Page 1

Cat. No. W132-E1-4

SYSMAC

C500

Programmable Controller

Page 2

C500 Programmable Controller

Installation Guide

Revised May 2000

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

!

WARNING Indicates information that, if not heeded, could possibly result in loss of life or serious injury .

!

Caution Indicates information that, if not heeded, could result in relatively serious or minor injury, dam-

!

age to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ii

Page 4

About this Manual:

This manual describes the installation of the C500 Programmable Controller and includes the sections

described below.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the C500 Programmable Controller. Be sure to read the following section before

operating the C500 Programmable Controller.

Section 1

ble Controller can do and how a Programmable Controller works is provided.

Section 2

of each Unit are given.

Section 3

vided.

Section 4

tems.

Section 5

venting electrical noise are included.

Section 6

Section 7

Appendixes

is an introduction to Programmable Controllers. General information about what a Programma-

provides a description of all the components of the C500. The names of all the individual parts

explains how to assemble the C500. A detailed description of how to mount each Unit is pro-

outlines the system connections involved in installing a C500 Programmable Controller Sys-

contains the requirements for the installation environment of the C500. Suggestions for pre-

explains the power considerations involved in installing the C500.

lists safety considerations that should be kept in mind while installing the C500.

, a

Glossary

, and an

Index

are also included.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

iii

Page 5

TABLE OF CONTENTS

PRECAUTIONS vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 What is a Control System? 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Input Devices 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Output Devices 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Description of All Components 9 . . . . . . . . . . . . . . . . . . . . . . .

2-1 CPU Rack 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 CPU Power Supply 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Expansion I/O Backplane 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 I/O Power Supply 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 I/O Control Unit 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 I/O Interface Unit 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 I/O Units 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Memory Packs 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Assembly 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Mounting the Units 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Memory Packs 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 System Configurations 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – System Connections 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Current Consumption 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 I/O Connections 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – Installation Environment 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Cooling 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Mounting Requirements 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Duct Work 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Preventing Noise 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – Power Considerations 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – Safety Considerations 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Inspection and Maintenance 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Standard Models 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 6

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the PC. You must read

this section and understand the information contained before attempting to set up or operate a PC system.

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON PCs.

Be sure to read this manual before attempting to use the software and keep this

manual close at hand for reference during operation.

3Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the abovementioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

viii

Page 8

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5Application Precautions

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not con-

necting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Units, or any other

Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

ix

Page 9

• Interlock circuits, limit circuits, and similar safety measures in external circuits

(i.e., not in the Programmable Controller) must be provided by the customer.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse ef fect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

5Application Precautions

x

Page 10

SECTION 1

Introduction

1-1 What is a Control System? 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Input Devices 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Output Devices 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 11

Introduction

This section provides general information about Programmable Controllers

(Systems) and how they fit into a Control System.

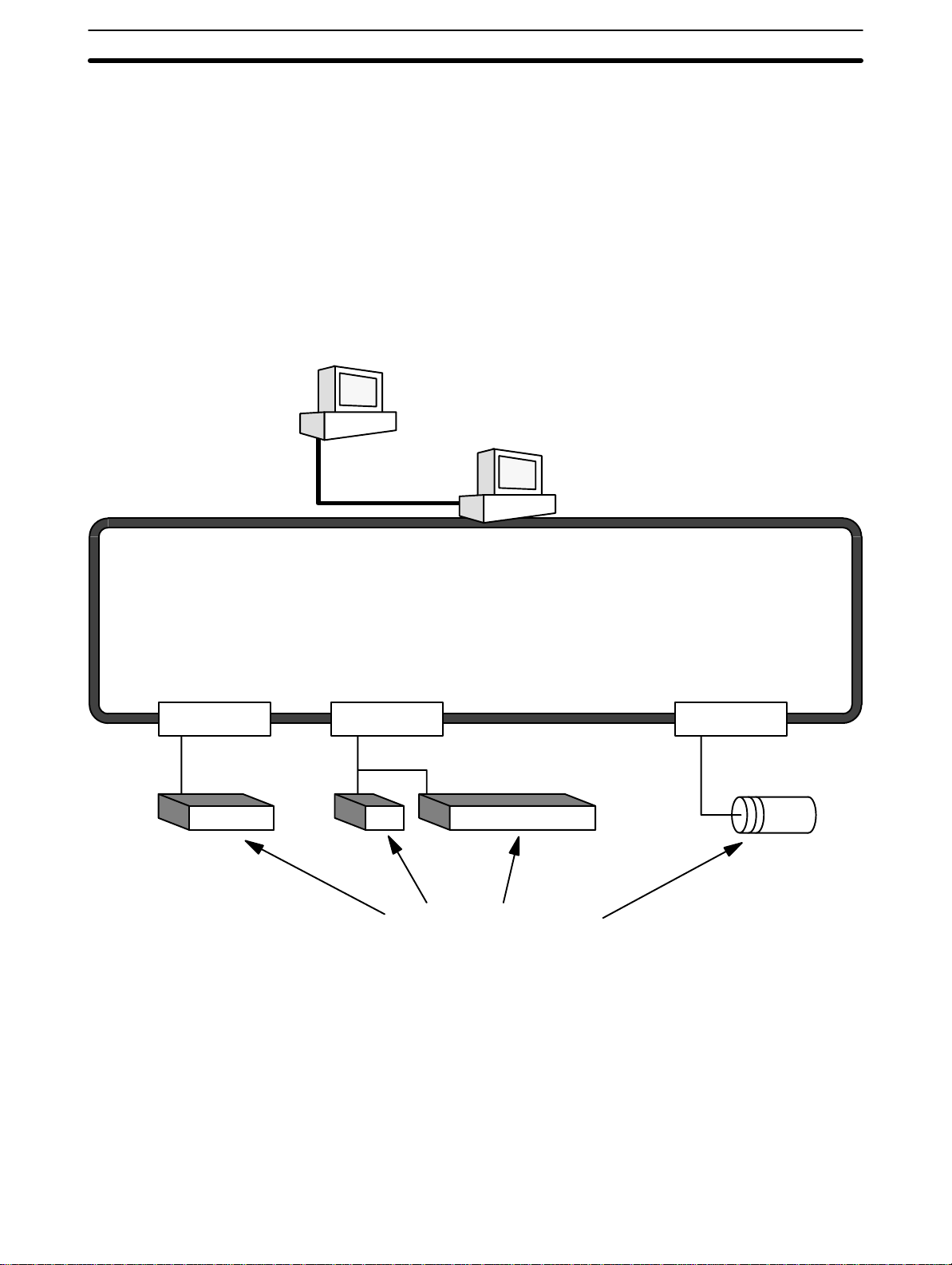

1-1 What is a Control System?

A Control System is the electronic equipment needed to control a particular

process. It may include everything from a process control computer, if one is

used, to the factory computer, down through the PCs (and there may be

many of them networked together), and then on down through the network to

the control components: the switches, stepping motors, solenoids, and sensors which monitor and control the mechanical operations.

Process Control Computer

Section 1Introduction

Factory Computer

PCs

PC PC PC

Control Components

A Control System can involve very large applications where many different

models of PC are networked together or it could be an application as small

as a single PC controlling a single output device.

2

Page 12

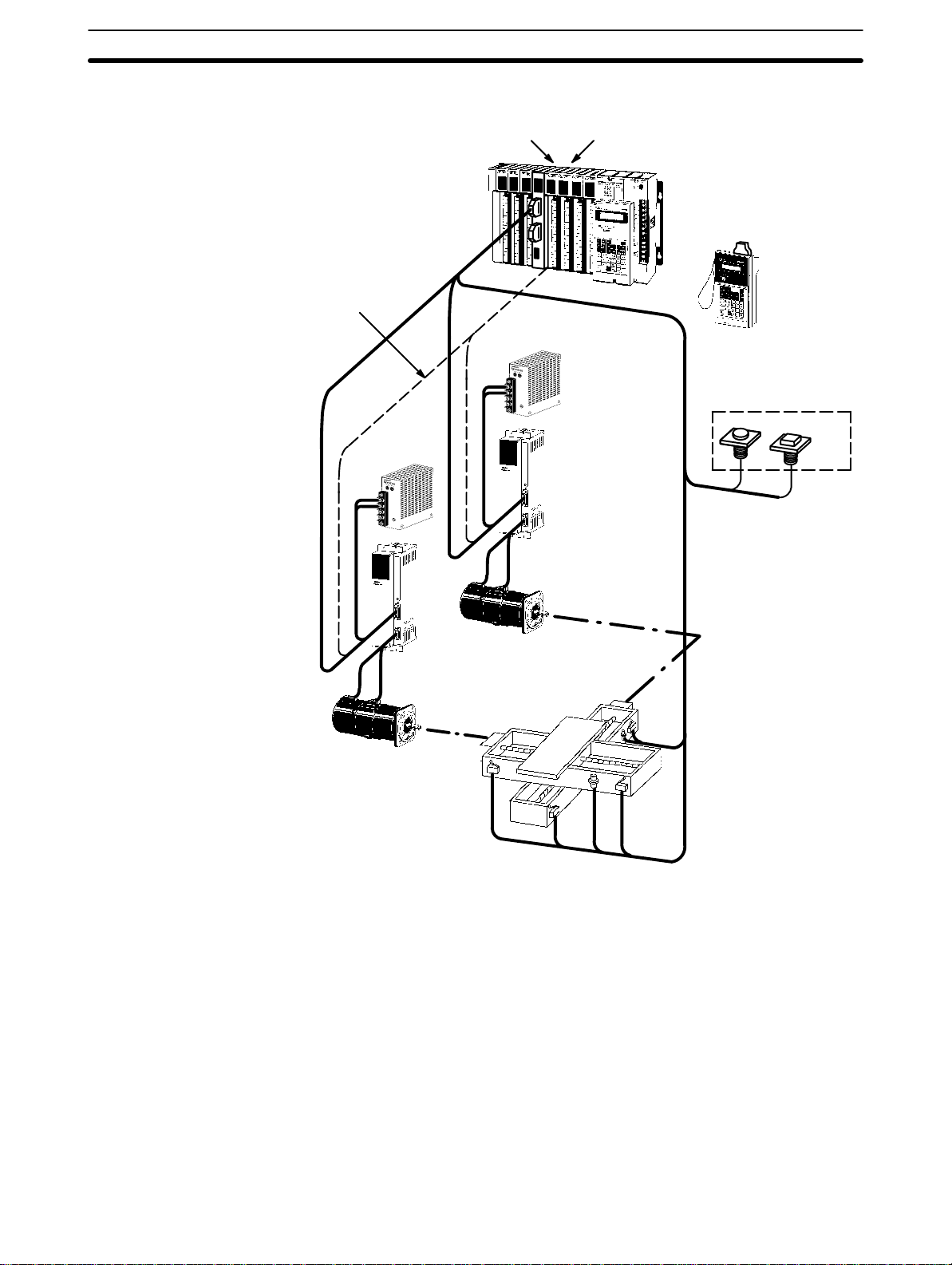

Position Control System

Section 1Introduction

Position Control Unit Input Unit

PC

Signal line for

Servomotor

driver control

Power

source

DC Servomotor

Driver

DC Servomotor

Power

source

DC Servomotor

Driver

DC Servomotor

Handheld

Programming

Console

Control panel

Control switch

In the typical Control System example shown above, a PC controls the movement of the workpiece bed across two horizontal axes using Limit Switches

and Servomotors to monitor and control movement.

1-2 The Role of the PC

The PC is the part of the Control System that directly controls the manufacturing process. According to the program stored in its memory, the PC accepts data from the input devices connected to it, and uses this data to monitor the controlled system. When the program calls for some action to take

place, the PC sends data to the output devices connected to it to cause that

action to take place. The PC may be used to control a simple, repetitive task,

or it may be connected to other PCs, or to a host computer in order to integrate the control of a complex process.

