Omron NV3W-MR20-V1, NV3W-MR40-V1, NV3W-MG20L-V1, NV3W-MG20-V1, NV3W-MG40-V1 Operation Handbook

...Page 1

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

NV-series PT

Simple Operation

Handbook

- A case of connection to a CP1E PLC -

Table of Contents

Preparation

Required Devices 2

Wiring and Connection 4

Turning on the Power 6

Displaying the NV System Menu 7

Setting the CPIE Serial Port 8

Designing Screens

Creating New Screen Data 12

Setting the NV Communications 15

Creating Switch Parts 16

Creating Lamp Parts 19

Creating Data Parts 21

Creating Keyboard Screens 23

Creating Character Stings26

Connecting with CP1E PLC

Transferring Screen Data 28

Checking Operation 31

Advanced Usage

Switching Screens from CP1E 32

Changing Backlight Colors

from CP1E 34

Connecting PC and PLC via NV 35

The NV3W-V1 is added.

Page 2

2

These are the devices required to connect an NV-series PT to a CP1E PLC.

Required Devices

Application Models

CP1E-NxxS1-type (built-in 3 ports), CP1E-NxxS-type (built-in 2 ports)

-RS-232C type (24 VDC) -

NV3Q-MR21 NV3Q-SW21

-RS-422A type (24 VDC) -

NV3Q-MR41 NV3Q-SW41

Power supply for Programmable Terminals

Use a 24-VDC power supply unit for an NV3W-V1 (24-VDC type), NV4W or NV3Q.

A power supply unit is not necessary for an NV3W-V1 RS-232C type (5-VDC type), since the 5-

V power is supplied from the PLC via the cable (XW2Z-200T-4).

PT: NV Series

PLC: CP1E Series

Compact Horizontal Models: NV3W-V1 (3.8 inch)

- RS-232C type (5 VDC) -

NV3W-MR20L-V1 NV3W-MG20L-V1

- RS-232C type (24 VDC) -

NV3W-MR20-V1 NV3W-MG20-V1

- RS-422A type (24 VDC) -

NV3W-MR40-V1 NV3W-MG40-V1

QVGA Models: NV3Q (3.6 inch)

Package PLCs with Exceptional Cost: CP1E

Three color LED backlight

of white, pink and red

NV3W-MRxx(x)-V1

Three color LED backlight

of green, orange and red

NV3W-MGxx(x)-V1

Three color LED backlight

of white, pink and red

NV3Q-MRxx

STN color

(Display colors: 4096 colors)

NV3Q-SWxx

-RS-232C type (5 VDC) -

XW2Z-200T-4 (2 m with 5-V Line)

-RS-232C type (24 VDC) -

XW2Z-200T-3 (2 m without 5-V Line)

XW2Z-500T-3 (5 m without 5-V Line)

-RS-422A type (24 VDC) -

Prepare one by referring to the Manual.

PT-to-PLC Connecting Cable

Compact Horizontal Models: NV4W (4.6 inch)

- RS-232C type (24 VDC) -

NV4W-MR21 NV4W-MG21

- RS-422A type (24 VDC) -

NV4W-MR41 NV4W-MG41

Three color LED backlight

of white, pink and red

NV4W-MRxx

Three color LED backlight

of green, orange and red

NV4W-MGxx

Note: E-type CP1E CPU Units (Basic Models) can not be used with an NV-series

PT, since they do not have a RS-232C port.

< Renewal type >

Page 3

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

3

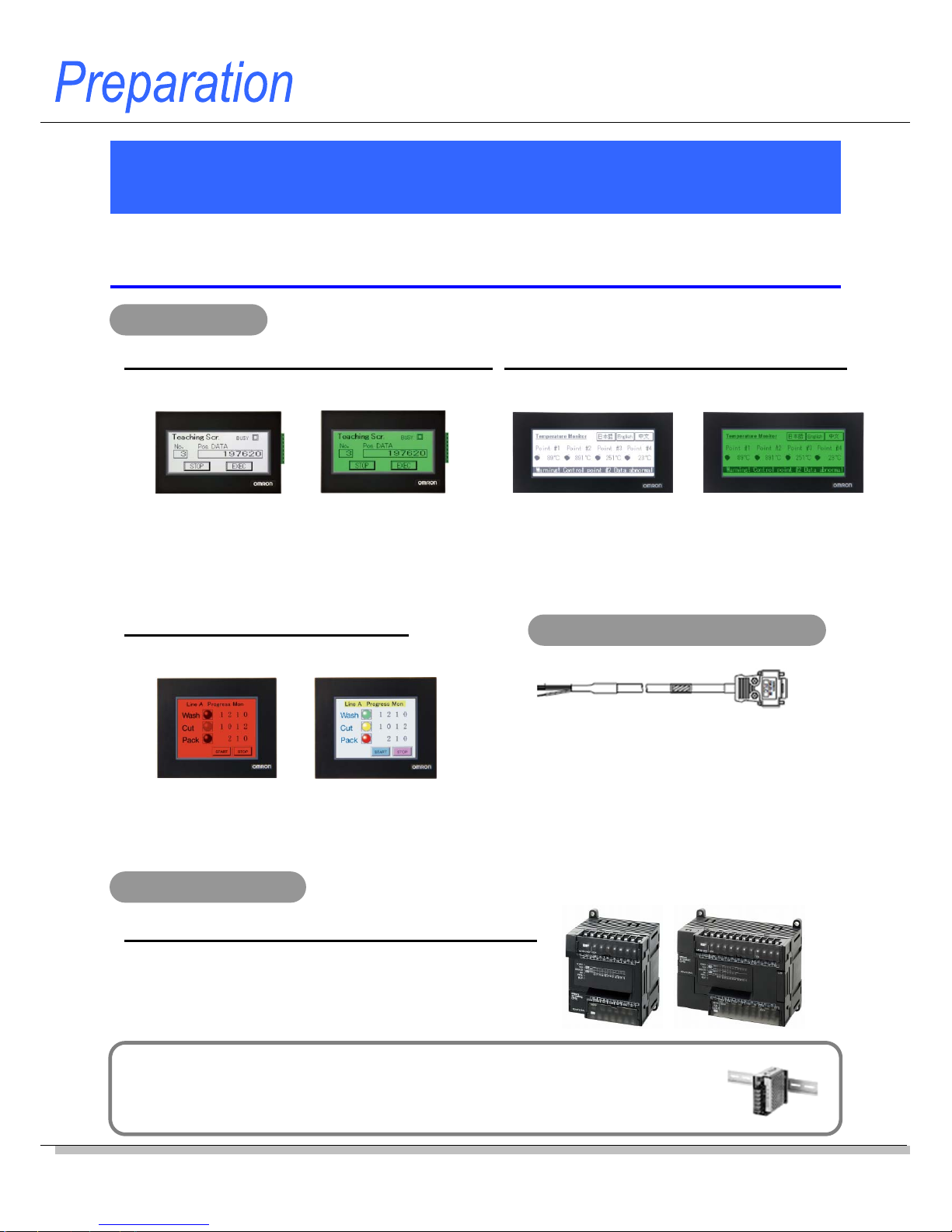

FA Integrated Tool Package

CX-One Ver.4.x (4.03 or higher)

The CX-One is a package that integrates the

Support Software for OMRON PLCs and

components.

CX-One Lite Ver.4.x (4.03 or higher)

The CX-One Lite is a subset of the complete CXOne package that provides only the Support

Software required for micro PLC applications.

Select from two packages: Included in both packages of CX-One Lite Ver.4 and CX-

One Ver.4.

* It cannot be purchased individually.

NV-Designer Ver.1.1 or higher

Screen designing software for NV

Programming software for PLC

Included in a package of CX-One Lite Ver.4.

Micro PLC Edition CX-Programmer Ver.9.

Included in a package of CX-One Ver.4.

CX-Programmer Ver.9

Select from two types of software:

NV-PC connection cable

Use a commercially available USB cable (Mini-B) to connect the NV3W-V1 or NV4W to a PC.

Use a commercially available USB cable (Type B) to connect the NV3Q to a PC.

Preparation

PC

Use a commercially available USB cable.

