Cat. No. I55E-EN-04

Programmable Controller

SYSMAC CJ-series

CJ1W-MCH72

Motion Control Unit

OPERATION MANUAL

Notice

OMRON products are manufactured for use by a trained operator and only for the purposes described in this

manual.

The following conventions are used to classify and explain the precautions in this manual. Always heed the

information provided with them.

!WARNING Indicates information that, if not heeded, could possibly result in serious injury or loss of life.

!Caution Indicates information that, if not heeded, could possibly result in minor or relatively serious injury,

damage to the product or faulty operation.

OMRON product references

All OMRON products are capitalized in this manual.

The first letter of the word Unit is also capitalized when it refers to an OMRON product, regardless of whether it

appears in the proper name of the product.

The abbreviation PLC means Programmable Logic Controller.

Visual aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

iii

Trademarks and copyrights

MECHATROLINK is a registered trademark of Yaskawa Corporation.

Trajexia is a registered trademark of OMRON.

All other product names, company names, logos or other designations mentioned herein are trademarks of their

respective owners.

Copyright

Copyright © 2009 OMRON

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained in this publication.

iv

TABLE OF CONTENTS

Precautions vii

1 Intended audience...................................................................................................................................vii

2 General precautions ................................................................................................................................vii

3 Safety precautions...................................................................................................................................vii

4 Operating environment precautions .......................................................................................................viii

5 Application precautions ........................................................................................................................... ix

6 Conformance to EC Directives................................................................................................................ xi

SECTION 1

Introduction 1

1-1 Overview .................................................................................................................................................. 1

1-2 System philosophy ................................................................................................................................... 2

1-3 Motion control concepts ...........................................................................................................................4

1-4 Servo system principles ......................................................................................................................... 13

1-5 Trajexia system architecture ................................................................................................................ 16

1-6 Cycle time .............................................................................................................................................. 17

1-7 Program control and multi-tasking.......................................................................................................... 22

1-8 Motion sequence and axes .................................................................................................................... 23

1-9 Motion buffers ....................................................................................................................................... 31

1-10 Mechanical system................................................................................................................................. 33

1-11 Axis numbers.......................................................................................................................................... 34

SECTION 2

Installation and wiring 35

2-1 Unit components .................................................................................................................................... 35

2-2 Wiring ..................................................................................................................................................... 40

2-3 Installation .............................................................................................................................................. 50

2-4 Specifications ......................................................................................................................................... 55

SECTION 3

Data exchange 59

3-1 Introduction............................................................................................................................................. 59

3-2 Memory areas ........................................................................................................................................ 60

3-3 Data........................................................................................................................................................ 62

3-4 FINS commands..................................................................................................................................... 65

SECTION 4

BASIC commands 73

4-1 Categories.............................................................................................................................................. 73

4-2 All BASIC commands .............................................................................................................................84

SECTION 5

Examples 265

5-1 How-to’s ............................................................................................................................................... 266

5-2 Practical examples ............................................................................................................................... 320

v

TABLE OF CONTENTS

SECTION 6

Troubleshooting 347

6-1 Items to Check First ............................................................................................................................. 348

6-2 Error Indicators..................................................................................................................................... 349

6-3 Troubleshooting Errors......................................................................................................................... 350

6-4 Miscellaneous....................................................................................................................................... 356

Revision history 357

vi

Intended audience 1

Precautions

1 Intended audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General precautions

The user must operate the product according to the performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the CJ1W-MCH72. Be sure to read

this manual before attempting to use the Unit and keep this manual close at

hand for reference during operation.

!WARNING It is extremely important that the CJ1W-MCH72 and related devices be used for the

specified purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying the CJ1W-MCH72 and related devices to the above

mentioned applications.

3 Safety precautions

!WARNING Never short-circuit the positive and negative terminals of the batteries, charge the

batteries, disassemble them, deform them by applying pressure, or throw them into a

fire.

The batteries may explode, combust or leak liquid.

!WARNING The CJ1W-MCH72 outputs will go off due to overload of the output transistors

(protection). As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

!WARNING The CJ1W-MCH72 will turn off the WDOG when its self-diagnosis function detects any

error. As a countermeasure for such errors, external safety measures must be provided

to ensure safety in the system.

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing so may

result in serious electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may

result in malfunction, fire, or electric shock.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may result in

serious electric shock.

vii

Operating environment precautions 4

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable Controller)

to ensure safety in the system if an abnormality occurs due to malfunction of the PLC,

malfunction of the CJ1W-MCH72, or external factors affecting the operation of the PLC

or CJ1W-MCH72. Not providing sufficient safety measures may result in serious

accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures

must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects any error

or when a severe failure alarm (FALS) instruction is executed. As a countermeasure

for such errors, external safety measures must be provided to ensure safety in the

system.

• The PLC or CJ1W-MCH72 outputs may remain ON or OFF due to deposits on or

burning of the output relays, or destruction of the output transistors. As a

countermeasure for such problems, external safety measures must be provided to

ensure safety in the system.

• When the 24 V DC output (service power supply to the PLC) is overloaded or shortcircuited, the voltage may drop and result in the outputs being turned OFF. As a

countermeasure for such problems, external safety measures must be provided to

ensure safety in the system.

• External safety measures must also be taken to ensure safety in the event of

unexpected operation when connecting or disconnecting the connectors of the

CJ1W-MCH72.

!Caution User programs written to the CJ1W-MCH72 will not be automatically backed up in the

CJ1W-MCH72 flash memory (flash memory function).

!Caution Tighten the screws on the terminal block of the Power Supply Unit to the torque

specified in this manual. Loose screws may result in burning or malfunction.

!Caution When positioning to a position determined using the teaching function, set the position

designation setting in the positioning sequence to absolute positioning. If it is set to

relative positioning, positioning will be performed to a position other than the one

obtained with the teaching function.

!Caution Execute online edit only after confirming that no adverse effects will be caused by

extending the cycle time. Otherwise, the input signals may not be readable.

!Caution Confirm the safety of the destination node before transferring a program to the node or

changing the contents of I/O memory. Doing either of these without confirming safety

may result in injury.

!Caution Do not save data into the flash memory during memory operation or while the motor is

running. Otherwise, unexpected operation may be caused.

4 Operating environment precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

viii

!Caution Take appropriate and sufficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

Application precautions 5

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the longevity

and reliability of the system. Improper operating environments can lead to malfunction,

failure, and other unforeseeable problems with the PLC System. Be sure that the

operating environment is within the specified conditions at installation and remains

within the specified conditions during the life of the system.

5 Application precautions

!WARNING Do not start the system until you check that the axes are present and of the correct

type. The numbers of the axis will change if MECHATROLINK-II network errors occur

during start-up or if the MECHATROLINK-II network configuration changes.

!WARNING Check the user program for proper execution before actually running it in the Unit. Not

checking the program may result in an unexpected operation.

!WARNING Observe the following precautions when using the CJ1W-MCH72 or the PLC. Failure to

abide by the following precautions could lead to serious or possibly fatal injury. Always

heed these precautions.

• Always connect to a ground of 100 Ω or less when installing the Units. Not

connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PLC before attempting any of the

following. Not turning OFF the power supply may result in malfunction or electric

shock.

- Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Memory

Cassettes, or any other Units.

- Assembling the Units.

- Setting DIP switches or rotary switches.

- Connecting cables or wiring the system.

- Connecting or disconnecting the connectors.

!Caution Be sure that all mounting screws, terminal screws, and cable connector screws are

tightened to the torque specified in this manual. Incorrect tightening torque may result

in malfunction.

!Caution Wire correctly. Incorrect wiring may result in burning.

!Caution Mount the Unit only after checking the terminal block completely.

!Caution Resume operation only after transferring to the new CJ1W-MCH72 Unit the contents of

the VR and table memory required for operation. Not doing so may result in an

unexpected operation.

!Caution When replacing parts, be sure to confirm that the rating of a new part is correct. Not

doing so may result in malfunction or burning.

!Caution Use the dedicated connecting cables specified in operation manuals to connect the

Units. Using commercially available RS-232C computer cables may cause failures in

external devices or the Unit.

!Caution Outputs may remain on due to a malfunction in the built-in transistor outputs or other

internal circuits. As a countermeasure for such problems, external safety measures

must be provided to ensure the safety of the system.

!Caution Failure to abide by the following precautions may lead to faulty operation of the PLC,

the CJ1W-MCH72 or the system, or could damage the PLC or CJ1W-MCH72. Always

heed these precautions.

ix

Application precautions 5

• Fail-safe measures must be taken by the customer to ensure safety in the event of

incorrect, missing, or abnormal signals caused by broken signal lines, momentary

power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e.,

not in the Programmable Controller) must be provided by the customer.

• Install external breakers and take other safety measures against short-circuiting in

external wiring. Insufficient safety measures against short-circuiting may result in

burning.

• Install the PLC Unit as far as possible from sources of strong harmonic noise.

• Lock the sliders securely until they click into place when connecting the Power

Supply Unit, CPU Unit, I/O Units, Special I/O Units, or CPU Bus Units. Functions

may not work correctly if the sliders are not locked properly.

• Always attach the End Cover provided with the CPU Unit to the Unit on the right end

of the PLC. The CJ-series PLC will not operate properly if the End Cover is not

attached.

• Always use the power supply voltages specified in the operation manuals. An

incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied in places where the power supply is unstable. An

incorrect power supply may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• Leave the label attached to the Unit when wiring. Removing the label may result in

malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation.

Leaving the label attached may result in malfunction.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess

voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Check the user program for proper execution before actually running it on the Unit.

Not checking the program may result in an unexpected operation.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other items

with locking devices are properly locked into place. Improper locking may result in

malfunction.

• Double-check all wiring and switch settings before turning ON the power supply.

Incorrect wiring may result in burning.

• Disconnect the LR and GR terminals when performing insulation resistance or

withstand voltage tests. Not disconnecting the functional ground terminal may result

in burning.

!Caution Confirm that no adverse effect will occur in the system before attempting any of the

following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the operating mode at power

up).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

!Caution Do not pull on the cables or bend the cables beyond their natural limit. Doing either of

these may break the cables.

!Caution Do not place objects on top of the cables or other wiring lines. Doing so may break the

cables.

!Caution Resume operation only after transferring the system parameter data to the CJ1W-

MCH72 and saving the data to flash memory. Not doing so may result in an unexpected

operation.

!Caution Confirm that set parameters and data operate properly.

!Caution Check the pin numbers before wiring the connectors.

x

Conformance to EC Directives 6

!Caution Perform wiring according to specified procedures.

!Caution Before touching a Unit, be sure to first touch a grounded metallic object in order to

discharge any static build-up. Not doing so may result in malfunction or damage.

!Caution Do not drop the Unit or subject it to abnormal shock or vibration.

!Caution Confirm the safety of the destination node before transferring a program to the node or

changing the contents of I/O memory. Doing either of these without confirming safety

may result in injury.

6 Conformance to EC Directives

6-1 Applicable directives

•EMC Directives

6-2 Concepts

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other

conditions of the equipment or control panel in which the OMRON devices are

installed. The customer must, therefore, perform final checks to confirm that

devices and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

• EMS (Electromagnetic Susceptibility): EN61000-6-2

• EMI (Electromagnetic Interference): EN61000-6-4

(Radiated emission: 10-m regulations)

6-3 Conformance to EC Directives

The CJ1W-MCH72 complies with EC Directives. To ensure that the machine

or device in which a CJ1W-MCH72 is used complies with EC Directives, the

CJ1W-MCH72 must be installed as follows:

1 The CJ1W-MCH72 must be installed within a control panel.

2 Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3 Units complying with EC Directives also conform to the Common Emission

Standard (EN61000-6-4). With regard to the radiated emission (10-m

regulations), countermeasures will vary depending on the devices

connected to the control panel, wiring, the configuration of the system, and

other conditions. The customer must, therefore, perform final checks to

confirm that devices and the overall machine conform to EC Directives.

xi

Conformance to EC Directives 6

6-4 Installation within Control Panel

Unnecessary clearance in cable inlet or outlet ports, operation panel mounting

holes, or in the control panel door may cause electromagnetic wave leakage

or interference. In this case, the product may fail to meet EC Directives. In

order to prevent such interference, fill clearances in the control panel with

conductive packing. (In places where conductive packing comes in contact

with the control panel, ensure electrical conductivity by removing the paint

coating or masking these parts when painting.)

xii

Overview Section 1-1

SECTION 1

Introduction

1-1 Overview

The CJ1W-MCH72 is a Trajexia-style motion control unit that can be

connected to a CJ1-series PLC. It acts as an interface between PLC systems

and Trajexia-style motion control systems.

Trajexia is the OMRON motion platform that offers you the performance and

the ease of use of a dedicated motion system. It maximum flexibility and

scalability. At the heart of Trajexia lies the TJ1 multi-tasking motion

coordinator. Powered by a 32-bit DSP, it can do motion tasks such as e-cam,

e-gearbox, registration control and interpolation, all using simple motion

commands.

The CJ1W-MCH72 has the following features:

• A MECHATROLINK-II connection for a MECHATROLINK-II network with

up to 30 axes. The motion cycle time is selectable: 0.5 ms, 1 ms, 2 ms or 4

ms.

• An Encoder Interface connection. It supports the main absolute encoder

protocols allowing the connection of an external encoder to the system.

• The possibility to exchange analogue and digital input and output data with

the PLC CPU.

• A wide choice of rotary, linear and direct-drive servos as well as Inverters

are available to fit your needs in compactness, performance and reliability.

The Inverters connected to the MECHATROLINK-II are driven at the same

update cycle time as the Servo Drivers.

Note The Trajexia system supports 3 kinds of MECHATROLINK-II slaves: Servo Drivers,

Inverters and I/Os.

The CJ1W-MCH72 only supports 2 kinds of MECHATROLINK-II slaves: Servo Drivers

and Inverters. It does not support I/Os.

