Page 1

General Precauti ons

General Precautions

Observe th e following Precautions when using the SYSDRIVE Inv erters and peripheral devices.

This manual may include illustrations of the product with protecti ve covers removed in order to

describe the components of the product in detail. Make sure that these protective covers are on the

product before use.

Consult your OMRON representative when using the pro du ct af ter a long period of storage.

Definition of Precautionary Information

DANGER

WARNING

Caution

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

WARNING

WARNING

WARNING

Do not touch the inside of the Inverter. Doing so may result in electric shock or

injury.

Wiring or inspection must be performed only after turning OFF the power supply, confirming that the CHARGE indicator (or status indicator) is OFF and

after waiting for the time specified on the front cover. Not doing so may result

in electrical shock.

Do not damage, pull on, apply stress to, place heavy objects on or pinch the

cables. Doing so may result in electrical shock.

WARNING

WARNING

Caution

Do not touch the rotating parts of the motor under operation. Doing so may

result in injury.

Do not modify the product. Doing so may result in injury or damage to the

product.

Do not store, install or operate the product in the following places. Doing so

may result in electrical shock, fire or damage to the product.

Locations subject to direct sunlight.

•

Locations subject to temperatures or humidity outside the range

•

specified in the specifications.

Locations subject to condensation as the result of severe changes in

•

temperature.

Locations subject to corrosive or flammable gasses.

•

Locations very close to combustable materials.

•

Locations subject to dust (especially iron dust) or salts.

•

Locations subject to exposure to water, oil or chemicals.

•

Locations subject to shock or vibrations.

•

i

Page 2

Caution

Do not touch the Inverters cooling fins, regenerative resistor or the motor

while the power is being supplied or soon after the power is turned OFF. Doing

so may result in a skinburn due to the hot surface.

Caution

Caution

Do not conduct a dielectric stregth test on any part of the Inverter. Doing so

may result in damage to the product or malfunction.

Take appropriate and sufficient countermeasures when installing systems in

the following locations. Not doing so may result in equipment damage.

•

Locations subject to static electricity or other forms of noise.

•

Locations subject to strong electromagnetic fields and magnetic

fields.

•

Locations subject to possible exposure to radio activity.

•

Locations close to power supplies.

ii

Page 3

Transportation Precautions

Transportation Precautions

Caution

Caution

Caution

Do not hold by front cover or panel. Instead hold by the cooling fins (heat

sink) while transporting the product. Doing so may result in injury.

Do not pull on the cables. Doing so may result in damge to the product or malfunction.

Use the eyebolts only for transport of the Inverter. Using them to transport the

Inverter and attached equipment may result in injury or malfunction.

Installation Precautions

Provide an appropriate stopping device on the machine side to secure safety. (

WARNING

WARNING

Caution

A holding brake is not a stopping device for securing safety) Not doing so may

result in injury.

Provide an external emergency stopping device that allows an instantaneous

stop of operation and power interruption. Not doing so may result in injury.

Be sure to install the product in the correct direction and provide specified

clearances between the Inverter and control panel or with other devices to

allow for proper cooling. Not doing so may result in fire or malfunction.

Caution

Caution

Do not allow foreign objects to enter inside the product. Doing so may result in

fire and malfunction.

Do not apply any strong imact. Doing so may result in damage to the product

or malfunction.

Wiring Precautions

WARNING

WARNING

WARNING

Required

Wiring must be performed only after turning OFF the power supply. Not

doing so may result in electrical shock.

Wirin g must be pe rform ed by auth orized pe rsonne l. Not do ing so may re sult in

electrical shock.

Be sur to confirm operation only after wiring the emergency stop circuit. Not

doing so may result in injury.

Always connect the ground terminals to a ground of 100 Ohm or less for 200V AC class or 10 Ohm or less for the 400-V class. Not connecting to a proper

ground may result in electrical shock or fire.

iii

Page 4

Caution

Caution

Install external circuit breakers and take other safety measures against shortcircuiting in external wiring. Not doing so may result in fire.

Confirm that the rated input voltage of the Inverter is the same as the AC

power supply voltage. An incorrect power supply may result in fire, injury or

malfunction.

Caution

Caution

Caution

Caution

Caution

Connect the Braking Resistor or Braking Resistor Unit as specified in th e manual. Not doing so may result in fire.

Be sure to wire correctly and securely. Not doing so may result in injury or

damage to the product .

Be sure to firmly tighten the screws on the terminal block. Not doing so may

result in fire, injury or damage to the product.

Do not conne c t a n A C pow e r s our c e to the U,V,W output. Doi n g so may result

in damage to the product or malfunction.

Do not connect a load to the machine during auto-tuning. Not doing so may

result in equipment damage.

iv

Page 5

Operation and Adjustment Precautions

Operation and Adjustment Precautions

Turn ON the input power supply only after mounting the front cover, terminal

WARNING

WARNING

covers, bottom cover, Operator and optional items. Not doing so may result in

electrical shock.

Do not remove the front cover, terminal covers, bottom cover, Operator or

optional items while the power is being supplied. Doing so may result in electrical shock or damage to the product

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Caution

Caution

Do not operate the Operator or switches with wet hands. Doing so may result

in electrical shock.

Do not touch the Inverter terminals while the power is being supplied. Doing

so may result in electrical shock.

Do not come close to the machine when using the error retry function because

the machine may abrupt ly star t when stopped by an al arm. Doin g so m ay result

in injury.

Do not come close to the machine immediately after resetting momentary

power interruption to avoid an unexpected restart (if operation is set to be continued in the processing selection function after momentary power is reset).

Doing so may result in injury.

Provide a separate em ergency stop switc h b eca u se the ST O P K ey on t h e Ope r ator is valid only when function settings are performed. Not doing so may

result in injury.

Be sure to confirm that the RUN signal is turned OFF before tuning ON the

power supply, resetting the alarm or switching the LOCAL/REMOTE selector.

Doing so while the RUN signal is turned ON my result in injury.

Be sure to confirm permissible ranges of motors and machines before operation because the Inverter speed can be easily changed from low to high. Not

doing so may result in damage to the product.

Provide a separate holding brake when neccessary. Not doing so may result in

injury.

Caution

Caution

Do not perform a signal check during operation. Doing so may result in injury

or damage to the product.

Do not carelessly change settings. Doing so may result in injury or damage to

the product.

v

Page 6

Maintenance and Inspection Precautions

WARNING

WARNING

WARNING

Prohibited

Caution

Caution

Do not touch the Inverter terminals while the power is being supplied. Doing

so may result in electrical shock.

Maintenance or inspection must be performed only after turning OFF the

power supply, confirming that the CHARGE indicator (or status indicator) is

OFF and after waiting for the time specified on the front cover. Not doing so

may result in electrical shock.

Maintenance, inspection or parts replacement must be performed by authorized personnel. Not doing so may result in electrical shock or injury.

Do not attempt to disassemble or repair the product. Doing so may result in

electrical shock or injury.

Carefully handle the Inverter because it uses semiconductor elements. Careless

handling may result in malfunction.

Do not exchange, wiring, the Operator, optional cover, disconnect connectors

or replace fans while power is being supplied. Doing so may result in injury,

damage to the product or malfunction.

vi

Page 7

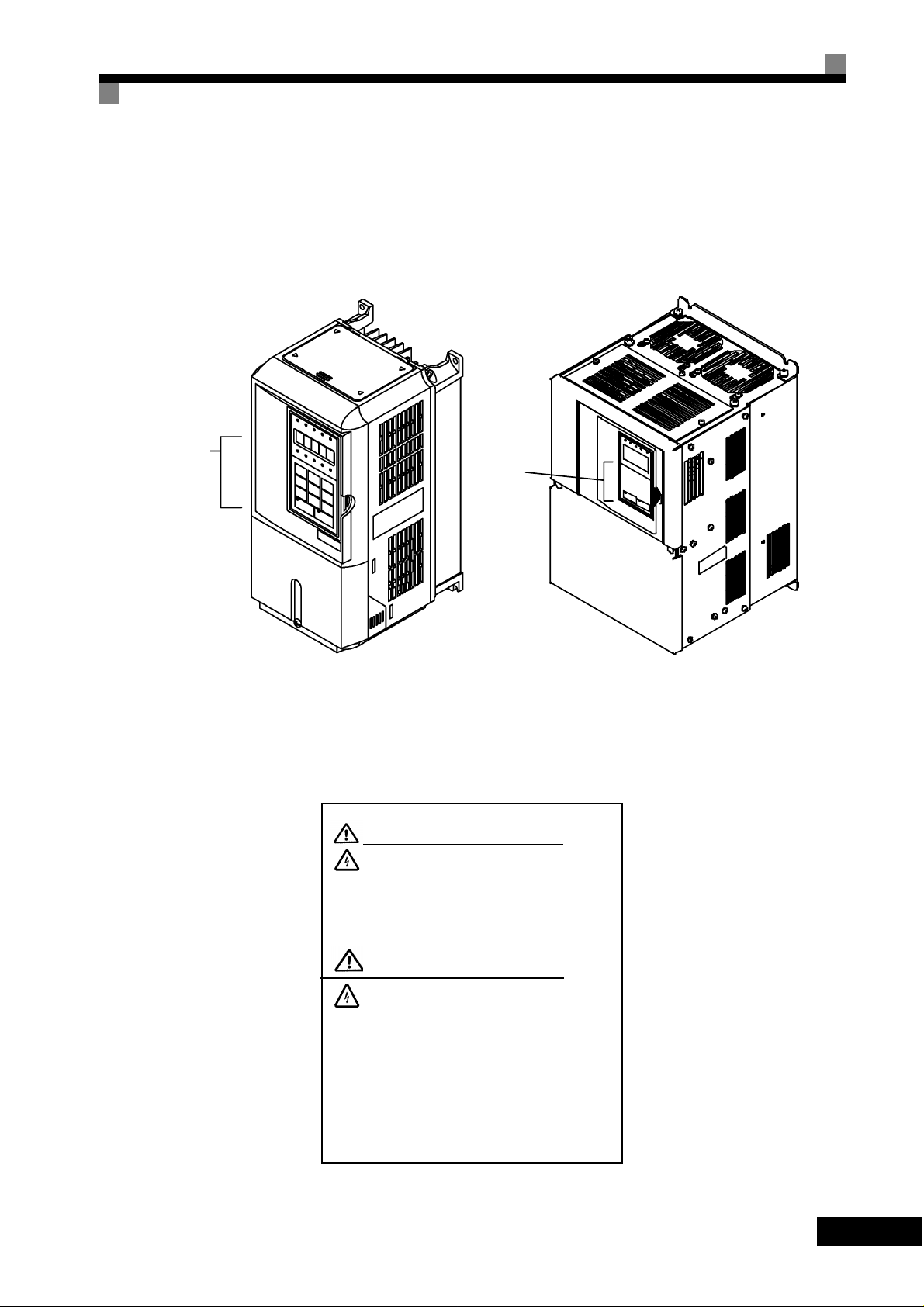

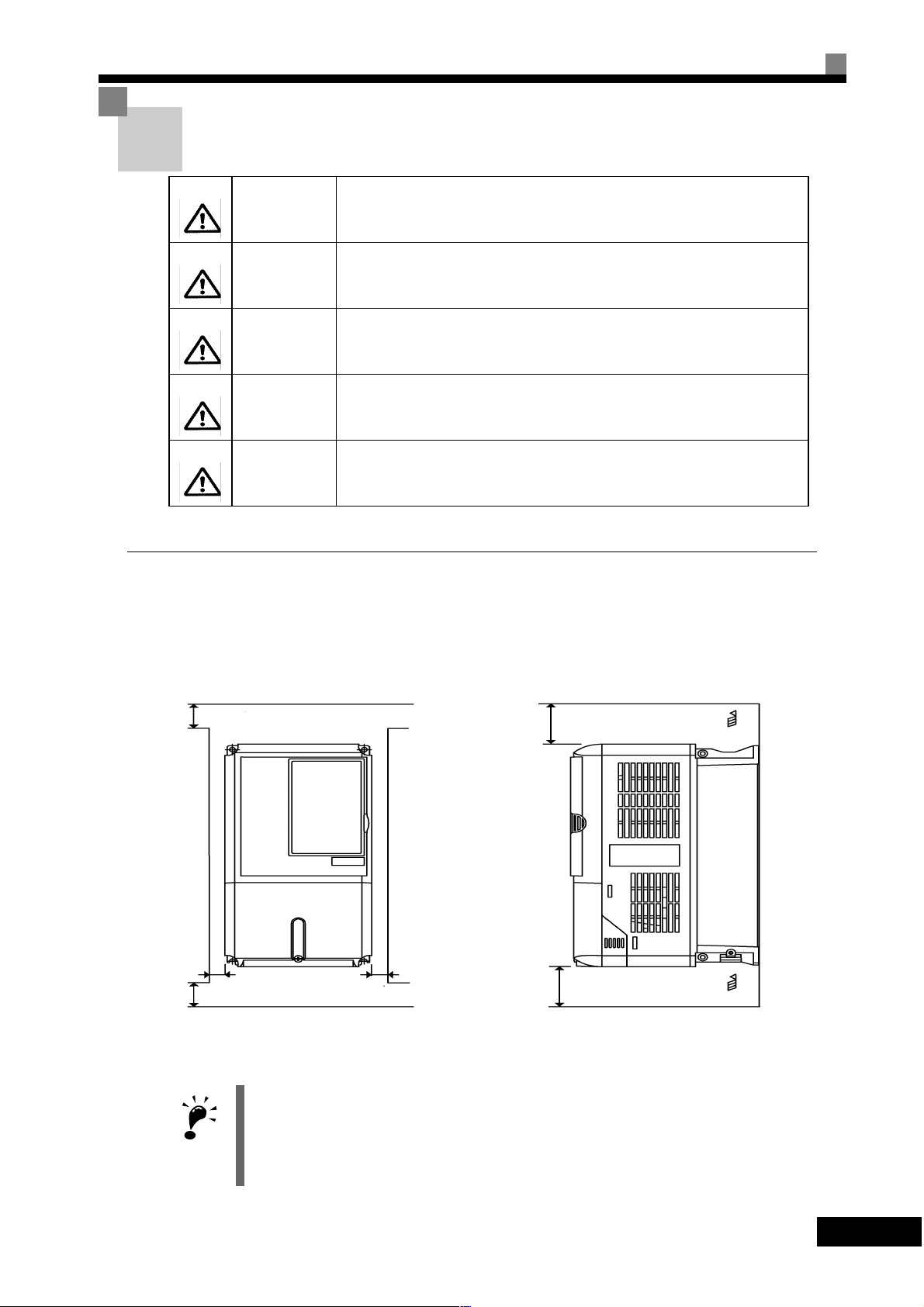

Warning Information and Position

Warning Information and Position

There is warning information on the Inverter in the positon shown in the following illustration.

