Page 1

Cat. No. W541-E1-02

SYSMAC CJ Series

CJ1W-ECT21

EtherCAT® Slave Unit

OPERATION MANUAL

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• Safety over EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing a CJ-series CJ1W-ECT21 EtherCAT Slave Unit.

This manual contains information that is necessary to use the CJ-series CJ1W-ECT21 EtherCAT Slave

Unit for a CJ-series CPU Unit. Please read this manual and make sure you understand the functionality

and performance of the CJ-series CPU Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Introduction

Applicable Products

This manual covers the following product.

• CJ-series EtherCAT Slave Unit

CJ1W-ECT21

CJ-series EtherCAT Slave Units Operation Manual (W541)

1

Page 4

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products..................................................................................................................................... 1

CONTENTS................................................................................................................2

Manual Structure ......................................................................................................7

Page Structure and Icons ............................................................................................................................ 7

Special Information...................................................................................................................................... 8

Precautions on Terminology ........................................................................................................................ 8

Terms and Conditions Agreement .......................................................................... 9

Warranty, Limitations of Liability ..................................................................................................................9

Application Considerations ........................................................................................................................ 10

Disclaimers ................................................................................................................................................ 10

Safety Precautions ................................................................................................. 11

Definition of Precautionary Information...................................................................................................... 11

Symbols..................................................................................................................................................... 11

Warnings.................................................................................................................................................... 12

Cautions..................................................................................................................................................... 14

Precautions for Safe Use.......................................................................................15

Precautions for Correct Use.................................................................................. 18

Regulations and Standards...................................................................................19

Conformance to EC Directives .................................................................................................................. 19

Conformance to UL and CSA Standards................................................................................................... 19

Conformance to Shipbuilding Standards ................................................................................................... 20

Conformance to KC Standards.................................................................................................................. 20

Unit Versions ..........................................................................................................21

Unit Versions.............................................................................................................................................. 21

Unit Versions and CX-Programmer Versions............................................................................................. 22

Related Manuals .....................................................................................................23

Terminology ............................................................................................................25

Revision History .....................................................................................................27

Sections in this Manual .........................................................................................29

Section 1 Features and System Configuration

1-1 Introduction to EtherCAT...................................................................................................... 1-2

1-1-1 How EtherCAT Works .................................................................................................................1-2

1-1-2 Types of EtherCAT Communications ..........................................................................................1-3

1-2 EtherCAT Slave Unit Features .............................................................................................. 1-5

1-3 System Configuration of CJ-series EtherCAT Slave Unit.................................................. 1-7

1-4 Specifications ........................................................................................................................ 1-9

1-4-1 General Specifications ................................................................................................................1-9

1-4-2 Functional and Performance Specifications................................................................................ 1-9

2

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 5

1-4-3 Dimensions............................................................................................................................... 1-10

1-5 Setting Procedures.............................................................................................................. 1-11

Section 2 Nomenclature and Installation

2-1 Nomenclature......................................................................................................................... 2-2

2-1-1 Nomenclature and Functions...................................................................................................... 2-2

2-1-2 Indicators .................................................................................................................................... 2-3

2-1-3 Switch Settings ........................................................................................................................... 2-6

2-2 Installing the EtherCAT Slave Unit....................................................................................... 2-8

2-2-1 System Configuration Precautions ............................................................................................. 2-8

2-2-2 Mounting to a CJ-series PLC...................................................................................................... 2-8

2-2-3 Handling Precautions.................................................................................................................. 2-9

2-3 EtherCAT Network Wiring ................................................................................................... 2-10

2-3-1 Installation Standards ............................................................................................................... 2-10

2-3-2 Installation Precautions............................................................................................................. 2-10

2-3-3 Preparations for Installation.......................................................................................................2-11

2-3-4 Pin Arrangements of Communications Connectors.................................................................. 2-12

2-3-5 Connecting Communications Cables and Connectors ............................................................. 2-13

2-3-6 Connecting Communications Cables to Units .......................................................................... 2-13

CONTENTS

Section 3 Memory Allocations

3-1 Overview of the Memory Allocated to the EtherCAT Slave Unit ....................................... 3-2

3-2 CIO Area Allocations............................................................................................................. 3-3

3-2-1 Overview of the Allocated CIO Area Words................................................................................ 3-3

3-2-2 Details of the Allocated CIO Area Words....................................................................................3-4

3-3 DM Area Allocations.............................................................................................................. 3-9

3-3-1 Overview of the Allocated DM Area Words ................................................................................ 3-9

3-3-2 Details of the Allocated DM Area Words .................................................................................... 3-9

3-4 I/O Communication Area Settings ..................................................................................... 3-16

3-4-1 The Unit Edit Parameters Dialog Box ....................................................................................... 3-16

3-4-2 Setting Procedure with the CX-Programmer ............................................................................ 3-19

Section 4 EtherCAT Communications

4-1 Structure of CAN Application Protocol over EtherCAT (CoE)........................................... 4-2

4-2 EtherCAT Slave Information Files (ESI Files) ..................................................................... 4-3

4-3 Transitions of Communications States ............................................................................... 4-4

4-4 Process Data Objects (PDOs)............................................................................................... 4-5

4-4-1 Introduction................................................................................................................................. 4-5

4-4-2 PDO Mappings ........................................................................................................................... 4-5

4-4-3 Assigning PDOs.......................................................................................................................... 4-7

4-5 Service Data Objects (SDOs)................................................................................................ 4-9

4-5-1 Introduction................................................................................................................................. 4-9

4-5-2 Abort Codes................................................................................................................................ 4-9

4-6 Communications Performance .......................................................................................... 4-10

4-6-1 I/O Response Time................................................................................................................... 4-10

4-6-2 SDO Message Response Time ................................................................................................ 4-12

CJ-series EtherCAT Slave Units Operation Manual (W541)

3

Page 6

CONTENTS

Section 5 Troubleshooting

5-1 Error Notification and Checking Methods........................................................................... 5-2

5-1-1 Error Notification Methods........................................................................................................... 5-2

5-1-2 How to Check for Errors..............................................................................................................5-3

5-1-3 Procedures to Check Errors........................................................................................................5-4

5-2 Troubleshooting with Indicators.......................................................................................... 5-5

5-2-1 Checking for Errors and Troubleshooting with the Indicators ..................................................... 5-5

5-2-2 Corrective Actions When the CPU Unit’s Indicators are Lit or Flashing....................................5-12

5-3 Error Log Function .............................................................................................................. 5-13

5-3-1 Error Log Data Specifications....................................................................................................5-13

5-3-2 Error Log Registration............................................................................................................... 5-14

5-3-3 FINS Commands for Error Logs................................................................................................5-14

5-3-4 Error Log Error Codes...............................................................................................................5-15

5-4 Troubleshooting with Emergency Messages.................................................................... 5-16

5-4-1 Emergency Message Notification.............................................................................................. 5-16

5-4-2 Emergency Error Codes............................................................................................................ 5-16

5-5 Troubleshooting with AL Status......................................................................................... 5-18

Section 6 Maintenance and Replacement

6-1 Cleaning and Inspection ....................................................................................................... 6-2

6-1-1 Cleaning......................................................................................................................................6-2

6-1-2 Inspection.................................................................................................................................... 6-2

6-2 Replacing Faulty Units.......................................................................................................... 6-4

6-2-1 Precautions .................................................................................................................................6-4

6-2-2 Settings When Replacing EtherCAT Slave Units ........................................................................ 6-4

Appendices

A-1 Example of Operations for EtherCAT Slave Unit Communications..................................A-2

A-1-1 System Configuration..................................................................................................................A-2

A-1-2 Setting Condition.........................................................................................................................A-3

A-1-3 Flow of the Setting Procedure.....................................................................................................A-3

A-1-4 CJ1W-ECT21 Setting Procedure ................................................................................................A-4

A-1-5 EtherCAT Master Setting Procedure...........................................................................................A-5

A-1-6 Start EtherCAT Communication ..................................................................................................A-7

A-2 Programming Example To Detect Valid I/O Process Data .................................................A-8

A-3 Process Data Exchange in PROGRAM Mode......................................................................A-9

A-3-1 Detection Method and Timing Considerations ............................................................................A-9

A-3-2 Program Example for the EtherCAT Master..............................................................................A-10

A-3-3 Program Example for the EtherCAT Slave Unit ........................................................................A-11

A-4 CoE Objects .........................................................................................................................A-13

A-4-1 Object Dictionary Area ..............................................................................................................A-13

A-4-2 Data Type..................................................................................................................................A-13

A-4-3 Format of Objects......................................................................................................................A-13

A-4-4 Communication Objects............................................................................................................A-14

A-4-5 PDO Mapping Objects ..............................................................................................................A-16

A-4-6 Sync Manager Communication Objects....................................................................................A-19

A-4-7 Device Profile Area ...................................................................................................................A-22

A-5 Creating I/O Tables ..............................................................................................................A-24

A-5-1 I/O Table Overview....................................................................................................................A-24

A-5-2 Connecting Programming Devices to the PLC..........................................................................A-24

A-5-3 Procedure for Creating I/O Tables.............................................................................................A-25

