Page 1

Handheld

2D Code Reader

V400-H101/201

User's Manual

Cat. No.

Z222-E1-01

Page 2

Introduction

Thank you for purchasing the OMRON V400-H101/H201.

This manual describes the functions, performance, and application

methods of the V400-H101/H201.

This manual is intended for personnel with knowledge of electrical

systems. Be sure to read and understand this manual thoroughly before

using the product, and keep this manual in an easily accessible location

for quick reference when required.

Page 3

ÇÕǹÇ?Ç ëÊ 1 èÕ ëÊ 2 èÕ ëÊ 3 èÕ ëÊ 4 èÕ

Introduction

Introduction

Section 1

Section 2

Section 3

Section 4

Section 5

Application Considerations (Read and understand this information first.)

Section 1 Section 2 Section 3 Section 4 Section 5

Product Overview

Installation and Connections

Reading 2D Code

System Settings

Troubleshooting

Appendices

Appendices

Specifications and Dimensions

Handheld 2D Code Reader

User's Manual

V400-H101/201

Page 4

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer

to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

V400-H101/H201

User’s Manual

2

Page 5

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

Introduction

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

V400-H101/H201

User’s Manual

3

Page 6

Introduction

Introduction

Meanings of Signal Words

In this manual, precautions are indicated using the following symbols and signal words to ensure safe

use of the

important for safety and must be observed.

V400-H101/H201. The precautions indicated by these symbols and signal words are

Indicates a potentially hazardous situation which, if not avoided, will

WARNING

result in minor or moderate injury, or may result in serious injury or death.

Additionally there may be significant property damage.

Meanings of Alert Symbols

Indicates the possibility of explosion under specific conditions.

Indicates general prohibitions for which there is no specific symbol.

Alert Statements in this Manual

● WARNINGS

WARNING

This product is not designed or rated for ensuring safety of persons and cannot be

used in safety applications designed to either directly or indirectly detect persons.

Do not use it for such purposes.

A lithium battery is built into the Controller and may occasionally combust, explode,

or burn if not treated properly, which may occasionally result in serious injury.

Dispose of the Controller as industrial waste, and never disassemble, apply

pressure that would deform, heat to 100

°C or higher, or incinerate the Controller.

V400-H101/H201

User’s Manual

4

Page 7

Introduction

Regulations and Standards

The V400-H101/H201 complies with the international regulations and standards listed below.

EC Directives EMC Directive:No.89/336/EEC

EN Standards

(European Standards)

EN61326: 1997, +A1: 1998 +A2: 2001 (EMI: Class A)

Power line: 10 m max. Signal line: 30 m max.

Precautions for Safe Use

Observe the following precautions to ensure safe use of the product.

■ Installation Environment Precautions

• Do not use the product in environments with flammable or explosive gases.

• Do not install outdoors.

Introduction

■ Power Supply and Wiring Precautions

• Use the product with the power supply voltages specified in this manual.

• Use the cables specified in this manual.

• Keep the power supply cable as short as possible (10 m maximum).

• Use a DC power supply with countermeasures against high-voltage spikes (safe extra

low-voltage circuits on the secondary side).

p.26

■ Other Precautions

• Do not attempt to disassemble, repair, or modify the product. Doing so may cause

product failure or a fire.

• If the product becomes extremely hot, or abnormal odors or smoke occurs, stop using

the product immediately, turn OFF the power, and consult with your OMRON representative.

• Dispose of the product as industrial waste.

• Do not apply pressure or deform the product when disposing of it.

V400-H101/H201

User’s Manual

5

Page 8

Introduction

Introduction

Precautions for Correct Use

Always observe the following precautions to prevent operation failures, malfunctions, and

adverse effects on performance and equipment.

■ Operating Environment

Do not install the product in the following locations:

• Locations subject to ambient temperature that exceeds the rated temperature range

• Locations subject to rapid changes in temperature (causing condensation)

• Locations subject to relative humidity that exceeds the rated humidity range

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salt, or metallic powder

• Locations subject to direct vibration or shock outside the specified ranges

• Locations subject to direct sunlight

• Locations subject to oil or chemical spray

■ Installation and Handling of Components

• Use the cables specified in this manual.

p.18

■ Connecting and Removing Cables

• Do not connect a cable to the Handheld 2D Code Reader if the other end of the cable

is connected to a personal computer or a Programmable Controller.

• To prevent damage from static electricity, use a wrist strap or another device for pre-

venting electrostatic charges when touching terminals or signal lines inside connectors.

■ Memory Cards

• Do not remove the Memory Card when the Memory Card indicator is lit. Doing so may

result in damage to the Memory Card or the Handheld 2D Code Reader.

• OMRON shall not be responsible in any way for damage or loss of Memory Card data

as a result of mishandling.

p.29

V400-H101/H201

User’s Manual

6

■ Turning OFF the Power Supply

• Do not turn OFF the power supply while a message is being displayed indicating that

processing is being performed. Data in memory will be destroyed, and the product

may not operate correctly the next time it is started.

Page 9

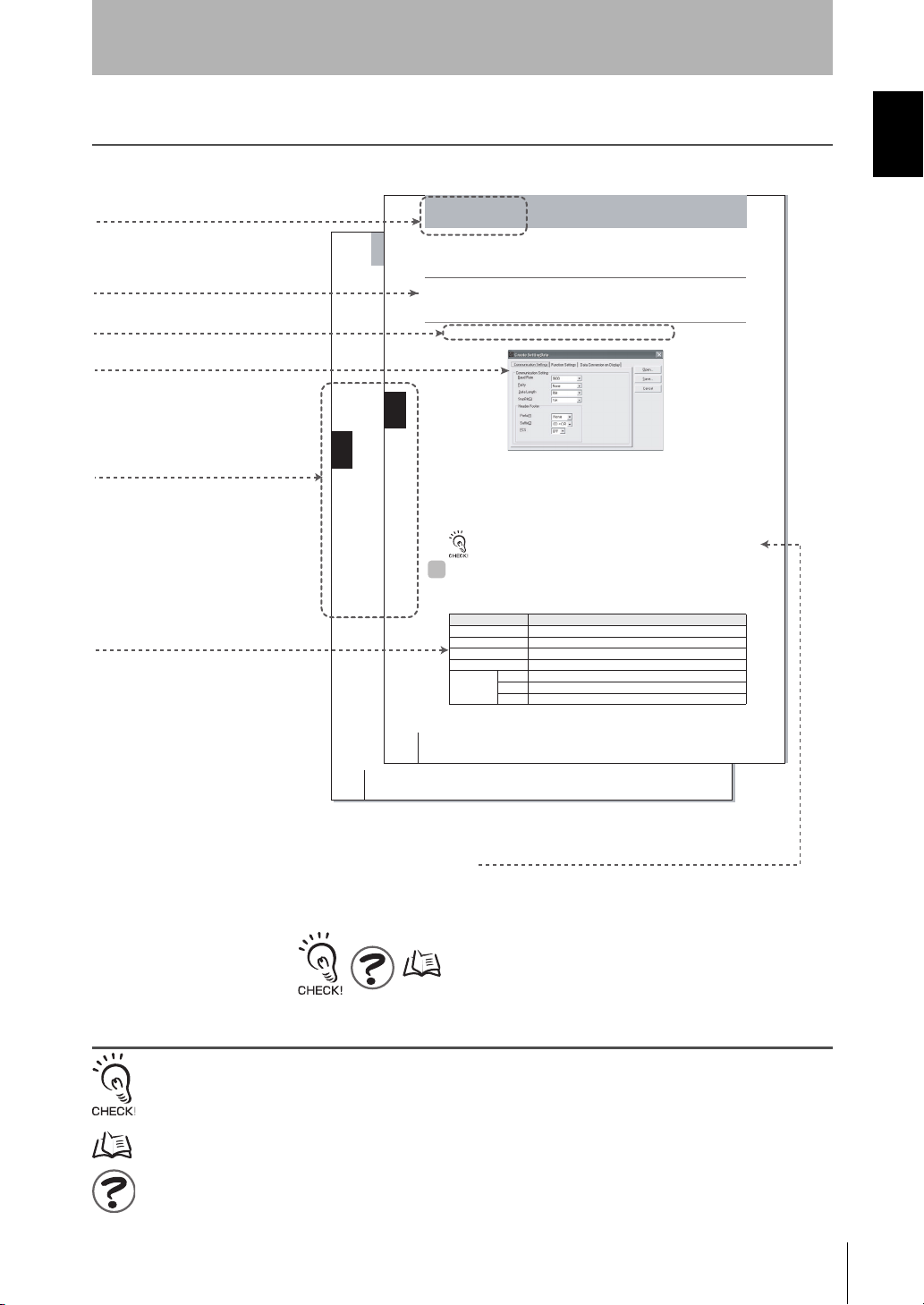

How to Use This Manual

Introduction

Introduction

Page Format

Section Title

Outline

Move to the Setting Screen.

Screen display

Index label

Provides the section number

and subject matter. Can be

used to immediately open the

desired page.

Describes the settings.

Section 4

System Settings

Creating Setting Files Using the 2DCR Con-

Section 4

System Settings

figear

Create the data setting file for loading setting data to the Handheld 2D C ode Reader.

Make the settings for the communications conditions, functions, and dis play conversion.

▲

The following window for creating the setting data file will be displayed.

Section 4 Creating Setting Files Using the 2DCR Configear

Section 4 Uploading from the Memory Card

■ Open

Opens the previously created data setting file for editi ng.

■ Save

Saves the created data setting file.

Communications Settings

The settings shown in the following table are set in the Communications Settings Tab

Page in the Create Setting Data Window.

The asterisks indicate default settings.

V400-H101/201

User’s Manual

46

V400-H101/201

User’s Manual

48

Select Setting Reader - Create Setting Data from the menu.

To save data to the Memory Card, create a folder with the name SETTINGS, and save. The Handheld 2D Code Reader's setting mode cannot start if the data is saved in a folder of a different name.

Setting item Settings

Baud Rate

Parit y

Data Length 7 bits or 8 bits

Stop Bit 1 bit* or 2 bits

Header/Footer Prefix

*

9600

, 19,200, or 38,400

*

None

, odd, or even

*

*

None

, 02 <STX> or 1B <ESC>

Suffix 03 <ETX>, 0A <LF>,

FCS ON or

OFF

*

0D<CR>

*

, or 0D0A <CR+LF>

How to Use This Manual

Visual Aids

Indicates points that are important in using product functions or in application procedures.

Indicates page numbers providing related information.

Indicates helpful information when a problem occurs and explanations of technical terms.

Procedure and additional explanations

Information useful during the operation and reference pages are provided here with special marks

to indicate the kind of information being provided.

