Page 1

Automation Software

Sysmac Studio

Version 1

Drive Functions Operation Manual

SYSMAC-SE2

I589-E1-06

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• NVIDIA, the NVIDIA logo, GeForce, and the GeForce logo are the trademarks or registered trademarks of NVIDIA

Corporation in the USA and other countries.

• ATITM, RadeonTM is a trademark of Advanced Micro Devices, Inc..

• Celeron, Intel and Intel Core are trademarks of Intel Corporation in the U.S. and / or other countries.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing Sysmac Studio Automation Software.

Sysmac Studio allows you to use a computer to program and set up Sysmac devices.

Introduction

This manual describes the operating procedures of Sysmac

Use this manual together with the Sysmac

user’s manuals of the devices that you use.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA sy

• Personnel in charge of managing FA systems and facilities.

For

programming, this manual is intended for pers

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Notice

This manual contains information that is necessary to use the Sysmac Studio. Please read and understand this manual before using the Sysmac S

available for reference during operation.

Studio mainly for drive functions.

Studio Version 1 Operation Manual (Cat. No. W504) and the

stems.

onnel who understand the programming language

tudio. Keep this manual in a safe place where it will be

Sysmac Studio Drive Functions Operation Manual (I589)

1

Page 4

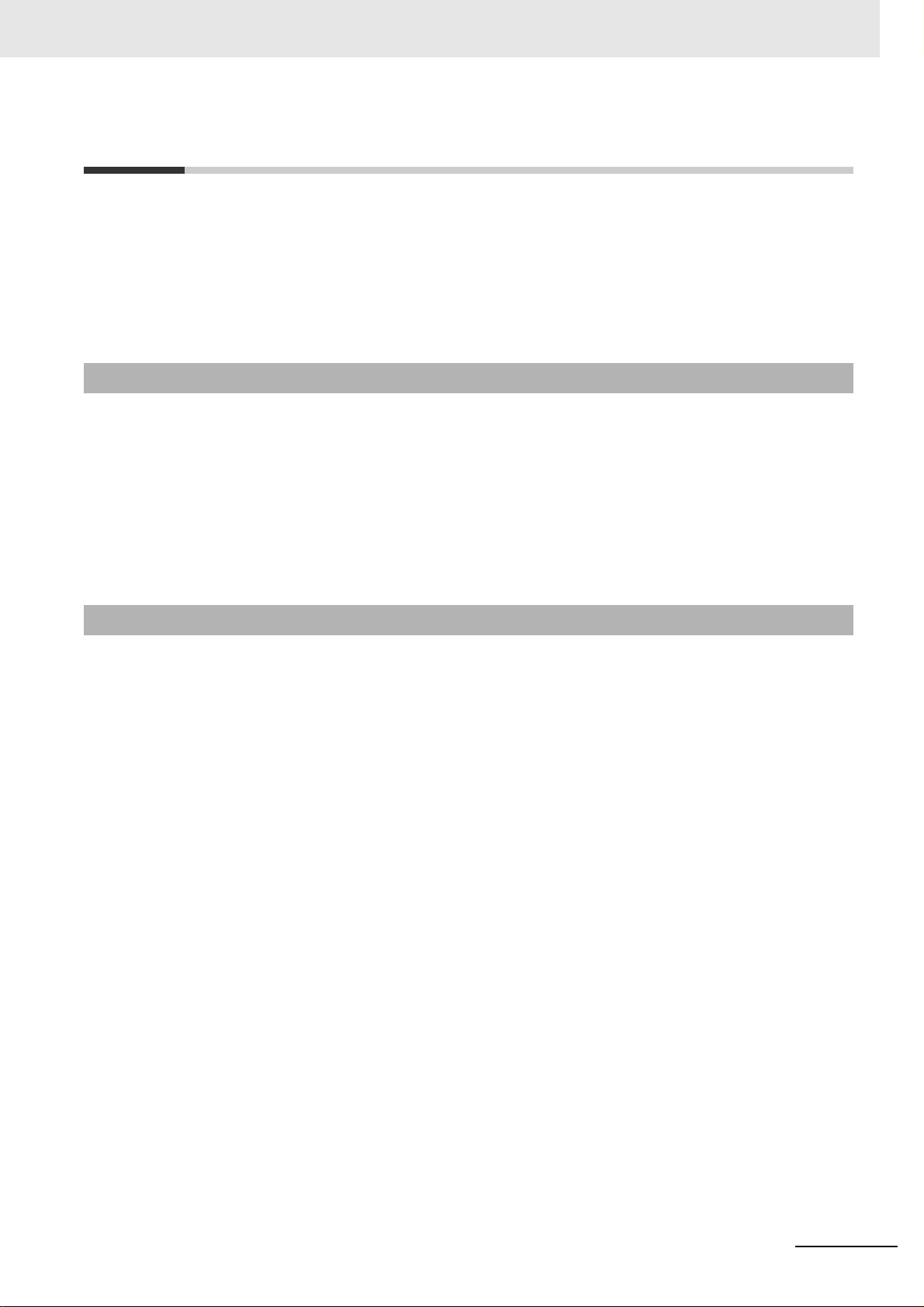

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locki ng the slide rs by moving the m toward the back of the U nits. The End Cover is connect ed in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

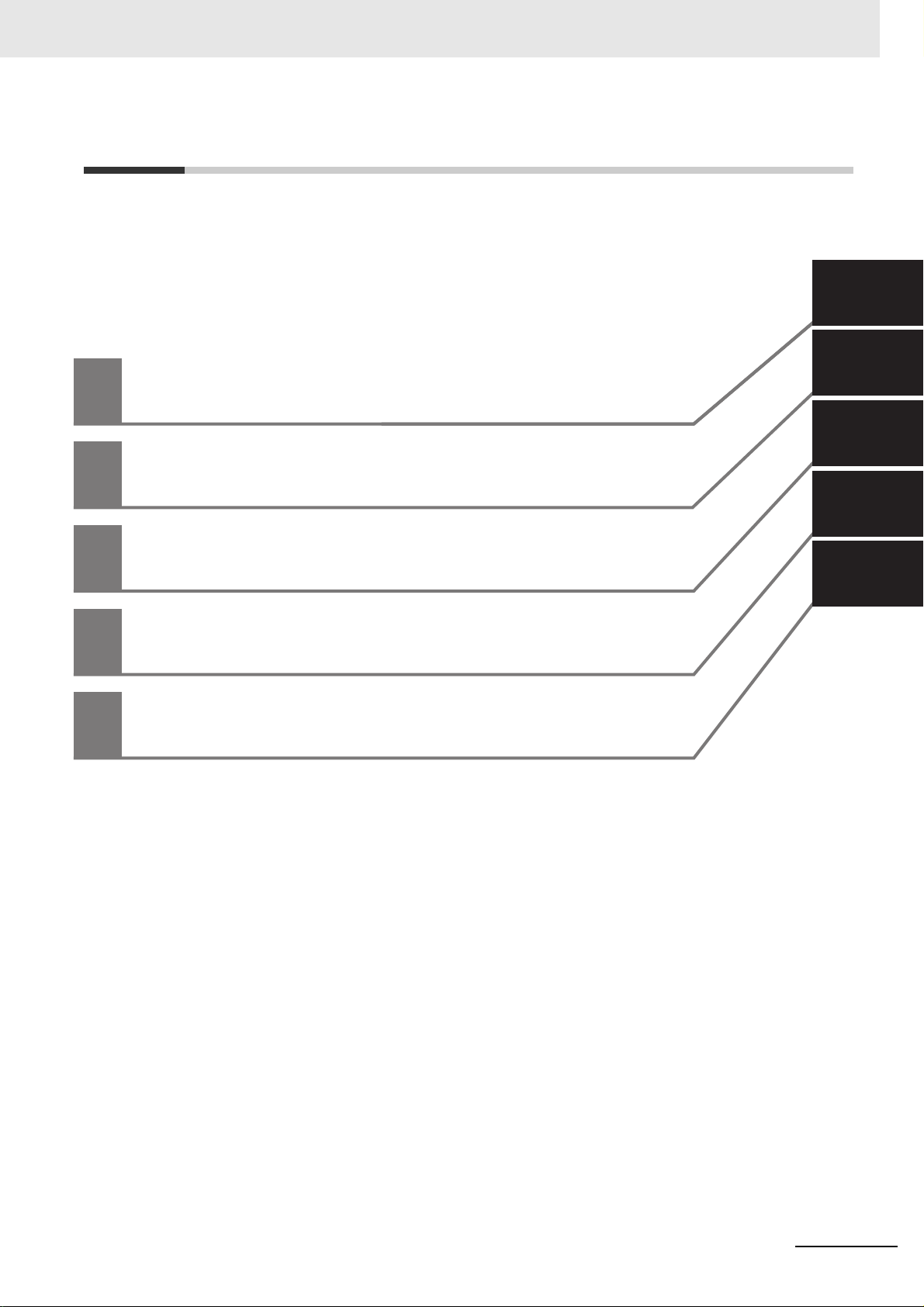

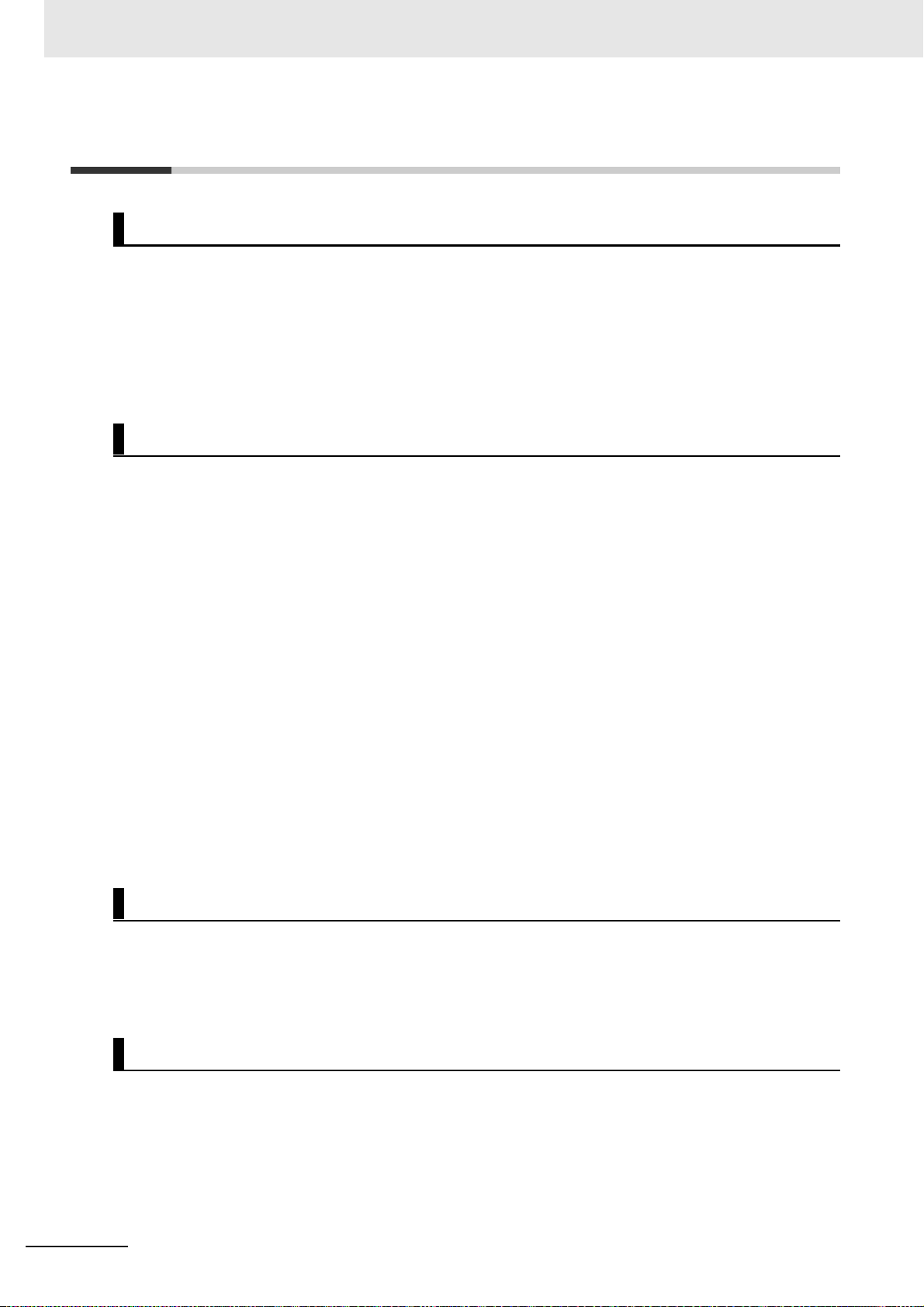

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Page Structure

The following page structure is used in this manual.

This illustration is provided only as a sample.

It may not literally appear in this manual.

2

Sysmac Studio Drive Functions Operation Manual (I589)

Page 5

Special Information

Manual Structure

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to incre

Version Information

Information on differences in specifications and functionality for CPU Units

and for different versions of the Sysmac Studio is given.

Note References are provided to more detailed or related information.

Precaution on Terminology

• In this manual, “download” refers to transferring data from the Sysmac Studio to the physical Controller and “upload” refers to transferring data from the ph

For the Sysmac Studio, synchronization is used to both upload and download data. Here, “synchronize” means to automatically compare the data for th

in the physical Controller and transfer the data in the direction that is specified by the user.

• The Sysmac Studio supports the NJ/NX/NY-series Contro

specified, the operating procedures and screen captures used in the manual are examples for the

NJ-series Controllers.

a

se understanding or make operation easier.

with different unit versions

ysical Controller to the Sysmac Studio.

e Sysmac Studio on the computer with the data

llers. Unless another Controller series is

Terminology

For descriptions of the Controller terms that are used in this manual, refer to information on terminology

in the manuals that are listed in Related Manuals on

page 19.

Sysmac Studio Drive Functions Operation Manual (I589)

3

Page 6

Manual Structure

4

Sysmac Studio Drive Functions Operation Manual (I589)

Page 7

1

2

3

4

5

1

2

3

4

5

Sysmac Studio Drive Functions

Overview of the Operations

Basic Servo Drive Operations

Applied Servo Drive Operations

Other Servo Drive Operations

Sections in this Manual

Sections in this Manual

Sysmac Studio Drive Functions Operation Manual (I589)

5

Page 8

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Notice............................................................................................................................

Manual Structure ......................................................................................................2

Special Information...................................................................................................................................... 3

Sections in this Manual ...........................................................................................5

Terms and Conditions Agreement.......................................................................... 8

Safety Precautions ...................................................................................................9

Definition of Precautionary Information........................................................................................................ 9

Symbols..............................................................................................................................

Precaution for Safe Use......................................................................................... 12

............................... 1

......................... 9

Precautions for Correct Use.................................................................................. 14

Regulations and Standards...................................................................................15

Software Licenses and Copyrights ............................................................................................................ 15

Versions ..................................................................................................................16

Unit Versions ............................................................................................................................................. 16

Checking Versions..................................................................................................................................... 16

Unit Versions and Sysmac Studio Versions .............................................................................................. 18

Related Manuals .....................................................................................................19

Revision History .....................................................................................................20

Section 1 Sysmac Studio Drive Functions

1-1 Sysmac Studio Drive Functions........................................................................................... 1-2

1-2 System Configuration ...........................................................................................................

1-2-1 Connection to Drive.....................................................................................................................1-3

1-2-2 Applicable Drives and Communications Types..............

Section 2 Overview of the Operations

1-3

.............................................................1-5

2-1 Basic Operation Flow............................................................................................................ 2-2

2-1-1 1S Series.....................................................................................................................................2-2

2-1-2 G5 Series .......................................................................................................................

2-2 Installation and Uninstallation ............................................................................................. 2-8

2-3 Creating a Project................................................................................................................

2-3-1 Using a Drive with an OMRON NJ/NX/NY-series Controller.......................................................2-9

2-3-2 Using a Drive Independently.....................................................................................................

2-4 Areas of the Application Window ...................................................................................... 2-12

2-4-1 Overview of the Application Window .........................................................................................2-12

2-4-2 Multiview Explorer............................................................................................................

2-4-3 Toolbar........................................................................................................................

2-5 Project Data.......................................................................................................................... 2-17

6

Sysmac Studio Drive Functions Operation Manual (I589)

.............2-6

.. 2-9

2-10

......... 2-13

..............2-16

Page 9

2-5-1 Project Management................................................................................................................. 2-17

2-5-2 Project Data..................................................................................................................

2-5-3 Import and Export ..................................................................................................................... 2-19

2-6 Functions, Use Cases, and Operation Procedures .......................................................... 2-20

2-6-1 1S Series .................................................................................................................................. 2-20

2-6-2 G5 Series.................................................................................................................................. 2-22

2-6-3 Function and Operation Procedures for Each Drive ................................................................. 2-23

2-7 Online Connection Procedure............................................................................................ 2-24

Section 3 Basic Servo Drive Operations

3-1 Displaying and Editing Parameters ..................................................................................... 3-2

3-1-1 Displaying and Editing Drive Parameters ................................................................................... 3-2

3-1-2 Displaying and Editing Multi-drive Parameters (Drive Setting Ta

3-2 Auto Tuning ......................................................................................................................... 3-11

3-2-1 Auto Tuning for 1S Series......................................................................................................... 3-11

3-2-2 Auto Tuning for G5 Series .....................................................................................................

