Omron R7D-APA3H, R7D-AP02H, R7D-APA5H, R7D-AP01H, R7D-AP04H System Configuration Manual

...Page 1

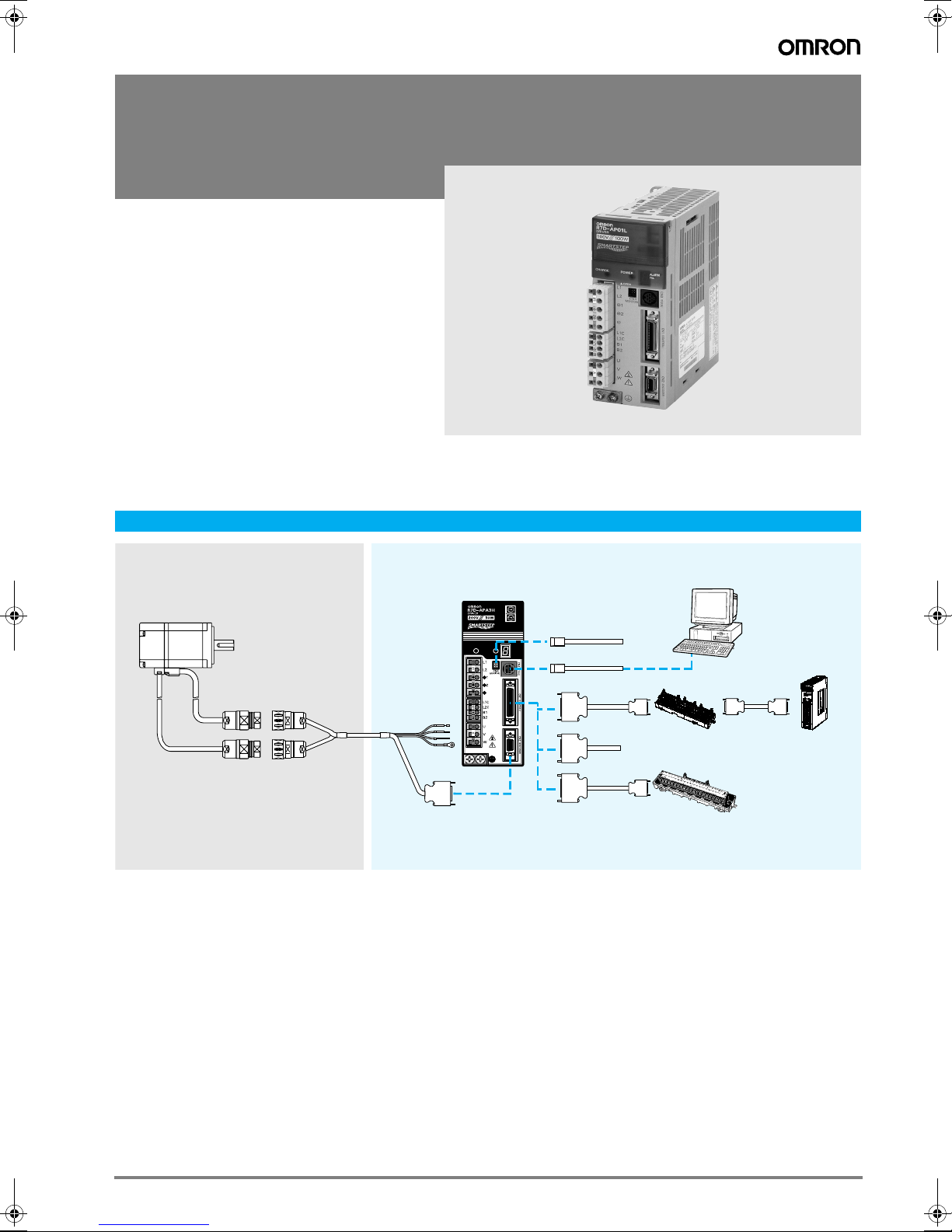

R7D-AP@

SmartStep servo drive

A new concept in servo systems

the smart alternative to stepper motors

• Easy to setup, easy to operate. SmartStep is as

easy to use as a stepper motor

• Front-panel switches make settings easy and

eliminate the need for time-consuming parameter

settings

• Auto-tuning on-line mode, dynamic brake setting,

alarm display, high torque performance

• Easy to wire with prebuilt cables

• Oscilloscope available via CX-Drive software

(CX-One)

• Windows based configuration and commissioning

software

Ratings

• 230 VAC single-phase 30 W to 750 W (2.39 Nm)

