Page 1

Medium &

Heavy Payload Series

Hardware Installation Manual

Corresponding models: TM12/14 Series

Original Instruction

I624-E-09

Page 2

This Manual contains information of the Techman Robot product series (hereinafter referred to as the TM Robot).The

information contained herein is the property of Techman Robot Inc. (hereinafter referred to as the Corporation). No part

of this publication may be reproduced or copied in any way, shape or form without prior authorization from the

Corporation. No information contained herein shall be considered an offer or commitment. It may be subject to change

without notice. This Manual will be reviewed periodically. The Corporation will not be liable for any error or omission.

logo is registered trademark of TECHMAN ROBOT INC. in Taiwan and other countries and the company

reserves the ownership of this manual and its copy and its copyrights.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 2

Page 3

Contents

Revision History Table ....................................................................................................................................................... 9

1. Product Dscription ....................................................................................................................................................... 10

1.1 Product Description ............................................................................................................................................ 10

1.2 How Can I Get Help? ......................................................................................................................................... 10

2. Safety Information ....................................................................................................................................................... 11

2.1 Overview ............................................................................................................................................................ 11

2.2 Warning and Caution Symbols .......................................................................................................................... 11

2.3 Safety Precautions ............................................................................................................................................. 11

2.4 Validation and Liability ....................................................................................................................................... 12

2.5 Limitations on Liability ........................................................................................................................................ 12

2.6 General Safety Warning ..................................................................................................................................... 12

2.7 Risk Assessment ................................................................................................................................................ 13

2.8 Emergency Stop ................................................................................................................................................ 13

2.9 Movement without Drive Power ......................................................................................................................... 13

2.10 Labels .............................................................................................................................................................. 15

3. Transportation and Storage......................................................................................................................................... 17

4. System Hardware ........................................................................................................................................................ 18

4.1 Overview ............................................................................................................................................................ 18

4.2 System Overview ............................................................................................................................................... 18

4.2.1 Robot Arm ................................................................................................................................................... 19

4.2.1.1 Dimension Drawings of Robot .............................................................................................................. 19

4.2.1.2 Robot Assembly Diagram ..................................................................................................................... 22

4.2.1.3 Range of Motion ................................................................................................................................... 27

4.2.1.4 Robot Hazard Zone Diagram and Operator Position Diagram ............................................................. 30

4.2.1.5 Payload and Torque .............................................................................................................................. 32

4.2.1.6 Robot Arm Installation .......................................................................................................................... 34

4.2.2 Robot End Module....................................................................................................................................... 36

4.2.2.1 End Module Components ..................................................................................................................... 36

4.2.2.2 End Flange Surface .............................................................................................................................. 38

4.2.2.3 End Mounting Caution .......................................................................................................................... 39

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 3

4.2.2.4 End Indication Light Ring Table ............................................................................................................ 39

4.2.3 Control Box .................................................................................................................................................. 39

4.2.3.1 Robot Stick ........................................................................................................................................... 40

4.2.4 Robot Light Module ..................................................................................................................................... 42

4.2.4.1 Light Module Surface ............................................................................................................................ 42

Page 4

4.2.4.2 Install Light Module ............................................................................................................................... 42

4.3 Operating Position of TM Robot with AGV/AIV .................................................................................................. 44

4.4 Working distance and field of view of TM Robot’s EIH camera ......................................................................... 45

5. Electrical Interface ....................................................................................................................................................... 47

5.1 Overview ............................................................................................................................................................ 47

5.2 Electrical Warnings and Cautions ...................................................................................................................... 47

5.3 Control Box ........................................................................................................................................................ 47

5.3.1 Safety Connector ......................................................................................................................................... 49

5.3.1.1 Safety Input Connector ......................................................................................................................... 49

5.3.1.2 Safety Output Connector ...................................................................................................................... 51

5.3.2 Power Connector ......................................................................................................................................... 53

5.3.3 Digital In/Out ................................................................................................................................................ 53

5.3.3.1 Digital Input ........................................................................................................................................... 53

5.3.3.2 Digital Output ........................................................................................................................................ 55

5.3.4 Analog In ..................................................................................................................................................... 57

5.3.5 Analog Out ................................................................................................................................................... 58

5.3.6 System Remote Power ON/OFF ................................................................................................................. 58

5.3.7 EtherCAT: For EtherCAT Slave I/O Expansion ........................................................................................... 59

5.3.8 USB Port ..................................................................................................................................................... 59

5.4 Tool End I/O Interface ........................................................................................................................................ 59

5.4.1 I/O Terminals ............................................................................................................................................... 59

5.4.2 Connecting Tool End Digital Output ............................................................................................................ 61

5.4.3 Connecting Tool End Digital Input ............................................................................................................... 62

5.4.4 Connecting Tool End Analog Input .............................................................................................................. 62

5.5 Control Box Interfaces ....................................................................................................................................... 63

5.6 Control Box Power Interface and Robot Interface ............................................................................................. 65

5.6.1 Control Box Power Interface ....................................................................................................................... 65

5.6.2 Robot Interface ............................................................................................................................................ 66

5.6.3 SEMI Emergency Off Interfaces (SEMI series exclusive) ........................................................................... 67

5.6.3.1 TM12M SEMI / TM14M SEMI Series ................................................................................................... 67

5.6.4 Detachable I/O Panel .................................................................................................................................. 67

6. Unboxing & Installation ............................................................................................................................................... 69

6.1 Overview ............................................................................................................................................................ 69

6.2 Inspecting the Equipment .................................................................................................................................. 69

6.2.1 Before Unpacking ........................................................................................................................................ 69

6.2.2 Upon Unpacking .......................................................................................................................................... 69

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 4

Page 5

6.3 Unboxing ............................................................................................................................................................ 70

6.3.1 Carton Types ............................................................................................................................................... 70

6.3.2 Contents of Each Carton ............................................................................................................................. 70

6.4 Installing Your Robot .......................................................................................................................................... 73

6.4.1 Remove the Control Box ............................................................................................................................. 74

6.4.2 Verification Before Removal of the Robot Arm ............................................................................................ 75

6.4.3 Removal of the Robot Arm and Tightening ................................................................................................. 75

6.4.4 Connect the Robot and the Control Box ..................................................................................................... 77

7. Maintenance and Repair ............................................................................................................................................. 78

Appendix A. Technical Specifications .............................................................................................................................. 80

Tables

Table 1: Manual Title & Description .................................................................................................................. 10

Table 2: Danger, Warning, and Caution Symbols ............................................................................................. 11

Table 3: Denotation of Labels ........................................................................................................................... 16

Table 4: Rated Torque and Limit for Repeated Peak Torque of Regular Payload Robot Series ...................... 34

Table 5: Robot Stick Basic Functions ............................................................................................................... 41

Table 6: Robot Stick Advanced Functions ........................................................................................................ 41

Table 7: Reference of the Symbol and Unit in Calculation the Torque Load of the Light Module .................... 42

Table 8: Electrical Specification of the Light Module ........................................................................................ 43

Table 9: The Relation between the Working Distance and the Field of View ................................................... 46

Table 10: Definitions of Safety Connectors....................................................................................................... 48

Table 11: Analog In & Analog Out ..................................................................................................................... 58

Table 12: 8-pin Digital I/O Connectors of Cable ............................................................................................... 60

Table 13: 8-pin Digital I/O Connector of Robot ................................................................................................. 60

Table 14: 5-pin Analog I/O Connector of Cable ................................................................................................ 61

Table 15: 5-pin Analog I/O connector of Robot ................................................................................................. 61

Table 16: Analog Input Range .......................................................................................................................... 62

Table 17: TM12 / TM14 / TM12X / TM14X Series Electrical Specifications ..................................................... 66

Table 18: TM12M / TM14M Series Electrical Specifications............................................................................. 66

Table 19: The Robot Arm Carton Contents ....................................................................................................... 71

Table 20: The Control Box Carton Contents ..................................................................................................... 73

Table 21: The SEMI Emergency OFF Switch Carton Contents ........................................................................ 73

Table 22: Summary of the Preventive Maintenance Procedures and Guidelines ............................................ 78

Table 23: Technical Specifications .................................................................................................................... 80

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 5

Page 6

Figures

Figure 1: References of Joints by Models ........................................................................................................ 14

Figure 2: Reference of Brake Solenoid by Joints ............................................................................................. 15

Figure 3: Locations of Labels ........................................................................................................................... 16

Figure 4: System Overview............................................................................................................................... 18

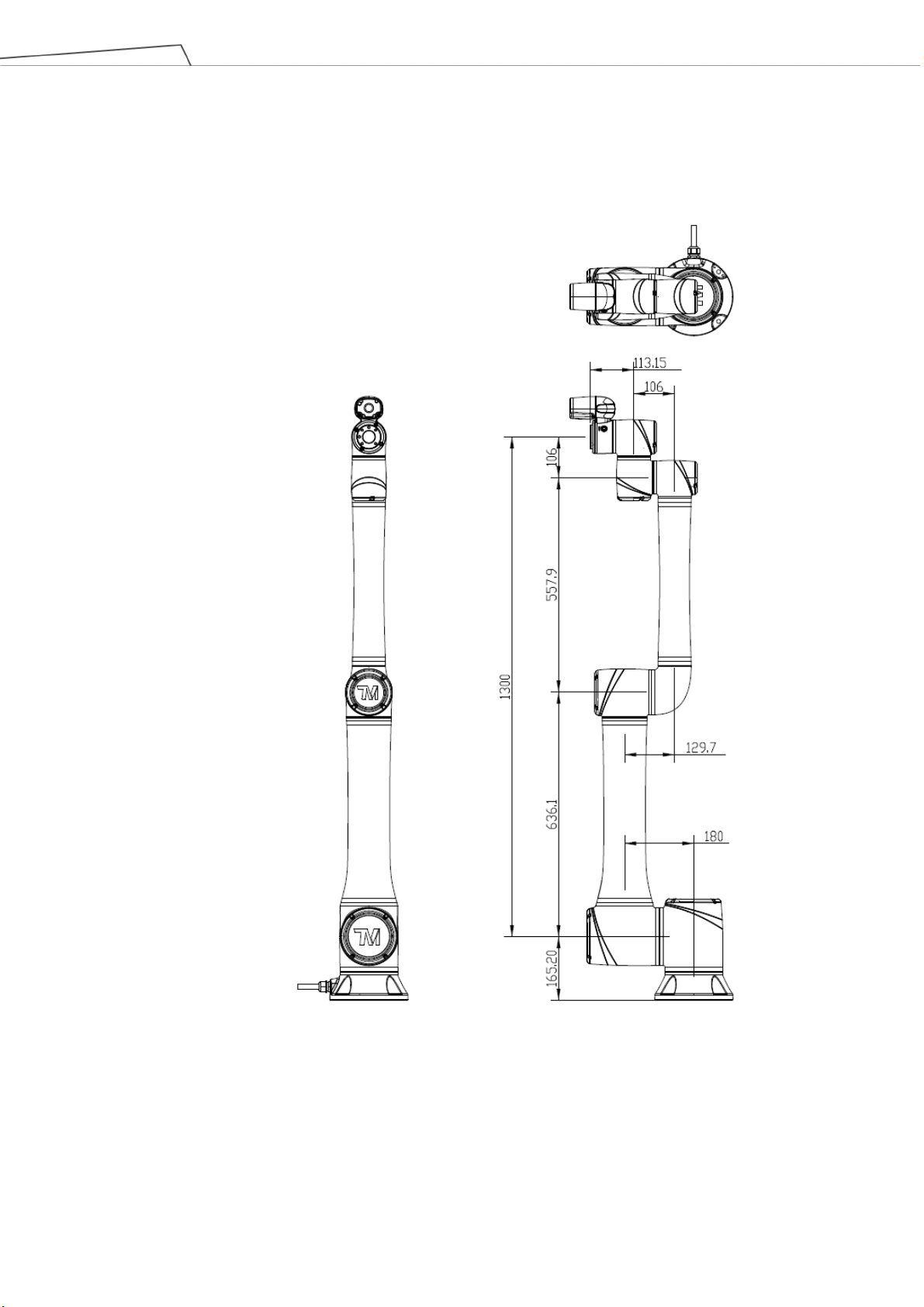

Figure 5: Dimension of TM12 / TM12M ............................................................................................................ 19

