Page 1

Machine Automation Controller

NX-series

IO-Link Master Unit

User’s Manual

NX-ILM

IO-Link Master Unit

W567-E1-05

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• Safety over EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an NX-series IO-Link Master Unit.

This manual contains information that is necessary to use the NX-series IO-Link Master Unit. Please

read this manual and make sure you understand the functionality and performance of the NX-series

IO-Link Master Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Introduction

Applicable Products

This manual covers the following product.

• NX-series IO-Link Master Unit

NX-ILM400

NX-series IO-Link Master Unit User’s Manual (W567)

1

Page 4

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products..................................................................................................................................... 1

Relevant Manuals .....................................................................................................6

Manual Structure ......................................................................................................7

Page Structure and Icons ............................................................................................................................ 7

Special Information...................................................................................................................................... 8

Precaution on Terminology .......................................................................................................................... 8

Terms and Conditions Agreement........................................................................ 11

Warranty, Limitations of Liability ................................................................................................................ 11

Application Considerations ........................................................................................................................ 12

Disclaimers ................................................................................................................................................ 12

Safety Precautions .................................................................................................13

Definition of Precautionary Information...................................................................................................... 13

Symbols..................................................................................................................................................... 13

Warnings.................................................................................................................................................... 14

Cautions..................................................................................................................................................... 15

Precautions for Safe Use....................................................................................... 17

Precautions for Correct Use.................................................................................. 22

Regulations and Standards................................................................................... 23

Conformance to EU Directives .................................................................................................................. 23

Conformance to UL and CSA Standards................................................................................................... 24

Conformance to Shipbuilding Standards ................................................................................................... 24

Conformance to KC Standards.................................................................................................................. 24

Software Licenses and Copyrights ............................................................................................................ 24

Unit Versions ..........................................................................................................25

Unit Versions.............................................................................................................................................. 25

Unit Versions and Support Software Versions ........................................................................................... 26

Related Manuals .....................................................................................................27

Terminology ............................................................................................................31

Revision History .....................................................................................................33

Sections in this Manual .........................................................................................35

Section 1 Features and System Configuration

1-1 Features of the IO-Link Master Units ................................................................................... 1-2

1-1-1 Introduction .................................................................................................................................1-2

1-1-2 Features...................................................................................................................................... 1-2

1-2 System Configuration ........................................................................................................... 1-4

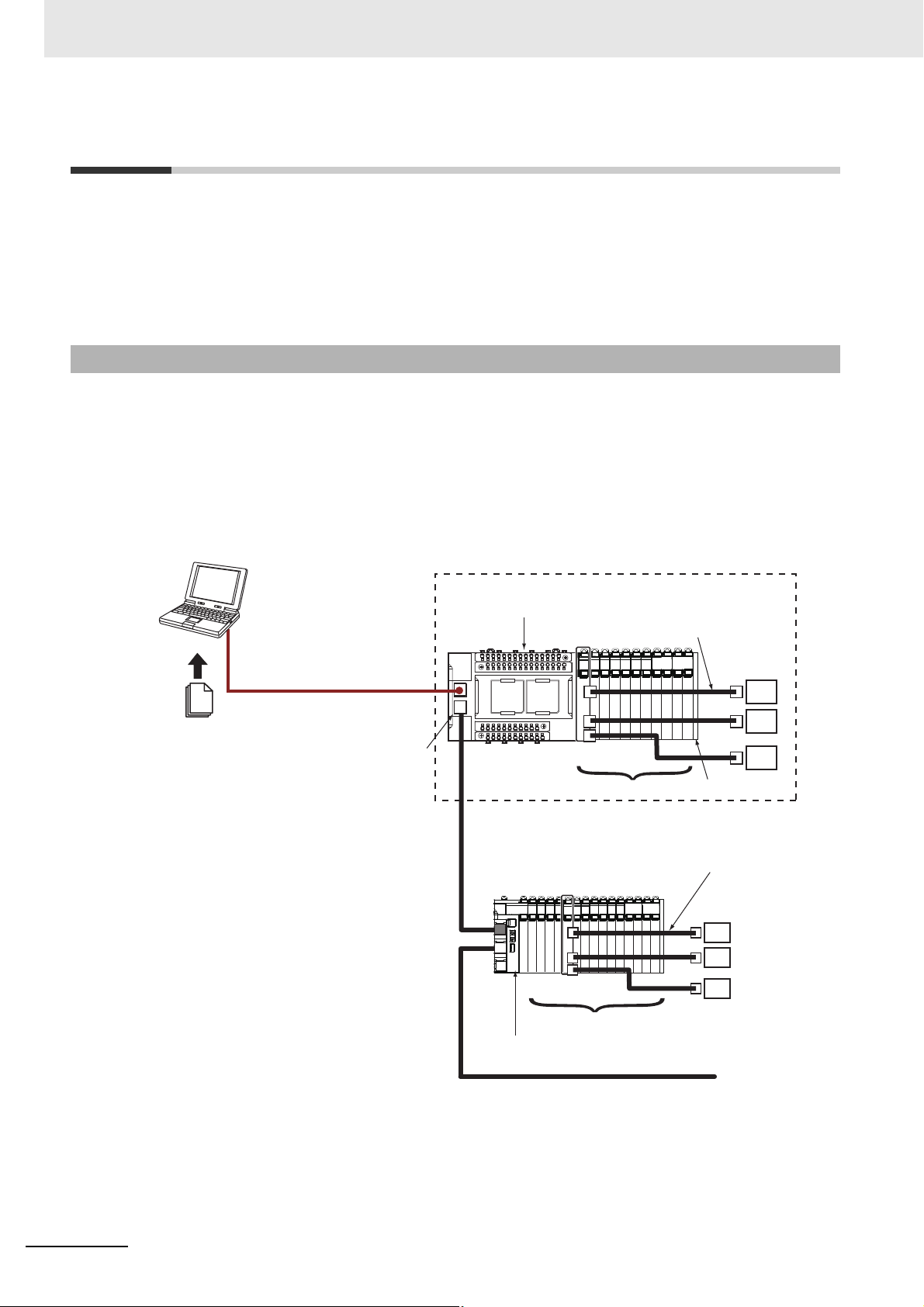

1-2-1 System Configuration with CPU Unit .......................................................................................... 1-4

1-2-2 System Configurations of Slave Terminals..................................................................................1-5

2

NX-series IO-Link Master Unit User’s Manual (W567)

Page 5

1-3 Model List............................................................................................................................... 1-8

1-3-1 Model Notation............................................................................................................................ 1-8

1-4 List of Functions.................................................................................................................... 1-9

1-5 Support Software................................................................................................................. 1-10

Section 2 Specifications

2-1 General Specifications.......................................................................................................... 2-2

2-2 Individual Specifications ...................................................................................................... 2-3

Section 3 Part Names and Functions

3-1 Part Names............................................................................................................................. 3-2

3-1-1 IO-Link Master Unit..................................................................................................................... 3-2

3-2 Indicators ............................................................................................................................... 3-4

3-2-1 TS Indicator ................................................................................................................................ 3-4

3-2-2 C Indicator .................................................................................................................................. 3-5

3-2-3 E Indicator................................................................................................................................... 3-5

3-2-4 C/Q Indicator............................................................................................................................... 3-5

CONTENTS

Section 4 Installation and Wiring

4-1 Installing NX Units................................................................................................................ 4-2

4-1-1 Installing NX Units ...................................................................................................................... 4-2

4-1-2 Attaching Markers....................................................................................................................... 4-4

4-1-3 Removing NX Units .................................................................................................................... 4-6

4-1-4 Installation Orientation................................................................................................................ 4-7

4-2 Connecting the Power Supply and Ground Wires ............................................................. 4-9

4-2-1 I/O Power Supply Methods and Applications.............................................................................. 4-9

4-2-2 Calculating the Total Current Consumption from I/O Power Supply ......................................... 4-10

4-3 Wiring the Terminals ........................................................................................................... 4-12

4-3-1 Wiring to the Screwless Clamping Terminal Block.................................................................... 4-12

4-3-2 Checking the Wiring.................................................................................................................. 4-28

4-4 Wiring Examples and Wiring Precautions ........................................................................ 4-29

4-4-1 IO-Link Mode ............................................................................................................................ 4-29

4-4-2 SIO (DI) Mode........................................................................................................................... 4-29

4-4-3 SIO (DO) Mode......................................................................................................................... 4-30

4-5 Wiring Precautions.............................................................................................................. 4-31

4-5-1 Wiring Precautions for SIO (DI) Mode ...................................................................................... 4-31

4-5-2 Wiring Precautions for SIO (DO) Mode .................................................................................... 4-31

Section 5 I/O Refreshing

5-1 I/O Refreshing ........................................................................................................................ 5-2

5-1-1 I/O Refreshing from the CPU Unit to NX Units ........................................................................... 5-2

5-1-2 I/O Refreshing from the CPU Unit or Industrial PC to Slave Terminals ...................................... 5-2

5-2 I/O Refreshing Methods ........................................................................................................ 5-5

5-2-1 Types of I/O Refreshing Methods ............................................................................................... 5-5

5-2-2 Setting the I/O Refreshing Methods............................................................................................ 5-6

5-2-3 Refreshing Operation of the IO-Link Master Unit........................................................................ 5-6

NX-series IO-Link Master Unit User’s Manual (W567)

3

Page 6

CONTENTS

5-3 Communications Performance ............................................................................................ 5-7

5-3-1 Maximum I/O Response Time When the EtherCAT Coupler Unit Is Connected......................... 5-7

5-3-2 Maximum I/O Response Time When the EtherNet/IP Coupler Unit Is Connected ..................... 5-8

5-3-3 Maximum I/O Response Time When the CPU Unit Is Connected ..............................................5-9

5-3-4 Determining the IO-Link Communications Cycle ...................................................................... 5-11

Section 6 Types and Functions of IO-Link Master Units

6-1 Types and Connection Configurations of IO-Link Master Units ....................................... 6-2

6-1-1 Types of IO-Link Master Units.....................................................................................................6-2

6-1-2 Connection Configuration with the Communications Coupler Unit or CPU Unit and

IO-Link Devices...........................................................................................................................6-2

6-2 Specifications of I/O Data ..................................................................................................... 6-4

6-2-1 Allocatable I/O Data ....................................................................................................................6-4

6-3 List of Settings....................................................................................................................... 6-6

6-4 Functions ............................................................................................................................... 6-8

Section 7 Troubleshooting

7-1 How to Check for Errors ....................................................................................................... 7-2

7-2 Checking for Errors with the Indicators .............................................................................. 7-3

7-3 Checking for Errors and Troubleshooting on the Support Software................................ 7-4

7-3-1 Checking for Errors from the Sysmac Studio .............................................................................. 7-4

7-3-2 Checking for Errors from Support Software Other Than the Sysmac Studio ..............................7-5

7-3-3 Event Codes and Corrections for Errors .....................................................................................7-5

7-4 Resetting Errors .................................................................................................................... 7-6

7-5 Troubleshooting Flowchart .................................................................................................. 7-7

Section 8 Inspection and Maintenance

8-1 Cleaning and Inspection ....................................................................................................... 8-2

8-1-1 Cleaning...................................................................................................................................... 8-2

8-1-2 Periodic Inspection...................................................................................................................... 8-2

8-2 Maintenance Procedures ...................................................................................................... 8-5

Appendices

A-1 Data Sheet ..............................................................................................................................A-2

A-1-1 Models.........................................................................................................................................A-2

A-1-2 IO-Link Master Unit .....................................................................................................................A-3

A-2 Dimensions ............................................................................................................................A-8

A-2-1 NX-series IO-Link Master Unit ....................................................................................................A-8

A-3 List of NX Objects................................................................................................................A-10

A-3-1 Format of Object Descriptions...................................................................................................A-10

A-3-2 IO-Link Master Unit ...................................................................................................................A-11

A-4 List of Screwless Clamping Terminal Block Models ........................................................A-35

A-4-1 Model Notation..........................................................................................................................A-35

A-4-2 List of Terminal Block Models....................................................................................................A-35

4

NX-series IO-Link Master Unit User’s Manual (W567)

Page 7

Index

CONTENTS

A-5 Version Information with CPU Units ..................................................................................A-36

A-5-1 Relationship between Unit Versions of Units............................................................................ A-36

A-5-2 Functions That Were Added or Changed for Each Unit Version ..............................................A-36

A-6 Version Information with Communications Coupler Units..............................................A-38

A-6-1 Connection to an EtherCAT Coupler Unit................................................................................. A-38

A-6-2 Connection to an EtherNet/IP Coupler Unit.............................................................................. A-40

NX-series IO-Link Master Unit User’s Manual (W567)

