Page 1

Cat. No. W137-E1-04

SYSMAC

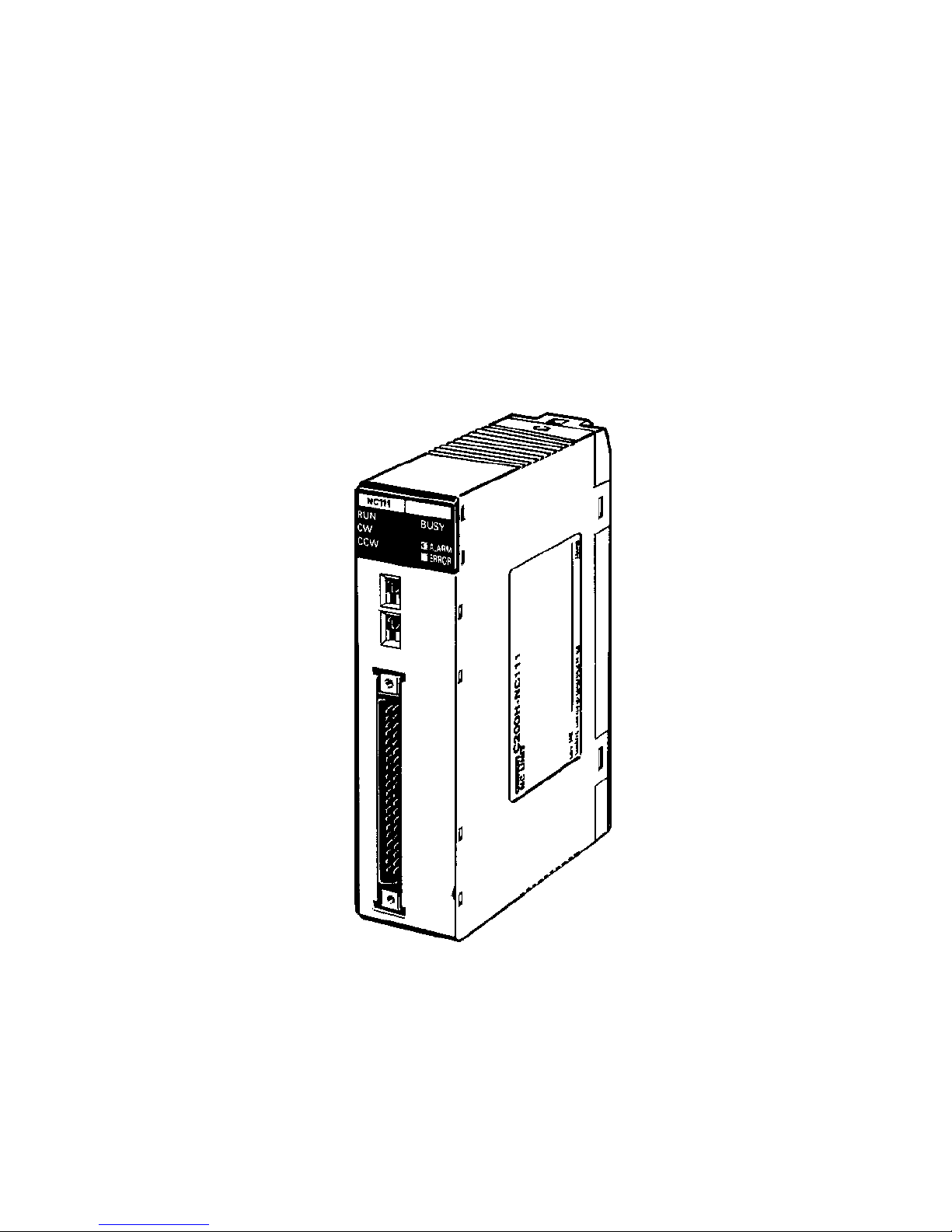

C200H-NC111

Position Control Unit

Page 2

SYSMAC C200H-NC111

Position Control Unit

Operation Manual

Revised September 2003

Page 3

iv

Page 4

!

!

!

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high–quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 5

vi

Page 6

vii

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Components 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 Control System Principles 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Before Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1 Switch Settings 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Wiring 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Operation 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 Operational Flow 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Output Pulses 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Writing Data 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Data Configuration and Allocation 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 IR Area Data Format 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Flags and Other Input Data 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 DM Area Allocation 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Commands 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1 Start 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 Origin Search 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3 Origin Return 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4 Release Prohibit 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–5 Read Error 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6 Reset Origin 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–7 Teach 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–8 Transfer Data 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–9 Manual Operations 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–10 External Interrupt Commands 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

viii

SECTION 5

Programming Examples 91. . . . . . . . . . . . . . . . . . . . . . . . . .

5–1 Operation with Minimum Data: Displaying JOG Positions 92. . . . . . . . . . . . . . . . . . . . . . .

5–2 Positioning at Intervals: Using RESET ORIGIN 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–3 Feeding Selectively with START 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–4 Transfer Data from Other PC Areas 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–5 Transfer Data from External Switches 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–6 Using START to Carry Out Positioning Actions 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–7 Using Origin and Origin Proximity Signals 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–8 Using Zones to Control Jogging 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–9 Controlling an R88D-EP06 Servodriver 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–10 Controlling a V-series Servodriver 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Error Processing 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–1 Alarms and Errors 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–2 Outputs to the IR Area 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–3 Alarm/Error Indicators 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–4 Troubleshooting from the PC 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–5 Basic Troubleshooting Chart 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–6 Detection of Abnormal Pulse Outputs 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Alarm Code List 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Error Code List 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C DM Area Allocations 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D IR Area Allocations 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Specifications 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Standard Models 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

ix

About this Manual:

The C200H–NC111 Position Control Unit is a Special I/O Unit for C200H PCs. It is designed to control

equipment positioning through pulse train outputs to a motor driver. The degree of movement is

based on the program installed into the PC and the external control inputs.

This manual covers the specifications and procedures necessary for installation and efficient operation. Before attempting to operate the C200H Position Control Unit, be sure to thoroughly familiarize

yourself with the information contained within this and any other relevant manuals.

Section 1 describes the basic features and components of the Position Control Unit. It also gives details on configurations for positioning control systems and their principles of operation.

Section 2 describes how to incorporate the Positioning Control Unit into a system. It provides information on how to set switches so that the Unit provides the desired operating functions. It also gives

mounting and wiring information.

Section 3 gives details on the procedures for setting up and operating a positioning control system. It

includes information on PC operations (such as flags, zone settings, the range of output pulses, backlash compensation, etc.), data areas and data formats.

Section 4 outlines the thirteen commands available on the Positioning Control Unit. It describes each

command, how it works, the data required,and the data areas used. Examples are given (in timing

chart form) which show the status of the relevant inputs, outputs, bits, and flags during the execution

of the commands.

Section 5 provides programming examples which give practical illustrations of how the Positioning

Control Unit commands can be used to implement effective positioning control.

Section 6 explains various error and alarm conditions and the steps that can be taken to avoid and/or

prevent them.

Appendix A provides more detailed information on alarm codes, including the type of operations in

which the alarm may arise, the type of error, the alarm code, and the most probable cause.

Appendix B lists the error codes in numeric sequence and provides information on the cause of, and

remedy for, the existing problem.

Appendix C describes the functions that each of the different parts of the DM Area performs.

Appendix D describes the functions for which each of the different parts of the IR Area can be used.

Appendix E provides the performance and electrical specifications for the Positioning Control Unit.

Appendix F lists the models which are used with the Positioning Control Unit.

A comprehensive Glossary is provided which explains many of the terms and abbreviations commonly used when referring to Positioning Control Units and PC Systems.

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

!

Page 9

xi

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC), Position Control Unit (PCU), and

related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller and the Position Control Unit. You must read this section and understand the information contained before

attempting to set up or operate a PC system.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

!

!

!

5Safety Precautions

xii

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating Position Control Unit. Be sure to read this manual before attempting to use the PCU and keep

this manual close at hand for reference during operation.

3 Safety Precautions

WARNING Never attempt to disassemble any Units while power is being supplied. Doing so

may result in serious electrical shock or electrocution.

WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to

ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposits on or burning of the

output relays, or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-V DC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF . As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

Page 11

!

!

5Application Precautions

xiii

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

• Take appropriate and sufficient countermeasures when installing systems in

the following locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electric fields or magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the Position Control Unit (PCU)

and Programmable Controller (PC).

WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to protect against electrical shock.

• Always turn off the power supply to the PC before attempting any of the following:

• Mounting or dismounting the Power Supply Unit, I/O Units, CPU Unit,

other Units, or Memory Casettes.

• Assembling the devices.

• Setting DIP switches or rotary switches.

• Wiring or connecting cables.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

PC or the system or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures must be provided

by the customer as external circuits.

• Install external breakers and take other safety measures against short-circuiting in external wiring.

• Tighten the PC mounting screws, terminal block screws, and cable screws to

the torque specified in this manuals.

• Always use the power supply voltage specified in this manual.

Page 12

5Application Precautions

xiv

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals.

• Leave the dustproof labels affixed to the top of the Unit when wiring. After wiring, remove the labels for proper heat radiation.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity.

• Check the user program for proper execution before actually running it in the

Unit.

• Be sure that the terminal blocks, memory units, extension cables, and other

items with locking devices are properly locked.

• Double-check all the wiring before turning on the power supply.

• Disconnect the functional ground terminal when performing withstand voltage

tests.

• Confirm that no adverse effect will occur in the system before performing the

following operations:

• Changing the operating mode of the PC.

• Force-setting/resetting the relay contacts.

• Changing the present values or set values.

• Changing positioning data or parameters.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM and HR Areas required for operation.

• Do not attempt to disassemble, repair, or modify any Units.

• Do not pull on or bend the cables beyond their natural limit. Doing so may break

the cables.

• Do not place heavy objects on top of the cables. Doing so may break the

cables.

• Resume operation only after saving in the Position Control Unit the parameters

and position data required for resuming operation.

• Be sure that the set parameters and data operate properly.

• Be sure to check the pin numbers before wiring the connectors.

• Perform wiring according to specified procedures.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static build-up from your body. Not doing so may result in malfunction or damage

Page 13

1

SECTION 1

Introduction

The C200H-NC111 Position Control Unit is a Special I/O Unit that receives positioning commands either externally or

from a Programmable Controller (PC) and uses that data to output control voltages to a stepping motor driver or a servomotor driver.

This section describes the basic features and components of the Position Control Unit, as well as the basic configuration

and operating principles of positioning control systems. Be sure to read and study these sections carefully; an understanding of the control system is essential for successful operation.

1–1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Components 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 Control System Principles 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4–1 Open-loop System 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4–2 Semi-closed-loop System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 14

2

1–1 Features

Applicable Motor Drivers

The pulse train output can be easily connected to either of the following devices:

1) Stepping motor driver

2) Servomotor driver designed for pulse train input

Number of Control Axes

and Controlling Capacity

The Position Control Unit is designed exclusively to control a single axis and

is capable of controlling speeds and positions through parameters recorded

in the DM area of the C200H PC.

Manual Operation

Three commands enable manual positioning control: HIGH-SPEED JOG,

LOW-SPEED JOG, and INCH.

Data Transfer

Positioning actions, speeds, and other data contained in the DM area or

other areas of the PC can be quickly transferred via a TRANSFER DATA

command. Control scale can thus be expanded to exceed the data capacity

of the Position Control Unit.

Establishing Position

The TRANSFER DATA command can also be used to change the present

position to any target value, including 0 (origin), anytime the Position Control

Unit is not outputting pulses.

Teaching

The present position can be written into the memory of the PC as positioning

data whenever pulses are not being output.

