Page 1

Machine Automation Controller

NJ-series

SECS/GEM

CPU Units

User’s Manual

NJ501-1340

CPU Unit

W528-E1-01

Page 2

© OMRON, 2014

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Windows, Windows XP, Windows Vista, Windows 7, Windows 8, and Excel are either registered trademarks or

trademarks of Microsoft Corporation in the USA and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Page 3

Introduction

Thank you for purchasing an NJ-series CPU Unit.

This manual contains information that is necessary to use the NJ-series CPU Unit. Please read this

manual and ma

before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for

Intended Audience

ke sure you understand the functionality and performance of the NJ-series CPU Unit

Introduction

reference during operation.

This ma

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

•

• Personnel in charge of installing and maintaining FA s

• Personnel in charge of managing FA systems and facilities.

This

• For programming, the programming language specifications in intern

• The contents of the SEMI E5, SEMI E30, and SEMI E37 documents

nual is intended for the following personnel, who must also have kno

Personnel in charge of designing FA systems.

manual is intended also for personnel with the following knowledge.

Japanese standard JIS B 3503

Applicable Products

manual covers the following products.

This

J-series SECS/GEM CPU Unit

• N

• NJ501-1340

• Sysmac Studio Automation Software

• SYSMAC-SE2 version 1.10

• GEM Setting Tools, SECS/GEM Configurator

•WS02-GCTL1

wledge of electrical sys-

ystems.

ational standard IEC 61131-3 or

or higher

Part of the specifications and restriction

vant Manuals on pag

NJ-series SECS/GEM CPU Units User’s Manual (W528)

e 2 and Related Manuals on page 22.

