Page 1

OPERATION MANUAL

CX-PROFIBUS Ver. 1.0

WS02-9094G

Cat. No. W05E-EN-01

Page 2

SYSMAC

WS02-9094G

CX-PROFIBUS Ver. 1.0

Operation Manual

Produced July 5, 2005

Page 3

iv

Page 4

v

Notice:

OMRON products are manufactured for use by a trained operator and only for the purposes described

in this manual.

The following conventions are used to classify and explain the precautions in this manual. Always

heed the information provided with them.

!DANGER Indicates information that, if not heeded, is likely to result in serious injury or loss of life.

!WARNING Indicates information that, if not heeded, could possibly result in serious injury or loss of

life.

!Caution Indicates information that, if not heeded, could possibly result in minor or relatively serious

injury, damage to the product or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The first letter of the word Unit is also capitalized

when it refers to an OMRON product, regardless of whether it appears in the proper name of the product.

The abbreviation Ch appears in some displays and on some OMRON products. It often means word

and is abbreviated as Wd in the documentation.

The abbreviation PLC means Programmable Logic Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1, 2, 3...Indicates various lists such as procedures, checklists etc.

Page 5

vi

Trademarks and Copyrights

PROFIBUS, PROFIBUS FMS, PROFIBUS DP, PROFIBUS DP-V1, and PROFIBUS PA are trademarks of PROFIBUS International.

Microsoft, Windows, Windows NT, Windows 2000, Windows XP, Windows Explorer and ActiveX are

trademarks of Microsoft Corporation.

Sycon and CIF are trademarks of Hilscher GmbH.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

The copyright of the PROFIBUS Master Units belongs to OMRON Corporation.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 6

vii

TABLE OF CONTENTS

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

SECTION 1

Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Setting up a PROFIBUS DP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 CX-Profibus Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SECTION 2

Configuration Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 CX-Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3 CS1/CJ1W-PRM21 PROFIBUS Master DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-4 C200HW-PRM21 PROFIBUS Master DTM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-5 Generic Slave Device DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SECTION 3

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-2 Setting up a network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-3 Configuring the Slave Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3-4 Configuring the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3-5 I/O Communication Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3-6 Operating the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3-7 Monitoring the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SECTION 4

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 113

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4-2 Troubleshooting the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

4-3 Troubleshooting Using the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Appendices

A Configurator Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Page 7

viii

TABLE OF CONTENTS

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Page 8

ix

About this Manual

This manual describes the CX-Profibus Configurator for the CS1W-PRM21 and CJ1W-PRM21

PROFIBUS DP and PROFIBUS DP-V1 Master Units.

This manual describes CX-Profibus and the PROFIBUS Master and slave DTM supplied with it. how to

operate it. These software components are required to control and operate the CS1/CJ1W-PRM21

PROFIBUS DP and PROFIBUS DP-V1 Master units. or more information on the CS1/CJ1W-PRM21

Master unit, refer to the CS1/CJ1W-PRM21 PROFIBUS Master Units Operation Manual (W409-E2-@).

Please read this manual carefully so that you understand the information provided before using CXProfibus and the PROFIBUS Master Units. Start with the precautions in the following section. They

describe the operating environment and application safety measures which must be observed prior to

and when using the PROFIBUS Master Unit.

The sections of this manual are as follows:

Section 1 introduces PROFIBUS and Cx-Profibus.

Section 2 describes Cx-Profibus and the DTMs in detail.

Section 3 describes the operational aspects of CX-Profibus.

Section 4 provides procedures for troubleshooting the PROFIBUS network and the Units.

The Appendices contain information supplementary to the information in the main body of the manual. They are referred to in the various sections as required.

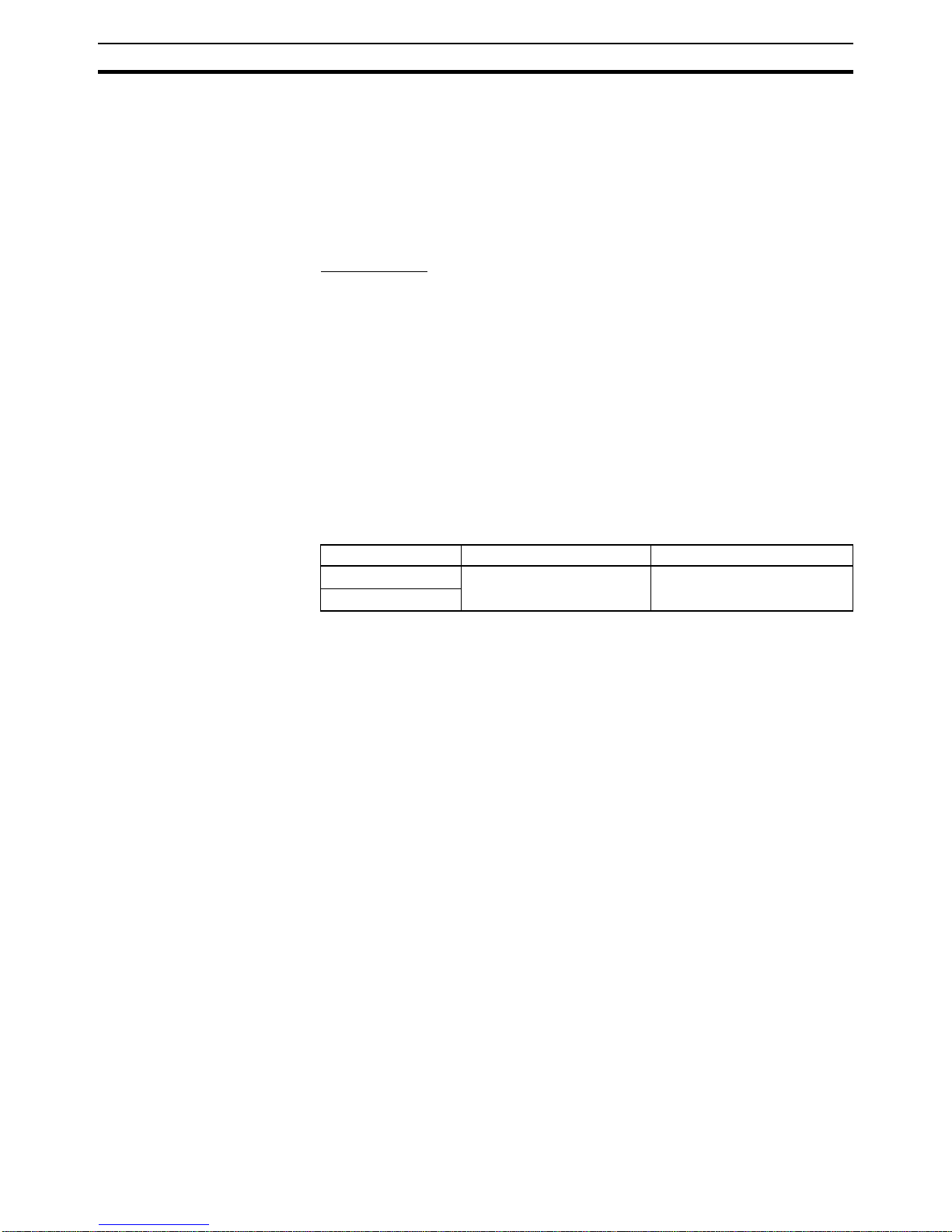

Manual Products Contents Cat. No.

CS-series

Programmable Controllers

Operation Manual

SYSMAC CS-series

CS1G/H-CPU@@-E

Describes the installation and operation of

the CS-series PLCs.

W339-E1-@

CJ-series

Programmable controllers

operation Manual

SYSMAC CJ-series

CJ1G-CPU@@

Describes the installation and operation of

the CJ-series PLCs.

W393-E1-@

CS/CJ-series

Programmable Controllers

Programming Manual

SYSMAC CS/CJ-series

CS1G/H-CPU@@-E, CJ1GCPU@@

Describes the ladder diagram programming

instructions supported by CS/CJ-series

PLCs.