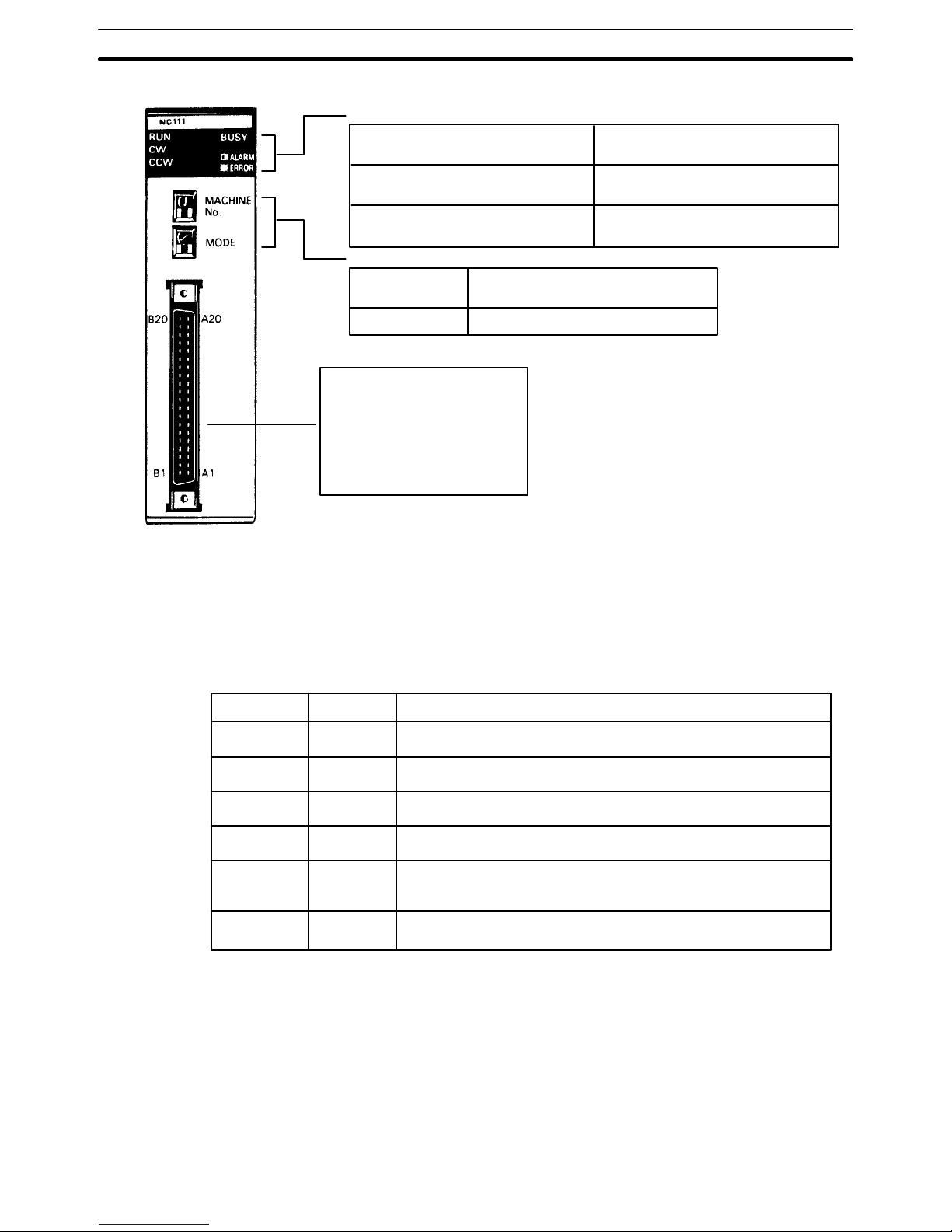

1–2 Components

In addition to the front-panel components described on the following page,

there is a DIP switch located on the back panel. Pin settings for this switch,

which are described under 2–1 Switch Settings, determine certain aspects of

control system operation.

Components Section 1–2

Page 15

3

Indicators

RUN: indicates operation

is in progress

CW: indicates controlled system

(motor) is revolving clockwise

CCW: indicates controlled system

(motor) is revolving counterclockwise

BUSY: indicates operation/transfer

is in progress

ALARM: blinks when an abnormality

has occurred

ERROR: lights when an error has occurred

Setting switches

MACHINE No.

MODE

Allocates a unit number (0 to 9) to

the Position Control Unit

Not used

Connector

Used to connect the Position

Control Unit to a stepping motor driver or servomotor driver.

Attach the enclosed connector

to the proper cable.

When setting the switches, use a

screwdriver if necessary.

Do not apply an excessive force to the

switches.

Do not leave the switches halfway between two setting points or the Position

Control Unit may malfunction.

Before operating these switches, make

sure that power to the PC is off.

Indicators

Position Control Unit indicators (LEDs) are used to quickly determine operating status. They are particularly valuable in initial system activation and debugging, but can also be used to monitor and check Unit operation.

Indicator Color Function

Lit during normal operation. Goes out for errors.

Lit during output of CW (clockwise) pulses.

Lit during output of CCW (counterclockwise) pulses.

Lit during positioning or data transfer.

Flashing when a BCD error exists in initial data, speed

data, or positioning data updated with TRANSFER DATA.

Lit when an error has occurred causing operation to stop.

Green

Green

Green

Green

Red

Red

RUN

CW

CCW

BUSY

ALARM

(flashing)

ERROR

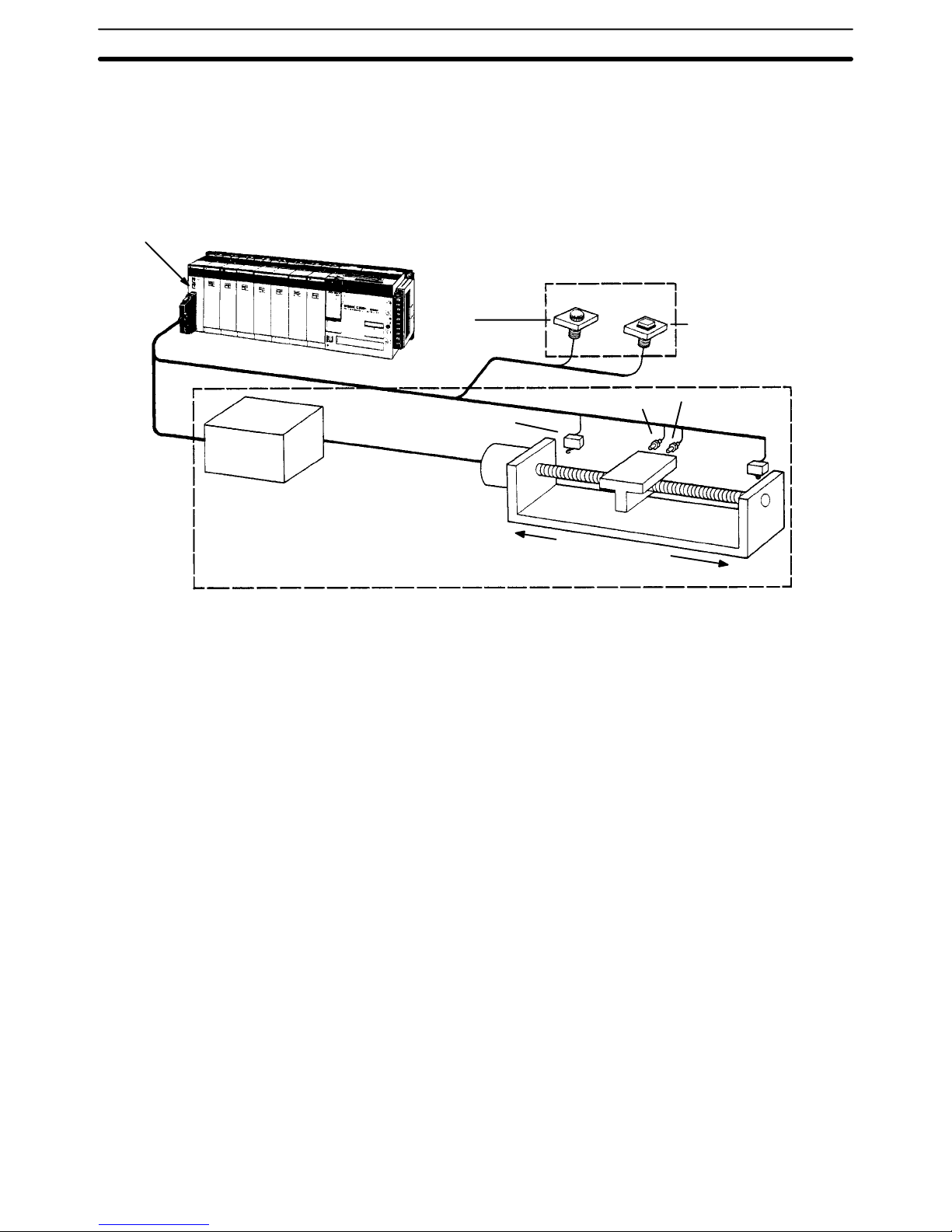

1–3 System Configuration

The basic system configuration is shown below. Position Control Unit outputs

are connected to a motor driver, either for a stepping motor or for a servomotor (either AC or DC) capable of receiving pulse train inputs. The Unit is

controlled by inputs from devices and/or a control panel. It, in turn, outputs

pulse trains and direction signals to control the motor driver.

System Configuration Section 1–3

Page 16

4

The motor driver controls either a stepping motor or a servomotor, depending

on whether an open-loop or semiclosed-loop system is employed. (See 1–4

Control System Principles). The stepping motor (or servomotor) controls

some type of positioning device (such as a feed screw, for example). An independent power supply must be used. Some configurations also require an

Input Unit on the C200H PC to control the motor driver.

Maximum Number of

Special I/O Units per PC

A maximum of 10 Special I/O Units, including Position Control Units,

High-Speed Counters, etc., can be mounted under the same PC, regardless

of whether they are on the CPU Rack, an Expansion I/O Rack, or a rack containing a Remote I/O Slave Unit controlled by the PC. No more than four of

these can be mounted onto any one rack containing a Remote I/O Slave

Unit.

Mounting Location

The Position Control Unit can be mounted to any but the 2 rightmost CPU

Rack slots. Mounting the Unit to either of these slots will prevent you from

mounting devices directly to the PC’s CPU. The back-panel DIP switch must

be set before the Unit is mounted. This switch is inaccessible on a mounted

Unit. (See 2–1 Switch Settings.)

Basic Configuration

Although Unit operation can be indirectly controlled from a host computer,

Remote I/O Master Unit, or other control system or peripheral device, direct

control comes from the program of the PC or from connections to external

inputs (e.g., control panel switches). (A list of Position Control Unit inputs and

outputs can be found under I/O Circuits in 2–2 Wiring.) The following configuration diagrams show only the positioning system itself. Refer to the operating manuals for other Omron control devices for details on extended control

system operation.