5

Page 8

Relevant Manuals

Relevant Manuals

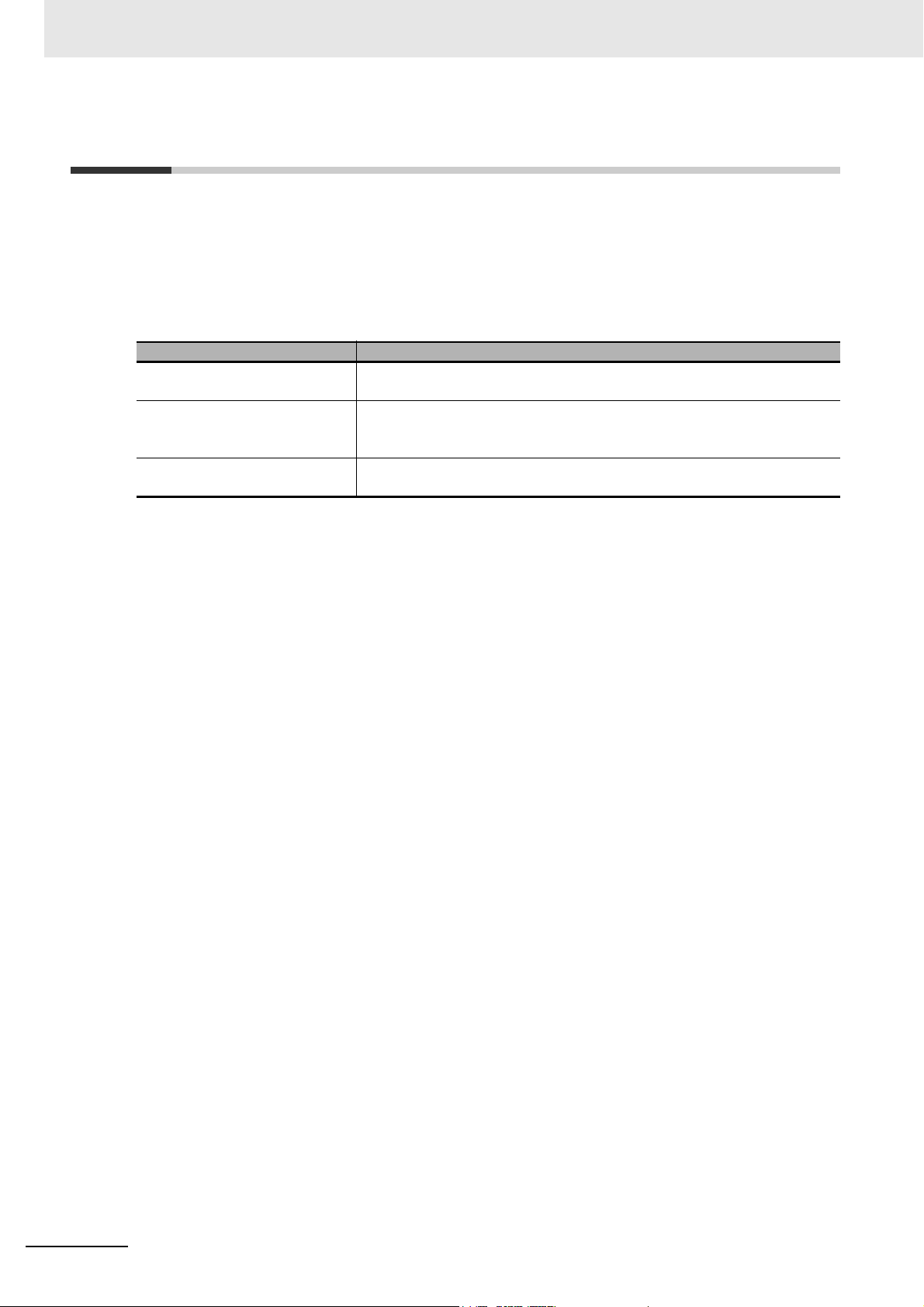

The table below provides the relevant manuals for the NX-series IO-Link Master Unit.

Read all of the manuals that are relevant to your system configuration and application to make the most

of the NX-series IO-Link Master Unit.

Other manuals, such as related product manuals, are necessary for specific system configurations and

applications. Refer to Related Manuals on page 27 for the related manuals.

Manual name Application

NX-series IO-Link Master Unit

User’s Manual

IO-Link System User’s Manual Learning general information on how to build IO-Link Systems that does not

NX-series Data Reference Manual

Learning how to use the NX-series IO-Link Master Unit

rely on the unique specifications of individual IO-Link Master Units and

IO-Link devices.

Referencing lists of the data that is required to configure systems with

NX-series Units

6

NX-series IO-Link Master Unit User’s Manual (W567)

Page 9

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

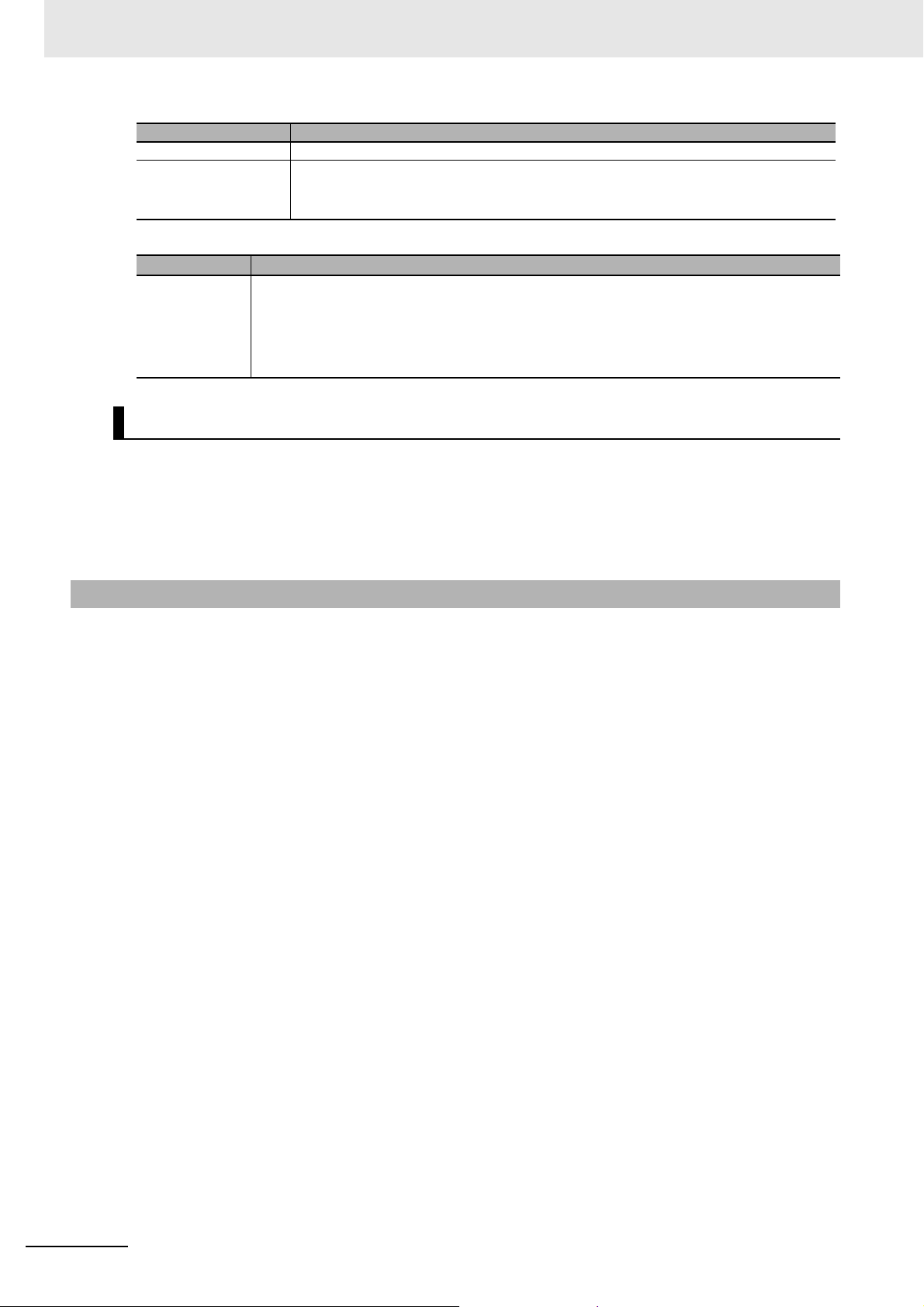

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Page Structure and Icons

The following page structure and icons are used in this manual.

Manual Structure

Note This illustration is provided only as a sample. It may not literally appear in this manual.

NX-series IO-Link Master Unit User’s Manual (W567)

7

Page 10

Manual Structure

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Information on differences in specifications and functionality for CPU Units, Industrial PCs, and

Communications Coupler Units with different unit versions and for different versions of the Support Software is given.

Note References are provided to more detailed or related information.

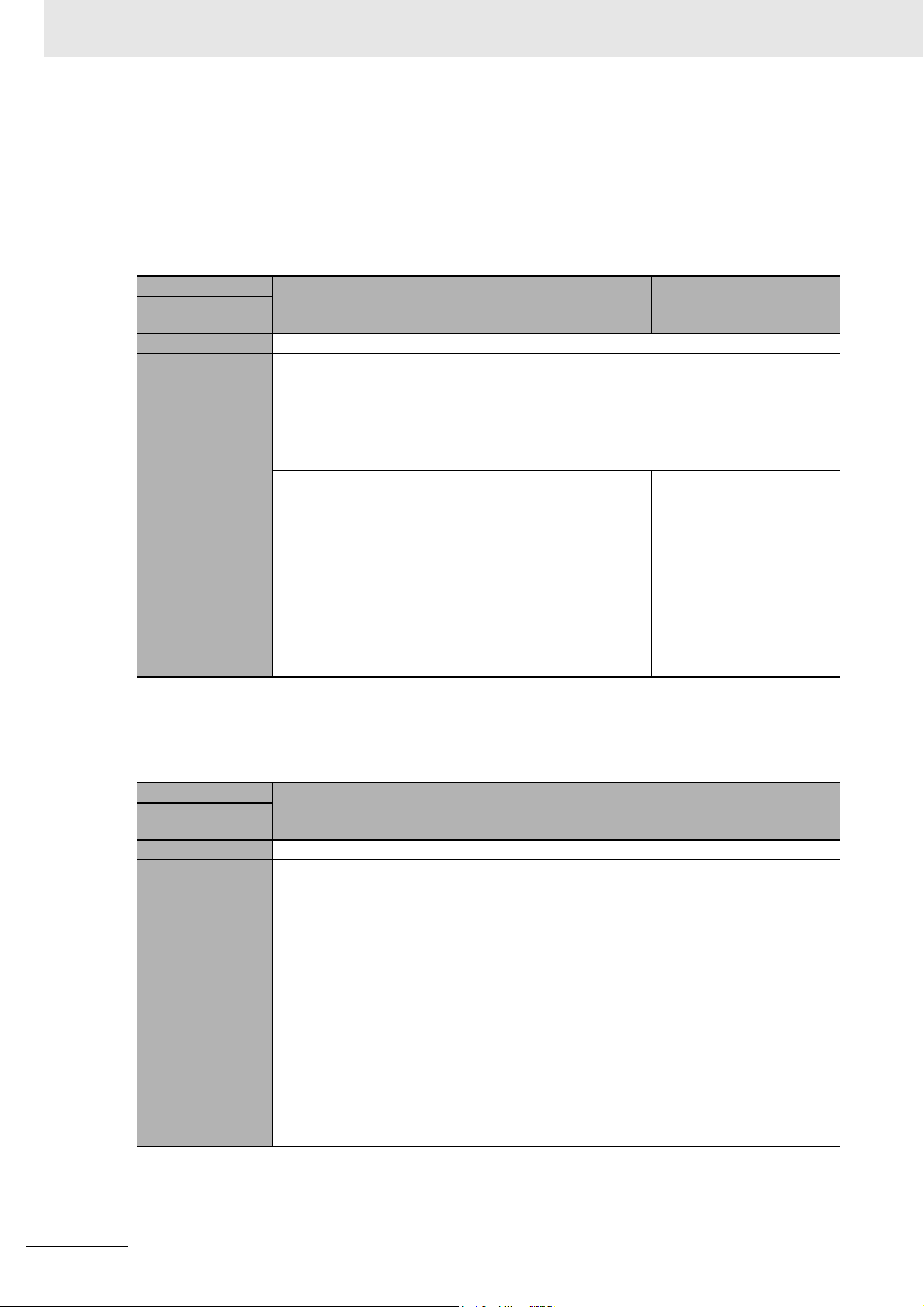

Precaution on Terminology

• In this manual, “download” refers to transferring data from the Support Software to a physical device

and “upload” refers to transferring data from a physical device to the Support Software.