CP1E PLC-PC connection cable

CP1E

Type B Type A

NV4W

Connecting an NV4W

Mini-B Type A

Use a commercially available USB cable (Mini-B).

* Supporting Windows 7

(32-bit version)!

NV3Q

Connecting an NV3Q

Use a commercially available USB cable (Type B).

Type B Type A

NV3W-V1

Connecting an NV3W-V1

Mini-B Type A

Use a commercially available USB cable (Mini-B).

Note: The NV-Designer

Ver.2.0 or higher is

required to use the

NV3W-V1.

Page 4

4

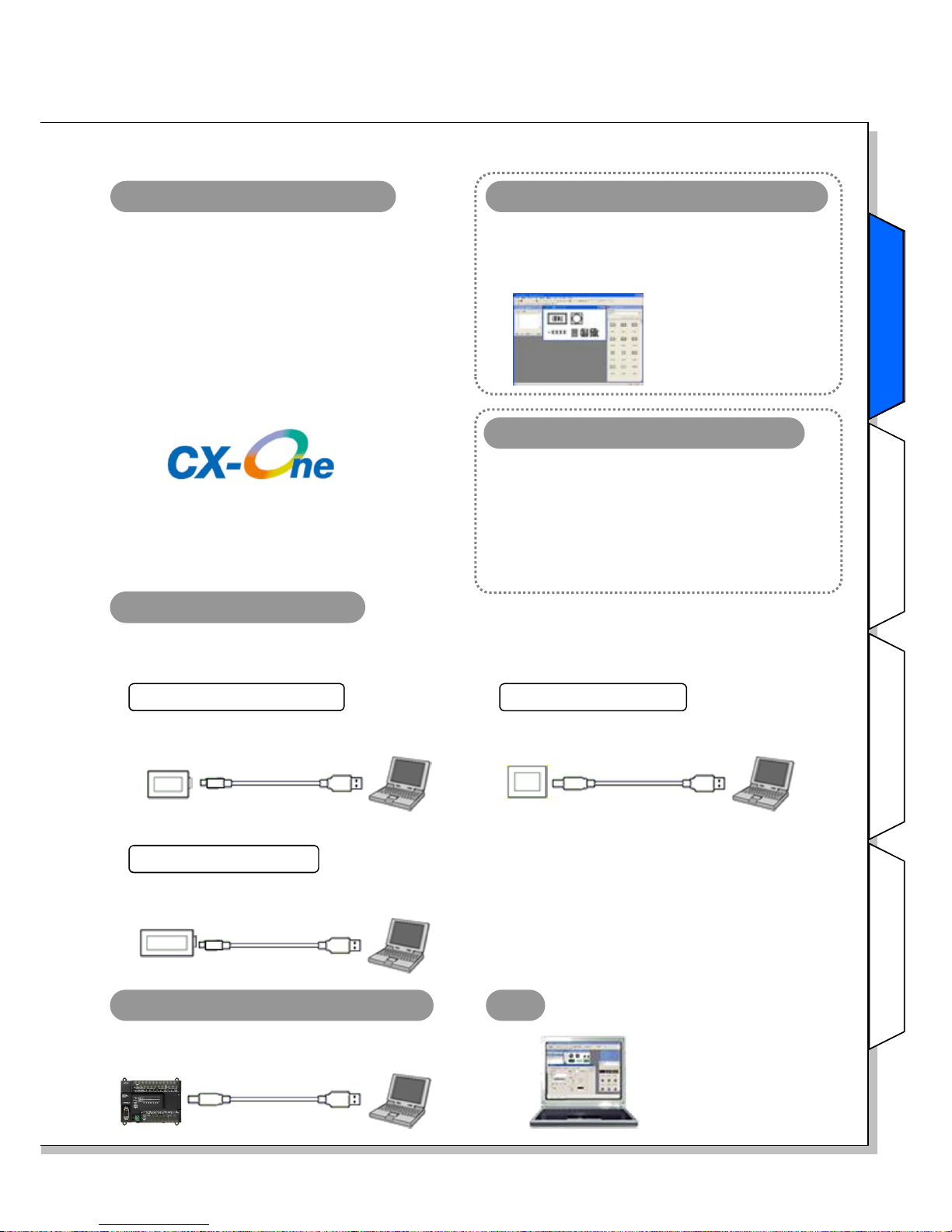

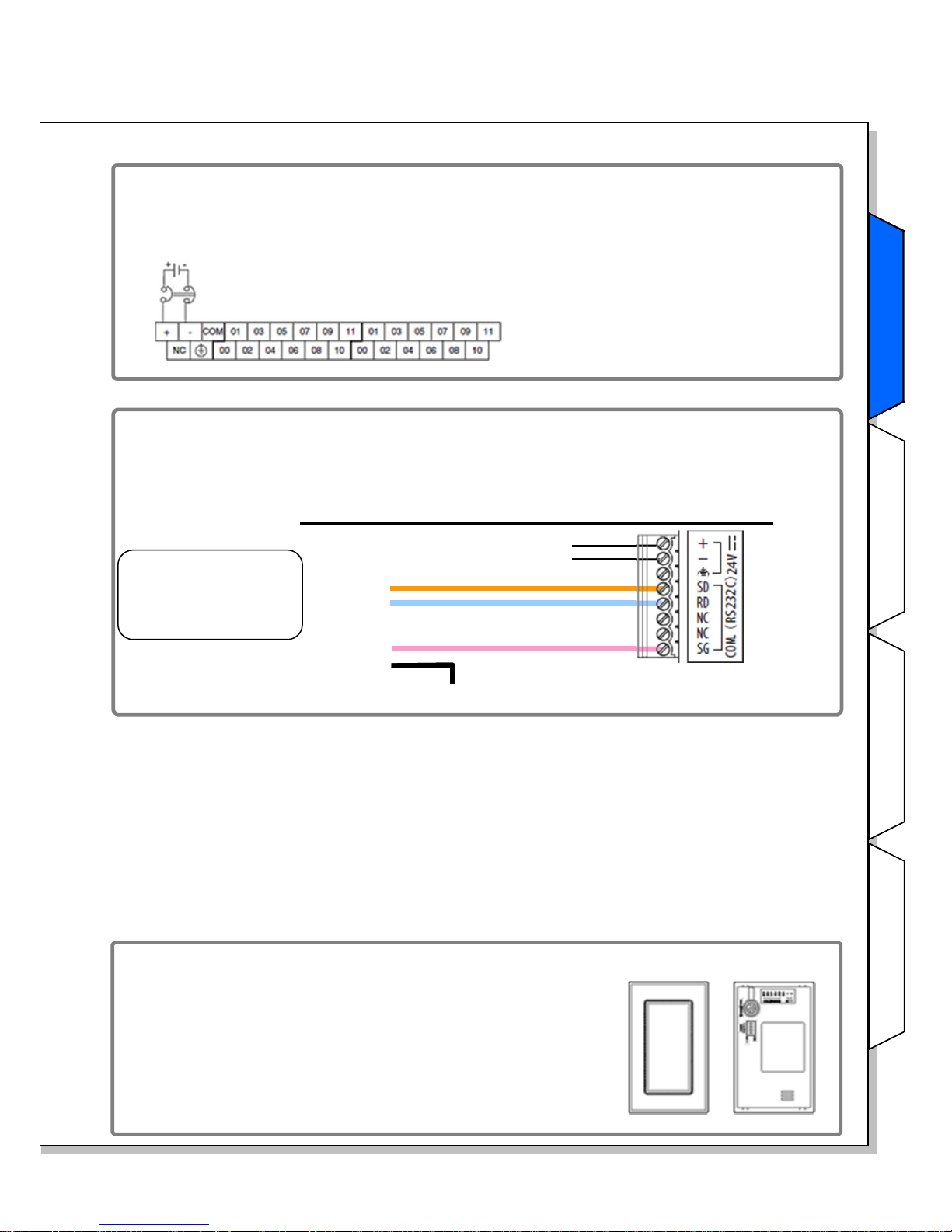

Wiring and Connection

Connect the devices.

* This section explains the procedure to connect an NV3W-V1 (5-VDC type) PT to a CP1E PLC.