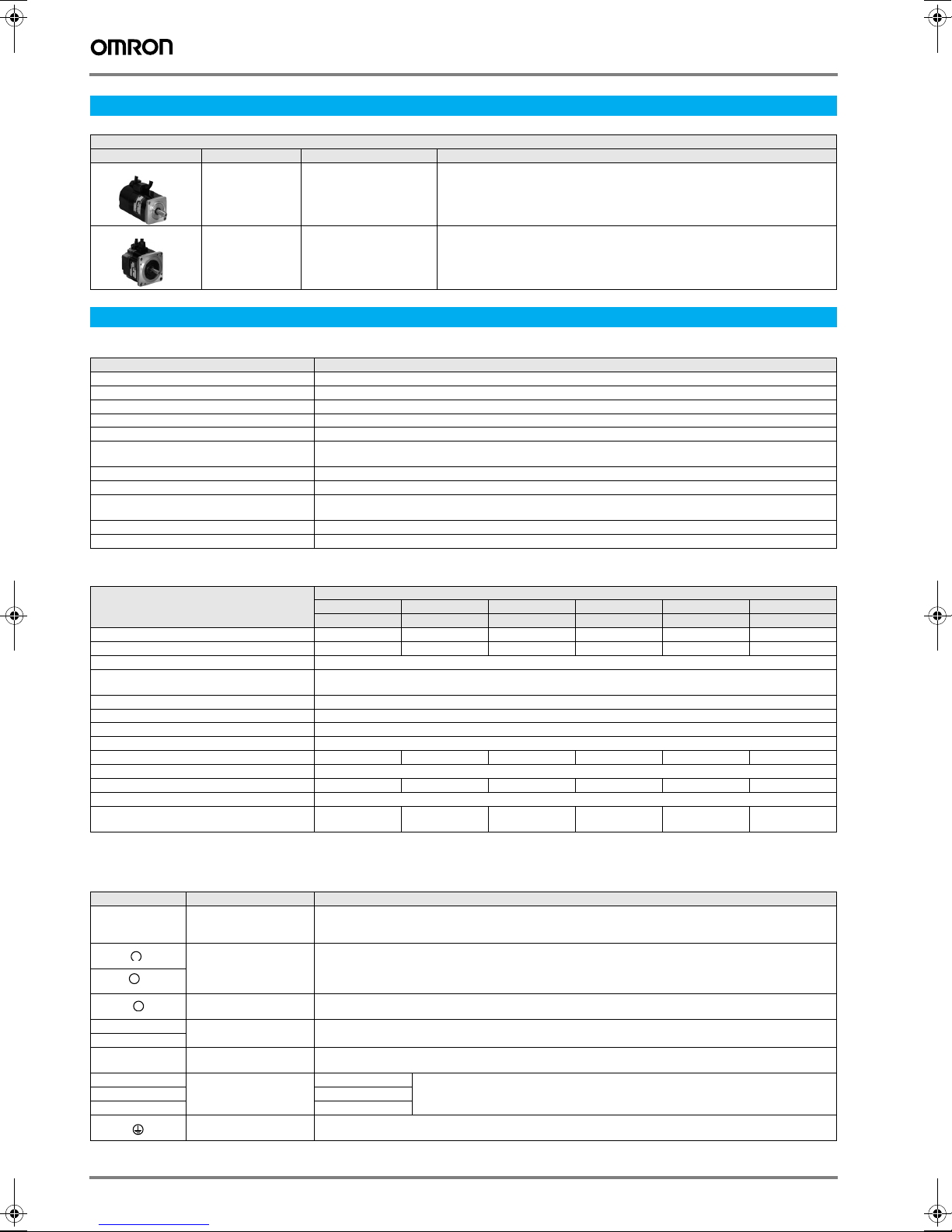

System configuration

(Refer to chapter SmartStep servo motors)

SmartStep

Servo Motor

SmartStep

Servo Drive

Personal computer

Position control

unit

Connector terminal block

General purpose controller

(with pulse output)

153SmartStep servo drive

Page 2

Servo motor supported

Family Voltage Models rated torque Remarks

R7M-A (3000 min

R7M-AP(3000 min

-1

) 230 V 0.095 Nm to 2.39 Nm Refer to the SmartStep servo motors chapter for details

-1

) 230 V 0.318 Nm to 2.39 Nm Refer to the SmartStep servo motors chapter for details

Servo motor

Servo drive specifications

General specifications

Item Specification

Ambient operating temperature 0 to 55 °C

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature -20 to 85 °C

Ambient storage humidity 90% max. (with no condensation)

Storage/operating atmosphere No corrosive gases.

