Page 1

Quattro

650H/650HS/800H/800HS

User’s Guide

I597-E-05

Page 2

Copyright Notice

The information contained herein is the property of Omron Adept Technologies, Inc., and shall not be

reproduced in whole or in part without prior written approval of Omron Adept Technologies, Inc. The

information herein is subject to change without notice and should not be construed as a commitment by

Omron Adept Technologies, Inc. The documentation is periodically reviewed and revised.

Omron Adept Technologies, Inc., assumes no responsibility for any errors or omissions in the documentation. Critical evaluation of the documentation by the user is welcomed. Your comments assist us

in preparation of future documentation. Please submit your comments to: techpubs@adept.com.

Copyright 2010-2019 by Omron Adept Technologies, Inc. All rights reserved.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Created in the United States of America

Page 3

Table of Contents

Chapter 1: Introduction 13

1.1 Quattro Robots, Product Description

Controllers 13

Sizes and Materials 13

Major Differences between Quattro H and HS Robots 13

eAIB 15

Quattro Robot Base 16

Inner Arms 16

Ball Joints, Outer Arms 16

Platforms 17

SmartController EX 20

1.2 Installation Overview

1.3 How Can I Get Help?

Related Manuals 22

13

21

22

Chapter 2: Safety 23

2.1 What to Do in an Emergency / Abnormal Situation

Releasing the Brakes 23

General Hazards 23

Releasing an E-Stop 23

2.2 Dangers, Warnings, and Cautions

Alert Levels 24

Alert Icons 24

Special Information 25

2.3 User's Responsibilities

Electrical Hazards 25

Pinch Hazard 25

Qualification of Personnel 25

2.4 Robot Behavior

Hardstops 26

2.5 Intended and Non-intended Use

Intended Use 26

Non-Intended Use 27

Robot Modifications 27

2.6 Additional Safety Information

Robot Safety Guide 28

T20 Manual Control Pendant (Option) 28

Disposal 28

23

24

25

26

26

27

09955-000 Rev. N Quattro User's Guide 3

Page 4

Table of Contents

Chapter 3: Robot Installation - H 29

3.1 Transport and Storage

3.2 Unpacking and Inspecting the Equipment

Before Unpacking 29

Upon Unpacking 29

Unpacking 29

3.3 Repacking for Relocation

3.4 Environmental and Facility Requirements

3.5 Mounting Frame

Frame Orientation 33

Frame Construction 33

Robot-to-Frame Considerations 33

Mounting 34

Gussets 34

3.6 Mounting the Robot Base

Robot Orientation 34

Mounting Surfaces 35

Mounting Options 35

Mounting Procedure from Above the Frame 35

Mounting Procedure from Below the Frame 37

Install Mounting Hardware 37

3.7 Attaching the Outer Arms and Platform

Clocking the Platform to the Base 40

Attaching the Outer Arms 41

3.8 Mounting the Front Panel

29

29

31

31

32

34

39

44

Chapter 4: Robot Installation - HS 45

4.1 Transport and Storage

4.2 Unpacking and Inspecting the Quattro Equipment

Before Unpacking 45

Upon Unpacking 45

Unpacking 45

4.3 Repacking for Relocation

4.4 Environmental and Facility Requirements

4.5 Mounting Frame

Frame Mounting Tabs 48

Robot-to-Frame Considerations 49

Mounting 49

Gussets 49

4.6 Cable Inlet Box

Assembling Cable Inlet Box 50

Connecting the Cables 54

4 Quattro User's Guide 09955-000 Rev. N

45

45

47

47

48

50

Page 5

Table of Contents

Installing the Cable Inlet Box 55

4.7 Mounting the Robot Base

Robot Orientation 56

Mounting Surfaces 56

Mounting Options 56

Mounting Procedure from Above the Frame 57

Mounting Procedure from Below the Frame 58

Install Mounting Hardware 59

4.8 Attaching the Outer Arms and Platform

Clocking the Platform to the Base 61

Attaching the Outer Arms 62

4.9 Mounting the Front Panel

4.10 Attaching the Cable Tray

56

60

65

65

Chapter 5: System Installation 71

5.1 System Cable Diagram

5.2 Installing the SmartController EX

List of Cables and Parts 72

Cable Installation Overview 74

5.3 Optional Cables

XIOBreakout Cable 75

DB9 Splitter Cable 75

eAIB XBELTIOAdapterCable 75

SmartController Belt Encoder Y-Adapter Cable 75

5.4 Connecting User-Supplied PC to Robot

PC Requirements 80

5.5 Installing ACE Software

5.6 Description of Connectors on Robot Interface Panel

5.7 Cable Connections from Robot to SmartController

5.8 Connecting 24 VDC Power to Robot

Specifications for 24 VDC Robot and Controller Power 83

Details for 24 VDC Mating Connector 84

Procedure for Creating 24 VDC Cable 84

Installing 24 VDC Robot Cable 85

5.9 Connecting 200-240 VAC Power to Robot

Specifications for AC Power 86

Details for AC Mating Connector 89

Procedure for Creating 200-240 VAC Cable 89

Installing AC Power Cable to Robot 90

5.10 Grounding the Quattro Robot System

Quattro Robot Base 90

Quattro HS Robot Base 91

71

72

75

80

81

81

82

83

86

90

09955-000 Rev. N Quattro User's Guide 5

Page 6

Table of Contents

Robot-Mounted Equipment 91

Configuration 92

5.11 Installing User-Supplied Safety Equipment

Emergency Stop Circuits 99

Remote Manual Mode 100

User Manual/Auto Indication 101

User High Power On Indication 101

Remote High Power On/Off Control 101

High Power On/Off Lamp 102

Remote Front Panel or User-Supplied Control Panel Usage 102

Remote Pendant Usage 103

94

Chapter 6: System Operation 105

6.1 Robot Status Display Panel

6.2 Status Panel Fault Codes

6.3 Using the Brake-Release Button

Brakes 107

Brake-Release Button 107

6.4 Front Panel

6.5 Connecting Digital I/O to the System

6.6 Using Digital I/O on Robot XIO Connector

Optional I/O Products 114

XIO Input Signals 114

XIO Output Signals 116

XIO Breakout Cable 119

6.7 Starting the System for the First Time

Verifying Installation 121

Turning on Power and Starting ACE 122

Enabling High Power 123

Verifying E-Stop Functions 123

Verify Robot Motions 123

6.8 Quattro Motions

Straight-line Motion 124

Containment Obstacles 124

Tool Flange Rotation Extremes 124

6.9 Learning to Program the Quattro Robot

105

106

107

109

110

112

121

124

128

Chapter 7: Optional Equipment Installation 129

7.1 End-Effectors

Attaching 129

Aligning 129

Grounding 129

Accessing Vacuum 129

6 Quattro User's Guide 09955-000 Rev. N

129

Page 7

Table of Contents

7.2 Routing End-effector Lines

7.3 Ball Stud Locks

Installing a Ball Stud Lock 132

Removing a Ball Stud Lock 133

130

131

Chapter 8: Technical Specifications 135

8.1 Dimension Drawings

8.2 Internal Connections

8.3 XSYS/XSYSTEM Connector

8.4 Robot Specifications

8.5 Payload Specifications

Torque and Rotation Limits 147

Payload Mass vs. Acceleration 147

Payload Inertia vs. Acceleration 149

8.6 Stopping Times and Distances

8.7 Robot Mounting Frame, Quattro 650H Robot

135

144

145

145

147

150

158

Chapter 9: Maintenance - H 165

9.1 Periodic Maintenance Schedule

9.2 Warning Labels

9.3 Checking Safety Systems

9.4 Checking Robot Mounting Bolts

9.5 Checking Robot Gear Drives

9.6 Checking Fan Operation

9.7 Replacing the eAIB Chassis

Removing the eAIB Chassis 170

Installing a New eAIB Chassis 173

9.8 Commissioning a System with aneAIB

Safety Commissioning Utilities 175

E-Stop Configuration Utility 176

E-Stop Verification Utility 177

