Page 1

Autofocus Multicode Reader

MicroHAWK V320-F/V330-F/V420-F/

V430-F Series

User Manual for Communication Settings

Z407-E1-04

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the MicroHAWK V320-F/V330-F/V420-F/V430-F Series.

This manual contains information that is necessary for using MicroHAWK V320-F/V330-F/V420-F/

V430-F Series.

Please read this manual and make sure you understand the functions and capabilities before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing barcoding systems.

• Personnel in charge of designing barcoding systems.

• Personnel in charge of installing and maintaining barcoding systems.

• Personnel in charge of managing barcoding systems and facilities.

Introduction

Applicable Products

This manual covers the following products:

• MicroHAWK V320-F/V330-F/V420-F/V430-F Series

Parts of the specifications and restrictions for each product may be listed in other manuals. Please refer to Related Manuals on page 16.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1

Page 4

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

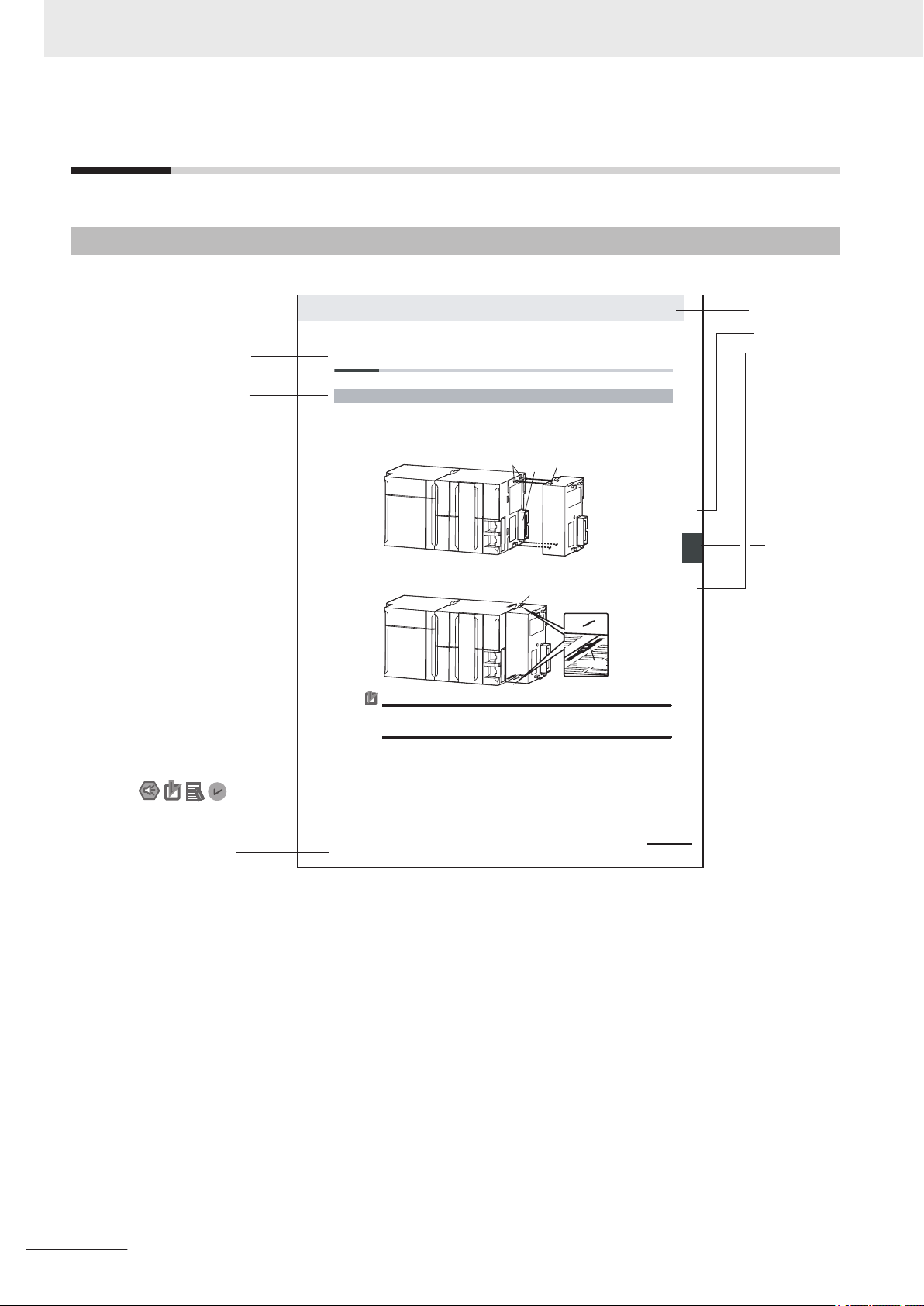

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note : This page is a sample for the purpose of describing the page structure. It differs in its actual content.

2

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 5

Icons

Manual Structure

The icons used in this manual have the following meanings.

Precautions for Safe Use

Precautions on what to do and what to avoid doing to ensure the safe use of the product.

Precautions for Correct Use

Precautions on what to do and what to avoid doing to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

3

Page 6

Manual Structure

4

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 7

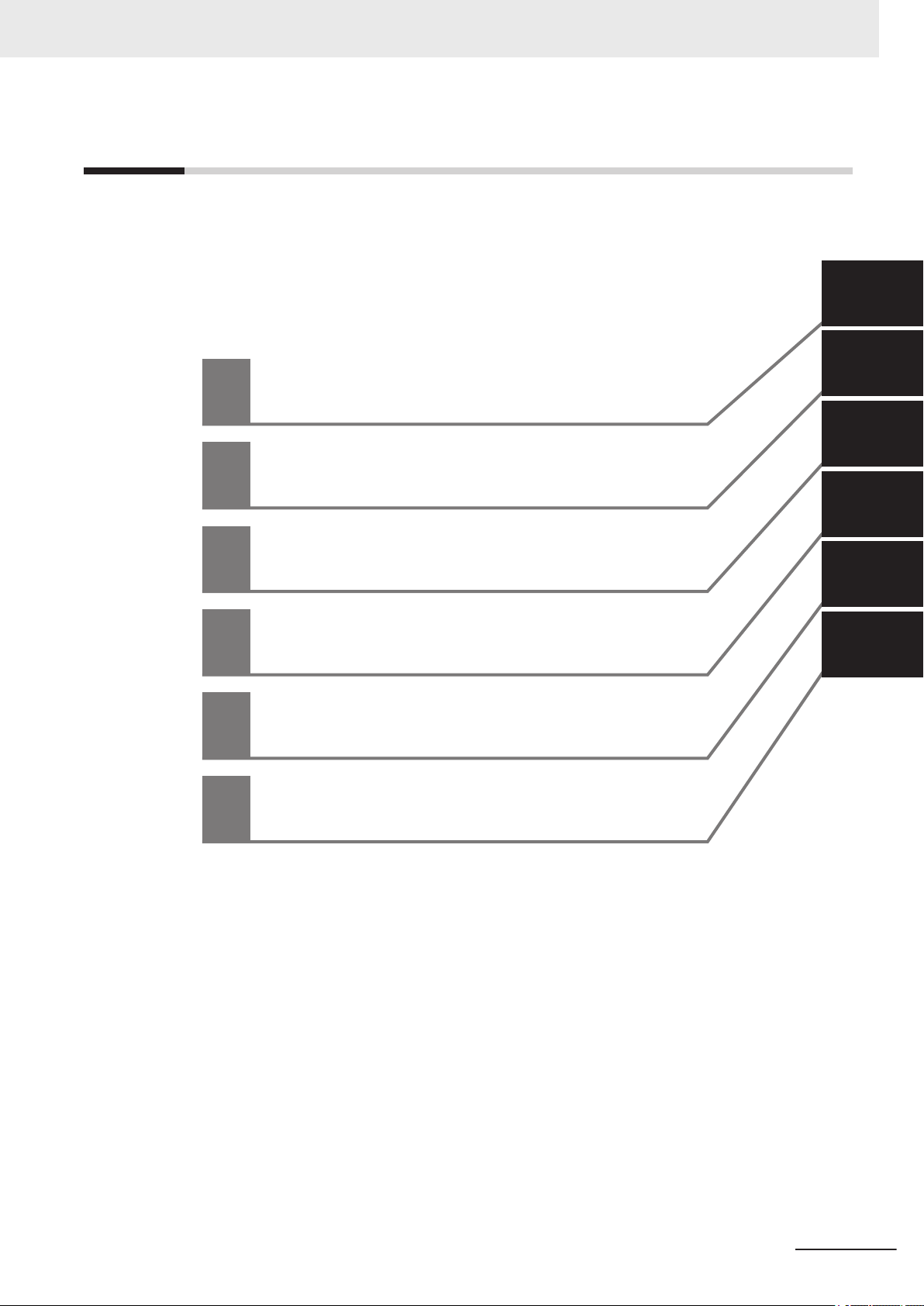

Sections in this Manual

1

2

3

4

5

1

2

3

4

5

Communication Specifications Overview

Controlling Operation and Data Output

with Parallel I/O

Controlling Operation and Data Output

with Ethernet

Controlling Operation and Data Output

with PROFINET

Controlling Operation and Data Output

with RS-232C

A

A

Appendices

Sections in this Manual

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

5

Page 8

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products ......................................................................................................................................... 1

Manual Structure...................................................................................................... 2

Page Structure.................................................................................................................................................2

Icons ................................................................................................................................................................3

Sections in this Manual ........................................................................................... 5

Terms and Conditions Agreement.......................................................................... 9

Warranty, Limitations of Liability ......................................................................................................................9

Application Considerations ............................................................................................................................10

Disclaimers ....................................................................................................................................................10

Safety Precautions................................................................................................. 12

Precautions for Safe Use ...................................................................................... 13

Precautions for Correct Use ................................................................................. 14

Regulations and Standards .................................................................................. 15

Related Manuals..................................................................................................... 16

Revision History..................................................................................................... 17

Section 1 Communication Specifications Overview

1-1 Confirming the System Configuration ................................................................................. 1-2

1-1-1 V430-F Series System Configuration..........................................................................................1-2

1-1-2 V420-F Series System Configuration..........................................................................................1-4

1-1-3 V330-F Series System Configuration..........................................................................................1-5

1-1-4 V320-F Series System Configuration..........................................................................................1-6

1-2 Communicating with an External Device.............................................................................1-7

1-2-1 Basic Control Operations of the Code Reader............................................................................1-7

1-2-2 Applicable Communications Protocols for the MicroHAWK V320-F/V330-F/V420-F/

V430-F Series .............................................................................................................................1-8

Section 2 Controlling Operation and Data Output with Parallel I/O

2-1 Controlling Operation and Data Output with Parallel I/O ................................................... 2-2

2-1-1 Basic Operation with a Parallel I/O Connection ..........................................................................2-2

2-1-2 Wiring and Electrical Specifications for Parallel I/O (for V430-F)................................................2-4

2-1-3 Change the Behavior of Operation..............................................................................................2-6

2-1-4 Change the Type of Trigger.........................................................................................................2-7

2-1-5 Timing Charts for each Trigger Mode..........................................................................................2-8

2-1-6 Sample Ladder Program .............................................................................................................2-9

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON Condition .........................2-10

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) ............................................2-20

2-1-9 Change the Polarity of Output Signal (Output 1 to 3)................................................................2-23

2-1-10 Controlling Operation with Signals from an External Device.....................................................2-24

6

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 9

CONTENTS

Section 3 Controlling Operation and Data Output with Ethernet

3-1 Controlling Operation and Data Output with EtherNet/IP ..................................................3-2

3-1-1 EtherNet/IP Overview..................................................................................................................3-2

3-1-2 Communication with the Code Reader over EtherNet/IP Connection.........................................3-4

3-1-3 Communication Flow Between PLC and Code Reader ..............................................................3-5

3-1-4 Communication Settings (EtherNet/IP) .......................................................................................3-6

3-1-5 Tag Data Link Setting Methods ...................................................................................................3-8

3-1-6 Status and Control Signals for Each Input and Output Assembly............................................. 3-11

3-1-7 Timing Charts by Assembly Type ..............................................................................................3-12

3-1-8 Sample Ladder Program ...........................................................................................................3-14

3-1-9 Accessing the NJ-series Controller Communication Areas using Variables ............................3-15

3-1-10 Communicating with the Code Reader with EtherNet/IP Message...........................................3-28

3-2 Controlling Operation and Data Output with Serial (TCP) ...............................................3-30

3-2-1 Serial (TCP) Overview ..............................................................................................................3-30

3-2-2 Communications Processing Flow ............................................................................................3-30