3-3 Test Run ............................................................................................................................... 3-18

3-4 Status Monitor ..................................................................................................................

3-5 Troubleshooting ..................................................................................................................

CONTENTS

............ 2-18

ble) ......................................... 3-9

... 3-12

... 3-22

3-23

3-6 Data Tracing......................................................................................................................

3-7 Motors and Encoders..........................................................................................................3-

3-7-1 Motor Properties ....................................................................................................................... 3-34

3-7-2 Encoder Properties ................................................................................................................... 3-35

3-8 Setup and Tuning Wizard ................................................................................................... 3-36

3-8-1 Overview................................................................................................................................... 3-36

3-8-2 Quick Parameter Setup and I/O Monitor................................................................................... 3-37

3-8-3 Test Run and Function Status .................................................................................................. 3-45

4 Easy Tuning (Single Drive)....................................................................................................... 3-48

3-8-

3-8-5 Easy Tuning (Multiple Drives)................................................................................................... 3-59

Section 4 Applied Servo Drive Operations

4-1 Manual Tuning ....................................................................................................................... 4-2

4-1-1 1S Series Advanced Tuning ....................................................................................................... 4-2

4-1-2 1S Series Manual Tuning (Single Drive)................................................................................... 4-14

4-1-3 1S Series Manual Tuning (Multiple Drives) .............

4-1-4 G5 Series Manual Tuning .........................................................................................................

4-2 Other Tuning Functions...................................................................................................... 4-19

4-2-1 FFT ........................................................................................................................................... 4-19

4-2-2 Damping Control....................................................................................................................... 4-23

4-3 Motor Settings (only for Linear Motor Type of G5 Series)............................................... 4-27

................................................................. 4-17

... 3-24

34

4-18

Section 5 Other Servo Drive Operations

5-1 Initialization of the Drive ....................................................................................................... 5-2

5-2 Drive Properties................................................................................................................

Sysmac Studio Drive Functions Operation Manual (I589)

..... 5-3

7

Page 10

Terms and Conditions Agreement

Terms and Conditions Agreement

WARRANTY

• The warranty period for the Software is one year from the date of purchase, unless otherwise specifically agreed.

• If the User discovers defect of the Software (substan

return it to OMRON within the above warranty period, OMRON will replace the Software without

charge by offering media or download from OMRON’s website. And if the User discovers defect of

media which is attributable to OMRON and return it to OMRON within the above warranty period,

OMRON will replace defective media without charge. If OMRON is unable to replace defective

media or correct the Software, the liability of OMRON and the User’s remedy shall be limited to

the refund of the license fee paid to OMRON for the Software.

LIMITATION OF LIABILITY

• THE ABOVE WARRANTY SHALL CONSTITUTE THE USER’S SOLE AND EXCLUSIVE REMEDIES AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRE

IMPLIED, INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT, OMRON W

LOST PROFITS OR OTHER INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF USE OF THE SOFTW

• OMRON SHALL HAVE NO LIABILITY FOR DEFECT

CATION OR ALTERNATION TO THE SOFTWARE BY THE

• OMRON SHALL HAVE NO LIABILITY FOR SOFTWARE DEVELOPED B

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

tial non-conformity with the manual), and

ILL BE LIABLE FOR ANY

ARE.

OF THE SOFTWARE BASED ON MODIFI-

USER OR ANY THIRD PARTY.

SSED OR

Y THE USER OR ANY

APPLICABLE CONDITIONS

USER SHALL NOT USE THE SOFTWARE FOR THE PURPOSE THAT IS NOT PROVIDED IN

THE ATTACHED USER MANUAL.

CHANGE IN SPECIFICATION

The software specifications and accessories may be changed at any time based on improvements

and other reasons.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

8

Sysmac Studio Drive Functions Operation Manual (I589)

Page 11

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the drive functions of Sysmac Studio.

The safety precautions that are provided are extremely important to safety. Always read and heed the

ation provided in all safety precautions.

inform

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in death or serious injury. Additionally, there may be

severe property damage.

Safety Precautions

Symbols

Indicates a potentially hazardous situation which, if not avoided,

Caution

may result in minor or moderate injury, or property damage.

Precautions for Safe Use

Indicates precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Indicates precautions on what to do and what no

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

t to do to ensure proper operation and performance.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the

This example indicates a general precaution.

Sysmac Studio Drive Functions Operation Manual (I589)

triangle and explained in text.

triangle and explained in text.

9

Page 12

Safety Precautions

WARNING

Always confirm safety at the destination node before you transfer parameters

or data from Sysmac Studio to another node. Not doing so may result in

injury.

When you change the Drive’s mode to Test Run mode or RUN mode, the

motor opera

mac Studio. Ensure safety before changing the mode.

tion generator is switched between the host controller and Sys-

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the

circle and explained in text.

This example shows a general precaution for something that you must do.

Sometimes you may be unable to stop the motor from your computer. Install

an

external emergency stop device so that you can stop the motor immedi-

ately if needed.

Confirm the axis number carefully before you perfo

rm an operation from Sys-

mac Studio.

Caution

Please check the safety of the machines during FFT analysis which requires

some drastic movements of motor.

To prevent the dangers please monitor the machine and be ready to make

the servo OFF any time.

Please do not use FFT analysis if there are any risks of damaging machine

by moving the motor in wide range.

Please do analysis under setting the gain as low as possible.

Check the parameters for proper execution before you use them for actual

operation

.

10

Don't turn OFF the power supply to the Drive while flash memory is being

written.

In the worst

If the absolute encoder setting function is executed, the mu

case, the flash memory may be damaged.

ltiturn counter

and encoder alarm are reset in the absolute serial encoder. When the multiturn counter in the absolute serial encoder is reset to 0, the previously

de

ned machine system changes to a different coordinate system. After the

fi

encoder is set normally, reset the zero point of the mechanical system.

Sysmac Studio Drive Functions Operation Manual (I589)

Page 13

Confirm that the machine will not be adversely affected before you enable

the function to automatically transfer the changed parameters to the Drive.

Safety Precautions

During autotuning or during automatic moto

motor operates and the workpiece moves greatly. Provide a means so that

you can turn OFF the Servo immediately during autotuning.

If you perform FFT analysis, the motor velocity may change drastically. Provide a means so that you can turn OF

FFT analysis.

If you use the damping control function, the motor

drastically. Provide a means so that you can turn OFF the Servo Drive during

the damping control.

Conform that the related parameters have

performing the automatic motor setting for the Linear Motor in order to prevent unintended operation.

r setting for a Linear Motor, the

F the Servo immediately During the

response may change

been applied to the Drive before

Sysmac Studio Drive Functions Operation Manual (I589)

11

Page 14

Precaution for Safe Use

Precaution for Safe Use

Displaying and Editing Parameters

• When you restart a Servo Drive, the ESM state of the Servo Drive will change in the following order:

Operational → Init → Operational.

• By the above state transition, the commands to the Serv

ning, make sure to stop the operation before executing the restart operation.

• When you use the NJ/NX/NY-series, the Controller will enter

state transition. Therefore, connect Sysmac Studio to the Controller and execute troubleshooting to

reset the error.

Auto Tuning

omotor will be stopped. If the device is run-

the minor fault state due to the ESM

• The motor operates during the adjustment. Confir

• If abnormal noise or vibration occurs, immediately turn OFF the power supply or the Servo.

• Gain adjustment is automatically performed by the Servo

adjustment. Follow the following safety precautions.

(1) Provide a means to perform an emergency stop (i

response may greatly change during the adjustment.

(2) Confirm safety around all moving par

movement range and directions of the motor and that the motor can operate safely. Provide

protective measures for unexpected motion.

(3) Before you start the adjustment, make sure that the device

of place. Before you start normal operation, make sure to perform homing to reset the position. If home is not reset before the adjustment is performed, the motor may run away, creating a very hazardous condition. Co

Make sure that the object that is being adjusted does not fall when the Servo is turned OFF.

(4) If vibration or oscillation occurs when

until the system is stable.

• During auto tuning, the motor operates and the work

you can turn OFF the Servo immediately during auto tuning.

• Always confirm safety at the destination node before

m safety at the destination node.

Drive. The motor operates during the

.e., to turn OFF the power supply). The

ts. Always confirm that there are no obstacles in the

that is being adjusted is not out

nfirm

the safety of the system if you use a vertical axis.

auto tuning is performed, manually reduce the gain

piece moves greatly. Provide a means so that

you perform easy tuning on multiple Drives.

Manual Tuning

12

• The advanced tuning for 1S Series is made through a simulation of motor operations. The actual

oper

ation may be different from the simulated operations. Ensure safety before the actual operation

after the tuning.

• Always confirm safety at the destination node before

you perform manual tuning on multiple Drives.

Test Run

• Confirm the axis number carefully before you perform a test run.

• A test run operation involves motor operation. Refer

test run.

Be particularly careful of the following points.

Confirm safety around all moving parts.

•

• When you click the start button, the motor begins actual oper

the motor operation only when you are absolutely sure there is no danger if you start the motor.

to the operation manual before you execute a

ation at the specified velocity. Begin

Sysmac Studio Drive Functions Operation Manual (I589)

Page 15

Precaution for Safe Use

• Always have an external emergency stop device available.

• Sometimes you may be unable to stop the motor from your computer. Install an external emergency stop device so that you can stop the motor immediately if needed.

• Only operate the motor when you can clearly confirm the motor operation so that you can react

ickly in the case of any danger that may arise due to operation of the motor.

qu

• When you perform a test run via an NJ/NX/NY-series Con

after establishing EtherCAT communications.

• A communications error will occur if you attempt to begin operations w

cations. Always establish EtherCAT communications first.

• When operation is performed, such data as a travel distance and velocity

conversion settings for the axes assigned on the project file is displayed. Before performing operation, carefully check safety by using units of drive

• Precautions during Test Run Operation

• During test run execution, only Sysmac Studio has an

from motion control instructions are ignored.

• Make sure that you are operating the correct axis.

measurement such as command units.

troller, perform the test run operations

ithout EtherCAT communi-

calculated from the unit

y control of the operation. Any commands

Motors and Encoders

If the absolute encoder setting function is executed, the mu

reset in the absolute serial encoder. When the multiturn counter in the absolute encoder is reset to

0, the previously defined machine system changes to a different coordinate system. After the

encoder is set normally, reset the zero point of the mechanical system.

ltiturn counter and encoder alarm are

Damping Control

Damping control is automatically performed by the

adjustment. Follow the following safety precautions.

• Provide a means to perform an emergency stop (i.e., to turn OFF the power supply). The

sponse may greatly change during the adjustment.

re

• Confirm safety around all moving

ment range and directions of the motor and that the motor

measures for unexpected motion.

• Before you start the adjustment, make sure that the device that is being adjusted is not out of

ace. Before you start normal operation, make sure to perform homing to reset the position. If

pl

home is not reset before the adjustment is performed, the motor may run away, creating a very

hazardous condition. Confirm the safety of the system if you use a vertical axis. Make sure that

the object that is being adjusted does not fall when the Servo is turned OFF.

parts. Always confirm that there are no obstacles in the move-

Servo Drive. The motor operates during the

can operate safely. Provide protective

Motor Setup (only for Linear Motor Type of

• After the completion of processing, the related parame

memory.

• Before moving to the next step, perform the following operations.

• Go offline with the Servo Drive.

• Cycle the power supply to the Servo Drive to apply the setti

valid at the startup.

• If an EtherCAT cable is connected to the Servo Drive, remove it.

• Go online with the Servo Drive.

Sysmac Studio Drive Functions Operation Manual (I589)

G5 Series)

te

rs are automatically saved to the non-volatile

ngs of the parameters that become

13

Page 16

Precautions for Correct Use

Precautions for Correct Use

• Observe the following precautions while the Drive is in Test Run mode.

• Commands from Sysmac Studio are disabled when you restart the Controller, clear all memory,

backu

p and restore the Controller, or disconnect an EtherCAT slave. Confirm the safety of the

system before you perform the operations.

• If Sysmac Studio goes offline with the Controller or Dr

cally. In RUN mode, commands from Sysmac Studio are disa

troller are enabled. Confirm the safety of the system before you perform the operation.

• Do not perform following operations from other computers during a test run for the Drive:

restarting the Controller, clearing all memory, restoring the Controller, or disconnecting an EtherCAT slave. Communications between Sysmac Studio and the Drive is disconnected and commands from Sysmac Studio are disabled.

• If you change more than one Drive to Test Run mode, command transmission time to each Drive

become

will

• Test Run mode may be cancelled if the personal computer

system requirements for Sysmac Studio because the sending time for each command for drive

may become longer than expected. As a result, the drive may detect a disconenction of the cable.

The system requirements for recommended environment can be seen at 'Applicable Computers',

section 1 'Introduction' in the 'Sysmac Studio Version 1 Operation Manual (W504)'.

• Be sure to set the value before applying electronic ge

when you perform the operation.

longer and the Test Run mode may be cancelled.

ive, the Drive enters RUN mode automati-

a

r ratio in the Drive as the step distance

bled, and commands from the Con-

does not satisfy the 'recommended'

• Do not perform go online to a Drive from more than one copy of Sysmac Studio in one personal computer via USB connection. Communication between Sysmac Studio and the Drive is stopped.

14

Sysmac Studio Drive Functions Operation Manual (I589)

Page 17

Regulations and Standards

Software Licenses and Copyrights

• This product incorporates certain third party software. The license and copyright information associated with this software is available at http://ww

• This software uses knowledge media technology that was

(VBL) of Hokkaido University.

w.fa.omron.co.jp/nj_info_e/.

Regulations and Standards

developed by the Meme Media Laboratory

Sysmac Studio Drive Functions Operation Manual (I589)

