Omron Sysmac NY-, Sysmac NY512-1400, Sysmac NY512-1300, Sysmac NY532-1500, Sysmac NY532-1400 Installation Manual

...Page 1

Industrial PC Platform

-series

NY

Motion Control Instructions Reference Manual

NY532-1500

NY532-1400

NY532-1300

NY512-1500

NY512-1400

NY512-1300

W561-E1-05

Page 2

NOTE

1. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the prior written permission of OMRON.

2. No patent liability is assumed with respect to the use of the information contained herein.

Moreover

mation contained in this manual is subject to change without notice.

3. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON as-

sumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

, because OMRON is constantly striving to improve its high-quality products, the infor-

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Microsoft, Windows, Excel, and V

crosoft Corporation in the United States and other countries.

• EtherCAT

GmbH, Germany.

®

is registered trademark and patented technology, licensed by Beckhoff Automation

isual Basic are either registered trademarks or trademarks of Mi-

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• Intel and Intel Core are trademarks of Intel Corporation in the U.S. and / or other countries.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

• This product incorporates certain third party software. The license and copyright information associ-

ated with this software is available at

http://www.fa.omron.co.jp/nj_info_e/.

Page 3

Introduction

Thank you for purchasing an NY-series IPC Machine Controller Industrial Panel PC / Industrial Box

PC.

In this manual, the Industrial Panel PCs and Industrial Box PCs may be collectively referred to as “NY-

series Industrial PCs”. In this manual, the range of devices that are directly controlled by the Controller

functions embedded in the Real-Time OS in the NY-series Industrial PC may be expressed as the

Controller.

This manual describes the motion control instructions. Please be sure that you sufficiently understand

the operations and handling procedures, and use the Motion Control Function Module (abbreviated as

“MC Function Module”) correctly.

Use this manual together with user's manuals for the NY-series Controller.

When you have finished reading this manual, keep it in a safe location where it will be readily available

for future use.

Introduction

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Applicable Products

This manual covers the following products.

• NY-series IPC Machine Controller Industrial Panel PC

• NY532-15££

• NY532-14££

• NY532-13££

• NY532-5400

• NY-series IPC Machine Controller Industrial Box PC

• NY512-15££

• NY512-14££

• NY512-13££

Part of the specifications and restrictions for the products may be given in other manuals.

Refer to Relevant Manuals on page 2 and Related Manuals on page 22.

NY-series Motion Control Instructions Reference Manual (W561)