W394-E1-@

CS/CJ-series

Programmable Controllers

Instructions Reference Manual

SYSMAC CS/CJ-series

CS1G/H-CPU@@-E, CJ1GCPU@@

Describes the ladder diagram programming

instructions supported by CS-series and

CJ-series PLCs.

W340-E1-@

CX-Programmer

Operation Manual

SYSMAC WS02-CXP@@-E

CX-Programmer

Provides information on how to use the CXProgrammer, programming software which

supports CS1/CJ1-series PLCs.

W414-E1-@

CX-Server

Run Time User Manual

CX-Server Provides information on how to use the CX-

Server communication driver software

which supports CS1/CJ1-series PLCs.

W391-E2-@

CS1/CJ1W-PRM21

Operation Manual

SYSMAC CS/CJ-series

CS1/CJ1W-PRM21

PROFIBUS DP Master Units

Operation Manual

Provides information on how to install and

use the CS1/CJ1-PRM21 PROFIBUS Master units.

W409-E2-@

C200H-series PROFIBUS DP

Master Units

Operation Manual

C200HW-PRM21 PROFIBUS DP Master Unit

Describes the Installation and Operation of

the C200HW-PRM21 PROFIBUS DP Master Units.

W349-E2-@

Page 9

x

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

Page 10

xi

PRECAUTIONS

This section provides general precautions for using the PROFIBUS Master Units, Programmable Controllers and related

devices.

The information contained in this section is important for the safe and reliable operation of the PROFIBUS Master

Units. You must read this section and understand the information contained before attempting to set up or operate

a PROFIBUS Master Unit and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Page 11

xii

Intended Audience

1

1 Intended Audience

This manual is intended for the following personnel, who must also have a

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

PROFIBUS Master Units. Be sure to read this manual before attempting to

use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that all PLC Units be used for their specified pur-

poses and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult your OMRON representative before using a PLC System in the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Do not touch the Power Supply Unit while power is being supplied or immedi-

ately after power has been turned OFF. Doing so may result in electric shock.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. Loose screws may result in burning

or malfunction.

Page 12

xiii

Operating Environment Precautions

4

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PC on a

network.

!WARNING Execute online edits only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

4 Operating Environment Precautions

!Caution Do not operate the Unit in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidities outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salt.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

!Caution The operating environment of the PLC system can have a large effect on the

longevity and reliability of the system. Unsuitable operating environments can

lead to malfunction, failure and other unforeseeable problems with the PLC

system. Ensure that the operating environment is within the specified conditions at installation time and remains that way during the life of the system.

Follow all installation instructions and precautions provided in the operation

manuals.

Page 13

xiv

Application Precautions

5

5 Application Precautions

Observe the following precautions when using the PROFIBUS Master Unit.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always connect to a class-3 ground (100

Ω or less) when installing the

Units.

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Install double safety mechanisms to ensure safety against incorrect signals that may be produced by broken signal lines or momentary power

interruptions.

• When adding a new device to the network, make sure that the baud rate

is the same as other nodes.

• When adding a new slave device to the network, make sure that the

PROFIBUS Master Unit is in the OFFLINE state, to prevent unexpected

results when starting up the slave device.

• Use specified communications cables.

• Do not extend connection distances beyond the ranges given in the specifications.

• Always turn OFF the power supply to the personal computer, Slaves, and

Communications Units before attempting any of the following.

• Mounting or dismounting the PROFIBUS Master Unit, Power Supply

Units, I/O Units, CPU Units, or any other Units.

• Assembling a Unit.

• Setting DIP switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting connectors.

• Be sure that the terminal blocks, connectors, Memory Units, expansion

cables, and other items with locking devices are properly locked into

place. Improper locking may result in malfunction.

• Be sure that all the mounting screws, terminal screws, Unit mounting

screws, and cable connector screws are tightened to the torque specified

in the relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Always use the power supply voltage specified in this manual.

• Double-check all the wiring and connection of terminal blocks and connectors before mounting the Units.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

Page 14

xv

Application Precautions

5

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Be sure to wire communications cable inside ducts.

• Use appropriate communications cables.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuits in external wiring. Insufficient safety measures against short-circuits

may result in burning.

• Double-check all the wiring and switch settings before turning ON the

power supply.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

and other data required for resuming operation. Not doing so may result

in an unexpected operation.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

• Do not attempt to disassemble, repair, or modify any Units.

• Do not attempt to remove the cover over the non-used connector hole on

the front of the CS1W-PRM21 Unit.

Page 15

xvi

Conformance to EC Directives

6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low voltage directive EN 61131-2:1994+A12:2000

6-2 Concepts

EMC Directives

OMRON Units complying with EC Directives also conform to related EMC

standards making them easier to incorporate in other Units or machines. The

actual products have been checked for conformity to EMC standards. (See

the following note.) Whether the products conform to the standards in the system used by the customer, however, must be checked by the customer.

EMC-related performance of OMRON Units complying with EC Directives will

vary depending on the configuration, wiring, and other conditions of the equipment or control panel in which OMRON devices are installed. The customer

must, therefore, perform final checks to confirm that units and the overall system conforms to EMC standards.

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference standards in the EMC (Electromagnetic Compatibility) standards

are as follows:

6-3 Conformance to EC Directives

Units that meet EC directives also meet the common emission standard

(EN50081-2). The measures necessary to ensure that the standard is met will

vary with the overall configuration. You must therefore confirm that EC directives are met for the overall configuration, particularly any radiated emission

requirement (10 m).

