Page 1

HAWK MV-4000

Smart Camera Guide

84-9007433-02 Rev D

Page 2

Copyright ©2021

Omron Microscan Systems, Inc.

Tel: +1.425.226.5700 / 800.762.1149

Fax: +1.425.226.8250

All rights reserved. The information contained herein is proprietary and is provided solely for the purpose of

allowing customers to operate and/or service Omron Microscan-manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of Omron Microscan.

Throughout this manual, trademarked names might be used. We state herein that we are using the names to the

benefit of the trademark owner, with no intention of infringement.

Disclaimer

The information and specifications described in this manual are subject to change without notice.

Latest Manual Version

For the latest version of this manual, see the Download Center on our web site at: www.microscan.com.

Technical Support

For technical support, e-mail:

Americas_support@microscan.com

EMEA_support@microscan.com

APAC_support@microscan.com

China_support@microscan.com

Warranty

For current warranty information, see: www.microscan.com/warranty.

Omron Microscan Systems, Inc.

United States Corporate Headquarters

+1.425.226.5700 / 800.762.1149

United States Northeast Technology Center

+1.603.598.8400 / 800.468.9503

European Headquarters

+31.172.423360

Asia Pacific Headquarters

+65.6846.1214

Page 3

Statements of Compliance

FCC

HAWK MV-4000 Smart Cameras have been tested for compliance with FCC (Federal Communications

Commission) requirements and have been found to conform to applicable FCC standards.

To comply with FCC RF exposure compliance requirements, this device must not be co-located

with or operate in conjunction with any other antenna or transmitter.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

CE

HAWK MV-4000 Smart Cameras have been tested for compliance with CE (Conformité Européenne)

requirements, and have been found to conform to applicable CE standards.

The CE Declaration of Conformity for this product is available from Omron Microscan upon request.

HAWK MV-4000 Smart Cameras have been tested by an independent electromagnetic compatibility

laboratory in accordance with the applicable specifications and instructions.

UL

HAWK MV-4000 Smart Cameras have been tested for compliance with UL (Underwriters Laboratories)

standards and guidelines, and have been found to conform to applicable UL standards.

Restricted Substances

See www.microscan.com/quality for Omron Microscan compliance statements related to all

applicable restricted substances.

Page 4

FCC Compliance Statement

Warning: Changes or modifications to these units not expressly approved by the party responsible for the compliance

could void the user's authority to operate this equipment.

The use of shielded cables for connections of these devices to other peripherals is required to meet the regulatory

requirements.

Note: These devices comply with Part 15 of FCC Rules. Operation is subject to the following two conditions:

1. These devices may not cause harmful interference, and

2. These devices must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for Class A digital devices, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of these devices in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his/her own expense.

Industry Canada Compliance Statement

These digital apparatuses do not exceed the Class A limits for radio noise emission from digital apparatuses set out

in the Radio Interference Regulations of Industry Canada.

Ces appareils numériques n’émettent pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de Classe A prescrites dans le Règlement sur le brouillage radioélectrique édicté par Industrie Canada.

EU Notice (European Union)

WARNING: These are class A products. In a domestic environment these products may cause radio interference in

which case the user may be required to take adequate measures.

AVERTISSEMENT: Ces appareils sont des produits informatiques de Classe A. Lorsque ces appareils sont utilisent

dans un environnement résidentiel, ces produits peuvent entraîner des interférences radioélectriques. Dans ce cas,

l'usager peut être prié de prendre des mesures correctives appropriées.

This device complies with Directive 2004/108/EC for Class A digital devices. They have been tested and found to

comply with EN55022/CISPR22 and EN55024/CISPR24.

Ces unités sont conformes à la Directive communautaire Directive 2004/108/EC pour les unités numériques de

Classe A. Les tests effectués one prouvé qu’elles sont conformes aux normes EN55022/CISPR22 et EN55024/CISPR24.

Directive on Waste Electrical and Electronic Equipment (WEEE)

Europe

(English) European user’s information – Directive on Waste Electrical and Electronic Equipment (WEEE)

Please refer to the Omron Microscan website (www.microscan.com) for recycling information.

(Français) Informations aux utilisateurs Européens – Règlementation des déchets d’équipements électriques

et électroniques (DEEE)

Se référer au site Web de Omron Microscan (www.microscan.com) pour l’information concernant le recyclage.

(Deutsch) Information für europäische Anwender – Europäische Regelungen zu Elektro- und Elektronikaltgeräten

(WEEE)

Bitte wenden Sie sich an dem Omron Microscan-Website (www.microscan.com) für Recycling Informationen.

(Italiano) Informazioni per gli utenti europei – Direttiva sui rifiuti di apparecchiature elettriche ed elettroniche

(RAEE)

Si prega di riferirsi al sito Web Omron Microscan (www.microscan.com) per le informazioni di riciclaggio.

Page 5

HAWK MV-4000 Safety Warnings and Symbols Key

Before using the HAWK MV-4000 Smart Camera, you should be aware of the meanings of the

safety warnings and symbols on the device. The following is a list of HAWK MV-4000 symbols and

their meanings.

Symbol

a

Description

• Caution: Read the HAWK MV-4000 Smart Camera Guideb (this document)

before using the device. The guide contains product specifications, hardware

configurations, connector and cable pin assignments, wiring instructions,

accessory

operation of the device.

•

This product must be used as specified. The protection provided by its components

may be compromised if the product is used improperly.

• Refer to the electrical specifications section in the HAWK MV-4000 Smart

Camera Guide for voltage and current ratings.

• There are no user-serviceable parts inside this product. Contact Omron

Microscan for repair or replacement.

• To maintain IP67 conformity, all unused connectors on the HAWK MV-4000

must be capped and the optional IP case must be screwed firmly into place.

• This product meets Category 1 installation requirements per industry standards.

• This product is designed for use in a Pollution Degree 2 environment per

industry standardsc.

configuration instructions, and additional information related to the

• This product is designed for indoor use only.

•

This product is designed for operation at temperatures ranging from 0° C to 50° C.

• This product is not intended for use at altitudes exceeding 2000 meters.

• DC current only.

• The HAWK MV-4000 can only be powered using a 24VDC power source.

a. Symbol color or shape may be slightly different on the product.

b. HAWK MV-4000 Smart Camera Guide available on Tools Drive (P/N 37-000010-01) or at www.microscan.com.

c. Per CAN/CSA-C22.2 No 61010-1-12, UL std. No 61010-1 (3rd edition), and EN Std. No. 61010-1 (3rd edition).

Page 6

Contents

PREFACE Welcome viii

Purpose of This Manual viii

Manual Conventions viii

CHAPTER 1 Introduction 1-1

Product Summary 1-2

Features and Benefits 1-3

Applications 1-4

Package Contents 1-4

HAWK MV-4000 Smart Camera Models 1-5

HAWK MV-4000 Part Number Structure 1-6

CHAPTER 2 System Components 2-1

Hardware Components and Accessories 2-2

HAWK MV-4000 Dimensions 2-6

Label Information 2-10

Mounting, Connecting, and Wiring 2-11

Connecting to the I/O Interface 2-17

Connectors and Pinouts 2-19

Outputs 2-20

Inputs 2-29

Input/Output Wiring Using Flying Lead Cable 61-9000151-01 2-38

Ground and Shield Considerations 2-39

Electrical and I/O Specifications 2-41

Environmental Specifications 2-42

Status Indicators 2-43

Adding a HAWK MV-4000 to a Network 2-44

Setting Up a Job in AutoVISION 2-45

Trigger Debounce 2-50

Setting Up Partial Scan 2-52

CHAPTER 3 Lighting 3-1

Illumination 3-2

External Illumination Control and Wiring 3-3

HAWK MV-4000 Smart Camera Guide vi

Page 7

APPENDIX A

APPENDIX B

APPENDIX C

APPENDIX D

APPENDIX E

APPENDIX F

APPENDIX G

APPENDIX H

Selecting a Lens A-1

Lens Selection A-2

Lens Specifications A-4

Cable Specifications B-1

61-9000132-01 Cable, Adapter, HAWK MV-4000 to QX-1 B-2

61-9000134-0X Cable, Ethernet, X-Code/RJ45 CAT 6A, 1 m, 3 m, 5 m B-3

M12 to Smart Series and Camera Cables B-4

97-000012-01 Power Supply, M12 12-Pin Socket, 1.3 m B-5

99-9000016-01 Photo Sensor, VIS, NPN, Light On/Dark On B-6

General Specifications C-1

Sensor Board C-2

CPU Board C-3

VGA/USB Port C-4

Electrical Specifications C-5

Environmental Specifications C-6

Dimensions C-7

Digital I/O and Power Adapter Cable Connector C-8

100/1000 Base-T Connector C-10

VGA/USB Connector C-11

Liquid Lens Connector C-13

MVMonitor Web Page D-1

Using the MVMonitor Web Page D-2

CloudLink Web HMI E-1

Connecting E-2

Application Overview E-3

Application Bar E-4

Pages, Panels, and Widgets E-5

Serial Commands F-1

Operating System Save and Restore G-1

Restore to Omron Microscan Factory Settings G-2

Access Omron Microscan Rescue Utility G-7

Back Up/Restore/Capture the OS Image with Omron Microscan Rescue

Utility G-11

OS Config Application H-1

Global Settings Tab H-2

Write Filter Tab H-3

Capture OS Tab H-4

Languages Tab H-5

eMMC Tab H-6

EULA Tab H-7

vii HAWK MV-4000 Smart Camera Guide

Page 8

Preface

PREFACE Welcome

Purpose of This Manual

This manual contains detailed information about how to configure and operate the HAWK

MV-4000 Smart Camera.

Manual Conventions

• Items emphasizing important information are bolded.

• Menu selections, menu items, and entries in screen images are indicated as: Run

(triggered), Modify..., etc.

HAWK MV-4000 Smart Camera Guide viii

Page 9

1

CHAPTER 1 Introduction

HAWK MV-4000 Smart Camera

1

Introduction

HAWK MV-4000 Smart Camera Guide 1-1

Page 10

Chapter 1 Introduction

Product Summary

The HAWK MV-4000 is Omron Microscan’s high-performance smart camera. It is the

middle tier in a suite of products that includes MicroHAWK MV Smart Cameras at the

lower end and Visionscape PC-Based GigE Camera systems at the higher end.