1

System philosophy Section 1-2

r

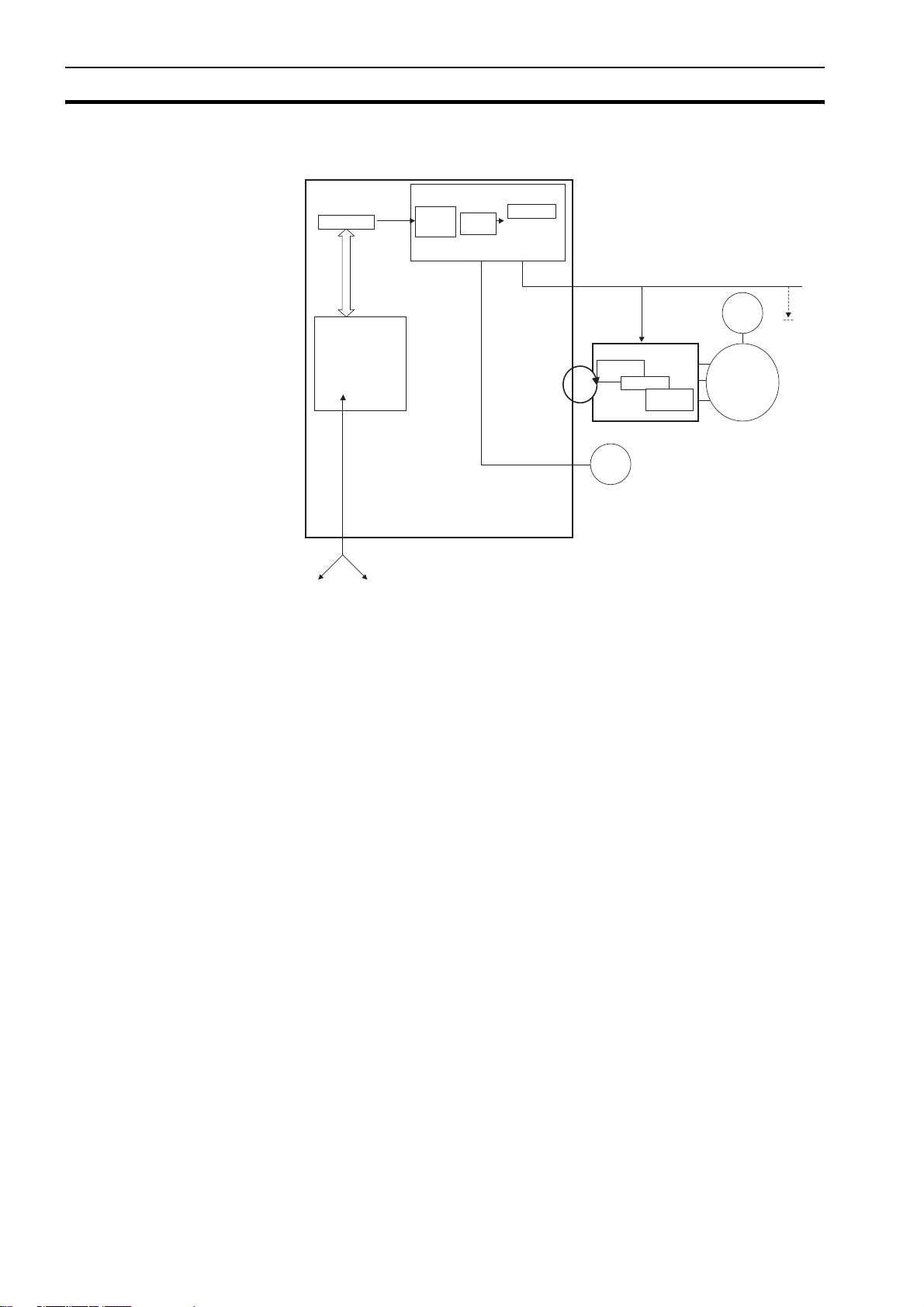

1-2 System philosophy

CJ1W-MCH72

Program Buffer

Buffer &

Buffer &

profile

profile

gererator

gererator

AXIS CONTROL LOOP

Position

Position

Loop

Loop

AXIS TYPE

AXIS TYPE

AXIS TYPE

ML

BASIC PROGRAMS

Process 1

Process 2

Process 3

…

Process 14

Comms

I/O

BUILT-IN TJ1-PLC interface

Servo Driver

Position

Position

Loop

Loop

Speed Loop

Speed Loop

ENC

Torque

Torque

Loop

Loop

ENC

MOTOR

The system philosophy is centred around the relationship between:

•System architecture

•Cycle time

• Program control and multi-tasking

• Motion sequence and axes

• Motion buffers

All othe

Servo

Drivers

A clear understanding of the relationship between these concepts is

necessary to obtain the best results for the Trajexia system.

1-2-1 Glossary

1-2-1-1 Motion sequence

The Motion Sequence is responsible for controlling the position of the axes.

1-2-1-2 Servo period

Defines the frequency at which the Motion Sequence is executed. The servo

period must be set according to the configuration of the physical axes. The

available settings are 0.5 ms, 1 ms, 2 ms or 4 ms.

1-2-1-3 Cycle time

Is the time needed to execute one complete cycle of operations in the CJ1WMCH72. The cycle time is divided in 4 time slices of equal time length, called

"CPU Tasks". The cycle time is 1ms if SERVO_PERIOD = 0.5 ms or

SERVO_PERIOD = 1 ms, 2 ms if the SERVO_PERIOD = 2 ms and 4 ms if the

SERVO_PERIOD = 4 ms

2

System philosophy Section 1-2

1-2-1-4 CPU tasks

The operations executed in each CPU task are:

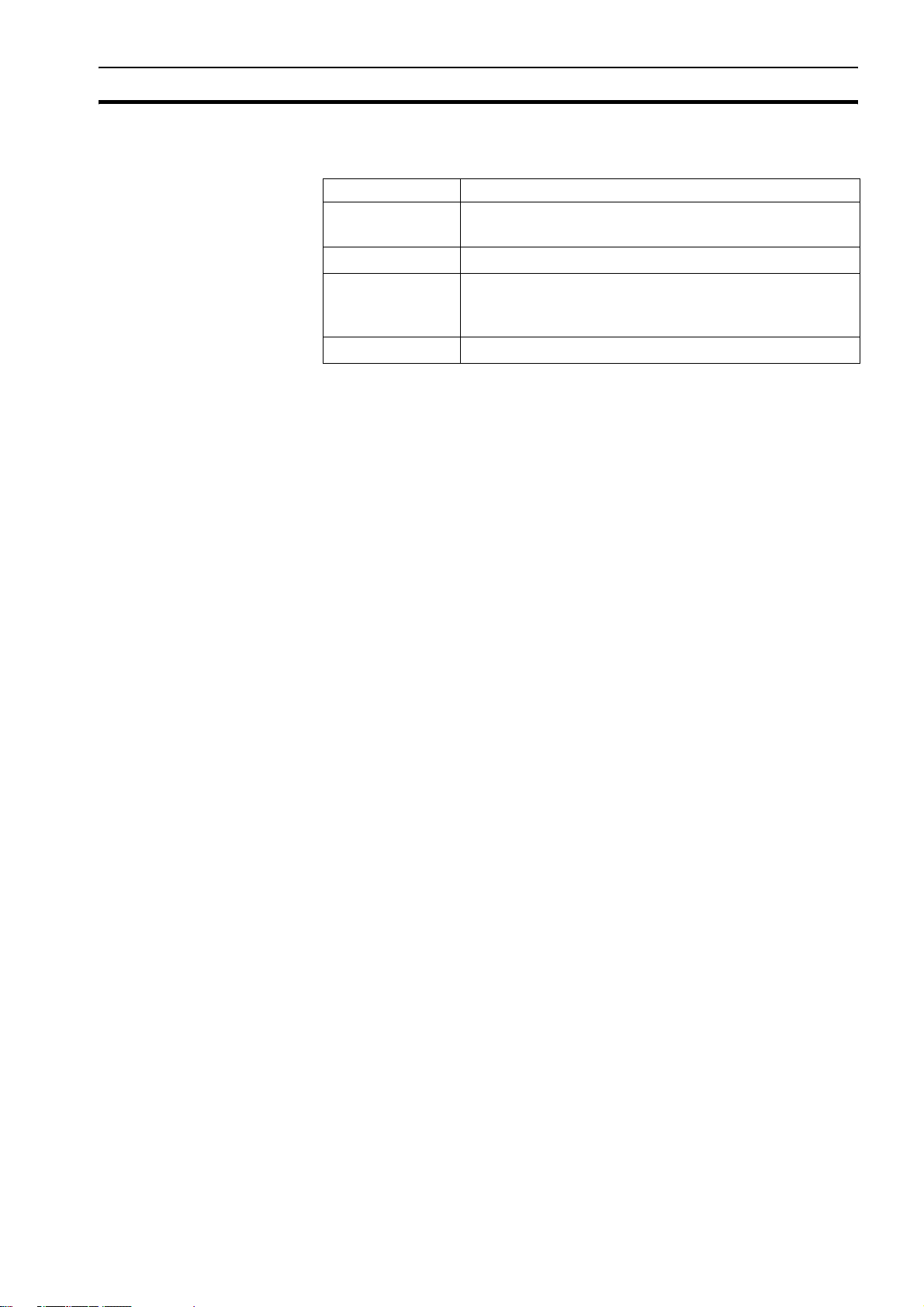

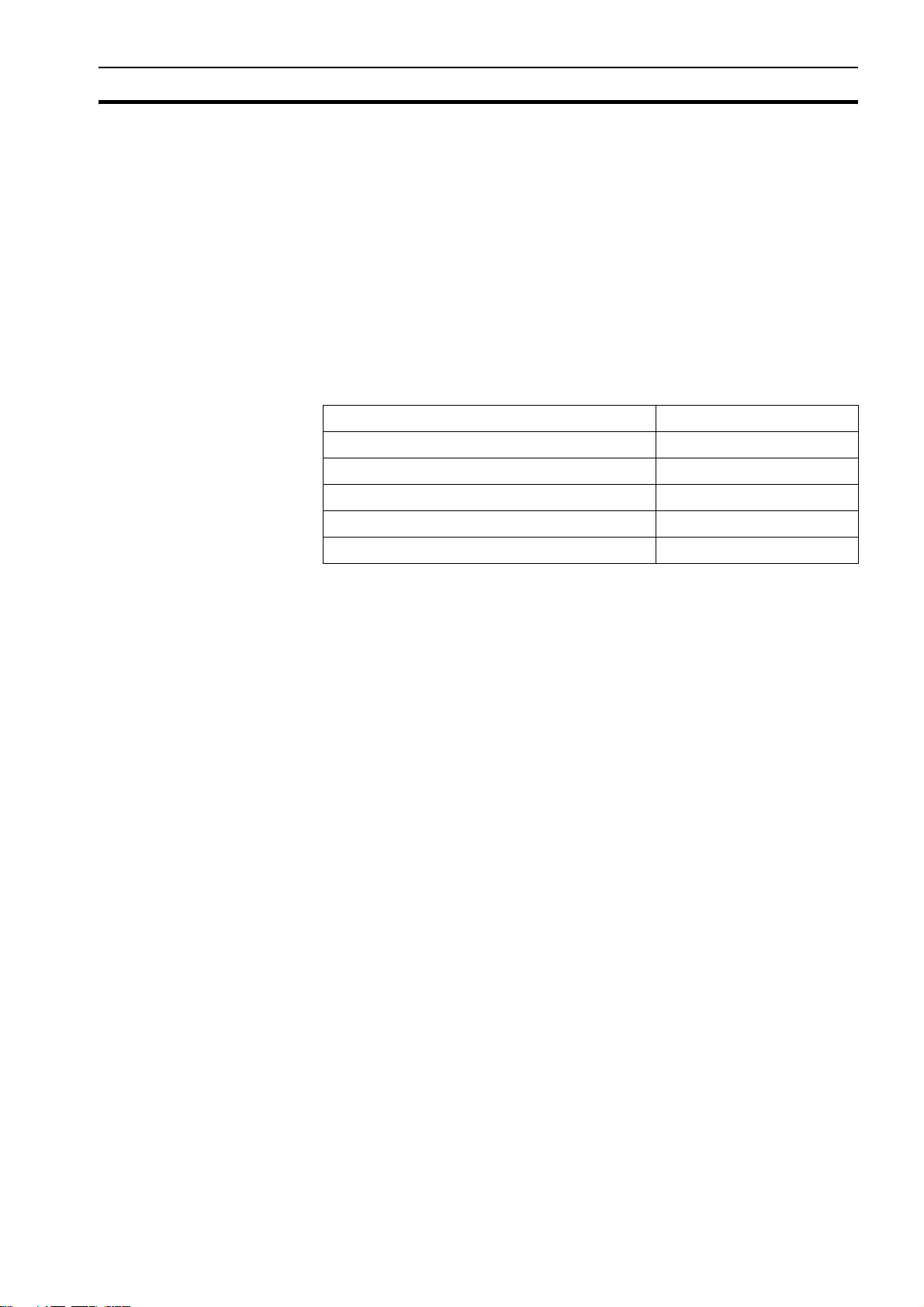

CPU task Operation

First CPU task Motion Sequence

Low priority process

Second CPU task High priority process

Third CPU task Motion Sequence (only if SERVO_PERIOD = 0.5 ms)

LED Update

High priority process

Fourth CPU task External Communications

1-2-1-5 Program

A program is a piece of BASIC code.

1-2-1-6 Process

Is a program in execution with a certain priority assigned. Process 0 to 12 are

Low priority processes and Process 13 and 14 are High priority processes.

First the process priority, High or Low, and then the process number, from high

to low, will define to which CPU task the process will be assigned.

3

Motion control concepts Section 1-3

1-3 Motion control concepts

The CJ1W-MCH72 offers these types of positioning control operations:

1 Point-to-Point (PTP) control

2 Continuous Path (CP) control

3 Electronic Gearing (EG) control.

This section introduces some of the commands and parameters used in the

BASIC programming of the motion control application.

Coordinate system

Positioning operations performed by the CJ1W-MCH72 are based on an axis

coordinate system. The CJ1W-MCH72 converts the position data from either

the connected Servo Driver or the connected encoder into an internal absolute

coordinate system.

The engineering unit that specifies the distances of travelling can be freely

defined for each axis separately. The conversion is performed through the use

of the unit conversion factor, which is defined by the UNITS axis parameter.

The origin point of the coordinate system can be determined using the

DEFPOS command. This command re-defines the current position to zero or

any other value.