15

Page 18

Versions

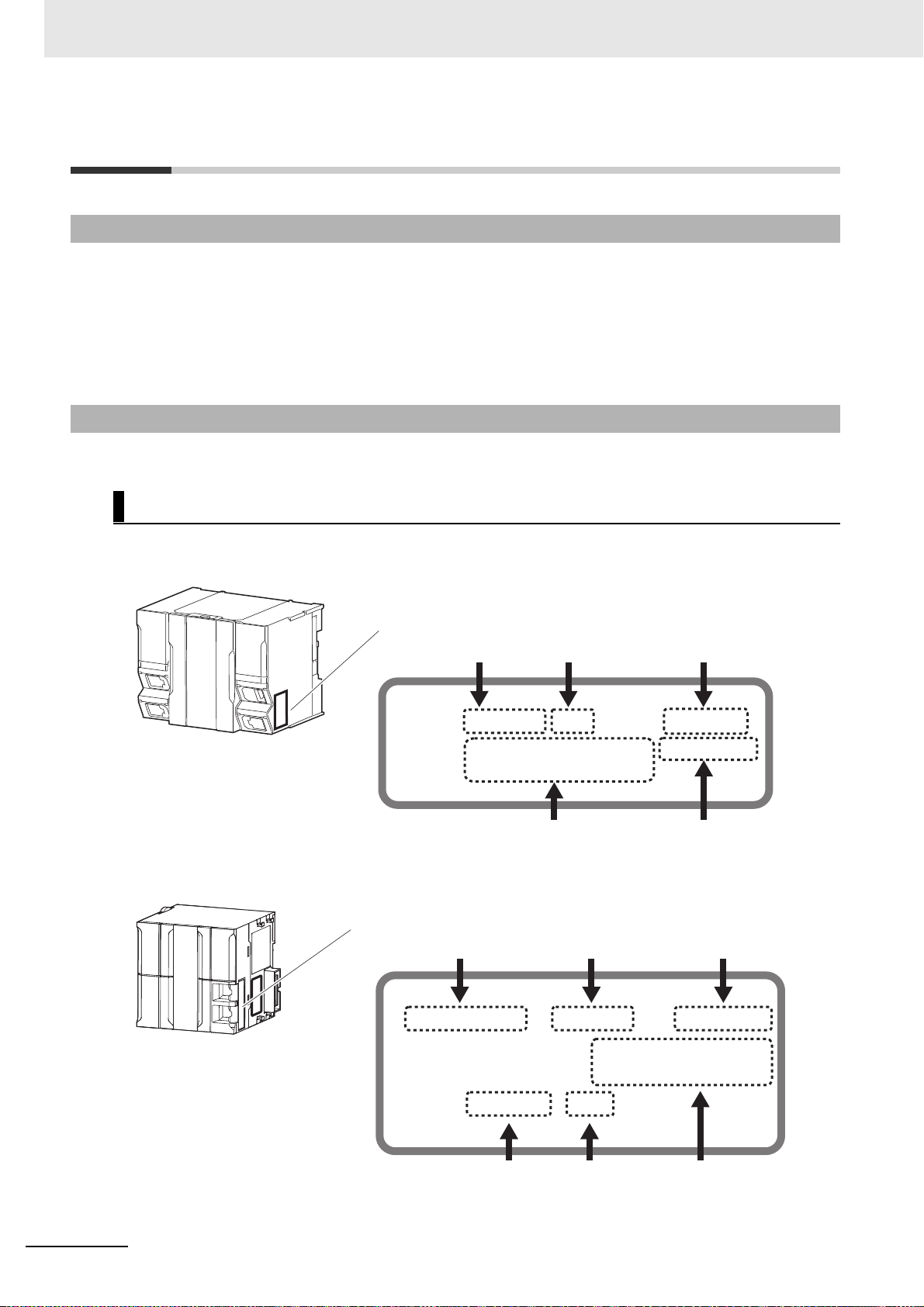

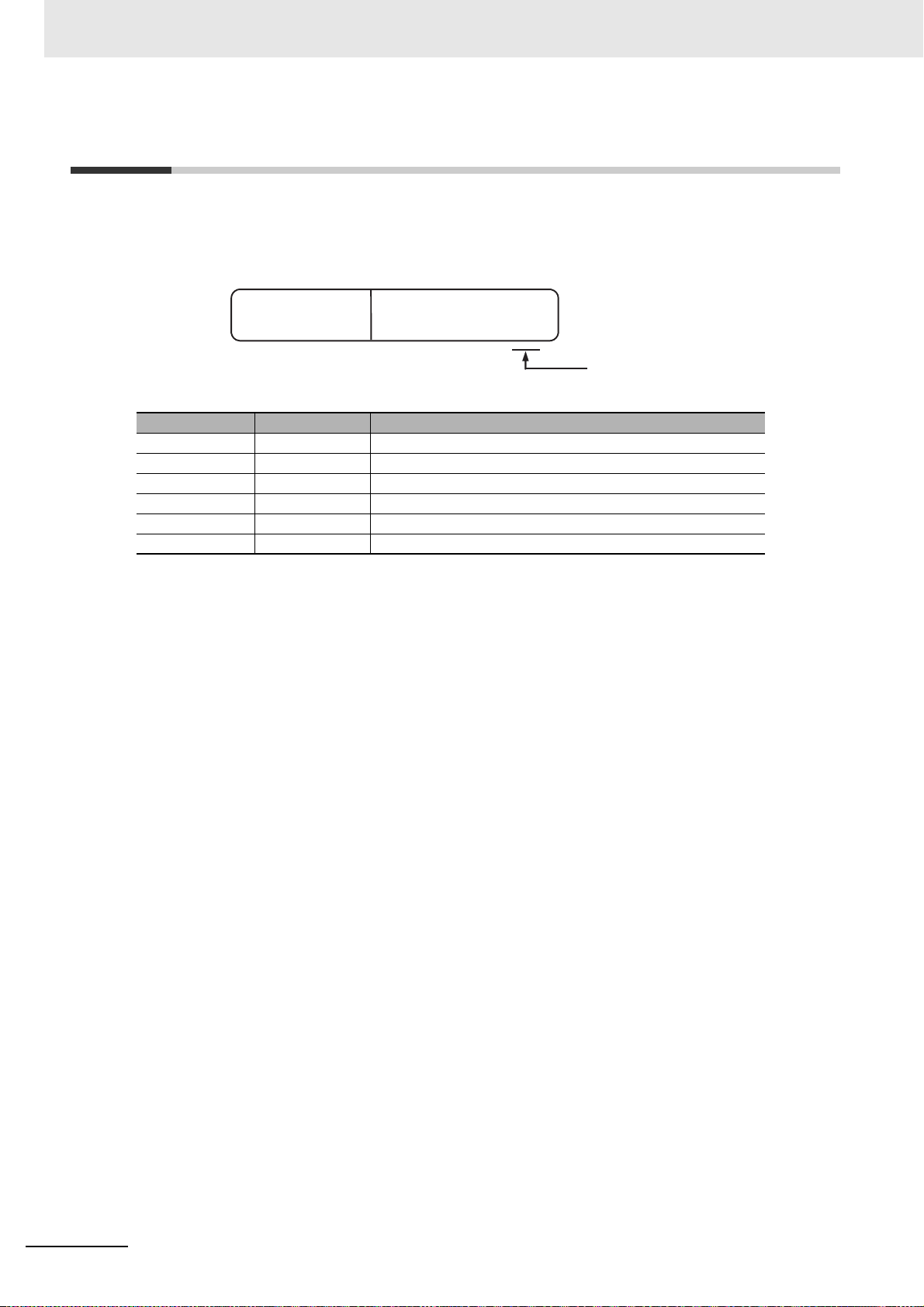

ID information indication

Lot number Serial number Unit version

MAC address Hardware revision

LOT No. DDMYY xxxx Ver.1.

PORT1 : HW Rev.

PORT2 :

ID information indication

Unit model

Lot number Serial number MAC address

Unit version Hardware revision

NJ501

-

Ver.1.

PORT1 MAC ADDRESS:

PORT2 MAC ADDRESS:

Lot No. DDMYY

xxxx

HW Rev.

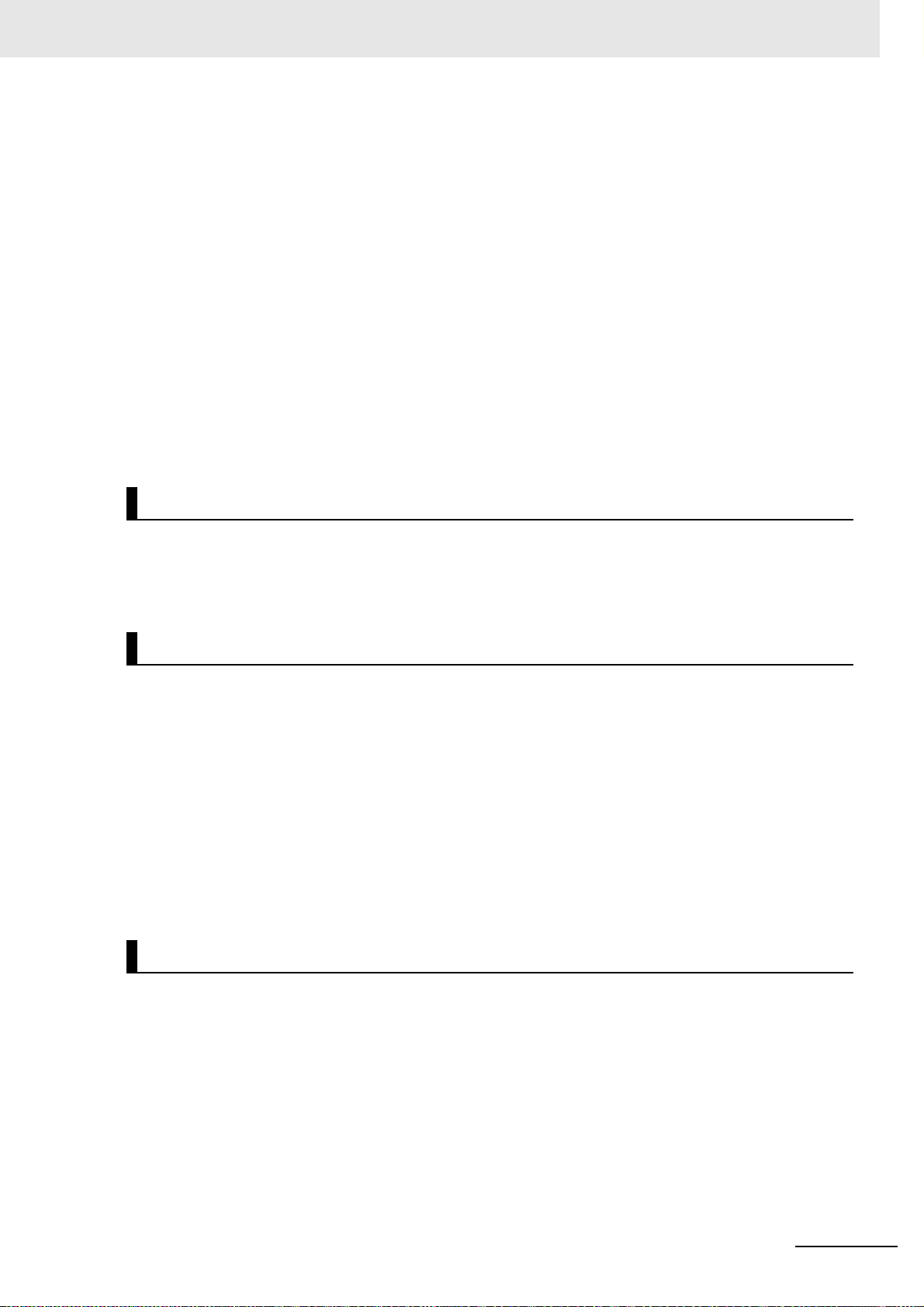

Versions

Unit Versions

Hardware revisions and unit versions are used to manage the hardware and software in NJ/NX-series

Units and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hardware revisions or unit versions.

This section describes NJ/NX-series CPU Un

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

its an

d EtherCAT slaves as examples.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the side of the product.

The ID information on an NX-series NX701- CPU

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

The ID information on an NJ-series NJ501- CPU Unit is shown below.

Unit is shown below.

16

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

Sysmac Studio Drive Functions Operation Manual (I589)

Page 19

Versions

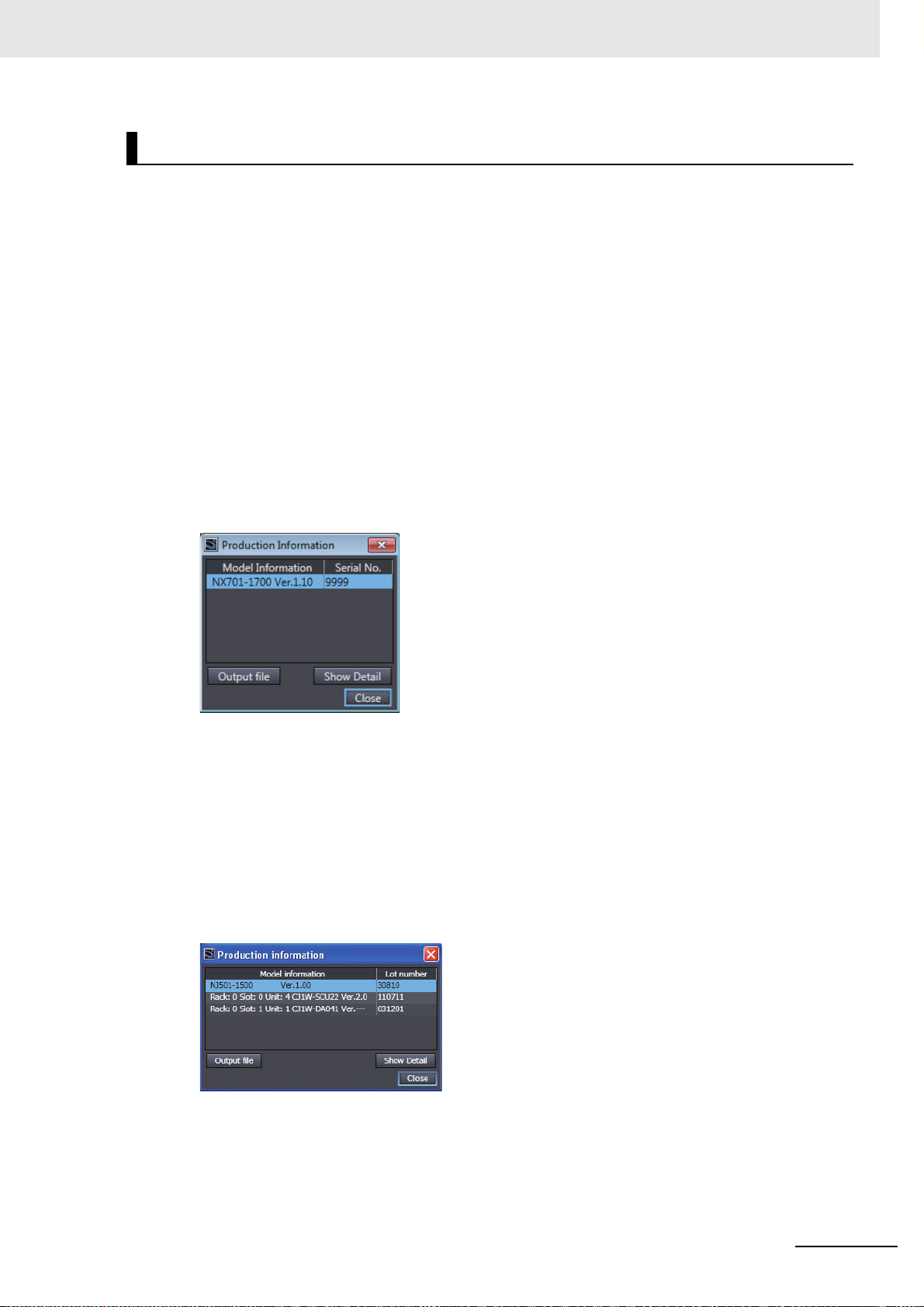

Checking Unit Versions with the Sysmac Studio

You can use the Production Information Dialog Box while the Sysmac Studio is online to check the unit

version of a Unit.

You can check the unit version of the following Units.

•CPU Units

• CJ-series Special I/O Units and CPU

• EtherCAT slaves

The unit versions of CJ-series Basic I/O

Refer to the Sysma

tion information displays.

c Studio Version 1 Operation Manual (Cat. No. W504) for details on the Unit produc-

Bus Units

Units cannot be checked from the Sysmac Studio.

NX-series CPU Units

1 Right-click CPU Rack under Configurations and Setup CPU/Expansion Racks in the Multi-

view Explorer and select Display Prod

The Production Information Dialog Box is displayed.

The unit version is displayed after Ver. to the r

uction Information.

ight of the Unit model number.

NJ-series CPU Units and CJ-series Units

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after Ver. to the r

ight of the Unit model number.

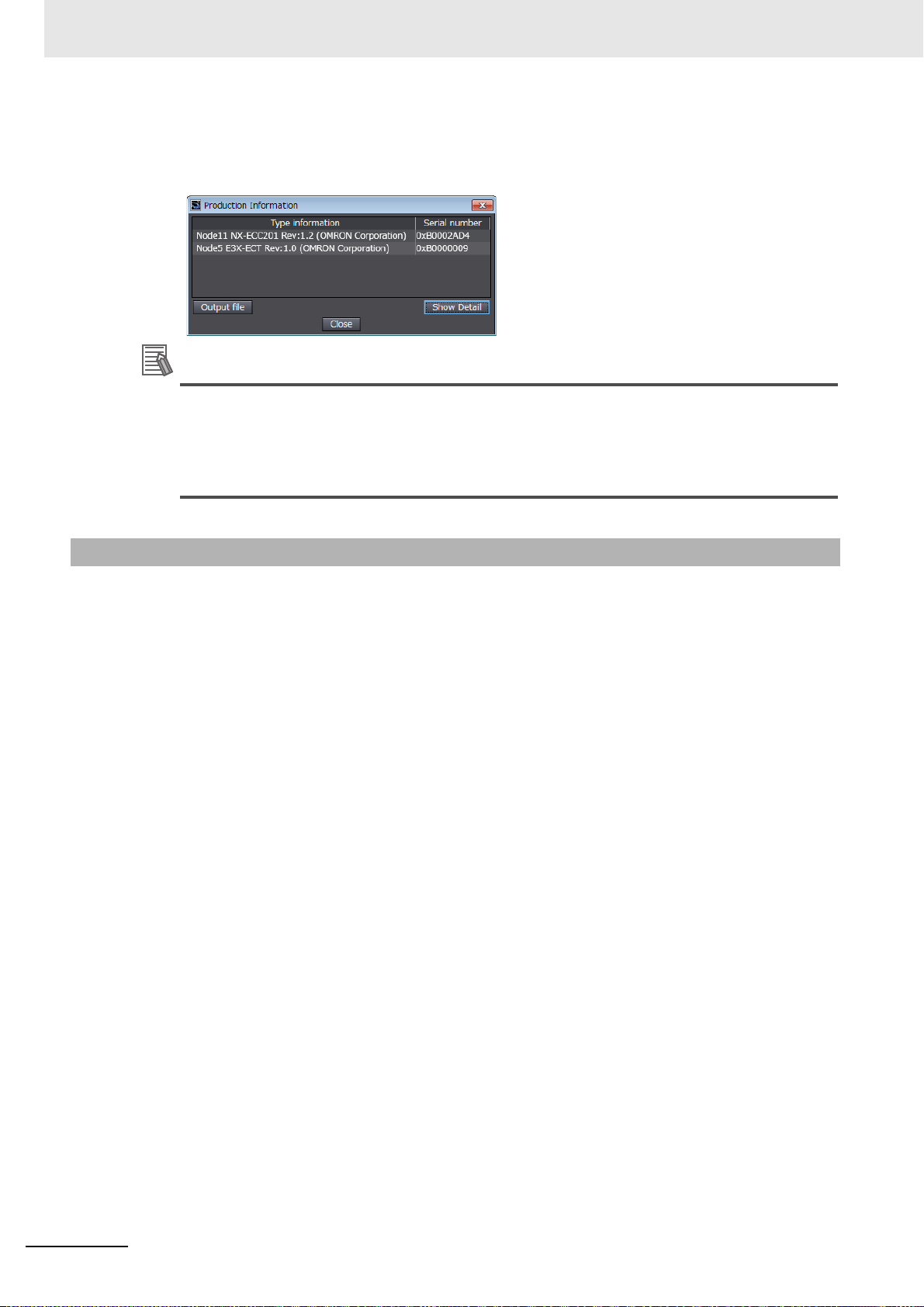

EtherCAT Slaves

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or,

right-click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

Sysmac Studio Drive Functions Operation Manual (I589)

17

Page 20

Versions

Additional Information

2 Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.The unit version is display

the right of the Unit model number.