*This page does not actually exist in this manual.

V400-H101/H201

User’s Manual

7

Page 10

Introduction

Introduction

Internet Information

Internet Information

Information on the Handheld 2D Code Reader is available on the Internet.

Contact the OMRON representative nearest you regarding the website address.

V400-H101/H201

User’s Manual

8

Page 11

Table of Contents

Introduction

Introduction

Introduction 2

Application Considerations (Read and understand this information first.) 2

Meanings of Signal Words 4

Regulations and Standards 5

Precautions for Safe Use 5

Precautions for Correct Use 6

How to Use This Manual 7

Visual Aids 7

Internet Information 8

Table of Contents 9

Section 1 Product Overview 11

Features 12

Operation Overview 15

Table of Contents

Section 2 Installation and Connections 17

Basic System Configuration 18

Component Names and Functions 19

Cable 20

Power Supply 26

Contactor (Optional) 27

Stand (Optional) 28

Memory Cards 29

V400-H101/201

User’s Manual

9

Page 12

Preface Table of Contents

Preface

Section 3 Reading 2D Code 31

Basic Operation 32

Startup 33

Reading 2D Code 34

Outputting Results 35

Functions 37

Section 4 System Settings 39

Overview 40

Installing the 2DCR Configear 41

Communications Using the 2DCR Configear 43

Creating Setting Files Using the 2DCR Configear 46

Uploading from the Memory Card 52

Section 5 Troubleshooting 55

Troubleshooting 56

Appendices 57

Maintenance 58

Specifications and Dimensions 59

ASCII Table 64

FCS Calculation Method 65

Data Capacity Tables 67

Revision History 70

V400-H101/201

User’s Manual

10

Page 13

Section 1 Product Overview

This section provides an introduction to the Handheld 2D Code Reader's features, functions, basic configuration, and operation flow.

Features 12

Operation Overview 15

Section 1 Product Overview

V400-H101/201

User’s Manual

11

Page 14

Section 1

Product Overview

Features

Section 1 Features

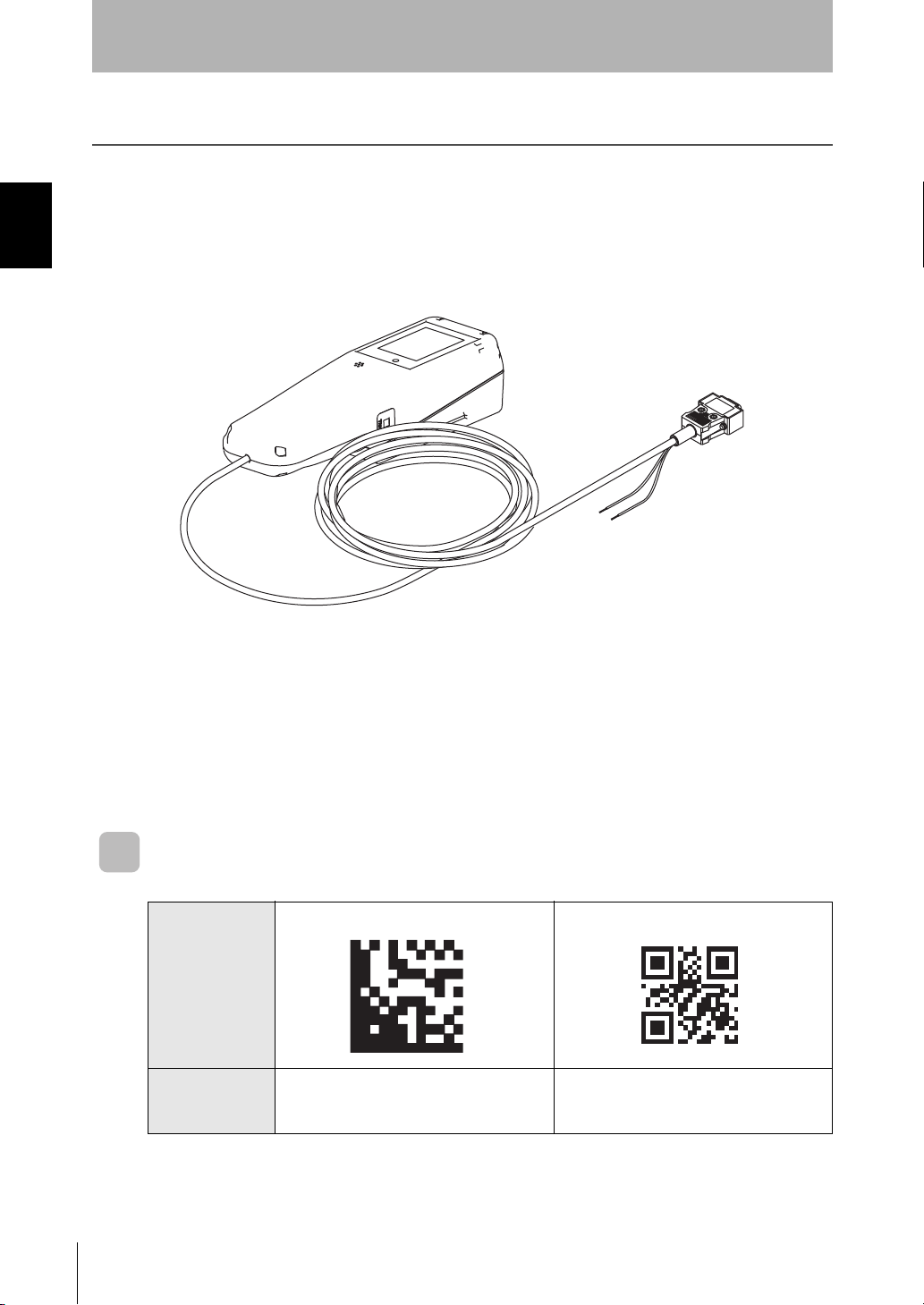

The 2D Code Reader is designed to read two-dimensional code. A built-in monitor and zoom

lens are ideal for reading directly marked 2D code. A Memory Card Slot is also provided along

with a range of useful functions.

Readable Codes

Readable codes DataMatrix QR Code

Readable sizes

(symbol size)

• ECC200

× 10 to 64 × 64

10

8

× 18 to 16 × 48

Model 1 or 2

× 21 to 57 × 57

21

(Version 1 to Version 10)

V400-H101/201

User’s Manual

12

Page 15

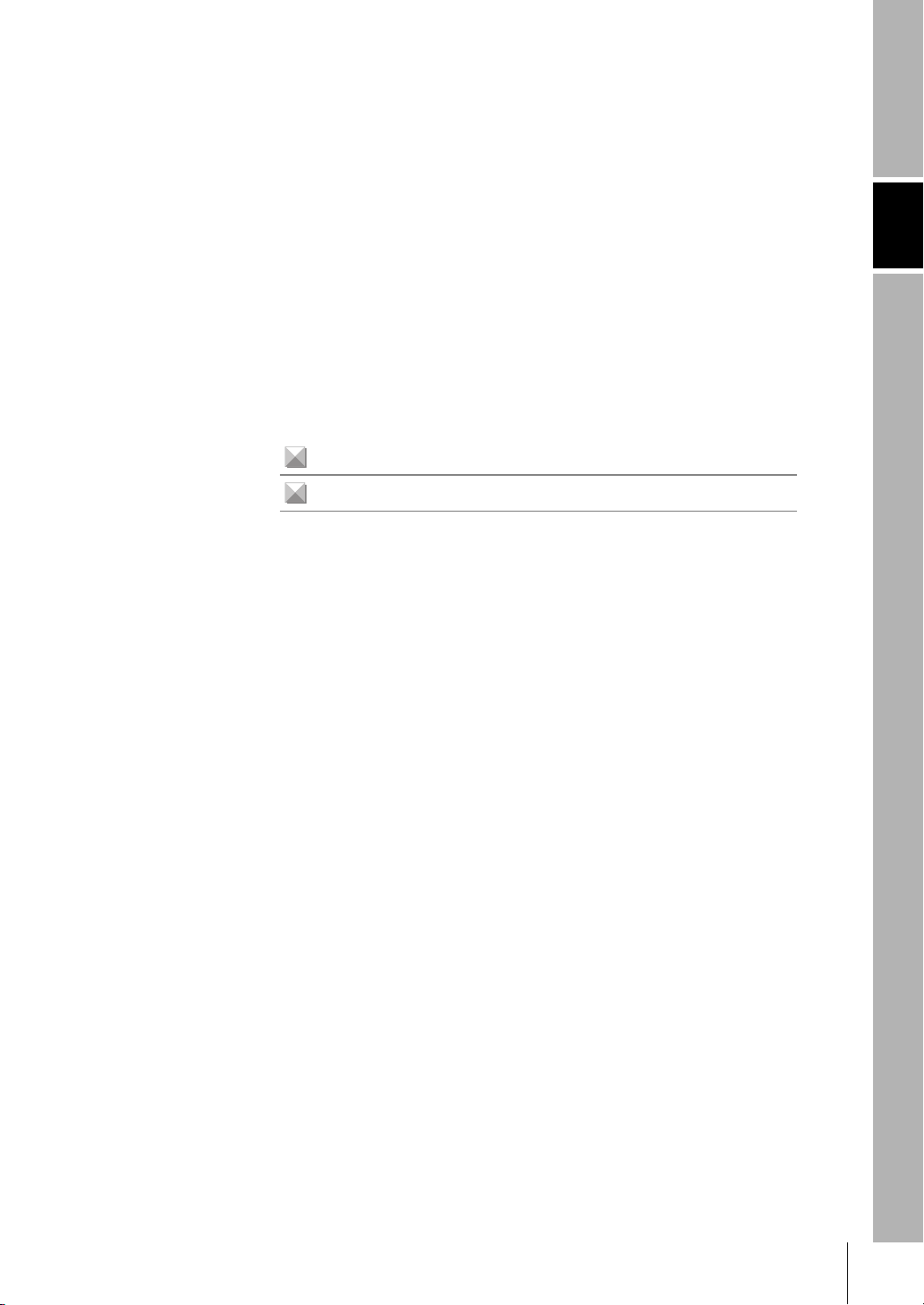

Zoom Lens (Manual)

The zoom lever can be used to change the

field of view, enabling a variety of applications with a single Unit. Two lens variations

provide wide-angle and telescopic views,

covering all viewing needs from paper level

to complicated code.

Dual System Lighting

Coaxial lighting and oblique lighting are provided in a single Unit. The type of the

lighting is automatically selected.

