For use in locations

WL@-139 Hermetic seal

(molded terminals

and anti-coolant

models)

WL@-140 Hermeti-

WL@-141

WL@-145

WL@-RP40 The connector can be

WL@-RP60 Rubber parts are made

WL@-TC Low-temperature Can be used at a tem-

WL@-TH Heat-resistive Can be used in tem-

WL@-RP Corrosion-proof For use in locations

WL@-P1 Outdoor specifica-

tions

Note: 1. Consult your OMRON representative for the microload WL01@ models.

2. Use the SC Connector for the conduit opening.

3. The actuator can be created using the standard model.

4. The actuator can be created using the standard model. For WL-@141 and -145, only WLG2, WLCA2, WLGCA2, and WLH2 can be used.

subject to splashes of

water and anti-coolant

perature of

–40°C (The operating

temperature range is

–40°C to 40°C), but

cannot withstand icing.

peratures of 120°C

(The operating temperature range is 5°C to

120°C).

subject to corrosive

gases and chemicals.

For use in parking lots

and other such outdoor

locations.

Uses the W-10FB3-55 Airtight Built-in Switch. (See note 2.) All models except the

Generalpurpose

built-in

switch

callysealed

built-in

switch

Uses the general-purpose built-in switch.

Silicone rubber is used for rubber parts such as the O-ring,

gasket, etc.

Uses a special built-in switch made from heat-resistant resin.

Silicone rubber is used for rubber parts such as the O-ring,

gasket etc.

Diecast parts such as the switch box are made of corrosionproof aluminum.

Rubber sealing parts are made of fluorine rubber which aids

in resisting oil, chemicals and adverse weather conditions.

Exposed nuts and screws (except the actuator section) are

made of stainless steel.

Moving and rotary parts such as rollers are made of sintered stainless steel or stainless steel.

Rubber parts are made from silicone rubber, which has a

high-tolerance to deterioration over time, and changes in

temperature.

Rollers are made of stainless steel to improve corrosion resistance.

Exposed nuts and screws are made of stainless steel.

Connection lead wires:

Standard 5-m VCT (vinyl cabtire cable) cable

attached. Finished diameter: 11.5 mm, 4core.

Connection lead wires:

Standard 5-m VCT cable, with high flexibility

and good anti-oil properties attached. Finished diameter:

11.5 mm, 4-core.

The case cover and

conduit opening are

molded from epoxy

resin. The cover cannot be removed.

The case cover, cover

box and conduit opening are molded from

epoxy resin. The cover

cannot be removed

(141, 145).

The Head opening is

protected from cutting

powder. (WL@-141)

removed, so it is possible to use flexible wires

in the cable.

from fluorine rubber.

low-temperature and

heat-resistive models.

(See note 3.)

All models except the

low-temperature and

heat-resistive models.

(See note 4.)

All models except airtight, hermetic, heatresistive, corrosionproof, or lampequipped models.

All models except airtight, hermetic, lowtemperature, corrosion-proof, lampequipped, nylon roller

(WLCA2-26N), seal

roller models, and resin rod (WLNJ-2) models.

All models except overtravel model (-2N), fork

lever lock models

(WLCA32-41 to -43),

low-temperature, heatresistive, and lampequipped models.

Only the general-purpose overtravel models

(WLH2/12), the overtravel high-sensitivity

models (WLG2/12)

and some standard

models (e.g., WLCA2)

can be used. Excluding

heat-resistive models.

F-66 Two-circuit Limit Switch WL

Page 11

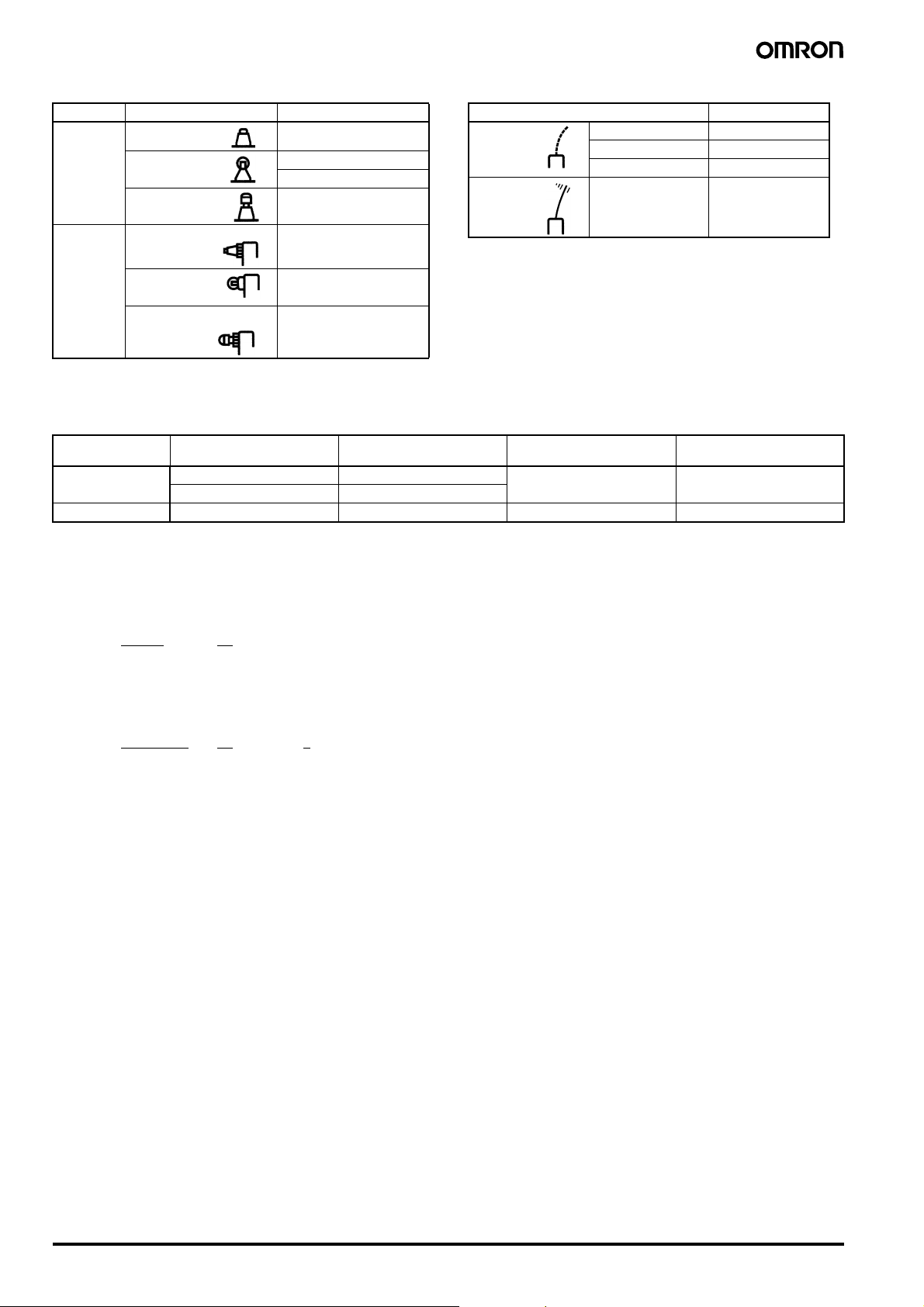

Ordering Information

Use the following as a guide when ordering environment-resistant

models.