3

Page 13

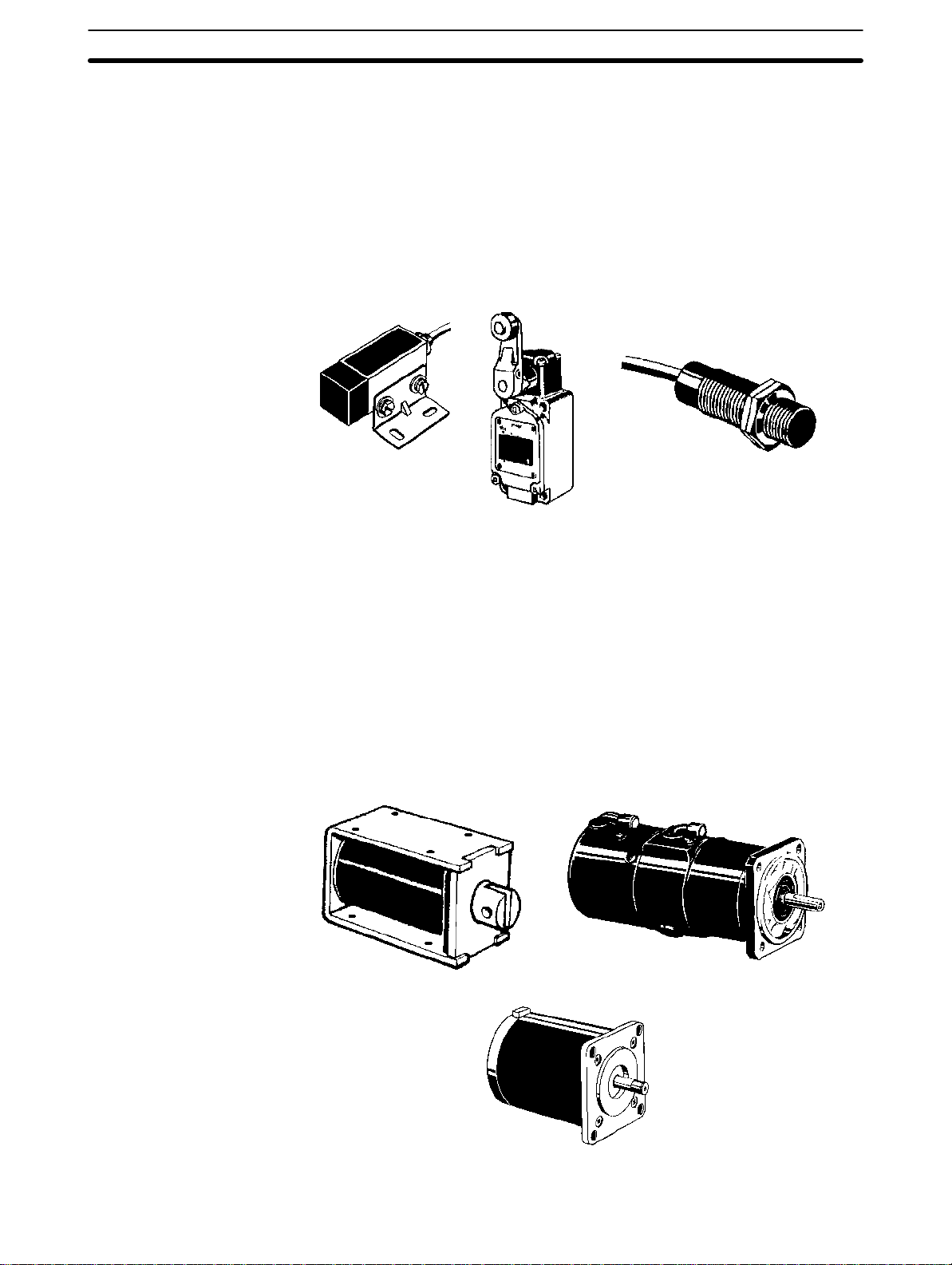

1-2-1 Input Devices

PCs can receive input from either automated or manual devices. The PC

could receive data from the user via a pushbutton switch, keyboard, or similar device. Automated input could come from a variety of devices: microswitches, timers, encoders, photosensors, and so on. Some devices, like the

Limit Switch shown below, turn ON or OFF when the equipment actually

makes contact with them. Other devices, like the Photoelectric Switch and

Proximity Switch shown below, use other means, such as light or inductance,

in order to get information about the equipment being monitored.

Section 1Introduction

Photoelectric Switch

1-2-2 Output Devices

A PC can output to a myriad of devices for use in automated control. Almost

anything that you can think of could be controlled (perhaps indirectly) by a

PC. Some of the most common devices are motors, Solenoids, Servomotors,

Stepping Motors, valves, switches, indicator lights, buzzers, and alarms.

Some of these output devices, such as the motors, Solenoids, Servomotors,

Stepping Motors, and valves, affect the controlled system directly. Others,

such as the indicator lights, buzzers, and alarms, provide output to notify personnel.

Proximity Switch

Limit Switch

Solenoid

Stepping Motor

Servomotor

4

Page 14

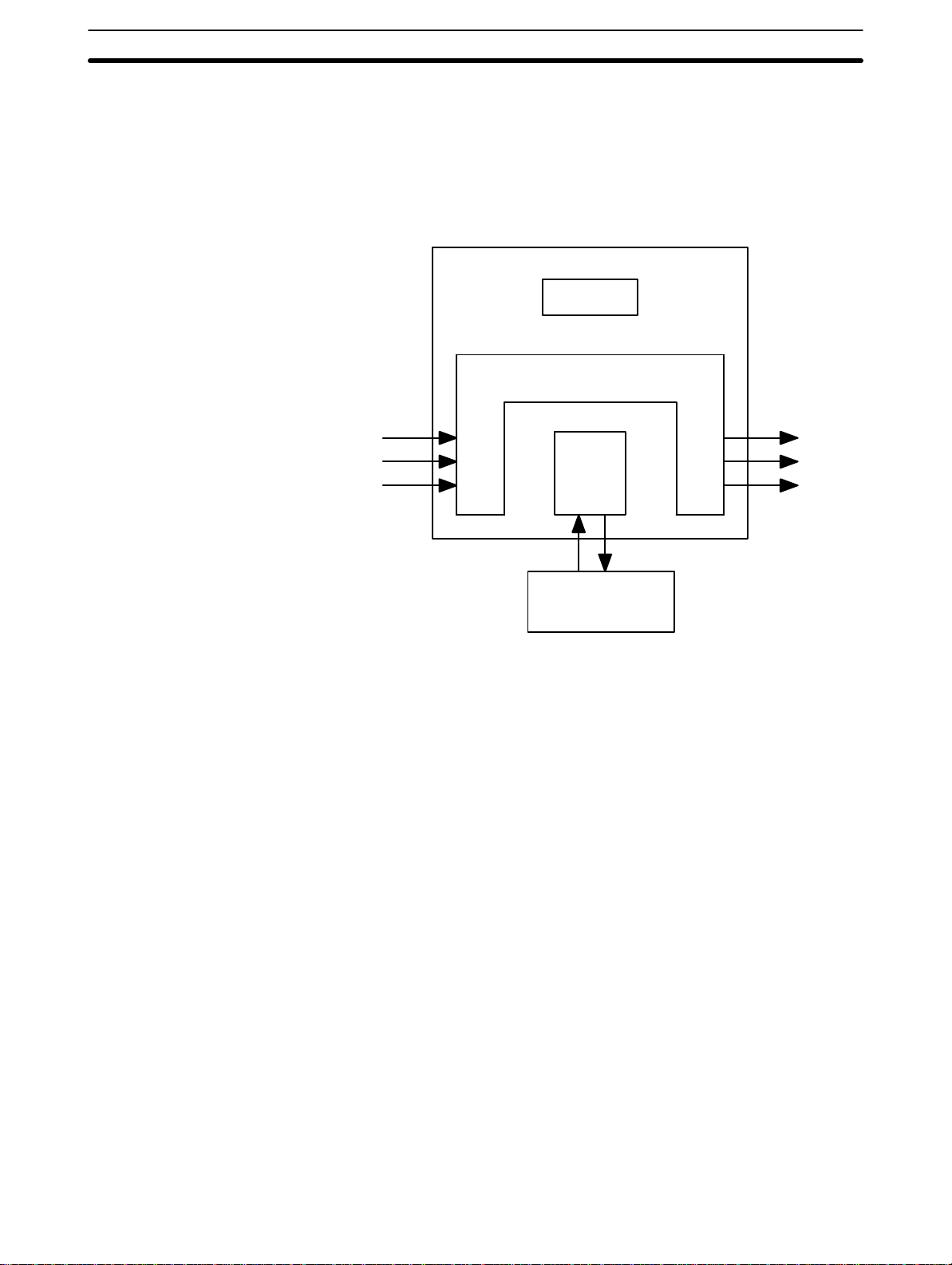

1-3 How Does a PC Work?

PCs operate by monitoring input signals and providing output signals. When

changes are detected in the signals, the PC reacts, through the user-programmed internal logic, to produce output signals. The PC continually cycles

the program in its memory to achieve this control.

Block Diagram of PC

Section 1Introduction

Power Supply

Memory

Scanning Cycle

Signals

from

switches,

sensors,

etc.

Input Output

CPU

Programming

Device

Signals

to Solenoids,

motors,

etc.

A program for your applications must be designed, and stored in the PC. This

program is then executed as part of the cycle of internal operations of the

PC.

When a PC operates, that is, when it executes its program to control an external system, a series of operations are performed inside the PC. These internal operations can be broadly classified into the following four categories:

1. Common (or overseeing) processes, such as watchdog timer operation

and testing the program memory.

2. Data input and output.

Cycle Time

3. Instruction execution.

4. Peripheral device servicing.

The total time required for a PC to perform all these internal operations is

called the cycle time. The flowchart and diagram on page 7 illustrate these

internal operations for a typical PC.

Timing is one of the most important factors in designing a Control System.

For accurate operations, it is necessary to have answers to such questions

as these:

• How long does it take for the PC to execute all the instructions in its memory?

5

Page 15

Section 1Introduction

• How long does it take for the PC to produce a control output in response to

a given input signal?

The cycle time of the PC can be automatically calculated and monitored, but

it is necessary to have an understanding of the timing relationships within the

PC for effective System design and programming.

6

Page 16

Section 1Introduction

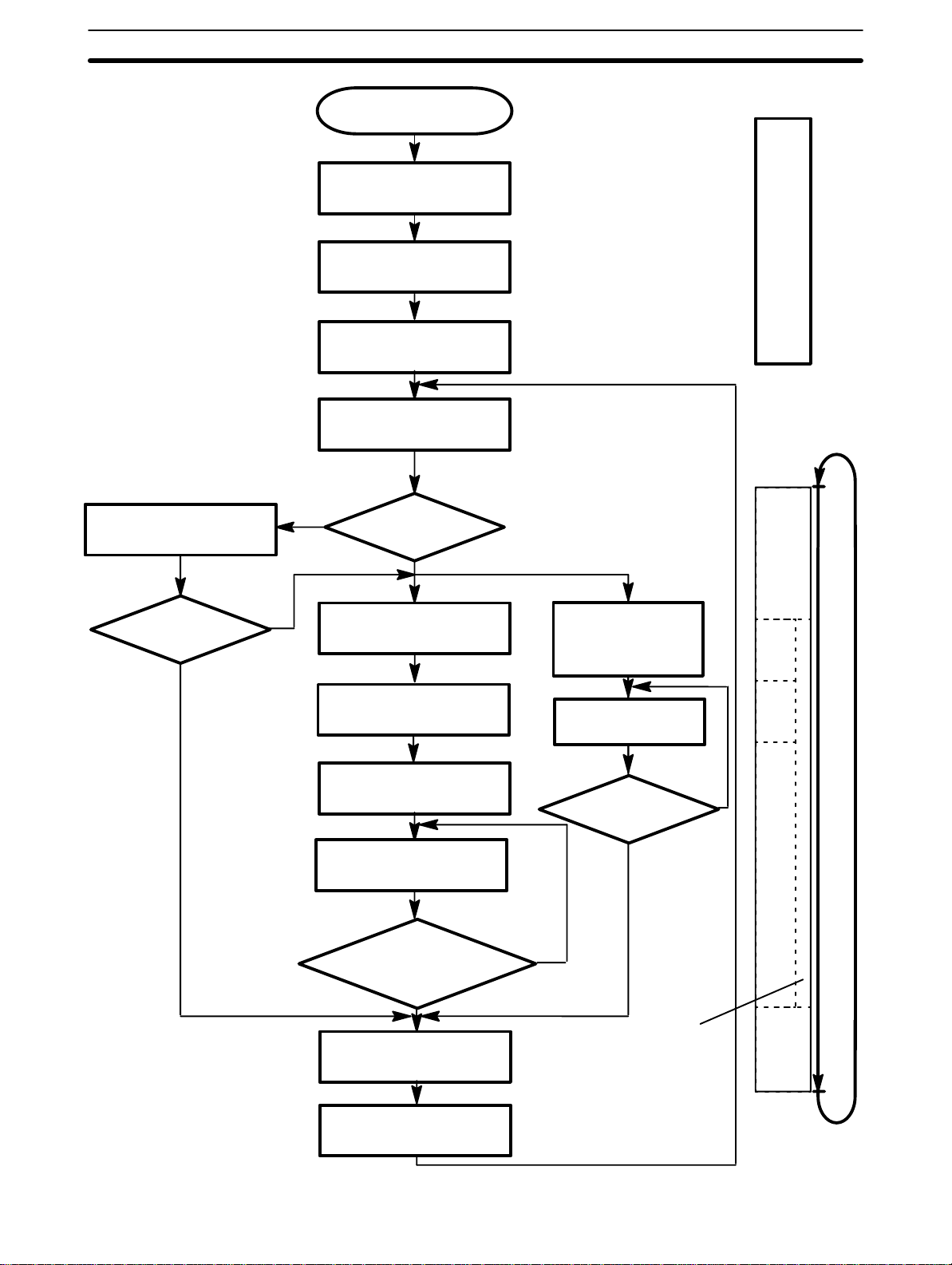

PC Operation

Flowchart

Sets error flag and

lights indicator

Power application

Clears data areas and re-

sets System counters

Checks I/O Unit connection

Resets watchdog timer

Checks hardware and

program memory

No

Check OK?

Initial

processing

on

power

application

Common

processes

Error or alarm?

Error

Alarm

IR data to Output Units

Processes Remote I/O

Resets watchdog timer

Services peripheral devices

Has the application program

been completely executed?

