Omron R7D-ZP, R7M-Z ok

USER´S MANUAL

SMARTSTEP Junior

Servomotors/Servo Drivers

MODELS R7M-Z

@@

(Servomotors)

R7D-ZP

@@

(Servo Drivers)

Cat. No. I553-E1-01

Thank you for choosing this SMARTSTEP Junior product.

This manual provides information on installation, wiring, and switch setting for the SMARTSTEP Junior

Servomotors and Servo Drivers. For information about troubleshooting, refer to the S MARTSTEP Junior

User’s Manual (Cat. No. I553).

Intended Audiences

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

NOTICE

This manual contains information necessary for the operation of the SMARTSTEP Junior

Servomotors and Servo Drivers. Please read this manual thoroughly and understand its

contents before attempting to operate the product. Please keep this manual handy for

future reference after reading it.

Be sure that this manual accompanies the product to its final user.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to th e use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparati on of this manual. Nevertheless, OM RON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

2

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

3

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

•

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

4

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

5

General Warnings

To ensure safe and proper use of SMARTSTEP Junior Servomotors and Servo Drivers, read the general

warnings provided below along with the rest of this manual to gain sufficient knowledge of the devices, safety

information, and precautions before actual use.

This OPERATION MANUAL is to be delivered to the actual end users of the products.

Please keep this manual close at hand for future reference.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

6

General Warnings

• This manual may include illustrations of the product with protective covers or shields removed in order

to describe the components of the product in detail. Make sure that these protective covers and shields

are on the product before use.

• Consult your OMRON representative when using the product after a long period of storage.

WARNING

Always connect the frame ground terminals of the Servo Driver and the Servomotor to a

class-3 ground (to 100 Ω or less). Not connecting to a class-3 ground may result in electric

shock.

Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

Do not remove the front cover, terminal covers, cables, or optional items while the power is

being supplied. Doing so may result in electric shock.

Installation, operation, maintenance, or inspection must be performed by authorized

personnel. Not doing so may result in electric shock or injury.

Wiring or inspection must not be performed for at least five minutes after turning OFF the

power supply. Doing so may result in electric shock.

Do not damage, press, or put excessive stress or heavy objects on the cables.

Doing so may result in electric shock.

Do not touch the rotating parts of the Servomotor in operation. Doing so may result in injury.

Do not modify the product. Doing so may result in injury or damage to the product.

Provide a stopping mechanism on the machine to ensure safety. The holding brake is not

designed as a stopping mechanism for safety purposes.

Provide an external emergency stopping mechanism that can stop operation and shutting

off the power supply immediately. Not doing so may result in injury.

Do not come close to the machine immediately after resetting momentary power

interruption to avoid an unexpected restart. (Take appropriate measures to secure safety

against an unexpected restart.) Doing so may result in injury.

7

General Warnings

CAUTION

Use the Servomotors and Servo Drivers in a specified combination. Using them incorrectly

may result in fire or damage to the products.

Do not store or install the product in the following places. Doing so may result in fire, electric

shock, or damage to the product

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

Do not touch the Servo Driver radiator, Servo Driver regeneration resistor, or Servomotor

while the power is being supplied or soon after the power is turned OFF.

Doing so may result in a skin burn due to the hot surface.

Storage and Transportation Precau tions

CAUTION

Do not hold the product by the cables or motor shaft while transporting it. Doing so may result

in injury or malfunction.

Do not place any load exceeding the figure indicated on the product. Doing so may result in

injury or malfunction.

8

General Warnings

Installation and Wiring Precautions

CAUTION

Do not step on or place a heavy object on the product. Doing so may result in injury.

Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product.

Doing so may result in fire.

Be sure to install the product in the correct direction. Not doing so may result in malfunction.

Provide the specified clearances between the Servo Driver and the control panel or with other

devices. Not doing so may result in fire or malfunction.

Do not apply any strong impact. Doing so may result in malfunction.

Be sure to wire correctly and securely. Not doing so may result in motor runaway, injury, or

malfunction.

Be sure that all the mounting screws, terminal screws, and cable connector screws are

tightened to the torque specified in the relevant manuals. Incorrect tightening torque may

result in malfunction.

Use crimp terminals for wiring. Do not connect bare stranded wires directly to terminals.

Connection of bare stranded wires may result in burning.

Always use the power supply voltage specified in the User’s Manual. An incorrect voltage may

result in malfunction or burning.

Take appropriate measures to ensure that the specified power with the rated voltage and

frequency is supplied. Be particularly careful in places where the power supply is unstable. An

incorrect power supply may result in malfunction.

Install external breakers and take other safety measures against short-circuiting in external

wiring. Insufficient safety measures against short-circuiting may result in burning.

Take appropriate and sufficient countermeasures when installing systems in the following

locations. Failure to do so may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

9

General Warnings

Operation and Adjustment Precautions

CAUTION

Confirm that no adverse effects will occur in the system before performing the test operation.

Not doing so may result in equipment damage.

Check the newly set parameters and switches for proper execution before actually running

them. Not doing so may result in equipment damage.

Do not make any extreme adjustments or setting changes. Doing so may result in unstable

operation and injury.

Separate the Servomotor from the machine, check for proper operation, and then connect to

the machine. Not doing so may cause injury.

When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then

resume operation. Not doing so may result in injury.

Do not use the built-in brake of the Servomotor for ordinary braking. Doing so may result in

malfunction.

Do not operate the Servomotor connected to a load that exceeds the applicable load moment

of inertia. Doing so may result in malfunction.

Maintenance and Inspection Precautio ns

CAUTION

Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may result

in malfunction, fire, or electric shock.

Resume operation only after transferring to the new Unit the contents of the data required

for operation. Not doing so may result in an unexpected operation.

10

General Warnings

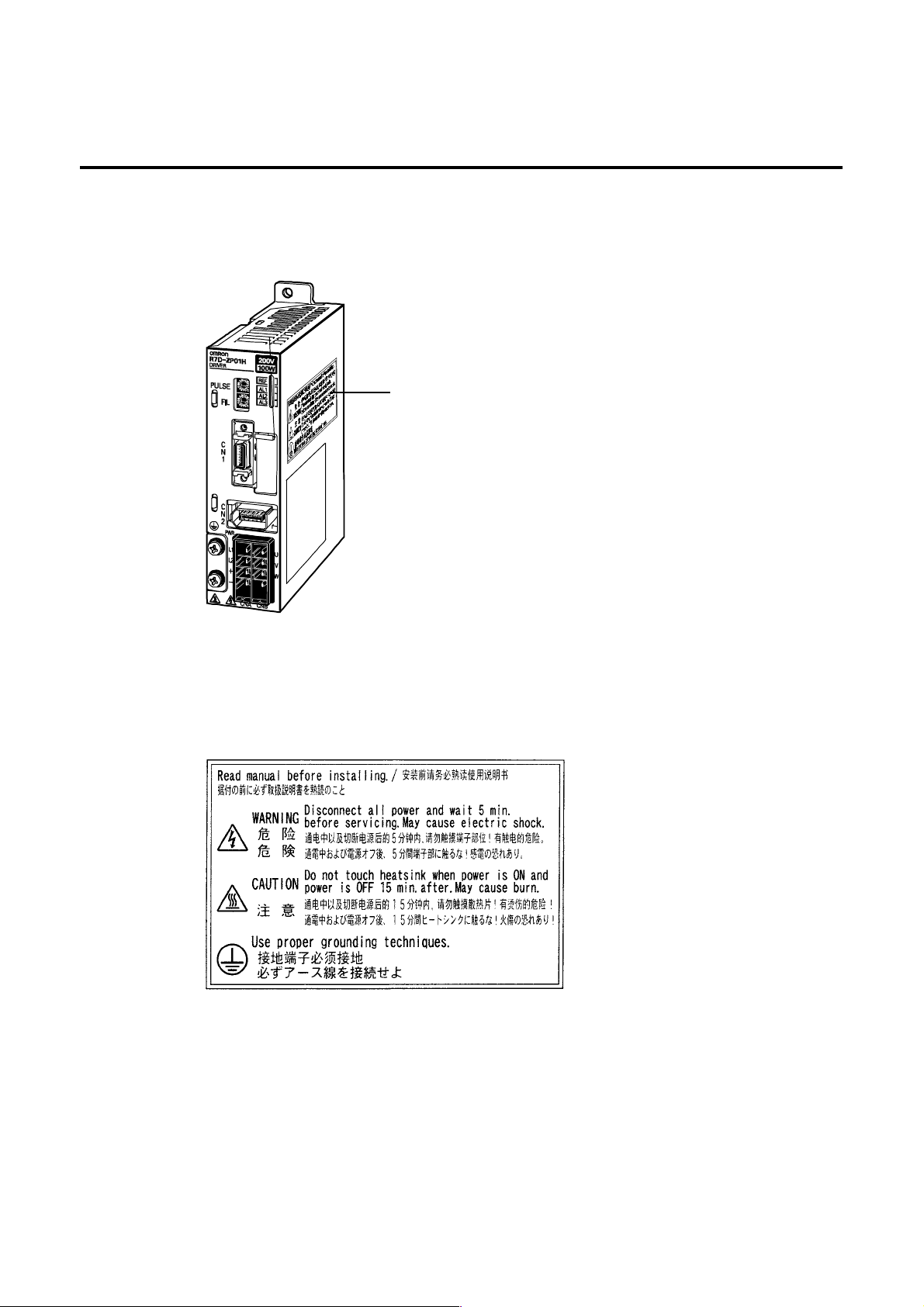

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

Warning label

Example from R7D-ZP01H

Warning Label Contents

11

Items to Check When Unpacking

Check the following items after removing the product from the package.

