Page 1

Cat. No. V103-E1-06

NV Series

NV3W(-V1)

NV4W

NV3Q

Programmable Terminals

SETUP MANUAL

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Trademarks

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

NV Series

NV3W(-V1)

NV4W

NV3Q

Programmable Terminals

Revised May 2015

Page 4

iv

Page 5

Notice

Precautions

for Sa fe Use

Precautions

for Correct Use

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury . Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury . Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this man ual. The w ord “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller.

The abbreviation “host” means a controller, such as an IBM PC/AT or compatible computer, that con-

trols a PT (Programmable Terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

CS1G-CPU@@-V1 Boxes in model numbers indicate v ariable characters. For example, “CS1G-CPU@@-

Indicates precautions on handling the product to ensure that the product is used safely.

Indicates precautions to ensure that product functions and performances are realized, to

ensure that the reliability of the product is maintained, and to ensure that the product is

otherwise used correctly.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

Reference Indicates supplementary information on procedures, descriptions, and settings.

1,2,3... 1. Indicates lists of one sort or another , such as procedures, checklists, etc.

EV1” indicates the following models: CS1G-CPU42-EV1, CS1G-CPU43-EV1, CS1GCPU44-EV1, and CS1G-CPU45-EV1.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features of NV-series PTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1-6 System Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SECTION 2

Part Names, Functions, and Internal Configuration. . . . . . 33

2-1 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2-2 Internal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION 3

Preparations for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-1 Preparations for Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SECTION 4

Installing and Wiring the PT. . . . . . . . . . . . . . . . . . . . . . . . . 45

4-1 Installing the PT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-2 Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-3 Communications/Power Connector Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-4 Wiring the Power Supply and Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4-5 Precautions When Grounding (24-V Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4-6 Starting an NV-series PT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SECTION 5

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5-1 Configuration Settings from the System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5-2 Self-diagnosis from the System Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SECTION 6

Connecting and Setting PLCs or Temperature Controllers 97

6-1 Connecting and Setting an OMRON PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6-2 PT Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6-3 PLC Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-4 SPMA (Single Port Multiple Access) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 07

6-5 Connecting to EJ1 Temperature Controllers Using Modbus-RTU . . . . . . . . . . . . . . . . . . . . 110

vii

Page 8

TABLE OF CONTENTS

SECTION 7

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . 113

7-1 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 14

7-2 Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7-3 Troubleshooting the NV3W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7-4 Troubleshooting the NV3W-V1, NV4W or NV3Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7-5 Error Codes and Countermeasures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

viii

Page 9

About this Manual

This manual describes installing and setting up the NV -series PTs and includes the sections described

below .

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate an NV -series PT. Be sure to read the precautions provided in the following section.

Precautions

This section provides general precautions for using the NV-series PTs and related devices.

Section 1 Overview

This section introduces the NV-series PTs, including the system configuration, a vailable models, and

specifications.

Section 2 Part Names, Functions, and Internal Configuration

This section describes the functions of the various parts of an NV-series PT and how the NV-series

PTs operate internally.

Section 3 Preparations for Operation

This section outlines the steps required to prepare an NV-series PT for operation.

Section 4 Installing and Wiring the PT

This section describes how to install and wire an NV-series PT and start the PT for the first time.

Section 5 System Menu

This section describes the operations and settings that can be performed on the System Menu of an

NV-series PT.

Section 6 Connecting and Setting PLCs or Temperature Controllers

This section provides inf ormation and procedures required to connect an NV-series PT to an OMR ON

PLC.

Section 7 Maintenance and Troubleshooting

This section describes the maintenance and inspections required for NV-series PTs and provides

troubleshooting information for when problems occur with NV-series PTs.

ix

Page 10

x

Page 11

Related Manuals

This

Manual

The following manuals are used for NV-series PTs. (The boxes at the end of the catalog

numbers indicate the revision code.)

NV-series PT Setup Manual..................................... V103-E1-@

This manual describes how to connect an NV-series PT to an OMRON PLC, features and

specifications, methods to set up communications and operation, and procedures for

maintenance and troubleshooting.

Refer to the NV-series PT Programming Manual (V104-E1-@) for more information on PT

functions and specific operating procedures.

NV-series PT Programming Manual......................... V104-E1-@

This manual describes the software functionality of NV-series PTs, how to install the NVDesigner, and the features of the NV-Designer.

For more information on NV-Designer operating procedures, refer to the online help in the

NV-Designer.

NV-series PT Host Connection Manual.................... V105-E1-@

This manual describes how to connect an NV-series PT to a PLC produced by a man u facturer other than OMRON, including PLC memor y ar ea designat ions, communications settings, and connection method s.

xi

Page 12

Terminology

The following terminology is used in this manual.

PT In this manual, indicates an NV-series Programmable Terminal.

NV Series Indicates products in the OMRON NV Series of Programmable Terminals.

PLC Indicates a Programmable Controller in the OMRON SYSMAC CS/CJ/CP,

C, or CVM1/CV Series of Programmable Controllers.

CPU Unit Indicates a CPU Unit in the OMRON SYSMAC CS/CJ/CP, C, or CVM1/CV

Series of Programmable Controllers.

NV-Designer Indicates the OMRON NV -Designer.

Host Indicates the PLC, IBM PC/AT or compatible computer, or personal com-

puter functioning as the control device and interfaced with the NV-series PT.

xii

Page 13

Introduction

● Intended Audience

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

● General Precautions

• T he user must operate the product according to the performance specifications

described in the operation manuals.

• Do not use the PT touch switch input functions for applications where danger to

human life or serious property damage is possible, or for emergency switch applications.

• Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines and equipment that may have a serious

influence on lives and property if used improperly, consult your OMRON representative.

• Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems,

machines, and equipment with double safety mechanisms.

• This manual provides information for connecting and setting up an NV-series PT. Be

sure to read this manual before attempting to use the PT and keep this manual close

at hand for reference during installation and operation.

xiii

Page 14

Safety Precautions

Notation Used for Safety Information

The following notation is used in this manual to provide precautions required to ensure

safe usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Definition of Precautionary Information

!WARNING

Symbols

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Prohibition

Indicates a general prohibition.

Caution

Indicates general cautionary, warning, or danger level information.

!WARNING

Always ensure that the personnel in charge confirm that installation,

inspection, and maintenance were properly performed for the PT. “Personnel in charge” refers to individuals qualified and responsible for

ensuring safety during machine design, installation, operation, maintenance, and disposal.

Ensure that installation and post-installation checks are performed by

personnel in charge who possess a thorough understanding of the

machinery to be installed.

Do not use the input functions of the PT, such as the function switches

or switches on the touch panel, in applications that involve human life,

in applications that may result in serious injury, or for emergency stop

switches.

Do not attempt to disassemble, repair, or modify the PT. Doing so may

impair the safety functions.

Do not attempt to take the Unit apart and do not touch any internal

parts while the power is being supplied. Doing either of these may

result in electrical shock.

The PT uses an analog touch panel. Never press more than two points

on the panel at a time. Otherwise, it may activate a switch somewhere

between the two points.

xiv

Page 15

Precautions for Safe Use

1. When unpacking the Units, chec k carefully for any external scratches or other damage.

Also, shake the Units gently and check for any abnormal sound.

2. The PT must be installed in a control panel.

3. The mounting panel must be between 1.6 and 4.8 mm thick. Tighten the Mounting

Bracket s evenly to a torque of b etw een 0 .1 and 0 .25 N· m for the NV3W/NV3Q and between 0.2 and 0.3 N·m f or the NV3W- V1/NV4W to maintain water and dust resistance.

Make sure the panel is not dirty or warped and that it is strong enough to hold the Units .

4. Do not let metal particles enter the Units when preparing the panel.

5. Do not connect an AC power supply to the DC power terminals.

6. Do not perform a dielectric voltage test.

7. Use a DC power supply that will provide a stable output ev en if the input is momentarily

interrupted for 10 ms, and which has reinforced or double insulation.

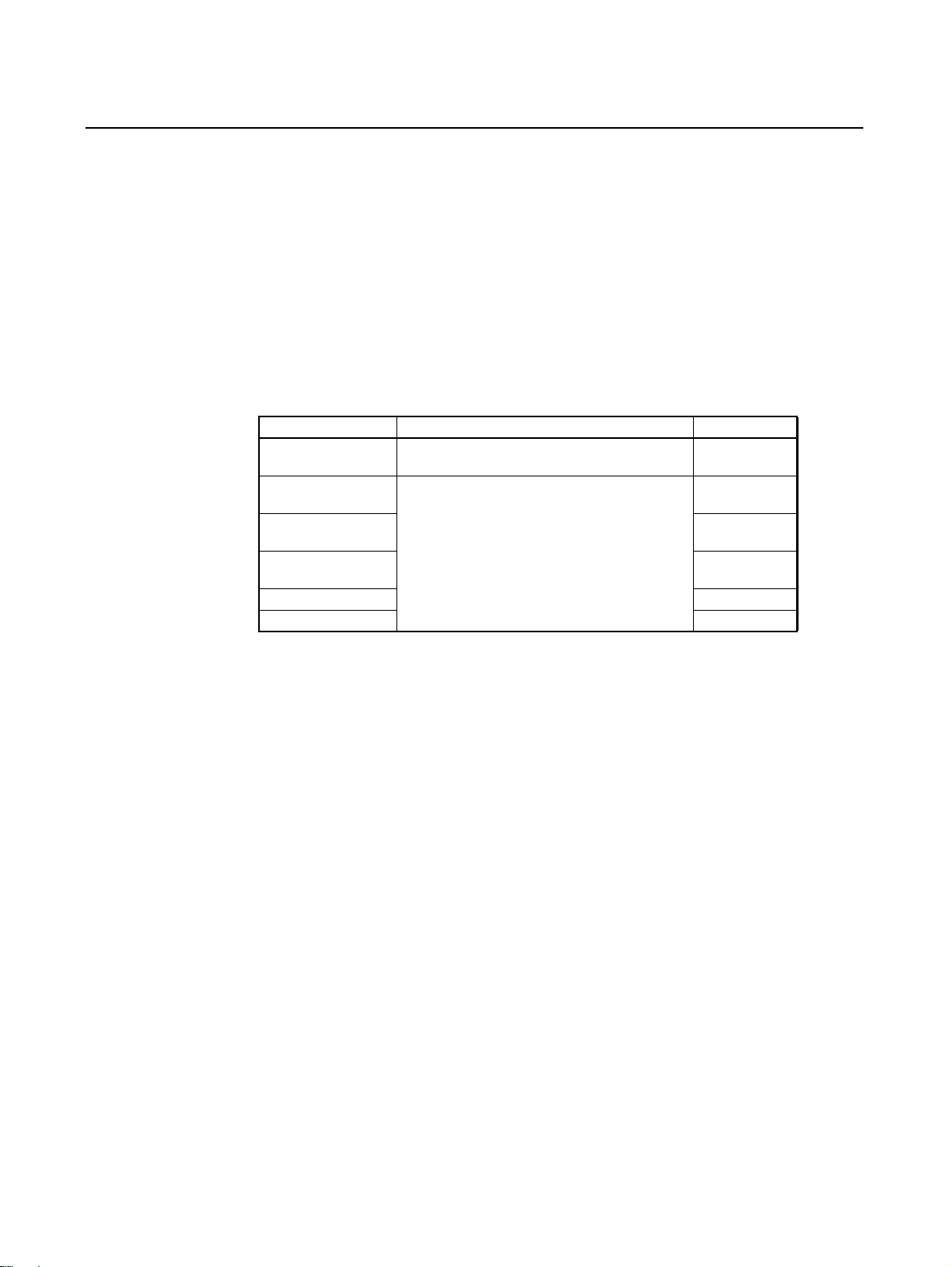

Model Rated power supply voltage Capacity

NV3W-M@20L

NV3W-M@20L-V1

NV4W-M@21

NV4W-M@41

NV3W-M@20

NV3W-M@40

NV3W-M@20-V1

NV3W-M@40-V1

NV3Q-MR@@ 2.4 W min.