The HAWK MV-4000 is a C-Mount camera fully accessorized for use with Omron

Microscan’s NERLITE Smart Series of machine vision lighting products.

The HAWK MV-4000 features a full range of sensors, from 0.3 MP to 5 MP in both

monochrome and color. The sensors are all based on the ON Semiconductor PYTHON

CMOS series. All sensors have a 4.8 μm pixel size enabling them to capture very high-quality

images at very high frame rates.

The combination of C-Mount lens, external lighting, and 0.3 to 5 MP sensors allows users

to configure the system to accomplish virtually any application, from reading tiny 1D or 2D

symbols on flat panel displays to inspecting entire automotive assemblies.

The processor is a Dual-Core Intel Celeron N2807 with 2 GB of RAM and 32 GB of eMMC

(flash disk) storage memory. The HAWK MV-4000 is able to store, load, and run up to 50 simple

or complex jobs. Processing times reach near-PC speeds, enabling the camera to keep up with

line rates of up to 6,000 parts per minute and speeds of over 300 inches per second.

The camera is also equipped with real-time Digital I/O, RS-232, and GigE Ethernet ports.

Through these communication channels, the user can control and trigger the unit, as well as

receive results and images. The GigE port allows images to be ported to a display at nearly

the same speed as the frame rate. EtherNet/IP allows seamless integration with most of the

key PLC platform devices on the market.

Finally, like MicroHAWK MV or Visionscape PC-Based GigE Camera systems, the HAWK

MV-4000 can be programmed through a variety of user interfaces. This includes

AutoVISION, which is a highly intuitive and simple UI that can be mastered by a casual

user on the factory floor. It also includes Visionscape FrontRunner, which is the full

professional UI offering the entire Visionscape tool set to the user, including scripting tools

that allow the user to create custom tools and algorithms. The HAWK MV-4000 can be

controlled and monitored through custom web interfaces or UIs specifically designed and

programmed for the application using Visionscape’s powerful .NET controls.

1-2 HAWK MV-4000 Smart Camera Guide

Page 11

Features and Benefits

Features and Benefits

• Standard-fidelity and high-fidelity C-Mount optics;

• Designed for use with NERLITE Smart Series machine vision illuminators;

• Full range of sensors with speeds up to 290 frames per second;

– 0.3 MP (640 x 480), 1.3 MP (1280 x 1024), 2.0 MP (1920 x 1200), and 5.0 MP

(2592 x 2048) resolution;

– Monochrome and color versions;

1

Introduction

–4.8

• Dual-Core Intel processor capable of near-PC processing speeds

• 32 GB of eMMC and 2 GB of RAM for storing and running many large and complex jobs;

• Real-time Digital I/O, RS-232, and GigE comm. channels;

• IP67-rated design (when lens cover is installed) for use in industrial environments;

• Simplified configuration with AutoVISION Software;

• Advanced configuration with Visionscape FrontRunner software;

• Custom UI creation and machine integration using Visionscape .NET controls, Rest

APIs, and serial command set;

• HMI via VGA and USB connectivity, or via web using CloudLink UI;

• Scalable down to Omron Microscan’s MicroHAWK MV Smart Camera;

• Scalable up to Omron Microscan’s Multi-GigE Camera PC-Based Systems.

μm

pixel size;

HAWK MV-4000 Smart Camera Guide 1-3

Page 12

Chapter 1 Introduction

Applications

• Fast-moving consumer goods inspection;

• Automotive assembly inspection and verification;

• High-precision gauging and guidance;

• Electronics assembly verification and identification;

• Semiconductor packaging and component inspection;

• 1D, 2D, and OCR symbol reading for any size mark;

• Fast inline 1D and 2D symbol verification and validation;

• Color inspection and verification.

Package Contents

Before you install AutoVISION Software and connect the HAWK MV-4000 Smart Camera,

please take a moment to confirm that the following items are present:

• HAWK MV-4000 Smart Camera;

• HAWK MV-4000 Adapter Cable, 61-9000132-01;

• Omron Microscan Tools Drive – USB flash drive containing AutoVISION Software and

full recovery image for the HAWK MV-4000;

• Required accessories such as a power supply cable.

1-4 HAWK MV-4000 Smart Camera Guide

Page 13

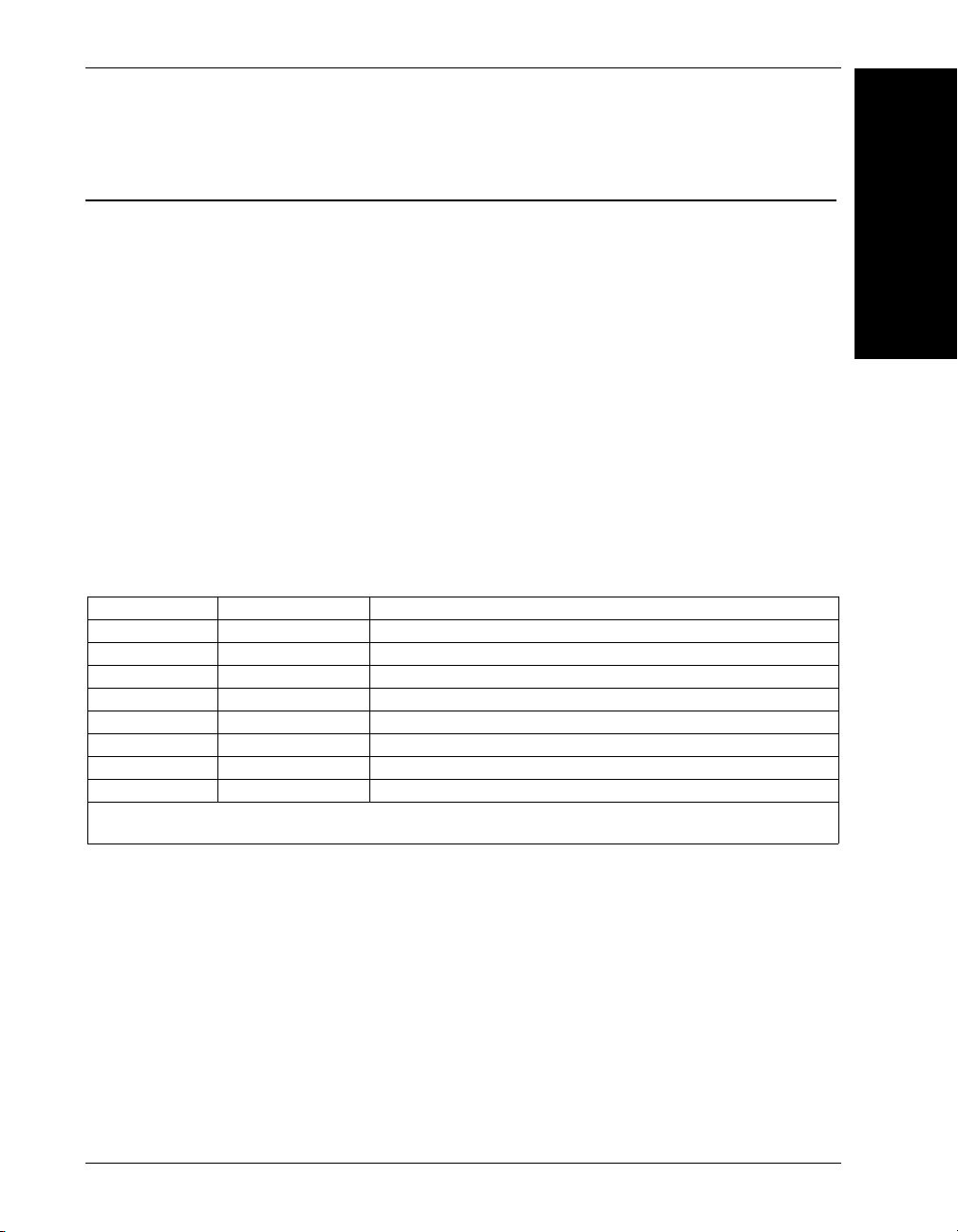

HAWK MV-4000 Smart Camera Models

HAWK MV-4000 Smart Camera Models

The table below lists and describes the basic HAWK MV-4000 Smart Camera models not

including lenses, lens caps, accessories, and lighting. PPP at the end of each part number

represents the license level. Each model can be ordered with one of the following five

license levels:

100 – AutoVISION Sensor (Includes

101 – AutoVISION (Includes AutoVISION’s machine vision and auto ID tools);

102 – AutoVISION + Visionscape (Includes AutoVISION’s machine vision and auto ID

tools and full Visionscape);

103 – AutoVISION + Verification/OCV (Includes AutoVISION’s machine vision and auto ID

, symbol verification, and optical character verification);

tools

104 – AutoVISION + Visionscape + Verification/OCV (Includes all AutoVISION and

Visionscape capabilities).

Additional part numbers that include lenses and lens caps are available in the Omron

Microscan Product Pricing Catalog and through Omron Microscan’s Order Management

System. Additional accessories and lights can be purchased separately.

Part Number Camera Name Description

8X11-0000-PPPP HAWK MV-4000-03 HAWK MV-4000, Monochrome, 0.3 MP (640 x 480), 1/4” CMOS Sensor

8X12-0000-PPPP HAWK MV-4000-13 HAWK MV-4000, Monochrome, 1.3 MP (1280 x 1024), 1/2” CMOS Sensor

8X13-0000-PPPP HAWK MV-4000-20 HAWK MV-4000, Monochrome, 2.0 MP (1920 x 1200), 2/3” CMOS Sensor

8X14-0000-PPPP HAWK MV-4000-50 HAWK MV-4000, Monochrome, 5.0 MP (2592 x 2048), 1” CMOS Sensor

8X15-0000-PPPP HAWK MV-4000-03C HAWK MV-4000, Color, 0.3 MP (640 x 480), 1/4” CMOS Sensor

8X16-0000-PPPP HAWK MV-4000-13C HAWK MV-4000, Color, 1.3 MP (1280 x 1024), 1/2” CMOS Sensor

8X17-0000-PPPP HAWK MV-4000-20C HAWK MV-4000, Color, 2.0 MP (1920 x 1200), 2/3” CMOS Sensor

8X18-0000-PPPP HAWK MV-4000-50C HAWK MV-4000, Color, 5.0 MP (2592 x 2048), 1” CMOS Sensor

Note:

All models include dual-core Celeron® CPU, 2 GB of memory, 32 GB eMMC storage memory, and run Microsoft® Windows®

10 IoT Enterprise (64 bit).

AutoVISION’s machine vision tools only);

1

Introduction

HAWK MV-4000 Smart Camera Guide 1-5

Page 14

Chapter 1 Introduction

HAWK MV-4000 Part Number Structure

HAWK MV-4000 part numbers follow the format 8ABS-LFFA-LPPP.

