Page 1

=;76HULHV

&DW1R,((1

352),1(7

86(5¶60$18$/

6&$5$5RERWV

<5&;6HULHV

Page 2

Page 3

CONTENTS

Important information before reading this manual 1

Introduction 1

Safety Precautions (Always read before starting use) 2

Warranty 4

1. Overview of functions 5

2. Controller status transitions 6

3. Input/output assignments 7

4. Part names and functions 9

5. Flow until operation begins 10

PROFINET

User’s Manual

6. Connection 11

6.1 Network structure 11

6.2 Cabling 13

6.3 Noise countermeasures 13

7. GSDles 14

8. Settings 15

8.1 Communication parameter settings 15

9. Monitoring communication data 16

9.1 Using the programming box 16

9.1.1 Switching the port number 17

9.1.2 Input/output list display 18

9.1.3 Input/output details display 18

9.1.4 Switching the output status 19

9.2 Using SCARA-YRCX Studio support software 20

T- 1

Page 4

CONTENTS

10. Disabling an option unit 23

10.1 Making settings 24

10.1.1 Using the programming box 24

10.1.2 Using SCARA-YRCX Studio support software 25

11. Actions to take if communication is not established 27

11.1 Reconsider the startup steps 27

11.2 Viewing the alarm codes in the 7-segment LED 28

11.3 Diagnostics by alarm message 28

11.3.1 Alarms related to network unit connections and settings 28

11.3.2 AlarmsrelatedtoI/Oon/ostatus 29

11.3.3 Alarms that the customer cannot resolve 29

11.3.4 Checking alarm codes in the programming box 30

11.3.5 Checking alarm codes in SCARA-YRCX Studio support software 30

PROFINET

User’s Manual

11.4 Detailed diagnostics using the indicators 31

11.4.1 Common situations and LED illumination patterns 32

12.Specications 33

12.1 Networkspecications 33

12.2 Input/outputspecications 34

13. Reserved word list 35

T- 2

Page 5

Important information before reading this manual

Introduction

The OMRON network interface unit documentation consists of a User's Manual that is specific to each network

unit that describes the specifications and communication settings of that unit, and a Remote I/O Manual

describing the remote I/O specifications that are common to all network units.

OMRON network interface unit manuals

Content specific to each network unit

(network communication settings, etc.)

(remote I/O and remote command specifications etc.)

Content common to all networks

Important information before reading this manual

PROFINET user’s manual

(this document)

For details on network unit specifications and communication settings, refer to this User's Manual.

For details on communication functions between the controller and the host control device, such as remote I/O

and remote commands, refer to the Remote I/O Manual.

For details on the functions of the robot controller unit, refer to the following manuals.

YRCX Operator’s Manual ..................... for operation of the controller unit

YRCX User’s Manual ............................ for specifications and settings of the controller unit

YRCX Programming Manual ................. for the programming language used by OMRON robot controllers

Remote I/O Manual

1

Page 6

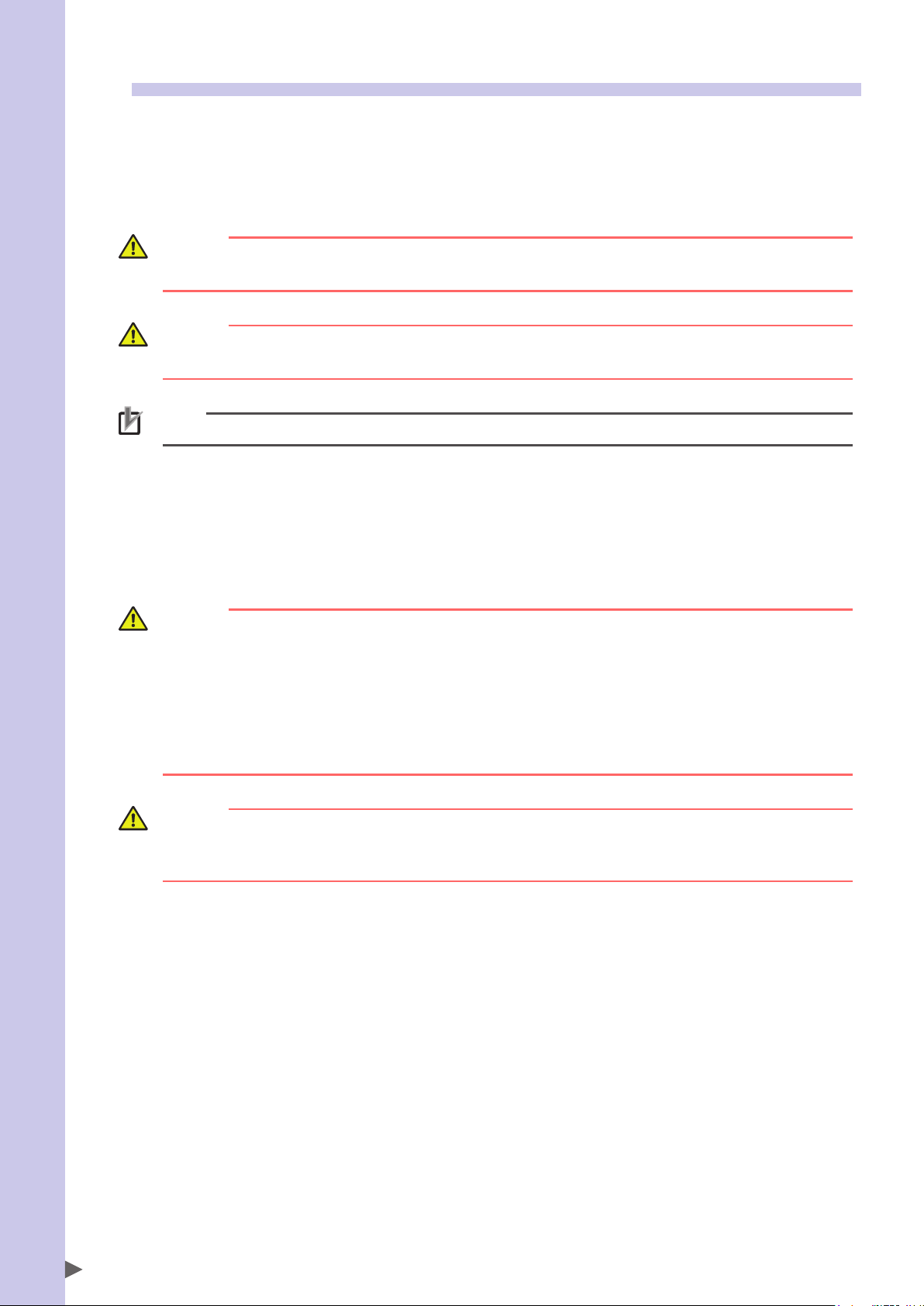

Safety Precautions (Always read before starting use)

Important information before reading this manual

Before using this product, be sure to read this manual carefully as well as the robot controller user's manual

and programming manual. Take sufficient precautions to ensure safety and handle the product correctly.

The cautions given in this manual are related to this product. Refer to the robot controller user's manual for

details on the cautions to be taken with the robot controller system using this product.

The safety precautions are ranked as "WARNING" and "CAUTION" in this manual.

WARNING

FAILURE TO FOLLOW WARNING INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH TO THE OPERATOR OR

PERSON SERVICING THE PRODUCT.

CAUTION

Failure to follow CAUTION instructions may result in injury to the operator or person servicing product, or damage

to the product or peripheral equipment.

NOTE

The key points in the operation are explained simply and clearly.

Note that some items described as "CAUTION" may lead to serious results depending on the situation. In any

case, important information that must be observed is explained.

Store this manual where it can be easily referred to, and make sure that it is delivered to the end user.

■Precautions for design

WARNING

• FOR INFORMATION ABOUT THE STATUS OF THE NETWORK SYSTEM AND ROBOT CONTROLLER IN THE EVENT THAT A

COMMUNICATION PROBLEM OCCURS IN THE NETWORK SYSTEM, REFER TO THE MANUAL OF THE HOST CONTROL

DEVICE AS WELL AS TO THIS DOCUMENT. CONFIGURE AN INTERLOCK CIRCUIT IN THE SEQUENCE PROGRAM SO

THAT THE SYSTEM, INCLUDING THE ROBOT CONTROLLER, WILL WORK SAFELY WITH USING THE COMMUNICATION

STATUS INFORMATION.

• THE SAFETY CONNECTOR HAS AN EMERGENCY STOP TERMINAL TO TRIGGER EMERGENCY STOP OF THE ROBOT

CONTROLLER. BY USING THIS TERMINAL, PREPARE A PHYSICAL INTERLOCK CIRCUIT SO THAT THE SYSTEM INCLUDING

THE ROBOT CONTROLLER WILL WORK SAFELY.

CAUTION

The control line and communication cable must not be bound with or placed near the main circuit or power line.

Separate these by at least 100mm. Failure to observe this could lead to communication error or declining

throughput caused by noise.

2

Page 7

■Precautions for installation

WARNING

• ALWAYS CRIMP, PRESS-FIT OR SOLDER THE CONNECTOR WIRING WITH THE MAKER-DESIGNATED TOOL, AND

SECURELY FIX THE CONNECTOR TO THE MODULE.

• ALWAYS SHUT OFF ALL PHASES OF THE POWER SUPPLY EXTERNALLY BEFORE STARTING INSTALLATION OR WIRING

WORK.

FAILURE TO SHUT OFF ALL PHASES COULD LEAD TO ELECTRIC SHOCKS OR PRODUCT DAMAGE.

CAUTION

• Use the robot controller in the environmental conditions specified in this manual. Operation outside the

specified environmental range may cause electric shocks, fire, malfunction or product damage or

deterioration.

• Do not directly touch the conductive portions or electronic components of a network module.

• Never directly touch the controller's interior areas.

• Accurately connect each cable connector to the mounting section.

Failure to observe this could lead to malfunctions caused by a connection fault.

WARNING

ALWAYS SHUT OFF ALL PHASES OF THE POWER SUPPLY EXTERNALLY BEFORE STARTING INSTALLATION OR WIRING

WORK. FAILURE TO SHUT OFF ALL PHASES COULD LEAD TO ELECTRIC SHOCKS OR PRODUCT DAMAGE.