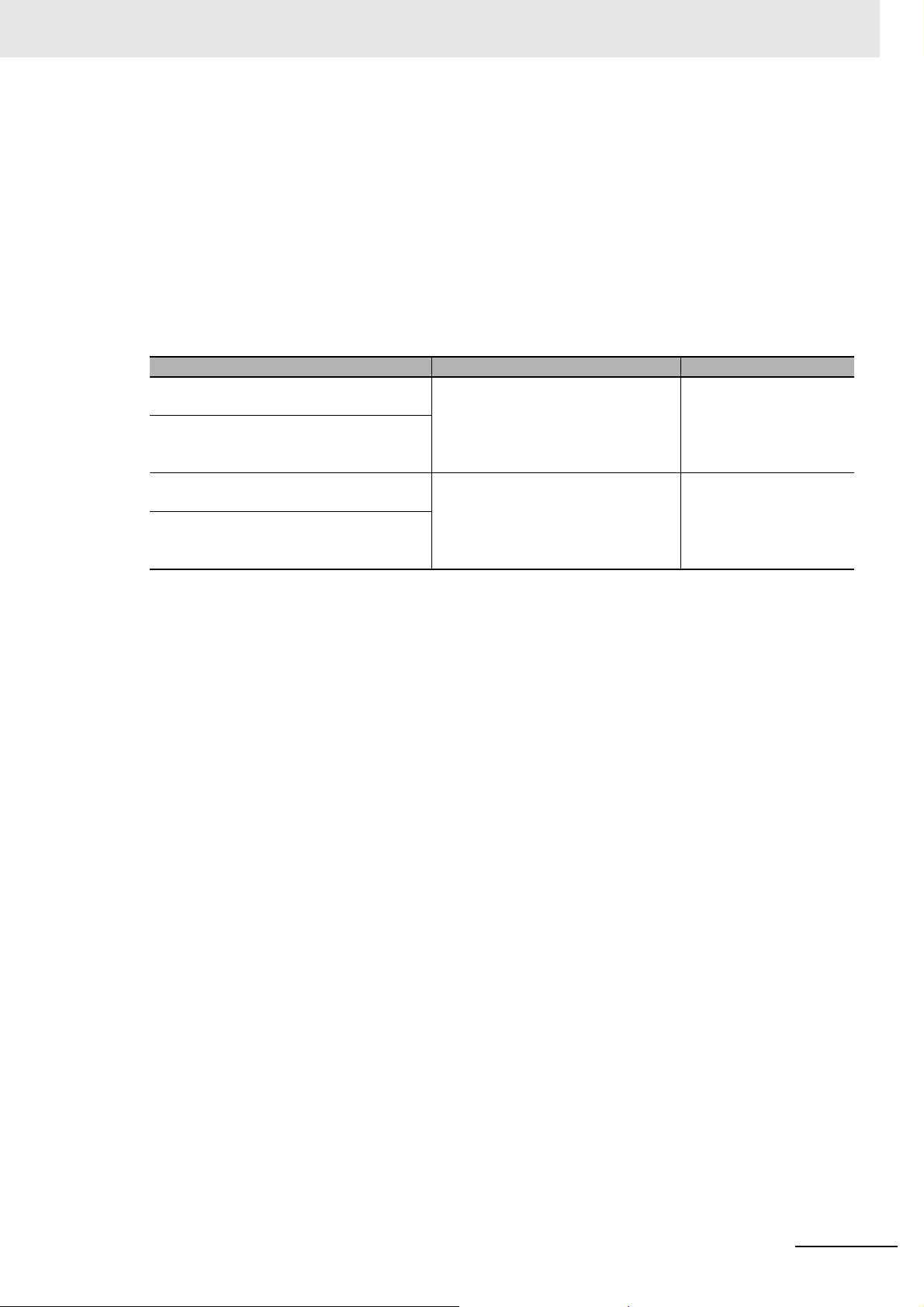

• In this manual, the directions in relation to the Units are given in the following figure, which shows

upright installation.

Up

RightLeft

8

Down

NX-series IO-Link Master Unit User’s Manual (W567)

Page 11

Manual Structure

• This user's manual refers to NY-series IPC Machine Controller Industrial Panel PCs and Industrial

Box PCs as simply Industrial PCs or as NY-series Industrial PCs.

• This user's manual refers to the built-in EtherCAT port on an NJ/NX-series Controller or NY-series

Industrial PC as simply a built-in EtherCAT port.

• This user's manual may omit manual names and manual numbers in places that refer to the user's

manuals for CPU Units and Industrial PCs. The following table gives some examples. When necessary, refer to Related Manuals on page 27 to determine the appropriate manual based on the common text for the omitted contents.

Examples

Manual name Omitted contents Common text

NJ/NX-series CPU Unit Software User's

Manual

NY-series IPC Machine Controller Industrial Panel PC / Industrial Box PC Software

User’s Manual

NJ/NX-series CPU Unit Built-in EtherCAT

Port User's Manual

NY-series IPC Machine Controller Industrial Panel PC / Industrial Box PC Built-in

EtherCAT Port User’s Manual

Software user's manual for the connected CPU Unit or Industrial PC

User's manual for the built-in EtherCAT port on the connected CPU Unit

or Industrial PC

Software User's Manual

Built-in EtherCAT port

• This user's manual may omit manual names and manual numbers in places that refer to the user's

manuals for Communications Coupler Units. If you will use a Communications Coupler Unit, refer to

Related Manuals on page 27 to identify the manual for your Unit.

NX-series IO-Link Master Unit User’s Manual (W567)

9

Page 12

Manual Structure

10

NX-series IO-Link Master Unit User’s Manual (W567)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

NX-series IO-Link Master Unit User’s Manual (W567)

11

Page 14

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

12

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NX-series IO-Link Master Unit User’s Manual (W567)

Page 15

Safety Precautions

WARNING

Caution

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Additionally, there may be

severe property damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of an

NX-series IO-Link Master Unit.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

Safety Precautions

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

NX-series IO-Link Master Unit User’s Manual (W567)

13

Page 16

Safety Precautions

WARNING

Warnings

During Power Supply

Do not touch the terminal section while power is ON.

Electric shock may occur.

Do not attempt to take any Unit apart.

In particular, high-voltage parts are present in Units that supply power while power is supplied or immediately after power is turned OFF. Touching any of these parts may result in

electric shock. There are sharp parts inside the Unit that may cause injury.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if an abnormality

occurs due to malfunction of the CPU Unit, Industrial PC, other Units, or slaves or due to

other external factors affecting operation.

Not doing so may result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures must

be provided in external control circuits.

The CPU Unit or Industrial PC will turn OFF all outputs from Output Units in the following

cases. The remote I/O slaves will operate according to the settings in the slaves.

• If a power supply error occurs.

• If the power supply connection becomes faulty.

• If a CPU watchdog timer error or CPU reset occurs.

• If a Controller error in the major fault level occurs.

• While the CPU Unit is on standby until RUN mode is entered after the power is turned ON

External safety measures must be provided to ensure safe operation of the system in such

cases.

The outputs may remain ON or OFF due to deposition or burning of the output relays or

destruction of the output transistors. As a countermeasure for such problems, external

safety measures must be provided to ensure safe operation of the system.

If external power supplies for slaves or other devices are overloaded or short-circuited, the

voltage will drop, outputs will turn OFF, and the system may be unable to read inputs. Provide external safety measures in control with monitoring of external power supply voltage

as required so that the system operates safely in such a case.

You must take fail-safe measures to ensure safety in the event of incorrect, missing, or

abnormal signals caused by broken signal lines, momentary power interruptions, or other

causes.

Not doing so may result in serious accidents due to incorrect operation.

14

NX-series IO-Link Master Unit User’s Manual (W567)

Page 17

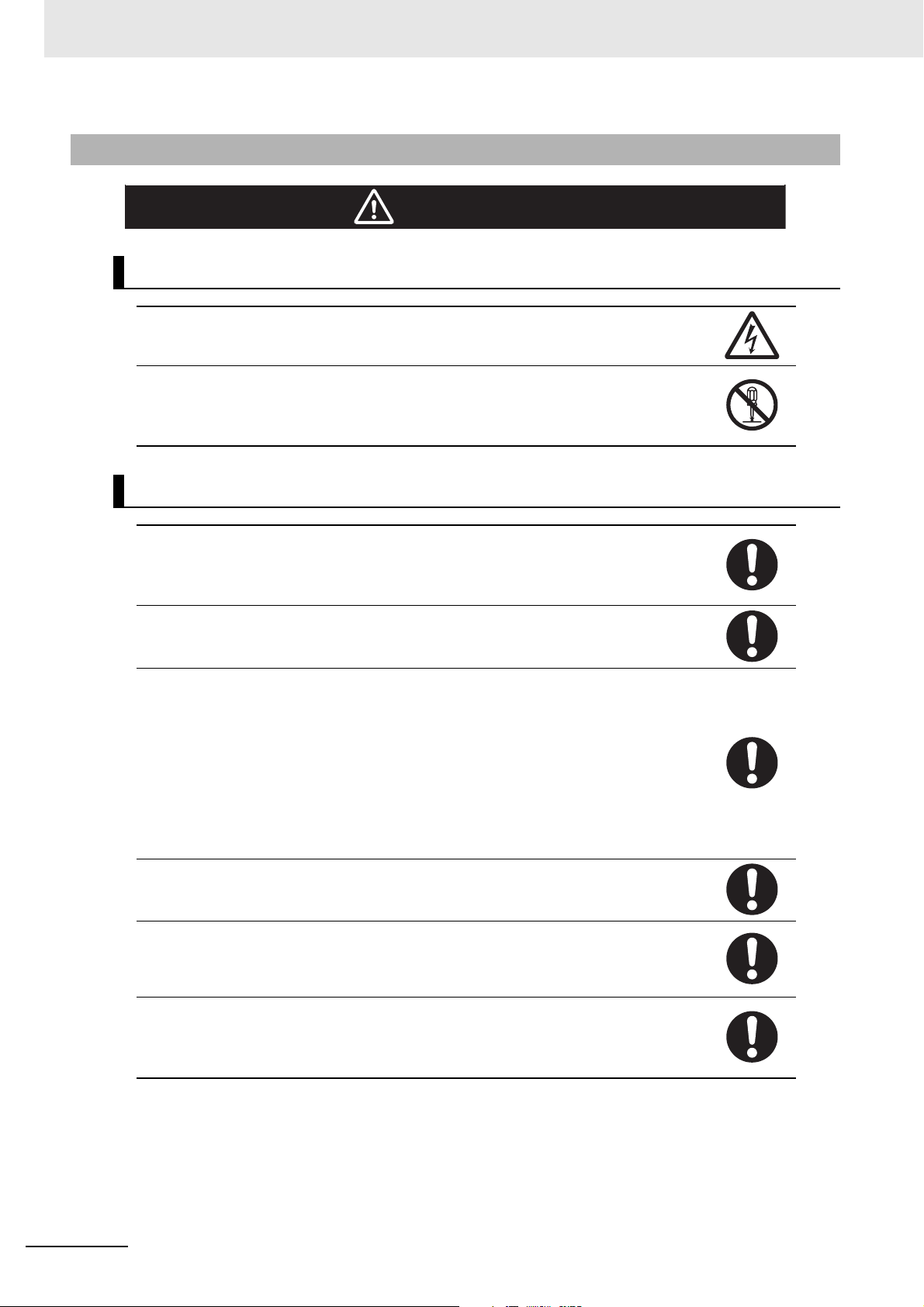

Voltage and Current Inputs

Caution

Make sure that the voltages and currents that are input to the Units and slaves are within

the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may cause accidents

or fire.

Transferring

Always confirm safety at the destination node before you transfer Unit configuration information, parameters, settings, or other data from tools such as the Sysmac Studio.

The devices or machines may operate unexpectedly, regardless of the operating mode of

the Controller.