Aways read the warnings.

Warning

information

position

Warning

information

position

Illustration shows the 3G3PV-A2004-E

Warning information

Illustration shows the 3G3PV-B2220-E

WARNING

Risk of electric shock.

• Read manual before installing.

• Wait 5 minutes for capacitor discharge

after disconnecting powe r supply.

AVERTISSEMENT

Risque de décharge électrique.

• Lire le manual avant l’installation.

• Attendre 5 minutes aprés la coupure de

l’allmentation. Pour permettre la décharge

des condensateurs.

vii

Page 8

Registered Trademarks

The following registered trademarks are used in this manual.

DeviceNet is a registered trademark o f the ODVA (Open DeviceNet Vendors Association,

•

Inc.).

MODBUS is a trademark of the AEG Schneider Automation, Inc.

•

viii

Page 9

Contents

1 Handling Inverters......................... ............................ ............. 1-1

SYSDRIVE PV Introduction..........................................................................1-2

SYSDRIVE PV Applications ...........................................................................................1-2

SYSDRIVE PV Models...................................................................................................1-2

Confirmations upon Delivery ........................................................................1-4

Checks............................................................................................................................1-4

Nameplate Information............................. .... ............................ ..... ........................... ..... .1-4

Component Names.........................................................................................................1-6

Exterior and Mounting Dimensions...............................................................1-8

Open Chassis Inverters (IP00)................................... ............................ .... ....................1-8

Enclosed Wall-mounted Inverters (NEMA 1)..................................................................1-8

Checking and Controlling the Installation Site............................................1-10

Installation Site.............................................................................................................1-10

Controlling the Ambient Temperature...........................................................................1-10

Protecting the Inverter from Foreign Matter..................................................................1-10

Installation Orientation and Space..............................................................1-11

Inverter Installation Orientation and Space...................................................................1-11

Removing and Attaching the Terminal Cover .............................................1-12

Removing the Terminal Cover ......................................................................................1-12

Attaching the Terminal Cover........................................................................................1-12

Removing/Attaching the Digital Operator and Front Cover........................1-13

Inverters of 18.5 kW or Less.........................................................................................1-13

Inverters of 22 kW or More...........................................................................................1-16

2 Wiring....................................................................................... 2-1

Wiring ...........................................................................................................2-2

Connections to Peripheral Devices ..............................................................2-3

Connection Diagrams...................................................................................2-4

Circuit descriptions.........................................................................................................2-5

Terminal Block Configuration........................................................................2-6

Wiring Main Circuit T erminals.......................................................................2-7

Applicable Wire Sizes and Closed-loop Connectors......................................................2-7

Main Circuit Terminal functions ....................................................................................2-12

Main Circuit configurations ...........................................................................................2-13

Standard Connection Diagrams....................................................................................2-14

Wiring the Main Circuits................................................................................................2-15

ix

Page 10

Wiring Control Circuit Terminals.................................................................2-22

Wire Sizes ....................................... ..... .... ............................ .... ..... ............................ ..2-22

Control Circuit Terminal Functions...............................................................................2-24

Control Circuit Terminal Connections...........................................................................2-27

Control Circuit Wiring Precautions ...............................................................................2-28

Wiring Check..............................................................................................2-29

Checks .........................................................................................................................2-29

Installing and Wiring Option Cards.............................................................2-30

Option Card Models and Specifications.......................................................................2-30

Installation....................................................................................................................2-30

3 Digital Operator and Modes....................................................3-1

Digital Operator............................................................................................3-2

Digital Operator Keys.....................................................................................................3-3

Modes ..........................................................................................................3-5

Inverter Modes .......................................... ..... ........................... ..... ..... ...........................3-5

Switching Modes............................................................................................................3-6

Drive Mode.....................................................................................................................3-7

Quick Programming Mode..............................................................................................3-8

Advanced Programming Mode.......................................................................................3-9

Verify Mode.................................................................................................................. 3-11

Autotuning Mode......................... ..... ..... ........................... ..... ........................... ..... .......3-12

4 Trial Operation.........................................................................4-1

Cautions and Warnings................................................................................4-2

Trial Operation Flowchart.............................................................................4-3

Trial Operation Procedures ..........................................................................4-4

Application Confirmation................................................................................................4-4

Setting the Power Supply Voltage Jumper (400-V Class Inverters of 75 kW or Higher) 4-4

Power ON.......................................................................................................................4-4

Checking the Display Status ..........................................................................................4-5

Basic Settings.................................................................................................................4-6

Selecting the V/f pattern.................................................................................................4-7

Application Settings......................................................................................................4-10

No-load Operation..................................... ............................ .... ............................ ..... ..4-10

Loaded Operation......................................................................................................... 4-11

Adjustment Suggestions ............................................................................4-13

5 Parameters...............................................................................5-1

Parameter Descriptions................................................................................5-2

Description of Parameter Tables ....................................................................................5-2

Digital Operator Display Functions and Levels ............................................5-3

x

Page 11

Parameters Settable in Quick Programming Mode........................................................5-4

Parameter Tables .........................................................................................5-7

A: Setup Settings............................................................................................................5-7

Application Parameters: b........... ..... .... ............................ .... ............................ ..... .... ......5-8

Tuning Parameters: C...................................................................................................5-13

Reference Parameters: d..............................................................................................5-16

Motor Constant Parameters: E.....................................................................................5-18

Option Parameters: F...................................................................................................5-19

Terminal Function Parameters: H.................................................................................5-20

Protection Function Parameters: L...............................................................................5-26

N: Special Adjustments.................................................................................................5-32

Digital Operator Parameters: o.....................................................................................5-33

T: Motor Autotuning......................................................................................................5-36

U: Monitor Parameters.................................................................................................. 5-37

Factory Settings that Change with the Inverter Capacity (o2-04).................................5-44

6 Parameter Settings by Function............................................ 6-1

Application and Overload Selections............................................................6-2

Select the Overload to Suit the Application....................................................................6-2

Frequency Reference...................................................................................6-4

Selecting the Frequency Reference Source...................................................................6-4

Using Multi-Step Speed Operation......................................................... .... ....................6-6

Run Command .............................................................................................6-8

Selecting the Run Command Source ............................................................................. 6 -8

Stopping Methods..... ................................. ..... ...... ................................ ......6-10

Selecting the Stopping Method when a Stop command is Input..................................6-10

Using the DC Injection Brake........................................................................................6-13

Using Highslip Braking........... ..... ............................ .... ............................ .... ..................6-14

Using an Emergency Stop............................................................................................6-16

Acceleration and Deceleration Characteristics...........................................6-17

Setting Acceleration and Deceleration Times...............................................................6-17

Preventing the Motor from Stalling During Acceleration

(Stall Prevention During Acceleration Function)...........................................................6-19

Preventing Overvoltage During Decelera tion

(Stall Prevention During Deceleration Function)...........................................................6-21

Adjusting Frequency References ...............................................................6-22

Adjusting Analog Frequen cy Refer en ces........................ .... ..... ............................ ........6-22

Operation Avoiding Resonance (Jump Frequency Function).......................................6-24

Speed Limit (Frequency Reference Limit Function)...................................6-26

Limiting Maximum Output Frequency...........................................................................6-26

Limiting Minimum Frequency........................................................................................6-26

Improved Operating Efficiency ...................................................................6-27

Field-weakening option........................ ............................ .... ............................ ..... ........6-28

Hunting-prevention Function.........................................................................................6-29

xi

Page 12

Machine Protection ....................................................................................6-30

Preventing Motor Stalling During Operation.................................................................6-30

Detecting Motor Torque................................................................................................6-30

Motor Overload Protection ...........................................................................................6-33

Motor Overheating Protectio n Using PT C Therm is tor Input s.......................................6-35

Continuing Operation .................................................................................6-37

Restarting Automatically After Power Is Restored .................... ..... ............................ ..6-37

Speed Search...............................................................................................................6-38

Continuing Operation at Con sta nt Sp ee d When Fre qu en cy Reference Is Lost...........6-43

Restarting Operation After Transient Fault (Auto Restart Function) ............................6-43

Inverter Protection......................................................................................6-45

Reducing Inverter Overheating Pre-Alarm Warning Levels .........................................6-45

Input Terminal Functions............................................................................6-46

Temporarily Switching Operation between Digital Operator

and Control Circuit Terminals.......................................................................................6-46

Blocking Inverter Outputs (Baseblock Commands)......................................................6-46

Hold Analog Frequency Using User-set Timing...........................................................6-47

Switching Operations between a Communications Option Card

and Control Circuit Terminals.......................................................................................6-48

Jog Frequency Operation wit hout Forward and Reverse Commands

(FJOG/RJOG) ..............................................................................................................6-48

Stopping the Inverter by Notifying Programming Device Errors to the Inverter

(External Error Function)..............................................................................................6-49

Monitor Parameters....................................................................................6-50

Using the Analog Monitor Parameters .........................................................................6-50

Individual Functions ...................................................................................6-52

Using PI Control...........................................................................................................6-65

Energy-saving..............................................................................................................6-72

Setting Motor Constant Parameters.............................................................................6-73

Setting the V/f Pattern..................................................................................................6-74

Digital Operator Functions .........................................................................6-80

Setting Digital Operator Functions ...............................................................................6-80

Copying Parameters.....................................................................................................6-82

Prohibiting Writing Parameters from the Digital Operator............................................6-86

Setting a Password ......................................................................................................6-86

7 Troubleshooting......................................................................7-1

Protective and Diagnostic Functions............................................................7-2

Fault Detection........................ .... ..... ............................ .... ............................ .... ..... .........7-2

Alarm Detection..............................................................................................................7-7

Operation Errors.............................................................................................................7-9

Errors During Autotuning.............................................................................................7-10

Errors when Using the Digital Operator Copy Function ...............................................7-11

xii

Troubleshooting..........................................................................................7-12

Page 13

If Parameters Cannot Be Set........................................................................................7-12

If the Motor Does Not Operate......................................................................................7-13

If the Direction of the Motor Rotation is Reversed........................................................7-14

If the Motor Does Not Put Out Torque or If Acceleration Is Slow..................................7-15

If the Motor Operates Higher Than the Reference .......................................................7-15

If Motor Deceleration Is Slow........................................................................................7-15

If the Motor Overheats..................................................................................................7-16

If peripheral devices are influenced by starting the Inverter......................................... 7-16

If the Ground Fault Interrupter Operates When the Inverter Is Run.............................7-17

If There Is Mechanical Oscillation.................................................................................7-17

If the Motor Rotates Even When Inverter Output Is Stopped.......................................7-17

If 0 V Is Detected When the Fan Is Started, or the Fan Stalls......................................7-18

If Output Frequency Does Not Rise to Frequency Reference......................................7-18

8 Maintenance and Inspection.................................................. 8-1

Maintenance and Inspection.........................................................................8-2

Daily Inspection..............................................................................................................8-2

Periodic Inspection................................... .... ..... ............................ .... ............................ .8-2

Periodic Maintenance of Parts........................................................................................8-3

Cooling Fan Replacement Outline..................................................................................8-4

Removing and Mounting the Control Circuit Terminal Card...........................................8-6

9 Specifications ......................................................................... 9-1

Standard Inverter Specifications...................................................................9-2

Specifications by Model............................ ........................... ..... ............................ .... ..... .9-2

Common Specifications..................................................................................................9-5

Specifications of Options and Peripheral Devices........................................9-6

Options and Peripheral Devices...................................................................9-7

Special Mounted Options................................................................................................9-9

Separately Installed Options.........................................................................................9-10

10 Inverter application Precautionspendix ............................. 10-1

Selection.......................................................................................................................10-2

Installation.....................................................................................................................10-3

Settings.........................................................................................................................10-3

Handling........................................................................................................................10-4

Motor Application Precautions......................................................... ..... ......10-5

Using the Inverter for an Existing Standard Motor........................................................10-5

Using the Inverter for Special Motors...........................................................................10-6

Power Transmission Mechanism (Speed Reducers, Belts, and Chains)......................10-6

Wiring Examples.........................................................................................10-7

Using a Braking Resistor Unit.......................................................................................10-7

Using a Braking Unit and Braking Resistor Unit...........................................................10-7

Using a Braking Unit and Three Braking Resistor Units in Parallel..............................10-9

xiii

Page 14

Using an Analog Operator..........................................................................................10-10

Parameters............................................................................................... 10-11

Revision History ................. ................................. ...... ..... ..........................10-14

xiv

Page 15

1

Chapter 1

Handling Inverters

This chapter describes the checks required upon receiving or installing an Inverter.

SYSDRIVE PV Introduction..................................................1-2

Confirmations upon Delivery.................................................1-4

Exterior and Mounting Dimensions.......................................1-8

Checking and Controlling the Instal lat io n Site....................1-11

Installation Orientation and Space.......................................1-12

Removing and Attaching the Terminal Cover......................1-13

Removing/Attaching the Digital Oper ator

and Front Cover....................................................................1-14

Page 16

SYSDRIVE PV Introduction

SYSDRIVE PV Applications

The SYSDRIVE PV is ideal for the following applications.

•

Fan, blower and pump applications

Settings must be adjusted to the application for optimum operation. Refer to Chapter 4 Trial Operation.