Vibration resistance 10 to 55 Hz in X, Y, and Z directions with 0.1 mm double amplitude or acceleration of 4.9 m/s

Impact resistance Acceleration 19.6 m/s

Insulation resistance Between power line terminals and case:0.5 MΩ min. (at 500 VDC)

Dielectric strength Between power line terminals and case:1,500 VAC for 1 min at 50/60 Hz

Protective structure Built into panel (IP10).

International standards Approval obtained for UL, cUL, and EN (EMC directiveand low-voltage directive)

whichever is smaller

Between each control signal and case: 500 VAC for 1 min

2

max., in X, Y, and Z directions, three times

Performance specifications

Item 200 VAC input type

Continuous output current (rms) 0.42 0.6 0.89 2.0 2.6 4.4

Momentary maximum output current (rms) 1.3 1.9 2.8 6.0 8.0 13.9

Control power supply Single-phase 200/230 VAC (170 to 253 V) 50/60 Hz

Main-circuit power supply Single-phase 200/230 VAC (170 to 253 V) 50/60 Hz

Control method All-digital servo

Speed feedback 2,000 pulses/revolution incremental encoder

Inverter method PWM method based on IGBT

PWM frequency 11.7 kHz

Weight 0.8 0.8 0.8 0.8 1.1 1.7

Compatible motor voltage 200 V

Compatible motor capacity 30 W 50 W 100 W 200 W 400 W 750 W

Command pulse response 250 kHz

Applicable servo motor

(R7M-)

30 W 50 W 100 W 200 W 400 W 750 W

R7D-APA3H R7D-APA5H R7D-AP01H R7D-AP02H R7D-AP04H R7D-AP08H

(three-phase 200/230 VAC can be used with the 750 W model.)

A03030 A05030 A10030

AP10030

A20030

AP20030

A40030

AP40030

2

max.,

A75030

AP75030

I/O specifications

Terminal specifications

Symbol Name Function

L1 and L2

or

L1, L2, and L3

+

+

2

−

L1C Control circuit power

L2C

B1 and B2 or

B1, B2, and B3

U Servo motor

V White

WBlue

Main-circuit power supply

terminals

DC reactor terminals Normally short-circuit between +1 and +2.

Main-circuit DC output Do not connect anything to this terminal.

supply terminals

External regeneration

resistance terminals

terminals

Frame ground This is the ground terminal.

These are the input terminals for the main-circuit power supply.

If harmonic control measures are required, connect a DC reactor between +1 and +2.

These are the input terminals for the control power supply.

Connect an external regeneration resistor to these terminals if the regenerative capacity of the internal capacitor is

exceeded. (An external regeneration resistor cannot be connected to the 30 to 200 W models.)

Red These are the terminals for outputs to the servo motor.

154 AC servo systems

Page 3

Control I/O (CN1) specifications

Pin Symbol Name Function

1 +PULS/CW/A Feed pulses, reverse pulses,

2 −PULS/CW/A

3 +SIGN/CCW/B Direction signal, forward pulses,

4 −SIGN/CCW/B

5 +ECRST Deviation counter reset Line-driver input: 7 mA at 3 V

6 −ECRST

7 BKIR Brake interlock output Outputs holding brake timing signals.

8 INP Positioning completed output ON when the position error is within the positioning completed range.

10 OGND Output ground common Ground common for output signals (pins 7 and 8).

13 +24V +24 VDC power input for control Power supply input (+24 VDC) for pins 14 and 18.

14 RUN RUN command input ON: servo ON (starts power to servo motor)

18 RESET Alarm reset input ON: servo alarm status is reset.

19 GND RS-422A ground Ground for RS-422A

20 RXD+ RS-422A reception data Interface for RS-422A data transfers

21 RXD−

22 TXD+ RS-422A transmission data

23 TXD−

24 RT Termination resistance terminal Connect to RXD- (pin 21) in the unit at the end of the line.

32 Z Encoder phase-Z open-collector output Output goes ON when the encoder’s phase-Z signal (1 pulse/revolution)

33 ZCOM

34 ALM Alarm output Output goes OFF when alarm is detected.

35 ALMCOM

Shell FG Cable shield ground Ground for cable's shield wire.

or 90° phase difference pulses (A phase)

or 90° phase difference pulses (B phase)

Line-driver input: 7 mA at 3 V

Open-collector input

Input impedance: 200 Ω

Maximum response frequency: 250 kpps

Position control is performed based on the pulses that have been input.

Open-collector input: 16 mA at 5 V

Input impedance: 200 Ω

ON: resets deviation counter.

is detected.

