Page 1

SJDE-@ANA-OY

Junma ML-II servo drive

A new concept in drive simplicity

Save space, save wiring, save time

• Ultra compact drive size reduces panel space

• Tuning-less technology, no gain parameters need to

be set

• Peak torque 300% of nominal for 3 seconds

• High response, high speed, high torque and high

accuracy

• Drive version with MECHATROLINK-II port built-in

• MECHATROLINK-II simplifies wiring and reduces

installation time

• MECHATROLINK-II provides access to the system

from one point

Ratings

• 230 VAC Single-phase 100 W to 750 W (2.39 Nm)

AC Servo systems

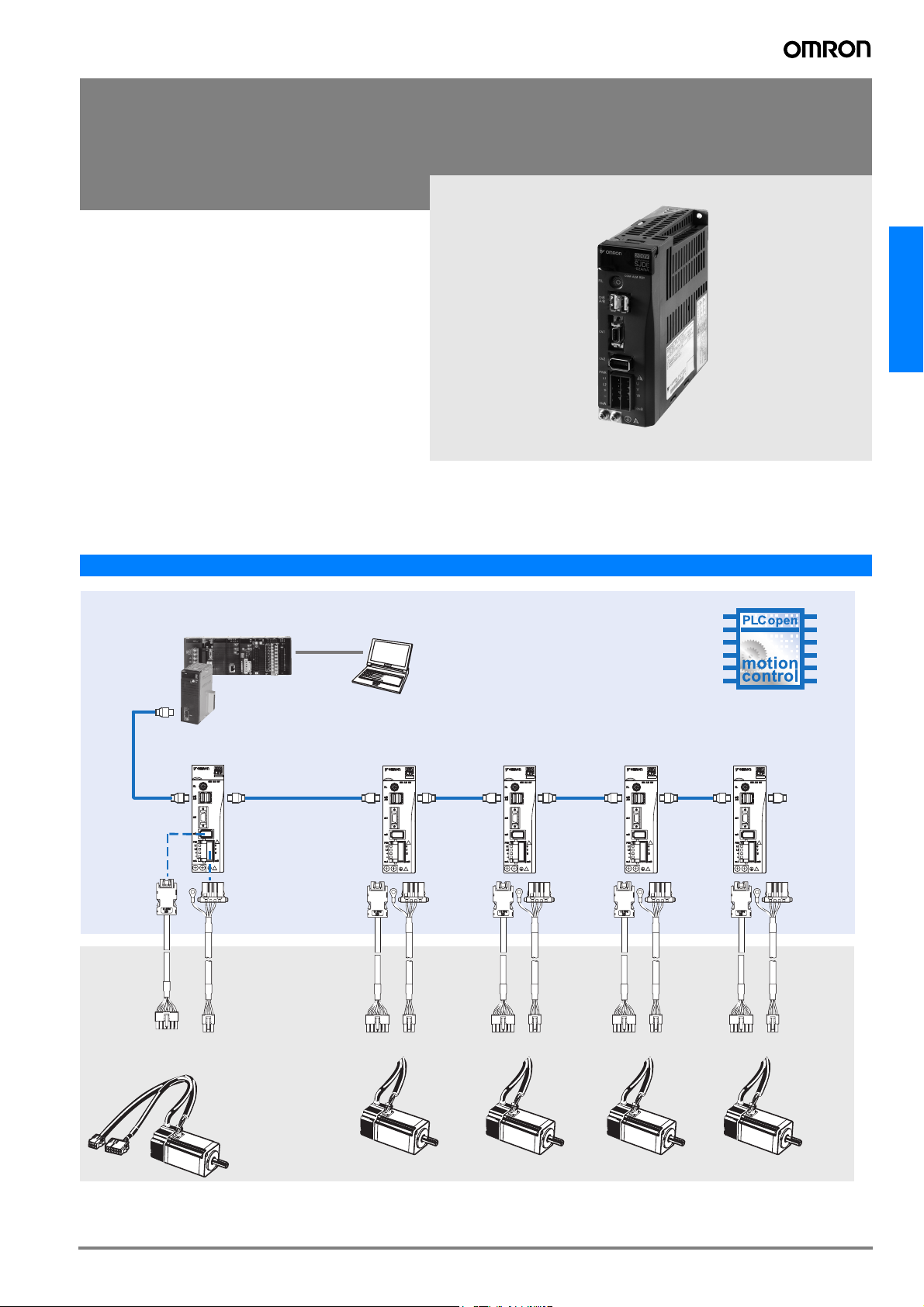

System Configuration

Junma MECHATROLINK-II Servo Drive Configuration

CJ-series PLC

CJ1 series

Position control unit

CJ1W-NCF71

Encoder

cable

Junma ML-II

Servo Drive

MECHATROLINK-II

Power

cable

Junma ML-II

Servo Drive

Personal computer

software: CX-One

Junma ML-II

Servo Drive

Junma ML-II

Servo Drive

Junma ML-II

Servo Drive

Terminator

Junma Servo Motor

3,000 rpm

(100-750 W)

