Page 1

Cat. No. I546-E1-02

0675398-6B

SETUP MANUAL

SYSDRIVE 3G3JV

Compact Simplified Inverters

Page 2

Thank you for choosing this SYSDRIVE 3G3JV-series product. Proper use

and handling of the product will ensure proper product performance, will

lengthen product life, and may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product

with care.

1. To ensure safe and proper use of the OMRON Inverters, please read this SETUP

MANUAL and the USER’S MANUAL (Cat. No. I528-E1) to gain sufficient knowledge

of the devices, safety information, and precautions before actual use.

2. The products are illustrated without covers and shieldings for closer look in this SETUP MANUAL and the USER’S MANUAL. For actual use of the products, make sure to

use the covers and shieldings as specified.

3. This SETUP MANUAL and other related user’s manuals are to be delivered to the actual end users of the products.

4. Please keep this manual close at hand for future reference.

5. If the product has been left unused for a long time, please inquire at our sales representative.

NOTICE

1. This manual describes the functions of the product and relations with other

products. You should assume that anything not described in this manual is

not possible.

2. Although care has been given in documenting the product, please contact your

OMRON representative if you have any suggestions on improving this manual.

3. The product contains potentially dangerous parts under the cover. Do not attempt

to open the cover under any circumstances. Doing so may result in injury or death

and may damage the product. Never attempt to repair or disassemble the product.

4. We recommend that you add the following precautions to any instruction manuals

you prepare for the system into which the product is being installed.

S Precautions on the dangers of high-voltage equipment.

S Precautions on touching the terminals of the product even after power has been

turned OFF. (These terminals are live even with the power turned OFF.)

5. Specifications and functions may be changed without notice in order to improve

product performance.

Items to Check Before Unpacking

Check the following items before removing the product from the package:

S Has the correct product been delivered (i.e., the correct model number and speci-

fications)?

S Has the product been damaged in shipping?

S Are any screws or bolts loose?

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death

!

or serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor

!

or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products,

often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 4

Read and Understand this Manual

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

БББББББББББББББББББББББББББББББ

a period of one year (or other period if specified) from date of sale by OMRON.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

БББББББББББББББББББББББББББББББ

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

БББББББББББББББББББББББББББББББ

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

БББББББББББББББББББББББББББББББ

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

БББББББББББББББББББББББББББББББ

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

БББББББББББББББББББББББББББББББ

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

БББББББББББББББББББББББББББББББ

STRICT LIABILITY.

БББББББББББББББББББББББББББББББ

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

БББББББББББББББББББББББББББББББ

which liability is asserted.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

БББББББББББББББББББББББББББББББ

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

БББББББББББББББББББББББББББББББ

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 5

Application Considerations

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББББББББББББББББББББББББ

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

БББББББББББББББББББББББББББББББ

complete determination of the suitability of the products in combination with the end product, machine,

БББББББББББББББББББББББББББББББ

system, or other application or use.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

БББББББББББББББББББББББББББББББ

uses listed may be suitable for the products:

БББББББББББББББББББББББББББББББ

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

БББББББББББББББББББББББББББББББ

or uses not described in this manual.

БББББББББББББББББББББББББББББББ

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

БББББББББББББББББББББББББББББББ

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

БББББББББББББББББББББББББББББББ

industry or government regulations.

БББББББББББББББББББББББББББББББ

• Systems, machines, and equipment that could present a risk to life or property.

БББББББББББББББББББББББББББББББ

Please know and observe all prohibitions of use applicable to the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

БББББББББББББББББББББББББББББББ

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

БББББББББББББББББББББББББББББББ

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

БББББББББББББББББББББББББББББББ

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

БББББББББББББББББББББББББББББББ

consequence thereof.

Page 6

Disclaimers

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББББББББББББББББББББББББ

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

It is our practice to change model numbers when published ratings or features are changed, or when

БББББББББББББББББББББББББББББББ

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

БББББББББББББББББББББББББББББББ

key specifications for your application on your request. Please consult with your OMRON representative

БББББББББББББББББББББББББББББББ

at any time to confirm actual specifications of purchased products.

БББББББББББББББББББББББББББББББ

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

БББББББББББББББББББББББББББББББ

tolerances are shown.

БББББББББББББББББББББББББББББББ

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

БББББББББББББББББББББББББББББББ

must correlate it to actual application requirements. Actual performance is subject to the OMRON

БББББББББББББББББББББББББББББББ

Warranty and Limitations of Liability.

БББББББББББББББББББББББББББББББ

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

БББББББББББББББББББББББББББББББ

Page 7

General Precautions

Observe the following precautions when using the SYSDRIVE Inverters and peripheral devices.

This manual may include illustrations of the product with protective covers removed in order

to describe the components of the product in detail. Make sure that these protective covers

are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

WARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

!

WARNING Operation, maintenance, or inspection must be performed after turning OFF the

!

power supply, confirming that the CHARGE indicator (or status indicators) are OFF,

and after waiting for the time specified on the front cover. Not doing so may result in

electrical shock.

WARNING Do not damage, pull on, apply stress to, place heavy objects on, or pinch the cables.

!

Doing so may result in electrical shock.

WARNING Do not touch the rotating parts of the motor under operation. Doing so may result in

!

injury.

WARNING Do not modify the product. Doing so may result in injury or damage to the product.

!

Caution Do not store, install, or operate the product in the following places. Doing so may

!

result in electrical shock, fire or damage to the product.

S Locations subject to direct sunlight.

S Locations subject to temperatures or humidity outside the range specified in the

specifications.

S Locations subject to condensation as the result of severe changes in temperature.

S Locations subject to corrosive or flammable gases.

S Locations subject to exposure to combustibles.

S Locations subject to dust (especially iron dust) or salts.

S Locations subject to exposure to water, oil, or chemicals.

S Locations subject to shock or vibration.

Caution Do not touch the Inverter radiator, regenerative resistor, or Servomotor while the

!

power is being supplied or soon after the power is turned OFF. Doing so may result in

a skin burn due to the hot surface.

Caution Do not conduct a dielectric strength test on any part of the Inverter. Doing so may

!

result in damage to the product or malfunction.

Caution Take appropriate and sufficient countermeasures when installing systems in the fol-

!

lowing locations. Not doing so may result in equipment damage.

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

Page 8

Transportation Precautions

Caution Do not hold by front cover or panel, instead, hold by the radiation fin (heat sink) while

!

transporting the product. Doing so may result in injury.

Caution Do not pull on the cables. Doing so may result in damage to the product or malfunc-

!

tion.

Caution Use the eye-bolts only for transporting the Inverter. Using them for transporting the

!

machinery may result in injury or malfunction.

Installation Precautions

WARNING Provide an appropriate stopping device on the machine side to secure safety. (A

!

holding brake is not a stopping device for securing safety.) Not doing so may result in

injury.

WARNING Provide an external emergency stopping device that allows an instantaneous stop of

!

operation and power interruption. Not doing so may result in injury.

Caution Be sure to install the product in the correct direction and provide specified clear-

!

ances between the Inverter and control panel or with other devices. Not doing so

may result in fire or malfunction.

Caution Do not allow foreign objects to enter inside the product. Doing so may result in fire or

!

malfunction.

Caution Do not apply any strong impact. Doing so may result in damage to the product or

!

malfunction.

Wiring Precautions

WARNING Wiring must be performed only after confirming that the power supply has been

!

turned OFF. Not doing so may result in electrical shock.

WARNING Wiring must be performed by authorized personnel. Not doing so may result in

!

electrical shock or fire.

WARNING Be sure to confirm operation only after wiring the emergency stop circuit. Not doing

!

so may result in injury.

WARNING Always connect the ground terminals to a ground of 100 Ω or less. Not connecting to

!

a proper ground may result in electrical shock.

Page 9

Caution Install external breakers and take other safety measures against short-circuiting in

!

external wiring. Not doing so may result in fire.

Caution Confirm that the rated input voltage of the Inverter is the same as the AC power sup-

!

ply voltage. An incorrect power supply may result in fire, injury, or malfunction.

Caution Connect the Braking Resistor and Braking Resistor Unit as specified in the manual.

!

Not doing so may result in fire.

Caution Be sure to wire correctly and securely. Not doing so may result in injury or damage to

!

the product.

Caution Be sure to firmly tighten the screws on the terminal block. Not doing so may result in

!

fire, injury, or damage to the product.

Caution Do not connect an AC power to the U, V, or W output. Doing so may result in damage

!

to the product or malfunction.

Caution Set the multi-function contact input parameter for NC contact terminals (e.g., 3-wire

!

sequence) before wiring them. If the parameter’s default setting is used, the motor

may start running when the input terminal S2 is turned ON.

Operation and Adjustment Precautions

WARNING Turn ON the input power supply only after mounting the front cover, terminal covers,

!

bottom cover, Operator, and optional items. Not doing so may result in electrical

shock.

WARNING Do not remove the front cover, terminal covers, bottom cover, Operator, or optional

!

items while the power is being supplied. Doing so may result in electrical shock or

damage to the product.

WARNING Do not operate the Operator or switches with wet hands. Doing so may result in

!

electrical shock.

WARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

!

WARNING Do not come close to the machine when using the error retry function because the

!

machine may abruptly start when stopped by an alarm. Doing so may result in injury.

WARNING Do not come close to the machine immediately after resetting momentary power

!

interruption to avoid an unexpected restart (if operation is set to be continued in the

processing selection function after momentary power interruption is reset). Doing so

may result in injury.

Page 10

WARNING Provide a separate emergency stop switch because the STOP Key on the Operator

!

is valid only when function settings are performed. Not doing so may result in injury.

WARNING Be sure to confirm that the RUN signal is turned OFF before turning ON the power

!

supply, resetting the alarm, or switching the LOCAL/REMOTE selector. Doing so

while the RUN signal is turned ON may result in injury.

Caution Be sure to confirm permissible ranges of motors and machines before operation be-

!

cause the Inverter speed can be easily changed from low to high. Not doing so may

result in damage to the product.

Caution Provide a separate holding brake when necessary. Not doing so may result in injury.

!

Caution Do not perform a signal check during operation. Doing so may result in injury or dam-

!

age to the product.

Caution Do not carelessly change settings. Doing so may result in injury or damage to the

!

product.

Maintenance and Inspection Precautions

WARNING Do not touch the Inverter terminals while the power is being supplied.

!