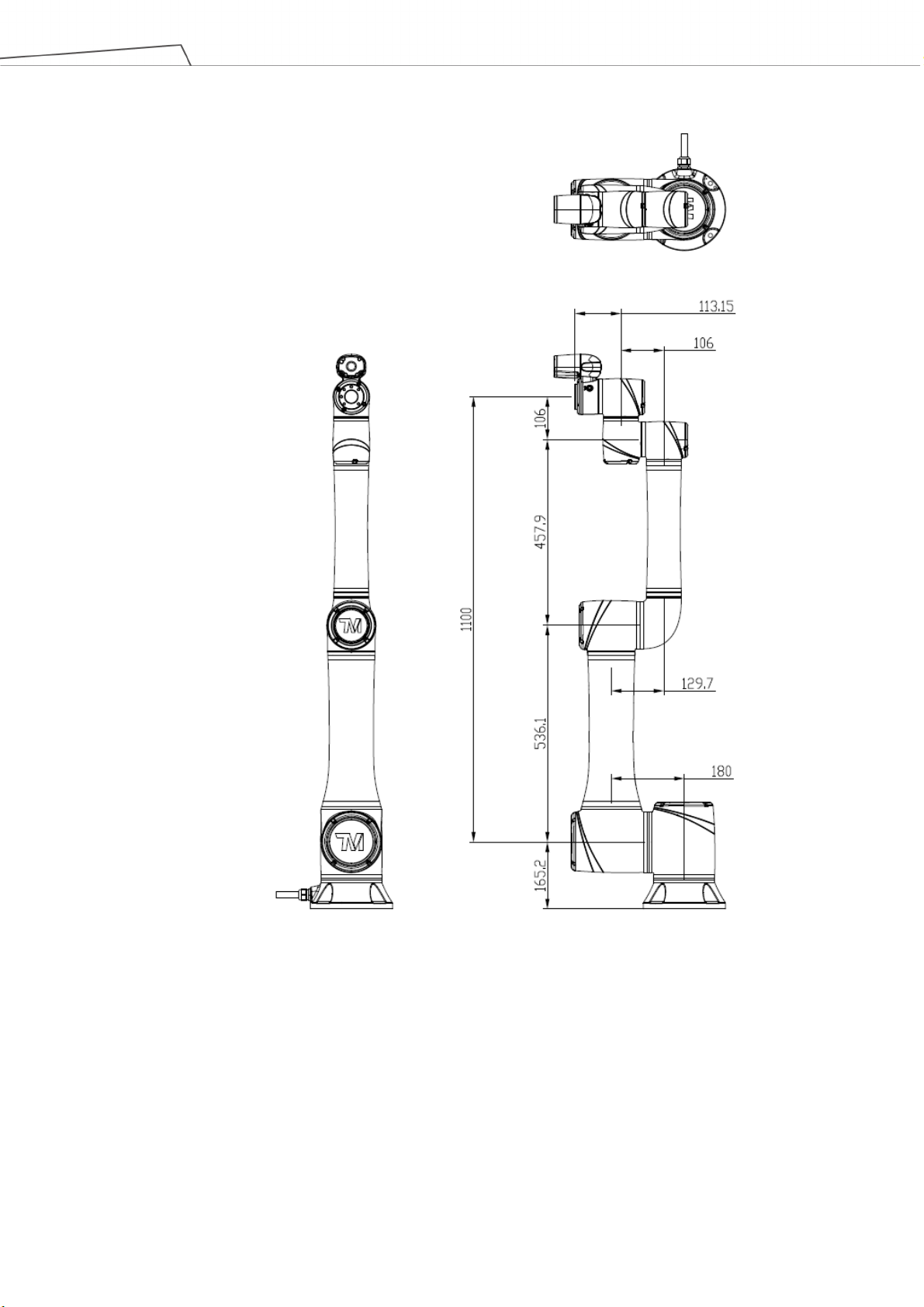

Figure 6: Dimension of TM14 / TM14M ............................................................................................................ 20

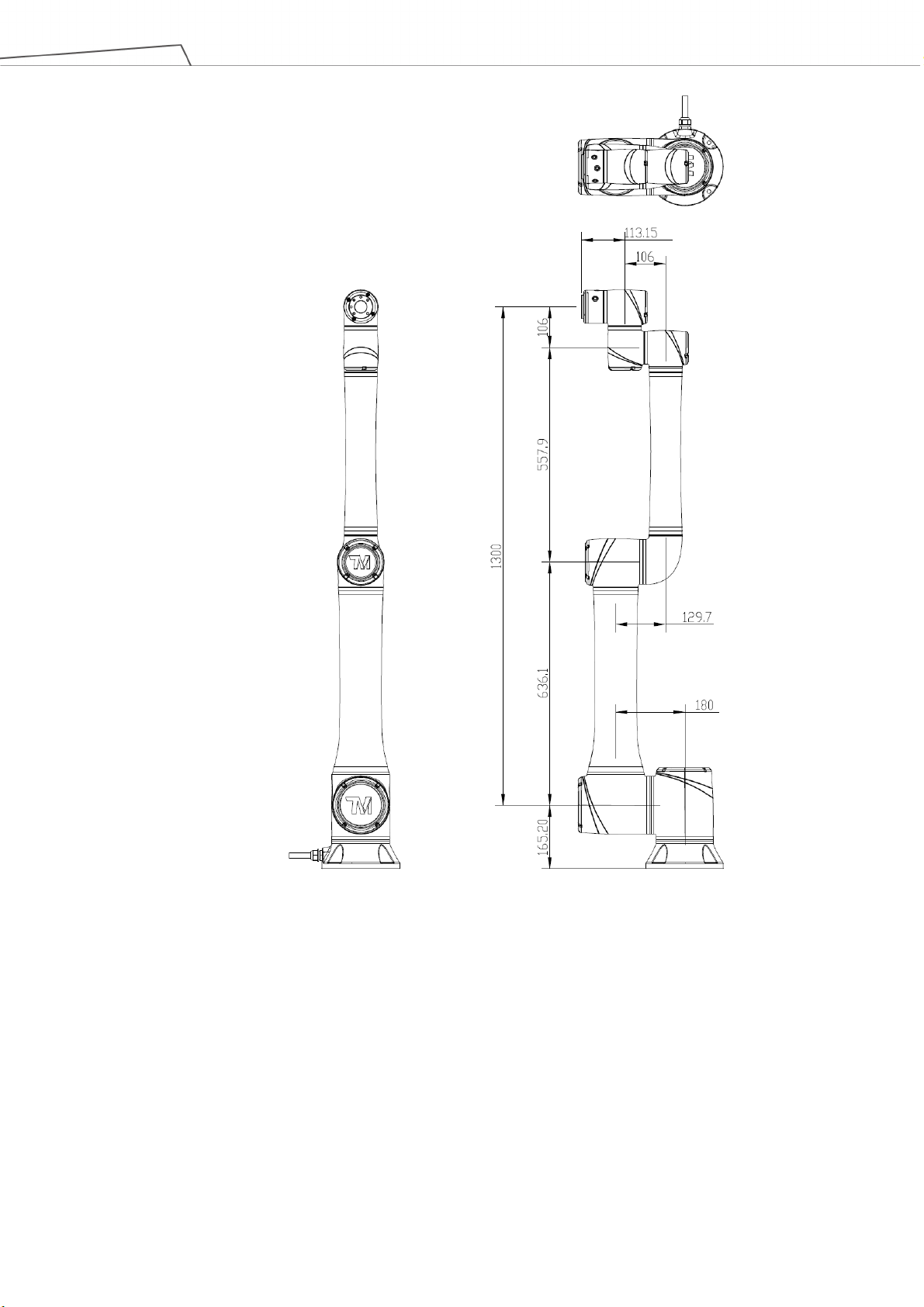

Figure 7: Dimension of TM12X ......................................................................................................................... 21

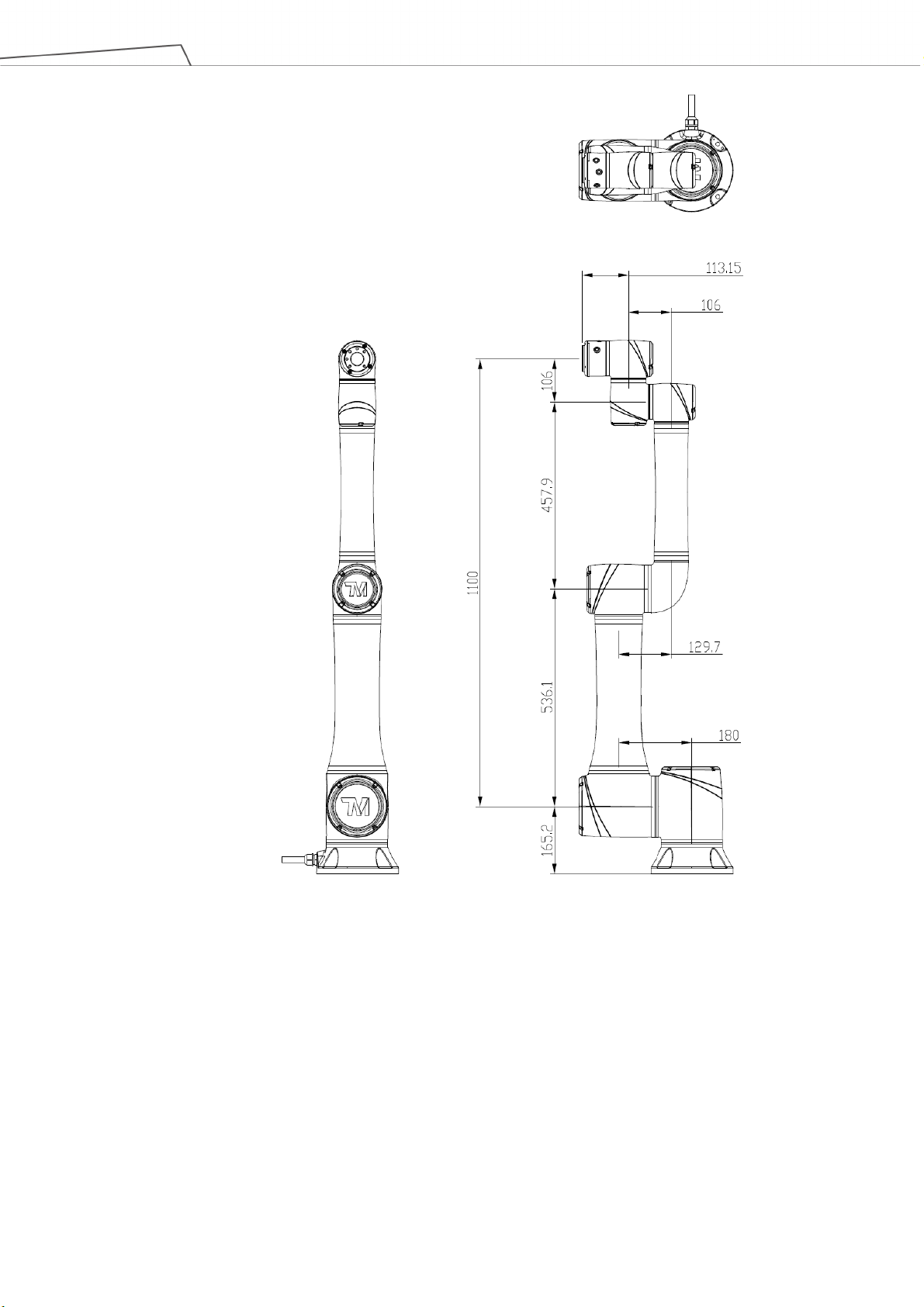

Figure 8: Dimension of TM14X ......................................................................................................................... 22

