Page 1

Cat. No. W900--E2--1

PRT1-COM & GT1 Series

PROFIBUS-DP

MULTIPLE I/O TERMINAL

Page 2

PRT1-COM

GT1 Series

PROFIBUS-DP

MULTIPLE I/O TERMINAL

Operation Manual

Produced December 1999

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

DANGER

!

WARNING

!

Caution

!

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for

anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Indicates information of particular interest for efficient and convenient operation

Note

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

Motorola is a registered trademark of Motorola, Inc.

Intel is a registered trademark of Intel, Inc.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS xi

1 Intended Audience xii...........................................................

2 General Precautions xii..........................................................

3 Safety Precautions xii...........................................................

4 Operating Environment Precautions xii.............................................

5 Application Precautions xiii.......................................................

6 EC Directives xv...............................................................

......................................................

SECTION 1

PROFIBUS-DP 1

1-1 Introduction 2............................................................

1-2 Protocol architecture 3......................................................

1-3 Device types 4............................................................

1-4 PROFIBUS-DP characteristics 5..............................................

1-5 Device Data Base files 8....................................................

1-6 Profiles 9................................................................

........................................................

SECTION 2

Installation of PROFIBUS-DP Network 11..............

2-1 PROFIBUS-DP MULTIPLE I/O TERMINAL 12..................................

2-2 Communication Unit PRT1-COM 13...........................................

2-3 Setting up a PROFIBUS-DP network 18.........................................

SECTION 3

MULTIPLE I/O TERMINAL 23.......................

3-1 MULTIPLE I/O TERMINAL 24...............................................

3-2 Functions 29..............................................................

SECTION 4

Hardware Setup and Operational Check 37.............

4-1 Basic Procedure 38.........................................................

4-2 Specific Example 39........................................................

SECTION 5

Sample Programs 43.................................

5-1 Examples of Counter Unit Operation 44.........................................

SECTION 6

Basic I /O Unit Specifications 51.......................

6-1 Common Specifications for Basic I/O Units 52....................................

6-2 Transistor Input Units 54.....................................................

6-3 Transistor Output Units 74....................................................

6-4 Relay Output Units 97.......................................................

SECTION 7

Special I/O Unit Specifications 103......................

7-1 Analog Input Units 104.......................................................

7-2 Analog Output Units 120......................................................

7-3 Counter Units 134...........................................................

vii

Page 7

TABLE OF CONTENTS

SECTION 8

Communications Timing 151...........................

8-1 Remote I/O Communications Characteristics 152...................................

SECTION 9

Troubleshooting and Maintenance 157...................

9-1 Normal Indication 158........................................................

9-2 Troubleshooting 159.........................................................

9-3 Maintenance 164............................................................

Appendices

A GSD file for PRT1-COM 167.....................................................

B Connectible Devices 171.........................................................

Index 175...........................................

Revision History 177..................................

viii

Page 8

About this Manual:

This manual describes the installation and operation of the PROFIBUS-DP MULTIPLE I/O TERMINAL. A

modular system of I/O units (GT1 Series) connected by a communication unit (PRT1-COM) to

PROFIBUS-DP. The manual includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempt-ing to install and operate the PROFIBUS-DP Communication Unit and Multiple I/O units.

to read the precautions provided in the following section.

Section 1 gives a brief description of PROFIBUS-DP.

Section 2 describes the specification and installation of the PRT1-COM in a PROFIBUS-DP Network.

Section 3 provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

Section 4 provides the basic procedure for operation and includes an actual example.

Section 5 provides some examples of programs used with the Counter Unit.

Section 6 provides the specifications for the basic I/O Units, the transistor Input and Output Units, and

Relay Output Units.

Section 7 provides the specifications for Special I/O Units, including the Analog Input and Output Unit,

and the Counter Unit.

Section 8 provides characteristics for communications by the PROFIBUS-DP Communication unit and

describes how to calculate the times required for communication between the various I/O units.

Section 9 describes the troubleshooting procedures and maintenance operations.

Appendix A provides a listing of the PRT1-COM GSD file.

Appendix B provides an overview of connectable devices.

Be sure

!

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) Systems and related devices.

The information contained in this section is important for the safe and reliable application of PC Systems. You must

read this section and understand the information contained before attempting to set up or operate a PC System.

1 Intended Audience xii...........................................................

2 General Precautions xii..........................................................

3 Safety Precautions xii...........................................................

4 Operating Environment Precautions xii.............................................

5 Application Precautions xiii.......................................................

6 EC Directives xv...............................................................

xi

Page 11

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent):

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

This manual provides information for programming and operating OMRON PC

Systems. Be sure to read this manual before attempting to use the software and

keep this manual close at hand for reference during operation.

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

4Operating Environment Precautions

WARNING

!

It is extremely important that a PC System and all PC Units be used for the

specified purpose and under the specified conditions, especially in applications

that can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PC System to the above mentioned

applications.

3 Safety Precautions

WARNING

!

WARNING

!

Never attempt to disassemble any Units while power is being supplied. Doing so

may result in serious electrical shock or electrocution.

Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in

temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

xii

Page 12

• Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of electrical

interference.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5Application Precautions

Caution

!

The operating environment of the PC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the operating environment is within the specified

conditions at installation and remains within the specified conditions during the

life of the system.

5 Application Precautions

Observe the following precautions when using the MULTIPLE I/O TERMINAL.

WARNING

!

Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to

protect against electrical shock.

• Always turn OFF the power supply to the system before attempting any of the

following. Performing any of the following with the power supply turned ON

may lead to electrical shock:

• Mounting or removing any Units (e.g., I/O Units, CPU Unit, etc.) or memory

cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any cables, connectors, or wiring.

Caution

!

Failure to abide by the following precautions could lead to faulty operation of or

damage to the MULTIPLE I/O TERMINAL. Always heed these precautions.

• Use the Units only with the power supplies and voltages specified in the

operation manuals. Other power supplies and voltages may damage the

Units.

• Take measures to stabilize the power supply to conform to the rated supply if it

is not stable.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Do not apply voltages exceeding the rated input voltage to Input Units. The

Input Units may be destroyed.

• Do not apply voltages exceeding the maximum switching capacity to Output

Units. The Output Units may be destroyed.

• Install all Units according to instructions in the operation manuals. Improper

installation may cause faulty operation.

• Be sure to tighten Backplane screws, terminal screws, and cable connector

screws securely.

• Do not attempt to take any Units apart, to repair any Units, or to modify any

Units in any way.

• Do not use communications cables or I/O cables in parallel to or close to

high-tension, high-rate current carrying lines. Doing so may cause faulty

operation

xiii

Page 13

• Be sure to install the MULTIPLE I/O TERMINAL in the proper direction. Not

doing so may cause faulty operation.

• When attaching Units to the DIN rail, be sure to attach them securely. Not doing

so may cause the Units to be damaged.

• Use this product within the specified ranges for communications distances and

connection distances. Not doing so may lead to faulty operation.

• Use the specified cables when making communications connections. Not

doing so may cause faulty operation.

• Be sure to wire the communications paths, the communications power

supplies, the internal power supplies, and the I/O power supplies correctly.

Use voltages for the power supplies that are within the specified ranges. Not

doing so may cause malfunction.

• Do not, under any circumstances, use this product with loads exceeding the

contact rating values. Doing so may cause deterioration of insulation and

damage.

• The life-expectancy of the relays depends greatly on the switching conditions.

Before practical use of the product, perform a trial operation of the product in

the actual conditions in which it will be used. Use the product at a switching

frequency that will allow efficient operation. Continued use of the product in

conditions causing reduced efficiency will cause deterioration of insulation and

damage.

5Application Precautions

• Connection Cables

• Before switching ON power supplies, check that the connectors are

mounted securely.

• Check that the connectors for the I/O Unit interfaces are securely locked.

• Tightening Torques

Check that all the screws for the Units are tightened to the correct torque. Not

doing so may cause faulty operation.

• Internal power supplies, I/O power supplies, terminal screws:

0.3to0.5NS m

• Communications cable, communications connector screws:

0.25 to 0.35 N S m

• High-density I/O Unit connector screws: 0.25 to 0.35 N S m

• Cleaning

• Do not used thinner-based products for cleaning. Doing so may dissolve

attachment areas or cause discoloration.

• Power Supply

• Use separate power supplies for communications power supplies, internal

power supplies, I/O power supplies, load power supplies, and encoder

power supplies. Not doing so may lead to faulty operation.

Caution

!

The following precautions are necessary to ensure the general safety of the

system. Always heed these precautions.

• Provide double safety mechanisms to handle incorrect signals that can be

• Provide external interlock circuits, limit circuits, and other safety circuits in

xiv

generated by broken signal lines or momentary power interruptions.

addition to any provided within the PC System to ensure safety.

Page 14

6 EC Directives

The MULTIPLE I/O TERMINAL conforms to EMC and Low Voltage Directives as

follows:

EMC

Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however,must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Low Voltage

Always ensure that devices (Relay Units) operating at voltages of 50 to

1,000 VAC and 75 to 1,500 VDC meet the required safety standards (IEC255).

The MULTIPLE I/O TERMINALS that comply with EC Directives must be

installed as follows:

Directive

6EC Directives

1, 2, 3... 1. MULTIPLE I/O TERMINALS are designed for installation inside control

panels. All MULTIPLE I/O TERMINALS must be installed within control

panels.

2. Used reinforced insulation or double insulation for the DC power supplies

used for the communications power supply, internal circuit power supply,

and the I/O power supplies.

3. MULTIPLE I/O TERMINAL products that meet EC Directives also meet the

Common Emission Standard (EN50081-2). However, radiated emission (at

10 m) will vary with the overall configuration of the control panel, other

devices connected to the control panel, and other conditions. You must

therefore confirm that EC Directives are satisfied for the overall machine or

device.

xv

Page 15

This section gives a brief description of PROFIBUS-DP.

1-1 Introduction 2............................................................

1-2 Protocol architecture 3......................................................

1-3 Device types 4............................................................

1-4 PROFIBUS-DP characteristics 5..............................................

1-4-1 Bus Access Protocol 5...............................................

1-4-2 Data throughput 6..................................................

1-4-3 Diagnostics functions 6..............................................

1-4-4 Protection mechanisms 7.............................................

1-4-5 Network states 7...................................................

1-5 Device Data Base files 8....................................................

1-6 Profiles 9................................................................

SECTION 1

PROFIBUS-DP

1

Page 16

1-1 Introduction

1-1SectionIntroduction

Standard EN50170-2

High speed

Process Automation

Higher level

Uniform bus access

protocol

PROFIBUS (

standard for a wide range of applications in manufacturing, process and building

automation. Vendor independence and openness are guaranteed by the

PROFIBUS standard EN50170-2. With PROFIBUS, devices of different

manufacturers can communicate without special interface adjustments.

