Page 1

Q2A

Driving Quality

Installation & Operation Instructions

Item code: Q2A-Axxxx-xxx

200 V class 0.55 kW to 110 kW

400 V class 0.55 kW to 315 kW

Page 2

1 English

1 English

◆ General Information

Do not use this manual as a replacement for the Technical Manual. The products and specifications given in this

manual and the manual contents can change without notice to make the product and manual better. Be sure to

always use the most recent version of this manual. Use the manual for the correct installation, wiring, adjustment,

and operation of this product. This manual is available for download on our documentation website. Refer to the

back page of this manual.

◆ Qualifications for the Intended User

This manual is created for electrical specialists and engineers who have experience with AC drive installation,

adjustment, repair, inspection, and parts replacement. Persons without technical training, minors, persons with

disabilities or mental problems, persons with perception problems, and persons with pacemakers must not use or

operate this product.

◆ Safety

Read the safety guidelines carefully before installing, wiring, or operating this product.

■ Explanation of Signal Words

DANGER

WARNING

CAUTION

NOTICE

Identifies a hazardous situation, which, if not avoided, will cause death or serious injury.

Identifies a hazardous situation, which, if not avoided, can cause death or serious injury.

Identifies a hazardous situation, which, if not avoided, can cause minor or moderate injury.

Identifies a property damage message.

■ General Safety Instructions

The manufacturer manufactures and supplies electronic components for a variety of industrial applications. The

selection and application of products is the responsibility of the designer of the equipment or the customer that

assembles the final product. The manufacturer is not responsible for how our products are incorporated into the

final system design. In all cases, our products should not be incorporated into a product or design as the exclusive

or sole safety control function. All control functions are designed to dynamically detect failures and operate safely

without exception. All products that are designed to incorporate parts manufactured by us must be provided to the

end user and include proper warnings and instructions regarding their safe use and operation. All warnings from

the manufacturer must be promptly issued to the end user. The manufacturer offers warranties only for the quality

of our products, in compliance with standards and specifications that are described in the manual. The

manufacturer does not offer other warranties, either explicit or implied. Injuries, property damage, and lost

business opportunities caused by improper storage or handling and negligence oversight on the part of your

company or your customers will void our warranty for the product.

Note:

Failure to obey the safety messages in the manual can cause serious injury or death. The manufacturer is not responsible for injuries or

damage to equipment caused by ignoring the safety messages.

• Read this manual carefully when mounting, operating, and repairing AC drives.

• Obey all warnings, cautions, and notices.

• Approved personnel must perform all work.

• Install the drive in an area with these conditions.

DANGER

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make

sure that the drive is safe. Failure to obey will cause death or serious injury.

WARNING

power supply wiring to main circuit input terminals R/L1, S/L2, and T/L3. Failure to obey can cause death or serious injury.

WARNING

cause death or serious injury from falling equipment.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

Fire Hazard. Do not connect power supply wiring to drive output terminals U/T1, V/T2, and W/T3. Connect

Crush Hazard. Only approved personnel can operate a crane or hoist to move the drive. Failure to obey can

EN 2 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 3

1 English

WARNING

Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

death or serious injury and will void warranty. The manufacturer is not responsible for changes to the product made by the user.

WARNING

Electrical Shock Hazard. Only let authorized persons install, wire, maintain, examine, replace parts, and

repair the drive. Failure to obey can cause death or serious injury.

WARNING

Electrical Shock Hazard. Always ground the motor-side grounding terminal. Contacting the motor case can

cause death or serious injury from incorrect equipment grounding.

WARNING

Electrical Shock Hazard. Do not work on the drive or around the drive while wearing loose clothing or jewelry.

Tighten loose clothing and remove all metal objects such as watches or rings. Failure to obey can cause death or serious injury.

WARNING

2007 standard specifies that users must wire the power supply to automatically turn off when the protective ground wire

disconnects. Users can also connect a protective ground wire that has a minimum cross-sectional area of 10 mm

or 16 mm

2

WARNING

Electrical Shock Hazard. The leakage current of the drive will be more than 3.5 mA. The IEC/EN 61800-5-1:

(aluminum wire). Failure to obey these standards can cause death or serious injury.

Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and load

2

(copper wire)

before starting Auto-Tuning. The drive and motor can start suddenly during Auto-Tuning and cause death or serious injury.

WARNING

Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and

machine area and attach covers, couplings, shaft keys, and machine loads before energizing the drive. Failure to obey can

cause death or serious injury.

WARNING

Fire Hazard. Do not use the main circuit power supply (Overcurrent Category III) at incorrect voltages. Make

sure that the drive rated voltage aligns with the power supply voltage before energizing the drive. Failure to obey can cause

death or serious injury.

WARNING

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not install the drive

near flammable or combustible materials. Attach the drive to metal or other noncombustible material. Failure to obey can cause

death or serious injury.

WARNING

Fire Hazard. Tighten all terminal screws to the correct tightening torque. Connections that are too loose or too

tight can cause incorrect operation and damage to the drive. Incorrect connections can also cause death or serious injury from

fire.

WARNING

Fire Hazard. Tighten screws against the bit at an angle in the specified range described in this manual.

Tightening screws at an angle outside of the specified range can cause damage the terminal block or start a fire if the

connection is loose.

WARNING

Crush Hazard. Use a lifting mechanism made to move large drives when necessary. Failure to obey can

cause death or serious injury from falling equipment.

WARNING

Electrical Shock Hazard. Do not cause a short circuit on the drive output circuit. Failure to obey can cause

death or serious injury.

WARNING

Electrical Shock Hazard. Always use a type B Residual Current Monitor/Residual Current Device (RCM/RCD)

where a residual current operated protective or monitoring device protects against direct or indirect contact as specified by IEC/

EN 60755 The drive can cause a residual current with a DC component in the protective earthing conductor. Failure to obey can

cause death or serious injury.

WARNING

Electrical Shock Hazard. Ground the neutral point on the power supply to comply with the EMC Directive

before turning on the EMC filter or if there is high resistance grounding. If the EMC filter is switched ON without the neutral point

being grounded or if there is high resistance grounding, it can cause death or serious injury.

WARNING

Electrical Shock Hazard. Do not immediately energize the drive or operate peripheral devices after the drive

blows a fuse or trips an RCM/RCD. Wait for the time specified on the warning label at a minimum and make sure that all

indicators are OFF. Then check the wiring and peripheral device ratings to find the cause of the problem. Contact the

manufacturer before energizing the drive or peripheral devices if the cause is not known. Failure to obey can cause death or

serious injury and damage to the drive.

WARNING

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by applicable codes and this

manual. The drive is suited for circuits that supply not more than 100,000 RMS symmetrical amperes, 240 Vac maximum (200 V

Class), 480 Vac maximum (400 V Class). Failure to obey can cause death or serious injury.

CAUTION

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

moving the drive. Failure to obey can cause minor to moderate injury.

CAUTION

Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait 15 minutes minimum, and make

sure that the heatsink is cool to replace the cooling fans. Failure to obey can cause minor to moderate injury.

NOTICE

Observe correct electrostatic discharge (ESD) procedures when touching the drive and circuit boards. Failure

to obey can cause ESD damage to the drive circuitry.

NOTICE

Do not connect or disconnect the motor from the drive while the drive is supplying voltage. Incorrect

equipment sequencing can cause damage to the drive.

NOTICE

Do not do a withstand voltage test or Megger test on the drive. Failure to obey can cause damage to the drive.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 3

Page 4

1 English

NOTICE

damage to the drive and connected equipment.

NOTICE

NOTICE

ground terminal of the drive. Failure to obey can cause electrical interference and unsatisfactory system performance.

NOTICE

drive, make sure that you review “Braking Unit, Braking Resistor Unit Instruction Manual (TOBPC72060001)”. Failure to obey

can cause damage to the drive and braking circuit.

NOTICE

Failure to obey can cause damage to the drive.

NOTICE

cause damage to the drive, phase-advancing capacitors, LC/RC noise filters, and leakage breakers (ELCB, GFCI, or RCM/

RCD).

Do not connect or operate damaged equipment or equipment with missing parts. Failure to obey can cause

Install fuses and an RCM/RCD. Failure to obey can cause damage to the drive.

Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the

Do not allow unqualified personnel to use the product. Before you connect a dynamic braking option to the

Make sure that all connections are correct after you install the drive and connecting peripheral devices.

Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits. Failure to obey can

■ Intended Use

This AC drive is electrical equipment that controls the speed and rotational direction of a motor in a commercial

application. Do not use this product for other functions.

1. Read and understand all safety precautions.

2. Wire and ground the drive as specified by all applicable standards and safety precautions.

3. Tightly attach all parts and protective covers.

4. Always use the product in the correct environmental conditions as specified in this manual.

Note:

This product is not designed and manufactured for use in life-support machines or systems.

WARNING

devices to minimize the risk of accidents when installing the product where its failure could cause a life-or-death situation, loss

of human life, or a serious accident or physical injury.

Injury to Personnel. This product is manufactured with strict quality-control guidelines. Install applicable safety

■ Exclusion of Liability

The manufacturer cannot be held responsible for any damages to the product, equipment or persons if this product

is used in any other way than specified in Intended Use on page 4.

◆ Moving the Drive

Obey local laws and regulations when moving and installing this product.

CAUTION

moving the drive. Failure to obey can cause minor to moderate injury.

< 15 kg (33 lbs.) 1

≥ 15 kg (33 lbs.) 2 + using appropriate lifting equipment

Use the hanging brackets attached to the drive to temporarily lift the drive when you install the drive to a control

panel or wall or when you replace the drive. Do not let the drive stay vertically or horizontally suspended or move

the drive over a long distance while it is suspended.