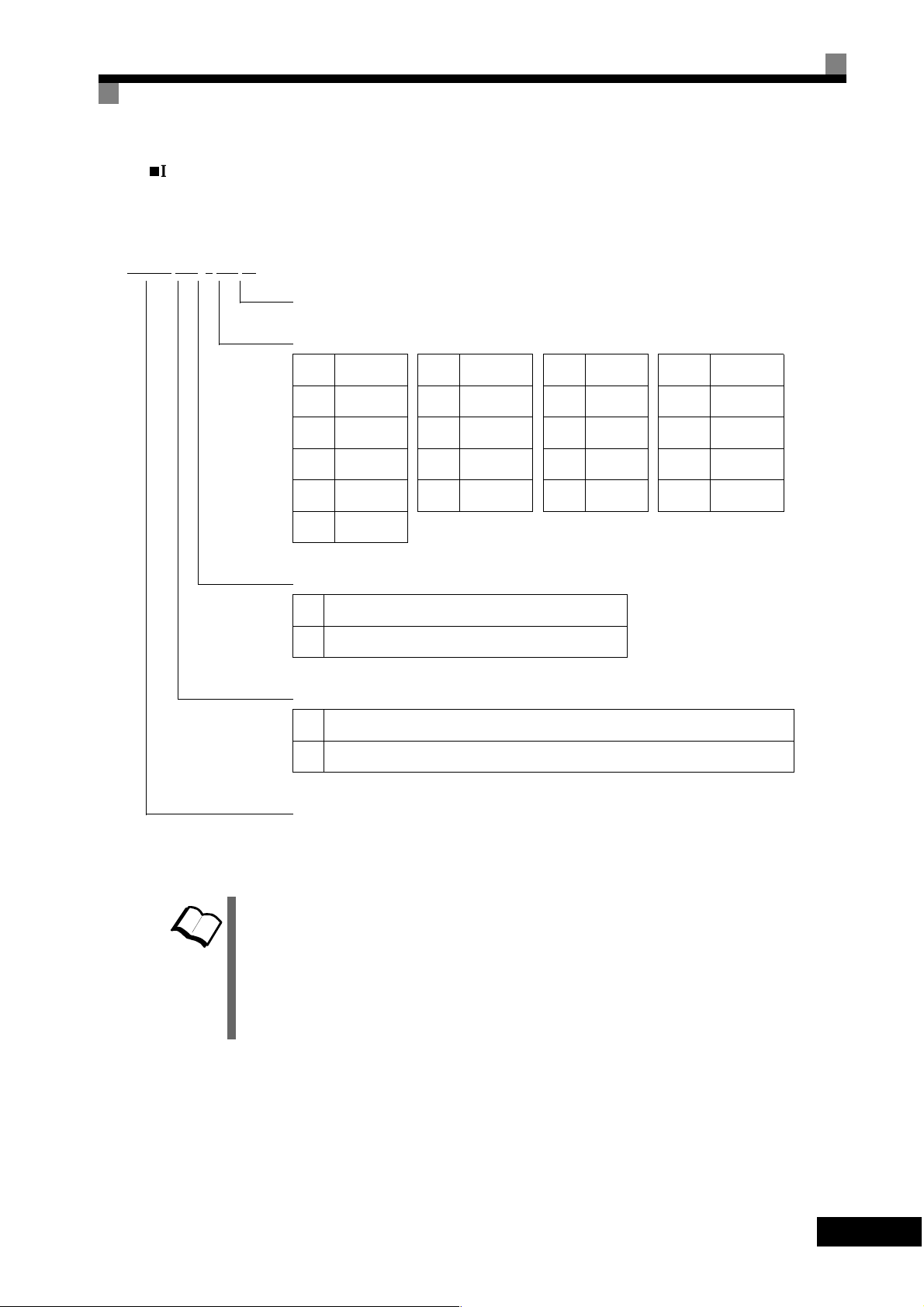

SYSDRIVE PV Models

The SYSDRIVE PV Series of Inverters inclu des two kinds of Inverters in two voltage classes: 200 V and

400 V. Maximum motor capacities vary from 0.4 to 160 kW.

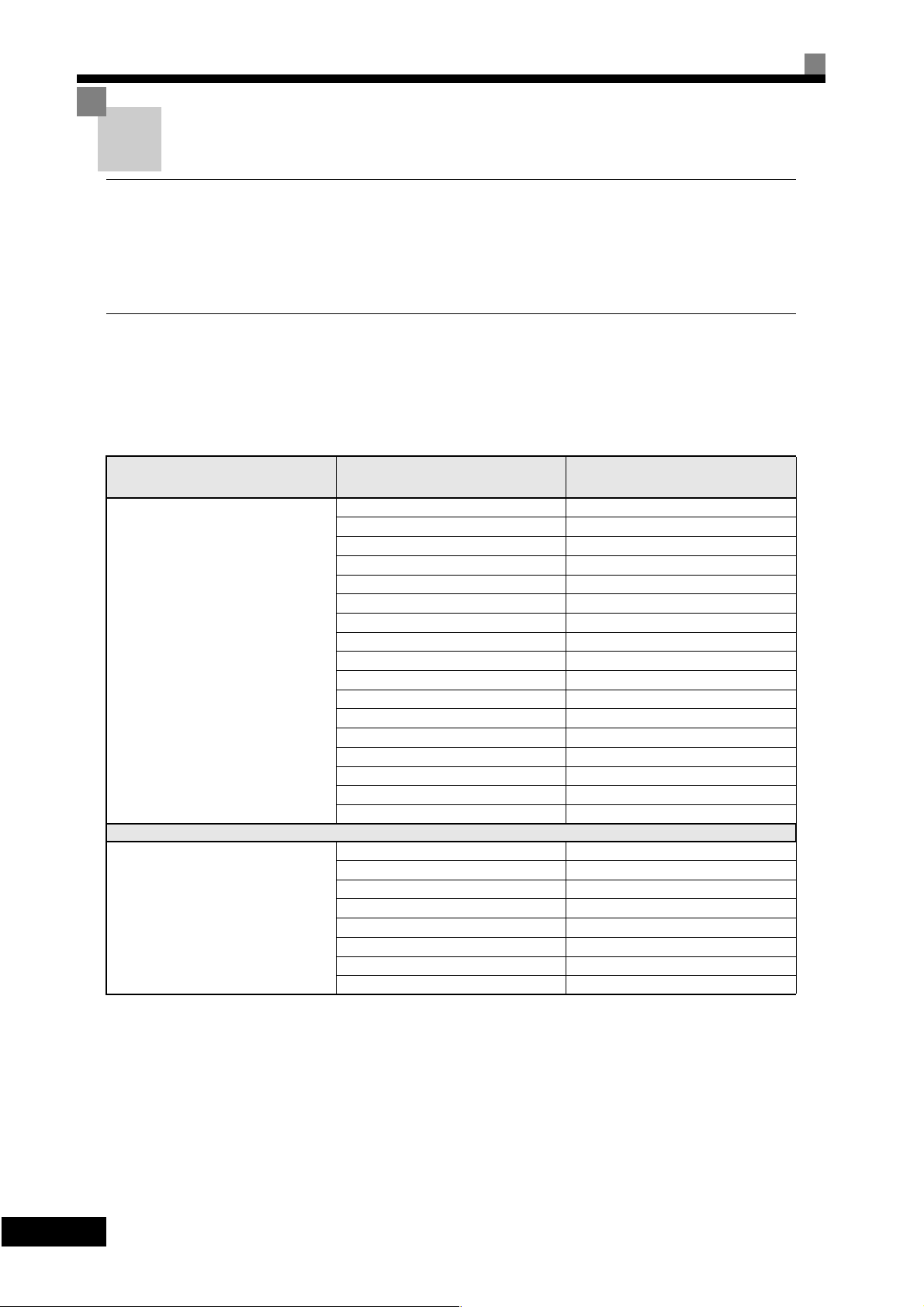

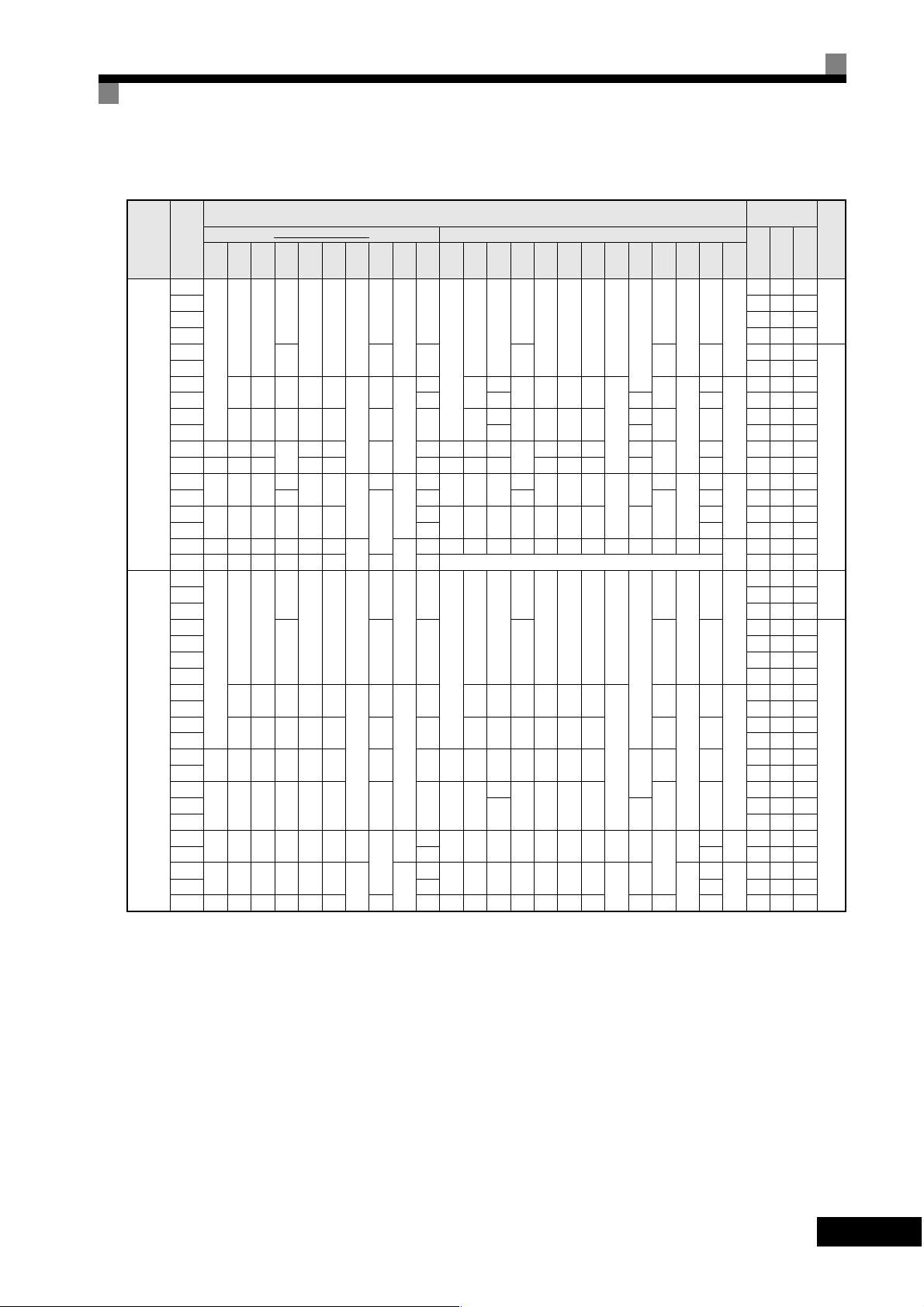

Table 1.1 SYSDRIVE PV Models

Protective Structure Maximum Motor Capa city Basic Model Number

NEMA 1 type

IP20

(200 V class)

Open Chassis type

IP00

(200 V class)