WARNING Maintenance or inspection must be performed only after turning OFF the power

!

supply, confirming that the CHARGE indicator (or status indicators) is turned OFF,

and after waiting for the time specified on the front cover. Not doing so may result in

electrical shock.

WARNING Maintenance, inspection, or parts replacement must be performed by authorized

!

personnel. Not doing so may result in electrical shock or injury.

WARNING Do not attempt to take the Unit apart or repair. Doing either of these may result in

!

electrical shock or injury.

Caution Carefully handle the Inverter because it uses semiconductor elements. Careless

!

handling may result in malfunction.

Caution Do not change wiring, disconnect connectors, the Operator, or optional items, or re-

!

place fans while power is being supplied. Doing so may result in injury, damage to

the product, or malfunction.

Page 11

Warnings for UL/cUL Marking

• Do not connect or disconnect wiring, or perform signal checks while the power supply is turned ON.

• The Inverter internal capacitor is still charged even after the power supply is turned OFF. To prevent

electrical shock, disconnect all power before servicing the Inverter. Then wait at least one minute after

the power supply is disconnected and all indicators are OFF.

• Do not perform a withstand voltage test on any part of the Inverter. This electronic equipment uses

semiconductors and is vulnerable to high voltage.

• Do not remove the Digital Operator or the blank cover unless the power supply is turned OFF. Never

touch the printed control board (PCB) while the power supply is turned ON.

• The Inverter is not suitable for use on a circuit capable of delivering more than 5,000 RMS symmetrical

amperes, 250 volts maximum (100-V-class Units).

• Take measures against overcurrent, overload, and overheating by using the Motor Protection Settings.

CAUTION

Use 75°C copper wires or equivalent.

Low voltage wires shall be wired with Class I Wiring.

H Motor Protection Settings

Rated Motor Current (n32)

• Set the rated motor current (n32) in order to prevent the motor from burning due to overloading.

• Check the rated current on the motor nameplate and set the parameter.

• This parameter is used for the electronic thermal function for motor overload detection (OL1). By set-

ting the correct parameter, the overloaded motor will be protected from burning.

n32 Rated Motor Current Changes during

operation

Setting

range

0.0% to 120% (A) of rated

output current of Inverter

Unit of

setting

0.1 A Default setting (see note 1)

No

Note 1. The standard rated current of the maximum applicable motor is the default rated motor cur-

rent.

Note 2. Motor overload detection (OL1) is disabled by setting the parameter to 0.0.

Motor Protection Characteristics (n33 and n34)

• This parameters setting is for motor overload detection (OL1).

n33 Motor Protection Characteristic Selection Changes during

operation

Setting

range

0 to 2 Unit of

setting

1 Default setting 0

D Set Values

Value Description

0 Protection characteristics for general-purpose induction motors

1 Protection characteristics for Inverter-dedicated motors

2 No protection

No

Page 12

• This parameter is used to set the electric thermal characteristics of the motor to be connected.

• Set the parameter according to the motor.

• If a single Inverter is connected to more than one motor, set the parameter to 2 for no protection. The

parameter is also disabled by setting n32 for rated motor current to 0.0. Provide thermal relays or other

methods separately for each motor to protect equipment from overloads.

n34 Motor Protection Time Changes during

operation

Setting

range

1 to 60 (min) Unit of

setting

1 min Default setting 8

No

D Set Values

• This parameter is used to set the electronic thermal protection constant of motor overload detection

OL1.

• The default setting does not need any changes in normal operation.

• To set the parameter according to the characteristics of the motor, confirm the thermal time constant

with the motor manufacturer and set the parameter with some margin. In other words, set the value a

little shorter than the thermal time constant.

• To detect motor overloading more quickly, reduce the set value, provided that it does not cause any

application problems.

Page 13

Checking Before Unpacking

H Checking the Product

On delivery, always check that the delivered product is the SYSDRIVE 3G3JV Inverter that you ordered.

Should you find any problems with the product, immediately contact your nearest local sales

representative.

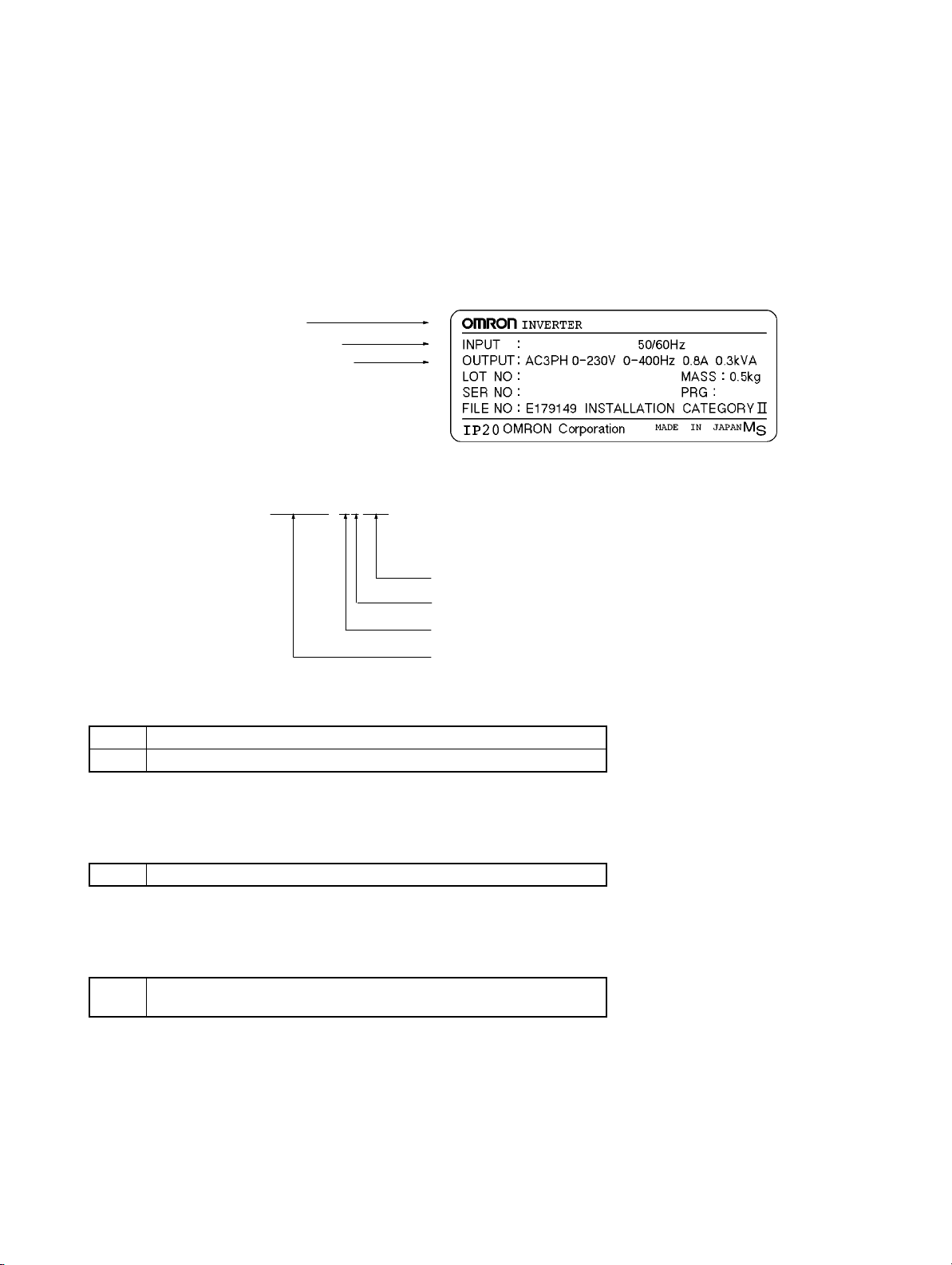

D Checking the Nameplate

Inverter model

Input specifications

Output specifications

D Checking the Model

3G3JV-A1001

Maximum applicable motor capacity

Voltage class

Installation type

Series name: 3G3JV Series

Maximum Applicable Motor Capacity

001 0.1 (0.1) kW

002 0.25/0.37 (0.2) kW

3G3JV-A1001

AC3PH 100-115V

3.2A

Note The figures in parentheses indicate capacities for motors used outside Japan.

Voltage Class

1 Single-phase 100-V AC input (100-V class)

Note The output is 3-phase 200 V AC.

Installation Type

A Panel-mounting models (IP10 min.) or

Closed wall mounting

D Checking for Damage

Check the overall appearance and check for damage or scratches resulting from transportation.

H Checking the Accessories

This manual is the only accessory provided with the 3G3JV. Set screws and other necessary parts must

be provided by the user.

Page 14

Table of Contents

Chapter 1. Design 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Installation 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Dimensions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Removing and Mounting the Covers 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Wiring 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Terminal Block 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Standard Connections 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 Wiring around the Main Circuit 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-4 Optional Accessories 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Specifications 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Preparing for Operation and Monitoring 2-1. . . . . . . . . . . . .

2-1 Using the Digital Operator 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Nomenclature 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Accepting Operation Commands While Changing Parameters 2-4. . . . . . . . . . . . . . . . . .