Teach Restrict Configuration Utility 177

Teach Restrict Verification Utility 178

9.9 Replacing the Encoder Battery Pack

Battery Replacement Interval 179

Battery Replacement Procedure 180

9.10 Replacing a Platform

Replacement 182

9.11 Configuration

9.12 Replacing a Ball Joint Insert

165

168

169

169

169

170

170

174

179

182

182

182

09955-000 Rev. N Quattro User's Guide 7

Page 8

Table of Contents

9.13 Replacing Outer Arm Spring Assemblies

Removing Outer Arm Spring Assemblies 183

Installing Outer Arm Spring Assemblies 184

9.14 Changing the Lamp in the Front Panel High-Power Indicator

182

186

Chapter 10: Maintenance - HS 189

10.1 Cleaning

Water Shedding 189

Wash-Down 189

Chemical Compatibility 190

10.2 Warning Labels

10.3 Periodic Maintenance

10.4 Checking Safety Systems

10.5 Checking Robot Mounting Bolts

10.6 Checking Robot Gear Drives

10.7 Checking Fan Operation

10.8 Removing and Installing the Cable Inlet Box

Removing the Cable Inlet Box 197

Installing the Cable Inlet Box 198

10.9 Replacing the eAIB Chassis

Removing the eAIB Chassis 199

Installing a New eAIBChassis 201

10.10 Commissioning a System with aneAIB

Safety Commissioning Utilities 203

E-Stop Configuration Utility 204

E-Stop Verification Utility 205

Teach Restrict Configuration Utility 205

Teach Restrict Verification Utility 206

10.11 Replacing the Encoder Battery Pack

Battery Replacement Interval 207

Battery Replacement Procedure 208

10.12 Replacing a Platform

Replacement 211

Configuration 212

10.13 Replacing a Ball Joint Insert

10.14 Replacing Outer Arm Spring Assemblies

Removing Outer Arm Spring Assemblies 213

Installing Outer Arm Spring Assemblies 214

10.15 Replacing the Front Panel

189

190

191

195

195

195

196

197

199

202

207

211

212

213

216

8 Quattro User's Guide 09955-000 Rev. N

Page 9

Table of Contents

Chapter 11: Robot Cleaning/ Environmental Concerns- H 217

11.1 Ambient Environment

Humidity 217

Temperature 217

11.2 Cleaning

Caustic Compatibility 218

Water Shedding 218

Wipe-Down 218

11.3 Cleanroom Classification

11.4 Design Factors

Robot Base and Components 218

Inner Arms 219

Ball Joints 219

Outer Arms 219

Springs 219

Platforms 219

11.5 Installing Cable Seal Kit

Overview 220

Installation Procedure 221

217

218

218

218

220

Chapter 12: Environmental Concerns - HS 227

12.1 Ambient Environment

Humidity 227

Temperature 227

12.2 Cleanroom Classification

12.3 Design Factors

Robot Base and Components 228

Inner Arms 228

Ball Joints 228

Outer Arms 228

Spring Assemblies 229

Platforms 229

227

228

228

Chapter 13: Status Codes 231

13.1 Status Panel Display

13.2 Status Codes

231

232

09955-000 Rev. N Quattro User's Guide 9

Page 10

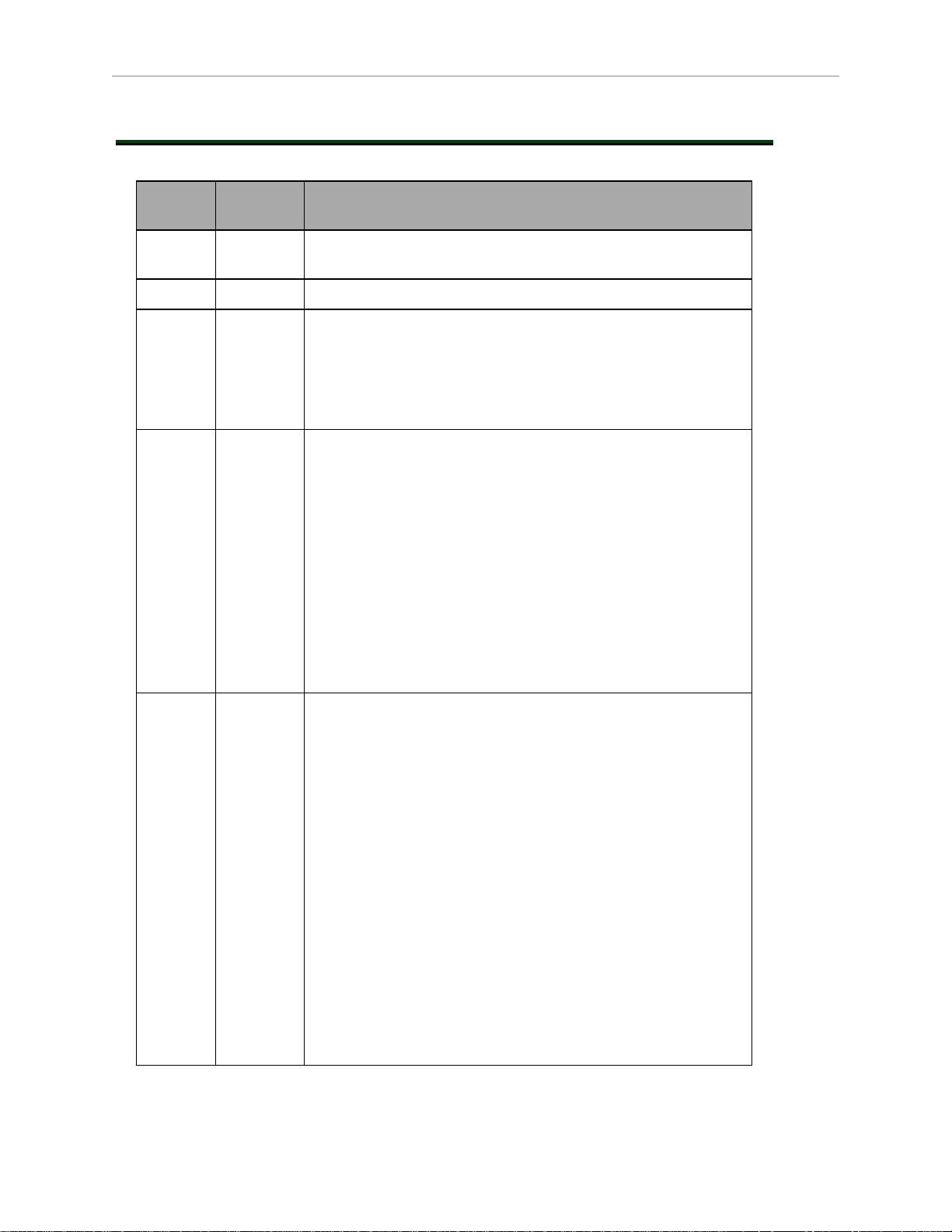

Revision History

Revision

Code

01 June,

Date Revised Content

Original release.

2016

02 May, 2017 Regulatory updates.

03 November,

2017

l Added the Quattro 800HS to USDA approved list.

l Clarified that Line E-Stop Input can be used for pro-

duction lines.

l Clarified note on emergency stop circuits.

l Clarified that the ball joint inserts are made of special

acetal material.

04 April, 2018 l Updated safety chapter format and alert levels through-

out user guide.

l Clarified that USDA approved platforms are stainless

steel.

l Updated unpacking instructions with new crate con-

figuration.

l Updated recommended power supply model numbers.

l Updated images of platform to show Omron Adept logo.

l Changed ACE software disk to ACEsoftware media.

l Updated pictures to show painted inner arms.

l Add note to firmly hold end of arm tooling when attach-

ing to the flange to prevent damage to platform belt.

l Minor updates to fix broken links and incorrect ref-

erences.

05 March,

2019

l Updated copyright for 2019.

l Added WEEEdisposal information.

l Removed www.adept.com from Chapter 1: Introduction.

l Updated safety chapter format and added fire and ESD

alert icons.

l Added addition information regarding intended and non-

intended use of Quattro robots.

l Made a note that Hardstops have been moved to the

base.

l Added Max Allowable Center of Gravity (CG) table in

chapter 8.

l Graphics improved and modified for translation and

added call-out tables.

l Added Status Codes chapter.

l Added Platform configuration procedure to System

Installation chapter and removed configuration procedure from Maintenance chapters.

l Revised encoder battery replacement interval.

l Revised Ball Stud Lock section with new part number for

individual locks.

10 Quattro User's Guide 09955-000 Rev. N

Page 11

Revision

Code

Date Revised Content

l Many changes to Chapter 5: System Installation includ-

ing new and improved figures, content removal and additions.

l Operating temperature range, changed to 1 to 40°C

from previously noted 5 to 40°C.

l Added red CADversion of status codes to Status Panel

Fault Codes section in chapter 5.

l Dual robot configuration renamed to single and multiple

robot configuration.

l Removed references to obsolete sDIO module.

l Added IOBlox device to Table 6-3. Digital I/O Connection

Options

l Added a note about typical IOBlox configurations in

Chapter 6: System Operation.

09955-000 Rev. N Quattro User's Guide 11

Page 12

Page 13

Chapter 1: Introduction

1.1 Quattro Robots, Product Description

The Quattro robot is a four-axis parallel robot. The four identical axis motors control movement of the robot tool in X, Y, and Z directions, as well as Theta rotation.

Controllers

The Quattro robot requires a SmartController EX motion controller for control. That controller

can be combined with a user-supplied PLC, for programming.

The robot servo code runs on an SmartServo distributed-motion control platform embedded in

the robot base as part of the power amplifiers.

Sizes and Materials

There are two sizes of Quattro robots, each available with anodized aluminum or stainless

steel platforms:

l

Quattro 650H (AnodizedAluminum & SS) and Quattro 650HS (SS)

and

l

Quattro 800H (Anodized Aluminum &SS) and Quattro 800HS (SS)

The Quattro 650H and 800H areavailable with anodized aluminum or stainless

steel (SS) platforms, and anodized aluminum outer arm spoons. The eAIB and

cable box used with the two H models are anodized aluminum.

The Quattro 650HS and 800HS are USDAAccepted, and therefore only available

with stainless steel platforms and stainless steel outer arm spoons. The eAIB and

cable box used with the two HS models are electroless nickel (EN).

In most aspects, the robots are similar enough that they will be covered together. In areas

where there are significant differences, the Quattro H and Quattro HS robots will be presented

in two chapters, using titles such as Robot Installation—H for the 650H and 800H robots, and

Robot Installation—HS for the 650HS and 800HS robots.

Major Differences between Quattro H and HS Robots

Note that either anodized aluminum or stainless steel platforms can be used on the Quattro

650H and 800H robots.

The Quattro 650HS and 800HS are only available with stainless steel platforms.