The PROFIBUS family consists of three compatible versions:

PROFIBUS-DP

stands forDecentralisedPeriphery. It is optimised for high speed and

DP

low-cost interfacing, especially designed for communication between

automation control systems and distributed I/O at the device level.

PROFIBUS-PA

stands forProcessAutomation. It permits sensors and actuators to be

PA

connected on one common bus line even in intrinsically-safe areas. It permits

data communication and power supply over the bus using 2-wire technology

according to the international standard IEC 1158-2.

PROFIBUS-FMS

stands forFieldbusMessageSpecification. This version is the

FMS

general-purpose solution for communication tasks at a higher level. Powerful

services open up a wide range of applications and provide great flexibility. It can

also be used for extensive and complex communications tasks.

PROFIBUS-DP and PROFIBUS-FMS use the same transmission technology

and a uniform bus access protocol. Thus, both versions can be operated

simultaneously on the same cable. However, FMS field devices cannot be

controlled by DP masters or vice versa.

cessField

Pro

) is a vendor-independent, open fieldbus

Bus

Caution

!

It is not possible to exchange one of these family members by another family

member. This will cause faulty operation.

The remainder of this Operation Manual only describes PROFIBUS-DP.

2

Page 17

1-2 Protocol architecture

NOTDEFINE

D

1-2SectionProtocol architecture

OSI

Layer 1, 2 and user

interface

The PROFIBUS-DP protocol architecture is oriented on the Open System

Interconnection (OSI) reference model in accordance with the international

standard ISO 7498.

DP-Profiles

DP-Extensions

User Interface Layer DP Basic Functions

(7) Application Layer

(6) Presentation Layer

(5) Session Layer

(4) Transport Layer

(3) Network Layer

(2) Data Link Layer Fieldbus Data Link (FDL)

(1) Physical Layer RS-485 / Fibre Optics

OSI layer model of PROFIBUS-DP

PROFIBUS-DP uses layers 1 and 2, and the user interface. Layers 3 to 7 are not

defined.

Layer 1 (physical layer) defines the physical transmission characteristics.

Layer 2 (data link layer) defines the bus access protocol.

This streamlined architecture ensures fast and efficient data transmission. The

application functions which are available to the user, as well as the system and

device behaviour of the various PROFIBUS-DP device types, are specified in

the user interface.

NOT DEFINED

Transmission medium

Easy installation

Cable length

RS-485 transmission technology or fibre optics are defined as transmission

medium. RS-485 transmission is the most frequently used transmission

technology. Its application area includes all areas in which high transmission

speed and simple inexpensive installation are required. Twisted pair shielded

copper cable with one conductor pair is used.

The RS-485 transmission technology is very easy to handle. Installation of the

twisted pair cable does not require expert knowledge. The bus structure permits

addition and removal of stations or step-by-step commissioning of the system

without influencing the other stations. Later expansions have no effect on

stations which are already in operation.

Various transmission speeds between 9.6 kbit/s and 12 Mbit/s can be selected.

One unique transmission speed is selected for all devices on the bus when the

system is commissioned.

The maximum cable length depends on the transmission speed (see section

2-3-1). The length can be increased by the use of repeaters. The use of more

than 3 repeaters in series is not recommended.

3

Page 18

1-3 Device types

1-3SectionDevice types

PROFIBUS-DP distinguishes between master devices and slave devices.

Master devices

DPM1, DPM2

Slave devices

Master devices control the data communication on the bus. PROFIBUS-DP

allows more then one master in the network. A master can send messages

without an external request, as long as it holds the bus access right (the token).

Masters are also called active stations in the PROFIBUS-DP standard.

There are two types of master devices: DP master class 1 (DPM1) and DP

master class 2 (DPM2).

A DPM1 is a central controller, which exchanges information with the

decentralised stations (i.e. DP slaves) within a specified message cycle.

DPM2 devices are programmers, configuration devices or operator panels.

They are used during commissioning for configuration of the DP system or for

operation and monitoring purposes.

Slave devices are peripheral devices. Typical slave devices include input/output

devices, valves, drives and measuring transmitters. They do not have bus

access rights and they can only acknowledge received messages or send

messages to the master when requested to do so. Slaves are also called

passive stations.

The PRT1-COM is a modular slave device.

4

Page 19

1-4 PROFIBUS-DP characteristics

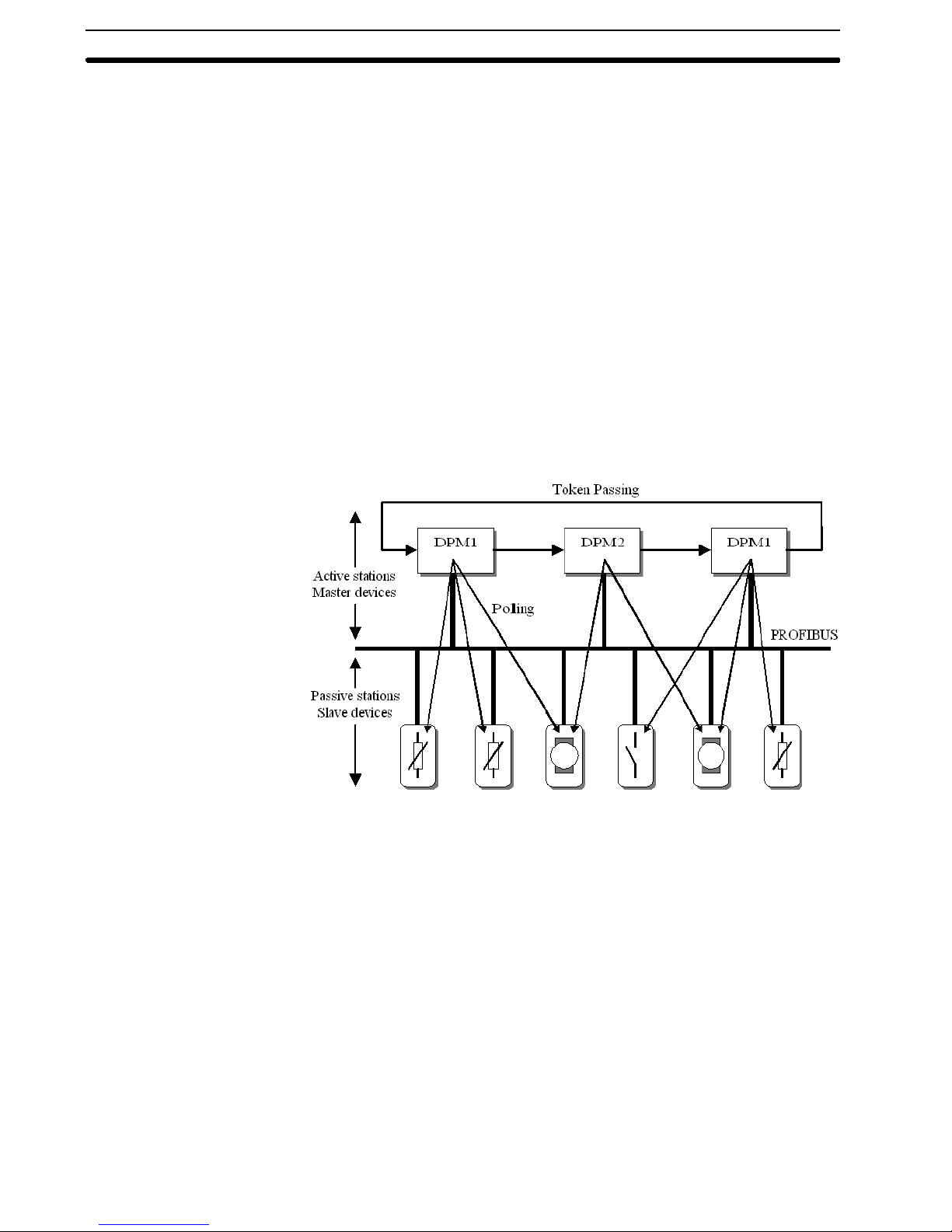

1-4-1 Bus Access Protocol

1-4SectionPROFIBUS-DP characteristics

Layer 2

Medium Access Control

T oken passing

Polling procedure

The bus access protocol is defined by layer 2. This protocol also includes data

security and the handling of the transmission protocols and messages.

The Medium Access Control (MAC) specifies the procedures, which determine

when a station is permitted to transmit data. A token passing procedure is used

to handle the bus access between master devices, and a polling procedure is

used to handle the communication between a master device and its assigned

slave device(s).

The token passing procedure guarantees that the bus access right (the token) is

assigned to each master within a precisely defined time frame. The token

message, a special message for passing access rights from one master to the

next master, must be passed around the logical token ring - once to each master

- within a specified target rotation time.

The polling or master-slave procedure permits the master, which currently owns

the token, to access its assigned slaves. The picture below shows a possible

configuration.

Token passing and Slave polling mechanisms

The configuration shows three active stations (masters) and six passive stations

(slaves).

The three masters form a logical token ring. When an active station receives the

token message, it can perform its master role for a certain period of time. During

this time it can communicate with all assigned slave stations in a master-slave

communication relationship. In addition a DPM2 master can take the initiative to

communicate with DPM1 master stations in a master-master communication

relationship.

Multi-peer

communication

In addition to logical peer-to-peer data transmission, PROFIBUS-DP provides

multi-peer communication (broadcast and multicast).

Broadcast communication: an active station sends an unacknowledged

Multicast communication: an active station sends an unacknowledged

message to all other stations (master and slaves).

message to a predetermined group of stations

(master and slaves).

