Sysmac Library

User’s Manual

for EtherCAT® 1S Series Library

SYSMAC-XR011

W571-E1-07

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Introduction

Thank you for purchasing an NJ/NX-series CPU Unit or an NY-series Industrial PC.

This manual contains information that is necessary to use the function blocks in the EtherCAT 1S

Series Library. (“Function block” is sometimes abbreviated as “FB”.) Please read this manual and make

sure you understand the functionality and performance of the NJ/NX-series CPU Unit before you

attempt to use it in a control system.

This manual provides function block specifications. It does not describe application restrictions or combination restrictions for Controllers, Units, and components.

Refer to the user’s manuals for all of the products in the application before you use any of the products.

Keep this manual in a safe place where it will be available for reference during operation.

Features of the Library

The EtherCAT 1S Series Library is used to initialize the absolute encoder, back up and restore the

parameters for an OMRON 1S-series Servo Drive with built-in EtherCAT communications.

You can use this library to reduce manpower of programming when implementing the processing for a

Servo Drive.

Introduction

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems(an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Applicable Products

For the model numbers and versions of an NJ/NX-series CPU Unit, NY-series Industrial PC, and the

Sysmac Studio that this library supports, refer to Sysmac Library Version Information in the SYS-

MAC-XR

OMRON website (http://www.ia.omron.com/products/family/3459/download/catalog.html).

Sysmac Library Catalog (Cat. No. P102). This catalog can be downloaded from the

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

1

Manual Structure

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

Manual Structure

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Information on differences in specifications and functionality for CPU Units and Industrial PCs

with different unit versions and for different versions of the Sysmac Studio are given.

Note References are provided to more detailed or related information.

2

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Manual Structure

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

3

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Features of the Library................................................................................................................................. 1

Intended Audience....................................................................................................................................... 1

Applicable Products..................................................................................................................................... 1

Manual Structure ......................................................................................................2

Special Information......................................................................................................................................2

CONTENTS................................................................................................................4

Terms and Conditions Agreement ..........................................................................6

Warranty, Limitations of Liability .................................................................................................................. 6

Application Considerations .......................................................................................................................... 7

Disclaimers .................................................................................................................................................. 7

Safety Precautions ...................................................................................................8

Definition of Precautionary Information........................................................................................................ 8

Symbols....................................................................................................................................................... 8

Cautions....................................................................................................................................................... 9

Precautions for Correct Use..................................................................................10

Related Manuals ..................................................................................................... 11

Revision History .....................................................................................................14

Procedure to Use Sysmac Libraries .............................................................................................. 15

Procedure to Use Sysmac Libraries Installed Using the Installer .............................................................. 16

Procedure to Use Sysmac Libraries Uploaded from a CPU Unit or an Industrial PC................................ 20

Common Specifications of Function Blocks ................................................................................ 23

Common Variables .................................................................................................................................... 24

Precautions................................................................................................................................................ 30

Individual Specifications of

Function Blocks...................................................................................................................... 31

InitEncoder_1S .......................................................................................................................................... 32

Backup_1S ................................................................................................................................................ 41

Restore_1S................................................................................................................................................ 55

MotorSetup_1S.......................................................................................................................................... 64

Restart_1S................................................................................................................................................. 73

EasyTuning_1S ......................................................................................................................................... 78

Appendix .......................................................................................................................................... 91

Referring to Library Information ................................................................................................................. 92

Referring to Function Block and Function Source Codes .......................................................................... 95

Objects to Back up and Restore................................................................................................................ 96

4

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

CONTENTS

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

5

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

6

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

7

Safety Precautions

WARNING

Caution

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury. Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or

property damage.

Safety Precautions

Definition of Precautionary Information

The following notation is used in this user’s manual to provide precautions required to ensure safe

usage of an NJ/NX-series Controller and an NY-series Industrial PC.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must

do.

8

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Cautions

Safety Precautions

Caution

Read all related manuals carefully before you use this library.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures

must be provided in external control circuits.

Check the user program, data, and parameter settings for proper execution before

you use them for actual operation.

The Sysmac Library and manuals are assumed to be used by personnel that is

given in Intended Audience in this manual. Otherwise, do not use them.

The sample programming shows only the portion of a program that uses the function or function block from the library.

When using sample programming in actual devices, also program safety circuits,

device interlocks, I/O with other devices, and other control procedures.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

9

Precautions for Correct Use

Precautions for Correct Use

Using the Library

• When you use the library, functions or function blocks that are not described in the library manual

may be displayed on the Sysmac Studio. Do not use functions or function blocks that are not

described in the manual.

• Do not change the names and the contents of any object list.

• Setting the NoProductChk input variable to TRUE allows you to execute restore even when the product code in the backup data differs from the product code of the restore destination. Make sure that

the restore destination is a 1S-series Servo Drive before you attempt to restore the parameters.

• Do not attempt to turn OFF the power supply to the Controller and EtherCAT slaves or stop the EtherCAT communications until the processing for this function block ends normally or ends in an error.

• After completion of Restore_1S function block, cycle the control power supply to the 1S-series Servo

Drive to apply the restored parameters.

• When the model which was backed up differs from the model to be restored, confirm that the restore

can be performed with the object list which was backed up, and then change NoproductChk of this

function block to TRUE.

• Confirm that the models to be backed up are applicable models and versions before you perform the

backup.

Using Sample Programming

• Create a user program that will produce the intended device operation.

• Check the user program for proper execution before you use it for actual operation.

10

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Related Manuals

Related Manuals

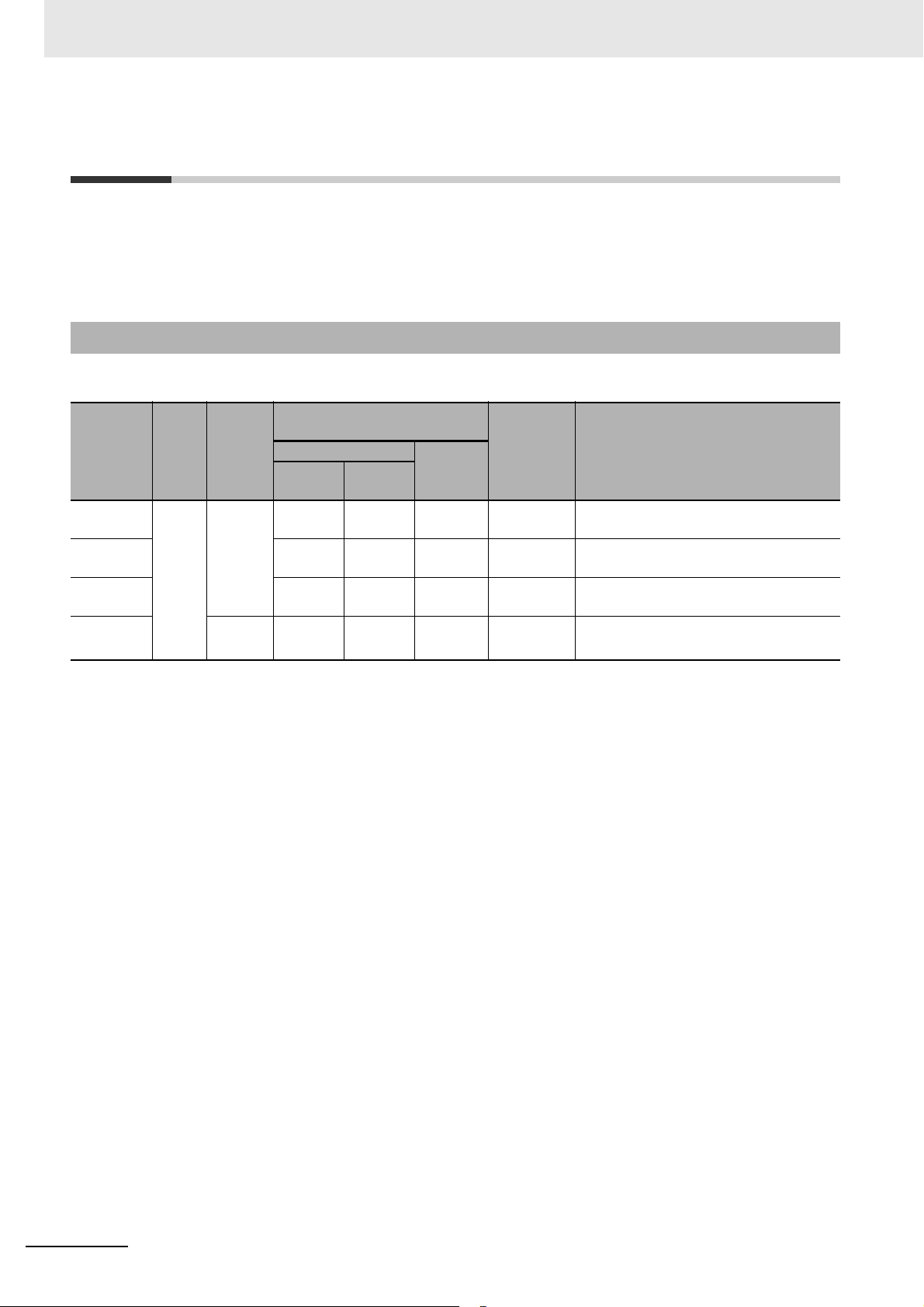

The following are the manuals related to this manual. Use these manuals for reference.

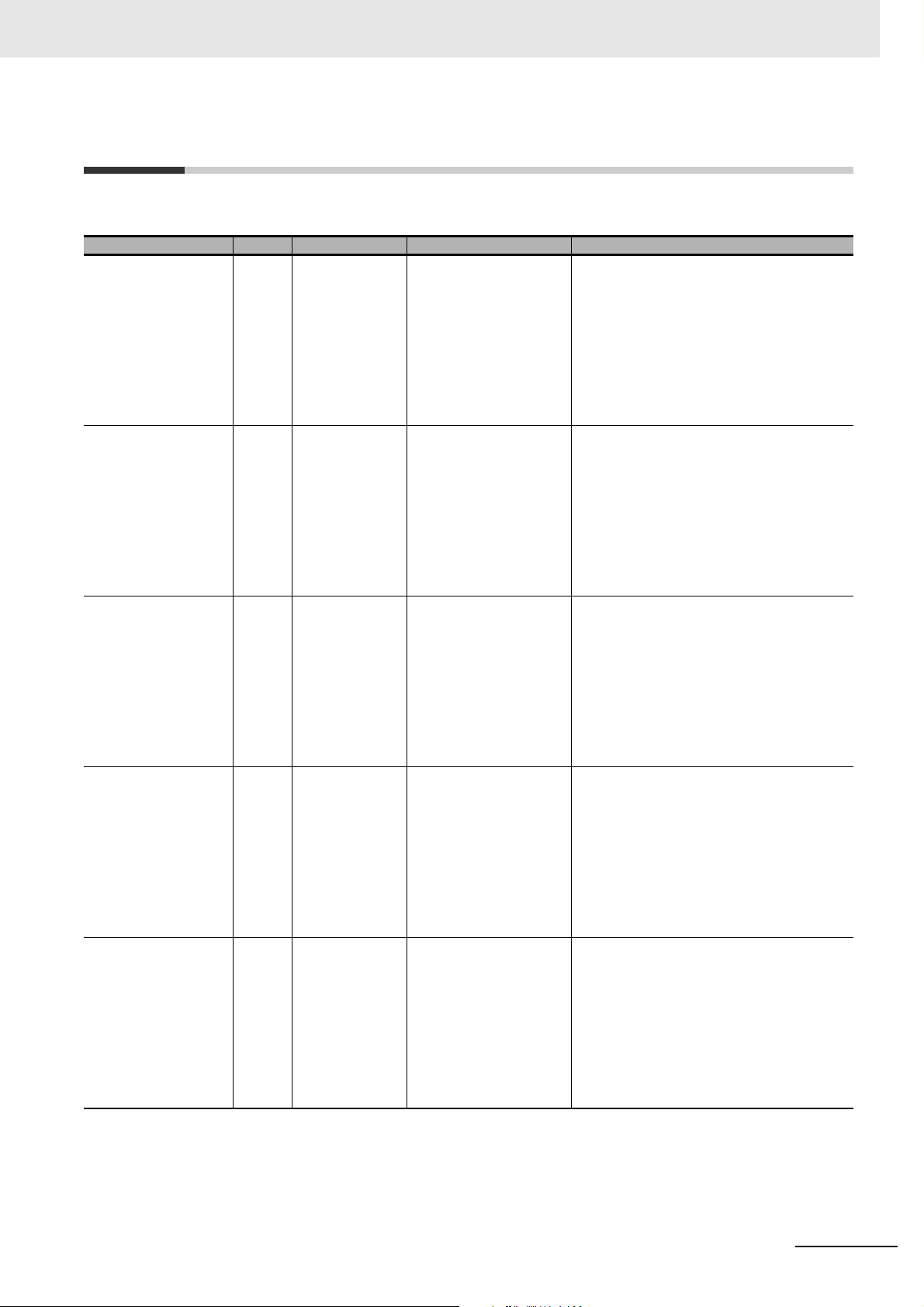

Manual name Cat. No. Model numbers Application Description

NX-series CPU Unit

Hardware User’s Manual

NX-series NX102 CPU

Unit Hardware

User’s Manual

NX-series NX1P2 CPU

Unit Hardware User’s

Manual

NJ-series CPU Unit

Hardware User’s Manual

NY-series IPC Machine

Controller Industrial

Panel PC Hardware

User’s Manual

W535 NX701- Learning the basic specifi-

cations of the NX-series

NX701 CPU Units, including introductory information,

designing, installation, and

maintenance. Mainly hardware information is provided

W593 NX102- Learning the basic specifi-

W578 NX1P2- Learning the basic specifi-

W500 NJ501-

NJ301-

NJ101-

W557 NY532- Learning the basic specifi-

cations of the NX102 CPU

Units, including introductory

information, designing,

installation, and maintenance. Mainly hardware

information is provided.

cations of the NX-series

NX1P2 CPU Units, including introductory information,

designing, installation, and

maintenance. Mainly hardware information is provided

Learning the basic specifications of the NJ-series

CPU Units, including introductory information, designing, installation, and

maintenance.

