Omron SYSMAC C200H-NC112 Operation Manual

Cat. No. W128-E1-4

SYSMAC

C200H-NC112

Position Control Unit

C200H-NC112 Position Control Unit

Operation Manual

September 2000

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

Reference Indicates supplementary information on related topics that may be of interest to

the user.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

ii

About this Manual:

The OMRON C200H-NC112 Position Control Unit is a Special I/O Unit for C200H PCs. It is designed

to control positioning actions through pulse train outputs to a motor driver, based on PC programming

and external control inputs.

This manual covers the specifications and procedures necessary for operation and installation. Before

attempting to operate the C200H Position Control Unit, be sure to thoroughly familiarize yourself with

the information contained herein.

During operation, refer to the C200H PC Operation Manual as necessary for programming and system details. Note that the term “channel” employed in the C200H PC Operation Manual (and other

earlier manuals) has been replaced by the term “word” in this manual, where it refers to a 16-bit address. Wherever the term “channel” (either written in full or abbreviated as “ch”) continues to appear,

whether in earlier manuals, on displays, or on the Units themselves, it can be taken to have the same

meaning as “word.”

Section 1

well as the basic configuration and principles of positioning control systems. Reading this section first

will give you a familiarity with the essential terminology used in this manual and an understanding of

the fundamentals necessary for successful operation.

Section 2

Section 3

Position Control Unit operation other than commands.

Section 4

Section 5

Section 6

Unit operation.

The appendices contain lists of error and alarm codes, DM and IR area data allocation charts, specifi-

cations, and a table of standard models. There are also an index and a glossary of terms at the back

of the manual.

describes the basic features, components, and operation of the Position Control Unit, as

covers procedures such as wiring and switch setting which are necessary before operation.

explains data format and configuration, basic operating procedure, and various aspects of

covers commands and the data settings which are necessary for their execution.

provides examples of possible applications of PCU commands, inputs, and outputs.

outlines the procedures for handling errors and alarms that occur during Position Control

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

iii

TABLE OF CONTENTS

PRECAUTIONS vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – Introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1 Features 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Components 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 Basic Operating Principles 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 I/O Configuration 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5 Positioning System Principles 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5–1 Open-loop System 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5–2 Semiclosed-loop System 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Before Operation 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1 Switch Settings 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1–1 Switch Setting Examples 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Wiring 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–1 Input Connection Examples 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–2 Output Connection Examples 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–3 Wiring Precautions 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Operation 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 Operational Flow 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Output Pulses 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Writing Data 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Data Configuration and Allocation 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 DM Area Data Format 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Flags and Other Input Data 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 DM Area Allocation 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–1 Zones 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–2 Backlash Compensation 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–3 Internal CW/CCW Limits 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–4 Data Calculations 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – Commands 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1 START 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1–1 DM Area Settings 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 Positioning Actions 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2–1 IR Area Settings 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2–2 Execution Examples 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3 ORIGIN SEARCH 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3–1 DM Area Settings 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3–2 IR Area Settings 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3–3 Execution Examples 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3–4 Completion Examples 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4 ORIGIN RETURN 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4–1 DM Area Settings 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4–2 IR Area Settings 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4–3 Execution Example 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Table of contents

4–5 RELEASE PROHIBIT 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6 READ ERROR 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6–1 Execution Example 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6–2 Reading from the Programming Console 92 . . . . . . . . . . . . . . . . . . . . . .

4–7 RESET ORIGIN 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8 TEACH 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8–1 IR Area Settings 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8–2 Execution Example 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8–3 Teaching From the Programming Console 94 . . . . . . . . . . . . . . . . . . . . .

4–9 TRANSFER DATA 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–9–1 Normal Transfer 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–9–2 IR Area Settings 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–9–3 Present Position Preset 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10 Manual Operations 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10–1 DM Area Settings 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10–2 IR Area Settings 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10–3 HIGH-SPEED JOG 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10–4 LOW-SPEED JOG 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10–5 INCH 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–11 External Interrupt Commands 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–11–1 STOP 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–11–2 CHANGE SPEED 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – Programming Examples 117 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–1 Operation with Minimum Data (Displaying JOG Positions) 118 . . . . . . . . . . . . . . . .

5–2 Positioning at Intervals Using RESET ORIGIN 119 . . . . . . . . . . . . . . . . . . . . . . . . .

5–3 Feeding Selectively with START 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–4 TRANSFER DATA from Other PC Areas 123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–5 TRANSFER DATA from External Switches 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–6 Using START to Carry Out Positioning Actions 128 . . . . . . . . . . . . . . . . . . . . . . . . .

5–7 Using Origin and Origin Proximity Signals 132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–8 Using Zones to Control Jogging 132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–9 Setting Speeds 134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–10 Using a Multiple Bank Program 134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – Error Processing 137 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–1 Alarms and Errors 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–2 Outputs to the IR Area 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–3 Alarm/Error Indicators 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–4 Error Code Output 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–5 Troubleshooting from the PC 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–5–1 Error List for Special I/O Units 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–5–2 AR Area Error and Restart Bits for Special I/O Units 140 . . . . . . . . . . . .

6–6 Basic Troubleshooting Chart 141 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–7 Detection of Abnormal Pulse Outputs 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A – Standard Models 145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Specifications 147 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – DM Area Allocations 149 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E – Alarm Code List 159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F – Error Code List 161 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G – Using the C200H-NC112 with CS1-series PCs 165 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Glossary 173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 179 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller. You must read this section and understand the information contained before attempting to set up or operate a

PC system.

1 Intended Audience viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions viii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the relevant manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

4Operating Environment Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC system to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

Caution Confirm safety at the destination node before transferring a program to another

!

node or changing contents of the I/O memory area. Doing either of these without

confirming safety may result in injury.

4 Operating Environment Precautions

viii

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

5Application Precautions

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not con-

necting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits

(i.e., not in the Programmable Controller) must be provided by the customer.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

ix

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse ef fect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

5Application Precautions

x

SECTION 1

Introduction

The C200H-NC112 Position Control Unit is a Special I/O Unit that outputs pulse trains to control a stepping motor driver

or a servomotor driver in accordance with a PC program or external inputs.

This section describes the basic features, components, and operation of the Position Control Unit, as well as the basic

configuration and principles of positioning control systems. Reading this section first will give you a familiarity with the

essential terminology used in this manual and an understanding of the fundamentals necessary for successful operation.

1–1 Features 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Components 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 Basic Operating Principles 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 I/O Configuration 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5 Positioning System Principles 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5–1 Open-loop System 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–5–2 Semiclosed-loop System 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Features Section 1–1

1–1 Features

Applicable Motor Drivers

Number of Control Axes

and Controlling Capacity

Manual Operation

Data Transfer

Establishing Position

Teaching

The pulse train output can be easily connected to either of the following devices:

1. Stepping motor driver

2. Servomotor driver designed for pulse train input

The Position Control Unit is designed to control a single axis and is capable

of controlling speeds and positions in accordance with data recorded in the

DM area of the C200H PC.

Three commands enable manual positioning control: HIGH-SPEED JOG,

LOW-SPEED JOG, and INCH.

PCU positioning actions, speeds, and other data can be stored in the DM

area or other areas of the PC and quickly transferred to the PCU via a

TRANSFER DATA command. This effectively increases the amount of

memory available to the PCU.

The TRANSFER DATA command can also be used to change the present

position to any desired value, including 0 (origin), any time the Position Control Unit is not outputting pulses.

The present position can be written into the memory of the PC as positioning

data whenever pulses are not being output.

Operation in Four Modes

Choice of Origin Detection

Method

Expanded Speed Range

Greater Switching Capacity

Optional Speed Numbers

Smoother Acceleration and

Deceleration

The C200H-NC112 Position Control Unit can be operated in any of four

modes, which are selected via the mode switch on the Unit. Mode 0 is equivalent to the C200H-NC111 Position Control Unit; the other three are for use

with servomotor drivers. Mode 3 is designed especially for use with the OMRON R88D-EP/SR (marketed in Japan) servomotor driver.

The method employed to detect the origin may be selected via the rear-panel

DIP switch.

The speed range has been expanded to enable settings anywhere from 1 to

250,000 pps (compared with 1 to 99,990 for the NC111). In addition, acceleration and deceleration speeds between 2 and 2,000 pps/ms are now possible (compared with 1 to 999 pps/ms for the NC111).

The minimum switching capacity has been increased from 2.5 mA (in the

NC111) to 7 mA at 5 VDC.

In the NC111, the speed number currently being executed is always incremented by one to obtain the subsequent target speed, but in the NC112, the

next speed number can be set in the DM area of the C200H PC. If desired,

speed numbers may be allowed to increment one by one as in the NC111.

Acceleration and deceleration have been made smoother by reducing each

incremental step from the NC111’s 10 ms to 4 ms.

More Completion Codes

2

In addition to the five completion codes possible with the NC111, the NC112

allows for a sixth, i.e., “extended with positioning”.

Basic Operating Principles Section 1–3

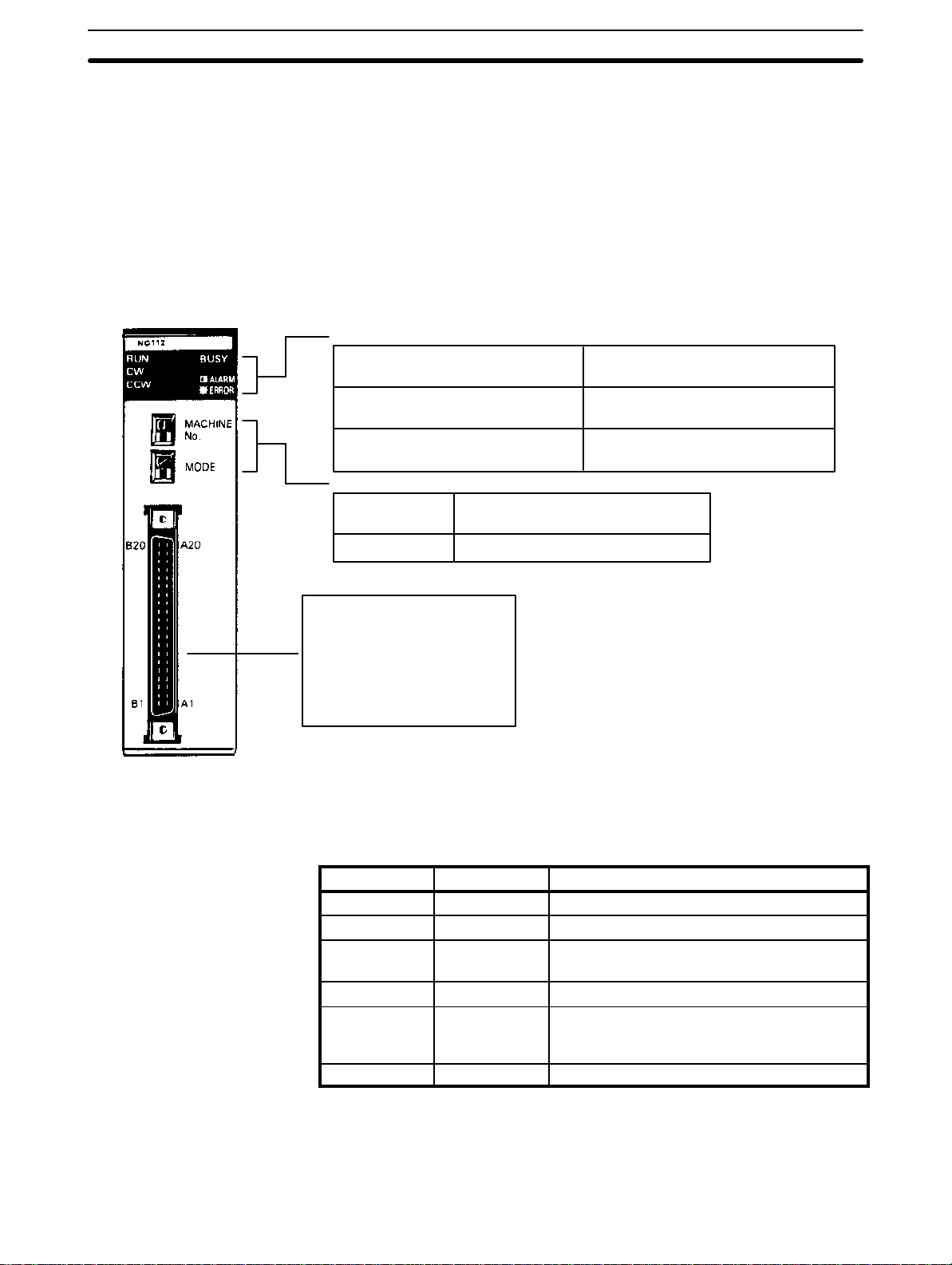

1–2 Components

In addition to the front-panel components described below, there is a DIP

switch located on the back panel. Pin settings for this switch, which are described in

Section 2–1

When setting the switches, use a screwdriver if necessary.

