Page 1

OPERATION MANUAL

ID Sensor

SYSMAC

C200H-IDS01-V1/IDS21

Cat. No. W153-E1-04

Page 2

C200H-IDS01-V1/IDS21 ID Sensor

Operation Manual

Revised May 2003

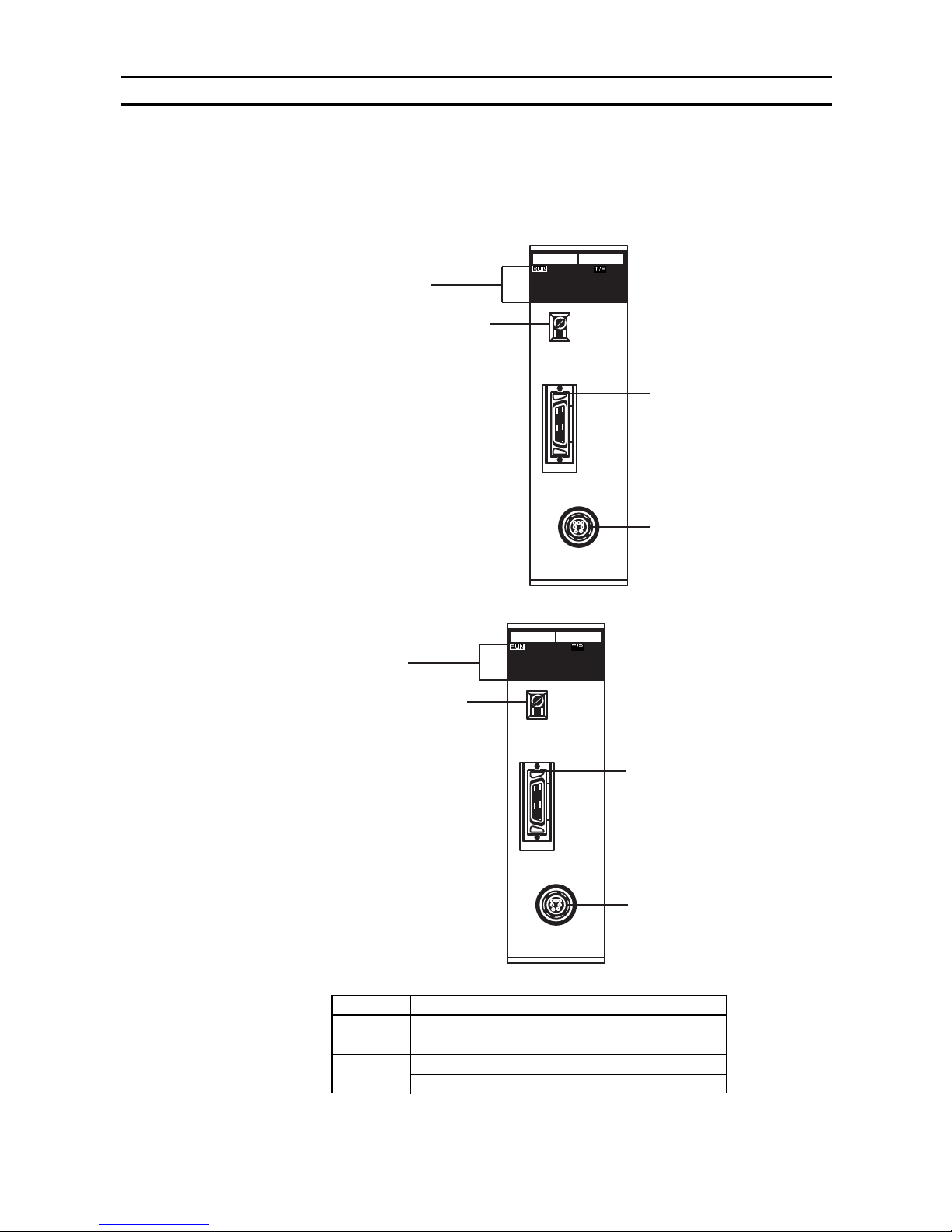

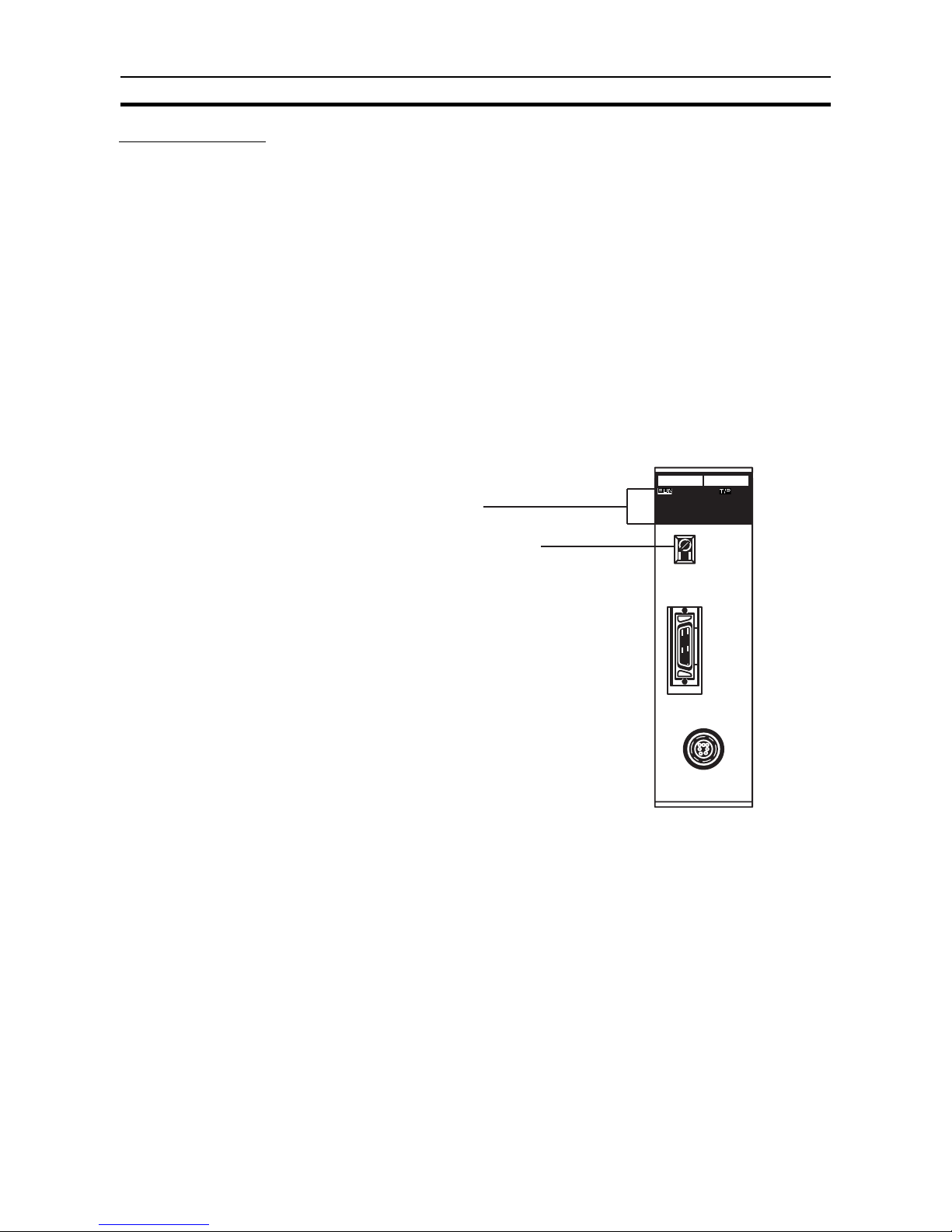

IDS01-V1

MONITOR

MACHINE

No

HEAD

IDS21

MONITOR

MACHINE

No

ANTENNA

Page 3

iv

Page 4

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 5

vi

Page 6

vii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

SECTION 1

System Description and Installation . . . . . . . . . . . . . . . . . . . 1

1-1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Components and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Maximum Distance Between ID Sensor Unit and R/W Head . . . . . . . . . . . . . . . . . . . . . . . 9

1-7 Maximum Distance Between ID Sensor Unit and R/W Antenna . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Word Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 The User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 3

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-1 Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-2 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3-3 Timing Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SECTION 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4-1 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-2 What To Do If a Malfunction Occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-3 Diagnostic Flowcharts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

C ASCII Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

D Using the C200H ID Sensor Unit with CS1-series PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Page 7

viii

TABLE OF CONTENTS

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Page 8

ix

About this Manual:

This manual explains the operation of two non-contact information detection

systems: C200H–IDS01–V1 Electromagnetic Inductor ID Sensor Unit and

C200H–ID21 Microwave ID Sensor Unit. Both Units, having long-range sensing capabilities, can read information from or write information to a Data Carrier mounted to a moving work piece. Refer to separate manuals for

specifications and operation of the R/W Heads and Data Carriers. The table

below shows a list of manuals available for the V600/V620 FA ID System.

Before operating an ID Sensor Unit, thoroughly familiarize yourself with both

the Unit and this manual.

Section 1 describes the features, components, configuration, and installation

of the ID Sensor systems.

Section 2 describes operation of the ID Sensor Units, and covers switch settings, bit allocation, and communication commands, and introduces the user

program.

Section 3 describes programming and includes example programs that illustrate data transfer between the Unit and the CPU. Monitoring functions and

timing considerations are also covered in this section.

Section 4 contains information on maintenance and troubleshooting.

Four Appendices provide information on specifications and standard models,

and also includes an ASCII code list.

Name Catalog no.

Handheld ID Controller Operation Guide Z43

V600 FA ID System Serial Interface Operation Manual Z44

V600 FA ID System Parallel Interface Operation Manual Z45

FA ID System V620 ID System with Serial Interface System Manual Z68

FA ID System V620 ID System with Parallel Interface System Manual Z69

V600/620 FA ID System Operation Manual Z83

V600 FA ID System R/W Heads and SRAM Data Carriers

Operation Manual

Z95

V600 FA ID System R/W Heads and EEPROM Data Carriers

Operation Manual

Z96

V600 FA ID System R/W Heads and SRAM Data Carriers Supplement Z98

V600 FA ID System R/W Heads and EEPROM Data Carriers

Supplement

Z99

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

Page 9

Page 10

xi

PRECAUTIONS

This section provides general precautions for using the C500-IDS@@ ID Sensors and related devices.

The information contained in this section is important for the safe and reliable application of C500-IDS

@@ ID

Sensors. You must read this section and understand the information contained before attempting to set up or

operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Page 11

xii

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing control devices.

• Personnel in charge of designing control systems.

• Personnel in charge of managing control systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for operating the ID Sensor system. Be sure

to read this manual before attempting to use the ID Sensor systems and keep

this manual close at hand for reference during operation.

Since the V620 ID Sensor system uses microwaves of 2,450 MHz, permission

is required from the local electrical communications regulatory board before

installing the system.