Yes

Resets watchdog timer

Resets watchdog

timer and application

program counter

Executes the program

End of Program?

No

Yes

Mathematical

processes

No

Out

refresh

Remote

I/O

processes

Servicing peripheral

devices

In refresh

PC

cycle

time

Data from Input

Units to IR Area

7

Page 17

SECTION 2

Description of All Components

2-1 CPU Rack 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 CPU Power Supply 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Expansion I/O Backplane 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 I/O Power Supply 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 I/O Control Unit 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 I/O Interface Unit 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 I/O Units 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Memory Packs 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Page 18

Introduction

2-1 CPU Rack

Section 2Description of All Components

This section provides information about the individual Units that make up the

C500 PC. First the names of all the parts of the PC are given, followed by

any details that apply to the Units that make up the PC. For a description of

how the Units fit together to become a PC, refer to

. For information about the model numbers of any of the parts described

tions

in this section, refer to

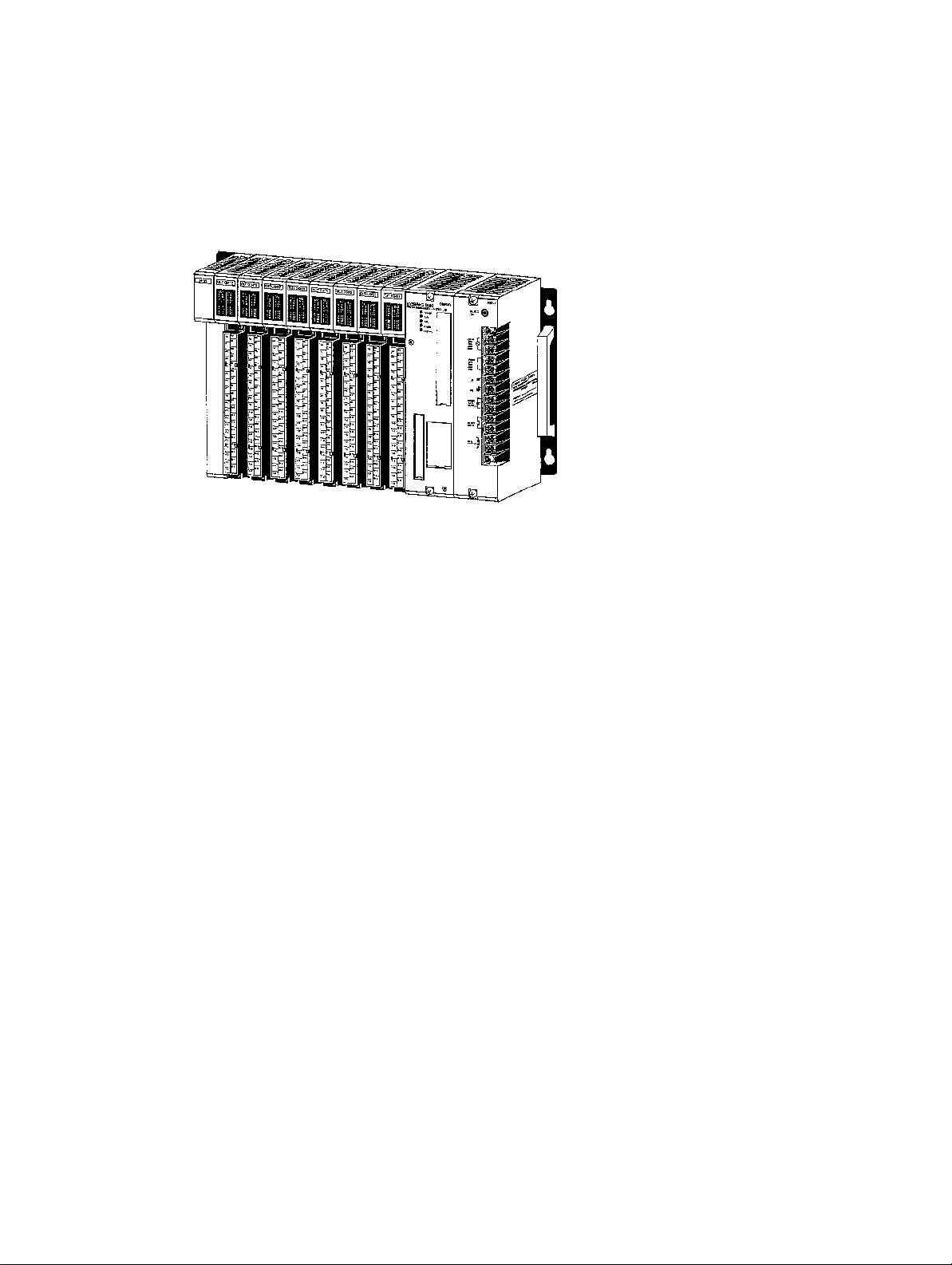

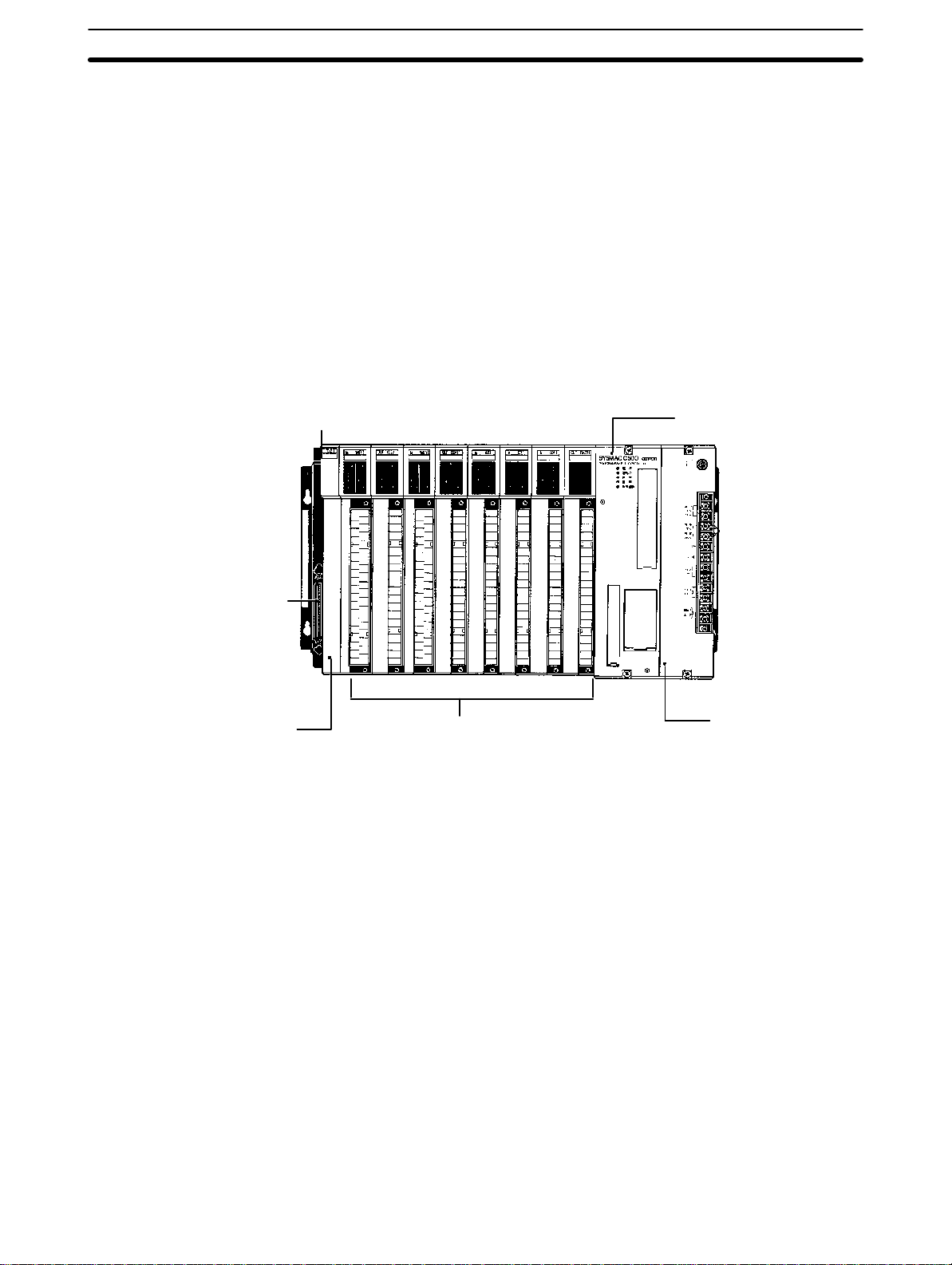

The following figure shows the names of all the parts of the CPU Rack.

There are seven models of CPU Racks available for the C500 PC. Choose a

Backplane with 3, 5 (2 models), 6, 8 (2 models), or 9 I/O slots, depending on

your application. Connect the CPU Backplane to an Expansion I/O Rack via

the Expansion I/O Connector.

Appendix C Standard Models

3-3 System Configura-

.

Expansion I/O Connector

Connects the CPU Rack

to an Expansion I/O

Rack. When not used,

cover with cap.

I/O Control Unit

An I/O Control Unit must be

mounted to the Rack in order to connect the CPU

Rack to an Expansion I/O

Rack.

Backplane

I/O Units

(3, 5, 6, 8, or 9 I/O Units depending on the Backplane

used)

CPU

CPU Power Supply

10

Page 19

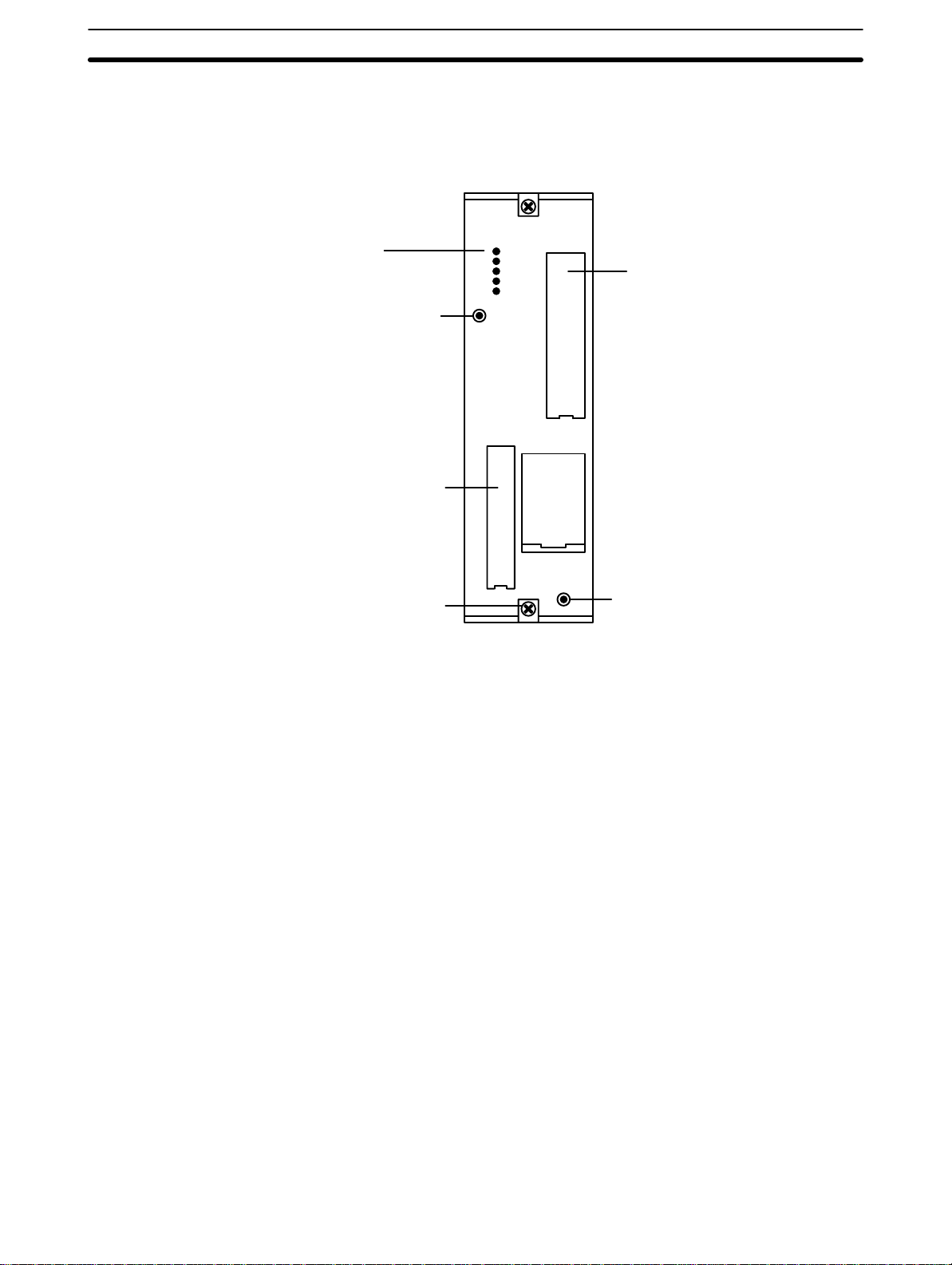

CPU

Section 2Description of All Components

The CPU executes the user program. The model available for the C500 PC

does not have a built-in Power Supply or Memory Pack. Choose the Power

Supply and memory pack suitable for your application. A peripheral device

connector and a memory pack compartment are provided.