5

Page 20

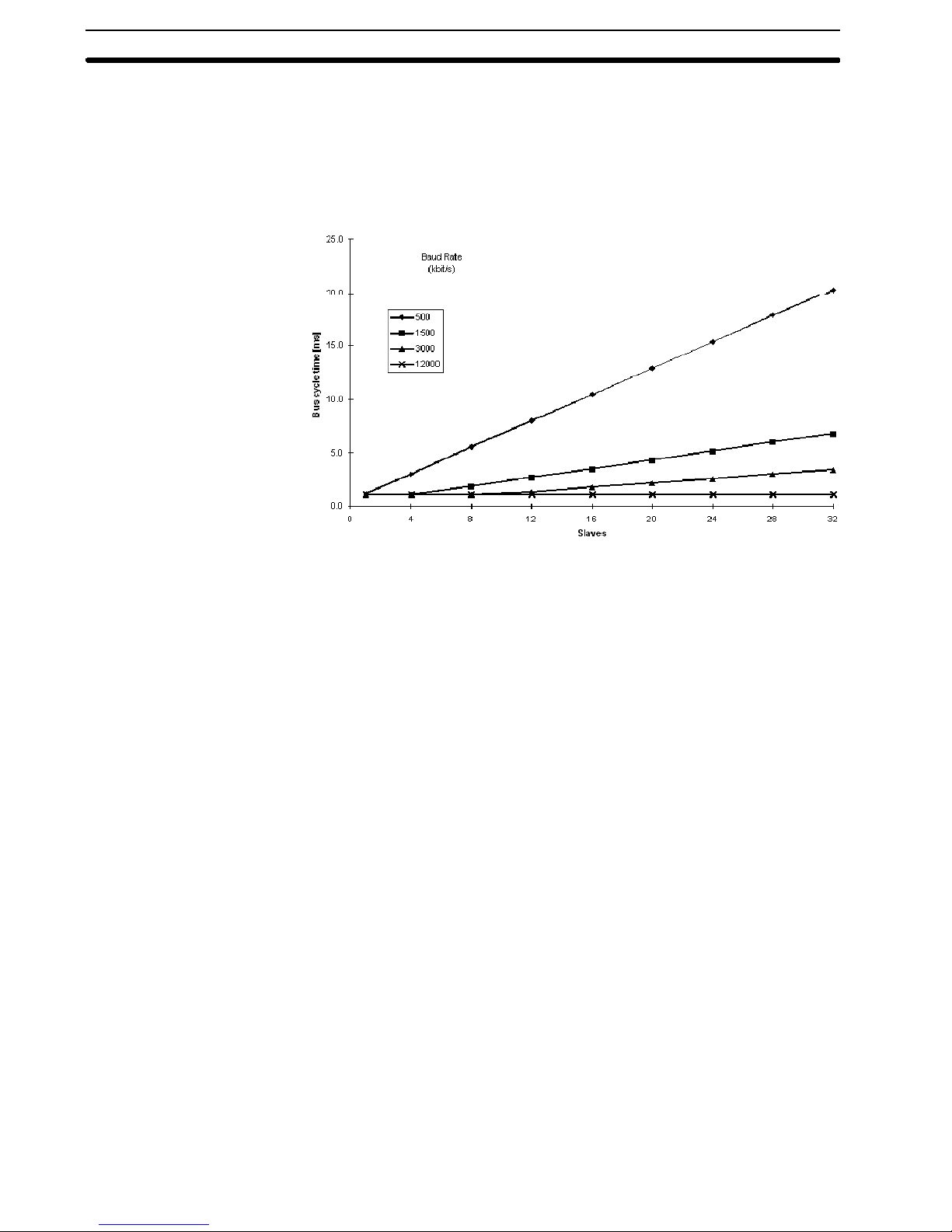

1-4-2 Data throughput

1-4SectionPROFIBUS-DP characteristics

Transmission time

At 12 Mbit/s, PROFIBUS-DP requires approximately 1 ms for the transmission

of 512 bits of input data and 512 bits of output data distributed over 32 stations.

The figure below shows the typical PROFIBUS-DP transmission time

depending on the number of stations and the transmission speed. The data

throughput will decrease when more than one master is used.

Bus cycle time vs number of slaves

Conditions: Each slave has 2 bytes of input data and 2 bytes of output data.

1-4-3 Diagnostics functions

Extensive diagnostics

Device related

diagnostics

Module related

diagnostics

Channel related

diagnostics

The extensive diagnostic functions of PROFIBUS-DP enable fast location of

faults. The diagnostic messages are transmitted over the bus and collected at

the master. These messages are divided into three levels:

• Device related diagnostics

This diagnostic level concerns the general operational status of the whole

device (e.g. overtemperature or low voltage).

• Module related diagnostics

This diagnostic level indicates that a fault is present in a specific I/O range

(e.g. an 8-bit output module) of a station.

• Channel related diagnostics

This diagnostic level indicates an error at an individual input or output (e.g.

short circuit on output 5).

6

Page 21

1-4-4 Protection mechanisms

1-4SectionDevice types

Time monitoring

At the master

At the slave

PROFIBUS-DP provides effective protection functions against

parameterisation errors or failure of the transmission equipment. Time

monitoring is provided at the DP master and at the DP slaves. The monitoring

interval is specified during the configuration.

• Protection mechanism at the master.

The DPM1 master monitors data transmission of its active slaves with the

Data_Control_Timer. A separate control timer is used for each slave. This

timer expires, when correct data transmission does not occur within the

monitoring interval.

If the master’s Auto_Clear Mode has been enabled, the DPM1 will exit its

Operate state, switches the outputs of all assigned slaves to fail-safe status

and changes to its Clear status (see also section 1-4-5).

• Protection mechanisms at the slave.

The slave uses the watchdog control to detect failures of the master or the

transmission line. If no data communication with the master occurs within the

watchdog control interval, the slave automatically switches its outputs to the

fail-safe status. This mechanism can be enabled or disabled for each

individual slave.

Also, access protection is available for the inputs and outputs of the DP

slaves operating in multi-master systems. This ensures that direct access

can only be performed by the authorised master. For all other masters, the

slaves offer an image of their inputs and outputs, which can be read from any

master, even without access rights.

1-4-5 Network states

Off-line

Stop

Clear

Operate

Auto_clear

PROFIBUS-DP distinguishes four different network states.

• Off-line

Communication between all PROFIBUS-DP devices on a network is

stopped.

• Stop

Communication between DPM1 and DP slaves is stopped. Only

communication between DPM1 and DPM2 is possible.

• Clear

DPM1 master attempts to set parameters, check the configuration, and

subsequently perform data exchange with its associated DP-slaves. The

data exchange comprises reading the inputs of the DP-slaves and writing

zeros to the outputs of the DP-slaves.

• Operate

DPM1 master exchanges data with its assigned slaves, inputs are read and

outputs are written. Beside this, the DPM1 cyclically sends its local status to

all assigned DP slaves (using a multicast message) at a configurable time

interval.

When an error occurs during the data exchange phase of the DPM1, the

’Auto_clear’ configuration parameter determines the subsequent actions. If this

parameter is set to false, the DPM1 remains in the Operate state. If set to true,

the DPM1 switches the outputs of all assigned DP slaves to the fail-safe state

and the network state changes to the Clear state.

7

Page 22

1-5 Device Data Base files

1-5SectionDevice Data Base files

Plug-and-play

DDB-file, GSD-file

General section

DP-master section

DP-slave section

Configurator

To achieve simple plug-and-play configuration of the PROFIBUS-DP network,

the characteristic features of a device are specified in a file. This file is called a

DDB-file (Device Data Base file) or a GSD-file (Gerätestammdaten file). The

GSD files are prepared individually by the vendor for each type of device,

according a fixed format. Some parameters are mandatory, some have a default

value and some are optional.

The device data base file is divided into three parts:

• General specifications

This section contains vendor and device names, hardware and software

release versions, station type and identification number, protocol

specification and the baud rates supported.

• DP master-related specifications

This section contains all parameters, which only apply to DP master devices

(e.g. maximum memory size for master parameter set, maximum number of

entries in the list of active stations or the maximum number of slaves the

master can handle).

• DP slave-related specifications

This section contains all specifications related to slaves (e.g. minimum time

between two slave poll cycles, specification of the inputs and outputs and

consistency of the I/O data).

The device data base file of each device is loaded in the configurator and

downloaded to the master device.

Refer to the Operation Manual of the PROFIBUS-DP Master Unit (W349) for

usage of the GSD file in the master’s configuration software.

8

Page 23

1-6 Profiles

1-6SectionProfiles

Exchanging devices

To enable the exchange of devices from different vendors, the user data has to

have the same format. The PROFIBUS-DP protocol does not define the format

of user data, it is only responsible for the transmission of this data.

The format of user data may be defined in so called profiles. Profiles can reduce

engineering costs since the meaning of application-related parameters is

specified precisely. Profiles have been defined for specific areas like drive

technology, encoders, and for sensors / actuators.

9

Page 24

Installation of PROFIBUS-DP Network

This section describes the installation of the PRT1-COM within the PROFIBUS-DP Network

2-1 PROFIBUS-DP MULTIPLE IO TERMINAL 12..................................

2-2 Communication Unit PRT1-COM 13...........................................

2-2-1 Specification of PRT1-COM 13........................................

2-2-2 PRT1-COM Components 14...........................................

2-3 Setting up a PROFIBUS-DP network 18.........................................

2-3-1 Fieldbus cabling 18..................................................

2-3-2 Configuring PROFIBUS-DP system 20..................................

SECTION 2

11

Page 25

2-1 PROFIBUS-DP MULTIPLE I/O TERMINAL

The PROFIBUS-DP MULTIPLE I/O TERMINAL is a system with a

communication Unit and various MULTIPLE I/O Units.

The communication Unit (PRT1-COM) connects the MULTIPLE I/O Units to the

PROFIBUS-DP Network. A maximum of eight MULTIPLE I/O Units can be

connected to one PRT1-COM.

The PRT1-COM Unit is described in this section, the total MULTIPLE I/O

TERMINAL system is described in the next section.

