Page 1

Cat. No. W120-E1-08

SYSMAC

C-series Rack PCs

Wired Remote I/O

Page 2

Wired Remote I/O

System Manual

Revised April 2003

Page 3

iv

Page 4

!

!

!

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1989

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 5

vi

Page 6

TABLE OF CONTENTS

vii

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Remote I/O Systems 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Wired Remote I/O Systems 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

System Design 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Basic System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 C200H Systems 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Combined Systems 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Optical Connections in Wired Systems 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Multilevel Systems 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Data Exchange and Operations 21. . . . . . . . . . . . . . . . . . . .

3-1 Block Diagrams 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Unit Numbers and I/O Word Allocation 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Setting Procedure 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Delayed Activation of Slaves 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Unit Components and Switch Settings 45. . . . . . . . . . . . . . .

4-1 Masters and Slaves 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Remote Terminal 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

System Installation 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Dimensions 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Differentiating Units 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 I/O Block Connections 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Mounting and Wiring Precautions 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Wiring 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

I/O Response Times 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Introduction 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 C500 Systems 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 C1000H and C2000H Systems 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 C200H Systems 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

TABLE OF CONTENTS

viii

SECTION 7

Error Processing 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Self-Diagnosis 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Error Codes and Monitoring 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Locating Transmission Errors 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 CONTINUE and STOP Mode Operation 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 Recovery in STOP Mode 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 I/O Table Creation Problems 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 Slave Unit Numbers with Multiple Terminators 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Standard Models 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C When Using CS1-series PCs 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

ix

About this Manual:

This manual describes the means and Units necessary to construct a Wired Remote I/O System consisting of at least one Remote I/O Master Unit and one or more Remote I/O Slave Units or Remote

Terminals. (The term “Wired” refers to the links used to create the Remote I/O System, e.g., that between a Remote I/O Master Unit and a Remote I/O Slave Unit.) Remote I/O Systems reduce wiring

requirements for remote control from a PC by performing distributed control actions through execution

of a program in the memory of a single PC’s CPU. The 3G2A5-RM201 Remote I/O Master Unit can

be used with any C-series Rack PC except the C200H PC. The C200H-RM201 Remote I/O Master

Unit is used with a C200H PC. Remote I/O Slave Units, though generally used with the corresponding

Remote I/O Master Unit, can be used in “combined” system configurations.

This manual has been prepared to explain how to incorporate Wired Remote I/O Systems into C120,

C500, C200H, C1000H, and C2000H PC Systems. It provides the necessary information, such as

system configuration, settings, and I/O word allocation, for connecting Remote I/O Master Units, Remote I/O Slave Units, and I/O Units.

Before attempting to set up and operate your Remote I/O System, familiarize yourself with all relevant

parts of this manual. For more detailed descriptions of manual content, refer to the introductions for

individual sections.

Section 1 introduces Wired I/O Systems and describes their characteristics.

Section 2 describes some of the many possible system configurations and the limitations of each

type of system.

Section 3 provides names and descriptions of basic functions, internal circuits, and methods for dif-

ferentiating differentiating unit types. Settings required to operate the system and successfully communicate program actions are explained, and example system settings are provided.

Section 4 provides details on Wired Remote I/O Systems, and the main Units used to build these

Systems, included within these are mounting restrictions and wiring considerations of the systems.

Parts of the Units, switch setting, and examples of switch settings are provided.

Section 5 explains how to install Wired I/O Systems and includes information on dimensions, differences between Units, and wiring.

Section 6 offers details on response time computations.

Section 7 describes error indications and error processing. Both indicator lights and dedicated error-

related flags are provided.

Appendix A provides a list of the basic specifications and complete model numbers of products used

in Wired I/O Systems.

Appendix B provides technical specifications.

Appendix C provides information on using CS1-series PCs.

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

!

Page 9

xi

PRECAUTIONS

This section provides general precautions for using the Wired Remote I/O System and related devices.

The information contained in this section is important for the safe and reliable application of the Wir ed Remote I/O

System. You must read this section and understand the information contained before attempting to set up or operate

the Wired Remote I/O System.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

!

!

!

!

!

!

!

5Safety Precautions

xii

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the relevant manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the System.

Be sure to read this manual before attempting to use the System and keep this

manual close at hand for reference during operation.

WARNING It is extremely important that the Wired Remote I/O System be used for the

specified purpose and under the specified conditions, especially in applications

that can directly or indirectly affect human life. You must consult with your

OMRON representative before applying the Wired Remote I/O System to the

above-mentioned applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in burning

or malfunction.

Caution Execute online edit only after confirming that no adverse effects will be caused

by extending the cycle time. Otherwise, the input signals may not be readable.

WARNING Do not attempt to disassemble, repair , or modify any Units. Any attempt to do so

may result in malfunction, fire, or electric shock.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, in order to ensure safety in the system

if an abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

Page 11

!

!

!

!

5Application Precautions

xiii

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the Wired Remote I/O System can have a large

effect on the longevity and reliability of the system. Improper operating environments can lead to malfunction, failure, and other unforeseeable problems with

the System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of

the System.

5 Application Precautions

Observe the following precautions when using the Wired Remote I/O System.

WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Units, or any other

Units.

Page 12

!

5Application Precautions

xiv

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

Wired Remote I/O System, or could damage the PC or PC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring . In su f ficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

Page 13

6EC Directives

xv

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

6 EC Directives

Remote I/O products conform to EMS and low-voltage level directives as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards, so that they can more easily be built in to other devices or the

overall machine. The actual products have been checked for conformity to EMC

standards. Whether they conform to the standards in the system used by the

customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel on which the OMRON devices are installed. The customer must, therefore, perform the final check to confirm that devices and the

overall machine conform to EMC standards.

Low-voltage Level Directives

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to

1,500 VDC meet the necessary safety standard for the PC (EN61131-2).

DeviceNet products that comply with EC Directives must be installed as follows:

1, 2, 3... 1. Remote I/O Units are designed for installation inside control panels. All Re-

mote I/O Units must be installed within control panels.

2. Use reinforced insulation or double insulation for the DC power supplies

used for the communications power supply, internal circuit power supply,

and the I/O power supplies.

3. Remote U/O products that comply with EC Directives also conform to the

Common Emission Standard (EN50081-2). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions. You must therefore confirm that the overall machine or

equipment complies with EC Directives.

4. Remote I/O products that comply with EC Directives have configurations

with less than 30 m of I/O wiring, and less than 10 m of power supply wiring.

Page 14

1

SECTION 1

Introduction

This section introduces Wired I/O Systems and describes their characteristics.

1-1 Remote I/O Systems 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Wired Remote I/O Systems 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

2

Remote I/O Systems Section 1-1

1-1 Remote I/O Systems

Assembly lines are often extremely long, making it difficult if not impossible to

wire all I/O devices directly from CPU Racks or Expansion I/O Racks. A Remote I/O System can be used to solve this problem. In a Remote I/O System,

a Rack can be located farther from the CPU Rack than is possible with Expansion I/O Racks connected directly to the CPU Rack.

By locating a Rack farther from the CPU Rack, a Remote I/O System eliminates the time and mess in wiring (or changing wiring) to many devices that

are separated from the CPU Rack. Although all I/O points must ultimately be

wired individually, the question is one of distance: Do you want to wire dozens of terminals all the way across a factory complex or do you want to run a

single cable for most of the distance and then wire individual terminals locally?

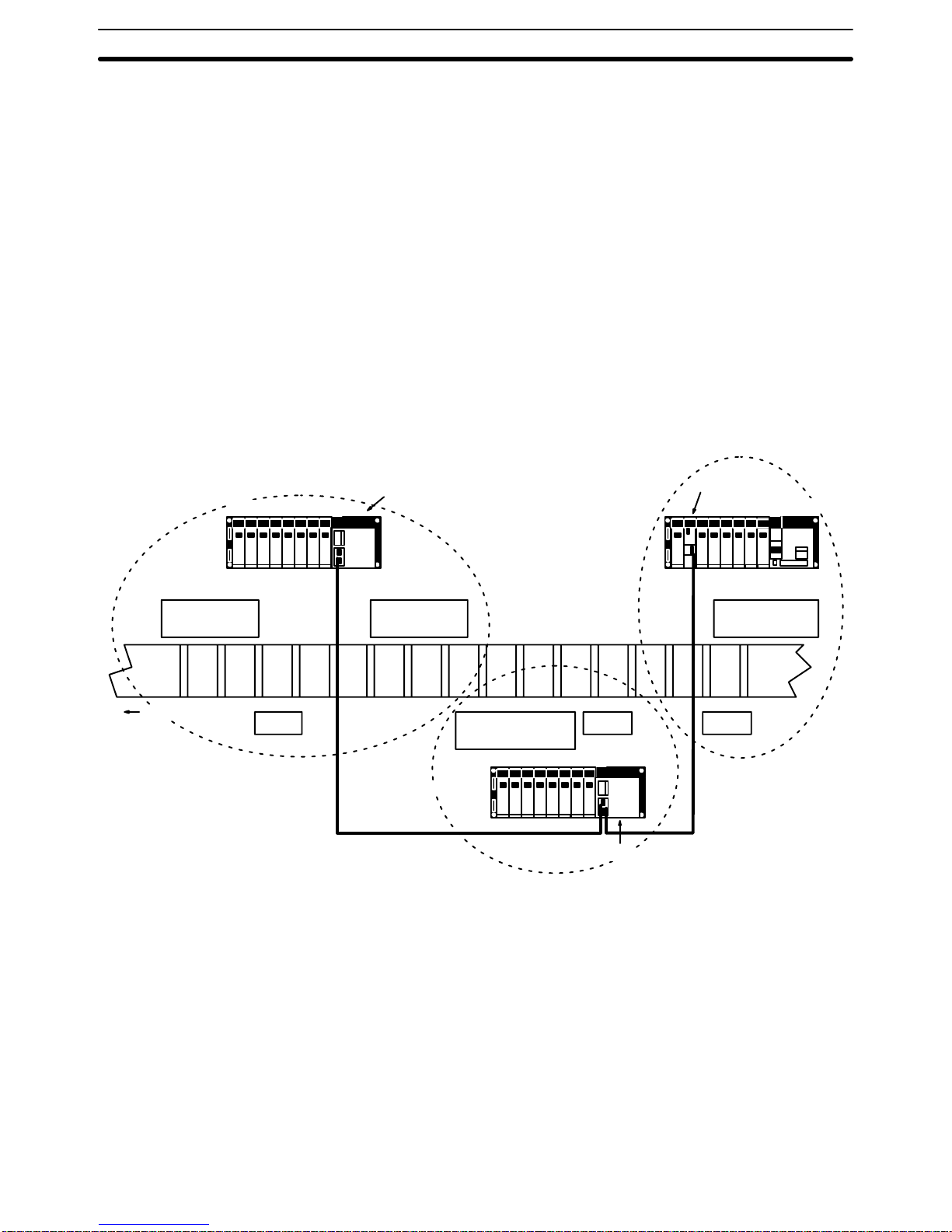

The following diagram illustrates how a simple Remote I/O System would be

set up. Slave Racks, described below, are controlled by the CPU Unit

through the Master. The dotted circles show the devices that would be controlled through the Units on each Rack.

Processing

machine

Processing

machine

Processing

machine

Processing

machine

Sensor Sensor Sensor

CPU Rack

Master

Slave Rack

Slave

Slave Rack

Slave

Assembly line

Wiring distance could also be reduced by placing an independent CPU Rack

near every location that required control, but in doing so, each PC would

have to be programmed independently and the activities of all the PC programs would need to be coordinated, a very difficult job. Here too, a Remote

I/O System simplifies the task by allowing a single CPU Unit, and thus a single program, to integrate control of the entire process. A Remote I/O System

thus has these two advantages: Racks can be located a greater distance

from the CPU Rack and coordinating control actions is simplified because all

control is exerted by one program.

A third advantage of Remote I/O Systems is reduced noise interference. This

is the result of the single cable that replaces the otherwise numerous wires

that would be required all the way from the CPU and Expansion I/O Racks to

the I/O devices.

Page 16

3

Remote I/O Systems Section 1-1

A Remote I/O System directly involves only one PC and the program in it and

through it a large number of I/O points can be controlled a greater distance

from the PC. This is achieved by mounting a Remote I/O Master Unit to the

CPU Rack to control I/O points located possibly many kilometers away. Each

Master serves as a ‘switching point’ for controlling all of the I/O points accessed through it. These I/O points are accessed through the Master, not

controlled by it. All I/O control comes from the program in the CPU Unit.

More than one Master can be mounted to a single PC, with each Master

forming the starting point of a Remote I/O Subsystem, i.e., a Remote I/O

Subsystem includes one Master plus all of the Remote I/O Units controlled

through it.