165Junma ML-II servo drive

Page 2

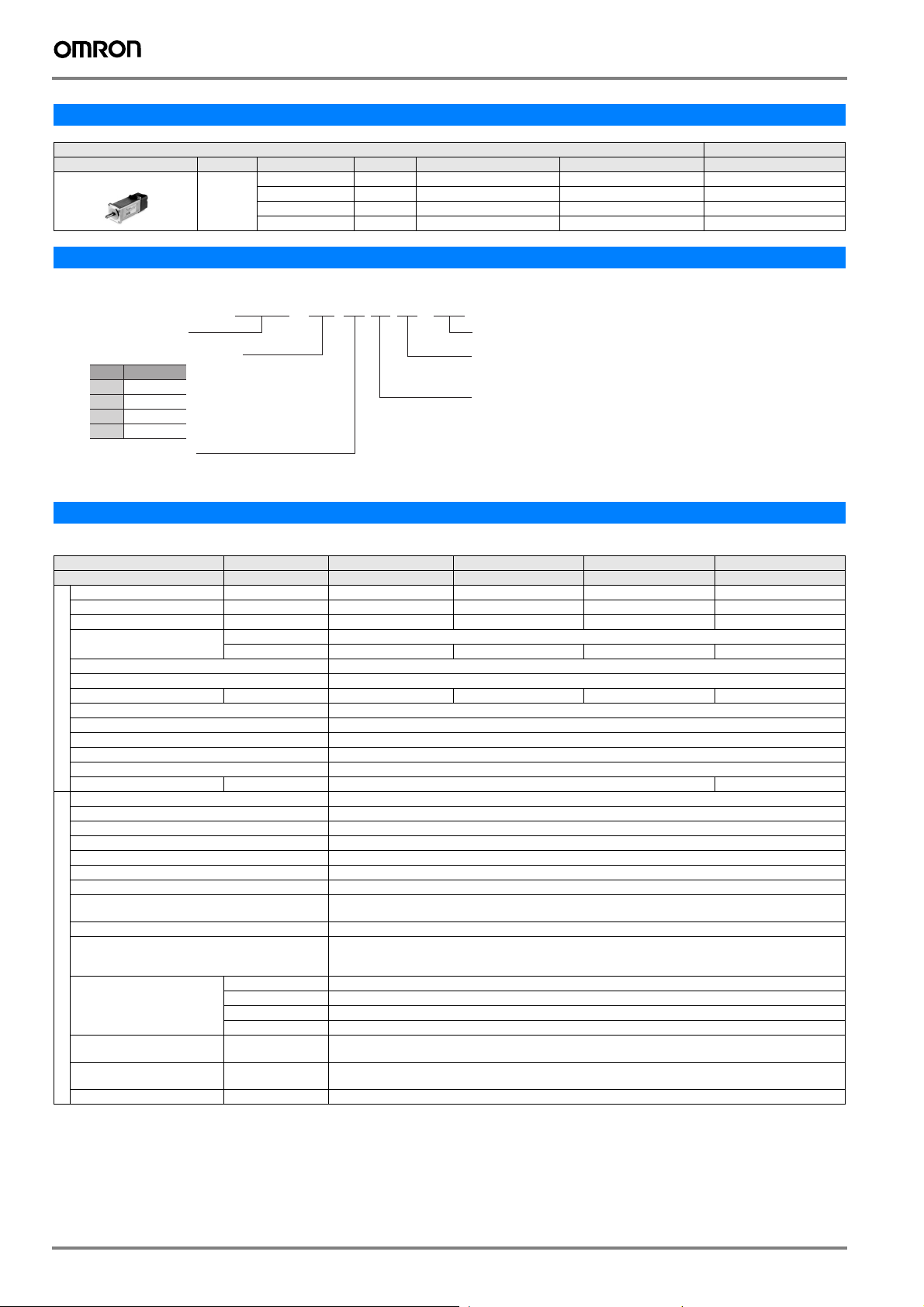

Servomotor / Servo Drive Combination

A

A

Junma Servomotor Junma servo drive

-1

SJME- (3000 min

) 200 V 0.318 Nm 100 W SJME-01AMB41-OY SJME-01AMB4C-OY SJDE-01ANA-OY

Voltage Rated Torque Capacity Model without brake Model with brake MECHATROLINK-II