NV3Q-SW@@ 3.6 W min.

8. Use a twisted-pair cable to connect to the po wer terminals. Tighten the terminal screws

to a torque of between 0.22 and 0.30 N·m. Make sure the screws are properly tightened.

9. To prevent malfunctions caused by noise, ground the PT correctly.

10. Do not touch the surfa ce of the circuit boards or the componen ts mounted on them with

your bare hands. Discharge any static electricity from your body before handling the

boards.

11. Turn OFF the power supply before connecting or disconnecting cables.

12. The maximum tensile load for cables is 30 N. Do not apply loads greater than this.

13. Confirm the safety of the system before turning ON or OFF the power supply.

14. Cycle the power supply after changing the DIP switch settings.

15. Do not perform the following operations while the SD memory card is being accessed

(NV4W and NV3Q only):

• Turning OFF the power supply to the PT

• Removing the memory card

Always follow the specified procedure when removing the memory card.

16. Start actual system application only after sufficiently checking screen data and t he operation of the program in the PLC (host).

17. Do not press the touch switch with a force greater than 30 N.

18. Do not use a screwdriver or any ot her tool to press a touch switch.

19. Confirm the safety of the system before pressing any touch switch.

20. Do not accidentally press touch switches whe n the backlight is not lit or when the display does not appear . Conf irm the safety of the system bef ore pressing touch s witches .

5 VDC (allowable range: 4.5 to 5.5 VDC) 1 W min.

24 VDC (allowable range: 21.6 to 26.4 VDC) 1.7 W min.

2 W min.

1.9 W min.

xv

Page 16

21. Before initializing screen data, co nfirm that existing data is back ed up at the NV -Designer.

22. When changing the password with the system menu, do not reset or turn OFF the pow-

er supply until writing is finished.

23. Before using the SPM A function to change memory values in the PLC or tr ansfer ladder

programming, confirm that the PT is oper ating. The SPMA fu nction cannot be used unless the PT is operating.

24. Dispose of any battery that has been dropped on the floor or otherwise subject ed to

excessive shoc k.

25. Dispose of the Units and batteries according to local ordinances as they apply.

26. When mounting the Battery, be sure to use the correct Battery and mount it correctly.

27. Do not disassemble or short-circuit the battery.

28. Do not connect a USB connector to any device that is not applicable.

29. Before connecting a USB connector to a device, make sure that the device is free of

damage.

30. Do not turn OFF the power supply to the PT while downloading or uploading screen

data or the system program. Doing so ma y corrupt the screen data or system pr ogr am.

31. Periodically inspect the installation condition of the PT if it is being used in an environ-

ment subject to contact with water.

32. The whole system may stop depe nding on how the po wer su pply is turned ON or OFF.

Turn ON or OFF the power supply according to the specified procedure.

33. Signals from the touch switches may not be input if the switches are p ressed consecu-

tively at high speed. Confirm each input before proceeding to the next one.

34. To use numeric input functions safely, always make maximum and minimum limit set-

tings.

35. Do not use benzene, pa int thinner , or other v olatile solv ents, and do not use chemically

treated cloths.

36. The PT uses an analog touch panel. De terioration over time can cause the touch points

to move. Calibrate the touch panel if the touch points move too much.

37. Water resistance will be lost if the front sheet is torn or is peeling off. Do not use the PT

if the front sheet is torn or is peeling off.

38. The Rubber Packing will deteriorate, shrink, or harden depending on the oper ating en-

vironment. Inspect and replace the Rubber Packing periodically (approximately once

per year).

39. T o use the NV3W in an environment with strong noise, connect the following noise filter

to the power supply line:

RSEL-2001W manufactured by TDK-Lambda Corp.

40. A Waterproof Packing cannot be reused. To ensure waterproof performance, replace

the Waterproof Packing with a new one each time you reinstall the PT.

41. Screen burn-in will occur if the same pattern is continuously displayed for a long period

of time (24 hours or longer, as a guideline). To prevent screen burn-in, use a screen

saver or switch displays periodically (NV3W only).

xvi

Page 17

Precautions for Correct Use

1. Do not install the PT in any of the following locat ions.

• Locations subject to rapid changes in temperature

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of high humidity

• Locations subject to splashing chemicals or solvents

• Locations subject to oil splashes

• Locations subject to continuous water splashing

• Locations subject to corrosive or flammable gases

• Locations subject to strong shock or vibration

• Locations outdoors subject to direct wind and rain

• Locations subject to strong ultraviolet light

• Locations subject to dust

• Locations subject to direct sunlight

2. T a ke appropriate and sufficient countermeasures when installing systems in the following locations.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic or magnetic fields

• Locations close to power supply lines

• Locations subject to possible exposure to radioactivity

xvii

Page 18

Conformance to EC Directives

This product is EMC compliant.

● Concepts

OMRON products are electronic devices that are incorporated in machines and manufacturing installations. OMRON PTs conform to the related EMC Directives (see note) so that

the devices and machines into which the y are built can more easily conform to EMC directives. However, customers may use a wide variety of equipment and manufacturing installations. Therefore the customer must check whether the Directives are satisfied for the

actual system. EMC-related performance will vary depending on the configuration, wiring,

and other conditions of the equipment or control panel in which the PT is installed. The

customer must, therefore, perform final checks to confirm that the overall machine or

device conforms to EMC standards.

Note The applicable EMC (Electromagnetic Compatibility) standards for NV-series

PTs are as follows:

NV3W: EN 61000-6-2, EN 61000-6-4

NV3W-V1/NV4W or NV3Q: EN 61131-2

● Conformance to EC Directives

NV-series PTs conform to EC Directives. To ensure that the machine or device in which

the NV-series PT is used complies with EC Directives, the PT must be installed as follows:

• The NV-series PT must be installed in a control panel.

• You must use reinforced insulation or double insulation for the DC power supply and

the DC power supply must ha ve minimal voltage fluctuations and provide a stable output even if the power supply input is interrupted for 10 ms.

• NV-series PTs complying with EC Directives also conform to the Common Emission

Standard (EN 61131-2 or EN 61000-6-4). Radiated emission characteristics (10-m

regulations) may vary depending on the configuration of the control panel used, other

devices connected to the control panel, wiring, and other conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

• This is a class A product. It may cause radio interf erence in r esidential are as, in which

case the user may be required to take adequate measures to reduce interference.

Conformance to KC Standards

Observe the following precaution if you use NA-series PTs in Korea.

Class A Device (Broadcasting Communications Device for Business Use)

This device obtained EMC registration for office use (Class A), and it is intended to be

used in places other than homes. Sellers and/or users need to take note of this.

xviii

Page 19

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

● Exclusive Warranty Omron’s exclusive warranty is that the Products will be free from defects in

materials and workmanship for a period of twelve months from the date of

sale by Omron (or such other period expressed in writing by Omron). Omron

disclaims all other warranties, express or implied.

● Limitations OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS. BUYER

ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED

USE.

Omron further disclaims all warranties and responsibility of any type for claims

or expenses based on infringement by the Products or otherwise of any intellectual property right.

● Buyer Remedy Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace

(in the form originally shipped with Buyer responsible for labor charges for

removal or replacement thereof) the non-complying Product, (ii) repair the

non-complying Product, or (iii) repay or credit Buyer an amount equal to the

purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, re pair, indemnity or any other claims or

expenses regarding the Products unless Omron’s analysis confirms that the

Products were properly handled, stored, installed and maintained and not

subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or

the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given

orally or in writing, are not to be construed as an amendment or addition to

the above warranty.

Limitation on

Liability; Etc

See http://www.omron.com/global/ or contact your Omron representative for

published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

xix

Page 20

Application Considerations

Suitability of Use Omron Compan ies sha ll not be respon sible for conf ormity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer

shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable

Products

Omron Companies shall not be responsible for the user’s programming of a

programmable Product, or any consequence thereof.

Disclaimers

Performance Data Data presented in Omron Company websites, catalogs and other materials is

provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the

user must correlate it to actual application requirements. Actual performance

is subject to the Omron’s Warranty and Limitations of Liability.

Change in

Specifications

Errors and Omissions Information presented by Omron Companies has been checked and is

Product specifications and accessories may be chan ged at an y time ba sed on

improvements and other reasons. It is our practice to change part numbers

when published rating s or features are changed, or when significan t cons truction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish ke y specificat ions for your application. Please consult with your Omron’s representative at any time to confirm actual specifications of purchased Product.

believed to be accurate; however, no responsibility is assumed for clerical,

typographical or proofreading errors or omissions.

xx

Page 21

SECTION 1

Overview

This section introduces the NV-series PTs, including the system configuration, available models, and specifi cations.

1-1 Features of NV-series PTs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Features and Functions of NV-series PTs. . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-2 Connectable OMRON PLCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2-3 Connectable OMRON Temperature Controllers . . . . . . . . . . . . . . . 8

1-3 Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-1 NV-series PTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-2 Screen Design Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-3 Other Optional Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4-1 NV3W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4-2 NV3W-V1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-4-3 NV4W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-4-4 NV3Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-4-5 Battery Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1-5 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1-6 System Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-6-1 NV-series PT Models and System Versions . . . . . . . . . . . . . . . . . . . 30

1-6-2 NV System Version Upgrade Procedure. . . . . . . . . . . . . . . . . . . . . . 31

1

Page 22

Features of NV-series PTs Section 1-1

r

1-1 Features of NV-series PTs

The NV-series Programmable Terminals (PTs) are easy to use and compact.