!WARNING It is extremely important that ID Sensor systems be used for the specified pur-

pose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying ID Sensor systems to the above-mentioned

applications.

3 Safety Precautions

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not throw the Data Carrier into fire or heat the Data Carrier to a tempera-

ture exceeding 100

°C. Doing so may cause ignition or burning of the built-in

lithium battery.

!WARNING Do not short the battery terminals or charge, disassemble, heat, or incinerate

the battery. Doing any of these may result in leakage, rupture, heat generation, or ignition of the battery.

Page 12

xiii

Operating Environment Precautions 4

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as "PC"), in order

to ensure safety in the system if an abnormality occurs due to malfunction of

the PC or another external factor affecting the PC operation. Not doing so

may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

4 Operating Environment Precautions

!Caution Do not operate the ID Sensor system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the ID Sensor system can have a large effect on

the longevity and reliability of the system. Improper operating environments

can lead to malfunction, failure, and other unforeseeable problems with the ID

Sensor system. Be sure that the operating environment is within the specified

conditions at installation and remains within the specified conditions during

the life of the system.

5 Application Precautions

Observe the following precautions when using the ID Sensor system.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

Page 13

xiv

Application Precautions 5

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

Ω or less when installing the ID Sen-

sor systems. Not connecting to a ground of 100

Ω or less may result in

electric shock.

• Always turn OFF the power supply to the PC before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Cassettes, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PC or the system, or could damage the PC or PC Units. Always heed

these precautions.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the system. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

Page 14

xv

Application Precautions 5

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

Page 15

xvi

Application Precautions 5

Page 16

1

SECTION 1

System Description and Installation

This section describes the features, components, configuration, and installation of the ID Sensor systems.

1-1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Components and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Maximum Distance Between ID Sensor Unit and R/W Head . . . . . . . . . . . . 9

1-7 Maximum Distance Between ID Sensor Unit and R/W Antenna . . . . . . . . . . 9

Page 17

2

System Description Section 1-1

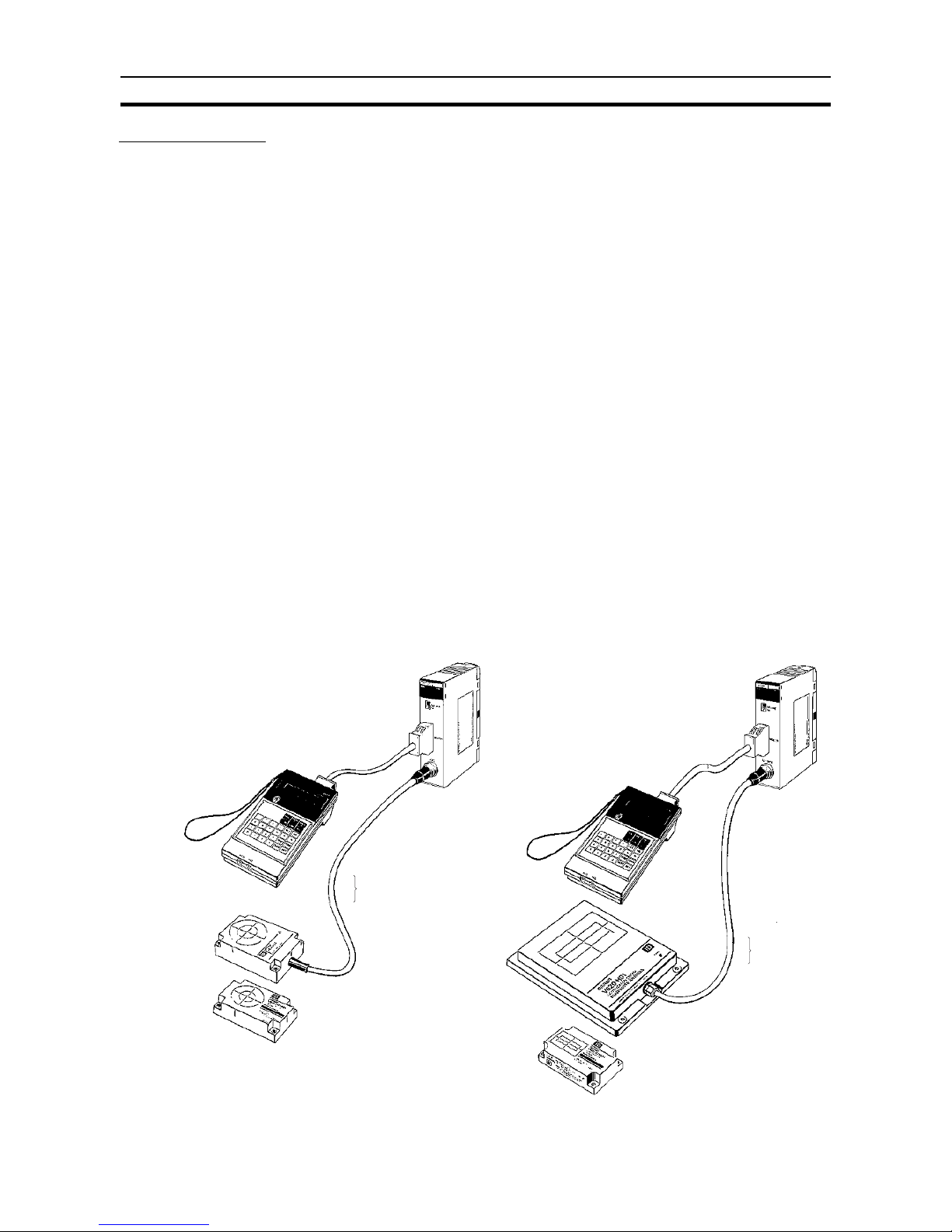

Section Overview This manual covers the operation of two ID Sensor models, the C200H-

IDS01-V1 Electromagnetic Induction ID Sensor Unit and the C200H-IDS21

Microwave ID Sensor Unit. The main difference between the Units is the distance at which the ID Sensor can read data from or write data to the Data Carrier. The Microwave ID Sensor Unit allows the Data Carrier to be placed

farther from the Unit.

This section describes the components, installation, and configuration of both

models.

1-1 System Description

The ID Sensor system is a versatile noncontact identification system comprising an ID Sensor Unit, a single Read/Write (R/W) Head or Antenna, and a

Data Carrier.

The ID Sensor mounts to a C200H Programmable Controller (PC); the Data

Carrier mounts to a moving workpiece or workpiece carrier. The R/W Head or

Antenna, connected to the ID Sensor Unit by a cable, must be positioned

within communication range of the travel path of the Data Carrier. Responding

to commands from the user program in the CPU of the PC, the ID Sensor

reads data from or writes data to the Data Carrier through the R/W Head or

Antenna. The operation of the ID Sensor can be monitored and tested with

the Handheld Programming Console; messages appear on the display of the

Console.

The following diagram illustrates two ID Sensor systems, one using a C200HIDS01-V1 ID Sensor and one using a C200H-IDS21 ID Sensor.

C200H ID Sensor Systems

Connecting Cable

R/W Antenna

V620 series

Data Carrier

V620 series

Connecting Cable

Hand-held Programming Console*

C200H-PRO27-E

30.5 m max. when using the V600-H07

50.5 m max. when using the V600-H11/H51/H52

10 m max.

Hand-held Programming Console*

C200H-PRO27-E

Read/Write

Head V600

series

Data Carrier

V600 series

Microwave ID Sensor

Unit (C200H-IDS21)

Electromagnetic Induction ID

Sensor Unit (C200H-IDS01-V1)

Connecting Cable

Page 18

3

Features Section 1-2

1-2 Features

The ID Sensor systems have the following features:

Seven Dedicated

Commands

Data is transferred between the ID Sensor Unit and the Data Carrier with the

following six dedicated commands:

Read

Write

Auto Read

Auto Write

Clear-all

Auto Read/Write Abort

Data management (C200H-IDS01-V1 only)

Up to 1024 bytes of data can be read from or written to the Data Carrier at

one time. Clear-all clears all data in the Data Carrier’s memory (2K bytes).

These commands are compatible with the V600 and V620 ID Controllers.

Monitoring with the

Handheld Programming

Console

The Handheld Programming Console can be used for monitoring data transfer

as well as errors that have occurred during operation. A keyboard sheet for

the Handheld Programming Console is included with the ID Sensor Unit.

Storage of Error

Information

Error information is stored in the internal memory of the ID Sensor Unit. A

built-in capacitor stores the information for 15 days (at 25

°C).