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

22

30

37

45

55

75

90

110

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

3G3PV-A2004-E

3G3PV-A2007-E

3G3PV-A2015-E

3G3PV-A2022-E

3G3PV-A2037-E

3G3PV-A2055-E

3G3PV-A2075-E

3G3PV-A2110-E

3G3PV-A2150-E

3G3PV-A2185-E

3G3PV-A2220-E

3G3PV-A2300-E

3G3PV-A2370-E

3G3PV-A2450-E

3G3PV-A2550-E

3G3PV-A2750-E

3G3PV-A2900-E

3G3PV-B2220-E

3G3PV-B2300-E

3G3PV-B2370-E

3G3PV-B2450-E

3G3PV-B2550-E

3G3PV-B2750-E

3G3PV-B2900-E

3G3PV-B211K-E

1

-2

Page 17

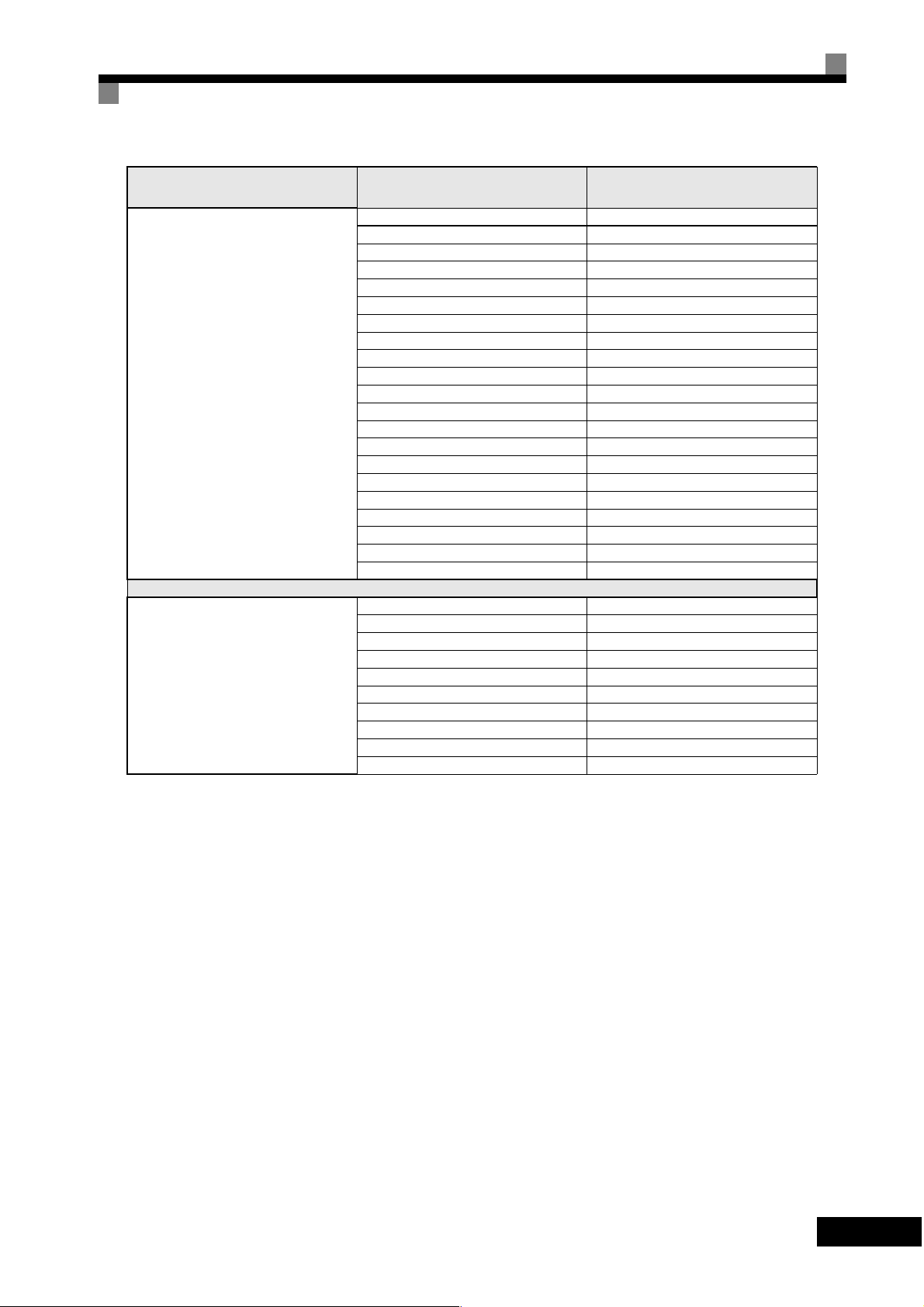

SYSDRIVE PV Introduction

Protective Structure Maximum Mo to r Capacity Basic Model Number

0.4 kW 3G3PV-A4004-E

0.75 kW 3G3PV-A4007-E

1.5 kW 3G3PV-A4015-E

2.2 kW 3G3PV-A4022-E

3.7 kW 3G3PV-A4037-E

4.0 kW 3G3PV-A4040-E

5.5 kW 3G3PV-A4055-E

7.5 kW 3G3PV-A4075-E

NEMA 1 type

IP20

400 V class

11 kW 3G3PV-A4110-E

15 kW 3G3PV-A4150-E

18.5 kW 3G3PV-A4185-E

22 kW 3G3PV-A4220-E

30 kW 3G3PV-A4300-E

37 kW 3G3PV-A4370-E

45 kW 3G3PV-A4450-E

55 kW 3G3PV-A4550-E

75 kW 3G3PV-A4750-E

90 kW 3G3PV-A4900-E

110 kW 3G3PV-A411K-E

132 kW 3G3PV-A413K-E

160 kW 3G3PV-A416K-E

Open Chassis type

IP00

(400 V class)

22 kW 3G3PV-B4220-E

30 kW 3G3PV-B4300-E

37 kW 3G3PV-B4370-E

45 kW 3G3PV-B4450-E

55 kW 3G3PV-B4550-E

75 kW 3G3PV-B4750-E

90 kW 3G3PV-B4900-E

110 kW 3G3PV-B411K-E

132 kW 3G3PV-B413K-E

160 kW 3G3PV-B416K-E

1

-

3

Page 18

Confirmations upon Delivery

Checks

Check the following items as soon as the Inverter is delivered.

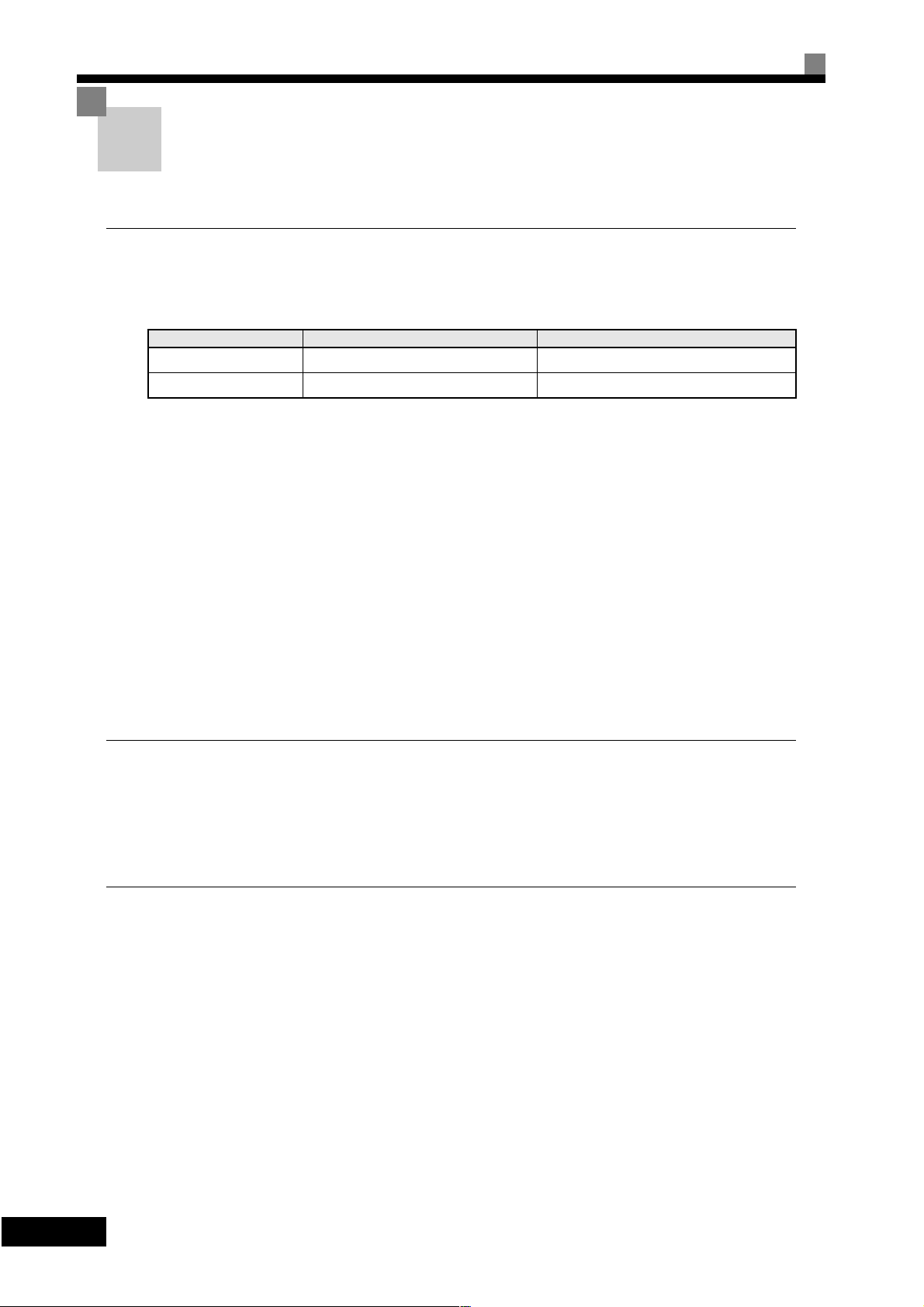

Table 1.2 Checks

Item Method

Has the correct model of Inverter been

delivered?

Is the Inverter damaged in any way?

Are any screws or other compone nts

loose?

If you find any irregularities in the above items, contact the agency from which you purchased the In verter or

your OMRON representative immediately.

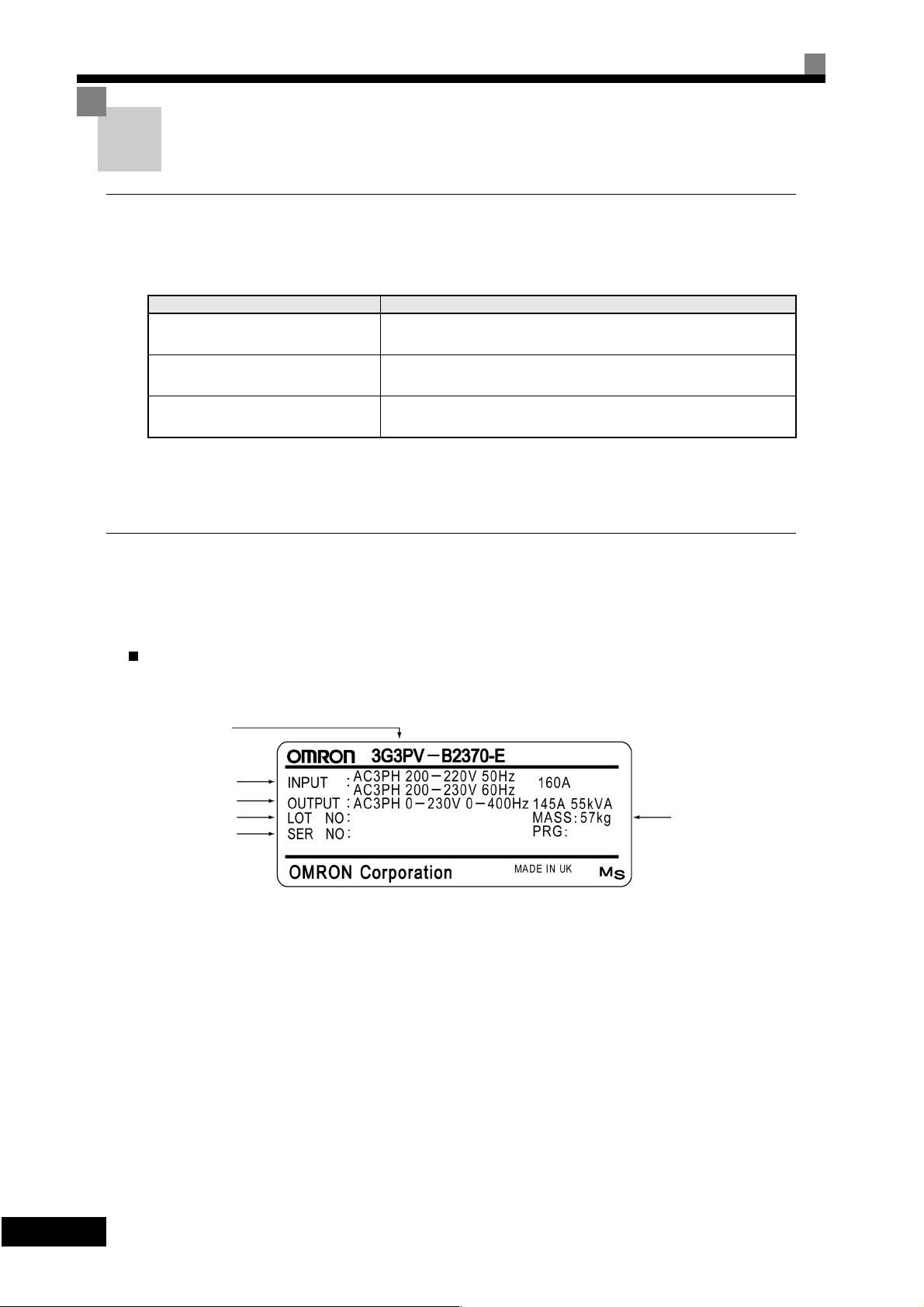

Nameplate Information

Check the model number on the nameplate on t he side of the I nverter.

Inspect the entire exterior of the Inverter to see if there are any scratches or

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

There is a nameplate attached to the side of each Inverter. The nameplate shows the model n umber, specifications, lot number, serial number and other information on the Inverter.

Example Nameplate

The following nameplate is an example for an European Inverter: 3-phase, 200 VAC, 37 kW, IEC IP00

Inverter model

Input specification

Output specification

Lot number

Serial number

Fig 1.1 Namepla te

Mass

1

-4

Page 19

Confirmations upon Delivery

Inverter Model Numbers

The model number of the Inverte r on the nameplate indicates the specification, vo ltage class and maximum

motor capacity of the Inverter in alphanumeric codes.

G3PV -A 2 037 -E

Specifications -E (European Model)

Maximum Applicable Motor Capacity

004 0.4 kW 055 5.5 kW 220 22 kW 750 75 kW

007 0.75 kW 075 7.5 kW 300 30 kW 900 90 kW

015 1.5 kW 110 11 kW 370 37 kW 11K 110 kW

022 2.2 kW 150 15 kW 450 45 kW 13K 130 kW

037 3.7 kW 185 18.5 kW 550 55 kW 16K 160 kW

TERMS

040 4.0 kW

Voltage Class

2 AC-input, 3-phase, 200 V (200-V Class)

4 AC-input, 3-phase, 400 V (400-V Class)

Installation type

A Panel mounting or closed wall-mounting (IEC IP20, NEMA 1)

B Open Chassis (IEC IP00)

Series Name 3G3PV Series

Fig 1.2 Inverter Model Numbers

Open Chassis Type (IEC IP00)

Protected so that parts of the human b ody cannot reach electrically charged pa rts from the front when the

Inverter is mounted in a control panel.

Enclosed Wall-mounted Type (IEC IP20, NEMA Type 1)

The Inverter is structured so that the Inverter is shielded from the exterior and can t hus be mounted to the

interior wall of a standard building (not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA 1 in the USA.

Top protective cover (Fig. 1.3) has to be installed to conform with IEC IP20 and NEMA Type 1 requirements.