• Refer to the manual for the specific Unit for the unit versions of the CPU Units to which the

database connection service and other functions were added, as well as for the unit versions

of the Communications Coupler Units, NX Units, and Safety Control Units.

• This manual sometimes refers to the unit version of the CPU Unit as the unit version of the

Controller.

Unit Versions and Sysmac Studio Versions

The functions that are supported by a Unit depend on its unit version. The version of Sysmac Studio

that supports the functions that were added for an upgrade is required to use those functions. Refer to

the NJ/NX-series CPU Unit Software User’s Manual (Cat. No. W501) for the relationship between the

unit versions of the NJ/NX-series CPU Units and the Sysmac Studio versions, and for the functions that

are supported by each unit version. Refer to the relevant manuals for the Communications Coupler Unit

and NX Units for differences in the functional support provided by each unit version.

ed after Rev. to

18

Sysmac Studio Drive Functions Operation Manual (I589)

Page 21

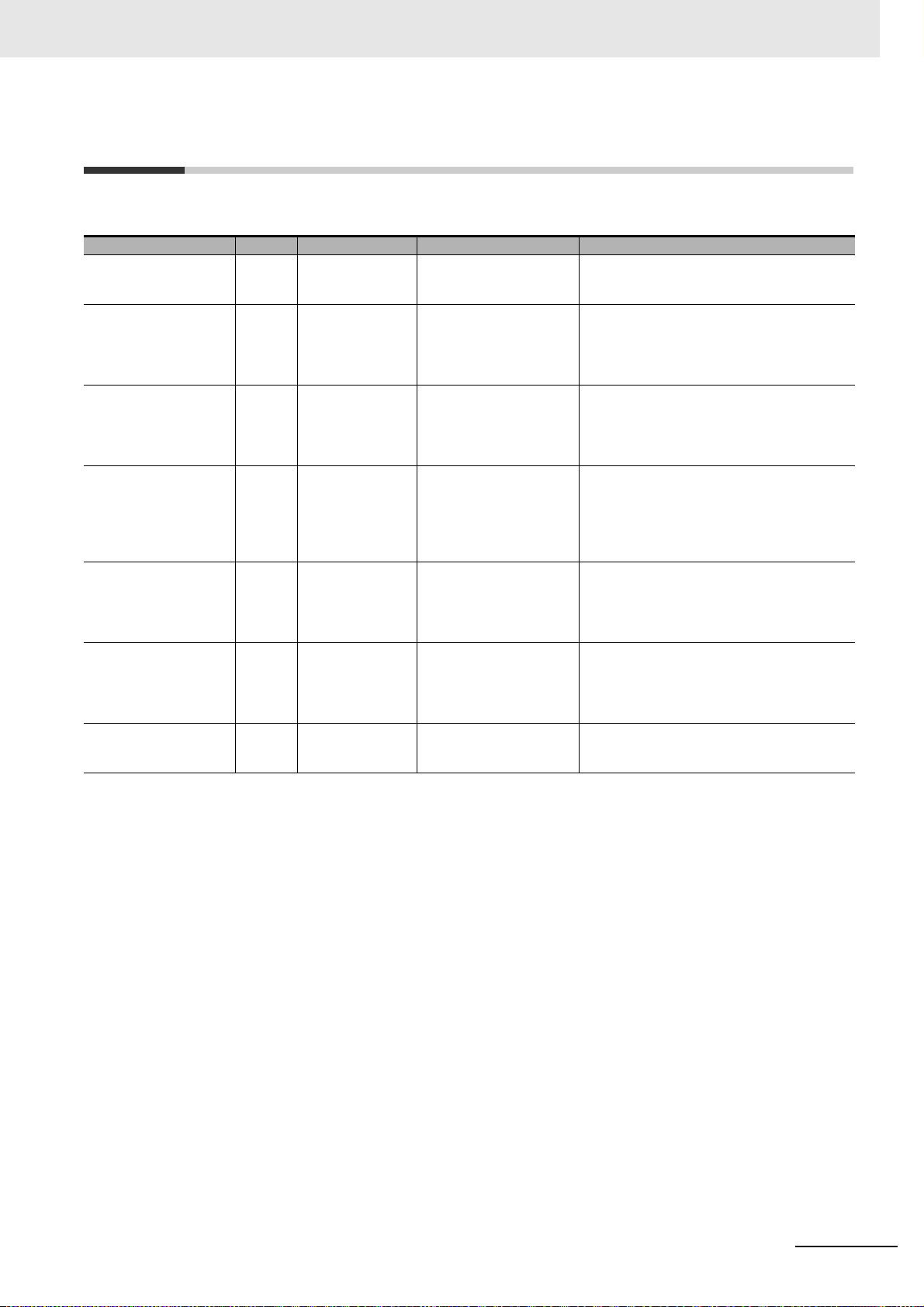

Related Manuals

Related Manuals

The following manuals are related. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

Sysmac Studio Drive

Functions Operation

Manual (t

Sysmac Studio Version 1

Operation Manual

1S-ser

tors and Servo Drives

User’s Manual (with

Built-i

munications)

1S-Series AC Servomotors and Servo Drives

User’s Manual (with

Buil

munications and Safety

F

G5-series AC Servomotors and Servo Drives

User’s Manual (with

Buil

munications)

G5-series Linear

Motors/Servo Drives

User’s Manual (with

Buil

munications)

CJ1W-NC81/82

Position Control Unit

User's Manual

his manual)

ies AC Servomo-

n EtherCAT® Com-

t-i

n EtherCAT® Com-

unctionality)

n EtherCAT® Com-

t-i

n EtherCAT® Com-

t-i

I589 SYS-

MAC-SE2

W504 SY

I586 R88M-1,

I621 R88M-1

I576 R88M-K,

I577 R88L-EC-,

W487 CJ1W-NC81/82Learning about the

S-

MAC-SE2

1

SN-ECT

R88D-

AL/

1AM,

SAN-EC

R88D-1

T

K

N-ECT

R88D-

R88D-KN-ECT-L

Learning about the drive

functions of Sysm

dio.

Learning about the operating procedures and functions of Sysmac Studio

besides the drive functio

Learning about the

1S-series AC Servomotors and Servo Drives with

builtnications

Learning about the

1S-series A

tors and Servo Drives with

built-i

nications and Safety Functionality.

Learning about the

G5-series AC Servomotors and Servo Drives with

builtnications.

Learning about the

G5-series Linear Motors

and Servo Drives with

built-in EtherCAT communications.

CJ-series Position Control

Unit CJ1W-NC8.

ns.

i

n EtherCAT commu-

C

Servomo-

n EtherCAT commu-

i

n EtherCAT commu-

ac Stu-

Describes the operating procedures for the drive

s of Sysmac Studio.

function

Describes the operating procedures for other

functions of Sysmac Studio.

Describes the hardware, setting methods, and

functions of 1SServo Drives with built-in EtherCAT communications.

Describes the hardware, setting methods, and

s of 1S-

function

Servo Drives with built-in EtherCAT communications and Safety Functionality.

Describes the hardware, setting methods, and

functions of G5Servo Drives with built-in EtherCAT communications.

Describes the hardware, setting methods, and

s of G5-series Linear Motors and Servo

function

Drives with built-in EtherCAT communications.

Describes the hardware, setting methods, and

functions of CJ1W-NC8 Position Control

Unit.

series AC Servomotors and

series AC Servomotors and

series AC Servomotors and

Sysmac Studio Drive Functions Operation Manual (I589)

19

Page 22

Revision History

I589-E1-06

Revision code

Cat. No.

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 July 2016 Original production

02 April 2017 Revisions for an upgrade to Sysmac Studio version 1.18.

03 October 2017 Revisions for an upgrade to Sysmac Studio version 1.20.

04 April 2018 Revisions for an upgrade to Sysmac Studio version 1.22.

05 July 2019 Revisions for an upgrade to Sysmac Studio version 1.29.

06 April 2020 Revisions for an upgrade to Sysmac Studio version 1.40.

20

Sysmac Studio Drive Functions Operation Manual (I589)

Page 23

Sysmac Studio Drive Functions

This section provides an overview of the Sysmac Studio drive functions and describes

its features, system configuration, and use cases.

1-1 Sysmac Studio Drive Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-1 Connection to Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-2 Applicable Drives and Communications Types . . . . . . . . . . . . . . . . . . . . . . . 1-5

1

Sysmac Studio Drive Functions Operation Manual (I589)

1 - 1

Page 24

1 Sysmac Studio Drive Functions

1-1 Sysmac Studio Drive Functions

Sysmac Studio Automation Software provides an integrated development environment to set up, program, debug, and maintain SYSMAC NJ/NX/NY-series Controllers and other Machine A

trollers, as well as EtherCAT slaves. Sysmac Studio offe

as EtherCAT slaves, for example, parameter settings, transfer, and comparison as well as test runs,

tuning, monitoring, and data tracing. These functions are collectively called “drive functions”.

This manual describes the operation procedur

es of Sysmac Stu

Support for OMRON Drives

rs various functions for specific Drives installed

dio drive functions.

utomation Con-

Easy and Secure Drive Parameter Settings

1S-series Servo Drives and G5-series Servo Drives are supported.

Parameters can be selected by specifying a category or filtering the list.

You can customize a category to make your own favorite category.

Efficient Drive Setup and Tuning Navigate

d by the Setup and Tuning

Wizard (1S Series Only)

For 1S-series Drives, the Setup and Tuning wizard is provided to perform a series of operations from

*1

basic parameter settings

and transfer, test run, and tuning to data tracing. With the wizard, you can

reduce the time required for drive settings and tuning.

*1. With the Setup and Tuning wizard for a 1S-series Drive, you can assign functions to external I/O signals (i.e.,

control I/O connectors) easily while checking the connector pin numbers and arrangement diagram.

Support of Various Tuning Methods (1S Series Only)

For 1S Series, three kinds of tuning methods are provided; easy tuning, advanced tuning, and manual

tuning.

In Easy tuning and Manual tuning, tuning can be simultaneo

• Easy tuning: Gains and filters are automatically adjusted by repeating motor operations. Use this

method when you want to perform the tuning easily.

• Advanced tuning: You can adjust gains and filters by minimum motor operations through a simulation. Gain

and filter settings can be adjusted individually.

• Manual tuning: You can adjust gains and filters at the same time by editing only one parameter.

usly performed on multiple Drives.

1 - 2

Sysmac Studio Drive Functions Operation Manual (I589)

Page 25

1-2 System Configuration

R

U

N

E

R

R

IN

L

/

A

R

8

8D

-1SN

L

/

A

F

S

O

U

T

Et

her

CA

T

ID21

1

0

1

3

2

4

5

7

6

8

9

11

1

0

12

13

14

1

5

DC

2

4

V

7

mA

C

OM

MAC

H

N

o

.

AD

04

2

R

U

N

ERC

ERH

B

1

A

1

x

1

0

1

x1

0

0

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0 1 234

5

6 7

8

9

10

111213 14 15

Commercially available USB

cable or Ethernet cable

NJ/NX-series

CPU Unit

Sysmac Studio

EtherCAT

Drive

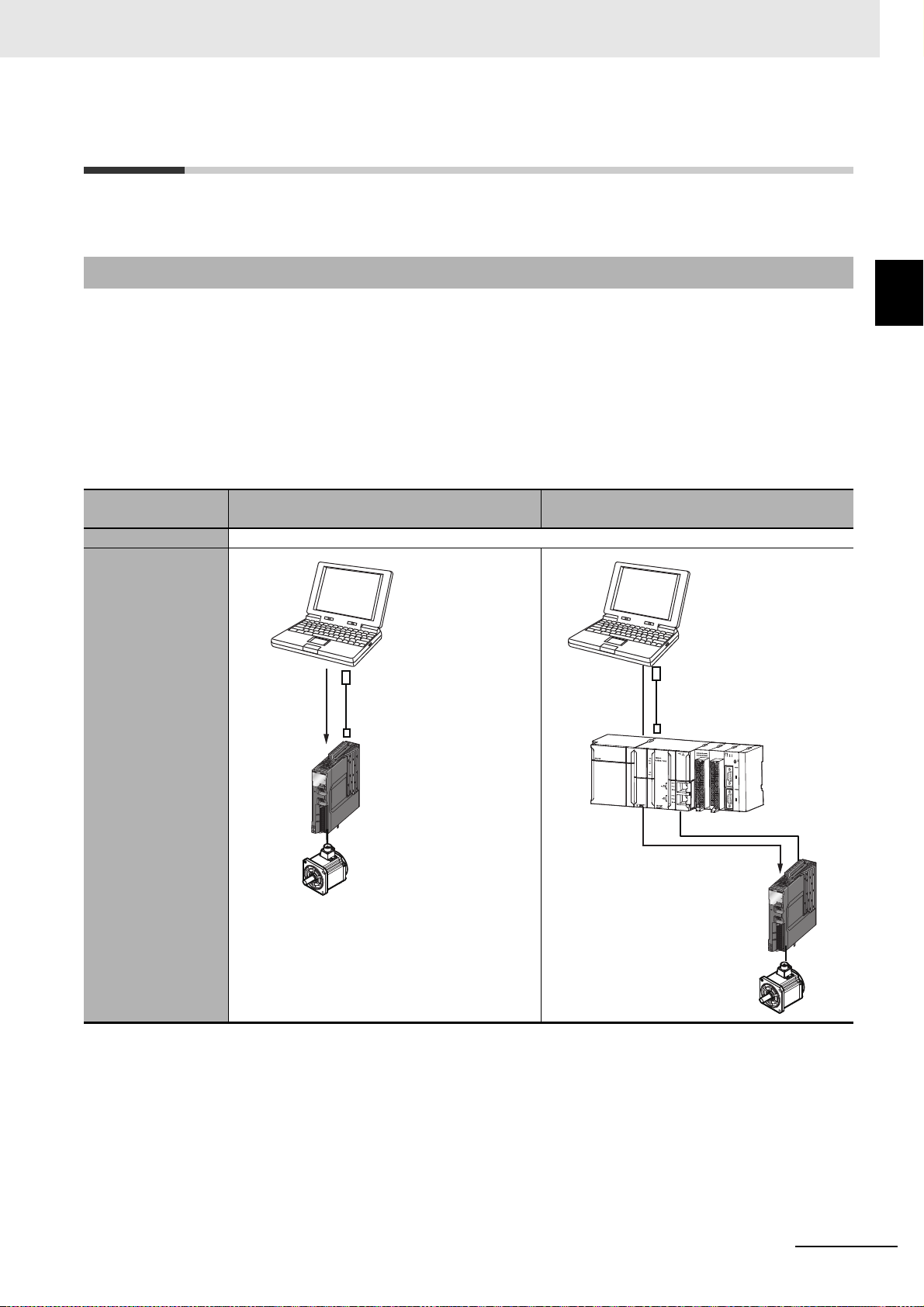

This section describes the system configuration for the functions available when Drive is selected in a

1-2-1 Connection to Drive

Connection method Direct connection via USB

Drive 1S Series and G5 Series

Sysmac Studio project.

Sysmac Studio can be connected to a Drive by the following four methods.

• Direct connection to a Drive via USB

• Connection to a Drive on an EtherCAT network thro

ugh an NJ/NX-series CPU Unit connected via

USB or Ethernet

• Connection to a Drive on an EtherCAT network thro

ugh a Programmable Multi-Axis Controller con-

nected via Ethernet

• Connection to a Drive on an EtherCAT network thro

ugh a CJ-series CPU unit connected via USB or

Ethernet, equiped with a CJ1W-NC8 Position Control Unit

EtherCAT connection via an NJ/NX-series

CPU Unit

1 Sysmac Studio Drive Functions

1-2 System Configuration

1

1-2-1 Connection to Drive

Connection diagram

Sysmac Studio

Commercially available

USB cable *1

Et

R8

her

8

CA

D

T

1

SN

L

/

R

A

U

L

N

/

A

E

R

R

IN

O

U

T

F

S

Drive

*1. Refer to the manuals of each Servo Drive

for the

USB

cable.

