Page 1

D-61TL-T

TL-T

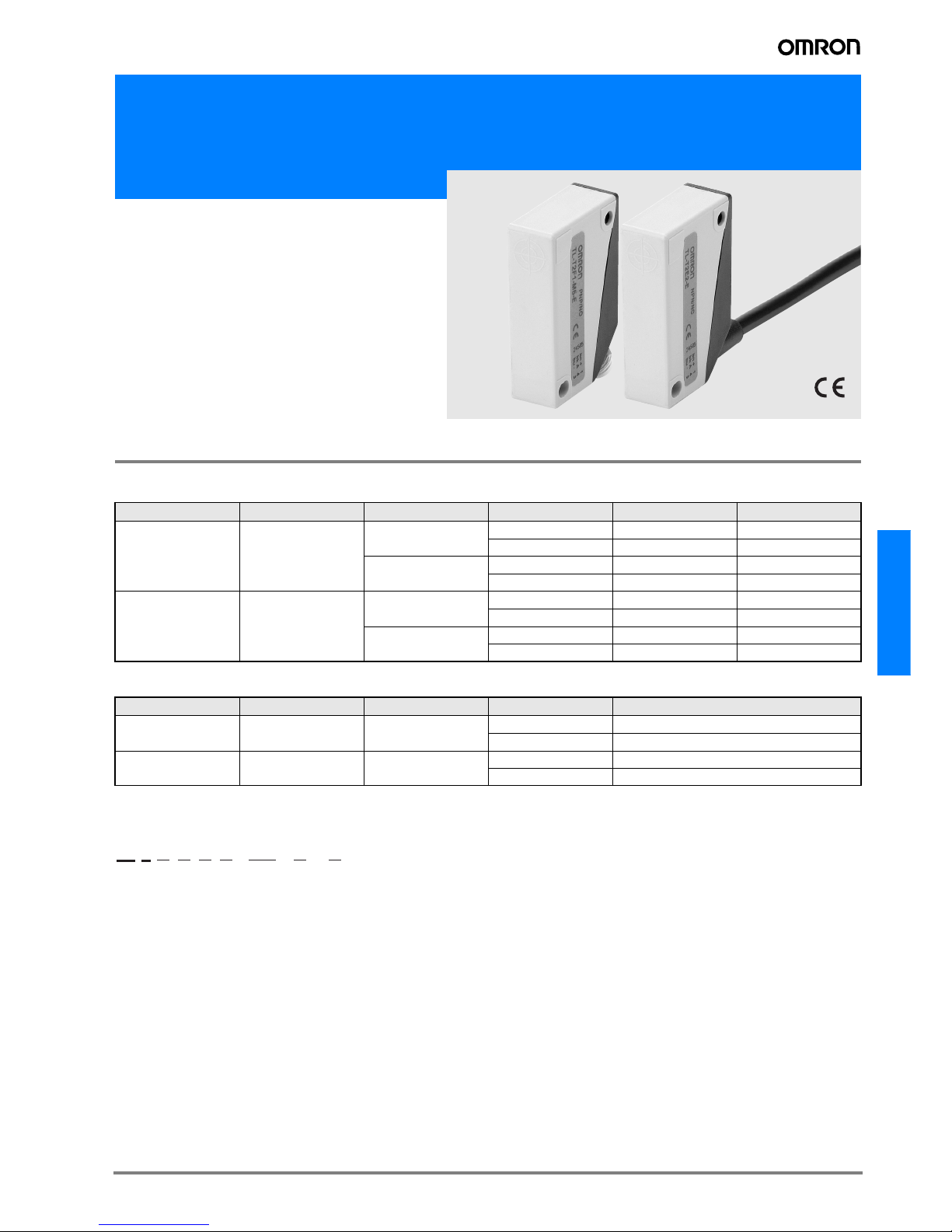

Standard (thin shape) Inductive Proximity Sensor

TL-T

• Thin shape for space saving surface mounting

• Direct side wall mounting for bracket-less installation

Ordering Information

DC 3-wire Models

DC 4-wire Models (NO + NC)

