Omron WS02-SIMC1-E - V1.9 REV 12-2009, SYSMAC WS02-SIMC1-E, CX-Simulator 1.9 Operation Manual

Page 1

Cat. No. W366-E1-10

CX-Simulator Ver. 1.9

SYSMAC

WS02-SIMC1-E

OPERATION MANUAL

Page 2

Page 3

SYSMAC

WS02-SIMC1-E

CX-Simulator Ver. 1.9

Operation Manual

Revised December 2009

Page 4

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the

information provided with them. Failure to heed precautions can result in injury to people or damage to

property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation "Ch," which appears in some displays and on some OMRON products, often means

"word" and is abbreviated "Wd" in documentation in this sense.

In this manual, "PLC" is used as the abbreviation for Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2008

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 5

vi

About Upgrades:

Version 1.1

The following functions have been added to the CX-Simulator with the upgrade from Version 1.0 to

Version 1.1.

Actual Serial Communications Possible

In Ver.1.0, the contents of messages sent by serial communications instructions are displayed on the computer screen. In Ver.1.1, actual serial communications to an external serial communications device connected to a COM

port on the computer are also possible.

NT Link (1:N Mode) Possible

In Ver.1.1, communications with OMRON’s Programmable Terminal (PT)

connected to a COM port on the computer via NT Link are possible.

Multipoint Data Collection Tool Added

Time-series I/O memory data acquired from the actual PLC can be saved as a

Data Replay File (CSV format). Unlike Data Trace, data can not be acquired

every cycle. However, data of more than 50 words can be acquired.

WindowsMe/2000 Supported

Serial Number Entry on Installing Added

Version 1.2

The following functions have been added to the CX-Simulator with the upgrade from Version 1.1 to

Version 1.2.

New PLCs Supported

Simulation is newly supported for the following PLCs.

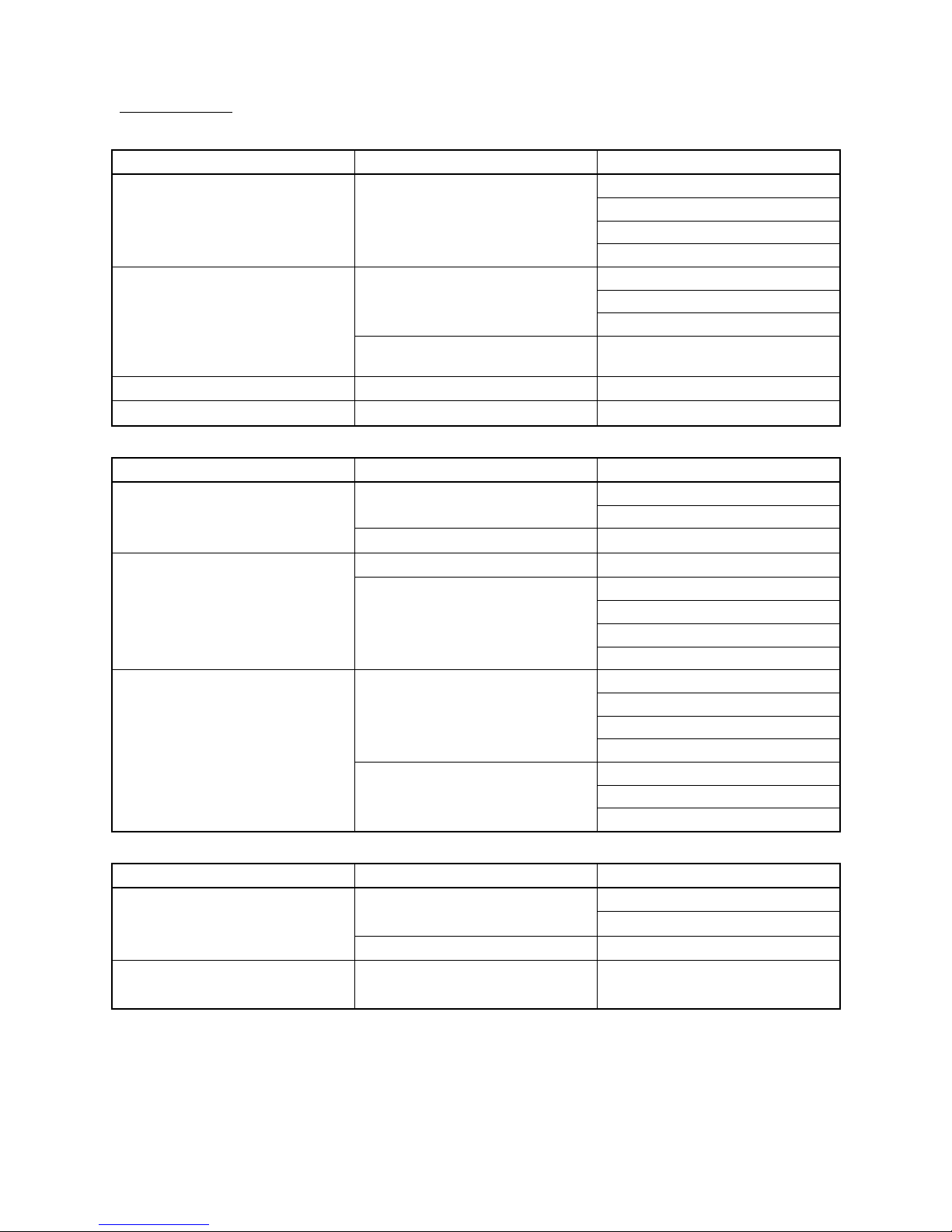

Series CPU Unit model numbers

CS CS1H-CPU67H/66H/65H/64H/63H

CS1G-CPU45H/44H/43H/42H

CJ CJ1H-CPU66H/65H

CJ1G-CPU45H/44H/43H/42H

CJ1G-CPU45/44

Functionality Improved

The following functions have been improved so that the same operation as

that performed by the actual PLC is performed by the CX-Simulator. (There

were some differences in operation with version 1.1.)

• Processing when using index registers for automatic incrementing or

decrementing with sequence output instructions.

• Processing the current EM bank is changed during execution of the ladder

program.

• Break processing for nested FOR-NEXT loops.

• Processing for decrementing counters in certain ladder program struc-

tures.

Page 6

vii

Simplified System Exit Processing

When the system is exited while the CX-Simulator is connected, a confirmation dialog box will appear and, upon confirmation, the CX-Simulator will be

disconnected and the system shut down.

Version 1.3

The following functions have been added to the CX-Simulator with the upgrade from Version 1.2 to

Version 1.3.

New PLCs Supported

Simulation is newly supported for the following PLCs.

Series CPU Unit model numbers

CJ CJ1M-CPU23/22/13/12

New Units in the CS and CJ Series are also supported for PLC Unit registration.

Starting and Connecting the CX-Simulator from the CX-Programmer

With CX-Programmer version 3.0 or higher, the CX-Simulator can be started

and connected (placed online) from the CX-Programmer. After going online,

program transfer to the CX-Simulator can be started immediately.

Windows XP Supported

Version 1.4

The following functions have been added to the CX-Simulator with the upgrade from Version 1.3 to

Version 1.4.

New PLCs Supported

Simulation is newly supported for the following PLCs.

Series CPU Unit model numbers

CS CS1D-CPU67H/65H

CS1D-CPU67S/65S/44S/42S

CJ CJ1M-CPU23/22/21/13/12/11

New Units in the CS and CJ Series are also supported for PLC Unit registration.

Version 1.5

The changes that have been made from version 1.4 to version 1.5 of the CX-Simulator to enable support of new

CPU Unit models are explained here.

New PLCs Supported

CX-Simulator version 1.5 supports the following new CPU Units.

Series CPU Unit model

CS CJ1H-CPU67H

CPU Unit Version Upgrade Compatibility

CX-Simulator version 1.5 supports the following CS/CJ-series CPU Units with

unit version 3.0.

Series Device type

CS/CJ CS1G-H, CS1H-H, CJ1G-H, CJ1H-H, CJ1M

Page 7

viii

Function Block (Ladder Programming Language) Simulation

CX-Simulator version 1.5 can be used to simulate function blocks that are supported for CS/CJ-series

CPU Units with unit version 3.0 (function block algorithms can be written in the ladder programming

language or in the structured text (ST)). Step execution of instructions contained in ladder programming

language or structured text within a function block, however, is not supported.

Precautions

CX-Simulator version 1.5 can simulate the operations of a CS/CJ-series CPU Unit with version 3.0 on a

personal computer. The simulation, however, operates differently from the actual CS/CJ-series CPU

Unit with unit version 3.0 in the system.

• Processing when using index registers for automatic incrementing or decrementing with sequence output instructions. No-protocol communications instructions sent to the serial port of

the Serial Communications Unit will not be executed.

CX-Simulator version 1.5 does not support no-protocol instructions (TXDU(256) and

RXDU(255)) sent to the serial port of the Serial Communications Unit and will not execute these

instructions.

• The Comms Instructions Settings in FB field in PLC Settings is disabled.

The Comms Instructions Settings in FB field (CPU Settings Tab) is a PLC setting specific to the

OMRON FB library. Therefore, this setting is disabled when using CX-Simulator version 1.5.

• Free Running Timers in Auxiliary Area words A000 and A001 are disabled.

The Auxiliary Area word 10-ms Incrementing Free Running Timer (A000) and 100-ms Incrementing Free Running Timer (A001) that are supported for CS/CJ-series CPU Units with version 3.0 or later cannot be used in simulation operations.

Version 1.6

The changes that have been made from version 1.5 to version 1.6 of the CX-Simulator to enable

support of new functions are explained here.

New PLCs Supported

CX-Simulator version 1.6 supports the following new CPU Units.

Series CPU Unit model

CP CP1H-XA/X

NSJ

(Controller

Section)

G5D (Used for the NSJ5-TQ0@-G5D, NSJ5-SQ0@-G5D,

NSJ8-TV0@-G5D, NSJ10-TV0@-G5D, and NSJ12-TS0@-G5D)

CX-Programmer Simulation Functions

If CX-Programmer version 6.1 or higher and CX-Simulator version 1.6 or

higher are installed, the following CX-Programmer simulation functions can be

used.

• Applicability: Ladder programs or programs in function blocks (ladder programs or ST)

• Simulation functions: Step execution, continuous step execution, scan

execution, and break-point operation (Note: I/O conditions cannot be set.)

Refer to the CX-Programmer Operation Manual (W446) for details.

Version 1.7

The changes that have been made from version 1.6 to version 1.7 of the CX-Simulator to enable

support of new functions are explained here.

Page 8

ix

New PLCs Supported

CX-Simulator version 1.7 supports the following new CPU Units.

Series CPU Unit model

CP

CP1H-XA@@@@-@

CP1H-X@@@@-@

CP1H-Y@@@@-@

NSJ

(Controller

Section)

M3D (Used for the NSJ5-TQ0@-M3D, NSJ5-SQ0@-M3D, and

NSJ8-TV0@-M3D)

Integrated Simulation with Screen Operations for Virtual PT

(Programmable Terminal)

The PLC-PT Integrated Simulation icon can be used to perform integrated

simulations using CX-Designer version 2.0 or higher and CX-Simulator version 1.7 or higher. This enables debugging by linking user program execution

on a virtual PLC with the CX-Programmer/CX-Simulator with screen operations for a virtual PT using the CX-Designer’s Test Tool.

• Starting the CX-Simulator:

The CX-Simulator is started by selecting the PLC-PT Integrated Simulation

menu item from CX-Designer version 2.0 or higher. (The user program is

automatically transferred to the CX-Simulator when it starts.)

• Connecting the CX-Simulator to virtual PT screens:

Automatically executed.

Refer to the operation manual for CX-Designer version 2.0 or higher for details.

Version 1.8

The changes that have been made from version 1.7 to version 1.8 of the CX-Simulator to enable

support of new functions are explained here.

New PLCs Supported

CX-Simulator version 1.8 supports the following new CPU Units.

Series CPU Unit model

CP

CP1L-M@@@@-@

CP1L-L@@@@-@

CJ CJ1H-CPU67H-R/66H-R/65H-R/64H-R

Version 1.9

The changes that have been made from version 1.8 to version 1.9 of the CX-Simulator to enable

support of new functions are explained here.

New PLCs Supported

CX-Simulator version 1.9 supports the following new CPU Units.

Series CPU Unit model

CJ CJ2H-CPU68-EIP/67-EIP/66-EIP/65-EIP/64-EIP

Version 1.91

The changes that have been made from version 1.9 to version 1.91 of the CX-Simulator to enable

support of new functions are explained here.

New PLCs Supported

CX-Simulator version 1.91 supports the following new CPU Units.

Series CPU Unit model

CJ CJ2H-CPU68/67/66/65/64

Page 9

x

Version 1.94

The changes that have been made from version 1.9 to version 1.94 of the CX-Simulator to enable

support of new functions are explained here.

Support for Windows 7

Note This upgrade accompanies the upgrade of CX-One version 3.2 to CX-One

version 4.03.

Page 10

xi

Unit Versions of CS/CJ/CP/NSJ-series CPU Units

Unit Versions

A “unit version” has been introduced to manage CPU Units in the

CS/CJ/CP/NSJ Series according to differences in functionality accompanying

Unit upgrades. This applies to the CJ2H, CS1-H, CJ1-H, CJ1M, CS1D, and

CP1H CPU Units.