• V400-H101 RGB 3 color coaxial, red

oblique lighting

• V400-H201 Red coaxial, red oblique light-

ing

Workpieces with different optical characteristics can be read with a single Unit, and

workpieces with a range of direct markings can also be read.

Section 1

Product Overview

Section 1 Features

Liquid Crystal Display

The Handheld 2D Code Reader is equipped

with a 1.8-inch Liquid Crystal Monitor,

enabling you to view an image of positioning

while reading.

The Handheld 2D Code Reader enables

confirmation of read data and images, previously not possible with handheld readers.

O K

ABCDEFGHIJKLMNOPQRST

V400-H101/201

SD

User’s Manual

13

Page 16

Section 1

Product Overview

Memory Card Slot

A Memory Card slot is provided to back up settings on Memory Cards and upload data

Section 1 Features

from Memory Cards. A function is also provided for saving 2D code data that was read

as files in the Memory Card.

p.29

Memory Card

Useful Functions

■ Data Conversion on Display

This function converts data that is read and displays it as a separate text string.

p.49

■ Data Accumulation

This function writes data that is read to the Memory Card.

p.48

V400-H101/201

User’s Manual

14

Page 17

Operation Overview

Section 1

Product Overview

Installation and Connections

Prepare the required components and connect them.

Main Peripheral Devices

• Cable

• Power supply device

• Contactor

• Stand

Reading 2D Code

Turn ON the power and press the trigger buttons to

read the code.

• Reading method

• Field of view setting

• Display details

Section 2 p.17

Section 3 p.31

Section 1 Operation Overview

System Settings

Basic settings for the Handheld 2D Code Reader

are not required, but settings must be changed

using the Special Tool 2DCR Configear under

the following circumstances.

• To change the communication condi-

tions (See note.)

• To use various functions

These settings can be changed in the Handheld

2D Code Reader using a Memory Card or the communications functions of the 2DCR

Configear.

Note: The default settings are as follows:

Baud rate: 9, 600 bps; Parity: None; Data length: 8 bits; Stop bits: 1 bit

Section 4 p.39

V400-H101/201

User’s Manual

15

Page 18

Section 1 Operation Overview

Section 1

Product Overview

MEMO

V400-H101/201

User’s Manual

16

Page 19

Section 2 Installation and Connections

This section describes the methods used to connect cables and perform

other installation procedures and connections.

Basic System Configuration 18

Component Names and Functions 19

Cable 20

Power Supply 26

Contactor (Optional) 27

Stand (Optional) 28

Memory Cards 29

Section 2 Installation and Connections

V400-H101/201

User’s Manual

17

Page 20

Section 2

Installation and Connections

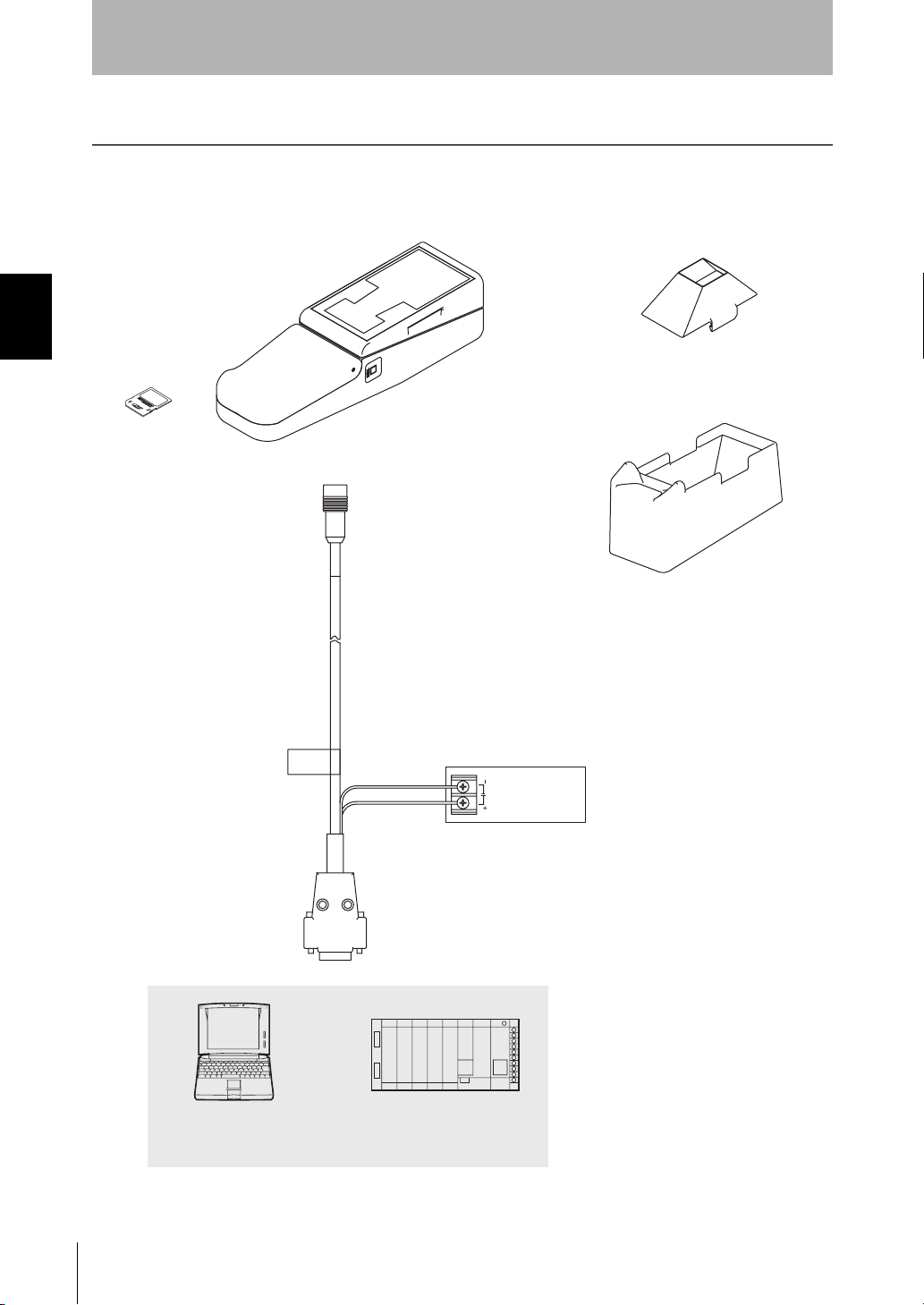

Basic System Configuration

The basic system configuration is shown in the following diagram.

Section 2 Basic System Configuration

V400-AC1

Contactor

K

C

O

L

Memory Card

(SD card)

V400-H101/H201

Handheld 2D Code Reader

(optional)

Host Devices

V400-W20-2M

V400-W21-2M

Cable

(recommended)

Power supply

5VDC

device

Recommended product:

OMRON S82K-00705

V400-AS1

Stand

(optional)

V400-H101/201

User’s Manual

18

Personal computer

Programmable Controller:

CJ Series

CS Series

Page 21

Installation and Connections

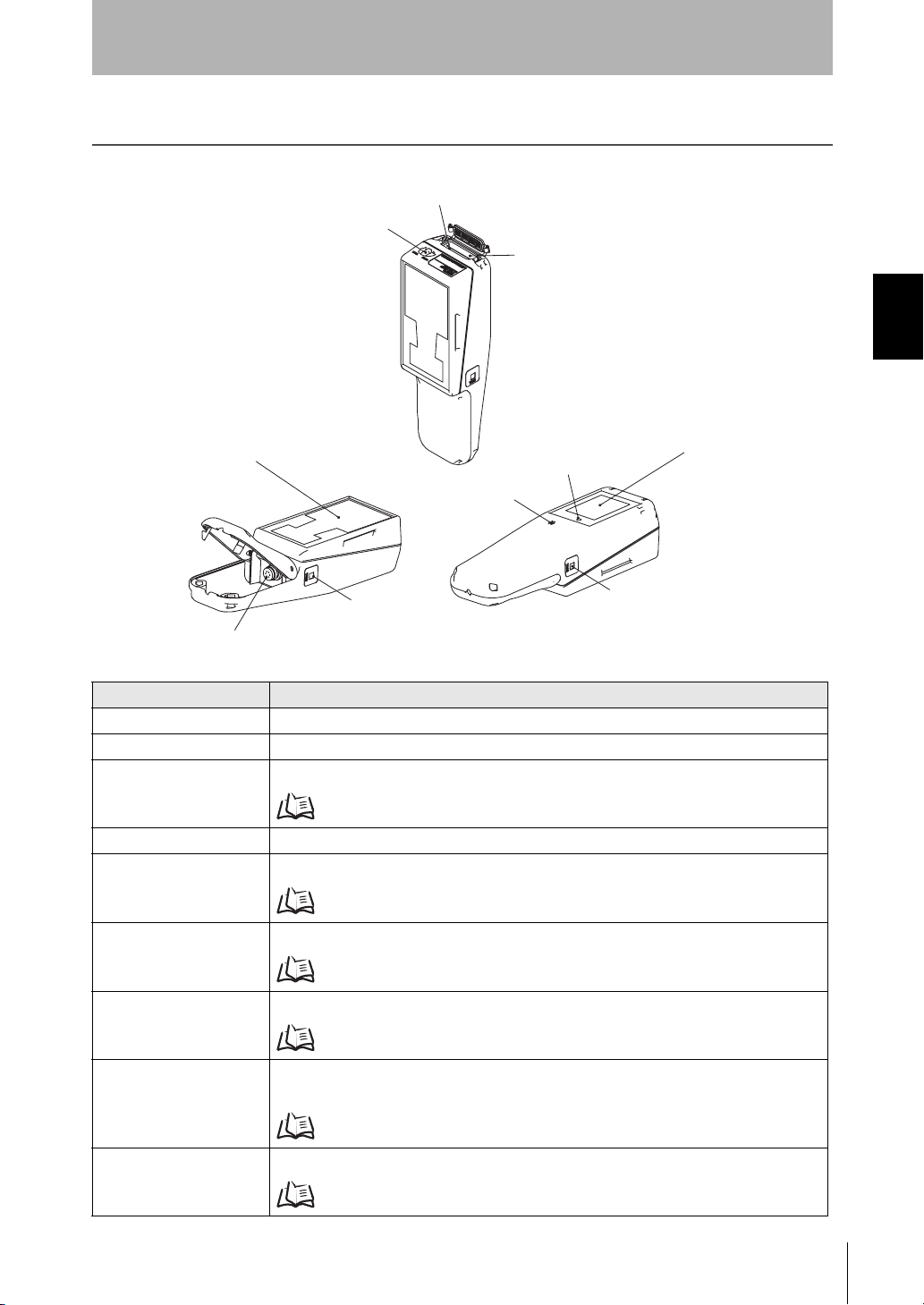

Component Names and Functions

(8) Memory Card indicator

(4) Zoom lever

(1) Memory Card slot

Section 2

Section 2 Component Names and Functions

(2) Image plane

(3) Left trigger button

(9) Cable connector

Name Details

(1) Memory Card slot Slot for inserting Memory Card.