4

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 7

Index

CONTENTS

A-6 FINS Commands..................................................................................................................A-29

A-6-1 Introduction............................................................................................................................... A-29

A-6-2 Details on FINS Commands .....................................................................................................A-29

A-7 Version Information.............................................................................................................A-33

CJ-series EtherCAT Slave Units Operation Manual (W541)

5

Page 8

CONTENTS

6

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 9

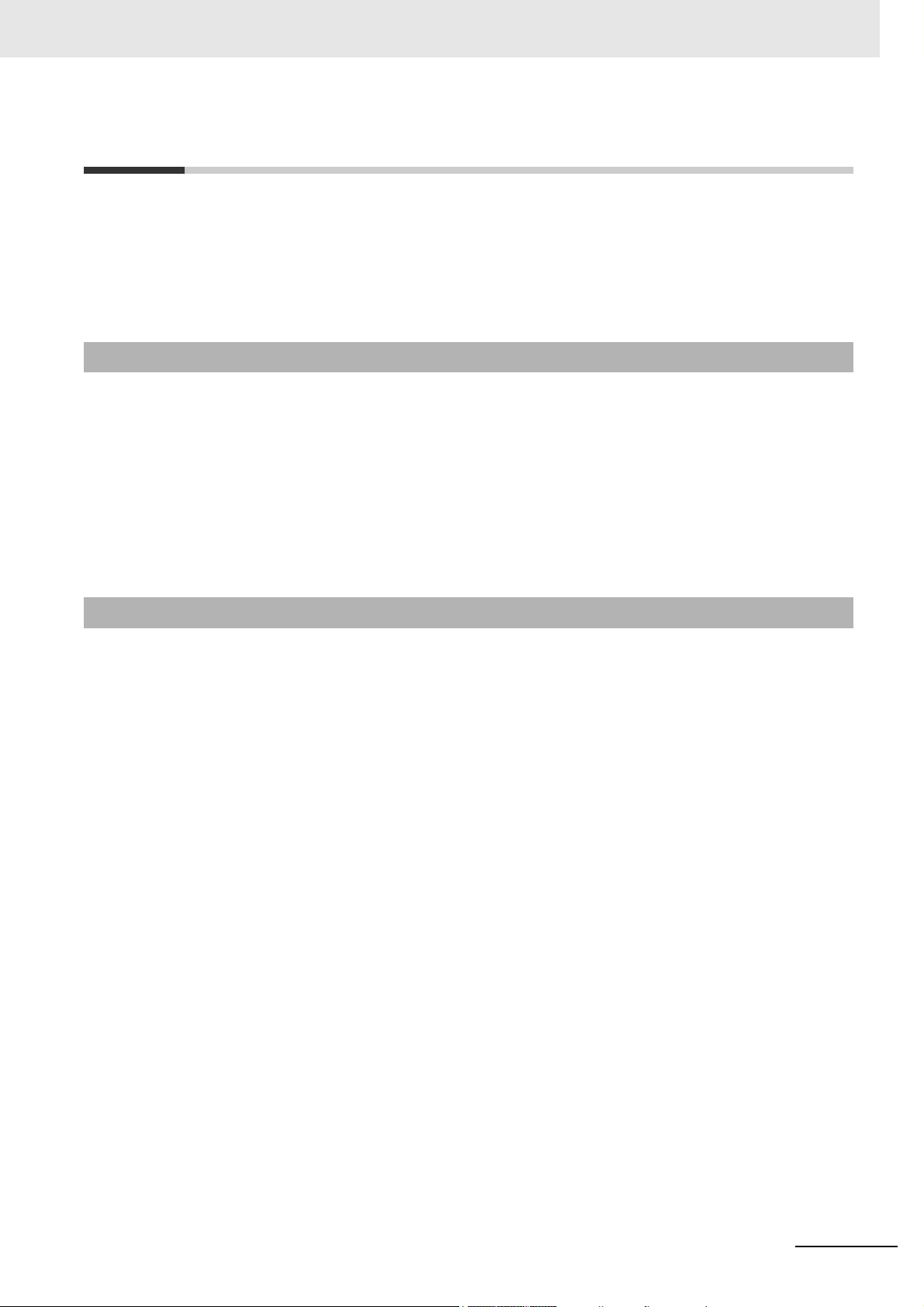

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locki ng the slide rs by moving them toward the back of the U nits. The End Cover is connecte d in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

£

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

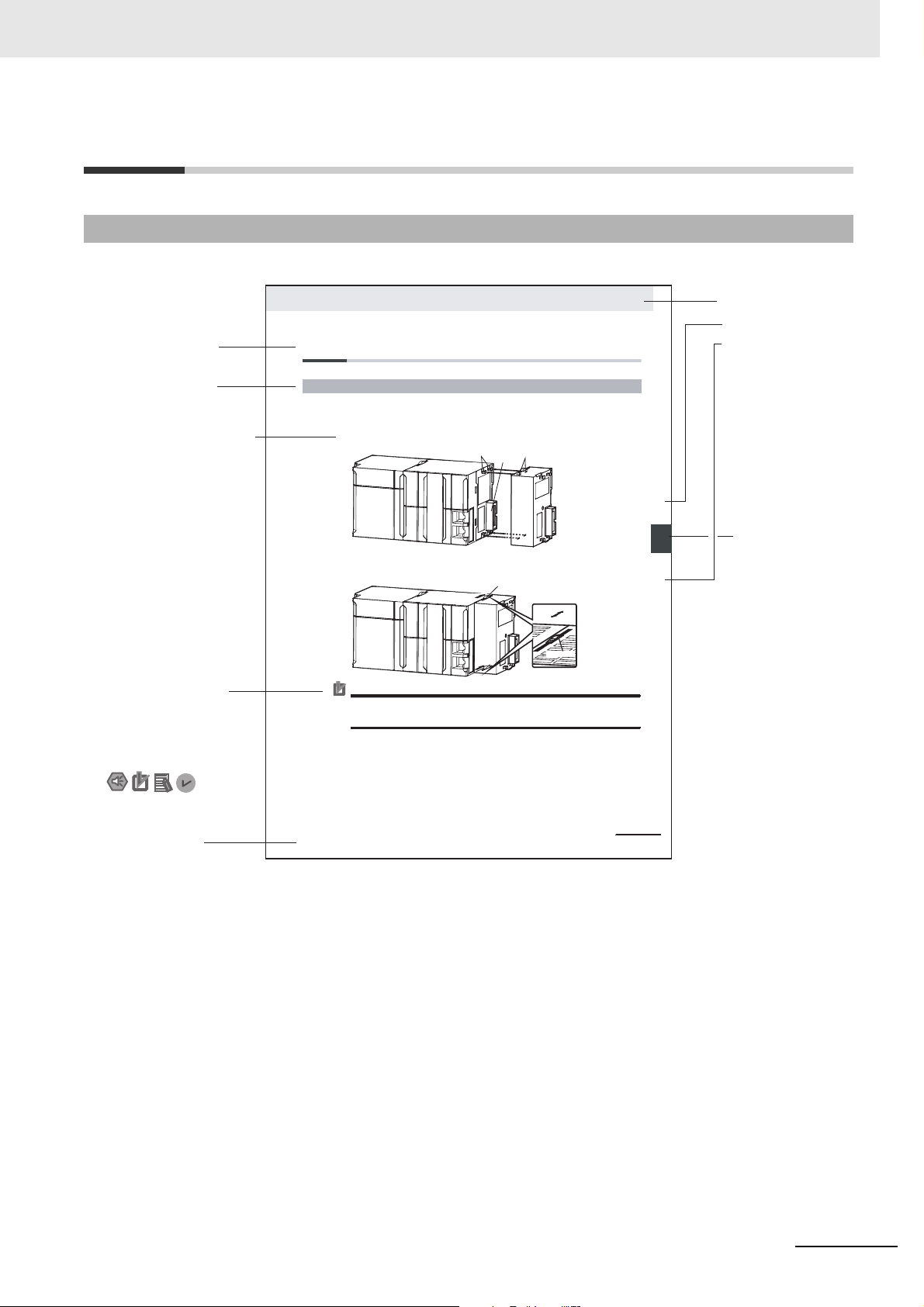

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Page Structure and Icons

The following page structure is used in this manual.