1

-

5

Page 20

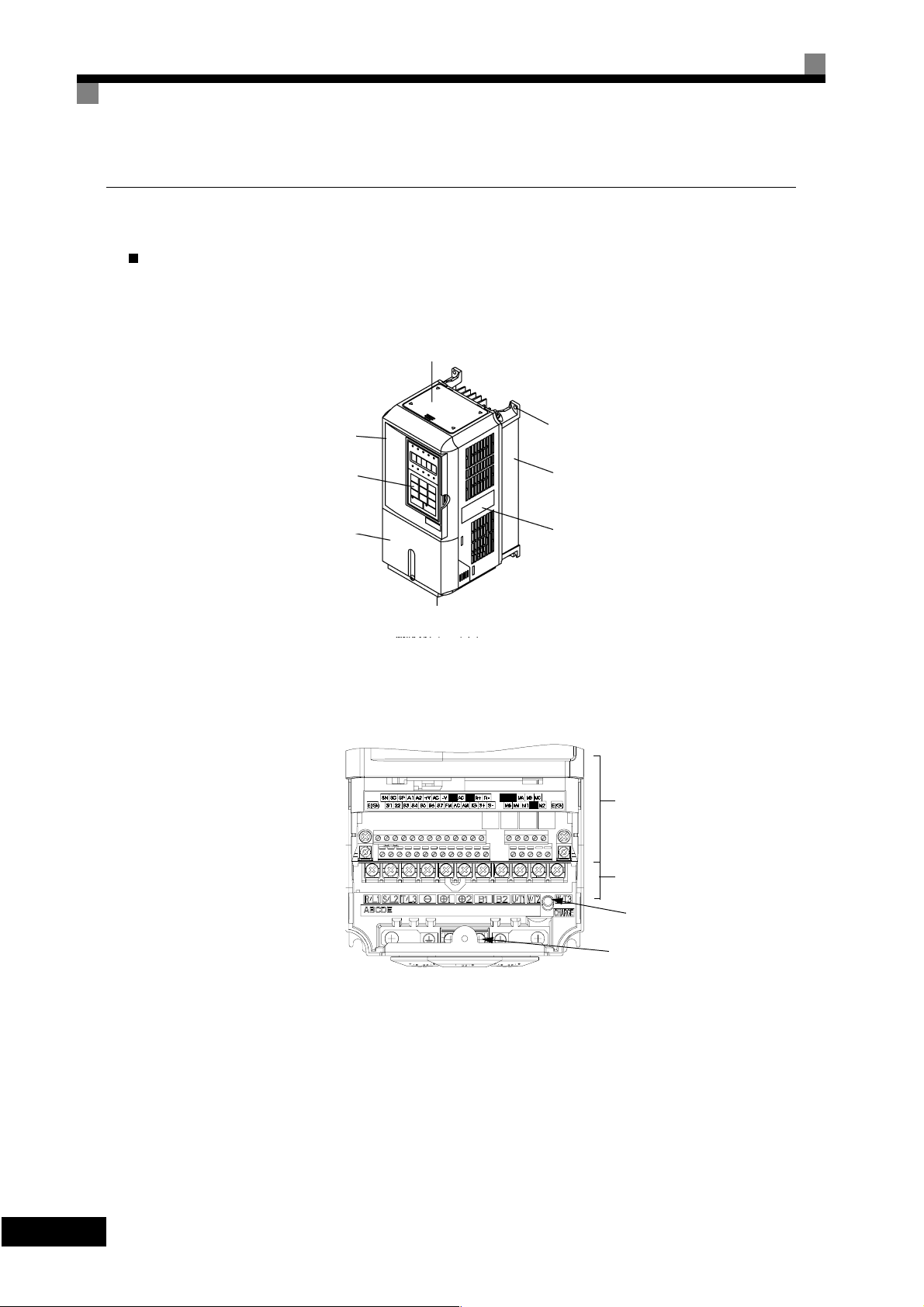

Component Names

Inverter Appearance

The external appearance and component names of the Inverter are shown in Fig 1.3. The Inverter with the terminal cover removed is shown in Fig 1.4.

Top protective cover (Part of Enclosed Wall-

mounted Type (IEC IP20, NEMA Type 1)

Front cover

Digital Operator

Terminal cover

Mounting hole

Diecast case

Nameplate

Bottom protective cover

Fig 1.3 Inverter Appeara nce (18.5 kW or Less)

Control circuit terminals

Main circuit termina l s

1

Charge indicator

Ground terminal

Fig 1.4 Terminal Arra ngement (18. 5 kW or Less)

-6

Page 21

Confirmations upon Delivery

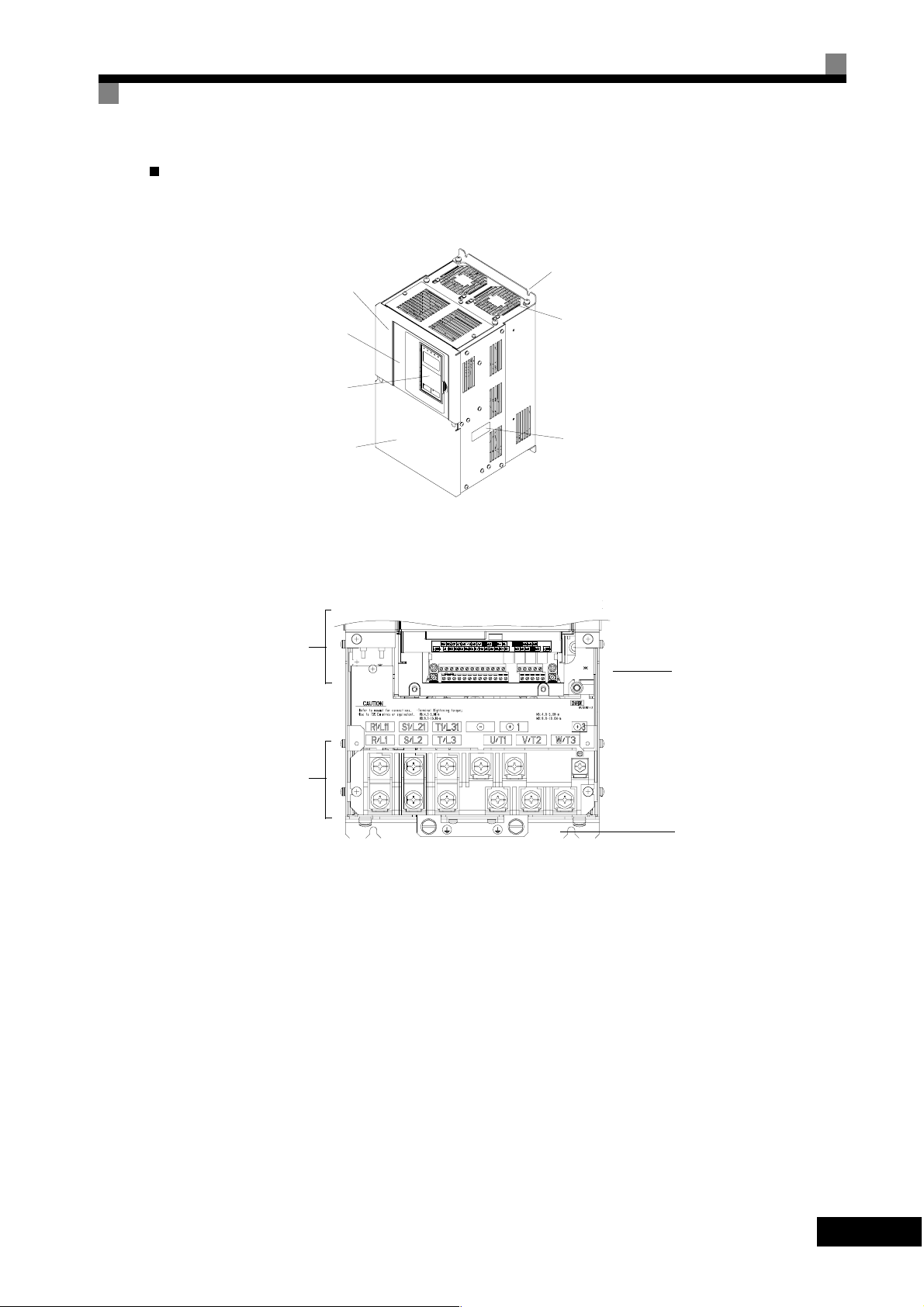

Inverters of 22 kW or More

The external appearance and component names of the Inverter are shown in Fig 1.5. The Inverter with the terminal cover removed is shown in Fig 1.6.

Mounting holes

Inverter cover

Front cover

Digital Operator

Cooling fan

Terminal cover

Control

Control

circuit

circuit

terminals

terminals

Main

circuit

terminals

Nameplate

Fig 1.5 Inverter Appearanc e (22 kW or More)

Charge indicator

Ground terminal

Fig 1.6 Terminal Arrangement (22 kW or More )

1

-

7

Page 22

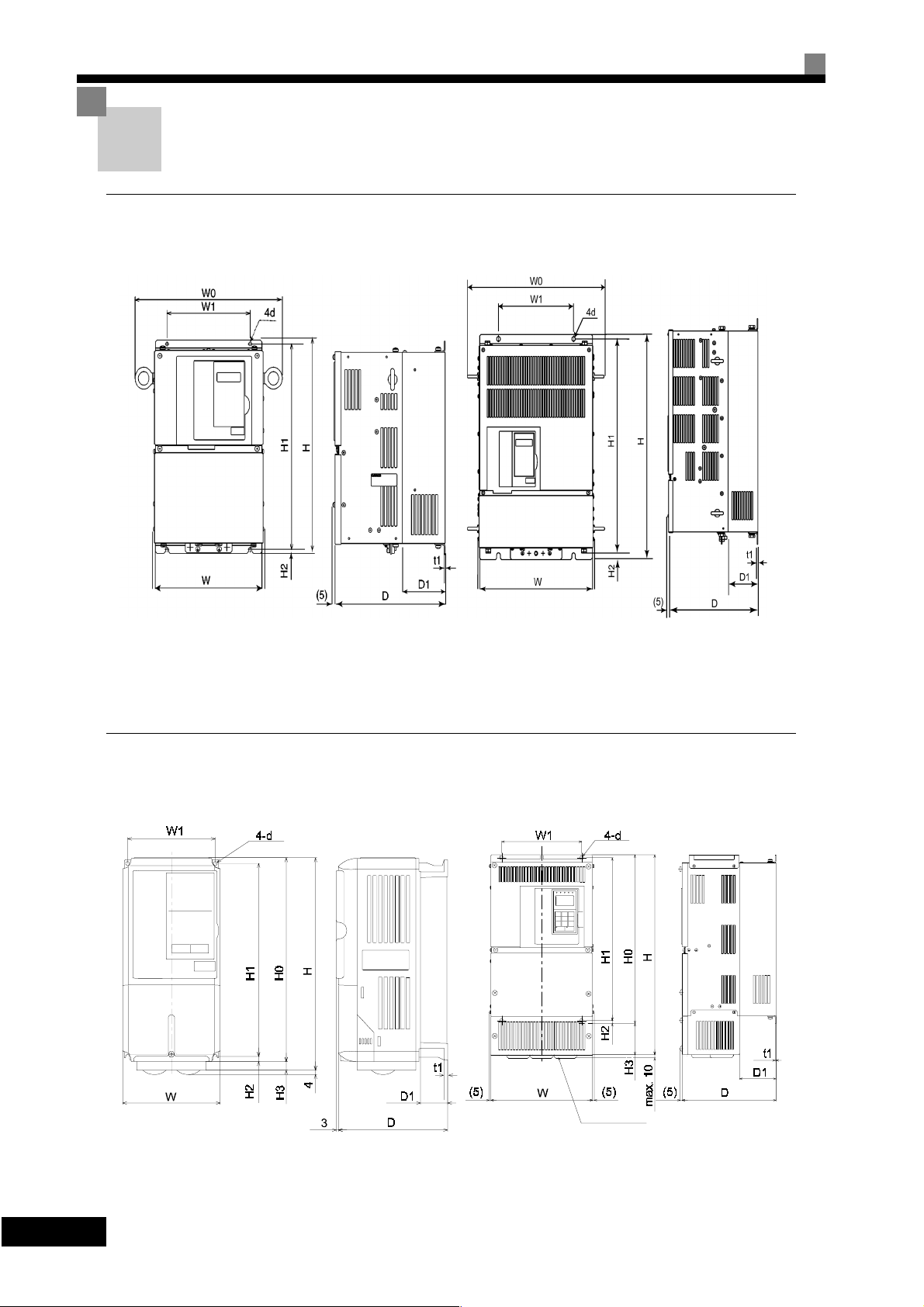

Exterior and Mounting Dimensions

Open Chassis Inverters (IP00)

Exterior diagrams of the Open Chassis Inverters are shown below.

200 V Class Inverters of 22 or 30 kW

400 V Class Inverters of 22 to 55 kW

Fig 1.7 Exterior Diagrams of Open Chassis Inverters

Enclosed Wall-mounted Inverters (NEMA1)

Exterior diagrams of the Enclosed Wall-mounted Inverters (NEMA1) are shown below.

200 V Class Inverters of 37 to 110 kW

400 V Class Inverters of 75 to 160 kW

1

-8

200 V/400 V Class Inverters of 0.4 to 18.5 kW

Fig 1.8 Exterior Diagrams of Enclosed Wall-mounted Inverters

Grommet

200 V Class Inverters of 22 to 90 kW

400 V Class Inverters of 22 to 160 kW

Page 23

Table 1.3 Inverter Dimensions (mm) and Masses (kg)

Max.

Appli-

Voltage

cable

Class

Motor

Output

W0 W H D W1 H1 H2 D1 t1

[kW]

0.4

0.75 27 42 69

1.5 50 50 100

2.2 70 59 129

3.7

-

5.5 164 84 248

7.5

11 7 310 10 7 374 170 544

(3-phase)

18.5 380 30 501 211 712

15

200 V

22 345 254 400

30 370 279 450 220 435 24 370 280 615 220 450 435 165 27 865 352 1217

37

470 379 600

45 328

55

545 454 725 348 325 700

75 87 95 2019 838 997

90 615 505 850 358 370 820

110 690 579 885 378 445 855 140 150 Not available. Use IP00 type.- 2733 1242 3975

0.4

0.75 17 41 58

1.5 36 48 84

2.2

3.7 80 68 148

-

4.0 70 91 161

5.5 127 82 209

7.5

11 252 158 410

15

400 V

(3-phase)

18.5 426 208 634

22

370 280 450 258 220 435 100 21 370 280 535 258 220 450 435

30 678 317 995

37

420 329 550 283 260 535 105 36 420 329

45

55 1203 495 1698

75

545 454 725 348 325 700 13

90 89 97 1614 671 2285

110

615 505 850 358 370 820

132 120 130 2388 1002 3390

160 689 579 916 378 445 855 140 160 689 579 1325 378 445 916 855 400 140 170 2791 1147 3938

* Same for Open Chassis and Enclosed Wall-mounted Inverters.