The Remote I/O Units that can be included in each Subsystem depend on

the specifications of the Master. Masters are available either with optical or

wire specifications. Optical Remote I/O Systems transfer data through opti-

cal fiber cables to enable the greatest transmission distance and the greatest resistance to electrical noise. Wired Remote I/O Systems use wire ca-

bles which don’t offer as great a distance as Optical Subsystems, but do

greatly reduce the burden of wiring remote I/O and afford greater resistance

to noise than independently wired I/O points. Both types of Master can be

mounted to the same PC to meet specific distance and noise-resistance requirements.

Master

on Rack

Label printer

Remotely Controlled I/O Devices

Glue coater

PC

Optical and

Wired Masters

on Rack

Auto welder

Conveyer

Packing machine

Optical Subsystem

Wired Subsystem

Polisher

PC

All Remote I/O Systems consist of at least one Remote I/O Master Unit connected in series to one or more Units accessed through it. One of these Units

that is common to most Remote I/O Systems is a Remote I/O Slave Unit.

Page 17

4

Wired Remote I/O Systems Section 1-2

A Master is mounted to the CPU Rack or an Expansion I/O Rack; a Slave is

mounted to a Backplane to form what is called a Slave Rack. To a Slave

Rack is mounted the same other Units as those mounted to the CPU or Expansion I/O Rack, with only a few exceptions (e.g., Link Units other than

Slaves cannot be mounted to Slave Racks). The advantage of a Slave Rack

is that it can be located a considerable distance from the CPU Rack with the

only connection required being a cable running from the Master to the Slave.

The actual distance a Slave Rack can be removed from the Master, as well

as the other Units used to configure a Remote I/O System, depends on the

type of Remote I/O System being used. Collectively, all of the Units connected in a Remote I/O System are referred to as Remote I/O Units.

This manual describes Wired Remote I/O Systems. Optical Remote I/O Units

are described in the Optical Remote I/O System Manual (W136).

1-2 Wired Remote I/O Systems

In a Wired Remote I/O System, the Master is connected to other Remote I/O

Units through wire cable. These Remote I/O Units include Wired Masters,

Wired Slaves, and Remote Terminals. Link Adapters can also be included in

the System to enable the use of optical cable links.

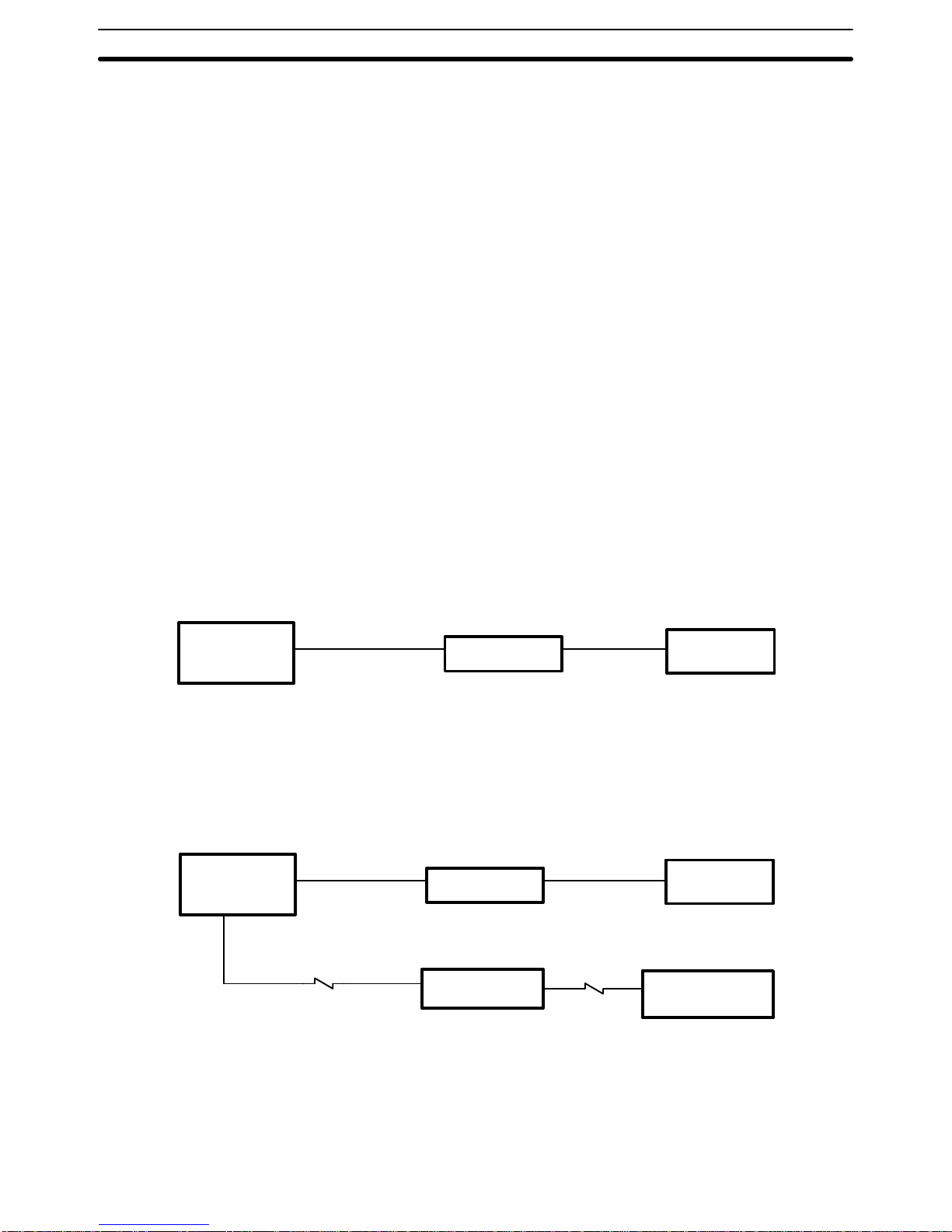

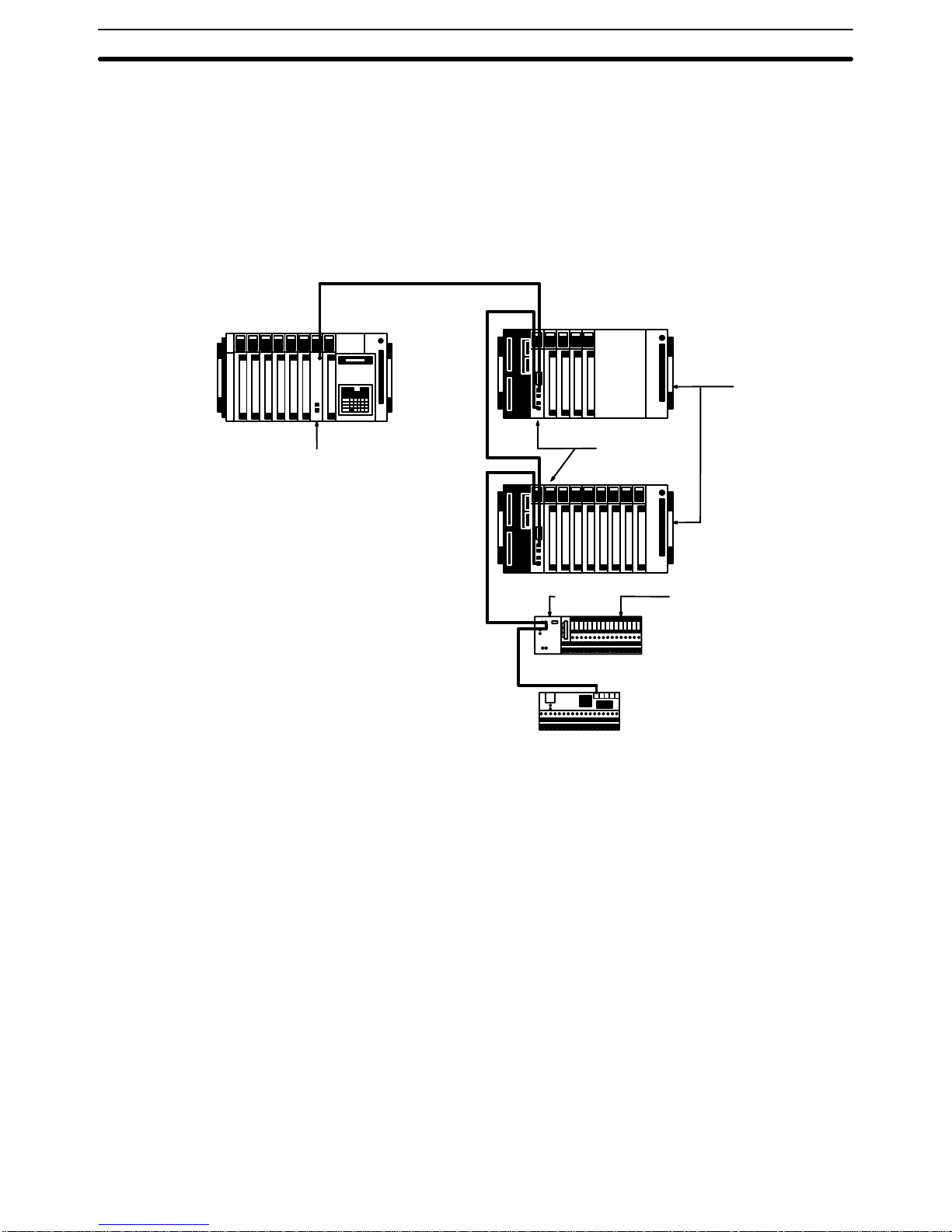

A basic Wired Remote I/O System is shown below.

C2000H CPU Rack Slave Rack

Slave Rack

Remote

Terminal

Remote

Terminal

Master

Slave

Slave

Wire cable

A Remote Terminal can be used when there is only a limited number of I/O

points required in a single location. Each Remote Terminal provides up to 16

input or output points.

There are two basic types of Remote Terminal. A G72C Remote Terminal is a

‘stand-alone’ Unit that occupies one location in the Remote I/O System. It

provides 16 fixed transistor inputs or outputs and can be used for any application suited to these.

Remote Terminals

Page 18

5

Wired Remote I/O Systems Section 1-2

The other basic type of Remote Terminal consists of two parts: a Remote

Interface and an I/O Block. The Remote Interface functions to transmit input

or output signals between the Remote I/O System and the I/O Block. I/O

Blocks enable easy removal and replacement of individual relays, including

relays with a large switching capacity, making them ideal for controlling

large motors, heavy equipment, etc. An I/O Block is available for either 16

input points or 16 output points.

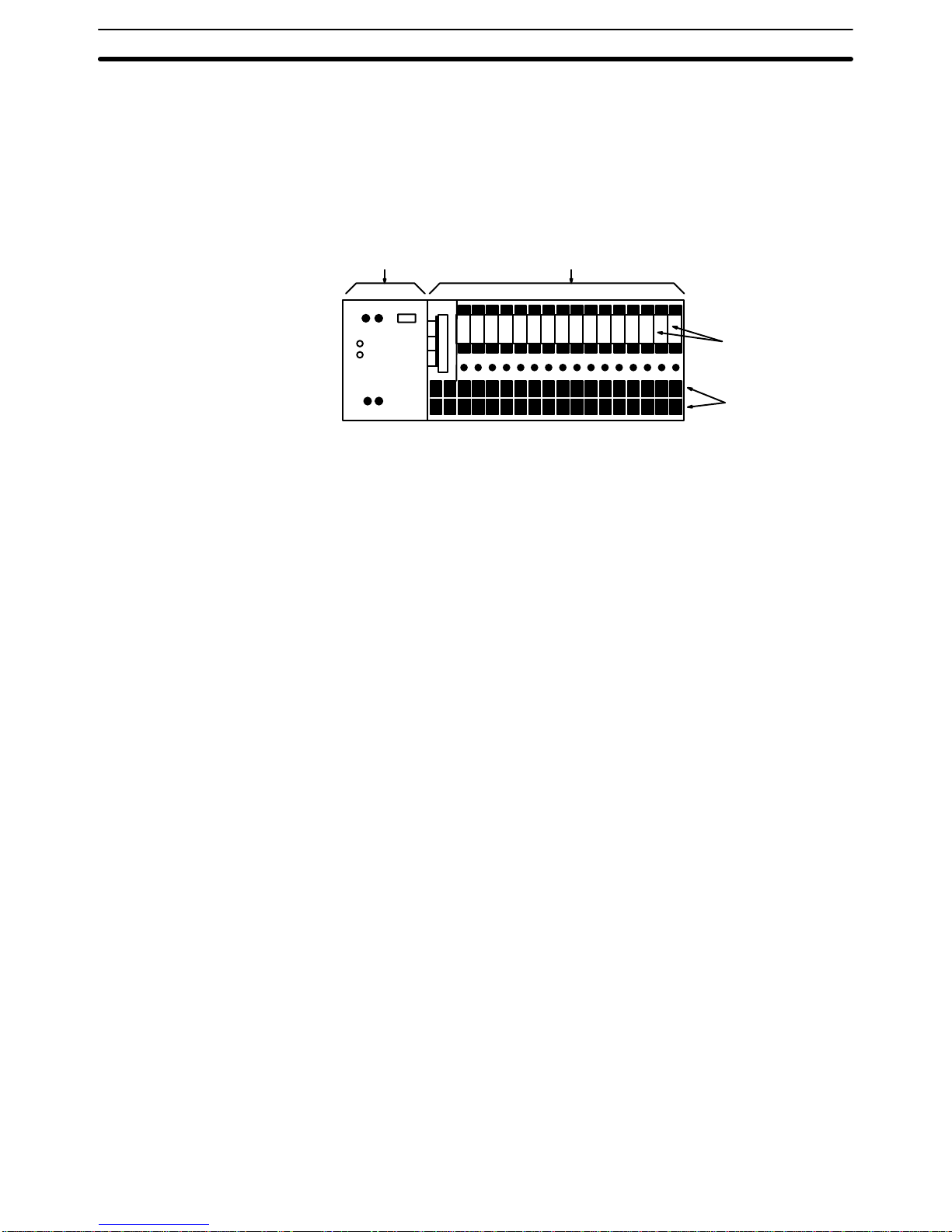

Remote Interface Input Block

Replaceable

relays

Terminals

The types of field devices that can be handled is the only functional difference between G72C Remote Terminals and Remote Interfaces connected to