Item Method

Has the correct product been delivered? Check the model number on the namepl ate on the side of

the product.

Has the product been damaged in

shipping?

Inspect the outside of the product and carefully check that

there has been no damage during shi pping.

• Accessories

1. Special screw driver for setting the rotary switch × 1

2. Safety Precautions document × 1

No connectors or mounting screws are provided. Obtain these separately.

If something is missing, the Servo Driver is damaged, or some other fault exists, please

contact the point of purchase or your OMRON representative.

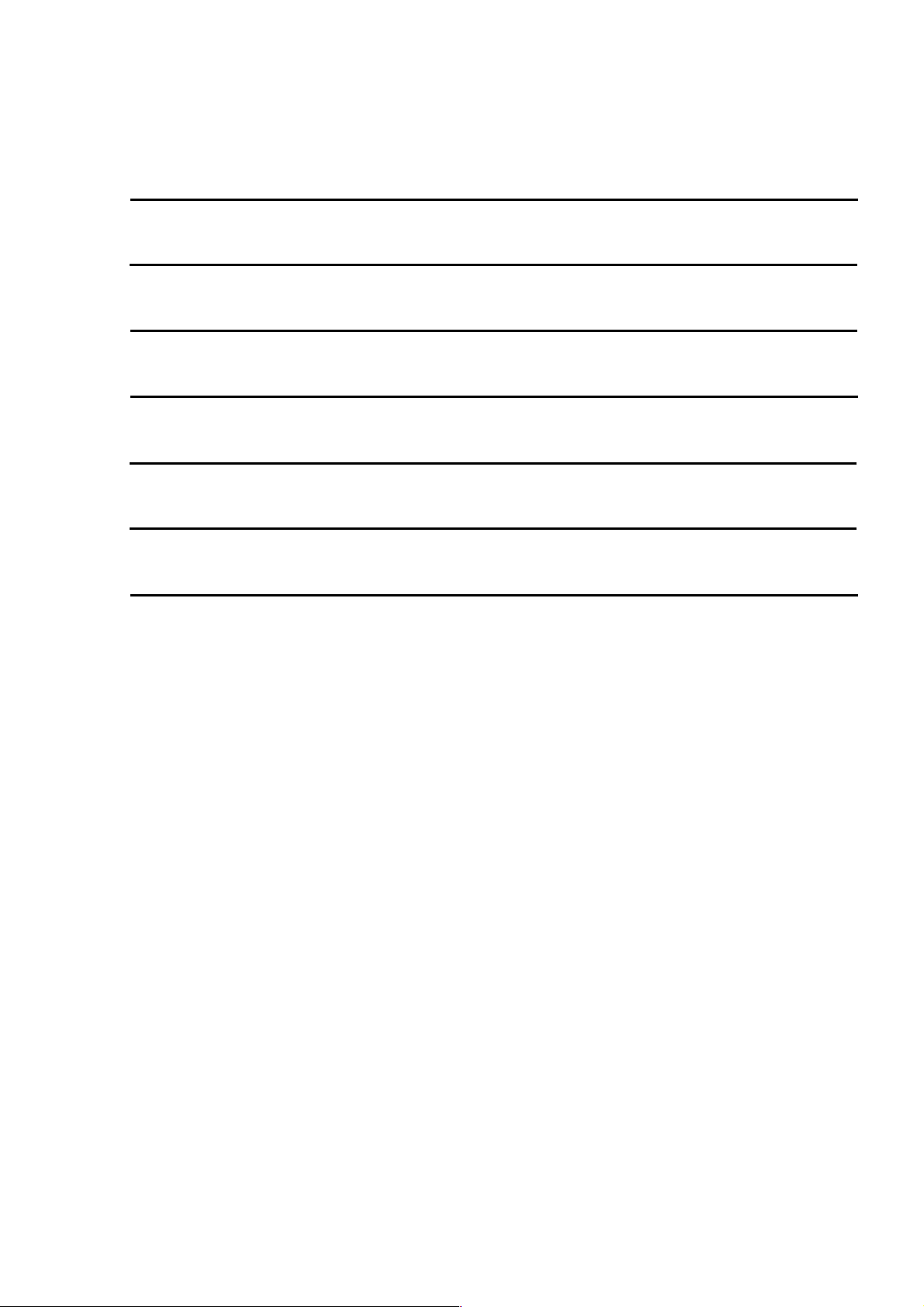

• Interpreting the Model Number

The model number provides information such as the Servo Driver type, the applicable

Servomotor capacity, and the power supply voltage.

R7D-ZP01H

SMARTSTEP Junior

Servo Driver

Driver Type

P: Pulse string input

Applicable Servomotor Capacit y

01: 100 W

02: 200 W

04: 400 W

08: 750 W

Power Supply Voltage

H: 200 VAC

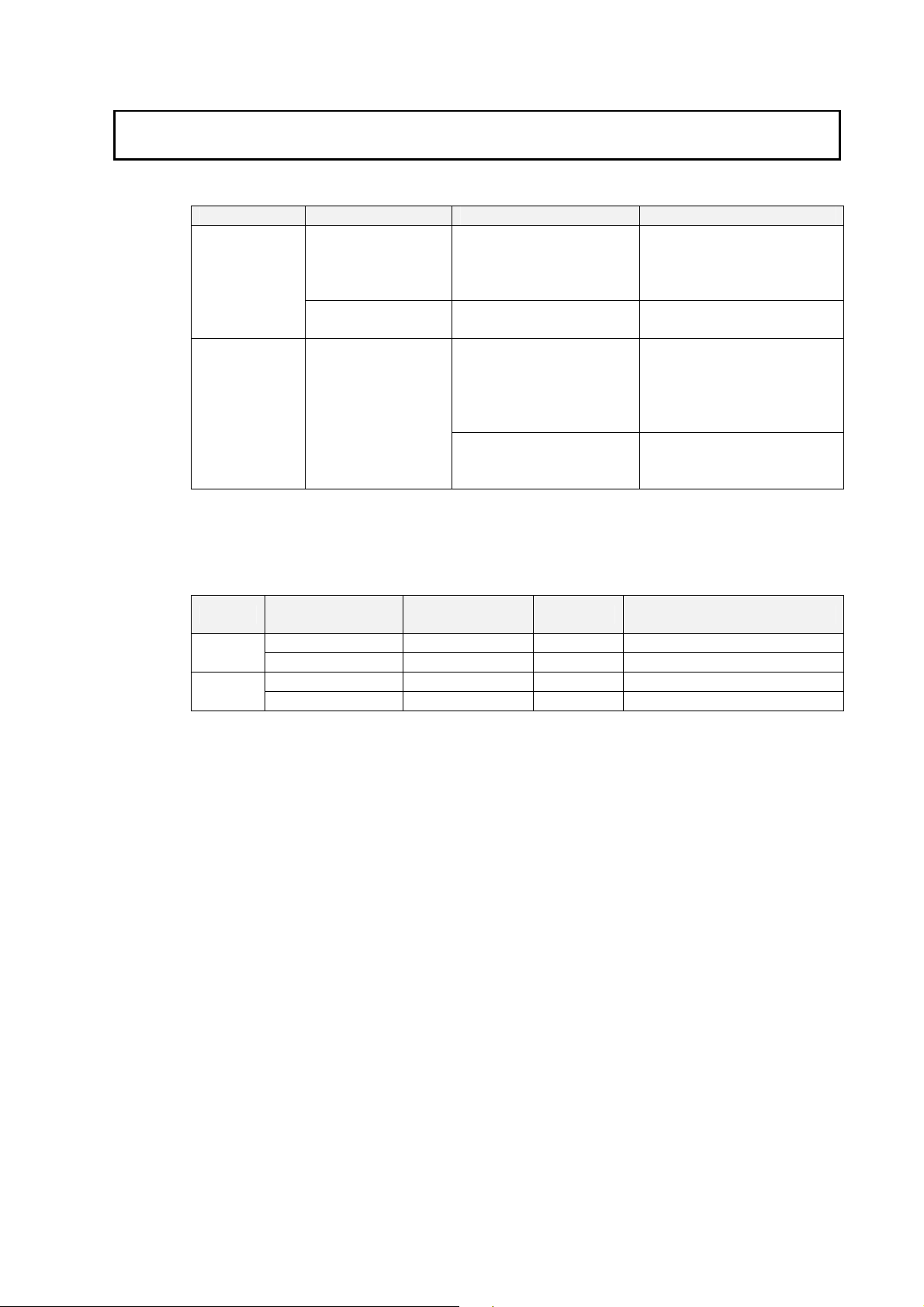

• Servo Driver and Servomotor Combinations

Servomotor Servo Driver

Rated

output

Without brake With brake Pulse string input

100 W R7M-Z10030-S1 R7M-Z10030-B S1 R7D-ZP01H

200 W R7M-Z20030-S1 R7M-Z20030-B S1 R7D-ZP02H

400 W R7M-Z40030-S1 R7M-Z40030-B S1 R7D-ZP04H

750 W R7M-Z75030-S1 R7M-Z75030-B S1 R7D-ZP08H

12

13

Section 1 Features and System Configuration

Section 2 Standard Models and Dimensions

Section 3 Specifications

Section 4 System Design

Section 5 Operation

Section 6 Troubleshooting

Appendix

Contents

Read and Understand this Manual.................................................................................3

