Page 1

Machine Automation Controller

NJ-series

CPU Unit

Motion Control

User’s Manual

NJ501-1300

NJ501-1400

NJ501-1500

CPU Unit

W507-E1-01

Page 2

OMRON, 2011

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 3

Introduction

Thank you for purchasing an NJ-series CPU Unit.

This manual contains information that is necessary to use the Motion Control Function Module of an

NJ-series CPU Unit. Please read this manual and make sure you understand the functionality and performance of the NJ-series CPU Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B3503.

Introduction

Applicable Products

This manual covers the following products.

• NJ-series CPU Units

• NJ501-1300

• NJ501-1400

• NJ501-1500

NJ-series CPU Unit Motion Control User’s Manual (W507)

1

Page 4

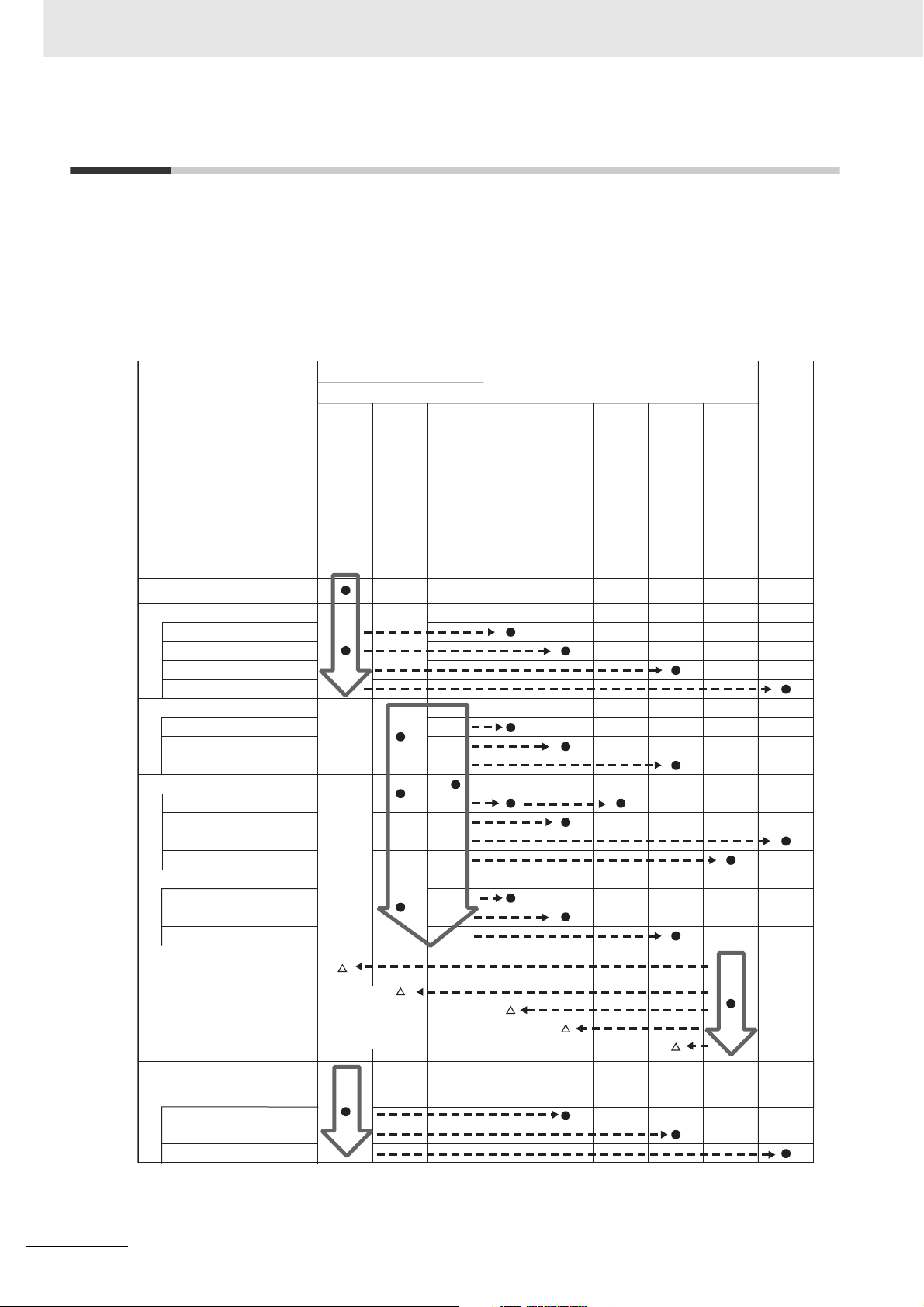

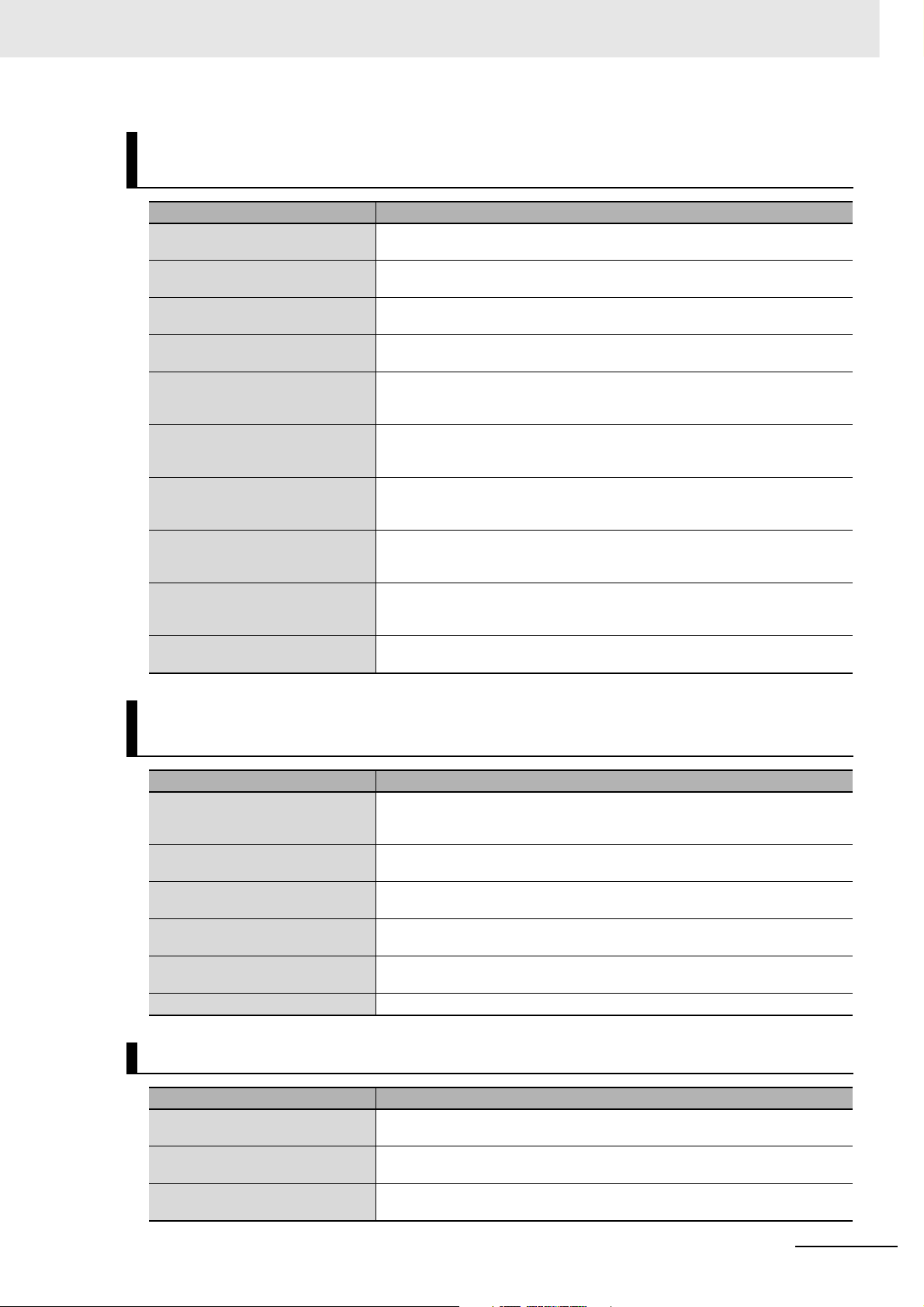

Relevant Manuals

Relevant Manuals

There are three manuals that provide basic information on the NJ-series CPU Units: the NJ-series CPU

Unit Hardware User’s Manual, the NJ-series CPU Unit Software User’s Manual (this manual), and the

NJ-series Instructions Reference Manual.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Other manuals are necessary for specific system configurations and applications.

Read all of the manuals that are relevant to your system configuration and application to make the most

of the NJ-series CPU Unit.

Basic information

NJ-series User’s Manuals

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Programming

Using motion control

Using EtherCAT

Using CJ-series Units

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Troubleshooting and managing

errors in an NJ-series Controller

NJ-series CPU Unit

Hardware User´s Manual

Use the

relevant

manuals for

references

according to

any error that

occurs.