1

Page 4

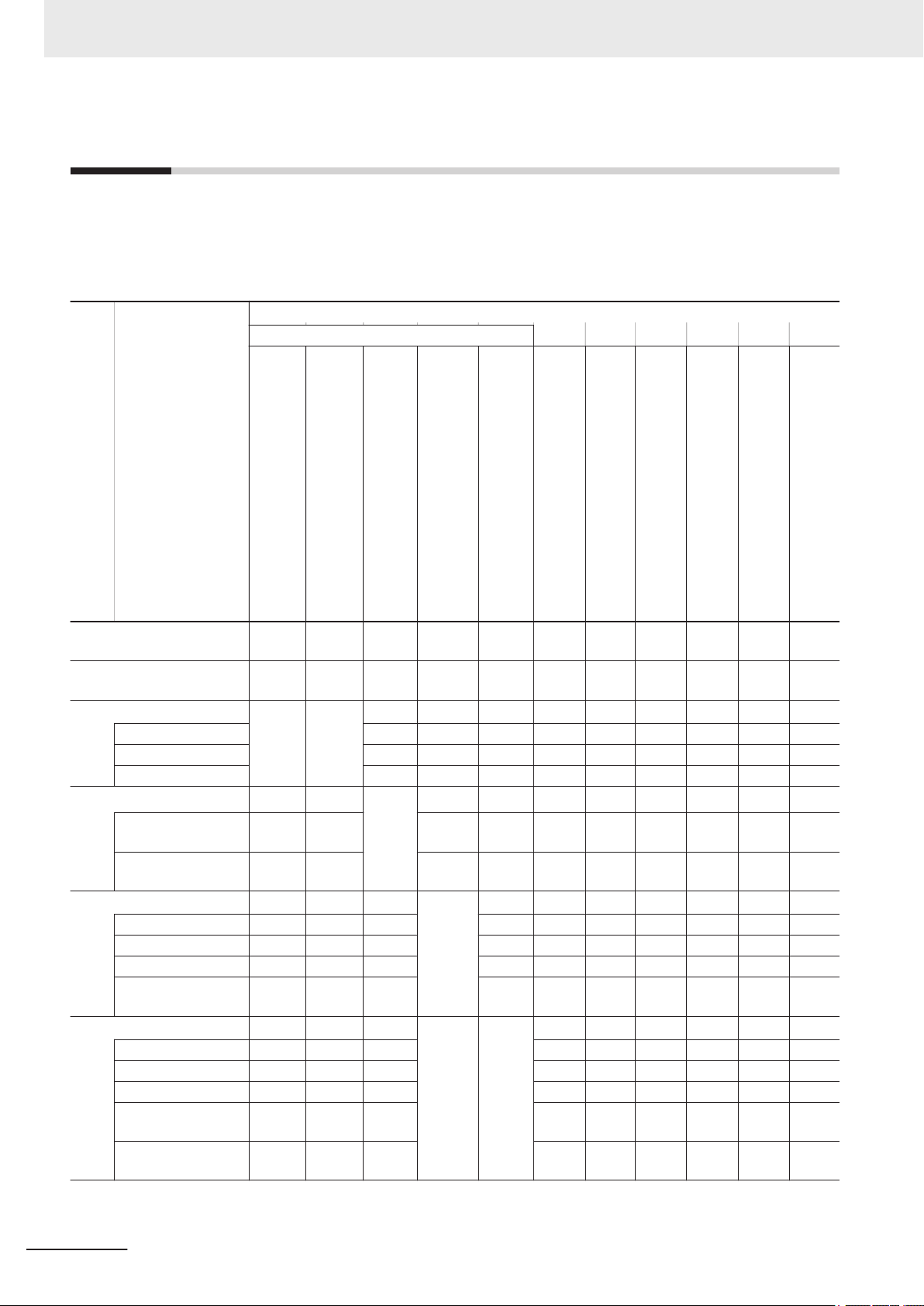

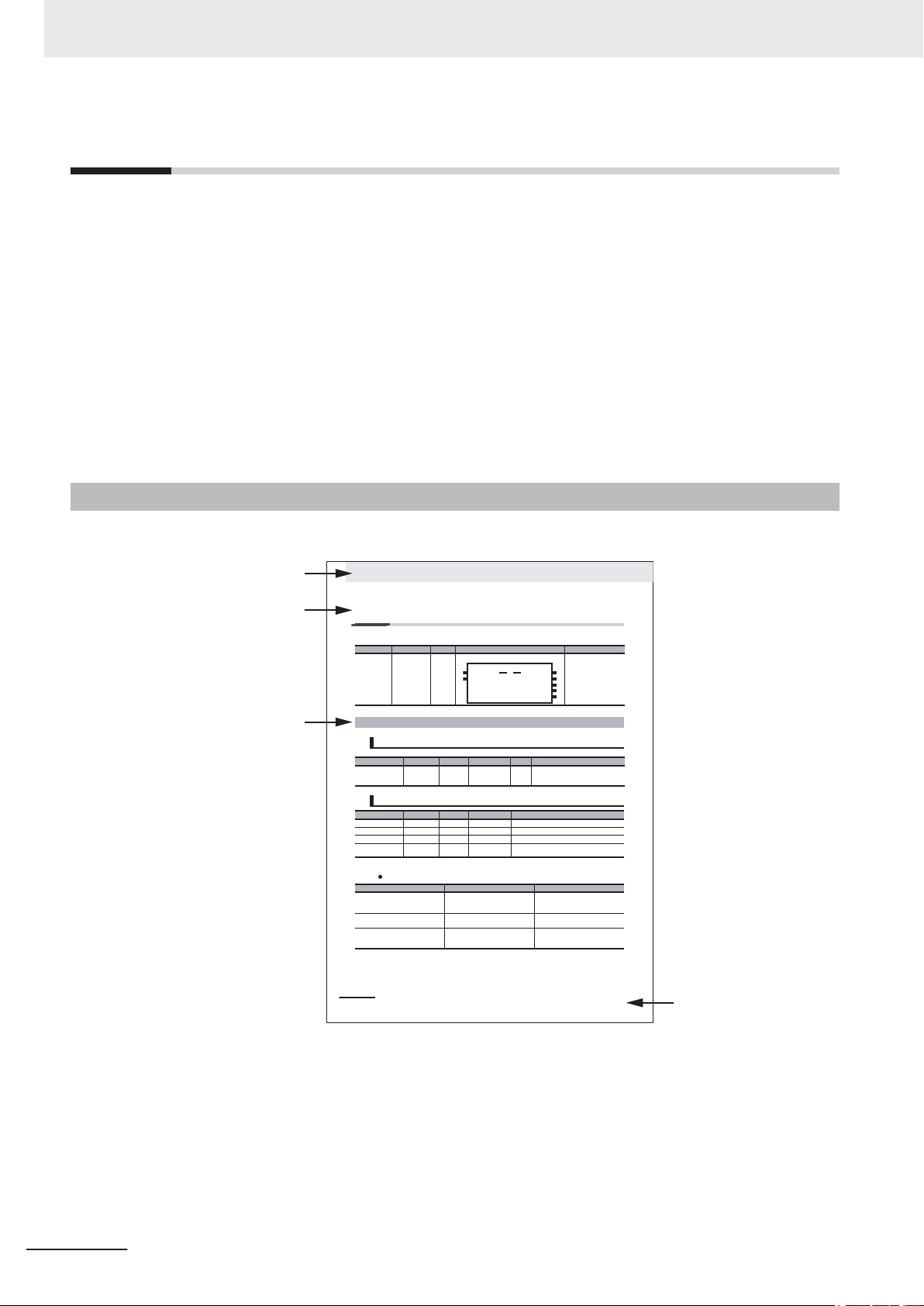

Relevant Manuals

Relevant Manuals

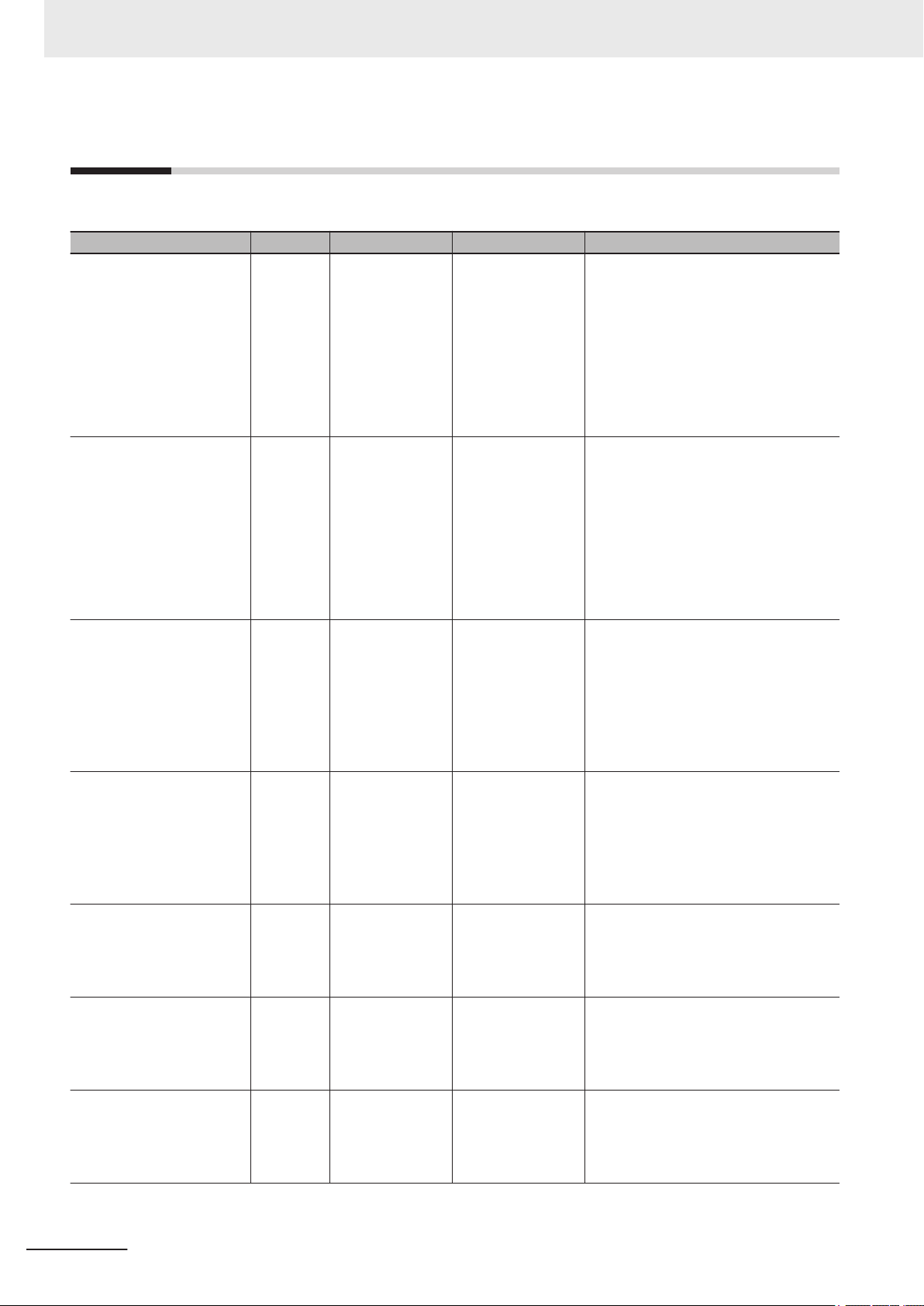

The following table provides the relevant manuals for the NY-series Controller. Read all of the manuals

that are relevant to your system configuration and application before you use the NY-series Controller.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac

Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

NY-series IPC Machine Controller

Industrial Panel PC

Hardware User's Manual

Basic information

NY-series IPC Machine Controller

Industrial Box PC

Hardware User's Manual

Manual

NY-series

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Setup User's Manual

Industrial Panel PC / Industrial Box PC

Software User

Instructions Reference Manual

NY-series IPC Machine Controller

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Motion Control User's Manual

NY-series

Motion Control Instructions Reference Manual

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherCA

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherNet/IP Port User's Manual

NJ/NY-series NC Integrated Controller

User's Manual

NY-series

T

roubleshooting Manual

Purpose of use

Introduction to NY-series Panel PCs

Introduction to NY-series Box

PCs

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Making setup

Software settings

Writing the user program

*1

Making the initial settings

Preparing to use Controllers

Using motion control

Using EtherCAT

Using EtherNet/IP

Using numerical control

Using motion control

Using EtherCAT

Using EtherNet/IP

Using numerical control

Programming error

processing

¡

¡ ¡

’s Manual

¡

¡

¡

¡

¡

¡ ¡

¡ ¡

T Port User’s Manual

¡

¡

¡

¡

¡

¡

¡

¡

¡

2

NY-series Motion Control Instructions Reference Manual (W561)