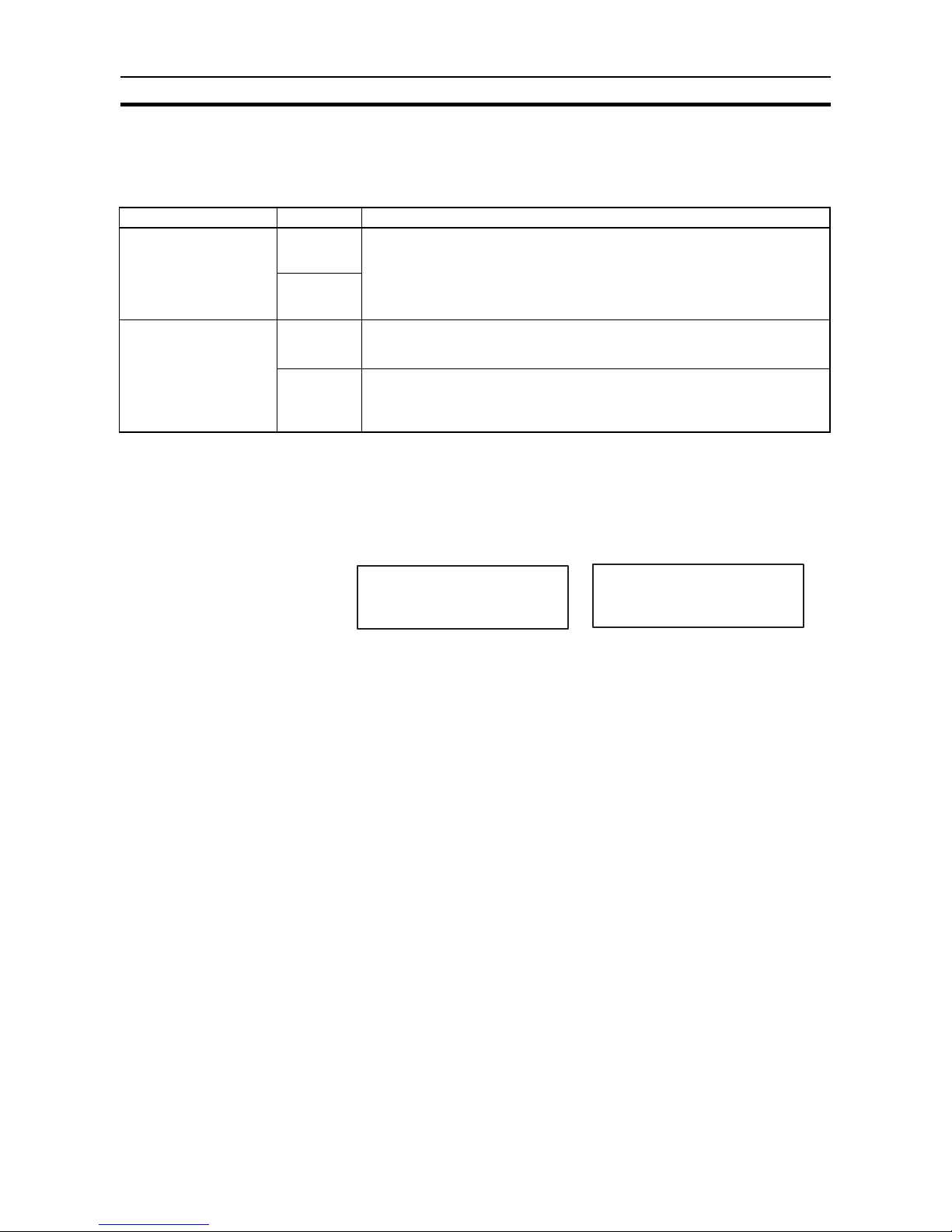

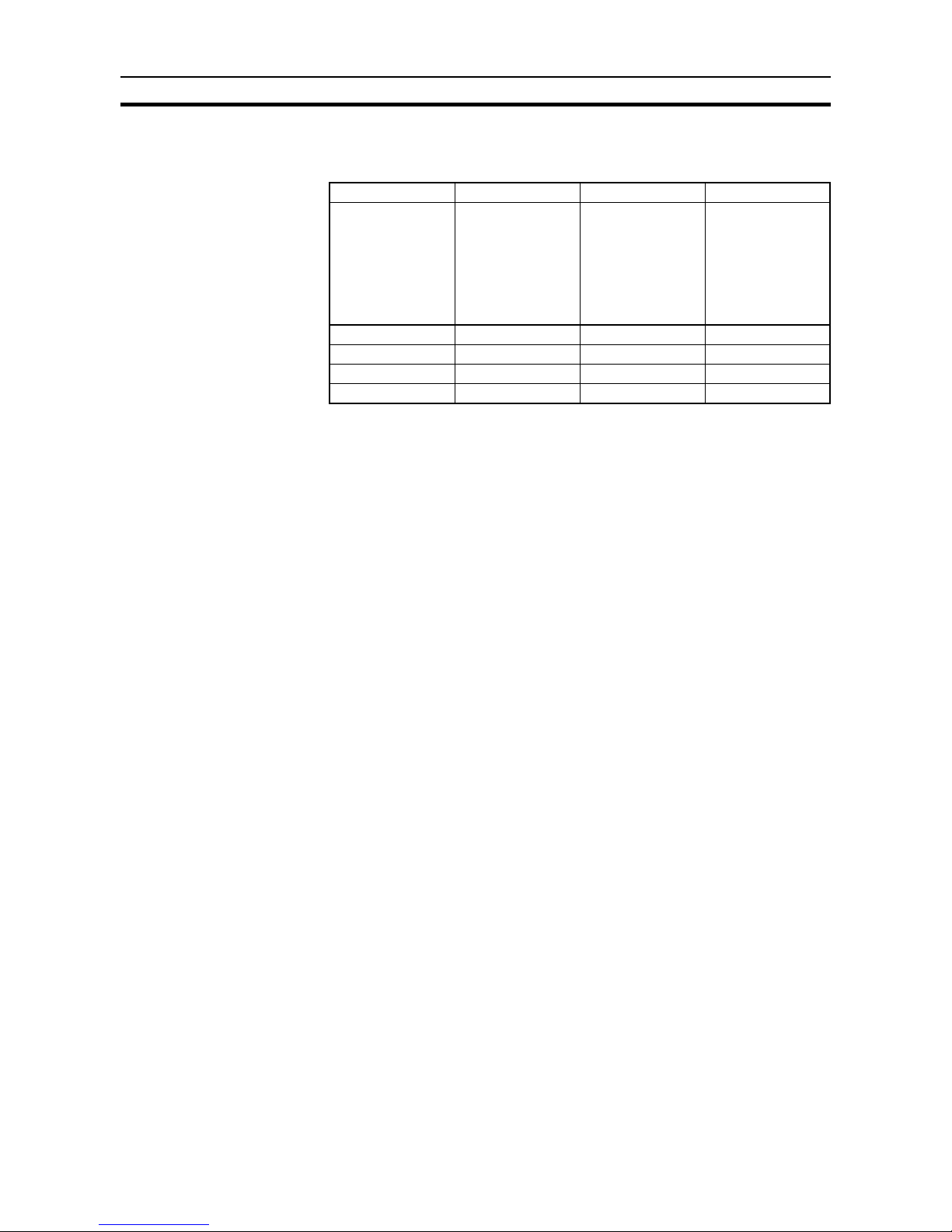

Compatibility The following table lists the compatibility between the I/D Sensor Unit and the

R/W Head, R/W Antenna, or Data Carrier.

Note Refer to the list of applicable manuals in the About this Manual section.

Differences between

C200H-IDS01 and

C200H-IDS01-V1

The C200H-IDS01-V1, which is an updated version of the C200H-IDS01, has

the following three new features in addition to all the capabilities that the

C200H-IDS01 possesses. The C200H-IDS01 is compatible with the C200HIDS01-V1.

1,2,3... 1. Connecting to Data Carrier Incorporating EEPROM

The C200H-IDS01-V1 reads data from and writes data to the V600-D@@P@@

containing an EEPROM. To read data, the user can select the communications distance priority mode or communications speed priority mode with the

local communications mode pin (pin 3 of the DIP switch). Neither of these

modes are, however, available when the ID Sensor Unit is connected to the

SRAM Data Carrier.

ID Sensor Electromagnetic induction Microwave

V600-H@@ R/W

Head

V600-D@@R@@

Data Carrier (with

built-in battery)

V600-D@@P@@

Data Carrier (with

no built-in

battery)

V620-H@@ R/W

Antenna

V620-D@@R@@

Data Carrier (with

built-in battery)

C200H-IDS01-V1 Yes Yes Yes No No

C200H-IDS01 Yes Yes No No No

C200H-IDS21 No No No V620-H01/-H02 V620-D8KR01

3

4

1

2

Local communications mode pin

Page 19

4

Features Section 1-2

2. New Commands

The C200H-IDS01-V1 incorporates data management commands, with which

it is possible to check the reliability of the Data Carrier’s data. The details of

the commands are as follows:

3. Hexadecimal Page Number Display

The page number is displayed in hexadecimal, in which case the rightmost

two digits of the address are displayed as the page number.

In the following example, the user has access to address 0A00 or 1000.

Function Command Meaning

Checking of data MD-K By adding a check code to the Data Carrier’s data, it is possible to detect a data

error due to the battery of the Data Carrier that incorporates SRAM, or

excessive overwriting operations of the Data Carrier that incorporates

EEPROM. Use the MD-K command to calculate and write the check code to the

Data Carrier. Use the MD-C command to collate the check code. The MD-K

command and MD-C command must be always used together.

MD-C

Checking of the number

of overwriting operations

MD-L Check the life of the Data Carrier’s EEPROM by counting the number of

overwriting operations. The Data Carrier’s EEPROM allows a total of 100,000

overwriting operations.

MD-S Use this command to specify the number of overwriting operations in the life of

the EEPROM in advance. Every time a write operation is performed, 1 is

subtracted and the Data Carrier will detect when the life has expired. This command is only available with models of lot number @@55 (May 1995) or later.

C200H-IDS01-V1 C200H-IDS01

C200H-IDS21

HEAD 1 PAGE 0A

STadrs00 data 00

ANT. PAGE 10

STadrs00 data 00

Page 20

5

Components and Indicators Section 1-3

1-3 Components and Indicators

Although similar in appearance, note that the C200H-IDS01-V1 ID Sensor

reads or writes data through a Read/Write Head and the C200H-IDS21 reads

or writes data through a Read/Write Antenna.

C200H-IDS01-V1 Front Panel

C200H-IDS21 Front Panel

Indicators The table below explains the status of the indicators on both models.

Indicators

Unit number switch

( "Machine No.")

Handheld Programming

Console connector

Read/Write Head

connector

IDS01-V1

MONITOR

MACHINE

No

HEAD

Indicators

Unit number switch

( "Machine No.")

Handheld Programming

Console connector

Read/Write Antenna

connector

IDS21

MONITOR

MACHINE

No

ANTENNA

Indicator Function

RUN Lit (green) while the ID Sensor is operating.

Unlit if an error occurs in the ID Sensor Unit.

T/R Lit (green) during data communication.

Unlit when data is not transmitted.