Open-collector output: 20 mA max. at 30 VDC

Open-collector output: 50 mA max. at 30 VDC

Encoder connector (CN2) specifications

Pin Symbol Name Function

1, 2, 3 E0V Encoder power supply GND Power supply output for encoder

4, 5, 6 E5V Encoder power supply +5 V

8 S+ Encoder + phase-S input Line driver input (conforms to EIA-RS422A)

9S− Encoder − phase-S input

10 A+ Encoder + phase-A input Line driver input (conforms to EIA-RS422A)

11 A− Encoder − phase-A input

12 B+ Encoder + phase-B input Line driver input (conforms to EIA-RS422A)

13 B− Encoder − phase-B input

Shell FG Cable shield ground Ground for cable's shield wire.

(Input impedance: 220 Ω ± 5%)

(Input impedance: 220 Ω ± 5%)

(Input impedance: 220 Ω ± 5%)

Communications connector (CN3) specifications

Pin Symbol Name Function

1 /TXD Transmission data Transmission data: RS-232C output

2 /RXD Reception data

3 PRMU Unit switching Switching terminal for a parameter unit

7 +5V +5 V output This is the +5 V power supply output to the parameter unit.

8 GND Ground

Shell FG Cable shield ground Ground for cable's shield wire.

Reception data: RS-232C input

Monitor output (CN4) specifications

Pin Symbol Name Function

1 NM Speed monitor Speed monitor output: 1 V per 1,000 r/min

2 AM Current monitor Current monitor: 1 V / rated torque

3 GND Ground Grounds for monitor output

4 GND Ground

SmartStep servo drive 155

Page 4

Digital operator specifications

SCROLL

MODE/SET

DATA

JO G

RU N

DRIVERޓ

PRPRPRPRޓ

DRIVER

READ

WRITE

B.B

INP

VCMP

TGON

REF

POWER

General specifications

Item Specification

Ambient operating temperature 0 to 55 °C

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature -20 to 85 °C

Ambient storage humidity 90% max. (with no condensation)

Storage/operating atmosphere No corrosive gases.

Vibration resistance 10 to 55 Hz in X, Y, and Z directions with 0.1 mm double amplitude or

acceleration of 9.8 m/s

Impact resistance Acceleration 19.6 m/s

Function specifications

Item Function

Setting mode Display or change parameter settings.

Monitor mode Display monitor values.

Execute function mode Execute each function mode.

Display alarms Display alarms that have occurred.

Copy parameters Read or save parameters from the servo drive.

Write parameters to the servo drive.

Compare parameters in the servo drive with parameters in the

parameter unit.

Mode change specifications

Power ON

Parameter/monitor mode

MODE/SET

2

max., whichever is smaller

2

max., in X, Y, and Z directions, three times

BB BB

-PRM/MON-

Un000 = 3000r/min

Un002 = 40%

Un008 = 00100pulse

Un00D = 10000000

B.B

R7A–PR02A

RESET

JOG

RUN

DRIVER

R7A-PR02A

Pn000 = 0000

Un002 = 40%

Un008 = 00100pulse

Un00D = 10000000

INP

VCMP

PARAMETER UNIT

SCROLL

READ

-PRM/MON-

TGON

REF

MODE/SET

DATA

WRITE

POWER

DRIVER

MODE/SET

Function mode

BB BB

Fn000

Fn001

MODE/SET

Copy parameters mode

Fn002

Fn003

BB BB

1: DRIVER→PR

2: PR→DRIVER

3: Verify

4: LIST

A. 70 A. 70

Display alarms mode

1: A.00

2: A.02

3: A.10

4: A.71

-FUNCTION-

Fn001

Fn002

Fn003

Fn005

-COPY-

1: DRIVER→PR

2: PR→DRIVER

3: Verify

4: LIST

-ALARM-

2: A.02

3: A.10

4: A.71

5: A.72

-FUNCTION-

-COPY-

-ALARM-

156 AC servo systems

Page 5

Operation

Components

Unit number switch

Gain adjustment switch

Charge indicator

Main-circuit power terminals

DC reactor terminals

Control-circuit power terminals

External regeneration

Resistor terminals

Servo motor power terminals

Ground terminals for

power supply and

servo motor power

Switch operations

Gain adjustment switch

Adjusts the motor’s responsiveness.

When this switch is set to 0, the unit will operate according to the set-

tings in the internal parameters (Pn100, Pn101, Pn102, and Pn401).

When this switch is set to 1 through F, the unit will operate according to

the rotary switch’s setting.

0

F1

2

Decrease the switch setting to lower the motor’s responsiveness

(i.e., so that it moves more smoothly).

Increase the switch setting to raise the motor’s responsiveness

(i.e., so that it moves faster).

