Page 1

Read and Understand this Catalog

Please read and understand this catalog before purchasing the product. Please consult your OMRON representative if you have any

questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT

THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS

UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND

MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of the

product in the customer's application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will be

used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT

THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

NS12-V2

12-inch Model

NS5-V2

5-inch Model

NS10-V2

10-inch Model

NSH5

5-inch Hand-held Model

NS8-V2

8-inch Model

Programmable Terminals

NS-CXDC1-V1

Ver. 1

NS-series Screen Creation Software

Installing a Navigator: A Totally New Concept in

Programmable Terminals

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with your

OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements.

Actual performance is subject to the OMRON Warranty and Limitations of Liability.

Printed on 100%

Note: Do not use this document to operate the Unit.

OMRON Corporation

Control Devices Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530

Japan

Tel: (81)75-344-7109

Fax: (81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel:(31)2356-81-300/

Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel: (1)847-843-7900/ Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel:(65)6835-3011/Fax:(65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120 China

Tel:(86)21-5037-2222/Fax:(86)21-5037-2200

Authorized Distributor:

Note: Specifications subject to change without notice.

Recycled Paper

Cat. No. V078-E1-09

Printed in Japan

0206-1M

NSH5

5-inch

Hand-held

Model

NS5-V2

5-inch Model

NS8-V2

8-inch Model

NS Series

NS10-V2

10-inch Model

NS12-V2

12-inch Model

Page 2

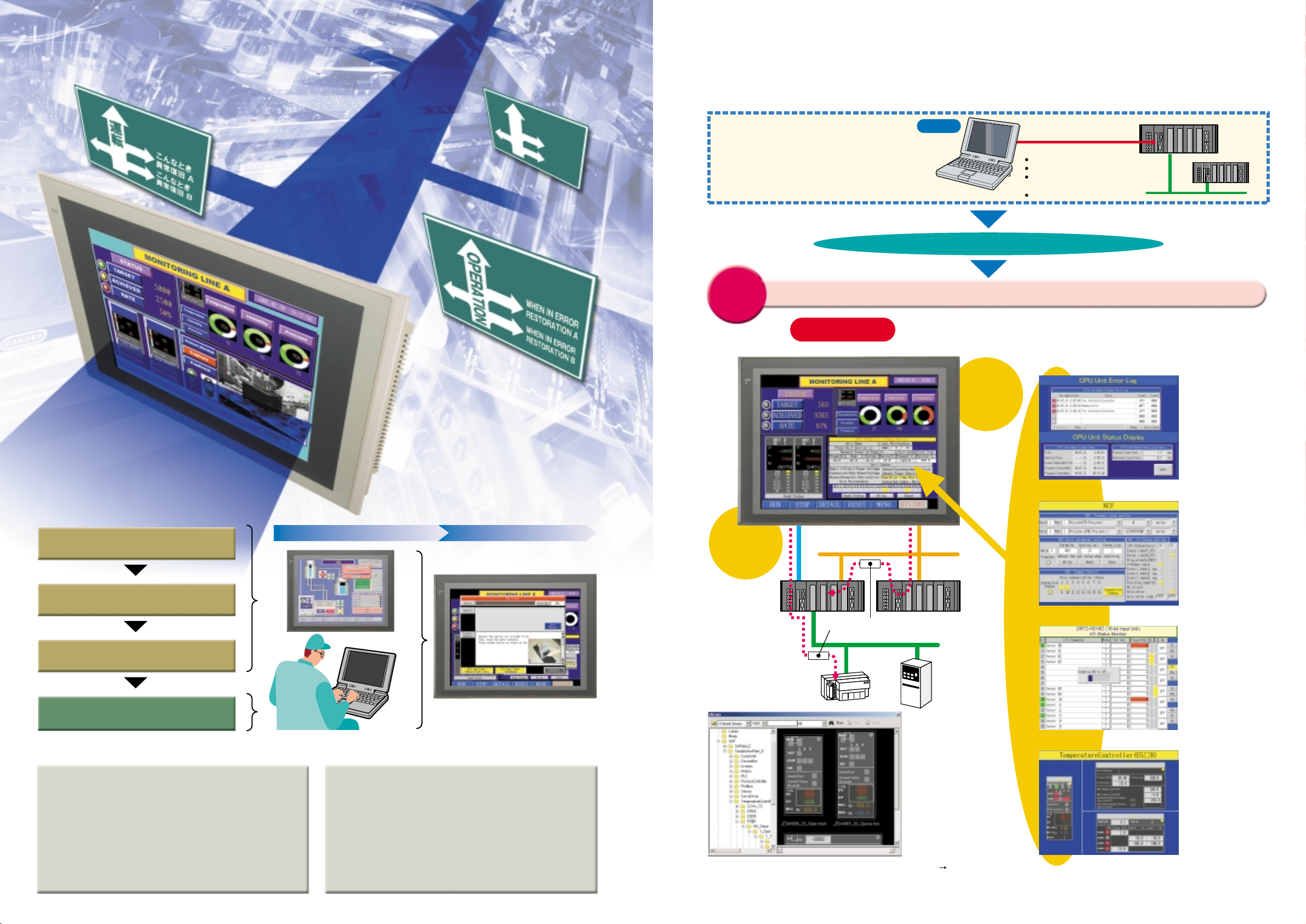

Make it More Simple

Make it More Simple

The NS is moving to the next stage, from a touch screen

The NS is moving to the next stage, from a touch screen

to an advanced machine management tool.

to an advanced machine management tool.

It's convenient

but…

Touch Screen Operation

Touch Screen Operation

Switch Operation

Switch Operation

Machine Management

Machine Management

Smart

We are always trying to

Seamless

Turning switches into Touch Screens brings

Turning switches into Touch Screens brings

enhancements, such as minimum wiring,

enhancements, such as minimum wiring,

space savings, and improved local operation

space savings, and improved local operation

efficiency. Moreover, OMRON works to

efficiency. Moreover, OMRON works to

minimize the customer's energy expenditure

minimize the customer's energy expenditure

from machine design to troubleshooting.

from machine design to troubleshooting.

provide solutions that will

give the highest added

value to your system.

We strive to solve on-site

problems with our

solutions instead of just

providing touch screen

functions. That is what

OMRON is focused on.

NS Enters a New Zone

From PLC Memory Allocation

to Device Access

Previous PTs shared data that was

allocated in advance to specific words in

the CPU Unit, and they were used to

assist with device operations, and to

display error locations, and

countermeasures.

PT

Previous PT

PLC

It's convenient

but…

CPU Unit

Previous zone

NS Series

PLC

Special I/O Units

Network

Example: DeviceNet

OK!

New zone

New zone

The NS Series achieves

flexible data access to a

variety of devices. It

enables operators to reach

the devices on the network

including Special I/O Units,

intelligent devices, and

PLCs.

Sharing allocated

data with CPU Unit

2 3

Allocated data

Smart Active Parts

(Functional software parts)

Example: Monitoring maintenance information

for various DeviceNet Smart Slave models

It's time for

switch inspection.

The cylinder

speed is strange.