1-3-1 PTP control

MOVEABS(30)

MOVE(60)

MOVEABS(50)

MOVE(50)

MOVE(30)

0

50 100

A

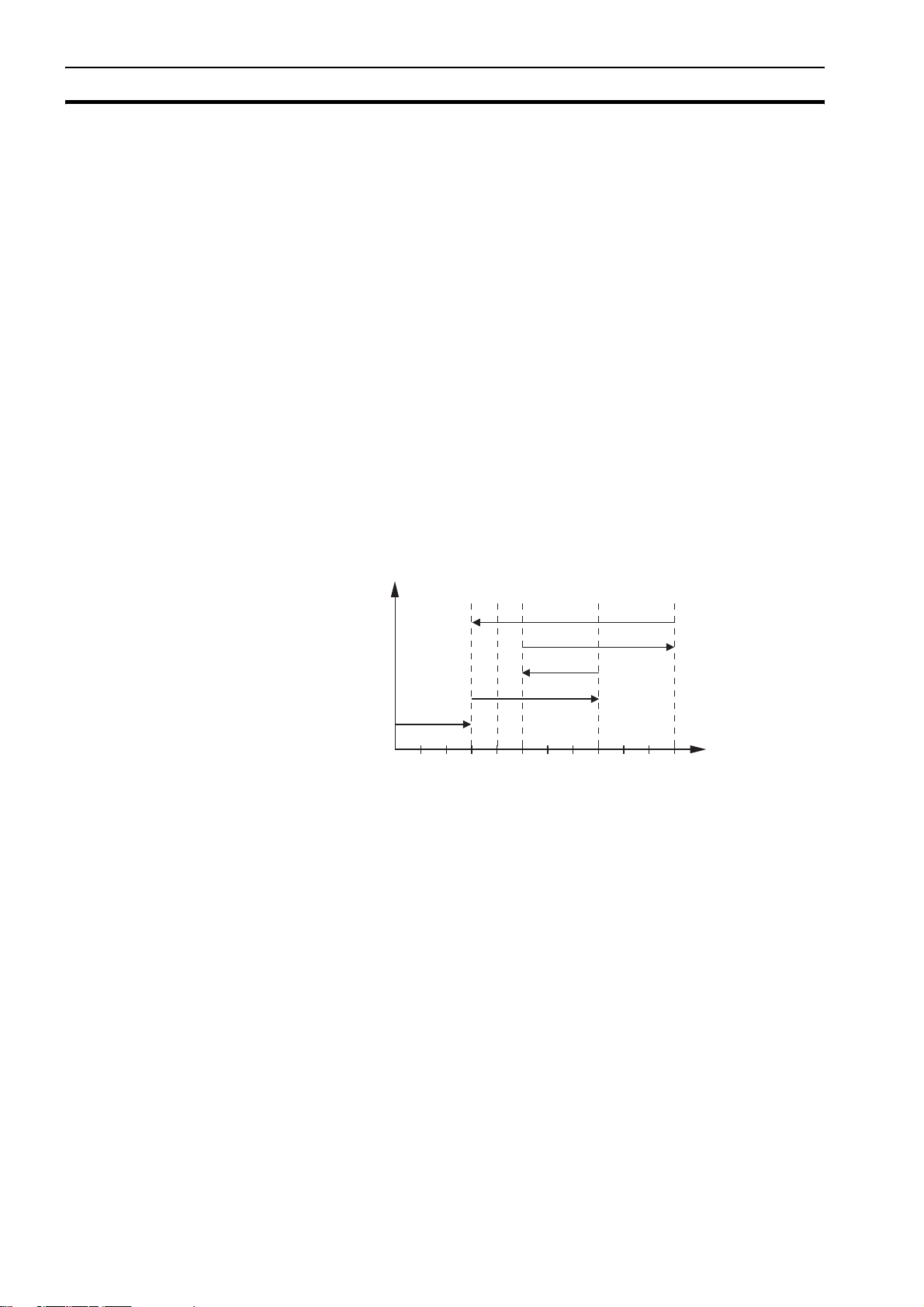

A move is defined in either absolute or relative terms. An absolute move takes

the axis (A) to a specific predefined position with respect to the origin point. A

relative move takes the axis from the current position to a position that is

defined relative to this current position. The figure shows an example of

relative (command MOVE) and absolute (command MOVEABS) linear moves.

In point-to-point positioning, each axis is moved independently of the other

axis. The CJ1W-MCH72 supports the following operations:

• Relative move

• Absolute move

• Continuous move forward

• Continuous move reverse.

4

Motion control concepts Section 1-3

1-3-1-1 Relative and absolute moves

50

B

0

50

MOVEABS(100) AXIS(0)

MOVEABS(50) AXIS(1)

100

A

To move a single axis either the command MOVE for a relative move or the

command MOVEABS for an absolute move is used. Each axis has its own

move characteristics, which are defined by the axis parameters.

Suppose a control program is executed to move from the origin to an axis no.

0 (A) coordinate of 100 and axis no. 1 (B) coordinate of 50. If the speed

parameter is set to be the same for both axes and the acceleration and

deceleration rate are set sufficiently high, the movements for axis 0 and axis 1

will be as shown in the figure.

At start, both the axis 0 and axis 1 moves to a coordinate of 50 over the same

duration of time. At this point, axis 1 stops and axis 0 continues to move to a

coordinate of 100.

The move of a certain axis is determined by the axis parameters. Some

relevant parameters are:

/i

Parameter Description

UNITS Unit conversion factor

ACCEL Acceleration rate of an axis in units/s

DECEL Deceleration rate of an axis in units/s

2

2

SPEED Demand speed of an axis in units/s

Defining moves

B

ACCEL=10

10

0

123 456

DECEL=10

SPEED=10

MOVE(40)

A

5

Motion control concepts Section 1-3

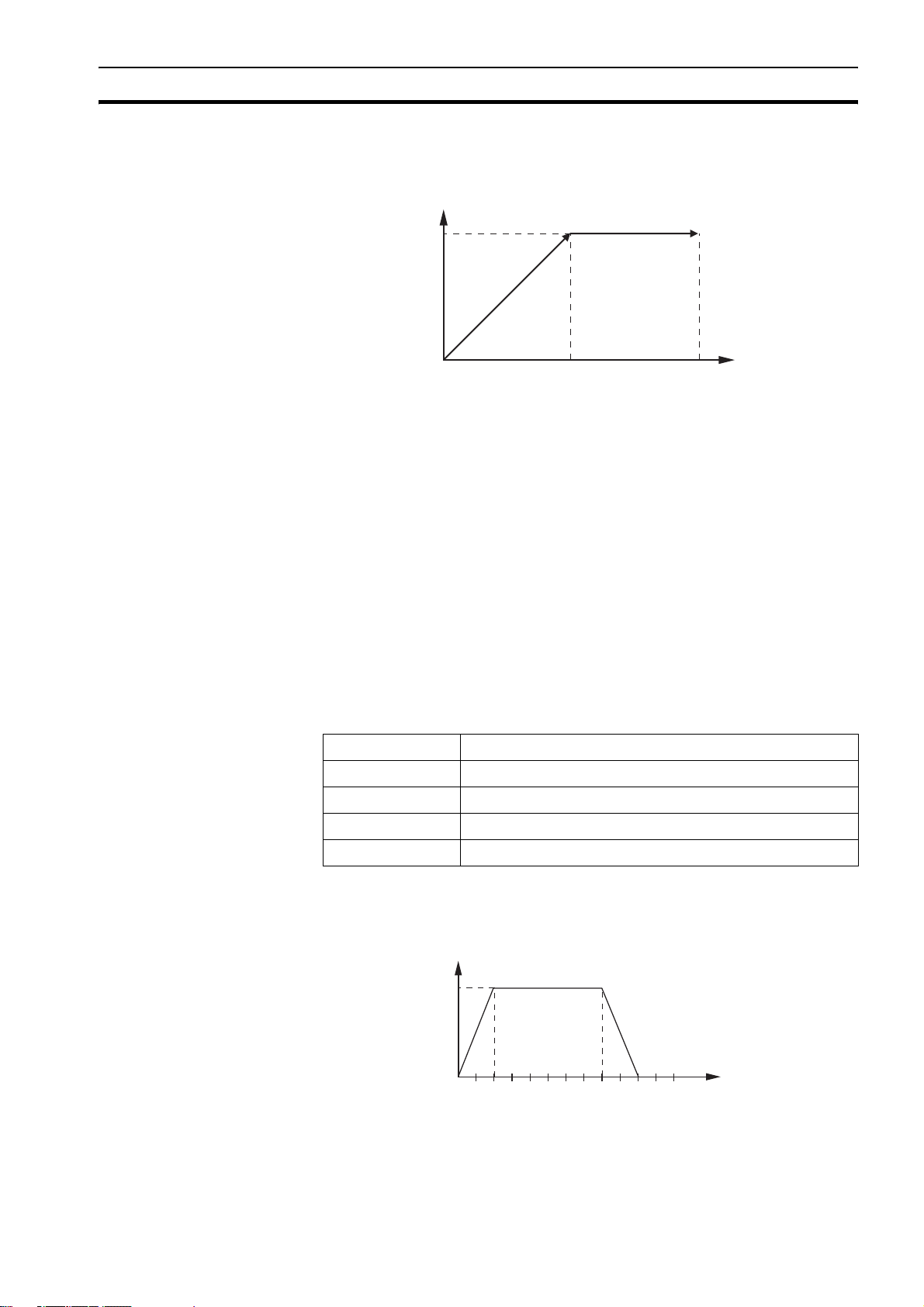

The speed profile in this figure shows a simple MOVE operation. Axis A is the

time, axis B is the speed. The UNITS parameter for this axis has been defined

for example as meters. The required maximum speed has been set to 10 m/s.

In order to reach this speed in one second and also to decelerate to zero

speed again in one second, both the acceleration as the deceleration rate

have been set to 10 m/s

travelled during the acceleration, constant speed and deceleration segments.

Suppose the distance moved by the MOVE command is 40 m, the speed

profile is given by the figure.

2

. The total distance travelled is the sum of distances

B

ACCEL=5

DECEL=10

SPEED=10

MOVE(40)

010123 456

A

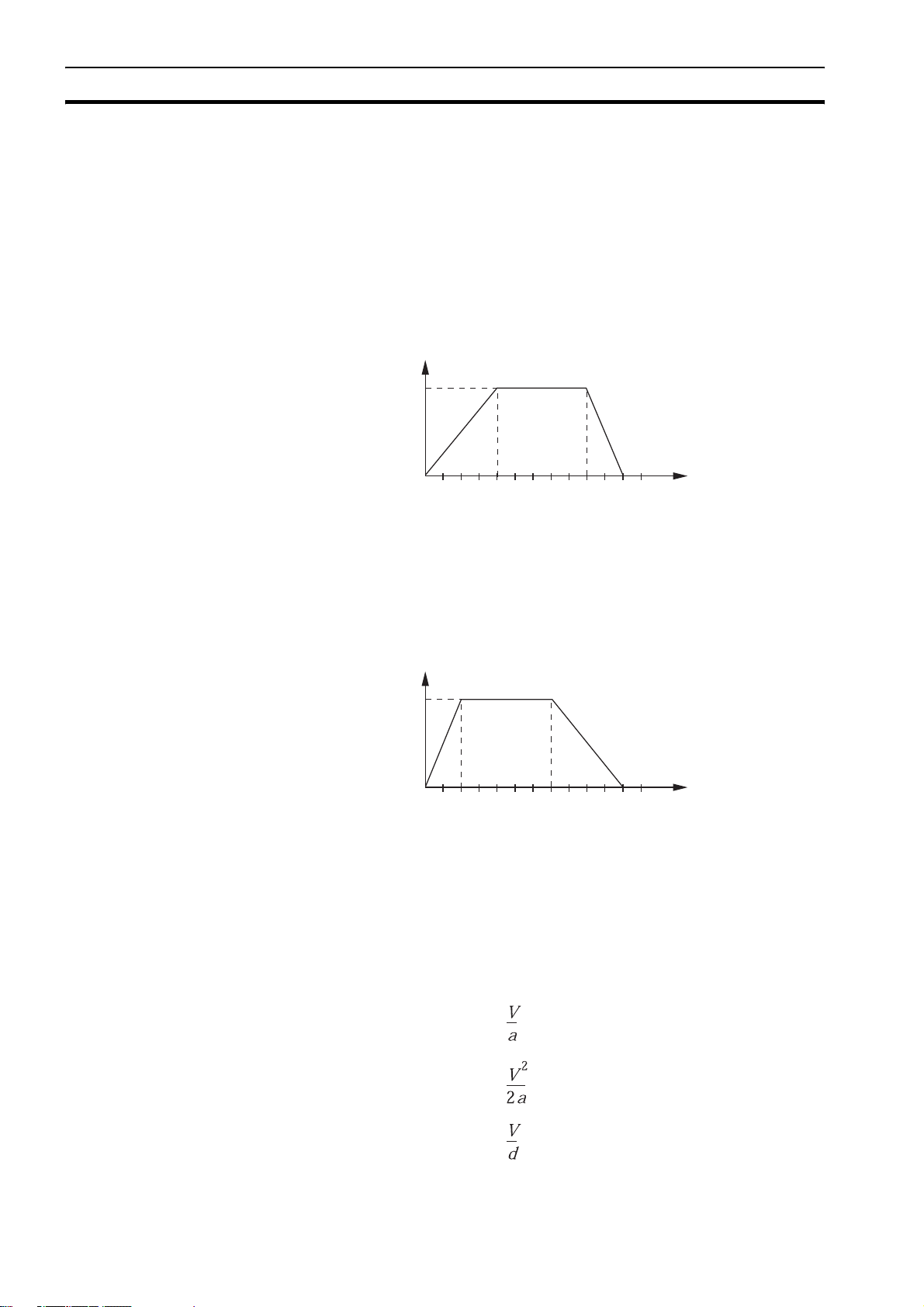

The two speed profiles in these figures show the same movement with an

acceleration time respectively a deceleration time of 2 seconds. Again, Axis A

is the time, axis B is the speed.