Connecting example

Commercially available USB cable

(Type A connector – Type B connector)

XW2Z-200T-4

(2 m with 5-V Line)

Connecting the NV and CP1E

Connecting an NV3W-V1 (5-VDC type) PT to the USB port on a PC

5 V power (green)

Name (color)

RD (orange)

SD (blue)

SG (pink)

NV3W-V1 (5-VDC)

* The NV3W-V1 (5-VDC type) does not need a pow er supp l y unit. The 5-V power is supplied from the PLC through the XW2Z-200T-4

Special Cable.

NV3W-MR20L-V1

PC

CP1E-N30SDx-x

Wiring for the CP1E AC power supply

Wire for the CP1E AC power supply.

Connect the NV and the CP1E with the XW2Z-200T-4 Special Cable.

FG (black)

Ground to 100 ohm or less

XW2Z-200T-4

Special Cable

(2 m with 5-V Line)

Upper terminal block

100 to 240 VAC, 50/60 Hz

Commercially available USB cable (Mini-B)

Page 5

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

5

The NV3W-V1 and NV4W PTs can be mounted vertically.

Mount the PT with the serial communications/power supply

connector on top.

Using a Vertically Mounted PT (NV3W-V1 and NV4W only)

When the CP1E uses a 24-VDC power supply

Wire the 24-VDC power supply as shown below.

XW2Z-200T-3

(2 m, without 5-V Line)

XW2Z-500T-3

(5 m, without 5-V Line)

When the NV3W-V1 (24-VDC type), the NV4W, or the NV3Q is connected

with a RS-232C cable

Wire the NV and the PLC as follows. The power is supplied from the external supply unit to

the PT.

Name (color)

RD (orange)

SD (blue)

SG (pink)

NV3W-V1 (24-VDC)/NV4W/NV3Q

FG (black)

Ground to 100 ohm or less

24-VDC power supply

Upper terminal block

24-VDC power supply

Preparation

Page 6

6

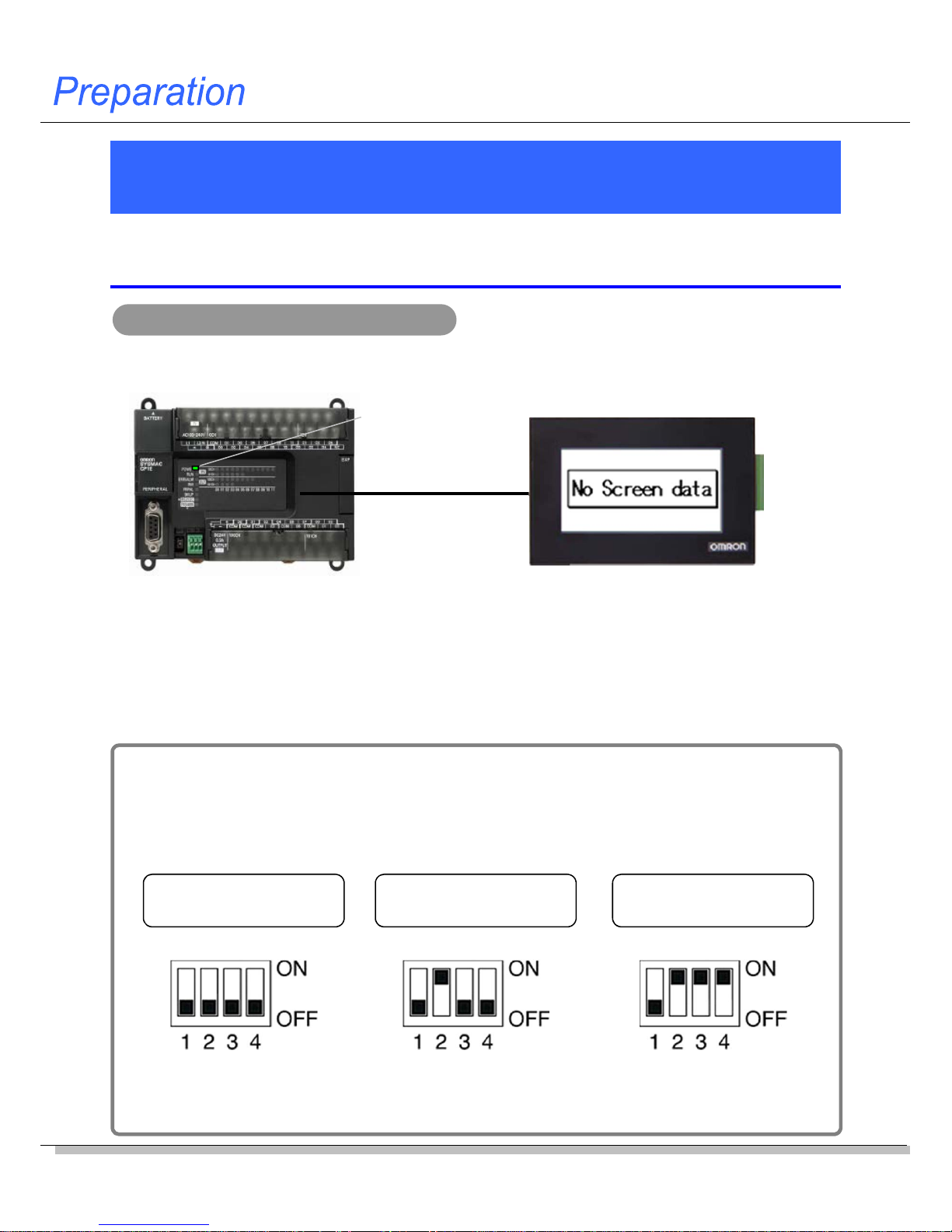

Turning on the Power

Turn on the power to the CP1E. The power is also supplied to the NV

through the RE-232C serial port on the CP1E.

If you turn ON the power to the NV after you change the DIP switch pins on the NV back face to

any setting other than default setting, the NV starts up in a special operation mode. You can use

the functions to prohibit accessing the System Menu and to clear the F-ROM.

* Do not use the NV in any settings other than shown below.

Normal operation

(default )

Prohibiting moving to

System Menu

F-ROM clear

Note 1: The data saved in the F-ROM includes screen data and NV configuration data.

Note 2: Other than the DIP switch setting, you can clear the F-ROM from the System Menu.

Turning on the power to the CP1E

NV startup mode

Turn on the power to the CP1E. The POWER LED indicator on the front of the CP1E lights in

green. The NV screen shows a message as follows:

Note: The message “No Screen data” is shown when the NV has no screen data.

As the NV contains no data at factory shipping, This message is shown accordingly.

Turn OFF all pins. Turn ON pin 2. Turn ON pins 2, 3, and 4.