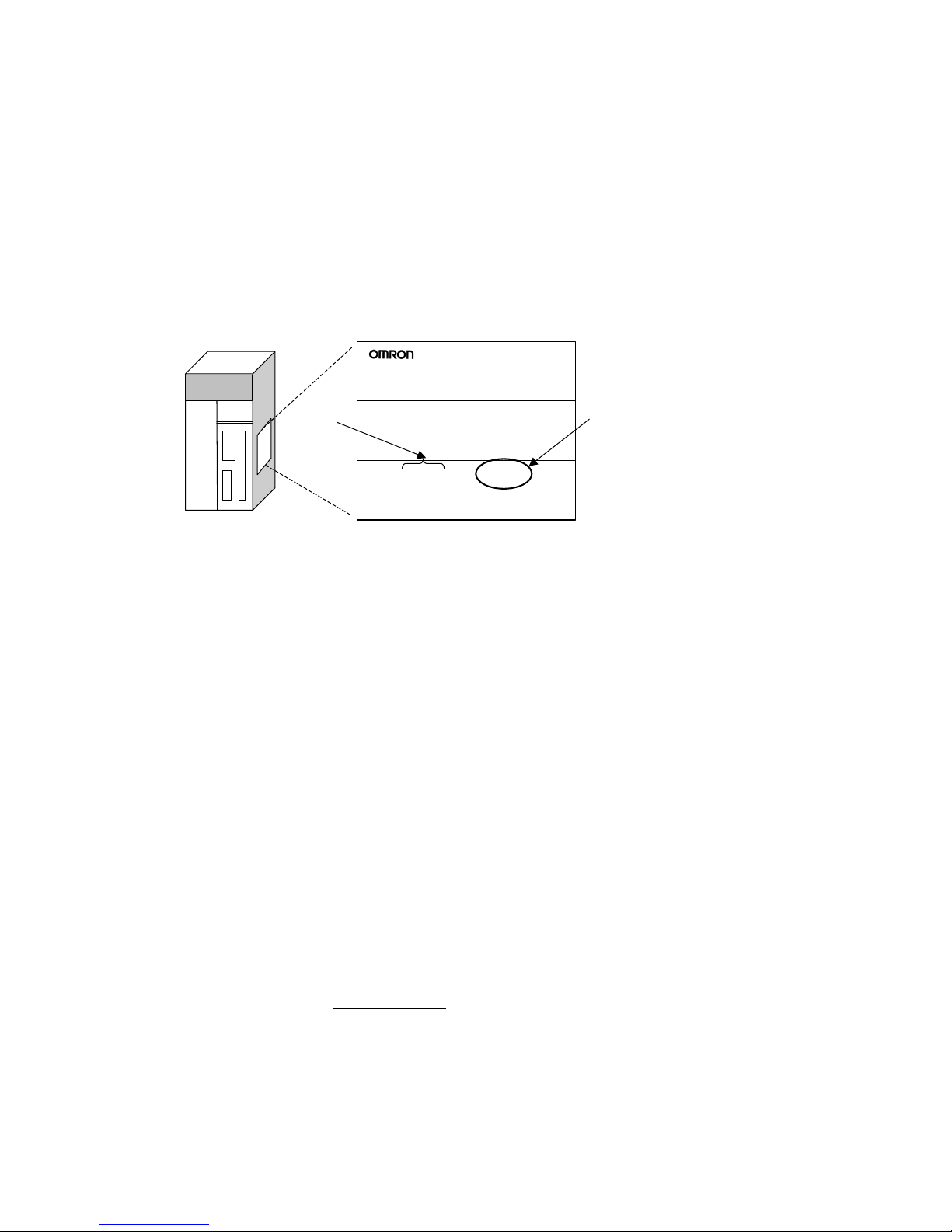

Notation of Unit Versions on Products

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Unit version

Example for unit version 2.0

CS1H-CPU67H

CPU UNIT

Lot No. 031001 0000 Ver.2.0

OMRON Corporation MADE IN JAPAN

Produce nameplate CS/CJ/CP-series CPU Unit

Lot No.

• CS1-H, CJ1-H, and CJ1M CPU Units manufactured on or before November 4, 2003 do not have a unit version given on the CPU Unit (i.e., the location for the unit version shown above is blank).

• The unit version of the CJ1-H-R CPU Units begins at version 4.0.

• The unit version of the CS1-H, CJ1-H, and CJ1M CPU Units, as well as the

CS1D CPU Units for Single-CPU Systems, begins at version 2.0.

• The unit version of the CS1D CPU Units for Duplex-CPU Systems begins

at version 1.1.

• The unit version of the CP1H/CP1L CPU Units begins at version 1.0, except for the CP1H-Y@@@@-@, for which the unit version begins at version

1.1.

• CPU Units for which a unit version is not given are called Pre-Ver.

@.@

CPU Units, such as Pre-Ver. 2.0 CPU Units and Pre-Ver. 1.1 CPU Units.

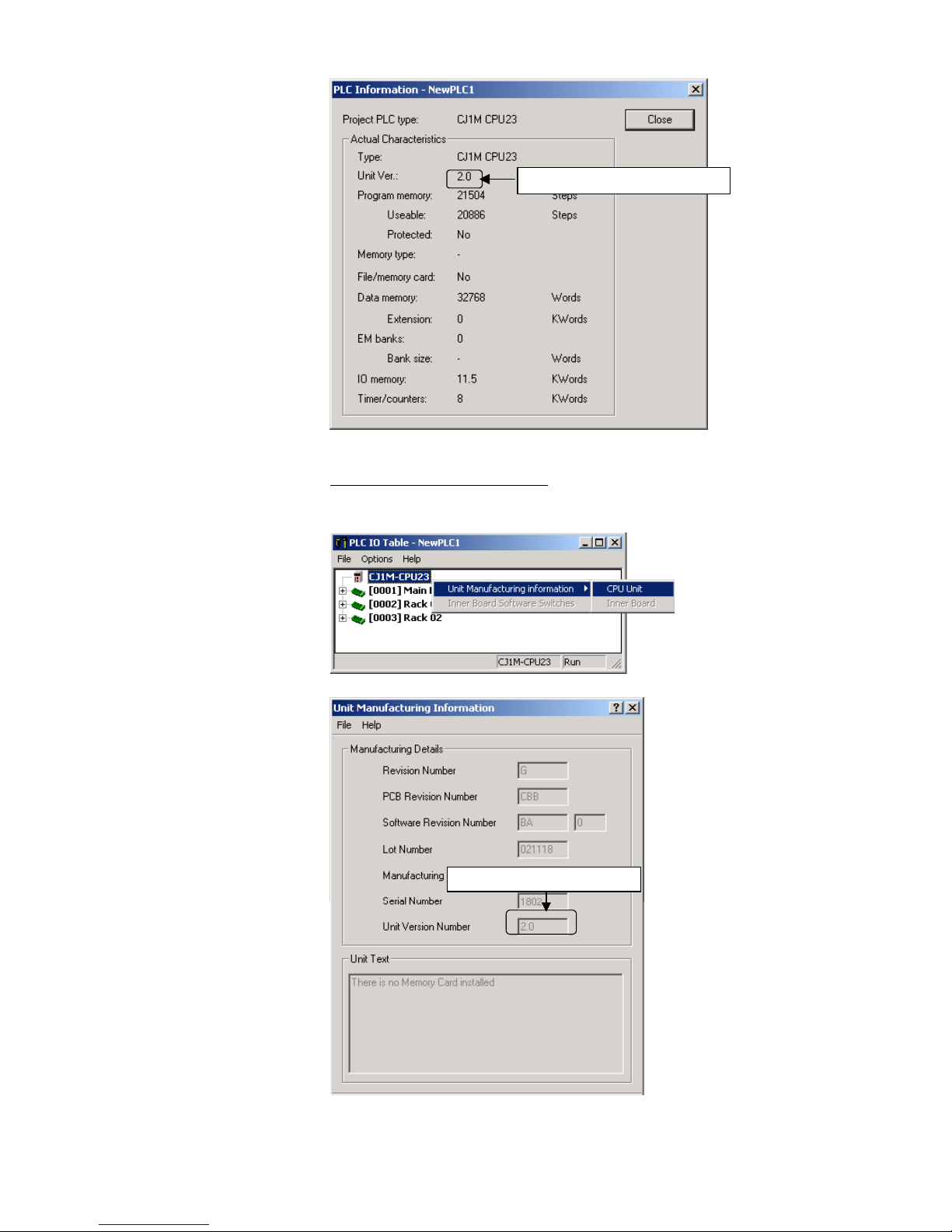

Confirming Unit Versions

with Support Software

CX-Programmer version 4.0 or later can be used to confirm the unit version

using one of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can be used for

Special I/O Units and CPU Bus Units as well.)

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit ver-

sions.

PLC Information

• If you know the device type and CPU type, select them in the Change PLC

Dialog Box, go online, and select PLC - Edit - Information from the

menus.

• If you don’t know the device type and CPU type, but are connected directly

to the CPU Unit on a serial line, select PLC - Auto Online to go online,

and then select PLC - Edit - Information from the menus.

In either case, the following PLC Information Dialog Box will be displayed.

Page 11

xii

Unit version

Use the above display to confirm the unit version of the CPU Unit.

Unit Manufacturing Information

In the IO Table Window, right-click and select Unit Manufacturing information - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed

Unit version

Use the above display to confirm the unit version of the CPU Unit connected

online.

Page 12

xiii

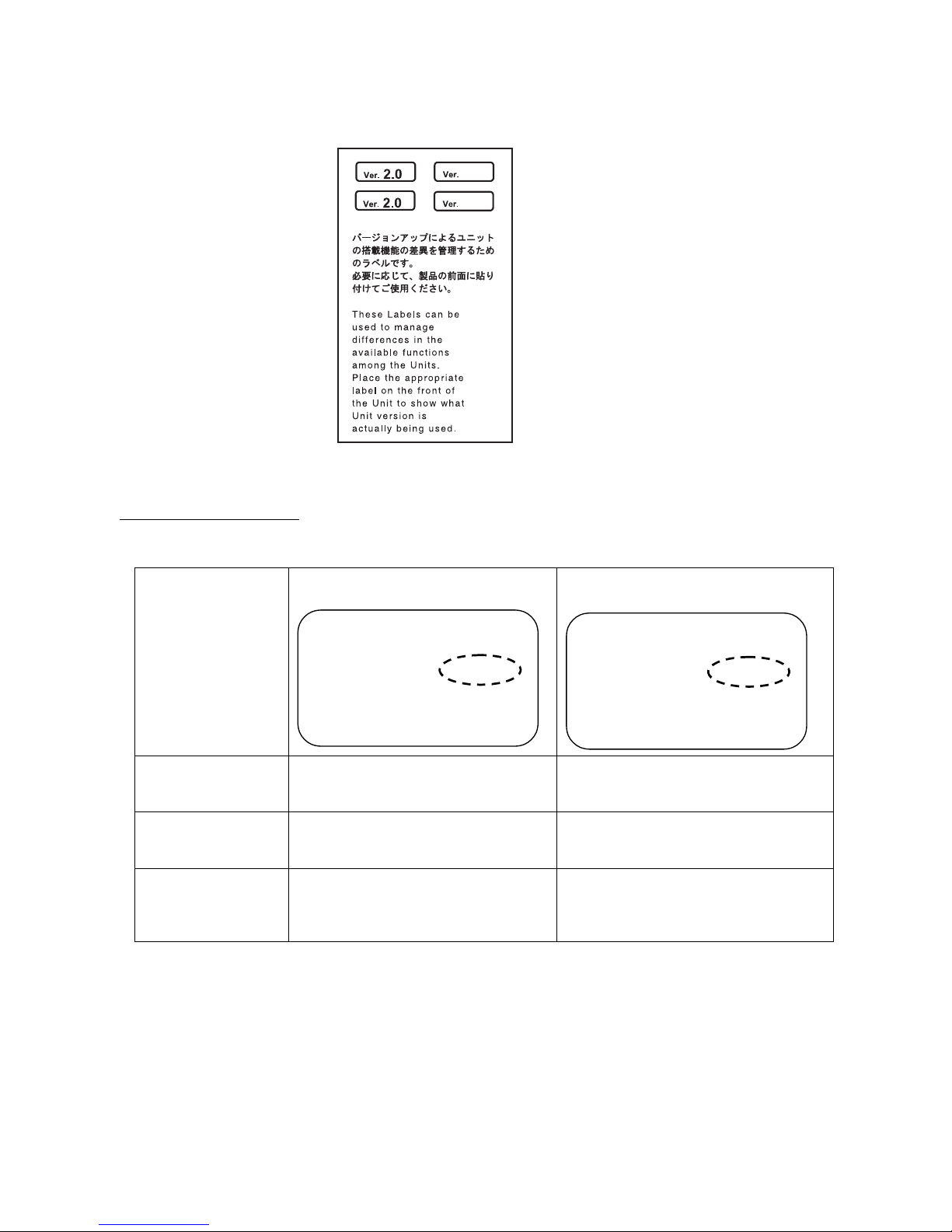

Using the Unit Version Labels

The following unit version labels are provided with the CPU Unit.

These labels can be attached to the front of previous CPU Units to differentiate

between CPU Units of different unit versions.

Unit Version Notation

In this manual, the unit version of a CPU Unit is given as shown in the following

table.

Product nameplate

Meaning

CPU Units on which no unit version is

given

Lot No. XXXXXX XXXX

OMRON Corporation MADE IN JAPAN

Units on which a version is given

(Ver.

@.@)

Lot No. XXXXXX XXXX

Ver.@.

@

OMRON Corporation MADE IN JAPAN

Designating individual

CPU Units (e.g., the

CS1H-CPU67H)

Pre-Ver. 2.0 CS1-H CPU Units

CS1H-CPU67H CPU Unit Ver. @.@

Designating groups of

CPU Units (e.g., the

CS1-H CPU Units)

Pre-Ver. 2.0 CS1-H CPU Units

CS1-H CPU Units Ver. @.@

Designating an entire

series of CPU Units

(e.g., the CS-series

CPU Units)

