Page 1

Cat. No. I533-E1-04

SMARTSTEP A SERIES

R7M-A@ (Servomotors)

R7D-AP@ (Servo Drivers)

Servomotors/Servo Drivers

USER’S MANUAL

Page 2

Thank you for choosing this SMARTSTEP A-series product. Proper use and handling

of the product will ensure proper product performance, will lengthen product life, and

may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product with care.

Please keep this manual handy for reference after reading it.

1.To ensure safe and proper use of the OMRON Inverters, please read this USER'S MANUAL (Cat. No.

I533-E1) to gain sufficient knowledge of the devices, safety information, and precautions before actual

use.

2.The products are illustrated without covers and shieldings for closer look in this USER'S MANUAL. For

actual use of the products, make sure to use the covers and shieldings as specified.

3.This USER'S MANUAL and other related user's manuals are to be delivered to the actual end users of the

products.

4.Please keep this manual close at hand for future reference.

5.If the product has been left unused for a long time, please inquire at our sales representative.

NOTICE

1.This manual describes information about installation, wiring, switch setting, and troubleshooting of the

SMARTSTEP A-series Servomotors and Servo Drivers. For information about actual operating procedures using a Parameter Unit, refer to the SMARTSTEP A Series Operation Manual (I534).

2.Be sure that this manual accompanies the product to its final user.

3.Although care has been given in documenting the product, please contact your OMRON representative

if you have any suggestions on improving this manual.

4.Assume that anything not specifically described in this manual is not possible.

5.Do not allow the Servomotor or Servo Driver to be wired, set, or operated (from a Parameter Unit) by

anyone that is not a profession electrical engineer or the equivalent.

6.We recommend that you add the following precautions to any instruction manuals you prepare for the

system into which the product is being installed.

• Precautions on the dangers of high-voltage equipment.

• Precautions on touching the terminals of the product even after power has been turned OFF. (These

terminals are live even with the power turned OFF.)

7.Specifications and functions may be changed without notice in order to improve product performance.

8.Positive and negative rotation of AC Servomotors described in this manual are defined as looking at the

end of the output shaft of the motor as follows: Counterclockwise rotation is positive and clockwise rotation is negative.

9.Do not perform withstand-voltage or other megameter tests on the product. Doing so may damage internal components.

10.Servomotors and Servo Drivers have a finite service life. Be sure to keep replacement products on hand

and to consider the operating environment and other conditions affecting the service life.

11.Do not set values for any parameters not described in this manual. Operating errors may result. Consult

your OMRON representative if you have questions.

12.Before using the product under conditions which are not described in the manual or applying the product

to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical

equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult your OMRON representative.

Items to Check Before Unpacking

1.Check the following items before removing the product from the package:

• Has the correct product been delivered (i.e., the correct model number and specifications)?

• Has the product been damaged in shipping?

2.Check that the following accessories have been delivered.

• Safety Precautions

No connectors or mounting screws are provided. Obtain these separately.

Page 3

USER’S MANUAL

SMARTSTEP A SERIES

MODELS R7M-A@ (Servomotors)

R7D-AP@ (Servo Drivers)

Servomotors/Servo Drivers

Page 4

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything

else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 6

Page 7

General Warnings

Observe the following warnings when using the SMARTSTEP Servomotor and Servo Driver and all

connected or peripheral devices.

This manual may include illustrations of the product with protective covers removed in order to

describe the components of the product in detail. Make sure that these protective covers are on the

product before use.

Consult your OMRON representative when using the product after a long period of storage.

!WARNING Always connect the frame ground terminals of the Servo Driver and the Servomo-

tor to a class-3 ground (to 100

result in electric shock.

!WARNING Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

!WARNING Do not remove the front cover, terminal covers, cables, or optional items while the

power is being supplied. Doing so may result in electric shock.

!WARNING Installation, operation, maintenance, or inspection must be performed by autho-

rized personnel. Not doing so may result in electric shock or injury.

Ω or less). Not connecting to a class-3 ground may

!WARNING Wiring or inspection must not be performed for at least five minutes after turning

OFF the power supply. Doing so may result in electric shock.

!WARNING Do not damage, press, or put excessive stress or heavy objects on the cables.

Doing so may result in electric shock.

!WARNING Do not touch the rotating parts of the Servomotor in operation. Doing so may

result in injury.

!WARNING Do not modify the product. Doing so may result in injury or damage to the product.

!WARNING Provide a stopping mechanism on the machine to ensure safety. The holding

brake is not designed as a stopping mechanism for safety purposes.

!WARNING Provide an external emergency stopping mechanism that can stop operation and

shutting off the power supply immediately. Not doing so may result in injury.

!WARNING Do not come close to the machine immediately after resetting momentary power

interruption to avoid an unexpected restart. (Take appropriate measures to secure

safety against an unexpected restart.) Doing so may result in injury.

!Caution Use the Servomotors and Servo Drivers in a specified combination. Using them

incorrectly may result in fire or damage to the products.

Page 8

!Caution Do not store or install the product in the following places. Doing so may result in

fire, electric shock, or damage to the product.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the

specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

!Caution Do not touch the Servo Driver radiator, Servo Driver regeneration resistor, or Ser-

vomotor while the power is being supplied or soon after the power is turned OFF.

Doing so may result in a skin burn due to the hot surface.

Storage and Transportation Precautions

!Caution Do not hold the product by the cables or motor shaft while transporting it. Doing so

may result in injury or malfunction.

!Caution Do not place any load exceeding the figure indicated on the product. Doing so

may result in injury or malfunction.

Installation and Wiring Precautions

!Caution Do not step on or place a heavy object on the product. Doing so may result in

injury.

!Caution Do not cover the inlet or outlet ports and prevent any foreign objects from entering

the product. Doing so may result in fire.

!Caution Be sure to install the product in the correct direction. Not doing so may result in

malfunction.

!Caution Provide the specified clearances between the Servo Driver and the control panel

or with other devices. Not doing so may result in fire or malfunction.

!Caution Do not apply any strong impact. Doing so may result in malfunction.

!Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway,

injury, or malfunction.

Page 9

!Caution Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

!Caution Use crimp terminals for wiring. Do not connect bare stranded wires directly to ter-

minals. Connection of bare stranded wires may result in burning.

!Caution Always use the power supply voltage specified in the User’s Manual. An incorrect

voltage may result in malfunction or burning.

!Caution Take appropriate measures to ensure that the specified power with the rated volt-

age and frequency is supplied. Be particularly careful in places where the power

supply is unstable. An incorrect power supply may result in malfunction.

!Caution Install external breakers and take other safety measures against short-circuiting in

external wiring. Insufficient safety measures against short-circuiting may result in

burning.

!Caution Take appropriate and sufficient countermeasures when installing systems in the

following locations. Failure to do so may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Operation and Adjustment Precautions

!Caution Confirm that no adverse effects will occur in the system before performing the test

operation. Not doing so may result in equipment damage.

!Caution Check the newly set parameters and switches for proper execution before actually

running them. Not doing so may result in equipment damage.

!Caution Do not make any extreme adjustments or setting changes. Doing so may result in

unstable operation and injury.

!Caution Separate the Servomotor from the machine, check for proper operation, and then

connect to the machine. Not doing so may cause injury.

!Caution When an alarm occurs, remove the cause, reset the alarm after confirming safety,

and then resume operation. Not doing so may result in injury.

!Caution Do not use the built-in brake of the Servomotor for ordinary braking. Doing so may

result in malfunction.

Page 10

Maintenance and Inspection Precautions

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

may result in malfunction, fire, or electric shock.

!Caution Resume operation only after transferring to the new Unit the contents of the data

required for operation. Not doing so may result in an unexpected operation.

Page 11

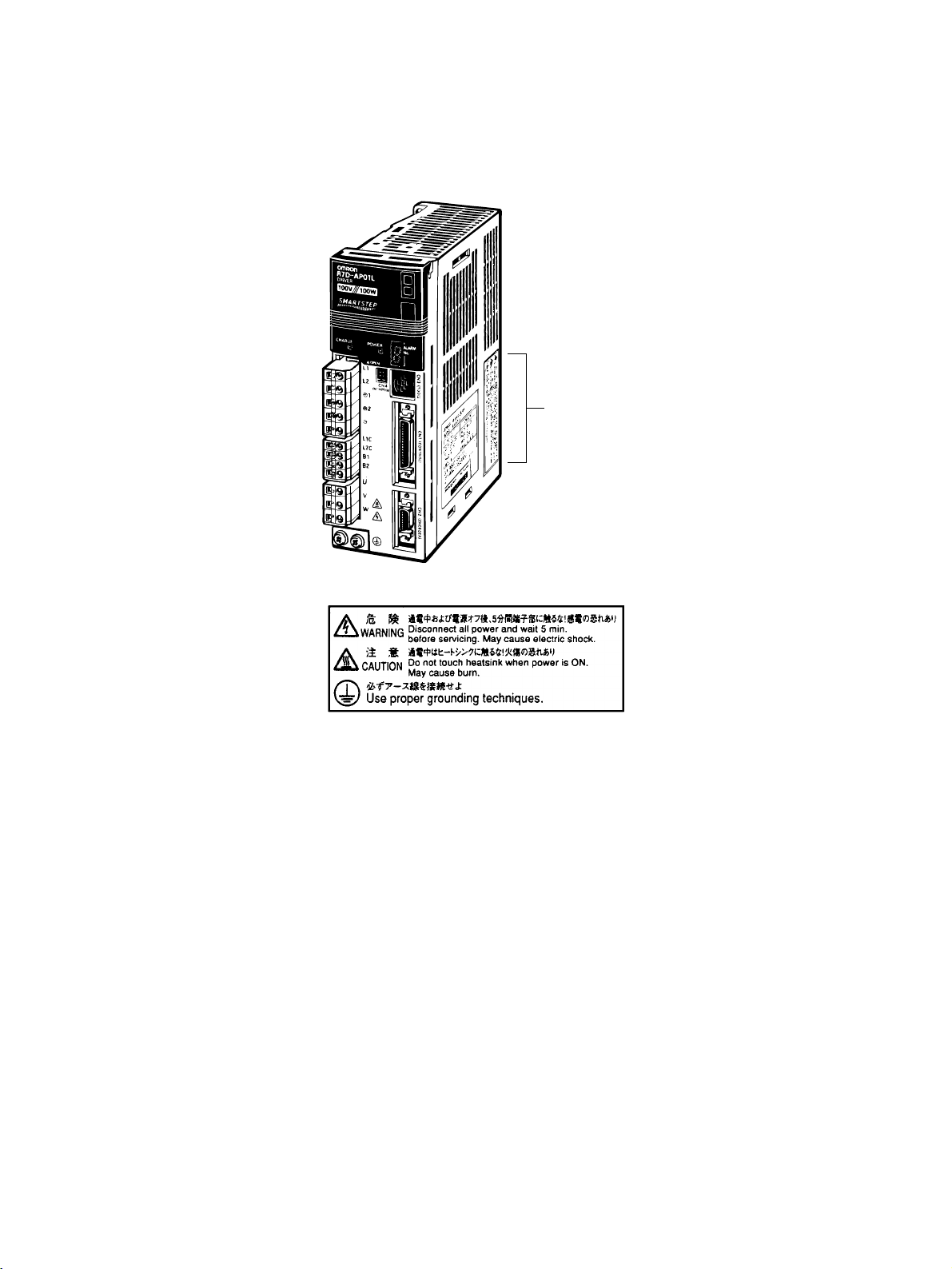

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to follow the

instructions given there.