3-2-3 Communication Settings (Serial (TCP)) ....................................................................................3-31

3-2-4 Setting the Data to Output after a Read....................................................................................3-33

3-2-5 Controlling Operation from an External Device.........................................................................3-39

3-2-6 Serial Command List.................................................................................................................3-42

Section 4 Controlling Operation and Data Output with PROFINET

4-1 Overview of PROFINET .........................................................................................................4-2

4-1-1 Types of PROFINET ...................................................................................................................4-2

4-2 Code Reader Communications for PROFINET Connections.............................................4-5

4-2-1 Types of Communications Areas ................................................................................................4-5

4-3 Setting Up PROFINET Communications..............................................................................4-7

4-3-1 Configuring Network Settings in the Code Reader .....................................................................4-7

4-4 Timing Charts by Module Type ...........................................................................................4-11

4-4-1 Read is Executed by the Read (TRIG) Signal........................................................................... 4-11

4-5 Sample Ladder Program .....................................................................................................4-13

Section 5 Controlling Operation and Data Output with RS-232C

5-1 Controlling Operation and Data Output with RS-232C.......................................................5-2

5-1-1 Communications Processing Flow ..............................................................................................5-2

5-1-2 RS-232C Wiring ..........................................................................................................................5-2

5-1-3 Communication Settings (Serial (RS-232C)) ..............................................................................5-4

5-1-4 Setting Data to be Output after Reading a Code (Serial (RS-232C))..........................................5-7

5-1-5 Additional Symbol Information that can be Appended (Serial (RS-232C)) .................................5-7

5-1-6 Controlling Operation with Serial (RS-232C) from an External Device .......................................5-8

5-1-7 Serial Command List (RS-232C).................................................................................................5-8

Appendices

A-1 Command List ....................................................................................................................... A-2

A-1-1 Command List ............................................................................................................................ A-2

A-2 EtherNet/IP Specifications ................................................................................................... A-3

A-2-1 EDS Files by Firmware Version ................................................................................................. A-3

A-2-2 Assembly Memory Allocation ..................................................................................................... A-3

A-3 PROFINET - V430-F/V330-F Input and Output Modules .................................................. A-31

A-3-1 Module Types........................................................................................................................... A-31

A-3-2 Data Types............................................................................................................................... A-32

A-3-3 PROFINET Base Information................................................................................................... A-33

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

7

Page 10

CONTENTS

A-3-4 Timing Diagrams ...................................................................................................................... A-34

8

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 11

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

9

Page 12

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

10

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 13

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

11

Page 14

Safety Precautions

Safety Precautions

For details on Safety Precautions, please refer to Safety Precautions in Autofocus Multicode Reader

MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual (Z432-E).

12

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 15

Precautions for Safe Use

For details on Precautions for Safe Use, please refer to Precautions for Safe Use in Autofocus

Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual (Z432-E).

Precautions for Safe Use

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

13

Page 16

Precautions for Correct Use

Precautions for Correct Use

For detailed precautions on the correct use of the product, please refer to Precautions for Correct Use

in Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual

(Z432-E).

14

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 17

Regulations and Standards

For details on Regulations and Standards, please refer to Regulations and Standards in Autofocus

Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual (Z432-E).

Regulations and Standards

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

15

Page 18

Related Manuals

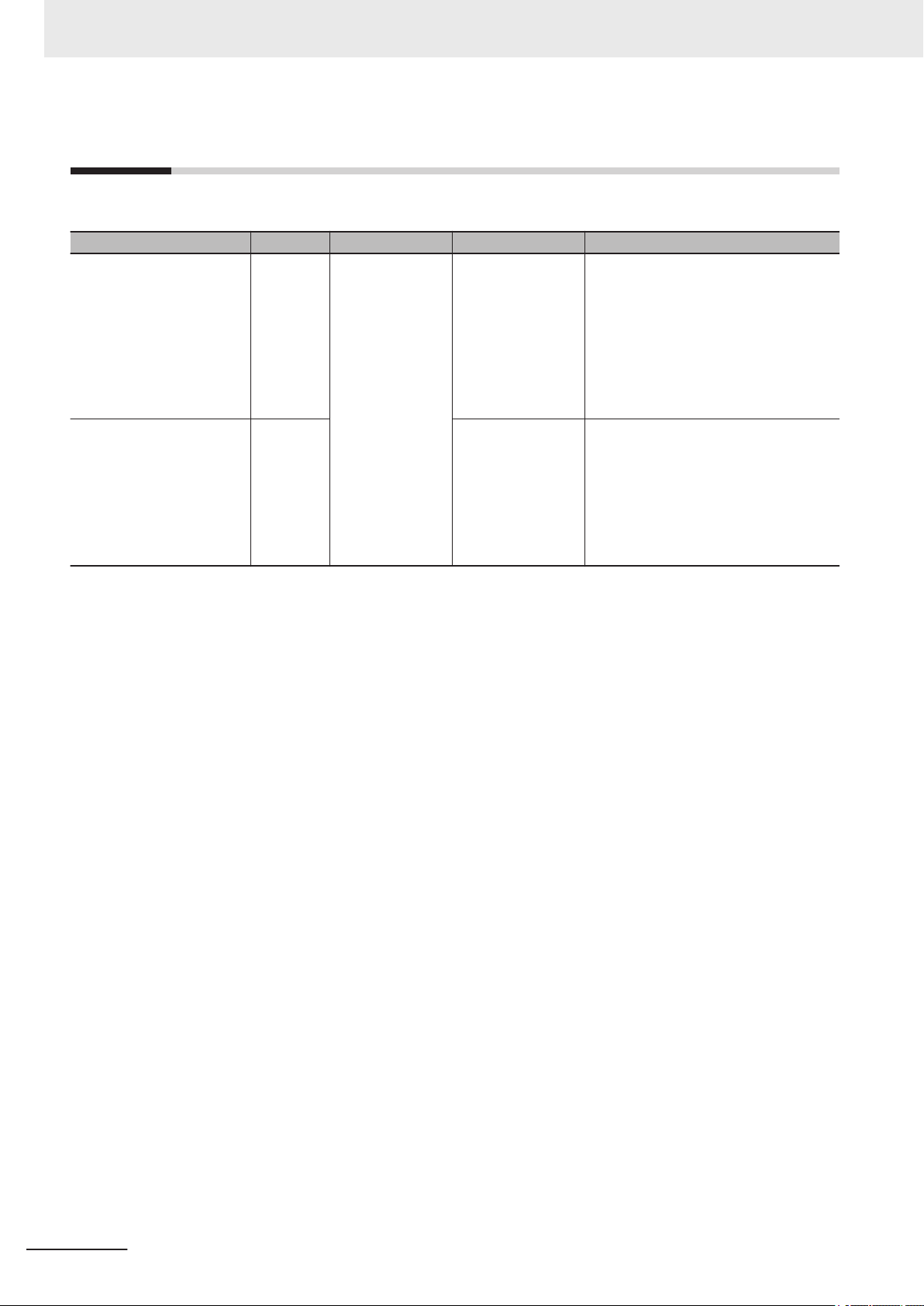

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Name of Manual Cat. No. Model Usage Description

MicroHAWK V320-F/V330-F/

V420-F/V430-F Series Autofocus Multicode Reader

User Manual

MicroHAWK V320-F/V330-F/

V420-F/V430-F Series Autofocus Multicode Reader

User Manual for Communications Settings

Z432 MicroHAWK V320-

F/V330-F/V420-F/

V430-F Series

Z407 When you want to

When you want to

know the product

specifications and

basic settings for using the MicroHAWK

V320-F/V330-F/

V420-F/V430-F Series Autofocus Multicode Reader

operate the MicroHAWK V320-F/V330F/V420-F/V430-F

Series Autofocus

Multicode Reader

from an external device

MicroHAWK V320-F/V330-F/V420-F/V430F Series specifications, getting started, explanation of settings, command parameters.

It describes the system configuration, control methods, I/O specifications, supported

network types and communication setting

for using the MicroHAWK V320-F/V330-F/

V420-F/V430-F Series.

16

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 19

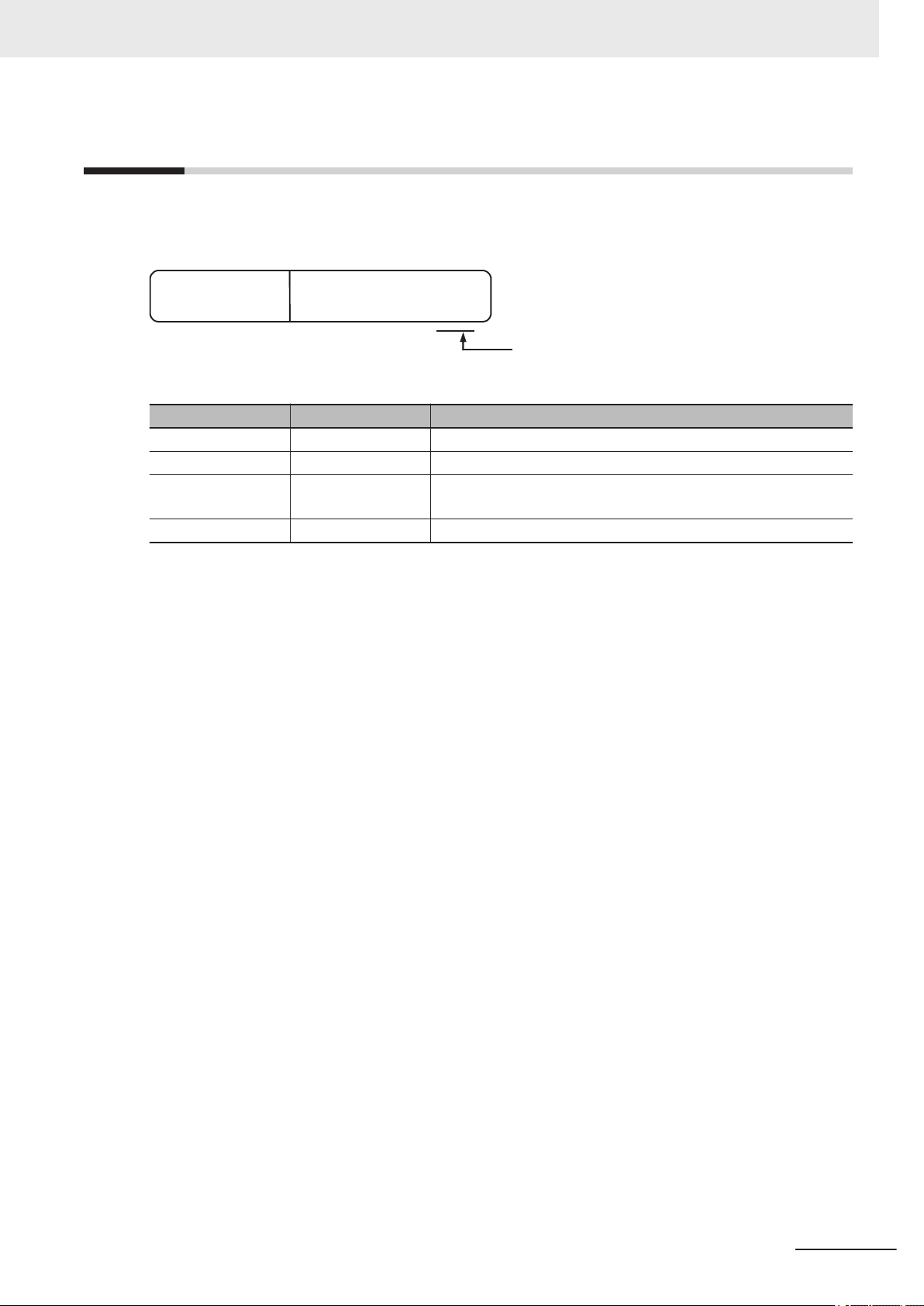

Revision History

Z407-E1-04

Revision code

Cat. No.

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision Code Date Revised Content

01 Dec. 2018

02 Apr. 2019

03 Dec. 2020

04 Mar. 2021

Revision History

• First Publication.

• Addition of PROFINET content.

• Corresponding to changes to new models of V430-F.

• Added information on the V320-F / V330-F / V420-F Series.

• General improvements.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

17

Page 20

Revision History

18

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 21

1

Communication Specifications

Overview

This section provides a basic overview of the communications specifications and

methods for controlling the code readers. This information is required before performing communications between the MicroHAWK V320-F/V330-F/V420-F/V430-F Series

and an external device.