2-1SectionPROFIBUS-DP M ULTIPLE I/O TERMINAL

12

Page 26

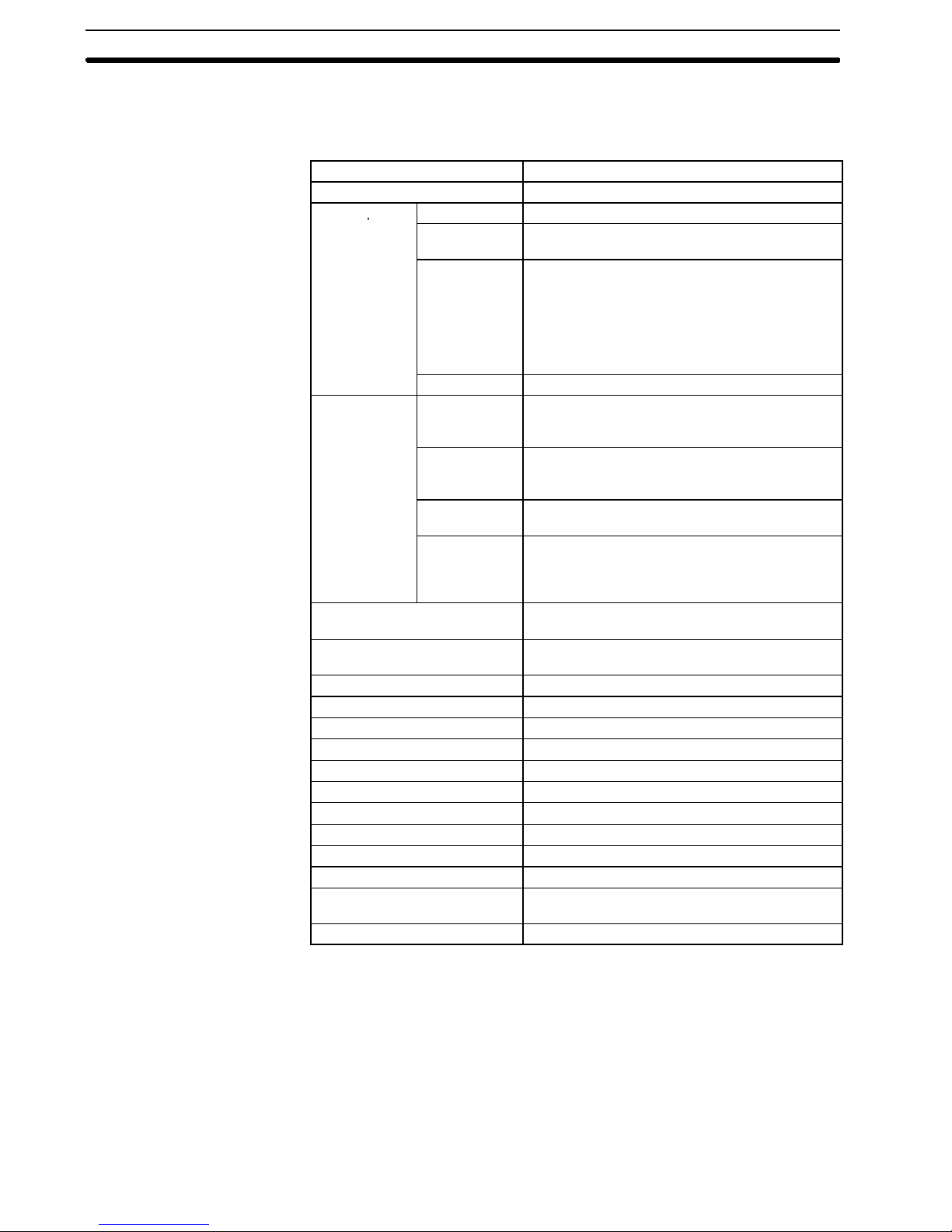

2-2 Communication Unit PRT1-COM

p

2-2-1 Specification of PRT1-COM

Item Specification

Model PRT1-COM

Internal power

supply

I/O Unit

interface

Noise immunity 1,500 V p-p Pulse width: 0.1 to 1 ms, Pulse rise

Vibration resistance 10 to 150 Hz, 1.0-mm double amplitude or 70

Shock resistance 200 m/s

Dielectric strength 500 VAC (between isolated circuits)

Ambient temperature -10 °Cto55°C

Ambient humidity 25% to 85% (with no condensation)

Operating atmosphere No corrosive gases

Storage temperature -25 °Cto65°C

EMC directives EN50081-2, EN50082-2

Mounting DIN 35-mm rail

Mounting strength 100 N

Terminal strength 100 N

I/O Unit interface connector lock

strength

Weight Approx. 165 g

Voltage range 24VDC +10% - 15% (20.4 to 26.4 VDC)

Unit current

consumption

Maximum

current

Inrush current 30 A max.

Number of

Units

connected

Total number

of inputs /

outputs

Rated output

Current

Overcurrent

Protection

function.

2-2SectionCommunication Unit PRT1-COM

0.18 A max. (at 24 VDC)

0.6 A (with maximum output to I/O Unit) the

capacity required for the internal power supply of

the Communication Unit can be obtained using

the following formula: Communication Unit

internal power supply current = Communication

Unit internal current consumption + total current

Consumption for the I/O Unit interfaces.

8Unitsmax.

Total inputs (IN): 128 bytes max.

Total outputs (OUT): 128 bytes max.

0.3 A max.

105% of rated current or higher. When an

over-current occurs, the power supply to the I/O

Units will remain OFF until the PRT1-COM power

supply is turned OFF and ON again.

time: 1 ns (via noise simulator)

2

m/s

2

50 N

13

Page 27

Characteristics of

PROFIBUS-DP

Applicable standard EN 50170 vol. 2

Type PROFIBUS-DP SLAVE

Bus connector 9-pin sub-D female

Bus termination Not included

Baud rates

(Auto--detect)

PROFIBUS address range 0to125

Communication cable Type A (EN 50170-2)

Minimum slave interval time 1ms

Input data 4 status bytes + max. 128 data bytes

Output data max. 128 data bytes

Supported PROFIBUS-DP functions

9.6 k, 19.2 k, 45.45 k, 93.75 k, 187.5 k,

500 k, 1.5 M, 3 M, 6 M, 12 M bits/s

• Data_Exchange

• Slave_Diag

• Set_Prm

• Chk_Cfg

• Global Control

(SYNC, FREEZE, CLEAR)

• Get_Cfg

• RD_Inp

• RD_Outp

PROFIBUS-DP GSD file OC_047D.GSD

2-2SectionCommunication Unit PRT1-COM

This product has been tested in the test laboratory of PNO (PROFIBUS

Note

Nutzerorganisation) and has been approved as conforming to the

PROFIBUS-DP standard. (EN 50170-2)

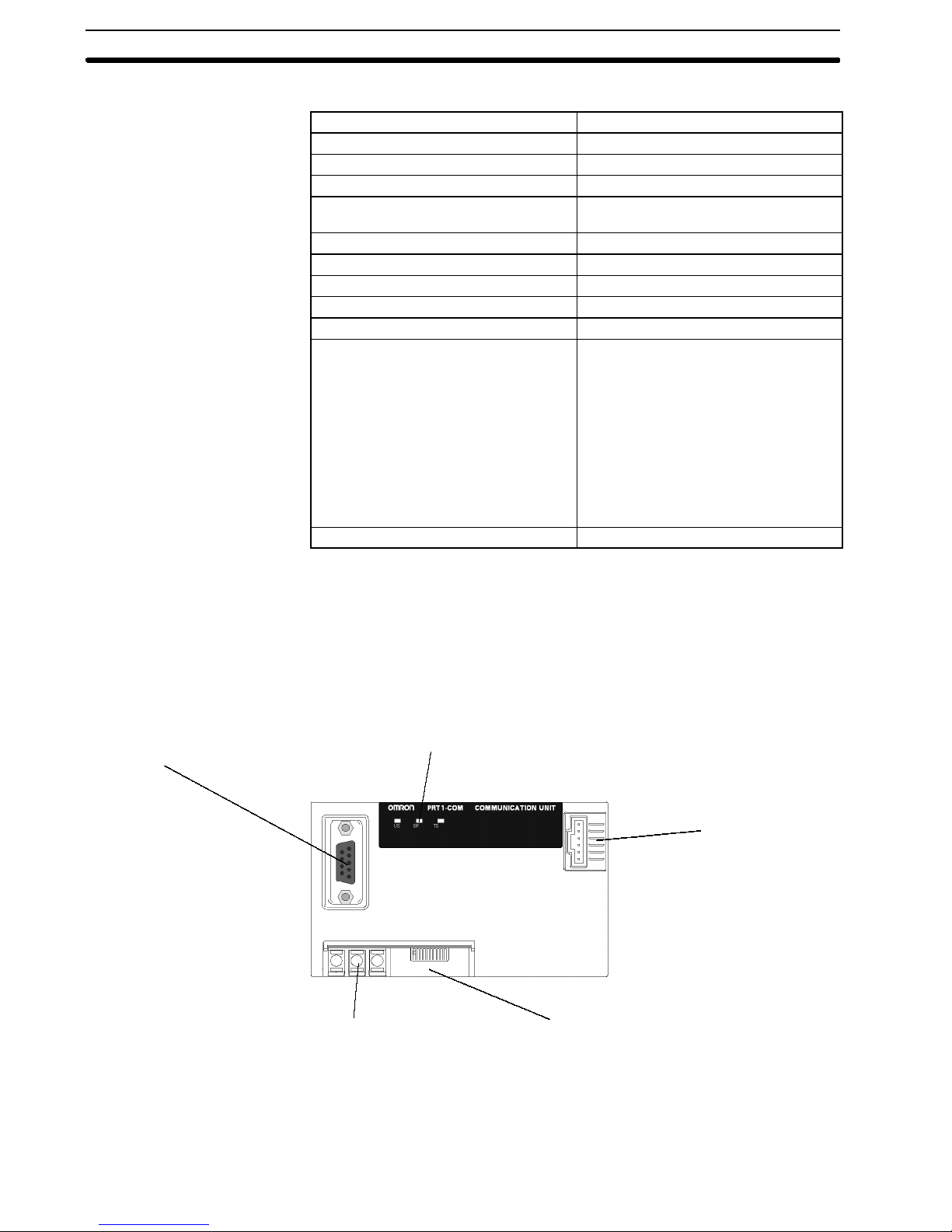

2-2-2 PRT1-COM Components

The following overview shows the various components of PRT1-COM.

PROFIBUS-DP

Communication connector

Power Terminals

LED Indicators

MULTIPLE I/O Unit

Interface connector

DIP Switches

Power Terminals

MULTIPLE I/O Unit

Connect to the power supply for operation and connect to the functional earth.

Connects to the MULTIPLE I/O Unit communication cable.

interface

14

Page 28

2-2SectionCommunication Unit PRT1-COM

(multipleI/O

)

Led Indicators

PRT1-COM has 3 LEDs to indicate the status of the Unit.

1. The Unit specific status is indicated with the US-LED

2. The BF-LED indicates the status of PROFIBUS-DP

3. The MULTIPLE I/O Bus status is indicated with the TS-LED

US LED Colour Description

Unit Status Bicolor

BF LED Color Description

Bus Failure

(Profibus-DP)

TS LED Color Description

Terminal

Status

Green / Red

Red

Bicolor

Green / Red

OFF PWR not OK

Green ON Unit OK

Green BLINK Initialising

Red ON Unit error

OFF No errors

ON

OFF Power overload

Green ON Communication OK

Green BLINK Special I/O Unit Error

Red ON

S Response monitoring time has

elapsed. The master did not

address PRT1-COM within

the configured watchdog time.

S PRT1-COM was not

parameterised or not properly

configured on start-up.