1-1-1 Features and Functions of NV-series PTs

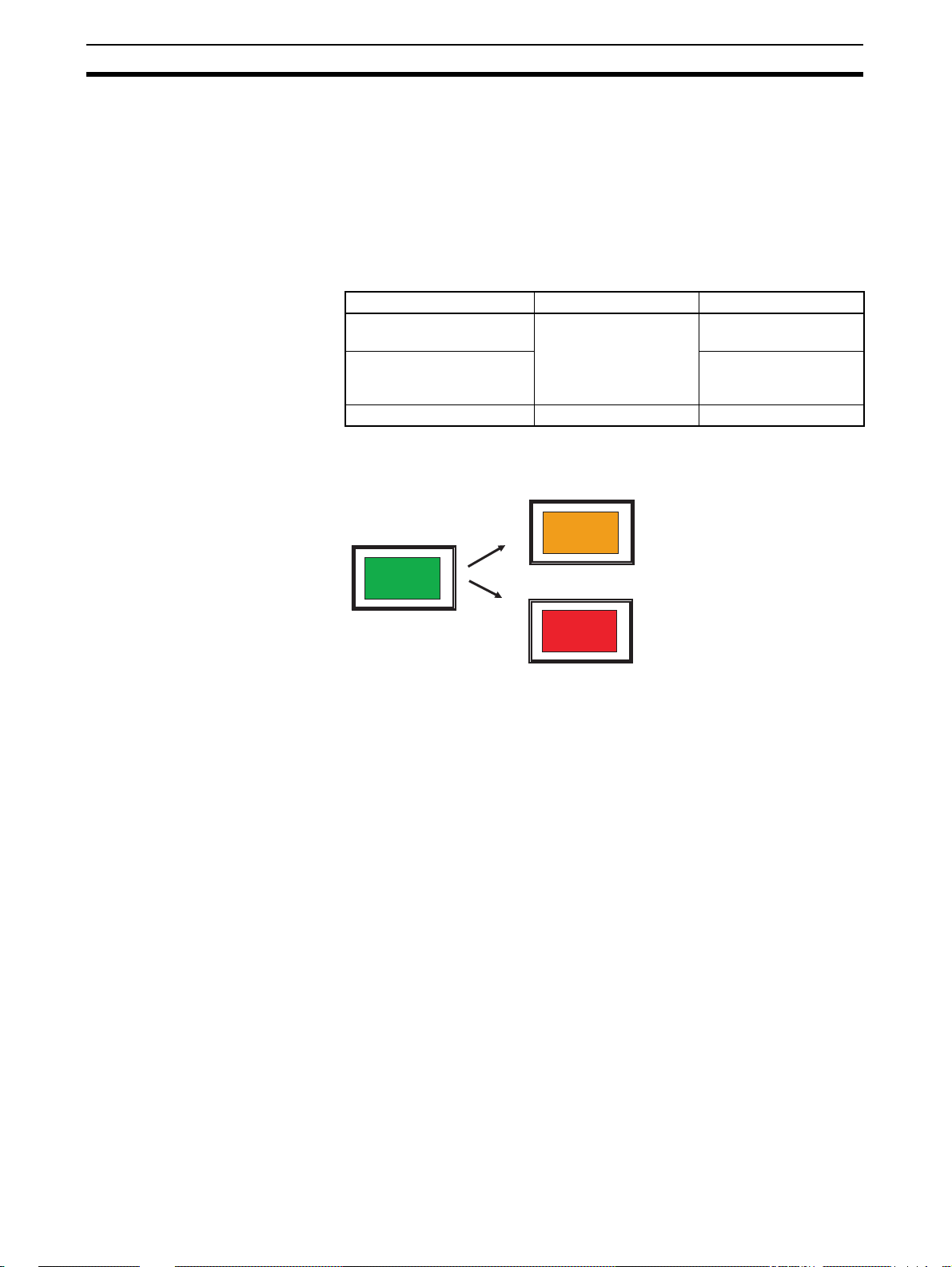

Models Available with

Color Backlight or

Monochrome Backlight

with Switchable Colors

• Switching the backlight of the NV3W(-V1) monochrome, NV4W monochrome, or NV3Q monochrome PTs lets you determine system status

from a distance.

• The NV3Q color PTs can display 4,096 colors.

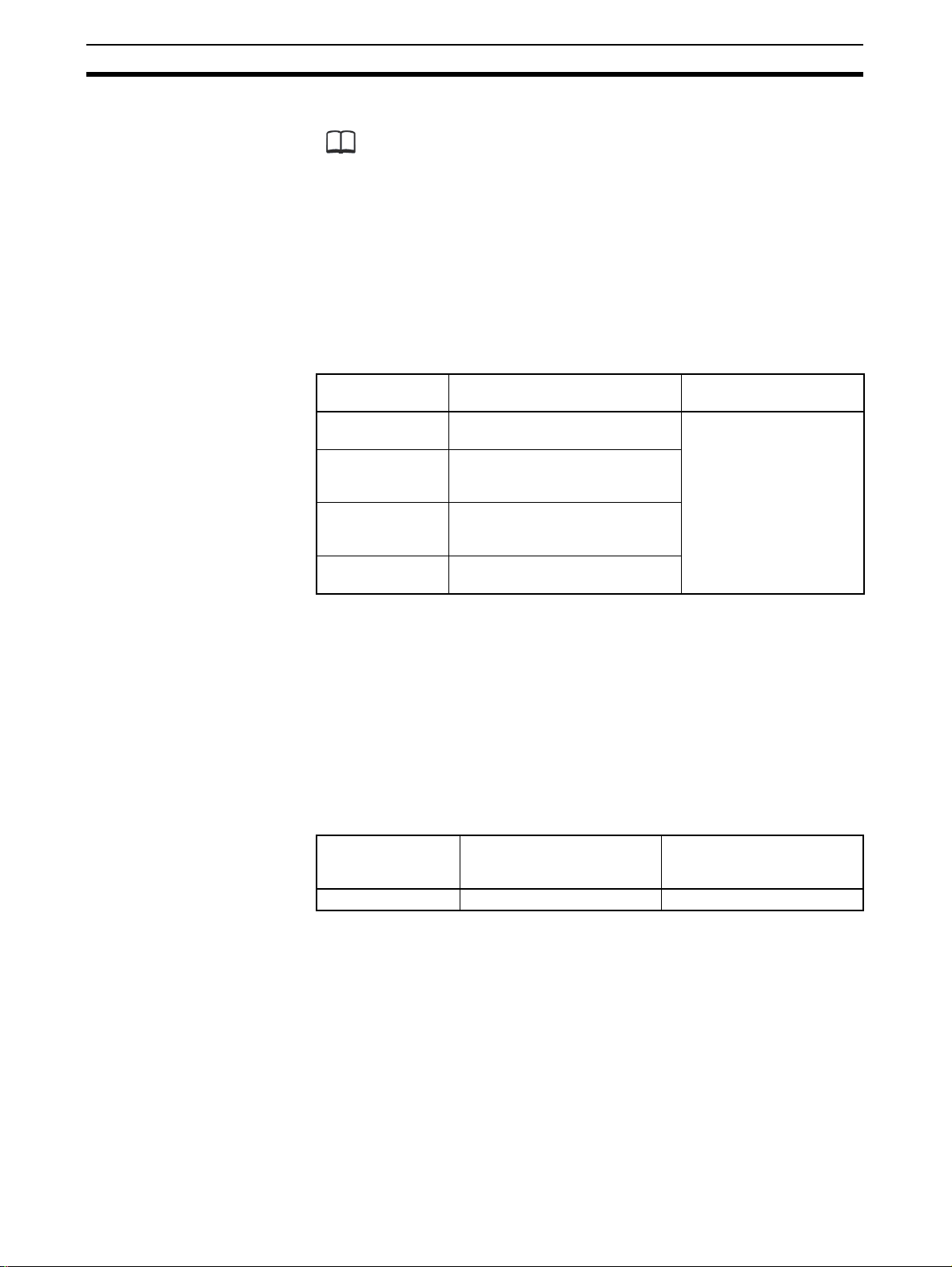

NV Series Display color Backlight color

NV3W-MG(-V1) and NV4WMG(-V1)

NV3W-MR(-V1), NV4WMR(-V1), and NV3Q monochrome

NV3Q color 4,096 colors ---

Application Example That Switches the Backlight Colo

Color That Indicates

Normal Operation

"Green"

Monochrome Green, orange, or red

White, red, and pink

Color That Indicates an Alarm

"Orange"

Color That Indicates an Alarm

"Red"

Bright LEDs, Eliminate the

Bright LED are used in the PT, eliminating the need to replace the backlights.

need to Replace

Backlights

Each Screen Creation The screens displayed on an NV-series PT are created on the NV-Designer.

Screens can be easily created by simply selecting parts from a library and

arranging them.

Parts are available to match the application that is used.

The NV3W is connected using a special RS-232C cable. The NV3W-V1,

NV4W or NV3Q is connected using a commercially available USB cable.

Convert the PT Model for

Screen Data

Communicate with

OMRON PLCs using Host

Link

The NV model conversion function enables screen data to be converted and

reused from a model with a small screen to one with a large screen.

You can connect the PT to an OMRON CP-series, CS/CJ-series, C-series, or

CVM1/CV- series PT using the Host Link protocol.

Communications with PLCs is possible using RS-232C or RS-422A connections.

Multivendor Support with

PLC Model Conversion

You can connect the PT to OMRON PLC or many other global PLC manufacturers.

Even if you are using different PLCs for different systems, you can easily convert the PLC model in the screen data.

Supply Power to the PT

via the PLC Connecting

Cable (NV3W(-V1) Only)

With 5-V NV3W(-V1) models, 5 V can be supplied from the CS/CJ-series or

CP-series PLC via the PLC Connecting Cable. This eliminates the need for a

power supply for the PT, thereby reducing wiring work.

2

Page 23

Features of NV-series PTs Section 1-1

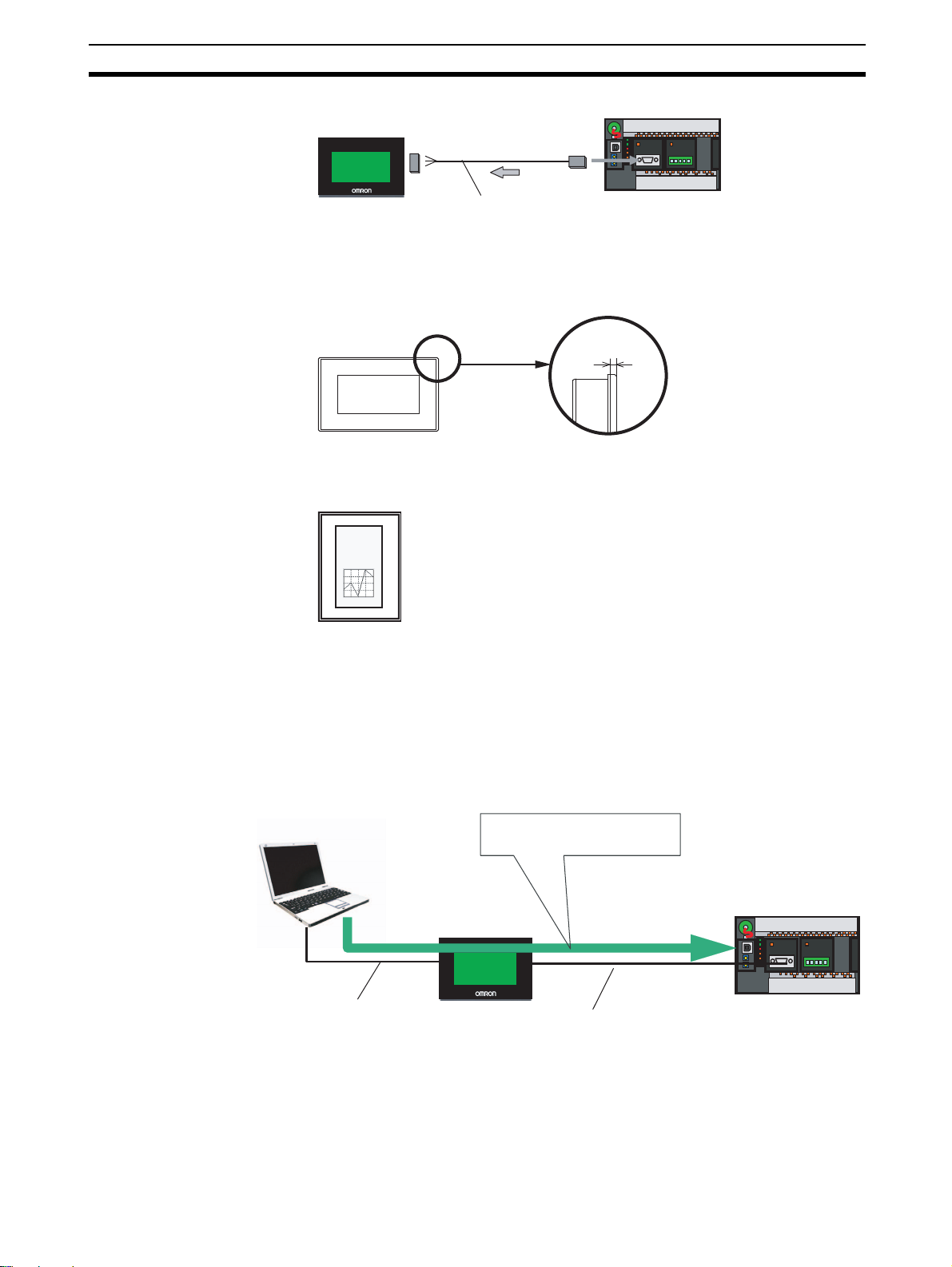

CS/CJ-series or CP-series PLC

NV3W-M@20L

Host Link connection

PLC Connecting Cable

with 5-V Line

Space-saving Installation The compact size and thin design save space when mounting.