s for the CPU Units are given in other manuals. Refer to Rele-

1

Page 4

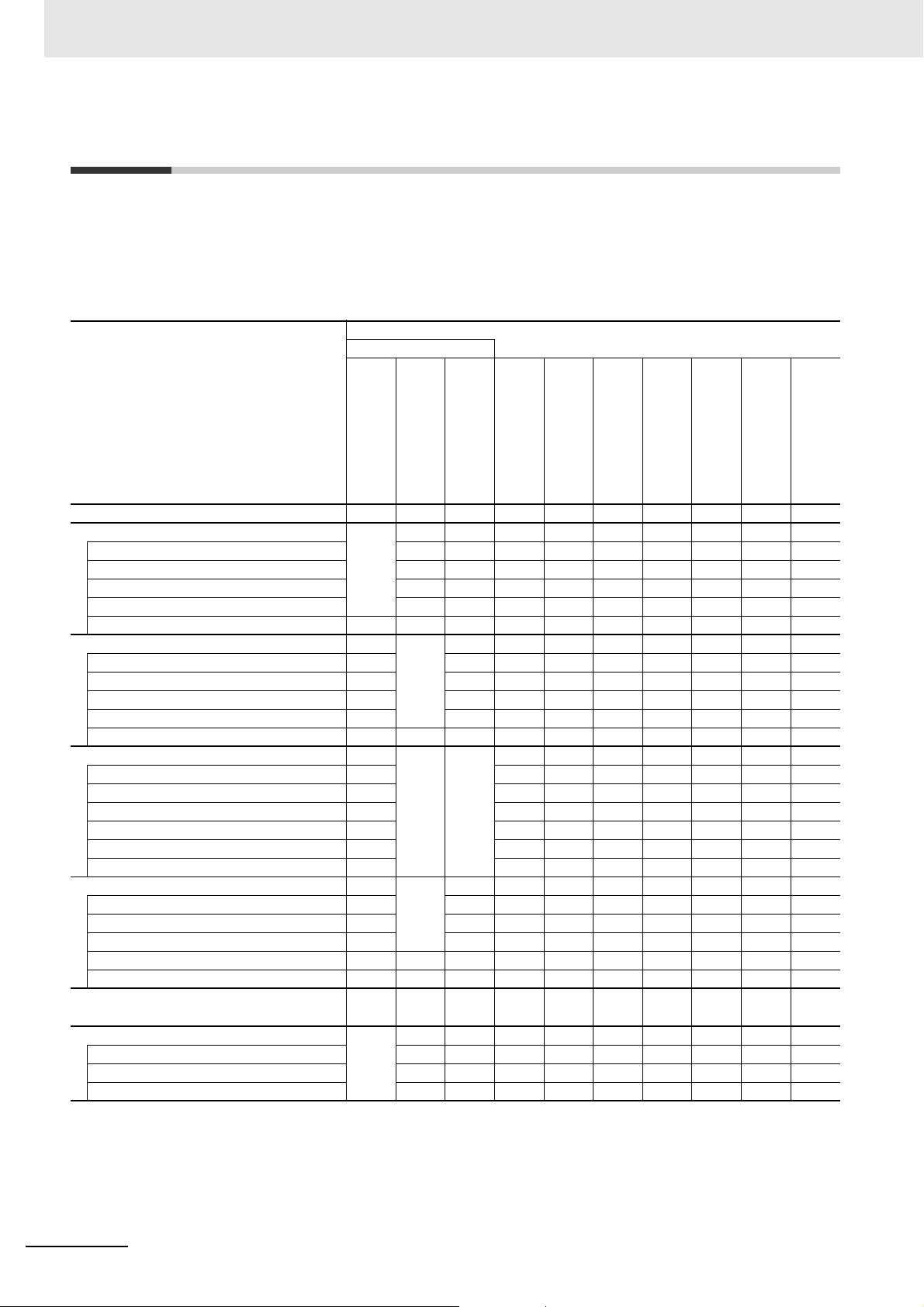

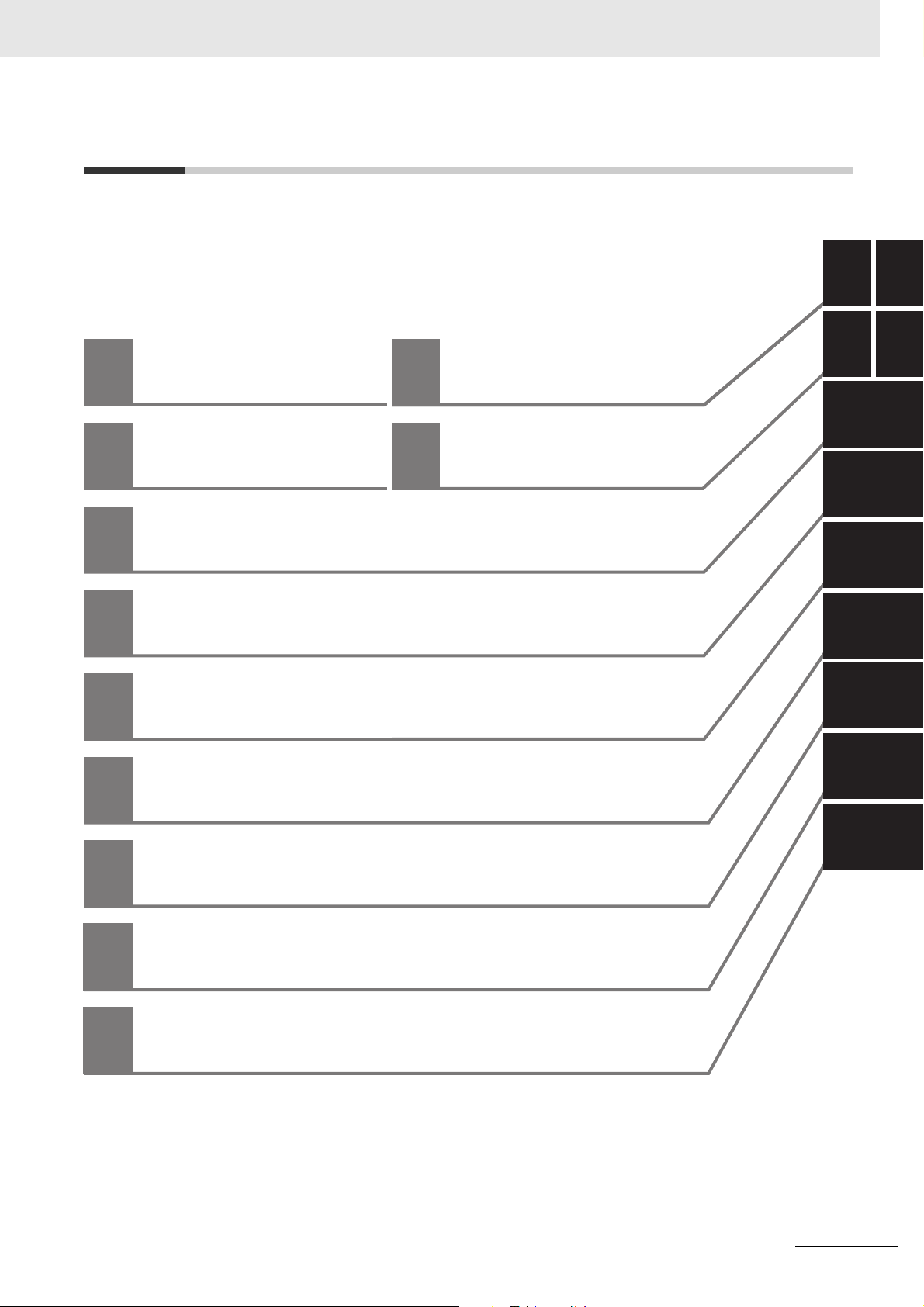

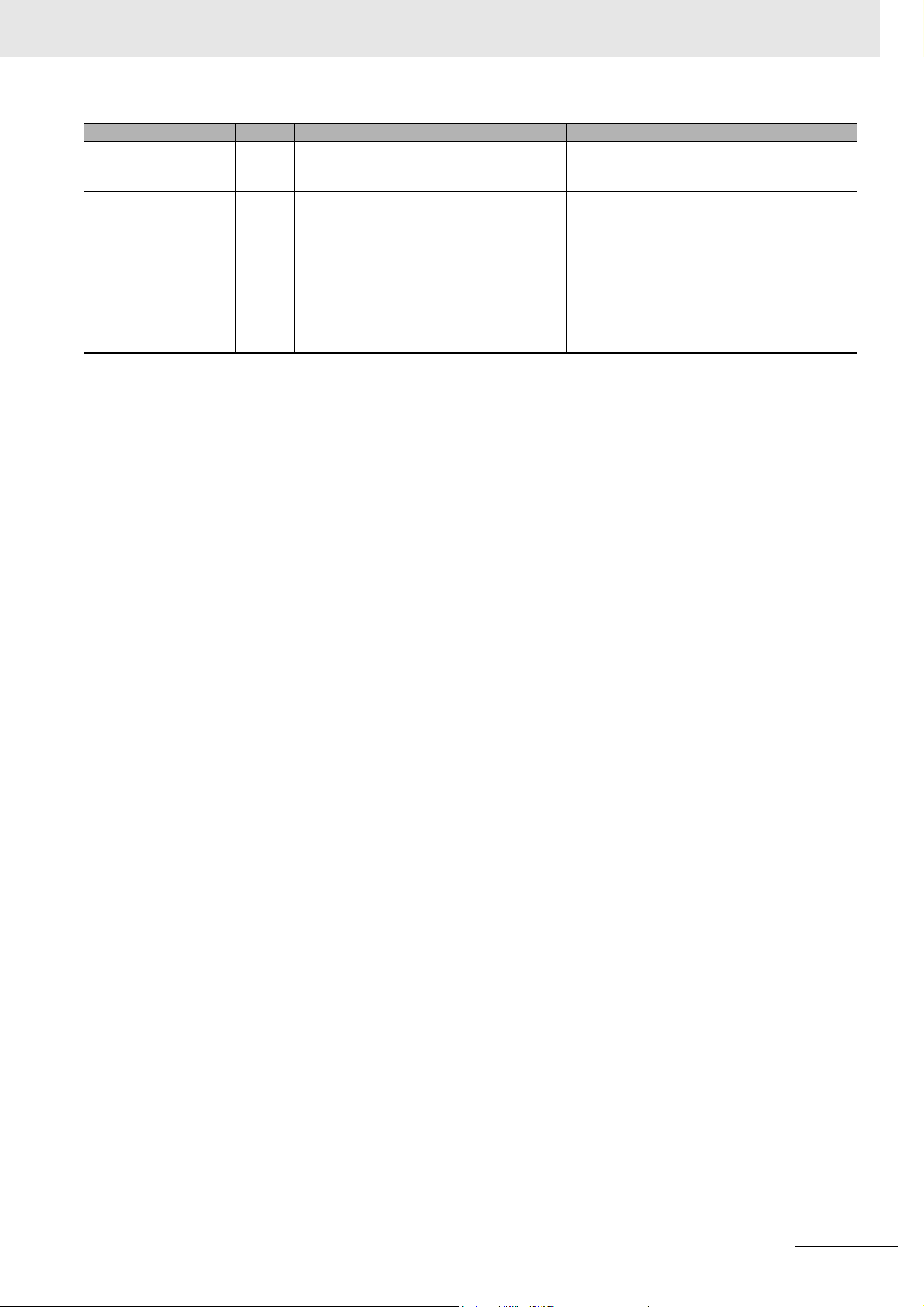

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for the NJ-series CPU Units.

Read all of the manuals that are relevant to your system configuratio

the NJ-series CPU Unit.

Most operations are performed from the Sysmac Stud

dio Version 1 Operation Manual (Cat. No.

Basic information

Hardware User’s

Purpose of use

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection se

Using GEM Services

tware settings

Sof

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection se

Using GEM Services

riting the user program

W

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using GEM Services

amming error processing

Progr

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection se

Using GEM Services

Le

arning about error management and

corrections

Maintenance

*1

Using motion control

Using EtherCAT

Using EtherNet/IP

rvice

rvice

rvice

*1. Refer to the NJ-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and an overview of

the error items. Refer to the manuals that are indicated with triangles for details on errors for the corresponding Units.

Manual

W504) for information on the Sysmac Studio.

NJ-series CPU Unit

NJ-series CPU Unit

Software User’s

Manual

io Automation Software. Refer to the Sysmac Stu-

NJ-series Instructions

Mot

Reference Manual

i

on

C

Manual

o

ntrol User’s

NJ-series CPU

Reference Manu

Unit

al

n and application before you use

Manual

Control I

nstructions

Built-in EtherCA

NJ-series Motion

User’s Manual

T Port

Built-in EtherNet/IP

NJ-series CPU Unit

Port User’s Manu

al

Connection

NJ-series CPU Unit

NJ-series Database

User’s Manual

CPU Unit

NJ-series SECS/GEM

User's Manual

shooting Manual

CPU Unit

NJ-series T

rouble-

2

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 5

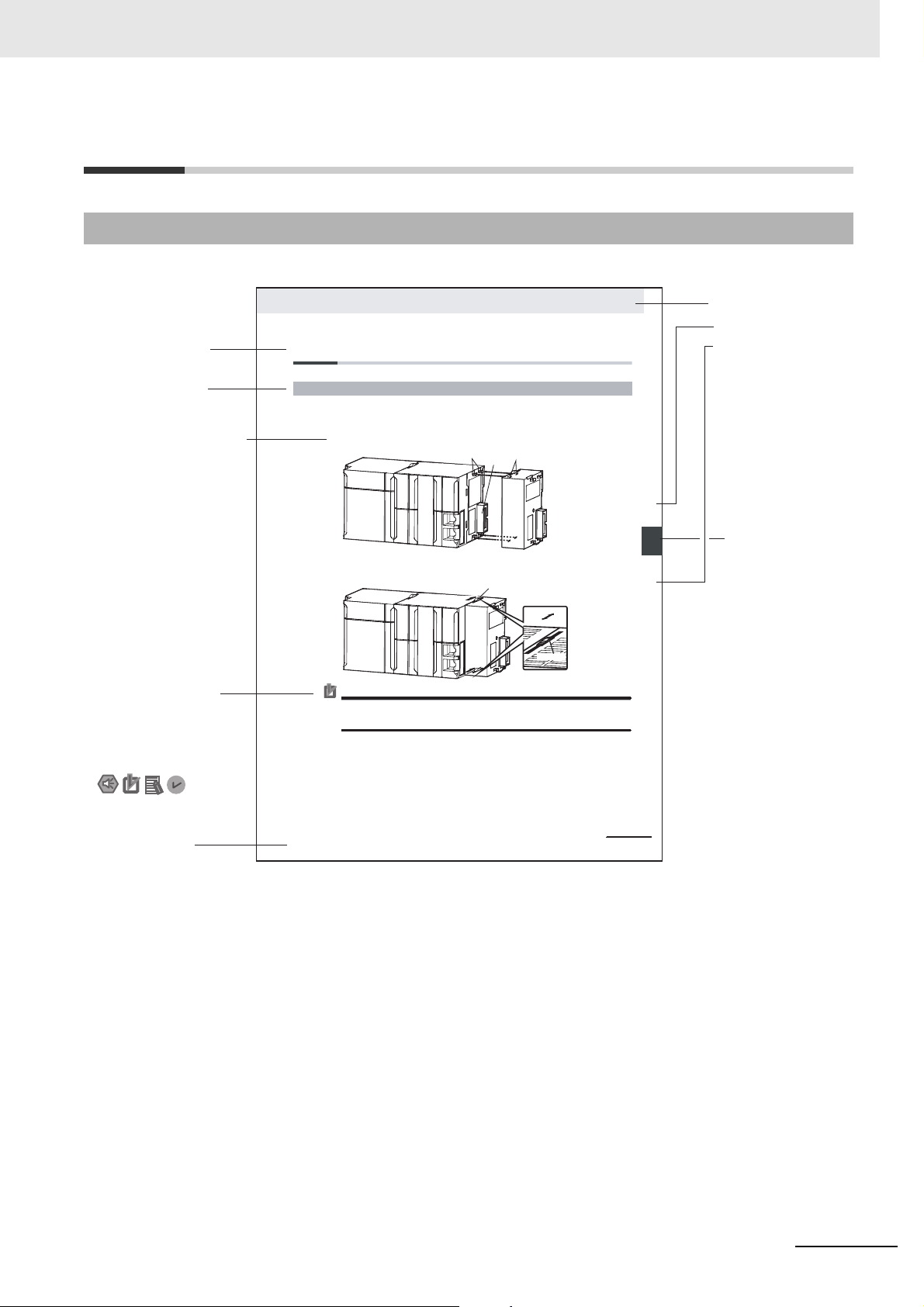

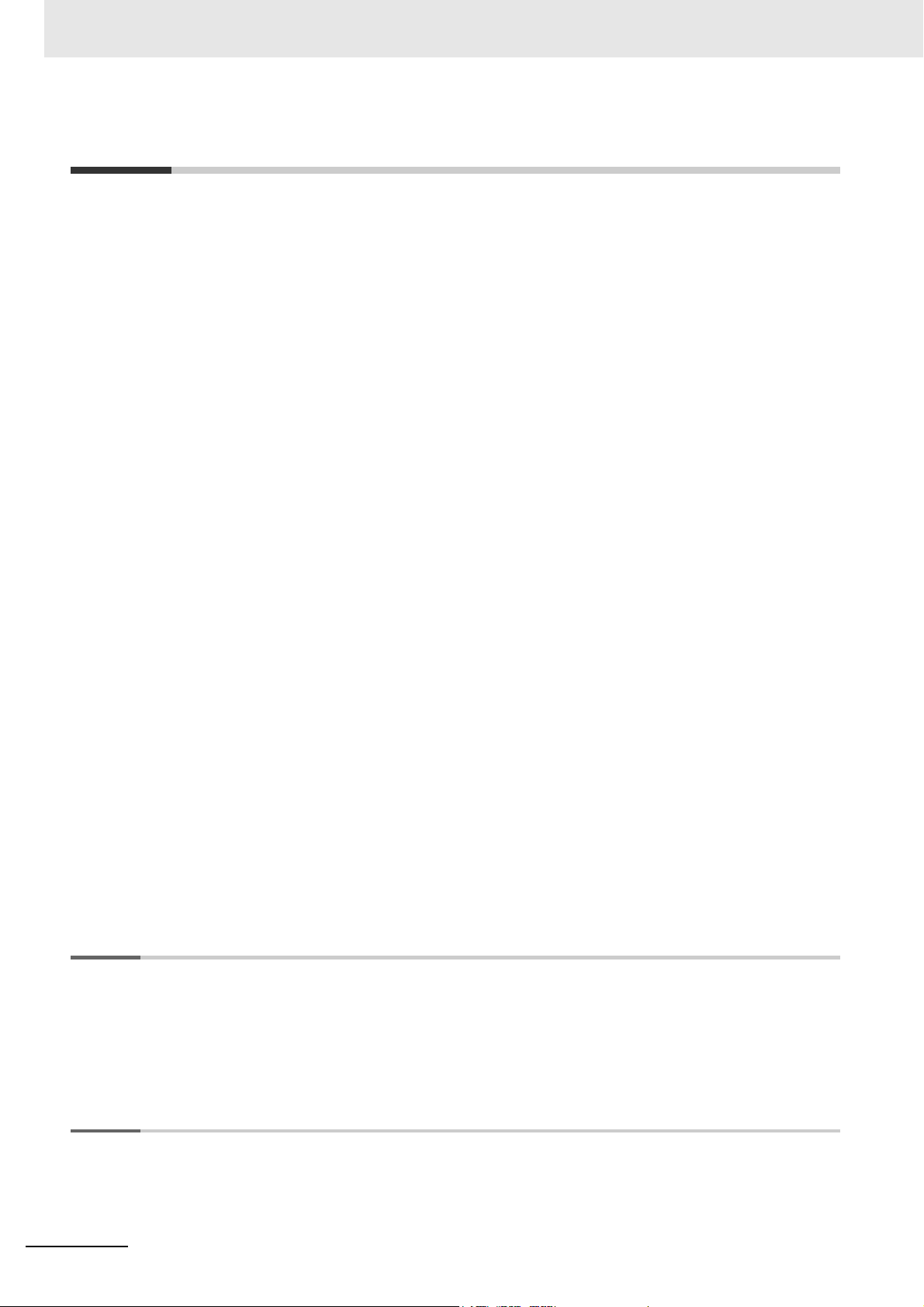

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Page Structure

The following page structure is used in this manual.

Manual Structure

NJ-series SECS/GEM CPU Units User’s Manual (W528)

3

Page 6

Manual Structure

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on differences in specifications and functionality for

and for different versions of the Sysmac Studio is given.

CPU Units with different unit versions

Note References are provided to more detailed or related information.