Intelligent devices

Example: DRT2-series Smart Slave

Page 3

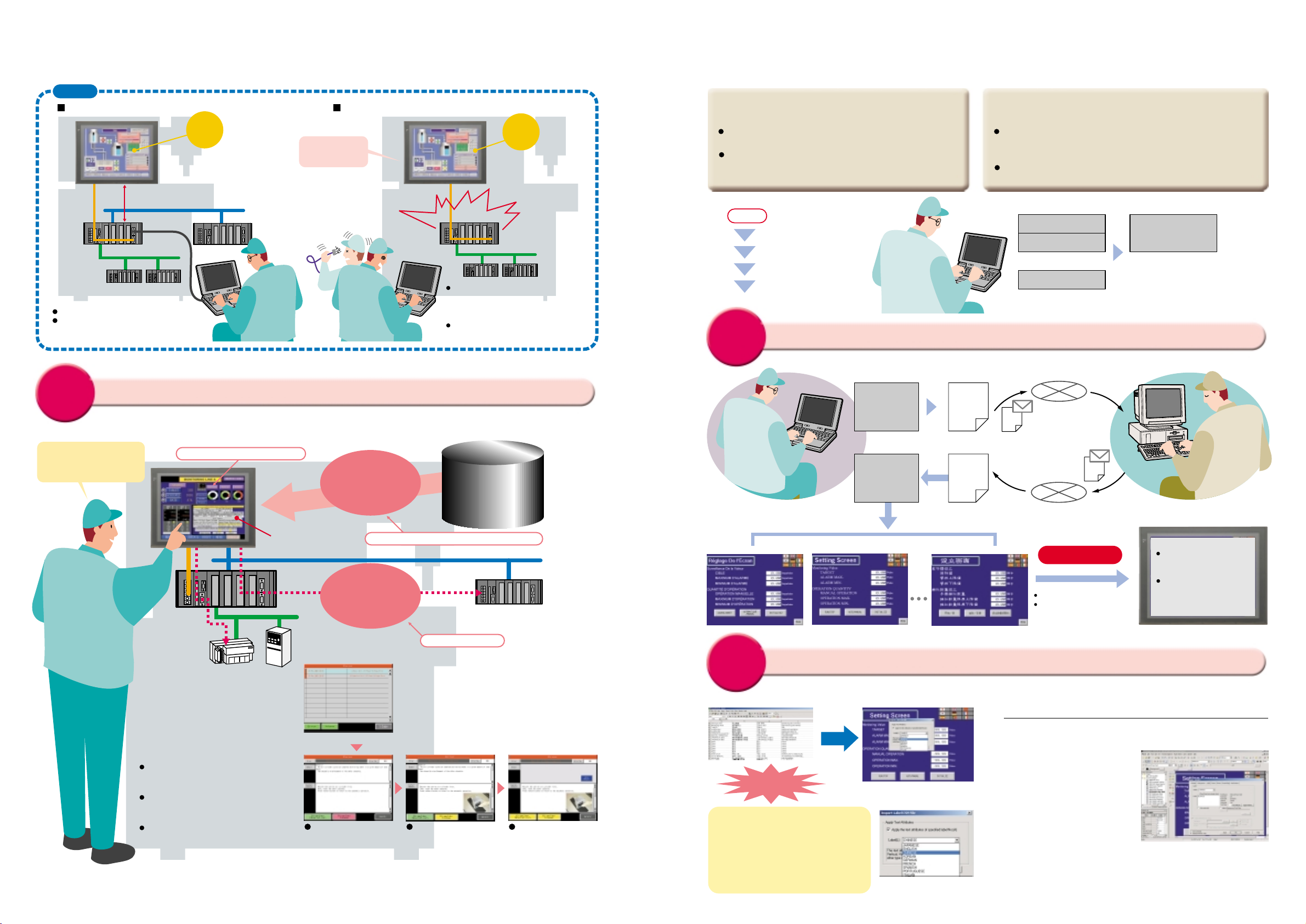

PTs as a Machine Navigator

PTs as a Machine Navigator

NS-series PTs navigate all areas of machine operation,

NS-series PTs navigate all areas of machine operation,

from daily operation to error recovery.

from daily operation to error recovery.

Don't you have these problems?

The Smart Active Parts are the solution.

Device operations

Previous

The PT is traditionally a

terminal that exchanges data in

allocated areas with the PLC's CPU

Unit. The internal and external control

of a PLC with only this type of data

exchange is, however, difficult.

A NS-series PT, however, uses

communications functions and Smart

Active Parts to incorporate

software computer functions to

operate as a Device Navigator.

NS Series

PT

NS: Device Navigator

Using all of the device-specific

Previous

personal computer tools at startup is

okay, but using the personal

computer tools for error recovery

during operation is overly difficult.

Wouldn't it be simpler to use the PT instead?

OMRON

With an NS-series PT, just drag and drop Smart Active Parts to customize the interface

for your machine.

ORIGINAL

NS-series PTs provide Smart Active Parts that allow direct data access

to a variety of devices.

Colors and

sizes can be

changed.

Only with NS!

Example: RS-232C

Example: Ethernet

Personal computer tools

Just

attach to

a screen.

NS Series

Various device-specific tools

Peripheral Devices for PLC

Network control

Temperature settings and

monitoring tools

Setting tool for position control

PLC System Objects

Previously

a CX-Programmer

was required.

Position Control Objects

Ensures easy

screen settings

in the NCF.

Displaying device error locations

Personal computer tool

Displaying countermeasures

Internal device monitoring

and resetting

(Supporting recovery methods)

With version 2 PTs (V2 suffix in model number), hardware functions are upgraded.

Increased VisibilityLarge Capacity

NS8-V2/NS10-V2/NS12-V2: 60 MB

(-V1: 20 MB, same as before)

NS5-V2: 20 MB

Note: The NS5-V1 has a capacity of 6 MB.

4

NS8-V2: Increased from 8.0 to 8.4 inches

NS5-V2(STN)/NS12: Wider field of vision

Devices accessed without a program.

Example: DeviceNet

The Smart Active Parts are accessed by selecting

Use Library

from the menu bar of the CX-Designer.

Tools

DeviceNet Objects

Previously

a DeviceNet

Configurator was

required.

Smart Active Parts

Temperature Controller Parts

ThermoTool was

required in the

past.

Refer to page 15 of this catalog to see the wide variety of Smart

Active Parts.

5

Page 4

Do you have the following problems when starting

the system or when errors occur?

Previous

When the System is Started

Data exchange is the main function.

A PT mainly exchanges data with a PLC.

Dedicated PC software is required to

gain access to other devices.

Only

with

NS!

Minor maintenance

can be performed on

the PT during operation.

With the Smart Active Parts

The PT can be customized according to the specifications of the device manufacturer to optimize

operation as a tool. This enables equipment maintenance by personnel other than engineers.

Create a screen like this as

a device troubleshooter.

When an error occurs, rapid recovery

is critical. With the NS Series, the

following type of screen can be easily

prepared to guide on-site workers to

carry out the operations required for

recovery.

Display explanations of error

contents and methods for recovery.

(Text file direct specification)

Use diagrams to show error

locations and methods for recovery.

(Bit map file direct specification)

Display only the buttons required for

recovery operations.

Note: In addition to the Troubleshooter for the machine above, there is a PLC troubleshooter for CS/CJ-series PLCs. Contact your OMRON representative for information on Troubleshooters.

PT used for operation

after startup.

Special personal

computer tool

Customizing and optimizing PT

Setting specified

parameters and checking status

An error occurs,

and…

Notification that an error

has occurred

1 2 3

When an Error Occurs during Operation

Simply paste one of

the Smart Active

Parts! Then make only

a few device node

settings.

Improved efficiency in creating maintenance screen

Smart Active Parts

access data without

any special

programming.

No ladder program

Error Recovery Screen Example

Text and BMP files can be directly specified, so

operations such as correcting contents for recovery and

replacing diagrams and photographs can be executed

without requiring any special tools. For example, if the

recovery operation procedure is changed by system

improvements, screens can be changed by simply

replacing text and BMP files, allowing for rapid

implementation of improvements and countermeasures.

Note: Transfer tools must be used for transfers.

Error contents and

recovery methods are

displayed.

Error location and

explanations of recovery

methods can be further

displayed by bit maps.

There is no way for

the PT to recover

following an error.

(Creating a screen

is quite

troublesome.)

Error

Use a dedicated computer, and you

have to wade through functionality

that is not being used or that does

not need to be reset.

Recovery can only be performed by a

specialist (i.e., an engineer).

Smart Active Parts

Recovery operation screen

is displayed. (Only the

buttons required for

operations are shown.)

Multi-language Terminal

Machine Localization with PTs

A Multi-language Input Environment

Using Excel

No special PT tools are required for translation

operations.

Translations can be requested using e-mail

attachments.

Previous

Either a single screen

data file was divided

between Japanese

and English screens,

or else multiple

screen data files

had to be created.

Only

with

NS!

Note: Windows 2000 or XP is required

for multi-language support.

Label 0

With

You can get multi-language support in Excel. Switching to as many as 16 languages is as

easy as switching labels.

Language A screen

data

NS project

Dual-language

screen data

NS project

Label 1

Multi-language conversion has become much easier!

CX-Designer

Multi-language CSV data

Import

Convenient!

When importing screen data, the text

attributes of user-specified labels can be

applied to all other imported text. With this

function, entire Japanese text attributes

(e.g., MS Gothic in blue or other colors) can

be used in Chinese labels. Furthermore, by

using the just-fit function, long labels in

English will fit within the frame limits after

automatic font adjustment.

Language A

Excel data

CSV

Language A and B

Excel data

CSV or

Unicode

16 languages max.

Label 15

Label Switching Function for Up to

16 Languages

Devices can be started with Japanese-language

screens, and then operated with screens in other

languages.

The languages can be switch to the one preferred by

the device operators.

CSV

text

Creating Chinese, Korean, or Other Language

Screens in Any Language Version of Windows

Multi-language Input (When Windows 2000 or XP is Used)

When Windows 2000 or XP is being used, Simplified

Chinese (see note),

Traditional Chinese (see

note), Korean, and other

language text can be input in

CX-Designer. Select the

desired language with Global

IME to input a different

language.

Note:

English and Japanese

screen data

Japanese-language

screen

English-language

screen

Chinese screen data

Chinese-language

screen

Dual-language

screen data

NS project

Because multiple labels can be

set, screen data needs to be set

only once. Multi-language

capability is simply a matter of

switching labels.

Dual-language input in Excel by translation

companies and local

companies

Attachment

Attachment

CSV

NS Series

Multi-Language PT

Only with NS!

Support for 17 languages

Switching to as many as

16 languages by simply

switching the labels

Simplified Chinese: Chinese with partially simplified characters, mostly used in

Mainland China.

Traditional Chinese: Chinese with traditional characters, mostly used in Hong

Kong and Taiwan.

Asian Languages

Japanese, Simplified Chinese (see note

1), Korean, and Traditional Chinese

(see note 2)

European Languages

English, French, German, Italian,

Portuguese, Spanish, Swedish, Dutch,

Finnish, Norwegian,

Basque, Catalan, and Danish

6 7

Page 5

The 5-inch screen expands your application range.

Price

Price

The NS5 Hand-held PT has joined the NS family!

The NS5 Hand-held PT has joined the NS family!

It expands your application range.

It expands your application range.

NS5

NS features in a compact

5.7-inch high-costperformance model. And,

screen capacity has been

increased to 20 MB!

20 MB

NS-series Lineup

Series

Appearance

Dimensions

(WxHxD)

Effective display area

Display device

Number of dots

Basic colors

(objects,

background, etc.)

Image data

Display

(BMP or JPG

colors

images)

Images displayed

via video input

Screen data capacity

Memory Card

Ladder Monitor function

Video Input Unit support

Controller Link

Interface Unit support

NS12

NS10

NS8

Larger, easy-to-operate,

10-inch model with 60 MB

screen data capacity

displays images from

digital cameras.

A bright 8-inch TFT with video

board mounting capability. A screen

data capacity drastically expanded

from 20 to 60 MB. High-definition

20 60 MB

model with 640 x 480 dots.