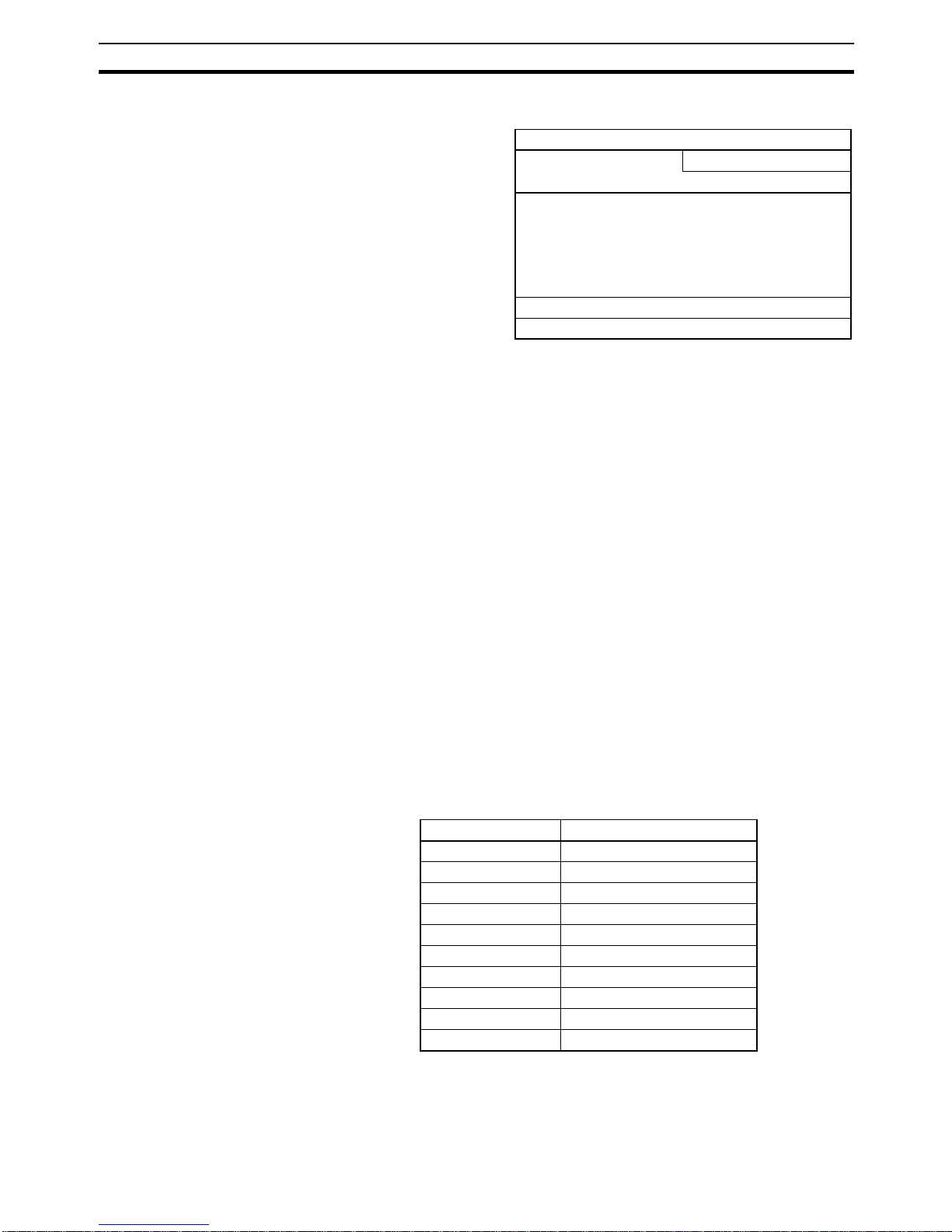

Unit EMS EMI

CS1W-PRM21 EN 61000-6-2:2001 EN 61000-6-2:2001

CJ1W-PRM21

Page 16

1

SECTION 1

Features and Specifications

This section provides an introductory overview of PROFIBUS, its functions and how to setup and configure a network. It

also addresses the PROFIBUS Master Units and the configurator, their features and specifications.

1-1 Overview of PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 PROFIBUS Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-3 Device Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-4 Bus Access Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-5 Diagnostic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1-6 Protection Mechanisms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-1-7 Network Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2 Setting up a PROFIBUS DP Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 Configuring the PROFIBUS Master . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-2 FDT/DTM Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-3 GSD file Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 CX-Profibus Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-1 CX-Profibus Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 17

2

Overview of PROFIBUS

Section 1-1

1-1 Overview of PROFIBUS

1-1-1 Introduction

Standard EN50170 PROFIBUS (PROcess FIeldBUS) is an open fieldbus standard for a wide

range of applications in manufacturing, processing and building automation.

The Standard, EN 50170 (the Euronorm for field communications), to which

PROFIBUS adheres, guarantees vendor independence and transparency of

operation. It enables devices of various manufacturers to intercommunicate

without having to make any special interface adaptations.

The PROFIBUS family comprises three mutually compatible versions:

PROFIBUS FMS, PROFIBUS DP and PROFIBUS PA.

PROFIBUS FMS FMS means Fieldbus Message Specification. This version is the general-pur-

pose solution for high-level extensive and complex communication tasks.

Powerful services open up a wide range of applications and provide great

flexibility.

PROFIBUS DP DP means Decentralized Periphery. PROFIBUS DP is optimized for high

speed and low-cost interfacing. It is specially designed for communication

between automation control systems and distributed I/O at the device level.

PROFIBUS PA PA means Process Automation. It permits sensors and actuators to be con-

nected to one common bus even in areas where intrinsically safe products are

required. It also permits data and power to be supplied over the bus using

2-wire technology according the international standard IEC 1158-2.

Uniform Bus Access

Protocol

PROFIBUS DP and PROFIBUS FMS use the same transmission technology

and uniform bus access protocol. Consequently, both versions can be operated simultaneously on the same bus. FMS field devices, however, cannot be

controlled by DP masters and vice versa.

!Caution It is not possible to exchange one of these family members by another family

member. This will cause faulty operation.

The rest of this section describes the PROFIBUS DP Protocol architecture.

1-1-2 PROFIBUS Communication Protocol

OSI reference model

ISO-7498

In general, the PROFIBUS communication protocol is based on the Open

System Interconnection (OSI) reference model in accordance with the international standard ISO-7498 (see the following illustration). The model defines

7 layers of communication functions, three of which - layers 1, 2, and 7 - are

used in PROFIBUS.

• Layer 1, the Physical Layer of this model, defines the physical transmission characteristics.

• Layer 2, the Data Link Layer of this model, defines the bus access protocol. This protocol also includes data security and the handling of transmission protocols and telegrams.

• Layer 7, the Application Layer of this model, defines the application functions. This Layer is only applicable to PROFIBUS FMS.

Page 18

3

Overview of PROFIBUS

Section 1-1

PROFIBUS DP In the rest of this manual, only PROFIBUS DP is considered.

OSI Layer 1, 2 and User

Interface

PROFIBUS DP uses layers 1 and 2, and the user interface. Layers 3 to 7 are

not defined for PROFIBUS DP. The user interface Layer defines the interface

functions for specific application areas, i.e. the PROFIBUS DP basic functions

and communication profiles.This streamlined architecture ensures fast and

efficient data transmission. The application functions which are available to

the user, as well as the system and device behaviour of the various PROFIBUS DP device types, are specified in the user interface.

OSI Layer 1: Transmission

Medium

RS-485 transmission technology or fibre optics are available for transmission.

RS-485 transmission is the most frequently used transmission technology. Its

application area includes all areas in which high transmission speed and simple inexpensive installation are required. PROFIBUS modules are interconnected by single twisted-pair shielded copper wires.

RS-485 Technology The RS-485 transmission technology is very easy to handle. Installation of the

twisted pair cable does not require expert knowledge. The bus structure permits addition and removal of devices or step-by-step commissioning of the

system without influencing the other devices. Later expansions have no effect

on devices which are already in operation.

RS-485 Transmission

Speed

Transmission speeds between 9.6 kbit/s and 12 Mbit/s can be selected as

shown in the table below. One unique transmission speed must selected for

all devices on the bus when the system is commissioned.

Cable length The maximum cable length values depend on the transmission speed. The

length can be increased by the use of repeaters. However, it is not recommended to use more than three repeaters in series in a PROFIBUS network.

DP-Profiles

DP-Extensions

User Interface Layer DP Basic Functions

(7) Application Layer

(6) Presentation Layer

(5) Session Layer NOT DEFINED

(4) Transport Layer

(3) Network Layer

(2) Data Link Layer Fieldbus Data Link (FDL)

(1) Physical Layer RS485 / Fibre Optics

Baud rate (kbit/s) Distance / segment (m)

9.6 1200

19.2 1200

45.45 1200

93.75 1200

187.5 1000

500 400

1500 200

3000 100

6000 100

12000 100

Page 19

4

Overview of PROFIBUS

Section 1-1

1-1-3 Device Types

PROFIBUS distinguishes between master devices and slave devices.

Master Devices Master devices determine the data communication on the bus. A Master can

send messages without an external request, as long as it holds the bus

access right (the token). Masters are also referred to as active devices in the

PROFIBUS standard.

There are two types of master devices:

Class 1 Master (DPM1) A PROFIBUS DP Class 1 Master (DPM1) device is a central controller, which

exchanges information with the decentralized devices (i.e. DP slaves) within a

specified message cycle.

Class 2 Master (DPM2) PROFIBUS DP class 2 Master (DPM2) devices are programmers, configura-

tion devices or operator panels. They are used during commissioning, for configuration of the DP system, or for operation and monitoring purposes.

The CS1W-PRM21 and the CJ1W-PRM21 are both PROFIBUS DP Class 1

Master devices.

Slave Devices Slave devices are peripheral devices. Typical slave devices include input/out-

put devices, valves, drives, and measuring transmitters. They do not have bus

access rights and they can only acknowledge received messages or send

messages to the master when requested to do so. Slave devices are also

called passive devices

Device Profile To enable the exchange of devices from different vendors, the user data has

to have the same format. The PROFIBUS DP protocol does not define the format of user data, it is only responsible for the transmission of this data. The

format of user data may be defined in so called profiles. Profiles can reduce

engineering costs since the meaning of application-related parameters is

specified precisely. Profiles have been defined for specific areas like drive

technology, encoders, and for sensors / actuators.