Do not apply excessive force to the switches.

Do not leave the switches halfway between two setting points or the Position

Control unit may malfunction.

Before operating these switches, make sure that power to the PC is off.

Indicators

RUN: indicates operation

is in progress

CW: indicates motor

is revolving clockwise

CCW: indicates motor

is revolving counterclockwise

Setting switches

MACHINE No.

MODE

, determine certain aspects of Unit operation.

BUSY: indicates operation/transfer

is in progress

ALARM: flashes when an abnormality has occurred

ERROR: lights when an error has occurred

Allocates a unit number (0 to 9) to

the Position Control Unit

Selects an operating mode (0 to 3).

Indicators

Connector

Used to connect the Position

Control Unit to a stepping motor driver or servomotor driver.

Attach the enclosed connector

to the proper cable.

Position Control Unit indicators (LEDs) are used to quickly determine operating status. They are particularly valuable in initial system activation and debugging, but can also be used to monitor Unit operation.

Indicator Color Function

RUN Green Lit during normal operation. Goes out on errors.

CW Green Lit during output of CW (clockwise) pulses.

CCW Green Lit during output of CCW (counterclockwise)

pulses.

BUSY Green Lit during positioning or data transfer.

ALARM

(flashing)

ERROR Red Lit when an error has caused operation to stop.

Red Flashing when a BCD error exists in initial data,

speed data, or positioning data updated with

TRANSFER DATA.

1–3 Basic Operating Principles

The basic operation of the C200H-NC112 Position Control Unit is fairly simple. It controls either a stepping motor or a servomotor in accordance with

3

I/O Configuration Section 1–4

data stored in the DM area of the PC. This data includes directions, speeds,

positions, and other information necessary for effective control. Before the

Position Control Unit can be operated, you must first input the essential data.

This is generally done via the Programming Console, although you can also

input data with the TEACH command.

The way in which the Position Control Unit makes use of this data is determined by the program in the PC. The program does not control all of the Position Control Unit’s operations directly, but rather, executes the Unit’s commands by turning command bits ON and OFF. The commands control such

functions as the starting and stopping of positioning, returning to the origin,

and so on. (The origin is simply the point which is designated as 0 at any given time.) Thus, while the Position Control Unit functions as an integral part of

your overall control system, it also exercises a good deal of autonomy. This

capability is essential to the concept of distributed control, whereby control of

each portion of an automated system is located near the devices actually

being controlled.

The fundamental unit of positioning is the positioning action. A particular positioning action moves the workpiece along the positioning axis in a direction,

at a speed, and to a position determined by the data which has previously

been set. The positioning action begins when the appropriate command bit

(START) is turned ON by the program.

A single positioning action may be executed by itself, or a bank of several

positioning actions may be executed in sequence. A particular bank of actions may be repeated again and again. Before beginning execution of positioning actions, it is necessary to define the origin as a reference point by, for

example, executing ORIGIN SEARCH.