E.g.: For a hermetic model of WLCA2

WLCA2 - 55

↑↑

Standard Specifications No.

An additional catalog is available for outdoor specifications models.

Spatter-prevention Models

These models are most effective in an arc welding line or places where cutting powder is spattered.

Standard Models

Type Total travel (TT) Actuators Neon lamp LED

125 VAC 250 VAC 10 to 115 VAC/DC

Approx. 0.6 mA Approx. 1.9 mA Approx. 0.5 mA

Standard WLCA2-LEAS WLCA2-LDAS

One-side operation

is possible

Double nut lever

Allen-head lever

Overtravel General Double nut lever WLH2-LEAS WLH2-LDAS

High-sensitivity

High-precision WLGCA2-LEAS WLGCA2-LDAS

One-side operation

is impossible

One-side operation

Allen-head lever WLH2-LES WLH2-LDS

Double nut lever WLG2-LEAS WLG2-LDAS

Allen-head lever WLG2-LES WLG2-LDS

Double nut lever

WLCA2-LES WLCA2-LDS

is possible

Allen-head lever

Note: Consult your OMRON representative for the microload WL01@ models.

WLGCA2-LES WLGCA2-LDS

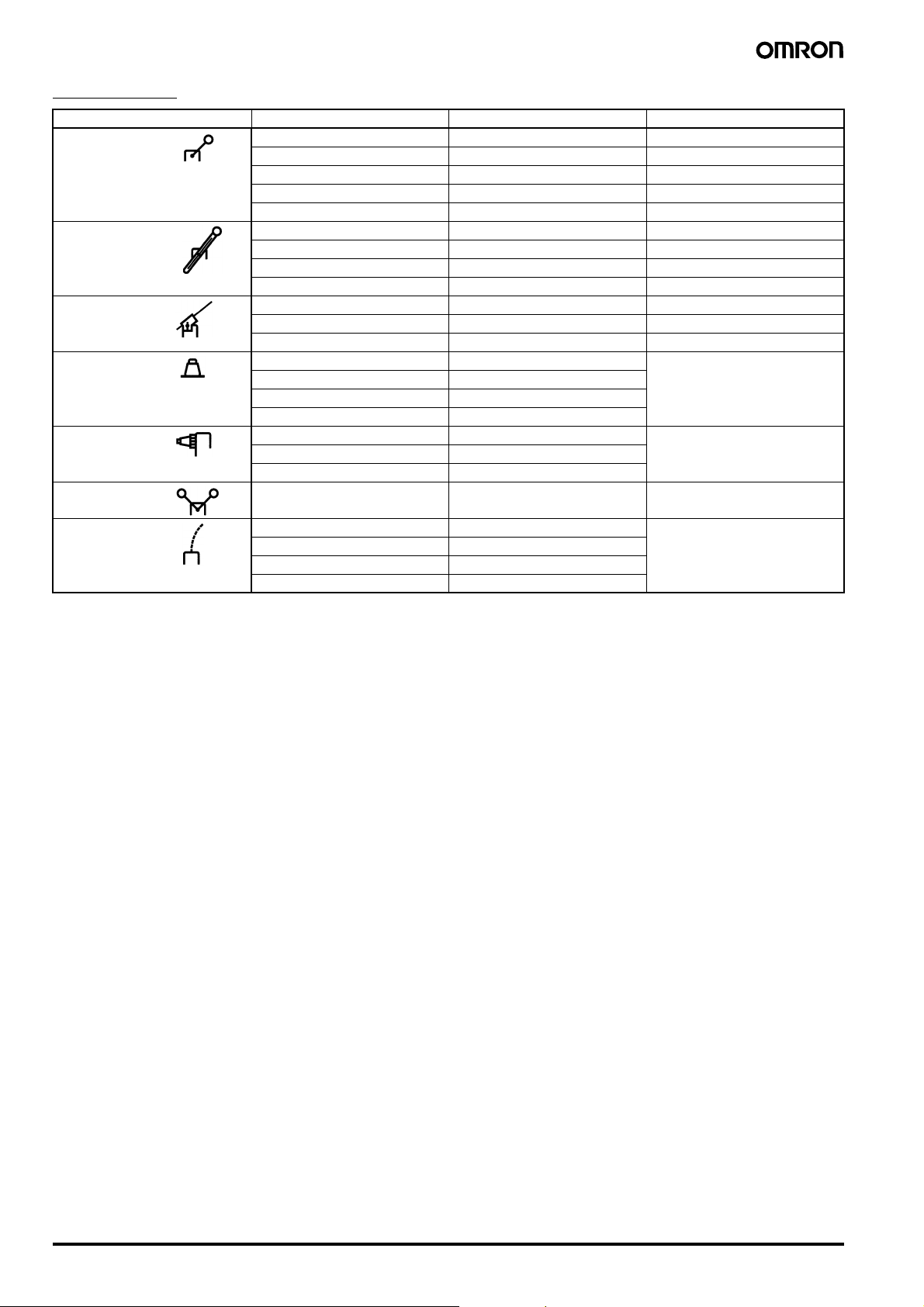

Levers/Lamp-equipped Covers

Type

Without lever

Complete Head

(lever with Head)

Double nut lever

Allen-head lever

Lamp-equipped

cover

Limit

Switches

Model Add an “R” to the product

number to order.

E.g.: WL@CA2-LES

WL-1H1100S

(in case of WLCA2-@,

WLGCA2-@)

WL-2H1100S

(in case of WLH2-@,

WLG2-@)

Switches Without Lever

WLRCA2-LES, WLRCA2-LDS

WLRH2-LES, WLRH2-LDS, WLRG2-LES

WLRG2-LDS

WLRGCA2-LES, WLRGCA2-LDS

WL-1A105S

(forward and backward lever)

WL-1A103S

(forward and backward lever)

WL-LES

(Neon Lamp)

WL-LDS

(LED)

Two-circuit Limit Switch WL F-67

Page 12

Head Models

Actuators Set model Head model Head model without lever

Roller lever

Adjustable roller lever

Adjustable rod lever

Top plunger

Horizontal plunger

Fork lever lock

WLCA2 WL-1H1100 WLRCA2

WLGCA2 WL-1H1100-1 (See note.) WLRGCA2

WLG2 WL-2H1100 WLRG2

WLH2 WL-2H1100-1 (See note.) WLRH2

WLCA2-2N WL-6H1100 WLRCA2-2N

WLCA12 WL-1H2100 WLRCA2

WLG12 WL-2H2100 WLRG2

WLH12 WL-2H2100-1 (See note.) WLRH2

WLCA12-2N WL-6H2100 WLRCA2-2N

WLCL WL-4H4100 WLRCL

WLGL WL-2H4100 WLRG2

WLCL-2N WL-6H4100 WLRCA2-2N

WLD WL-7H100 --WLD2 WL-7H200

WLD3 WL-7H300

WLD28 WL-7H400

WLSD WL-8H100 --WLSD2 WL-8H200

WLSD3 WL-8H300

WLCA32-41 WL-5H5100 WLRCA32

Coil spring

Note: For the model number of Heads without lever, simply remove the numbers after WL-@H. For example, WL-1H1100 becomes WL-1H. WLH2

and WLH12 however, become WL-2H-1, and WLGCA2 becomes WL-1H-1. Other Head models are available, but must be ordered separately.