Warranty and Limitations of Liability...............................................................................3

Application Considerations.............................................................................................4

Disclaimers....................................................................................................................5

General Warnings..........................................................................................................6

Items to Check When Unpacking................................................................................. 12

Contents ..................................................................................................................... 14

Section 1 Features and System Configuration

1-1 Introduction....................................................................................................1-2

1-1-1 Introduction ................................................................................................................... 1-2

1-1-2 SMARTSTEP Junior Features...................................................................................... 1-2

1-2 System Configuration.....................................................................................1-3

1-3 Nomenclature and Functions.........................................................................1-4

1-3-1 Servo Driver Nomenclature and Functions................................................................... 1-4

1-4 System Block Diagrams.................................................................................1-6

1-4-1 Pulse-train Input Servo Driver....................................................................................... 1-6

1-5 Applicable Standards.....................................................................................1-7

1-5-1 EC Directives ................................................................................................................ 1-7

1-5-2 UL and cUL Standards ................................................................................................. 1-7

Section 2 Standard Models and Dimensions

2-1 Standard Models ............................................................................................2-2

2-1-1 Servo Drivers................................................................................................................ 2-2

2-1-2 Servomotors.................................................................................................................. 2-2

2-1-3 Servo Driver-Servomotor Combinations....................................................................... 2-2

2-1-4 Decelerators (Straight Shaft with Key).......................................................................... 2-3

2-1-5 Accessories and Cables ............................................................................................... 2-4

2-2 External and Mounted Dimensions ................................................................2-5

2-2-1 Servo Drivers................................................................................................................ 2-5

2-2-2 Servomotors.................................................................................................................. 2-7

2-2-3 Decelerator Dimensions ............................................................................................... 2-9

Section 3 Specifications

3-1 Servo Driver Specifications............................................................................3-2

3-1-1 General Specifications.................................................................................................. 3-2

3-1-2 Characteristics .............................................................................................................. 3-3

3-1-3 Main Circuit and Servomotor Connector Specifications (CNA and CNB) .................... 3-3

14

3-1-4 Control I/O Specifications (CN1)................................................................................... 3-5

3-1-5 Control Input Circuits .................................................................................................... 3-7

3-1-6 Control Input Details ..................................................................................................... 3-8

3-1-7 Control Output Circuits ...............................................................................................3-10

3-1-8 Control Output Details ................................................................................................ 3-10

3-1-9 Encoder Connector Specifications (CN2)...................................................................3-11

3-2 Servomotor Specifications...........................................................................3-13

3-2-1 General Specifications................................................................................................ 3-13

3-2-2 Characteristics ............................................................................................................ 3-14

3-2-3 Encoder Specifications ............................................................................................... 3-16

3-3 Decelerator Specifications...........................................................................3-17

3-3-1 Standard Models and Specifications .......................................................................... 3-17

3-4 Cable and Connector Specifications............................................................3-18

3-4-1 Control Cable Specifications....................................................................................... 3-18

3-4-2 Servomotor Power Cable Specifications .................................................................... 3-19

3-4-3 Encoder Cable Specifications..................................................................................... 3-21

3-4-4

Connector Specifications............................................................................................ 3-22

3-5 Regeneration Resistance Unit......................................................................3-24

3-5-1 Regeneration Resistance Unit (R88A-RG08UA) Specifications ................................ 3-24

3-6 AC Reactors................................................................................................3-26

3-6-1 AC Reactor Specifications..........................................................................................3-26

Section 4 System Design

4-1 Installation Conditions....................................................................................4-2

4-1-1 Servo Drivers................................................................................................................ 4-2

4-1-2 Servomotors.................................................................................................................. 4-3

4-1-3 Decelerators.................................................................................................................. 4-5

4-2 Wiring ............................................................................................................4-6

4-2-1 Connecting Cables........................................................................................................ 4-6

4-2-2 Selecting Connecting Cables........................................................................................ 4-7

4-2-3 Peripheral Device Connection Examples ..................................................................... 4-8

4-2-4 Wiring the Main Circuit and Servomotor Connections.................................................. 4-9

4-2-5 Conforming to EMC Directives ................................................................................... 4-11

4-3 Regenerative Energy Absorption .................................................................4-21

4-3-1 Calculating the Regenerati ve Ener g y ......................................................................... 4-21

4-3-2 Servo Driver Regenerative Energy Absorption Capacity............................................ 4-23

4-3-3 Absorbing Regenerati ve Ener g y with an External Res is tor........................................ 4-23

Section 5 Operation

5-1 Operational Procedure...................................................................................5-2

5-1-1 Operational Procedure.................................................................................................. 5-2

5-2 Switch Settings..............................................................................................5-3

5-2-1 Switch Names...............................................................................................................5-3

15

5-2-2 Switch Functions........................................................................................................... 5-3

5-3 Preparing for Operation..................................................................................5-5

5-3-1 Turning ON the Power and Checking Indicators .......................................................... 5-5

5-4 Trial Operation...............................................................................................5-7

5-4-1 Preparing for Trial Operation ........................................................................................ 5-7

5-4-2 Trial Operation .............................................................................................................. 5-7

5-5 Operating Functions.......................................................................................5-9

5-5-1 Brake Interlock..............................................................................................................5-9

Section 6 Troubleshooting

6-1 Error Processing............................................................................................6-2

6-1-1 Preliminary Checks when a Problem Occurs ............................................................... 6-2

6-1-2 Precautions When Troubleshooting.............................................................................. 6-3

6-1-3 Replacing the Servomotor and Servo Driver................................................................6-3

6-2 Alarm Table...................................................................................................6-4

6-2-1 Alarm Table................................................................................................................... 6-4

6-3 Troubleshooting.............................................................................................6-5

6-3-1 Error Diagnosis using the Alarm Indicators .................................................................. 6-5

6-3-2 Error Diagnosis using the Operating Stat us ................................................................. 6-8

6-4 Overload Characteristics (Electronic Thermal Function)...............................6-11

6-4-1 Overload Character istics Graphs................................................................................ 6-11

6-5 Periodic Maintenance ..................................................................................6-12

6-5-1 Servomotor Maintenance............................................................................................ 6-12

6-5-2 Servo Driver Maintenance .......................................................................................... 6-13

6-5-3 Replacing the Cooling Fan ......................................................................................... 6-13

Appendix

A-1 Connection Examples....................................................................................A-2

Revision History......................................................................................................... R-1

16

Section 1

Configuration

Features and System

1-1 Introduction

1-1-1 Introduction

1-1 Introduction

1-1-1 Introduction

The SMARTSTEP Junior is a Servo Driver with a pulse-string input for position control.

The SMARTSTEP Junior is easy to set up and start because it does not require the

complex parameter settings and Servo adjustments normally associated with Servos.

The SMARTSTEP Junior Servomotor and Servo Driver are easy-to-use, yet provide the

responsiveness, high-speed, high-torque, and precision of traditional Servo systems.

This manual describes the SMARTSTEP Junior as a pulse-string input Servo Driver for

position control.

1-1-2 SMARTSTEP Junior Features

The SMARTSTEP Junior has the following features.

No Setup Parameters

No parameter settings are required for setup, so you can start using the Servo Driver

immediately simply by removing it from the box and wiring it. If it is necessary to set the

positioning resolution or reference pulse method, these settings can be set or changed

easily with the rotary switches on the front of the Servo Driver.

No Servo Adjustments Required

With the newest auto-tuning function, it isn’t necessary to adjust the Servo Driver to

achieve excellent responsiveness. Auto-tuning achieves excellent responsiveness while

providing compatibility with a range of stepping motors. A Servomotor with moderate

inertia is used to improve control system stability.