CAUTION

• Make sure that foreign matter, such as cutting chips or wire scraps, does not enter the robot controller.

• Communication cables that contact network modules must be kept inside a duct or secured by clamps. Failure

to place the cable in a duct or secure it by a clamp could damage the cable or module by shifting, movement

or unintentional pulling the cable, or cause malfunction by poor contact condition.

• When disconnecting a connector from the network module, grasp the connector rather than pulling on the

cable. Pulling on the cable could damage the cable and module, possibly causing a poor contact condition

which could result in malfunctions.

Important information before reading this manual

■Precautions for starting and maintenance

WARNING

• DO NOT TOUCH THE TERMINALS WHILE THE POWER IS ON. FAILURE TO OBSERVE THIS COULD LEAD TO

MALFUNCTIONS.

• ALWAYS SHUT OFF ALL PHASES OF THE POWER SUPPLY EXTERNALLY BEFORE PERFORMING CLEANING OR WIRING

WORK. FAILURE TO SHUT OFF ALL PHASES COULD LEAD TO ELECTRIC SHOCKS, PRODUCT DAMAGE OR

MALFUNCTIONS.

• NEVER DISASSEMBLE OR MODIFY ANY OF THE ROBOT CONTROLLER MODULES.

FAILURE TO OBSERVE THIS COULD LEAD TO TROUBLE, MALFUNCTIONS, INJURIES OR FIRES.

CAUTION

Power must be supplied to the robot controller only after supplying power to the host control device. The robot

controller will enter an error state if communication is not established within a certain length of time after the

controller starts.

■Precautions for disposal

CAUTION

Dispose of this product as industrial waste.

3

Page 8

Warranty

Important information before reading this manual

The OMRON robot and/or related product you have purchased are warranted against the defects or

malfunctions as described below.

■Warranty description

If a failure or breakdown occurs due to defects in materials or workmanship in the genuine parts constituting this

OMRON robot and/or related product within the warranty period, then OMRON shall supply free of charge the necessary

replacement/repair parts.

■Warranty period

The warranty period ends 24 months after the date of manufacturing as shown on the products.

■Exceptions to the warranty

This warranty will not apply in the following cases:

1. Fatigue arising due to the passage of time, natural wear and tear occurring during operation (natural fading of painted

or planted surfaces, deterioration of parts subject to wear, etc.)

2. Minor natural phenomena that do not affect the capabilities of the robot and/or related product (noise from computers,

motors, etc.)

3. Programs, point data and other internal data were changed or created by the user.

Failures resulting from the following causes are not covered by warranty.

1. Damage due to earthquakes, storms, floods, thunderbolt, fire or any other natural or man-made disaster.

2. Troubles caused by procedures prohibited in this manual.

3. Modifications to the robot and/or related product not approved by OMRON or OMRON sales representative.

4. Use of any other than genuine parts and specified grease and lubricant.

5. Incorrect or inadequate maintenance and inspection.

6. Repairs by other than authorized dealers.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUERIMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WETHER SUCH CLAIM

IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE OR INAPPROPIATE MODIFICATION OR REPAIR.

4

Page 9

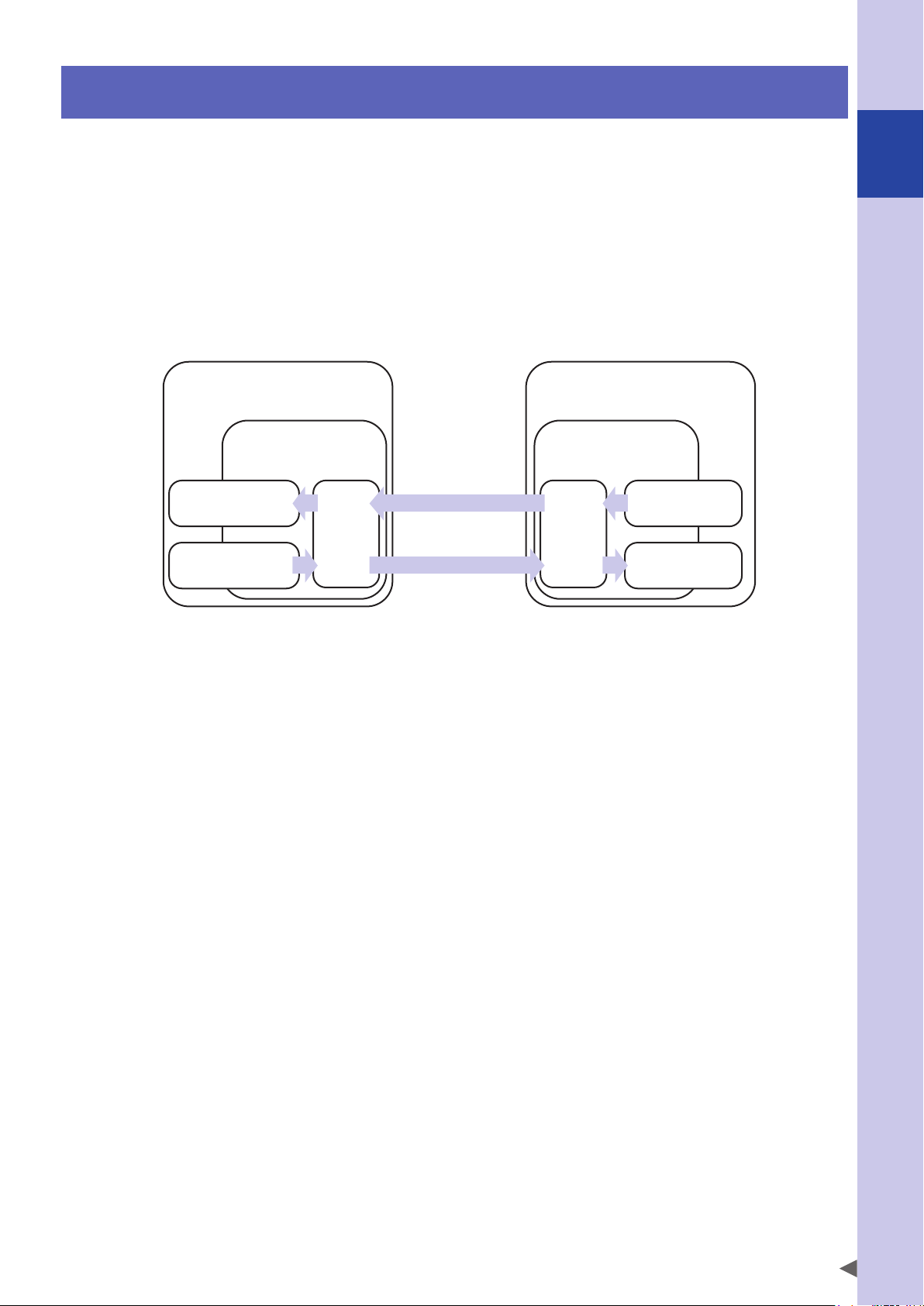

1. Overview of functions

A network interface unit is a device that transmits and receives I/O information via a communication protocol

between a controller and a host control device.

We provide a lineup of products that support fieldbus (DeviceNet, PROFIBUS, etc.) or industrial Ethernet

(EtherNet/IP, PROFINET, etc.).

In any of these networks, the robot controller (slave device) operates in accordance with commands via I/O

control from a host (master device).

While acting as distributed I/O for the host control device, the network interface unit simultaneously shares

I/O information with the controller. The I/O update cycle time between the controller and the network

interface unit is 5 ms.

The I/O update cycle time between the network interface unit and the host control device will vary depending

on the structure of the applicable network.

1

Overview of functions

Host control device

Network unit

(master / I/O controller)

←Status output

Input

m, m+1, ..., m+x

←General-purpose I/O→ ConversionConversion

Output

n, n+1, ..., n+y

Command input→

I/O consists of a general-purpose input/output area, and a dedicated input/output area that has specific

significance such command input and status output that is optimized for control of robot controllers. Using

these, the robot controller can be controlled from the host control device.

The following methods can be used for control via I/O. Combining these methods makes it possible to control

the robot.

(slave / distributed I/O device)

Robot controller

(robot, I/O control)

Network unit

Output

SO, SOW

Input

SI, SIW

1. Controlling the robot controller directly using simple commands and status queries via remote

I/O's dedicated input/output.

Example) Dedicated input: cancel emergency stop, servo on, reset, start program execution, etc.

Dedicated output: CPU_OK, return-to-origin complete, etc.

2. Using remote commands to programlessly control the robot controller directly with advanced

instructions and status queries.

Example) < Transmission >

SIW0 = 0x1031 (absolute reset command for robot no.1)

SIW2 = 0x0015 (axis designation: axis 1 through axis 4)

< Reception >

SOW = 0x0100 (executing command)

SOW = 0x0200 (normal end)

↓

3. Using remote I/O's general-purpose input/output to exchange desired information with an

external peripheral device, and load it into a robot program or sequence program for execution.

Example) WAIT SI(20)=1, 1000 ; Wait until SI(20) turns on; stop command if it does not turn on after 1 second

OUT SO2(), 200 ; SO(27--20) turns on, and turns off after 200 ms

* For details on remote I/O and remote commands, refer to the Remote I/O Manual. For details on robot programs, refer

to the YRCX Programming Manual.