NJ-series CPU Unit

Software User´s Manual

NJ-series Instructions

Reference Manual

NJ-series CPU Unit Motion

Control User´s Manual

NJ-series CPU Unit Built-in

EtherCAT Port User´s Manual

NJ-series Motion Control

Instructions Reference Manual

NJ-series CPU Unit Built-in

EtherNet/IP Port User´s Manual

NJ-series Troubleshooting Manual

CJ-series Special Unit Operation

Manuals for NJ-series CPU Unit

Maintenance

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

2

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 5

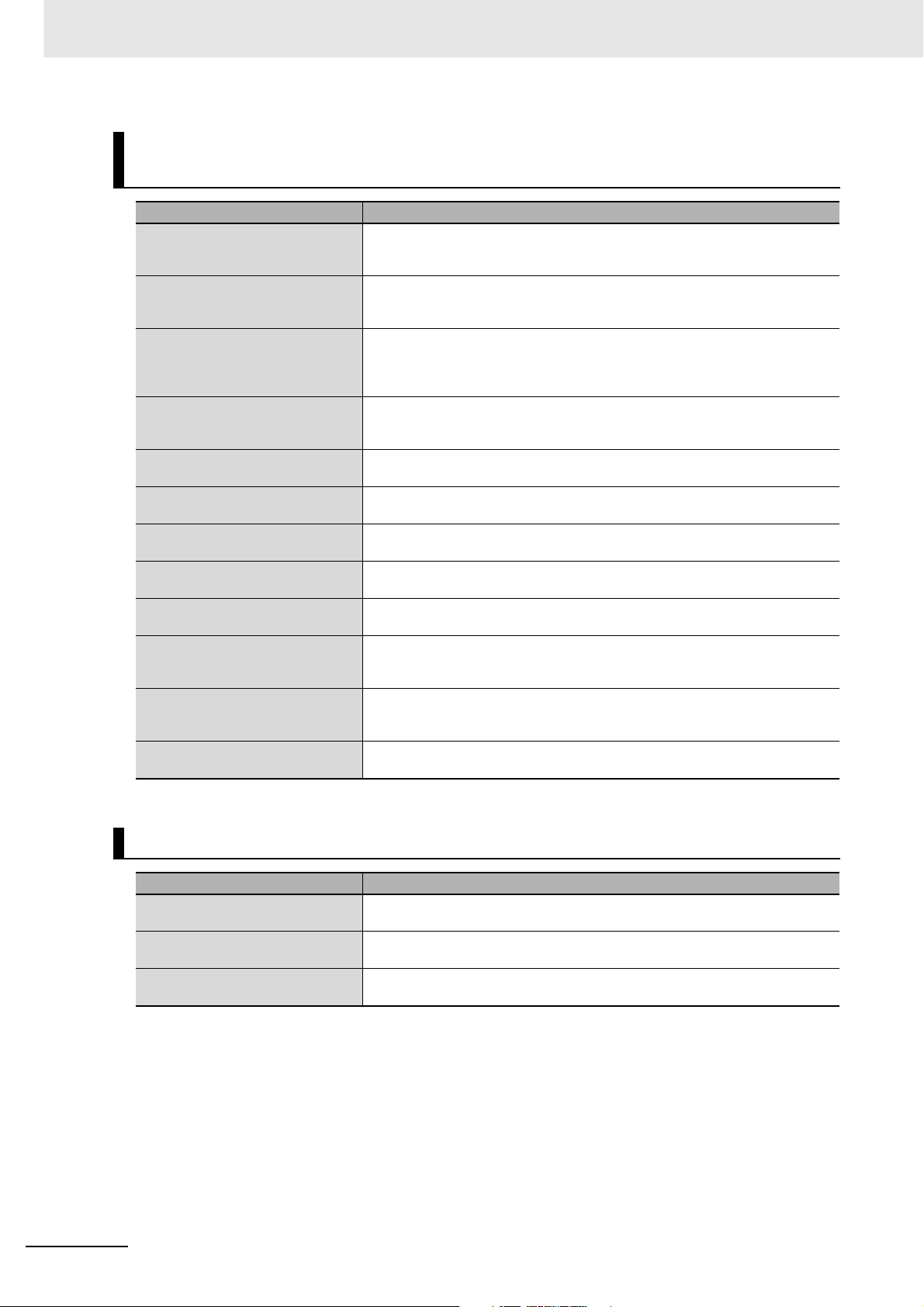

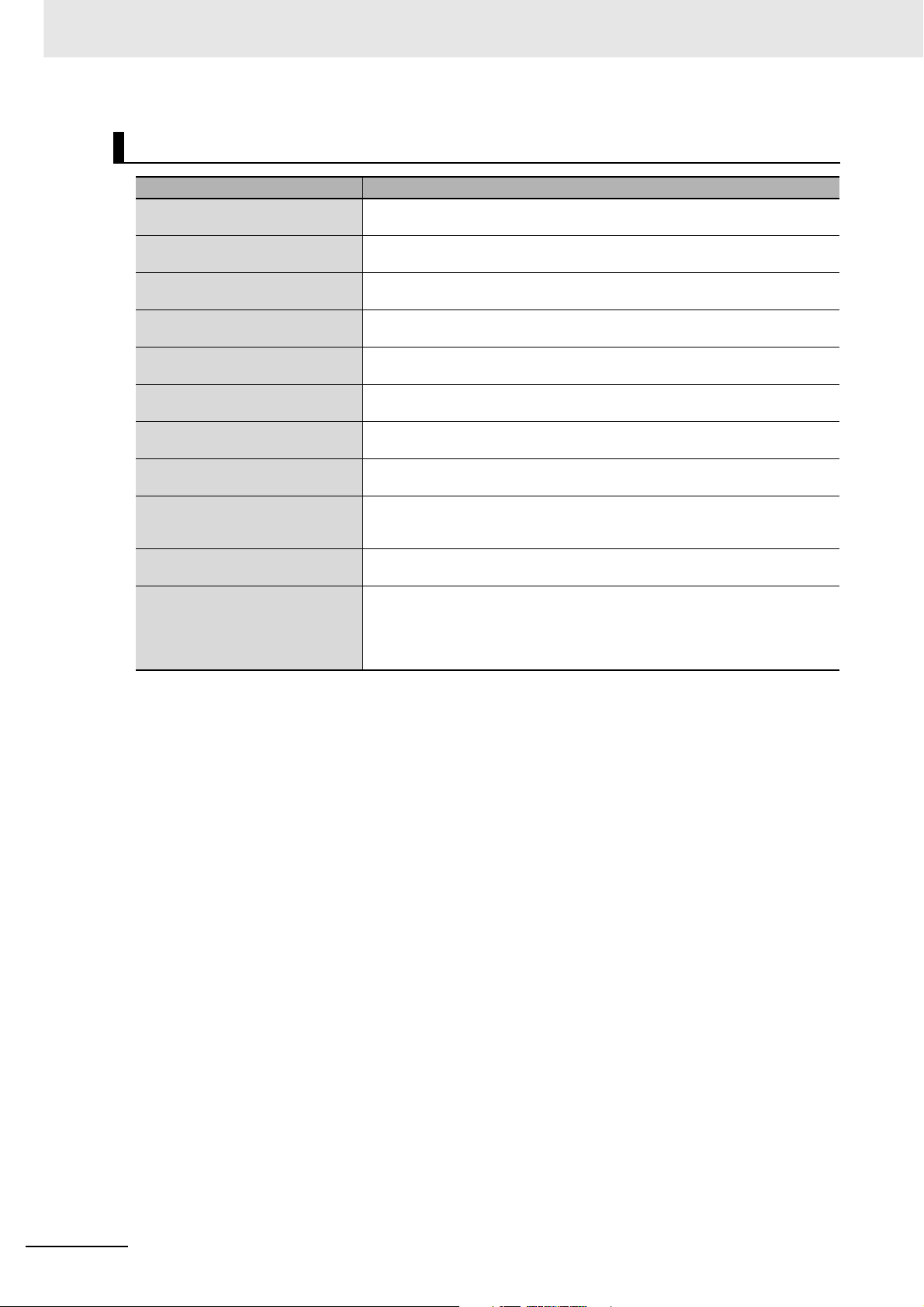

Manual Configuration

NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Section Description

Section 1

Introduction

Section 2

System Configuration

Section 3

Configuration Units

Section 4

Installation and Wiring

Section 5

Troubleshooting

Section 6

Inspection and Maintenance

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section describes the system configuration used for NJ-series Controllers.

This section describes the parts and functions of the configuration devices in the NJseries Controller configuration, including the CPU Unit and Configuration Units.

This section describes where and how to install the CPU Unit and Configuration Units

and how to wire them.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

This section describes the contents of periodic inspections, the service life of the Battery and Power Supply Units, and replacement methods for the Battery and Power

Supply Units.

The appendices provide the specifications of the Basic I/O Units, Unit dimensions,

load short-circuit protection detection, line disconnection detection, and measures for

EMC Directives.

Manual Configuration

NJ-series CPU Unit Software User’s Manual (Cat. No. W501)

Section Description

Section 1

Introduction

Section 2

CPU Unit Operation

Section 3

I/O Ports, Slave Configuration, and

Unit Configuration

Section 4

Controller Setup

Section 5

Designing Tasks

Section 6

Programming

Section 7

Simulation, Transferring Projects to

the Physical CPU Unit, and Operation

Section 8

CPU Unit Status

Section 9

CPU Unit Functions

Section 10

Communications Setup

Section 11

Example of Actual Application Procedures

Section 12

Troubleshooting

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section describes the variables and control systems of the CPU Unit and CPU

Unit status.

This section describes how to use I/O ports, how to create the slave configuration

and unit configuration and how to assign functions.

This section describes the initial settings of the function modules.

This section describes the task system and types of tasks.

This section describes programming, including the programming languages and the

variables and instructions that are used in programming.

This section describes simulation of Controller operation and how to use the results

of simulation.

This section describes CPU Unit status.

This section describes the functionality provided by the CPU Unit.

This section describes how to go online with the CPU Unit and how to connect to

other devices.

This section describes the procedures that are used to actually operate an NJ-series

Controller.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

The appendices provide the CPU Unit specifications, task execution times, systemdefined variable lists, data attribute lists, CJ-series Unit memory information, CJseries Unit memory allocation methods, and data type conversion information.