(2) Image plane Camera image plane

(3) Trigger buttons

(Right, Left)

(4) Zoom lever Changes the field of view.

(5) Monitor Displays the read image/results, and other data.

(6) Power indicator Lit when power is first turned ON and remains lit during operation.

Cancels sleep state for a trigger input or when setting mode is entered.

p.34

p.35

(6) Power indicator

(7) Buzzer

(3) Right trigger button

(5) Monitor

p.35

(7) Buzzer A high- or low-tone buzzer sounds depending on the operation.

p.33

(8) Memory Card indicator Lit while the Memory Card is being accessed. (Do not remove the Memory Card if the

indicator is lit.)

p.35

(9) Cable connector Connects to a V400-W20-2M or V400-W21-2M Cable.

p.22

V400-H101/201

User’s Manual

19

Page 22

Section 2

Installation and Connections

Cable

The Cables are specifically designed for the V400. Using other Cables may damage the

devices.

Section 2 Cable

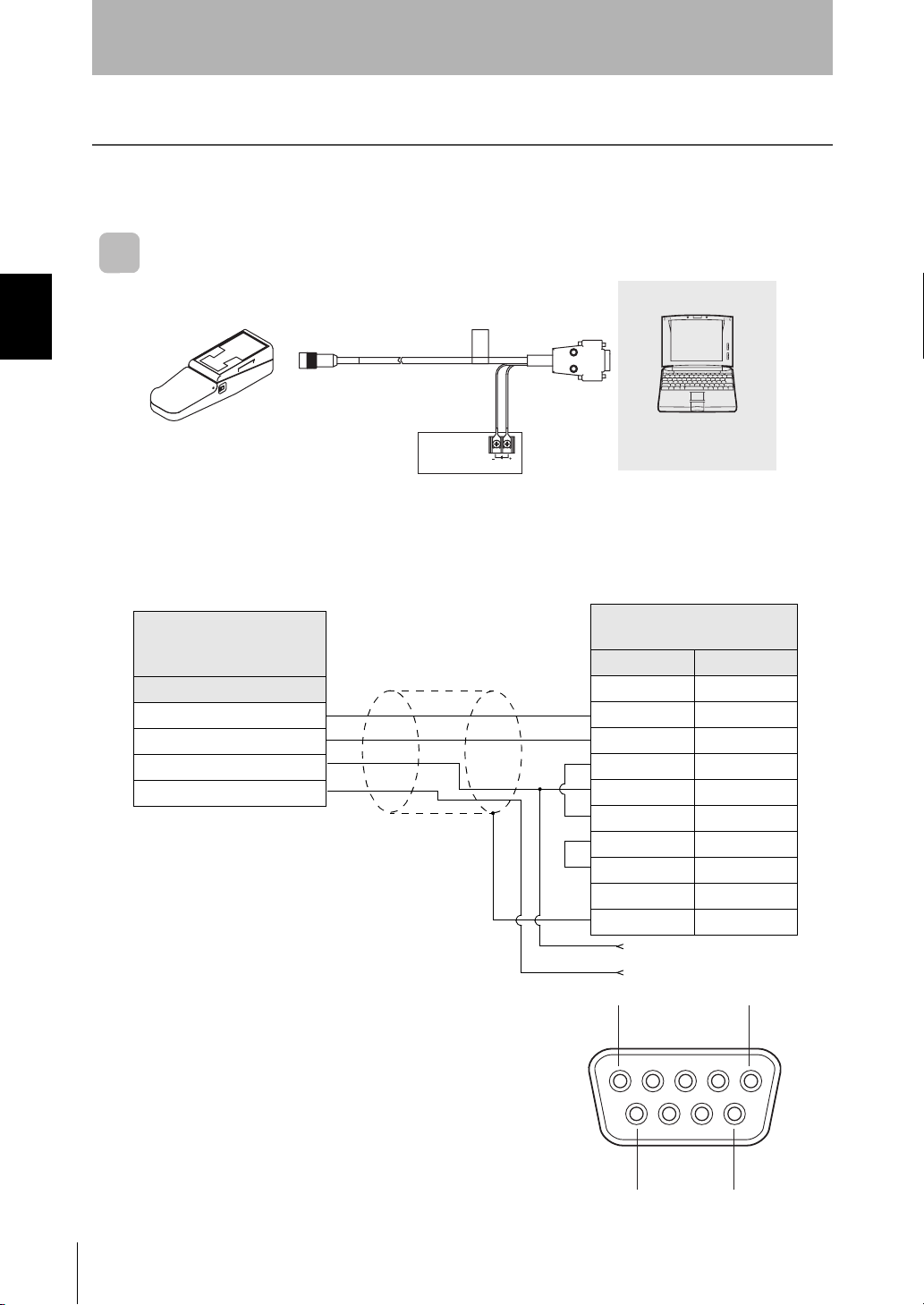

Connecting a Personal Computer (V400-W21-2M Cable)

V400-H101/H201

Handheld 2D Code Reader

V400-W21-2M

Cable

Power supply

device

Recommended product:

OMRON S82K-00705

5VDC

Host device

Personal computer

● Connector

The connector used for V400-W21-2M Cable is a D-sub, 9-pin connector (female).

The connector is compatible with the connection port on the IBM PC/AT or compatible.

Special round connector on

V400-H101/H201

2D Code Reader

Name

SD

RD

SG

+5 V

IBM PC/AT or compatible

D-sub, 9-pin

Pin No. Name

1-

2RD

3SD

4ER

5SG

6DR

7RS

8CS

9-

Connector cover

0 V

+5 V

51

Shield wire

V400-H101/201

User’s Manual

20

9

(View of mating section)

6

Page 23

Section 2

Installation and Connections

Connecting a Programmable Controller (V400-W202M Cable)

V400-H101/H201

Handheld 2D Code Reader

V400-W20-2M

Cable

Power supply

device

Recommended product:

OMRON S82K-00705

Host device

Programmable Controller:

CJ Series

CS Series

● Connector

The connector used for V400-W20-2M Cable is a D-sub, 9-pin connector (male).

The connector is compatible with the connection port on OMRON CJ-series and CSseries Programmable Controller.

Special round connector on

V400-H101/H201

2D Code Reader

Name

SD

RD

SG

+5 V

Programmable Controller

D-sub, 9-pin

Pin No. Name

1-

2SD

3RD

4RS

5CS

6-

7-

8-

9SG

Connector cover

0 V

+5 V

Shield wire

Section 2 Cable

15

6

(View of mating section)

9

V400-H101/201

User’s Manual

21

Page 24

Section 2

Installation and Connections

Connecting Cables to the Handheld 2D Code Reader

Connect one end of the cable to a personal computer or Programmable Controller before connecting

the other end of the cable to the Handheld 2D Code Reader.

Section 2 Cable

1. Attach the provided ferrite cores to the cable.

Attach the ferrite cores in two locations; one at the Handheld 2D Code Reader end of the cable, and the other

at the host device end of the cable.

Close the ferrite cores until a click is heard. Separate from the power lines.

Ferrite cores

V400-H101/201

User’s Manual

22

2. Connect the cable.

Grasp the cable plug (part A). Line up the alignment mark

on the plug with the alignment mark on the Handheld 2D

Code Reader connector and push the plug in straight.

Cable

Cable port

Plug

A

D

C

D

Alignment marks

C

Page 25

Section 2

Installation and Connections

Use a force of no more than 15 to 20 N to plug in the connector. Pull gently on the cable (approximately 10 N) to make sure the connector is securely connected. After the connector is plugged in,

do not apply a force of more than 30 N to the connector in the following directions. Excessive force

will damage the connector.

30 N

30 N

30 N

Section 2 Cable

3. Place the cable in the groove provided for it in

the case.

4. Close the cover.

Keep fingers clear when closing the case to prevent the case closing on them.

V400-H101/201

User’s Manual

23

Page 26

Section 2

Installation and Connections

Disconnecting the Cable from the Handheld 2D Code Reader

1. Disconnect the cable connector from the host device.

Section 2 Cable

p.25

2. Open the cover.

Press down on the indentations on both sides of the cover

as you open it.

Do not apply excessive force to the cover.

3. Disconnect the cable.

Grasp the coupling (part B) on the plug and pull the plug

out straight as shown in the diagram below.

Coupling

Cable

B

4. Close the cover.

Keep fingers clear when closing the case to prevent the case closing on them.

V400-H101/201

User’s Manual

24

Page 27

Installation and Connections

Connecting the Cable to the Host Device

1. Connect the cable connector to the RS-232C

interface on the host device, making sure that

the connector is oriented correctly and not

inserted at an angle. Secure the connector

using the screws on both sides of the connector.

Section 2

Section 2 Cable

Removing the Cable from the Host Device

1. Remove the cable.

Loosen the screws on both sides of the connector and pull

the connector out straight.

Be sure to loosen the screws on both sides of the

connector sufficiently before removing the connector and do not use excessive force.

V400-H101/201

User’s Manual

25

Page 28

Section 2

Installation and Connections

Power Supply

Power must be supplied to the V400-H101/H201 via the cable. Wire the power supply

independently of other devices. In particular, keep the power supply wired separately from

inductive loads. Use a power supply that meets the following requirements.

Section 2 Power Supply

Power Supply Requirements

Output current Power supply voltage

1 A min. 5 VDC±10%

Recommended Power Supply

Model

S82K-00705

Use a DC power supply with safe extra-low-voltage circuits to prevent high voltage. If UL recognition is

required for the overall system, use a UL Class II DC power supply.

■ Connection Method

Wire the power supply cables as shown in the following diagram.

V400-H101/201

User’s Manual

26

Connect the brown wire to the positive (+) side of the power supply and connect the blue wire to the

negative (

−) side of the power supply.

Page 29

Section 2

Installation and Connections

Contactor (Optional)

The Contactor functions as a guide for the distance from the image plane to the code to be

read. By making contact with the read code, the read distance can be easily aligned.

Mounting Procedure

1. Align the grips on the Contactor with the

grooves on the Handheld 2D Code Reader to

mount it.

Mount by clicking the notches of the grips into the

grooves of the Handheld 2D Code Reader.

Section 2 Contactor (Optional)

Removal Procedure

1. Remove the grips of the Contactor from the

grooves on the Handheld 2D Code Reader

pulling in the direction of the arrow shown in

the diagram on the right

Do not use excessive force when removing the

Contactor grips from the grooves.