Peripheral Device

Connector

Indicators

SYSMAC C500

PROGRAMMABLE CONTROLLER

POWER

RUN

ERR

ALARM

OUT INMB

OMRON

Memory Pack

and Battery

Compartment

Peripheral device

mounting screw

Peripheral device

•

connector cover

CPU mounting

screw

Peripheral device

mounting screw

The CPU is equipped with one connector for peripheral devices. A peripheral

device, such as the CPU-Mounting Programming Console, can be mounted

directly to the CPU and does not require a connecting cable. To mount the

CPU-Mounting Programming Console or any other peripheral device directly

to the CPU, follow these steps:

1. Detach the cover of the peripheral device connector with a standard

screwdriver.

2. Connect the CPU-Mounting Programming Console to the peripheral de-

vice connector.

3. To ensure a positive connection, secure the Programming Console to

the CPU by tightening the mounting screws located on the surface of the

CPU.

11

Page 20

2-2 CPU Power Supply

C

The CPU Power Supply is mounted to the rightmost slot of the CPU Rack.

Three models of Power Supplies are available: 100 to 120 VAC, 200 to 240

VAC, and 24 VDC. The following table summarizes the output capacity of the

three models and the current available for I/O Units mounted on the CPU

Rack.

Section 2Description of All Components

3G2A5-PS221-E

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Mounting screw

Do not loosen this screw.

3G2A5-PS221-E

3G2A5-PS223-E

3G2A5-PS213-E 24 VDC 9 A 5 VDC 5 A Not provided

Note Be sure to keep the total power consumed by all the Units mounted

Terminals for

external connections

Model Supply Voltage Output

Capacity

100 to 120/

200 to 240 VA

(selectable)

7 A 5 VDC 5 A Provided

12 A 5 VDC 10 A Not provided

Available Current

for I/O Units

24 VDC Output

Terminal

on a Rack within the value stated in the table above. For example, do

not mount I/O Units with a total current consumption of 6 A to a Rack

supplied by a 7 A Power Supply. As shown in the table above, the

available current for I/O Units is only 5 A. For details concerning current consumption, refer to

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

LG

GR

+

+

0.8 A, 24 VDC output

–

START input

RUN output

Section 4 System Connections

Connect a 100 to 120 VAC or 200 to

240 VAC power source.

Short these terminals to select 100 to

120 VAC. Open them to select 200 to

240 VAC.

Ground this terminal at a resistance of

less than 100

munity or prevent electric shock.

Ground this terminal at a resistance

of less than 100

shock.

Use these terminals to supply power

to DC Input Units. Use a separate

Power Supply if the I/O Unit requires

more than 0.8 A. If a current higher

than 0.8 A is output, the PC stops.

These terminals are short-circuited as

a factory-set condition. Remove the

short-circuit bracket to start or stop

the PC with an external signal. Normally, leave them short-circuited.

These terminals are turned ON during RUN operation.

Ω to improve noise im-

.

Ω to prevent electric

12

Page 21

3G2A5-PS223-E

Section 2Description of All Components

Mounting screw

Do not loosen this screw.

•

3G2A5-PS213-E

Fuse holder

Contains a MF61NR fuse

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

Mounting screw

Do not loosen this screw.

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

LG

GR

START input

RUN output

+

Connect a 100 to 120 VAC or 200

to 240 VAC power source.

Short these terminals to select 100

to 120 VAC. Open them to select

200 to 240 VAC.

Ground this terminal at a resistance of less than 100

prove noise immunity or prevent

electric shock.

Ground this terminal at a resis-

tance of less than 100

vent electric shock.

24 VDC output terminals are not

provided.

These terminals are short-circuited

as a factory-set condition. Remove

the short-circuit bracket to start or

stop the PC with an external signal.

Normally, leave them shortcircuited.

These terminals are turned ON

during RUN operation.

Ω to im-

Ω to pre-

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

24 VDC input

-

LG

GR

START input

RUN output

Connect a 24 VDC power source

(2.3 A min.)

Ground this terminal at a resistance

of less than 100

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100

tric shock.

24 VDC output terminals are not

provided.

These terminals are short-circuited

as a factory-set condition. Remove

the short-circuit bracket to start or

stop the PC with an external signal.

Normally, leave them shortcircuited.

These terminals are turned ON during RUN operation.

Ω to improve noise

Ω to prevent elec-

13

Page 22

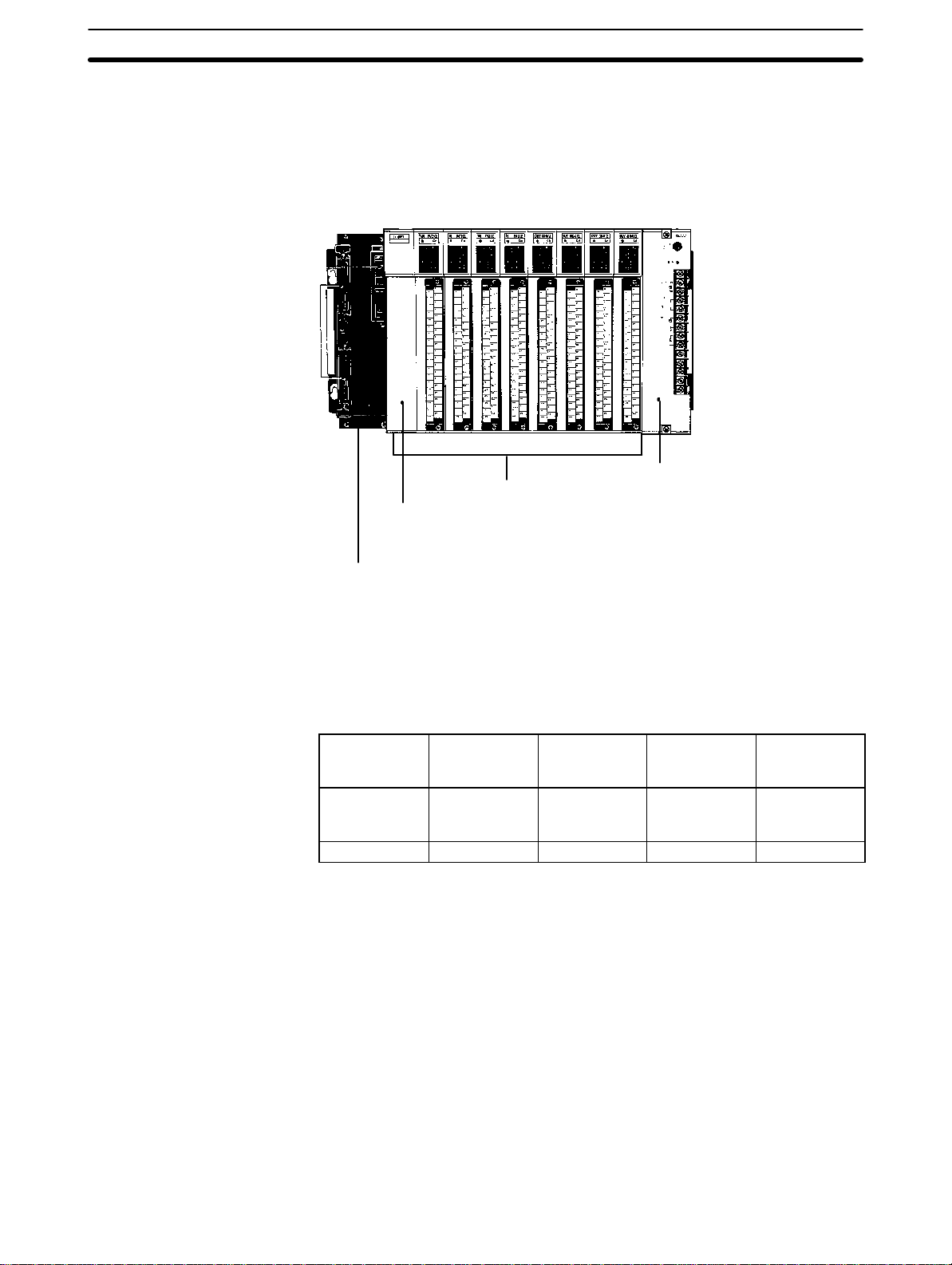

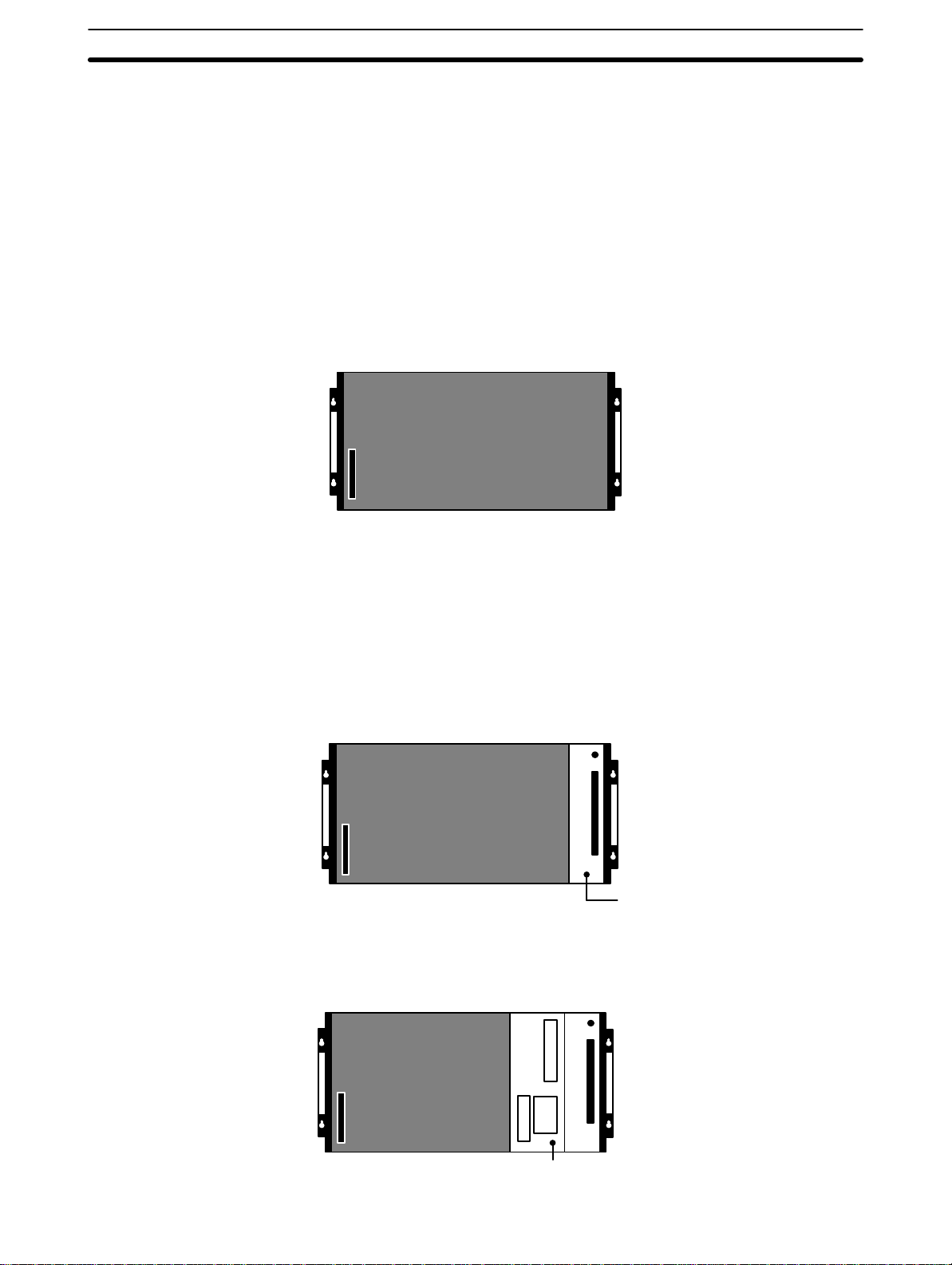

2-3 Expansion I/O Backplane

The Expansion I/O Backplane shown in the following diagram, can be used

to expand the C500 PC. An Expansion I/O Rack is just like a CPU Rack, except a CPU is not mounted. However, a Power Supply is needed for each

Expansion I/O Rack. There are three models of Expansion I/O Backplane

available.

I/O Units

I/O Interface Unit

An I/O Interface Unit must be mounted to an Expansion I/O Rack in order to connect the Expansion I/O Rack to another Expansion I/O Rack.