1-1 Confirming the System Configuration .........................................................1-2

1-1-1 V430-F Series System Configuration .............................................................. 1-2

1-1-2 V420-F Series System Configuration .............................................................. 1-4

1-1-3 V330-F Series System Configuration .............................................................. 1-5

1-1-4 V320-F Series System Configuration .............................................................. 1-6

1-2 Communicating with an External Device..................................................... 1-7

1-2-1 Basic Control Operations of the Code Reader ................................................ 1-7

1-2-2 Applicable Communications Protocols for the MicroHAWK V320-F/

V330-F/V420-F/V430-F Series........................................................................ 1-8

1

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1-1

Page 22

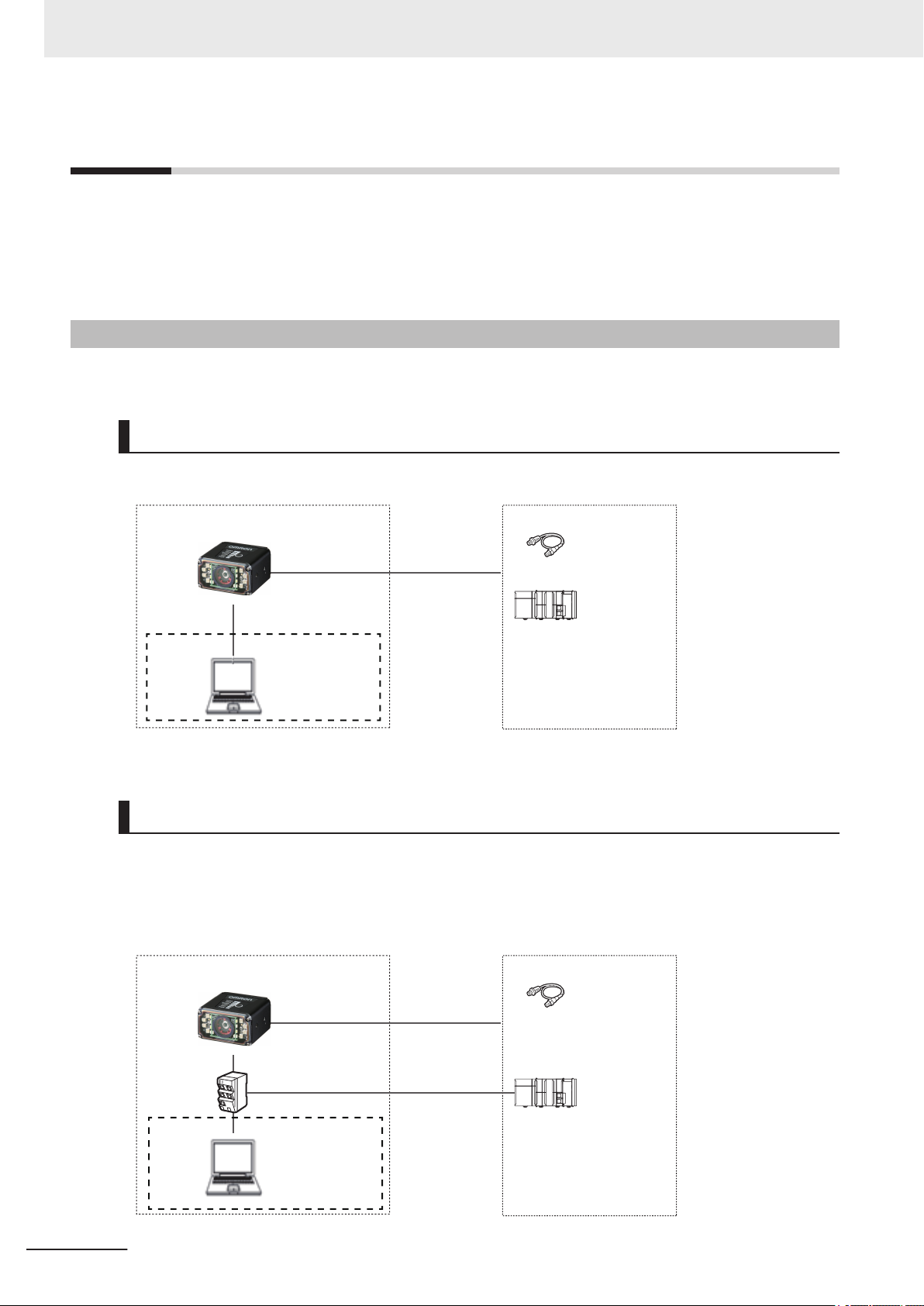

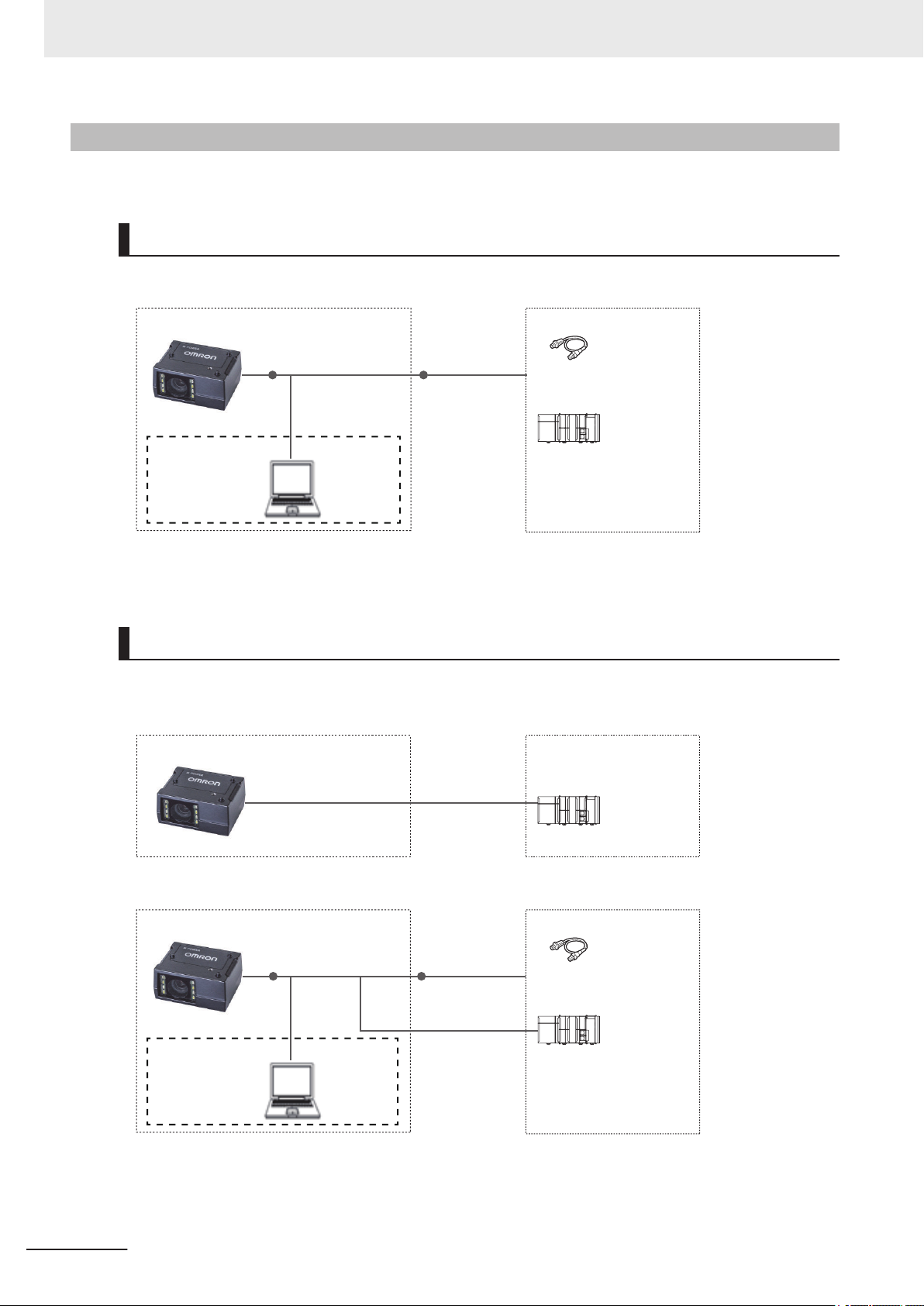

I/O control PLC

I/O cable

V430-W8-3M

Basic configuration

Code Reader (V430-F)

External devices

Trigger sensor

WebLink or ESP

*1

Computer

Special Ethernet cable

V430-WE-3M

Switching hub

for EtherNet/IP

(industrial

Ethernet)

*1

Basic configuration

Code Reader (V430-F)

I/O control PLC

I/O cable

V430-W8-3M

Trigger sensor

Special Ethernet cable

V430-WE-3M

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

WebLink or ESP

Computer

External devices

1 Communication Specifications Overview

1-1

1-1-1

Confirming the System Configuration

This product is a multi-code reader that captures images of 1D symbols (barcodes) and 2D Symbols

and reads and processes their embedded data.

In a system configuration in which it is connected to a PLC, PC, or other external device, serial commands can be received from, and code reading results can be output to the external device.

V430-F Series System Configuration

The V430-F can be used in the following types of system configurations.

Connection using Parallel I/O Interface

Trigger inputs and OK/NG Judgement result outputs are received and sent over I/O cable.

1-2

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

Connecting over Ethernet (EtherNet/IP, Serial (TCP), PROFINET)

Establish network connections via an Ethernet cable to input triggers and communication commands

and to output reading results (Judgment results and decoded content). Triggers can also be input over

parallel I/O. Using the data link function for each network (excluding Serial), data transfer can be done

periodically between the code reader and the external device.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 23