NS12 NS10 NS8 NS5 NSH5

315 x 241 x 48.5 mm 315 x 241 x 48.5 mm

12.1 inches

TFT

800 x 600 dots

256 colors 256 colors 256 colors

32,768 colors 32,768 colors 32,768 colors

260,000 colors 260,000 colors 260,000 colors

60 Mbytes 60 Mbytes 60 Mbytes 20 Mbytes

10.4 inches

TFT

640 x 480 dots

60 MB

232 x 177 x 48.5 mm

8.4 inches

TFT

640 x 480 dots

Visualizing large amounts of

information, this powerful, 800

x 600-dot, 12-inch-width model

allows variable combinations of

object arrangements and

expands your application range.

The NS5 in a 5.7-inch STN

high-performance hand-held

model.

5.7 inchs

320 x 240 dots

STN

195 x 142 x 54 mm

5.7 inches

TFT/STN/monochrome

320 x 240 dots

256 colors/

256 colors/

16 gradations

32,768 colors/

4,096 colors/

16 gradations

Screen size

Screen size

223 x 176 x 70.5 mm

(Not including depth of

emergency stop button)

5.7 inches

STN

320 x 240 dots

256 colors

4,096 colors

20 Mbytes

Version 2 Released for All NS-series Models.

Greater Screen Capacity and Increased Visibility!

Create 20 MB of screens for the NS5, and an impressive 60 MB of screens for the NS8/NS10/NS12.

Models

NS 5

NS 8

NS 10

NS 12

Display device model

(monochrome)

MQ

TQ (TFT)

SQ (STN)

TV (TFT)

TV (TFT)

TS (TFT)

V 1 V 2

6 MB

20 MB

20 MB

20 MB

20 MB

20 MB

20 MB

60 MB

60 MB

60 MB

Use digital photos to

your hearts content

with less worry about

screen capacity.

Increased Visibility for the NS5-SQ0 (B)-V2, NS8-TV0 (B)-V2,

and NS12-TS0 (B)-V2

NS5-SQ0 (B)-V2: STN Models

Field of vision from the top increased by 15°.

NS8-TV0 (B)-V2: TFT Models

LCD increased from 8.0 to 8.4 inches and left/right field of vision increased by 5°.

(External size and panel cutout are the same as previous version.)

NS12-TS0 (B)-V2: Bottom field of vision increased by 20°.

Now On Sale: The NSH5 5-inch Hand-held PT

Just What You've Been Waiting for: The NS5 (STN) in a Hand-Held Model!

Hold the NS5 in the palms of your hands.

Use the Smart Active Parts Library, multi-language functionality, Programming Console feature, and all the other familiar functions of the NS5.

Function

Switches

Use the ten functions

switches.

F1, F2, F6, F7: Wired

outputs

F3 to F5, F8 to F10:

Communications

outputs

3-Position

Enable Switch

Increased safety with

DPST-NO structure

(wired outputs).

Superior Shock Resistance

Consistent with JIS B 3502, IEC 61131-2

(drop shock).

cULus certification is scheduled for the near future for the NSH5 5-inch Hand-held PT.

Memory Card Interface and

USB Slave Connector.

Easily transfer screens or save logs at

high speed using a USB connection.

Emergency Stop Switch.

3PST-NC Structure

DPST-NC: Increase safety (wired

outputs).

SPST-NC: Input to internal NSH5

memory, output to a lamp for

emergency stop switch operation, or

output via communications, e.g., to a

PLC.

Water Resistance to IP65

The water-resistant structure is

equivalent to IP65 on all surfaces.

PT and Cable Sold

Separately

Select the Cable according to the

application (RS-232C/

RS-422A). Connectorloose wires, UL

connector,

3 m or 10 m.

8 9

Page 6

New functionality added in Ver. 6 extends

the ease of use of the NS-series PTs.

Smart Active Parts greatly reduce the number of drawing and programming steps.

Tool Functions Provided with Smart Active Parts

All you need to do is select the required Smart Active

Part in the CX-Designer and drag & drop it on the

screen see page 5).

Smart Active Parts not only reduce the number of

screen drawing and ladder programming steps, but

they also eliminate the need to debug.

Software functions are achieved on the screen

without software such as the CX- Programmer,

CX-Position, and DeviceNet Configurator.

Make PID settings for temperature

control without connecting software.

Drastically reduce

your programming

and development

time.

Want to check an error or adjust

settings without any software

tools. But realization of Touch

screen and PLC program are

really time consuming.

Also, it is dangerous to use

software tools since they can do

anything. Isn't it possible to

show or set one only part of the

information?

See the error log of the PLC without

As an error

connecting software.

Solution

monitor

Only one single part is on the screen!

Refer to page 15 of this catalog to see the wide variety of Smart Active Parts.

Only three parts are on the screen!

Easy screen transfer from anywhere at higher speed.

Data can be transferred over USB through a single

High-speed screen

transfer through

USB.

Note: Lot number 0325 or later is required

for USB screen transfer with NS-V1

models.

Most computers now have an

USB port, and no serial

RS-232C ports are provided.

You may want to transfer

screens more easily at higher

speeds.

Solution

cable between the computer and PT. No devices for

serial RS-232C and USB conversion are required.

Moreover, USB allows high-speed screen transfer by

just connecting the cable.

Screen transfers

equivalent to

Ethernet.

PT System

Ver. 6 or Higher

As a setting

device for

temperature

control

OMRON's

Temperature

Controller

(Direct Connection)

PT System

Ver. 6 or Higher

Improved Data Logging

Number of logging points greatly increased.

For example, the PT can log data at 2-second

intervals 24 hours a day (for a 43,200-point log).

The number of Always Log points has increased from 1,000 to 50,000

max. per line.

The total number of Always Log points increased from 5,000 to 50,000.

Example:

Logging 1 word and 1 address at 1-second intervals:

50,000 points, with 50,000 logging points per line.

Logging 1 word and 3 addresses at 1-second intervals:

50,000 points, with 16,666 logging points per line.

The number of logging points for one line depends on the number of

logging words and the number of logging addresses. For details, refer to

the manual.

Logging continues.

For example, you may want to log data at

2-second intervals 24 hours a day (a 302,400-point

log). This is possible with the NS Series.

When the logging data reaches the number of preset logging points,

the logging data can be automatically saved in a Memory Card in CSV

format. After automatic saving, the logging data will be cleared.

Therefore, it will be possible to continue logging. (The Memory Card

can hold a maximum of 1,000 files.)

Example:

Example: Logging 1 word and 1 address at 2-second intervals with

the number of logging points set to

43,200 (i.e., at 2-second intervals for 24 hours a day).

Memory

Card

Automatically

saved

Logging data for each

day (43,200 points) is

saved in the Memory

Card in CSV format.

LOG001.CSV 04/06/04 10:00

LOG002.CSV 04/06/05 10:00

LOG003.CSV 04/06/06 10:00

LOG004.CSV 04/06/07 10:00

LOG005.CSV 04/06/08 10:00

LOG006.CSV 04/06/09 10:00

LOG007.CSV 04/06/10 10:00

Suffixes are automatically

added to file names set in

the CX-Designer.

50 times

10 times

It is possible to

make a one-week

log by

automatically

saving the data

seven times.

Past logs can be seen.

You may want to see logs saved in the past in a

Memory Card on the screen. This is possible with

the NS Series.

Log data in a Memory Card can be read on the screen with the read

file button. A list of files with time stamps will appear on the screen.

By selecting the desired file, the past log in the Memory Card can be

read.

The log data files in the Memory Card

appear as shown below when the read file

button is pressed.

Read file button

Standard data can be displayed in the data log.

You may want to save the present log data as

standard data in the Memory Card. This is

possible with the NS Series.

By pressing the save to file button, the displayed log data can be

saved in the Memory Card in CSV format. The saved log data can be

overlapped as standard data on the screen by pressing the read file

button. By turning the log start address ON and OFF, logged data can

be controlled to enable/disable logging.

Save to file button Read file button

PT System

Ver. 6 or Higher

Log start address

Standard data

NS-V2 Hardware Means High Quality, High Performance, and High Capacity

Screen transfers using Memory Cards are possible

from the maintenance menu. No physical switch

Screen transfers

using Memory

Cards are possible

from the

maintenance

menu.

Screen transfer

through modems is

now possible.

It is very convenient to make

backups without using a

computer. It is, however,

troublesome to operate a DIP

switch on the back of the PT

each time backups are required.

You may want to make backups

periodically, but worry because

the DIP switch pins may break.

Even a single screen change in

a shipped machine involves a

risk, because a screen sent by

e-mail needs to be transferred

to a person familiar with

operation. Training workers to

understand operation is a hard

job. Or service personnel need

to visit the site to change

screens.

Solution

Solution

operations are required on the rear panel.

Furthermore, easy operation is ensured with no wear

and tear of hardware, including the switch.

Memory

Select from

the system menu.

Start downloading/

uploading.

Card

The screens can be transferred from a computer in an

office through modems. The maintenance of

the screens is possible without touching the device.

Therefore, no training or engineer visits are required.

RS-232C

Modem

Modem

High definition

Displays image data (BMP and JPG) beautifully.

NS-V2: 32,000 colors

NS5

4,096 colors

NS8

32,768 colors

NS10

32,768 colors

NS12

32,768 colors

Note: NS5-SQ0 (B)-V2: STN models have 4,096 colors.

NS5-TQ0 (B)-V2: TFT models have 32,768 colors.

