Page 1

Cat. No.

I51E-EN-03

TJ1-MC04, TJ1-MC16, TJ1-ML04, TJ1-ML16, TJ1-PRT, TJ1-DRT, TJ1-FL02

Page 2

Notice

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in

this manual. Always heed the information provided with them. Failure to

heed precautions can result in injury to people or damage to property.

Definition of precautionary information

DANGER

Indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

/i

Caution

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury, or property damage.

© OMRON, 2007

Trademarks and Copyrights

PROFIBUS is a registered trademark of PROFIBUS International.

MECHATROLINK is a registered trademark of Yaskawa Corporation.

DeviceNet is a registered trademark of Open DeviceNet Vendor Assoc INC.

CIP is a registered trademark of Open DeviceNet Vendor Assoc INC.

Revision 3.0

Trajexia is a registered trademark of OMRON.

Motion Perfect is a registered trademark of Trio Motion Technology Ltd.

HARDWARE REFERENCE MANUAL 2

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying,

recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein.

Moreover, because OMRON is constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without notice. Every precaution

has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Page 3

About this manual

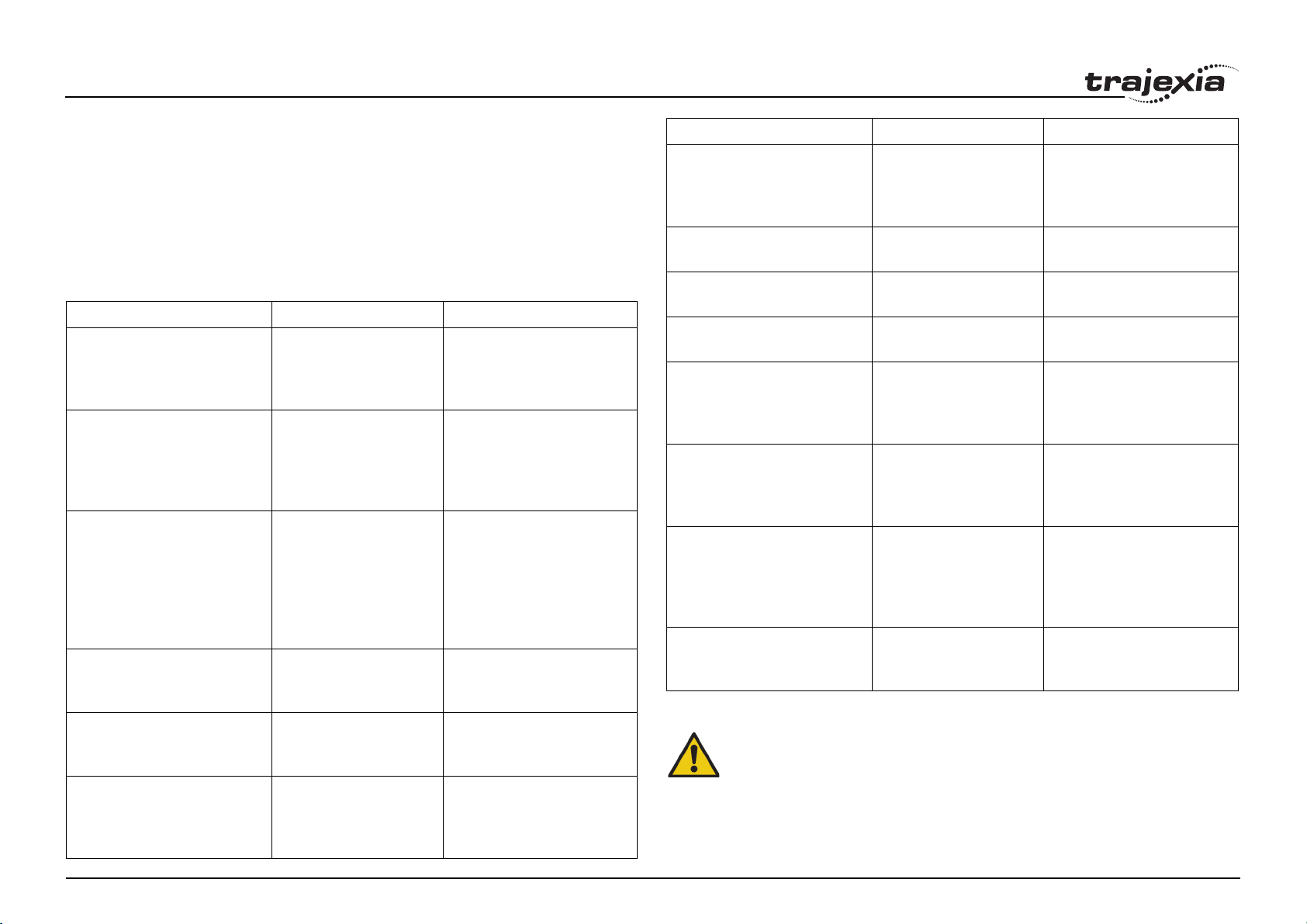

Name Cat. No. Contents

This manual describes the installation and operation of the Trajexia Motion

Control System.

Please read this manual and the related manuals listed in the following table

carefully and be sure you understand the information provided before

attempting to install or operate the Trajexia Motion Control units. Be sure to

read the precautions provided in the following section.

/i

Name Cat. No. Contents

Trajexia motion control system

QUICK START GUIDE

Trajexia motion control system

HARDWARE REFERENCE

MANUAL

Trajexia motion control system

PROGRAMMING MANUAL

Sigma-II Servo Driver manual SIEP S800000 15 Describes the installation and

JUNMA series servo drive

manual

JUSP-NS115 manual SIEP C71080001 Describes the installation and

Revision 3.0

I50E Describes how to get quickly

familiar with Trajexia, moving

a single axis using MECHATROLINK-II, in a test set-up.

I51E Describes the installation and

hardware specification of the

Trajexia units, and explains

the Trajexia system philosophy.

I52E Describes the BASIC com-

mands to be used for programming Trajexia, explains

the communication protocols

and Trajexia Tools software,

gives practical examples and

troubleshooting information.

operation of Sigma-II servo

drives

TOEP-C71080603 01-OY Describes the installation and

operation of JUNMA servo

drives

operation of the MECHATROLINK-II application module

Sigma-III with MECHATROLINK interface manual

V7 Inverter TOEP C71060605 02-OY Describes the installation and

F7Z Inverter TOE S616-55 1-OY Describes the installation and

G7 Inverter TOE S616-60 Describes the installation and

SI-T MECHATROLINK interface for the G7 & F7

ST-T/V7 MECHATROLINK

interface for the V7

MECHATROLINK IO Modules SIE C887-5 Describes the installation and

SYSMAC CS/CJ Series Communications Commands

SIEP S800000 11 Describes the installation and

operation of Sigma-III servo

drives with MECHATROLINK interface

operation of V7 inverters

operation of F7Z inverters

operation of G7 inverters

SIBP-C730600-08 Describes the installation and

operation of MECHATROLINK interfaces for G7 and

F7 inverters

SIBP-C730600-03 Describes the installation and

operation of MECHATROLINK interfaces for V7 inverters

operation of MECHATROLINK input and output modules and the

MECHATROLINK-II repeater

W342 Describes FINS communica-

tions protocol and FINS commands

WARNING

Failure to read and understand the information provided in this

manual may result in personal injury or death, damage to the product, or product failure. Please read each section in its entirety and

be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

HARDWARE REFERENCE MANUAL 3

Page 4

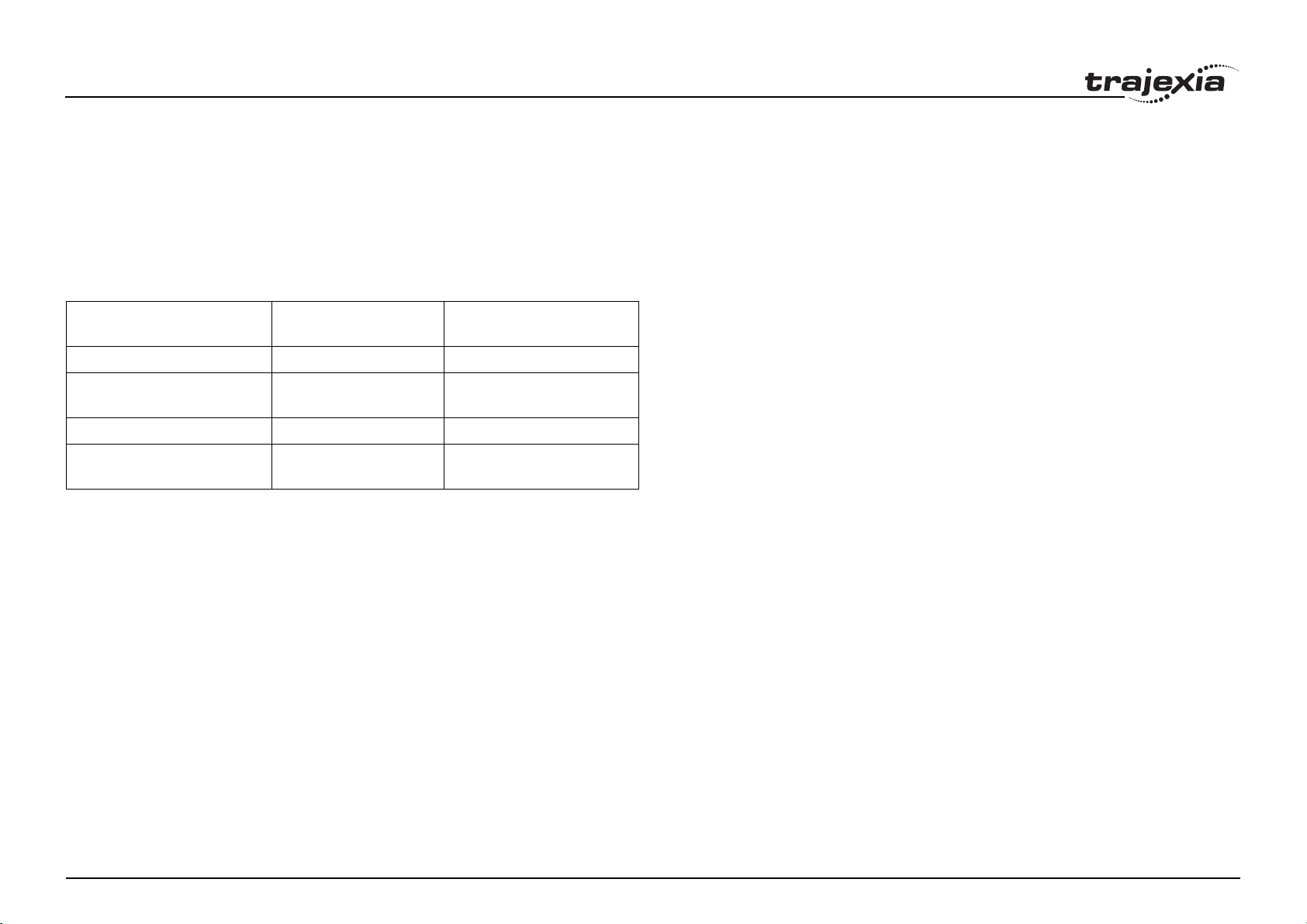

Functions supported by unit versions

During the development of Trajexia new functionality was added to the

controller unit after market release.

This functionality is implemented in the firmware, and/or the FPGA of the

controller unit.

In the table below, the overview of the applicable functionality is shown

related to the firmware and FPGA version of the TJ1-MC__.

/i

Functionality TJ1-MC__ Firmware

version

Full support TJ1-FL02 V1.6509 21 and higher.

Support BASIC commands

FINS_COMMS

Support TJ1-DRT V1.6509 All versions

Support TJ1-MC04 and

TJ1-ML04

V1.6509 All versions

V1.6607 21 and higher

TJ1-MC__ FPGA version

Verify the firmware and FPGA versions of the TJ1-MC__

Connect the TJ1-MC__ to Trajexia Tools software. Refer to the

Programming Manual.

Open the terminal window and type the following commands:

Type

PRINT VERSION in the terminal window. The version parameter returns

the current firmware version number of the motion controller.

PRINT FPGA_VERSION SLOT(-1) in the terminal window. The

Type

parameter returns the current FPGA version number of the TJ1-MC__.

