Page 1

Cat. No. W147-E1-02B

Page 2

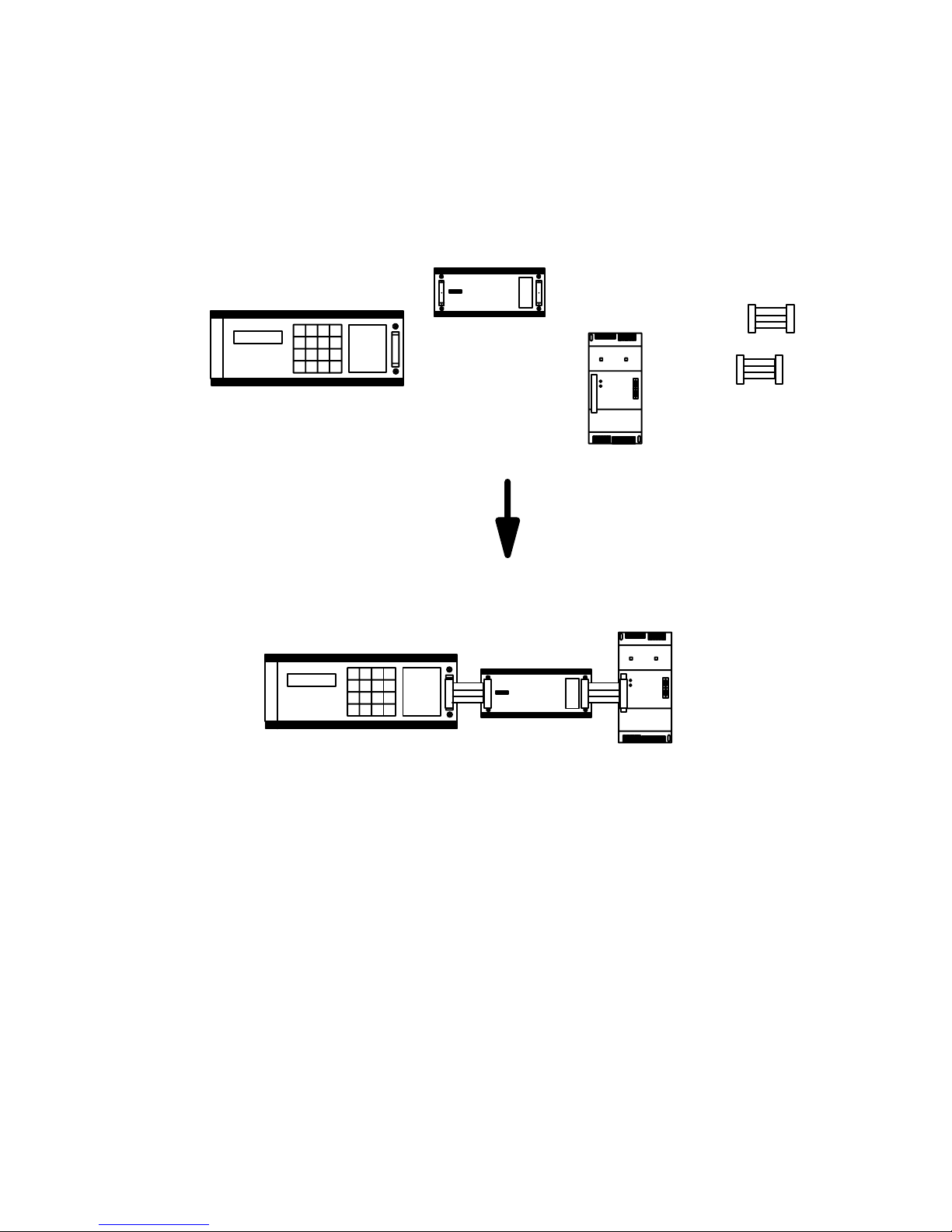

K-type Programmable Controllers

Installation Guide

Revised August 1993

C20P

C60K

C60K

C20P

Page 3

iv

Page 4

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to head precautions can result in injury to people or damage to the product.

DANGER! Indicates information that, if not heeded, is likely to result in loss of life or serious

injury.

WARNING Indicates information that, if not heeded, could possibly result in loss of life or

serious injury.

Caution Indicates information that, if not heeded, could result in relative serious or minor

injury, damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, means

“word” and is abbreviated “Wd” in documentation.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Indicates information of particular interest for efficient and convenient operation of the product.

Indicates lists of one sort or another, such as procedures, precautions, etc.

OMRON, 1989

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high–quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note

1, 2, 3...

Page 5

vi

Page 6

vii

TABLE OF CONTENTS

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1 Nomenclature 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 System Configuration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

System Installation and Wiring 9. . . . . . . . . . . . . . . . . . . . .

2–1 General 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Installation Environment 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions and Installation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 I/O Connecting Cable 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 Wiring CPUs and Expansion I/O Units 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6 I/O Wiring 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7 Special Wiring Precautions 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8 Settings 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Maintenance and Inspection 47. . . . . . . . . . . . . . . . . . . . . . .

3–1 General 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Self–Diagnostic Functions 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Replacing Parts 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Preventive Measures 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 Inspection 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Standard Models 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Programming Console Operations 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Programming Instructions 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E System Configuration Chart 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

ix

About this Manual:

This manual has been prepared to provide the information necessary to install, set up, and maintain

your C-series K-type Programmable Controller, a low-cost, compact, versatile industrial control system providing up to 148 I/O points. For information regarding system programming and operation,

refer to the operation manual.

Refer to the Appendix for a complete list of all products covered in this manual, along with their full

model numbers.

Page 8

x

Page 9

1

SECTION 1

Introduction

1–1 Nomenclature 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1–1 CPUs 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1–2 Expansion I/O Units 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1–3 Analog Timer Unit 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1–4 I/O Link Units 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 System Configuration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

2

1–1 Nomenclature

This section gives the names and functions of the various components of

K–Type PCs and the basic Units with which they can be combined in a

System.

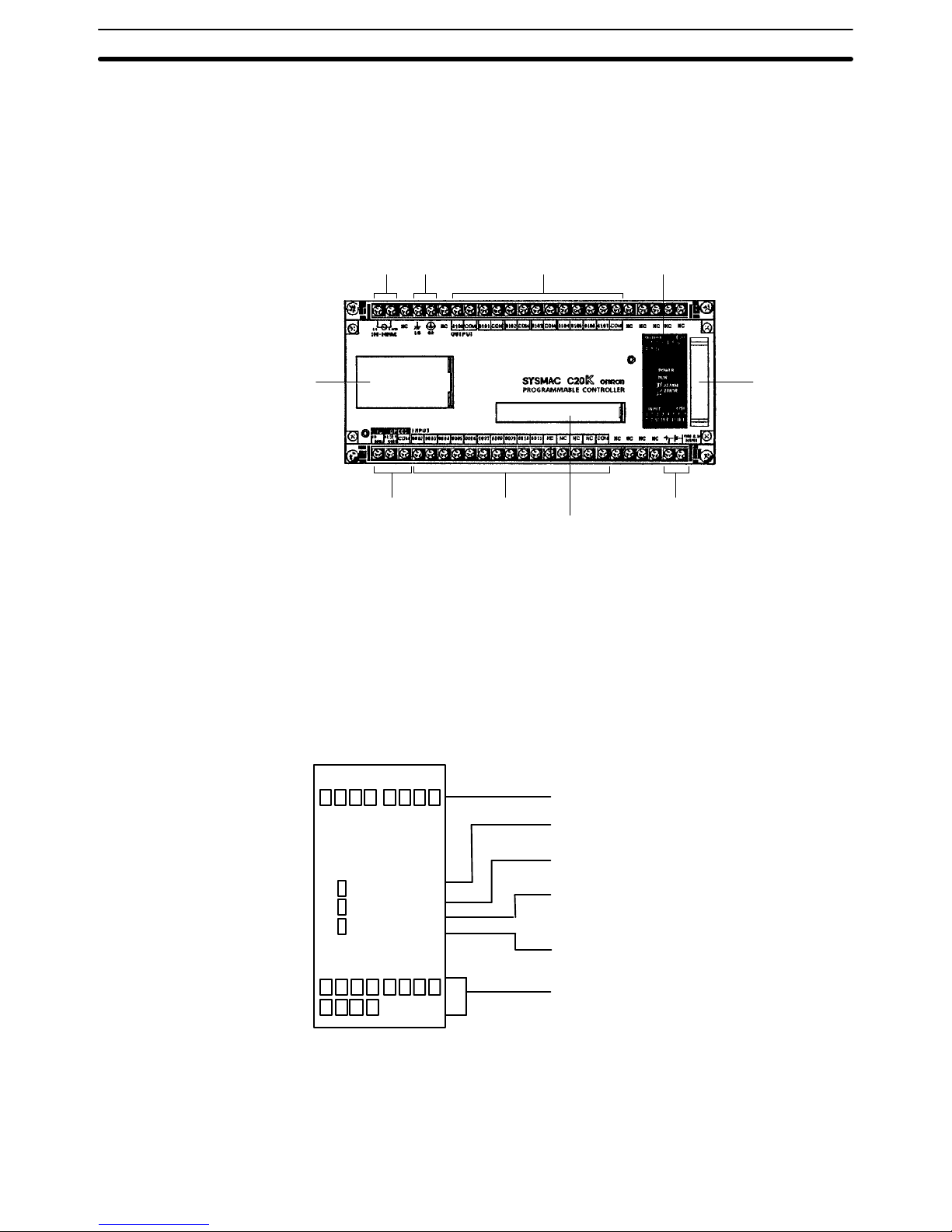

1–1–1 CPUs

In the diagram below, the C20K is shown as a representative model. Refer to

Appendix A Standard Models for your model’s exact specifications.

Power supply Ground Outputs Indicators

Expansion

I/O Unit,

Analog

Timer Unit, or

I/O Link Unit

connector

24–VDC output

Peripheral connector

InputsHigh–speed counter

(HDM) inputs

EP–ROM socket,

DIP switch

High–speed Counter When the high–speed counter (HDM(61)) is not being used, the two high–

speed counter input terminals can be used as normal DC input terminals.

Their ON/OFF response time, however, will be shorter (0.15 ms max.). Regardless of whether or not the high–speed counter command is being used,

DIP switch pins 7 and 8 must be off whenever the hardware reset is not being used.

Indicators The diagram below shows the functions of the various indicators, taking the

C20K as an example.

8 9 10 11

0 1 2 3 4 5 6 7

OUTPUT 1 CH

POWER

RUN

ALARM

ERROR

INPUT 0 CH

OUTPUT: Shows whether the output is ON or OFF.

POWER: Stays lit while power is turned on to the

PC.

RUN: Stays lit while the PC is operating normally.

ALARM: Blinks during battery abnormality or cycle

time overrun. At this time PC operation will be

intermittent.

ERROR: Lights when self–diagnosis detects an

abnormality. The PC will stop operating.

INPUT: Shows whether the input is ON or OFF.

0 1 2 3 4 5 6 7

Memory Each of the C–Series K–Type PCs is provided with a built–in RAM (random–

access memory), as well as a ROM (read–only memory) chip socket. Either

may be used with ease. It is recommended to use the RAM for programming

and, when the program is completed, to save it in a ROM chip for protection.

The memory capacity in either case is 1,194 addresses.

Nomenclature Section 1–1

Page 11

3

Beneath the cover are the DIP switch and the socket where an EP–ROM

chip may be installed. For details, see 2–7–1 Setting the CPU Dipswitch and

2–7–2 EP–ROM Installation. Only DIP switch pins 1 and 2 are on when the

CPU is delivered.

ROM socket

8 Turn ON to use hardware reset (0001).

7 Turn OFF if HDM(61) is not used.

6 Turn ON for English display.

5 Turn ON to inhibit ALARM indicator.

4, 3 ROM: ON (RAM: OFF)

2, 1 RAM: ON (ROM: OFF)

CAUTION: In case of battery failure, data stored in

the RAM, the DM area, the HR area, etc., will not be preserved.