Cautions

Safety Precautions

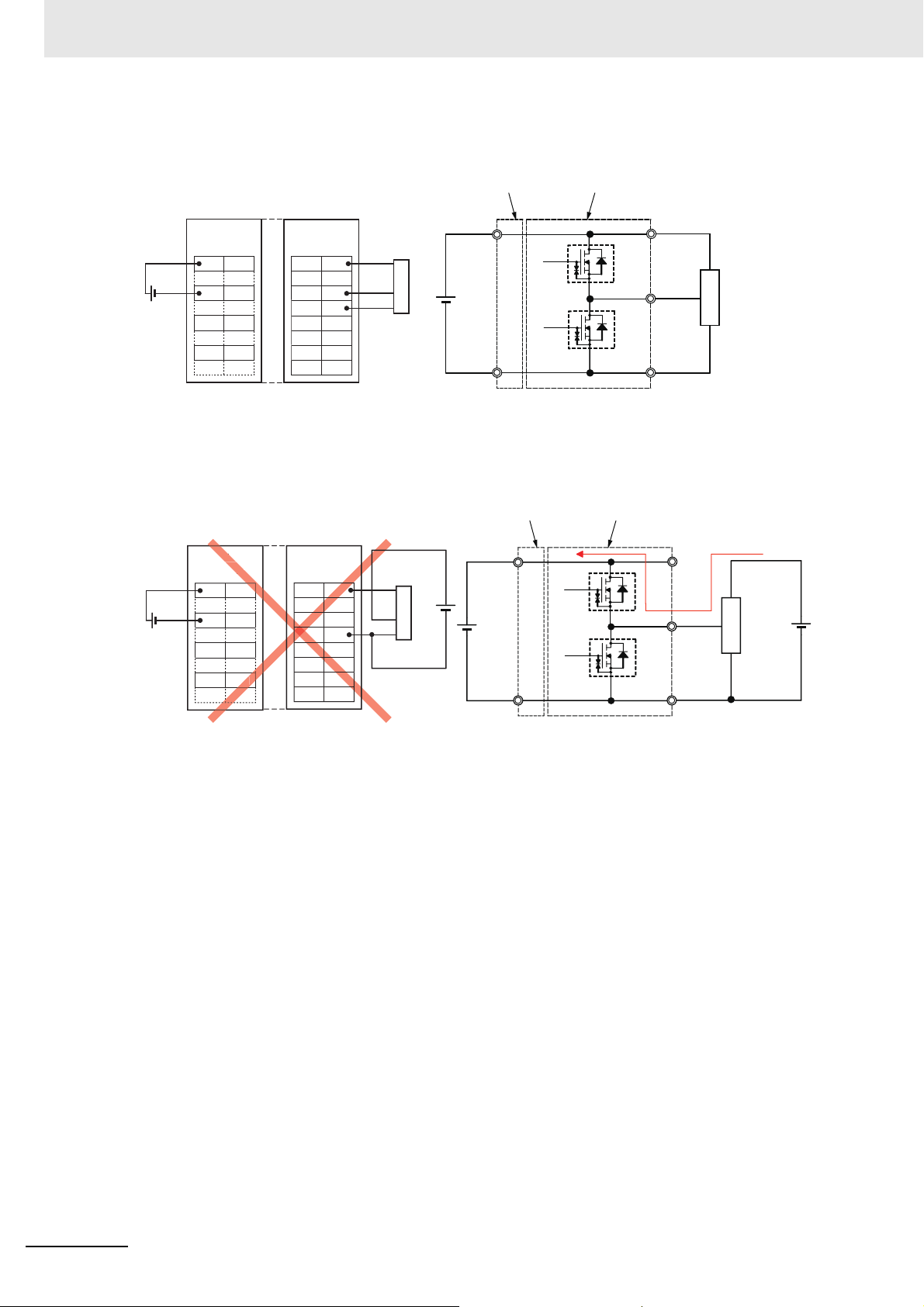

Wiring

When you connect a computer or other peripheral device to a Communications Coupler

Unit that has a non-isolated DC power supply, either ground the 0-V side of the external

power supply (i.e. Unit power supply) or do not ground it at all.

If the peripheral devices are grounded incorrectly, the external power supply (i.e. Unit

power supply) may be short-circuited.

Never ground the 24-V side of the power supply, as shown in the following figure.

NX Unit power

supply

0 V

Peripheral device

(e.g., computer)

Communications Coupler Unit

Non-isolated DC power

supply (internal power

supply circuit)

Peripheral device

cable

24 V

Be sure that all terminal screws and cable connector screws are tightened to the torque

specified in the relevant manuals. The loose screws may result in fire or malfunction.

NX-series IO-Link Master Unit User’s Manual (W567)

Ground terminal

Unit power

supply

15

Page 18

Safety Precautions

Online Editing

Execute online editing only after confirming that no adverse effects will be caused by deviations in the timing of I/O. If you perform online editing, the task execution time may exceed

the task period, I/O may not be refreshed with external devices, input signals may not be

read, and output timing may change.

16

NX-series IO-Link Master Unit User’s Manual (W567)

Page 19

Precautions for Safe Use

Transporting

• When transporting any Unit, use the special packing box for it.

Also, do not subject the Unit to excessive vibration or shock during transportation.

• Do not drop any Unit or subject it to abnormal vibration or shock.

Doing so may result in Unit malfunction or burning.

Mounting

• Mount terminal blocks and connectors only after checking the mounting location carefully.

• Be sure that the terminal blocks, expansion cables, and other items with locking devices are properly

locked into place.

Precautions for Safe Use

Installation

• Do not apply labels or tape to the Unit. When the Unit is installed or removed, adhesive or scraps

may adhere to the pins in the NX bus connector, which may result in malfunctions.

• Do not touch the pins in the NX bus connector on the Unit. Dirt may adhere to the pins in the NX bus

connector, which may result in malfunctions.

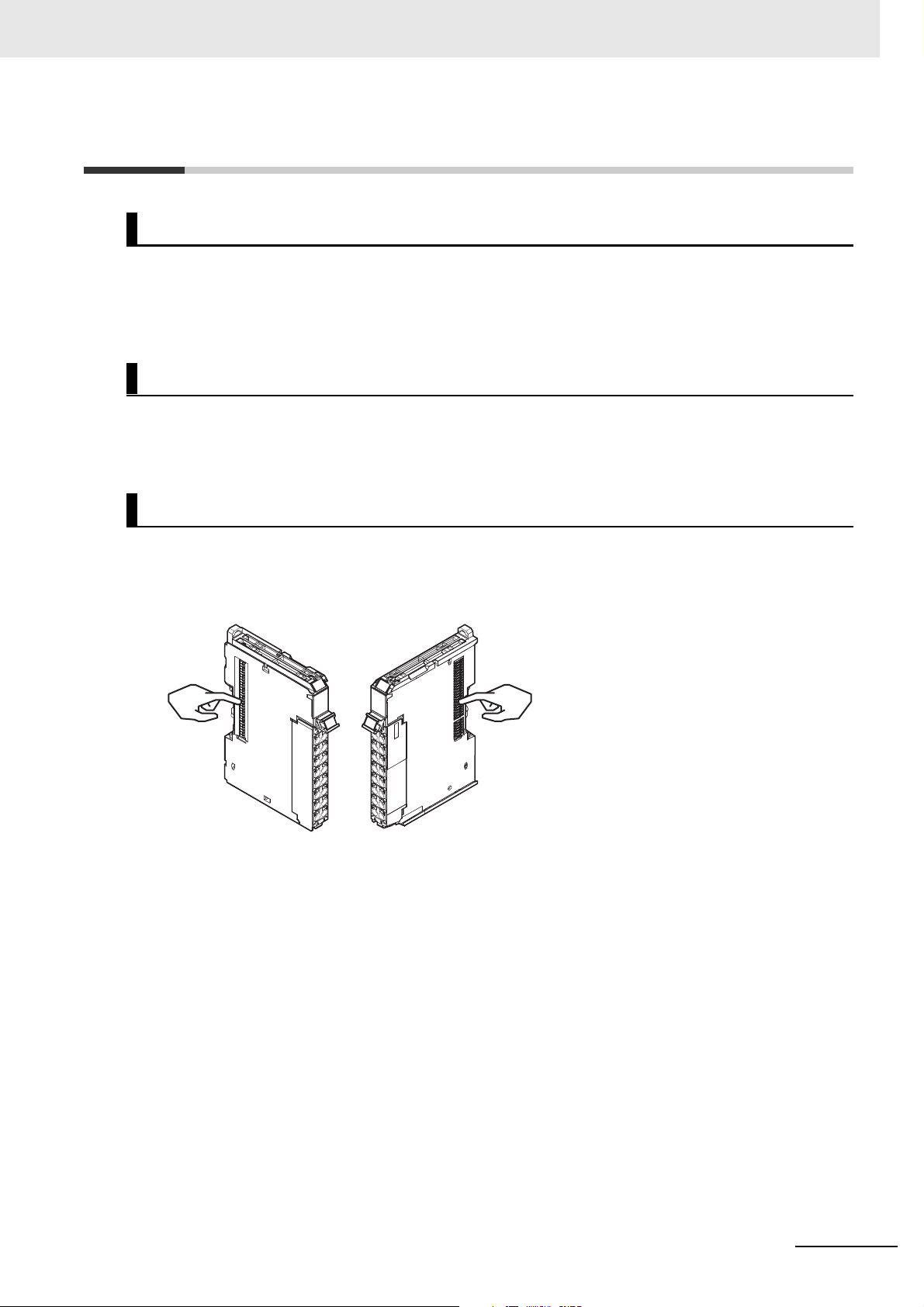

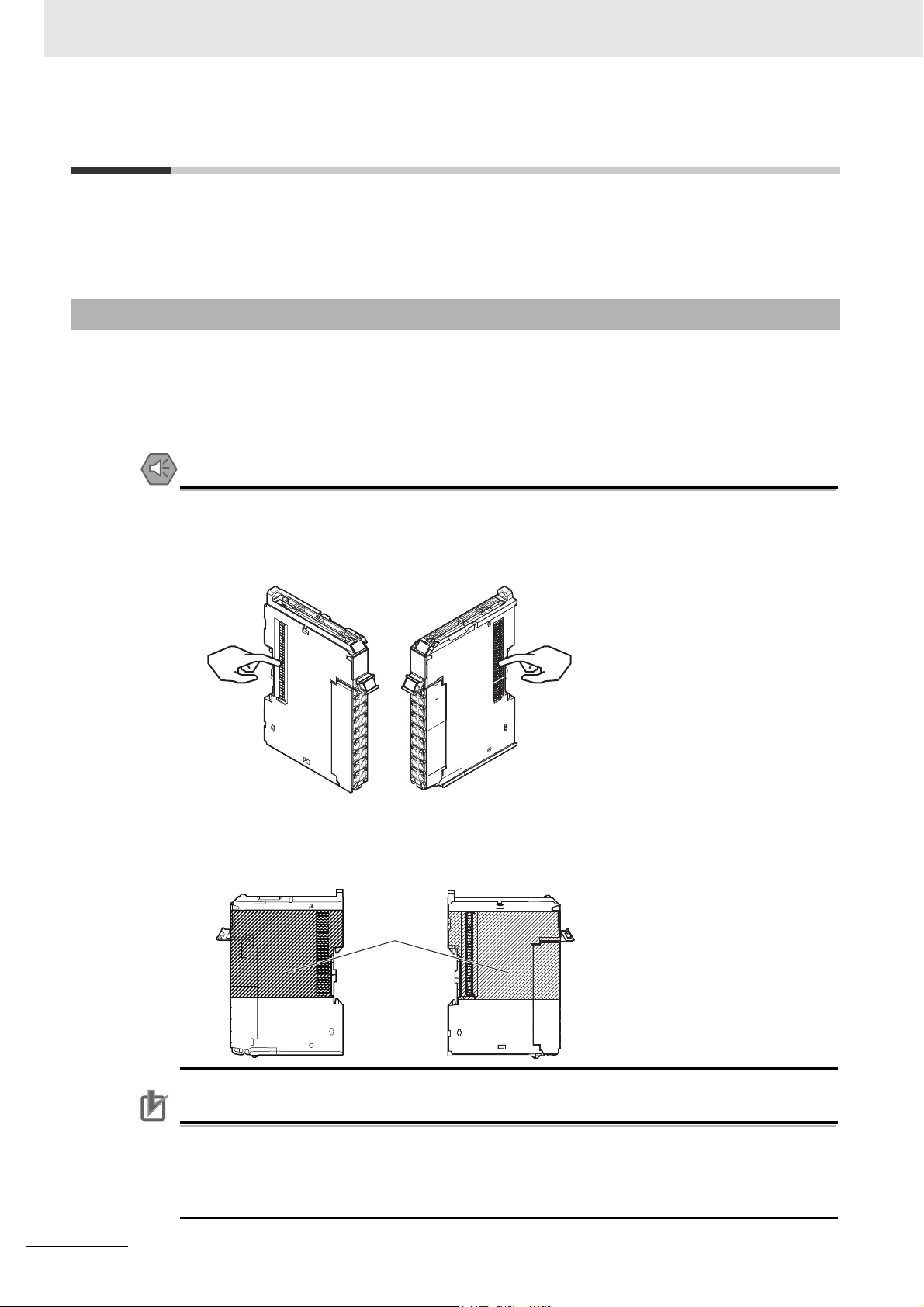

NG NG

Example: NX Unit (12 mm width)

NX-series IO-Link Master Unit User’s Manual (W567)