Open Chassis (IP00) Enclosed Wall-moun ted (NEMA1, IP20)

140 280

157

126 266 7

39

177 59 4 177 59 4

200 300 197 186 285

240 350 207 216 335 78 11 240

195 385

258

298

250 575

65.5

7.5

100

100

13

130

15 4.5

140 280

157

126 266 7

39

177 59 4 177 59 4

200 300 197 186 285

65.5

240 350 207 216 335 78 10 240 350 207 216 350 335 78 10

7.5

130

15 4.5

Exterior and Mounting Dimensions

Dimensions (mm)

Ap-

prox.

W0 W H D W1 H0 H1 H2 H3 D1 t1

Mass

3

5

140 280

-

6

200

2.3

21 345 255 535

57

470 380 809

63 330

3.2

86

545 455 1027 350 325 725 700 305

108 615 504 1243 360 370 828 820 7.8 408 130 4.5 114

3

5

140 280

-

6 200 300 197 186 300 285

2.3

88

3.2

545 454 1100 348 325 725 700 13 305

102

615 505 1245 358 370 850 820

157

126 280 266 7

300

197 186 300 285

350

207 216 350 335

195 400 385 135

258

300

250 600 575

7.5

13

210

0

65.5

0

100

100

130

157

126 280 266 7

0

65.5

7.5

100 24

85

635

283 260 550 535 105 40

715 165

130

395

15

39

78 11

39

Exter

Mount-

Ap-

ing

Holes

d*

nal

prox.

Mass

20 39 59

3

5

M5

112 74 186

6

219 113 332

2.3

429 183 612

M6

24 586 274 860

62

1015 411 1426

68 1266 505 1771

3.2

M10

94 1588 619 2207

2437 997 3434

M12

14 39 53

3

5

M5

59 56 115

193 114 307

6

326 172 498

2.3

466 259 725

M6

784 360 1144

901 415 1316

96

122

1399 575 1974

M10

2097 853 2950

M12

3.2

4.5

Caloric

Value(W)

Inter-

nal

Tot a l

Heat

Gen-

eration

Cool-

ing

Method

Natu-

ral

Fan

Natu-

ral

Fan

1

-

9

Page 24

Checking and Controlling the Installation Site

Install the Inverter in the installation site described below and maintain optimum conditions.

Installation Site

Install the Inverter under the following conditions in a pollution degree 2 environment.

Table 1.4 Installation Site

Type Ambient Operating Temperature Humidity

Enclosed wall-mounte d -10 to + 40 °C 95% RH or less (no condensation)

Open chassis -10 to + 45 °C 95% RH or less (no condensation)

Protection covers are attached to the top and bo ttom of the Inverter. Be sure to remove the protection covers

before installing a 200 or 400 V Class Inverter with an output of 18.5 kW or less in a panel.

Observe the following precautions when mounting the Inverter.

•

Install the Inverter in a clean location which is free from oil mist and dust. It can be installed in a totally

enclosed panel that is completely shielded from floating dust.

•

When installing or operating the Inverter, always take special care so that metal powder, oil, water or other

foreign matter does not get into the Inverter.

•

Do not install the Inverter on combustible material, such as wood.

•

Install the Inverter in a location free from radioactive materials and combustible materials.

•

Install the Inverter in a location free from harmful gasses and liquids.

•

Install the Inverter in a location without excessive oscillation.

•

Install the Inverter in a location free from chlorides.

•

Install the Inverter in a location not in direct sunlight.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme

temperature increases. If the Inverter is installed in an enclosed environment, such as a box, use a cooling fan

or air conditioner to maintain the internal air temperature below 45×C.

Protecting the Inverter from Foreign Matte r

Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter after completing installation. Otherwise, ventilation will be

reduced, causing the Inverter to overheat.

-10

1

Page 25

Installation Orientation and Space

Provide an appropriate stopping device on the machine side to secure safety. (

WARNING

A holding brake is not a stopping device for securing safety) Not doing so may

result in injury.

Installation Orientation and Space

WARNING

Caution

Caution

Caution

Inverter Installation Orientation and Space

Install the Inverter vertically so as not to r educe the cooling effect. When installing the In verter, always

provide the following installation space to allow normal heat dissipation.

50 mm min.

Provide an external emergency stopping device that allows an instantaneous

stop of operation and power interruption. Not doing so may result in injury.

Be sure to install the product in the correct direction and provide specified

clearances between the Inverter and control panel or with other devices to

allow for proper cooling. Not doing so may result in fire or malfunction.

Do not allow foreign objects to enter inside the product. Doing so may result in

fire and malfunction.

Do not apply any strong imact. Doing so may result in damage to the product

or malfunction.

120 mm min.

Air

50 mm min.

IMPORTANT

30 mm min.

1. The same space is required horizontally and v ertically for both Open Chas sis (IP00) and Enclos ed Wall-

2. Always re move the protection covers before installing a 200 or 400 V Class Inverter with an outpu t of

30 mm min.

Fig 1.9 Inverter Installation Orientation and Space

mounted ( I P20, NEMA 1) Invert ers.

18.5 kW or less in a panel.

Always provide enough space for suspension eye bolts and the main circuit lines when installing a 200 or

400 V Class Inverter with an output of 22 kW or more in a panel.

120 mm min.

Vertical SpaceHorizontal Space

Air

1

-

11

Page 26

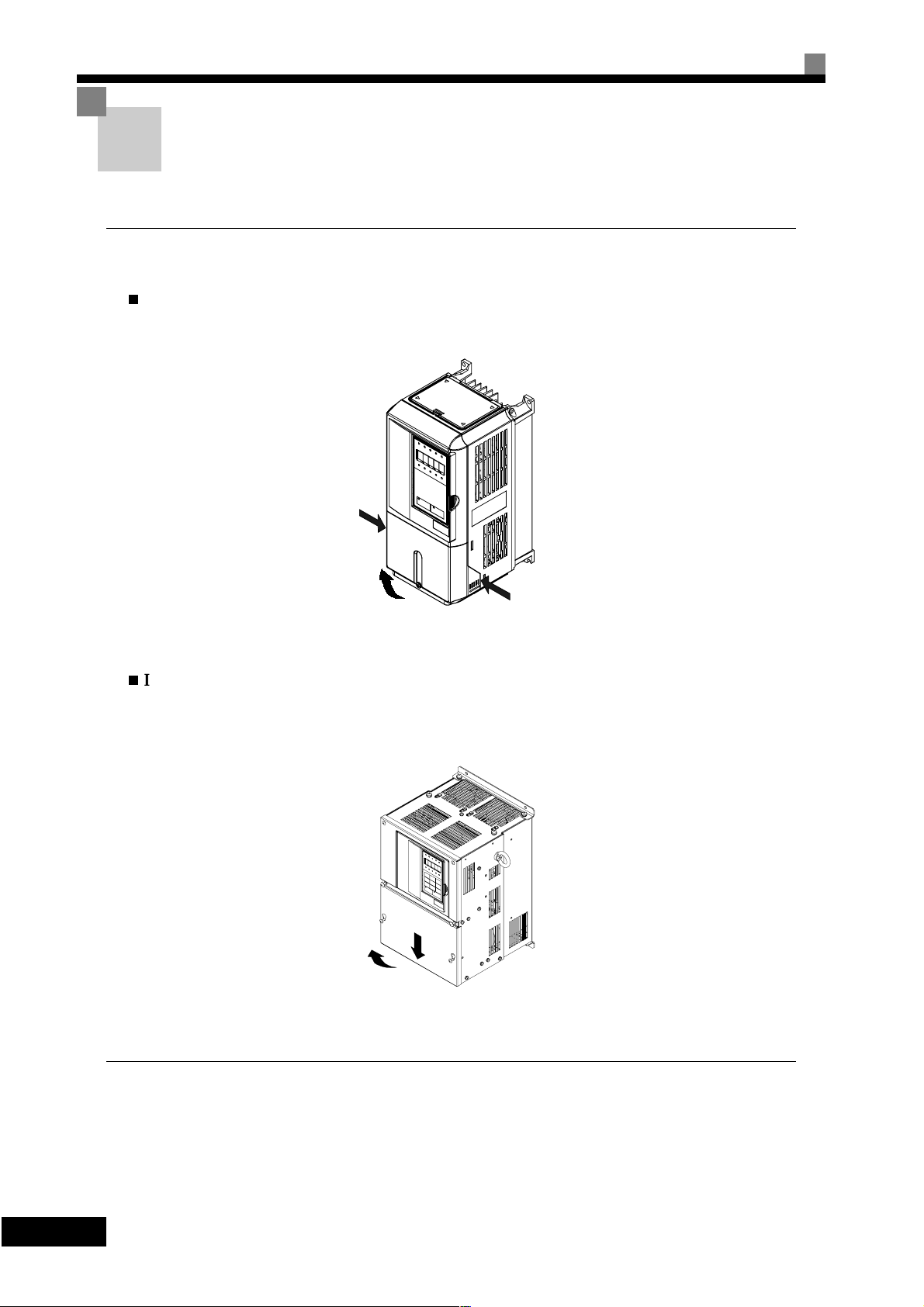

Removing and Attaching the Terminal Cover

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

Removing the Terminal Cover

Inverters of 18.5 kW or Less

Loosen the screw at the bottom of the terminal cover, press in on the sides of the terminal cover in the direc tions of arrows 1 and then lift up on the terminal in the direction of arrow 2.

1

2

1

Fig 1.10 Removing the Terminal Cover (Model 3G3PV-A2055-E Shown Above)

Inverters of 22 kW or More

Loosen the screws on the left and right at the top of the terminal cover, pull out the terminal cover in the direction of arrow 1 and then lift up on the terminal in the direction of arrow 2.

1

2

Fig 1.11 Removing the Terminal Cover (Model 3G3PV-B2220-E Shown Above)

Attaching the Terminal Cover

-12

1

When wiring the terminal block has been completed, attach the terminal cover by reversing the removal procedure.

For Inverters with an output of 18.5 kW or less, insert the tab on the top of the terminal cover into the groove

on the Inverter and press in on the bottom of the terminal cover until it clicks into place.

Page 27

Removing/Attaching the Digital Operator and Front Cover

Removing/Attaching the Digital Operator and Front

Cover

Inverters of 18.5 kW or Less

To attach optional cards or change the terminal card connector, remove the Digital Operator and front cover in

addition to the terminal cover. Always remove the Digital Operator from the front cover before removing the

terminal cover.

The removal and attachment procedures are given below.

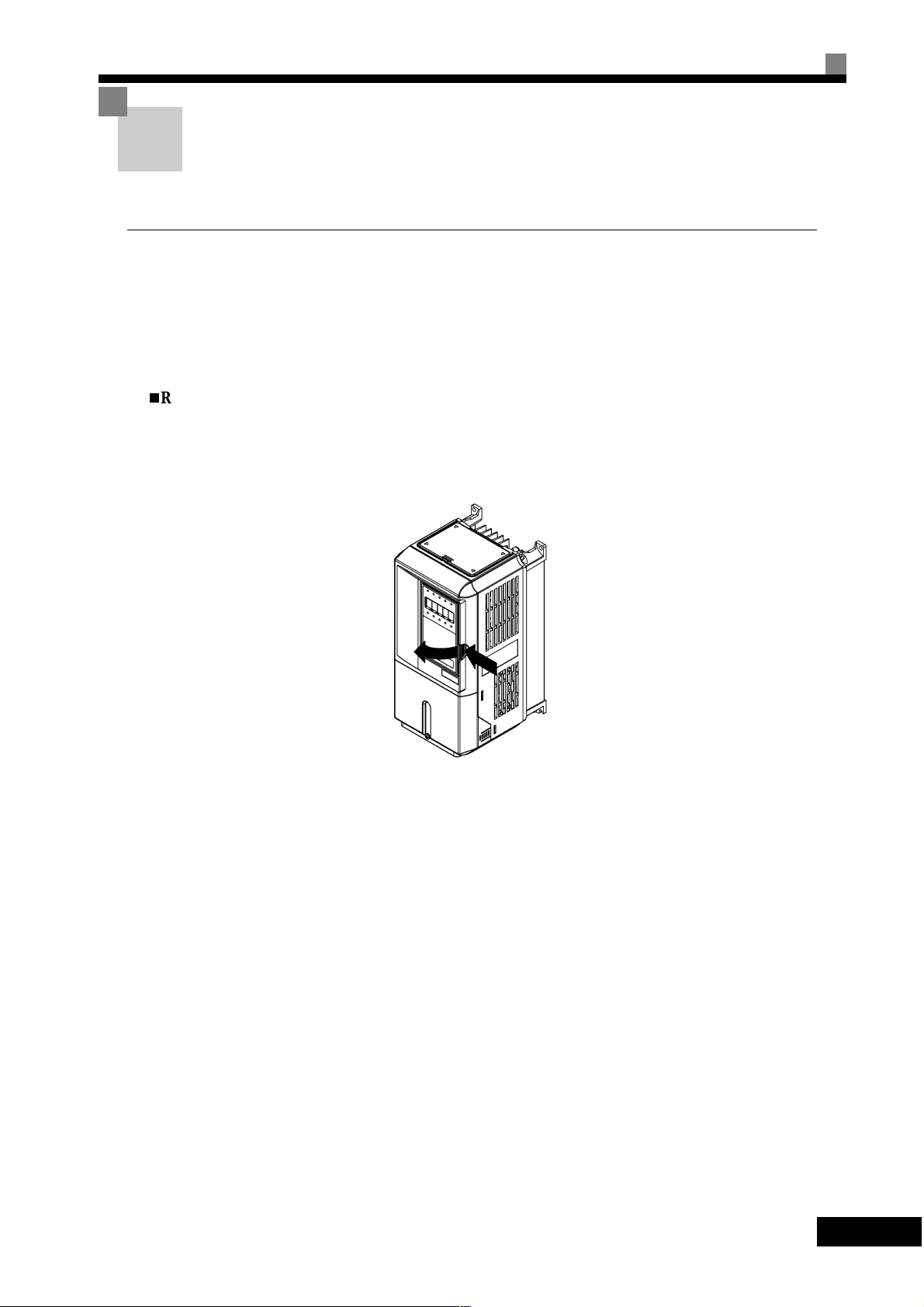

Removing the Digit al Operator

Press the lever on the side of the Digital Operator in the direction of arrow 1 to unlock the Digital Operator

and lift the Digital Operator in the direction of arrow 2 to remove the Digital Operator as shown in the following illustration.