Manual Structure

CJ-series EtherCAT Slave Units Operation Manual (W541)

7

Page 10

Manual Structure

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

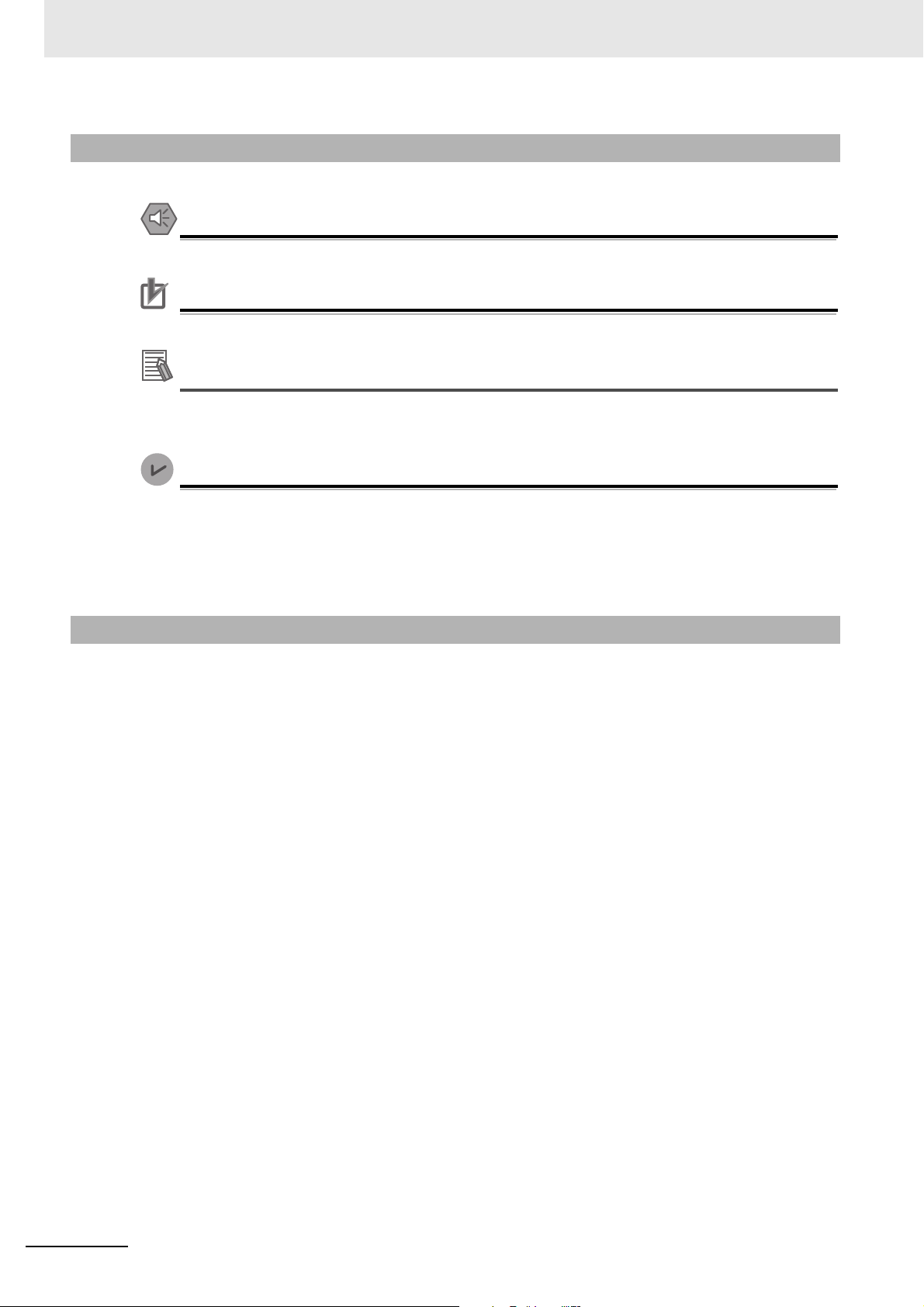

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Information on the differences in specifications and functionality for CPU Units and EtherCAT

Slave Units with different unit versions and for different versions of the CX-Programmer is

given.

Note References are provided to more detailed or related information.

Precautions on Terminology

• In this manual, “download” refers to transferring data from the CX-Programmer to the physical PLC

and “upload” refers to transferring data from the physical PLC to the CX-Programmer.

• The CJ-series EtherCAT Slave Unit can connect with the CJ-series CPU Unit, CP-series CPU Unit

and the NSJ-series CPU Unit. In this manual, the CJ-series CPU Unit is used as an example.

8

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 11

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

CJ-series EtherCAT Slave Units Operation Manual (W541)

9

Page 12

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

10

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 13

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

EtherCAT Slave Unit.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in death or serious injury. Additionally, there may be

severe property damage.

Safety Precautions

Symbols

Caution

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates the precaution for high temperatures.

CJ-series EtherCAT Slave Units Operation Manual (W541)

11

Page 14

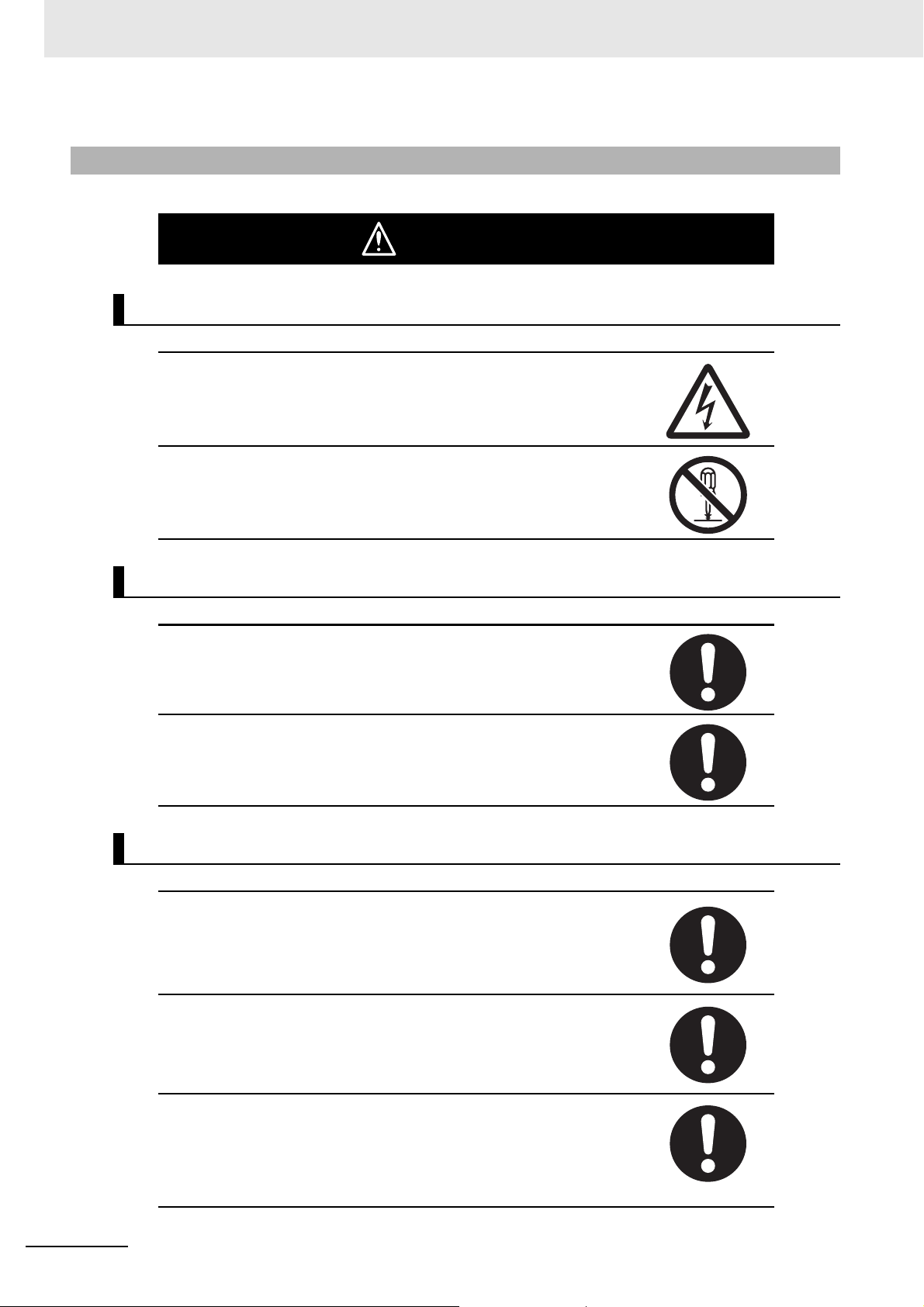

Safety Precautions

Warnings

During Power Supply

Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

Do not attempt to take any Unit apart. In particular, high-voltage parts are

present in the Power Supply Unit while power is supplied or immediately

after power is turned OFF. Touching any of these parts may result in electric

shock. There are sharp parts inside the Unit that may cause injury.

WARNING

Transferring

Always confirm safety at the destination node before transferring a program

to another node or changing contents of the I/O memory area. Doing either

of these without confirming safety may result in injury.

Confirm safety before transferring data files stored in the file memory (Memory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

programming device. Otherwise, the devices connected to the output Unit

may malfunction regardless of the operation mode of the CPU Unit.

Fail-safe Measures

Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

Unintended outputs may occur when an error occurs in memory used for

CJ-series Units. As a countermeasure for such problems, external safety

measures must be provided to ensure safe operation of the system.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

Unexpected operation, however, may still occur for errors in the I/O control

section, errors in I/O memory, and other errors that cannot be detected by

the self-diagnosis function. As a countermeasure for all such errors, external

safety measures must be provided to ensure safety in the system.

12

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 15

The Controller outputs may remain ON or OFF due to deposition or burning

of the output relays or destruction of the output transistors.

As a countermeasure for such problems, external safety measures must be

provided to ensure safe operation of the system.