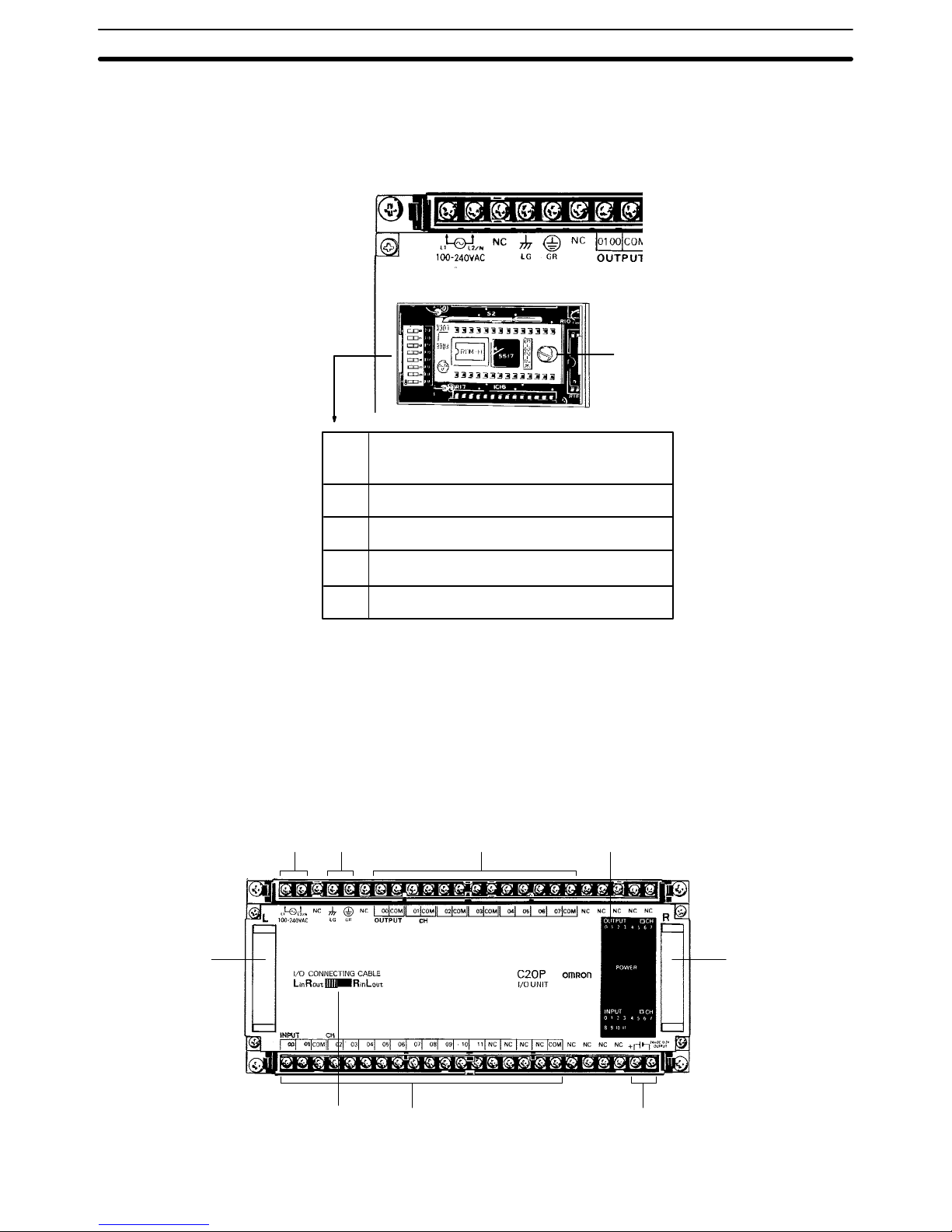

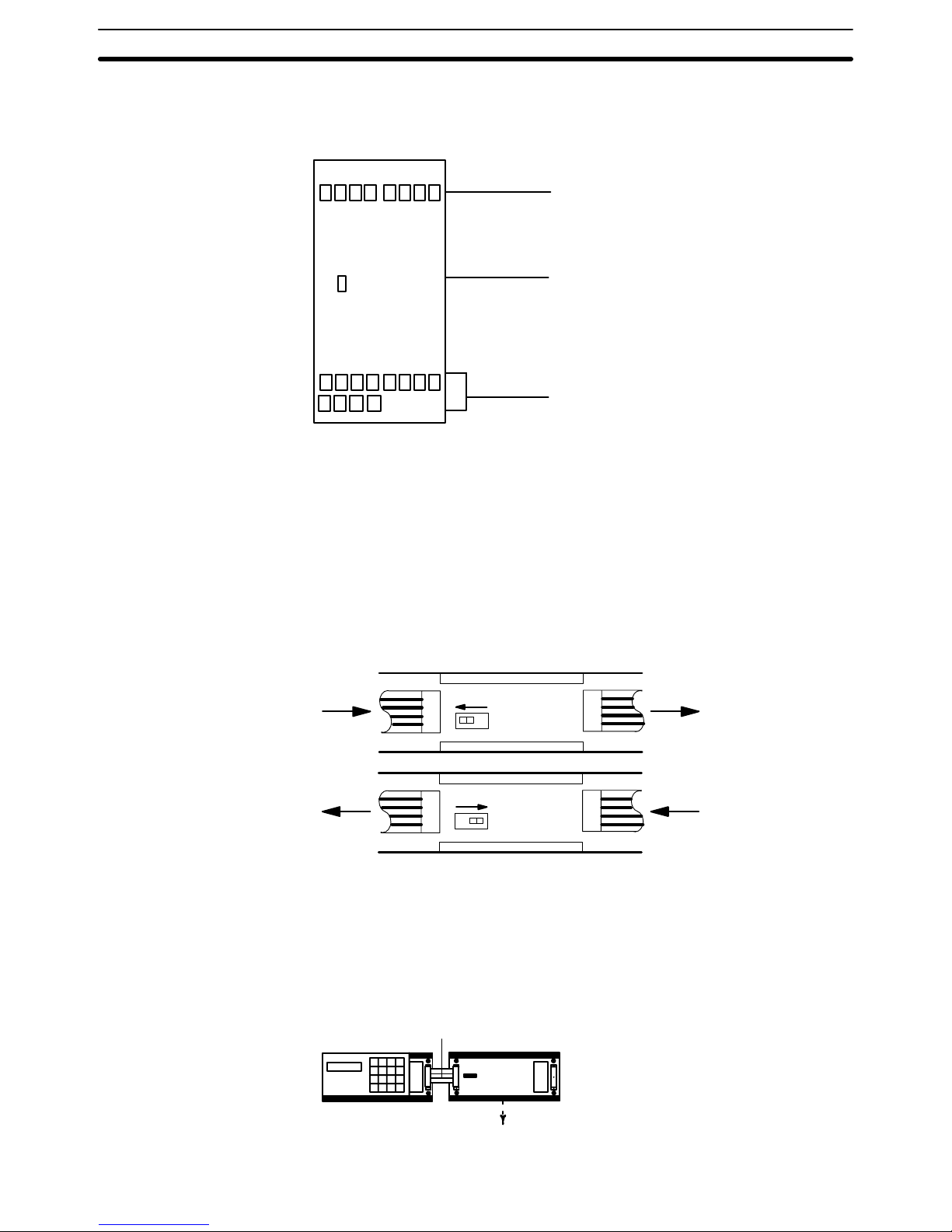

1–1–2 Expansion I/O Units

In the diagram below, the C20P is shown as a representative model. Refer to

Appendix A Standard Models for your model’s exact specifications.

Power supply Ground Outputs Indicators

CPU,

Expansion

I/O Unit,

Analog

Timer Unit, or

I/O Link Unit

connector

24–VDC outputInputsCPU left/right

selector

CPU,

Expansion

I/O Unit, or

I/O Link Unit

connector

ROM Socket and DIP

Switch

Nomenclature Section 1–1

Page 12

4

Indicators The following diagram shows the functions of the various indicators, taking

the C20P as an example.

8 9 10 11

0 1 2 3 4 5 6 7

OUTPUT 5 CH

POWER

INPUT 0 CH

OUTPUT: Shows whether the output is ON or OFF.

POWER: Stays lit while power is turned ON to the

I/O Unit.

INPUT: Shows whether the input ON or OFF.

0 1 2 3 4 5 6 7

CPU Left/Right Selector The C20P, C28P, C40P, and C60P Expansion I/O Units all have CPU left/

right selector switches. The C16P and C4K do not. For those models which

have the switch, care must be taken to set it so that it corresponds with the

direction of the I/O Connecting Cable. If the switch is set in the wrong direction, the System will operate as if the I/O Unit were not there. Set the switch

so that the CPU connector side (Left or Right) is ”in,” as shown in the following diagram. Do not change the switch setting after power has been turned

ON, as this will cause the I/O bus to malfunction.

Lin Rout

To I/O

Link

Unit

From

CPU

LR

Rin Lout

To I/O

Link

Unit

From

CPU

LR

The following example diagrams show the proper switch settings for horizontal and vertical mounting of Units.

Horizontal Mounting (All Units can be positioned horizontally.)

Set to Left in Right out

C20P–CN501

CPU

I/O Unit

Nomenclature Section 1–1

Page 13

5

Vertical Mounting (All Units except the C16P and C4K can be positioned vertically.)

C20P–CN411

Set to Right in Left out

CPU

I/O Unit

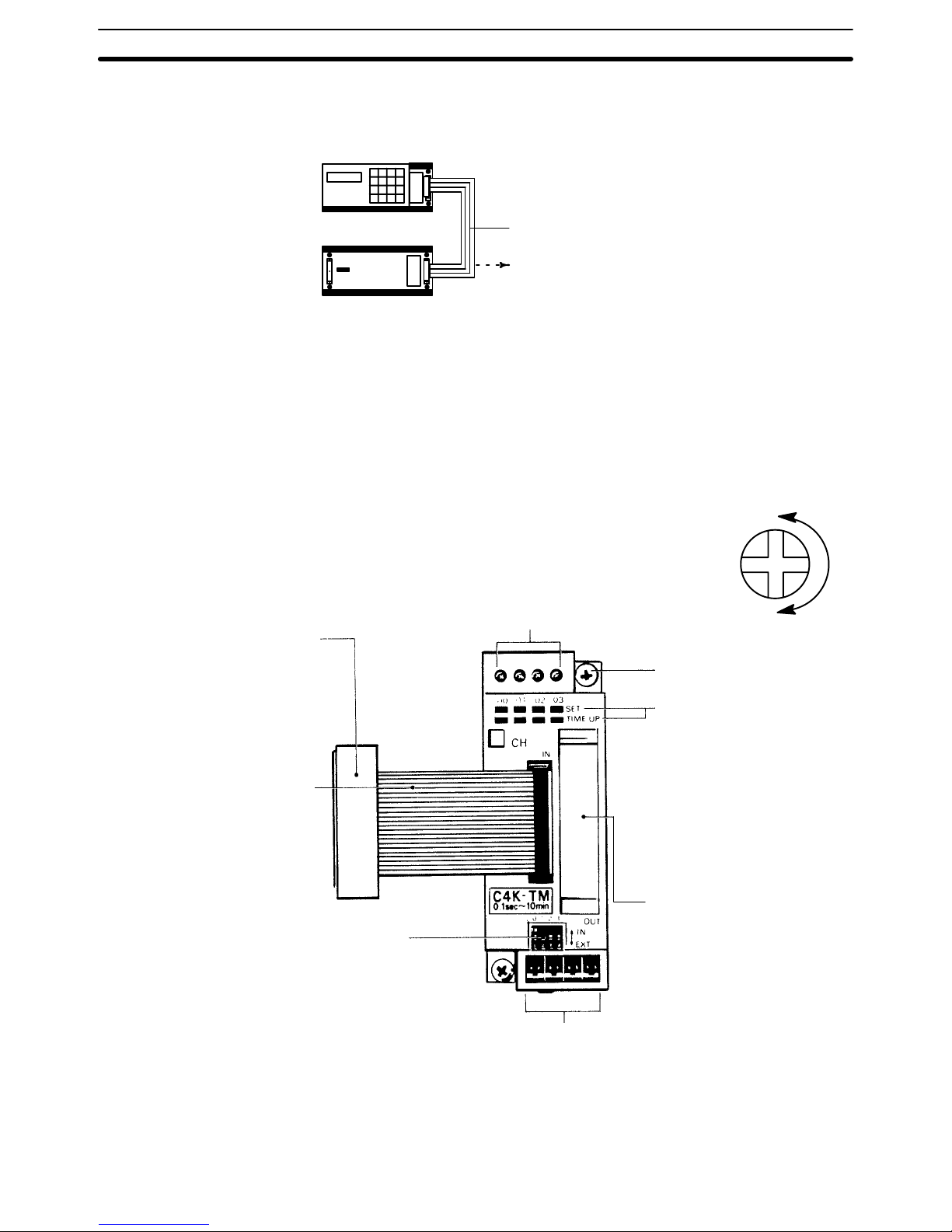

1–1–3 Analog Timer Unit

Internal variable resistors

These variable resistors are used to set the timers

and, from left to right, correspond to T0 to T3. The

settings of these resistors are effective only when the

corresponding IN/EXT selector is set to IN. To set or

adjust the time, use the screwdriver supplied with the

Analog Timer Unit. Turn the variable resistor shafts

clockwise to increase the time value.

Min.

Max.

Two M4 mounting screws

(self–rising pressure plate)

Indicators

The SET indicators in the top

row light while timer values

are being set. The TIME UP

indicators in the bottom row

light when the corresponding

timer contact (T0 to T3) turns

ON. Numbers 00 to 03 correspond to T0 to T3.

This connector is not used.

Do not remove the cover.

External variable resistor connectors

When using external variable resistors to set the timers, connect the

resistors to these connectors. The corresponding IN/EXT selector

must be set to the EXT position. These connectors correspond to

T0 to T3 from left to right. Use 20 k

Ω external variable resistors.

CPU connector

Install and connect the Expansion

I/O Unit and the CPU horizontally;

otherwise the Analog Timer Unit

cannot be connected to the CPU.

I/O Connecting Cable

C4K–CN502

One cable is supplied with the

Analog Timer Unit

IN/EXT selectors

When using the internal variable

resistor, set the corresponding pin to

IN; when using an external variable

resistor, set the corresponding pin to

EXT. These selectors correspond to

T0 to T3 from left to right.

Nomenclature Section 1–1

Page 14

6

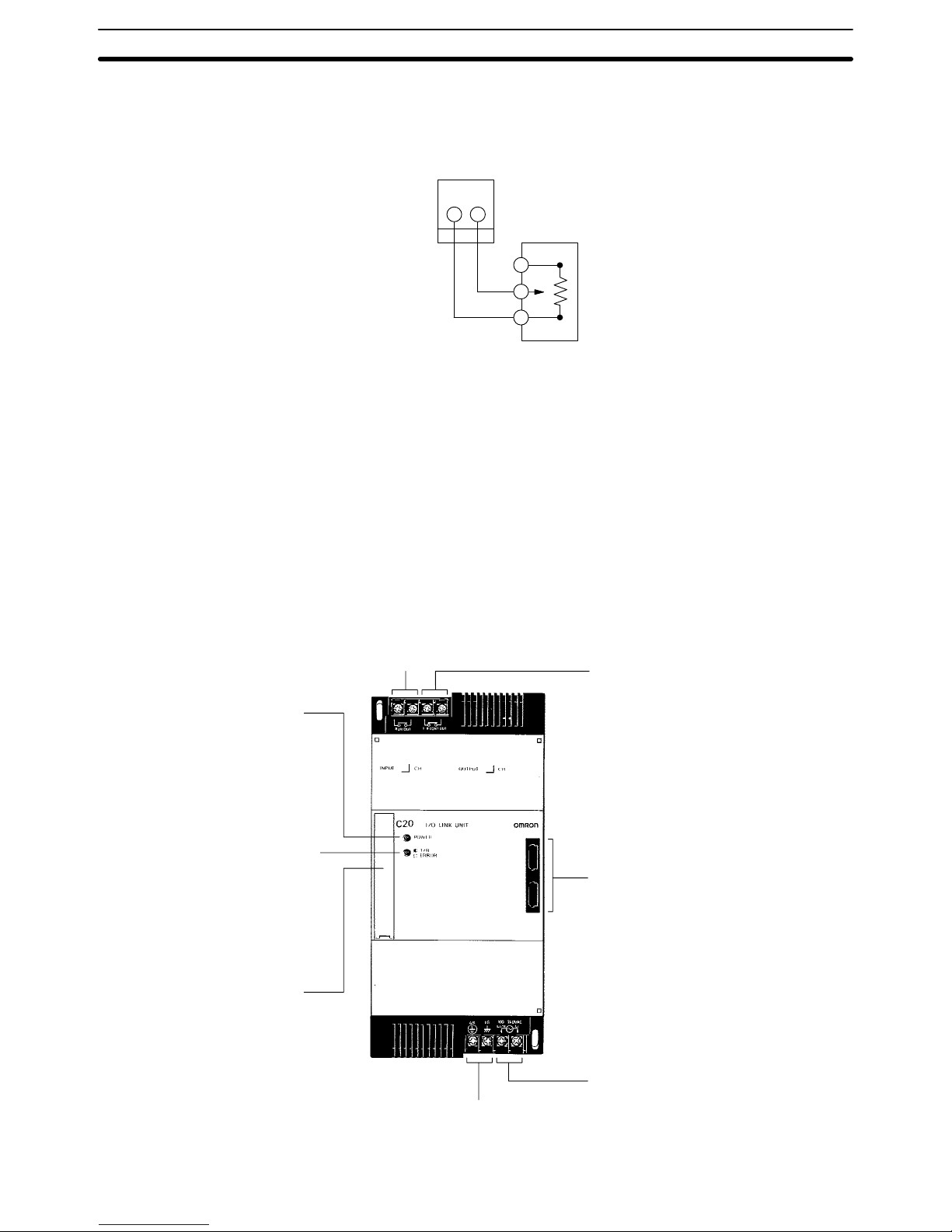

External Variable Resistor The contactor employs solderless terminals and must be wired as shown be-

low, using AWG 28 to 22 lead wires.

Analog Timer Unit

connector

External variable

resistor (20 k

Ω)

1–1–4 I/O Link Units

The I/O Link Unit must be used as a Remote I/O Slave, and must be used

with a Remote I/O Master. Refer to the Remote I/O Unit Operation Guide for

details.

Operation output terminal

Indicates that the power is ON

and that the CPU is in RUN or

MONITOR mode with no errors.

Repeater Output Terminal

Sends repeater signals to a Link

Adapter. The repeater output is ON

when power is ON in the CPU and

I/O Link Unit. (See the Link Adapter

manual for details.)

Optical fiber connectors

Transmitting error indicator

Blinks during normal transmission.

Lights continuously to indicate a

transmission or connection error.