09955-000 Rev. N Quattro User's Guide 13

Page 14

1.1 Quattro Robots, Product Description

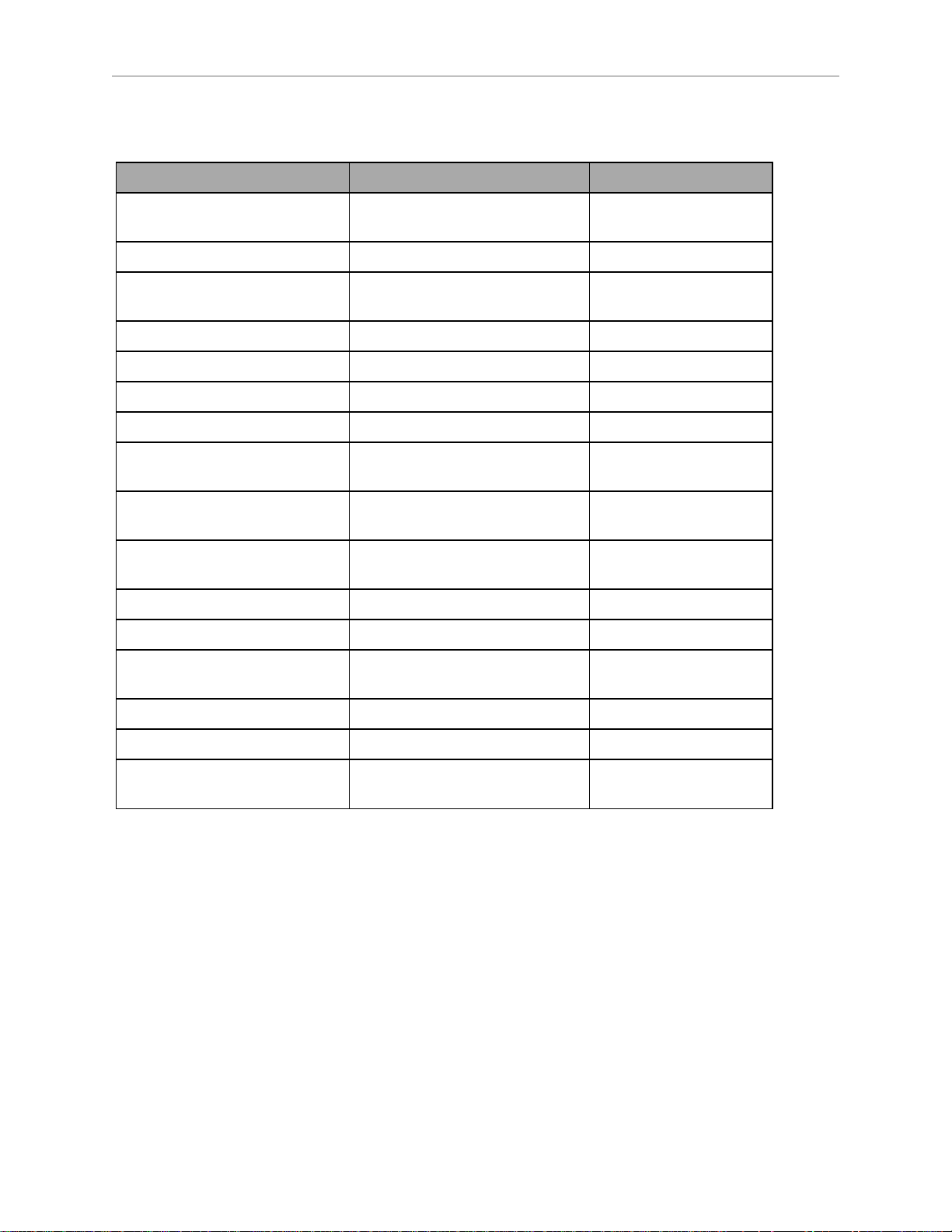

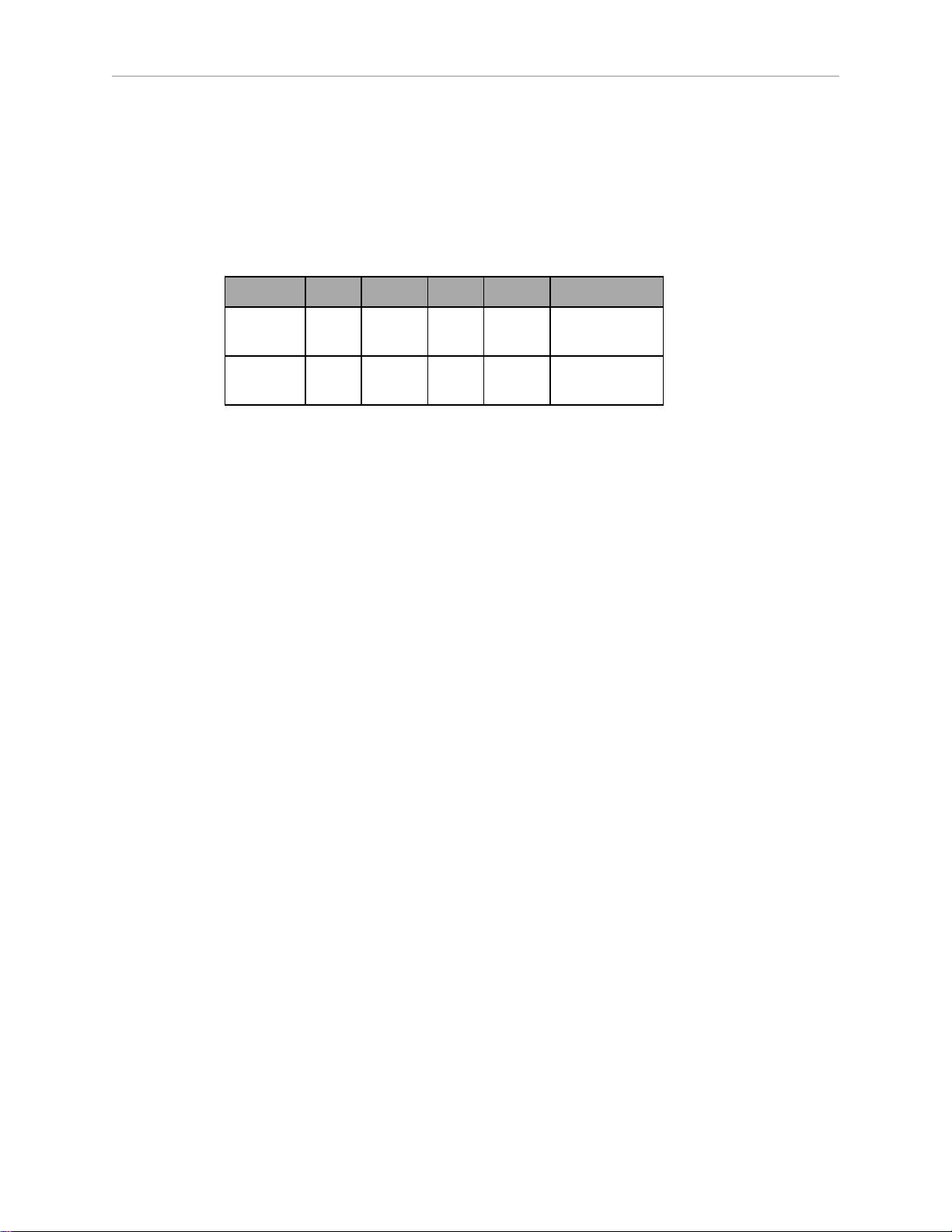

Table 1-1. Quattro H/HS Differences

Standard (650H/800H) HS (650HS/800HS)

USDA Accepted

No Yes

(Meat and Poultry)

IP rating IP65, Option IP66, Standard

P30 Platform, no rotation Hard-anodized or Stainless Steel

Stainless Steel (SS)

(SS)

P31 Platform, 46.25° Hard-anodized or SS SS

P32 Platform, 92.5° Hard-anodized or SS SS

P34 Platform, 185° Hard-anodized or SS SS

Outer Arm Spoons Hard-Anodized Stainless Steel

Base Mounting Pad Holes M16-2.0, through-hole M16-2.0, blind, 40 mm

bolt

Base Coating material White polyurethane

powder

eAIB Black Anodized, Single-bolt

White ETFE, USDA

approved

EN, 6-bolt installation

installation

Cable Inlet box Hard-Anodized, Option EN, Standard

Cable Tray Not required Required (for USDA)

Status Display Half-height Full-height, to shield

labels

Protective Earth Ground On base-mounting pad In cable inlet box

Motor covers White Solid white, no label

Exposed bolts and screws all

No Yes

gasketed

Similarities Between the Quattro Robots

l

All models use the same motors

l

All models share the same base casting, although the H and HS have some machining

and coating differences. Platform coatings/materials differ for HS robots, but dimensions

do not.

l

The mounting hole pattern for the bases is the same.

l

All share the same inner arm design.

l

All have an eAIB.

14 Quattro User's Guide 09955-000 Rev. N

Page 15

Chapter 1: Introduction

Figure 1-1. Major Robot Components, Isometric View (650HS shown)

Callout Description Callout Description

A Mounting Pads F Motor Cover

B eAIB G Outer Arms

C Cable Inlet Box H Platform

D Base J Ball Joints (Spring Assemblies not shown)

E Inner Arm

eAIB

The power amplifiers for the Quattro robot are embedded in the base of the robot. This amplifier section is known as the Amplifiers in Base (eAIB)distributed motion control platform,

and provides closed-loop servo control of the robot amplifiers, as well as robot I/O. The eAIB is

available in either an anodized or electroless nickel finish.

The eAIB features:

l

On-board digital I/O: 12 inputs, 8 outputs

l

Low EMI for use with noise-sensitive equipment

l

No external fan for quiet operation

09955-000 Rev. N Quattro User's Guide 15

Page 16

1.1 Quattro Robots, Product Description

l

8 kHz servo rate to deliver low positional errors and superior path following

l

Sine-wave commutation to lower cogging torque and improve path following

l

Digital feed-forward design to maximize efficiency, torque, and velocity

l

Temperature sensors on all amplifiers and motors for maximum reliability and easy

troubleshooting

l

Hardware-based E-Stop and Teach Restrict controls

These are for improved safety relative to European standards implemented in 2012.

NOTE: The H and HSamplifiers and their cable inlet boxes are not interchangeable.

Quattro Robot Base

The Quattro robot base is an aluminum casting that houses the four drive motors, and supports the power amplifiers. It provides four mounting pads for attaching the base to a rigid

support frame. The Status Display Panel is mounted on the side of the robot base.

Inner Arms

The four robot motors attach directly to the inner arms through a high-performance gear reducer. Other than optional, user-supplied hardware mounted on the platform, these are the only

drive motors in the Quattro robot. The following figure shows an inner arm from a Quattro

robot. RIA-compliant hard stops limit the inner arm motion to -52° and +124°.

Figure 1-2. Inner Arm

Ball Joints, Outer Arms

The inner arm motion is transmitted to the platform through the outer arms, which are connected between the inner arms and platform with precision ball joints. The outer arms are carbon fiber epoxied assemblies with identical ball joint sockets at each end. A bearing insert in

16 Quattro User's Guide 09955-000 Rev. N

Page 17

Chapter 1: Introduction

D

A

E

F

C

G

H

B

each socket accepts the ball joint studs on the inner arms and platform, and allows for approximately ± 60° of relative motion. No ball joint lubrication is required.

Platforms

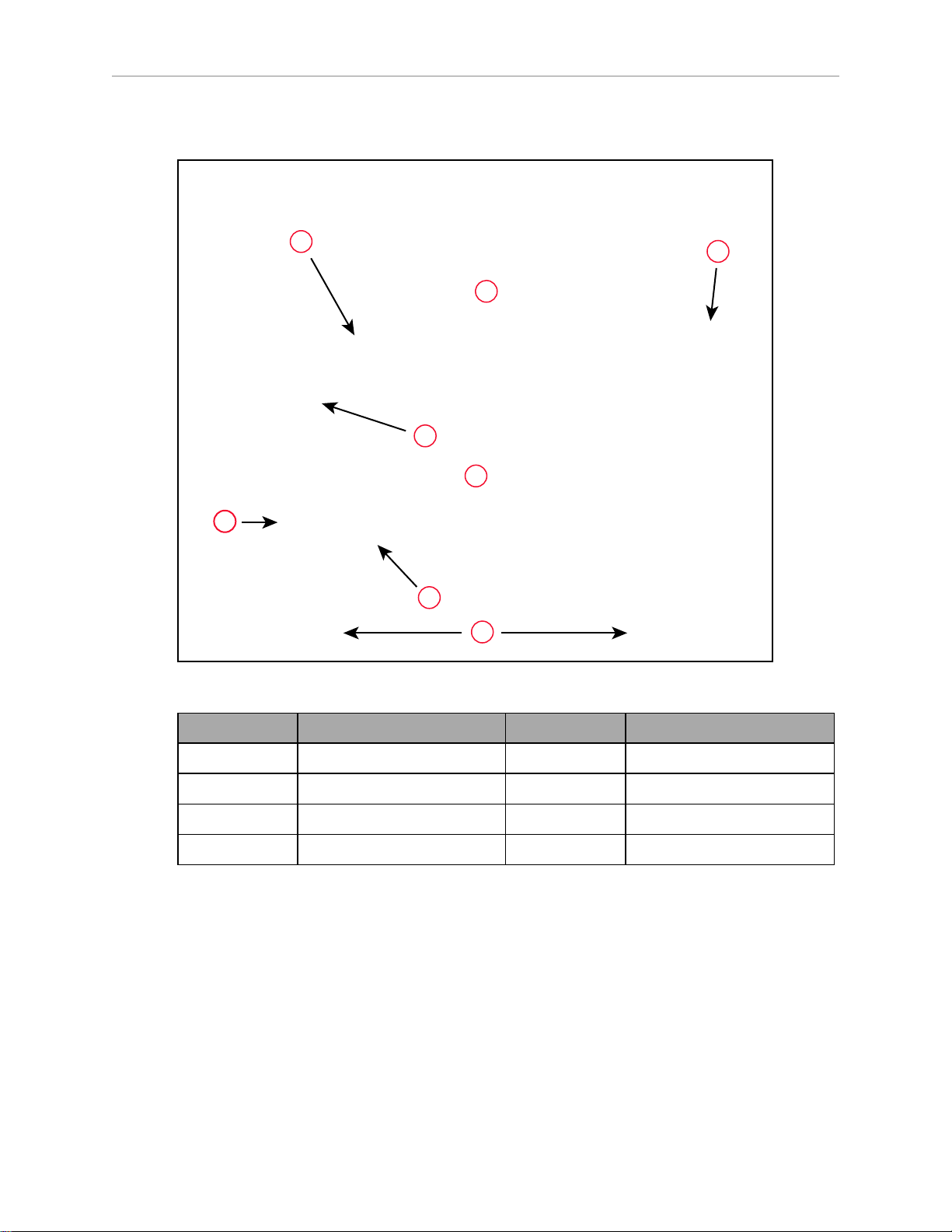

Figure 1-3. Quattro Ball Joint Assembly, Quattro HS Robot shown

Callout Description Callout Description

A Ball Joint Stud E Ball Joint Socket Insert

B Inner Arm F Outer Arm Springs

C Ball Joint Socket G Spring Horseshoe

D Pressed Pin H Outer Arms

Each pair of outer arms is held together with spring assemblies that pre-tension the ball joints.