Page 5

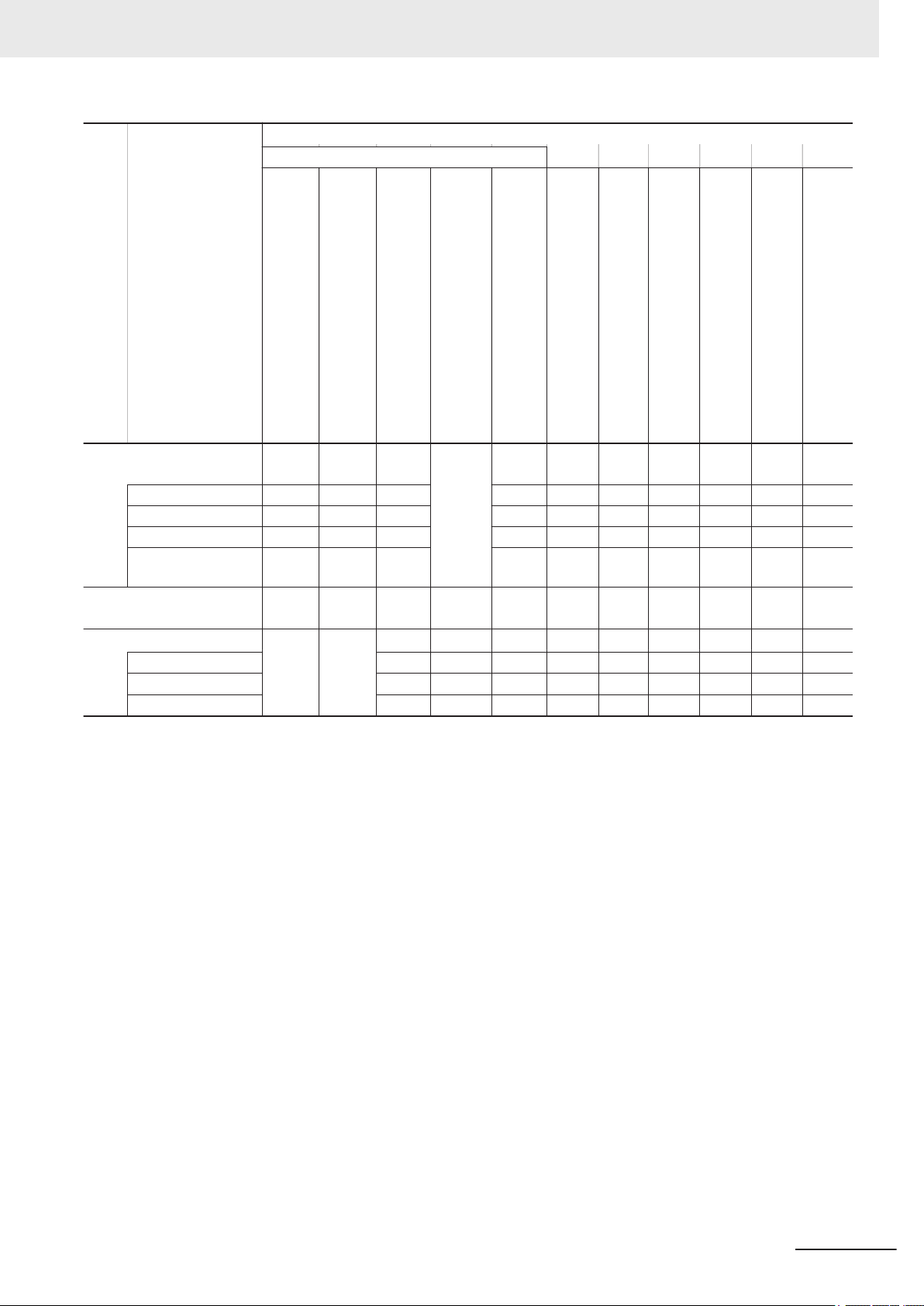

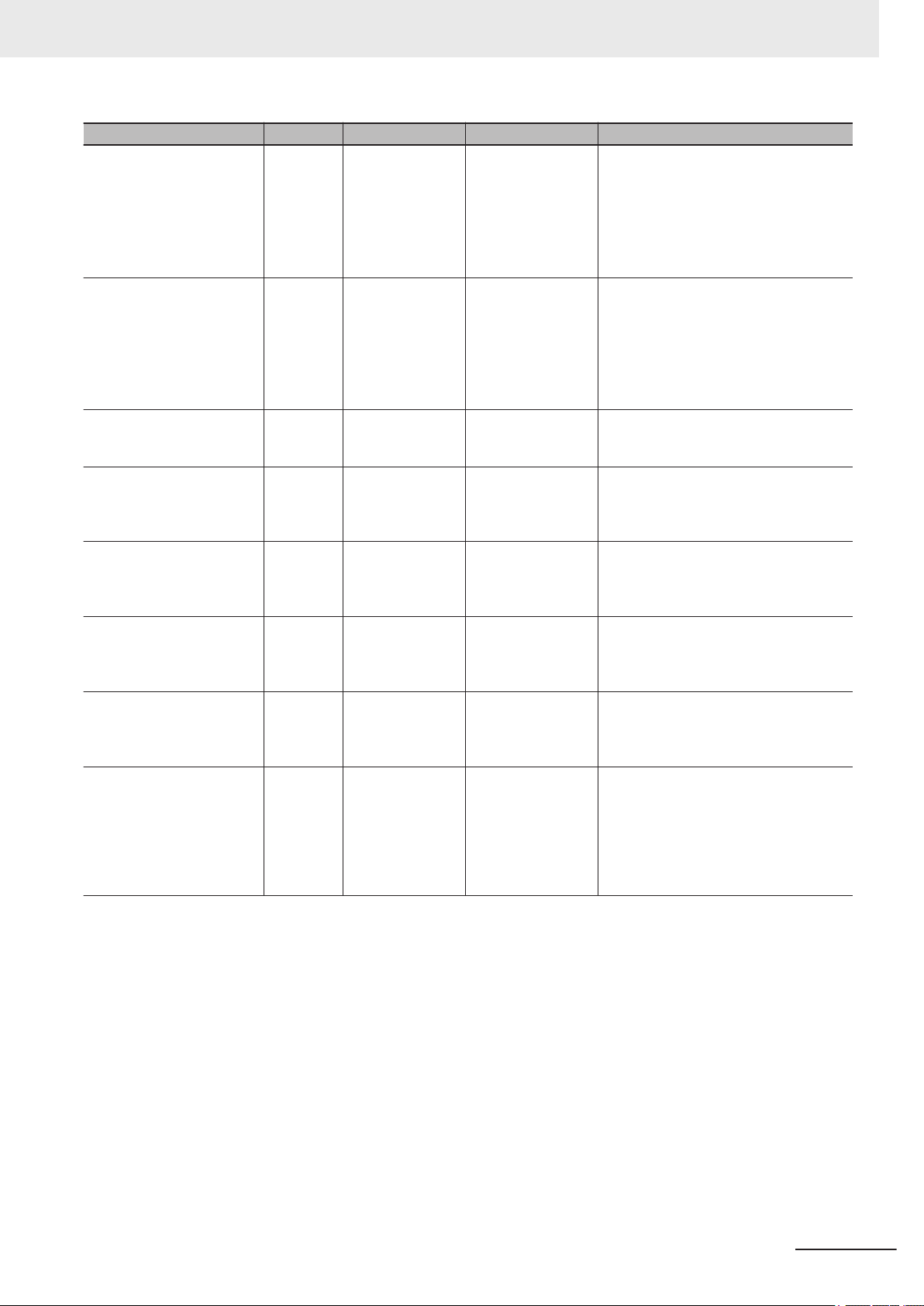

NY-series IPC Machine Controller

Industrial Panel PC

Hardware User's Manual

Basic information

NY-series IPC Machine Controller

Industrial Box PC

Hardware User's Manual

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Setup User's Manual

Manual

NY-series

Instructions Reference Manual

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Software User

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Motion Control User's Manual

NY-series

Motion Control Instructions Reference Manual

Relevant Manuals

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherCA

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherNet/IP Port User's Manual

NJ/NY-series NC Integrated Controller

User's Manual

NY-series

T

roubleshooting Manual

’s Manual

Purpose of use

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using numerical control

Learning about error manage-

ment and corrections

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

*1. Refer to the NY

the utilities on Windows.

*2. Refer to the NY-series Troubleshooting Manual (Cat. No. W564) for the error management concepts and an overview of the error

items.

*2

¡ ¡

-series Industrial Panel PC / Industrial Box PC Setup User’s Manual (Cat. No. W568) for how to set up and how to use

¡

¡

¡

T Port User’s Manual

¡

¡

¡

¡

¡

¡

NY-series Motion Control Instructions Reference Manual (W561)