Expansion I/O Backplane

Section 2Description of All Components

Expansion I/O Power Supply

2-4 I/O Power Supply

Just as a Power Supply must be mounted to the CPU Rack, a Power Supply

must also be mounted to each Expansion I/O Backplane. There are two

Power Supplies available; 100 to 120/200 to 240 VAC and 24 VDC, both of

which are explained below. For details, refer to

Model Supply Voltage Output

3G2A5-PS222-E 100 to 120/200

3G2A5-PS212-E 24 VDC 7 A 5 VDC 6.5 A Not provided

Note Be sure to keep the total power consumed by all the Units mounted

on a Rack within the value stated in the table above. For example, do

not mount I/O Units with a total current consumption of 7A to a Rack

supplied by a 7 A Power Supply. As shown in the table above, the

available current for I/O Units is only 6.5 A. For details concerning

current consumption, refer to

to 240 VAC

(selectable)

Appendix B Specifications

Available

Capacity

7A 5 VDC 6.5 A Provided

Current for I/O

Units

240 VDC

Output

Terminal

Section 4 System Connections

.

.

14

Page 23

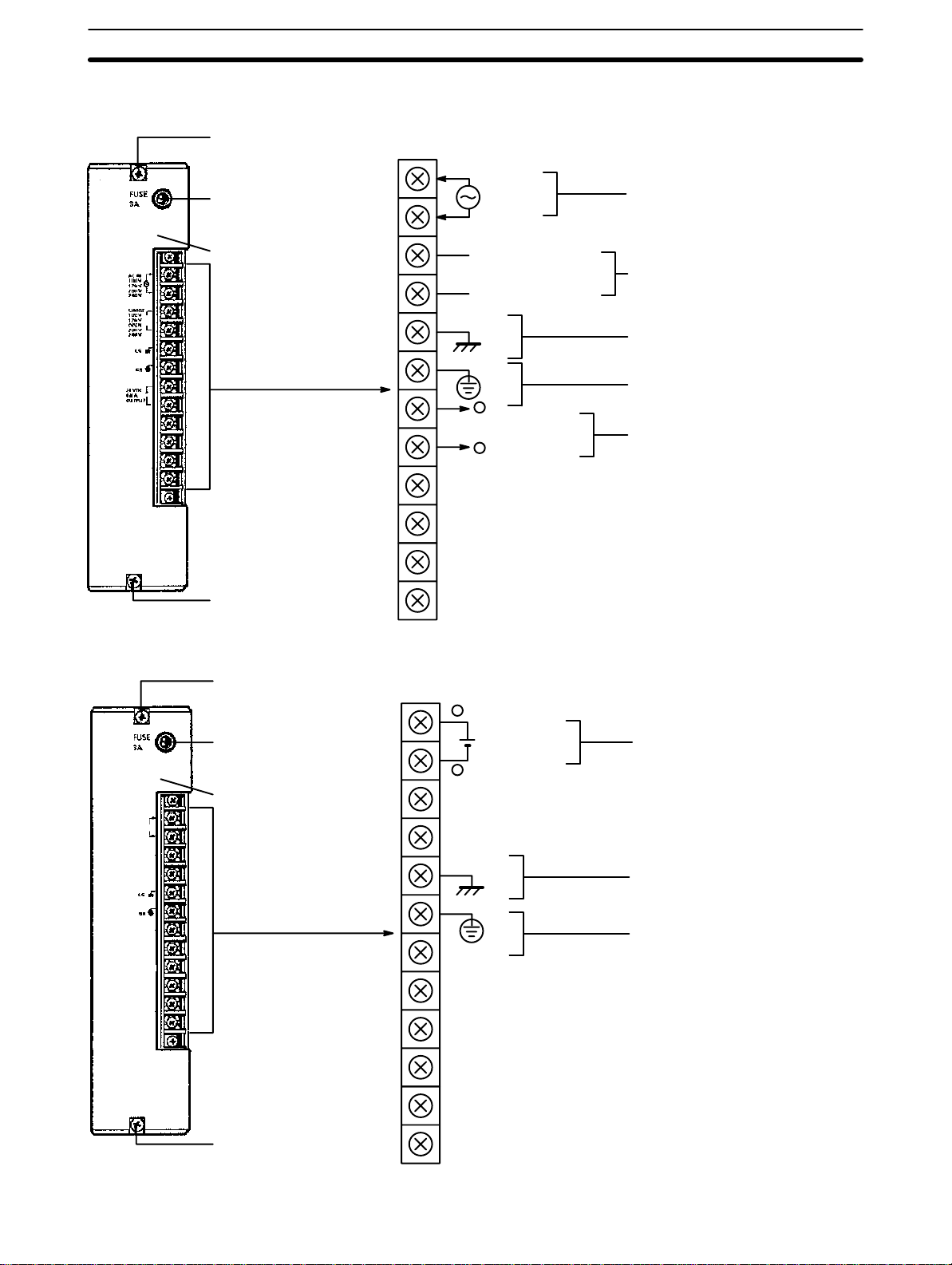

3G2A5-PS222-E

Mounting screw

Do not loosen this screw.

Section 2Description of All Components

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Mounting screw

Do not loosen this screw.

3G2A5-PS212-E

Terminals for

external connections

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

LG

GR

+

0.8 A, 24 VDC output

-

Connect a 100 to 120 VAC or 200 to

240 VAC power source

Short these terminals to select 100 to

120 VAC. Open them to select 200 to

240 VAC.

Ground this terminal at a resistance

of less than 100

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100

shock.

Use these terminals to supply power

to DC Input Units. Use a separate

Power Supply if the I/O Unit operate

on more than 0.8 A. If a current higher

than 0.8 A is output, the PC stops.

These terminals are used to supply

external DC Input Units. If the Unit requires more than 0.8 A a separate

supply must be used. The PC shuts off

automatically if a current of more than

0.8 A is drawn from the supply.

Ω to improve noise

Ω to prevent electric

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

+

-

24 VDC input

LG

GR

Connect a 24-VDC power source (2.3

A min.)

Ground this terminal at a resistance

of less than 100

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100

shock.

Ω to improve noise

Ω to prevent electric

15

Page 24

2-5 I/O Control Unit

An I/O Control Unit must be mounted to the CPU Rack in order to connect

the CPU Rack to an Expansion I/O Rack. An I/O Control Unit can be

mounted even if no Expansion I/O Rack is used.

2-6 I/O Interface Unit

An I/O Interface Unit is needed on each Expansion I/O Rack, in order to expand the PC. If there is not an I/O Interface Unit on each Expansion I/O

Rack, data communication cannot take place. The I/O Interface Unit is

mounted to the leftmost I/O position on the Expansion I/O Backplane.

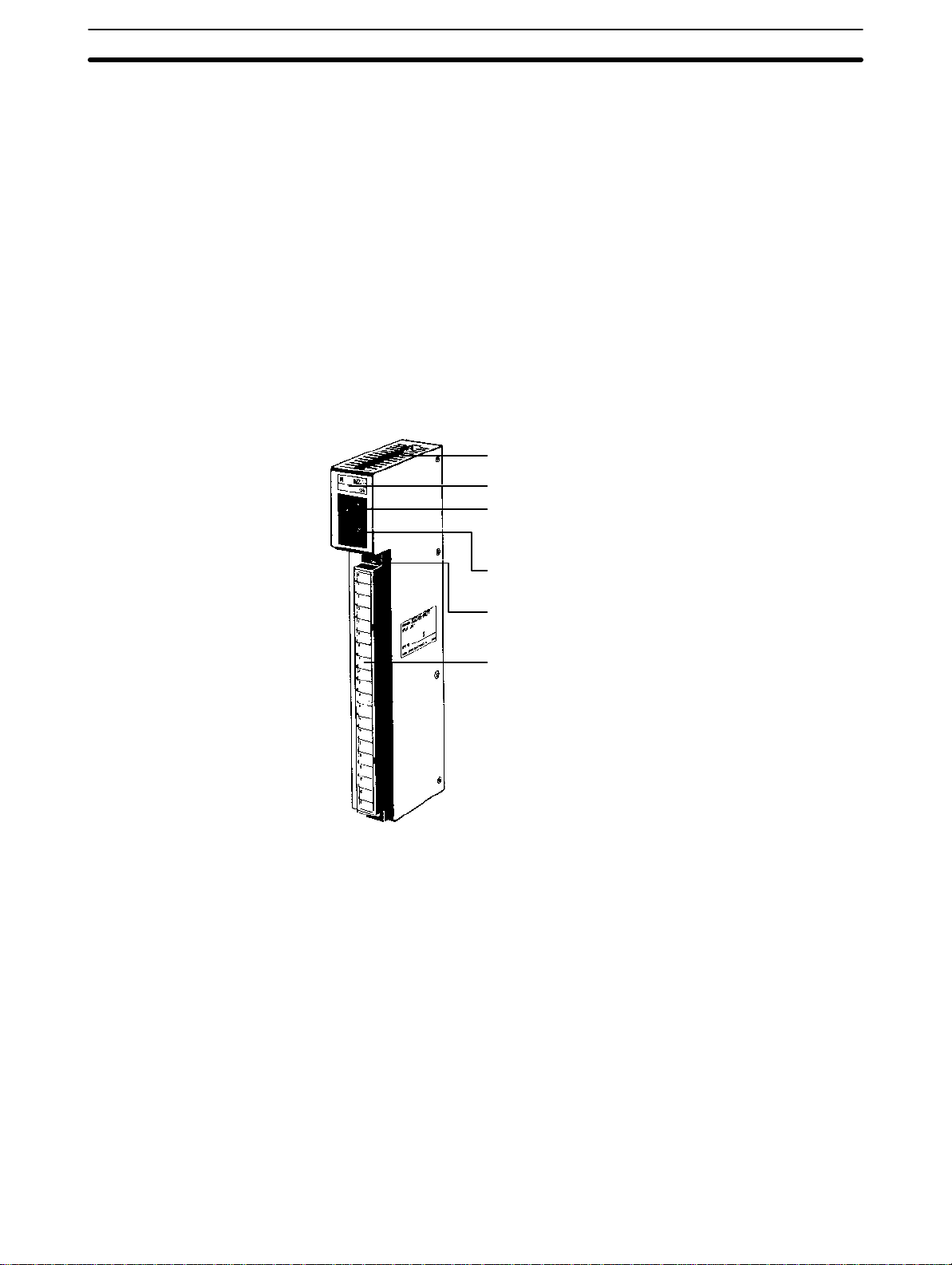

2-7 I/O Units

I/O Units come in 5 shapes; A-shape, B-shape, C-shape, D-shape, and Eshape. Refer to

A-shape

Appendix B Specifications

Mounting screw

Provided at top and bottom

Nameplate

Fuse blowout alarm indicator

Provided on OD411/OA121/

OD217/OA222

Section 2Description of All Components

for the dimensions of each Unit.

I/O indicators

Indicate ON/OFF status points

Terminal block mounting screw

Provided at top and bottom

20-terminal terminal block

Removable

16

Page 25

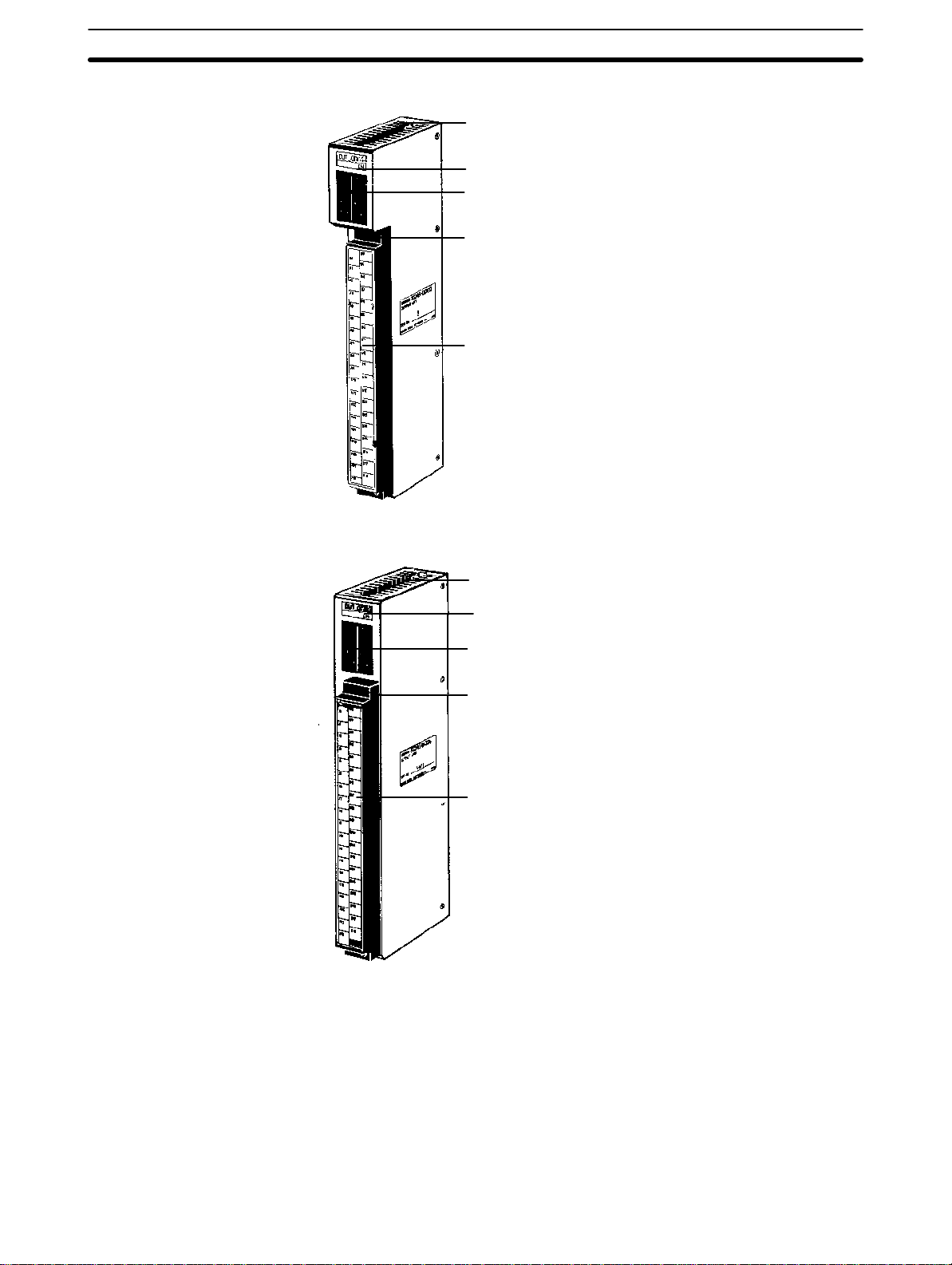

B-shape

Section 2Description of All Components

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of I/O

signal

Terminal block mounting screw

Provided at top and bottom

38-terminal terminal block

Removable

C-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Terminal block mounting screw