Pre-Ver. 2.0 CS-series CPU Units

CS-series CPU Units Ver. @.@

Page 13

xiv

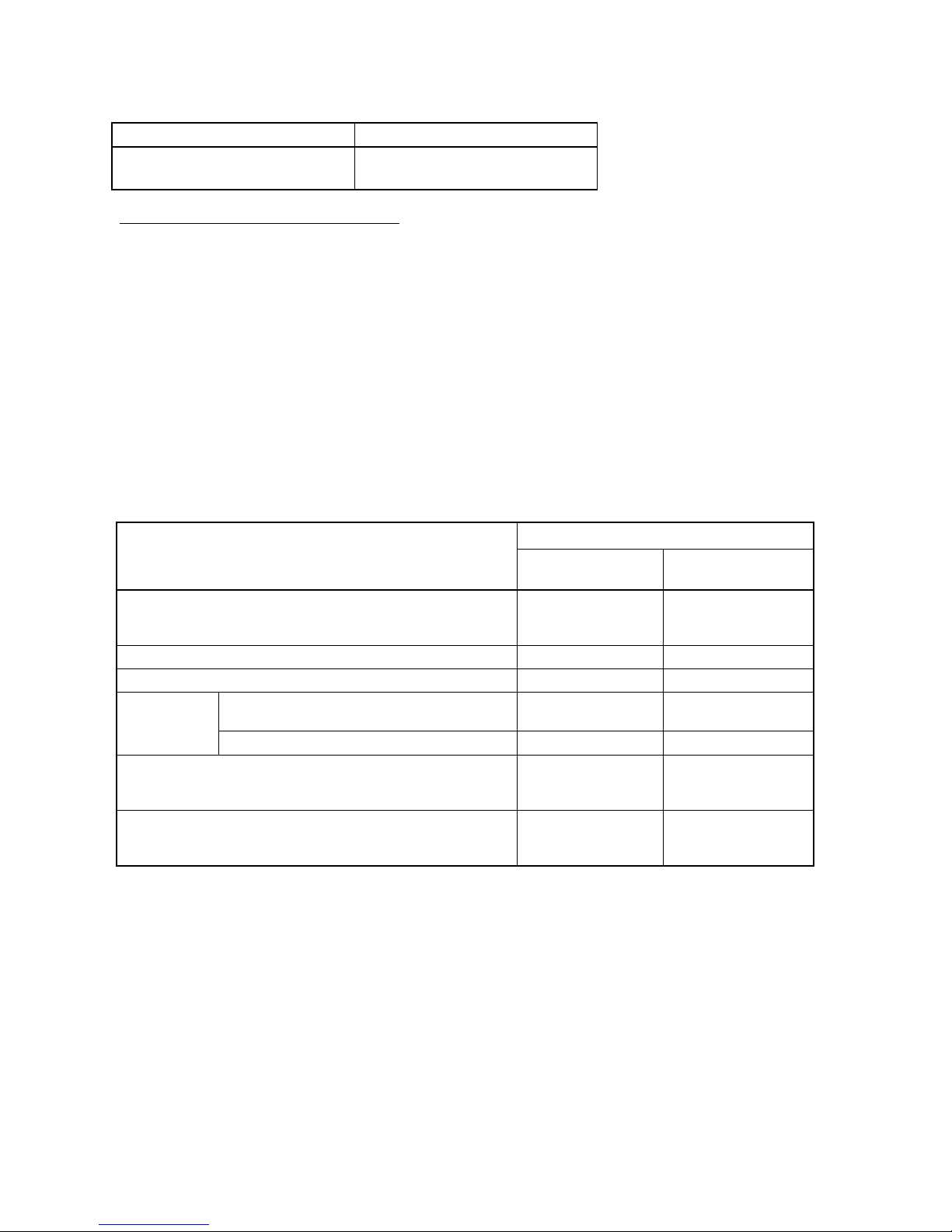

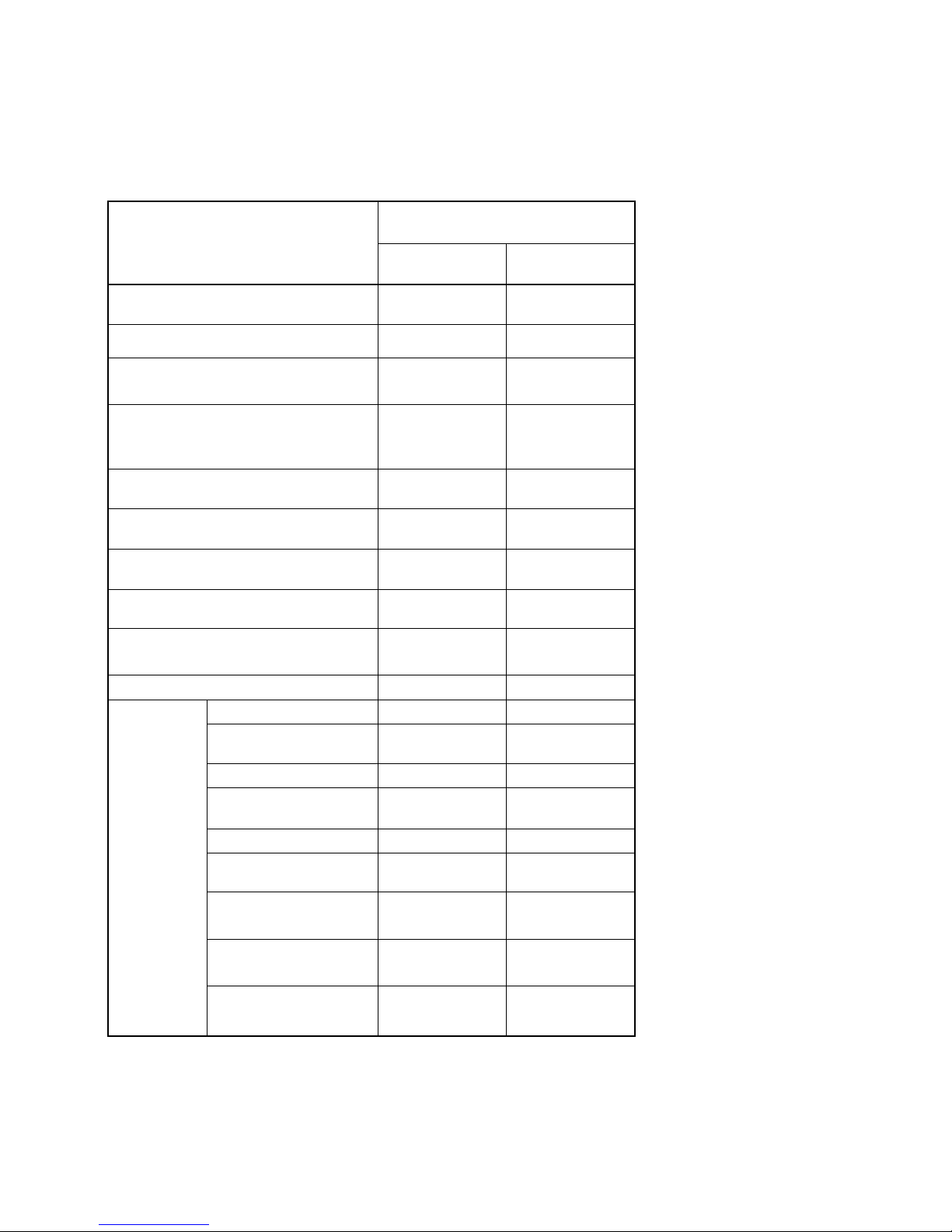

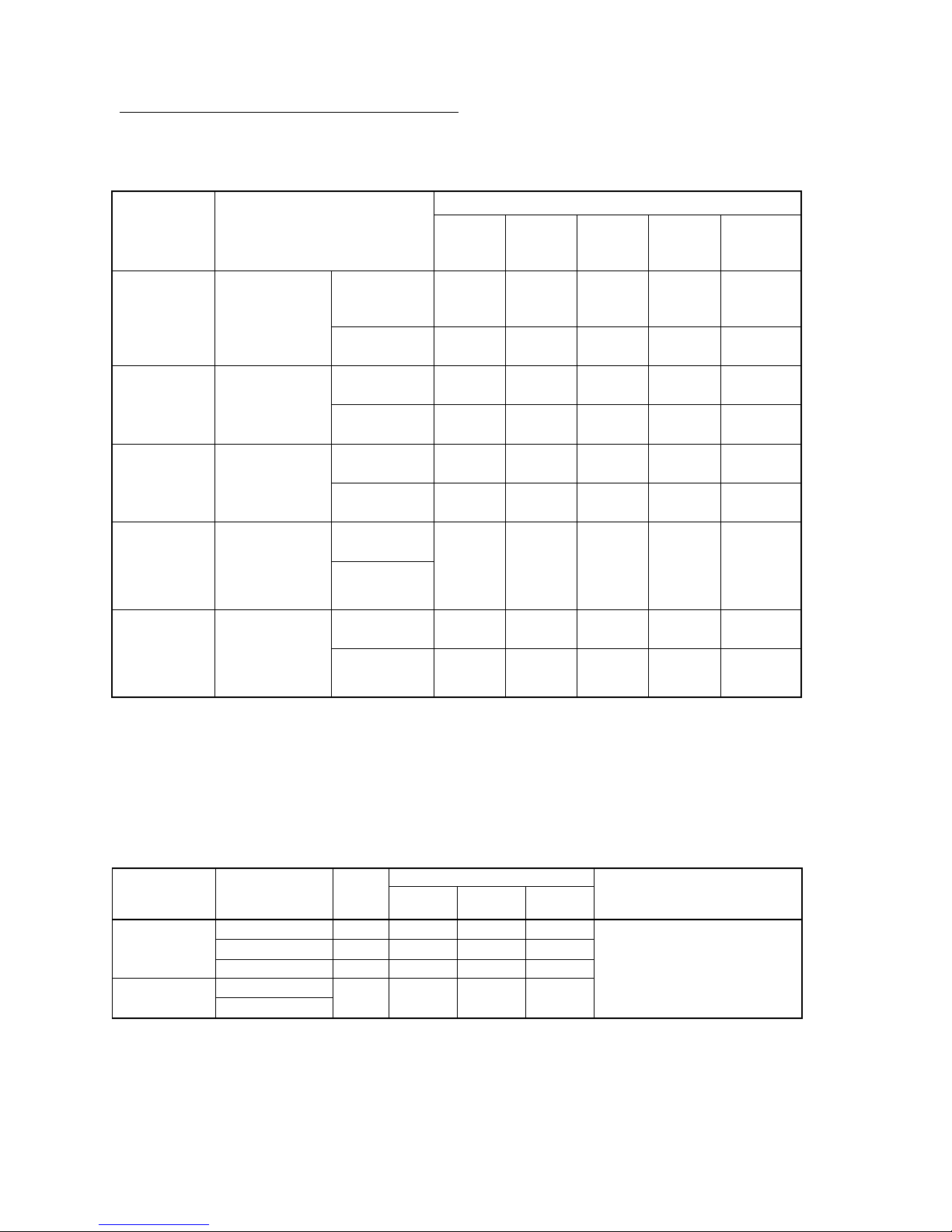

Unit Versions

CS Series

Units Models Unit versions

Unit version 4.0

Unit version 3.0

Unit version 2.0

CS1-H CPU Units

CS1@-CPU@@H

Pre-Ver. 2.0

Unit version 1.2

Unit version 1.1

Duplex-CPU Systems

CS1D-CPU@@H

Pre-Ver. 1.1

CS1D CPU Units

Single-CPU Systems

CS1D-CPU@@S

Unit version 2.0

CS1 CPU Units

CS1@-CPU@@

No unit version.

CS1 Version-1 CPU Units

CS1@-CPU@@-V1

No unit version.

CJ Series

Units Models Unit versions

Unit version 1.1

CJ2H-CPU6@-EIP

Unit version 1.0

CJ2 CPU Units

CJ2H-CPU6@

Unit version 1.1

CJ1H-CPU@@H-R

Unit version 4.0

Unit version 4.0

Unit version 3.0

Unit version 2.0

CJ1-H CPU Units

CJ1@-CPU@@H

CJ1@-CPU@@P

Pre-Ver. 2.0

Unit version 4.0

Unit version 3.0

Unit version 2.0

CJ1M-CPU12/13

CJ1M-CPU22/23

Pre-Ver. 2.0

Unit version 4.0

Unit version 3.0

CJ1M CPU Units

CJ1M-CPU11/21

Unit version 2.0

CP Series

Units Models Unit versions

Unit version 1.1

CP1H- X@@@@-@

CP1H- XA@@@-@

Unit version 1.0

CP1H CPU Units

CP1H- Y@@@@-@

Unit version 1.1

CP1L CPU Units

CP1L- M@@@@-@

CP1L- L@@@@-@

Unit version 1.0

Note: CP-series Unit Versions and Supported Functions

Unit version 1.0 or 1.1 of the CP-series CP1H/CP1L CPU Units is equivalent to unit version 3.0 of the

CS/CJ-series CPU Units. Functions added for unit version 4.0 or later of the CS/CJ-series CPU Units

are not supported by the CP-series CP1H/CP1L CPU Units.

Page 14

xv

NSJ Series

Models Unit versions

NSJ@-TQ@@(B)-G5D

NSJ@-TQ@@(B)-M3D

Unit version 3.0

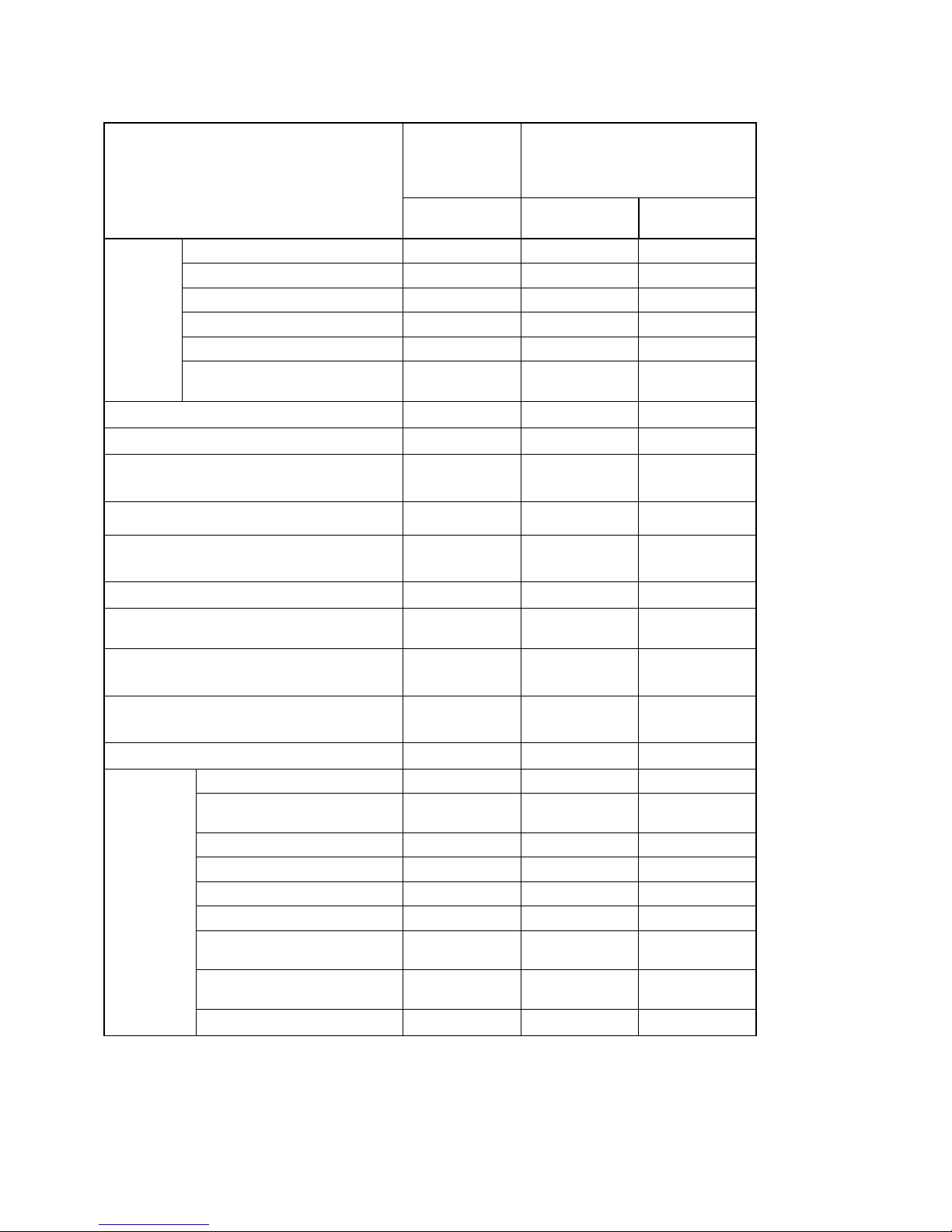

Function Support by Unit Version

The following tables show the functions supported by the CX-Programmer and

CX-Simulator depending on the unit version of the CPU Unit. Refer to 1-1-4

Summary of CX-Simulator Functions (Comparisons with Actual PLC) and 1-6

Comparison of CX-Simulator and SYSMAC CS/CJ-series PLCs for compari-

sons between CX-Simulator functions and the actual PLC.