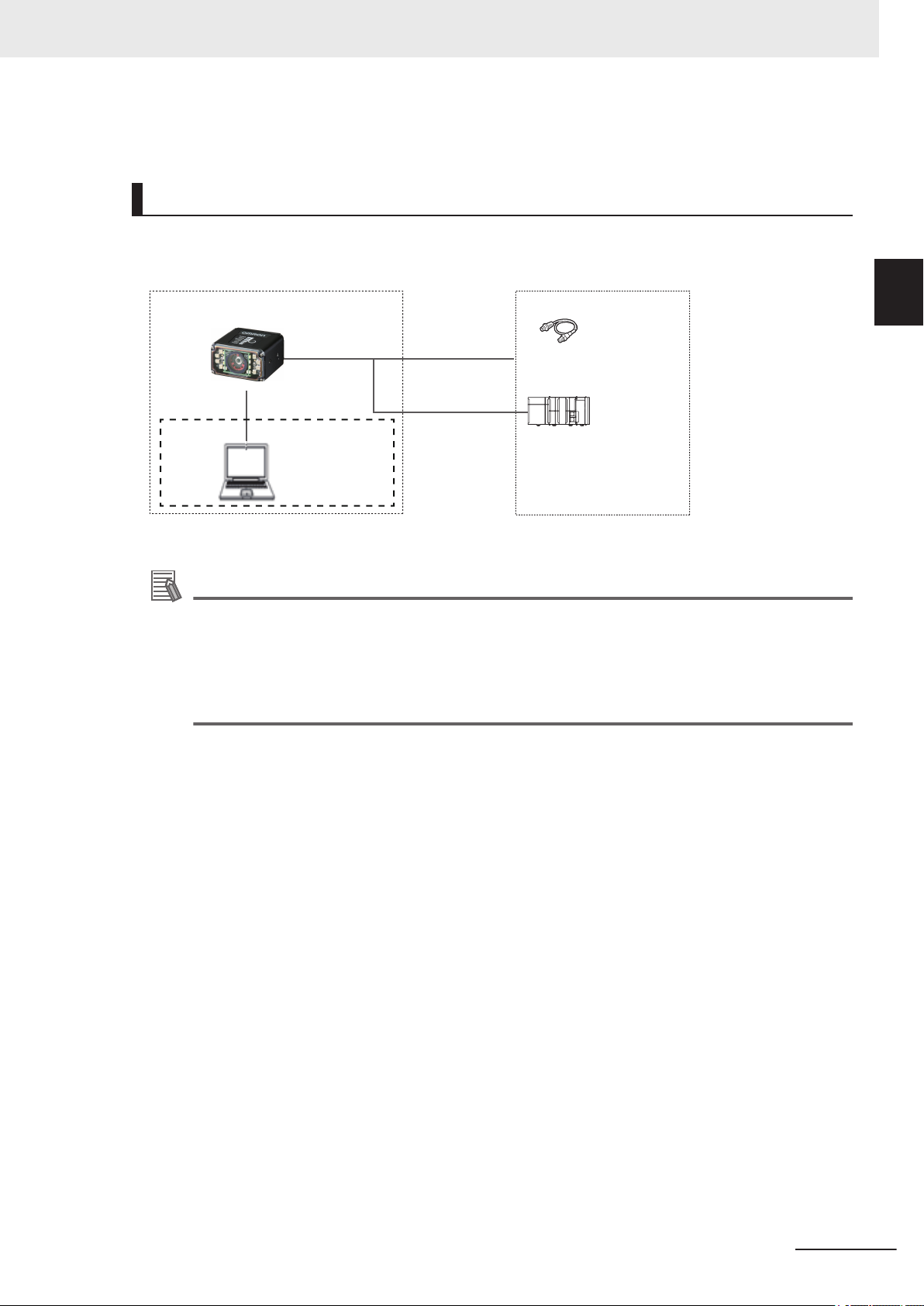

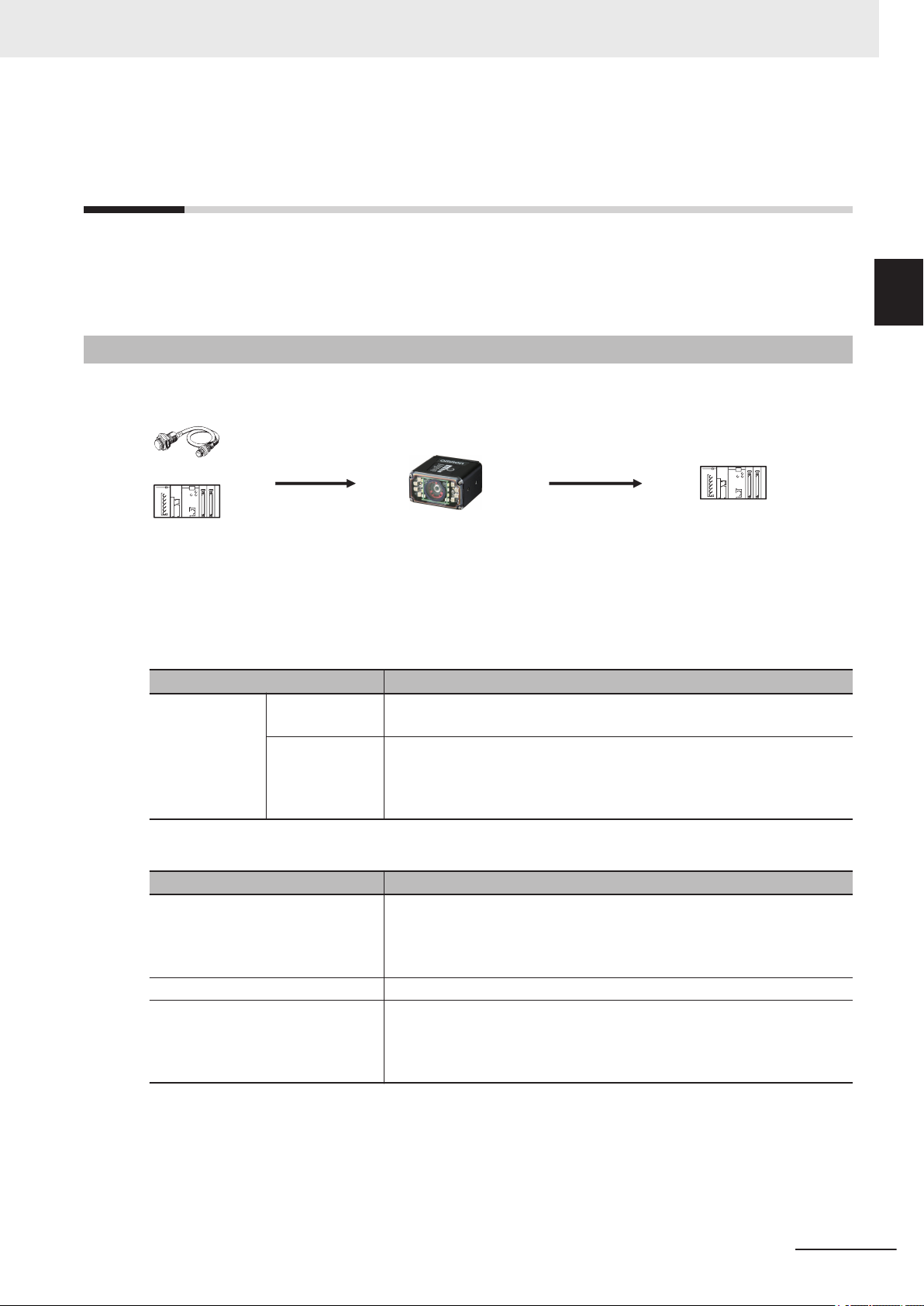

Special I/O cable

V430-W8-3M

Code Reader (V430-F)

RS-232C- I/O

2-way cable

V430-WQR-3M

*1

Basic configuration External devices

I/O control PLC

Trigger sensor

Special Ethernet cable

V430-WE-3M

WebLink or ESP

Computer

1 Communication Specifications Overview

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

Connecting by Serial (RS-232)

Triggers and Serial command input, as well as Read result judgement and Read string content data

output is transmitted over RS-232C cable. Triggers can also be input over parallel I/O.

1-1 Confirming the System Con-

figuration

1

1-1-1 V430-F Series System Configuration

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

Additional Information

The cable to use for Serial (RS-232C) communication is RS-232C- I/O 2-way cable (V430WQR-3M) specifically for the V430-F / V440-F. Please use this cable when connecting to a PC

by RS-232C.

For wiring different from that of IBM compatible PC, either make your own converter cable, or

use the discrete wire cable type (V430-W8£ Series) with its RxD signal and TxD signal converted.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1-3

Page 24

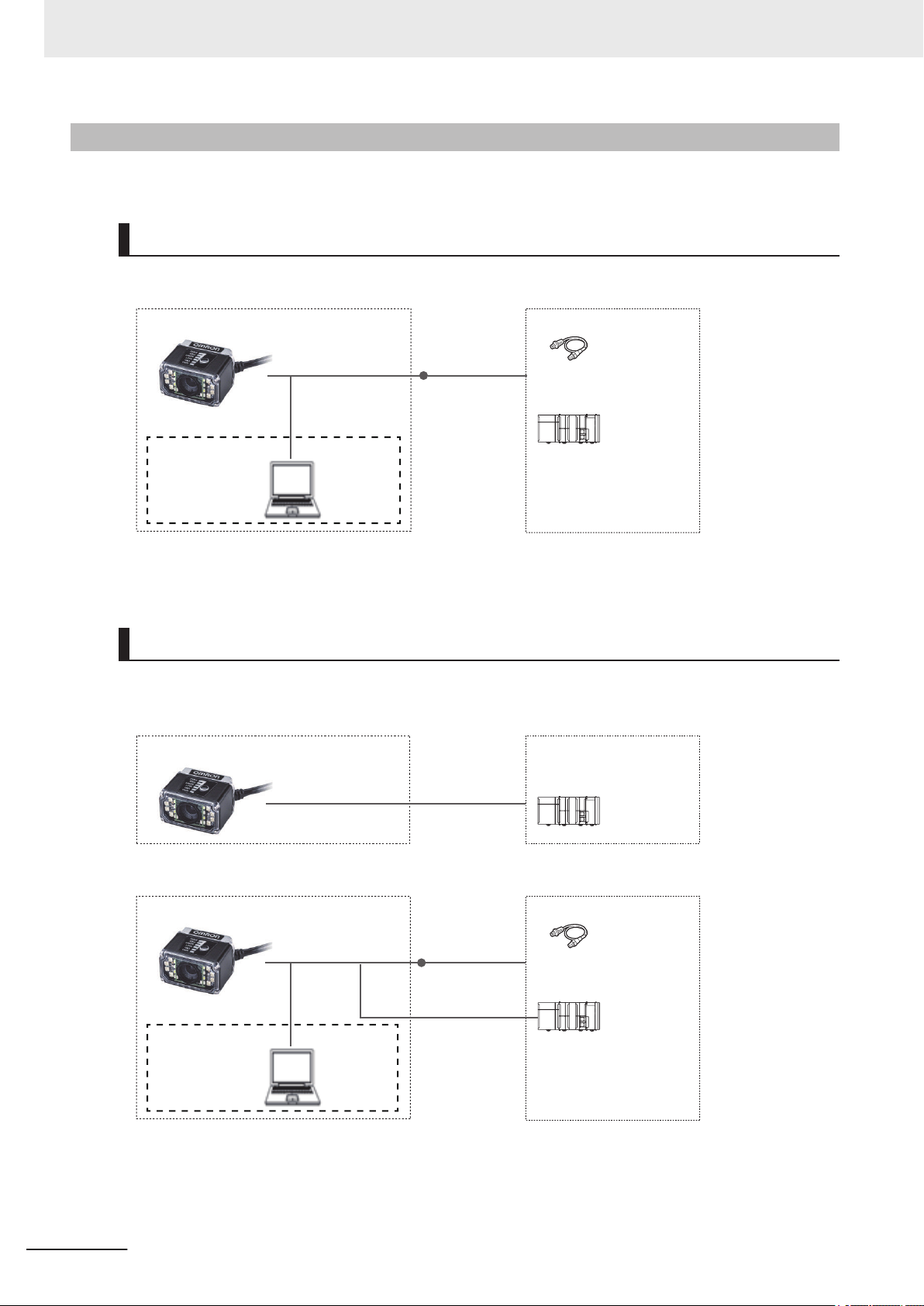

*1

Basic configuration

Code Reader (V420-F)

I/O control PLC

I/O cable

61-000151-01

Trigger sensor

Special DB-15 - USB/

I/O cable

V420-WU8X-1M

*2

WebLink or ESP

Computer

External devices

Basic configuration

Code Reader (V420-F)

I/O control PLC

Special DB-15 - RS-232C

cable

V420-WRX-1M

*1

External devices

*1

Basic configuration

Code Reader (V420-F)

I/O control PLC

I/O cable

61-000151-01

Trigger sensor

Special DB-15 - RS-232C/

USB/ I/O cable

V420-WRU8X-1M

*2

WebLink or ESP

Computer

External devices

1 Communication Specifications Overview

1-1-2

V420-F Series System Configuration

V420-F can be used in the following types of system configurations.

Connection using Parallel I/O Interface

Trigger inputs and OK/NG Judgement result outputs are received and sent over I/O cable.

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

*2 The V420-WU8X-1M requires power supply from the external power source (97-900011-02).

1-4

Connecting by Serial (RS-232)

Triggers and Serial command input, as well as Read result judgement and Read string content data

output is transmitted over RS-232C cable. Triggers can also be input over parallel I/O.

*1 The V420-WRX-1M requires power supply from the external power source (97-900006-01).

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

*2 The V420-WRU8X-1M requires power supply from the external power source (97-900011-02).

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 25

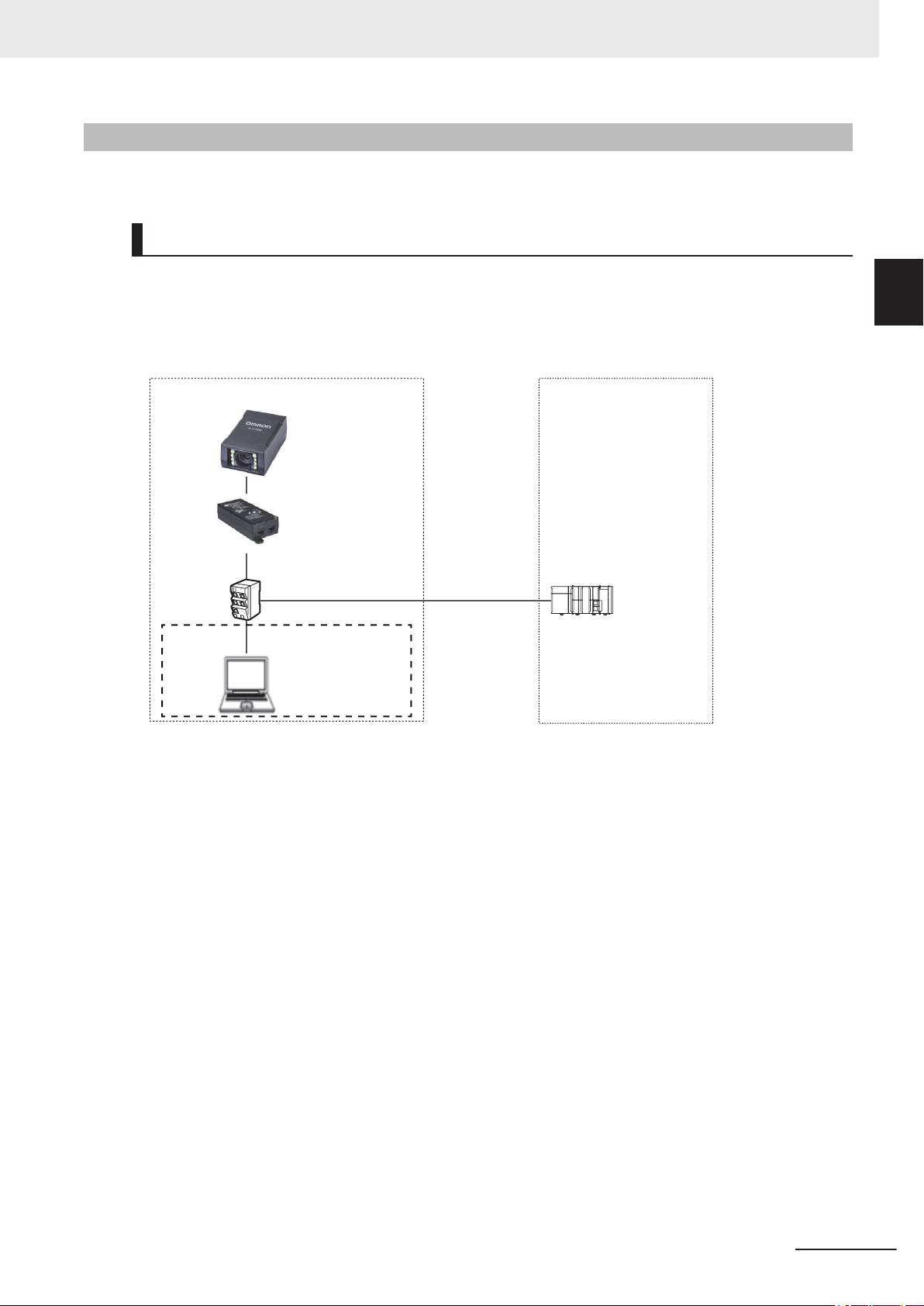

Basic configuration

Code Reader (V330-F)