The outer arms can be installed and removed without tools.

The platform converts the motion of the four Quattro motors into Cartesian motion and, for all

but the fixed platform, Theta rotation of the robot tool.

The Quattro robot currently supports four models of platforms, depending on the amount of

Theta rotation and inertia needed.

NOTE: The four models of platforms require different robot parameters.

09955-000 Rev. N Quattro User's Guide 17

Page 18

1.1 Quattro Robots, Product Description

The suffix on the part numbers that follow indicates the finish or material of the platform.

Refer to Materials and Finishes on page 20.

P31 Platform (P/N 09503-xxx)

The P31 platform has a rotation range of ±46.25°. The tool flange is machined into one of the

pivot links. It does not rotate in relation to the pivot link, so there are no gears or belts

involved. See P31 Platform on page 18.

P30 Platform (P/N 09730-xxx)

The P30 platform is a fixed platform that provides no Theta rotation. The tool flange is

machined into the one-piece platform. See P30 Platform on page 19.

P32 Platform (P/N 09732-xxx)

The P32 platform has a rotation range of ±92.5°. The tool flange is mounted on one of the pivot

links. See P32 Platform on page 19.

P34 Platform (P/N 09734-xxx)

The P34 platform has a rotation range of ±185°. The tool flange is mounted on one of the pivot

links.

Figure 1-4. P31 Platform

18 Quattro User's Guide 09955-000 Rev. N

Page 19

Figure 1-5. P30 Platform

Chapter 1: Introduction

Figure 1-6. P32 Platform

NOTE: The only visible difference between the P32 and P34 platforms is the

model number, and the two or four dots immediately below that number. Two

dots designate a P32 platform.

09955-000 Rev. N Quattro User's Guide 19

Page 20

1.1 Quattro Robots, Product Description

Materials and Finishes

Platforms are available in:

l

Aluminum with hard-anodized finish

l

Stainless steel

The following table shows which materials and finishes are compatible with which robots:

650H 650HS 800H 800HS Part Number

Hard

Yes No Yes No XXXXX-000

Anodized

Stainless

Yes Yes Yes Yes XXXXX-200

Steel

Platform Clocking

Rotational platforms are constructed such that the clocking, or rotational alignment, of the platform relative to the robot base is critical. This is detailed in Clocking the Platform to the Base

on page 40.

Platform Shipping

l

The platform and outer arms are removed.

l

The platform is shipped pre-assembled as a unit.

You will need to connect the outer arms between the inner arms and the platform to

reassemble the robot. The outer-arm assemblies are interchangeable.

Any end-effectors and their air lines and wiring are user-supplied.

SmartController EX

The SmartController motion controller is the foundation of our family of high-performance, distributed motion controllers. The SmartController EX is designed for use with:

l

Quattro robots

l

eCobra 600/800 robots

l

Viper robots

The controller supports a conveyor tracking option, as well as other options. The SmartController EX uses the eV+ operating system. It offers scalability and support for IEEE 1394-based

digital I/O and general motion expansion modules. The IEEE 1394 interface is the backbone of

SmartServo, our distributed controls architecture supporting our products. The SmartController

EX also includes Fast Ethernet and DeviceNet.

20 Quattro User's Guide 09955-000 Rev. N

Page 21

Refer to the SmartController EX User’s Guide for SmartController specifications.

1.2 Installation Overview

The system installation process is summarized in the following table. Also, refer to System

Installation on page 71.

NOTE: For multi-robot installations, see the Single and Multiple Robot Configuration Guide.

Chapter 1: Introduction

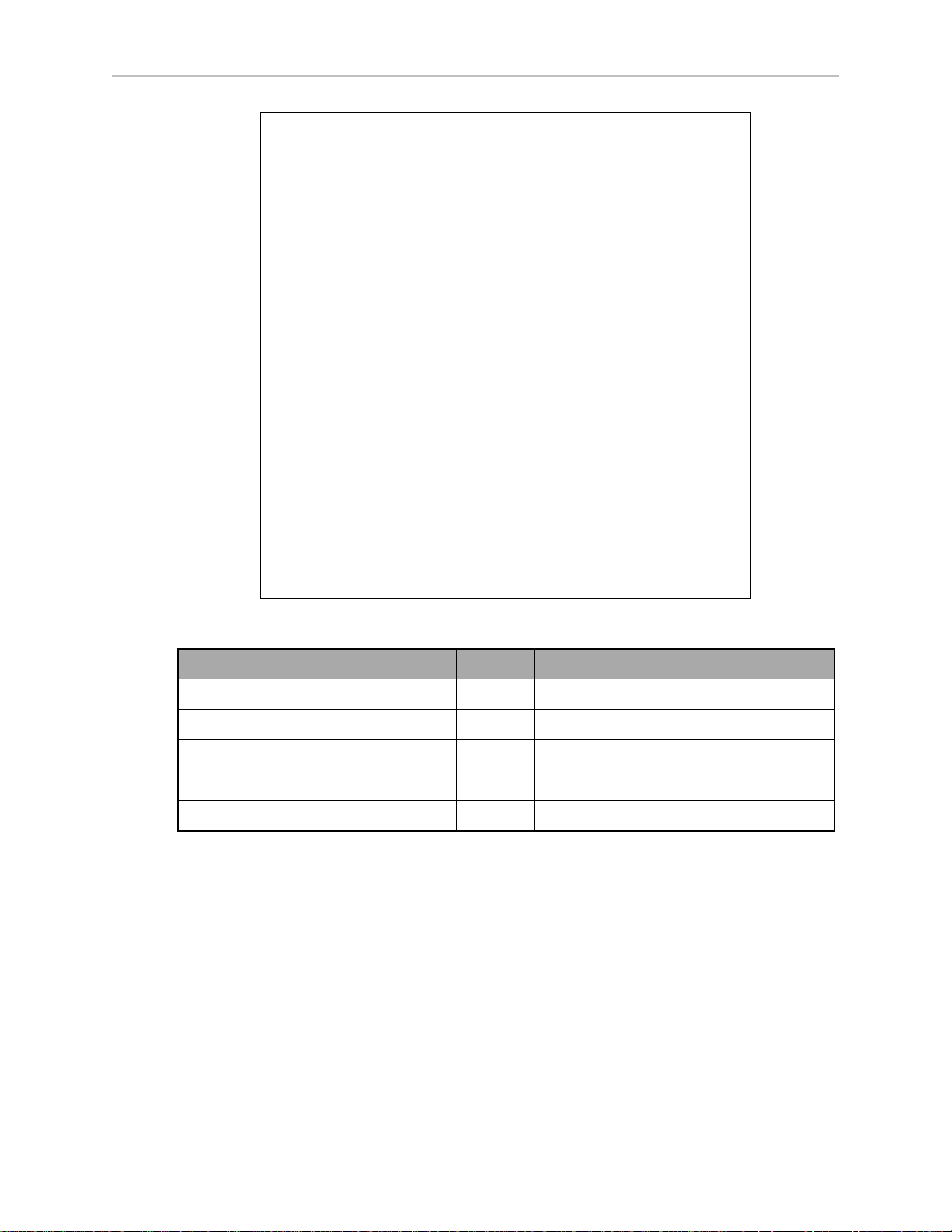

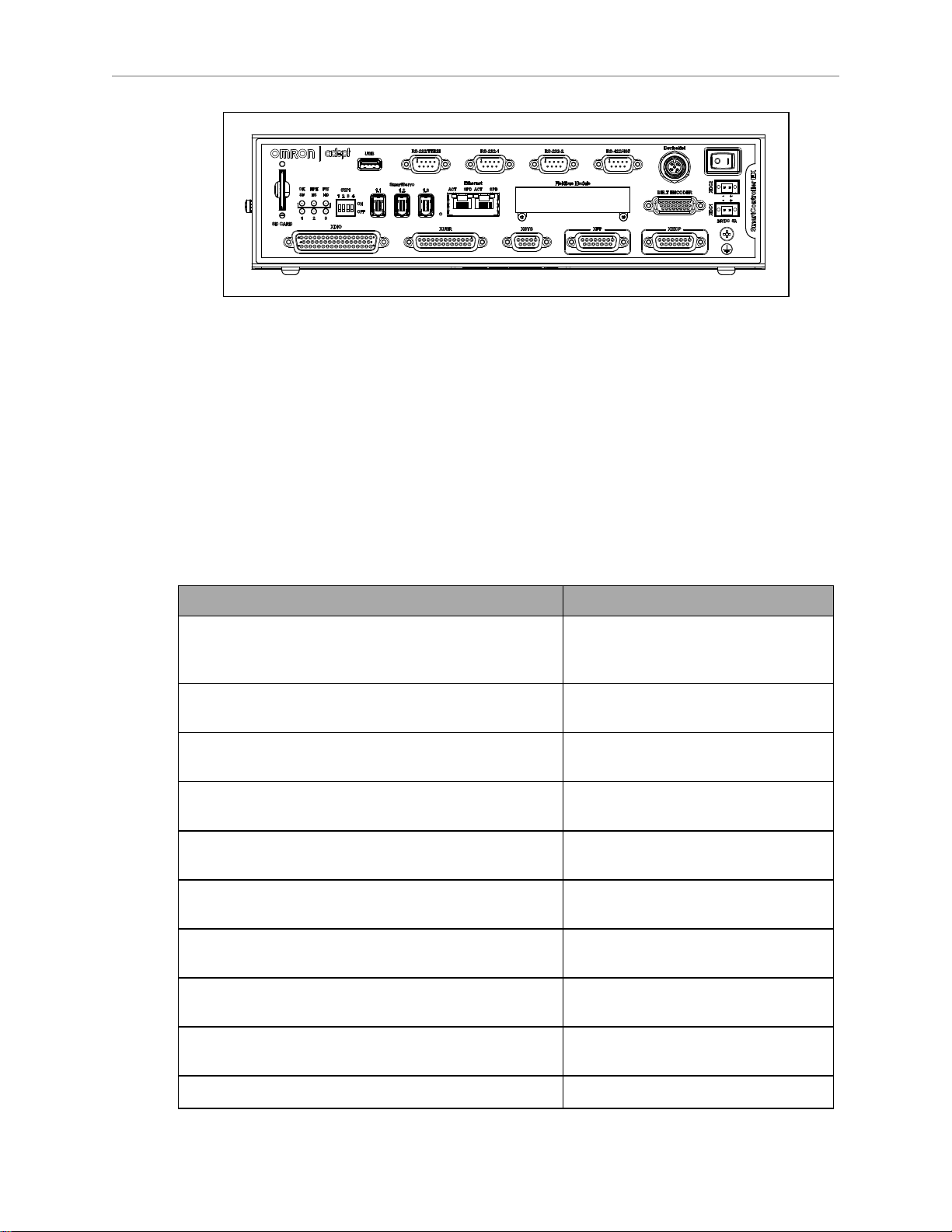

Figure 1-7. SmartController EX

Table 1-2. Installation Overview

Task to be Performed Reference Location

Mount the cable box (Quattro HS robot or Quattro H

robot with IP65 option).

Mount the robot to a level, stable mounting frame. Mounting the Robot Base on page

Attach the robot outer arms and platform. Attaching the Outer Arms and Plat-

Install the SmartController, Front Panel, Pendant (if

purchased), and ACE software.

