Page 1

Cat.No. W141–E1–4

SYSMAC

C200H-CT001-V1/CT002

High-speed Counter Units

OPERATION MANUAL

Page 2

Page 3

C200H-CT001-V1/CT002

High-speed Counter Units

Operation Manual

Revised September 2000

Page 4

iv

Page 5

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

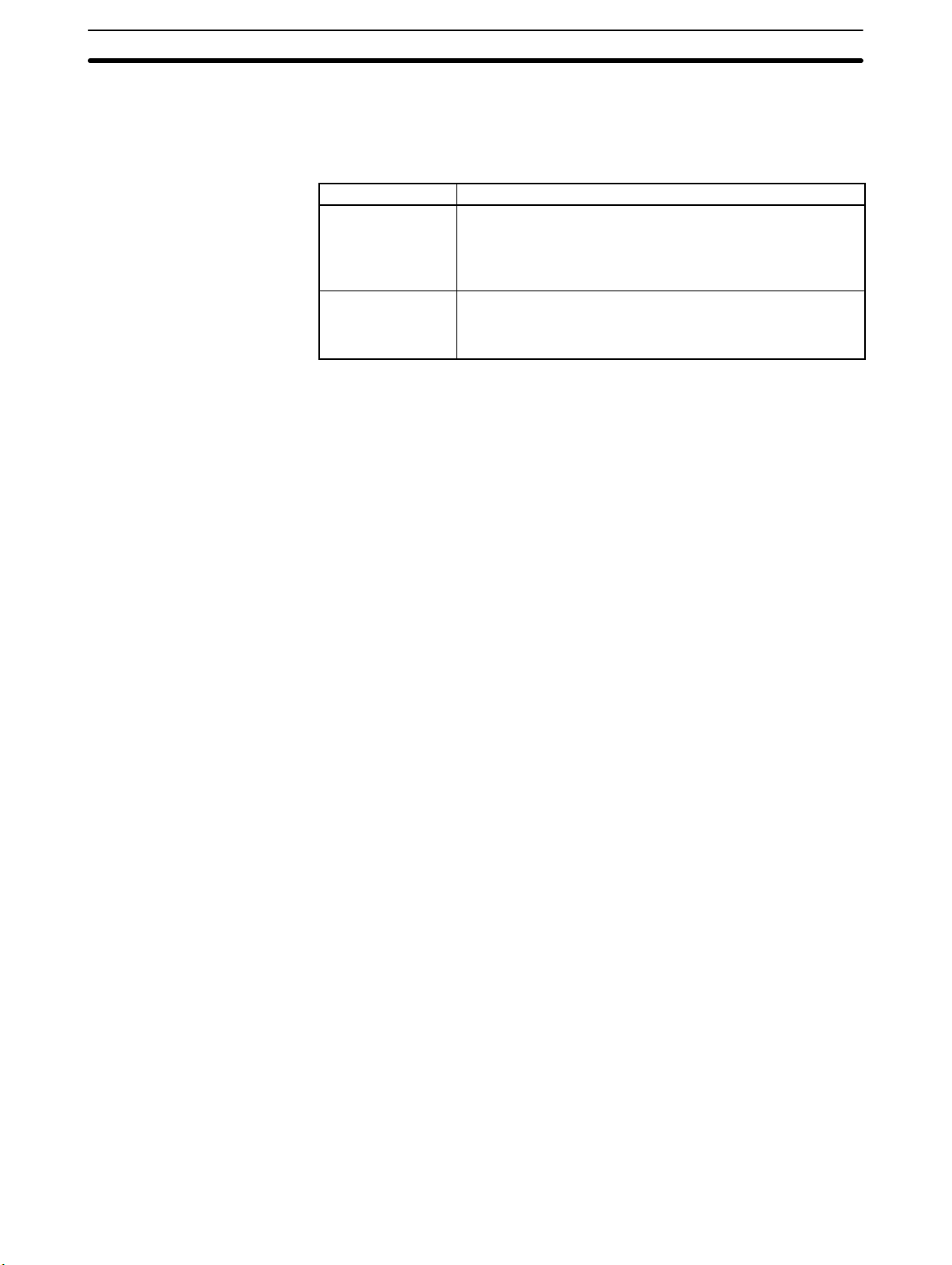

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1990

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Nomenclature 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Operating Modes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Switch Settings and Wiring 7. . . . . . . . . . . . . . . . . . . . . . . .

2-1 Switch Settings 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Input Circuit Wiring Examples 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Dimensions 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Operation 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Operational Flow 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Input Selection 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Counter Reset Conditions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Data Transfer Timing 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Data Allocation and Operating Modes 33. . . . . . . . . . . . . . .

4-1 Data Configuration and Allocation 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Linear and Circular Modes 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Preset Mode 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Gate, Latch, and Sampling Modes 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Error Processing 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Error Indications 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Troubleshooting from the PC 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Error Codes 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C IR Area Allocations 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D DM Area Coding Sheets 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 8

Page 9

About this Manual:

This manual covers specifications and procedures necessary for the installation and operation of the

C200H-CT001-V1 and C200H-CT002 High-speed Counter Units. It includes example system configurations to ease the implementation cycle. The C200H-CT001-V1 and C200H-CT002 are Special I/O

Units for C200H PCs. The C200H-CT001-V1 is a high-speed, reversible counter capable of counting

at a maximum of 50 kcps. The C200H-CT002 is a high-speed, reversible counter capable of counting

at a maximum of 75 kcps.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the C200H-CT001-V1 and C200H-CT002 High-speed Counter Units.

Section 1 contains a brief description of the Units and how they can be used. The Units are displayed

and their indicators are explained. An example system configuration is included to demonstrate Unit

application. The operating modes and their associated ranges of operation are also described.

Section 2 shows the Unit settings and connector cable pin specifications. Instructions for the construction of input and output connectors are provided. Electrical schematics and examples are presented to further explain Unit operation.

Section 3 describes the operational flow of the counting system. The input types are identified along

with instructions for their use. Data transfer timing is described in relation to the PC cycle time.

Section 4 describes the various operating modes in detail. Each mode is described by data allocation, timing charts, commands, flags, and examples. Data formats are explained.

Section 5 presents possible errors and solutions and describes how to handle errors from the PC.

The AR area Error and Restart Flags are described.

The following Appendices are also provided: Error Codes, Specifications, IR Area Allocations, and

DM Area Coding Sheets.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 10

Page 11

PRECAUTIONS

This section provides general precautions for using C200H-CT001-V1/CT002 High-speed Counter Units and related

devices.

The information contained in this section is important for the safe and reliable application of the C200HCT001-V1/CT002 High-speed Counter Units. You must read this section and understand the information contained

before attempting to set up or operate a C200H-CT001-V1/CT002 High-speed Counter Unit.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 12

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the relevant manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

3Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC system to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

xii

Page 13

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5Application Precautions

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

xiii

Page 14

• Interlock circuits, limit circuits, and similar safety measures in external circuits

(i.e., not in the Programmable Controller) must be provided by the customer.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

5Application Precautions

xiv

Page 15

SECTION 1

Introduction

This section introduces the High-speed Counter Unit. It starts by describing Unit nomenclature and then describes the

type of system the Units are generally incorporated it. This section ends with an introduction to the six operating modes,

which are described in more detail in Section 4.

1-1 Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Nomenclature 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Operating Modes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 16

Nomenclature Section 1-2

1-1 Introduction

The C200H-CT001-V1 and C200H-CT002 are Special I/O Units for C200H PCs.

The C200H-CT001-V1 can be connected directly to an incremental encoder

with an open-collector output or source output to function as a high-speed, reversible counter capable of counting at a maximum of 50 kcps.

The C200H-CT002 can be connected directly to an incremental encoder with an

RS-422 line driver output or through an Encoder Adapter to an incremental encoder with a open-collector output to function as a high-speed, reversible counter capable of counting at a maximum of 75 kcps.

The C200H-CT002 is more resistive to noise than the C200H-CT001-V1 and

should be used wherever excessive cable length or a noise-prone environment

is anticipated. Unless otherwise specified, all information presented applies to

both High-Speed Counter Units. Both the High-Speed Counter Units are referred to generically as the Counter Unit.

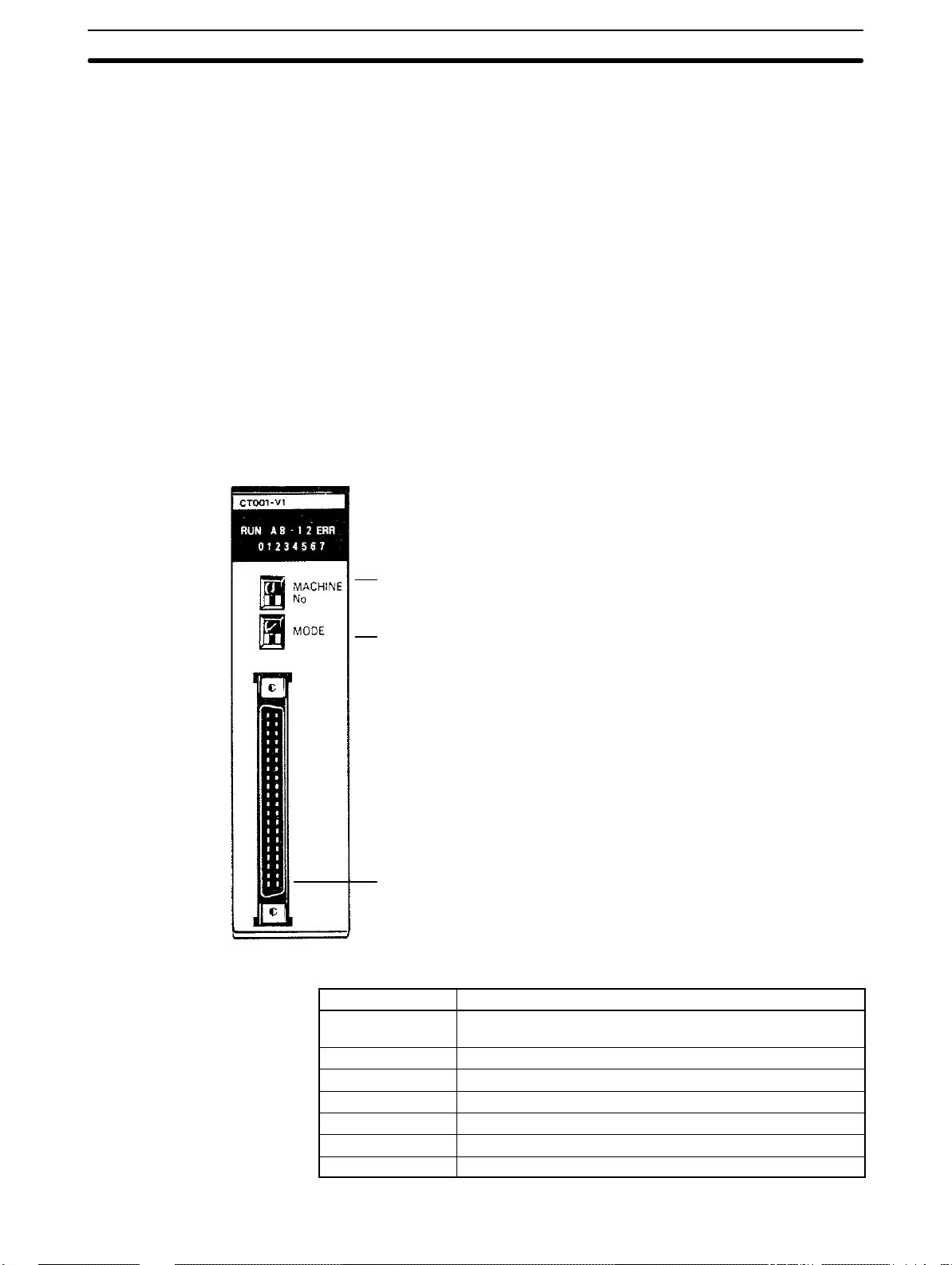

1-2 Nomenclature

The nomenclature is the same for both the C200H-CT001-V1 and the C200HCT002. The C200H-CT001-V1 is shown below.