NJ-series CPU Unit Motion Control User’s Manual (W507)

3

Page 6

Manual Configuration

NJ-series CPU Unit Motion Control User’s Manual (Cat. No. W507)

(This Manual)

Section Description

Section 1

Introduction to the Motion Control

Function Module

Section 2

Motion Control Configuration and

Principles

Section 3

Configuring Axes and Axes Groups

Section 4

Checking Wiring from the Sysmac

Studio

Section 5

Motion Control Parameters

Section 6

Motion Control Programming

Section 7

Manual Operation

Section 8

Homing

Section 9

Motion Control Functions

Section 10

Sample Programming

Section 11

Troubleshooting

Appendices

This section describes the features, system configuration, and application flow for the

Motion Control Function Module.

This section outlines the internal structure of the CPU Unit and describes the configuration and principles of the MC Function Module.

This section describes the concept of axes and axes groups, the settings for axes

that are required for the MC Test Run operations to function on the Sysmac Studio,

and the instructions for creating and configuring axes and axes groups using the Sysmac Studio.

This section describes the MC Test Run operations of the Sysmac Studio. You can

use the MC Test Run operations to monitor sensor signals, check Servomotor wiring,

and more, all without any programming.

This section provides information on the axis parameters and axes group parameters

that are used for motion control.

This section provides the specifications of a motion control program and the operating procedures that are required up through actual program development.

This section describes manual operation when the MC Function Module is used

together with an OMRON G5-series Servo Drive.

This section describes homing.

This section describes the motion control functions that are used when connected to

OMRON G5-series Servo Drives with built-in EtherCAT communications.

This section describes basic application methods for homing, error monitoring, and

other functions, and provides programming samples for absolute positioning, cam

operation, and other axis operations.

This section describes the items to check when problems occur in the MC Function

Module. It includes error diagnosis and countermeasures for error indications, and

error diagnosis and countermeasures for operating conditions.

The appendices describe settings and connection methods for OMRON G5-series

Servo Drive objects.

NJ-series Instructions Reference Manual (Cat. No. W502)

Section Description

Section 1

Instruction Set

Section 2

Instruction Descriptions

Appendices

4

This section provides a table of the instructions that are described in this manual.

This section describes instruction specifications in detail.

The appendices provide a table of error codes and other supplemental information to

use instructions.

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 7

Manual Configuration

NJ-series CPU Unit Built-in EtherCAT Port User’s Manual

(Cat. No. W505)

Section Description

Section 1

Introduction

Section 2

Part Names and Slave Settings

Section 3

EtherCAT Communications

Section 4

EtherCAT Network Wiring

Section 5

Setting Up EtherCAT Communications with the Sysmac Studio

Section 6

Process Data Communications and

SDO Communications

Section 7

System-defined Variables That Are

Related to the Built-in EtherCAT Port

Section 8

Example of Operations for EtherCAT

Communications

Section 9

Troubleshooting

Appendices

This section provides an overview of EtherCAT communications, describes the system configuration and specifications, and provides operating procedures.

This section provides the part names and describes the slave settings and Sysmac

device functions.

This section describes the different types of EtherCAT communications, EtherCAT

settings, and state transitions.

This section describes how to connect and wire an EtherCAT network.

This section describes how to set the network configuration information and how to

check EtherCAT communications from the Sysmac Studio.

This section describes the timing of communications, response times, and special

instructions for process data communications and SDO communications. It also provides sample programming.

This section describes the system-defined variables that are related to the built-in

EtherCAT port.

This section provides a series of example operations for when an NJ-series CPU Unit

is connected to slaves.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur for EtherCAT communications. It also describes how to

replace slaves.

The appendices describe the relation of EtherCAT communications to overall CPU

Unit status, packet monitoring functions, and multi-vendor application.

NJ-series Motion Control Instructions Reference Manual

(Cat. No. W508)

Section Description

Section 1

Introduction to Motion Control

Instructions

Section 2

Variables and Instructions

Section 3

Axis Command Instructions

Section 4

Axes Group Instructions

Section 5

Common Command Instructions

Appendices The appendices describe the error codes that are generated by the instructions.

This section gives an introduction to motion control instructions supported by NJseries CPU Units.

This section describes the variables and instructions for the Motion Control Function

Module.

This section describes the instructions that are used to perform single-axis control for

the MC Function Module.

This section describes the instructions to perform multi-axes coordinated control for

the MC Function Module.

This section describes the instructions that are used for both axes and axes groups.

NJ-series Troubleshooting Manual (Cat. No. W503)

Section Description

Section 1

Overview of Errors

Section 2

Error Troubleshooting Methods

Section 3

Error Tables

This section describes the errors that can occur on an NJ-series Controller, the operation that occurs for errors, and methods to confirm errors.

This section describes how to handle errors.

This section lists all of the error events that can occur on NJ-series Controllers.

NJ-series CPU Unit Motion Control User’s Manual (W507)

5

Page 8

Manual Configuration

Sysmac Studio Version 1 Operation Manual (Cat. No. W504)

Section Description

Section 1

Introduction

Section 2

Installation and Uninstallation

Section 3

System Design

Section 4

Programming

Section 5

Online Connections to a Controller

Section 6

Debugging

Section 7

Other Functions

Section 8

Reusing Programming

Section 9

Support Software Provided with the

Sysmac Studio

Section 10

Troubleshooting

Appendices

This section provides an overview and lists the specifications of the Sysmac Studio

and describes its features and components.

This section describes how to install and uninstall the Sysmac Studio.

This section describes the basic concepts for designing an NJ-series System with the

Sysmac Studio and the basic operating procedures.

This section describes how to create programs with the Sysmac Studio.

This section describes how to go online with a Controller.

This section describes how to debug the programs online on the Controller or debug

it offline with the Simulator.

This section describes Sysmac Studio functions other than system design functions.

This section describes how to reuse the programs that you create with the Sysmac

Studio.

This section describes the Support Software that is provided with the Sysmac Studio.

This section describes the error messages that are displayed when you check a program on the Sysmac Studio and how to correct those errors.

The appendices describe the following:

Driver Installation for Direct USB Cable Connection

Specifying One of Multiple Ethernet Interface Cards

Online Help

Simulation Instructions

6

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 9

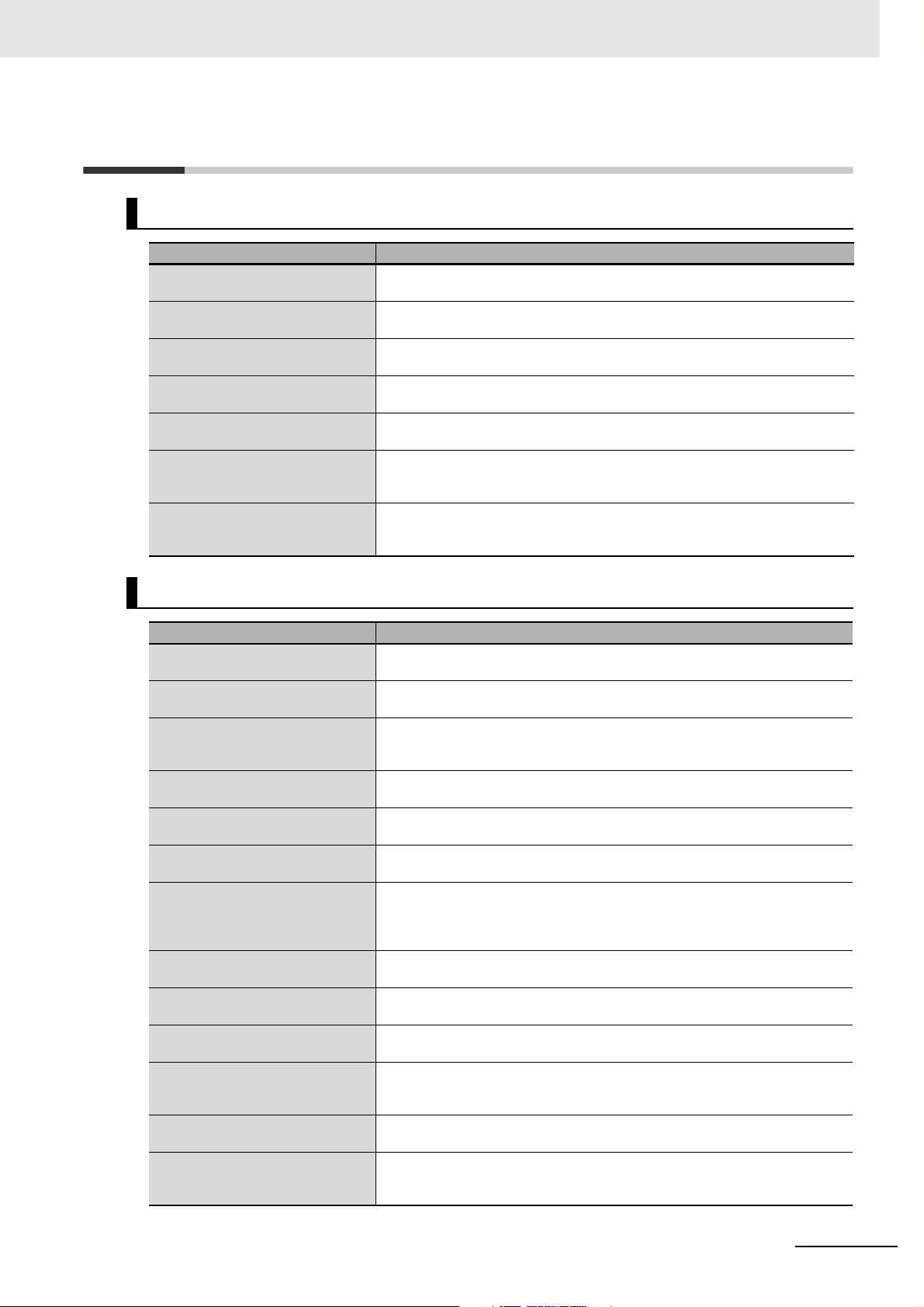

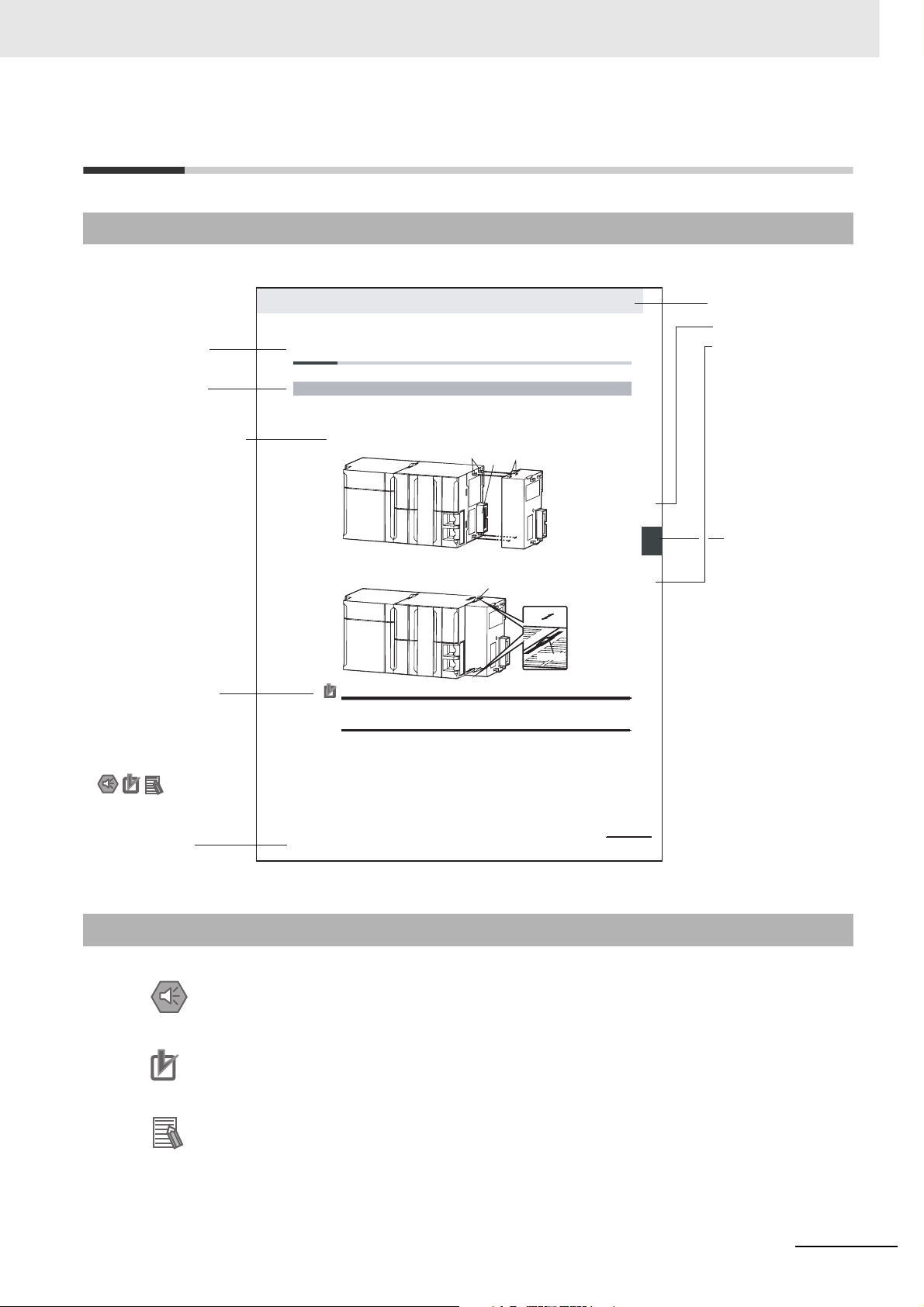

Manual Structure

Page Structure

The following page structure is used in this manual.

Manual Structure

Level 2 heading

Level 3 heading

A step in a procedure

Indicates a procedure.

Special information

Icons indicate

precautions, additional

information, or reference

information.

4 Installation and Wiring

4-3 Mounting Units

4-3-1 Connecting Controller Components

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Hook

Connector

Move the sliders toward the back

until they lock into place.

Hook holes

Release

Lock

Slider

Level 1 heading

Level 2 heading

Level 3 heading

Gives the current

headings.

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

Page tab

Gives the number

of the main section.

Manual name

NJ-series CPU Unit Hardware User’s Manual (W500)

This illustration is provided only as a sample. It may not literally appear in this manual.

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Note References are provided to more detailed or related information.

NJ-series CPU Unit Motion Control User’s Manual (W507)

4-9

7

Page 10

Manual Structure

Precaution on Terminology

In this manual, “download” refers to transferring data from the Sysmac Studio to the physical Controller

and “upload” refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio, synchronization is used to both upload and download data. Here, “synchronize”

means to automatically compare the data for the Sysmac Studio on the computer with the data in the

physical Controller and transfer the data in the direction that is specified by the user.

8

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 11

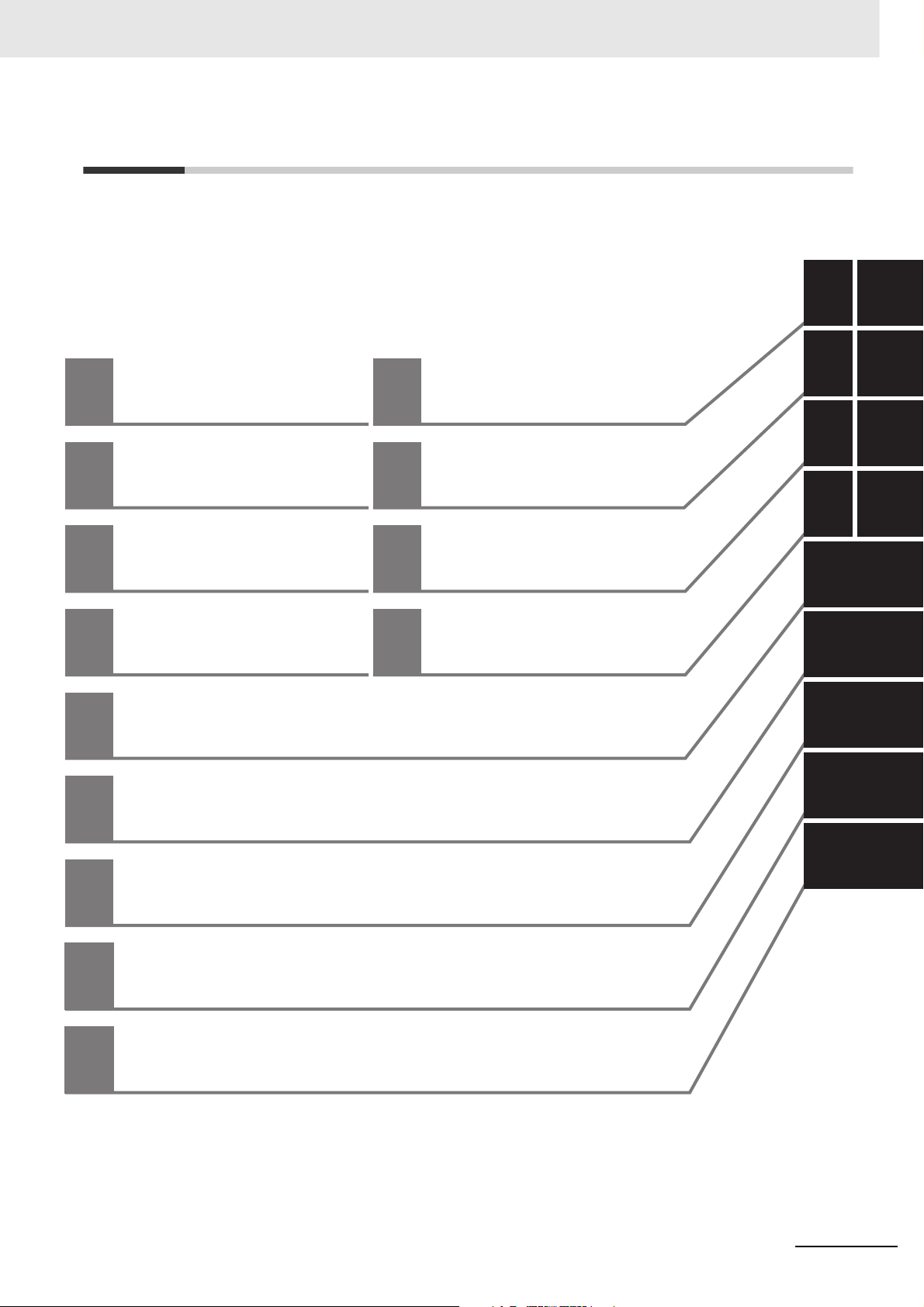

Sections in this Manual

Sections in this Manual

1

2

3

4

5

Introduction to the

Motion Control

Function Module

Motion Control

Configuration and

Principles

Configuring Axes

and Axes Groups

Checking Wiring from

the Sysmac Studio

Motion Control Parameters

10

11

A

I

Sample Programming

Troubleshooting

Appendices

Index

1

2

3

4I

10

11

A

5

6

7

6

7

8

9

8

Motion Control Programming

9

Manual Operation

Homing

Motion Control Functions

NJ-series CPU Unit Motion Control User’s Manual (W507)

9

Page 12

Sections in this Manual

10

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 13

CONTENTS

Introduction............................................................................................................... 1

Relevant Manuals...................................................................................................... 2

Manual Configuration............................................................................................... 3

Manual Structure ...................................................................................................... 7

Sections in this Manual............................................................................................ 9

Read and Understand this Manual........................................................................ 17

Safety Precautions ................................................................................................. 21

Precautions for Safe Use ....................................................................................... 22

CONTENTS

Precautions for Correct Use .................................................................................. 23

Regulations and Standards ................................................................................... 24

Unit Versions ........................................................................................................... 26

Related Manuals ..................................................................................................... 29

Revision History ..................................................................................................... 31

Section 1 Introduction to the Motion Control Function Module

1-1 Features.................................................................................................................................... 1-2