Page 21

6

System Configuration Section 1-4

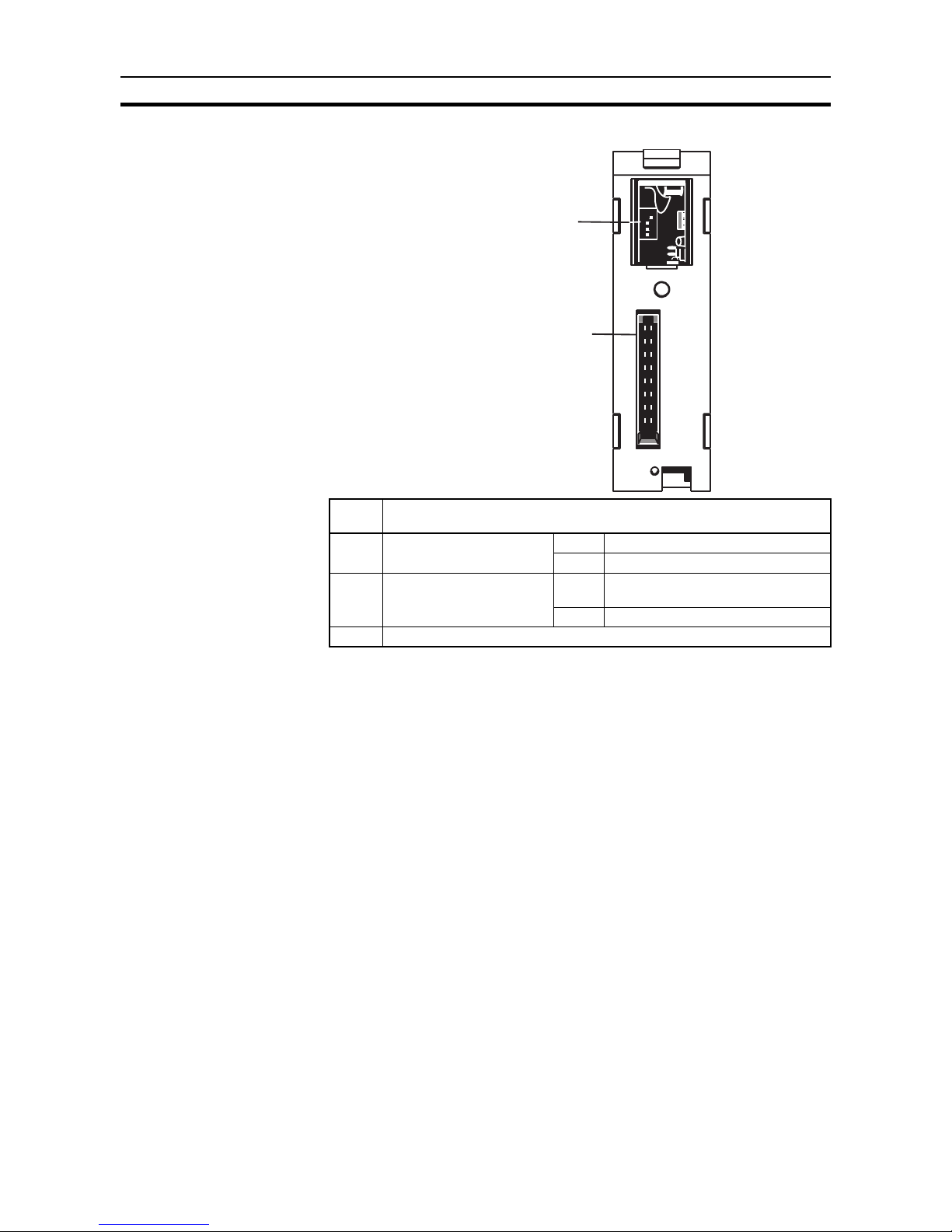

Back Panel C200H-IDS01-V1/IDS21

Note The user can select the communications distance priority mode or

communications speed priority mode with pin 2 of the DIP switch

when the C200H-IDS01-V1 accesses the EEPROM Data Carrier.

Neither of these modes are, however, available when the ID Sensor

Unit accesses the SRAM Data Carrier or when the C200H-IDS21 accesses any Data Carrier, in which case turn pin 2 OFF. Refer to the

V600 FA ID System R/W Heads and EEPROM Data Carriers Operation Manual for the communications distance and speed of the EE-

PROM Data Carrier.

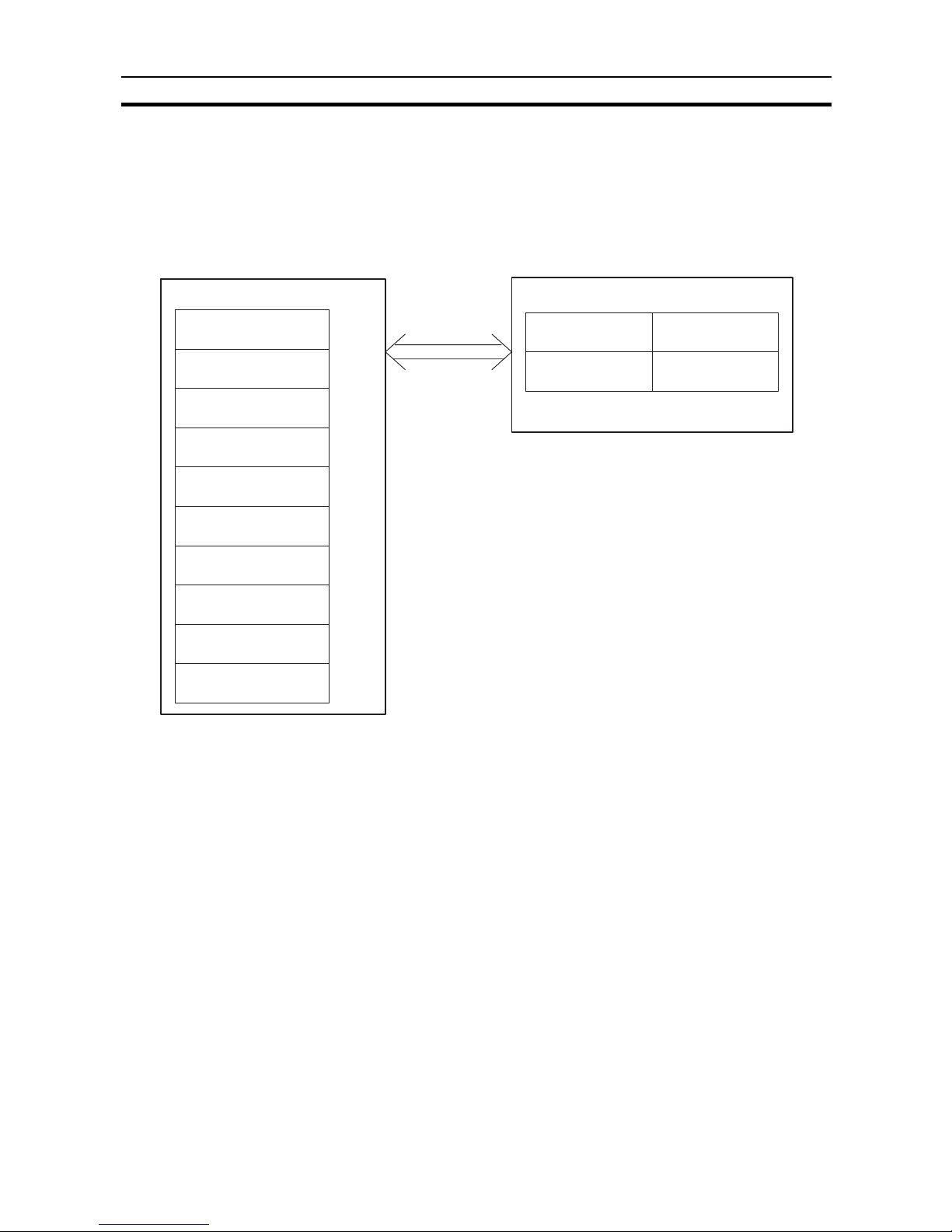

1-4 System Configuration

The diagrams below illustrate the system configurations of the C200H-IDS01V1 Electromagnetic Induction ID Sensor Unit and the C200H-IDS21 Microwave ID Sensor Unit.

The ID Sensor Unit transfers data through the Read/Write Head (or Antenna)

to a Data Carrier, which is mounted on a moving workpiece. The ID Sensor

Unit transfers the desired data according to instructions from the user program in the CPU (refer to 2-3 The User Program). Only one Read/Write Head

(or Antenna) can be connected to the ID Sensor Unit.

Data and error information can be monitored through a Handheld Programming Console connected to the ID Sensor Unit. The data is displayed on the

screen of the Programming Console.

Pin

No.

Function

1 Screen messages OFF Japanese

ON English

2 Local communications

mode (see note)

OFF Communications distance priority

mode

ON Communications speed priority mode

3, 4 Always OFF

DIP switch

Backplane connector

Page 22

7

System Connections Section 1-5

C200H-IDS01-V1 Electromagnetic Induction ID Sensor

C200H-IDS21 Microwave ID Sensor Unit

1-5 System Connections

Mounting the ID Sensor

Unit

As a Special I/O Unit, an ID Sensor Unit can be mounted to any slot on the

C200H PC Backplane except the two rightmost slots; these two slots are

reserved for peripheral devices.

Up to ten Special I/O Units can be mounted to a PC system. (The PC Link

Unit, used to link two PCs, is a Special I/O Unit.) The number of ID Sensor

Units which can be connected may be limited by the size of the Backplane,

the Power Supply, and the current consumption of each Unit. For details, refer

to the C200H Programmable Controller Installation Guide.

Mounting to a Remote I/O

Slave Rack

The maximum number of Special I/O Units that can be mounted to a Remote

Slave Rack differs depending on the group (A, B, C, or D, as shown in the following table) to which they belong.

C200H

ID Sensor Unit

C200H

Connecting Cable

Read/

Write Head

Read/Write

data

Data Carrier

Work

piece

Movement

Work

Hand-held Programming Console

(Attach the keyboard accessory

sheet, supplied with the ID Sensor

Unit, to the Programming Console.)

Read/Write

Head

C200H

ID Sensor Unit

C200H

Connecting Cable

R/W

Antenna

Read/Write

data

Data Carrier

Work

piece

Movement

Work

R/W

Antenna

Hand-held Programming Console

(Attach the keyboard accessory

sheet, supplied with the ID Sensor

Unit, to the Programming Console.)

Page 23

8

System Connections Section 1-5

The information in this table applies only when no other Special I/O Units are

mounted to other Racks (PC or Expansion I/O Racks) and the Units in this

table are mounted only to a Remote I/O Slave Rack.

When combining Units from groups A, B, C, and D, use the following formulae:

3A + B + 2C + 6D

≤ 12

A + B + C + D

≤ 8

A maximum of ten Units can be mounted to one Remote I/O Slave Rack.

However, when mounting ten Units, the NC211 Position Control Unit is

counted as two Units and, if a PC Link Unit is used, it is counted as one Unit.

Connecting the ID System Refer to page 2 for an illustration of system connections.

Before connecting and wiring the ID Sensor Unit, turn OFF the power to the

PC.

Connect the R/W Head or Antenna to the ID Sensor Unit connector marked

“HEAD” or “Antenna”. (To disconnect the cable, pull while grasping the outer

ring of the cable; do not pull at an angle.)

Connecting the Handheld

Programming Console

Refer to 3-2 Monitoring for information on connecting the Handheld Program-

ming Console.

The Next Step Once you have completed installation of the ID Sensor system, turn to

SEC-

TION 2 Operation

for details on setup and operation.

ABCD

High-speed

Counter, Position

Control Unit

(NC111/NC112),

ASCII Unit, Analog

I/O Unit, ID Sensor

Unit, Fuzzy Logic

Unit

High-density I/O

Units, Temperature

Control Units, Cam

Positioner Unit

Temperature

Sensor Unit, Voice

Unit

Position Control

Unit (NC211)

4 Units max. --- --- ---

--- 8 Units max. --- ---

--- --- 6 Units max. ---

--- --- --- 2 Units max.