8 = HAWK MV-4000 Smart Camera

(A) Enclosure

0 = No Lens Cover

1 = 50 mm Lens Cover

2 = 70 mm Lens Cover

(B) Software = 1 (Machine Vision)

(S) Sensor Type

1 = VGA, Mono

2 = 1.3 MP, Mono

3 = 2 MP, Mono

4 = 5 MP, Mono

5 = VGA, Color

6 = 1.3 MP, Color

7 = 2 MP, Color

8 = 5 MP, Color

(L) Lens

0 = No Lens

1 = 2/3” Standard Def.

2 = 2/3” High Def.

3 = 1” High Def.

(FF) Lens Focal Length

00 = No Lens

XX = Focal Length (mm)

(A) Accessories = 0

(L) Lighting = 0

(PPP) License

100 = AutoVISION Sensor

101 = AutoVISION

102 = AutoVISION + Visionscape

103 = AutoVISION + Verific

104 = AutoVISION + Visionscape + Verification/OCV

1-6 HAWK MV-4000 Smart Camera Guide

ation/OCV

Page 15

2

CHAPTER 2 System Components

This section contains specific information about system components as well

as information to help you connect your HAWK MV-4000 Smart Camera.

Note: There are no user-serviceable parts inside the camera.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-1

Page 16

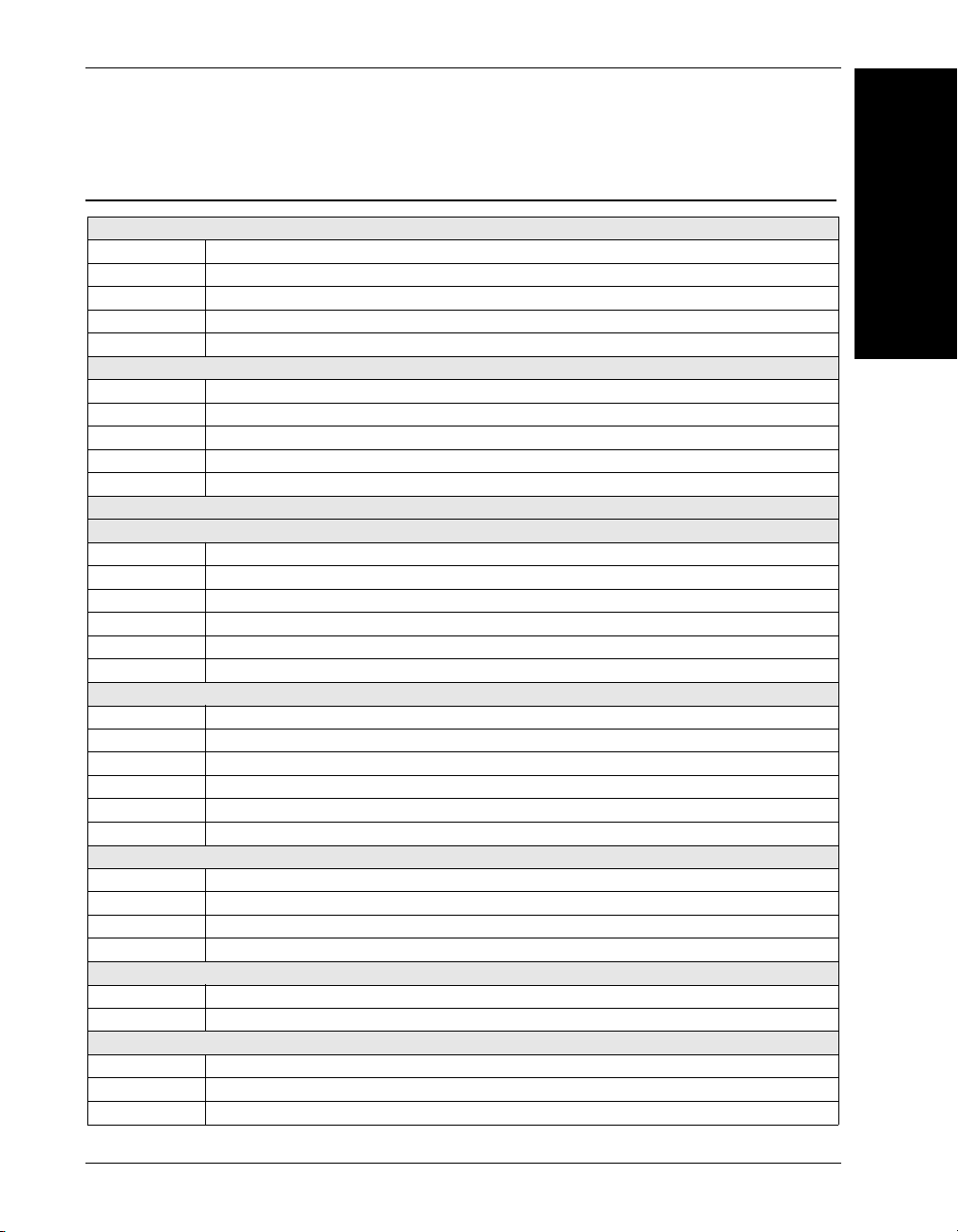

Chapter 2 System Components

Hardware Components and Accessories

This section contains information about system components as well as information to help

you connect the HAWK MV-4000 Smart Camera. Specific information describes connectors,

adapters, cables, pinouts, and signals.

HAWK MV-4000 Smart Cameras (All cameras ship with an adapter cable.)

0.3 Megapixel Mono

8011-0000-0100 HAWK MV-4000-03, 0.3 Megapixel (640 x 480), Mono, AutoVISION Sensor

8011-0000-0101 HAWK MV-4000-03, 0.3 Megapixel (640 x 480), Mono, AutoVISION

8011-0000-0102 HAWK MV-4000-03, 0.3 Megapixel (640 x 480), Mono, AutoVISION + Visionscape

8011-0000-0103 HAWK MV-4000-03, 0.3 Megapixel (640 x 480), Mono, AutoVISION + Verification / OCV

8011-0000-0104 HAWK MV-4000-03, 0.3 Megapixel (640 x 480), Mono, AutoVISION + Visionscape + Verification / OCV

1.3 Megapixel Mono

8012-0000-0100 HAWK MV-4000-13, 1.3 Megapixel (1280 x 1024), Mono, AutoVISION Sensor

8012-0000-0101 HAWK MV-4000-13, 1.3 Megapixel (1280 x 1024), Mono, AutoVISION

8012-0000-0102 HAWK MV-4000-13, 1.3 Megapixel (1280 x 1024), Mono, AutoVISION + Visionscape

8012-0000-0103 HAWK MV-4000-13, 1.3 Megapixel (1280 x 1024), Mono, AutoVISION + Verification / OCV

8012-0000-0104 HAWK MV-4000-13, 1.3 Megapixel (1280 x 1024), Mono, AutoVISION + Visionscape + Verification / OCV

2.0 Megapixel Mono

8013-0000-0100 HAWK MV-4000-20, 2.0 Megapixel (1920 x 1200), Mono, AutoVISION Sensor

8013-0000-0101 HAWK MV-4000-20, 2.0 Megapixel (1920 x 1200), Mono, AutoVISION

8013-0000-0102 HAWK MV-4000-20, 2.0 Megapixel (1920 x 1200), Mono, AutoVISION + Visionscape

8013-0000-0103 HAWK MV-4000-20, 2.0 Megapixel (1920 x 1200), Mono, AutoVISION + Verification / OCV

8013-0000-0104 HAWK MV-4000-20, 2.0 Megapixel (1920 x 1200), Mono, AutoVISION + Visionscape + Verification / OCV

5.0 Megapixel Mono

8014-0000-0100 HAWK MV-4000-50, 5.0 Megapixel (2592 x 2048), Mono, AutoVISION Sensor

8014-0000-0101 HAWK MV-4000-50, 5.0 Megapixel (2592 x 2048), Mono, AutoVISION

8014-0000-0102 HAWK MV-4000-50, 5.0 Megapixel (2592 x 2048), Mono, AutoVISION + Visionscape

8014-0000-0103 HAWK MV-4000-50, 5.0 Megapixel (2592 x 2048), Mono, AutoVISION + Verification / OCV

8014-0000-0104 HAWK MV-4000-50, 5.0 Megapixel (2592 x 2048), Mono, AutoVISION + Visionscape + Verification / OCV

0.3 Megapixel Color

8015-0000-0100 HAWK MV-4000-03C, 0.3 Megapixel (640 x 480), Color, AutoVISION Sensor

8015-0000-0101 HAWK MV-4000-03C, 0.3 Megapixel (640 x 480), Color, AutoVISION

8015-0000-0102 HAWK MV-4000-03C, 0.3 Megapixel (640 x 480), Color, AutoVISION + Visionscape

8015-0000-0103 HAWK MV-4000-03C, 0.3 Megapixel (640 x 480), Color, AutoVISION + Verification / OCV

8015-0000-0104 HAWK MV-4000-03C, 0.3 Megapixel (640 x 480), Color, AutoVISION + Visionscape + Verification / OCV

1.3 Megapixel Color

8016-0000-0100 HAWK MV-4000-13C, 1.3 Megapixel (1280 x 1024), Color, AutoVISION Sensor

8016-0000-0101 HAWK MV-4000-13C, 1.3 Megapixel (1280 x 1024), Color, AutoVISION

8016-0000-0102 HAWK MV-4000-13C, 1.3 Megapixel (1280 x 1024), Color, AutoVISION + Visionscape

8016-0000-0103 HAWK MV-4000-13C, 1.3 Megapixel (1280 x 1024), Color, AutoVISION + Verification / OCV