Model Number Legend

Example: TL-T2F1-E 2M Square housing (40x12x26 mm), Sn=2 mm, shielded, PNP-NO,

made by OMG, pre-wired PVC cable (3x0,25 mm²) 2 m

TL-T4MF1-M5-E Square housing (40x12x26 mm), Sn=4 mm, not shielded,

PNP-NO, M8 (3-pole) connector, made by OMG

1. Basic name

TL

2. Housing & shape material

Square plastic 40 x 12 x 26 mm

3. Sensing distance

2: 2mm

4: 4mm

4. Shield

Blank: Shielded

M: Non-shielded

5. Power source & output

E: NPN voltage output

F: PNP voltage output

6. Operation mode

1: Normally open (NO)

2: Normally closed (NC)

3: Antivalent (NO + NC)

7. Kind of connection

Blank: Pre-wired, PVC dia 4mm

WA: Pre-wired, PUR/PVC dia 4mm

WR: Robot cable, PVC dia 4mm

M5: M8 connector (3-pole)

M1J: M12 connector (4-pole)

with pig-tail cable (PVC)

M3J: M8 connector (4-pole)

with pig-tail cable (PVC)

M5J: M8 connector (3-pole)

with pig-tail cable (PVC)

8. Production site

E: European Union

9. Cable length

Blank: Connector type

Numeral: Cable type

Installation Sensing distance Connection Output configuration Operation mode NO Operation mode NC

Shielded 2.0 mm Pre-wired NPN TL-T2E1-E TL-T2E2-E

PNP TL-T2F1-E TL-T2F2-E

M8 Connector (3-pin) NPN TL-T2E1-M5-E TL-T2E2-M5-E

PNP TL-T2F1-M5-E TL-T2F2-M5-E

Non-Shielded 4.0 mm Pre-wired NPN TL-T4ME1-E TL-T4ME2-E

PNP TL-T4MF1-E TL-T4MF2-E

M8 Connector (3-pin) NPN TL-T4ME1-M5-E TL-T4ME2-M5-E

PNP TL-T4MF1-M5-E TL-T4MF2-M5-E

Installation Sensing distance Connection Output configuration Operation mode antivalent (NO + NC)

Shielded 2.0 mm Pre-wired NPN TL-T2E3-E

PNP TL-T2F3-E

Non-Shielded 4.0 mm Pre-wired NPN TL-T4ME3-E

PNP TL-T4MF3-E

TL

-T

@ @ @ @ - @@ - @ @

1 2 3 5 7 8 9 46

Page 2

D-62 Inductive Sensors

Specifications

DC 3-wire and DC 4-wire Models

Note: 1. The response frequency is an average value. Measurement conditions are as follows: standard target, a distance of twice the standard target distance between

targets, and a setting distance of half the sensing distance

2. PUR Cable and other legth request

Type

Item

Shielded Non-shielded

TL-T2E1-@@-E

TL-T2F1-@@-E

TL-T2E2-@@-E

TL-T2F2-@@-E

TL-T2E3-E

TL-T2F3-E

TL-T4ME1-@@-E

TL-T4MF1-@@-E

TL-T4ME2-@@-E

TL-T4MF2-@@-E

TL-T4ME3-E

TL-T4MF3-E

Sensing distance

2 mm ±10% 4 mm ±10%

Setting distance

0 to 1.6 mm 0 to 3.2 mm

Differential travel

15% max. of sensing distance

Target

Ferrous metal (The sensing distance decreases with non-ferrous metal)

Standard target

12 x 12 x 1 mm 12 x 12 x 1 mm

Response frequency (See note 1.)

3000 Hz

1500 Hz

Rated power supply voltage

(operating voltage range)

24 VDC. Ripple (p-p): 10% max.

(10 to 35 VDC)

Current consumption

DC 3-wire: ≤15 mA at 24 VDC

DC 4-wire: ≤15 mA at 24 VDC

Output type

TL-T@@E models: NPN voltage output

TL-T@@F models: NPN voltage output

Control output

Load current

300 mA max. each output

Residual voltage

≤2.0 VDC

Leakage current

DC 3-wire: <0,5 mA

DC 4-wire: <1 mA each output

Indicator

Output indicator (Yellow LED)

Operation mode

(with sensing object approaching)

TL-T@@E1/F1 models: NO

TL-T@@E2/F2 models: NC

TL-T@@E3/F3 models: NO + NC

For details, refer to Timing Charts.