Page 24

9

Maximum Distance Between ID Sensor Unit and R/W Head Section 1-6

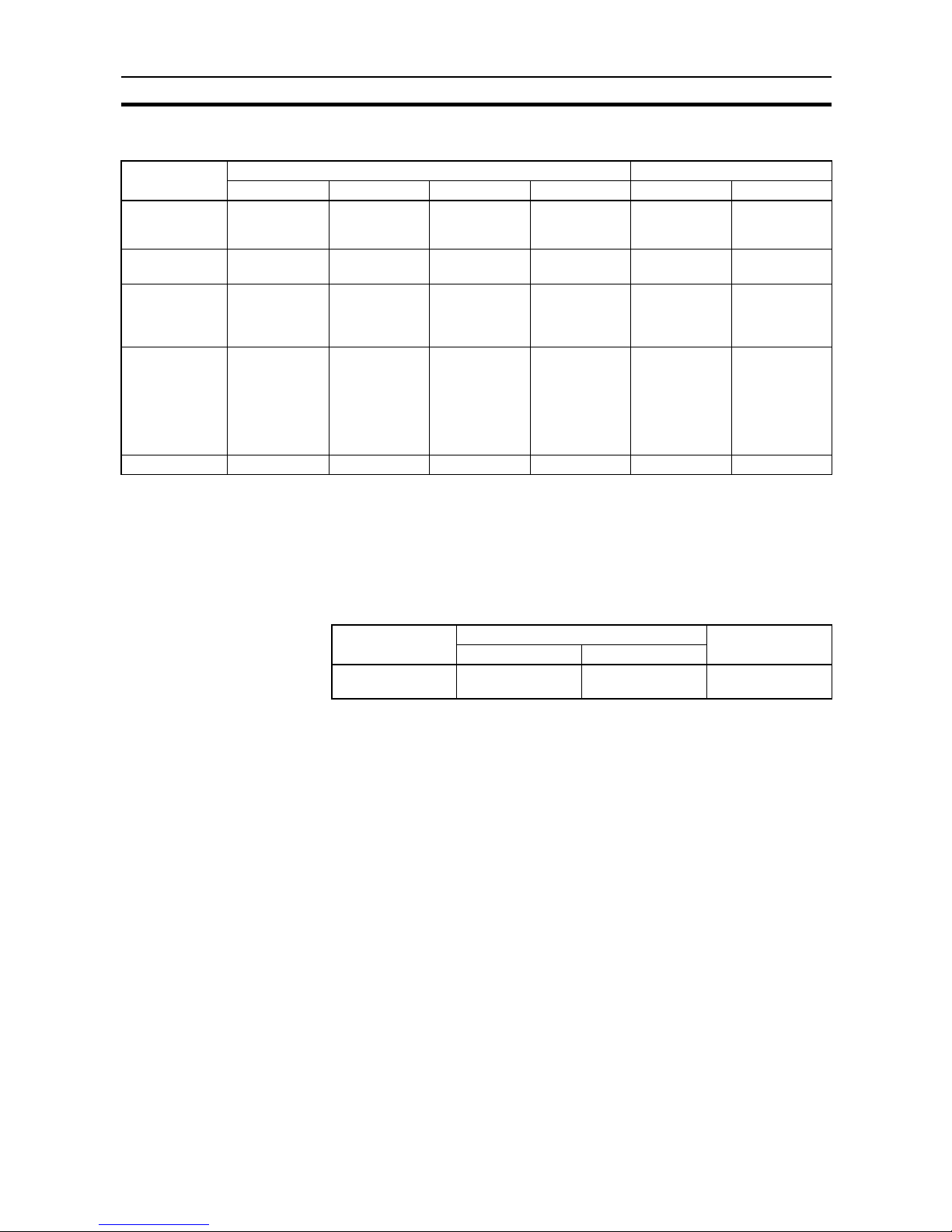

1-6 Maximum Distance Between ID Sensor Unit and R/W Head

Note With the C500-IDS02 (V1), the maximum cable length between the IDS02

(V1) and IDA02 is 200 m max. The length shown above is a distance between

the IDA02 and the R/W Head.

1-7 Maximum Distance Between ID Sensor Unit and R/W

Antenna

Note With the C500-IDS22, the maximum cable length between the IDS22 and

IDA22 is 200 m max. This length shown above is a distance between the

IDA22 and the R/W Head.

R/W Head C500 C200

IDS01-V1 IDS01-V2 IDS02 IDS02-V1 IDS01 IDS01-V1

V600-H52

(V600-D23P52)

(V600-D23P54)

--- 50.5 m --- 10 m --- 50.5 m

V600-H51

(V600-D23P61)

--- 50.5 m --- 10 m --- 50.5 m

V600-H11

(V600-D23P72)

(V600-D23P61)

(V600-D2KR16)

--- 50.5 m --- 10 m --- 50.5 m

V600-H07

(V600-D23P71)

(V600-D23P72)

30.5 m for lots

manufactured

in or after 1991

and 10 m for

lots manufactured before

1991.

30.5 m 10 m 10 m 30.5 m for lots

manufactured

in or after 1992

and 10 m for

lots manufactured before

1992.

30.5 m

V600-H06 10 m 30.5 m 10 m 10 m 10 m 30.5 m

R/W Antenna C500 C200H-IDS21

IDS21 IDS22

V620-H01

(microwave)

10 m 10 m 10 m

Page 25

Page 26

11

SECTION 2

Operation

This section describes operation of the ID Sensor Units, and covers switch settings, bit allocation, and communication

commands, and introduces the user program.

2-1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Word Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 The User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3-1 Communication Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3-2 Data Carrier Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3-3 Write Protection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3-4 Write Protection Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3-5 The Data Carrier’s Production Date . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-3-6 Detection of Data Carrier’s Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 27

12

Switch Settings Section 2-1

Section Overview This section contains information on switch settings, bit allocation, and setup

of both ID Sensor systems, as well as explanations of the user program, communication commands, and the write-protect function.

2-1 Switch Settings

Unit Number Switch Before beginning operation, use the unit number switch on the front panel to

set the unit number (0 through 9) of the ID Sensor Unit. Each Special I/O Unit

must be assigned its own number; if the same number is assigned to more

than one Unit, an I/O Unit Over error will occur, preventing system operation.

To set the unit number:

1,2,3... 1. Determine the appropriate unit number (refer to 1-5 System Connections

for information on Special I/O Units).

2. Turn OFF the power to the PC.

3. Using a small standard screwdriver, turn the dial to the desired number.

The dial clicks into position at each number setting; do not leave the dial

between settings.

Back Panel DIP Switch (Refer to the diagram of the back panel on page 5.) Pin 1 is used to select the

language of the Programming Console display; leave this pin at the ON (left)

position for English message display. Pins 2 through 4 are for reserved for

expansion; leave these pins at the OFF (right) position.

Indicators

Unit number switch

(MACHINE No.)

IDS01-V1

MONITOR

MACHINE

No

ANTENNA

Page 28

13

Word Settings Section 2-2

2-2 Word Settings

Words 100 through 199 in the IR area of the PC are reserved for Special I/O

Units. Each Special I/O Unit is assigned ten words, of which five are needed.

These five words, used by the ID Sensor or other Special I/O Units for data

communication, are referred to as I/O refresh data (stored in the I/O refresh

data area). The five words that are not used can be used as work bits.

Note Each Unit must be assigned a different unit number. If two or more Special I/O

Units are assigned the same unit number, the system is unable to determine

which Unit is to be accessed and an I/O Unit Over error occurs, halting the

system.

PC (C200H)

IR area

words 100 through 104

words 110 through 114

words 120 through 124

words 130 through 134

words 140 through 144

words 150 through 154

words 160 through 164

words 170 through 174

words 180 through 184

words 190 through 194

Unit 0

Unit 1

Unit 2

Unit 3

Unit 4

Unit 5

Unit 6

Unit 7

Unit 8

Unit 9

I/O refresh data

is transferred to

each Unit.

ID Sensor Unit

I/O refresh

words n through

n+3

word n+4

OUT refresh

IN refresh

5 words are used.

(n = 100 + 10 x unit number)

Page 29

14

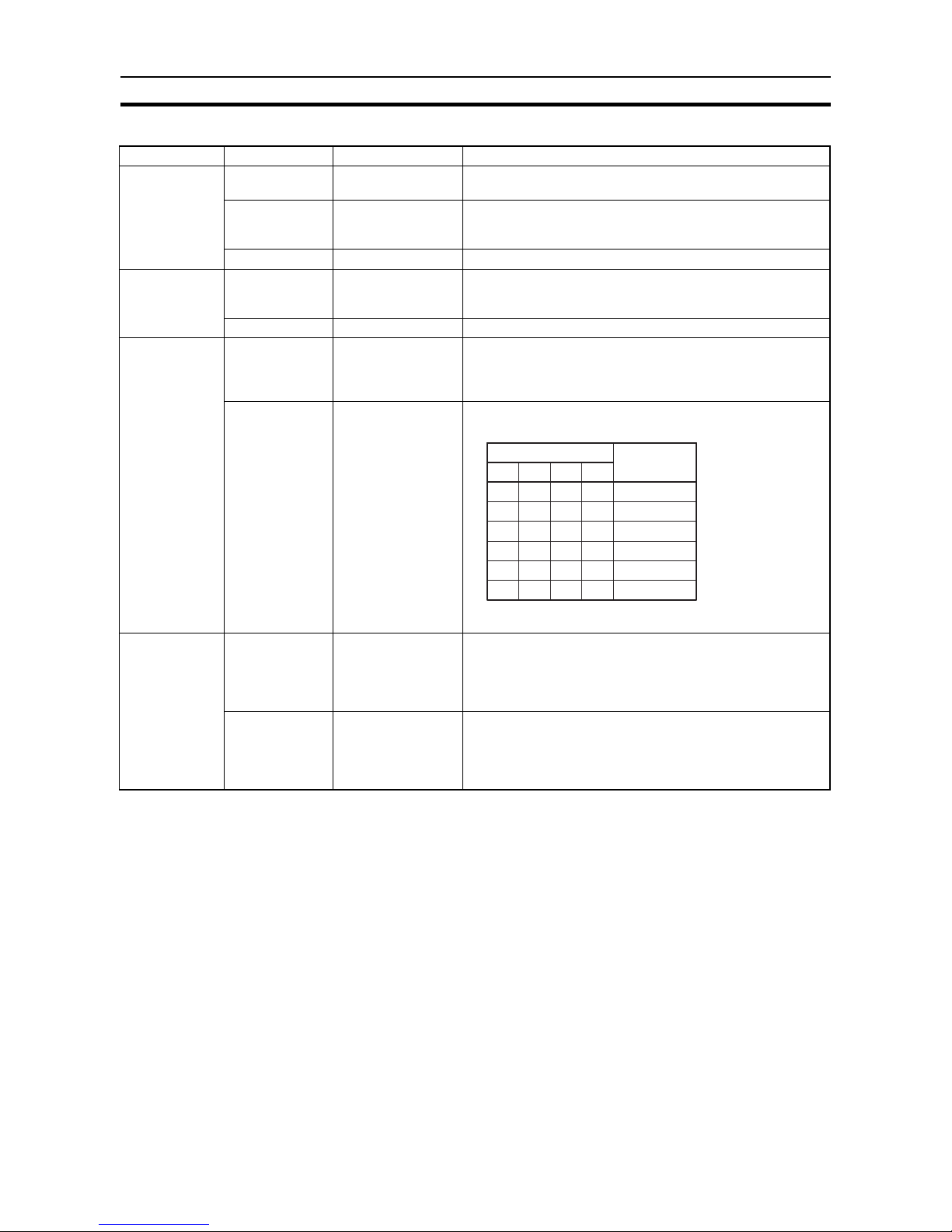

Word Settings Section 2-2

IR Bit Allocation

Note 1. Only 512 words of data can be read or written, 4 words are used for com-

mand data.