Warning label

Example from R7D-AP01L

Example from R7D-AP01L

Page 12

Page 13

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 14

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 15

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 16

Page 17

Table of Contents

Chapter 1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Servo Driver Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-4 Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-5 System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Chapter 2. Standard Models and Specifications. . . . . . . . . . . . . . . . 2-1

2-1 Standard Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 External and Mounted Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-3 Servo Driver Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2-4 Servomotor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2-5 Reduction Gear Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

2-6 Cable and Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

2-7 Servo Relay Units and Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2-8 Parameter Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-111

2-9 External Regeneration Resistor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-113

2-10 DC Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-114

Chapter 3. System Design and Installation . . . . . . . . . . . . . . . . . . . . 3-1

3-1 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-3 Regenerative Energy Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Chapter 4. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-4 Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-5 Gain Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-6 User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-7 Operating Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 Measures when Trouble Occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-4 Overload Characteristics (Electron Thermal Characteristics) . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5-5 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Chapter 6. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1 Connection Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-1

Page 18

Page 19

Introduction

1-1 Features

1-2 System Configuration

1-3 Servo Driver Nomenclature

1-4 Applicable Standards

1-5 System Block Diagrams

Chapter 1

Page 20

Introduction

Chapter 1

1-1 Features

The SMARTSTEP A-series Servomotors and Servo Drivers have been developed as pulse string

input-type Position Controllers to replace stepping motors in simple positioning systems. The

SMARTSTEP A-series Servomotors and Servo Drivers combine the stepping motor’s ease of use

with faster positioning resulting from high speed and high torque, higher reliability with no loss of

positioning accuracy even during sudden load changes, and other advanced features.

■ Faster Response and Rotation Speed

SMARTSTEP A-series Servomotors and Servo Drivers incorporate the same high-speed and hightorque features, unachievable with stepping motors, as the OMNUC W Series. The SMARTSTEP Aseries Servomotors provide faster rotation speeds of up to 4,500 r/min, with constant operation possible at this speed. Faster output torque of up to 1 s can output up to approximately 300% of the

rated torque, providing even faster middle- and long-stroke positioning.

■ Constant Accuracy

The A-series product line’s higher encoder resolution of 2,000 pulses/rotation provides feedback

control enabling continuous operation without loss of positioning accuracy, even with sudden load

changes or sudden acceleration or deceleration.

■ Minimal Setting with Servo Driver Front Panel Switches

The SMARTSTEP A Series can be operated immediately without time-consuming parameter setting.

The A-series Servo Drivers’ front panel switches enable easier alteration of function or positioning

resolution settings.

● Resolution Settings

SMARTSTEP A-series Servomotor resolution can be selected from the following four levels:

500 pulses/rotation (0.72

rotation (0.072

● Command Pulse Input Setting

SMARTSTEP A-series command pulse input setting can be switched between CW/CCW (2-pulse)

and SIGN/PULS (single-pulse) methods to easily adapt to Position Controller output specifications.

● Dynamic Brake Setting

SMARTSTEP A-series Servomotors can be forcibly decelerated to a stop at RUN OFF or when

an alarm occurs.

● Gain Setting

°/step); or 10,000 pulses/rotation (0.036°/step)

°/step); 1,000 pulses/rotation (0.36°/step) (default setting); 5,000 pulses/

A special rotary switch on SMARSTEP A-series Servo Drivers enables easy gain setting. Online

autotuning can also be activated with the flick of a switch, and responsiveness can be easily

matched to the machinery to be used.

1-2

Page 21

Introduction

Note Using a Parameter Unit or personal computer enables operation with parameter settings.

■ Cylinder-style and Flat-style Servomotors

The SMARTSTEP A Series offers Flanged Cylinder-style Servomotors, with a smaller mounting

area, and Flat-style Servomotors, with a shorter overall length. The Flat Servomotor depth dimensions are approximately the same as those of stepping motors of the same output capacity. Servomotors can be selected by size, thereby making equipment more compact.

■ A Wider Selection of Programming Devices

Special SMARTSTEP A-series Parameter Units and personal computer monitoring software are

available. The special monitoring software enables performing parameter setting, speed and current

monitoring, speed and current waveform displays, I/O monitoring, autotuning, jogging, and other

operations from a computer. It is also possible to perform multiple-axis communications that set the

parameters and monitor operations for multiple Servo Drivers. For details, refer to the Servo Driver

Personal Computer Monitor Software (CD-ROM) for Windows 95/98, Version 2.0 (WMON Win

Ver.2.0) (Catalog No.: SBCE-011).

Chapter 1

1-3

Page 22

Introduction

SCROLL

MODE/SET

DATA

JOG

RUN

DRIVER PR

PR DRIVER

READ

WRITE

B.B

INP

VCMP

TGON

REF

POWER

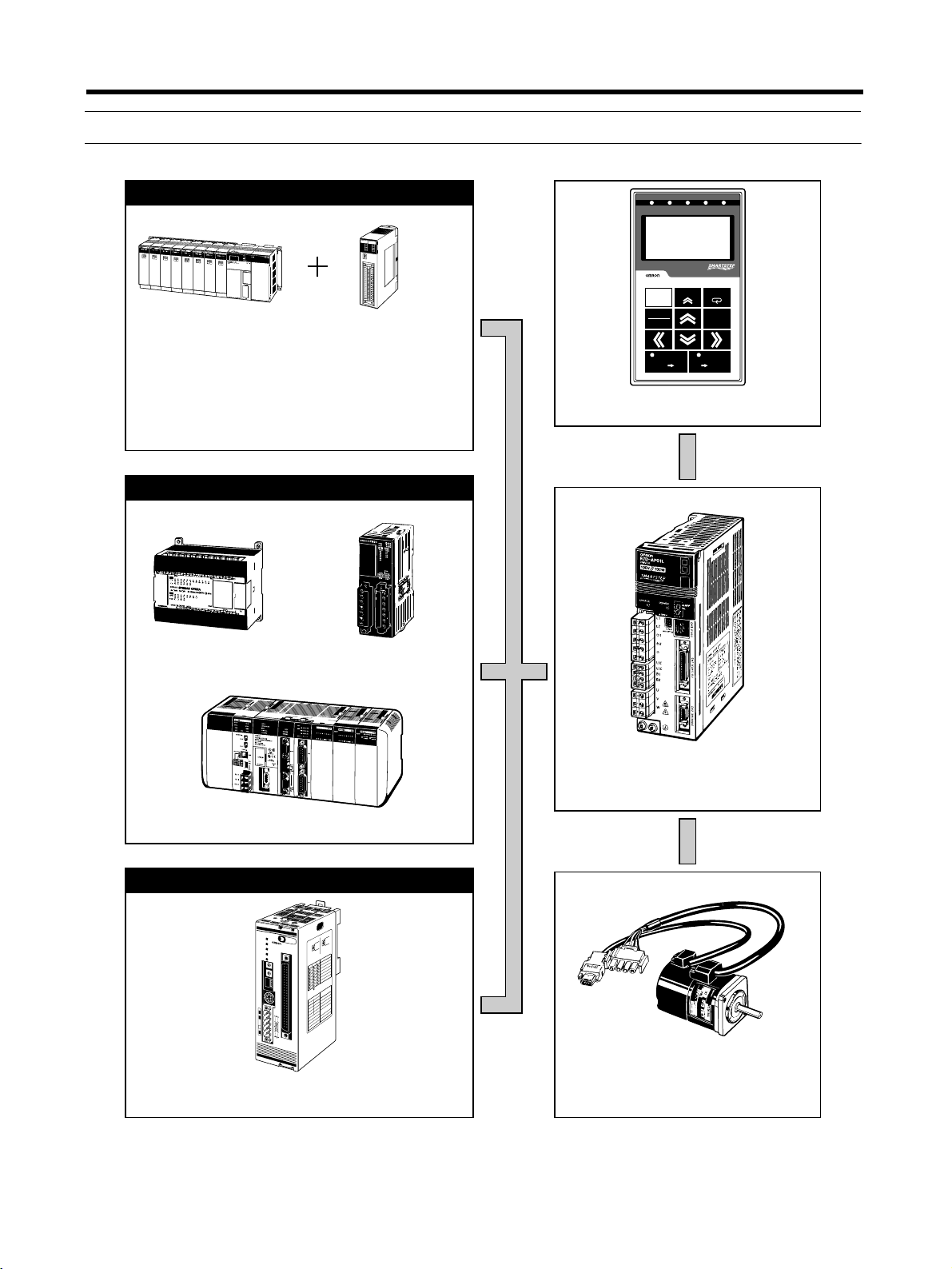

1-2 System Configuration

SYSMAC + Position Control Unit with pulse string output

N

C

4

1

3

R

U

N

X

E

R

R

O

R

Y

S

E

N

S

Z

D

A

T

A

U

M

A

C

H

IN

E

N

o

.

C

N

1

C

N

2

B

2

4

A

2

4

B

1

A

1

SYSMAC CJ/CS/C/CV

Programmable Controller

SYSMAC Programmable Controllers with pulse outputs

Position Control Units

CJ1W-NC113/213/413

CJ1W-NC133/233/433

CS1W-NC113/213/413

CS1W-NC133/233/433

C200HW-NC113/213/413

C500-NC113/211

Pulse String

Chapter 1

B.B

INP

TGON

REF

SCROLL

MODE/SET

DATA

WRITE

PR DRIVER

POWER

VCMP

R7A–PR02A PARAMETER UNIT

RESET

JOG

RUN

READ

DRIVER PR

R7A-PR02A Parameter Unit

(Hand-held)

SYSMAC CPM2A

P

A

20

3

P

O

W

E

R

SYSMAC CPM2C

/

SYSMAC CQM1H

Single-shaft Positioner with pulse string output

N

E

P

M

S

N

S

3

F

8

M

0

1

A

X

M

1

M

2

3

2

4

1

5

0

N

A

6

9

7

8

×

1

0

3

2

4

1

5

0

6

9

7

8

×

1

123

ON↓

DR0

DR1

L/R

3F88M-DRT141 Single-shaft

Positioner for DeviceNet

O

N

E

P

N

o

.