B

ACCEL=10

DECEL=5

SPEED=10

MOVE(40)

010123 456

Move calculations

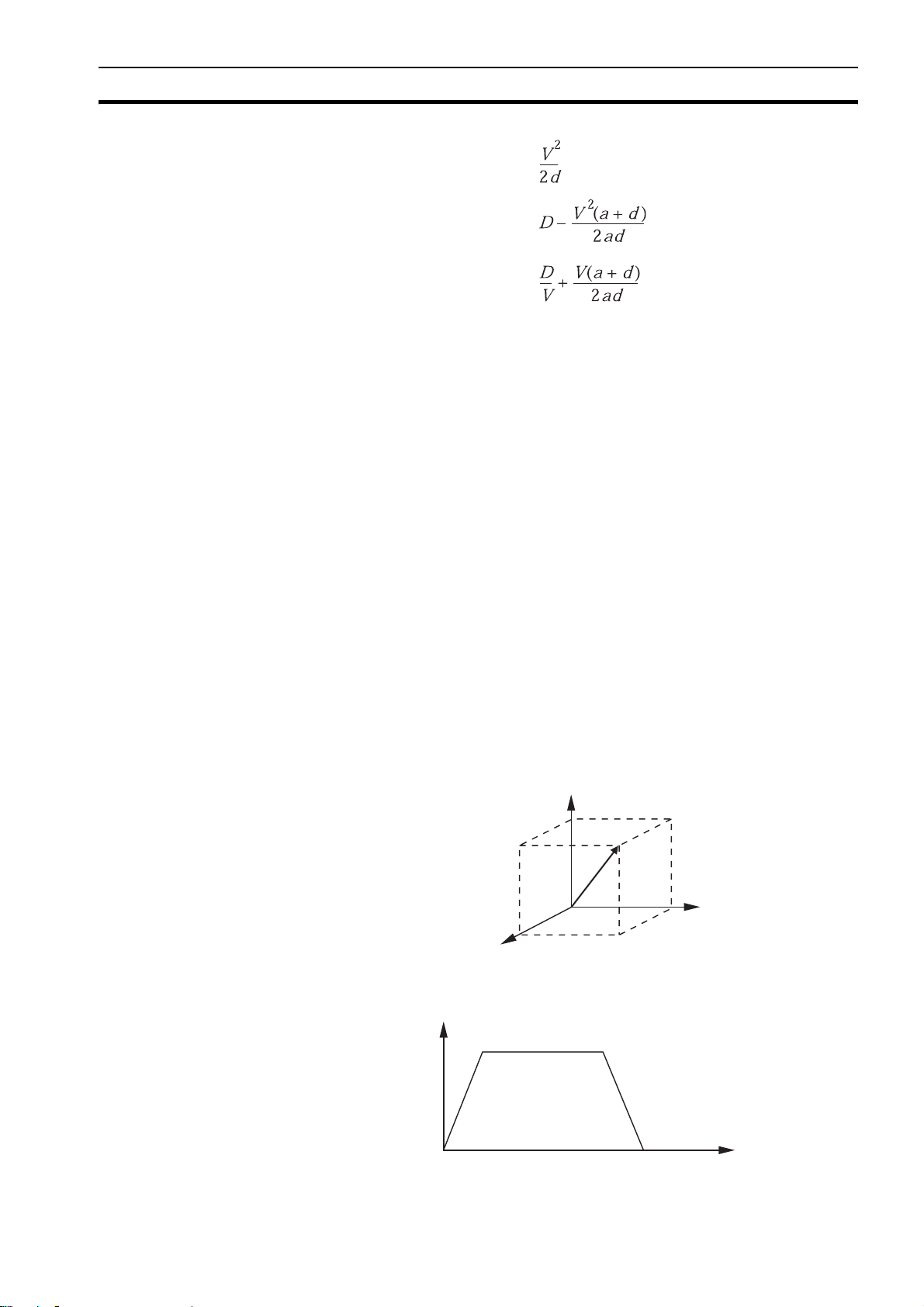

The following equations are used to calculate the total time for the motion of

the axes.

• The moved distance for the MOVE command is D.

• The demand speed is V.

• The acceleration rate is a.

• The deceleration rate is d.

A

/i

Acceleration time =

Acceleration distance =

Deceleration time =

6

Motion control concepts Section 1-3

Deceleration distance =

Constant speed distance =

Total time =

1-3-1-2 Continuous moves

The FORWARD and REVERSE commands can be used to start a continuous

movement with constant speed on a certain axis. The FORWARD command

moves the axis in positive direction and the REVERSE command in negative

direction. For these commands also the axis parameters ACCEL and SPEED

apply to specify the acceleration rate and demand speed.

Both movements can be cancelled by using either the CANCEL or

RAPIDSTOP command. The CANCEL command cancels the move for one

axis and RAPIDSTOP cancels moves on all axes. The deceleration rate is set

by DECEL.

1-3-2 CP control

Continuous Path control enables to control a specified path between the start

and end position of a movement for one or multiple axes. The CJ1W-MCH72

supports the following operations:

• Linear interpolation

• Circular interpolation

•CAM control.

1-3-2-1 Linear interpolation

2

1

3

B

A

7

Motion control concepts Section 1-3

In applications it can be required for a set of motors to perform a move

operation from one position to another in a straight line. Linearly interpolated

moves can take place among several axes. The commands MOVE and

MOVEABS are also used for the linear interpolation. In this case the

commands will have multiple arguments to specify the relative or absolute

move for each axis.

Consider the three axis move in a 3-dimensional plane in the figure. It

corresponds to the MOVE(50,50,50) command. The speed profile of the

motion along the path is given in the diagram. The three parameters SPEED,

ACCEL and DECEL that determine the multi axis movement are taken from

the corresponding parameters of the base axis. The MOVE command

computes the various components of speed demand per axis.

A is the time axis, B is the speed axis.

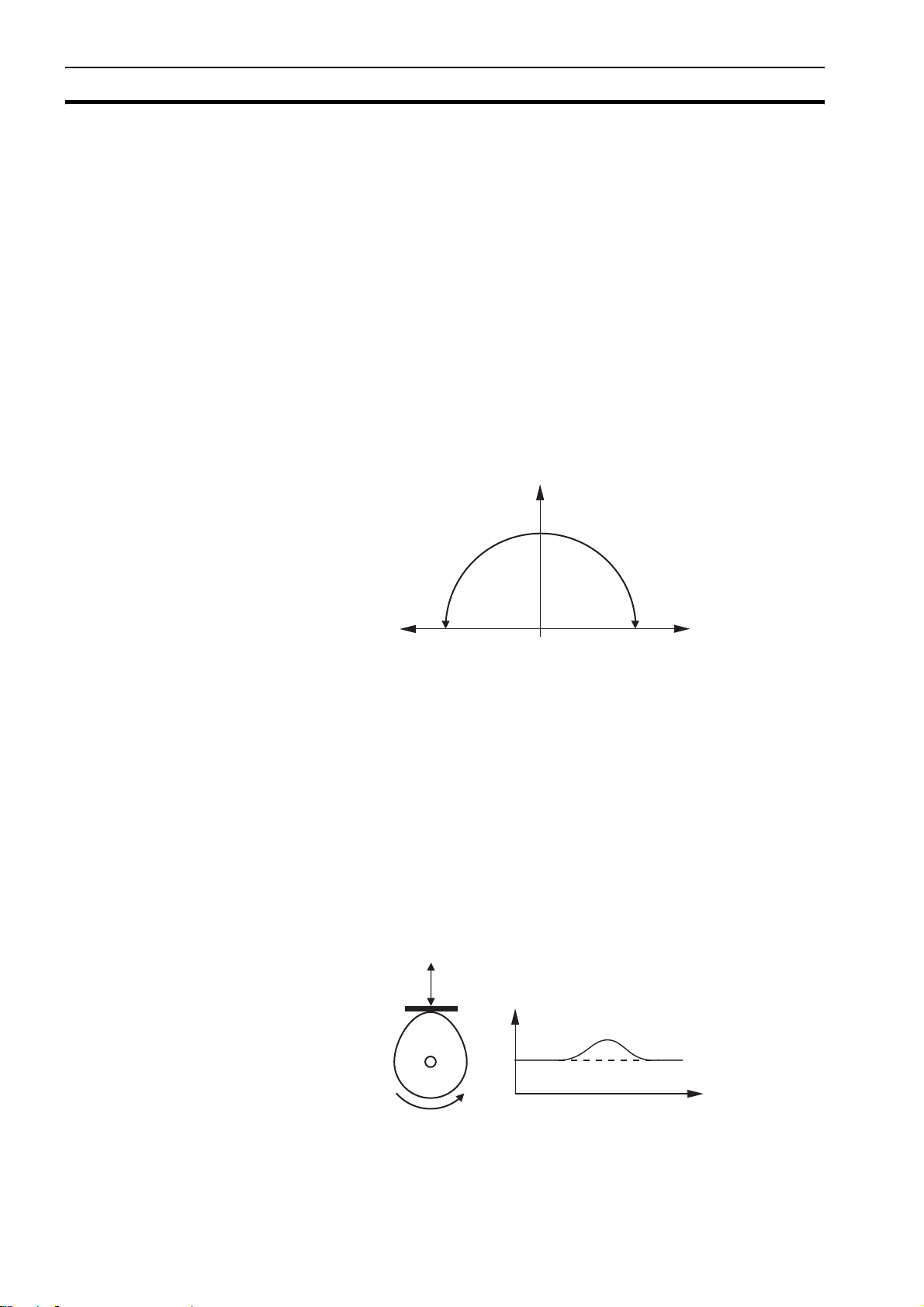

1-3-2-2 Circular interpolation

50

1-3-2-3 CAM control

-50

It may be required that a tool travels from the starting point to the end point in

an arc of a circle. In this instance the motion of two axes is related via a

circular interpolated move using the MOVECIRC command.

Consider the diagram in the figure. It corresponds to the MOVECIRC(-100,0,-

50,0,0) command. The centre point and desired end point of the trajectory

relative to the start point and the direction of movement are specified. The

MOVECIRC command computes the radius and the angle of rotation. Like the

linearly interpolated MOVE command, the ACCEL, DECEL and SPEED

variables associated with the base axis determine the speed profile along the

circular move.

050

B

A

8

Motion control concepts Section 1-3

Additional to the standard move profiles the CJ1W-MCH72 also provides a

way to define a position profile for the axis to move. The CAM command

moves an axis according to position values stored in the CJ1W-MCH72 Table

array. The speed of travelling through the profile is determined by the axis

parameters of the axis.

The figure corresponds to the command CAM(0,99,100,20). A is the time axis,

B is the position axis.

1-3-3 EG control

Electronic Gearing control allows you to create a direct gearbox link or a linked

move between two axes. The MC Unit supports the following operations.

• Electronic gearbox

•Linked CAM

• Linked move

• Adding axes

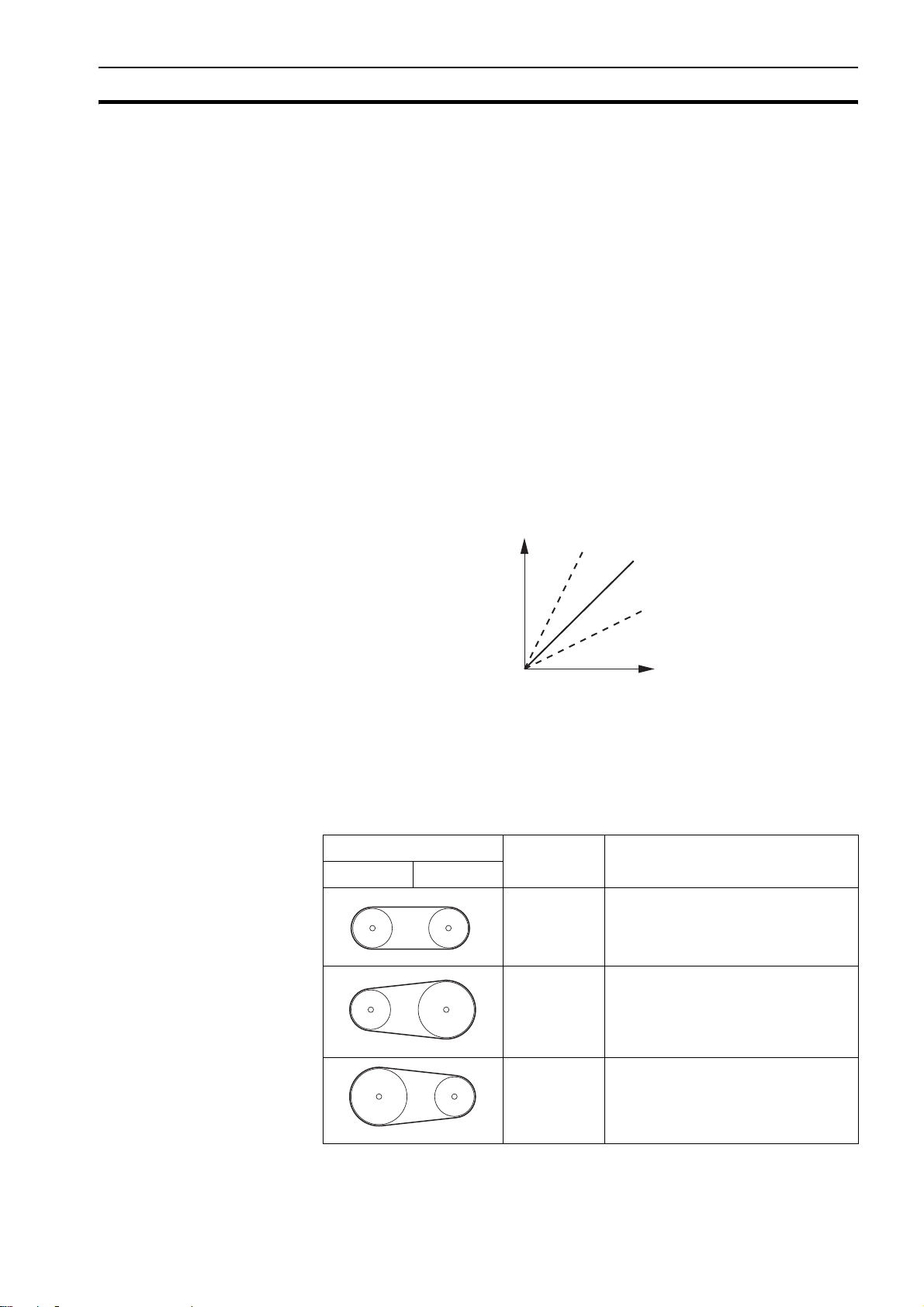

1-3-3-1 Electronic gearbox

B

2:1

1:1

1:2

A

The CJ1W-MCH72 is able to have a gearbox link from one axis to another as if

there is a physical gearbox connecting them. This can be done using the

CONNECT command in the program. In the command the ratio and the axis to

link to are specified.

In the figure, A is the Master axis, and B is the CONNECT axis.