Install the IEEE 1394 and XSYS cables between the

robot and SmartController.

Create a 24 VDC cable and connect it between the

SmartController and the user-supplied power supply.

Create a 24 VDC cable and connect it between the

robot and the user-supplied 24 VDC power supply.

Create a 200-240 VAC cable and connect it between

the robot and the facility AC power source.

Cable Inlet Box on page 50 and

Installing Cable Seal Kit on page

220.

34.

form on page 39.

Installing the SmartController EX on

page 72.

Cable Connections from Robot to

SmartController on page 82.

Installing the SmartController EX on

page 72.

Connecting 24 VDC Power to Robot

on page 83.

Connecting 200-240 VAC Power to

Robot on page 86.

Install user-supplied safety barriers in the workcell. Installing User-Supplied Safety

Equipment on page 94.

Connect digital I/O through the robot XIO connector. Using Digital I/O on Robot XIO Con-

09955-000 Rev. N Quattro User's Guide 21

Page 22

1.3 How Can I Get Help?

Task to be Performed Reference Location

nector on page 112.

Start the system, including system start-up and testing operation.

Install optional equipment, including end-effectors,

user air and electrical lines, external equipment, etc.

1.3 How Can I Get Help?

For support or service, contact your local Omron support.

Refer to additional information sources on our corporate website:

http://www.ia.omron.com

Related Manuals

This manual covers the installation, operation, and maintenance of an Quattro robot system.

There are additional manuals that cover programming the system, reconfiguring installed components, and adding optional components. See the following table. These manuals are available on the software media shipped with each system.

Manual Title Description

Starting the System for the First Time

on page 121.

End-Effectors on page 129.

Table 1-3. Related Manuals

Robot Safety Guide Contains safety information for our robots.

SmartController EX User’s

Guide

ePLC Connect 3 User’s Guide Describes the installation and use of the ePLC Connect 3 soft-

ACE User’s Guide Describes the installation and use of ACE software.

Single and Multiple Robot

Configuration Guide

T20 Pendant User's Guide Describes the use of the optional T20 manual control pendant.

Contains complete information on the installation and operation of the SmartController EX.

ware, for using a user-supplied PLC as controller.

Contains cable diagrams and configuration procedures for a

single and multi-robot system.

22 Quattro User's Guide 09955-000 Rev. N

Page 23

Chapter 2: Safety

!

2.1 What to Do in an Emergency / Abnormal Situation

Press the E-Stop button (a red push-button on a yellow background) and then follow the

internal procedures of your company or organization for a robot emergency situation. If a fire

occurs, use a type D extinguisher: foam, dry chemical, or CO2.

Releasing the Brakes

In case of an emergency or abnormal situation, the platform can be manually moved without

electric power. However, only qualified personnel who have read and understood this manual

and the Robot Safety Guide should manually move the platform to a safe state. The brakes can

be released with the brake release button on Status Display Panel, see Robot Status Display

Panel on page 105. This requires 24 V power, and an E-Stop must be pressed on the robot. All

robot axes are held by brakes, which can be released with the brake release button. Remote

brake release feature is also available via XIO Input 6.2 (Pin 18) configuration, see Remote

Brake Release Feature on page 108.

General Hazards

IMPORTANT: The following situations could result in injury or damage to the

equipment.

l

Do not place objects on the Platform or Base of the robot.

l

Do not exceed the maximum payload capacity.

l

Do not exceed the maximum recommended limits given in technical specifications. See

Technical Specifications on page 135.

Rotational speed becomes more significant when the payload’s center of gravity is

farther away (vertically and/ or horizontally) from the platform’s center of gravity.

l

Do not drop the robot, put uneven weights on the outer arms or otherwise operate it irresponsibly.

l

Do not use unauthorized parts.

Releasing an E-Stop

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

If the robot’s E-Stop is triggered, ensure that the cause of the E-Stop is resolved,

before releasing the E-Stop.

After the E-Stop button has been manually released, the robot will wait until the motors are

manually enabled.

There are three ways to enable the motors:

09955-000 Rev. N Quattro User's Guide 23

Page 24

2.2 Dangers, Warnings, and Cautions

!

!

!

!

l

Enable power through ACE software installed on your PC

l

Press the green ROBOT POWER button on the Front Panel

l

Press the ROBOTPOWER button on the Pendant

Once the motors are enabled, the robot will wait two seconds and then resume commanded

motion, if there is adequate space to maneuver.

2.2 Dangers, Warnings, and Cautions

Alert Levels

There are three levels of alert notation used in our manuals. In descending order of importance, they are:

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in fatality or

severe property damage.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury, fatality, or significant property damage.

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

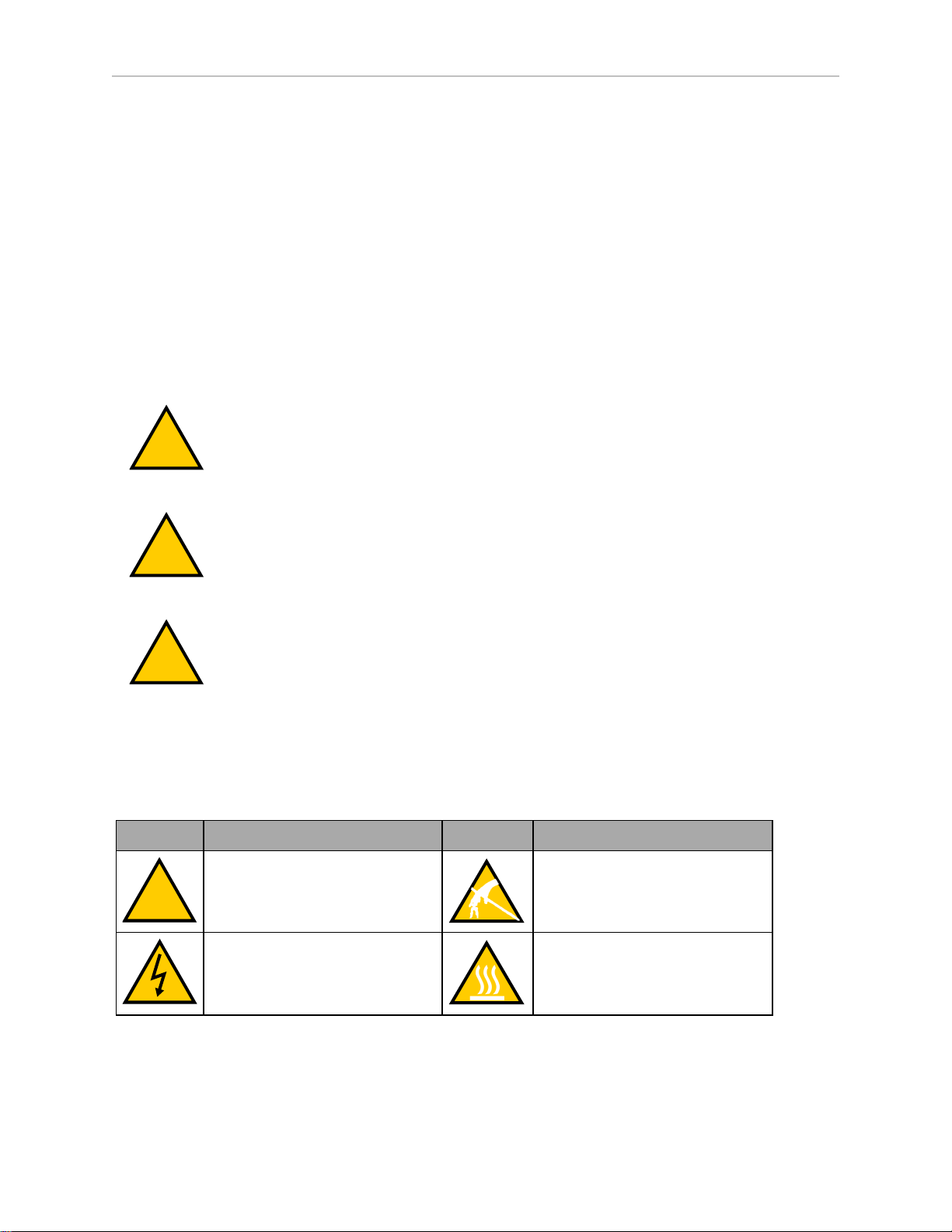

Alert Icons

The icon that starts each alert can be used to indicate the type of hazard. These will be used

with the appropriate signal word - Danger, Warning, or Caution - to indicate the severity of the

hazard. The text following the signal word will specify what the risk is, and how to avoid it.

Icon Meaning Icon Meaning

This is a generic alert icon. Any

specifics on the risk will be in the

text following the signal word.

This identifies a hazardous electrical situation.

This identifies a hazardous ESD

situation.

This identifies a hazardous burnrelated situation.

24 Quattro User's Guide 09955-000 Rev. N

Page 25

Special Information

!

There are several types of notation used to call out special information.

IMPORTANT: Information to ensure safe use of the product.

NOTE: Information for more effective use of the product.

Additional Information: Offers helpful tips, recommendations, and best prac-

tices.

Version Information: Information on differences in specifications for different

versions of hardware or software.

2.3 User's Responsibilities

Safe use of the Quattro robot is your responsibility. Safe use includes:

l

Reading the installation and operation instructions, as well as the Robot Safety Guide,

before using the equipment.

Chapter 2: Safety

l

Ensuring that the environment is suitable for safe operation of the robot.

l

Ensuring that anyone working with or near a robot has been adequately trained, and is

following this guide and the Robot Safety Guide for safe robot operation.

l

Maintaining the robots so that their control and safety functions continue to work properly.

Electrical Hazards

WARNING: ELECTROCUTIONRISK

Quattro robots use 200-240 VAC power. Thus, appropriately-sized branch circuit protection and lockout/ tagout capability must be provided in accordance

with National Electrical Code and any local codes.

Pinch Hazard

Robots' Arm Spring Assemblies

CAUTION: PINCHRISK

Ball joints are spring-loaded. Be careful not to pinch your fingers.

Qualification of Personnel

It is the end-user’s responsibility to ensure that all personnel who will work with or around

robots have attended an appropriate Omron training course and have a working knowledge of

the system. The user must provide the necessary additional training for all personnel who will

be working with the system.

09955-000 Rev. N Quattro User's Guide 25

Page 26

2.4 Robot Behavior

!

As noted in this and the Robot Safety Guide, certain procedures should be performed only by

skilled or instructed persons. For a description of the level of qualification, we use the standard

terms:

l

Skilled persons have technical knowledge or sufficient experience to enable them to

avoid the dangers, electrical and/or mechanical

l

Instructed persons are adequately advised or supervised by skilled persons to enable

them to avoid the dangers, electrical and/or mechanical

All personnel must observe industry-prescribed safety practices during the installation, operation, and testing of all electrically-powered equipment.

IMPORTANT: Before working with the robot, every entrusted person must confirm that they:

l

Have the necessary qualifications

l

Have received the guides (both this user’s guide, and the Robot Safety Guide)

l

Have read the guides

l

Understand the guides

l

Will work in the manner specified by the guides

2.4 Robot Behavior

Hardstops

The robot’s hardstops are located at the base. If the robot runs into one of its hardstops, the

robot’s motion will stop completely, the system will generate an envelope error, and power

will be cut to the robot motors.

The robot cannot continue to move after hitting a hardstop until you clear the error.