2. At the leading edge of a command signal, the data of word n+1 through

word n+3 is valid.

3. The unused bits are provided for expansion. Do not use as work bits.

Word Bit number Bit name Function

n 00 Command

execution flag

At the leading edge of the signal, the ID Sensor Unit reads

and executes the command.

01 Error reset flag While the ID Sensor Unit is waiting for a command, the error

reset flag is turned ON and the error flags in word n+4, bits 08

through 15 are turned OFF.

02 through 15 – Not used (see note 3).

n+1

(see note 2)

00 through 11 No. of command

data words

Indicates, in Binary Coded Decimal (BCD), the number of

words in the command to be executed. The maximum number

of words is 516 (see note 1).

12 through 15 – Not used (see note 3).

n+2

(see note 2)

00 through 11 Command data

storage area

beginning word

number

Indicates, in BCD, the beginning word of the command to be

executed (stored in the CPU).

When the DM area exceeds DM 1000, turn ON bit 12.

12 through 15 Command data

storage area

n+3

(see note 2)

00 through 11 Read data receiving

area beginning word

number

The CPU reads the data from the Data Carrier using Read or

Auto Read. Specifies the beginning word of the area (in the

CPU) where the data is stored. The data is ignored when

Write, Auto Write, Clear-all, or Auto Read/Write Abort is

executed.

12 through 15 Read data receiving

area

Specifies the area in the CPU in which the data read from the

Data Carrier (using Read or Auto Read) is stored. Refer to

word n+2, bits 12 through 15, to determine data areas. The

data is ignored when Write, Auto Write, Clear-all or Auto Read

or Auto Read/Write Abort is executed.

Indicates the area where the command to be executed is

stored.

Bit number

15 14 13 12

0

1

00

0

0

0

0

0

0

0

0

0

0

0

0

0

***

1

1

1

11

1

Area name

DM area

IR area

HR area

AR area

LR area

TIM/CNT

***When the DM area exceeds DM 1000, turn ON bit 12.

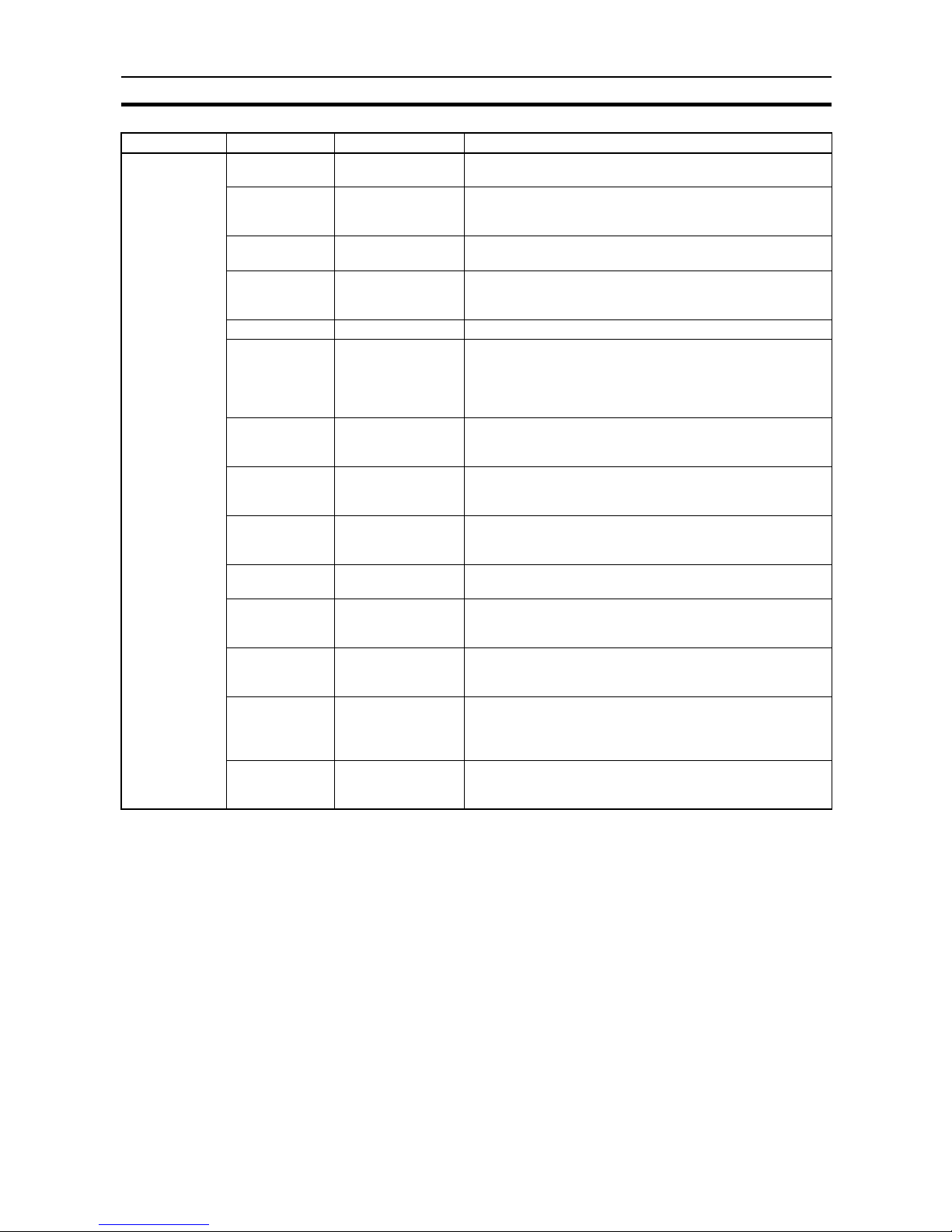

Page 30

15

Word Settings Section 2-2

Word Bit number Bit name Function

n+4 00 ID busy This flag turns ON while the ID Sensor Unit is executing a

command.

01 Waiting for Data

Carrier

During the execution of Auto Read or Auto Write, this flag is

ON while it is waiting for the Data Carrier to approach the

Read/Write Head (or Antenna).

02 Auto Read/Write

Abort end

This flag turns ON when the ID Sensor Unit has received

(from the CPU) and completed Auto Read/Write Abort.

03 Programming

Console MONITOR

mode

This flag turns ON when the Programming Console

(connected to the ID Sensor Unit) is in MONITOR mode.

04 through 06 – Not used

07 Data Carrier warning This flag turns ON when the Data Carrier’s battery is almost

dead. This flag also turns ON when the MD-C command

detects a data check error or when the MD-L/MD-S command

detects that the number of overwriting operations reaches the

specified number.

08 Read format error During the execution of Read or Auto Read, this flag is ON

when the data in the Data Carrier exceeds the capacity of the

receiving area. (Refer to Read/Write Bit Areas page 16.)

09 Command error This flag is ON when the ID Sensor Unit cannot process the

command sent from the CPU. The command may be

undefined or may not have a terminator.

10 No Data Carrier

error

This flag turns ON when the Data Carrier is undetected by the

ID Sensor after the ID Sensor has received Read, Write, or

Clear-all from the CPU.

11 Write protect error This flag turns ON when an attempt is made to write data to a

write-protected area of the ID Sensor Unit’s memory.

12 Data Carrier

communication

error

This flag turns ON if an error has occurred during data

communication between the ID Sensor Unit and Data Carrier.

13 Data Carrier

address over

This flag turns ON when the ID Sensor Unit attempts to

access an address of the Data Carrier which is beyond the

Data Carrier’s memory capacity.

14 Data verification

error

As the ID Sensor Unit reads data from or writes data to the

Data Carrier, the ID Sensor Unit compares the current data

with previously read or written data. If the data is not identical,

an error occurs and this flag turns ON.

15 Read/Write Head (or

Antenna)

disconnect error

This flag turns ON when the Read/Write Head is improperly

connected to the ID Sensor Unit.

Page 31

16

Word Settings Section 2-2

Read/Write Bit Areas The following table shows the memory areas (bits) that the ID Sensor Unit

uses when reading data from or writing data to the Data Carrier.

If, during execution of Read or Auto Read, the data read from the Data Carrier

exceeds the capacity of the receiving area, a Read Format error occurs and

word n+4, bit 08 turns ON.

Example:

Data Carrier Read data: 40 bytes = 20 words

Beginning word number (receiving data): DM 1990

As the above table shows, the words specified in the DM area are DM 0000

through DM 1999. If the beginning word number is DM 1990, only 10 words

(DM 1990 through 1999) are available for receiving data. In this example, the

quantity of data to be read is too large for the available space in the DM area.

A Read Format error will occur and the data will not be written to the DM area.

To correct the error, change the beginning word number (receiving data) to a

word number less than DM 1980, or reduce the quantity of data in the Data

Carrier to fewer than 10 words.

Error Storage Area The error information storage area of the ID Sensor Unit is undefined at ship-

ment. Before using the ID Sensor Unit, clear the newest error information and

statistical error information. (Refer to 3-2-9 Error Log Display (ERR) for

details).

Error Messages and Reset

Flags

The ID Sensor Unit’s error messages and reset flags are located in the AR

area as “Special I/O Unit Error Message” and “Special I/O Unit Reset Flag”.

Refer to the C200H Programmable Controller Operation Manual for details.

When the error message flag for a particular unit number is ON, the RUN LED

of the corresponding Special I/O Unit turns OFF.

Area

DM area

IR area

HR area

AR area

LR area

TC area

Bits

DM 0000 through 1999

000 through 246

HR 00 through 99

AR 07 through 22

LR 00 through 63

TC 000 through 511

Special I/O Unit Error Message

Special I/O Unit Reset Flag

AR 0000 through AR 0009

AR 0100 through AR 0109

Page 32

17

The User Program Section 2-3

2-3 The User Program

The ID Sensor Unit will not function unless the PC is programmed to control

the operation of the Unit. The Unit communicates with the Data Carrier

through the Read/Write Head by means of the commands provided by the

user program of the PC.

Program examples with detailed explanations are provided in Section 3-1

Program Examples.

The following figure shows the basic operation outline of the program.

Operation Outline

Effect of CPU Status on ID

Sensor Unit

The ID Sensor Unit is controlled by the program contained in the CPU; if an

error occurs in the CPU, an error will also occur in the ID Sensor Unit.

The ID Sensor Unit will continue to execute commands when the PC is in

PROGRAM mode.

Communication with the

CPU

The ID Sensor Unit reads data from and writes data to the Data Carrier in

accordance with the commands sent from the CPU.

PC

Word data

Dedicated command

Read data

User program

MOV, OUT etc.

(Command execution flag)

MOV, LD instruction etc.

(Error information)

Common

memory

I/O word

words n

through

n+4

ID Sensor Unit

Internal program

Analyzes the

command

and transfers

the data

between PC

and Data

Carrier

Executes

handshaking

and processes error

information

R/W

Head

Data

Carrier

Page 33

18

The User Program Section 2-3

Writing Data to the Data

Carrier from the CPU

The CPU, via the Write, Auto Write, and Clear-all commands, directs the ID

Sensor Unit to write data to the Data Carrier. The following diagram shows

how the program writes data to the Data Carrier.