With the edge protruding only 4 mm from the panel surface, the PT is also

attractive in appearance.

The NV3W(-V1) or NV4W can be installed vertically for vertical screen displays.

5-V power supply

4 mm

Construction with

Resistance to the

Environment

Transfer, Monitor, or

Debug Ladder Diagrams

from the CX-Programmer

Connected to the PT

Computer running NV-Designer

Temperature

Monitor

SP: 300

PV: 299

The NV3W and NV3Q provide IP65 protection against dust and water drops.

The NV3W-V1 and NV4W provides IP67 protection.

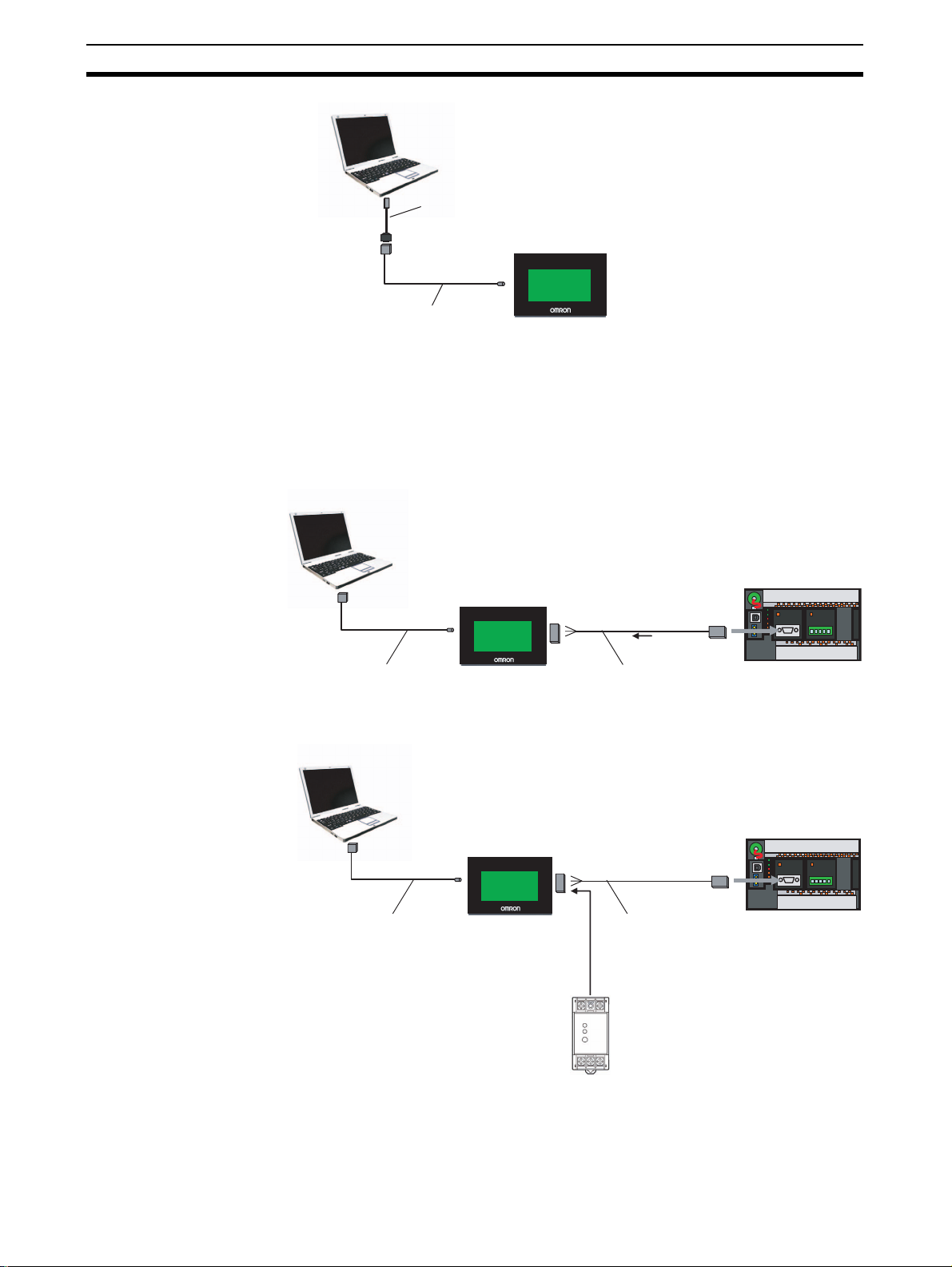

You can transfer, monitor, or debug ladder diagrams in a PLC from the CXProgrammer running on a computer connected to the PT with the convenient

SPMA (Single Port Multiple Access) function while the PLC and PT are communicating with each other.

This function is effective during system installation and debugging.

CX-Programmer

Communicate through the PT.

Ladder diagrams can be transferred

and the PLC can be monitored from

the CX-Programmer.

CS/CJ/CP-series PLC

Host Link connection

Use the same cable as

for the NV-Designer.

Reduce the Load on the

PLC with the Write

Address Function

Also, there is no need to change the

cable between the PT and PLC.

Note The CX-Programmer and NV-Designer, however, cannot be con-

nected online at the same time.

You can use the W rite Address fu nction to execute operations to set or reset

bits, set values, perform calculations, and more in PLC memory when conditions in the PLC are met. This reduces the load on the ladder program in the

PLC in communicating with the PT.

3

Page 24

Features of NV-series PTs Section 1-1

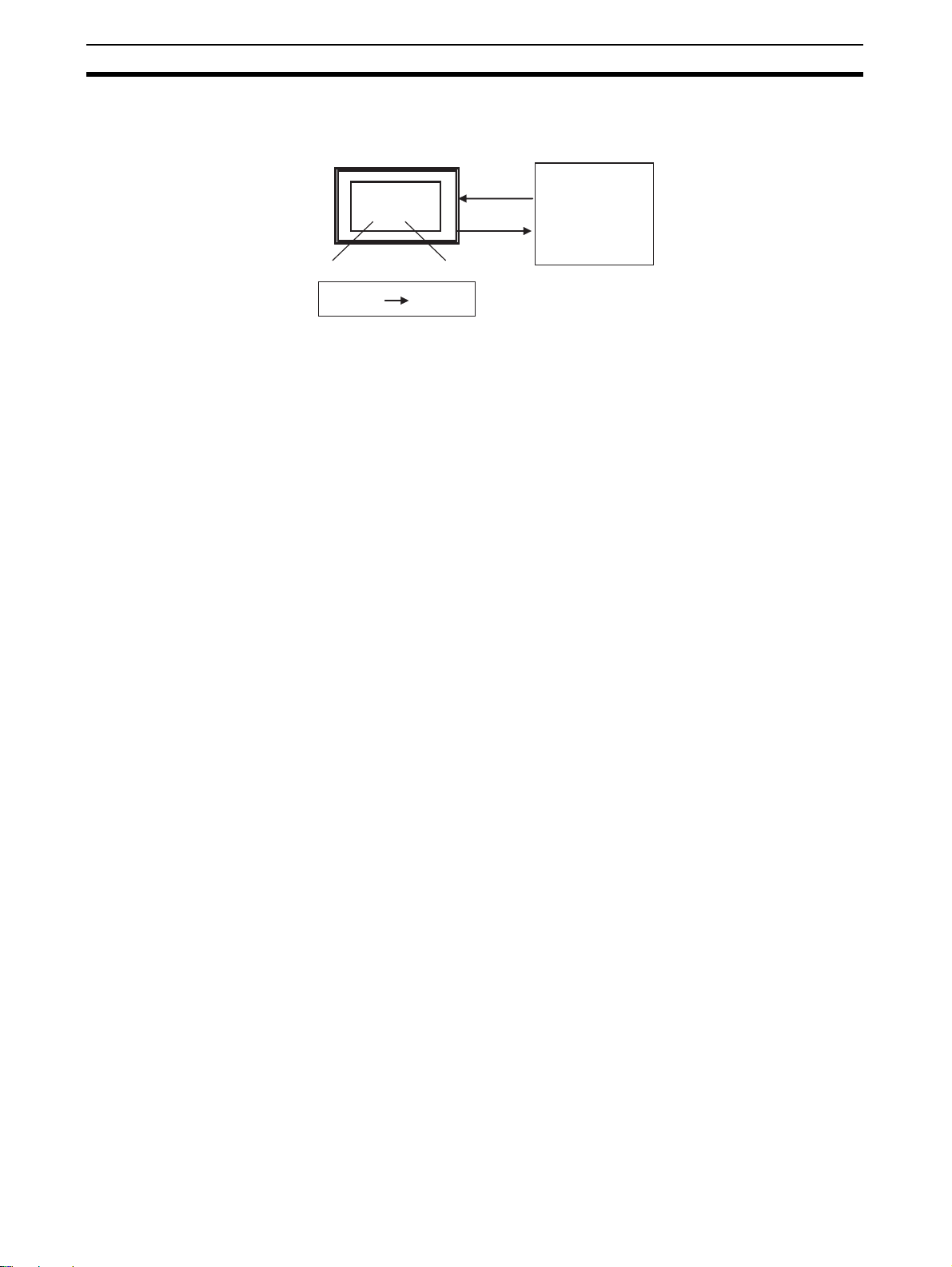

NV

Specified screen

PLC

Writing memory (Write Address)

Condition

met.

Operation

performed.

Condition

met.

Operation

performed.

Condition, such as a

bit turning ON or a

word reaching a value

Set bit, reset bit, write

value, add value, etc.

For example, you can set the Write Bit to write recipes or reset the Data Log/

Alarm History Clear Bit.

Operations are also possible for conditions set for memory in the PT and to

manipulate memory in th e PT.

Switch Label Language You can register up to 16 languages and corresponding character strings for

each part in advance and then change all registered parts at the same time

using a function switch or a command from the PLC.

This allows you to switch the language during operation or s witch t he labe ls in

the same language.

Backup PLC Data in the

PT with the Memory Hold

Function (NV4W and

NV3Q Only and Only

When Battery Is Mounted)

You can constantly back up specified words from the PLC in SRAM in th e PT.

This allows you, for e xample, to bac k up memory areas that are not held in the

PLC when using a CP1E PLC without a battery.

You can also back up the specified data from the internal memory in the PT.

Data Transfer Security You can set a password of up to eight alphanum eric characters f or transferring

screen data from the NV-Designer to an NV-series PT, to prevent screen data

from being transferred when anyone other than the administrator attempts to

read PT screen data.

Operation Security

(NV3W-V1/NV4W/NV3Q

Only)

Transferring Screens with

an SD Memory Card

(NV4W and NV3Q Only)

Communications between

OMRON EJ1 Temperature

Controllers and a ModbusRTU Master (NV3W-V1,

NV4W and NV3Q Only)

Monochrome Displa y with

Eight Shades of Gray

(NV4W Only)

You can set a password for each operation level of a part to restrict displays

and operations.

Security passwords are managed according to operator level.

The screens can be transf er red using an SD m emory card even if the PT cannot be connected to the NV-Designer.

Project data can be transferred directly by using SD memory cards.

The NV3W-V1, NV4W or NV3Q can connect an OMRON EJ1 Temperature

Controller using Modbus-RTU. The EJ1 Temperature Controllers are connected using RS-485 with the PT as the master. Up to 31 Temperature Controllers can be connected.

In addition to the previous monochrome display with two shades of gray, you

can now also select a monochrome display with eight shades of gray for

improved screen display quality.

4

Page 25

System Configuration Section 1-2

1-2 System Configuration

This section describes the types of system configurations in which an NVseries PT can be used.