S Bus error

S Configuration error

S End station error

S Max. I/O Unit over

S Basic I/O Unit Error

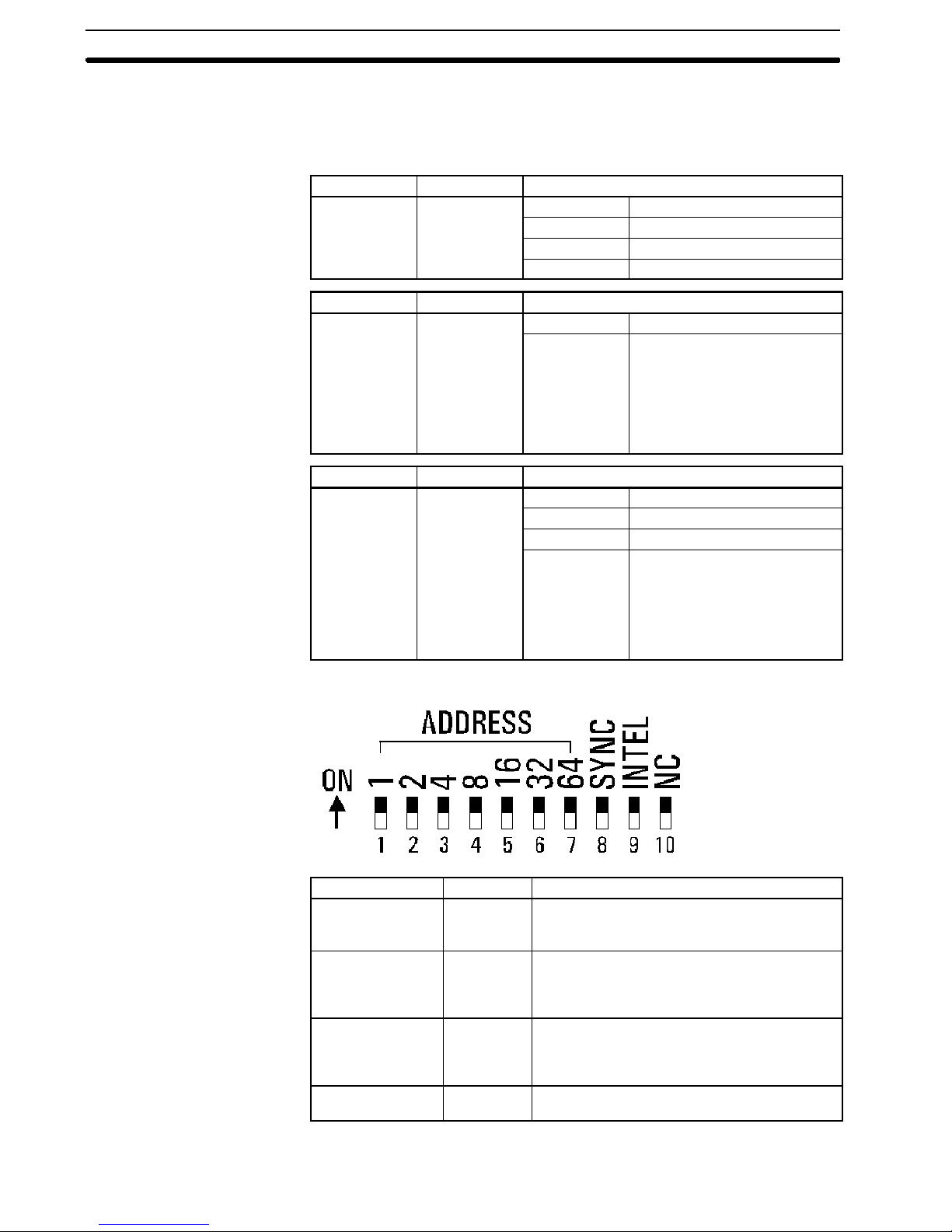

DIP Switch Settings

Switch Name Purpose

1to7 ADDRESS PROFIBUS-DP station address

All OFF = station address 0, (default, see Note)

All ON = station address 127

8 SYNC Data exchange method: Synchronous /

Asynchronous

OFF = Asynchronous, (default)

ON = Synchronous

9 INTEL Double byte transfer method:

INTEL / Motorola

OFF = Motorola, (default)

ON = Intel

10 NC Reserved for system use.

Always off

PROFIBUS-DP address setting is default set to 0.

15

Page 29

2-2SectionCommunication Unit PRT1-COM

– This setting should always be changed to appropriate value.

– Station addresses 126 and 127 are invalid and should not be used.

-- Do not use station address 0 in combination with the C200HW-PRM21

PROFIBUS-DP Master.

Data exchange method

Double byte transfer

method

1. Asynchronous mode:

The MULTIPLE I/O Bus transmit/receive cycles are independent of the

messages being transmitted/received at the PROFIBUS-DP interface.

2. Synchronous mode:

A MULTIPLE I/O Bus transmit/receive cycle will only be initiated if new data

has been received at the PROFIBUS-DP interface.

More information can be found in: section 8-1-4.

Synchronous mode has no meaning when only input MULTIPLE I/O Units are

Note

attached. In this case the switch setting is ignored and asynchronous mode is

used.

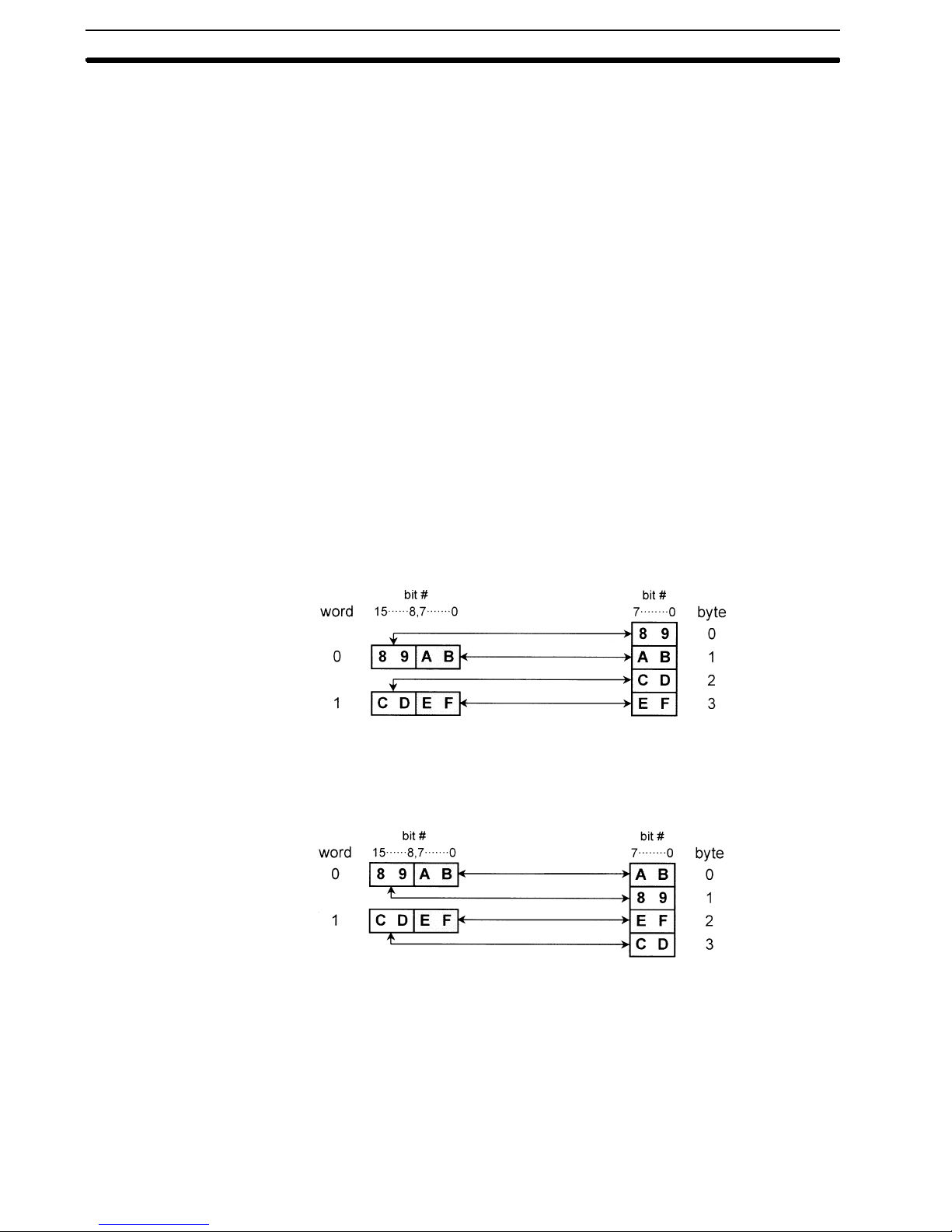

The INTEL switch is used for selection of the little-endian/big-endian mode, to

define the transfer method for double-byte data transfer between

PROFIBUS-DP and MULTIPLE I/O Bus.

This allows for adjustment of the data format if required by the PROFIBUS-DP

master.

1. Big-endian mode (Often referred to as Motorola mode):

The first byte transmitted over PROFIBUS-DP is the most-significant byte

whereas the second byte is the least-significant byte.

MULTIPLE I/O Bus

PROFIBUS-DP message

Mounting

I/O Unit Bus Connectors

16

2. Little-endian mode (Often referred to as Intel mode):

The first byte transmitted over PROFIBUS-DP is the least-significant byte

whereas the second byte is the most-significant byte.

MULTIPLE I/O Bus PROFIBUS-DP message

Changing the transfer method to ’Little-endian’ mode will also have impact on

Note

the transfer of the status bytes, see also section 3-2-4.

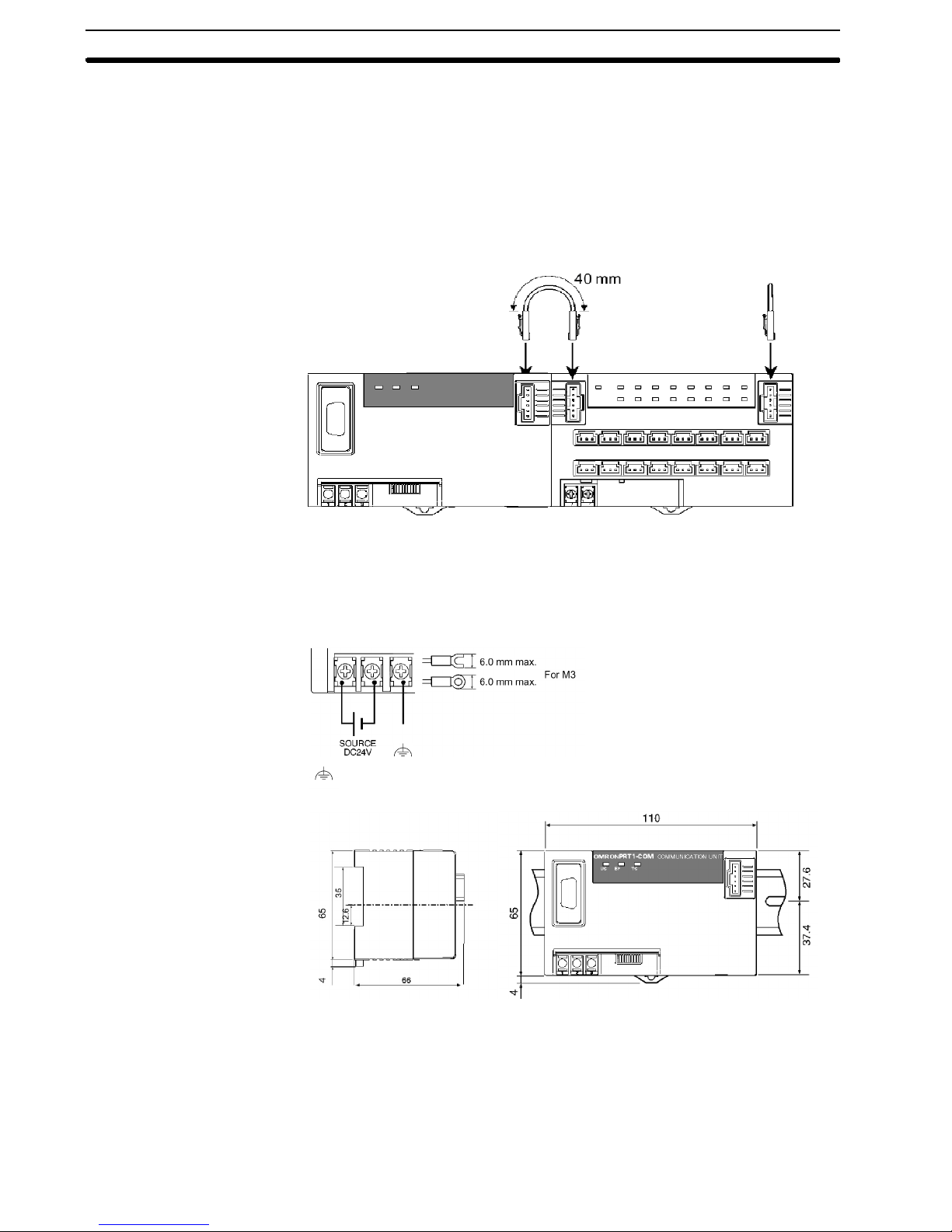

Mount the Unit on DIN 35-mm rail using the DIN Track Mounting Hook.