WLNJ WL-9H100 --WLNJ-30 WL-9H200

WLNJ-2 WL-9H300

WLNJ-S2 WL-9H400

F-68 Two-circuit Limit Switch WL

Page 13

Specifications

■ Approved Standards

Agency Standard File No.

UL UL508 E76675

CSA CSA C22.2 No. 14 LR45746

TÜV Rheinland EN60947-5-1 R9551016

Note: Contact your OMRON representative for more information on approved models.

■ Approved Standard Ratings

General-purpose Models

UL/CSA

Standard Models: A600

Rated voltage Carry current Current Volt-amperes

Make Break Make Break

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

480 VAC 15 A 1.5 A

600 VAC 12 A 1.2 A

Microload Models:

0.1 A at 125 VAC, 0.1 A at 30 VDC

Limit

Switches

TÜV (EN60947-5-1)

(Only Ground Terminal Models are Approved)

Model Category/rating Thermal

WL@-@ AC-15 2 A/250 V

DC12 2 A/48 V

WL01@ AC-14 0.1 A/125 V

DC12 0.1 A/48 V

WL@-LE AC-15 2 A/250 V 10 A Neon lamp

WL01@-LE AC-14 0.1 A/125 V 0.5 A Neon lamp

WL@-LD AC-15 2 A/115 V

DC12 2 A/48 V

WL01@-LD AC-14 0.1 A/115 V

DC12 0.1 A/48 V

current

10 A ---

0.5 A ---

10 A LED

0.5 A LED

Indicator

Spatter-prevention Models

UL/CSA

LE (Neon Lamp) A300

Rated

voltage

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

LD (LED)

115 VAC 10 A

115 VDC 0.8 A

Carry

current

Rated voltage Carry current

Current Volt-amperes

Make Break Make Break

Note: As an example, AC-15 2 A/250 V means the following:

Application category AC-15

Rated operating current (Ie) 2 A

Rated operating voltage (Ue) 250 V

Two-circuit Limit Switch WL F-69

Page 14

■ Ratings

General-purpose Models/Environment-resistant Models

Standard Load Models

Type Rated

Standard,

overtravel

(except high-sensitivity models), and

high-precision

models.

Overtravel

(high-sensitivity

models)

Note: 1. The above figures are for standard currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. For PC loads, use the microload models.

Inrush current NC 30 A max. (15 A max. (See note.))

Note: Only for high-sensitivity overtravel models.

voltage

125 VAC 10 A 3 A 1.5 A 10 A 5 A 2.5 A

250 VAC 10 A 2 A 1 A 10 A 3 A 1.5 A

500 VAC 10 A 1.5 A 0.8 A 3 A 1.5 A 0.8 A

8 VDC 10 A 6 A 3 A 10 A 6 A

14 VDC 10 A 6 A 3 A 10 A 6 A

30 VDC 6 A 4 A 3 A 6 A 4 A

125 VDC 0.8 A 0.2 A 0.2 A 0.8 A 0.2 A

250 VDC 0.4 A 0.1 A 0.1 A 0.4 A 0.1 A

125 VAC 5 A --- --- --250 VAC 5 A

125 VDC 0.4 A --- --- --250 VDC 0.2 A

NO 20 A max. (10 A max. (See note.))

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

Non-inductive load Inductive load

Microload Models

Rated voltage Resistive load

125 VAC 0.1 A

30 VDC

Operation within the three zones illustrated in the following diagram

will produce optimum performance.

Recommended Load Range: 5 to 30 VDC, 0.5 to 100 mA

Voltage (VDC)

5 mW

0.8 W

Current (mA)

Lamp-equipped Models

Neon lamp (WL-LE) LED (WL-LD)

125 VAC 250 VAC 10 to 115 VAC/DC

Approx. 0.6 mA Approx. 1.9 mA Approx. 0.5 mA

WLD28-LES WLD28-LDS

F-70 Two-circuit Limit Switch WL

Page 15

Sensor I/O Connector Models

Type Rated

For DC 12 VDC 1 A 1 A 1 A 1 A 1 A 1 A 1 A 1 A

For AC 115 VAC 1 A 1 A 1 A 1 A 1 A 1 A 1 A 1 A

Note: 1. The above figures are for standard currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

voltage

24 VDC 1 A 1 A 1 A 1 A 1 A 1 A 1 A 1 A

48 VDC 1 A 1 A 1 A 1 A 1 A 1 A 1 A 1 A

115 VDC 0.8 A 0.8 A 0.2 A 0.2 A 0.8 A 0.8 A 0.2 A 0.2 A

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

Non-inductive load Inductive load

Spatter-prevention Models

Model Rated

WL@-LES 125 VAC 10 A 3 A 1.5 A 10 A 5 A 2.5 A

WL@-LDS 115 VAC 10 A 3 A 1.5 A 10 A 5 A 2.5 A

Note: 1. The above figures are for standard currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

Inrush current NC 30 A max.

Operating temperature –10°C to 80°C (with no icing)

Operating humidity 95% max.

current

250 VAC 10 A 2 A 1 A 10 A 3 A 1.5 A

125 VDC 0.8 A 0.2 A 0.2 A 0.8 A 0.2 A 0.2 A

250 VDC 0.4 A 0.1 A 0.1 A 0.4 A 0.1 A 0.1 A

12 VDC 10 A 6 A 3 A 10 A 6 A

24 VDC 6 A 4 A 3 A 6 A 4 A

48 VDC 3 A 2 A 1.5 A 3 A 2 A

NO 20 A max.

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

Non-inductive load Inductive load

Limit

Switches

Two-circuit Limit Switch WL F-71

Page 16

■ Characteristics

General-purpose Models/Environment-resistant Models

Degree of protection IP67

Durability (See note 3.) Mechanical: 15,000,000 operations min. (See note 4.)

Operating speed 1 mm to 1 m/s (for WLCA2)

Operating frequency Mechanical: 120 operations/minute min.

Rated frequency 50/60 Hz

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 25 mΩ max. (initial value)

Dielectric strength 1,000 VAC (600 VAC), 50/60 Hz for 1 min between non-continuous terminals.

Rated insulation voltage (U

Switching overvoltage 1,000 V max. (EN60947-5-1)

Pollution degree (operating environment) 3 (EN60947-5-1)

Short-circuit protective device (SCPD) 10 A, fuse type gG or gI (IEC269)

Conditional short-circuit current 100 A (EN60947-5-1)

Conventional enclosed thermal current

)

(I

the

Protection against electric shock Class I

Vibration resistance 10 to 55 Hz, 1.5-mm double amplitude (See note 6.)