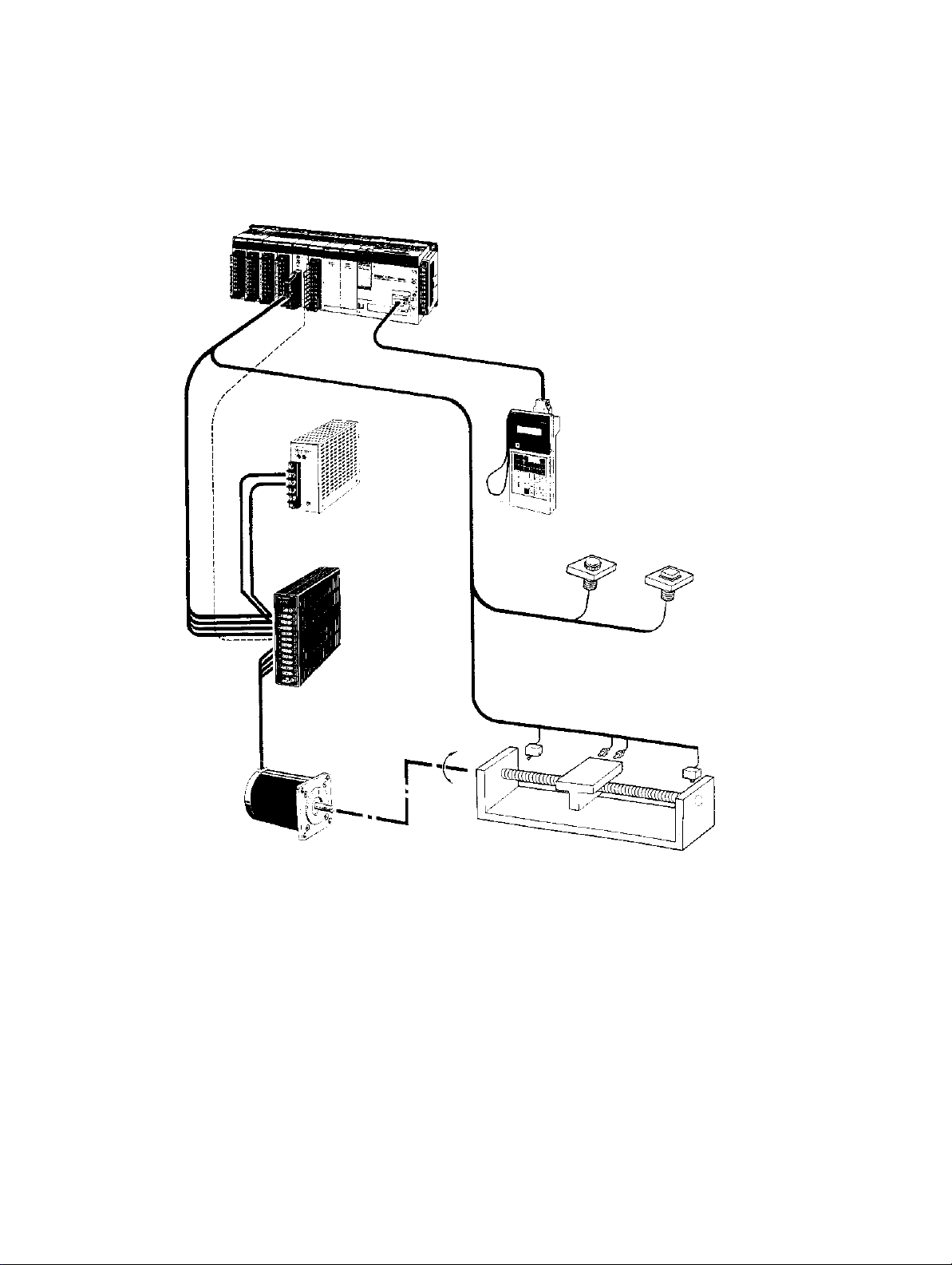

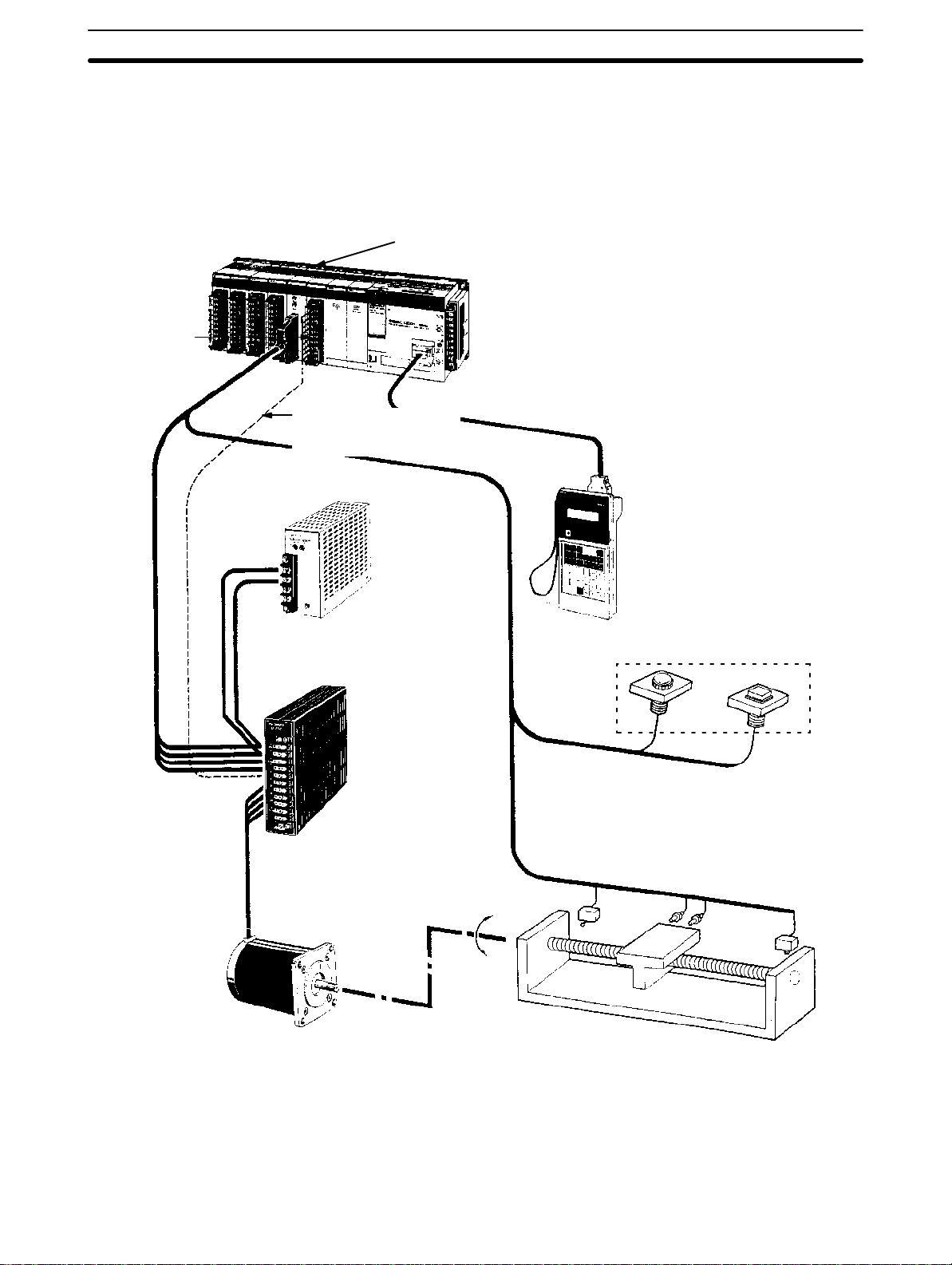

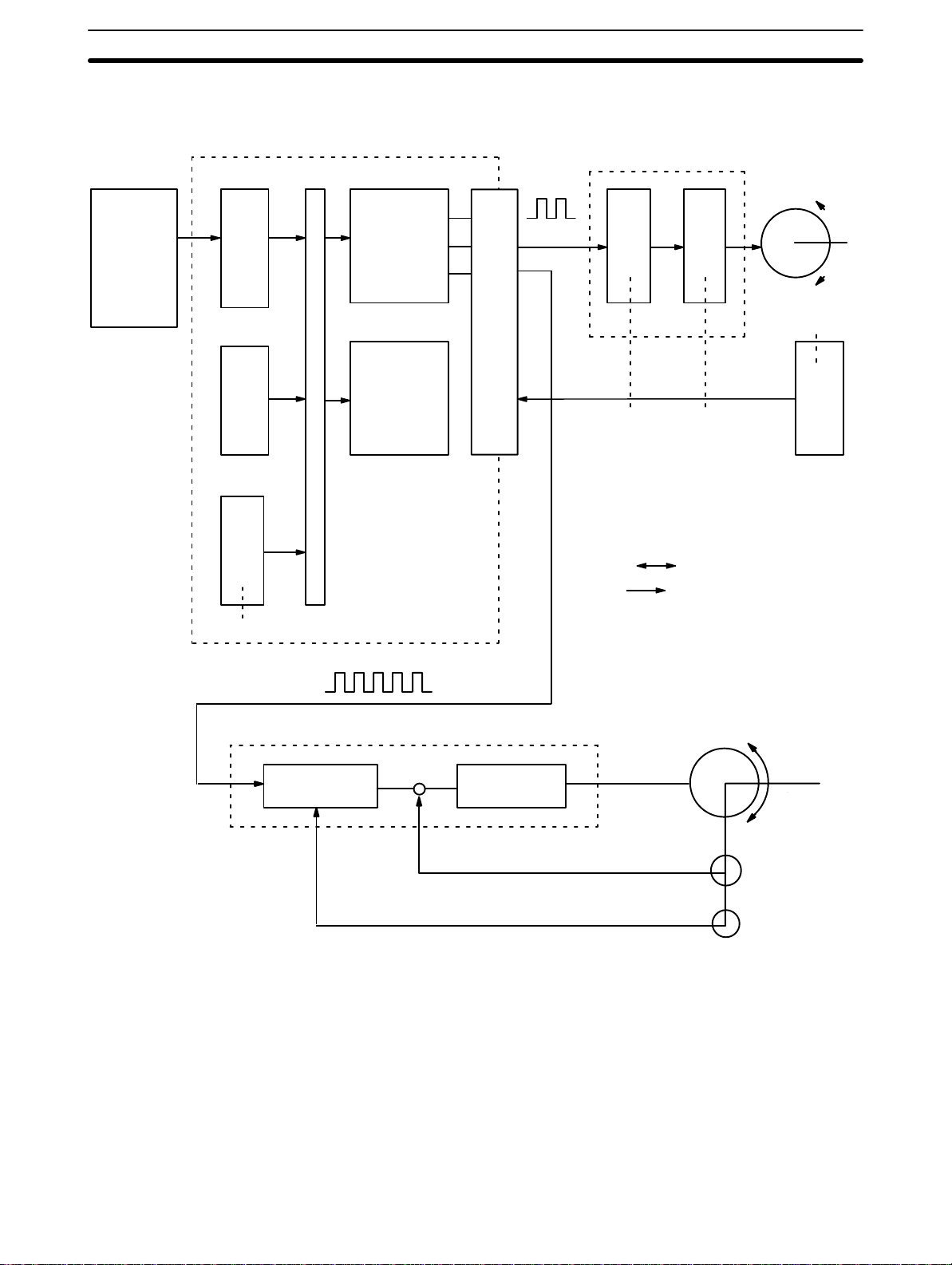

1–4 I/O Configuration

The basic I/O configuration is shown on the following page. Position Control

Unit outputs are connected to a motor driver, either for a stepping motor or

for a servomotor (AC or DC) capable of receiving pulse train inputs. The Unit

is controlled by inputs from devices and/or a control panel. It, in turn, outputs

pulse trains and direction signals to control the motor driver.

The motor driver controls either a stepping motor or a servomotor, depending

on whether you choose to employ an open-loop or semiclosed-loop system.

Section 1–5

(See

positioning device (such as a feed screw). An independent power supply

must be used for the motor driver. Some configurations also require an Input

Unit on a C200H Rack to control the motor driver.

Maximum Number of

Special I/O Units per PC

A maximum of 10 Special I/O Units, including Position Control Units,

High-Speed Counters, etc., can be mounted under the same PC, regardless

of whether they are on the CPU Rack, an Expansion I/O Rack, or a Slave

Rack. No more than four of these can be mounted onto any one Slave Rack.

Refer to the

). The stepping motor or servomotor controls some type of

Remote I/O System Operation Manuals

for further restrictions.

Mounting Location

Basic Configuration

4

The Position Control Unit can be mounted to any slot on any Rack except for

the two rightmost CPU Rack slots. Mounting the Unit to either of these slots

will prevent you from mounting devices directly to the CPU. The back-panel

DIP switch must be set before the Unit is mounted. This switch is inaccessible on a mounted Unit. (See

Although Unit operation can be indirectly controlled from a host computer,

Remote I/O Master Unit, or other control system or peripheral device, direct

Section 2–1

.)

Positioning System Principles Section 1–5

control comes from the program of the PC or from connections to external

inputs (e.g., control panel switches). (Lists of Position Control Unit inputs and

outputs can be found under

uration diagrams show only the positioning system itself. Refer to the operating manuals for other OMRON control devices for details on extended control

system operation.

I/O Circuits

in

Section 2–2

.) The following config-

C200H PC

Input Unit

Position Control Unit C200H-NC112

Stepping motor (or servomotor) driver control

signal line

Power supply

Stepping motor driver

(or servomotor driver)

Hand-held Programming

Console C200H-PRO27

Operation panel

Operation switch

Stepping motor

(or servomotor)

1–5 Positioning System Principles

Positioning systems can be quite simple or relatively complex. The most basic is an open-loop system, in which a particular operation is carried out according to programmed instructions, but in which feedback is not provided for

Control signal input switches

5

Positioning System Principles Section 1–5

automatic adjustments. The C200H-NC112 Position Control Unit can be used

in an open-loop system in conjunction with a stepping motor.

In a closed-loop system, on the other hand, the PC controls an external process without human intervention. The servomotor provides direct feedback

so that actual values (of positions, speeds, and so on) are continuously adjusted to bring them more closely in line with target values. In some systems,

the digital feedback signals will be transmitted to a digital-to-analog converter

to complete the feedback loop, thereby permitting automated control of the

process.

A semiclosed-loop system is similar to a closed-loop system, except that

feedback is provided by a tachogenerator and a rotary encoder rather than

directly by the servomotor. If the C200H-NC112 Position Control Unit is used

with a servomotor, the servomotor driver must be able to handle digital signals. There is therefore no need for a D/A converter. Here, the servomotor is

also connected to a tachogenerator and a rotary encoder.

Both open-loop and semiclosed-loop systems are described in more detail on

the following pages.

6

Positioning System Principles Section 1–5

Data Flow

Position Control Unit C200H-NC112

Stepping motor driver

Magnetizing

distributor

circuit

Power

amplifier

Stepping motor

External

input

C200H PC

PC

PC

bus

BUS

I/F

I/F

MPU

Pulse

train

Pulse

generator

I/O Connector

I/O

interface

Memory

Pulse train

Servomotor driver

Error counter Power amplifier

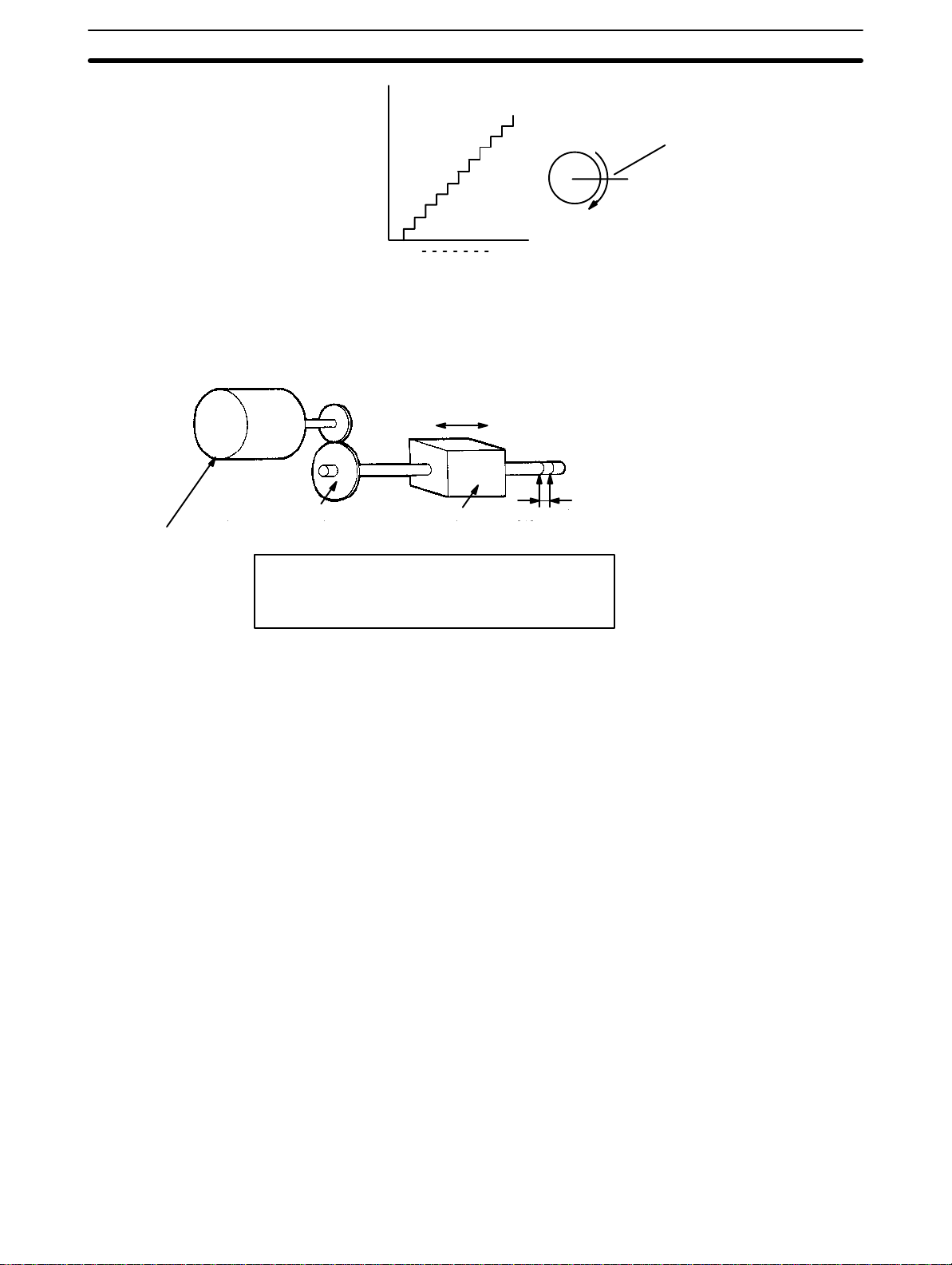

1–5–1 Open-loop System

In an open-loop system, the Position Control Unit outputs pulse trains as

specified by the PC program to control the angle of rotation of the motor. Because the Unit outputs pulse trains, it is generally used with a stepping motor.