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

Drive Weight Persons Necessary to Move the Drive

EN 4 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 5

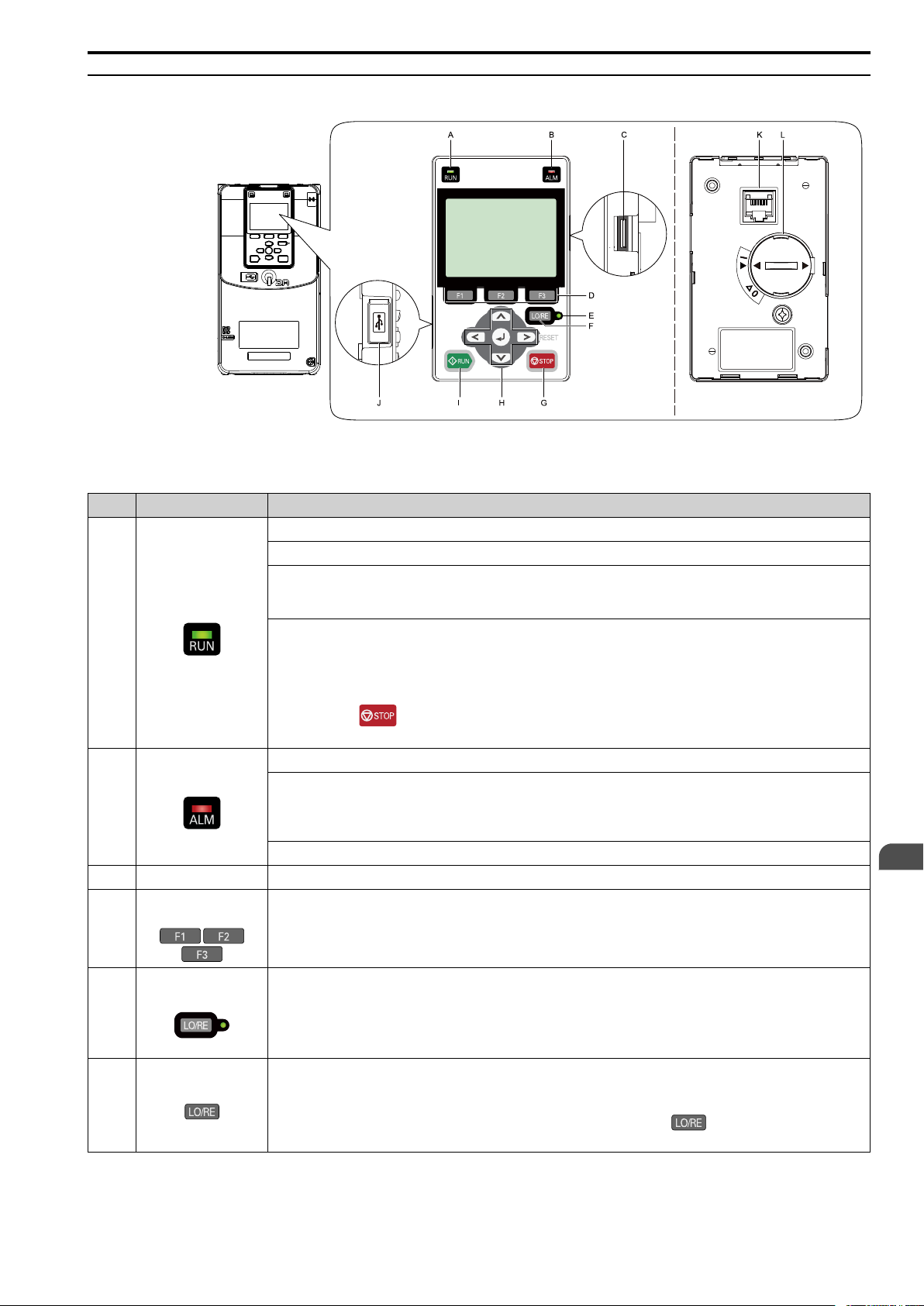

◆ User Interface Elements

Figure 1.1 Keypad

Table 1.1 Keypad Components and Functions

Symbol Name Function

Illuminates to show that the drive is operating the motor.

The LED turns OFF when the drive stops.

Flashes to show that:

• The drive is decelerating to stop.

RUN LED

A

• The drive received a Run command with a frequency reference of 0 Hz, but the drive is not set for zero speed control.

Flashes quickly to show that:

• The drive received a Run command from the MFDI terminals while switching from LOCAL Mode to REMOTE Mode.

• The drive received a Run command from the MFDI terminals when the drive is not in Drive Mode.

• The drive received a Fast Stop command.

• The safety function shuts off the drive output.

1 English

ALM LED

B

C microSD Card Insertion Slot

Function Keys

D

E

F

F1, F2, F3

LOCAL/REMOTE

indicator

LO/RE Selection Key

• The user pushed on the keypad while the drive is operating in REMOTE Mode.

• The drive is energized with an active Run command and b1-17 = 1 [RUN@PowerUp Selection = Disregard RUN].

Illuminates when the drive detects a fault.

Flashes when the drive detects:

• Alarm

• Operation Errors

• A fault or alarm during Auto-Tuning

The light turns off during regular drive operation. There are no alarms or faults.

The insertion point for a microSD card.

The menu shown on the keypad sets the functions for function keys.

The name of each function is in the lower half of the display window.

Illuminated: The keypad controls the Run command (LOCAL Mode).

OFF: The control circuit terminal or serial transmission device controls the Run command (REMOTE Mode).

Note:

• LOCAL: Operated using the keypad. Use the keypad to enter Run/Stop commands and the frequency reference command.

• REMOTE: Operated from the control circuit terminal or serial transmission. Use the frequency reference source entered in b1-01

and the Run command source selected in b1-02.

Switches drive control for the Run command and frequency reference between the keypad (LOCAL) and an external source

(REMOTE).

Note:

• The LOCAL/REMOTE Selection Key continuously stays enabled after the drive stops in Drive Mode. Set o2-01 = 0 [LO/RE Key

Selection of Function = Disabled] to disable switching from REMOTE to LOCAL by .

• The drive will not switch between LOCAL and REMOTE when it is receiving a Run command from an external source.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 5

Page 6

1 English

Symbol Name Function

Stops drive operation.

G

STOP Key

Left Arrow Key • Moves the cursor to the left.

Note:

Uses a stop-priority circuit. Push to stop the motor even when a Run command is active at MFDI terminals. Set o2-02 = 0

[STOP Key Selection of Function = Disabled] to disable the priority in .

• Back to the previous screen.

Up Arrow Key/Down

Arrow Key

H

Right Arrow Key (RESET)

I

J

K RJ-45 Connector

L Clock Battery Cover

WARNING

/

ENTER Key

RUN Key

USB Terminal

Sudden Movement Hazard. The drive may start unexpectedly if switching control sources when setting b1-07

• Scrolls up or down to display the next item or the previous item.

• Selects parameter numbers, and increments or decrements setting values.

• Moves the cursor to the right.

• Continues to the next screen.

• Restarts the drive to clear a fault.

• Enters parameter values and settings.

• Selects menu items to move the user between keypad displays.

• Selects each mode, parameter, and set value.

Starts the drive in LOCAL Mode.

Starts the operation in Auto-Tuning Mode.

Note:

Push on the keypad to set the drive to LOCAL Mode before operating the motor with the keypad.

Insertion point for a USB cable (USB 2.0, type: A - mini-B). Use the USB cable to connect the drive to a PC.

Connects to the drive using an RJ-45 8-pin straight through UTP CAT5e cable or keypad connector.

Remove this cover to install or replace the clock battery.

= 2 [LO/RE Run Selection = Accept RUN]. Clear all personnel from rotating machinery and electrical connections prior to

switching control sources. Failure to comply may cause death or serious injury.

■ Keypad Mode and Menu Displays

Note:

• Energize the drive with factory defaults to show the Initial Setup screen. Push (Home) to show the HOME screen.

–Select [No] from the [Show Initial Setup Screen] setting to skip Initial Setup screen during power up.

• Push from the Home screen to show drive monitors.

• Push to set d1-01 [Reference 1] when the Home screen shows U1-01 [Frequency Reference] in LOCAL Mode.

• The keypad will show [Rdy] when the drive is in Drive Mode. The drive is prepared to accept a Run command.

• The drive will not accept a Run command in Programming Mode in the default setting. Set b1-08 [RUN@PRG Mode Selection] to

accept or reject a Run command from an external source while in Programming Mode.

–Set b1-08 = 1 [NoRUN@Program] to reject the Run command from an external source while in Programming Mode (default).

–Set b1-08 = 2 [RUN@Program] to accept the Run command from an external source while in Programming Mode.

–Set b1-08 = 3 [Program@Stop only] to prevent changes from Drive Mode to Programming Mode while the drive is operating.

EN 6 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 7

Table 1.2 Drive Modes, Menu Screens and Functions

Mode Menu Screen Function

Drive Mode MONITORS

AUTOTUNING

INITIALIZATION

APPLICATION

TUNING

REFERENCE

MOTOR

Programming Mode

OPTIONS

TERMINALS

PROTECTION

SPECIAL

KEYPAD

Q2PACK PARAMETERS

Q2PACK JOINTS

Sets monitor items to display.

Auto-Tunes the drive.

Changes initial settings.

Changes application settings.

Changes tuning settings.

Changes reference settings.

Changes motor settings.

Changes external options settings.

Changes terminals settings.

Changes protection settings.

Changes settings for special applications.