1-2

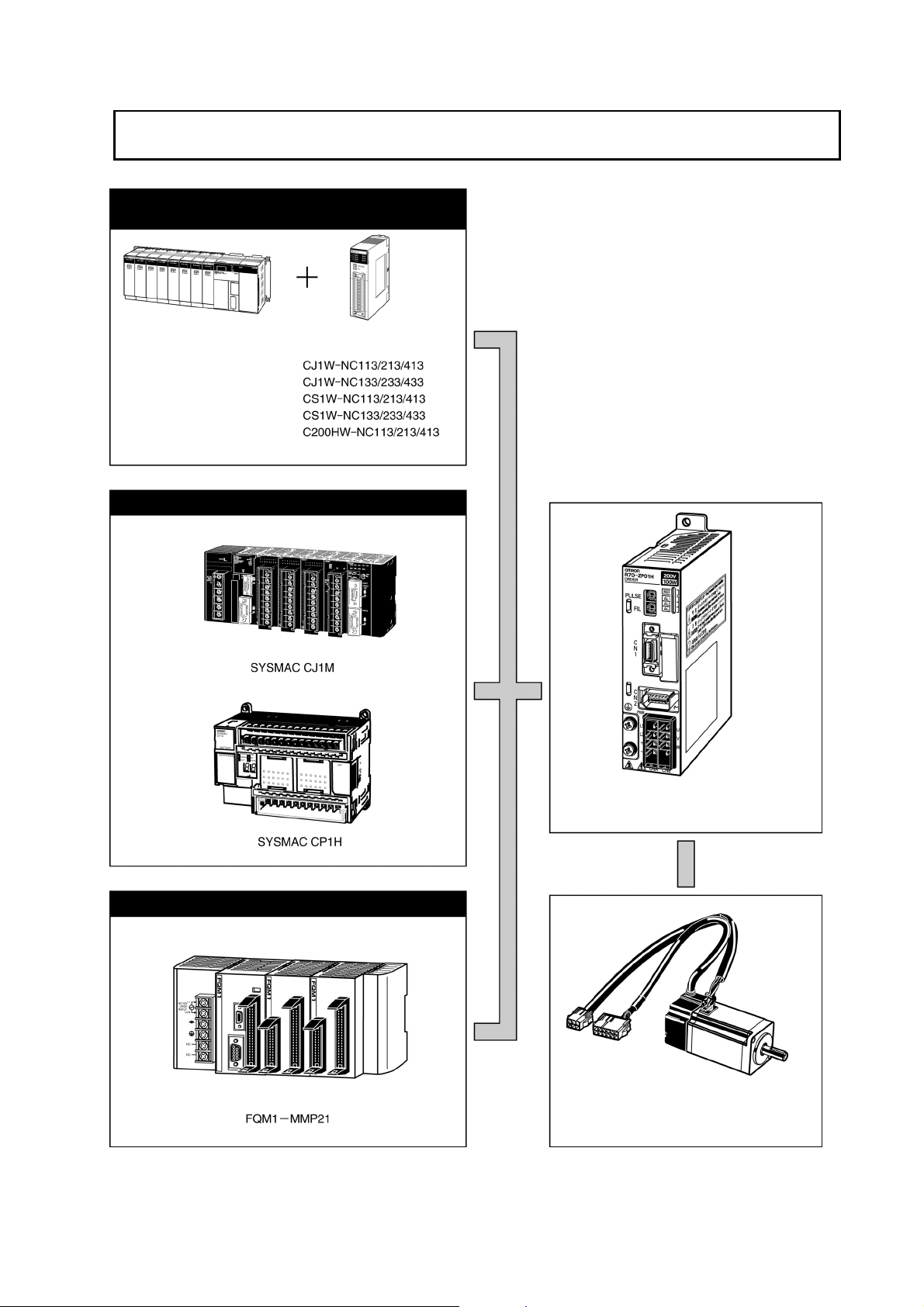

1-2 System Configuration

1-2 System Configuration

SYSMAC PLC + Position Control Unit

with pulse-string output

SYSMAC PLC with pulse output functions

Flexible Motion Controller with pulse I/O

SYSMAC

CJ1/CS1/C-series

Programmable Controlle r

SMARTSTEP Junior Servo Driver

R7D-ZP

@

SMARTSTEP Junior Servomotor

R7M-Z

@

Pulse string

Position Control Unit

1-3

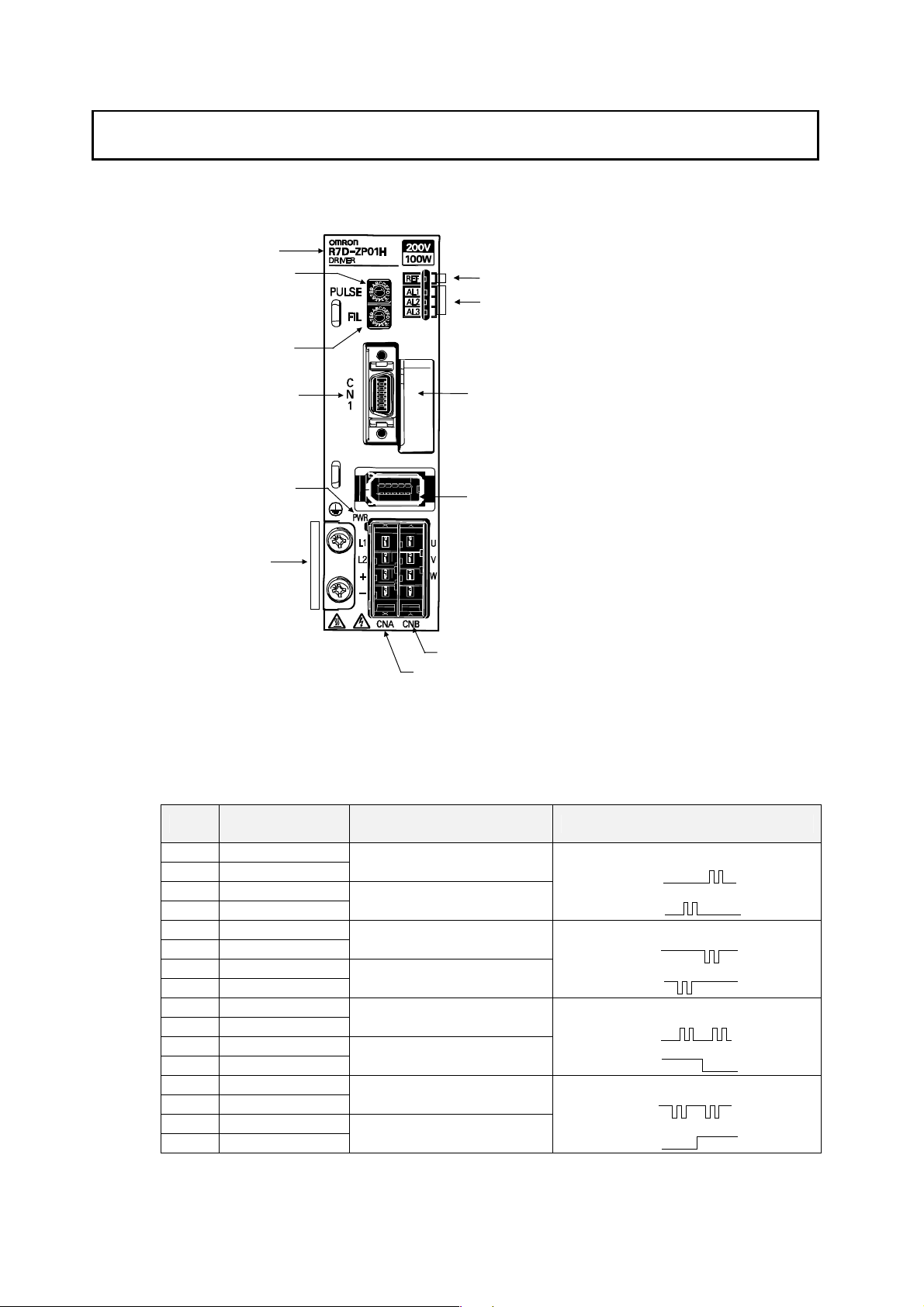

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

Model

Rotary switch for settin g

command pulse (PULSE) Command indicators (REF)

Alarm indicators (AL1 to AL3)

Note: Do not remove the protective cov ers f or

these connectors.

These connectors are for manufacturer

adjustments.

Do not use these connectors.

The Servo Driver may malfunction if

these connectors are used.

Encoder input connector (CN2)

Moto

r

connector (CNB)

Main circuit connector (CNA)

FG terminals fo

r

power supply and

servomotor power

Power supply indicato

r

(PWR)

Rotary switch for settin g

command filter (FIL)

Control I/O

connector (CN1)

Rotary Switch for Setting Command Pulse (PULSE)

Always turn OFF the power supply before setting the rotary switch. (The switch is

factory-set to 0.)