The angle of rotation of a stepping motor can be controlled through the number of pulse signals supplied to the motor driver. The number of rotations of

the stepping motor is proportional to the number of pulses supplied by the

Unit, and the rotational speed of the stepping motor is proportional to the frequency of the pulse train.

Servomotor

(Positioning output)

Tachogenerator

Rotary encoder

7

Positioning System Principles Section 1–5

Angle of rotation

Angle of

rotation

Positioning output

1 2 n

Positioning pulse

Simplified Positioning

System Design

S

Reduction gear

Stepping motor

The following diagram and parameters illustrate a simplified positioning system.

V

M

M: Reduction ratio

P: Feed screw pitch (mm/revolution)

V: Feed velocity of object being positioned (mm/s)

Object being

positioned

Feed screw pitch

P

S: Stepping angle per pulse (degree/pulse)

The positioning accuracy in mm/pulse is computed as follows:

Positioning precision = P/(pulses per revolution x M)

= P/((360/S) x M))

= (P x S)/(360 x M)

The required pulse frequency from the Unit in pulses per second is computed

as follows:

Pulse frequency = V/Positioning precision

The required number of pulses to feed an object by a distance L (in mm) is

computed as follows:

Number of pulses = L/Positioning precision

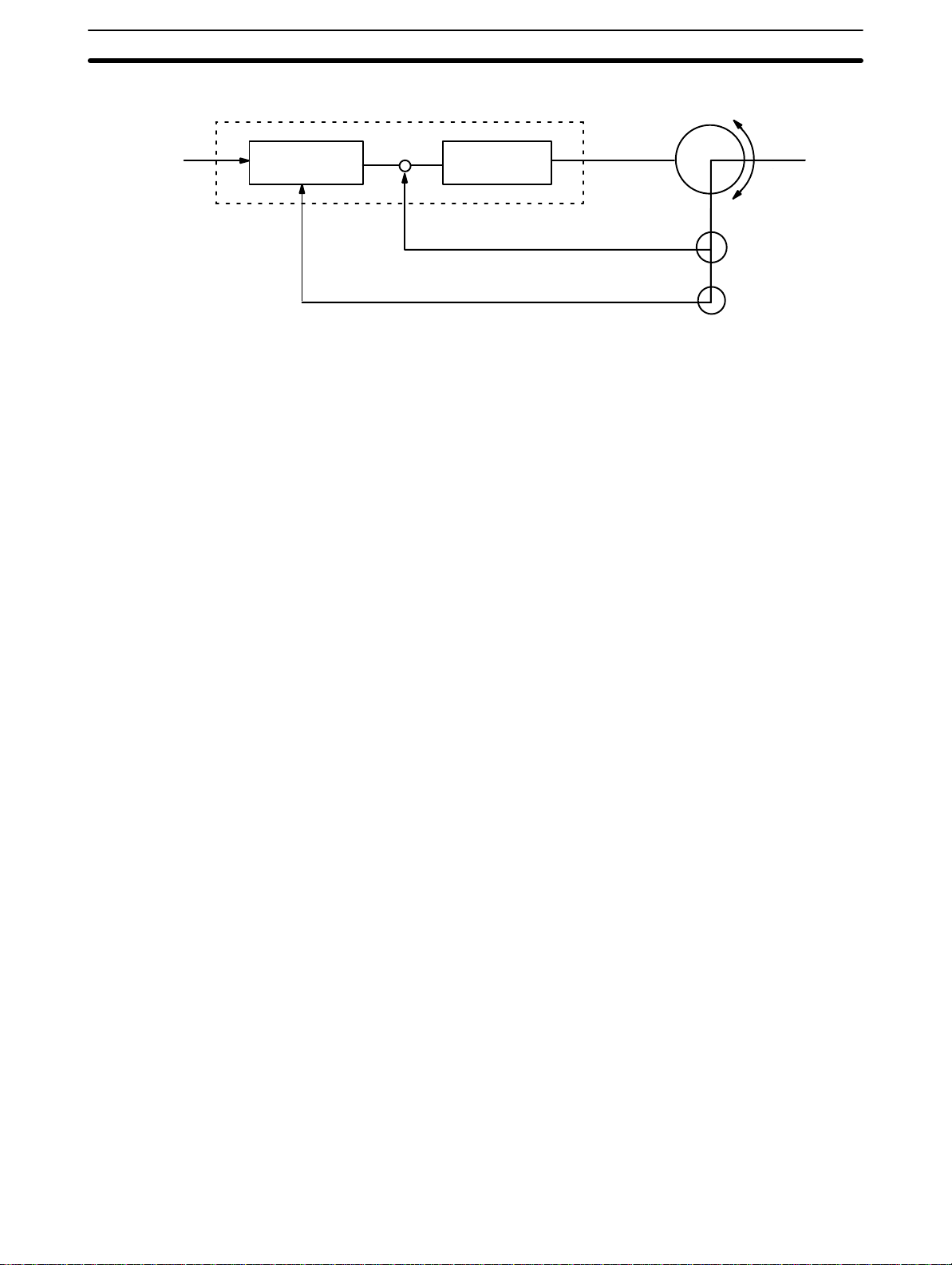

1–5–2 Semiclosed-loop System

When the Position Control Unit is used in a semiclosed-loop system, the system supplies feedback which is used to compensate for any discrepancy between target values and actual values in position or speed. This system detects motor rotation amounts, for example, computes the error between the

target value and actual movement value, and zeroes the error through feedback. The diagram below illustrates the basic configuration of a semiclosed-loop system.

8

= (360 x M x V)/(P x S)

= (360 x M x L)/(P x S)

Positioning System Principles Section 1–5

Target position

Servomotor driver

Error counter Power amplifier

Speed feedback

Position feedback (feedback pulses)

1, 2, 3...

1. First, the target position is transmitted to the error counter in units of encoder pulses. The servomotor driver must be able to handle digital input.

2. The motor rotates at a speed corresponding to the speed voltage. The

rotary encoder connected to the motor axis rotates in sync with the motor, generates feedback pulses, and decrements the error counter.

3. Consequently, the encoder rotation is equivalent to the target position,

and the motor stops rotating when the error counter count and the

speed voltage become zero.

4. While the motor is stopped, the rotary encoder constantly maintains the

stopped position through correction. In the event that the motor axis

moves slightly, the error counter receives a feedback pulse from the

rotary encoder, causing a rotation voltage to be emitted in the reverse

direction from which the rotary encoder moved. This makes the motor

rotate toward its original position. This operation is called servolock or

servoclamp.

5. In order to execute positioning with acceleration and deceleration, target

positions are set consecutively in the error counter for processing.

6. The target position becomes the count for the error counter and controls

the motor by conversion to a speed voltage for the servomotor driver.

The position thus equals the total count of target positions and the

speed will depend on the target position per unit time.

Servomotor

Position output

Tachogenerator

Rotary encoder

9

SECTION 2

Before Operation

Before the Position Control Unit can be operated, switch settings and wiring must be correct. This section presents the

settings and functions of switches, provides examples of and precautions for wiring, and gives dimensions of Units both

when unmounted and mounted. Be sure that all settings and wiring match your positioning system specifications.

2–1 Switch Settings 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1–1 Switch Setting Examples 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Wiring 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–1 Input Connection Examples 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–2 Output Connection Examples 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2–3 Wiring Precautions 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Switch Settings Section 2–1

2–1 Switch Settings

Always turn off PC power before setting the unit number switch. Use a regular screwdriver, being careful not to damage the slot in the screw. Be sure not

to leave the switch midway between settings.

Switch Function

Unit number

(Machine no.)

Mode Used to set the mode from 0 to 3.

Used to set the unit number (between 0 and 9).

Do not set the same number for more than one Special I/O Unit.

Doing so will cause an error and prevent operation.