2

Fig 1.12 Removing the Digital Operator (Model 3G3PV-A4055-E Shown Above)

1

1

-

13

Page 28

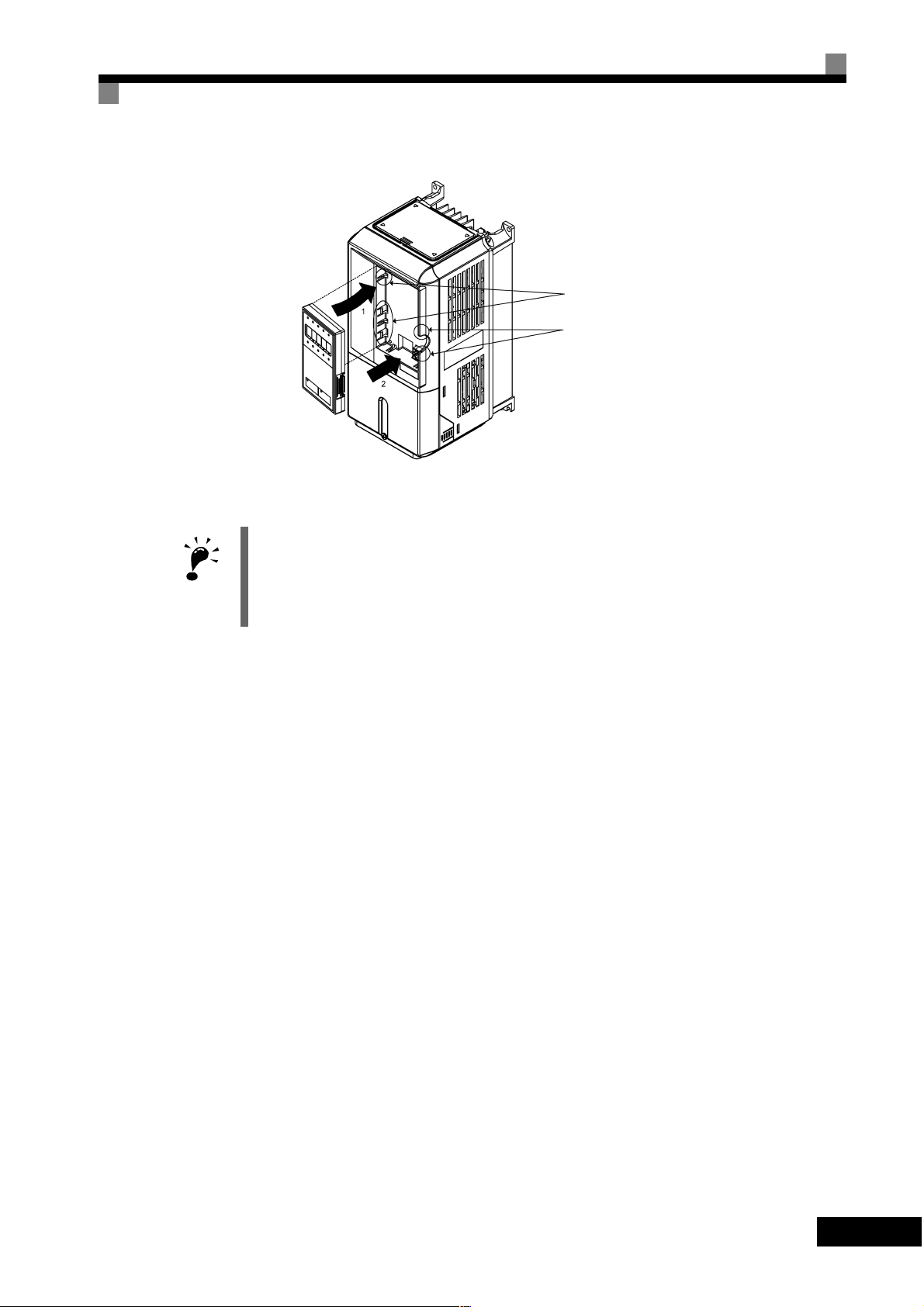

Removing the Front Cove r

Press the left and right sides of the front cover in the directions of arrows 1 and lift the bottom of the cover in

the direction of arrow 2 to remove the front cover as shown in the following illustration.

1

2

Fig 1.13 Removing the Front Cover (Model 3G3PV-A4055-E Shown Above)

Mounting the Front Cover

After wiring the terminals, mount the fron t cover to the Inverter b y performing the steps to rem ove the front

cover in reverse order.

1. Do not mount the front cover with the Digital Operator attached to the front cover; otherwise, Digital

Operator may malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groo ve of th e Inverter and press the lower part of

the front cover onto the Inverter until the front cover snaps shut.

Mounting the Digital O perator

After attaching the terminal cover, mount the Digital Operator onto the Inverter using the following procedure.

1. Hook the Digital Operator at A (two locations) on the front cover in the direction of arrow 1 as shown in

the following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

-14

1

Page 29

Removing/Attaching the Digital Operator and Front Cover

Fig 1.14 Mounting the Digital Operator

A

B

IMPORTANT

1. Do not remo ve or attach the Digital O perator or mount or remove the front cover using method s other

than those described above, otherwise the Inverter may break or malfunction due to imperfect contact.

2. Never attach the front cover to the Inverter with the Digital Operator attached to the front cover. Imperfect

contact can result.

Always attach the front cover to the Inverter by itself first and then attach the Digital Operator to the front

cover.

1

-

15

Page 30

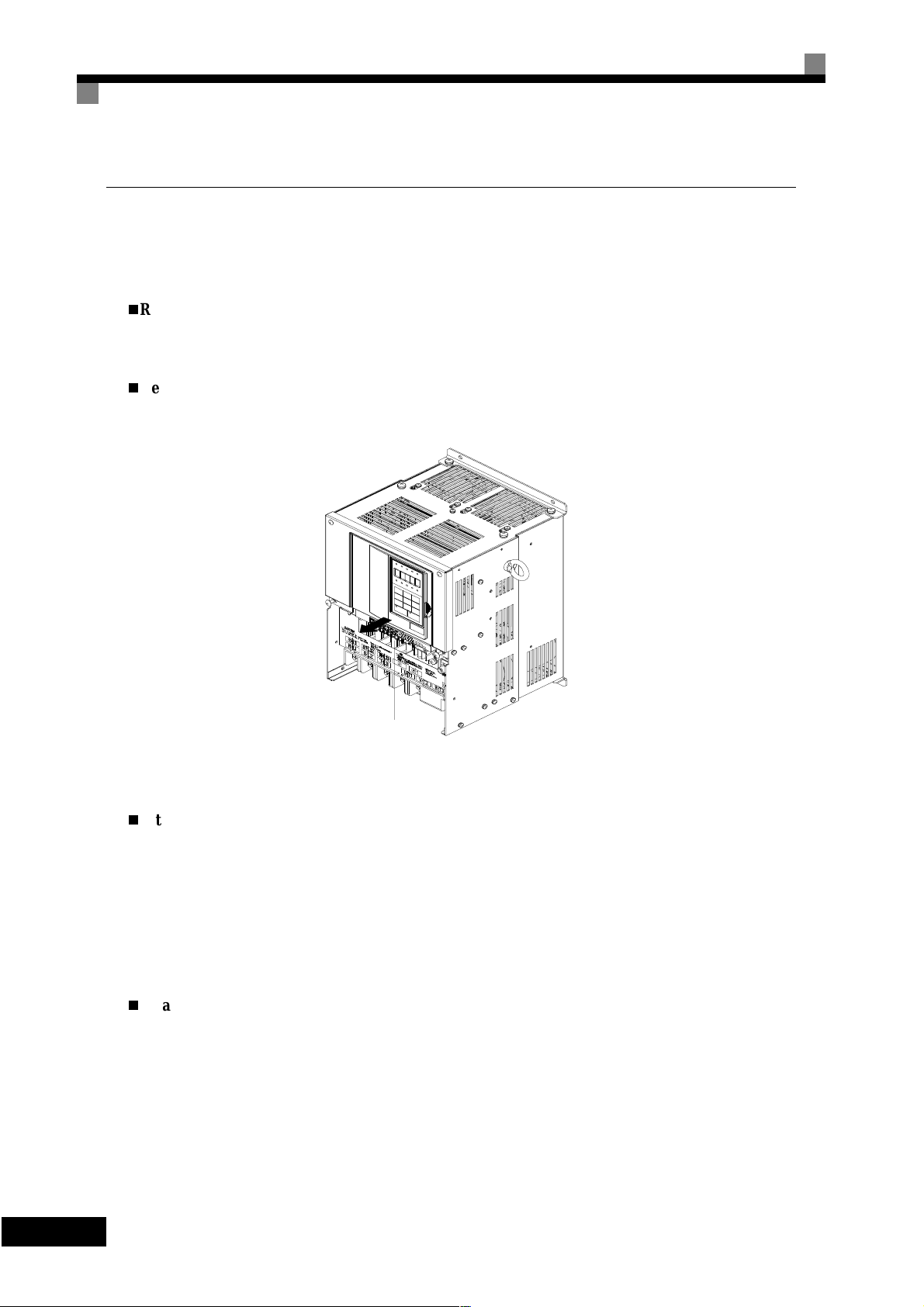

Inverters of 22 kW or More

For Inverters with an output of 22 kW or mor e, remove the terminal cover and then use the following procedures to remove the Digital Operator and main cover.

Removing the Digital Operator

Use the same procedure as for Inverters wi th an output of 18.5 kW or less .

Removing the Front Cove r

Lift up at the location label 1 at the top of the control circuit terminal card in the direction of arrow 2.

2

1

Fig 1.15 Removing the Front Cover (Model 3G3PV-B2220-E Shown Above)

Attaching the Front Cover

After completing required work, such as mounting an optional card or setting the terminal card, attach the

front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator is not mounted on the front cover. Contact faults can occur if the cover is

attached while the Digital Operator is mounted to it.

2. Insert the tab on the top of the front cover into the slot on the Inverter and pr ess in on the cover until it

clicks into place on the Inverter.

Attaching the Digital Operator

Use the same procedure as for Inverters wi th an output of 18.5 kW or less .

-16

1

Page 31

2

Chapter 2

Wiring

This chapter describes wiring terminals, main circuit terminal connections, main c ircuit terminal wiring specifications, control circuit terminals and control circuit wiring specifications.

Wiring....................................................................................2-2

Connections to Peripheral Devices........................................2-3

Connection Diagram..............................................................2-4

Terminal Block Configuration...............................................2-6

Wiring Main Circuit Terminals .............................................2-7

Wiring Control Circuit Terminals........................................2-22

Wiring Check.......................................................................2-29

Installing and W ir ing Op ti on Card s .................... ... .............2-30

Page 32

Wiring

WARNING

WARNING

WARNING

Required

Caution

Caution

Caution

Wiring must be performed only after turning OFF the power supply . No t doing

so may result in electrical shock.

Wiri ng must be per formed by authori zed per sonnel. N ot doing so may result in

electrical shock.

Be sure to confirm operation only after wiring the emergency stop circuit. Not

doing so may result in injury.

Always connect the ground terminals to a ground of 100 Ohm or less for 200V AC class or 10 Ohm or less for the 400-V class. Not connecting to a proper

ground may resul t in electrica l shock or fire.

Install external circuit breakers and take other safety measures against shortcircuiting in external wiring. Not doing so may result in fire.

Confirm that the rated input voltage of the Inverter is the same as the AC

power supply voltage. An incorrect power supply may result in fire, injury or

malfunction.

Connect the Braking Resistor or Braking Resistor Unit as specified in th e manual. Not doing so may result in fire.

Caution

Caution

Caution

Caution

Be sure to wire correctly and securely. Not doing so may result in injury or

damage to the product .

Be sure to firmly tighten the screws on the terminal block. Not doing so may

result in fire, injury or damage to the product.

Do not conne c t a n A C pow e r s our c e to the U,V,W output. Doi n g so may result

in damage to the product or malfunction.

Do not connect a load to the machine during auto-tuning. Not doing so may

result in equipment damage.

2

-2

Page 33

Connections to Peripheral Devices

Examples of connections between the Inverter and typical peripheral devices are shown in Fig 2.1.

Power supply

Molded-case

circuit breaker

or ground fault

interrupter

Magnetic contactor (MC)

AC reactor for power

factor improvement

Connections to P eripheral Devic es

Input noise filter

Inverter

Ground

Output noise filter

DC reactor for power

factor improvement

Motor

Ground

Fig 2.1 Example Connections to Peripheral Devices

2

-

3

Page 34

Connection Diagram

The connection diagram of the Inverter is shown in Fig 2.2.

When using the Digital Operator, the motor can be operated by wiring only the main circuits.

SKDVH SRZHU

WR 9

+]

0XOWLIXQFWLRQ DQDORJXH

RXWSXW WR 9

0XOWLIXQFWLRQ DQDORJXH

RXWSXW WR 9

2

Fig 2.2 Connection Diagram

-4

Page 35

Circuit Descriptions

Refer to the numbers indicated in the diagram on the previous page.

•

These circuits are hazardous and are separated from accessible surfaces by protective separation.

•

These circuits are separated from all other circuits by protective separation consisting of double and

reinforced insulation. These circuits may b e interconnected with SELV (or equivalent) or non-SELV

circuits, but not both.