Mainly hardware information is provided

cations of the NY-series

Industrial Panel PCs,

including introductory information, designing, installation, and maintenance.

Mainly hardware information is provided

An introduction to the entire NX701 CPU Unit

system is provided along with the following information on the CPU Unit.

Features and system configuration

Overview

Part names and functions

General specifications

Installation and wiring

Maintenance and inspection

An introduction to the entire NX102 system is

provided along with the following information on

the CPU Unit.

Features and system configuration

Introduction

Part names and functions

General specifications

Installation and wiring

Maintenance and Inspection

An introduction to the entire NX1P2 CPU Unit

system is provided along with the following information on the CPU Unit.

Features and system configuration

Overview

Part names and functions

General specifications

Installation and wiring

Maintenance and Inspection

An introduction to the entire NJ-series system is

provided along with the following information on

the CPU Unit.

Features and system configuration

Overview

Part names and functions

General specifications

Installation and wiring

Maintenance and inspection

An introduction to the entire NY-series system is

provided along with the following information on

the Industrial Panel PC.

Features and system configuration

Introduction

Part names and functions

General specifications

Installation and wiring

Maintenance and inspection

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

11

Related Manuals

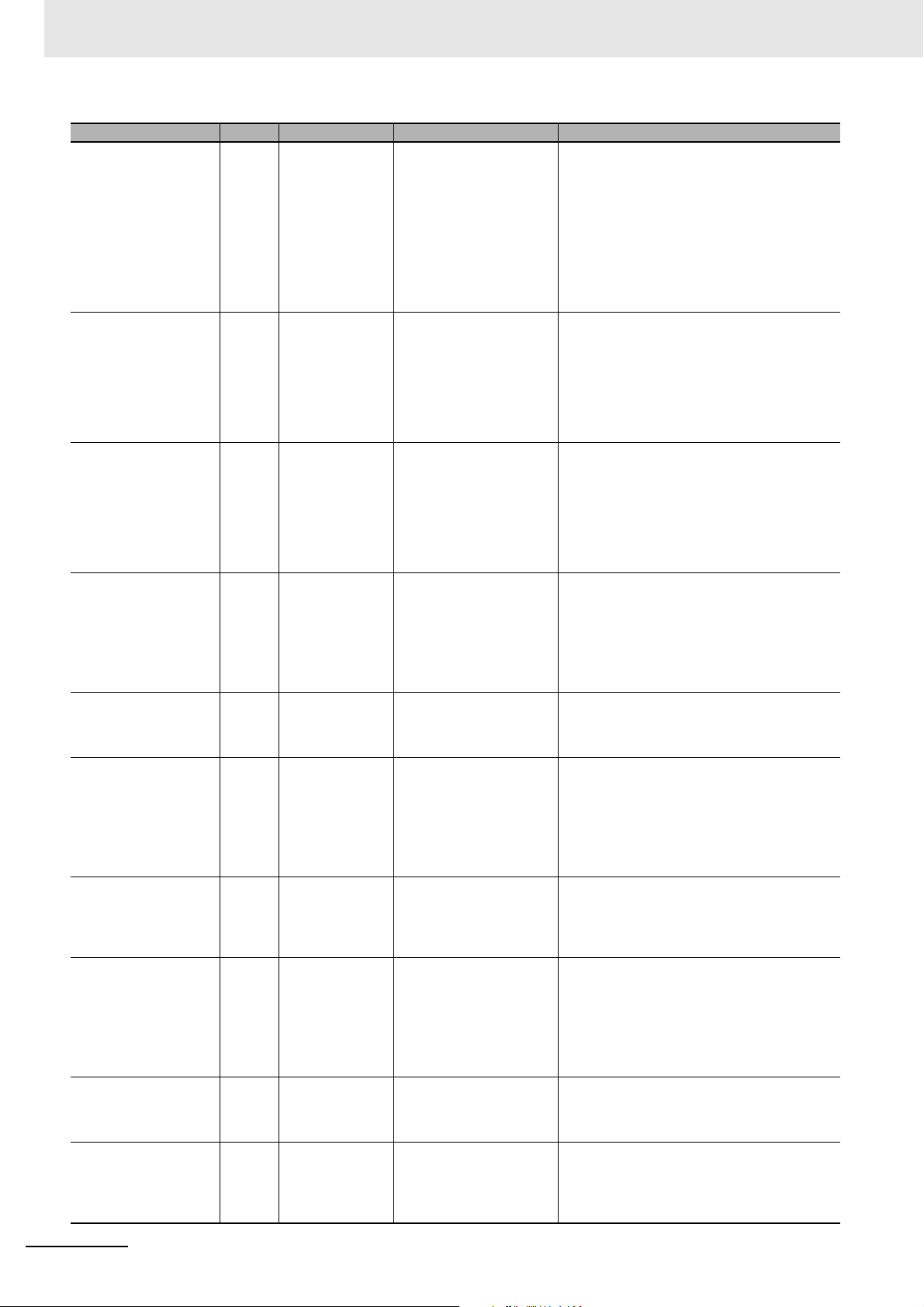

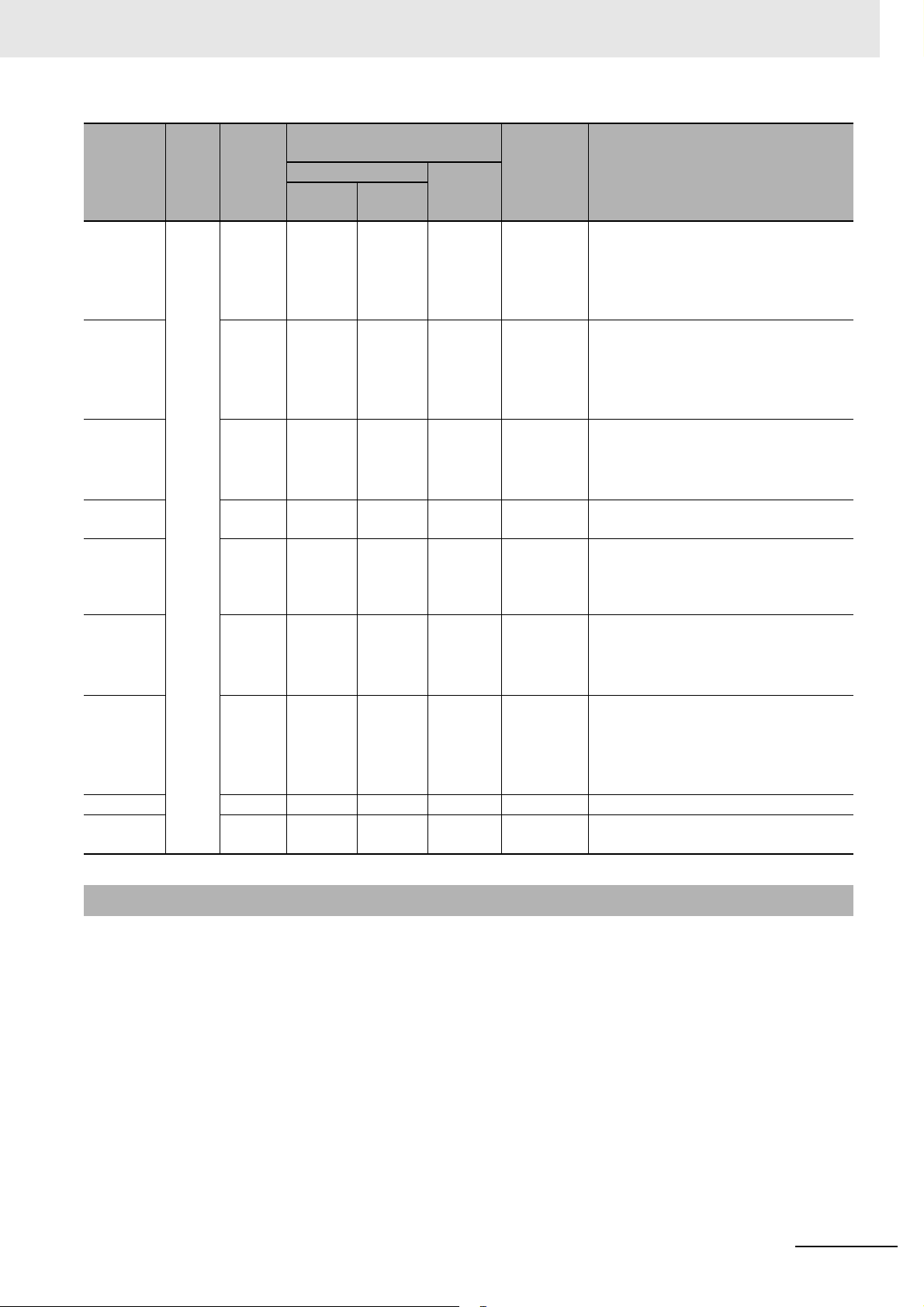

Manual name Cat. No. Model numbers Application Description

NY-series IPC Machine

Controller Industrial Box

PC Hardware User's

Manual

NJ/NX-series CPU Unit

Software User’s Manual

NY-series IPC Machine

Controller Industrial

Panel PC / Industrial Box

PC Software User’s

Manual

NJ/NX-series Instructions

Reference Manual

NY-series Instructions

Reference Manual

NJ/NX-series CPU Unit

Motion Control User's

Manual

NY-series IPC Machine

Controller Industrial

Panel PC / Industrial Box

PC Motion Control

User’s Manual

NJ/NX-series Motion

Control Instructions Reference Manual

NY-series Motion Control

Instructions Reference

Manual

NJ/NY-series NC Integrated Controller User’s

Manual

W556 NY512- Learning the basic specifi-

cations of the NY-series

Industrial Box PCs, including introductory information,

designing, installation, and

maintenance. Mainly hardware information is provided

W501 NX701-

NX102-

NX1P2-

NJ501-

NJ301-

NJ101-

W558 NY532-

NY512-

W502 NX701-

NX102-

NX1P2-

NJ501-

NJ301-

NJ101-

W560 NY532-

NY512-

W507 NX701-

NX102-

NX1P2-

NJ501-

1-

NJ30

1-

NJ10

W559 NY532-

NY512-

W508 NX701-

NX102-

NX1P2-

NJ501-

NJ301-

NJ101-

W561 NY532-

NY512-

O030 NJ501-5300

NY532-5400

Learning how to program

and set up an NJ/NX-series

CPU Unit.

Mainly software information is provided

Learning how to program

and set up the Controller

functions of an NY-series

Industrial PC

Learning detailed specifications on the basic instructions of an NJ/NX-series

CPU Unit

Learning detailed specifications on the basic instructions of an NY-series

Industrial PC

Learning about motion control settings and programming concepts of an

NJ/NX-series CPU Unit.

Learning about motion control settings and programming concepts of an

NY-series Industrial PC.

Learning about the specifications of the motion control instructions of an

NJ/NX-series CPU Unit.

Learning about the specifications of the motion control instructions of an

NY-series Industrial PC.

Performing numerical control with NJ/NY-series Controllers.

An introduction to the entire NY-series system is

provided along with the following information on

the Industrial Box PC.

Features and system configuration

Introduction

Part names and functions

General specifications

Installation and wiring

Maintenance and inspection

The following information is provided on a Controller built with an NJ/NX-series CPU Unit.

CPU Unit operation

CPU Unit features

Initial settings

Programming based on IEC 61131-3 language

specifications

The following information is provided on

NY-series Machine Automation Control Software.

Controller operation

Controller features

Controller settings

Programming based on IEC 61131-3 language

specifications

The instructions in the instruction set (IEC

61131-3 specifications) are described.

The instructions in the instruction set (IEC

61131-3 specifications) are described.

The settings and operation of the CPU Unit and

programming concepts for motion control are

described.

The settings and operation of the Controller and

programming concepts for motion control are

described.

The motion control instructions are described.

The motion control instructions are described.

