Omron R88A-MCW151 DATASHEET

R88A-MCW151-@

PORT0

,1

RUN

STS

I/O/O

+

24V

0V

25

1

26

2

000000

RD SD

MCW151

PORT2

PORT0

,1

RUN

STS

I/O/O

+

24V

0V

25

1

26

2

000000

RD SD

MCW151

PORT2

1.5 axis motion controller

Advanced motion made perfectly intuitive

• Connects directly to the Sigma-II series drive

• Controls 1 real axis, 1 virtual axis and a configurable

third axis

• Provides an additional encoder input/output to the

servo drive

• Simple to develop and modify using BASIC

• Built-in local I/O for easy operation

• Provides two additional hardware registration inputs

to the drive

• Electronic CAM profiles and axes synchronization

• Multi-tasking functionality

• Friendly and powerful Windows-based software

• Network connectivity via HostLink or DeviceNet

• Supports HMI connection without the need of a PLC

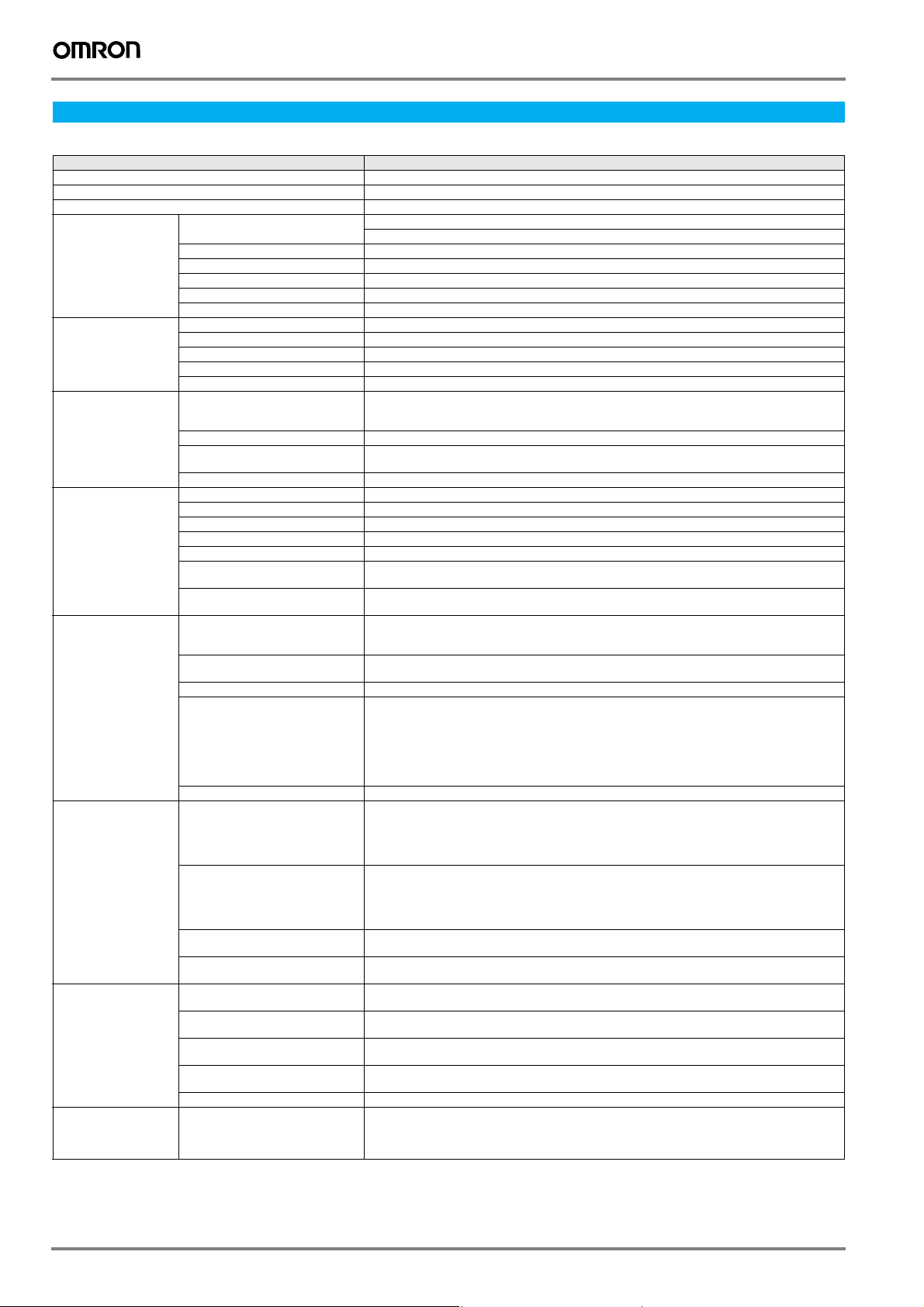

System configuration

Sigma-II series

Servo Drive

Input

Limit switches

contact sensors

Cable connection

SERVOPACK

Sigma-II

SGDH-

200V

Ver.