3

Page 6

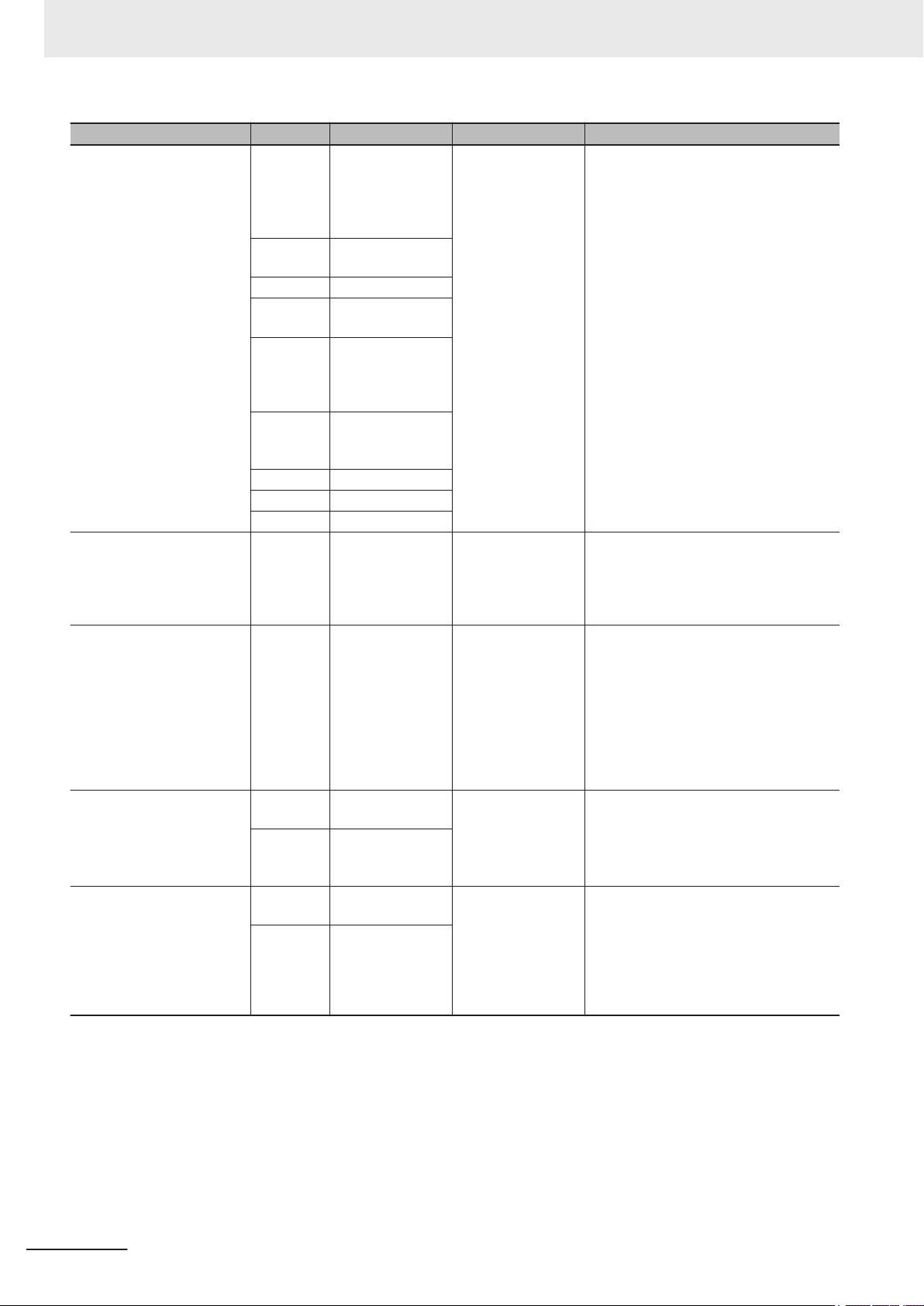

Manual name

Le

vel-1 section heading

3 Axis Command Instructions

3-2

NJ-series Motion Control Instructions Reference Manual (W508)

MC_Power

The MC_Power instruction makes a Servo Drive ready to operate.

* Refer to A-1 Error Codes.

Output Variable Update Timing

Instruction Name FB/FUN Graphic expression ST expression

MC_Power Power Servo FB MC_Power_instance (

Axis :=parameter,

Enable :=parameter,

Status =>parameter,

Busy =>parameter,

Error =>parameter,

ErrorID =>parameter

);

Variables

Input Variables

Name Meaning Data type Valid range Default Description

Enable Enable BOOL TRUE or FALSE FALSE The device is ready for operation when

Enable is TRUE, and not ready when it is

FALSE.

Output Variables

Name Meaning Data type Valid range Description

Status Servo ON BOOL TRUE or FALSE TRUE when the device is ready for operation.

Busy Executing BOOL TRUE or FALSE TRUE when the instruction is acknowledged.

Error Error BOOL TRUE or FALSE TRUE while there is an error.

ErrorID Error Code WORD

*

Contains the error code when an error occurs.

A value of 16#0000 indicates normal execution.

Name Timing for changing to TRUE Timing for changing to FALSE

Status When the specified axis becomes

ready for operation.

• When operation ready status for the

specified axis is cleared.

• When Error changes to TRUE.

Bu

sy When Enable changes to TRUE. • W

hen Enable changes to FALSE.

• When Error changes to TRUE.

E

rror When there is an error in the execution

conditions or input parameters for the

instruction.

When the error is cleared.

MC_Power_instance

Error

Axis Axis

Enable Status

Busy

MC_Power

ErrorID

Level-2 section heading

Level-3 section heading

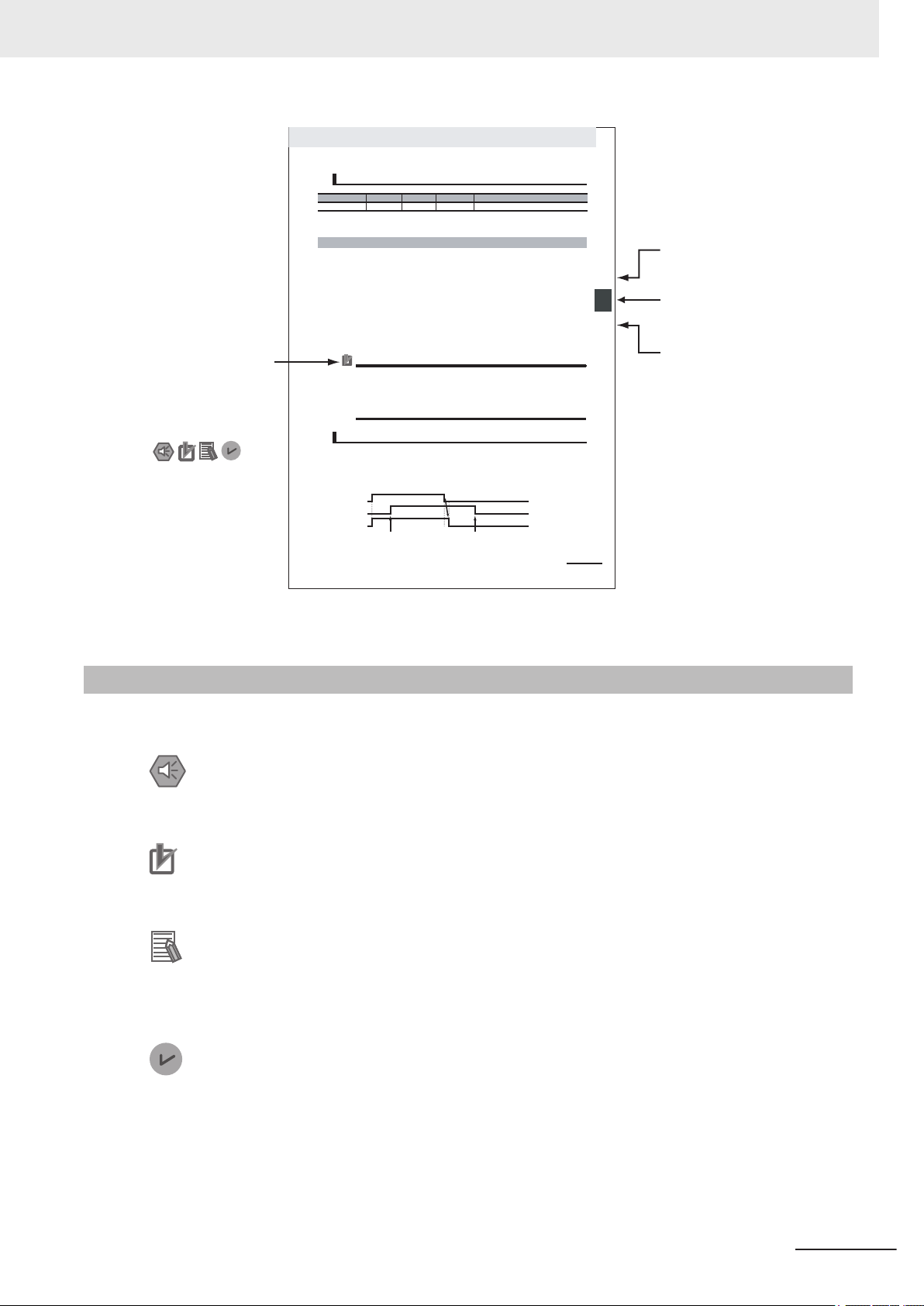

Manual Structure

Manual Structure

Some of the instructions described in this manual are common to the NJ/NX-series.

Therefore, note the following conditions.

• You cannot connect a CJ-series Unit with NY-series Controllers. In explanation of the instructions,

skip items and samples related to CJ-series Units.

• In explanation of the instructions, replace the term “CPU Unit” with “NY-series Controller.”

• NY-series Controllers have no SD Memory Card slots. Instead, they provide the Virtual SD Memory

Card function that uses the Windows shared folder. Therefore, replace the term “SD Memory Card”

with “Virtual SD Memory Card.”

Refer to the NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No.

W558) and NY-series Industrial Panel PC / Industrial Box PC Setup User’s Manual (Cat. No. W568)

for details on the Virtual SD Memory Card function.

Page Structure

The following page structure is used in this manual.

4

NY-series Motion Control Instructions Reference Manual (W561)

Page 7

Special information

Icons indicate

precautions, additional

information, or reference

information.

Level-2 section heading

Level-1 section number

Level-3 section heading

The level-1 section number

is given.

The level-2 section heading

is given.

The level-3 section heading

is given.

3-3

3

Axis Command Instructions

NJ-series Motion Control Instructions Reference Manual (W508)

r

ew

oP

_

C

M

3

noitcnuF

* Specify an Axis Variable that was created in the Axis Basic Settings of the Sysmac Studio. (The default axis variable names

are MC_Axis***.)

• When

Enable changes to TRUE, the axis specified by Axis is made ready to operate.

You can control the axis when it is ready to operate.

• When Enable changes to FALSE, the ready status is cleared for the axis specified by Axis.

You cannot control the axis after the ready status is cl eared because it will not acknowledge operation commands. Also, an error occurs if a motion command is executed for an axis for which the

ready status is cleared. You can execute the MC_Power (Power Servo) and MC_Reset (Reset Axis

Error) instructions even for axes that are not ready.