POWER

LED

XW2Z-200T-4

Page 7

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

7

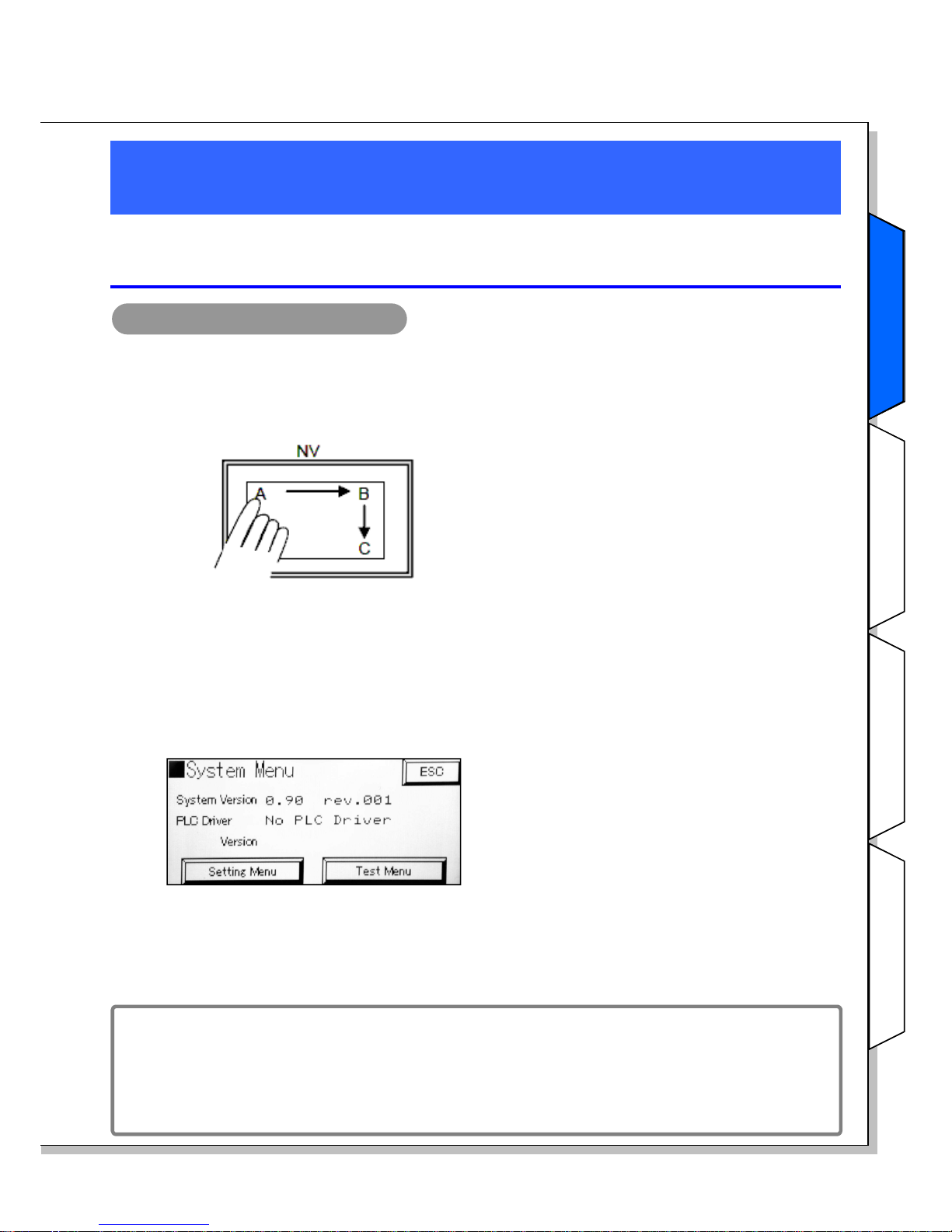

Displaying the NV System Menu

The System Menu is the special screen that is used to configure the NV.

Some settings such as touch switch adjustment can only be done on the

System Menu.

Accessing the System Menu

Follow the steps below to access the System Menu.

1. Touch the touch panel on the PT as shown below.

(This is common for the entire NV Series.)

1) Touch the upper left corner (A) for at least 2

seconds.

2) Then immediately touch the upper right

corner (B) and lower right corner (C) in order.

Note: Touch the points A, B, and C, one at a time in order. Do not press these points at the

same time.

2. The startup screen of the System Menu will be displayed.

The startup screen of the System Menu will be

displayed.

The next screen will be displayed if you touch

the Setting Menu or Test Menu Key.

To return to normal operating status, touch the

ESC Key.

Note: The system version is the version of the system ROM in the PT.

The default language for the System Menu is English, if there is no screen data in the PT.

The System Menu depends on the PT model. The default System Menu for the NV3W-V1

is used here.

Changing the System Menu language

The language is switchable between English and Japanese on the NV System Menu.

Select Setting Menu - Language.

Touch A for at least 2 seconds, then press B and C in order.

Preparation

Page 8

8

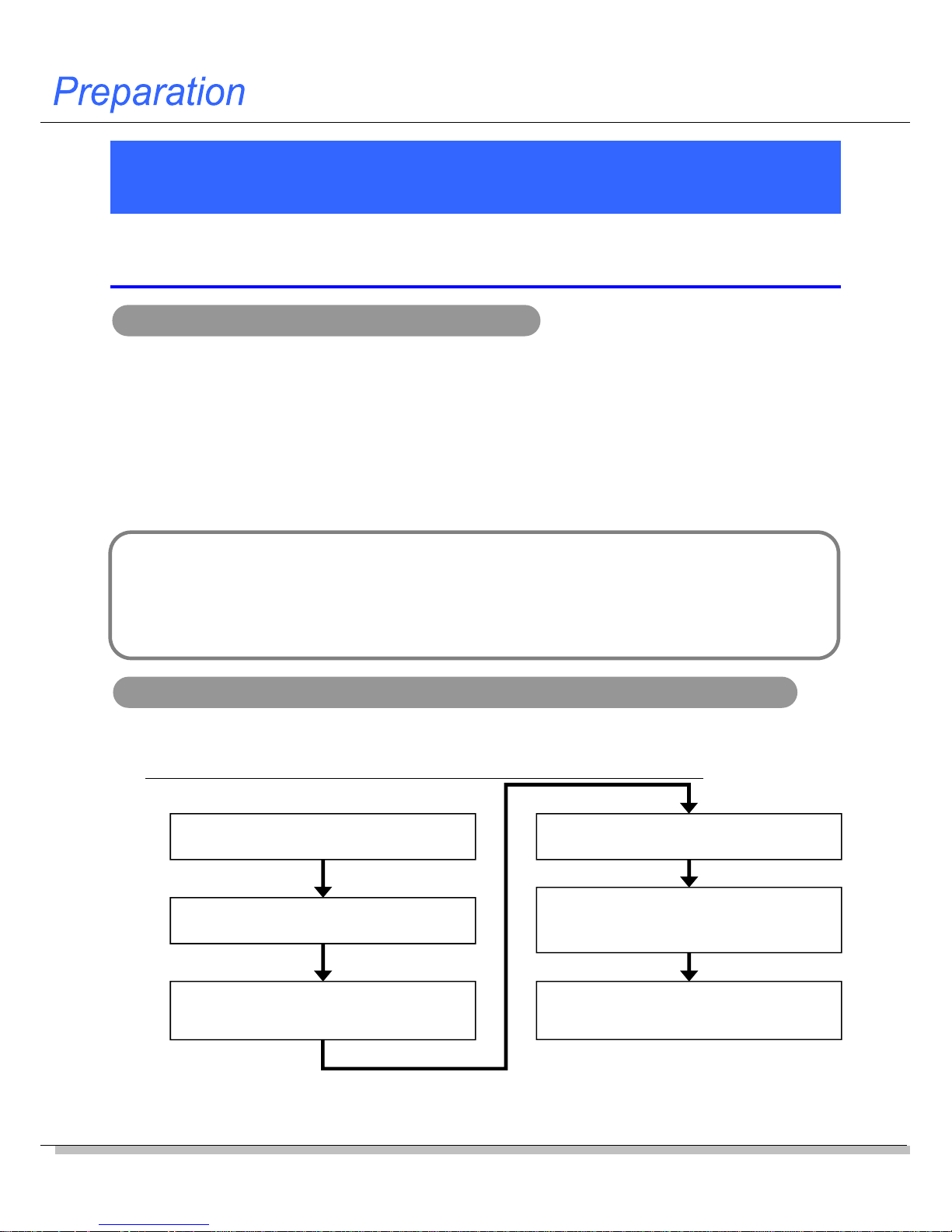

Setting the CP1E Serial Port

To have the NV and the CP1E communications, the both serial ports must

have the same setting. Use the PLC programming tool CX-Programmer to

set the communications on the CP1E.

Be sure to change the stop bit on the PLC from the default 2 to 1

The stop bit for the NV serial communications is fixed to 1 . Therefore, the stop bit of the

PLC serial port must be changed from the default 2 to 1.

NV-CP1E communications setting example

Both the NV and the CP1E support the high speed communication of 115,200 bps.

Connect them in this baud rate.

Set the RS-232C serial ports on both of the NV and the CP1E as follows:

Mode: Host Link

Baud rate: 115,200 bps

Data length: 7

Stop bit: 1

Parity bit: Even

Communications setting for the RS-232C serial port built in the CP1E

Use the PLC programming tool CX-Programmer. Follow the steps below to set the RS-232C

serial port built in the CP1E.

* After this setting is completed, turn OFF and then ON the power of the CP1E.

Connect the CX-Programmer and the

CP1E online using a USB cable.

Change the CP1E operation mode to

“Program Mode” (Stopped).

Upload the PLC settings (including the

built-in RS-232C serial port setting)

from the CP1E.