V400-H101/201

User’s Manual

27

Page 30

Section 2

Installation and Connections

Stand (Optional)

The Stand is for holding the V400-H101/H201.

Mounting Procedure

Section 2 Stand (Optional)

1. Use two M4 screws to mount the Stand.

Mounting Hole Dimensions

Two, M4 or

4.2-dia. holes

(Unit: mm)

20.0

V400-H101/201

User’s Manual

28

Placing the Handheld 2D Code Reader on the Stand

1. Place the Handheld 2D Code Reader in

the Stand as shown in the diagram on

the right.

The Stand is designed to be placed on a horizontal surface. Do not mount the Stand to a wall or

other similar surface.

Page 31

Section 2

Installation and Connections

Memory Cards

The Handheld 2D Code Reader uses Memory Cards to upload or backup setting data and

data to be read. SD Memory Cards are supported.

• Conforms to SD Memory Card "Physical Layer Specification 1.01"

• File format: FAT16

Save the data to the Memory Card, insert the Memory Card in the personal computer, and

upload the data to easily backup the data to the personal computer. SD Memory Cards are

provided with a write prohibit switch to prohibit writing to or formatting of the Memory Card.

When the switch is set to LOCK, data cannot be written to or deleted from the Memory Card,

and the Memory Card cannot be formatted. These functions are possible by setting the switch

to the unlocked state.

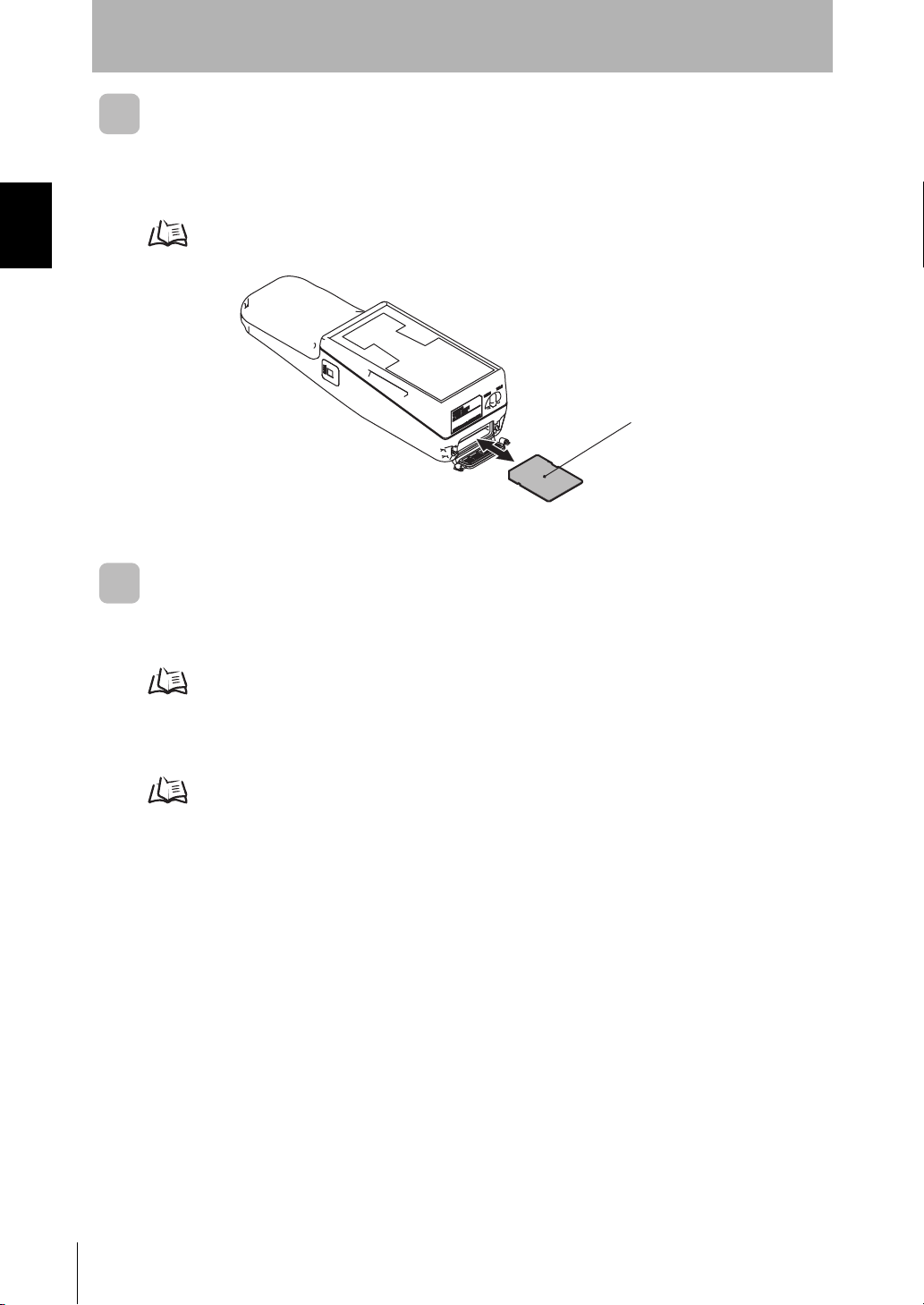

Inserting the Memory Card

Section 2 Memory Cards

1. Open the Memory Card slot cover.

Lift the cover gently, without using excessive

forc e.

2. Position the Memory Card in the correct

direction and insert in the slot until a click is

heard.

Insert the Memory Card in the direction with the

label side facing the same direction as the monitor of the Handheld 2D Code Reader.

3. Close the Memory Card slot cover.

V400-H101/201

User’s Manual

29

Page 32

Section 2

Installation and Connections

Removing Memory Cards

1. Open the Memory Card slot cover.

Section 2 Memory Cards

Lift the cover gently, without using excessive

forc e.

2. Make sure that the indicator on the Memory Card slot is not lit.

Do not remove the Memory Card while the indicator is lit. Doing so may damage the Memory Card

and the Handheld 2D Code Reader.

3. Push the Memory Card in gently until a click

is heard.

The Memory Card will eject slightly.

V400-H101/201

User’s Manual

30

4. Pull out the Memory Card straight.

5. Close the Memory Card slot cover.

Page 33

Section 3 Reading 2D Code

This section provides information required for reading 2D code.

Basic Operation 32

Startup 33

Reading 2D Code 34

Outputting Results 35

Functions 37

Section 3 Reading 2D Code

V400-H101/201

User’s Manual

31

Page 34

Section 3

Reading 2D Code

Basic Operation

Startup

Turn ON the power to the power supply device and start the Handheld 2D Code Reader.

Section 3 Basic Operation

Press the trigger buttons and keep pressed while

moving the Handheld 2D Code Reader close to the

2D code.

Reading 2D Code

Outputting Results

The read data is output to the monitor and RS-232C

communications.

OK

ABCDEFGHIJKLMNOPQRST

SD

p.33

p.34

p.35

The following functions are provided with the Handheld 2D Code Reader.

V400-H101/201

User’s Manual

32

If no operation is performed during a fixed interval, the Handheld 2D Code Reader will enter a sleep state.

Pressing the trigger buttons will release the sleep state.

Functions

• Sleep

• Data Conversion on Display

• Data Accumulation

p.37

Page 35

Startup

Section 3

Reading 2D Code

When the power of the power supply device is

turned ON, the screen on the right will be displayed, the power indicator will light, and the

buzzer will sound.

■ Buzzer

The buzzer will sound under the following conditions.

• When starting the V400

• When reading is successful

• When operating in setting mode

When the buzzer is set to OFF, the buzzer will not sound for any operation.

2D Code Reader

V400-H201

Ver,0.963

(C) Copyright

OMRON CORPORATION

2005

All Rights Reserved

2005/01/05 20:00

SD

Section 3 Startup

V400-H101/201

User’s Manual

33

Page 36

Section 3 Reading 2D Code

Section 3

Reading 2D Code

Reading 2D Code

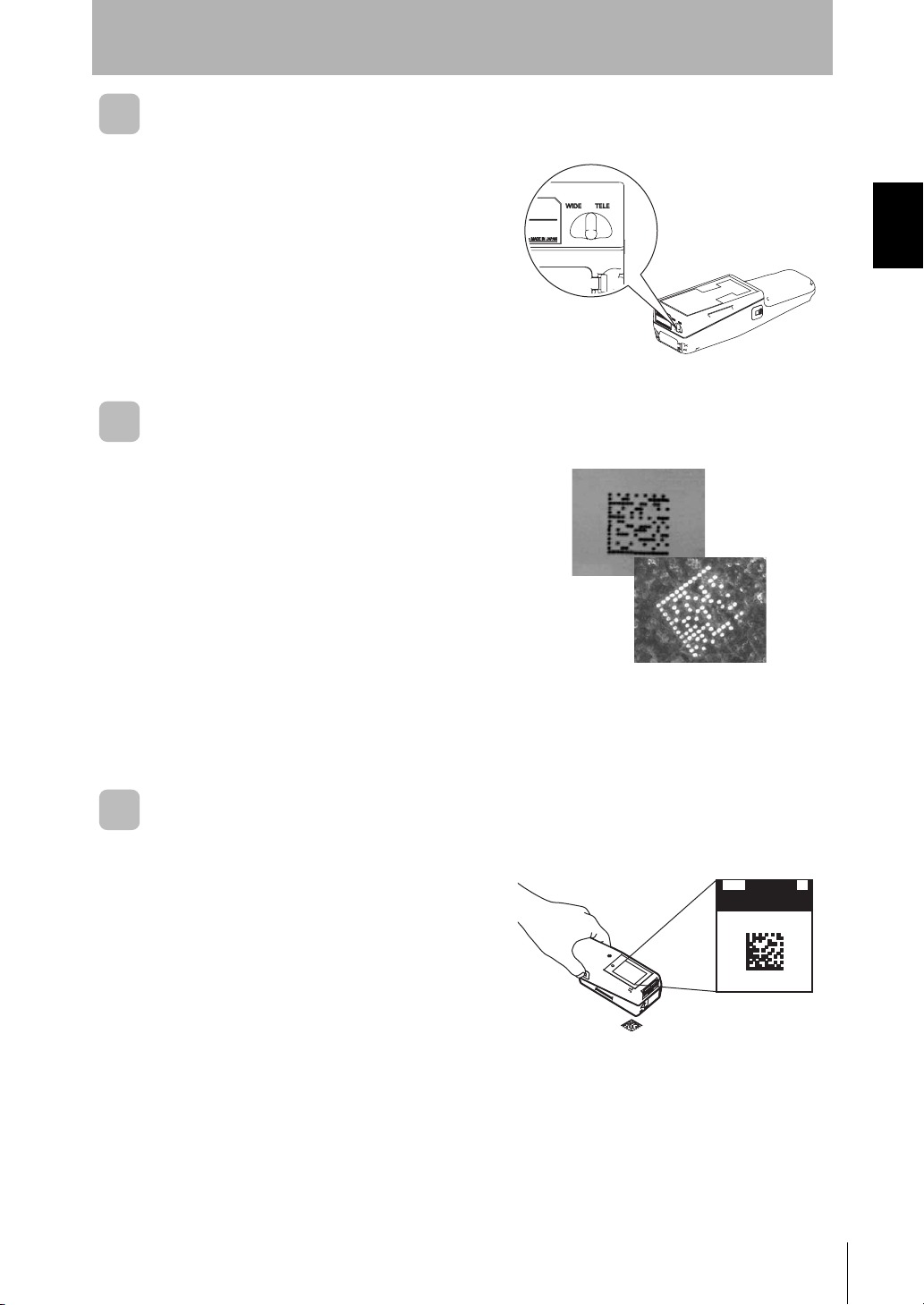

■ Trigger Buttons

The trigger buttons on the left and right side of the Handheld 2D Code Reader perform

the same operations. When a trigger button is pressed, the 2D Code Reader will start

reading code.