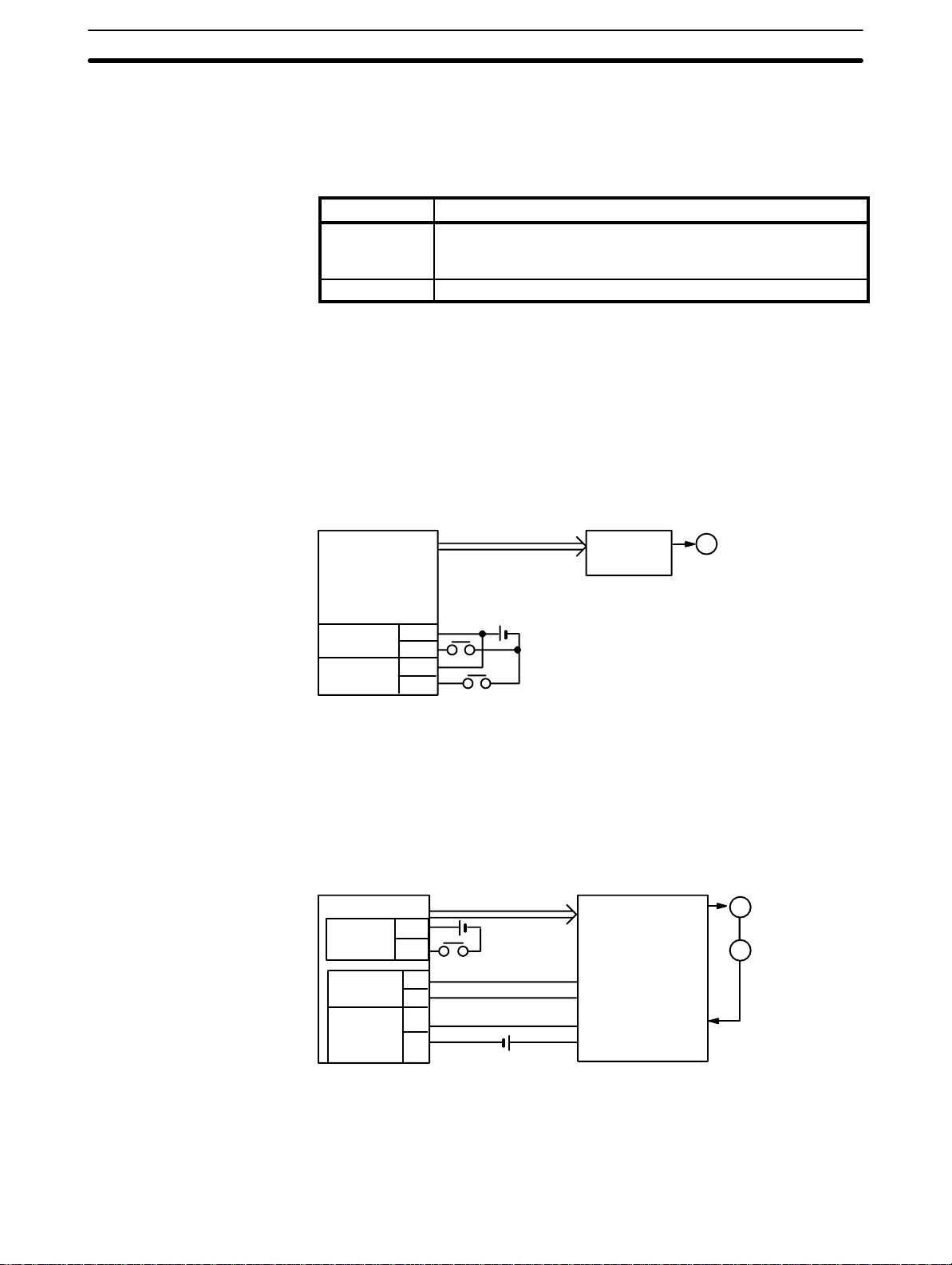

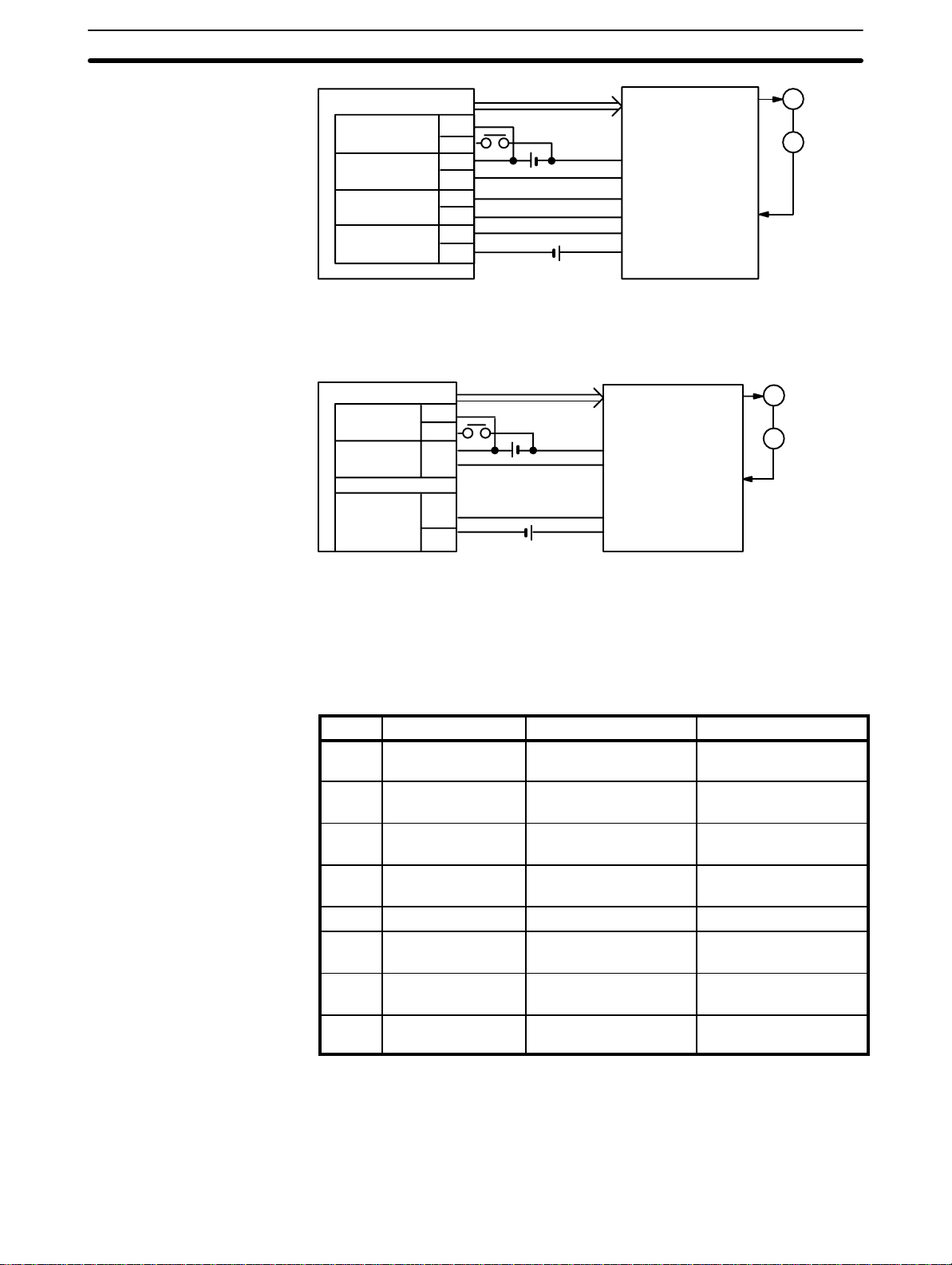

Mode Switch

Mode 0

Mode 1

This switch sets one of operation modes 0 to 3. Select an appropriate operation mode in accordance with the motor driver or signal lines to be used.

Set the Position Control Unit in this mode when it controls a stepping motor

driver. In this mode, connect a sensor to the origin signal lines (connector pin

nos. A11 and B11). The response time of the origin signal is 1 ms.

NC112

Origin

Origin

proximity

A11

B11

A10

B10

Pulse

24 VDC

Pulse motor

driver

M

This mode is used to control a servomotor driver. In this mode, the origin line

driver input signal lines and deviation counter reset output signal lines are

connected, but the driver completed signal lines are not used. The response

time of the origin line driver input signal is 0.1 ms.

Mode 2

12

NC112

Origin

proximity

Origin

line driver

Deviation

counter

reset

A10

B10

A8

B8

A6

B6

Pulse

24 VDC

5 VDC

Servomotor driver

+

Z-phase output

–

Deviation counter

reset input

M

E

Use this mode when controlling a servomotor driver, and when the driver

completed signal is necessary.

Switch Settings Section 2–1

Mode 3

NC112

Origin

proximity

Positioning

completed

Origin line

driver

Deviation

counter reset

A10

B10

A9

B9

A8

B8

A6

B6

Pulse

5 VDC

24 VDC

Servomotor driver

Driver completed

signal output

+

Z-phase output

–

Deviation counter

reset input

M

E

This mode is used when a servomotor driver having an origin adjustment signal (such as OMRON Model R88D) is used.

NC112

Origin

proximity

Positioning

completed

Origin

adjustment

command

A10

B10

A9

B9

A7

B7

Pulse

24 VDC

5 VDC

Servomotor driver

Driver completed

signal output

Origin adjustment

signal input

M

E

Back Panel DIP Switch

Note The above wiring diagrams for modes 1, 2, and 3 are applicable when an

OMRON R88D Servomotor Driver is used.

Adjust the servomotor driver so that its positioning complete signal turns OFF

while the motor is operating and ON when the motor stops.

These pins must be set before the Unit is mounted.

Pin no. Name ON OFF

1 Output pulse

selector

2 Origin search

direction

3 Origin proximity

present/absent

4 Origin proximity

signal type

5 Origin signal type NO input NC input

6 External interrupt

signal type

7 External interrupt

signal definition

8 Origin proximity

reverse

Nondirectional pulse and

direction signal outputs.

CCW CW

Present Absent

NO input NC input

Fixed via pin #7 Determined by IR word

CHANGE SPEED STOP

Present Absent

Separate CW and CCW

pulse outputs

n, bit 06

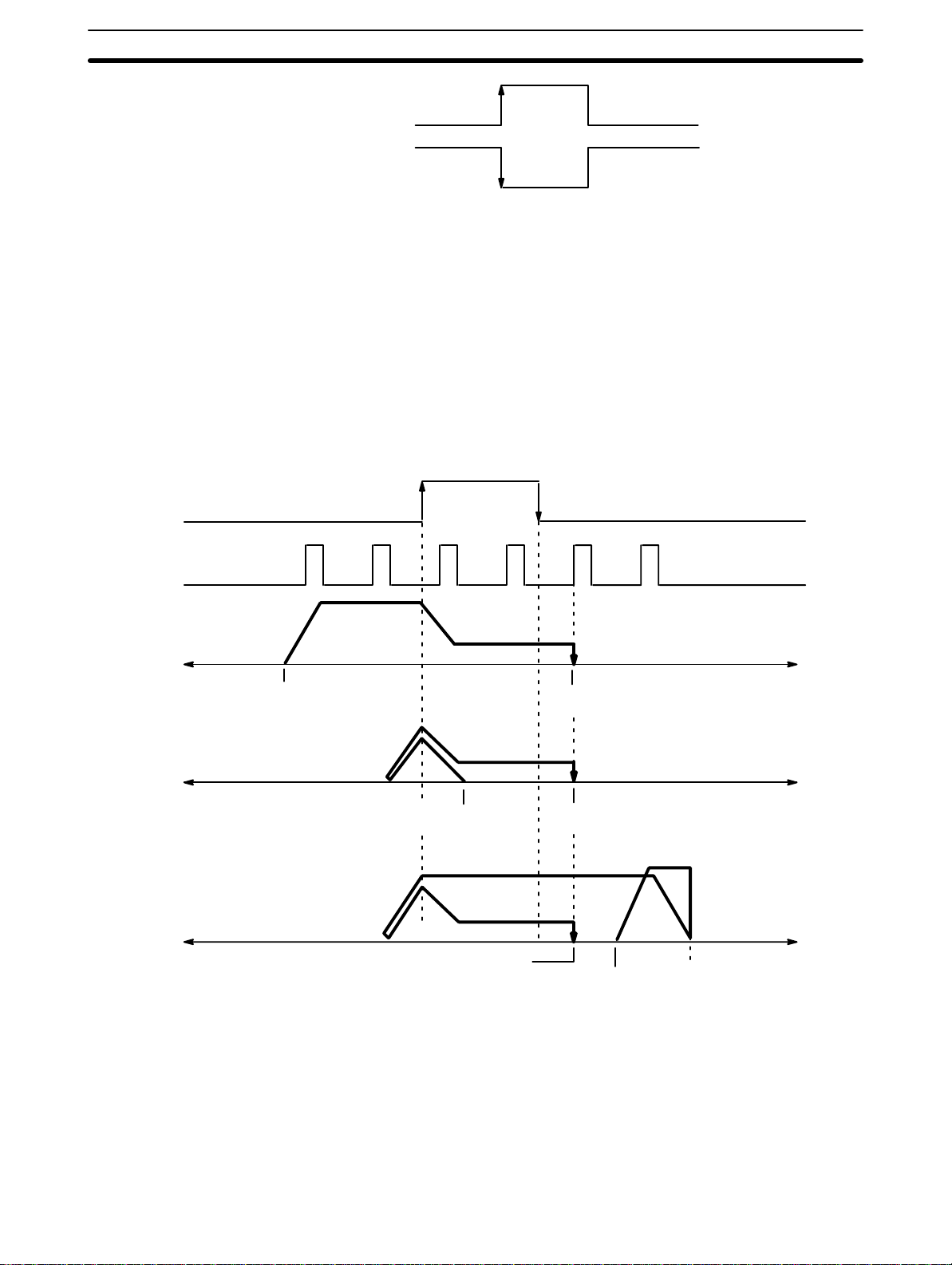

Pin 1: Output Pulse

Selector

Note Setting origin proximity to absent is possible in mode 0, but in modes 1, 2, or

3, even if origin proximity is set to absent, operation is performed with origin

proximity present.