When the 24-V DC output (service power supply to the PLC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures

must be provided to ensure safety in the system.

Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes. Serious accidents

may result from abnormal operation if proper measures are not provided.

The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing

the status of any part of memory allocated to I/O Units, Special I/O Units, or

CPU Bus Units. Any changes to the data allocated to any Unit may result in

unexpected operation of the loads connected to the Unit. Any of the following

operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a programming device.

• Changing present values in memory from a programming device.

• Force-setting/-resetting bits from a programming device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

Safety Precautions

Actual Operation

Check the user program, data, and parameter settings for proper execution

before you use them for actual operation.

Voltage and Current Inputs

Make sure that the voltages and currents that are input to the Units and

slaves are within the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may

cause accidents or fire.

CJ-series EtherCAT Slave Units Operation Manual (W541)

13

Page 16

Safety Precautions

Cautions

Application

Do not touch any Unit when power is being supplied or immediately after the

power supply is turned OFF. Doing so may result in burn injury.

Wiring

Caution

Be sure that all terminal screws and cable connector screws are tightened to

the torque specified in the relevant manuals. The loose screws may result in

fire or malfunction.

Online Editing

Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

14

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 17

Precautions for Safe Use

Disassembly and Dropping

• Do not attempt to disassemble, repair, or modify any Units. Doing so may result in malfunction, fire or

electric shock.

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunctioning or burning.

Mounting

• After connecting Power Supply Units, CPU Units, I/O Units, Special I/O Units, or CPU Bus Units

together, secure the Units by sliding the sliders at the top and bottom of the Units until they click into

place. Correct operation may not be possible if the Units are not securely properly.

• Be sure to attach the end cover provided with the CPU Unit to the right-most Unit. CJ-series PLCs

will not operate properly if the end cover is not attached.

Precautions for Safe Use

Transporting

• When transporting the Unit, use special packing boxes and protect it from being exposed to excessive vibration or impact during transportation.

Installation

• Always connect to a ground of 100 Ω or less when installing the Units. A ground of 100 Ω or less

must be installed when shorting the GR and LG terminals on the Power Supply Unit.

Wiring

• Follow the instructions in this manual to correctly perform wiring.

Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may

result in burning.

• Use parts and tools appropriate for wiring.

• Do not pull on the cables or bend the cables beyond their natural limit.

Do not place heavy objects on top of the cables or other wiring lines. Doing so may break the cables.

• Mount terminal blocks and connectors only after checking the mounting location carefully.

Be sure that the terminal blocks, Memory Units, expansion cables, and other items with locking

devices are properly locked into place. Improper locking may result in malfunction.

• Before you connect a computer to the PLC, disconnect the power supply plug of the computer from

the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG terminal has the same electrical potential as the FG (GR) terminal on the Power Supply Unit. A difference

in electric potential between the computer and PLC may cause failure or malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to terminals. Connection

of bare stranded wires may result in burning.

CJ-series EtherCAT Slave Units Operation Manual (W541)

15

Page 18

Precautions for Safe Use

Power Supply Design

• Do not exceed the rated supply capacity of the Power Supply Units in the CJ-series PLC. The rated

supply capacities are given in the operation manual of the CPU Units.

If the capacity is exceeded, operation may stop, malfunctions may occur, or data may not be backed

up normally for power interruptions.

Use CJ-series Power Supply Units for both the CJ-series CPU Rack and Expansion Racks.

Operation is not possible if an NJ/NX-series Power Supply Unit is used with a CJ-series CPU Unit.

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to the relevant manuals for surge current specifications. Refer to the operation manual of the

CPU Units for surge current specifications.

• If the full dielectric strength voltage is applied or turned OFF using the switch on the tester, the generated impulse voltage may damage the Power Supply Unit. Use the adjustment on the tester to gradually increase and decrease the voltage.

• Apply the voltage between the Power Supply Unit's L1 or L2 terminal and the GR terminal when testing insulation and dielectric strength.

• Do not supply AC power from an inverter or other device with a square-wave output. Internal temperature rise may result in smoking or burning. Always input a sinusoidal wave with the frequency that is

given in the operation manual of the CPU Units.

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Turning ON the Power Supply

• Always turn ON power to the PLC before turning ON power to the control system. If the PLC power

supply is turned ON after the control power supply, temporary errors may result in control system signals because the output terminals on DC Output Units and other Units may momentarily turn ON

when power is turned ON to the PLC.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may

result in burning.

Actual Operation

• Check the user program, data, and parameter settings for proper execution before you use them for

actual operation.

• Confirm that the I/O Communication Area Setting Table and I/O Reference Area Setting Table settings are correct. Incorrect system settings can cause unexpected behavior.

Turning OFF the Power Supply

• Do not disconnect the cable or turn OFF the power supply to the PLC when downloading data or the

user program from Support Software.

• Always turn OFF the power supply to the PLC before attempting any of the following.

a) Mounting or removing I/O Units or the CPU Unit

b) Assembling the Units

c) Setting DIP switches or rotary switches

d) Connecting cables or wiring the system

e) Connecting or disconnecting the connectors

• Do not touch the terminals on the Power Supply Unit immediately after turning OFF the power supply.

Residual voltage may cause electrical shock.

16

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 19

Precautions for Safe Use

Operation

• Confirm that no adverse effect will occur in the system before you attempt any of the following.

a) Changing the operating mode of the CPU Unit (including changing the setting of the Operating

Mode at Startup)

b) Changing the user program or settings

c) Changing set values or present values

d) Forced refreshing

• After you change any slave or Unit settings, carefully check the safety of the controlled system before

you restart the Unit.

EtherCAT Communications

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCAT are within specifications.

• Do not connect EtherCAT communications to EtherNet/IP, a standard in-house LAN, or other networks. An overload may cause the network to fail or malfunction.

• The maximum length between nodes is 100 m. However, some cables are specified for less than 100

m. Generally speaking, if the conductors are twisted wire rather than solid wire, transmission performance will be lower, and reliable communications may not be possible at 100 m. Confirm details with

the cable manufacturer.

• If noise occurs or an EtherCAT slave is disconnected from the network, any current communications

frames may be lost. If frames are lost, slave I/O data is not communicated, and unintended operation

may occur. The slave outputs will behave according to the slave specifications. Confirm that the system will not be adversely affected before you disconnect a slave.

• When an EtherCAT slave is disconnected or disabled, communications will stop and control of the

outputs will be lost not only for the disconnected slave, but for all slaves connected after it. Confirm

that the system will not be adversely affected before you disconnect or disable a slave.

Unit Replacement

• When replacing parts, be sure to confirm that the rating of a new part is correct. Not doing so may

result in malfunction or burning.

• After replacing Units, resume operation only after transferring to the new CPU Unit and/or Special I/O

Units the contents of the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in unexpected operation.

• If you replace a CPU Bus Unit or Special I/O Unit, refer to operation manual for the Unit for information on the data required for individual Units and redo the necessary settings.

Disposal

• Dispose of the product according to local ordinances as they apply.

CJ-series EtherCAT Slave Units Operation Manual (W541)

17

Page 20

Precautions for Correct Use

Precautions for Correct Use

Storage, Mounting, and Wiring

• Do not operate the control system in the following locations. Operation may stop or malfunctions may

occur.

a) Locations subject to direct sunlight

b) Locations subject to temperatures or humidity outside the range specified in the specifications

c) Locations subject to condensation as the result of severe changes in temperature

d) Locations subject to corrosive or flammable gases

e) Locations subject to dust (especially iron dust) or salts

f) Locations subject to exposure to water, oil or chemicals

g) Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Controller in the following locations.

a) Locations subject to static electricity or other forms of noise

b) Locations subject to strong electromagnetic fields

c) Locations subject to possible exposure to radioactivity

d) Locations close to power lines

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Use the rated power supply voltage for the Power Supply Units. Take appropriate measures to

ensure that the specified power with the rated voltage and frequency is supplied in places where the

power supply is unstable.

• Install the control system away from sources of heat and ensure proper ventilation. Not doing so may

result in malfunction, in operation stopping, or in burning.

• Use proper connection methods and EtherCAT communication cables. Otherwise, communications

may be faulty. Refer to 2-3 EtherCAT Network Wiring on page 2-10.

• Do not allow foreign matter to enter the openings in the Unit. Doing so may result in Unit burning,

electric shock, or failure.

• Do not allow wire clippings, shavings, or other foreign material to enter any Unit. Otherwise, Unit

burning, failure, or malfunction may occur. Cover the Units or take other suitable countermeasures,

especially during wiring work.

18

EtherCAT Communications

• Do not disconnect the EtherCAT slave cables during operation. The outputs will become unstable.

Operating Environment

• The operating environment of the PLC System can have a large effect on the longevity and reliability

of the system. Improper operating environments can lead to malfunction, failure, and other unforeseeable problems with the PLC System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 21

Regulations and Standards

Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directive

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.

*1

Regulations and Standards

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61131-2.

Conformance to EC Directives

The CJ-series PLCs comply with EC Directives. To ensure that the machine or device in which the

CJ-series PLC is used complies with EC Directives, the PLC must be installed as follows:

• The CJ-series PLC must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies used for the

communications power supply and I/O power supplies.