2-1-3 Outline of Operation 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Copying and Verifying Parameters 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Parameters Used to Copy and Verify Parameters 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Outline of Copying Parameters 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Procedures 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Error Messages for Copying and Verifying Parameters 2-12. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3. List of Parameters 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4. Maintenance Operations 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Protective and Diagnostic Functions 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Fault Detection (Fatal Error) 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Warning Detection (Nonfatal Error) 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Inspection and Maintenance 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

Design

1-1 Installation

1-2 Wiring

1-3 Specifications

1

Chapter 1

Page 16

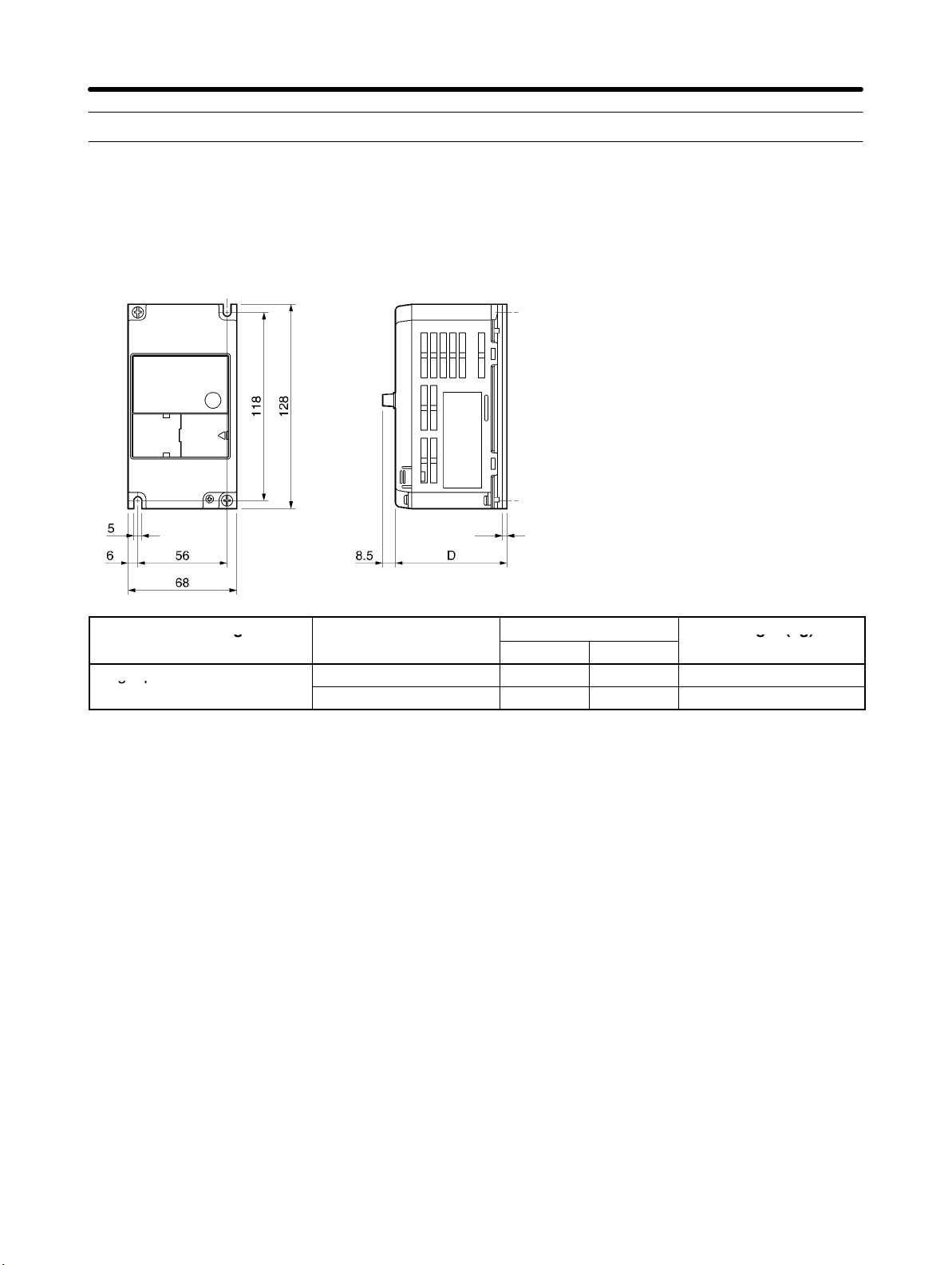

g

g(g)

gp

Design Chapter 1

1-1 Installation

1-1-1 Dimensions

D 3G3JV-A1001, -A1002 (0.1 to 0.2 kW) Single-phase 100-V AC Input

t

Rated voltage Model 3G3JV-

Single-phase 100 V AC

A1001 80 3 Approx. 0.5

A1002 112 5 Approx. 0.8

Dimensions (mm)

D t

Weight (kg)

H Installation Direction and Dimensions

• Install the Inverter under the following conditions.

Ambient temperature for operation (panel-mounting): –10°C to 50°C

Humidity: 95% or less (no condensation)

• Install the Inverter in a clean location free from oil mist and dust. Alternatively, install it in a totally enclosed panel that is completely protected from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or

other foreign matter does not get into the Inverter.

• Do not install the Inverter on inflammable material such as wood.

H Direction

• Install the Inverter on a vertical surface so that the characters on the nameplate are oriented upward.

1-2

Page 17

Design Chapter 1

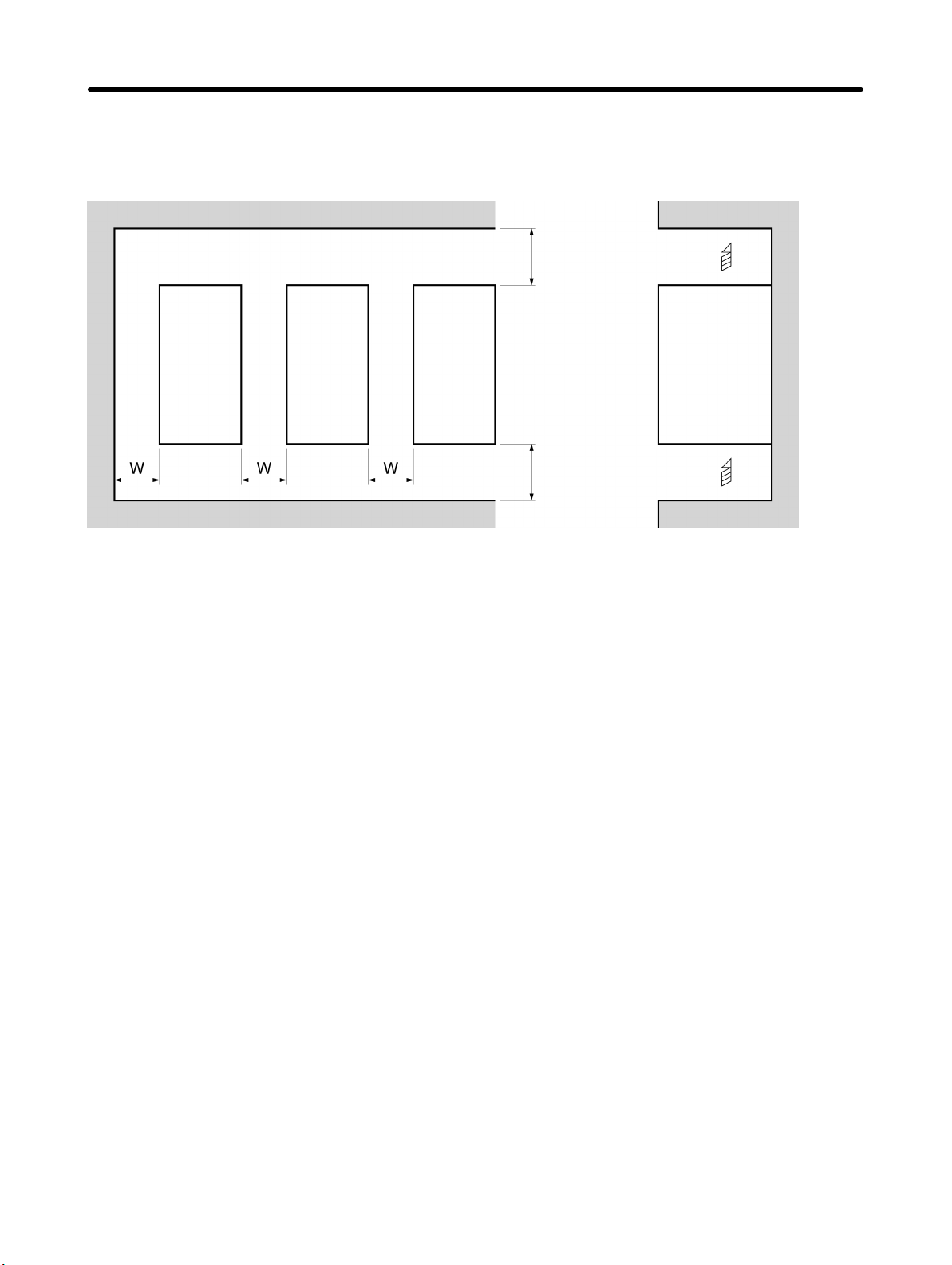

H Dimensions

• When installing the Inverter, always provide the following clearances to allow normal heat dissipation

from the Inverter.

W = 30 mm min.

Inverter

100 mm min. Air

SideInverter Inverter

100 mm min. Air

H Ambient Temperature Control

• To enhance operation reliability, the Inverter should be installed in an environment free from extreme

temperature changes.

• If the Inverter is installed in an enclosed environment such as a box, use a cooling fan or air conditioner

to maintain the internal air temperature below 50°C.

The life of the built-in electrolytic capacitors of the Inverter is prolonged by maintaining the internal air

temperature as low as possible.

• The surface temperature of the Inverter may rise approximately 30°C higher than the ambient temperature. Be sure to keep away equipment and wires from the Inverter as far as possible if the equipment

and wires are easily influenced by heat.

H Protecting Inverter from Foreign Matter during Installation

• Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Upon completion of installation, always remove the cover from the Inverter. Otherwise, ventilation will

be affected, causing the Inverter to overheat.