Describes the functionality to perform the numerical control. Use this manual together with the

NJ/NY-series G code Instructions

Reference Manual (Cat. No. O031) when pro-

gramming.

12

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

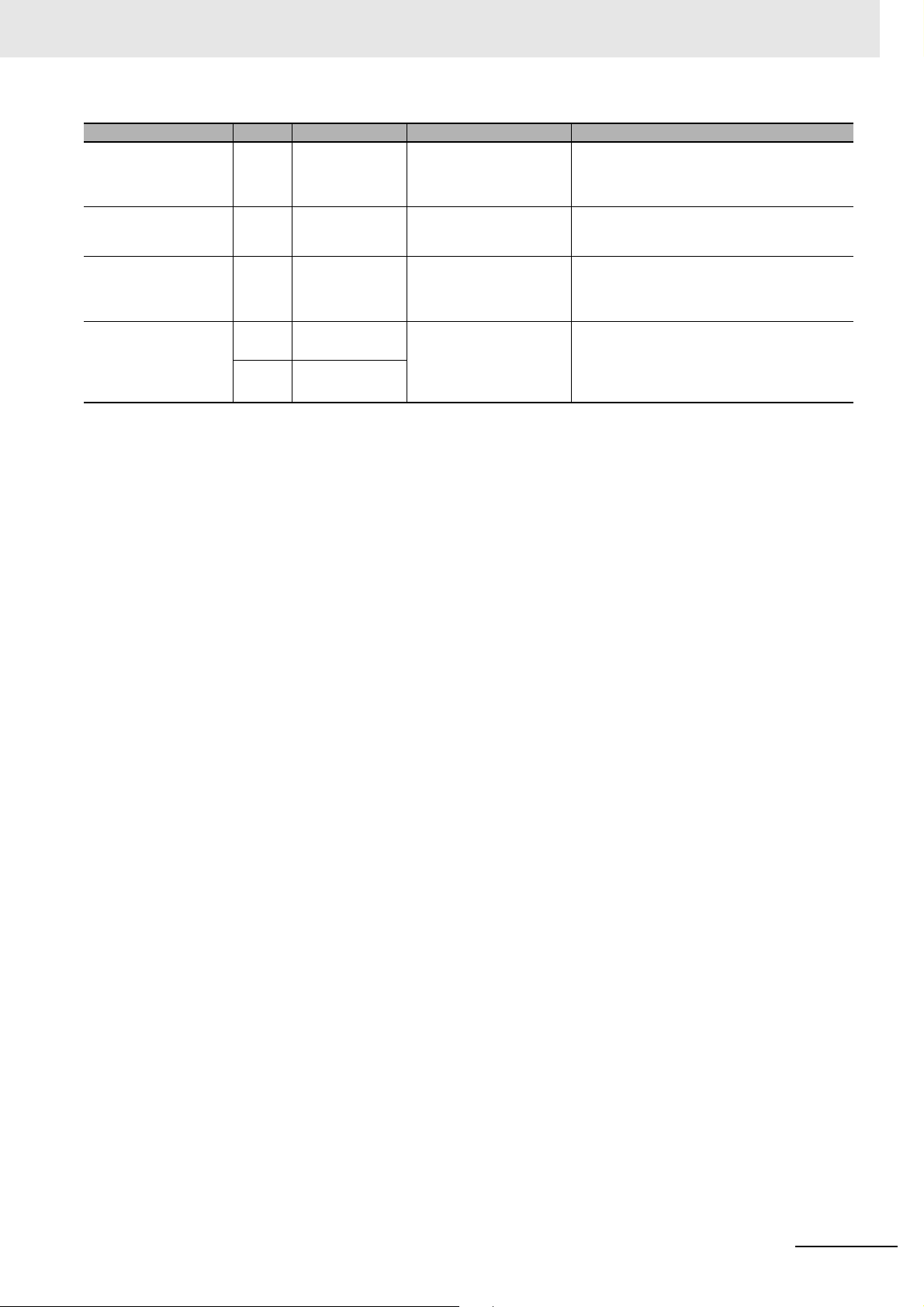

Manual name Cat. No. Model numbers Application Description

G code Instructions Reference Manual

Sysmac Studio Version 1

Operation Manual

CNC Operator

Operation Manual

AC Servomotors/Servo

Drivers 1S-series with

Built-in EtherCAT

Communications User’s

Manual

O031 NJ501-5300

NY532-5400

W504 SYSMAC

-SE2

O032 SYSMAC

-RTNC0D

I586 R88M-1

R88D-1SN-ECT

I621 R88M-1A

R88D-1SAN-ECT

Learning about the specifications of the G code/M

code instructions.

Learning about the operating procedures and functions of the Sysmac Studio.

Learning an introduction of

the CNC Operator and how

to use it.

Learning how to use the

Servomotors/Servo Drives

with built-in EtherCAT Communications.

The G code/M code instructions are described.

Use this manual together with the NJ/NY-series

NC Integrated Controller User’s Manual (Cat. No.

O030) when programming.

Describes the operating procedures of the Sysmac Studio.

An introduction of the CNC Operator, installation

procedures, basic operations, connection operations, and operating procedures for main functions are described.

Describes the hardware, setup methods and

functions of the Servomotors/Servo Drives with

built-in EtherCAT Communications.

Related Manuals

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

13

Revision History

Revision History

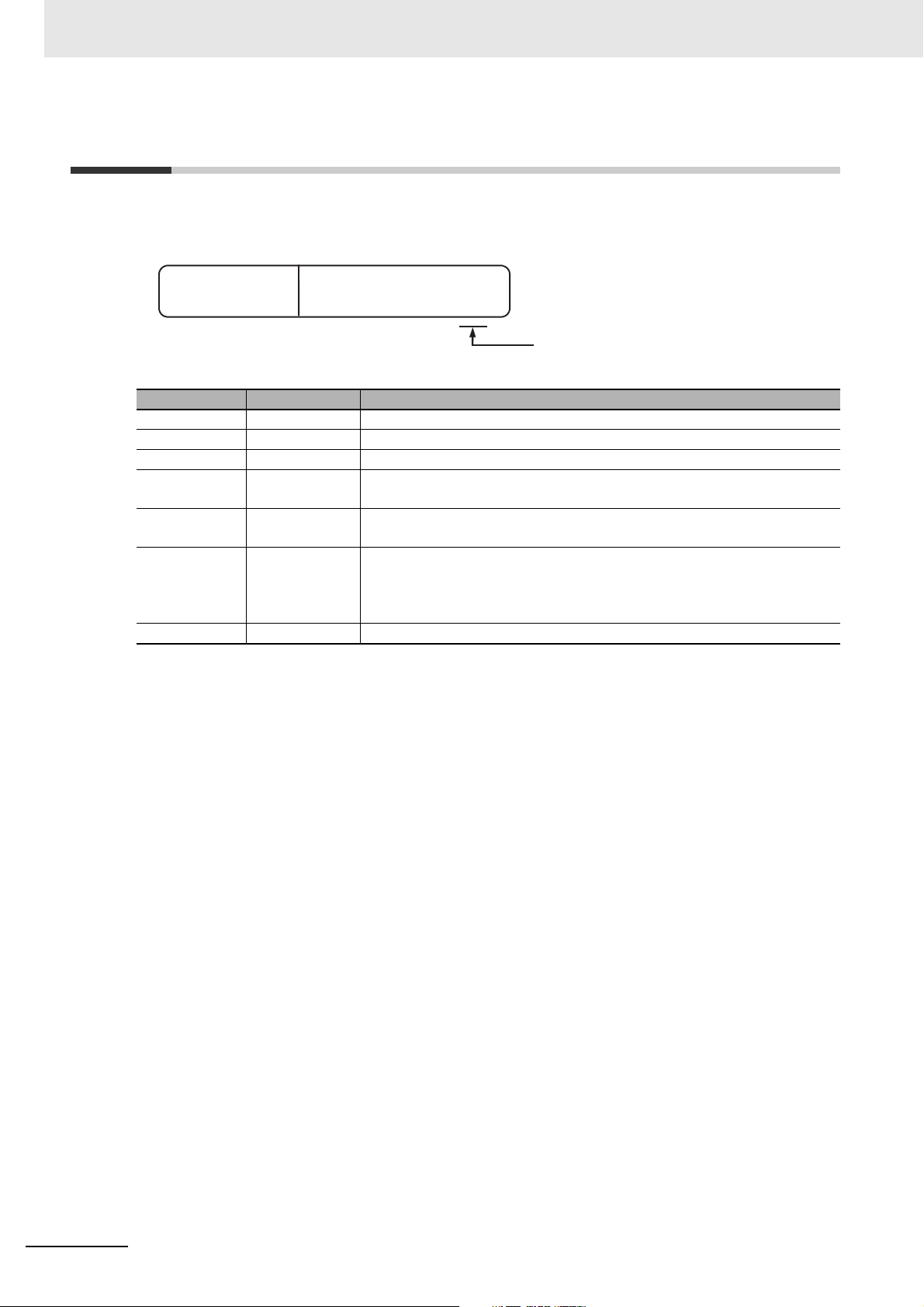

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Cat. No.

Revision code Date Revised content

01 July 2016 Original production

02 November 2016 Changed the manual name.

03 March 2017 Compatible with R88D-1SN

04 January 2019 • Added compatible models.

05 April 2019 • Added compatible models.

06 July 2019 Added following function blocks:

07 October 2020 Compatible with R88D-1SN

W571-E1-07

• Compatible with R88D-1SN

• Compatible with 1S Series other than R88D-1SN

• MotorSetup_1S

•Restart_1S

• EasyTuning_1S

Revision code

-ECT Version 1.1

-ECT Version 1.2

-ECT Version 1.4

-ECT

14

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Procedure to Use Sysmac Libraries

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

15

Procedure to Use Sysmac Libraries Installed Using the Installer

Version Information

Precautions for Correct Use

Procedure to Use Sysmac Libraries Installed Using the Installer

This section describes the procedure to use Sysmac Libraries that you installed using the installer.

There are two ways to use libraries.

• Using newly installed Sysmac Libraries

• Using upgraded Sysmac Libraries

To use Sysmac Libraries, you need the Sysmac Studio version 1.14 or higher.

Using Newly Installed Libraries

1 Start the Sysmac Studio and open or create a new project in which you want to use Sysmac

Libraries.

If you create a new project, be sure to configure the settings as follows to enable the use of

Sysmac Libraries. If you do not configure the following settings, you cannot proceed to the step

2 and later steps.

• Set the project type to Standard Project or Library Project.

• Set the device category to Controller.

• Set the device version to 1.01 or later.

16

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Procedure to Use Sysmac Libraries Installed Using the Installer

Precautions for Correct Use

Device

Drug & Drop

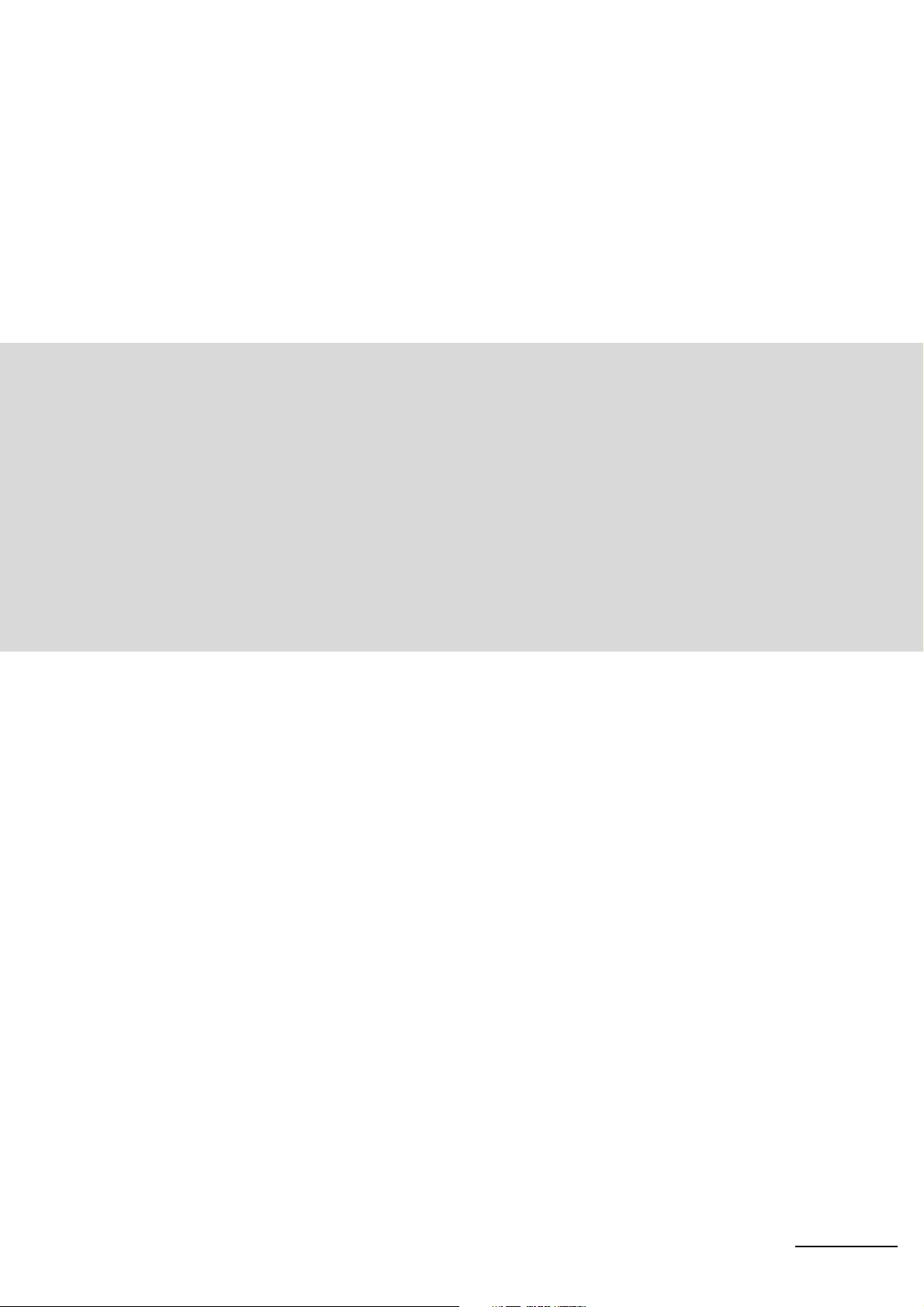

2 Select Project – Library – Show References.

If you have more than one registered device in the project, make sure that the device selected

currently is an NJ/NX-series CPU Unit or an NY-series Industrial PC. If you do not select an

NJ/NX-series CPU Unit or an NY-series Industrial PC as the device, Library References does

not appear in the above menu. When the device selected currently is an NJ/NX-series CPU

Unit or an NY-series Industrial PC, the device icon is displayed in the Multiview Explorer.