DIP switch

• Resolution setting

• Command pulse input setting

• Dynamic brake setting

Autotuning switch

Alarm indicator

Power indicator

Communications connector (CN3)

Monitor output connector (CN4)

Control I/O connector (CN1)

Encoder input connector (CN2)

Setting Position loop

0 Enables parameter settings

1 15 15 4,000 250

2 20 20 3,500 200

3 30 30 3,000 150

4 40 40 2,000 100

560601,50070

685851,00050

7 120 120 800 30

8 160 160 600 20

9 200 200 500 15

A 250 250 400 10

B 250 250 400 10

C 250 250 400 10

D 250 250 400 10

E 250 250 400 10

F 250 250 400 10

gain

(including settings other than gain settings).

Speed loop

gain

Speed loop

integral

constant

Torque

command filter

time constant

SmartStep servo drive 157

Page 6

Enable switch/parameter setting

Pin 6 of the DIP switch selects whether the servo drive operates according to the

DIP switch settings or parameter settings

ON OFF

6

5

.

Pin 6 Function

OFF Enables the DIP switch settings.

ON Enables the parameter settings.

4

3

2

1

(Default setting)

Command pulse input setting

Pin 3 selects the command pulse mode. Select “Forward pulse/reverse

pulse: positive logic” or “feed pulses/direction signal: positive logic.”

ON OFF

6

5

4

3

2

1

(Default setting)

Pin 3 Command pulse mode

OFF Forward pulse/reverse pulse:

ON Feed pulses/direction signal:

positive logic

positive logic

Online autotuning setting

The autotuning switch selects whether the gain will be adjusted automatically during operation.

ON OFF

Perform online autotuning.

1

Dynamic brake setting

Pin 2 enables or disables dynamic brake operation. If the dynamic brake is enabled, the motor can be brought to an emergency stop when the RUN command

goes OFF or an alarm occurs.

ON OFF

6

ON OFF

1

Resolution setting

Pins 4 and 5 select the positioning resolution.

If the resolution is set to 1,000 (the default setting), the motor makes

Complete online autotuning.

The result is stored in the inertia ratio

parameter (Pn103) and the servo drive

runs.

5

4

3

2

1

(Default setting)

Pin 2 Dynamic brake mode

OFF Dynamic brake disabled.

ON Dynamic brake enabled.

one revolution for every 1,000 pulses input.

ON OFF

6

5

4

3

2

1

Pins Resolution

5 4

OFF OFF 1,000 pulses/revolution

OFF ON 10,000 pulses/revolution

ON OFF 500 pulses/revolution

ON ON 5,000 pulses/revolution

(0.36°/step)

(0.036°/step)

(0.72°/step)

(0.072°/step)

(Default setting)

Alarm Table

Display ALM output Error detection function Display ALM output Error detection function

A.04*

A.10*

A.30

A.32

A.40

A.51

A.70

A.73

A.74

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Parameter setting error A.7A

Overcurrent A.bF*

Regeneration error A.C1

Regeneration overload A.C2*

Overvoltage/undervoltage A.C3*

Overspeed A.d0

Overload CPF00

Dynamic brake overload CPF01

Inrush resistance overload A.91

A.92

OFF

OFF

OFF

OFF

OFF

OFF

---

---

---

---

Overheat

System error

Runaway detected

Phase not detected

Encoder disconnect detected

Deviation counter overflow

Parameter unit transmission error 1

Parameter unit transmission error 2

Overload warning

Regeneration overload warning

Note: 1. These parameters are read when the power is turned

ON. Parameter Pn110.2 is valid when online.

158 AC servo systems

2. When using a regeneration resistor, set the resistor’s

capacity when the temperature has risen to 120 °C.

Set this parameter to 0 if a regeneration resistor is not

being used.

Page 7

Dimensions

Servo drives

R7D-APA3H/APA5H/AP01H/AP02H (230 V, 30 to 200 W) R7D-AP04H (230 V, 400 W)

160

55

(75) 130

17

R7D-AP08H (230 V, 750 W)

94

96

Mounting dimensions

5 dia. hole

160

35 55

90

Two, M4

5.5

160

±0.5

149.5

5

(5)

55

(75) 180

5 dia. hole

5.5

160

149.5

5

(5)

12

(63)

75

Mounting dimensions

5.5

160

±0.5

149.5

27

(5)

Two, M4

90

(75) 130

17

Mounting dimensions

Two, M4

5.5

160

±0.5

149.5

12

(5)

75

17

Filters

R88A-FIW104-SE R88A-FIW107-SE, R88A-FIW115-SE

28.25(1.11)

56(2.20)

(φ0.20)