Revision 3.0

HARDWARE REFERENCE MANUAL 4

Page 5

Contents

1 Safety warnings and precautions................................................................................................................................................................8

1.1 Intended audience ............................................................................................................................................................................................................................8

1.2 General precautions .........................................................................................................................................................................................................................8

1.3 Safety precautions............................................................................................................................................................................................................................8

1.4 Operating environment precautions..................................................................................................................................................................................................9

1.5 Application precautions...................................................................................................................................................................................................................10

1.6 Unit assembly precautions..............................................................................................................................................................................................................13

1.7 Conformance to EC Directives Conformance.................................................................................................................................................................................13

1.7.1 Concepts ..........................................................................................................................................................................................................................13

1.7.2 Conformance to EC Directives .........................................................................................................................................................................................13

2 System philosophy .....................................................................................................................................................................................14

2.1 Introduction.....................................................................................................................................................................................................................................14

2.2 Motion control concepts..................................................................................................................................................................................................................16

2.2.1 PTP control.......................................................................................................................................................................................................................17

2.2.2 CP control.........................................................................................................................................................................................................................20

2.2.3 EG control.........................................................................................................................................................................................................................22

2.2.4 Other operations...............................................................................................................................................................................................................25

2.3 Servo system principles..................................................................................................................................................................................................................27

2.4 Trajexia system architecture .........................................................................................................................................................................................................30

2.5 Cycle time ......................................................................................................................................................................................................................................31

2.6 Program control and multi-tasking ..................................................................................................................................................................................................37

2.7 Motion sequence and axes.............................................................................................................................................................................................................40

2.7.1 Profile generator ..............................................................................................................................................................................................................41

2.7.2 Position loop ....................................................................................................................................................................................................................41

2.7.3 Axis sequence .................................................................................................................................................................................................................41

2.7.4 Type of axis .....................................................................................................................................................................................................................41

2.8 Motion buffers ...............................................................................................................................................................................................................................48

2.9 Mechanical system .........................................................................................................................................................................................................................50

3 Hardware reference .................................................................................................................................................................................... 51

3.1 Introduction.....................................................................................................................................................................................................................................51

3.1.1 Trajexia High-Lights .........................................................................................................................................................................................................52

3.1.2 Trajexia Tools ...................................................................................................................................................................................................................53

3.1.3 This manual ......................................................................................................................................................................................................................53

3.2 All units ..........................................................................................................................................................................................................................................54

Revision 3.0

HARDWARE REFERENCE MANUAL 5

3.2.1 System installation ...........................................................................................................................................................................................................54

3.2.2 Environmental and storage for all units ..........................................................................................................................................................................61

3.2.3 Unit dimensions ...............................................................................................................................................................................................................62

3.2.4 Wire the Weidmüller connectors.......................................................................................................................................................................................64

Page 6

Contents

Revision 3.0

3.3 Power Supply Unit (PSU) ...............................................................................................................................................................................................................66

3.3.1 Introduction.......................................................................................................................................................................................................................66

3.3.2 PSU Connections .............................................................................................................................................................................................................66

3.3.3 PSU Specifications ...........................................................................................................................................................................................................67

3.3.4 PSU box contents.............................................................................................................................................................................................................67

3.4 TJ1-MC__ .....................................................................................................................................................................................................................................68

3.4.1 Introduction.......................................................................................................................................................................................................................68

3.4.2 LED Display......................................................................................................................................................................................................................69

3.4.3 TJ1-MC__ Connections....................................................................................................................................................................................................70

3.4.4 Battery ..............................................................................................................................................................................................................................76

3.4.5 TJ1-MC__ Specification ..................................................................................................................................................................................................77

3.4.6 TJ1-TER ...........................................................................................................................................................................................................................78

3.4.7 TJ1-MC__ box contents ...................................................................................................................................................................................................78

3.5 TJ1-ML__........................................................................................................................................................................................................................................79

3.5.1 Introduction.......................................................................................................................................................................................................................79

3.5.2 LED Description................................................................................................................................................................................................................80

3.5.3 TJ1-ML__ Connection ......................................................................................................................................................................................................80

3.5.4 TJ1-ML__ Specifications .................................................................................................................................................................................................84

3.5.5 TJ1-ML__ box contents ....................................................................................................................................................................................................85

3.5.6 MECHATROLINK-II Servo Drivers Sigma-II series ..........................................................................................................................................................85

3.5.7 MECHATROLINK-II Servo Drivers Junma series.............................................................................................................................................................92

3.5.8 MECHATROLINK-II Inverter V7 .......................................................................................................................................................................................98

3.5.9 MECHATROLINK-II Inverter F7 and G7.........................................................................................................................................................................102

3.5.10 MECHATROLINK-II digital I/O slaves ...........................................................................................................................................................................107

3.5.11 MECHATROLINK-II 4-Channel analogue input module ................................................................................................................................................117

3.5.12 MECHATROLINK-II 2-Channel analogue output module ..............................................................................................................................................123

3.5.13 MECHATROLINK-II repeater .........................................................................................................................................................................................128

3.6 TJ1-PRT .......................................................................................................................................................................................................................................131

3.6.1 Introduction.....................................................................................................................................................................................................................131

3.6.2 LEDs description ............................................................................................................................................................................................................131

3.6.3 Node number selectors ..................................................................................................................................................................................................132

3.6.4 TJ1-PRT Connections ................................................................................................................................................................................................... 132

3.6.5 TJ1-PRT Specifications .................................................................................................................................................................................................133

3.6.6 TJ1-PRT unit box contents .............................................................................................................................................................................................133

3.7 TJ1-DRT .......................................................................................................................................................................................................................................134

3.7.1 Introduction.....................................................................................................................................................................................................................134

3.7.2 LEDs description ...........................................................................................................................................................................................................134

3.7.3 Node number selectors ..................................................................................................................................................................................................135

3.7.4 TJ1-DRT Connections ...................................................................................................................................................................................................136

3.7.5 TJ1-DRT Specifications .................................................................................................................................................................................................137

HARDWARE REFERENCE MANUAL 6

Page 7

Contents

3.7.6 TJ1-DRT unit box contents.............................................................................................................................................................................................137

3.8 TJ1-FL02 ......................................................................................................................................................................................................................................138

3.8.1 Introduction.....................................................................................................................................................................................................................138

3.8.2 LED description .............................................................................................................................................................................................................139

3.8.3 TJ1-FL02 connections ...................................................................................................................................................................................................140

3.8.4 TJ1-FL02 specifications .................................................................................................................................................................................................146

3.8.5 Incremental encoder.......................................................................................................................................................................................................147

3.8.6 Absolute encoder............................................................................................................................................................................................................149

3.8.7 Stepper ...........................................................................................................................................................................................................................153

3.8.8 Registration ....................................................................................................................................................................................................................153

3.8.9 Hardware PSWITCH ......................................................................................................................................................................................................154

3.8.10 TJ1-FL02 box contents...................................................................................................................................................................................................154

A Differences between Sigma-II and Junma .............................................................................................................................................. 162

Revision 3.0

HARDWARE REFERENCE MANUAL 7

Page 8

Safety warnings and precautions

1 Safety warnings and precautions

1.1 Intended audience

This manual is intended for personnel with knowledge of electrical systems

(electrical engineers or the equivalent) who are responsible for the design,

installation and management of factory automation systems and facilities.

WARNING

Never short-circuit the positive and negative terminals of the batteries, charge the batteries, disassemble them, deform them by

applying pressure, or throw them into a fire.

The batteries may explode, combust or leak liquid.

1.2 General precautions

The user must operate the product according to the performance

specifications described in this manual.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, safety equipment, petrochemical plants, and

other systems, machines and equipment that can have a serious influence

on lives and property if used improperly, consult your OMRON

representative.

1.3 Safety precautions

WARNING

Do not attempt to take the Unit apart and do not touch any of the

internal parts while power is being supplied.

Doing so may result in electrical shock.

WARNING

Do not touch any of the terminals or terminal blocks while power is

being supplied.

Doing so may result in electric shock.

Revision 3.0

WARNING

Fail-safe measures must be taken by the customer to ensure

safety in the event of incorrect, missing, or abnormal signals

caused by broken signal lines, momentary power interruptions, or

other causes.

Not doing so may result in serious accidents.

WARNING

Emergency stop circuits, interlock circuits, limit circuits, and similar

safety measures must be provided by the customer as external circuits, i.e., not in the Trajexia motion controller.

Not doing so may result in serious accidents.

WARNING

When the 24 VDC output (I/O power supply to the TJ1) is overloaded or short-circuited, the voltage may drop and result in the

outputs being turned off.As a countermeasure for such problems,

external safety measures must be provided to ensure safety in the

system.

WARNING

The TJ1 outputs will go off due to overload of the output transistors

(protection).As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

HARDWARE REFERENCE MANUAL 8

Page 9

Safety warnings and precautions

WARNING

The TJ1 will turn off the WDOG when its self-diagnosis function

detects any error.As a countermeasure for such errors, external

safety measures must be provided to ensure safety in the system.

WARNING

Provide safety measures in external circuits, i.e., not in the Trajexia Motion Controller (referred to as "TJ1"), in order to ensure

safety in the system if an abnormality occurs due to malfunction of

the TJ1 or another external factor affecting the TJ1 operation.

Not doing so may result in serious accidents.

WARNING

Do not attempt to disassemble, repair, or modify any Units.

Any attempt to do so may result in malfunction, fire, or electric

shock.

Caution

Confirm safety at the destination unit before transferring a program

to another unit or editing the memory.

Doing either of these without confirming safety may result in injury.

Caution

Pay careful attention to the polarity (+/-) when wiring the DC power

supply.A wrong connection may cause malfunction of the system.

Caution

Tighten the screws on the terminal block of the Power Supply Unit

to the torque specified in this manual.

Loose screws may result in burning or malfunction.

1.4 Operating environment precautions

Caution

Do not operate the Unit in any of the following locations.

Doing so may result in malfunction, electric shock, or burning.

- Locations subject to direct sunlight.

- Locations subject to temperatures or humidity outside the

range specified in the specifications.

- Locations subject to condensation as the result of severe

changes in temperature.

- Locations subject to corrosive or flammable gases.

- Locations subject to dust (especially iron dust) or salts.

- Locations subject to exposure to water, oil, or chemicals.

- Locations subject to shock or vibration.

Caution

Caution

User programs written to the Motion Control Unit will not be automatically backed up in the TJ1 flash memory (flash memory function).

Revision 3.0

Take appropriate and sufficient countermeasures when installing

systems in the following locations.

Inappropriate and insufficient measures may result in malfunction.

- Locations subject to static electricity or other forms of noise.

- Locations subject to strong electromagnetic fields.

- Locations subject to possible exposure to radioactivity.

- Locations close to power supplies.

HARDWARE REFERENCE MANUAL 9

Page 10

Safety warnings and precautions

Caution

The operating environment of the TJ1 System can have a large

effect on the longevity and reliability of the system.

Improper operating environments can lead to malfunction, failure,

and other unforeseeable problems with the TJ1 System.

Make sure that the operating environment is within the specified

conditions at installation and remains within the specified conditions during the life of the system.

1.5 Application precautions

WARNING

Do not start the system until you check that the axes are present

and of the correct type.

The numbers of the Flexible axes will change if MECHATROLINKII network errors occur during start-up or if the MECHATROLINK-II

network configuration changes.

WARNING

Check the user program for proper execution before actually running it in the Unit.

Not checking the program may result in an unexpected operation.

Caution

Take appropriate measures to ensure that the specified power with

the rated voltage and frequency is supplied. Be particularly careful

in places where the power supply is unstable.

An incorrect power supply may result in malfunction.

Caution

Install external breakers and take other safety measures against

short-circuiting in external wiring.

Insufficient safety measures against short-circuiting may result in

burning.

Caution

Do not apply voltage to the Input Units in excess of the rated input

voltage.

Excess voltage may result in burning.

Caution

Do not apply voltage or connect loads to the Output Units in

excess of the maximum switching capacity.

Excess voltage or loads may result in burning.

Caution

Always use the power supply voltage specified in this manual.

An incorrect voltage may result in malfunction or burning.

Caution

Disconnect the functional ground terminal when performing withstand voltage tests.

Not disconnecting the functional ground terminal may result in

Revision 3.0

HARDWARE REFERENCE MANUAL 10

burning.

Page 11

Safety warnings and precautions

Caution

Always connect to a class-3 ground (to 100Ω or less) when installing the Units.

Not connecting to a class-3 ground may result in electric shock.

Caution

Always turn off the power supply to the system before attempting

any of the following.

Not turning off the power supply may result in malfunction or electric shock.

- Mounting or dismounting expansion Units, CPU Units, or any

other Units.

- Assembling the Units.

- Setting dipswitches or rotary switches.

- Connecting or wiring the cables.

- Connecting or disconnecting the connectors.

Caution

Be sure that all mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in this manual.

Incorrect tightening torque may result in malfunction.

Caution

Remove the dust protective label after the completion of wiring to

ensure proper heat dissipation.

Leaving the dust protective label attached may result in malfunction.

Caution

Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

Connection of bare stranded wires may result in burning.

Caution

Double-check all the wiring before turning on the power supply.

Incorrect wiring may result in burning.

Caution

Wire correctly.

Incorrect wiring may result in burning.

Caution

Leave the dust protective label attached to the Unit when wiring.

Removing the dust protective label may result in malfunction.

Caution

Mount the Unit only after checking the terminal block completely.

Caution

Revision 3.0

Be sure that the terminal blocks, expansion cables, and other

items with locking devices are properly locked into place.

Improper locking may result in malfunction.

HARDWARE REFERENCE MANUAL 11

Page 12

Safety warnings and precautions

Caution

Confirm that no adverse effect will occur in the system before

changing the operating mode of the system.

Not doing so may result in an unexpected operation.

Caution

Resume operation only after transferring to the new CPU Unit the

contents of the VR and table memory required for operation.

Not doing so may result in an unexpected operation.

Caution

When replacing parts, be sure to confirm that the rating of a new

part is correct.