I/O control PLC

PoE injector *2

External devices

Switching hub

for EtherNet/IP

(industrial

Ethernet)

*1

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

General-purpose

Ethernet cable

XS6W-5PUR8SS100CM-G

WebLink or ESP

Computer

1 Communication Specifications Overview

1-1 Confirming the System Con-

1-1-3

V330-F Series System Configuration

The V330-F can be used in the following types of system configurations.

Connecting over Ethernet (EtherNet/IP, Serial (TCP), PROFINET)

Establish network connections via an Ethernet cable to input triggers and communication commands

and to output reading results (judgment results and decoded content). Using the data link function for

each network (excluding Serial), data transfer can be done periodically between the code reader and

the external device.

figuration

1

1-1-3 V330-F Series System Configuration

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

*2 The PoE injector requires power supply from an external power source.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1-5

Page 26

*1

Basic configuration

Code Reader (V320-F)

I/O control PLC

I/O cable

61-000151-01

Trigger sensor

Special DB-15 - USB/

I/O cable

V420-WU8X-1M

*2

Special RJ50 - DB-15 cable

V320-WR-1M

WebLink or ESP

Computer

External devices

Basic configuration

Code Reader (V320-F)

I/O control PLC

Special RJ50 - RS-232C cable

V320-WRX-2M

*1

External devices

*1

Basic configuration

Code Reader (V320-F)

I/O control PLC

I/O cable

61-000151-01

Trigger sensor

Special RJ50 - DB-15 cable

V320-WR-1M

Special DB-15

- RS-232C/ USB/

I/O cable

V420-WRU8X-1M

*2

WebLink or ESP

Computer

External devices

1 Communication Specifications Overview

1-1-4

V320-F Series System Configuration

The V320-F can be used in the following types of system configurations.

Connection using Parallel I/O Interface

Trigger inputs and OK/NG Judgement result outputs are received and sent over I/O cable.

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

*2 The V420-WU8X-1M requires power supply from the external power source (97-900011-02).

Connecting by Serial (RS-232)

Triggers and Serial command input, as well as Read result judgement and Read string content data

output is transmitted over RS-232C cable. Triggers can also be input over parallel I/O.

*1 The V320-WRX-2M requires power supply from the external power source (97-900006-01).

1-6

*1 If monitor display is not required, it is not necessary to connect with a PC during operation.

*2 The V420-WRU8X-1M requires power supply from the external power source (97-900011-02).

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 27

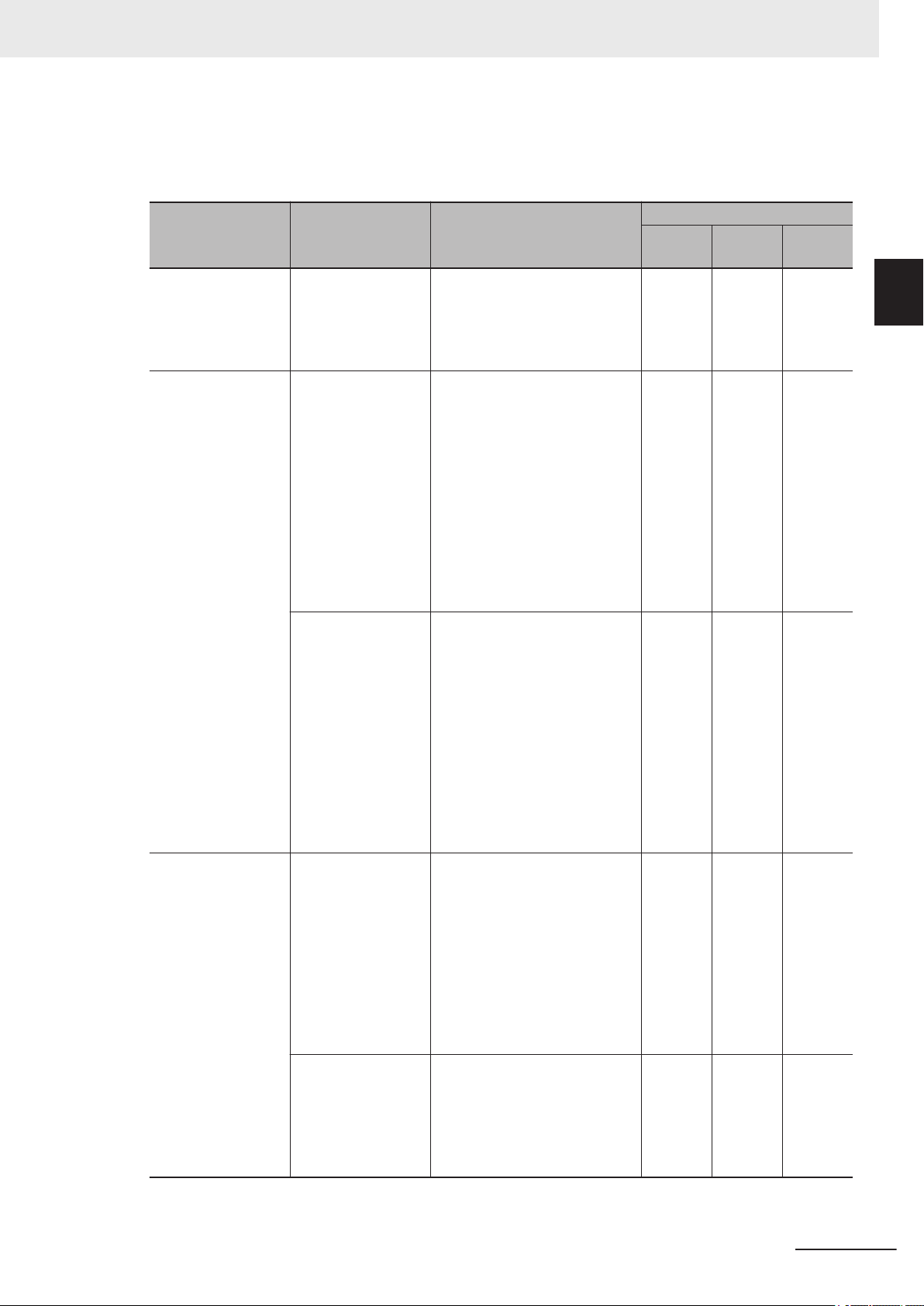

Trigger sensor

PLC PLC

The reading results are output.

- Status signals

- Read character string output

- Additional information

(read time, quality grade and so on)

Triggers and other

control commands

are input.

Code Reader

1 Communication Specifications Overview

1-2 Communicating with an Ex-

1-2

1-2-1

Communicating with an External Device

This section gives the communications specifications, describes the control methods that you can use

for communications, and describes the settings that are required before starting communications with

an external device.

Basic Control Operations of the Code Reader

The following figure shows basic communications between an external device and the code reader

and the flow of signals and data.

The following methods can be used to exchange data between an external device and the code reader.

ternal Device

1

1-2-1 Basic Control Operations of the Code Reader

Commands that can be input to the code reader from an external device

Type Description

Control Commands

Status Signals When the code reader confirms the input of a control signal or communi-

Read Character String Output You can output the character string read from barcodes, or 2D Codes

Additional Information Additional data such as print quality grade and code position coordinates

Control Signals

(Input Signals)

Communication

Command Input

Data output from the code reader to an external device

Type Description

Reading is executed when a trigger (TRIG signal: ON) is input.

Various commands can be executed, such as a Read commands (trigger)

and commands to change settings.

The communication commands differ depending on the communications

protocol that you use.

cation command and starts the reading process, it notifies the external

device of its status (by signals such as InReadCycle, etc.) and its judgement with the OK/NG Judgment signal.

can be output.

For these items to be appended to the output, they must be setup in advance in the detailed settings menu.

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1-7

Page 28

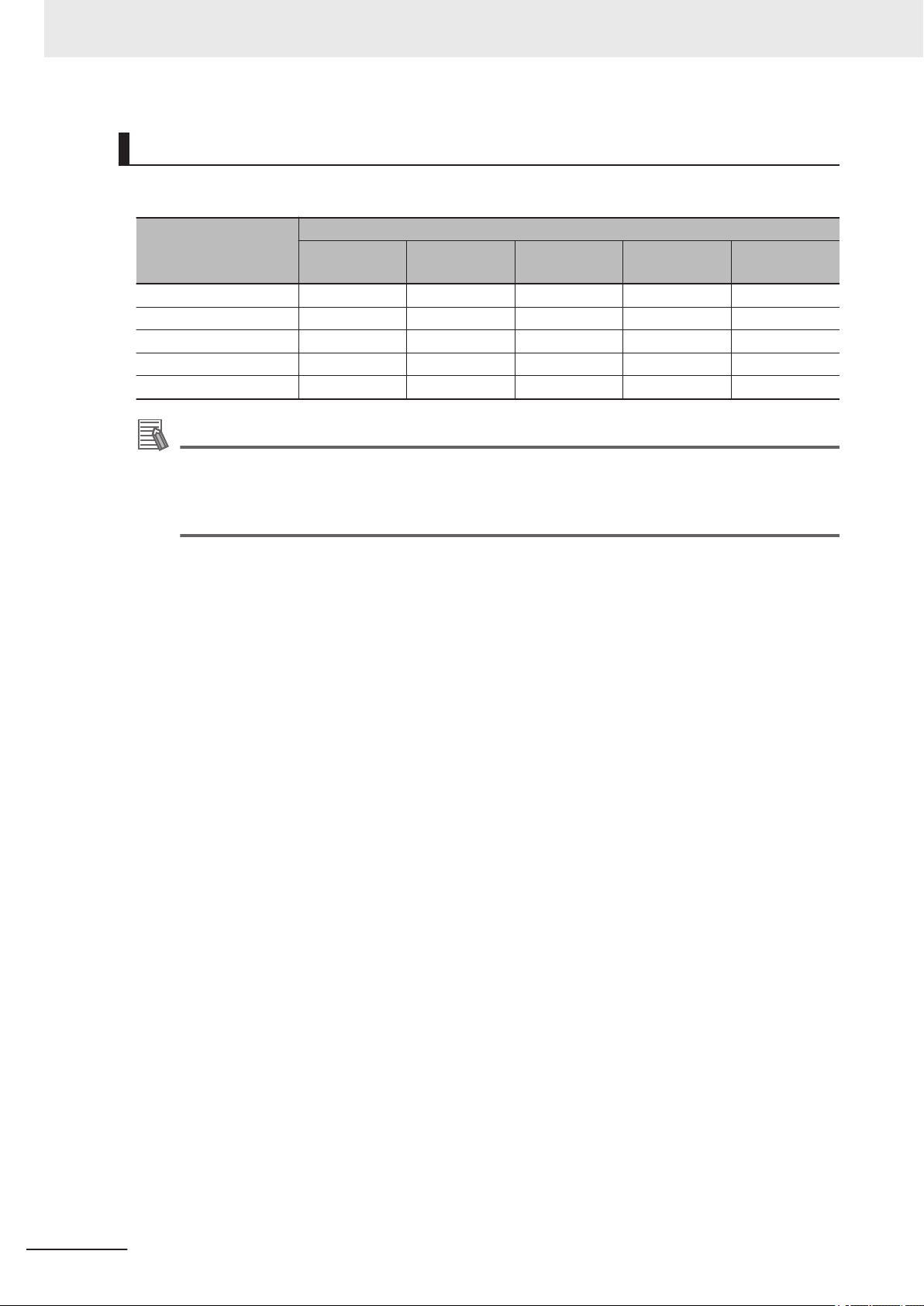

Code Reader (V430-F)

PLC

Computer

Control can be performed through different communications protocols.