5.5(0.22)

14(0.55)

19(0.75)

Units: mm (in)

32(1.26)

M4

φ5

φ10(φ0.39)

70(2.76)

+0.20

0

+5

0

240 (9.45 )

202(7.95)

192(7.56)

149.5(5.89)

wires AWG16

168(6.61)

GNYE

1

(0.04)

11.5(0.45)

5

(0.20)

M4(2

×

)

+0.20

0

6(0.24)

+5

0

M4

265 (10.43 )

33(1.30)

15(0.59)

Model R88A-FIW107-SE R88A-FIW115-SE

Dimensions

in mm

A75 90

B240

+5

C50 60

D12 15

E1 1.2

Units: mm

32

16

202

192

15028

M4

A

φ5

5.5

10

14

19

70

wires AWG16

B

GNYE

168

300+5

E

D

5

M4(2×)

+5

0

M4

265

C

15

SmartStep servo drive 159

Page 8

Installation

Single-phase 200 to 230 VAC +10%/-15% (50/60 Hz)

(the 750 W servo drives can input three-phase 200 to 230 VAC.)

1MCCB

Noise filter

If necessary, connect a

DC Reactor to these

terminals to suppress

high harmonics in the

Always ground

this terminal.

Position

commands

Deviation

power supply.

Reverse

Pulses

Forward

Pulses

Counter

Reset

Main-circuit

power supply

1MC

+CW

−CW

+CCW

−CCW

+ECRST

−ECRST

Main-circuit

ONOFF

1MC X

L1

L2

L1C

L2C

+

1

+

2

CN1

200 Ω

1

2

200 Ω

3

4

200 Ω

5

6

contactor

Surge

suppressor

*

B2B1

SMARTSTEP A-series

Servo drive

1MC

220 Ω

CN2

Servo motor

U

V

W

M

Encoder

RE

Attach the shield wire to

the terminal securely.

22

23

20

21

24

TXD+

TXD−

RXD+

RXD−

RT

Transmission

data

Reception

data

Terminating

resistor

RS-422 Interface

Compatible line drivers

Texas Inst. SN75174,

MC3487 or equivalent

Compatible Line Receivers

Texas Inst. SN75175,

MC3486 or equivalent

Positioning

8

completed

INP

output

Max. operating voltage: 30 VDC

Max. output current: 50 mA

(Phase-z output is 20 mA max.)

24 VDC

RUN

command

Alarm reset

+24VIN

RUN

RESET

13

14

3.3k

18

3.3k

10

32

33

34

35

7

BKIR

OGND

Z

ZCOM

ALM

ALMCOM

Brake

interlock

output

Phase Z

Alarm output

Shell

FG (frame ground)

Connect the shield wire to the

connector shell.

Note: * A regeneration resistor can be connected across the B1 and B2 terminals with 400 W and 750 W servo drives.

When using an external regeneration resistor with a 400 W servo drive, just connect it across the B1 and B2 terminals.

When using an external regeneration resistor with a 750 W servo drive, remove the jumper bar from the B2 and B3 terminals and then

connect the regeneration resistor across the B1 and B2 terminals.