Protection circuits

Output reverse polarity protection, Power source circuit reverse polarity protection, Surge suppressor,

Short-circuit protection

Ambient air temperature

Operating/Storage: –25° C to 70° C

Temperature influence

≤±10% max. of Sn at 23°C in temperature range of –25° C to 70° C

Humidity

35% to 95% RH

Voltage influence

±1% max. of sensing distance in the rated voltage range ±15%

Insulation resistance

>10 MΩ between current-carrying parts and case

Dielectric strength

1000 VAC at 50/60 Hz between current-carrying parts and case

Vibration resistance

0 to 55 Hz with 30 min. dwell time at resonance frequency or 55 Hz each in X, Y, and Z directions

55 to 2000 Hz, 150 m/s

2

, double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance

300 m/s2 6 times each in X, Y, and Z directions

Degree of protection

in accordance with IEC 60529:

Pre-wired models: IP67

M8 connector models: IP65

Product standard

EN60947-5-2

Connection method

Pre-wired (See

note 2)

2m cable, 3x 0,25 mm2 for DC 3-wire models

4x 0,25 mm

2

for DC 4-wire models

Connector

M8 connector

Weight

(packaged)

Pre-wired model

Approx. 70 g

M8 connector

models

Approx. 20 g

Material

Case

PBT

Cable

PVC

Page 3

D-63TL-T

TL-T

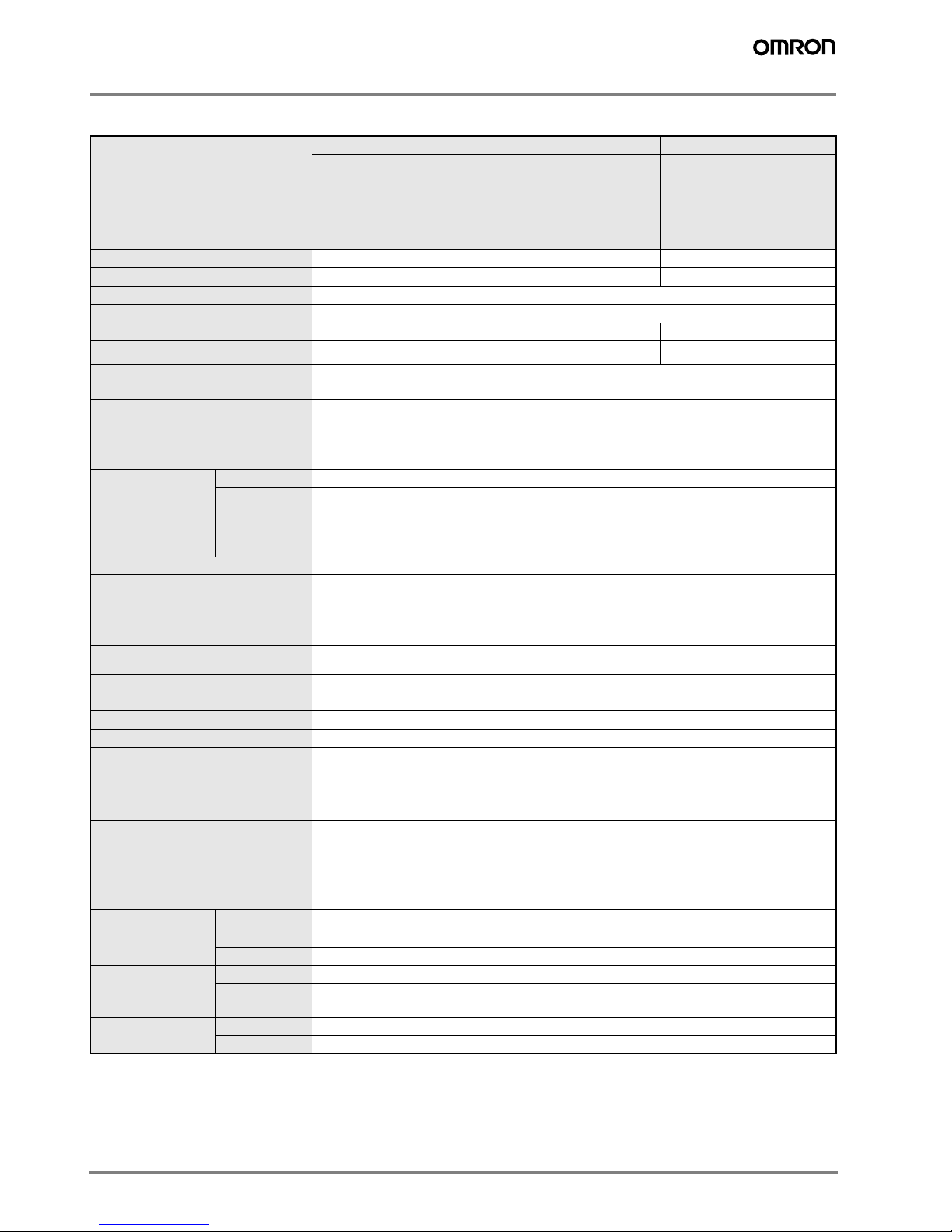

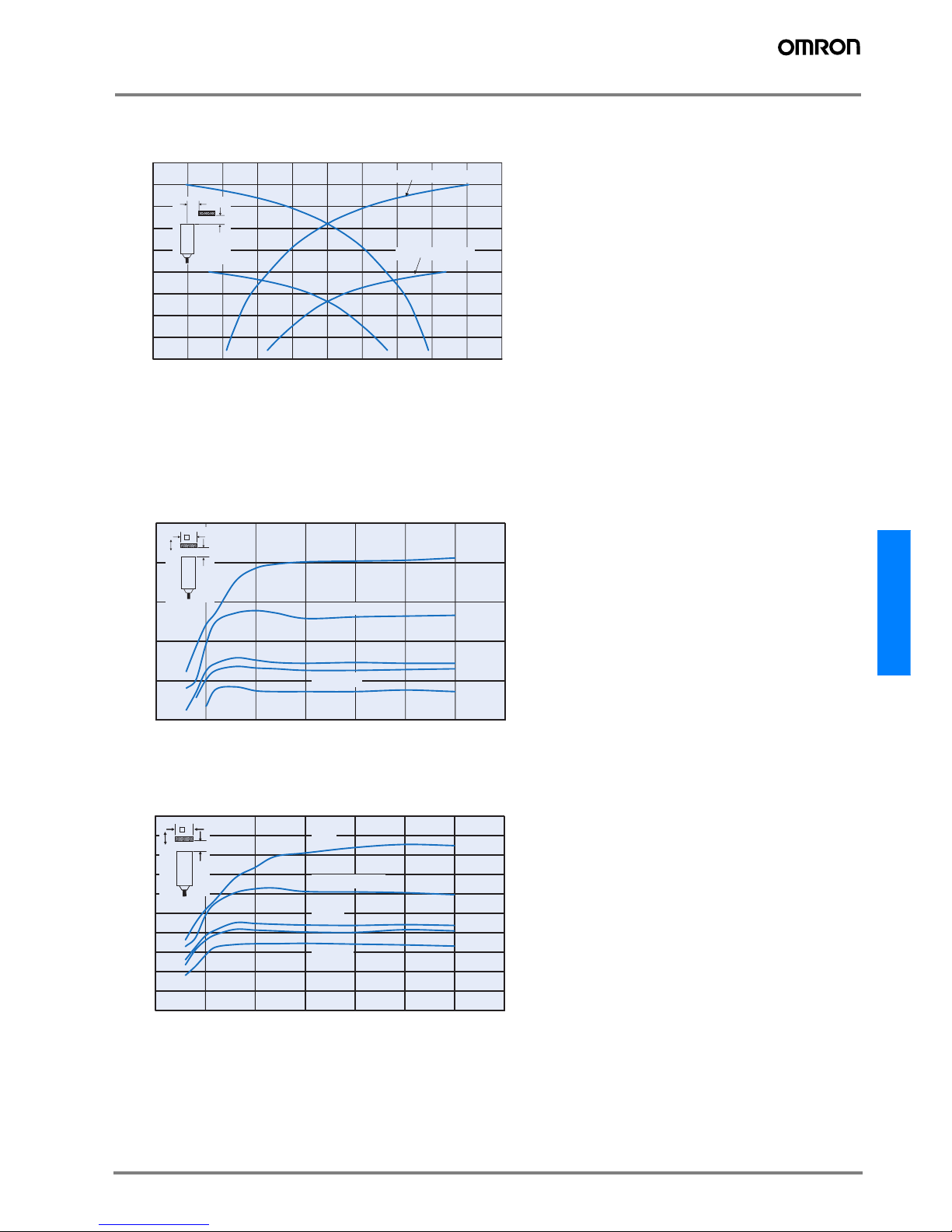

Engineering Data