The I/O Unit Bus connectors on the MULTIPLE I/O Units must be connected with

the appropriate cables to provide I/O Unit interface and allow power to be

supplied to the I/O Units.

An End connector cable must be connected to the right-side connector of the last

I/O Unit (terminator).

Page 30

2-2SectionCommunication Unit PRT1-COM

One I/O Unit connecting cable (cable length 40 mm) is included with each I/O

Unit. One End connector is supplied with the Communication Unit. An I/O Unit

connecting cable with a cable length of 1 m (GCN1-100) is sold separately.

Connect the I/O Unit connecting cable to the right connector on the

Communication Unit and to the left connector of the I/O Unit as shown in the

following figure.

Wiring

I/O Unit Connecting Cable

(included with the I/O Unit)

End connector

(included with the

Communication Unit)

Be sure to connect the End connector to the right I/O Unit Bus connector of the

last I/O Unit.

Provide the internal power supply as shown in the following diagram.

Dimensions

Side view Front view

is connected to the shield of the PROFIBUS-DP connector.

17

Page 31

2-3 Setting up a PROFIBUS-DP network

2-3-1 Fieldbus cabling

2-3SectionSetting up a PROFIBUS-DP network

Bus structure

Cable type

Cable

All PROFIBUS-DP devices are connected in a line structure. Each RS485 bus

segment may contain up to 32 stations (masters, slaves, repeaters). When more

than 32 stations are required, repeaters must be used to link the individual bus

segments. The bus must be terminated at the beginning and at the end of each

segment.

The standard EN50170-2 specifies the use of shielded twisted pair cables with

the following parameters (PROFIBUS-DP line type A):

PROFIBUS-DP Cable parameters

Parameter Value

Impedance 135 to 165 Ω (3~20 MHz)

Capacitance per unit length <30pF/m

Loop resistance <110Ω/km

Core diameter >0.64mm

Core cross section >0.34mm2(22 AWG)

The PROFIBUS-DP User Group recommends the following colour coding for

the data signal lines:

A-line - green

B-line - red

Maximum length

Stub lines

Fieldbus connector

The maximum length of the cable depends on the transmission speed. The

cable lengths specified in the table below are based on the above cable

specifications.

Cable length vs. Baud rate

Baud rate (kbit/s) length/segment (m)

9.6, 19.2, 45.45, 93.75 1200

187.5 1000

500 400

1500 200

3000, 6000, 12000 100

Stub lines should be avoided for data transmission speeds of more than 500 kbit/s.

Plug connectors available on the market permit the incoming data cable and the

outgoing data cable to be connected directly in the plug connector. This means

that stub lines do not have to be used, and the bus plug connector can be

connected and disconnected at all times without interrupting data

communication with the other stations.

The connector plug to connect to the PRT1-COM is a 9-pin male sub-D

connector, preferably with a metal case, conducting screws and a solder lip for

connecting the shield of the cable. The cable should at least be connected to pin

3 (B-line) and pin 8 (A-line) of the connector.

18

Page 32

At baud rates over 1.5 Mbit/s, always use

special PROFIBUS-DP connectors with

built-in series inductances, to ensure that

cable reflections caused by the

capacitive load of each unit are

minimised.

Connectors with built-in inductors and

termination resistors, as shown here, are

available from various manufacturers

.

PROFIBUS-DP Connector

Pin No. Signal Description

1 Shield Shield / protective ground

2 – –

3 B-line Data signal

4 RTS Direction control signal for repeaters (TTL)

5 DGND Data ground for terminator resistance (0 Vdc)

6 VP Supply voltage for terminator resistance (+5Vdc)

7 – –

8 A-line Data signal

9 – –

Case Shield Protective ground

2-3SectionSetting up a PROFIBUS-DP network

PROFIBUS-DP Connector with

built-in inductors and

termination

RTS

VP, DGND

Shielding

The signal RTS (TTL signal relative to DGND) is meant for the direction control

of repeaters in case repeaters without self control capability are used.

The signals VP and DGND are meant to power

an externally mounted bus terminator (see

figure). The powering of the 220 Ω termination

resistor ensures a defined idle state potential

on the data lines. To ensure proper functioning

up to the highest baud rate, the bus cable has

to be terminated at both ends of the cable.

PROFIBUS-DP Termination

To ensure electro-magnetic compatibility (EMC), the shield of the cable should

be connected to the metal case and to pin 1 of the connector.

If the Unit is installed within a control cabinet, the cable shield of the incoming

bus cable should be electrically connected to a grounding rail as close as

possible to the cable lead-through using a shield grounding clamp or similar.The

cable shield should continue within the cabinet to the fieldbus device and be

connected there in accordance with the manufacturers instructions.

Ensure that the PLC and the control cabinet in which the device is mounted have

the same ground potential by providing a large-area metallic contact to ground

(use e.g. galvanised steel to ensure a good connection). Grounding rails should

not be attached to painted surfaces.

19

Page 33

2-3SectionSetting up a PROFIBUS-DP network

If the above measures are observed, electro-magnetic interference is diverted

through the cable’s shield.

You may find further information about

• Commissioning of PROFIBUS-DP equipment

• Testing the PROFIBUS-DP cable and bus connectors

• Determining the loop resistance

• Testing for correct bus termination

• Determining the segment length and cable route

• Other test methods

• Example of an equipment report

in the PROFIBUS-DP guideline ”Installation Guideline for PROFIBUS-DP/FMS”

(PNO Order No- 2.112), which is available at every regional PROFIBUS-DP

User Organisation.

Repeaters

The maximum communication distance can be increased by the use of

repeaters. The repeater must be included in the count of the number of stations

per segment. Even though repeaters do not have a node address, they

represent an electrical load on the bus segment like any master or slave station.

If a repeater is located at the end of a bus segment, it should provide bus

termination as well.

It is recommended to limit the number of repeaters in series between any two

stations in the system to a maximum of three units, as shown in the following

example (3 repeaters are encountered in communication between section 6 and

sections 1, 2 and 4).

Example of a PROFIBUS system using repeaters

2-3-2 Configuring PROFIBUS-DP system

After making the physical connections of the network, the PROFIBUS-DP

system needs to be configured. For each master and its assigned slaves, a

configuration has to be defined using a dedicated configuration program.

20

Page 34

2-3SectionSetting up a PROFIBUS-DP network

Configurator

C200HW-PRM21

GSD file

Example

Limits defined

by GSD file

List of available

I/O Units type

The configurator provides the master with information about:

• The slaves that are connected to the master.

• The assignment of slaves to groups for broadcast / multicast messages.

• The mapping of the slaves into the memory of the master.

• The bus parameters (e.g. baud rate, target rotation time etc.).

For more details about the configurator for the C200HW-PRM21 Master Unit,

refer to OMRON Catalog No. W349-E1.

To configure a master Unit to communicate with the PRT1-COM together with

the MULTIPLE I/O Units, the PRT1-COM device database file OC_047D.GSD is

required. Based on the contents of this file, the configuration program for the

master Unit will allow the user to select the MULTIPLE I/O Units.

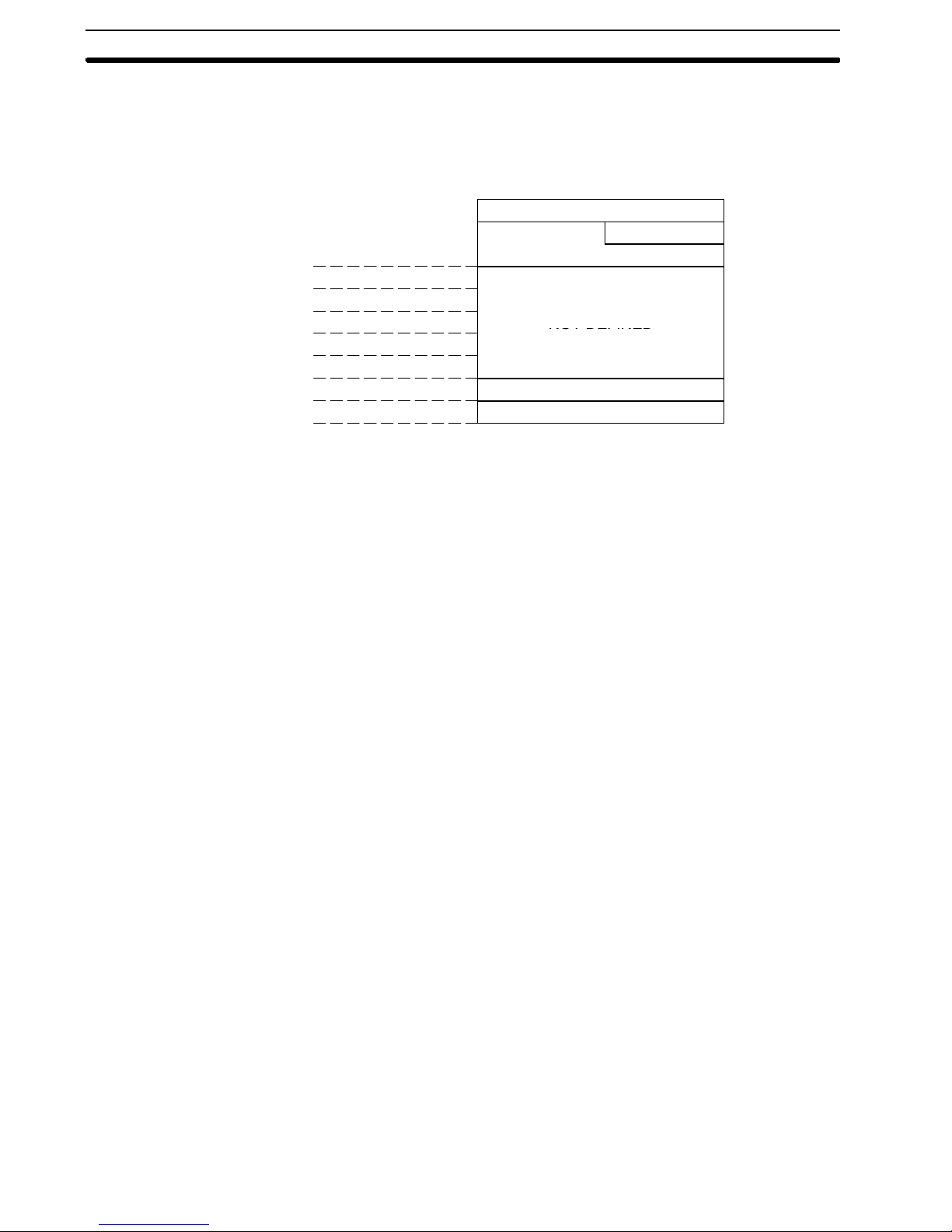

The example below shows a configuration screen of the PRT1-COM. Here the

PRT1-COM is configured as a slave with 5 MULTIPE I/O Units.