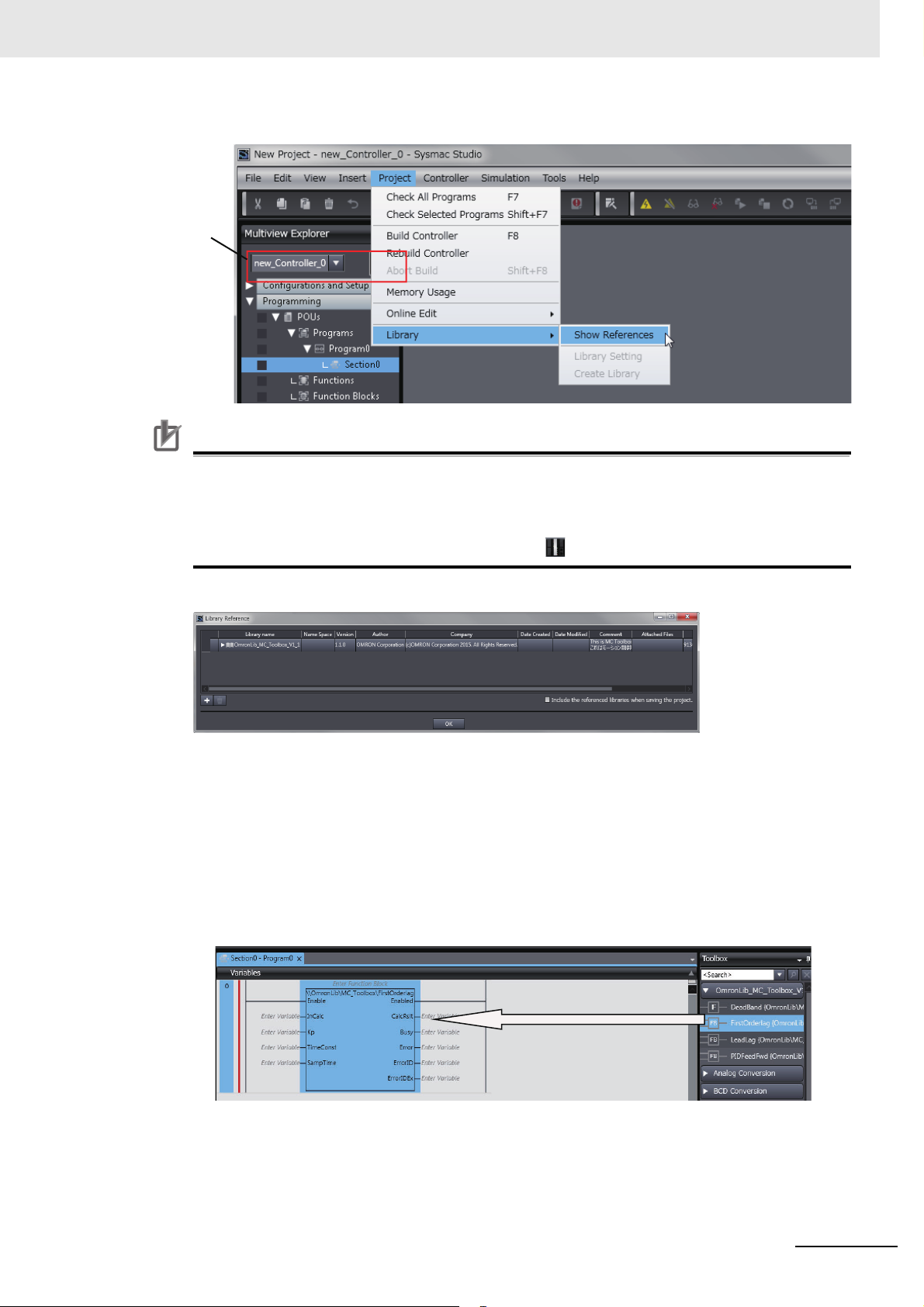

3 Add the desired Sysmac Library to the list and click the OK Button.

The Sysmac Library file is read into the project.

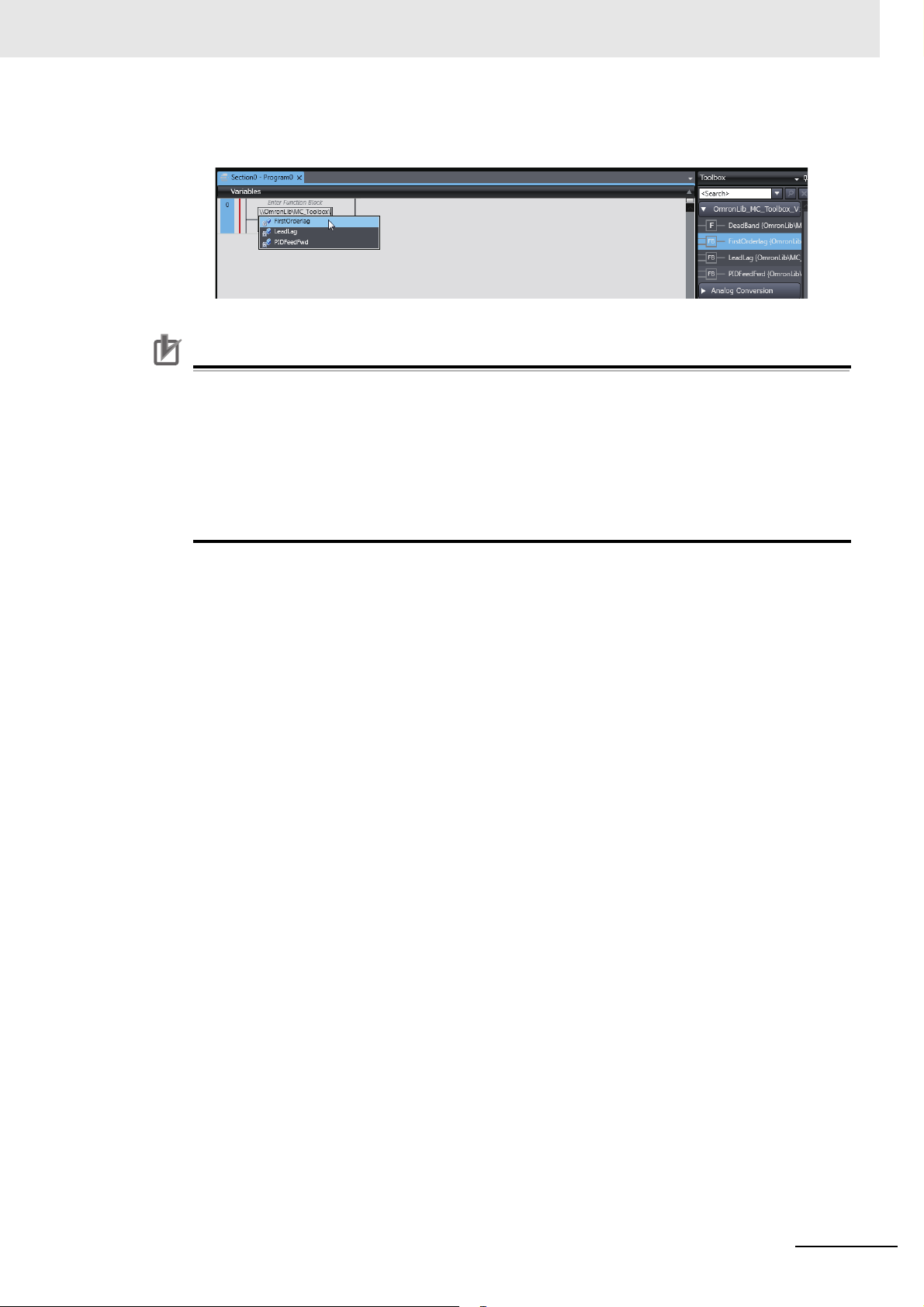

Now, when you select the Ladder Editor or ST Editor, the function blocks and functions included

in a Sysmac Library appear in the Toolbox.

For the procedure for adding and setting libraries in the above screen, refer to the Sysmac Stu-

dio Version 1 Operation Manual (Cat. No. W504).

4 Insert the Sysmac Library’s function blocks and functions into the circuit using one of the follow-

ing two methods.

• Select the desired function block or function in the Toolbox and drag and drop it onto the programming editor.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

17

Procedure to Use Sysmac Libraries Installed Using the Installer

Precautions for Correct Use

Precautions for Correct Use

Device

• Right-click the programming editor, select Insert Function Block in the menu, and enter the

fully qualified name (\\name of namespace\name of function block).

After you upgrade the Sysmac Studio, check all programs and make sure that there is no error

of the program check results on the Build Tab Page.

Select Project

– Check All Programs from the Main Menu.

Using Upgraded Libraries

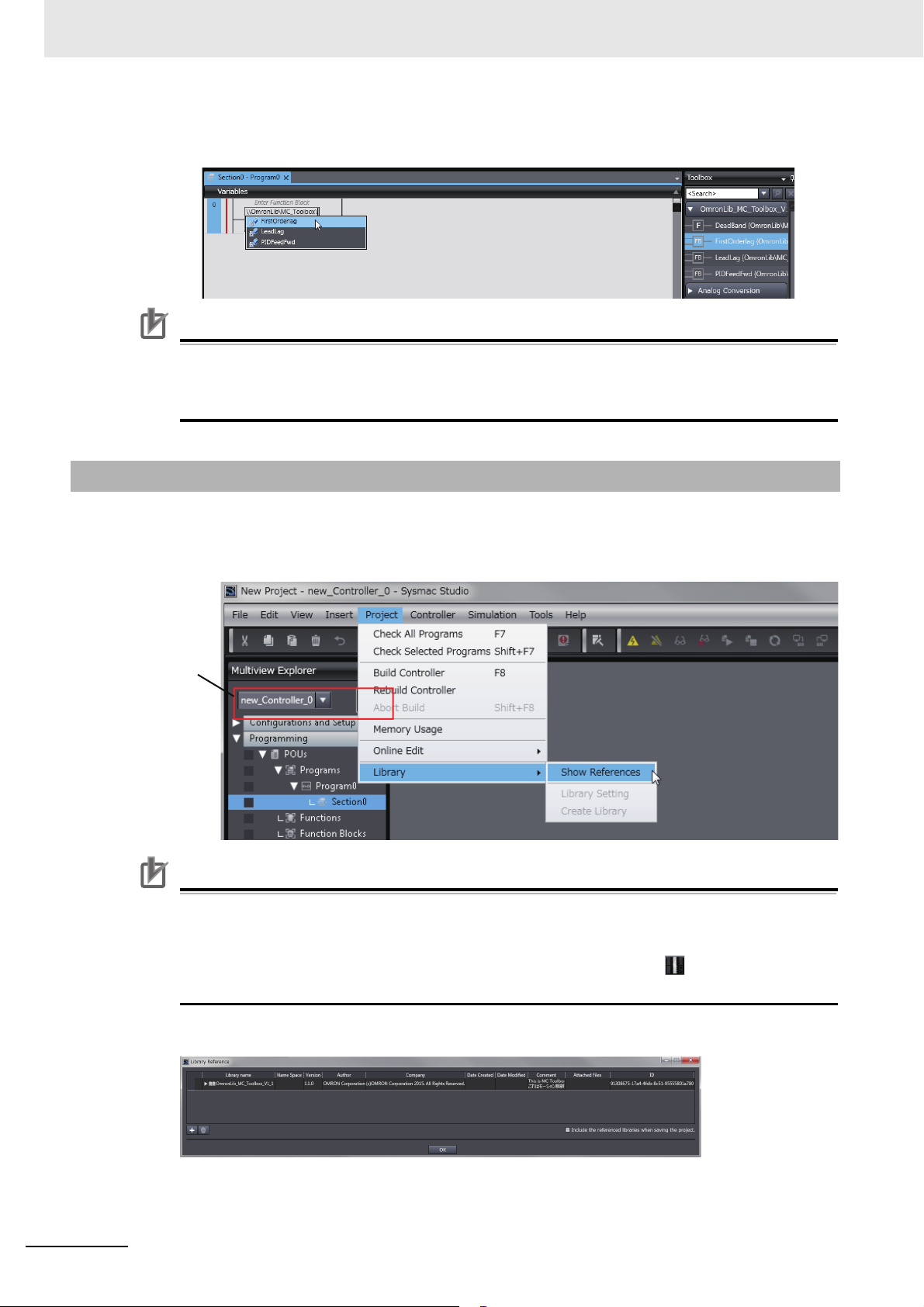

1 Start the Sysmac Studio and open a project in which any old-version Sysmac Library is

included.