AC power supply

Ground

CPU or Expansion

I/O Unit connector

Power indicator

Nomenclature Section 1–1

Page 15

7

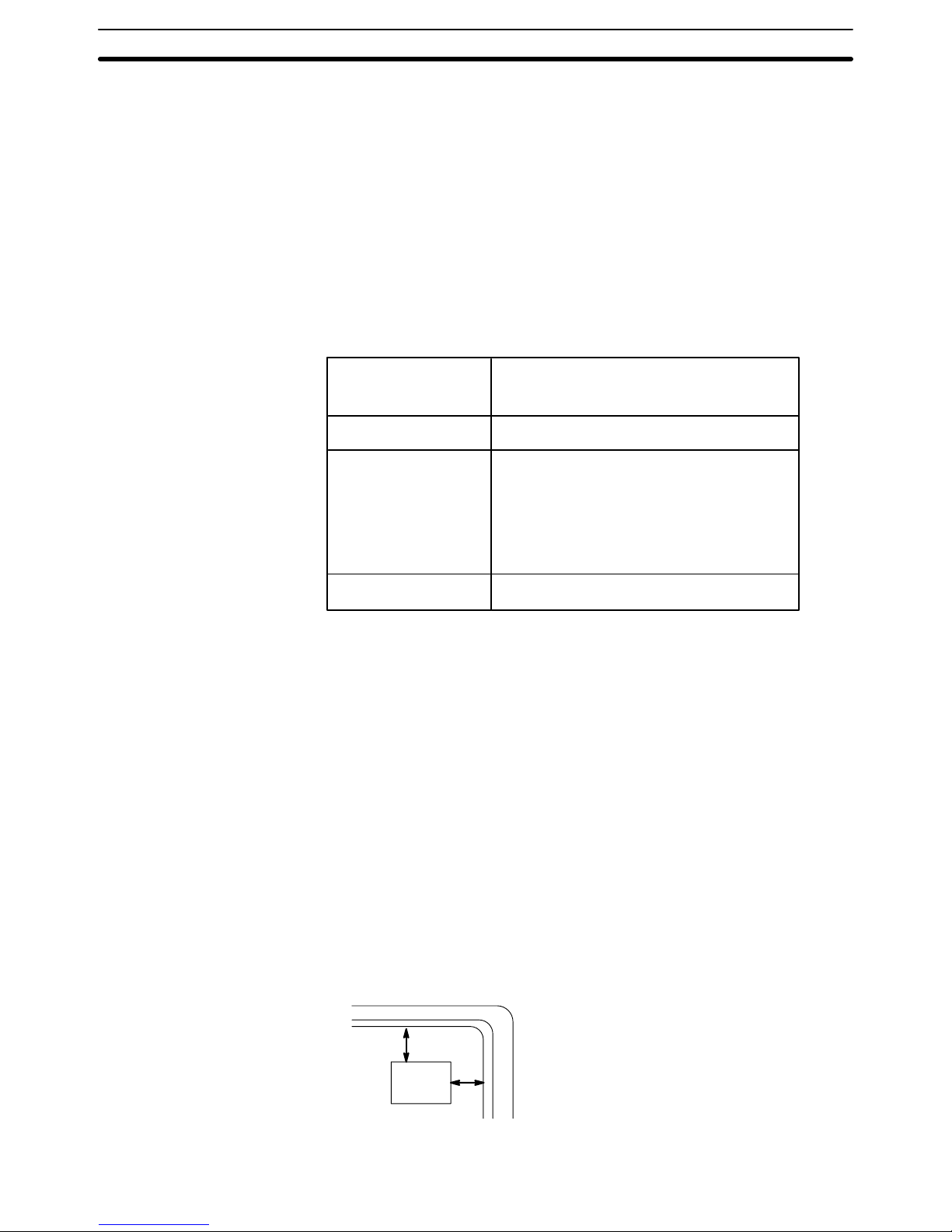

1–2 System Configuration

Depending on your control requirements, you can combine various Units for

a total number of I/O points ranging anywhere from 20 to 148.

For example, a single C20K CPU, with no Expansion I/O Units connected,

has a total of 20 I/O points, broken down into 12 input points and 8 output

points. If it is used in combination with a C4K Input Unit, there will be a total

of 16 input points and 8 output points. If combined with a C4K Output Unit,

the total will be 12 input points and 12 output points.

If the C20K is combined with a C16P Expansion I/O Unit, there will be a sum

total of 36 I/O points. If the C16P is an Input Unit, they will be broken down

into 28 input points and 8 output points; if it is an Output Unit, there will be 12

input points and 24 output points. For a listing of possible Unit combinations

and numbers of I/O points, see Appendix E System Configuration Chart.

Only one Expansion I/O Unit with the suffix ”P” can be connected to any

given CPU. It is possible to add more than one C4K, but under no circumstances can the total number of I/O points exceed 148. Either one Analog

Timer Unit or one I/O Link Unit can be added to any other possible combination of Units.

When determining which configuration to use, another factor to consider is

the ease with which I/O points can be assigned. In order to make the process

as simple as possible, it is recommended that a CPU be used which has

more I/O points than the largest Expansion I/O Unit. For example, rather than

combining a C20P CPU with a C20P Expansion I/O Unit, it would be preferable to use a C40P CPU. Similarly, combining a C60P CPU with a C40 Expansion I/O Unit would be better than using a C40P CPU and a C60P Expansion I/O Unit.

This is intended only as a brief overview of system configuration possibilities.

In addition to Appendix E System Configuration Chart (mentioned above),

see the I/O tables in the operation manual for details on various possible

combinations of Units and the particular I/O bits and IR area work bits which

are available for use in each configuration.

System Configuration Section 1–2

Page 16

9

SECTION 2

System Installation and Wiring

2–1 General 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Installation Environment 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions and Installation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 I/O Connecting Cable 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 Wiring CPUs and Expansion I/O Units 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6 I/O Wiring 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6–1 Unit Wiring Diagrams 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6–2 I/O Device Connection Examples 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7 Special Wiring Precautions 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8 Settings 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8–1 Setting the CPU DIP Switch 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8–2 EP–ROM Installation 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8–3 High–Speed Counter 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8–4 Inhibiting the ALARM Indicator 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8–5 Setting the I/O Link Unit 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 17

10

2–1 General

This section explains how to install and set up your Control System, with specifics on the proper environment, actual mounting, applicable cable, wiring,

and switch settings.

2–2 Installation Environment

Although the K–Type Programmable Controller is quite durable, the following

conditions must be observed in order for your System to operate at its highest level of reliability.

Ambient temperature Operating: 0° to 55°C*

Storage: –20 to 65

°C

Humidity 35% to 85% RH (without condensation)

Must be free from the following:

• Corrosive gases

• Abrupt temperature changes

• Direct sunlight

Atmosphere

• Concentration of dust, salt, iron particles

• Splatter from water, oil, other chemicals

Vibration and shock Must not receive direct impact or vibration

*The ambient operating temperature for the Programming Console is 05 to 455

CAUTION

In low humidity conditions, excessive static electricity of over 8 KV can damage internal components such as ICs. Therefore, before touching the PC, be

sure to first touch a grounded metallic object to discharge any static electricity buildup.

Noise Prevention Use twisted pair cables with cross–sectional areas of at least 2 mm

2

/conductor (AGW 14) to prevent noise. Avoid mounting the PC close to high–power

equipment, and be sure to mount it at least 200 mm away from power lines.

Wherever possible, use wiring ducts to contain and protect the PC wiring.

The I/O wiring should not be placed in the same duct with the power line or

other wiring. Standard wiring conduits are sufficient as long as the I/O wiring

and power lines are kept separate.

200mm

min.

200mm min.

PC

Installation Environment Section 2–2

Page 18

11

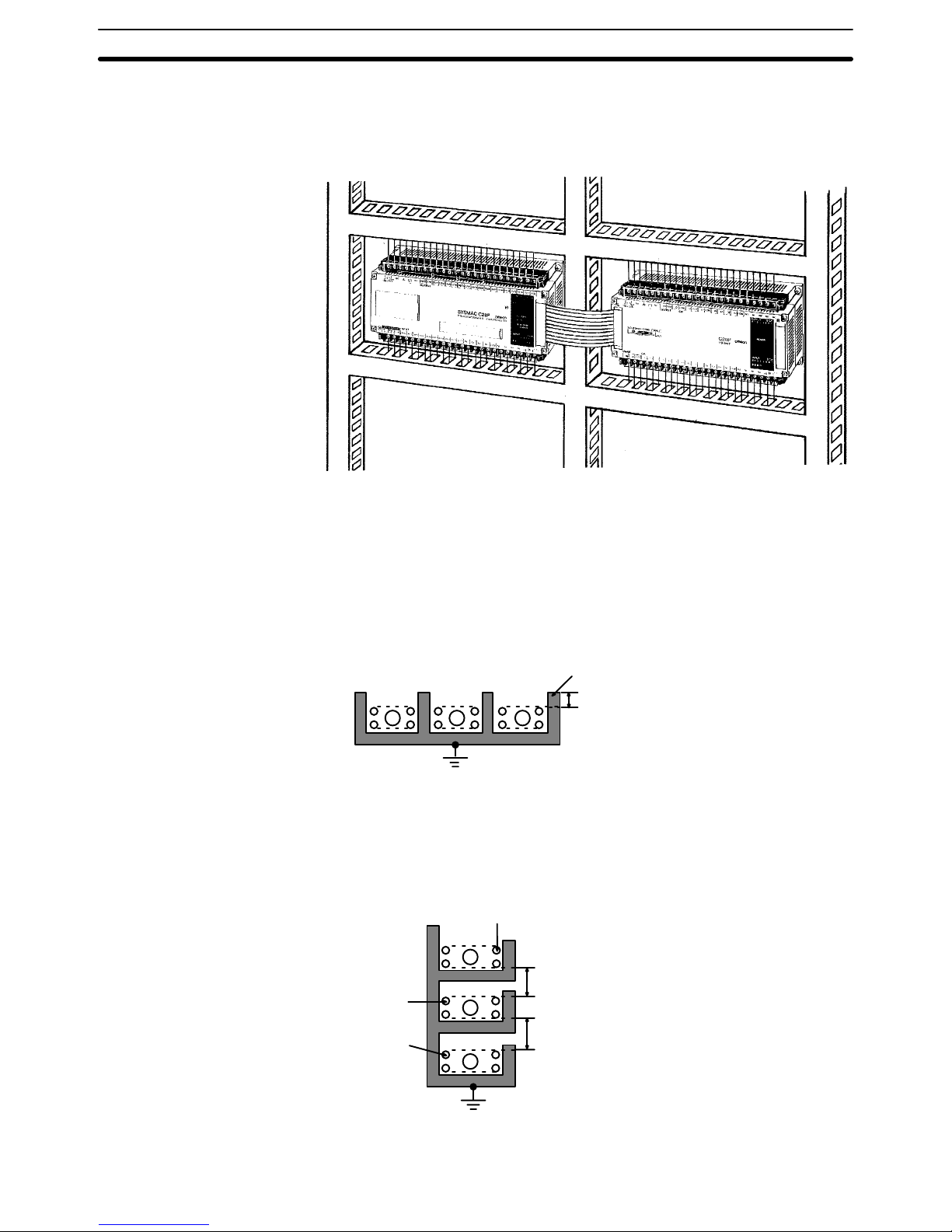

Duct Work When CPUs and Expansion I/O Units are mounted horizontally, be sure that

no ducts or wiring passes between them. The diagram shows an example of

unacceptable mounting.

If the controlled system requires either 10 A at 400 V max. or 20 A at 220 V

max. power cables, and if the conduits are run parallel to each other, a minimum distance of 300 mm must be provided between the I/O lines and the

power cable. If the I/O lines and the power cables must be placed in the

same duct at the point of connection to the equipment, be sure to screen

them with a grounded metal plate.

3

Metal (iron) plate

200 mm min.

Grounding (at a ground resistance of less than 100

Ω )

1 PC I/O circuit

2 PC power circuit

3 General control circuit/Power circuit

1

2

Weak current cable

300 mm min.

300 mm min.

Control cable

Power cable

Ground (at a resistance of

less than 100

Ω )

1

2

3

Installation Environment Section 2–2

Page 19

12

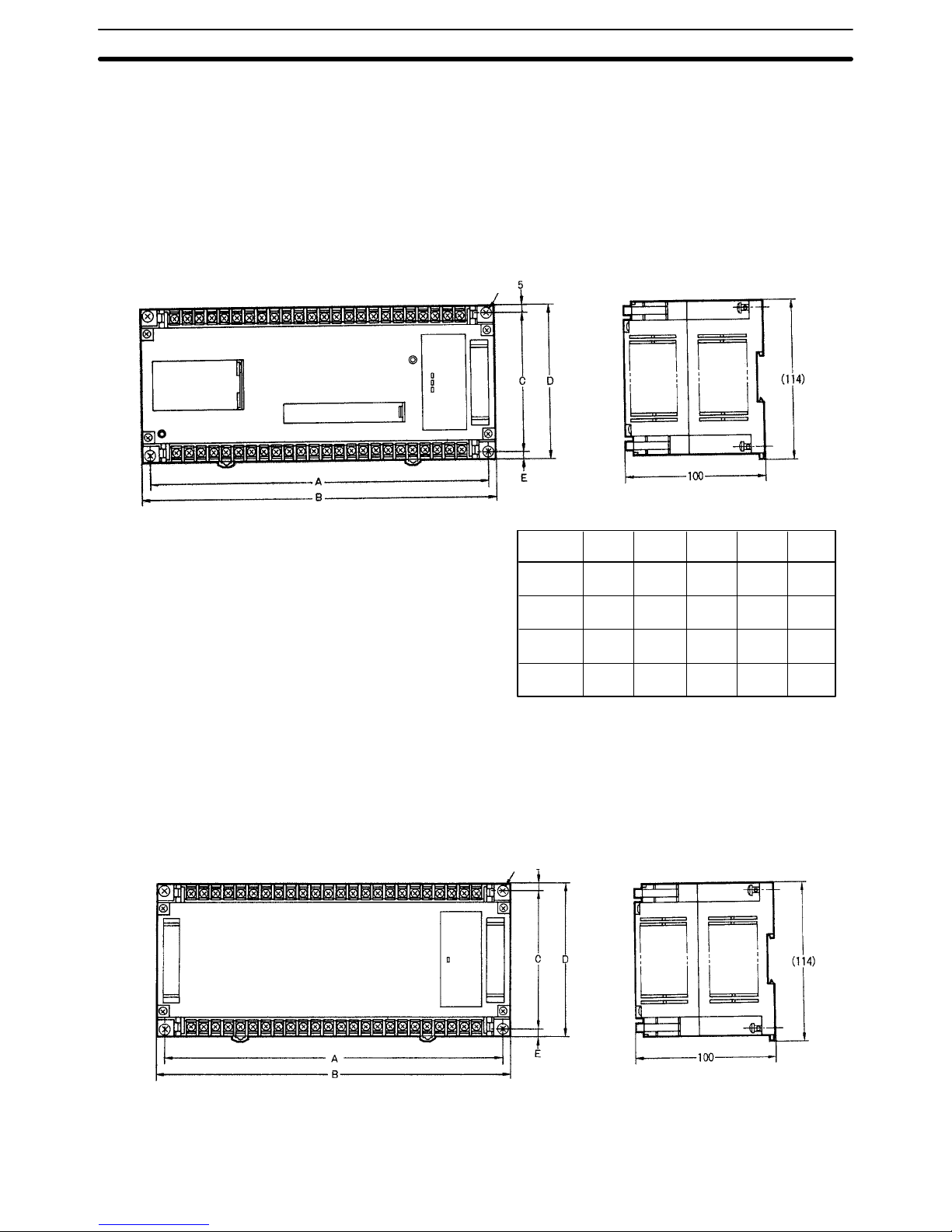

2–3 Dimensions and Installation

This section gives dimensions and other information necessary for mounting

the CPUs, Expansion I/O Units, Analog Timer Units, and I/O Link Units. All

measurements are in mm.