1-2 System Configuration ............................................................................................................. 1-3

1-3 Application Procedure ............................................................................................................ 1-4

1-4 Specifications .......................................................................................................................... 1-6

1-4-1 General Specifications................................................................................................................ 1-6

1-4-2 Performance Specifications ........................................................................................................ 1-6

1-4-3 Function Specifications............................................................................................................... 1-7

Section 2 Motion Control Configuration and Principles

2-1 Internal Configuration of the CPU Unit.................................................................................. 2-2

2-2 Motion Control Configuration.................................................................................................2-3

2-3 Motion Control Principles....................................................................................................... 2-4

2-3-1 CPU Unit Tasks........................................................................................................................... 2-4

2-3-2 Example of Task Operations for Motion Control ......................................................................... 2-7

2-4 EtherCAT Communications and Motion Control ................................................................ 2-11

2-4-1 CAN Application Protocol over EtherCAT (CoE)....................................................................... 2-11

2-4-2 Relationship between EtherCAT Master Function Module and MC Function Module .............. 2-12

2-4-3 Relationship between Process Data Communications Cycle and Motion Control Period ........ 2-13

NJ-series CPU Unit Motion Control User’s Manual (W507)

11

Page 14

CONTENTS

Section 3 Configuring Axes and Axes Groups

3-1 Axes .......................................................................................................................................... 3-2

3-1-1 Introduction to Axes ....................................................................................................................3-2

3-1-2 Introduction to Axis Parameters ..................................................................................................3-3

3-1-3 Introduction to Axis Variables......................................................................................................3-5

3-1-4 Specifying an Axis in the User Program...................................................................................... 3-7

3-2 Axis Setting Procedure ........................................................................................................... 3-8

3-2-1 Axis Configuration Procedure .....................................................................................................3-8

3-2-2 Setting Procedure .......................................................................................................................3-8

3-3 Axes Groups .......................................................................................................................... 3-17

3-3-1 Introduction to Axes Groups......................................................................................................3-17

3-3-2 Introduction to Axes Group Parameters .................................................................................... 3-18

3-3-3 Introduction to Axes Group Variables........................................................................................3-19

3-3-4 Specifying an Axes Group in the User Program........................................................................3-21

3-4 Setting Procedures for Axes Groups................................................................................... 3-22

3-4-1 Setting Procedure for an Axes Group .......................................................................................3-22

3-4-2 Setting Procedure .....................................................................................................................3-22

Section 4 Checking Wiring from the Sysmac Studio

4-1 Functions of the Sysmac Studio ............................................................................................ 4-2

4-1-1 MC Test Run Function.................................................................................................................4-2

4-1-2 Application Procedure .................................................................................................................4-4

4-1-3 Axis Parameter Setting Example.................................................................................................4-5

4-1-4 Starting the MC Test Run Function .............................................................................................4-6

4-2 Monitoring Sensor Signals ..................................................................................................... 4-7

4-3 Checking Motor Operation...................................................................................................... 4-8

4-3-1 Turning ON the Servo ................................................................................................................. 4-8

4-3-2 Jogging........................................................................................................................................ 4-8

4-3-3 Homing........................................................................................................................................4-9

4-3-4 Absolute Positioning..................................................................................................................4-10

4-3-5 Relative Positioning ...................................................................................................................4-11

Section 5 Motion Control Parameters

5-1 Introduction.............................................................................................................................. 5-2

5-2 Axis Parameters....................................................................................................................... 5-4

5-2-1 Axis Parameters..........................................................................................................................5-4

5-2-2 Axis Basic Settings......................................................................................................................5-5

5-2-3 Unit Conversion Settings............................................................................................................. 5-8

5-2-4 Operation Settings ....................................................................................................................5-11

5-2-5 Other Operation Settings .......................................................................................................... 5-12

5-2-6 Limit Settings............................................................................................................................. 5-13

5-2-7 Position Count Settings.............................................................................................................5-13

5-2-8 Servo Drive Settings .................................................................................................................5-15

5-2-9 Homing Settings........................................................................................................................5-16

5-2-10 Axis Parameter Setting Example...............................................................................................5-17

5-3 Axes Group Parameters........................................................................................................5-20

5-3-1 Axes Group Parameters ............................................................................................................5-20

5-3-2 Axes Group Basic Settings ....................................................................................................... 5-21

5-3-3 Axes Group Operation Settings ................................................................................................5-22

5-3-4 Enabling an Axes Group ...........................................................................................................5-23

12

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 15

Section 6 Motion Control Programming

6-1 Introduction.............................................................................................................................. 6-2

6-2 Motion Control Instructions.................................................................................................... 6-3

6-2-1 Function Blocks for PLCopen Motion Control............................................................................. 6-3

6-2-2 Motion Control Instructions of the MC Function Module............................................................. 6-3

6-3 State Transitions...................................................................................................................... 6-4

6-3-1 Status of the Motion Control Function Module............................................................................ 6-4

6-3-2 Axis States.................................................................................................................................. 6-4

6-3-3 Axes Group States...................................................................................................................... 6-6

6-4 Execution and Status of Motion Control Instructions.......................................................... 6-8

6-4-1 Basic Rules for Execution of Instructions ................................................................................... 6-8

6-4-2 Execution Timing Charts .......................................................................................................... 6-10

6-4-3 Timing Chart for Re-execution of Motion Control Instructions .................................................. 6-12

6-4-4 Timing Chart for Multi-execution of Motion Control Instructions ............................................... 6-13

6-5 Positions................................................................................................................................. 6-14

6-5-1 Types of Positions..................................................................................................................... 6-14

6-5-2 Valid Positions for Each Axis Type............................................................................................ 6-14

6-6 System-defined Variables for Motion Control..................................................................... 6-15

6-6-1 Overview of System-defined Variables for Motion Control........................................................ 6-15

6-6-2 System for System-defined Variables for Motion Control ......................................................... 6-17

6-6-3 Tables of System-defined Variables for Motion Control ............................................................ 6-18

6-7 Cam Tables and Cam Data Variables ................................................................................... 6-28

CONTENTS

6-8 Programming Motion Controls............................................................................................. 6-32

6-9 Creating Cam Tables ............................................................................................................. 6-34

Section 7 Manual Operation

7-1 Outline ...................................................................................................................................... 7-2

7-2 Turning ON the Servo.............................................................................................................. 7-3

7-2-1 Turning ON the Servo................................................................................................................. 7-3

7-2-2 Setting Axis Parameters ............................................................................................................. 7-4

7-2-3 Programming Example ............................................................................................................... 7-4

7-3 Jogging..................................................................................................................................... 7-5

7-3-1 Jogging Procedure...................................................................................................................... 7-5

7-3-2 Setting Axis Parameters ............................................................................................................. 7-6

7-3-3 Setting Example for Input Variables............................................................................................ 7-6

7-3-4 Programming Example ............................................................................................................... 7-7

Section 8 Homing

8-1 Outline ...................................................................................................................................... 8-2

8-2 Homing Procedure................................................................................................................... 8-5

8-2-1 Setting Homing Parameters........................................................................................................ 8-5

8-2-2 Monitoring the Homing Operation............................................................................................. 8-10

8-3 Homing Operation ................................................................................................................. 8-11

8-4 Homing with an Absolute Encoder ...................................................................................... 8-12

8-4-1 Outline of Function.................................................................................................................... 8-13

8-4-2 Setting Procedure..................................................................................................................... 8-13

8-5 High-speed Homing............................................................................................................... 8-15

NJ-series CPU Unit Motion Control User’s Manual (W507)

13

Page 16

CONTENTS

Section 9 Motion Control Functions

9-1 Single-axis Position Control................................................................................................... 9-3

9-1-1 Outline of Operation.................................................................................................................... 9-3

9-1-2 Absolute Positioning....................................................................................................................9-4

9-1-3 Relative Positioning .....................................................................................................................9-4

9-1-4 Interrupt Feeding.........................................................................................................................9-5

9-1-5 Stopping...................................................................................................................................... 9-6

9-1-6 Override Factors.......................................................................................................................... 9-9

9-2 Single-axis Synchronized Control ....................................................................................... 9-11

9-2-1 Overview of Synchronized Control............................................................................................9-11

9-2-2 Gear Operation .........................................................................................................................9-11

9-2-3 Positioning Gear Operation .......................................................................................................9-12

9-2-4 Cam Operation..........................................................................................................................9-13

9-2-5 Cam Tables ............................................................................................................................... 9-14

9-2-6 Synchronous Positioning...........................................................................................................9-19

9-2-7 Combining Axes........................................................................................................................9-21

9-2-8 Master Axis Phase Shift............................................................................................................ 9-22

9-3 Single-axis Velocity Control .................................................................................................9-23

9-3-1 Velocity Control ......................................................................................................................... 9-23

9-3-2 Cyclic Synchronous Velocity Control.........................................................................................9-24

9-4 Single-axis Torque Control ...................................................................................................9-25

9-5 Common Functions for Single-axis Control ....................................................................... 9-26

9-5-1 Positions....................................................................................................................................9-26

9-5-2 Velocity ......................................................................................................................................9-28

9-5-3 Acceleration and Deceleration ..................................................................................................9-29

9-5-4 Jerk ........................................................................................................................................... 9-31

9-5-5 Specifying the Operation Direction............................................................................................9-32

9-5-6 Re-executing Motion Control Instructions .................................................................................9-35

9-5-7 Multi-execution of Motion Control Instructions (Buffer Mode) ...................................................9-41

9-6 Multi-axes Coordinated Control ........................................................................................... 9-46

9-6-1 Outline of Operation.................................................................................................................. 9-46

9-6-2 Linear Interpolation ...................................................................................................................9-48

9-6-3 Circular Interpolation................................................................................................................. 9-49

9-6-4 Stopping Under Multi-axes Coordinated Control....................................................................... 9-50

9-6-5 Overrides for Multi-axes Coordinated Control........................................................................... 9-51