PROFIBUS DP-V1 PROFIBUS DP-V1 is an extension to the PROFIBUS DP protocol standard. It

defines acyclic message services between a PROFIBUS DP-V1 Master and a

PROFIBUS DP-V1 slave device. These acyclic message services allow

exchange of extended parameter settings as well as extended diagnostics

and alarm information, during regular I/O data exchange. PROFIBUS DP-V1

devices must at least support PROFIBUS DP.

PROFIBUS DP-V1 services are designated as MSACn services (M

aster-

S

lave Acyclic, Class n), in which n designates the Master Class (i.e. 1 or 2).

The CS1W-PRM21 and the CJ1W-PRM21 both support PROFIBUS DP-V1

Class 1 Master functions as of Unit version 2.0.

1-1-4 Bus Access Protocol

OSI Layer 2: Bus Access

Protocol

The PROFIBUS bus access protocol is implemented by OSI layer 2. This protocol also includes data security and the handling of the transmission protocols and messages.

Medium Access Control The Medium Access Control (MAC) specifies the procedures which determine

when a device is permitted to transmit data. A token passing procedure is

used to handle the bus access between master devices, and a polling procedure is used to handle the communication between a master device and its

assigned slave device(s).

Page 20

5

Overview of PROFIBUS

Section 1-1

Token Passing The token passing procedure guarantees that the bus access right (the token)

is assigned to each master within a precisely defined time frame. The token

message, a special message for passing access rights from one master to the

next master, must be passed around the logical token ring - once to each

master - within a specified target rotation time. Each master executes this procedure automatically.

Polling Procedure The polling or master-slave procedure permits the master, currently in pos-

session of the token, to access its assigned slaves. The figure below shows a

possible configuration The configuration shows three active devices (masters)

and six passive devices (slaves).

The three masters form a logical token ring. When an active device receives

the token message, it can perform its master role for a certain period of time.

During this time it can communicate with all assigned slave devices in a master-slave communication relationship, and a DPM2 master can take the initiative to communicate with DPM1 master devices in a master-master

communication relationship.

Multi-peer Communication In addition to logical peer-to-peer data transmission, PROFIBUS DP provides

multi-peer communication (broadcast and multicast).

Broadcast

Communication

In the case of broadcast communication a master device sends an unacknowledged message to all other devices (masters and slaves).

Multicast Communication In the case of multicast communication a master device sends an un-acknowl-

edged message to a predetermined group of slave devices.

1-1-5 Diagnostic functions

Extensive Diagnostics Extensive diagnostic functions defined in PROFIBUS DP enable the fast loca-

tion of error at slave devices. Diagnostic messages are transmitted over the

bus and collected at the master. Three diagnostic message types are defined:

Device Related

Diagnostics

• Messages concerning the general operational status of the whole device,

e.g. over temperature, low voltage.

Module Related

Diagnostics

• Messages indicating that an error is present in a specific I/O range of a

device, e.g. an 8-bit output module.

Channel Related

Diagnostics

• Messages indicating an error at a given input or output, e.g. short circuit

on Output 5.

DPM1 DPM2 DPM1

Token Passing

Polling

PROFIBUS

Passive stations

Slave devices

Active stations

Master devices

Page 21

6

Overview of PROFIBUS

Section 1-1

1-1-6 Protection Mechanisms

Monitoring Time PROFIBUS DP provides effective protection functions against parameteriza-

tion errors or failure of the transmission equipment. Time monitoring is provided both at the master and the slave devices. The monitoring interval is

specified when the system is configured.

Monitoring at the Master The PROFIBUS Master monitors data transmission of the slaves with the

Data-Control-Timer. A separate control timer is used for each slave. This timer

expires if response data is not correctly transmitted by the slave within the

monitoring interval. The user is informed when this happens. If the automatic

error reaction (Auto-CLEAR) has been enabled, the PROFIBUS Master exits

its OPERATE state, switches the outputs of all assigned slaves to the fail-safe

status and changes to the CLEAR state.

Monitoring at the Slave Slave devices use a watchdog to detect failures of the master or the bus. If

data communication with the master does not occur within the set watchdog

time interval, a slave automatically switches its outputs to the fail-safe mode.

Also, access protection is provided for the inputs and outputs of the slaves

operating in multi-master systems. Only authorized masters can access their

slaves.

1-1-7 Network Operation Modes

PROFIBUS DP distinguishes four different network operation modes:

OFFLINE • Communication with all PROFIBUS DP participants (masters and slaves)

is stopped. The Master ceases to access the PROFIBUS network.

STOP • Communication between the master and its slaves is stopped. Only com-

munication between the master and other masters is still possible.

CLEAR • The master tries to set parameters, check the configuration, and perform

data exchange with its associated slaves. Data exchange involves reading

the inputs of the PROFIBUS DP slaves and writing zeros to the outputs of

the slaves.

OPERATE • The master exchanges data with its assigned slaves, inputs are read and

outputs are written. Also, the master cyclically sends its local status to all

its assigned PROFIBUS DP slaves (using a broadcast message).

The PROFIBUS Master Unit will always be in one of these four modes. Mode

transitions from one mode to another will be performed via intermediate

modes. For example, a mode transition from OFFLINE to OPERATE, will be

performed as OFFLINE

→ STOP → CLEAR → OPERATE.

Auto-CLEAR

Fail-safe State

If an error occurs during the data exchange phase of the master, the ‘AutoCLEAR’ function determines the subsequent actions. If this function has been

disabled, the master remains in the OPERATE mode. If the function has been

enabled, the master automatically changes the network to the CLEAR mode,

in which the outputs of the assigned PROFIBUS DP slaves are switched to

zero, i.e. the ‘fail-safe’ state. The master continues to read the inputs of the

slaves.

Page 22

7

Setting up a PROFIBUS DP Network

Section 1-2

1-2 Setting up a PROFIBUS DP Network

1-2-1 Configuring the PROFIBUS Master

In order to operate a PROFIBUS network, each master in the network needs

to be configured. This process of configuration involves

• setting up the network topology, i.e. assigning the slave devices with

which the master will be exchanging data,

• defining the parameterization data, which the master will send to each of

the slave devices, before process data exchange can commence

• defining the configuration data, i.e. defining the process data, which will

be exchanged,

• setting up the bus parameters, which define the baud rate and the bus

timing parameters.

• downloading the configuration setup to the master device.

Configuration Technology The configuration process is usually facilitated by a special Computer based

program, often referred to as a configurator. The configurator requires special

configuration files, defining the configuration options for each device, which is

to participate in data exchange. The files must be provided by the manufacturer of the device.

Two types of configuration technology exist:

• Configuration technology based on FDT/DTM technology

• Configuration technology based on GSD-files

1-2-2 FDT/DTM Technology

FDT/DTM Technology The newer configuration tools are based on FDT/DTM technology.

FDT/DTM Concept The FDT/DTM concept specifies the interfaces between the engineering sys-

tems called Field Device Tools (FDT), and the device-specific software components called Device Type Managers (DTM).

The FDT/DTM concept separates the device dependent functionality (which is

in the DTM) from the application. It provides separate interfaces for device

configuration, monitoring and maintenance solutions, which before largely

depended on the manufacturer of the application. Because of this concept,

FDT/DTM technology is not limited to PROFIBUS applications. In concept,

any type of network can be configured and accessed, provided the appropriate DTMs are available.

FDT Container Application A FDT container application facilitates configuration of network devices and

parameterizing and/or manipulating their operational modes. All device

dependent functionality is concentrated in the DTM.

FDT container applications can be stand-alone tools, or can be part of other

engineering tools such web browsers providing FDT interfaces.Since FDT

standardizes the interfaces, it allows devices from different manufacturers to

be integrated in any automation system, regardless of the fieldbus system.

CX-Profibus is an example of a FDT container application. It is described in

detail in the following sections.