Provided at top and bottom

38-terminal terminal block

Removable

17

Page 26

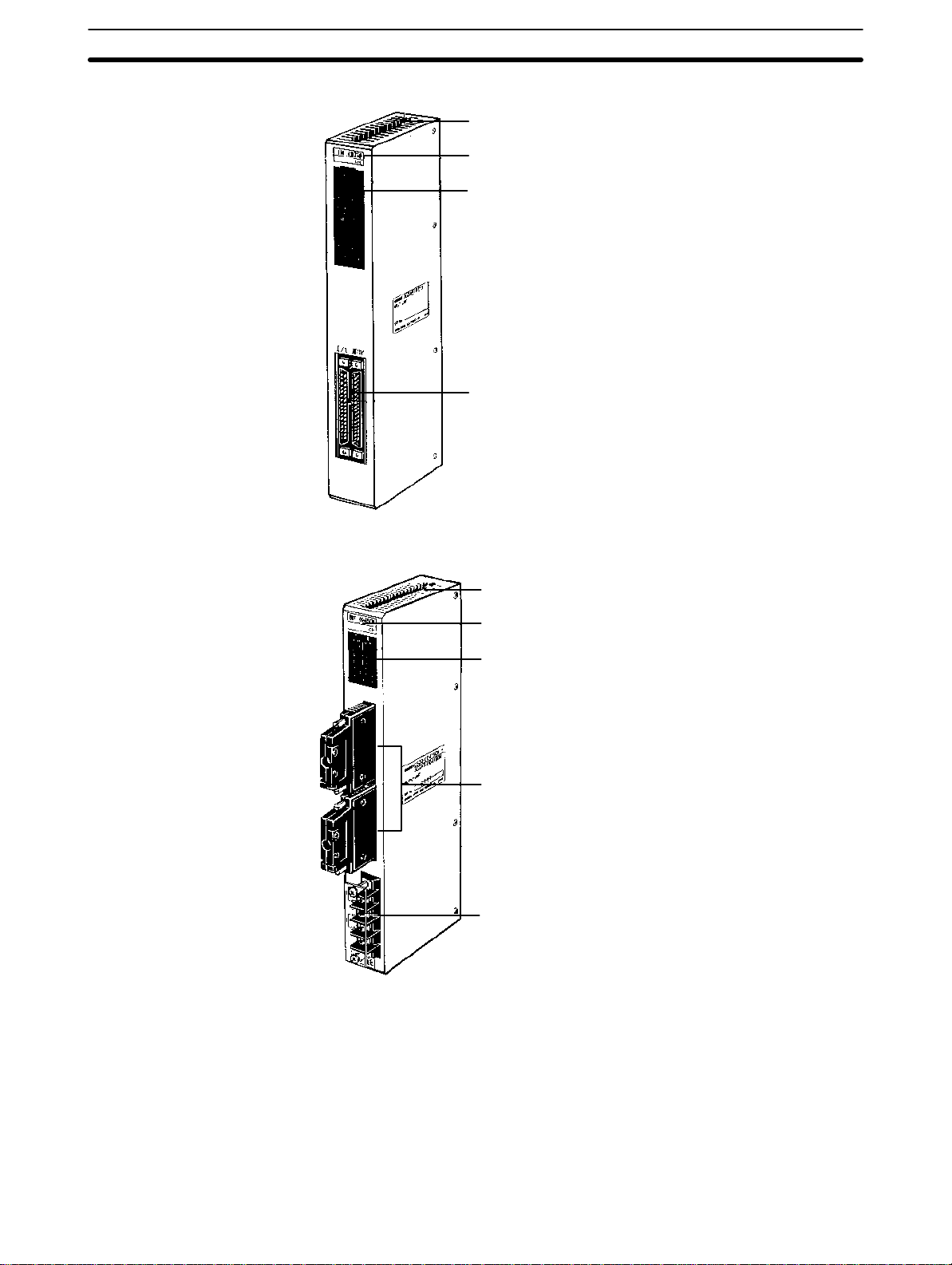

D-shape

Section 2Description of All Components

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Two 40-terminal terminal

block connectors

Removable

E-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Two 24-terminal terminal block plugs

4-terminal terminal block

18

Page 27

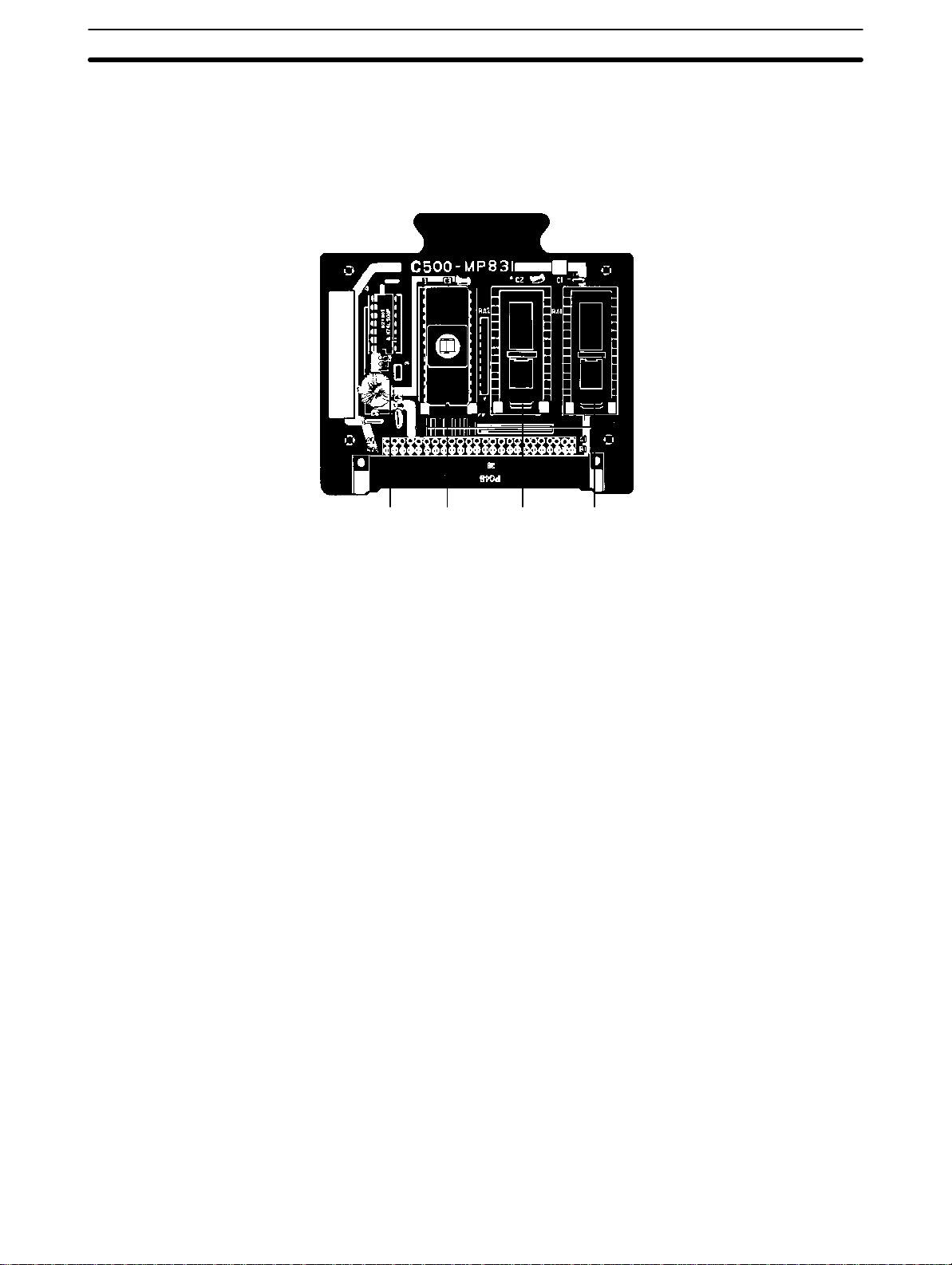

2-8 Memory Packs

The Memory Pack fits into the slot located on the left side of the CPU. Because the Memory Pack is not provided with the PC upon delivery, a Memory

Pack must be selected and installed in the CPU. There are two Memory

Packs available, either RAM or ROM, that can be used in the C500H PC.

RAM Pack

Data can be randomly written to and read from the RAM Pack, making it possible to enter your own program into the CPU. However, because this is not a

fixed program, the memory of the RAM Pack is erased when power is not

supplied to the CPU or when the RAM Pack is removed from the CPU.

Caution Do not remove the battery in the CPU when the RAM Pack has been removed

!

from the CPU.

Section 2Description of All Components

CHIP 0 CHIP 1 CHIP 264 128

RAM Pack

Two models of RAM Packs are available, which vary in memory capacity:

16K, and 24K words. Refer to

bers.

Using a Programming Console, execute FUN (01) and a search operation to

check the amount of memory available.

Appendix C Standard Models

for model num-

19

Page 28

ROM Pack

Section 2Description of All Components

Data contained in the ROM Pack is stored on EPROM chips and cannot be

altered or erased during the CPU’s operation. Write the user’s program to the

EPROM chips and mount the chips (3 max.) on the ROM chip. The entire

pack is installed in the CPU. Once the data is written to the chip the data will

not be lost when the power to the PC is OFF.

CHIP 0 CHIP 1 CHIP 264 128

RAM Pack

20

Page 29

SECTION 3

Assembly

3-1 Mounting the Units 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Memory Packs 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 System Configurations 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Page 30

Introduction

When we speak of a PC, we usually think of it as a single object. But actually

even the simplest PCs are usually composed of several different devices. In

fact a single PC can be physically spread throughout a building, but we still

call it one PC.

In this section, we will start with a Backplane and use all the Units discussed

Section 2 Description of All Components

in

3-1 Mounting the Units

There is no single Unit that can be said to constitute a Rack PC. To build a

Rack PC, we start with a Backplane. The Backplane for the C500 is shown

below.

Section 3Assembly

to build a PC.

C500 Backplane

The Backplane is a simple device having two functions. The first is to provide

physical support for the Units to be mounted to it. The second is to provide

the connectors and electrical pathways necessary for connecting the Units

mounted to it.

The first device we will add to the Backplane is a Power Supply. The Power

Supply fits into the rightmost position on the Backplane and provides electricity at the voltages required by the other Units of the PC. It can also be used

to power devices other than the PC if necessary.

Power Supply

The core of the PC is the CPU. The CPU contains the program consisting of

the series of steps necessary for the control task. The CPU fits into the position directly to the left of the Power Supply.

22

CPU

Page 31

Section 3Assembly

Unlike the CPU of the Package-type PC, the CPU of the Rack PC has no I/O

points built in. So, in order to complete this kind of PC we need to mount one

or more I/O Units to the Backplane. Mount the I/O Units to the Backplane by

pressing the I/O Unit firmly into position, making sure the connectors are

properly mated. Secure the Unit by tightening the mounting screws located

on the top and bottom of the Unit.

Mounting screws

Provided at the top and

bottom of the Unit

Connector

Make sure the connectors

are properly mated.

The figure below shows one I/O Unit mounted directly to the left slot of the

CPU Rack.

I/O Unit

I/O Units are where the control connections are made from the PC to all the

various input devices and output devices. As you can see from the figure,

there is still some space available on the right side of the Backplane. This

space is for any additional I/O Units that may be required.

The figure above shows a total of eight I/O Units mounted to the Backplane.

Backplanes are available in different lengths, and can hold a different number

of I/O Units accordingly. Of course, not all I/O Units look exactly alike, but the

ones in the figure show their typical appearance. This configuration of Backplane, Power Supply, CPU, and I/O Units is called a CPU Rack. This term

refers to the Backplane and all the Units mounted to it. However, if we want

to include more than eight I/O Units in our configuration we can add an addi-

23

Page 32

Section 3Assembly

tional Backplane. First, though, we have to mount an I/O Control Unit to the

leftmost slot of the CPU Rack.