Changes keypad settings.

Changes parameters of Q2Pack software.

Changes joints of Q2Pack software.

◆ Mechanical Installation

1 English

WARNING

Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not install the drive

near flammable or combustible materials. Attach the drive to metal or other noncombustible material. Failure to obey can cause

death or serious injury.

CAUTION

Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

moving the drive. Failure to obey can cause minor to moderate injury.

NOTICE

Do not put drive peripheral devices, transformers, or other electronics near the drive. Shield the drive from

electrical interference if components must be near the drive. Failure to obey can cause incorrect operation.

NOTICE

Do not let unwanted objects, for example metal shavings or wire clippings, fall into the drive during drive

installation and project construction. Put a temporary cover over the top of the drive during installation. Remove the temporary

cover before start-up or the drive will overheat. Failure to obey can cause damage to the drive.

NOTICE

Install the drive as specified by EMC Guidelines. Failure to obey can cause incorrect operation and damage to

electrical devices.

■ Installation Environment

The installation environment is important for the lifespan of the product and to make sure that the drive

performance is correct. Make sure that the installation environment agrees with these specifications.

Environment

Area of Use

Power Supply

Ambient Temperature

Setting

Humidity

Storage Temperature

Surrounding Area

Indoors

Overvoltage Category III

IP20 enclosure: -10 °C to +60 °C (14 °F to 140 °F). Derate the output current and output voltage if the drive is installed in areas with ambient

temperatures from +50 °C to +60 °C (122 °F to 140 °F).

UL Type 1 enclosure: -10 °C to +50 °C (14 °F to 122 °F). Derate the output current and output voltage if the drive is installed in areas with ambient

temperatures from +40 °C to +50 °C (104 °F to 122 °F).

• Drive reliability is better in environments that do not have wide temperature fluctuations.

• When installing the drive in an enclosure, use a cooling fan or air conditioner to keep the internal air temperature in the permitted range.

95% RH or less, non-condensing

-20 °C to +70 °C (-4 °F to +158 °F)

Pollution degree 2 or less

Install the drive in an area without:

• Oil mist, corrosive or flammable gas, or dust

• Metal powder, oil, water, or other unwanted materials

• Radioactive materials or flammable materials, including wood

• Harmful gas or fluids

• Salt

• Direct sunlight

Keep wood and other flammable materials away from the drive.

Conditions

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 7

Page 8

1 English

Environment

Altitude

Vibration

Installation Position

1000 m (3281 ft.) maximum

Note:

Derate the output current by 1% for each 100 m (328 ft.) to install the drive in altitudes between 1000 m to 4000 m (3281 ft. to 13123 ft.).

It is not necessary to derate the rated voltage in these conditions:

• When installing the drive at 2000 m (6562 ft.) or lower

• When installing the drive between 2000 m to 4000 m (6562 ft. to 13123 ft.) and grounding the neutral point on the power supply.

Contact the manufacturer or your nearest sales representative when not grounding the neutral point.

• 10 Hz to 20 Hz: 1 G (9.8 m/s

• 20 Hz to 55 Hz:

Models 2004 to 2211, 4002 to 4168: 0.6 G (5.9 m/s

Models 2257 to 2415, 4208 to 4675: 0.2 G (2.0 m/s

Install the drive vertically for sufficient cooling airflow.

2

, 32.15 ft/s2)

2

, 19.36 ft/s2)

2

, 6.56 ft/s2)

Conditions

■ Removing the Covers

DANGER

then remove the covers. Failure to obey could cause death or serious injury.

Electrical shock Hazard. Disconnect the power to the drive and wait for the charge indicator LED to go off,

◆ Electrical Installation

DANGER

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make

sure that the drive is safe. Failure to obey will cause death or serious injury.

WARNING

before energizing the drive. Use terminals for their intended function only. Incorrect wiring or ground connections, and incorrect

repair of protective covers can cause death or serious injury.

WARNING

can cause death or serious injury.

WARNING

manual for more information about the I/O terminals. Wiring and grounding incorrectly or modifying the cover may damage the

equipment or cause injury.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

Electrical Shock Hazard. Make sure that all electrical connections are correct and install all drive covers

Electrical Shock Hazard. Correctly ground the drive before turning on the EMC filter switch. Failure to obey

Electrical Shock Hazard. Use the terminals for the drive only for their intended purpose. Refer to the technical

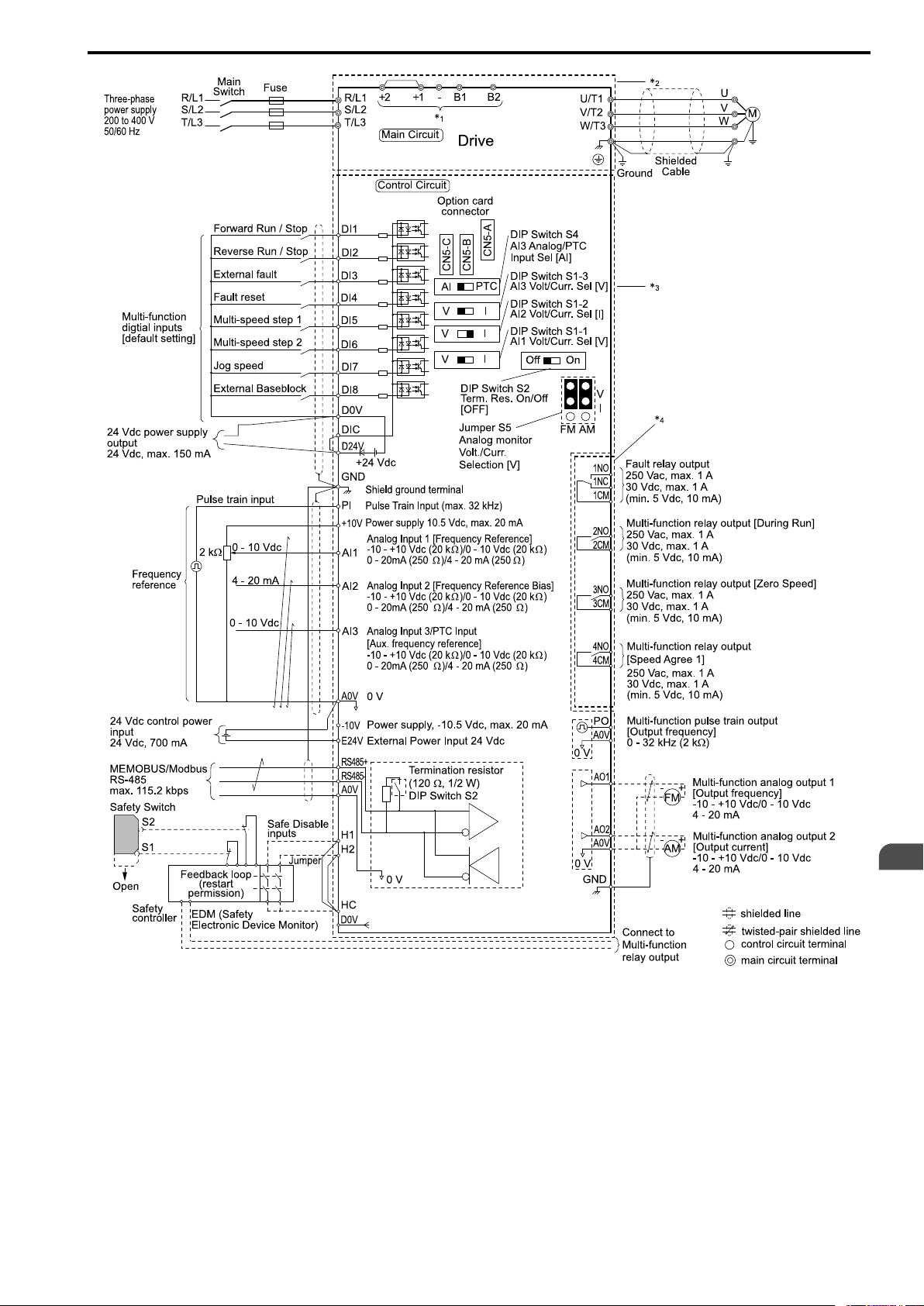

■ Standard Connection Diagram

Wire the drive as specified by Figure 1.2.

WARNING

Incorrect Run/Stop circuit sequence settings can cause death or serious injury from moving equipment.

WARNING

Momentarily closing a digital input terminal can start a drive that is programmed for 3-Wire control. Failure to obey can cause

death or serious injury from moving equipment.

WARNING

When using a 3-Wire sequence:

• Set the drive for 3-Wire sequence.

• Set b1-17 = 1 [RUN@PowerUp Selection = Disregard RUN]

• Wire the drive for 3-Wire sequence.

If these three conditions are correct, the motor can rotate in reverse when energizing the drive:

• The drive is wired for 3-Wire sequence.

• The drive is set for a 2-Wire sequence (default).

• b1-17 = 2 [Accept RUN]

Failure to obey can cause death or serious injury from moving equipment.

NOTICE

manual. The drive is suited for circuits that supply not more than 100,000 RMS symmetrical amperes, 240 Vac maximum (200 V

Class), 480 Vac maximum (400 V Class). Failure to obey can cause death or serious injury.

NOTICE

a drive duty motor or carefully monitor the motor insulation voltage. Failure to obey can cause damage to the motor insulation.

NOTICE

control circuit operation.

Sudden Movement Hazard. Set the MFDI terminal parameters before you close the control circuit wiring.

Sudden Movement Hazard. Correctly wire the start/stop and safety circuits before energizing the drive.

Sudden Movement Hazard.