1-3

Page 18

Design Chapter 1

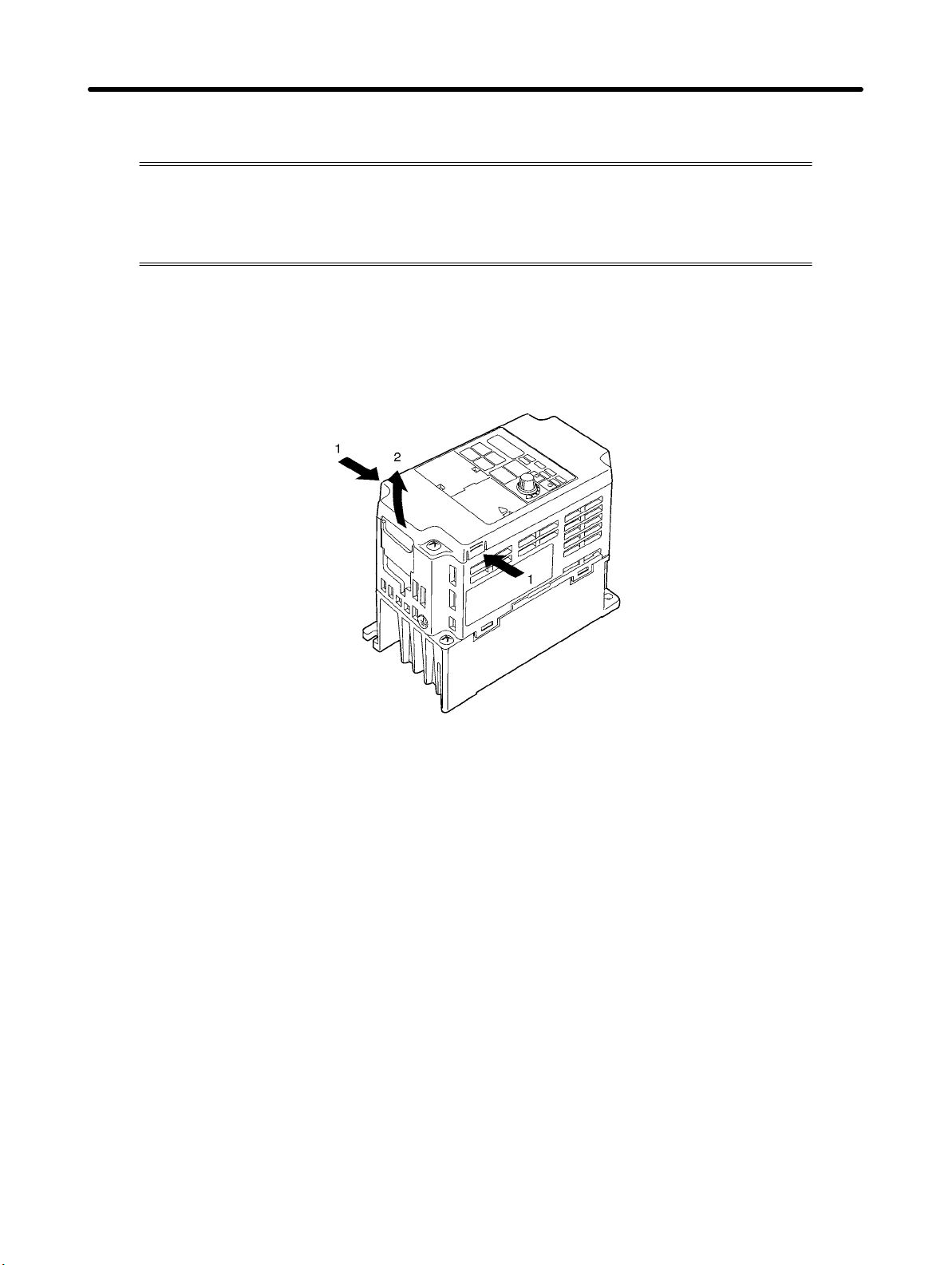

1-1-2 Removing and Mounting the Covers

It is necessary to remove the front cover, optional cover, top protection cover, and the

bottom protection cover from the Inverter to wire the terminal block.

Follow the instructions below to remove the covers from the Inverter.

To mount the covers, take the opposite steps.

H Removing the Front Cover

• Loosen the front cover mounting screws with a screwdriver.

• Press the left and right sides of the front cover in the arrow 1 directions and lift the bottom of the cover in

the arrow 2 direction to remove the front cover as shown in the following illustration.

H Removing the Top and Bottom Protection Covers and Optional Cover

D Removing the Top and Bottom Protection Covers

• After removing the front cover, pull the top and bottom protection covers in the arrow 1 directions.

1-4

Page 19

Design Chapter 1

D Removing the Optional Cover

• After removing the front cover, lift the optional cover in the arrow 2 direction based on position A as a

fulcrum.

Note The front cover functions as a terminal cover. The Digital Operator cannot be removed.

1-5

Page 20

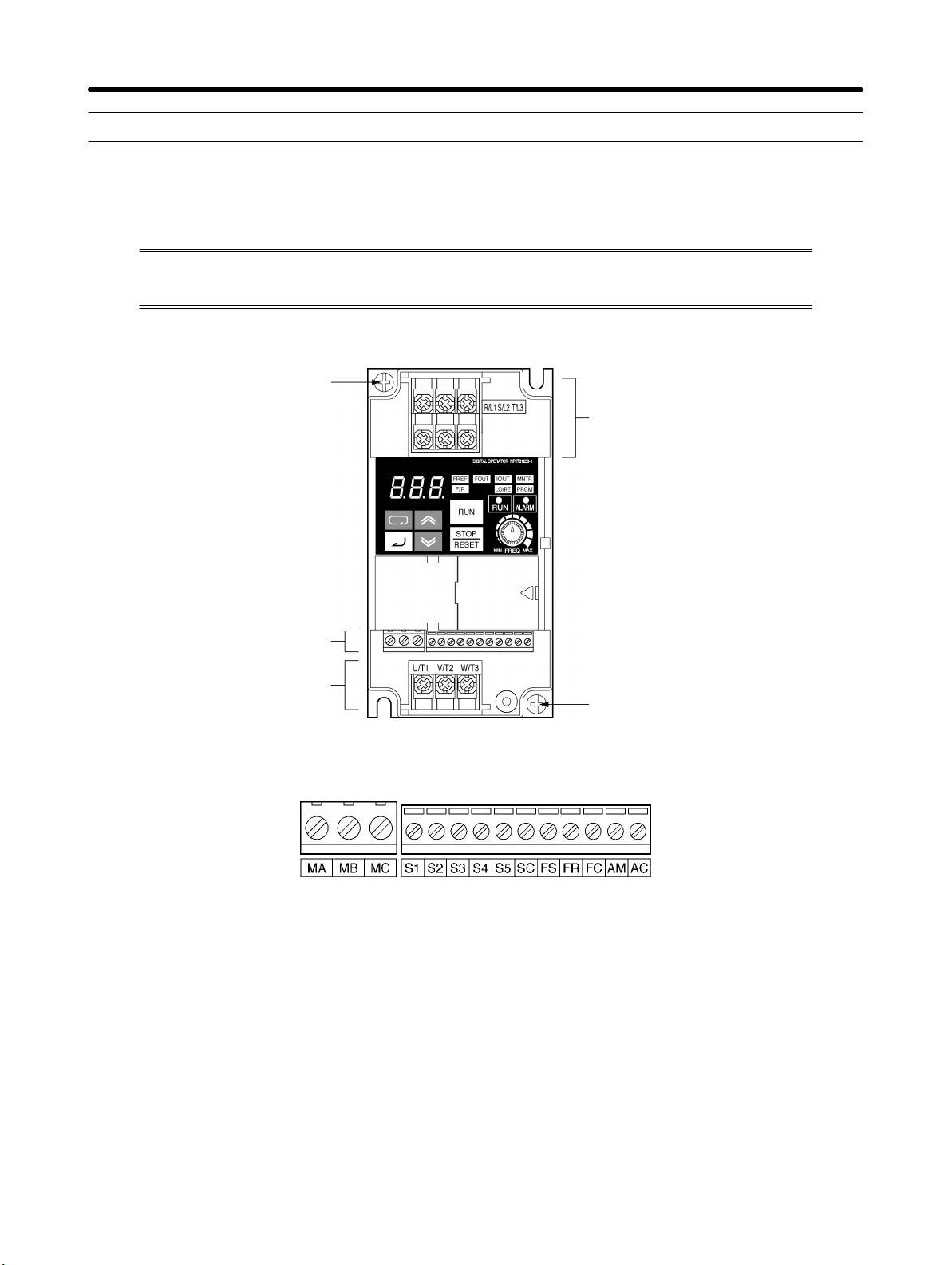

Design Chapter 1

1-2 Wiring

1-2-1 Terminal Block

Before wiring the terminal block, be sure to remove the front cover, top protection cover,

and the bottom protection cover.

H Position of Terminal Block

Ground terminal

Main circuit input terminals

Control circuit terminals

Main circuit output terminals

H Arrangement of Control Circuit Terminals

Ground terminal

1-6

Page 21

pp y p

gp

p

pp ppyp g

3G3JV A1j: 3 phase 200 to 230 V AC

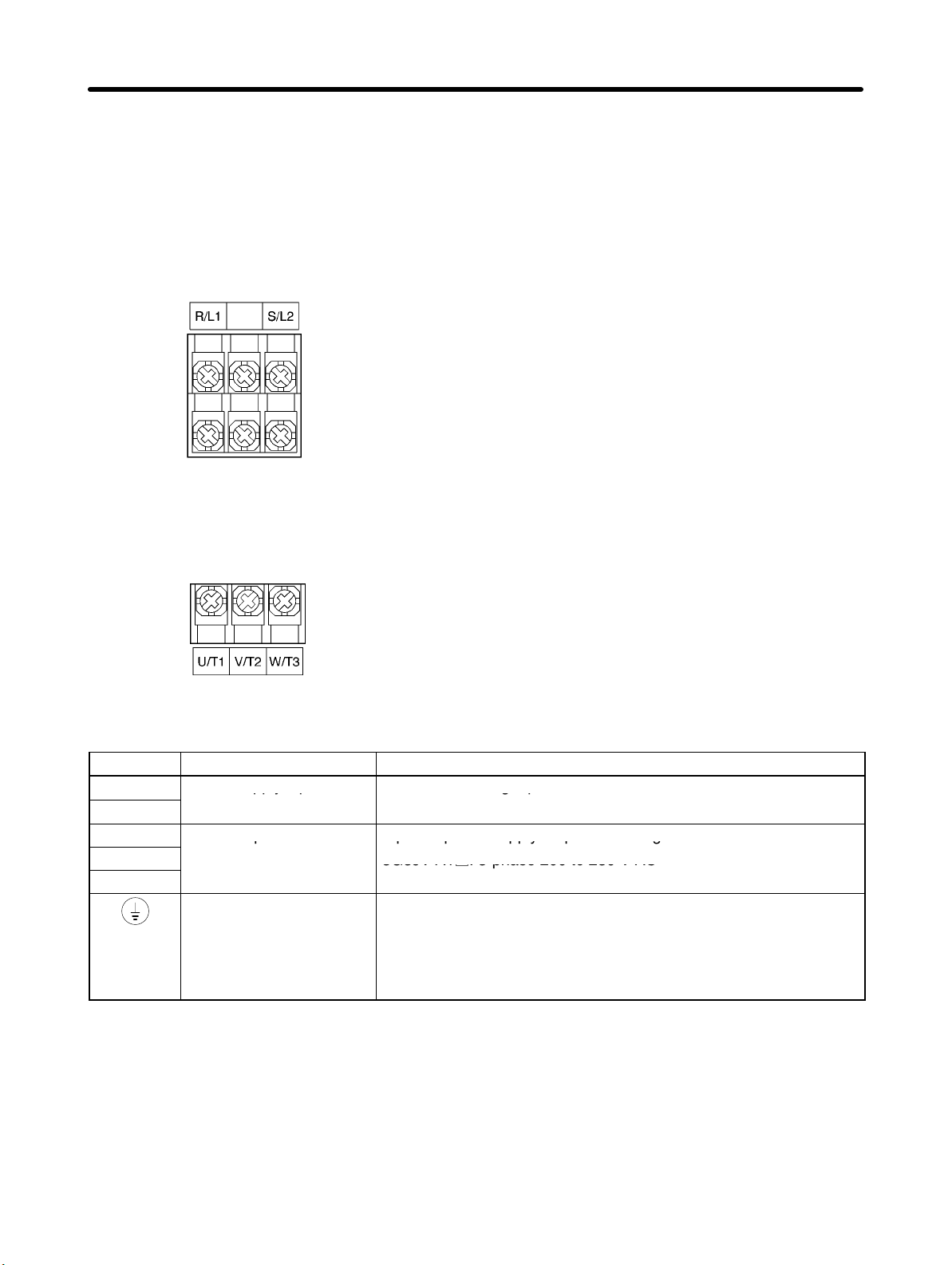

Design Chapter 1

H Arrangement of Main Circuit Terminals

D 3G3JV-A1001, -A1002

Main Circuit Input Terminals

(Upper Side)