17

Page 20

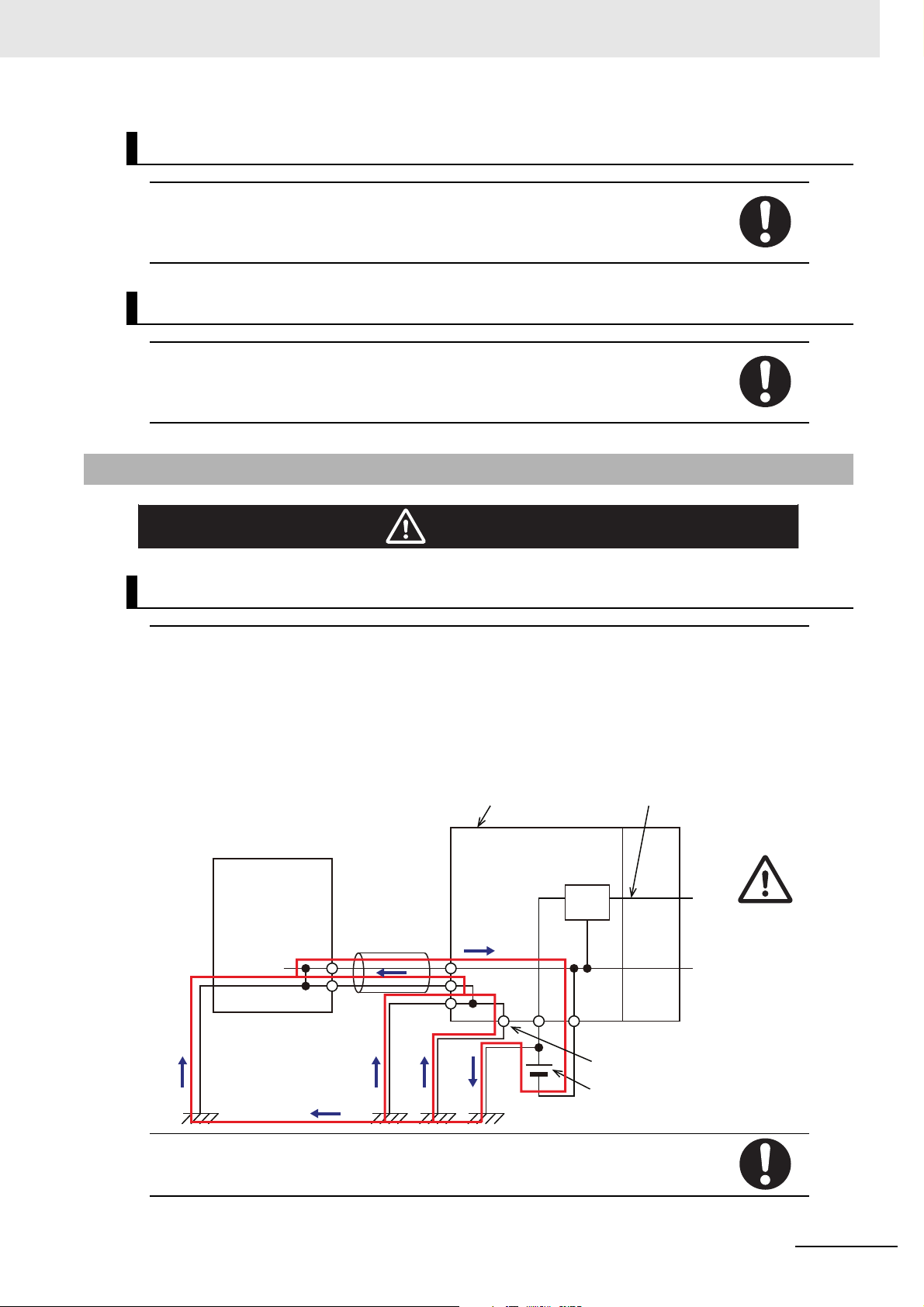

Precautions for Safe Use

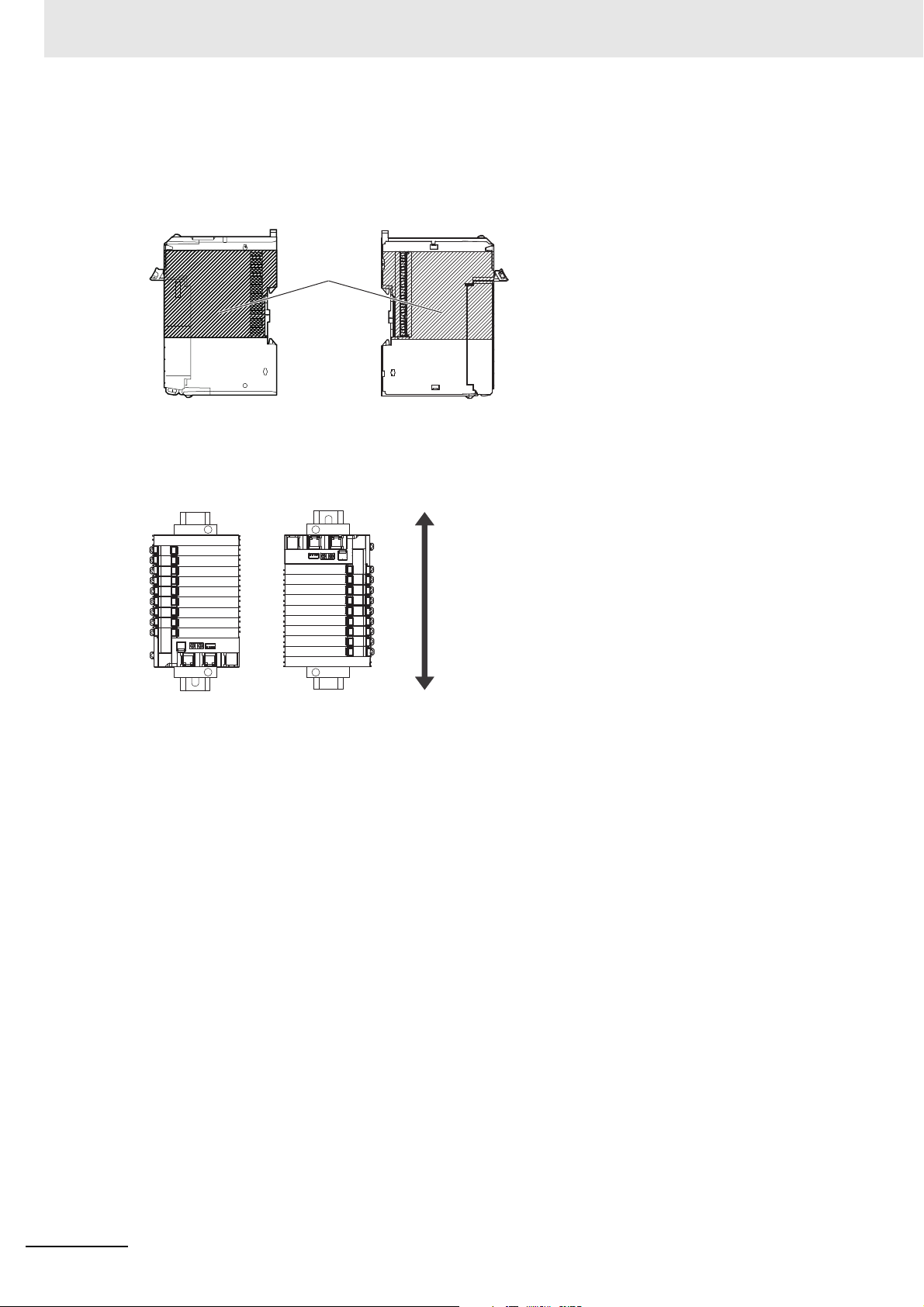

Restricted

region (shaded

portion)

Up

Down

• Do not write on an NX Unit with ink within the restricted region that is shown in the following figure.

Also do not get this area dirty. When the Unit is installed or removed, ink or dirt may adhere to the

pins in the NX bus connector, which may result in malfunctions in the CPU Rack or Slave Terminal.

Refer to the user's manual for the connected CPU Unit or Communications Coupler Unit for details

on the restricted region on the CPU Unit or Communications Coupler Unit.

• For the installation orientations in the following figure, support the cables, e.g., with a duct, so that the

End Plate on the bottom is not subjected to the weight of the cables. The weight of the cables may

cause the bottom End Plate to slide downward so that the Slave Terminal is no longer secured to the

DIN Track, which may result in malfunctions.

18

NX-series IO-Link Master Unit User’s Manual (W567)

Page 21

Precautions for Safe Use

NG OK

NG NG

Wiring

• Double-check all switches and other settings and double-check all wiring to make sure that they are

correct before turning ON the power supply.

• Use the correct wiring parts and tools when you wire the system.

• Do not pull on the cables or bend the cables beyond their natural limit. Also, do not place heavy

objects on top of the cables or other wiring lines. Doing so may break the cable.

• When wiring or installing the Units, do not allow metal fragments to enter the Units.

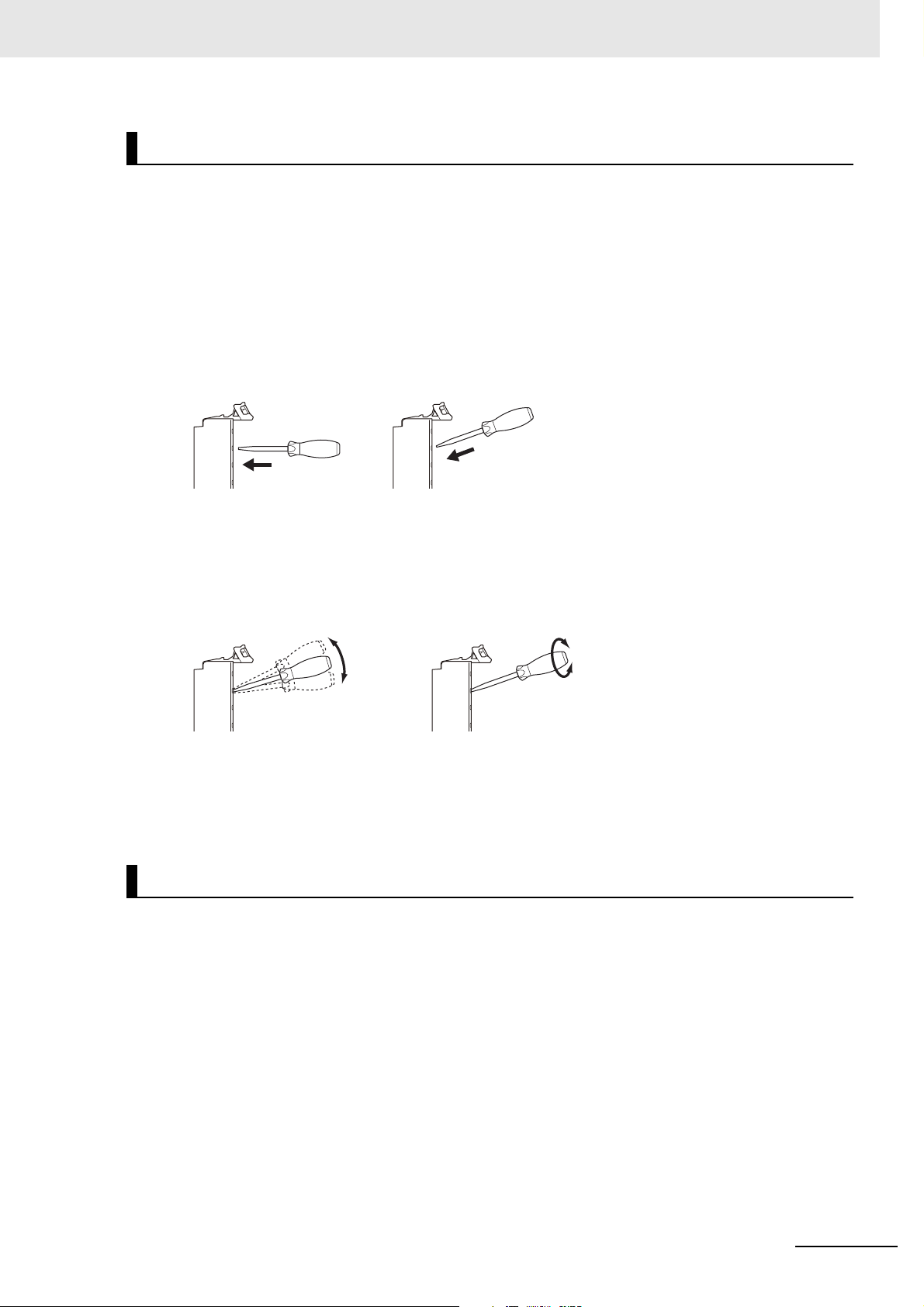

• Do not press the flat-blade screwdriver straight into the release holes on a screwless clamping terminal block. Doing so may damage the terminal block.

• When you insert a flat-blade screwdriver into a release hole on a screwless clamping terminal block,

press it down with a force of 30N or less. Applying excessive force may damage the terminal block.

• Do not incline or twist the flat-blade screwdriver while it is in a release hole on a screwless clamping

terminal block. Doing so may damage the terminal block.

• If you use reed switches for the input contacts for AC Input Units, use switches with an allowable current of 1 A or greater. If the capacity of the reed switches is too low, inrush current may fuse the contacts.

• Use crimp terminals for wiring the M3 screw terminal blocks. Do not connect bare stranded wires

directly to the M3 screw terminal blocks.

Power Supply Design

• Use all Units within the I/O power supply ranges that are given in the specifications.

• Use the I/O power supply current for the CPU Rack of the NX-series NX1P2 CPU Unit at 4 A or less.

Using the currents that are outside of the specifications may cause failure or damage.

• Supply sufficient power according to the contents of this manual.

• Use the power supply voltage that is specified in this manual.

• Do not apply voltages that exceed the rated value to any Input Unit.

• Do not apply voltages or connect loads to the Output Units or slaves in excess of the maximum ratings.