Indicators

Unit number switch (“Machine No.”)

Operating mode switch

I/O Connector

Connect to the input device(s) and to any outputs used.

Attach the enclosed connector to the proper cable(s).

Indicator Function

RUN Lit during normal operation or when waiting for input.

Goes out for errors.

A Lit when input A is ON.

B Lit when input B is ON.

1 Lit when control input IN1 is ON.

2 Lit when control input IN2 is ON.

ERR Lit when an error has occurred.

0 to 7 Lit when corresponding output is ON.

2

Page 17

System Configuration Section 1-3

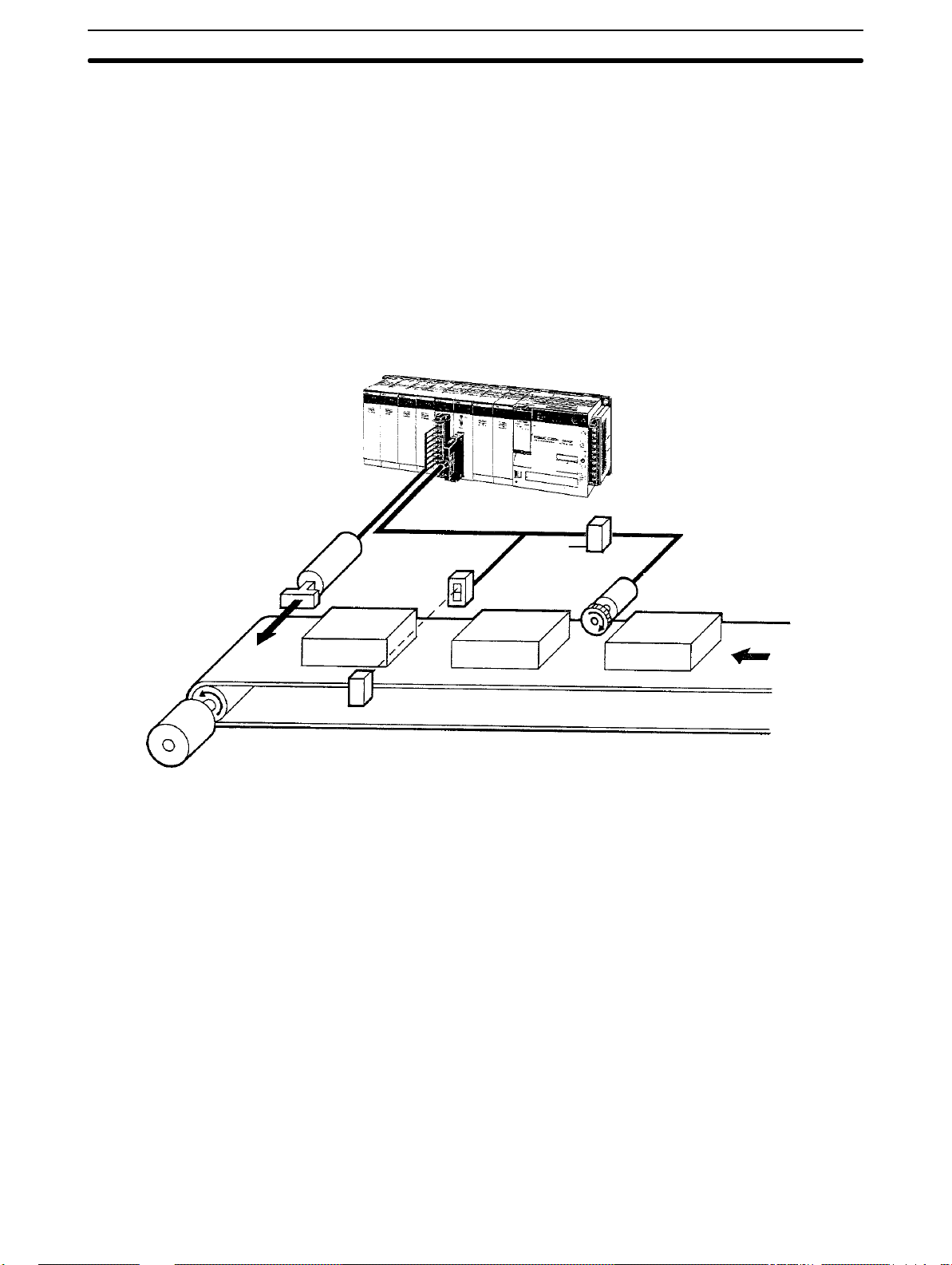

1-3 System Configuration

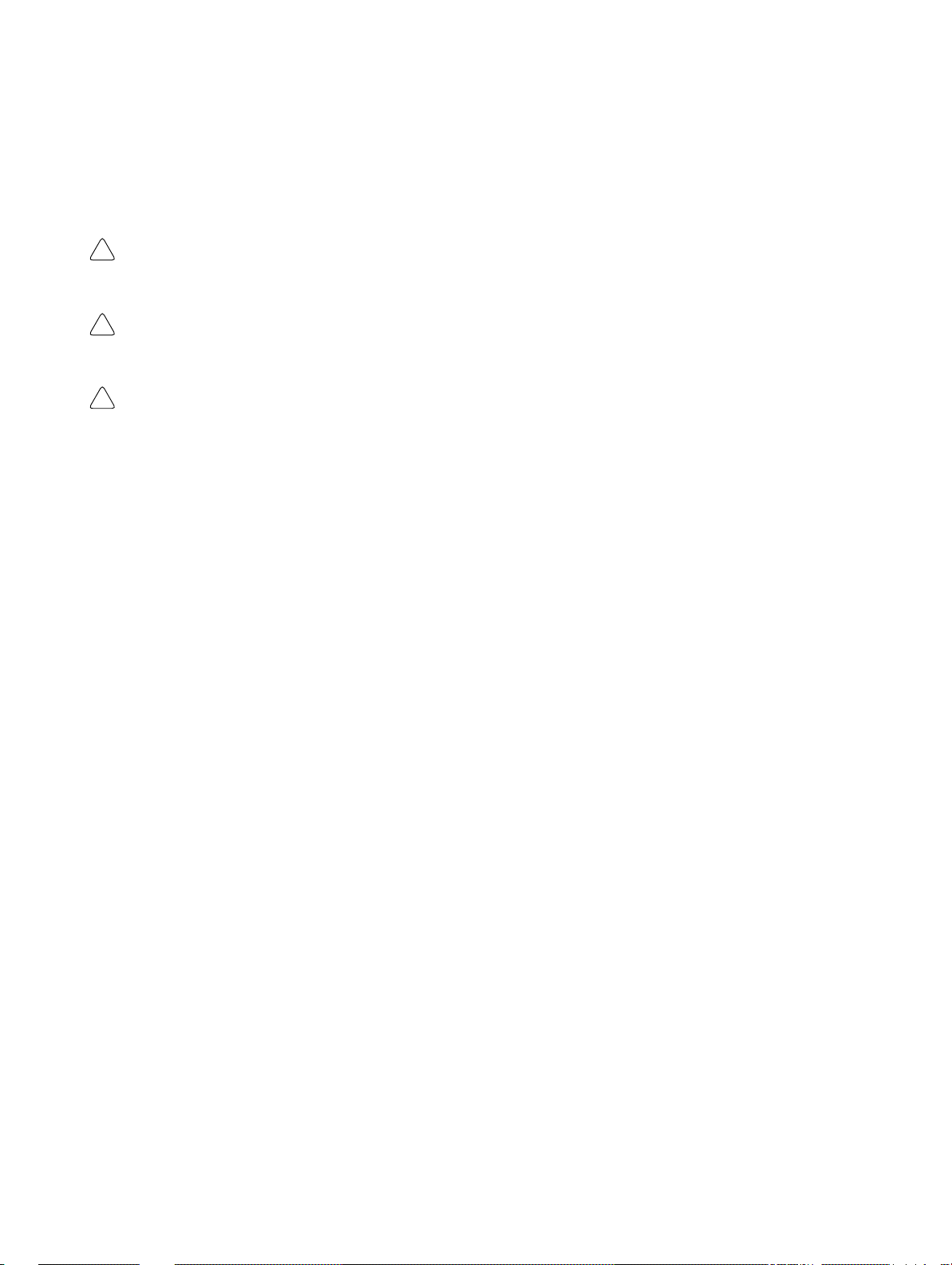

Example Configuration The following example system configuration uses the Counter Unit to deter-

mine whether or not product length is acceptable. The length of the products

passing by on the conveyor is measured by using the output from a photoelectric switch to initiate and end counting of pulses output from an encoder.

Product length is checked against standards and the product is ejected if it is

out of the acceptable range.

Electromagnetic solenoid

(for ejecting defective

products)

C200H-OA221

Output Unit

Photoelectric switch

(for detecting

products)

Counter Unit

SYSMAC C200H

An encoder adapter is required if

the C200H-CT002 is used with

an open-collector encoder.

Encoder

adapter

Encoder (for detecting

conveyor movement

ConveyorMotor

Many other applications are possible by combining other types of inputs and outputs. Refer to Section 4 Data Allocation and Operating Modes for other application examples.

Maximum number of

Special I/O Units per PC

A maximum of 10 Special I/O Units, including Position Control Units, Counter

Units, etc., can be mounted under the same PC, regardless of whether they

are on the CPU Rack, the Expansion I/O Rack, or the rack containing a Remote I/O Slave Unit controlled by the PC. No more than four of these can be

mounted onto any one rack containing a Remote I/O Slave Unit.

Mounting Location The Counter Unit can be mounted to any but the 2 rightmost CPU Rack slots.

Mounting the Counter Unit to either of these slots will prevent you from

mounting devices directly to the PC’s CPU.

The back panel DIP switch must be set before the Counter Unit is mounted.

(Refer to 2-1 Switch Settings.)

3

Page 18

Operating Modes Section 1-4

1-4 Operating Modes

The Counter Unit can be operated in any one of the six operating modes described below. External outputs are available in only 3 modes: linear, circular,

and preset. The function of these outputs depends on the mode. (The mode is

selected using the mode selector on the front panel of the Counter Unit, as described in 2-1 Switch Settings.) The following is merely an introduction to the op-

erating modes, all of which are covered in detail in Section 4 Data Allocation and

Operating Modes.

Linear Mode In linear mode, the counter value is incremented and decremented between

–8,388,608 and 8,388,607 and is continually compared with preset ranges.

When the counter value is within a range (or ranges), specified outputs are

turned ON. The same output may be specified for one or more overlapping

ranges, in which case the output will be turned ON whenever the counter value i s

within one or more of the ranges.

A maximum of 16 ranges may be specified, each with upper and lower limits.

These limits must be within the counter range, i.e., between –8,388,608 and

8,388,607. Data can be transferred from the PC to change range limits or to set

the present counter value as desired.

Circular Mode In circular mode, the counter value restarts from zero after reaching a preset

maximum value or returns to the preset maximum value when the counter

value is decremented past zero. In all other respects, including data transfer,

circular mode functions exactly as the linear mode. The preset maximum value must be between 0 and 65,535.

Preset Mode In preset mode, the counter value is normally decremented from a preset

value (between 1 and 8,388,607) to zero, although it can also be incremented. During this decrement phase, a total of 3 outputs may be switched ON

and OFF according to ON/OFF counter values. When the counter value

reaches zero, a total of 4 outputs may be turned ON, either indefinitely or for

a preset time, T. Data can be transferred from the PC to change ON/OFF

counter values as desired.