Set the built-in RS-232C serial port on

the PLC Settings.

Write the PLC settings (including the

built-in RS-232C serial port setting) into

the CP1E.

Turn OFF and then ON the power of

the CP1E. (The settings are reflected

only after the power is turned ON.)

1

2

3

4

5

6

Note: Communications may be enabled, even when the stop bit on the PLC is 2 while the bit on the NV is 1. However,

be sure to set the both to 1.

Page 9

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

9

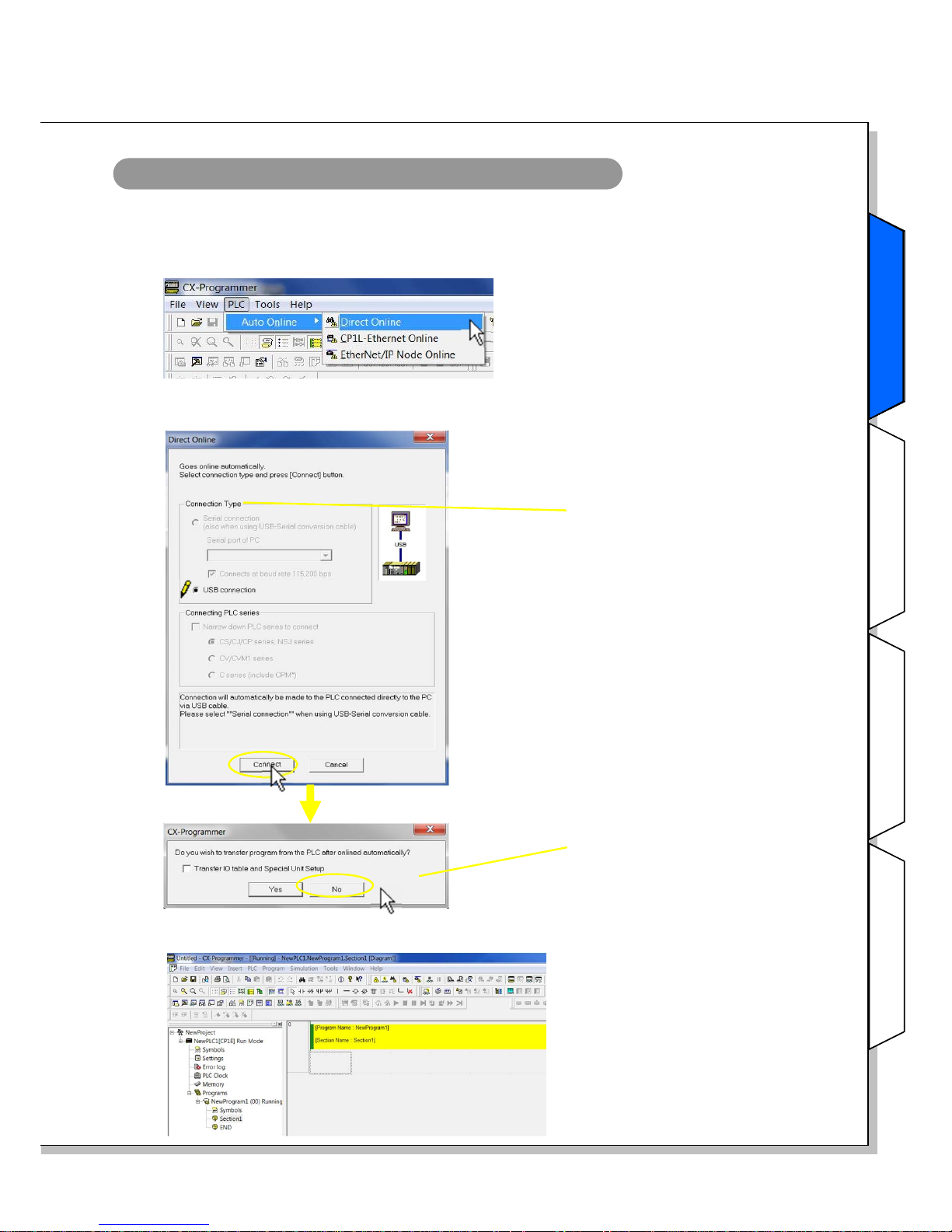

Online connection of the CX-Programmer and CP1E

1. Select Program – OMRON – CX-One – CX-Programmer – CX-Programmer from the

Windows Start Menu to start the CX-Programmer.

2. Select PLC – Auto Online – Direct Online from the menu bar.

3. In the Direct Online Dialog Box, select USB connection for the PC – PLC (CP1E)

connection type. Click the Connect Button.

Connection Type:

Select either

Serial connection or

USB connection.

1) Click the No Button.

* Click the Yes Button to upload

the program to the PC.

4. When the PC is connected with the CP1E, a new project will start.

Preparation

Page 10

10

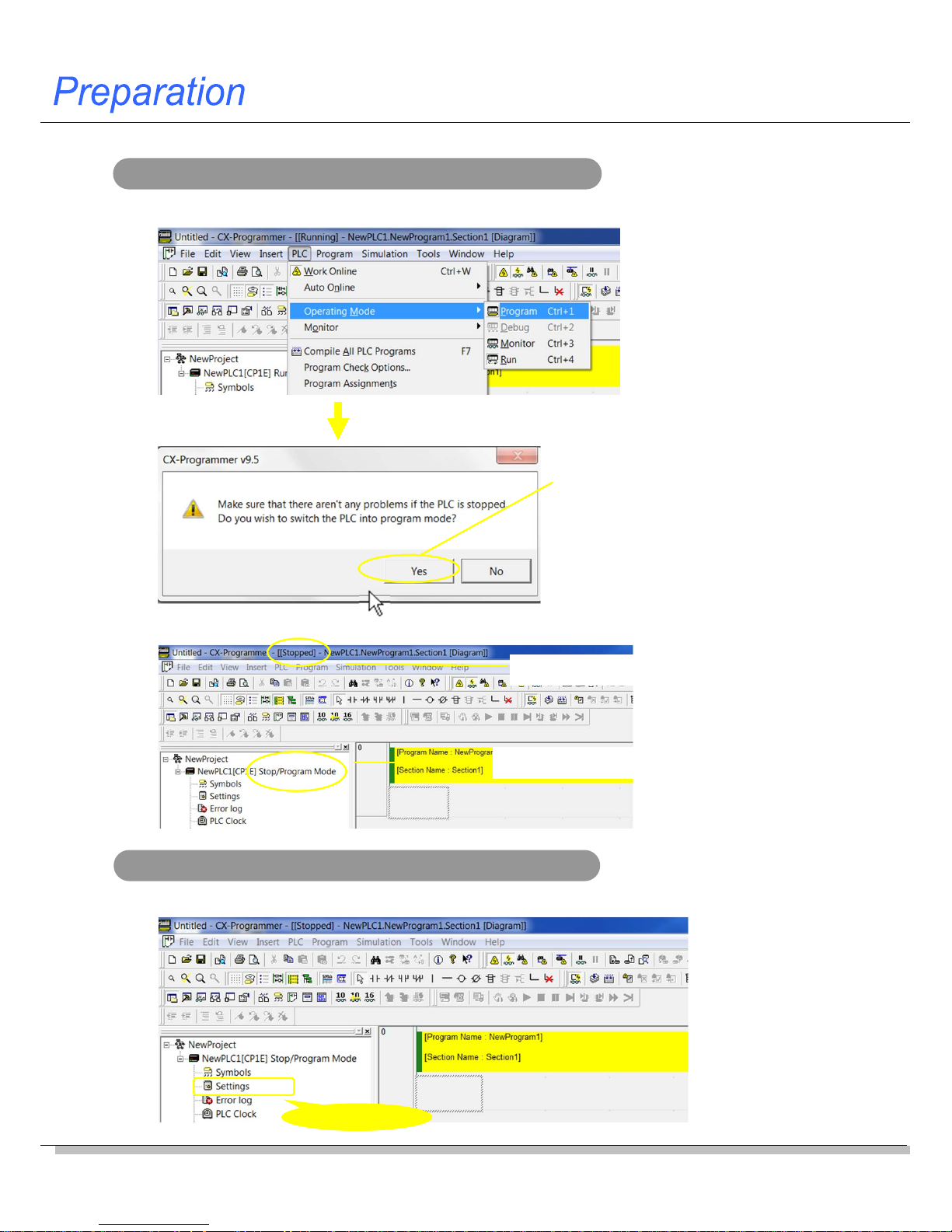

Changing the CP1E operation mode into Program

1. Select PLC – Operation Mode – Program from the menu bar.

1) Confirm that stopping the ladder

program do not cause any

problem. Click the Yes Button.