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by applicable codes and this

When the input voltage is 440 V or higher or if the wiring distance is longer than 100 m (328 ft.) be sure to use

Do not connect the AC control circuit ground to the drive enclosure. Failure to obey can cause incorrect

EN 8 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 9

1 English

Figure 1.2 Standard Connection Diagram

*1 Connect peripheral options to terminals -, +1, +2, B1, and B2.

*2 For circuit protection, the main circuit is separated from the surface case that can touch the main circuit.

*3 The control circuit is a Safety Extra-Low Voltage circuit. Separate this circuit from other circuits with

reinforced insulation. Make sure that the Safety Extra-Low Voltage circuit is connected as specified.

*4 Reinforced insulation separates the output terminals from other circuits. Users can also connect circuits that

are not Safety Extra-Low Voltage circuits if the drive output is 250 Vac 1 A max. or 30 Vdc 1 A maximum.

■ Control Circuit Wire Gauges and Tightening Torques

Use shielded wire for control circuit terminal wiring. Use crimp ferrules on the wire ends for more reliable wiring.

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 9

EN

Page 10

1 English

Table 1.3 Wire Gauges

Bare Wire Crimp Ferrule

Terminal

DI1-DI8, DIC, D0V, D24V

H1, H2, HC

PI, +10V, -10V, AI1, AI2, AI3, A0V

PO, AO1, AO2, A0V

RS485+, RS485-, A0V

1NO, 1NC, 1CM, 2NO, 2CM, 3NO, 3CM, 4NO,

4CM

E24V, GND

Recommended Gauge

2

mm

(AWG)

0.75

(18)

Applicable Gauge

mm2(AWG)

• Stranded wire

0.2 to 1.0

(24 to 18)

• Solid wire

0.2 to 1.5

(24 to 16)

Recommended Gauge

mm2(AWG)

0.5

(20)

Applicable Gauge

mm2(AWG)

0.25 to 0.5

(24 to 20)

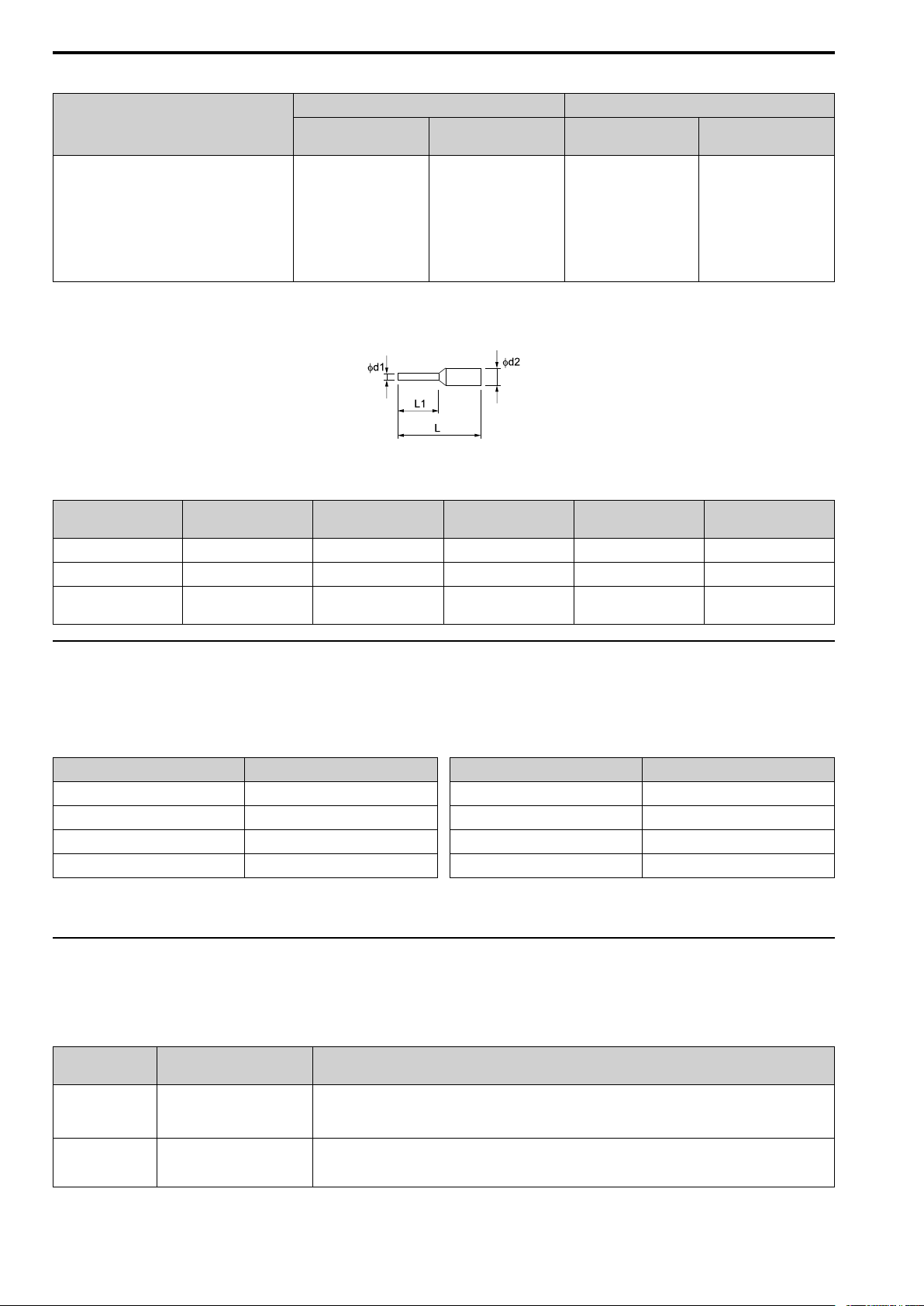

Crimp Ferrules

Attach an insulated sleeve to the wire when connecting crimp ferrules. We recommend the CRIMPFOX 6

crimping tool from PHOENIX CONTACT.

Figure 1.3 Crimp Ferrule Dimensions

Table 1.4 Crimp Ferrule Models and Dimensions

Wire Gauge

2

mm

(AWG)

0.25 (24) AI 0.25-8YE 12.5 8 0.8 2.0

0.34 (22) AI 0.34-8TQ 12.5 8 0.8 2.0

0.5 (20) AI 0.5-8WH,

Model L (mm) L1 (mm) d1 (mm) d2 (mm)

14 8 1.1 2.5

AI 0.5-8OG

◆ Drive Start-Up

■ Setup Wizard

Refer to the motor nameplate and record the information in this table before you start the drive.

Item Value

Motor Rated Power kW

Motor Rated Voltage V

Motor Rated Current A

Motor Rated Frequency Hz

Motor Maximum Frequency Hz

Number of Motor Poles

Motor Base Rotation Speed min

Number of Motor Encoder Pulses ppr

Item Value

Open the clock battery cover to put in a battery to use the clock functions. Select a type CR2016 battery with a

nominal voltage of 3 V.

◆ Drive Parameters

Refer to the following table when setting the most important parameters.

Note:

You can change parameters with “RUN” in the “No.” column during Run.

No.

(Hex.)

A1-00

(0100)

RUN

A1-03

(0103)

Language Selection Sets the language for the LCD keypad.

Init Parameters Sets parameters to default values.

Name Description

0: English, 1: Japanese, 2: German, 3: French, 4: Italian, 5: Spanish, 6: Portuguese, 7: Chinese, 8: Czech, 9: Russian,

10: Turkish, 11: Polish, 12: Greek

0: No Initialization, 1110: User / Solution Initialization, 2220: 2-Wire Initialization, 3330: 3-Wire Initialization,

4440: Q2pack Init

-1

(r/min)

EN 10 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 11

1 English

No.

(Hex.)

b1-01

(0180)

b1-02

(0181)

b1-03

(0182)

b1-04

(0183)

C1-01

(0200)

RUN

C1-02

(0201)

RUN

C2-01

(020B)

C2-02

(020C)

C2-03

(020D)

C2-04

(020E)

C6-01

(0223)

C6-02

(0224)

d1-01 to d1-16

(0280 - 0291)

RUN

d1-17

(0292)

RUN

d2-01

(0289)

d2-02

(028A)

E1-01

(0300)

E1-04

(0303)

E1-05

(0304)

E1-06

(0305)

E1-09

(0308)

E2-01

(030E)

E2-11

(0318)

H1-01 - H1-08

(0438, 0439, 0400 -

0405)

H2-01

(040B)

H2-02

(040C)

Name Description

Freq. Ref. Sel. 1 Sets the input method for the frequency reference.

Run Comm. Sel 1 Sets the input method for the Run command.

Stopping Method Selection Sets the method to stop the motor after removing a Run command or entering a Stop command.

Reverse Operation Selection Sets the reverse operation function. Disable reverse operation in fan or pump applications where reverse rotation is

Accel Time 1 Sets the length of time to accelerate from zero to maximum output frequency.

Decel Time 1 Sets the length of time to decelerate from maximum output frequency to zero.

Jerk@Start of Accel Sets the jerk acceleration time at start.

Jerk@End of Accel Sets the jerk acceleration time at completion.

Jerk@Start of Decel Sets the jerk deceleration time at start.

Jerk@End of Decel Sets the jerk deceleration time at completion.

ND/HD Duty Selection Sets the drive duty rating.

Carrier Frequency Selection Sets the carrier frequency for the transistors in the drive.

Reference 1 to Reference 16 Sets the frequency reference in the units from o1-03 [FrqDisplay Unit Selection].