8016-0000-0104

HAWK MV-4000-13C, 1.3 Megapixel (1280 x 1024), Color, AutoVISION + Visionscape + Verification / OCV

2-2 HAWK MV-4000 Smart Camera Guide

Page 17

Hardware Components and Accessories (continued)

Hardware Components and Accessories (continued)

2.0 Megapixel Color

8017-0000-0100 HAWK MV-4000-20C, 2.0 Megapixel (1920 x 1200), Color, AutoVISION Sensor

8017-0000-0101 HAWK MV-4000-20C, 2.0 Megapixel (1920 x 1200), Color, AutoVISION

8017-0000-0102 HAWK MV-4000-20C, 2.0 Megapixel (1920 x 1200), Color, AutoVISION + Visionscape

8017-0000-0103 HAWK MV-4000-20C, 2.0 Megapixel (1920 x 1200), Color, AutoVISION + Verification / OCV

8017-0000-0104

5.0 Megapixel Color

8018-0000-0100 HAWK MV-4000-50C, 5.0 Megapixel (2592 x 2048), Color, AutoVISION Sensor

8018-0000-0101 HAWK MV-4000-50C, 5.0 Megapixel (2592 x 2048), Color, AutoVISION

8018-0000-0102 HAWK MV-4000-50C, 5.0 Megapixel (2592 x 2048), Color, AutoVISION + Visionscape

8018-0000-0103 HAWK MV-4000-50C, 5.0 Megapixel (2592 x 2048), Color, AutoVISION + Verification / OCV

8018-0000-0104

HAWK MV-4000 Lenses and Lens Caps

Standard Resolution for 2/3" Sensors (General Inspection, Reading, Some Verification)

98-9000167-01 Lens, C-Mount, 6 mm, Standard Resolution, 2/3" Sensor

98-9000168-01 Lens, C-Mount, 9 mm, Standard Resolution, 2/3" Sensor

98-9000169-01 Lens, C-Mount, 12.5 mm, Standard Resolution, 2/3" Sensor

98-9000170-01 Lens, C-Mount, 16 mm, Standard Resolution, 2/3" Sensor

98-9000171-01 Lens, C-Mount, 25 mm, Standard Resolution, 2/3" Sensor

98-9000172-01 Lens, C-Mount, 35 mm, Standard Resolution, 2/3" Sensor

High Resolution for 2/3" Sensors (Gauging, Verification)

98-9000192-01 Lens, C-Mount, 6 mm, High Resolution, 2/3" Sensor

98-9000165-01 Lens, C-Mount, 8 mm, High Resolution, 2/3" Sensor

98-9000166-01 Lens, C-Mount, 12 mm, High Resolution, 2/3" Sensor

98-9000154-01 Lens, C-Mount, 16 mm, High Resolution, 2/3" Sensor

98-9000164-01 Lens, C-Mount, 25 mm, High Resolution, 2/3" Sensor

98-9000163-01 Lens, C-Mount, 35 mm, High Resolution, 2/3" Sensor

High Resolution for 1" Sensors (All applications. Required for 1" 5 Megapixel Sensor)

98-9000174-01 Lens, C-Mount, 12.5 mm, High Resolution, 1" Sensor

98-9000175-01 Lens, C-Mount, 16 mm, High Resolution, 1" Sensor

98-9000176-01 Lens, C-Mount, 25 mm, High Resolution, 1" Sensor

98-9000177-01 Lens, C-Mount, 35 mm, High Resolution, 1" Sensor

C-Mount Liquid Lens

98-9000179-01 Lens, Liquid, C-Mount, F2.8/16 mm, 2/3" Sensor, I2C Interface

98-9000178-01 Lens, Liquid, C-Mount, F4/25 mm, 2/3" Sensor, I2C Interface

Lens Accessories

98-9000155-01 IP67 Lens Cover for HAWK MV-4000, 50 mm Length

98-9000156-01 IP67 Lens Cover HAWK MV-4000, 70 mm Length

98-CO206 Lens Extension Tube Set, 0.5 mm, 1 mm, 5 mm, 10 mm, 20 mm, 40 mm

HAWK MV-4000-20C, 2.0 Megapixel (1920 x 1200), Color, AutoVISION + Visionscape + Verification / OCV

HAWK MV-4000-50C, 5.0 Megapixel (2592 x 2048), Color, AutoVISION + Visionscape + Verification / OCV

2

System Components

HAWK MV-4000 Smart Camera Guide 2-3

Page 18

Chapter 2 System Components

Hardware Components and Accessories (continued)

HAWK MV-4000 Cables, Smart Series Illuminator Control Cable, and Power Supply

HAWK MV-4000 X-CODE Ethernet Port Cables

61-9000134-01 Cable, HAWK MV-4000 Ethernet, X-CODE / RJ45 CAT 6A, 1 m

61-9000134-02 Cable, HAWK MV-4000 Ethernet, X-CODE / RJ45 CAT 6A, 3 m

61-9000134-03 Cable, HAWK MV-4000 Ethernet, X-CODE / RJ45 CAT 6A, 5 m

HAWK MV-4000 VGA / USB Port Connector Cables

61-9000143-01 Cable, HAWK MV-4000 M12 to USB Socket, 1 m

61-9000147-

HAWK MV-4000 Digital I/O Port Connector Cables

61-9000132-01 Cable, Adapter, HAWK MV-4000 to Accessory Cables / Power Supply (Supplied with camera)

61-9000151-01 Cable, HAWK MV-4000 M12 to Flying Leads, 3 m (No Adapter Required)

QX-1 Interface Cables and Accessories

61-000162-02 QX Cordset, HAWK MV-4000 Adapter to QX-1 M12 Plug (Screw-On), 1 m

61-000148-02 QX Cordset, HAWK MV-4000 Adapter to QX-1 M12 Plug (Screw-On), 3 m

98-000103-02 QX-1 Interface Device

99-9000016-01 Photo Sensor, VIS, NPN, Light On/Dark On

20-610024-01 Trigger Connector, 4-Pin Plug (Screw Terminal, Field-Wireable) (Self-Wiring)

Smart Series Illuminator Control Cables

61-9000135-01 Y Cable, HAWK MV-4000 Adapter to Smart Series Illuminator and QX-1, Power, 1 m

61-9000137-01 Y Cable, HAWK MV-4000 Adapter to Smart Series Illuminator and QX-1, Strobe, 1 m

61-000204-01 Cable, QX-1 to Smart Series Illuminator, Continuous Power

61-000218-01* Cable, QX-1 to Smart Series Illuminator, Strobe

Power Supply

97-000012-01 Power Supply, 100-240VAC, +24VDC, M12 12-pin Socket

HAWK MV-4000 and Smart Series Illuminator Mount

Standard Mount

98-9000209-01 Universal Mount, HAWK MV-4000

Smart Series Illuminator / HAWK MV-4000 Mounting Kits

98-9000120-01 Kit, Bracket, MAX 300 to HAWK MV-4000

98-9000121-01 Kit, Bracket, DOAL to HAWK MV-4000

98-9000122-01 Kit, Bracket, Ring 60 / 70 to HAWK MV-4000

98-9000123-01 Kit, Bracket, Ring 100 to HAWK MV-4000

98-9000137-01 Kit, Smart Series Pharmalite, HAWK MV-4000

01 Cable, HAWK MV-4000 M12 to VGA and USB, 1 m

2-4 HAWK MV-4000 Smart Camera Guide

Page 19

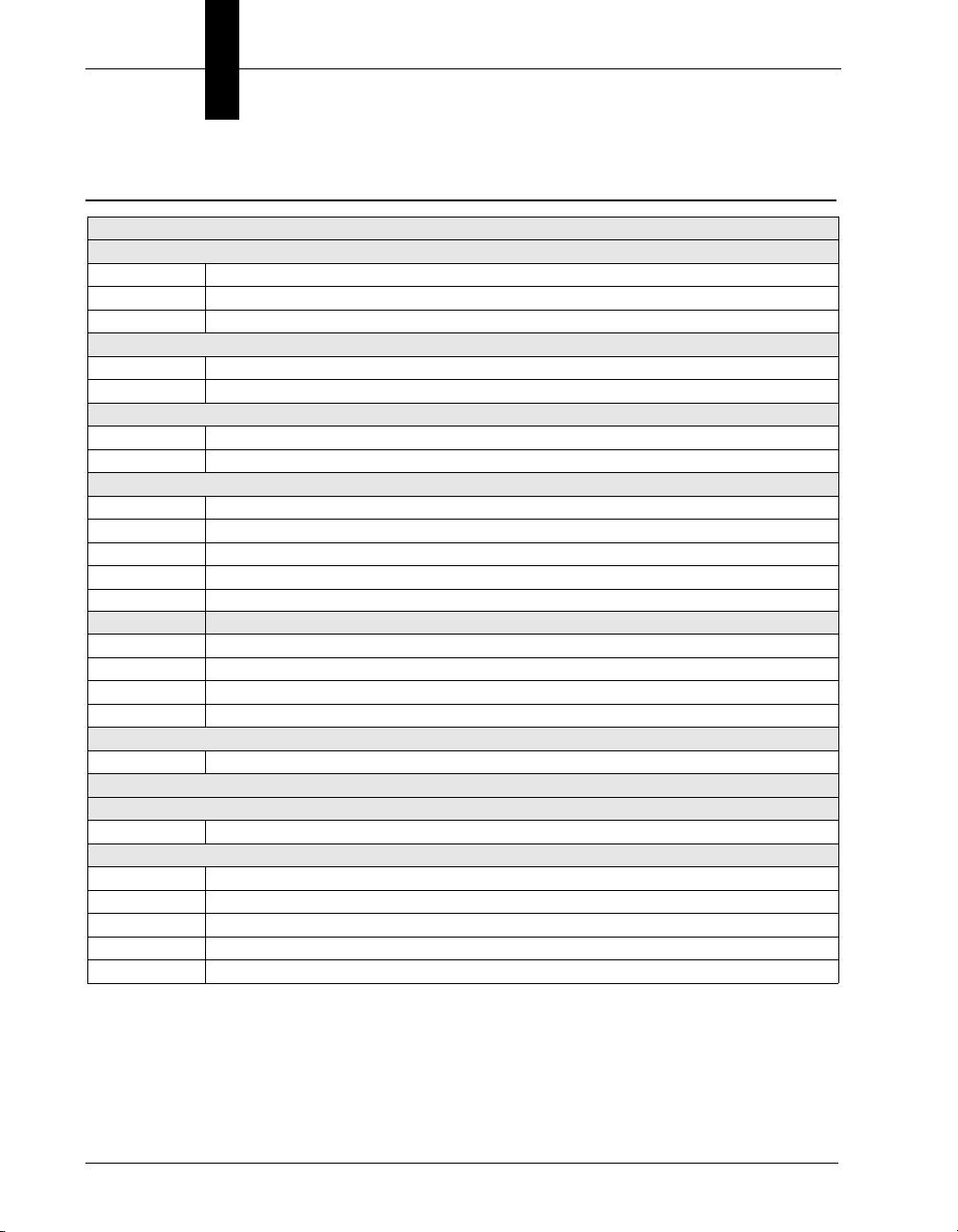

Hardware Components and Accessories (continued)