2 Select Project – Library – Show References.

If you have more than one registered device in the project, make sure that the device selected

currently is an NJ/NX-series CPU Unit or an NY-series Industrial PC. Otherwise, Library References does not appear in the above menu. When the device selected currently is an

NJ/NX-series CPU Unit or an NY-series Industrial PC, the device icon is displayed in the

Multiview Explorer.

3 Select an old-version Sysmac Library and click the Delete Reference Button.

18

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Procedure to Use Sysmac Libraries Installed Using the Installer

4 Add the desired Sysmac Library to the list and click the OK Button.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

19

Procedure to Use Sysmac Libraries Uploaded from a CPU Unit or an Industrial PC

Version Information

Procedure to Use Sysmac Libraries Uploaded from a CPU Unit or

an Industrial PC

You can use Sysmac Libraries uploaded from a CPU Unit or an Industrial PC to your computer if they

are not installed.

The procedure to use uploaded Sysmac Libraries from a CPU Unit or an Industrial PC is as follows.

To use Sysmac Libraries, you need the Sysmac Studio version 1.14 or higher.

1 Start the Sysmac Studio and create a new project in which you want to use Sysmac Libraries.

2 Connect the computer to the CPU Unit or the Industrial PC and place it online.

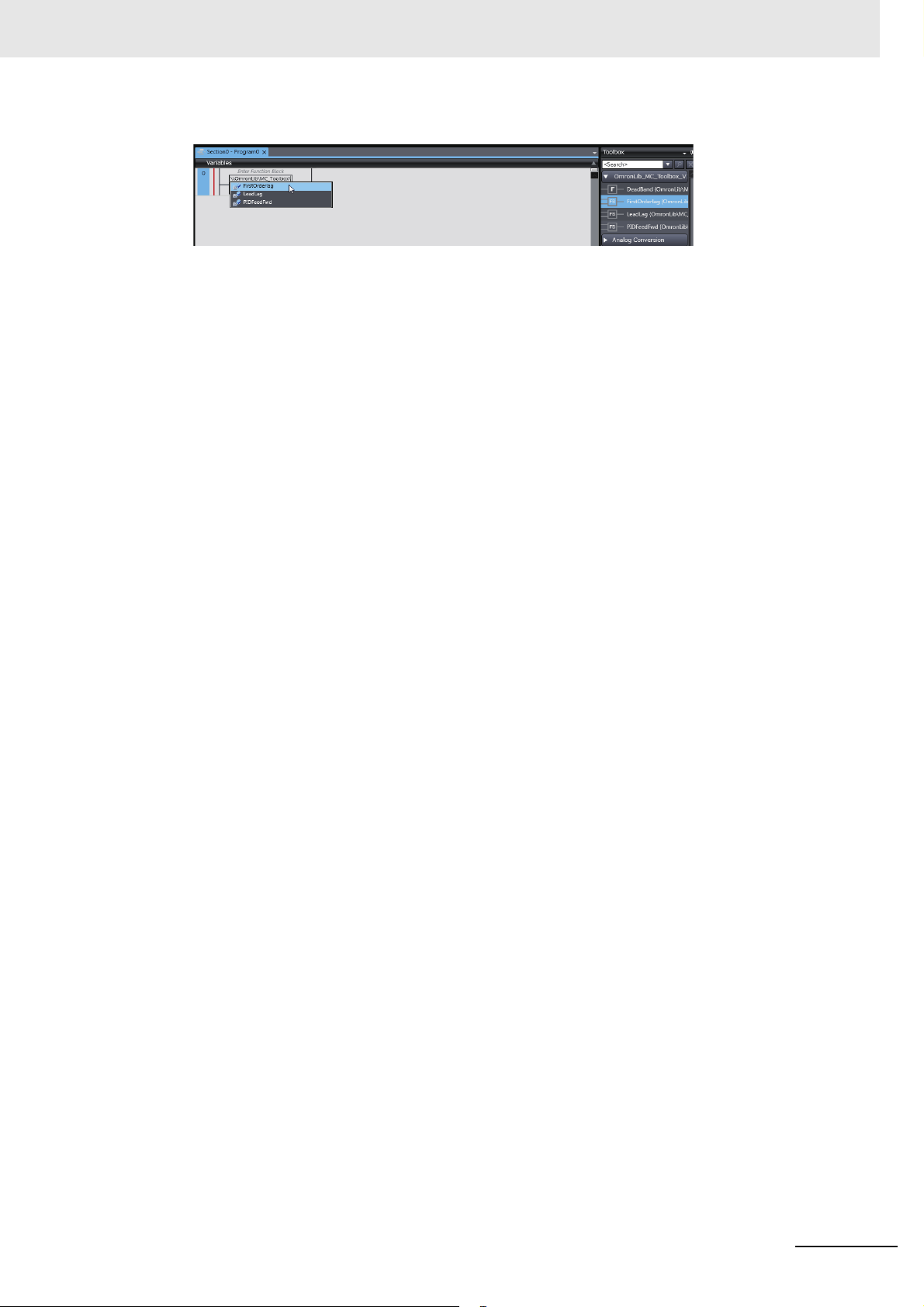

3 Upload POUs in which any Sysmac Library is used to the computer.

Now, when you select the Ladder Editor or ST Editor, the function blocks and functions included

in the Sysmac Library used in the uploaded POUs appear in the Toolbox.

4 Insert the Sysmac Library’s function blocks and functions into the circuit using one of the follow-

ing two methods.

• Select the desired function block or function in the Toolbox and drag and drop it onto the Ladder Editor.

20

Drug & Drop

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Procedure to Use Sysmac Libraries Uploaded from a CPU Unit or an Industrial PC

Precautions for Correct Use

• Right-click the programming editor, select Insert Function Block in the menu, and enter the

fully qualified name (\\name of namespace\name of function block).

• The Sysmac Studio installs library files of the uploaded Sysmac Stutio to the specified folder

on the computer if they are not present. However, the Sysmac Studio does not install library

files to the specified folder on the computer if they are present.

The specified folder here means the folder in which library files are installed by the installer.

• Note that uploading Sysmac Libraries from a CPU Unit or an Industrial PC does not install

the manual and help files for the Sysmac Libraries, unlike the case where you install then

using the installer. Please install the manual and help files using the installer if you need

them.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

21

Procedure to Use Sysmac Libraries Uploaded from a CPU Unit or an Industrial PC

22

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Common Specifications of Function Blocks

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

23

Common Variables

Common Variables

This section describes the specifications of variables (EN, Execute, Enable, Abort, ENO, Done, CalcRslt, Enabled, Busy, CommandAborted, Error, ErrorID, and ErrorIDEx) that are used for more than

one function or function block. The specifications are described separately for functions, for execute-type function blocks, and for enable-type function blocks.

Definition of Input Variables and Output Variables

Common input variables and output variables used in functions and function blocks are as follows.

Function/function

Var iabl e I/O

EN Input BOOL OK Execute The processing is executed while the

Execute OK Execute The processing is executed when the

Enable OK Run The processing is executed while the

Abort BOOL OK Abort The processing is aborted.

Data

type

block type to use

Execute-

type

Enable-

type

Meaning DefinitionFunction block

Function

variable is TRUE.

variable changes to TRUE.

variable is TRUE.

You can select the aborting method.

24

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Common Variables

Function/function

Variable I/O

ENO Output BOOL OK Done The variable changes to TRUE when the

Done BOOL OK Done The variable changes to TRUE when the

Busy BOOL OK OK Executing The variable is TRUE when the process-

CalcRslt LREAL OK Calculation

Enabled BOOL OK Enabled The variable is TRUE when the output is

Command

Aborted

Error BOOL OK OK Error This variable is TRUE while there is an

ErrorID WORD OK OK Error Code An error code is output.

ErrorIDEx DWORD OK OK Expansion

Data

type

BOOL OK Command

block type to use

Execute-

type

Enable-

type

Function

Meaning DefinitionFunction block

Result

Aborted

Error Code

processing ends normally.

It is FALSE when the processing ends in

an error, the processing is in progress, or

the execution condition is not met.

processing ends normally.

It is FALSE when the processing ends in

an error, the processing is in progress, or

the execution condition is not met.

ing is in progress.

It is FALSE when the processing is not in

progress.

The calculation result is output.

enabled. It is used to calculate the control amount for motion control, temperature control, etc.

The variable changes to TRUE when the

processing is aborted.

It changes to FALSE when the processing is re-executed the next time.

error.

It is FALSE when the processing ends

normally, the processing is in progress,

or the execution condition is not met.

An expansion error code is output.

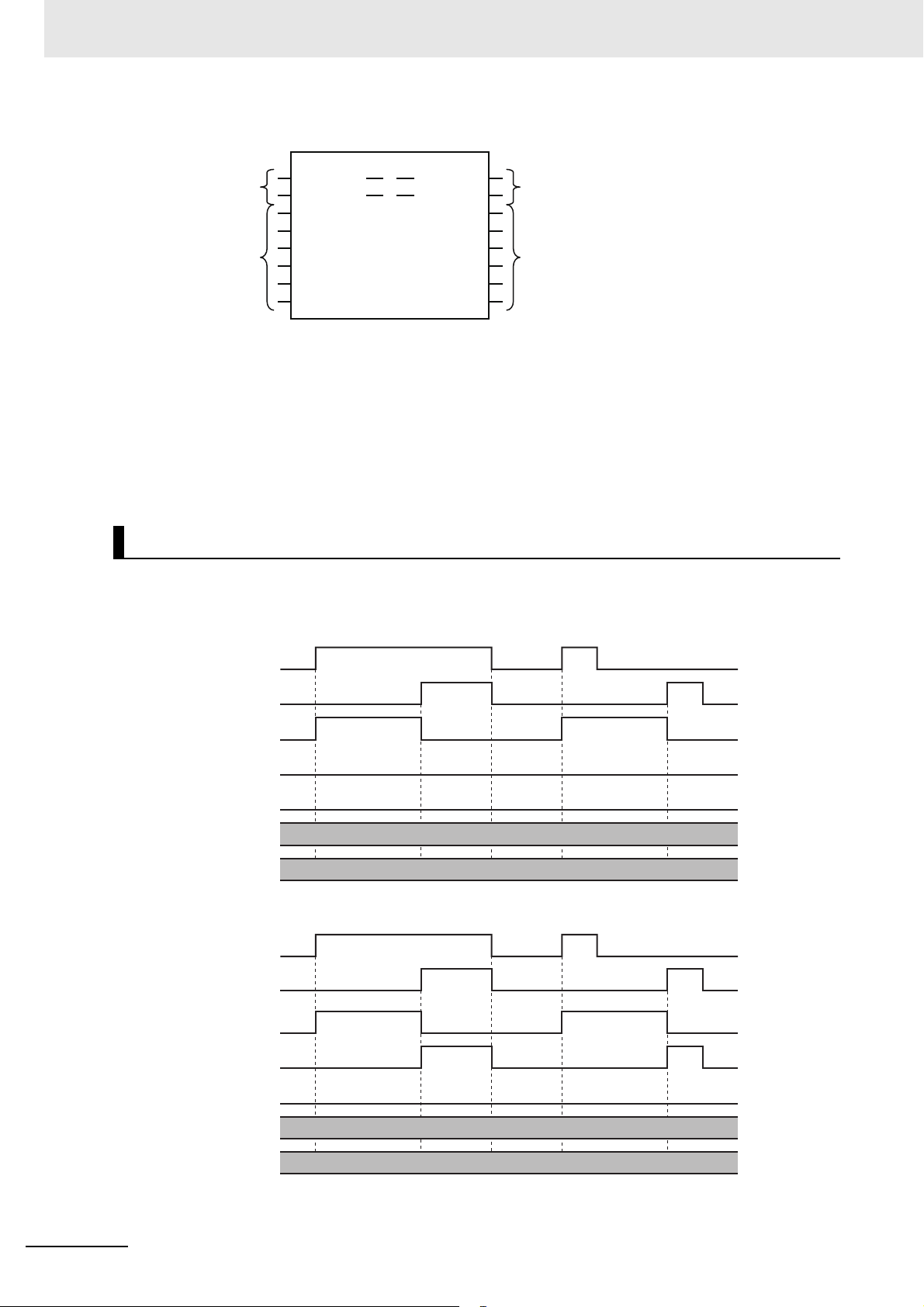

Execute-type Function Blocks

• Processing starts when Execute changes to TRUE.