Operating Range (Typical)

Shielded and non-shielded models

Influence of Sensing Object Size and Material

Shielded models

Non-shielded models

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

-5,0 -4,0 -3,0 -2,0 -1,0 0,0 1,0 2,0 3,0 4,0 5,0

Distance Y (mm)

Sensing distance X (mm)

X

Y

TL-T2 @@-@@-@

TL-T4M

@@- @@

-

@

0,0

0,5

1,0

1,5

2,0

2,5

0 5 10 15 20 25 30 35

Side length of sensing object d (mm)

Sensing distance x (mm)

Iron

Stainless steel

Brass

Aluminum

Copper

X

d

TL-T2@@ -@@ -@

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

0 5 10 15 20 25 30 35

Side length of sensing object d (mm)

Sensing distance x (mm)

X

d

Iron

Stainless steel

Brass

Aluminum

Copper

Page 4

D-64 Inductive Sensors

Operation

PNP Output

Operation mode Model Timing chart Output circuit

NO TL-T@-F1-@-@

NC TL-T@-F2-@-@

NO+NC TL-T@-F3-@-@

ON

OFF

ON

OFF

Non-sensing zone Sensing zone

Control output

Y

ellow indicato

r

(%)

100 0

Sensing

object

Rated

sensing

distance

Load

Main

circuit

+V

0 V

Brown

1

Black

4

Blue

3

1

4

3

M8 connector (3 pin)

Pin Arrangement

ON

OFF

ON

OFF

Non-sensing zone Sensing zone

Control output

Yellow indicato

r

(%)

100 0

Sensing

object

Rated

sensing

distance

Load

+V

0 V

Brown

1

Black

4

Blue

3

1

4

3

Main

circuit

M8 connector (3 pin)