/i

Axes Ratio CONNECT command

0 1

1:1 CONNECT(1,0) AXIS(1)

2:1 CONNECT(2,0) AXIS(1)

1:2 CONNECT(0.5,0) AXIS(1)

9

Motion control concepts Section 1-3

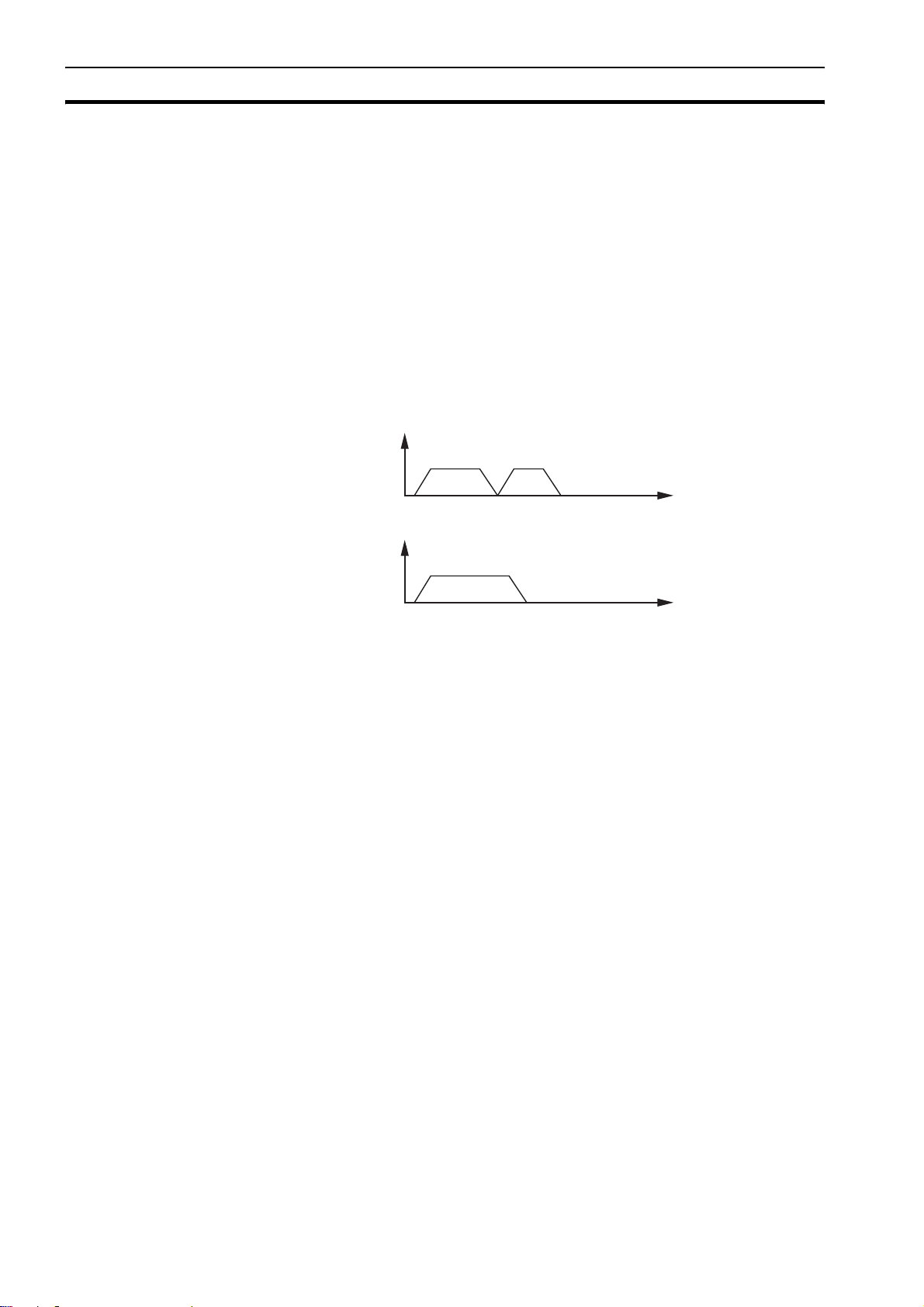

1-3-3-2 Linked CAM control

B

A

Next to the standard CAM profiling tool the CJ1W-MCH72 also provides a tool

to link the CAM profile to another axis. The command to create the link is

called CAMBOX. The travelling speed through the profile is not determined by

the axis parameters of the axis but by the position of the linked axis. This is

like connecting two axes through a cam.

In the figure, A is the Master axis (0) position, and B is the CAMBOX Axis (1)

position.

1-3-3-3 Linked move

B

DC

E

A

The MOVELINK command provides a way to link a specified move to a

master axis. The move is divided into an acceleration, deceleration and

constant speed part and they are specified in master link distances. This can

be particularly useful for synchronizing two axes for a fixed period.

The labels in the figure are:

A Time axis.

B Speed axis.

C Master axis (1).

D Synchronized.

E MOVELINK axis (0).

10

Motion control concepts Section 1-3

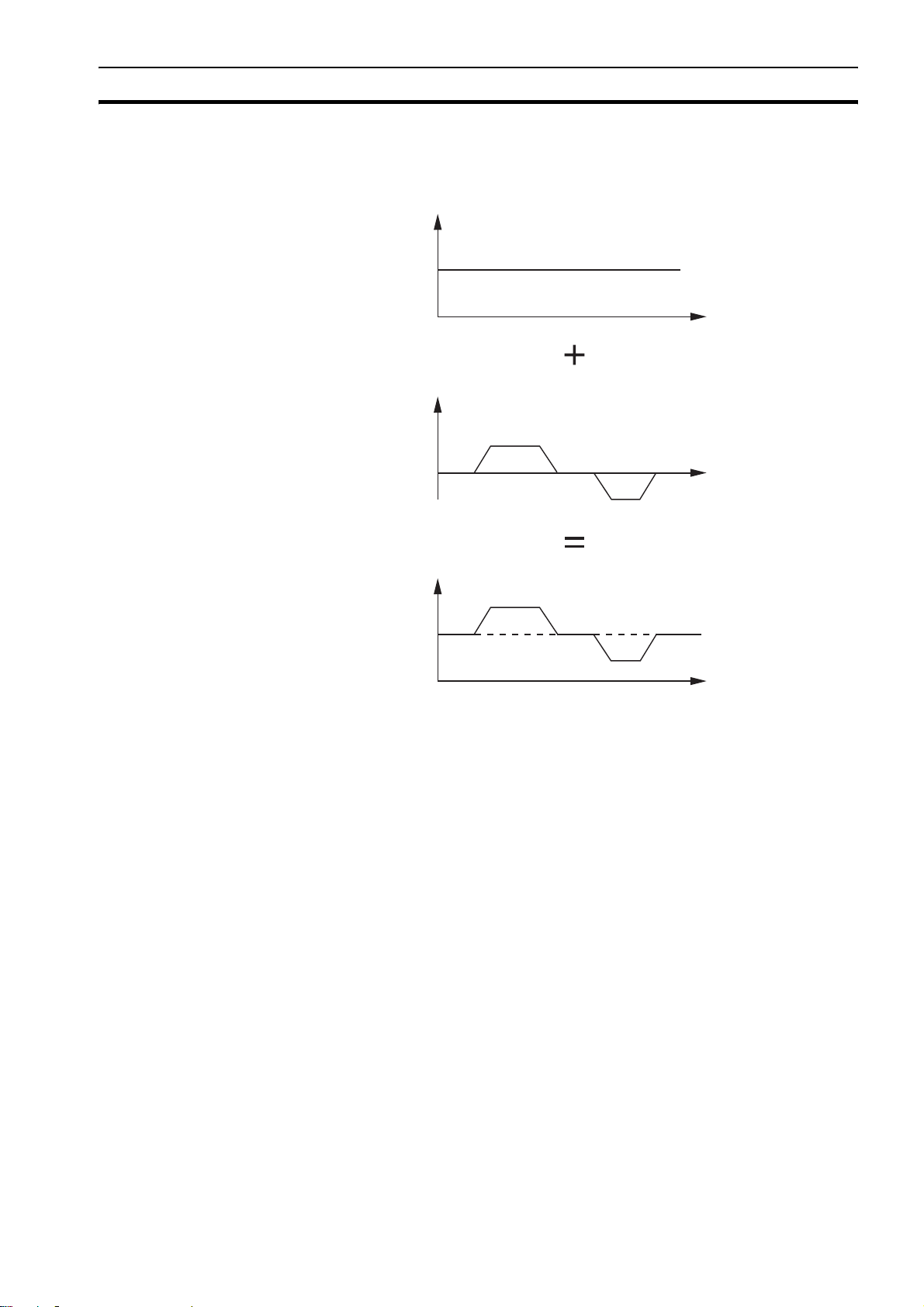

1-3-3-4 Adding axes

B

B

B

BASE(0)

ADDAX(2)

FORWARD

MOVE(100) AXIS(2)

MOVE(-60) AXIS(2)

A

A

It is very useful to be able to add all movements of one axis to another. One

possible application is for instance changing the offset between two axes

linked by an electronic gearbox. The CJ1W-MCH72 provides this possibility by

using the ADDAX command. The movements of the linked axis will consists of

all movements of the actual axis plus the additional movements of the master

axis.

In the figure, A is the time axis and B is the speed axis.

1-3-4 Other operations

1-3-4-1 Cancelling moves

In normal operation or in case of emergency it can be necessary to cancel the

current movement from the buffers. When the CANCEL or RAPIDSTOP

commands are given, the selected axis respectively all axes will cancel their

current move.

1-3-4-2 Origin search

The encoder feedback for controlling the position of the motor is incremental.

This means that all movement must be defined with respect to an origin point.

The DATUM command is used to set up a procedure whereby the CJ1W-

MCH72 goes through a sequence and searches for the origin based on digital

inputs and/or Z-marker from the encoder signal.

A

11

Motion control concepts Section 1-3

1-3-4-3 Print registration

The CJ1W-MCH72 can capture the position of an axis in a register when an

event occurs. The event is referred to as the print registration input. On the

rising or falling edge of an input signal, which is either the Z-marker or an

input, the CJ1W-MCH72 captures the position of an axis in hardware. This

position can then be used to correct possible error between the actual position

and the desired position. The print registration is set up by using the REGIST

command.

The position is captured in hardware, and therefore there is no software

overhead and no interrupt service routines, eliminating the need to deal with

the associated timing issues.

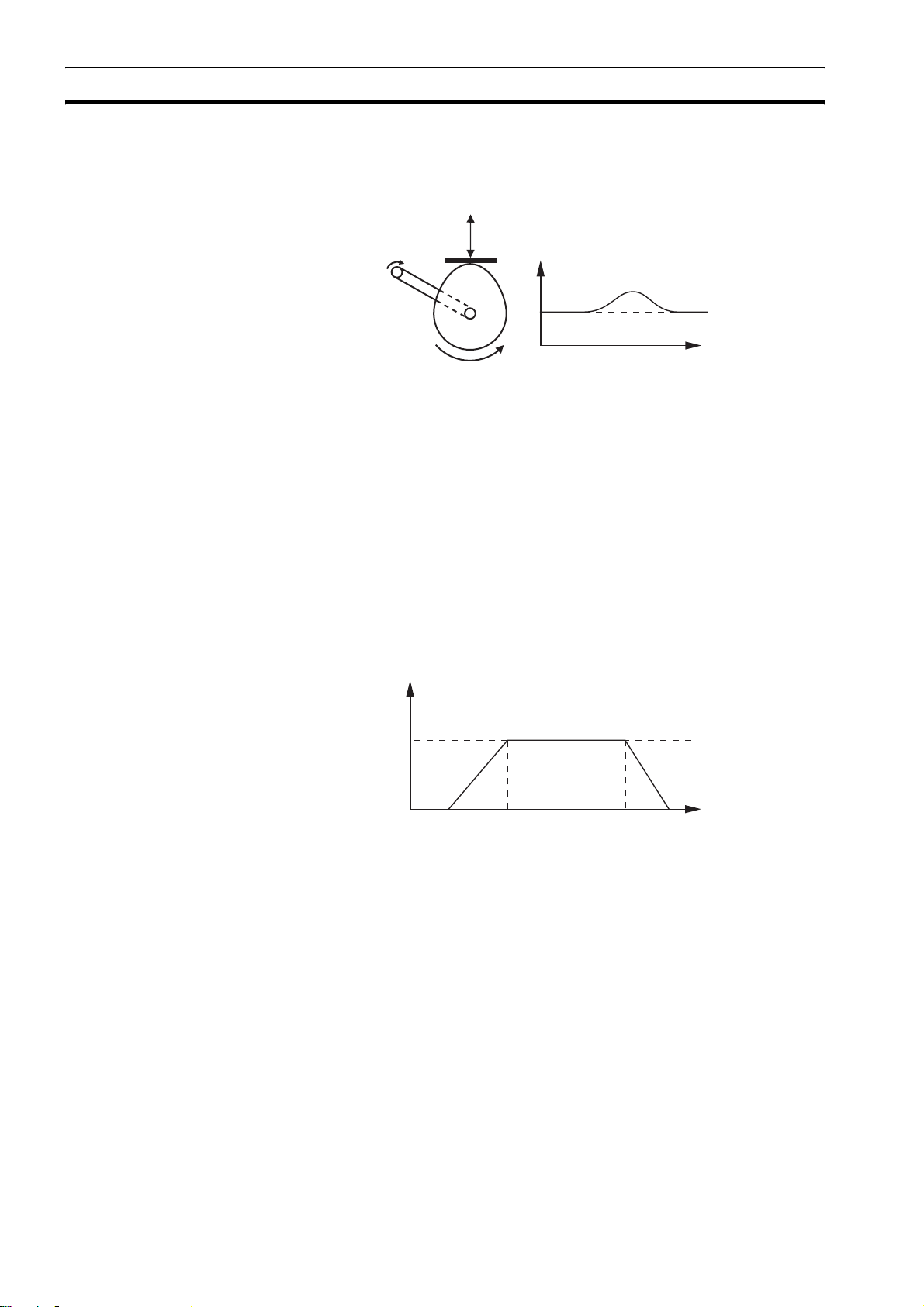

1-3-4-4 Merging moves

1-3-4-5 Jogging

B

MERGE=0

A

B

MERGE=1

A

If the MERGE axis parameter is set to 1, a movement is always followed by a

subsequent movement without stopping. The figures show the transitions of

two moves with MERGE value 0 and value 1.

In the figure, A is the time axis and B is the speed axis.

Jogging moves the axes at a constant speed forward or reverse by manual

operation of the digital inputs. Different speeds are also selectable by input.

Refer to the FWD_JOG, REV_JOG and FAST _JOG axis parameters.

12

Servo system principles Section 1-4

1-4 Servo system principles

The servo system used by and the internal operation of the CJ1W-MCH72 are

briefly described in this section.

1-4-1 Semi-closed loop system

The servo system of the CJ1W-MCH72 uses a semi-closed or inferred closed

loop system. This system detects actual machine movements by the rotation

of the motor in relation to a target value. It calculates the error between the

target value and actual movement, and reduces the error through feedback.