• When Execute changes to TRUE, Busy also changes to TRUE. When processing is completed normally, Busy changes to FALSE and Done changes to TRUE.

• When continously executes the function blocks of the same instance, change the next Execute to

TRUE for at least one task period after Done changes to FALSE in the previous execution.

• If the function block has a CommandAborted (Instruction Aborted) output variable and processing is

aborted, CommandAborted changes to TRUE and Busy changes to FALSE.

• If an error occurs in the function block, Error changes to TRUE and Busy changes to FALSE.

• For function blocks that output the result of calculation for motion control and temperature control,

you can use the BOOL input variable Abort to abort the processing of a function block. When Abort

changes to TRUE, CommandAborted changes to TRUE and the execution of the function block is

aborted.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

25

Common Variables

Busy

Done

CommandAborted

Error

16#00000000

16#0000

ErrorID

ErrorIDEx

Execute

Busy

Abort

CommandAborted

Error

16#00000000

16#0000

ErrorID

ErrorIDEx

Execute

In-out variables

Input variables

• If Execute is TRUE and Done, CommandAborted, or Error changes to TRUE, Done, CommandAborted, and Error changes to FALSE when Execute is changed to FALSE.

• If Execute is FALSE and Done, CommandAborted, or Error changes to TRUE, Done,CommandAborted, and Error changes to TRUE for only one task period.

• If an error occurs, the relevant error code and expansion error code are set in ErrorID (Error Code)

and ErrorIDEx (Expansion Error Code). The error codes are retained even after Error changes to

FALSE, but ErrorID is set to 16#0000 and ErrorIDEx is set to 16#0000 0000 when Execute changes

to TRUE.

Abcd_instance

Abcd

InOut_Val InOut_Val

Execute Done

Busy

CommandAborted

Error

ErrorID

ErrorIDEx

In-out variables

Output variables

Timing Charts

This section provides timing charts for a normal end, aborted execution, and errors.

Normal End

Canceled Execution

26

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

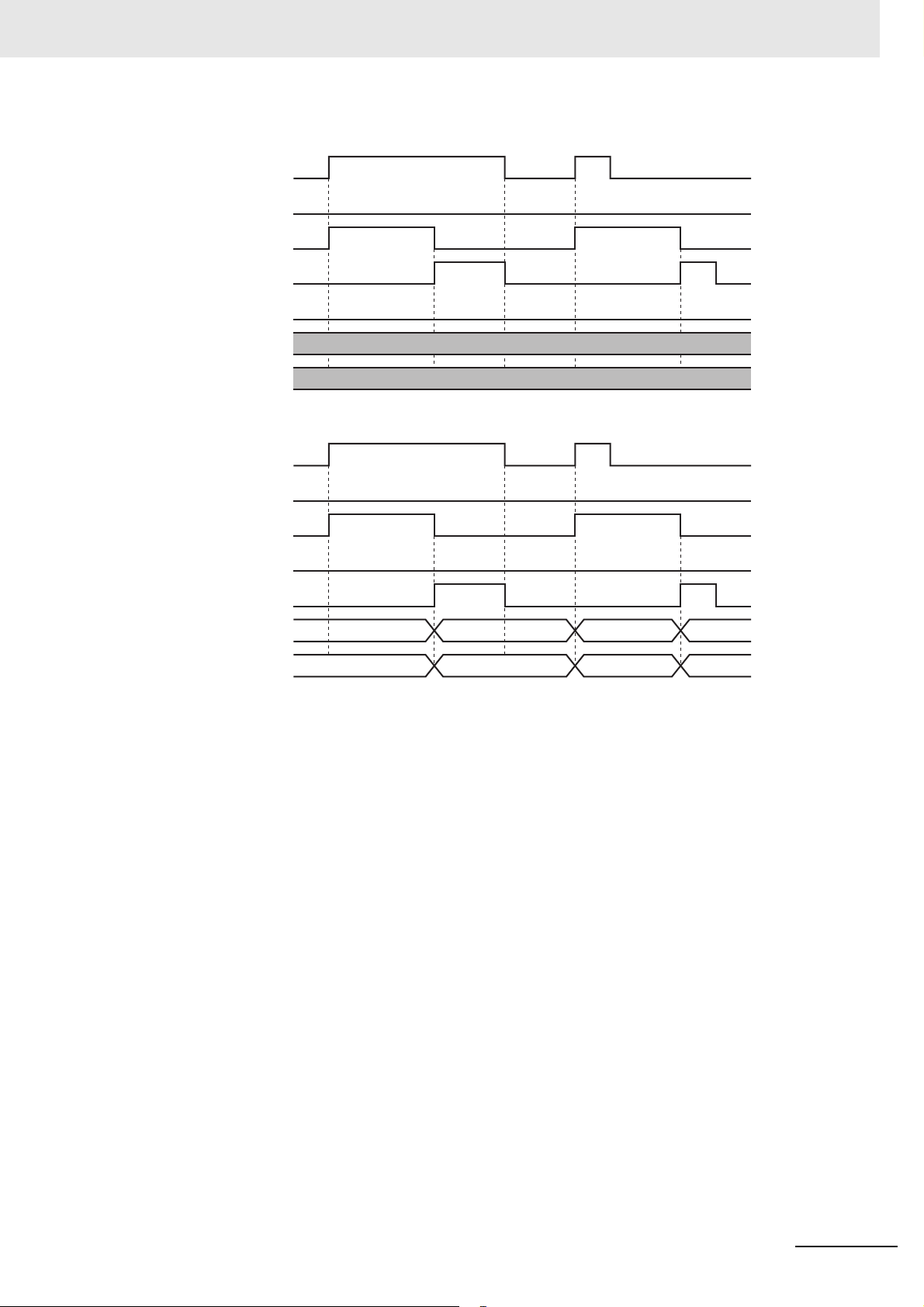

Aborted Execution

Busy

Done

CommandAborted

Error

16#00000000

16#0000

ErrorID

ErrorIDEx

Execute

Busy

Done

CommandAborted

Error

16#0000 16#0000

ErrorID

16#00000000 16#00000000ErrorIDEx ErrorIDEx

ErrorIDEx

Execute

ErrorIDErrorIDErrorID ErrorID

Errors

Common Variables

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

27

Common Variables

Busy

Enabled

Error

16#00000000

16#0000

ErrorID

ErrorIDEx

Enable

CalcRslt

Retained

Retained

Enable-type Function Blocks

• Processing is executed while Enable is TRUE.

• When Enable changes to TRUE, Busy also changes to TRUE. Enabled is TRUE during calculation of

the output value.

• If an error occurs in the function block, Error changes to TRUE and Busy and Enabled change to

FALSE. When Enable changes to FALSE, Enabled, Busy, and Error change to FALSE.

Abcd_instance

In-out variables

Input variables

InOut_Val InOut_Val

Enable Enabled

Abcd

CalcRslt

Busy

Error

ErrorID

ErrorIDEx

In-out variables

Output variables

• If an error occurs, the relevant error code and expansion error code are set in ErrorID (Error Code)

and ErrorIDEx (Expansion Error Code). The error codes are retained even after Error changes to

FALSE, but ErrorID is set to 16#0000 and ErrorIDEx is set to 16#0000 0000 when Enable changes to

TRUE.

• For function blocks that calculate the control amount for motion control, temperature control, etc.,

Enabled is FALSE when the value of CalcRslt (Calculation Result) is incorrect. In such a case, do not

use CalcRslt. In addition, after the function block ends normally or after an error occurs, the value of

CalcRslt is retained until Enable changes to TRUE. The control amount will be calculated based on

the retained CalcRslt value, if it is the same instance of the function block that changed Enable to

TRUE. If it is a different instance of the function block, the control amount will be calculated based on

the initial value.

Timing Charts

This section provides timing charts for a normal end and errors.

Normal End

28

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Errors

Busy

Enabled

Error

16#000016#0000 16#0000

ErrorID

ErrorIDEx

Enable

ErrorIDErrorIDErrorID ErrorID

16#00000000

16#00000000

ErrorIDErrorIDErrorID ErrorID

16#0000

CalcRslt

Retained

Retained

Common Variables

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

29

Precautions

Precautions

This section provides precautions for the use of this function block.

Nesting

You can nest calls to this function block for up to four levels.

For details on nesting, refer to the software user’s manual.

Instruction Options

You cannot use the upward differentiation option for this function block.

Re-execution of Function Blocks

Execute-type function blocks cannot be re-executed by the same instance.

If you do so, the output value will be the initial value.

For details on re-execution, refer to the motion control user’s manual.

30

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Individual Specifications of

Function Blocks

Function block name Name Page

InitEncoder_1S 1S-series Servo Drive

Absolute Encoder Initialize

Backup_1S 1S-series Servo Drive

Parameter Backup

Restore_1S 1S-series Servo Drive

Parameter Restore

MotorSetup_1S 1S-series Servo Drive

Motor Replacement Detected

Restart_1S 1S-series Servo Drive

Function Block Restarts

EasyTuning_1S 1S-series Servo Drive

Easy tuning

P. 3 2

P. 4 1

P. 5 5

P. 6 4

P. 7 3

P. 7 8

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

31

InitEncoder_1S

TimeOut

NodeAdr

Execute

InitEncoder_1S_instance

\\OmronLib\EC_1S

\InitEncoder_1S

Error

ErrorID

ErrorIDEx

Busy

Done

InitEncoder_1S

The InitEncoder_1S function block initializes the absolute encoder (clears the multi-rotation counter for

Function block

InitEncoder_1S 1S-series Servo

the absolute encoder) for a 1S-series Servo Drive.

FB/

FUN

FB InitEncoder_1S_instance(

name

Name

Drive Absolute

Encoder Initialize

Graphic expression ST expression

Execute,

NodeAdr,

TimeOut,

Done,

Busy,

Error,

ErrorID,

ErrorIDEx);

Library Information

Item Description

Library file name OmronLib_EC_1S_V2_0.slr

Namespace OmronLib\EC_1S

Function block and function number 00042

Source code published/not published Not published

Function block and function version 1.00

Compatible Models

Item Name Model numbers Ve r sion

Device 1S-series Servo Drive

R88D-1SN-ECT

R88D-1SAN-ECT

Version 1.00 or later

32

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

InitEncoder_1S

Variables

Name Meaning I/O Description Valid range Unit Default

TRUE: Executes the instruction.

Execute Execute Input

FALSE: Does not execute the

instruction.

NodeAdr

Slave Node

Address

Input

TimeOut Timeout time Input

Node address of the Servo Drive

to initialize

0: 2.0 s

1 to 65535: 0.1 to 6553.5 s

TRUE: Normal end

Done Done Output

FALSE: Error end, execution in

progress, or execution condition

not met

TRUE: Execution processing is in

Busy Executing Output

progress.

FALSE: Execution processing is

not in progress.

TRUE: Error end

Error Error Output

FALSE: Normal end, execution in

progress, or execution condition

not met

This is the error ID for an error

ErrorID Error Code Output

end.

The value is WORD#16#0 for a

normal end.

This is the error ID for an Expan-

ErrorIDEx

Expansion Error

Code

Output

sion Unit Hardware Error.

The value is DWORD#16#0 for a

normal end.

*1. The valid range is 1 to 192 for NJ-series CPU Units.

*2. For details, refer to Troubleshooting on page 37

TRUE or

FALSE

1 to 512

*1

--- FALSE

--- 1

0 to 65535 0.1 s

TRUE or

FALSE

TRUE or

FALSE

TRUE or

FALSE

*2

*2

--- ---

--- ---

--- ---

--- ---

--- ---

0

(2.0 s)

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

33

InitEncoder_1S

Bo

ole

an

Name

BOOL

Execute OK

NodeAdr OK

TimeOut OK

Done OK

Busy OK

Error OK

ErrorID OK

ErrorIDEx OK

Bit strings Integers

BYTE

WORD

DWORD

LWORD

USINT

Real

num-

UINT

UDINT

ULINT

SINT

INT

DINT

LINT

bers

REAL

Times, durations,

dates, and text strings

LREAL

TIME

DATE

TOD

DT

STRING

34

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Execute

Done

Busy

Error

ErrorID

ErrorIDEx

#0000

#00000000 #00000000 #00000000 #00000000

#0000 #0000 #0000

Execute

Done

Busy

Error

ErrorID

ErrorIDEx

#0000

#00000000 ErrorIDEx #00000000 ErrorIDEx

ErrorID #0000 ErrorID

Function

This function block initializes the absolute encoder (clears the multi-rotation counter for the absolute

encoder) for the specified Servo Drive. When the Servo Drive changes to a Fault state (Error No. 27)

after the initialization is completed, cycle the control power supply to the Servo Drive.