CPUs (The C20K is shown as an example.)

A

240

240

290

340

Model

C20K

C28K

C40K

C60K

B

250

250

300

350

C

100

100

100

120

Four M4 screws

D

110

110

110

140

E

5

5

5

15

Expansion I/O Units (The C20P is shown as an example.)

Four M4 screws

Dimensions and Installation Section 2–3

Page 20

13

Expansion I/O Units cont.

Model

C16P

C20P

C28P

C40P

C60P

A

145

240

240

290

340

B

155

250

250

300

350

C

100

100

100

100

120

D

110

110

110

110

140

E

5

5

5

5

15

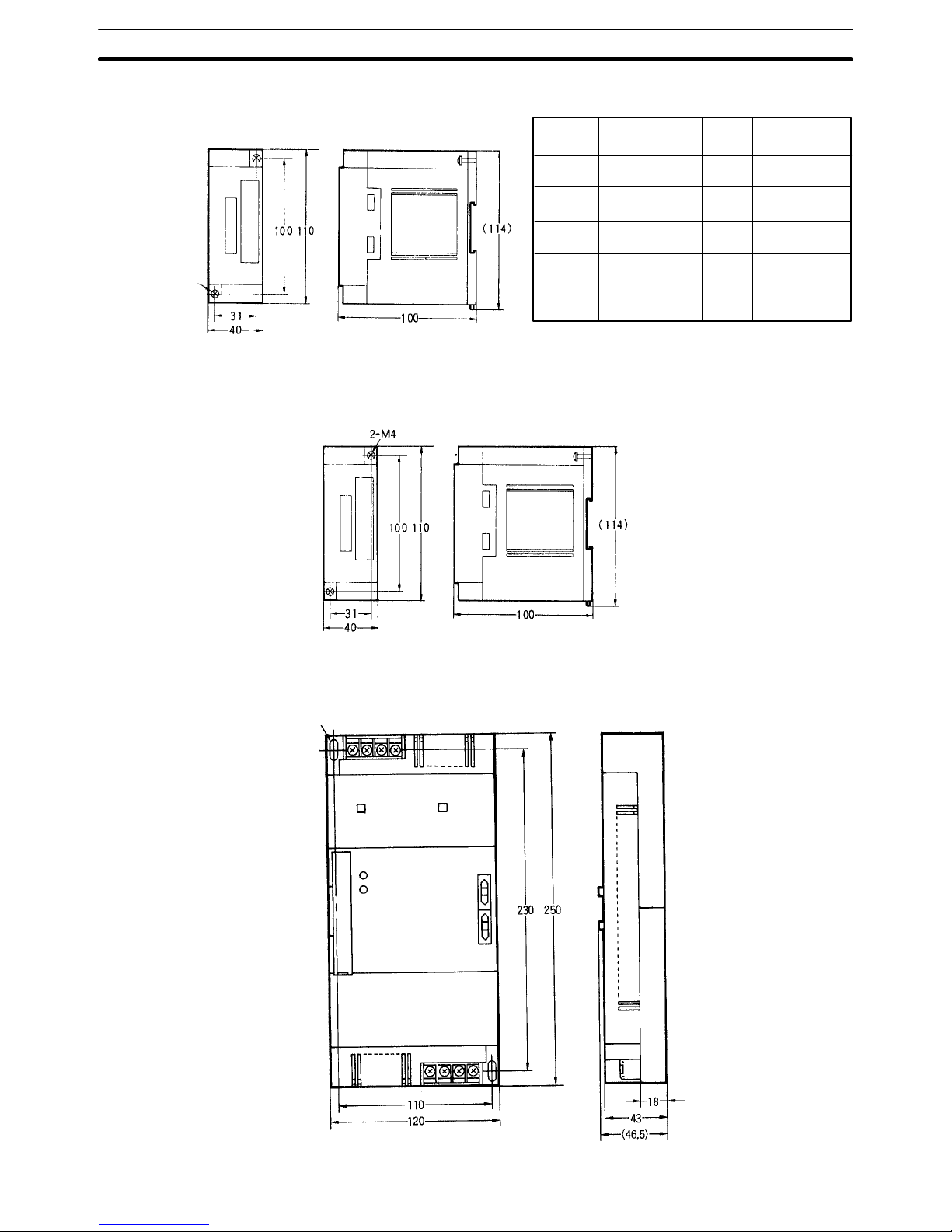

2–M4

C4K

Analog Timer Units C4K–TM

I/O Link Units C20–LK011(–P)

Two M4 holes

Dimensions and Installation Section 2–3

Page 21

14

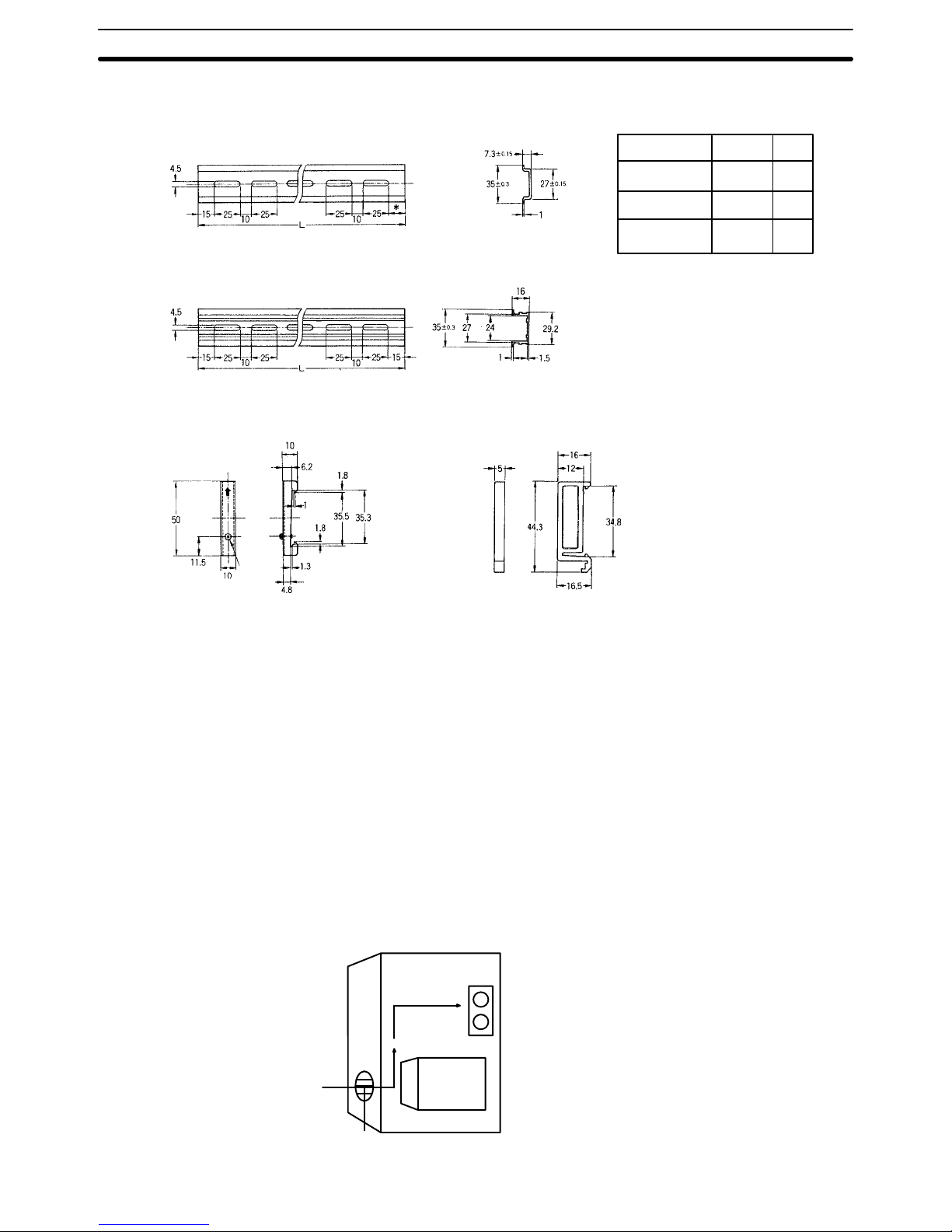

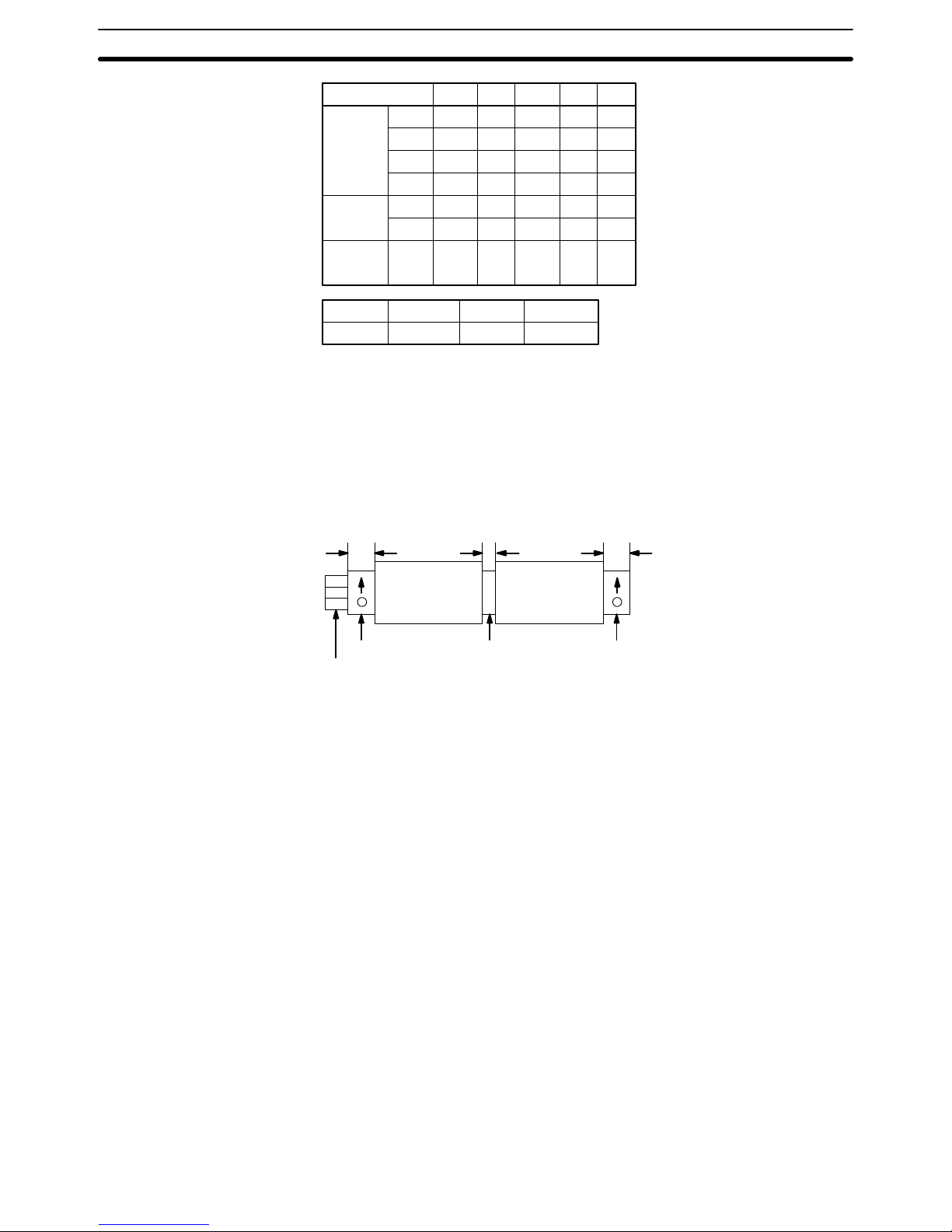

DIN Rails

*

5

15

––

Model

PFP–50N

PFP–100N

PFP–100N2

L

50 cm

1 m

1 m

* Use the PFP–100N2 for the C60P.

If the PFP–50N or PFP–100N are

used, the Unit will be slanted.

PFP–50N/PFP–100N

PFP–100N2

Endplate PFP–M

Eight M4

panhead

screws

Spacer PFP–S

Mounting A CPU and Expansion I/O Unit may be mounted either vertically or horizon-

tally in relation to each other but the orientation of each unit itself must remain horizontal as described by the following mounting diagrams. If mounting

the units vertically, position the CPU above the Expansion I/O Unit; if mounting horizontally, position the CPU to the left.

When installing the CPUs, Expansion I/O Units, and I/O Link Units, allow sufficient space between the Units for cooling. Models taking a 100– to

240–VAC power supply require a minimum cooling space of 10 mm between

Units. Avoid mounting any units in warm areas or over a heat source of any

kind.In addition, if the CPU is installed in a control box, allow sufficient space

for maintenence and ventilation. It may be necessary to install a ventilation

fan in the control box to maintain the required ambient temperature as indicated in Appendix B Specifications.

Control Box

Fan

PC

Vent

Dimensions and Installation Section 2–3

Page 22

15

Another factor to consider is the I/O wiring (see 2–5 I/O Wiring). If the CPU

and/or Expansion I/O Units are mounted vertically, a minimum of 70 mm

open space is required for ease of I/O wiring. The spacing of the mounting

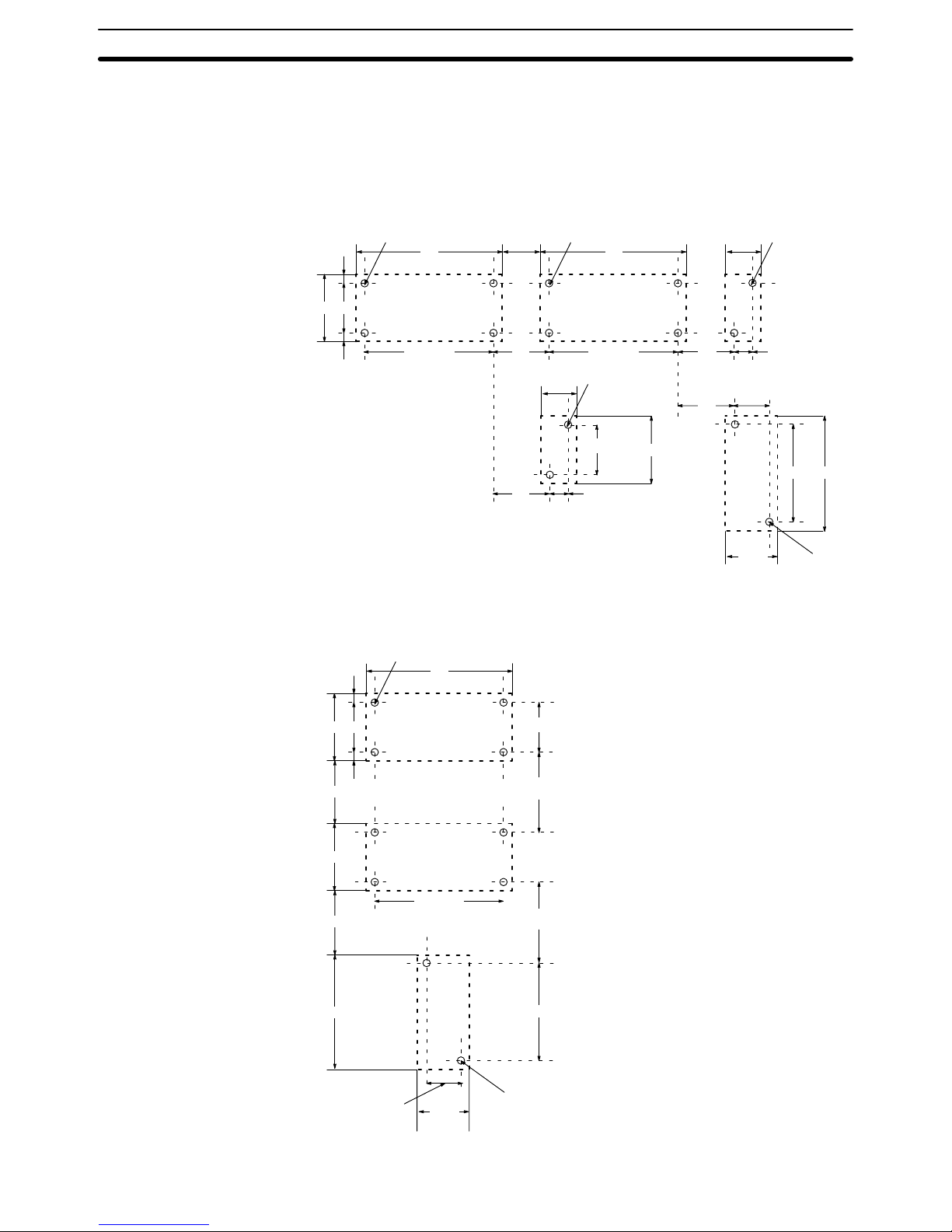

holes, for both vertical and horizontal mounting is as shown below.