Gate Mode Two types of gate mode operation are available on the C200H-CT002: nor-

mal and cumulative. Only the normal type is available on the C200HCT001-V1. In normal gate mode, pulses are counted while control input IN1

(the count signal) is ON. The counter value is retained when input IN1 goes

OFF until input IN1 goes ON again, at which point counting restarts from

zero. In the cumulative type, control input IN1 serves as the reset signal and

counting continues while control input IN2 (the count signal) is ON. Each time

input IN2 is turned ON, counting continues from the current counter value

until it is reset to zero by input IN1. In either type of gate mode, the counting

range is between –8,388,608 and 8,388,607 and counting may be in either

direction. This mode does not support data transfer or external outputs from

the Counter Unit.

Latch Mode In latch mode, counting begins from zero when control input IN1 (count sig-

nal) is turned ON and ranges between –8,388,608 and 8,388,607. Pulses are

counted continuously (regardless of whether input IN1 is ON or OFF) , but

the current counter value is always the counter value latched the last time

control input IN2 (the latch signal) was turned ON, i.e., the current counter

value remains unchanged while the latch signal (control input IN2) is ON and

is updated to the actual count while the latch signal is OFF. Counting may be

restarted from zero at any time be activating control input IN1. Control inputs

4

Page 19

Operating Modes Section 1-4

IN1 and IN2 may originate either externally or internally. This mode does not

support external outputs from the Counter Unit or data transfer.

Sampling Mode In sampling mode, pulses are counted for a preset interval after control input

IN1 (the count signal) is turned ON. Counting may be in either direction.

Counting always begins at zero and ranges between –8,388,608 and

8,388,607. The time interval must be between 10 and 9,999 ms.

Control input IN1 may originate either externally or internally. This mode does

not support external outputs from the Counter Unit or data transfer.

5

Page 20

Page 21

SECTION 2

Switch Settings and Wiring

This section provides the Unit settings and connector cable pin specifications. Instructions for the construction of input

and output connectors are provided. Electrical schematics and examples are presented to further explain Unit operation.

2-1 Switch Settings 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Input Circuit Wiring Examples 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 C200H-CT001-V1 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 C200H-CT002 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Dimensions 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Page 22

Switch Settings Section 2-1

2-1 Switch Settings

Always turn off the Counter Unit before setting the unit number and mode selectors. Use a regular screwdriver , being careful not to damage the slot in the screw.

Be sure not to leave a selector midway between settings.

Front Panel DIP Switch

Switch name Function

Unit no. Used to set the unit number. Unit numbers run from 0 through

9 and are the same for all Special I/O Units, i.e. unit number 0

may be assigned to a Position Control Unit; unit number 1, to

a High-speed Counter Unit; etc. Do not set the same number

for more than one Special I/O Unit.

Mode Used to set the operating mode. Modes run from 1 through 6,

as follows:

1: Linear 2: Circular 3: Preset

4: Gate 5: Latch 6: Sampling

8

Page 23

Switch Settings Section 2-1

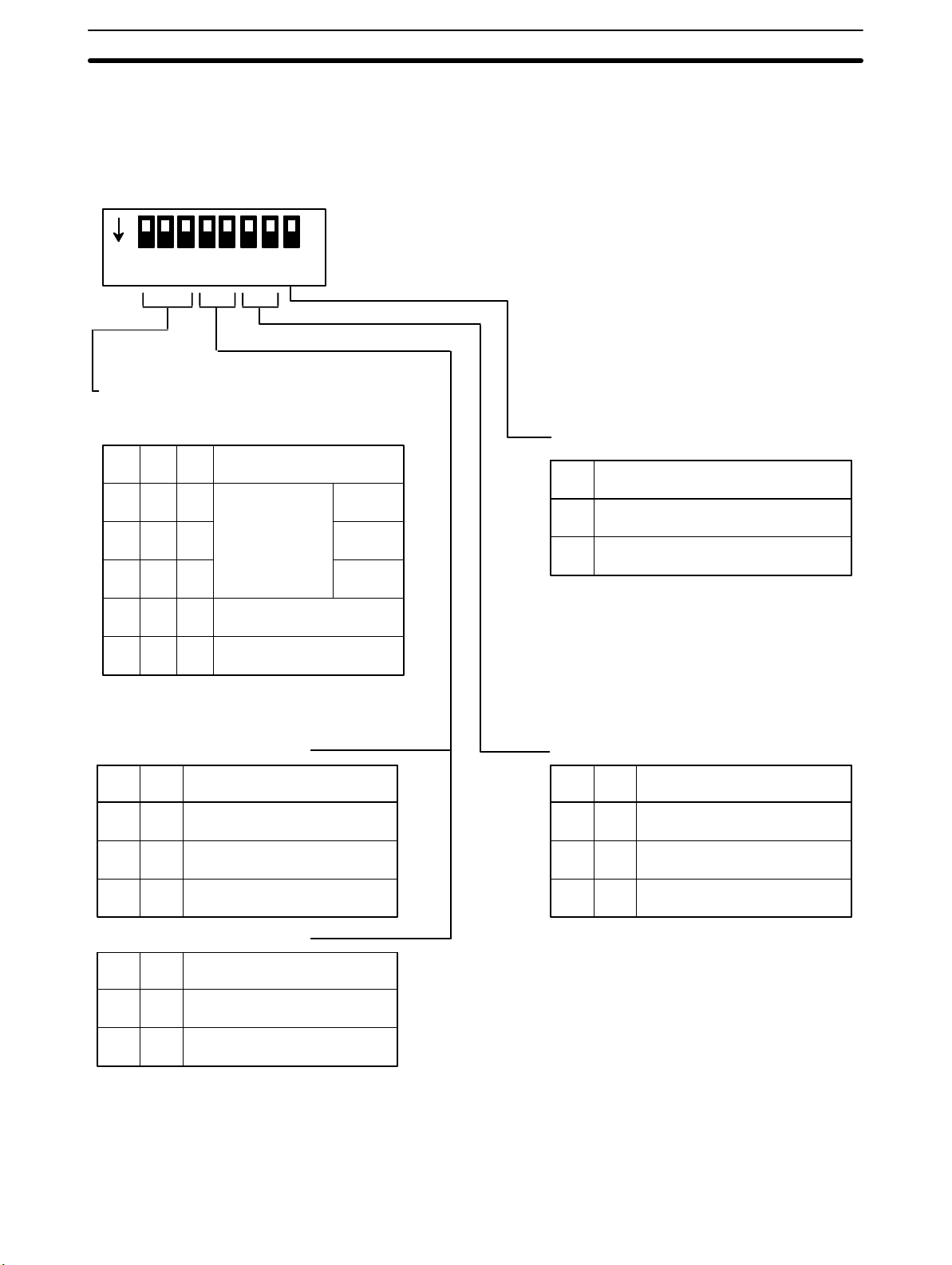

Back Panel DIP Switch

ON

12345678

Input Selection

Pins 1 through 3 are used to select the type

of inputs for inputs A and B.

1 2 3 Input type

OFF OFF OFF

Offset phases

ON

OFF

ON

*

*

Up and down pulses

OFF OFF

OFF

ON

This switch must be set before the Counter Unit is mounted. It is not necessary to set all the pins for all operating modes. Refer to 3-2 Input Selection

and Section 4 Data Allocation and Operating Modes for operational details.

Internal Reset Bit

8 Function

Normal

x2

x4

OFF Reset bit inoperative

ON Reset bit effective on rising edge.

This setting is effective only for operating

modes 1,2, and 3.

ONON

*

Pulse and direction

For Operating Mode 1 or 2: Input Z

4 5 Function

OFF Input Z inoperative*

OFFON

For Operating Mode 3: Start Input

4 5 Function

OFF

Input Z effective on falling edge.

ONON

Input Z effective on rising edge.

Start on START command

*

(IR n, bit 00).

*ON

Start on control input IN2.

Control Input IN1

6 7 Function

OFF Control input IN1 inoperative*

OFFON

This setting is effective only for operating

modes 1,2, and 3.

In modes 4, 5, and 6, control inputs IN1 and IN2

are always effective on their rising edges

Control input IN1 effective on

falling edge.

Control input IN1 effective on

ONON

rising edge.

*Pins marked with asterisks are not used.

9

Page 24

Wiring Section 2-2

2-2 Wiring

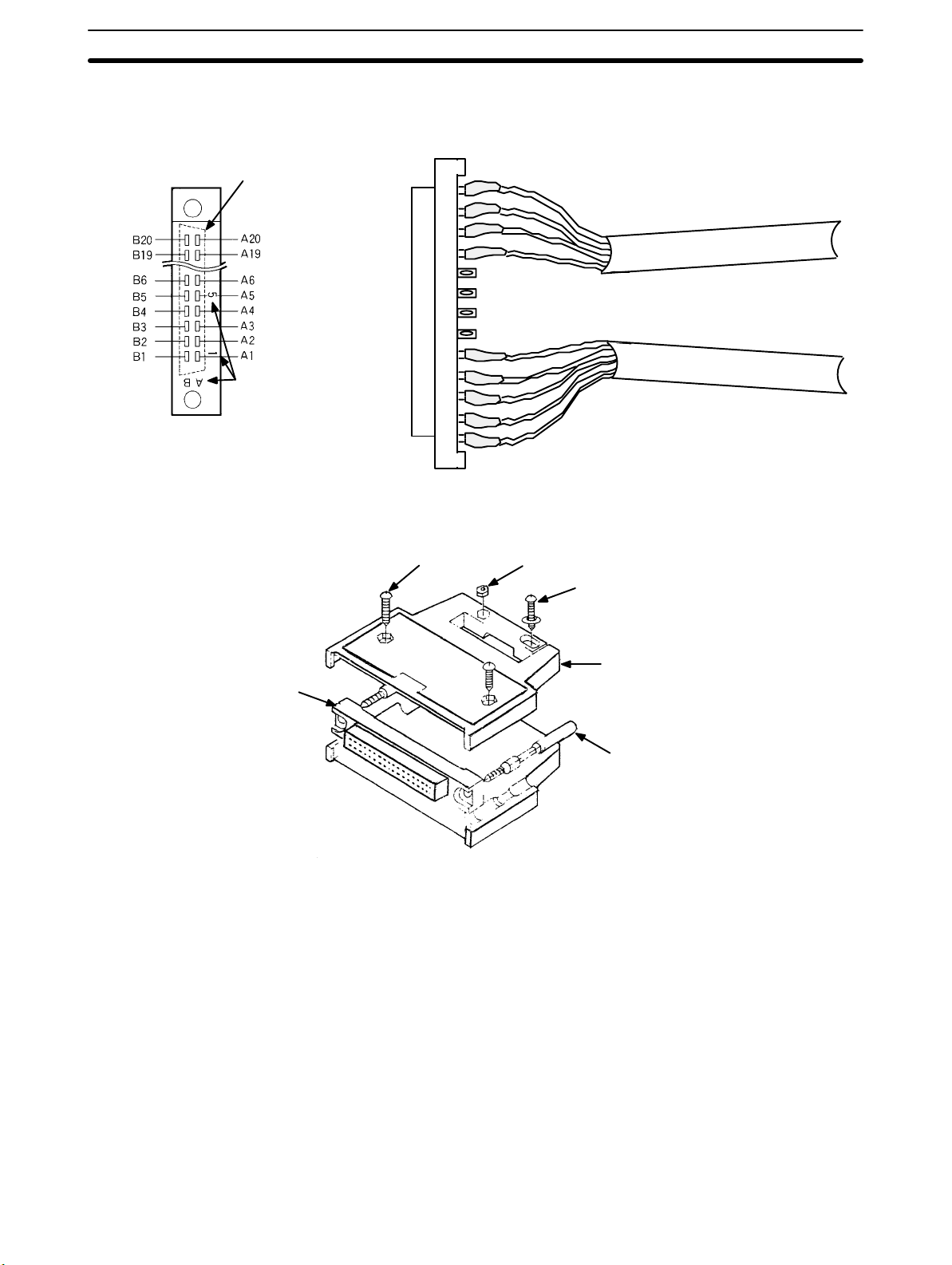

Connector Pin Arrangement

C200H-CT001-V1

Names of inputs and outputs and the pin arrangement of the connector are

shown below (as viewed from the front). The connector is a Fujitsu

FCN-361J040 (solder type), and is included with the Counter Unit.