series

CHARGE POWER

Servo Drive

CN3

CN1

(CN10)

CN2

R88A-MCW151_

Motion controller unit

SERVOPACK

SGDH-

200V

Ver.

CHARGE POWER

CN3

CN1

CN2

Sigma-II series

Servo Motor

25

000000

,1

26

24V

0V

Rotary

cutter

Fast

registration

input

External

encoder

R88A-MCW151

,1

Motion controller unit

(Port 2) HostLink or DeviceNet network

(I/O) External I/O

25

26

(Port 0) Computer connecting cable

24V

0V

000000

- Host link network

- DeviceNet network

- PROFIBUS-DP network

NS/NT terminals

931.5 axis motion controller

Specifications

General specifications

Item Details

Type R88A-MCW151-E, R88A-MCW151-DRT-E

Applicable servo drive SGDH-@@@E models (software version 14 or later)

Installation method Mounted on the SGDH servo drive side: CN10.

Basic

specifications

Environment Operating temperature 0 … +55 °C

Functional specifications Number of axes - 1 controlled servo drive axis

Programming Programming language BASIC

Motion control Speed control Inferred closed loop with PID, output speed and speed feed forward gains

Servo drive access Motion control Speed control

External I/O Encoder input Line receiver input; maximum response frequency: 1500 kHz pulses (before multiplication)

Serial communications RS-232C Port 0: Connection to PC (motion perfect software)

Power supply method 24 VDC (supplied from external power supply)

Power consumption 4.0 W

External dimensions 20x142x128 mm (HxWxD)

Approx. mass 200 g

Current consumption 170 mA for 24 VDC

Output power supply 5 VDC, maximum 160 mA (to external encoder)

Storage temperature -20 … +75 °C

Operating and storage humidity 90% RH max. (no condensation)

Vibration resistance 0.5 G (4.9 m/s

Shock resistance 2 G (19.6 m/s

Servo loop cycle Selectable to 0.5 ms or 1.0 ms.

Registration inputs 2x MCW151 unit for encoder input axis

Measurement units User definable

Number of tasks Up to 3 tasks running simultaneously plus the command line task

Max. number of programs 14

Available memory for user programs 128 KB

Data storage capacity 251 (VR) + 8000 (table)

Saving program data,

motion controller

Saving program data,

personal computer

Torque control Torque reference (open loop)

Control switch Speed / torque control switching during operation

Positioning operations Linear interpolation

Acceleration/deceleration curves Trapezoidal or S-curve

Monitoring Driver alarm and warning status

General control Driver alarm reset

Parameter access Read and write Pn parameters

Encoder output Line receive output; maximum frequency: 500 kHz pulses

Digital inputs Total of 8 digital inputs can be wired and used for instance for limit switches, emergency stop and

Digital outputs Total of 6 digital outputs can be wired and used for position dependent switching or other general

Registration inputs Two registration inputs can be used (simultaneously) to capture the position in hardware.

5 VDC (supplied from the servo drive control power supply)

2

)

2

)

- 1 master axis, encoder output axis or virtual axis

- 1 virtual axis

1x Sigma-II servo drive axis

Random access memory (RAM) and flash memory backup.

Motion perfect software manages a backup on the hard disk of the personal computer.

Speed reference (open loop)

Possible torque limit operation

Possible speed limit operation

Circular interpolation

CAM profile movement

Electronic gearbox link

Linked CAM profile movement

Linked move for any two axes

Adding axes

Torque control

Position feedback

Driver enable

Driver print registration

General driver status

Driver digital input

Driver analogue input

Driver limit switches

Driver reset

Read Un parameters

Pulse multiplication: x4

Internal counts to output pulse ratio: 64:1

proximity inputs. Two inputs can be used for registration of the encoder input/output axis.

purposes.

Port 1: Host link master protocol

Host link slave protocol

General-purpose

94 Motion controllers

Loading...

Loading...