System Configuration Section 1–3

Page 17

5

Control signal input switches

C200H PC

Position Control Unit C200H-NC111

Input Unit

Stepping motor (or servomotor) driver control

signal line

Power supply

Hand-held Programming

Console C200H-PRO27

Stepping motor driver

(or servomotor driver)

Operation panel

Operation switch

Stepping motor

(or servomotor)

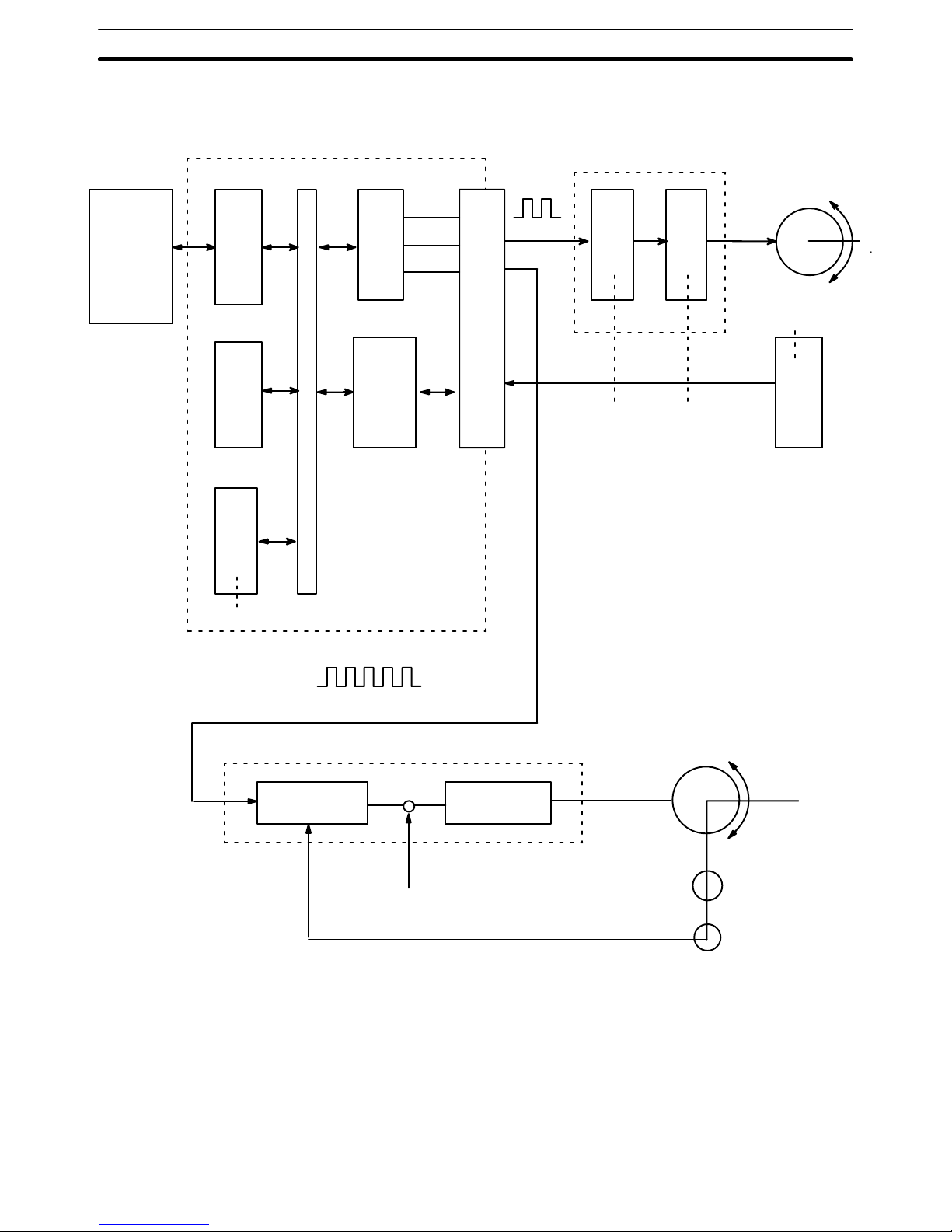

1–4 Control System Principles

Control systems can be quite simple or relatively complex. The most basic is

an open-loop system, in which a particular operation is carried out, according

to programmed instructions, but in which adjustments are not made directly

by the PC. Instead, the open-loop system typically displays or prints out information to assist a human operator in making any required adjustments. The

C200H-NC111 Position Control Unit can be used in an open-loop system in

conjunction with a stepping motor.

In a closed-loop system, on the other hand, the PC controls an external process without human intervention. The servomotor provides direct feedback so

that actual values (of positions, speeds, and so on) are continuously adjusted

Control System Principles Section 1–4

Page 18

6

to bring them more closely in line with target values. In some systems, the

digital feedback signals will be transmitted to a digital-to-analog converter to

complete the feedback loop, thereby permitting automated control of the

process.

A semiclosed-loop system is similar to a closed-loop system, except that

feedback is provided by a tachogenerator and a rotary encoder rather than

directly by the servomotor. If the C200H-NC111 Position Control Unit is used

with a servomotor, the servomotor driver must be able to handle digital signals, and there is no need for a D/A converter. In addition, the servomotor is

connected to a tachogenerator and a rotary encoder. The Unit can thus be

used in either an open-loop or a semiclosed-loop system.

Both open-loop and semiclosed-loop systems are described in more detail on

the following pages.

Control System Principles Section 1–4

Page 19

7

Data Flow

PC

BUS

I/F

C200H PC

Position Control Unit C200H-NC111

Rotary encoder

Tachogenerator

Servomotor driver

Pulse train

Power

amplifier

Pulse

train

Stepping motor driver

I/O

interface

MPU

Memory

Pulse

generator

Magnetizing

distribution

circuit

Servomotor

(Positioning output)

PC

BUS

I/F

External

input

Stepping motor

Error counter Power amplifier

I/O connector

1–4–1 Open-loop System

In an open-loop system, the Position Control Unit outputs pulse trains as

specified by the PC program to control the angle of rotation of the motor. Because the Unit outputs pulse trains, it is generally used with a stepping motor.

The angle of rotation of a stepping motor can be controlled through the number of pulse signals supplied to the motor driver. The number of rotations of

the stepping motor is proportional to the number of pulses supplied by the

Unit, and the rotational speed of the stepping motor is proportional to the

Control System Principles Section 1–4

Page 20

8

frequency of the pulse train.

Positioning pulse

1 2 n

Positioning output

Angle of

rotation

Angle of rotation

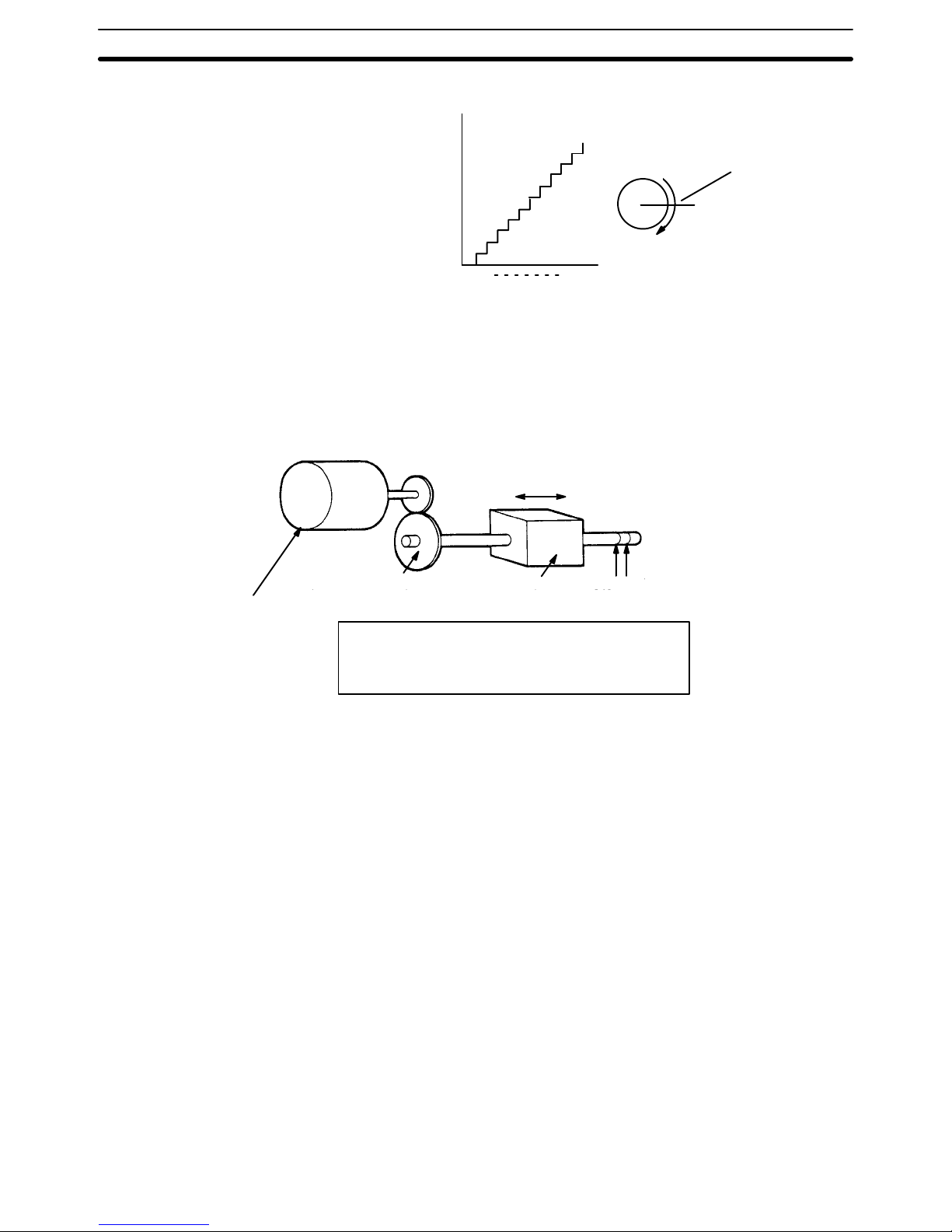

Simplified Positioning

System Design

The following diagram and parameters illustrate a simplified positioning system.

P

Stepping motor

Reduction gear

Object being

positioned

M: Reduction ratio

P: Feed screw pitch (mm/revolution)

V: Feed velocity of object being positioned (mm/s)

θs: Stepping angle per pulse (degree/pulse)

N

M

V

Feed screw pitch

The positioning accuracy in mm/pulse is computed as follows:

Positioning accuracy = P/(pulses per revolution x M)

= P/((360/S) x M))

= (P x S)/(360 x M)

The required pulse frequency from the Unit in pulses per second is computed

as follows:

Pulse frequency = V/Positioning accuracy

= (360 x M x V)/(P x S)

And the required number of pulses to feed an object by a distance L in mm is

computed as follows:

Number of pulses = L/Positioning accuracy

= (360 x M x L)/(P x S)

1–4–2 Semi-closed-loop System

When the Position Control Unit is used in a semiclosed-loop system, the system supplies feedback to compensate for any discrepancy between target

values and actual values in position or speed. This system detects motor ro-

Control System Principles Section 1–4

Page 21

9

tation amounts, for example, computes the error between the target value

and actual movement value, and zeroes the error through feedback. The diagram below illustrates the basic configuration of a semiclosed-loop system.

Rotary encoder

Tachogenerator

Servomotor driver

Servomotor

Position output

Error counter Power amplifier

Position feedback (feedback pulses)

Speed feedback

Target position

1) First, the target position is transmitted to the error counter in units of en-

coder pulses. The servomotor driver must be able to handle digital input.

2) The motor rotates at a speed corresponding to the speed voltage. The ro-

tary encoder connected to the motor axis rotates in sync with the motor, generates feedback pulses, and subtracts error counter contents.

3) Consequently, the encoder rotation is equivalent to the target position, and

the motor stops rotating when the error counter count and the speed voltage

become zero.

4) While the motor is stopped, the rotary encoder constantly maintains the

stopped position through correction. In the event that the motor axis slightly

moves, the error counter receives a feedback pulse from the rotary encoder,

whereby a rotation voltage is emitted in the reverse direction from which the

rotary encoder moved, causing the motor to rotate toward its original position. This operation is called servolock or servoclamp.