The robot’s hardstops can stop the robot at any speed, load, and maximum or minimum extension.

2.5 Intended and Non-intended Use

Intended Use

The normal and intended use of these robots does not create hazards. The Quattro robot has

been designed and constructed in accordance with the relevant requirements of IEC60204-1.

The Quattro robot is intended for use in parts assembly and material handling for payloads up

to 6.0 kg (13.2 lb), for anodized platforms, and payloads up to 3 kg (6.6 lb) for stainless steel

platforms. See Technical Specifications on page 135 for complete information on the robot specifications. Refer to the Robot Safety Guide for details on the intended use of our robots.

WARNING: PERSONALINJURYRISK

Quattros are not collaborative robots. They require a dedicated work area that

will prevent personnel from coming into contact with them during operation.

26 Quattro User's Guide 09955-000 Rev. N

Page 27

Guidelines for safe use:

l

Clean, dry surfaces— The Quattro robot is designed to be compatible with standard

cleaning and operational needs for secondary food packaging, as well as less stringent

requirements. The platform and the arms, are IP67 rated. The base of the Quattro H

robot, is IP65 rated, and for the Quattro HS robot, the rating is IP66.

IMPORTANT: For standard Quattro H robot, the topside of the base is

IP20 rated, and therefore must not be exposed to liquid.

l

Temperature — 1 to 40°C (34 to 104°F), with a recommended humidity range of 5% to

90%, non-condensing.

Non-Intended Use

The Quattro robots are not intended for use in any of the following situations:

l

Use in the presence of ionizing or non-ionizing radiation

l

Use in potentially explosive atmospheres

l

Use in medical or life saving applications

Chapter 2: Safety

l

Use in a residential setting (they are for industrial use only)

l

Use before performing a risk assessment

l

Where the equipment will be subject to extremes of heat or humidity

Non-intended use of Quattro robots can:

l

Cause injury to personnel

l

Damage itself or other equipment

l

Reduce system reliability and performance

If there is any doubt concerning the application, ask your Omron Support to determine if it is

an intended use or not.

Robot Modifications

If the user or integrator makes any changes to the robot, it is their responsibility to ensure that

there are no sharp edges, corners, or protrusions.

Note that any change to the robot can lead to loss in safety or functionality. The user or integrator must ensure that all safety features are operational after modifications.

2.6 Additional Safety Information

Contact your local Omron support for other sources of safety information:

09955-000 Rev. N Quattro User's Guide 27

Page 28

2.6 Additional Safety Information

Robot Safety Guide

The Robot Safety Guide, which ships with every robot system, provides detailed information

on safety for Omron Adept Technologies, Inc. robots. It also gives resources for information on

relevant standards.

T20 Manual Control Pendant (Option)

The protective stop category for the pendant enable switch is category 1, which complies with

the requirements of ISO 10218-1. The pendant's design is in accordance with the requirements

of IEC 60204-1 and ISO 13849. The E-Stop button complies with ISO 13850.

NOTE: Omron Adept Technologies, Inc. does not offer a wireless pendant.

The manual control pendant can only move one robot at a time, even if your network contains

multiple robots.

Disposal

Dispose of in accordance with applicable regulations.

Customers can contribute to resource conservation and protecting the environment by the

proper disposal of WEEE (Waste Electronics and Electrical Equipment). All electrical and electronic products should be disposed of separately from the municipal waste system via designation collection facilities. For information about disposal of your old equipment, contact

your local Omron support.

28 Quattro User's Guide 09955-000 Rev. N

Page 29

Chapter 3: Robot Installation - H

3.1 Transport and Storage

This equipment must be shipped and stored in a temperature-controlled environment, within

the range –25 to +60°C (-13 to 140°F). The recommended humidity range is 5% to 90%, non-condensing. It should be shipped and stored in the supplied crate, which is designed to prevent

damage from normal shock and vibration. You should protect the crate from excessive shock

and vibration.

Use a forklift, pallet jack, or similar device to transport and store the packaged equipment.

The robot must always be stored and shipped in an upright position in a clean, dry area that

is free from condensation. Do not lay the crate on its side or any other non-upright position.

This could damage the robot.

The Quattro robot weighs 118 to 123 kg (260 to 271 lb) with no options installed.

3.2 Unpacking and Inspecting the Equipment

Before Unpacking

Before unpacking, carefully inspect all shipping crates for evidence of damage during transit. If

any damage is indicated, request that the carrier’s agent be present at the time the container is

unpacked.

Upon Unpacking

Before signing the carrier’s delivery sheet, compare the actual items received (not just the packing slip) with your equipment purchase order. Verify that all items are present and that the

shipment is correct and free of visible damage.

l

If the items received do not match the packing slip, or are damaged, do not sign the

receipt. Contact your local Omron support as soon as possible (see How Can I Get

Help? on page 22).

l

If the items received do not match your order, please contact your local Omron support

immediately.

Retain all containers and packaging materials. These items may be necessary to settle claims

or, at a later date, to relocate the equipment.

Unpacking

The Quattro robot is shipped in a wooden crate that holds the robot base, outer arms, platform,

controller, miscellaneous hardware, and any accessories ordered.

The top of the crate should be removed first.

09955-000 Rev. N Quattro User's Guide 29

Page 30

3.2 Unpacking and Inspecting the Equipment

Figure 3-1. Robot Base in Crate, (A) Outer Arms

The robot base is shipped with the inner arms attached. The outer arms are assembled in

pairs, packed in a cardboard box at the bottom of the crate. The platform is shipped fully

assembled, but separate from the robot base and outer arms.

1. Remove the ancillary items (controller, outer arms, platform, etc.) that are in cardboard

boxes and attached to the crate bottom.

Figure 3-2. Outer Arms

2.

The robot base is secured to the crate with four machine bolts, one in each crate post.

Place a protective pad over the eAIB to protect it from damage from tools during the

removal of the bolts.

3.

Remove the bolt from each crate post.

30 Quattro User's Guide 09955-000 Rev. N

Page 31

3.3 Repacking for Relocation

!

Chapter 3: Robot Installation - H

Figure 3-3. Removal ofBolt

If the robot or other equipment needs to be relocated, reverse the steps in the installation procedures in this chapter. Reuse all original packing containers and materials and follow all

safety notes used for installation. Improper packaging for shipment will void your warranty.

CAUTION: PROPERTYDAMAGERISK

The robot must always be shipped in an upright orientation.

3.4 Environmental and Facility Requirements

The Quattro robot system installation must meet the operating environment requirements

shown in the following table.

Table 3-1. Robot System Operating Environment Requirements

Ambient temperature 1 to 40°C (34 to 104°F)

Humidity 5% to 90%, non-condensing

Altitude up to 2000 m (6500 ft)

Pollution degree 2

Protection class: robot base IP65 (with optional cable sealing kit)

Protection class: arms, platform IP67

Note: For robot dimensions, see Technical Specifications on page 135.

Note: For power requirements, see Connecting 24 VDC Power to Robot on page 83 and Con-

necting 200-240 VAC Power to Robot on page 86.

09955-000 Rev. N Quattro User's Guide 31

Page 32

3.5 Mounting Frame

A

4x

A

4x

2x

B

20x

A

4x

C

1800.0

2000.0

2000.0

A

B

A

Note: The SmartController must be installed inside a NEMA-1 rated enclosure. The controller must not come into contact with liquids.

3.5 Mounting Frame

The Quattro robot is designed to be mounted above the work area suspended on a user-supplied frame. The frame must be adequately stiff to hold the robot rigidly in place while the

robot platform moves within the workspace.

While we do not offer robot frames for purchase, and the frame design is the responsibility of

the user, we provide here some general guidelines as a service to our users. We make no representation or warranty with respect to these guidelines, or the rigidity and longevity of the

structure designed and built by the user or for the user by a third party using these guidelines.

In addition, when the robot is mounted on the structure based on these guidelines, We do not

guarantee that the robot will perform to the specifications given in this product documentation, due to user’s frame or user’s production environmental factors.

As an example, a sample frame design is presented and discussed. For generalized application

performance, frames built to the specifications of this sample should experience no degradation in robot performance due to frame motions. Applications requiring higher than 6 kg * 10

g forces across the belt and/or 6 kg * 3 g along the belt may require a stiffer frame design.

Figure 3-4. Sample Quattro Mounting Frame, (A) See Detail 1, (B) See Detail 2

NOTE: More specifications for the sample frame are provided in Robot Mounting Frame, Quattro 650H Robot on page 158.

32 Quattro User's Guide 09955-000 Rev. N

Page 33

Chapter 3: Robot Installation - H

Any robot’s ability to settle to a fixed point in space is governed by the forces, masses, and

accelerations of the robot. Since “every action has an equal and opposite reaction”, these forces

are transmitted to the robot frame and cause the frame and base of the robot to move and possibly vibrate in space. As the robot system works to position the tool flange relative to the base

of the robot, any frame or base motion will be “unobservable” to the robot system, and will be

transmitted to the tool flange. This transmitted base motion will result in inertial movement of

the tool flange mass, and will cause disturbance forces to be introduced into the robot control

system. These disturbance forces cause “work” to be done by the robot servo control system

which may result in longer settling times for robot operations.

It is important to note that, even after the system reports the robot to be fully settled, the tool

flange will still be moving by any amount of motion that the suspended base of the robot may

be experiencing.

Frame Orientation

The sample robot frame design is stiffer in one direction than the other. This is to accommodate conveyor belt applications where the robot is moving with much more acceleration

across a conveyor belt than along it. The conveyor should generally be aligned so that the belt

travel is along the robot World Y-axis, and the mid-height frame members cross the belt at a

90° angle. The across-the-belt dimension of the frame should be minimized to get the best performance of the robot in that direction. While this frame design assumes a 1.8 m across-thebelt frame dimension, a 1.5 m dimension would offer increased stiffness and possibly

increased robot performance at high accelerations and payloads. The mid-height horizontal

members are important to the frame stiffness, and should be located as close to the belt as possible.

For applications requiring high accelerations along the direction of belt travel, consideration

should be given to strengthening the frame in that direction.

Frame Construction

Typically, the frame is constructed of welded steel members. Hygiene-sensitive applications

may call for stainless steel fabrication, with care taken to seal up all possible voids and grind

smooth all weld joints. For other applications, it may be suitable to manufacture the frame of

carbon steel and paint the resulting assembly. The frame design presented here is based on a

stainless steel construction using 10 mm thick members. It may be reasonable to use a reduced

thickness for carbon steel assemblies. Some customers may choose to use tubular members, or

turn horizontal members at 45° angles to facilitate water runoff from the flat frame surfaces.

Robot-to-Frame Considerations

The Quattro has a moderately-complex mounting requirement due to the nature of the parallelarm kinematics and the need to minimize the robot size and mass. Arm Travel Volume (650

shown) (units in mm) on page 143 shows the inner arm travel and how it may encroach on

the robot mounting points. As a starting point, for a frame that is 2 meters in each direction,

(allowing use of the full range of the Quattro 650 robots), you should attempt to attain a frame

frequency of 25 Hz.

For specialized applications, such as heavy payloads and/or aggressive moves, you may want

to attain a frame frequency of 40 Hz.

In general, a smaller frame will yield a higher frequency. If you aren’t going to use the entire

work envelope, you can increase the frequency simply by using a smaller frame.

09955-000 Rev. N Quattro User's Guide 33

Page 34

3.6 Mounting the Robot Base

!