Precaution on Terminology

In this manual, “download” refers to transferring data from the Sysmac Studio to the physical Controller

and “upload” refers to transferring data from the physical Controller to the Sysmac Studio.

For the Sysmac Studio, synchronization is used to both upload and download data. Here, “synchronize”

means to au

physical Controller and transfer the data in the direction that is specified by the user.

The streams and functions that are defined in SEMI E5-0707 (SEM

dard 2 Message Content (SECS-II)) are given as

Function_name (Sstream_number

Example: Abort Transaction (S1,F0)

tomatically compare the data for the Sysmac Studio on the computer with the data in the

follows:

,Ffunction number)

I Equipme

nt Communications Stan-

4

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 7

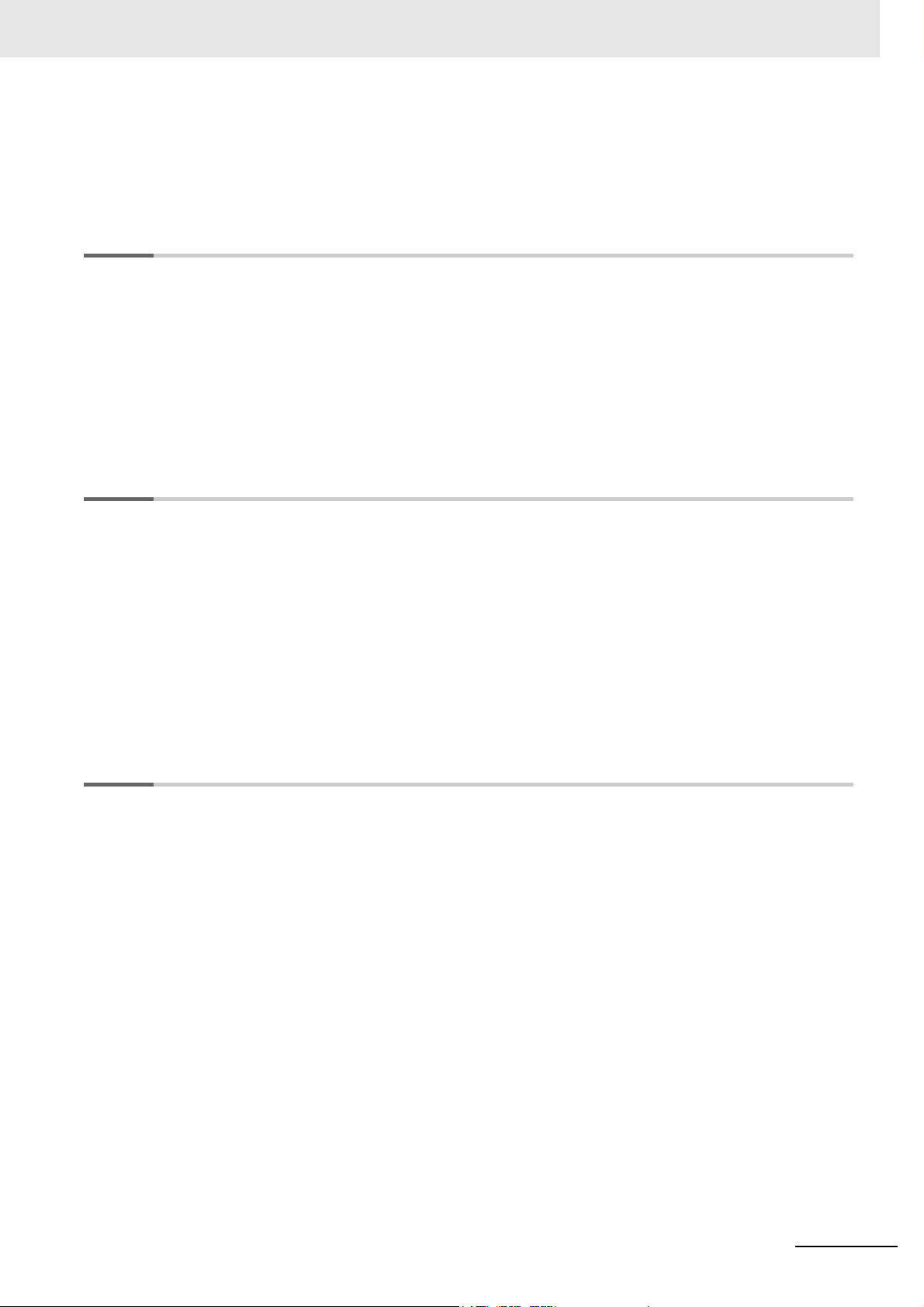

Sections in this Manual

Appendices

Index

SECS/GEM CPU Unit

Capabilities

1

2

3

4

5

6

7

8

9

1

A

6

5

4

3

7

8

9

I

I

A

2

I

System Configuration and

Functional Configuration

GEM Service Design Procedure

Functions Related to All GEM Services

Host Connection Function

GEM Service Logs

Functionality Other Than the GEM Services

SECS/GEM Configurator

Troubleshooting

Sections in this Manual

NJ-series SECS/GEM CPU Units User’s Manual (W528)

5

Page 8

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products..................................................................................................................................... 1

Relevant Manuals .....................................................................................................2

Manual Structure ......................................................................................................3

Special Information...................................................................................................................................... 4

Sections in this Manual ...........................................................................................5

Terms and Conditions Agreement........................................................................12

Warranty, Limitations of Liability ................................................................................................................ 12

Application Considerations ........................................................................................................................ 13

Disclaimers ................................................................................................................................................ 13

Safety Precautions .................................................................................................14

Precautions for Safe Use....................................................................................... 15

Precautions for Correct Use.................................................................................. 16

Regulations and Standards................................................................................... 18

Conformance to EC Directives .................................................................................................................. 18

Conformance to KC Standards.................................................................................................................. 19

Conformance to Shipbuilding Standards ................................................................................................... 19

Software Licenses and Copyrights ............................................................................................................ 19

Versions ..................................................................................................................20

Types of Versions ......................................................................................................................................20

Checking Versions..................................................................................................................................... 20

Unit Versions of CPU Units and Sysmac Studio Versions ......................................................................... 21

Related Manuals .....................................................................................................22

Terminology ............................................................................................................24

Revision History .....................................................................................................26

Section 1 SECS/GEM CPU Unit Capabilities

1-1 SECS/GEM CPU Unit Features ............................................................................................. 1-2

1-2 Standard Compliance of the SECS/GEM CPU Unit ............................................................ 1-4

1-2-1 SEMI Standard Compliance........................................................................................................1-4

1-2-2 SECS/GEM Standard Compliance..............................................................................................1-4

1-2-3 Supported SECS Messages ....................................................................................................... 1-5

Section 2 System Configuration and Functional Configuration

2-1 System Configuration ........................................................................................................... 2-2

2-2 Functional Configuration of SECS/GEM CPU Unit............................................................. 2-5

6

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 9

2-3 Overview of GEM Service Operation ................................................................................... 2-7

2-3-1 SECS Messages When Host Sends the Primary Message........................................................ 2-7

2-3-2 SECS Messages When Equipment Sends the Primary Message.............................................2-11

2-3-3 Link Variables .....................................................................................................................

Section 3 GEM Service Design Procedure

3-1 Overview of GEM Service Design Procedure ..................................................................... 3-2

3-2 Using the SECS/GEM Configurator to Create the GEM Setting Data ...

CONTENTS

...... 2-15

............................ 3-4

3-3 Using the Sysmac Studio to Create the SECS/GEM Operation Programming

3-3-1 Starting the Sysmac Studio and Creating a Project .................................................................... 3-6

3-3-2 FTP Settings..........................................................................................................................

3-3-3 Creating the SECS/GEM Operation Programming..................................................................... 3-7

3-3-4 Restrictions When Defining Link Variables for User-defined Variables ...................................... 3-8

3-4 Debugging.............................................................................................................................. 3-9

Section 4 Functions Related to All GEM Services

4-1 Starting the GEM Services....................................................................................................4-2

4-1-1 Procedure to Change the GEM Service Status to Run............................................................... 4-2

4-1-2 Conditions That Prevent the GEM Service Status from Entering Run.

4-2 Ending the GEM Services ..................................................................................................... 4-3

4-2-1 Executing a Shutdown................................................................................................................ 4-3

4-2-2 Operation When Shutdown Processing Is Completed...........

..................................................... 4-3

4-3 GEM Service Status............................................................................................................... 4-4

4-3-1 GEM Service Status.................................................................................................................... 4-4

4-3-2 Changes in the GEM Service Status ..........................................................................................4-5

4-3-3 C

4-3-4 Relation between GEM Service Status and GEM Instructions .........

hecking the GEM Service Status.............................................................................................. 4-6

Section 5 Host Connection Function

................ 3-6

..... 3-7

....................................... 4-2

.......................................... 4-7

5-1 Basic Processing of the Host Connection Function.......................................................... 5-3

5-1-1 Starting and Pausing the Host Connection Function .................................................................. 5-3

5-1-2 Interlocks ............................................................................................................................

5-1-3 Transaction Processing ..............................................

5-1-4 Checking the Number of Buffered SECS Messages ................................................................ 5-12

................................................................ 5-6

........ 5-5

5-2 HSMS Communications ...................................................................................................... 5-13

5-2-1 Setting HSMS Conditions ......................................................................................................... 5-13

5-2-2 HSMS Communications Connection States ............................................................................. 5-14

5-2-3 Checking the HSMS Communications State ............................................................................ 5-15

5-3 Item Definitions.................................................................................................................... 5-16

5-4 Variable Data Definitions ....................................................................................................5-20

5-4-1 Types of Variable Data.............................................................................................................. 5-20

5-4-2 Variable Data Attributes and Initialization ................................................................................. 5-20

5-4-3 Variable Data List Structure and Link Variable Assignment Settings........................................ 5-21

5-4-4 Standard Variable Data............................................................................................................. 5-23

5-5 GEM Capabilities ................................................................................................................. 5-25

5-5-1 Communications State Model................................................................................................... 5-26

5-5-2 Control State Model.................................................................................................................. 5-30

3 Equipment Processing States................................................................................................... 5-36

5-5-

5-5-4 Event Notification...................................................................................................................... 5-39

5-5-5 Error Messages ........................................................................................................................ 5-42

6 Documentation.......................................................................................................................... 5-43

5-5-

5-5-7 Dynamic Event Report Configuration ....................................................................................... 5-44

NJ-series SECS/GEM CPU Units User’s Manual (W528)

7

Page 10

CONTENTS

5-5-8 Variable Data Collection............................................................................................................5-47

5-5-9 Trace Data Collection................................................................................................................5-48

5-5-10 Status Data Collection...............................................................................................................5-50

5-5-11 Alarm Management...................................................................................................................5-52

5-5-12 Host Commands ....................................................................................................................... 5-55

-5-13 Enhanced Remote Commands ................................................................................................. 5-59

5

5-5-14 Equipment Constants................................................................................................................5-61

5-5-15 Process Program Management ................................................................................................5-65

5-5-16

5-5-17 Equipment Terminal Service .....................................................................................................5-87

5-5-18 Clock ...................................................................................................................................