Hardware Components and Accessories (continued)

Licensing

HAWK MV-4000 License Upgrades

LIC-0700-003* License, Machine Vision, AutoVISION

LIC-0700-006* License, Machine Vision, Visionscape

LIC-0700-009* License, Machine Vision,Verification / OCV

LIC-0700-011* License, Machine Vision, AutoVISION Sensor

LIC-0700-325* License, Machine Vision, Machine Vision Unlock

Camera Kits with License, Lens, IP Cover, and Mount

0.3 Megapixel, Standard Lens

8211-1090-0102 HAWK MV-4000-03, AutoVISION + Visionscape, 9 mm Standard Lens, IP Cover, Universal Mount

8111-1160-0102 HAWK MV-4000-03, AutoVISION + Visionscape, 16 mm Standard Lens, IP Cover, Universal Mount

1.3 Megapixel, Standard Lens

8112-1120-0104 HAWK MV-4000-13, AutoVISION + Visionscape + Verification / OCV, 12.5 mm Std. Lens, IP Cover, Universal Mount

8112-1250-0104 HAWK MV-4000-13, AutoVISION + Visionscape + Verification / OCV, 25 mm Std. Lens, IP Cover, Universal Mount

1.3 Megapixel, High Resolution Lens

8212-2160-0104

8212-2250-0104

8212-2350-0104

2.0 Megapixel, Standard Lens

8113-1160-0104

8113-1350-0104

2.0 Megapixel, High Resolution Lens

8213-2160-0104

8213-2250-0104

8213-2350-0104

2.0 Color, Standard Lens

8117-1090-0102 HAWK MV-4000-20C, AutoVISION + Visionscape, 9 mm Standard Lens, IP Cover, Universal Mount

8117-1160-0102 HAWK MV-4000-20C, AutoVISION + Visionscape, 16 mm Standard Lens, IP Cover, Universal Mount

8117-1350-0102 HAWK MV-4000-20C, AutoVISION + Visionscape, 35 mm Standard Lens, IP Cover, Universal Mount

5.0 Megapixel, 1" Lens

8014-3160-0104

8214-3250-0104

8214-3350-0104

HAWK MV-4000-13, AutoVISION + Visionscape + Ver. / OCV, 16 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-13, AutoVISION + Visionscape + Ver. / OCV, 25 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-13, AutoVISION + Visionscape + Ver. / OCV, 35 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-20, AutoVISION + Visionscape + Verification / OCV, 16 mm Std. Lens, IP Cover, Universal Mount

HAWK MV-4000-20, AutoVISION + Visionscape + Verification / OCV, 35 mm Std. Lens, IP Cover, Universal Mount

HAWK MV-4000-20, AutoVISION + Visionscape + Ver. / OCV, 16 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-20, AutoVISION + Visionscape + Ver. / OCV, 25 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-20, AutoVISION + Visionscape + Ver. / OCV, 35 mm High Res. Lens, IP Cover, Universal Mount

HAWK MV-4000-50, AutoVISION + Visionscape + Verification / OCV, 16 mm 1" Lens, No Cover, Universal Mount

HAWK MV-4000-50, AutoVISION + Visionscape + Verification / OCV, 25 mm 1" Lens, IP Cover, Universal Mount

HAWK MV-4000-50, AutoVISION + Visionscape + Verification / OCV, 35 mm 1" Lens, IP Cover, Universal Mount