I/O Blocks. There is no difference that affects the software operation of the

Remote I/O System. In the remainder of this manual, the term Remote Terminal will be used to refer collectively to both types of Remote Terminals unless

there is a reason to specify one or the other.

Converting Link Adapters can be used to create optical cable links within an

otherwise Wired System. The connections to Masters, Slaves, and Remote

Terminals are still wire cable; the optical connections are only between Link

Adapters. Refer to 2-4 Optical Connections in Wired Systems for details.

Branching Wired Remote I/O Systems through Branching Link Adapters is

not possible.

Link Adapters

Page 19

7

SECTION 2

System Design

Although there are many possible Remote I/O Systems that can be built out of Masters, Slaves and Remote Terminals,

each System is limited by the capacity of the PC and the nature of the other Units in the System. Section 2-1 describes

System configurations based on the C500-RM201 Master and C500-RT201 Slave (i.e., for C120, C500, C1000H, and

C2000H Systems), and outlines connection requirements, mounting restrictions, and System size limitations. Section 2-2

provides the same information for C200H Systems. Section 2-3 explains combining Masters and Slaves from different

Systems. Finally, Section 2-4 describes how to incorporate optical links into Wired Remote I/O Systems.

2-1 Basic System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 C120 Systems 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 C500 Systems 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 C1000H and C2000H Systems 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 C200H Systems 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Combined Systems 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Optical Connections in Wired Systems 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Multilevel Systems 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 20

Basic System Section 2-1

8

2-1 Basic System

The following figure shows a basic System configuration illustrating some

aspects of Wired Remote I/O Systems designed with the C500-RM201 Master. Refer to following subsections for specific examples and limitations.

C500(F), C1000H(F),

C2000H, CV500, CV1000,

CV2000, CVM1 CPU Rack

2-conductor cable

Slave Racks

Wired Slaves

C500-RT201

Remote Terminal

I/O Block

Remote Terminal

Wired Master

C500-RM201

At least one Master is always necessary to connect Slaves and/or Remote

Terminals. Connect each Master and all the Remote I/O Units controlled

through it in series. All Units can be combined in any fashion and connected

in any order as long as they are in series and the Master is on one end of the

line. I/O Blocks are mounted to Remote Interfaces.

Masters can be mounted to any I/O slot on the CPU or Expansion I/O Rack in

all but C120 Systems. In C120 Systems, Masters must be mounted to the I/O

Interface Unit’s position (leftmost slot) on C500 Backplanes.

Unit Connection

Mounting Remote I/O Units

Page 21

Basic System Section 2-1

9

Remote Interface and I/O Blocks are used in pairs, each of which provides

16 points. The I/O Block is easily connected to the Remote Terminal by way

of a connector. G72C Remote Terminals, on the other hand, do not require a

separate I/O Block. Remote Interface and I/O Blocks are paired as follows:

I/O I/O Block Remote Terminal

AC Input G7TC-IA16 100/110 VAC or

G7TC-IA16 200/220 VAC

G71-IC16 12 VDC or G71-IC16

24 VDC

DC Input G7TC-ID16 12 VDC

G7TC-ID16 24 VDC

G71-IC16 12 VDC

G71-IC16 24 VDC

Output G7TC-OC16 12 VDC

G7TC-OC16 24 VDC

G71-OD16 12 VDC

G71-OD16 24 VDC

The number of Units in any one System is limited by the capacity of the PC.

Detailed limitations are provided in the following table. These totals include

all Optical and Wired Master Subsystems controlled by the PC.

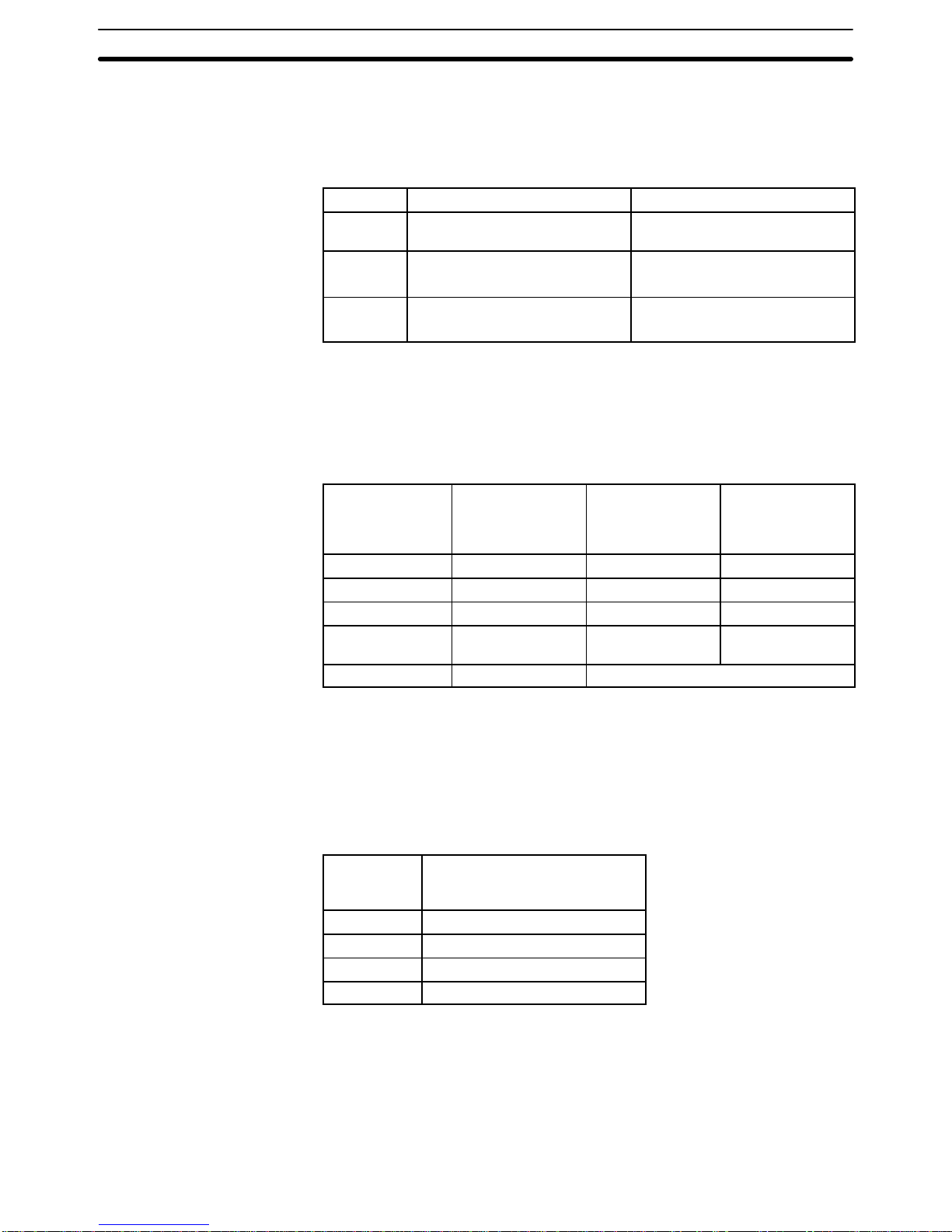

PC C120 C500, CV500,

CVM1-CPU01-EV2

C1000H, C2000H,

CV1000, CV2000,

CVM1-CPU11-EV2

/CPU21-EV2

Masters per PC 4 4 8

Slaves per Master 2 2 8 (see note)

Slaves per PC 8 8 16 (see note)

Remote Terminals

per Master

16 32 32

Words per Master 16 (256 points) 32 (512 points)

Always set the address number of the Remote I/O Unit in order starting from

#0. The CPU Unit will determine the number of Slaves connected according

to the address number of the Remote I/O Unit, as shown in the following

table, even if only one Slave is actually connected. Therefore, if the address

number is designated from the larger number, the actual total number of Remote I/O Units that can be connected to one PC will be limited.

Largest Unit

No. Set

Number of Slaves Connected

(as Determined by the CPU

Unit)

0 or 1 2

2 or 3 4

4 or 5 6

6 or 7 8

If three Slaves connected to separate Masters mounted to the same CPU

Rack were set as Unit number 4, the PC would assume, as shown above,

that each Master had six Slaves attached, for a total of 18, or two more than

allowed in the System. An error would thus be generated, even if the three

Slaves were actually the only Slaves in the System.

Remote Terminals

Maximum Number of

Connectable Remote I/O

Units

Note

Example

Page 22

Basic System Section 2-1

10

The total number of I/O points in the System must not exceed the number of

I/O points provided by the PC to which the Master(s) is mounted or

connected.

PC Maximum Number of I/O Points

C2000H 2,048

C1000H 2,048*

C500 512

C120 256

*The total number of I/O points in a C1000H System can be up to 2,048, as

long the number of I/O points on the CPU Rack and Expansion I/O Racks

connected to the CPU Rack (i.e., not I/O points on Slave Racks) is limited to

1,024.