5) In order to execute positioning with acceleration and deceleration, target

positions are set consecutively in the error counter for processing.

6) The target position becomes the count for the error counter and controls

the motor by conversion to a speed voltage for the servomotor driver. The

position thus equals the total count of target positions and the speed will depend on the target position per unit time.

Control System Principles Section 1–4

Page 22

11

SECTION 2

Before Operation

Before the Position Control Unit can be operated, switch settings and wiring must be correct. This section presents the

settings and functions of switches, provides examples of and precautions for wiring, and gives dimensions of Units both

when mounted and unmounted. Be sure that all settings and wiring match your positioning system specifications.

2–1 Switch Settings 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 Wiring 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 Dimensions 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 23

12

2–1 Switch Settings

Always turn off PC power before setting the unit number switch. Use a regular screwdriver, being careful not to damage the slot in the screw. Be sure not

to leave the switch midway between settings.

Switch

Function

Used to set the unit number (between 0 and 9).

Do not set the same number for more than one Unit.

Doing so will cause an error and prevent operation.

Not used.

Unit number

(”Machine no.”)

Mode

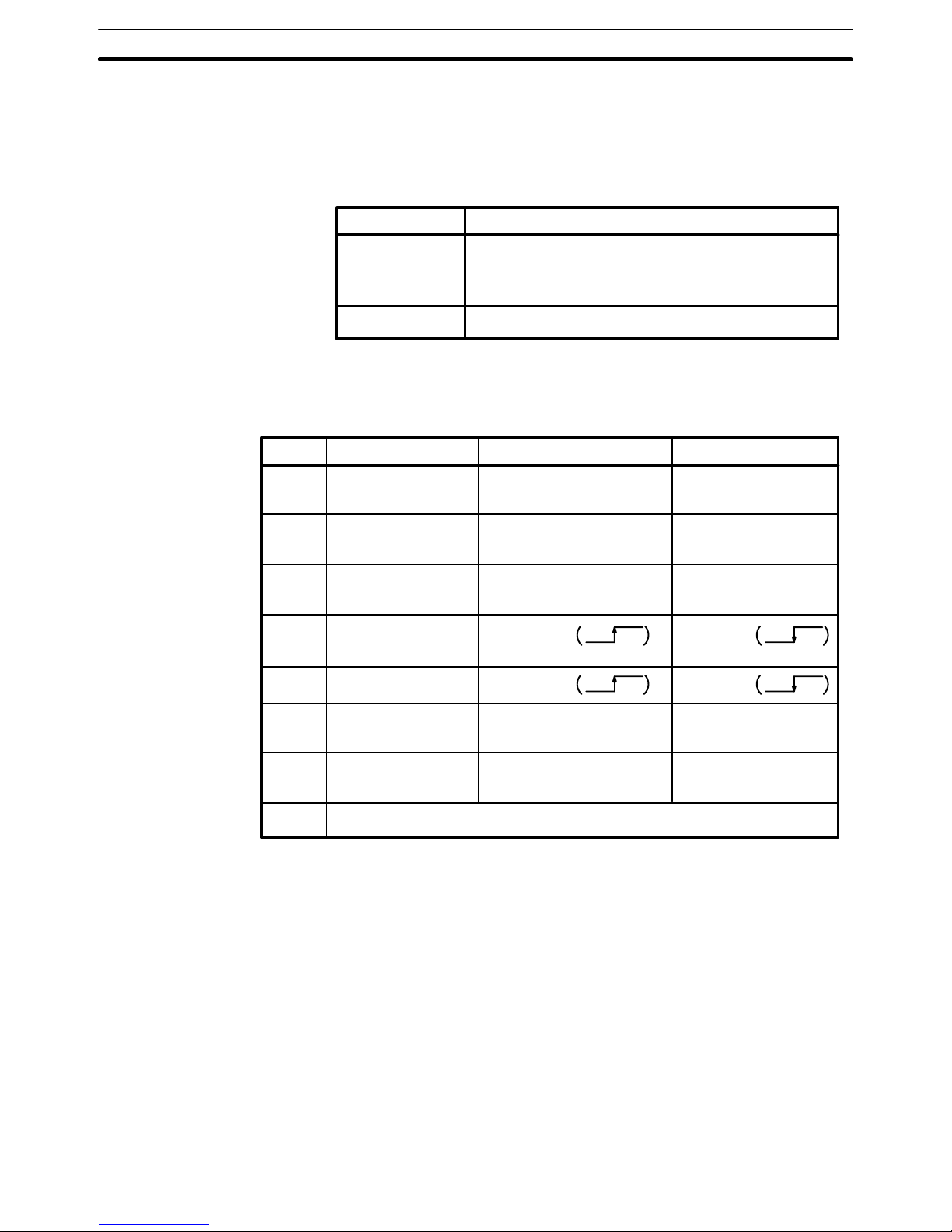

Back Panel DIP Switch

These pins must be set before the Position Control Unit is mounted.

Pin no.

Name

Output pulse

selector

Origin search

direction

Origin proximity

present/absent

Origin proximity

signal type

Origin signal type

External interrupt

selection*

External interrupt

response*

Nondirectional pulse and

direction signal outputs.

CCW

Present

N.O. input

N.O. input

Fixed via pin #7

CHANGE SPEED

Not used.

Separate CW and

CCW pulse outputs

CW

Absent

N.C. input

N.C. input

Determined by

IR bit (word n, bit 06)

STOP

ON

OFF

1

2

3

4

5

6

7

8

*External interrupt processing is determined by pins #6 and #7 in combination with bit 06 of IR word n (n = 100 + 10 x unit

number). Refer to 4–10 External Interrupt Commands for details.

Switch Settings Section 2–1

Page 24

13

2–2 Wiring

External I/O Connections

The example diagram below shows I/O connections.

Position Control Unit

C200H-NC111

Output

C200H PC

Input

Motor

driver

Control panel

Emergency stop

switch

External interrupt

switch

CCW limit switch

Motor

Mechanical system

CW limit

switch

Origin switch (sensor)

CCW

CW

Origin proximity

switch

Wiring Section 2–2

Page 25

!

14

Connector Pin

Arrangement

The following I/O connector pin arrangement is as viewed from the front of

the Position Control Unit.

Emergency stop input (0 V) 20 Emergency stop input (12 to 24 VDC)

Emergency interrupt input (0 V) 19 External interrupt input (12 to 24 VDC)

18

17

16

15

14

CW limit input (0 V) 13 CW limit input (12 to 24 VDC)

CCW limit input (0 V) 12 CCW limit input (12 to 24 VDC)

Origin input (0 V) 11 Origin input (12 to 24 VDC)

Origin proximity input (0 V) 10 Origin proximity input (12 to 24 VDC)

9

8

7

6

Output power (0 V) 5 Output power (0 V)

CW pulse or nondirectional 4 CW pulse or nondirectional pulse output (1.6 k

Ω)

pulse output

CW pulse or direction signal output 3 CCW pulse or direction signal output (1.6 k

Ω)

5-VDC power supply input 2

1 24-VDC power supply input

Row B

Pin no.

Row A

External connector: FCN-361J040 (Fujitsu solder-type; included as an accessory.)

Caution Output power should be either 24 or 5 VDC. Never connect both the 24 and

5 VDC pins at the same time. In other words, never use power supplies of different voltages.

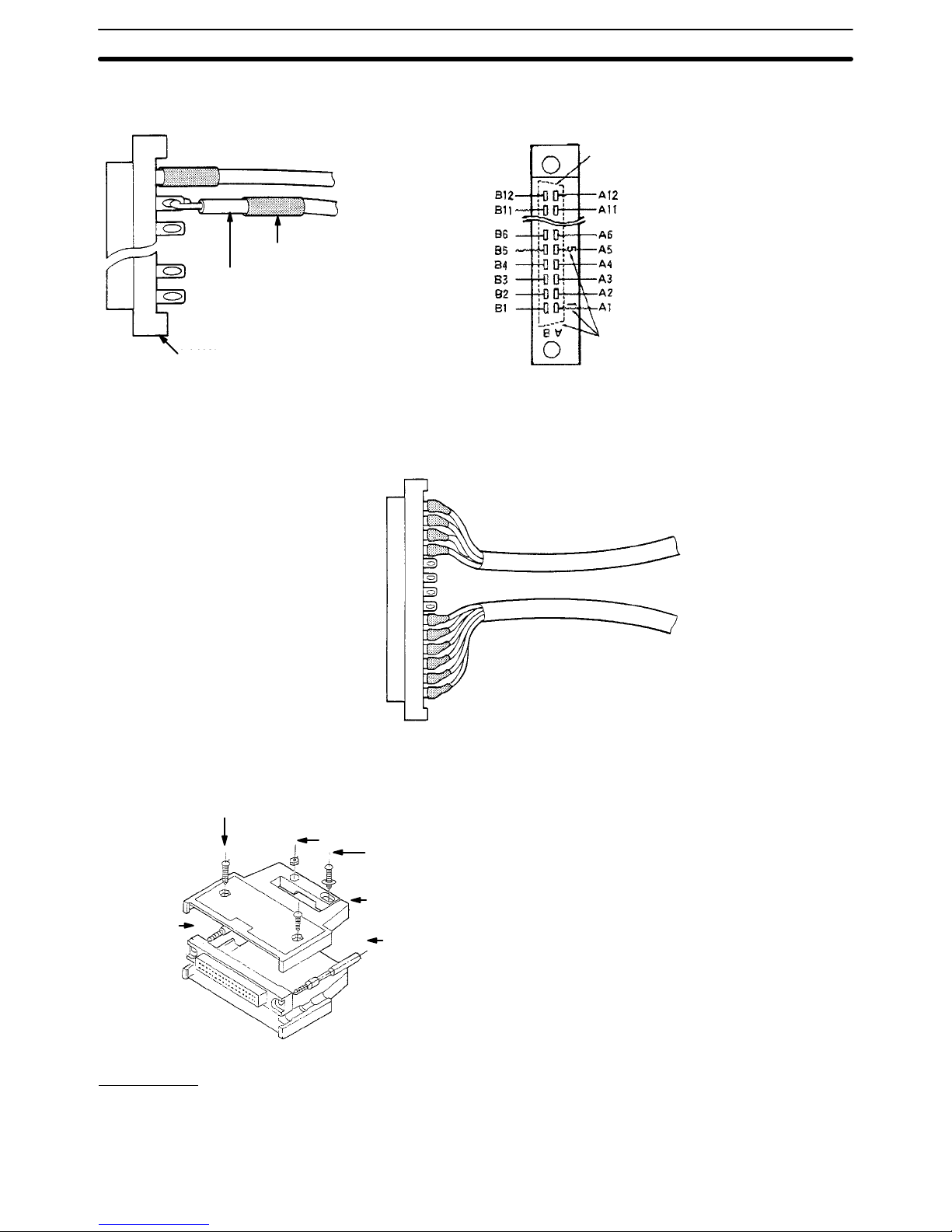

Wiring to Connectors

• Solder-type connectors are included with the Unit.

• Use wire with a cross-sectional area of 0.3 mm

2

or less.

• When soldering, do not short-circuit an adjacent terminal; cover the soldered section with an insulation.

• When using multi-core cable, wire output and input cables separately.

Wiring Section 2–2

Page 26

15

Insulator

Lead (0.3 mm

2

max.)

Connector

Connector Viewed from Soldered Side

Connector Pin Numbers

The connector pin numbers are shown in

the following figure. Wire the connector

correctly according to the pin numbers.