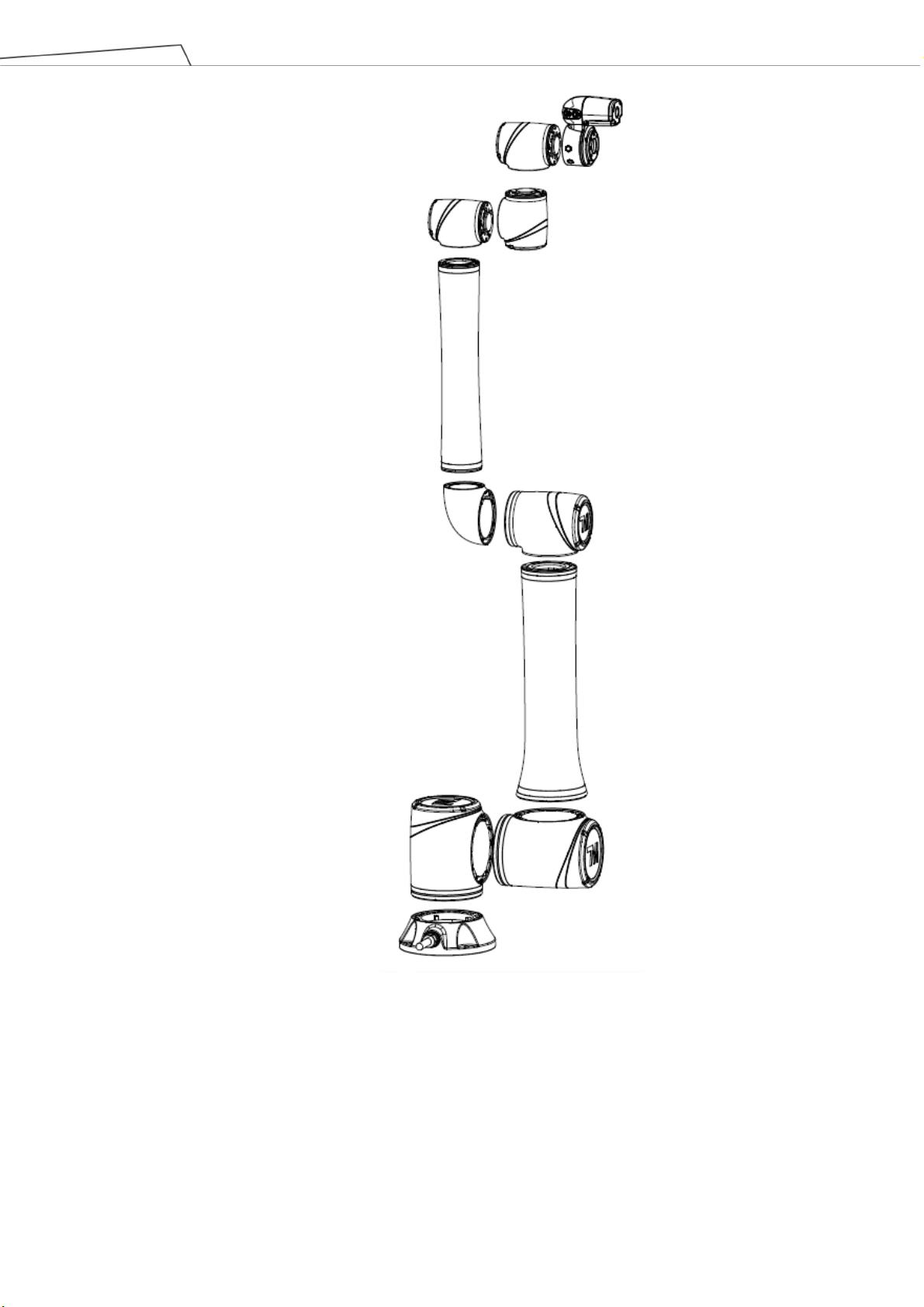

Figure 9: Assembly of TM12 / TM12M .............................................................................................................. 23

Figure 10: Assembly of TM14 / TM14M ............................................................................................................ 24

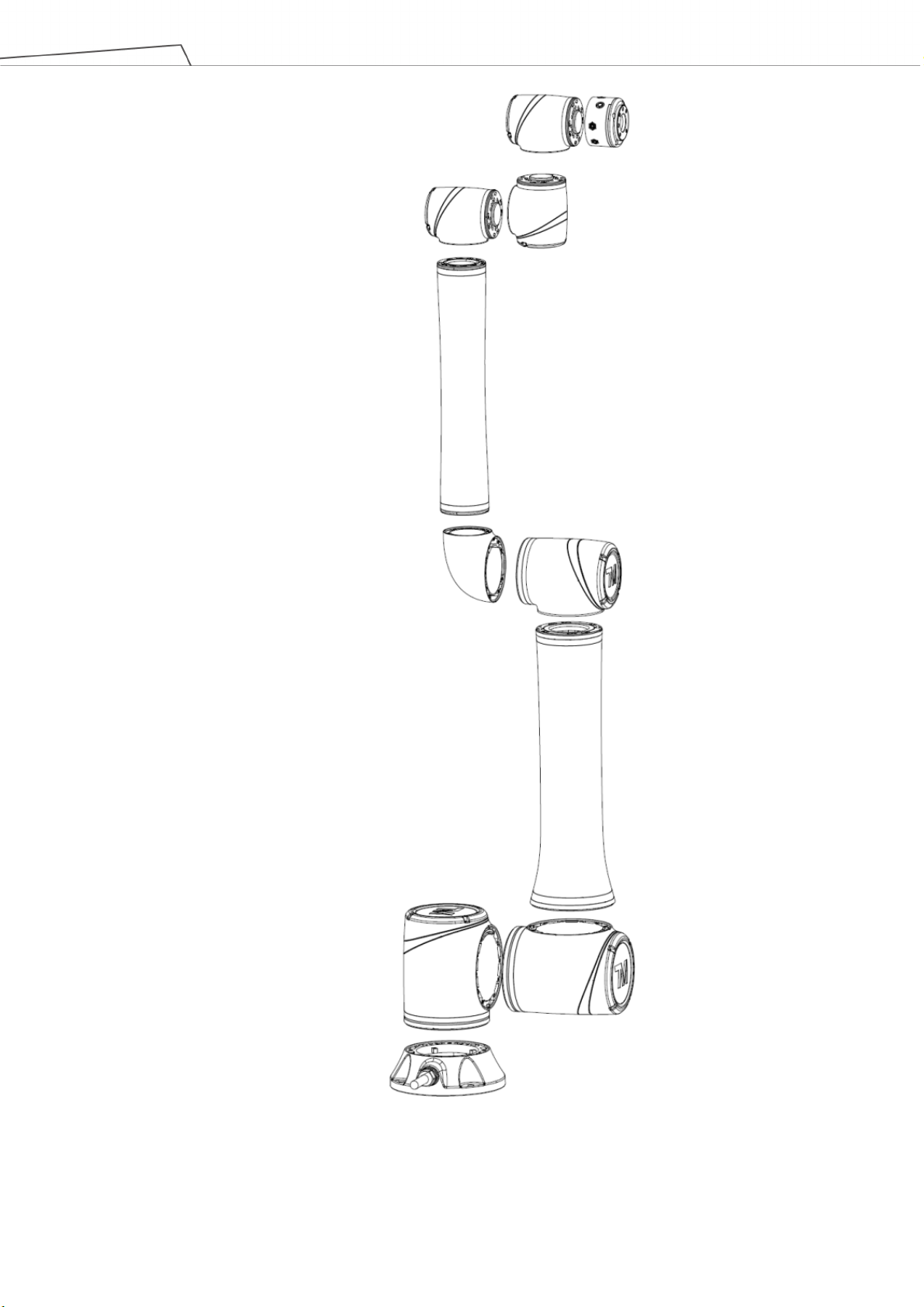

Figure 11: Assembly of TM12X ......................................................................................................................... 25

Figure 12: Assembly of TM14X......................................................................................................................... 26

Figure 13: Side View of TM12 / TM12M / TM12X Movement Range Diagram ................................................ 27

Figure 14: Pictorial view of TM12 / TM12M / TM12X Movement Range Diagram ........................................... 28

Figure 15: Top view of TM12 / TM12M / TM12X Movement Range Diagram .................................................. 28

Figure 16: Side view of TM14 / TM14M / TM14X Movement Range Diagram ................................................. 29

Figure 17: Pictorial view of TM14 / TM14M / TM14X Movement Range Diagram ........................................... 29

Figure 18: Top View of TM14 / TM14M / TM14X Movement Range Diagram .................................................. 30

Figure 19: Robot Hazard Zone Diagram and Operator Position Diagram of TM12 / TM12M / TM12X ........... 31

Figure 20: Robot Hazard Zone Diagram and Operator Position Diagram of TM14 / TM14M / TM14X ........... 32

Figure 21: Relationship between Payload and the Center of Gravity Offset in TM12 / TM12M / TM12X ........ 33

Figure 22: Relationship between Payload and the Center of Gravity Offset in TM14 / TM14M / TM14X ........ 33

Figure 23: Bottom View of Robot Base ............................................................................................................ 35

Figure 24: Securing the ground wire with the robot .......................................................................................... 35

Figure 25: References of TM12 / TM12M / TM14 / TM14M End Module Components ................................... 36

Figure 26: References of TM12X / TM14X End Module Components ............................................................. 37

Figure 27: References of End Flange Surface ................................................................................................. 38

Figure 28: The Exterior and Diagram of the Control Box ................................................................................. 39

Figure 29: Securing the ground wire with control box ...................................................................................... 40

Figure 30: Robot Stick ...................................................................................................................................... 40

Figure 31: Light Module Surface ...................................................................................................................... 42

Figure 32: Calculation the Torque Load of the Light Module ............................................................................ 43

Figure 33: Electrical Polarity of Fill Light Cable ................................................................................................ 44

Figure 34: Top View of TM Robot Placed on the AGV/AIV ............................................................................... 45

Figure 35: Working Distance and Field of View of TM Robot’s EIH camera .................................................... 46

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 6

Page 7

Figure 36: Control Box I/O Configuration (1/2) ................................................................................................. 47

Figure 37: Control Box I/O Configuration (2/2) ................................................................................................. 48

Figure 38: Safety Input Connector .................................................................................................................... 49

Figure 39: The Wiring Diagram Example of Switch Type Safety Device. ......................................................... 50

Figure 40: The Wiring Diagram Example of PNP Output Type Safety Device ................................................. 50

Figure 41: The Wiring Diagram Example of PNP Output Type Safety Device ................................................. 51

Figure 42: Safety Output Connector ................................................................................................................. 52

Figure 43: Safety Output Connector Wiring Diagram ....................................................................................... 52

Figure 44: Power Connector ............................................................................................................................. 53

Figure 45: Digital Input ...................................................................................................................................... 54

Figure 46: Set to Sink Input Type ..................................................................................................................... 54

Figure 47: Set to Source Input Type ................................................................................................................. 55

Figure 48: Digital Output ................................................................................................................................... 55

Figure 49: Set to Sink Output Type .................................................................................................................. 56

Figure 50: Set to Source Output Type .............................................................................................................. 57

Figure 51: Analog In .......................................................................................................................................... 57

Figure 52: Analog Out ....................................................................................................................................... 58

Figure 53: System Remote Power ON/OFF ..................................................................................................... 58

Figure 54: EtherCAT ......................................................................................................................................... 59

Figure 55: Connecting Tool End Digital Output ................................................................................................ 61

Figure 56: Connecting Tool End Digital Input ................................................................................................... 62

Figure 57: Connecting Tool End Analog Input .................................................................................................. 62

Figure 58: Front View of the Control Box ......................................................................................................... 63

Figure 59: Interfaces of the TM12 / TM14 / TM12X / TM14X Series ................................................................ 63

Figure 60: Interfaces of the TM12M / TM14M Series ....................................................................................... 64

Figure 61: Interfaces of the TM12M SEMI / TM14M SEMI Series ................................................................... 64

Figure 62: Control Box Power Interfaces .......................................................................................................... 65

Figure 63: Robot Interface ................................................................................................................................ 66

Figure 64: The TM12M SEMI / TM14M SEMI SEMI Emergency Off Interface .............................................. 67

Figure 65: Detachable I/O Panel ...................................................................................................................... 68