2

System Components

HAWK MV-4000 Smart Camera Guide 2-5

Page 20

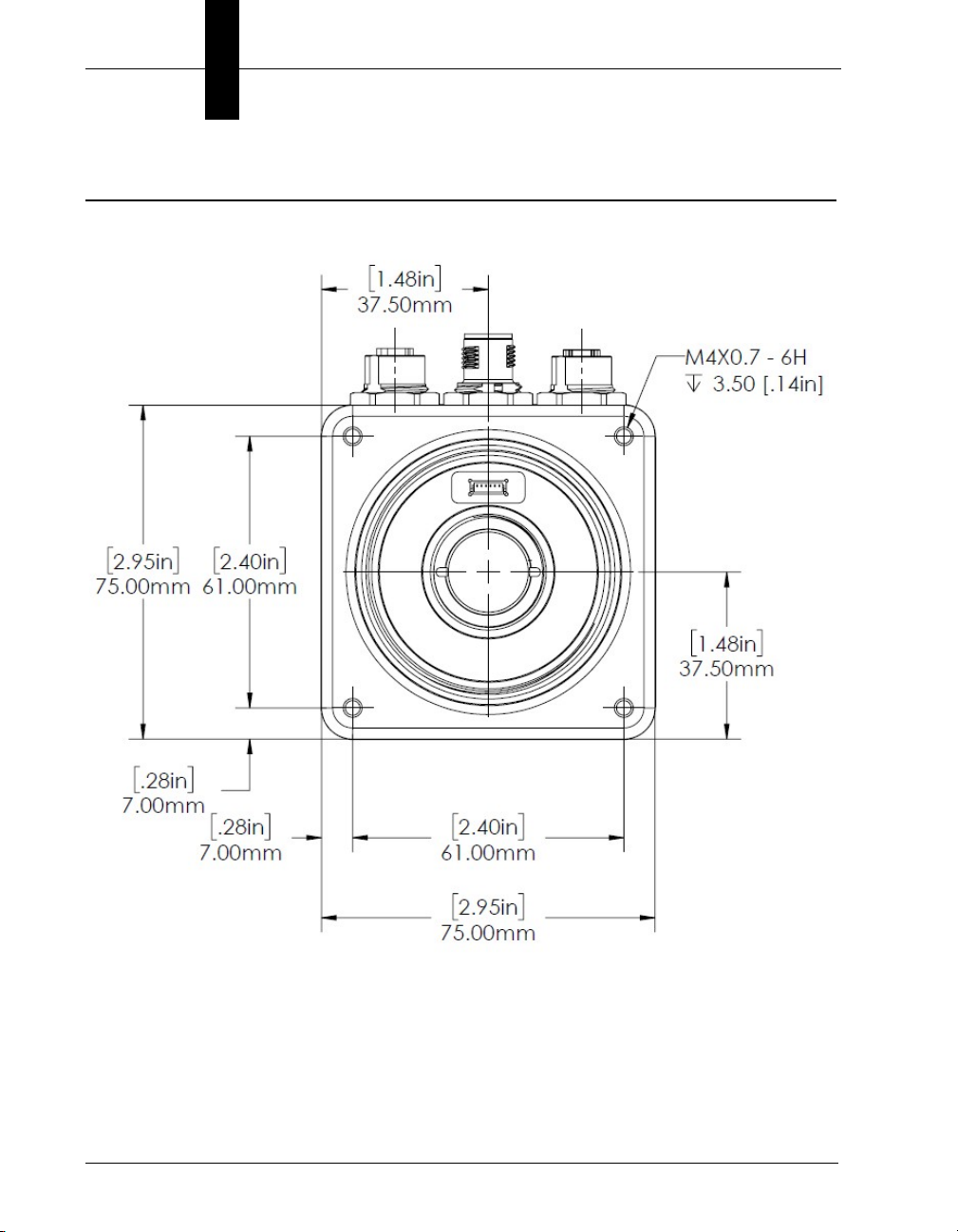

Chapter 2 System Components

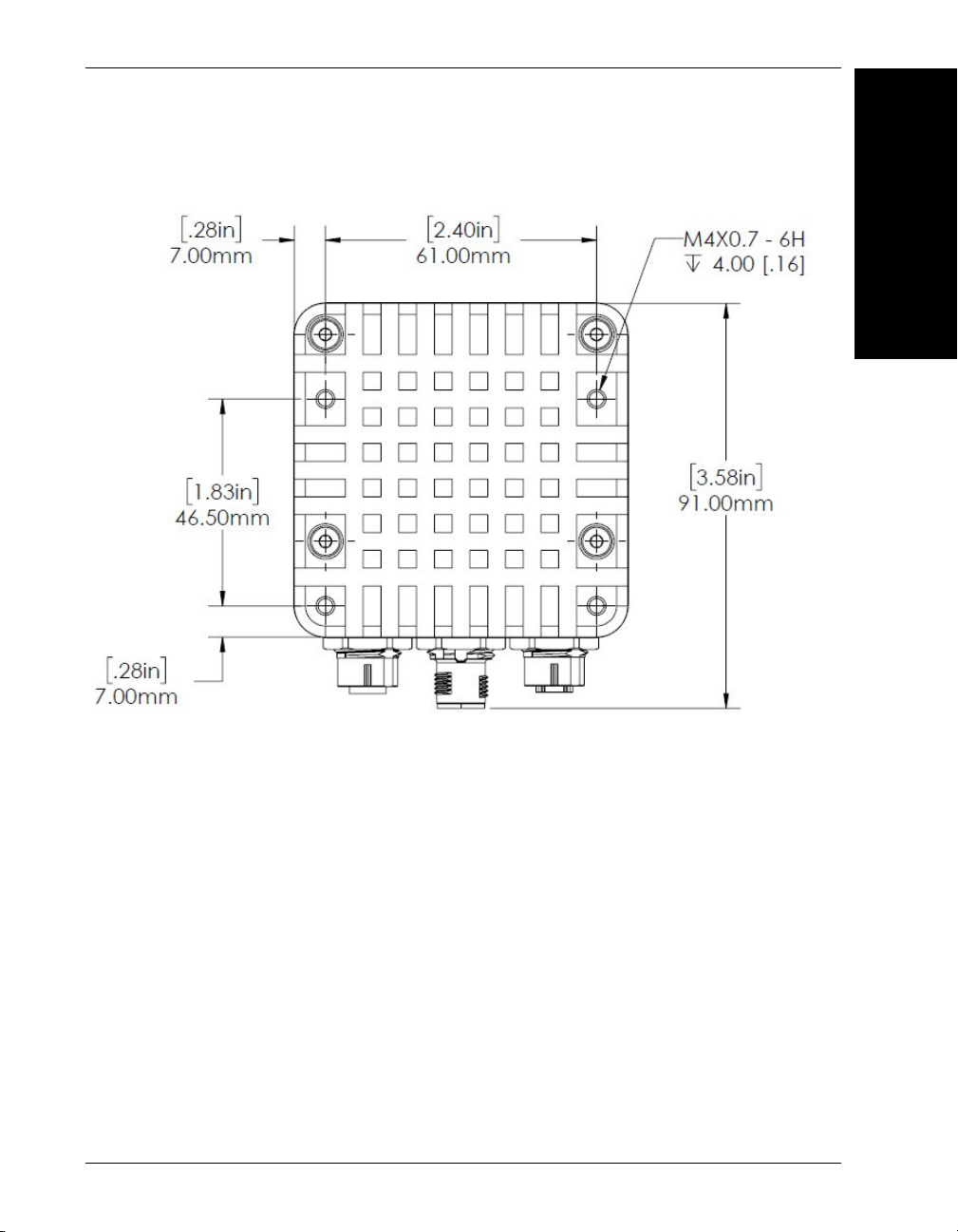

HAWK MV-4000 Dimensions

Standard HAWK MV-4000 Front

2-6 HAWK MV-4000 Smart Camera Guide

Page 21

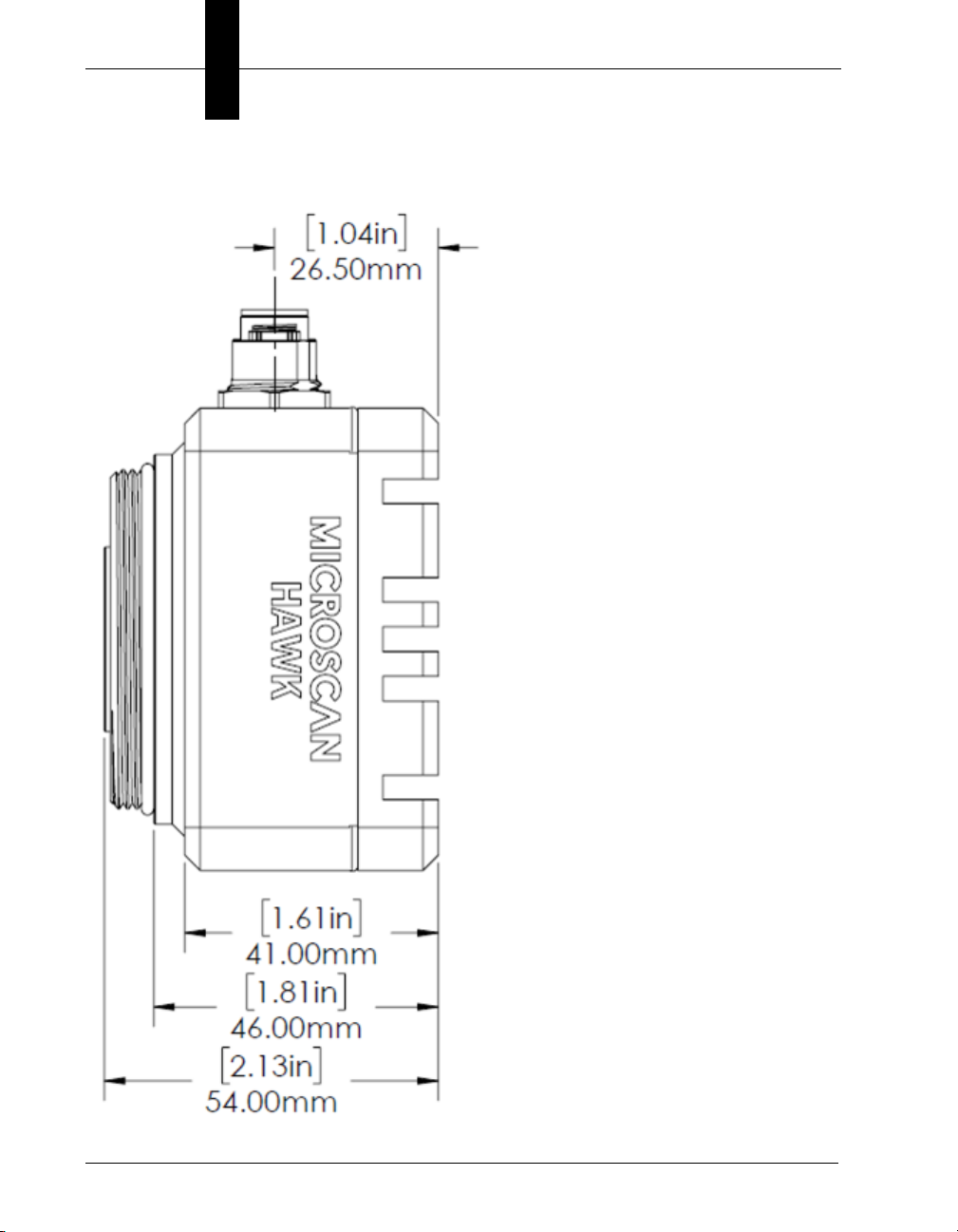

Standard HAWK MV-4000 Back

HAWK MV-4000 Dimensions

2

System Components

HAWK MV-4000 Smart Camera Guide 2-7

Page 22

Chapter 2 System Components

Standard HAWK MV-4000 Side

2-8 HAWK MV-4000 Smart Camera Guide

Page 23

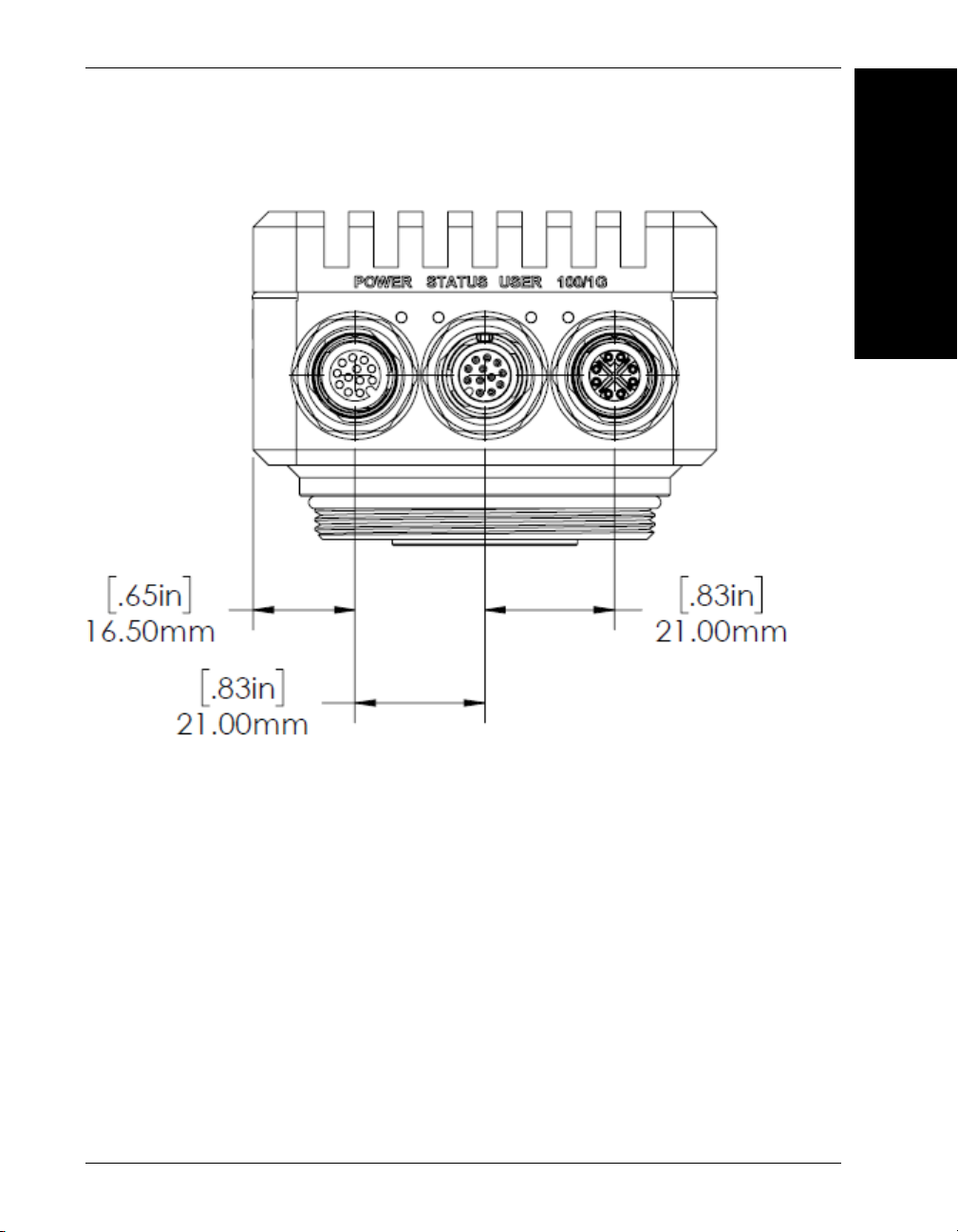

Standard HAWK MV-4000 Base

HAWK MV-4000 Dimensions

2

System Components

HAWK MV-4000 Smart Camera Guide 2-9

Page 24

Chapter 2 System Components

Label Information

Each HAWK MV-4000 Smart Camera has a label that contains important information about

that camera.