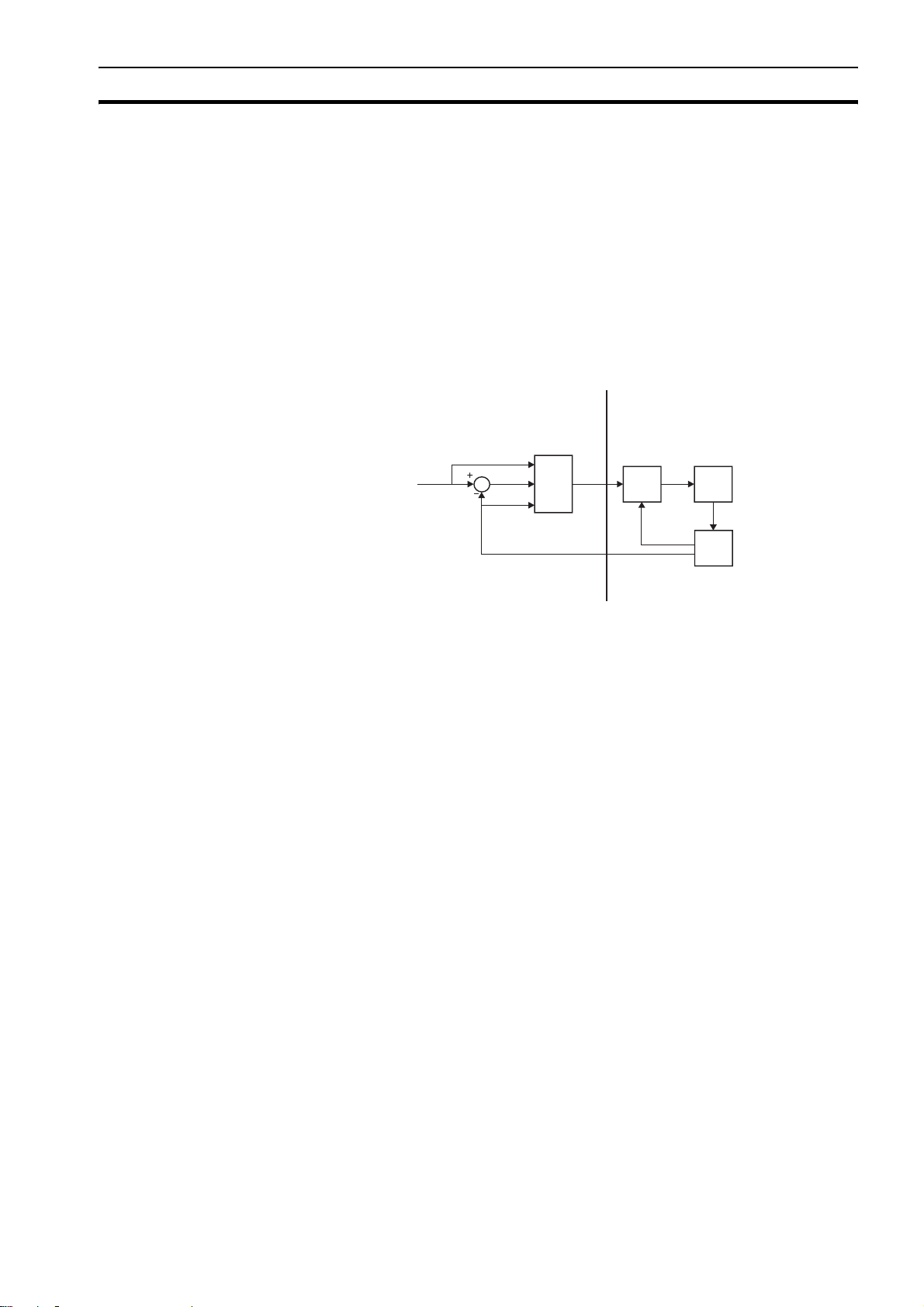

1-4-2 Internal operation of the CJ1W-MCH72

AB

C

2

1

D

E

3

F

G

4

I

H

J

Inferred closed loop systems occupy the mainstream in modern servo systems

applied to positioning devices for industrial applications. The figure shows the

basic principle of the servo system as used in the CJ1W-MCH72.

1 The CJ1W-MCH72 performs actual position control. The main input of the

controller is the Following Error, which is the calculated difference between

the demand position and the actual measured position.

2 The Position Controller calculates the required speed reference output

determined by the Following Error and possibly the demanded position and

the measured position. The speed reference is provided to the Servo

Driver.

3 The Servo Driver controls the rotational speed of the servo motor

corresponding to the speed reference. The rotational speed is proportional

to the speed reference.

4 The rotary encoder generates the feedback pulses for both the speed

feedback within the Servo Driver speed loop and the position feedback

within the CJ1W-MCH72 position loop.

The labels in the figure are:

A CJ1W-MCH72.

B Servo system.

C Demand position.

D Position control.

E Speed reference.

F Speed control.

G Motor.

H Encoder.

I Measured speed.

J Measured position.

13

Servo system principles Section 1-4

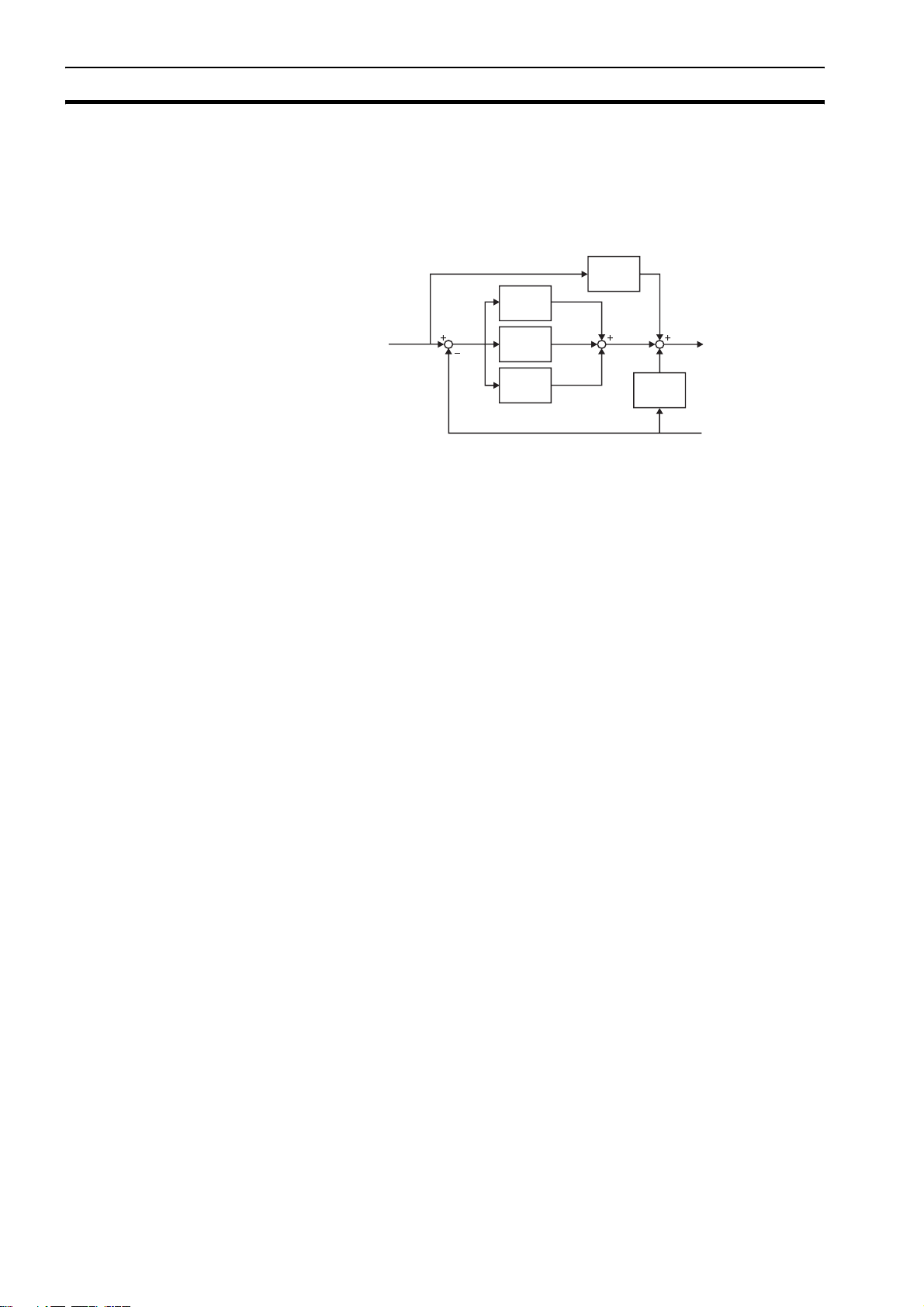

1-4-3 Motion control algorithm

The servo system controls the motor by continuously adjusting the speed

reference to the Servo Driver. The speed reference is calculated by the motion

control algorithm of the CJ1W-MCH72, which is explained in this section.

∑

K

vff

K

p

AB C

∑

K

i

∆

K

d

∆

K

ov

D

The motion control algorithm uses the demand position (A), the measured

position (D) and the Following Error (B) to determine the speed reference. The

Following Error is the difference between the demanded and measured

position. The demand position, the measured position and the Following Error

are represented by the axis parameters MPOS, DPOS and FE. Five gain

values have been implemented for the user to be able to configure the correct

control operation for each application.

C is the output signal.

• Proportional gain

The proportional gain K

Following Error E.

O

= Kp · E

p

All practical systems use proportional gain. For many just using this gain

parameter alone is sufficient. The proportional gain axis parameter is called

P_GAIN.

• Integral gain

The integral gain K

the Following Errors that have occurred during the system operation.

O

= Ki · ΣE

i

Integral gain can cause overshoot and so is usually used only on systems

working at constant speed or with slow accelerations. The integral gain axis

parameter is called I_GAIN.

• Derivative gain

The derivative gain K

change in the Following Error E and speeds up the response to changes in

error while maintaining the same relative stability.

O

= Kd · ∆E

d

Derivative gain may create a smoother response. High values may lead to

oscillation. The derivative gain axis parameter is called D_GAIN.

• Output speed gain

The output speed gain K

the change in the measured position P

O

= Kov · ∆P

ov

m

creates an output Op that is proportional to the

p

creates an output Oi that is proportional to the sum of

i

produces an output Od that is proportional to the

d

produces an output Oov that is proportional to

ov

and increases system damping.

m

14

Servo system principles Section 1-4

The output speed gain can be useful for smoothing motions but will

generate high Following Errors. The output speed gain axis parameter is

called OV_GAIN.

• Speed feed forward gain

The speed feedforward gain K

proportional to the change in demand position P

Following Error at high speed.

O

= K

vff

· ∆P

d

vff

The parameter can be set to minimise the Following Error at a constant

machine speed after other gains have been set. The speed feed forward

gain axis parameter is called VFF_GAIN.

The default settings are given in the table along with the resulting profiles.

Fractional values are allowed for gain settings.

/i

Gain Default value

Proportional gain 0.1

Integral gain 0.0

Derivative gain 0.0

Output speed gain 0.0

produces an output O

vff

and minimizes the

d

that is

vff

Speed feedforward gain 0.0

15

Trajexia system architecture Section 1-5

1-5 Trajexia system architecture

The system architecture of the Trajexia is dependant upon these

concepts:

• Program control

• Motion Sequence

• Motion buffers

• Communication

•Peripherals

These concepts depend upon the value set in the SERVO_PERIOD

parameter. The relationship between the value of SERVO_PERIOD and the

different concepts of the system architecture are describes as follows.

1-5-1 Program control

Programs make the system work in a defined way. The programs are written in

a language similar to BASIC and control the application of the axes and

modules. 14 Programs can be executed in parallel. The programs can be set

to run at system power-up, started and stopped from other programs and

executed from Trajexia Studio.

Programs execute commands to move the axes, control inputs and outputs

and make communication via BASIC commands.

1-5-2 Motion sequence

The motion sequence controls the position of all 32 axes with the actions as

follows:

• Reading the Motion buffer

• Reading the current Measured Position (MPOS)

• Calculating the next Demanded Position (DPOS)

• Executing the Position loop

• Sending the Axis reference

• Error handling

1-5-3 Motion buffers

Motion buffers are the link between the BASIC commands and the Axis control

loop. When a BASIC motion command is executed, the command is stored in

one of the buffers. During the next motion sequence, the profile generator

executes the movement according to the information in the buffer.

When the movement is finished, the motion command is removed from the

buffer.

1-5-4 Communication

The CJ1W-MCH72 can exchange data with memory areas in the PLC. This

enables the CJ1W-MCH72 to use the inputs and outputs connected to the

PLC. Also, programs in the CJ1W-MCH72 and PLC programs can exchange

control and status data.

For more information on communication and data exchange, refer to chapter

3.

1-5-5 Peripherals

16

All inputs and outputs are used with the set of parameters (IN, OP, AIN,

AOUT). The inputs and outputs are automatically detected and mapped in

Trajexia. Inverters are considered a peripheral device and have a set of

BASIC commands to control them.

Cycle time Section 1-6

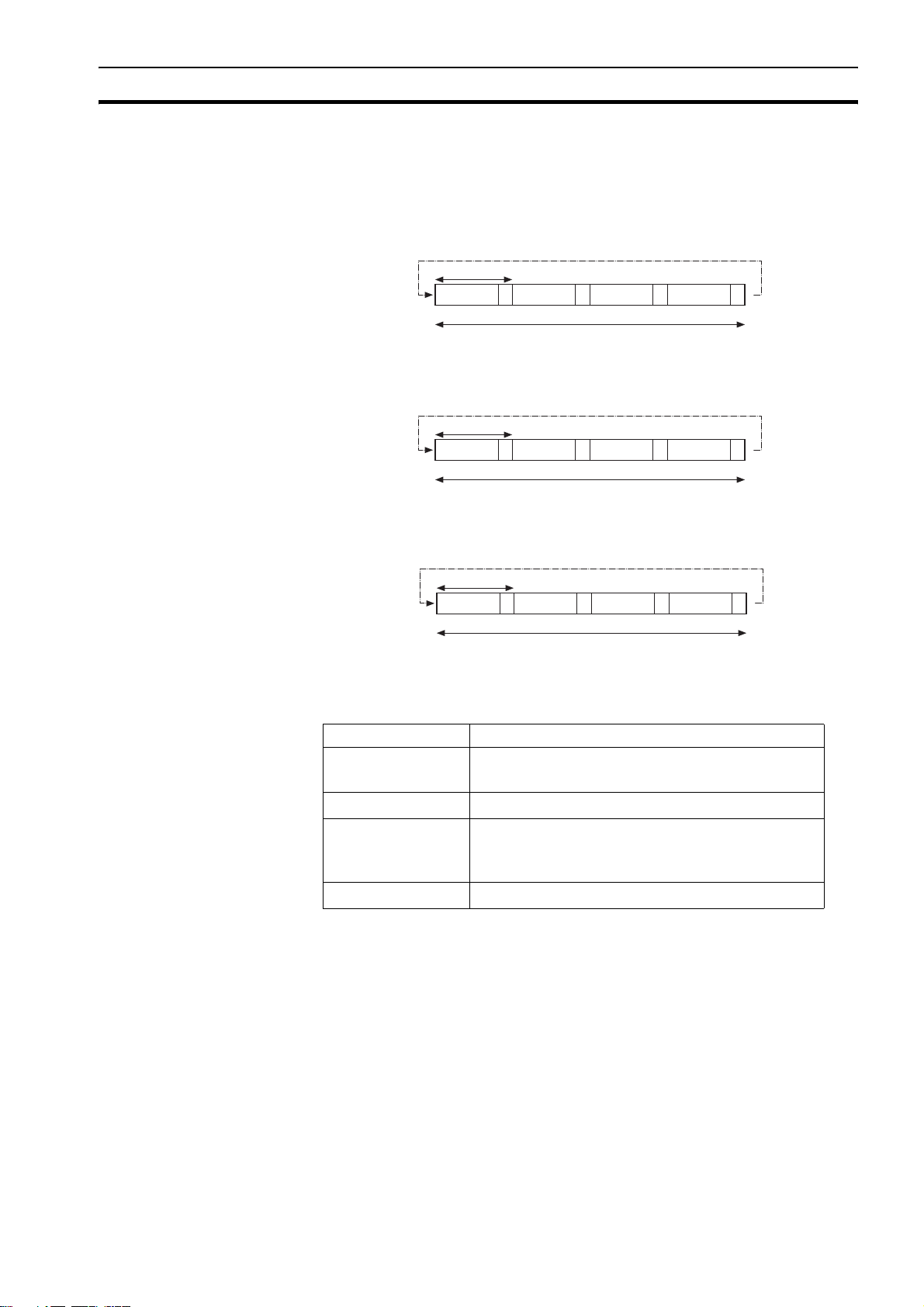

1-6 Cycle time

All processes in the Trajexia system are based on the cycle time. The cycle

time is divided into four CPU tasks:

•250 µs time intervals for a SERVO_PERIOD of 0.5 and 1.0 ms

250µs

1

2

Cycle time = 1ms

3

4

•500 µs time intervals for a SERVO_PERIOD of 2.0 ms

500 µs

1

2

Cycle time = 2 ms

3

4

• 1 ms time intervals for a SERVO_PERIOD of 4.0 ms

1 ms

1

2

Cycle time = 4 ms

3

4

The processes that can be carried out in each time interval depends on the

SERVO_PERIOD that is set.