Shock resistance

Ambient temperature Operating: –10°C to 80°C (with no icing) (See note 7.)

Ambient humidity Operating: 95% max.

Weight Approx. 275 g (in the case of WLCA2)

) 250 V (EN60947-5-1)

i

Electrical: 750,000 operations min. (See note 5.)

Electrical: 30 operations/minute min.

2,200 VAC, 50/60 Hz for 1 min/Uimp 2.5 kV non-current-carrying metal part and ground.

2,200 VAC, 50/60 Hz for 1 min Uimp 2.5 kV between each terminal and non-current-carrying metal

part.

10 A, 0.5 A (EN60947-5-1)

2

Destruction: 1,000 m/s

Malfunction: 300 m/s

min.

2

min. (See note 6.)

Note: 1. The above figures are initial values.

2. The figures in parentheses for dielectric strength, are those for the overtravel (high-sensitivity) model.

3. The values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your OMRON

sales representative for more detailed information on other operating environments.

4. 10,000,000 operations min. for general-purpose, high-sensitivity, and flexible rod overtravel models.

5. 500,000 operations min. for high-precision and outdoor specifications models. All microload models however, are 1,000,000 operations

min.

6. Except the flexible rod models. The shock resistance (malfunction) for microload models is 200 m/s

7. For low temperature models this is –40°C to 40°C (no icing). For heat-resistive models the range is +5°C to 120°C.

2

min.

F-72 Two-circuit Limit Switch WL

Page 17

■ Contact Form

General-purpose Models

Standard (WL@)/Microload (WL01@) Models

Environment-resistant Models

(White) (Blue)

(Black) (Red)

Spatter-prevention Models

Standard Model

Limit

Switches

Lamp-equipped Models

Light-ON when operating

(See note 1.)

Light-ON when not operating

(See note 2.)

Note: 1. Light-ON when operating means that the lamp lights when the Limit Switch contacts (NC) release, or when the actuator rotates or is

pushed down.

2. Light-ON when not operating means the lamp remains lit when the actuator is free, or when the Limit Switch contacts (NO) close when

the actuator rotates or is pushed down.

WL-LE

WL-LD

WL-LE

WL-LD

Power supply

Built-in switch

Load

Internal circuit

Power supply

Internal circuit

Load

Built-in switch

Two-circuit Limit Switch WL F-73

Page 18

Internal circuit of Lamp-equipped Models

WL-LE WL-LD

Neon lamp

Contact

spring

Contact

Resistance

spring Rated current

Resistance

Rectifier stack

diode

Zener

diode

Light-emitting

diode (LED)

■ Wiring Specifications of Sensor I/O Connector Models

Direct-wired Connector Pre-wired Connector

2-core 4-core 2-core 4-core 3-core

K13 (DC)

K13A (AC)

Built-in

switch

1 (NC) --- 1 (NC) 1 1 (NC) --- 1 (NC) --- 1 (NC) 3 1 (NC) 1 1 (NC) --2 (NC) --- 2 (NC) 2 2 (NC) --- 2 (NC) --- 2 (NC) 2 2 (NC) 2 2 (NC) 2

3 (NO) 3 3 (NO) 3 3 (NO) 3 3 (NO) 1 3 (NO) --- 3 (NO) 3 3 (NO) 3

4 (NO) 4 4 (NO) 4 4 (NO) 4 4 (NO) 4 4 (NO) --- 4 (NO) 4 4 (NO) 4

Connec-

tor

K43 (DC)

K43A (AC)

Built-in

switch

Connec-

tor

M1J (DC) M1GJ (DC) M1JB (DC) DGJ03 (DC)

Built-in

switch

Connec-

tor

Built-in

switch

Connec-

tor

Built-in

switch

Connec-

tor

AGJ03 (AC)

Built-in

switch

Connec-

tor

DK1EJ03 (DC)

Built-in

switch

Connec-

tor

Engineering Data

General-purpose Models/Spatter-prevention Models/Environment-resistant Models

Electrical Durability

Operating temperature: 5°C to 30°C

Operating humidity: 40% to 70%.

Operating frequency: 30 operations/min

cosφ = 1

125 VAC

250 VAC

operations)

4

480 VAC

Durability (x 10

Switching current (mA)

F-74 Two-circuit Limit Switch WL

Page 19

Nomenclature

■ General-purpose Models

Set Position Marker Plate Roller

After operation, set the indicator needle on the

marker plate so that is in the convex section of the

bearing. For the WLD2, insert the needle so that is

is between the two main wires on the plunger.

Requires maintenance (excessive overtravel)

Proper range

Requires maintenance

(insufficient overtravel)

Proper range

Requires maintenance

(excessive overtravel)

Head

The Head used in the roller lever type, adjustable

rod lever type, or horizontal plunger type (except

the -2N Series) can be mounted in any of the four

directions by removing the screws at the four corners of the Head.

Shaft Section Seal

By fitting an O-ring to the rotary shaft and with an

appropriate interference of the screws, high-sealing properties are maintained.

Bearing

The bearing smooths the plunger movement.

Built-in Switch

The built-in switch (for all models except the microload models) has an extended mechanical life of 15

million operations or more.

Note: 1. The display for conduit threads has changed from PF1/2 to G1/

so the thread size and pitch have not changed. (Conduit threads Pg 13.5 and

Head-mounting

Screws

Conduit Opening (See note 1.)

The conduit threads are parallel threads for G

tube and offer further increased sealing properties

when used in conjunction with the SC connector.

according to revisions of JIS B 0202. This is only a change in the display,

2,

1

/

1

/2-14NPT are also available.)

The roller is made of self-lubricating sintered stainless steel and boasts high resistance to wear.

Lever

The lever forged of anti-corrosive aluminium alloy

features high corrosion resistances and outstanding ruggedness. With roller lever, adjustable rod

and flexible rod models, the actuator position can

be set anywhere within 360°. (The lever cannot be

mounted in the opposite direction.)

Roller Lever Setscrew

Operational Plunger (See note 2.)

Cover Seal

By using an O-ring as the cover seal, an optimum

squeeze can be obtained and high sealing properties are assured as well.

Terminal Screws

M4 screws

Cover

Insulator

The insulator has outstanding insulation properties and prevents the generation of any gases

which may corrode the internal parts.

Cover Setscrew

A Phillips screw is used to ensure ease of use.

2

2. By changing the orientation of the operational plunger, three operational directions can be selected electrically. (This is only possible with

general-purpose roller lever, adjustable roller lever, and adjustable rod lever models. For the overtravel models, only -2N Series models

have this function.)

Limit

Switches

Lamp-equipped Models

The operating status of the Switch can be checked using a neon

lamp of LED indictor.

Circuit checks and troubleshooting errors are easy done.

Light-emitting diode (LED)

Indictor window

The built-in switch’s terminal screws are used to connect the lamp

terminal (indicator cover). Since the connection spring (coil spring) is

used for this connection, it will not be necessary to connect to the

lamp terminal. When a ground terminal is provided however, lead

wire method must be used.