• CJ-series PLCs complying with EC Directives also conform to the Common Emission Standard

(EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions. You must therefore confirm that the overall machine or equipment complies with

EC Directives.

Conformance to UL and CSA Standards

Some CJ-series PLCs comply with UL and CSA standards. Refer to the OMRON website

(http://www.ia.omron.com/) or consult your OMRON representative for the applicable standards for

each model. The Instruction Sheet is provided with the product depending on the models. The Instruc-

tion Sheet provides the application conditions for complying with the standards.

CJ-series EtherCAT Slave Units Operation Manual (W541)

19

Page 22

Regulations and Standards

Conformance to Shipbuilding Standards

Some CJ-series PLCs comply with shipbuilding standards. Refer to the OMRON website

(http://www.ia.omron.com/) or consult your OMRON representative for the applicable standards for

each model. If you use a CJ-series product that complies with shipbuilding standards and the machinery or system in which you use the CJ-series products must also comply with the standards, consult

with your OMRON representative. Application conditions are defined according to the installation location. Application may not be possible for some installation locations.

Usage Conditions for NK and LR Shipbuilding Standards

• The CJ-series PLC must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other material.

• The following noise filter must be connected to the power supply line.

Name Manufacturer Model

Noise filter Cosel Co., Ltd. TAH-06-683

Conformance to KC Standards

Observe the following precaution if you use CJ-series CJ1W-ECT21 EtherCAT Slave Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

20

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 23

Unit Versions

Precautions for Correct Use

CJ1W-

UNIT

Lot No. YYMMDD xxxx Ver.1.0

OMRON Corporation

MADE IN JAPAN

Product nameplate

Unit version

Example for unit version 1.0

Lot No.

Unit model

Serial No.

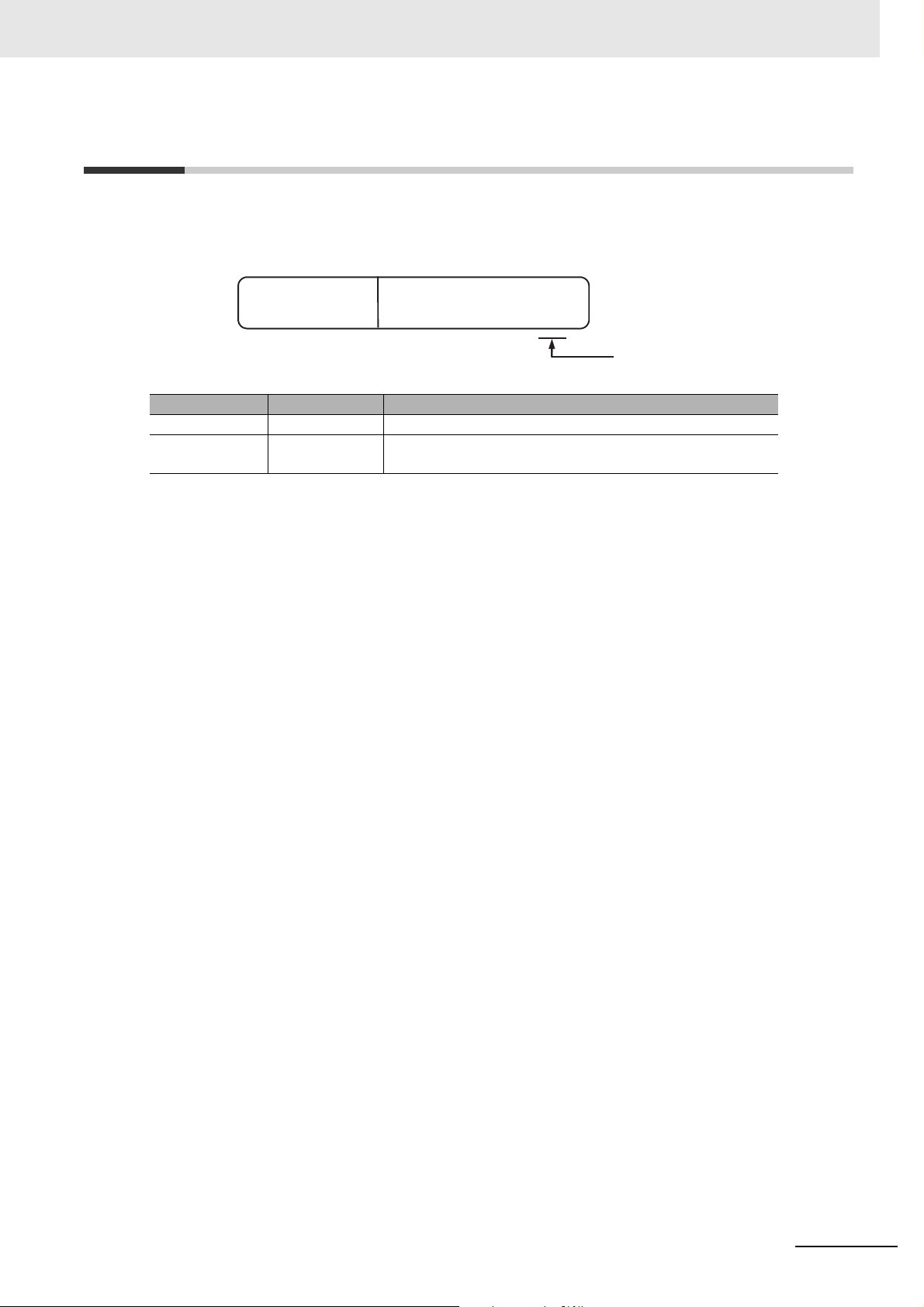

Unit Versions

A “unit version” has been introduced to manage CPU Units in the CJ Series according to differences in

functionality accompanying Unit upgrades.

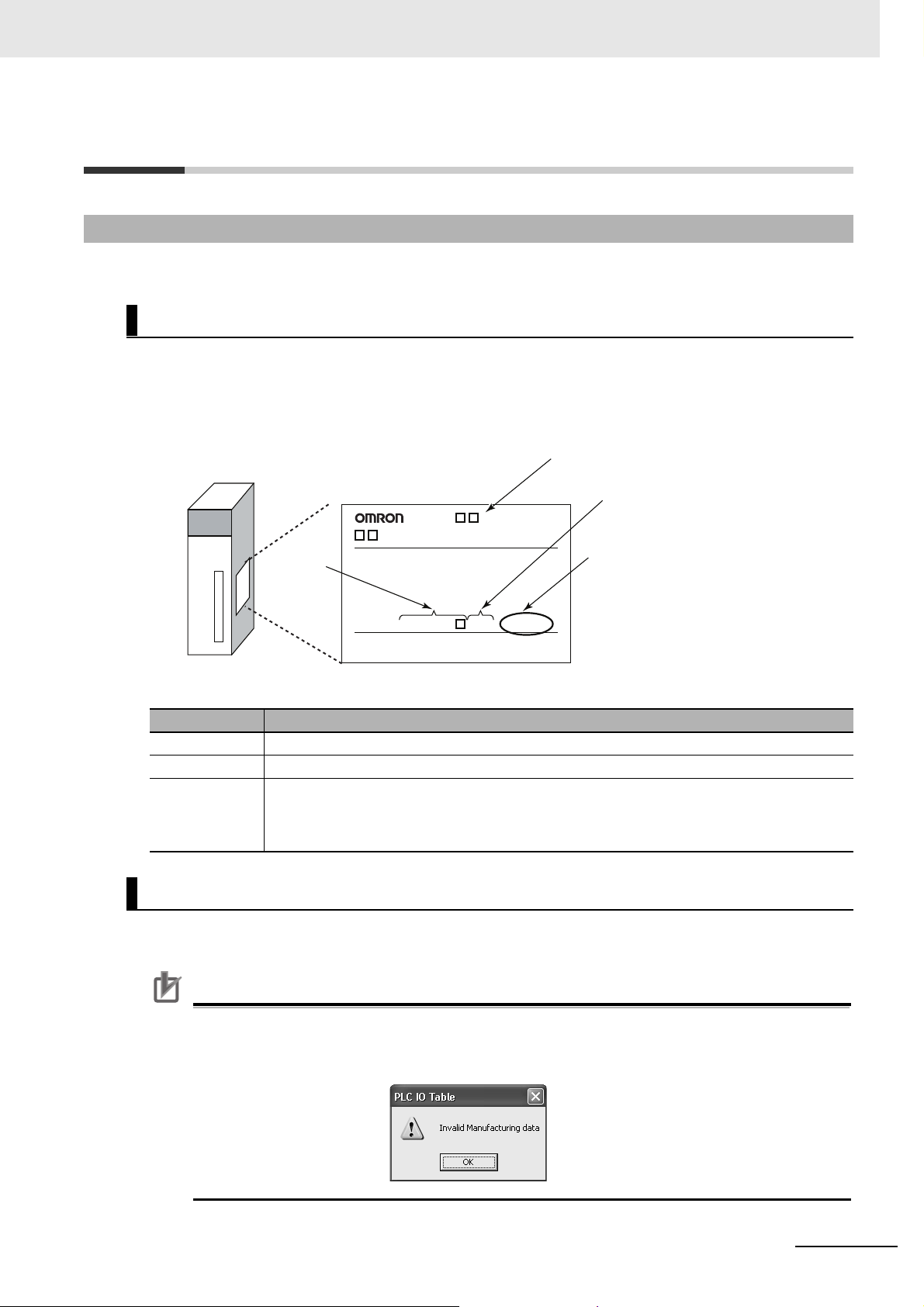

Notation of Unit Versions on Products

The Unit version is given to the right of the lot number on the nameplate of the products for which unit

versions are being managed, as shown below.