• You can use this instruction to disable the operation of axes while they are in motion. In this case,

CommandAborted will change to TRUE. Output of the operation comman

d will stop and the axis will

not longer be ready for operation.

• If home is not defined for a Servomotor with an absolute encoder, compensation is performed using

the absolute encoder home offset to define home when the axis is ready to operate.

For details on the absolute encoder home offset, refer to the

NJ-series CPU Unit Motion Control

U

ser’s Manual (Cat. No. W507).

Precautions for Correct UsePrecautions for Correct Use

• You can use this instruction for servo axes and virtual servo axes. If the instruction is used for

encoder axes or virtual encoder axes, an error will occur.

• Executing this Instruction for the Master Axis of Synchronized Control

When master axis operation is disabled for a vertical axis, the position of the master axis may

change rapidly. This may cause the motion of th e slave axis to change rapidly. Take suitable

measures to prevent the slave axis from moving rapidly, such as applying a brake to the master axis or leaving master axis operation enabled until after synchronized control is completed.

• W

hen Enable changes to TRUE, Busy (Executing) changes to TRUE to indicate that the instruction

was acknowledged.

• After the axis becomes ready for operation, Status (Ser vo ON) changes to TRUE.

• W

hen Enable changes to FALSE, Busy (Executing) changes to FALSE. Status (Servo ON) changes

t

o FALSE when ready status is cleared. Status (Servo ON) outputs the axis ready status regardless

o

f whether Enable is TRUE or FALSE.

In-Out

Variables

Name Meaning Data type Valid range Description

Axis Axis _sAXIS_REF ---

Specify the axis.

*

Function

Timing Charts

Enable

Status

Busy

The specified axis becomes

ready for operation.

Rea

dy status is cleared for the

specified axis.

Manual Structure

Special Information

NY-series Motion Control Instructions Reference Manual (W561)

Note These pages are for illustrative purposes only. They may not literally appear in this manual.

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier

Information on dif

and for different versions of the Sysmac Studio is given.

Version Information

ferences in specifications and functionality for Controller with different unit versions

.

5

Page 8

Manual Structure

6

NY-series Motion Control Instructions Reference Manual (W561)

Page 9

Sections in this Manual

1

2

3

4

5

A

I

1

2

3

4

5

A

I

Introduction to Motion Control Instructions

V

ariables and Instructions

Axis Command Instructions

Axes Group Instructions

Common Command Instructions

Appendices

Index

Sections in this Manual

NY-series Motion Control Instructions Reference Manual (W561)

7

Page 10

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

Sections in this Manual ........................................................................................... 7

Terms and Conditions Agreement........................................................................ 13

Warranty, Limitations of Liability ....................................................................................................................13

Application Considerations ............................................................................................................................14

Disclaimers ....................................................................................................................................................14

...........................................................................................................................................1

Safety Precautions................................................................................................. 16

Precautions for Safe Use ...................................................................................... 17

Precautions for Correct Use ................................................................................. 18

Regulations and Standards .................................................................................. 19

Versions.................................................................................................................. 20

Checking Versions.........................................................................................................................................20

Related Manuals..................................................................................................... 22

Revision History..................................................................................................... 25

Section 1 Introduction to Motion Control Instructions

1-1 Motion Control Instructions..................................................................................................1-2

1-1-1

1-1-2 Overview of Motion Control Instructions .....................................................................................1-2

1-1-3 Precautions for Master and Auxiliary Axes in Synchronized Control ..........................................1-6

1-2 Basic Information on Motion Control Instructions ............................................................. 1-8

1-2-1 Motion Control Instruction Names...............................................................................................1-8

1-2-2 Languages for Motion Control Instructions .................................................................................1-8

1-2-3 Motion Control Instruction Locations...........................................................................................1-9

1-2-4 Multi-execution of Motion Control Instructions ..........................................................................1-17

1-2-5 Online Editing of Motion Control Instructions ............................................................................1-18

1-2-6 Changes in the Operating Mode of the Controller.....................................................................1-18

Function Blocks for PLCopen® Motion Control ...........................................................................1-2

Section 2 Variables and Instructions

2-1 Variables ................................................................................................................................. 2-2

2-1-1

2-1-2 Axis Variables..............................................................................................................................2-4

8

MC Common Variables ...............................................................................................................2-3

NY-series Motion Control Instructions Reference Manual (W561)

Page 11

2-1-3 Axes Group Variables................................................................................................................2-10

2-1-4

2-1-5 Output Variables for Motion Control Instructions.......................................................................2-27

2-1-6 In-Out Variables for Motion Control Instructions........................................................................2-30

Input Variables for Motion Control Instructions..........................................................................2-12

2-2 Instructions ..........................................................................................................................2-33

2-2-1 Common Commands ................................................................................................................2-33

2-2-2 Axis Commands ........................................................................................................................2-33

2-2-3 Axes Group Commands............................................................................................................2-35

2-3 PDO Mapping .......................................................................................................................2-37

2-3-1 Required Objects ......................................................................................................................2-37

2-3-2 Objects Required for Specific Instructions ................................................................................2-38

Section 3 Axis Command Instructions

MC_Power.........................................................................................................................................3-3

V

ariables .......................................................................................................................................................3-3

Function ........................................................................................................................................................3-4

MC_MoveJog .................................................................................................................................... 3-8

Variables.......................................................................................................................................................3-8

Function ........................................................................................................................................................3-9

MC_Home........................................................................................................................................3-18

Variables.....................................................................................................................................................3-18

Function ......................................................................................................................................................3-19

MC_HomeWithParameter ..............................................................................................................3-41

Variables.....................................................................................................................................................3-41

Function ......................................................................................................................................................3-45

MC_Move ........................................................................................................................................3-48

Variables.....................................................................................................................................................3-48

Function ......................................................................................................................................................3-50

MC_MoveAbsolute ......................................................................................................................... 3-53

Variables.....................................................................................................................................................3-53

Function ......................................................................................................................................................3-55

Sample Programming 1 ..............................................................................................................................3-61

Sample Programming 2 ..............................................................................................................................3-70

MC_MoveRelative...........................................................................................................................3-80

Variables.....................................................................................................................................................3-80

Function ......................................................................................................................................................3-82

MC_MoveVelocity...........................................................................................................................3-88

Variables.....................................................................................................................................................3-88

Function ......................................................................................................................................................3-90

Sample Programming .................................................................................................................................3-94

MC_MoveZeroPosition ................................................................................................................3-104

Variables...................................................................................................................................................3-104

Function ....................................................................................................................................................3-106

MC_MoveFeed .............................................................................................................................. 3-111

Variables................................................................................................................................................... 3-111

Function .................................................................................................................................................... 3-115

Sample Programming ...............................................................................................................................3-127

MC_Stop........................................................................................................................................3-140

Variables...................................................................................................................................................3-140

Function ....................................................................................................................................................3-141

MC_ImmediateStop......................................................................................................................3-149

Variables...................................................................................................................................................3-149

Function ....................................................................................................................................................3-150

MC_SetPosition............................................................................................................................3-154

CONTENTS

NY-series Motion Control Instructions Reference Manual (W561)

9

Page 12

CONTENTS

MC_SetOverride ...........................................................................................................................3-161

MC_ResetFollowingError ............................................................................................................3-167

MC_CamIn.....................................................................................................................................3-174

MC_CamOut..................................................................................................................................3-232

MC_CamMonitor...........................................................................................................................3-237

MC_GearIn ....................................................................................................................................3-246

MC_GearInPos..............................................................................................................................3-267

MC_GearOut .................................................................................................................................3-289

MC_MoveLink ............................................................................................................................... 3-294

MC_CombineAxes........................................................................................................................3-317

MC_Phasing..................................................................................................................................3-328

MC_TorqueControl.......................................................................................................................3-335

MC_SetTorqueLimit .....................................................................................................................3-348

MC_ZoneSwitch ...........................................................................................................................3-355

MC_TouchProbe...........................................................................................................................3-361

MC_AbortTrigger..........................................................................................................................3-381

Variables ...................................................................................................................................................3-154

Function

Variables ...................................................................................................................................................3-161

Function ....................................................................................................................................................3-162

Variables ...................................................................................................................................................3-167

Function ....................................................................................................................................................3-168

Variables ...................................................................................................................................................3-174

Function ....................................................................................................................................................3-178

Sample Programming 1 ............................................................................................................................3-201

Sample Programming 2 ............................................................................................................................3-212

Variables ...................................................................................................................................................3-232

Function ....................................................................................................................................................3-233

Variables ...................................................................................................................................................3-237

Function ....................................................................................................................................................3-240

Precautions for Correct Use .....................................................................................................................3-245

Variables ...................................................................................................................................................3-246

Function ....................................................................................................................................................3-248