Serial (RS-232C)

EtherNet/IP

PROFINET

USB

Serial (TCP)

Parallel I/O

Code Reader (V420-F)

PLC

Computer

Control can be performed through different communications protocols.

Serial (RS-232C)

USB

Parallel I/O

Code Reader (V330-F)

PLC

Computer

Control can be performed through different communications protocols.

Serial (TCP)

PROFINET

EtherNet/IP

Code Reader (V320-F)

PLC

Computer

Control can be performed through different communications protocols.

Serial (RS-232C)

USB

Parallel I/O

1 Communication Specifications Overview

1-2-2

Applicable Communications Protocols for the MicroHAWK V320F/V330-F/V420-F/V430-F Series

The MicroHAWK V320-F/V330-F/V420-F/V430-F Series can be controlled from a PLC, computer, or

other external device using various communication protocols.

The following types of communication protocols can be used for controlling the MicroHAWK V320-F/

V330-F/V420-F/V430-F Series from an external device.

1-8

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 29

1 Communication Specifications Overview

1-2 Communicating with an Ex-

Applicable Communications Protocols

Communication

Method

Contact Input Interface

Data Sharing EtherNet/IP This is an open communica-

Frame Transmission Serial (TCP) Command frames are sent to

Communication

Protocol

Parallel I/O Data is exchanged between an

external device and the code

reader through combinations of

ON/OFF signals from multiple

physical contacts.

tions protocol. Tag Data Links

are used for communication

with the code reader. On the

PLC, structured variables are

created that correspond to the

control signals, Command/

Response data, and Read data.

These variables are then used

as I/O Tag Data Links to exchange data between the PLC

and the code reader.

PROFINET This is an open communica-

tions protocol. Software-based

RT (Real-time) communications, (SRT) is used for communication with the code reader.

The control signals, Command

Area/Response Area, and area

to store Read result data are

assigned in the I/O memory of

the PLC, and data is exchanged cyclically between the

PLC and the code reader.

the code reader and Response

frames are received from the

code reader without the use of

any specific protocol.

Data can be exchanged between the PLC, computer, or

other external device and the

code reader in ASCII or binary

format.

Serial (RS-232C) Data can be exchanged in AS-

CII format over the RS-232C

cable connection between the

code reader and its controlling

device (PLC, PC, or other external device).

Description

○: Supported ×: Not supported

Communication Cable Type

Parallel

I/O

Ethernet RS-232C

○ × ×

× ○ ×

× ○ ×

× ○ ×

× × ○

ternal Device

1

1-2-2 Applicable Communications Protocols for the MicroHAWK V320-F/V330-F/V420-F/V430-F Series

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

1-9

Page 30

1 Communication Specifications Overview

Simultaneous Use of Communication Methods and Connections

○: Supported ×: Not Supported -: N/A

Code reader Connec-

tion Method

EtherNet/IP - × ○ ○ ○

PROFINET × - ○ ○ ○

Serial (TCP) ○ ○ - ○ ○

Serial (RS-232C) ○ ○ ○ - ○

Parallel I/O ○ ○ ○ ○ -

EtherNet/IP PROFINET Serial (TCP)

Simultaneous Connection Method

Serial

(RS-232C)

Parallel I/O

Additional Information

About connections over network routers

WebLink can connect to code readers on different networks across routers.

• To connect to the code reader, enter its IP address from the browser.

• Set a fixed IP address for the code reader you wish to connect to.

1-10

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 31

2

Controlling Operation and Data

Output with Parallel I/O

2-1 Controlling Operation and Data Output with Parallel I/O ...........................2-2

2-1-1 Basic Operation with a Parallel I/O Connection .............................................. 2-2

2-1-2 Wiring and Electrical Specifications for Parallel I/O (for V430-F) .................... 2-4

2-1-3 Change the Behavior of Operation.................................................................. 2-6

2-1-4 Change the Type of Trigger ............................................................................. 2-7

2-1-5 Timing Charts for each Trigger Mode.............................................................. 2-8

2-1-6 Sample Ladder Program ................................................................................. 2-9

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON

Condition ....................................................................................................... 2-10

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3)................. 2-20

2-1-9 Change the Polarity of Output Signal (Output 1 to 3).................................... 2-23

2-1-10 Controlling Operation with Signals from an External Device......................... 2-24

2

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-1

Page 32

Trigger sensor

External devices

(1) Trigger input

Code Reader

(3) Judgement results

are output.

(2) Read is execute.

1. Trigger input

(TRIG signal)

OFF

ON

2. Output1

In Read Cycle

OFF

ON

OFF

ON

3. Output2

Match

(or Good Read)

In Read Cycle

Turns ON on Good Read.

Read executed by Trigger Input.

Length of time to hold the signal

can be changed in settings. *1

OFF

ON

4. Output3

Mismatch

(or No Read)

Turns ON when No Read.

Length of time to hold the signal

can be changed in settings. *1

2 Controlling Operation and Data Output with Parallel I/O

2-1

2-1-1

Controlling Operation and Data Output with Parallel I/O

This section explains how to connect the code reader to an external device by the I/O cable and the

methods that you can use to control the code reader from the external device.

Basic Operation with a Parallel I/O Connection

This section describes the basic connections and signal flow with external devices.

Operation for one of the primary uses is described in the example below.

Example of Trigger Input and OUTPUT signal

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

It turns ON while the code reader is in its Read cycle.

• Output 2: On Match (or Good Read)

It turns ON when there is a Good Read or when it matches with the Master Symbol (if using the

Matchcode function).

• Output 3 : On Mismatch (or No Read)

It turns ON when there is a No Read or when it does not match with the Master Symbol (if using the

Matchcode function).

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

2-2

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 33

2 Controlling Operation and Data Output with Parallel I/O

*1 For how to change the length of time to hold the signal, please refer to 2-1-8 Change the ON/OFF

Timing of the Output Signal (Output 1 to 3) on page 2-20.

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-1 Basic Operation with a Parallel I/O Connection

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-3

Page 34

Code Reader

Brown 24V

Blue 0V

Red COM_IN

Red / Black COM_OUT

White TRIG

Black SD

Purple RD

Gray OUTPUT1

Gray / Red OUTPUT2

Pink OUTPUT3

Green DEFAULT

Yellow NEW MASTER

None (Shield)

2 Controlling Operation and Data Output with Parallel I/O

2-1-2

Wiring and Electrical Specifications for Parallel I/O (for V430-F)

The following is the wiring diagram of the power cable to connect to the V430-F (All V430-W8).

Wire color Pin No. Signal Name Function

Brown 2 24V Power supply

Blue 7 0V GND

Red 8 COM_IN Common Input Signals (Input Common)

Red / Black 12 COM_OUT Common Output Signals (Output Common)

White 1 TRIG Read Trigger Input (Trigger)

Black 9 SD Send Data (SD)

Purple 10 RD Receive Data (RD)

Gray 5 OUTPUT 1 (Output 1)

Gray / Red 11 OUTPUT 2 (Output 2)

Pink 6 OUTPUT 3 (Output 3)

Green 3 DEFAULT (Default)

Yellow 4 NEW MASTER (New Master)

None - - (Shield)

2-4

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 35

Code reader

NPN device

+V

GND

COM_IN

INPUT

- TRIG

- DEFAULT

- NEW MASTER

CLC

CLC = Current Limiting Circuit

NPN device

GND

COM_OUT

OUTPUT

- OUTPUT1

- OUTPUT2

- OUTPUT3

+V

Input

Code reader

COM_IN

INPUT

- TRIG

- DEFAULT

- NEW MASTER

CLC

CLC = Current Limiting Circuit

+V

GND

Code reader

PNP device

COM_OUT

OUTPUT

- OUTPUT1

- OUTPUT2

- OUTPUT3

GND

+V

Input

Code reader

PNP device

2 Controlling Operation and Data Output with Parallel I/O

• Input circuit diagram (V430-F ↔ External device) when NPN connected

2-1 Controlling Operation and Data Output

with Parallel I/O

2

• Output circuit diagram (V430-F ↔ External device) when NPN connected

• Input circuit diagram (V430-F ↔ External device) when PNP connected

2-1-2 Wiring and Electrical Specifications for Parallel I/O (for V430-F)

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

• Output circuit diagram (V430-F ↔ External device) when PNP connected

2-5

Page 36

2 Controlling Operation and Data Output with Parallel I/O

2-1-3

Change the Behavior of Operation

The following changes are possible depending on the system configuration and usage.

Type Modification

Change the type of Trigger You can change the method used to trigger a Read

(Triggered, or Continuous).

Change the assignments for the Output Signal (Output

1 to 3) ON Condition

Change the ON/OFF timing of the Output Signal (Output 1 to 3)

Change the Output polarity of Output Signal (Output 1

to 3)

Change the ON condition for Output 1 to 3.

Change the OFF timing of the Output 1 to 3 signals after they turn ON.

Change the Output polarity for Output 1 to 3.

2-6

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 37

2 Controlling Operation and Data Output with Parallel I/O

2-1 Controlling Operation and Data Output

2-1-4

Change the Type of Trigger

It is possible to change the Input method for the trigger used by the code reader to execute Image

capture.

• WebLink - Setup - Gear Icon - Advanced Settings - Read Cycle - Trigger

Setting Item Setting Value Description

Mode Continuous Read With no Parallel TRIG signal used, the code reader executes Con-

tinuous Read.

The data is continually output as each code is read.

External Trigger Signal Filter (Rising

Edge)

External Trigger Signal Filter (Falling

Edge)

External Trigger

State

Continuous Read 1

Output

External Level While TRIG signal is ON, Read is executed.

External Edge While TRIG signal is ON, Read is executed.

Serial Data Read is executed when you send the serial command "<>" (de-

Serial Data and

Edge

Continuous Read

Auto

0 to 2097120 μs When the TRIG signal is ON for more than a set time, the trigger

0 to 2097120 μs When the TRIG signal is OFF for more than a set time, the trigger

Active Open When the TRIG signal turns from OFF → ON, it is recognized as

Active Closed When the TRIG signal turns from ON → OFF, it is recognized as

With no Parallel TRIG signal used, the code reader executes Continuous Read.

If the data of a read code is the same as the previously read code,

it is not output.

When TRIG signal turns OFF, Read ends.

On Good Read or when End of Read Cycle condition is met,

Read ends.

fault value) to the code reader.

On Good Read or when End of Read Cycle condition is met,

Read ends.

Read is executed when TRIG signal turns ON or when you send

the serial command "<>" (default value) to the code reader.

On Good Read or when End of Read Cycle condition is met,

Read ends.

With no Parallel TRIG signal used, the code reader executes Continuous Read.

Exposure time and Gain is automatically adjusted for every Read

performed.

is input as ON.

If it is ON for less than the set time, it is not regarded as ON, so

no trigger is input.

is input as OFF.

If it is OFF for less than the set time, it is not regarded as OFF, so

no trigger is input.

the rising edge of the Trigger.

When the TRIG signal turns from ON → OFF, it is recognized as

the falling edge of the Trigger.

the rising edge of the Trigger.

When the TRIG signal turns from OFF → ON, it is recognized as

the falling edge of the Trigger.

with Parallel I/O

2

2-1-4 Change the Type of Trigger

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-7

Page 38

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

Match

(or Good Read)

4. Output3

Mismatch

(or No Read)

OFF

ON

OFF

ON

OFF

ON

Turns ON on Good Read.

OFF

ON

Read is executed only

while Trigger Input is ON.

Read is executed only

while Trigger Input is ON.

Turns ON when No Read.

2 Controlling Operation and Data Output with Parallel I/O

2-1-5

Timing Charts for each Trigger Mode

There are two methods for Trigger input.

Trigger Input Method Overview Trigger Mode

Triggered Execute Read when the input on

the Parallel TRIG signal is ON.

Continuous Read With no Parallel TRIG signal used,

the code reader executes Continuous Read.

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

It turns ON while the code reader is in its Read cycle.