2. The CP1E operation mode changes to the Program Mode.

“Stopped” is displayed.

“Program Mode” is displayed.zzzzz

Transferring, setting and wr iting the PLC settings

1. Double-click Settings in the project tree.

Double-click!!

Page 11

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

11

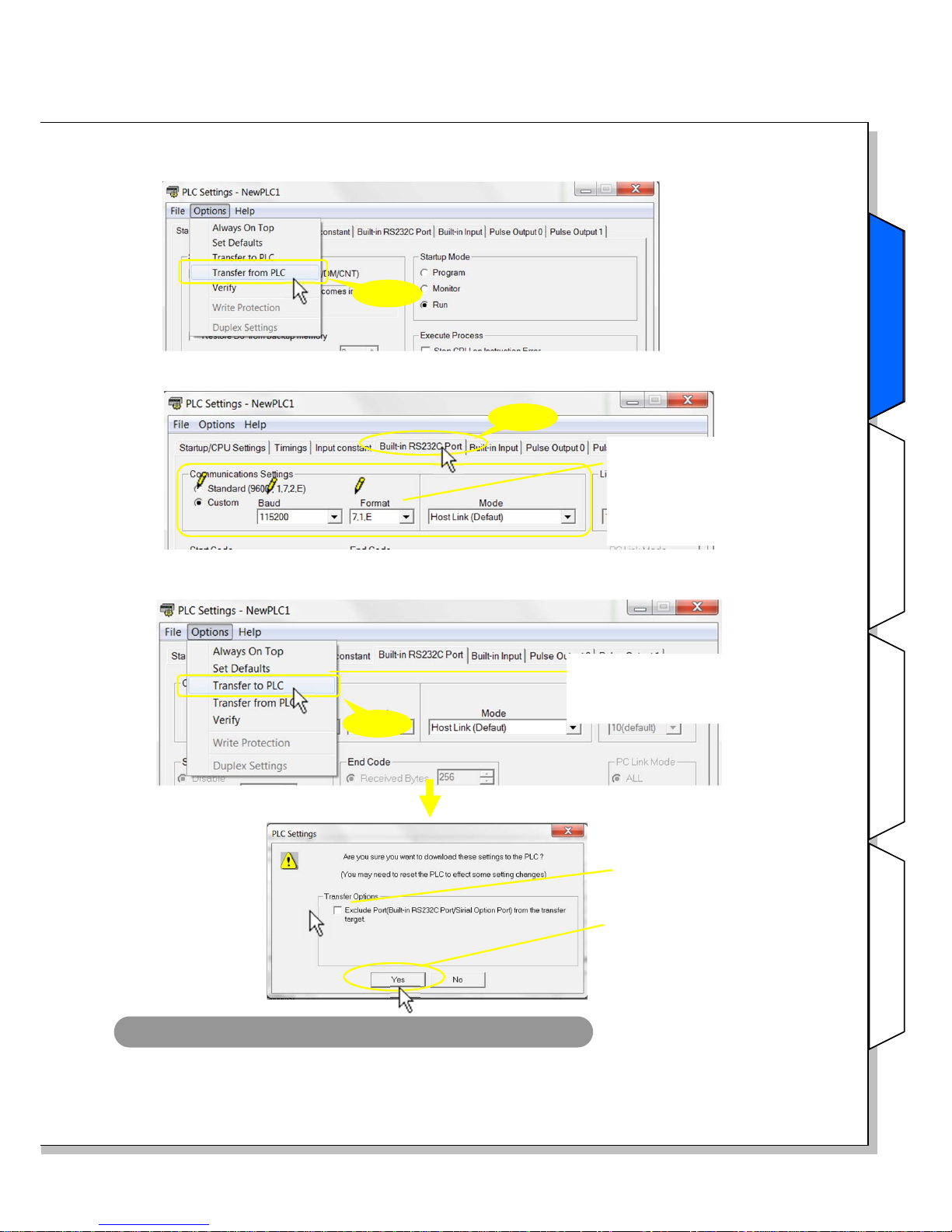

4. Select Options – Transfer to PLC from the menu bar.

Click!!

* It is not selectable, when the PLC

operation mode is not in Program

Mode.

1) Do not select.

2) Click the Yes Button.

2. The PLC Settings Dialog Box appears .

Select Options – Transfer from PLC from the menu bar.

* The second value from the

left of Format is the stop bit.

Be sure to set it to “1” when

the PLC is connected to an

NV.

Click!!

Click!!

3. The PLC settings for the CP1E are uploaded to the PC. Make the setting on the Built-in

RS232C Port Tab Page as follows.

Turning OFF and then ON the power of the CP1E

1. Turn OFF and then ON the power of the CP1E. The RS-232C serial port setting becomes

effective when the power is turned ON. This completes the CP1E communications setting.

Preparation

Page 12

12

Creating New Screen Data

The NV communications setting is set by transferring the screen data to the NV.

Create screen data by using the screen designing software NV-Designer.

Starting the NV-Designer and creating a new project

1. Select Program – OMRON – CX-One – NV-Designer - NV-Designer from the

Windows Start Menu,.

3. On the Select Model Dialog Box, select the NV model and the NV type and enter the project

name. Click the Next Button.

NV Model:

Select the PT model.

2. When the NV-Designer is started, the NV-Designer Dialog Box will be displayed.

Select Create New Project. Click the OK Button.

NV Type:

Select one from monochrome,

color and vertical.

File Name:

Enter a project file name. In the

left example, a file “New Project.

nvp” and a folder “New Project”

are created.

Page 13

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

13

4. Select the PLC model to connect. Click the Next Button.

PLC Model:

Select the PLC model to

connect.

5. In the System Memory Area Field, set the Word Area and the Bit Area.

Click the OK Button.

Three consecutive words are allocated for the Word Area to read and write data in word units

such as Screen No., and three consecutive words are allocated for the Bit Area to read and write

data in bit units such as Backlight Light/Blink. In total six words are allocated.

The system memory is used for the PLC to control the basic operations such as switching

screens. The specified words in the PLC memory are allocated for communications, which are

performed constantly.

System memory

Number of w ords allocated for the system memory

System Memory Area:

Specify the areas for controlling

the NV in the PLC internal

memory.

Note: The default word for the Bit

Area is CIO 0. As CIO 0 is

allocated to the CP1E input

word, be sure to change to a

word in the Work Area.

Designing Screens

Note: The words allocated to the system memory can be changed from the menu bar.

Select PT – NV Configuration.

Page 14

14

6. The Main Window of the NV-Designer will be displayed.

Double-click “0” in the Screen Manager. Base screen 0 and the Parts Library will open.

Character strings and parts are positioned on the screen to create a base screen.

Manu bar

Toolbar

Graphic bar

Base Screen Parts LibraryScreen Manager

Base Screen

Parts Library

A parts library contains parts, such as switches, lamps, data displays, and keyboa rds.

Your own parts library can be created by registering customized parts to reuse them.

Screen Manager

Screens can be copied, pasted, cut, and deleted using the Screen Manager. Multiple projects

can be started simultaneously and editing can be performed between the Screen Managers.

Double-click!!

Size-Position

Bar

Note: The Size-Position Bar is a new function added to the NV-Designer Ver.2.0.

Page 15

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

Setting the NV Communications

Set the NV - CP1E communications as the screen data.

Setting the NV communications

1. Select PT – NV Configuration from the menu bar.

Click!!

NV-CP1E communications setting example

The CP1E communications was set as follows. Set the same for the NV communications.

Mode: Host Link

Baud rate: 115,200 bps

Data length: 7

Stop bit: 1

Parity bit: Even

The stop bit for the NV serial communications is fixed to 1.

Therefore, the stop bit of the PLC serial port must be changed from the default 2 to 1.