Sample Programming ...............................................................................................................................3-255

Variables ...................................................................................................................................................3-267

Function ....................................................................................................................................................3-270

Sample Programming ...............................................................................................................................3-277

Variables ...................................................................................................................................................3-289

Function ....................................................................................................................................................3-290

Variables ...................................................................................................................................................3-294

Function ....................................................................................................................................................3-297

Sample Programming ...............................................................................................................................3-306

Variables ...................................................................................................................................................3-317

Function ....................................................................................................................................................3-319

Variables ...................................................................................................................................................3-328

Function ....................................................................................................................................................3-330

Variables ...................................................................................................................................................3-335

Function ....................................................................................................................................................3-337

Variables ...................................................................................................................................................3-348

Function ....................................................................................................................................................3-350

Variables ...................................................................................................................................................3-355

Function ....................................................................................................................................................3-356

Variables ...................................................................................................................................................3-361

Function ....................................................................................................................................................3-364

Sample Programming ...............................................................................................................................3-374

Variables ...................................................................................................................................................3-381

....................................................................................................................................................3-155

10

NY-series Motion Control Instructions Reference Manual (W561)

Page 13

CONTENTS

Function ....................................................................................................................................................3-382

MC_AxesObserve

Variables ...................................................................................................................................................3-385

Function ....................................................................................................................................................3-387

MC_SyncMoveVelocity ................................................................................................................ 3-391

Variables ...................................................................................................................................................3-391

Function ....................................................................................................................................................3-393

MC_SyncMoveAbsolute ..............................................................................................................3-401

Variables ...................................................................................................................................................3-401

Function ....................................................................................................................................................3-403

MC_Reset......................................................................................................................................3-408

Variables ...................................................................................................................................................3-408

Function ....................................................................................................................................................3-409

MC_ChangeAxisUse ....................................................................................................................3-412

Variables ...................................................................................................................................................3-412

Function ....................................................................................................................................................3-413

MC_DigitalCamSwitch .................................................................................................................3-416

Variables ...................................................................................................................................................3-416

Function ....................................................................................................................................................3-418

Sample Programming ...............................................................................................................................3-427

MC_TimeStampToPos .................................................................................................................3-436

Variables ...................................................................................................................................................3-436

Function ....................................................................................................................................................3-437

Sample Programming ...............................................................................................................................3-440

MC_SyncOffsetPosition ..............................................................................................................3-448

Variables ...................................................................................................................................................3-448

Function ....................................................................................................................................................3-450

MC_OffsetPosition ....................................................................................................................... 3-458

Variables ...................................................................................................................................................3-458

Function ....................................................................................................................................................3-460

.........................................................................................................................3-385

Section 4 Axes Group Instructions

MC_GroupEnable ............................................................................................................................. 4-2

V

ariables .......................................................................................................................................................4-2

Function ........................................................................................................................................................4-3

MC_GroupDisable ............................................................................................................................ 4-6

Variables.......................................................................................................................................................4-6

Function ........................................................................................................................................................4-7

MC_MoveLinear.............................................................................................................................. 4-11

Variables.....................................................................................................................................................4-11

Function ......................................................................................................................................................4-13

Sample Programming .................................................................................................................................4-24

MC_MoveLinearAbsolute ..............................................................................................................4-40

Variables.....................................................................................................................................................4-40

Function ......................................................................................................................................................4-42

MC_MoveLinearRelative................................................................................................................4-43

Variables.....................................................................................................................................................4-43

Function ......................................................................................................................................................4-45

MC_MoveCircular2D ......................................................................................................................4-46

Variables.....................................................................................................................................................4-46

Function ......................................................................................................................................................4-49

Sample Programming .................................................................................................................................4-61

MC_GroupStop...............................................................................................................................4-74

Variables.....................................................................................................................................................4-74

NY-series Motion Control Instructions Reference Manual (W561)

11

Page 14

CONTENTS

MC_GroupImmediateStop

MC_GroupSetOverride ..................................................................................................................4-86

MC_GroupReadPosition................................................................................................................4-91

MC_ChangeAxesInGroup..............................................................................................................4-95

MC_GroupSyncMoveAbsolute......................................................................................................4-99

MC_GroupReset ........................................................................................................................... 4-106

Function ......................................................................................................................................................4-76

.............................................................................................................4-82

Variables .....................................................................................................................................................4-82

Function ......................................................................................................................................................4-83

Variables .....................................................................................................................................................4-86

Function ......................................................................................................................................................4-87

Variables .....................................................................................................................................................4-91

Function ......................................................................................................................................................4-92

Variables .....................................................................................................................................................4-95

Function ......................................................................................................................................................4-96

Variables .....................................................................................................................................................4-99

Function ....................................................................................................................................................4-101

Variables ...................................................................................................................................................4-106

Function ....................................................................................................................................................4-107

Section 5 Common Command Instructions

MC_SetCamTableProperty ..............................................................................................................5-2

V

ariables .......................................................................................................................................................5-2

Function ........................................................................................................................................................5-3

MC_SaveCamTable ..........................................................................................................................5-8

Variables.......................................................................................................................................................5-8

Function ........................................................................................................................................................5-9

MC_Write.........................................................................................................................................5-13

Variables.....................................................................................................................................................5-13

Function ......................................................................................................................................................5-16

MC_GenerateCamTable .................................................................................................................5-18

Variables.....................................................................................................................................................5-18

Function ......................................................................................................................................................5-20

Sample Programming .................................................................................................................................5-33

MC_WriteAxisParameter ...............................................................................................................5-47

Variables.....................................................................................................................................................5-47

Function ......................................................................................................................................................5-48

MC_ReadAxisParameter................................................................................................................5-61

Variables.....................................................................................................................................................5-61

Function ......................................................................................................................................................5-63

Appendices

A-1 Instructions for Which Multi-execution Is Supported ....................................................... A-2

A-1-1

A-1-2 State Transitions and Instructions for which Multi-execution Is Supported................................ A-4

A-2 Connecting to NX Units...................................................................................................... A-10

A-3 Version Information ............................................................................................................ A-11

Index

12

Axis and Axes Group Status ...................................................................................................... A-2

NY-series Motion Control Instructions Reference Manual (W561)

Page 15

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

NY-series Motion Control Instructions Reference Manual (W561)

13

Page 16

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

W

ARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

’s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIP-

MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

. It may represent the result of

14

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

NY-series Motion Control Instructions Reference Manual (W561)

, some specifications of the Product may

Page 17

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’

time to confirm actual specifications of purchased Product.

s representative at any

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NY-series Motion Control Instructions Reference Manual (W561)

15

Page 18

Safety Precautions

Safety Precautions

Refer to the following manuals for safety precautions.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

16

NY-series Motion Control Instructions Reference Manual (W561)

Page 19

Precautions for Safe Use

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

NY-series Motion Control Instructions Reference Manual (W561)

17

Page 20

Precautions for Correct Use

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

18

NY-series Motion Control Instructions Reference Manual (W561)

Page 21

Regulations and Standards

Refer to the following manuals for Regulations and Standards.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

Regulations and Standards

NY-series Motion Control Instructions Reference Manual (W561)