Large-capacity image data

Three times the image data capacity for standard models

V 1 V 2

20 MB

6 MB

NS5

NS8

NS10

NS12

20 MB

20 MB

20 MB

60 MB

60 MB

60 MB

NS8/10/12-V1

20 MB

NS8/10/12-V2

60 MB

USB port compatibility with commercially available printers

Hard copies of screens can be printed out in color by USBcompatible printers.

Not

NS5

Supported

Supported

NS8

Supported

NS10

Supported

NS12

EPSON and Canon

printers supported.

USB port included as

standard equipment

USB cable

General printer compatible

with USB port

Manufacturer: EPSON or Canon

Recommended models

EPSON: PM-2200C, PM-930C, PM-870C,

PM-740C, PM-900C, PM-D600,

PM-G720, PM-G730, PX-A650,

PM-G730, PM-D600, PX-A650

Canon: BJ-M70, BJ-M40, PIXUS550i, 50i, 80i,

IP2000, IP3100, IP4100, IP4100R, IP90

Faster drawing speed

High-speed screen switching

See note.

NS5

Yes

NS8

Yes

NS10

Yes

NS12

Note: The NS5

uses a different

graphic controller

from other models.

200-MHz RISC CPU

High-speed graphics controller

10 11

Page 7

The NS Series is more beautiful and user-friendly.

More beautiful

You can make beautiful screens with simple operations.

Beautiful BMP Parts Collection has

been newly added. Simply select

Windows fonts can be used for

switches and lamps Ver.5

Auto font resizing function Ver.5

Automatically resizes fonts to the

object size.No need to adjust font

sizes manually anymore!

Furthermore, just-fit font size

adjustments have been possible

since version 6.

the desired part, paste it on your

screen, and make your screens

neat!

32,768-color display

The color variation displays

pictures brilliantly!

More strength in applications

The NS can be connected to a Board PC. The NS can also be directly

connected to an OMRON Temperature Controller.

Memory link

CompoWay/F

Host Link CS/CJ-series,

CVM1/CV-series,

or C-series PLC

PLC

System Configurations

Various connections, such as 1:1, 1:2, 1:N, and M:N, are supported with Ethernet or serial connections.

PT:PLC = 1:1

NS-series PT

Communications without

programming

(1:1 NT Link, 1:N NT Link,

or Host Link)

PLC

PT:PLC = 1:N

NS-series PT NS-series PT

Communications without

programming

(1:N NT Link)

PLC

Host Registration Function

It is possible to register two or more PLCs as hosts and communicate with the PLCs by specifying the host ID and address when connected via Ethernet or

Controller Link.

A Memory Link has been added

to the communications method.

It allows the NS to communicate

with a Board PC.

OMRON Temperature

Control Unit

RS-232C

NS-AL002 Converter

(Converts between

RS-232C and RS-422A.)

The NS can be directly

connected to the OMRON

Temperature Controllers listed

on the right.

More user-friendly

You can partially replace text and pictures from

your computer.

FTP (File Transfer Protocol) has been

added! Texts, lists, and recipes can be

replaced with the put/get command from

your computer! You can even replace

BMP files from your computer easily.

Screens, bitmaps, text, recipe data

The following models, which have an RS-485 communications port and

PT:PLC = 1:2

CS/CJ-series PLC

PT:PLC = M:N

Ethernet

CS/CJ-series

PLC

support CompoWay/F communications, can be connected to the NS.

Unit Series and Models

Modular Temperature Controllers

E5ZN-SCT24S

E5ZN

(Terminal Unit)

Digital Controllers

E5AR

E5AR- 03 -FLK

E5ER

E5ER- 03 -FLK

NS-series PT

RS-232C

Communications without

programming

Ethernet Unit

Unit Series and Models

Temperature Controllers

E5AN/EN

Series

E5CN

Series

E5GN

Series

NS-series PT

RS-232C

NS-series PT

E5AN- TC

E5AN- P

E5EN- TC

E5EN- P

E5AN- T

E5AN- L

E5EN- T

E5EN- L

E5CN- TC

E5CN- P

E5CN- T

E5CN- L

E5GN- TC

E5GN- P

Communications without

C200HX/HG/HE PLC

CS/CJ-series PLC

Thermocouple input

Temperature-resistance input

Thermocouple input

Temperature-resistance input

Temperature input

Analog input

Temperature input

Analog input

Thermocouple input

Temperature-resistance input

Temperature input

Analog input

Thermocouple input

Temperature-resistance input

RS-232C

programming

PLC

Powerful Networking

Exchanging Data with a PLC over a Network (Multihost)

Communicating with a PLC via NT Link,

using Ethernet without Special PLC Programming

Ethernet Communications without

Programming

NS-series PTs can communicate with a CS/CJseries PLC (equipped with an Ethernet Unit)

through “program-free” communications just

like NT Link communications. Data is transferred

through Ethernet through a simple PLC address

and initial communications setup.

Personal

computer

Ethernet

Direct access

CS/CJ-series

ControllerLink

CS/CJ-series

PLC

PLC

Direct access

CS/CJ-series

PLC

Direct access

NS-series PT

SPMA (Single Port Multi Access) Function

Screen data can be transferred through the PLC from the CX-Designer to the PT connected to the PLC in series or via a network.

You may want to transfer screens to a PT through the PLC without changing

computer connections or to transfer a ladder program to the PLC through the PT

by using the Ethernet or Controller Link.

Ladder programs can be monitored or transferred from the CX-Programmer through the NS-series PT to PLCs connected to the PT

in series or via a network.

Screen data or Data in Memory Card

SPMA

Ethernet

NS-series PT

Controller Link

Screen transfer

from the

Controller Link

is supported

from version 6.

(From CX-Designer through PLC to NS-series PT)

Ladder program

(From CX-Programmer through NS-series PT to PLC)

CS/CJseries

PLC

Serial

NT Link

Peripheral

(or RS-232C)

Serial

Peripheral

bus

(Tool bus)

RS-232C

NS-series PT NS-series PT

Computer

CS/CJ-series PLC

Using Data Links between the PT and the PLC

Controller Link Interface Unit

The Controller Link is an FA network that can send and

receive large data packets flexibly and easily among

OMRON PLCs and IBM PC/AT or compatible computers. The

NS12 and NS10 PTs can be connected to the Controller Link

network easily via a Controller Link Interface Unit. When a

Controller Link network is used, data can be transferred

between multiple PLCs and NS12/NS10 PTs without writing

ladder programming to manage the communications.

NS-series

PT

Direct access

NS-series

PT

Computer

NS-series PT

Serial

NT Link

Serial

NT Link

CS/CJ-series PLC

CS/CJ-series PLC

Direct access

To use the SPMA function through the PLC, the following

*

software and hardware versions are required.

NS-series PT: System version 3.0 or higher

NS Designer: Version 3.0 or higher or

CX-Designer: Version 1.0 or higher

CX-Programmer: Version 3.1 or higher

PLC: Lot No. 030201 and later (Refer to the following table.)

PLC series

CJ Series

CS Series

Direct access

CPU model Lot number

CJ1H-CPU65H

CJ1H-CPU66H

CJ1G-CPU42H

CJ1G-CPU43H

CJ1G-CPU44H

CJ1G-CPU45H

CJ1M-CPU11

CJ1M-CPU12

CJ1M-CPU13

CJ1M-CPU21

CJ1M-CPU22

CJ1M-CPU23

CS1H-CPU63H

CS1H-CPU64H

CS1H-CPU65H

CS1H-CPU66H

CS1H-CPU67H

CS1G-CPU42H

CS1G-CPU43H

CS1G-CPU44H

CS1G-CPU45H

CS1D-CPU42S

CS1D-CPU44S

CS1D-CPU65S

CS1D-CPU67S

NS-series

PT

030201

030201

1312

Page 8

The NS monitors machine status for who and how machines

are managed to help speed recover from problems.

Using Video Inputs

The NS-CA002 has joined the NS-CA001 Video Input Unit.

You may want to input moving images

from a video camera or the image

output from a Vision Sensor, arrange

them on the PT screen, and capture

(save) the images or display the capture

data on the PT.

Display PC Screens with the NS-CA002

NS-CA002 RGB/Video Input Unit

(Supported by the NS12-V /NS10-V /NS8-V .)

An analog RGB input terminal is provided in addition to two

video input interface terminals. A single video or analog

RGB display is possible on the NS-series PT. In that case,

video display is possible in user-defined positions and sizes.

Touch switches and parts, such as lamps, can be

overlapped on the video display. The display of parts will

not disappear.

RGB

Console

Camera

Note: Two video signals cannot be simultaneously input to a

single screen.

NS-CA001 Video Input Unit

(Supported by the NS12-V /NS10-V /NS8-V .)

Four video input interfaces are provided, so four video or

CCD cameras can be connected. Up to four images can be

displayed simultaneously if the image size is 320x240

pixels.

Console

Camera

Saving Displayed Video Images to a Memory

Card in BMP Format

Image Capture Function

When necessary, the displayed image can be captured and

saved in a Memory Card in BMP format. The saved image

can then be uploaded from remote personal computer via

Ethernet or Serial connection.

The number of images that can be saved depends on the

capacity of Memory Card. As an example, about 50 images

from a 640x480 display (about 600 Kbytes each) can be

saved in a 30-Mbyte Memory Card.

Image capture data read function

BMP data captured and saved in a Memory Card can be

read on the PT. BMP data displayed in thumbnails

can be selected and displayed on the captured data display

screen that will appear for the command button.

If an error occurs, the image when the error occurred can be displayed

on the NS screen. This is useful for on-site error analysis.