Figure 66: Robot Arm Carton ............................................................................................................................ 70

Figure 67: Control Box Carton .......................................................................................................................... 70

Figure 68: Moving the Control Box (1/2) ........................................................................................................... 74

Figure 69: Moving the Control Box (2/2) ........................................................................................................... 75

Figure 70: Moving the Robot Arm (1/2) ............................................................................................................ 76

Figure 71: Moving the Robot Arm (2/2) ............................................................................................................ 76

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 7

Page 8

Figure 72: Connecting the Robot and the Control Box ..................................................................................... 77

Figure 73: Air Filter Tray ................................................................................................................................... 79

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 8

Page 9

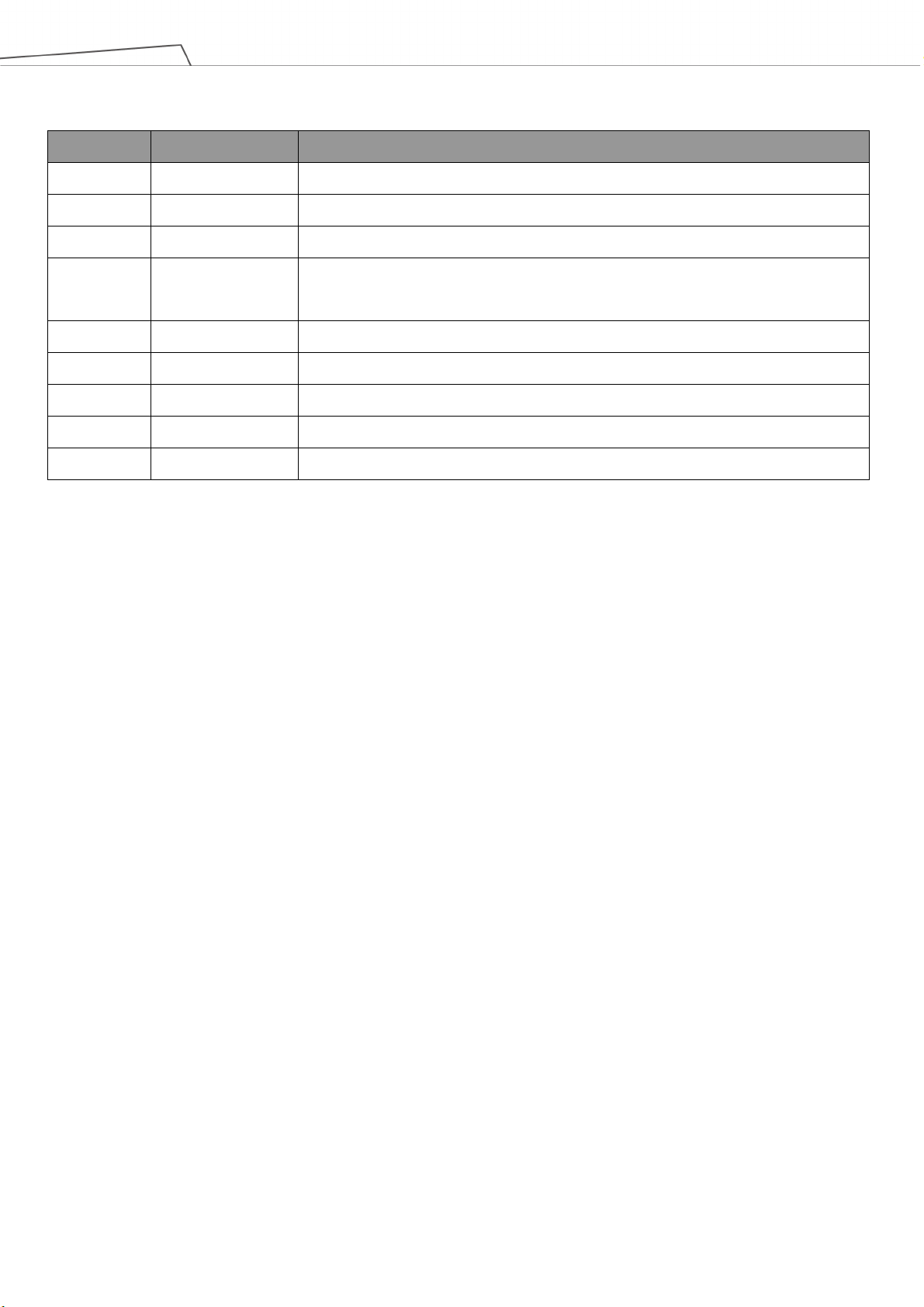

Revision History Table

Revision Date Revised Content

01 October 2018 Original release

02 December 2018 Updated cover page, minor test fixes

03 August 2019 Minor text fixes. Added cables length

04 August 2019

05 December 2019 Added Hardware 3.2 changes

06 January 2020 Updated Chapter 6.3

07 April 2020 Minor text fixes. Added product brief information

08 August 2020 Added Warning Indications

09 February 2021 Added Omron Landmark

Updated Table of Rated Torque and Limit for Repeated Peak Torque.

Added X Model information.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 9

Page 10

1. Product Dscription

1.1 Product Description

The TM Robot is a six-axis robot with power and force limiting function featuring simple programming, innovative

integrated vision capabilities together with the latest safety functionality to run at full speed with barriers and

operate in collaborative workspace.

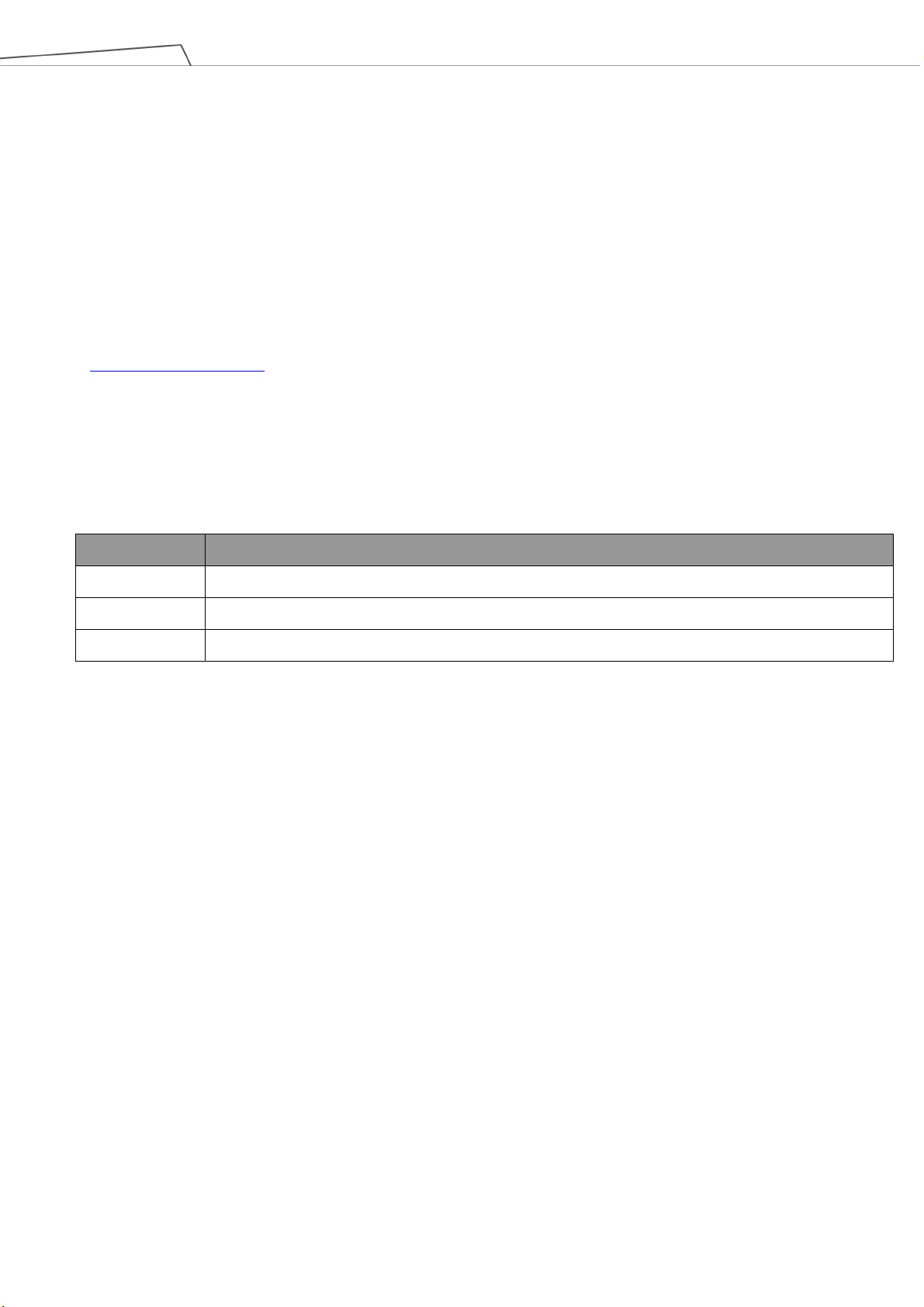

1.2 How Can I Get Help?

You can access information sources on the corporate website:

http://www.ia.omron.com/

Related Manuals

This manual covers the hardware installation, operation and user maintenance of TM Robot. See the following

table for additional available manuals.

Manual Title Description

Safety Manual Contains safety information for TM Robots.

TMflow Instructions for use of TMflow software.

TMvision Instructions for use of TMvision software.

Table 1: Manual Title & Description

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 10

Page 11

serious injury, and might result in death or severe property damage.

moderate injury, and might result in serious injury, death, or significant property damage.

injury, moderate injury, or property damage.

Read Manual and Impact Warning Labels

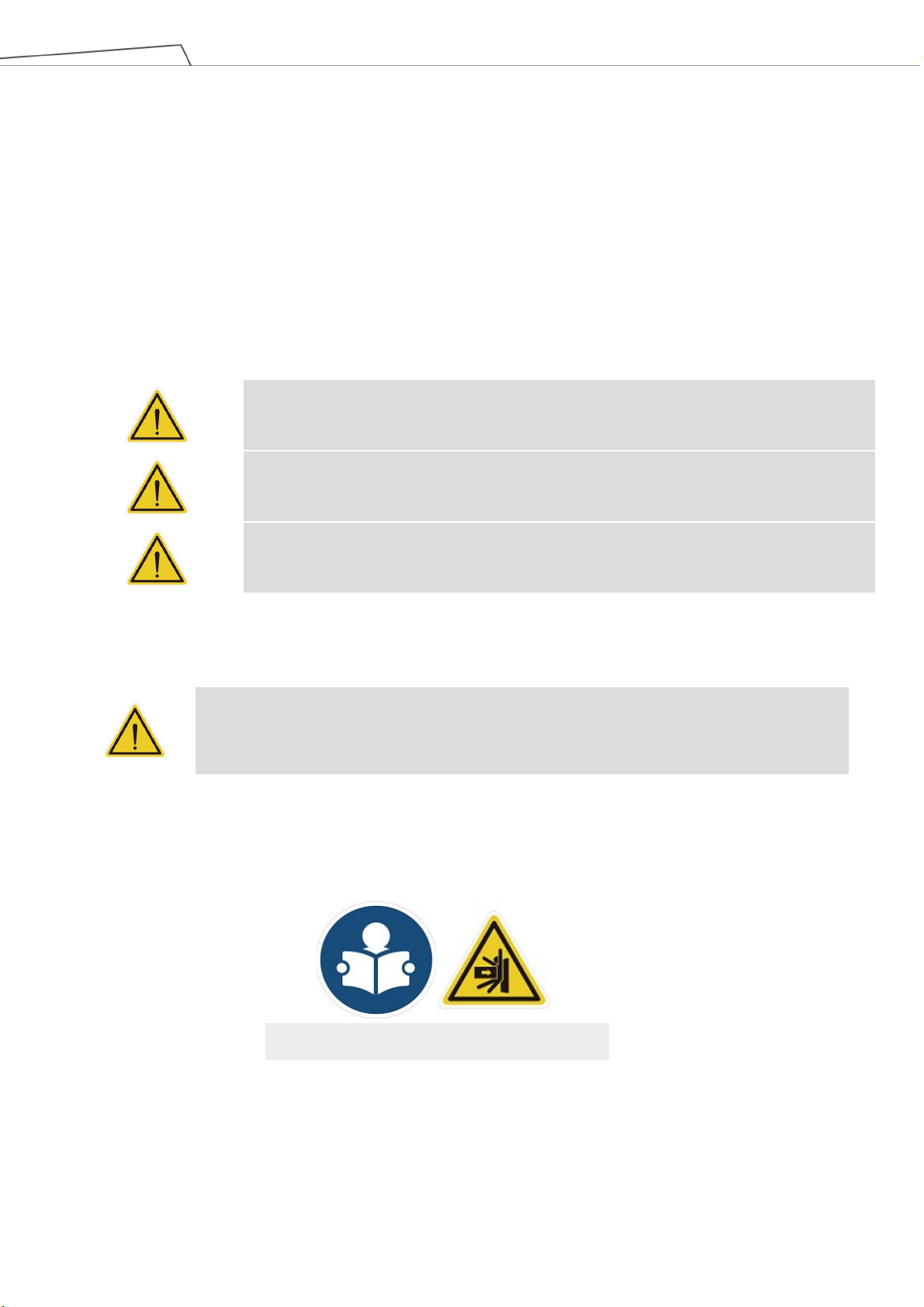

2. Safety Information

2.1 Overview

Users should read, understand and abide by the safety information provided in this manual before using the TM

Robot.