The terms input and output are to be interpreted as seen from the

PROFIBUS-DP master unit.

List of selected

I/O Units

Calculated total

sizes

Check configuration

PRT1-COM Configuration example

The System status module is mandatory. It is required for the PRT1-COM, and

Note

shall always be returned to the master, no matter how many I/O Units have been

connected. It

be selected as the first “I/O Unit”.

must

The list of selected I/O Units should exactly match the attached MULTIPLE I/O

Units. The first I/O Unit (in the example specified in the second row: GT1-ID16-1)

should be placed next to the PRT1-COM. The consecutive selected I/O Units

should be physically placed in this order from left to right. The last I/O Unit

(example: GT1-CT01) should be placed at the right end. This I/O Unit requires

the End connector.

Upon startup of the PROFIBUS-DP communication, the master will send a

Chk_Cfg message so that PRT1-COM can verify that the master’s expected I/O

configuration for the PRT1-COM is correct.

On power-up PRT1-COM determines an I/O table of the attached I/O Units. The

I/O table is compared with the I/O configuration by:

– Amount of I/O bytes per I/O Unit

21

Page 35

2-3SectionSetting up a PROFIBUS-DP network

– Consistency per I/O Unit

– Order of I/O Units (physical position)

If it does not match completely, PRT1-COM will give a negative response to the

PROFIBUS-DP master and will not exchange I/O data.

Re-use the configurator program again to match the selected I/O Units with the

physically attached I/O Units in case the configuration is changed.

22

Page 36

SECTION 3

MULTIPLE I/O TERMINAL

This section provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

3-1 MULTIPLE I/O TERMINAL 24...............................................

3-1-1 Overview 24.......................................................

3-1-2 System Configuration 24..............................................

3-1-3 Features 24........................................................

3-1-4 Communication Units and I/O Units 25..................................

3-1-5 List of Models 26...................................................

3-2 Functions 29..............................................................

3-2-1 I/O Unit Interface Specifications 29.....................................

3-2-2 Exchanging Data 31.................................................

3-2-3 Allocating I/O 32....................................................

3-2-4 I/O Unit Interface Status 33............................................

3-2-5 I/O Configuration Changes 35..........................................

23

Page 37

3-1 MULTIPLE I/O TERMINAL

3-1-1 Overview

A MULTIPLE I/O TERMINAL is a modular PROFIBUS-DP Slave that consists of

a Communication Unit providing an interface to one or more I/O Units. The I/O

Unit interface supports up to 8 I/O Units and a total of up to 128 byte input + 128

byte output. I/O Units are connected using simple connections via I/O Unit

Connecting Cables. Allocation and address settings on the I/O Unit interface are

not required, enabling simple, flexible distributed I/O control.

3-1-2 System Configuration

3-1SectionMULTIPLE I/O TERMINAL

3-1-3 Features

Simple Connections

Status Notification

Many Types of I/O Unit

Total number of input bytes: 128. Total number of output bytes: 128

The Communication Unit and the I/O Units are separate, and the

Communication Unit and the I/O Units are connected through an I/O Unit

interface. I/O can be expanded simply by connecting additional I/O Units to the

I/O Unit interface.

Status information about the I/O Unit interface is transmitted as input data to the

PROFIBUS-DP Master Unit (two words).

The following I/O Units are available.

• 16- or 32-point Transistor Input Units (terminal block, connector, 25-pin D-sub

connector, or high-density connector)

• 16- or 32-point Transistor Output Units (terminal block, connector, 25-pin

D-sub connector, or high-density connector)

• 8-point/16-point Relay Output Unit

• 4- or 8-point Analog Input Unit (terminal block or connector)

• 4-point Analog Output Unit (terminal block or connector)

• 1-point Pulse Input Unit (high-speed counter)

An I/O-intensive System

Can be Built at Low Cost

Compared with fixed I/O Terminals, a high cost-performance ratio can be

achieved if I/O Units are used.

24

Page 38

3-1-4 Communication Units and I/O Units

3-1SectionMULTIPLE I/O TERMINAL

Communication Unit

I/O Units

The Communication Unit interfaces the I/O Units to the PROFIBUS-DP

Network.

• It automatically recognizes the configuration of the I/O Units when the I/O Unit

interface is initialised.

• It notifies the connection status (status information) of the I/O Units to the

PROFIBUS-DP Master Unit.

• It provides a dip-switches to set the stations address of the MULTIPOINT I/O

TERMINAL as a PROFIBUS-DP Slave.

There are various I/O Units that can be connected to the I/O Unit interface.

• I/O Units are connected to the Communication Unit using an I/O Unit

Connecting Cable (included with the I/O Unit, a 1-m I/O Unit Connecting Cable

(GCN1-100) is also available).

• No address or baud rate settings are required on the I/O Units.

• The connection order of I/O Units is flexible.

25

Page 39

3-1-5 List of Models

p

Uni

t

Uni

t

O

p

3-1SectionMULTIPLE I/O TERMINAL

Unit I/O

Communication Unit None Status

Basic

I/O Units

Transistor

Input

s

Transistor

Output

s

Relay

Output

Units

points

16

inputs

16

inputs

16

inputs

16

inputs

32

inputs

16

outputs

16

outputs

16

outputs

16

outputs

32

outputs

8

outputs

16

outputs

Words allocated

in PC memory

Input Output

two

words

1word 0

1word 0

1word 0

1word 0

2 words 0

0 words 1word M3 terminal

0 words 1word Connectors

0 words 1word Connectors

0 words 1word Connectors

0 words 2

0 words 1word M3 terminal

0 words 1word M3 terminal

0

words

words

words

words

words

words

words

I/O connec-

tions

None PRT1-COM ---

M3 terminal

block

Connectors

(made by

MOLEX)

Connectors

(made by

FUJITSU)

Connectors

(25-pin

D-sub connectors)

High-density

connector

(made by

FUJITSU)

block

(made by

MOLEX)

(made by

FUJITSU)

(25-pin

D-sub connectors)

High-density

connector

(made by

FUJITSU)

block

block

Model number Remarks Unit

GT1-ID16

GT1-ID16-1

GT1-ID16MX

GT1-ID16MX-1

GT1-ID16ML

GT1-ID16ML-1

GT1-ID16DS

GT1-ID16DS-1

GT1-ID32ML

GT1-ID32ML-1

GT1-OD16

GT1-OD16-1

GT1-OD16MX

GT1-OD16MX-1

GT1-OD16ML

GT1-OD16ML-1

GT1-OD16DS

GT1-OD16DS-1

GT1-OD32ML

GT1-OD32ML-1

GT1-ROP08 ---

GT1-ROS16 ---

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

NPN

PNP

power

supply

voltage

24 VDC

(supplied

from

outside)

Installa-

tion

DIN

track

26

Page 40

3-1SectionMULTIPLE I/O TERMINAL

(Se

e

Units

0to20mA

plied

Special

I/O Units

(See

note.)

Unit Installa-

Unit Installa-

Analog

Input

Units

Analog

Output

Units

Counter

Units

I/O

I/O

points

points

4 inputs 4 words 0word M3 terminal

8 inputs 8 words 0word Connectors

4 outputs

4 outputs

1 input 3 words 3

Words allocated

in PC memory

OutputInput

0 words 4

0 words 4

The front-panel indicators and other parts of Analog Input Units, Analog Output

Note

words

words

words

tions

tions

block

(made by

MOLEX)

M3 terminal

block

Connectors

(made by

MOLEX)

M3 terminal

block

GT1-AD04

GT1-AD08MX

GT1-DA04 Outputs:

GT1-DA04MX Outputs:

GT1-CT01 1 external

RemarksModel numberI/O connec-

RemarksModel numberI/O connec-

Inputs:

4to20mA,

0to20mA,

0to5V,

1to5V,

0to10V,

--10 to 10 V

4to20mA,

0to5V,

1to5V,

0to10V,

--10 to 10 V

0to5V,

1to5V,

0to10V,

--10 to 10 V

input

2 external

outputs

voltage

voltage

24 VDC

(sup-

,

plied

from

outside)

Unit

Unit

power

power

supply

supply

tion

tion

DIN

track

Units, and Counter Units differ from those of other I/O Units. These Units belong

to a group called Special I/O Units.

An end connector is attached to the Communication Unit, and a 40-mm I/O Unit

Connecting Cable is included with each I/O Unit. Several I/O Unit Connecting

Cables are also available.

1m

Number: Length:

GCN1 - 010 10 cm

GCN1 - 030 30 cm

GCN1 - 040 40 cm

GCN1 - 060 60 cm

GCN1 - 100 (see figure) 1m

27

Page 41

3-1SectionMULTIPLE I/O TERMINAL

adeby

acs

p

g

p

g

spondin

g

corre

FUJITSU

Applicable Connectors

The applicable connectors are shown in the following table.

Connector Model number Remarks

Connectors

made by

MOLEX

Connectors

made by

FUJITSU

corre-

ondin

s

to 16-point

connectors

Recommended

connectors

corresponding

to 25-pin

D-sub connectors

Connectors

made by

Pressurewelded

Crimp

Soldered FCN361J024-AU

Pressure-welded FCN367J024-AU/F

Crimp FCN363J024-AU

Hood XW2S-2513 OMRON

Plug XW2A-2501 OMRON

Soldered FCN361J040-AU

Housing 52109-0390 For AWG#24

Housing 51030-0330

Reeled contacts

Loose contacts

Crimping

tool

(See note.)

50083-8014 For AWG#24 to 30

50084-8014 For AWG#22 to 24

50083-8114

(See note.)

50084-8114 For AWG#22 to 24

57036-5000 For AWG#22 to 26

57037-5000

(See note.)

For AWG#24 to 30

For AWG#24 to 30

corresponding

to highdensity

connectors

Refer to page 173, High-density Connector Cables for MULTIPLE I/O

Note

Pressure-welded FCN367J040-AU/F

Crimp FCN363J040-AU

TERMINALs for details.