PT System

Ver. 6 or Higher

Monitoring and Setting PLC Data

For Operators

Display machine

Display machine

status simply.

status simply.

Do not want to be aware of

ladder programs and PLC

memory areas.

Only want to display I/O

comments and I/O status.

Display PLC memory

Display PLC memory

areas without using tools.

areas without using tools.

Want to display and change the

PLC memory areas without

showing the PLC program.

Display program

Display program

without using tools

without using tools

Want to identify the fault location

by checking the actual PLC

program.

Want to change part of the

program, a timer/counter, without

connecting tools.

For Experts

Solve with the Switch Box

function

Solve with the Device Monitor

function

Solve with the Ladder Monitor

function

Easily Displaying the Status of

Particular Bits in Ladder Programs

when Errors Occur

Switch Box Function

The Switch Box Function has been added to the

NS-series Programmable Terminals. The Switch

Box Function can be used to monitor the status

of each bit in a word or a combination of userselected bits organized like a ladder program

section. The Switch Box Function makes it

possible to perform basic troubleshooting on

the factory floor even without a computer.

Monitoring PLC I/O Data for

the Purpose of Device Debugging

and Maintenance

Device Monitor Function

The Device Monitor Function is a standard feature

in the NS-series Programmable Terminals. Data in

the PLC’s I/O memory can be accessed directly

(read and written.) The Device Monitor provides

functions that can significantly reduce the time

needed to set up the system, such as displaying a

block of consecutive PLC data area addresses and

inputting/verifying parameters in CPU Bus Units

and Special I/O Units.

Monitoring Execution of

the PLC's Ladder Program

Ladder Monitor Function

(NS12-V /NS10-V /NS8-V )

The Ladder Monitor Software provided with the

CX-Designer can be used to monitor states,

search for addresses and instructions, and

monitor multiple I/O points at the same time in

CS/CJ-series PLCs ladder programs via a serial,

Controller Link, or Ethernet connection. Copy

the Ladder Monitor software to a Memory Card

and install the Memory Card in the NS-series PT

to enable these monitoring and searching

operations. It is also possible to display I/O

comments created with the CX-Programmer

using an I/O Comment Extract Tool.

From CX-Designer version 1.0, the Ladder Monitor software is

stored in the following folder on the CD-ROM. Copy it to a Memory

Card (sold separately) to use it.

CX-One Disk 3: \Utility\CX-Designer\English\

LadderMonitorFunc.

CX-Designer CD-ROM: \Utility\English\LadderMonitorFunc.

Facilitate Equipment Maintenance

Integrating Special Unit Functions or Component Peripheral Tool Functions into PTs

Smart Active Parts

The following Smart Active Parts are provided and can be installed on the NS-Designer (version 6 or higher).

For CS/CJ AND CS1D CPU Unit

Error Log Monitor, Online Battery Change Button, etc.

For Serial Communications Boards/Units

Communications Status Displays (Error Monitor), Ports Settings, etc.

For Ethernet Units/CLK Units

Network Status Displays (Error Monitor and Network Node Status), etc.

For MC/MCH Unit

JOG Running, Search Zero Position, Program Running, Error Displays,

I/O Status Monitor, PV Monitor, etc.

For NC/NCF Unit

JOG Running, Direct Running, Memory Running (NC Only), Error

Displays I/O Status Monitor, PV Monitor, etc.

Wireless Terminals for WT30

Monitoring Slave Operating Status in a Wireless Environment

For Servo (R88D-WT, R7D-AP) (See note.)

PV Monitor, Parameter Settings, Error Displays, Driver Information

Displays, I/O Status Monitor, etc.

For Inverters (See note.)

Rotation Speed/Monitoring Output Frequency, Other Parameter

Settings, etc.

For DeviceNet

DRT2 Maintenance/Status Information, IN/OUT Information, etc.

For Temperature Controllers (E5 R, E5ZN, E5 N and

CJ1W-TC)

Run Monitor, PID Settings SP Settings, Alarm Settings, Input

Correction Settings, etc.

For Sensors (E3X-DRT)

Threshold Settings, Monitoring Light Reception Levels, Etc.

For the SmartSlice GRT1 Series

Communications Unit Status, Warning/Alarm Flags, Network

Joining/Leaving Status

Note: Smart Active Parts require a Serial Communications Units/Boards

(version 1.2 or later).

14 15

Page 9

High-reliability and Advanced Functions in

the Industry’s Slimmest PT

Using a Personal Computer to Check PT Operation

Using a Personal Computer to Check the

Operation of Created Functional Objects

Simulation via the “Test Function”

When a test is started, a test screen and virtual PLC will be

displayed on the computer.

Test mode

CX-Designer

Set values:

Present values:

300

500

Virtual

PLC address

1

300

500

Start of Test

Set value:

Present values:

9999

9999

Created screen

Transferring Screen Data to the PT On-site from a Memory Card

Memory Card: Upload/Download Function

It is possible to download the screen data and system

program to Memory Card and upload the same data from

the Memory Card. It is also possible to automatically

upload the data from the Memory Card to CX-Designer or

automatically download the data from Memory Card to PT

when the power of PT is turned ON.

Test Mode Window

Operating (clicking with the mouse) the functional objects

on the test screen will change the corresponding address in

the virtual PLC. Conversely, changing the content of a

virtual PLC address will change the corresponding

functional objects. It is also possible to confirm pop-up

screens. This function can be used to confirm the actual

operation of a screen during the editing.

The test function enables debugging screens without NS

and PLC Hardware.

CX-Designer

Screen data

Memory

Card

NS-series PT

Virtual PLC address

Screen data

Automatic transfer

when power of PT

is turned ON.

Memory Card

NS-series PT

Super-thin 48.5-mm Body for a Slimmer Control Panel

This thin-profile model has few protrusions so it can be incorporated easily into a panel or machine.

The PT can help save space when space is at a premium.

NS12, NS10

Memory Card interface

Memory Card

Note: Colors shown in photographs and product

names may differ from actual colors and

names.

Expansion interface

Battery

RS-232C serial port A

RS-232C serial port B

Power Supply (24 VDC)

USB HOST (for printer) USB SLAVE (For screen data transfer)

Ethernet (10Base-T or 100Base-TX)

NS8

Memory Card interface

A bar code reader can be connected

to the serial port.

Recommended bar code reader: V520-RH21-6

Using General Software

Setting Functional Object Properties in Excel

CSV File Input/Output

The property settings for each functional object can be

exported in CSV format. The settings data can be imported

again after it has been edited with a program such as Excel.

Editing Text and Bitmap File with Your

Favorite Text Editor

Editor Specifying Function

The user can select the editor when editing text or bitmap

files.

Creating System-related Documents

Outputting Project Information in RTF

Data such as screen information and object information can

be output in an RTF file. The RTF file can be read into Word

Processor to produce a system manual.

Example of an RTF File Read into Word Processor

Pasted Screen Data as

RTF Data

Object Properties as

RTF Data

Using Excel to Analyze Data, Such as the Alarm/Event

History, Operation Log, and Error Log, and to Create

Daily Reports

Memory Card: Data Logging Function

Logging data (trend data, up to 50,000 points with a

sampling cycle of 0.5 or 1 to 86,400 s/group) can be stored

in the Memory Card in CSV format.

Logging of

trend data

Memory Card

Using Excel to Analyze Time-series Data and

to Create Daily Reports

Memory Card: History Storage Function

The following data can be saved to the Memory Card in

CSV format.

Alarm/Event History (Alarm/ Event history data)

Operation Log (Screen operation history data)

Error Log (Error log data recorded during macro program

execution)

Power

Supply

(24 VDC)

Built-in Expansion Interface

The NS-series PTs have a built-in Expansion Interface for

future expandability.

Expansion interface

Memory Card

Note: Colors shown in photographs and product

names may differ from actual colors and

names.

Battery

RS-232C serial port A

RS-232C serial port B

Ethernet

(10Base-T or 100Base-TX)

USB SLAVE (For screen data transfer)

USB HOST (for printer)

A bar code reader can be connected

to the serial port.

Recommended bar code reader: V520-RH21-6

USB Ports

A printer can be connected to the USB HOST port.

Refer to

printers.

Printer Support

on page 10 for recommended

16 17

Page 10

Dimensions

NS5

Battery

Power Supply

(24 VDC)

Optional Products

Video Input Unit

NS-CA001(with Cover)

RGB/Video Input Unit

NS-CA002 (with cover)

Memory Card interface

Memory Card

Note: Colors shown in photographs and product names

may differ from actual colors and names.

Expansion interface

Ethernet (10Base-T or 100Base-TX)

USB SLAVE (For screen data transfer)

RS-232C serial port A

RS-232C serial port B

A bar code reader can be connected

to the serial port.

Recommended bar code reader: V520-RH21-6

Controller Link Interface Unit

NS-CLK21

(with Cover)

RS-422A Adapter

CJ1W-CIF11

NS12/10 PT Units: mm

15.5

264

315

323

301

24V

DC

SLAVEHOST

3.8

23

ETHERNET

PORT APORT B

13. 7

49.9

90.4

NS5 PT Units: mm

39.83

140

241

7.5

48.5

227 249

39 (min.)

42 (max.)

NS8 PT

Units: mm

15.5

180

232

177

165 188

5

48.5

39 (min.)

42 (max.)