O

E

IN

L

8

M

-

E

D

IN

R

L

T

W

IS

1

C

4

P

1

O

S

IT

IO

N

E

R

W

C

C

ALARM

LS

IT

M2

IM

L

T

M1

F

G

O

N

S

H

R

M0

S

M

G

L

R

A

O

R

E

D

O

C

N

P

E

O

T

S

M

L

A

R

E

IV

R

R

D

E

H

T

O

N

)

:

D

UNICATIO

E

M

R

(

M

CO

SPEED

s

p

b

H

k

C

5

T

2

I

1

W

1

S

R

P

I

D

D

250kbps

F

F

0

O

R

D

500kbps

F

F

−

F

O

F

O

ON

ON

LOCAL/REMOTE

ON

OFF

E

H

D

C

N

T

O

I

O

W

M

S

REMOTE MODE

L

P

A

I

C

D

/R

LO

L

F

F

O

N

O

I/O

SMARTSTEP A-series

R7D-AP@ Servo Driver

SMARTSTEP A-series

R7M-A@ Servomotor

1-4

Page 23

Introduction

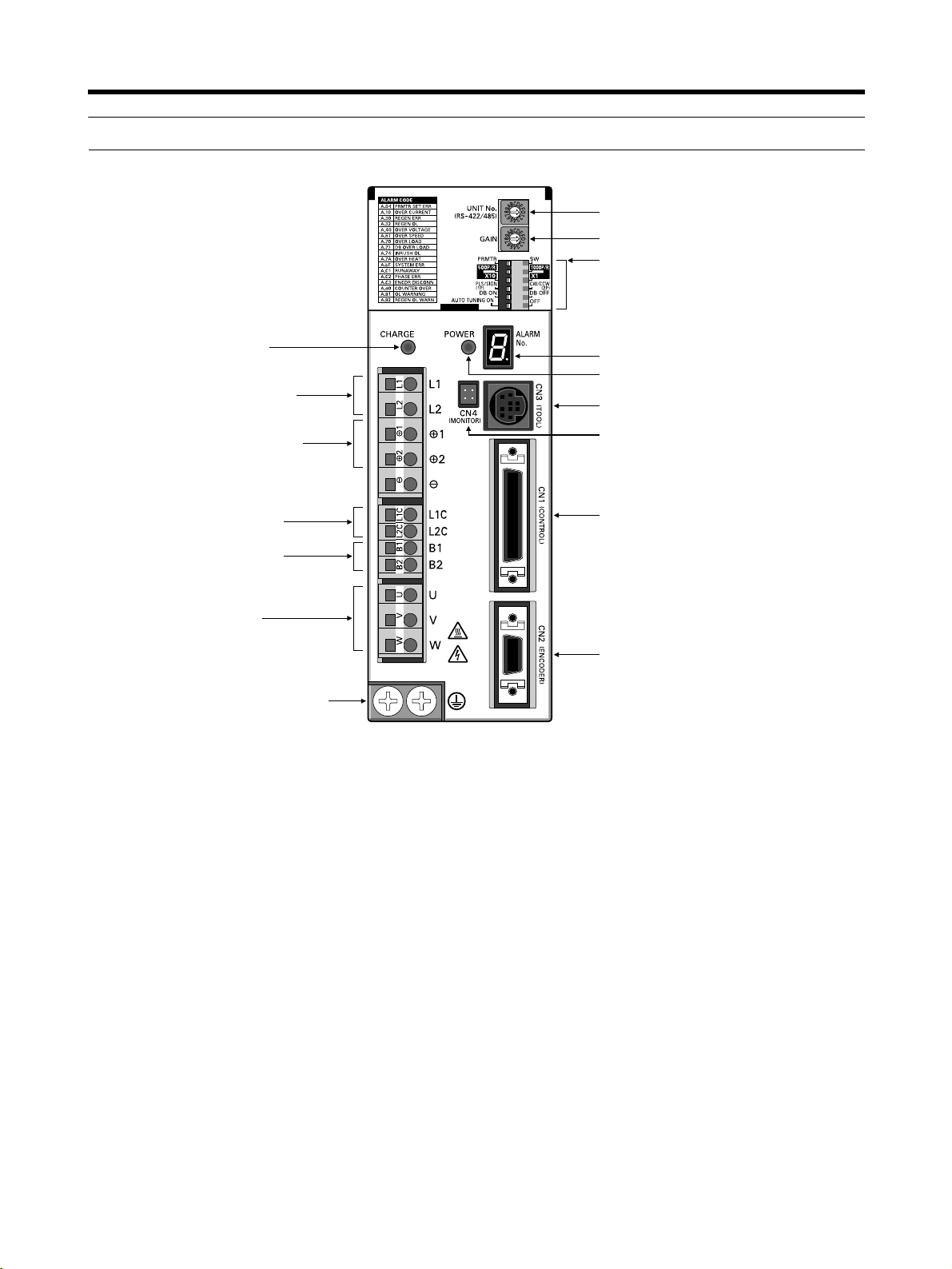

1-3 Servo Driver Nomenclature

Main-circuit power supply

indicator

Main-circuit power

supply input terminals

Chapter 1

Rotary switch for unit No. selection

Rotary switch for gain adjustment

Function selection switches:

• Switch/parameter setting enable switch

• Resolution setting

• Command pulse input setting

• Dynamic braking setting

• Online autotuning switch

Alarm display

Control-circuit power supply indicator

Communications connector (CN3)

DC reactor connection terminals

Control-circuit power supply

input terminals

External regeneration

resistance terminals

Servomotor power terminals

FG terminals for power supply and

servomotor power

Monitor output connector (CN4)

Control I/O connector (CN1)

Encoder input connector (CN2)

1-5

Page 24

Introduction

Chapter 1

1-4 Applicable Standards

■ EC Directives

EC Directives Product Applicable standards Remarks

Low Voltage

Directive

EMC Directives AC Servo Drivers and

Note Installation under the conditions stipulated in 3-2-5 EMC-compatible Wiring must be met to

ensure conformance to EMC Directives.

AC Servo Drivers EN50178 Safety requirements for electrical

devices for measurement, control,

and research facilities

AC Servomotors IEC60034-1, -5, -8, -9

EN60034-1, -9

EN55011 class A group 1 Wireless interference and measure-

AC Servomotors

EN61000-6-2 Electromagnetic compatibility and

Rotating electrical equipment

ment methods for radio-frequency

devices for industry, science, and

medical application

immunity standards for industrial

environments

■ UL and cUL Standards

Standards Product Applicable standards File No. Remarks

UL AC Servo Drivers UL508C E179149 Power conversion devices

AC Servomotors UL1004 E179189 Electric motors

cUL AC Servo Drivers cUL C22.2 No. 14 E179149 Industrial control devices

AC Servomotors cUL C22.2 No. 100 E179189 Motors and generators

1-6

Page 25

Introduction

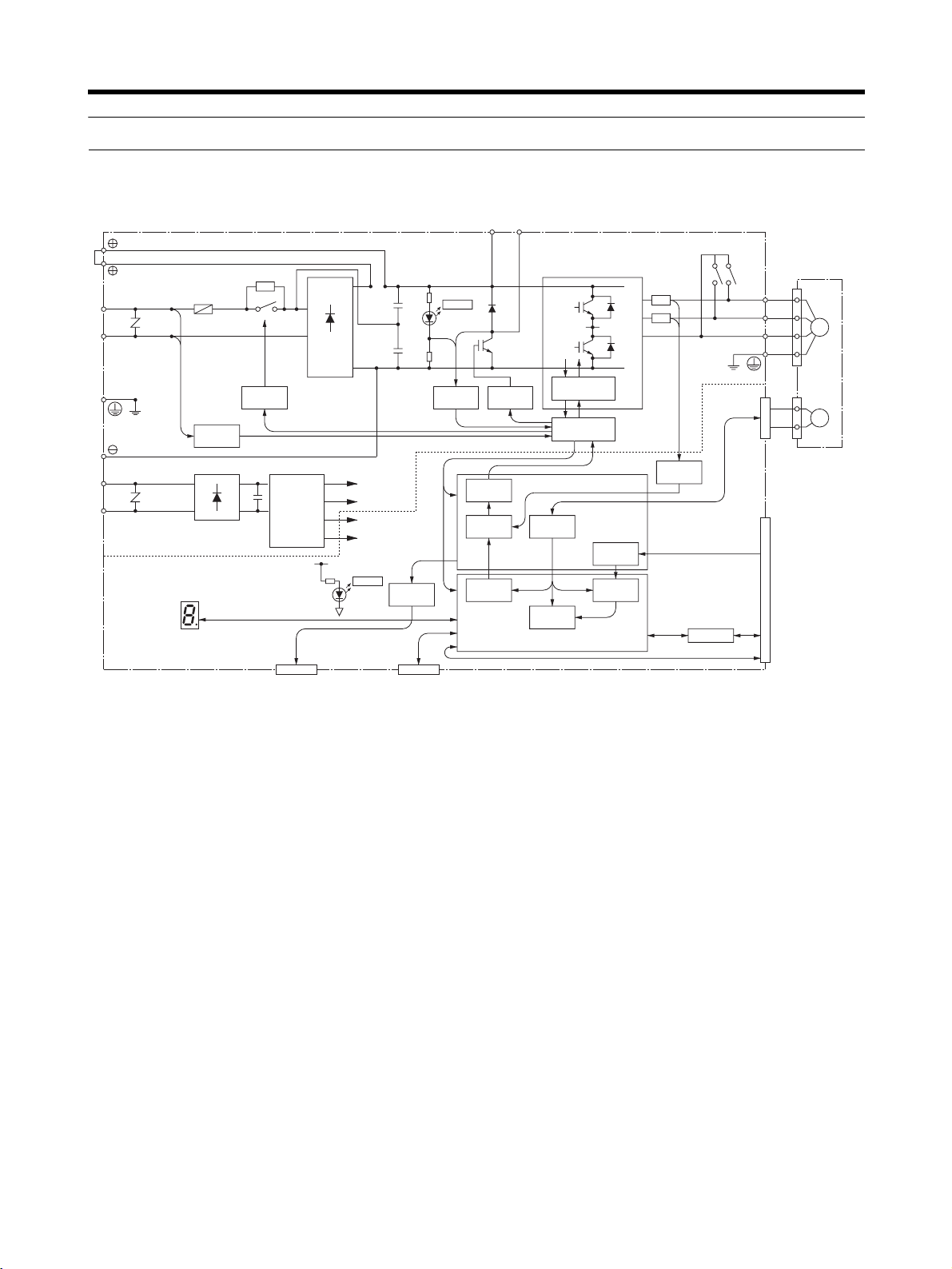

1-5 System Block Diagrams

■ 100 V AC: R7D-APA3L/-APA5L/-AP01L/-AP02L/-AP04L

AC Servo Driver

Gate drive

PWM

generation

Digital

current amp

Current

command

processing

Serial port

B1 B2

(See note.)

Encoder signal

P2

N2

Gate drive

overcurrent protection

Interface

processing

Speed

control

U

V

W

Current

detection

ASIC

Command

pulse

processing

Position

control

CPU

Note Only on R7D-AP04H/AP04L.