Device DTM DTMs are provided by the manufacturer of the device. A DTM is comparable

to a printer driver, which allows interactive configuration and diagnostics.

Page 23

8

Setting up a PROFIBUS DP Network

Section 1-2

The DTM provides not only the configuration, manipulation and monitoring

functions for a device including the user interface functions, it also provides

the connection technology to the device.

DTM Properties In general, a DTM is a Microsoft COM-component, which can be executed

from within a FDT container application. A DTM is not a stand-alone tool, it

requires a FDT container application to be executed. The DTM provides a

number of interface functions, through which it can be controlled and

accessed in order to transfer data to or from the DTM.

A DTM provides all the options for configuration and monitoring of a device,

which it can present to the user through its own user interface.

ActiveX User Interface The user interface for a DTM is provided using ActiveX windows. Control of

these windows is done by the DTM, but the FDT container application can

request specific user input from the DTM, based on which the DTM will provide the necessary ActiveX windows. In general multi-language user interface

windows, including DTM specific Help files are supported by the DTM.

XML based Data Transfer Data transfer to and from a DTM is provided using XML-documents. The

XML-documents are standardized for the communication between the FDT

container application and for communication between DTMs.

An additional specification covers the definition of XML-data formats for the

transfer of application specific data, such as PROFIBUS data.

Communication DTM In general, a device configuration DTM is accompanied by a communication

DTM. This specific DTM facilitates device specific communication, e.g. for

downloading a configuration to a PROFIBUS Master Unit and/or for retrieving

monitoring information from PROFIBUS Master Unit. It may incorporate the

specific communication protocol, or rely on other available drivers.

CX-Profibus CX-Profibus is a FDT container application. Together with this container appli-

cation, OMRON provides four DTMs:

• A DTM to facilitate configuration and operation of the CS1/CJ1W-PRM21

PROFIBUS DP-V1 Master Units (As of Unit version 2.0)

• A DTM to facilitate configuration of the CS1/CJ1W-PRM21 PROFIBUS

DP Master Units (Unit version 1.0)

• A DTM to facilitate configuration of the C200HW-PRM21 PROFIBUS

Master Unit

• A DTM to facilitate integration of GSD file based devices into CX-Profibus

(see section 1-2-3 GSD file Technology for more information)

1-2-3 GSD file Technology

GSD file Technology The older and most commonly used configuration technology is the based on

GSD files (General Slave Data file). A GSD file is a text file, containing the

characteristic features and configuration options of a device. The device data

base file of each device is loaded in the configurator and downloaded to the

master device.

GSD files are usually supplied with a Unit, or can be downloaded from the

Internet, either from the manufacturer's site, or from the GSD library of the

PROFIBUS International at http://www.profibus.com.

Page 24

9

Setting up a PROFIBUS DP Network

Section 1-2

GSD File Language The language used in the GSD file is indicated by the last letter of the file

extension, *.GS?:

Default = GSD

English = GSE

German = GSG

Italian = GSI

Portuguese = GSP

Spanish = GSS

The GSD files are prepared individually by the vendor for each type of device,

according to a fixed format. Some parameters are mandatory, some have a

default value and some are optional. The device data base file is divided into

three parts:

General Section • General specifications

This section contains the vendor name, the device name, hardware- and software release versions, device type and identification number, protocol specification and supported baud rates.

DP-master Section • DP master-related specifications

This section contains all parameters which only apply to DP master devices

(e.g. maximum memory size for the master parameter set, maximum number

of entries in the list of active devices, or the maximum number of slaves the

master can handle).

DP-slave Section • DP slave-related specifications

This section contains all specification related to slaves (e.g. minimum time

between two slave poll cycles, specification of the inputs and outputs, and

consistency of the I/O data).

For PROFIBUS DP-V1 devices this section also specifies what services for

PROFIBUS DP-V1 are supported.

DTM versus GSD File When comparing the two configuration technologies, a GSD file only provides

information on the device characteristics and configuration options. It has no

GUI of its own, nor can it connect to the device itself. A GSD file always

requires a separate configurator program to interpret the data. In the FDT/

DTM concept all these device related functions are included in the DTM. The

DTM can be executed from any program, which provides FDT interfaces.

Sending PROFIBUS DP-V1 commands to a device from the configuration tool

is only possible using DTM technology. The GSD file does not provide this

means.

Page 25

10

CX-Profibus Configurator

Section 1-3

1-3 CX-Profibus Configurator

1-3-1 CX-Profibus Features

CX-Profibus The PROFIBUS Master Unit requires a configuration before it can exchange I/

O data with the slave devices. For this purpose OMRON provides the CXProfibus Configuration program, which runs under Microsoft Windows™ NT

4.0, Windows™ 2000 or Windows™ XP

Together with CX-Profibus, OMRON provides four DTM COM Objects:

• A DTM to configure the CS1/CJ1W-PRM21 PROFIBUS DP-V1 Master

• A DTM to configure the CS1/CJ1W-PRM21 PROFIBUS DP Master

• A DTM to configure the C200HW-PRM21 PROFIBUS DP Master

• A DTM to allow the handling of classic GSD files in CX-Profibus

The following provides a quick overview of the functions.

CX-Profibus FDT

Container Application

CX-Profibus provides an FDT environment in which DTMs can be executed.

The main function of CX-Profibus is to facilitate the DTMs and the data

exchange between them. It provides:

• Network setup functions: A tree view shows the relations between the

DTMs, i.e. the relation between the Master and slave devices.

• Device Catalogue functions: A Device Catalogue containing the installed

DTMs is maintained, to which the user can add new DTMs or delete them.

Device DTMs can be added to the network from this Catalogue.

• Project maintenance functions: CX-Profibus provides the functions to create, save and open project files. It facilitates user access control, which

limits of use to authorized personnel only, using password protection.

• Additional functions: CX-Profibus provides additional functions like printing, error logging, FDT Communication logging and help files.

CS1/CJ1W-PRM21 DTM The two CS1/CJ1W-PRM21 DTMs provided to configure the CS1/CJ1W-

PRM21 PROFIBUS Master Units and the CS1/CJ1W-PRM21 PROFIBUS DPV1 Master Units both provide the same basic PROFIBUS DP functions. These

DTMs consist of three parts:

• The Settings DTM, which handles the configuration for the PROFIBUS

Master Unit. This includes the bus parameters settings, the I/O data mappings and Master specific settings. The Settings DTM provides its own

user interface.

• The Monitoring DTM, which handles the status monitoring and control

over the PROFIBUS Master Unit, when it is on-line and communicating

over the PROFIBUS network. It provides its own user interface to read out

Master status flags and Error log, as well as Slave status flags and the

Slave diagnostics messages received by the Unit. It also allows the user

to send Global-Control messages over the network and to change the

PROFIBUS Master Unit’s mode on the PROFIBUS network.

• The communication DTM, which provides the interface between the two

DTMs mentioned above and CX-Server. CX-Server, provided with the

CX-Profibus package, is the driver for communication between the PC

and the PLC CPU.

Page 26

11

CX-Profibus Configurator

Section 1-3

CS1/CJ1W-PRM21

PROFIBUS DP-V1 DTM

In addition to the PROFIBUS DP functions, the CS1/CJ1W-PRM21 PROFIBUS DP-V1 DTM provides:

• A communication channel to the user to change a remote slave device

address. This channel has its own user interface.

• Communication channels to facilitate data transfer, PROFIBUS DP-V1

MSAC1 acyclic message transfer between a PROFIBUS DP-V1 slave

device DTM and the physical slave device.

C200HW-PRM21 DTM The C200HW-PRM21 DTM allows configuration of the C200HW-PRM21

PROFIBUS DP Master Unit. This predecessor of the CS1/CJ1W-PRM21 can

be used on existing C200H PLC CPU Systems as well as CS1 PLC Systems,

except for the CS1D.