Example of a CJ-series Unit:

Unit Versions

The following information is provided on the ID information label.

Item Description

Unit model Gives the model of the Unit.

Unit version Gives the unit version of the Unit.

Lot number and

serial number

Gives the lot number and serial number of the Unit.

• YYMMDD: Lot number (

• xxxx: Serial number

: For use by OMRON)

Confirming Unit Versions with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using the Unit Manufacturing

Information.

The unit versions of Pre-Ver.1.0 Units cannot be confirmed in Unit Manufacturing Information.

The following dialog box is displayed.

CJ-series EtherCAT Slave Units Operation Manual (W541)

21

Page 24

Unit Versions

In the IO Table Window, right-click the Unit to check the Unit Version and select Unit Manufacturing

Information.

The following Unit Manufacturing Information Dialog Box will be displayed.

Unit Versions and CX-Programmer Versions

The functions that are supported depend on the unit version of the Unit. The version of CX-Programmer

that supports the functions that were added for an upgrade is also required to use those functions.

Refer to A-7 Version Information on page A-33 for the functions that are supported by each version.

22

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 25

Related Manuals

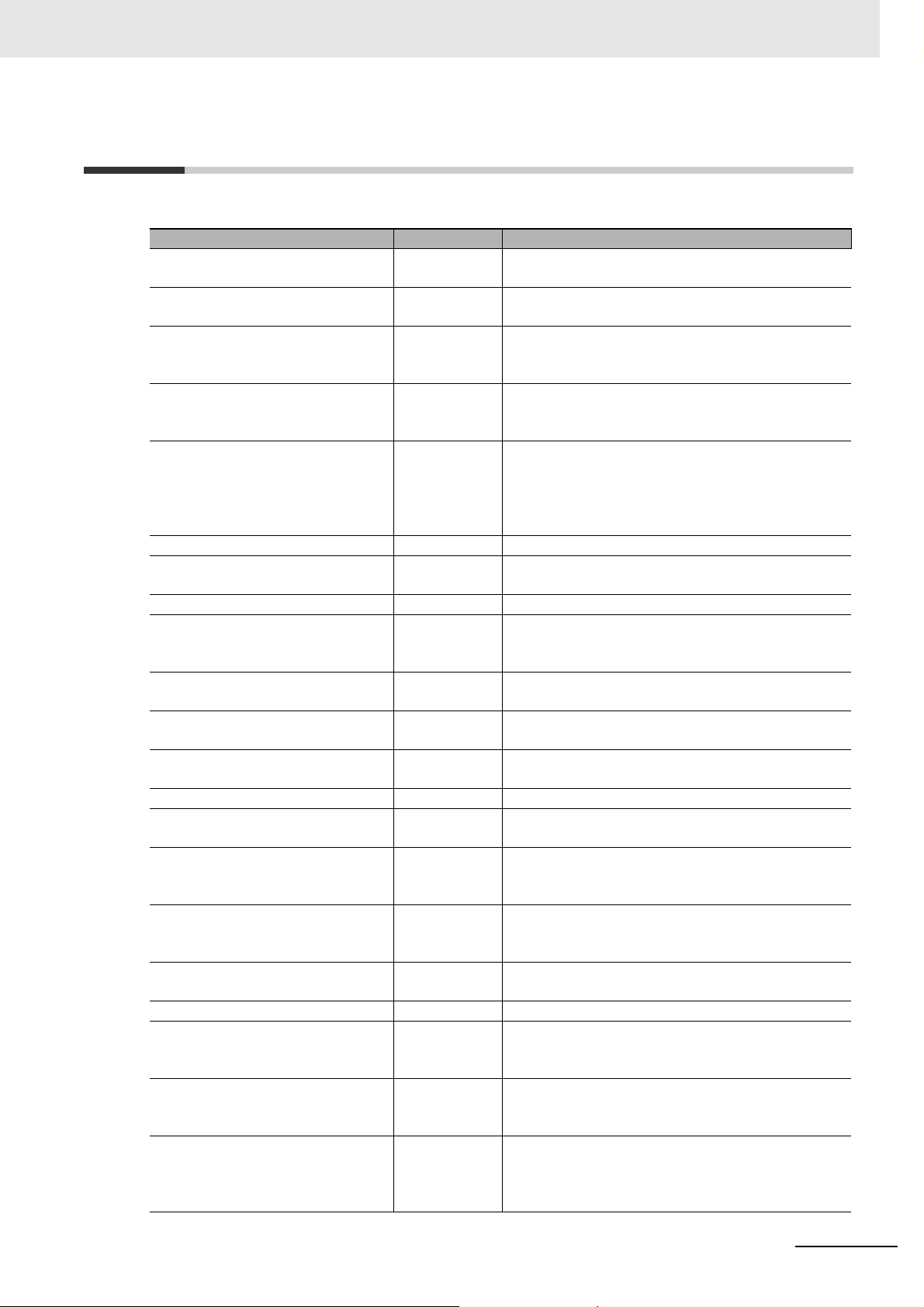

The following manuals are related. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

CJ-series EtherCAT®

Slave Units Operation

Manual

CX-Programmer Operational Manual

SYSMAC CJ Series Programmable Controllers

Operation Manual

SYSMAC CJ Series CJ2

CPU Unit Software

User’s Manual

SYSMAC CJ Series CJ2

CPU Unit Hardware

User’s Manual

SYSMAC ONE NSJ

Series Controllers Operation Manual

SYSMAC CP Series

CP1H CPU Unit Operation Manual

W541 CJ1W-ECT21 Learning how to use an

EtherCAT Slave Unit.

W446 CXONE-ALC-V4

W393 CJ1G-CPU

W473 CJ2H-CPU6-EIP

W472 CJ2H-CPU6-EIP

W452 NSJ5-TQ(B)-G5D

W450 CP1H-X40D-

CXONE-ALD-V4

CJ1M-CPU

CJ1G-CPUP

CJ1G/H-CPUH

CJ2H-CPU6

CJ2M-CPU

CJ2H-CPU6

CJ2M-CPU

NSJ5-SQ(B)-G5D

NSJ8-TV(B)-G5D

NSJ10-TV(B)-G5D

NSJ12-TS

NSJ5-TQ

NSJ5-SQ(B)-M3D

NSJ8-TV(B)-M3D

NSJW-ETN21

NSJW-CLK21-V1

NSJW-IC101

CP1H-XA40D-

CP1H-Y20DT-D

(B)-

(B)-M3D

G5D

Learning the functions and

application methods of the

CX-Programmer software.

Learning the functions and

application methods of the

CJ Series PLC.

Learning the functions and

application methods of the

CJ2 Series PLC Software.

Learning the functions and

application methods of the

CJ2 Series PLC Hardware.

Learning the functions and

application methods of the

NSJ Series Controller.

Learning the functions and

application methods of the

CP1H Series Controller.

The following items are described: the

overall system and configuration methods of an EtherCAT Slave Unit, information on hardware and functions to set up,

control and monitor the EtherCAT Slave

Unit.

Provides information on how to use the

CX-Programmer for all functionality

except for function blocks.

Provides an outline of, and describes the

design, installation, maintenance, and

other basic operations for the CJ-series

PLCs.

Describes the following for CJ2 CPU

Units:

• CPU Unit operation

• Internal memory

• Programming

• Settings

• Function built into the CPU Unit

Use together with the SYSMAC CJ

Series CJ2 CPU Unit Hardware User’s

Manual (W472).

Describes the following for CJ2 CPU

Units:

• Overview and features

• Basic system configuration

• Part nomenclature and functions

• Mounting and setting procedure

• Remedies for errors

Use together with the SYSMAC CJ

Series CJ2 CPU Unit Software User’s

Manual (W473).

Provides basic specifications on NSJ

Controllers, including an overview,

designing, installation, and maintenance.

Provides basic specifications on

CP-series CP1H PLCs, including an

overview, designing, installation, and

maintenance.

Related Manuals

CJ-series EtherCAT Slave Units Operation Manual (W541)

23

Page 26

Related Manuals

Manual name Cat. No. Model numbers Application Description

NJ/NX-series CPU Unit

Software User’s Manual

Sysmac Studio Version 1

Operation Manual

NJ/NX-series CPU Unit

Built-in EtherCAT® Port

User’s Manual

W501

W504

W505

NX701-

NJ501-

NJ301-

NJ101-

SYSMAC-SE2

NX701-

NJ501-

NJ301-

NJ101-

Learning how to program

and set up an

NJ/NX-series CPU Unit.

Mainly software information is provided.

Learning about the operating procedures and functions of the Sysmac Studio.