WL-LD has a built-in rectifier stack, so it will not be necessary to

change the polarity.

The indicator cover is molded from diecast aluminum and has outstanding sealing properties. Furthermore, regardless of whether the

power is connected or not, the operating status is shown (operating

or not operating), and indicators can be switched from light-ON when

operating and light-ON when not operating, by simply rotating the

lamp holder by 180°. (Molded terminals do not have this switching

capacity.)

The lamp-equipped models are ideal in locations using a conveyor

belt where items need to be checked, or locations that are difficult to

inspect for faults.

Lamp holder

Contact spring

Light-ON when Operating

LED at top

Light-ON when Not Operating

LED at bottom

Two-circuit Limit Switch WL F-75

Page 20

■ Environment-resistant Models

Airtight Built-in Switch

Sealed by the rubber boot

of the plunger

Sealed by the resin molded

into the case cover

Four, M4 ±terminal screws

■ Spatter-prevention Models

Double Nut Lever

Roller, Roller Axis

Using stainless steel prevents

spatter from adhering.

Operating Lever

Melamine sinter-painted, it is easy to

peel off the spatter.

Lamp Cover

Heat-resistant resin is used for the

lamp cover.

By using spherical surface for the

display part, it disperses the direction of spatter.

Hermetic Seal Model

The lead wires are sealed to the Limit Switch with

resin, providing a hermetically sealed construction.

Filled with epoxy resin

Leads for molding

Exclusive connector

SUS304 is used for double nut.

Screws

SUS304 is used, preventing spatter

from adhering.

Head Cap

Using Teflon prevents spatter from adhering.

Note: Spatter means the Zn powder pro-

duced when welding.

Adhering spatter to the Limit Switch

may cause malfunction of lever or

lamp cover.

The lack of gap prevents spatter powder from clogging.

F-76 Two-circuit Limit Switch WL

Page 21

Dimensions

■ General-purpose Models

Standard Models

Note: 1. Rotating Lever Models: For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Roller Lever Roller Lever

WLCA2

WL01CA2

17.5 dia. × 7 (see note)

38R

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four, 5.2

Three, M4

(lengh:13)

+0.2

o

holes

60 max.

dia.

WLCA2-7

WL01CA2-7

17.5 dia. × 15 (see note)

50R

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four, 5.2

Three, M4

(length: 13)

+0.2

o

holes

67.2 max.

dia.

42 max.

Four, M6

Depth: 15 min.

JIS B0202 G1/2

Effective thread:

4 threads min.

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: Stainless sintered roller Note: Stainless steel roller

Roller Lever Adjustable Roller Lever

WLCA2-8

WL01CA2-8

17.5 dia. × 7 (see note)

63R

Four, M3.5

Four, 5.2

M5 (length: 12)

Allen-head bolt

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

+0.2

o

holes

60 max.

dia.

42 max.

WLCA12

WL01CA12

Four, M6

Depth: 15 min.

17.5 dia. × 7 (see note)

Adjustable range:

25 to 89

Four, M3.5

M5 (length:

16) Allen-

head bolt

Four, 5.2

dia. holes

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

+0.2

Four, M6

Depth: 15 min.

42 max.

67 max.

o

Four, M6

Depth: 15 min.

42 max.

Limit

Switches

Note: Stainless sintered roller Note: Stainless sintered roller

Operating characteristics WLCA2

WL01CA2

WLCA2-7

WL01CA2-7

WLCA2-8

WL01CA2-8

Operating force: OF max. 13.34 N 10.2 N 8.04 N 13.34 N

Release force: RF min. 2.23 N 1.67 N 1.34 N 2.23 N

Pretravel: PT 15±5° 15±5° 15±5° 15±5°

Overtravel: OT min. 30° 30° 30° 30°

Movement differential: MD max. 12° 12° 12° 12°

Note: The operating characteristics for WLCA12 and WL01CA12 are measured at the lever length of 38 mm.

Two-circuit Limit Switch WL F-77

WLCA12

WL01CA12

(See note.)

Page 22

OF and RF for WLCA12, with a lever length of 89 mm.

Operating characteristics WLCA12, WL01CA12

OF 5.68 N

RF 0.95 N

Rotating Lever Models: For all models WL indicates a standard model and WL01@ indicates a microload model.

Adjustable Rod Lever Fork Lever Lock

WLCL

WL01CL

55 max.

WLCA32-41 to 44

WL01CA32-41 to 44

(For details see pages 40 and 42.)

62.5 max.

3±0.2 dia. (length:

Adjustable range:

25 to 140

160) (see note)

Four, M3.5

M5 × 12

Allen-head bolt

Four,

+0.2

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

M8×12

Allen-head

set screw

dia. holes

42 max.

Four, M6

Depth: 15 min.

Note: Stainless steel rod

Note: Unless otherwise indicated, a tolerance of ±0.4 mm applies to

all dimensions.

Operating characteristics WLCL, WL01CL

Operating force: OF max. 1.39 N

Release force: RF min. 0.27 N

Pretravel: PT 15±5°

Overtravel: OT min. 30°

Movement differential: MD max. 12°

Two, 17.5 dia.

(length: 7)

(see note)

Four, M3.5

M5 × 16

Allen-head

bolt

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Note: Plastic roller. This illustration shows the external dimen-

sions of the WLCA32-41. (Models WLCA32-041 to -044

and WL01CA32-041 to -044 have stainless steel rollers.)

WLCA32-41 WLCA32-42 WLCA32-43 WLCA32-44

Note: The operating characteristics for WLCA12 and WL01CA12 are

measured at the lever length of 140 mm.

Operating characteristics WLCA32-41 to 44,

Force necessary to reverse the

direction of the lever: Max.

Movement until the lever reverses 50±5°

Movement until switch operation:

Max.

Movement after switch operation:

Min.

WL01CA32-41 to 44

11.77 N

55°

35°

F-78 Two-circuit Limit Switch WL

Page 23

Note: 1. Plunger Models: For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Top Plunger

WLD

WL01D

9 dia.

OP

Note: Stainless steel plunger

Top-ball Plunger

WLD3

WL01D3

15.5 dia.

1R (see note)

Four, M3.5

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

1/2 dia. (see note)

42 max.

Four, M6

Depth: 15 min.

Top-roller Plunger

WLD2

WL01D2

17 dia. (length: 5) (see note)

OP

Note: Stainless sintered roller

Four, M3.5

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

Sealed Top-roller Plunger

WLD28

WL01D28

11.2 dia. (length: 5) (see note)

42 max.

Four, M6

Depth: 15 min.

Limit

Switches

OP

Note: Stainless steel ball

Four, M3.5

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

OP

Note: Stainless steel roller

Four, M3.5

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Two-circuit Limit Switch WL F-79

Page 24

Note: Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Horizontal Plunger

WLSD

WL01SD

Four, M3.5

Four,

5.2

Note: 1. Stainless steel plunger

2. Cosmetic nuts.

Horizontal-ball Plunger

WLSD3

WL01SD3

1R (see note 1)

25 dia. (see

note 2.)