5-5-19 Limit Monitoring.........................................................................................................................5-92

5-5-20 Spooling ....................................................................................................................................5-95

Material Movement....................................................................................................................5-86

5-6 Message Settings .............................................................................................................. 5-101

5-6-1 GEM Standard Messages .......................................................................................................5-101

5-6-2 User-defined Messages ..........................................................................................................5-103

Section 6 GEM Service Logs

...... 5-90

6-1 GEM Service Logs ................................................................................................................. 6-2

6-1-1 Types of GEM Service Logs........................................................................................................6-2

6-1-2 Saving Destinations for GEM Service Logs ................................................................................6-2

6-1-3 Restrictions on GEM Service Logs .............................................................................................6-2

6-2 Application Procedures for the GEM Service Logs ........................................................... 6-4

6-2-1 Setting the Numbers of Records Saved in the GEM Service Logs .............................................6-4

6-2-2 Displaying the Contents of the GEM Service Logs .....................................................................6-4

6-3 Log Viewer Operations.......................................................................................................... 6-6

6-3-1 Installation of GEM Setting Tools ................................................................................................6-6

6-3-2 Starting and Stopping the Log Viewer ......................................................................................... 6-6

6-3-3 Configuration of the Main Window ..............................................................................................6-7

6-3-4 Procedure to Display a GEM Service Log...........................

6-3-5 Displaying the SECS Message Log ..........................................................................................6-12

6-3-6 Displaying the HSMS Communications Log .............................................................................6-15

6-3-7 Displaying the Execution Log....................................................................................................6-17

6-3-8 Filters

6-3-9 Saving the Current Settings ......................................................................................................6-18

6-3-10

6-3-11 Windows....................................................................................................................................6-22

6-3-12 Help.....................................................................................................................................

...............................................................................................................................

Outputting Logs to Files ........................................

.................................................................... 6-19

........................................................6-8

Section 7 Functionality Other Than the GEM Services

7-1 SD Memory Cards.................................................................................................................. 7-2

7-1-1 Directory Structure of the SD Memory Card................................................................................7-2

7-1-2 Restrictions When No SD Memory Card Is Inserted...................................................................7-2

7-1-3 Operation When Data Cannot Be Saved in the SD Memory Card..........

7-1-4 Operation When the SD Memory Card Is Replaced ................................................................... 7-3

7-2 Backup Functions ................................................................................................................. 7-5

7-2-1 Data That Is Backed Up..............................................................................................................7-5

7-2-2 Data That Is Not Backed Up .......................................................................................................7-5

7-2-3 Backup Functions for GEM Setting Data .................................................................................... 7-5

7-2-4 Compatibility between CPU Unit Models ....................................................................................

7-2-5 Compatibility between Versions of CPU Units ............................................................................7-6

7-2-6 Restrictions for Backup Function Execution................................................................................7-7

....................................7-2

......... 6-18

...... 6-22

7-6

8

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 11

Section 8 SECS/GEM Configurator

8-1 Installing and Uninstalling the GEM Setting Tools............................................................. 8-3

8-1-1 Installation Precautions............................................................................................................... 8-3

8-1-2 Applicable Operating Systems for the GEM Setting Tools.....

8-1-3 Installed Application Software..................................................................................................... 8-3

8-1-4 Installation Procedure for the GEM Setting Tools ....................................................................... 8-4

8-1-5 Uninstallation Procedure for the GEM Setting Tools................................................................... 8-7

8-2 Starting and Exiting the SECS/GEM Configurator.............................................................. 8-8

8-2-1 Starting the SECS/GEM Configurator.........................................................................................8-8

8-2-2 Exiting the SECS/GEM Configurator ..........................................................................................8-9

8-3 Configuration of the SECS/GEM Configurator ................................................................. 8-10

8-3-1 Window Configuration............................................................................................................... 8-10

8-3-2 Menu Structure .........................................................................................................................

8-3-3 Operating Buttons..................................................................................................................... 8-14

8-4 Menu Bar Functions ............................................................................................................ 8-15

8-4-1 File............................................................................................................................................ 8-15

8-4-2 Build.......................................................................................................................................... 8-19

8-4-3 Controller .................................................................................................................................. 8-21

8-4-4 Tool ..................................................................................................................................

8-4-5 Documentation.......................................................................................................................... 8-30

8-4-6 Window..................................................................................................................................... 8-34

8-4-7 Help .................................................................................................................................

8-5 Toolbar Configuration ......................................................................................................... 8-36

8-6 Basic Operations on the List Menus ..............................

8-6-1 List Menu Dialog Boxes ............................................................................................................ 8-37

8-6-2 Setting Dialog Boxes ................................................................................................................ 8-38

8-6-3 Variable Dialog Boxes............................................................................................................... 8-40

8-7 Configuration ....................................................................................................................... 8-42

8-7-1 GEM Service Log...................................................................................................................... 8-42

8-8 HSMS Settings ..................................................................................................................... 8-43

8-8-1 HSMS Condition ....................................................................................................................... 8-43

8-9 Data Definition ..................................................................................................................... 8-45

8-9-1 Item........................................................................................................................................... 8-45

8-9-2 Equipment Constant (EC)......................................................................................................... 8-47

8-9-3 Status Variable (SV).................................................................................................................. 8-50

8-9-

4 Discrete Variable (DV) .............................................

8-9-5 List Structure Definitions........................................................................................................... 8-56

8-10 Model Settings ..................................................................................................................... 8-58

8-10-1 Communications State Model ................................................................................................... 8-58

8-10-2 Control State Model .................................................................................................................. 8-59

8-11 GEM Capability Settings .....................................................................................................8-60

8-11-1 Event Notification ...................................................................................................................... 8-61

8-11-2 Alarm Management .................................................................................................................. 8-69

-3 Host Command ......................................................................................................................... 8-72

8-11

8-1

1-4 Enhanced Remote Command .................................................................................................. 8-76

8-11-5 Equipment Constants ............................................................................................................... 8-80

-6 Process Program Management ................................................................................................8-81

8-11

8-11-7 Equipment Terminal Service.......................................

8-11-8 Limit Monitoring ..................................................................................................................

8-11-9 Spooling ..............................................................................................................................

8-12 Message Settings ................................................................................................................ 8-95

8-12-1 GEM Standard Messages......................................................................................................... 8-95

8-12-2 User-defined Messages............................................................................................................ 8-96

CONTENTS

..................................................... 8-3

.8-11

......... 8-26

......... 8-35

................................................... 8-37

................................................................. 8-53

.............................................................. 8-90

...... 8-92

...... 8-93

NJ-series SECS/GEM CPU Units User’s Manual (W528)

9

Page 12

CONTENTS

8-13 Confirm Settings................................................................................................................ 8-101

8-13-1 Item List...................................................................................................................................8-101

8-13-2 Message List...................................

8-13-3 Event List ................................................................................................................................8-102

8-13-4 Report List...............................................................................................................................8-103

8-13-5 Alarm List ............................................................................................................................

Section 9 Troubleshooting

9-1 Operation for Errors and Error Confirmation Methods...................................................... 9-2

9-2 Errors Related to SECS/GEM ............................................................................................... 9-3

9-2-1 Error Table...................................................................................................................................9-3

9-2-2 Error Descriptions .......................................................................................................................9-5

Appendices

A-1 GEM Instructions...................................................................................................................A-3

A-1-1 Table of GEM Instructions ...........................................................................................................A-3

A-1-2 Common Variables in GEM Instructions .............................

A-1-3 Common Precautions for Correct Use of GEM Instructions........................................................A-4

A-1-4 Error Codes That Occur for GEM Instruction Execution .............................................................A-5

A-1-5 Global Variables Used in the Sample Programming for GEM Instructions ...

A-1-6 Specifications of Individual GEM Instructions .............................................................................A-9

A-1-7 Events That Occur for GEM Instruction Execution..................................................................A-185

A-2 System-defined Variables.................................................................................................A-209

A-2-1 Package Version .....................................................................................................................A-210

A-2-2 Equipment Information............................................................................................................A-210

A-2-3 GEM Service Status................................................................................................................A

A-2-4 SECS Communications...........................................................................................................A-211

A-2-5 Interlocks.............................................................................................................................

A-2-6 HSMS Communications..........................................................................................................A-213

A-2-7 Communications State Model .................................................................................................A-216

A-2-8 Equipment Processing State.................

A-2-9 Control State Model.................................................................................................................A-216

A-2-10 Remote Control .......................................................................................................................A-217

A-2-11 Equipment Constants...............................................

A-2-12 Process Program Management ..............................................................................................A-218

A-2-13 Equipment Terminal Services......................................

A-2-14 Error Messages .......................................................................................................................

A-2-15 Clock ...................................................................................................................................

A-2-16 Spooling ..................................................................................................................................A-225

A-2-17 User-defined Messages ..........................................................................................................A-226

A-3 Correspondence between Formats and Data Types ......................................................A-228

........................................................................................8-102

.... 8-103

........................................................A-4

..............................A-6

-210

....A-213

..................................................................................A-216

...............................................................A-218

............................................................A-222

A-224

....A-225

Index

10

A-4 Designing Tasks to Use the GEM Services.......................

A-4-1 GEM Service Startup Time......................................................................................................A-229

A-4-2 Communications Performance of GEM Instructions ...............................................................A-230

A-4-3 Checking the Task Execution Time Ratio................................................................................A-232

..............................................A-229

A-5 Basic Specifications, Performance Specifications, and Functional Specifications ...A-233

A-6 Version Information...........................................................................................................A-234

A-6-1 Unit Version and GEM Service Version...................................................................................A-234

A-6-2 Unit Versions and Sysmac Studio Versions ............................................................................A-234

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 13

CONTENTS

NJ-series SECS/GEM CPU Units User’s Manual (W528)

11

Page 14

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

12

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 15

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

13

Page 16

Safety Precautions

Safety Precautions

Refer to the following manuals for safety precautions.

• NJ-series CPU Unit Hardware User’s Man

• NJ-series CPU Unit Software User’s

ual (Cat No. W500)

Manual (Cat No. W501)

14

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 17

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NJ-series CPU Unit Hardware User’s

• NJ-series CPU Unit Software User’s Manual (Cat No. W501)

Manual (Cat No. W500)

Precautions for Safe Use

NJ-series SECS/GEM CPU Units User’s Manual (W528)

15

Page 18

Precautions for Correct Use

Precautions for Correct Use

Refer to the following manuals for safety precautions.

• NJ-series CPU Unit Hardware User’s Manual (Cat No. W500)

• NJ-series CPU Unit Software User’s Manual (Cat No. W501)

Host Connection Function

• Normal communications with the host may not be possible if incorrect settings are made for the host

connection function. Also, if you specify an incorrect host address, you may communicate with the

wrong host.

Make all settings carefully when you transfer the GEM setting data to the Controller.

• The host connection function will not operate if the variables assigned to the host connection function

do not exist in the Controller. Also, the host connection function may not operate normally if the data

types of the variables are not correct.

Confirm that the variables assigned to the host connection function agree with the variables in the

Controller before you transfer the GEM setting data to the controller.

• If you delete a variable used for the host connection function or change a variable name or data type,

make the same change in the variable assigned in the host connection function.

Testing Operation

• If you cannot connect to the host, check the value of the _GEM_HSMSState (HSMS Communications Status) system-defined variable. If the value of _GEM_HSMSState is FALSE, check the EtherNet/IP settings and cable wiring to see if they are correct.