Using the built-in EtherCAT

port on an NJ/NX-series

CPU Unit.

The following information is provided on

an NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3

language specifications

Use this manual together with the

NX-series CPU Unit Hardware User’s

Manual (Cat. No. W535) or the NJ-series

CPU Unit Hardware User’s Manual (Cat.

No. W500).

Describes the operating procedures of

the Sysmac Studio.

Information on the built-in EtherCAT port

is provided.

This manual provides an introduction and

provides information on the configuration,

features and setup.

Use this manual together with the

NX-series CPU Unit Hardware User’s

Manual (Cat. No. W535) or NJ-series

CPU Unit Hardware User’s Manual (Cat.

No. W500) and with the NJ/NX-series

CPU Unit Software User’s Manual (Cat.

No. W501).

24

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 27

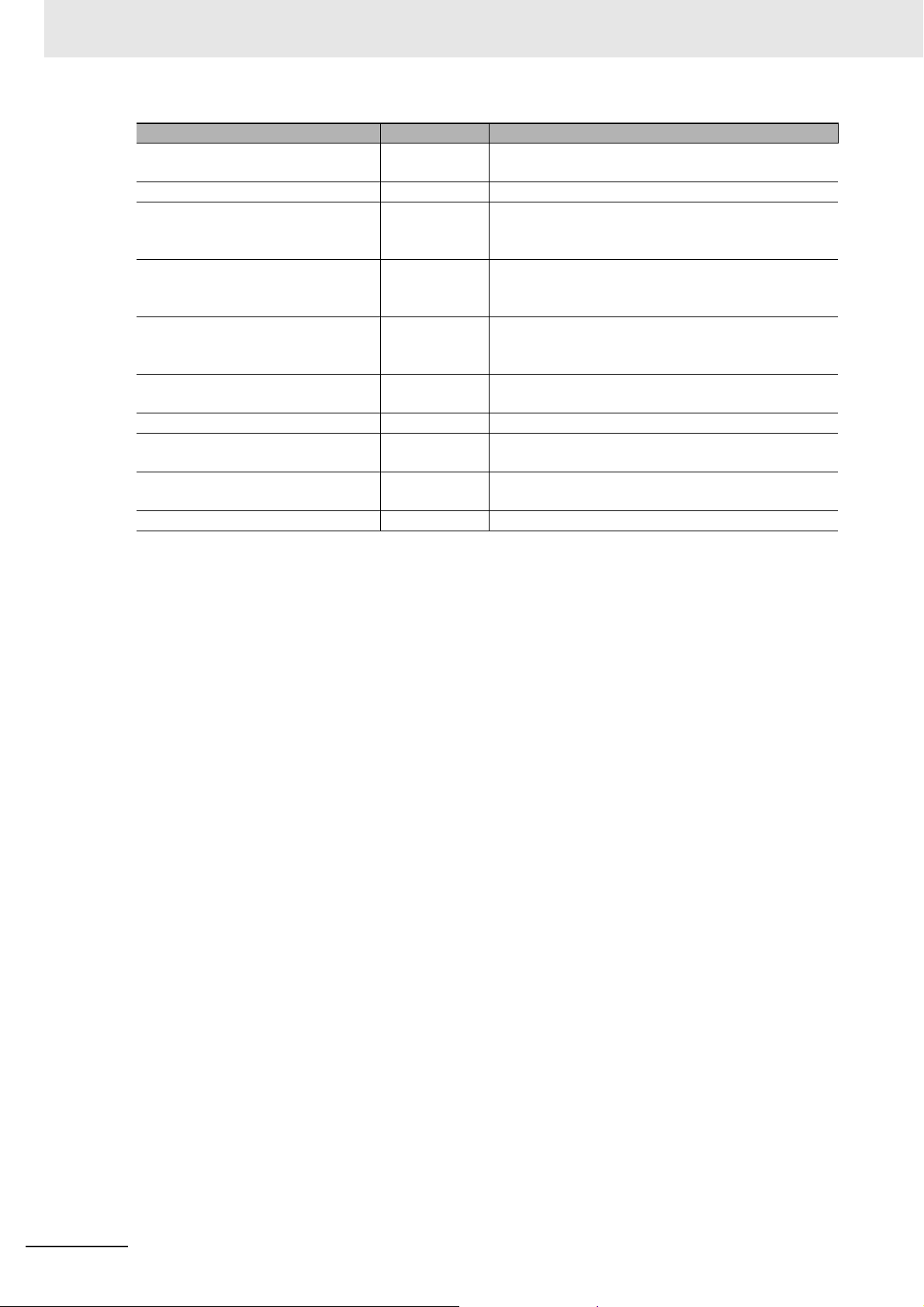

Terminology

Term Abbreviation Description

application layer status, AL status --- Status for indicating information on errors that occur in

CAN application protocol over EtherCAT

CAN in Automation CiA CiA is the international users' and manufacturers'

device profile --- A collection of device dependent information and func-

device variable --- A variable in the NJ/NX-series CPU Unit to which pro-

EtherCAT slave controller ESC A controller for EtherCAT slave communications.

EtherCAT slave information ESI An XML file that contains setting information for an

EtherCAT state machine ESM An EtherCAT communications state machine.

EtherCAT Technology Group ETG The ETG is a global organization in which OEM, end

I/O map settings --- Settings that assign variables to I/O ports. Assignment

I/O port --- A logical interface that is used by the CPU Unit to

I/O refreshing --- Cyclic data exchange with external devices that is per-

index --- Address of an object within an application process.

network configuration information --- The EtherCAT network configuration information held

object --- An abstract representation of a particular component

object dictionary OD Data structure that contains description of data type

Operational --- A state in EtherCAT communications where SDO com-

PDO communications --- An acronym for process data communications.

Pre-Operational --- A state in EtherCAT communications where only SDO

process data --- Collection of application objects designated to be

process data communications --- One type of EtherCAT communications in which pro-

Terminology

an application on a slave.

CoE A CAN application protocol service implemented on

EtherCAT.

group that develops and supports higher-layer protocols.

tionality providing consistency between similar devices

of the same device type.

cess data on an EtherCAT slave is allocated. Slave

process data is accessed by directly reading and writing device variables from user applications on the

NJ/NX-series CPU Unit.

EtherCAT slave.

users, and technology providers join forces to support

and promote the further technology development.

information between I/O ports and variables.

exchange data with an external device (slave or Unit).

formed with predetermined memory addresses.

by the EtherCAT master.

within a device, which consists of data, parameters,

and methods.

objects, communication objects and application

objects.

munications and I/O are possible.

communications are possible with the slaves, i.e., no

I/O can be performed.

downloaded cyclically or acyclically for the purpose of

measurement and control.

cess data objects (PDOs) are used to exchange information cyclically and in realtime. This is also called

PDO communications.

CJ-series EtherCAT Slave Units Operation Manual (W541)

25

Page 28

Terminology

process data object PDO A structure that describes the mappings of parameters

receive PDO RxPDO A process data object received by an EtherCAT slave.

Safe-Operational --- A state in EtherCAT communications where only SDO

SDO communications --- One type of EtherCAT communications in which ser-

service data object SDO CoE asynchronous mailbox communications where all

Slave Information Interface SII Slave information that is stored in non-volatile memory

subindex --- Sub-address of an object within the object dictionary.

Sync Manager SM Collection of control elements to coordinate access to

task period --- The interval at which the primary periodic task or a

transmit PDO TxPDO A process data object sent from an EtherCAT slave.

Term Abbreviation Description

that have one or more process data entities.

communications and reading input data from slaves

are possible. Outputs from slaves are not performed.

vice data objects (SDOs) are used to transmit information whenever required.

objects in the object dictionary can be read and written.

in the slave.

concurrently used objects.

periodic task is executed.

26

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 29

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision History

Cat. No.

Revision code Date Revised content

01 April 2015 Original production

02 April 2019 Added information on the unit version that supports a ring

W541-E1-02

Revision code

topology.

CJ-series EtherCAT Slave Units Operation Manual (W541)

27

Page 30

Revision History

28

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 31

1

2

3

4

5

6

A

I

1

2

3

4

5

6

A

I

Features and System

Configuration

EtherCAT

Communications

Troubleshooting

Appendices

Maintenance and Replacement

Index

Nomenclature and

Installation

Memory Allocations

Sections in this Manual

Sections in this Manual

CJ-series EtherCAT Slave Units Operation Manual (W541)

29

Page 32

Sections in this Manual

30

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 33

Features and System Configuration

This section provides an introduction to EtherCAT networks and includes features, system configurations, specifications and setting procedures.

1-1 Introduction to EtherCAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 How EtherCAT Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Types of EtherCAT Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 EtherCAT Slave Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 System Configuration of CJ-series EtherCAT Slave Unit . . . . . . . . . . . . . 1-7

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-4-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-4-2 Functional and Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-4-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-5 Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1

CJ-series EtherCAT Slave Units Operation Manual (W541)

1 - 1

Page 34

1 Features and System Configuration

Slave

• Output data addressed to the local node is read.

• Input data is written.

Ethernet frames

EtherCAT master

Slave

data

Slave

IN

OUT

1-1 Introduction to EtherCAT

EtherCAT (Ethernet Control Automation Technology) is a high-performance industrial network system

that enables faster and more efficient communications based on Ethernet.