Not doing so may result in malfunction or burning.

Caution

Do not pull on the cables or bend the cables beyond their natural

limit. Doing so may break the cables.

Caution

UTP cables are not shielded. In environments that are subject to

noise use a system with shielded twisted-pair (STP) cable and

hubs suitable for an FA environment.

Do not install twisted-pair cables with high-voltage lines.

Do not install twisted-pair cables near devices that generate noise.

Do not install twisted-pair cables in locations that are subject to

high humidity.

Do not install twisted-pair cables in locations subject to excessive

dirt and dust or to oil mist or other contaminants.

Caution

Use the dedicated connecting cables specified in operation manuals to connect the Units.

Using commercially available RS-232C computer cables may

cause failures in external devices or the Motion Control Unit.

Caution

Outputs may remain on due to a malfunction in the built-in transistor outputs or other internal circuits.

As a countermeasure for such problems, external safety measures

must be provided to ensure the safety of the system.

Caution

Before touching the system, be sure to first touch a grounded

metallic object in order to discharge any static build-up.

Caution

The TJ1 will start operating in RUN mode when the power is

turned on and if a BASIC program is set to Auto Run mode.

Otherwise it might result in a malfunction or damage.

Revision 3.0

HARDWARE REFERENCE MANUAL 12

Page 13

Safety warnings and precautions

1.6 Unit assembly precautions

Caution

Install the unit properly.

Improper installation of the unit may result in malfunction.

Caution

Be sure to mount the TJ1-TER supplied with the TJ1-MC__ to the

right most Unit.

Unless the TJ1-TER is properly mounted, the TJ1 will not function

properly.

1.7 Conformance to EC Directives Conformance

1.7.1 Concepts

The concepts for the directives EMC and Low Voltage are as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards. Whether the products conform to the standards in the system

used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other

conditions of the equipment or control panel in which the OMRON devices

are installed. The customer must, therefore, perform final checks to confirm

that devices and the over-all machine conform to EMC standards.

1.7.2 Conformance to EC Directives

The Trajexia Motion Controllers comply with EC Directives.

To ensure that the machine or device in which a system is used complies

with EC directives, the system must be installed as follows:

1. The system must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC

power supplies used for the communications and I/O power supplies.

Low Voltage Directive

Revision 3.0

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC meet the required safety standards.

HARDWARE REFERENCE MANUAL 13

Page 14

System philosophy

r

2 System philosophy

2.1 Introduction

The system philosophy is centred around the relationship between:

• System architecture

• Cycle time

• Program control and multi-tasking

• Motion sequence and axes

• Motion buffers

A clear understanding of the relationship between these concepts

is necessary to obtain the best results for the Trajexia system.

2.1.1 Glossary

Motion sequence

The Motion Sequence is responsible for controlling the position of

the axes.

Servo period

Defines the frequency at which the Motion Sequence is executed.

The servo period must be set according to the configuration of the

physical axes. The available settings are 0.5ms, 1ms or 2ms.

Cycle time

Is the time needed to execute one complete cycle of operations in

the TJ1-MC__. The cycle time is divided in 4 time slices of equal

time length, called "CPU Tasks". The cycle time is 1ms if

SERVO_PERIOD 0.5ms or 1ms and 2ms if the

SERVO_PERIOD=2ms.

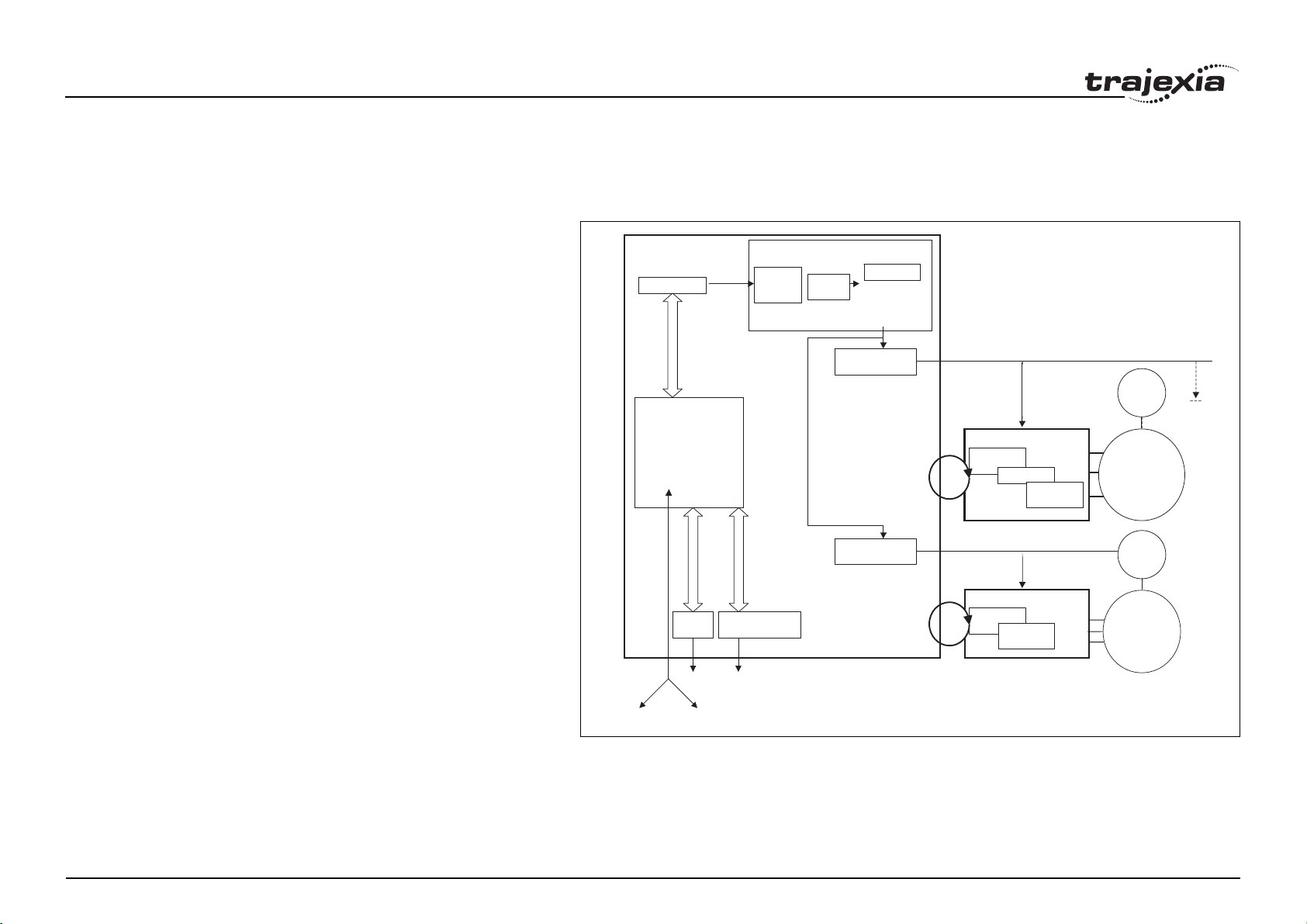

TJ1-MC16

Progra m Buffer

BASIC PROGRAMS

Process 1

Process 2

Process 3

…

Process 14

Co mms

MC I/O

Ethernet

FINS

Ethernet

BUILT-IN TJ1-ML16

Via

Buffer &

Buffer &

profile

profile

generator

gererat or

TJ1-PRT

Profibus

AXIS CONTROL LOOP

Position

Posit ion

Loop

Loop

TJ1-ML16

-

TJ1 FL02

fig. 1

AXIS TYPE

AXIS TYPE

AXIS TYPE

Servo drive.

Posit ion

Position Loop

Loop

Speed Loop

Speed Loop

Servo drive.

Speed Loop

Torque Loop

To rqu e

Torque Loop

Loop

ENC

All othe

Servo

drives

MOT OR

ENC

MOT OR

Revision 3.0

HARDWARE REFERENCE MANUAL 14

Page 15

System philosophy

CPU tasks

The operations executed in each CPU task are:

CPU task Operation

First CPU task Motion Sequence

Low priority process

Second CPU task High priority process

Third CPU task Motion Sequence (only if SERVO_PERIOD=0.5ms)

LED Update

High priority process

Fourth CPU task External Communications

Program

A program is a piece of BASIC code.

Process

Is a program in execution with a certain priority assigned. Process 0

to 12 are Low priority processes and Process 13 and 14 are High

priority processes. First the process priority, High or Low, and then

the process number, from high to low, will define to which CPU task

the process will be assigned.

Revision 3.0

HARDWARE REFERENCE MANUAL 15

Page 16

System philosophy

2.2 Motion control concepts

The TJ1-MC__ offers these types of positioning control operations:

1. Point-to-Point (PTP) control

2. Continuous Path (CP) control

3. Electronic Gearing (EG) control.

This section introduces some of the commands and parameters

used in the BASIC programming of the motion control application.

Coordinate system

Positioning operations performed by the TJ1-MC__ are based on

an axis coordinate system. The TJ1-MC__ converts the position

data from either the connected Servo Driver or the connected

encoder into an internal absolute coordinate system.

The engineering unit that specifies the distances of travelling can

be freely defined for each axis separately. The conversion is

performed through the use of the unit conversion factor, which is

defined by the UNITS axis parameter. The origin point of the

coordinate system can be determined using the DEFPOS

command. This command re-defines the current position to zero or

any other value.

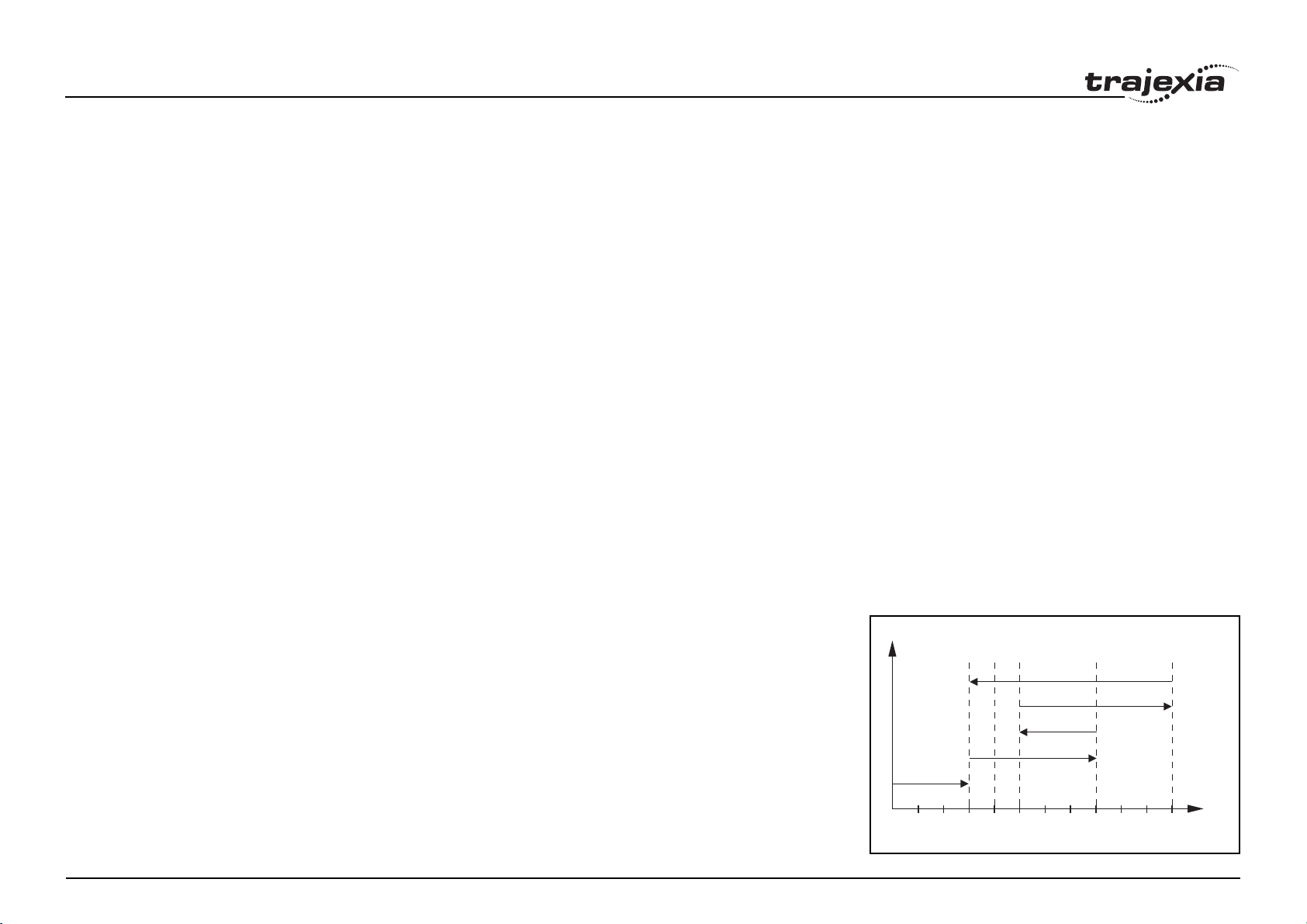

A move is defined in either absolute or relative terms. An absolute

fig. 2

move takes the axis (A) to a specific predefined position with

respect to the origin point. A relative move takes the axis from the

current position to a position that is defined relative to this current

position. The figure shows an example of relative (command

MOVE) and absolute (command MOVEABS) linear moves.