Sysmac Studio Drive Functions Operation Manual (I589)

1 - 3

Page 26

1 Sysmac Studio Drive Functions

R

U

N

E

R

R

IN

L

/

A

R

8

8D

-1SN

L

/

A

F

S

O

U

T

Et

her

CA

T

Commercially available

Ethernet cable

Programmable

Multi-Axis

Controller

Sysmac Studio

EtherCAT

Drive

R

U

N

ER

R

IN

L

/A

R88

D-1S

N

L

/A

F

S

OU

T

E

th

e

r

C

A

T

Commercially available USB

cable or Ethernet cable

Sysmac Studio

EtherCAT

Drive

CJ-series

CPU Unit

CJ1W-NC8

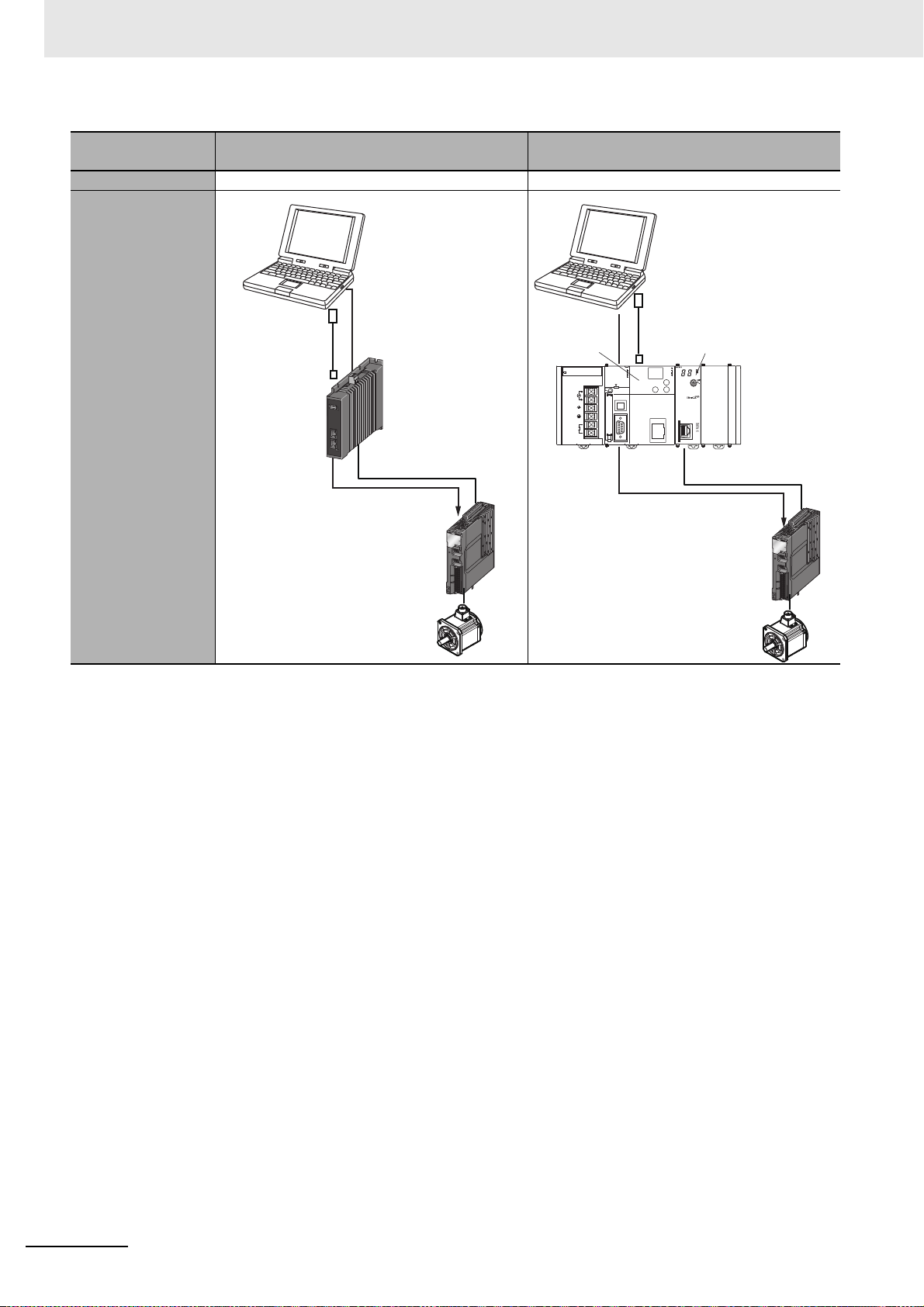

Connection method

EtherCAT connection via a Programmable

Multi-Axis Controller

Drive 1S Series and G5 Series 1S Series

Connection diagram

EtherCAT connection via CJ1W-NC8

Position Controller

Refer to 2-7 Online Connection Procedure on page 2-24 for the online connection procedure with the

Drive.

1 - 4

Sysmac Studio Drive Functions Operation Manual (I589)

Page 27

1 Sysmac Studio Drive Functions

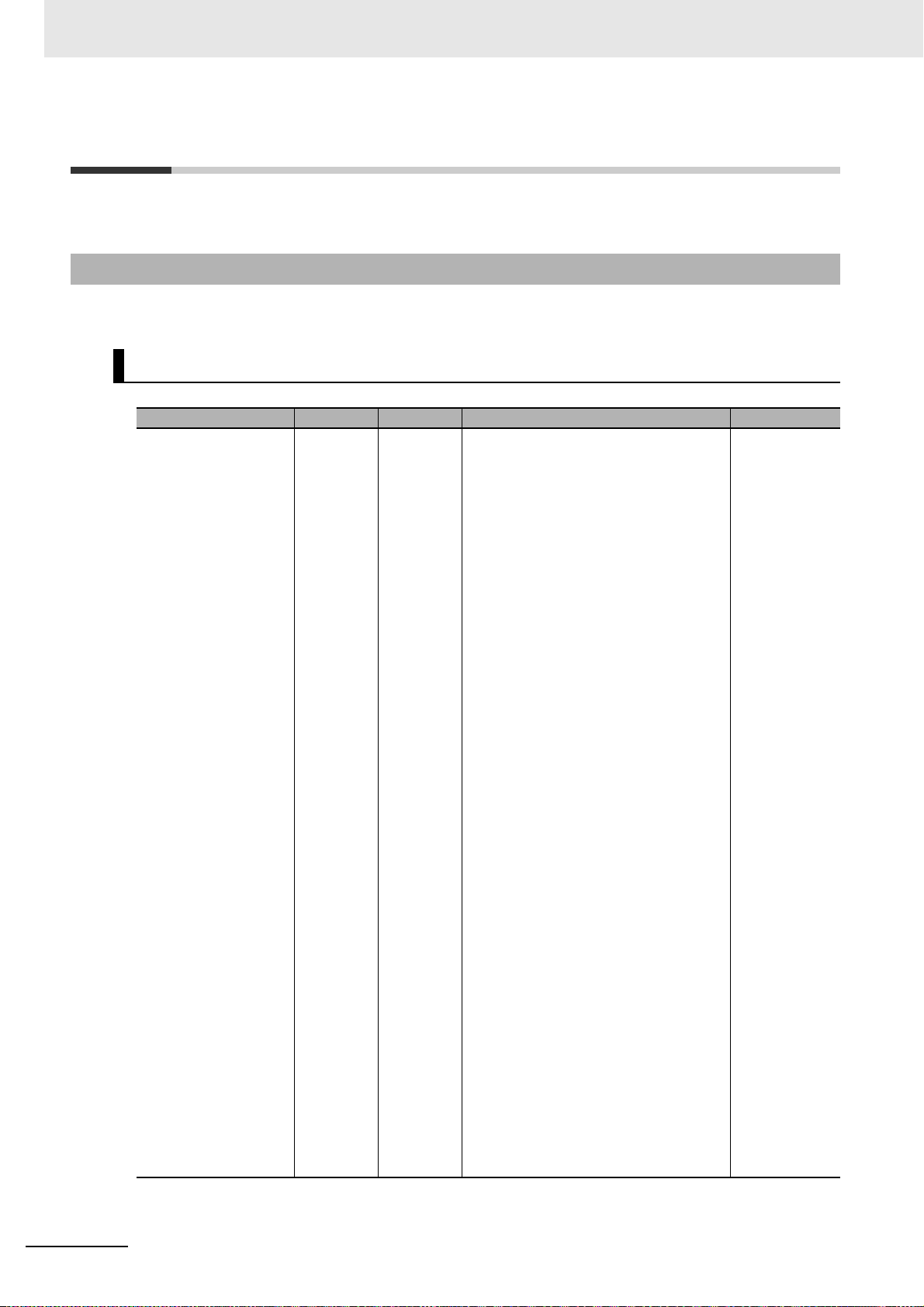

1-2-2 Applicable Drives and Communications Types

Sysmac Studio supports the following Drives. Each Drive supports the communications given in the

Device

cate-

gory

Servo

Drive

table.

Drive

name

AC

Servo

Drive

Linear

Drive

Type Model

1S-series AC

Se

rvomotors and

Servo Drives with

Built-in EtherCAT

Communications

1S-Series AC

Se

rvomotors and

Servo Drives with

Built-in EtherCAT

Communications

and Safety Functionality

G5-series AC

Se

motors and

rvo

Servo Drives with

Built-in EtherCAT

Communications

G5-series Linear

Motors and

S

ervo

Drives with

Built-in EtherCAT

Communications

Communications with Sysmac Studio

EtherCAT

Refer-

ence

manual

Direct

connec-

tion via

tion via an

NJ/NX/NY-

USB

CPU Unit

R88D-1SN-ECT I586 Possible Possible Possible Possible

R88D-1SAN-ECTI621 Possible

R88D-KN-ECT I576 Not possi-

R88D-KN-ECT-L I577 Not possi-

connec-

series

EtherCAT

connec-

tion via

Program-

mable

Multi-Axis

Controller

EtherCAT

connec-

tion via

C

-NC

J1W

8 Posi-

tion Con-

troller

ble

ble

1-2 System Configuration

1

1-2-2 Applicable Drives and Communications Types

Sysmac Studio Drive Functions Operation Manual (I589)

1 - 5

Page 28

1 Sysmac Studio Drive Functions

1 - 6

Sysmac Studio Drive Functions Operation Manual (I589)

Page 29

Overview of the Operations

This section describes the basic drive operation flow and user interfaces of Sysmac

Studio.

2-1 Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-1 1S Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-2 G5 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-2 Installation and Uninstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3 Creating a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-3-1 Using a Drive with an OMRON NJ/NX/NY-series Controller . . . . . . . . . . . . . 2-9

2-3-2 Using a Drive Independently . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-4 Areas of the Application Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-4-1 Overview of the Application Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-4-2 Multiview Explorer . . . . . . . . . . . . . . . . .

2-4-3 Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-5 Project Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2-5-1 Project Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2-5-2 Project Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2-5-3 Import and Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2-6 Functions, Use Cases, and Operation Procedures . . . . . . . . . . . . . . . . . . 2-20

2-6-1 1S Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2-6-2 G5 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2-6-3 Function and Operation Procedures for Each Drive . . . . . . . . . . . . . . . . . . . 2-23

2-7 Online Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 1

Page 30

2 Overview of the Operations

2-1 Basic Operation Flow

This section describes the basic Sysmac Studio operation flows for the Drives.

2-1-1 1S Series

This section gives the basic operation flow for 1S Series.

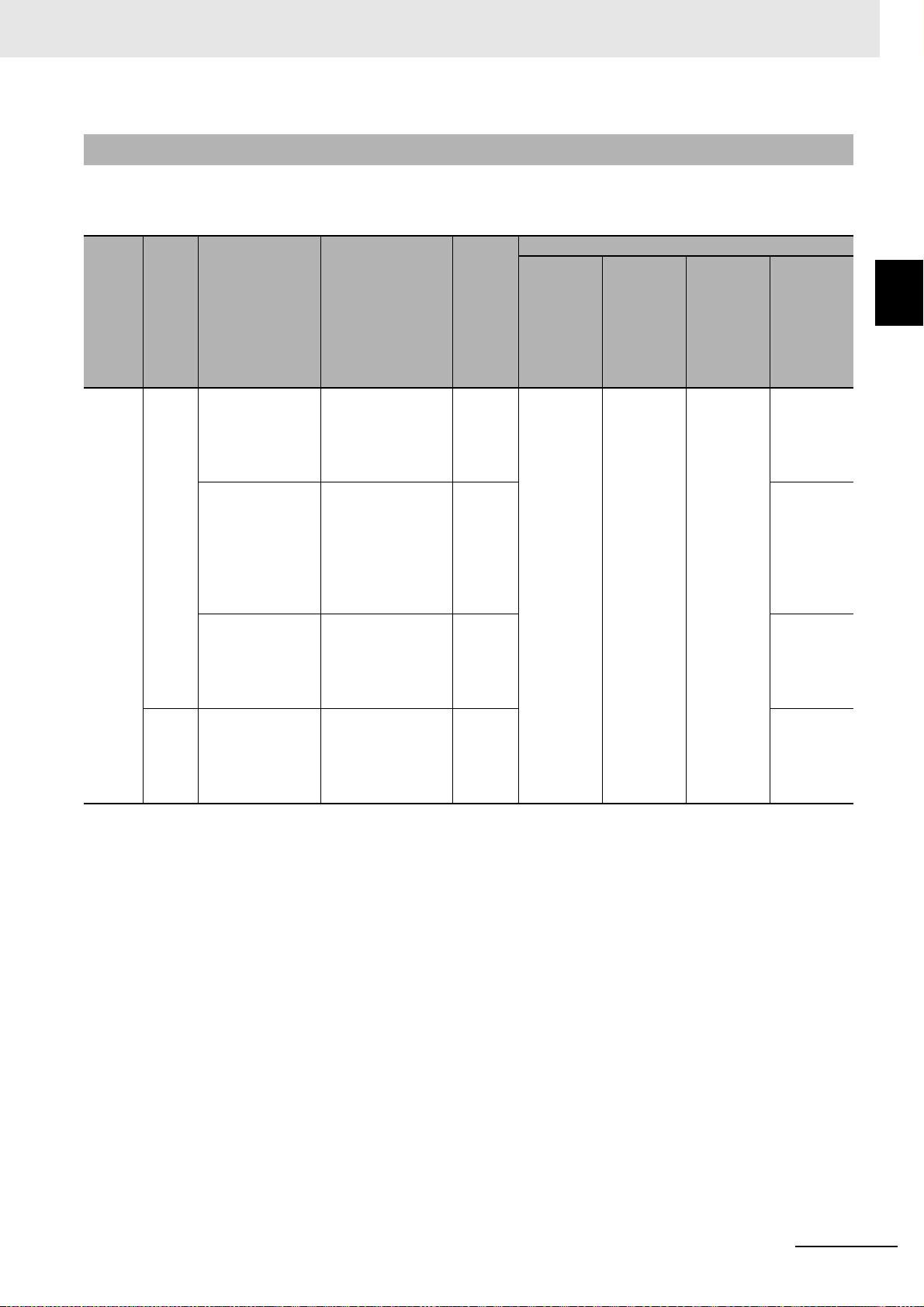

Creating a Project

Procedure Online Offline Operation Reference

Starting Sysmac Studio and creating a new

project o

page.

n the start

Possible Possible • Setup and Tuning for Independent

Drives:

Select New Pr

in the Category field and the applicable

model number in the Device field.

Then, click the Create button.

• Using the Drive with an OMRON

N

J/NX/NY-series Controller:

After creating a project for the Controller, register the applicable model to the

EtherCAT

Sysmac Studio Version 1 Operation

Manual (Cat. No. W504) for details.)

• Using the Drive with an OMRON Programmable Multi-Axis Controller:

Select New Pr

in the Category field and the applicable

model number in the Device field.

Then, click the C

Once the drive project is created,

right-cli

ck on the drive and select Com-

munications Setup fro

Once opened, configure the Remote

connection via Programmable

Multi-Axis Controller (EtherCAT).

• Using the Drive with an OMRON

CJ-serie

CJ1W-NC8 Position Control Unit:

Select New Pr

in the Category field and the applicable

model number in the Device field.

Then, click the C

Once the drive project is created,

right-cli

munications Setup fro

Once opened, configure the Remote

connection via CJ1W-NC[]8[] Position Controller (EtherCAT).

s CPU Unit equiped with

ck on the drive and select Com-

oject, and sel

configuration. (Refer to the

, and select Drive

oject

eate button.

r

oject, and select Drive

eate button.

r

ect Drive

the menu.

m

the menu.

m

2-3 Creating a

Project on page

9

2-

2 - 2

Sysmac Studio Drive Functions Operation Manual (I589)

Page 31

2 Overview of the Operations

Setup and Tuning through Troubleshooting

Procedure

Step

1: Going online/offline with the Drive Possible Possible Select Online or

Online

Offline

Operation Reference

2-7 Online

Offline.

Connection

2-1 Basic Operation Flow

Procedure on

page 2-24

Step

2: Startup --- --- Select Setup and

Tuning.

1. Setup of an absolute encoder Possible --- Select Quick

Par

2. Function assignment to external

I/O si

gnal

s

Possible Possible

ameter Setup

and I/O Monitor

in the Setup and

Tuning wizard.

3-8 Setup and

Tuning Wizard

on page 3-36

3-8-2 Quick

Parameter

Setup and I/O

Monitor on

page 3-37

2

2-1-1 1S Series

3. Test run Possible --- 3-8-3 Test Run

and Function

Status on

page

3-45

4. Tuning

Note Refer to Tuning Method

Possible --- Select Setu

Tuning.

p and

Selection Flow on page

2-5 below for how to

select a tuning method.

Easy Tuning Possible --- Select Easy Tun-

in

g in the Setup

an

d Tuning wiz-

ard.

Advance

d Tuning Possible --- Select Advanced

Tuning in the

Setup and Tuning

3-8-4 Easy

Tuning (Single

Drive) on

page

3-48

4-1 Manual

Tuning on

page

4-2

wizard.

Ma

nual Tuning Possible --- Select Manual

Tu

ng in the

ni

Setup and Tuning

wizard.

Step

3: Detailed Settings and Tuning

1. Editing the parameters (except

for the

function assignment to

external I/O signals)

Possible Possible Double-click

Par

ameters.

3-1 Displaying

and Editing

Parameters on

page 3-2

2. Test run Possible --- Select T

est Run. 3-3 T

est Run

on page 3-18

3. Data tracing Possible --- Right-click Data

Trace Settings

and select Add -

3-6 Data Tracing o

n page

3-24

Data Trace from

the menu. Then,

double-click the

data trace created.