• Output 2: On Match (or Good Read) Output Mode: Pulse

It turns ON when there is a Good Read or when it matches with the master symbol (if using the

Matchcode function).

• Output 3: Mismatch (or on No Read) Output Mode: Pulse

It turns ON when there is a No Read or when it does not match with the master symbol (if using the

Matchcode function).

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

• External Level

• External Edge

• Serial Data

• Continuous Read

• Continuous Read 1 Output

• Continuous Read Auto

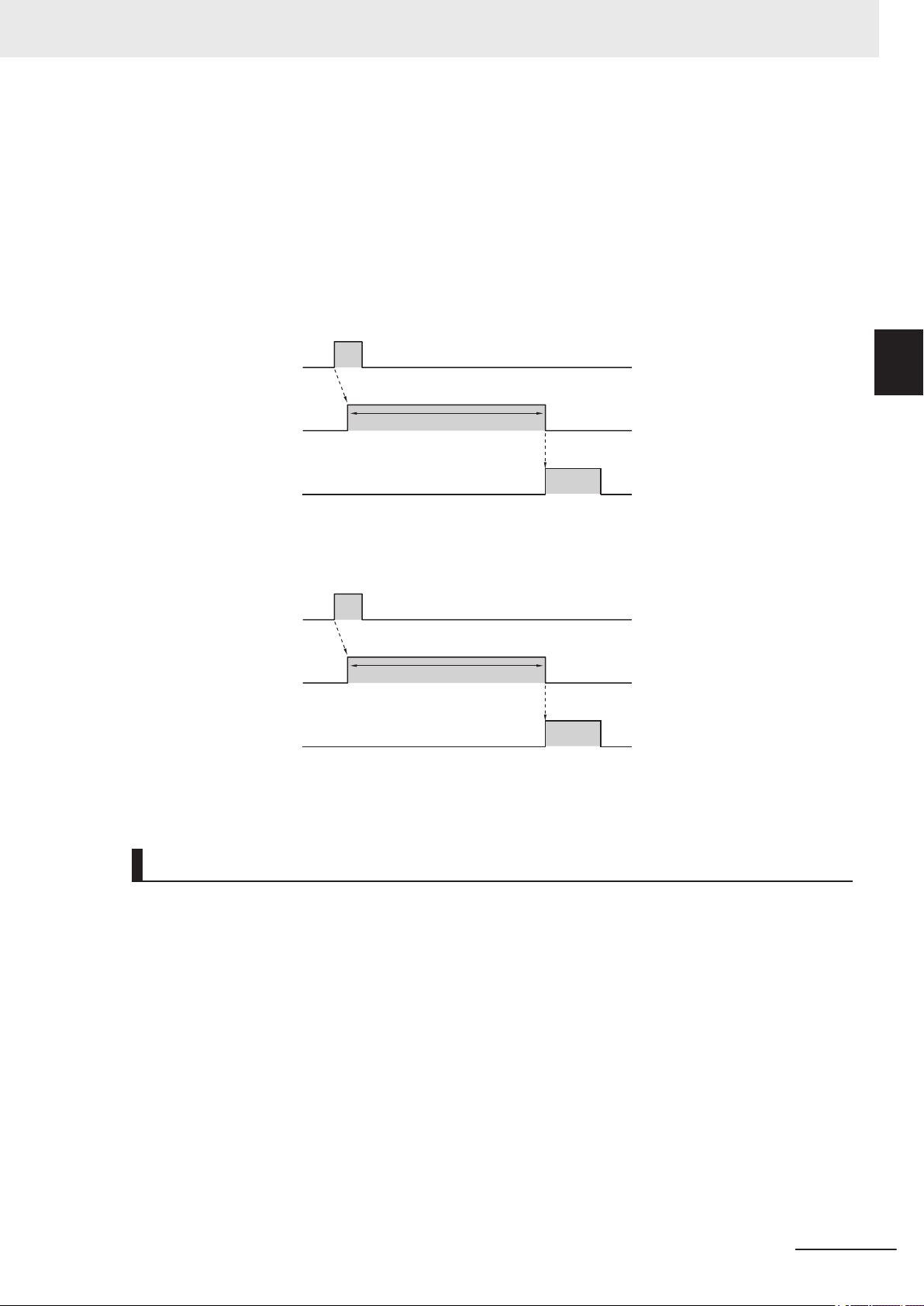

<Timing Chart (External Level)>

<Timing Chart (External Edge)>

2-8

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 39

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

Match

(or Good Read)

4. Output3

Mismatch

(or No Read)

OFF

ON

OFF

ON

OFF

ON

In Read Cycle

Turns ON on Good Read.

Read executed by Trigger Input.

OFF

ON

Turns ON when No Read.

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

Match

(or Good Read)

4. Output3

Mismatch

(or No Read)

OFF

ON

OFF

ON

In Read Cycle

Turns ON on Good Read.

TRIG Signal not used.

OFF

ON

Turns ON if No Read occurs.

Always in Read Cycle *1

Either Output 2 or Output 3 will

continue as ON.

2 Controlling Operation and Data Output with Parallel I/O

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-6

<Timing Chart (Continuous Read)>

*1 Output 1 turns OFF for about 300 μs at the end of each Read Cycle.

Sample Ladder Program

This is a sample ladder program that inputs the TRIG signal to execute a Triggered Read.

Triggered Read is executed by W0.00 ON.

2-1-6 Sample Ladder Program

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-9

Page 40

SET When the single read command bit (W0.00) turns ON,

the TRIG signal is turned.

The TRIG signal is kept ON for 2 ms and then turned OFF.

TRIG

W0.00

Single read

command bit

OUT1

InReadCycle

signal

0000

#2

TRIG

TRIG signal

TMHH

TRIG

T0000

RSET

W0.00

++L

1000

++L

1002

OUT2

OUT3

OUT1

In Read

Cycle

Match (or Good Read)

Mismatch (or No Read)

The judgement result is added to the total count.

OK: 1000, NG: 1002

RSET

2 Controlling Operation and Data Output with Parallel I/O

2-1-7

Input and Output Signal Assignment

Signal Type Address

Output Signal Output 1 0.00

Output 2 0.01

Output 3 0.02

Input Signal TRIG 1.00

Precautions for Correct Use

The time at which Read is executed is the same time the InReadCycle signal turns ON.

The following Output signal assignments are made in WebLink.

• Output 1: In Read Cycle

• Output 2: On Match or On Good Read Output Mode: Pulse

• Output 3: On Mismatch (or No Read)

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

Change the Assignments for the Output Signal (Output 1 to 3) ON Condition

The condition for turning the Output signals, Output 1, 2, 3 to ON can be set.

The following conditions for output can be set.

Mismatch or No Read It turns ON when there is a No Read or when it does not match with the

Match or Good Read It turns ON when there is a Good Read or when it matches with the Mas-

2-10

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Output On Parameter meaning

Master Symbol (if using the Matchcode function).

ter Symbol (if using the Matchcode function).

Page 41

2 Controlling Operation and Data Output with Parallel I/O

Output On Parameter meaning

Mismatch It turns ON when it does not match with the Master Symbol (if using the

Matchcode function). When the Matchcode function is not used, it is always OFF.

No Read It turns ON when there is a No Read result.

Trend Analysis Turns ON when the conditions set for Trend Analysis (Output 1 to 3) are

matched.

Symbol Quality Turns ON when the ISO/IEC xxx Code Quality conditions set for (Output

1 to 3) are met. Select 15415, 15416, 16022, or 29158.

Diagnostic Warning Turns ON when the conditions set for Diagnostics (Output 1 to 3) are met.

In Read Cycle ON while the code reader is in its Read cycle. Confirm the output when it

changes from ON to OFF.

Use as Ext.Illumination Strobe

- Can only be assigned to Output 3.

It is the signal used to illuminate with external lighting

Turns ON when Light Source is set to External Strobe and a Trigger is

input.

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON Condition

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-11

Page 42

2 Controlling Operation and Data Output with Parallel I/O

How to Assign the Output Signals

The Output signals can be assigned using WebLink.

1 From the WebLink screen, select Setup → Outputs.

2 The Digital Output Editor dialog opens.

3 The Output condition for each Output signal can be set or changed in Output On.

4 Advanced Settings for Trend Analysis, Symbol Quality and Diagnostic Warning are displayed

by clicking on the Text string at the bottom of the Output setting screen. Here you can change

any settings as needed.

2-12

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 43

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

Mismatch

(or No Read)

OFF

ON

OFF

ON

OFF

ON

In Read Cycle

Turns ON if No Read. *1

Read executed by Trigger Input.

2 Controlling Operation and Data Output with Parallel I/O

Mismatch or No Read

The assigned output signal turns ON when one of the following conditions is met.

• On No Read (NOREAD)

• If using the Matchcode function, when it does not match with the master symbol

• Triggered Mode must be External or Serial

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

• Output 2: Mismatch (or No Read) Output Mode: Pulse

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON Condition

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

Match (or On Good Read)

The assigned output signal turns ON when one of the following conditions is met.

• On Good Read

• If using the Matchcode function, when it matches with the master symbol

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

• Output 2: On Match (or On Good Read) Output Mode: Pulse

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

• Trigger Input → On Good Read

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-13

Page 44

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

Match

(or Good Read)

OFF

ON

OFF

ON

OFF

ON

In Read Cycle

Turns ON on Good Read *1

Read executed by Trigger Input.

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

OFF

ON

OFF

ON

OFF

ON

3. Output2

Mismatch

In Read Cycle

Turns ON on Good Read or Character string Mismatch *1

Read executed by Trigger Input.

2 Controlling Operation and Data Output with Parallel I/O

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

Mismatching Character String (Mismatch)

If using the Matchcode function, the assigned output signal for a Mismatch with the Master Symbol

turns ON.

When the Matchcode function is not used, the signal state is OFF.

Note

Matchcode functionality is only used when Triggering mode is External or Serial.

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

• Output 2: Character string Mismatch Output Mode: Pulse

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

• Trigger Input → No Read (Mismatch with Master Symbol)

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

2-14

No Read

The assigned Output signal turns ON when there is a No Read.

Note

Triggered mode must be External or Serial.

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

• Output 2: No Read Output Mode: Pulse

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 45

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

3. Output2

No Read

OFF

ON

OFF

ON

OFF

ON

In Read Cycle

Turns ON if No Read *1

Read executed by Trigger Input.

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

OFF

ON

OFF

ON

In Read Cycle

Read executed by Trigger Input.

2 Controlling Operation and Data Output with Parallel I/O

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

• Trigger Input → On No Read

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON Condition

In Read Cycle

The assigned output signal turns ON when the code reader is In Read Cycle. The setting selected for

Output Mode is disabled.

This signal turns ON when the Read Cycle starts. The timing for when it turns OFF depends on what is

set for the End of Read Cycle condition.

• When the End of Read Cycle condition is Timeout

On Good Read: Turns OFF when there is a Good Read.

No Read: Turns OFF when the Timeout period is exceeded.

• When the End of Read Cycle condition is Last Frame

On Good Read: Turns OFF when there is a Good Read.

On No Read: Turns OFF when all the image capture executed by 1 trigger input is completed.

• When the End of Read Cycle condition is New Trigger

On Good Read: Turns OFF when there is a Good Read.

On No Read: Turns OFF when a trigger is input and there is a New Read Cycle. At this time, since

the New Read Cycle is in progress, it will turn ON again.

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

• Trigger input

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-15

Page 46

2 Controlling Operation and Data Output with Parallel I/O

Trend Analysis

Monitors the frequency of Mismatches and No Reads as well as the Number of Reads per Trigger, and

turns ON when a certain threshold is met.

This can be used to monitor quality indicators like the percentage of Matches and Read Rate.

The following settings are set independent for each Output signal.

Change the Output signal number selection as needed for your application.

• WebLink - Setup - Gear Icon - Advanced Settings - I/O - Trend Options (Output 1, 2, 3)

Setting Item Setting Value Description

Trend Analysis

Mode

Number of Triggers 0 to 255 The number of triggers in the Trend Analysis.

Number to OutputOn0 to 255 This is the threshold for turning on the Output signal Trend Analy-

Decodes per Trigger

Threshold

• Mismatch

• No Read

• Decodes per Trig-

ger

• Mismatch

Turns ON when the number of Mismatches for the most recent

Number of Triggers cycle reaches the number set for Number

to Output On.

• No Read

Turns ON when the number of No Reads for the most recent

Number of Triggers cycle reaches the number set for Number

to Output On.

• Decodes per Trigger

Turns ON when the Number Of Decodes for the most recent

Number of Triggers cycle reaches the number set for Number

to Output On.

For example, if you set this to 25, the Trend Analysis will be done

for the most recent 25 trigger inputs.

sis is assigned to.