• If you operate the system while connected to the host, use the Host Simulator to sufficiently check

functionality.

Operation

• If there are network problems during operation, the host will be disconnected and message communications will not be performed. Do not replace network devices or disconnect the LAN cable during

operation.

• If an SD Memory Card is not inserted, the GEM Service logs and spool data will not be recorded.

Also, it will not be possible to upload or download the GEM setting data between the SECS/GEM

Configurator and the CPU Unit.

Inset an SD Memory Card to use the host connection function.

• Stop the GEM Services before you replace the SD Memory Card. Do not upload or download the

GEM setting data between the SECS/GEM Configurator and the CPU Unit while you are replacing

the SD Memory Card.

• Before you turn OFF the power supply to the Controller, execute the GEM_Shutdown instruction and

save the GEM Service logs and spool data to the SD Memory Card.

If you do not execute the GEM_Shutdown instruction before you turn OFF the power supply to the

Controller, the GEM Service logs and spool data may be corrupted.

• To prevent loosing data for unexpected power interruptions, we recommend that you implement

countermeasures for power interruptions, such as installing an uninterruptible power supply.

16

Unit Replacement

• The GEM Service logs and spool data in the SD Memory Card are not backed up. If you replace the

CPU Unit, you cannot continue to use the previous GEM Service logs and spool data.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 19

Precautions for Correct Use

SD Memory Card Replacement

• If you replace the SD Memory Card, any existing GEM Service logs and spool data are deleted. If

necessary, use the Log Viewer to back up the GEM Service logs to a computer.

• Do not replace the SD Memory Card when the value of the _GEM_Spoo

system-defined variable is SPOOL ACTIVE. If you do, the sppl data will be deleted.

• We recommend that you use a new SD Memory Card when you re

replace the SD Memory Card with one that was previously used, format it to delete any old files.

lingState (Spooling State)

place the SD Memory Card. If you

NJ-series SECS/GEM CPU Units User’s Manual (W528)

17

Page 20

Regulations and Standards

Regulations and Standards

Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directive

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2

(Radiated emission: 10-m regulations).

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61131-2.

Conformance to EC Directives

The NJ-series Controllers comply with EC Directives. To ensure that the machine or device in which

the NJ-series Controller is used complies with EC Directives, the Controller must be installed as follows:

• The NJ-series Controller must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ-series Controllers that comply with EC Directives also conform to the Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EC Directives.

18

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 21

Conformance to KC Standards

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

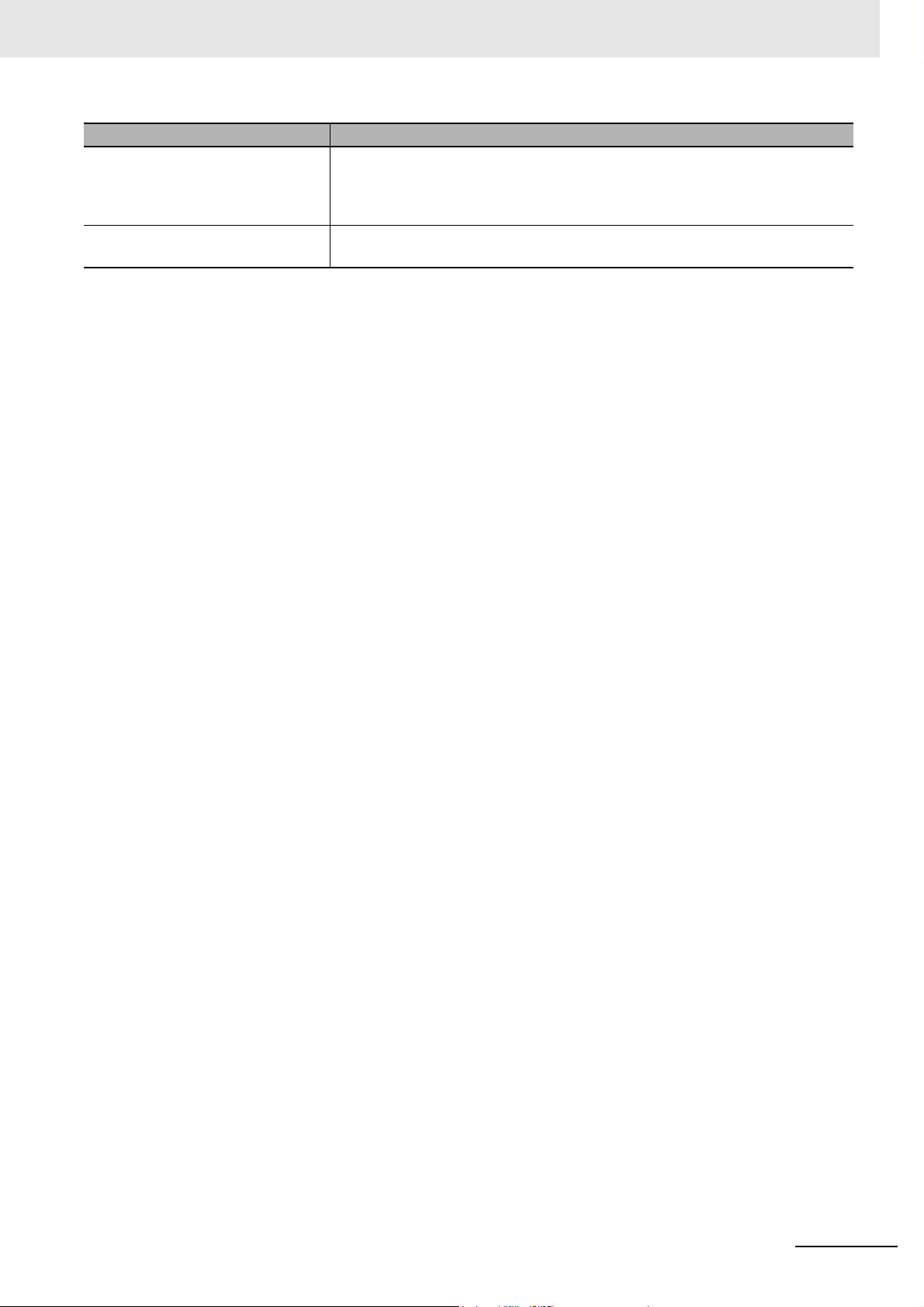

Conformance to Shipbuilding Standards

Regulations and Standards

The NJ-series Controllers comply with the following shipbuilding standards. Applicability to the shipbuilding standards is based on certain usage conditions. It may not be possible to use the product in

some locations. Contact your OMRON representative before attempting to use a Controller on a

ship.