The functions supported for CJ2 CPU Units with unit version 1.0 correspond to

those for CS/CJ Units with unit version 4.0 or later.

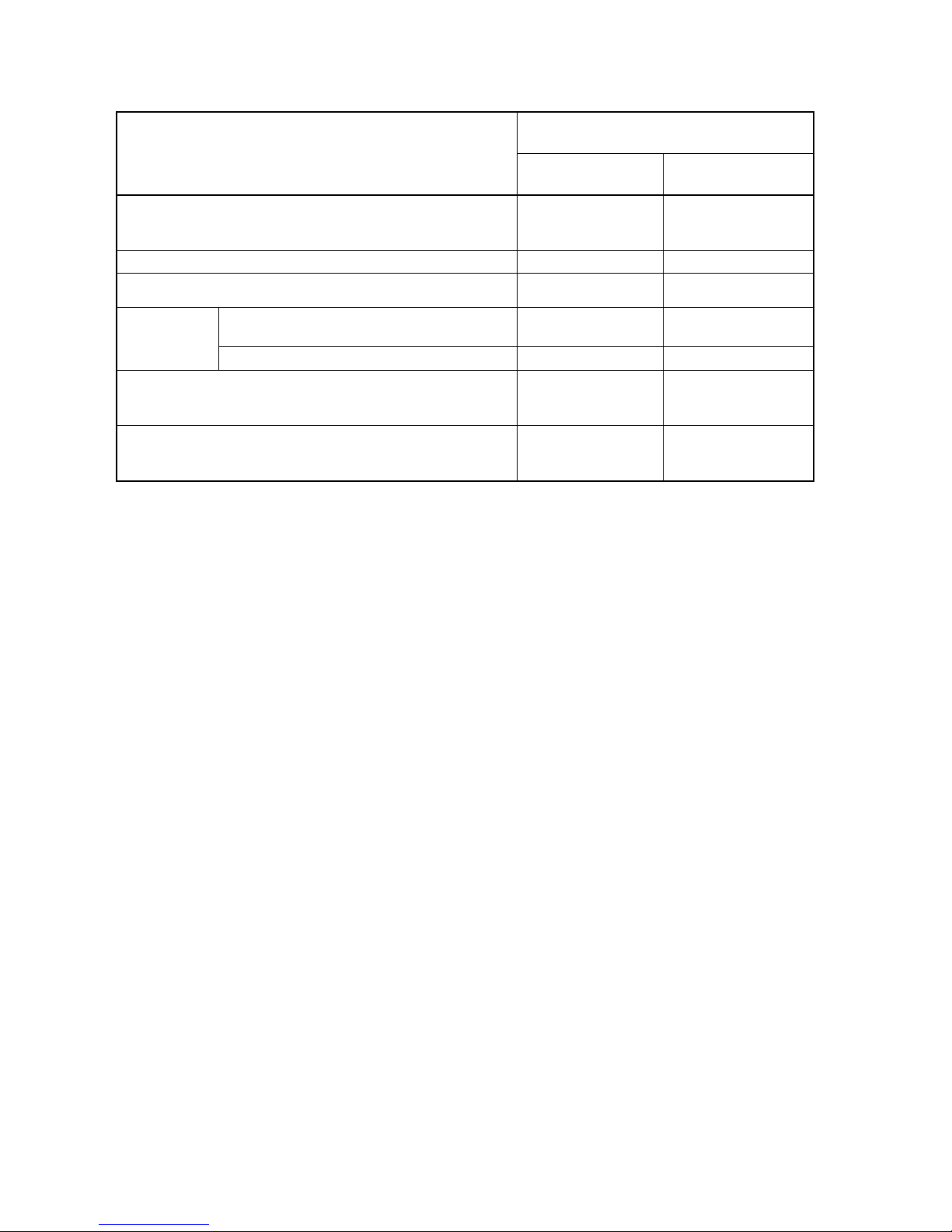

• Functions Supported for Unit Version 4.0 or Later

The following tables list the functions added for unit version 4.0 and supported

by the CX-Programmer. CX-Programmer version 7.0 or higher and

CX-Simulator version 1.7 or higher are required to use these functions.

Additional functions are supported if CX-Programmer version 7.2 or higher is

used.

CS1-H CPU Units

CS1@-CPU@@H

Function

Unit version 4.0 or

later

Other unit versions

Online editing of function blocks

Note: This function cannot be used for simulations on the

CX-Simulator.

OK ---

Input-output variables in function blocks OK ---

Text strings in function blocks OK ---

Number-Text String Conversion Instructions:

NUM4, NUM8, NUM16, STR4, STR8, and STR16

OK --- New application

instructions

TEXT FILE WRITE (TWRIT) OK ---

Using ST language programming in tasks OK with CX-

Programmer Ver. 7.2 or

higher

---

Using SFC programming in tasks OK with CX-

Programmer Ver. 7.2 or

higher

---

CS1D CPU Units

Unit version 4.0 is not supported.

Page 15

xvi

CJ1-H/CJ1M CPU Units

CJ1@-CPU@@H, CJ1G-CPU@@P,

CJ1M-CPU@@

Function

Unit version 4.0 or

later

Other unit versions

Online editing of function blocks

Note: This function cannot be used for simulations on the

CX-Simulator.

OK ---

Input-output variables in function blocks OK ---

Text strings in function blocks OK ---

Number-Text String Conversion Instructions:

NUM4, NUM8, NUM16, STR4, STR8, and STR16

OK --- New application

instructions

TEXT FILE WRITE (TWRIT) OK ---

Using ST language programming in tasks OK with CX-

Programmer Ver. 7.2 or

higher

---

Using SFC programming in tasks OK with CX-

Programmer Ver. 7.2 or

higher

---

Page 16

xvii

• Functions Supported for Unit Version 3.0 or Later

The following tables list the functions added for unit version 3.0 and supported

by the CX-Programmer. CX-Programmer version 5.0 or higher and

CX-Simulator version 1.5 or higher are required to use these functions.

CS1-H CPU Units

CS1@-CPU@@H

Function

Unit version 3.0 or

later

Other unit versions

Function blocks OK ---

Serial Gateway (converting FINS commands to CompoWay/F

commands at the built-in serial port)

OK ---

Comment memory (in internal flash memory) OK ---

Expanded simple backup data

TXDU(256), RXDU(255) (support no-protocol

communications with Serial Communications

Units with unit version 1.2 or later)

OK ---

Model conversion instructions: XFERC(565),

DISTC(566), COLLC(567), MOVBC(568),

BCNTC(621)

OK ---

New application

instructions

Special function block instructions: GETID(286) OK ---

Additional instruction functions

TXD(235) and RXD(236) instructions (support

no-protocol communications with Serial Communications Boards with unit version 1.2 or later)

OK ---

CS1D CPU Units

Unit version 3.0 is not supported.

CJ1-H/CJ1M CPU Units

CJ1@-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

Function

Unit version 3.0 or

later

Other unit versions

Function blocks

OK ---

Serial Gateway (converting FINS commands to CompoWay/F

commands at the built-in serial port)

OK ---

Comment memory (in internal flash memory)

OK ---

Expanded simple backup data

OK ---

TXDU(256), RXDU(255) (support no-protocol

communications with Serial Communications

Units with unit version 1.2 or later)

OK ---

Model conversion instructions: XFERC(565),

DISTC(566), COLLC(567), MOVBC(568),

BCNTC(621)

OK ---

New application instructions

Special function block instructions: GETID(286)

OK ---

Additional instruction functions

PRV(881) and PRV2(883) instructions: Added

high-frequency calculation methods for calculating pulse frequency. (CJ1M CPU Units only)

OK ---

Page 17

xviii

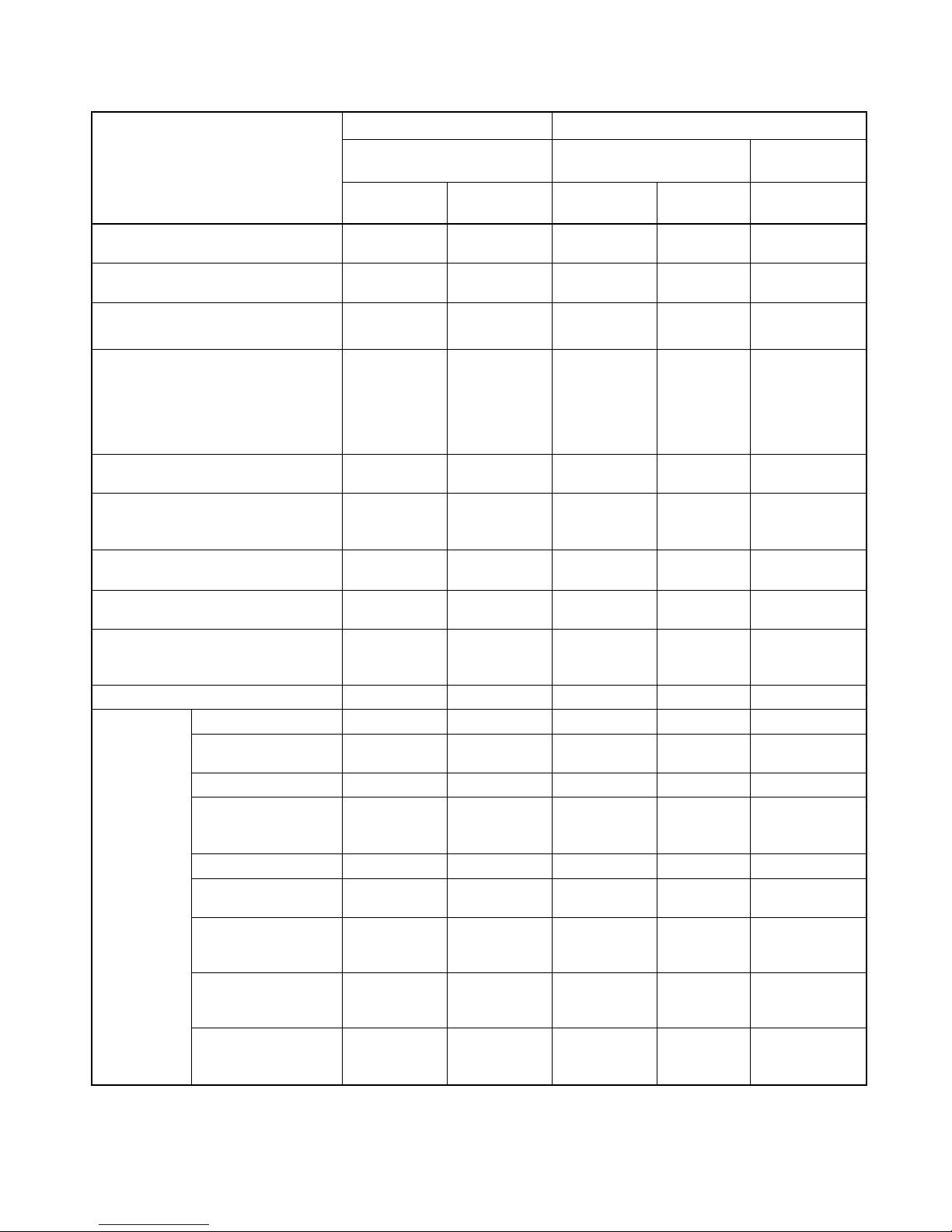

• Functions Supported for Unit Version 2.0 or Later

The following tables list the functions added for unit version 2.0 and supported

by the CX-Programmer. CX-Programmer version 4.0 or higher and

CX-Simulator version 1.4 or higher are required to use these functions.

CS1-H CPU Units

CJ1-H CPU Units

(CJ1@-CPU@@H)

Function

Unit version 2.0 or

later

Other unit ver-

sions

Downloading and Uploading Individual

Tasks

OK ---

Improved Read Protection Using Passwords

OK ---

Write Protection from FINS Commands Sent

to CPU Units via Networks

OK ---

Online Network Connections without I/O Tables

OK ---

Communications through a Maximum of 8

Network Levels

OK ---

Connecting Online to PLCs via NS-series

PTs

OK OK from lot number

030201

Setting First Slot Words

OK for up to 64

groups

OK for up to 8

groups

Automatic Transfers at Power ON without a

Parameter File

OK ---

Automatic Detection of I/O Allocation

Method for Automatic Transfer at Power ON

--- ---

Operation Start/End Times

OK ---

MILH, MILR, MILC

OK ---

=DT, <>DT, <DT, <=DT,

>DT, >=DT

OK ---

BCMP2

OK ---

GRY

OK OK from lot number

030201

TPO

OK ---

DSW, TKY, HKY, MTR,

7SEG

OK ---

EXPLT, EGATR, ESATR,

ECHRD, ECHWR

OK ---

Reading/Writing CPU Bus

Units with IORD/IOWR

OK OK from lot number

030418

New Application Instructions

PRV2

--- ---

Page 18

xix

CS1D CPU Units

CS1D CPU Units

for Single-CPU

Systems

(CS1D-CPU@@S)

CS1D CPU Units for Duplex-CPU

Systems (CS1D-CPU@@H)

Function

Unit version 2.0 Unit version 1.1

or later

Pre-Ver. 1.1

Duplex CPU Units --- OK OK

Online Unit Replacement OK OK OK

Duplex Power Supply Units OK OK OK

Duplex Controller Link Units OK OK OK

Duplex Ethernet Units --- OK OK

Functions

unique to

CS1D CPU

Units

Unit removal without a Programming Device

--- OK (Unit version

1.2 or later)

---

Downloading and Uploading Individual Tasks

OK --- ---

Improved Read Protection Using Passwords

OK --- ---

Write Protection from FINS Commands Sent to

CPU Units via Networks

OK --- ---

Online Network Connections without I/O Tables

OK --- ---

Communications through a Maximum of 8 Net-

work Levels

OK --- ---

Connecting Online to PLCs via NS-series PTs

OK --- ---

Setting First Slot Words

OK for up to 64

groups

--- ---

Automatic Transfers at Power ON without a Pa-

rameter File

OK --- ---

Automatic Detection of I/O Allocation Method for

Automatic Transfer at Power ON

--- --- ---

Operation Start/End Times

OK OK ---

MILH, MILR, MILC

OK --- ---

=DT, <>DT, <DT, <=DT, >DT,

>=DT

OK --- ---

BCMP2

OK --- ---

GRY

OK --- ---

TPO

OK --- ---

DSW, TKY, HKY, MTR, 7SEG

OK --- ---

EXPLT, EGATR, ESATR,

ECHRD, ECHWR

OK --- ---

Reading/Writing CPU Bus Units

with IORD/IOWR

OK --- ---

New application instructions

PRV2

OK --- ---

Page 19

xx

CS1-H/CJ1M CPU Units

CJ1-H CPU Units CJ1M CPU Units

(CJ1@-CPU@@H)

(CJ1G-CPU@@P)

CJ1M-CPU12/13/22/23 CJ1M-CPU11/21

Function

Unit version

2.0 or later

Other unit ver-

sions

Unit version

2.0 or later

Other unit

versions

Unit version 2.0

or later

Downloading and Uploading Individual

Tasks

OK --- OK --- OK

Improved Read Protection Using Passwords

OK --- OK --- OK

Write Protection from FINS Commands

Sent to CPU Units via Networks

OK --- OK --- OK

Online Network Connections without I/O

Tables

OK --- (Supported if

I/O tables are

automatically

generated at

startup.)