MOVE(30)

Revision 3.0

0

HARDWARE REFERENCE MANUAL 16

MOVEABS(30)

MOVE(60)

MOVEABS(50)

MOVE(50)

50 100

A

Page 17

System philosophy

2.2.1 PTP control

In point-to-point positioning, each axis is moved independently of

the other axis. The TJ1-MC__ supports the following operations:

• Relative move

• Absolute move

• Continuous move forward

• Continuous move reverse.

Relative and absolute moves

To move a single axis either the command MOVE for a relative

move or the command MOVEABS for an absolute move is used.

Each axis has its own move characteristics, which are defined by

the axis parameters.

Suppose a control program is executed to move from the origin to

an axis no. 0 (A) coordinate of 100 and axis no. 1 (B) coordinate of

50. If the speed parameter is set to be the same for both axes and

the acceleration and deceleration rate are set sufficiently high, the

movements for axis 0 and axis 1 will be as shown in the figure.

At start, both the axis 0 and axis 1 moves to a coordinate of 50 over

the same duration of time. At this point, axis 1 stops and axis 0

continues to move to a coordinate of 100.

fig. 3

B

50

MOVEABS(100) AXIS(0)

MOVEABS(50) AXIS(1)

0

50

100

A

The move of a certain axis is determined by the axis parameters.

Some relevant parameters are:

/i

Parameter Description

UNITS Unit conversion factor

ACCEL Acceleration rate of an axis in units/s

DECEL Deceleration rate of an axis in units/s

SPEED Demand speed of an axis in units/s

Revision 3.0

HARDWARE REFERENCE MANUAL 17

2

2

2

Page 18

System philosophy

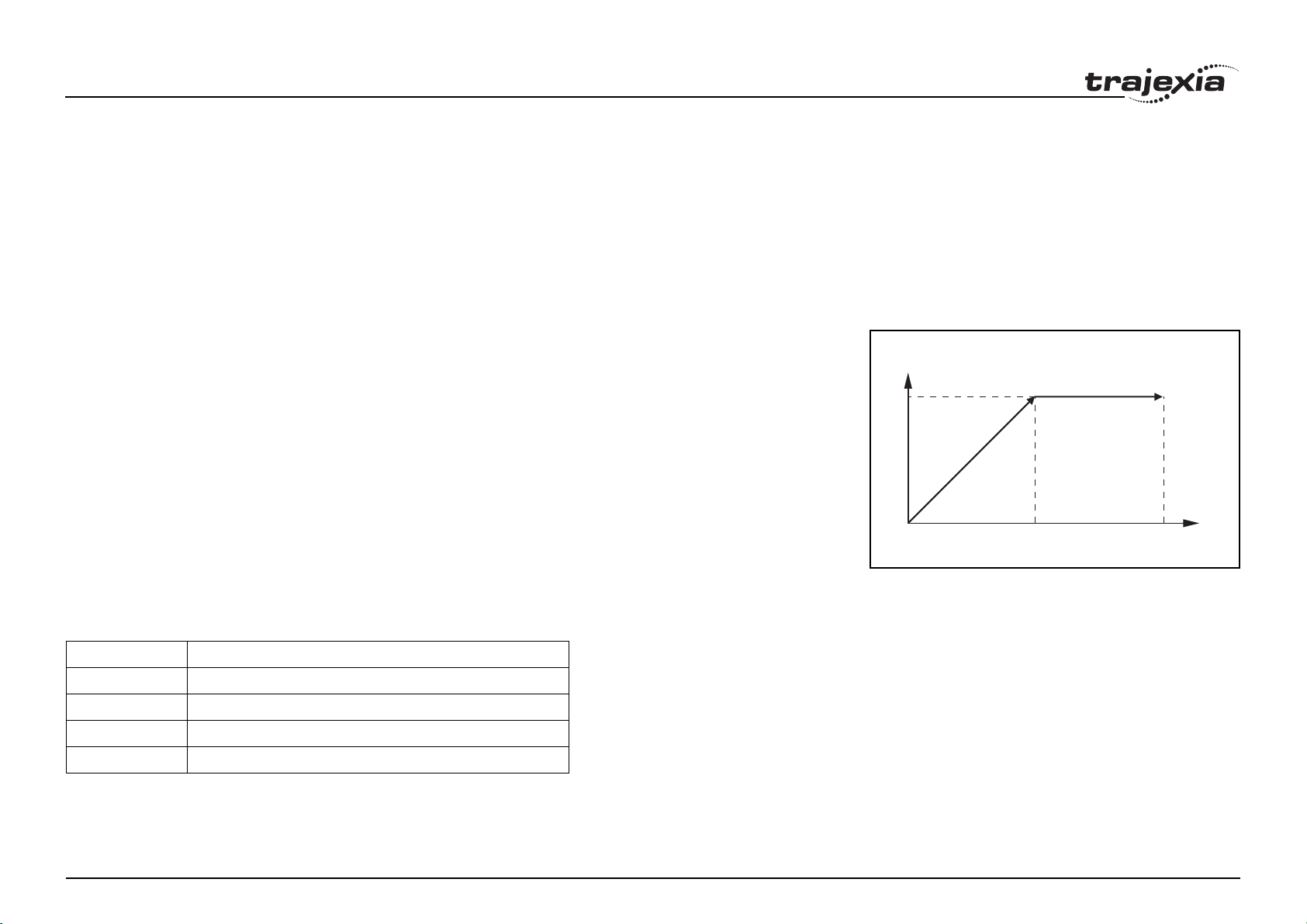

Defining moves

The speed profile in this figure shows a simple MOVE operation.

Axis A is the time, axis B is the speed. The UNITS parameter for

this axis has been defined for example as meters. The required

maximum speed has been set to 10 m/s. In order to reach this

speed in one second and also to decelerate to zero speed again in

one second, both the acceleration as the deceleration rate have

2

been set to 10 m/s

. The total distance travelled is the sum of

distances travelled during the acceleration, constant speed and

deceleration segments. Suppose the distance moved by the MOVE

command is 40 m, the speed profile is given by the figure.

fig. 4

B

010123 456

ACCEL=10

DECEL=10

SPEED=10

MOVE(40)

A

The two speed profiles in these figures show the same movement

with an acceleration time respectively a deceleration time of 2

seconds. Again, Axis A is the time, axis B is the speed.

Revision 3.0

fig. 5

B

010123 456

fig. 6

B

010123 456

ACCEL=5

DECEL=10

SPEED=10

MOVE(40)

A

ACCEL=10

DECEL=5

SPEED=10

MOVE(40)

A

HARDWARE REFERENCE MANUAL 18

Page 19

System philosophy

Move calculations

The following equations are used to calculate the total time for the

motion of the axes.

• The moved distance for the MOVE command is D.

• The demand speed is V.

• The acceleration rate is a.

• The deceleration rate is d.

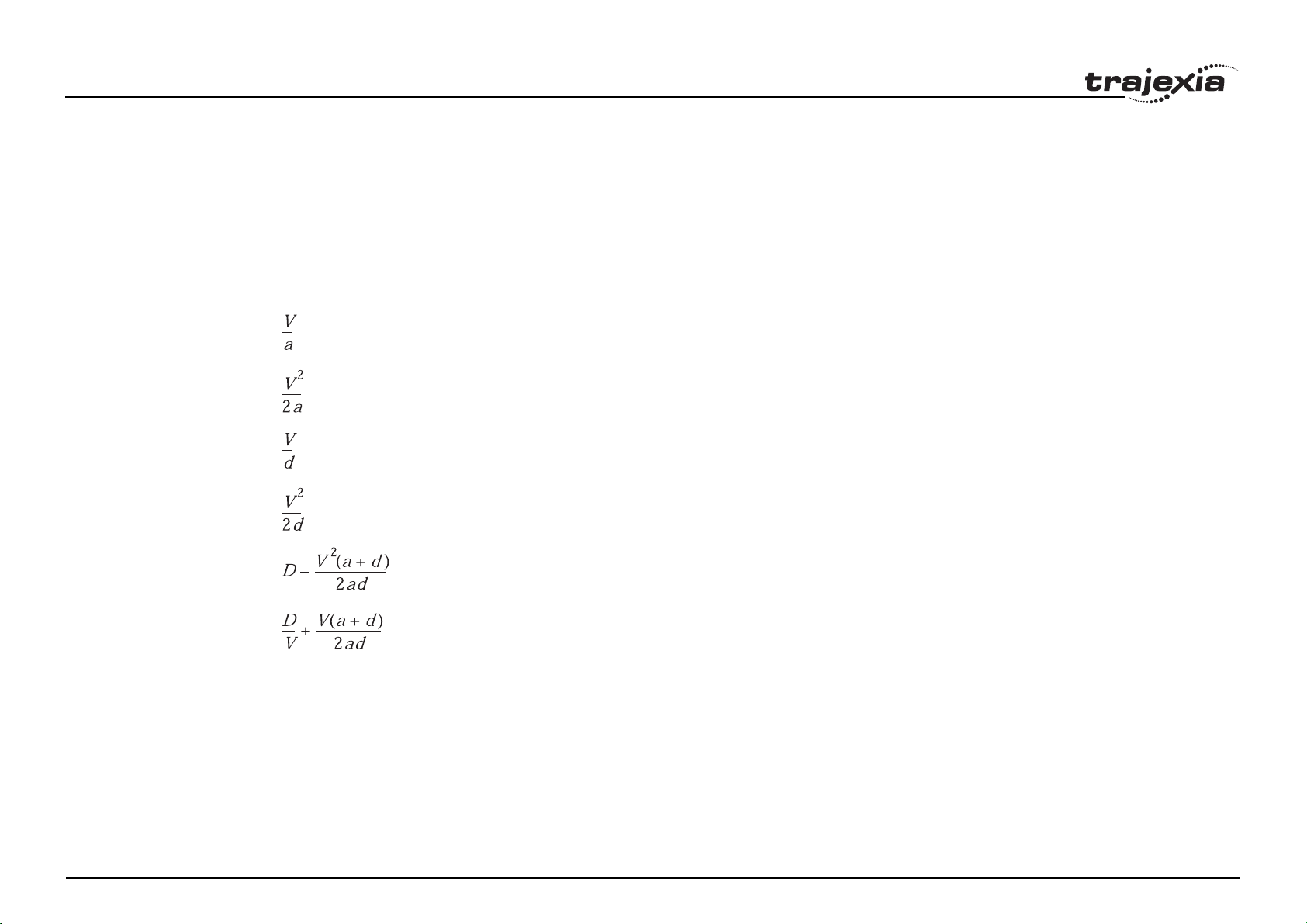

/i

Acceleration time =

Acceleration distance =

Deceleration time =

Deceleration distance =

Constant speed distance =

Total time =

Continuous moves

The FORWARD and REVERSE commands can be used to start a

continuous movement with constant speed on a certain axis. The

FORWARD command moves the axis in positive direction and the

REVERSE command in negative direction. For these commands

also the axis parameters ACCEL and SPEED apply to specify the

Revision 3.0

acceleration rate and demand speed.

HARDWARE REFERENCE MANUAL 19

Page 20

System philosophy

Both movements can be canceled by using either the CANCEL or

RAPIDSTOP command. The CANCEL command cancels the

move for one axis and RAPIDSTOP cancels moves on all axes.

The deceleration rate is set by DECEL.

2.2.2 CP control

Continuous Path control enables to control a specified path

between the start and end position of a movement for one or

multiple axes. The TJ1-MC__ supports the following operations:

• Linear interpolation

• Circular interpolation

•CAM control.

Revision 3.0

HARDWARE REFERENCE MANUAL 20

Page 21

System philosophy

Linear interpolation

In applications it can be required for a set of motors to perform a

move operation from one position to another in a straight line.

Linearly interpolated moves can take place among several axes.

The commands MOVE and MOVEABS are also used for the linear

interpolation. In this case the commands will have multiple

arguments to specify the relative or absolute move for each axis.