A lower frequency frame, more aggressive robot moves, and heavier payloads will all contribute to longer settling times.

Mounting

The robot mounts in four locations, as detailed in the drawings. The holes are tapped for an

M16 x 2.0 bolt. The Quattro robot may be mounted from the top or bottom of the frame. A

crane or forklift should be used to position the robot. If lifted from above, the robot must be lifted by user-supplied eyebolts and slings.

Mounting Hole Dimensions, Quattro H Robots, (A) Detail A, (B) Detail B (units in mm) on

page 136 shows the mounting hole pattern for the Quattro robot. Note the hole location and

mounting pad tolerances for position and flatness.

Deviation from this flatness specification will, over time, cause a possible loss of robot calibration. If the frame does not meet this flatness specification, use shims to achieve it.

NOTE: We suggest welding the robot mounting tabs as a last step in the frame

fabrication, using a flat surface as a datum surface during the tack welding operation.

Gussets

The triangular gussets are an integral part of the frame stiffness. The vibrational strength of a

structural assembly is strongly governed by controlling the shear forces between members. The

250 mm gussets, shown in Sample Quattro Mounting Frame, (A) See Detail 1, (B) See Detail 2

on page 32, are nominally sufficient for transferring the load from the vertical members into

the horizontal cross pieces. Preferably, gussets should be placed at the edges of the frame members to transfer the loading into the walls of the members, instead of the faces, and enable

easier cleaning. Some frame designs may benefit from extending these gussets to 500 mm in

the vertical direction, as the design intent of the gussets is mainly to secure the long vertical

members from rotating out of position. For this reason, the gussets to the across-the-belt horizontal member should be at the bottom of the member, as shown in Sample Quattro Mounting

Frame, (A) See Detail 1, (B) See Detail 2 on page 32, and as close to the vertical midplane of the

frame as feasible (15 mm thickness is adequate for most situations).

3.6 Mounting the Robot Base

NOTE: All mounting hardware is user-supplied.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

Remove all ancillary components (controller, outer arms, platform, etc.) from

the shipping crate before lifting the robot base.

Robot Orientation

We recommend mounting the Quattro robot so that the Status Display Panel faces away from

the conveyor belt. Although the work envelope of the robot is symmetrical, this orientation

gives better access to the status display, status LED, and Brake-Release button. It also balances

the arm loading for aggressive moves across the belt.

34 Quattro User's Guide 09955-000 Rev. N

Page 35

Chapter 3: Robot Installation - H

!

!

This orientation places the robot World Y-axis along the conveyor belt, and the X-axis across

the belt.

Mounting Surfaces

Mounting surfaces for the robot mounting flanges must be within 0.75 mm of a flat plane. If

the surfaces do not meet this tolerance, use shims to attain it.

NOTE: Failure to mount the Quattro robot within 0.75mm of a flat plane will

result in inconsistent robot motions.

Mounting Options

Using the mounting frame design provided, there are several options for mounting the Quattro

robot:

l

Lower the robot into the frame from above, or

Lift the robot into the frame from below.

l

Place the robot mounting pads on top of the frame mounting pads, or

Place the robot mounting pads under the frame mounting pads.

l

Mounting hardware can be bolts threaded directly into the robot base mounting pads,

or bolts that go through the robot base mounting pads into nuts.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Do not attempt to lift the robot from any points other than with eyebolts or

slings as described here, or with a padded board, as described here.

Mounting Procedure from Above the Frame

The Quattro robot has four mounting pads. Each pad has one M16 x 2.0 threaded throughhole. The robot can be mounted either on top of the frame pads, using the bottom surface of the

robot base mounting pads, or to the bottom of the frame pads, using the top surface of the

robot base mounting pads.

Mounting to Top of Frame Pads

This procedure uses two user-supplied M16 x 2.0 eyebolts and jam nuts.

1.

Remove all lag bolts from the robot base mounting pads.

2.

Screw the M16 eyebolts into opposing robot mounting pads, so that the robot will be balanced when lifted.

3.

Lock each eyebolt with a jam nut.

4.

Connect slings to the M16 eyebolts and take up any slack in the slings.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Do not to lift the robot from any points other than the eyebolts. Failure to comply could result in the robot falling and causing either injury or equipment

damage.

09955-000 Rev. N Quattro User's Guide 35

Page 36

3.6 Mounting the Robot Base

A

A

5.

Lift the robot and position it directly over the mounting frame.

6.

Slowly lower the robot while aligning the M16 holes in the robot mounting pads with

the holes in the frame mounting pads.

7.

When the mounting pad surfaces are touching, start a bolt in each of the two unused

mounting holes. Refer to Install Mounting Hardware on page 37.

8.

Remove the slings and M16 eyebolts.

9.

Follow the instructions in Install Mounting Hardware on page 37.

Mounting to Bottom of Frame Pads

NOTE: Since eyebolts would be in the way of this mounting method, you will

have to use slings or other means to lift the robot base. Nylon slings can be

wrapped across the center of the robot base, away from the inner arms. See the

following figure.

1.

Remove all lag bolts from the mounting pads before lifting the robot base.

2.

Wrap slings around the robot base. See the following figure for two methods.

NOTE: Make sure the slings do not touch the status panel or inner arms.

Figure 3-5. Location of Slings for Lifting Robot Base, (A) Slings

3.

Lift the robot and position it directly over the mounting frame.

4.

Slowly lower the robot while rotating it slightly, so that the four mounting pads are

lowered past the frame mounting pads without touching.

5.

When the robot base mounting pads are below the lower surface of the frame mounting

pads, rotate the robot base so that the M16 threaded holes in the robot base mounting

pads align with the holes in the frame mounting pads.

6.

Lift the robot base up, keeping the holes in the robot base pads and the frame pads

aligned, until the top surfaces of the robot base pads are touching the bottom surface of

36 Quattro User's Guide 09955-000 Rev. N

Page 37

Chapter 3: Robot Installation - H

the frame mounting pads.

7.

Follow the instructions in Install Mounting Hardware on page 37.

Mounting Procedure from Below the Frame

The Quattro robot has four mounting pads. Each pad has one M16 x 2.0 threaded hole. The

robot can be mounted either on top of the frame pads, using the bottom surface of the robot

base pads, or to the bottom of the frame pads, using the top surface of the robot base pads.

The Quattro robot can be mounted from beneath the mounting frame using a forklift. Use a

padded board as a support under the robot base. The robot base can be rotated by hand, once

mounted on the lifting pad on a forklift, when needed for clearing obstacles.

Mounting to Bottom of Frame Pads

1.

Remove all lag bolts from the mounting pads before lifting the robot base.

2.

Lift the robot and position the robot directly under the mounting frame.

3.

Slowly lift the robot and align the M16 holes in the robot mounting pads with the holes

in the frame mounting pads.

4.

Lift the robot until the top of the robot base mounting pads are touching the bottom of

the frame mounting pads.

5.

Follow the instructions in Install Mounting Hardware on page 37.

Mounting to Top of Frame Pads

1.

Remove all lag bolts from the mounting pads before lifting the robot base.

2.

Lift the robot so the mounting pads are directly under the mounting pads of the frame.

3.

Slowly lift the robot while rotating it slightly, so that the four mounting pads are raised

past the frame mounting pads without touching.

4.

When the robot base mounting pads are above the top surface of the frame mounting

pads, rotate the robot base back, so that the M16 threaded holes in the robot base mounting pads align with the holes in the frame mounting pads.

5.

Slowly lower the robot base while aligning the M16 holes in the robot mounting pads

with the holes in the frame mounting pads.

6.

Continue lowering the robot base until the bottom surface of the robot base mounting

pads are touching the top surface of the frame mounting pads.

7.

Follow the instructions in Install Mounting Hardware on page 37.

Install Mounting Hardware

NOTE: When mounting the robot, note the following:

l

The base casting of the robot is aluminum and can be dented if bumped against a

harder surface.

l

Verify that the robot is mounted squarely before tightening the mounting bolts.

l

All mounting hardware is user-supplied.

09955-000 Rev. N Quattro User's Guide 37

Page 38

3.6 Mounting the Robot Base

1.

Place split lock, then flat washers on the bolts.

Bolts are M16 x 2.0 if threaded into the robot base mounting tabs.

Bolts are M12 or ½ in. if going through the robot base mounting tabs into nuts.

NOTE: When M16 x 2.0 bolts are used, the bolt must engage at least 24 mm

into the threads of the base mounting pad.

2.

Insert the bolts through the holes in the frame mounting pads and into the threaded

holes in the robot base mounting pads.

If using through-bolts, insert the bolts through the holes in both the mounting pads and

through the threaded holes in the robot base mounting pads into nuts.

3.

Tighten the mounting hardware to the specifications listed in the following table.

NOTE: Check the tightness of the mounting bolts one week after initial installation, and then recheck every 6 months. For periodic maintenance, see Periodic

Maintenance Schedule on page 165.

Table 3-2. Mounting Bolt Torque Specifications

Standard Size Minimum Specification Torque

Threaded into base (aluminum):

Metric M16 x 2.0 ISO Property Class 5.8 98 N·m (74 ft-lb)

Using base mounting pad hole as through-hole:

Metric M12 ISO Property Class 9.8 100 N·m (75 ft-lb)

SAE ½ in. 100 N·m (75 ft-lb)

38 Quattro User's Guide 09955-000 Rev. N

Page 39

3.7 Attaching the Outer Arms and Platform

D

A

E

F

C

G

H

J

B

E

Chapter 3: Robot Installation - H

Callout Description Callout Description

A Mounting Pads F Motor Cover

B eAIB G Outer Arms

C Cable Inlet Box H Platform

D Base J Ball Joints (Spring Assemblies not shown)

Figure 3-6. Major Robot Components, Top View

E Inner Arm

The Quattro robot platform is attached to the inner arms by the outer arms.

NOTE: Except for attaching the outer arms and end-effector tooling, the platform

is shipped fully assembled.

09955-000 Rev. N Quattro User's Guide 39

Page 40

3.7 Attaching the Outer Arms and Platform

Clocking the Platform to the Base

The rotational alignment (clocking) of the platform to the base is critical to the correct operation of the Quattro robot.

NOTE: Incorrect clocking of the platform will result in incorrect robot performance.

l

On the hard-anodized and stainless steel platforms, the ends of the platform crosspieces (between each pair of ball studs) are labeled with numbers (1–4).

In addition, +X and +Y World Coordinates are labeled on the platform near the flange.

See the following figure.

l

When installing the platform, the numbers on the platform must match the numbers on

the underside of the robot base.

Figure 3-7. Platform Orientation Labeling (P32 shown)

Version Information: The labeling on all anodized platforms is the same except

for the part number.

40 Quattro User's Guide 09955-000 Rev. N

Page 41

Chapter 3: Robot Installation - H

X+

Y+

3

41

2

A

!

Figure 3-8. Platform Orientation, P31 Platform, (A) Tool Flange

Attaching the Outer Arms

One pair of outer arms attaches between each inner arm and the platform. No tools are needed

to install or remove the outer arms.

l

Each outer arm has a ball joint socket at each end.

l

The inner arms and the platform have corresponding pairs of ball studs.

CAUTION: PINCHRISK

Ball joints are spring-loaded. Be careful not to pinch your fingers.

Figure 3-9. Inner Arm Ball Studs

09955-000 Rev. N Quattro User's Guide 41

Page 42

3.7 Attaching the Outer Arms and Platform

D

A

E

F

C

G

H

B

!

l

Outer arm pairs are shipped assembled. Each pair has two springs and two horseshoes

at each end.