Inverter supplied by four-wire-system source (neutral grounded)

•

These circuits are SELV (Safety Extra Low Voltage) circuits and are separated from all other circuits

by protective separation consisting of double and reinforced insulation. These circuits may only be

interconnected with other SELV (or equivalent) circuits. These circuits can be accessible or interconnected with other accessible SELV circuits.

Inverter supplied by three-wire-system source (ungrounded or corner grounded)

•

These circuits are not separated from hazardous circuits by protectiv e separation, but only with basic

insulation. These circuits cannot be accessed and must not be interconnected with any circuits which

are accessible, unless they are isolated from accessible circuits by supplemental insulation.

1. Control circuit terminals are arranged as shown below.

Connection Diagram

IMPORTANT

2. The output current capacity of the +V terminal is 20 mA.

3. Disable the stall prevent ion during dec eleration (set parameter L3-04 to 0) when using a Brak ing Resistor Unit. If this user parameter is not changed to disable stall prevention, the system may no t sto p wi thin

deceleration time.

4. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single circles.

5. Sequence input signals S1 to S7 are labeled for sequence connections (0 V common and sinking mode)

for no-voltage contacts or NPN transistors. These are the default settings .

For PNP transistor sequence connections (+24V common and sourcing mode) or to provide a 24-V

external power supply, refer to

6. The master speed frequency reference can set to input either a voltage (terminal A1) or current (terminal

A2) by changing the setting of parameter H3-13. The default setting is for a voltage reference input.

7. The mu lti-function analog output is a dedicated meter output for an analog frequency m eter, current

meter, voltmeter, wattmeter, etc. Do not use this output for feedback control or for any other control purpose.

8. DC reactors to im prove the inp ut pow er factor built into 200 V Clas s Inverters for 22 to 110 kW and 400

V Class Inverters for 22 to 160 kW. A DC reactor is thu s an option only for Inverters for 18.5 k W or less.

Remove the short bar when connecting a DC reactor to Inverters for 18.5 kW or less.

Set parameter L8-01 to 1 when using an optional braking resistor unit and braking unit. When using this,

a shutoff sequence for the power supply must be made using a thermal relay trip.

Table 2.11

.

2

-

5

Page 36

Terminal Block Configuration

The terminal arrangement for 200 V Class Inverters are shown in Fig 2.3 and Fig 2.4.

Fig 2.3 Terminal Arrangement (200 V/400 V Class Inverter for 0.4 kW shown above)

Control circuit terminals

Main circuit termina l s

Charge indicator

Ground terminal

Control

Control

circuit

circuit

terminals

terminals

Main

circuit

terminals

Fig 2.4 Terminal Arrangement (200 V/400 V Class Inverter for 22 kW)

Charge indicator

Ground terminal

2

-6

Page 37

Wiring Main Circuit Terminals

Wiring Main Circuit Terminals

Applicable Wire Sizes and Closed-loop Connector

Select the appropriate wires and crimp terminals from Table 2.1 to Table 2.3. Refer to users m anual

(I526-E1-

Inverter

Model

3G3PV-

A2004-E

A2007-E

A2015-E

A2022-E

A2037-E

A2055-E

) for wire sizes for Braking Resistor Units and Braking Units.

Table 2.1 200 V Class Wire Sizes

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3 M4 1.2 to 1.5

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

Termial

Screws

Tightening

Torque

(N•m)

M4 1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

Possible

Wire Sizes

2

(AWG)

mm

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

3.5 to 5.5

(12 to 10)

5.5

(10)

Recom-

mended

Wire Size

2

mm

(AWG)

2

(14)

2

(14)

2

(14)

2

(14)

3.5

(12)

5.5

(10)

Wire Type

A2075-E

A2110-E

A2150-E

A2185-E

A2220-E

B2220-E

A2300-E

B2300-E

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2,

W/T3

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2,

W/T3

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

M5 2.5

M5 2.5

M6 4.0 to 5.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

8 to 14

(8 to 6)

14 to 22

(6 to 4)

30 to 38

(4 to 2)

22

(4)

30 to 38

(3 to 2)

22

(4)

30 to 60

(3 to 1)

8 to 22

(8 to 4)

22 to 38

(4 to 2)

50 to 60

(1 to 1/0)

8 to 22

(8 to 4)

22 to 38

(4 to 2)

8

(8)

14

(6)

30

(4)

22

(4)

30

(3)

22

(4)

30

(3)

-

22

(4)

50

(1)

-

22

(4)

Power cables,

e.g., 600 V vinyl

power cables

2

-

7

Page 38

Inverter

Model

Terminal Symbol

3G3PV-

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

A2370-E

3

B2370-E

r/l1, ∆/l2 M4 1.3 to 1.4

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

A2450-E

3

B2450-E

∆

/l2 M4 1.3 to 1.4

r/l1,

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

A2550-E

B2550-E

3

∆

/l2 M4 1.3 to 1.4

r/l1,

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

A2750-E

B2750-E

3

∆

/l2 M4 1.3 to 1.4

r/l1,

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12 31.4 to 39.2

A2900-E

B2900-E

3

∆

/l2 M4 1.3 to 1.4

r/l1,

R/L1, S/L2, T/L3, , 1

B211K

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12 31.4 to 39.2

3

∆

/l2 M4 1.3 to 1.4

r/l1,

* The wire thickness is set for copper wires at 75°C

Termial

Screws

Tightening

Torque

(N•m)

M10 17.6 to 22.5

M8 8.8 to 10.8

M10 17.6 to 22.5

M10 17.6 to 22.5

M8 8.8 to 10.8

M10 17.6 to 22.5

M12 31.4 to 39.2

M8 8.8 to 10.8

M10 17.6 to 22.5

M12 31.4 to 39.2

M8 8.8 to 10.8

M10 17.6 to 22.5

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

Possible

Wire Sizes

2

(AWG)

mm

Recom-

mended

Wire Size

mm

(AWG)

60 to 100

(2/0 to 4/0 )60(2/0)

5.5 to 22

(10 to 4)

30 to 60

(2 to 2/0)

0.5 to 5.5

(20 to 10)

1.25

(16)

80 to 100

(3/0 to 4/0 )80(3/0)

5.5 to 22

(10 to 4)

38 to 60

(1 to 2/0)

0.5 to 5.5

(20 to 10)

50 to 100

(1/0 to 4/0 )

100

(4/0)

1.25

(16)

50 × 2P

(1/0 × 2P)

100

(4/0)

5.5 to 60

(10 to 2/0)

30 to 60

(3 to 4/0)

0.5 to 5.5

(20 to 10)

80 to 125

(3/0 to 250 )

80 to 100

(3/0 to 4/0 )

(1/0)

1.25

(16)

80 × 2P

(3/0 × 2P)

80 × 2P

(3/0 × 2P)

5.5 to 60

(10 to 2/0)

100 to 200

(3/0 to 400 )

0.5 to 5.5

(20 to 10)

150 to 200

(250 to 400)

100 to 150

(4/0 to 300 )

100

(3/0)

1.25

(16)

150 × 2P

(250 × 2P)

100 × 2P

(4/0 × 2P)

5.5 to 60

(10 to 2/0)

60 to 150

(2/0 to 300 )

0.5 to 5.5

(20 to 10)

60 × 2P

(2/0 × 2P)

1.25

(16)

200 × 2P

200 to 325

(350 to 600)

or 50 × 4P

(350 × 2P

or 1/0 ×

2P)

150 × 2P

150 to 325

(300 to 600)

or 50 × 4P

(300 × 2P

or 1/0 ×

4P)

5.5 to 60

(10 to 2/0)

150

(300)

0.5 to 5.5

(20 to 10)

150 × 2P

(300 × 2P)

1.25

(16)

2

–

30

(2)

–

38

(1)

–

50

–

–

–

Wire Type

Power cables,

e.g., 600 V vinyl

power cables

2

-8

Page 39

Inverter

Model

3G3PV-

A4004-E

Table 2.2 400 V Class Wire Sizes

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

Tightening

Termi-

nal

Screws

M4 1.2 to 1.5

Torque

(N•m)

Wiring Main Circuit Terminals

Possible

Wire Sizes

2

(AWG)

mm

2 to 5.5

(14 to 10)

Recom-

mended

Wire Size

2

mm

(AWG)

2

(14)

Wire Type

A4007-E

A4015-E

A4022-E

A4037-E

A4040-E

A4055-E

A4075-E

A4110-E

A4150-E

A4185-E

A4220-E

B4220-E

A4300-E

B4300-E

A4370-E

B4370-E

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2,

W/T3

R/L1, S/L2, T/L3, , 1, 3, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, 3, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, U/T1, V/T2, W/

T3, R1/L11, S1/L21, T1/L31

3

M4 1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

M4

1.2 to 1.5

M4 1.2 to 1.5

M4 1.2 to 1.5

M5 2.5

M5 2.5

M5

(M6)

M6 4.0 to 5.0

M6 4.0 to 5.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

2.5

(4.0 to 5.0)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

2 to 5.5

(14 to 10)

3.5 to 5.5

(12 to 10)

2 to 5.5

(14 to 10)

5.5(10)

3.5 to 5.5

(12 to 10)

5.5 to 14

(10 to 6)

8 to 14

(8 to 6)

5.5 to 14

(10 to 6)

8 to 38

(8 to 2)

8 to 22

(8 to 4)

14 to 22

(6 to 4)

14 to 38

(6 to 2)

22

(4)

22 to 38

(4 to 2)

22 to 60

(4 to 1/0)

8 to 22

(8 to 4)

22 to 38

(4 to 2)

2

(14)

2

(14)

2

(14)

3.5

(12)

2

(14)

3.5

(12)

2

(14)

3.5

(12)

2

(14)

5.5

(10)

3.5

(12)

8

(8)

5.5

(10)

8

(8)

5.5

(10)

8

(8)

8

(8)

14

(6)

14

(6)

22

(4)

22

(4)

38

(2)

-

22

(4)

Power cables,

e.g., 600 V vinyl

power cables

2

-

9

Page 40

Inverter

Model

Terminal Symbol

3G3PV-

R/L1, S/L2, T/L3, , 1, U/T1, V/T2, W/

A4450-E

B4450-E

T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

A4550-E

B4550-E

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

A4750-E

B4750-E

3

r/l1, ∆200/

200, ∆400/l2400

l2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

A4900-E

B4900-E

3

r/l1, ∆200/

200, ∆400/l2400

l2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M12 31.4 to 39.2

A411K-E

B411K-E

3

r/l1, ∆200/

200, ∆400/l2400

l2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M12 31.4 to 39.2

A413K-E

3

B413K-E

r/l1, ∆200/

200, ∆400/l2400

l2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M12 31.4 to 39.2

A416K-E

B416K-E

* The wire thickness is set for copper wires at 75°C.

3

r/l1, ∆200/

200, ∆400/l2400

l2

Tightening

Termi-

nal

Screws

Torque

(N•m)

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M8 9.0 to 10.0

M6 4.0 to 5.0

M8 9.0 to 10.0

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M4 1.3 to 1.4

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M4 1.3 to 1.4

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M4 1.3 to 1.4

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M4 1.3 to 1.4

M12 31.4 to 39.2

M8 8.8 to 10.8

M12 31.4 to 39.2

M4 1.3 to 1.4

Possible

Wire Sizes

2

(AWG)

mm

Recom-

mended

Wire Size

mm

(AWG)

38 to 60

(2 to 1/0)

8 to 22

(8 to 4)

22 to 38

(4 to 2)

50 to 60

(1 to 1/0)

8 to 22

(8 to 4)

22 to 38

(4 to 2)

60 to 100

(2/0 to 4/0 )60(2/0)

50 to 100

(1/0 to 4/0 )50(1/0)

5.5 to 22

(10 to 4)

38 to 60

(2 to 2/0)

0.5 to 5.5

(20 to 10)

80 to 100

(3/0 to 4/0 )

(4/0)

80 to 100

(3/0 to 4/0 )

(4/0)

8 to 22

(8 to 4)

50 to 100

(1 to 4/0)

0.5 to 5.5

(20 to 10)

50 to 100

(1/0 to 4/0 )

50 to 100

(1/0 to 4/0 )

50

(1/0 × 2P)

50 × 2P

(1/0 × 2P)

8 to 60

(8 to 2/0)

60 to 150

(2/0 to 300 )

(2/0)

0.5 to 5.5

(20 to 10)

80 to 100

(3/0 to 4/0 )

60 to 100

(2/0 to 4/0 )

80 × 2P

(3/0 × 2P)

60 × 2P

(2/0 × 2P)

8 to 60

(8 to 2/0)

100 to 150

(4/0 to 300 )

(4/0)

0.5 to 5.5

(20 to 10)

100 to 200

(4/0 to 400 )

80 to 200

(3/0 to 400 )

100 × 2P

(4/0 × 2P)

80 × 2P

(3/0 × 2P)

80 to 60

(8 to 2/0)

50 to 150

(1/0 to 300 )

50 × 2P

(1/0 × 2P)

0.5 to 5.5

(20 to 10)

38

(2)

22

(4)

50

(1)

22

(4)

38

(2)

1.25

(16)

100

100

50

(1)

1.25

(16)

×

600

1.25

(16)

100

1.25

(16)

1.25

(16)

2

-

-

-

-

2P

-

-

-

Wire Type

Power cables,

e.g., 600 V vinyl

power cables

-10

2

Page 41

Table 2.3 Closed-loop Connector Sizes (JIS C2805) (200 V Class and 400 V Class)

Wire Thickness (mm2)

0.5

0.75

1.25

2

3.5/5.5

8

14

22

30/38 M8 38 to 8

50/60

80

100 100 to 10

100

150 150 to 12

200 200 to 12

325

Wiring Main Circuit Terminals

Terminal Screws Size

M3.5 1.25 to 3.5

M4 1.25 to 4

M3.5 1.25 to 3.5

M4 1.25 to 4

M3.5 1.25 to 3.5

M4 1.25 to 4

M3.5 2 to 3.5

M4 2 to 4

M5 2 to 5

M6 2 to 6

M8 2 to 8

M4 5.5 to 4

M5 5.5 to 5

M6 5.5 to 6

M8 5.5 to 8

M5 8 to 5

M6 8 to 6

M8 8 to 8

M6 14 to 6

M8 14 to 8