1

2

P1

R

T

N1

CHARGE

+

−

Voltage

detection

±5 V

+16.5 V

+5 V

L1

L2

L1C

L2C

Fuse

Voltage

detection

∼

∼

Relay

drive

+

+

DC/DC

−

−

conversion

±15 V

+5 V

POWER

Analog

voltage

0 V

Alarm code display

CN4

Analog monitor output

conversion

CN3

Parameter Unit/computer

Chapter 1

CN2

CN1

I/O

AC Servomotor

U

V

M

W

E

Command

pulse input

Control I/O

RS-422

1-7

Page 26

Introduction

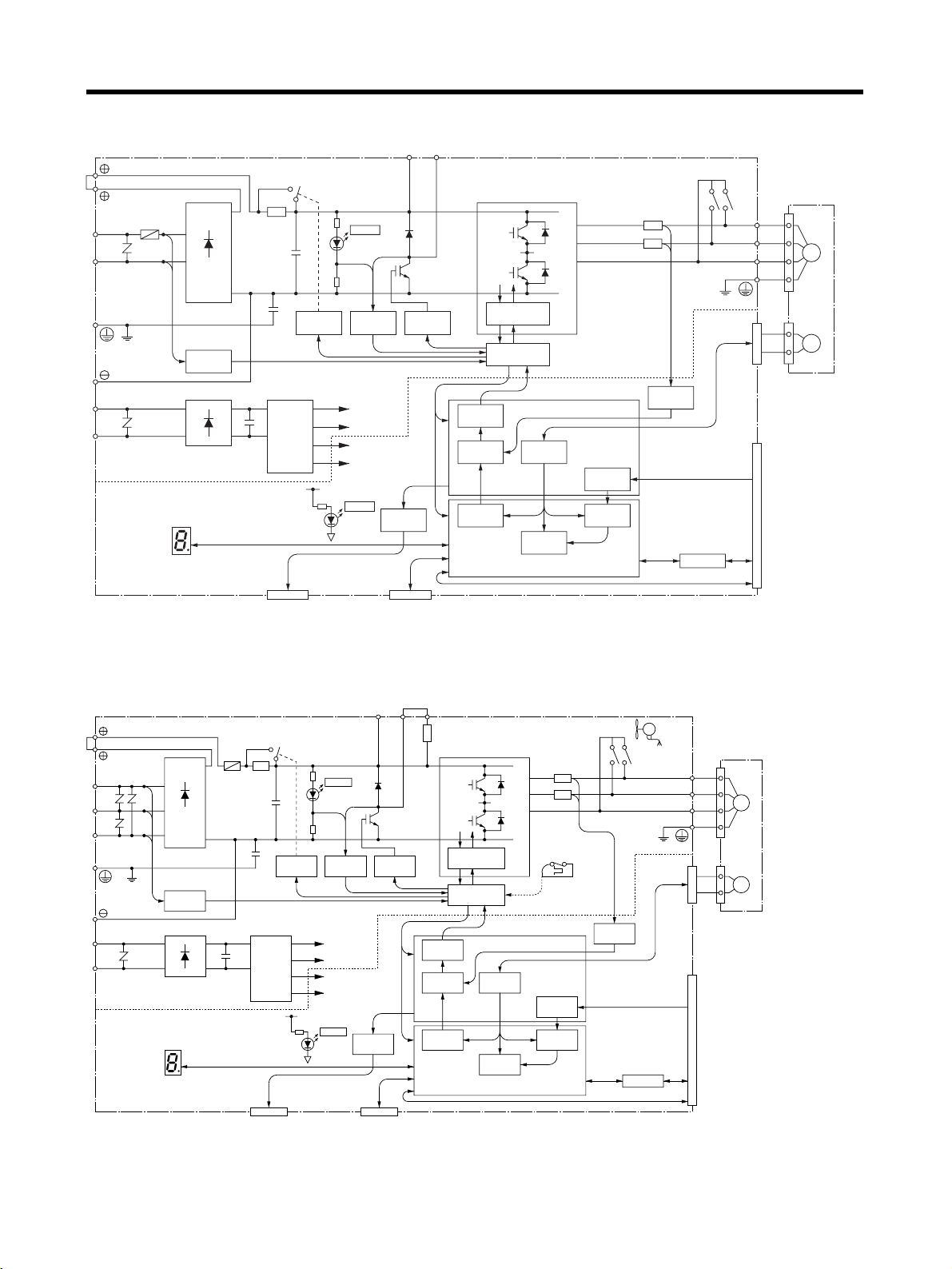

■ 200 V AC: R7D-APA3H/-APA5H/-AP01H/-AP02H/-AP04H

AC Servo Driver

1

B1 B2

Chapter 1

2

L1

L2

L1C

L2C

Fuse

R

T

Voltage

detection

∼

∼

Alarm code display

P1

N1

AC Servomotor

CHARGE

+

−

(See note.)

P2

U

V

W

U

V

M

W

N2

Gate drive

PWM

generation

Digital

current amp

Current

command

processing

Serial port

overcurrent protection

Interface

Encoder signal

processing

Speed

control

CN2

Current

detection

ASIC

CN1

Command

pulse

processing

Position

control

CPU

I/O

Command

pulse input

Control I/O

RS-422

Note Only on R7D-AP04H/AP04L.

E

Relay

+

+

DC/DC

−

−

conversion

drive

Voltage

detection

±5 V

+16.5 V

+5 V

Gate drive

±15 V

+5 V

POWER

Analog

voltage

conversion

0 V

CN4

Analog monitor output

CN3

Parameter Unit/computer

■ 200 V AC: R7D-AP08H

AC Servo Driver

1

2

L1

L2

L3

L1C

L2C

Alarm code display

R

S

T

Voltage

detection

∼

P

Fuse

CHARGE

+

−

N

Relay

detection

drive

+∼

+

DC/DC

−

−

conversion

±5 V

+16.5 V

+5 V

±15 V

+5 V

POWER

0 V

CN4

Analog monitor output

B1 B2 B3

Voltage

Gate

Analog

voltage

conversion

CN3

Parameter Unit/computer

drive

P

N

PWM

generation

Digital

current amp

Current

command

processing

Serial port

Gate drive over-

current protection

Interface

Encoder

processing

Speed

control

signal

FAN

±12 V

AC Servomotor

CN2

U

V

W

M

E

U

V

W

Thermistor

Current

detection

ASIC

CN1

Command

pulse

processing

Position

control

CPU

I/O

Command

pulse input

Control I/O

RS-422

1-8

Page 27

Chapter 2

Standard Models and Specifications

2-1 Standard Models

2-2 External and Mounted Dimensions

2-3 Servo Driver Specifications

2-4 Servomotor Specifications

2-5 Reduction Gear Specifications

2-6 Cable and Connector Specifications

2-7 Servo Relay Units and Cable Specifications

2-8 Parameter Unit Specifications

2-9 External Regeneration Resistor Specifications

2-10 DC Reactors

Page 28

Standard Models and Specifications

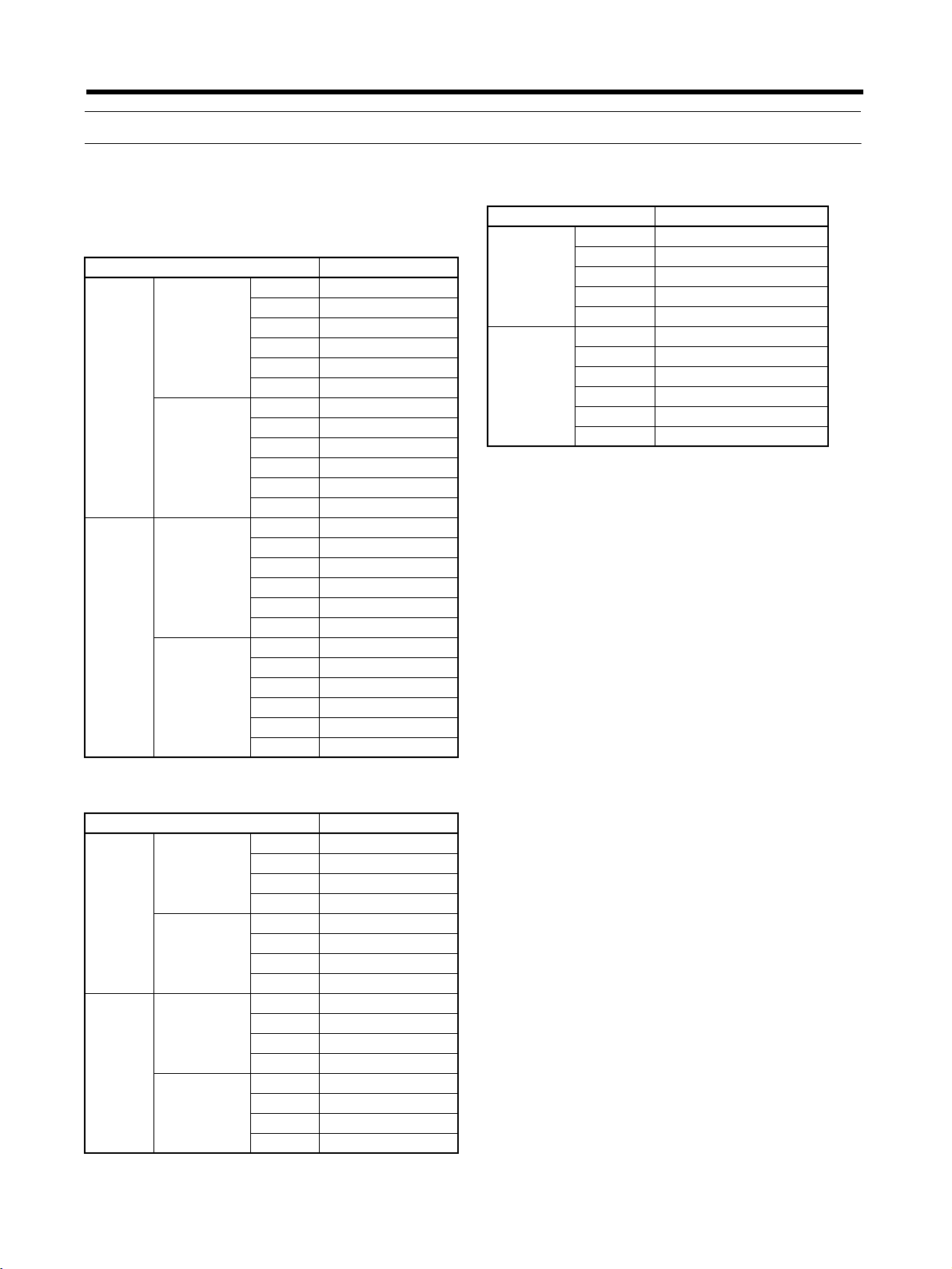

2-1 Standard Models

Chapter 2

■ Servomotors

● 3,000-r/min Cylinder-style Servomotors

Specifications Model

Without

brake

With

brake

Straight shaft

without key

Straight shaft

with key

Straight shaft

without key

Straight shaft

with key

30 W R7M-A03030

50 W R7M-A05030

100 W R7M-A10030

200 W R7M-A20030

400 W R7M-A40030

750 W R7M-A75030

30 W R7M-A03030-S1

50 W R7M-A05030-S1

100 W R7M-A10030-S1

200 W R7M-A20030-S1

400 W R7M-A40030-S1

750 W R7M-A75030-S1

30 W R7M-A03030-B

50 W R7M-A05030-B

100 W R7M-A10030-B

200 W R7M-A20030-B

400 W R7M-A40030-B

750 W R7M-A75030-B

30 W R7M-A03030-BS1

50 W R7M-A05030-BS1

100 W R7M-A10030-BS1

200 W R7M-A20030-BS1

400 W R7M-A40030-BS1

750 W R7M-A75030-BS1

■ Servo Drivers

Specifications Model

Single-phase

100 V AC

Single-phase

200 V AC

30 W R7D-APA3L

50 W R7D-APA5L

100 W R7D-AP01L

200 W R7D-AP02L

400 W R7D-AP04L

30 W R7D-APA3H

50 W R7D-APA5H

100 W R7D-AP01H

200 W R7D-AP02H

400 W R7D-AP04H

750 W R7D-AP08H

● 3,000-r/min Flat-style Servomotors

Specifications Model

Without

brake

With

brake

Straight shaft

without key

Straight shaft

with key

Straight shaft

without key

Straight shaft

with key

100 W R7M-AP10030

200 W R7M-AP20030

400 W R7M-AP40030

750 W R7M-AP75030

100 W R7M-AP10030-S1

200 W R7M-AP20030-S1

400 W R7M-AP40030-S1

750 W R7M-AP75030-S1

100 W R7M-AP10030-B

200 W R7M-AP20030-B

400 W R7M-AP40030-B

750 W R7M-AP75030-B

100 W R7M-AP10030-BS1

200 W R7M-AP20030-BS1

400 W R7M-AP40030-BS1

750 W R7M-AP75030-BS1

2-2

Page 29

Standard Models and Specifications

■ Reduction Gears (Straight Shaft with Key)

Chapter 2

● For Cylinder-style Servomotors

(Backlash = 3′ Max.)