Main Circuit Output Terminals

(Lower Side)

H Main Circuit Terminals

Symbol Name Description

R/L1

S/L2

U/T1

V/T2

W/T3

Power supply input

terminals

Motor output terminals 3-phase power supply output for driving motors.

Ground terminal Be sure to ground the terminal under the following conditions.

Note The maximum output voltage corresponds to the power supply input voltage of the Inverter.

3G3JV-A1j: Single-phase 100 to 115 V AC

Note Connect single-phase input to terminals R/L1 and S/L2.

3G3JV-A1j: 3-phase 200 to 230 V AC

3G3JV-A1j: Ground at a resistance of 100 Ω or less, and connect

to the power supply’s neutral phase to conform to EC Directives.

Note Be sure to connect the ground terminal directly to the

motor frame ground.

1-7

Page 22

external power supply is

g

PNP

t

(p p 0 )

(g g)

30 C

Design Chapter 1

H Control Circuit Terminals

Symbol Name Function Signal level

Input

Output

S1 Forward/Stop Forward at ON. Stops at

OFF.

S2 Multi-function input 1

(S2)

S3 Multi-function input 2

(S3)

S4 Multi-function input 3

(S4)

S5 Multi-function input 4

(S5)

SC Sequence input com-

mon

FS Frequency reference

power supply

FR Frequency reference in-

put

FC Frequency reference

common

MA Multi-function contact

output (Normally open)

MB Multi-function contact

output (Normally closed)

MC Multi-function contact

output common

AM Analog monitor output Set by parameter n44

AC Analog monitor output

common

Set by parameter n36

(Reverse/Stop)

Set by parameter n37

(Fault reset)

Set by parameter n38

(External fault: Normally

open)

Set by parameter n39

(Multi-step reference 1)

Common for S1 through

S5

DC power supply for frequency reference use

Input terminal for frequency reference use

Common for frequency

reference use

Set by parameter n40

(during running)

Common for MA and

MB use

(Output frequency)

Common for AM use

Photocoupler

8 mA at 24 V DC

Note NPN is the default setting

for these terminals. Wire

them by providing a

common ground. No

required. To provide an

external power supply and

wire the terminals through

a common positive line,

however, set the SW7 to

and make sure tha

the power supply is at

24 V DC ±10%.

20 mA at 12 V DC

0 to 10 V DC

(input impedance: 20 kΩ)

Relay output

1 A max. at 30 V DC

1 A max. at 250 V AC

2 mA max. at 0 to 10 V DC

Note 1. Depending on the parameter settings, various functions can be selected for multi-function in-

puts and multi-function contacts outputs.

Note 2. Functions in parentheses are default settings.

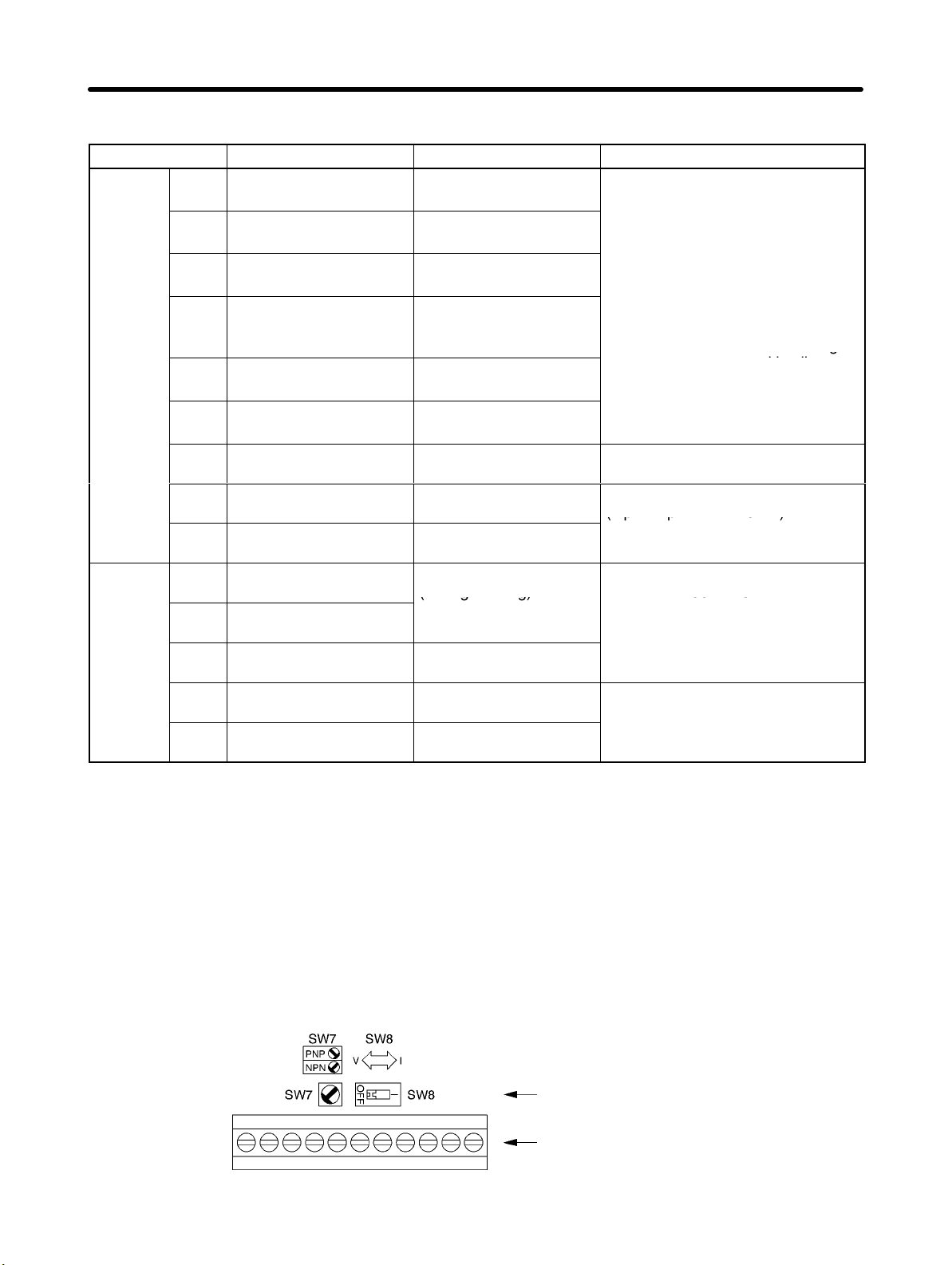

H Selecting Input Method

• Switches SW7 and SW8, both of which are located above the control circuit terminals, are used for

input method selection.

Remove the front cover and optional cover to use these switches.

1-8

Selector

Control circuit terminal

block

Page 23

Design Chapter 1

D Selecting Sequence Input Method

• By using SW7, NPN or PNP input can be selected as shown below.

SW7

SW7

D Selecting Frequency Reference Input Method

Frequency reference input

method

Voltage input V (OFF) Set value 2

Current input I (ON) Set value 3 or 4

SW8 setting Frequency reference selection

(parameter n03)

1-9

Page 24

,gp

Design Chapter 1

1-2-2 Standard Connections

DC reactor

(optional)

Single-phase 100 V AC

Forward/Stop

Multi-function input 1 (Reserve/Stop)

Multi-function input 2 (S3) (Fault Reset)

Multi-function input 3 (S4) (External fault

Normally open)

Multi-function input 4 (S5) (Multi-step speed

reference 1)

Sequence input common

Frequency reference power

supply 20 mA at +12 V

FREQ

adjuster

(2 kΩ, 1/4 W min.)

Frequency reference input

Frequency reference common

Noise Filter

3-phase 200 V AC

Multi-function contact output

NO

NC

Common

Analog monitor output

Analog monitor output common

Note 1. The braking resistor cannot be connected because no braking transistor is incorporated.

Note 2. A DC Reactor can be connected in series between the R input and L1 terminal or between the

S input and L2 terminal to use it as an AC reactor.

D DC Reactor Wiring Example

Noise Filter

Single-phase 100 V AC

DC Reactor

Applicable Noise Filters

Inverter Applicable Filter Specifications

3G3JV-A1001

3G3JV-A1002

3G3JV-PRS1010J

(for either 0.1 kW or 0.2 kW)

10 A at 250 V AC, single-phase

Applicable DC Reactors

Inverter Applicable Reactor Specifications

3G3JV-A1001 3G3HV-PUZDAB5.4A8MH 5.4 A, 8 mH

3G3JV-A1002 3G3HV-PUZDAB18A3MH 18 A, 3 mH

1-10

Page 25

Design Chapter 1

D Example of 3-wire Sequence Connections

Stop

switch

(NC)

RUN

switch

(NO)

Direction switch

RUN input (Operates with the stop switch and RUN switch closed.)

Stop input (Stops with the stop switch opened.)