The C200HW-PRM21 DTM consist of three parts:

• The Settings DTM, which handles the settings for the C200HW-PRM21

PROFIBUS DP Master Unit, including the bus parameters settings, and

the I/O data mappings.

• The Monitoring DTM, to handle the Unit’s status monitoring. The DTM’s

user interface displays the Master status and Slave status.

• The communication DTM, providing the interface between the two DTMs

mentioned above and the serial communication driver, to the C200HWPRM21 PROFIBUS DP Master Unit.

Note 1. This Operation Manual does not contain a detailed description of the

C200HW-PRM21 Unit, only a description of the DTM. For more details on

the C200HW-PRM21 refer to C200H-series PROFIBUS DP Master Units

Operation Manual (W349-E2-@).

2. The C200HW-PRM21 Unit and DTM do not support PROFIBUS DP-V1.

Generic Slave DTM The Generic Slave DTM allows the handling of classic GSD files of up to GSD

revision 3 within CX-Profibus. Upon allocating a slave device, for which only a

GSD file is available to a Master Unit in the network, this DTM will be invoked.

This DTM consists of two parts:

• The Settings DTM will provide the user interface to display the device’s

information and the selectable values, as defined in the GSD. After making the necessary configuration settings, and saving them, these will be

transferred to the Master DTM.

• The monitoring DTM will provide a diagnostics interface to the user, allowing him to check the Slave’s status. This DTM obtains the necessary information from the PROFIBUS Master Unit’s monitoring DTM.

Note The Generic Slave DTM provides parameter settings related to PROFIBUS

DP-V1. However, it does not support PROFIBUS DP-V1 communication.

Downloading the

Configuration

After setting up the configuration, it must be downloaded to the PROFIBUS

Master Unit. The type of serial connection to use for downloading, depends on

the Unit:

• CS1/CJ1W-PRM21: Connection to the Unit is achieved through the serial

port of the PLC CPU, using CX-Server. CX-Server also allows routing the

download through multiple systems, if supported by these systems. The

CS1/CJ1W-PRM21 does not support message routing.

• C200HW-PRM21: Connection to the C200HW-PRM21 is achieved

through a serial RS-232c Connection between one of the PC’s Serial

COM Ports and the dedicated configuration connector at the front of the

Page 27

12

CX-Profibus Configurator

Section 1-3

Unit. For details, refer to the C200HW-PRM21 Manual: W349-E2-2. The

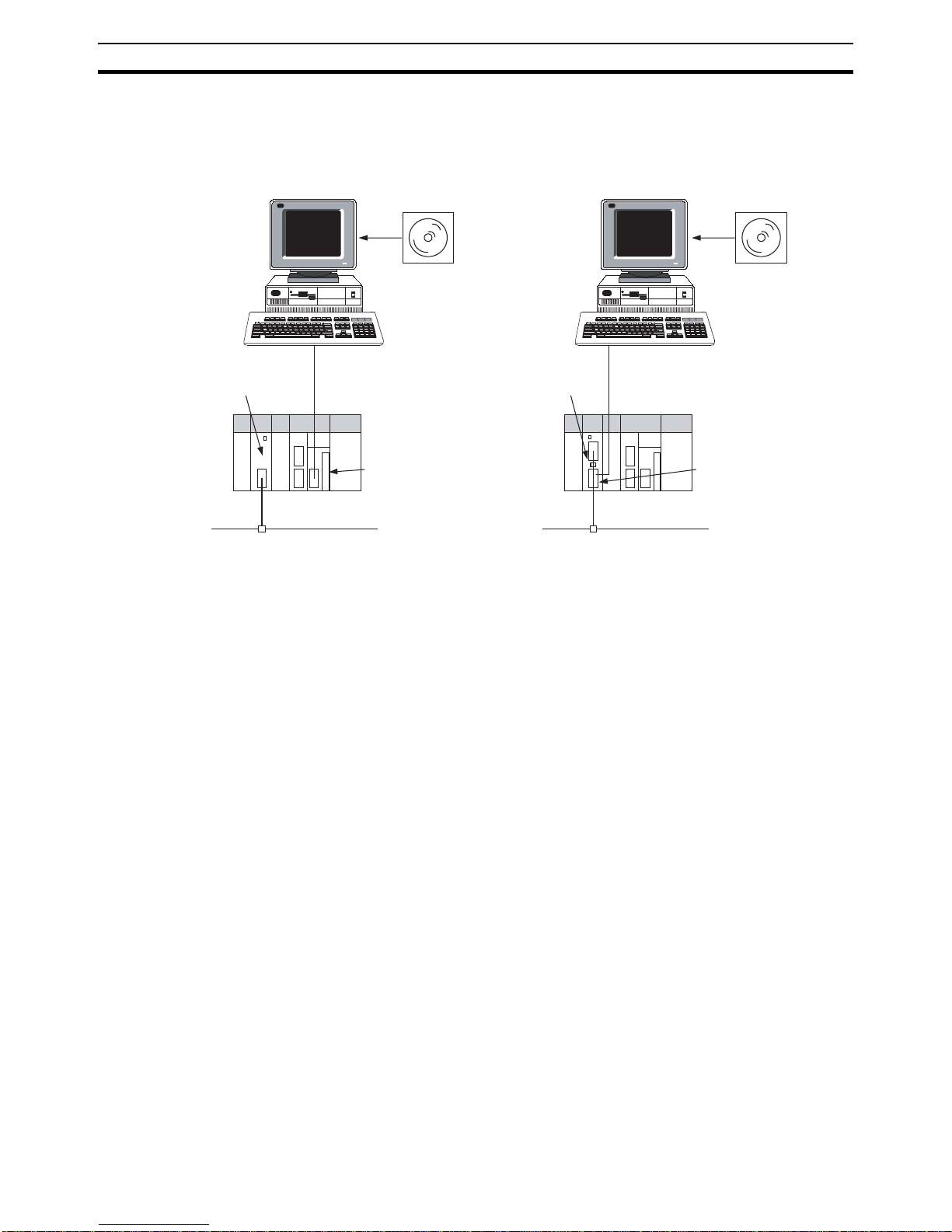

figure below shows the connection methods, for both types.

CX-Profibus

Configurator

OMRON

SYSMAC CS1G

PROGRAMMABLE

CONTROLLER

S/CJ-series

PROFIBUS

Master Unit

PROFIBUS Network

COM Port on PC

Peripheral Bus or

Host LINK

Peripheral or RS232C

Port of CPU Unit

Serial connection to CS/CJ-series

PROFIBUS Master Unit

CX-Profibus

Configurato

r

OMRON

SYSMAC CS1G

PROGRAMMABLE

CONTROLLER

C200H-series

PROFIBUS DP

Master Unit

PROFIBUS Network

Configuration Port on

PROFIBUS DP

Master Unit

COM Port on PC

Serial connection to C200H-series

PROFIBUS DP Master Unit

Page 28

13

CX-Profibus Configurator

Section 1-3

1-3-2 Specifications

Functional Specifications

Item Specification

Operating environment

Model number WS02-9094G

Hardware platform • Personal computer: IBM PC/AT or compatible

• Processor: Pentium 500 MHz or higher

• Memory: 256 Mbytes

• Hard disk: A minimum of 256 Mbytes

• CD-ROM drive

• Graphics resolution: 800 x 600 pixels minimum

• Serial port: RS-232C

Operating System • MS Windows NT4.0, SP6

• MS Windows 2000, SP2

• MS Windows XP

Note Internet Explorer 5.01 is also required.

Connection to CS1/CJ1W-PRM21 • Peripheral or RS-232C port of PC with PLC CPU. Serial communica-

tions mode: Peripheral bus, Host Link, Toolbus, supported by CXServer.

• Communication cable: Cable CS1W-CN226 to connect to the peripheral port on the CPU (Not included in package).

Connection to C200HW-PRM21 • RS-232C port of PC with Configuration port on the Unit.

CX-Profibus

General Project functions File handling: CX-Profibus supports overall handling of project files as

well as network data.