Total number of points for the PC

Total number of points on CPU Racks and

Expansion I/O Racks

Total number of points on Slave Racks

Total number of points on Remote Terminal

+

=

+

+

Total number of points in Optical Remote Subsystems

Total I/O Points

Page 23

Basic System Section 2-1

11

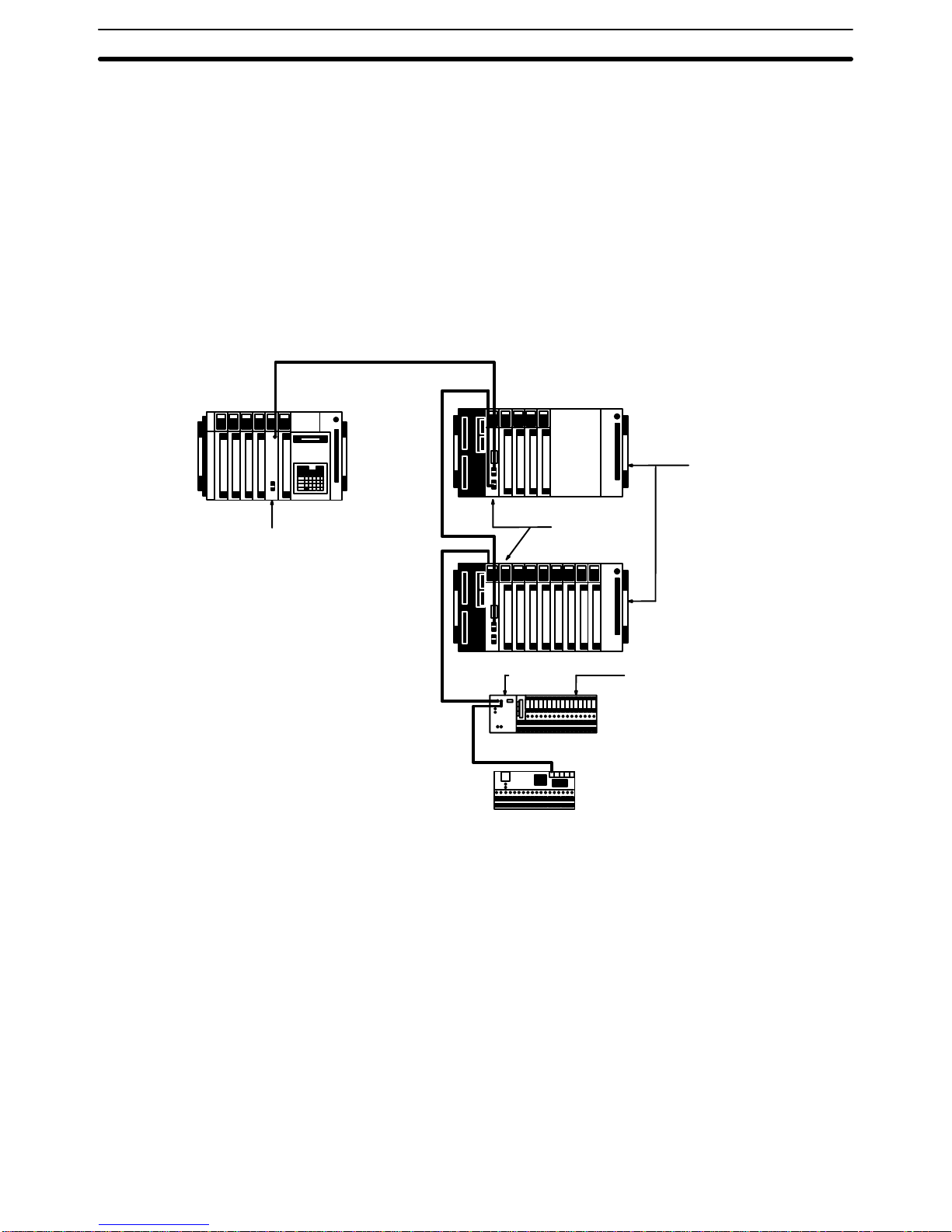

2-1-1 C120 Systems

In C120 Systems, up to four Masters can be connected to the same PC, and

up to two Slaves and 16 Remote Terminals can be connected to any one

Master. Note that a Master in a C120 System must be mounted to an I/O slot

on a C500 Expansion I/O Rack.

C120 PCs provide 256 I/O points. This means that the total number of points

used in the System must be 256 or less. If, for example, 256 points are controlled by one Master connected to a C120 PC, there cannot be any more

Masters or I/O points employed for that C120 PC.

C120 CPU Rack

C500 Expansion

I/O Rack

C500 Master

C500-RM201

C500 Slaves

C500-RT201

Slave Racks

Remote Interface

G7TC I/O Block

Remote Terminal

Page 24

Basic System Section 2-1

12

2-1-2 C500 Systems

In C500 Systems, up to four Masters can be connected to the same PC, and

up to two Slaves and 32 Remote Terminals can be connected to any one

Master.

C500 PCs provide 512 I/O points. This means that the total number of points

used in the System must be 512 or less. If, for example, 512 points are controlled by one Master connected to a C500 PC, no more Masters or I/O

points can be employed for that C500 PC.

Remote Interface

I/O Block

Remote Terminal

Slave

Racks

C500 CPU Rack

C500 Master

C500-RM201

C500 Slaves

C500-RT201

Page 25

Basic System Section 2-1

13

2-1-3 C1000H and C2000H Systems

In C1000H and C2000H Systems up to eight Masters can be connected to

the same PC. In C1000H and C2000H Systems, up to eight Slaves and 32

Remote Terminals can be connected to any one Master.

When a Remote I/O System is included, C1000H and C2000H PCs provide

2,048 I/O points. This means that the total number of points used in the System must be 2,048 or less. If, for example, 2,048 points are controlled by four

Masters on C1000H and C2000H PCs, no more Masters or I/O points can be

employed on the PCs. (The number of I/O points for the I/O Units on a

C1000H CPU Rack and Expansion I/O Racks must be kept to within

1,024.)The number of points for any one Master, must be kept to 512 or less.

Remote Interface

I/O Block

Remote Terminal

Slave Rack

C1000H

or

C2000H

CPU

Rack

C500 Master

C500-RM201

C500 Slaves

C500-RT201

Page 26

C200H Systems Section 2-2

14

2-2 C200H Systems

When constructing a Remote I/O System from C200H Masters and Slaves,

up to 2 Masters, 5 Slaves (regardless of the number of Masters), and 32 Remote Terminals can be included. Optical Masters and Slaves, if controlled by

the PC, must be included in these totals. Expansion I/O Racks can be connected to Slave Racks, however this limits the number of Slaves which the

PC can control i.e., each such Expansion I/O Rack must be counted as a

Slave Rack. The basic rules for Remote I/O Systems apply, e.g., each Master

Subsystem must be connected in series with a Master on one end and a terminator (either a Remote Terminal or Slave) on the other end.

Masters can be mounted to any slot on the C200H CPU Rack or Expansion

I/O Rack. Masters should not be mounted, however, to either of the rightmost

two slots of the CPU Rack, as this would prevent mounting devices directly to

the CPU Unit. I/O Blocks are mounted to the Remote Interface, just as in

Systems using C500-RM201 Masters (see 2-1 Basic System). Masters

cannot be mounted to Slave Racks or to Expansion I/O Racks connected to

Slave Racks

Note 1. The only Units that can be mounted to Remote I/O Slave Racks are Basic

I/O Units and Special I/O Units.

2. High-density I/O Units (Group 2) and B7A Interface Units (Group 2) cannot

be used on Remote I/O Slave Racks.

3. A Remote I/O Master Unit cannot be used if the CPU Unit is the

C200H-CPU02.

4. High-density I/O Units mounted on a Remote I/O Slave Rack can be used

only if the Remote I/O Master Unit is the C200H-RM201.

The numbers of Special I/O Units that can be mounted to any one Slave

Rack are shown in the following table. These figures assume that Units are

used only from one of the three groups.

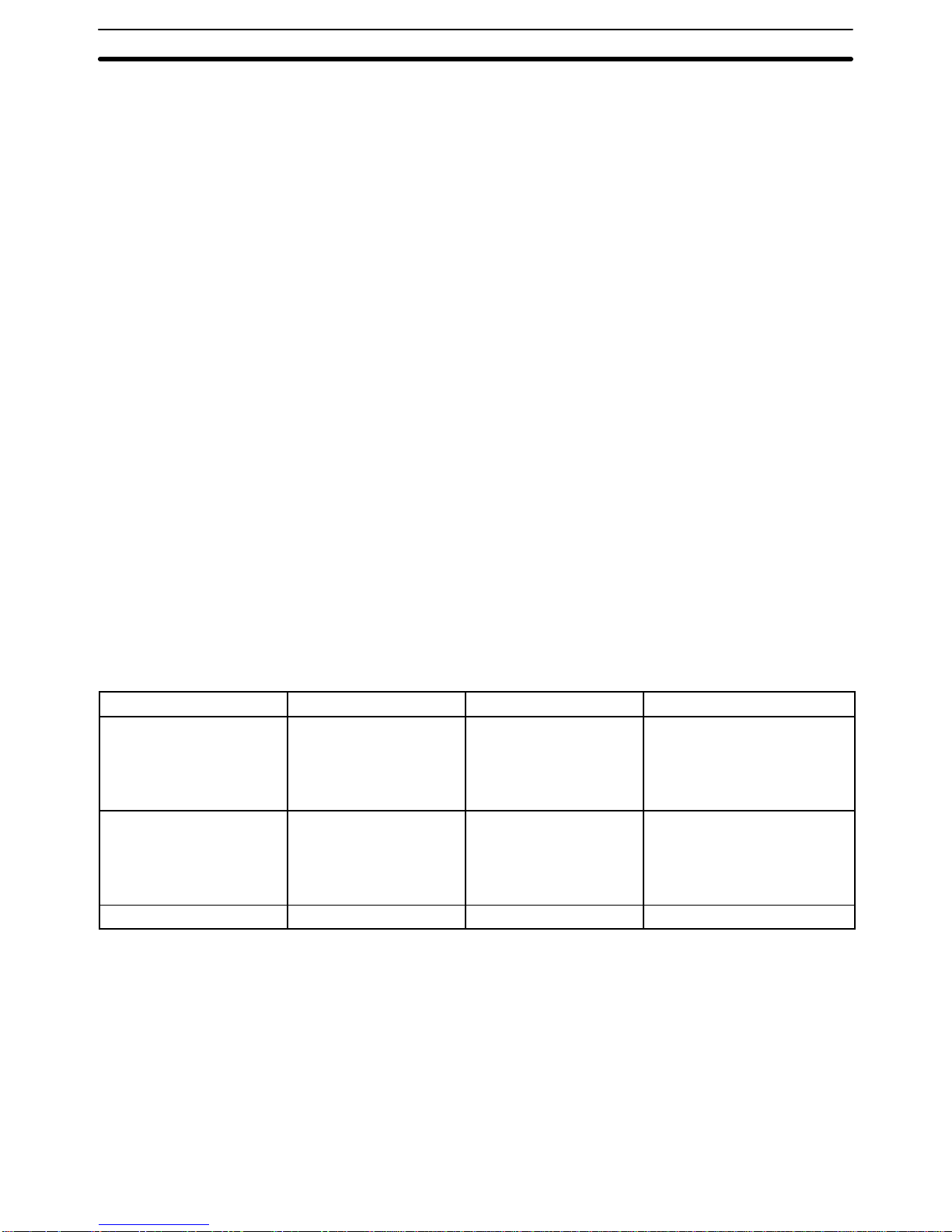

Group A

Group B Group C Group D

High-Speed Counter Unit Multi-Point I/O Temperature Sensor

Voice Unit

Position Control Unit

(C200H-NC211, C200HWNC413)

Motion Control Unit (C200HMC221)

Position Control Unit

(C200H-NC111/112,

C200HW-NC113/213)

ASCII Unit

Analog I/O Units

--- --- ---

4 total 8 total 6 total 2 total

If Units from more than one group are used, the following equations must be

met:

3A + B + 2C + 6D ≤ 12

A + B + C + D ≤ 8

The total number of Special I/O Units that can be used on all Racks com-

bined is 10. If PC Link Units are also used in the PC System, they must also

be included in the total.

Transmission time will be decreased with the same number of Slaves if two

Masters are used rather than one. Refer to Section 6 I/O Response Times.