•M/N: The model name of the camera.

• P/N: The Omron Microscan part number of the camera.

• MAC: The MAC address of the camera.

• S/N: The serial number of the camera.

2-10 HAWK MV-4000 Smart Camera Guide

Page 25

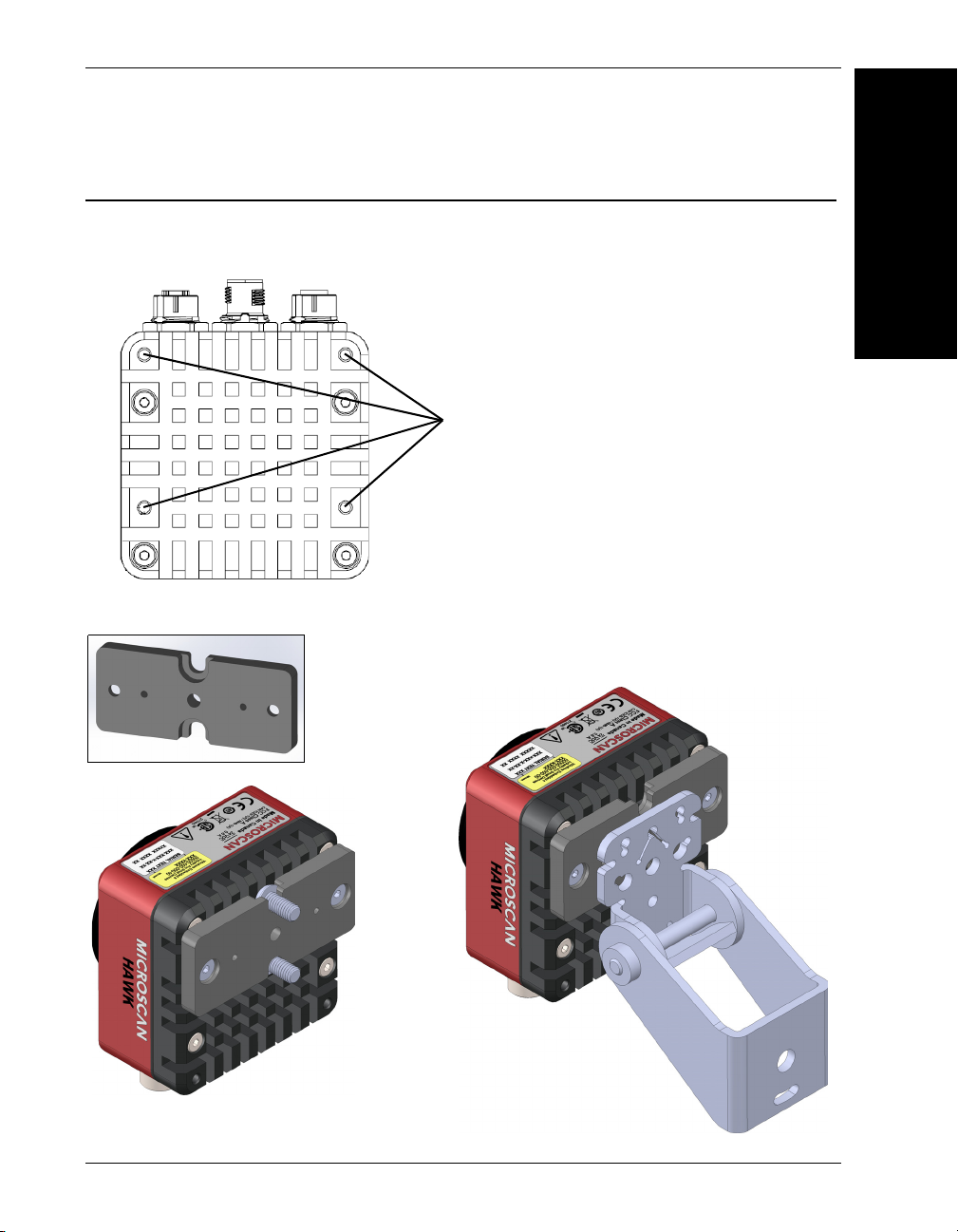

Mounting, Connecting, and Wiring

Mounting holes

(M4x0.7 thread,

4 mm deep)

¼-20 tripod

mounting hole

Mounts on standard tubing

with 6 mm hardware.

Adapter to

standard

APG mount.

Mounting, Connecting, and Wiring

Mounting the HAWK MV-4000

• Mount the camera (1) securely as required by the application.

Universal Mount and APG Mount

2

System Components

HAWK MV-4000 Smart Camera Guide 2-11

Page 26

Chapter 2 System Components

100/1000Base-T

Connector

Digital I/O and

Power Connector

VGA/USB

Connector

Connecting the HAWK MV-4000

• The HAWK MV-4000 Smart Camera has the following interfaces:

• 100/1000 Base-T Connector. Provides connectivity between the HAWK MV-4000

and your computer or your network. The HAWK MV-4000 can gain access to a LAN

via Gigabit Ethernet (GigE, 1G Base-T, or 1000Base-T), fast Ethernet (100Base-T), or

twisted pair Ethernet (10Base-T).

• VGA/USB Connector. Provides connectivity between the HAWK MV-4000 and a

display device and/or USB device (such as a keyboard or a mouse).

• Digital I/O and Power Connector. Receives power from an external power source.

This connector can also receive trigger input and send/receive general auxiliary I/O

signals to/from third-party I/O devices. In addition, the connector has a specialized

analog dimmer output intended to be used with advanced Illumination lighting devices.

2-12 HAWK MV-4000 Smart Camera Guide

Page 27

Mounting, Connecting, and Wiring

5

2

4

1

15

61-9000132-01

CAMERA End

POWER End

6

14

7

Power Supply

(12-Pin Socket)

Hardware Configurations

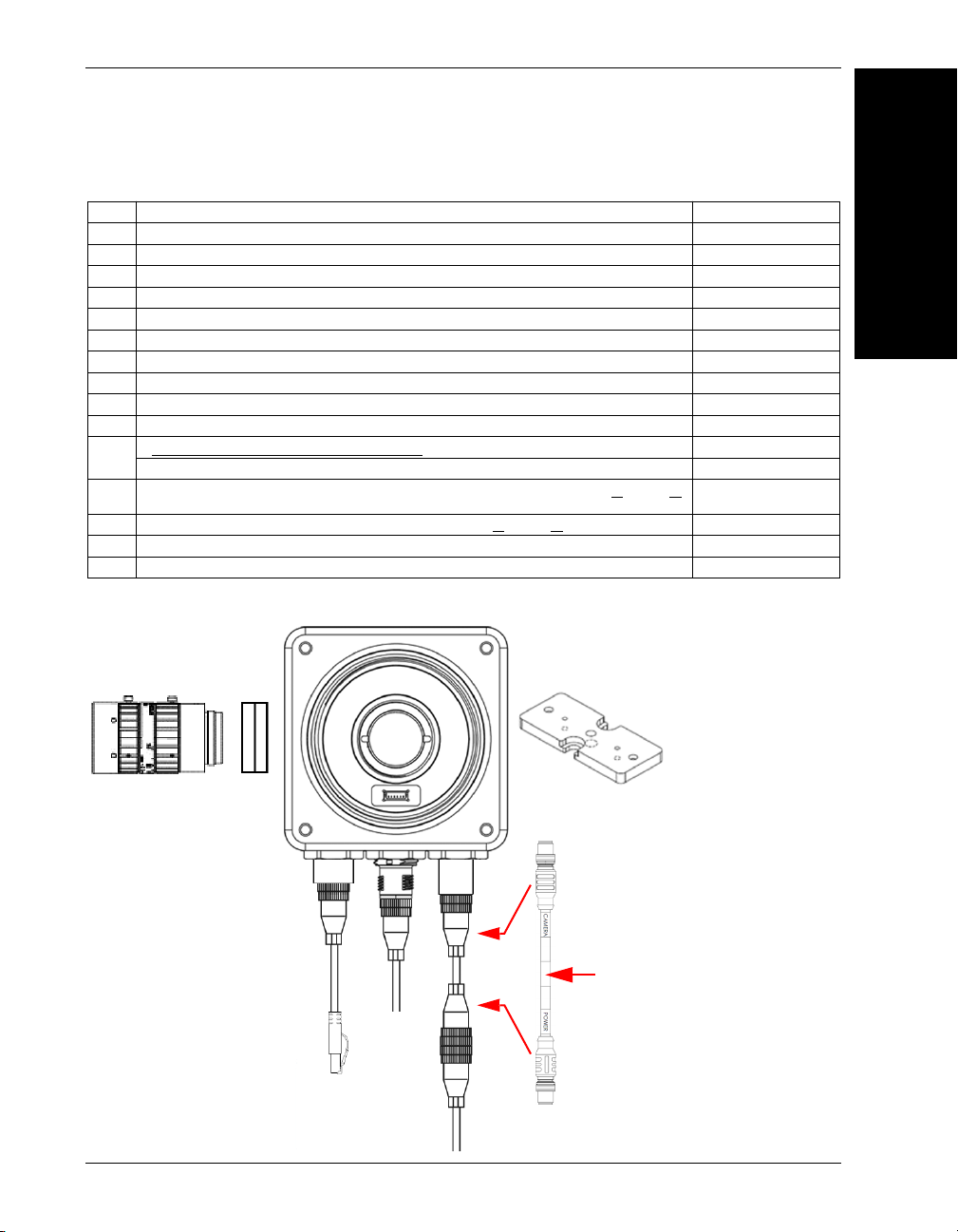

Item Description Part Number

1 HAWK MV-4000 Smart Camera 8X1X-XXX0-010X

2 Lens, C-Mount 98-90001XX-01

3 IP67 Lens Cover for HAWK MV-4000, 50 mm or 70 mm (not shown) 98-900015X-01

4 Lens Extension Tube Set, 0.5 mm, 1 mm, 5 mm, 10 mm, 20 mm, 40 mm 98-CO206

5 Cable, HAWK MV-4000 Ethernet, X-CODE / RJ45 CAT 6A, 1 m, 3 m, or 5 m 61-9000134-0X

6 Cable, HAWK MV-4000 M12 to USB Socket or VGA / USB, 1 m 61-900014X-01

7 Cable, Adapter, HAWK MV-4000 to Accessory Cables / Power Supply (supplied with camera) 61-9000132-01

8 Cable, HAWK MV-4000 M12 to Flying Leads, 3 m (no adapter required) 61-9000151-01

9 QX Cordset, HAWK MV-4000 Adapter to QX-1 M12 Plug (Screw-On), 1 m or 3 m 61-0001XX-02

10 QX-1 Interface Device 98-000103-02

Assembly, Photo Sensor, VIS, NPN, Light-ON/DA

11

Trigger Connector, 4-Pin Plug (Screw Terminal, Field-Wireable) (Self-Wiring) 20-610024-01