Usage Conditions for NK and LR Shipbuilding Standards

• The NJ-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

Manufacturer Model

Cosel Co., Ltd. TAH-06-683

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

19

Page 22

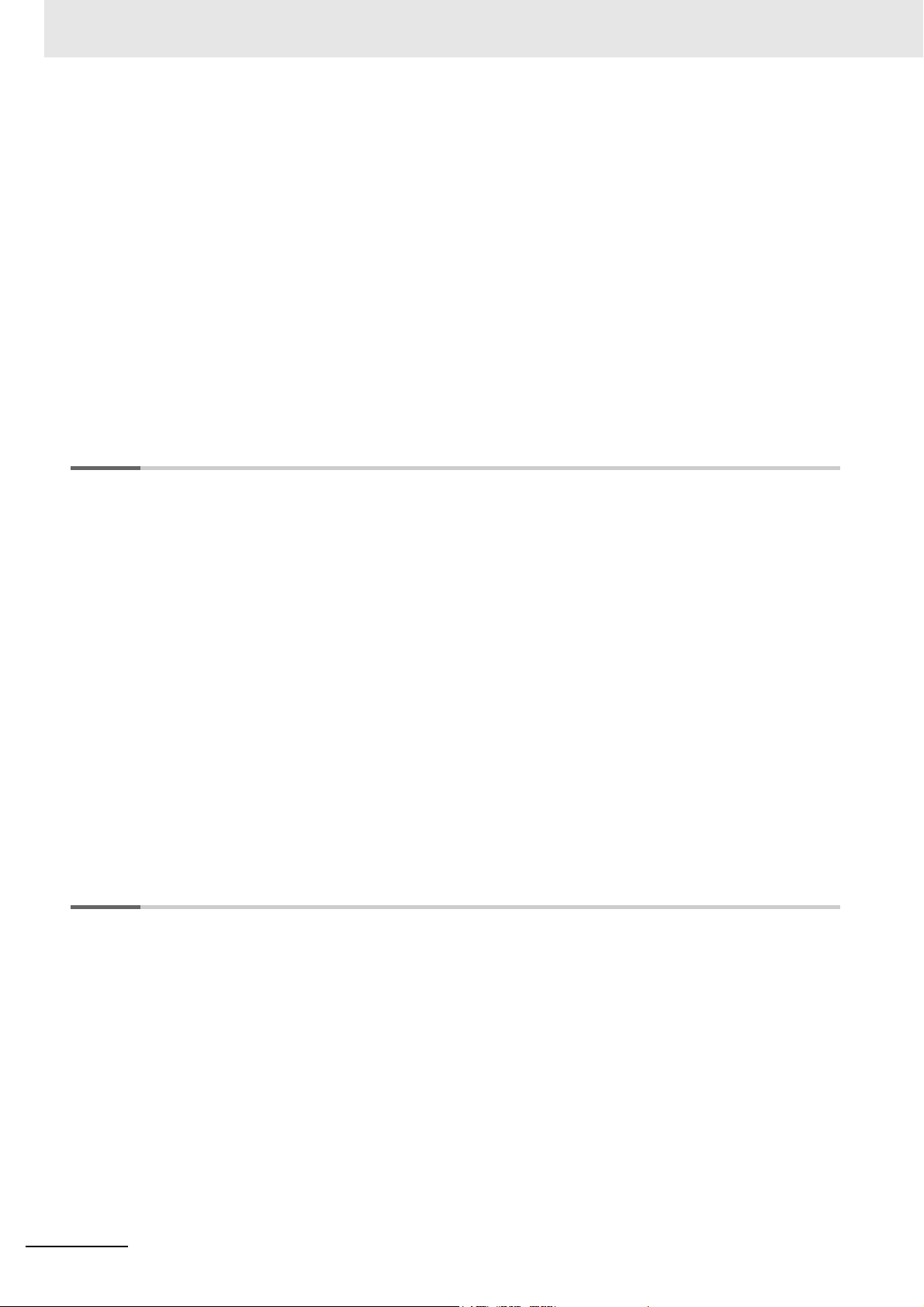

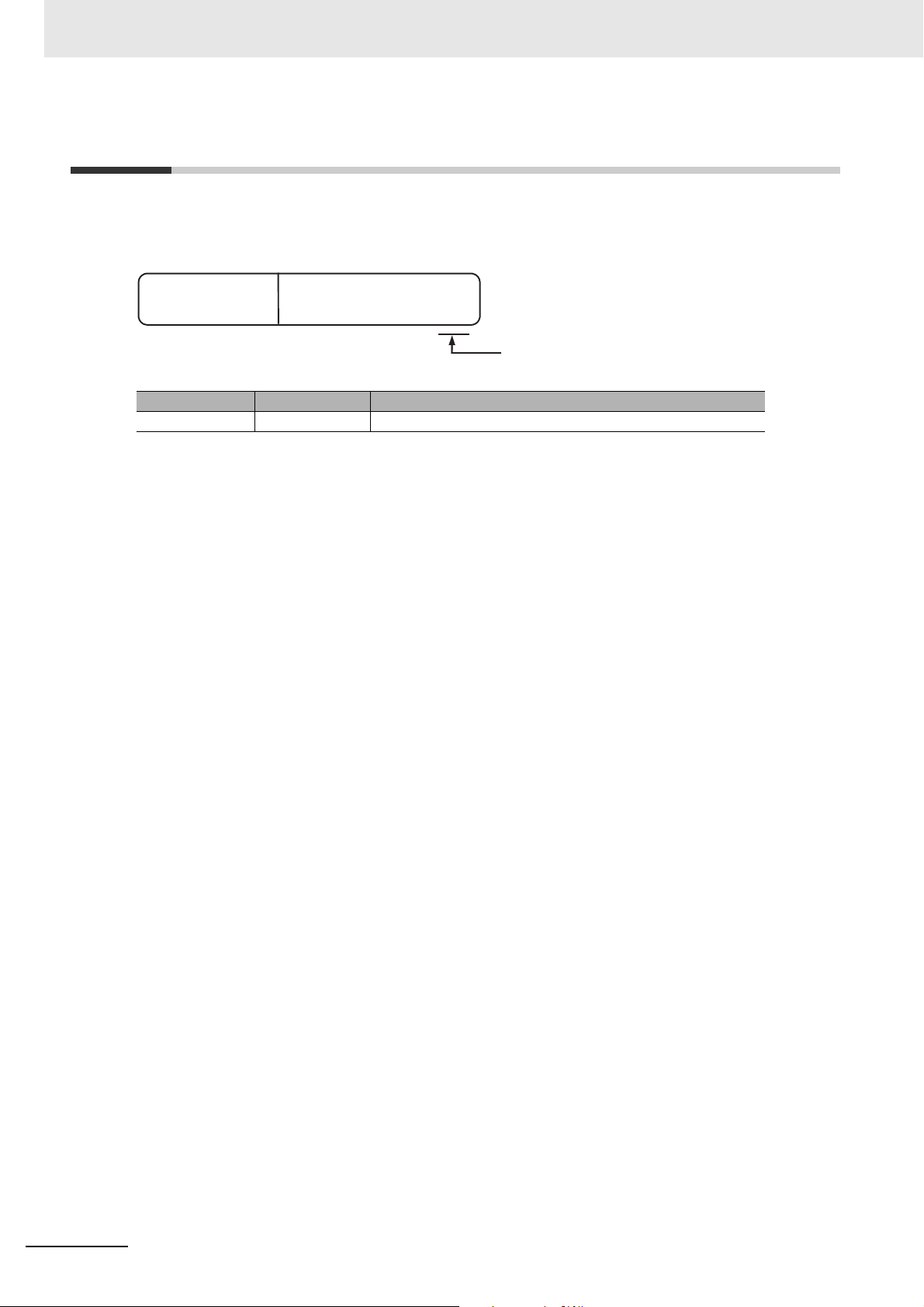

Versions

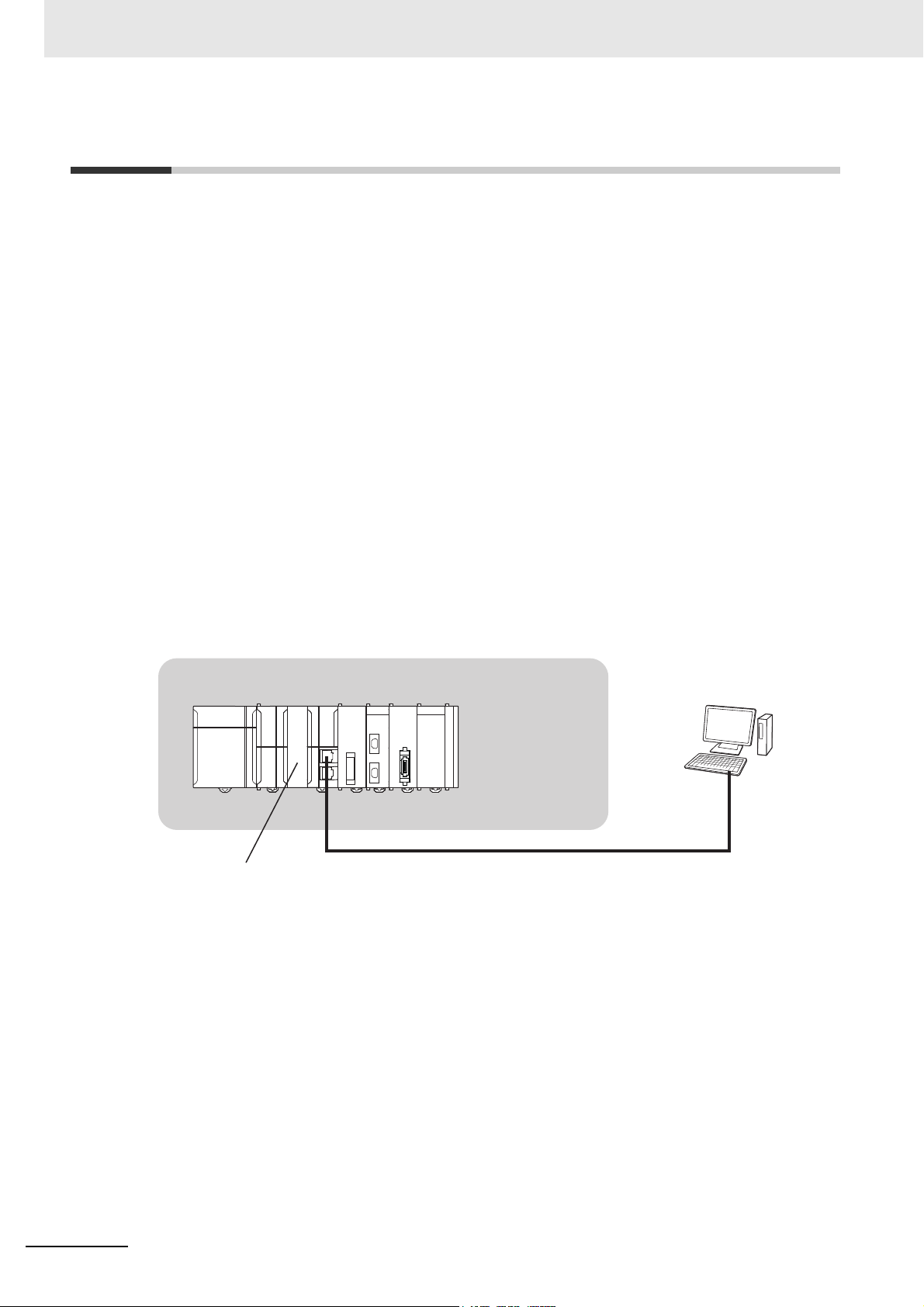

ID information label

NJ501

- 1340 Ver.1.00

PORT1 MAC ADDRESS:

GEM Ver.1.00

PORT2 MAC ADDRESS:

Lot No. 10513 A 1234

Model number

GEM Service

version

Lot number

Serial number MAC address

Unit version

Versions

Hardware and software versions are used to manage NJ-series Units. You can check versions on the

ID information labels attached to the Units or with the Sysmac Studio or a system-defined variable.

Types of Versions

There are two types of versions: the unit version and the GEM Service version. These versions are

managed separately, so either version can be updated without updating the other version.

Unit Version

The unit version applies to the hardware and software in the Unit. The unit version is updated each

time there is a change in hardware or software specifications. Even when two Units have the same

model number, they will have functional or capability differences if they have different unit versions.

GEM Service Version

The GEM Service version gives the version of the GEM Services that are implemented in the

SECS/GEM CPU Unit. The GEM Service version is updated when there are changes to the specifications for the GEM Services.

Checking Versions

You can check versions on the ID information labels or with the Sysmac Studio or a system-defined

variable.

Checking Versions on ID Information Labels

The version is given on the ID information label on the side of the product.

The ID information label on the NJ-series NJ501-1340 CPU Unit is shown below.

20

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 23

Versions

Outline View Detail View

Confirming Versions with the Sysmac Studio

You can use the Sysmac Studio to check versions.

Checking the Unit Version of a Unit

You can use the Unit Production Information while the Sysmac Studio is online to check the unit version of a Unit. You can do this for the CPU Unit, CJ-series Special I/O Units, and CJ-series CPU Bus

Units. You cannot check the unit versions of CJ-series Basic I/O Units with the Sysmac Studio.

Use the following procedure to check the unit version.

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

3 Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

The information that is displayed is different for the Outline View and Detail View. The Detail View

displays the unit version and GEM Service version. The Outline View displays only the unit version.

Unit Versions of CPU Units and Sysmac Studio Versions

The functions that are supported depend on the unit version of the NJ-series CPU Unit. The version

of Sysmac Studio that supports the functions that were added for an upgrade is also required to use

those functions.

For functions that are shared with the NJ-series CPU Units, refer to the NJ-series CPU Unit Soft-

ware User’s Manual (Cat. No. W501) for the relationship between the unit versions of the CPU Units

and the Sysmac Studio versions, and for the functions that are supported by each unit version.

Refer to A-6-2 Unit Versions and Sysmac Studio Versions for the relationship between the unit ver-

sions of the SECS/GEM CPU Unit and the Sysmac Studio versions.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