I/O Control Unit

Now we can use a cable to connect the CPU Rack to another Backplane.

This Backplane has a Power Supply and I/O Units mounted to it, but it has no

CPU of its own. The additional Backplane must also have an I/O Interface

Unit mounted to its leftmost position. This configuration of additional Backplane, Power Supply, I/O Units, and I/O Interface Unit is called an Expansion

I/O Rack.

CPU Rack

Expansion I/O Rack

I/O Interface Unit

The CPU Rack and Expansion I/O Rack shown above are connected by a

cable. Remember that this whole configuration is still referred to as one PC.

It is possible to keep adding Expansion I/O Racks in this way until the maximum number of I/O points for the system is reached. Each Expansion I/O

Rack needs an I/O Interface Unit.

24

Page 33

3-2 Memory Packs

y

pg

128

64

8

128

The CPU has a removable Memory Pack that stores the user program. Two

Memory Packs are available, in either RAM or ROM. You can write your own

program into the RAM Pack or you can copy a program that has already

been written to an EPROM chip and mount it in the ROM Pack. The EPROM

Chip must be mounted to the PROM Writer in order for the program to be

written to it. Then the EPROM Chip must be mounted to the ROM Pack.

Mounting the EPROM

Chip to the ROM Pack

Depending on the amount of memory required for your application, use 1, 2,

or 3 chips. Refer to

EPROM chips.

Using the diagram and the table below as a reference, mount the EPROM

chips to the correct IC sockets.

Appendix B Specifications

Section 3Assembly

for specifications of the

Memory size Jumper setting

8K bytes

16K bytes

24K bytes

16K bytes

24K bytes

How to Install the

Memory Pack

Caution Do not attempt to install the Memory Pack in the CPU while the power to the PC

!

CHIP 0 CHIP 1 CHIP 264 128

RAM Pack

The table below summarizes the programming capacity.

IC Socket

CHIP 0 CHIP 1 CHIP 2

128

12

64

2764 – –

2764 2764 –

2764 2764 2764

27128 – –

27128 – 2764

Take the following steps to install the Memory Pack in the CPU.

1. Turn the power to the PC OFF.

is ON. Doing so may cause data to be lost, or may damage the CPU or Memory

Pack.

25

Page 34

Section 3Assembly

2. Using a standard screwdriver, remove the Memory Pack compartment

cover located on the front panel of the CPU. Push in the latch on the

cover and slide the cover upward.

SYSMAC C500

PROGRAMMABLE CONTROLLER

POWER

RUN

ERR

ALARM

OUT INMB

OMRON

•

Use a standard screwdriver to remove the Memory

Pack compartment cover.

3. Insert the Memory Pack (component side facing left) into the Memory

compartment. When the Unit is almost completely inserted into the CPU,

there may be a slight resistance as the Memory Pack connector mates

with the connector inside the CPU. Continue pushing on the Memory

Pack until it is inserted completely into the CPU.

Memory Unit guide

Memory Pack

(ROM or RAM Pack)

How to Remove the

Memory Pack

26

4. Reattach the memory compartment cover.

Follow the steps below to remove the Memory Pack from the CPU.

1. Turn the power to the PC OFF.

2. Using a standard screwdriver, remove the Memory Pack compartment

cover located on the front panel of the CPU. Push in the latch on the

cover and slide the cover upward.

3. Pull the Memory Pack up and out.

Page 35

Note Memory in the RAM Pack is erased when the Memory Pack is

removed from the CPU and when the CPU Unit is removed from

the Rack.

3-3 System Configurations

The following figure shows an assembled C500 CPU Rack and one Expansion I/O Rack. When three Expansion I/O Racks are connected to a CPU

Rack, a maximum of 512 I/O points are available. (Include the Remote I/O

Units)

I/O Control Unit

Section 3Assembly

CPU

CPU

Power Supply

CPU Rack

Where I/O Units Can Be

Mounted

Connecting Cable

I/O Interface Unit

Programming

Console

Expansion I/O

Power Supply

The table below summarizes the Units that can be used in the systems described in this manual.

Special I/O Units The number of Special I/O Units that can be used depends

upon the number of points available and the number of

points the Special I/O Unit requires.

Host Link Units Up to one Host Link Units can be mounted. Only one

I/O Units Standard I/O Units are available with 16, 32, or 64 points.

Memory Packs RAM or ROM Packs are available. The ROM Pack requires

Remote I/O Master

Unit

Rack-Mounting Host Link Unit can be mounted to the CPU

Rack. A CPU-Mounting Host Link Unit can also be mounted

directly to the CPU. Host Link Units cannot be mounted to

Expansion I/O Racks.

However, these Units cannot be mounted when the

SYSMAC Net Link Unit is mounted.

Refer to

a separately available EPROM chip.

Up to four Remote I/O Master Units can be mounted to both

the I/O Rack and the Expansion I/O Racks. When the

Remote I/O Unit is mounted to a Rack, a Rack number must

be set so that the CPU can identify the Remote I/O Unit.

Mount the Remote I/O Slave Unit to the leftmost position

(the I/O Interface Unit position) on the Slave Rack. For

details, refer to the C500 Operation Manual.

Section 2 Description of All Components

for details.

27

Page 36

Section 3Assembly

The following table summarizes specific Units that can and cannot be

mounted in the CPU and Expansion Racks and the number that can be used

in each PC. For more information about the Units, refer to the

tion Manual

Unit CPU Rack Expansion Rack

16-, 32-, 64-point I/O YES YES

Special I/O YES YES

I/O Link YES YES

PC Link YES (2 max.)

Host Link YES (2 max.)* NO

SYSMAC Net Link YES (1 max.) NO

Remote I/O Master YES YES

Remote I/O Slave NO YES

*One Rack-mounting Host Link Unit can be mounted to the CPU Rack and one CPU-mounting Host Link Unit can be mounted directly to

the CPU Unit.

.

NO

Notes 1. The Position Control Unit and the PID Unit each require two I/O

slots on the CPU Rack and the Expansion I/O Racks

2. The following Units can only be mounted to one of the three or

five rightmost slots on the CPU Backplane, depending on which

Backplane is used.

PC Link

Host Link

SYSMAC Net Link

C500 Opera-

3. When two or more PCs are linked by the PC Link Unit, a maximum of 32 PC Link Units can be used (linking 31 PCs), in any

number of subsystems.

4. SYSMAC Net Link and Host Link cannot be mounted simultaneously.

28

Page 37

SECTION 4

System Connections

4-1 Current Consumption 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 I/O Connections 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Page 38

Introduction

y

In the preceding sections we have covered all the parts of a PC and how they

should be assembled. This section provides detailed information on PC connections.

4-1 Current Consumption

The Power Supplies are limited in the total current they can supply to I/O Units.

The following table shows the maximum currents allowed.

Power Supplies

Unit Model Output Capacity Current Available

CPU Power Supply

I/O Power Supply

Note Do not exceed the maximum current ratings for each of the voltages

supplied by any single Unit listed above. In addition, do not exceed

the total maximum power output for any single Unit listed above. Refer to the tables on the following page for the current consumption of

individual I/O Units.

3G2A5-PS221-E

3G2A5-PS211-E

3G2A5-PS213-E 9 A 5 VDC

3G2A5-PS223-E 12 A 5 VDC 10 A

3G2A5-PS222-E

3G2A5-PS212-E

7 A 5 VDC

7 A 5 VDC 6.5 A

5 A

Section 4System Connections

for I/O Units

Input Units

Unit Model Current

DC Input

AC Input

TTL Input 3G2A5-ID501CN 0.2

AC/DC Input

3G2A5-ID112 0.01

3G2A5-ID114 0.34

3G2A5-ID213 0.02

3G2A5-ID215 0.16

3G2A5-ID218 0.16

3G2A5-ID218CN 0.2

3G2A5-ID212 0.3

3G2A5-ID219 0.34

3G2A5-IA121 0.01

3G2A5-IA222 0.012

3G2A5-IA223 0.06

3G2A5-IA122 0.06

3G2A5-IM211 0.01

3G2A5-IM212 0.2

Consumption (A)

30

Page 39

Output Units

Unit Model Current

Contact Output

Transistor Output

Triac Output

TTL Output C500-OD501CN 0.25

DC Input/Transistor Output

Unit

Dummy I/O 3G2A5-DUM01 0.035

3G2A5-OC221 0.1

3G2A5-OC223 0.1

3G2A5-OC224 0.2

3G2A5-OD411 0.16

3G2A5-OD215 0.2

3G2A5-OD412 0.23

3G2A5-OD212 0.23

3G2A5-OD211 0.3

3G2A5-OD213 0.46

3G2A5-OD217 0.16

C500-OD218 0.23

C500-OD219 0.16

3G2A5-OD415CN 0.23

3G2A5-OA121 0.3

3G2A5-OA222 0.3

3G2A5-OA223 0.45

C500-OA225 0.2

C500-OA226 0.45

3G2A5-MD211CN 0.26

Section 4System Connections

Consumption (A)

31

Page 40

Special I/O Units

g

y

Unit Model Current

Consumption (A)

A/D Converter Input

D/A Converter Output

High-speed Counter

Magnetic Card Reader 3G2A5-MGC01 1.0

PID 3G2A5-PID01-E 1.4

Position Control

ASCII C500-ASC04 0.5 each

ID Sensor

Ladder Program I/O 3G2A5-LDP01-V1 0.8

File Memory

Cam Positioner C500-CP131 0.35

3G2A5-AD001 to- AD005 0.3 each

3G2A5-AD006

3G2A5-AD007

C500-AD101 0.88

C500-AD501 1.2

3G2A5-DA001 to -DA005 0.55 each

C500-DA101 1.3

3G2A5-CT001 0.3

3G2A5-CT012 0.55

C500-CT041 1.0

3G2A5-NC103-E

3G2A5-TU001-E

3G2A5-NC111-EV1

3G2A5-TU001-E

3G2A5-NC221-E

3G2A5-TU001

C500-IDS01-V2/IDS02-V1

C500-IDS21/IDS22

C1000H-FMR11

C1000H-FMR21

0.75 each

Total 1.4

Total 1.0

Total 1.3

0.4 each

0.35 each

Section 4System Connections

Link Units and Remote

I/O Units

Unit Model Current

I/O Link 3G2A5-LK010-(P)E 0.6

PC Link C500-LK009-V1 0.9

Host Link

Optical Remote I/O Master 3G2A5-RM001-(P)EV1 0.7

SYSMAC Net Link C500-SNT31-V4 1.4

Wired Remote I/O Master C500-RM201 0.3

C500-LK103 (-P)

C500-LK203

1.0 each

Consumption (A)

32

Page 41

4-2 I/O Connections

Connect the I/O Devices to the I/O Units using AWG (cross-sectional area:

0.3 mm

tional area: 0.3 to 0.75 mm

screws with 3.5-mm diameter heads and self-raising pressure plates. Connect

the lead wires to the terminals as shown. Always use solderless (crimp) terminals. Tighten the screws to a torque of 0.8 N S m.

Use M3.5 self-rising screws for the terminal screws of the Power Supply Units.

Always attach crimp terminals to the ends of the lead wires before attaching

them to the terminals. Never attach loose or twisted wires.

2

) for 19-terminal terminal blocks and AWG 22 to lead wire (cross-sec-

Section 4System Connections

2

) for 10-terminal terminal blocks. The terminals have

Tighten the screws on the terminal block to a torque of 0.8 N S m. Use crimp terminals for M3.5 screws of the dimensions shown below.

7 mm max.7 mm max.

33

Page 42

Terminal Block

Section 4System Connections

The terminal block of an I/O Unit can be removed by loosening the mounting

screws. You do not have to remove the lead wires from the terminal block in order to remove it from an I/O Unit.

Note Putting I/O Lines and high-tension lines or power lines in the same

duct or conduit may cause the I/O Lines to be affected by noise. This

may cause a malfunction in the I/O Unit or may cause damage to the

I/O Unit or I/O devices.

Terminal block mounting screws

Loosen the terminal block mounting screws to remove

the terminal block from the I/O Unit. Make sure the

mounting screws on the terminal block are tightened after wiring is complete, and the terminal block is remounted to the I/O Unit.

Wiring Examples

DC Input Units

Note When a Triac Output Unit is used to drive a low-current load, the load

may not turn completely OFF due to a leakage current. To compensate for the leakage current, connect a bleeder resistor in parallel

with the load.

The following are examples of how to connect I/O devices to I/O Units. During

wiring, work slowly and carefully. If an input device is connected to an Output

Unit, damage may result. Check all I/O devices to make sure they meet the

specifications (refer to

Appendix B Specifications

). Be sure to allow for leakage

current and load inductance.

Contact output

IN DC input

COM

When using the following configurations, the sensor and Input Unit should receive their power from the same supply.

34

Page 43

NPN current output

Current

regulator

NPN open-collector output

PNP current output

+

Output

+

Output

7 mA

0 V

+

Output

7 mA

0 V

Section 4System Connections

IN DC input

COM

Sensor

Power

Supply

IN DC input

COM

Sensor

Power

Supply

IN AC/DC input

AC Input

7 mA

0 V

Contact output

AC Switching

Prox.

switch

main

circuit

COM

IN AC input

COM

IN AC input

COM

Note If a reed switch is used as the input contact of the AC Input Unit, the

reed switch must have a permissible current capacity of 1 A minimum, otherwise contact weld may result due to inrush current.