Jog Reference Sets the JOG frequency reference in the units from o1-03 [FrqDisplay Unit Selection]. Set H1-xx: MFDI Function

FRef Upper Limit Sets maximum limit for all frequency references. This value is a percentage of E1-04 [Max Output Frequency].

FRef Lower Limit Sets minimum limit for all frequency references. This value is a percentage of E1-04 [Max Output Frequency].

Input AC Supply Voltage Sets the drive input voltage.

Max Output Frequency Sets the maximum output frequency for the V/f pattern.

Max Output Voltage Sets the maximum output voltage for the V/f pattern.

Base Frequency Sets the base frequency for the V/f pattern.

Min Output Frequency Sets the minimum output frequency for the V/f pattern.

Mot Rated Current (FLA) Sets the motor rated current in amps.

Motor Rated Power (kW) Sets the motor rated output in 0.01 kW increments.

DI1 Function Selection to DI8

Function Selection

2NO-2CM Func Selection Sets the function for MFDO terminal 2NO-2CM.

3NO-3CM Func Selection Sets the function for MFDO terminal 3NO-3CM.

0: Keypad, 1: Analog Input, 2: Modbus, 3: Option PCB, 4: Pulse Train Input

0: Keypad, 1: Analog Input, 2: Modbus, 3: Option PCB

0: Ramp->Stop, 1: Coast->Stop, 2: DC Inj->Stop, 3: Timed Coast->Stop, 9: Distance Stop

dangerous.

0: Enabled, 1: Disabled

0: HD Rating, 1: ND Rating

1: 2.0 kHz, 2: 5.0 kHz (4.0 kHz for AOLV/PM), 3: 8.0 kHz (6.0 kHz for AOLV/PM),

4: 10.0 kHz (8.0 kHz for AOLV/PM), 5: 12.5 kHz (10.0 kHz for AOLV/PM), 6: 15.0 kHz (12.0 kHz AOLV/PM),

7: Swing PWM 1 (Audible Sound 1), 8: Swing PWM 2 (Audible Sound 2), 9: Swing PWM 3 (Audible Sound 3),

A: Swing PWM 4 (Audible Sound 4), F: User (C6-03 to C6-05)

Select = 6 [Jog Reference] to use the Jog frequency reference.

Sets the functions for MFDI terminals DI1 to DI8.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 11

Page 12

1 English

No.

(Hex.)

H2-03

(040D)

H3-01

(0410)

H3-02

(0434)

H3-03

(0411)

RUN

H3-04

(0412)

RUN

H3-05

(0413)

H3-06

(0414)

H3-07

(0415)

RUN

H3-08

(0416)

RUN

H3-09

(0417)

H3-10

(0418)

H3-11

(0419)

RUN

H3-12

(041A)

RUN

H3-13

(041B)

H3-14

(041C)

H4-01

(041D)

H4-02

(041E)

RUN

H4-03

(041F)

RUN

H4-04

(0420)

H4-05

(0421)

RUN

H4-06

(0422)

RUN

H4-07

(0423)

H4-08

(0424)

L1-01

(0480)

Name Description

4NO-4CM Funct Selection Sets the function for MFDO terminal 4NO-4CM.

AI1 Signal Level Select Sets the input signal level for MFAI terminal AI1.

AI1 Function Selection Sets a function for MFAI terminal AI1.

AI1 Gain Setting Sets the gain of the analog signal input to MFAI terminal AI1.

AI1 Bias Setting Sets the bias of the analog signal input to MFAI terminal AI1.

AI3 Signal Level Select Sets the input signal level for MFAI terminal AI3.

AI3 Function Selection Sets a function for MFAI terminal AI3.

AI3 Gain Setting Sets the gain of the analog signal input to MFAI terminal AI3.

AI3 Bias Setting Sets the bias of the analog signal input to MFAI terminal AI3.

AI2 Signal Level Select Sets the input signal level for MFAI terminal AI2.

AI2 Function Selection Sets a function for MFAI terminal AI2.

AI2 Gain Setting Sets the gain of the analog signal input to MFAI terminal AI2.

AI2 Bias Setting Sets the bias of the analog signal input to MFAI terminal AI2.

An.In FilterTime Constant Sets the time constant to apply a primary delay filter to the MFAI terminal.

An.In Term.Enable Sel Sets the enabled terminal or terminals when H1-xx: MFDI Function Select = 12 [AI Input Sel] is ON.

AO1 An.Out Select Sets the monitor number to send from MFAO terminal AO1.

AO1 An.Out Gain Sets the gain of the monitor signal that is sent from MFAO terminal AO1.

AO1 An.Out Bias Sets the bias of the monitor signal that is sent from MFAO terminal AO1.

AO2 An.Out Select Sets the monitoring number to be output from the MFAO terminal AO2.

AO2 An.Out Gain Sets the gain of the monitor signal that is sent from MFAO terminal AO2.

AO2 An.Out Bias Sets the bias of the monitor signal that is sent from MFAO terminal AO2.

AO1 Signal Level Select Sets the MFAO terminal AO1 output signal level.

AO2 Signal Level Select Sets the MFAO terminal AO2 output signal level.

Motor Cool Type for OL1 Calc Sets the motor overload protection with electronic thermal protectors.

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA, 3: 0 to 20 mA

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA, 3: 0 to 20 mA

0: 0 to 10V (Lower Limit at 0), 1: -10 to +10V (Bipolar Reference), 2: 4 to 20 mA, 3: 0 to 20 mA

1: AI1 only, 2: AI2 only, 3: AI1 and AI2, 4: AI3 only, 5: AI1 and AI3, 6: AI2 and AI3, 7: AI1, AI2, and AI3

1: 0 to 10 Vdc, 2: -10 to +10 Vdc, 3: 4 to 20 mA

1: 0 to 10 Vdc, 2: -10 to +10 Vdc, 3: 4 to 20 mA

0: Disabled, 1: VTorque, 2: CT 10:1 Speed Range, 3: CT 100:1 SpeedRange, 4: PM VTorque, 5: PM CTorque,

6: VT (50Hz)

EN 12 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 13

1 English

No.

(Hex.)

L1-02

(0481)

L3-04

(0492)

L3-50

(0458)

OL1 Protect Time Sets the operation time for the electronic thermal protector of the drive to prevent damage to the motor. Usually it is

StallP@Decel Enable Enables Stall Prevention during deceleration.

StallP@Decel Mode Sets the method that the drive will use to prevent overvoltage faults when decelerating.

Name Description

not necessary to change this setting.

0: Disabled, 1: Enabled

0: General Purpose, 1: Automatic Decel Reduction, 2: Gen Purpose w/ DB Resistor, 3: HiFlux Overexcitation,

4: HiFlux2 Overexcitation

◆ Troubleshooting

If the drive or motor do not operate correctly, look at the drive keypad for fault and alarm information.

• For drive faults:

– The keypad shows the fault code.

– illuminates continuously.

– The drive shuts off output and the fault relay output activates. The motor coasts to stop.

• For drive alarms:

– The keypad shows the alarm code.

– flashes.

– Usually, the drive will continue to operate the motor. Some alarms let you select a motor stopping method.

■ Fault Reset

1. Remove the cause of the fault or alarm.

2. While the keypad is showing the fault or alarm code, push (RESET) or on the keypad.

This table lists the most frequent faults and alarms with possible causes and solutions.

Refer to the Technical Manual for a full list of faults and alarms.

Code Name Causes Possible Solutions

bb Baseblock

CrST Cannot Reset

EF

EF1 to EF8 External Fault (Terminal DIx)

GF Ground Fault

oC Overcurrent

FWD/REV Run Command Input

Error

An external baseblock command was entered

through MFDI terminal DI1 to DI8, and the drive

output stopped as shown by an external baseblock

command.

The drive received a fault reset command when a

Run command was active.

A forward command and a reverse command were

input at the same time for longer than 500 ms.

One of the digital inputs caused an external fault

through an external device.

The digital input settings are incorrect.

Overheating caused damage to the motor or the

motor insulation is not satisfactory.

The motor main circuit cable is contacting ground

to make a short circuit.

An increase in the stray capacitance of the cable and

the ground terminal caused an increase in the

leakage current.

There was a problem with the drive hardware. Replace the control board or the drive. For information about

The load is too heavy. • Measure the current flowing into the motor.

Overheating caused damage to the motor or the

motor insulation is not satisfactory.

Examine the external sequence and timing of the baseblock

command input.

Turn off the Run command then de-energize and re-energize the

drive.

Make sure that the sequence is correct. Do not set the forward and

reverse inputs at the same time.

• Find the device that caused the external faults. Remove the

cause and reset the fault.

• Make sure that the digital input terminal functions are correct.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

• Examine the motor main circuit cable for damage, and repair

short circuits.

• Measure the resistance between the motor main circuit cable

and the ground terminal. If there is electrical conduction,

replace the cable.

• If the wiring length of the cable is more than 100 m, decrease

the carrier frequency.

• Decrease the stray capacitance.

replacing the control board, contact the manufacturer or your

nearest sales representative.

• Replace the drive with a larger capacity model if the current

value is more than the drive rated current.

• Decrease the load or replace with a larger drive to prevent

sudden changes in the current level.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 13

Page 14

1 English

oL1 Motor Overload

The motor main circuit cable is contacting ground

to make a short circuit.

A short circuit or ground fault on the drive output

side caused damage to the output transistor of the

drive.

The acceleration time is too short. • Calculate the torque necessary during acceleration related to

The drive is trying to operate a specialized motor or

a motor that is larger than the maximum applicable

motor output of the drive.