Shape of connector flange on other side

Pin number marks

Differentiating Cables

Output cables

Input cables

Assembling Connectors

Usable connectors:

Fujitsu model 360 jack

1. FCN-361J040-AU (solder)

FCN-360C040-B (connector cover)

2. FCN-363J040 (solderless)

FCN-363J-AU (contact)

FCN-360C040-B (connector cover)

3. FCN-367J040-AU/F (solderless)

1. is included as an accessory.

Two 8-mm M2 pan-head

screws (short)

Connector

(jack)

Four M2 nuts

Two 10-mm M2

pan-head screws (long)

Case

Lock screw

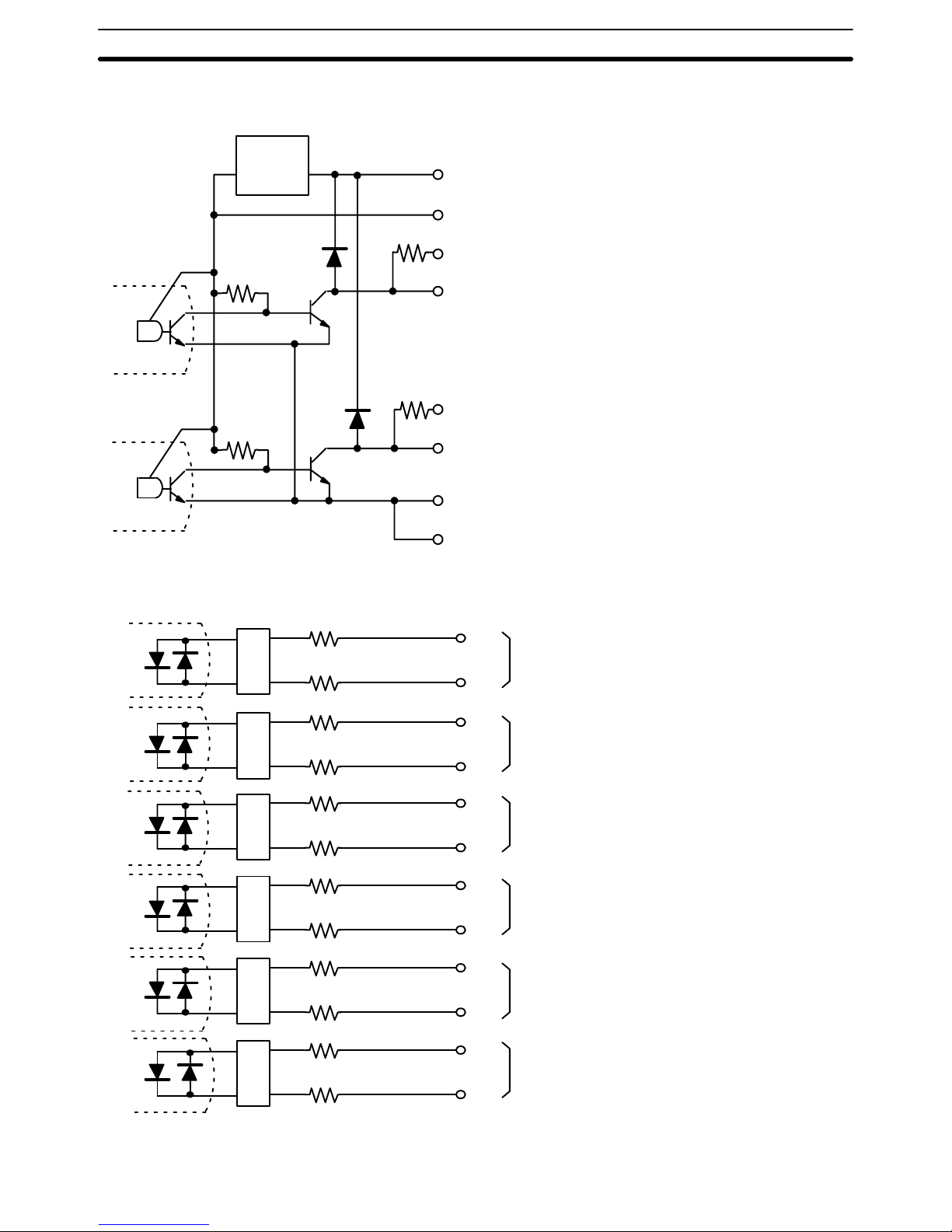

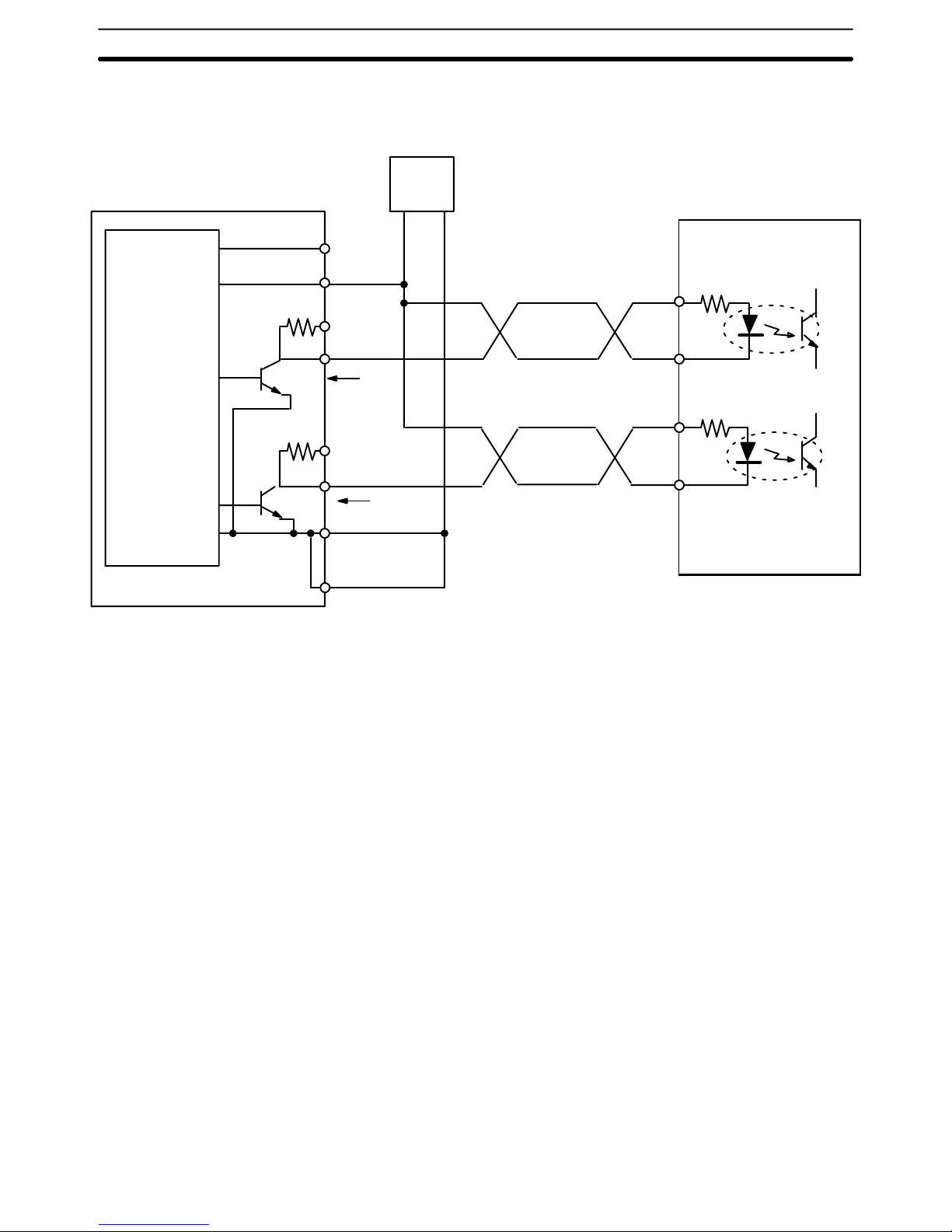

I/O Circuits

In the I/O circuits depicted in the following diagrams, pin numbers on the connector actually start from 1 at the bottom of the connector and run through 20

at the top.

Wiring Section 2–2

Page 27

16

Outputs

1.6 kΩ (1/2W)

Constantvoltage

circuit

A1

B2

1.6 k

Ω (1/2W)

A3

B3

A4

B4

A5

B5

Power for output, 24 VDC

Power for output, 5 VDC

CCW pulse output/direction output (w/1.6 k

Ω resistor)

CCW pulse output/direction output

Note: Either of the output signals is selected by

the DIP switch on the rear panel.

CW pulse output or nondirectional pulse output

(w/1.6 k

Ω resistor)

CW pulse output or nondirectional pulse output

0 V

0 V

Supply a voltage of either

5 or 24 VDC; the internal

circuit will be damaged if

both the power sources

are connected.

Inputs

1 kΩ

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 kΩ

1 k

Ω

1 kΩ

1 k

Ω

1 k

Ω

B11

A12

B12

A13

B13

A19

B19

A20

B20

CCW limit input

(NC input)

External interrupt input

(N.O. input)

Emergency stop input

(NC input)

(12 to 24 VDC)

(0 V)

(12 to 24 VDC)

(0 V)

(12 to 24 VDC)

(12 to 24 VDC)

(12 to 24 VDC)

(0 V)

(0 V)

(0 V)

1 kΩ

1 k

Ω

(12 to 24 VDC)

(0 V)

A10

B10

Origin proximity input

(Select either N.O. or N.C.

inputs via the back-panel

DIP switch.)

Origin input

(Select either N.O. or N.C.

inputs via the back-panel

DIP switch.)

CW limit input

(NC input)