160 AC servo systems

Page 9

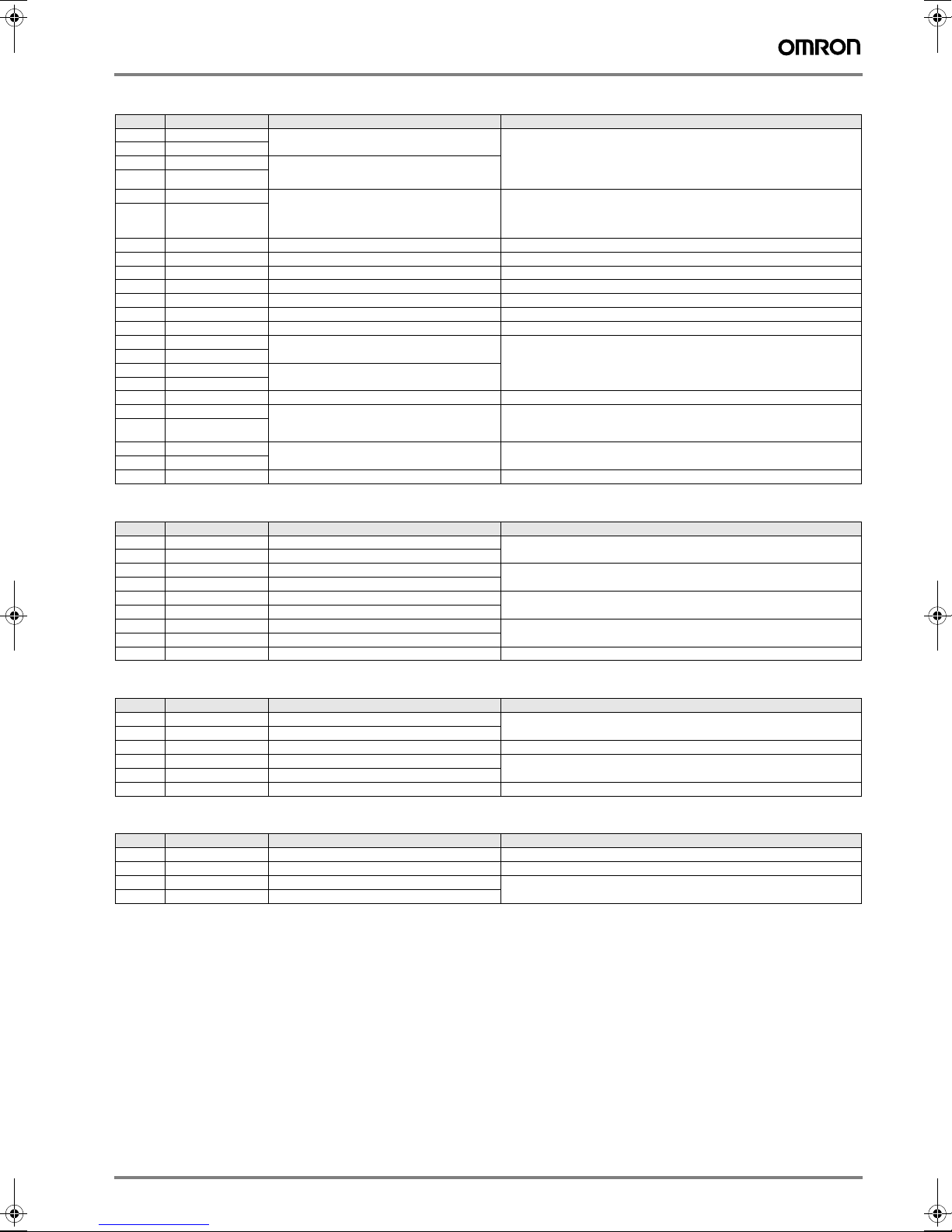

Ordering information

(Refer to chapter SmartStep servo motors)

SmartStep

A

Servo Motor

C

SmartStep

Servo Drive

Personal computer

J

K

I

E

D

F

G

B

H

Note: The symbols ABCDE... show the recommended sequence to select the components in a SmartStep servo system

Servo motors

Note: A Refer to the SmartStep servo motor chapter for detailed motor specifications and selection

Servo drives

Symbol Specifications SmartStep drive

C

200 VAC 30 W R7D-APA3H R7M-A03030-@ -

50 W R7D-APA5H R7M-A05030-@ -

100 W R7D-AP01H R7M-A10030-@ R7M-AP10030-@

200 W R7D-AP02H R7M-A20030-@ R7M-AP20030-@

400 W R7D-AP04H R7M-A40030-@ R7M-AP40030-@

750 W R7D-AP08H R7M-A75030-@ R7M-AP75030-@

model

Servo motor cables (for CN2)

Standard cable (power + encoder)

Symbol Drive Specifications Power cable model Encoder cable model Appearance

SmartStep For servo motors

B

without brake

R7M-A(P)@@@30-S1-D

For servo motors

with brake

R7M-A(P)@@@30-BS1-D

3 m R7A-CEA003S-DE

5 m R7A-CEA005S-DE

10 m R7A-CEA010S-DE

15 m R7A-CEA015S-DE

20 m R7A-CEA020S-DE

3 m R7A-CEA003B-DE

5 m R7A-CEA005B-DE

10 m R7A-CEA010B-DE

15 m R7A-CEA015B-DE

20 m R7A-CEA020B-DE

Compatible servo motors A

Cylindrical type Flat type

Only for brake

models

H

Connector terminal block

General purpose controller

(with pulse output)

R7A-CEA0___-DE

Position control

unit

Flexible cables (power + encoder)