5

Page 10

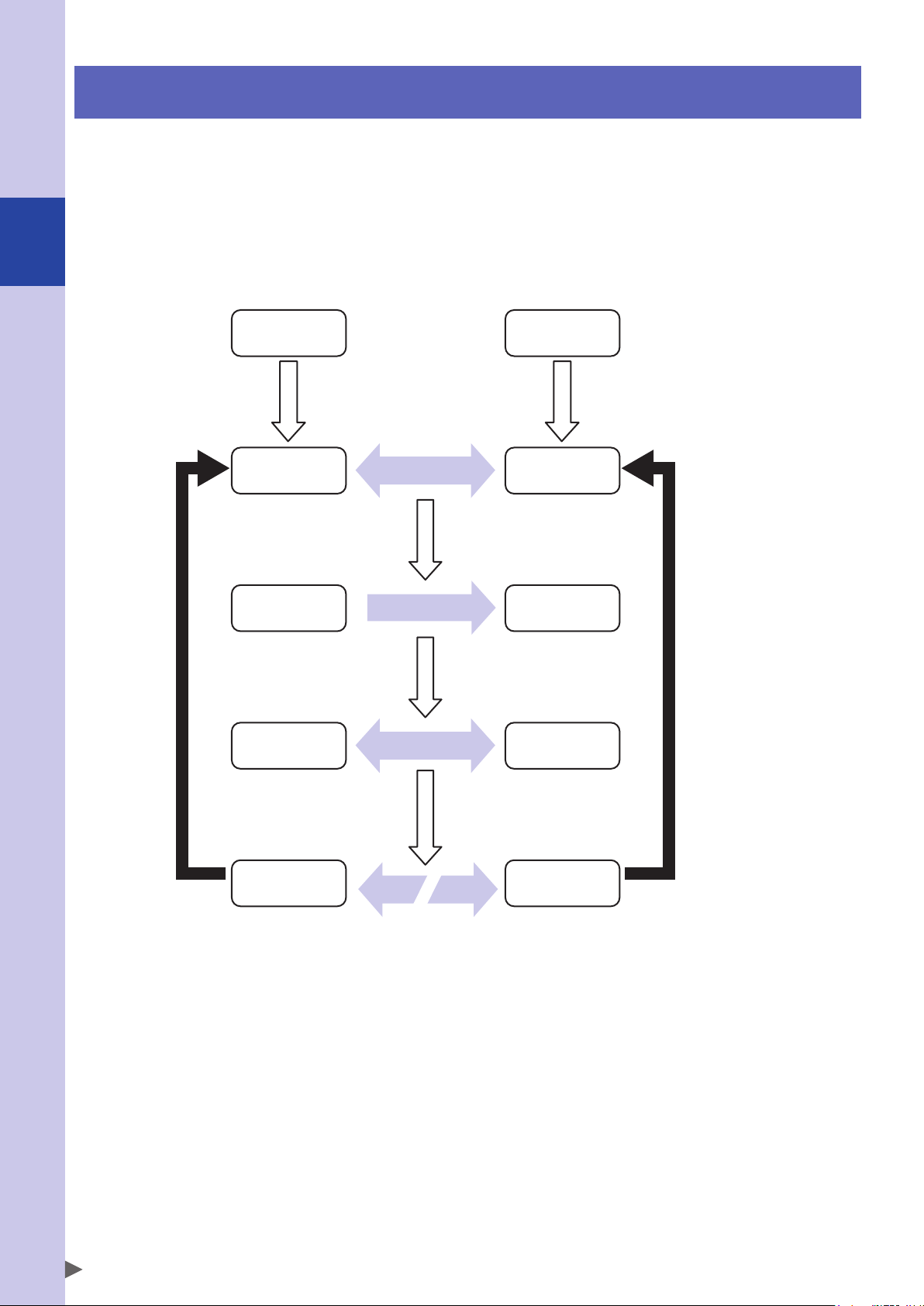

2. Controller status transitions

Power on, controller starts

StartupStartup

Here we explain the status transitions of a robot controller equipped with a network interface unit. A

controller equipped with a network interface unit will initially start up in the emergency stop state. In order

for robot operation to be possible, communication must be established with the host control device, and a

sign that cancels the emergency stop state must be input.

If communication with the host control device is interrupted for any reason, the controller will again transition

to the emergency stop state regardless of the I/O status. In order to resume operation, I/O processing is

2

Controller status transitions

required, such as reestablishing communication, cancelling the emergency stop state, and resetting any error.

Robot controllerHost control device

in emergency stop state

Host control device

Host control device

Host control device

Host control device

Establish communication

Input signals

Exchange I/O information

Robot controller

After both the host control

device and the controller

have started up and

established communication,

cyclic communication begins.

Robot controller

Signals are input to cancel

emergency stop or errors,

putting the robot in an

operable state.

Robot controller

The robot is controlled via

remote commands or

programs

Robot controller

6

Cease communication

When communication

ceases, the robot transitions

to the emergency stop state,

robot power is shut down,

and the program also stops.

Page 11

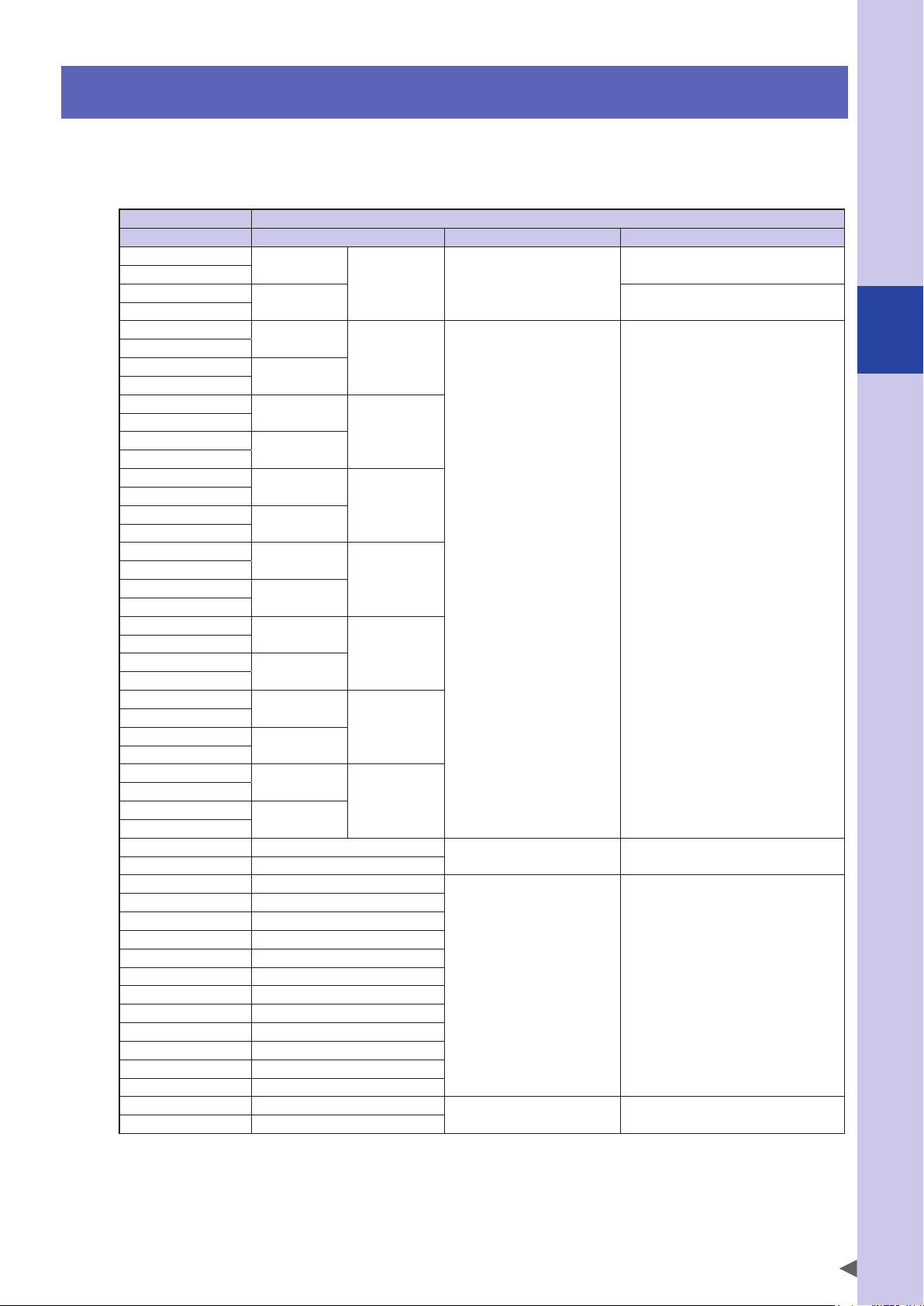

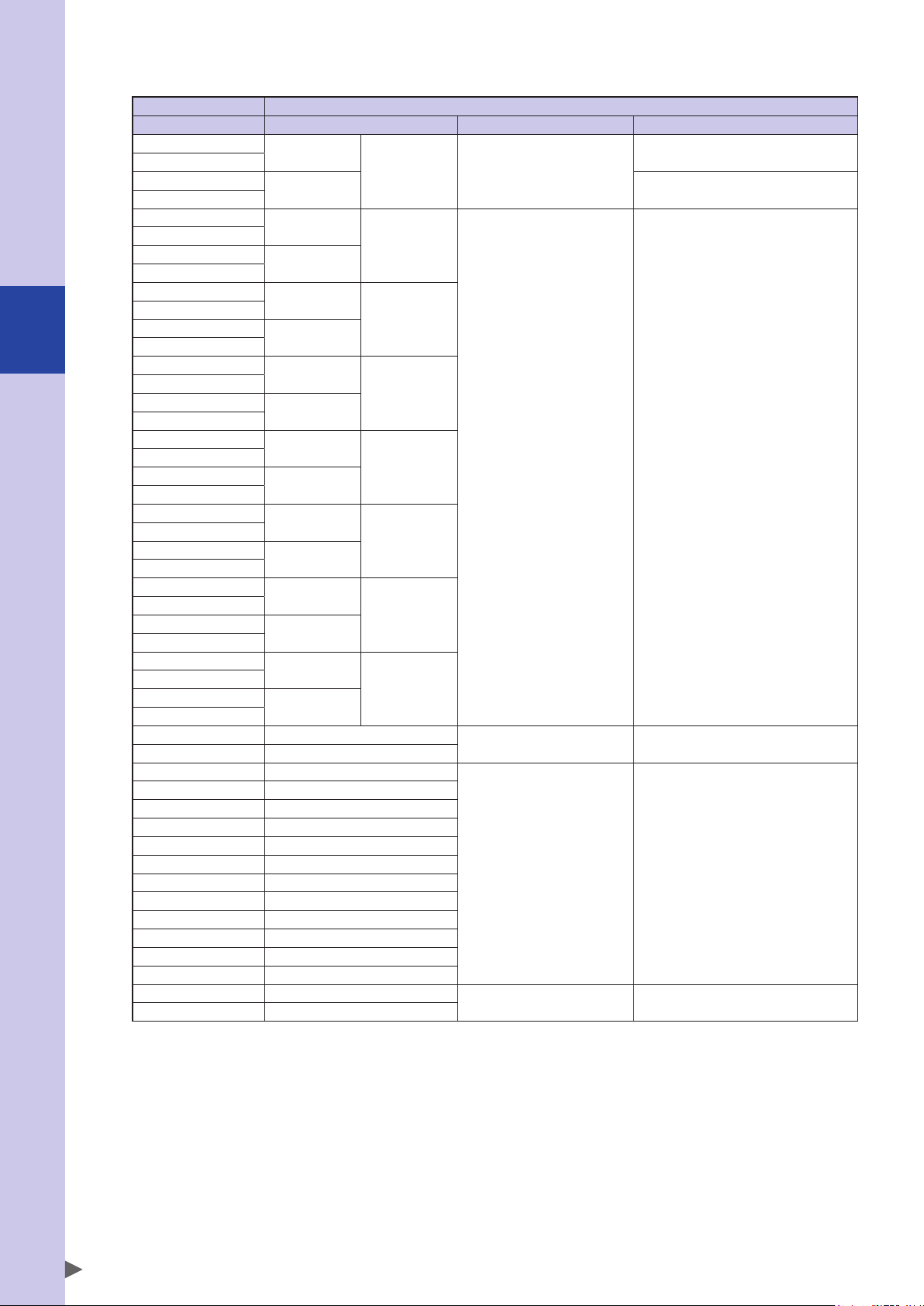

3. Input/output assignments

Here we show the correspondence between the robot controller's serial input/output data and the input/

output data on the network.