• Inrush current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider their fusing and detection characteristics as well as the above precautions

and allow sufficient margin in shut-off performance.

• Install external breakers and take other safety measures against short-circuiting and overcurrents in

external wiring.

NX-series IO-Link Master Unit User’s Manual (W567)

19

Page 22

Precautions for Safe Use

Turning ON the Power Supply

• When you set the Operating Mode at Startup, confirm that no adverse effect will occur in the system.

Actual Operation

• Before you start operation, always register the NX Units that are connected to the Communications

Coupler Unit in the host communications master as the Unit Configuration Information.

• Check the user program, data, and parameter settings for proper execution before you use them for

actual operation.

• If you change the fail-soft operation setting, the output status when the error occurs may also change.

Confirm safety before you change the fail-soft operation setting.

• If you use fail-soft operation, write programming to determine whether Unit I/O data is valid. Without

such programming, the user program cannot distinguish between Units for which I/O refreshing is

continued and Units for which I/O refreshing is stopped.

Turning OFF the Power Supply

• Do not disconnect the cable or turn OFF the power supply to the Controller or a Slave Terminal when

downloading data or the user program from Support Software.

• Always turn OFF the external power supply to the Units before attempting any of the following.

Mounting or removing an NX Unit, Communications Coupler Unit, CPU Unit, or Industrial PC

Assembling Units

Setting DIP switches or rotary switches

Connecting or wiring cables

Attaching or removing terminal blocks or connectors

Units that supply power continue to supply power to the Units for up to several seconds after the

power supply is turned OFF. The PWR indicator remains lit as long as power is supplied. Confirm that

the PWR indicator is not lit before you perform any of the above.

Operation

• Confirm that the controlled system will not be adversely affected before you perform any of the following operations.

Changing the operating mode of the CPU Unit or Industrial PC (including changing the setting of the

Operating Mode at Startup)

Changing the user program or settings

Changing set values or present values

Forced refreshing

• Always sufficiently check the safety at the connected devices before you change the settings of a

slave or Unit.

20

General Communications

• Do not exceed the ranges that are given in the specifications for the communications distance and

number of connected Units.

• Refer to the user’s manual for the Communications Coupler Unit for precautions for the safe use of

communications with the connected Communications Coupler Unit.

NX-series IO-Link Master Unit User’s Manual (W567)

Page 23

Precautions for Safe Use

Unit Replacement

• When you replace a Unit, start operation only after you transfer the settings and variables that are

required for operation to the new Unit.

• Default values of I/O allocation differ between the IO-Link Master Unit with unit version 1.0 and one

with unit version 1.1.

If you replace a Unit with unit version 1.0 with a Unit with unit version 1.1 or later, set the I/O allocation to the same setting as the Unit with unit version 1.0. Replacing the Unit without changing the I/O

allocation may result in erroneous output, erroneous input, and a change in the timing of I/O.

Disposal

• Dispose of the product according to local ordinances as they apply.

NX-series IO-Link Master Unit User’s Manual (W567)

21

Page 24

Precautions for Correct Use

Precautions for Correct Use

Storage, Mounting, and Wiring

• Follow the instructions in this manual to correctly perform installation and wiring.

• Do not operate or store the Units in the following locations. Doing so may result in malfunction, in

operation stopping, or in burning.

Locations subject to direct sunlight

Locations subject to temperatures or humidity outside the range specified in the specifications

Locations subject to condensation as the result of severe changes in temperature

Locations subject to corrosive or flammable gases

Locations subject to dust (especially iron dust) or salts

Locations subject to exposure to water, oil, or chemicals

Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures during installation in the following locations.

Locations subject to strong, high-frequency noise

Locations subject to static electricity or other forms of noise

Locations subject to strong electromagnetic fields

Locations subject to possible exposure to radioactivity

Locations close to power lines

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Use the rated power supply voltage for the Units that supply power. Take appropriate measures to

ensure that the specified power with the rated voltage and frequency is supplied in places where the

power supply is unstable.

• Install the Units away from sources of heat and ensure proper ventilation. Not doing so may result in

malfunction, in operation stopping, or in burning.

• Do not allow foreign matter to enter the openings in the Unit. Doing so may result in Unit burning,

electric shock, or failure.

Actual Operation

• If you change the event level of an error, the output status when the error occurs may also change.

Confirm safety before you change an event level.

Turning OFF the Power Supply

• Do not turn OFF the power supply while data is being transferred.

• Do not turn OFF the power supply while parameters are being written to the CPU Unit, Communications Coupler Unit, or NX Units.

General Communications

• Refer to the user’s manual for the Communications Coupler Unit for precautions for the correct use of

communications with the connected Communications Coupler Unit.

22

NX-series IO-Link Master Unit User’s Manual (W567)

Page 25

Regulations and Standards

Conformance to EU Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*1

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

Regulations and Standards

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations).

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61010-2-201.

Conformance to EU Directives

The NX-series Units comply with EU Directives. To ensure that the machine or device in which the

NX-series Units are used complies with EU Directives, the following precautions must be observed.

• The NX-series Units must be installed within a control panel.

• The SELV requirements must be satisfied for the DC power supplies that are connected as the

Unit power supplies and I/O power supplies for the NX-series Units.

For CPU Racks with NX-series NX1P2 CPU Units, we recommend that you use OMRON

S8VK-S-series Power Supplies. For Slave Terminals, we recommend that you use OMRON

S8JX-series Power Supplies. EMC standard compliance was confirmed for these recommended

Power Supplies.

• NX-series Units that comply with EU Directives also conform to the Common Emission Standard

(EN 61131-2). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions.

You must therefore confirm that the overall machine or equipment in which the NX-series Units

are used complies with EU Directives.

• You must use power supplies with an output hold time of 10 ms or longer for the DC power supplies that are connected as the Unit power supplies and I/O power supplies for the NX-series

Units.

NX-series IO-Link Master Unit User’s Manual (W567)

23

Page 26

Regulations and Standards

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate measures.

Conformance to UL and CSA Standards

Some NX-series products comply with UL and CSA standards. If you use an NX-series product that

complies with UL or CSA standards and the machinery or system in which you use the NX-series product must also comply with the standards, refer to the Instruction Sheet that is provided with the product.

The Instruction Sheet provides the application conditions for complying with the standards.

Conformance to Shipbuilding Standards

Some NX-series products comply with shipbuilding standards. If you use an NX-series product that

complies with shipbuilding standards and the machinery or system in which you use the NX-series

product must also comply with the standards, consult with your OMRON representative. Application

conditions are defined according to the installation location. Application may not be possible for some

installation locations. For shipbuilding standard usage conditions, refer to Conformance to Shipbuilding

Standards in the user’s manual for the Communications Coupler Unit or CPU Unit that the NX Units are

connected to.

Conformance to KC Standards

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated

with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

24

NX-series IO-Link Master Unit User’s Manual (W567)

Page 27

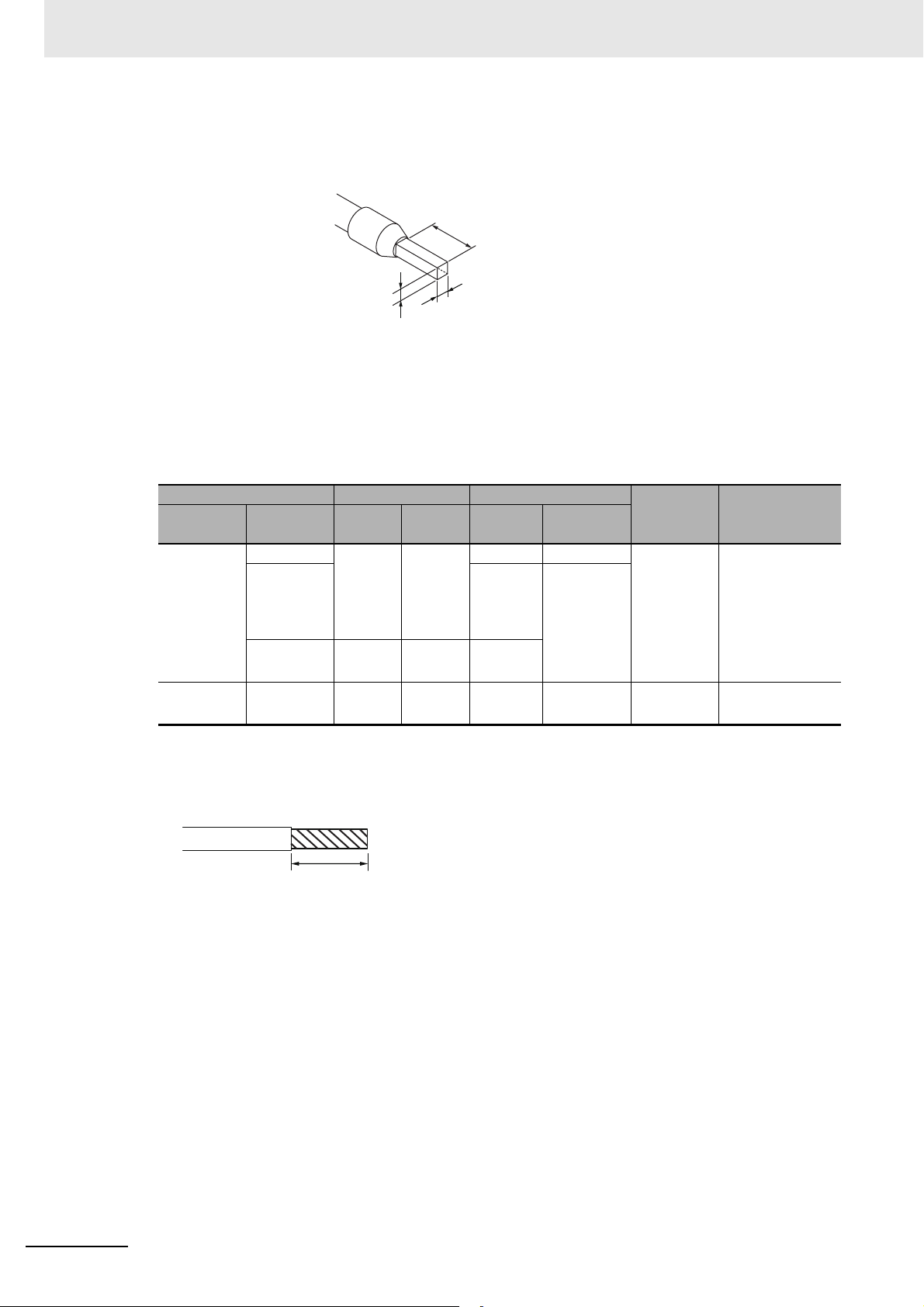

Unit Versions

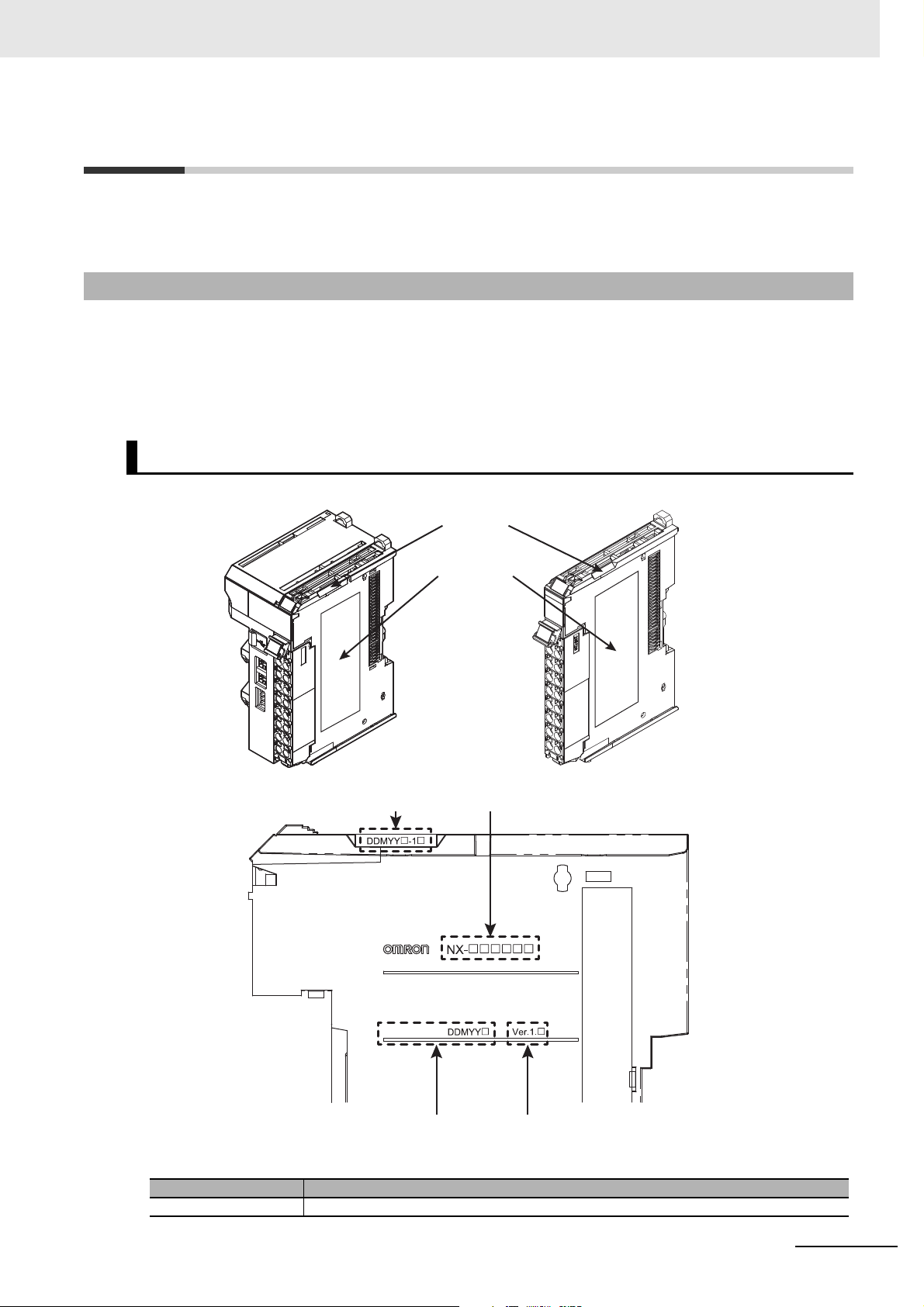

Notched

area

Unit

specifications

LOT No.