When this pin is set to the ON position, the Position Control Unit outputs nondirectional pulses and a direction signal; when it is set to the OFF position,

13

Switch Settings Section 2–1

separate CW and CCW pulses are output. When nondirectional pulses are

output, the direction signal determines the direction of positioning. Set this

pin in accordance with the specifications of the motor and motor driver to be

used.

CW

CCW

ON:

OFF:

Pulses

Direction

CW

CCW

Pin 2: Origin Search

Direction

Pin 3: Origin Proximity

Signal Present/Absent

Output transistor is ON

Output transistor is OFF

This pin selects the direction in which the origin is searched for and the direction from which the origin is reached. If the present position of the positioning

system is near the origin, the origin is searched for in the direction opposite

to that set by this pin.

This pin enables or disables the origin proximity signal. When the pin is set to

ON, ORIGIN SEARCH is executed using the origin and origin proximity signals. (Note that the origin proximity signal is necessary in modes 1, 2, and 3.)

14

Switch Settings Section 2–1

Origin proximity

Origin

(When searching for the

origin in the CCW direction)

CCW

Positioning axis

ORIGIN SEARCH (Start)

CCW

CCW

Origin

(When searching for the

origin in the CW direction)

Origin (Stop)

CW

Origin (Stop)

ORIGIN SEARCH (Start)

CW

Origin (Stop)

ORIGIN SEARCH (Start)

CW limit

When the pin is set to OFF, ORIGIN SEARCH is executed completely at

proximity speed (low speed).

CCW

ORIGIN SEARCH (Start)

CCW

CCW

Pin 4: Origin Proximity

Signal Type and

Pin 5: Origin Signal Type

Origin (Stop)

Origin (Stop)

ORIGIN SEARCH (Start)

ORIGIN SEARCH (Start)Origin (Stop)

Positioning axis

CW limit

CW

CW

CW

These pins determine whether the origin proximity and origin signals are input from NO or NC contacts. When the pin is set to ON, the corresponding

signal is input from an NO contact; when set to OFF, from an NC contact.

15

Switch Settings Section 2–1

NO contact

NC contact

Pin 6: External Interrupt

Signal Type and

Pin 7: External Interrupt

Signal Definition

Pin 8: Origin Proximity

Reverse

Origin proximity

Origin (Z phase)

Pulse output

CCW

ORIGIN SEARCH (Start)

External interrupt processing is determined by pins 6 and 7 in combination

with bit 06 of IR word n (n = 100 + 10 x unit number). See

Section 4–10

for

details.

This pin selects whether the origin is detected after the origin proximity signal

has turned ON or after it has turned ON once and then OFF.

When the pin is set to ON, origin proximity reverse is enabled. You can use

this function to make sure that a sufficient deceleration period elapses when

there are multiple origin signals. Set the origin proximity signal such that it

remains on longer than the deceleration period. In the following example diagram, ORIGIN SEARCH is executed in the counterclockwise direction.

CW

Origin (Stop)

Positioning axis

16

CCW

CCW

CW

Origin (Stop)ORIGIN SEARCH (Start)

CW

Origin (Stop)

ORIGIN SEARCH (Start)

CW limit

When the pin is set to OFF, origin proximity reverse is disabled and the origin

signal is detected after the origin proximity signal has turned ON. Note, however, that the origin signal is not detected in modes 1, 2, and 3 during deceleration, and that the origin adjustment signal is not output in mode 3 during

deceleration. Make sure, therefore, that deceleration is completed by the

time the first origin signal is output after the origin proximity signal is turned

on.

For details, refer to

Section 4–2

.

Switch Settings Section 2–1

Origin proximity

Origin (Z phase)

Pulse output

Positioning axis

CCW

CW

ORIGIN SEARCH (Start)

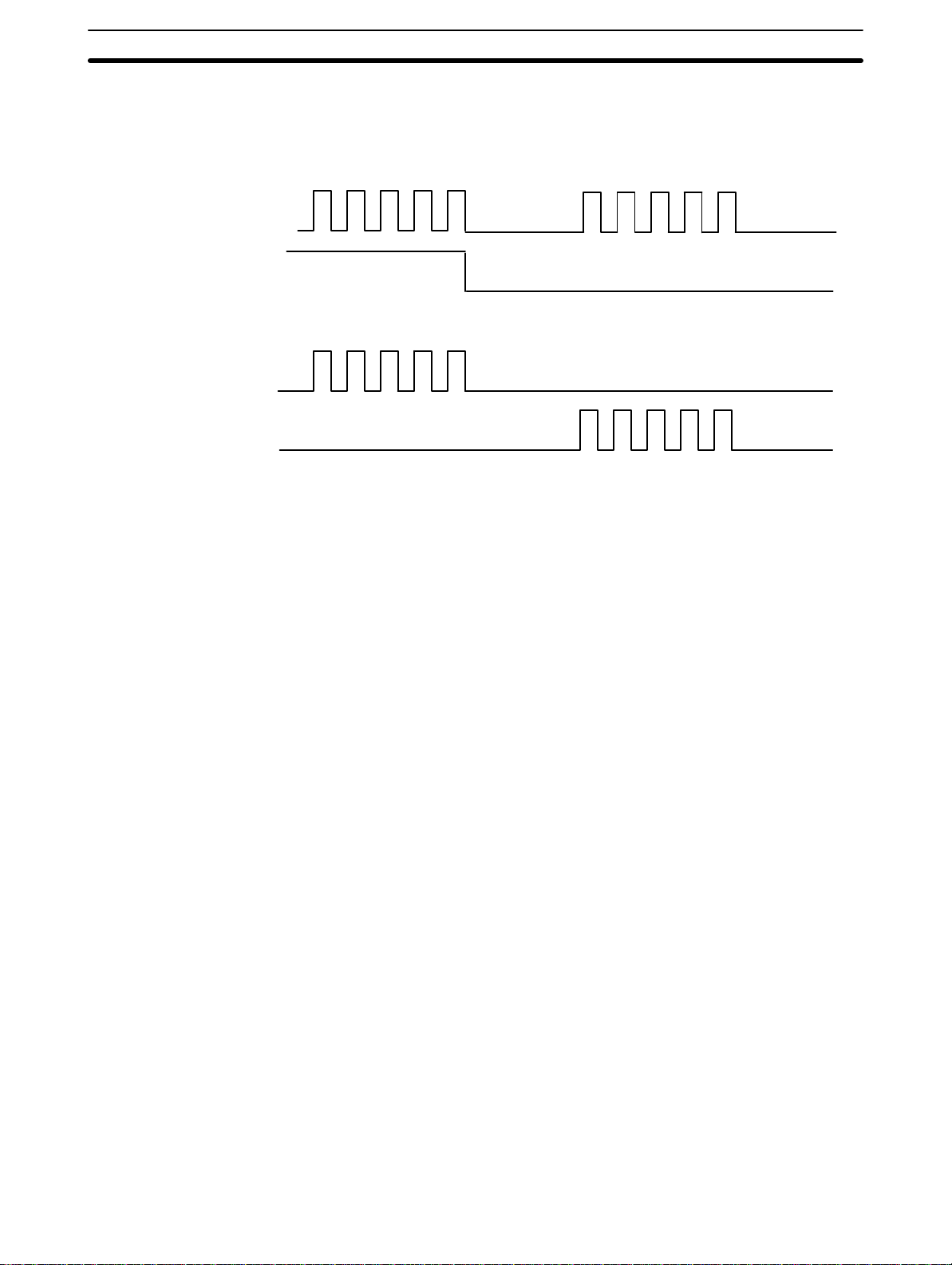

2–1–1 Switch Setting Examples

The examples in this section show switch settings for ORIGIN SEARCH in

each of the four Position Control Unit modes. In every case, set the appropriate unit number and mode first, as described at the beginning of

Example 1:

Settings in Mode 0

See also

In this example, the mode switch is set to 0 and the DIP switch pins are set

as follows:

1 OFF CW/CCW output

2 ON Origin search direction: CCW

3 ON Origin proximity present

4 ON Origin proximity signal from NO input (rising edge)

5 ON Origin signal from NO input (rising edge)

6 Refer to

7

8 OFF Origin proximity reverse absent (rising edge)

Origin search is started after the rising edge of the origin proximity signal and

ends with the rising edge of the origin signal.

Section 4–2

Origin (Stop)

.

Section 4–10 External Interrupt Commands

Section 2–1.

.