The operations executed in each CPU task are:

CPU task Operation

First CPU task Motion Sequence

Low priority process

Second CPU task High priority process

Note The Motion sequence execution depends on setting of the SERVO_PERIOD parame-

1-6-1 Servo period

Third CPU task Motion Sequence (only if SERVO_PERIOD=0.5ms)

LED Update.

High priority process

Fourth CPU task External Communications

ter.

The SERVO_PERIOD can be set at 0.5, 1, 2 or 4 ms. The processes that take

place within the cycle time depend on the setting of the SERVO_PERIOD

parameter. The SERVO_PERIOD parameter is a Trajexia parameter that must

be set according to the system configuration.

The factory setting is 1ms (SERVO_PERIOD=1000). A change is set only

after a restart of the CJ1W-MCH72.

17

Cycle time Section 1-6

Note Only the Sigma-III Servo Driver and the Sigma-V Servo Driver support the 0.5 ms trans-

mission cycle.

1-6-1-1 Servo period 0.5 ms

The SERVO_PERIOD has a value of 0.5ms and the motion sequence is

executed every 0.5ms.

1-6-1-2 Servo period 1 ms

CPU task 1

CPU task 2

CPU task 3

CPU task 4

CPU task 1

CPU task 2

CPU task 3

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

Motion sequence

LED refresh

High priority task (13,14)

Communication

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

LED refresh

High priority task (13,14)

1ms

1ms

The SERVO_PERIOD has a value of 1ms and the motion sequence is

executed every 1ms. As the motion sequence is not executed during CPU task

3, there is more time for the program execution. High priority programs run

faster.

1-6-1-3 Servo period 2 ms

The SERVO_PERIOD has a value of 2ms and the motion sequence is

executed every 2.0ms.

CPU task 4

CPU task 1

CPU task 2

CPU task 3

CPU task 4

Communication

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

LED refresh

High priority task (13,14)

Communication

2ms

18

Cycle time Section 1-6

1-6-1-4 Servo period 4 ms

The SERVO_PERIOD has a value of 4ms and the motion sequence is

executed every 4.0ms.

1-6-1-5 Servo period rules

The number of axes and MECHATROLINK-II slaves in the Trajexia system

determines the value of the SERVO_PERIOD system parameter.

There are 2 types of MECHATROLINK-II slaves that are supported by the

CJ1W-MCH72 units:

• Servo Drivers

• Inverters

You should comply with the most restrictive rules when you set the

SERVO_PERIOD parameter. An incorrect value of the SERVO_PERIOD

parameter results in an incorrect detection of the MECHATROLINK-II slaves.

The most restrictive rules are given in the tables below. For each unit the table

lists the maximum number of slaves the unit can control at the given

SERVO_PERIOD setting.

/i

CPU task 1

CPU task 2

CPU task 3

CPU task 4

Motion sequence

Low priority task (0,1,2,3...)

High priority task (13,14)

LED refresh

High priority task (13,14)

Communication

The CJ1W-MCH72 considers Servo Drivers as axes.

The CJ1W-MCH72 does not consider Inverters as axes.

SERVO_PERIOD Total number

of axes

Number of

MECHATROLINK-II

stations

axes inverters

4ms

Total number of

MECHATROLINK-II

stations

0.5 ms 8 4 4 4

1.0 ms 16 8 8 8

2.0 ms 16 16 8 16

4.0 ms 32 30 8 30

19

Cycle time Section 1-6

1-6-1-6 Configuration examples

Example 1

Servo Driver

Address

43

Axis 0

• 1x CJ1W-MCH72

• 3x Sigma-V Servo Driver

• 1x Encoder (Axis 0)

• SERVO_PERIOD = 0.5ms

The CJ1W-MCH72 supports 0.5ms SERVO_PERIOD with 4 axes.

If Sigma-II Servo Drivers were used in this example, the SERVO_PERIOD

would be 1.0ms, since Sigma-II servo Drivers do not support the

SERVO_PERIOD of 0.5ms.

Axis 2 Axis 3

Address44Address

45

Terminator

Axis 4

20

Cycle time Section 1-6

Example 2

Servo Driver

Axis 16

Address41Address42Address43Address44Address45Address46Address47Address

Axis 0

Address

Axis 8

Axis 1

Address4AAddress4BAddress4CAddress4DAddress4EAddress4FAddress

49

Axis 9

Axis 2

Axis 10

Axis 3

Axis 11

Axis 4

Axis 12

Axis 5

Axis 13

Axis 14

Axis 6

48

Axis 7

50

Axis 15

• 1x CJ1W-MCH72

• 16x Sigma-II Servo Driver

• 1x Encoder (Axis 16)

• SERVO_PERIOD = 4ms

The CJ1W-MCH72 supports 4ms SERVO_PERIOD with 17 axes.

Terminator

21

Program control and multi-tasking Section 1-7

1-7 Program control and multi-tasking

The Trajexia system has program, processes and multi tasking control.

1-7-1 Program control

The Trajexia system can control 14 processes that are written as BASIC

programs. When the program is set to run, the program is executed.

Processes 1 to 12 are low priority, 13 and 14 are high priority.

1-7-2 Processes

The low-priority process 0 is reserved for the Terminal window of Trajexia

Studio. This terminal window is used to write direct BASIC commands to the

CJ1W-MCH72 independent to other programs. These commands are

executed after you press the Enter button.

1-7-3 Multi-tasking

LT HT #1 HT #2

Cycle time

Each cycle time is divided into 4 time slices called CPU tasks. Processes run

in the first 3 CPU tasks according to the priority of the process.

Motion sequence and low-priority processes (A) are executed in the Low Task

(LT) period.

High priority processes (B) are executed in the high Task (HT) periods.

A

LT HT #1 HT #2

External communication that are not related to the motion network are

updated in the communications (COMS) period in the fourth CPU task.

Trajexia can control up to 14 programs at the same time.

In contrast to low priority processes, a high priority process is always available

for execution during two of the four CPU tasks. The high-priority tasks are

executed faster than the low-priority tasks, it is that they have more time

available for their execution. All the low-priority tasks must share one slot of

time and the high-priority task have their own two slots of time.

B

Cycle time

COMS.

COMS.

22

Motion sequence and axes Section 1-8

1-7-4 Multi-tasking example

1

14

10

(c/l)

1ms

1ms

141

1ms

13

1ms

14

1ms

140

1ms

13

COMS.

COMS.

(c/l)

0

(c/l)

(c/l)

3

COMS.

210

1

14

3

2

3

321

1ms

1ms

143

1ms

13

COMS.

COMS.

COMS.

2

0

(c/l)

1ms

13

14

1ms

142

1ms

32

COMS. COMS.

COMS. COMS.

COMS. COMS.

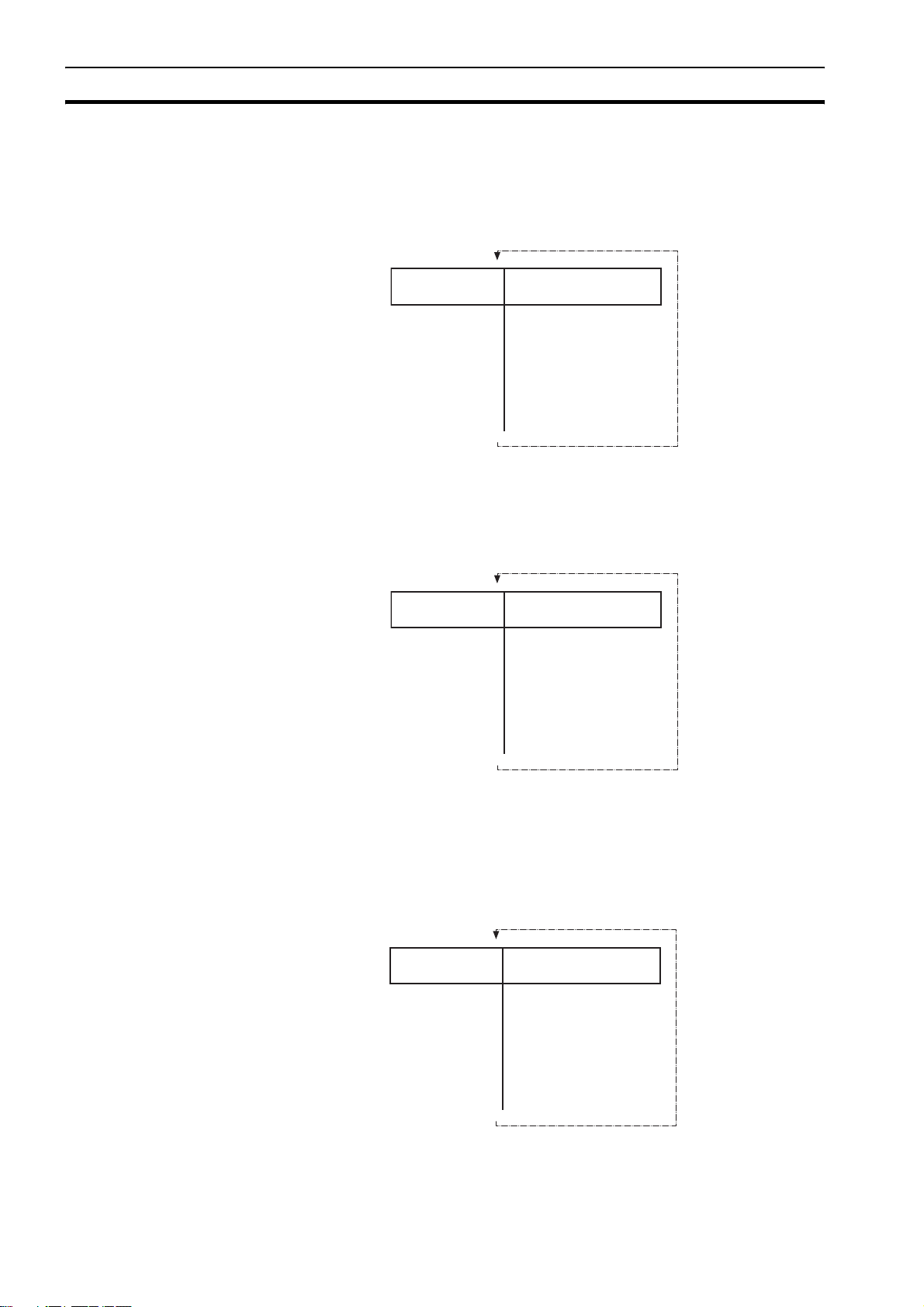

In the example 1, there are two high-priority processes, 13 and 14. The two HT

periods are reserved for these processes, one for processes 13 and one for

processes 14. The low-priority processes 3, 2, 1 and 0 are executed in the LT

period, one process per Cycle time here set to 1.0ms.

In the middle example, there is only one high-priority process, 14. Both HT

periods are reserved for this process. The low-priority processes, 3, 2, 1 and 0

are executed in the LT period, one process per cycle time.

In the lower example, there are no high-priority processes. Therefore, the HT

periods can be used for the low-priority processes. The LT period is also used

for the low-priority processes.

1-8 Motion sequence and axes

• block

•

AXIS PARAMETER

Position loop

Position loop

+

+

Profile generatorProfile generator

Demanded

Demanded

position

position

Mea s ur ed

Mea s ur ed

position

position

Motion sequence is the part of the CJ1W-MCH72 that controls the axes. The

actual way that the motion sequence operates depends on the axis type. The

axis type can be set and read by the parameter ATYPE. At start-up the

Trajexia system automatically detects the configuration of the axes.

• The default value for the parameter ATYPE for MECHATROLINK-II axes is

40 (MECHATROLINK-II position).

• The default value for the parameter ATYPE for the Encoder Interface is 44

(incremental encoder).

-

Following

Following

error

error

Speed

Speed

command

command

Servo Drive

OFF

ON

Speed loop

Torq ue

loop

M

E

23

Motion sequence and axes Section 1-8

All non allocated axes are set as a virtual axis. The value for the parameter

ATYP E is 0.

Every axis has the general structure as shown in the illustration above .

The motion sequence which will be executed at the beginning of each servo

period will contain the following elements:

1 Transfer any moves from BASIC process buffers to motion buffers (see

section 1-9).

2 Read digital inputs.

3 Load moves. (See note.)

4 Calculate speed profile. (See note.)

5 Calculate axis positions. (See note.)

6 Execute position servo. For axis 0 this also includes the Servo Driver

communications. (See note.)

7 Update outputs.

Note Each of these items will be performed for each axis in turn before moving on to the next

item.

1-8-1 Profile generator

The profile generator is the algorithm that calculates the demanded position

for each axis. The calculation is made every motion sequence.

The profile is generated according to the motion instructions from the BASIC

programs.