After sending the initialization command to the Servo Drive, the command part waits for the response

for the time specified with TimeOut (Timeout). The value of ErrorIDEx is 0 for a normal end.

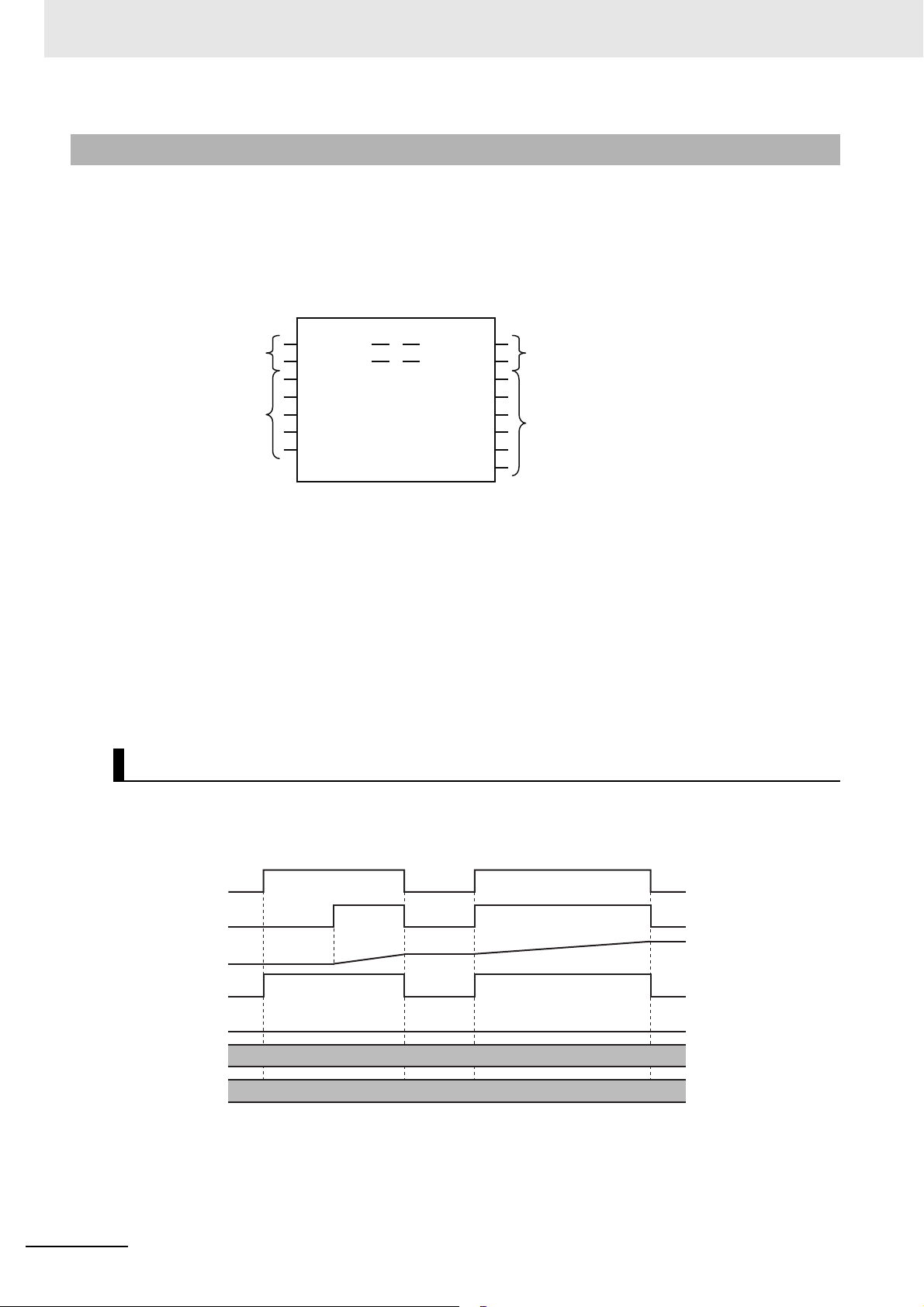

Timing Charts

The following figures show the timing charts for the function block.

• Busy (Executing) changes to TRUE when Execute changes to TRUE.

• Done changes to TRUE when the initialize process is ended.

• If an error occurs when execution of the function block is in progress, Error changes to TRUE and

•If Execute changes to FALSE before execution of the function block is ended, Done and Error are

•If Execute remains TRUE even after execution of the function block is ended, the output values of

InitEncoder_1S

Busy (Executing) changes to FALSE.

You can find out the cause of the error by accessing the values output to ErrorID (Error Code) and

ErrorIDEx (Expansion Error Code).

TRUE only for one task period after execution of the function block is ended.

Done and Error are held.

Timing Chart for Normal End

Timing Chart for Error End

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

35

InitEncoder_1S

Related System-defined Variables

Name Meaning Data type Description

Message Communica-

_EC_MBXSlavTbl

*1. The valid is 192 for NJ-series CPU Units.

tions Enabled Slave

Ta bl e

Additional Information

This function block initializes absolute encoders by writing 6a64 6165 hex to the object of servo parameter Index:4510 hex Subindex:F1 hex (Absolute Encoder Setup) with SDO mailbox communications.

Array[1..512

*1

] OF BOOL

This table indicates the slaves that

can perform message communications. Slaves are given in the table in

the order of slave node addresses.

TRUE: Message communications

are possible.

FALSE: Message communications

are not possible.

Precautions for Correct Use

• Execution of this function block will be continued until processing is ended even if the value of Execute changes to FALSE or the execution time exceeds the task period. The value of Done changes to

TRUE when processing is ended. Use this to confirm normal ending of processing.

• This function block executes one EC_CoESDOWrite instruction or one EC_CoESDORead instruction within the part. Refer to the EC_CoESDOWrite instruction in the instructions reference manual

for the maximum number of instructions that can be executed at the same time.

• After completion of the function block, the 1S-series Servo Drive changes to a Fault state. Cycle the

control power supply to the Servo Drive.

• Execute the function block while the Servo is OFF.

• If the Servo Drive is assigned to the Motion Control Function Module, make sure that the Axis Disabled (_MC_AX[***].Status.Disabled) in the Axis Variable is TRUE before you execute the function

block.

• Make sure that the Servo Drive is a compatible model before executing this function block.

• Do not attempt to turn OFF the power supply to the Controller and EtherCAT slaves or stop the EtherCAT communications until the processing for this function block ends normally or ends in an error.

• Sample programming shows only the portion of a program that uses the function or function block

from the library.

• When using sample programming in actual devices, also program safety circuits, device interlocks,

I/O with other devices, and other control procedures.

• Create a user program that will produce the intended device operation.

• Check the user program for proper execution before you use it for actual operation.

• An error will occur in the following cases. Error will change to TRUE.

a) The EtherCAT master is not in a state that allows message communications.

b) The slave specified with NodeAdr does not exist.

c) The slave specified with NodeAdr is not in a state that allows communications.

d) The slave is not in a state that allows writing of parameters.

e) The number of EtherCAT communications instructions such as EC_CoESDOWrite exceeded the

maximum number of instructions that can be executed at the same time.

36

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

InitEncoder_1S

Troubleshooting

Error code

16#0000 16#00000000 Normal End --- --16#0400 16#00000000 Input Value Out

16#1800 16#00000000 EtherCAT Com-

16#1801 16#00000000 EtherCAT Slave

16#1802 16#00000000 EtherCAT Time-

16#1803 16#00000000 Reception Buf-

16#1804 SDO Abort

16#1808 16#00000000 Communica-

16#3C2C 16#00000001 VendorID Not

*1. An SDO abort code is shown here. Refer to SDO Abort Codes in the instructions reference manual for a list of SDO abort

codes.

Expansion

error code

Status Description Correction

of Range

munications

Error

Does Not

Respond

out

fer Overflow

SDO Abort Error The cause of this error

*1

Code

tions Resource

Overflow

Matched

16#00000003 Initialization Fail-

ure

16#00000004 Unsupported

Device

The value of NodeAdr is out

of range.

The EtherCAT network is

not in a usable status.

The target slave does not

exist.

The target slave is not in an

operating condition.

Communications with the

target slave timed out.

The receive data from an

EtherCAT slave overflowed

the receive buffer.

depends on the specifications of the EtherCAT slave.

More than 32 EtherCAT

communications instructions were executed at the

same time.

The device is not supported

by this function block (A

non-OMRON device is

specified).

The encoder initialization

was not completed within

one minute.

The device is not supported

by this function block.

Set the value of NodeAdr cor-

rectly.

Check the operation status of the

EtherCAT network by checking

the status of the EtherCAT master. Use this information to correct

the cause of the problem.

Specify an existing node address.

Check the status of the target EtherCAT slave. Make sure that the

target slave is in a usable status.

Check the operating status of the

target slave and correct the cause

of the problem.

Set the size of the reception buffer

to a value larger than the size of

the receive data from the slave.

Refer to the manual for the EtherCAT slave and correct the problem.

Correct the user program so that

no more than 32 EtherCAT communications instructions are executed at the same time.

Check that the specified device is

a 1S-series Servo Drive.

Execute the function block again.

The encoder was located near the

position of one rotation at the start

of the initialization and fell in a

state of a multi-rotation due to

vibration etc. This may be

assumed as an initialization failure when the Servo Drive checks

the completion of the initialization.

Replace the 1S-series Servo

Drive.

Check that the specified device is

a 1S-series Servo Drive.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

37

InitEncoder_1S

Sample Programming

Conditions

This sample programming initializes the absolute encoder for a Servo Drive.

• The target Servo Drive is Node 1.

• The target Servo Drive is assigned to axis 0 in the Motion Control Function Module.

• The timeout time is 2 s (default).

Processing

1 Make sure that the target slave is in a state that allows communications, that axis 0 is disabled,

and that the same instance is not being executed.

2 Execute INITENCODER_1S_instance.

LD

Internal Variables

Name Data type Default Comment

INITENCODER_1S_instance OmronLib\EC_1S\InitEncoder_1S

OperatingEnd BOOL Processing completed

Trigger BOOL FALSE Execution condition

Operating BOOL Processing

RS_instance RS

InitEncoderBusy BOOL

External Variables

Variable Data type Constant Comment

_EC_MBXSlavTbl

MC_Axis000 _sAXIS_REF Servo off

*1. N = 192 for NJ501, NJ301 and NJ101. N = 512 for NX701.

ARRAY[1..N

*1

] OF BOOL

Message Communications Enabled Slave

Ta bl e

38

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

InitEncoder_1S

ST

Internal Variables

Name Data type Default Comment

INITENCODER_1S_instance OmronLib\EC_1S\InitEncoder_1S

Trigger BOOL FALSE Execution condition

LastTrigger BOOL FALSE

OperatingStart BOOL FALSE Processing started.

Operating BOOL FALSE Processing

InitEncoderBusy BOOL FALSE

External Variables

Variable Data type Constant Comment

_EC_MBXSlavTbll

ARRAY[1..N

*1

] OF BOOL

MC_Axis000 _sAXIS_REF Servo off

*1. N = 192 for NJ501, NJ301 and NJ101. N = 512 for NX701.

Message Communications Enabled Slave

Table

Value of Trigger from previous task

// Detect when Trigger changes to TRUE.

IF ( (Trigger=TRUE) AND (LastTrigger=FALSE) AND (_EC_MBXSlavTbl[1]=TRUE) AND

MC_Axis000.Status.Disabled=TRUE) AND(InitEncoderBusy=FALSE) ) THEN

OperatingStart:=TRUE;

Operating :=TRUE;

END_IF;

LastTrigger:=Trigger;

// Initialize InitEncoder_1S instruction.

IF (OperatingStart=TRUE) THEN

INITENCODER_1S_instance(

Execute :=FALSE);

OperatingStart:=FALSE;

END_IF;

// Execute Backup_1S instruction.

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

39

InitEncoder_1S

IF (Operating=TRUE) THEN

INITENCODER_1S_instance(

Execute :=TRUE,

NodeAdr:=UINT#1,

TimeOut:=UINT#0,

Busy=>InitEncoderBusy);

IF (INITENCODER_1S_instance.Done=TRUE) THEN

// Processing after normal end.

Operating:=FALSE;

END_IF;

IF (INITENCODER_1S_instance.Error=TRUE) THEN

// Processing after error end.