Figure 3-10. Ball Joint Assembly (Quattro HS shown)

Callout Description Callout Description

A Ball Joint Stud E Ball Joint Socket Insert

B Inner Arm F Outer Arm Springs

C Ball Joint Socket G Spring Horseshoe

D Pressed Pin H Outer Arms

CAUTION: PROPERTYDAMAGERISK

Ensure that the bearing insert is in place in the end of each outer arm. If an

insert has fallen out of the arm, press it back into place, ensuring that the insert

is centered and bottomed-out in the ball joint socket.

NOTE: In the following steps, take care not to trap debris between the ball studs

and their sockets.

42 Quattro User's Guide 09955-000 Rev. N

Page 43

Chapter 3: Robot Installation - H

!

NOTE: The procedure for attaching outer arms is the same for all platforms.

1.

Attach one pair of outer arms to each inner arm.

a.

As illustrated in the following figure, this is most easily achieved by pivoting the

two arms away from each other lengthwise.

This requires the least stretching of the spring to attach the ball joints.

b.

Slip one ball joint socket over the corresponding ball stud.

c.

Swing the bottom end of the outer arm pair sideways as you slip the other ball

joint socket over the corresponding ball stud.

CAUTION: PROPERTYDAMAGERISK

Do not overstretch the outer arm springs. Separate the ball joint sockets only

enough to fit them over the ball studs.

Figure 3-11. Installing Outer Arms (Quattro HS shown)

2.

Attach one pair of outer arms to each of the four pairs of ball studs on the platform.

NOTE: Ensure that the numbers on the platform match the numbers on the

underside of the robot base. This will place the platform tool flange closest to the

Status Display Panel. See Clocking the Platform to the Base on page 40. The platform is installed flange-down.

a.

Swing the bottom end of the outer arm pair to the right, as far as possible.

b.

Slip the right ball joint socket over the right ball stud. (Move the platform

as needed to do this.)

c.

Move the platform and outer arm pair to the left as you slip the left ball

joint socket over the corresponding ball stud.

3.

Ensure that all spring hooks are fully-seated in the grooves of the horseshoes, as shown

in the following figure:

09955-000 Rev. N Quattro User's Guide 43

Page 44

3.8 Mounting the Front Panel

Figure 3-12. Horseshoe and Spring Assembly

3.8 Mounting the Front Panel

The Front Panel must be installed outside of the workspace.

NOTE: European standards require that the remote High Power push-button be

located outside of the workspace of the robot.

44 Quattro User's Guide 09955-000 Rev. N

Page 45

Chapter 4: Robot Installation - HS

4.1 Transport and Storage

This equipment must be shipped and stored in a temperature-controlled environment, within

the range –25 to +60°C (-13 to 140°F). The recommended humidity range is 5% to 90%, non-condensing. It should be shipped and stored in the supplied crate, which is designed to prevent

damage from normal shock and vibration. You should protect the crate from excessive shock

and vibration.

Use a forklift, pallet jack, or similar device to transport and store the packaged equipment.

The robot must always be stored and shipped in an upright position in a clean, dry area that

is free from condensation. Do not lay the crate on its side or any other non-upright position.

This could damage the robot.

The Quattro robot weighs 118 to 123 kg (260 to 271 lb) with no options installed.

4.2 Unpacking and Inspecting the Quattro Equipment

Before Unpacking

Carefully inspect all shipping crates for evidence of damage during transit. If any damage is

indicated, request that the carrier’s agent be present at the time the container is unpacked.

Upon Unpacking

Before signing the carrier’s delivery sheet, compare the actual items received (not just the packing slip) with your equipment purchase order. Verify that all items are present and that the

shipment is correct and free of visible damage.

l

If the items received do not match the packing slip, or are damaged, do not sign the

receipt. Contact your local Omron support as soon as possible.

l

If the items received do not match your order, please contact your local Omron support

immediately.

Retain all containers and packaging materials. These items may be necessary to settle claims

or, at a later date, to relocate the equipment.

Unpacking

The Quattro HS robot is shipped in a crate that holds the robot base, outer arms, platform, controller, miscellaneous hardware, and any accessories ordered.

The top of the crate should be removed first.

09955-000 Rev. N Quattro User's Guide 45

Page 46

4.2 Unpacking and Inspecting the Quattro Equipment

Figure 4-1. Robot Base in Crate, (A) Outer Arms

The robot base is shipped with the inner arms attached. The outer arms are assembled in

pairs, packed in a cardboard box at the bottom of the crate. The platform is shipped fully

assembled, but separate from the robot base and outer arms.

1. Remove the ancillary items (controller, outer arms, platform, etc.) that are in cardboard

boxes and attached to the crate bottom.

Figure 4-2. Outer Arms

2.

The robot base is secured to the crate with four machine bolts, one in each crate post.

Place a protective pad over the eAIB to protect it from damage from tools during the

removal of the bolts.

3.

Remove the bolt from each crate post.

46 Quattro User's Guide 09955-000 Rev. N

Page 47

Chapter 4: Robot Installation - HS

!

Figure 4-3. Removal of Bolt

4.3 Repacking for Relocation

If the robot or other equipment needs to be relocated, reverse the steps in the installation procedures that follow in this chapter. Reuse all original packing containers and materials and follow all safety notes used for installation. Improper packaging for shipment will void your

warranty.

CAUTION: PROPERTYDAMAGERISK

The robot must always be shipped in an upright orientation.

4.4 Environmental and Facility Requirements

The Quattro HS robot system installation must meet the operating environment requirements

shown in the following table.

Table 4-1. Robot System Operating Environment Requirements

Ambient temperature 1 to 40°C (34 to 104°F)

Humidity 5% to 90%, non-condensing

Altitude up to 2000 m (6500 ft) above sea level

09955-000 Rev. N Quattro User's Guide 47

Page 48

4.5 Mounting Frame

Pollution degree 2

Protection class: robot base IP66

Protection class: platform, arms IP67

NOTE: For robot dimensions, see Top Dimensions, Work Envelope, 650 (HS shown) (units

in mm) on page 135.

NOTE: For power requirements, see Connecting 24 VDC Power to Robot on page 83 and Connecting 200-240 VAC Power to Robot on page 86.

NOTE: The SmartController must be installed inside a NEMA-1 rated enclosure. The controller must not come into contact with liquids.

NOTE: For chemical cleaning information, refer to Chemical Compatibility on page 190.

4.5 Mounting Frame

The design of the robot mounting frame is the user’s responsibility.

l

The sample given for the 650H robot, while stiff enough for use with the Quattro HS

robots, was not designed for USDA applications.

l

The thickness of the frame mounting tabs is critical, as is the flatness of those tabs. See

Frame Mounting Tabs (following) and Mounting Surfaces on page 56.

l

The frame must be stiff enough to prevent excessive vibration.

l

You may want to design the frame so that the robot can be installed by lowering it from

the top.

The Quattro HS robot is designed to be mounted above the work area suspended on a user-supplied frame. The frame must be adequately stiff to hold the robot rigidly in place while the

robot platform moves within the workspace.

While we do not offer robot frames for purchase, and the frame design is the responsibility of

the user, we provide some general guidelines as a service to our users.

Any robot’s ability to settle to a fixed point in space is governed by the forces, masses, and

accelerations of the robot. Since “every action has an equal and opposite reaction”, these forces

are transmitted to the robot frame and cause the frame and base of the robot to move and possibly vibrate in space. As the robot system works to position the tool flange relative to the base

of the robot, any frame or base motion will be “unobservable” to the robot system, and will be

transmitted to the tool flange. This transmitted base motion will result in inertial movement of

the tool flange mass, and will cause disturbance forces to be introduced into the robot control

system. These disturbance forces cause “work” to be done by the robot servo control system

which may result in longer settling times for robot operations.

It is important to note that, even after the system reports the robot to be fully settled, the tool

flange will still be moving by any amount of motion that the suspended base of the robot may

be experiencing.

Frame Mounting Tabs

To achieve the correct compression of the sealing gaskets, the mounting tabs on the frame

must be 12.7 mm, +1.3, -0.7 mm thick (0.5 in., +0.05, -0.028 in.).

48 Quattro User's Guide 09955-000 Rev. N

Page 49

Chapter 4: Robot Installation - HS

Because the junction of the robot base mounting pad and the frame mounting pad is sealed

with a gasket, the frame mounting pads must be at least as big as the robot base mounting

pads. If the frame pad does not cover the entire robot pad, the gasket will not seal properly.

The design of the Quattro HS robot mounting bolts and seals requires fairly tight tolerances for

the robot mounting holes in the frame. These should be 17.25 ± 0.75 mm (0.68 ± 0.03 in.) in diameter.

Robot-to-Frame Considerations

The Quattro robot has a moderately-complex mounting requirement due to the nature of the

parallel-arm kinematics and the need to minimize the robot size and mass. Arm Travel

Volume (650 shown) (units in mm) on page 143 shows the inner arm travel and how it may

encroach on the robot mounting points. As a starting point, for a frame that is 2 meters in each

direction, (allowing use of the full range of the Quattro 650 robots), you should attempt to

attain a frame frequency of 25 Hz.

For specialized applications, such as heavy payloads and/or aggressive moves, you may want

to attain a frame frequency of 40 Hz.

In general, a smaller frame will yield a higher frequency. If you aren’t going to use the entire

work envelope, you can increase the frequency simply by using a smaller frame.

A lower frequency frame, more aggressive robot moves, and heavier payloads will all contribute to longer settling times.

Mounting

Mounting Hole Dimensions, Quattro HS Robots (units in mm) on page 137 shows the mounting hole pattern for the Quattro HS robot. Note the hole location and mounting pad tolerances

for position and flatness.

Deviation from this flatness specification will, over time, cause a possible loss of robot calibration.

NOTE: We suggest welding the robot mounting tabs as a last step in the frame

fabrication, using a flat surface as a datum surface during the tack welding operation.

Gussets

The triangular gussets are an integral part of the frame stiffness. The vibrational strength of a

structural assembly is strongly governed by controlling the shear forces between members. The

250 mm gussets, shown in Sample Quattro Mounting Frame, (A) See Detail 1, (B) See Detail 2

on page 32, are nominally sufficient for transferring the load from the vertical members into

the horizontal cross pieces. Preferably, gussets should be placed at the edges of the frame members to transfer the loading into the walls of the members, instead of the faces, and enable

easier cleaning. Some frame designs may benefit from extending these gussets to 500 mm in

the vertical direction, as the design intent of the gussets is mainly to secure the long vertical

members from rotating out of position. For this reason, the gussets to the across-the-belt horizontal member should be at the bottom of the member, as shown in Sample Quattro Mounting

Frame, (A) See Detail 1, (B) See Detail 2 on page 32, and as close to the vertical midplane of the

frame as feasible (15 mm thickness is adequate for most situations).

09955-000 Rev. N Quattro User's Guide 49

Page 50

4.6 Cable Inlet Box

4.6 Cable Inlet Box

The cable inlet box (P/N 09564-000) must be mounted on the top of the robot during the robot

installation process. This is best done before the robot is mounted on the frame.

Assembling Cable Inlet Box

The cables entering the cable inlet box are sealed with a Roxtec compression block kit.

Figure 4-4. Cable Inlet Box and Cover