Row B Pin no. Row A

Input A: 24 VDC 20 Input A: 12 VDC

Input A: 0 V 19 Input A: 5 VDC

Input B: 24 VDC 18 Input B: 12 VDC

Input B: 0 V 17 Input B: 5 VDC

Input Z: 24 VDC 16 Input Z: 12 VDC

Input Z: 0 V 15 Input Z: 5 VDC

14

13 Control input IN1: 12/24 VDC

Control input IN1: 0 V 12 Control input IN1: 5 VDC

11 Control input IN2: 12/24 VDC

Control input IN2: 0 V 10 Control input IN2: 5 VDC

9

Outputs 0 through 3

Power supply: 5 to 24 VDC

Outputs 0 through 3, COM: 0 V 6 Output 2

Outputs 4 through 7

Power supply: 5 to 24 VDC

Outputs 4 through 7, COM: 0 V 2 Output 6

8 Output 0

7 Output 1

5 Output 3

4 Output 4

3 Output 5

1 Output 7

10

Page 25

Wiring Section 2-2

C200H-CT002

Row B Pin no. Row A

20

Input A: neg. 19 Input A: pos.

18

Input B: neg. 17 Input B: pos.

16

Input Z: neg. 15 Input Z: pos.

14

13 Control input IN1: 12/24 VDC

Control input IN1: 0 V 12 Control input IN1: 5 VDC

11 Control input IN2: 12/24 VDC

Control input IN2: 0 V 10 Control input IN2: 5 VDC

9

Outputs 0 through 3

Power supply: 5 to 24 VDC

Outputs 0 through 3, COM: 0 V 6 Output 2

Outputs 4 through 7

Power supply: 5 to 24 VDC

Outputs 4 through 7, COM: 0 V 2 Output 6

8 Output 0

7 Output 1

5 Output 3

4 Output 4

3 Output 5

1 Output 7

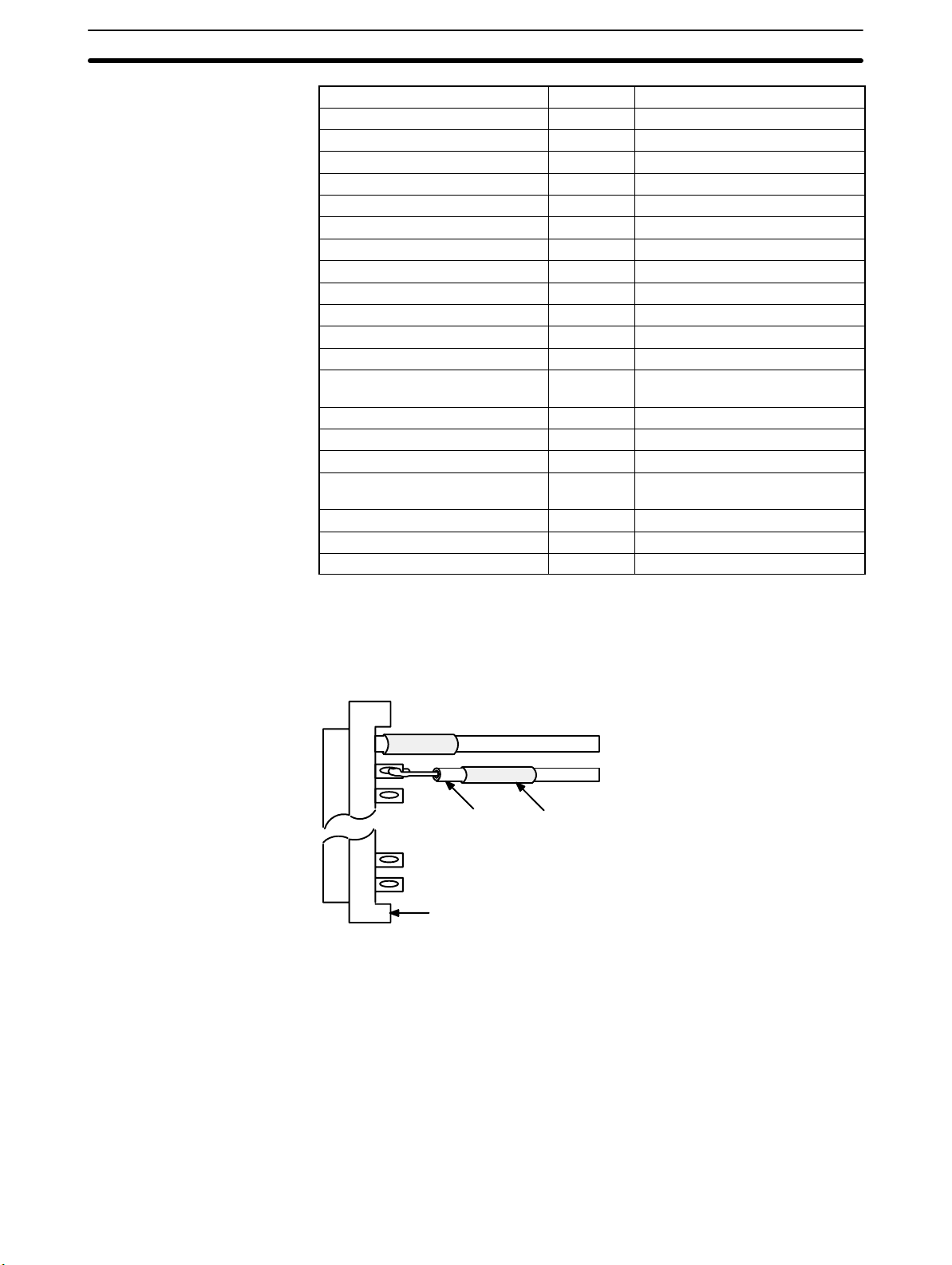

Wiring Connectors Solder-type connectors are included with the Counter Unit.

2

Use wire with a cross-sectional area of 0.3 mm

or less. When soldering, do not

short-circuit an adjacent terminal; cover the soldered section with an insulation

tube. When using multicore cable, wire output and input cables separately.

Wire Insulation tube

Connector

11

Page 26

Wiring Section 2-2

Differentiating Cables and

Connector Pin Numbers

Input and output cables can be differentiated by position, as shown on the

right below. Alignment with the connector pin numbers is also as shown on

the left below. Please make sure you are wiring to the correct pins.

Shape of connector

on the reverse side.

Pin number

marks

Connector pins as viewed

from the solder side.

Assembling Connectors Assemble connectors as shown below.

Round head screw

(8mm M2, two total)

Nut (M2, four total)

Input cables

Output cables

Round head screw

(10mm M2, two total)

Case

Connector

Lock screw

Note Any of the following connectors can be used as required by operating condi-

tions. The jack is a Fujitsu model 360.

1, 2, 3... 1. FCN-361J040 (solder-type, included with Counter Unit)

FCN-360C040-B (connector cover)

2. FCN-363J040 (crimp type, housing)

FCN-363J-AU (connector)

FCN-360C040 (connector cover)

3. FCN-367J040-A V/F (crimp type)

Wiring Precautions For the C200H-CT001-V1, the terminals that are used depend upon the pow-

er supply of inputs A, B, and Z.

For the C200H-CT002, inputs A, B, and Z must be line driver inputs

(Am26LS31-compatible). Positive and negative terminals must be wired correctly. The terminals that are used depend upon the power supply of the control

inputs. Be careful to connect to the correct terminals. Supply only one voltage for

12

Page 27

Wiring Section 2-2

each input. The terminals for output power supply , 5 t o 2 4 VDC and COM (0 V),

are separated into two: those for outputs 0 through 7. These are not interconnected internally. If the 5 to 24 VDC and COM (0 V) terminals for the output power supply are connected incorrectly, an internal fuse will burn out, preventing operation. This fuse is not user serviceable. This fuse will also burn out if the output

current exceeds 0.5 A/common, again preventing operation. When wiring inputs

A, B, and Z, the following measures must be taken to prevent interference from

noise:

1, 2, 3... 1. Use shielded twisted pair cable and ground the shield.

2. Keep wiring as short as possible and do not place lines parallel to pos-

sible sources of noise, such as power lines.

3. Use a stabilized power supply that is independent from other input and

output power supplies.

The external power supply must be greater than or equal to the load power supply. (An error may occur if the external power supply is less than the load power

supply .) I n the example on the following page, E1 must be greater than or equal

to E2.

5 to 24 VDC

Output 0

D

r

i

v

e

c

i

rc

u

i

t

Output 1

Output 2

Output 3

Fuse COM

0.5A (0 V)

B8

A8

A7

A6

A5

B6

Counter Unit

Relay

Relay

Relay

Relay

Variable

resistors

E1

0 V

E2

0 V

~

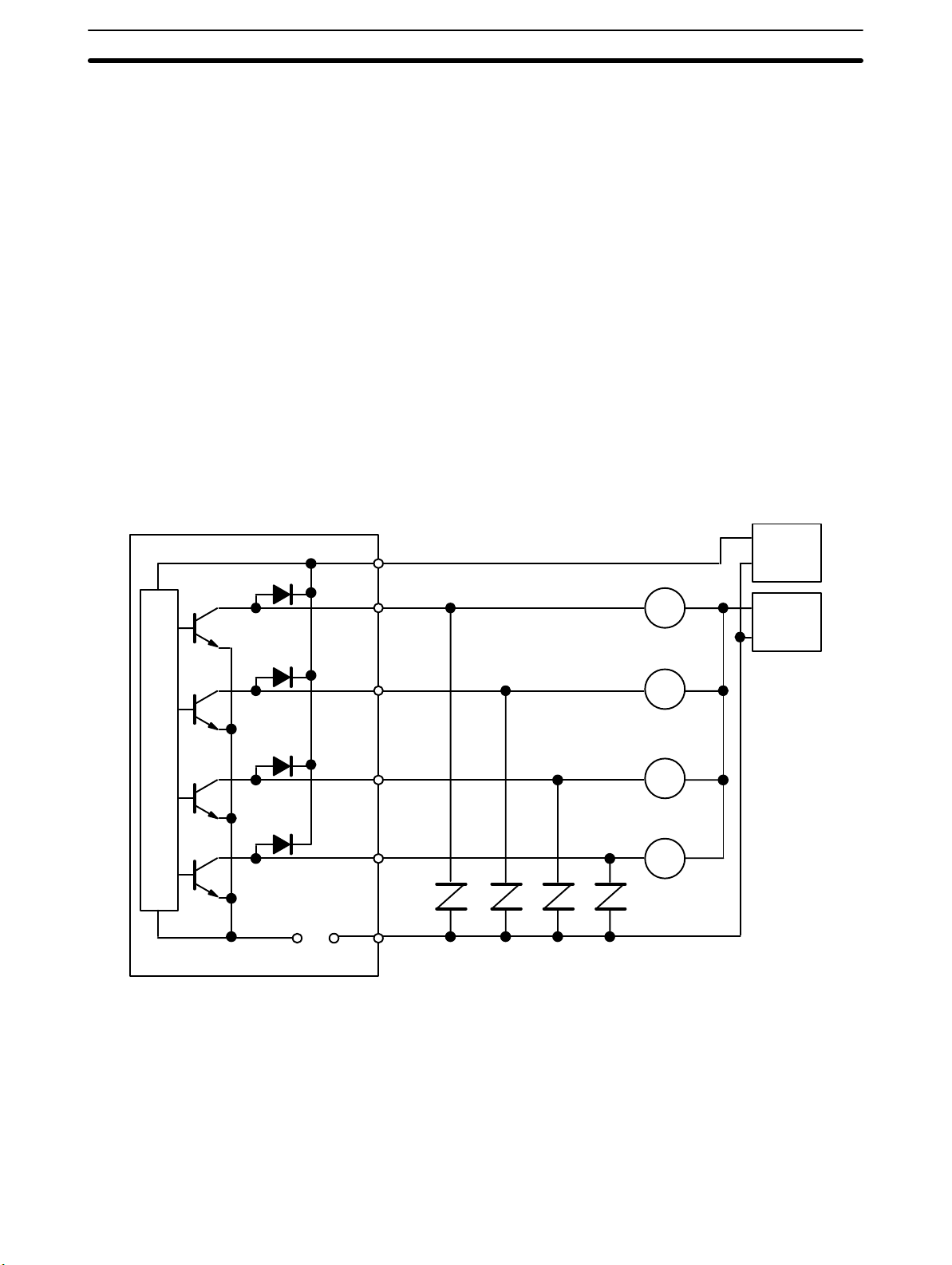

Input and Output Circuits Actual pin numbers are arranged in order from the top of the connector start-

ing with A20 and B20. For each input, connect the 0-V terminal and only one

of the other terminals, i.e., do not supply more than one voltage for any input.