4. FF

T (Fast Fourier Transform)

analysis

Possible --- Double-click FFT. 4-2-1 FFT on

page 4-19

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 3

Page 32

2 Overview of the Operations

Procedure

5. Damping control Possible --- Select Damping

Step

4: Status monitoring and trouble-

shooting

Online

Possible --- Select Status

Offline

Operation Reference

Control.

Monitor or Troubleshooting.

4-2-2 Damping

Control on

page 4-23

3-4 Status

Monitor on

p

age 3-22

3-5 Troubleshooting on

p

age 3-23

2 - 4

Sysmac Studio Drive Functions Operation Manual (I589)

Page 33

2 Overview of the Operations

Yes

Save to non-volatile memory

Auto tuning?

Operation OK?

Tuning through

simulation?

Operation OK?

Tuning start

Tuning complete

Easy tuning

Easy tuning

Manual tuning

Advanced tuning

Adjust each gain in the

Parameters tab page.

No

Manual tuning Fine tuning

Yes

No

Yes

No

Yes

No

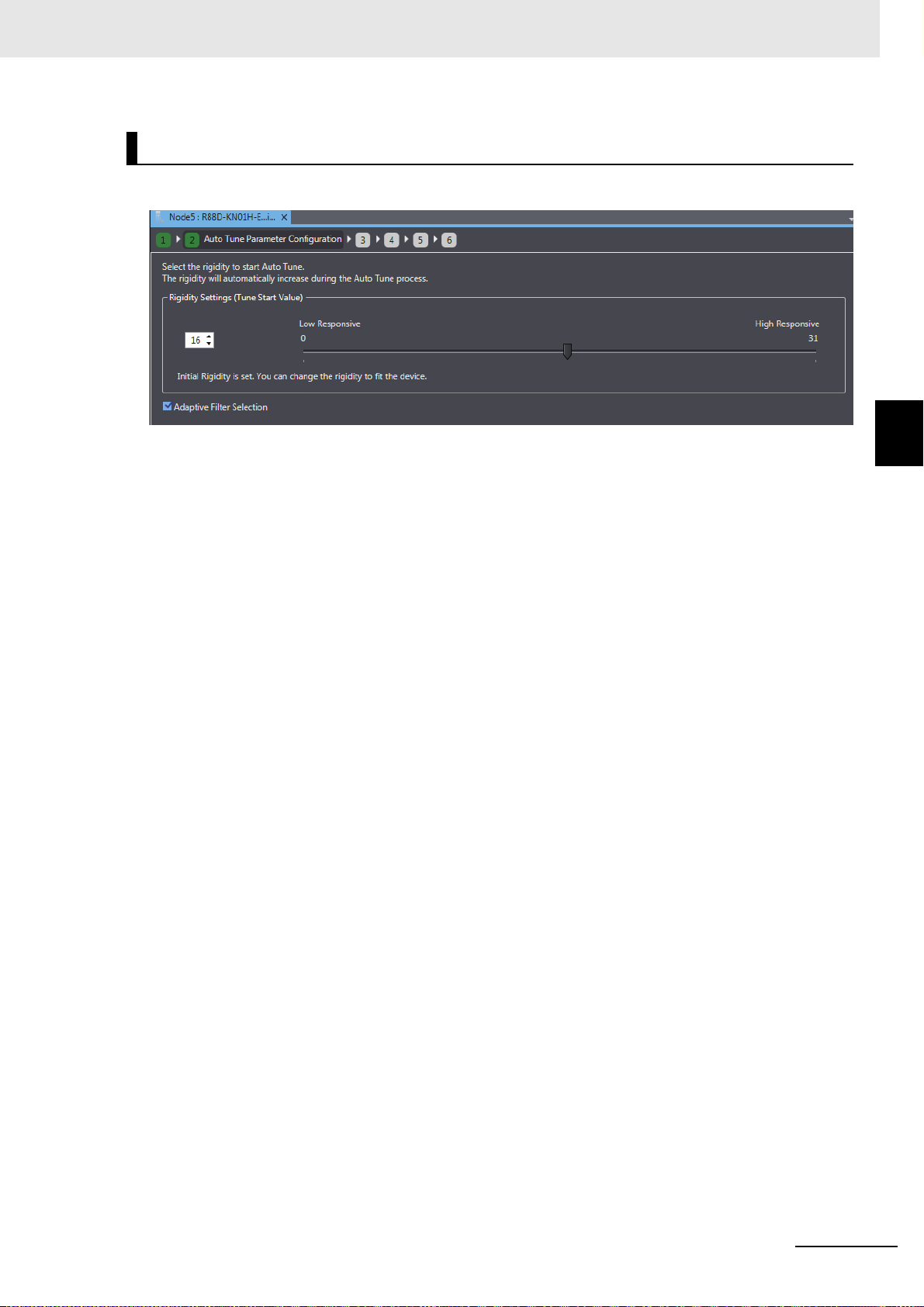

Tuning Method Selection Flow

Follow this flow to select a tuning method.

2-1 Basic Operation Flow

2

2-1-1 1S Series

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 5

Page 34

2 Overview of the Operations

2-1-2 G5 Series

Creating a Project

Procedure Online Offline Operation Reference

This section gives the basic operation flow for G5 Series.

Starting Sysmac Studio and creating a project on the start page.

Possible Possible • Setup and Tuning for Independent

Drives:

Select New Pr

oject, and sel

ect Drive

in the Category field and the applicable

model number in the Device field.

Then, click the Create button.

• Using the Drive with an OMRON

N

J

/NX/NY-series Controller:

After creating a project for the Controller, register the applicable model to the

EtherCAT

configuration. (Refer to the

Sysmac Studio Version 1 Operation

Manual (Cat. No. W504) for details.)

• Using the Drive with an OMRON Programmable Multi-Axis Controller:

Select New Pr

oject, and select Drive

in the Category field and the applicable

model number in the Device field.

Then, click the C

reate button.

Once the drive project is created,

right-cli

ck on the drive and select Com-

munications Setup fro

the menu.

m

Once opened, configure the Remote

connection via Programmable

Multi-Axis Controller (EtherCAT).

2-3 Creating a

Project on page

2-

9

2 - 6

Sysmac Studio Drive Functions Operation Manual (I589)

Page 35

2 Overview of the Operations

Setup and Tuning through Troubleshooting

2-1 Basic Operation Flow

Procedure Online Offline Operation Reference

Step 1: Going online/offline with the Drive

To be also executed in the subsequent

steps as

necessary.

Possible Possible

Select Online

Offline.

*1

or

2-7 Online

Connection

Procedure on

page 2-24

Step 2: Editing the parameters Possible Possible Double-click

Param

ters.

e

3-1 Displaying

and Editing

Parameters on

Step 3: Test run

Possible --- Select Test Run. 3-3 Test Run

(To be also executed in the subsequent

steps as

necessary)

Step 4: Setup of an absolute encoder Possible --- Select M

Encoder.

Step 5: Data tracing (To be also executed in the

subsequent steps as necessary)

Possible --- Right-click Data

Trace Settings

and select Add -

otor and

page 3-2

on page 3-18

tors and

3-7 Mo

Encoders on

pa

ge 3-34

3-6 Data Tracing o

n page

3-24

2

2-1-2 G5 Series

Data Trace from

the menu. Then,

double-click the

data trace created.

Step 6: Auto tu

ning

Easy tuning

Possible --- Select Auto Tun-

ing.

3-2-2 Auto Tuning for G5

Series on p

age

3-12

Step 7: FFT (Fast Fourier Transform) analysis

and d

amping control, as necessary

Possible --- Double-click FFT.

Select Damping

4-2-1 FFT on

page 4-19

Control.

Step 8: Status monitoring (To be also executed

in the earl

er steps as necessary) and

i

troubleshooting

Possible --- Select St

itor or Troubl

shooting.

atus Mon-

e-

3-4 Status

Monitor on

page 3-22

3-5 Troubleshooting on

page 3-23

*1. In the EtherCAT connection via an NJ/NX/NY-series CPU Unit, when Sysmac Studio goes online with the CPU

Unit, the online status with each Drive is established automatically.

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 7

Page 36

2 Overview of the Operations

2-2 Installation and Uninstallation

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

2 - 8

Sysmac Studio Drive Functions Operation Manual (I589)

Page 37

2-3 Creating a Project

Precautions for Correct Use

This section describes how to create a project including Drives in Sysmac Studio.

Use the following two methods to register a Drive to a project in Sysmac Studio.

• Registering a Drive as an EtherCAT slave in a project

• Registering an independent Drive in a project

2 Overview of the Operations

2-3 Creating a Project

2-3-1 Using a Drive with an OMRON NJ/NX/NY-series Controller

When you use a Drive with an OMRON NJ/NX/NY-series Controller, you register the Drive as an EtherCAT slave in a project. Register the applic

project.

able Drive to the EtherCAT configuration in the Controller

1 When creating a new project, select Controller in the Category field of the Select Device area.

Then, select an NJ/NX/NY-series CPU Unit in the Device field.

Or, add a Controller to an existing project and select

an NJ/NX/NY-series CPU Unit as Device.

2 Select the Controller that was registered in the previous step and register the applicable Drive in

the EtherCAT configuration tab page.

n

Refer to 2-5 Project Data o

project. Refer to EtherCAT Co

(Cat. No. W504) for details of the registration in the EtherCAT configuration tab page.

page 2-17 for positioning of the drive-related data in the Sysmac Studio

nfiguration and Setup of the Sysmac Studio Version 1 Operation Manual

Changing the Model of a Drive

You can change the model of a registered Drive.

1 Right-click a Drive on the EtherCAT Tab Page and select Change Model.

The Drives that you can change to are displayed in the Change Model dialog box.

2

2-3-1 Using a Drive with an OMRON NJ/NX/NY-series Controller

2 Select the Drive to change to and then click the OK button.

A dialog box that alerts you to the change o

3 Click the OK button.

The Drive is changed to the selected model and unit version.

• For G5-series unit version earlier than 2.0 (excluding Linear Servo Drives) and between different types of Servo Drives, you ca

• Any settings in the Drive before the change that are not supp

change will be lost when you change the model.

Sysmac Studio Drive Functions Operation Manual (I589)

f the model is displayed.

nnot change the model.

orted by the Drive after the

2 - 9

Page 38

2 Overview of the Operations

2-3-2 Using a Drive Independently

An independent Drive is registered to the Drive group in a project. Use the following two methods for

registration:

• Selecting Drive in the Category field of the Selec

• Adding the Driv

e to an existing project

t Device area when you create a new project

Refer to 2-5 Project Data on

page 2-17 for positioning of the drive-related data in the Sysmac Studio

project.

Refer to the Sysmac

Studio Version 1 Operation Manual (Cat. No. W504) for basic operations of Sys-

mac Studio.

Selecting a Drive as a Device when Creating a New Project

When creating a new project file, select a Drive as a device.

1 Click the New Project button in the project window.

2 In the Project Properties dialog box, enter values in the Project name, Author (optional) and

Comment (optional) fields and select the following in the Category and Device fields in the

Select Device area.

Field Item to select

Category Drive

Device Applicable Drive model

2 - 10

Note When the computer with Sysmac Studio running is directly connected to a Drive via USB, a new project

can be automatically created for the connected Drive. To do so, click the Connect to Device button

without opening a project in the above start page of Sysmac Studio. Refer to Going Online from the

Start Page of Sysmac Studio on pa

details.

ge 2-26 of 2-7 Online Connection Procedure on page 2-24 for

Sysmac Studio Drive Functions Operation Manual (I589)

Page 39

2 Overview of the Operations

3 Click the Create button at the bottom right of the Select Device area.

A new project is created and the following window is

displayed.

2-3 Creating a Project

2

2-3-2 Using a Drive Independently

Adding a Drive to an Existing Project

1 Select Drive from the Insert menu in the main menu bar.

Or, right-click Devi

ce Group in the Multiview Explorer and select Add from the menu.

2 The following Add Device dialog box is displayed. Select the applicable model number.

3 Click the OK button. The selected Drive is registered.

Changing the Model of a Registered Drive

1 Right-click a registered Drive and select Change Device from the menu.

2 The drive selection dialog box is displayed. Change the Drive to the model that you want to set.

3 Click the OK button. If the following dialog box is displayed, confirm that no problem will occur,

and then click the Yes Button.

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 11

Page 40

2 Overview of the Operations

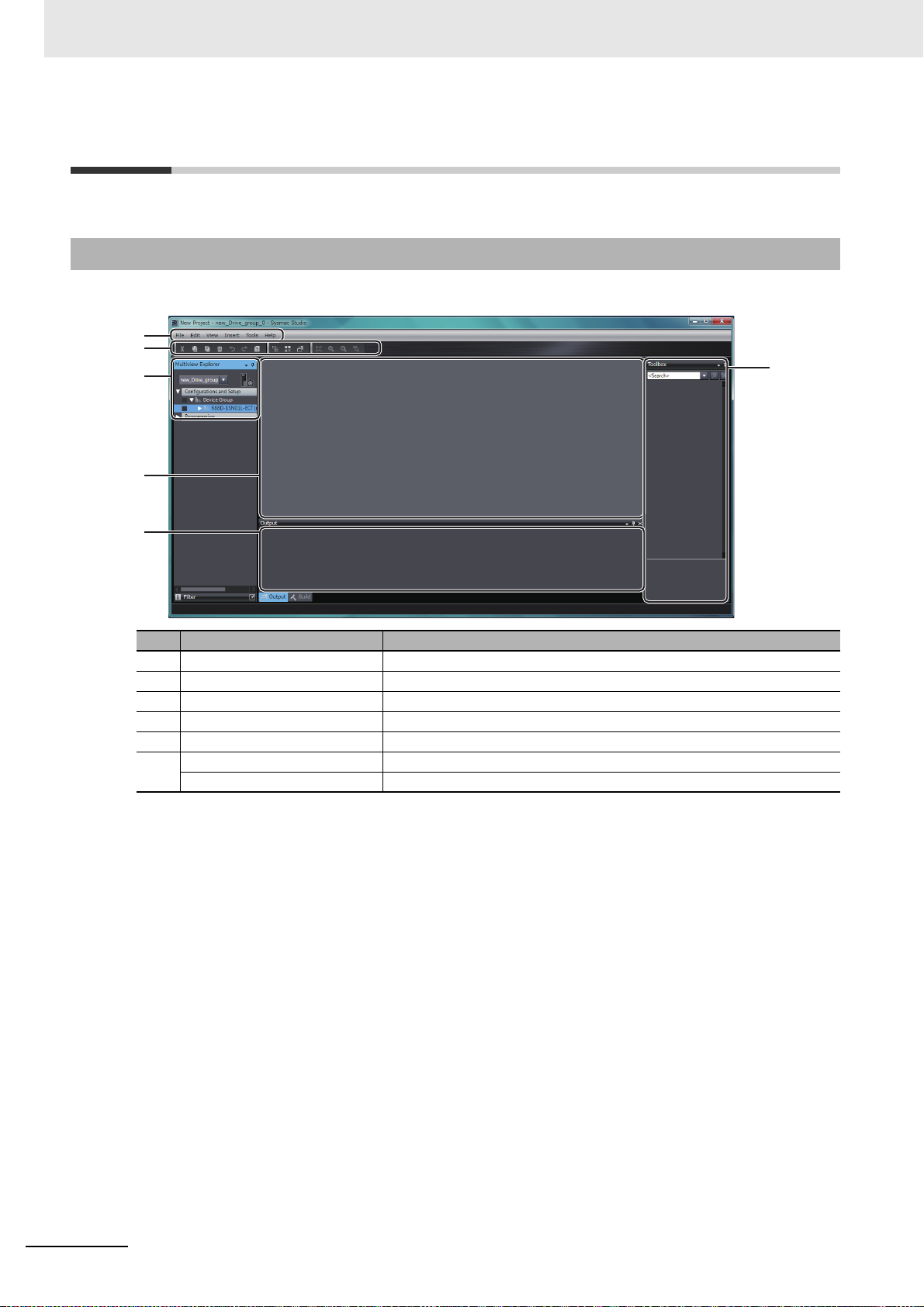

(a)

(b)

(c)

(f)

(d)

(e)

2-4 Areas of the Application Window

This section gives the names of the parts specific to Sysmac Studio.

2-4-1 Overview of the Application Window

When you open a project, the following application window is displayed.

No. Name Description

(a) Menu bar Menu names are displayed in this bar.

(b) Toolbar Buttons and icons are displayed in this bar.

(c) Multiview Explorer This pane is your access point

(d) Edit pane The edit pane is used to display and edit the data for any of the items.

(e) Output tab page Operation execution status and errors are displ

(f) Toolbox Not used.

Properties pane The data trace and FFT properties are displayed in this pane.

for all Sysmac

Studio data.

a

yed in this tab page.

2 - 12

Sysmac Studio Drive Functions Operation Manual (I589)

Page 41

The following context

menu is displayed by

right-clicking a Drive.

2-4-2 Multiview Explorer

2 Overview of the Operations

2-4 Areas of the Application Window

Drive Display Position and Method

This pane is your access point for all Drive data.

Drives Independently Registered in the Project

For each Drive, its model number is displayed under Configurations and Setup - Device Group.

Drives Registered as EtherCAT Slaves in the Project

For each Drive, its node address, and model number followed by the Drive name in parentheses are

displayed under Configurations and Setup - EtherCAT.

2

2-4-2 Multiview Explorer

Operation Procedure for Each Function

The operation procedure of Sysmac Studio differs according to the functions.