Specifications Model

Servomotor

capacity

50 W 1/5 R7G-VRSFPB05B50

100 W 1/5 R7G-VRSFPB05B100

200 W 1/5 R7G-VRSFPB05B200

400 W 1/5 R7G-VRSFPB05C400

750 W 1/5 R7G-VRSFPB05C750

Reduction gears

(deceleration ratio)

1/9 R7G-VRSFPB09B50

1/15 R7G-VRSFPB15B50

1/25 R7G-VRSFPB25B50

1/9 R7G-VRSFPB09B100

1/15 R7G-VRSFPB15B100

1/25 R7G-VRSFPB25B100

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

1/25 R7G-VRSFPB25C200

1/9 R7G-VRSFPB09C400

1/15 R7G-VRSFPB15C400

1/25 R7G-VRSFPB25D400

1/9 R7G-VRSFPB09D750

1/15 R7G-VRSFPB15D750

1/25 R7G-VRSFPB25E750

● For Cylinder-style Servomotors

(Backlash = 45′ Max.)

Specifications Model

Servomotor

capacity

50 W 1/5 R7G-RGSF05B50

100 W 1/5 R7G-RGSF05B100

200 W 1/5 R7G-RGSF05B200

400 W 1/5 R7G-RGSF05C400

750 W 1/5 R7G-RGSF05C750

Reduction gears

(deceleration ratio)

1/9 R7G-RGSF09B50

1/15 R7G-RGSF15B50

1/25 R7G-RGSF25B50

1/9 R7G-RGSF09B100

1/15 R7G-RGSF15B100

1/25 R7G-RGSF25B100

1/9 R7G-RGSF09C400

1/15 R7G-RGSF15C400

1/25 R7G-RGSF25C400

1/9 R7G-RGSF09C400

1/15 R7G-RGSF15C400

1/25 R7G-RGSF25C400

1/9 R7G-RGSF09C750

1/15 R7G-RGSF15C750

1/25 R7G-RGSF25C750

Note There are no reduction gears for 30-W Servo-

motors.

● For Flat-style Servomotors

(Backlash = 3′ Max.)

Specifications Model

Servomotor

capacity

100 W 1/5 R7G-VRSFPB05B100P

200 W 1/5 R7G-VRSFPB05B200P

400 W 1/5 R7G-VRSFPB05C400P

750 W 1/5 R7G-VRSFPB05C750P

Reduction gears

(deceleration ratio)

1/9 R7G-VRSFPB09B100P

1/15 R7G-VRSFPB15B100P

1/25 R7G-VRSFPB25C100P

1/9 R7G-VRSFPB09C400P

1/15 R7G-VRSFPB15C400P

1/25 R7G-VRSFPB25C200P

1/9 R7G-VRSFPB09C400P

1/15 R7G-VRSFPB15C400P

1/25 R7G-VRSFPB25D400P

1/9 R7G-VRSFPB09D750P

1/15 R7G-VRSFPB15D750P

1/25 R7G-VRSFPB25E750P

Note There are no reduction gears for 30-W Servo-

motors.

● For Flat-style Servomotors

(Backlash = 45′ Max.)

Specifications Model

Servomotor

capacity

100 W 1/5 R7G-RGSF05B100P

200 W 1/5 R7G-RGSF05B200P

400 W 1/5 R7G-RGSF05C400P

750 W 1/5 R7G-RGSF05C750P

Reduction gears

(deceleration ratio)

1/9 R7G-RGSF09B100P

1/15 R7G-RGSF15B100P

1/25 R7G-RGSF25B100P

1/9 R7G-RGSF09C400P

1/15 R7G-RGSF15C400P

1/25 R7G-RGSF25C400P

1/9 R7G-RGSF09C400P

1/15 R7G-RGSF15C400P

1/25 R7G-RGSF25C400P

1/9 R7G-RGSF09C750P

1/15 R7G-RGSF15C750P

1/25 R7G-RGSF25C750P

2-3

Page 30

Standard Models and Specifications

Chapter 2

■ Servo Relay Units for CN1

Specifications Model

Servo

Relay Unit

Servo

Driver

Cable

Position

Control

Unit Cable

For CS1W-NC113/133

CJ1W-NC113/133

C200HW-NC113

C200H-NC112

3F88M-DRT141

(No communications supported.)

For CS1W-NC213/233/413/433

CJ1W-NC213/233/413/433

C200HW-NC213/413

C500-NC113/211

C200H-NC211

(No communications supported.)

For CS1W-HCP22

CQM1H-PLB21

CQM1-CPU43-V1

(No communications supported.)

For CS1W-NC213/233/413/433

CJ1W-NC213/233/413/433

(Communications supported.)

For CJ1M-CPU21/CPU22/

CPU23

For CS1W-HCP22-V1 and

FQM1-MMP21

No communications

supported.

Communications supported.

For FQM1-MMP21 1 m XW2Z-100J-B10

For CS1W-HCP22-V1 1 m XW2Z-100J-B12

For CQM1H-PLB21,

CQM1-CPU43-V1

For C200H-NC112 0.5 m XW2Z-050J-A4

For C200H-NC211,

C500-NC113/211

For CS1W-NC113,

C200HW-NC113

For CS1W-NC213/413,

C200HW-NC213/413

For CS1W-NC133 0.5 m XW2Z-050J-A12

For CS1W-NC233/433 0.5 m XW2Z-050J-A13

For CJ1W-NC113 0.5 m XW2Z-050J-A16

For CJ1W-NC213/413 0.5 m XW2Z-050J-A17

For CJ1W-NC133 0.5 m XW2Z-050J-A20

For CJ1W-NC233/433 0.5 m XW2Z-050J-A21

For CS1W-HCP22

(1 axis)

For CS1W-HCP22

(2 axes)

For 3F88M-DRT141 0.5 m XW2Z-050J-A25

1 m XW2Z-100J-B5

2 m XW2Z-200J-B5

1 m XW2Z-100J-B7

2 m XW2Z-200J-B7

2 m XW2Z-200J-B10

2 m XW2Z-200J-B12

0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

1 m XW2Z-100J-A4

0.5 m XW2Z-050J-A5

1 m XW2Z-100J-A5

0.5 m XW2Z-050J-A8

1 m XW2Z-100J-A8

0.5 m XW2Z-050J-A9

1 m XW2Z-100J-A9

1 m XW2Z-100J-A12

1 m XW2Z-100J-A13

1 m XW2Z-100J-A16

1 m XW2Z-100J-A17

1 m XW2Z-100J-A20

1 m XW2Z-100J-A21

0.5 m XW2Z-050J-A22

1 m XW2Z-100J-A22

0.5 m XW2Z-050J-A23

1 m XW2Z-100J-A23

1 m XW2Z-100J-A25

XW2B-20J6-1B

XW2B-40J6-2B

XW2B-20J6-3B

XW2B-40J6-4A

XW2B-20J6-8A

XW2B-40J6-9A

XW2B-80J7-1A

Specifications Model

Position

Control

Unit Cable

For CJ1M-CPU21/

CPU22/CPU23

For FQM1-MMP21 for

general-purpose I/O

For CS1W-HCP22-V1

for general-purpose I/O

For FQM1-MMP21 for

special I/O

For CS1W-HCP22-V1

for special I/O

1 m XW2Z-100J-A26

0.5 m XW2Z-050J-A28

1 m XW2Z-100J-A28

0.5 m XW2Z-050J-A29

1 m XW2Z-100J-A29

0.5 m XW2Z-050J-A30

1 m XW2Z-100J-A30

0.5 m XW2Z-050J-A32

1 m XW2Z-100J-A32

■ Control Cables for CN1

Specifications Model

General-purpose Control Cable

(with Connector on one end)

Connector Terminal Block Cable 1 m R88A-CTU001N

Connector Terminal Blocks XW2B-40F5-P

1 m R88A-CPU001S

2 m R88A-CPU002S

2 m R88A-CTU002N

■ Integrated Servomotor Cables

Specifications Model

For Servomotors without

brakes (both Cylinder- and

Flat-style)

For Servomotors with

brakes (both Cylinder- and

Flat-style)

3 m R7A-CEA003S

5 m R7A-CEA005S

10 m R7A-CEA010S

15 m R7A-CEA015S

20 m R7A-CEA020S

3 m R7A-CEA003B

5 m R7A-CEA005B

10 m R7A-CEA010B

15 m R7A-CEA015B

20 m R7A-CEA020B

■ Separate Servomotor Cables

● Power Cables

Specifications Standard cable

For Servomotors without brakes

(both Cylinder- and

Flat-style)

For Servomotors with

brakes (both

Cylinderand Flatstyle)

3 m R88A-CAWA003S R88A-CAWA003SR

5 m R88A-CAWA005S R88A-CAWA005SR

10 m R88A-CAWA010S R88A-CAWA010SR

15 m R88A-CAWA015S R88A-CAWA015SR

20 m R88A-CAWA020S R88A-CAWA020SR

3 m R88A-CAWA003B R88A-CAWA003BR

5 m R88A-CAWA005B R88A-CAWA005BR

10 m R88A-CAWA010B R88A-CAWA010BR

15 m R88A-CAWA015B R88A-CAWA015BR

20 m R88A-CAWA020B R88A-CAWA020BR

model

Robot cable

model

● Encoder Cables

Specifications Standard cable

For Servomotors (Cylinder-style or

Flat-style)

3 m R7A-CRA003C R7A-CRA003CR

5 m R7A-CRA005C R7A-CRA005CR

10 m R7A-CRA010C R7A-CRA010CR

15 m R7A-CRA015C R7A-CRA015CR

20 m R7A-CRA020C R7A-CRA020CR

model

Robot cable

model

Note Use a robot cable if cable flexibility is required.