17

Switch Settings Section 2–1

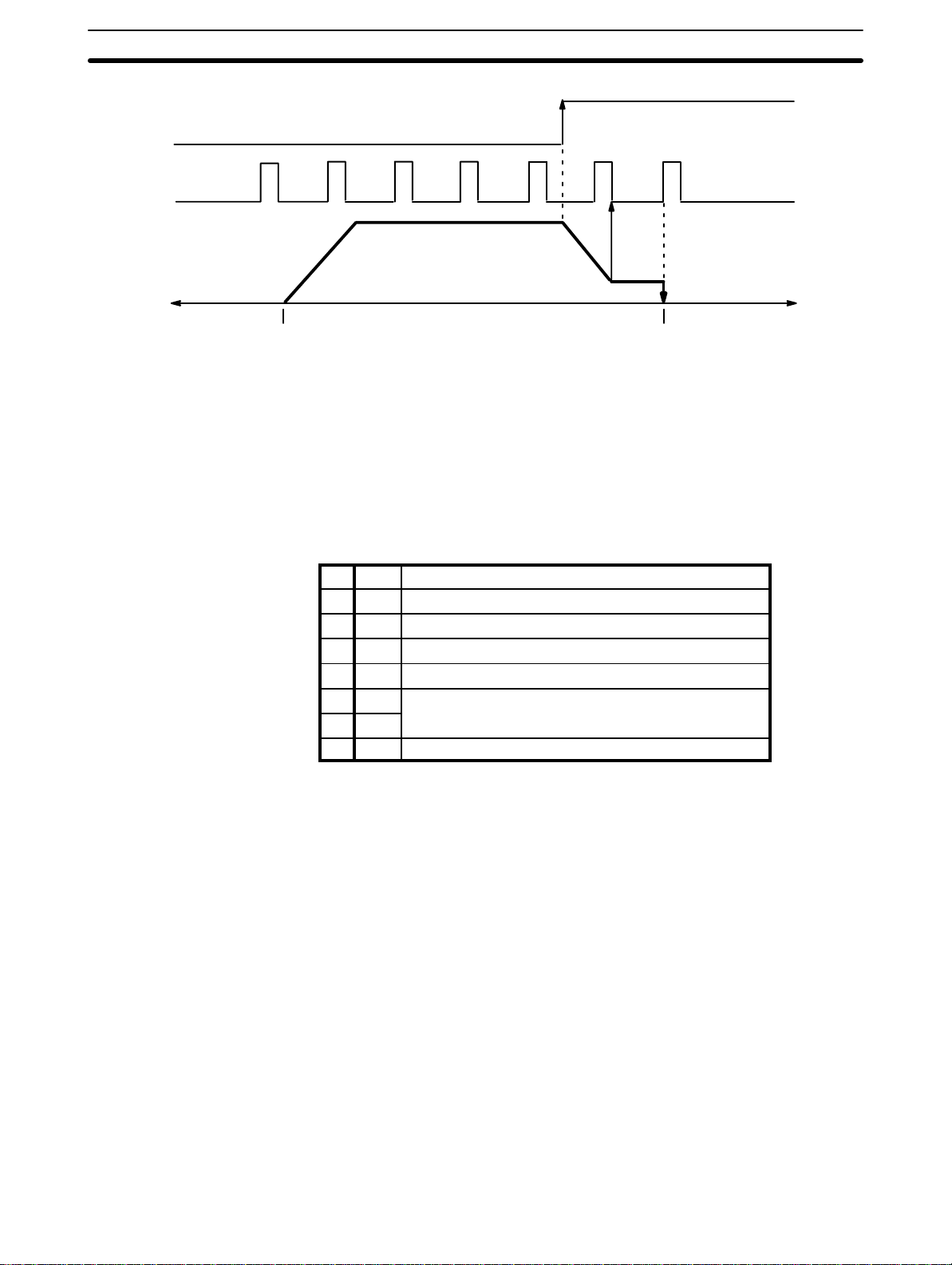

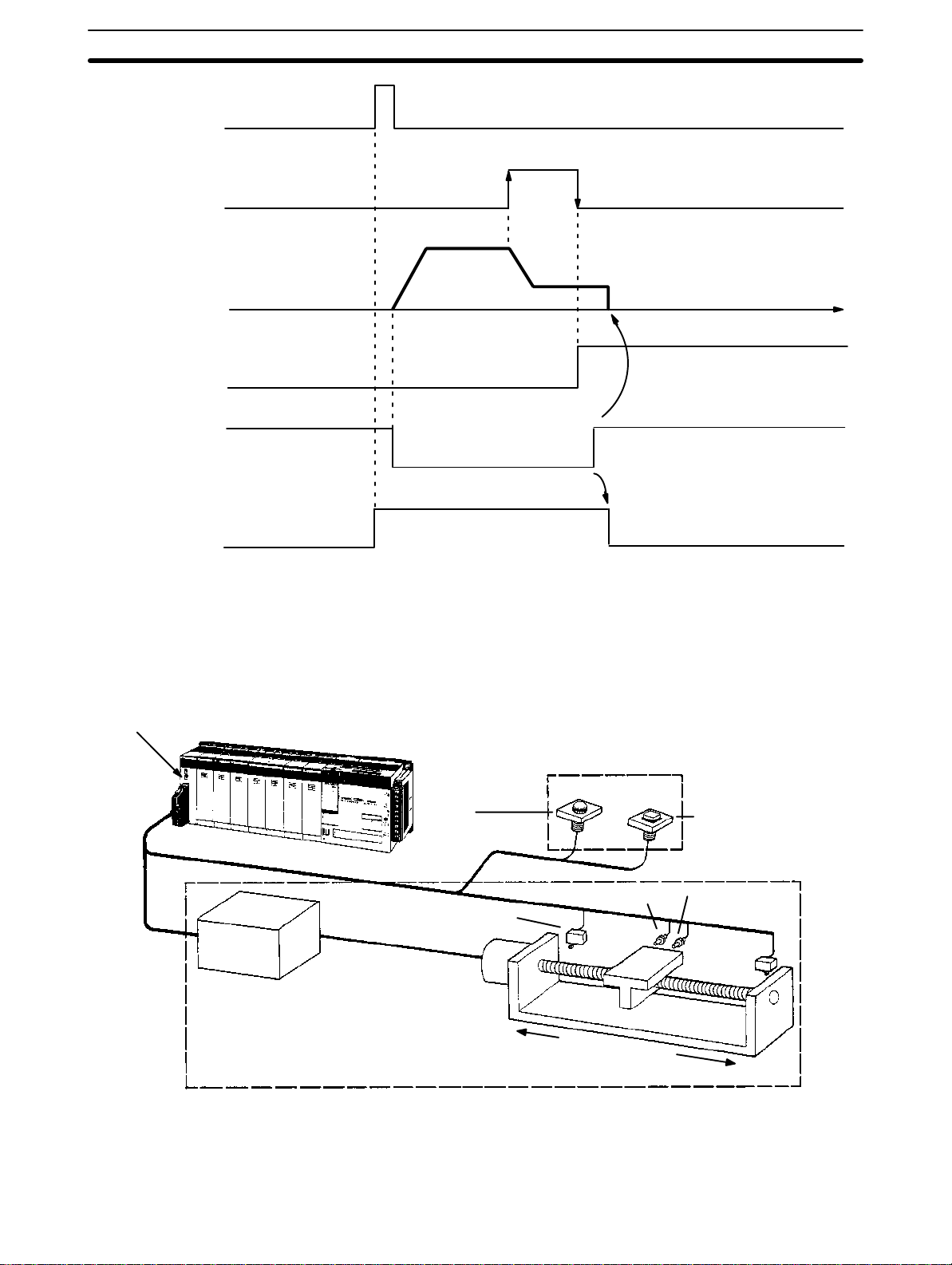

ORIGIN SEARCH

Origin proximity signal

Origin signal

Pulse output

Busy flag

Example 2: Settings in

Mode 1

Time

In this example, the mode switch is set to 1 and the DIP switch pins are set

as follows:

1 OFF CW/CCW output

2 ON Origin search direction: CCW

3 ON Origin proximity present

4 ON Origin proximity signal from NO input (rising edge)

5 ON Origin signal from NO input (rising edge)

6 Refer to

7

8 ON Origin proximity reverse present (rising, falling edge)

Section 4–10 External Interrupt Commands

.

Origin search is started after the origin proximity signal has risen and fallen,

and stops with completion of the first Z-phase signal after deceleration has

stopped.

18

Switch Settings Section 2–1

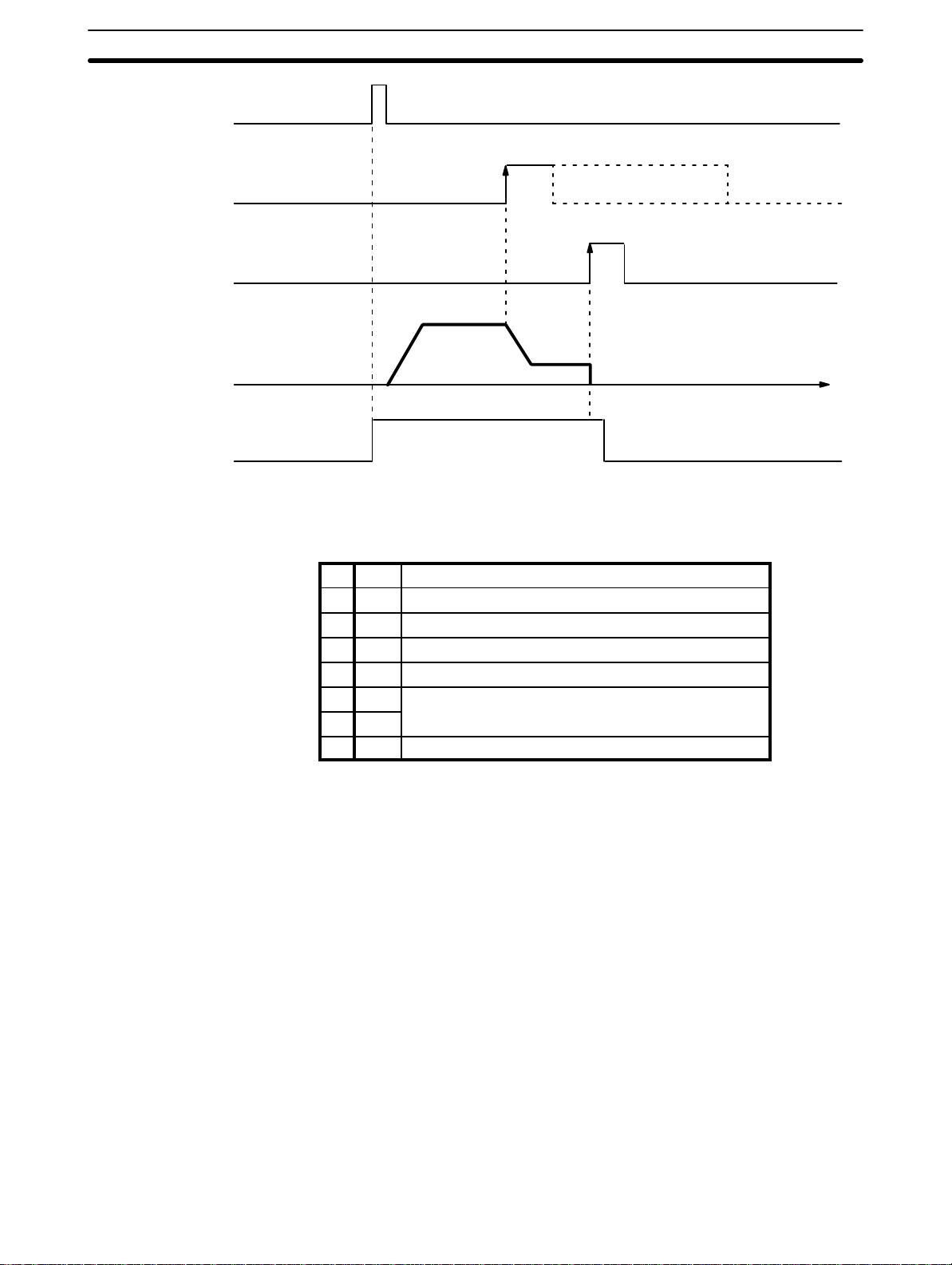

ORIGIN SEARCH

Origin proximity signal

Z-phase signal

Pulse output

Deviation counter reset output

Busy flag

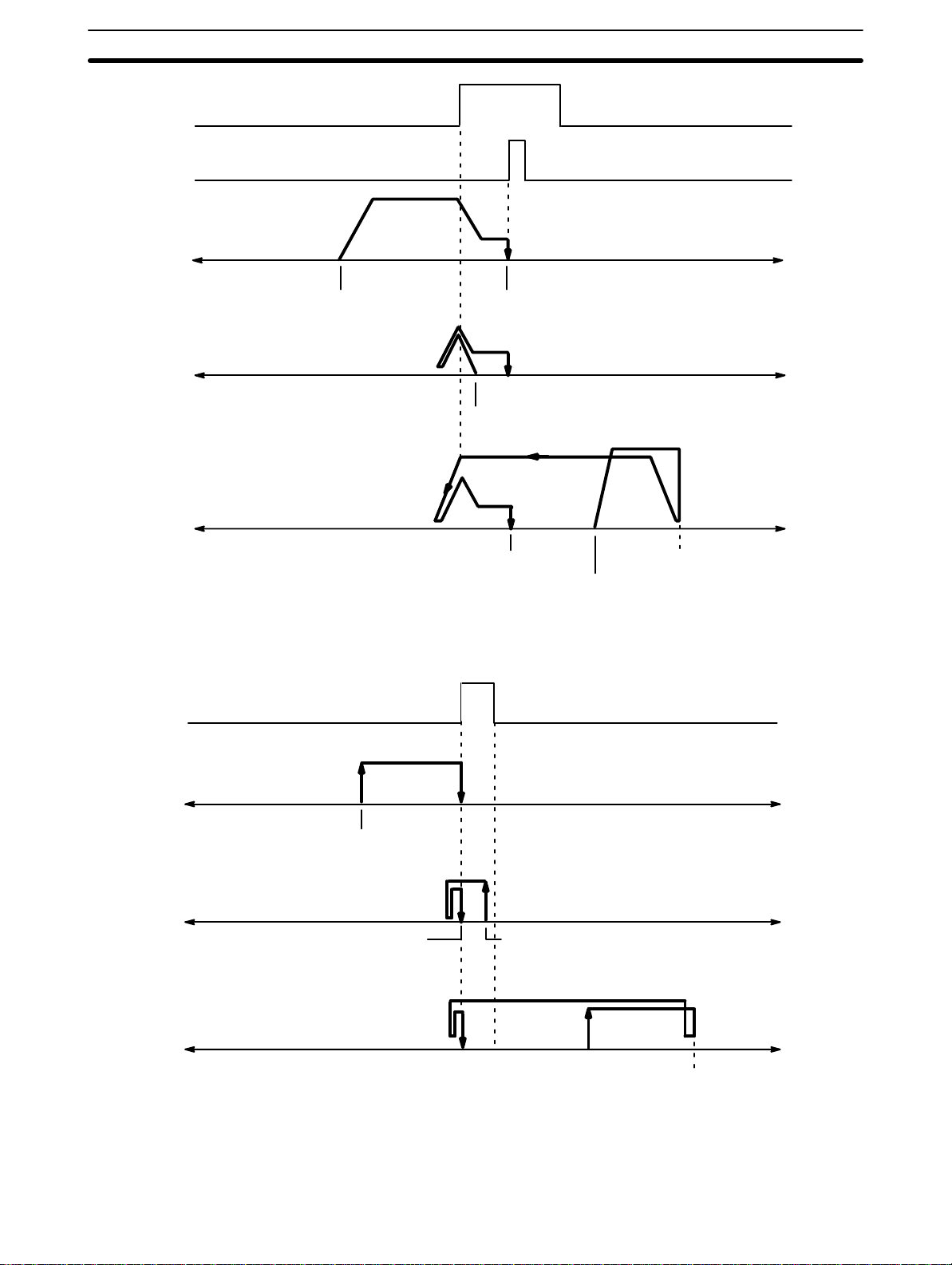

Example 3:

Settings in Mode 2

Time

Approx. 30 ms

In this example, the mode switch is set to 2 and the DIP switch pins are set

as follows:

1 OFF CW/CCW output

2 ON Origin search direction: CCW

3 ON Origin proximity present

4 ON Origin proximity signal from NO input (rising edge)

5 ON Origin signal from NO input (rising edge)

6 Refer to

7

8 ON Origin proximity reverse present (rising, falling edge)

Section 4–10 External Interrupt Commands

.

Origin search is started after the origin proximity signal has risen and fallen,

and stops with completion of the first Z-phase signal after deceleration has

stopped.

19

Switch Settings Section 2–1

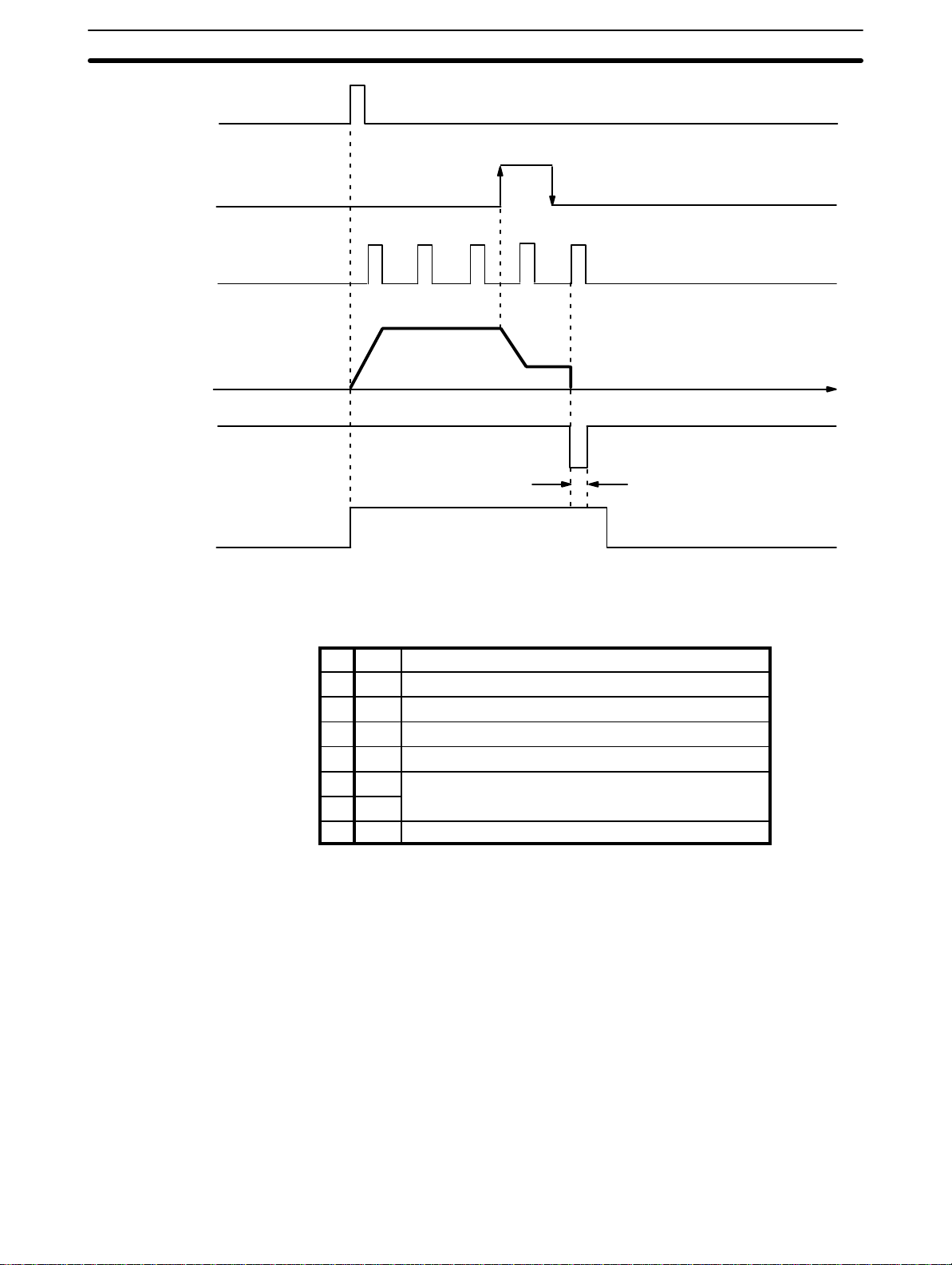

ORIGIN SEARCH

Origin proximity signal

Z-phase signal

Pulse output

Deviation counter

reset output

Driver completed input

Busy flag

Example 4:

Settings in Mode 3

Time

Approx. 30 ms

In this example, the mode switch is set to 3 and the DIP switch pins are set

as follows:

20

1 OFF CW/CCW output

2 ON Origin search direction: CCW

3 ON Origin proximity present

4 ON Origin proximity signal from NO input (rising edge)

5 ON Origin signal from NO input (rising edge)

6 Refer to

7

8 ON Origin proximity reverse present (rising, falling edge)

Section 4–10 External Interrupt Commands

.

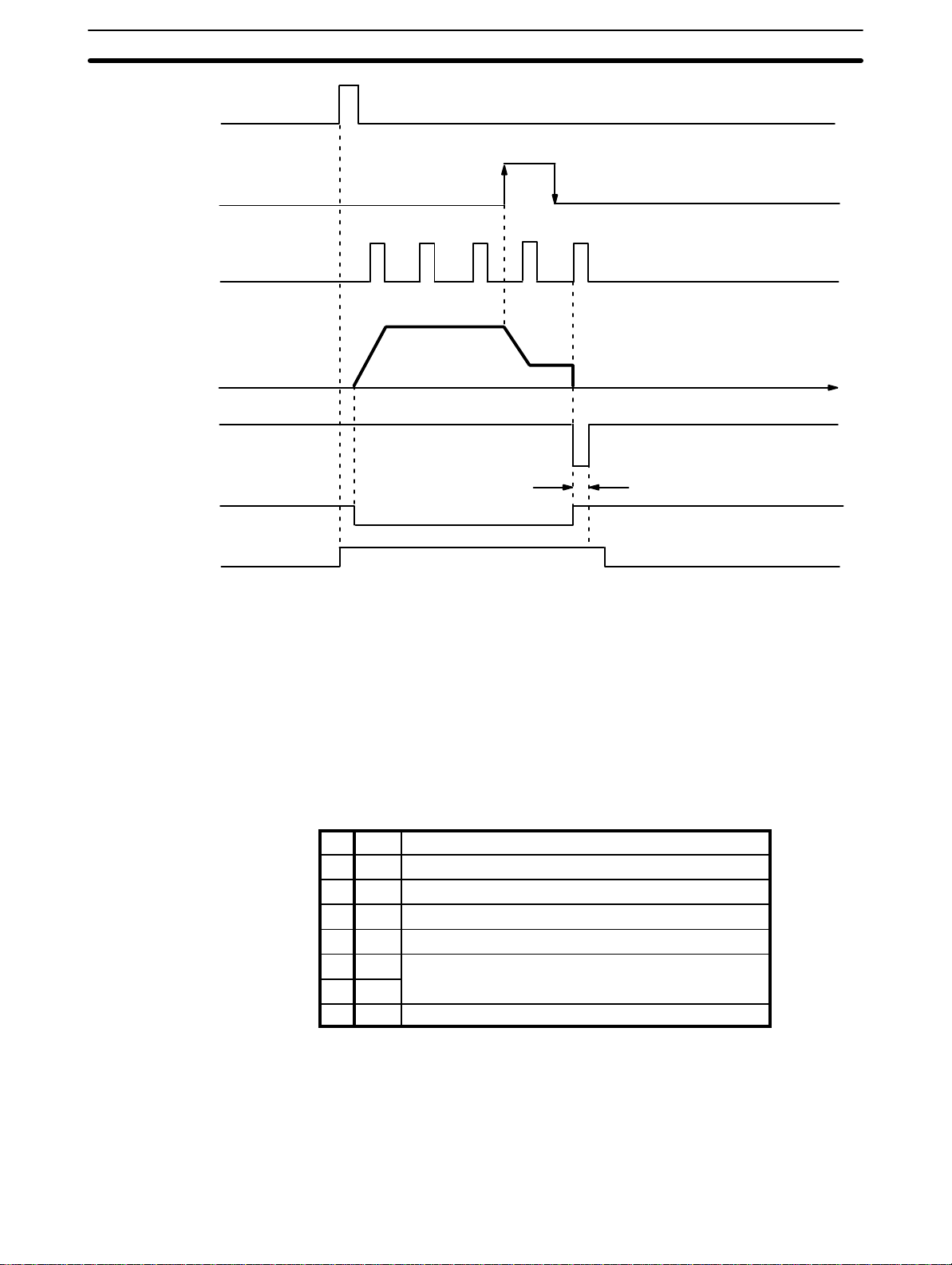

Origin search is started after the origin proximity signal has risen and fallen,

and the origin adjustment signal is output to the servomotor driver after deceleration is completed. The positioning completed signal is then input from

the servomotor driver and origin search ends. The servomotor driver stops

automatically with the first Z-phase input after it has received the origin adjustment signal.

Wiring Section 2–2

ORIGIN SEARCH

Origin proximity signal

Pulse output

Origin adjustment

command output

Driver completed input

Busy flag

2–2 Wiring

External I/O Connections

Position Control Unit

C200H-NC112

Time

The example diagram below shows I/O connections.

C200H PC

Control panel

Output

Input

Motor

driver

Emergency stop

switch

CCW limit switch

Motor

Origin switch (sensor)

CCW

CW

External interrupt

switch

Mechanical system

Origin proximity

switch

CW limit

switch

Connector Pin Arrangement The following I/O connector pin arrangement is as viewed from the front of

the Position Control Unit.

21

Loading...

Loading...