Mounting Locations

Special I/O Units

Transmission Time

Page 27

C200H Systems Section 2-2

15

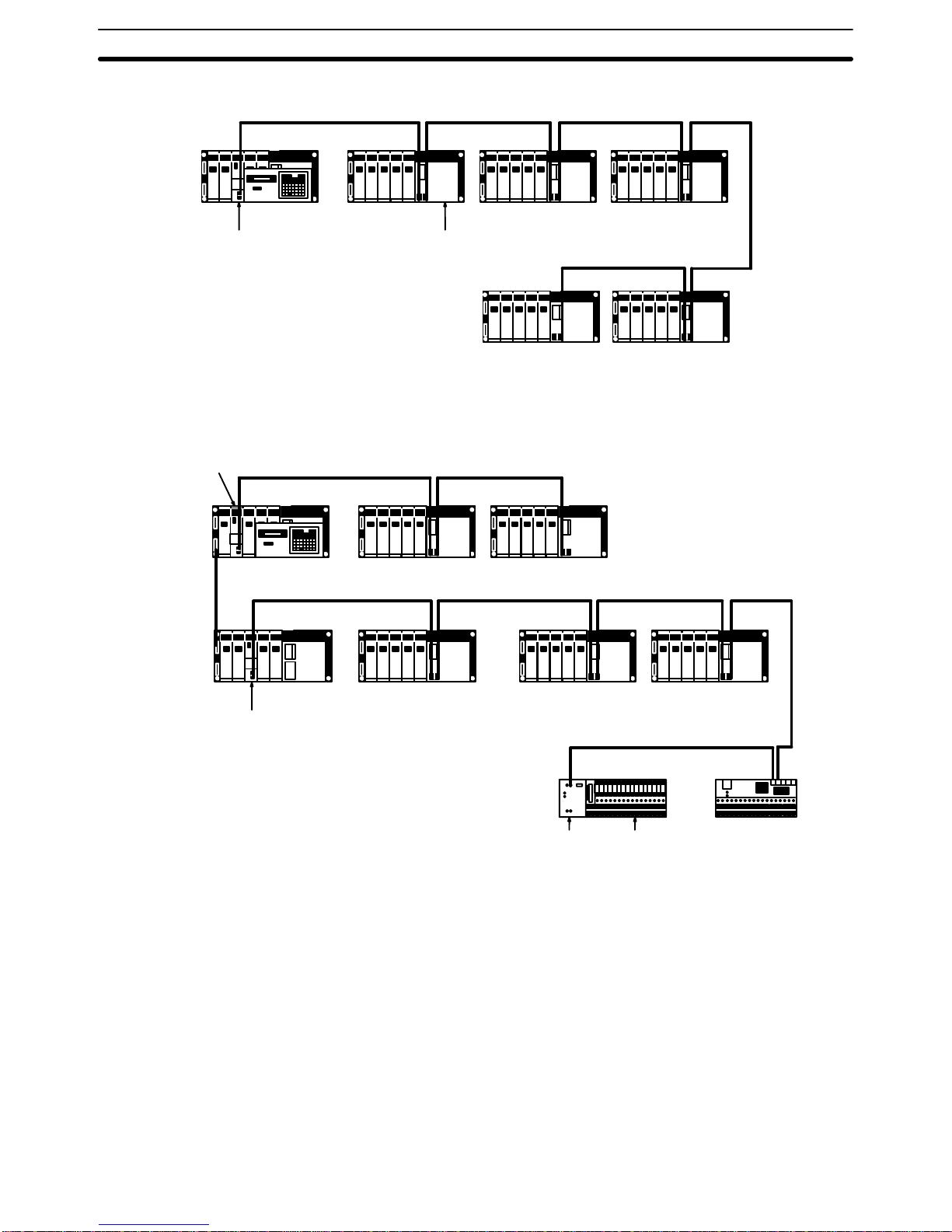

Example System 1: One Master

Slave Rack Slave Rack Slave Rack

Slave RackSlave Rack

C200H SlaveC200H Master

C200H PC

Example System 2: Two Masters

Remote Interface I/O Block

Remote Terminal

Slave Rack Slave Rack

Slave Rack

Slave Rack

C200H PC

Expansion

I/O Rack

C200H Master

C200H Master

Slave Rack

A maximum of two C200H Expansion I/O Racks can be connected to a Slave

Rack. I/O Connecting Cable (2-conductor cable) is used to connect the extra

Expansion I/O Racks.

Example System 3: Master

with Extra Expansion I/O

Racks

Page 28

Combined Systems Section 2-3

!

16

Individual sections of cable must not be longer than 2 m. Each extra Expansion I/O Rack must be counted as a ‘Slave’ when computing the number of

Slaves controlled by the PC.

I/O Connecting

Cable

I/O Connecting

Cable

Slave Rack

Slave Rack

Expansion I/O Rack

Expansion I/O Rack

Expansion I/O Rack

C200H PC

C200H Master

2-3 Combined Systems

C500 and C200H Remote I/O Units can be combined into the same System.

That is, C500 Slaves can be connected to C200H Masters; C200H Slaves, to

C500 Masters.

The maximum number of connectable Units is the same as in any Remote

I/O System based on the C500-RM201 (see 2-1 Basic System). Word

assignments will be based on the C500 PC, i.e., based on the order and

positions of I/O Units mounted, and not on fixed slot words. Special I/O Units

cannot be mounted to C200H Slave Racks controlled by a C500 Master; all

mounted Units will be assigned only one word each. The “type of Master”

switch an all C200H Slaves controlled by C500 Masters must be turned ON

to designate a Master other than the C200H Master.

C-Series

PC other

than the

C200H

C200H

Slave Rack

C200H Slave

Remote Interface

G7TC I/O

Block

Remote Terminal

C200H

Slave Rack

C500 Master

Caution When C200H Slave Racks are connected to Masters on PCs other than the

C200H/C200HS, all Output Units on these Slave Racks will be treated as having

at least 16 output points. disabling the Fuse-burnout and Alarm Detection Bits on

Units that normally provide them (e.g., C200H-OD411, C200H-OD213,

C200H-OD214, and C200H-OA221).

When using the C200H Backplane for 10 slots as a remote I/O Slave for the

CVM1/CV500/CV1000/CV2000, only the 8 slots from the left can be used; the

9th and 10th slots from the left cannot be used.

Example 1: C500 Master

and C200H Slaves

Page 29

Optical Connections in Wired Systems Section 2-4

17

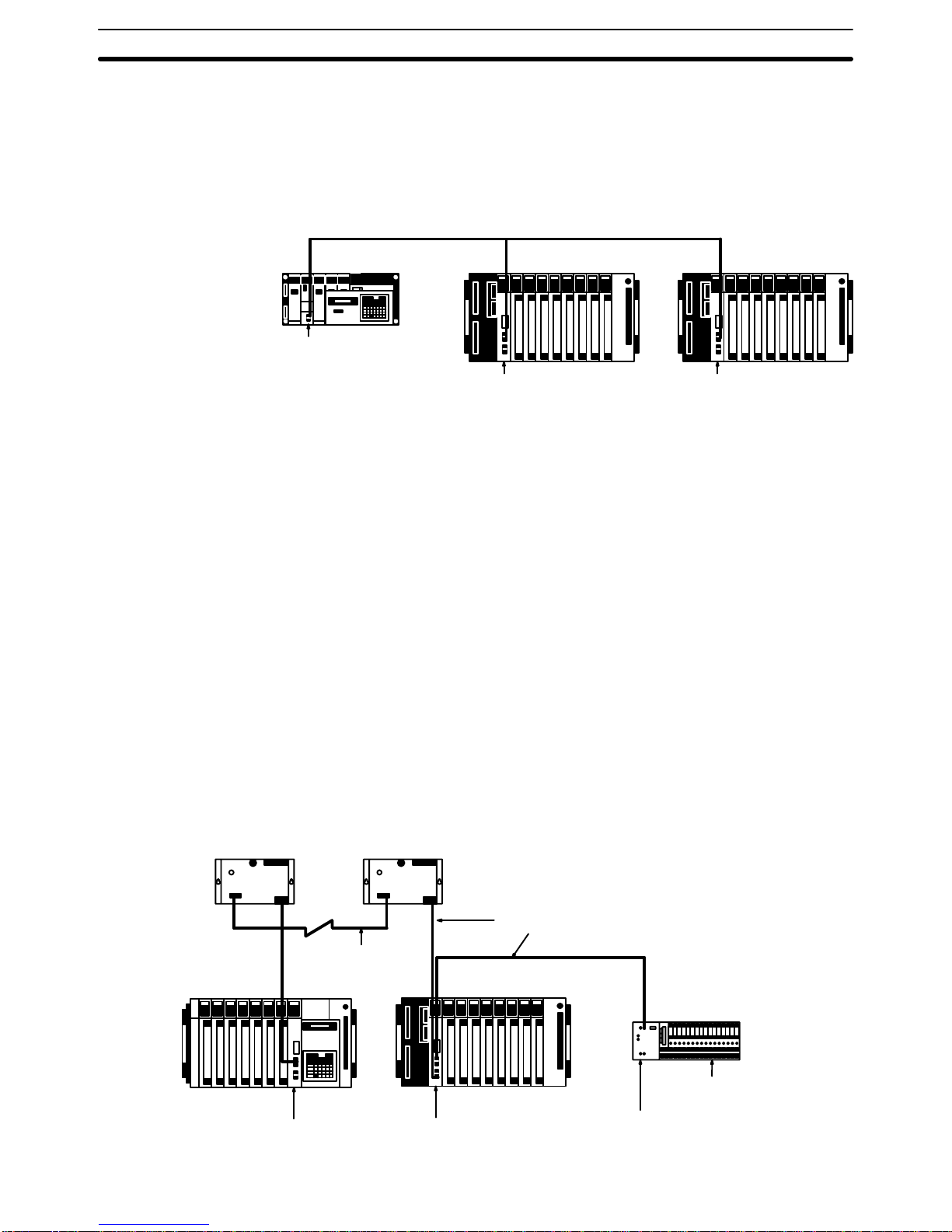

When connecting C500 Slaves to C200H Masters, each C500 Slave must be

counted as 2 Slaves when figuring the total number of Slaves. This total,

which includes all optical and wired Slaves, must be no greater than 5 for any

one C200H PC. Here, Special I/O Units can be mounted to C500 Slave

Racks. Word assignments will be based on the C500 PC’s System, i.e.,

based on the order and positions of I/O Units mounted (starting at the left),

and not on fixed slot words.

C200 Master

C500 Slave

C500 Slave Rack

C200H PC

C500 Slave

C500 Slave Rack

2-4 Optical Connections in Wired Systems

Two B500-AL007-P Link Adapters can be used to extend the transmission

distance and/or to prevent interference from noise by inserting an optical link

between two Remote I/O Units. The two Link Adapters convert between wire

and optical signals, transmitting over the optical link between them. The

AL007-P Link Adapter is thus always used in pairs, and always between

Wired Remote I/O Units. The entire Master Subsystem, from Master to terminator, must still be connected in series.

Up to 8 Link Adapters (4 pairs) can be used for each Master. To take full advantage of an optical link, shorten wire links as much as possible, even to the

point of placing the Link Adapter on the same control panels as the Remote

I/O Units.

Maximum cable length for any one section of optical cable is 20 m for

all-plastic optical fiber cable (APF); 200 m for plastic clad optical fiber cable

(PCF).

Refer to the Link Adapter manual for details on this and other uses of Link

Adapters.

Link Adapter

B500-AL007-P

Link Adapter

B500-AL007-P

APF/PCF

optical

cable

RS-485

cable

C500 CPU Rack

C500 Master

C500 Slave

C500 Slave Rack

RS-485 cable

Remote

Interface

Terminator

I/O Block

Example 2: C200H Master

and C500 Slaves

Page 30

Multilevel Systems Section 2-5

18

Although special characteristics of optical fibers call for care in connecting

optical devices, laying optical fiber cables basically does not differ from laying

wire cables. All OMRON PCF Cables and the 3G5A2-PF101 APF (length: 1

m) Cable come with connectors attached. Connectors for all other APF

Cables must be assembled by the customer. Note the following precautions

when handling optical fiber cables:

1. Always turn the power off to the Link Adapter when connecting or disconnecting an optical fiber cable.

2. Always hold the connect when disconnecting an optical fiber cable;

never pull on the cable.

3. APF and PCF connectors are designed to be inserted only in one direct;

do not try to force them in the wrong way.

4. Insert APF and PCF connectors until they lock into position.

5. Always place the protective caps on unused Link Adapter modules.

6. If dirty, clean connectors gently with a tissue or sanitary cotton, using

ethyl alcohol if necessary. Do not use any solvent other than ethyl alcohol.

7. Do not allow heavy objects to fall on optical cable or otherwise subject it

to excessive shock or strain.

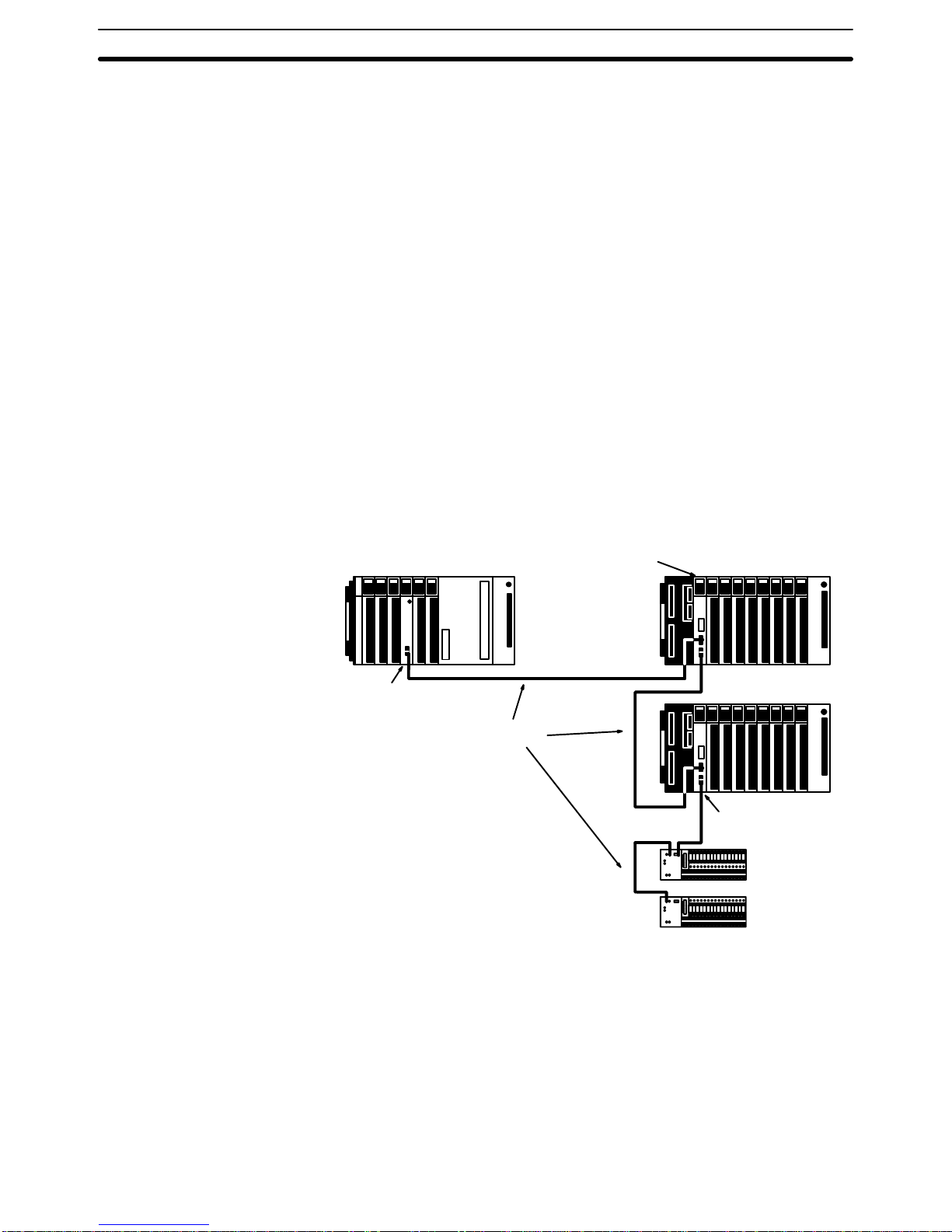

2-5 Multilevel Systems

There is no reason that a Remote I/O System must remain restricted to either

wired or optical communications. PCs support multiple Masters, some of

which can be Wired and some of which can be Optical.