Forward/Stop reference (Forward with the direction switch opened

and reverse with the direction switch closed.)

Sequence input common

Note Set parameter n37 for 3-wire sequence input.

1-2-3 Wiring around the Main Circuit

H Wire Size, Terminal Screw, Screw Tightening Torque, and Molded-case

Circuit Breaker Capacities

• For the main circuit and ground, always use 600-V polyvinyl chloride (PVC) cables.

• If any cable is long and may cause voltage drops, increase the wire size according to the cable length.

D Single-phase 100-V AC Model

Model

3G3JV-

A1001

A1002

Terminal symbol Terminal

R/L1, S/L2, U/T1, V/T2, W/T3

R/L1, S/L2, U/T1, V/T2, W/T3

Screw

screw

M3.5 0.8 to 1.0 0.75 to 2 2

M3.5 0.8 to 1.0 0.75 to 2 2

tightening

torque

(NSm)

H Wiring

Control Circuit

Terminal symbol Terminal

screw

MA, MB, MC M3 0.5 to 0.6 (4.4 to 5.3) Stranded wire:

S1 to S5, SC, FS,

FR, FC, AM, AC

M2 0.22 to 0.25 (2 to 2.2) Stranded wire:

Screw tightening

torque NSm (lbSin)

Wire size

2

mm

(AWG)

0.5 to 1.25 (20 to 16)

Single wire:

0.5 to 1.25 (20 to 16)

0.5 to 0.75 (20 to 18)

Single wire:

0.5 to 1.25 (20 to 16)

Wire size

2

(mm

)

Recommended

wire size (mm

Recommended

wire size

2

mm

(AWG)

0.75 (18)

0.75 (18)

2

)

1-11

Page 26

p

p

p

gp

j

Design Chapter 1

1-2-4 Optional Accessories

Option Specifications Model

EMC-compliant

Noise Filter

DC Reactor

DIN Track Mounting Bracket --- 3G3IV-PEZZ08122A

Adapter Panel

Operator Cable

Digital Operator

For A1001

For A1002

For A1001 3G3HV-PUZDAB5, 4A8MH

For A1002 3G3HV-PUZDAB18A3MH

Standard installation 3G3JV-PSI232J

Removable 3G3JV-PSI232JC

1 m 3G3IV-PCN126

3 m 3G3IV-PCN326

Without adjuster (with case) 3G3IV-PJVOP146

With adjuster

Main Unit 3G3IV-PJVOP140

Case 3G3IV-PEZZ08386

3G3JV-PRS1010J

1-12

Page 27

p

qyp (p

Design Chapter 1

1-3 Specifications

100-V AC Models 3G3JV-A1001 3G3JV-A1002

Power

supply

Heating radiation (W) 14.6 21.1

Weight (kg) 0.5 0.8

Cooling method Natural cooling

Maximum motor capacity (kW) 0.1 0.2

Output

specifications

Control

characteristics

Rated voltage and power supply Single-phase 100 to 115 V AC at 50/60 Hz

Allowable voltage fluctuation –15 to 10%

Allowable frequency fluctuation ±5%

Input current (for rated output) (A) 3.2 6.2

Rated output capacity (kVA) 0.3 0.6

Rated output current (A) 0.8 1.6

Rated output voltage (V) Three-phase 200 to 230 V (Handles twice the input volt-

age.)

Maximum output frequency 400 Hz (Set in a parameter.)

Power supply harmonics counter-

measures

Control method Sine wave PWM (V/f control)

Carrier frequency 2.5 to 10.0 kHz (Switched in steps.)

Frequency control range 0.1 to 400 Hz

Frequency precision (tempera-

ture characteristics)

Frequency setting resolution

Output frequency resolution 0.01 Hz (data processing resolution)

Overload capacity 150% of rated output current for 1 min

External frequency set signal Switchable: 0 to 10 V DC (20 kΩ), 4 to 20 mA (250 Ω), 0 to

Acceleration/deceleration times 0.0 to 999 s (Acceleration and deceleration times set sepa-

Braking torque Approx. 20%

Voltage/frequency characteristics User-set V/f pattern

DC Reactor (optional) can be connected.

Digital reference: ±0.01% (–10 to 50°C)

Analog reference: ±0.5% (25°C ±10°C)

Digital reference: 0.1 Hz (less than 100 Hz), 1 Hz (100 Hz

or greater)

Analog reference: 0.06 Hz/60 Hz (equivalent to 1/1000)

20 mA (250 Ω), or frequency adjustment

rately: Switches between 2 settings.)

Note: A Braking Resistor or Braking Resistor Unit cannot be

connected.

1-13

Page 28

Design Chapter 1

3G3JV-A10023G3JV-A1001100-V AC Models

Protective

functions

Environment

Degree of protection Mounted in a panel (equivalent to IP20)

Motor protection Protection by electronic thermal

Instantaneous overcurrent

protection

Overload protection Stops in 1 min at approximately 150% of rated output cur-

Overvoltage protection Stops when main-circuit DC voltage is approximately 410 V.

Undervoltage protection Stops when main-circuit DC voltage is approximately 160 V.

Momentary power interruption

compensation (selection)

Radiation fin overheated Detected at 110°C ±10°C

Grounding protection Rated output current level protection

Charge indicator CHARGE indicator lights until the main circuit DC voltage

Location Indoors (with no corrosive gas, dust, etc.)

Ambient operating temperature –10 to 50°C

Ambient operating humidity 95% max. (with no condensation)

Storage temperature –20 to 60°C

Altitude 1,000 m max.

Insulation resistance 5 MΩ min. (Do not carry out any insulation resistance or

Vibration resistance 9.8 m/s2 max. between 10 and 20 Hz, 2.0 m/s2 max. be-

Stops at approx. 250% of rated output current.

rent.

None (Stops at 15 ms or longer.)

Select between continuing operation if power is restored

within approx. 0.5 s or continuing operation regardless of

length of interruption.

reaches 50 V or less.

withstand voltage tests.)

tween 20 and 50 Hz

1-14

Page 29

2

Chapter 2

Preparing for

Operation and

Monitoring

2-1 Using the Digital Operator

2-2 Copying and Verifying Parameters

Page 30

Preparing for Operation and Monitoring Chapter 2

2-1 Using the Digital Operator

2-1-1 Nomenclature

Data display

Keys

Appearance Name Function

Data display Displays relevant data items, such as frequency reference,

output frequency, and parameter set values.

FREQ adjuster Sets the frequency reference within a range between 0 Hz

and the maximum frequency.

FREF indicator The frequency reference can be monitored or set while this

indicator is lit.

FOUT indicator The output frequency of the Inverter can be monitored

while this indicator is lit.

IOUT indicator The output current of the Inverter can be monitored while

this indicator is lit.

MNTR indicator The values set in U01 through U10 are monitored while

this indicator is lit.

F/R indicator The direction of rotation can be selected while this

indicator is lit, when operating the Inverter with the RUN

Key.

LO/RE indicator The operation of the Inverter through the Digital Operator

or according to the parameters set is selectable while this

indicator is lit.

Indicators

Setting/Monitor item indicators

FREQ adjuster

2-2

Note This status of this indicator can be only monitored

while the Inverter is in operation. Any RUN command

input is ignored while this indicator is lit.

PRGM indicator The parameters in n01 through n79 can be set or

monitored while this indicator is lit.

Note While the Inverter is in operation, the parameters can

be only monitored and only some parameters can be

changed. The RUN command input is ignored while

this indicator is lit.

Mode Key Switches the setting and monitor item indicators in

sequence.

Parameter setting being made is canceled if this key is

pressed before entering the setting.

Increment Key Increases multi-function monitor numbers, parameter

numbers, and parameter set values.

Page 31

Preparing for Operation and Monitoring Chapter 2

Appearance FunctionName

Decrement Key Decreases multi-function monitor numbers, parameter

numbers, and parameter set values.

Enter Key Enters multi-function monitor numbers, parameter

numbers, and internal data values after they are set or

changed.

RUN Key Starts the Inverter running when the 3G3FV is in operation

with the Digital Operator.

STOP/RESET Key Stops the Inverter unless n06 is set to disable the STOP

Key. Functions as a Reset Key when an Inverter error

occurs. (See note.)

Note For safety’s reasons, the reset will not work while a RUN command (forward or reverse) is in ef-

fect. Wait until the RUN command is OFF before resetting the Inverter.

2-3

Page 32

()

Preparing for Operation and Monitoring Chapter 2

2-1-2 Accepting Operation Commands While Changing

Parameters

With the default settings, the Inverter will not accept operation commands when parameter settings are being changed. This functions as a safety measure to prevent the motor

from rotating if the operation command is mistakenly set to ON when changing parameters.

Depending on the operating conditions, however, the user may want to have operation

commands accepted even while parameters are being changed. In that case, change

the following settings.

H Using the Indicators to Determine When Operation Commands Can Be

Accepted

The indicators on the Digital Operator can be used to determine if operation commands will be accepted

or not while changing parameters.

Green: Operation commands will be accepted if the indicator lights green.

Red: Operation commands will not be accepted after the Inverter stops if an indicator lights red.

Therefore, if the indicator lights red when changing parameters or when switching between local and

remote operation, operation will continue, but once the Inverter stops, the Inverter will not operate even

if the operation command is set to ON again.

The FREF indicator will light when the power supply is turned ON.

Indicator Color Name

FREF Green Frequency Reference/Monitor

FOUT Green Output Frequency Monitor

IOUT Green Output Current Monitor

MNTR Green Multi–function Monitor

F/R Green Operator RUN command forward/reverse

operation selection

LO/RE Red Local/Remote Selection

PRGM Red Parameter Number/Setting

Note Perform the settings given in the following description to have operation commands accepted

while the red indicator is lit (i.e., while changing parameters or switching between local and remote.)

Set n01 (Parameter write–prohibit selection/parameter initialization) to 5.

S The default value for n01 is 1.

S Operation commands will not be accepted when n01 itself is being changed.

S Some parameters cannot be changed during operation. Those parameters cannot be changed

during operation even if the setting for n01 is changed.

Acceptance of operation

commands

During

operation

Yes Yes

Yes No (See note.)

Stopped

S When n01 is changed to 5, an operation command will be accepted even when changing pa-

rameters, such as during trial operation. Thoroughly check safety before changing any setting.