■Output from the controller, input to the host device

Host control device Controller

Address (READ) Address (WRITE) Input/output type Use

I (n)

I (n+1)

I (n+2)

I (n+3)

I (n+4)

I (n+5)

I (n+6)

I (n+7)

I (n+8)

I (n+9)

I (n+10)

I (n+11)

I (n+12)

I (n+13)

I (n+14)

I (n+15)

I (n+16)

I (n+17)

I (n+18)

I (n+19)

I (n+20)

I (n+21)

I (n+22)

I (n+23)

I (n+24)

I (n+25)

I (n+26)

I (n+27)

I (n+28)

I (n+29)

I (n+30)

I (n+31)

I (n+32) SO07 - SO00

I (n+33) SO17 - SO10

I (n+34) SO27 - SO20

I (n+35) SO37 - SO30

I (n+36) SO47 - SO40

I (n+37) SO57 - SO50

I (n+38) SO67 - SO60

I (n+39) SO77 - SO70

I (n+40) SO107 - SO100

I (n+41) SO117 - SO110

I (n+42) SO127 - SO120

I (n+43) SO137 - SO130

I (n+44) SO147 - SO140

I (n+45) SO157 - SO150

I (n+46) (Reserve)

I (n+47) (Reserve)

• I(n), I(n+1), ..., (n+47) assume data memory that is divided at each byte (8-bits).

• SOx() is handled as unsigned 8-bit integer data. (x=2-7, 10-17)

• SOW(y) is handled as unsigned 16-bit integer data. (y=0 - 15)

• The upper byte and lower byte of SOW(y) correspond to I(2y+1) and I(2y) respectively.

• SOD(z) is handled as signed 32-bit integer data. (z=2, 4, ..., 14)

• The upper word and lower word of SOD(z) correspond to SIW(z+1) and SIW(n), respectively.

SOW(0)

- Word output

SOW(1) Remote command error code area

SOW(2)

SOD(2)

SOW(3)

SOW(4)

SOD(4)

SOW(5)

SOW(6)

SOD(6)

SOW(7)

SOW(8)

SOD(8)

SOW(9)

SOW(10)

SOD(10)

SOW(11)

SOW(12)

SOD(12)

SOW(13)

SOW(14)

SOD(14)

SOW(15)

Word output /

Double word output

Bit output Status output area

Bit output /

Byte output

Reserved area Use is prohibited

I(n) : Starting address of the input data area for the target controller

Command status area

Command response area /

General-purpose output area

General-purpose output area

3

Input/output assignments

7

Page 12

■Output from the host control device, input to the controller

Host control device Controller

Address (WRITE) Address (READ) Input/output type Use

Q m

Q m+1

Q m+2

Q m+3

Q m+4

Q m+5

Q m+6

Q m+7

Q m+8

Q m+9

3

Input/output assignments

Q m+10

Q m+11

Q m+12

Q m+13

Q m+14

Q m+15

Q m+16

Q m+17

Q m+18

Q m+19

Q m+20

Q m+21

Q m+22

Q m+23

Q m+24

Q m+25

Q m+26

Q m+27

Q m+28

Q m+29

Q m+30

Q m+31

Q m+32 SI07 - SI00

Q m+33 SI17 - SI10

Q m+34 SI27 - SI20

Q m+35 SI37 - SI30

Q m+36 SI47 - SI40

Q m+37 SI57 - SI50

Q m+38 SI67 - SI60

Q m+39 SI77 - SI70

Q m+40 SI107 - SI100

Q m+41 SI117 - SI110

Q m+42 SI127 - SI120

Q m+43 SI137 - SI130

Q m+44 SI147 - SI140

Q m+45 SI157 - SI150

Q m+46 (Reserve)

Q m+47 (Reserve)

• Q(m), Q(m+1), ..., Q(m+47) assume data memory that is divided at each byte (8-bits).

• SIx() is handled as unsigned 8-bit integer data. (x=2-7, 10-17)

• SIW(y) is handled as unsigned 16-bit integer data. (y=0 - 15)

• The upper byte and lower byte of SIW(y) correspond to Q(2y+1) and Q(2y) respectively.

• SID(z) is handled as signed 32-bit integer data. (z=2, 4, ..., 14)

• The upper word and lower word of SID(z) correspond to SIW(z+1) and SIW(n), respectively.

SIW(0)

SIW(1) Command data area

SIW(2)

SIW(3)

SIW(4)

SIW(5)

SIW(6)

SIW(7)

SIW(8)

SIW(9)

SIW(10)

SIW(11)

SIW(12)

SIW(13)

SIW(14)

SIW(15)

- Word input

SID(2)

SID(4)

SID(6)

SID(8)

SID(10)

SID(12)

SID(14)

Q(m) : Starting address of the output data area for the target controller

Word input /

Double word input

Bit input Command input area

But input /

Byte input

Reserved area Use is prohibited

Remote command area

Command data area /

General-purpose input area

General-purpose input area

* For details on the functions that are assigned to each serial input/output data, refer to the separate Remote

I/O Manual.

* The reserved area cannot be used.

8

Page 13

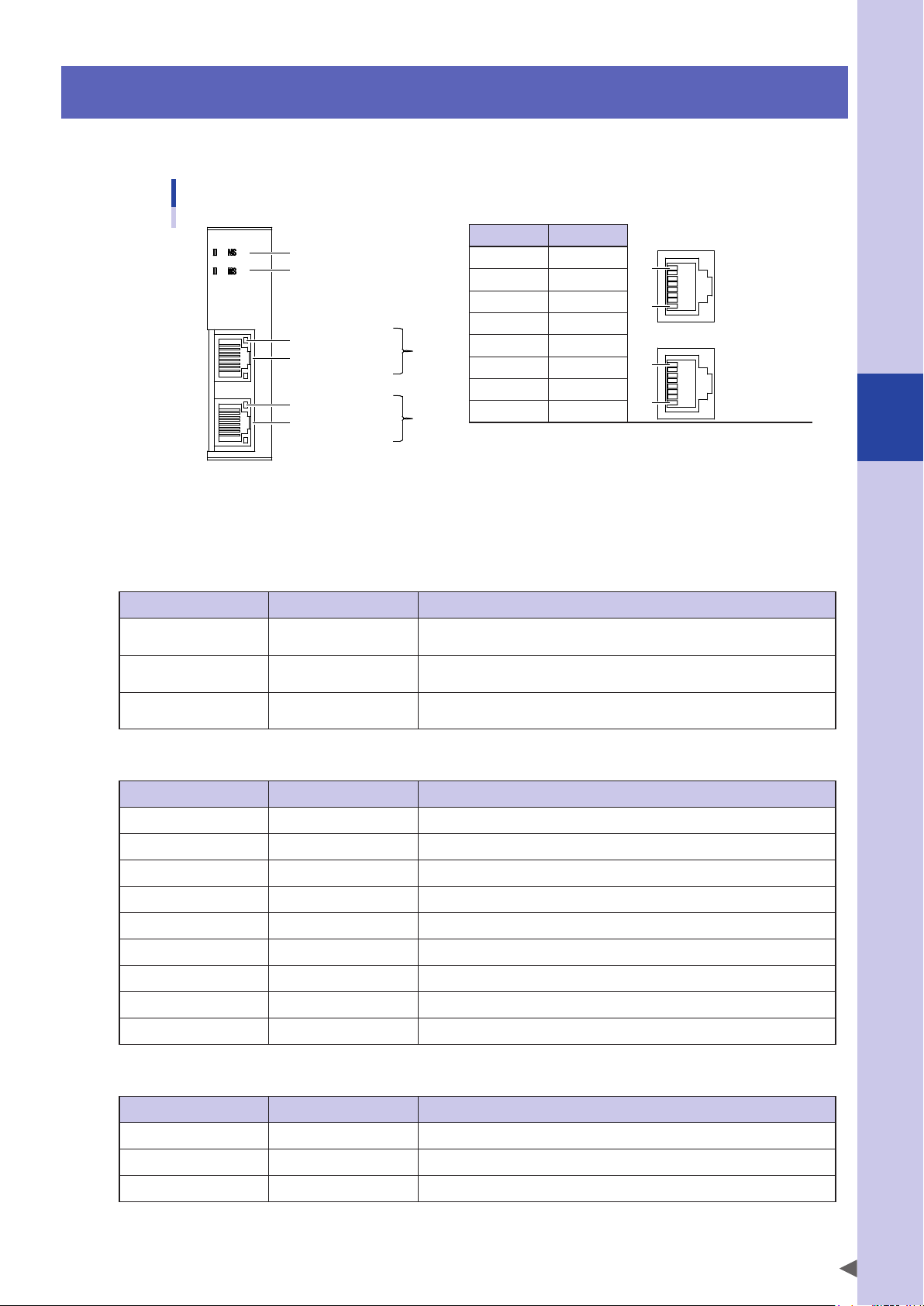

4. Part names and functions

Here we explain the part names and functions of the network interface unit.