2-4

Page 31

Standard Models and Specifications

■ Peripheral Cable Connectors

Specifications Model

Analog Monitor Cable (CN4) 1 m R88A-CMW001S

Computer Monitor Cable (CN3) DOS 2 m R7A-CCA002P2

PC98 2 m R7A-CCA002P3

Control I/O Connector (CN1) R88A-CNU01C

Encoder Connector (CN2) R7A-CNA01R

Encoder Connector (Servomotor end) R7A-CNA02R

Communications Cable 1 m XW2Z-100J-C1

2 m XW2Z-200J-C1

■ Parameter Units

Specifications Model

Hand-held (with 1-m cable) R7A-PR02A

■ External Regeneration Resistors

Specifications Model

Resistor 220 W 47

■ DC Reactors

Specifications Model

For R7D-APA3L/APA5L/APA01L R88A-PX5063

For R7D-AP02L R88A-PX5062

For R7D-AP04L R88A-PX5061

For R7D-APA3H/APA5H/AP01H R88A-PX5071

For R7D-AP02H R88A-PX5070

For R7D-AP04H R88A-PX5069

For R7D-AP08H R88A-PX5061

Ω R88A-RR22047S

Chapter 2

■ Front-panel Brackets

Specifications Model

For the SMARTSTEP A Series R88A-TK01W

2-5

Page 32

Standard Models and Specifications

Chapter 2

2-2 External and Mounted Dimensions

2-2-1 Servo Drivers

■ Single-phase 100 V AC: R7D-APA3L/-APA5L/-AP01L/-AP02L (30 W to 200 W)

Single-phase 200 V AC: R7D-APA3H/-APA5H/-AP01H/-AP02H (30 W to 200 W)

● Wall Mounting

External dimensions

Mounted dimensions

Two, M4

5.5

160

55

(75) 130

17

● Front Panel Mounting (Using Mounting Brackets)

External dimensions

7.5(7.5)

5 dia. 24.5

52661.5

2

160

149.5±0.5

5

(5)

55

Mounted dimensions

7.5(7.5)

10

Two, M4

2-6

195

180

195

180±0.5

5

32.5

11.542

(168)

Page 33

Standard Models and Specifications

■ Single-phase 100 V AC: R7D-AP04L (400 W)

Single-phase 200 V AC: R7D-AP04H (400 W)

● Wall Mounting

External dimensions

5 dia.

Mounted dimensions

Chapter 2

5.5

Two, M4

160

149.5 5.5(5)

5

12

75

(75) 130

17

● Front Panel Mounting (Using Mounting Brackets)

External dimensions

7.5

52 1.5

5 dia.

24.5

2

160

149.5±0.5

12

(5)

75

Mounted dimensions

7.5(7.5)

10

Two, M4

195

180

(7.5)

195

180±0.5

5

32.5

11.542

(168) 66

2-7

Page 34

Standard Models and Specifications

■ Single-phase/Three-phase 200 V AC: R7D-AP08H (750 W)

● Wall Mounting

External dimensions

5 dia.

Mounted dimensions

5.5

Chapter 2

Two, M4

160

149.5 5.5(5)

90

(75) 180

17

160

149.5±0.5

(5)

● Front Panel Mounting (Using Mounting Brackets)

External dimensions Mounted dimensions

7.5(7.5)

5 dia.

52 12.5

24.5

2

7.5(7.5)

10

27

90

Two, M4

2-8

195

180

195

180±0.5

5

43.5

42

22.5

(168) 66

Page 35

Standard Models and Specifications

DRIVER PR

PR DRIVER

WRITE

B.B

INP

VCMP

TGON

REF

POWER

2-2-2 Parameter Unit

■ R7A-PR02A Hand-held Parameter Unit

70

B.B

INP

TGON

REF

POWER

1201000

VCMP

R7A–PR02A PARAMETER UNIT

RESET

SCROLL MODE/SET

1.5

17

Chapter 2

0.8

42

JOG

RUN

READ

DRIVER PR

6

DATA

WRITE

PR DRIVER

4.8 dia.

13.2 dia.

2-9

Page 36

Standard Models and Specifications

2-2-3 Servomotors

■ Cylinder-style Servomotors without a Brake

● 30 W/50 W/100 W R7M-A03030(-S1)/-A05030(-S1)/-A10030(-S1)

300±30

Chapter 2

6 dia.

19.5 20

9.5

7 dia.

300±30

11

LL 25

S dia.

30h7 dia.

Two, 4.3 dia.

46 dia.

21.5 5

Dimensions of shaft end with key (-S1)

b

40

14

4052.5

Model Dimensions (mm)

LL S b h t1

R7M-A03030-@ 69.5 6h6 2 2 1.2

R7M-A05030-@ 77 6h6 2 2 1.2

R7M-A10030-@ 94.5 8h6 3 3 1.8

■ Cylinder-style Servomotors with a Brake

● 30 W/50 W/100 W R7M-A03030-B(S1)/-A05030-B(S1)/-A10030-B(S1)

300±30

h

t1

6 dia. 7 dia.

19.5 27

9.5

11

LL 25

300±30

S dia.

Two, 4.3 dia.

30h7 dia.

21.5 5

46 dia.

Dimensions of shaft end with key (-BS1)

h

b

40

14

405 2.5

t1

Model Dimensions (mm)

LL S b h t1

R7M-A03030-B@ 101 6h6 2 2 1.2

R7M-A05030-B@ 108.5 6h6 2 2 1.2

R7M-A10030-B@ 135 8h6 3 3 1.8

2-10

Page 37

Standard Models and Specifications

■ Cylinder-style Servomotors without a Brake

● 200 W/400 W/750 W R7M-A20030(-S1)/-A40030(-S1)/-A75030(-S1)

300±30

Chapter 2

6 dia.

13

9

7 dia.

20

11

LL LR

300±30

G3

S dia.

21.5

Four, Z dia.

D1 dia.

D2 dia.

C

Dimensions of output section of 750-W Servomotors

2

Dimensions of shaft end with key (-S1)

C

QK

5

5

3

Model Dimensions (mm)

LL LR C D1 D2 G Z S QK

R7M-A20030-@ 96.5 30 60 70 50h7 6 5.5 14h6 20

R7M-A40030-@ 124.530607050h76 5.514h620

R7M-A75030-@ 14540809070h78 7 16h630

■ Cylinder-style Servomotors with a Brake

● 200 W/400 W/750 W R7M-A20030-B(S1)/-A40030-B(S1)/-A75030-B(S1)

300±30

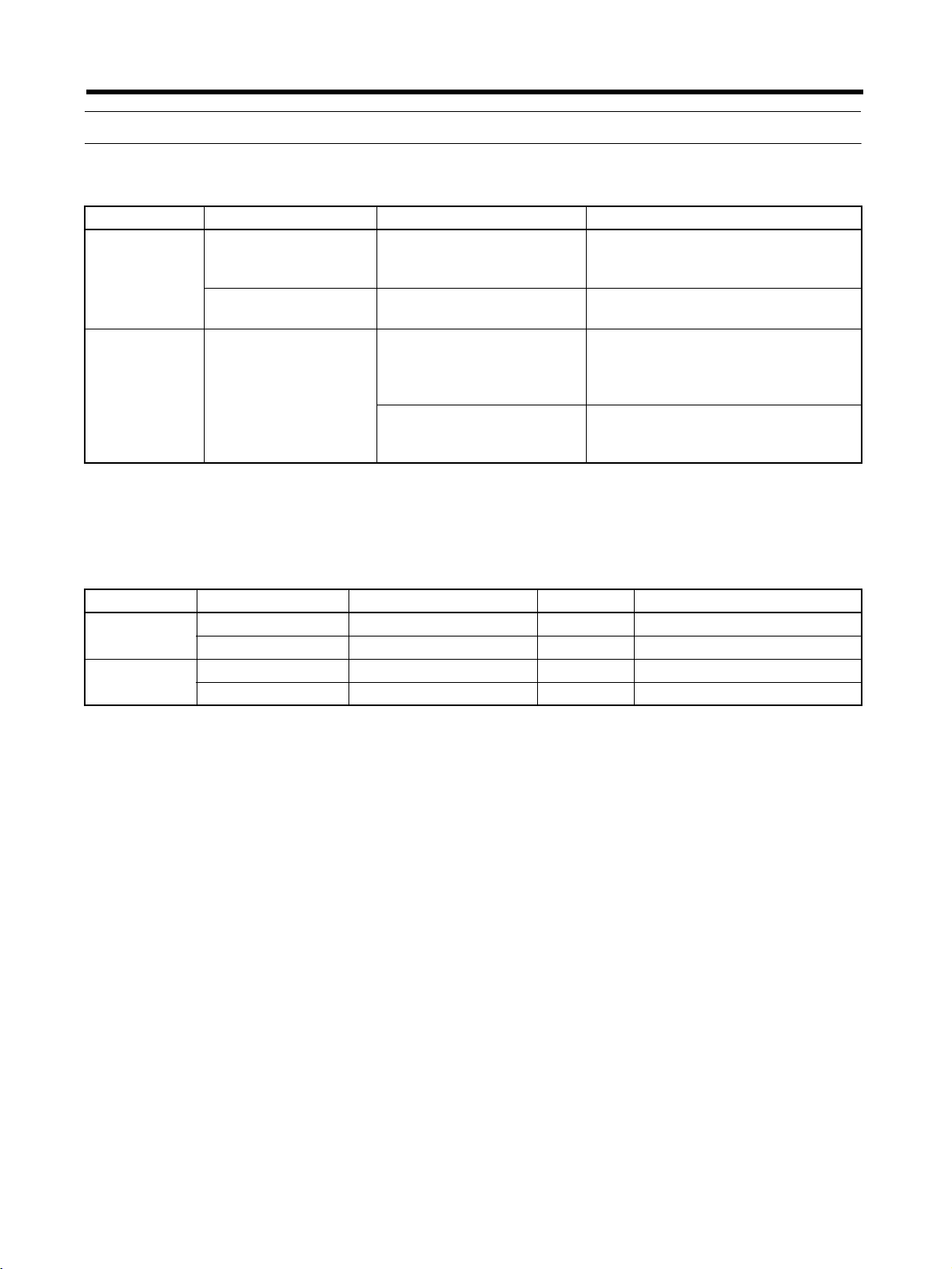

Dimensions of output section of

6 dia. 7 dia.

13 27

9

11

LL LR

300±30

G3

S dia.

Four, Z dia.

D

D2 dia.

21.5

1 dia.

C

750-W Servomotors

2

Dimensions of shaft end with key (-BS1)

C

QK

5

5

3

Model Dimensions (mm)

LL LR C D1 D2 G Z S QK

R7M-A20030-B@ 13630607050h76 5.514h620

R7M-A40030-B@ 16430607050h76 5.514h620

R7M-A75030-B@ 189.540809070h78 7 16h630

2-11

Page 38

Standard Models and Specifications

Chapter 2

■ Flat-style Servomotors without a Brake

● 100 W/200 W/400 W/750 W R7M-AP10030(-S1)/-AP20030(-S1)/-AP40030(-S1)/AP75030(-S1)

300±30

6 dia.7 dia.

13

300±30

A2

A1

A5

GF

LL LR

S dia.

D1 dia.

D2 dia.