Unit version

Lot number

Unit model number

Lot number and unit version

This section describes the notation that is used for unit versions, the confirmation method for unit versions, and the relationship between unit versions and Support Software versions.

Unit Versions

A “unit version” has been introduced to manage the Units in the NX Series according to differences in

functionality accompanying Unit upgrades.

An example is provided below for Communications Coupler Units and NX Units. For the notation that is

used for the unit versions of CPU Units or Industrial PCs and the confirmation method for unit versions,

refer to the user's manual for each Unit.

Notation of Unit Versions on Products

Unit Versions

The unit version is given with the Unit specifications on the side of the Unit or in the notched area.

The following information is provided in the Unit specifications on the Unit.

Unit model number Gives the model of the Unit.

NX-series IO-Link Master Unit User’s Manual (W567)

Name Function

25

Page 28

Unit Versions

Unit version Gives the unit version of the Unit.

Lot number Gives the lot number of the Unit.

The following information is provided in the notched area on the Unit.

Name Function

Lot number and

unit version

Confirming Unit Versions with the Support Software

If your NX Unit is connected to a CPU Unit, refer to the user’s manual of the connected CPU Unit for the

confirmation method for the unit version of the NX Unit.

Name Function

DDMYY: Lot number, : Used by OMRON.

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

Gives the lot number and unit version of the Unit.

• DDMYY: Lot number, : Used by OMRON.

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

•1: Unit version

The decimal portion of the unit version is omitted. (It is provided in the Unit specifications.)

If your NX Unit is connected to a Communications Coupler Unit, refer to the user’s manual of the connected Communications Coupler Unit for the confirmation method for the unit version of the Communications Coupler Unit and NX Unit.

Unit Versions and Support Software Versions

The functions that are supported depend on the unit version of the Unit. The version of Support Software that supports the functions that were added for an upgrade is required to use those functions.

Refer to A-5 Version Information with CPU Units on page A-36 or A-6 Version Information with Commu-

nications Coupler Units on page A-38 for the functions that are supported by each unit version.

26

NX-series IO-Link Master Unit User’s Manual (W567)

Page 29

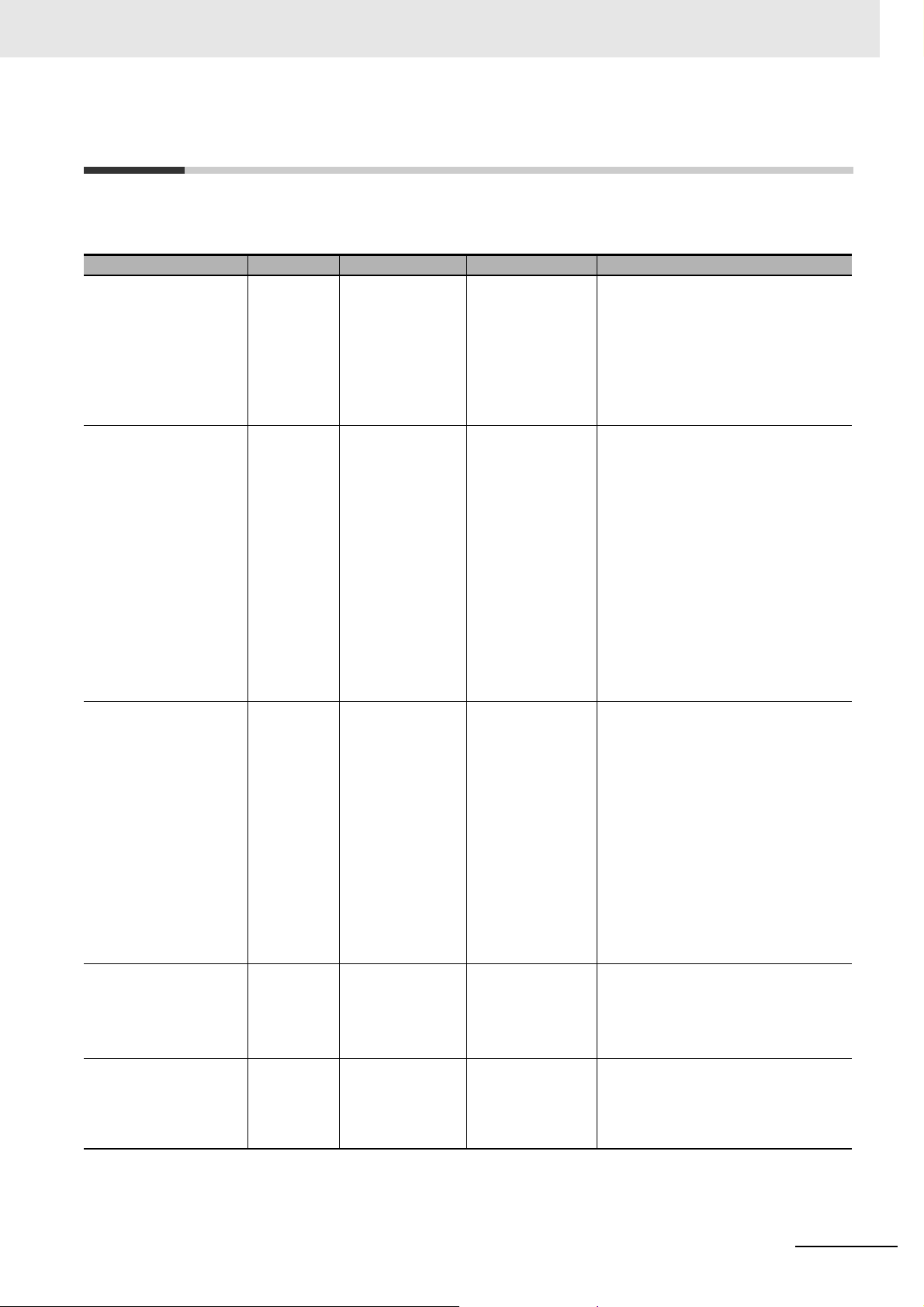

Related Manuals

The following table describes terms used for NX Units. Refer to the IO-Link System User’s Manual (Cat.

No. W570) for information on terms used for IO-Link Master Units.

Manual name Cat. No. Model numbers Application Description

NX-series IO-Link Master Unit (this manual)

IO-Link System User’s

Manual

GX-series EtherCAT

Slave Units

NX-series Data Reference Manual

NX-series System Units

User’s Manual

W567 NX-ILM400 Learning hard-

ware information,

wiring, and specifications for the

NX-series IO-Link

Master Unit and

checking a list of

NX objects.

W570 NX-ILM400

GX-ILM08C

W488 GX-ID

GX-OD

GX-OC

GX-MD

GX-AD

GX-DA

GX-EC

GX-ILM

XWT-ID

XWT-OD

W525 NX- Referencing lists of

W523 NX-PD1

NX-PF0

NX-PC0

NX-TBX01

Learning everything from an introduction to details

about IO-Link Systems, including

mainly software

information common to all IO-Link

masters, Support

Software operating methods, and

troubleshooting.

Learning hardware information,

wiring, and specifications for the

GX-series IO-Link

Master Unit and

checking a list of

objects

(W488-E1-05 or

later). Or, learning

how to use

GX-series EtherCAT Slave Terminals.

the data that is

required to configure systems with

NX-series Units

Learning how to

use NX-series

System Units

Describes part names, functions, installation, and wiring and also provides

tables of specifications and NX objects

for the NX-series IO-Link Master Unit.

Provides an overview of IO-Link Systems and explains the system configuration, communications specifications,

communications methods, I/O data,

parameters, models, Support Software,

and troubleshooting.

Refer to the following manuals for the

individual IO-Link Master Units for

hardware information and specifications specific to each Master Unit and a

list of the objects for each Master Unit.

NX-series IO-Link Master Unit: W568

GX-series IO-Link Master Unit:

W488-E1-05 or later

Describes part names, functions, installation, and wiring and also provides

tables of specifications and objects for

the GX-series IO-Link Master Unit

(W488-E1-05 or later). Also describes

the hardware, setup methods, and

functions of the EtherCAT Remote I/O

Terminals.

Lists of the power consumptions,

weights, and other NX Unit data that is

required to configure systems with

NX-series Units are provided.

The hardware and functions of the

NX-series System Units are described.

Related Manuals

NX-series IO-Link Master Unit User’s Manual (W567)

27

Page 30

Related Manuals

Manual name Cat. No. Model numbers Application Description

Sysmac Studio Version

1 Operation Manual

NX-IO Configurator

Operation Manual

NJ/NX-series Troubleshooting Manual

NY-series Troubleshooting Manual

NX-series EtherCAT

Coupler Unit User’s

Manual

NX-series Ether-

TM

Net/IP

User’s Manual

NX-series CPU Unit

Hardware User’s Manual

Coupler Unit

W504 SYSMAC-

SE2

W585 CXONE-ALD-V4Learning about the

W503 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W564 NY532-1

NY512-1

W519 NX-ECC20 Learning how to

W536 NX-EIC202 Learning how to

W535 NX701- Learning the basic

Learning about the

operating procedures and functions of the

Sysmac Studio.

operating procedures and functions of the NX-IO

Configurator.

Learning about the

errors that may be

detected in an

NJ/NX-series Controller.

Learning about the

errors that may be

detected in an

NY-series Industrial PC.

use an NX-series

EtherCAT Coupler

Unit and EtherCAT Slave Terminals

use an NX-series

EtherNet/IP Coupler Unit and EtherNet/IP Slave

Terminals.

specifications of

the NX701 CPU

Units, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

Describes the operating procedures of

the Sysmac Studio.

Describes the operating procedures of

the NX-IO Configurator.

Concepts on managing errors that may

be detected in an NJ/NX-series Controller and information on individual

errors are described.

Concepts on managing errors that may

be detected in an NY-series Controller

and information on individual errors are

described.

The following items are described: the

overall system and configuration methods of an EtherCAT Slave Terminal

(which consists of an NX-series EtherCAT Coupler Unit and NX Units), and

information on hardware, setup, and

functions to set up, control, and monitor

NX Units through EtherCAT.

The following items are described: the

overall system and configuration methods of an EtherNet/IP Slave Terminal

(which consists of an NX-series EtherNet/IP Coupler Unit and NX Units), and

information on hardware, setup, and

functions to set up, control, and monitor

NX Units.

An introduction to the entire NX701

CPU Unit system is provided along with

the following information on the CPU

Unit.