■ Trigger Mode

Triggers can be input two different ways. Select the input method to suit the required

application.

◆ Level Trigger (Default)

Press and hold the trigger button to read code continuously until code is successfully

read or until the trigger button is released.

Trigger button ON

Trigger button OFF

Reading status

Reading

◆ Alternate Trigger

Press the trigger button once to read code continuously until code is successfully read

or until the trigger button is pressed again.

Trigger button ON

Trigger button OFF

Reading status

Reading

■ Zoom Lever

The zoom lever is used to change the field

of vision to suit the size of the code to be

read.

Model Setting range

V400-H101 5 mm (TELE) to 10 mm (WIDE)

V400-H201 15 mm (TELE) to 30 mm (WIDE)

V400-H101/201

User’s Manual

34

Page 37

Outputting Results

■ Monitor Description

OK

ABCDEFGHIJKLMNOPQRST

SD

Section 3

Reading 2D Code

Image area

Tex t d i s p l a y

Image display

◆ Image Area

This area indicates whether reading was successful and Memory Card status.

Item Details

OK Displayed in green on the top left side of the screen when 2D codes are read suc-

cessfully.

Memory Card Displays the SD mark when a Memory Card is inserted.

Displays the SD mark in red when the Memory Card is active to indicate that the

Memory Card is being accessed.

◆ Text Display

This area displays reading results and data converted by the display conversion

function. Up to 38 characters can be displayed.

◆ Image Display

This area displays images taken by the Camera.

Section 3 Outputting Results

■ LED Indicators

Indicator Location Details

Power On the bottom of the

monitor

Memory Card Beside the Memory Card

slot

Lit when power is turned ON, and remains lit during operation

Lit when the Memory Card is being accessed. Do not

remove the Memory Card while this indicator is lit.

V400-H101/201

User’s Manual

35

Page 38

Section 3 Outputting Results

Section 3

Reading 2D Code

■ RS-232C Communications Output

◆ Output for Successful Readings

Read data is output in the following format.

Header Read data Footer

◆ Output for Unsuccessful Readings

Nothing is output with the default setting.

An error code output, however, can be set for unsuccessful readings. (See note.)

Note: NG output setting

When the NG output is set to ON, the output contents can be changed.

Output contents when NG output is ON:

• The NG mark is displayed on the monitor in red.

• The data ?E000 is sent via RS-232C communications.

Header

?E000

Footer

V400-H101/201

User’s Manual

36

Page 39

Functions

■ Sleep

The Handheld 2D Code Reader is equipped with a sleep function for reducing power

consumption. The Code Reader is automatically set to sleep when operation is not performed for a specified period of time.

• 30 Seconds Lapsed (Default Setting)

Press either of the trigger buttons to return to resume normal operating status from

sleep status.

■ Data Conversion on Display

Normally, 2D code data that is read is displayed as is on the monitor. This function compares the read data, converts into separate text strings and displays the converted

data.

p.49

Section 3

Reading 2D Code

Section 3 Functions

O K

DS1300

Example display when function is OFF Example display when function is ON

SD

O K

Produced January

DS1300

SD

■ Data Accumulation

The read data is not only output via RS-232C communications, but is created as a file

in the Memory Card and saved in CSV format.

p.48

V400-H101/201

User’s Manual

37

Page 40

Section 3 Functions

Section 3

Reading 2D Code

MEMO

V400-H101/201

User’s Manual

38

Page 41

Section 4 System Settings

This section describes the methods used to install and set the 2DCR Configear software.

Overview 40

Installing the 2DCR Configear 41

Communications Using the 2DCR Configear 43

Creating Setting Files Using the 2DCR Configear 46

Uploading from the Memory Card 52

Section 4 System Settings

V400-H101/201

User’s Manual

39

Page 42

Section 4

System Settings

Overview

Section 4 Overview

Installing the Setting Software

Obtain the 2DCR Configear application software from the Internet and install it on a personal

computer.

Creating the Setting File

Create the setting file using the 2DCR Configear.

Specify the required settings using the 2DCR

Configear, and create as a file.

The following items can be set.

1. Communications settings

2. Function settings

Uploading Data

p.41

p.46

p.52

Upload the created setting data to the Handheld 2D Code

Reader.

The following two loading methods are available.

• Using the Memory Card

• Using the 2DCR Configear

V400-H101/201

User’s Manual

40

Page 43

System Settings

Installing the 2DCR Configear

Obtain the 2DCR Configear and install it on a personal computer.

Contact the OMRON representative nearest you regarding the 2DCR Configear.

1. Open the setup.exe file downloaded from the Sensing Web website.

The following window will be displayed.

2. Click the OK Button.

Section 4

Section 4 Installing the 2DCR Configear

3. Click the Button.

V400-H101/201

User’s Manual

41

Page 44

Section 4

System Settings

4. Click the Continue Button.

Setup will start when the Continue Button is clicked.

Section 4 Installing the 2DCR Configear

5. Click the OK Button.

V400-H101/201

User’s Manual

42

Page 45

Section 4

System Settings

Communications Using the 2DCR Configear

The 2DCR Configear can be used to communicate with the Handheld 2D Code Reader.

Menu

Communication

Setting

Connect Button

Connects or disconnects

from the port.

Status display

Section 4 Communications Using the 2DCR Configear

Direct Command Input

Sends the input text string

to the Handheld 2D Code Reader.

■ Communication Setting

The following items can be set.

Setting item Settings

Por t No.

Baud Rate

Parity

Data Length 7 bits or

Stop Bit 1sbit* or 2 bits

Header/Footer Prefix Send

Suffix Send 03 <ETX>, 0A <LF>,

FCS Send ON or

Same as Send Sets the header, footer, and FCS for receiving to the same settings as for

Communication Log

Display Form

Selects the communication log display format

as either text format or hexadecimal.

*

COM1

9,600

None

Receive

Receive 03 <ETX>, 0A <LF>,

Receive ON or OFF

sending.

to COM 9

*

, 19,200, or 38,400

*

, odd, or even

*

8 bits

*

None

, 02 <STX>, or 1B <ESC>

*

None

, 02 <STX>, or 1B <ESC>

*

OFF

*

0D <CR>

0D <CR>

*

, or 0D0A <CR+LF>

*

or 0D0A <CR+LF>

The default settings are indicated with an asterisk.

Operation is not possible when the port is connected.

V400-H101/201

User’s Manual

43

Page 46

Section 4

System Settings

■ Menu

◆ File

◆ Edit

Section 4 Communications Using the 2DCR Configear

Save Log...

Saves the data displayed in the communication log as a text file.

Save Environment

Saves the settings made in the communications settings.

End

Ends the 2DCR Configear.

Copy Log

Copies the log displayed in the communication log to the clipboard.

Erase Log

Deletes the log displayed in the communication log.

◆ Setting Reader

Create Data...

Creates the data setting file for loading set data to the Handheld 2D Code Reader.

p.46

Auto Scan

Automatically obtains the conditions required for communicating with the Handheld 2D

Code Reader.

Operation is not possible when the port is connected.

Send Setting

Sends the data setting file from the host to the Handheld 2D Code Reader.

Operation is not possible when the port is disconnected.

Receive Setting

Sends the setting data for the Handheld 2D Code Reader to the host.

Operation is not possible when the port is disconnected.

Set Date, Time

Sends the clock time of the personal computer in which 2DCR Configear is installed to

the Handheld 2D Code Reader.

Operation is not possible when the port is disconnected.

V400-H101/201

User’s Manual

44

The clock is factory set to Japanese Standard Time.

Page 47

Section 4

System Settings

◆ Help

Version

Displays the software version of the 2DCR Configear installed.

■ Buttons

◆ Connect

Connects or disconnects the port.

■ Display Form

Selects the format for displaying data in the communication log.

Either text display or hexadecimal display can be selected. (Default setting: Text display)

■ Direct Command Input

Sends the input text string to the Handheld 2D Code Reader.

Operation is not possible when the port is disconnected.

Section 4 Communications Using the 2DCR Configear

■ Status Display

◆ On Line/Off Line

Indicates the port status (On Line: Connected; Off Line: Disconnected)

◆ COM1 9600,n,8,1

Displays the current communications conditions.

This is not displayed when the port is disconnected.

◆ 26/1/2005

Displays the current date.

◆ 9:27

Displays the current time.

V400-H101/201

User’s Manual

45

Page 48

Section 4

System Settings

Creating Setting Files Using the 2DCR Configear

Create the data setting file for loading setting data to the Handheld 2D Code Reader.

Make the settings for the communications conditions, functions, and display conversion.

▲

Select Setting Reader - Create Data... from the menu.

The following window for creating the setting data file will be displayed.

Section 4 Creating Setting Files Using the 2DCR Configear

■ Open

Opens the previously created data setting file for editing.

■ Save

Saves the created data setting file.

To save data to the Memory Card, create a folder with the name SETTINGS, and save. The Handheld 2D Code Reader's setting mode cannot start if the data is saved in a folder of a different name.

Communication Settings

The settings shown in the following table are set in the Communication Settings Tab

Page in the Create Setting Data Window.