Part names

• Pin configuration and connector specifications

Number Name

Network status LED

Module status LED

Link/activity LED

RJ45 modular jack

Link/activity LED

RJ45 modular jack

Port 1

Port 2

1 TXD+

2 TXD-

3 RXD+

4 -

5 -

6 RXD-

7 -

8 -

* An RJ45 modular plug is not included.

8

Port 1

1

8

Port 2

1

4

Connector: RJ45 modular jack

Connect a CAT 5e or higher STP (Shielded Twisted Pair) cable to the connector. From the standpoint of

durability and noise rejection, double-shielded LAN cable for industrial use is recommended.

Network status (NS) LED

LED status Explanation Comment

OFF Offline

Green Online (RUN)

Flashing green Online (STOP)

Power is off

IO controller is not connected

Connection with IO controller is not established

IO controller is in RUN state

Connection with IO controller is not established

IO controller is in STOP state

Module status (MS) LED

LED status Explanation Comment

OFF Not initialized Power is off, or module is in SETUP or "NW_INIT" state

Green Normal operation Module has transitioned from "NW_INIT" state

Flash green once Diagnostic event Diagnostic event is occurring

Flash green at 1 Hz DCP flashing An engineering tool is being used to identify a node on the network

Red Exception error Module is in the "EXCEPTION" state

Part names and functions

Flash red once Setting error Expected ID differs from actual ID

Flash red twice IP address error IP address is not set

Flash red three times Station name error Station name is not set

Flash red four times Internal error A serious error occurred inside the module

Link/activity LED: Port 1 / Port 2

LED status Explanation Comment

OFF No link A link is not established, and communication is not occurring

Green Link detected An Ethernet link is established, but communication is not occurring

Flashing green Activity An Ethernet link is established, and communication is occurring

9

Page 14

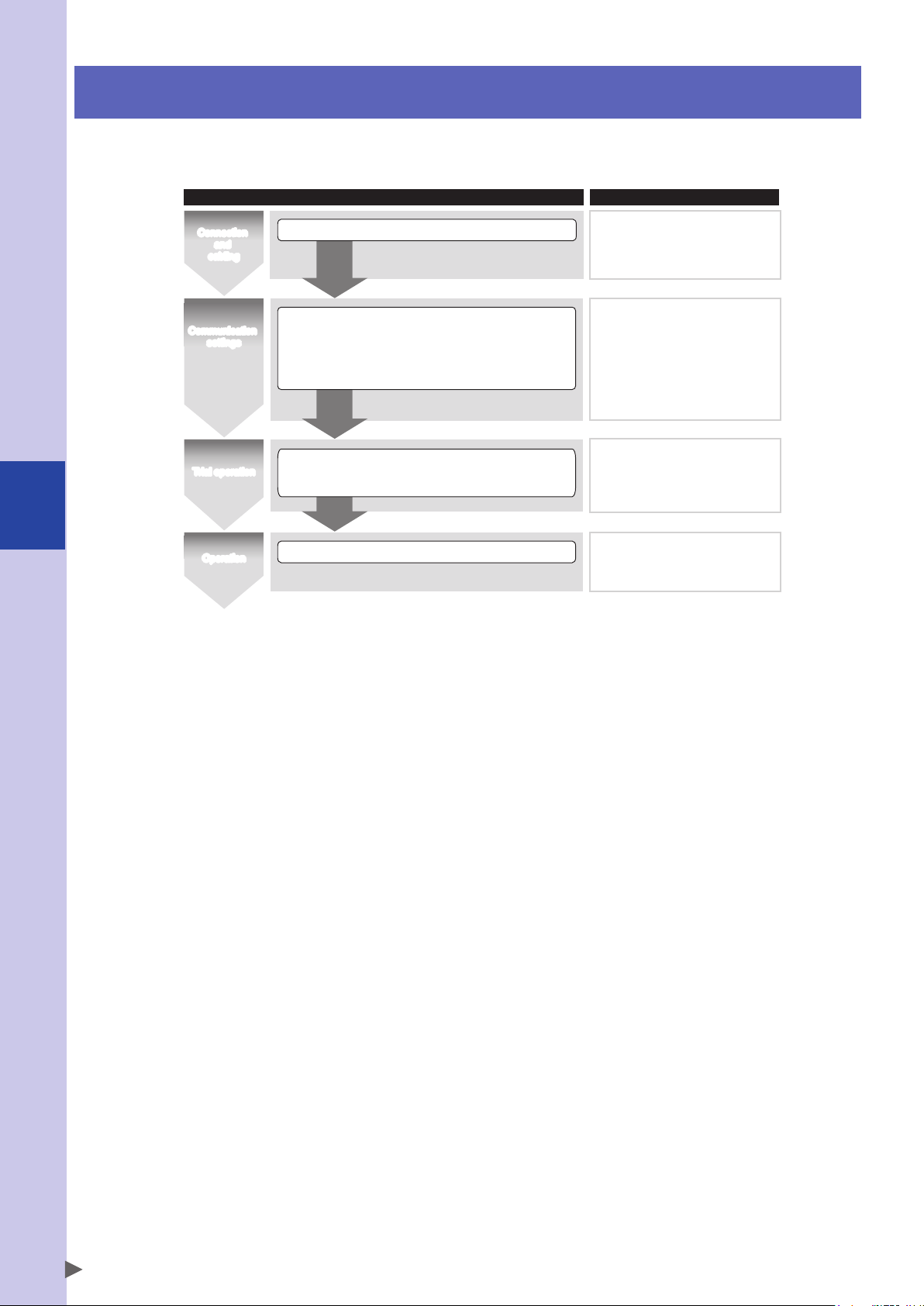

5. Flow until operation begins

Here we explain the flow from startup until operation begins. Proceed with the flow shown in the illustration

below, and consult the appropriate manuals as necessary for each step.

Work steps Refer to:

5

Flow until operation begins

Connection

and

cabling

Communication

Communication

settings

settings

Trial operation

Operation

• Connect connectors and cables

Controller

• No setting items

Host device

• Register the network settings file (GSD)

• Set the communication parameters

• Begin cyclic communication

• Check remote I/O and remote command input/output

• Debug the program

Start operation

6.1 Network structure

6.2 Cabling

6.3 Noise countermeasures

8.1 Communication parameter settings

YRCX user’s manual

Remote I/O Manual

YRCX user’s manual

Remote I/O Manual

10

Page 15

6. Connection

Here we provide an overview of the steps for connecting the robot controller to the network.

Network structure and cable specifications should be designed according to the materials provided by the

network interest group (PI: PROFIBUS & PROFINET International).

6.1 Network structure

PROFINET is an industrial multi-vendor network system based on Ethernet technology that is open and

promoted by PI (PROFIBUS & PROFINET International).

Since it uses standard Ethernet as its lower-level protocol, the network can coexist with general-purpose

Ethernet equipment.

A PROFINET network is typically constructed in a star topology via a switch, but since the robot controller's

PROFINET unit contains a two-port switch, a cable-saving linear network can also be constructed by daisychained connection.

CAUTION

The two Ethernet ports of a PROFINET unit are for the purpose of allowing a versatile network topology within a

single subnet without using a switch. It is not possible for the two ports to be connected to different subnets.

■Example of a cable-saving linear network using daisy-chaining

Host unit

(PROFINET I/O controller)

YRCX

CAUTION

Network equipment such as switches can be used if it satisfies the requirements of the PROFINET network.

However if the equipment is to be used in an environment where noise is a concern, such as a factory, equipment

that meets EMC industrial standards should be selected.

YRCX

Max. 100m

Connection

YRCX

YRCX

6

11

Page 16

■Example of a cable-saving layout that combines PROFINET with a general-purpose Ethernet

network

6

CAUTION

The general-purpose Ethernet ports built into the controller unit do not support the PROFINET communication

protocol. Also, communication settings are made separately from the PROFINET unit.

For details on settings for the general-purpose Ethernet ports, refer to the user's manual of the controller unit.

Host unit

(PROFINET I/O controller)

General-purpose Ethernet port

built into the robot controller

YRCX

General-purpose computer

YRCX YRCX

YRCX

General-purpose Ethernet port

built into the robot controller

Connection

When cabling via option boards as shown above, do not set the option board setting parameter to "disable."

As setting the option board setting parameter to "disable" causes the option board's internal switch to stop

functioning, the general-purpose Ethernet communication pathway to the controller will be shut off.

12

Page 17

6.2 Cabling

WARNING

SHUT OFF THE POWER SUPPLY INPUT TO THE ROBOT CONTROLLER BEFORE PERFORMING THIS WORK.

Insert the LAN cable's modular plug into the controller's modular jack until you hear it click into place.

■Cable specifications

Use LAN cables that meet the following specifications.

Category 5e (CAT 5e) or higher

Shielded Twisted Pair (STP: Shielded Twist Pair)

Double-shielded

100 m or shorter (solid-core cable is recommended if it is over 10 m)

(Example selections) SIEMENS AG

Connector plug IE FC RJ45 Plug 180 6GK1 901-1BB10-2AOO

Cable material IE FC TP standard cable 6XV1 840-2AH10

Tool Stripping tool for IE FC cable 6GK1 901-1GA00

* OO indicates the number of metal housings (A0: 1 / B0: 10 / E0: 50).

* The cable length can be specified in 1-meter units from a minimum of 20 m to a maximum of 1,000 m.

6.3 Noise countermeasures

Although the robot controller unit complies with EMC standards and has a certain amount of resistance to

external noise, there may be cases in which communication is affected by noise depending on the environment

in which the equipment and cable are located.

If communication is affected by noise, a communication error occurs, possibly causing the robot to enter an

emergency stop state, or causing throughput to decline. If there is a source of noise, and this noise is suspected

of affecting communication, please take the following countermeasures.

1. Equipment and cable selection

As the equipment to be connected to the network, select units that conform to EMC directives. Be sure to use cable of the

prescribed specifications.

2. Equipment and cable placement and grounding

If the noise source is nearby, create an appropriate distance between the noise source and the network environment

including the cable. For the robot controller unit and equipment connected to it, be sure to attach an appropriate ground

as directed by the manual of each unit.