1-2-1 System Configuration

NV3W System

Configuration

■ Using 5-V Power Supplied from the PLC on a Serial Communications

Cable

NV-Designer Screen

Design Software

PLC

NV3W

Host Link connection

5-V power supply

Programming Device

Connecting Cable (RS-232C

cable with a round DIN pin

connector for the NV3W)

NV-TOL-3M

PLC Connecting Cable

XW2Z-200T-4 (2 m with 5-V line)

■ Using an External 24-V Power Supply

NV-Designer Screen

Design Software

NV3W

Programming Device

Connecting Cable (RS-232C

cable with a round DIN pin

connector for the NV3W)

NV-TOL-3M

Additional Information

To connect to a USB connector on the personal computer, insert a CS1W-CIF31

USB-Serial Conversion Cable as shown below.

Host Link connection

PLC Connecting Cable

XW2Z-200T-3 (2 m without 5-V line)

XW2Z-500T-3 (5 m without 5-V line)

24-V power supply

PLC

5

Page 26

System Configuration Section 1-2

NV-Designer Screen

Design Software

Host Link connection

NV3W-V1

PLC

5-V power supply

PLC Connecting Cable

XW2Z-200T-4 (2 m with 5-V line)

Commercially available USB

cable (Type mini-B)

NV-Designer Screen

Design Software

Note: The USB driver included with the

CS1W-CIF must be installed.

USB-Serial Conversion Cable

CS1W-CIF31

NV3W

Programming Device

Connecting Cable (RS-232C

cable with a round DIN pin

connector for the NV3W)

NV-TOL-3M

NV3W-V1 System

Configuration

■ Using 5-V Power Supplied from the PLC on a Serial Communications

Cable

6

■ Using an External 24-V Power Supply

NV-Designer Screen

Design Software

NV3W-V1

Commercially available USB

cable (Type mini-B)

PLC

Host Link connection

PLC Connecting Cable

XW2Z-200T-3 (2 m without 5-V line)

XW2Z-500T-3 (5 m without 5-V line)

24-V power supply

Page 27

System Configuration Section 1-2

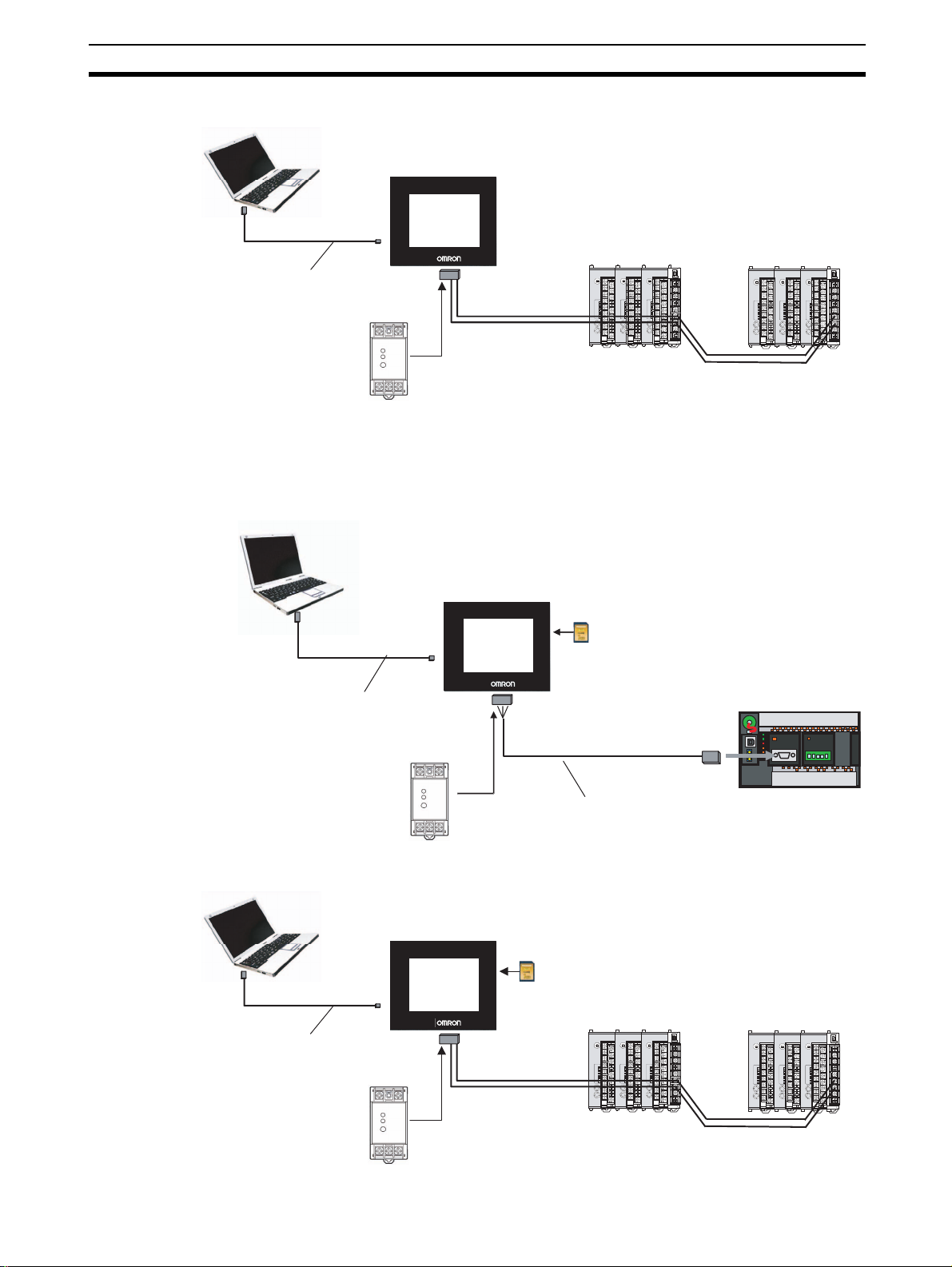

Commercially available USB cable

(Type mini-B)

Modbus-RTU

24-V power supply

NV-Designer Screen

Design Software

RS-485

EJ1 Modular

Temperature Controller

EJ1 Modular

Temperature Controller

Up to 31 Temperature

Controllers can be

connected.

NV3W-V1

NV-Designer Screen

Design Software

Commercially available USB cable

NV4W or NV3Q

SD memory card

(Used to backup and restore

screen data.)

Host Link connection

PLC Connecting Cable

XW2Z-200T-3 (2 m without 5-V line)

XW2Z-500T-3 (5 m without 5-V line)

24-V power supply

PLC

*1

*1 NV3Q: Type B

NV4W: Type mini-B

■ Connecting Temperature Controllers

NV4W/NV3Q System

Configuration

■ Connecting PLCs

■ Connecting Temperature Controllers

NV-Designer Screen

Design Software

Commercially available USB cable

*1 NV3Q: Type B

NV4W: Type mini-B

24-V power supply

NV4W or NV3Q

*1

SD memory card

(Used to backup and restore

screen data.)

EJ1 Modular

Temperature Controller

Modbus-RTU

RS-485

EJ1 Modular

Temperature Controller

Up to 31 Temperature

Controllers can be

connected.

7

Page 28

System Configuration Section 1-2

Additional Information

NV-series PTs do not support the 1:N NT Link protocol. Modbus-RTU (PLC:

Master, PTs: Slaves) is required to connect multiple NV-series PTs to one PLC.

(Up to 31 PT can be connected.)

To use Modbus, a communications program for the master is required in the

PLC. Also, notification cannot be performed from the PT. Therefore, response

and updating may be slow or it may not be possible to read all inputs of touch

switches, lamps, and numbers.

For details, ref e r to the NV-series Host Connection Manual (Cat. No. V105).

1-2-2 Connectable OMRON PLCs

Series PLC Serial communications

CP Series N-type CP1E, CP1L (except for 10-

point models), and CP1H

CS/CJ Series CS1G/CS1H, CS1G-H/CS1H-H,

CS1D, CJ1G, CJ1G-H/CJ1H-H,

CJ1M, CJ2H and CJ2M

C Series

CVM1/CV Series

*1

C200HX/HG/HE(-Z), CQM1H,

CPM2A/CPM2C, CPM1/CPM1A,

and SRM1-C02-V2

*1

CV500, CV1000, CV2000, and

CVM1

*1 If the PT is connected to a C-series or CV/CVM1-series PLC, keep the

PLC in MONITOR mode. If the PLC is in RUN mode and the PT attempts

to write to PLC memory, an error code of ER01 will be displayed and memory will not be written. If the PT is connected to a CP-ser ies or CS/CJseries PLC, the PLC can be in either RUN or MONITOR mode.

You can connect to th e PLC using a built-in serial port on the CPU Unit, a

serial port on a Serial Communications Unit (includes serial connection

through peripheral port), Serial Communications Board, or Host Link Unit.

Use RS-232C or RS-422A to connect to OMR ON PLCs. Do not use RS-485.

1-2-3 Connectable OMRON Temperature Controllers

Series Temperature Controllers Serial communications

EJ1 Series EJ1 Modbus-RTU

mode for PT connection

Host Link

mode for connecting to NV-

series PT

The NV3W-V1, NV4W or NV3Q can connect to OMRON EJ1 Temperature

Controllers using Modbus-RTU. The EJ1 Temperature Controllers are connected using RS-485 with the PT as the master. Up to 31 Temperature Controllers can be connected.

8

Page 29

Models Section 1-3

1-3 Models

This section provides a list of the models of PTs in the NV Series.