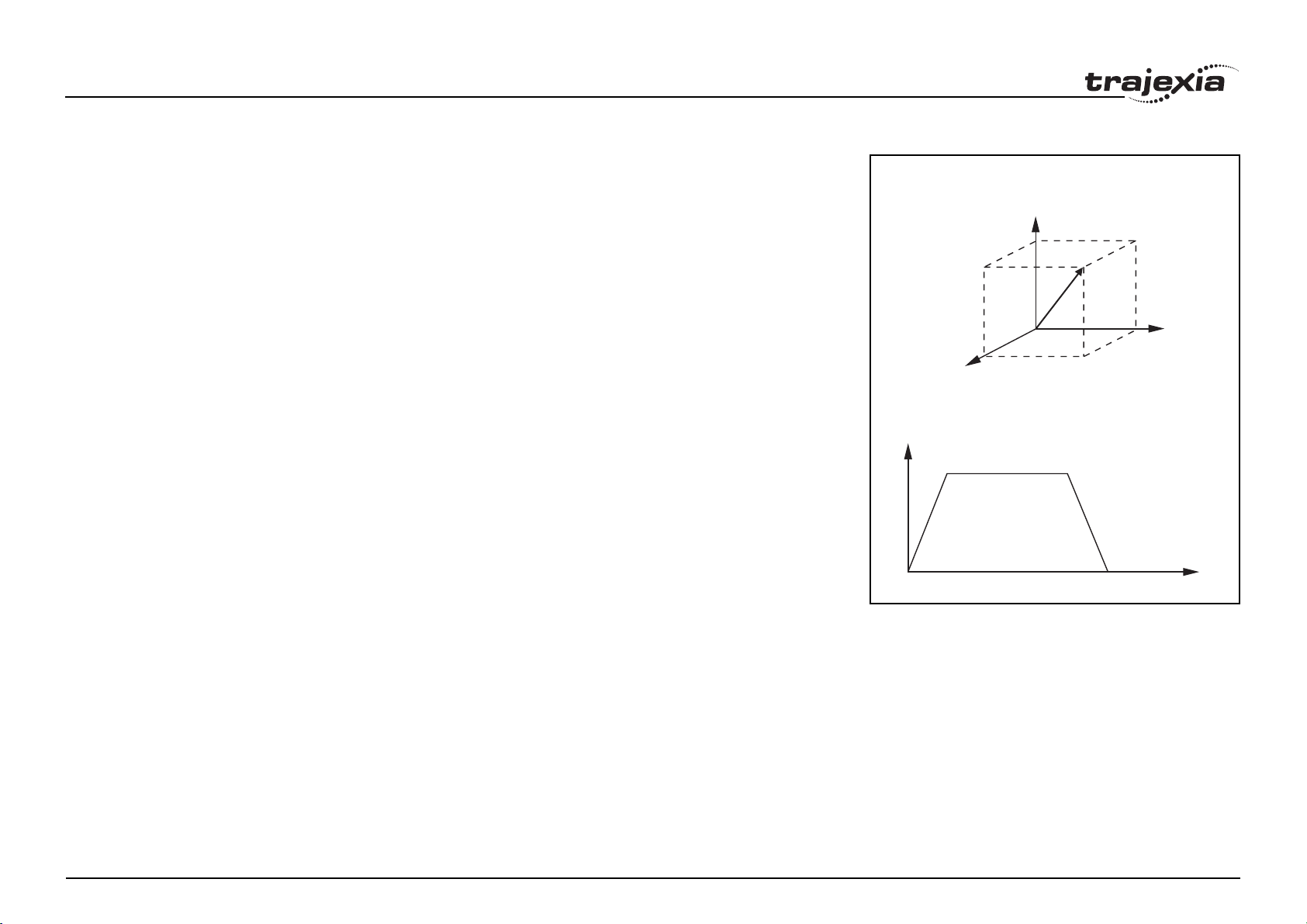

Consider the three axis move in a 3-dimensional plane in the figure.

It corresponds to the MOVE(50,50,50) command. The speed profile

of the motion along the path is given in the diagram. The three

parameters SPEED, ACCEL and DECEL that determine the multi

axis movement are taken from the corresponding parameters of the

base axis. The MOVE command computes the various

components of speed demand per axis.

A is the time axis, B is the speed axis.

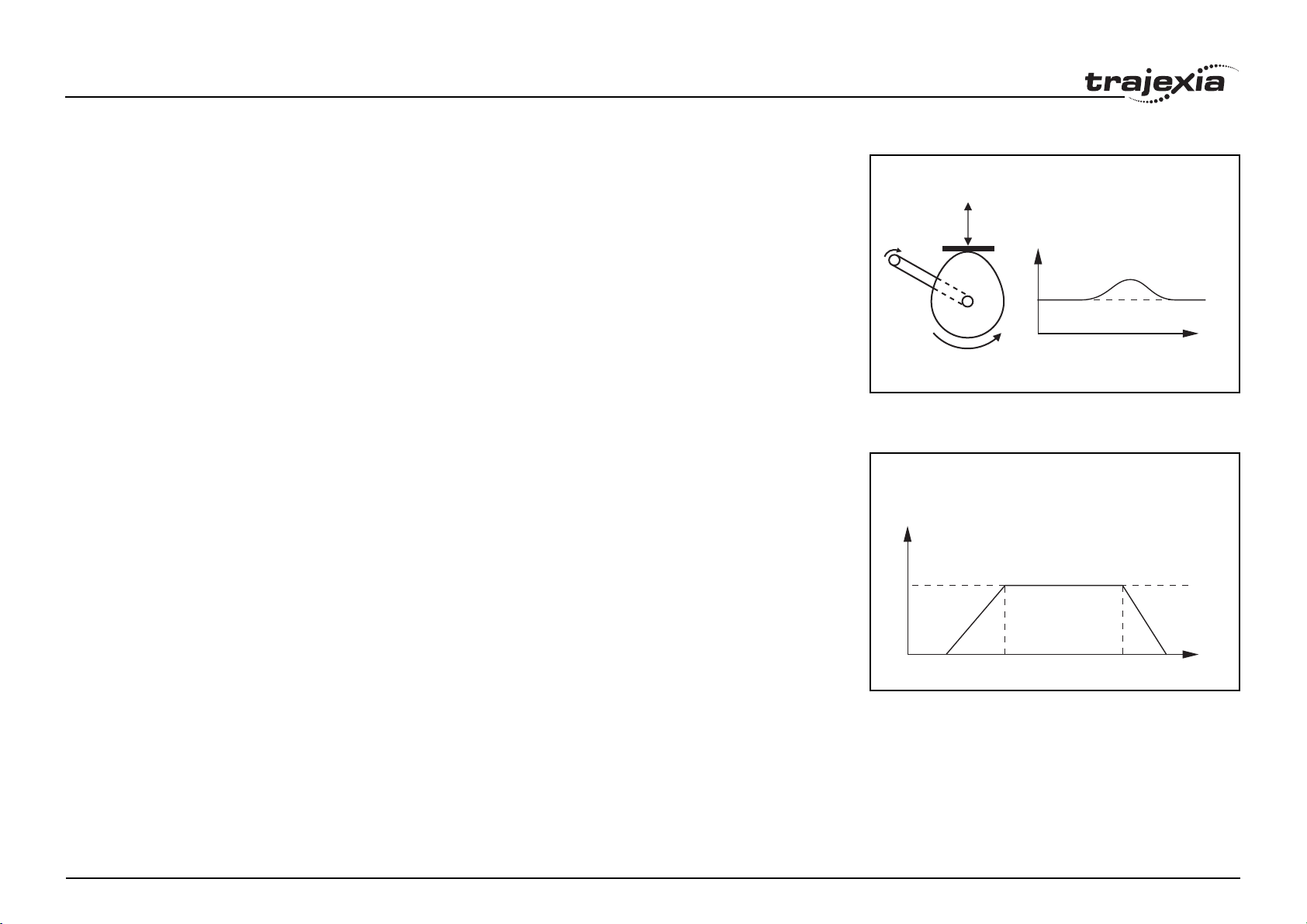

fig. 7

2

1

3

B

Revision 3.0

HARDWARE REFERENCE MANUAL 21

A

Page 22

System philosophy

Circular interpolation

It may be required that a tool travels from the starting point to the

end point in an arc of a circle. In this instance the motion of two

axes is related via a circular interpolated move using the

MOVECIRC command.

Consider the diagram in the figure. It corresponds to the

MOVECIRC(-100,0,-50,0,0) command. The centre point and

desired end point of the trajectory relative to the start point and the

direction of movement are specified. The MOVECIRC command

computes the radius and the angle of rotation. Like the linearly

interpolated MOVE command, the ACCEL, DECEL and SPEED

variables associated with the base axis determine the speed profile

along the circular move.

CAM control

Additional to the standard move profiles the TJ1-MC__ also

provides a way to define a position profile for the axis to move. The

CAM command moves an axis according to position values stored

in the TJ1-MC__ Table array. The speed of travelling through the

profile is determined by the axis parameters of the axis.

The figure corresponds to the command CAM(0,99,100,20). A is

the time axis, B is the position axis.

fig. 8

fig. 9

-50

50

050

B

2.2.3 EG control

Electronic Gearing control allows you to create a direct gearbox link

or a linked move between two axes. The MC Unit supports the

following operations.

Revision 3.0

• Electronic gearbox

• Linked CAM

HARDWARE REFERENCE MANUAL 22

A

Page 23

System philosophy

• Linked move

• Adding axes

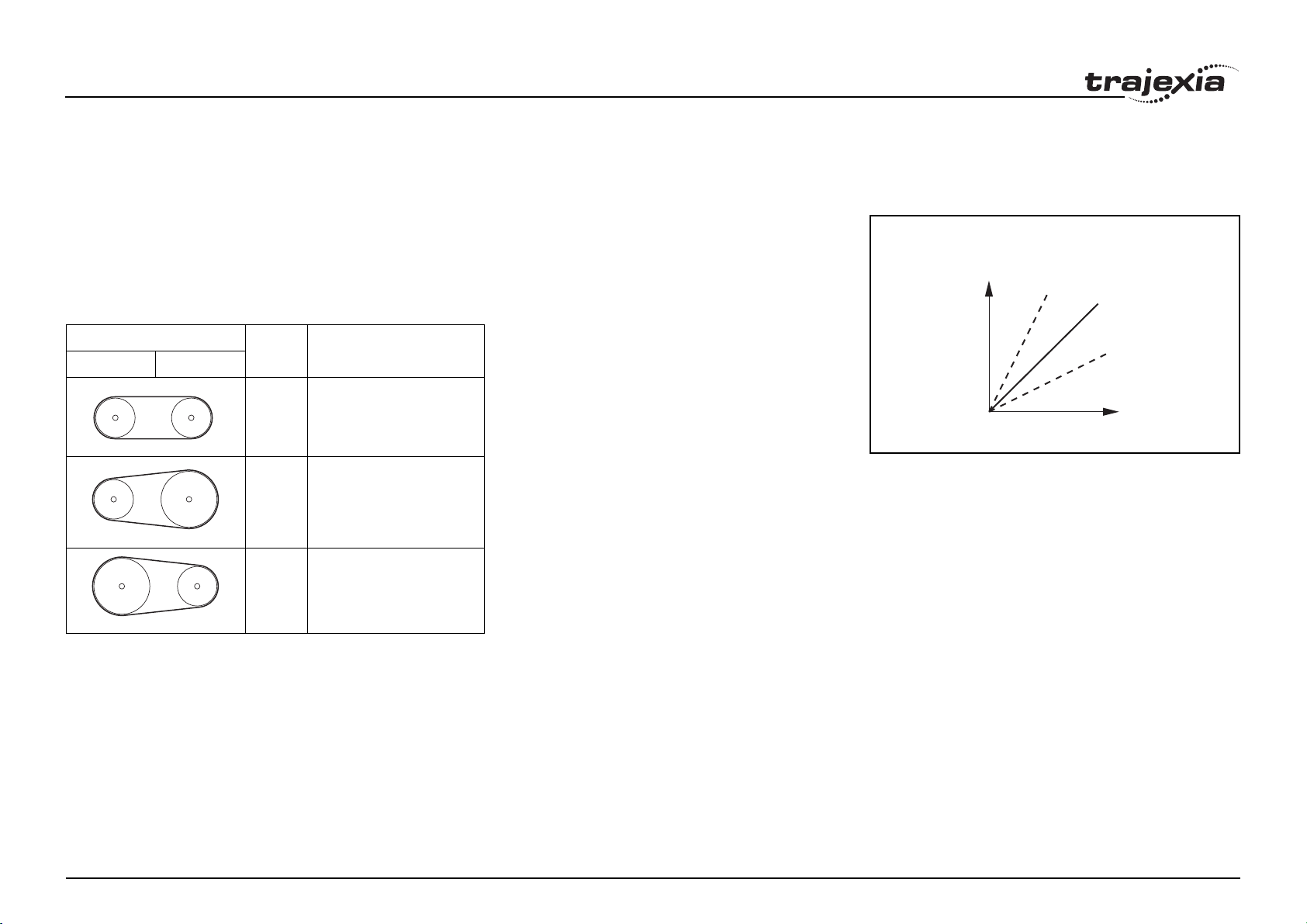

Electronic gearbox

The TJ1-MC__ is able to have a gearbox link from one axis to

another as if there is a physical gearbox connecting them. This can

be done using the CONNECT command in the program. In the

command the ratio and the axis to link to are specified.

In the figure, A is the Master axis, and B is the CONNECT axis.

/i

fig. 10

B

2:1

1:1

Axes Ratio CONNECT command

0 1

1:1 CONNECT(1,0) AXIS(1)

2:1 CONNECT(2,0) AXIS(1)

1:2 CONNECT(0.5,0) AXIS(1)

1:2

A

Revision 3.0

HARDWARE REFERENCE MANUAL 23

Page 24

System philosophy

Linked CAM control

Next to the standard CAM profiling tool the TJ1-MC__ also

provides a tool to link the CAM profile to another axis. The

command to create the link is called CAMBOX. The travelling

speed through the profile is not determined by the axis parameters

of the axis but by the position of the linked axis. This is like

connecting two axes through a cam.