1. The CPU sends the command data (the number of words in the command to be sent, the beginning word number of the command, and

the command execution start) to the ID Sensor Unit by using MOV or

OUT.

2. The ID Sensor Unit analyzes the command received from the CPU.

3a. If the command is legal, the ID Sensor Unit writes the required data to

the Data Carrier.

3b. If the command is illegal, the ID Sensor Unit sets the Command Error

flag (word n+4 bit 09) to ON and returns the data to the CPU. At this

time, the ID Busy flag (word n+4 bit 00) is turned OFF.

4. When the ID Sensor Unit has completed communication with the

Data Carrier, the Unit turns OFF the ID Busy flag as the command is

completed, and returns the data to the CPU.

If communication with the Data Carrier fails, or if an error occurs during communication, the ID Sensor Unit stops data communication with the Data Carrier, turns ON the Data Carrier communication error flags, returns the data to

the PC, and turns OFF the ID Busy flag.

Steps 1 to 4 compose one write operation.

Reading Data from the

Data Carrier to the CPU

The CPU, via the Read and Auto Read commands, directs the ID Sensor Unit

to read data from the Data Carrier to the CPU. The following diagram shows

how the program reads data from the Data Carrier.

1. The CPU sends command data (the number of words in the command, the beginning word number of the command, and the beginning word number of the data to be received) to the ID Sensor Unit by

using MOV or OUT.

2. The ID Sensor Unit analyzes the command received from the CPU.

3a. If the command is legal, the ID Sensor Unit reads the required data to

the Data Carrier.

CPU

ID Sensor

Unit

1

3b

4

2

3a

R/W

Head

Data

Carrier

CPU

ID Sensor

Unit

1

3b

4

2

3a

R/W

Head

Data

Carrier

Page 34

19

The User Program Section 2-3

3b. If the command is illegal, or the Read format is illegal, the ID Sensor

Unit turns ON both the Command Error flag (word n+4 bit 09) and the

Read Format Error flag (word n+4 bit 08), and returns the data to the

PC. At this time, the ID Busy flag (word n+4 bit 00) is turned OFF.

4. When the ID Sensor Unit has completed communication with the

Data Carrier (step 4), the ID Sensor Unit forwards the read data to the

CPU; the Unit turns OFF the ID Busy flag as the command is completed.

If communication with the Data Carrier fails, or if an error occurs during communication, the ID Sensor Unit stops data communication with the Data Carrier, turns ON the Data Carrier communication error flags, returns the data to

the CPU, and turns OFF the ID Busy flag.

Steps 1 to 4 compose one read operation.

2-3-1 Communication Commands

The ID Sensor Unit is provided with seven dedicated commands for communicating with the Data Carrier through the Read/Write Head. The following table

outlines these commands.

Note The Clearall command clears the Data Carrier’s internal memory, regardless

of write protection.

When transferring data between the Data Carrier and the ID Sensor Unit, up

to 1024 bytes (512 words) of data per scan can be written to or read from the

Data Carrier. However, when transferring data between the PC and the ID

Sensor Unit, only 20 words can be transferred per scan. Data is transferred

between the PC and the ID Sensor Unit at a rate of 0.2 ms per word.

If data is to be read and written simultaneously, the read data can be up to 20

words (40 bytes) in length and the write data can be up to 16 words (32 bytes)

in length. (Because the write data is transferred with the command data,

which requires 4 of the 20 words, only 16 words are available to carry the

write data.) If the data exceeds 20 words, more than one scan is required to

transfer the data between the CPU and the ID Sensor Unit, making simultaneous processing impossible.

For details refer to 3-3 Timing Considerations.

Command name Mnemonic ASCII

code

Function

Write WT 57 54 Writes data to the internal memory of the Data Carrier; up to1024 bytes

(512 words) of data can be written at a time.

Read RD 52 44 Reads data from the internal memory of the Data Carrier; up to 1024

bytes (512 words) of data can be read at a time.

Auto Write AW 41 57 Waits until the Data Carrier approaches the Read/Write Head and then

writes data to the internal memory of the Data Carrier as it comes within

detection range of the Read/Write Head. Up to 1024 bytes (512 words) of

data can be written at a time.

Auto Read AR 41 52 Waits until the Data Carrier approaches the Read/Write Head and then

reads data from the internal memory of the Data Carrier as it comes

within detection range of the Read/Write Head. Up to 1024 bytes (512

words) of data can be read at a time.

Clear-all

(see note)

CA 43 41 Clears the contents of the Data Carrier’s internal memory.

Auto Read/Write Abort AA 41 41 Aborts Auto Read and Auto Write. When this command is executed, the

ID Sensor Unit is initialized and waits for the next command.

Data management

(C200H-IDS01-V1

only)

MD 4D 44 Checks the Data Carrier’s internal memory. The reliability of data is

checked using the MD-K and MD-C commands and the number of

overwriting operations is checked using the MD-L and MD-S commands.

Page 35

20

The User Program Section 2-3

Write Command This command writes data to the internal memory of the Data Carrier. Up to

1024 bytes (512 words) of data can be written per scan. Specify the first

address in hexadecimal.

Specifies the type of

data to be written,

which can be ASCII

characters or hexadecimal numbers. Code A

(41) specifies ASCII

characters, while H (48)

specifies hexadecimal

numbers.

15

W

57

A/H

41/48

2

*

A

00

T

54

1

31

0D

This is OP (operation) code indicating

that the command is Write.

This is OP code represented in

ASCII code.

This code selects a Read/Write Head

and is always fixed to 1.

ASCII code

Specifies the first address of the Data

Carrier memory to which data is to be

written. Addresses $0000 through

$FFFF can be specified in hexadecimal.

Write data

Terminator

ASCII code

• 1024 bytes max. = 512 words

Page 36

21

The User Program Section 2-3

Read Command The Read command reads data from the internal memory of the Data Carrier.

Up to 1024 bytes (512 words) of data can be read at a time. Specify the first

address and the number of bytes in hexadecimal.

15

R

52

A/H

41/48

2

*

A

00

D

44

1

31

0D

This is OP (operation) code indicating

that the command is Read.

This is OP code represented in ASCII

code.

This code selects a Read/Write Head

and is always fixed to 1.

ASCII code

Specifies the first address of the Data

Carrier memory to which data is to be

read. Addresses $0000 through $FFFF

can be specified in hexadecimal.

Terminator

ASCII code

This field specifies

whether the data to

be read from the

Data Carrier is ASCII

characters or hexadecimal code. When

ASCII characters are

to be read, this field

contains code A (41

in ASCII code); when

hexadecimal code is

to be read, it contains

code H (48 in ASCII

code).

Specifies the number of bytes, which

can range from $0001 through $0400 (1

through 1024 in decimal), to be read in

hexadecimal code.

Page 37

22

The User Program Section 2-3

Auto Write Command The Auto Write command executes when the Data Carrier approaches the

Read/Write Head. When the Data Carrier comes within detection range of the

Read/Write Head, Auto Write writes data to the internal memory of the Data

Carrier. Up to 1024 bytes (512 words) of data can be written at a time. Specify

the first address in hexadecimal.

Specifies the

type of data to be

written, which

can be ASCII

characters or

hexadecimal

numbers. Code

A (41) specifies

ASCII characters, while H (48)

specifies hexadecimal numbers.

15

A

41

A/H

41/48

2

*

A

00

W

57

1

31

0D

This is OP (operation) code indicating that

the command is Auto Write.

This is OP code represented in ASCII code.

This code selects a Read/Write Head and is

always fixed to 1.

ASCII code

Specifies the first address of the Data Carrier

memory to which data is to be written. Addresses $0000 through $FFFF can be

specified in hexadecimal.

Write data

Terminator

ASCII code

• 1024 bytes max. = 512 words

Page 38

23

The User Program Section 2-3

Auto Read Command Auto Read executes when the Data Carrier approaches the R/W Head. When

the Data Carrier comes within detection range of the R/W Head, Auto Read

reads data from the internal memory of the Data Carrier. Up to 1024 bytes

(512 words) of data can be read at a time. Specify the first address and the

number of bytes in hexadecimal.

Clear-all Command Clear-all clears the Data Carrier’s internal memory, regardless of write protec-

tion. The number of command data words are fixed to three. (Refer to 2-3-5

The Data Carrier’s Production Date.)

15

A

41

A/H

41/48

2

*

A

00

R

52

1

31

0D

This is OP (operation) code indicating that

the command is Auto Read.

This is OP code represented in ASCII

code.

This code selects a R/W Head and is

always fixed to 1.

ASCII code

Specifies the first address of the Data

Carrier memory to which data is to be

read. Addresses $0000 through $FFFF

can be specified in hexadecimal.

Terminator

ASCII code

This field specifies

whether the data to

be read from the

Data Carrier is

ASCII characters or

hexadecimal code.

When ASCII characters are to be read,

this field contains

code A (41 in ASCII

code); when hexadecimal code is to

be read, it contains

code H (48 in ASCII

code).

Specifies the number of bytes, which can

range from $0001 through $0400, to be

read in hexadecimal code.

15

C

43

2

*

A

00

A

41

1

31

0

D

This is OP (operation) code indicating

that the command is Clear-all.

This is OP code represented in ASCII code.

This code selects a R/W Head and is

always fixed to 1.

ASCII code

Terminator

ASCII code

Blank (no

specification)

0

0

Page 39

24

The User Program Section 2-3

Auto Read/Write Abort This command aborts Auto Read and Auto Write. When this command is exe-

cuted, the ID Sensor Unit is initialized and waits for the next command.

If, after initialization, the ID Sensor Unit receives Auto Read/ Write Abort from

the CPU, the Unit recognizes it as an undefined command and waits for further command input from the CPU. While the Unit is waiting for a command,

Waiting for Data Carrier (word n+4 bit 01) is ON.

Data Management

(IDS01-V1 Only)

Data Check By adding a check code to the Data Carrier data, it is possible to detect a data

error due to the battery of the SRAM Data Carrier or excessive overwriting

operations of the EEPROM Data Carrier. Use the MD-K command to calculate and write the check code to the Data Carrier. Use the MD-C command to

collate the check code.

Usage After data is written to the Data Carrier, use the MD-K command to calculate

and add the check code to the data. To check whether or not the Data Carrier’s data is corrupted, use the MD-C command before reading the data and

collate the check code.

Command It is possible to calculate, write, or collate the CRC code (see note) in the

check area designated by the command. The CRC code is calculated by

using the generating function X

16

+ X12 + X5 + 1.

Note CRC stands for cyclic redundancy check. The cyclic redundancy

check is an error detection method.

15

A

41

2

*

A

00

A

41

D

This is OP (operation) code indicating

that the command is Auto Read/Write

Abort.

This is OP code represented in ASCII code.