The circuits are shown on the following pages.

13

Page 28

Wiring Section 2-2

C200H-CT001-V1 Input Circuits

1.6 kΩ

B20...... Input A: 24 VDC

560 Ω

A20...... Input A: 12 VDC

A19...... Input A: 5 VDC

Rectifier

B19...... Input A: 0 V

1.6 kΩ

B18...... Input B: 24 VDC

560 Ω

A18...... Input B: 12 VDC

A17...... Input B: 5 VDC

Rectifier

B17...... Input B: 0 V

1.6 kΩ

B16...... Input Z: 24 VDC

560 Ω

A16...... Input Z: 12 VDC

A15...... Input Z: 5 VDC

Rectifier

B15...... Input Z: 0 V

Filter

Filter

1.3 kΩ

1.3 kΩ

A13......

A12......

B12......

A11......

A10......

B10......

Control input

IN1: 12/24 VDC

Control input

IN1: 5 VDC

Control input

IN1: 0 V

Control input

IN1: 12/24 VDC

Control input

IN1: 5 VDC

Control input

IN1: 0 V

14

Page 29

Wiring Section 2-2

C200H-CT001-V1 Output Circuits

B8......Output power

supply: 5 to 24 VDC

A8......Output 0

A7......Output 1

A6......Output 2

Fuse

0.5 A

~

Fuse

0.5 A

~

A5......Output 3

B6......Output COM: 0 V

B4......Output power

supply: 5 to 24 VDC

A4......Output 4

A3......Output 5

A2......Output 6

A1......Output 7

B2......Output COM: 0 V

15

Page 30

Wiring Section 2-2

C200H-CT002 Input Circuits

A19...... Input A: pos.

B19...... Input A: neg.

A17...... Input B: pos.

B17...... Input B: neg.

A15...... Input Z: pos.

B15...... Input Z: neg.

Filter

Filter

1.3 kΩ

1.3 kΩ

A13......

A12......

B15......

A11......

A10......

B10......

Control input

IN1: 12/24 VDC

Control input

IN1: 5 VDC

Control input

IN1: 0 V

Control input

IN1: 12/24 VDC

Control input

IN1: 5 VDC

Control input

IN1: 0 V

16

Page 31

Wiring Section 2-2

C200H-CT002 Output Circuits

B8......Output power

supply: 5 to 24 VDC

A8......Output 0

A7......Output 1

A6......Output 2

Fuse

0.5 A

~

Fuse

0.5A

~

A5......Output 3

B6......Output COM: 0 V

B4......Output power

supply: 5 to 24 VDC

A4......Output 4

A3......Output 5

A2......Output 6

A1......Output 7

B2......Output COM: 0V

17

Page 32

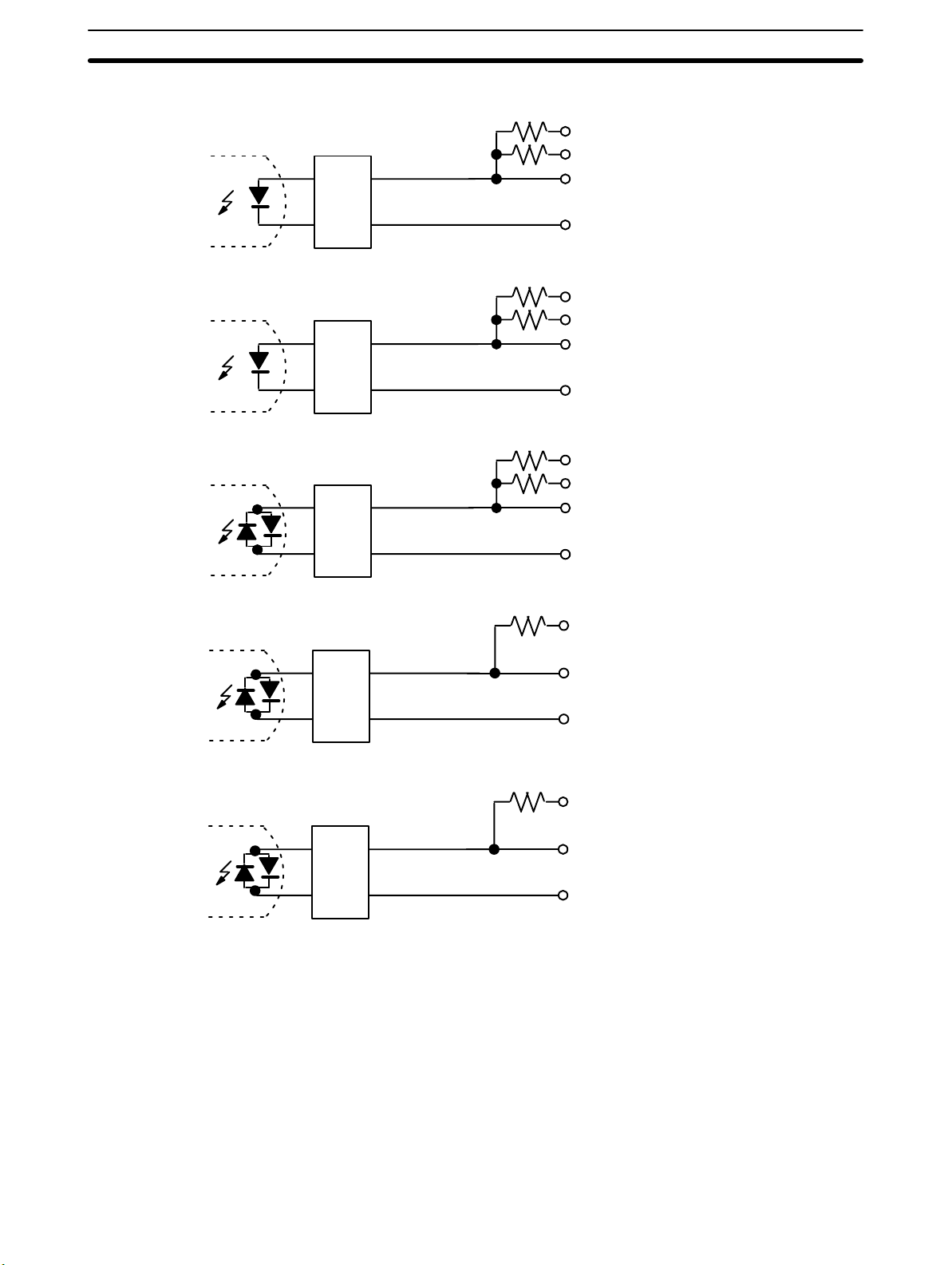

Input Circuit Wiring Examples Section 2-3

2-3 Input Circuit Wiring Examples

2-3-1 C200H-CT001-V1

Examples The following wiring examples show connections between encoders and in-

puts A, B, and Z.

Example 1

12-VDC, Open-collector

Encoder

C200H-CT001-V1 Counter Unit

Input A

Rectifier

Input B

Rectifier

This example shows the connections that would be used for a 12-VDC power

supply and an incremental encoder with a open-collector output.

+

12-VDC

power

supply

24 V

12 V

5 V

0 V

24 V

12 V

5 V

0 V

Shielded twisted pair cable

A IA

I

IB IB

12 VDC

0 V

Power supply

–

Encoder

Input Z

Filter

24 V

12 V

5 V

IZ IZ

0 V

E

18

Page 33

Input Circuit Wiring Examples Section 2-3

Example 2

12-VDC, Voltage-output,

Sync-load Encoder

C200H-CT001-V1 Counter Unit

Input A

Rectifier

Input B

Rectifier

This example shows the connections that would be used for a 12-VDC power

supply and a sync-load encoder with a voltage output. When the encoder

output is high, the input to the Counter Unit turns OFF. When the encoder

output is low, the input to the Counter Unit turns ON.

+

12-VDC

power

supply

24 V

12 V

5 V

0 V

24 V

12 V

5 V

0 V

Shielded twisted pair cable

A IA

I

IB IB

12 VDC

0 V

Power supply

–

Encoder

Input Z

Filter

24 V

12 V

5 V

IZ IZ

0 V

E

19

Page 34

Input Circuit Wiring Examples Section 2-3

Example 3

5 VDC, Voltage-output,

Source-load Encoder

CT001-V1 Counter Unit

Input A

Rectifier

Input B

Rectifier

This example shows the connections that would be used for a 5-VDC power

supply and a source-load encoder with a voltage output. Here, attention must

be paid to the ON voltage.