In the figure, A is the Master axis (0) position, and B is the

CAMBOX Axis (1) position.

Linked move

The MOVELINK command provides a way to link a specified move

to a master axis. The move is divided into an acceleration,

deceleration and constant speed part and they are specified in

master link distances. This can be particularly useful for

synchronizing two axes for a fixed period.

The labels in the figure are:

A. Time axis.

B. Speed axis.

C. Master axis (1).

D. Synchronized.

E. MOVELINK axis (0).

fig. 11

B

A

fig. 12

B

DC

E

A

Revision 3.0

HARDWARE REFERENCE MANUAL 24

Page 25

System philosophy

Adding axes

It is very useful to be able to add all movements of one axis to

another. One possible application is for instance changing the

offset between two axes linked by an electronic gearbox. The TJ1MC__ provides this possibility by using the ADDAX command. The

movements of the linked axis will consists of all movements of the

actual axis plus the additional movements of the master axis.

In the figure, A is the time axis and B is the speed axis.

fig. 13

B

B

BASE(0)

ADDAX(2)

FORWARD

MOVE(100) AXIS(2)

MOVE(-60) AXIS(2)

A

A

B

A

2.2.4 Other operations

Canceling moves

In normal operation or in case of emergency it can be necessary to

Revision 3.0

cancel the current movement from the buffers. When the CANCEL

or RAPIDSTOP commands are given, the selected axis

respectively all axes will cancel their current move.

HARDWARE REFERENCE MANUAL 25

Page 26

System philosophy

Origin search

The encoder feedback for controlling the position of the motor is

incremental. This means that all movement must be defined with

respect to an origin point. The DATUM command is used to set up

a procedure whereby the TJ1-MC__ goes through a sequence and

searches for the origin based on digital inputs and/or Z-marker from

the encoder signal.

Print registration

The TJ1-MC__ can capture the position of an axis in a register

when an event occurs. The event is referred to as the print

registration input. On the rising or falling edge of an input signal,

which is either the Z-marker or an input, the TJ1-MC__ captures

the position of an axis in hardware. This position can then be used

to correct possible error between the actual position and the

desired position. The print registration is set up by using the

REGIST command.

The position is captured in hardware, and therefore there is no

software overhead and no interrupt service routines, eliminating the

need to deal with the associated timing issues.

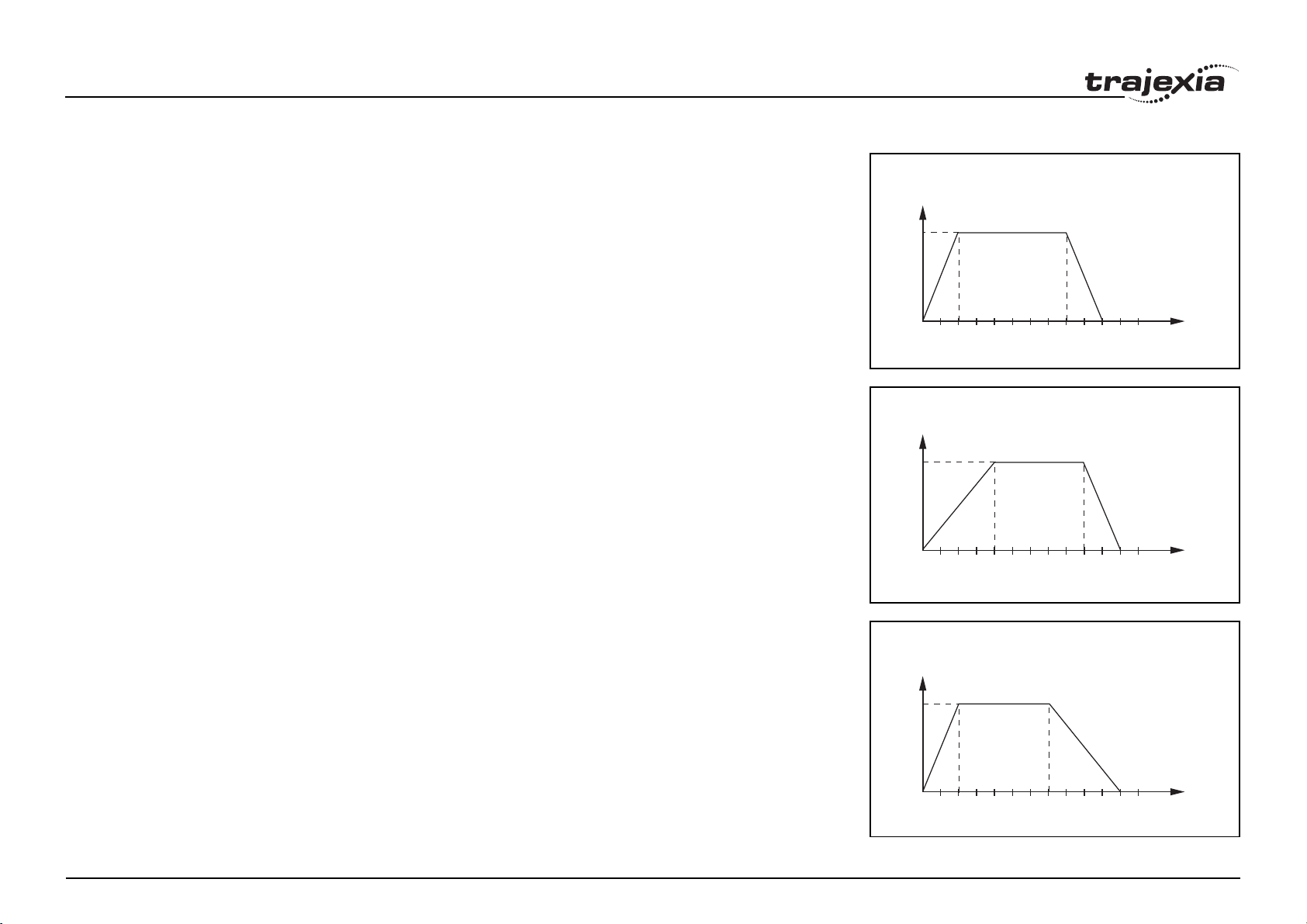

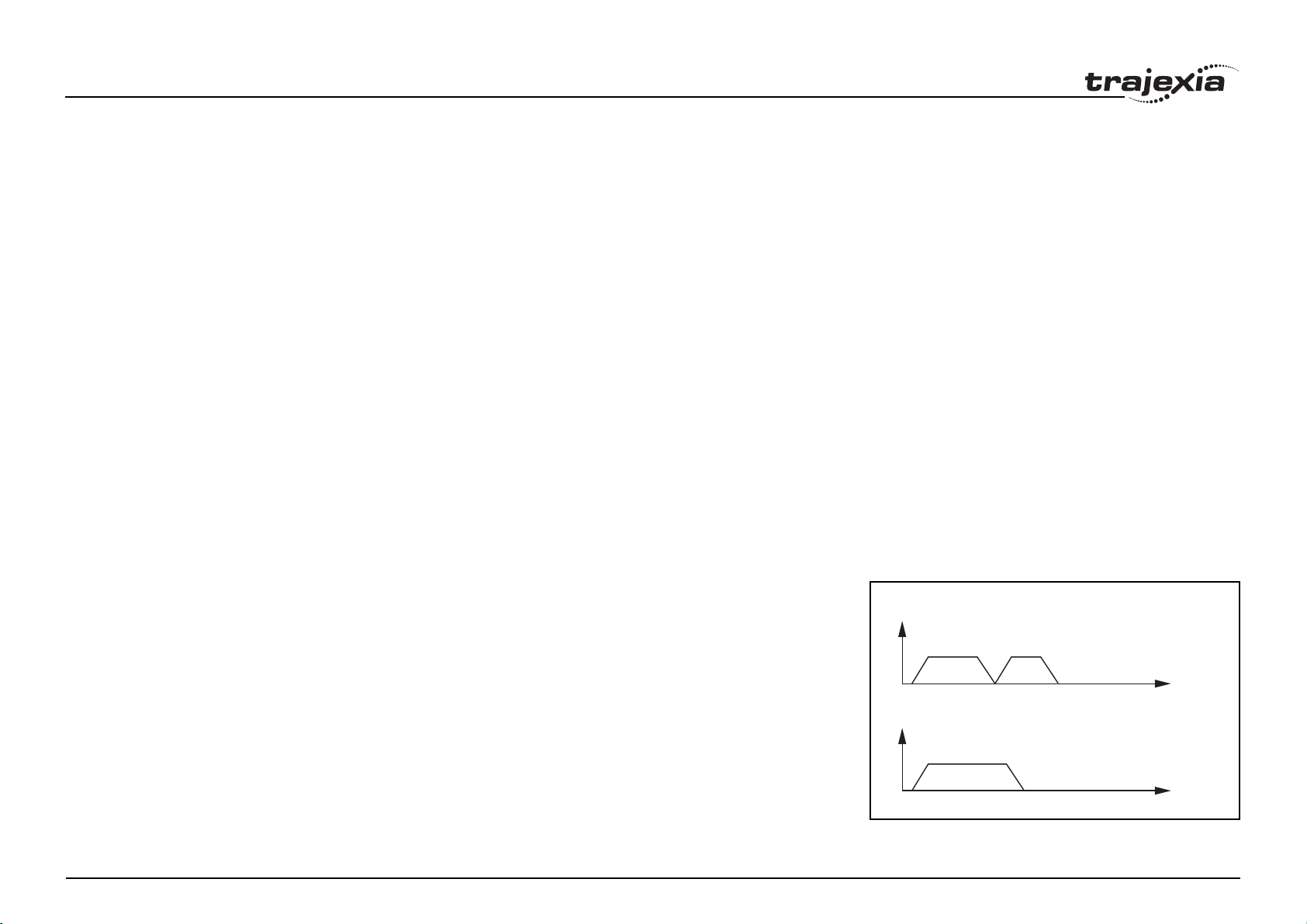

Merging moves

If the MERGE axis parameter is set to 1, a movement is always

followed by a subsequent movement without stopping. The figures

show the transitions of two moves with MERGE value 0 and value

1.

In the figure, A is the time axis and B is the speed axis.

fig. 14

B

MERGE=0

Jogging

Jogging moves the axes at a constant speed forward or reverse by

manual operation of the digital inputs. Different speeds are also

selectable by input. Refer to the FWD_JOG, REV_JOG and

FAST_JOG axis parameters.

Revision 3.0

HARDWARE REFERENCE MANUAL 26

B

MERGE=1

A

A

Page 27

System philosophy

2.3 Servo system principles

The servo system used by and the internal operation of the TJ1MC__ are briefly described in this section.

2.3.1 Semi-closed loop system

The servo system of the TJ1-MC__ uses a semi-closed or inferred

closed loop system. This system detects actual machine

movements by the rotation of the motor in relation to a target value.

It calculates the error between the target value and actual

movement, and reduces the error through feedback.

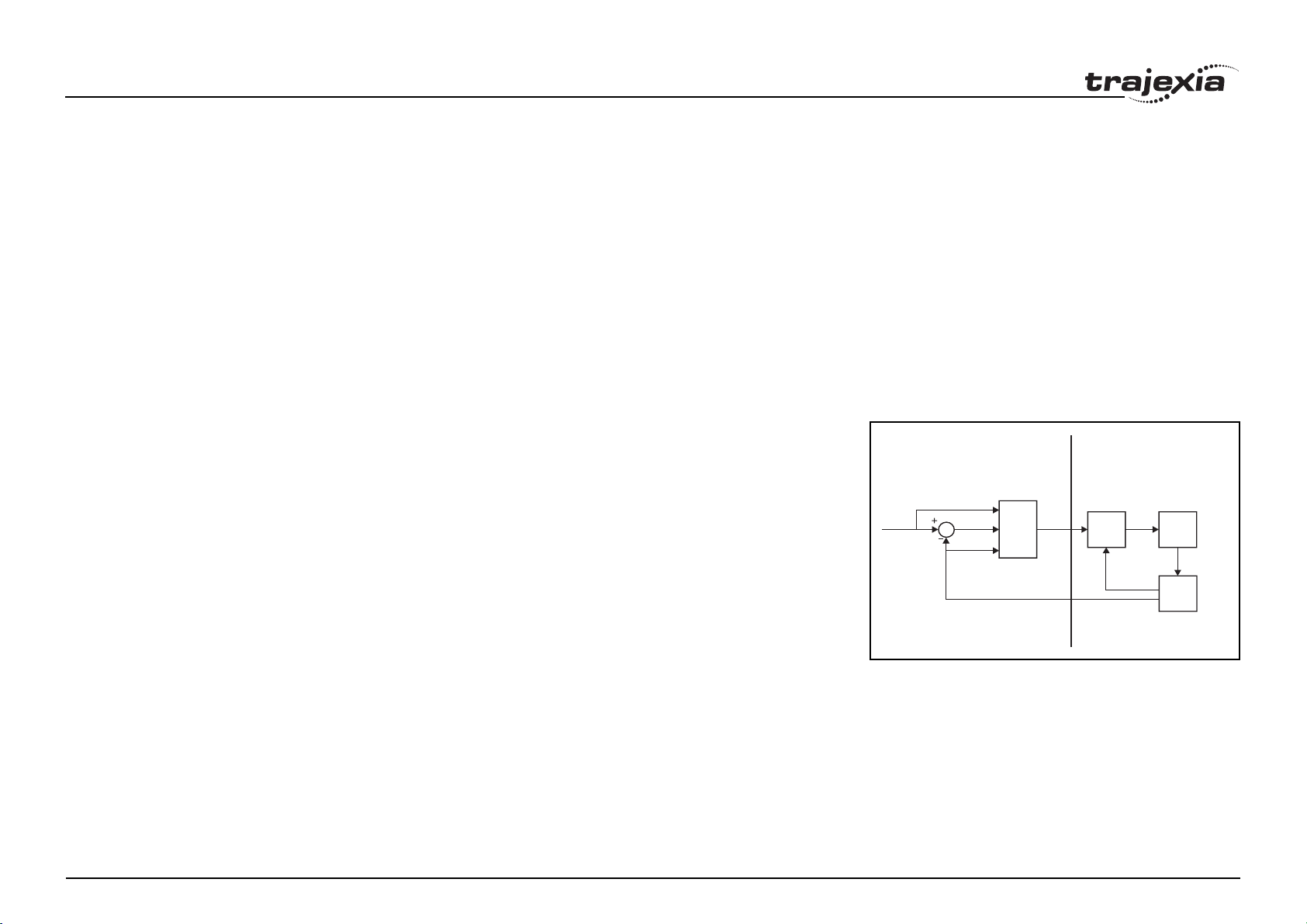

2.3.2 Internal operation of the TJ1-MC__

Inferred closed loop systems occupy the mainstream in modern

servo systems applied to positioning devices for industrial

applications. The figure shows the basic principle of the servo

system as used in the TJ1-MC__.