19

Page 22

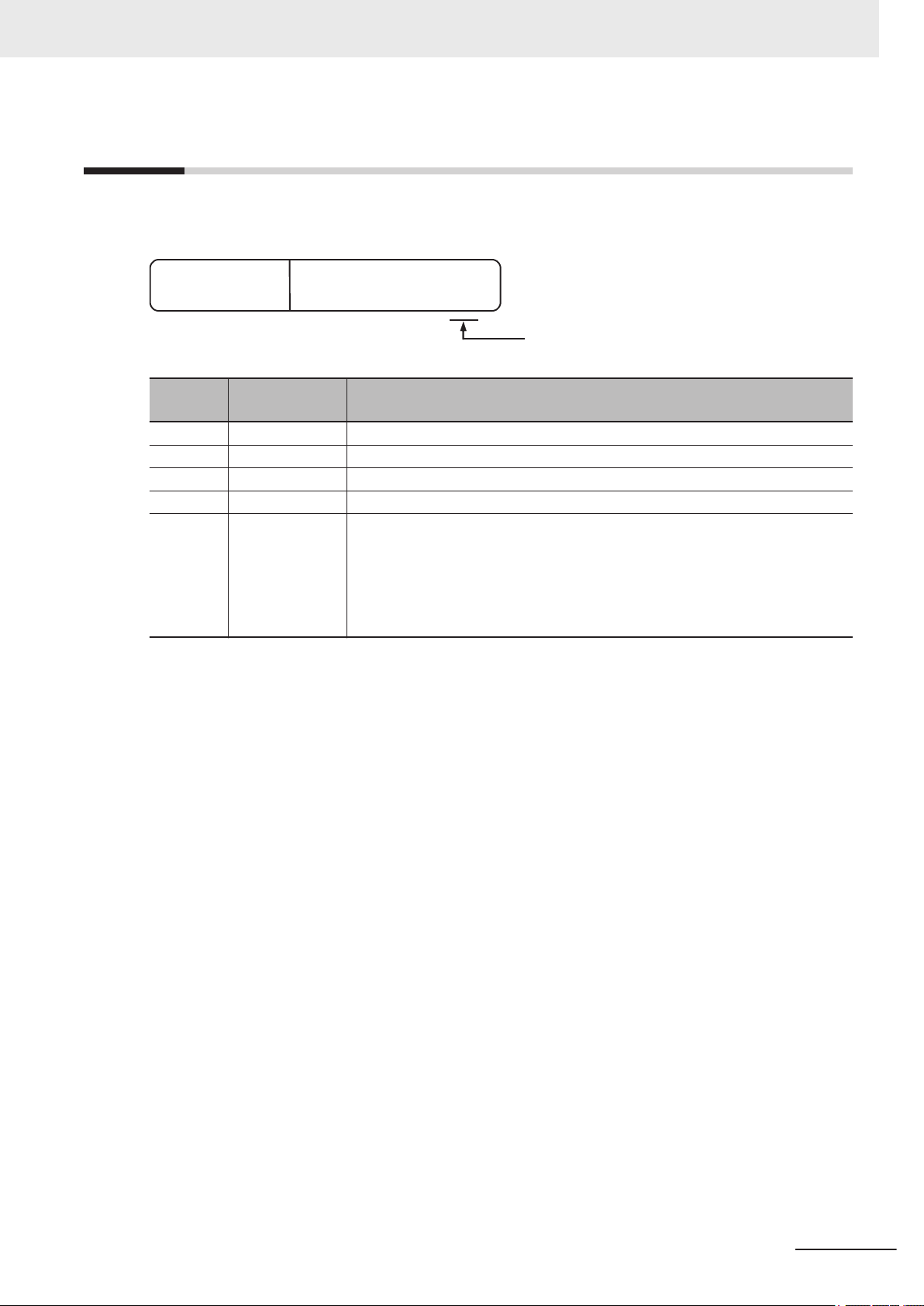

ID information indication

Unit version

Ver.1.£

£

Versions

Versions

Hardware revisions and unit versions are used to manage the hardware and software in NY-series

Controllers and EtherCAT slaves. The hardware revision or unit version is updated each time there is

a change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hard-

ware revisions or unit versions.

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the side of the product.

The ID information on an NY-series NY5£2-££££ Controller is shown below.

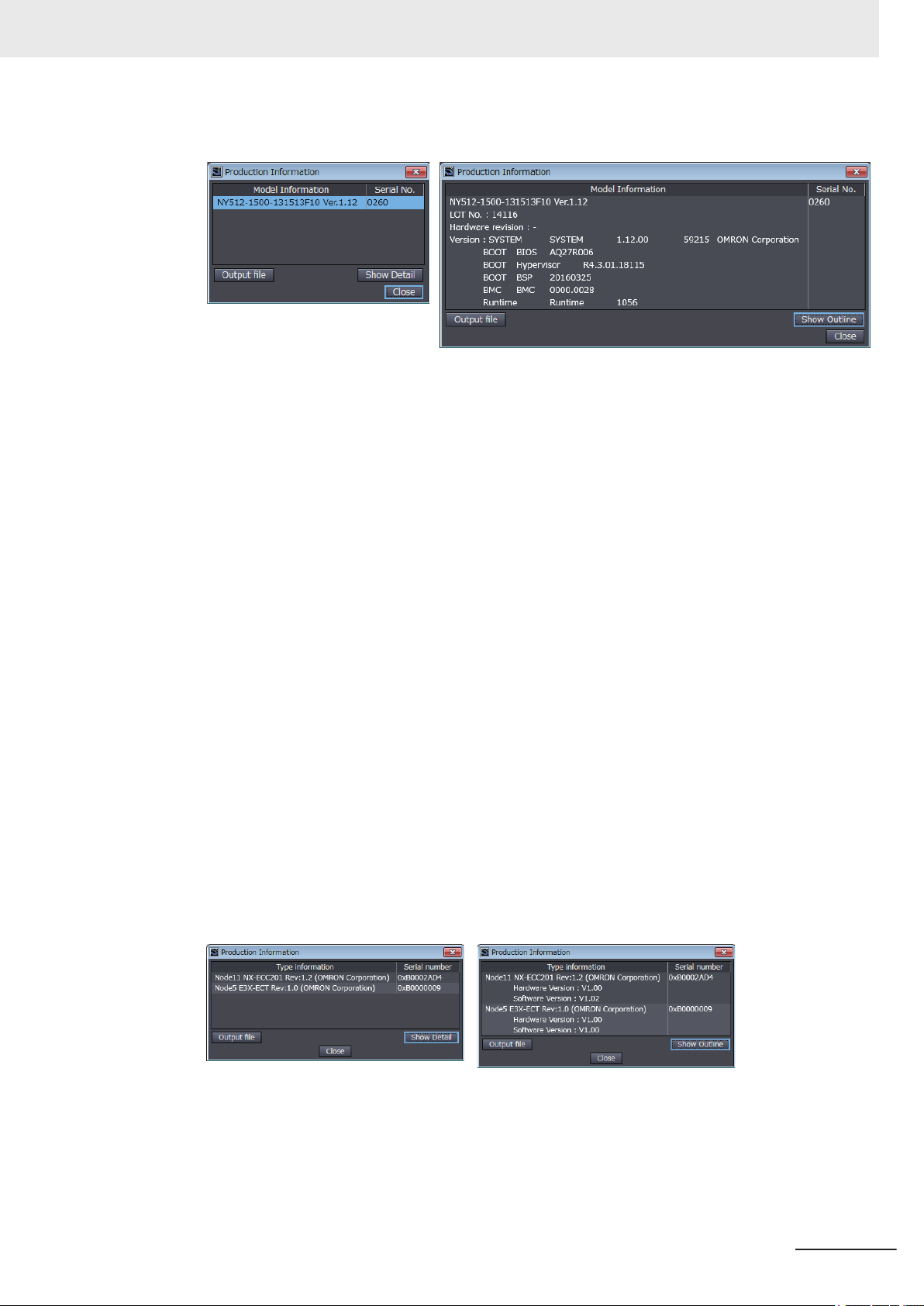

Checking Unit Versions with the Sysmac Studio

You can use the Sysmac Studio to check unit versions. The procedure is different for Units and for

EtherCA

T slaves.

Checking the Unit Version of an NY-series Controller

20

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this only for the Controller.

1 Right-click CPU Rack under Configurations and Setup - CPU/Expansion Racks in the Multi-

view Explorer

The Production Information Dialog Box is displayed.

Changing Information Displayed in Production Information Dialog Box

, and select Production Information.

1 Click the Show Outline or Show Detail Button at the lower right of the Production Information

Dialog Box.

NY-series Motion Control Instructions Reference Manual (W561)

Page 23

Versions

The view will change between the production information details and outline.

Outline View Detail View

The information that is displayed is different for the Outline View and Detail View. The Detail

iew displays the unit version, hardware revision, and other versions. The Outline View dis-

V

plays only the unit version.

Checking the Unit Version of an EtherCAT Slave

You can use the Production Information while the Sysmac Studio is online to check the unit version

of an EtherCAT slave.

Use the following procedure to check the unit version.

1 Double-click EtherCA

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

T under Configurations and Setup in the Multiview Explorer. Or, right-

2 Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after “Rev

Changing Information Displayed in Production Information Dialog Box

.”

1 Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

Outline View Detail View

NY-series Motion Control Instructions Reference Manual (W561)

21

Page 24

Related Manuals

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NY-series

IPC Machine Controller

Industrial Panel PC

Hardware User

NY-series

IPC Machine Controller

Industrial Box PC

Hardware User

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial

Box PC

Setup User

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial

Box PC

Software User

NY-series

Instructions Reference Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial

Box PC

Motion Control User

NY-series

Motion Control Instructions

Reference Manual

’s Manual

’s Manual

’s Manual

’s Manual

’s Manual

W557

W556

W568

W558

W560

W559

W561

NY532-££££

NY512-££££

NY532-££££

NY512-££££

NY532-££££

NY512-££££

NY532-££££

NY512-££££

NY532-££££

NY512-££££

NY532-££££

NY512-££££

Learning the basic

specifications of the

NY-series Industrial

Panel PCs, including

introductory information, designing, installation, and maintenance.

Mainly hardware information is provided.

Learning the basic

specifications of the

NY-series Industrial

Box PCs, including

introductory information, designing, installation, and maintenance.

Mainly hardware information is provided.

Learning about initial

setting of the NY-series Industrial PCs

and preparations to

use Controllers.

Learning how to program and set up the

Controller functions

of an NY-series Industrial PC.