1-3-1 NV-series PTs

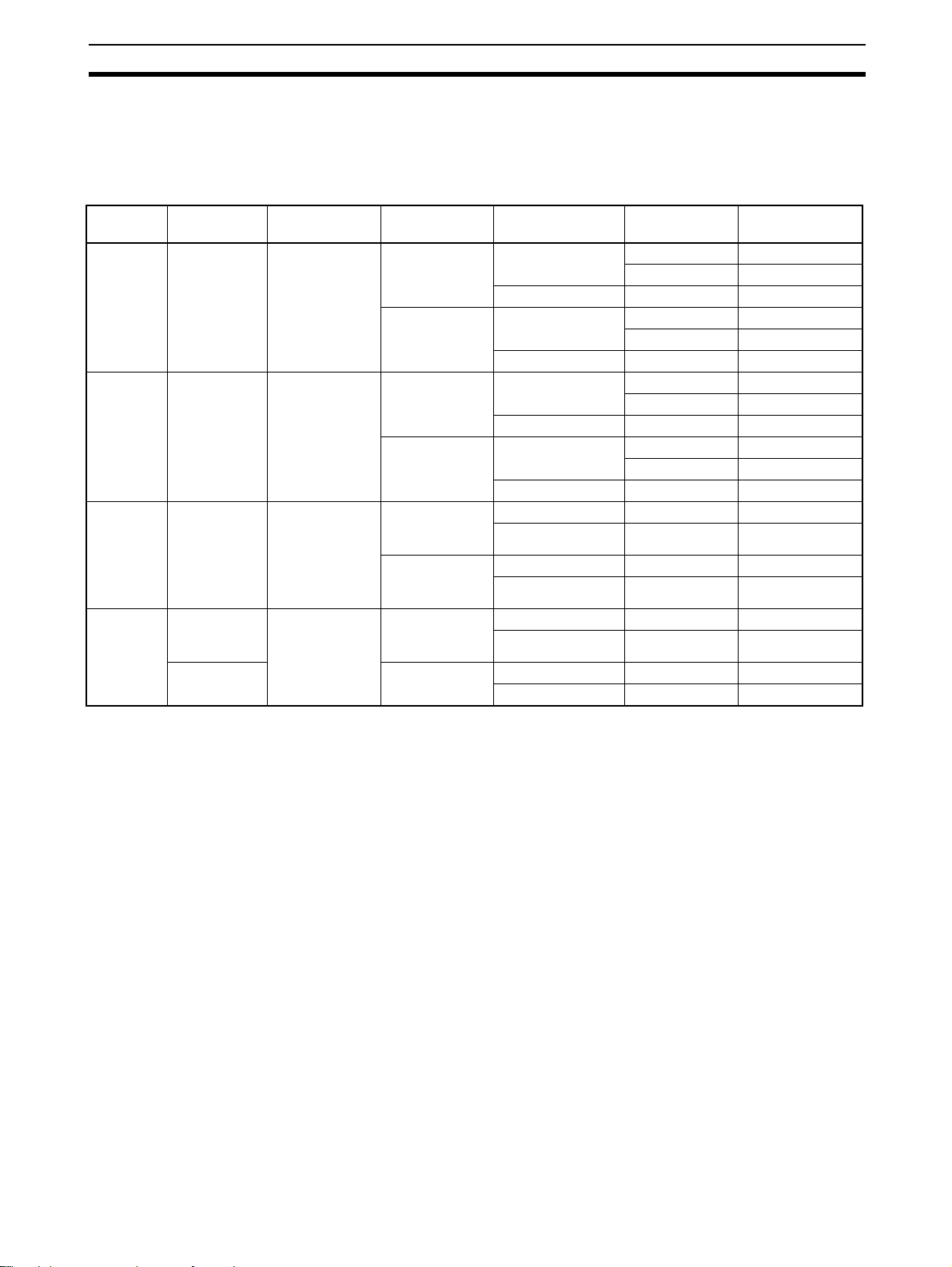

Screen size Number of

NV3W PT 3.1-in, STN

monochrome

NV3W-V1 PT3.8-in, STN

monochrome

NV4W PT 4-in, STN

monochrome

NV3Q PT 3.6-in, STN

monochrome

3.6-in, TFT

color

dots

128 × 64 dots LEDs, 3 colors

240 × 96 dots LEDs, 3 colors

320 ×120 dots LEDs, 3 colors

320 ×240 dots

(QVGA)

Backlight Communications Power supply

(green, orange,

and red)

LEDs, 3 colors

(white, pink,

and red)

(green, orange,

and red)

LEDs, 3 colors

(white, pink and

red)

(green, orange,

and red)

LEDs, 3 colors

(white, pink,

and red)

LEDs, 3 colors

(white, pink,

and red)

White LED RS-232C 24 VDC NV3Q-SW21

voltage

Model

RS-232C 5 VDC NV3W-MG20L

24 VDC NV3W-MG20

RS-422A/485 24 VDC NV3W-MG40

RS-232C 5 VDC NV3W-MR20L

24 VDC NV3W-MR20

RS-422A/485 24 VDC NV3W-MR40

RS-232C 5 VDC NV3W-MG20L-V1

24 VDC NV3W-MG20-V1

RS-422A/485 24 VDC NV3W-MG40-V1

RS-232C 5 VDC NV3W-MR20L-V1

24 VDC NV3W-MR20-V1

RS-422A/485 24 VDC NV3W-MR40-V1

RS-232C 24 VDC NV4W-MG21

RS-422A/485 24 VDC NV4W-MG41

RS-232C 24 VDC NV4W-MR21

RS-422A/485 24 VDC NV4W-MR41

RS-232C 24 VDC NV3Q-MR21

RS-422A/485 24 VDC NV3Q-MR41

RS-422A/485 24 VDC NV3Q-SW41

9

Page 30

Models Section 1-3

PT end

Computer end (RS-232C connector)

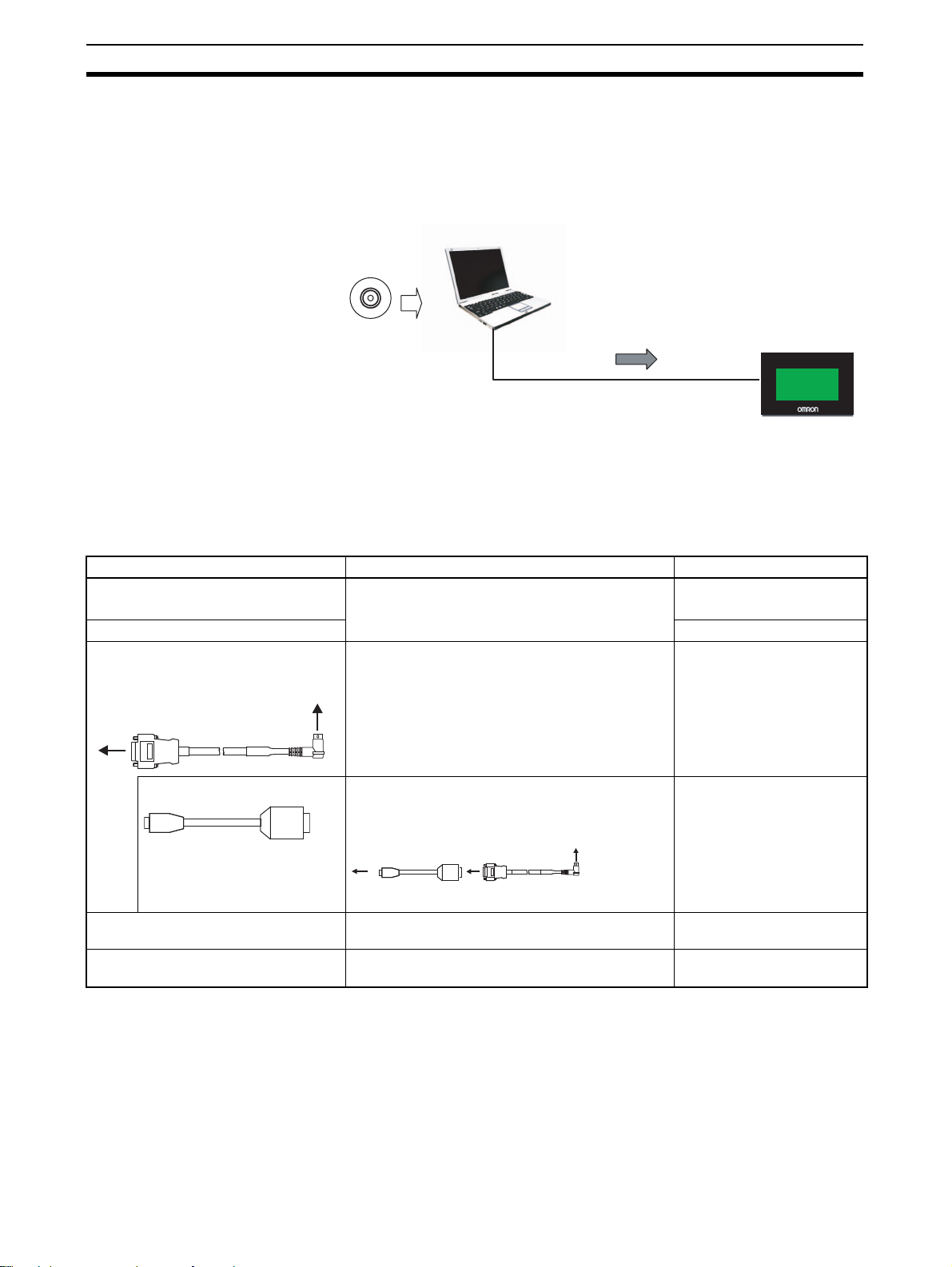

1-3-2 Screen Design Software

The NV-Designer is used as the Screen Design Software for the NV-series

PTs.

The NV -Designer is included in CX-One version 4.@ or in CX-One Lite version

4.@.

Personal computer

CX-One version 4.@ or

CX-One Lite version 4.@

NV-Designer Screen

Design Software

Project data is transferred.

NV

• The NV3W is connected using an NV-TOL-3M RS-232C Cable with a

round DIN pin connector on the NV end.

To connect to a USB connector on the computer, connect the NV-TOL-3M

cable through a CS1W-CIF31 USB-Serial Conversion Cable.

• You can connect to the NV3W-V1, NV4W or NV3Q using a commercially

avail able USB cable.

Name Description Model

CX-One version 4.@ Includes the NV-Designer. On CD: CXONE-AL01C-V4

On DVD: CXONE-AL01D-V4

CX-One Lite version 4. @ On CD: CXONE-L T01C-V4

Programming Device Connecting

Cable for NV3W

USB-Serial Conversion Cable For the NV3W (sold separately)

For the NV3W (sold separately) RS-232C cable

with a round DIN pin connector on the NV3W end

Use this Cable together with the NV-TOL-3M to

connect to a USB connector on the computer.

Computer end (USB connector)

PT end

NV-TOL-3M

CS1W-CIF31

Programming Device Connecting

Cable for NV3W-V1 or NV4W

Programming Device Connecting

Cable for NV3Q

10

Note The enclosed USB driver must be installed.

For the NV3W-V1 or NV4W (sold separately)

(USB: Type mini-B)

For the NV3Q (sold separately)

(USB: Type B)

Commercially available USB

cable

Commercially available USB

cable

Page 31

Models Section 1-3

PLC

XM2S-09

PT end PLC end

1-3-3 Other Optional Products

Name Description Model

PLC Connecting Cable For the NV3W(-V1) with 5-V

power (sold separately)

For the NV3W(-V1), NV4W, and

NV3Q (sold separately)

Battery For the NV4W, and NV3Q (sold

separately)

XW2Z-200T-4 (2 m with 5-V line)

XW2Z-200T-3 (2 m without 5-V line)

XW2Z-500T-3 (5 m without 5-V line)

NV-BAT01

Display Protective Sheets For the NV3W, contains 10 sheets

(sold separately)

For the NV3W-V1, contains 10

sheets (sold separately)

For the NV4W , contains 10 sheets

(sold separately)

For the NV3Q, contains 10 sheets

(sold separately)

Waterproof Packings For the NV3W, contains 10 pack-

ings (sold separately)

For the NV4W, contains 10 pack-

ings (sold separately)

For the NV3Q, contains 10 pack-

ings (sold separately)

SD memory card For the NV4W/NV3Q

Memory capacity: 32 MB to 2 GB

For backing up and restoring base

screen data for the PT (except fo r

the NV3W(-V1)) and NV-Designer .

*1 This does not apply to NV3W-V1.

*2 The capacity of the SD memory card is 32 MB to 1 GB for system program

version 1.0@ of the NV3Q-series PT.

NV3W-KBA04

NV3W-KBA04-V1

NV4W-KBA04

NV3Q-KBA04

NV3W-RP001

NV4W-RP001

*1

One Packing is provided

on the PT as a standard

feature.

NV3Q-RP001

Commercially available SD cards

Panasonic card with capacity of 32 MB to 2 GB

*2

11

Page 32

Specifications Section 1-4

+10+1

0

1-4 Specifications

1-4-1 NV3W

General Specifications

Item Specifications

Type 24 V 5 V

Model NV3W-M@20 and NV3W-M@40 NV3W-M@20L

Rated power supply 24 VDC 5 VDC

Operating voltage range 21.6 to 26.4 VDC 4.5 to 5.5 VDC

Pow er consumption (current con-

sumption)

Ambient operating temperature 0 to 50°C

Ambient operating humidity 20% to 85% (with no condensation)

Ambient storage temperature −20 to 60°C

Ambient storage humidity 10% to 85% (with no condensation)

Dielectric strength Between the power supply terminals and the case

Insulation resistance Between the power supply terminals and the case

Vibration resistance 10 to 55 Hz with 0.75-amplitude for 10 min each in X, Y, and Z directions, 1 sweep per

Shock resistance

Noise immunity 1,000 V

Resistance to environment IP65 (at initial state)

Dimensions 110 × 72 × 28 mm (W × H × D)

Panel cutout dimensions

Degree of protection Operating section on front panel: IP65

Safety standards UL 508, EC Directives and Korea Certification Mark

Weight 160 g max.