+

5 VDC

0 V

–

Encoder

24 V

12 V

5 V

0 V

24 V

12 V

5 V

0 V

5-VDC

power

supply

Shielded twisted pair cable

A

I

IB

Input Z

Filter

24 V

12 V

5 V

IZ

0 V

E

20

Page 35

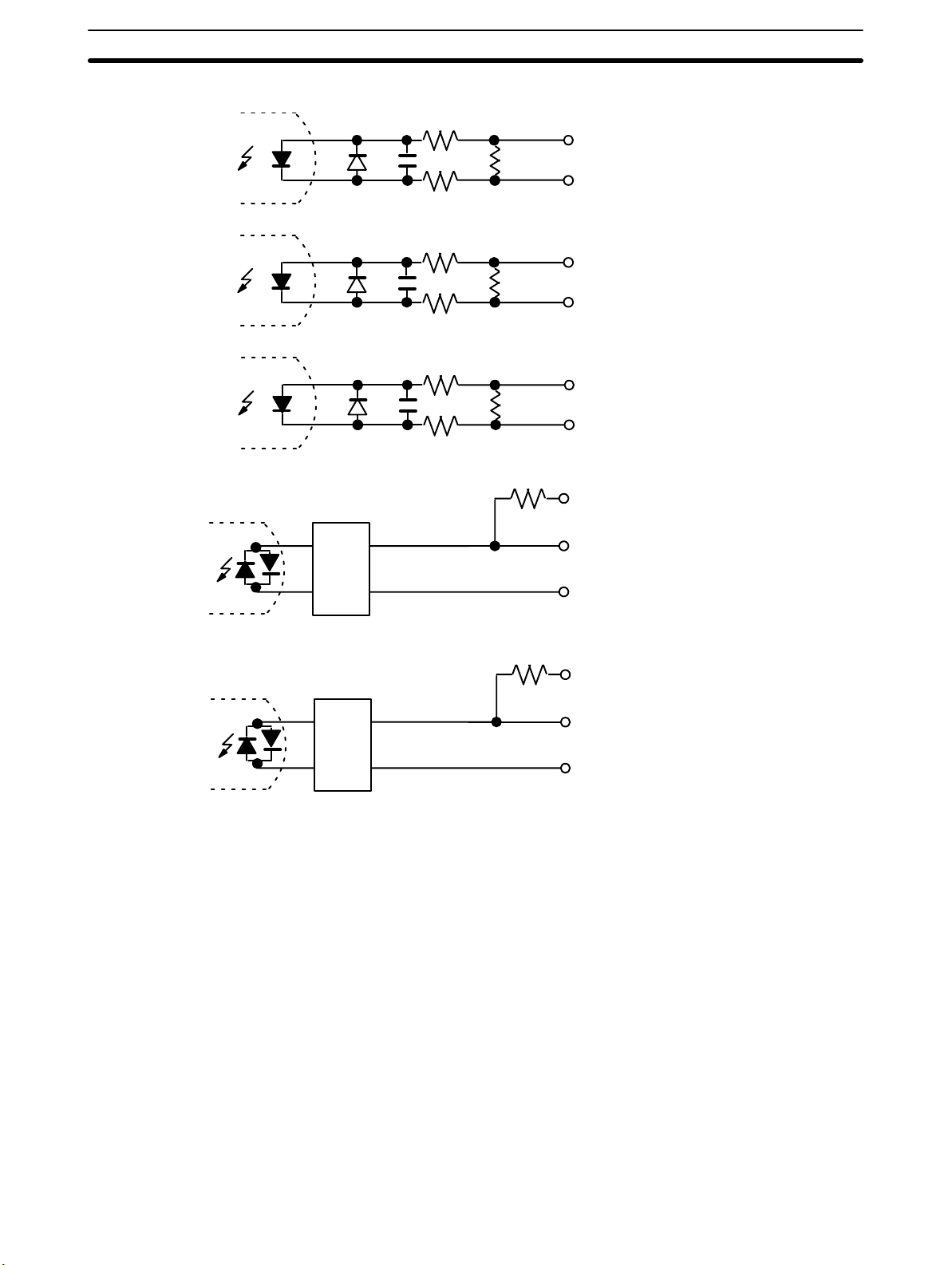

Input Circuit Wiring Examples Section 2-3

2-3-2 C200H-CT002

Example 1

Line-driver Encoder

C200H-CT002 Counter Unit

Input A

Input B

Input Z

The following wiring examples shows connections between a line-driver encoder (Am26LS31-compatible) with outputs A, B, Z and inputs A, B, and Z.

Power supply

Encoder

Shielded twisted pair cable

+

–

+

–

+

–

E

A+

A–

B+

B–

C+

C–

Example 2

Open-collector Encoder

and Encoder Adapter

C200H-CT002 Counter Unit

Input A

Input B

Input Z

The following wiring example shows connections between an open-collector

encoder and an Encoder Adapter (C500-AE001), and between the Encoder

Adapter and inputs A, B, and Z. Connections should be wired so that Counter

Unit inputs go ON when encoder outputs go ON. Because the C500-AE001

Encoder Adapter uses an Am26LS31-compatible line driver, high voltage is

impressed on the positive terminal and low voltage is impressed on the negative terminal when the output is high.

Shielded twisted pair cable

+

–

+

–

+

–

5- to

12-VDC

power

supply

+

–

C500-AE001 Encoder Adapter

A–

A+

B–

B+

Z–

Z+

E

V

CC

0 V

Voltage

regulator

Shielded

twisted

pair cable

CC

V

0 V

Encoder

E

CC

V

0 V

21

Page 36

Input Circuit Wiring Examples Section 2-3

Control Input Wiring

Examples

Counter Unit

Control input IN1

Filter

Filter

In order to prevent chattering, install the input wiring with as few contacts as

possible.

+

0 V

–

Sensor

Sensor

output

Sensor

Sensor

output

12/24 V

5 V

0 V

12/24 V

5 V

0 V

12- to

24-VDC

power

supply

Twisted pair cable

12 to 24 VDC

22

Page 37

Input Circuit Wiring Examples Section 2-3

External Output Wiring

Example

Drive circuitDrive circuit

5 to 24 VDC

Output 0

Output 1

Output 2

Output 3

The following example shows output wiring with outputs 0 through 3 connected to relays and outputs 4 through 7 connected to TTL devices.

A8

A8

A7

A6

A5

Counter Unit

Relay

Relay

Relay

Relay

+

5 to 24 VDC

5- to

24-VDC

0 V

power

supply

–

Switching capacity

depends upon the

voltage. Refer to Appendix B Specifications.

Fuse COM

0.5 A (0 V)

~

5 to 24 VDC

Output 4

Output 5

Output 6

Output 7

Fuse COM

0.5 A (0 V)

~

B6

B4

A4

A3

A2

A1

B2

Counter Unit

Pull-up resistors

(4.7 k

Ω)

Variable

resistors

–

5 VDC

0 V

Output 4

Output 5

Output 6

Output 7

Low

High

+

Buffers

Output Voltages for Outputs 0 through 7

Output ON.

Output OFF.

5 VDC

23

Page 38

Dimensions Section 2-4

2-4 Dimensions

Unit Dimensions (Unit: mm)

130

Mounted Dimensions (Unit: mm)

Connecting

cable

35

100.5

Rack

117

Approx. 200

24

Page 39

SECTION 3

Operation

This section describes the operational flow of the counting system. The input types are identified along with instructions

for their use. Data transfer timing is described in relation to the PC cycle time.

3-1 Operational Flow 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Input Selection 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Offset Phases 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Up and Down Pulses 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Pulse and Direction 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Counter Reset Conditions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Data Transfer Timing 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

Page 40

Input Selection Section 3-2

3-1 Operational Flow

Each Special I/O Unit mounted under a C200H PC is assigned a unit number

between 0 and 9. The unit number assigned to the Counter Unit determines the

100 DM words and 10 IR words that will be allocated to it. DM words are used for

Counter Unit parameters; IR words, for command bits and flags. (Refer to 4-1

Data Configuration and Allocation for details.) The following procedure outlines

the steps necessary to operate the Counter Unit.

1, 2, 3... 1. Set the mode selector on the front panel to the desired operating mode,

and then set the DIP switch on the rear panel accordingly. (Refer to 2-1

Switch Settings.)

2. Set the unit number with the selector on the front panel. (Refer to 2-1

Switch Settings.)

3. Using the Programming Console, set data required in the DM area under the unit number.

4. Prepare the user program to operate the Counter Unit using the allocated IR area words and bits.

It is also possible to set parameters and counter values in any data area using

the user program or the Programming Console. This data can then be transferred to the Counter Unit by using the TRANSFER DATA command bit. (Refer

to page 40 TRANSFER DATA Command.)

3-2 Input Selection

Any one of three types of inputs can be selected: offset phase inputs (i.e., two

inputs with offset phases), individual up and down inputs, and pulse and direction inputs. All three types of inputs include a reset input. Any type of any input

can be used with any of the operating modes, although not all operating modes

support resetting. (Refer to Section 4 Data allocation and Operating Modes for

details.) The type of inputs is selected with the back panel DIP switch.

3-2-1 Offset Phases

Offset phase inputs use the difference in phase between two inputs to determine

whether the counter value will be incremented or decremented. An input multiplier, either x 2 or x 4, is available with offset phase inputs to increase accuracy. I f

the x 2 multiplier is selected, the counter value will be incremented or decremented twice for each input A pulse; if the x 4 multiplier is selected, the counter

value will be incremented or decremented four times for each input A pulse. The

multiplier is set with the back panel DIP switch. (Refer to 2-1 Switch Settings.)

The counter can be reset in the linear or circular operating modes by using the

Z-phase output of the encoder. Refer to 3-3 Reset Conditions for details.

Encoder

Phase A

Phase B

Wire according

to the counting

direction

Counter Unit

Input A

Input B

Phase Z (reset input)

Counting Speed The maximum pulse frequency possible for offset phase inputs is determined

by the specifications of the incremental encoder connected to the Counter

Input Z

26

Page 41

Input Selection Section 3-2

Units. The following example shows calculations E6B-CWZ3C Incremental

Encoder when used with the C200H-CT001-V1. Rotational directions are given as viewed from the end of the encoder shaft.

Encoder Specifications

Power supply 4.75 to 13.2 VDC, ripple (p-p): 5% max.

Current consumption 50 mA max.

Resolution 500 pulses/revolution

Outputs Phase A, phase B, phase Z

Output type Open collector

Output capacity Applied voltage: 30 VDC max.

Sync. current: 80 mA max.

Residual voltage: 1 V max

Max. frequency 30 kHz

Output phase difference

(between phase A and B)

Output fall/rise time

90°±45° (1/4T±1/8T)

1.0 µs max.

CW Rotation Here, input A is advanced by 1/4T±1/8T over input B.

Towards CW

Input A

Input B

ON

OFF

ON

OFF

T

°)

(360

1/4 T±1/8 T (90°±45°)

CCW Rotation Here, input A is delayed by 1/4T±1/8T over input B.

Towards CCW

Input A

Input B

ON

OFF

ON

OFF

T

°)

(360

1/4 T + 1/8 T (90°+ 45°)

Since the output phase difference is 90°±45°, the minimum phase difference

produced by this encoder is as follows:

90° – 45° = 45°

Because the C200H-CT001-V1 requires a minimum phase difference of 4.5 4.5

must be less than 45°/360°. T must therefore be less than 36 meaning the maximum frequency, 1/T, would be 27.7 kcps (54 rps for 500 pulses per revolution).

This would be the maximum frequency at which this encoder could be used with

the C200H-CT001-V1. With the C200H-CT002, a minimum phase difference of

3 is required. Computing as above shows a maximum frequency of 41.7 kcps

when using the C200H-CT002 with this encoder.

Note The minimum pulse width must be considered when using input Z to reset

the counter. With the C200H-CT001-V1, the pulse width of input Z must be

0.1 ms or greater, and the return frequency must be 5 kcps or less. With the

27

Page 42

Input Selection Section 3-2

C200H-CT002, the pulse width of input Z must be 10 or greater, and the return frequency, allowing for software processing time, must be 10 kcps or

less.

3-2-2 Up and Down Pulses

With separate up and down pulse inputs, the counter value is incremented or

decremented on the rising edge of the appropriate input. Here, sensors could

replace the encoders to provide inputs A and B.

In the linear or circular operating modes, the counter can be reset by connecting

input Z to a sensor or switch.

Encoder or sensor

Encoder or sensor

Sensor or switch

3-2-3 Pulse and Direction

With pulse and direction inputs, the counter value is incremented or decremented on the rising edge of the pulse input. If the direction input is OFF, the

counter value is incremented; if the direction input is ON, the counter value is

decremented. The direction input should be switched between ON and OFF

only when the pulse input is OFF.

Counter Unit

Increment pulse

Input A

Decrement pulse

Input B

Reset input

Input Z

28

In the linear or circular operating modes, the counter can be reset by connecting

input Z to a sensor or switch.

Encoder or sensor

Sensor or switch

Counter Unit

Pulse Input

Input A

Direction input

Input B

Reset input

Input Z

Page 43

Counter Reset Conditions Section 3-3

3-3 Counter Reset Conditions

Counter reset conditions vary according to the combination of inputs used and

pin settings on the back panel DIP switch. The DIP switch settings required for

the input combinations shown in the following table and the operating modes

that can be used with each are shown on the next page. (The numbers 1 through

17 above the input patterns correspond to the settings.) Resetting is not possible

in the gate, latch, and sampling operating modes. All inputs for each pattern

must be in the status shown for setting to be ef fective. The minimum input pulse

width for the input Z is 0.1 ms;that for the control input IN1, 1 ms.

In the following table, input Z is indicated by Z; control input IN1, by IN1, and the

internal reset bit, by IRB. The point at which the reset actually takes place is indicated by the arrow at the bottom of each pattern. The DIP switch settings for

each pattern are described on the following page.