A magnetic contactor was switched at the output. Set the operation sequence to not turn ON or OFF the magnetic

The V/f pattern settings are incorrect. • Examine the ratios between the V/f pattern frequency and

The torque compensation gain is too large. Decrease the value set in C4-01 [Trq Comp Gain] to make sure

Electrical interference caused a problem. Examine the control circuit lines, main circuit lines, and ground

The gain during overexcitation operation is too

large.

The drive received a Run command while the motor

was coasting.

The motor code is set incorrectly for PM Control

Methods.

If the drive detects the fault at start or in the low

speed range (10% or less) and n8-57 = 1 [High-

Freq Injection = Enabled] for PM Control methods,

the high frequency injection gain is too high.

The current flowing in the motor is more than the

value set in L8-27 [OverCurr Det Gain] for PM

Control.

The control method is set incorrectly for the motor. Set A1-02 [Control Method] correctly.

The motor main circuit cable is too long. Replace the drive with a larger capacity model.

Speed search does not complete at start when you

use an induction motor in EZOLV control.

The load is too heavy. Decrease the load.

The acceleration/deceleration times or cycle times

are too short.

Overload occurred while running at low speed. • Lower the load when running at low speed.

• Examine the motor main circuit cable for damage, and repair

short circuits.

• Measure the resistance between the motor main circuit cable

and the ground terminal. If there is electrical conduction,

replace the cable.

• Make sure that there is not a short circuit in terminal B1 and

terminals U/T1, V/T2, and W/T3. Make sure that there is not a

short circuit in terminals - and terminals U/T1, V/T2, and W/

T3.

• If there is a short circuit, contact the manufacturer or your

nearest sales representative.

the load inertia and the specified acceleration time.

• Increase the values set in C1-01 [Accel Time 1], C1-03 [Accel

Time 2], C1-05 [Accel Time 3], or C1-07 [Accel Time 4] until

you get the necessary torque.

• Increase the values set in C2-01 [Jerk@Start of Accel], C2-02

[Jerk@End of Accel], C2-03 [Jerk@Start of Decel], and C204 [Jerk@End of Decel] until you get the necessary torque.

• Replace the drive with a larger capacity model.

• Examine the motor nameplate, the motor, and the drive to

make sure that the drive rated current is larger than the motor

rated current.

• Replace the drive with a larger capacity model.

contactor while the drive is outputting voltage.

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust V/f Pattern Parameters E1-04 to E1-10. For motor 2,

adjust E3-04 to E3-10.

that the motor does not stall.

wiring, and decrease the effects of electrical interference.

• Find the time when the fault occurs.

• If the fault occurs at the same time as overexcitation operation,

decrease the value set in n3-13 [OverExcBr Gain] and

consider the motor flux saturation.

• Examine the sequence and input the Run command after the

motor fully stops.

• Set b3-01 = 1 [SpSrch@Start Selection = Enabled] or set H1-

xx = 67, 68 [Speed Srch 1 or 2] to input speed search

commands from the MFDI terminals.

• Enter the correct motor code to E5-01 [PM Mot Code

Selection] as specified by the PM motor.

• For specialized motors, refer to the motor test report and set

E5: PM MOTOR SETTINGS correctly.

• Set E5: PM MOTOR SETTINGS correctly or do Rotational

Auto-Tuning.

• Decrease the value of n8-41 [HFI PoleDet Pgain] in 0.5 unit

increments.

Note:

Set n8-41 > 0.0 for IPM motors.

Correct the value set in L8-27.

When E9-01 = 0 [Motor Type Selection = IM], set b3-24 = 2

[SpSrch Method Selection = Current Det2].

Note:

Reset oL1 when U4-16 [MotorOLEstimate (oL1)] < 100.

• Examine the acceleration/deceleration times and the motor

start/stop frequencies (cycle times).

• Increase the value set in Acceleration/Deceleration Times C1-

01 to C1-08.

• Increase the motor speed.

• If the motor is run frequently at low speeds, replace the motor

with a larger motor or use a drive-dedicated motor.

Note:

For general-purpose motors, overload can occur while

running at low speed when operating at below the rated

current.

EN 14 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 15

1 English

oL2 Drive Overload

ov Overvoltage

L1-01 [Motor Cool Type for OL1 Calc] is set

incorrectly.

The V/f pattern does not fit the motor qualities. • Examine the ratios between the V/f pattern frequency and

E1-06 [Base Frequency] is set incorrectly. Set E1-06 to the rated frequency shown on the motor nameplate.

One drive is operating more than one motor. Set L1-01 = 0 [Motor Cool Type for OL1 Calc = Disabled],

The electronic thermal protector qualities and the

motor overload properties do not match.

The electronic thermal protector is operating at an

incorrect level.

There is increased motor loss from overexcitation

operation.

The speed search-related parameters are set

incorrectly.

Phase loss in the input power supply is causing the

output current to change.

The load is too heavy. Decrease the load.

The acceleration/deceleration times or cycle times

are too short.

The V/f pattern does not fit the motor qualities. • Examine the ratios between the V/f pattern frequency and

The drive capacity is too small. Replace the drive with a larger capacity model.

Overload occurred while running at low speed. • Decrease the load when running at low speed.

The torque compensation gain is too large. Decrease the value set in C4-01 [Trq Comp Gain] to make sure

The speed search-related parameters are set

incorrectly.

Phase loss in the input power supply is causing the

output current to change.

Deceleration time is too short and regenerative

energy is flowing from the motor into the drive.

The acceleration time is too short. • Make sure that sudden drive acceleration does not cause the

The braking load is too large. Connect a dynamic braking option to the drive.

Set L1-01 in as specified by the motor qualities for a drivededicated motor.

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust V/f Pattern Parameters E1-04 to E1-10. For motor 2,

adjust E3-04 to E3-10. Decrease the values set in E1-08 [Mid

A Voltage] and E1-10 [Min Output Voltage].

Note:

If E1-08 and E1-10 are set too low, the overload tolerance will

decrease at low speeds.

connect thermal overload relay to each motor to prevent damage

to the motor.

• Examine the motor qualities and set L1-01 [Motor Cool Type

for OL1 Calc] correctly.

• Connect a thermal overload relay to the motor.

Set E2-01 [Mot Rated Current (FLA)] to the value shown on the

motor nameplate.

• Lower the value set in n3-13 [OverExcBr Gain].

• Set L3-50 ≠ 3 or 4 [StallP@Decel Mode ≠ HiFlux

Overexcitation or HiFlux2 Overexcitation].

• Set L3-04 = 0 [StallP@Decel Enable = Disabled].

• Examine the settings for all speed search related parameters.

• Adjust b3-03 [SpSrch Deceleration Time].

• Set b3-24 = 1 [SpSrch Method Selection = Speed Estimation]

after Auto-Tuning.

Make sure that there is no phase loss, and repair problems.

• Examine the acceleration/deceleration times and the motor

start/stop frequencies (cycle times).

• Increase the value set in Acceleration/Deceleration Times C1-

01 to C1-08.

voltage. Lower the voltage if it is too high compared to the

frequency.

• Adjust V/f Pattern Parameters E1-04 to E1-10. Lower the

values set in E1-08 [Mid A Voltage] and E1-10 [Min Output

Voltage] For motor 2, adjust E3-04 to E3-10.

Note:

If E1-08 and E1-10 are set too low, the overload tolerance is

will decrease at low speeds.

• Replace the drive with a larger capacity model.

• Decrease the value set in C6-02 [Carrier Frequency

Selection].

that the motor does not stall.

• Examine the settings for all speed search related parameters.

• Adjust b3-03 [SpSrch Deceleration Time].

• Set b3-24 = 1 [SpSrch Method Selection = Speed Estimation]

after Auto-Tuning.

• Correct any wiring errors in the main circuit drive input power.

• Make sure that there is no phase loss, and repair problems.

• Set L3-04 = 1 [StallP@Decel Enable = Enabled] and L3-50 =

0 [StallP@Decel Mode = General Purpose].

• Increase the values set in C1-02 [Decel Time 1], C1-04 [Decel

Time 2], C1-06 [Decel Time 3], or C1-08 [Decel Time 4].

• Connect a dynamic braking option to the drive.

• Perform Deceleration Rate Auto-Tuning.

fault.

• Increase the values set in C1-01 [Accel Time 1], C1-03 [Accel

Time 2], C1-05 [Accel Time 3], or C1-07 [Accel Time 4].

• Increase the value set in C2-02 [Jerk@End of Accel].

• Set L3-11 = 1 [Overvolt Supression Select = Enabled].

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 15

Page 16

1 English

PF Input Phase Loss

STo Safe Torque OFF

SToF Safe Torque OFF Hardware

There are surge voltages in the input power supply. Connect a DC reactor to the drive.

The drive output cable or motor is shorted to ground

(the current short to ground is charging the main

circuit capacitor of the drive through the power

supply).

If the drive detects ov in these conditions, the speed

search-related parameters are incorrect:

• During speed search

• During momentary power loss recovery

• When the drive starts again automatically

The power supply voltage is too high. Decrease the power supply voltage to match the drive rated

The braking resistor or braking resistor unit wiring

is incorrect.

The encoder cable is disconnected or wired

incorrectly.

Noise interference along the encoder cable. Isolate the encoder cable from the drive output line or a different

Electrical interference caused a drive malfunction. • Examine the control circuit lines, main circuit lines, and

The load inertia is set incorrectly. • Examine the load inertia settings with KEB, overvoltage

The Short Circuit Braking function used in OLV/

PM control method.

There is motor hunting. • Adjust n1-02 [HuntPrev Gain Setting] settings.

Speed search does not complete at start when you

use an induction motor in EZOLV control.