2. Select the Communication Parameters Tab. Set the communications with the CP1E.

Click the OK Button to close the dialog box. This completes the NV communication setting.

Click!!

Set these items for

communications with the

CP1E.

Designing Screens

15

Page 16

16

Creating Switch Parts

This and the following few pages describe the procedure to create parts on

the screen, and confirming the NV-CP1E operations. Firstly, create a switch

part that turns ON and OFF the specified bit in the PLC.

Example of creating a switch part

CIO 10.00 in the PLC is turned ON when the switch is pressed and turned OFF when it is

released. (Momentary operation)

Normally the OFF label is displayed. While the

switch is pressed, the ON label is displayed.

Creating a switch part

Drag a switch part from the library and drop it at any desired space on the base screen.

Drag and drop!!

When pressed

When released

1) Use the Parts Library

Standard (NV3W-V1).

2) Use the part SW2.

Page 17

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

17

Setting the function for the switch part

Double-click the switch part. Select the Basic Setup Tab. Set the Operation Mode and

ON/OFF Indication Fields.

Operation Mode:

It specifies the operation and the bit

address in the PLC.

ON/OFF Indication:

Select either On to switch the

ON/OFF indication or Off not to switch

it. When you select On, set also the

switch timing.

Creating the switch labels

1. Select the Label tab.

ON/OFF:

Set the label each when the

switch is ON and OFF.

* Click the OFF Button.

Character String:

Enter a character

string to show.

Font:

Set the front type and

the position to show

the character string.

Size:

Set the front size of

the character string.

Color:

Set the character color

and the background

color.

Designing Screens

Page 18

18

2. Click the ON Button. Click the COPY from OFF Button. Then the setting for OFF is copied to

ON. The two have the same setting.

1) ON/OFF:

Click the ON Button.

2) Click the COPY from

OFF Button.

Click!!

3. Change the character color for ON to white.

After setting, click the OK Button to close the setting dialog box. This completes creating a

switch part.

1) Change the

character color

to white.

Confirming the part ON/OFF state by preview

Select the part. Change the status between OFF and ON by the Parts State Button on the

toolbar and check the displays.

Parts State

OFF (Normal) ON (When pressed)

1) Select a part. (You

can select multiple

parts.)

2) Switch the ON/OFF

state by the Parts

State Button.

Page 19

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

19

Creating Lamp Parts

A lamp part changes the display color when the specified bit in the PLC

turns ON and OFF.

Example of creating a lamp part

The lamp changes color depending on the ON/OFF state of CIO 10.00 in the PLC.

The lamp is white when CIO10.00 is OFF. It

turns black when CIO10.00 is turned ON.

Bit OFF

Bit ON

Creating a lamp part

Drag a lamp part from the library and drop it at any desired space on the base screen.

Drag and drop!!

Designing Screens

2) Use the part Lamp0.

1) Use the Parts Library

Standard (NV3W-V1).

Page 20

20

Setting the function for the lamp part

Double-click the lamp part. Select the Basic Setup Tab. Set the ON/OFF Bit Field. Click the OK

Button to close the dialog box. This completes creation of the lamp part.

ON/OFF Bit:

Set the bit address of the PLC.

Page 21

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

21

Creating Data Parts

Create data parts which display the contents of addresses in the PLC on the

PT screen. Data parts can be used for indication only (no entries allowed) or

for changing the values from the keyboard screen as well.

Example of creating a data part

This data part indicates the value of D100 in the PLC in a decimal number.

The keyboard screen appears by touching the part. Enter a value on the keyboard and

change the value for D100.

Creating a data part

Drag a data part from the library and drop it at any desired space on the base screen.

1) Use the Parts Library

Standard (NV3W-V1).

2) Use the part Data.

Drag and drop!!

The screen changes to the

keyboard screen.

Enter a numeric valueTouch the part

Designing Screens

Page 22

22

Setting the function for the data part

Double-click the data part. Select the Basic Setup Tab. Make a necessary setting as shown

below. Note: This example uses the default setting.

Address:

Set the PLC word address.

Data to Display:

Set Number of Digits, Data

Format and Zero Suppression.

Note: Select ASCII for Data Format

when the data is indicated or

entered as a character string.

Setting to enable or disable input and other setting items

Click the Input Tab. Select On. Make the input settings.

Click the OK Button to lose the setting dialog box. This completes the data part setting.

Supported Keyboard:

Specify the keyboard input method.

Keyboard Screen:

Input after switching to the keyboard

screen.

Keyboard Parts:

Input from the keyboard part that is on the

same screen as the data part.

Input:

Select either On to enter values from the

screen or Off not to do it.

Note: When the Off is selected, the part is for

indication only (no entry allowed).

Startup Condition:

Select the value input timing.

Conditions

When the specified bit address satisfies

the conditions, the data part enables

inputs.

Page 23

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

23

Creating Keyboard Screens

Create a keyboard screen to enter values for the data part.

Creating a keyboard screen

1. Select File – Keyboard Screen from the menu bar.

Click!!

2. The Edit Keyboard Screen Dialog Box will be displayed. Click [ ] 0, and then click the Draw

Button to open the keyboard screen No. 0.

Click!!

Example of creating a keyboard screen

On this keyboard screen, you can enter decimal numbers and signs. Also you can

confirm the values entered from the keyboard before they are set.

Designing Screens

Page 24

24

Creating a keyboard part

Drag a keyboard part from the library and drop it at any desired space on the keyboard screen.

1) Use the Parts Library

Standard (NV3W-V1).

3) Use the part DEC

Sign1.

Drag and drop!!

2) Click the Parts Group

Selection Button, and

then select Keyboard.

* Parts are displayed by

type.

Setting the function for the keyboard part

Double-click the keyboard part. Select the Basic Setup Tab. Make a necessary setting as

shown below. Note: This example uses the default setting.

Click the OK Button to close the dialog box.

Image:

The setting can be checked here.

Clicking a key will show the key setting dialog

box. You can change the setting for each key.

Number of Keys:

Set the vertical (column) and

horizontal (row) number of keys.

Click!!

Key Size:

Specify the size (height/width)

of keys.

Change the Keyboard:

Keyboard keys can be

selected among upper case,

lower case, and

alphanumerical + symbols.

When On is selected, specify

the keyboard number between

1 and 8.

Page 25

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

25

Creating a data part

Place a data part to show the value entered from the screen.

Drag a data part from the library and drop it at any desired space on the keyboard screen.

1) Use the Parts Library

Standard (NV3W-V1).

3) Use the part Data.

Drag and drop!!

2) Click the Parts Group

Selection Button, and

then select Data.

Setting the function for the data part

Make a necessary setting as shown below. Note: This example uses the default setting.

Click the OK Button to close the dialog box. This completes creating a keyboard screen.

Data to Display:

Set the number of digits.

Designing Screens

Page 26

26

Creating Character Strings

This section explains the procedures to show texts or character strings on a

screen. It also describes how to change the character attributes such as

font, size and color. This way, the character string will stand out.

Example of creating a character string

In this example, the character string “Value” is outlined.

Creating a character string

1. Click the Character String Button on

the graphic bar

2. Click the position on the base screen where

you want to input a character string.

3. Enter a character string.

4. Click the Character Type Button on the

graphic bar.

5. The Character Attributes Dialog Box will be displayed. Select the Outlined Check Box.

Click the OK Button to close the setting dialog box. This completes creating a character string.

Click!!

Page 27

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

27

To show a picture image such as bitmap on the NV screen

The NV-series PTs can display picture images such as bitmap images.

You can paste images from the Windows clipboard to the NV screens.

1. On the workspace of graphic software such as MS Paint, open an image file to show on

the NV.

2. Select the range of the image to show on the NV and copy it.

3. On the NV-Designer, open the screen to paste the image. Right-click on the screen and

select Paste from the context menu. Alternatively, press Ctrl + V to paste the image.

Right-click!!

1) Select Paste.

Note: Images that are larger than the screen (NV3W-V1: 240 x 96 (W x H), NV4W: 320 x 120 (W

x H), NV3Q: 320 x 240 (W x H) ) cannot be pasted. Scale down the image to any size

smaller than the screen before you paste it.