OK --- (Supported

if I/O tables

are automatically generated at

startup.)

OK

Communications through a Maximum of

8 Network Levels

OK --- OK --- OK

Connecting Online to PLCs via NS-series

PTs

OK OK from lot

number 030201

OK OK from lot

number

030201

OK

Setting First Slot Words

OK for up to 64

groups

OK for up to 8

groups

OK for up to 64

groups

OK for up to 8

groups

OK for up to 64

groups

Automatic Transfers at Power ON without a Parameter File

OK --- OK --- OK

Automatic Detection of I/O Allocation

Method for Automatic Transfer at Power

ON

OK --- OK --- OK

Operation Start/End Times

OK --- OK --- OK

MILH, MILR, MILC

OK --- OK --- OK

=DT, <>DT, <DT, <=DT,

>DT, >=DT

OK --- OK --- OK

BCMP2

OK --- OK OK OK

GRY

OK OK from lot

number 030201

OK OK from lot

number

030201

OK

TPO

OK --- OK --- OK

DSW, TKY, HKY, MTR,

7SEG

OK --- OK --- OK

EXPLT, EGATR,

ESATR, ECHRD,

ECHWR

OK --- OK --- OK

Reading/Writing CPU

Bus Units with

IORD/IOWR

OK --- OK --- OK

New application instructions

PRV2

--- --- OK, but only for

CPU Units with

built-in I/O

--- OK, but only for

CPU Units with

built-in I/O

Page 20

xxi

Functions Supported by Unit Version for CP-series CPU Units

Functions Supported by Unit Version 1.0 and 1.1

Functionality is the same as that for CS/CJ-series CPU Units with unit version 3.0.

The functionality added for CS/CJ-series CPU Unit unit version 4.0 is not

supported.

CP1H CPU Units

• CX-Programmer version 6.11 or higher is required to use

CP1H-X@@@@-@/XA@@@@-@ with unit version 1.1 or 1.0.

• CX-Programmer version 6.20 or higher is required to use

CP1H-Y@@@@-@ with unit version 1.1.

CPU Unit CP1H CPU Unit

Model CP1H-X@@@@-@

CP1H-XA@@@@-@

(See note 1.)

CP1H-Y@@@@-

@

(See note 2.)

Unit version

Function

Ver. 1.1 or

later

Ver. 1.0 Ver. 1.1

Allocated

built-in I/O terminals

4 axes at

100 kHz

2 axes at

100 kHz

2 axes at

30 kHz

2 axes at 100

kHz

Pulse

outputs

Special pulse

output terminals

None 2 axes at 1 kHz

Note 1: The unit version for the CP1H-X@@@@-@/XA@@@@-@ begins at 1.0.

2: The unit version for the CP1H-Y@@@@-@ begins at 1.1.

3: CX-Programmer version 7.11 or higher is required to use CP1L CPU Units

with unit version 1.0.

Page 21

xxii

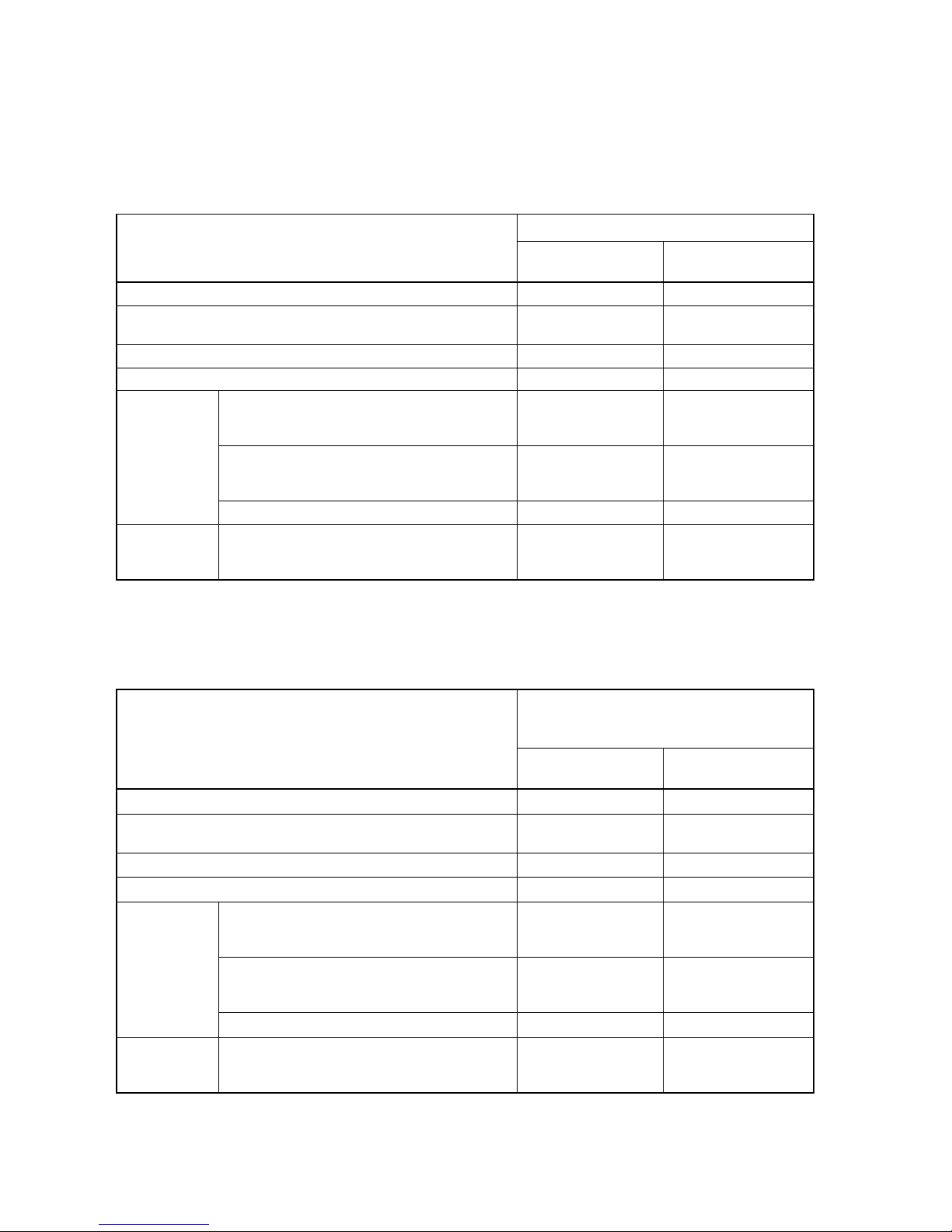

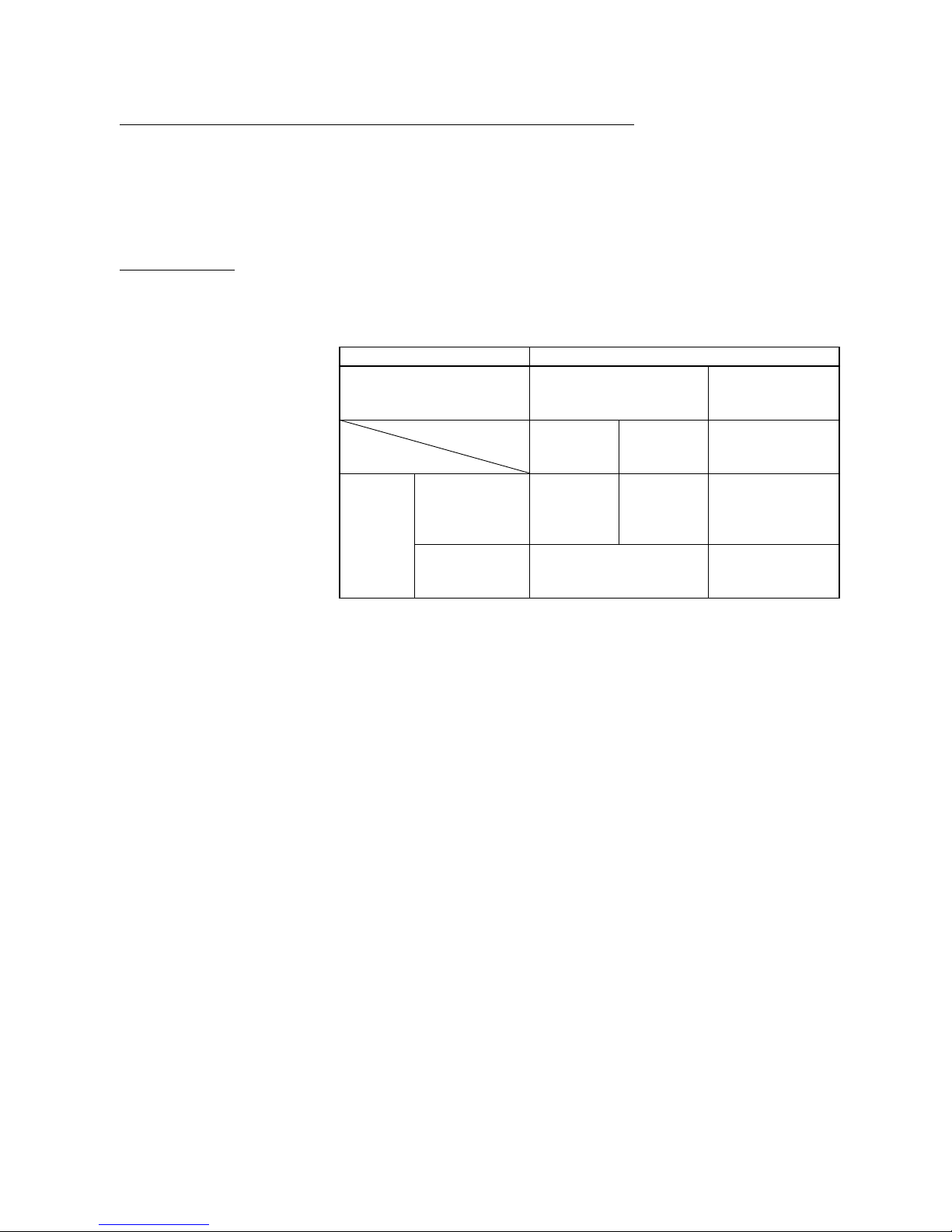

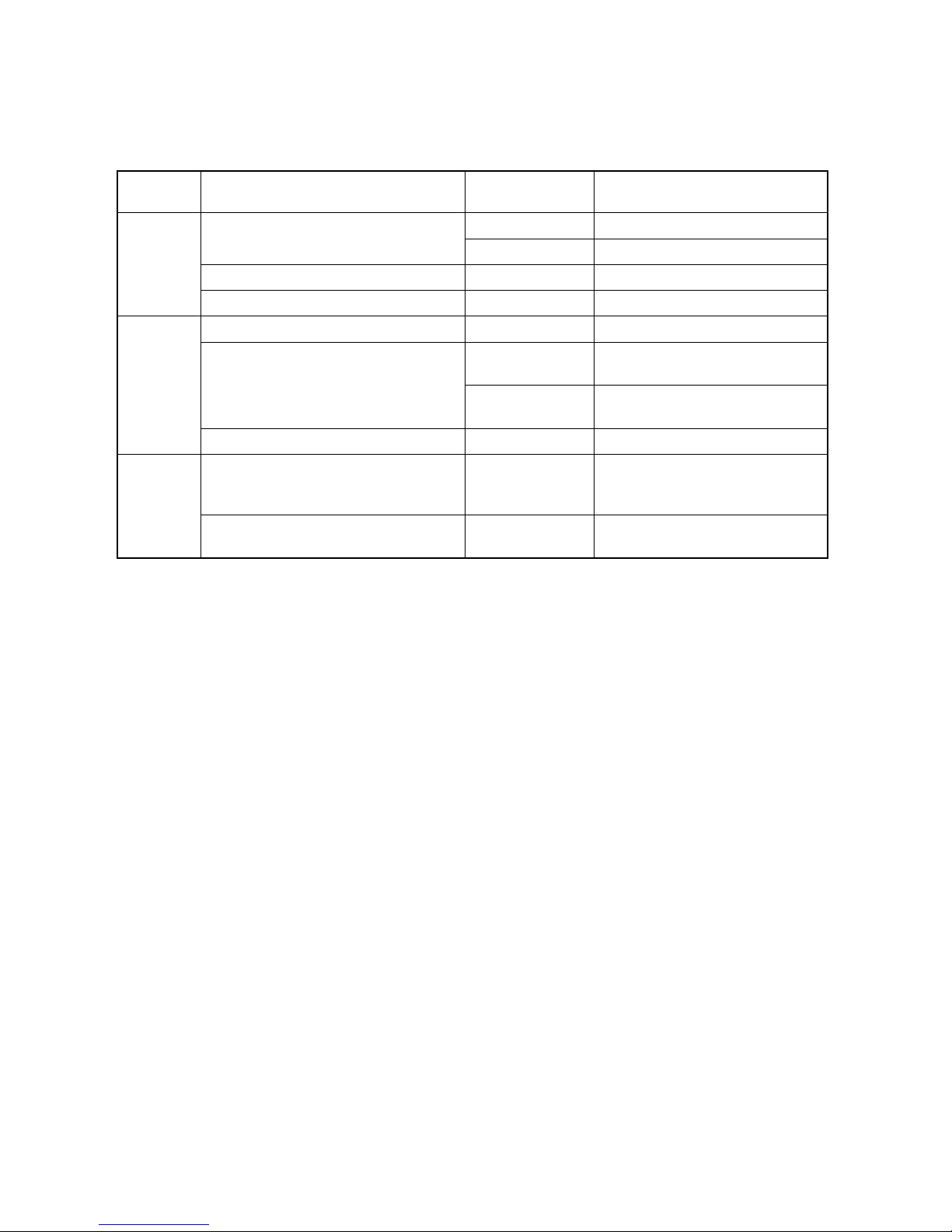

Unit Versions and Programming Devices

The following tables show the relationship between unit versions and

CX-Programmer versions.