Inputs used Reset conditions and timings

1 2 3 4

Input Z

Control input IN1

Internal reset bit

Input Z

Control input IN1

Z

IN1

IRB

5 6 7 8

Z

IN1

Z

IN1

IRB

Z

IN1

Z

IN1

IRB

Z

IN1

Z

IN1

IRB

Z

IN1

Input Z

Internal reset bit

Control input IN1

Internal reset bit

Input Z

Control input IN1

Internal reset bit

9 10

Z

IRB

11 12

IN1

IRB

13 14

Z Z

15 16

IN1 IN1

17

IRB

Z

IRB

IN1

IRB

29

Page 44

Data Transfer Timing Section 3-4

DIP Switch Settings Pins 1 through 3 do not affect resetting

Pattern number on

previous page

1 ON ON ON ON ON OK OK OK

2 ON ON ON OFF ON OK OK OK

3 ON OFF ON ON ON OK OK OK

4 ON OFF ON OFF ON OK OK OK

5 ON ON ON ON OFF OK OK OK

6 ON ON ON OFF OFF OK OK OK

7 ON OFF ON ON OFF OK OK OK

8 ON OFF ON OFF OFF OK OK OK

9 ON ON OFF * ON OK OK OK

10 ON OFF OFF * ON OK OK OK

11 OFF * ON ON ON OK OK OK

12 OFF * ON OFF ON OK OK OK

13 ON ON OFF * OFF OK OK OK

14 ON OFF OFF * OFF OK OK OK

15 OFF * ON ON OFF OK OK OK

16 OFF * ON OFF OFF OK OK OK

17 OFF * OFF * ON OK OK OK

Pin Settings Possible operating modes

4 5 6 7 8 Linear Circular Preset

*These pins may be either ON or OFF.

3-4 Data Transfer Timing

Data transfer is available in linear and circular modes to change ranges limit settings or the current counter value and in preset mode to change range limit settings. The data to be transferred must be prepared in the appropriate form in a

PC data area. Data transfer specifications and procedures are described under

the relevant operating modes. This section describes only data transfer timing in

relation to the PC cycle time.

C200H Cycle Time The C200H PC cycle consists of the following operations.

Cycle time Cycle time

Common

processing

Host

link

servicing

Peripheral device

servicing

Processing

I/O refresh

cycle

Common

processing

Host

link

servicing

Peripheral device

servicing

Processing

I/O refresh

cycle

30

Page 45

Data Transfer Timing Section 3-4

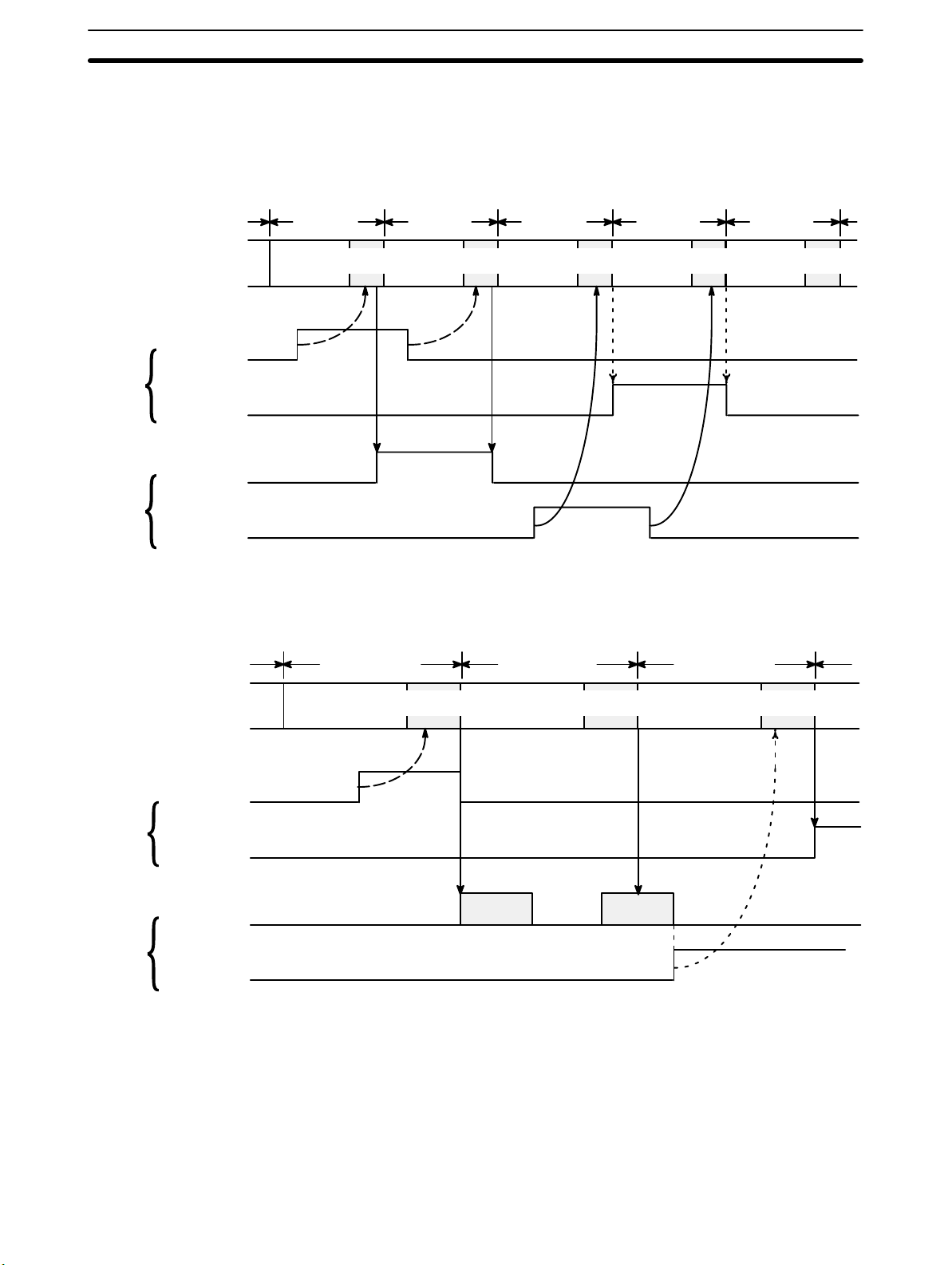

Data Transfer Input and output data is transferred during the I/O refresh cycle. This means

that PC acknowledgement of inputs from the Counter Unit (e.g., status) and

Counter Unit acknowledgement of outputs from the PC (e.g., commands) are

delayed until the next I/O refresh cycle, as shown below.

Cycle time Cycle time Cycle time Cycle time Cycle time

C200H

Counter

Unit

START and other outputs

Counting flag

and other inputs

START and other outputs

Counting flag

and other inputs

I/O

refresh cycle

I/O

refresh cycle

I/O

refresh cycle

I/O

refresh cycle

Data transfer would enter into the cycle time as shown below:

Cycle time Cycle time Cycle time

I/O

refresh cycle

I/O

refresh cycle

I/O

refresh cycle

I/O

refresh cycle

Data transfer

C200H

Transfer completed flag

Internal processing

Counter

Unit

Transfer completed flag

Data Transfer in Remote I/O

Systems

Data transfer acknowledged. Data transfer executed.

Note: The transfer completed flag reverses status (ON to OFF

or OFF to ON) each time a transfer is completed.

When the Counter Unit is mounted on a Rack containing a Remote I/O Slave

Unit, a delay will occur due to data transfer between the Remote I/O Master

Unit and the Remote I/O Slave Unit. See the C200H Programming Manual

for details.

31

Page 46

Page 47

SECTION 4

Data Allocation and Operating Modes

This section describes the various operating modes in detail. Each mode is described by data allocation, timing charts,

commands, flags, and examples. Data formats are explained.

4-1 Data Configuration and Allocation 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 Data Allocation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-2 DM Area Settings 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-3 IR Area Settings 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-4 Timing Chart 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-5 Application Examples 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Preset Mode 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Data Allocation 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-2 DM Area Settings 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-3 IR Area Settings 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-4 Timing Chart 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-5 Application Example 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Gate, Latch, and Sampling Modes 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-1 Data Allocation 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-2 DM Area Settings 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-3 IR Area Settings 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-4 Timing Charts 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-5 Application Examples 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Page 48

Data Configuration and Allocation Section 4-1

4-1 Data Configuration and Allocation

IR words 100 through 199 are allocated as I/O refresh areas. Each Counter Unit

is allocated 10 consecutive words (although not all modes use all 10 words). The

first IR word for each Counter Unit, designated in this manual as n, can be computed from the unit numbers as follows:

n = 100 + 10 x unit number.

IR words are refreshed during the PC’s I/O refresh cycle. Note that input and out-

put designations are in reference to the PC, e.g., command bits are outputs, status bits are inputs.

Each Counter Unit is also allocated 100 consecutive words as a parameter area

(although not all modes use all 100 words). These words are in the DM area and

run from DM 1000 through DM 1999. The first DM word for each Counter Unit, m,

can also be computed from the unit number:

m = 1000 + 100 x unit number.

All DM area data for the Counter Unit is transferred to it whenever power is

turned ON or the Counter Unit is reset.

34

Page 49

Data Configuration and Allocation Section 4-1

These allocations are shown below for all unit numbers. Details of allocations

within these words are given under the operating modes to which they apply. A

quick overview of word and bit allocations is available in Appendix C IR Area Al-

locations and Appendix D DM Area Coding Sheets.

C200H PC Counter Unit

DM area

Unit #0

DM 1000 through 1099

DM 1100 through 1199Unit #1

DM 1200 through 1299Unit #2

DM 1300 through 1399Unit #3

DM 1400 through 1499Unit #4

DM 1500 through 1599Unit #5

DM 1600 through 1699Unit #6

DM 1700 through 1799Unit #7

DM 1800 through 1899Unit #8

DM 1900 through 1999Unit #9

Data is automatically transferred to the

Counter Unit when

power is turned or

when its restart flag

in the AR area is

turned ON.

Parameter area

Word m

∫

Word m+99

Data is transferred to the Counter Unit

when the TRANSFER DATA command

bit of the IR area si turned ON after setting the TRANSFER DATA command to

the specified data area.

Specified Data Area

(DM, fixed DM, I/O, LR, HR, or AR)

IR area

Data transfer

Data is transferred

when TRANSFER

DATA is set.

100 through 109Unit #0

110 through 119Unit #1

120 through 129Unit #2

130 through 139Unit #3

140 through 149Unit #4

150 through 159Unit #5

160 through 169Unit #6

170 through 179Unit #7

180 through 189Unit #8

190 through 199Unit #9

Data is transferred to the

Counter Unit each

I/O refresh.

Word n to n+4

Word n+4 to n+9

I/O Area

Output data area

Input data area

35

Page 50

Linear and Circular Modes Section 4-2

Data Format Data is allocated by either bit or by word, though it is often input and output

by decimal digit, i.e., four bits (BCD), or by hexadecimal digit. Counter values, upper and lower limits of ranges, and some other data are held in two

adjacent words, sometimes with a sign digit, in the following format.

Highest word Lowest word

sign x 106x 105x 104x 103x 102x 101x 10

0

1

+

–

Note that the rightmost word is always the lowest word, i.e., if the two words were

m+10 and m+11, the rightmost word would be m+10; the leftmost, m+11. Furthermore, the rightmost digit in each word begins in the lowest bits, i.e., the digits

4

and x 100 above would be held in, bits 00 through 03 of their respective

x 10

words. Even when only one word or part of a word is required to hold data, e.g.,

the error code or error location, the rightmost digit is also always held in the lower

bits. Although decimal notation is generally used for data in this manual, data is

handled in the system as binary-coded decimal (BCD) unless otherwise noted.

Note that this data is generally input as decimal, whereas hexadecimal data is

input as hexadecimal. The number of digits given for certain data refers to the

decimal digits, e.g., “7 digits with sign” indicates that the lowest word and right-

most 12 bits of the highest word are allocated to the 7-digit decimal value; the

leftmost four bits are allocated to the sign digit.

4-2 Linear and Circular Modes

In both linear and circular modes counter values are incremented and decremented according to any of the three types of input pulses. All functional aspect

and data allocations for these two modes are the same, except that in linear

mode, counter values range linearly between –8,388,608 and 8,388,607, while

in circular mode, counter values range from 0 to a preset maximum value (used

only in circular mode), with the maximum value and 0 being adjacent to each

other in sequence. That is, decrementing below 0 results in the current counter

value going to the maximum value; incrementing past the maximum value results in the current counter value going to zero.