2 W max. (80 mA max.) 1 W max. (200 mA max.)

500 VAC for 1 min with a cutoff current of 10 mA (at initial state)

100 MΩ (at 500 VDC) (at initial state)

min

98 m/s2 4 times each in X, Y, and Z directions

with pulse widths of 50 ns and 1 μs between power supply terminals (via

simulator)

Dust proof and drip proof only from the front of the panel (using Waterproof Packing at

the contact surface with the panel)

*Replace the Waterproof Packing each time you reinstall the PT.

105.0 × 67.0 mm (H × V), Panel thickness: 1.6 to 4.8 mm

p-p

12

Page 33

Specifications Section 1-4

Performance Specifications

Item Specifications

Type All NV3W models

Model NV3W-MG@@(@) and NV3W-MR@@(@)

Display device STN monochrome LCD

Number of dots 128 × 64 dots (H × V)

Effective display size 70 × 35 mm (H × V)

Life expectancy

Backlights NV3W-MG: LED backlights, 3 colors (green, orange, and red)

Touch switches Method Analog resi stance membrane

Operating force 0.5 N max.

Life expectancy 100 million operations min. (at 25°C)

Switches

Size

External memory --Host communications NV3W-MS@20(@): RS-232C (not isolated), Transmission distance: 15 m,

Support Software communications RS-232C (not isolated) via Mini DIN 5-pin connector

Applicable Support Software NV -Designer v ersion 1.0 or higher (Included with CX-One version 4.@ or in

50,000 hours min.

NV3W-MR: LED ba cklights, 3 colors (white, pink, and red)

50 max. per screen

8 dots × 8 dots min.

Connector: 8-pin)

NV3W-M@40: RS-422A/485 (not isolated), Transmission distance: 500 m,

Connector: 8-pin)

CX-One Lite version 4.@.)

*1

*2

*3

*1 This is the estimated time before brightness is reduced by half at room

temperature and humidity. It is not a guaranteed value.

*2 The estimate applies to operation when only custom switches are placed

on the screen.

*3 This is the effective area of a touch switch. It does not include the 1-dot

frame line.

13

Page 34

Specifications Section 1-4

Functional Specifications

Item Specifications

Type All NV3W models

Displayable fonts Fixed (NV-Designer): Half-size characters (8 × 8 dots) or normal characters

Displayable characters Japanese, English, Korean, German, French, Italian, Spanish, Simplified

Maximum number of screens Approx. 160 screens

Screen numbers that can be registered Base screens: 0 to 1,023

Screen types Base screens (These screens can be switched externally and parts can be

Graphics Straight lines, continuous lines, rectangles, circles, ovals, circular arcs, oval

Parts Messages, lamps, switches, data, bar graphs, keyboards, line graphs, and

Other functions Recipes, flowing displays, address writing, and language switching

SPMA functions Communications with a PLC are possible if the computer running the CX-

(8 × 16 dots) (Magnification is possible on the display to 1×, 2×, and 4×.)

True Type (NV-Designer): 10 to 64 dots

Windows: 10 to 64 dots

Chinese, Traditional Chinese, Turkish, Russian, and Vietnamese

*The number of screens that can be registered depends on the contents of

the screens.

Keyboard screens: 0 to 7

pasted on these screens.)

Keyboard screens (These screens can be used to directly enter data for data

parts.)

arcs, sectors, oval sectors, rounded rectangles, and bitmaps

clocks*

*Clock parts can access external clock data and display it. There is no clock

in the PT itself.

Programmer is connected to the tool port and a CS/CJ/CP-series PLC is

connected to the COM port.

Memory Specifications

Item Type

Type All NV3W models

Memory type FROM (built-in Flash Memory)

Memory capacity

384 Kbytes

*1

*1 Refer to 1-4-5 Battery Backup for the data that is saved in memory.

14

Page 35

Specifications Section 1-4

Communications Interface Specifications

PLC/External Device Interface

■ COM Port

Item Specifications

Type RS-232C RS-422A/485

Model NV3W-M@20(@)NV3W-M@40

Communications standard RS-232C (not isolated)

Communications

conditions for

external device

Transmission distance (total length) 15 m max. (baud rate: 19,200 bps) 500 m max. (baud rate: 115,200 bps)

Protocols •Host Link (OMRON protocol for PLCs)

Connector

Applicable cable PLC Connecting Cable

Baud rate (bps) 9,600, 19,200, 38,400, 57,600, 115,200

Data length 7 or 8 bits

Parity None, even, or odd

Stop bits 1 bit

•Modbus-RTU

•Protocols for PLCs from other companies (Refer to the NV-series PT Host Connec-

tion Manual (Cat. No. V105) for details.)

8-pin connector

(Without 5-V line: XW2Z-200T-3 (2 m) or

XW2Z-500T-3 (5 m),

with 5-V line: XW2Z-200T-4 (2 m))

*2*3*4

RS-422A/485 (not isolated)

Shielded twisted-pair cable

*1

*1 The PTs cannot be connected to OMRON PLCs using RS-485 (2-wire)

connections and the Host Link protocol.

*2 “+” and “−” are the power supply pins to drive the PT.

*3 Be sure to consider the cable length and ensure that the voltage supplied

to the PT is within the operating voltage range.

*4 If power is being supp lied from a source other than the PLC f or a PT with a

5-VDC power supply, make sure the power supply cable is 10 m or less in

length.

Transfer Interface for Screen Data

■ Tool Port

Item Specifications

Communications standard RS-232C (not isolated)

Communications

conditions for NVDesigner

Protocols Special protocol for NV -series PTs

Connector Mini DIN 5-pin connector

Applicable cable NV-TOL-3M

Baud rate (bps) Always 115,200

Data length Always 8 bits

Parity Always no parity

Stop bits 1 bit

15

Page 36

Specifications Section 1-4

+10+1

0

1-4-2 NV3W-V1

General Specifications

Item Specifications

Type 24 V 5 V

Model NV3W-M@20-V1 and NV3W-M40-V1 NV3W-M@20L-V1

Rated power supply 24 VDC 5 VDC

Operating voltage range 21.6 to 26.4 VDC 4.5 to 5.5 VDC

Power consumption (current

consumption)

Ambient operating temperature 0 to 50°C

Ambient operating humidity 20% to 85%RH (with no condensation)

Ambient storage temperature −20 to 60°C

Ambient storage humidity 10% to 85%RH (with no condensation)

Dielectric strength Between the power supply terminals and the case

Insulation resistance Between the power supply terminals and the case

Vibration resistance

Shock resistance

Noise immunity 1,000 V

Resistance to environment IP67 (at initial state)

Dimensions 112 × 74 × 27 mm (W × H × D)

Panel cutout dimensions

Degree of protection Operating section on front panel: IP67

Safety standards UL 508, EC Directives and Korea Certification Mark

Weight 170 g max.

1.9 W max. (80 mA max.) 1 W max. (200 mA max.)

500 VAC for 1 min with a cutoff current of 10 mA (at initial state)

100 MΩ (at 500 VDC) (at initial state)

2

5 to 8.4 Hz, 3.5 mm single amplitude, 8.4 to 150 Hz, 9.8m/s

directions (1 octave/min)

2

147 m/s

ulator)

Dust proof and drip proof only from the front of the panel (using Waterproof Packing at

the contact surface with the panel)

*Replace the Waterproof Packing each time you reinstall the PT.

105.0 × 67 mm (H × V), Panel thickness: 1.6 to 4.8 mm

min. 3 times each in x, y, and z directions

with pulse widths of 50 ns and 1 µs between power supply terminals (via sim-

p-p

, 10 times each in x, y , and z

16

Page 37

Specifications Section 1-4

Performance Specifications

Item Specifications

Type All NV3W-V1 models

Model NV3W-MG@@(L)-V1/NV3W-MR@@(L)-V1

Display device STN monochrome LCD

Number of dots 240 × 96 dots (H × V)

Effective display size 88.5 × 35.4 mm (H × V)

Life expectancy

Backlights NV3W-MG@@(L)-V1: LED backlights, 3 colors (green. orange and red)

Touch switches Method Analog resistance membrane

Operating force 0.8 N max.

Life expectancy 100 million operations min. (at 25°C)

Switches

Size

Host communications NV3W-M@20(L)-V1: RS-232C (not isolated), Transmission distance: 15 m,

Support Software communications USB 1.1 Mini-B, Transmission distance: 5 m max.

Applicable Support Software NV -Designer version 2.0 or higher (Included with CX-One version 4.34 or in

50,000 hours min.

NV3W-MR@@-V1: LED backlights, 3 colors (white, pink and red)

50 max. per screen

8 dots × 8 dots min.

Connector: 8-pin

NV3W-M@40-V1: RS-422A/485 (not isolated), Transmission distance: 500 m,

Connector: 8-pin

CX-One Lite version 4.34.)

*1

*2

*3

*1 This is the estimated time before brightness is reduced by half at room

temperature and humidity. It is not a guaranteed value.

*2 The estimate applies to operation when only custom switches are placed

on the screen.

*3 This is the effective area of a touch switch. It does not include the 1-dot

frame line.

17

Page 38

Specifications Section 1-4

Functional Specifications

Item Specifications

Type All NV3W-V1 models

Displayable fonts Fixed (NV-Designer): quarter square character (8 × 8 dots), half-size character (8 × 16 dots) or nor-

Displayable characters

Maximum number of

screens

Screen numbers that

can be registered

Screen types Base screens (These screens can be switched externally and parts can be pasted on these

Graphics Straight lines, continuous lines, rectangles, circles, ovals, circular arcs, ov al arcs, sectors, oval sec-

Parts

Other functions Recipes, flow displays, address writing, display language switching, alarm lists, passwords, and

SPMA functions Communications with a PLC are possible if the computer running the CX-Programmer is con-

mal characters (16 × 16 dots) (Magnification is possible on the display to 1×, 2×, 4× and 8×.)

True Type (NV-Designer): 10 to 96 dots

Windows: 10 to 96 dots

Japanese, English, Korean, German, French, Italian, Spanish, Simplified Chinese, Traditional Chi-

nese, Turkish, Russi an, and Vietnamese

Approx. 250 screens

*The number of screens that can be registered depends on the contents of the screens.

Base screens: 0 to 1,023

Keyboard screens: 0 to 7

screens.)

Keyboard screens (These screens can be used to directly enter data for data parts.)

tors, and rounded rectangles

Messages, lamps, switches, data, bar graphs, keyboards, line graphs, alarm lists, and clocks

*Clock parts can access external clock data and display it.

*The PLC features no function of watch.

multifunction

nected to the USB port and a CS/CJ/CP-series PLC is connected to the COM port.

*

Memory Specifications

Item Specifications

Type Monochrome

Model All the NV3W-V1 models

Base screen data, keyboard

screen data, and flow display

data

Recipe data Memory type FROM (built-in Flash Memory)

Write Address Memory type FROM (built-in Flash Memory)

Memory type FROM (built-in Flash Memory)

Memory capacity

Memory capacity

Memory capacity

2048 Kbytes

64 Kbytes

64 Kbytes

*1

*1

*1

*1 Refer to 1-4-5 Battery Backup for the data that is saved in memory.

18

Page 39

Specifications Section 1-4

Communications Interface Specifications

PLC/External Device Interface

Items Specifications

Type RS-232C RS-422A/485

Model NV3W-M@20(@)-V1 NV3W-M@40-V1

Communications standard RS-232C (not isolated)

Communications

conditions for

external device

Transmission distance (total length) 15 m max.