49

49

220

Recommended

Panel Cutout Dimensions

Recommended

Panel Cutout Dimensions

SW

RESET

121

228

+1

–0

134

+1

302

–0

24V

DC

SLAVEHOST

ETHERNET

26.6 9.6

44.1 50.1

63.4

RESET

PORT ASWPORT B

19.1

107.6120.5

+0.5

220.5

–0

165.5

+0.5

–0

NS5 Hand-held PT Units: mm

195

223

16.5

70.5

RS-232/RS-422A Conversion

Unit

NS-AL002

Communications Cable

XW2Z-S002

Protective Cover/Anti-reflection

Sheet for NS-series PT

NS -KBA0(N)

NT30/NT31C-KBA05(N)

USB Serial Conversion Cable

CS1W-CIF31

27.3

44.55

ÇqÇtÇm

142

15.5

90

145

206.3

5

53.8

54.8

153.3

130.5

34 (min.)

38 (max.)

176

183.5

Recommended

Panel Cutout Dimensions

68.48

184

NS-CA002 Video Input Unit

Units: mm

+0.5

131

–0

+0.5

–0

NS-CLK21

Controller Link Interface Unit

Note: Colors shown in photographs and product names may differ from actual colors and names.

ÇrÇv

OFF

5

1

2

OFF

6

3

OFF

4

OFF

PORT B PORT A

RESET

19.5

51.7

ETHERNET

21

77

NS-CA001 Video Input Unit

Units: mm

OFF

OFF

Units: mm

118.3

81.3

(102.7)

21.4

5

20.4

9.7

11

39.3

57.3

82.8

(33.9)

(1.9)

(169)

164

151.5

(183)

31.5

5

10.8

32

95.6

11

(22.3)

81.3

(102.7)

9.6

164

(169)

(1.9)

10.6

127.3

104.3

21.4

5

20.4

9.7

11

50.3

68.3

86.3

(22.3)

9.6

(1.9)

11.1

(169)

164

18 19

Page 11

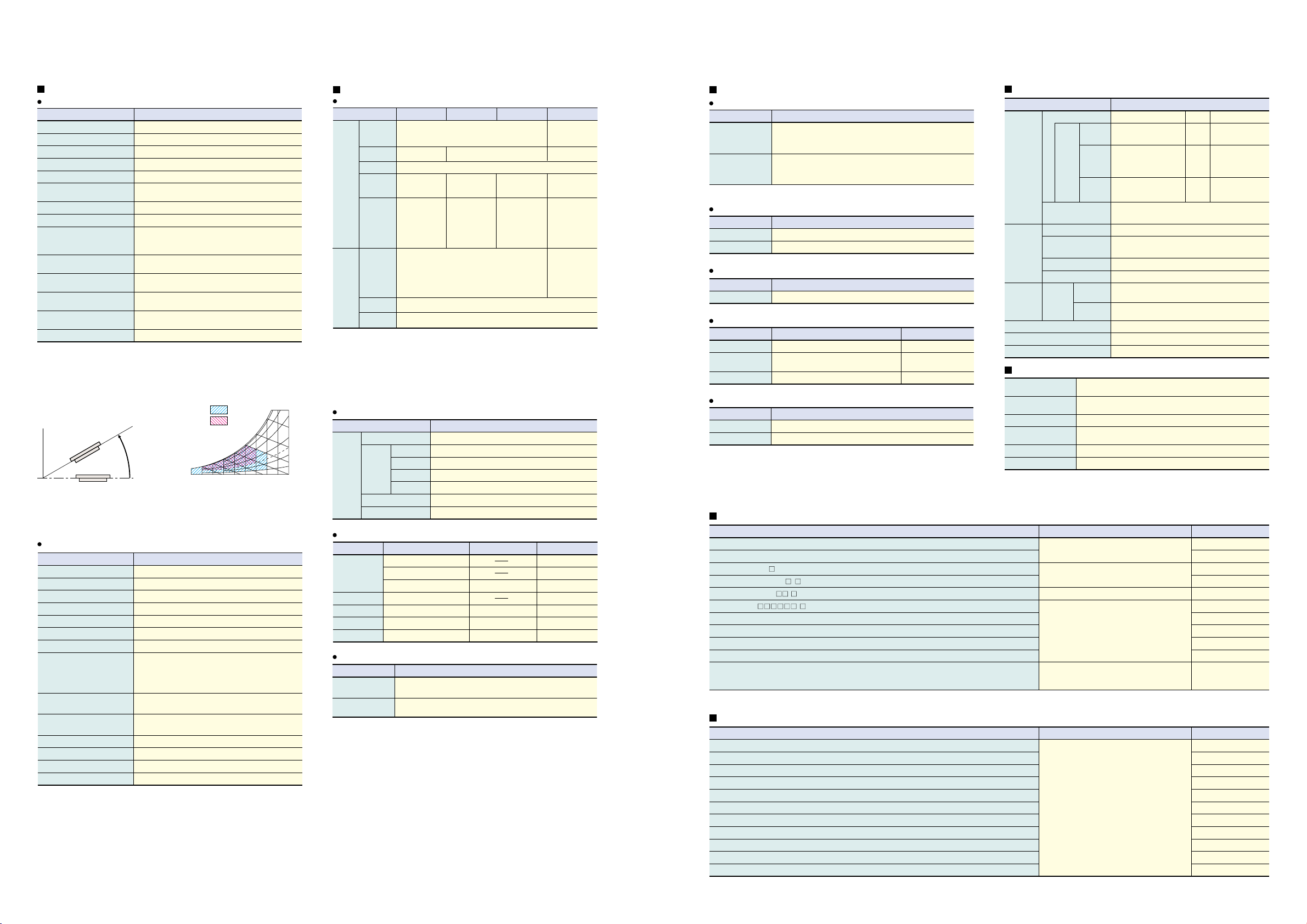

Performance/Specifications

General Specifications

NS12/NS10/NS8/NS5-V2

Item Specifications

Rated power supply voltage

24 VDC

Allowable voltage range 20.4 to 27.6 VDC (24 VDC ±15%)

Power consumption

Ambient operating temperature

25 W max. (15 W max. for the NS5)

0 to 50°C (See notes 1 and 4.)

Storage temperature – 20 to 60°C (See note 2.)

Ambient operating humidity

35% to 85% (0 to 40°C) with no condensation

35% to 60% (40 to 50°C) with no condensation

Operating environment No corrosive gases.

Noise immunity Conforms to IEC61000-4-4, 2 kV (power lines)

Vibration resistance

(during operation)

Shock resistance

(during operation)

Weight

Enclosure rating

Battery life

Conforms to JIS C0040.

10 to 57 Hz, 0.075 mm amplitude, 57 to 150 Hz,

2

30 min each in X, Y, and Z directions

9.8 m/s

Conforms to JIS C0041.

2

3 times each in direction of X, Y, and Z.

147 m/s

NS12: 2.5 kg max.; NS10: 2.3 kg max.;

NS8: 2.0 kg max.; NS5: 1.0 kg max.

Front operating panel: IP65F and NEMA4 compliant

(See note 3.)

5 years (at 25°C) Replace battery within 5 days

after the battery runs low (indicator lights orange).

Applicable standards cULus and EC directives

Note 1: The operating temperature is subject to the following restrictions according to the mounting

angle.

Mounting angle of 0 to 30° to the horizontal: Operating temperature range of 0 to 45°C

When a Video Input Unit or a Controller Link Interface Unit is mounted, the ambient operating

temperature is 0 to 35°C.

Mounting angle of 30 to 90° to the horizontal: See note 4.

Note 2: Operate the PT within the temperature and humidity ranges shown in the following diagram.

Storage

0

20

10

Operation

50

40

30

Temperature (°C)

90°

Temperature (°C)

Display surface

Note 3: May not be applicable in locations with long-term exposure to oil.

Note 4:

•NS12/NS10/NS5

Mounting angle of 30° to 90° or less to the horizontal: Operating temperature range of 0 to 50°C

•NS8

Mounting angle of 30° to less than 90° to the horizontal: Operating temperature range of 0 to 45°C

Mounting angle of 90° to the horizontal: Operating temperature range of 0 to 50°C

30°

Horizontal

(0°)

NSH5-SQROOB-V2

Item Specification

Rated power supply voltage 24 VDC

Allowable voltage range

Power consumption 10 W max.

Ambient operating temperature

Storage temperature –20 to 60°C

Ambient operating humidity

Operating environment No corrosive gases.

Noise immunity

Vibration resistance

(during operation)

Shock resistance

(during operation)

Weight 1 kg max.

Enclosure rating IP65 compliant

Ground Ground to 100 Ω or less.

Applicable standards UL508 and EC directives

20.4 to 26.4 VDC (24 VDC –15%/+10%)

0 to 40°C

35% to 85% with no condensation

Common mode: 1,000 Vp-p (between power

supply terminals and panel)

Normal mode: 300 Vp-p

Pulse width: 100 ns to 1 µs, Rise time: 1-ns pulse

Conforms to JIS C0911.

Conforms to JIS C0912.

20

Humidity (%)

60

Characteristics

Display Specifications

(See note 4.)

NS5-V2/NSH5-V2

TFT color LCD

STN color LCD

Monochrome LCD

320 dot horizontal x

240 dot vertical

Width 117.2 mm x

height 88.4 mm

(5.7 inches)

TFT: Left/right 70°,

Top 70°, bottom 50°

STN: Left/right 50°,

Top 45°, bottom 50°

Monochrome:

Left/right 45°,

Top 20°, bottom 40°

TFT, STN: 75,000

hours min. (See

note 2.)

Monochrome:

50,000 hours min.

(See note 2.)

256 colors

Width 170.9 mm x

height 128.2 mm

(8.4 inches)

Left/right ±65°,

Top 50°, bottom 60°

NS8-V2NS12-V2

Item NS10-V2

Display device

Number of dots

800 dot horizontal x

600 dot vertical

High-definition TFT color LCD

640 dot horizontal x 480 dot vertical

Display color

Display

Effective

panel

display area

Field of vision

Service life

Backlight

(See note

5.)