28

Page 42

3-2 Functions

3-2-1 I/O Unit Interface Specifications

Item Specification

Communications method Special protocol

Number of I/O Units 8Unitsmax.

Maximum number of data bytes Input data: 128 bytes

Communications distance

Communications power supply Supplied from the Communication Unit to the I/O

Relationship to PROFIBUS-DP After the I/O Unit interface is established, PROFI-

Addresses Automatically recognised when the power to the

I/O configuration Automatically recognised when the power to the

Self-diagnostic

functions

Error detection Frame error check; CRC-CCITT check

Total length 3mmax.

Between

Units

Configuration

errors

Special I/O

Unit errors

I/O Unit interface errors

Power supply

overload to

I/O Units

3-2SectionFunctions

Output data:128 bytes

1 m max. (Cable i ncluded with Unit is 40 mm.)

Unit (0.3 A max.)

BUS-DP communications continue normally, even

if an error occurs on the I/O Unit interface.

Communication Unit is turned ON.

Communication Unit is turned ON. If the configuration is changed while the power supply is ON, a

configuration error will occur.

The I/O Unit configuration is constantly checked

while power is supplied. If a mismatch occurs

while the power is turned ON, I/O refreshing for all

I/O Units is s topped.

Errors are detected in the Special I/O Units (Analog Input, Analog Output Units, and Counter Units)

on the I/O Unit interface.

Communications stop when there is no communications response from an I/O Unit.

Communications stop when there is no specific

response from the last I/O Unit (terminator).

Communications stop when nine or more I/O

Units are connected.

The power supply to the I/O Units and I/O refreshing for all I/O Units are stopped when the power

supply to the I/O Units through the Communication Unit exceeds 0.3 A.

29

Page 43

3-2SectionFunctions

I/O Interface Current

Consumption

Make sure that the power supply from the Communication Unit to the I/O Units is

less than the total rated output current (300 mA). The I/O interface current

consumption for each I/O Unit is shown in the following table.

I/O Unit I/O interface current consumption

GT1-ID16(-1) 35 mA max.

GT1-ID16MX(-1) 35 mA max.

GT1-ID16ML(-1) 35 mA max.

GT1-ID16DS(-1) 35 mA max.

GT1-ID32ML(-1) 55 mA max.

GT1-OD16(-1) 35 mA max.

GT1-OD16MX(-1) 35 mA max.

GT1-OD16ML(-1) 35 mA max.

GT1-OD16DS(-1) 35 mA max.

GT1-OD32ML(-1) 65 mA max.

GT1-ROP08 40 mA max.

GT1-ROS16 50 mA max.

GT1-AD04 50 mA max.

GT1-AD08MX 50 mA max.

GT1-DA04 50 mA max.

GT1-DA04MX 50 mA max.

GT1-CT01 90 mA max.

I/O Unit Interface

Addresses

Calculation Example

When three GT1-ID32ML Input Units and three GT1-OD16 Output Units are

used, the total current consumption is calculated as follows:

(GT1-ID32ML current consumption) x 3 Units

+ (GT1-OD16 current consumption) x 3 Units

= 55 mA x 3 + 35 mA x 3 = 270 mA ≤ 300 mA

The addresses of the I/O Units on the I/O Unit interface are automatically set

when the Communication Unit is started. The addresses are from 0 to 7 in

ascending order from the I/O Units closest to the Communication Unit.

Checking the I/O Unit

Interface Status

The following two methods are used to check the I/O Unit interface status:

• Checking the Communication Unit and I/O Unit indicators

• Checking the status of the Communication Unit

30

Page 44

Indicators

Unit Normal Error

Communication

Unit

I/O Units TS indicator:

TS Indicator:

green ON

green ON

U.ERR

indicator: OFF

PWR indicator:

green ON

TS indicator

I/O Unit interface error: red ON

Special I/O Unit error: green BLINKING

Maximum power supply

overload to I/O Units: OFF

TS indicator

I/O Unit interface error: red ON

U.ERR indicator

Special I/O Unit error: red ON

PWR indicator

No internal power supply: OFF

3-2SectionFunctions

For details, refer to page 161, Troubleshooting via Indicators.

Checking the I/O Unit Interface

The first two words of the CPU Unit allocation input area are always allocated to

the status of the I/O Unit interface received via PROFIBUS-DP.

3-2-2 Exchanging Data

Initialization

When the Communication Unit is started, it automatically recognizes the

configuration of the I/O Units and registers this status as the normal

configuration (in RAM memory). At the same time, addresses 0 to 7 are

allocated to the I/O Units in ascending order from the I/O Unit closest to the

Communication Unit. This I/O table is compared with the PROFIBUS-DP

Chk-cfg message. These processes are performed each time the power is

turned ON.

Status

Status, two words

I/O Unit connection information

Error slaves Registered slaves

For details, see section 3-2-4

I/O Unit Interface Status.

Note

1. If the configuration of the I/O Units is to be changed, a number of precautions

2. For details of data exchange timing, see 8-1-1 I/O Response Time.

must be noted. For details, see 3-2-5 I/O Configuration Changes.

31

Page 45

3-2SectionFunctions

Error Processing

3-2-3 Allocating I/O

Even if an error occurs in the I/O Unit interface after initialization is completed,

PROFIBUS-DP communications will continue normally. Therefore, an error

processing program section must be included in the CPU Unit to check the

status of the Communication Unit for errors that have occurred and to identify the

error type and location.

This section explains how words for a MULTIPLE I/O TERMINAL are allocated

in the output area and input area of the Master. For details of remote I/O

functions in the output area and input area of the Master such as word

specification, fixed allocation, and user-set allocation, refer to the

PROFIBUS-DP Master Unit Operation Manual (W349).

Output

Area

The output area contains output bits in the same order as the I/O Units are

connected on the I/O Unit interface.

Area

Input

The input area contains the Communication Unit status (two words), and input

bits in the same order as the I/O Units are connected on the I/O Unit interface.

Output area Input area

Area corresponding to

Communication Unit

Output bits on

the I/O Unit

interface

I/O Unit interface

status

Input bits on the I/O

Unit interface

The input and output bits for the I/O Unit interface are allocated in the

PROFIBUS-DP input and output areas in 16-point (one word) increments.

32

Page 46

Example: C200HW Series with PRM21 default I/O mapping

p

/

d

d

d

d

g

p

/

d

d

1

2

g

p

d

d

1

2

p

3-2SectionFunctions

PRT1-COM with

station address 05

Area allocated

to station

a

ress05

Area allocated

to station

a

ress

I/O Unit

addresses

IR50

IR51

IR52

IR53

IR54

IR55

IR56

IR57

IR58

IR59

IR60

IR61

PROFIBUS-DP Network

#0

32 outputs

#1

4-point

Analog

Output Unit

#2

16 inputs

#3

16 inputs

PRT1-COM with

station address 12

#0

16 inputs#14-point

Analog

Output Unit

Output area Input area

32 output bits for

Unit #0 to station

4 analog outputs for

Unit #1

4 analog outputs for

Area allocated

a

ress05

Area allocated

to station

a

ress

IR350

IR351

I/O Unit interface

status for station 05

IR352 16 input bits for Unit #2

IR353 16 input bits for Unit #3

IR354

IR355

I/O Unit interface

status for station 12

IR356 16 input bits for Unit #0

Unit #1

32 output bits for

Unit #2

#2

32 outputs

3-2-4 I/O Unit Interface Status

The following I/O Unit interface status is maintained in the CPU Unit.

• I/O Unit connection information (I/O Unit interface status)

• Registered I/O Unit addresses

• Error I/O Unit addresses

As shown in the following diagram, the status consists of two words. The first two

words of the Communication Unit allocation input area in the CPU Unit are

allocated for this status. Include a program section in the CPU Unit to check this

status and perform error processing.

0wd

+1 wd

I/O Unit connection information

Error I/O Unit addresses Registered I/O Unit addresses

33

Page 47

I/O Unit Connection Information

0wd

1: Error (OR of bits 0 to 4)

1: Refreshing I/O

3-2SectionFunctions

Bit

1: Special I/O Unit Error

1: Configuration Error

1: I/O Unit Interface Error

1: I/O Unit Power Supply Overload

1: I/O Unit Error

Bit Flag name Meaning Content

15 Refreshing

I/O

14 Error OR of bits 0 to 4 1: Any one of bits 0 to 4 is

4 Multipoint I/O

Unit Error

3 I/O Unit

Power Supply

Overload

2 I/O Unit Inter-

face Error

1 Configuration

Error

0 Special I/O

Unit Error

Refreshing I/O 1: Communications

A multipoint I/O Unit error was

detected.

An overcurrent to an I/O Unit

was detected.

An I/O Unit interface error was

detected.

Data Transfer Error:

In the I/O Unit interface, there

was no response to a command after the fixed time has

elapsed. Alternatively, the

response expected to be

returned from the end I/O Unit

(terminator) was not received.

Too many I/O Units:

Nine or more I/O Units are

connected.

The I/O configuration was

changed after the Communication Unit was started.

An error occurred in a Special

I/O Unit.

between the Communication Unit and I/O

Units is normal.

0: Communications error

(no response is received

from an I/O Unit)

ON

0:Bits0to4areallOFF

1: Unit error

0: Unit normal

1: Overcurrent detected

0: Normal

1: I/O Unit interface error

0: Normal

1: I/O configuration change

after startup

0: No I/O configuration

change during startup

1: Special I/O Unit error

0: Special I/O Unit normal

The high and low bytes in this status word are swapped when the transfer mode

Note

is set to Little Endian (see section 2-2-2).

34

Page 48

Abnormal I/O Unit Addresses and Registered I/O Unit Addresses

+1 wd

3-2SectionFunctions

Bit

The high and low bytes in this status word are swapped when the transfer mode

Note

is set to Little Endian (see section 2-2-2).

3-2-5 I/O Configuration Changes

The I/O Unit interface automatically recognizes the I/O Unit configuration each

time the Communication Unit is started up.

Note

1. If the I/O Unit configuration is changed while the Communication Unit is

turned ON, a configuration error will occur. Do not change the I/O Unit

configuration while power is being supplied to the Communication Unit.

2. If a configuration error occurs on the I/O Unit interface, I/O refreshing of all

I/O Units will stop. Even if a configuration error occurs, communications with

the PROFIBUS-DP Network will continue, using the initial I/O Unit

configuration. An error processing program section must therefore be

included in the CPU Unit to regularly check whether or not a configuration

error has occurred (status bit 1) and to process abnormal I/O Unit

addresses.

If the I/O configuration is changed, then the PROFIBUS-DP System should be

reconfigured, see 2-3-2.

The bits corresponding

to I/O Unit with errors

are turned ON. Bits 8 to

15 correspond to

addresses 0 to 7.

1: Error

0: No error, or not

part of network