9-7 Common Functions for Multi-axes Coordinated Control................................................... 9-53

9-7-1 Velocity Under Multi-axes Coordinated Control......................................................................... 9-53

9-7-2 Acceleration and Deceleration Under Multi-axes Coordinated Control ..................................... 9-54

9-7-3 Jerk for Multi-axes Coordinated Control....................................................................................9-55

9-7-4 Re-executing Motion Control Instructions for Multi-axes Coordinated Control.......................... 9-56

9-7-5 Multi-execution (Buffer Mode) of Motion Control Instructions for Multi-axes Coordinated Control 9-

56

9-8 Other Functions..................................................................................................................... 9-65

9-8-1 Changing the Current Position .................................................................................................. 9-65

9-8-2 Torque Limit............................................................................................................................... 9-66

9-8-3 Latching.....................................................................................................................................9-66

9-8-4 Zone Monitoring ........................................................................................................................9-67

9-8-5 Software Limits..........................................................................................................................9-68

9-8-6 Following Error Monitoring ........................................................................................................ 9-69

9-8-7 Following Error Counter Reset..................................................................................................9-70

9-8-8 Axis Following Error Monitoring ................................................................................................9-70

9-8-9 In-position Check ...................................................................................................................... 9-71

Section 10 Sample Programming

10-1 Overview of Sample Programming ...................................................................................... 10-2

10-1-1 Devices .....................................................................................................................................10-2

14

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 17

CONTENTS

10-1-2 Installation and Wiring .............................................................................................................. 10-2

10-1-3 Setup ........................................................................................................................................ 10-3

10-2 Basic Programming Samples ............................................................................................... 10-4

10-2-1 Monitoring EtherCAT Communications and Turning ON Servos .............................................. 10-4

10-2-2 Interlocking Axis Operation with Master Control Instructions ................................................... 10-6

10-2-3 Error Monitoring and Error Resetting for Single-axis Operation and Synchronized Operation. 10-8

10-2-4 Error Monitoring and Error Resetting for Multi-axes Coordinated Operation.......................... 10-10

10-2-5 Monitoring for Instruction Errors ............................................................................................. 10-16

10-2-6 Checking to See If Errors Are Reset....................................................................................... 10-18

10-2-7 Stopping Axes during Single-axis Operation .......................................................................... 10-20

10-2-8 Stopping an Axes Group in Coordinated Motion .................................................................... 10-24

10-2-9 Homing and Absolute Positioning........................................................................................... 10-30

10-2-10 Changing the Target Position by Re-execution of an Instruction ............................................ 10-35

10-2-11 Interrupt Feeding .................................................................................................................... 10-41

10-2-12 Changing the Cam Table by Re-execution of an Instruction ................................................... 10-45

10-2-13 Using a Cam Profile Curve to Correct the Sync Start Position............................................... 10-54

10-2-14 Shifting the Phase of a Master Axis in Cam Motion................................................................ 10-64

10-2-15 Changing the Actual Position during Velocity Control............................................................. 10-72

10-2-16 Changing a Cam Data Variable and Saving the Cam Table ................................................... 10-78

10-2-17 Temporarily Changing Axis Parameters.................................................................................. 10-87

10-2-18 Updating the Cam Table End Point Index ............................................................................... 10-90

Section 11 Troubleshooting

11-1 Overview of Errors................................................................................................................. 11-2

11-1-1 How to Check for Errors............................................................................................................ 11-3

11-1-2 Errors Related to the Motion Control Function Module............................................................. 11-5

11-2 Troubleshooting................................................................................................................... 11-10

11-2-1 Error Table .............................................................................................................................. 11-10

11-2-2 Error Descriptions................................................................................................................... 11-19

11-2-3 Error Causes and Remedies .................................................................................................. 11-53

Appendices

A-1 Connecting the Servo Drive....................................................................................................A-2

A-1-1 Wiring the Servo Drive................................................................................................................A-2

A-1-2 Servo Drive Settings...................................................................................................................A-2

A-2 Connecting to Encoder Input Terminals .............................................................................A-11

A-2-1 Wiring to Encoder Input Terminals............................................................................................A-11

A-2-2 Settings for Encoder Input Terminals........................................................................................A-11

A-3 Terminology ...........................................................................................................................A-15

A-3-1 NJ-series Controller.................................................................................................................. A-15

A-3-2 Motion Control ..........................................................................................................................A-16

A-3-3 EtherCAT Communications.......................................................................................................A-17

Index

NJ-series CPU Unit Motion Control User’s Manual (W507)

15

Page 18

CONTENTS

16

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 19

Read and Understand this Manual

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative

if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

NJ-series CPU Unit Motion Control User’s Manual (W507)

17

Page 20

Read and Understand this Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

18

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 21

Read and Understand this Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

NJ-series CPU Unit Motion Control User’s Manual (W507)

19

Page 22

Read and Understand this Manual

20

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 23

Safety Precautions

Definition of Precautionary Information

Refer to the following manuals for safety precautions.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

• NJ-series CPU Unit Software User’s Manual (Cat. No. W501)

Safety Precautions

NJ-series CPU Unit Motion Control User’s Manual (W507)

21

Page 24

Precautions for Safe Use

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

• NJ-series CPU Unit Software User’s Manual (Cat. No. W501)

22

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 25

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

• NJ-series CPU Unit Software User’s Manual (Cat. No. W501)

Precautions for Correct Use

NJ-series CPU Unit Motion Control User’s Manual (W507)

23

Page 26

Regulations and Standards

Regulations and Standards

Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

z EMC Directive

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform the

final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2 and EN 61000-6-2

EMI (Electromagnetic Interference): EN 61131-2 and EN 61000-6-4 (Radiated emission: 10-m regulations)

z Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61131-2.

z Conformance to EC Directives

The NJ-series Controllers comply with EC Directives. To ensure that the machine or device in which

the NJ-series Controller is used complies with EC Directives, the Controller must be installed as follows:

• The NJ-series Controller must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ-series Controllers that comply with EC Directives also conform to the Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EC Directives.

24

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 27

Conformance to Shipbuilding Standards

The NJ-series Controllers comply with the following shipbuilding standards. Applicability to the shipbuilding standards is based on certain usage conditions. It may not be possible to use the product in

some locations. Contact your OMRON representative before attempting to use a Controller on a

ship.

Usage Conditions for NK and LR Shipbuilding Standards

• The NJ-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

Manufacturer Model

Cosel Co., Ltd. TAH-06-683

Regulations and Standards

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Windows, Windows 98, Windows XP, Windows Vista, and Windows 7 are registered trademarks of

Microsoft Corporation in the USA and other countries.

•EtherCAT is a registered trademark of Beckhoff Automation GmbH for their patented technology.

• The SD logo is a trademark of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

NJ-series CPU Unit Motion Control User’s Manual (W507)

25

Page 28

Unit Versions

Unit Versions

Unit Versions

A “unit version” has been introduced to manage CPU Units in the NJ Series according to differences in

functionality accompanying Unit upgrades.

Notation of Unit Versions on Products

The unit version is given on the ID information label of the products for which unit versions are managed, as shown below.

Example for NJ-series NJ501-@@@@ CPU Unit:

ID information label

Unit model

NJ501 -1500 Ver.1.@@

PORT1 MAC ADDRESS: @@@@@@@@@@@@

PORT2 MAC ADDRESS: @@@@@@@@@@@@

Lot No. DDMYY@ xxxx

Unit version

Lot number and serial number MAC address

The following information is provided on the ID information label.

Item Description

Unit model Gives the model of the Unit.

Unit version Gives the unit version of the Unit.

Lot number and

serial number

MAC address Gives the MAC address of the built-in port on the Unit.

Gives the lot number and serial number of the Unit.

DDMYY: Lot number, @: For use by OMRON, xxxx: Serial number

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

26

Confirming Unit Versions with Sysmac Studio

You can use the Unit Production Information on the Sysmac Studio to check the unit version of the CPU

Unit, CJ-series Special I/O Units, CJ-series CPU Bus Units, and EtherCAT slaves. The unit versions of

CJ-series Basic I/O Units cannot be checked from the Sysmac Studio.