A3

A4

Dimensions of shaft end with key (-S1)

h

b

C

QK

C

Four, Z dia.

t1

Model Dimensions (mm)

Basic servomotor dimensions With key (shaft

Cable outlet dimensions

end dimensions)

LLLRCD1 D2 F G Z SQKb h t1A1A2A3A4A5

R7M-AP10030-@ 62 25 60 70 50h7 3 6 5.5 8h6 14 3 3 1.8 9 18 25 21 14

R7M-AP20030-@ 67 30 80 90 70h7 3 8 7 14h6 16 5 5 3

R7M-AP40030-@ 87

R7M-AP75030-@ 86.5 40 120 145 110h7 3.5 10 10 16h6 22 5 5 3 28 38 19

■

Flat-style Servomotors with a Brake

● 100 W/200 W/400 W/750 W R7M-AP10030-B(S1)/-AP20030-B(S1)/-AP40030-B(S1)/AP75030-B(S1)

300±30

6 dia.

7 dia.

13

A2

A1

A5

LL LR

300±30

D1 dia.

S dia.

D2 dia.

GF

A3

A4

Dimensions of shaft end with key (-BS1)

h

b

C

QK

C

Four, Z dia.

t1

Model Dimensions (mm)

Basic servomotor dimensions With key (shaft

Cable outlet dimensions

end dimensions)

LL LR C D1 D2 F G Z S QK b h t1 A1 A2 A3 A4 A5

R7M-AP10030-B@ 91 25 60 70 50h7 3 6 5.5 8h6 14 3 3 1.8 9 18 25 21 23

R7M-AP20030-B@ 98.5 30 80 90 70h7 3 8 7 14h6 16 5 5 3

R7M-AP40030-B@ 118.5

R7M-AP75030-B@ 120 40 120 145 110h7 3.5 10 10 16h6 22 5 5 3 28 38 26

2-12

Page 39

Standard Models and Specifications

Chapter 2

2-2-4 Reduction Gears

■ For Cylinder-style Servomotors (Backlash = 3′ Max.)

Model Dimensions (mm)

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2 AT* l Key dimensions

QK b h t1

50 W 1/5 R7G-VRSFPB05B50 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-VRSFPB09B50 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/15 R7G-VRSFPB15B50 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.7

1/25 R7G-VRSFPB25B50 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.7

100 W 1/5 R7G-VRSFPB05B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-VRSFPB09B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/15 R7G-VRSFPB15B100 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.7

1/25 R7G-VRSFPB25C100 92 50 78 40 46 90 70 62 17 3 6 19 30 M4 M6 M3 20 22 6 6 3.5 1.7

200 W 1/5 R7G-VRSFPB05B200 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-VRSFPB09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15 R7G-VRSFPB15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

1/25 R7G-VRSFPB25C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

400 W 1/5 R7G-VRSFPB05C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/9 R7G-VRSFPB09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15 R7G-VRSFPB15C400 100 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 2.1

1/25 R7G-VRSFPB25D400 104 61 98 60 70 115 90 75 18 5 8 24 40 M5 M8 M4 20 30 8 7 4 3.2

750 W 1/5 R7G-VRSFPB05C750 93.5 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.1

1/9 R7G-VRSFPB09D750 97.5 61 98 80 90 115 90 75 18 5 10 24 40 M6 M8 M4 20 30 8 7 4 3.4

1/15 R7G-VRSFPB15D750 110 61 98 80 90 115 90 75 18 5 10 24 40 M6 M8 M4 20 30 8 7 4 3.8

1/25 R7G-VRSFPB25E750 135 75 125 80 90 135 110 98 17 5 10 32 55 M6 M10 M4 20 45 10 8 5 7.2

* "AT" in the table refers to the set bolt.

Weig ht

(kg)

External Diagrams

Four, Z1 dia.

D1 dia.

@C2

Set bolt (AT)

G

LM

Key dimensions

QK

E3

F

D4 dia.

Sh6 dia.

T

LR

b

t1

h

D3h7 dia.

Four, Z2 dia.

(effective depth: l)

D2 dia.

@C1

2-13

Page 40

Standard Models and Specifications

Chapter 2

■ For Cylinder-style Servomotors (Backlash = 45′ Max.)

Model Dimensions (mm)

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2 AT* l Key dimensions

QK b h t1

50 W 1/5 R7G-RGSF05B50 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-RGSF09B50 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/15R7G-RGSF15B5078 3252 404660 50 451036 1220M4M5M31216442.50.70

1/25R7G-RGSF25B5078 3252 404660 50 451036 1220M4M5M31216442.50.70

100 W 1/5 R7G-RGSF05B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/9 R7G-RGSF09B100 67.5 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.55

1/15 R7G-RGSF15B100 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.70

1/25 R7G-RGSF25B100 78 32 52 40 46 60 50 45 10 3 6 12 20 M4 M5 M3 12 16 4 4 2.5 0.70

200 W 1/5 R7G-RGSF05B200 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-RGSF09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15R7G-RGSF15C400100 5078 60 7090 70 621738 1930M5M6M42022663.52.1

1/25R7G-RGSF25C400100 5078 60 7090 70 621738 1930M5M6M42022663.52.1

400 W 1/5 R7G-RGSF05C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/9 R7G-RGSF09C400 89.5 50 78 60 70 90 70 62 17 3 8 19 30 M5 M6 M4 20 22 6 6 3.5 1.7

1/15R7G-RGSF15C400100 5078 60 7090 70 621738 1930M5M6M42022663.52.1

1/25R7G-RGSF25C400100 5078 60 7090 70 621738 1930M5M6M42022663.52.1

750 W 1/5 R7G-RGSF05C750 93.5 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.1

1/9 R7G-RGSF09C750 93.5 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.1

1/15 R7G-RGSF15C750 110 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.5

1/25 R7G-RGSF25C750 110 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 2.5

Weig ht

(kg)

External Diagrams

Four, Z1 dia.

D1 dia.

@C2

Set bolt (AT)

G

LM

Key dimensions

* "AT" in the table refers to the set bolt.

E3

F

D4 dia.

Sh6 dia.

T

LR

b

D3h7 dia.

Four, Z2 dia.

(effective depth: l)

D2 dia.

@C1

2-14

QK

t1

h

Page 41

Standard Models and Specifications

Chapter 2

■ For Flat-style Servomotors (Backlash = 3′ Max.)

Model Dimensions (mm)

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2 AT* l Key dimensions

QK b h t1

100 W 1/5 R7G-VRSFPB05B100P 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-VRSFPB09B100P 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/15 R7G-VRSFPB15B100P 83 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.77

1/25 R7G-VRSFPB25C100P 92 50 78 60 70 90 70 62 17 3 10 19 30 M5 M6 M3 20 22 6 6 3.5 1.8

200 W 1/5 R7G-VRSFPB05B200P 72.5 32 52 80 90 60 50 45 10 3 12 12 20 M6 M5 M4 12 16 4 4 2.5 0.85

1/9 R7G-VRSFPB09C400P 93.5 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/15 R7G-VRSFPB15C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

1/25 R7G-VRSFPB25C200P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

400 W 1/5 R7G-VRSFPB05C400P 93.5 50 78 80 90 90 70 62 17 3 10 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/9 R7G-VRSFPB09C400P 93.5 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/15 R7G-VRSFPB15C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

1/25 R7G-VRSFPB25D400P 109 61 98 80 90 115 90 75 18 5 12 24 40 M6 M8 M4 20 30 8 7 4 3.4

750 W 1/5 R7G-VRSFPB05C750P 98 50 78 120 145 90 70 62 17 3 15 19 30 M8 M6 M4 20 22 6 6 3.5 2.6

1/9 R7G-VRSFPB09D750P 97.5 61 98 120 145 115 90 75 18 5 15 24 40 M8 M8 M4 20 30 8 7 4 3.8

1/15 R7G-VRSFPB15D750P 110 61 98 120 145 115 90 75 18 5 15 24 40 M8 M8 M4 20 30 8 7 4 4.2

1/25 R7G-VRSFPB25E750P 155 75 125 120 145 135 110 98 17 5 15 32 55 M8 M10 M4 20 45 10 8 5 7.8

* "AT" in the table refers to the set bolt.

Weig ht

(kg)

External Diagrams

D1 dia.

@C2

Set bolt (AT)

Four, Z1 dia.

G

Key dimensions

QK

LM

E3

F

D4 dia.

Sh6 dia.

T

LR

b

t1

D3h7 dia.

Four, Z2 dia.

(effective depth: l)

D2 dia.

@C1

h

2-15

Page 42

Standard Models and Specifications

Chapter 2

■ For Flat-style Servomotors (Backlash = 45′ Max.)

Model Dimensions (mm)

LM LR C1 C2 D1 D2 D3 D4 E3 F G S T Z1 Z2 AT* l Key dimensions

QK b h t1

100 W 1/5 R7G-RGSF05B100P 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/9 R7G-RGSF09B100P 72.5 32 52 60 70 60 50 45 10 3 10 12 20 M5 M5 M4 12 16 4 4 2.5 0.72

1/15 R7G-RGSF15B100P 78 32 52 60 70 60 50 45 10 3 8 12 20 M5 M5 M4 12 16 4 4 2.5 0.77

1/25 R7G-RGSF25B100P 78 32 52 60 70 60 50 45 10 3 8 12 20 M5 M5 M4 12 16 4 4 2.5 0.77

200 W 1/5 R7G-RGSF05B200P 72.5 32 52 80 90 60 50 45 10 3 12 12 20 M6 M5 M4 12 16 4 4 2.5 0.85

1/9 R7G-RGSF09C400P 89.5 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/15 R7G-RGSF15C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

1/25 R7G-RGSF25C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

400 W 1/5 R7G-RGSF05C400P 89.5 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/9 R7G-RGSF09C400P 89.5 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 1.8

1/15 R7G-RGSF15C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

1/25 R7G-RGSF25C400P 100 50 78 80 90 90 70 62 17 3 12 19 30 M6 M6 M4 20 22 6 6 3.5 2.2

750 W 1/5 R7G-RGSF05C750P 93.5 50 78 120 145 90 70 62 17 3 15 19 30 M8 M6 M4 20 22 6 6 3.5 2.5

1/9 R7G-RGSF09C750P 93.5 50 78 120 145 90 70 62 17 3 15 19 30 M8 M6 M4 20 22 6 6 3.5 2.5

1/15 R7G-RGSF15C750P 110 50 78 120 145 90 70 62 17 3 15 19 30 M8 M6 M4 20 22 6 6 3.5 2.9

1/25 R7G-RGSF25C750P 110 50 78 120 145 90 70 62 17 3 15 19 30 M8 M6 M4 20 22 6 6 3.5 2.9

* "AT" in the table refers to the set bolt.

Weight

External Diagrams

(kg)

D1 dia.

@C2

Set bolt (AT)

Four, Z1 dia.

G

Key dimensions

QK

LM

E3

F

D4 dia.

Sh6 dia.

T

LR

b

t1

h

Four, Z2 dia.

(effective depth: l)

D2 dia.

D3h7 dia.

@C1

2-16

Page 43

Standard Models and Specifications

Chapter 2

2-3 Servo Driver Specifications

■ SMARTSTEP A-series R7D-AP@ Servo Drivers

Select a Servo Driver to match the Servomotor to be used.

2-3-1 General Specifications

Item Specifications

Ambient operating temperature 0 to 55

Ambient operating humidity 90% max. (with no condensation)

Ambient storage temperature –20 to 85

Ambient storage humidity 90% max. (with no condensation)

Storage and operating atmo-

sphere

Vibration resistance 10 to 55 Hz in X, Y, and Z directions with 0.1-mm double amplitude; accel-

Impact resistance

Insulation resistance Between power line terminals and case: 0.5 M

Dielectric strength Between power line terminals and case: 1,500 V AC for 1 min at 50/60 Hz

Protective structure Built into panel (IP10).