Pin Arrangement

ON

OFF

NC output

ON

OFF

ON

OFF

Non-sensing zone Sensing zone

NO output

Yellow indicato

r

(%)

100 0

Sensing

object

Rated

sensing

distance

0 V

Blue

+V

Brown

Load

Black NO output

Load

White

NC output

Main

circuit

Page 5

D-65TL-T

TL-T

NPN Output

Operation mode Model Timing chart Output circuit

NO TL-T@-E1-@-@

NC TL-T@-E2-@-@

NO+NC TL-T@-E3-@-@

ON

OFF

ON

OFF

Non-sensing zone Sensing zone

Control output

Yellow indicato

r

(%)

100 0

Sensing

object

Rated

sensing

distance

+V

Load

Brown

1

Black

4

Blue

3

M8 connector (3 pin)

Pin Arrangement

1

4

3

Main

circuit

0 V

ON

OFF

ON

OFF

Non-sensing zone Sensing zone

Control output

Yellow indicato

r

(%)

100 0

Sensing

distance

Rated

sensing

distance

+V

Load

Brown

1

Black

4

Blue

3

M8 connector ( 3 pin)

Pin Arrangement

1

4

3

Main

circuit

0 V

ON

OFF

NC output

ON

OF

ON

OFF

Non-sensing zone Sensing zone

NO output

Yellow indicato

r

(%)

100 0

Sensing

object

Rated

sensing

distance

Blue

0 V

+V

Brown

Load

Black

NO output

Load

White NC output

Main

circuit

Page 6

D-66 Inductive Sensors

Dimensions

Note: All units are in millimeters unless otherwise stated

Pre-wired Models (shielded and non-shielded)

TL-T2@@-E 2M and TL-T4M@@-E 2M

M8 Connector Models (shielded and non-shielded)