Although the number of Subsystems supported by each PC is limited, each

Subsystem can be considered independently from the others as long as the

total capacity of the PC is not exceeded. It is important to note that although

both Wired and Optical Masters can be controlled by the same CPU Unit,

Optical and Wired Remote I/O Units cannot be combined in the same Subsystem, i.e., Optical Masters can be connected only to Optical Slaves, Optical I/O Units, and I/O Link Units; Wired Masters can be connected only to

Wired Slaves and Remote Terminals.

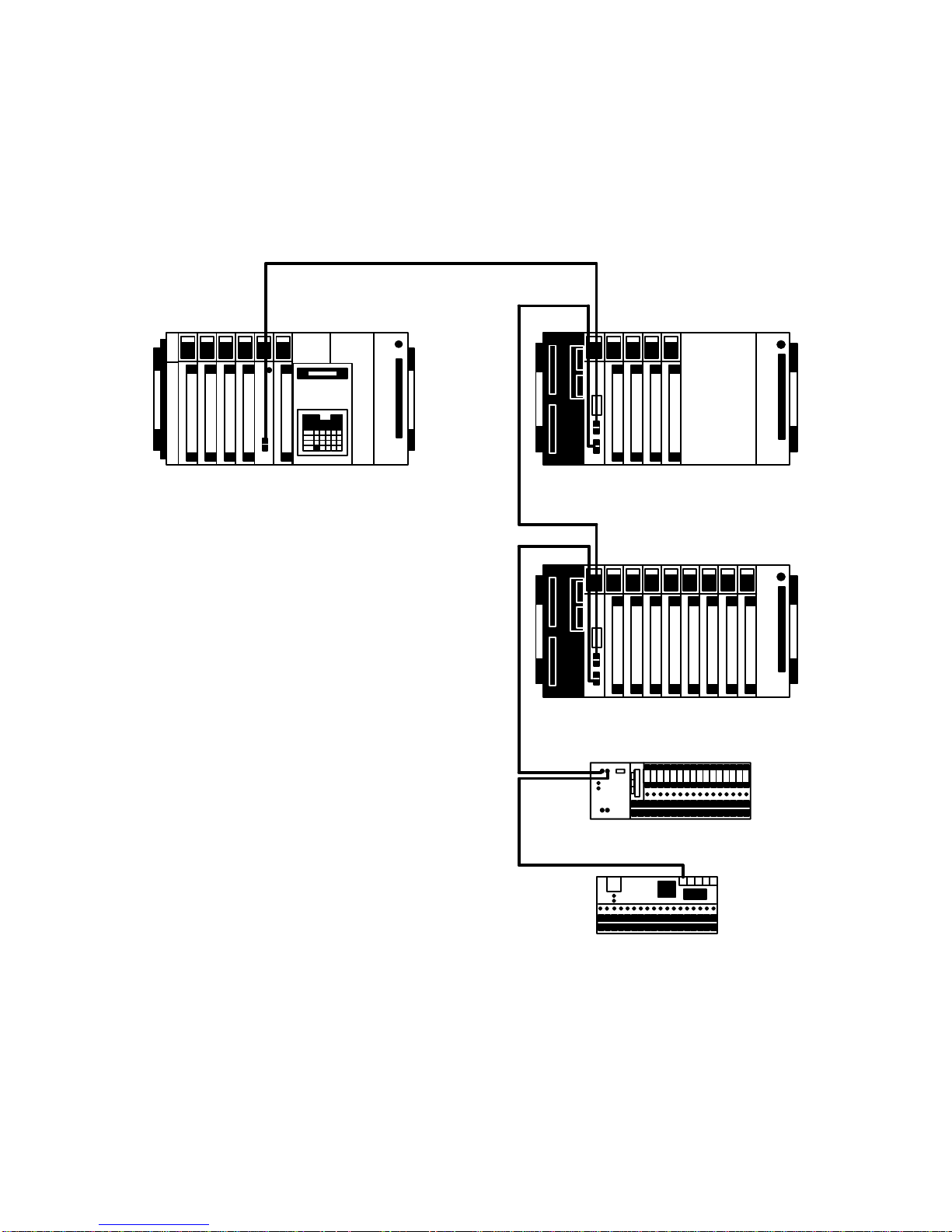

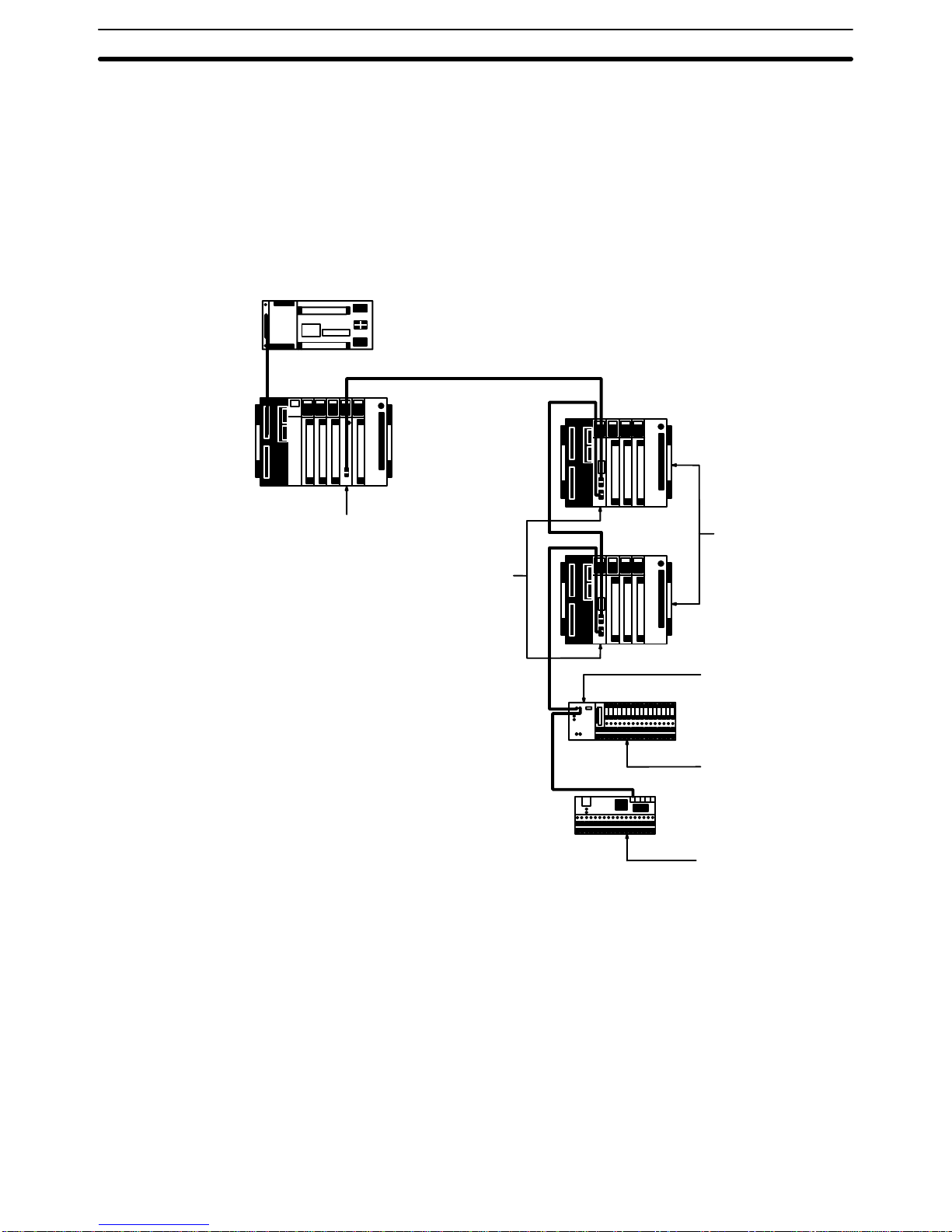

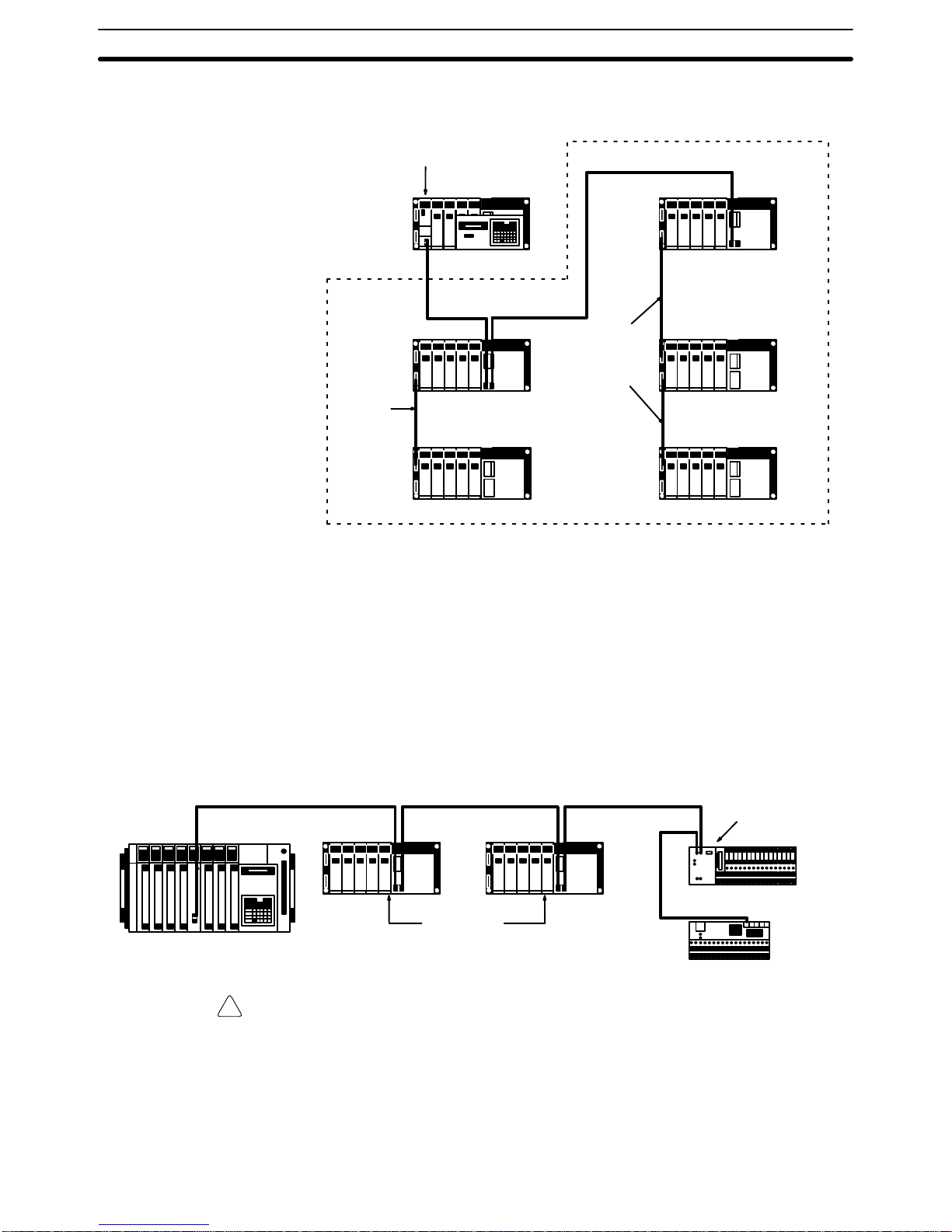

In the following example, two CPU Racks are used. The one in the upper left

corner controls two Remote I/O Subsystems, one Wired and one Optical.