Category

Functions executed from the

Multiview

Explore

r

Functions (item name/menu

name)

• Parameters

•FFT

• Data Trace Settings

Operation

Select an item from the tree structure in the Multiview

Expl

orer.

nctions exe-

Fu

cuted from the

context men

• Setup and Tuning (1S Series

*1

• Auto Tuning (G5 Series only

u

• Troubleshooting

• Status Monitor

• Motor and Encoder

•Test Run

• Damping Control

•Initialize

• Properties

only)

(both th

and linear motor type))

servomotor type

e AC

The following items

are displayed in the

Multiview Explorer.

· Parameters

· FFT

· Data Trace Settings

Right-click the Drive and select a command from the

menu.

Sysmac Studio Drive Functions Operation Manual (I589)

Refer to the following page for the differences between

Dri

v

e types.

2 - 13

Page 42

2 Overview of the Operations

Drive type 1S Series

G5 Series (Except for linear

motor type)

G5 Series (Linear motor

type)

Registered as

an EtherCAT

slave in the

project

Registered

independently in the

project

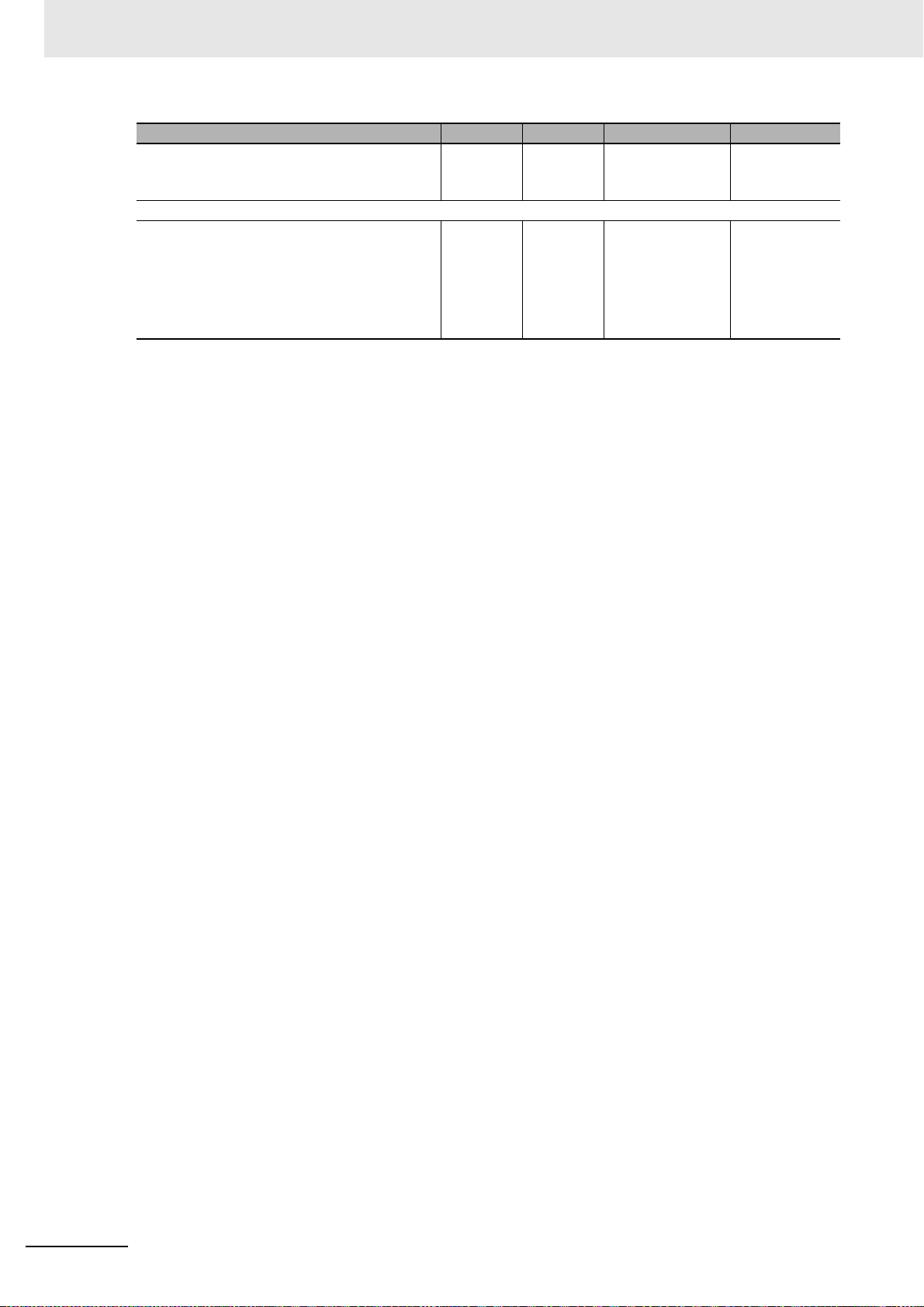

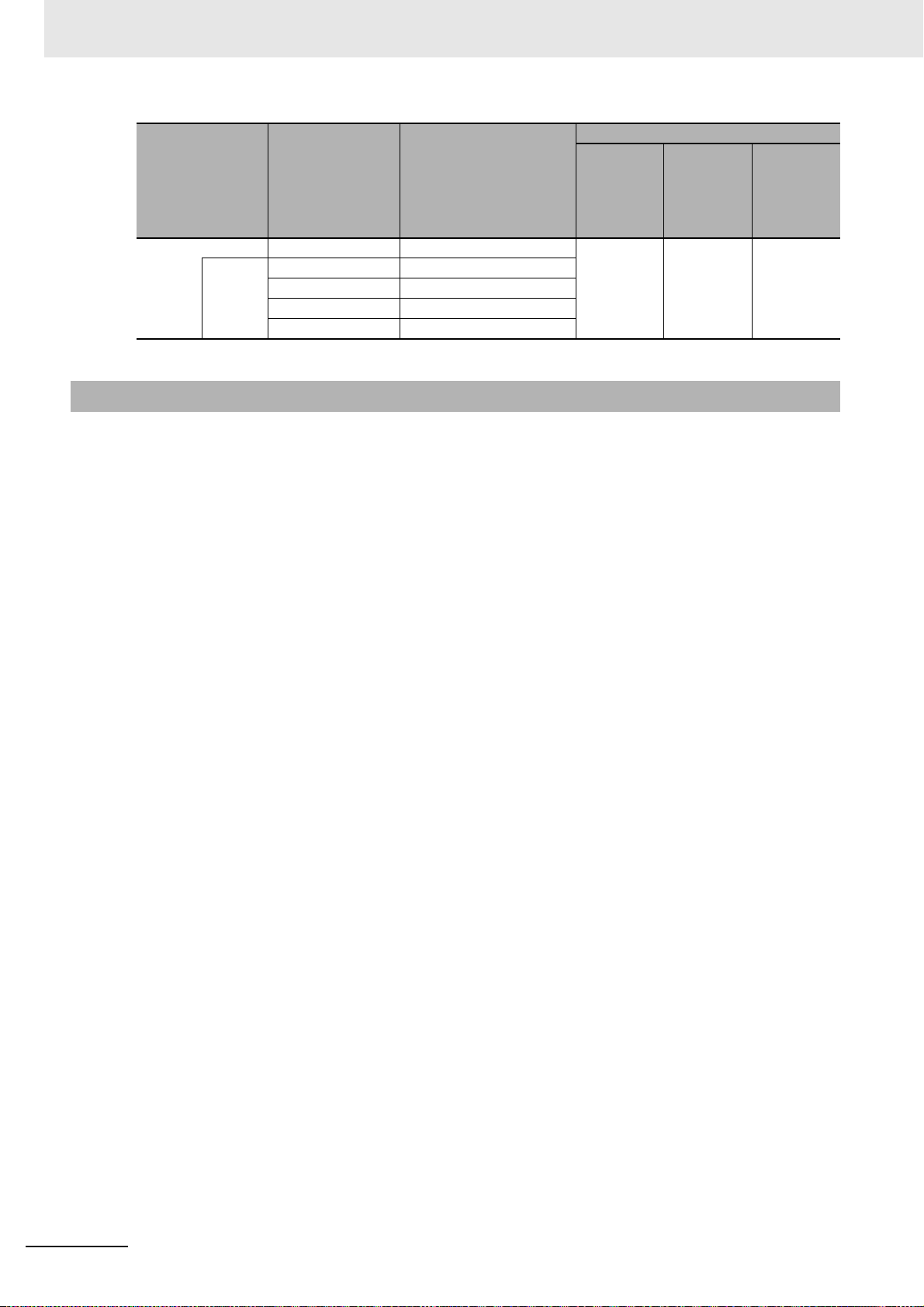

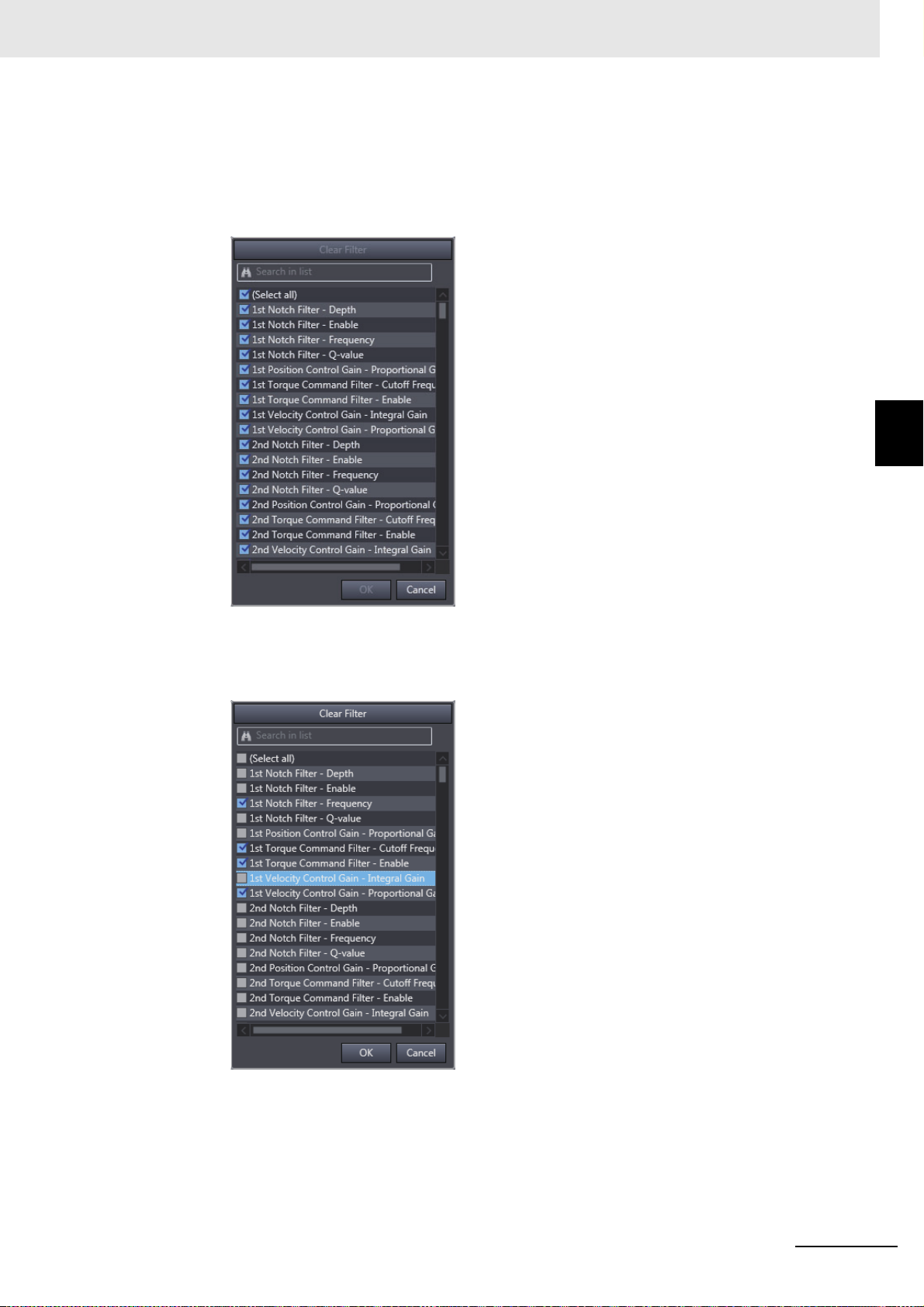

*1. Context menu displayed by right-clicking each Drive type

The context menu displayed by right-clicking each Drive differs by the Drive types as shown below.

The displayed menu also differs according to how the Drive is registered in the project, i.e., whether the Drive

is registered as an EtherCAT slave or the Drive is independently registered in the project.

2 - 14

Sysmac Studio Drive Functions Operation Manual (I589)

Page 43

2 Overview of the Operations

2-4 Areas of the Application Window

Right-click Menu Variation

Drive type

Item selected in

the Multiview

Explorer

Right-click menu Description

1S Series

Servo Drive Delete Deletes the Servo Drive. Available Available Available

Rename Changes the name of the

S

e

rvo Drive.

Available Available Available

Change Device Changes the device. Available Available Available

Setup and Tuning Performs the quick param-

Available Not availeter setup, I/O monitoring, and tuning easily.

Auto Tuning Invokes the auto tuning

fun

c

tion.

Motor Setup Sets the parameters

re

lated to the linear motor.

Troubleshooting Invokes the troubleshoot-

Not avail-

able

Not avail-

able

Available Available Available

ing function.

Status Monitor Invokes the status monitor

Available Available Available

function.

Motor and Encoder Sets up an absolute

Available Available Not availencoder.

Displa

ys the properties of

the Servomotor.

Test Run Starts a test run. Available Available Available

Damping Control Invokes the damping con-

Available Available Available

trol function.

Initialized Invokes the initialize func-

Available Available Available

tion.

Properties Displays the properties of

e Servo Drive.

th

Print Prints the Drive parame-

Available Available Available

Available Available Available

ter settings, FFT, and data

traces

.

Online/Offline Goes online with the con-

Available Available Available

nected Servo Drive.

Direct connection

(USB)

Directly connects to the

Drive th

rough a USB

Available Available Available

cable. This menu command can be executed

when

the Drive is regis-

tered as an EtherCAT

Communications

Setup

sl

ave in the proj

Configures connection

type and settings. This

ect.

Available Available Available

menu command can be

executed when the Drive

is independently registered in the project.

Parameters Edit Edits the parameters. Available Available Available

FFT Edit Invokes the FFT fu

nct

ion. Available Available Available

G5 Series

(Except for

linear

motor

type)

G5 Series

(Linear

motor

type)

Not avail-

able

able

Available Available

Not avail-

Available

able

able

2

2-4-2 Multiview Explorer

Sysmac Studio Drive Functions Operation Manual (I589)

2 - 15

Page 44

2 Overview of the Operations

Item selected in

the Multiview

Explorer

Data

Trace

Settings

Data

Trace

Right-click menu Description

Add - Data Trace Adds a data trace. Available Available Available

Edit Edits a data trace.

Cut Cuts a data trace.

Copy Copies a data trace.

Delete Deletes a data trace.

2-4-3 Toolbar

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for details.