A11

Wiring Section 2–2

Page 28

17

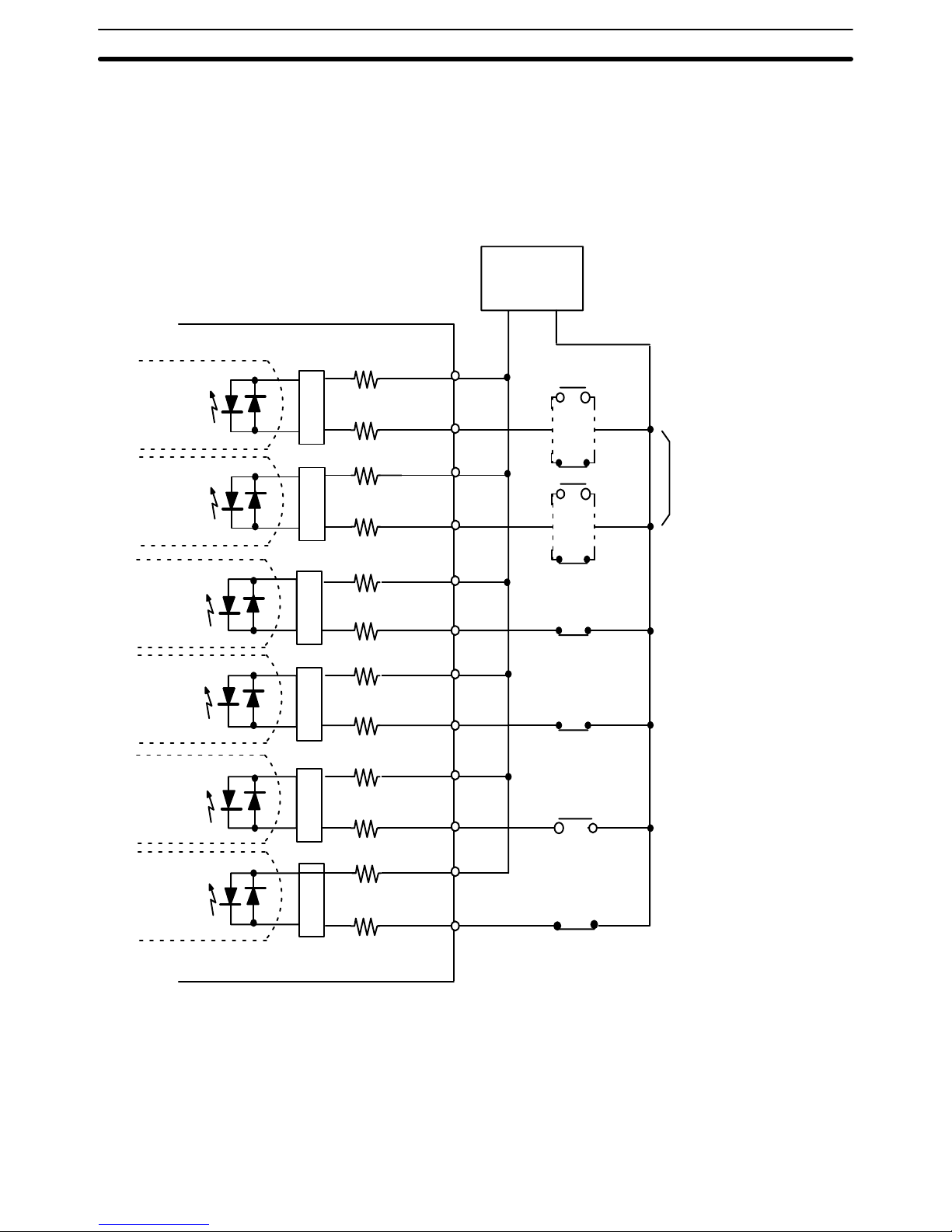

Input Connection

Example

Each input is provided with both a N.O. (normally open) input or N.C. (normally closed) input that can be used according to specifications.

Leave unused N.O. inputs open and connect unused N.C. inputs to the

power supply.

A10

B10

A12

B12

A13

B13

A19

B19

A20

B20

N.O. input

N.C. input

N.C. input

Position Control Unit

Origin proximity input

CCW limit input

CW limit input

External interrupt input

Emergency stop input

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 k

Ω

1 kΩ

1 k

Ω

+ –

N.C. input

A11

B11

Origin input

1 k

Ω

1 k

Ω

Power supply

(12 to 24 VDC)

Select either

N.O. or N.C.

inputs via the

back-panel

DIP switch.

• All inputs have independent grounds (commons) and are bidirectional. Connect switches of at least 12-mA capacity.

• Use a non-contact sensor (such as a proximity sensor) for the origin input to

reduce wear and deterioration.

Wiring Section 2–2

Page 29

!

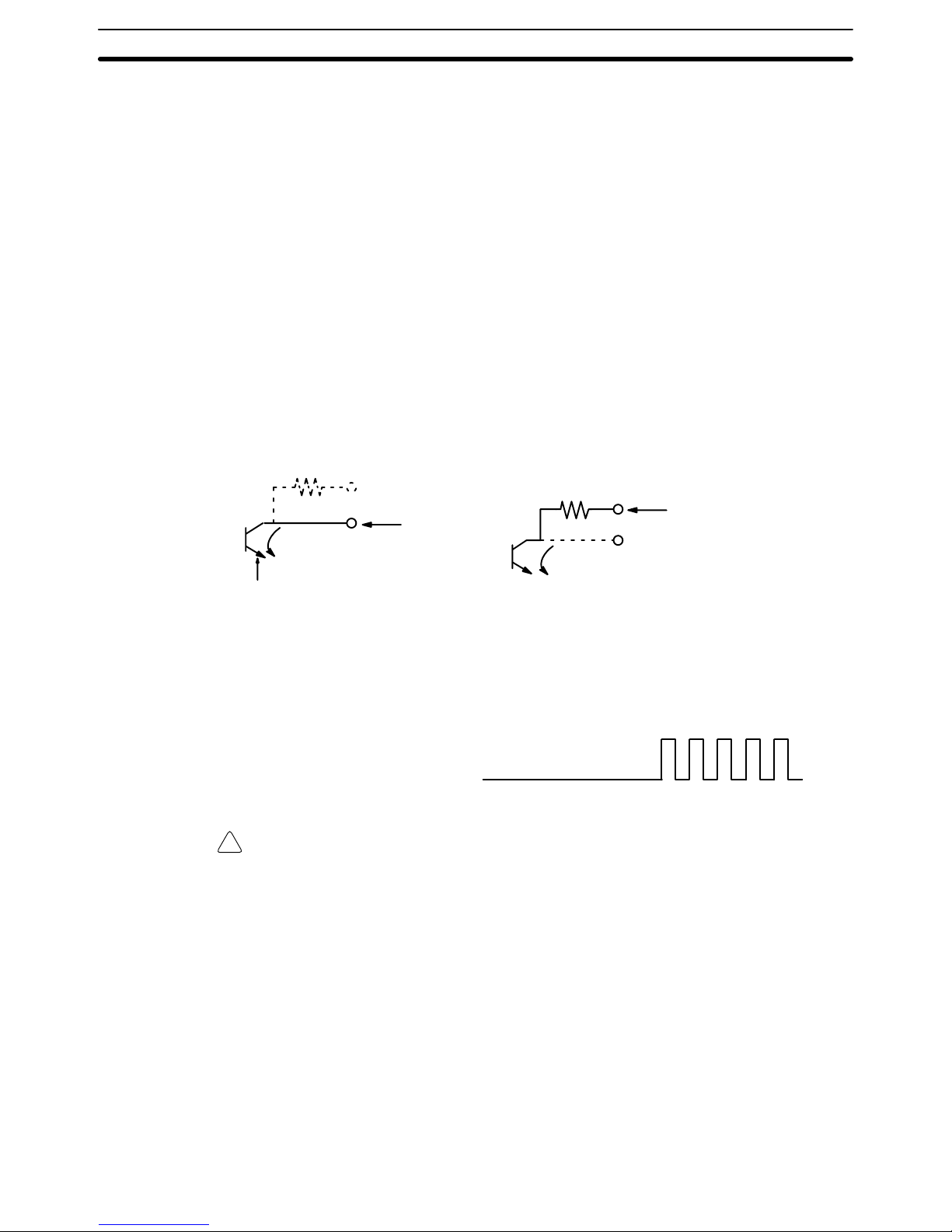

18

Output Connection

Examples

The following figures illustrate examples of connections to motor drivers. Always confirm motor driver specifications before making connections.

The Unit outputs only pulse trains and a direction output, or separate CW

and CCW pulse trains, to control the motor driver. If other control signals,

such as a deflection counter reset signal or motor excitation release signal,

are required, use a C200H I/O Unit and program in the required control actions.

Connect between 2.5-mA and 30-mA loads to outputs of the Unit, or add bypass resistance for loads less than 2.5 mA. Some output terminals have

1.6-kΩ (0.5 W) resistance built in. Use these as necessary according to

power supply and motor driver specifications. For voltage-level outputs, the

output goes low for ON and high for OFF.

Open collector output

Open collector output with 1.6 k

Ω series resistance

Output

2.5 to 30 mA

Output transistor

Output

2.5 to 30 mA

Pulses are not output when the output transistor in the pulse output section is

OFF. (For direction output, OFF indicates CCW.)

Output transistor

ON

OFF

Pulses are output

Caution Output power should be either 24 or 5 VDC. Never connect both the 24 and

5 VDC pins at the same time. In other words, never use power supplies of different voltages.

Wiring Section 2–2

Page 30

19

Example 1:

Outputting CW and CCW

Pulses With a 5-VDC

Power Supply

CCW input

CW input

Position Control Unit

24 VDC input

5 VDC input

CCW pulse output

CW pulse output

1.6 k

Ω

1.6 k

Ω

A1

B2

A3

B3

A4

B4

A5

B5

5-VDC

power

supply

+ –

Approx.

15 mA

Approx.

15 mA

Twisted pair cable

(+)

(–)

(+)

(–)

(Do not share this power supply with other pins.)

Motor driver (rated at 5 VDC)

(Example: R = 220

Ω)

Wiring Section 2–2

Page 31

20

Example 2:

Outputting CW and CCW Pulses With a 24-VDC Power Supply and a Motor Driver

Rated at 5 VDC

B4

(–)

(Example: R= 220Ω)

Position Control Unit

24-VDC input

5-VDC input

CCW pulse output

CW pulse output

1.6 k

Ω

1.6 kΩ

A1

B2

A3

B3

A4

A5

B5

24-VDC

power

supply

+ –

Approx.

12 mA

Approx.

12 mA

(Do not share this power source with other pins.)

Motor driver (rated at 5 VDC)

(+)

(–)

(+)

Twisted pair cable

Note In this example, a 5-V input motor driver is being used with a 24-V DC power

supply. The limit resistors (1.6 KΩ) of the NC111 are thus being used. Check

the driver current of the motor driver.

Example 3:

Outputting Pulse and Direction Signals with a 5-VDC Power Supply

Pulse (CW+CCW)

output

Pulse input

Position Control Unit

24-VDC input

5-VDC input

Direction output

1.6 k

Ω

1.6 k

Ω

A1

B2

A3

B3

A4

B4

A5

B5

5-VDC

power

supply

+

–

7 to 30 mA

7 to 30 mA

Motor driver (rated at 5 VDC)

Direction input

Wiring Section 2–2

Page 32

21

When the Position Control Unit is used to output voltage levels, the low level

is obtained when the output transistor turns ON, while the level goes high

when the transistor turns OFF.

Example 4:

Stepping–Motor Driver

Connection

Signal

24 V/0 V

B20

B13

B12

A12

B11

A10

B5

B2

A20

A13

A11

B4

+CW

+CCW

–CCW

E32

Stepping motor UPH599

Limit switch

(N.C. contact)

Position Control Unit

Power for

output

Origin

CCW

limit

CW limit

CW

CCW

0 V

B3

B10

+

5 VDC

+

Stepping motor driver Oriental UDX5114

Limit switch (N.O. or N.C. contact)

OMRON Photoelectric Switch

E3S-X3 CE4

(NPN output type)

–CW

Origin

proximity

Emergency

stop

24

VDC

Example 5:

Servomotor Driver

Connection

When applying the servomotor driver Z-phase output to the origin input of the

Position Control Unit, the line input/open collector conversion circuit is re-

Wiring Section 2–2

Page 33

22

quired, as shown in the example diagram on the following page.

23

Signal

24 V/0 V

+

A20

B20

B13

A13

A12

B12

A10

B10

B5

A5

B2

CCW

B3

B4

5 V

24

N.C. switches

EM

Position Control Unit

Power for

output

CCW limit

CW limit

Emergency stop

CW

0 V

5 VDC

12 to 24 VDC

+

1

2

3

4

+CW

–CW

+CCW

14

OMRON R88M-E

Servomotor (marketed in Japan)

OMRON R88DEP06

Servomotor Driver (marketed in Japan)

RUN

33

22

–CCW

–

+

Z-phase output

A11

Origin proximity

Origin

B11

E32

+

12 to 24 VDC

Toshiba TLP521-1 (GB)

Photocoupler

50-75Ω

Limit switch

(N.O or N.C.)

N.C. limit

switches

OMRON E3S-X3 CE4

(NPN output)

Photoelectric switch

Wiring Precautions

Operational errors can occur in most electronic control devices if they are

subjected to electronic noise from nearby power lines or loads. Recovery

from such errors is usually very difficult and time-consuming. To avoid such

noise-originating operational errors and thus improve system reliability, always abide by the following precautions in wiring the system.