+0.2

dia. holes

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

OP

42 max.

Four, M6

Depth: 15 min.

Horizontal-roller Plunger

WLSD2

WL01SD2

Four, M3.5

17 dia.

(length: 5)

(see note 1)

Four,

5.2

dia. holes

Note: 1. Stainless sintered roller

2. Cosmetic nuts

3. The WLSD21 model, which has the roller rotated by 90°

is also available.

25 dia.

+0.2

0

(see

note 2.)

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Four, M3.5

1/2 dia.

(see note)

Four,

5.2

dia. holes

Three, M4

(length: 13)

25 dia.

+0.2

(see

0

note 2)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Note: 1. Stainless steel ball

2. Cosmetic nuts

Operating characteristics WLD

WL01D

WLD2

WL01D2

WLD3

WL01D3

WLD28

WL01D28

WLSD

WL01SD

WLSD2

WL01SD2

WLSD3

WL01SD3

Operating force: OF max. 26.67 N 26.67 N 26.67 N 16.67 N 40.03 N 40.03 N 40.03 N

Release force: RF min. 8.92 N 8.92 N 8.92 N 4.41 N 8.89 N 8.89 N 8.89 N

Pretravel: PT max. 1.7 mm 1.7 mm 1.7 mm 1.7 mm 2.8 mm 2.8 mm 2.8 mm

Overtravel: OT min. 6.4 mm 5.6 mm 4 mm 5.6 mm 6.4 mm 5.6 mm 4 mm

Movement differential: MD

1 mm 1 mm 1 mm 1 mm 1 mm 1 mm 1 mm

max.

Operating position: OP 34±0.8 mm 44±0.8 mm 44.5±0.8 mm 44±0.8 mm 40.6±0.8 mm 54.2±0.8 mm 54.1±0.8 mm

Total travel position: TTP

29.5 mm 39.5 mm 41 mm 39.5 mm --- --- ---

max.

F-80 Two-circuit Limit Switch WL

Page 25

Note: 1. Flexible Rod Models: For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Coil Spring Coil Spring (Multi-wire)

WLNJ

WL01NJ

(See note 3.)

(See note 1.)

6.5 dia.

(See note 2.)

WLNJ-30

WL01NJ-30

(See note 1.)

(See note 3.)

4.8 dia.

(See note 2.)

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

Four, M6

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: 1. The coil spring may be operated from any direc-

tion except the axial direction (↓).

2. Stainless steel coil spring

3. Optimum operating range of the coil spring is

within 1/3 of the entire length from the top end.

Depth: 15 min.

42 max.

Note: 1. The coil spring may be operated from any

direction except the axial direction (↓).

2. Piano wire coil

3. Optimum operating range of the coil spring is

within 1/3 of the entire length from the top end.

Coil Spring (Resin Rod) Steel Wire

WLNJ-2

WL01NJ-2

(See note 3.)

(See note 1.)

26 dia.

8 dia.

(See note 2.)

WLNJ-S2

WL01NJ-S2

(See note 3.)

Four,

+0.2

5.2

0

dia. holes

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

(See note 1.)

M3 (length: 3) Allenhead set screw

42 max.

Four, M6

Depth: 15 min.

1 dia.

(See note 2.)

Limit

Switches

Four,

+0.2

dia. holes

5.2

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

42 max.

Four, M6

Depth: 15 min.

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: 1. The coil spring may be operated from any direction

except the axial direction (↓).

2. Polyamide resin rod

3. Optimum operating range of the rod is within 1/3 of

the entire length from the top end.

Operating characteristics WLNJ

WL01NJ

(See note.)

Note: 1. The coil spring may be operated from any direction

except the axial direction (↓).

2. Stainless steel wire

3. Optimum operating range of the wire is within 1/3 of

the entire length from the top end.

WLNJ30

WL01NJ30

(See note.)

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

WLNJ-2

WL01NJ-2

(See note.)

42 max.

WL01NJ-S2

(See note.)

Operating force: OF max. 1.47 N 1.47 N 1.47 N 0.28 N

Pretravel: PT 20±10 mm 20±10 mm 40±20 mm 40±20 mm

Note: These values are taken from the top end of the wire or spring.

Four, M6

Depth: 15 min.

WLNJ-S2

Two-circuit Limit Switch WL F-81

Page 26

Overtravel Models

Overtravel models are Limit Switches which are provided with a greater OT to facilitate dog setting.

The overtravel models are classified into three types; general-purpose, high-sensitivity, and models which are capable of one-side 90° operation,

the -2N Series.

The -2N Series can also be installed on either side.

Since this model is identical to the standard model in dimensions, both models are interchangeable.

Like the standard model, it is oil-tight, waterproof, and dustproof (complies with IP67).

General-purpose, high sensitivity models Side-installation models

Head can be mounted in any of the four directions.

The lever operates on either side at 80°.

One-side operation is impossible.

The Head can be mounted in two directions, forward and backward.

The lever operates on either side at 90°.

One side operation is possible.

General-purpose/High Sensitivity Models

Note: 1. For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. One-side operation is not possible with the general-purpose and high-sensitivity models.

3. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Roller Lever Adjustable Rod Lever

WLH2

WL01H2

WLG2

WL01G2

17.5 dia. (length: 7) (see note 1)

38R

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

60 max.

42 max.

Four, M6

Depth: 15 min.

WLHL

WL01HL

WLGL

WL01GL

Adjustable range:

25 to 140

3±0.2 dia.

(length: 160)

(see note 1)

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four,

+0.2

5.2

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

Allen-head

lock screw

dia. holes

55 max.

42 max.

Four, M6

Depth: 15 min.

Note: 1. Stainless sintered roller

2. WL@G2 is identical to other models except in

the shape of the set position marker plate.

3. The built-in switch for WLH2 is W-10FB3.

4. The built-in switch for WLG2 is W-10FB3-8.

Note: 1. WL@GL is identical to other models except in

the shape of the set position marker plate.

2. The built-in switch for WLHL is W-10FB3.

3. The built-in switch for WLGL is W-10FB3-8.

F-82 Two-circuit Limit Switch WL

Page 27

Adjustable Roller Lever

2

WLH12

WL01H12

WLG12

WL01G12

17.5 dia. (length: 7)

Adjustable range:

25 to 89

Four, M3.5

M5 (length:

12) Allenhead bolt

Four,

+0.2

5.2

0

dia. holes

Three, M4

(length: 13)

67 max.

42 max.

Four, M6

Depth: 15 min.

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: 1. Stainless sintered roller

2. WL@G12 is identical to other models except in

the shape of the set position marker plate.

3. The built-in switch for WLH12 is W-10FB3.

4. The built-in switch for WLG12 is W-10FB3-8.

Operating characteristics WLH2

WL01H2

WLG2

WL01G2

WLHL

WL01HL

(See note 2.)

WLGL

WL01GL

(See note 2.)

WLH12

WL01H12

(See note 1.)

(See note 1.)