Protocols •Host Link (OMRON protocol for PLCs)

Connector

Applicable cable PLC connecting cable for OMRON Host

Baud rate (bps) 9,600, 19,20 0, 38,400, 57,600, or 115,200

Data length 7 or 8 bits

Parity None, even, or odd

Stop bits 1 bit

(baud rate: 19,200 bps)

•Modbus-RTU

•Protocols for PLCs from other companies (Refer to the NV-series PT Host Connec-

tion Manual (Cat. No. V105) for details.)

8-pin connector

link (Without 5-V line: XW2Z-200T-3(2m)

or XW2Z-500T-3(5m), with 5-V line:

XW2Z-200T-4 (2 m))

*2*3*4

RS-422A/485 (not isolated)

500 m max.

(baud rate: 115,200 bps)

Shielded twisted-pair cable

*1

*1 The PTs cannot be connected to OMRON PLCs using RS-485 (2-wire)

connections and the Host Link protocol.

*2 “+” and “−” are the power supply pins to drive the PT.

*3 Be sure to consider the cable length and ensure that the voltage supplied

to the PT is within the operating voltage range.

*4 If power is being supp lied from a source other than the PLC f or a PT with a

5-VDC power supply, make sure the power supply cable is 10 m or less in

length.

Transfer Interface for Screen Data

■ USB port

Type All the NV3W-V1 models

Communications standard USB 1.1

Connector type

Number of PTs connected to

computer

Transmission distance 5 m max.

Protocols Special protocol for NV-series PTs

Applicable cable Commercially available USB cable

*1 Do not subject the metal parts of the connector to excessive static electric-

ity.

Item Specifications

*1

USB type mini-B

1

19

Page 40

Specifications Section 1-4

+10+1

0

1-4-3 NV4W

General Specifications

Item Specifications

Type Monochrome

Model NV4W-M@@1

Rated power supply 24 VDC

Operating voltage range 21.6 to 26.4 VDC

Power consumption (current

consumption)

Powe r supply section isolation Transformer

Ambient operating tempera-

ture

Ambient operating humidity 20% to 85% (with no condensation)

Ambient storage temperature −20 to 60°C

Ambient storage humidity 10% to 85% (with no condensation)

Dielectric strength

Insulation resistance

Vibration resistance

Shock resistance

Noise immunity 1,000 V

Resistance to environment IP67 (at initial state)

Dimensions 146 × 74 × 30 mm (W × H × D)

Panel cutout dimensions

Degree of protection Operating section on front panel: IP67

Battery life expectancy Battery life expectancy: 5 yr (at 25°C)*

Battery backup PT clock data, PLC memory hold data, PT internal memory hold data, and alarm history

Safety standards UL 508 and EC Directives

Weight 240 g max.

*1

*1

1.7 W max. (70 mA max.)

0 to 50°C

Between the power supply terminals and the case

500 VAC for 1 min with a cutoff current of 10 mA (at initial state)

Between the power supply terminals and the case

100 MΩ (at 500 VDC) (at initial state)

2

5 to 9 Hz, 3.5-mm single amplitude, 9 to 150 Hz, 9.8 m/s

directions (1 octave/min)

2

147 m/s

lator)

Dust proof and drip proof only from the front of the panel (using Waterproof Packing at the

contact surface with the panel)

*Replace the Waterproof Packing each time you reinstall the PT.

139 × 67 mm (H × V), Panel thickness: 1.6 to 4.8 mm

*The SRAM (internal RAM) is backed up by the battery . If backing up the data is required,

purchase a Battery separately.

The battery life expectancy is for when no power is supplied. The actual value may be

shorter depending on application conditions.

data (if Battery is mounted)

*Purchase an NV-BAT01 separately.

3 times each in X, Y, and Z directions

with pulse widths of 50 ns and 1 μs between power supply terminals (via simu-

p-p

, 10 times each in X, Y, and Z

*1 The USB port and COM port are not isolated from the internal digital cir-

cuits.

20

Page 41

Specifications Section 1-4

Performance Specifications

Item Specifications

Model NV4W-M@@1

Display device STN monochrome LCD

Number of dots 320 × 120 dots (H × V)

Effective display size 109 × 41 mm (H × V)

Life expectancy

Backlights NV4W-MG: LED backlight, 3 colors (green, orange, and red)

Grayscale display 2 shades of gray or 8 shades of gray (selectable using NV-Designer)

Touch switches Method Analog resistance membrane

Operating force 0.8 N max.

Life expectancy 100 million operations min. (at 25°C)

Switches

Size

External memo ry SD memory card (32 MB to 2 GB)

Host communications

Support Software communications USB 1.1 Mini-B, Transmission distance: 5 m max.

Applicable Support Software NV-Designer version 1.1 or higher (Included with CX-One version 4.@ or in

COM Port NV4W-M@21: RS-232C (not isolated), Transmission distance: 15 m, Connec-

50,000 hours min.

NV4W-MR: LED backlight, 3 colors (white, pink, and red)

100 max. per screen

8 dots × 8 dots min.

Manufacturers for which operation has been confirmed: Panasonic

SD standard

tor: 8-pin)

NV4W-M@41: RS-422/A485 (not isolated), Transmission distance: 500 m,

Connector: 8-pin)

CX-One Lite version 4.@.)

*1

*2

*3

*4

*1 This is the estimated time before brightness is reduced by half at room

temperature and humidity. It is not a guaranteed value.

*2 The estimate applies to operation when only custom switches are placed

on the screen.

*3 This is the effective area of a touch switch. It does not include the 1-dot

frame line.

*4 Do not reformat the SD memory card using standard Windows functions,

such as Windows Explorer.

21

Page 42

Specifications Section 1-4

Functional Specifications

Item Specifications

Type Monochrome

Model NV4W-M@@1

Displayable fonts Fixed (NV-Designer): Half-size characters (8 × 8 dots) or normal characters (8 × 16 dots) (Magnifi-

Displayable characters

Maximum number of

screens

Screen numbers that

can be registered

Screen types Base screens (These screens can be switched externally and parts can be pasted on these

Graphics Straight lines, continuous lines, rectangles, circles, ovals, circular arcs, ov al arcs, sectors, oval sec-

Parts Messages, lamps, switches, data, bar graphs, keyboards, line graphs, alarm lists, and clocks*

Other functions Recipes, flow displays, address writing, display language switching, alarm lists, alarm history, pass-

SPMA functions Communications with a PLC are possible if the computer running the CX-Programmer is con-

cation is possible on the display to 1×, 2×, 4× and 8×.)

True Type (NV-Designer): 10 to 240 dots

Windows: 10 to 240 dots

Japanese, English, Korean, German, French, Italian, Spanish, Simplified Chinese, Traditional Chi-

nese, Turkish, Russi an, and Vietnamese

2 shades of gray: 250 screens, 8 shades or gray: 200 screens

*The number of screens that can be registered depends on the contents of the screens.

Base screens: 0 to 1,023

Keyboard screens: 0 to 7

screens.)

Keyboard screens (These screens can be used to directly enter data for data parts.)

tors, and rounded rectangles

*Clock parts can access external clock data and display it.

*Clock accuracy is ±180 s per month.

words, and Multifunction Objects

nected to the USB port and a CS/CJ/CP-series PLC is connected to the COM port.

Memory Specifications

Item Specifications

Type Monochrome

Model NV4W-M@@1

Base screen data, keyboard

screen data, and flow display data

Recipe data Memory type FROM (built-in Flash Memory)

Writing memory (Write Address) Memory type FROM (built-in Flash Memory)

PLC memory hold data and PT

internal memory hold data

Memory type FROM (built-in Flash Memory)

Memory capacity 2,048 Kbytes

Memory capacity 64 Kbytes

Memory capacity 64 Kbytes

Used memory SRAM (internal RAM)

*The SRAM (internal RAM) is backed up by the battery. If backing

up the data is required, purchase an NV-BAT01 Battery separately.

Memory capacity PLC/PT Memory Hold Area (24 words max.)

External Memory Specifications

SD Memory Card Slot

Item Specifications

Type All NV4W models

Supported

media

Applicable for-

mat

SD memory card (32 MB to 2 GB)

Manufacturers for which operation has been confirmed: Panasonic

SD standard compliant

22

Note

The SD access indicator will be lit while the SD memory card is being accessed.

Page 43

Specifications Section 1-4

Communications Interface Specifications

PLC/External Device Interface

■ COM Port

Item Specifications

Type RS-232C RS-422A/485

Model NV4W-M@21 NV4W-M@41

Communications standard RS-232C (not isolated)

Communications

conditions for

external device

Transmission distance (total length) 15 m max. (baud rate: 115,200 bps) 500 m max. (baud rate: 115,200 bps)

Protocols Host Link (OMRON protocol for PLCs)

Connector

Applicable cable XW2Z-200T-3 (2 m) or XW2Z-500T-3

Baud rate (bps) 9,600, 19,200, 38,400, 57,600, or 115,200

Data length 7 or 8 bits

Parity None, ev en, or odd

Stop bits 1 bit

Modbus-RTU

Protocols for PLCs from other companies (Refer to the NV-series PT Host Con-

nection Manual (Cat. No. V105) for details.)

8-pin connector

(5 m) PLC Connecting Cable

*2*3

RS-422A/485 (not isolated)

Shielded twisted-pair cable

*1

*1 The PTs cannot be connected to OMRON PLCs using RS-485 (2-wire)

connections and the Host Link protocol.

*2 “+” and “−” are the power supply pins to drive the PT.

*3 Be sure to consider the cable length and ensure that the voltage supplied

to the PT is within the operating voltage range.

Transfer Interface for Screen Data

■ USB port

Type All NV4W models

Communications standard USB 1.1

Connector type

Number of PTs connected to

computer

Transmission distance 5 m max.

Protocols Special protocol for NV-series PTs

Applicable cable Commercially available USB cable

*1 Do not subject the metal parts of the connector to excessive static electric-

ity.

Item Specifications

*1

USB type mini-B

1

23

Page 44

Specifications Section 1-4

+10+1

0

1-4-4 NV3Q

General Specifications

Item Specifications

Type Monochrome Color

Model NV3Q-MR@1 NV3Q-SW@1

Rated power supply 24 VDC

Operating voltage range 21.6 to 26.4 VDC

Power consumption (current

consumption)

Powe r supply section isolation Transformer

Ambient operating tempera-

ture

Ambient operating humidity 20% to 85% (with no condensation)

Ambient storage temperature −20 to 60°C

Ambient storage humidity 10% to 85% (with no condensation)

Dielectric strength

Insulation resistance

Vibration resistance 10 to 55 Hz with 0.75-amplitude for 10 min each in X, Y, and Z directions, 1 sweep per

Shock resistance

Noise immunity 1,000 V

Resistance to environment IP65 (at initial state)

Dimensions 110 × 92.2 × 33.8 mm (W × H × D)

Panel cutout dimensions

Degree of protection Operating section on front panel: IP65

Battery life expectancy Battery life expectancy: 5 yr (at 25°C)* Battery life expectancy: 3 yr (at 25°C)*

Battery backup PT clock data, PLC memory hold data, PT internal memory hold data, and alarm history

Safety standards UL 508 and EC Directives

Weight 240 g max.

*1

*1

2.4 W max. (100 mA max.) 3.6 W max. (150 mA max.)

0 to 50°C

Between the power supply terminals and the case

500 VAC for 1 min with a cutoff current of 10 mA (at initial state)

Between the power supply terminals and the case

100 MΩ (at 500 VDC) (at initial state)

min

2

98 m/s

ulator)

Dust proof and drip proof only from the front of the panel (using Waterproof Packing at

the contact surface with the panel)

*Replace the Waterproof Packing each time you reinstall the PT.