For example,

Trend Analysis Mode : No Read,

Number of Triggers : 25,

Number to Output On : 4

With these settings, the output signal turns ON when there are 4

No Read in the last 25 triggers.

0 to 65535 When the number of codes read within the Read Cycle falls below

the Decodes per Trigger threshold, the Output signal turns ON.

2-16

Setting Example

• Read Cycle

Trigger - Mode : External Edge

End of Read Cycle - Mode : Timeout

Capture Mode - Captures Mode : Continuous

• I/O

Decodes per Trigger Output - Decodes/Trigger Status :

Enabled

Trend Analysis (Output 1) - Trend Analysis Mode : Decodes

per Trigger

Trend Analysis (Output 1) - Number of Triggers : 1

Trend Analysis (Output 1) - Number to Output On : 1

Trend Analysis (Output 1) - Decodes per Trigger : 10

10 or more Reads in the Read Cycle : Signal OFF

9 or less Reads in the Read Cycle : Signal ON

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 47

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

OFF

ON

OFF

ON

OFF

ON

3. Output2

Trend Analysis

In Read Cycle

Turns ON when Trend Analysis Output On

condition is met. *1

Read executed by Trigger Input.

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

OFF

ON

OFF

ON

OFF

ON

3. Output2

Trend Analysis

In Read Cycle

Turns ON when Trend Analysis Output On

condition is met. *1

Read executed by Trigger Input.

2 Controlling Operation and Data Output with Parallel I/O

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

• Output 2: Trend Analysis Output Mode: Pulse

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

• Trigger Input → Trend Analysis Output On Condition met

2-1 Controlling Operation and Data Output

with Parallel I/O

2

2-1-7 Change the Assignments for the Output Signal (Output 1 to 3) ON Condition

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

• Trigger Input → Decodes per Trigger count falls below threshold

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

Symbol Quality Grade

If a read barcode or 2D Code's Symbol Quality Grade falls below the set threshold value by one, the

assigned output signal turns ON.

This can be used when you want to monitor trends in deterioration of Symbol Quality Grades.

The ISO standards for which threshold values can be set are as follows.

• ISO/IEC 15415

• ISO/IEC 15416

• ISO/IEC 16022

• ISO/IEC 29158

For more information on each of these, please refer to Autofocus Multicode Reader MicroHAWK

V320-F/V330-F/V420-F/V430-F Series User Manual (Z432-E)–Symbol Quality Grading.

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: In Read Cycle

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

2-17

Page 48

1. Trigger input

(TRIG signal)

2. Output1

In Read Cycle

OFF

ON

OFF

ON

OFF

ON

3. Output2

Symbol Quality

In Read Cycle

Turns ON when Symbol Quality Grade falls below threshold. *1

Read executed by Trigger Input.

2 Controlling Operation and Data Output with Parallel I/O

• Output 2: Symbol Quality Output Mode: Pulse

ISO/IEC 15415 Output on Overall Grade: B

* In this case, when the Overall ISO Judgement of the Symbol Quality is lower than a B, this signal

will turn ON.

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals

on page 2-12.

<Timing Chart>

• Trigger Input → The read code symbol's quality grade falls below the set threshold

*1 You can change the length of time the signal is ON. For further information, please refer to

2-1-8 Change the ON/OFF Timing of the Output Signal (Output 1 to 3) on page 2-20.

Diagnostic Warning

This signal turns ON and a text string is sent over Serial communications according to the interval set

in Diagnostics - Service Message - Threshold - Resolution.

This can be used to regularly transmit a specified message from the code reader at a desired interval.

• WebLink - Setup - Gear Icon - Advanced Settings - Diagnostics - Service Message

Setting Item Setting Value Description

Status

Service Message Optional

Threshold Value 1 to 65535 Interval at which to send Service Message

Unit

• Disabled

• Enabled

(Default: SERVICE)

• Seconds

• Minutes

• Disabled:

Service Message is not used.

• Enabled:

The Service Message is used.

The text string set in Service Message is sent from the code

reader by Serial communications at the interval set in

Threshold - Resolution.

The default message ”SERVICE” will continue to be output at the

interval set in Threshold - Resolution.

• Seconds: Treat thresholds in seconds.

• Minutes: Treat thresholds in minutes.

2-18

Below is an Output assignment example and Timing chart.

[Example assignment of OUTPUT signals]

• Output 1: Diagnostic Warning

Threshold: 2 Resolution: Seconds Output Mode: Pulse (500ms)

For how to set up the Output signal assignments, please refer to How to Assign the Output Signals on

page 2-12.

<Timing Chart>

Autofocus Multicode Reader MicroHAWK V320-F/V330-F/V420-F/V430-F Series User Manual for Communication Settings (Z407-E1)

Page 49

OFF

ON

500ms

ON for 500ms at 2000ms intervals.

2000ms 500ms 2000ms 500ms

1. Output1

Diagnostic

Warning

2 Controlling Operation and Data Output with Parallel I/O

Use as Ext.Illumination Strobe - (Output 3 Signal Only)

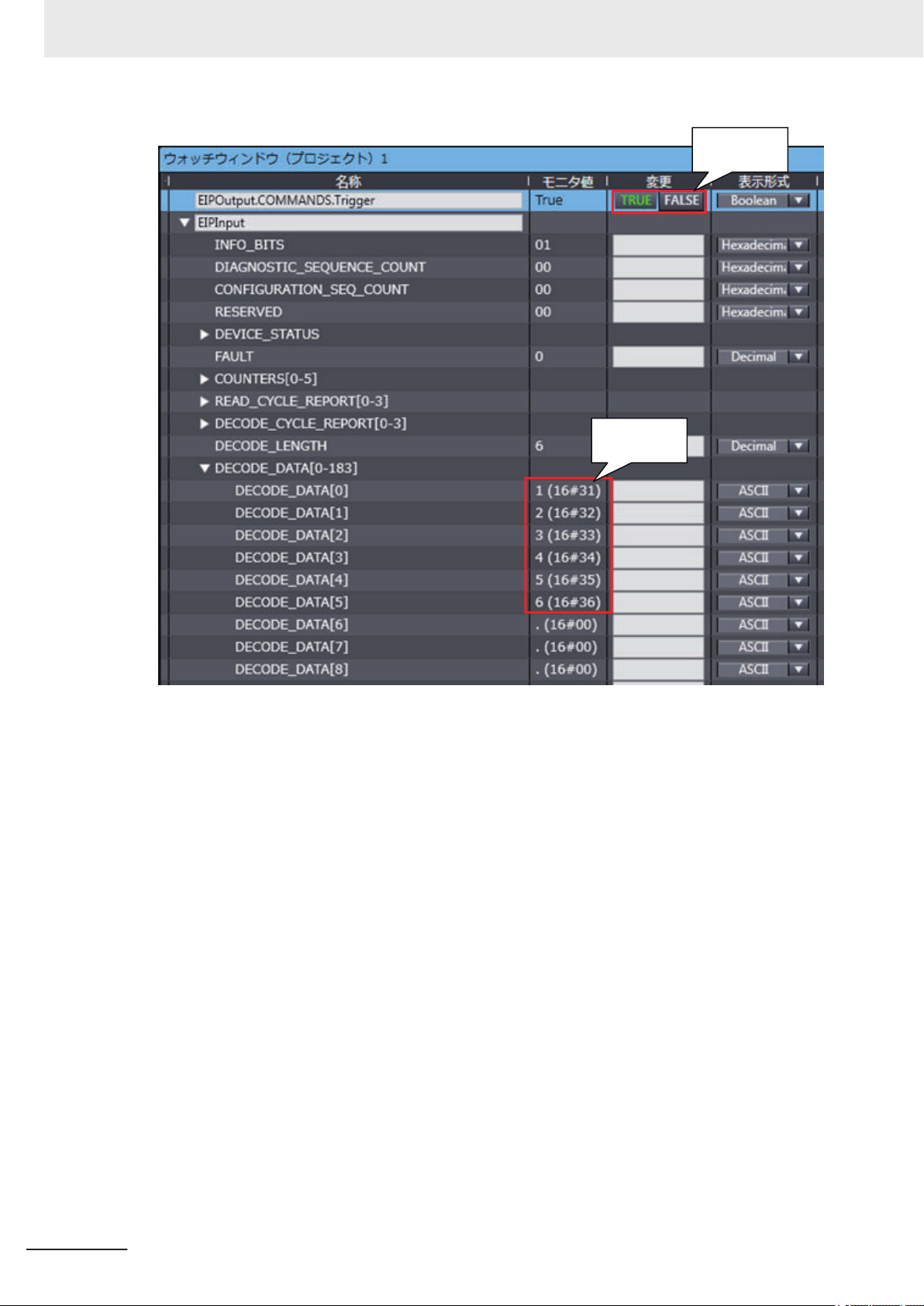

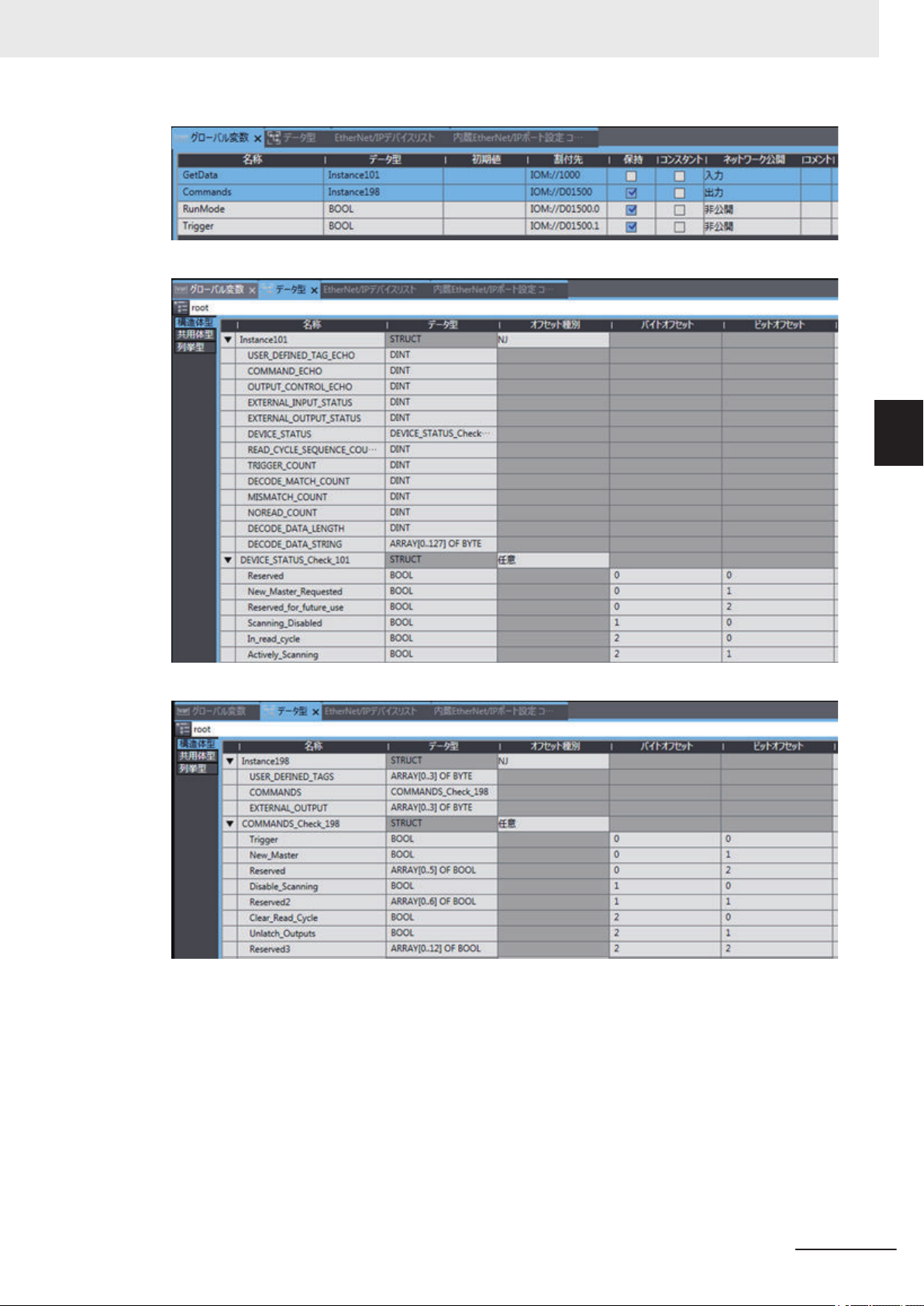

Outputs the signal used to illuminate with external lighting.