Horizontal Mounting

A ± 0.2 A ± 0.2

G

A ± 0.2

D C

4–M4 4–M4 2–M4

Expansion

I/O Unit

CPU

Analog

Timer Unit

B B

F–10

A ± 0.2

2–M4

B

F

F

C ± 0.2

D

C4K

230 250

5

E

H

110

± 0.2

120

2–M4

I/O

Link

Unit

Vertical Mounting

D C

4–M4

CPU

B

5

A ± 0.2

Expansion

I/O Unit

D

230

120

2–M4

110 ± 0.2

230

I–10

I–10

C ± 0.2

I

I

I/O

Link

Unit

Dimensions and Installation Section 2–3

Page 23

16

Model

CPU

I/O Unit

I/O Unit

Analog

Timer

Unit

C20K

C28K

C40K

C60K

C16P

C4K

C4K

–TM

A

±0.2

240

240

290

340

145

31

31

B

250

250

300

350

155

40

40

C±0.2

100

100

100

120

100

100

100

D

110

110

110

140

110

110

110

E

5

5

5

15

5

5

5

F

15 to 40G15 to 35H20 to 40I80 to 130

Attach End Plates (PFP–M) to both ends (as shown below) when connecting

CPUs, Expansion I/O Units, or Analog Timer Units to a DIN Rail. It is also

recommended that a Spacer (PFP–S) be installed between a CPU and Expansion I/O Unit when they are mounted horizontally.

XX

510 10

End plate

DIN Rail

Spacer End plate

CPU I/O Unit

Mounting screws are included with CPUs, Expansion I/O Units, and Analog

Timer Units. They must be purchased separately for I/O Link Units.

2–4 I/O Connecting Cable

Applicable connecting cable will vary according to which Units are connected

and whether they are mounted horizontally or vertically. All Expansion I/O

Units except the C16P and C4K use C20P–CN501 cable (5 cm) for horizontal mounting and C20P–CN411 cable (40 cm) for vertical mounting. The

C16P and C4K cannot be mounted vertically. The C16P can use either of the

above–mentioned cables for horizontal mounting. The C4K can use only

C4K–CN501 cable (5 cm). For connecting I/O Link Units, use C20P–CN711

cable (70 cm).

CAUTION:

Always be sure to use only the cable that is included with the Unit. Using the

wrong cable (such as the C20 I/O Connecting Cable or I/O Link Connecting

Cable) for connecting Expansion I/O Units can cause serious damage to the

Units.

I/O Connecting Cable Section 2–4

Page 24

17

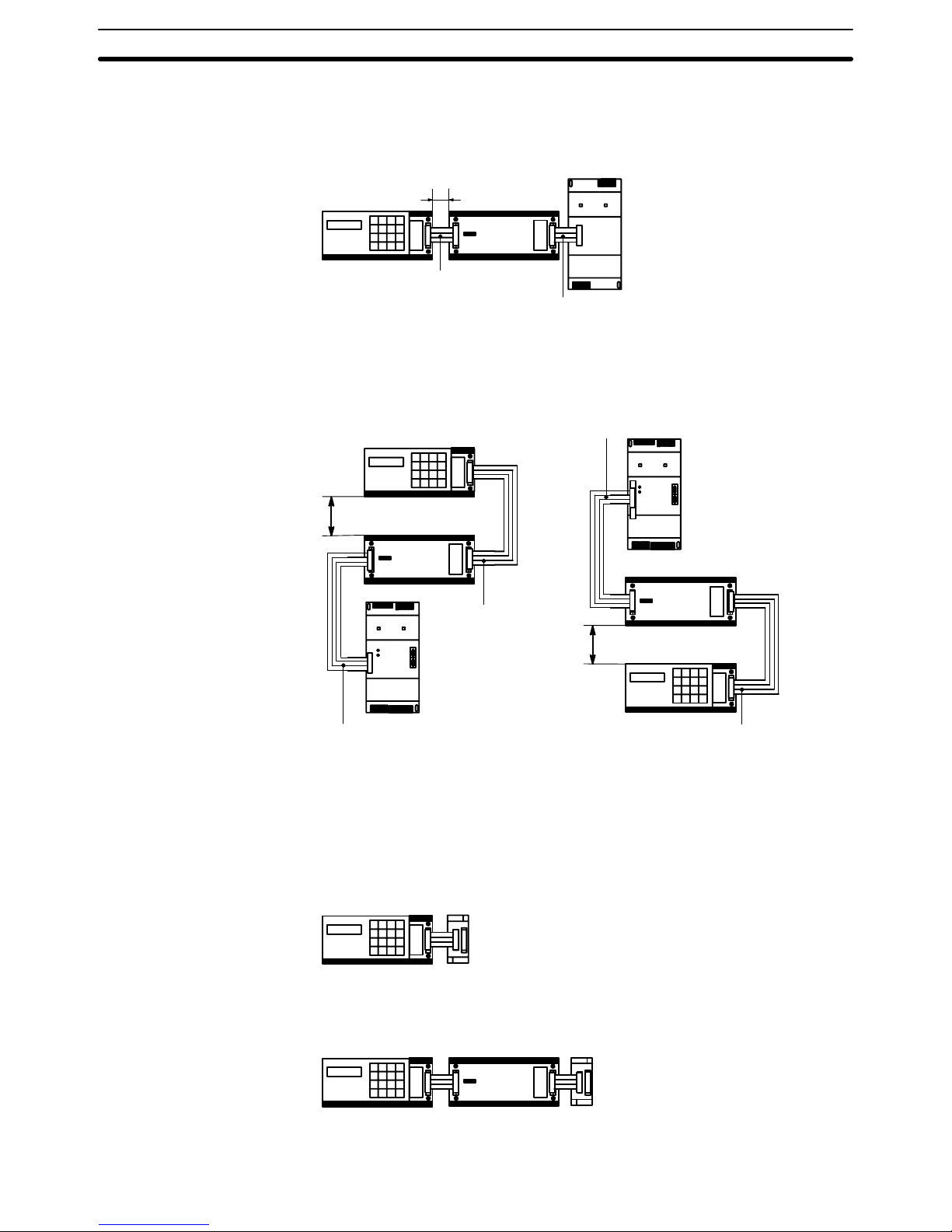

The following diagrams illustrate the appropriate cables for connecting CPUs,

Expansion I/O Units, and I/O Link Units either horizontally or vertically.

5 to 30 cm

I/O Connecting

Cable C20P–CN501

100 to 200mm

100 to 200mm

Horizontal Mounting

CPU

I/O Unit

CPU

I/O Unit

I/O Unit

CPU

I/O Link Connecting

Cable C20P–CN711

I/O Link

Unit

I/O Link

Unit

I/O Link

Unit

Vertical Mounting

I/O Connecting

Cable C20P–CN411

I/O Link Connecting

Cable C20P–CN711

I/O Link Connecting

Cable C20–CN711

I/O Connecting

Cable C20P–CN411

One Analog Timer Unit can be connected directly to a CPU or to any combination of a CPU and Expansion I/O Units. In either case, as shown in the following diagram, the Units must be mounted horizontally.

Analog

Timer Unit

Connecting Cable

C4K–CN501

Analog

Timer Unit

Connecting Cable

C4K–CN501

CPU

CPU

I/O Unit

Connecting Cable

C20P–CN501

Connecting Analog Timer

Units

I/O Connecting Cable Section 2–4

Page 25

18

Connecting I/O Link Units One I/O Link Unit can be connected directly to a CPU or to any combination

of a CPU and Expansion I/O Units. It cannot be used in the same PC System

with an Analog Timer Unit.

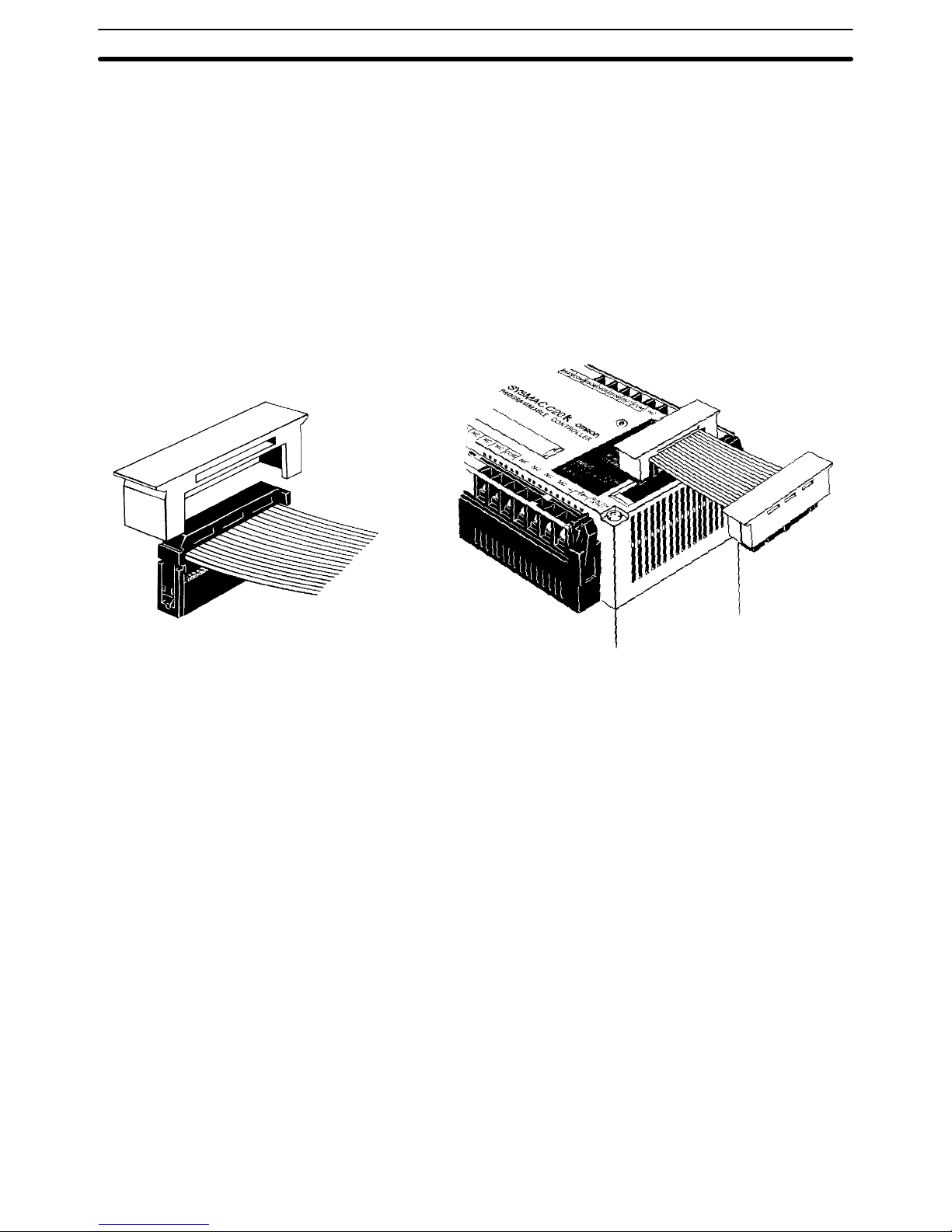

Connection Procedure Follow these four steps to connect Expansion I/O Unit, Analog Timer, and I/O

Link Unit Connecting Cables.

1, 2, 3... 1. Remove the connector cover from the CPU, using a screwdriver if nec-

essary.

2. Insert one of the cable’s connectors into the cover. (Once inserted, the

connector cannot be removed.)

3. Reinsert the cover/connector combination into the CPU.

4. Repeat this procedure on the other end of the cable.

Cover

Optical Fiber Cable Optical fiber cable can be used for extending transmission distance and re-

ducing noise. There are three types, and the appropriate cable for any given

situation will depend on the desired transmission distance and the particular

Units which need to be connected.

All–plastic optical fiber cable (APF) is for short–distance transmission (up to

20 m) and can be used only by Units with the suffix ”–P” attached. Plastic–

clad optical fiber cable (PCF) is for middle–distance transmission (up to 200

m for Units with ”–P” and 800 m for Units without ”–P”). Crystal optical fiber

cable (AGF) is for long–distance transmission (up to 3 km) and can be connected only to certain Link Adapters.

Although laying optical fiber cable does not basically differ from laying wire

cable, there are certain precautions which should be observed. For details,

refer to the Optical Remote I/O Systems manual.

Link Adapters Although it is normally possible to connect Units in series, a failure (power

failure, disconnection, etc.) in one of the Units will cause all the subsequent

Units to cease operating. You can use Link Adapters to prevent this type of

situation from occuring. Even if a power failure occurs in a Unit connected to

a branch line of a Link Adapter, the Link Adapter will bypass that Unit and

continue to transmit signals to the other Units. You can also use Link Adapters for branching and for converting between various types of wire and optical cable. For details on these and other functions of Link Adapters, refer to

the Link Adapter manual.

I/O Connecting Cable Section 2–4

Page 26

19

2–5 Wiring CPUs and Expansion I/O Units

Power Supply Use a commercially available 24–VDC, 100– to 120VAC, or 200– to

240–VAC power supply (depending on your model) for the CPU. When an

Expansion I/O Unit(s) or an I/O Link Unit is used, the power supply must also

be connected to each of these Units. Where possible, use independent

power sources for the inputs, the output loads, and the CPU. All of the CPUs

and Expansion I/O Units may be connected to the same power source. If a

CPU and an Expansion I/O Unit are connected to separate power supplies,

then the CPU (as well as the Programming Console, etc.) will not operate

unless power is turned on to the Expansion I/O Unit.