2.2 Warning and Caution Symbols

The Table below shows the definitions of the warning and caution levels used in this manual. Pay close attention

to them when reading the manual, and observe them to avoid personal injuries or equipment damage.

DANGER:

Identifies an imminently hazardous situation which, if not avoided, is likely to result in

WARNING:

Identifies a potentially hazardous situation which, if not avoided, will result in minor or

CAUTION:

Identifies a potentially hazardous situation which, if not avoided, might result in minor

Table 2: Danger, Warning, and Caution Symbols

2.3 Safety Precautions

DANGER:

This product can cause serious injury or death, or damage to itself and other equipment, if the

following safety precautions are not observed.

All personnel who install, operate, teach, program, or maintain the system must read the Hardware

installation Manual, Software Manual, and Safety Manual according to the software and hardware version of

this product, and complete a training course for their responsibilities in regard to the robot.

All personnel who design the robot system must read the Hardware installation Manual, Software Manual,

and Safety Manual according to the software and hardware version of this product, and must comply with all

local and national safety regulations for the location in which the robot is installed.

The TM Robot must be used according to its intended use.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 11

Page 12

This product is a partly complete machine. The design and installation of the complete system

and prevent major hazards from occurring in the complete system.

Results of the risk assessment may require the use of additional risk reduction measures.

Power to the robot and its power supply must be locked out and tagged out or have means to control

hazardous energy or implement energy isolation before any maintenance is performed.

Dispose of the product in accordance with the relevant rules and regulations of the country or area

where the product is used.

2.4 Validation and Liability

The information contained herein neither includes how to design, install, and operate a complete robotic arm

system, nor involves the peripherals that may affect the safety of the complete system. The integrators of the robot

should understand the safety laws and regulations in their countries and prevent hazards from occurring in the

complete system.

This includes but is not limited to:

Risk assessment of the whole system

Adding other machines and additional risk reduction measures based on the results of the risk assessment

Using appropriate software safety features

Ensuring Users will not modify any safety measures

Ensuring all systems are correctly designed and installed

Clearly labeling user instructions

Clearly marking the contact information for the integrator

Making relevant documents accessible, including the risk assessment, and this manual

CAUTION:

must comply with the safety standards and regulations in the country of use. Users and

integrators of the robot should understand the safety laws and regulations in their countries

2.5 Limitations on Liability

Even if the safety instructions are followed, any safety information in the manual shall not be considered as a

guarantee that the product will not cause any personal injury or property damage.

2.6 General Safety Warning

1. The noise measured in a factory setting is about 49.3 dB (A) without production. (Measured 1m from the robot

and 1.6m above the floor, at 80% of maximum speed). If the sound pressure is over 80 dB(A) while operating,

wear proper ear protection.

2. Environmental Conditions:

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 12

Page 13

Ambient air temperature: 0˚C ~ +50˚C

Ambient relative humidity: < 85%

Transportation & Storage condition: -20˚C ~ +60˚C

Transportation & Storage humidity: < 75%

The robot needs to be protected from shock or vibration

Observe ESD precautions when installing or removing robot

2.7 Risk Assessment

Before installing or using this product, Users must first carry out the necessary risk assessment based on the

conditions of use, and pay attention to the potential remaining risk addressed by the Corporation. Refer to and

abide by the relevant chapters in Safety Manual in accordance with its software and hardware version.

2.8 Emergency Stop

If any accidents occur during the operation of the robot, Users can stop all movement by pressing the Emergency

Stop switch. When the robot stops, Users must ensure that all hazards are eliminated before manually restarting

the robot. The Emergency Stop switch is only for use in critical conditions. To stop the robot during normal

operations use the Stop Button on the system controller. When Users presses the Emergency Stop switch, the TM

Robot will disconnect power from the robot and activate the brakes after the robot motion is stopped. The

indication light ring of the robot will not display light, and the three lights from the robot stick will be constantly

blinking.

Once the risk assessment has been conducted, if an Emergency Stop switch needs to be installed, the selected

device must comply with the requirements of IEC 60204-1. After an Emergency Stop, factory reset, or any other

safety incident, refer and abide by the relevant chapters in Safety Manual in accordance with its software and

hardware version.

2.9 Movement without Drive Power

Robot without Drive Power could be found in three circumstances: Emergency stop, when disengaging packaging

posture to initial booting, and power loss. The first two could enter Safe Start up Mode by means of releasing the

Emergency Switch; the latter one is when robot loses external power. Regarding how to operate as well as safety

precautions refer and abide by the relevant chapters in the Safety Manual.

If the robot loses power, and joints need to be moved in order to clear error conditions, you will need to release

the brake for each joint as follows:

1. Remove joint cover screws (M3, Torx-T10) and joint cover.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 13

Page 14

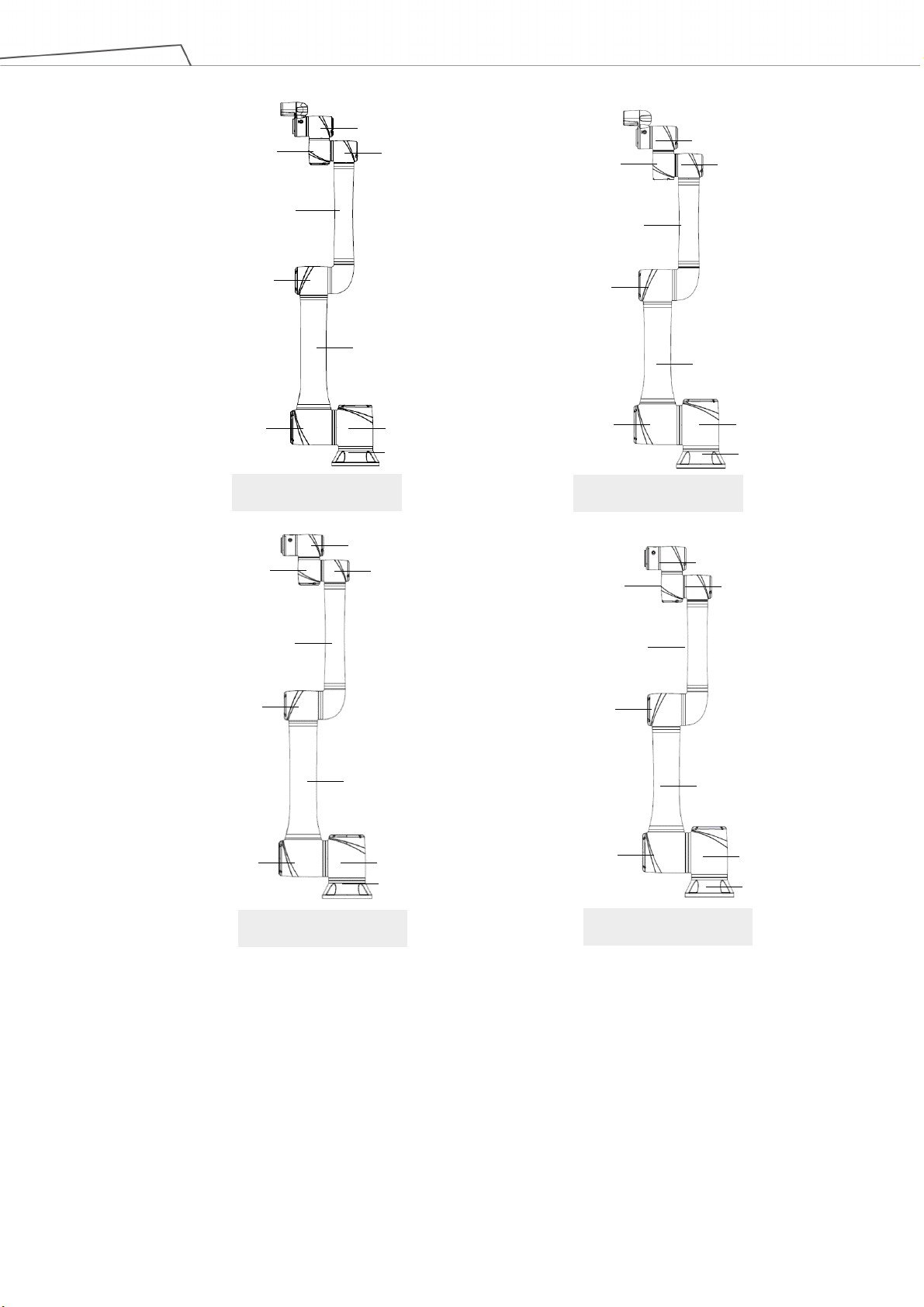

TM12 / TM12M

TM14 / TM14M

2nd Joint

3rd Joint

TM12X

1st Joint

2nd Joint

6th Joint

TM14X

6th Joint

5th Joint

Lower arm

3rd Joint

2nd Joint

5th Joint 4th Joint

4th Joint

Upper arm

1st Joint

Base

5th Joint

Lower arm

5th Joint

6th Joint

4th Joint

Upper arm

1st Joint

Base

6th Joint

4th Joint

Lower arm

3rd Joint

Upper arm

Base

Lower arm

3rd Joint

2nd Joint

Figure 1: References of Joints by Models

2. Release the brake by pushing the pin on the brake solenoid shown in the following figures.

Upper arm

1st Joint

Base

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 14

Page 15

when manually releasing the brake.

+/- 45。.