1. The TJ1-MC__ performs actual position control. The main input

of the controller is the Following Error, which is the calculated

difference between the demand position and the actual

measured position.

2. The Position Controller calculates the required speed reference

output determined by the Following Error and possibly the

demanded position and the measured position. The speed

reference is provided to the Servo Driver.

3. The Servo Driver controls the rotational speed of the servo

motor corresponding to the speed reference. The rotational

speed is proportional to the speed reference.

4. The rotary encoder generates the feedback pulses for both the

speed feedback within the Servo Driver speed loop and the

position feedback within the TJ1-MC__ position loop.

The labels in the figure are:

Revision 3.0

A. TJ1-MC__.

B. Servo system.

fig. 15

C

AB

2

1

D

E

3

F

G

4

I

H

J

HARDWARE REFERENCE MANUAL 27

Page 28

System philosophy

C. Demand position.

D. Position control.

E. Speed reference.

F. Speed control.

G. M otor.

H. Encoder.

I. Measured speed.

J. Measured position.

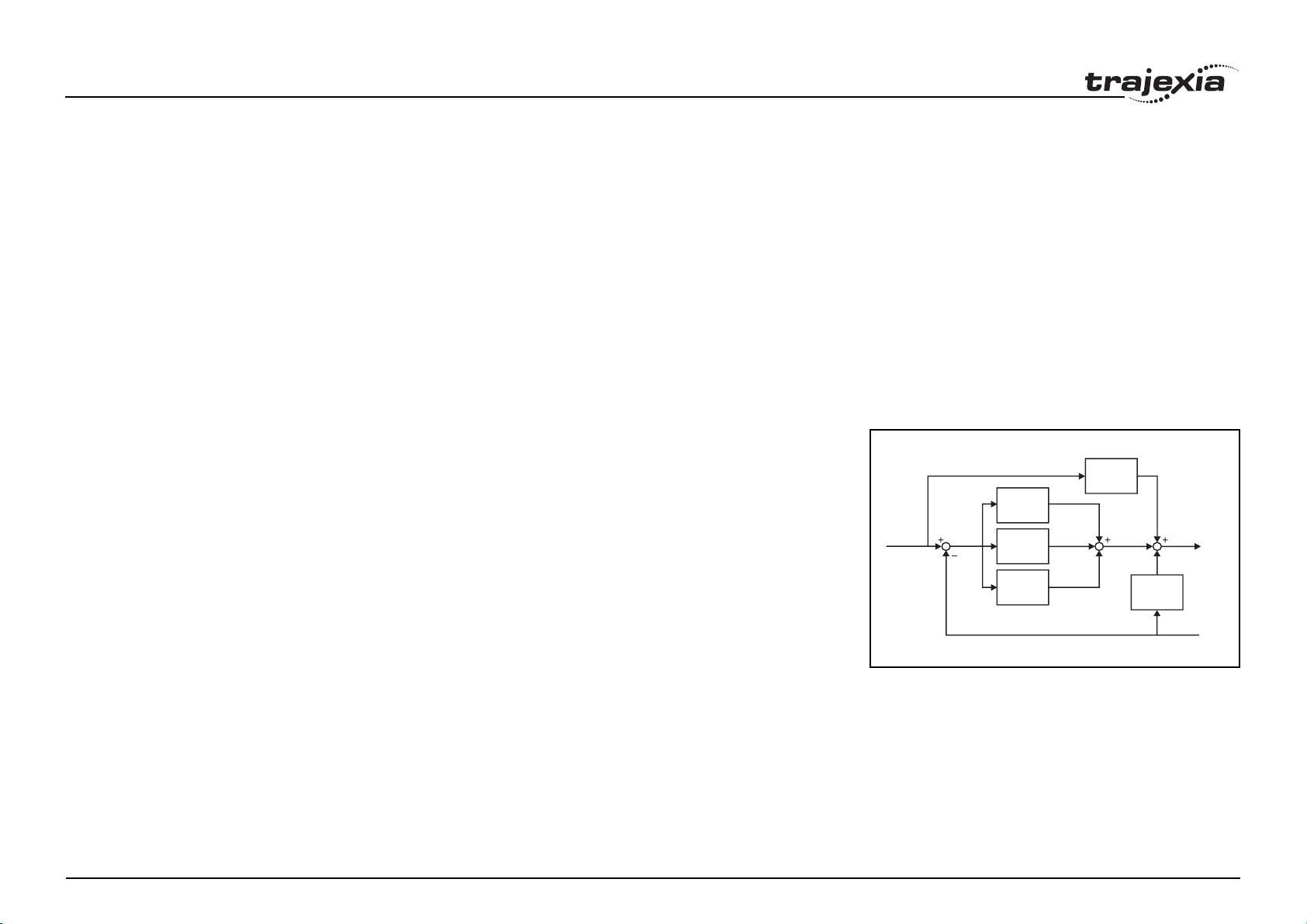

2.3.3 Motion control algorithm

The servo system controls the motor by continuously adjusting the

speed reference to the Servo Driver. The speed reference is

calculated by the motion control algorithm of the TJ1-MC__, which

is explained in this section.

The motion control algorithm uses the demand position (A), the

measured position (D) and the Following Error (B) to determine the

speed reference. The Following Error is the difference between the

demanded and measured position. The demand position, the

measured position and the Following Error are represented by the

axis parameters MPOS, DPOS and FE. Five gain values have

been implemented for the user to be able to configure the correct

control operation for each application.

C is the output signal.

• Proportional gain

The proportional gain K

proportional to the Following Error E.

O

= Kp · E

p

All practical systems use proportional gain. For many just using

this gain parameter alone is sufficient. The proportional gain

axis parameter is called P_GAIN.

• Integral gain

The integral gain K

the sum of the Following Errors that have occurred during the

Revision 3.0

system operation.

O

= Ki · ΣE

i

creates an output Op that is

p

creates an output Oi that is proportional to

i

fig. 16

∑

K

vff

K

p

AB C

∑

K

i

Δ

K

d

Δ

K

ov

D

HARDWARE REFERENCE MANUAL 28

Page 29

System philosophy

Integral gain can cause overshoot and so is usually used only

on systems working at constant speed or with slow

accelerations. The integral gain axis parameter is called

I_GAIN.

• Derivative gain

The derivative gain K

produces an output Od that is

d

proportional to the change in the Following Error E and speeds

up the response to changes in error while maintaining the same

relative stability.

O

= Kd · ΔE

d

Derivative gain may create a smoother response. High values

may lead to oscillation. The derivative gain axis parameter is

called D_GAIN.

• Output speed gain

The output speed gain K

proportional to the change in the measured position P

produces an output Oov that is

ov

m

increases system damping.

O

= Kov · ΔP

ov

m

The output speed gain can be useful for smoothing motions but

will generate high Following Errors. The output speed gain axis

parameter is called OV_GAIN.

• Speed feed forward gain

The speed feedforward gain K

proportional to the change in demand position P

produces an output O

vff

d

and

minimizes the Following Error at high speed.

= K

O

vff

vff

· ΔP

d

The parameter can be set to minimise the Following Error at a

constant machine speed after other gains have been set. The

speed feed forward gain axis parameter is called VFF_GAIN.

and

that is

vff

The default settings are given in the table along with the resulting

profiles. Fractional values are allowed for gain settings.

/i

Revision 3.0

Gain Default value

Proportional gain 0.1

Integral gain 0.0

HARDWARE REFERENCE MANUAL 29

Page 30

System philosophy

Gain Default value

Derivative gain 0.0

Output speed gain 0.0

Speed feedforward gain 0.0

2.4 Trajexia system architecture

The system architecture of the Trajexia is dependant upon these

concepts:

• Program control

• Motion Sequence

• Motion buffers

• Communication

• Peripherals

These concepts depend upon the value set in the SERVO_PERIOD

parameter. The relationship between the value of SERVO_PERIOD and the

different concepts of the system architecture are describes as follows.

2.4.1 Program control

Programs make the system work in a defined way. The programs are written

in a language similar to BASIC and control the application of the axes and

modules. 14 Programs can be executed in parallel. The programs can be set

to run at system power-up, started and stopped from other programs and

executed from Trajexia Tools.

Programs execute commands to move the axes, control inputs and outputs

and make communication via BASIC commands.

• Executing the Position loop

• Sending the Axis reference

• Error handling

2.4.3 Motion buffers

Motion buffers are the link between the BASIC commands and the Axis

control loop. When a BASIC motion command is executed, the command is

stored in one of the buffers. During the next motion sequence, the profile

generator executes the movement according to the information in the buffer.

When the movement is finished, the motion command is removed from the

buffer.

2.4.4 Communication

All communication is carried out in the forth CPU task. A set of BASIC

communication commands are used to configure the communications.

When the Trajexia is a communication slave (as in the PROFIBUS

communication) it is only necessary to configure the communication in an

initial task. The values are exchanged from the configured global variables in

a transparent way. When the Trajexia is a communications master, the

BASIC communication commands are used to write and read.

2.4.5 Peripherals

All inputs and outputs are used with the set of parameters (IN, OP, AIN,

AOUT). The inputs and outputs are automatically detected and mapped in

Trajexia. Inverters are considered a peripheral device and have a set of

BASIC commands to control them. Various MECHATROLINK-II input and

output modules can be connected to a TJ1-ML__ unit.

2.4.2 Motion sequence

The motion sequence controls the position of all 16 axes with the actions as

follows:

Revision 3.0

• Reading the Motion buffer

• Reading the current Measured Position (MPOS)

• Calculating the next Demanded Position (DPOS)

HARDWARE REFERENCE MANUAL 30

Page 31

System philosophy

2.5 Cycle time

All processes in the Trajexia system are based on the cycle time.

The cycle time is divided into four CPU tasks:

•250μs time intervals for a SERVO_PERIOD of 0.5 and 1.0ms

•500μs time intervals for a SERVO_PERIOD of 2.0ms

The processes that can be carried out in each time interval

depends on the SERVO_PERIOD that is set.

The operations executed in each CPU task are:

CPU task Operation

First CPU task Motion Sequence

Low priority process

Second CPU task High priority process

Third CPU task

Fourth CPU task External Communications

1

Note

1

Motion Sequence (only if SERVO_PERIOD=0.5ms)

LED Update.

High priority process

The Motion sequence execution depends on setting of

the SERVO_PERIOD parameter.

fig. 17

fig. 18

250μs

1

500μs

1

2

Cycle time = 1ms

2

Cycle time = 2 ms

3

3

4

4

2.5.1 Servo period

The SERVO_PERIOD can be set at 0.5, 1 or 2ms. The processes

that take place within the cycle time depend on the setting of the

SERVO_PERIOD parameter. The SERVO_PERIOD parameter is a

Trajexia parameter that must be set according to the system

configuration.

The factory setting is 1ms (SERVO_PERIOD=1000). A change is

set only after a restart of the TJ1-MC__.

Revision 3.0

HARDWARE REFERENCE MANUAL 31

Page 32

System philosophy

Note

Only the Sigma-III servo-driver supports 0.5ms transmission cycle.

Example 1

The SERVO_PERIOD has a value of 0.5ms and the motion

sequence is executed every 0.5ms.

fig. 19

CPU task 1

CPU task 2

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

Example 2

The SERVO_PERIOD has a value of 1ms and the motion

sequence is executed every 1ms. As the motion sequence is not

executed during CPU task 3, there is more time for the program

execution. High priority programs run faster.