• New: Start a new project.

• Open: Open an existing project file.

• Save (As): Save a project file.

• Export: Export project data to HTML.

• Properties:Edit project property information.

User management: Functionality of CX-Profibus can be limited as

defined by several password protected access levels:

• Administrator

• Planning engineer

• Maintenance

• Operator

• Observer

Network setup functions CX-Profibus provides network tree view, from which hierarchy between

Master and slave devices can clearly be distinguished.

The following network functions are available:

• Network DTMs (i.e. devices) can be added or deleted, using drag and

drop from the Device Catalogue.

• Network DTMs can be copied and moved from one location to

another in the network view.

• DTM names can be edited by the user.

• Any change to the parameters of a DTM is clearly marked in the tree

view, until the project is downloaded to the Master Unit.

Device Catalogue functions The Device Catalogue maintains the installed device DTMs. After instal-

lation of a new DTM, the user must refresh the database. The Device

Catalogue provides the following functions:

• Update Device Catalogue.

• Add device DTMs to the network directly.

• Install a GSD file. This function allows copying of GSD files to a specific directory, after which they are available for the Generic Slave

DTM.

Support functions CX-Profibus provides the following additional support functions:

• Context sensitive help functions.

• Error logging.

• Monitoring of FDT communication between DTMs.

• Multi-language support.

Page 29

14

CX-Profibus Configurator

Section 1-3

CS1/CJ1W-PRM21 DTM

Device setup Device setup allows the user to:

• Select the PROFIBUS Master Unit’s unit number.

• Configure the communication link between the PC and the Unit. This

function invokes the user interface of CX-Server.

• Test the Units communication link and read out the Unit’s information.

Master setup It allows enabling of Auto Addressing, to facilitate I/O data mapping, as

well as defining the Unit’s behaviour in case of

• a network malfunction.

• a PLC mode change between PROGRAM and RUN/MONITOR

mode.

Bus parameter setup The bus parameter setup allows the selection of baud rate and calcula-

tion and editing of specific bus parameters.

Slave area setup The Slave area setup allows the user to define the I/O Data mapping of

the I/O Data from each of the slave devices on to the PLC memory

areas.

Monitoring functions • Master status read out.

• Slave status and slave diagnostics read-out.

• Read out of the Unit’s error log.

Additional Master functions • Set remote slave address.

• Provide communication channels for PROFIBUS DP-V1 MSAC1

messages.

Note These functions are implemented as of Unit version 2.0.

Support functions • Context sensitive help functions.

• Multi-language support.

C200HW-PRM21 DTM

Bus parameter setup The bus parameter setup allows the selection of baud rate and calcula-

tion and editing of specific bus parameters.

Address mapping setup The address mapping setup shows an overview of the mapping of the I/

O data of each Slave on to the Unit’s memory. The mapping can be

accomplished automatically, but the function also allows editing of individual address mappings.

Monitoring functions • Master status read out.

• Slave status read-out.

Support functions • Context sensitive help functions.

• Multi-language support.

Generic Slave DTM

General functions The Generic Slave DTM reads the contents of a specific GSD file

located in a special sub-directory, and displays the setup options to the

user. It supports

• GSD file revisions 1 and 2 (PROFIBUS DP functionality).

• GSD file revisions 3 (PROFIBUS DP-V1 functionality).

I/O configuration setup The I/O configuration setup function allows:

• Selection of device address.

• Enable/disable watchdog.

• Overview of available I/O modules.

• Selection of I/O modules, including Addition, Insertion and Removal of

multiple modules.

Parameter setup The Parameter setup function:

• Setting of common as well as module dependent parameters.

• Setting of PROFIBUS DP Extension parameters.

• Setting of PROFIBUS DP-V1 dependent parameters.

Group setting The Group setup function allows definition of the group to which the

associated slave device will belong.

Monitoring functions The Monitoring functions provides a display of

• Standard Slave diagnostics flags.

• Extended diagnostics messages.

Support functions • Context sensitive help functions.

• Multi-language support.

Item Specification

Page 30

15

SECTION 2

Configuration Software

This section contains the procedures for installing the configuration software. It also presents an overview of the

Configuration software and discusses the main aspects of defining a PROFIBUS configuration. A more detailed description

of the use of the Configuration software can be found in SECTION 3 Operation.

2-1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 CX-Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-1 Starting CX-Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-2 CX-Profibus Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2-3 Device Catalogue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2-4 Updating the Device Catalogue . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-2-5 Adding Devices to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-2-6 Saving and Opening Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-2-7 Exporting to HTML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-2-8 Error Logging and FDT Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2-9 Access Control and User Management. . . . . . . . . . . . . . . . . . . . . . . 26

2-3 CS1/CJ1W-PRM21 PROFIBUS Master DTM . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-1 Configuration User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-2 Diagnostics User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-3-3 Connecting to the CS1/CJ1W-PRM21 . . . . . . . . . . . . . . . . . . . . . . . 45

2-4 C200HW-PRM21 PROFIBUS Master DTM . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-4-1 Configuration User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-4-2 Diagnostics User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2-4-3 Connecting to the C200HW-PRM21 . . . . . . . . . . . . . . . . . . . . . . . . 56

2-5 Generic Slave Device DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2-5-1 Configuration User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2-5-2 Diagnostics User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Page 31

16

Installation Requirements

Section 2-1

2-1 Installation Requirements

CX-Profibus Configuration software is required to configure the PROFIBUS

Master before operating the network. Without a valid configuration the

PROFIBUS Master Unit will not be able to achieve data communication with

the slave devices on the network.

The following are the minimum requirements for a PC to install the CX-Profibus configurator software:

• PC Pentium III or higher, 500 MHz minimum

• Operating System: Windows 2000 SP2 / Windows NT 4.0, SP6 /

Windows XP

• RAM: 256 MB minimum

• Hard disk space: 256 MB minimum

• Graphics resolution: 1024 x 768 pixels minimum

• Serial port: RS-232C; COM1 to COM4 supported

• CD-ROM drive

• Communication cable: Cable CS1W-CN226 to connect to the peripheral

port on the CPU (Not included with CX-Profibus)

2-2 CX-Profibus

2-2-1 Starting CX-Profibus

Starting CX-Profibus Select Program, OMRON, and CX-Profibus, from the Start Menu if the

default program folder name is used.

At startup, the CX-Profibus splash screen will appear, on top of which a login

window as shown below will be displayed.

Login Window The Login window provides the selection of the access level as well as the

entry of the password belonging to the access level selected.

Default Password The default password at the first start up of CX-Profibus is “password” and is

applicable to all access levels. Type in “password” (without the quotes) at the

password entry line and select OK.

!Caution If access limitation to CX-Profibus is required by the application, the password

should be changed as soon as possible. Changing passwords is only possible

on the Administrator level. Refer to Changing the Passwords for an explanation on how to change passwords.

Generating the Device

Catalogue

After entering the correct password, CX-Profibus will start up and open. The

first time CX-Profibus is started, the Device Catalogue will still be empty.

Page 32

17

CX-Profibus

Section 2-2

Therefore, the following window will be displayed on top of the CX-Profibus

application window.

Select Yes to generate the Device Catalogue for the first time. This action may

take several minutes depending on the number of installed DTMs.

After updating the Device Catalogue, it will open in the CX-Profibus application window.

2-2-2 CX-Profibus Main Window

The main application window of CX-Profibus will open with a New Project.

After the first start up, the Device Catalogue will be opened automatically. If

not, the Device Catalogue may be opened from the menu.

The figure below shows the opened CX-Profibus application window with a

Project already containing a network, and the Device Catalogue window

opened.

The main components in this window are

• The Network view.

• The DTM / Catalogue view.

• The Error Log view.

• The FDT Monitoring view (not shown in the figure above).

Network view Device Catalogue

Error Log and FDT Monitoring view DTM view

Status Bar

Tool Bar

Page 33

18

CX-Profibus

Section 2-2

• The Main menu.