Setting item Settings

Baud Rate

Par ity

Data Length 7 bits or

Stop Bit 1 bit* or 2 bits

Header/Footer Prefix

Suffix 03 <ETX>, 0A <LF>,

FCS ON or

*

9600

, 19,200, or 38,400

*

None

, odd, or even

8 bits

*

None

, 02 <STX> or 1B <ESC>

*

OFF

*

0D<CR>

*

, or 0D0A <CR+LF>

V400-H101/201

User’s Manual

46

The asterisks indicate default settings.

Page 49

The format when FCS is ON is as follows:

Section 4

System Settings

Header (Prefix)

For details on FCS calculation methods, refer to FCS Calculation Method.

Read data

p.65

FCS (2 bytes)

Footer (Suffix)

Section 4 Creating Setting Files Using the 2DCR Configear

V400-H101/201

User’s Manual

47

Page 50

Section 4

(

)

System Settings

Function Settings

Make the following settings in the Initialize Tab of the Create Setting Data Window.

Setting item Settings

30 sec

*

*

or Alternate

*

and 120 sec

Section 4 Creating Setting Files Using the 2DCR Configear

Trigger Mode

Buzzer

Sleep Shift Time Between

Output of NG ON or

Data Accumulation OFF* or ON

Level Trigger

*

ON

or OFF

OFF

The asterisks indicate default settings.

■ Data Accumulation

Set whether to collect data.

The Memory Card must be inserted in the Handheld 2D Code Reader to use this function.

When this function is ON, read data will be saved in a file with the following name in the

Memory Card's READDATA folder. The READDATA folder will be automatically generated if it does not already exist.

READ****.csv

Note. The digits indicated by **** start at 0000 and increment by 1 for approximately

each 400 kilobytes.

After reading is completed, the data is written to the Memory Card, which will

take several seconds.

When Appending at date is selected, the date and time will be added to the read data.

Example of Saved File

ABC0001,2005/01/27,12:48:30

ABC0003,2005/01/27,12:51:02

ABC0109,2005/01/27,12:59:41

ABC0075,2005/01/27,12:59:47

V400-H101/201

User’s Manual

48

Data Date

Y/M/D

Time

Page 51

Section 4

System Settings

Data Conversion on Display

Click the Data Conversion on Display Tab in the Create Setting Data Window to con-

vert a CSV file for display.

◆ Setting Method

1. Create the CSV file for the display

conversion function.

To use this function, CSV files for display conversion must be created using separate

spreadsheet software or a text editor for the

personal computer.

The following formatting restrictions apply.

• File: CSV format (comma delimited)

• Maximum No. of records: 1,000

• Maximum No. of comparison characters: 19

• Maximum No. of conversion characters: 19

• Comment row: Add a semicolon (;) to the

beginning of the row.

Enter comparison text and conversion text in each row.

The symbols and text in the following table function as special characters with specific meanings.

Symbol Name Details

* Wild card Any data OK

!a Alphabet Any lower-case character OK

!A Alphabet Any upper-case character OK

!n Numeric value Any numeral OK

ELSE Condition for no match Enter at end.

Comment row

Comparison characters Conversion text string

;Data file for displaying production date

**1*** , "Manufact Jan."

**2*** , "Manufact Feb."

**3*** , "Manufact Mar."

**4*** , "Manufact Apr."

**5*** , "Manufact May"

ELSE ,

Section 4 Creating Setting Files Using the 2DCR Configear

"Warning:Improper"

Comparison Principle

With display conversion, comparison is performed with the data contained in the file, and the display

contents is changed to the registered text strings for characters that match. Matching processing is

performed in order starting from the beginning of the file. Once a match is found, no further comparisons are made, i.e., matching processing is affected by the entry order. Therefore, when comparing

complicated patterns, make sure that the optimum order is used.

V400-H101/201

User’s Manual

49

Page 52

Section 4

System Settings

2. Click the Import Button.

Import the created file to the 2DCR Configear to convert the created file to a format that can be uploaded to

the Handheld 2D Code Reader

Section 4 Creating Setting Files Using the 2DCR Configear

3. Select the CSV file to be uploaded and click the Open Button.

V400-H101/201

User’s Manual

50

4. The CSV file will be read and displayed as shown in the following diagram.

5. Select ON in Data Conversion on Display field.

Page 53

Section 4

System Settings

Saving

1. Save the settings.

Click the Save Button, specify the save destination for the data settings in the Save Setting Data Window,

and then click the Save Button.

Section 4 Creating Setting Files Using the 2DCR Configear

2. Exit the 2DCR Configear.

Click File - End to exit the 2DCR Configear.

V400-H101/201

User’s Manual

51

Page 54

Section 4

System Settings

Uploading from the Memory Card

The Memory Card can be used to upload the setting data to the Handheld 2D Code Reader.

Starting Setting Mode

1. Save the data setting file to the Memory Card.

To save data to the Memory Card, create a folder named SETTINGS, and save the data in this folder.

If another folder is used, setting mode will not function correctly.

To save data to the Memory Card, create a folder named SETTINGS, and save the data in this

folder. If a folder other than SETTINGS is used, setting mode will not start even if the following oper-

Section 4 Uploading from the Memory Card

2. Start setting mode.

Keeping the right and left trigger buttons pressed, insert the

Memory Card into the Memory Card slot.

ations are performed.

The setting mode menu window will be displayed.

Trigger Button Operations in Setting Mode

Use the trigger buttons to select (or move) items and confirm (execute) selections.

In setting mode, the function of the left and right trigger buttons are different.

Left: Selection button (Select)

Right: Confirmation button (Execute)

V400-H101/201

User’s Manual

52

Page 55

Uploading Setting Data to the 2D Code Reader

1. Select Upload Settings.

In the menu window, press the left trigger button and select Upload Settings.

After selection, press the right trigger button to confirm the setting.

The file selection window will be displayed.

2. Select the data setting file.

In the file selection window, press the left trigger button and select the data setting

file to be used.

After selection, press the right trigger button to confirm the setting.

Section 4

System Settings

Section 4 Uploading from the Memory Card

The contents of the SETTINGS folder in the Memory Card will be displayed.

After the load window is displayed, the save selection window will be displayed.

3. Save the setting data.

In the save selection window, press the left trigger button and select YES.

After selection, press the right trigger button to confirm the setting and save the

data.

After the save window is displayed, the menu window will be displayed.

4. Exit setting mode.

In the menu window, press the left trigger button and select Exit.

After selection, press the right trigger button to exit setting mode.

V400-H101/201

User’s Manual

53

Page 56

Section 4

System Settings

Backing Up 2D Code Reader Data

1. Select Backup Settings.

In the menu window, press the left trigger button and select Backup Settings.

After selection, press the right trigger button to confirm the setting.

The save selection window will be displayed.

Section 4 Uploading from the Memory Card

2. Save the setting data.

In the save selection window, press the left trigger button and select YES.

After selection, press the right trigger button to confirm the setting and save the

data.

The setting data file will be backed up in the SETTINGS folder in the

Memory Card.

The SETTINGS folder will be automatically created if it does not already

exist. The file name will be SETTINGS.DAT.

After the save window is displayed, the menu window will be displayed.

3. Exit setting mode.

In the menu window, press the left trigger button and select Exit.

After selection, press the right trigger button to exit setting mode.

V400-H101/201

User’s Manual

54

Page 57

Section 5 Troubleshooting

This section explains the countermeasures to take when reading cannot be

executed correctly or when a problem occurs.

Troubleshooting 56

Section 5 Troubleshooting

V400-H101/201

User’s Manual

55

Page 58

Section 5 Troubleshooting

Section 5

Troubleshooting

Troubleshooting

Status Cause and countermeasures Page

The POWER indicator is not

lit.

The video monitor image is

not clear.

Cannot write data to Memory

Card

The saved data is corrupted. The Memory Card was removed while it was being accessed. p.35

The time stamp on saved data

is not correct.

Cannot communicate with the

host device.

The power supply is not connected properly.

Not enough power is available.

Some pixels on the monitor may not light and some may always light.

This is a result of the monitor's construction and does not indicate a

malfunction.

The write-protect switch on the Memory Card is ON.

The Memory Card capacity is insufficient.

The Memory Card is damaged.

The Memory Card has not been formatted.

The Memory Card is the wrong type.

The clock is not set correctly.

The clock is factory set to Japanese Standard Time. Set the clock as

required.

The cable model is incorrect.

The cable connections are loose.

The communications settings are not correct.

p.26

p.44

p.20

p.43

-

-

V400-H101/201

User’s Manual

56

Page 59

Appendices

Maintenance 58

Specifications and Dimensions 59

ASCII Table 64

FCS Calculation Method 65

Data Capacity Tables 67

Appendices

V400-H101/201

User’s Manual

57

Page 60

Appendices

Appendices

Maintenance

Handling the Handheld 2D Code Reader

• Do not touch the lens or monitor with your fingers or any pointed object.

• Do not use the Handheld 2D Code Reader in locations subject to dust or other con-

taminants.

Inspection

To maintain the Handheld 2D Code Reader in optimum condition, perform the following

inspections regularly.

• Use a lens cloth or air brush to clean the lens and monitor.

• Use a soft cloth to clean other parts of the Handheld 2D Code Reader.

Inspection items Details Required tools

Power supply

Ambient operating

temperature

Ambient operating

humidity

The voltage measured at the power supply terminals on the terminal block must be 5 VDC_10%.

The ambient operating temperature must be between 0 and 40

The ambient operating humidity must be between 35% and 85%.

°C.

Multimeter

Thermometer

Hygrometer

Maintenance

• Turn OFF the power and take safety precautions before conducting maintenance or inspections.

• Do not use thinners or benzene.

V400-H101/201

User’s Manual

58

Page 61

Specifications and Dimensions

Handheld 2D Code Reader

■ V400-H101/H201

Appendices

(Unit: mm)

Zoom lever

Memory Card slot

Monitor

Lighting

50

42

Reading surface

170

Power indicator (green)

Lighting

Trigger button

Appendices

Specifications and Dimensions

Buzzer

V400-H101/201

User’s Manual

59

Page 62

Appendices

Appendices

V400-H101 V400-H201

Field of vision 5 to 10 mm 15 to 30mm

Working distance 40 mm (contact with the code when the Contactor is mounted)

Power supply voltage 5 VDC±10%

Current consumption 1 A max.

Serial interface RS-232C

Applicable code DataMatrix ECC200 10

QR Code Model 1.2 21

Operating method Pushbutton control using the trigger buttons

Settings Uploading settings from the Memory Card or using communications.

Memory Card SD card

Monitor 1.8-inch TFT liquid crystal image and read data display.