Both modes provide 16 outputs, all of which can be output internally (i.e., to the

PC) and eight of which can be output externally (i.e., without passing through the

PC) as well as internally. These outputs are sometimes referred to by number

and sometimes as either internal inputs and external inputs. The term internal

outputs refers to all outputs sent to the PC; external outputs, to all outputs set to

the external connector.

Both modes provide 16 ranges for counter values during which the outputs can

be set to turn ON. These ranges can be enabled or disabled during operations.

Data transfer from the PC data area is also available in both modes to change

either range settings or the current counter value.

Although control input IN1 is supposed by both modes, control input IN2 is not

used.

Note Stop counter operation before changing the present value to 0 or resetting

the Counter Unit in the ring mode. If either of these is performed without

stopping counter operation, the maximum value preset operation will not be

performed correctly.

0

4-2-1 Data Allocation

The commands, parameters, flags, and other information in the following tables

are described in detail in 4-2-2 DM Area Settings and 4-2-3 IR Area Settings.

36

Page 51

Linear and Circular Modes Section 4-2

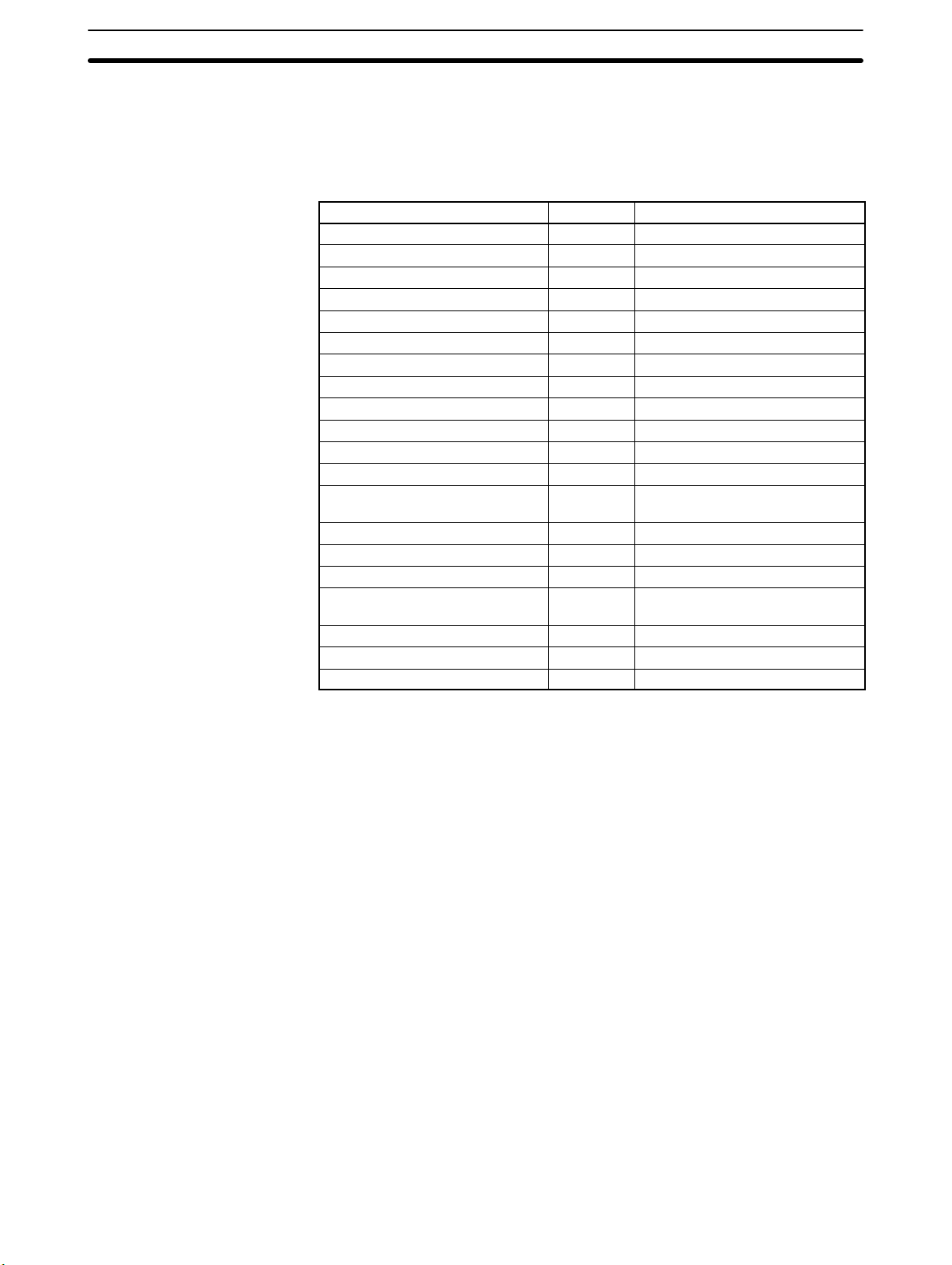

DM Area The DM area contains user parameters that are to be set into the Counter

Unit, including the operating mode and output range limits. The first DM word

for each Counter Unit is indicated by m and equals 1,000 plus 100 times the

unit number.

Word Bit Function

m 07 through 00 Set to 0.

11 through 08 Operating mode (Here, either 1: linear or 2: circular)

15 through 12 Set to 0.

m + 1 15 through 00 Effective range bits (bit numbers correspond to range numbers)

m + 2

m + 3 15 through 00 6 digits (Bits 15 to 04 not used.)

m + 4

m + 9

m + 10 15 through 00 Lower limit for range #0, 7 digits with sign digit

m + 11 15 through 00

m + 12 15 through 00 Upper limit for range #0, 7 digits with sign digit

m + 13 15 through 00

m + 14 15 through 00 Output pattern for range #0 (bit numbers correspond to output numbers)

m + 15

m + 19

m + 20

m + 24

m + 25

m + 29

m + 30

m + 34

m + 35

m + 39

m + 40

m + 44

m + 45

m + 49

m + 50

m + 54

m + 55

m + 59

m + 60

m + 64

m + 65

m + 69

m + 70

m + 74

m + 75

m + 79

m + 80

m + 84

m + 85

m + 89

m + 89

m + 99

15 through 00 Maximum counter value (for circular mode only)

Not used.

Lower limit, upper limit, and output pattern for range #1 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #2 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #3 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #4 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #5 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #6 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #7 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #8 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #9 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #10 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #11 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #12 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #13 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #14 (Format same as

that for range #0.)

Lower limit, upper limit, and output pattern for range #15 (Format same as

that for range #0.)

Not used.

37

Page 52

Linear and Circular Modes Section 4-2

IR Area The IR area contains commands and status information. Inputs and outputs

are given in reference to the PC, i.e., output data is sent from the PC to the

Counter Unit; input data, from the Counter Unit to the PC. The first IR word

for each Counter Unit is indicated by n and equals 100 plus 10 times the unit

number.

Outputs

Word Bit Function

00

START command

01

TRANSFER DATA command

02

ENABLE OUTPUT command

03

Not used.

04

CHANGE RANGES command

05

READ ERROR command

06

RESET COUNTER command

07

n

n+1

n+2

n+3

ENABLE FORCED OUTPUT command

08

Output #0 force bit

09

Output #1 force bit

10

Output #2 force bit

11

Output #3 force bit

12

Output #4 force bit

13

Output #5 force bit

14

Output #6 force bit

15

Output #7 force bit

00

Range #0 enable bit

01

Range #1 enable bit

02

Range #2 enable bit

03

Range #3 enable bit

04

Range #4 enable bit

05

Range #5 enable bit

06

Range #6 enable bit

07

Range #7 enable bit

08

Range #8 enable bit

09

Range #9 enable bit

10

Range #10 enable bit

11

Range #11 enable bit

12

Range #12 enable bit

13

Range #13 enable bit

14

Range #14 enable bit

15

Range #15 enable bit

TRANSFER DATA beginning word

15

−00

number, 4 digits

TRANSFER DATA data area, 0 to 4

03−00

Not used. (Set to 0.)

07

−04

Number of transfers, 1 to 3

15

−08

Inputs

Word Bit Function

Counting flag

00

Z flag

01

IN1 flag

02

IN2 flag

03

n+4

n+5

n+6

n+7

n+8

n+9

Transfer completed flag

04

Error flag

05

Count overflow flag

06

Reset flag

07

Not used

08

Error location

07−00

Error code

15

−08

Current counter value, 7 digits with sign

−00

15

(–8,388,608 to +8,388,607)

15

−00

Range #0 flag

00

Range #1 flag

01

Range #2 flag

02

Range #3 flag

03

Range #4 flag

04

Range #5 flag

05

Range #6 flag

06

Range #7 flag

07

Range #8 flag

08

Range #9 flag

09

Range #10 flag

10

Range #11 flag

11

Range #12 flag

12

Range #13 flag

13

Range #14 flag

14

Range #15 flag

15

Output #0 flag (external output possible)

00

Output #1 flag (external output possible)

01

Output #2 flag (external output possible)

02

Output #3 flag (external output possible)

03

Output #4 flag (external output possible)

04

Output #5 flag (external output possible)

05

Output #6 flag (external output possible)

06

Output #7 flag (external output possible)

07

Output #8 flag (internal output only)

08

09

Output #9 flag (internal output only)

10

Output #10 flag (internal output only)

11

Output #11 flag (internal output only)

12

Output #12 flag (internal output only)

13

Output #13 flag (internal output only)

14

Output #14 flag (internal output only)

15

Output #15 flag (internal output only)

38

Page 53

Linear and Circular Modes Section 4-2

4-2-2 DM Area Settings

Operating Mode DM word m, bits 11 through 08

The operating mode is set with the mode selector on the front panel. Refer to 1-4

Operating Modes for an overview of available modes.

Effective Range Bits DM word m+1

Bit numbers correspond to range numbers, i.e., but 0 corresponds to range #0;

bit 1, to range #1, etc. Range data is allocated to words m+10 through m+89.

Turn ON (set to 1) the bits for all ranges that are to be effective. These bits are

effective immediately after the power supply is turned ON or the Counter Unit is

restarted. The effective ranges can also be changed using CHANGE RANGES.

Refer to 4-3-3 IR Area Settings for details.

Maximum Counter Value

(Circular Mode Only)

Range Settings Words m+10 through m+89

Lower Limit Words m+10 and m+11 (Range #0)

Upper Limit Words m+12 and m+13 (Range #0)

DM word m+2 and m+3

Set to between 0 and 65,535.

The counter value will return to zero when incremented past this value and return to this value when decremented below zero.

Each of the 16 ranges is allocated 5 consecutive words for its lower limit, upper

limit, and output pattern. Refer to 4-3-1 Data Allocation for the specific words for

each range; the following allocations are for range #0. In circular mode, a range

will span zero if the lower limit is greater than the upper limit. Ranges may overlap, in which case all outputs specified for each are set. Set all data for unused

ranges to zeros.

The lower limit must be within the limits of the counter value, i.e., between 0 and

the maximum counter value in circular mode and between –8,388,608 and

8,388,607 in linear mode. Bits 15 through 12 of DM word m+11 (leftmost digit in

higher word) is the sign digit (not used in circular mode).

The upper limit must also be within the limits of the counter value, i.e., between 0

and the maximum counter value in circular mode and between –8,388,608 and

8,388,607 in linear mode. Bits 15 through 12 of DM word m+13 (leftmost digit in

higher word) is the sign digit (not used in circular mode).

Output Pattern DM word m+14 (Range #0)

Each bit corresponds to the output of the same number . Each output whose bit is

ON will be turned ON (set to 1) when the counter value is within range. An output

may not be activated, however, if the range is too narrow in comparison to the