The Optical System contains an I/O Link to the other CPU Rack (at the right),

which has one Remote I/O Subsystem controlled by it.

The Optical I/O Units, Slave Rack, and Expansion I/O Rack beneath the CPU

Rack at the right are controlled through the Optical Master on this CPU Rack.

Note that if there was no Master on this Rack and the Optical I/O Units and

Slave Rack were connected through the I/O Link Unit, they would become

the last Units in the Optical Remote I/O Subsystem controlled by the CPU

Unit at the upper left, and be controlled by it.

Handling Optical Fiber

Cable

1, 2, 3...

Page 31

Multilevel Systems Section 2-5

19

Another aspect of Remote I/O Systems demonstrated by this diagram is the

presence of Expansion I/O Racks, both connected to a CPU Rack and to

Slave Racks. Although normally not shown in system diagrams for Link Systems, Expansion I/O Racks can be used to increase the number of I/O Units

mountable at any one location.

C200H CPU Rack

Expansion I/O Rack

Expansion I/O Rack

Expansion I/O Rack

C200H Optical Slave Rack

Remote

Terminal

Remote

Terminal

C500 Wired Slave Rack

Optical I/O Units

C2000H

CPU Rack

C200H Wired Slave Rack

C200H Optical Slave Rack

Optical Slave

Optical

Slave

Optical Master

Wired Master

Optical cable

Wire cable

Wire cable

Wire cable

Wire cable

Wired

Slave

Optical

Master

I/O Link Unit

Wired

Slave

Optical cable

Optical cable

Optical cable

Wire cable

Wire cable

Wire cable

Wire cable

Optical cable

Page 32

21

SECTION 3

Data Exchange and Operations

PCs transmit I/O data through Masters, Slaves, and Remote Terminals according to allocated words.

Although words are not allocated to Masters and Slaves, they are allocated to all I/O Units and Remote Terminals in the

System. To enable proper word allocation, Unit numbers must be set for all Slaves and, in some Systems, word multipliers must be set for Masters. A Slave or Remote Terminal must also be set as a terminator for each Master.

Section 3-1 provides block diagrams of various Remote I/O Units. Section 3-2 provides details and examples of Unit

connections, word settings, terminator settings, word multiplier registration, and the word allocations that result from

these. The basic setting procedure for the entire System is outlined in Section 3-3. Finally, Section 3-4 provides example

program sections used to start System operation when power is turned on to a Slave, rather than to the Master as it normally is.

3-1 Block Diagrams 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Unit Numbers and I/O Word Allocation 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 C500 Masters 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 C200H Masters 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Combined Systems 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Setting Procedure 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Delayed Activation of Slaves 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 33

22

Block Diagrams Section 3-1

3-1 Block Diagrams

The following block diagrams are for Units available in Wired Remote I/O

Systems.

C500 Master and Slave

PC

interface

Bus

controller

Transmission

interface

CPU

Common

RAM

C120,

C500,

C1000H,

or

C2000H

CPU Unit

System

ROM

I/O

interface

DC-DC

converter

Indicators

Switches

Master

PC I/O

interface

Transmission

interface

CPU

System

ROM

I/O

interface

DC-DC

converter

DIP

switch

Slave

Work

RAM

Relay

output

2-conductor

cable

Switches

RUN output

Indicators

RS-485

interface

RS-485

interface

Backplane

Page 34

23

Block Diagrams Section 3-1

C200H Master and Slave

RS-485

interface

Transmission

interface

DC-DC

converter

C200H

Backplane

CPU

Data

memory

Power

section

Slave

System

memory

Work

memory

I/O

interface

Indicators

RS-485

interface

Transmission

interface

DC-DC

converter

C200H,

C200HX,

C200HG,

C200HE,

or

C200HS

CPU Unit

CPU

Master

System

memory

Work

memory

I/O

interface

Indicators

Switches

C200H PC

interface

Indicators

Switches

C200H PC

interface

2conductor

cable

RUN output

Power supply

X

Page 35

24

Block Diagrams Section 3-1

Remote Interface and I/O Blocks

I/O Block

Remote Interface

Protection

circuit

Indicators

Relay interface

I/O

devices

Power supply 12 or 24 VDC

I/O

interface

Transmission

interface

CPU

System

ROM

I/O

interface

Indicators

DIP

switch

Work

RAM

Relay

output

RUN output

RS-485

interface

Switches

DC-DC

converter

Page 36

25

Unit Numbers and I/O Word Allocation Section 3-2

G72C Remote Terminal

Power supply

12 or 24 VDC

I/O

devices

I/O

interface

Transmission

interface

CPU

System

ROM

I/O

interface

Indicators

DIP

switch

Work

RAM

Relay

output

RUN output

RS-485

interface

Switches

DC-DC

converter

AL007-P Link Adapter

Code

converter

Electrical-optical

converter

To other AL-007

Link Adapter

+ –

5V

0V

Fuse

To Wired Remote I/O Unit

or Remote Terminal

AC power supply

100 to 240 VAC

LG

FG

Line and frame

grounds

3-2 Unit Numbers and I/O Word Allocation

Word allocations on Racks in Remote I/O Systems follow basically the same

pattern as the PC to which the Master is mounted, i.e., by the mounting order

of and by the number of words required for each Unit mounted for C120,

C500, C1000H, and C2000H Systems and by fixed slot words in C200H Systems.

Basic Allocation

Page 37

26

Unit Numbers and I/O Word Allocation Section 3-2

In either case, allocations start from the lowest word starting on the left side

of the CPU Rack. When a Master is reached on a Rack, allocation jumps to

the leftmost Unit mounted on the first Slave Rack connected to the Master,

and then to the second Slave Rack, etc, until the terminator is reached. Then

allocations return to the Unit following the Master and continue across the

CPU Rack and Expansion I/O Racks until all the Units on all Racks have

been allocated. Details on and examples of allocation are provided below.

Words for Units not mounted to Racks (i.e., Remote Terminals) are not determined as described above, but according to switch settings on the Units, as

described below.

There must be one terminator set for each Master, and it must be the Unit at

the opposite end of the I/O bus from the Master.The terminator may be a

Slave or a Remote Terminal. The Master checks for a terminator immediately

upon power application. If the terminator is properly set, the other Units connected to the I/O bus are acknowledged. All following operation is based on

this initial check. Therefore, if a Unit is not attached properly or if the power

to a Unit is not on when this check is performed, that Unit will be ignored during actual operation.

3-2-1 C500 Masters

Because more than one Slave can be attached to each Master, Unit number

settings are necessary to distinguish the Slaves. Unit numbers 0 through 7

can be set for C1000H and C2000H, Slaves; unit numbers 0 and 1, for all

others. The Slave assigned unit number 0 is referred to as Slave #0; the

Slave assigned unit number 1, as Slave #1, etc. The same unit number cannot be used on more than one Slave under the same Master. Setting unit

numbers other than those listed above will prevent Slave operation.

Set the Slave directly connected to a Master as Slave #0, the Slave connected to Slave #0 as Slave #1, and so on. Setting unit numbers and a terminator is necessary for every Master, even when only one Slave is connected.

Refer to Section 4 Switch Settings for details on setting procedures.

I/O Units can be mounted to Slave Racks in any location desired numbers are

automatically allocated left to right in the order the I/O Units are mounted.

A PC I/O word must be allocated for each Remote Terminal connected in the

System; words are not automatically allocated. Any word from 0 through 31

can be set in all Systems but C120 Systems, where words between 0 and 15

must be set.

In C1000H and C2000H Systems, words 0 through 127 are allocated by the

PC’s CPU Unit to enable use of up to 128 words even though actual word

settings are from 0 through 31. This is achieved by combining word settings

with word multipliers, which are explained next.

Because the C1000H and C2000H PCs can handle up to 2,048 points (or

128 words), words 32 to 127 of these PCs cannot be allocated without some

identification other than word settings. It is therefore necessary to assign

word multipliers to the Masters to which Remote Terminals are mounted and

identify the words with these multipliers as well. These numbers run from 0

through 3.

Word numbers, word settings, and word allocations are related as shown by

the following equation:

I/O word allocation = (32 words x word multiplier) + (word set on Unit)

Terminator

Setting Slave Unit Numbers

and Terminators

Setting Remote Terminal

Words

Word Multipliers in C1000H

and C2000H Systems

Page 38

27

Unit Numbers and I/O Word Allocation Section 3-2

For example, suppose word 28 is set on a Remote Terminal and word multiplier 2 is assigned to the Master of that Remote Terminal. The I/O word allocated to the Remote Terminal, viewed from the PC, is computed as follows:

32 words x 2 + 28 words = word 92

A word multiplier is not assigned to a Master to which only Slaves are con-

nected because words will be automatically allocated to the I/O Units on

these Slaves. The I/O words assigned in Remote I/O Systems must not be

the same as the I/O words allocated elsewhere.

The same word multiplier can be assigned to more than one Master as long

as the word settings for the Units connected to the Masters are different, i.e.,

as long as the allocated words differ.

Page 39

28

Unit Numbers and I/O Word Allocation Section 3-2

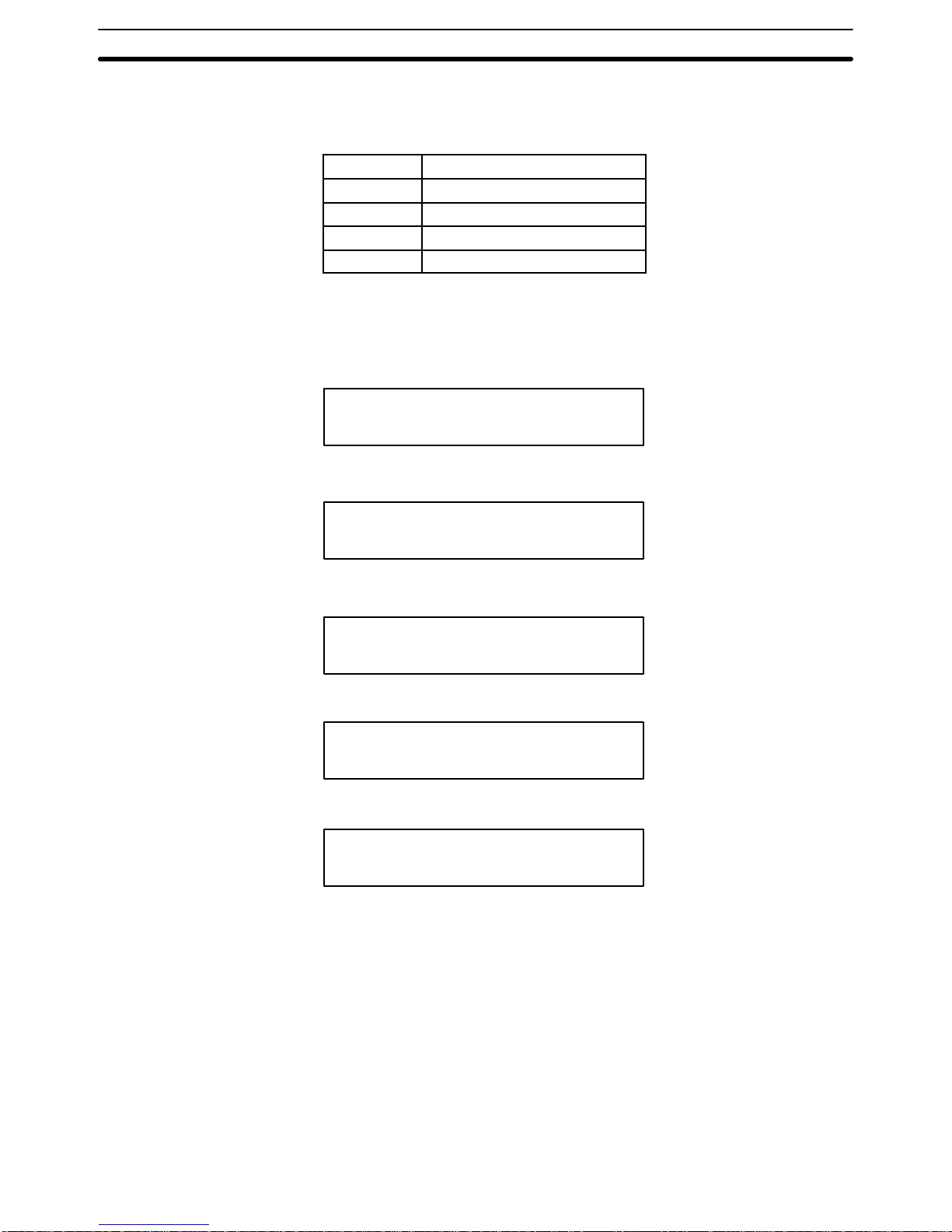

Set the word multipliers in a C1000H and C2000H System using the Programming Console as shown below. Before setting word multipliers, set the

mode selector to PROGRAM. Word multipliers must be assigned only to the

Masters to which Remote Terminals are connected. Displays for word multipliers are not displayed for Masters to which only Slaves are connected.