There is a phase loss in the drive input power. Correct errors with the wiring for main circuit drive input power.

Loose wiring in the input power terminals. Tighten the terminal screws to the correct tightening torque.

The drive input power voltage is changing too

much.

Unsatisfactory balance between voltage phases. • Examine the input power for problems.

The main circuit capacitors have become

unserviceable.

Safe Disable inputs H1-HC and H2-HC are open. • Make sure that the Safe Disable signal is input from an

There is internal damage to the two Safe Disable

channels.

One of the two terminals H1-HC or H2-HC

received the Safe Disable input signal.

The Safe Disable input signal is wired incorrectly.

There is internal damage to one Safe Disable

channel.

Note:

If you turn the phase advancing capacitors ON and OFF and

use thyristor converters in the same power supply system,

there can be surge voltages that irregularly increase the input

voltage.

1. Examine the motor main circuit cable, terminals, and motor

terminal box, and then remove ground faults.

2. Re-energize the drive.

• Examine the settings for all speed search related parameters.

• Set b3-19 ≠ 0 [Speed Retry Times ≠ 0 times].

• Adjust b3-03 [SpSrch Deceleration Time] settings.

• Do Stationary Auto-Tuning for Line-to-Line Resistance and

then set b3-24 = 1 [SpSrch Method Selection = Speed

Estimation].

voltage.

Correct wiring errors in the connection to the braking resistor or

braking resistor unit.

Examine for wiring errors or disconnected wires in the encoder

cable, and repair problems.

source of electrical interference.

ground wiring, and decrease the effects of electrical

interference.

• Make sure that a magnetic contactor is not the source of the

electrical interference, then use a Surge Protective Device if

necessary.

suppression, or stall prevention during deceleration.

• Adjust L3-25 [Load Inertia Ratio] to match the qualities of the

machine.

Connect a braking resistor to the drive.

• Adjust n2-02 [AFR Time 1] and n2-03 [AFR Time 2] settings.

• Adjust n8-45 [SpdFbck Det.Gain] and n8-47 [Pull-In Comp.

Time Constant] settings.

When E9-01 = 0 [Motor Type Selection = IM], set b3-24 = 2

[SpSrch Method Selection = Current Det2].

• Examine the input power for problems.

• Make the drive input power stable.

• Make the drive input power stable.

• If the input power supply is good, examine the magnetic

contactor on the main circuit side for problems.

• Examine the capacitor maintenance time in monitor U4-05

[Capacitor Maintenance].

• If U4-05 is more than 90%, replace the capacitor. Contact the

manufacturer or your nearest sales representative for more

information.

• Examine the input power for problems.

• Re-energize the drive.

• If the alarm stays, replace the circuit board or the drive.

Contact the manufacturer or your nearest sales representative

for more information.

external source to terminal H1-HC and H2-HC.

• When the Safe Disable function is not in use, connect

terminals H1-HC and H2-HC.

Replace the board or the drive. For information about replacing

the control board, contact the manufacturer or your nearest sales

representative.

• Make sure that the Safe Disable signal is input from an

external source to terminal H1-HC and H2-HC.

• When the Safe Disable function is not in use, connect

terminals H1-HC and H2-HC.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

EN 16 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 17

1 English

◆ Disposal Instructions

Correctly discard the drive, packing material, battery, and microSD card as specified by regional, local, and

municipal laws and regulations for this product.

Note:

• Remove the battery and microSD card from the keypad before you discard the drive.

• We recommend that customers physically destroy the microSD card in a shredder or use data wipe software to fully erase the card.

◆ European Standards

Figure 1.4 CE Mark

The CE Mark identifies that the product meets environmental and safety standards in the European Union.

Products manufactured, sold, or imported in the European Union must display the CE Mark.

European Union standards include standards for electrical appliances (Low Voltage Directive), standards for

electrical noise (EMC Directive), and standards for machinery (Machinery Directive).

This product displays the CE Mark in accordance with the Low Voltage Directive, the EMC Directive, and the

Machinery Directive.

Table 1.5 Harmonized Standard

European Directive Harmonized Standard

CE Low Voltage Directive Compliance

2014/35/EU

EMC Directive

2014/30/EU

Machinery Directive

2006/42/EC

IEC/EN 61800-5-1:2007

EN 61800-3 2004+A1:2012

• EN ISO 13849-1:2015 (Cat. 3, PL e)

• IEC 62061/A1:2012 (SIL CL 3)

• EN 62061/A1:2013 (SIL CL 3)

• IEC/EN 61800-5-2:2007 (SIL3)

■ CE Low Voltage Directive Compliance

This product is tested according to IEC/EN 61800-5-1:2007 and complies with the CE Low Voltage Directive.

The following conditions must be satisfied for machines and devices incorporating this product to comply with

the CE Low Voltage Directive.

EN

■ Area of Use

Install this product in a location with overvoltage category III and pollution degree 2 or less. These standards are

defined by IEC/EN 60664.

■ Guarding against Debris

When installing IP20 enclosure drives, use an enclosure that does not let unwanted material enter the drive from

above or below.

■ Connect a Fuse to the Input Side (Primary Side)

The drive circuit protection must comply with IEC/EN 61800-5-1:2007 for protection against a short circuit in the

internal circuitry. Connect a semiconductor protection fuse on the input side for branch circuit protection.

Refer to Factory Recommended Branch Circuit Protection on page 34.

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 17

Page 18

1 English

WARNING

blows a fuse or trips an RCM/RCD. Wait for the time specified on the warning label at a minimum and make sure that all

indicators are OFF. Then check the wiring and peripheral device ratings to find the cause of the problem. Contact the

manufacturer before energizing the drive or peripheral devices if the cause is not known. Failure to obey can cause death or

serious injury and damage to the drive.

Electrical Shock Hazard. Do not immediately energize the drive or operate peripheral devices after the drive

■ EMC Directive

All drives were tested in accordance with European standard IEC/EN 61800-3:2004/A1:2012, and comply with

the EMC Directive.

Use drives with built-in EMC filters or install external EMC filters to the drive input side to comply with the

EMC Directive.

■ Install a Drive to Conform to the EMC Directive

Install drives with this procedure to comply with the EMC Directive when the drive is a single unit or installed in

a larger device.

1. Install the drive on a grounded metal plate.

2. Wire the drive and motor.

3. Enable the internal EMC filter.

4. Ground the wire shielding on the drive side and motor side.

A - Drive

B - 10 m (32.8 ft.) maximum

C - Motor

Figure 1.5 Wiring the Drive and Motor

D - Metal conduit

E - Grounding wire

5. Use a cable clamp to ground the motor cable to the metal plate.

Note:

Make sure that the protective ground wire complies with technical specifications and local safety standards.

6. Connect an AC or DC reactor to decrease harmonic distortion.

Note:

• To maintain compliance with IEC/EN 61000-3-2 on drive models 2004, 2006, 4002, and 4004, install a DC reactor.

• The main circuit terminal block for the drive and the terminal blocks for the DC reactor come in different shapes. Correctly

prepare the ends of the wiring.

■ Enable the Internal EMC Filter

Move the screw or screws to turn ON and OFF (enable and disable) the EMC filter. The EMC filter switch screw

or screws are installed in the OFF position by default.

WARNING

before you move the EMC filter screw or screws. Failure to obey could cause death or serious injury.

WARNING

obey can cause death or serious injury.

WARNING

before turning on the EMC filter or if there is high resistance grounding. If the EMC filter is switched ON without the neutral point

being grounded or if there is high resistance grounding, it can cause death or serious injury.

WARNING

injury.

NOTICE

torque. Completely removing the screws or tightening the screws to an incorrect torque may cause drive failure.

Electrical Shock Hazard. Make sure that the power to the drive is OFF and the CHARGE LED light is OFF

Electrical Shock Hazard. Do not remove covers or touch circuit boards while the drive is energized. Failure to

Electrical Shock Hazard. Ground the neutral point on the power supply to comply with the EMC Directive

Electrical Shock Hazard. Connect the ground cable correctly. Failure to obey can cause death or serious

When disabling the internal EMC filter, move the screws from ON to OFF and then tighten to the specified

EN 18 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 19

1 English

NOTICE

Failure to obey can cause damage to the drive.

Move the EMC switch screw or screws to the OFF position for networks that are not symmetrically grounded.

Make sure that the symmetric grounding network is applied, and install the screw or screws in the ON position to

enable the built-in EMC filter in compliance with the EMC Directive.

Figure 1.6 Symmetric Grounding

NOTICE

network, install the screw or screws in the OFF position to disable the built-in EMC filter. Failure to obey the instructions can

damage the drive.

When operating the drive with a non-grounding network, high resistance grounding, asymmetric grounding

If you lose an EMC filter switch screw, install the correct size screw with the correct tightening torque.

NOTICE

Only use the screws specified in this manual. Failure to obey could damage the drive.

Table 1.6 Screw Sizes and Tightening Torques

Model Screw Size

2004 - 2082, 4002 - 4060 M4 × 20

2110 - 2211, 4075 - 4168 M4 × 25

2257 - 2415, 4208 - 4675 M5 × 25 2.0 - 2.5

Tightening Torque

N∙m

1.0 - 1.3

1.0 - 1.3

◆ Safe Disable Input

Figure 1.7 TUV Mark

The TUV mark identifies that the product complies with the safety standards.

This section gives precautions to support the Safe Disable input. Contact the manufacturer for more information.