Terminator

ASCII code

0

Write

stage

Read

stage

Data right

Check code calculation

Check code collation

Data read

Page 40

25

The User Program Section 2-3

The number of check area bytes is 256 (0100) maximum and the number of

command data words is fixed at 5.

If the check codes do not coincide, the DC warning bit (word n+4 bit 07) will

be turned ON.

Command Processing All the check areas that are designated by the first address and number of

bytes except the last two bytes is collectively the calculation objective area.

The last two bytes are used as the check code area.

If check code calculation or check code writing is designated using processing

code K, the CRC of the data in the calculation objective area is calculated and

the result is written to the check code area, in which case if the check block is

a write protection area, a write protection error will result.

If data collation is designated using processing code C, the CRC of the data in

the calculation objective area is calculated and the result is compared with the

data in the check code area. If they do not coincide, the DC warning bit will be

turned ON.

15

M

4D

K/C

4B/43

2*A

00

D

44

1

31

0D

Terminator

Select K to designate

data check code

calculation and C to

designate data check

collation.

Memory management command

R/W Head no. (fixed to 1)

Designates the first address of the check

area within the range 0000 through FFFF.

Designates the number of check area

bytes within the range 0003 through 0100.

Page 41

26

The User Program Section 2-3

Note The last two bytes of a check area are for the check code area, to which noth-

ing must be written.

Management of

Overwriting Operations 1

By counting the number of writing operations, it is possible to detect if the

EEPROM DC has been overwritten for 100,000 times.

Usage After writing data to the most frequently used address, renew the number of

overwriting operations in order to check the life of the EEPROM. It is possible

to overwrite data to each address for 100,000 times. Therefore, it is necessary

to count the number of overwriting operations of the most frequently used

address. It is also possible to check the life of the EEPROM without renewing

the number of overwriting operations.

0000

0001

Address

First address

No. of area bytes

CRC (upper digit)

CRC (lower digit)

Check code calculation area

(no. of check bytes − 2)

Check code area (2 bytes)

Check area

Renewal of the number of

writing operations/Life check

Right

stage

Life check

stage

Data right

Life check

Page 42

27

The User Program Section 2-3

Command Add an appropriate number (up to 255 (00FF)) to the data of the address des-

ignated by the user in order to judge if the address has been overwritten

100,000 times. If 0 (0000) is added, only the life of the address will be

checked. The number of command data words is fixed at 5.

Note Designate the first address on the EEPROM DC so that the terminator will be

___0 to ___5 or ___8 to ___D, otherwise an address error will result.

When the command is executed and the address is found to have been overwritten 100,000 times, the DC warning bit will be turned ON.

Command Processing Overwriting operation management area consists of three bytes from the first

address, to which the appropriate number (up to 255 (00FF)) that the user

designates is added. If the result is larger than 100,000, the DC warning bit

will be turned ON. If the area has been overwritten 100,000 times, the value in

the overwriting operation management area will not be renewed.

Management of

Overwriting Operations 2

By counting the number of writing operations, it is possible to detect if the DC

with EEPROM has been overwritten for the number of operations set by the

user.

A0

15

M

4D

L

2

*

00

D

44

1

31

D

4C

Management of the number

of writing operations

Memory management command

R/W Head no. (fixed to 1)

Designates the first address of the management area

within the range 0000 through FFFF (see note).

Designates the number of adding operations

within the range 0000 through 00FF.

Terminator

First address

Upper digit

Middle digit

Lower digit

3 bytes

Page 43

28

The User Program Section 2-3

Usage: Using the write command, write in advance the number of desired overwriting

operations onto the overwriting operation management area of the DC.

After writing data to the most frequently used address, renew the number of

overwriting operations in order to check the life of the EEPROM. The number

of overwriting operations is determined for each address by the DC specifications. Therefore, it is necessary to count the number of overwriting operations

of the most frequently used address. It is also possible to check the life of the

EEPROM without renewing the number of overwriting operations.

Command: Subtracts an appropriate number [up to 255 (00FF)] from the data of the

address designated by the user in order to judge if the address has been

overwritten for the number of operations set by the user. If 0 ($0000) is subtracted, only the life of the address will be checked. The number of command

data words is fixed to 5.

Note Designate the first address on the EEPROM DC so that the terminator will be

@@@0 to @@@5 or @@@8 to @@@D, otherwise an address error will result.

Renewal of the number of writing

operations/Life checking

Write

stage

Life check

stage

Data writing

Life checking

Writing the number of overwriting

operations

Initialization

stage

A0

15

M

4D

S

2

*

00

D

44

1

31

D

53

Management of the

number of writing

operations

Memory management command

R/W Head no. (fixed to 1)

Designates the first address of the

management area within the range 0000

through FFFF (see note).

Designates the number of subtracting

operations within the range 0000 through 00FF.

Terminator

Page 44

29

The User Program Section 2-3

When the command is executed and the address is found to have been overwritten for the number of operations set by the user, the Data Carrier warning

flag will be turned ON.

Command Processing: Overwriting operation management area consists of three bytes from the first

address, from which the appropriate number is subtracted. If the value set in

this area is smaller than 0, the Data Carrier warning flag will be turned ON. If

the data in the management area is already 0, the value in the overwriting

operation management area will not be renewed.

When using a DC with the number of overwriting operations set to 300,000,

make the settings as shown below.

2-3-2 Data Carrier Memory

The ID Sensor Unit has a memory access space of 64k bytes (0000 to FFFF),

the accessible space of which is decided according to the memory capacity of

the Data Carrier. The production year and month area, the write protection

area of the ID Sensor Unit, and the processing methods of the areas vary with

the memory capacity of the Data Carrier, the details of which are explained

below.

First address

Upper digit

Middle digit

Lower digit

3 bytes

First address

3 bytes

04

93

E0

Upper digit

Middle digit

Lower digit

Page 45

30

The User Program Section 2-3

Data Carrier Memory Map

2-3-3 Write Protection Function

The write protection function protects the data kept in the Data Carrier from

being purged by mistake. We recommend the user to write-protect any important data after the user writes them to the Data Carrier. The write protection

method is explained below.

Data Carrier with Memory up to 256 Bytes

Write Protection Method By writing write protection end address data to address 0000 of the Data Car-

rier, the area between address 0001 and the end address that has been designated will be write-protected. Whether or not to execute write protection is

specified by the leftmost bit of address 0000.

Write protection execution bit (the leftmost bit of address 0000).

1: Write protection (yes)

0000

0001

0002

0003

0000

0001

0002

0006

00FF

0100

to

0005

to to

toto

01FF

Address

Data

Write protected setting area

User area

1 byte

Write protected setting area

Production month and year area

1 byte

Address

Data

Data Carrier With a Memory Capacity of

256 Bytes Maximum

Data Carrier With a Memory Capacity of

More Than 256 Bytes

Address Bit

76543210

0000 Yes/No End address

Page 46

31

The User Program Section 2-3

2: Write protection (no)

End address available range:

00, 01 to 7F

Addresses between 80 to FD cannot be the end address. If the end address is

set to 00, addresses 01 to FD will be write-protected. Addresses FE and FF

are reserved for the system and the user cannot use these addresses.

Write Protection Example (DC with 254-byte Memory)

1,2,3... 1. In the following example, addresses 0001 to 0012 are write-protected.

2. If the end address is 00, all areas except address 0000 will be write-pro-

tected. In the following example, the end address is set to 00.

How to Cancel Write

Protection

To cancel write protection, set the leftmost bit of address 0000 to 0. When

write protection is cancelled, the data in address 0000 will be null and void.

Note a) Address 0000 is never write-protected.

b) Write protection is effective from address 0001 through the suc-

ceeding addresses. This means that the user must write any data

Address Bit

76543210

000010010010

92

Address Bit

76543210

000010000000

80

0000

0001

0012

00FD

Write protected zone

Address

0000

0001

00FD

Address

Write protected zone

Page 47

32

The User Program Section 2-3

to be write-protected to address 0001 and the succeeding addresses.

2-3-4 Write Protection Examples

Data written to the Data Carrier can be write-protected. First, write the data to

the desired area of the Data Carrier’s memory by using Write, then write-protect the area using the procedures described in this section.

Addresses 0002 through 0005 of the Data Carrier’s memory are used to

enable and clear the write protect function. Set these addresses as follows:

To clear the write protect function, turn OFF all address bits from 0002

through 0005.

Example 1:

Clearing Write Protection To disable or clear write protection, turn OFF address bits 0002 through 0007.

If the only 0 bit is the 7th bit of address 0002, the write protect function is

ignored.

Address 0002

Address 0003

Bit 7

6543210

X16

3

Address 0004

Address 0005

X16

1

X16

3

X16

1

X16

2

X16

0

X16

2

X16

0

Write

protect

Write protect beginning address

Setting range: 0006

through 07FF

Write protect end

address

Setting range: 0006

through FFFF

When 0800 is set to

FFFF; 07FF is assumed.

Bit 7 of address 0002

10Enables write protect function

Clears write protect function

Address 0002

Address 0003

Bit

7 6543210

Address 0004

Address 0005

0 0 000000

0 0000000

0 0000000

0 0000000

00

0

0

00

0

0

Page 48

33

The User Program Section 2-3

Example 2:

Write-protecting Addresses 0015 through 0120

Address 0002

Address 0003

Bit

76543 21

0

Address 0004

Address 0005

1 0 00000

0

00010 10

1

00000 00

1

00100 00

0

8

0

1

0

2

0

1

5

Setting

Result Data Carrier's memory

0000

0006

0015

0120

07FF

Write-protected area

Data can be written to

addresses 0006 through 0014,

and 0121 through 07FF.

Page 49

34

The User Program Section 2-3

Example 3:

Write-protecting Addresses 0700 through 0350

Address 0002

Address 0003

Bit 76543210

Address 0004

Address 0005

1 0 00 011 1

00000000

00000011

01010000

87

0

0

0

3

0

Setting

5

Result

0000

0006

0350

07FF

Write-protected

area

0700

Write-protected

area

Addresses 0006 through 0350 and 0700

through 07FF are write-protected. Data can

be written to addresses 0351 through 06FF.

Page 50

35

The User Program Section 2-3

Example 4:

Write-protecting Address 02BE Only

Address 0002

Address 0003

Bit 76 543 21 0

Address 0004

Address 0005

1 0 000010

10 111 11 0

00 000 01 0

10 111 11 0

82

B

0

E

2

E

Setting

B

Result

0000

0006

02BE

07FF

Write-protected

area

Only address 02BE is

write-protected.

Page 51

36

The User Program Section 2-3

Example 5:

Write-protecting Addresses 0600 through 07FF

How to Cancel Write

Protection

To cancel write protection, set the leftmost bit of address 0002 to 0. When

write protection is canceled, the data in address 0002 to 0005 will be null and

void.

2-3-5 The Data Carrier’s Production Date

The Data Carrier’s production date is registered in the first 2 bytes (addresses

0000 and 0001) of the Data Carrier’s internal memory before shipment from