Operating force: OF max. 9.81 N 9.81 N 2.84 N 2.84 N 9.81 N 9.81 N

Release force: RF min. 0.98 N 0.98 N 0.25 N 0.25 N 0.98 N 0.98 N

+2

Pretravel: PT 15±5° 15±5° 15±5°

10°

−1

10°

+

−1

10°

Overtravel: OT min. 55° 65° 55° 65° 55° 65°

Movement differential: MD

12° 7° 12° 7° 12° 7°

max.

Note: 1. The operating characteristics of WLH12, WL01HL12, WLG12, and WL01G12 are measured at the lever length of 38 mm.

2. The operating characteristics of WLHL, WL01HL, WLGL, and WL01GL are measured at the rod length of 140 mm.

OF and RF for WLH12 and WL01H12, with a lever length of 89 mm.

Operating

characteristics

WLH12,

WL01H12

WLG12,

WL01G12

OF 4.18 N 4.18 N

RF 0.42 N 0.42 N

WLG12

WL01G12

+2

−

1

Limit

Switches

Two-circuit Limit Switch WL F-83

Page 28

Note: 1. For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Adjustable Rod Lever Rod Spring Lever

WLHAL4

WL01HAL4

Adjustable range:

350 to 380

Note: Stainless steel rod Note: Piano wire

Operating characteristics WLHAL4

Operating force: OF max. 0.98 N 0.90 N

Release force: RF min. 0.15 N 0.09 N

Pretravel: PT 15±5° 15±5°

Overtravel: OT min. 55° 55°

Movement differential: MD

max.

Note: 1. With WLHAL4, WL01HAL4, WLHAL5, and WL01HAL5, the

actuator’s tare is large, so depending on the installation direction, they may not be properly reset. Always install so

that the actuator is facing downwards.

3.2 dia. (see note)

M5 (length:

16) Allenhead bolt

Four,

+0.2

5.2

dia. holes

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

WL01HAL4

(See note 2.)

12° 12°

42 max.

WL01HAL5

Four, M6

Depth: 15 min.

WLHAL5

WLHAL5

WL01HAL5

2. The operating characteristics of WLHAL4, and WL01HAL4

are measured at the rod length of 380 mm.

2.3 dia. (see note)

M5 (length: 16)

Allen-head bolt

Four,

+0.2

5.2

dia. holes

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Side-installation Models

90° operation on one side is possible by simply changing the direction of the cam.

Note: 1. For all models WL@ indicates a standard model and WL01@ indicates a microload model.

2. With the side-installation models, 90° operation on one side is possible by simply changing the direction of the cam.

3. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

60 max.

Roller Lever Adjustable Roller Lever

WLCA2-2N

WL01CA2-2N

17.5 dia. (length: 7) (see note)

Four, M3

38R

Two , M 5

(length: 18)

M5 (length:

12) Allenhead bolt

Four, 5.2

dia. holes

Two, 5.2

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

+0.2

+0.2

0

dia.

0

Four, M6

Depth: 15 min.

WLCA12-2N

WL01CA12-2N

Note: Stainless sintered roller Note: Stainless sintered roller

42 max.

17.5 dia. (length: 7) (see note)

Adjustable range:

25 to 89

Four, M3

Two , M 5

(length: 18)

M5 (length:

16) Allenhead bolt

Two, 5.2

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

+0.2

0

dia.

67 max.

42 max.

Four, M6

Depth: 15 min.

F-84 Two-circuit Limit Switch WL

Page 29

Adjustable Rod Lever

WLCL-2N

WL01CL-2N

Adjustable range:

25 to 140

3 ±0.2 dia. (length:

160) (see note)

M8 (length: 12)

Allen-head

lock screw

Four, M3

Two , M 5

(length: 18)

M5 (length:

12) Allenhead bolt

Four, 5.2

dia. holes

Two, 5.2

Three, M4

(length: 13)

+0.2

55 max.

+0.2

0

dia.

0

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: Stainless steel rod

Operating characteristics WLCA2-2N

42 max.

Four, M6

Depth: 15 min.

WL01CA2-2N

WLCA12-2N

WL01CA12-2N

(See note 1.)

WLCL-2N

WL01CL-2N

(See note 2.)

Operating force: OF max. 9.61 N 9.61 N 2.84 N

Release force: RF min. 1.18 N 1.18 N 0.25 N

Pretravel: PT max. 20° 20° 20°

Overtravel: OT min. 70° 70° 70°

Movement differential: MD max. 10° 10° 10°

Note: 1. The operating characteristics of WLCA12-2N and WL01CA12-2N are measured at the lever length of 38 mm.

2. The operating characteristics of WLCL-2N and WL01CL-2N are measured at the rod length of 140 mm.

OF and RF for WLCA12-2N and WL01CA12-2N, with a lever length of 89 mm.

Operating

WLCA12-2N, WL01CA12-2N

characteristics

OF 4.10 N

RF 0.50 N

High-precision Models

The high-precision models feature a pretravel of 5° (as compared with 15° for the standard models) and a repeat accuracy twice as great as standard models. The high-precision models are ideal for positioning control of machine tools.

For all models WL@ indicates a standard model and WL01@ indicates a microload model.

Note: Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

Limit

Switches

Roller Lever

WLGCA2

WL01GCA2

Note: Stainless sintered roller

17.5 dia. (length: 7) (see note)

38R

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four,

+0.2

5.2

dia. holes

0

Three, M4

(length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

60 max.

42 max.

Four, M6

Depth: 15 min.

Operating characteristics WLGCA2

Operating force: OF max. 13.34 N

Release force: RF min. 1.47 N

Pretravel: PT

+2

5°

0

Overtravel: OT min. 40°

Movement differential: MD max. 3°

WL01GCA2

Two-circuit Limit Switch WL F-85

Page 30

Lamp-equipped Models

y

Roller Lever

WLCA2-LE/LD

WL01CA2-LE/LD

17.5 dia. (length: 7)

Stainless steel roller

38R

Four, M3.5

M5 (length: 12)

Allen-head bolt

Four,

+0.2

5.2

0

Three, M4

(length: 13)

dia. holes

60 max.

Note: Unless otherwise indicated, a tolerance of ±0.4 mm

applies to all dimensions.

OF max. 13.34 N

RF min. 2.23 N

PT 15±5°

OT min. 30°

MD max. 12°

Four, M6

Depth: 15 min

Note:

Stainless steel roller

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Sensor I/O Connector Models

Roller Lever Models

Standard Model (WLCA2), High-precision Model (WLGCA2), Overtravel Model (WLH2), and Overtravel High-sensitivity

Model (WLG2)

Note: 1. For the WLG2 model, only the dimensions for the set position marker plate change.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

3. The above diagram is for a lamp-equipped model.

Direct-wired Connector Models

60 max.

17.5 dia.

(length: 7)

(see note)

38R

Four,, M3.5

M5 (length: 12)

Allen-head bolt

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

Pre-wired Connector Models

60 max.

17.5 dia.

(length: 7)

(see note)

38R

Four, M3.5

M5 (length:

12) Allenhead bolt

Four,

+0.2

dia. holes

5.2

0

Three, M4

(length: 13)

Four, M6

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: Stainless sintered roller

42 max.