3. Adding anti-noise components

Apply the following measures to the robot controller.

• Install a ferrite core on both ends of the cable immediately adjacent to the connector of the device.

• Install a ferrite core or noise filter on the power supply input of the controller.

6

Connection

13

Page 18

7. GSD files

GSD (General Station Description) is a type of network setting file. It contains settings for a device that

supports PROFIBUS or PROFINET.

The network settings file contains information necessary for connecting to a host device, such as I/O size and

communication settings, in a prescribed format. When constructing a network, the settings information of all

connected network devices must be loaded into the host control device.

The appropriate engineering or configuration tool is used to make settings for and write to the host control

device, and during this process it will be necessary to load each device's network settings file into the tool.

The steps for loading the file will depend on the host device used, and on the tool that supports it. Refer to the

manual for the device and tool.

7

GSD files

14

Page 19

8. Settings

Here we explain the parameters that must be set and the settings files that are required in order to begin

communication between the host control device and the robot controller.

8.1 Communication parameter settings

The robot controller does not have parameters related to PROFINET unit communication.

Communication with the host control device (IO controller) requires network parameter settings such as IP

address, subnet mask, and station name.

All of these are set by the corresponding engineering tool (IO Supervisor).

Tasks such as viewing the network parameters and performing "Reset to factory setting" are also all performed

from the engineering tool. For details on how to use the engineering tool, refer to the manual of the device and

software you're using.

■Network settings flow

If there is no topology setting for the host control device (IO controller), such as when the facility is being

started up:

With the robot controller and the engineering tool in a state where they can communicate with each other, specify the

IP address, subnet mask, gateway, and station name individually.

Also make the same settings for the host control device.

If you are replacing only one device within the network, such as when replacing a controller, and topology

settings have been made for the host control device (IO controller):

The network parameters that had been specified for the device before replacement can be automatically assigned by

PROFINET to the replacement device based on the address information of the peripheral device.

This means that in this case, there is no need to make communication settings.

CAUTION

Data of the robot controller other than network parameters is not passed on automatically.

Be sure to back up from the controller before replacing it, download this data to the controller following

replacement, and then connect the controller to the network.

8

Settings

15

Page 20

9

9. Monitoring communication data

On/off data for the host controller device and controller I/O can be monitored via the programming box or

the SCARA-YRCX Studio support software. This can be used to check the input/output addresses during setup

or for debugging.

Monitoring communication data

CAUTION

Since the display update interval of the programming box and of SCARA-YRCX Studio is longer than the data

update interval of I/O information, there may be cases in which accurate information is not shown if the on/off

interval of the I/O information is short.

9.1 Using the programming box

At the initial screen, select [Monitor]-[I/O] to access the monitor screen.

Valid keys and submenu descriptions in the MANUAL mode are shown below.

Valid keys Menu Function

DETAIL Switches between the input/output list and detail displays.

DI Displays the DI monitor.

DO Displays the DO monitor.

MO Displays the MO monitor.

LO Displays the LO monitor.

TO Displays the TO monitor.

SI

SO

SIW Displays the SIW monitor.

SOW Displays the SOW monitor.

NOTE

Four types of I/O data can be transmitted and received via the network: SI, SO, SIW, and SOW.

Displays the SI monitor.

Displays the SO monitor.

Switches the monitor number.

It is possible to change the port number display by switching the monitor number.

For details on the monitor number, refer to "9.1.1 Switching the port number."

16

Page 21

9.1.1 Switching the port number

■Monitor screen

By switching the monitor number the displayed port number can be changed.

The following table shows the correspondence between monitor number and port number.

Port name Monitor number Display range Display format

SI,SO

1

2

3

00-77

100-177

200-277

: ON

: OFF

9

Monitoring communication data

SIW

SOW

* The port name is shown in

shown, DO100-DO177 is shown.

The monitor number is shown in the upper left of the screen.

Press the MONITOR key to switch the monitor number.

1

2

. For example if "DO monitor 2" (monitor number 2 of the DO port) is

0-7

8-15

Monitor number

Monitor number

4-digit hexadecimal

■Monitor Detail screen

By switching the monitor number it is possible to change the tens digit in the order of 0 → 10 → 20. The ones digit can

be changed by using the cursor keys to select [

Changing the ones digit of the port number

For details on operation, refer to "9.1.3 Input/output detail view."

] or [ ] and pressing the enter key.

17

Page 22

9.1.2 Input/output list display

"SI MONITOR 1" screen

"SI MONITOR 1 DETAIL" screen

9

Monitoring communication data

Step1

Step2

At the initial screen, select

[MONITOR] → [I/O].

The "DI Monitor 1" screen then displays.

Select the input/output monitor to

be displayed.

Pressing the F2 key (DI)--F10 key (SOW)

displays the input/output monitor

corresponding to the key.

Pressing the MONITOR key changes the port

number.

Key Input/output

F2 DI

F3 DO

F4 MO

F5 LO

F6 TO

F7 SI

F8 SO

F9 SIW

F10 SOW

Press the [ESC] key to end the monitor

display.

9.1.3 Input/output details display

Step1

Step2

Step3

* There are no displays for SIW and SOW details.

Open the Input/Output Monitor

screen.

Press the [F1] (Details) key.

The "Input/Output Details" screen then

displays.

Changing the port number.

Changing the tens digit of port number

■

Pressing the MONITOR key changes the

tens digit of the port number in the order

of 0 → 10 → 20.

Changing the ones digit of port number

■

Use the cursor key to select [

then press the [enter] key. The port

number can then be changed.

Press the [ESC] key to end the monitor

display.

] or [ ] ,

18

Page 23

9.1.4 Switching the output status

Example of the output monitor detail screen:

In the "Input/output detail view" screen, DO, MO, LO, TO, and SO output can be switched on/off by individual

bits.

CAUTION

Step1

Step2

Step3

• In order to switch the output on/off, the programming box must have control authority.

• SO00-07, SO10-17, and DO00-07 and DO10-17 cannot be changed, since they are dedicated bit outputs that

indicate the status of the controller.

Display the output port "Monitor"

screen.

Press the F3 key (DO)--F6 key (TO) or F8 key

(SO) to display the "Monitor" screen.

Display the "Detail" screen.

Press the F1 key (Detail) to display the

"Detail" screen.

"SO MONITOR1 DETAIL"

Specify the port number.

Changing the tens digit of port number

■

Pressing the MONITOR key changes the

tens digit of the port number in the order

of 0 → 10 → 20.

Changing the ones digit of port number

■

Use the cursor key to select [

then press the [enter] key. The port

number can then be changed.

] or [ ] ,

9

Monitoring communication data

Step4

Switch the output status.

Use the cursor keys to select the ON or OFF

setting for the bit number which changes

the output status, then press the [enter] key

to switch that output status.

Press the [ESC] key to end the monitor

display.

19

Page 24

9

Monitoring communication data

9.2 Using SCARA-YRCX Studio support software

From the window tree, choose [Monitor] and then double-click a port name DI through SOW to monitor. The

monitor screen appears.

The monitor screen contains a list screen and a detail screen. When starting SCARA-YRCX Studio, the monitor

screen that appears first will always be the "Detail screen."

The explanation here uses the example of SI, SO, SIW, and SOW.

Tip

Once you open a monitor screen, it is shown as a tab at the bottom of the screen. The monitor screen can be

displayed by switching tabs.

Tab display

20

Page 25

■SI monitor

Name on/off

Save name Reload name

Name on/off Shows/hides the name.

Save name Sends the name that is entered in the name entry field to the controller.

Reload name Loads the name from the controller, updating the indication of the name entry field.

Check name

I/O name entry field

* For a list of reserved words and system variables, and for usage examples of variable names, refer to "13. Reserved word

list."

Check name

Checks whether the entered I/O name conforms to the prescribed rules. For details on the

naming rules for an I/O name, see "I/O name entry field" below.

Enters the I/O name. Observe the following naming rules when entering the name.

• The maximum is 16 characters.

• Single-byte alphanumeric characters and "_" (underscore) can be used.

• Uppercase and lowercase alphabetical characters are distinguished.

• A numeral cannot be used as the first character.

• It is not possible to assign an I/O name that is identical to a reserved word, or that starts

with a system variable name.

• It is not possible to assign the same I/O name to more than one I/O.

• Since SI00-07 and SI10-17 are dedicated bit inputs, the I/O name cannot be input.

Similarly, I/O name input is not possible for DI inputs (DI00-07 and DI10-17).

I/O name entry field

If the name is hidden

Name on/off

Function

9

Monitoring communication data

■SIW monitor

Display unit

Display unit Displays port values in hexadecimal or decimal.

Function

21

Page 26

9

Monitoring communication data

■SO monitor

Name on/off

Save name Reload name

Name on/off Shows/hides the name.

Save name Sends the name that is entered in the name entry field to the controller.

Reload name Loads the name from the controller, updating the indication of the name entry field.

Check name Checks whether the entered I/O name conforms to the prescribed rules.

ON/OFF button

Name entry field

Check name

ON/OFF button

I/O name entry field

Switches the bit output on/off.

However since SO00-07 and SO10-17 are dedicated bit outputs that indicate the status of the

controller, they cannot be switched on/off. Similarly, DO output (DO00-07 and DO10-17)

cannot be switched on/off.

Enters the I/O name.

However since SO00-07 and SO10-17 are dedicated bit outputs that indicate the status of the

controller, name entry is not possible. Similarly, DO output (DO00-07 and DO10-17) does not

allow name entry.

For details on the rules for I/O names, refer to "I/O name entry field" in the preceding "n SI

monitor (Detail screen)."

If the name is hidden

Name on/off

Function

ON/OFF button

CAUTION

• In order to switch SO or DO on/off, the programming box must release control authority, and the controller must

be in auto mode.

• SO00-07, SO10-17, DO00-07, and DO10-17 are dedicated bit outputs that indicate the status of the controller,

and therefore cannot be changed.

■SOW monitor

Display unit

Function

Display unit Displays port values in hexadecimal or decimal.

Tip

The SOW2-15 output values can be updated to desired values by rewriting the numerical value in the text box

during communication with the controller.

As SOW0 and 1 are dedicated outputs, their values cannot be changed.