21

Page 24

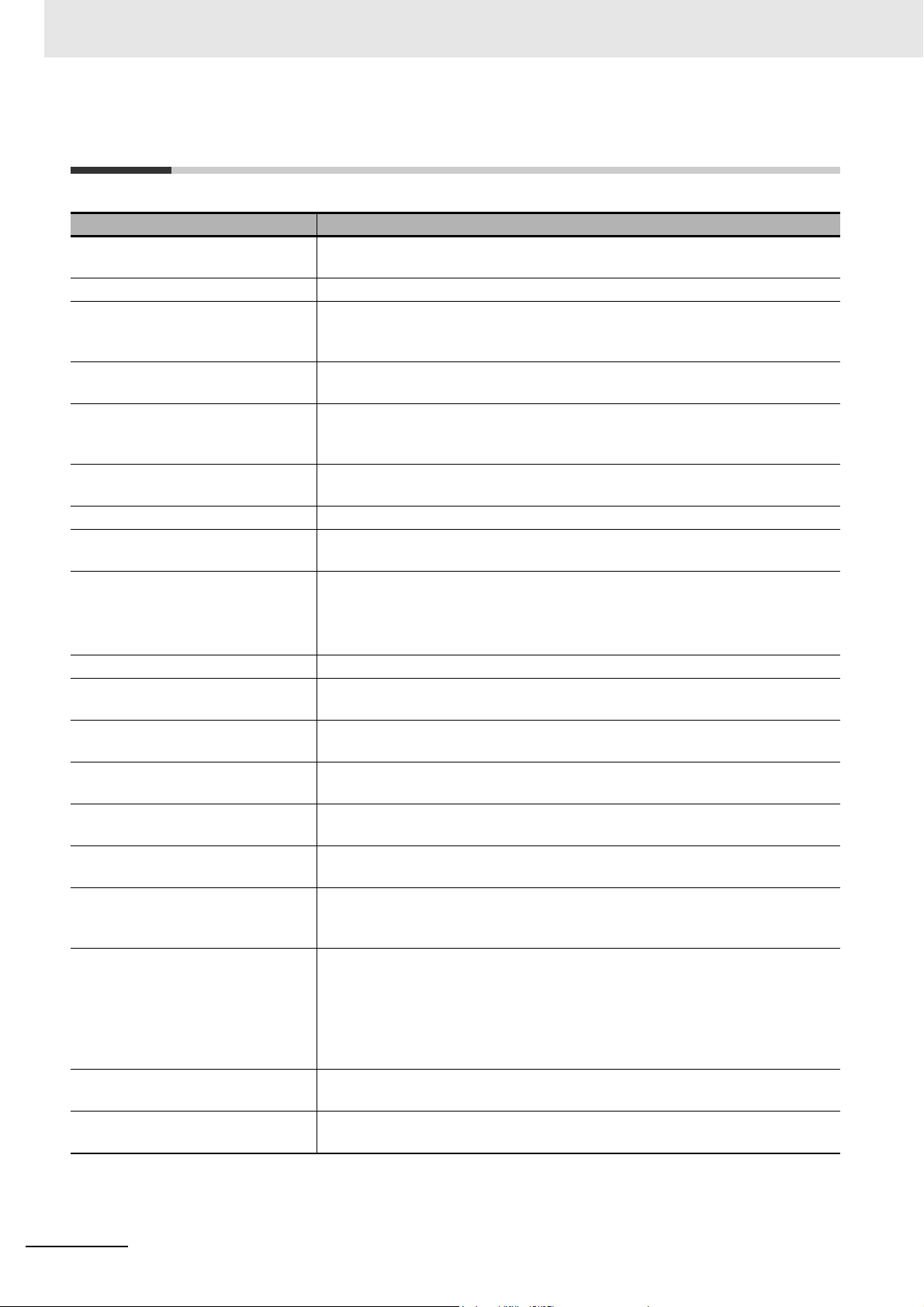

Related Manuals

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

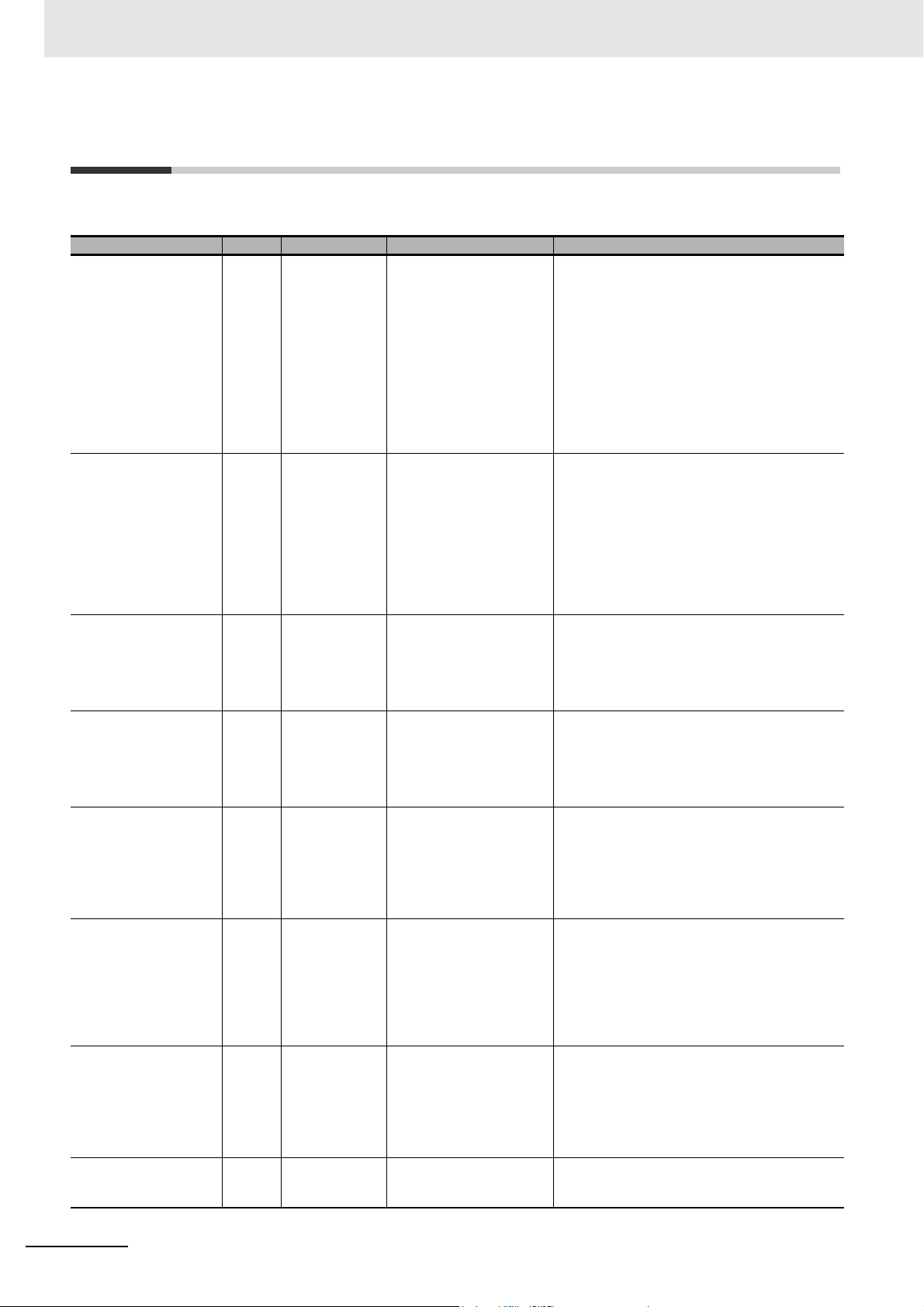

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit

Hardware User’s Manual

NJ-series CPU Unit Software User’s Manual

NJ-series Instructions

Reference Manual

NJ-series CPU Unit

Motion Control User’s

Manual

NJ-series Motion Control

Instructions Reference

Manual

NJ-series CPU Unit Builtin EtherCAT® Port

ser’

Manual

s

U

NJ-series CPU Unit Built-

in EtherNet/IP

User’s Manual

NJ-series Database Connection CPU Units User’s

Manual

TM

Port

W500 NJ501-

NJ301-

W501 NJ501-

NJ301-

W502 NJ501-

NJ301-

W507 NJ501-

NJ301-

W508 NJ501-

NJ301-

W505 NJ501-

NJ301-

W506 NJ501-

NJ301-

W527 NJ501-120 Using the database connec-

Learning the basic specifications of the NJ-series

CPU Units, including introductory information, designing, installation, and

maintenance. Mainly hardware information is provided.

Learning how to program

and set up an NJ-series

CPU Unit. Mainly software

information is provided.

Learning detailed specifications on the basic instructions of an NJ-series CPU

Unit.

Learning about motion control settings and programming concepts.

Learning about the specifications of the motion control

instructions that are provided by OMRON.

Using the built-in EtherCAT

port on an NJ-series CPU

Unit.

Using the built-in EtherNet/IP port on an NJ-series

CPU Unit.

tion service with NJ-series

Controllers

An introduction to the entire NJ-series system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the NJ-series CPU

Unit Software User’s Manual (Cat. No. W501).

The following information is provided on a Controller built with an NJ501 CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 language

specifications

Use this manual together with the NJ-series CPU

Unit Hardware User’s Manual (Cat. No. W500).

The instructions in the instruction set (IEC 61131-3

specifications) are described. When programming, use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

The settings and operation of the CPU Unit and

programming concepts for motion control are

described. Use this manual together with the NJ-

series CPU Unit Hardware User’s Manual (Cat.

No. W500) and NJ-series CPU Unit Software

User’s Manual (Cat. No. W501).

The motion control instructions are described.

When programming, use this manual together with

the NJ-series CPU Unit Hardware User’s Manual

(Cat. No. W500), NJ-series CPU Unit Software

User’s Manual (Cat. No. W501) and NJ-series

CPU Unit Motion Control User’s Manual (Cat. No.

W507).

Information on the built-in EtherCAT port is provided. This manual provides an introduction and

provides information on the configuration, features,

and setup.

Use this manual together with the NJ-series CPU

Unit Hardware User’s Manual (Cat. No. W500) and

NJ-series CPU Unit Software User’s Manual (Cat.

No. W501).

Information on the built-in EtherNet/IP port is provided. Information is provided on the basic setup,

tag data links, and other features.

Use this manual together with the NJ-series CPU

Unit Hardware User’s Manual (Cat. No. W500) and

NJ-series CPU Unit Software User’s Manual (Cat.

No. W501).

Describes the database connection service.

22

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 25

Manual name Cat. No. Model numbers Application Description

NJ-series SECS Connection CPU Units User’s

Manual

NJ-series Troubleshooting Manual

Sysmac Studio Version 1

Operation Manual

W528 NJ501-1340 Using the GEM Services

with NJ-series Controllers

W503 NJ501-

NJ301-

W504 SYSMAC-

SE2

Learning about the errors

that may be detected in an

NJ-series Controller.

Learning about the operating procedures and functions of the Sysmac Studio.

Information is provided on the GEM Services.

Concepts on managing errors that may be

detected in an NJ-series Controller and information

on individual errors are described.

Use this manual together with the NJ-series CPU

Unit Hardware User’s Manual (Cat. No. W500) and

NJ-series CPU Unit Software User’s Manual (Cat.

No. W501).

Describes the operating procedures of the Sysmac

Studio.

Related Manuals

NJ-series SECS/GEM CPU Units User’s Manual (W528)

23

Page 26

Terminology

Terminology

Term Description

controller variable A variable that is registered on the SECS/GEM Configurator and can be imported

and exported between the SECS/GEM Co

GEM An acronym for Generic Equipment Model.

GEM capability An operation that is executed by the equipment and spe

ations are executed using SECS-II message sequences and sce

communications interface.

GEM instruction An instruction that is related to the GEM Services. GEM instructions are used in the

user program in the same way as other instructions.

GEM Service logs Functionality to record the operation of the GEM Services. The following logs are

recorded: a SECS message log, an HSMS communications log, and an execution

log. All of the logs are recorded on an SD Memory Card.

GEM Services Functionality based on SECS/GEM standard for host communications, GEM capa-

bility execution, communications logging, etc.

GEM setting data Data required for the GEM Services to operate.

GEM Setting Tool A generic name for Support Software for the SECS/GEM CPU Unit. The Log

Viewer and SECS/GEM Configurator are included.

host A computer that performs communications with SECS-compliant equipment, col-

lects equipment data, and sends equipment commands.

A system consisting of ERP, MES, etc., in a semiconductor manufacturing system.

The overall system consists of the host and manufacturing equipment.

host connection function A function to connect to a host based on SECS/GEM standards.

HSMS An acronym for High-speed SECS Message Services. This communications proto-

col uses Ethernet as the physical layer and TCP/IP as the transport layer.

link variable A variable that is used to pass data between a host connection function item and

the user program.

Log Vie

primary message A SECS message with an odd-number function code. A primary message is sent at

secondary message A SECS message with an even-number function code. A secondary message is

SECS An acronym for Semiconductor Equipment Communications Standard. A communi-

SECS-II SEMI standard E5. The same as SEMI Equipment Communications Standard 2

SECS/GEM An industry standard for communications b

SECS/GEM Conf

wer A Support Software application that is used to view logs recorded in the

SECS/GEM CPU Unit on a computer screen.

the beginning of a transaction.

sent in response to a primary message.

cations standard that was created for communications between semiconductor

manufacturi

Message Content (SECS-II).