Initial clear all

Register I/O table

Continue registering word multipliers

by entering them with the WRITE key.

Automatically checks I/O table.

The CPU Unit takes about 2 s

here.

Indicates word multiplier not yet specified.

Once the word has been specified

and entered with the WRITE key,

proceed to the next master.

When a word has already been registered, it

will be displayed. Press the WRITE key to

continue without changing it, or input a new

multiplier before the WRITE key to change it.

Appears when all word multipliers have

been registered, completing the operation.

Setting Word Multipliers

Page 40

29

Unit Numbers and I/O Word Allocation Section 3-2

Meaning of Displays

Requesting input of word multiplier.

Word multiplier not yet specified.

Master number (0 to 7)

Indicates a Master

I/O slot number

Rack number

Page 41

30

Unit Numbers and I/O Word Allocation Section 3-2

I/O Word Allocation Examples

The following examples show four possible Systems and the word allocations

for them. They do not show all possible connections or the maximum number

of Units possible for each System. Refer to Section 4-1 for the maximum

number of connectable Units.

With two Slaves connected to one Master, the Slaves are set to unit numbers

0 and 1. The order does not matter. The last Unit must be set as the terminator. If only one Slave is connected, set it to unit number 0 and as the terminator. Words are automatically allocated for all I/O Units.

16 pts.

32 pts.

64 pts.

16 pts.

IR 7

IR 5 & 6

IR 1, 2, 3, & 4

IR 0

32 pts.

32 pts.

16 pts.

16 pts.

IR 18 & 19

IR 16 & 17

IR 15

IR 14

32 pts.

16 pts.

16 pts.

16 pts.

16 pts.

IR 24 & 25

IR 23

IR 22

IR 21

IR 20

Slave

Set to

Unit #0.

Slave Set

to Unit #1.

Set as terminator.

Slave

Set to Unit #0.

Set as terminator.

16 pts.

16 pts.

64 pts.

IR 13

IR 12

IR 8, 9, 10, & 11

16 pts.

32 pts.

IR 28

IR 26 & 27

Masters

CPU Rack

Expansion I/O

Rack

Slave Rack

Slave Rack

Slave Rack

Example 1: C500 with

Slaves

Page 42

31

Unit Numbers and I/O Word Allocation Section 3-2

Because the I/O Units are allocated words starting at the lower end (word

00), duplication can be avoided by starting Remote Terminal words from the

upper end, i.e., from 31 in all Systems except C120 Systems, where it is best

to start word settings backward from 15. Do not set words that are already

being used for other I/O points.

16 pts.

32 pts.

64 pts.

16 pts.

IR 7

IR 5 & 6

IR 1, 2, 3, & 4

IR 0

CPU Rack

Remote Terminal

IR 30

Remote Terminal

IR 31

Set as terminator

Master

Example 2: C500 with

Remote Terminals

Page 43

32

Unit Numbers and I/O Word Allocation Section 3-2

Here, as in Example 2, word duplication can be avoided by setting Remote

Terminal words starting from the upper end.

16 pts.

32 pts.

64 pts.

16 pts.

IR 7

IR 5 & 6

IR 1, 2, 3, & 7

IR 0

32 pts.

32 pts.

16 pts.

16 pts.

IR 12 & 13

IR 10 & 11

IR 9

IR 8

16 pts.

16 pts.

64 pts.

IR 19

IR 18

IR 14, 15, 16 & 17

Set to Unit #1.

Set as terminator.

Remote Terminal IR 30 Remote T erminal IR 31

Slave #1

Slave Rack

Slave #0

CPU Rack

Set to Unit #0

Master

Example 3: C500 with

Slaves and Remote

Terminals

Page 44

33

Unit Numbers and I/O Word Allocation Section 3-2

Duplication can be avoided here too by starting Remote Terminal words from

the upper end. (See Example 2, above, for details.)

Do not set words that are being used for other I/Os.

16 pts.

16 pts.

32 pts.

16 pts.

16 pts.

IR 5

IR 4

IR 2 & 3

IR 1

IR 0

Master

Master

Word

multiplier: 0

C500 Expansion

I/O Rack*

16 pts.

16 pts.

32 pts.

16 pts.

16 pts.

Master

C500

Expansion

I/O Rack

16 pts.

16 pts.

16 pts.

16 pts.

16 pts.

16 pts.

16 pts.

IR 19

IR 18

IR 17

IR 16

16 pts.

16 pts.

16 pts.

IR 22

IR 21

IR 20

IR 15

IR 14

IR 12 & 13

IR 11

IR 10

IR 25

IR 24

IR 23

Word

multiplier: 2

Master

16 pts.

16 pts.

16 pts.

IR 28

IR 27

IR 26

Word

multiplier: 1

Remote Terminal

Ser as terminator.

Set word: 31

Allocated word:31

Remote Terminal Remote Terminal

Set as terminator.

Set words:

31

30

Allocated

words:

95

94

Remote Terminal Remote Terminal

Set as terminator.

Set words:

31

30

Allocated

words:

63

62

32 pts.

16 pts.

16 pts.

IR 8 & 9

IR 7

IR 6

Slave

Set to Unit #0

Slave

Set to

Unit

#0.

Slave

Set to Unit #1.

Set as terminator.

*No word multiplier needed because no Remote Terminal is connected.

C1000H and C2000H CPU Rack

C500

Expansion

I/O Rack

Example 4: C1000H and

C2000H with Slaves and

Remote Terminals

Page 45

34

Unit Numbers and I/O Word Allocation Section 3-2

3-2-2 C200H Masters

I/O Units on C200H Slave Racks are allocated words according to the unit

number set on the Slave and the word assigned to the slot to which the I/O

Unit is mounted. For example, if the Slave is Unit #0, words 50 through 59

are allocated to the Slave Rack. I/O slots on the Rack would be, from left to

right, 50, 51, 52 ... 58, and 59. Slot words do not change even if an I/O Unit is

not mounted in every slot. Slot words not used on shorter Racks can be use

as work words. The following table shows the words allocated for each Slave

unit number. Note that the Slave will not operate if the same unit number is

set for more than one Slave or if a number not between 0 and 4 (inclusive) is

assigned. If an Expansion I/O Rack is connected to a C200H Slave Rack via

I/O Connecting Cable, the Expansion I/O Rack will be automatically assigned

the words for the next unit number. Such unit numbers cannot be set on any

other Slave.

Unit number Words

0 50 through 59

1 60 through 69

2 70 through 79

3 80 through 89

4 90 through 99

Remote Terminals connected to C200H Masters are allocated words 200

through 231. The actual word numbers will be 200 greater than the numbers

set on the Remote Terminals.

The last Slave, Remote Terminal in each Master Subsystem must be set as

the terminator no matter how large the Subsystem is. Without a terminator

set for each Master Subsystem, the I/O System and the PC will not operate,

and the END RS indicator on the PC will remain lit. If a Programming Console is mounted, the display will show that the CPU Unit is on standby.

C200H Masters must also be assigned unit numbers. These numbers determine response to error processing and AR area Error flags and Restart bits.

See 4-1 Remote I/O Units for unit number switch settings and 7-2 Error

Codes and Monitoring for details on error flags and restart bits.

C200H Masters must also be assigned Unit numbers. These numbers determine response to error processing and AR area error flags and restart bits.

See 4-1 Masters and Slaves for unit number switch settings and 7-2 Error

Codes and Monitoring for details on Error flags and Restart bits.

The Master to which a C200H Slave is connected must be designated on the

“type of Master” switch on each C200H Slave. See Section 4 for details on

switch settings.

I/O Unit Word Allocations

Remote Terminal Words

Terminators

Master Unit Numbers

Master Designations on

C200H Slaves

Page 46

35

Unit Numbers and I/O Word Allocation Section 3-2

This example System shows word allocations for two C200H Masters, one on

the CPU Rack and one on an Expansion I/O Rack, and four of the maximum

possible five C200H Slaves. (The unallocated I/O words may be used as

work words.)

C200H PC

IR 4

IR 3

IR 2

Set to Unit #0.

IR 0

IR 54

IR 53

IR 52

IR 51

IR 50

IR 64

IR 63

IR 62

IR 61

IR 60

IR 74

IR 73

IR 72

IR 71

IR 70

IR 84

IR 83

IR 82

IR 81

IR 80

C200H

Master

C200H Expansion I/O Rack

Slave Rack

Slave Rack

Slave Rack

Slave Rack

IR 14

IR 13

IR 12

Set to Unit #1.

IR 10

Set to Unit #0 and

“C200H Master.”

Set to Unit #1 and

“C200H Master.”

Set to Unit #2,

“C200H

Master,” and as

terminator.

Set to Unit #3,

“C200H

Master,” and as

terminator.

C200H

Master

Example 1: C200H Masters

and Slaves

Page 47

36

Unit Numbers and I/O Word Allocation Section 3-2

This example System shows word allocations for two C200H Masters, one on

the CPU Rack and one on an Expansion I/O Rack, two of the maximum possible five C200H Slaves, and two extra Expansion I/O Racks. The extra Expansion I/O Racks are counted as two more Slaves in the maximum of five

and automatically allocated word for unit numbers. (The unallocated I/O

words may be used as work words.)

C200H

Master

Slave Rack

IR 54

IR 53

IR 52

IR 51

IR 50

IR 4

IR 3

IR 2

Set to Unit #0.

IR 0

IR 64

IR 63

IR 62

IR 61

IR 60

IR 074

IR 073

IR 072

IR 071

IR 070

IR 84

IR 83

IR 82

IR 81

IR 80

IR 14

IR 13

IR 12

Set to Unit #1.

IR 10

Slave Rack

C200H

Master

C200H Expansion I/O Rack

C200H Expansion

I/O Rack

C200H Expansion

I/O Rack

I/O Connecting

Cable

Set to Unit #0 and

“C200H Master,”

and as terminator.

Automatically allocated words for

Unit #1.

Automatically allocated words for

Unit #2.

Set to Unit #2 and

“C200H Master,”

and as terminator.

C200H CPU Rack

#0

#3

Example 2: C200H Masters,

Slaves, and Extra

Expansion I/O Racks

Page 48

37

Unit Numbers and I/O Word Allocation Section 3-2

This example Systems shows word allocations for one C200H Master, and

two of the maximum possible 32 Remote Terminals. As shown, the words

actually allocated to Remote Terminals connected in C200H Master Subsystems are 200 higher than the settings. (Unallocated I/O words may be used

as work words.)

0

200

IR 4

IR 3

Set to Unit #0 or Unit #1.

IR 1

IR 0

C200H

Master

C200H CPU Rack

Remote Terminal

Word setting:

Allocated word:

Remote Terminal

Set as terminator.

31

231

Word setting:

Allocated word:

3-2-3 Combined Systems

C500 Slaves connected to C200H Masters must be counted as two Slaves in

counting the maximum possible Slaves connected to the Master. Each C500

Slave Rack is allocated the words shown in the following table. Word allocations overlap for consecutive unit numbers. Be sure that word allocations are

not duplicated. Note that unit number 4 cannot be designated. Words will be

allocated according to the C500 System, i.e., not according to slot words, but

left to right to actually mounted I/O Units. The total number of words used by

the Units mounted to a C500 Slave Rack must not exceed 20. Expansion I/O

Racks cannot be connected to C500 Slave Racks.

Unit number Allocated words

0 50 to 69

1 60 to 79

2 70 to 89

3 80 to 99

Example 3: C200H Masters

and Remote Terminals

C200H Masters and C500

Slaves

Page 49

38

Unit Numbers and I/O Word Allocation Section 3-2

The following example shows the maximum number of C500 Slaves that can