2-4

Page 33

Preparing for Operation and Monitoring Chapter 2

2-1-3 Outline of Operation

H Selecting Indicators

Whenever the Mode Key is pressed, an indicator is lit in sequence beginning with the

FREF indicator. The data display indicates the item corresponding to the indicator selected.

The FOUT or IOUT indicator will be lit by turning the Inverter on again if the Inverter is

turned off while the FOUT or IOUT indicator is lit. The FREF indicator will be lit by turning

the Inverter on again if the Inverter is turned off while an indicator other than the FOUR or

IOUT indicator is lit.

Power On

FREF (Frequency Reference)

Monitors and sets the frequency reference.

FOUT (Output Frequency)

Monitors the output frequency.

Note This indicator will be lit by turning the Inverter on again if the Inverter

is turned off while this indicator is lit.

IOUT (Output Current)

Monitors the output current.

Note This indicator will be lit by turning the Inverter on again if the Inverter

is turned off while this indicator is lit.

MNTR (Multi-function Monitor)

Monitors the values set in U01 through U10.

F/R (Forward/Reverse Rotation)

Selects the direction of rotation.

LO/RE (Local/Remote)

Selects the operation of the Inverter through the Digital Operator or

according to the parameters.

PRGM (Parameter Setting)

Monitors or sets the values in n01 through n79.

The FREF indicator is lit again.

2-5

Page 34

p

p

g(

Preparing for Operation and Monitoring Chapter 2

H Example of Multi-function Display

Key sequence Indicator Display Explanation

Power On

Press the Mode Key repeatedly until the MNTR

indicator is lit.

U01 will be displayed.

Use the Increment or Decrement Key to select the

monitor item to be displayed.

Press the Enter Key so that the data of the selected

monitor item will be displayed.

The monitor number display will appear again by

pressing the Mode Key.

D Status Monitor

Item Display Display

unit

U01 Frequency

reference

U02 Output frequency Hz Monitors the output frequency. (Same as FOUT)

U03 Output current A Monitors the output current. (Same as IOUT)

U04 Output voltage V Monitors the internal output voltage reference value of the

U05 DC bus voltage V Monitors the DC voltage of the internal main circuit of the

U06 Input terminal ---

status

Hz Monitors the frequency reference. (Same as FREF)

Inverter.

Inverter.

Shows the ON/OFF status of inputs.

Function

: Input ON : No input

Terminal S1: Forward/Stop

Terminal S2: Multi-function input 1 (S2)

Terminal S3: Multi-function input 2 (S3)

Not

used

U07 Output terminal ---

status

U09 Error log (most

recent one)

U10 Software No. --- OMRON use only.

U15 Receive data error --- The cause of the receive data error during MEMOBUS

---

Shows the ON/OFF status of outputs.

Not

used

Displays the latest error.

communications can be checked. (Same as the contents of

communications register number 003DM.)

Terminal S4: Multi-function input 3 (S4)

Terminal S5: Multi-function input 4 (S5)

: Closed : Open

Terminal MA: Multi-function contact

output

Error

2-6

Page 35

Preparing for Operation and Monitoring Chapter 2

2-2 Copying and Verifying Parameters

The 3G3IV-PJVOP140 and 3G3IV-PJOP146 Digital Operators contain an EEPROM.

All Inverter parameter settings, the Inverter capacity, and the software number are recorded in this EEPROM. The EEPROM can be used to copy parameter settings to other

Inverters.

Parameter settings can be copied between Inverters with the same power supply specifications, but some of the parameter settings are not copied.

2-2-1 Parameters Used to Copy and Verify Parameters

• The following parameters are used to read, copy (write), and verify parameter settings.

Param-

eter

No.

(Regis-

ter No.

(Hex))

n76

(014C)

n77

(014D)

Name Description Setting

Parameter

copy and

verify func-

tion

Parameter

read pro-

hibit selec-

tion

Selects the function for copying parameters.

rdy: Ready to accept the next command.

rED: Reads the Inverter parameters.

Cpy: Copies the parameter to the Inverter.

vFY: Verifies the Inverter parameters.

vA: Checks the Inverter capacity display.

Sno: Checks the software number.

Selects the copy-prohibit function.

Use this parameter to protect the data in the

EEPROM of the Digital Operator.

0: Read prohibited for Inverter parameters.

(Data cannot be written to EEPROM.)

1: Read possible for Inverter parameters.

(Data can be written to EEPROM.)

rdy to

Sno

0, 1 --- 0 No

range

Setting

unit

--- rdy No

Default

setting

Changes

during

opera-

tion

2-7

Page 36

Preparing for Operation and Monitoring Chapter 2

H Display Transitions

Reading

Writing

Verifying

Inverter capacity

Software number

Reading

finished

Writing

finished

Verification

finished

OR

OR

OR

OR

OR

Note The following display is an example of the capacity displayed. The values in parentheses indicate

the capacities for European motors.

10.1

Voltage Class

1: Single-phase 100 V

Max. applicable motor capacity

0.1: 0.1 kW (0.1 kW)

0.2: 0.25 kW/0.37 kW (0.2 kW)

Note The values in parentheses indicate Japanese motor capacities.

2-8

Page 37

Preparing for Operation and Monitoring Chapter 2

2-2-2 Outline of Copying Parameters

(1) Check setting of n01

0: Writing from Digital Operator prohibited.

1: Parameters can be changed (default setting).

(2) Clear prohibition of reading the copy function: n77

This function protects parameters stored in the Digital

Operator.

0: Reading copy function (rEd) prohibited (default setting).

1: Reading copy function (rEd) enabled.

(3) Perform the read operation for the copy function: n76

Read (rEd) the current parameter settings from the Inverter

to the EEPROM in the Digital Operator.

(4) Disconnect the Digital Operator and connect it to a

different Inverter. Always turn OFF the power supply

before connecting or disconnecting the Digital Operator

to protect against electric shock and product failure.

Set n01 to 1.

See operation on next page.

Set n77 to 1.

Same basic operation as for n01.

Set n76 to rEd.

Change Inverter connection.

Turn ON power after checking wiring.

(5) Perform the write operation for the copy function: n76

Write (CPy) the current parameter settings from the EEPROM in the Digital Operator to the Inverter.

(6) Perform the verify operation for the copy function: n76

Verify (vFy) the current parameter settings between the

EEPROM in the Digital Operator and the Inverter.

Set n76 to CPy.

Set n76 to vFy.

H Parameters That Cannot Be Copied

1. Copying is not possible between Inverters with different power supply specifications (e.g., from a

100-V Inverter to a 400-V Inverter).

2. The recorded hold output frequency and the following parameters cannot be copied:

n76: Parameter copy and verify function

n77: Parameter read prohibit selection

n78: Error log

n79: Software number

3. The following parameters cannot be copied if the Inverters have different capacities.

n09 to n15: V/f settings

n32: Rated motor current

n46: Carrier frequency selection

2-9

Page 38

Preparing for Operation and Monitoring Chapter 2

n64: Motor rated slip

n65: Motor no-load current

2-2-3 Procedures

Changing Parameters

The setting of n01 is changed so that n76 and n77 can be displayed.

D Setting n01 (Parameter Write-prohibit Selection/Parameter Initialization Parameter)

Key Indicator Display Description

--- (Display after the power supply is turned ON.)

Press the Mode Key until the PRGM indicator lights.

Confirm that n01 is displayed on the data display.

Press the Enter Key.

The setting of the specified parameter number will be

displayed.

Press the Increment Key until 4 is displayed. (The display will

flash.)

Press the Enter Key to confirm the setting. (The display will

stop flashing.)

After about 1 s The display of the parameter number will return in about 1 s.

2-10

Page 39

Preparing for Operation and Monitoring Chapter 2

Example of Copy Function

H Verifying Parameters (vFy)

• The Parameter Copy and Verify Function (n76) can be set to “vFy” to compare the parameter settings

in the Digital Operator with those in the Inverter.

D Verifying Parameters

Key Indicator Display Description

--- (Display after the power supply is turned ON.)

Press the Mode Key until the PRGM indicator lights.

Confirm that n01 is displayed on the data display.

Press the Increment/Decrement Key until “n76” is

displayed.

Press the Enter Key.

“rdy” will be displayed.

Press the Increment Key until “vFy” is displayed

(After

comparison is

finished.)

or

Press the Enter Key. The parameter settings will be

compared and the display will flash.

The parameter number of any parameter that has different

settings will be displayed.

Press the Enter Key.

The setting of the parameter in the Inverter will be displayed

(flashing) first.

Press the Enter Key again.

The setting of the parameter in the Digital Operator will be

displayed (flashing) next.

Press the Increment Key.

The comparison will be continued.

“End” will be displayed when the comparison has been

finished.

Press the Mode Key or Enter Key.

The display of the parameter number will return.

2-11

Page 40

Preparing for Operation and Monitoring Chapter 2

2-2-4 Error Messages for Copying and Verifying Parameters

The errors that can be displayed when reading, writing, or verifying parameter settings are described in

the following table along with corrective actions. All of these error displays will flash on the display.

Display Name Description Corrective action

pre

rde

cse

ndt

cpe

cye

Ure

ife

Protect error An attempt was made to read

parameter settings when the

Parameter Read Prohibit Selection

parameter (n77) was set to 0

(prohibiting reading).

Read error The parameter settings could not be

read normally or a low main circuit

voltage was detected while reading

parameter settings.

Checksum error A checksum error occurred for the

parameters recorded in the Digital

Operator.

No data error No parameters are recorded in the

Digital Operator.

Copy source

error

Voltage error

while copying

Capacity error Verification was attempted between

Communications

error

Copying or verifying parameter

settings was attempted between

Inverters with different voltage

classes.

A low main circuit voltage was

detected while reading parameter

settings.

Inverters of different capacities.

A communications error occurred

between the Inverter and Digital

Operator.

Confirm that it is necessary to read

the parameter settings. If it is, change

the Parameter Read Prohibit

Selection parameter (n77) to 1

(enabling reading).

Check the main circuit voltage and

then attempt reading again.

Read the parameter settings again to

record them in the Digital Parameter.

Read the parameter settings to record

them in the Digital Parameter.

Check the voltage classes. (They

must both be the same to copy

parameter settings.)

Check the main circuit voltage and

then attempt copying again.

Press the Enter Key to continue the

comparison.

Press the STOP/RESET Key to

cancel the comparison.

Check the connection between the

Inverter and the Digital Operator.

Correct any problems and then repeat

the operation.