Unit Versions of CS/CJ-series CPU Units and Programming Devices

CX-Programmer CPU Unit Functions

Ver. 3.3 Ver. 4.0 Ver. 5.0

Ver. 6.0

Ver. 7.0 Ver. 7.2

or

higher

Using new

functions

--- --- --- OK

(See

note 1.)

OK

(See note

1.)

CS/CJ Series,

unit version

4.0

Functions added

for unit version

4.0

Not using new

functions

OK OK OK OK OK

Using new

functions

--- --- OK OK OK CS/CJ Series,

unit version

3.0

Functions added

for unit version

3.0

Not using new

functions

OK OK OK OK OK

Using new

functions

--- OK OK OK OK CS/CJ Series,

unit version

2.0

Functions added

for unit version

2.0

Not using new

functions

OK OK OK OK OK

Using new

functions

CS1D CPU

Units for Single-CPU Systems, unit version 2.0

Functions added

for unit version

2.0

Not using new

functions

--- OK OK OK OK

Using new

functions

--- OK OK OK OK CS1D CPU

Units for Duplex-CPU

Systems, unit

version 1.

Functions added

for unit version

1.1

Not using new

functions

OK OK OK OK OK

Note 1: As shown above, there is no need to upgrade the CX-Programmer ver-

sion as long as the functions added newer unit versions are not used.

2: CX-Programmer version 7.0 or higher is required to use functions added

for unit version 4.0. Additional functions are supported if CX-Programmer

version 7.2 or higher is used.

Unit Versions of CP-series CPU Units and Programming Devices

CX-Programmer version CPU Unit Model Unit

version

Ver. 6.11 Ver. 6.20 Ver. 7.11

or higher

Programming Console

CP1H-X@@@@-@

Ver. 1.1 OK OK OK

CP1H-XA@@@@-@

Ver. 1.0 OK OK OK

CP1H CPU Units

CP1H-Y@@@@-@

Ver. 1.1 --- OK OK

CP1L-M@@@@-@ CP1L CPU Units

CP1L-L@@@@-@

Ver. 1.0 --- --- OK

Cannot be used.

Note 1: As shown above, there is no need to upgrade the CX-Programmer ver-

sion as long as the functions added newer unit versions are not used.

2: CX-Programmer version 7.0 or higher is required to use functions added

for unit version 4.0. Additional functions are supported if CX-Programmer

version 7.2 or higher is used.

Page 22

xxiii

Device Type Setting

The unit version does not affect the setting made for the device type on the

CX-Programmer. Select the device type as shown in the following table regardless of the unit version of the CPU Unit.

Series CPU Unit group CPU Unit model Device type setting on

CX-Programmer

CS1G-CPU@@H

CS1G-H CS1-H CPU Units

CS1H-CPU@@H

CS1H-H

CS1D CPU Units for Duplex-CPU Systems

CS1D-CPU@@H

CS1D-H (or CS1H-H)

CS Series

CS1D CPU Units for Single-CPU Systems

CS1D-CPU@@S

CS1D-S

CJ2 CPU Units

CJ2H-CPU6@(-EIP)

CJ2H

CJ1G-CPU@@H

CJ1G-CPU@@P

CJ1G-H CJ1-H CPU Units

CJ1H-CPU@@H-R

CJ1H-CPU@@H

CJ1H-H

CJ Series

CJ1M CPU Units

CJ1M-CPU@@

CJ1M

CP Series

CP1H CPU Units

CP1H-X@@@@-@C

P1H-XA@@@@-@

CP1H-Y@@@@-@

CP1H

CP1L CPU Units

CP1L-M@@@@-@

CP1L-L@@@@-@

CP1L

Note Device types not supported by the CX-Programmer version that is being used will not be

displayed on the pull-down list of the Device type Field.

Page 23

xxiv

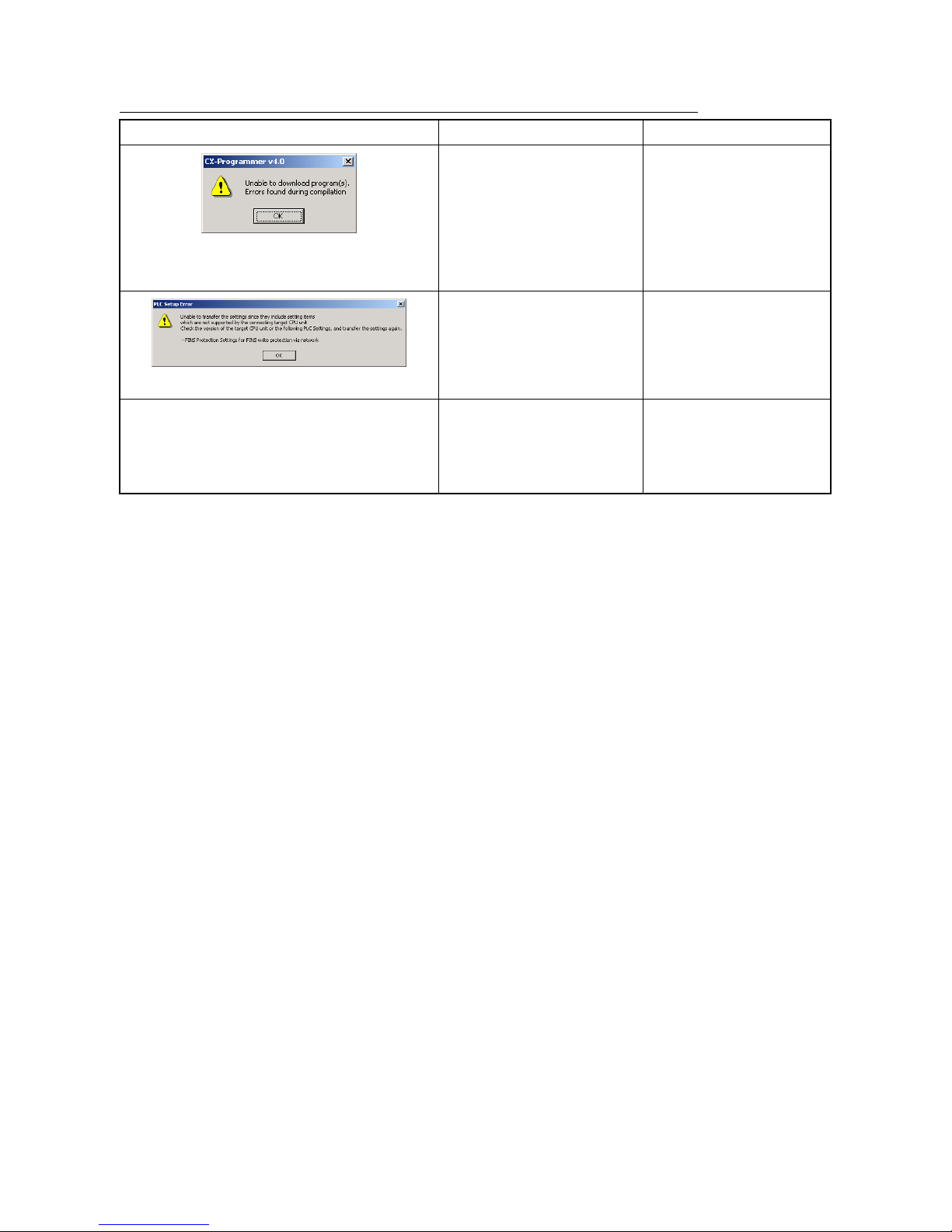

Troubleshooting Problems with Unit Versions on the CX-Programmer

Problem Cause Solution

After the above message is displayed, a compiling

error will be displayed on the Compile Tab Page in

the Output Window.

An attempt was made to

download a program containing

instructions supported only by

later unit versions or a CPU Unit

to a previous unit version.

Check the program or change

to a CPU Unit with a later unit

version.

An attempt was to download a

PLC Setup containing settings

supported only by later unit versions or a CPU Unit to a previous

unit version.

Check the settings in the PLC

Setup or change to a CPU

Unit with a later unit version.

"????" is displayed in a program transferred from the

PLC to the CX-Programmer.

An attempt was made to upload a

program containing instructions

supported only by higher versions of CX-Programmer to a

lower version.

New instructions cannot be

uploaded to lower versions of

CX-Programmer. Use a higher

version of CX-Programmer.

Page 24

xxv

Page 25

xxvi

TABLE OF CONTENTS

PRECAUTIONS..............................................................................................XXXVII

1 Intended Audience......................................................................................................................................... xxxviii

2 General Precautions ....................................................................................................................................... xxxviii

3 Safety Precautions .........................................................................................................................................xxxviii

4 Application Precautions................................................................................................................................... xxxix

SECTION 1

INTRODUCTION........................................................................................................1

1-1 What Is the CX-Simulator? ...................................................................................................................................... 2

1-2 Features .................................................................................................................................................................... 9

1-3 Convenient Functions............................................................................................................................................. 13

1-4 Applicable PLC models and Computers ................................................................................................................ 14

1-5 Operation List Arranged by Purpose...................................................................................................................... 16

1-6 Comparison of CX-Simulator and SYSMAC CS/CJ-series PLCs ......................................................................... 18

SECTION 2

SETUP ........................................................................................................................ 25

2-1 Installing and Uninstalling the Software ................................................................................................................ 26

SECTION 3

BASIC OPERATION ............................................................................................... 37

3-1 Starting Methods for the CX-Simulator ................................................................................................................. 38

3-2 Starting and Going Online from the CX-Programmer ........................................................................................... 39

3-3 Starting and Exiting from CX-Simulator Menus.................................................................................................... 42

3-4 Outline of Operation Procedure ............................................................................................................................. 44

3-5 Creating a New PLC............................................................................................................................................... 48

3-6 Each Part of the Windows ...................................................................................................................................... 58

3-7 System Status Setting Window .............................................................................................................................. 60

3-8 Connecting to the CX-Programmer Version 2.1 or Lower .................................................................................... 71

3-9 Debug Console Window ........................................................................................................................................ 76

SECTION 4

DEBUGGING PROGRAMS.................................................................................. 101

4-1 Debugging Using the CX-Programmer................................................................................................................ 102

4-2 Debugging Operation ........................................................................................................................................... 103

4-3 Step Run and Break.............................................................................................................................................. 107

4-4 Task Debugging ................................................................................................................................................... 115

SECTION 5

DEBUGGING SERIAL COMMUNICATIONS.................................................. 119

5-1 Outline of Serial Communications ....................................................................................................................... 120

5-2 Serial Communications Settings........................................................................................................................... 123

5-3 Serial Communications Connection ..................................................................................................................... 127

5-4 Connecting PT via NT Link ................................................................................................................................. 130

Page 26

xxvii

5-5 Examples of Serial Communications Debugging................................................................................................. 131

SECTION 6

DEBUGGING NETWORK COMMUNICATIONS ........................................... 135

6-1 Outline of Network Communications................................................................................................................... 136

6-2 Network Communications Settings...................................................................................................................... 139

6-3 Network Connection............................................................................................................................................. 142

6-4 Example of Debugging Network Communications.............................................................................................. 143

6-5 Available FINS Commands.................................................................................................................................. 147

SECTION 7

CONNECTION WITH APPLICATION PROGRAMS ..................................... 149

7-1 Outline of Connection .......................................................................................................................................... 150

7-2 Connection with Application Programs ............................................................................................................... 151

SECTION 8

DEBUGGING USING VIRTUAL EXTERNAL INPUTS.................................. 157

8-1 Outline of Virtual External Input Function .......................................................................................................... 158

8-2 Debugging Using Virtual External Inputs............................................................................................................ 159

8-3 Generating Virtual External Inputs ...................................................................................................................... 162

8-4 Running by Virtual External Inputs ..................................................................................................................... 176

8-5 Checking the Result.............................................................................................................................................. 184

SECTION 9

CPU UNIT OPERATION ...................................................................................... 187

9-1 CPU Unit Operation ............................................................................................................................................. 188

9-2 Cycle Time and Time ........................................................................................................................................... 192

9-3 I/O Memory Allocation ........................................................................................................................................ 200

9-4 Other Functions .................................................................................................................................................... 237

SECTION 10

TROUBLESHOOTING.......................................................................................... 239

10-1 Error Processing ................................................................................................................................................. 240

10-2 Alarms and Remedies......................................................................................................................................... 245

10-3 Other Tips for Troubleshooting.......................................................................................................................... 247

APPENDIX

HOW TO USE DATA TRACE RECORDING TOOL ....................................... 251

REVISION HISTORY............................................................................................ 263

Page 27

xxviii

About this Manual:

This manual describes operating procedures of the CX-Simulator for SYSMAC CS/CJ/CP/NSJ-series

Programmable Controllers (PLCs).

Please read this manual and all related manuals listed in the following table and be sure you understand

the information provided before attempting to operate the CX-Simulator.