Depth: 15 min.

F-86 Two-circuit Limit Switch WL

SC-1M

XS2H-D421

Note: Stainless sintered allo

42 max.

Four, M6

Depth: 15 min.

6 dia.

roller

Page 31

Operating characteristics Roller lever/Standard

model

Roller lever/High

precision model

Roller lever/Overtravel

model

Roller lever/Overtravel

high sensitivity model

Operating force: OF max. 13.34 N 13.34 N 9.81 N 9.81 N

Release force: RF min. 2.23 N 1.47 N 0.98 N 0.98 N

+2°

Pretravel: PT 15±5° 15±5°

5°

−

°

10°

Overtravel: OT min. 30° 40° 55° 65°

Movement differential: MD

12° 3° 12° 7°

max.

Top-roller Plunger

WLD2

Note: 1. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

2. The above diagram is for a lamp-equipped model.

+2°

−

°

Direct-wired Connector Models

17 dia. (length: 5)

(see note)

OP

Note: Stainless sintered roller

Operating characteristics Top-roller plunger

Operating force: OF max. 26.67 N

Release force: RF min. 8.92 N

Pretravel: PT max. 1.7 mm

Overtravel: OT min. 5.6 mm

Movement differential: MD max. 1 mm

Operating position: OP 44±0.8 mm

Total travel position: TTP max. 39.5 mm

Four, M3.5 (length: 10)

Four,

+0.2

dia. holes

5.2

0

Three, M4 (length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

actuator

Pre-wired Connector Models

17 dia. (length: 5)

(see note)

OP

Four, M3.5 (length: 10)

Four,

+0.2

dia. holes

5.2

0

Three, M4 (length: 13)

SC-1M

XS2H-D421

Note: Stainless sintered roller

42 max.

42 max.

Four, M6

Depth: 15 min.

6 dia.

Limit

Switches

Two-circuit Limit Switch WL F-87

Page 32

Sealed Top-roller Plunger

WLD28

Note: 1. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

2. The above diagram is for a lamp-equipped model.

Direct-wired Connector Models

11.2 dia. (length: 5)

(see note)

OP

Note: Stainless sintered alloy roller

Operating characteristics Sealed top-roller plunger

Operating force: OF max. 16.67 N

Release force: RF min. 4.41 N

Pretravel: PT max. 1.7 mm

Overtravel: OT min. 5.6 mm

Movement differential: MD max. 1 mm

Operating position: OP 44±0.8 mm

Total travel position: TTP max. 39.5 mm

Four, M3.5 (length: 10)

Four,

+0.2

dia. holes

5.2

0

Three, M4 (length: 13)

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

actuator

Pre-wired Connector Models

11.2 dia. (length: 5)

(see note)

OP

Four, M3.5 (length: 10)

Four,

+0.2

dia. holes

5.2

0

Three, M4 (length: 13)

SC-1M

XS2H-D421

Note: Stainless sintered alloy roller

42 max.

Four, M6

Depth: 15 min.

F-88 Two-circuit Limit Switch WL

Page 33

■ Environment-resistant Models

The dimensions and operating characteristics are the same as general-purpose, environment-resistant models.

■ Spatter-prevention Models

Roller Lever (Screw Terminals)

WLCA2-@S/WL01@-@S

WLH2-@S/WLG2-@S

WLGCA2-@S

60 max.

17.5 dia. (length: 7) (see note)

Four, M3.5 head

clamping screws

38R

Note: Stainless steel roller

Roller Lever (Pre-wired Connector)

WLCA2-@S-M1J/WL01@-@S-M1J

WLH2-@S-M1J/WLG2-@S-M1J

WLGCA2-@S-M1J

Note: The dimensions are the same regardless of the number of core lines.

17.5 dia. (length: 7) (see note)

Four, M3.5 head

clamping screws

Two, M5 Allenhead nut and

arm set screw

+0.2

Four, 5.2

0

dia. holes

Teflon cap

Three, M4

(length: 13)

Lamp cover

14.7

58.7±

5

(25)

300

+100

−50

38R

0.2

Two, M5 Allen-head

nut and arm set screw

Four, 5.2

Three, M4 (length: 13)

60 max.

1.5

53±

1.5

41.5±

1.5

40±

13.1

25.4

12.7

Four, M6

Depth: 15 min.

6 dia.

+0.2

dia. holes

0

Teflon cap

Lamp cover

JIS B0202 G1/2

Effective thread:

4 threads min.

25.4

68.7

SC-1M

42 max.

Four, M6

Depth: 15 min.

Limit

Switches

(15.1)

30.2±

40±

0.2

0.7

XS2H-D421

(4.9)

Note: Stainless steel roller

53.2±

21.6

29.2±

35

42 max.

0.8

1.2

Operating characteristics Standard Overtravel models High-precision

General High-sensitivity

Operating force: OF max. 13.34 N 9.81 N 9.81 N 13.34 N

Release force: RF min. 2.23 N 0.98 N 0.98 N 1.47 N

Pretravel: PT 15°±5° 15°±5°

10°

+2

−1

+2°

5°

−0°

Overtravel: OT min. 30° 55° 65° 40°

Movement differential: MD max. 12° 12° 7° 3°

Two-circuit Limit Switch WL F-89

Page 34

Sealed Top-roller Plunger (Screw Terminals)

WLD28-@S

11.2 dia. (length: 5) (see note)

OP

Four, M3.5

Four, 5.2

+0.2

dia. holes

0

Lamp cover

Three, M4 (length: 13)

Note: Stainless steel roller

JIS B0202 G1/2

Effective thread:

4 threads min.

42 max.

Four, M6

Depth: 15 min.

Sealed Top-roller Plunger (Pre-wired Connector)

WLD28-@S-M1J

Note: The dimensions are the same regardless of the number of core lines.

l

11.2 dia. (length: 5) (see note)

OP

58.7±

5

(25)

300

PT

0.2

+100

−50

Rubber cap (fluorosilicon)

Four, M3.5 (length: 10)

push-in mounting screws

with spring washers

+0.2

Four, 5.2

dia. holes

0

Three, M4

(length: 13)

Lamp cover

XS2H-D421

(15.1)

(4.9)

0.2

30.2±

0.7

40±

Note: Stainless steel roller

Operating characteristics WLD28-L@S

Operating force: OF max. 16.67 N

Release force: RF min. 4.41 N

Pretravel: PT max. 1.7 mm

Overtravel: OT min. 5.6 mm

Movement differential: MD max. 1 mm

Operating position: OP 44±0.8 mm

Total travel position: TTP max. 39.5 mm

Note: Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.

29.2±

35

42 max.

13.1

12.9

21.6

1.2

68.7

Four, M6

Depth: 15 min.

SC-1M

6 dia.

F-90 Two-circuit Limit Switch WL

Page 35

■ Actuators (Levers Only)

Note: 1. Lever: Only rotating lever models are illustrated.

2. Unless otherwise indicated, a tolerance of ±0.4 mm applies to all dimensions.