Brightness

adjustment

Backlight error

detection

Note 1: The bottom angle is 55° for V1 models.

2: This is the estimated time before brightness is reduced by half at room temperature

and humidity. It is not a guaranteed value. The service life will be drastically shortened

if PT is used at low temperatures. For example, using the PT at temperatures of 0°C

will reduce the service life to approximately 10,000 hours (reference value).

3: The brightness cannot be adjusted much.

4: This function does not indicate that the service life has been reached. It detects when

the backlight is not lit due to a disconnection or other errors. Backlight error detection

indicates that all backlights (2) are OFF.

5: Contact your nearest OMRON representative to replace the backlight.

80%95%

60%

Operating Specifications

Width 246.0 mm x

height 184.5 mm

(12.1 inches)

Left/right ±60°,

Top 45°, bottom 75°

(See note 1.)

50,000 hours min. (See note 2.)

Width 215.2 mm x

height 162.4 mm

(10.4 inches)

Left/right ±60°,

Top 35°, bottom 65°

There are 3 levels that can be set with the touch panel. (See note 3.)

Error is detected automatically, and the RUN

indicator flashes green as notification.

Item Specification

40%

35%

20%

10%

80706050403020100—20

Method Resistive membrane

NS12-V2

Number

Touch

panel

(Matrix

type)

of

switches

NS10-V2

NS8-V2

NS5-V2/NSH5

1,900 (50 horizontal x 38 vertical) 16 x 16 dots for each switch.

1,200 (40 horizontal x 30 vertical) 16 x 16 dots for each switch.

768 (32 horizontal x 24 vertical) 20 x 20 dots for each switch.

300 (20 horizontal x 15 vertical) 16 x 16 dots for each switch.

Input Pressure-sensitive

Service life 1,000,000 touch operations.

Communications Specifications

Serial Communications

Item Specification

Conforms to EIA RS-232C.

Port A

Port B

Note: The 5-V outputs of serial ports A and B cannot be used at the same time.

D-Sub female 9-pin connector

5-V output (250 mA max.) through pin 6 (See note.)

Conforms to EIA RS-232C.

D-Sub female 9-pin connector

5-V output (250 mA max.) through pin 6 (See note.)

Controller Link (Wired-type) Specifications

Item Specification

Baud rate 2M/1M/500K

Transmission path

Shielded twisted-pair cable (special cable)

Ethernet Specifications

Item Specification

Conformance standards

Conforms to IEEE 802.3/Ethernet (10Base-T/100Base-T).

Video Input Specifications

Item NS-CA001 NS-CA002

Resolution 320 x 240, 640 x 480, or 800 x 600 dots User-defined size

Input signal NTSC composite video or PAL

Cameras Number of cameras: 4 max.

NTSC composite

video or PAL

2 cameras + RGB

USB Specifications

Item Specifications

USB rating USB1.1

Connector Type A (Host), Type B (Slave)

Compatible OMRON PLCs

CPU Units (1:1 NT Link Connection)

Data Capacity Specification

Series

Display device model V 1 V 2

MQ (monochrome)

NS5

TQ (TFT)

SQ (STN)

NSH5

NS8

NS10

NS12

SQ (STN)

TV (TFT)

TV (TFT)

TS (TFT)

External Interface Specifications

Item Specifications

Memory card

interface

Expansion

interface

One ATA-Compact Flash interface slot.

Used to transfer and store screen data and to store history data.

For Expansion Interface Units

6 MB

20 MB

20 MB

20 MB

20 MB

20 MB

20 MB

20 MB

60 MB

60 MB

60 MB

CQM1-CPU41-V1/CPU42-V1/CPU43-V1/CPU44-V1

CQM1H-CPU21/CPU51/CPU61

CPM1-10/20CDR- + CPM1-CIF01 C-series CPM1

CPM1A-10/20/30/40CD - + CPM1-CIF01

CPM2A-30/40/60CD - + CPM1-CIF01

CPM2C-10/20 - (See note 1.)

C200HS-CPU21/CPU23/CPU31/CPU33

C200HE-CPU32(-Z) (See note 2.) /CPU42(-Z)

C200HG-CPU33(-Z) (See note 2.) /CPU43(-Z) /CPU53(-Z) (See note 2.) / CPU63(-Z)

C200HX-CPU34(-Z) (See note 2.) /CPU44(-Z) /CPU54(-Z) (See note 2.) / CPU64(-Z) /CPU65-Z/CPU85-Z

CV500/1000/2000-CPU01-V1

CVM1-CPU01-V2/CPU11-V2/CPU21-V2

Note 1: Use an Adapter Cable (CPM2C-CN111 or CS1W-CN114/118), CPM1-CIF01 RS-232C Adapter, or CPM1-CIF11 RS-422A Adapter to connect.

2: A C200HW-COM02(-V1), C200HW-COM04(-V1), C200HW-COM05(-V1), or C200HW-COM06(-V1) Communications Board is required.

CPU Units (1:N NT Link Connection)

Display Element Specifications

SpecificationItem

Raster font

Rough

Font

Standard

Display

text

name

Fine

Vector font

(text objects only)

Color

Text

attributes

Font style (only when

vector font is specified)

Vertical alignment Top, center, or bottom

Horizontal alignment

Functional

Objects

objects

Flicker

that can

flicker

Fixed

objects

Numeral units and scale settings

Displayable characters

Alphanumeric characters

or Japanese katakana

Alphanumeric characters

or Japanese, Chinese

(Simplified, Traditional)

or Korean

Alphanumeric characters

or Japanese katakana

Japanese kanji

Can be specified in CX-Designer.

Font, style, and size can be specified.

Base size

1 x 1, 1 x 2, 2 x 1,

8 x 8

2 x 2, 3 x 3, 4 x 4, 8 x 8

8 x 16

1 x 1, 1 x 2, 2 x 1,

16 x 16

2 x 2, 3 x 3, 4 x 4, 8 x 8

16 x 32

1 x 1, 1 x 2, 2 x 1,

32 x 32

2 x 2, 3 x 3, 4 x 4, 8 x 8

256 colors

Bold or italic

Left-justified, centered, or right-justified

Up to 10 types can be registered.

The flicker speed and flicker range can be set.

Select from 3 types.

The flicker speed and flicker range are fixed.

1,000 max.

Alarm/event settings 5,000 max.

Display colors 256 colors max. (32,768 colors for BMP)

CX-One Operating Environment

Compatible OS

Recommended CPU

Recommended memory

Hard disk free space

CD-ROM drive Required for installation

Display

Note 1: CX-One OS precaution

The CX-One will not run on Microsoft Windows 95 or any other OS not listed above.

If such an OS is being used on the client computer, the OS must be upgraded before installing the

CX-One. System requirements and hard disk space may vary with the system environment.

2: The amount of memory required varies the Support Software applications used in CX-One.

Refer to use documentation for Individual Support Software for details.

With RS-232C connector (9-pin type)

Connect to peripheral port.

Connect to RS-232C or peripheral port.

With RS-232C connector (9-pin type)

With RS-232C connector (switching/9-pin type)

Windows 98 SE, Me, NT 4.0 (Service Pack 6a), 2000 (Service

Pack 3 or higher), or XP (See note 1.)

Pentium II 333 MHz or faster processor (Pentium III 1 GHz or

faster recommended.)

256 Mbytes min. (See note 2.)

Approx. 1.8 GB or more available space is required to install

the complete CX-One package.

SVGA (800 x 600) or better high-resolution display with 256 colors min.

Specifications PLC model nameModel number

C-series CQM1

C-series CQM1H

C-series CPM1A

C-series CPM2A

C-series CPM2C

C-series C200HS

C-series C200HE (-Z)

C-series C200HG (-Z)

C-series C200HX (-Z)

CVM1/CV-series

CVM1 or CV500/

CV1000/CV2000

Specifications PLC model nameModel number

CS1G-CPU42H/CPU43H/CPU44H/CPU45H

CS1H-CPU63H/CPU64H/CPU65H/CPU66H/CPU67H

CS1D-CPU65H/CPU67H

CJ1G-CPU42H/CPU43H/CPU44H/CPU45H (See note 1.)

CJ1G-CPU42P/CPU43P/CPU44P/CPU45P

CJ1H-CPU65H/CPU66H/CPU67H (See note 1.)

CJ1M-CPU11/CPU12/CPU13/CPU21/CPU22/CPU23 (See note 1.)

CQM1H-CPU61/51 with a CQM1H-SCB41 Serial Communications Board

C200HE-CPU32(-Z) (See note 2.) /CPU42(-Z)

C200HG-CPU33(-Z) (See note 2.) /CPU43(-Z) /CPU53(-Z) (See note 2.) / CPU63(-Z)

C200HX-CPU34(-Z) (See note 2.) /CPU44(-Z) /CPU54(-Z) (See note 2.) / CPU64(-Z) /CPU65-Z/CPU85-Z

Note 1: The CJ1W-SCU21/SCU41 Serial Communications Unit can also be connected.

2: A C200HW-COM02/COM04/COM05/COM06(-V1) Communications Board is required.