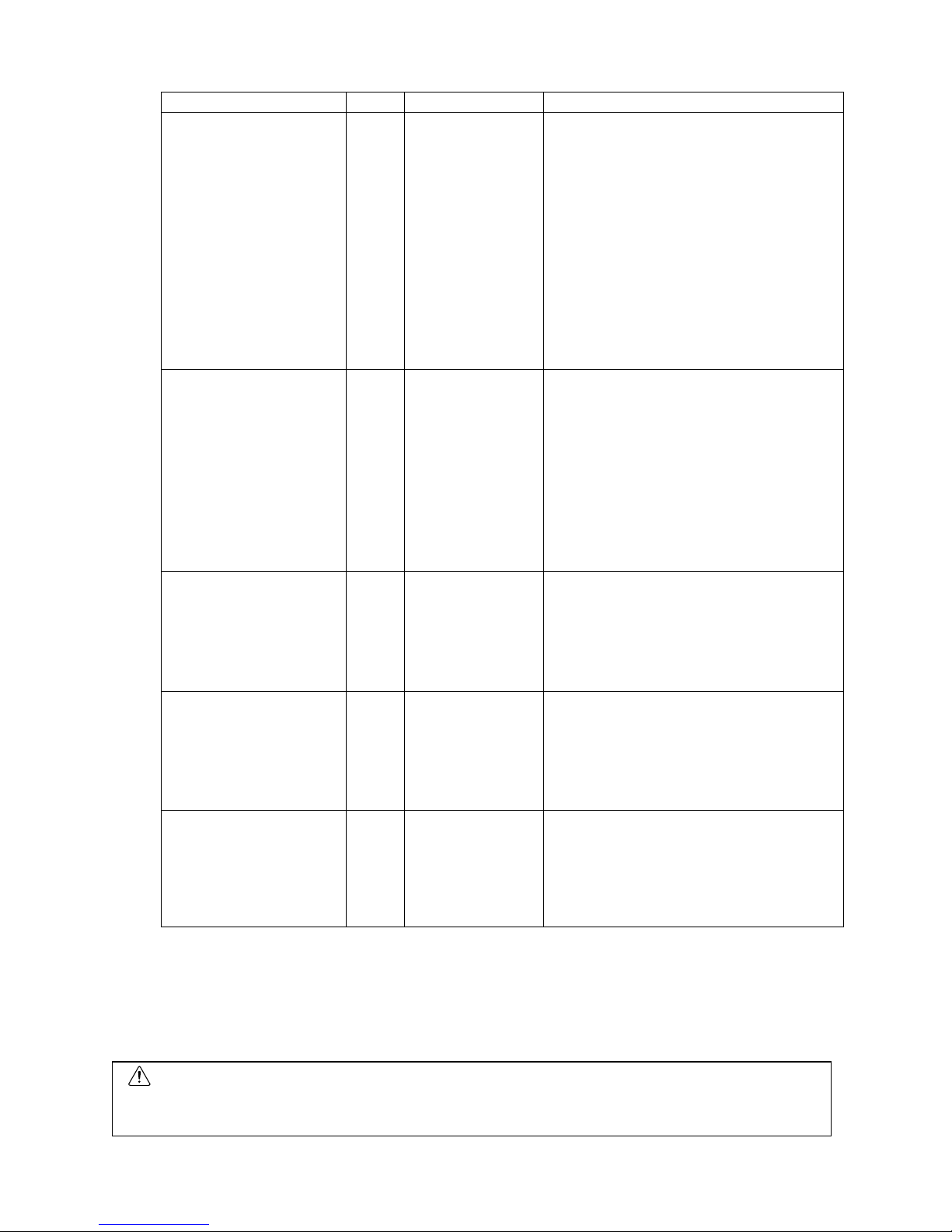

Name Cat. No. Use Contents

SYSMAC WS02-SIMC1-E

CX-Simulator Operation Manual (this

manual)

W366 To learn how to operate

CX-Simulator for Windows

personal computers. To

use simulation functions

on the CX-Programmer,

with CX-Programmer Ver.

6.1 or higher.

Describes the operation of the CX-Simulator.

Use this together with the CX-Programmer Operation Manual

(W446), CS Series and CJ Series Operation Manuals (CS

Series: W339, CJ Series: W393), and CS/CJ Series Instructions Reference Manual (W340).

CX-One Setup Manual W463 To install software from

CX-One.

Provides an outline of the CX-One FA integration software

package, and describes the method for installing CX-One.

CX-Programmer Ver. 9

Operation Manual

W446

CX-Programmer Ver. 9

Operation Manual

Function Blocks/Structured Texts

W447

To learn how to operate

CX- Programmer for Windows personal computers.

Describes the operation of the CX- Programmer.

For programming, use this together with the CJ2H Program-

mable Controllers Hardware User’s Manual (W472), the CJ2H

Programmable Controllers Software User’s Manual (W473),

and the Programmable Controllers Instructions Reference

Manual (W474).

CXONE-AL@@C-V4/ AL@@D-V4

CX-Integrator Operation Manual

W464 To make network settings

and monitor.

Describes the operation of the CX- Integrator.

CJ Series CJ2 CPU Unit Hardware

User’s Manual

CJ2H-CPU6@-EIP, CJ2H-CPU6@

W472 --- Provides the following information on the CJ2 CPU Units:

Overview, system design, hardware specifications, hardware

settings, installation, wiring, maintenance, and troubleshooting.

Use this manual together with the CJ2 CPU Unit Software

User’s Manual (W473).

CJ Series CJ2 CPU Unit Software

User’s Manual

CJ2H-CPU6@-EIP, CJ2H-CPU6@

W473 --- Provides the following information on the CJ2 CPU Units:

Overview of CPU Unit operation, programming, software

settings, CPU Unit functions, and system startup.

Use this manual together with the CJ2 CPU Unit Hardware

User’s Manual (W472).

SYSMAC CS Series

CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H

Programmable Controllers

Operation Manual

W339 To learn the basic specifi-

cations of the CS-series

PLCs, including a basic

outline, settings, installation, and maintenance.

Describes the features, system configuration design, installation, wiring, I/O memory allocation, and troubleshooting of the

CS-series PLCs.

Use this together with the Programming Manual (W394).

SYSMAC CJ Series

CJ1H-CPU@@H-R, CJ1G-CPU@@,

CJ1G/H-CPU@@H,

CJ1M-CPU@@

Programmable Controllers

Operation Manual

W393 To learn the basic specifi-

cations of the CJ-series

PLCs, including a basic

outline, settings, installation, and maintenance.

Describes the features, system configuration design, installation, wiring, I/O memory allocation, and troubleshooting of the

CJ-series PLCs.

Use this together with the Programming Manual (W394).

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S,

CJ1H-CPU@@H-R, CJ1G-CPU@@,

CJ1G/H-CPU@@H, CJ1M-CPU@@,

NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Programmable Controllers

Programming Manual

W394 To learn the functions of

the CS/CJ-series PLCs.

Describes the programming, task functions, file memory functions, and other functions of the CS/CJ-series PLCs.

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S,

CJ2H-CPU6@-EIP, CJ2H-CPU6@,

CJ1H-CPU@@H-R, CJ1G-CPU@@,

CJ1G/H-CPU@@H, CJ1M-CPU@@,

NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Programmable Controllers

Instructions Reference Manual

W474 To learn details of the

instruction language.

Describes the details of the instruction language.

For programming, use this together with the CS Series and CJ

Series Operation Manuals (CS Series: W339, CJ Series:

W393), and Programming Manual (W394).

Page 28

xxix

Name Cat. No. Use Contents

SYSMAC CS/CJ/CP/NSJ Series

CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S,

CJ2H-CPU6@-EIP, CJ2H-CPU6@,

CJ1H-CPU@@H-R, CJ1G-CPU@@,

CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H,

CS1W-SCU@@-V1,

CS1W-SCB@@-V1,

CJ1W-SCU@@-V1,

CP1H-X@@@@-@,

CP1H-XA@@@@-@,

CP1H-Y@@@@-@,

NSJ@-@@@@ (B)-G5D,

NSJ@-@@@@(B)-M3D

Communications Commands Reference Manual

W342 To learn about communi-

cations commands addressed to

CS/CJ/CP-series CPU

Units and NSJ-series

Controllers.

Describes the following information.

• C-mode commands

• FINS commands

Note: Refer to this manual when sending C-mode or FINS

commands to the CPU Unit.

This manual describes commands addressed to the

CPU Unit without reference to the communications path.

(Commands can be sent via the serial ports on the CPU

Unit, ports on a Serial Communications Board or Unit, or

ports on Communications Units.)

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NS12-TS@@(B)-G5D

NSJ Series NSJ Controllers

Operation Manual

W452 To learn the basic specifi-

cations of the NSJ-series

NSJ Controllers, including

a basic outline, settings,

installation, and maintenance.

Describes the following information about the NSJ-series NSJ

Controllers:

Overview and features

Designing the system configuration

Installation and wiring

I/O memory allocations

Troubleshooting and maintenance

Use this manual in combination with the following manuals:

SYSMAC CS Series Operation Manual (W339), SYSMAC CJ

Series Operation Manual (W393), SYSMAC CS/CJ Series

Programming Manual (W394), and NS-V1/-V2 Series Setup

Manual (V083)

CP1H-X@@@@-@,

CP1H-XA@@@@-@,

CP1H-Y@@@@-@,

SYSMAC CP Series

CP1H CPU Unit

Operation Manual

W450 To learn the basic specifi-

cations of the CP-series

CP1H CPU Units, including a basic outline, settings, installation, and

maintenance.

Provides the following information on the CP Series CP1H

CPU Unit:

• Overview/Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Programmable Con-

trollers Programming Manual (W451).

CP1L-M@@@@-@,

CP1L-L@@@@-@,

CP Series CP1L Operation Manual

W462 To learn the basic specifi-

cations of the CP-series

CP1L CPU Units, including

a basic outline, settings,

installation, and maintenance.

Provides the following information on the CP Series CP1L

CPU Unit:

• Overview/Features

• System configuration

• Mounting and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Programmable Con-

trollers Programming Manual (W451).

CP1H-X@@@@-@,

CP1H-XA@@@@-@,

CP1H-Y@@@@-@,

CP1L-M@@@@-@,

CP1L-L@@@@-@

SYSMAC CP Series

CP1H/CP1L CPU Unit Programming

Manual

W451 To learn about program-

ming CP-series

CP1H/CP1L CPU Units.

Provides the following information on the CP Series

CP1H/CP1L CPU Unit:

• Programming instructions

• Programming methods

• Tasks

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

Page 29

xxx

About this Manual, Continued

This manual contains the following sections.

Section 1 introduces the special features and functions of the CX-Simulator and a comparison between

SYSMAC CS/CJ/CP/NSJ-series PLCs

Section 2 provides the information on how to setup the CX-Simulator.

Section 3 describes the basic operation of the CX-Simulator.

Section 4 describes how to debug user programs.

Section 5 describes how to debug Serial Communications functions.

Section 6 describes how to debug Network Communications functions.

Section 7 describes how to connect with application programs.

Section 8 provides information on how to debug using virtual external inputs.

Section 9 describes operations of the CPU Unit including cycle times and I/O Memory allocation.

Section 10 provides information on errors and alarms that occur during the operation along with the

remedies.

Appendix provides information on how to use the Data Trace Recording Tool.

Page 30

xxxi

Page 31

xxxii

Read and Understand This Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

(1) The warranty period for the Software is one year from either the date of purchase or the date on which the

Software is delivered to the specified location.

(2) If the User discovers a defect in the Software (i.e., substantial non-conformity with the manual), and returns it

to OMRON within the above warranty period, OMRON will replace the Software without charge by offering

media or downloading services from the Internet. And if the User discovers a defect in the media which is attributable to OMRON and returns the Software to OMRON within the above warranty period, OMRON will replace the defective media without charge. If OMRON is unable to replace the defective media or correct the

Software, the liability of OMRON and the User’s remedy shall be limited to a refund of the license fee paid to

OMRON for the Software.

LIMITATIONS OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER’S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT WILL OMRON BE LIABLE FOR ANY LOST PROFITS OR OTHER INDIRECT,

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF USE OF THE SOFTWARE.

(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE BASED ON MODIFICATION

OR ALTERATION OF THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY THIRD

PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

Page 32

xxxiii

Application Considerations

SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT DESCRIBED IN THE

ATTACHED USER MANUAL.

Page 33

xxxiv

Disclaimers

CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at any time based on improvements or for other

reasons.

EXTENT OF SERVICE

The license fee of the Software does not include service costs, such as dispatching technical staff.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 34

xxxv

Notation

This manual describes operation items as follows:

Notation Examples

"[ ]" indicates a menu name, key, dialog box name, or button name. However, in some cases where

it is obviously a menu name, [ ] is not attached.

Example: [File] menu, [Tab] key, [Search] dialog box, [OK] button

"|" indicates the hierarchy for a menu or display.

Example:

• "Select [File] | [Create]" indicates "select [Create] from the [File] menu."

• "Select [PLC] | [Operation Mode] | [Monitor]" indicates "select [Operation Mode] from the [PLC] menu

and then select [Monitor]."

• "Select [System Status] | [Settings] | [UM Setting]" indicates "select the [Settings] button from the

[System Status] window and then select [UM Setting] from the pop-up menu."

"[ ] + [ ]" indicates pressing multiple keys simultaneously.

Example:

• "[Ctrl] + [S]" indicates "press [S] key with the [Ctrl] key held down."

• "[Ctrl] + [Shift] + [L]" indicates "press the [L] key with the [Ctrl] and [Shift] keys held down."

About Operation Examples

This manual describes operation and settings assuming that the target PLC is a CS/CJ-series PLC and

the Programming Device is the CX-Programmer.

Page 35

xxxvi

Page 36

xxxvii

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PLC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable

Controller. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience .................................................................................................................. xxxviii

2 General Precautions ................................................................................................................xxxviii

3 Safety Precautions................................................................................................................... xxxviii

4 Application Precautions ............................................................................................................ xxxix

Page 37

Safety Precautions 3

xxxviii

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

y Personnel in charge of installing FA systems.

y Personnel in charge of designing FA systems.

y Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this

manual close at hand for reference during operation.

WARNING

It is extremely important that a PLC and all PLC Units be used for the specified purpose and under the specified conditions, especially in applications

that can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PLC System to the

above-mentioned applications.

3 Safety Precautions

WARNING

The CX-Simulator simulates PLC operation. However, there are some differences in operation and timings between those of the CX-Simulator and the

actual PLC system. Be sure to confirm operation on the actual system as well

as debugging the programs on the CX-Simulator before running the actual

system. Unexpected operation may cause an accident.

Caution

Enabling serial communications function of the CX-Simulator may affect the

operation of devices connected to the computer. When external devices are

not being used, do not enable the serial communications function. Unexpected operation of the external devices may cause an accident.

Caution

When the CX-Simulator is used together with the Data Link function, the

Memory Mapping function of the FinsGateway, or the Cyclic Server of the

FinsServer Series, the operation of external devices connected to the personal computer may be affected. Do not activate these functions if they do

not need to be used simultaneously. Unexpected operation of the external

devices may cause an accident.

Page 38

Application Precautions 4

xxxix

4 Application Precautions

Observe the following precautions when using the CX-Simulator.

• Confirm the destination is the CX-Simulator when the CX-Simulator is connected online with the CX-Programmer or other applications. When the

CX-Simulator is disabled or not connected to the Simulator, the actual system may be activated.

• Confirm the destination is the PLC when another application connects online

with the actual system while the CX-Simulator is activated. Connection may

be made not with the actual system but with the CX-Simulator.