Output Units

A fuse placed in the output circuit will protect the output element, circuit board,

etc., in the event of a short circuit in the output circuit.

OUT

COM

Relay,

solenoid, etc.

+

35

Page 44

SECTION 5

Installation Environment

5-1 Cooling 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Mounting Requirements 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Duct Work 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Preventing Noise 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

Page 45

Introduction

Caution Static electricity can cause damage to PC components. Your body can carry an

!

5-1 Cooling

Clearance Between

Racks

Section 5Installation Environment

This section details the necessary environment and conditions for installation

of the PC. For specific instructions on mounting Units and wiring for I/O and

power, refer to

electrostatic charge, especially when the humidity is low . Before touching the PC

be sure to first touch a grounded metallic object, such as a water pipe, in order to

discharge any static build-up.

There are two points to consider in order to ensure that the PC does not

overheat. The first is the clearance between the Racks, and the second is

installation of a cooling fan.

The Racks need to have sufficient room between each other to allow for I/O

wiring, and additional room to ensure that the I/O wiring does not hamper

cooling. However, the Racks must be mounted so that the length of the connecting cable does not exceed 2 m, and the total length of the Connecting

Cables between all Racks does not exceed 12 m. For details about cable

lengths, refer to

120 mm should be left between any two Racks.

Section 3-3 System Configurations

Appendix C Standard Models

and

4-2 I/O Connections

. As a general rule, about 70 to

.

Cooling Fan

A cooling fan is not always necessary, but may be needed in some installations. Try to avoid mounting the PC in a warm area, or over a source of heat.

A cooling fan is needed if the ambient temperature may become higher than

that specified (refer to

enclosure install a cooling fan, as shown in the following diagram, to maintain

the ambient temperature within specifications.

Louver

Appendix B Specifications

PC

5-2 Mounting Requirements

The PC consists of from one to nine Racks. Each Rack must be mounted

vertically, that is with the printing on the front panels oriented as it would normally read. The Racks should be mounted one above the other with the CPU

Rack uppermost.

). If the PC is mounted in an

Fan

38

The PC may be directly mounted to any sturdy support meeting the environmental specifications (refer to

Appendix B Specifications

).

Page 46

Section 5Installation Environment

The duct work shown in the following diagram is not used for mounting the

Racks. Although optional, the duct work can be used to house the wires from

the I/O Units that run along the sides of the Racks, keeping the wires from

becoming entangled with other machines. The figures illustrate the correct

way to mount the Racks.

CPU Rack

Expansion I/O Rack

The following figure shows a side view of a mounted CPU and two Expansion

I/O Racks. There should be a distance of 70 to 120 mm between the

mounted Units.

CPU

Duct

70 to 120 mm

I/O

Duct

70 to 120 mm

I/O

Approx. 100 mm

39

Page 47

5-3 Duct Work

Section 5Installation Environment

If power cables carrying more than 10 A 400 V, or 20 A 220 V must be run

alongside the I/O wiring (that is, parallel to it), leave at least 300 mm between

the power cables and the I/O wiring as shown below.

Low current cable

1

Control cable

2

300 mm min.

300 mm min.

Power cable

3

Grounding at resistance

of less than 100

Ω

1 = I/O wiring

2 = General control wiring

3 = Power cables

If the I/O wiring and power cables must be placed in the same duct (for example, where they are connected to the equipment), shield them from each

other using grounded metal plates.

Metal plate (iron)

200 mm min.

123

1 = I/O wiring

2 = General control wiring

3 = Power cables

Grounding at resistance

of less than 100

Ω

40

Page 48

5-4 Preventing Noise

In order to prevent noise from interfering with the operation of the PC, use

AWG 14 twisted-pair cables (cross-sectional area: 2 mm

ing the PC close to high-power equipment, and make sure the point of installation is at least 200 mm away from power cables as shown below.

Power lines

200 mm min.

PC

Whenever possible, use wiring conduit to hold the I/O wiring. Standard wiring

conduit should be used, and it should be long enough to completely contain

the I/O wiring and keep it separated from other cables.

200 mm min.

Section 5Installation Environment

2

min.). Avoid mount-

41

Page 49

SECTION 6

Power Considerations

43

Page 50

Introduction

Grounding

Section 6Power Considerations

Use a commercially available 100 to 120 VAC, 200 to 240 VAC, or 24 VDC

power source, according to the PC you are using (refer to

fications

power source. If possible, use independent power sources for the PC, input

devices, and output devices. All Racks of the PC may be connected to one

power source.

The Line Ground (LG) terminal is a noise-filtered neutral terminal that does

not normally require grounding. If electrical noise is a problem, however, this

terminal should be connected to the Ground (GR) terminal.

). Expansion I/O Racks, if used, must also be connected to the

Appendix B Speci-

Power Failure

To avoid electrical shock, attach a grounded (earth ground) AWG 14 wire

(cross-sectional area: 2 mm

ground must be less than 100 Ω. Do not use a wire longer than 20 m. Care

must be taken, because ground resistance is affected by environmental conditions such as soil composition, water content, time of year, and the length

of time since the wire was laid underground.

PC operation may be adversely affected if the ground wire is shared with

other equipment, or if the ground wire is attached to the metal structure of a

building. When using an Expansion I/O Rack, the Rack must also be

grounded to the GR terminal. The same ground can be used for all connections.

A sequential circuit is built into the PC to handle power interruptions. This

circuit prevents malfunctions due to momentary power loss or voltage drops.

A timing diagram for the operation of this circuit is shown below.

Power Supply

Power failure

detection signal

2

min.) to the GR terminal. The resistance to

OFF ON

Momentary power

failure detection time

Wiring

44

CPU voltage (5 V)

Power reset

Approx. 1 s

Run monitor outputs

The PC ignores all momentary power failures if the interruption lasts no

longer than 10 ms. If the interruption lasts between 10 and 25 ms, the interruption may or may not be detected. If the supply voltage drops below 85%

of the rated voltage for longer that 25 ms (less for the DC Power Supply), the

PC will stop operating and the external outputs will be automatically turned

OFF. Operation is resumed automatically when the voltage is restored to

more than 85% of the rated value.

The following diagrams show the proper way to connect the power source to

the PC. The terminals marked “NC” are not connected internally.

Page 51

AC Connections

3G2A5-PS221-E/223-E

Screw (4 mm head with

selfraising pressure plate)

+

-

Voltage selector

Short: 100 to 120 VAC

Open: 200 to 240 VAC

Short-circuit these terminals with the shorting

bracket supplied as an

accessory to select 100

to 120 VAC supply voltage. For 200 to 240 VAC

leave them open.

Breaker

1:1 isolation

transformer

Isolation transformer

• Noise between the PC

and ground can be significantly reduced by

connecting a 1-to-1 isolation transformer. Do

not ground the secondary coil of the transformer.

AC power source

• Supply 100 to 120

or 200 to 240 VAC

• Keep voltage fluc-

tuations within the

specified range (refer

Appendix B Speci-

to

fications

Section 6Power Considerations

)

3G2A5-PS222-E

Screw (4 mm head with

selfraising pressure plate)

+

-

Voltage selector

Short: 100 to 120 VAC

Open: 200 to 240 VAC

Short-circuit these terminals

with the shorting bracket

supplied as an accessory to

select 100 to 120 VAC supply voltage. For 200 to 240

VAC, leave them open.

Power line

• Use AWG 14 twisted-

pair cable (cross-sectional area: 2 mm

Caution Tighten the screws on the terminal block of the AC

!

2

min.)

Be sure to use a wire of at least 1.25 mm2 in

thickness.

Use M4 screws for tightening crimp terminals. Use ring crimp terminals for wiring. Do

not connect bare stranded wires directly to

terminal blocks.

8.6 mm max.

Power Supply Unit to a torque of 1.2 N S m. Loose

screws may result in burning or malfunction.

45

Page 52

DC Connections

3G2A5-PS213-E

z

Screw (4 mm head with

selfraising pressure plate)

+

-

Breaker

• Supply 24 VDC

• Keep voltage fluctuations

within the specified range

(refer to

cations

Appendix B Specifi-

)

Section 6Power Considerations

3G2A5-PS212-E

Screw (4 mm head with

selfraising pressure plate)

+

-

Be sure to use a wire of at least 1.25 mm2 in thickness.

Use M4 screws for tightening crimp terminals. Use crimp terminals

for wiring. Do not connect bare stranded wires directly to terminal

blocks.

8.6 mm max.

Tighten the terminal block screws to a torque of 1.2 N S m.

Power line

• Use AWG 14 twisted-pair

cable (cross-sectional area: 2

2

mm

min.)

8.6 mm max.

46

Page 53

Grounding Connections

3G2A5-PS223-E/221-E/213-E

Section 6Power Considerations

Be sure to use a wire of at least 1.25 mm2 in thickness.

Use M4 screws for tightening crimp terminals. Use crimp terminals

for wiring. Do not connect bare stranded wires directly to terminal

blocks.

Screw (4 mm head with

selfraising pressure plate)

3G2A5-PS222-E/212-E

8.6 mm max.

Tighten the terminal block screws to a torque of 1.2 N S m.

For grounding use 2mm2 cable.

Be sure to keep the length of the

cable less than 20 meters.

8.6 mm max.

Screw (4 mm head with

selfraising pressure plate)

Caution Ground the Power Supplies separately from peripheral devices.

!

47

Page 54

SECTION 7

Safety Considerations

49

Page 55

Introduction

Interlock Circuits

Section 7Safety Considerations

There are certain safety requirements to be considered when installing the

PC. Some of these, such as the emergency stop circuit (refer to

), are part of the initial wiring. The considerations described below should

ply

be kept in mind when operating the PC and when connecting I/O devices to

the PC.

When the PC controls an operation such as the clockwise and counterclockwise operation of a motor, provide an external interlock such as the one

shown below to prevent both the forward and reverse outputs from turning

ON at the same time.

Interlock circuit

Power Sup-

Power Supply Output

Input Leakage Current

00501

PC

00502

MC2

MC1

Motor clockwise

MC1

Motor counterclockwise

MC2

This circuit prevents outputs MC1 and MC2 from both being ON at the same

time. Even if the PC is programmed improperly or malfunctions, the motor is

protected.

The 24 VDC output of the CPU and Expansion I/O Power Supply may be

used to power other devices. The output current of these supplies is limited

to 0.3 A. A separate Power Supply must be provided if the devices being

powered require a higher current.

When two-wire sensors, such as photoelectric sensors, proximity sensors or

limit switches with LEDs are connected to the PC as input devices, the input

bit may be turned ON erroneously by leakage current. In order to prevent

this, connect a bleeder resistor across the input as shown below.

50

Input

power

supply

Sensor

Bleeder

resistor

R

PC

If the leakage current is less than 1.3 mA, there should be no problem. If the

leakage current is greater than 1.3 mA, determine the value and rating for the

bleeder resistor using the following formulas.

I = leakage current in mA

R =

W =

7.2

2.4 x I – 3

2.3

R

kΩ max.

W min.

Page 56

Output Leakage Current

Section 7Safety Considerations

If there is a possibility of leakage current causing a transistor or triac to malfunction, connect a bleeder resistor across the output as shown below.

Output Surge Current

OUT

PC

COM

L

R

Bleeder resistor

Load Power Supply

Determine the value and rating for the bleeder resistor using the following

formula.

E

ON

R

I

Where

E

= ON voltage of the load

on

I = leakage current in mA

R = bleeder resistance

When connecting a transistor or triac Output Unit to an output device having

a high surge current (such as an incandescent lamp), care must be taken to

avoid damage to the Output Unit. The transistor and triac Output Units are

capable of withstanding a surge current of ten times the rated current. If the

surge current for a particular device exceeds this amount, use the circuit

shown below to protect the Output Unit.

Transistor Output

Residual Voltage

OUT

L

+

R

COM

Another way of protecting the Output Unit lets the load draw a small current

(about one third the rated current) while the output is OFF, significantly reducing the surge current. This circuit (shown below) not only reduces the

surge current, but also reduces the voltage across the load at the same time.

R

OUT

L

+

COM

When connecting TTL circuits to transistor Output Units, connect a pull-up

resistor and a CMOS IC between the two. This is because of the residual

voltage left on the transistor output after the output turns OFF.

51

Page 57

Inductive Load Surge

Suppressor

Section 7Safety Considerations

When an inductive load is connected to an I/O Unit, connect a surge suppressor or diode in parallel with the load as shown in the following diagram.

This is so that the back electromagnetic field generated by the load will be

absorbed.

Resistor: 50 W

Capacitor: 0.47

Voltage: 200 V

Diode: Must withstand voltages of more

than three times the load voltage and an average current of 1 A

µF

IN

Electrical Noise

L

Relay Output Unit

Triac Output Unit

Relay Output Unit

Transistor Output Unit

OUT

COM

OUT

COM

Diode

COM

L

Surge suppressor

L

Diode

DC Input

+

Take appropriate measures when any electrical device likely to produce

noise is connected to the PC as a load. Devices generating noise of more