Operating:=FALSE;

END_IF;

END_IF;

40

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Backup_1S

NodeAdr

DirName

OverWrite

TimeOut

Execute

Backup_1S_instance

\\OmronLib\EC_1S

\Backup_1S

Busy

SdoBusy

Error

ErrorID

ErrorIDEx

Done

The Backup_1S function block backs up the parameters for a 1S-series Servo Drive and stores them

Function block

Backup_1S 1S-series Servo

as a backup file on the SD Memory Card inserted in the Controller.

name

Name

Drive Parameter

Backup

Backup_1S

FB/

FUN

FB Backup_1S_instance(

Graphic expression ST expression

Execute,

NodeAdr,

DirName,

OverWrite,

TimeOut,

Done,

Busy,

SdoBusy,

Error,

ErrorID,

ErrorIDEx);

Library Information

Item Description

Library file name OmronLib_EC_1S_V2_0.slr

Namespace OmronLib\EC_1S

Function block and function number 00043

Source code published/not published Not published

Function block and function version 1.00

Compatible Models

Item Name Model numbers Ver sion

Device 1S-series Servo Drive R88D-1SN-ECT Version 1.00 or later

R88D-1SAN-ECT

SD Memory Card HMC-SD

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

41

Backup_1S

Variables

Name Meaning I/O Description Va lid ra nge Unit Default

TRUE: Executes the instruction.

Execute Execute Input

FALSE: Does not execute the

instruction.

NodeAdr

Slave Node

Address

Input Specifies the node address.

Specifies the directory on the SD

DirName Directory Name Input

Memory Card. The backup file(s)

stored in this directory will be

restored.

OverWrite Overwrite Enable Input

TimeOut Timeout Time Input

TRUE: Enables overwrite.

FALSE: Prohibits overwrite.

0: 2.0 s

1 to 65535: 0.1 to 6553.5 s

TRUE: Normal end

Done Done Output

FALSE: Error end, execution in

progress, or execution condition

not met

TRUE: Execution processing is in

Busy Executing Output

progress.

FALSE: Execution processing is

not in progress.

This flag is TRUE when an SDO

communications command is

sent to a 1S-series Servo Drive.

SdoBusy

Processing Sdo

Communications

Output

TRUE: Error end

Error Error Output

FALSE: Normal end, execution in

progress, or execution condition

not met

This is the error ID for an error

ErrorID Error Code Output

end.

The value is WORD#16#0 for a

normal end.

This is the error ID for an Expan-

ErrorIDEx

Expansion Error

Code

Output

sion Unit Hardware Error.

The value is DWORD#16#0 for a

normal end.

*1. The valid range is 1 to 192 for NJ-series CPU Units.

*2. If DirName is omitted, this specifies the root directory on the SD Memory Card.

*3. You can use it to identify that communications processing is in progress.

*4. For details, refer to Troubleshooting on page 48.

TRUE or

FALSE

1 to 512

*1

40 bytes max. ---

TRUE or

FALSE

0 to 65535 0.1 s

TRUE or

FALSE

TRUE or

FALSE

TRUE or

FALSE

*3

TRUE or

FALSE

*4

*4

--- FALSE

--- 1

''

--- FALSE

0

(2.0 s)

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

*2

42

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Backup_1S

Bo

Name

ole

an

BOOL

Bit strings Integers

BYTE

WORD

DWORD

LWORD

USINT

UINT

UDINT

ULINT

SINT

INT

DINT

Execute OK

NodeAdr OK

DirName OK

OverWrite OK

TimeOut OK

Done OK

Busy OK

SdoBusy OK

Error OK

ErrorID OK

ErrorIDEx OK

LINT

Real

num-

bers

REAL

Times, durations,

dates, and text strings

LREAL

TIME

DATE

TOD

DT

STRING

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

43

Backup_1S

Function

• The Backup_1S function block reads parameters for the 1S-series Servo Drive at the node address

• To use this function block, you need to create in advance a directory named OM_ObjList\Drive in the

• Object lists that are provided by OMRON are installed in ‘C:\OMRON\Data\Attachement’ when

• A backup file is binary data that has the name “BackupFile_Node

• If the directory specified with DirName (Directory Name) does not exist, the function block creates a

specified with NodeAdr (Node Address) when Execute changes to TRUE and creates a backup file in

the directory specified with DirName (Directory Name) on the SD Memory Card.

root directory on the SD Memory Card and store object lists provided by OMRON in it. Be sure to

store all the object lists. Then, access the object lists to back up the parameters with this function

block.

installing libraries. Uncompress a ZIP file for an applicable series and store the files in the SD Memory Card.

.Bin”. Here, is a

slave node address in decimal (e.g., 00001 for Node 1).

new directory with the specified directory name. If DirName (Directory Name) is omitted, the function

block assumes that the root directory on the SD Memory Card is specified.

CPU Unit or Industrial PC

1S-series

Servo Drive

Parameters

SD Memory Card

Root directory

Directory: OM_ObjList

Directory: Drive

ObjList_R88D-1SN01H-ECT_Rev00010000.bin

. . . . .

EtherCAT

Directory: DirName

BackupFile_Node00001.bin

Node1 Node10 Node100

44

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Backup_1S

Execute

Done

Busy

SdoBusy

Error

ErrorID

ErrorIDEx

#0000

#00000000 #00000000 #00000000 #00000000

#0000 #0000 #0000

Execute

Done

Done

Busy

SdoBusy

Error

ErrorID

ErrorIDEx

#0000

#00000000 ErrorIDEx #00000000 ErrorIDEx

ErrorID #0000 ErrorID

Procedure

1 Create a directory named OM_ObjList\Drive in the root directory on the SD Memory Card and

store all the object lists provided by OMRON in it.

2 Execute the function block.

For NodeAdr (Slave Node Address), specify the node address of the backup target slave.

If necessary, set DirName (Directory Name) and TimeOut (Timeout Time).

3 A backup file is created in the directory specified with DirName (Directory Name) when execu-

Timing Charts

The following figures show the timing charts for the function block.

• Busy (Executing) changes to TRUE when Execute changes to TRUE.

• When backup file creation is ended, Done changes to TRUE.

• If an error occurs when execution of the function block is in progress, Error changes to TRUE and

•If Execute changes to FALSE before execution of the function block is ended, Done and Error are

•If Execute remains TRUE even after execution of the function block is ended, the output values of

tion of the function block is ended.

Busy (Executing) changes to FALSE.

You can find out the cause of the error by accessing the values output to ErrorID (Error Code) and

ErrorIDEx (Expansion Error Code).

TRUE only for one task period after execution of the function block is ended.

Done and Error are held.

Timing Chart for Normal End

Timing Chart for Error End

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

45

Backup_1S

Related System-defined Variables

Name Meaning Data type Description

_Card1Ready

_EC_MBXSlavTbl

*1. The valid is 192 for NJ-series CPU Units.

SD Memory Card

Ready Flag

Message Communications Enabled Slave

Ta bl e

BOOL

Array[1..512

*1

] OF BOOL

TRUE when the SD Memory Card is

recognized. It is FALSE when the SD

Memory Card is not recognized.

TRUE: Can be used.

FALSE: Cannot be used.

This table indicates the slaves that

can perform message communications. Slaves are given in the table in

the order of slave node addresses.

TRUE: Message communications

are possible.

FALSE: Message communications

are not possible.

Additional Information

• An object list is binary data that stores, by the revision number of EtherCAT slaves, SDO parameter

information (Index, Subindex, and Complete Access) for the backup target parameters.

• For information on the characters that can be used in DirName, refer to Specifications of Supported

SD Memory Cards, Folders, and Files in the software user’s manual.

• In backup or restore processing, the value of SdoBusy is TRUE when data objects are being sent.

The value of SdoBusy is FALSE when data objects are not being sent due to the internal processing

of the function block.

• If you turn OFF the power supply to the 1S-series Servo Drive when replacing a 1S-series Servo

Drive or when applying the restored parameters, an EtherCAT slave communications error will occur.

• The EtherCAT slave communications error does not occur, if you perform EtherCAT slave disconnection before turning OFF the power supply to the 1S-series Servo Drive.

• Refer to Objects to Back up and Restore on page 96 for details on the objects to back up and restore.

46

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Precautions for Correct Use

• Execution of this function block will be continued until processing is ended even if the value of Execute changes to FALSE or the execution time exceeds the task period. The value of Done changes to

TRUE when processing is ended. Use this to confirm normal ending of processing.

• This function block executes one EC_CoESDORead instruction within the part. Refer to the

EC_CoESDORead instruction in the instructions reference manual for the maximum number of

instructions that can be executed at the same time.

• This function block executes one FileWriteVar instruction within the part. Refer to the FileWriteVar

instruction in the instructions reference manual for the maximum number of instructions that can be

executed at the same time.

• Do not change the names and the contents of any object list.

• If the Servo Drive is assigned to the Motion Control Function Module, make sure that the Axis Disabled (_MC_AX[***].Status.Disabled) in the Axis Variable is TRUE before you execute the function

block.

• Do not attempt to turn OFF the power supply to the Controller and EtherCAT slaves or stop the EtherCAT communications until the processing for this function block ends normally or ends in an error.

• Sample programming shows only the portion of a program that uses the function or function block

from the library.

• When using sample programming in actual devices, also program safety circuits, device interlocks,

I/O with other devices, and other control procedures.

• Create a user program that will produce the intended device operation.

• Check the user program for proper execution before you use it for actual operation.

• An error will occur in the following cases. Error will change to TRUE.

a) No object list exists.

b) The EtherCAT master is not in a state that allows message communications.

c) The slave specified with NodeAdr does not exist.

d) The slave specified with NodeAdr is not in a state that allows communications.

e) The slave is not in a state that allows reading of parameters.

f) The number of EtherCAT communications instructions such as EC_CoESDORead exceeded the

maximum number of instructions that can be executed at the same time.

g) SD Memory Card access failed (no SD Memory Card inserted, write protection enabled, etc.).

h) The number of SD Memory Card related instructions such as FileWriteVar exceeded the maxi-

mum number of instructions that can be executed at the same time.

Backup_1S

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

47

Backup_1S

Troubleshooting

Error code

16#0000 16#00000000 Normal End --- --16#0400 16#00000000 Input Value Out

16#1400 16#00000000 SD Memory

16#1401 16#00000000 SD Memory

16#1402 16#00000000 SD Memory

16#1403 16#00000000 File Does Not

16#1405 16#00000000 File Already in

16#1409 16#00000000 That File Name

16#140A 16#00000000 Write Access

16#140B 16#00000000 Too Many Files

Expansion

error code

Status Description Correction

of Range

The value of NodeAdr is out of

range.

The directory name specified

Set the value of NodeAdr correctly.

Set DirName correctly.

with DirName contains one or

more characters that cannot be

used.

The directory name specified

with DirName is too long.

Check the length of the direc-

tory name specified with Dir-

Name and set it to within the

valid range.

Insert an SD Memory Card cor-

rectly.

Replace the SD Memory Card

with one that operates nor-

Card Access

Failure

An SD Memory Card is either

not inserted or is not inserted

properly.

The SD Memory Card is broken.

mally.

The SD Memory Card slot is

broken.

If this error persists even after

making the above two correc-

tions, replace the CPU Unit or

the Industrial PC.

Remove write protection from

the SD Memory Card. Slide the

small switch on the side of the

Card Write-protected

An attempt was made to write

to a write-protected SD Memory Card.

SD Memory Card from the

LOCK position to the writable

position.

Card Insufficient

Capacity

The SD Memory Card ran out

of free space.

Replace the SD Memory Card

for one with sufficient available

capacity.

Object lists are not stored. Check the SD Memory Card

Exist

and store correct object lists on

it.

Correct the user program so

that this function block is exe-

cuted only when the Busy out-

put variable for all other

Use

An instruction attempted to

read or write a file already

being accessed by another

instruction.

instructions for the same file is

FALSE.

Change the directory in which

to store the backup file. Or,

delete the existing backup file

Already Exists

The backup file exists on the

SD Memory Card when Over-

Write is FALSE.

in advance.

Remove write protection from

the file or directory specified for

the function block. Or, change

Denied

The file or directory specified

for the function block to write is

write-protected.

the file name of the file to write.

Correct the user program to

decrease the number of open

files.

Open

The maximum number of open

files was exceeded when opening a file for the function block.

48

Sysmac Library Instructions Manual for EtherCAT 1S Series Library (W571)

Backup_1S

Error code

16#140E 16#00000000 SD Memory

16#1800 16#00000000 EtherCAT Com-

16#1801 16#00000000 EtherCAT Slave

16#1802 16#00000000 EtherCAT Time-

16#1803 16#00000000 Reception Buf-

16#1804 SDO Abort

16#1808 16#00000000 Communica-

16#3C2D 16#00000001 VendorID Not

*1. Refer to SDO Abort Codes in the instructions reference manual for a list of SDO abort codes.

Expansion

error code

*1

Code

16#00000002 ProductCode

16#00000003 Unsupported

Status Description Correction

Card Access

Failed

munications

Error

Does Not

Respond

out

fer Overflow

SDO Abort Error The cause of this error

tions Resource

Overflow

Matched

Not Matched

Device

The SD Memory Card is broken.

The SD Memory Card slot is

broken.

The EtherCAT network is not in

a usable status.

The target slave does not exist. Specify an existing node

The target slave is not in an

operating condition.

Communications with the target

slave timed out.