1-8-2 Position loop

The position loop is the algorithm that makes sure that there is a minimal

deviation between the measured position (MPOS) and the demand position

(DPOS) of the same axis.

1-8-3 Axis sequence

• The motion controller applies motion commands to an axis array that is

Basic Program

.........

.........

MOVE(1000)

.........

.........

Profile generator

Demand Position

defined with the BASE command. If the motion command concerns one

axis, it is applied to the first axis in the BASE array. If the motion command

concerns more than one axis, and makes an orthogonal move, the axes

are taken from the array in the order defined by the BASE command. For

24

Motion sequence and axes Section 1-8

more information on the BASE command and the definition of the axis

sequence in an axis array, refer to the Trajexia Programming Manual,

chapter 3 (BASIC commands).

• If SERVO=OFF for one axis, the motion commands for that axis are

ignored.

• If the Following Error (FE) in one axis exceeds the parameter value

FELIMIT, the next action occurs:

- WDOG is set to OFF and all axes stop.

- SERVO for the axis that causes the error goes to OFF.

- The current move is cancelled and removed from the buffer.

1-8-4 Type of axis

/i

ATYPE Applicable to Name Description

0 All axes Virtual axis Internal axis with no physical out-

put. It is the only valid setting for

non-allocated axes. That is, those

that are not MECHATROLINK-II

Servo Drivers.

40 MECHATROLINK-II

Servo Drivers

41 MECHATROLINK-II

42 MECHATROLINK-II

43 External driver con-

nected to encoder

input

MECHATROLINK-II

Position (default)

Speed

To rq ue

Stepper output Pulse and direction outputs. Posi-

Position loop in the Servo Driver.

CJ1W-MCH72 sends position reference to the Servo Driver via

MECHATROLINK-II.

Position loop in the Trajexia.

CJ1W-MCH72 sends speed reference to the Servo Driver via

MECHATROLINK-II.

Position loop in the Trajexia.

CJ1W-MCH72 sends torque reference to the Servo Driver via

MECHATROLINK-II.

tion loop is in the driver. CJ1WMCH72 sends pulses and

receives no feed back.

44 Servo axis

(Default)

Encoder

45 Encoder

output

47 Absolute EnDat Feedback is received from an

48 Absolute

SSI

49 MECHATROLINK-II

Inverters

Inverter as

axis

CJ1W-MCH72 receives position

from an incremental encoder.

The same as stepper, but with the

phase differential outputs emulating an incremental encoder.

EnDat absolute encoder.

Feedback is received from an SSI

absolute encoder.

Inverters (with built-in encoder

interface) are controlled on the

MECHATROLINK-II bus as servo

axes.

25

Motion sequence and axes Section 1-8

1-8-4-1 Virtual axis ATYPE=0

Profile generator

MEASURED

You can split a complex profile into two or more simple movements, each

assigned to a virtual axis. These movements can be added together with the

BASIC command ADDAX then assigned to a real axis.

1-8-4-2 MECHATROLINK-II position ATYPE=40

CJ1W-MCH72

SERVO = OFF SERVO = OFF

Profile generator

Demanded

position

Measured

position

Position loop

+

_

Following

error

Position Loop is

deactivated

(Gains are not

used!)

POSITION

Speed

command

=

DEMAND

POSITION

ML-II

Position

command

SERVO

Position Loop

Speed Loop

Torque Loop

M

E

With SERVO = ON, the position loop is closed in the Servo Driver. Gain

settings in the CJ1W-MCH72 have no effect. The position reference is sent to

the Servo Driver.

Note Although MPOS and FE are updated, the real value is the value in the Servo Driver.

The real Following Error can be monitored by the DRIVE_MONITOR parameter by setting DRIVE_CONTROL = 2.

Note The MECHATROLINK-II position ATYPE = 40 is the recommended setting to obtain a

higher performance of the servo motor.

26

Motion sequence and axes Section 1-8

1-8-4-3 MECHATROLINK-II speed ATYPE=41

CJ1W-MCH72

Demanded

position

Measured

position

Position loop

+

_

Following

SERVO = OFF SERVO = OFF

Profile generator

With SERVO = ON, the position loop is closed in the CJ1W-MCH72.

Speed reference is sent to the Servo Driver. For Mechatrolink Servo Drivers,

this axis type is not recommended, since there is one cycle delay in the loop

(DPOS(n) is compared with MPOS(n-1)).

With SERVO = OFF, the speed reference is sent via S_REF command.

0x40000000 means maximum speed of the servo motor. This is the

recommended setting.

1-8-4-4 MECHATROLINK-II torque ATYPE=42

error

Speed

command

ML-II

Speed

command

SERVO

Speed Loop

Torque Loop

E

M

SERVO

Torque Loop

E

M

Profile generator

CJ1W-MCH72

Demanded

position

Measured

position

Position loop

+

_

Following

error

Torque

command

SERVO = OFF SERVO = OFF

ML-II

Torque

command

With SERVO = ON, only the torque loop is closed in the Servo Driver. The

torque reference in the Servo Driver depends on the FE and the gain.

With SERVO = OFF, the torque reference is sent directly via the T_REF

command. 0x40000000 is the maximum torque of the servo motor.

Note To monitor the torque in the servo in DRIVE_MONITOR, set DRIVE_CONTROL=11.

27

Motion sequence and axes Section 1-8

1-8-4-5 Stepper output ATYPE=43

The position profile is generated and the output from the system is a pulse

train and direction signal. This is useful to control a motor via pulses or as a

position reference for another motion controller.

1-8-4-6 Servo axis ATYPE=44

CJ1W-MCH72

Measured

Position

With SERVO = OFF, the position of the external incremental encoder is read.

1-8-4-7 Encoder output ATYPE=45

Profile generator

AXIS 1

ATYPE = 45

Demanded

position

The position profile is generated and the output from the system is an

incremental encoder pulse. This is useful to control a motor via pulses or as a

position reference for another motion controller.

1-8-4-8 Absolute EnDat encoder ATYPE=47

With SERVO = OFF, the position of the external absolute EnDat encoder is

read.

1-8-4-9 Absolute SSI encoder ATYPE=48

With SERVO = OFF, the position of the external absolute SSI encoder is read.

CJ1W-MCH72

28

Motion sequence and axes Section 1-8

1-8-4-10 Inverter axis ATYPE=49

INVERTER

Speed Loop

E

M

Profile generator

SERVO = OFF

Demanded

position

Measured

position

CJ1W-MCH72

Position loop

+

_

Following

error

Speed

command

SERVO = OFF

ML-II

Speed

command

DPRAM

REFRESH

EVERY 5ms

This type allows Inverters (with built-in encoder interface) to be controlled on

the MECHATROLINK-II bus as servo axes.

From the controller point of view, Inverter axes are handled the same as servo

axes in MECHATROLINK-II Speed Mode (ATYPE=44).

Unlike the other axis types, this Inverter axis must be defined

programmatically with function 8 of the command INVERTER_COMMAND.

The Speed command to the Inverter and the feedback from the encoder is

refreshed in the Inverter with a few milliseconds delay. This is an inverter

limitation. This means that the use of the Inverter is similar to the use of a

Servo Driver, but the performance is lower.

1-8-4-11 Summary of axis types and control modes

The following table lists the axis types and their recommended modes for

speed control, position control and torque control.

/i

ATYPE SERVO Mode Comment

40 OFF Position

(MECHATROLINK-II)

40 ON Position

(MECHATROLINK-II)

41 OFF Speed

(MECHATROLINK-II)

41 ON Position

(MECHATROLINK-II)

42 OFF Torque

(MECHATROLINK-II)

42 ON Position via torque

(MECHATROLINK-II)

The position loop is closed in the Servo

Driver. No new motion command is

allowed.

Recommended mode for position control

with MECHATROLINK-II axes.

Recommended mode for speed control

with MECHATROLINK-II axes. Set the

speed with S_REF.

The position loop is closed in Trajexia.

This gives lower performance than closing

the position loop in the Servo Driver.

Recommended mode for torque control

with MECHATROLINK-II axes. Set the

torque with T_REF.

The position loop is closed in Trajexia.

The output of the position loop is sent as

the torque reference to the Servo Driver.

29

Motion sequence and axes Section 1-8

ATYPE SERVO Mode Comment

49 OFF Speed Inverter (with built-in encoder interface)

controlled on the MECHATROLINK-II bus

as a servo axis. Set the speed with

S_REF.

49 ON Position Inverter (with built-in encoder interface)

controlled on the MECHATROLINK-II bus

as a servo axis. The position loop is

closed in Trajexia.

30

Motion buffers Section 1-9

1-9 Motion buffers

AXIS BUFFER

BASIC PROGRAM

BASIC PROGRAM

..... ..

..... ..

MOVE(-500)

MOVE(-500)

..... ..

..... ..

MOVE(1000)

MOVE(1000)

..... ..

..... ..

CONNECT(1,1)

CONNECT(1,1)

..... ..

CONNECT(1,1) AXIS(2)

PROCESS BUFFER

The motion buffer is a temporary store of the motion instruction from the

BASIC program to the profile generator.

The BASIC program continues while the instruction waits in the buffer.

There are three types of buffer:

• MTYPE. The current movement that is being executed. MTYPE relates to

the axis and not to the process.

• NTYPE. The new movement that waits for execution. NTYPE relates to the

axis and not to the process.

• Process Buffer. The third buffered movement cannot be monitored. The

process buffer relates to the process and not to the axis.

(one per axis )

NTYPE

MTYPE

Profile generator

Waiting to be executed

MOTION COMMAND

Currently executed

MOTION COMMAND

DEMAND

POSITION

It is possible to check if the process buffer is full by checking the PMOVE

process parameter.

Process 1

Process 2

Process 3

Process 4

Process 5

Process 6

Process 7

Process 14

Process Buffer

Process Buffer

Process Buffer

Process Buffer

Process Buffer

Process Buffer

Process Buffer

Program Buffer

Each process has its own

“Process Buffer”

Axis 0

Axis 1

Axis 2

Axis 3

Axis 15

Each Axis has its own

2 buffers: NTYPE & MTYPE

WAITING EXEC UTING

NTYPE

NTYPE

NTYPE

NTYPE MTYPE

NTYPE MTYPE

MTYPE

MTYPE

MTYPE

When a motion instruction is executed in the BASIC program, the instruction is

loaded into the process buffer and distributed to the corresponding axis buffer

in the next motion sequence.

If a fourth motion instruction is executed and the three buffers are full, the

BASIC program stops execution until a process buffer is free for use.

31

Motion buffers Section 1-9

EXAMPLE:

BASIC PROGRAM

.......

MOVE(-500)

.......

MOVE(1000)

.......

DATUM (3)

.......

MOVE(200)

.......

BASIC PROGRAM

.......

MOV E(- 50 0)

.......

MOVE(1000)

.......

DATUM( 3)

.......

MOVE(200)

.......

BASIC PROGRAM

.......

MOVE (-500 )

.......

MOVE(1000)

.......

DATUM (3)

.......

MOVE(200)

.......

BASIC PROGRAM

BASIC PROGRAM

.......

.......

MOVE (-500 )

MOVE (-500 )

.......

.......

MOVE(1000)

MOVE(1000)

.......

.......

DATUM (3)

DATUM (3)

.......

.......

MOVE(200)

MOVE(200)

.......

.......

BASIC PROGRAM

BASIC PROGRAM

.......

.......

MOVE(-500)

MOVE(-500)

.......

.......

MOVE(1000)

MOVE(1000)

.......

.......

DATU M(3)

DATU M(3)

.......

.......

MOVE(200)

MOVE(200)

.......

.......

BASIC PROGRAM

BASIC PROGRAM

.......

.......

MOV E(-50 0)

MOV E(-50 0)

.......

.......

MOVE(1000)

MOVE(1000)

.......

.......

DATUM (3)

DATUM (3)

.......

.......

MOVE(200)

MOVE(200)

.......

.......

BUFFER

--------------------------------NTYPE IDLE

--------------------------------MTYPE MOVE(-500)

- - - -

BUFFER

- - - -

--------------------------------NTYPE MOVE(1000)

--------------------------------MTY PE MOV E( -50 0)

BUFFER

DATUM(3)

------------------------------- -NTYPE MOVE(1000)

------------------------------- -MTYPE MOVE(-500)

BUFFER

BUFFER

MOVE(200)

MOVE(200)

------------------------------- --

------------------------------- -NTYPE DATUM(3)

NTYPE DATUM(3)

------------------------------- --

------------------------------- -MTYPE MOVE(1000)

MTYPE MOVE(1000)

BUFFER

BUFFER

- - - - - -

- - - - - -

---------------------------------

--------------------------------NTYPE MOVE(200)

NTYPE MOVE(200)

---------------------------------

--------------------------------MTYPE DATUM(3)

MTYPE DATUM(3)

BUFFER

BUFFER

- - - - - -

- - - - - -

---------------------------------

--------------------------------NTYPE IDLE

NTYPE IDLE

---------------------------------

--------------------------------MTYPE MOVE(200)

MTYPE MOVE(200)

MOVE -500

MOVE -500

MOVE -500

MOVE -500

MOVE -500

MOVE -500

MOVE -500

MOVE -500

MOV E -50 0

MOVE 1000

MOVE 1000

MOVE 1000

MOVE 1000

MOVE 1000

MOVE 1000

DATUM (3)

DATUM (3)

DATU M (3)

DATU M (3)

MOVE 200

MOVE 200

1.- All buffers are empty

and a movement is

loaded. The movement

starts to execute.

2.- A second movement is

loaded while the first one

is not finished.

The new movemen t waits in the

second buffer.

3.- A third movement can

still be stored in the process buffer.

If the basic

‘MOVE(200)’ it will w ait.

4.- The first movement has

finished. Thebuffer moves

by one position .

The next movement starts to

execute.

5.- As the sent

movements are finished,

the buffer

6.- If no new movements

are executed, finally, the

buffer will become empty

and the profile generator

becomes inactive.

program reaches

empties.

Example of buffered instructions:

32

Mechanical system Section 1-10

1-10 Mechanical system

1-10-1 Inertia ratio

The inertia ratio is a stability criterion. The higher the intertia of the load in

relation to the intertia of the motor, the lower the gains you can set in your

system before you reach oscillation, and the lower the performance you can

reach.

With a ratio of 1:30 for small Servo Drivers and a ratio of 1:5 for big Servo

Drivers you can reach the maximum dynamic of the motor-driver combination.

1-10-2 Rigidity

If a machine is more rigid and less elastic, you can set higher gains without

vibration, and you can reach higher dynamic and lower Following Error.

1-10-3 Resonant frequency

A mechanical system has at least one resonant frequency. If you excite your

mechanical system to the resonant frequency, it starts oscillating. For motion