Page 39

Page 40

1

SECTION 1

Introduction

1-1 What Is the CX-Simulator? .......................................................................................................... 2

1-1-1 Summary .......................................................................................................................... 2

1-1-2 Software Configuration of CX-Simulator ........................................................................ 3

1-1-3 Basic Block Diagram........................................................................................................ 5

1-1-4 Summary of CX-Simulator Functions (Comparisons with Actual PLC) ......................... 6

1-2 Features......................................................................................................................................... 9

1-2-1 Features ............................................................................................................................ 9

1-3 Convenient Functions ................................................................................................................. 13

1-4 Applicable PLC models and Computers..................................................................................... 14

1-4-1 Applicable PLC models.................................................................................................. 14

1-4-2 Computer........................................................................................................................ 15

1-5 Operation List Arranged by Purpose ..........................................................................................16

1-5-1 Setting Operation Environment...................................................................................... 16

1-5-2 Program Execution.........................................................................................................16

1-5-3 Program Debugging ....................................................................................................... 16

1-5-4 Monitor the Status .......................................................................................................... 17

1-5-5 Set Serial Communications Settings............................................................................... 17

1-5-6 Set Network Communications Parameters..................................................................... 17

1-5-7 Execute Virtual External Input....................................................................................... 17

1-6 Comparison of CX-Simulator and SYSMAC CS/CJ-series PLCs ............................................. 18

Page 41

What Is the CX-Simulator? Section 1-1

2

1-1 What Is the CX-Simulator?

1-1-1 Summary

The CX-Simulator emulates the operation of the CS/CJ/CP-series CPU Unit

(see note 1) or the Controller Section of the NSJ Controller (see note 2) to the

computer, providing an equivalent development environment to that of an

actual PLC system only with software. Furthermore, various debugging functions and tools that are not available in the actual PLC allow more effective

development and debugging.

Note

1. In this manual, always assume that "CS/CJ-series PLC" also implies

CP-series PLCs unless otherwise specified. When performing simulations

for a CP-series PLC, use the instructions for the CS/CJ-series PLC.

Functions not supported by CP-series PLCs, however, cannot be simulated.

2. In this manual, always assume that "CJ-series PLC" also implies the Controller Section of an NSJ-series NSJ Controller unless otherwise specified.

When performing simulations for the Controller Section of the NSJ

Controller, use the instructions for the CJ-series PLC.

3. Emulation for units other than network communications units and Serial

Communications Boards/Units is not available. They are registered only

for calculating the I/O refresh time and peripheral servicing time.

CX-Simulator is used internally to simulate execution of ladder programs

or function blocks (ladder programs or ST) on CX-Programmer Ver. 6.1 or

higher.

4. The CX-Simulator does not support all of the instructions of the CPU Units.

Refer to 1-6 Comparison of the CX-Simulator and SYSMAC CS/CJ-series

PLCs for details.

The CX-Simulator runs on Windows 2000, XP, Vista, or Windows 7.

The CX-Simulator can execute the following operation by downloading programs from the CX-Programmer on the same computer to the virtual CPU Unit

and by driving the virtual CPU Unit without connecting with the actual

CS/CJ-series PLC.

1,2,3…

1. Debug programs with virtual external inputs to the virtual CPU Unit using

the Virtual External Input Tool or the Debugging Program.

2. Use various debugging functions such as address execution and break

point setting that are not available in CS/CJ-series PLCs.

3. Simulate the cycle time, enabling to simulate the CPU Unit without an

actual PLC.

4. Debug functions of network/serial communications.

Page 42

What Is the CX-Simulator? Section 1-1

3

1-1-2 Software Configuration of CX-Simulator

The CX-Simulator consists of the Ladder Engine, which is composed of the

virtual CPU Unit and other units (default: only the Simulator Communications

Unit), the FinsGateway (version 2 or higher) Virtual Communications Unit, the

Debugger, and the Virtual External Input Tool.

A

ctual PLC (CS/CJ/CP Series)

A

ctual

external I/O

CX- Programmer

User

program

CX-Simulator

CX- Programmer

User

program

Debugging

program

Various

input data

generation

tools

External inputs generation

Virtual Units

Virtual CPU Unit

(CS/CJ/CP Series)

Inside the computer

Note:

I/O Conditions

Tool, Data Replay Tool, and

Data Trace

Recording Tool

Computer

Application programs

(e.g. CX-Programmer)

Debugger

Virtual External

Input Tool

(See note)

FinsGateway (version 2 or higher)

FinsGateway Virtual Communications Unit

CPU Unit

Simulator Communications Unit

Virtual CPU Bus Unit

:CX-Simulator

Page 43

What Is the CX-Simulator? Section 1-1

4

Item Contents

A platform for CS/CJ/CP-series PLC Emulation

Consists of multiple units.

Default: Consists of the CPU Unit and the Simulator Communications Unit.

CPU Unit A virtual unit corresponding to the actual CPU Unit, in-

cluding application programs (UM1), debugging programs (UM2), and I/O memory areas.

Ladder Engine

Simulator Communications

Unit

The CX-Simulator's own virtual and general-purpose

communications unit, corresponding to PLC's network

communications unit. Possible to communicate with the

CX-Programmer.

FinsGateway (version 2 or higher)

Virtual Communications Unit (See

note.)

Connect Simulator Communications Unit in the Ladder Engine with FinsGateway version 2 or higher. Two types are available: Virtual Controller Link Unit and Virtual

Ethernet Unit. The CX-Programmer also performs FINS communications with the Ladder Engine via the Virtual Communications Unit.

Debugger Controls the Ladder Engine and executes various CX-Simulator's own debugging

functions.

Debugging program (UM2) Possible to simulate I/O operation with a program in the

program area for debugging other than the area for ap-

plications (UM1).

For virtual external

I/O functions

Command log The log for CX-Programmer's operations (e.g. I/O mem-

ory change, Force set/reset) is saved in a file (Command

log file).

Possible to replay operation for the Ladder Engine using

the Data Replay Tool.

Note

The FinsGateway Virtual Communications Unit is different from the FinsGateway

itself. CX-Simulator does not include the FinsGateway itself.

Page 44

What Is the CX-Simulator? Section 1-1

5

Item Contents

Data Replay

Tool

Read data in sequence from Command log file, Data

Trace file, and Data Replay file, and issue FINS com-

mands to the Ladder Engine to regenerate input data.

I/O Conditions Tool

Change contents of designated I/O memory areas when

the contents satisfy certain conditions.

Data Trace

Recording

Tool

Possible to input trace data (Data trace file) actually

obtained from PLC to the Ladder Engine using the Data

Replay Tool.

Possible to generate long-term data.

For virtual external

I/O functions

Virtual External Input

Tool

Multipoint

Data Collection Tool

Possible to acquire trace data of more than 50 words from

an actual PLC and to input to the Ladder Engine using the

Data Replay Tool.

For network communications

FinsGateway Virtual

comm. Unit/

Simulator

Communications Unit

FINS commands send/receive to/from application programs on the

Computers and the CPU Unit of FinsGateway are possible. Screen display of send messages is also possible. FINS commands send is not

possible (receive is possible).

1-1-3 Basic Block Diagram

Computer

Application programs

(e.g. CX-Programmer)

FinsGateway

FinsGateway Virtual

Communications unit

Simulator

Communications unit

CPU Unit

A

pplication

program

Debugging

program

Virtual

External Input

Tool

Virtual

external

input

Page 45

What Is the CX-Simulator? Section 1-1

6

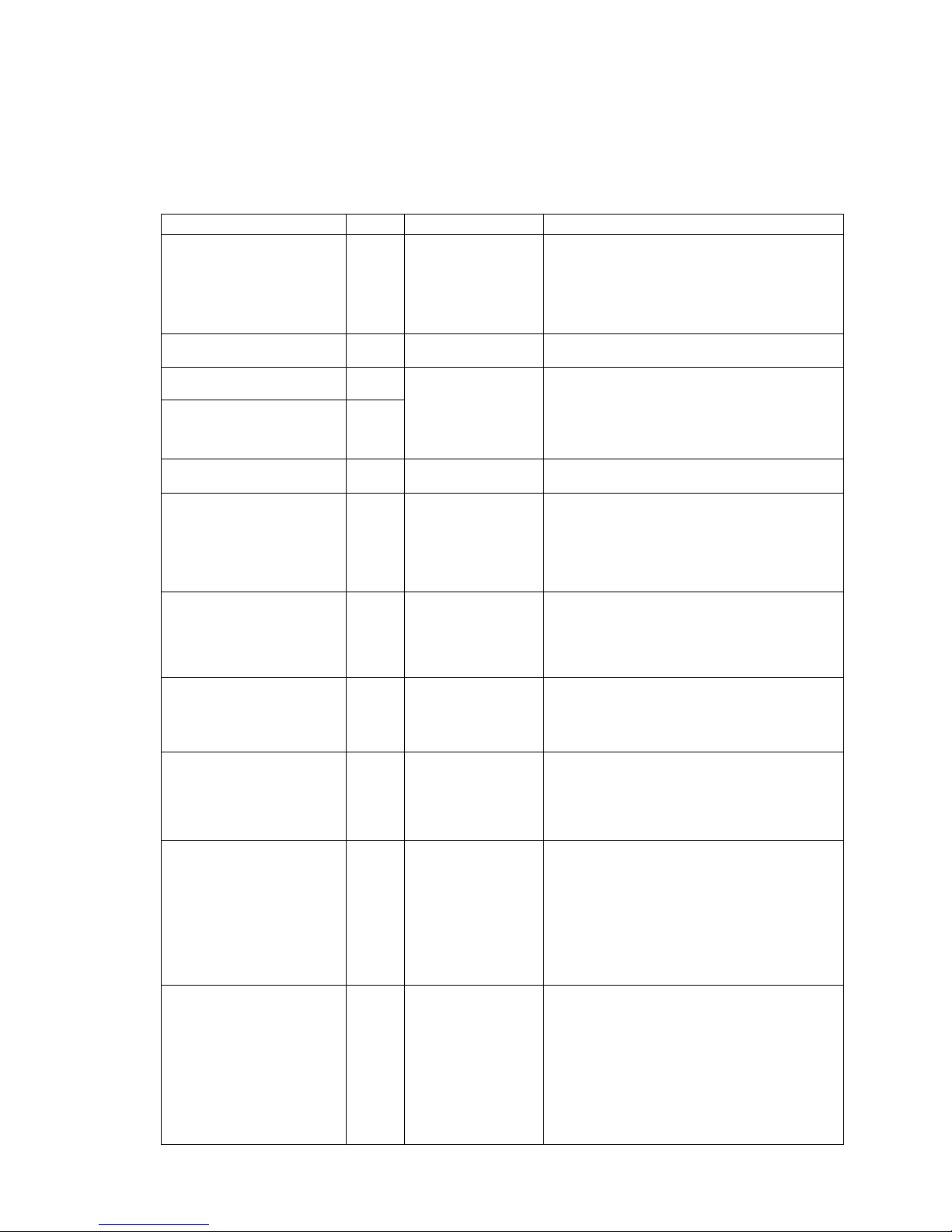

1-1-4 Summary of CX-Simulator Functions (Comparisons with Actual PLC)

Item Actual PLC CX-Simulator

Hardware CPU Unit

(CS/CJ/CP-series)

Virtual CPU Unit (CS/CJ-series)

Basic I/O unit Virtual Basic

I/O Unit

Special I/O unit Virtual Special

I/O Unit

CPU Bus Unit Virtual CPU

Bus Unit

*1: Excluding Controller Link

Unit,

Ethernet

Unit, and

Serial

Communications

Unit.

Inner Board Virtual Inner

Board

No operations (*1).

Registered

for calculating I/O

refresh time

and peripheral servicing time.

*1: Excluding Serial

Communications

Board

System configuration

Power Supply Unit None

CX-Programmer CX-Programmer on the same computer

(communicate via FinsGateway Virtual

Communications Unit)

Peripheral device

Programming Console unusable

Single user program Application program

(UM1)

Program

None Debugging program

(UM2): For external I/O

data generation

Share I/O memory areas.

CPU Unit basic

functions

Task function Available Available (equivalent)

Page 46

What Is the CX-Simulator? Section 1-1

7

Item Actual PLC CX-Simulator

Program mode Stop

Monitor mode and Run

mode

Continuous execution of scan

Minimum Cycle Time Logical cycle time: Substitute cycle time for

set value.

Actual cycle time: Regulate actual execution

time of one cycle on the computer.

Scan Run (only one scan)

Continuous Scan Run (one scan at regular

intervals)

Step Run (only one step)

Continuous Step Run (repeat address execution at regular intervals)

Block Run (Start point, break point, and I/O

break conditions can be set.)

None

Scan Replay (Return to the start point of the

scan when pausing.)

Operating mode

Operation when power

turns ON

Reset

I/O memory areas

Available Available

I/O area allocation

Required PLC unit registration instead (No slot set-

ting)

I/O refresh Available None (Only for cycle time calculation. Con-

troller Link Unit, Ethernet Unit, and Serial

Communications Board/Unit performs virtual

operation.)

Peripheral servicing

Available None (Only for cycle time calculation. Con-

troller Link Unit, Ethernet Unit, and Serial

Communications Board/Unit performs virtual

operation.)

External input Available Generate virtual external input by one of the

followings.

• Overwrite I/O memory areas using the

debugging program.

• Issue FINS commands using the com-

mand log and the Data Replay Tool.

• Issue FINS commands using the data

trace file and the Data Replay Tool.

• Issue FINS commands using the data

replay file and the Data Replay Tool.

• Overwrite I/O memory areas using the

I/O Conditions Tool.

Cycle time Virtual cycle time: Estimated cycle time if

operated on the actual CS/CJ/CP-series

CPU (Application program)

Computer cycle time: Actual cycle time on

the computer (Application program + de-

bugging program)

PLC setup Available Available

CPU Unit basic

functions

DIP switch setting

Available Available (By software, some functions only)

Page 47

What Is the CX-Simulator? Section 1-1

8

Item Actual PLC CX-Simulator

Network communications unit

Available (Ethernet Unit,

Controller Link Unit)

Available (Simulator Communications Unit,

Ethernet Unit, and Controller Link Unit)

Serial Communications

Board/Unit

Available Available (Using SYSMAC WAY Host Link

System, NT Link, or No-protocol)

Operation of

each unit

Other units Available None

Force-set/reset Available Available

Differential

monitor

Available Available

Data trace Available Available

Change set

value of

timer/counter

Available Available

Online edit Available Available

Serial communications

Available Available (Only message display)

Various functions

Network communications

Available Available (Using FinsGateway Virtual

Communications Unit, where send/receive

to/from the nodes in the computer.)

Page 48

Features Section 1-2

9

1-2 Features

Using the CX-Simulator with the following features can reduce man-days for

program debugging.

1-2-1 Features

Possible to simulate operation of the Virtual CPU Unit on the computer.

The CX-Simulator simulates operation of the SYSMAC CS/CJ/CP-series CPU

Unit. The operation of programs can be easily checked without an actual PLC

being connected. Using the CX-Simulator combined with the CX-Programmer

allows to develop/debug programs on a single computer.

Easily use the

CX-Programmer on the

same computer

Programs for the Virtual CPU Unit on the CX-Simulator can be seamlessly