Setting

Command pulse

resolution

Command pulse connection

method

Command pulse type

0 1000

1 2500

Open collector or line driver

2 5000

3 10000

Line driver

CW+CCW, positive logic

CW

CCW

4 1000

5 2500

Open collector or line driver

6 5000

7 10000

Line driver

CW+CCW, negative logic

CW

CCW

8 1000

9 2500

Open collector or line driver

A 5000

B 10000

Line driver

Sign + pulse string, positive

logic

PULS

SIGN

C 1000

D 2500

Open collector or line driver

E 5000

F 10000

Line driver

Sign + pulse string, negative

logic

PULS

SIGN

1-4

1-3 Nomenclature and Functions

1-3-1 Servo Driver Nomenclature and Functions

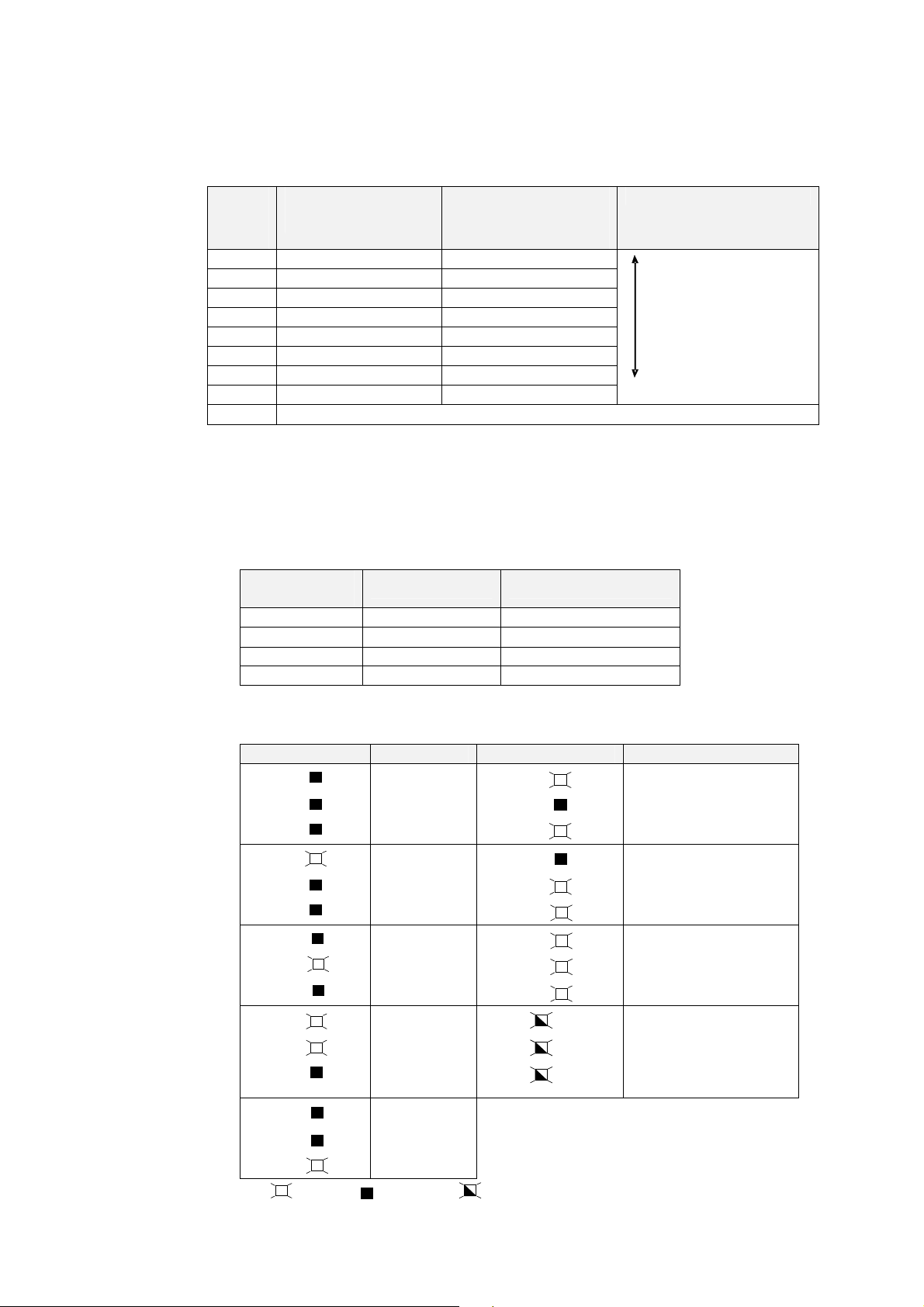

Rotary Switch for Setting Command Filter (FIL)

This switch does not need to be set if the machine is not subject to vibration. (The switch

is factory-set to 0.)

Filter

setting

(See

note 1.)

Acceleration/deceleration

time for STEP command

(See note 3.)

Approx. time from end of

command to end of

positioning (s ettling time)

(See note 2.)

Description

0 45 ms 100 to 200 ms

1 50 ms 110 to 220 ms

2 60 ms 130 to 260 ms

3 65 ms 150 to 300 ms

4 70 ms 170 to 340 ms

5 80 ms 200 to 400 ms

6 85 ms 250 to 500 ms

7 170 ms 500 to 1,000 ms

Smaller filter time

constant

(short positioning time)

Larger filter time constant

(longer positioning time

with little vibration)

8 to F

Do not set this switch to 8 to F.

Note 1. Increase the value of the filter setting if there is vibration when starting or stopping.

2. The settling time depends on the commanded acceleration/deceleration, the rigidity

of the machine motor drive, the encoder resolution, and other factors.

3. Use the acceleration/deceleration times as a guideline for determining the

Servomotor capacity that can be driven when using STEP commands without

commanded acceleration/deceleration.

Command Indicators (REF)

Indicator

(See note.)

Power to motor Command pulse

Lit orange. OFF None

Flashing orange. OFF Pulse being input.

Lit green. ON None

Flashing green. ON Pulse being input.

Note: The indicator stays lit (yellow) for 1 s when there is a deviation counter reset input.

Alarm Indicators (AL1/AL2/AL3)

Indicator status Alarm Indicator Alarm

AL1

AL2

AL3

Normal

AL1

AL2

AL3

Overcurrent

AL1

AL2

AL3

Overspeed

AL1

AL2

AL3

Servo Driver built-in fan is

stopped

AL1

AL2

AL3

Overload

AL1

AL2

AL3

System error

AL1

AL2

AL3

Encoder error

AL1

AL2

AL3

Flashing at a constant interval.

Rotary switch for setting

command pulse (PULSE)

has been changed.

AL1

AL2

AL3

Voltage error

Lit:

Not lit:

Flashing:

1-5

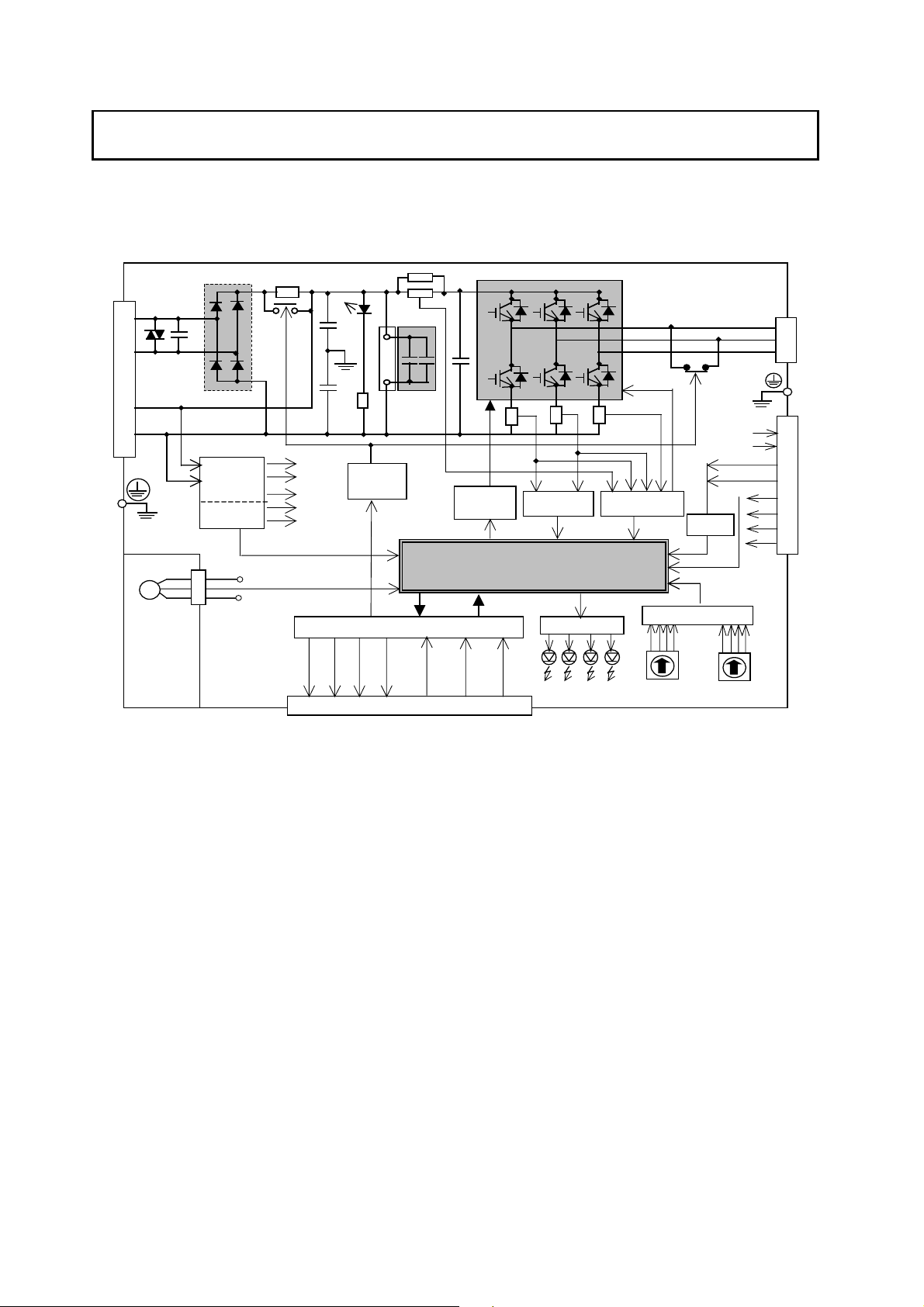

1-4 System Block Diagrams

1-4-1 Pulse-string Input Servo Driver

1-4 System Block Diagrams

1-4-1 Pulse-string Input Servo Driver

15V2

VCC2

+VCC

-VCC

G

Main circuit volta

g

e

detection

Relay

drive

Current

detection

Overcurrent

protection

Gate

drive

MPU & ASIC

Position, speed, and torque processor

ADC

FAN

‡

G

-VCC

Fan alarm

+VCC

G

+A,-

A

+B

,

-B

Phase U

Phase V

Phase W

Phase Z

Set value read circuit

Command

format setting

Command filter

setting

I/O and drive circuits

Display circuit

CW input

Alarm

output

INP output

Brake out

p

ut

Origin

output

Run input

CCW input

L1

L2

N

P

U

V

W

GR

GR

Control I/O connector

Encoder si

g

nal input connector

Control power

supply

Main circuit

control

SW power

supply

1-6

1-5 Applicable Standards

1-5-1 EC Directives

1-5 Applicable Standards

1-5-1 EC Directives

EC Directive Product Applicable standards Comments

AC Servo Drivers EN 50178

Safety requirements for

electronic equi pment for

measurement, contr ol, or

laboratory use

Low Voltage

Directive

AC Servomotors

IEC 60034-1, -5, -8, and -9

EN 60034-1 and -9

Rotating electric machines

EN 550011 Class A Group1

Limits and methods of

measurement of radio

disturbance of i ndustrial,

scientific, and medical

radio-frequency equi pment

EMC Directive

AC Servo Drivers and

AC Servomotors

EN 61000-6-2

Electromagnetic compatibility

(EMC): Immunity st andard for

industrial environments

Note: To conform to EMC Directives, the Units must be installed under the conditions described

in 4-2-5 Conforming to EMC Directives.

1-5-2 UL and cUL Standards

Standard Product

Applicable

standards

File number Comments

AC Servo Drivers UL 508C E179149 Power Conversion Equipment

UL

AC Servomotors UL 1004 E179189 Electric Motors

AC Servo Drivers cUL C22.2 No.14 E179149 Industrial Control Equipment

cUL

AC Servomotors cUL C22.2 No.100 E179189 Motors and Generation Equipment

1-7

1-5 Applicable Standards

1-5-2 UL and cUL Standards

1-8

Section 2

Dimensions

Standard Models and

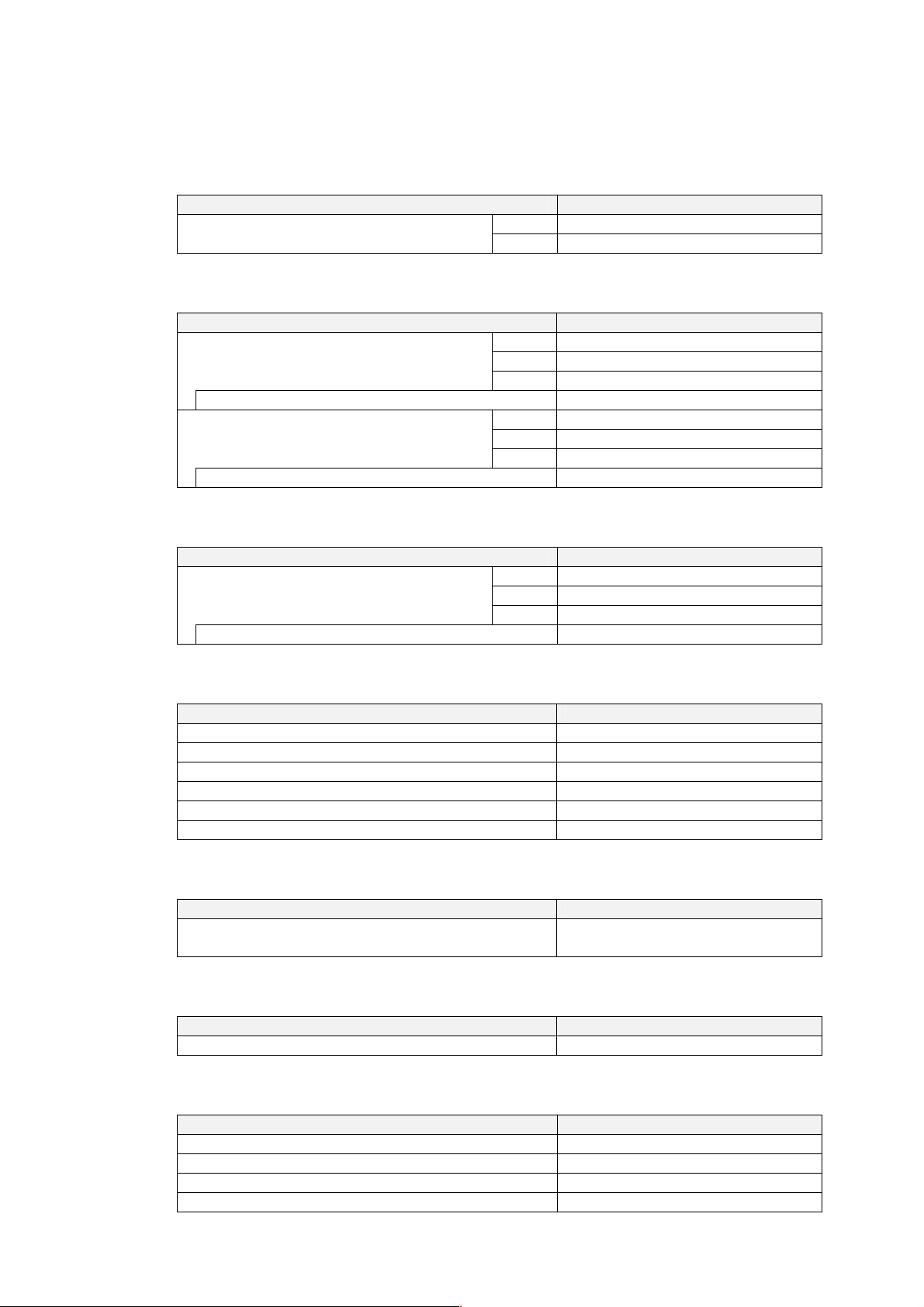

2-1 Standard Models

2-1-1 Servo Drivers

2-1 Standard Models

2-1-1 Servo Drivers

Specifications Model

100 W R7D-ZP01H

200 W R7D-ZP02H

400 W R7D-ZP04H

Pulse string input

750 W R7D-ZP08H

2-1-2 Servomotors

Specifications Model

100 W R7M-Z10030-S1

200 W R7M-Z20030-S1

400 W R7M-Z40030-S1

Without brake

750 W R7M-Z75030-S1

100 W R7M-Z10030-BS1

200 W R7M-Z20030-BS1

400 W R7M-Z40030-BS1

With brake

750 W R7M-Z75030-BS1

2-1-3 Servo Driver-Servomotor Combinations

Servomotor Servo Driver Rated

output

Without brake With brake Pulse string input

100 W

R7M-Z10030-S1 R7M-Z10030-BS1 R7D-ZP01H

200 W

R7M-Z20030-S1 R7M-Z20030-BS1 R7D-ZP02H

400 W

R7M-Z40030-S1 R7M-Z40030-BS1 R7D-ZP04H

750 W

R7M-Z75030-S1 R7M-Z75030-BS1 R7D-ZP08H

Note: Only the Servomotor and Servo Driver combinations listed here can be used. Do not use

other combinations.