• The Tool Bar and the Status Bar.

Network view The Network view displays the structure of the PROFIBUS network in a tree

view format. The tree has at least three levels:

• The Project Level.

• The master level.

• The slave level.

The highest level of the tree is the project. The next level is the PROFIBUS

Master level. On this level one or more PROFIBUS Master devices can be

allocated. The third level contains the slave DTMs.

The PROFIBUS network must be assembled in the Network view, i.e. the various DTMs are added to the network via this window. From the Network view

the individual DTM User Interfaces can be opened, and accessed.

CX-Profibus supports context menu in the Network view, which are made visible when selecting a device DTM and right clicking the mouse. The contents

of the menu may depend on the functionality supported by the DTM.

DTM / Device Catalogue

Window

The DTM / Device Catalogue window will hold the Device Catalogue as well

as every opened DTM User Interface. The window is an MDI type window, or

Multiple Document Interface. One or more user interface windows can be

opened, re-sized and moved inside this window.

Error Log view The Error Log view at the bottom of the CX-Profibus application window dis-

plays the error messages reported by DTMs to CX-Profibus. A Time stamp, a

Date stamp and the DTM name are added to the message.

The contents of the window can be cleared, or copied to the clipboard, to

allow pasting it into another document.

The Error Log view is opened by default, when starting CX-Profibus.

FDT Monitoring view The FDT Monitoring view at the bottom of the CX-Profibus application window

displays the FDT-DTM communication function calls between CX-Profibus

and the DTMs. A Time stamp, a Date stamp, the type of information and the

DTM name are added to the message.

The sequence of messages can be used to troubleshoot problems that may

occur when using third party DTMs in CX-Profibus.

The contents of the window can be cleared, or copied to the clipboard, to

allow pasting it into another document.

The FDT Monitoring view is not opened by default, when starting CX-Profibus.

It can be opened through the View - FDT Monitoring menu option.

Main Menu The main menu of CX-Profibus, provides all the necessary functionality to

handle a complete project. The table below lists the main menu and their sub

menu items.

Page 34

19

CX-Profibus

Section 2-2

Tool Bar The tool bar provides quick access buttons to the user for frequently used

menu commands. The table below lists the toolbar buttons.

Menu Command Short Key Description

File New CTRL-N Creates a new Project.

Open CTRL-O Opens an existing Project.

Save CTRL-S Saves the displayed Project to a file.

Save As... --- The Save as command is the same as Save, but the Filename Specifi-

cation Window is always displayed.

Export Project to HTML --- Exports Project data in HTML format and launches the browser.

Project Properties... --- Opens an edit window to add or edit Project information.

Recently used File List --- Lists the recently used Project files.

Exit --- Exits CX-Profibus.

Edit Cut CTRL-X Cuts devices and pastes them to the clipboard.

Copy CTRL-C Copies devices to the clipboard.

Paste CTRL-V Copies devices from the clipboard to the cursor position.

View Network view --- Hides or un-hides the Network view.

Device Catalogue --- Opens or closes the Device Catalogue.

Tool Bar --- Hides or un-hides the Tool Bar.

Status Bar --- Hides or un-hides the Status Bar.

Error Logging --- Hides or un-hides the Error Logging window.

FDT Monitoring --- Hides or un-hides the FDT Monitoring view.

Device Add Device... --- Opens up the Device Catalog Add window, from which devices can be

added to the selected network tree.

Upload Parameters --- Uploads the parameters from a device to its associated DTM.

Download Parameters --- Downloads the parameters from DTM to its associated device.

Export to HTML --- Exports the properties and parameters of the selected DTM, or the net-

work to a HTML file and opens the default browser.

Properties --- Displays the properties of the selected DTM, or the network.

Tools User Management... --- Displays the user management (i.e password management) window.

Window Cascade --- Cascades all open DTM User Interfaces.

Tile Horizontally --- Tiles all open DTM User Interfaces horizontally.

Tile Vertically --- Tiles all open DTM User Interfaces vertically.

Close All --- Closes all open DTM User Interfaces.

Help Contents --- Opens the Help dialog and lists the Help file contents.

Index --- Opens the Help dialog and lists the Help Index.

About CX-Profibus... --- Opens the About dialog window for CX-Profibus.

Icon Description Equivalent menu command

Creates a new project. File-New

Opens an existing project file. File-Open

Saves the displayed project to a file. File-Save

Connects the configurator to the selected devices. Device-Go Online

Downloads the parameters to the device. Device-Download Parameters

Page 35

20

CX-Profibus

Section 2-2

Status Bar The status bar displays the current user role, i.e. the login level.

In case the Error Log view has been closed, the status bar will additionally

display a symbol to indicate that new errors are available in the Error Log

view. Double-clicking the symbol will open the Error Log view.

2-2-3 Device Catalogue

Device Catalogue Main

Components

The Device Catalogue is one of the main components in CX-Profibus. Its

main functions are

• to maintain a list of installed DTM and GSD files.

• to provide convenient sorting and categorizing of the list.

• to allow updating the list, after installation of new DTMs or GSD files.

• to provide detailed information on selected DTMs

The main layout of the Device Catalogue is shown below.

Invoking the Device

Catalogue

The Device Catalogue window is opened by either selecting the icon in

the CX-Profibus toolbar or by selecting the View - Device Catalogue menu

option. Both options have toggle function: selecting one of them again will

close the Device Catalogue.

DTM view Layout The left view allows selection of specific groups of DTMs to be displayed. The

right view lists the DTMs, which are installed on the PC and which are avail-

Uploads the parameters from the device. Device-Upload Parameters

Opens the Device Catalogue. View-Device Catalogue

Icon Description Equivalent menu command

DTM categories

Device name

Version number

File date

Vendor name

Update Device Catalogue

Install a new GSD file

Add selected device to the network

Page 36

21

CX-Profibus

Section 2-2

able for setting up a network. A selection of DTMs is made by selecting a specific group in the left view.

Note The list makes no distinction between normal DTMs and GSD files which

have been loaded through the Generic Slave Device DTM.

DTM List Window The list items in the right view are described in the following table.

DTM Group Selection

Window

The left view allows selection of specific groups of device DTMs with common

attributes, e.g. Vendor name, Protocol type etc. If a group is selected, all

device DTMs which belong to that group will be listed in the right view. The

table below lists the possible groups that can be selected.

Note 1. The sub groups will be displayed by clicking on the + sign next to each

main group

2. Selecting the main group displays all devices in the group.

Additional DTM

Information

In order to obtain more information of a specific DTM, right-click the DTM in

the list, and from the pop-up menu, select DTM Information. This opens a

Column

Description

Device The Device column contains the names of the DTMs, as provided by

the DTM or the GSD file. If the device is defined by a GSD file, the

Generic Slave Device DTM reads out the GSD file entry “Model

Name”. The string provided by this variable is the name displayed in

the list.

Version The version number defines the revision number of the device. If the

device is defined by a GSD file, the Generic Slave Device DTM reads

out the GSD file entry “Revision”. The string provided by this variable is

the version number displayed in the list.

Date For DTMs, Date is the date associated with the revision. For GSD file

based slaves, the date listed in this column is the date the GSD file

was last modified.

Vendor The Vendor name is provided by the DTM or the GSD files.

List item

Description

Device

Ty pe s

Sub groups, which can be selected are:

• Communication DTMs, e.g. PROFIBUS Master devices

• Gateways, e.g. to another network type

• Modular devices

• Other devices, e.g. slave devices

Vendors Sub groups, which can be selected are all available vendors. This

information is provided by each DTM. It allows the user to select a

group of devices from one vendor.

Groups Sub groups are the device types, e.g. digital I/O, analog I/O etc.

Protocols Sub groups which can be selected are all the communication protocols

found in the Device Catalogue.

Page 37

22

CX-Profibus

Section 2-2

window with additional DTM information. The figure below provides an example for the CJ1W-PRM21 PROFIBUS Master DTM.