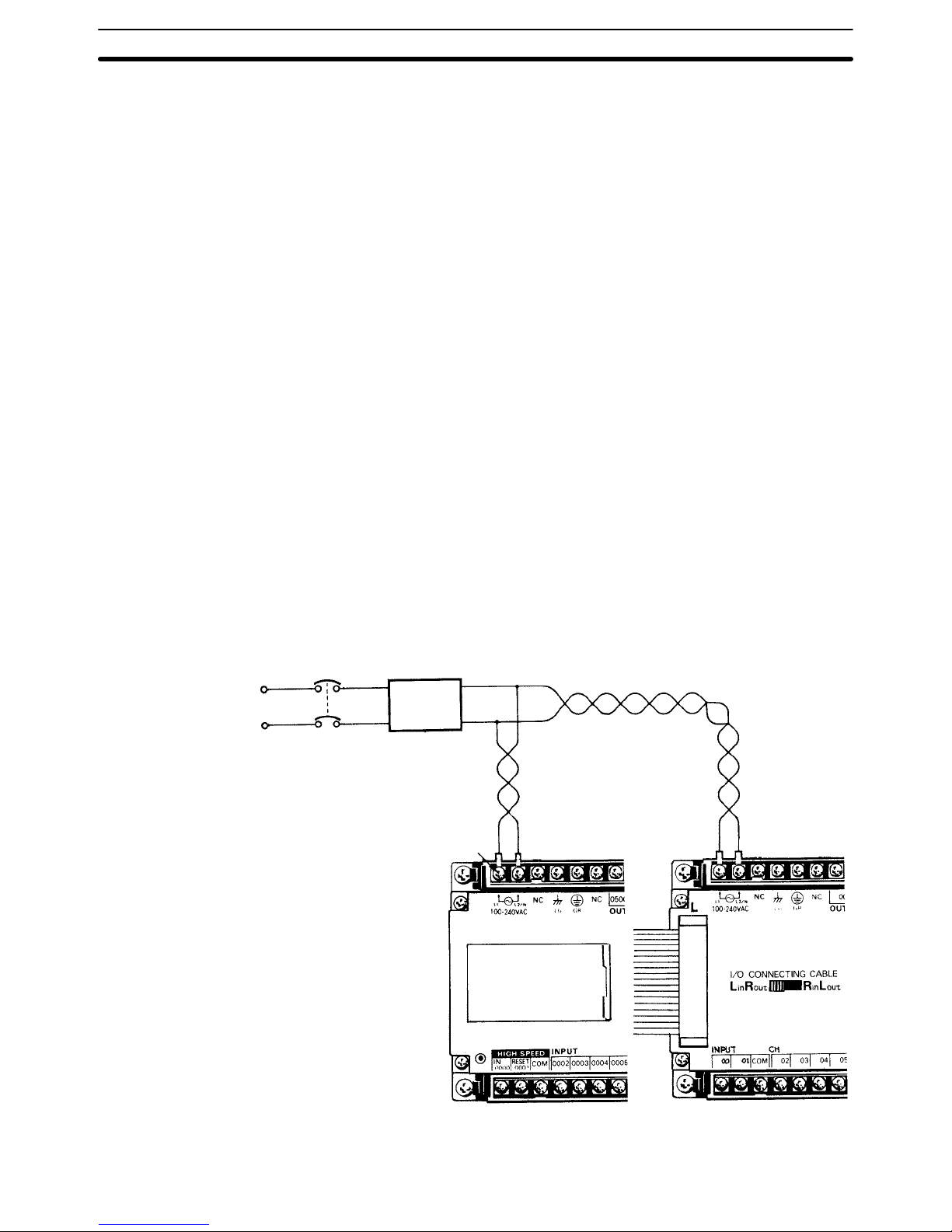

Wiring The following diagram illustrates the proper wiring for CPUs and Expansion

I/O Units with the suffix ”–A.” These models use a power supply of 100 to 240

VAC, with an operating voltage range of 85 to 264 VAC. The internal noise–

reduction system in these Units is sufficient for general power line noise, but

ground noise can be greatly reduced by using a 1:1 insulating transformer.

Ground only the primary side of the transformer. To prevent voltage drop, use

wires 2 mm2 or less in cross sectional area, twisting them as shown in the

diagram. When power is turned on, the incoming current will be approximately 10 A.

Breaker

Insulating

transformer

1:1

M3.5 screws

Wiring CPUs and Expansion I/O Units Section 2–5

Page 27

20

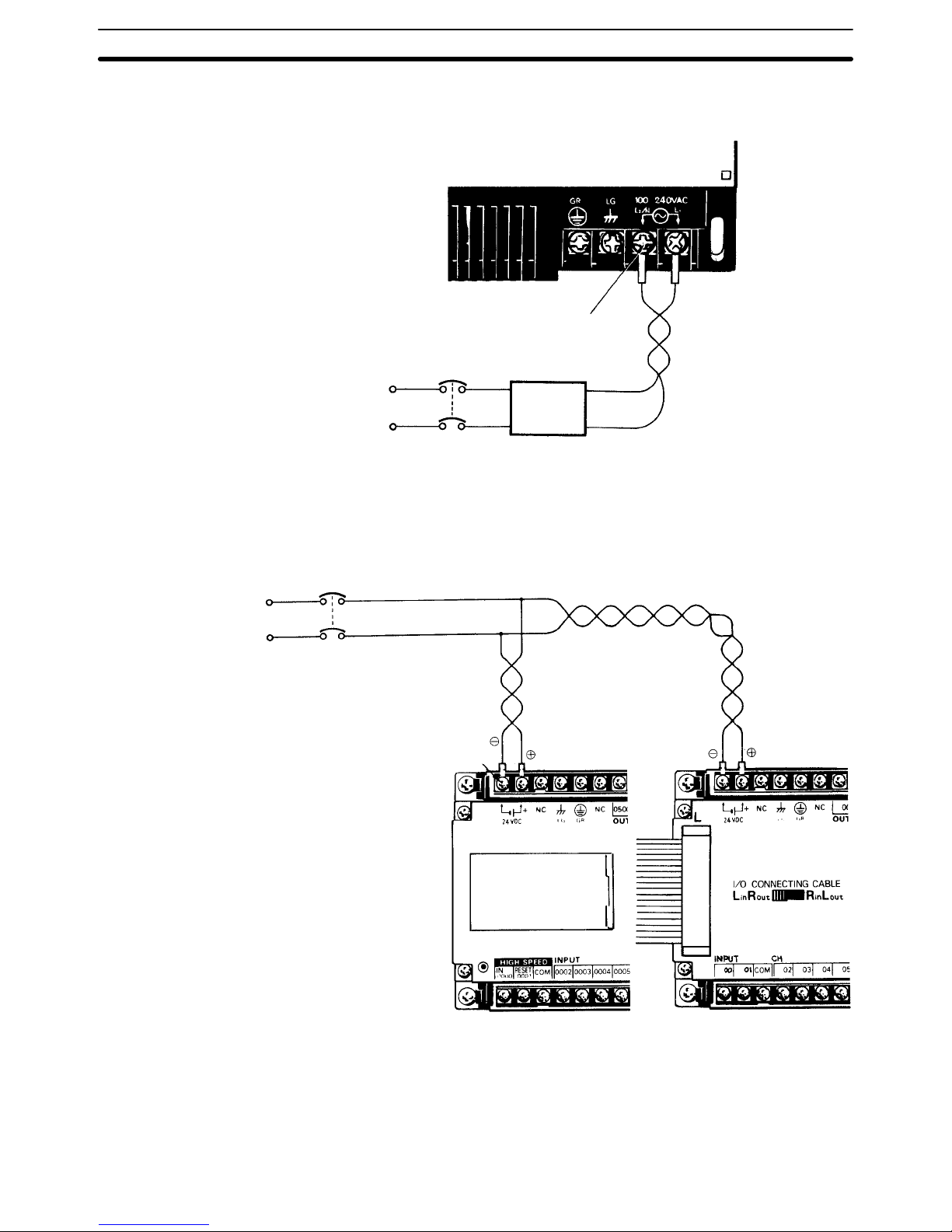

Connect an I/O Link Unit as shown in the following diagram, using M4 terminal screws.

M4 screws

100 to 240 VAC

Insulating

transformer

1:1

Breaker

The following diagram illustrates the proper wiring for CPUs and Expansion

I/O Units with the suffix ”–D.” These models use a power supply of 24 VDC

with an operating voltage range of 20.6 to 26.4 VDC. Be careful to connect

the positive and negative terminals correctly. When power is turned ON, the

incoming current will be approximately 30 A.

Breaker

M3.5 screws

Ground The Line Ground (LG) terminal is a noise filter neutral terminal which does

not normally require grounding. When electrical noise is a problem, however,

this terminal should be connected to the GR terminal.

Attach an independent ground–wire with a cross–sectional area of at least 2

mm

2

(AWG 14) to the GR terminal, to avoid electrical shock. Ground resis-

Wiring CPUs and Expansion I/O Units Section 2–5

Page 28

21

tance must be less than 100 Ω. Do not use a ground–wire longer than 20 m.

Care must be taken because ground resistance is affected by the nature of

the ground, water content, season, and the amount of time that has elapsed

since the wire was laid underground.

CPU operation may be adversely affected if the ground–wire is shared with

other equipment, or if grounding is attempted by attaching the ground–wire to

the metal superstructure of a building. When either Expansion I/O Units or

I/O Link Units are used, they also require grounding at the GR terminal.

These may all be included on the same ground.

LG

GR

Wiring CPUs and Expansion I/O Units Section 2–5

Page 29

22

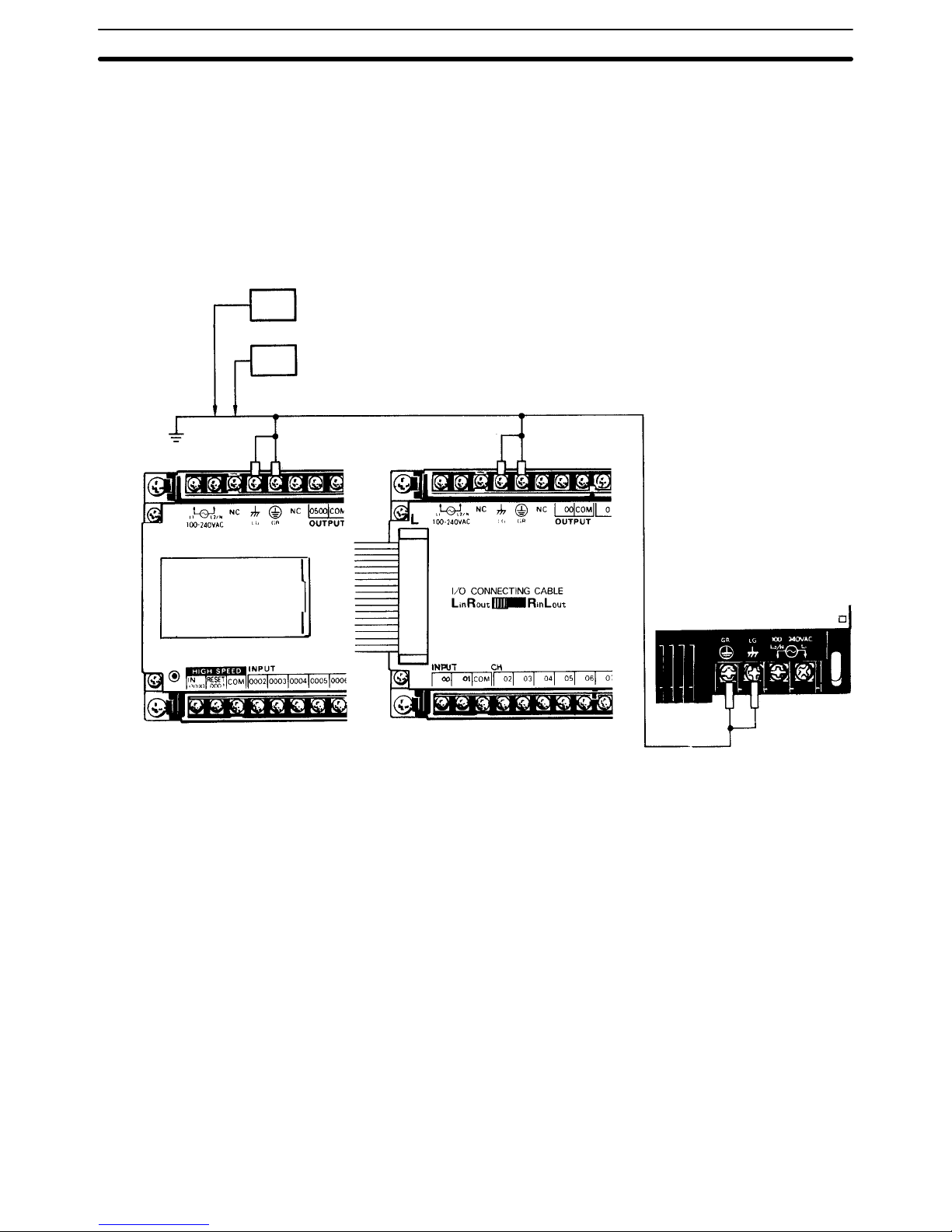

2–6 I/O Wiring

This section shows I/O wiring diagrams for representative models of all the

CPUs, Expansion I/O Units, and I/O Link Units covered in this manual. It also

gives connection examples for the sensors and switches which can be connected as input devices.

2–6–1 Unit Wiring Diagrams

The following items are all available for use as outputs. Do not mix them

within the same common circuit.

Output

Relay

Transistor

Triac

Load Power Supply

Up to 250 VAC/24 VDC

5 to 24 VDC

100 to 120/200 to 240 VAC

When using transistor outputs, connect the common line (COM) to the load

power supply negative side. For an induction load, connect the diode to the

load in parallel, as shown in the diagram, such that the cathode is on the

positive side of the power supply.

L

OUT COM

+

When using the high–speed counter instruction (HDM(61)), wire input 0000

as the high–speed counter input and input 0001 as the hardware reset input.

If the HDM is not used, inputs 0000 and 0001 may be used as general input

terminals. Their response time (0.15 ms), however, will be shorter than the

other inputs.

Do not connect the NC terminals to anything. The DC inputs in the following

I/O wiring diagrams are NPN (positive common). Reverse the polarity if PNP

(negative common) is used.

In the diagrams, representative models are sometimes used to cover several

models with similar wiring. In such cases, the type of Unit (i.e., CPU C60K) is

listed first, followed by the suffix of the applicable model number. A space left

blank (_) in the model number indicates that any of several numbers could be

inserted there.

I/O Wiring Section 2–6

Page 30

23

The inputs can use the Unit’s 24–VDC power supply output. If the maximum

output current of 0.2 A is not sufficient a separate DC power supply must be

used.

Load

power

supply

Relay contact outputs

Transistor outputs

Triac outputs

Inputs (24 VDC)

M3.5 screws

7.5 max.

Power

supply

(100 to

240 VAC)

NC

NC

Ground

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

High–

speed

counter

input

NC: Do not connect the NC terminals to anything.

COM

24 VDC

output

(0.2 A max.)

7.5 max.

Hardware reset input

CPU C20K, C28K, C40K

(CD_–A)

I/O Wiring Section 2–6

Page 31

24

Inputs 0000 and 0001 can use the Unit’s 24–VDC power supply output. If the

maximum output current of 0.2 A is not sufficient a separate DC power supply must be used. Inputs 0002 to 0107 take a 100–VAC power supply.

0000, 0001

24–VDC inputs

0002 to 0101

100–VAC inputs

Relay contact outputs

Triac outputs

Power

supply

(100 to

240 VAC)

NC

NC

Ground

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

High–

speed

counter

input

24 VDC

output

(0.2 A max.)