Symbol Drive Specifications Power cable model Encoder cable model Appearance

SmartStep For servo motors

B

without brake

R7M-A(P)@@@30-S1-D

For servo motors

with brake

R7M-A(P)@@@30-BS1-D

SmartStep servo drive 161

3 m R88A-CAWA003S-DE R7A-CRA003-FDE

5 m R88A-CAWA005S-DE R7A-CRA005-FDE

10 m R88A-CAWA010S-DE R7A-CRA010-FDE

15 m R88A-CAWA015S-DE R7A-CRA015-FDE

20 m R88A-CAWA020S-DE R7A-CRA020-FDE

3 m R88A-CAWA003B-DE R7A-CRA003-FDE

5 m R88A-CAWA005B-DE R7A-CRA005-FDE

10 m R88A-CAWA010B-DE R7A-CRA010-FDE

15 m R88A-CAWA015B-DE R7A-CRA015-FDE

20 m R88A-CAWA020B-DE R7A-CRA020-FDE

Only for brake

models

R7A-CRA0___-FDE

R88A-CAWA0___-DE

Page 10

Control cables (for CN1)

Symbol Name Compatible units Model Available lengths

D

E

F

G

H

Servo relay unit Use with position control units

Cable to servo drive Doesn’t support communications functions. (For the XW2B-@@J6-@B) XW2Z-@@@J-B5 1 m or 2 m

Cable to position

control unit

Control cable For general-purpose controllers R88A-CPU@@@S 1 m or 2 m

Connector terminal block

cable

Connector terminal block XW2B-40F5-P ---

(doesn’t support communications functions.)

Units: CS1W-NC113/133, CJ1W-NC113/133, C200HW-NC113, and

C200H-NC112

Use with position control units

(doesn’t support communications functions.)

Units: CS1W-NC213/233/413/433, CJ1W-NC213/233/413/433,

C200HW-NC213/413, C500-NC113/211, and C200H-NC211

Use with position control units

(doesn’t support communications functions.)

Units: CQM1H-PLB21, and CQM1-CPU43-V1

Use with position control units (supports communications functions.)

Units: CS1W-NC213/233/413/433, CJ1W-NC213/233/413/433

Use with CJ1M-CPU22/23

(doesn’t support communications functions.)

Supports communications functions. (For the XW2B-@@J6-4B) XW2Z-@@@J-B7

CQM1H-PLB21 and CQM1-CPU43-V1 XW2Z-@@@J-A3 0.5 m or 1 m

C200H-NC112 XW2Z-@@@J-A4

C200H-NC211 and C500-NC113/211 XW2Z-@@@J-A5

CS1W-NC113 and C200HW-NC113 XW2Z-@@@J-A8

CS1W-NC213/413 and C200HW-NC213/413 XW2Z-@@@J-A9

CS1W-NC133 XW2Z-@@@J-A12

CS1W-NC233/433 XW2Z-@@@J-A13

CJ1W-NC113 XW2Z-@@@J-A16

CJ1W-NC213/413 XW2Z-@@@J-A17

CJ1W-NC133 XW2Z-@@@J-A20

CS1W-NC233/433 XW2Z-@@@J-A21

CJ1M-CPU22/23 XW2Z-@@@J-A26

For general-purpose controllers R88A-CTU@@@N

XW2B-20J6-1B

(1 axis)

XW2B-40J6-2B

(2 axes)

XW2B-20J6-3B

(1 axis)

XW2B-40J6-4A

(2 axes)

XW2B-20J6-8A (1 axis)

XW2B-40J6-9A (2 axes)

---

(the cable length goes in

the empty boxes.)

(the cable length goes in

the empty boxes.)

(the cable length goes in

the empty boxes.)

Cable for CN3 Cable for CN4

Symbol Name Model

I

Computer monitor cable R7A-CCA002P2

Symbol Name Model

J

Analog monitor cable R88A-CMW001S

Filters

Symbol Applicable servo drive Filter model Rated current Rated voltage

K

R7D-APA3H, R7D-APA5H, R7D-AP01H, R7D-AP02H R88A-FIW104-E 4A 250 VAC single phase

R7D-AP04H R88A-FIW107-E 7A

R7D-AP08H R88A-FIW115-E 15A

Connectors

Specifications Model

Control I/O connector (for CN1) R88A-CNU01C

SmartStep connectors kit. Models included in kit R7A-CNA00K-DE

SmartStep encoder connector (for CN2) R7A-CNA01R

Hypertac power connector female SPOC-06K-FSDN169

Hypertac encoder connector female SPOC-17H-FRON169

Hypertac power connector male (used in the motor) SRUC-06J-MSCN236

Hypertac encoder connector male (used in the motor) SRUC-17G-MRWN087

External regeneration resistor

Specification Model

220 W, 47 Ω R88A-RR22047S

Parameter unit & computer software

Specifications Model

Parameter copy unit (with cable) R7A-PR02A

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.11 or higher) CX-drive

Complete OMRON software package including CX-drive. (CX-One version 1.1 or higher) CX-One

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I46E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

162 AC servo systems

Loading...

Loading...