1S Series

Drive type

G5 Series

(Except for

linear

motor

type)

G5 Series

(Linear

motor

type)

2 - 16

Sysmac Studio Drive Functions Operation Manual (I589)

Page 45

2-5 Project Data

Project data

Data related to NJ/NX/NY

-series Controllers

(Controller group)

Data related to FH Sensor

Controllers

(Vision Sensor group)

Data related to Drives

(Drive group)

Data related to other devices

such as Slave Terminals

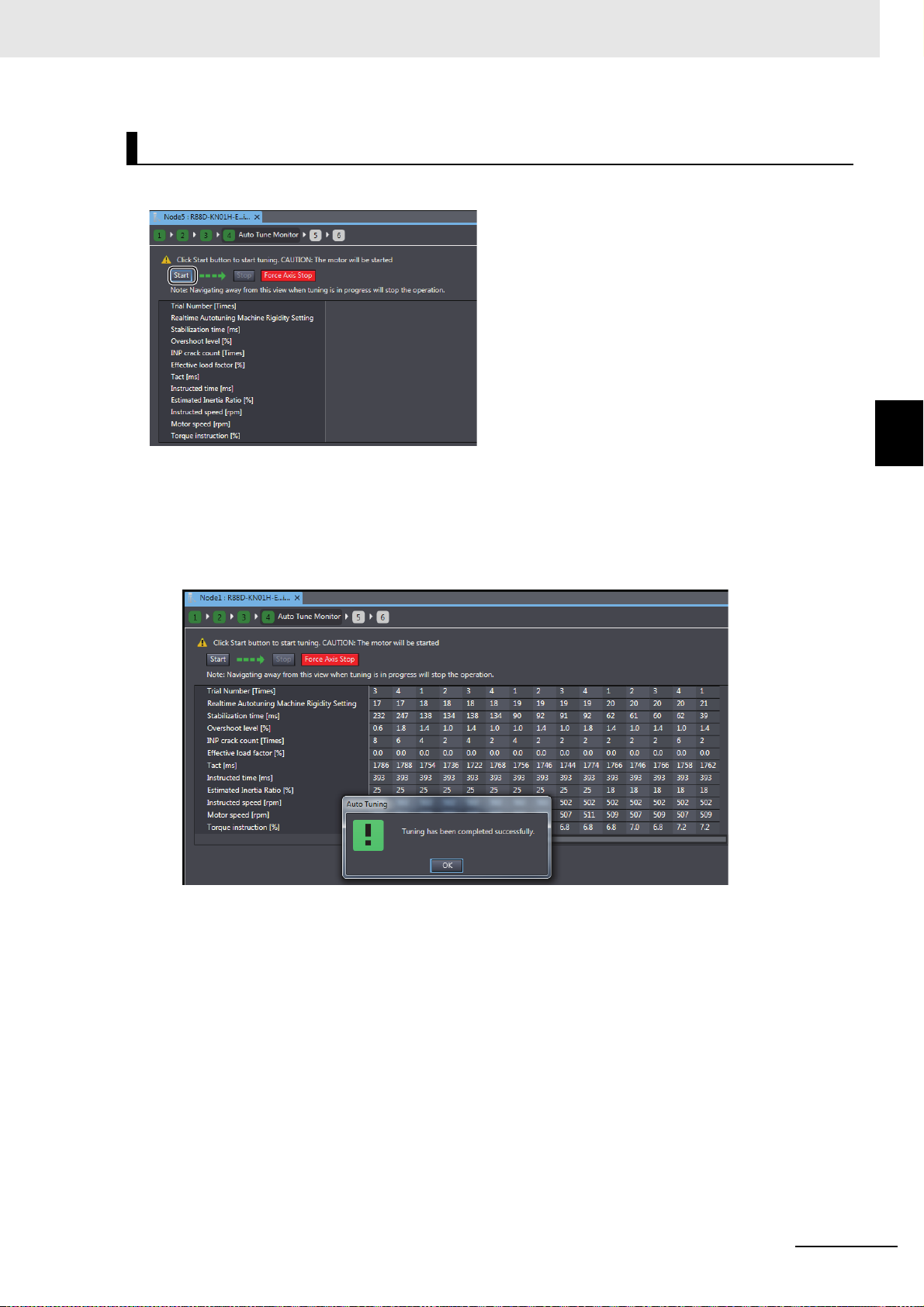

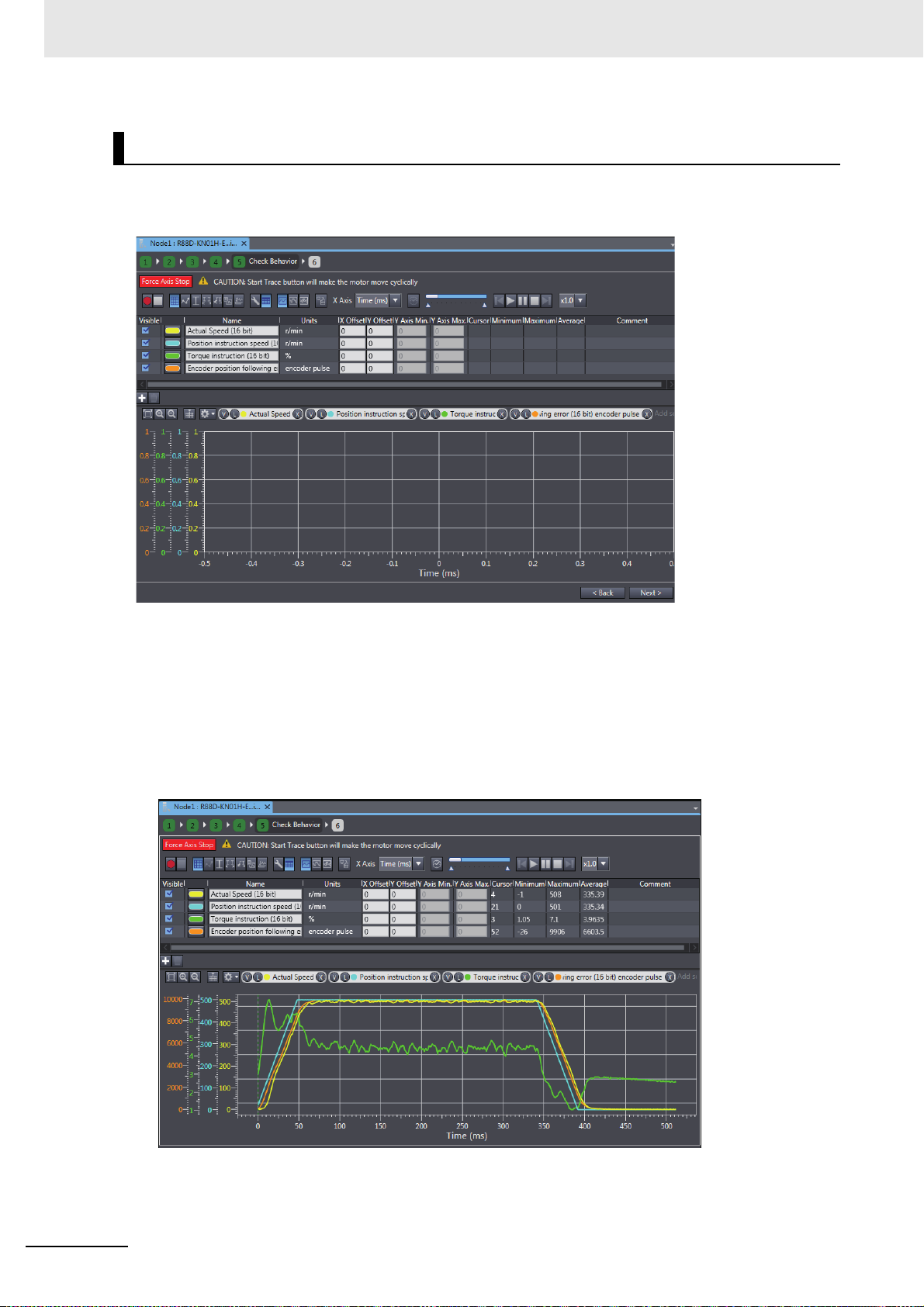

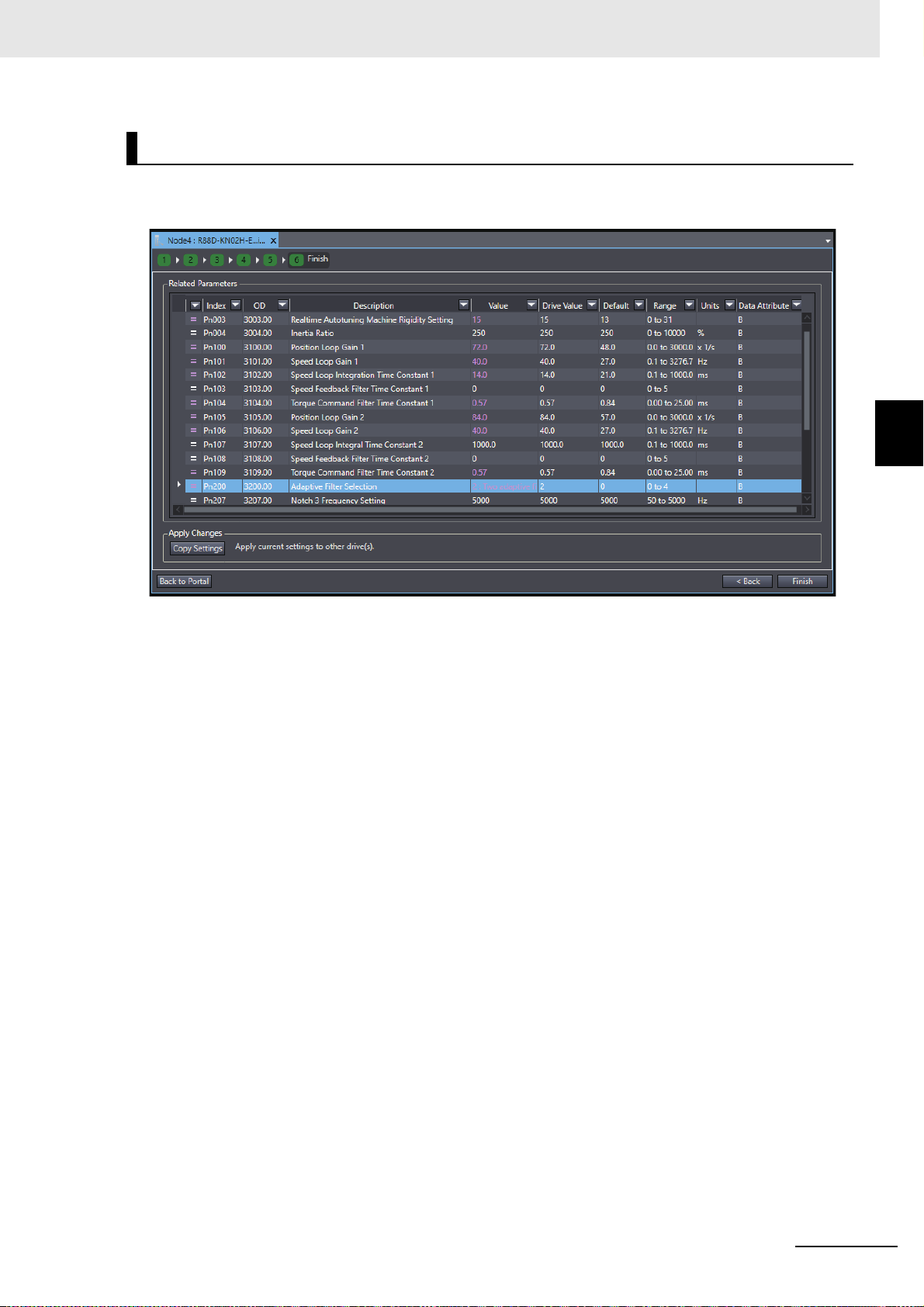

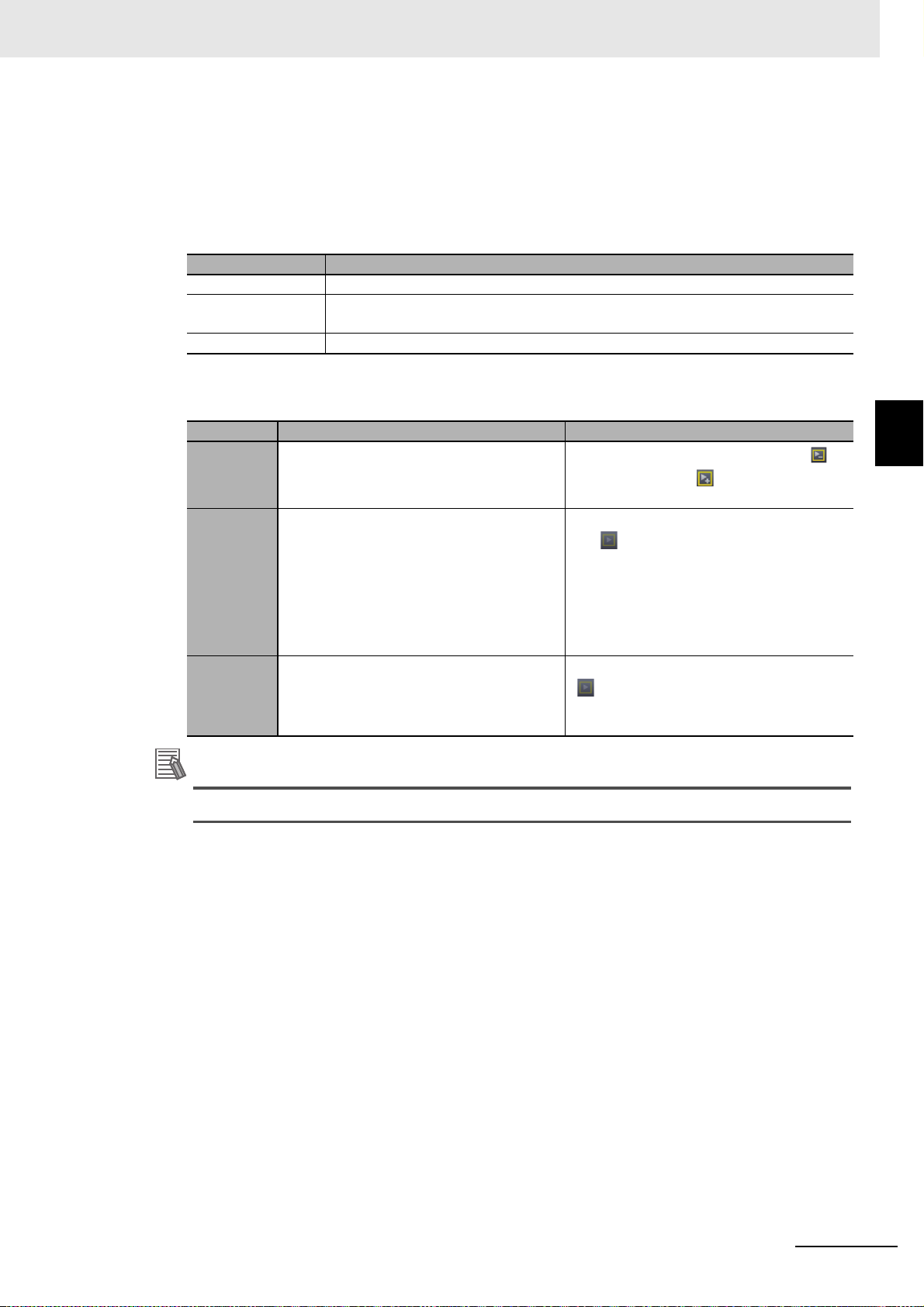

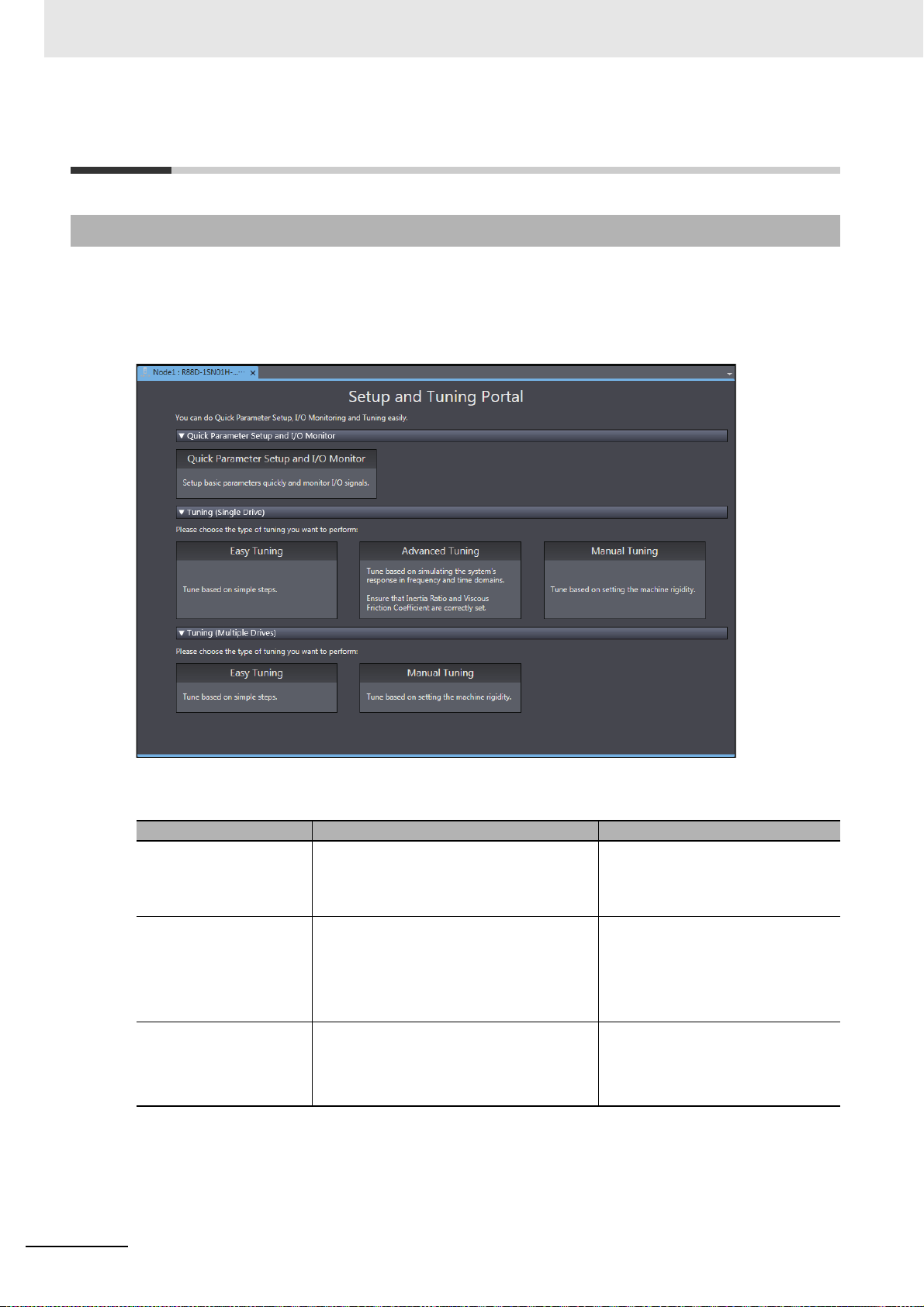

2 Overview of the Operations