2-2

2-1 Standard Models

2-1-4 Decelerators (Straight Shaft with Key)

2-1-4 Decelerators (Straight Shaft with Key)

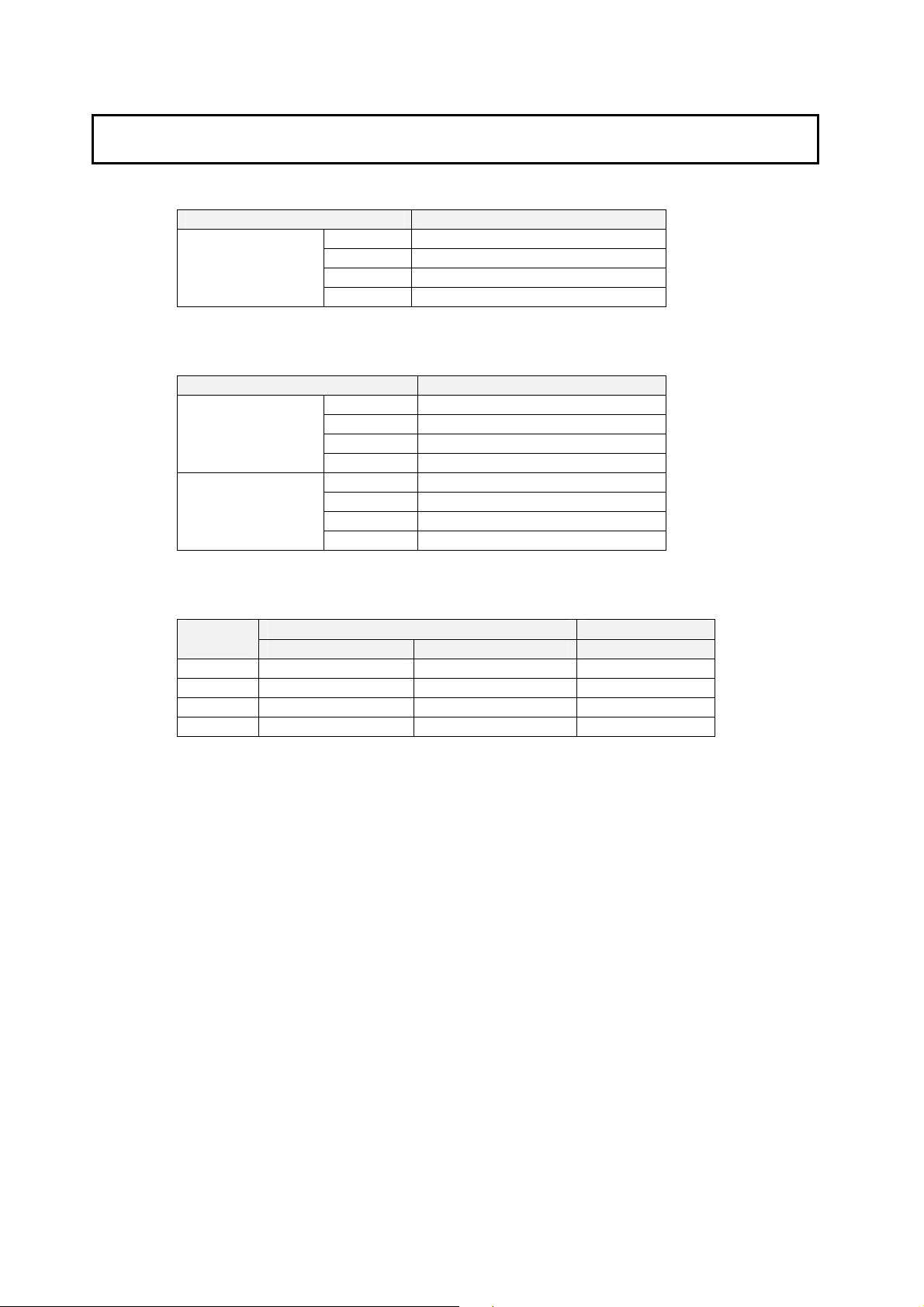

Backlash: 3 Arcminutes Max.

Specifications

Motor capacity Gear ratio

Model

1/5 R7G-VRSFPB05B100

1/9 R7G-VRSFPB09B100

1/15 R7G-VRSFPB15B100

100 W

1/25 R7G-VRSFPB25C100

1/5 R7G-VRSFPB05B200

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

200 W

1/25 R7G-VRSFPB25C200

1/5 R7G-VRSFPB05C400

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

400 W

1/25 R7G-VRSFPB25D400

1/5 R7G-VRSFPB05C750

1/9 R7G-VRSFPB09D750

1/15 R7G-VRSFPB15D750

750 W

1/25 R7G-VRSFPB25E750

Backlash: 45 Arcminutes Max.

Specifications

Motor capacity Gear ratio

Model

1/5 R7G-RGSF05B100

1/9 R7G-RGSF09B100

100 W

1/15 R7G-RGSF15B100

1/5 R7G-RGSF05B200

1/9 R7G-RGSF09C400

200 W

1/15 R7G-RGSF15C400

1/5 R7G-RGSF05C400

1/9 R7G-RGSF09C400

400 W

1/15 R7G-RGSF15C400

2-3

2-1 Standard Models

2-1-5 Accessories and Cables

2-1-5 Accessories and Cables

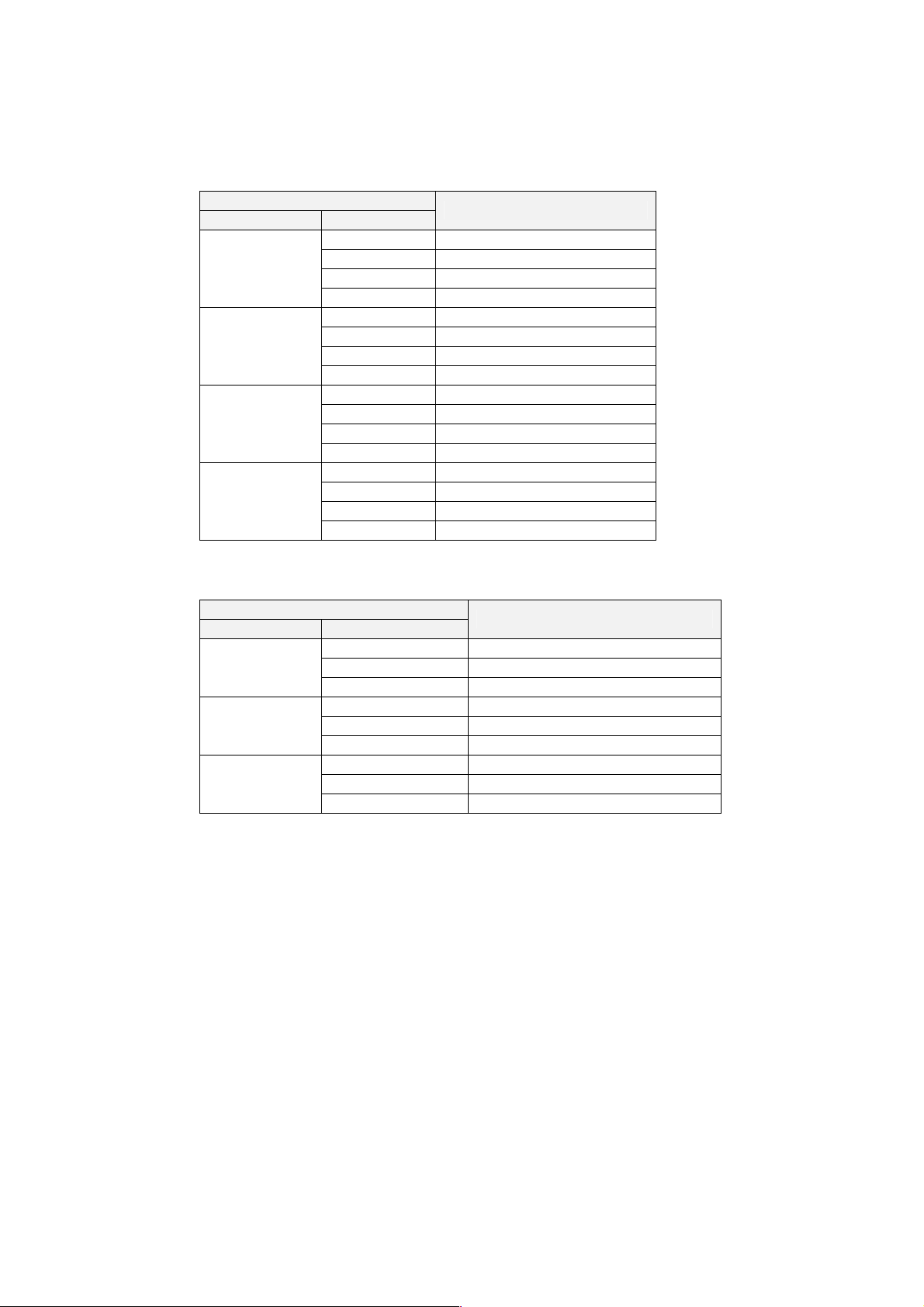

Control Cables (for CN1)

Specifications Model

1 m R7A-CPZ001S General-purpose Control Cables

2 m R7A-CPZ002S

Servomotor Power Cables (for CNB)

Specifications Model

3 m R7A-CAZ003S

5 m R7A-CAZ005S

Power Cables for Servomotors without B rakes

(connector attached)

10 m R7A-CAZ010S

Cable Only (in 1-m increment s) R7A-CAZ001

3 m R7A-CAZ003B

5 m R7A-CAZ005B

Power Cables for Servomotors with B rakes

(connector attached)

10 m R7A-CAZ010B

Cable Only (in 1-m increment s) R7A-CAZ01B

Encoder Cables (for CN2)

Specifications Model

3 m R7A-CRZ003C

5 m R7A-CRZ005C

Encoder Cables (connector attached)