100 to 120 VAC

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Hardware

reset input

CPU C20K, C28K, C40K

(CA_–A)

I/O Wiring Section 2–6

Page 32

25

A separate power supply must be used for the DC inputs.

Relay contact outputs

Transistor outputs

Inputs (24 VDC)

Power

supply

(24 VDC)

NCNC

Ground

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

High–

speed

counter

input

NC: Do not connect the NC terminals to anything.

COM +

24 VDC

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

NCNC

Hardware

reset input

CPU C20P, C28P, C40P

(CD_–D)

I/O Wiring Section 2–6

Page 33

26

The inputs can use the Unit’s 24–VDC power supply output. If the maximum

output current of 0.3 A is not sufficient, however, a separate DC power supply

must be used.

Relay contact outputs

Transistor outputs

Triac outputs

Power

supply

(100 to

240

VAC)

Ground

Upper terminal

block

Lower terminal

block

Inputs (24 VDC)

High–

speed

counter

input

Hardware reset input

24_VDC

output

(0.3 A

max.)

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load power

supply

CPU C60K (CD_–A)

I/O Wiring Section 2–6

Page 34

27

CPU C60K (CA_–A) Inputs 0000 and 0001 can use the Unit’s 24–VDC power supply output. If the

maximum output current of 0.3 A is not sufficient, however, a separate DC

power supply must be used. Inputs 0002 to 0115 take a 100–VAC power supply.

Relay contact outputs

Triac outputs

Power

supply

(100 to

240

VAC)

Ground

Load power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Upper terminal

block

Lower terminal

block

High–

speed

counter

input

24_VDC

output

(0.3 A

max.)

0000, 0001

24–VDC inputs

0002 to 0115

100–VAC inputs

100 to 120 VAC

M3.5 screws

7.5 max.

7.5 max.

Hardware

reset input

I/O Wiring Section 2–6

Page 35

28

CPU C60K (CD_–D) A separate power supply must be used for the DC inputs.

Relay contact outputs

Transistor outputs

Power

supply

(24

VDC)

Ground

Load power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Upper terminal

block

Lower terminal

block

Inputs (24 VDC)

High–

speed

counter

input

Hardware reset input

M3.5 screws

7.5 max.

7.5 max.

I/O Wiring Section 2–6

Page 36

29

The inputs can use the Unit’s 24–VDC power supply output. If the maximum

output current of 0.2 A is not sufficient, however, a separate DC power supply

must be used.

Relay contact outputs

Transistor outputs

Triac outputs

Inputs (24 VDC)

Power

supply

(100 to

240 VAC)

NC

NC

Ground

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

COM

24 VDC

output

(0.2 A max.)

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

I/O Unit C20P/C28P/C40P

(ED_–A)

I/O Wiring Section 2–6

Page 37

30

I/O Unit C20P/C28P/C40P (EA_–A)

Inputs (100 VAC)

Relay contact outputs

Triac outputs

Power

supply

(100 to

240 VAC)

NC

NC

Ground

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

COM

24 VDC

output

(0.2 A max.)

100 to 120 VAC

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

A separate power supply must be used for the DC inputs.

Inputs (24 VDC)

Relay contact outputs

Triac outputs

Power

supply

(24 VDC)

Ground

Not in C20K Not in C20K or C28K

Not in C20K

Not in C20K or C28K

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

NC

NC

I/O Unit C20P/C28P/C40P

(ED_–D)

I/O Wiring Section 2–6

Page 38

31

The inputs can use the Unit’s 24–VDC power supply output. If the maximum

output current of 0.3 A is not sufficient, however, a separate DC power supply

must be used.

Relay contact outputs

Transistor outputs

Triac outputs

Power

supply

(100 to

240

VAC)

Ground

Upper terminal

block

Lower terminal

block

Inputs (24 VDC)

24_VDC

output

(0.3 A

max.)

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load power

supply

100 240VAC

CH(00 15) CH(00 15)

CH(00 15)

CH(00 11)

INPUT

COM

NC NC

NC

I/O Unit C60P (ED_–A)

I/O Wiring Section 2–6

Page 39

32

I/O Unit C60P (EA_–A)

Relay contact outputs

Triac outputs

Power

supply

(100 to

240

VAC)

Ground

Upper terminal

block

Lower terminal

block

Inputs (100 VAC)

24_VDC

output

(0.3 A

max.)

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load power

supply

100 240VAC

CH(00 15) CH(00 15)

CH(00 15)

CH(00 11)

INPUT

COM

NC NC

NC

I/O Unit C60P (ED_–D) A separate power supply must be used for the DC inputs.

Relay contact outputs

Transistor outputs

Power

supply

(24

VDC)

Ground

Upper terminal

block

Lower terminal

block

Inputs (24 VDC)

M3.5 screws

7.5 max.

7.5 max.

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load power

supply

Load power

supply

100 240VAC

CH(00 15) CH(00 15)

CH(00 15)

CH(00 11)

INPUT

NC NC

NCNCNC

I/O Wiring Section 2–6

Page 40

33

I/O Unit C16P–ID–A The inputs can use the Unit’s 24–VDC power supply output. If the maximum

output current of 0.2 A is not sufficient, however, a separate DC power supply

must be used.

Inputs (24 VDC)

Power supply (100 to

240 VAC)

Ground

M3.5 screws

7.5 max.

7.5 max.

Input Unit C16P–ID A separate power supply must be used for the DC inputs.

Inputs (24 VDC)

Ground

24 VDC

24 VDC

M3.5 screws

7.5 max.

7.5 max.

NCNC NC

NC NC NC NC

I/O Wiring Section 2–6

Page 41

34

Input Unit C16P–IA

Inputs (100 VAC)

100 to 120 VAC

100 to 120 VAC

M3.5 screws

Ground

7.5 max.

7.5 max.

NC NC NC

NCNC NC NC

Output Unit C16P–O_–A

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Relay contact outputs

Transistor outputs

Triac outputs

Power

supply

(100 to

240

VAC)

Ground

M3.5 screws

7.5 max.

7.5 max.

I/O Wiring Section 2–6

Page 42

35

Output Unit C16P–O_–D

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Load

power

supply

Relay contact outputs

Transistor outputs

Power

supply

(24

VDC)

Ground

M3.5 screws

7.5 max.

7.5 max.

Input Unit C4K–ID The C4K–ID can use the 24–VDC output from the CPU if the current (0.3 A)

is sufficient. If this is not sufficient, a separate DC power source must be

used.

Inputs (24 VDC)

24 VDC

24 VDC

M3.5 screws

7.5 max.

7.5 max.

I/O Wiring Section 2–6

Page 43

36

Input Unit C4K–IA

Inputs (100 VAC)

100 to 120 VDC

100 to 120 VAC

M3.5 screws

7.5 max.

7.5 max.

Output Unit C4K–O__

Load

power

supply

Load

power

supply

Relay contact outputs

Transistor outputs

Triac outputs

M3.5 screws

7.5 max.

7.5 max.

I/O Wiring Section 2–6

Page 44

37

I/O Link Unit 3G2C7–LK011(–P)E

RUN output

M4 screws

Repeater output (Used only when connected to Link Adapter.)

Link Adapter

M4 screws

Optical fiber connector

Power supply

(100 to 240 VAC)

8.6 max.

8.6 max.

I/O Wiring Section 2–6

Page 45

38

2–6–2 I/O Device Connection Examples

The following diagrams show connection examples for the sensors and

switches which can be connected as input devices. Be sure to check all input

devices for voltage and amperage compatibility before connecting.

AC Input Devices

Prox

switch

main

circuit

10 mA

100 VAC

IN

COM

AC input

IN

COM –

AC input

Contact output

AC–switching

DC Input Devices

Sensor

power

supply

Sensor

power

supply

Sensor

power

supply

Contact output

7mA

24 VDC

0 V

IN

COM +

DC input

Output

Current

regulator

NPN open–collector

24 VDC

0 V

IN

COM +

DC input

24 VDC

0 V

IN

COM –

24 VDC

0 V

IN

COM +

DC input

DC input

7mA

0 V

NPN Contact output

PNP current output

+

Output

7mA

0 V

+

Output

7mA

0 V

High–Speed Counter Input Devices (Rotary Encoder)

24 VDC

0 V

IN(0000)

COM

24 VDC

0 V

IN (0000)

COM

24 VDC

0 V

IN(0000)

COM

Red

White

Black

Red

White(Green)

Black

Red

White(Green,Yellow)

Black

Shield

High–speed

counter

input

High–speed

counter

input

High–speed

counter

input

E6A–CS4C E6A–CW4C

E6C–CWZ5C

I/O Wiring Section 2–6

Page 46

39

2–7 Special Wiring Precautions

Emergency Stop Circuit An external relay circuit can be constructed to prevent a CPU breakdown or

malfunction from damaging the entire System. In the following diagram, SR

bit 1813 is always closed when the CPU is operating. If the program is set up

as shown in the diagram, then output 0100 will be ON whenever the CPU is

in either RUN or MONITOR mode, and it will function as an output to monitor

whether the CPU is operating properly or not.

1813

0100

Example

Normally

ON

RUN output

An I/O Link Unit’s RUN output terminal is wired to a CPU’s input terminal,

and can function as an output to monitor whether the entire PC System, including the I/O Link Unit, is operating properly or not. In the diagram below,

the I/O Link Unit is connected to input terminal 0002. If the program is set up

as shown in the diagram, then output 0100 wil be ON whenever the CPU is in

either RUN or MONITOR mode. The I/O Link Unit’s RUN output and the

CPU’s RUN or MONITOR output together comprise an AND in the external

relay circuit, and this can be used to construct an emergency stop circuit.

C20P

24 VDC

Output

0002

RUN output

I/O Link Unit

0002 1813

0100

Example

Normally

open (NO)

Emergency Stop Circuit

When an I/O Link Unit is

Used

Special Wiring Precautions Section 2–7

Page 47

40

Interlock Circuit There are sometimes cases in which a PC can direct a machine to do either

of two contrasting actions, and in which damage could result from a malfunction in the PC. For example, the PC could be set up to output commands to a

motor to operate alternately in forward and reverse. In such cases an interlock circuit can be set up to prevent damage in case of a malfunction. In the

example diagram below, the interlock circuit will prevent MC1 and MC2 from

turning ON at the same time even if the PC malfunctions and turns outputs

0101 and 0102 ON simultaneously.

MC1

MC2

Motor forward

Motor reverse

Interlock circuit

PC

0101

0102

Electric power systems, control systems, PC power supply systems, and I/O

power supply systems should all be wired separately, as shown in the following diagram.

CR1

DC power

supply

PC

Control system

Electric power system

PC RUN

output

Twisted pair cable

CR!

+

–

Surge suppressor

MCB2

MCB1

Power Failure Protection A power sequence circuit is incorporated in the PC to prevent malfunctioning

due to momentary power failures or voltage drops.

Wiring of Power Supply

Systems

Special Wiring Precautions Section 2–7

Page 48

41

The PC ignores all momentary power failures if the interruption lasts no

longer than 10 ms. If the interruption is between 10 ms and 25 ms, it may or

may not be detected. If the supply voltage drops below 85% for longer than

25 ms, the PC will stop operating and the external outputs will be automatically turned off. Operation automatically resumes when the supply voltage is

restored to more than 85% of the rated voltage. Detection time will be slightly

shorter when a DC power supply is used.

Momentary power

failure detection

time

Power Supply

Power failure

detection signal

CPU voltage (5V)

Power reset

Run monitor

outputs

Approx. 1 s

2–8 Settings

After writing the program and preparing the EP–ROM chip (see the Operation Manual), the CPU DIP switch must be set and the EP–ROM installed.

2–8–1 Setting the CPU DIP Switch

1, 2, 3... 1. Turn OFF the power to the CPU.

2. Remove the cover from the CPU, using a screwdriver if necessary.

3. Set DIP switch pins 1 and 2 to OFF, and pins 3 and 4 to ON.

ON

OFF

OFF

ON

Settings Section 2–8

Page 49

42

2–8–2 EPROM Installation

1, 2, 3... 1. Remove the cover as shown above.

2. Raise the lever to unlock the socket.

3. Holding the chip so as not to touch the pins, insert it into the socket with

the notch to the left.

4. Check to be sure the chip has been properly installed.

5. Return the lever to its original position, locking the chip in.

6. Replace the cover.

7. Turn the power ON and verify that the CPU is operating in MONITOR

mode.

Lever

I/C Socket

Insert with the notch to the left.

2–8–3 High–speed Counter

When the high–speed counter (HDM(61)) is used, input (0000) is used exclusively for this purpose and responds up to 2 kHz. Either the hardware reset

or software reset may be used. The software reset may be delayed, depending on the cycle time, since it is based on the program. The hardware reset is

unrelated to the cycle time and can operate at high speed. To use the hardware reset (input 0001), set DIP switch pins 7 and 8 to ON as shown below.

Be sure to set them to OFF whenever the hardware reset is not being used,

regardless of whether the high–speed counter is being used or not.

ON

ON

Settings Section 2–8

Page 50

43

2–8–4 Inhibiting the ALARM Indicator

To inhibit the ALARM indicator when using EP–ROM, set DIP switch pin 5 to

ON as shown below.

Connect a backup battery to preserve data memory, current counter value,

and HR area bits, in case of a power failure. In order to maintain the battery,

DIP switch pin 5 should normally be set to OFF. In any case, it must always

be OFF when using RAM.

2–8–5 Setting the I/O Link Unit

In order for the I/O Link Unit to operate, it is necessary to determine the assignment of I/O words between the I/O Link Unit and the Remote I/O Master

Unit controlled by the CPU. This is done with the DIP switch on the I/O Link

Unit. The following explanation is intended only to give a general outline of

the proper procedure. For details, refer to the Optical Remote I/O Systems

manual.

Caution Be certain that power is off before setting the DIP switch. Setting it with the

power ON can cause the Unit to malfunction.

1, 2, 3... 1. Check the last assigned word number on the CPU. When setting the I/O

Link Unit, be sure not to overlap the words or to exceed the number of

I/O points in the CPU.

2. Turn OFF the power to the I/O Link Unit.

3. Check to be sure that the power supply LED light is off. Remove the

cover on the side panel of the Unit, using a screwdriver if necessary.

Settings Section 2–8

Page 51

44

4. Use the 6 DIP switch pins to set the word number from 0 to 30. As

shown in the diagram below, the word numbers are set in binary, with

pin 5 being ”1” and pin 1 being ”16.” Beginning with pin 1, turn ON the

pins required to arrive at the desired number of words. Turn ON pin 6 to

set the termination resistance if the I/O Link Unit is a terminator (the final

Unit in the System). If the Unit is not a terminator, leave pin 6 OFF.

ON

123456

168421

The following example diagram illustrates the proper DIP switch setting for

word 26.

ON

1 2 34 56

16 8 4 2 1

Terminator: ON

Pins 1, 2, and 4, set ON

16 + 8 + 2 =Word 26

5. After initially setting the DIP switches, an I/O table check should be per-

formed on the CPU to ensure that there are no errors in the settings.

6. Replace the cover. In addition, to prevent dirt or outside light from caus-

ing a malfunction, be sure that any unused optical fiber connectors are

covered with the protective caps. The Unit should be ready to operate

as soon as power is turned on. If it does not operate normally, refer to

3–1 Self–Diagnostic Function.