0.637 Nm 200 W SJME-02AMB41-OY SJME-02AMB4C-OY SJDE-02ANA-OY

1.27 Nm 400 W SJME-04AMB41-OY SJME-04AMB4C-OY SJDE-04ANA-OY

2.39 Nm 750 W SJME-08AMB41-OY SJME-08AMB4C-OY SJDE-08ANA-OY

Servo Drive Type Designation

SJDE - 02 A N A - OY

JUNMA servo drive

pplicable servomotor capacity

Code

Output (W)

100

01

200

02

400

04

750

08

Power supply voltage

: 200 VAC

Servo Drive Specifications

Junma MECHATROLINK-II Servo Drive

Servo Drive Type SJDE- @ 01ANA-OY 02ANA-OY 04ANA-OY 08ANA-OY

Applicable servomotor SJME-@ 01A@ 02A@ 04A@ 08A@

Max. Applicable Motor capacity W 100 200 400 750

Continuous output current Arms 0.84 1.1 2.0 3.7

Max. output current Arms 2.5 3.3 6.0 11.1

Input power supply

(Main circuit and control circuit)

Control Method PWM control, sine wave current drive system

Feedback Analogue incremental encoder (13 bits incremental equivalent)

Allowable load inertia

Usage / storage temperature 0 to +55° C / -20 to 70° C

Usage / storage humidity 90%RH or less (non-condensing)

Basic specifications

Altitude 1000m or less above sea level

Vibration/shock Resistance 4.9m/s

Configuration Base mounted

Approx. mass Kg 1.0 1.4

Dynamic brake (DB) Operated at main power OFF, servo alarm, servo OFF.(OFF after motor stops; ON when motor power is off.)

Regenerative processing Optional (If the regenerated energy is too large, install a regenerative unit JUSP-RG08D)

Over-travel (OT) prevention function P_OT, N_OT

Emergency stop Emergency stop (E-STP)

LED display 4 LEDs (PWR, RDY, COM, ALM)

MECHATROLINK-II monitor MECHATROLINK-II under communication : COM LED (Light ON)

Servo ON/OFF monitor At Servo OFF : RDY LED (Light OFF), at Servo ON : RDY LED (Light Blinks)

Power supply status monitor Control / main-circuit power-supply OFF state: PWR LED (Light OFF)

Electronic gearing 0,01< A/B<100

Protection Overcurrent, overvoltage, undervoltage, overload, main circuit sensor error, board temperature error, exces-

MECHATROLINK

Built-in functions

Communication

Command input MECHATROLINK

Sequence Input signal Fixed input 5 points (fixed layout: external latch signal, zero return reduced speed signal, forward drive inhibiting signal,

Sequence Output signal Fixed output 2 points (fixed layout: servo alarm, brake interlock)

*1

Voltage Single-phase, 200 to 230 VAC, + 10 to -15% (50/60 Hz)

Capacity KVA 0.40 0.75 1.2 2.2

2

kg⋅m

Control / main-circuit power-supply ON state: PWR LED (Light ON)

sive position error overflow, overspeed, encoder signal error, overrun protection, system error, parameter er-

Comm. protocol MECHATROLINK-II

Transmission rate 10 Mbps

Transmission cycle 1ms, 1.5ms, 2ms, 3ms, 4ms

Data length 17 byte and 32 byte

communication

ror

MECHATROLINK-II commands

(For sequence, motion, data setting/reference, monitor, adjustment, and other commands)

reverse run inhibiting signal, emergency stop signal)

-4

0.6 × 10

2

(0.5G) / 19.6m/s2 (2G)

OMRON YASKAWA Motion Control BV

Design revision

A: Standard

Control Interface specification

N: MECHATROLINK-II

P: Pulse train input

-4

3.0 × 10

5.0 × 10

-4

10.0 × 10

-4

Note: *1. Value without external regeneration unit

166 AC Servo Systems

Page 3

Dimensions

Junma MECHATROLINK-II servo drives

SJDE-01, 02, 04ANA-OY (200V, 100 to 400W)

View A

5.5

150

139.5±0.5

(Mounting Pitch)

32±0.5

5

(5)

(Mounting

Pitch)

45

Detail view of installation

Cooling fan

2-M4 screw holes

Ground

Terminal

2-M4 screws

Outline

(8)

150

AIR FLOW

AIR FLOW

45

A

Model Cooling Fan

SJDE-01ANA-OY

SJDE-02ANA-OY

SJDE-04ANA-OY

CN6

CN1

CN2

CNA, CNB

Not mounted

Not mounted

Mounted

(75)