10 m R7A-CRZ010C

Cable Only (in 1-m increment s) R7A-CRZ001

Connectors

Specifications Model

Main Circuit Connector (CNA) with Ej ector Levers R7A-CNZ01P

Servomotor Connector (CNB) R7A-CNZ01A

Control Input Connector (CN1) R7A-CNA01R

Encoder Input Connector (CN2) R7A-CNZ01R

Servomotor Connector for E ncoder Cable R7A-CNZ02R

Servomotor Connector for S ervomotor Power Cable R7A-CNZ02A

Regeneration Resistance Unit

Specifications Model

Regeneration current: 8 A

Internal resistance: 50 Ω, 12 W

R88A-RG08UA

External Regeneration Resistor

Specifications Model

Regeneration capacity: 70 W, 47 Ω R88A-RR22047S

AC Reactors

Specifications Model

R7D-ZP01H R88A-PX5052

R7D-ZP02H R88A-PX5053

R7D-ZP04H R88A-PX5054

R7D-ZP08H R88A-PX5056

2-4

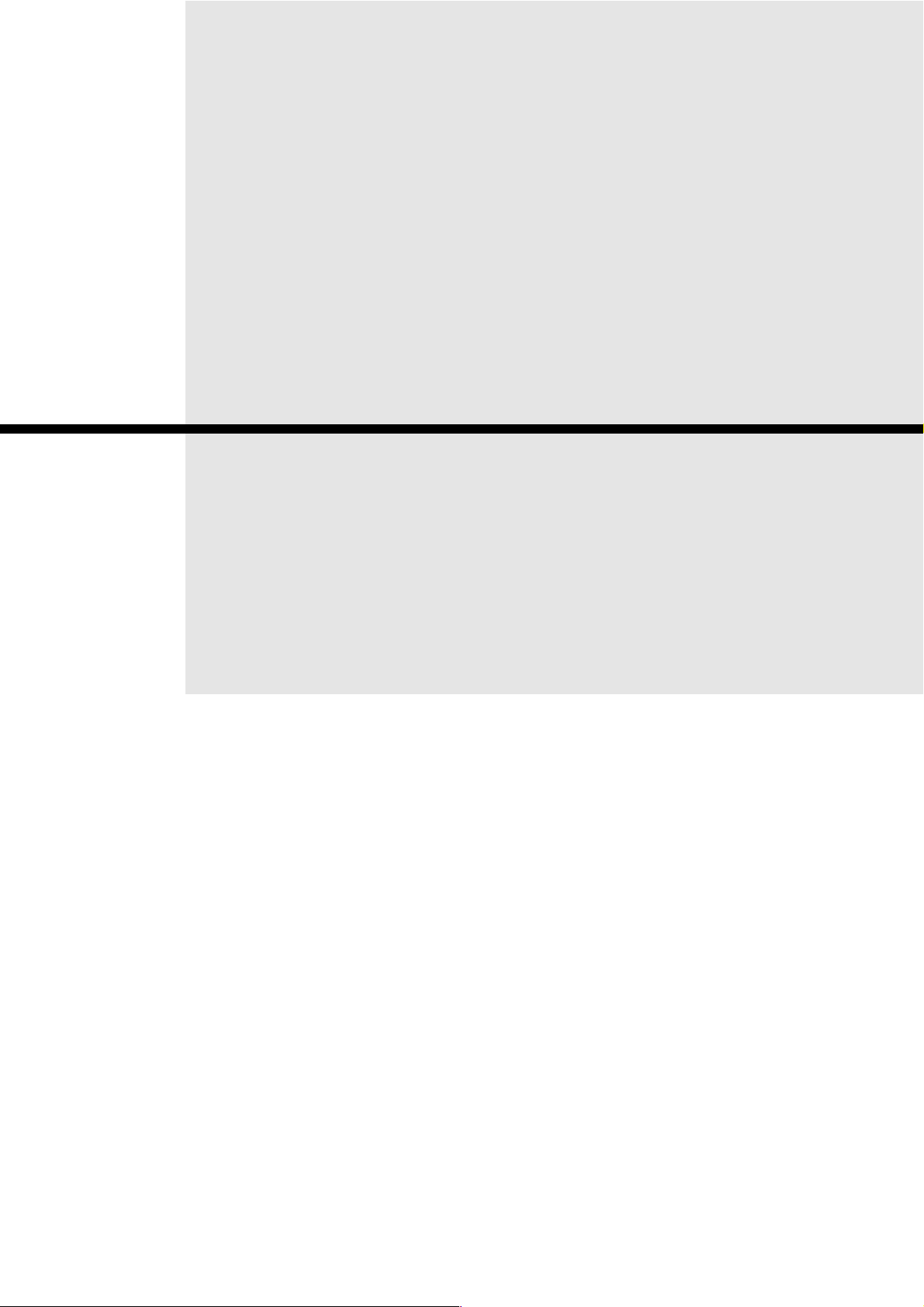

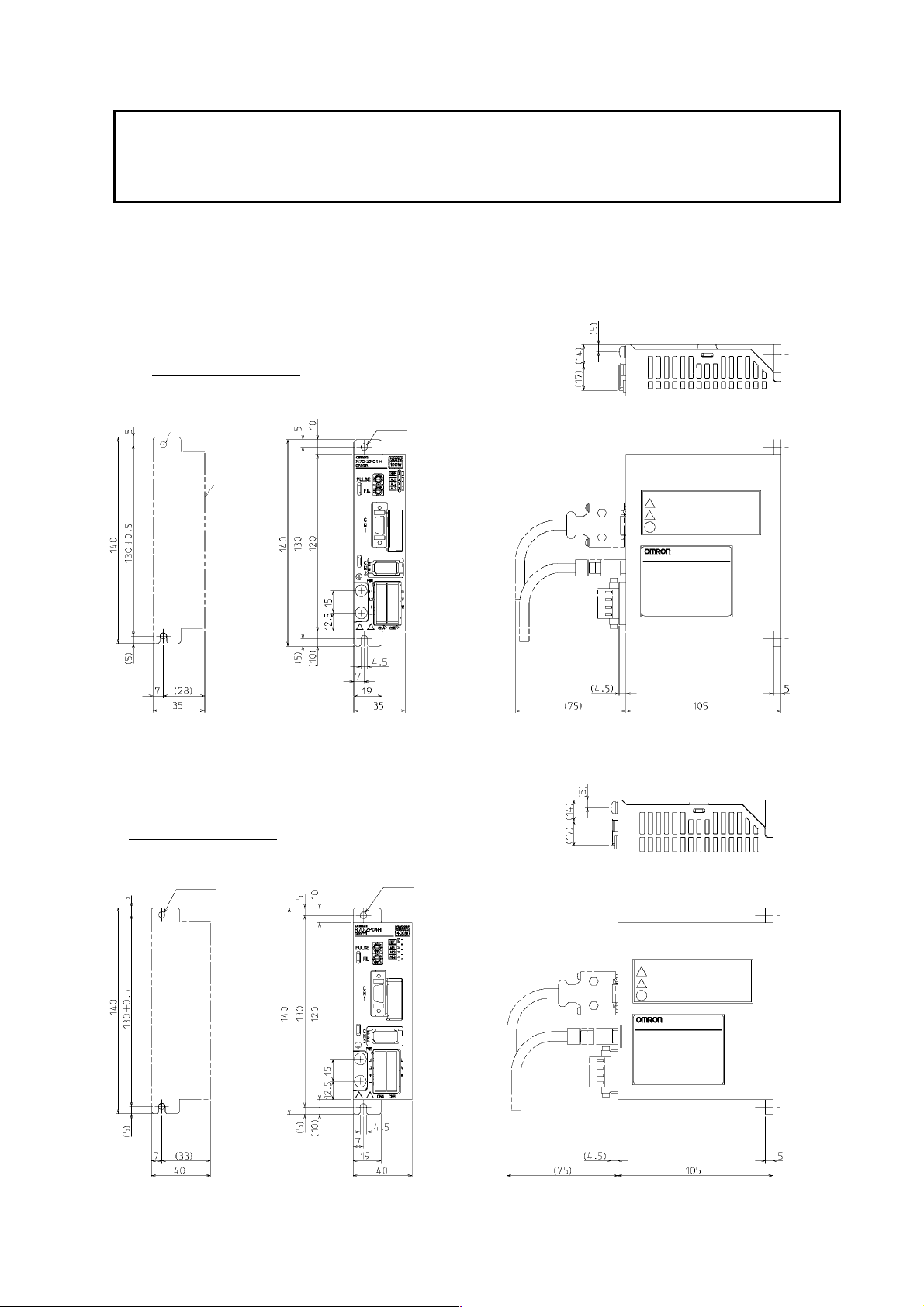

2-2 External and Mounted Dimensions

2-2-1 Servo Drivers

2-2 External and Mounted

Dimensions

2-2-1 Servo Drivers

R7D-ZP01H/-ZP02H (100 W/200 W)

Footprint

4.5-dia. hole

Two, M4 screw holes

Mountin

g

pitch

Mounting Hole Dimensions

R7D-ZP04H (400 W)

4.5-dia. hole

Two, M4 screw holes

Mountin

g

pitch

Mounting Hole Dimensions

2-5

Loading...

Loading...