• Features and system configuration

• Overview

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and Inspection

28

NX-series IO-Link Master Unit User’s Manual (W567)

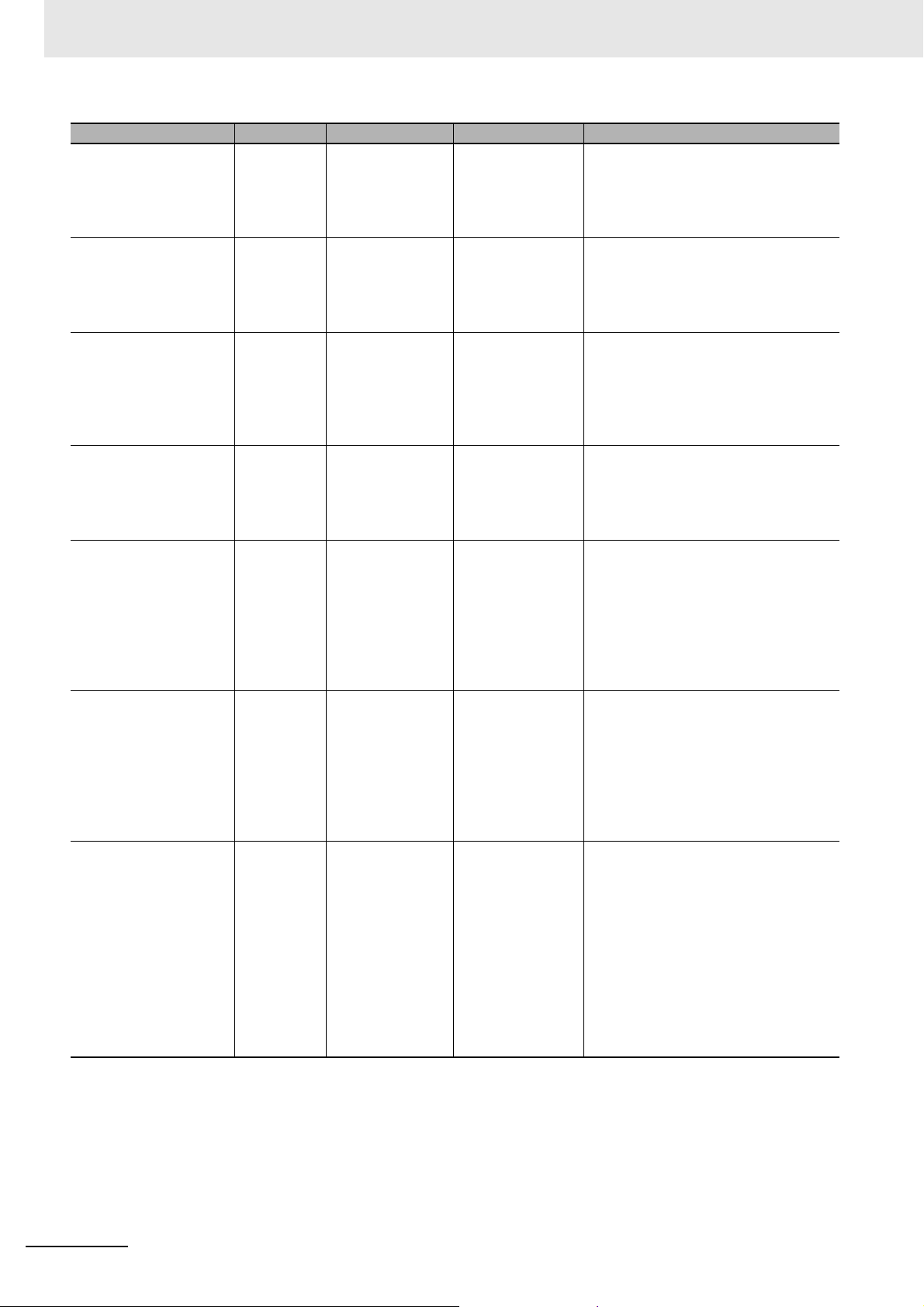

Page 31

Manual name Cat. No. Model numbers Application Description

NX-series NX1P2 CPU

Unit Hardware

User’s Manual

NJ-series CPU Unit

Hardware User’s Manual

NY-series IPC Machine

Controller Industrial

Panel PC Hardware

User’s Manual

NY-series IPC Machine

Controller Industrial Box

PC Hardware User’s

Manual

NJ/NX-series CPU Unit

Software User's Manual

W578 NX1P2- Learning the basic

specifications of

the NX-series

NX1P2 CPU Units,

including introductory information,

designing, installation, and maintenance.

Mainly hardware

information is provided.

W500 NJ501-

NJ301-

NJ101-

W557 NY532-1 Learning the basic

W556 NY512-1 Learning the basic

W501 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning the basic

specifications of

the NJ-series CPU

Units, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

specifications of

the NY-series

Industrial Panel

PCs, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

specifications of

the NY-series

Industrial Box PCs,

including introductory information,

designing, installation, and maintenance.

Mainly hardware

information is provided.

Learning how to

program and set

up an

NJ/NX-series CPU

Unit.

Mainly software

information is provided.

An introduction to the entire NX1P system is provided along with the following

information on the NX1P2 CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NJ-series

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Overview

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and Inspection

An introduction to the entire NY-series

system is provided along with the following information on the Industrial

Panel PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NY-series

system is provided along with the following information on the Industrial Box

PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided

on an NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3

language specifications

Related Manuals

NX-series IO-Link Master Unit User’s Manual (W567)

29

Page 32

Related Manuals

Manual name Cat. No. Model numbers Application Description

NJ/NX-series CPU Unit

Built-in EtherCAT Port

User's Manual

NJ/NX-series CPU Unit

Motion Control User's

Manual

NY-series IPC Machine

Controller Industrial

Panel PC / Industrial

Box PC Built-in EtherCAT® Port User’s Manual

NJ/NX-series Instructions Reference Manual

NY-series Instructions

Reference Manual

W505 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W507 NX701-

NJ501-

NJ301-

NJ101-

W562 NY532-1

NY512-1

W502 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

W560 NY532-1

NY512-1

Using the built-in

EtherCAT port on

an NJ/NX-series

CPU Unit.

Learning about

motion control settings and programming concepts.

Using the built-in

EtherCAT port in

an NY-series

Industrial PC.

Learning detailed

specifications on

the basic instructions of an

NJ/NX-series CPU

Unit.

Learning detailed

specifications on

the basic instructions of an

NY-series Industrial PC.

Information on the built-in EtherCAT

port is provided.

This manual provides an introduction

and provides information on the configuration, features, and setup.

The settings and operation of the CPU

Unit and programming concepts for

motion control are described. When

programming, use this manual together

with the NJ-series CPU Unit Hardware

User's Manual (Cat. No. W500) or

NX-series CPU Unit Hardware User's

Manual (Cat. No. W535) and with the

NJ/NX-series CPU Unit Software

User's Manual (Cat. No. W501).

Information on the built-in EtherCAT

port is provided.

This manual provides an introduction

and provides information on the configuration, features, and setup.

The instructions in the instruction set

(IEC 61131-3 specifications) are

described.

The instructions in the instruction set

(IEC 61131-3 specifications) are

described.

30

NX-series IO-Link Master Unit User’s Manual (W567)

Page 33

Terminology

The following table describes terms used for NX Units. Refer to the IO-Link System User’s Manual (Cat.

No. W570) for information on terms used for IO-Link Master Units.

Terminology

Term

CAN application protocol over EtherCAT

Communications Coupler Units --- The generic name of an interface unit for remote I/O communications on

CPU Rack --- A Rack with a CPU Unit mounted on it. With an NX-series NX1P2 CPU

device profile --- A collection of device dependent information and functionality providing

device variable --- A variable that is used by an NX-series CPU Unit or an NY-series Indus-

distributed clock DC Clock distribution mechanism used to synchronize EtherCAT slaves and

EtherCAT slave information ESI An XML file that contains setting information for an EtherCAT slave.

I/O map settings --- Settings that assign variables to I/O ports. Assignment information

I/O port --- A logical interface that is used by the NX-series CPU Unit or NY-series

I/O refreshing --- Cyclic data exchange with external devices that is performed with prede-

index --- Address of an object within an application process.

network configuration information --- The EtherCAT network configuration information held by the EtherCAT

NX bus --- The NX-series internal bus.

object --- An abstract representation of a particular component within a device,

object dictionary OD Data structure that contains description of data type objects, communi-

Operational --- A state in EtherCAT communications where SDO communications and

PDO communications --- An acronym for process data communications.

Pre-Operational --- A state in EtherCAT communications where only SDO communications

primary periodic task --- The task with the highest priority.

process data --- Collection of application objects designated to be downloaded cyclically

process data communications --- One type of EtherCAT communications in which process data objects

process data object PDO A structure that describes the mappings of parameters that have one or

Safe-Operational --- A state in EtherCAT communications where only SDO communications

Abbreviation

CoE A CAN application protocol service implemented on EtherCAT.

a network between NX Units and a host network master.

Unit, NX Units are mounted to the CPU Unit and End Covers are

mounted on it.

consistency between similar devices of the same device type.

trial PC to access a specific device through an I/O port. EtherCAT slave

process data is assigned to these variables. With an NX-series NX1P2

CPU Unit, the I/O data is assigned to NX Units in the CPU Unit. Connectable devices are accessed by directly reading and writing device

variables from user applications on the CPU Unit or Industrial PC.

the EtherCAT master.

between I/O ports and variables.

Industrial PC to exchange data with an external device (slave or Unit).

termined memory addresses.

master.

which consists of data, parameters, and methods.

cation objects and application objects.

I/O are possible.

are possible with the slaves, i.e., no I/O can be performed.

or acyclically for the purpose of measurement and control.

(PDOs) are used to exchange information cyclically and in realtime. This

is also called PDO communications.

more process data entities.

and reading input data from slaves are possible. Outputs from slaves are

not performed.

Description

NX-series IO-Link Master Unit User’s Manual (W567)

31

Page 34

Terminology

Term

SDO communications --- One type of EtherCAT communications in which service data objects

service data object SDO CoE asynchronous mailbox communications where all objects in the

Slave Terminal --- A building-block remote I/O terminal to which a Communications Cou-

subindex --- Sub-address of an object within the object dictionary.

task period --- The interval at which the primary periodic task or a periodic task is exe-

Abbreviation

Description

(SDOs) are used to transmit information whenever required.

object dictionary can be read and written.

pler Unit and NX Units are mounted

cuted.

32

NX-series IO-Link Master Unit User’s Manual (W567)

Page 35

Revision History

Cat. No.

W567-E1-05

Revision code

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 July 2016 Original production

02 October 2016 • Made revisions accompanying the addition of NY-series IPC Machine

03 February 2017 Corrected mistakes.

04 June 2017 • Made changes accompanying the upgrade of the NX-ECC203 unit ver-

05 October 2017 • Made changes accompanying the upgrade of the NX-ILM400 unit ver-

Revision History

Controller Industrial Panel PCs and Industrial Box PCs.

• Made revisions accompanying the addition of NX-series NX1P2 CPU

Units.

• Corrected mistakes.

sion to version 1.5.

• Made changes accompanying the upgrade of the NX-EIC202 unit version to version 1.2.

• Corrected mistakes.

sion to version 1.1.

NX-series IO-Link Master Unit User’s Manual (W567)

33

Page 36

Revision History

34

NX-series IO-Link Master Unit User’s Manual (W567)

Page 37

1

2

3

4

5

6

7

8

A

1I

2

3

4

5

6

7

8

A

Features and System

Configuration

Specifications

Part Names and

Functions

Installation and

Wiring

I/O Refreshing

I

Troubleshooting

Types and Functions of IO-Link Master Units

Inspection and Maintenance

Appendices

Index

Sections in this Manual

Sections in this Manual

NX-series IO-Link Master Unit User’s Manual (W567)

35

Page 38

Sections in this Manual

36

NX-series IO-Link Master Unit User’s Manual (W567)

Page 39

Features and System Configuration

This section describes the NX system configuration and the features of IO-Link Master

Units.

1-1 Features of the IO-Link Master Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 System Configuration with CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 System Configurations of Slave Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 Model List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3-1 Model Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-4 List of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1

1-5 Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

NX-series IO-Link Master Unit User’s Manual (W567)

1 - 1

Page 40

1 Features and System Configuration

1-1 Features of the IO-Link Master Units

This section describes the features of IO-Link Master Units.

1-1-1 Introduction

An IO-Link Master Unit is an NX Unit that has I/O processing functions for IO-Link communications with

IO-Link devices and I/O processing functions for digital I/O data (ON/OFF signals) with non-IO-Link

devices.

1-1-2 Features

The NX-series IO-Link Master Unit has the following features.

Connectable to CPU Units and Communications Coupler Units

NX-series IO-Link Master Units are NX Units. They can be connected to the following Units.

• NX-series NX1P2 CPU Unit

• NX-series Communications Coupler Units

If you use both CPU Units and Communications Coupler Units, you can use the same NX Unit mounting, wiring, and setup methods to reduce design costs.

*1

Reading of Control Signals, Status, Wiring, and Power Supply Status

of IO-Link Devices from the Controller

The controller can read the following information as IO-Link Master Unit status.

• Signals and status of the IO-Link devices (examples for photoelectric sensor: unstable detection and

sensor errors)

• Disconnections, short-circuits, I/O power ON status, etc., between the IO-Link master and devices

Inputting Digital Signals from Sensors and Other IO-Link Devices

during IO-Link Communications

With IO-Link devices that support digital inputs for pin 2,*1 the IO-Link Master Unit can simultaneously

perform both IO-Link communications and receive the digital inputs.

This enables rapid input during IO-Link communications.

*1. Digital inputs that use pin 2 of IO-Link Master Unit ports.

1 - 2

Combining IO-Link Devices with General-purpose Sensors and

Actuators

• You can connect a combination of IO-Link devices and non-IO-Link devices, such as general-purpose sensors and actuators, to the same IO-Link Master Unit. This allows a single master to function

as an IO-Link communications terminal, a digital input terminal, and a digital output terminal.