This standard defines the formats and meanings of the messages that are sent

between the host and equipment. Messages are organized functionally by streams

and assigned codes. Functions are assigned within each stream. The combination

of the stream and function identifies a message.

ment in a semiconductor manufacturing system.

igurator A Support Software application that is used to set GEM setting data and

upload/downl

ng equipment and a host.

oad data to/from a SECS/GEM CPU Unit.

nfigurator and the Sysmac Studio.

cified in the GEM. All oper-

narios through the

etween a host

and manufacturing equip-

24

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 27

Terminology

Term Description

SEMI An acronym for Semiconductor Equipment and Materials International. SEMI is an

international trade association that provides manufacturing equipment, materials,

and related services to the semiconductor, FPD, nanotechnology, MEMS, solar

power, and other industries.

stream and function

Note This manual uses terminology defined in SEMI standards. Refer to the SEMI standards for details on the

above terms and for information on terms that are not given above.

Identifiers of the contents of messages between host and equipment defined by

SECS-II.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

25

Page 28

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Cat. No.

Revision code Date Revised content

01 September 2014 Original production

W528-E1-01

Revision code

26

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 29

SECS/GEM CPU Unit Capabilities

A SECS/GEM CPU Unit is an NJ-series Standard CPU Unit that provides GEM Services. This section describes the capabilities that are provided by the GEM Services.

1-1 SECS/GEM CPU Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Standard Compliance of the SECS/GEM CPU Unit . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 SEMI Standard Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 SECS/GEM Standard Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-3 Supported SECS Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1

NJ-series SECS/GEM CPU Units User’s Manual (W528)

1 - 1

Page 30

1 SECS/GEM CPU Unit Capabilities

SECS/GEM CPU Unit

Semiconductor manufacturing equipment

SECS messages

Host

BS+

BD H

DB L

BS

-

1-1 SECS/GEM CPU Unit Features

The SYSMAC NJ-series Controllers are next-generation machine automation controllers that provide

the functionality and high-speed performance that are required for machine control.

They provide the safety, reliability, and maintainability that are required of indust

The NJ-series Controllers provide the functionality of previous OMRON PLCs, and they also provide

e functionality that is required for motion control. Synchronized control of I/O devices on high-speed

th

EtherCAT can be applied to safety devices, vision systems, motion equipment, discrete I/O, and more.

OMRON offers the new Sysmac Series of control de

vices design

fications and user interface specifications. The NJ-series Machine

ed with unified communications speci-

Automation Controllers are part of

the Sysmac Series. You can use them together with EtherCAT slaves, other Sysmac products, and the

Sysmac Studio Automation Software to achieve optimum functionality and ease of operation. With a

system that is created from Sysmac products, you can connect components and operate the system

through unified concepts and usability.

rial controllers.

In the same way as the NJ-series Standard CPU Unit

s, the SECS/GEM CPU Unit support

gramming languages defined in IEC 61131-3. It also provides GEM Se

rvices that can implement

s the pro-

streams and functions defined in the SEMI SECS/GEM standard.

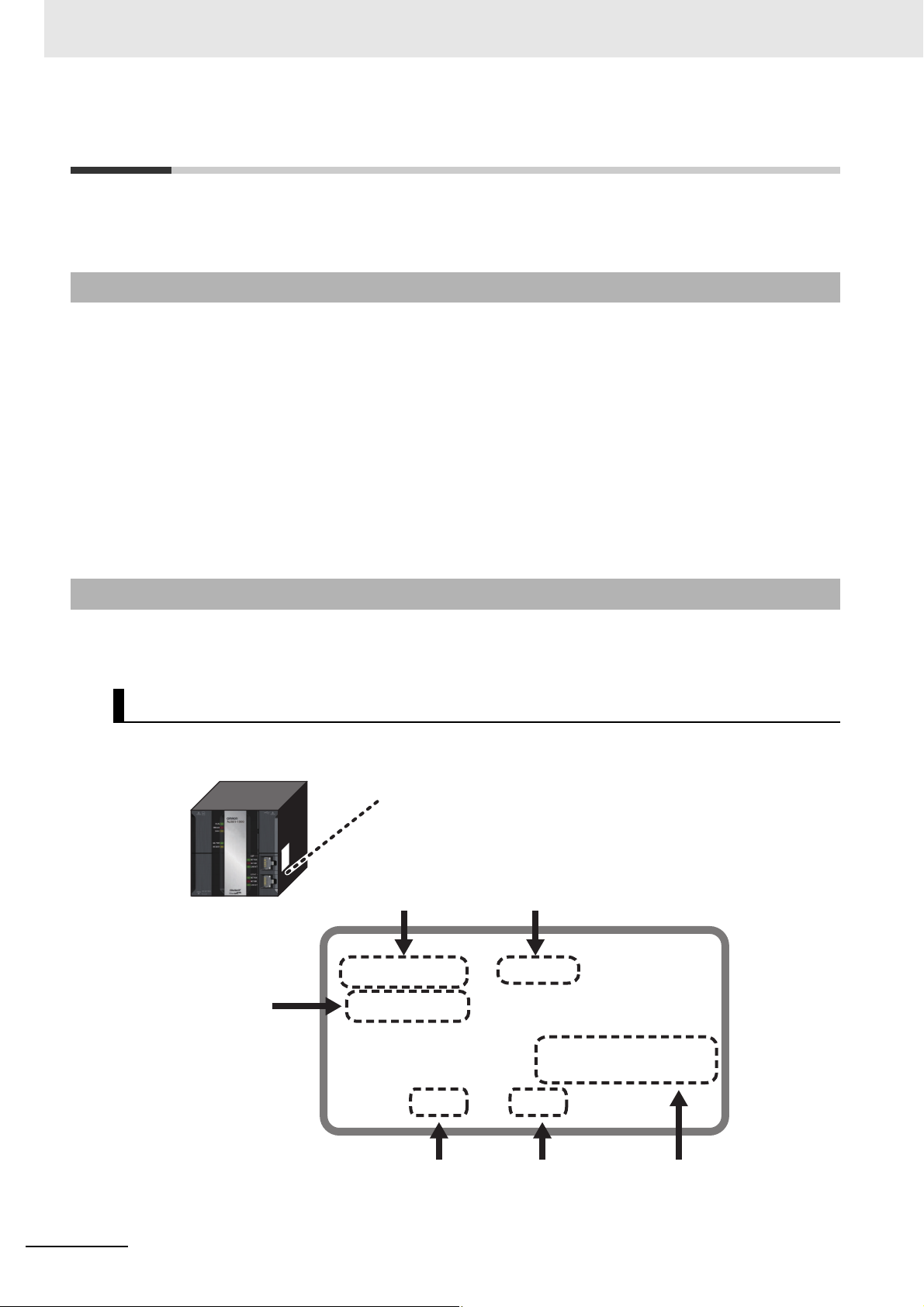

Processing Communications between Semiconductor Equipment Control

Processes and a Host

The SECS/GEM CPU Unit provides both the functionality of an NJ-series Standard CPU Unit and

functionality compliant with the SECS/GEM standard to enable processing communications

between semiconductor equipment control processes and a host with just one Controller.

1 - 2

Programming without Worrying about SECS Message Formats

A host connection function handles SECS messages between the host and equipment so you do

not have to handle it directly in the user program. The host connection function is one of the GEM

Services. It is located between the host and user program and transmits commands sent from the

host to the user program and transmits commands from the user program to the host.

Therefore, the user does not need to interpret SECS

messages sent

from the host or prepare SECS

message formats to send to the host.

For example, the following procedure is used to exe

cute a host command using the remote com-

mand GEM capability.

1 The host sends Host Command Send (S2,F41).

2 The host connection function interprets the SECS message and informs the user program that a

host command was received.

3 The user processes the host command.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

Page 31

1 SECS/GEM CPU Unit Capabilities

SECS/GEM CPU Unit

Communications

with host

User program

Instructions

Variables

Host connection function

4 When processing is completed, the user executes the Acknowledge Host Command

(GEM_AckHostCmd) GEM instruction.

5 The host connection function returns Host Command Acknowledge (S2,F42).

Commands from the user program to the host connection function ar

instructions. Information between the user program and host connection function is passed using

special variables called link variables.

e performed with special GEM

1-1 SECS/GEM CPU Unit Fea-

tures

1

User-defined Messages to Expand GEM Capabilities

In addition to the SECS messages defined in the SECS/GEM standard, the SECS/GEM CPU Unit

supports user-defined messages that are uniquely set by the user. This allows you to flexibly implement functions for unique user semiconductor

equipment.

Setting GEM Setting Data with the SECS/GEM Configurator

To use a SECS/GEM CPU Unit, you use the standard Sysmac Studio Support Software for

NJ-series Controllers, but you also use special Support Software called the SECS/GEM Configurator to make settings related to the GEM. You create the GEM setting data

figurator and then transfer it to the SECS/GEM CPU Unit.

with the SECS/GEM Con-

Work Separation for Host Communications Design and Control Sequence

Design

To execute an application with a SECS/GEM CPU Unit, you must design communications with the

host and you must design the control sequences, including I/O controls. Both of these can be performed in parallel because settings for host communications are performed on the SECS/GEM Configurator and control sequence programming is performed on the Sysmac Studio.

Complete Logging Functions

The SECS/GEM CPU Unit records three different logs on an SD Memory Card. You can check

these logs from the Log Viewer or from the user program. Checking the logs simplifies troubleshooting when unintended operation occurs when building or operating the system.

• The SECS message log records the SECS messages sent between

• The HSMS communications log records HSMS communications executed between the host and

equipment.

•

The execution log records GEM instruction execution in the user program and the writing of

shared va

riables by the host connection function.

the host and equipment.

NJ-series SECS/GEM CPU Units User’s Manual (W528)

1 - 3

Page 32

1 SECS/GEM CPU Unit Capabilities

1-2 Standard Compliance of the

SECS/GEM CPU Unit

The SECS/GEM CPU Unit complies with SEMI and SECS/GEM standards.

1-2-1 SEMI Standard Compliance

The SECS/GEM CPU Unit complies with the following SEMI standards.

Standard number Standard name

E37-0303 High-speed SECS Message Services (HSMS) Generic Services

E37.1-0

E5-0707 SEMI Equipment Communicati

E30-0307 Generic Model for Communications and Control of Manufacturing Equip-

*1. E42 recipes, large process programs, and E139 recipes are not supported.

702 High-speed SECS Message Services Single-session Mode (HSMS-SS

or HSMS-SSS)

(SECS-II)

ment (GEM)

ons Standard 2 Message

*1

Content

1-2-2 SECS/GEM Standard Compliance

The

SECS/GEM CPU Unit complies with the following SECS/GEM

GEM compliance

Fundamental GEM requirement Implemented GEM compliant

State models Yes No Ye s No

Equipment processing states Yes No

Host-initiated S1,F13/F

Event notification Yes No

On-line identifica

Error messages Ye

Control (o

Documentation Yes

Establish communications Yes No Ye s No

Dynamic event report configuration Yes No Yes No

Variab

Trace dat