2-12

Page 41

3

Chapter 3

List of Parameters

Page 42

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n01

(0101)

n02

(0102)

Name Description Setting

range

Parameter

writeprohibit

selection/

parameter initialization

Operation

command

selection

Used to prohibit parameters to be

written, sets parameters, or change

the monitor range of parameters.

Used to initialize parameters to

default values.

0: Sets or monitors parameter n01.

Parameters n02 through n79 can

be monitored only.

1: Sets or monitors parameters n01

through n79.

5: Operation commands can be ac-

cepted at any time (n01 to n79 can

be set or referenced). (See note.)

6: Clears the error log.

8: Initializes parameters to default

values in 2-wire sequence.

9: Initializes parameters to default

values in 3-wire sequence.

Note Operation commands will be ig-

nored in Program Mode (refer

to 2-1-2) when n01 is set to 0 or

1. Normally set n01 to 0 or 1.

Used to select the input method for

the RUN and STOP commands in

remote mode.

0: The RUN and STOP/RESET Keys

on the Digital Operator are enabled.

1: Multi-function inputs through the

control circuit terminals in 2- or

3-wire sequence.

2: Operation commands via

RS-422A/485 communications are

enabled.

Note The RUN command only

through key sequences on the

Digital Operator is acceptable

in local mode.

0, 1, 6, 8,91 No

0 to 2 0 No

Default

setting

Changes

during

opera-

tion

Memo

3-2

Page 43

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n03

(0103)

n04

(0104)

Frequency

reference

selection

Interruption

mode

selection

DescriptionName

Used to set the input method for the

frequency reference in remote mode.

0: Digital Operator

1: Frequency reference 1 (n21)

2: Frequency reference control circuit

terminal (0 to 10 V)

3: Frequency reference control circuit

terminal (4 to 20 mA)

4: Frequency reference control circuit

terminal (0 to 20 mA)

6: Frequency reference via

RS-422A/485 communications

Used to set the stopping method for

use when the STOP command is input.

0: Decelerates to stop in preset time.

1: Coasts to stop (with output shut off

by the STOP command)

Setting

range

0 to 4, 6 0 No

0, 1 0 No

Default

setting

MemoChanges

during

opera-

tion

n05

(0105)

n06

(0106)

n07

(0107)

n08

(0108)

Reverse

rotationprohibit

selection

STOP/

RESET

Key

function

selection

Frequency

selection in

local

mode

Key sequential

frequency setting

Used to select the operation with the

reverse command input.

0: Reverse enabled.

1: Reverse disabled.

Used to select the stop method in remote mode with n02 for operation

mode selection set to 1.

0: STOP/RESET Key of the Digital

Operator enabled.

1: STOP/RESET Key of the Digital

Operator enabled only when the

Digital Operator is selected for the

RUN command.

Used to set the input method for the

frequency reference in local mode.

0: The FREQ adjuster of the Digital

Operator enabled.

1: Key sequences on the Digital Op-

erator enabled.

Used to enable the Enter Key for setting the frequency reference with the

Increment and Decrement Keys.

0: The value is entered with the En-

ter Key pressed.

1: The value is enabled when the

value is input.

0, 1 0 No

0, 1 0 No

0, 1 0 No

0, 1 0 No

3-3

Page 44

()()()( )

(Acceleration/Deceleration

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n09

(0109)

Maximum

frequency

(FMAX)

n10

(010A)

Maximum

voltage

(VMAX)

n11

(010B)

Maxi-

mum

voltage

frequen-

cy (FA)

n12

(010C)

Middle

output

frequen-

cy (FB)

n13

(010D)

Middle

output

frequen-

cy volt-

age

(VC)

n14

(010E)

Mini-

mum

output

frequen-

cy

(FMIN)

n15

(010F)

Mini-

mum

output

frequen-

cy volt-

age

(VMIN)

n16

(0110)

n17

(0111)

n18

(0112)

n19

(0113)

Accel-

eration

time 3

Decel-

eration

time 3

Accel-

eration

time 4

Decel-

eration

time 4

DescriptionName

Used to set the V/f pattern as the basic characteristic of the Inverter with

output voltage per frequency set.

Output

voltage

n10

(VMAX)

n13

(VC)

n09

(FMAX)

Frequency

(Hz)

n15

(VMIN)

0 n14

(FMIN)

n12

(FB)

n11

(FA)

Note Set the parameters so that

the following condition will be

satisfied.

n14 x n12 < n11 x n09

Note The value set in n13 will be

ignored if parameters n14 and

n12 are the same in value.

Acceleration time: The time required

to go from 0% to 100% of the maximum frequency.

Deceleration time: The time required

to go from 100% to 0% of the maximum frequency.

Note The actual acceleration or de-

celeration time is obtained

from the following formula.

Acceleration/Deceleration time

=

=

time set value) × (Frequency

reference value) ÷ (Max. fre-

quency)

Setting

range

50.0 to

Default

setting

60.0 No

400

1 to 255 200 No

0.2 to 400 60.0 No

0.1 to 399 1.5 No

1 to 255 12 No

0.1 to 10.0 1.5 No

1 to 50

12.0 No

(see note

2)

0.0 to 999

10.0 Yes

10.0 Yes

10.0 Yes

10.0 Yes

MemoChanges

during

opera-

tion

3-4

Page 45

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n20

(0114)

S-shape

acceleration/

deceleration

characteristic

DescriptionName

Used to set S-shape acceleration/deceleration characteristics.

0: No S-shape acceleration/decelera-

tion (trapezoidal acceleration/deceleration)

1: S-shape acceleration/deceleration

characteristic time 0.2 s

2: S-shape acceleration/deceleration

characteristic time 0.5 s

3: S-shape acceleration/deceleration

characteristic time 1.0 s

Note When the S-shape accelera-

tion/deceleration characteristic

time is set, the acceleration

and deceleration times will be

lengthened according to the

S-shape at the beginning and

end of acceleration/deceleration.

Setting

range

0 to 3 0 No

Default

setting

MemoChanges

during

opera-

tion

3-5

Page 46

abled in remote mode with

ith

lti-st

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n21

(0115)

n22

(0116)

n23

(0117)

n24

(0118)

n25

(0119)

n26

(011A)

n27

(011B)

n28

(011C)

n29

(011D)

Frequency

reference 1

Frequency

reference 2

Frequency

reference 3

Frequency

reference 4

Frequency

reference 5

Frequency

reference 6

Frequency

reference 7

Frequency

reference 8

Inching

frequency command

DescriptionName

Used to set internal frequency references.

Note Frequency reference 1 is en-

abled in remote mode with

n03 for frequency reference

selection set to 1.

Note These frequency references

are selected w

speed references (multi-function input).

Used to set the inching frequency

command.

Note The inching frequency com-

mand is selected with the

inching command (multi-function input). The inching frequency command takes precedence over the multi-step

speed reference.

mu

ep

Setting

range

0.0 to max.

frequency

Default

setting

6.0 Yes

0.0 Yes

0.0 Yes

0.0 Yes

0.0 Yes

0.0 Yes

0.0 Yes

0.0 Yes

6.0 Yes

during

opera-

MemoChanges

tion

3-6

Page 47

p

than the minimum output fre-

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n30

(011E)

n31

(011F)

n32

(0120)

n33

(0121)

Frequency

reference

upper

limit

Frequency

reference

lower

limit

Rated

motor

current

Motor

protection

characteristics

DescriptionName

Used to set the upper and lower frequency reference limits in percentage based on the maximum frequency as 100%.

Note If n31 is set to a value less

than the minimum out

quency (n14), the Inverter will

have no output when a frequency reference less than

the minimum output frequency

input is input.

Used to set the rated motor current

for motor overload detection (OL1)

based on the rated motor current.

Note Motor overload detection

(OL1) is disabled by setting

the parameter to 0.0.

Note The rated motor current is

default to the standard rated

current of the maximum applicable motor.

Used to set the motor overload

detection (OL1) for the electronic

thermal characteristics of the motor.

0: Protection characteristics for gen-

eral-purpose induction motors

1: Protection characteristics for in-

verter-dedicated motors

2: No protection

Note If a single Inverter is con-

nected to more than one motor, set the parameter to 2 for

no protection. The parameter

is also disabled by setting n32

for rated motor to 0.0.

ut fre-

Setting

range

0 to 110 100 No

0 to 110 0 No

0.0 to

120% of

rated output current

of the Inverter.

0 to 2 0 No

Default

setting

Varies with

the capacity.

No

MemoChanges

during

opera-

tion

3-7

Page 48

List of Parameters Chapter 3

Parameter

No. (Reg-

ister No.

(Hex))

n34

(0122)

n35

(0123)

Motor

protective time

setting

Cooling

fan operation

function

DescriptionName

Used to set the electric thermal characteristics of the motor to be connected in 1-minute increments.

Note The default setting does not

require any changes in normal

operation.

Note To set the parameter accord-

ing to the characteristics of the

motor, check with the motor

manufacturer the thermal time

constant and set the parameter with some margin. In other

words, set the value slightly

shorter than the thermal time

constant.

Note To detect motor overloading

quicker, reduce the set value,

provided that it does not cause

any application problems.

Used to operate the Cooling Fan of

the Inverter while the Inverter is

turned on or only while the Inverter is

in operation.

0: Rotates only while RUN command

is input and for 1 minute after Inverter stops operating

1: Rotates while Inverter is turned on

Note This parameter is available

only if the Inverter incorporates a Cooling Fan.

Note If the operation frequency of

the Inverter is low, the life of

the fan can be prolonged by

setting the parameter to 0.

Setting

range

1 to 60 8 No

0, 1 0 No

Default

setting

MemoChanges

during

opera-

tion

3-8

Page 49

(0124)

p

0

tion input 4

10 to

List of Parameters Chapter 3

Param-

eter

No.

(Regis-

ter No.

(Hex))

n36

n37

(0125)

n38

(0126)

n39

(0127)

Name Description Set-

Multi-function input 1

(Input terminal S2)

Multi-function input 2

(Input terminal S3)

Multi-function input 3

(Input terminal S4)

Multi-func-

(Input terminal S5)

Used to select the functions of multi-function

input terminals S2 through S5.

Set

val-

0 Forward/

2 Reverse/

3 External

4 External

5 Fault reset ON: Fault reset (disabled

6 Multi-step

7 Multi-step

8 Multi-step

10 Inching fre-