As SIW is an external input value, it cannot be changed to an arbitrary value.

22

Page 27

10. Disabling an option unit

If the controller is equipped with a field network option unit, it normally communicates with the host control

device and controls the robot in accordance with the communicated content, so a ladder program is required

for the host device.

When performing teaching or trial operation of the robot by itself in a state in which the host device's ladder

program has not been provided, the robot can be operated without communicating with the host device by

setting the option board to "disabled".

10

CAUTION

When shipped from the factory, all functions of the option unit are set to "enabled." In the "enabled" state, the

robot first becomes operable when an emergency stop or stop signal is input from the host control device.

For details on I/O functionality, refer to the separate "Remote I/O Manual".

Option board setting parameters

Item Values Default value

Slot 1

Option board enabled

CAUTION

The "Option board enable" parameter is set individually for option slots 1 through 4. When changing the settings

of an option board, be sure to verify the location in which the target option board is installed, and change the

setting only for the target slot number.

The illustration below shows the correspondence between the location of each option slot and the actual

installation location.

Slot 2

0 : INVALID, 1 : VALID 1 : VALID

Slot 3

Slot 4

Disabling an option unit

1 2

3 4

YRCX

23

Page 28

10.1 Making settings

An option board can be disabled either from the programming box or from SCARA-YRCX Studio support

software.

10.1.1 Using the programming box

Step1

Open the Parameter Edit screen.

At the initial screen, select [Edit], press [Enter], then select [Parameter].

10

Disabling an option unit

Step2

Press the [F6] (OPTION) key to display the Option Parameters screen.

Step3

Select the desired parameter.

Use the cursor up/down keys to select the parameter to be edited, then press the [F1] (EDIT) key.

24

Page 29

Step4

NOTE

Edit the parameter.

Change the setting for the target slot, and press the enter key.

1 2

10

3 4

Disabling an option unit

YRCX

The values of the option board enable parameter correspond to slots 1 through 4 starting from the left.

Verify the slot in which the network unit is installed, and change the value only for the target slot number.

Step5

Press the [ESC] key to end the editing operation.

The specified content is applied after the controller is restarted.

10.1.2 Using SCARA-YRCX Studio support software

Step1

In the window tree, select the board parameters.

In the window tree, select [Parameter]-[Option], and double-click [Board Enable].

* C101-C104 correspond to slots 1--4.

Verify the slot in which the network unit is installed, and change the value only for the target slot

number.

25

Page 30

Step2

Select the option slot "Value" column, and choose either "VALID" or "INVALID."

C101 through C104 in the chart correspond to option slots 1 through 4 of controller 1.

If controllers are linked to each other in a YC-Link/E network, the option slots of controller 2 and following

are shown in C201 through C204.

10

Disabling an option unit

Option slots 1 through 4 Choose "VALID" or "INVALID"

Tip

Step3

If a cell's value is changed, its background color turns red.

Click the [Save] button to save the settings.

When saving is complete, the cell color changes from red to white.

The specified content is applied after the controller is restarted.

[Save] button

26

Page 31

11. Actions to take if communication is not established

Network unit7-segment LED

If communication is not established, diagnose the situation by referring to the alarm codes or alarm messages

of the controller unit and to the network unit's LED illumination pattern, and take the appropriate actions.

11

Actions to take if communication is not established

YRCX

11.1 Reconsider the startup steps

The following steps must be taken when starting up the network system.

If communication cannot be established after the cabling and settings have been completed, it is possible that

one of the steps was not performed correctly.

■Procedure

• Connections

Determine the network configuration

Connect cables

Noise countermeasures (only if necessary)

• Settings

Settings for the host control device (PROFINET IO controller)

Use GSD file to register device information

Network parameter settings for the robot controller

(station name, IP address, etc.)

→After settings, put the system in the RUN state

Settings on the robot controller (PROFINET IO device)

No items to set

Communication is established, and cyclic communication begins

If communication is not established, check the following points.

• Connections: Do the cables meet the network specifications, and are they securely connected?

• Parameter settings: Are parameters such as station name and IP address specified from the host control device

(IO controller)?

Is the topology specified?

• GSD file: Is the correct GSD file registered on the host control device (IO controller)?

27

Page 32

11

SOE

Actions to take if communication is not established

11.2 Viewing the alarm codes in the 7-segment LED

Normal state

• The "PWR" LED on the front of the controller is lit, and the 7-segment LED shows the following.

(Servo off, return-to-origin incomplete, emergency stop cancelled)

Abnormal state

• The "PWR" LED on the front of the controller is lit, and the 7-segment LED shows an alarm code.

• Note the alarm message on the programming box, and take the actions prescribed by the troubleshooting guidelines.

(Example) Display when an alarm occurs

"E + alarm group number" and "alarm type number" are displayed alternately.

* In the example above, alarm code "17.403" is indicated.

* For details on the alarm messages and content corresponding to each alarm code, refer to "11.3 Diagnostics by alarm

message," or the troubleshooting section of the YRCX controller user's manual.

11.3 Diagnostics by alarm message

Alarm messages related to the network unit are shown below.

Alarm messages not listed in this document may be alarms resulting from the robot controller unit.

Refer to the troubleshooting section of the robot controller user's manual.

11.3.1 Alarms related to network unit connections and settings

These errors occur if communication is not established, or if communication is unstable.

12.571 : PROFINET link error

Code : &H000C &H023B

a. There is a problem in the network cable.

Meaning/Cause

Action

12.572 : PROFINET overtime error

Code : &H000C &H023C

Meaning/Cause

Action

b. The communication settings of the network system are incorrect.

c. The host control device is not powered-on, or is stopped, or has malfunctioned.

d. The network unit has malfunctioned.

1. Check whether network cables might be broken, unconnected, mis-wired, or out-of-spec

(cable length, etc.).

2. Check the communication settings.

3. Check whether the host control device is operating correctly.

4. Replace the network unit.

a. A communication problem is occurring because of noise etc. on the network system.

b. The power supply of the host control device is shut off or stopped.

1. Apply noise countermeasures to the network system cables and controller.

2. Check whether the host control device is operating normally.

3. Check the network system cable connections.

28

Page 33

11.3.2 Alarms related to I/O on/off status

These errors occur depending on the state of the dedicated input/output.

If the robot controller is equipped with a network unit, the robot cannot be operated unless an emergency stop

or STOP signal is input from the host device, even if the robot is being controlled from somewhere other than

the host control device.

For details on I/O functions, refer to "Remote I/O Manual."

12.400 : Stop input on

Code : &H000C &H0190

Meaning/Cause

Action

a. Program execution or axis movement was attempted in the stop status.

b. Robot was put in the stop status during program running or axis movement.

1. Establish communication with the host control device, and put the unit in SIO6=1 status

(cancel stop).

12.600 : Emergency stop on

Code : &H000C &H0258

a. Communication with the host control device is not established.

b. Although communication with the host control device is established, SI00 (emergency

stop input) is not on.

Meaning/Cause

Action

c. The emergency stop terminal of the SAFETY connector is open, or the connector is not

connected.

d. The emergency stop button of the programming box is pressed, or a terminator is not

connected to the PB connector.

1. Establish communication with the host control device, and set SI00=1 (cancel emergency

stop).

2. Close the emergency stop terminals on SAFETY connector.

3.

Cancel the emergency stop button of the programming box, or connect a terminator

instead.

11.3.3 Alarms that the customer cannot resolve

These are error messages that are not expected to occur in the field.

If one of these errors occurs, please contact your distributor with details of the situation.

11

Actions to take if communication is not established

12.765 : PROFINET initialize error

Code : &H000C &H02FD

Meaning/Cause

Action

Failed to initialize the network unit.

Contact your distributor with details on this problem.

12.900 : Incorrect option setting

Code : &H000C &H0384

a. The ID setting on the option module is not correct.

Meaning/Cause

Action

b. Option modules that cannot be mixed were installed.

c. Unidentified option modules were installed.

Contact your distributor with details on this problem.

12.904 : SIO option board initialize error

Code : &H000C &H0338

Meaning/Cause

Action

Failed to initialize SIO option board.

Contact your distributor with details on this problem.

29

Page 34

11.3.4 Checking alarm codes in the programming box

11

Actions to take if communication is not established

Step1

Step2

Open the Parameter Edit screen.

At the initial screen, select [Edit], press [Enter], then select [Parameter].

Check the alarm code that is occurring.

Press the F1 key (RELOAD) to update the display to the current state.

In the illustration, alarm code 10.900 is occurring.

11.3.5 Checking alarm codes in SCARA-YRCX Studio support software

Alarm codes and alarm messages are shown in the "Controller Monitor" located in the lower left of the screen.

30

Page 35

11.4 Detailed diagnostics using the indicators

Illumination patterns

Details of the situation can be obtained from the illumination pattern of the network unit indicators.

■Network unit indicators and illumination patterns

Part names

Network status LED green (single color) LED

Module status LED green/red (two-color) LED

Link/activity LED

Port 1

green (single color) LEDs

Link/activity LED

Port 2

Network status (NS) LED

LED status Explanation Comment

OFF Offline

Green Online (RUN)

Flashing green Online (STOP)

Power is off

IO controller is not connected

Connection with IO controller is not established

IO controller is in RUN state

Connection with IO controller is not established

IO controller is in STOP state

lit green

flashing green

lit red

flashing red

unlit

11

Actions to take if communication is not established

Module status (MS) LED

LED status Explanation Comment

OFF Not initialized Power is off, or module is in SETUP or "NW_INIT" state

Green Normal operation Module has transitioned from "NW_INIT" state

Flash green once Diagnostic event Diagnostic event is occurring

Flash green at 1 Hz DCP flashing An engineering tool is being used to identify a node on the network

Red Exception error Module is in the "EXCEPTION" state

Flash red once Setting error Expected ID differs from actual ID

Flash red twice IP address error IP address is not set

Flash red three times Station name error Station name is not set

Flash red four times Internal error A serious error is occurring inside the module

Link/activity LED: Port 1 / Port 2

LED status Explanation Comment

OFF No link A link is not established, and communication is not occurring

Green Link detected An Ethernet link is established, but communication is not occurring

Flashing green Activity An Ethernet link is established, and communication is occurring

31

Page 36

11.4.1 Common situations and LED illumination patterns

■Illumination patterns when connection exists

1. PROFINET IO controller in RUN state, I/O control possible

11

Actions to take if communication is not established

Network Status

Module Status

Link/Activity

■Presumed state

Connection with the host control device (IO controller) is

established, and I/O control via cyclic communication is

possible.