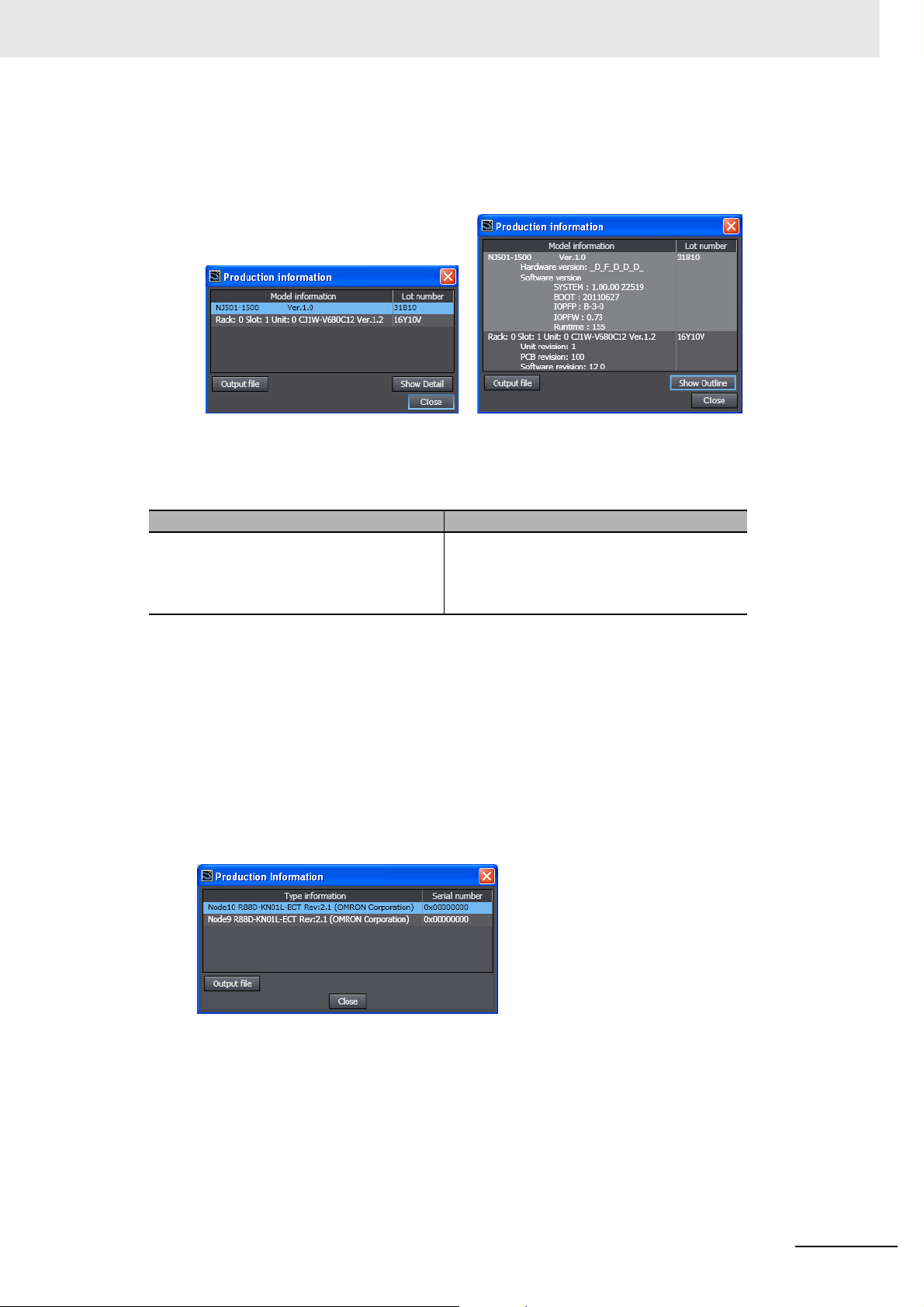

z CPU Unit and CJ-series Units

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed for the Controller Configurations and Setup layer.

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 29

Unit Versions

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

Simple Display Detailed Display

In this example, “Ver.1.0” is displayed next to the unit model.

The following items are displayed.

CPU Unit CJ-series Units

Unit model

Unit version

Lot number

Unit model

Unit version

Lot number

Rack number, slot number, and unit number

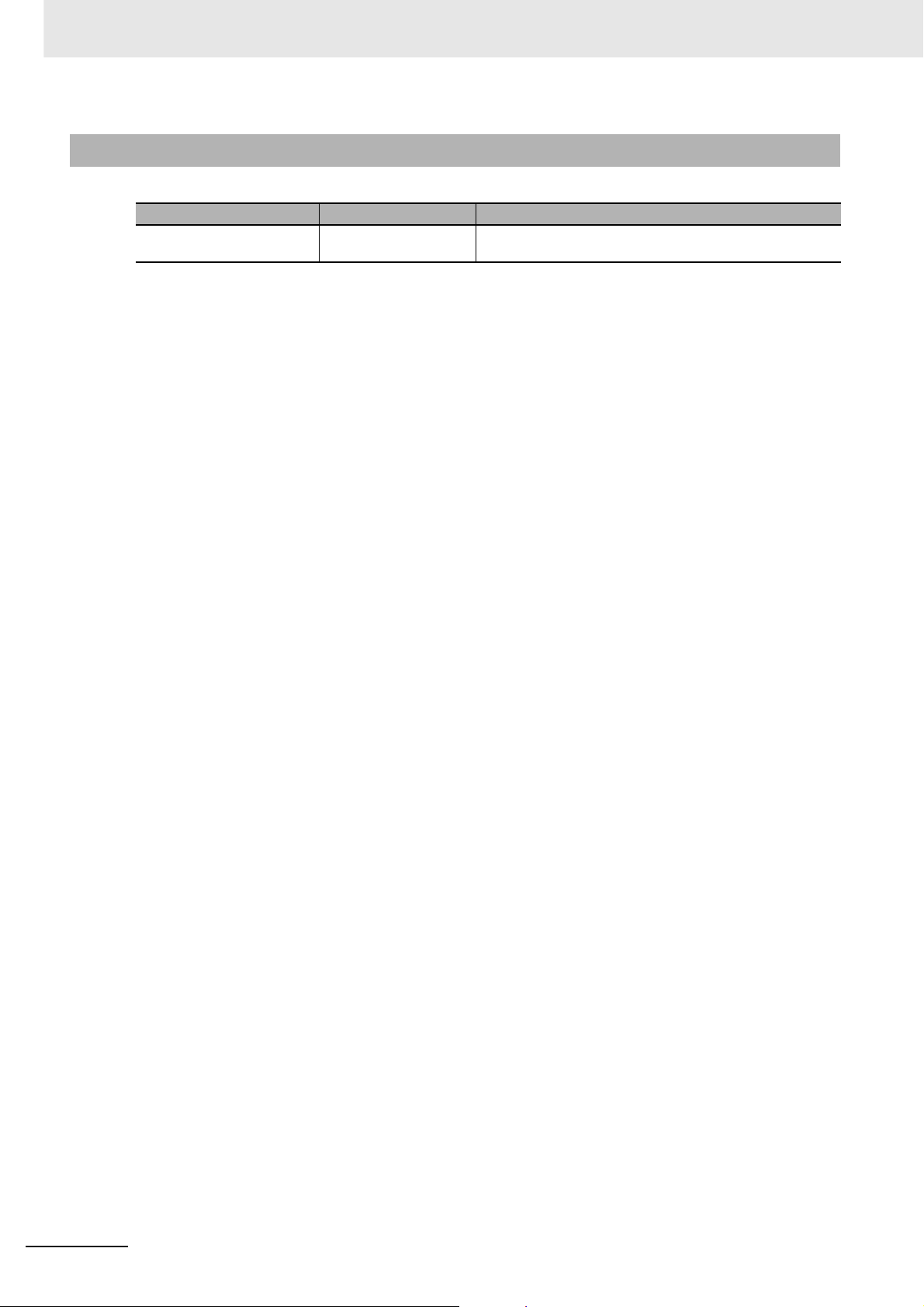

z EtherCAT Slaves

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, right-

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Configuration Tab Page is displayed for the Controller Configurations and Setup

layer.

2 Right-click the master in the EtherCAT Configurations Editing Pane and select Display Produc-

tion Information.

The Production Information Dialog Box is displayed.

The following items are displayed.

Node address

Type information*

Serial number

* If the model number cannot be determined (such as when there is no ESI file), the vendor ID, product

code, and revision number are displayed.

NJ-series CPU Unit Motion Control User’s Manual (W507)

27

Page 30

Unit Versions

Unit Version Notation

In this manual, unit versions are specified as shown in the following table.

Product nameplate Notation in this manual Remarks

“Ver.1.0” or later to the right of

the lot number

Unit version 1.0 or later Unless unit versions are specified, the information in this manual

applies to all unit versions.

28

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 31

Related Manuals

The following manuals are related to the NJ-series Controllers. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit

Hardware User’s Manual

NJ-series CPU Unit Software User’s Manual

NJ-series CPU Unit

Motion Control User’s

Manual

NJ-series Instructions

Reference Manual

NJ-series Motion Control

Instructions Reference

Manual

CJ-series Special Unit

Manuals for NJ-series

CPU Unit

W500 NJ501-@@@@ Learning the basic specifi-

cations of the NJ-series

CPU Units, including introductory information,

designing, installation, and

maintenance. Mainly hardware information is provided.

W501 NJ501-@@@@ Learning how to program

and set up an NJ-series

CPU Unit. Mainly software

information is provided.

W507 NJ501-@@@@ Learning about motion

control settings and programming concepts.

W502 NJ501-@@@@ Learning about the specifi-

W508 NJ501-@@@@ Learning about the specifi-

W490

W498

W499

W491

Z310

W492

W494

W497

CJ1W-@@@@ Learning how to use CJ-

cations of the instruction

set that is provided by

OMRON.

cations of the motion control instructions that are

provided by OMRON.

series Units with an NJseries CPU Unit.

An introduction to the entire NJ-series system is

provided along with the following information on

a Controller built with an NJ501 CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the NJ-series

CPU Unit Software User’s Manual (Cat. No.

W501).

The following information is provided on a Controller built with an NJ501 CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 language specifications

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500).

The settings and operation of the CPU Unit and

programming concepts for motion control are

described. Use this manual together with the

NJ-series CPU Unit Hardware User’s Manual

(Cat. No. W500) and NJ-series CPU Unit Soft-

ware User’s Manual (Cat. No. W501).

The instructions in the instruction set (IEC

61131-3 specifications) are described. When

programming, use this manual together with the

NJ-series CPU Unit Hardware User’s Manual

(Cat. No. W500) and NJ-series CPU Unit Software User’s Manual (Cat. No. W501).

The motion control instructions are described.

When programming, use this manual together

with the NJ-series CPU Unit Hardware User’s

Manual (Cat. No. W500), NJ-series CPU Unit

Software User’s Manual (Cat. No. W501) and

NJ-series CPU Unit Motion Control User’s Manual (Cat. No. W507).

The methods and precautions for using CJseries Units with an NJ501 CPU Unit are

described, including access methods and programming interfaces. Manuals are available for

the following Units.

Analog I/O Units, Insulated-type Analog I/O

Units, Temperature Control Units, ID Sensor

Units, High-speed Counter Units, Serial Communications Units, and DeviceNet Units.