1st / 2nd Joint

3rd Joint

4th / 5th /6th Joint

Figure 2: Reference of Brake Solenoid by Joints

WARNING:

1. Due to gravity, additional supports are recommended

2. When manually moving each robot joint, the movement angle must be within a range of

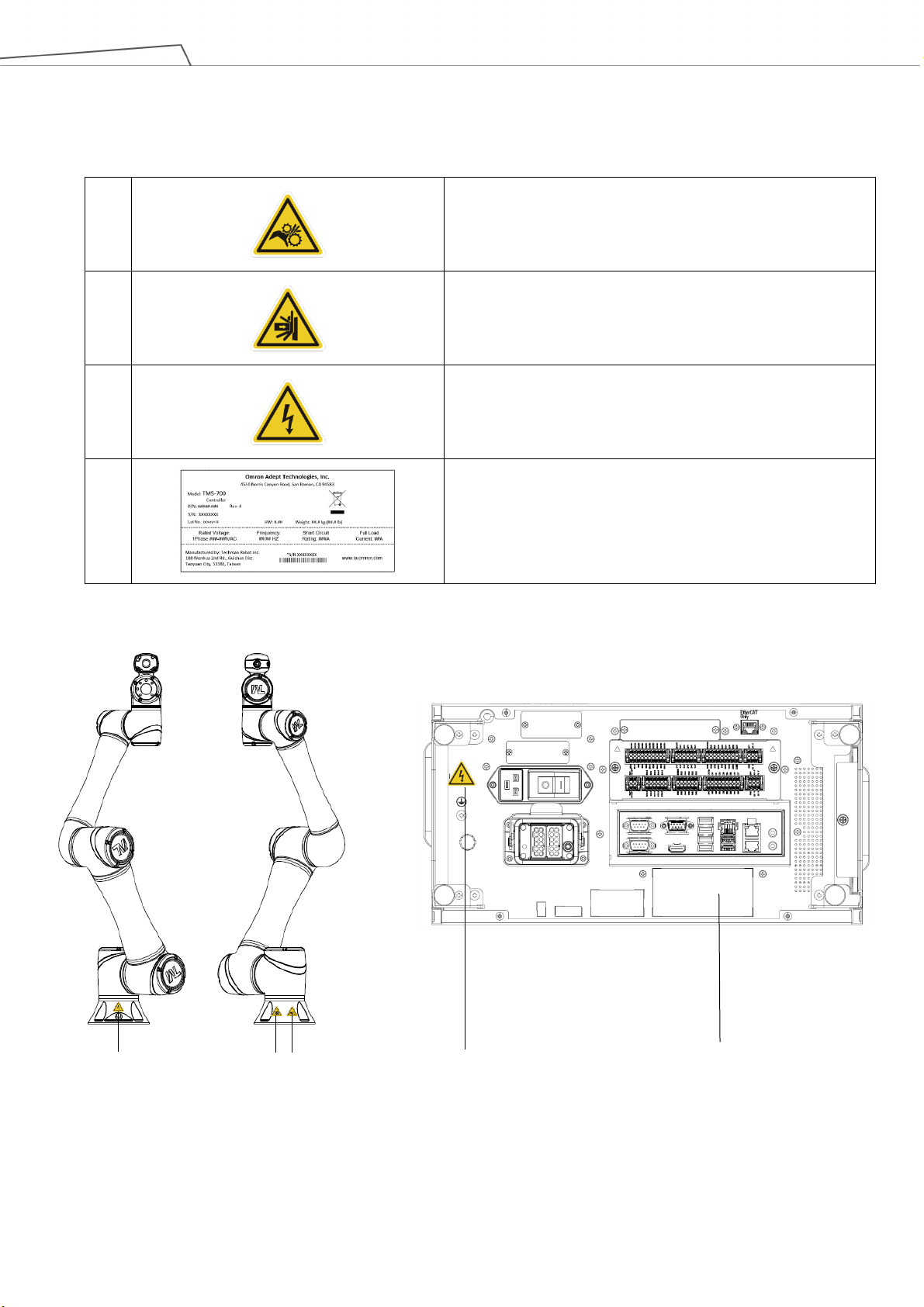

2.10 Labels

The following labels, especially the warning ones, are attached to the locations where specific dangers may occur.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 15

Page 16

c parts to avoid electric

Be sure to comply with description and warnings of the labels when operating to avoid accidents. Do not tear,

damage, or remove the labels. Be very careful if you need to handle the parts where the labels are attached.

A

Do not put your hand or fingers close to moving parts

Be careful not to be close to the moving parts and nearby

B

areas to avoid impact

Do not touch any internal electri

C

shock

D

Product label

Table 3: Denotation of Labels

C

B A

C

D

Figure 3: Locations of Labels

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 16

Page 17

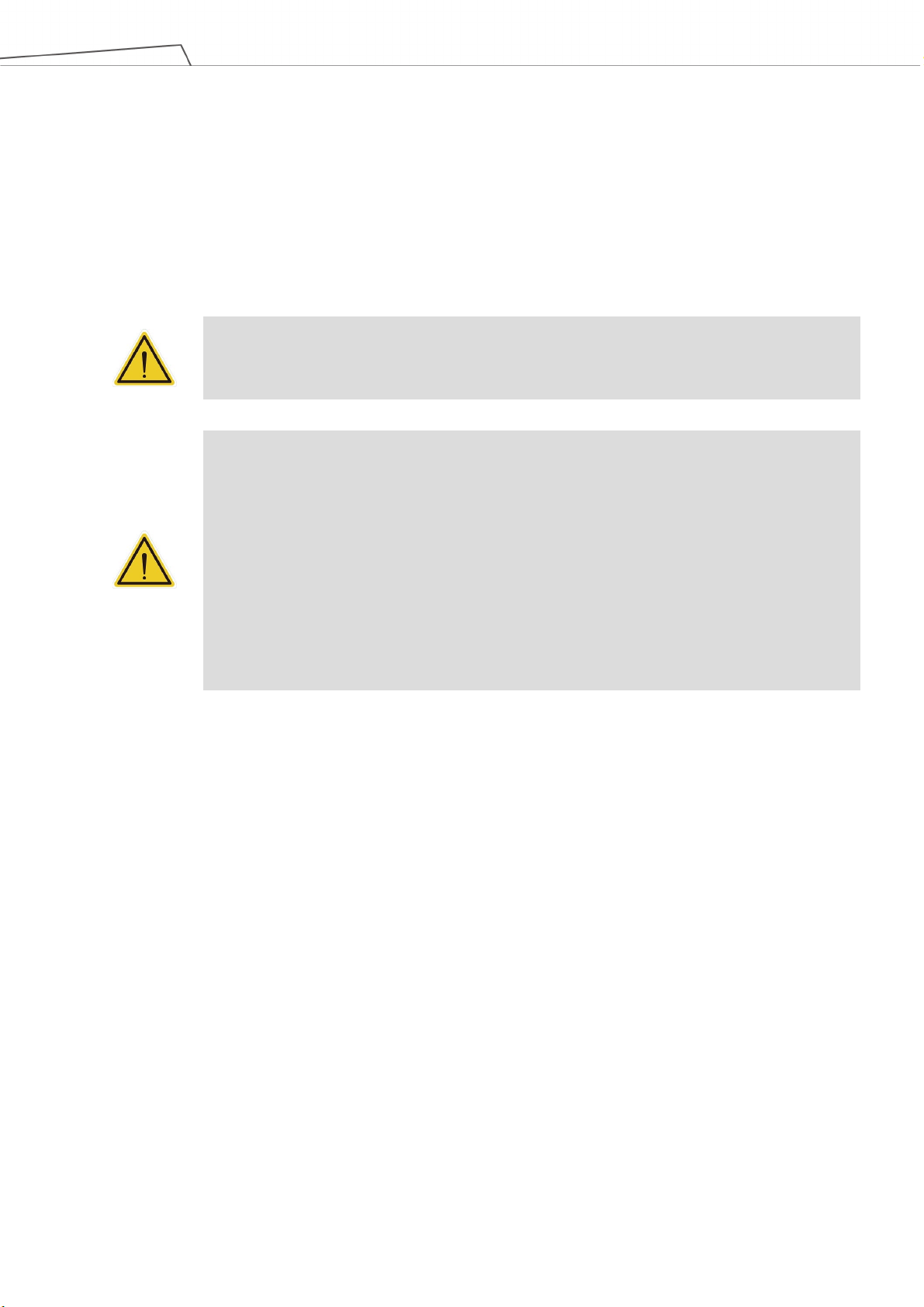

injury. The Corporation will not be liable for any injuries caused during transportation.

3. Transportation and Storage

Transport the TM Robot using its original packing materials. If you will need to transport the TM Robot after

unpacking, store the packing materials in a dry place. Hold both arms of the TM Robot during transportation.

Support the arms while tightening the base screws.

Lift the control box by its handles. Store the cables before transportation.

WARNING:

Pay attention to your posture when moving the arm and control box cartons to avoid back

WARNING:

This product must be shipped and stored in a temperature-controlled environment, within the

range -20°C to 60°C (-4°F to 140°F). The recommended humidity is up to 75 percent,

non-condensing. It should be shipped and stored in the supplied package, which is designed

to prevent damage from normal shock and vibration, You should protect the package from

excessive shock and vibration.

The product must always be stored and shipped in an upright position in a clean, dry area that

is free from condensation. Do not lay the package on its side or any other non-upright position.

This could damage the product.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 17

Page 18

Robot arm

Control Box

Robot Stick

4. System Hardware

4.1 Overview

This chapter introduces the mechanical interface of the TM Robot System.

4.2 System Overview

TM Robot is made up of the robot arm and control box (including a robot stick).

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 18

Page 19

4.2.1 Robot Arm

4.2.1.1 Dimension Drawings of Robot

Shown below is the dimension drawing of the robot

Figure 5: Dimension of TM12 / TM12M

*All measures are in mm.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 19

Page 20

Figure 6: Dimension of TM14 / TM14M

*All measures are in mm.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 20

Page 21

Figure 7: Dimension of TM12X

*All measures are in mm.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 21

Page 22

Figure 8: Dimension of TM14X

*All measures are in mm.

4.2.1.2 Robot Assembly Diagram

Shown below is an illustration of the robot components. To avoid safety risks, do not attempt to

disassemble any component on your own. Contact your local corporation support for any service

request.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 22

Page 23

Figure 9: Assembly of TM12 / TM12M

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 23

Page 24

Figure 10: Assembly of TM14 / TM14M

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 24

Page 25

Figure 11: Assembly of TM12X

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 25

Page 26

Figure 12: Assembly of TM14X

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 26

Page 27

enter to press any buttons on the robot stick.

TM12 / TM1M / TM12X Movement Range Diagram

4.2.1.3 Range of Motion

The working spherical (radius) range from the base is 1300 mm for the TM12 series and 1100 mm for

the TM14 series.

DANGER:

With the exception of an individual being in full control of robot motion during hand-guiding,

personnel shall be outside the safeguarded space when the robot is in motion while in manual

mode (i.e. teaching).

The emergency stop on the robot stick must be readily accessible during manual mode. At

least one emergency switch is installed outside of the motion range of the robot. When no

motion limit is set for the robot, the motion range of the robot is equal to the maximum motion

range of the robot arm. You can set a motion limit to avoid the situation whereby all operators

have to be outside of the maximum motion range of the robot arm.

The robot stick should be placed in an area that the robot cannot reach. Users should also

make sure that the movement of the robot will not be within any area where personnel will

Figure 13: Side View of TM12 / TM12M / TM12X Movement Range Diagram

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 27

*All measures are in mm.

Page 28

Operator Position

the operating area of the arm.

ning: Risk of collision within

the operating area of the arm.

Figure 14: Pictorial view of TM12 / TM12M / TM12X Movement Range Diagram

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 28

Warning: Risk of crushing within

War

Figure 15: Top view of TM12 / TM12M / TM12X Movement Range Diagram

*All measures are in mm.

Page 29

TM14 / TM14M / TM14X Movement Range Diagram

Figure 16: Side view of TM14 / TM14M / TM14X Movement Range Diagram

*All measures are in mm.

Pictorial view

Figure 17: Pictorial view of TM14 / TM14M / TM14X Movement Range Diagram

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 29

Page 30

Operator Position

Warning: Risk of crushing within

the operating area of the arm.

Warning: Risk of collision within

the operating area of the arm.

Figure 18: Top View of TM14 / TM14M / TM14X Movement Range Diagram

*All measures are in mm.

4.2.1.4 Robot Hazard Zone Diagram and Operator Position Diagram

Shown below is an illustration of the robot hazard zone and operator position diagrams. Do not operate

the robot while anyone is inside of the hazard zone to avoid safety risks.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 30

Page 31

Operator Position

the operating area of the arm.

Warning: Risk of crushing within

Warning: Risk of collision within

the operating area of the arm.

Figure 19: Robot Hazard Zone Diagram and Operator Position Diagram of TM12 / TM12M / TM12X

*All measures are in mm.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 31

Page 32

Operator Position

the operating area of the arm.

TM14 / TM14M / TM14X

Figure 20: Robot Hazard Zone Diagram and Operator Position Diagram of TM14 / TM14M / TM14X

4.2.1.5 Payload and Torque

The maximum allowed payload of the robot arm is related to its center of gravity offset, which is defined

as the distance from the center point of tool flange to the payload’s center of gravity.