1, 2, 3... 1. Cables must be of the required diameter.

2. Power lines (e.g., AC power supply, motor power line) and control lines

(e.g., pulse output lines, external I/O signal lines) must be wired separately. Never put these lines into the same duct or make them into a single bundle.

3. Use shielded cable for control lines.

4. Attach a surge absorber to all inductive loads, such as relays, solenoids,

and solenoid valves.

Wiring Section 2–2

Page 34

23

+

DC

–

Diode for surge absorption AC Surge absorber

RYRY

DC relays AC relays

Note:

Connect the diode and surge absorber as close as possible to the relay. Use

a diode capable of withstanding a voltage five times higher than the circuit

voltage.

SOL Surge absorber

Solenoids

5. Insert a noise filter into the power supply inlet if noise enters the power

line (e.g., when it is connected to the same power supply as an electric

welder or an electric spark machine or when there is any source generating high frequency noise).

6. Twisted pair cable is recommended for power lines.

7. For grounds, use thick cable with a cross-sectional area of at least 1.25

mm

2

.

Wiring Section 2–2

Page 35

24

2–3 Dimensions

Unit Dimensions

(Unit: mm)

35

130

100.5

Mounted Dimensions

(Unit: mm)

Cable

Approx. 200

117

Rack

Dimensions Section 2–3

Page 36

25

SECTION 3

Operation

This section covers all aspects of Position Control Unit operation other than commands, which are covered in the following section. Included in this section are the basic operating procedure, the type of output pulses possible, the basic data

format and configuration, some special features to aid operation, such as flags, zone settings, backlash compensation and

internal limits, and the internal data calculation methods used in processing user-input data.

3–1 Operational Flow 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Output Pulses 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Writing Data 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Data Configuration and Allocation 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 IR Area Data Format 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Flags and Other Input Data 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 DM Area Allocation 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–1 Zones 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–2 Backlash Compensation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–3 Internal CW/CCW Limits 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7–4 Data Calculations 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 37

26

3–1 Operational Flow

The basic procedure used to initially operate the Unit is outlined below. Refer

to applicable sections of the manual for details on each of these steps.

Item

Wiring

Data setting

Start

Wiring motor to

driver

Setting back-panel DIP switch

Data setting

Origin, origin proximity, CW/CCW

limits, emergency stop, external interrupt

.Output pulse selection

.Origin search direction

.Origin proximity signal type

.Origin signal type

.External interrupt signal type

DM area (key input via Programming Console)

.Parameters

.Positioning actions

.Speeds

Refer to:

Wiring external

inputs

Follow motor and driver and instruction

manuals for wiring details

Wiring Position Control

Unit to driver

2–2 Wiring

3–4 Data Configuration

2–1 Switch Settings

Section 4 Commands

3–7–4 Data Calculations

Section 5

Programming

Examples

Writing PC

program

Programming IR area (key input via

Programming Console)

Procedure

Operational Flow Section 3–1

Page 38

27

Item

ORIGIN SEARCH,

manual operation,

start, etc.

Correct error

Position Control

Unit reads DM area

Refer to:

Procedure

Restart by resetting

power or AR area

restart bit

Alarm/error

LED lit?

No

Yes

Error exists

READ ERROR

Alarm/error

LED flashes?

No

Yes

READ ERROR

Correct data

causing alarm

6–4 Troubleshooting

From the PC

AR area error and

restart bits for

Special I/O Units

4–5 READ ERROR

Section 6

Error

Processing

Trial run

Error processing

Operational Flow Section 3–1

Page 39

28

3–2 Output Pulses

The Position Control Unit can be set to output either independent CW and

CCW pulses or a nondirectional pulse and a direction signal. Set pin #1 on

the back-panel DIP switch to designate the target type of output. (See 2–1

Switch Settings.)

CW and CCW Pulse

Outputs

ON

OFF

CW pulse train

OFF

ON

CCW pulse train

Nondirectional Pulse

and Direction Signal

Outputs

Pulse train

Direction output

ON

OFF

ON

OFF

1 ms min.

CW: ON

CCW: OFF

CW

CCW

3–3 Writing Data

Data is written, via the Programming Console, into the section of the DM

area designated for Special I/O Units. The specific words are DM 1000-1999,

with 100 of these words allocated for each unit number assigned to a Position Control Unit. Written data is effective the next time power is turned on or

when the system is restarted with the restart bit in the AR area. To write data,

use the 3-word change operation of the Programming Console.

Key Input SequenceProgramming Console Display

D1824D1823D1822

0012 5000 2000

The above procedure prepares DM 1824 for change, and new data can be

keyed in. Pressing the CHG key again moves the cursor to DM 1823. After

inputting data, press the write key to execute the rewrite. In the above example, positioning action #0 of Unit #8 is shown.

Starting

When starting the Position Control Unit, the OUT refresh area is used. (The

OUT refresh area comprises the first five of the ten IR words allocated to

each Unit as refresh area. See 3–4 Data Configuration and Allocation for de-

Writing Data Section 3–3

Page 40

29

tails.) The busy flag and present position status can be read out from the IN

refresh area, the last five of these words.

To start the Unit, set (i.e., turn ON) the command bit regardless of whether

the Unit is in RUN or PROGRAM mode. Do not shift the mode between

MONITOR and PROGRAM while pulses are being output. Doing so will generate an error, preventing Unit operation.

Example: Starting Unit #8 in MONITOR or PROGRAM Mode

ST ART (command)

Start input

18000

In the above example, IR words 180 through 184 are allocated as the OUT

refresh area; IR words 185 through 190, as the IN refresh area.

Special I/O Unit

Restart Bits

AR Word 1

Restart bits can be used to transfer altered DM area data to the Unit without

turning power off and on. Refer to 6–3 Troubleshooting From the PC for re-

start bit allocations. The following Programming Console operation example

shows how to access the restart bit for Unit #0. The ladder diagram section

below it shows how to achieve the same operation through programming.

Programming Console Display Key Input Sequence

A0101

^ OFF

Program example: Unit #1

Restart switch

DIFU (13) AR0101

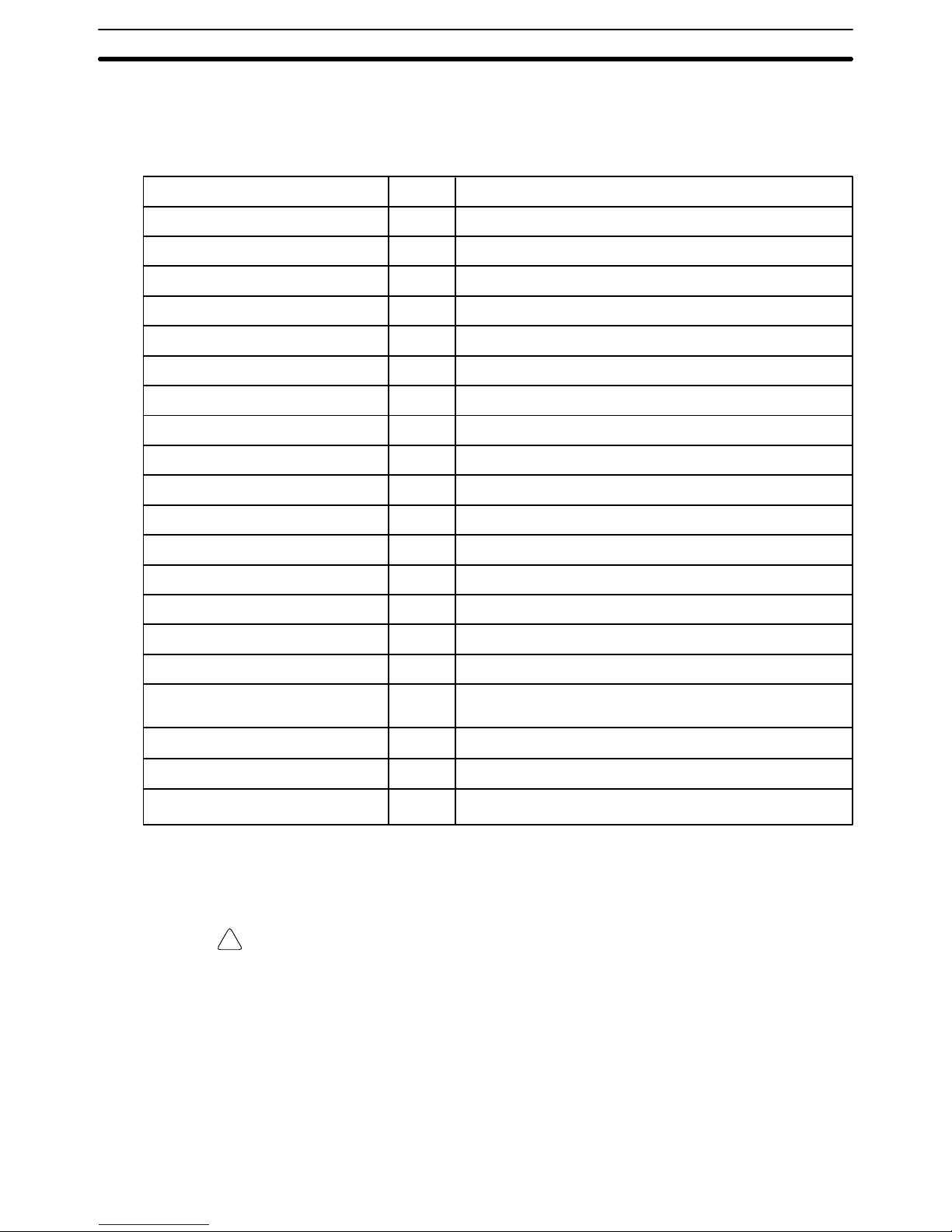

3–4 Data Configuration and Allocation

IR words 100 through 199 are allocated as I/O refresh areas. Each Position

Control Unit is allocated ten consecutive words. The first word for each Unit,

designated in this manual as n, can be computed from the unit number as

follows:

n = 100 + 10 x unit number.

Each Unit is also allocated 100 consecutive words as a fixed data area.

These words are in the DM area and run from DM 1000 through DM 1999.

The first word for each Unit, m, can also be computed from the unit number:

m = 1000 + 100 x unit number.

These allocations are shown below for all unit numbers. Details of allocations

within these words are given under the operations or commands to which

they apply. The tables on the following pages give a quick overview of word

and bit allocations. For a more complete overview, see Appendix C DM Area

Allocations and Appendix D IR Area Allocations.

Data Configuration and Allocation Section 3–4

Page 41

30

Data Configuration

C200H PC

IR Area

Words 100 to 109 Unit #0

Words 110 to 119 Unit #1

Words 120 to 129 Unit #2

Words 130 to 139 Unit #3

Words 140 to 149 Unit #4

Words 150 to 159 Unit #5

Words 160 to 169 Unit #6

Words 170 to 179 Unit #7

Words 180 to 189 Unit #8

Words 190 to 199 Unit #9

DM Area

Words 1000 to 1099 Unit #0

Words 1100 to 1199 Unit #1

Words 1200 to 1299 Unit #2

Words 1300 to 1399 Unit #3

Words 1400 to 1499 Unit #4

Words 1500 to 1599 Unit #5

Words 1600 to 1699 Unit #6

Words 1700 to 1799 Unit #7

Words 1800 to 1899 Unit #8

Words 1900 to 1999 Unit #9

Data is transferred

between the PC and

each Position Control

Unit each time I/O

data of the PC is refreshed.

Data is automatically transferred

from the PC to each Position Control Unit on power application or

when the AR area restart bit is

turned ON.

Position Control Unit

I/O refresh data areas

Words n to (n+4)

Words (n+5) to (n+9)

OUT refresh

IN refresh

Ten words are used

(n: 100 + 10 x unit no.)