Revision 3.0

CPU task 3

CPU task 4

fig. 20

CPU task 1

CPU task 2

CPU task 3

CPU task 4

Motion sequence

LED refresh

High priority task (13,14)

Communication

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

LED refresh

High priority task (13,14)

Communication

1ms

1ms

HARDWARE REFERENCE MANUAL 32

Page 33

System philosophy

Example 3

The SERVO_PERIOD has a value of 2ms and the motion

sequence is executed every 2.0ms.

Servo period rules

The number of axes and MECHATROLINK-II devices in the

Trajexia system determines the value of the SERVO_PERIOD

system parameter.

There are 3 types of MECHATROLINK-II devices that are

supported by the TJ1-MC__ units:

•Servo Drivers.

The TJ1-MC__ considers Servo Drivers as axes.

• Frequency inverters.

The TJ1-MC__ does not consider frequency inverters as axes.

• I/O units and slice bus couplers.

The TJ1-MC__ does not consider I/O units (analog and digital,

counter and pulse) and slice bus couplers as axes.

You must obey the most restrictive rules when you set the

SERVO_PERIOD parameter. An incorrect value of the

SERVO_PERIOD parameter results in an incorrect detection of the

MECHATROLINK-II devices.

The most restrictive rules are given in the tables below. For each

unit the table lists the maximum number of devices the unit can

control at the given SERVO_PERIOD setting.

/i

fig. 21

CPU task 1

CPU task 2

CPU task 3

CPU task 4

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

LED refresh

High priority task (13,14)

Communication

2ms

SERVO_PERIOD TJ1-MC16 TJ1-MC04 TJ1-ML16 TJ1-ML04

0.5 ms 8 axes 5 axes 4 devices 4 devices

4 non-axis

devices

1.0 ms 16 axes 5 axes 8 devices 4 devices

Revision 3.0

8 non-axis

devices

4 non-axis

devices

8 non-axis

devices

HARDWARE REFERENCE MANUAL 33

Page 34

System philosophy

SERVO_PERIOD TJ1-MC16 TJ1-MC04 TJ1-ML16 TJ1-ML04

2.0 ms 16 axes 5 axes 16 devices 4 devices

8 non-axis

devices

8 non-axis

devices

Configuration examples

Example 1

• 1x TJ1-MC__

• 1x TJ1-ML__

• 3x Sigma-II Servo Driver

• SERVO_PERIOD = 1ms

TJ1-MC__ Supports 0.5ms SERVO_PERIOD with 3 axes.

TJ1-MC__ Supports 0.5ms SERVO_PERIOD with 3 devices.

Sigma-II supports 1ms SERVO_PERIOD. This is the limiting factor.

fig. 22

Revision 3.0

HARDWARE REFERENCE MANUAL 34

Page 35

System philosophy

Example 2

• 1x TJ1-MC16

• 2x TJ1-ML16

• 16x Sigma-II Servo Driver

• SERVO_PERIOD = 1ms

TJ1-MC16 supports 1ms SERVO_PERIOD with 16 axes.

TJ1-ML16 supports 1ms SERVO_PERIOD with 8 devices.

Sigma-II supports 1ms SERVO_PERIOD.

fig. 23

Servo Drive

Address 41Address 42Address 43Address 44Address 45Address 46Address 47Address

48

Terminator

Axis 0

Address

49

Axis 8

Revision 3.0

HARDWARE REFERENCE MANUAL 35

Axis 1

Address 4AAddress 4BAddress 4CAddress 4DAddress 4EAddress 4FAddress

Axis 9

Axis 2

Axis 10

Axis 3

Axis 11

Axis 4

Axis 12

Axis 5

Axis 13

Axis 6

Axis 14

Axis 7

50

Axis 15

Terminator

Page 36

System philosophy

Example 3

• 1x TJ1-MC16

• 1x TJ1-ML16

• 8x Sigma-II Servo Driver

• 1x F7Z inverter with SI-T interface

• 3x MECHATROLINK-II I/Os

• SERVO_PERIOD = 2.0ms

TJ1-ML16 supports 2.0ms SERVO_PERIOD with 12 devices. This

is the limiting factor.

Sigma-II supports 1.0ms SERVO_PERIOD.

SI-T supports 1ms.

MECHATROLINK-II I/Os support 1.0ms.

Address

21

Address

0 31 32 95 96 159 160

I/O Memory Allocations

Address 62Address

61

fig. 24

63

Address 41Address 42Address 43Address 44Address 45Address 46Address 47Address

48

Revision 3.0

HARDWARE REFERENCE MANUAL 36

Page 37

System philosophy

Example 4

• 1x TJ1-MC16

• 1x TJ1-ML16

• 2x TJ1-FL02

• 1x TJ1-PRT (does not influence in the SERVO_PERIOD)

• 5x Sigma-II Servo Driver

• SERVO_PERIOD = 1.0ms

TJ1-MC16 supports 1.0ms SERVO_PERIOD with 9 axes (5

MECHATROLINK-II servo axes and 4 TJ1-FL02 axes)

TJ1-ML16 supports 1.0ms SERVO_PERIOD with 5 devices

TJ1-FL02 supports 0.5ms SERVO_PERIOD (2 axes each module)

Sigma-II supports 1.0ms SERVO_PERIOD.

fig. 25

Axis 8Axis 7 Axis 1Axis 0

Address43Address44Address45Address46Address

47

Axis 2 Axis 3 Axis 4 Axis 5 Axis 6

2.6 Program control and multi-tasking

The Trajexia system has program, processes and multi tasking

control.

2.6.1 Program control

The Trajexia system can control 14 processes that are written as

BASIC programs. When the program is set to run, the program is

executed.

Processes 1 to 12 are low priority, 13 and 14 are high priority.

Revision 3.0

HARDWARE REFERENCE MANUAL 37

Page 38

System philosophy

2.6.2 Processes

The low-priority process 0 is reserved for the "Terminal Window" of

Trajexia Tools. This terminal window is used to write direct BASIC

commands to the TJ1-MC__ independent to other programs.

These commands are executed after you press the Enter button.

2.6.3 Multi-tasking

Each cycle time is divided into 4 time slices called CPU tasks.

Processes run in the first 3 CPU tasks according to the priority of

the process.

Motion sequence and low-priority processes (A) are executed in

the Low Task (LT) period.

High priority processes (B) are executed in the high Task (HT)

periods.

External communication that are not related to the motion network

are updated in the communications (COMS) period in the fourth

CPU task.

Trajexia can control up to 14 programs at the same time.

In contrast to low priority processes, a high priority process is

always available for execution during two of the four CPU tasks.

The high-priority tasks are executed faster than the low-priority

tasks, it is that they have more time available for their execution. All

the low-priority tasks must share one slot of time and the highpriority task have their own two slots of time.

fig. 26

fig. 27

LT HT #1 HT #2

Cycle time

A

LT HT #1 HT #2

B

Cycle time

COMS.

COMS.

Revision 3.0

HARDWARE REFERENCE MANUAL 38

Page 39

System philosophy

2.6.4 Multi-tasking example

In the example 1, there are two high-priority processes, 13 and 14.

The two HT periods are reserved for these processes, one for

processes 13 and one for processes 14. The low-priority processes

3, 2, 1 and 0 are executed in the LT period, one process per Cycle

time here set to 1.0ms.

In the middle example, there is only one high-priority process, 14.

Both HT periods are reserved for this process. The low-priority

processes, 3, 2, 1 and 0 are executed in the LT period, one process

per cycle time.

In the lower example, there are no high-priority processes.

Therefore, the HT periods can be used for the low-priority

processes. The LT period is also used for the low-priority

processes.

1

14

3

2

3

321

1ms

1ms

143

1ms

13

COMS.

COMS.

COMS.

2

0

(c/l)

fig. 28

1ms

13

14

1ms

142

1ms

32

1ms

COMS. COMS.

1

COMS. COMS.

COMS. COMS.

10

14

(c/l)

1ms

141

1ms

13

0

(c/l)

3

COMS.

1ms

13

14

1ms

140

(c/l)

1ms

210

(c/l)

COMS.

COMS.

Revision 3.0

HARDWARE REFERENCE MANUAL 39

Page 40

System philosophy

2.7 Motion sequence and axes

Motion sequence is the part of the TJ1-MC__ that controls the

axes. The actual way that the motion sequence operates depends

on the axis type. The axis type can be set and read by the

parameter ATYPE. At start-up the Trajexia system automatically

detects the configuration of the axes.

• The default value for the parameter ATYPE for

MECHATROLINK-II axes is 41 (MECHATROLINK speed).

• The default value for the parameter ATYPE for the TJ1-FL02

axes is 44 (Servo axis with an incremental encoder).

All non allocated axes are set as a virtual axis. The value for the

parameter ATYPE is 0.

Every axis has the general structure as shown in fig. 29.

The motion sequence which will be executed at the beginning of

each servo period will contain the following elements:

1. Transfer any moves from BASIC process buffers to motion

buffers (see section 2.8).

2. Read digital inputs.

3. Load moves. (See note.)

4. Calculate speed profile. (See note.)

5. Calculate axis positions. (See note.)

6. Execute position servo. for axis 0 this also includes the Servo

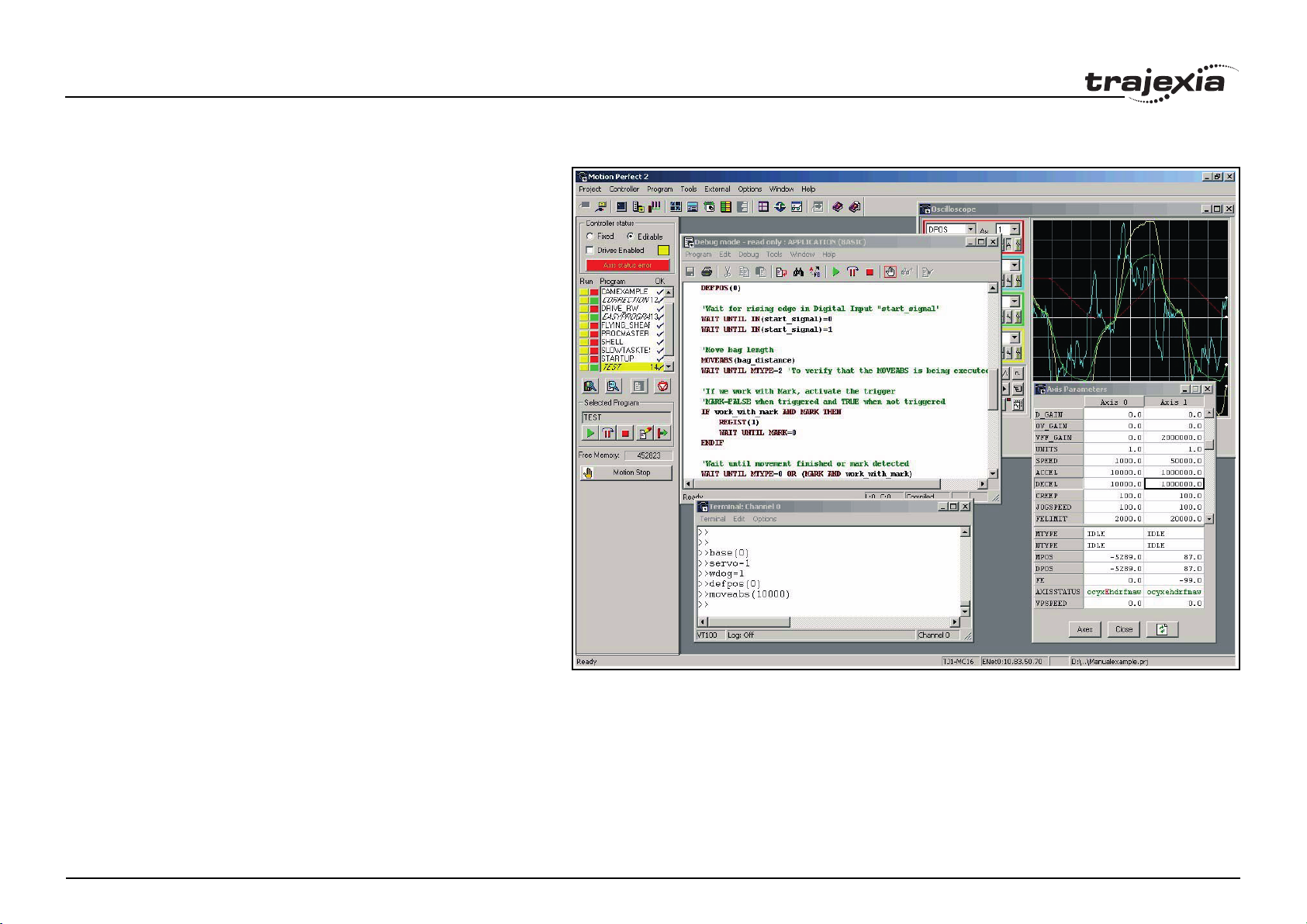

Driver communications. (See note.)