125

(6)

(4.5)

(16)

˚

AC Servo systems

(5)

19

130

Approx. mass : 1kg

Units in mm

SJDE-08ANA-OY (200V, 750W)

150

View A (Scale = 1/2)

3-M4 screw holes

5.5

150

139.5±0.5

(Mounting Pitch)

58±0.5

6

(5)

(Mounting Pitch)

Detail view of installation

(6)

70

Ground Terminal

2-M4 screws

Outline

CNA, CNB

CN6

CN1

CN2

AIR FLOW

AIR FLOW

70

A

AIR FLOW

(75)

(16)

125

(6)

(4)

˚

(5)

19

Cooling fan

180

Approx. mass : 1.4 kg

Units in mm

Junma ML-II servo drive 167

Page 4

Ordering Information

Junma MECHATROLINK-II Servo Drive Configuration

(Refer to servo motor chapter)

Junma Servo Motor

A

3,000 rpm

(100-750 W)

Junma ML-2

B

Servo Drive

Mechatrolink-II

F

cables

MECHATROLINK-II

E

Motion controller

Encoder cable

D

Power cable

C

Filter

G

H

I

Personal computer

software: CX-One

Servomotors and Servo drives

Symbol Specifications A Servomotor model B Servo drive model

AB

Voltage Encoder and Design Rated Torque Capacity

1 Phase

200 VAC

Analogue Incremental

Encoder

Straight shaft with key

Without brake 0.318 Nm 100 W SJME-01AMB41-OY SJDE-01ANA-OY

0.637 Nm 200 W SJME-02AMB41-OY SJDE-02ANA-OY

1.27 Nm 400 W SJME-04AMB41-OY SJDE-04ANA-OY

2.39 Nm 750 W SJME-08AMB41-OY SJDE-08ANA-OY

With brake 0.318 Nm 100 W SJME-01AMB4C-OY SJDE-01ANA-OY

0.637 Nm 200 W SJME-02AMB4C-OY SJDE-02ANA-OY

1.27 Nm 400 W SJME-04AMB4C-OY SJDE-04ANA-OY

2.39 Nm 750 W SJME-08AMB4C-OY SJDE-08ANA-OY

Power and encoder cables

Note: CD Refer to the Junma servo motor section for motor cables or connectors selection

MECHATROLINK-II Motion controllers

Symbol Name Model

E

Position Controller Unit for CJ1 PLC CJ1W-NCF71

Position Controller Unit for CS1 PLC CS1W-NCF71

Trajexia stand-alone motion controller, 16 axes TJ1-MC16

Trajexia stand-alone motion controller, 4 axes TJ1-MC04

MECHATROLINK-II cables

Symbol Specifications Model

MECHATROLINK-II Terminator resistor JEPMC-W6022

F

MECHATROLINK-II Cables 0.5 m JEPMC-W6003-A5

1 m JEPMC-W6003-01

3 m JEPMC-W6003-03

5 m JEPMC-W6003-05

10 m JEPMC-W6003-10

20 m JEPMC-W6003-20

30 m JEPMC-W6003-30

Cables for I/Os (for CN1)

Symbol Name Compatible units Model

G

Control

cable

Cable for servo drive I/O

signals

1 m R7A-CPZ001S

or JZSP-CHI003-01

2 m R7A-CPZ002S

or JZSP-CHI003-02

3 m JZSP-CHI003-03

Filters

Symbol Applicable servo

drive

SJDE-01ANA-OY

H

SJDE-02ANA-OY

SJDE-04ANA-OY

SJDE-08ANA-OY 9A 1.7 mA R7A-FIZN109-BE

Rated

Leakage

current

current

5A 1.7 mA 250 VAC

Rated

voltage

1- phase

Filter model

R7A-FIZN105-BE

Regenerative Unit Model (Option)

Symbol Specifications Model (Omron) Model (Yaskawa)

External regenerative unit

I

(Optional)

R88A-RG08UA JUSP-RG08D

Connectors

Specification Model (Omron) Model (Yaskawa)

Control I/O connector (for CN1) R7A-CNA01R JZSP-CHI9-1

Power input connector (for CNB).

(Included in drive the box)

R7A-CNZ01P JZSP-CHG9-1

Computer Software

Specifications Model

Configuration and monitoring software tool via ML2

(CX-Drive version 1.3 or higher)

Complete Omron software package including CX-Drive

(CX-One 2.0 or higher)

CX-DRIVE

CX-ONE

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I70E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

168 AC Servo Systems

Loading...

Loading...