Fixed data areas

Words m to m+21

Words m+22 to m+81

Words m+82 to m+97

Word m+98

Word m+99

Parameters

Position data

Speed data

Acceleration data

Deceleration data

100 words are used

(m: 1000 + 100 x unit no.)

Data Configuration and Allocation Section 3–4

Page 42

31

IR Area Allocations

”n” is the first IR word allocated to the Unit and equals 100 plus 10 times the

unit number.

00 START

01 Valid initial positioning

action number

02 ORIGIN SEARCH

03 ORIGIN RETURN

04 RELEASE PROHIBIT

05 READ ERROR

06 CHANGE SPEED

07 Valid speed coefficient

08 RESET ORIGIN

09 TEACH

10 TRANSFER DATA

11 HIGH-SPEED JOG

12 JOG direction

13 LOW SPEED JOG

14 INCH

15 STOP

Word n

Bit

n+1

Initial

positioning

action no.

Speed

coefficient

Beginning

word no.

(for TRANSFER DATA)

PC data area (for

TRANSFER DATA)

n+2 n+3 n+4

TEACH

positioning

action no.

00-19

Beginning

transfer no.

Number of

transfers (for

TRANSFER DATA)

TRANSFER

DATA type

(continued on next page)

Data Configuration and Allocation Section 3–4

Page 43

32

Emergency stop

signal

External

interrupt signal

Origin proximity

signal

00 Positioning completed

flag

01 Bank completed flag

02 At-origin flag

03 Alarm flag

04 Emergency stop flag

05 Error flag

06 Zone 0 flag

07 Zone 1 flag

08 Zone 2 flag

09 Teaching completed flag

10 Transfer completed flag

11 No-origin flag

12 Busy flag

13 CW limit flag

14 CCW limit flag

15 STOP flag

Word

Bit

n+6

n+7 n+8 n+9

Present

position

(rightmost 4

digits)

n+5

Origin signal

Output code

Positioning

action no.

Error

code

Direction digit

Present position

(leftmost 3 digits)

3–5 IR Area Data Format

Data is allocated either by bit or by word, though it is often input and output

by decimal digit, i.e., four bits (BCD). Position data is held in two adjacent

words, generally with a direction digit, in the following format.

direction

10310210110

0

10

4

10

5

10

6

0

1

CW

CCW

highest word

lowest word

Note that the rightmost word is always the lowest word. If the two words were

n+8 and n+9, for example, the rightmost word would be n+8 and the leftmost

would be n+9. Furthermore, the rightmost digit in each word begins in the

lowest bits. Thus, the digits x10

4

and x100 above would be held in bits 00

through 03 of their respective words. The direction digit also provides other

information when required.

Speeds, Acceleration,

and Deceleration

Only one word is used to store speeds, the acceleration, and the deceleration. The formats for these are as follows:

IR Area Data Format Section 3–5

Page 44

33

Speeds

10310210110

0

Acceleration and Deceleration

10210110

0

Data Coding

Although decimal notation is generally used for data in this manual, data is

handled in the system as binary-coded decimal (BCD) unless otherwise

noted. Note that this data is generally input as decimal, whereas hexadecimal data is input as hexadecimal. The number of digits given for certain data

refers to the decimal digits. For example, ”7 digits with direction” indicates

that the lowest word and rightmost 12 bits of the highest word are allocated

to the 7-digit decimal value; the leftmost four bits are allocated to the direction digit.

3–6 Flags and Other Input Data

IR words n+5 to n+9 are allocated to flags and other inputs that supply information about positioning system operation. Although some of these are described under specific operations or commands, they are presented together

in Appendix D IR Area Allocations for convenience. Of these, an output code

has been provided for user application and four signals, the last four in the

list, have been provided for system debugging.

3–7 DM Area Allocation

Coding Sheet

The table on the following page can serve as a general coding sheet for the

DM area. For a more detailed table describing the functions of all of the bits

in the DM area, see Appendix C DM Area Allocations.

The numbers shown for the DM words in the following table represent only

the final two digits of each word number. In other words, the first two digits

(which would be the same for all words) are not shown. The value of the first

two digits can be obtained by computing the first DM word allocated to the

Unit. This word, designated m, is equal to 1000 plus 100 times the unit number. Thus, for example, it would be 1000 for Unit #0, 1100 for Unit #1, and so

on.

DM Area Allocation Section 3–7

Page 45

34

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

15 00 Function W

Initial position nos.;

speed nos.

Origin compensation and direction

Backlash compensation

CW

limit

CCW

limit

Zone 0 CW limit

Zone 0 CCW limit

Zone 1 CW limit

Zone 1 CCW limit

Zone 2 CW limit

Zone 2 CCW limit

Not used

Positioning

action #0

0

Positioning

action #1

1

Positioning

action #2

2

Positioning

action #3

3

Transfer no.Transfer no.

15 00W Function

Positioning

action #4

4

Positioning

action #5

5

Positioning

action #6

6

Positioning

action #7

7

Positioning

action #8

8

Positioning

action #9

9

Positioning

action #10

10

Positioning

action #11

11

Positioning

action #12

12

Positioning

action #13

13

Positioning

action #14

14

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

W 15 00 Function

Positioning

action #15

15

Positioning

action #16

16

Positioning

action #17

17

Positioning

action #18

18

Positioning

action #19

19

Speed #1

Speed #2

Speed #3

Speed #4

Speed #5

Speed #6

Speed #7

Speed #8

Speed #9

Speed #10

Speed #11

Speed #12

Speed #13

Speed #14

Speed #15

Speed units

Acceleration

Deceleration

20

21

22

23

24

25

DM Area Allocation Section 3–7

Page 46

35

3–7–1 Zones

Up to three zones can be set in the DM area. If one or more zones have

been set, zone flags in the IR area can be used to determine if the present

position is within any established zones. A zone flag is ON (1) when the present position is within the zone; OFF (0) when it is not. Zones can be set to

cover a wide range of positions or narrowed to cover only part of a single positioning action. Zones can also be set to overlap, if target. For application

example, see programming example 8 in Section 5.

CW and CCW Limit

Settings

The CW and CCW limits for any one zone are set in separate word pairs, i.e.,

four words total are required to establish one zone. These words are allocated as follows:

Zone 0 CW limit: m+9 and m+10, 7 digits with direction

Zone 0 CCW limit: m+11 and m+12, 7 digits with direction

Zone 1 CW limit: m+13 and m+14, 7 digits with direction

Zone 1 CCW limit: m+15 and m+16, 7 digits with direction

Zone 2 CW limit: m+17 and m+18, 7 digits with direction

Zone 2 CCW limit: m+19 and m+20, 7 digits with direction

Note that the CW limit for any of the zones can be on the CCW side of the

origin; the CCW limit, on the CW side. In other words, a zone can either

cross the origin or be completely on one side of it. An alarm will be generated, however, if the CCW limit of a zone is set on the CW side of the CW

limit.

Zone 0 CW limit

CCW

Origin

CW

0

Zone 1 CCW limit

Zone 0 CCW limit

Inside zone

Inside zone

Zone 1 CW limit

Positioning axis

Example 1: Correct Setting

Zone 0 CCW limit

CCW

Origin

CW

0

Zone 0 CW limit

Positioning axis

Example 2: Incorrect Setting

DM Area Allocation Section 3–7

Page 47

36

Zone Flags

When the present position is in one or more of the zones, zone flags in the IR

area are turned ON (1). The PC’s scan time, however, can produce a delay in

indication during pulse output. Flag allocations are as follows:

0 Outside zone

1 Inside zone

08

n+5

0706

Zone 0 flag

Zone 1 flag

Zone 2 flag

3–7–2 Backlash Compensation

Backlash compensation can be used to compensate for the amount of mechanical play present in gears, particularly when the direction of positioning

actions changes.

Setting Parameters

There is only one parameter that needs to be set to compensate for backlash:

Backlash Compensation

DM word m+4

Set to between 0000 and 9999 pulses.

Backlash

DM Area Allocation Section 3–7

Page 48

37

Using Backlash

Compensation

When the feeding direction is reversed, the number of pulses set in DM area

is output at the initial speed, and the Unit then proceeds with normal operations.

Time

Compensation

If STOP is executed during backlash compensation for any operations requiring acceleration or deceleration (HIGH-SPEED JOG, ORIGIN SEARCH,

ORIGIN RETURN, and START), the Unit will stop feeding immediately after

outputting the initial step of the acceleration or deceleration, which will include the backlash compensation set above.

Stop position

Time

STOP executed

Compensation

3–7–3 Internal CW/CCW Limits

Limits on the CW and CCW sides of the origin can be set internally to restrict

Unit operation to within these limits.

CCW

Internally set value of CCW limit

0

Internally set value of CW limit

CW

Positioning axis

Internal CW Limit

DM words m+6 through m+5, 7 digits

Set to between 1 and 8388606.

Internal CCW Limit

DM words m+8 through m+7, 7 digits

Set to between 1 and 8388607.

The following values will be automatically set if the internal limit settings are

0.

CW: 8388607

CCW: 8388608

Operation

START (Positioning Actions)

DM Area Allocation Section 3–7

Page 49

38

If either of these limits is reached during execution of positioning actions,

pulse output will stop, and an error code, either 5030 or 5031, will be generated.

Manual Operation

If either of these limits is reached during execution of LOW-SPEED JOG,

HIGH-SPEED JOG, or INCH, pulse output will stop, and an error code, either

5070 or 5071, will be generated.

3–7–4 Data Calculations

Speeds

Slight differences exist between speeds set in the DM area and actual

speeds. These differences do not affect positioning accuracy.

Settings between 201

and 99,990 pps

where,

INT: Nearest integer

INT(4,000,000/set value): Divider ratio

pps: pulses per second

Actual speed (pps) =

4,000,000

INT(4,000,000/set value)

Pulse output (actual speed)

4 MHz

Divider

A 4-MHz source clock is divided by the integral divider ratio.

Example Values

Set Value (pps) Actual Speed (pps)

99,900 100,000.00

70,000 70,175.44

40,000 40,000.00

9,999 10,000.00

2,400 2,400.96

201 201.01

DM Area Allocation Section 3–7

Page 50

39

Settings between 1 and

200 pps

Actual speed (pps) =

62,500

INT(62,500/set value)

62.5 KHz

Pulse output (actual speed)

Divider

A 62.5-KHz source clock is divided by the integral divider ratio.

Example Values

Set Value (pps) Actual Speed (pps)

200 200.32

120 120.19

Trapezoidal Acceleration/Deceleration

An internal calculation process is used to create a trapezoidal figure from

speed, acceleration, and deceleration settings.

Speed

Time

When accelerating or decelerating between two speeds, the speed is varied

every unit time in a stepwise fashion. To achieve this, acceleration and deceleration tables are created internally when the Unit is first operated or when

TRANSFER DATA is used to alter data.

DM Area Allocation Section 3–7

Page 51

40

Table Creation

The internal processing of the Position Control Unit is as follows during table

creation.

1, 2, 3... 1. The speed difference, ∆V, is obtained to express the range of speed set-

tings.

∆

V = MAX – MIN

where,

MAX: Twice the maximum set value (not to exceed 100,000).

MIN: Speed indicated by initial speed number.

2. The number of division steps, L, is determined such that the unit time for

each step is 4 ms. The maximum number of steps is 250.

L = (∆V/R)

where,

R: Acceleration or deceleration data, whichever greater.

∆V/R: Acceleration (or deceleration) time between MAX and MIN

4

3. Next, the speed difference (∆υ) for each step is obtained.

∆υ

= (∆V/L)