Use these manuals together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

Related Manuals

NJ-series CPU Unit Motion Control User’s Manual (W507)

29

Page 32

Related Manuals

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit Builtin EtherCAT Port User’s

Manual

NJ-series CPU Unit Builtin EtherNet/IP Port

User’s Manual

NJ-series Troubleshooting Manual

Sysmac Studio Version 1

Operation Manual

CX-Integrator

CS/CJ/CP/NSJ-series

Network Configuration

Tool Operation Manual

CX-Designer User’s

Manual

CX-Protocol Operation

Manual

W505 NJ501-@@@@ Using the built-in EtherCAT

port on an NJ-series CPU

Unit.

W506 NJ501-@@@@ Using the built-in Ether-

Net/IP port on an NJ-series

CPU Unit.

W503 NJ501-@@@@ Learning about the errors

that may be detected in an

NJ-series Controller.

W504 SYSMAC-

SE2@@@

W464 Learning how to configure

V099 Learning to create screen

W344 Creating data transfer pro-

Learning about the operating procedures and functions of the Sysmac Studio.

networks (data links, routing tables, Communications Unit settings, etc.).

data for NS-series Programmable Terminals.

tocols for general-purpose

devices connected to CJseries Serial Communications Units.

Information on the built-in EtherCAT port is provided. This manual provides an introduction and

provides information on the configuration, features, and setup.

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

Information on the built-in EtherNet/IP port is

provided. Information is provided on the basic

setup, tag data links, and other features.

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

Concepts on managing errors that may be

detected in an NJ-series Controller and information on individual errors are described.

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

Describes the operating procedures of the Sysmac Studio.

Describes operating procedures for the CX-Integrator.

Describes operating procedures for the CXDesigner.

Describes operating procedures for the CX-Protocol.

30

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 33

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision History

Cat. No.

Revision code Date Revised content

01 July 2011 Original production

W507-E1-01

Revision code

NJ-series CPU Unit Motion Control User’s Manual (W507)

31

Page 34

Revision History

32

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 35

Introduction to the Motion Control

Function Module

This section describes the features, system configuration, and application flow for the

Motion Control Function Module.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Application Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4-3 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1

NJ-series CPU Unit Motion Control User’s Manual (W507)

1-1

Page 36

1 Introduction to the Motion Control Function Module

1-1 Features

The Motion Control Function Module (sometimes abbreviated to “MC Function Module”) is a software

function module that is built into the CPU Unit. The MC Function Module can perform motion control for

up to 64 axes through the EtherCAT port that is built into the CPU Unit. Cyclic communications are performed with Servo Drives that are connected to the EtherCAT port to enable high-speed, high-precision

machine control.

Motion Control Instructions Based on PLCopen

The motion control instructions of the MC Function Module are based on motion control function blocks

that are standardized by PLCopen. These instructions allow you to program single-axis PTP positioning, interpolation control, synchronized control (e.g., of electronic cams), velocity control, and torque

control. You can set the velocity, acceleration rate, deceleration rate, and jerk each time a motion control instruction is executed to flexibly control operation according to the application.

Additional Information

• PLCopen

PLCopen is an association that promotes IEC 61131-3. It has its headquarters in Europe and a

world-wide membership. PLCopen standardizes function blocks for motion control to define a

program interface for the languages specified in IEC 61131-3 (JIS B 3503).

•Jerk

Jerk is the rate of change in the acceleration rate or deceleration rate. If you specify the jerk, the

velocity graph will form an S-curve for acceleration and deceleration.

Data Transmission Using EtherCAT Communications

The MC Function Module can be combined with OMRON G5-series Servo Drives with built-in EtherCAT

communications to enable exchange of all control information with high-speed data communications.

The various control commands are transmitted via data communications. That means that the Servomotor's operational performance is maximized without being limited by interface specifications, such as

the response frequency of the encoder feedback pulses. You can use the Servo Drive's various control

parameters and monitor data on a host controller to unify management of system information.

Additional Information

1-2

What Is EtherCAT?

EtherCAT is an open high-speed industrial network system that conforms to Ethernet (IEEE

802.3). Each node achieves a short cycle time by transmitting Ethernet frames at high speed. A

mechanism that allows sharing clock information enables high-precision synchronized control

with low communications jitter.

NJ-series CPU Unit Motion Control User’s Manual (W507)

Page 37

1 Introduction to the Motion Control Function Module

1-2 System Configuration

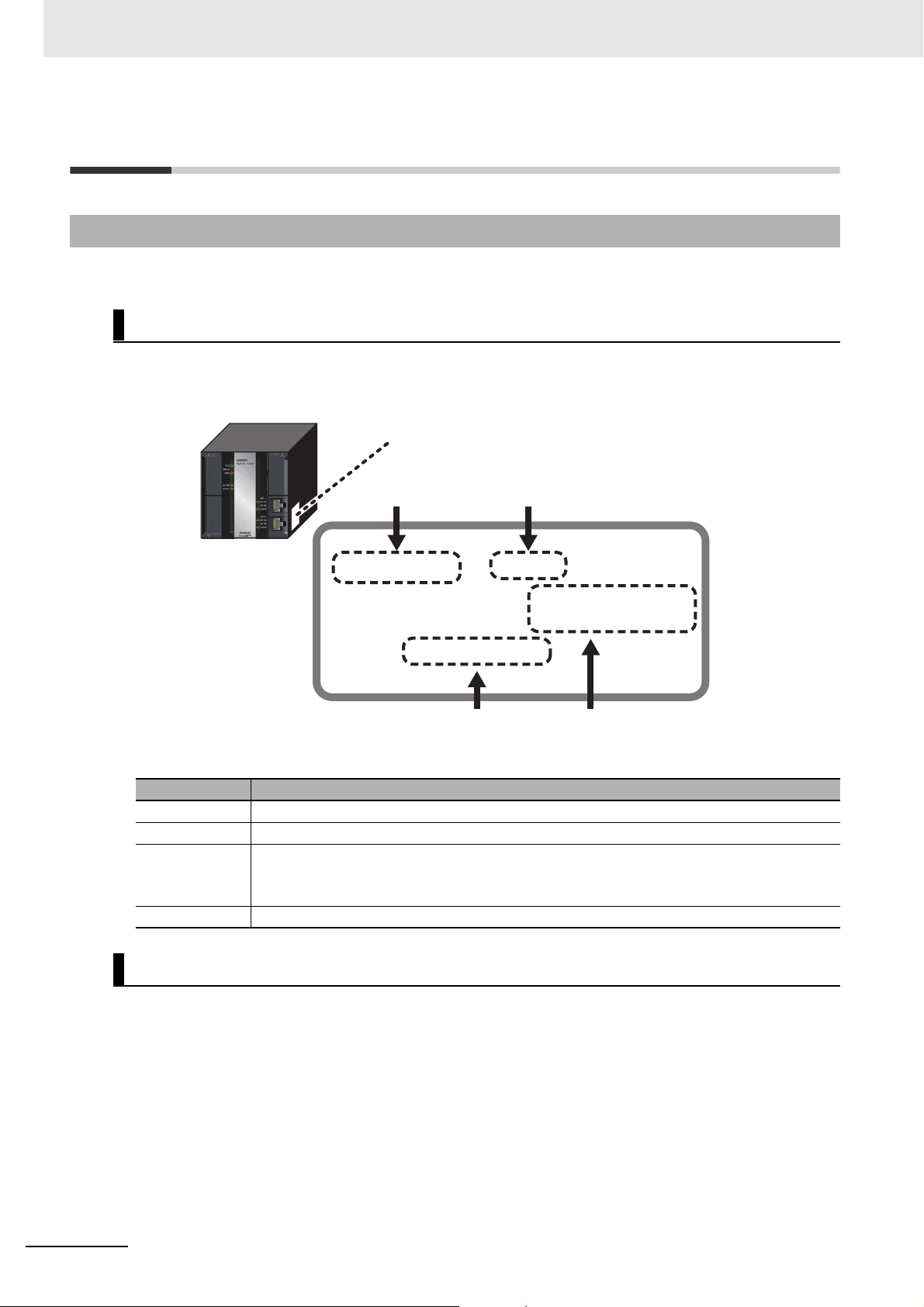

The MC Function Module receives sensor signal status from devices and control panels. It receives

commands from the motion control instructions that are executed in the user program. It uses both of

these to perform motion control with the Servo Drives and Encoder Input Terminals.

1-2 System Configuration

z Motion Control Configuration

The EtherCAT network configuration and Sysmac Studio are used for the MC Function Module.

• EtherCAT Network Configuration

The MC Function Module performs control for Servo Drives and Encoder Input Terminals through

the EtherCAT master port that is built into the CPU Unit. The EtherCAT network configuration is

used to perform precise motion control in a fixed period with very little deviation.

• Sysmac Studio

The Sysmac Studio is connected to the peripheral USB port on the CPU Unit with a commercially

available USB cable. You can also connect it to the built-in EtherNet/IP port on the CPU Unit with

Ethernet cable.

Sysmac Studio

Peripheral USB port

EtherCAT

G5-series Servo Drives with Built-in

EtherCAT Communications

EtherCAT Network

Configuration

Encoder Input Terminal

LAN

USB

Or

EtherNet/IP

NJ-series Controller

Power Supply Unit

Built-in EtherNet/IP port

Built-in EtherCAT port

Positive limit input

Negative limit input

Immediate stop input

Home proximity input

Home input

External latch input, etc.

CPU Unit

1

NJ-series CPU Unit Motion Control User’s Manual (W507)

1-3

Page 38

1 Introduction to the Motion Control Function Module

1-3 Application Procedure

This section provides the basic procedure to perform motion control with the MC Function Module.

Basic Flow of Operation

START

Transferring

Checking Wiring

Checking Operation

Create a project.Setup

Create the EtherCAT Network Configuration.

Add axes.

Assign the axes.

Set the axis parameters.

Set the Controller Setup.

Transfer the project to the Controller.

Open the MC Test Run Tab Page.

Monitor input signals to check the wiring.

Perform jogging.

Sysmac Studio Version 1 Operation Manual

(Cat. No. W504)

NJ-series CPU Unit Software User’s Manual

*

(Cat. No. W501)

Section 3 Configuring Axes and Axes Groups