Learning detailed

specifications on the

basic instructions of

an NY

-series Indus-

trial PC.

Learning about motion control settings

and programming

concepts of an NYseries Industrial PC.

Learning about the

specifications of the

motion control instructions of an NY

series Industrial PC.

-

An introduction to the entire NY-series system is provided along with the following information on the Industrial Panel PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NY-series system is provided along with the following information on the Industrial Box PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on an

introduction to the entire NY-series system.

• Two OS systems

• Initial settings

• Industrial PC Support Utility

• NYCompolet

• Industrial PC API

• Backup and recovery

The following information is provided on the

NY-series Controller functions.

• Controller operation

• Controller features

• Controller settings

• Programming based on IEC 61131-3 lan-

guage specifications

The instructions in the instruction set (IEC

61131-3 specifications) are described.

The settings and operation of the Controller

and programming concepts for motion control are described.

The motion control instructions are described.

22

NY-series Motion Control Instructions Reference Manual (W561)

Page 25

Manual name Cat. No. Model numbers Application Description

NY-series

IPC Machine Controller

Industrial Panel PC

/ Industrial

Box PC

Built-in EtherCA

Manual

NY-series

IPC Machine Controller

Industrial Panel PC

/ Industrial

Box PC

Built-in EtherNet/IP™ Port Us-

’s Manual

er

NJ/NY-series

NC Integrated Controller

’s Manual

User

NJ/NY-series

G code

Instructions Reference Manual

NY-series

roubleshooting Manual

T

Sysmac Studio Version 1

Operation Manual

CNC Operator

Operation Manual

NX-series

EtherCA

User’s Manual

T® Port User’s

T® Coupler Unit

W562

W563

O030 NJ501-5300

O031 NJ501-5300

W564

W504 SYSMAC

O032

W519

NY532-££££

NY512-££££

NY532-££££

NY512-££££

NY532-5400

NY532-5400

NY532-££££

NY512-££££

-SE2£££

SYSMAC-RTNC0£

££D

NX-ECC£££

Using the built-in

EtherCAT port in an

NY-series Industrial

PC.

Using the built-in

EtherNet/IP port in

an NY-series Industrial PC.

Performing numerical

control with NJ/NYseries Controllers.

Learning about the

specifications of the

G code/M code instructions.

Learning about the

errors that may be

detected in an NYseries Industrial PC.

Learning about the

operating procedures

and functions of the

Sysmac Studio.

Learning an introduction of the CNC Operator and how to

use it.

Learning how to use

the NX-series EtherCAT Coupler Unit

and EtherCAT Slave

Terminals.

Information on the built-in EtherCAT port is

provided.

This manual provides an introduction and

provides information on the configuration,

features, and setup.

Information on the built-in EtherNet/IP port

is provided.

Information is provided on the basic setup,

tag data links, and other features.

Describes the functionality to perform the

numerical control.

The G code/M code instructions are described.

Concepts on managing errors that may be

detected in an NY-series Controller and information on individual errors are described.

Describes the operating procedures of the

Sysmac Studio.

An introduction of the CNC Operator, installation procedures, basic operations, connection operations, and operating procedures for main functions are described.

The following items are described: the overall system and configuration methods of an

EtherCAT Slave Terminal (which consists of

an NX-series EtherCAT Coupler Unit and

NX Units), and information on hardware,

setup, and functions to set up, control, and

monitor NX Units through EtherCAT.

Related Manuals

NY-series Motion Control Instructions Reference Manual (W561)

23

Page 26

Related Manuals

Manual name Cat. No. Model numbers Application Description

NX-series

NX Units

’s Manual

User

NX-series

Data Reference Manual

GX-series EtherCAT Slave

Units

’s Manual

User

AC Servomotors/Servo Drives

1S-series with

Built-in EtherCA

cations User's Manual

AC Servomotors/Servo Drives

G5 Series with

Built-in EtherCA

cations User's Manual

T® Communi-

T® Communi-

W521

W522

W592

W566

W523

W524

W540

W565

W567

W525

W488

I586

I621

I576

I577

NX-ID££££

NX-IA££££

NX-OC££££

NX-OD££££

NX-MD££££

NX-AD££££

NX-DA££££

NX-HAD£££

NX-TS££££

NX-HB££££

NX-PD1£££

NX-PF0£££

NX-PC0£££

NX-TBX01

NX-EC0£££

NX-ECS£££

NX-PG0£££

NX-CIF£££

NX-RS££££

NX-ILM£££

NX-££££££

GX-ID££££

GX-OD££££

GX-OC££££

GX-MD££££

GX-AD££££

GX-DA££££

GX-EC££££

-ID££

XWT

XWT-OD££

R88M-1£

R88D-1SN£-ECT

R88M-1AL£/ -1AM

£

R88D-1SAN£-ECT

R88M-K£

R88D-KN£-ECT

R88L-EC-£

R88D-KN£-ECT

-L

Learning how to use

NX Units.

Referencing lists of

the data that is required to configure

systems with NX-series Units.

Learning how to use

the EtherCA

I/O terminals.

Learning how to use

the Servomotors/

Servo Drives with

built-in EtherCAT

Communications.

Learning how to use

the AC Servomotors/

Servo Drives with

built-in EtherCAT

Communications.

T remote

Describes the hardware, setup methods,

and functions of the NX Units.

Manuals are available for the following

Units.

Digital I/O Units, Analog I/O Units, System

Units, Position Interface Units, Communications Interface Units, Load Cell Input Unit,

and IO-Link Master Units.

Lists of the power consumptions, weights,

and other NX Unit data that is required to

configure systems with NX-series Units are

provided.

Describes the hardware, setup methods

and functions of the EtherCAT remote I/O

terminals.

Describes the hardware, setup methods

and functions of the Servomotors/Servo

Drives with built-in EtherCAT Communications.

Describes the hardware, setup methods

and functions of the AC Servomotors/Servo

Drives with built-in EtherCAT Communications.

The Linear Motor Type models and dedicated models for position control are available

in G5-series.

24

NY-series Motion Control Instructions Reference Manual (W561)

Page 27

Revision History

W561-E1-05

R

evision code

Cat. No.

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision History

Revision

code

01 September 2016 Original production

02 April 2017 Corrected mistakes.

03 October 2017 Corrected mistakes.

04 January 2019 Corrected mistakes.

05 July 2019

Date Revised content

• Made changes accompanying the addition of 1S-series AC Servomotors/

Servo Drives.

• Made changes accompanying th addition of the MC_CamMonitor (Cam Mon-

itor) instruction and the MC_Of

instruction.

• Made changes accompanying the release of Sysmac Studio version 1.29.

fsetPosition (Position Offset Compensation)

NY-series Motion Control Instructions Reference Manual (W561)

25

Page 28

Revision History

26

NY-series Motion Control Instructions Reference Manual (W561)

Page 29

1

Introduction to Motion Control Instructions

This section gives an introduction to motion control instructions supported by NY-series Controller

1-1 Motion Control Instructions .......................................................................... 1-2

1-1-1 Function Blocks for PLCopen® Motion Control............................................... 1-2

1-1-2 Overview of Motion Control Instructions ......................................................... 1-2

1-1-3 Precautions for Master and Auxiliary Axes in Synchronized Control.............. 1-6

1-2 Basic Information on Motion Control Instructions .....................................1-8

1-2-1 Motion Control Instruction Names .................................................................. 1-8

1-2-2 Languages for Motion Control Instructions ..................................................... 1-8

1-2-3 Motion Control Instruction Locations .............................................................. 1-9

1-2-4 Multi-execution of Motion Control Instructions.............................................. 1-17

1-2-5 Online Editing of Motion Control Instructions................................................ 1-18

1-2-6 Changes in the Operating Mode of the Controller ........................................ 1-18

s.

1

NY-series Motion Control Instructions Reference Manual (W561)

1-1

Page 30

1 Introduction to Motion Control Instructions

1-1

1-1-1

Motion Control Instructions

Motion control instructions are used in the user program to execute motion controls for an NY-series

Controller. These instructions are defined as function blocks.

The motion control instructions of the MC Function Module are based on the technical specifications of

function blocks for PLCopen® motion control.

There are two types of motion control instructions: PLCopen®-defined instructions and instructions that

are unique to the MC Function Module.

This section provides an overview of the PLCopen® motion control function blocks and motion control

instructions.

For details on motion control instructions, refer to the NY-series Industrial Panel PC / Industrial Box PC

Motion Control User’s Manual (Cat. No. W559).

Refer to the NX-series Position Interface Units User’s Manual (Cat. No. W524) for information on us-

ing the NX-series Position Interface Units.

Function Blocks for PLCopen® Motion Control

1-1-2

PLCopen® standardizes motion control function blocks to define a program interface for the languages

specified in IEC 61

Single-axis positioning, electronic cams, and multi-axes coordinated control are defined along with ba-

sic procedures for executing instructions.