■Action to take

None. Settings have completed normally, and communication

has begun.

2. PROFINET IO controller in idling state, I/O control not possible

Network Status

Module Status

Link/Activity

■Presumed state

Connection with the host control device (IO controller) is

established, but cyclic communication has not begun.

■Action to take

Use the host control device to switch the control mode to

START.

■Illumination patterns when connection does not exist

3. Unset parameters

Network Status

Module Status

Link/Activity

MS flashing red twice: IP address is not set.

MS flashing red three times:

■Presumed state

Parameters such as the IP address or station name have not

been set from the IO supervisor (e.g., engineering tool for the

host control device).

Network topology has not been specified, and neighbor

detection via LLDP is not functioning.

Station name is not set.

4. LAN cable unconnected

Network Status

Module Status

Link/Activity

5. Option invalid setting

Network Status

Module Status

Link/Activity

■Action to take

From the IO supervisor, manually specify the IP address and

station name.

Make topology settings for the IO controller.

■Presumed state

The cable between the host control device and robot controller

is unconnected.

■Action to take

Check the cabling. Check the connection state of the peripheral

devices.

■Presumed state

The option board setting parameter is set to "invalid."

Alternatively, the controller power is shut off.

■Action to take

Set the option board setting parameter to "valid," and restart

the robot controller. Alternatively, check the power supply

input to the controller.

32

Page 37

12. Specifications

12.1 Network specifications

Spec. Item Contents

YRCX : V1.21 or later

Supported software versions

Network specification

conformance

Conformance class Conformance Class B / IO Device

Product revision 1.00

GSD file name GSDML-V2.3-YMC-RCX3-20150203.xml

Transmission speed 100Mbps (Auto-negotiation)

Connector specifications RJ-45 connector (8-pole modular connector) 2 ports

Conforming cable specifications CAT 5e or higher STP cable (double shield)

Max. cable length 100m

Monitor LEDs Module Status(MS), Network Status(NS), Link/Activity:Port1-2

PBEX : V1.08 or later

SCARA-YRCX Studio : V1.0.1 or later

PROFINET IO V2.2

Dedicated word input 2 words (4 bytes)

General-purpose word input 14 words (28 bytes)

Input : 48bytes

Dedicated bit input 16 bits (2 bytes)

General-purpose bit input 96 bits (12 bytes)

12

Specifications

Input/output data size

Output : 48bytes

Reserved area 2 bytes

Dedicated word output 2 words (4 bytes)

General-purpose word output 14 words (28 bytes)

Dedicated bit output 16 bits (2 bytes)

General-purpose bit output 96 bits (12 bytes)

Reserved area 2 bytes

33

Page 38

12

Specifications

12.2 Input/output specifications

Controller ⇒ Host control device Host control device ⇒ Controller

Address (WRITE) I/O function Address (READ) I/O function

SOW(0)

SOW(1) Command response area SIW(1) Command data area

SOW(2)

SOW(3) SIW(3)

SOW(4)

SOW(5) SIW(5)

SOW(6)

SOW(7) SIW(7)

SOW(8)

SOW(9) SIW(9)

SOW(10)

SOW(11) SIW(11)

SOW(12)

SOW(13) SIW(13)

SOW(14)

SOW(15) SIW(15)

SO07 - SO00

SO17 - SO10

SO27 - SO20

SO37 - SO30 SI37 - SI30

SO47 - SO40 SI47 - SI40

SO57 - SO50 SI57 - SI50

SO67 - SO60 SI67 - SI60

SO77 - SO70 SI77 - SI70

SO107 - SO100 SI107 - SI100

SO117 - SO110 SI117 - SI110

SO127 - SO120 SI127 - SI120

SO137 - SO130 SI137 - SI130

SO147 - SO140 SI147 - SI140

SO157 - SO150 SI157 - SI150

(Reserve)

(Reserve) (Reserve)

-

SOD(2)

SOD(4)

SOD(6)

SOD(8)

SOD(10)

SOD(12)

SOD(14)

SO00

SO01 CPU_OK status output SI01 Servo on input

SO02 Servo on status output SI02

SO03 Alarm status output SI03

SO04 MPRDY status output SI04

SO05

SO06 SI06 Stop input

SO07 SI07 Reserved area (do not use)

SO10 Auto mode status output

SO11

SO12

SO13

SO14 Program reset status output SI14

SO15 Warning output SI15 Program reset input

SO16

SO17 SI17

Command status area SIW(0)

SIW(2)

SIW(4)

SIW(6)

Command response area /

General-purpose output area

Emergency stop status

output

Reserved area (do not use)

Return-to-origin complete

status output

Sequence program execution

status output

Robot program operating

output

Reserved area (do not use)

General-purpose output area

Reserved area (do not use)

SIW(8)

SIW(10)

SIW(12)

SIW(14)

SI07 - SI00

SI17 - SI10

SI27 - SI20

(Reserve)

-

SID(2)

SID(4)

SID(6)

SID(8)

SID(10)

SID(12)

SID(14)

SI00 Emergency stop input

SI05

SI10 Sequence control input

SI11 Reserved area (do not use)

SI12 Automatic operation start

SI13 Reserved area (do not use)

SI16 Alarm reset input

Remote command area

Command data area /

General-purpose input area

Reserved area (do not use)

Return-to-origin input

(incremental type axis)

Return-to-origin input

(absolute type axis)

General-purpose input area

Reserved area (do not use)

For details on each I/O function, refer to the separate "Remote I/O Manual".

34

Page 39

13. Reserved word list

Because the following names are reserved for the robot language, they cannot be used as I/O names.

A

ABS

ABSADJ

ABSRPOS

ACC

ACCEL

ACCESS

ACO

ALL

ALM

ALMRST

AND

ARCHP1

ARCHP2

ARM

ARMCND

ARMSEL

ARMTYP

ARP

ARY

ASPEED

ATN

ATN2

ATTR

AXWGHT

B

BIN

BREAK

C

CALL

CASE

CFG

CHANGE

CHGPRI

CHR

CLOSE

CMU

CNT

CONT

COPY

COS

CURTQST

CURTRQ

CUT

D

DATE

DBP

DEC

DECEL

DEF

DEGRAD

DELAY

DI

DIM

DIR

DIST

DO

DPM

DRIVE

DRIVEI

DRV

DS

DSPEED

E

ELSE

ELSEIF

EMG

END

ENDIF

EOF

EQV

ERA

ERL

ERR

ERROR

ETH

ETHSTS

EXIT

EXITTASK

F

FN

FOR

FREE

G

GEP

GEPSTS

GO

GOSUB

GOTO

H

HALT

HALTALL

HAND

HEX

HND

HOLD

HOLDALL

I

IDIST

IF

IMP

INCH

INCHT

INCHXY

INIT

INPUT

INT

ION

J

JL

JOG

JOGT

JOGXY

JTOXY

L

LEFT

LEFTY

LEN

LET

LINEMODE

LOAD

LOC1

LOC2

LOC3

LOC4

LOC5

LOC6

LOCF

LOG

LSHIFT

M

MAINPG

MCHREF

MEM

MID

MNS

MOD

MODE

MOTOR

MOVE

MOVEI

MOVET

MRF

MRKSET

MSG

MSGCLR

MSPEED

N

NAME

NEXT

NOT

O

OFF

OFFLINE

ON

ONLINE

OPEN

OPT

OR

ORD

ORGORD

ORGRTN

ORIGIN

OUT

OUTPOS

P

P

PATH

PC

PCM

PDEF

PGM

PGMTSK

PGN

PLS

PLT

PMOVE

PNM

PNT

PPNT

PRINT

PRM

PSHFRC

PSHJGSP

PSHMTD

PSHRSLT

PSHSPD

PSHTIME

PUSH

PWR

R

RADDEG

RBT

READ

REF

REM

13

Reserved word list

35

Page 40

13

REN

RESET

RESTART

RESUME

RETURN

RIGHT

RIGHTY

RSHIFT

RUN

RUNTO

S

S

SCK

SELECT

SEND

SEQCMPL

SEQUENCE

SERVO

SET

SETGEP

SETPW

SFT

SGI

SGR

SHARED

SHIFT

SI

SID

SIN

SIW

SKIP

SKIPTO

SO

SOD

SOW

SPEED

SQR

START

STEP

STOP

STOPON

STR

SUB

SUSPEND

SWI

SYNCHK

T

TAG

TAN

TASKS

TCHXY

TCOUNTER

TEACH

THEN

TIM

TIME

TIMER

TO

TOLE

TORQUE

TSKECD

TSKMON

TSKPGM

V

VAL

VAR

VEL

VER

W

WAIT

WEIGHT

WEND

WHERE

WHILE

WHRXY

WHRXYEX

WRITE

X

XOR

XY

XYTOJ

Y

YZ

Z

ZX

Reserved word list

■List of system variables

Because the following names are used as system variable names, they cannot be used at the beginning of other

variable names (n: numeric value).

A

Acn

D

DIn

DINMn Hn PNn TOn

DOn

DONMn LOn SIn

F M

FN MOn Sn

G P

GPn PCn SONMn

H

L S

Pn

SINMn

Son

T

■Variable name usage examples

• Although keywords which are reserved as robot language words cannot be used as they are, they can be used as

variable names if alphanumeric characters are added to them.

Example: "ABS" cannot be used, but "ABS1" or "ABSX" can be used.

• Keywords reserved as system variables cannot be used at the beginning of other variable names, even if alphanumeric

characters are added to them.

36

Example: "FN" cannot be used. "FNA" and "FN123" also cannot be used.

Page 41

Page 42

Revision history

A manual revision code appears as a suffix to the catalog number on the front cover manual.

Cat. No. I247E-EN-01

Revision code

The following table outlines the changes made to the manual during each revision.

Revision code

01 July 2016 Original production

Date Description

Page 43

Page 44

&DW1R,((1

$XWKRUL]HG'LVWULEXWRU

3ULQWHGLQ(XURSH

Loading...

Loading...