The following figure shows the relationship between payload and the center of gravity offset:

Warning: Risk of crushing within

the operating area of the arm.

*All measures are in mm.

Warning: Risk of collision within

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 32

Page 33

TM12 / TM12M / TM12X

Payload [kg]

TM14 / TM14M / TM14X

Payload [kg]

Center of gravity offset [mm]

Figure 21: Relationship between Payload and the Center of Gravity Offset in TM12 / TM12M / TM12X

Center of gravity offset [mm]

Figure 22: Relationship between Payload and the Center of Gravity Offset in TM14 / TM14M / TM14X

Refer the table below for the rated torque and the limit of repeated peak torque of the robot. Exceeding

torque may reduce the life of the robot or damage the robot.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 33

Page 34

entire system.

screwed down before use. The strength of the

N reaction force to the

mounting surface and screws. In order to avoid decreased performance caused by robot

mm or less, its surface roughness should be Rz25 or

immerse TM Robot in water. Installation in water or a humid environment will

Model TM12 Series TM14 Series

Limit for repeated

Item Rated torque

J1

J2

J3

J4

J5

J6

Table 4: Rated Torque and Limit for Repeated Peak Torque of Regular Payload Robot Series

WARNING:

Use the total weight of the end-effector and the payload to stay within the payload rating of the

robot. Ensure that the system never exceeds that maximum payload. Users should perform a

full risk assessment that includes the end-effector and payload samples to prevent hazards

such as shocks, vibrations, collisions, entanglements, stabbings, and piercings to secure the

311

311

118

34

34

34

peak torque

353

353

157

54

54

54

Rated torque

311

311

118

41

41

34

Limit for repeated

peak torque

353

353

157

54

54

54

Unit: Nm

4.2.1.6 Robot Arm Installation

The robot can be secured to another surface with the use of (4) M10 screws and washers. The mounting

pattern is shown below. The recommended tightening torque is 40 Nm.

Optional - Two openings for 6 mm position pins are provided for more secure position mounting.

Ensure the strength of the mounting surface and its surround area before installations for upside down

mounting and side mounting such as on the ceiling or the wall. Wherever the installation takes place, the

robot setting remains equivalent.

DANGER:

1. The TM Robot must be securely and tightly

mounting surface must be sufficient.

When operating at high speed, the robot can generate up to 710

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 34

slip or vibration, the recommended mounting surface should be a steel plate at least 20

mm thick, its flatness should be 0.1

less. The recommended screw should be M10 x L30 mm, at least 8.8 strength.

2. Do not

permanently damage the robot.

Page 35

WARNING:

In contact with liquids with chemical substances such as chemical solvents, lubricants,

sanitizers, cleansers, etc. may cause damage to the joint covers or other components of the

robot.

Use the M4L5 pan head screw to secure the ground wire with the robot as shown below.

Figure 23: Bottom View of Robot Base

*All measures are in mm.

Figure 24: Securing the ground wire with the robot

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 35

Page 36

GRIPPER Button

Camera module

Flange (ISO 9409-1-50-4-M6)

Digital I/O

Indication Light Ring

Analog I/O

FREE Button

VISION Button

POINT Button

4.2.2 Robot End Module

4.2.2.1 End Module Components

TM12 / TM12M / TM14 / TM14M End Module Components

Figure 25: References of TM12 / TM12M / TM14 / TM14M End Module Components

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 36

Light module

Page 37

GRIPPER Button

Flange (ISO 9409-1-50-4-M6)

POINT Button

Digital I/O

Analog I/O

FREE Button

TM12X / TM14X End Module Components

Indication Light Ring

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 37

Figure 26: References of TM12X / TM14X End Module Components

Page 38

4.2.2.2 End Flange Surface

Analog l/O

Digital l/O

Camera

Figure 27: References of End Flange Surface

*All measures are in mm.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 38

Page 39

it may result in short circuits or irreparable damages at the bottom of the flange

L

Length of the screw to secure tools. Unit: ㎜

8

Depth of the thread in the screw hole at the end of the flange. Unit: ㎜

T

Thickness of the object to be fixed. Unit: ㎜

The application of mounting an actuator in the tool end with high vibration or impact may cause

cylinder/system with shock absorb/buffer/cushion design to prevent this.

4.2.2.3 End Mounting Caution

The TM12/14 Series uses four M6 threaded holes on the end flange and four M6 screws for mounting

tools. The strength of the M6 screw should be 8.8 or above, and the tightening torque of 9 Nm is

recommended. If your application requires higher precision, you can use two positioning pins with a

diameter of 6 mm for a more secure mounting.

DANGER:

1. Tools must be properly tightened when using this product. Improper tightening may

cause the tool or part to fall out, or even cause personal injury and death.

2. Follow the rule L ≤ 8 + T to choose the screw to secure tools at the end of the flange,

otherwise

leading to the relevant parts replacement.

4.2.2.4 End Indication Light Ring Table

4.2.3 Control Box

CAUTION:

damage to the robot. Design the tool with proper anti-vibration/impact such as

damping/cushion or shock absorber, or use low impact actuator such as pneumatic

The Indication Light Ring of the TM Robot has several colors which represent different modes and error

status. Refer to the Software Manual for the definition of the light colors.

Figure 28: The Exterior and Diagram of the Control Box

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 39

Page 40

Emergency Switch

Default emergency button for the robot

Power Button

Power initiation (single press)/ Shutdown (long press)

Button

Play/Pause Button

Play/Pause Project (single press)

Stop Button

Press this button to stop any project.

CAUTION:

The control box can be placed on the floor or in your working cell. Note that 5 cm clearance

should be left at both sides for ventilation.

Use the M4L6 screw to secure the ground wire with the control box as shown below.

Figure 29: Securing the ground wire with control box

4.2.3.1 Robot Stick

The Robot Stick has 6 function buttons, 3 indicator lights, 1 Emergency Switch, 1 set of speed indicator,

and 1 QR-code. Their functions are as follow:

Power Button

Power Indicator

Mode Indicator Lights

Stop Button

Emergency Switch

Figure 30: Robot Stick

CAUTION:

When operating the robot stick, do not use other objects than fingers to press the robot stick.

M/ A Mode Switch Button

+ Button

QR Code Label

- Button

Play/Pause Button

Speed Indicator

Items Basic Function

M/ A Mode Switch

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 40

Toggle Manual/Auto Mode (single press). See Safety Manual for details.

Page 41

See Safety Manual for details.

Constant: Startup completed

always be on.

10% such as 4 in blue and 1 in green equals to 45%.

QR Code Label

The content of the SSID is also the robot's name in TCP/IP network.

- Press and release to enter Safe Start up Mode while booting.

Play/Pause Button

Play/pause visual calibration operation (single press)

Stop Button

Stop visual calibration operation (single press)

to lock/unlock the Robot Stick (except the Power Button)

damage caused by pulling.

when any of

dusty and

3. Be noted that the control box can only be in standing pose for the IP32 rating.

+- Button

Power Indicator

Adjust project speed (single press) under Manual Trial Run Mode.

This indicator shows the robot's power status.

Not on: Switched off

Flashing: Booting

Mode Indicator

Lights

Speed Indicator

One is Manual Mode, the other one is Auto Mode. They show the

robot's current operating mode. Once boot up is complete only one will

Display the current project speed. Lit in green for 5% and in blue for

Table 5: Robot Stick Basic Functions

Items Advanced Function

- Press and release, and then wait for 3 seconds to enter Safe Start up

Emergency Switch

Mode.

- Hold to jog the robot at the HMI robot controller page (Hold to Run).

See Safety Manual for details.

+- Button

- Lock/ Unlock: press and hold both the + button and the - button until

the mode indicator light flashes, then follow the sequence "-, +, -, -, +

"

CAUTION:

The robot stick is magnetic so that it can be attached to iron or steel surfaces. However, the risk

of falling or rotating caused by poor attachment should be taken into account. It is

recommended using the Robot Stick Stand (official accessory) to secure the robot stick. The

Robot Stick Stand should be fixed with screws. Always attach the robot stick when it is not in

use. The robot stick should be placed in a way such that the signal cables are routed to avoid

DANGER:

1. The control box, cables, power signal cables, and robot stick cannot be used

them is in contact with liquids. This may result in personal injury or death.

2. The control box comes with the IP32 rating, but it is not recommended to use in

humid environments. Pay extra attention to environments with conductive dust (such as

metal particles).

Table 6: Robot Stick Advanced Functions

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 41

Page 42

4.2.4 Robot Light Module

4.2.4.1 Light Module Surface

4.2.4.2 Install Light Module

The light module uses 4 of M3 screws to fix, and the recommended tightening torque is 1 Nm. For higher

accuracy on usages in demand, use both of the 2 mm diameter openings with the positioning pins to get

the better steadiness. Users can replace the light module by applications in demand. The choice

depends on the torque load of the light module, the available load of the robot, the possible influence the

other light module made to the camera's field of view, and the electrical specifications.

1. The torque load of the light module (M): this torque load must be lower than 900 kgfmm, which is

the available strength of the camera module M3 screw can be loaded.

Calculation formula: M = (L+59.2)*W

The weight of the light module W kgf

Figure 31: Light Module Surface

*All measures are in mm.

The center of gravity of the light module L mm

Table 7: Reference of the Symbol and Unit in Calculation the Torque Load of the Light Module

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 42

Page 43

Light Module

Figure 32: Calculation the Torque Load of the Light Module

2. The maximum allowed payload of the robot: the weight of the light module must match the relative

relationship between the maximum allowed payload and the center of gravity offset distance. If the

tool end flange goes with additional applications, it is required to generate the equivalent center of

gravity for its position and total load from the combination of the light module and the application

tool as well as follow 4.2.1.5 Payload and Torque of this manual.

3. Refer to 4.4 for Working distance and field of view of TM Robot’s EIH camera.

4. Electrical Specification of the Light Module

Voltage:

24V

Current:

< 900mA

The total current of the tool end and the light module has to be lower than 1.5A.

Table 8: Electrical Specification of the Light Module

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 43

Page 44

users replace with the other light modules.

Fill light cable:

(+)

(-)

Figure 33: Electrical Polarity of Fill Light Cable

Connector:

Dimming mode:

2P/1.5 mm pin pitch. Refer to JST model ZHR-4 series.

PWM control

NOTE:

The robot comes with the IP54 rating, but the Corporation does not guarantee this rating if

DANGER:

Be aware that the tool must be correctly and firmly secured to use with this product; otherwise,

personal injuries or death may occur should the tool or the workpiece fall.

4.3 Operating Position of TM Robot with AGV/AIV

When TM Robot is placed on an AGV/AIV in operation, the TM Robot should be paused and should not exceed

the footprint of the AGV/AIV.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 44

Page 45

AGV/AIV Footprint

Figure 34: Top View of TM Robot Placed on the AGV/AIV

4.4 Working distance and field of view of TM Robot’s EIH camera

The field of view of TM Robot’s EIH camera varies linearly in accordance with the working distance. The minimum

working distance is about 100 mm and the maximum working distance is about 300 mm. The zero working

distance point is approximately 49 mm in front of the flange surface and right behind the center of the protection

lens.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 45

Page 46

46.5

Working distance = 0

Figure 35: Working Distance and Field of View of TM Robot’s EIH camera

*All measures are in mm.

The relation between the working distance and the field of view is listed below.

Working distance (mm)

300 100

Field of view (mm)

Width

Height

281.6 96.9

211.2 72.7

Table 9: The Relation between the Working Distance and the Field of View

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 46

Page 47

Ensure all pieces of the equipment are kept dry. If water enters the equipment, disconnect

fire or electric shock.

install while arm is on to avoid abnormal shutdown.

Control Box I/O configuration

5. Electrical Interface

5.1 Overview

This chapter introduces all electrical interfaces of the robot arm and control box.

5.2 Electrical Warnings and Cautions

The application design and installation of the robot should comply with the following warnings.

DANGER:

1.

the power and contact your supplier.

2. Only use the original cables included with the robot. If you need longer cables, contact

your supplier.