Designing Screens

Right-click!!

<MS Paint>

1) Select the range.

(Press Ctrl + A to select all)

2) Right-click the image, and

select Copy from the

context menu. Alternatively,

press Ctrl + C to copy the

image to the clipboard.

Page 28

28

Transferring Screen Data

Transfer the created screen data to the NV.

Setting the transfer method

1. Select PT – Transfer – Transfer from the menu bar.

Click!!

2. Select USB in the Communication Method Field. Click the OK Button to close the Transfer

Data Dialog Box.

1) Communication Method:

Select USB.

When using an NV3W

Select RS232C in the Communication Method Field.

Page 29

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

29

Transferring the screen data

1. Set the transfer direction and data to transfer. Then transfer the data to the NV

1) Direction:

Select NV-Designer -> NV.

2) Data to Transfer:

Select the All

Data Check Box.

3) Click the OK Button to

start transferring.

The Transfer Data Dialog

Box closes.

Click!!

Use the shortcut Ctrl + T

Transfer is a frequently used operation. Use the shortcut for your convenience.

Transfer Data After Clear NV Screen:

When this check box is not selected, the NVDesigner will delete the screen data, but any

transferred data will not be deleted from the NV.

This method requires less transfer time.

When the message “Memory is full” is shown on

the screen, select this check box before

transferring the data.

Connecting with

CPIE PLC

2. When the transfer is completed, the screen is shown on the NV.

Page 30

30

“Screen No. Error” is displayed on the screen

The system memory has an area that is used to switch the NV screen from the PLC. If the

same screen No. stored in the area does not exist in the screen data, the error message

“Screen No. Error” is displayed on the screen.

As for the screen data created in this handbook, the area is allocated to D0 in the PLC.

Write “0” for the base screen 0 to D0 in the CX-Programmer.

Write “0” to D0.

Monitoring or changing the PLC parameters from the CX-Programmer

After connecting the NV and CP1E, confirm NV screen operations. This step is explained

in the next few pages. This subsection explains the Watch Window to monitor and

change the contents of PLC addresses from the CX-Programmer.

< Opening the Watch Window >

Select View –Window –Watchfrom the menu bar,

Double-click!!

Enter an address.

Enter a value.

< Monitoring the parameter values >

Double-click on the Watch Window. Enter an address to monitor.

When the PLC is connected online, the present value will be displayed.

< Changing values of addresses >

When the PLC is connected online, double-click on the line of the address in the Watch Window to

change the value.

Enter a hexadecimal value using a prefix of "#". (e.g. #1A)

Enter a decimal value using no prefix or a prefix of "&". (e.g.1234, &1234)

Specify the data type.

* The v alues cannot be changed when the PLC is in Run mode.

Change the PLC mode to Monitor (program is running) or Program (program is not executed) before changing values.

Page 31

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

31

Checking Operation

Check operation of the parts on an actual NV.

Checking operation of the switch and lamp

1. While you press the RUN switch, 2. When you release your finger from

the RUN switch,

the lamp lights.

the lamp goes off.

Checking operation of the data part and keyboard

When you touch the data part, the keyboard screen appears. You can enter a value.

The screen changes to

the keyboard screen.

Enter a numerical value.Touch the part.

If the power supply is interrupted for longer than the I/O memory backup time, values that

the NV writes to the DM Area of the CP1E are not backed up.

The contents in the DM Area data can be backed up to the backup memory by turning ON a

bit in the Auxiliary Area.

When using a CP1E PLC without a battery

Connecting with

CPIE PLC

Page 32

32

Switching Screens from CP1E

Switch the NV screen from the CP1E PLC by using its system memory.

Creating a new screen in an existing project

Add a base screen to an existing project. The screen is used to confirm the screen

switching operation.

1. Start the NV-Designer, and open a project.

Double-click “1” in the Screen Manager. Base screen 1 will open.

Double-click!!

2. Create a character string, and enter “Base scr. 1”. Place it at the center of the screen.

Transfer the screen data to the NV.

Base screen 1

Page 33

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

33

Setting and confirming the system memory

1. Select PT – NV Configuration from the menu bar.

Click!!

2. Click the Basic Setup Tab. In the System Memory Area Field, you can set or confirm the

allocated address.

Word area memory map (First address = N)

N: Screen number from PLC (PLCNV)

N+1: Do not use.

N+2: Current screen number (NVPLC)

Word Area:

- Screen number from PLC

This word contains the number in binary of

the screen specified by the PLC for the NV to

display.

- Current screen number

This word contains the number in binary of

the screen currently displayed by the NV.

Note: Cannot be specified in BCD.

Switching the screen from the CP1E PLC

1. Write “&0” to D0 to

display Screen 0.

2. Write “&1” to D0 to

display Screen 1.

When the screen has

been switched, “&0” is

notified to D2.

When the screen has

been switched, “&1” is

notified to D2.

On the CX-Programmer, overwrite the D0 value to switch the screens.

Advanced Usage

Advanced Usage

Page 34

34

The backlight will light in the color set in the screen properties (PT – Screen Property from

the menu bar).The backlight setting can be confirmed on the title bar of each base screen.

When the Backlight Control Enable Bit is OFF

Changing Backlight Colors from CP1E

Change the backlight color from the CP1E system memory.

* The NV3Q-SWxx (color) can be set backlight ON and OFF only.

Setting and confirming the system memory

The backlight is controlled in the Bit Area of the system memory.

Check the address allocated to the Bit Area in the System Memory Area Field on the Basic

Setup Tab Page of the NV Configuration Dialog Box.

Changing the backlight color from the CP1E

Change the values of W0.10 to W0.13 on the CX-Programmer to change the backlight status.

Set the bits for the backlight color and backlight light/blink, and then turn ON the Backlight

Control Enable Bit. (This is the example of NV3W-MGxxx-V1.)

Bit Area (First address = N)

* Backlight-related info only

N Bit10

N Bit11

N Bit12: Backlight lit (OFF)/flashing (ON)

N Bit13: Backlight Control Enable Bit

(OFF): Disables Bit10-12 settings

(ON): Enables Bit 10-12 settings

Backlight color. See the table below.

State of N Bit10 and Bit11

Bit10=OFF

Bit11=OFF

Bit10=ON

Bit11=OFF

Bit10=OFF

Bit11=ON

Bit10=ON

Bit11=ON

NV3W-MGxx(x)-V1 (Monochrome)

NV4W-MGxx (Monochrome)

Off Green Red Orange

NV3W-MRxx(x)-V1 (Monochrome)

NV4W-MRxx (Monochrome)

Off White Red Pink

NV3Q-MRxx (Monochrome) Off White Red Pink

NV3Q-SWxx (Color) Off On On On

* Backlight color specifications

Green, Light

W0.10: ON

W0.11: OFF

W0.12: OFF

W0.13: ON

Red, Blink

W0.10: OFF

W0.11: ON

W0.12: ON

W0.13: ON

(e.g. : Red, Blink)

Page 35

NV-series PT Simple Operation Handbook

Advanced Usage

Advanced Usage

Connecting with

CPIE PLC

Designing Screens

Preparation

35

Connecting PC and PLC via NV

Connect the PC and the PLC via the NV to transfer the ladder programs from

the PC (CX-Programmer) to the PLC and to monitor the PLC from the PC.

Configuration example

In this configuration, you can transfer the ladder programs and monitor the PLC from the

CX-Programmer through the NV.

PC

NV3W-V1/NV4W/NV3Q

Host Link

SYSMAC - CS / CJ / CP Series

PC connection cable

Setting

1. On the CX-Programmer, open a project of a CS, CJ or CP-series PLC.

Double-click the PLC in the project tree. The Change PLC Dialog Box will appear.

Double-click!!

2. Set Network Type to NV-Thru (USB Port). Click the OK Button.

3. Connect the PLC online.

The CX-Programmer and the NV-Designer use the same USB port. Therefore, only one of them is

online-connected with the NV at a time.

You can also connect the PLC through the NV with the CX-Programmer by selecting Auto Online -

Direct Connection from the PLC menu.

*The NV requires no setting.

Advanced Usage

Advanced Usage

Page 36

2015

0715 (0110)

V411-E1-02

Loading...

Loading...