No corrosive gasses.

eration: 4.9 m/s

Acceleration 19.6 m/s

Between each control signal and case: 500 V AC for 1 min

°C

°C

2

max.

2

max., in X, Y, and Z directions, three times

Ω min. (at 500 V DC)

Note 1. The above items reflect individual evaluation testing. The results may differ under compound

conditions.

Note 2. Absolutely do not conduct a withstand voltage test with a Megger tester on the Servo Driver.

If such tests are conducted, internal elements may be damaged.

Note 3. Depending on the operating conditions, some Servo Driver parts will require maintenance.

Refer to 5-5 Periodic Maintenance for details.

Note 4. The service life of the Servo Driver is 50,000 hours at an average ambient temperature of

°C at 80% of the rated torque.

40

2-17

Page 44

Standard Models and Specifications

Chapter 2

2-3-2 Performance Specifications

■ Control Specifications

● 100-V AC Input Type

Item R7D-APA3L R7D-APA5L R7D-AP01L R7D-AP02L R7D-AP04L

Continuous output current (rms)

Momentary maximum output current (rms)

Input power

supply

Heating value Main cir-

Control method All-digital servo

Speed feedback 2,000 pulses/revolution, incremental encoder

Inverter method PWM method based on IGBT

PWM frequency 11.7 kHz

Maximum applicable fre-

quency (command pulse

application)

Weight Approx. 0.8 kg Approx. 0.8 kg Approx. 0.8 kg Approx. 0.8 kg Approx. 1.1 kg

Applicable Servomotor

wattage

Applicable

Servomotor

(R7M-)

Main circuits

Control

circuits

cuits

Control

circuits

Cylinderstyle

Flat-style – – AP10030 AP20030 AP40030

0.42 A 0.6 A 0.89 A 2.0 A 2.6 A

1.3 A1.9 A2.8 A6.0 A8.0 A

Single-phase 100/115 V AC (85 to 127 V) 50/60 Hz (double voltage method)

Single-phase 100/115 V AC (85 to 127 V) 50/60 Hz

3.1 W4.6 W6.7 W13.3 W20.0 W

13 W13 W13 W13 W13 W

250 kpps

30 W 50 W 100 W 200 W 400 W

A03030 A05030 A10030 A20030 A40030

● 200-V AC Input Type (Single-phase Input)

Item R7D-

APA3H

Continuous output current (rms)

Momentary maximum

output current (rms)

Input power

supply

Heating

value

Control method All-digital servo

Main circuits

Control

circuits

Main circuits

Control

circuits

0.42 A 0.6 A 0.89 A 2.0 A 2.6 A 4.4 A

1.3 A 1.9 A 2.8 A 6.0 A 8.0 A 13.9 A

Single-phase 200/230 V AC (170 to 253 V) 50/60 Hz (for R7D–AP08H only, threephase input possible)

Single-phase 200/230 V AC (170 to 253 V) 50/60 Hz

3.1 W 4.6 W 6.7 W 13.3 W 20 W 47 W

20 W 20 W 20 W 20 W 20 W 20 W

R7D-

APA5H

2-18

R7D-

AP01H

R7D-

AP02H

R7D-

AP04H

R7D-

AP08H

Page 45

Standard Models and Specifications

Chapter 2

Item R7D-

APA3H

Speed feedback 2,000 pulses/revolution, incremental encoder

Inverter method PWM method based on IGBT

PWM frequency 11.7 kHz

Maximum applicable

frequency (command

pulse application)

Weight Approx.

Applicable Servomotor

wattage

Applicable

Servomotor

(R7M-)

Cylindertype

Flat-type – – AP10030 AP20030 AP40030 AP75030

250 kpps

0.8 kg

30 W 50 W 100 W 200 W 400 W 750 W

A03030 A05030 A10030 A20030 A40030 A75030

R7D-

APA5H

Approx.

0.8 kg

R7D-

AP01H

Approx.

0.8 kg

Approx.

0.8 kg

2-3-3 Terminal Block Specifications

Signal Function Condition

L1 Main circuits power

L2

L3

+1 DC Reactor termi+2

– Main circuit DC out-

L1C Control circuits

L2C

B1 External regeneraB2

B3

UServomotor conVWhite

WBlue

supply input

nal for power supply harmonic

control

put (Reverse)

power supply input

tion resistance connection terminals

nection terminals

Frame ground This is the ground terminal. Ground to a minimum of 100

R7D–AP@H: Single-phase 200/230 V AC (170 to 253 V AC) 50/60 Hz

R7D–AP@L: Single-phase 100/115 V AC (85 to 127 V AC) 50/60 Hz

Note: Only the R7D–AP08H (750 W) has an L3 terminal, enabling three-

phase input: Three-phase 200/230 V AC (170 to 253 V AC) 50/60 Hz

Normally short-circuit between +1 and +2.

If harmonic control measures are required, connect a DC Reactor between +1

and +2.

Do not connect anything.

R7D-AP@H: Single-phase 200/230 V AC (170 to 253 V AC) 50/60 Hz

R7D-AP@L: Single-phase 100/115 V AC (85 to 127 V AC) 50/60 Hz

30 to 200 W: No External Regeneration Resistor can be connected.

400 W: This terminal does not normally need to be connected. If regenerative

energy is high, connect an External Regeneration Resistor between B1 and

B2.

750 W: Normally shorted between B2 and B3. If there is high regenerative

energy, remove the short bar between B2 and B3 and connect an External

Regeneration Resistor between B1 and B2.

Red These are the terminals for outputs to the Servomotor. Be sure to

wire these terminals correctly.

Green/

Ye l l o w

R7D-

AP02H

R7D-

AP04H

Approx.

1.1 kg

Ω (class D, class 3).

R7D-

AP08H

Approx.

1.7 kg

2-19

Page 46

Standard Models and Specifications

2-3-4 Control I/O Specifications (CN1)

■ Control I/O and External Signals for Position Control

200 Ω

Reverse pulse

Forward pulse

Deviation

counter reset

+CW

−CW

+CCW

−CCW

+ECRST

−ECRST

1

2

3

4

5

6

200 Ω

200 Ω

(See

note 2.)

(See

note 2.)

(See

note 2.)

(See

note 2.)

INP8

Positioning

completed output

BKIR7

Brake interlock

OGND

10

Z32

Phase Z

ZCOM

33

ALM34

Alarm output

ALMCOM

35

Chapter 2

Maximum operating

voltage: 30 V DC

Maximum Output

Current:

Phase Z: 20 mA DC

Other than Phase Z:

50 mA DC

RUN command

Alarm reset

+24VIN24 V DC

13

14RUN

18RESET

3.3 k

3.3 k

22

23 TXD−

20 RXD+

21 RXD−

24 RT

Shell

TXD+

Transmission data

Reception data

Terminating

resistance terminal

FG

Frame ground

(See note 1.)

Note 1. Interface for RS-422:

• Applicable line driver: T.I. SN75174, MC3487 or equivalent

• Applicable line receiver: T.I. SN75175, MC3486 or equivalent

Note 2. Automatic-reset fuses are used for output protection. If overcurrent causes the fuse to oper-

ate, current will not flow, and after a fixed period of time it will automatically reset.

2-20

Page 47

Standard Models and Specifications

■ Control I/O Signals

● CN1 Control Inputs

Pin

Signal name Function Contents

No.

1 +PULS/CW/A Feed pulses, reverse

2–PULS/CW/A

3 +SIGN/CCW/B Direction signal, for4 –SIGN/CCW/B

5 +ECRST Deviation counter

6 –ECRST

pulses, or 90

difference pulses

(phase A)

ward pulses, or 90

phase difference

pulses (phase B)

reset

° phase

Pulse string input terminals for position commands.

Line-driver input: 7 mA at 3 V

Maximum response frequency: 250 kpps

Open-collector input: 7 to 15 mA

Maximum response frequency: 250 kpps

°

Any of the following can be selected by means of a Pn200.0

setting: feed pulses or direction signals (PULS/SIGN); forward

or reverse pulses (CW/CCW); 90

signals (A/B).

Line-driver input: 7 mA at 3 V

Open-collector input: 7 to 15 mA

ON: Pulse commands prohibited and deviation counter cleared.

Chapter 2

° phase difference (phase A/B)

Note Input for at least 20

13 +24VIN +24-V power supply

input for control DC

14 RUN RUN command input ON: Servo ON (Starts power to Servomotor.)

18 RESET Alarm reset input ON: Servo alarm status is reset.

● CN1 Control Outputs

Pin

No.

32 Z Phase Z output Outputs the Encoder’s phase Z. (1 pulse/revolution)

33 ZCOM

34 ALM

35 ALMCOM

7 BKIR Brake interlock output Outputs the holding brake timing signals.

8 INP Positioning completed

10 OGND

Note An open-collector output interface is used for pin-7 and -8 sequence outputs. (Maximum operating volt-

Signal

name

Alarm output When the Servo Driver generates an alarm, the output turns

output

Output ground common Ground common for sequence outputs (pins 7 and 8).

age: 30 V DC; maximum output current: 50 mA)

Function Contents

Power supply input terminal (+24 V DC) for sequence inputs

(pins 14 and 18).

Open collector output (maximum output voltage: 30 V DC max;

maximum output current: 20 mA)

OFF. Open collector output (maximum operating voltage: 30 V

DC; maximum output current: 50 mA)

ON when the position error is within the positioning completed

range (Pn500).

µs.

2-21

Page 48

Standard Models and Specifications

● Interface for RS-422

Pin

Signal name Function Contents

No.

20 RXD+

21 RXD–

22 TXD+

23 TXD–

24 RT

19 GND

■ CN1: Pin Arrangement

Reception data Interface for RS-422A transmission and reception.

Transmission data

Terminating resistance terminal Connect to pin 21 (RXD–) on the end Unit.

RS-422A ground Ground for RS-422A.

Chapter 2

−PULS

2

/−CW/−A

−SIGN

4

/−CCW

/−B

6

−ECRST

8

INP

10 OGND

12

RUN

14

− feed pulse,

− reverse pulse,

− phase A

− direction

signal,

− forward pulse,

− phase B

Deviation

counter reset

Positioning

completed

output

Output ground

common

RUN command

input

1

/+CW/+A

3

/+CCW/+B

5

+ECRST

7

9

11

13

15

+PULS

+SIGN

BKIR

+24VIN

+ feed pulse,

+ reverse pulse,

+ phase A

+ direction

signal,

+ forward pulse,

+ phase B

+ deviation

counter reset

Brake interlock

output

Control DC

+24-V input

20

22

24

26

28

30

32

RXD+

TXD+

RT

Z

Reception

data +

Transmission

data +

Terminating

resistance

terminal

Encoder

phase-Z

output

19

21

23

25

27

29

31

33

GND

RXD−

TXD−

ZCOM

Ground for

RS-422A

Reception

data −

Transmission

data −

Phase-Z

output ground

16

18

RESET

17

Alarm reset

input

34

36

ALM

Note Do not wire the empty pins.

● CN1 Connectors (36P)