3. Ensure that the robot is properly grounded. If the grounding is not correct, it may cause a

5.3 Control Box

WARNING:

The I/O cables used for the link between the control box and other pieces of equipment

should not be longer than 30 meters, unless testing shows that longer cables are feasible.

WARNING:

Except for USB ports, other interfaces have to be installed while arm is powered off. Do not

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 47

Figure 36: Control Box I/O Configuration (1/2)

Page 48

Figure 37: Control Box I/O Configuration (2/2)

Input Output

Safety

Connector

SI0-1

SI0-2

SI1-1

SI1-2

SI2-1

SI2-2

SI3-1

SI3-2

Definition SF Input

User Connected

SF1

ESTOP Input

User Connected

External Safeguard

SF3

Input

User Connected

External Safeguard

Input for Human–

SF9

Machine Safety

Settings

User Connected

Enabling Device

SF15

Input

Safety

Connector

SO0-1

SO0-2

SO1-1

SO1-2

SO2-1

SO2-2

SO3-1

SO3-2

Definition SF Output

Robot ESTOP

SF10

Output

User Connected

External Safeguard

SF11

Output

User Connected

External Safeguard

Output for Human–

SF12

Machine Safety

Settings

Robot Internal

Protective Stop

SF13

Output

User Connected

SI4-1

SI4-2

ESTOP Input without

Robot ESTOP

SF16

SO4-1

SO4-2

Robot Encoder

SF14

Standstill Output

Output

Table 10: Definitions of Safety Connectors

NOTE:

For details about safety functions, please refer to the Safety Manual.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 48

Page 49

5.3.1 Safety Connector

Safety I/O comes with dual redundant channel connector and has to keep both channel input/output the

same value simultaneously. Single fault on either one of the single channel will not result in failure of

safety functions.

5.3.1.1 Safety Input Connector

1. User Connected ESTOP Input Port is a N.C. contact (Normally closed). When User Connected

ESTOP Input Port is OPEN, the robot enters the Emergency STOP state.

2. User Connected External Safeguard Input Port is a N.C. contact (Normally closed). When User

Connected External Safeguard Input Port is OPEN, the robot enters the Protective Stop state.

3. User Connected External Safeguard Input Port for Human–Machine Safety Settings is a N.C. contact

(Normally closed). When User Connected External Safeguard Input Port for Human–Machine Safety

Settings is OPEN, the robot decrease the limits to which is set in Human-Machine Safety Settings

4. User Connected Enabling Device Input Port is an N.C. contact (Normally closed). When User

Connected Enabling Device Input Port is OPEN in Manual mode, the robot is unable to present

manual control operation. When User Connected Enabling Device Input Port is CLOSED in Manual

mode, the robot is able to present manual control operation.

5. User Connected ESTOP Input Port without Robot ESTOP Output functions as the User Connected

ESTOP Input Port above, but it does not trigger the function of Robot ESTOP output.

Figure 38: Safety Input Connector

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 49

Page 50

Figure 39: The Wiring Diagram Example of Switch Type Safety Device.

Figure 40: The Wiring Diagram Example of PNP Output Type Safety Device

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 50

Page 51

Figure 41: The Wiring Diagram Example of PNP Output Type Safety Device

5.3.1.2 Safety Output Connector

1. Robot ESTOP Output Port. When the robot triggers the Robot (stick) Emergency Stop signal, the

output will be LOW.

2. User Connected External Safeguard Output Port. When the robot triggers the User Connected

External Safeguard Input, the output will be LOW.

3. User Connected External Safeguard Output Port for Human–Machine Safety Settings. When the

robot triggers the User Connected External Safeguard Input for Human–Machine Safety Settings,

the output will be LOW.

4. Robot Internal Protective Stop Output Port. When the robot triggers the internal Protective Stop,

the output will be LOW.

5. Robot Encoder Standstill Output Port. When the Encoder Standstill is not monitoring (robot is

moving), the output will be LOW.

For details about the safety functions, please refer to the Safety Manual.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 51

Page 52

check the safety functions for a regular basis.

Figure 42: Safety Output Connector

Figure 43: Safety Output Connector Wiring Diagram

DANGER:

1. Do not connect the safety signals to a non-safety device without the fulfilled safety level.

Failure to do so may result in injury or death due to a malfunction of the safety stop.

2. All safety I/Os come with dual redundant channel connectors. Maintain both redundant

channels while pairing and connecting to make sure that single fault on either one of the

single channel will not result in failure of safety functions.

3. Before putting to use the robot, be sure to check the safety functions and schedule to

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 52

Page 53

5.3.2 Power Connector

1. During boot, the control box will check for an external 24V input. If none is found, then it will switch to

the internal 24V supply.

2. The control box itself offers a 24V/2A output (24_EX). If the 24V load exceeds 2A, it enters Safe Mode

and disables the 24V output.

3. EX24V provides an external 24V input port. If the load exceeds 2A an external power supply can be

used instead. The load on EX24V must not exceed 3.5A.

5.3.3 Digital In/Out

Digital input/output each has 16 channels, and its application is connected to the following sections.

5.3.3.1 Digital Input

Figure 44: Power Connector

Inputs can be set to either sink input or source input by selection.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 53

Page 54

Figure 45: Digital Input

Set to sink input type

When a device such as a transistor output sensor is connected, NPN open collector transistor output

can be used.

Figure 46: Set to Sink Input Type

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 54

Page 55

Set to Source input type

When a device such as a transistor output sensor is connected, PNP open collector transistor output can

be used.

Figure 47: Set to Source Input Type

5.3.3.2 Digital Output

Outputs can be set to either sink output or source output by selection.

The maximum drive current is 300mA per channel. If the load exceeds 300mA, a relay should be used to

drive it.

Figure 48: Digital Output

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 55

Page 56

Set to sink output type

Connect DO_COM terminal to the minus side of the power supply.

Figure 49: Set to Sink Output Type

Set to source output type

Connect DO_COM terminal to the plus side of the power supply.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 56

Page 57

5.3.4 Analog In

Figure 50: Set to Source Output Type

Figure 51: Analog In

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 57

Page 58

5.3.5 Analog Out

Figure 52: Analog Out

Range Resolution Accuracy Conversion Time

Analog In +10.00V~-10.00V 11bit ≤ 0.2% 1 ms

Analog Out +10.00V~-10.00V 11bit ± 0.07% 1 ms

5.3.6 System Remote Power ON/OFF

The function of Remote ON/OFF shares the same functionality of the Robot Stick Power Button.

Table 11: Analog In & Analog Out

Figure 53: System Remote Power ON/OFF

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 58

Page 59

connector while the robot is on.

5.3.7 EtherCAT: For EtherCAT Slave I/O Expansion

WARNING:

The robot must be powered off when installing the EtherCAT Slave. Do not plug or unplug the

5.3.8 USB Port

The USB port of the control box is used for connecting the keyboard, mouse and external storage devices.

External storage devices should only be used for the import/export functions of TMflow. No other device

Figure 54: EtherCAT

than those listed above should be connected. Be noted that the external storage device should be labelled

TMROBOT.

5.4 Tool End I/O Interface

There are two small connectors on the tool end of the robot: the 8-pin connector is for digital I/O and the 5-pin

connector is for analog I/O.

5.4.1 I/O Terminals

The tool end 24V has a total maximum output current of 1.5A included 900mA of the light module. If

overloaded, overload protection is activated and the robot will turn off the 24V output power.

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 59

Page 60

Pin Wire color Pin define

1 Brown +24v 24V output

2 Red DI_0 Digital Input0

3 Orange DI_1 Digital Input1

4 Yellow DI_2 Digital Input2

Digital

5 Green DO_0

Output0

Digital

6 Blue DO_1

Output1

Digital

7 Purple DO_2

Output2

8 Black +0V +0v

*The M8/8PIN connector complies with the regulation of IEC 61076-2-104.

Table 12: 8-pin Digital I/O Connectors of Cable

Pin Wire Color Pin Define

1 Brown +24v 24V output

2 Red DI_0 Digital intput0

3 Orange DI_1 Digital intput1

4 Yellow DI_2 Digital intput2

5 Green DO_0

6 Blue DO_1

7 Purple DO_2

8 Black +0V +0V

Digital

outtput0

Digital

outtput1

Digital

outtput2

Table 13: 8-pin Digital I/O Connector of Robot

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 60

Page 61

Pin Wire Color Pin Define

1 Black +24V 24V output

2 Brown DI_3 Digital Input3

3 Red DO_3

Digital

Output3

4 Orange AI Analog Input

5 Yellow +0V GND

*The M8/5PIN connector complies with the regulation of IEC 61076-2-104.

Table 14: 5-pin Analog I/O Connector of Cable

Pin Wire Color Pin Define

1 Black +24V 24V output

2 Brown DI_3 Digital Input3

3 Red DO_3 Digital Output3

4 Orange AI Analog Input

5 Yellow +0V GND

5.4.2 Connecting Tool End Digital Output

The following figure shows how to connect the tool end digital output:

Table 15: 5-pin Analog I/O connector of Robot

Figure 55: Connecting Tool End Digital Output

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 61

Page 62

-

+

5.4.3 Connecting Tool End Digital Input

The following figure shows how to connect the tool end digital input:

NOTE: If sensors are connected directly then they should be NPN.

Figure 56: Connecting Tool End Digital Input

5.4.4 Connecting Tool End Analog Input

Range Resolution Accuracy Conversion Time

+10.00V~-10.00V 11bit ≤ 0.2% 1 ms

Table 16: Analog Input Range

The following figure shows how to connect the tool end Analog input:

(Because AIN_GND is connected to ground, when AIN is a dead contact, a pressure difference will occur,

which is a normal phenomenon.)

Figure 57: Connecting Tool End Analog Input

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 62

Page 63

connection may cause the robot to stop.

USB3.0*2

COM1

USB 2.0 *4

HDMI

LAN for GigE Camera*2

Line-out

COM2

COM3

LAN

Mic-in

5.5 Control Box Interfaces

Robot Status Display

Figure 58: Front View of the Control Box

CAUTION:

The ETHERCAT interface can only be used to connect ETHERCAT devices. Improper

AC Adapter

AC Power Switch

Power Remote ON/OFF

I/O Interface

EtherCAT

v

Air Filter Screw

PE

Robot Cable Adapter

Figure 59: Interfaces of the TM12 / TM14 / TM12X / TM14X Series

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 63

Page 64

External Power Supply Remote Control

DC IN for External Power Supply

USB

3.0*2

COM1

Robot Cable Adapter

USB 2.0 *4

HDMI

LAN for GigE Camera*2

Line-out

COM2

COM3

LAN

Mic-in

External Power Supply Remote Control

DC IN for External Power Supply

USB

3.0*2

COM1

Robot Cable Adapter

USB 2.0 *4

HDMI

LAN for GigE Camera*2

Line-out

COM2

COM3

LAN

Mic-in

PE

DC IN Power

Power Remote ON/OFF

DC Power Switch

I/O Interface

Figure 60: Interfaces of the TM12M / TM14M Series

EtherCAT

Air Filter Screw

EtherCAT

Air Filter Screw

PE

EMO

DC IN Power

DC Power Switch

Power Remote ON/OFF

I/O Interface

Figure 61: Interfaces of the TM12M SEMI / TM14M SEMI Series

Medium & Heavy Payload Series-Hardware Installation Manual TM12/14 Series Hardware Version: 3.2 64

Page 65

(100V~120V)

AC Adapter

DC IN Power

External Power Supply Remote Control

DC IN for External Power Supply

-

+

TM12M / TM14M

TM12 / TM14 / TM12X / TM14X

5.6 Control Box Power Interface and Robot Interface

5.6.1 Control Box Power Interface

TM12 / TM14 / TM12X / TM14X:

The power cable of the control box has an IEC plug. The local power plug is connected to the IEC plug.

The AC power switch must be in OFF state before plugging in or out the power cable.

TM12M / TM14M:

The power cable of the control box has Hirose (HRS) DF60 series connector.

AC Adapter:IEC plug

DC IN Power Connector:( HRS)DF60-3EP-10.16C

DC IN for External Power Supply Connector: Contact the Corporation for

purchasing

External Power Supply Remote Control Connector:Contact the Corporation

for purchasing