Table 1.7 Applied Safety Standards and Unified Standards

Safety Standards Unified Standards

IEC/EN 61508:2010 (SIL3)

Functional Safety

Machine Safety

EMC

IEC/EN 62061/A2:2015 (SILCL3)

IEC/EN 61800-5-2:2007 (SIL3)

ISO/EN ISO 13849-1:2015 (Cat.3, PL e)

IEC/EN 61000-6-7:2015, IEC/EN61326-3-1:2008

SIL = Safety Integrity Level.

■ Safe Disable Specifications

The Safe Disable input provides the stop function compliant to “Safe Torque Off” defined in IEC/EN 61800-52:2007. The Safe Disable input is designed to meet the requirements of EN ISO 13849-1 and IEC/EN 61508. It is

also equipped with the safety status monitor to detect safety circuit errors.

When you install the drive as a component in a system, you must make sure that the system complies with the

applicable safety standards.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 19

Page 20

1 English

Table 1.8 Specifications for the Safety Function

Item Description

• Input: 2

Safe Disable input (H1, H2)

Input/output

Response time from opening the input to stopping the drive output 3 ms or less

Response time from opening H1 and H2 terminal inputs to operating the EDM

signal

Less frequent operation request mode PFD = 4.65E

Failure probability

Performance level

HFT (hardware fault tolerance) N = 1

Type of subsystem Type B

Frequent operation request mode or

continuous mode

Signal ON level: 18 Vdc to 28 Vdc

Signal OFF level: -4 Vdc to +4 Vdc

• Output: 1

MFDO safety monitor output for external device monitor (EDM)

20 ms or less

PFH = 1.11E

The Safe Disable input complies with the performance level requirements of EN ISO 13849-

1.

EDM = External Device Monitoring

PFD = Probability of Failure on Demand

PFH = Probability of Dangerous Failure per Hour

-6

-9

■ Safety Precautions

DANGER

used complies with safety requirements. When implementing the Safe Disable function into the safety system of a machine, do

a full risk assessment for the system to make sure that all parts of the system comply with applicable safety standards. Incorrect

application of the Safe Disable function will cause serious injury or death.

DANGER

Systems that use an external holding brake or dynamic brake with a drive output signal (including EDM) are not safe systems

because the drive output signal is not a safety component. You must use a system that satisfies the safety requirements. Failure

to obey will cause death or serious injury.

DANGER

requirements. Failure to obey will cause death or serious injury.

WARNING

through the motor winding and move the motor output axis 180 electrical degrees. This is possible when the Safe Disable

function turns off the drive output. Make sure that output transistors failure will not effect the safety of the application when with

the Safe Disable function. Failure to obey could cause death or serious injury.

WARNING

power supply and it cannot electrically isolate the drive output from the input. Always turn off the drive power supply during

maintenance and installations on the drive input and output sides. Failure to obey could cause death or serious injury.

WARNING

Safe Disable function is in operation. Failure to obey could cause serious injury or death.

WARNING

the Safe Disable inputs. Failure to obey will prevent correct operation of the Safe Disable circuit and could cause death or

serious injury.

WARNING

that does not operate correctly can cause death or serious injury.

WARNING

manual, and safety standards wire, examine, and maintain the Safe Disable input. Failure to obey could cause death or serious

injury.

NOTICE

Torque Off" status. Set the OFF status for terminals H1 and H2 to hold for at least 2 ms. The drive may not be able to switch to

the “Safe Torque Off” status if terminals H1 and H2 are only open for less than 2 ms.

NOTICE

Disable status or to find a malfunction in the Safe Disable inputs. The monitor output is not a safety output.

NOTICE

Sudden Movement Hazard. Make sure that the full system or machinery in which the Safe Disable function is

Sudden Movement Hazard. An external holding brake or dynamic brake are NOT drive safety components.

Sudden Movement Hazard. Connect the Safe Disable inputs to the devices as specified by the safety

Sudden Movement Hazard. With PM motors, the failure of two output transistors can cause current to flow

Electrical Shock Hazard. The Safe Disable function will turn off the drive output, but it will not stop the drive

Sudden Movement Hazard. An external gravitational force in the vertical axis will move the motor although the

Sudden Movement Hazard. Remove the pre-installed wire links between terminals H1-HC and H2-HC to use

Sudden Movement Hazard. Regularly examine the Safe Disable input and all other safety features. A system

Sudden Movement Hazard. Only let approved technicians with full knowledge of the drive, the instruction

A maximum of 3 ms will elapse from when terminals H1 or H2 shut off until the drive switches to the "Safe

Only use the Safe Disable Monitor (multi-function output terminal set to the EDM function) to monitor the Safe

Drives that have a built-in safety function must be replaced 10 years after first use.

EN 20 TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions

Page 21

1 English

■ Using the Safe Disable Function

Safe Disable Circuit

The Safe Disable circuit has two isolated channels (terminals H1 and H2) that stop the output transistors. The

input can use the internal power supply of the drive.

Set the EDM function to one of the MFDO terminals [H2-xx = E or 10E] to monitor the status of the Safe Disable

function. This is the “Safe Disable monitor output function”.

Figure 1.8 Safe Disable Function Wiring Example

Enabling and Disabling the Drive Output (“Safe Torque Off”)

Example of drive operation when as the drive changes from the "Safe Torque Off" status to usual operation.

Figure 1.9 Safe Disable Operation

Switching from Usual Operation to “Safe Torque Off”

Turn OFF (open) safety input terminal H1 or H2 to enable the Safe Disable function. When the Safe Disable

function is enabled while the motor is operating, the drive output and motor torque turn off and the motor always

coasts to stop. The b1-03 [Stopping Method Selection] setting does not have an effect on the stopping method.

The “Safe Torque Off” status is only possible with the Safe Disable function. Clear the Run command to stop the

drive. Turning off drive output (a baseblock condition) ≠ “Safe Torque Off”.

Note:

A maximum of 3 ms will elapse from when terminals H1 or H2 shut off until the drive switches to the "Safe Torque Off" status. Set the

OFF status for terminals H1 and H2 to hold for at least 2 ms. The drive may not be able to switch to the “Safe Torque Off” status if

terminals H1 and H2 are only open for less than 2 ms.

Turn OFF terminals H1 and H2 after the motor fully stops. This will prevent the motor from coasting to stop during usual operation.

EN

TOMPYEUOQ2A03B AC Drive Q2A Installation and Operation Instructions EN 21

Page 22

1 English

Going from “Safe Torque Off” to Usual Operation

The safety input will only release when there is no Run command.

• During Stop:

When the Safe Disable function is triggered during stop, close the circuit between terminals H1-HC and H2-HC

to disable “Safe Torque Off”. Enter the Run command after the drive stops correctly.

• During Run:

When the Safe Disable function is triggered during run, close the circuit between terminals H1-HC and H2-HC

to disable “Safe Torque Off” after clearing the Run command. Enter the Stop command, then enter the Run

command when terminals H1 and H2 are ON or OFF.

Safe Disable Monitor Output Function and Keypad Display

Information about the relation between the input channel status, Safety monitor output status, and drive output

status.

Table 1.9 Safe Disable Input and External Device Monitor (EDM) Terminal Status

Input Channel Status Safety Monitor Output Status

Input 1

(H1-HC)

ON

(Close the circuit)

OFF

(Open)

ON

(Close the circuit)

OFF

(Open)

Safety Function Status Monitor

Input 2

(H2-HC)

ON

(Close the circuit)

ON

(Close the circuit)

OFF

(Open)

OFF

(Open)

MFDO Terminal

(H2-xx = E)

OFF ON

OFF ON

OFF ON

ON OFF

MFDO Terminal

(H2-xx = 10E)

Drive Output Status Keypad Display LED Status Ring

Baseblock

(Drive ready)

Safety status

(STo)

Safety status

(STo)

Safety status

(STo)

Normally displayed Ready: Illuminated

SToF

(Flashing)

SToF

(Flashing)

STo

(Flashing)

ALM/ERR: Flashing

ALM/ERR: Flashing

Ready: Flashing

The drive Safety monitor output sends a feedback signal about the status of the Safety function. The Safety

monitor output is one of the possible settings available for the MFDO terminals. If there is damage to the Safe

Disable circuit, a controller (PLC or safety relay) must read this signal as an input signal to hold the “Safe Torque

Off” status. This will help verify the condition of the safety circuit. Refer to the manual for the safety device for

more information about the Safety function.

It is possible to switch polarity of the Safety monitor output signal with the MFDO function settings.

Keypad Display

If the two input channels are OFF (Open), the keypad will flash STo [Safe Torque OFF].

If there is damage to the Safe disable circuit or the drive, the keypad will flash SToF [Safe Torque OFF

Hardware] when one input channel is OFF (Open), and the other is ON (Short circuit). When you use the Safe

disable circuit correctly, the keypad will not show SToF.

If there is damage to the drive, the keypad will show SCF [Safety Circuit Fault] when the drive detects a fault in

the Safe disable circuit. Refer to the chapter on Troubleshooting for more information.

Validating the Safe Disable Function

After you replace parts or do maintenance on the drive, first complete all necessary wiring to start the drive, then

test the Safe Disable input with these steps. Keep a record of the test results.

• When the two input channels are OFF (Open), make sure that the keypad flashes STo [Safe Torque OFF], and

make sure that the motor is not running.

• Monitor the ON/OFF status of the input channels and make sure that MFDO set to the EDM function operates

correctly.

If one or more of the these items are true, the ON/OFF status of the MFDO may not display correctly on the

keypad:

– Incorrect parameter settings.

– A problem with an external device.

– The external wiring has a short circuit or is disconnected.

– There is damage to the device.

Find the cause and repair the problem to correctly display the status.

• Make sure that the EDM signal operates during usual operation.