Indicators Power indicator and Memory Card access indicator

Ambient temperature Operating: 0 to 40°C Storage: -25 to 60°C

Ambient humidity 35% to 85% (with no condensation)

Ambient environment No corrosive gases

Vibration resistance 10 to 150 Hz; half-amplitude: 0.35 mm (max. acceleration: 50 m

Shock resistance 150m

Weight Approx. 200 g

Degree of protection IEC 60529 (IP64)

Materials Case: ABS; Optical surface: PC; Surfaces: PMMA

2

/s 3 times in 6 directions

× 10 to 64 × 64, 8 × 18 to 16 × 48

× 21 to 57 × 57 (Ver. 1 to 10)

2

/s)

Specifications and Dimensions

V400-H101/201

User’s Manual

60

Page 63

Cables

■ V400-W20-2M/V400-W21-2M

29.8

12.6 dia.

Vinyl-insulated round cable, 5-dia. with 4 conductors Standard length: 2 m

Connector

2000

20 300

Appendices

(Unit: mm)

D-sub 9-pin

connector

30

Nameplate

V400-W20-2M V400-W21-2M

Interface connector D-sub, 9-pin, male D-sub, 9-pin, female

Ambient temperature Operating: 0 to 40°C Storage: -25 to 60°C

Ambient humidity 35% to 85% (with no condensation)

Ambient environment No corrosive gases

Materials Cable sheath: Heat-resistant vinyl chloride

Special connector: PPS, PBT, POM

D-sub connector: ABS

Minimum bending radius 30 mm

Weight Approx. 100 g

Appendices

Specifications and Dimensions

V400-H101/201

User’s Manual

61

Page 64

Appendices

Contactor

■ V400-AC1

(Unit: mm)

90.5

53

Appendices

Specifications and Dimensions

40

48.5

V400-AC1

Material POM (antistatic grade)

Weight Approx. 20 g

V400-H101/201

User’s Manual

62

Page 65

Stand

■ V400-AS1

Two 4.2 dia.

20

Appendices

(Unit: mm)

46.1

133.1

Material ABS

Weight Approx. 100 g

68

Appendices

58.4

Specifications and Dimensions

V400-AS1

V400-H101/201

User’s Manual

63

Page 66

Appendices

ASCII Table

Data read with no-protocol commands using the serial communications interface is output as

2 characters of ASCII. The ASCII characters correspond to the following characters.

Examples:

• When the read data is A, 41 is output.

• When the data read is T, 54 is output.

Upper 4 bits

Lower 4 bits

Appendices

ASCII Table

V400-H101/201

User’s Manual

64

Page 67

FCS Calculation Method

■ FCS Calculation Method

The FCS (Frame Check Sequence) is the result of taking the XOR for each byte

between the header and footer (8 bits) and converting it to 2 characters of ASCII. The

FCS can be attached to output data to improve the reliability of communications.

Each time data is received, the host calculates the FCS and checks it against the FCS

attached to the sent data so that the send data can be checked for errors.

■ Calculation Example for Sending FCS

Sample read data: ABCDEFG

The details of the read data and calculation method are as follows:

· Read data

Appendices

Header Footer

ABCDEFG40

Read data FCS

· Calculation method

Read data ASCII Hexadecimal

A

B

C

D

E

F

G

Conversion to

ASCII:

41

42

43

44

45

46

47

Conversion to

hexadecimal:

0100

0100

0100

0100

0100

0100

0100

0100 0000

0001

0010

0011

0100

0101

0110

0111

XOR

XOR

XOR

XOR

XOR

XOR

Obtaining the

exclusive OR:

Conversion to

ASCII:

Appendices

FCS Calculation Method

FCS data: 40

V400-H101/201

User’s Manual

65

Page 68

Appendices

■ Calculation Programming Example for Sending FCS

DATA$ Sample data string

L Data length

CODE$ Data character

A Exclusive OR

100 '* * * * * CALCULATE FCS * * * * *

110 '* FCSSET

120 L=LEN(DATA$)

130 A=0

140 FOR J=1 TO L

150 CODE$=MID$(DATA$,J,1)

160 A=ASC(CODE$)XOR A

170 NEXT J

180 FCS$=HEX$(A)

190 IF LEN(FCS$)=1 THEN FCS$="0"+FCS$

200 RETURN

Appendices

FCS Calculation Method

■ FCS Check Subroutine Example for Received Data

1000 '* * * * * FCSHECK * * * * *

1010 '* FCSHECK

1020 Q=0:FCSCK$="OK"

1030 PRINT RESPONSE $

1040 LENGS=LEN(RESPONSE$)-3

1050 FCSP$=MID$(RESPONSE$,LENGS+1,2) 'FCS in response data

1060 FOR J=1 TO LENGS 'Calculation range of FCS

1070 Q=ASC(MID$(RESPONSE$,J,1))XOR Q

1080 NEXT J

1090 FCSD$=HEX$(Q)

1100 IF LEN(FCSD$)=1 THEN FCSD$="0"+FCSD$ 'FCS calculated in a program

1110 IF FCSD$ < > FCSP$ THEN FCSCK$="ERR"

1120 PRINT "FCSD$=";FCSD$;"FCSP$=";FCSP$; 'FCS received correctly: OK

"FCSCK$=";"FCSCK$=" 'FCS not received correctly: ERR

1130 RETURN

V400-H101/201

User’s Manual

66

Page 69

Appendices

Data Capacity Tables

The maximum quantity of information that can be stored depends on the symbol size of the

code. Also the maximum data capacity in relation to the amount of information carried by the

code depends on the character type and the arrangement and combination of characters. The

relation between the symbol size (number of cells) and data capacity is shown in the following

table.

■ DataMatrix

◆ DataMatrix ECC200

In the following diagram, the symbol size is 12 x 12.

12 cells

12 cells

Data capacity

Symbol size

10 × 10 6 3 3 - 1

× 12 10 6 5 1 3

12

14

× 14 16 10 9 3 6

16

× 16 24 16 14 5 10

× 18 36 25 22 8 16

18

20

× 20 44 31 28 10 20

22

× 22 60 43 38 14 28

24

× 24 72 52 46 17 34

26

× 26 88 64 57 21 42

32

× 32 124 91 81 30 60

36

× 36 172 127 113 42 84

40

× 40 228 169 150 56 112

44

× 44 288 214 190 72 142

× 48 348 259 230 86 172

48

52

× 52 408 304 270 101 202

64

× 64 560 418 372 139 278

× 18 106513

8

8

× 32 20 13 12 4 8

12

× 26 32 22 20 7 14

× 36 44 31 28 10 20

12

16

× 36 64 46 41 15 30

16

× 48 98 72 64 23 47

Numerals Alphanumerics

Alphanumerics

and symbols

2-byte

characters

1-byte Japanese

characters

Appendices

Data Capacity Tables

V400-H101/201

User’s Manual

67

Page 70

Appendices

■ QR Code

◆ QR Code (Model 2)

In the following diagram, the symbol size is 21 x 21 (Version 1).

7 cells

7 cells

7 cells

Appendices

Data Capacity Tables

Symbol size

(version)

21

× 21

(Version 1)

25

× 25

(Version 2)

29

× 29

(Version 3)

33

× 33

(Version 4)

37

× 37

(Version 5)

41

× 41

(Version 6)

7 cells

Error correction level

(ECC level)

L (7%) 41 25 17 10

M (15%)342014 8

Q (25%)271611 7

H (30%) 17 10 7 4

L (7%) 77 47 32 20

M (15%)63382616

Q (25%)48292012

H (30%) 342014 8

L (7%) 127 77 53 32

M (15%) 101 61 42 26

Q (25%)77473220

H (30%) 58352415

L (7%) 187 114 78 48

M (15%) 149 90 62 38

Q (25%) 111 67 46 28

H (30%) 82503421

L (7%) 255 154 106 65

M (15%) 202 122 84 52

Q (25%) 144 87 60 37

H (30%) 106 64 44 27

L (7%) 322 195 134 82

M (15%) 255 154 106 65

Q (25%) 178 108 74 45

H (30%) 139 84 58 36

14 cells

Numerals

Data capacity

Alphanumeric

characters

(uppercase)

8-bit bytes

2-byte

Japanese

characters

V400-H101/201

User’s Manual

68

Page 71

Symbol size

(version)

45

× 45

(Version 7)

49

× 49

(Version 8)

× 53

53

(Version 9)

57

× 57

(Version 10)

Data capacity

Error correction level

(ECC level)

L (7%) 370 224 154 95

M (15%) 293 178 122 75

Q (25%) 207 125 86 53

H (30%) 154 93 64 39

L (7%) 461 279 192 118

M (15%) 365 221 152 93

Q (25%) 259 157 108 66

H (30%) 202 122 84 52

L (7%) 552 335 230 141

M (15%) 432 262 180 111

Q (25%) 312 189 130 80

H (30%) 235 143 98 60

L ( 7%) 652 395 271 167

M (15%) 513 311 213 131

Q (25%) 364 221 151 93

H (30%) 288 174 119 74

Numerals

Alphanumeric

characters

(uppercase)

8-bit bytes

Appendices

2-byte

Japanese

characters

Source: 2D Codes, Basic Specifications for QR Code (JIS X 0510)

Maximum Data Capacity

Even with the same 2D code, the maximum quantity of information that can be stored depends on

the symbol size of the code. In other words, the symbol size must be increased to increase the data

capacity. The data capacity also depends on the type of characters used for the information contained in the code. With QR and DataMatrix Code, the maximum number of characters for the same

symbol size will be greatest for numbers only and then for alphanumerics, and will be the least with

2-byte characters. The data capacity also depends on the character type, and the order and combination of characters used.

Appendices

Data Capacity Tables

V400-H101/201

User’s Manual

69

Page 72

Revision History

A manual revision code appears as a suffix to the catalog number at the bottom of the

front and rear pages.

Cat. No. Z222-E1-01

Revision code

Revision code Date Revised contents

01 March 2005 Original production

V400-H101/201

User’s Manual

70

Page 73

This document provides information mainly for selecting suitable models. Please read the Instruction Sheet carefully for information that the

user must understand and accept before purchase, including information on warranty, limitations of liability, and precautions.

OMRON Corporation

Industrial Automation Company

Application Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7068/Fax: (81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit,

Carl-Benz-Str. 4, D-71154 Nufringen,

Germany

Tel: (49)7032-811-0/Fax: (49)7032-811-199

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

239920 Singapore

Tel: (65)6835-3011/Fax: (65)6835-2711

OMRON CHINA CO., LTD. BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No. 88 West Chang'an Road,

Beijing, 100031 China

Tel: (86)10-8391-3005/Fax: (86)10-8391-3688

Cat. No. Z222-E1-01 Printed in Japan

Authorized Distributor:

0405

Loading...

Loading...