With RS-232C connector (9-pin type)

CS-series CS1G

CS-series CS1H

CS-series CS1D

CJ-series CJ1G

CJ-series CJ1G

CJ-series CJ1H

CJ-series CJ1M

C-series CQM1H

C-series C200HE(-Z)

C-series C200HG(-Z)

C-series C200HX(-Z)

21

Page 12

Connections through CPU Unit/Host Link

CPM1-10CDR/20CDR- /CPM1A-10CD/20CD/30CD/40CD -

CPM2A-30CD/40CD/60CD -

CPM2C-10/20 -

CQM1-CPU21/CPU41-V1/CPU42-V1/CPU43-V1/CPU44-V1

CQM1H-CPU11/CPU21/CPU51/CPU61

C200HS-CPU21/CPU23/CPU31/CPU33

C200HE-CPU32(-Z)(See note.)/CPU42(-Z)

C200HG-CPU33(-Z)(See note.)/CPU43(-Z)/CPU53(-Z)(See note.)/ CPU63(-Z)

C200HX-CPU34(-Z)(See note.)/CPU44(-Z)/ CPU54(-Z)(See note.)/CPU64(-Z)/CPU65-Z/CPU85-Z

CS1G-CPU42

CS1H-CPU63(-V1)/CPU64(-V1)/ CPU65(-V1)/CPU66(-V1)/CPU67(-V1)

CV500-CPU01-V1/CV1000-CPU01-V1/CV2000-CPU01-V1/

CVM1-CPU01-V2/CPU11-V2/ CPU21-V2

Note: The C200HW-COM02, C200HW-COM04, C200HW-COM05, or C200HW-COM06(-V1) Communications Board is required.

(-V1)

/CPU43

(-V1)

/CPU44

(-V1)

/CPU45

(-V1)

RS-232C connector (9-pin)

Communications connectors include both a peripheral port and

RS-232C port (branching possible through CPM2C-CN111

Conversion Cable).

Used as separate peripheral and RS-232C ports through CS1WCN114/118 Conversion Cable.

RS-232C connector (9-pin)

RS-232C connector (9-pin) (Only peripheral port for CQM1H-CPU11)

RS-232C connector (9-pin, selectable)

RS-232C connector (9-pin)

RS-232C connector (9-pin, selectable)

Standard Models

Model

name

NS12

NS10

NS8

NS5

NS5

Hand-held

Specifications

12-inch TFT

800 x 600 dots

10-inch TFT

640 x 480 dots

8-inch TFT

640 x 480 dots

5-inch STN

320 x 240 dots

5-inch TFT

320 x 240 dots

5-inch

monochrome

320 x 240 dots

5-inch STN

320 x 240 dots

Ethernet

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Case color

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Ivory

Black

Black

Model number

NS12-TS00-V2

NS12-TS00B-V2

NS12-TS01-V2

NS12-TS01B-V2

NS10-TV00-V2

NS10-TV00B-V2

NS10-TV01-V2

NS10-TV01B-V2

NS8-TV00-V2

NS8-TV00B-V2

NS8-TV01-V2

NS8-TV01B-V2

NS5-SQ00-V2

NS5-SQ00B-V2

NS5-SQ01-V2

NS5-SQ01B-V2

NS5-TQ00-V2

NS5-TQ00B-V2

NS5-TQ01-V2

NS5-TQ01B-V2

NS5-MQ00-V2

NS5-MQ00B-V2

NS5-MQ01-V2

NS5-MQ01B-V2

NSH5-SQR001B-V2

Standards

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CU, CE

CE,

CU

(approval

pending)

CX-One

FA Integrated

Tool Package

Ver. 1.1

The CX-Designer can also be ordered individually using the following model number.

Cable

(See note 1.)

NSH5 Cables

PT-to-PLC

Connecting Cable

NSH5 Wall-mounting Bracket

Note 1: Use an OMRON USB Host Cable to connect an NS-series PT to a printer.

2: Site licenses are also available for users that need to use the CX-One on many computers.

Ask your OMRON representative for details.

CX-Designer

Ver. 1.

Specifications PLC model nameModel number

The CX-One is an integrated

tool package that provides

programming and monitoring

software for OMRON PLCs and

components. The CX-One runs

on any of the following

operating systems:

Windows 98 SE, Me, NT 4.0

(Service Pack 6a), 2000 (Service

Pack 3 or higher), or XP.

CX-Designer version 1. is

included in the CX-One.

Refer to the CX-One catalog

(R134) for details.

(See note 2.)

OS: Window 98 SE, Me, NT 4.0

(Service Pack 6a),

2000 (Service Pack 3 or

higher), or XP.

The Ladder Monitor Software

is included.

Screen transfer cable for DOS/V

USB Host Cable, cable length: 5 m

USB Host Cable, cable length: 2 m

USB-RS-232C Conversion Cable,

cable length: 0.5 m

RS-422A cable (loose wires)

Cable length: 10 m

RS-232C cable (loose wires)

Cable length: 3 m

RS-232C cable (loose wires)

Cable length: 10 m

PT connection: 9 pins

PLC connection: 9 pins

1 license

3 licenses

10 licenses

30 licenses

50 licenses

1 license

Length: 2 m

Length: 5 m

C Series: CPM1RS-232C or RS-422A adapter connected to peripheral port

C Series: CPM2A

C Series: CPM2C

C Series: CQM1

C Series: CQM1H

C Series: C200HS

C Series: C200HE (-Z)

C Series: C200HG (-Z)

C Series: C200HX (-Z)

CS Series: CS1G

CS Series: CS1H

CVM1/CV Series:

CV500/1000/2000 or

CVM1

Model numberModel name Specifications

CXONE-AL01C-E

CXONE-AL03C-E

CXONE-AL10C-E

CXONE-AL30C-E

CXONE-AL50C-E

NS-CXDC1-V1

XW2Z-S002

NS-US52 (5 m)

NS-US22 (2 m)

CS1W-CIF31

NSH5-422CW-10M

NSH5-232CW-3M

NSH5-232CW-10M

XW2Z-200T

XW2Z-500T

NSH5-ATT02

Options

Specifications Model numberModel name

Inputs: 4 channels

Video Input

Unit

Special Cable for the Console

Controller Link

Interface Unit

RS-422A

Adapter

Sheet/Cover

(NT625C/631/631C Series to NS12/10 Series)

(NT625C/631/631C Series to NS12/NS10 Series) (Black)

(NT610C Series to NS12/10 Series)

(NT620S/620C/600S Series to NS8 Series)

Attachment

(NT600M/600G/610G/612G Series to NS8 Series)

Memory Card

Memory Card Adapter

Battery

Bar Code Reader

(Refer to the Catalog for details.)

Note: One screen cannot display two video inputs simultaneously.

Signal type: NTSC/PAL

Input channels: 2 video

channels and 1 RGB

channel (See note.)

Signal mode: NTSC/PAL

For Controller Link

Communications

Transmission distance:

500 m total length

Note: Use this model when

connecting PT models without a V

suffix.

Note: PT models with a suffix of V

can also be connected.

Transmission distance:

50 m total length

Note: Only PT models with a suffix

of V are connectable. Use the

NS-002 to connect models without

a V suffix.

Anti-reflection Sheets

(5 surface sheets)

Protective Covers

(5 pack)

(anti-reflection coating)

Protective Covers

(5 covers included)

(Transparent)

NS12/10

NS8 NS7-KBA04

NS5 NT30-KBA04

NS12/10

NS8 NS7-KBA05

NS5 NT31C-KBA05

NS12/10

NS8 NS7-KBA05N

NS5 NT31C-KBA05N

30 MB

64 MB

NS-CA001

NS-CA002

F150-VKP (2m)

F150-VKP (5m)

NS-CLK21

NS-AL002

CJ1W-CIF11

NS12-KBA04

NS12-KBA05

NS12-KBA05N

NS12-ATT01

NS12-ATT01B

NS12-ATT02

NS8-ATT01

NS8-ATT02

HMC-EF372

HMC-EF672

HMC-AP001

CJ1W-BAT01

V520-RH21-6

Superior environmental resistance

meets IP65F standards.

Flush surface construction is used for superior

environmental resistance and the enclosure rating for

the front of the PT is IP65F compliant.

IP International Protection

6 Dust and dirt will not enter interior.

(Enclosure protects against foreign objects.)

5 There are no adverse effects from a water stream

from any direction.

(Enclosure protects against water intrusion.)

F There are no harmful effects from oil droplets or

spray from any direction. (Enclosure protects

against oil intrusion.)

Note: May not be applicable in environments with long-term exposure to water or oil.

Meets International Standards and

Exports are Not Restricted

The PTs conform to UL standards (cULus) and EC

Directives.

In addition, there are no export restrictions on the PTs.

cULus certification is scheduled for the near future for

the NSH5 5-inch Hand-held PT.

Related Products

WS02-NSFC1-EV2 Face Plate

Auto-Builder for NS

Significantly reduces the engineering time required by

combining LCB/LCU and the NS Series.

Automatic generation of control screens and tuning screens. Automatic

generation of NS screen data by the software from tag information created with

CX-Process Tool.

NS communications address allocation, ladder programs, etc., are completely

unnecessary.

Data that has been generated can be freely edited and processed by

CX-Designer (NS screen creation software).

SYSMAC CS1 +LCB/LCU

CSV tag file for

LCB/LCU

NS project file

NS Series

Created screens are

easily transferred to the

NS by means of a

Memory Card or over

the network.

CX-Designer

(NS screen creation software)

Editing created data

Creation of other required screens

NS Faceplate Auto-Builder upgraded to version 2.0.

Maximum number of automatically generated loops

increased from 32 to 100.

Automatic generation from the CX-Process projects

that use multiple nodes.

Automatic generation of detailed setting screens for

Line Segment programs.

CX-Process Tool

(LCB/LCU programming software)

LCB/LCU program creation

(function block method)

CSV tag file output

Face Plate

Auto-Builder for NS