In the diagram below, a C20 CPU, a C40K CPU, a C20P I/O Unit and two I/O

Link Units can exchange data over a distance with a C500 Remote I/O Master Unit. The C20 I/O Link Unit is set for word 28 (which accesses word 29 as

well), and the C40K I/O Link Unit is set for word 30 (which accesses word 31

as well). The C40K I/O Link Unit is also set as the terminator.

C500 CPU Rack

C500 Remote I/O Master Unit

Optical fiber cable Optical fiber cable

C20 CPU I/O Link Unit

C40K CPU C20P I/O Unit

I/O Link Unit

System Configuration

Example

Settings Section 2–8

Page 52

45

When setting the I/O Link Unit, in this example, it is necessary to take into

account not only the I/O words of the C500 Remote I/O Master Unit, but also

those of the C20 CPU and the C40K CPU.

C20P

C20P

C40K

OUT

word 5

IN

word 0

OUT

word 6

IN

word 6

C500 Word Assignment

0

1

2

27

28

29

30

31

Auto-

matic

Man-

ual

C20 Word Assignment C40P Word Assignment

I/O Link

(C20)

I/O Link

(C40K)

OUT word 1, 3

IN word 0, 2 IN word 4

OUT word 5

OUT

word 7

IN

word 1

I/O Link Unit

DIP Switch Setting

Set for Word 28

Not terminator

Set for Word 30

Set as terminator

As seen from C20, C40P

Word 1: 16 input points

Word 6: 16 output points

Data input from C500

Data output to C500

Word 6: 16 input points

Word 7: 16 output points

Data input from C500

Data output to C500

ON

123456

ON

123456

Model

I/O Link

(20)

I/O Link

(40P)

As seen from C20

Word 28: 16 output points

Word 29: 16 input points

Data output to C20

Data input from C20

Word 30: 16 output points

Word 31: input points

Data output to C40K

Data input from C40K

Settings Section 2–8

Page 53

47

SECTION 3

Maintenance and Inspection

3–1 General 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Self–Diagnostic Functions 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Replacing Parts 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3–1 Fuses 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3–2 Relays 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3–3 Batteries 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Preventive Measures 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 Inspection 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 54

48

3–1 General

This section explains the proper maintenance and inspection procedures for

the K–Type PCs, including specifics on replacing parts and taking precautionary measures to ensure reliable, trouble–free operation.

3–2 Self–Diagnostic Functions

The K–Type PC has self–diagnostic functions to identify many types of abnormal system conditions. These functions minimize downtime and enable

quick, smooth error correction.

The ERROR light on the front panel of the Programming Console indicates

hardware errors such as CPU, Expansion I/O Unit, and Remote I/O Unit malfunctions. The ALARM light indicates such things as cycle time overrun, battery error, or user–defined errors. The following chart lists possible malfunctions, error messages, and correction procedures.

Correction

Check the power supply voltage and

power lines.

In PROGRAM mode, turn on power

again.

Check the user program again.

Check the program and fix the error.

Rerun the program.

Check that the DIP switch settings

are correct.

Check that the EP–ROM chip is

properly mounted.

Check that the battery is properly

inserted.

Clear the error after fixing it.

Write END in the final address of

the program.

Check that all the lines are properly

connected between the Units.

Check that the CPU Left/Right Selector on the Expansion I/O Unit is

properly set.

Clear the error after fixing it.

Make sure that there are no more

than 8 JMP–JME pairs in the program.

Check battery connections.

Replace battery.

Check the program again.

Situation

Fatal error

Non–fatal

error

Item

Power failure

CPU error (watchdog timer

over 130 ms)

Memory error

Missing END instruction

I/O bus error

JMP over

Battery error

Cycle time overrun (watch-

dog timer 100 to 130 ms)

ALARM

ERROR

Error Display

___

___

MEMORY ERR

NO END INST

I/O BUS ERR

JMP OVER

BATT LOW

CYCLE TIME

OVER

PC LED States

POWER

RUN

Stays lit. Blinks. Not lit.

I/O Link Unit Error

Item

Power failure

Transmission error

I/O Link Unit LED States

Correction

Check the power supply voltage and power lines.

Check connections of the optical fiber cable and connectors.

Check the channel and terminator settings.

POWER

*Note: Blinking ERROR LED indicates normal transmission.

*

ERROR

Self–Diagnostic Functions Section 3–2

Page 55

49

3–3 Replacing Parts

In order that your System be restored to operation as quickly as possible, it is

advisable to maintain an adequate stock of replaceable parts on hand.

CAUTION:

Replace all fuses, relays, and other parts as quickly as possible. If the cover

is left off for a long period the RAM’s contents may be erased.

3–3–1 Fuses

Replace fuses as follows:

1, 2, 3... 1. Turn off power to the Unit.

2. Using a Phillips screwdriver to loosen the 4 screws, remove the cover

from the Unit, lifting it from the left.

Phillips screwdriver

3. Remove the cover from the fuse socket as shown below.

Fuse socket

Fuse cover

Fuse socket

4. Using a standard screwdriver, remove the defective fuses and insert the

new ones.

5. Replace the cover, positioning it over the Unit and snapping it into place

by applying pressure to the area marked ”OMRON.”

The above procedure applies to CPUs and Expansion I/O Units. The procedure is similar for I/O Link Units except that the cover is secured by 4 catches

instead of 4 screws. Use a standard screwdriver to pop the cover off and insert the fuses as shown below.

Replacing Parts Section 3–3

Page 56

50

Catches

Catches

Standard screwdriver

Power fuse

1 A, 250 V

Refer to the chart below in selecting the proper fuses.

Power Supply Fuses φ 5.2 x 20 (MF1NR)

CPU’s,

Expansion

I/O Units

A–suffix

D–suffix

C16P

C20K, C28K, C40K

C60K

C16P

C20K, C28K, C40K

C60K

250 V, 1 A

250 V, 2 A

250 V, 3 A

125 V. 1 A

125 V, 3 A

125 V, 5 A

250 V, 1 A

I/O Link Units

24–VDC Output Fuses φ 5.2 x 20 (MF51NR)

CPUs, Expansion I/O Units

(A–suffix only)

C16P

C20K, C28K, C40K, C60K

125 V, 0.2 A

125 V, 0.5 A

3–3–2 Relays

Replace relays as follows:

1, 2, 3... 1. Turn off power to the Unit.

2. Using a Phillips screwdriver to loosen the 4 screws, remove the cover

from the Unit, lifting it from the left.

3. Using the relay puller attached to the right of the Unit, remove the defective relay and insert the new one.

Replacing Parts Section 3–3

Page 57

51

Relay

Relay puller

4. Replace the cover, positioning it over the Unit and snapping it into place

by applying pressure to the area marked ”OMRON.”

Relays are arranged as follows for the C16P, C20K, C28K, C40K, and C60K.

Among these Units, most models have relay sockets, although certain models do not. The C4K is not shown below; in this Unit the relays are directly

attached.

5601234567 701234 8910118 9 10 1112 1314 15

70123456

C16P C20K C28K

23111098

70123456

01 4 5 6

12 1314 15

891011

7

C40K C60K

012345678910110123

word n word n+1

word n word n+1

3–3–3 Batteries

The service life of the battery (3G2A9–BAT08) is five years at 25° C. It will be

shorter at higher temperatures. The ALARM indicator blinks when the battery

is discharged. If this happens, replace the battery within one week. The date

by which the first battery must be replaced is written on the side panel of the

CPU. If, for example, it says ”FIRST REPLACEMENT 93/12,” it means that

you should replace the battery not later than December 1993.

Caution The new battery must be connected within five minutes of removing the old

to preserve the data in the CPU. In addition, as there is danger of combustion, explosion or leakage, do not attempt to charge, heat or disassemble the

battery, or short–circuit the terminals. When disposing of a used battery, do

not throw it into a fire.

Replace the battery as follows:

1. Turn off the power to the Unit. If the power is off to begin with, turn it on

and wait for at least 10 seconds. Then turn it off.

Replacing Parts Section 3–3

Page 58

52

2. Using a Phillips screwdriver to loosen the 4 screws, remove the cover from

the Unit, lifting it from the left.

3. Pull the battery from the holder and install the new one within five minutes.

Battery in holder

4. Replace the cover, positioning it over the Unit and snapping it into place by

applying pressure to the area marked ”OMRON.”

5. Clear the ALARM on the Programming Console.

3–4 Preventive Measures

Load Circuit Fuses A fuse in the load circuit will protect the output elements, circuit board, etc., in

the event of a short in the output device.

Relay,

solenoid, etc.

+

OUT

COM

When two–wire sensors, such as photoelectric sensors and proximity sensors, or limit switches with neon lamp are connected to the CPU as input devices, the input signal may be erroneously turned ON by a leakage current

over 1.5 A. To prevent this, connect a bleeder resistor as shown below.

Determine the resistance of the bleeder resistor by the following equation,

where I is the leakage current.

Sensor

Input

Power

supply

Bleeder resistor

7.5 k

Ω max.

PC

R

R = 17.15/3.431 + 5 (k

Ω max.)

Likewise, if there is a danger of leakage current causing a transistor or triac

to malfunction, connect a bleeder resistor as shown below. Determine the

resistance of the bleeder resistor by the following equation.

Transistor

Triac

24 VDC

100 VAC

200 VAC

0.1 mA

2.0 mA

5.0 mA

R < Von/I

Von = ON voltage of the load (V)

I = leakage current (mA)

R = bleeder resistance (k

Ω)

L

Load power supply

OUT

COM

Bleeder resistor

Prevention of Input

Leakage Current

Prevention of Output

Leakage Current

Preventive Measures Section 3–4

Page 59

53

When connecting the resistor or triac output to a device (such as an incandescent lamp) which allows a high inrush current to flow, care must be taken

to ensure the safety of the transistor or triac. The transistors and triacs are

able to withstand an inrush current of ten times the rated current. If the actual

inrush current will exceed that amount, use one of the following two circuits

to reduce it.

This circuit allows a slight current

(about 1/3 of the rated current) to

flow through the load (i.e., the

lamp), thus eliminating any initial

surge of current.

This circuit acts directly on the

inrush current to limit it, but also

reduces the voltage across the

load.

L

+

OUT

COM

L

+

OUT

COM

When connecting TTL circuits to transistor outputs, it is necessary (because

of the transistor’s residual voltage) to connect a pull–up resistor and a CMOS

IC between the two.

When an inductive load is connected to the input or output of the CPU, it is

necessary to connect a surge suppressor or a diode in parallel with the load,

as shown below, to absorb the counter–electromotive force produced by the

load.

L

Surge supressor

OUT

COM

Relay, or triac

output

COM

IN

DC Input

L

Diode

L

OUT

COM

Relay, or transistor

output

+

Diode

Resistor: 50 Ω

Capacitor: 0.47 µF

Voltage: 200 V

Diode: Must withstand

voltages more

than three times

the load voltage

and an average

current of 1 A

Precautions for Inrush

Current

Transistor Output Residual

Voltage

Inductive Load Surge

Suppressors

Preventive Measures Section 3–4

Page 60

54

Output Loads Be sure to take appropriate measures when any electrical device likely to

produce noise is connected to the CPU as a load. For example, electromagnetic relays and valves generating noise of more than 1,200 V require noise

suppression. For AC–operated noise sources, connect a surge suppressor in

parallel with the coil of each device. For DC–operated noise sources, connect a diode in parallel with the coil of each device. When mounting a CPU

and an Expansion I/O Unit on a control panel, be sure to completely ground

the intermediate mounting plate. The mounting plate must be finished with

high–conductivity plating to ensure noise immunity.

RR

–

+

Surge

suppressor

AC power source DC power source

Diode

3–5 Inspection

In order for your PC to continue operating at optimum condition, periodic inspections are necessary. The main components of the PC are semiconductors and have a long service life, but, depending on the operating environment, there may be more or less deterioration of these and other parts. A

standard inspection schedule would be once every six months to one year,

but more frequent inspections may be advisable depending on the operating

environment. Try to maintain the inspection schedule once it has been set.

Check to be sure that the power supply, ambient temperature, humidity, and

so on, are within the specifications (see Appendix B). Be sure that there are

no loose screws in any of the Units and that all battery and cable connections

are secure. Clean any dust or dirt that has accumulated. Check all fuses, relays, and other replaceable parts.

Inspection Section 3–5

Page 61

55

Appendix A

Standard Models

There are four K–type C–series CPUs. A CPU can be combined with any of

six types of Expansion I/O Unit and/or an Analog Timer, Analog I/O Unit, or

I/O Link Unit.

CPUs Expansion I/O Units

Analog Timer Unit

Analog I/O Units

I/O Link Unit

C20K–C_ _–_

C28K–C_ _–_

C40K–C_ _–_

C60K–C_ _–_

C4K–I_/O_ _

C4K–TM

C16P–I_–_/O_–_

C20P–E_ _–_

C28P–E_ _–_

C40P–E_ _–_

C60P–E_ _–_

C1K–AD/DA

C4K–AD

C4K–CN502

(included with Unit)

To order cable

separately, specify

C4K–CN502

5 cm or 40 cm

One included with

each Expansion I/O

Unit.

(C20P-CN501/411)

Cable (70 cm)

C20P–CN711

(ordered separately)

C20–LK011/LK011–P

C20K

C28K

C40K

C60K

C20P

C28P

C16P

C60P

C40P

C4K – AD

Page 62

Standard Models Appendix A

56

CPUs

Name Power supply Inputs Outputs Model number

Standards

C20K 100 to 240 VAC 24 VDC, 12 pts Relay w/socket 8 pts C20K–CDR–A U, C

Transistor, 1 A C20K–CDT1–A –––

Triac, 1 A C20K–CDS1–A U, C

24 VDC, 2 pts

100 to 120 VAC,

10 pts

Relay w/socket C20K–CAR–A U, C

Triac, 1A C20K–CAS1–A U, C

24 VDC 24 VDC, 12 pts Relay w/socket C20K–CDR–D U, C

Transistor, 1 A C20K–CDT1–D –––

C28K 100 to 240 VAC 24 VDC, 16 pts Relay w/socket 12 pts C28K–CDR–A U, C

Transistor, 1 A C28K–CDT1–A –––

Triac, 1 A C28K–CDS1–A U, C

24 VDC, 2 pts

100 to 120 VAC,

14 pts

Relay w/socket C28K–CAR–A U, C

Triac, 1A C28K–CAS1–A U, C

24 VDC 24 VDC, 16 pts Relay w/socket C40K–CDR–D U, C

Transistor, 1 A C28K–CDT1–D –––

C40K 100 to 240 VAC 24 VDC, 16 pts Relay w/socket 16 pts C40K–CDR–A U, C

Transistor, 1 A C40K–CDT1–A –––

Triac, 1 A C40K–CDS1–A U, C

24 VDC, 2 pts Relay w/socket C40K–CAR–A C

100 VAC, 22 pts Triac, 1 A C40K–CAS1–A U, C

24 VDC 24 VDC, 24 pts Relay w/socket C40K–CDR–D U, C

Transistor, 1 A C40K–CDT1–D –––

Page 63

Appendix AStandard Models

57

Name

Standards

Model numberOutputsInputsPower supply

C60K 100 to 240 VAC 24 VDC, 32 pts Relay w/socket 28 pts C60K–CDR–A U, C

Transistor, 1 A C60K–CDT1–A –––

Triac, 1 A C60K–CDS1–A U, C

24 VDC, 2 pts Relay w/socket C60K–CAR–A C

100 VAC, 30 pts Triac, 1 A C60K–CAS1–A U, C

24 VDC 24 VDC, 32 pts Relay w/socket C60K–CDR–D U, C

Transistor, 1 A C60K–CDT1–D –––