TL-T2@@-M5-E and TL-T4M@@-M5-E

26

4

5

3.2

4

3.3

4

0.7

6

40

12

4

4.5

16

18

LED

insert nut M3

4

3.2

3.3

40

12

26

5

6

16

18

4

0.7

4

4.5

M8

LED

insert nut M3

Page 7

D-67TL-T

TL-T

Precautions

Safety Precautions

Power Supply

Do not impose an excessive voltage on the TL-T, otherwise it may be

damaged. Do not impose AC current (100 to 240 VAC) on any DC

model, otherwise it may be damaged.

Load Short-circuit

Do not short-circuit the load, or the TL-T may be damaged.

The TL-T’s short-circuit protection function will be valid if the polarity

of the supply voltage imposed is correct and within the rated voltage

range.

Wiring

Be sure to wire the TL-T and load correctly, otherwise it may be

damaged.

Do not expose the

product to flammable or explosive gases.

Do not disassemble, repair, or modify the product.

Correct Use

Designing

Power Reset Time

The Proximity Sensor is ready to operate within 100 ms after power

is supplied. If power supplies are connected to the Proximity Sensor

and load respectively, be sure to supply power to the Proximity

Sensor before supplying power to the load.

Effects of Surrounding Metal

When mounting the TL-T within a metal panel, ensure that the

clearances given in the following table are maintained.

Power OFF

The Proximity Sensor may output a pulse signal when it is turned

OFF. Therefore, it is recommended that the load be turned OFF

before turning OFF the Proximity Sensor.

Power Supply Transformer

When using a DC power supply, make sure that the DC power

supply has an insulated transformer. Do not use a DC power supply

with an auto-transformer.

Mutual Interference

When installing two or more Sensors face-to-face or side-by-side,

ensure that the minimum distances given in the following table are

maintained.

Type Dimension Minimum value

Shielded

w0

n-

D0

m6

Non-shielded

w12

n36

D8

m12

w

n

m D

w

(Unit: mm)

Typ e Dimension Minimum value

Shielded A 30

B10

Non-shielded A 40

B20

A B

(Unit: mm)

Page 8

D-68 Inductive Sensors

Wiring

High-tension Lines

Wiring through Metal Conduit:

If there is a power or high-tension line near the cable of the Proximity

Sensor, wire the cable through an independent metal conduit to

prevent against Proximity Sensor damage or malfunctioning.

Cable Extension

Standard cable length is less than 200 m.

The tractive force is 50 N.

Mounting

The Proximity Sensor must not be subjected to excessive shock with

a hammer when it is installed, otherwise the Proximity Sensor may

be damaged or lose its water-resistivity.

Do not tighten the screw with excessive force. A washer must be

used with the screw.

Maintenance and Inspection

Periodically perform the following checks to ensure stable operation

of the Proximity Sensor over a long period of time.

1. Check for mounting position, dislocation, looseness, or distortion

of the Proximity Sensor and sensing objects.

2. Check for loose wiring and connections, improper contacts, and

line breakage.

3. Check for attachment or accumulation of metal powder or dust.

4. Check for abnormal temperature conditions and other environ-

mental conditions.

5. Check for proper lighting of indicators (for models with a set indi-

cator.)

Never disassemble or repair the Sensor.

Environment

Water Resistivity

The Proximity Sensors are tested intensively on water resistance, but

in order to ensure maximum performance and life expectancy avoid

immersion in water and provide protection from rain or snow.

Operating Environment

Ensure storage and operation of the Proximity Sensor within the

given specifications.

Inrush Current

A load that has a large inrush current (e.g., a lamp or motor) will

damage the Proximity Sensor, in which case connect the load to the

Proximity Sensor through a relay.

<SUITABILITY FOR USE>

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of the products in

the customer’s application or use of the products.

Take all necessary steps to determine the suitability of the product

for the systems, machines, and equipment with which it will be used.

<CHANGE IN SPECIFICATIONS>

Product specifications and accessories may be changed at any time

based on improvements and other reasons. Consult with your

OMRON representative at any time to confirm actual specifications

of purchased product.

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E38E-EN-01

Loading...

Loading...