Each node achieves a short communications cycle time by transmitting Ethernet frames at high speed.

Although EtherCAT is a unique communications protocol, standard Ethernet technology is used for the

physical layer, which means you can use Ethernet cables for wider application.

The effectiveness of EtherCAT can be fully utilized not only in large control systems that require high

processing speeds and system integrity, but also in small and medium control systems.

1-1-1 How EtherCAT Works

With EtherCAT, Ethernet frames pass through all of the slave nodes.

When a frame passes through a slave node, the slave node reads and writes the data in the area that is

allocated to it in the frame in a few nanoseconds.

The Ethernet frames that are transmitted by the EtherCAT master pass through all EtherCAT slaves

without stopping. The last slave returns all of the frames, which again pass through all of the slaves

before returning to the EtherCAT master.

This mechanism ensures high speed and realtime data transmission.

The data exchanges that are cyclically performed between the EtherCAT master and EtherCAT slaves

use EtherCAT datagrams that are stored directly in the Ethernet frames.

Each EtherCAT datagram consists of a header (including the data length and one or more slave

addresses), data, and a working counter (i.e., check bits).

If you think of an Ethernet frame as a train, the EtherCAT datagrams would be the cars of the train.

1 - 2

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 35

1 Features and System Configuration

Ethernet

header

CRC

Ethernet data (1,498 bytes max.)

Data

Header

WKC

1st to nth EtherCAT datagrams

EtherCAT

header

1st EtherCAT

datagram

2nd EtherCAT

datagram

nth EtherCAT

datagram

. . . . .

EtherCAT frame

Ethernet frame

WKC: Working counter

1-1 Introduction to EtherCAT

1

1-1-2 Types of EtherCAT Communications

1-1-2 Types of EtherCAT Communications

The following 2 types of communications are available with EtherCAT.

PDO communications are executed in each EtherCAT communications cycle to refresh data continuously. SDO communications are executed between PDO communications.

Process Data Communications (PDO Communications)

PDO communications transfers process data cyclically and in realtime.

The EtherCAT master maps the logical process data space to the nodes to achieve cyclic communications between the EtherCAT master and slaves.

CJ-series EtherCAT Slave Units Operation Manual (W541)

1 - 3

Page 36

1 Features and System Configuration

EtherCAT master

Slave

Ethernet frame

Slave

Slave

Slave

Logical process data

CRC

Data a

Data b

Data c

Ethernet

header

Ether

CAT

header

1st EtherCAT

datagram

2nd EtherCAT

datagram

3rd EtherCAT

datagram

Mailbox Communications (SDO Communications)

SDO communications is used to perform message communications.

Whenever necessary, the EtherCAT master sends a command to a slave, and then the slave returns a

response to the EtherCAT master.

The following data communications can be performed.

• Reading and writing process data

• Setting slaves

• Monitoring slave status

1 - 4

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 37

1 Features and System Configuration

EtherCAT Slave Unit

EtherCAT master

RxPDO

Output data to

EtherCAT Slave Unit

TxPDO

Input data to

EtherCAT master

OUT data area

(CPU Unit)

IN data area

(CPU Unit)

EtherCAT network

1-2 EtherCAT Slave Unit Features

1-2 EtherCAT Slave Unit Fea-

The EtherCAT Slave Unit has the following features when used with the CJ-series CPU Unit.

Data Exchange Between EtherCAT Master and CPU Unit

Exchange data over the EtherCAT network between the EtherCAT master and the CPU Unit through

the EtherCAT Slave Unit.

tures

1

Adjustable Data Exchange Sizes

Choose the amount of data to exchange over the EtherCAT network from 0, 50, 100, 200 or 400 bytes.

CJ-series EtherCAT Slave Units Operation Manual (W541)

1 - 5

Page 38

1 Features and System Configuration

EtherCAT Slave Unit

EtherCAT master

DeviceNet Master Unit

DeviceNet network

EtherCAT network

DeviceNet slaves

CPU Unit

Integration with Other Networks

Interface with multiple networks such as EtherCAT and DeviceNet.

1 - 6

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 39

1 Features and System Configuration

(A) EtherCAT master

(E) Communications cable

Ethernet cables

(G) Configuration Software

(D) CX-Programmer

(F) ESI files

Built-in EtherCAT port

.xml

(B) CJ-series

EtherCAT Slave Unit

CJ1W-ECT21

(C) CJ-series

CPU Unit

Input port

Output port

1-3 System Configuration of CJ-series

EtherCAT Slave Unit

An example of a system configuration for a CJ-series EtherCAT Slave Unit is shown below.

CJ-series EtherCAT Slave Unit

1-3 System Configuration of

1

(A)

(B) CJ-series Ether-

(C) CJ-series CPU

(D)

Letter Item Description

EtherCAT master

CAT Slave Unit

(CJ1W-ECT21)

Unit

CX-Programmer

*1

*2

*3

The EtherCAT master manages the EtherCAT network, monitors the status

of the slaves and exchanges I/O data with the slaves.

The CJ-series EtherCAT Slave Unit can perform the following functions

over an EtherCAT network.

• Process data communications with the EtherCAT master.

• Message communications (SDO communications) with the EtherCAT

master.

• Exchange data between the CJ-series CPU Unit and the EtherCAT master.

The main Unit that controls a CJ-series PLC. The CPU Unit refreshes I/O

for other Units and slaves, etc.

The CX-Programmer runs on a personal computer and it is used to configure I/O Communication Area Setting Table to communicate between the

CJ-series CPU Unit and the EtherCAT Slave Unit and to program, monitor,

and debug the CJ-series PLC.

CJ-series EtherCAT Slave Units Operation Manual (W541)

1 - 7

Page 40

1 Features and System Configuration

Letter Item Description

(E) Communications

Cable

(F) ESI (EtherCAT

Slave Information

File)

(G) Configuration Soft-

ware

*1. An EtherCAT Slave Unit cannot be connected to any of the OMRON CJ1W-NC□81/□82 Position Control Units

even though they can operate as EtherCAT masters.

*2. Refer to A-7 Version Information on page A-33 for information on CPU Unit version compatibility when con-

necting EtherCAT Slave Units to CJ/CP/NSJ-series CPU Units.

*3. Refer to A-7 Version Information on page A-33 for information on the versions of the CX-Programmer that you

can use to set up CJ-series EtherCAT Slave Units.

Use a double-shielded cable with aluminum tape and braiding of category

5 (100BASE-TX) or higher, and use straight wiring.

The ESI files contain information unique to the EtherCAT slaves in XML

format. You can load an ESI file into the EtherCAT master Configuration

Software to easily allocate slave process data and make other settings.

Configuration Software runs on a personal computer and it is used to configure the EtherCAT network and EtherCAT slaves.

1 - 8

CJ-series EtherCAT Slave Units Operation Manual (W541)

Page 41

1 Features and System Configuration

1-4 Specifications

This section provides the general specifications of the EtherCAT Slave Unit.

1-4-1 General Specifications

The general specifications conform to those of the CJ-series PLCs, CP-series PLCs and NSJ-series

PLCs.

1-4-2 Functional and Performance Specifications

This section provides the functional and performance specifications of the EtherCAT Slave Unit.

Item Specification

Model number CJ1W-ECT21

Applicable PLCs CJ-series, CP-series, NSJ-series

Unit classification CPU Bus Unit

Applicable unit numbers 0 to F

Mounting position CPU Rack or Expansion Rack

Number of Units that can be mounted 16 Units max. (you must allocate unique words)

CPU Unit words

used

Transmission

specifications

Current consumption 340 mA max. at 5 V DC

Weight 97 g max.

Dimensions 31 × 90 × 65 mm (W × H × D)

*1. Set with allocated DM area words (CPU Bus Unit words) or CX-Programmer.

*2. The CJ-series EtherCAT Slave Unit conforms to EtherCAT standards. Confirm the specifications of the con-

nected EtherCAT master for the support topology. The EtherCAT Slave Unit with unit version 1.0 or later supports a ring topology.

Allocated CIO Area words

(CPU Bus Unit words)

Allocated DM Area words

(CPU Bus Unit words)

Other I/O memory

CPU Bus Unit setting area Not used

Communications protocol EtherCAT protocol

Modulation Baseband

Baud rate 100 Mbps

Physical layer 100BASE-TX (IEEE 802.3)

Topology

Transmission media Category 5 or higher twisted-pair cable (Recommended cable:

Transmission distance Distance between nodes: 100 m or less

Send/receive PDO data

sizes

Mailbox data size Input: 512 bytes

Mailbox Emergency messages and SDO requests

Refreshing methods Free-Run Mode

Node address setting

range

25 words/Unit (one unit number’s words)

Unit Status 1, Unit Status 2, Slave Status 1, Slave Status 2

100 words/Unit (one unit number’s words)

I/O Communication Area Setting Table, I/O Communication

Area Reference Table

I/O communication area in any area

Depends on the specifications of the EtherCAT master

double-shielded cable with aluminum tape and braiding)

Allocatable IN and OUT data area sizes of 0, 50, 100, 200 or