Y Cable, HAWK MV-4000 Adapter to Smart Series Illuminator and QX-1, Power or

12

Strobe, 1 m

13 Cable, QX-1 to Smart Series Illuminator, Continuous Power or

14 Power Supply, 100-240VAC, +24VDC, M12 12-Pin Socket 97-000012-01

15 Universal Mount, HAWK MV-4000 98-9000209-01

On/Off or Strobe 61-0002XX-01

On/Off or

Standard Ethernet Configuration

99-9000016-0X

61-900013X-01

2

System Components

HAWK MV-4000 Smart Camera Guide 2-13

Page 28

Chapter 2 System Components

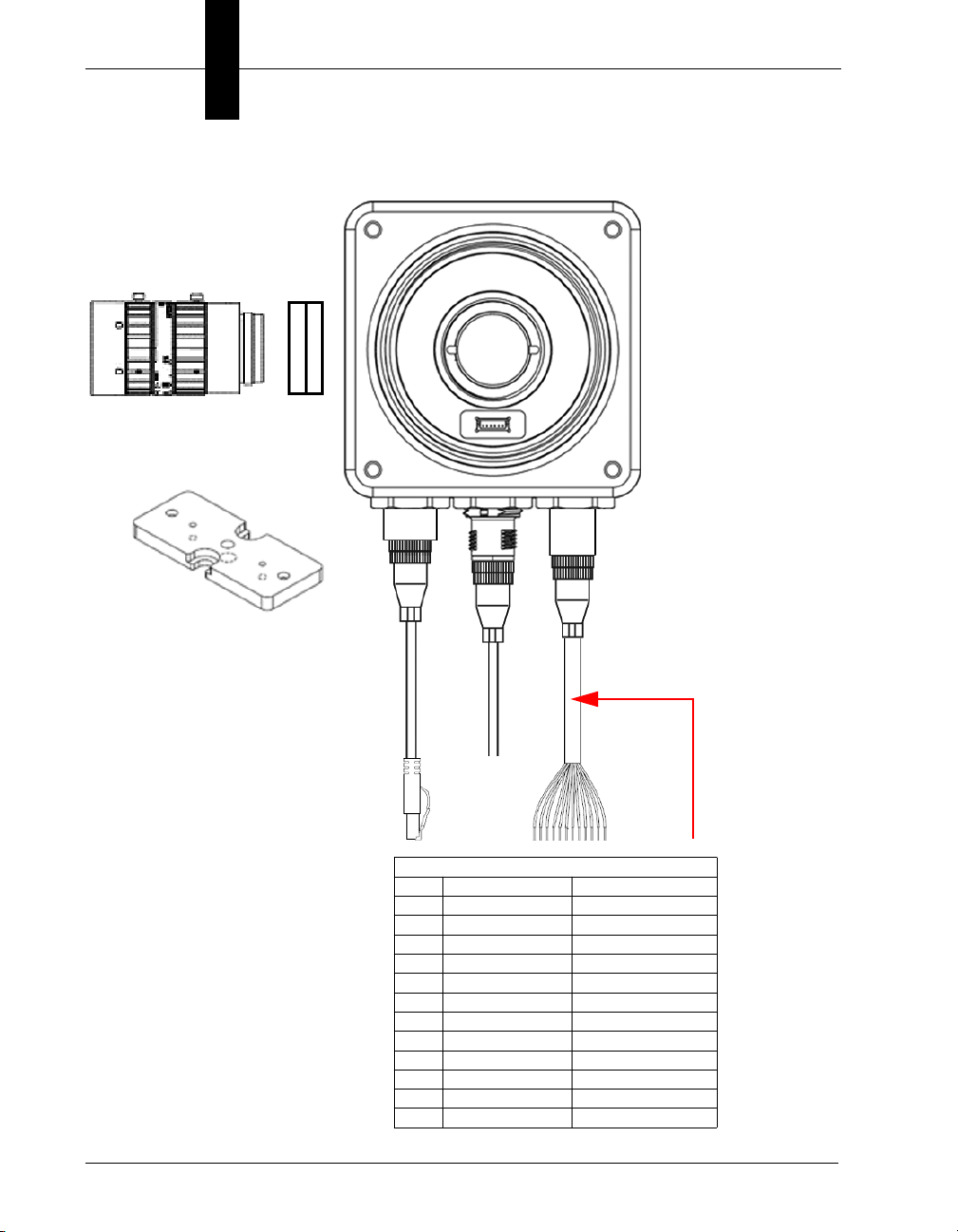

M12 to Flying Leads Cable, 3 m – 61-9000151-01

Pin Signal Wire Color

1 Output Common Red/Blue

2 Analog Output Black

3 Output 3 Pink

4 Power Brown

5 Trigger White

6 Input Common Red

7 Input 2 Green

8 Input 3 Violet

9 Input 1 Yellow

10 Output 1 Gray

11 Ground Blue

12 Output 2 Gray / Pink

5

2

4

1

15

6

8

Ethernet Configuration with Flying Leads

2-14 HAWK MV-4000 Smart Camera Guide

Page 29

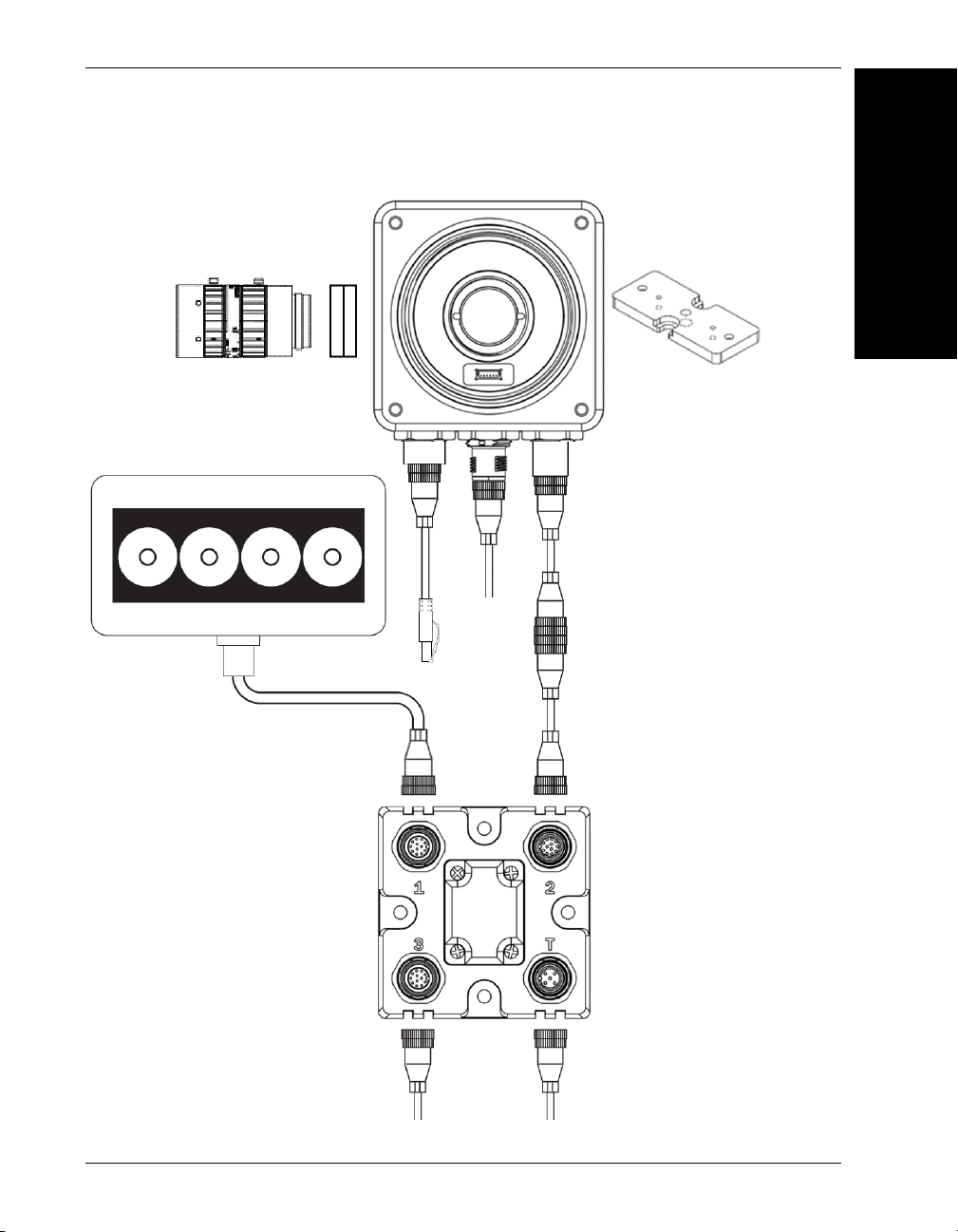

Mounting, Connecting, and Wiring

5

2

4

1

15

6

14

7

11

10

9

11

NERLITE Smart Series Illuminator

13

Power Supply

(12-Pin Socket)

Photo

Sensor

Ethernet Configuration with QX-1 and NERLITE Smart Series Illuminator

2

System Components

HAWK MV-4000 Smart Camera Guide 2-15

Page 30

Chapter 2 System Components

15

5

6

7

14

NERLITE Smart Series Illuminator

NERLITE

Smart Series

Illuminator

NERLITE

Smart Series

Illuminator

Power Supply

(12-Pin Socket)

12

2

4

1

Ethernet Configuration, Y Cable for Illuminator Control and Camera Power

2-16 HAWK MV-4000 Smart Camera Guide

Page 31

Connecting to the I/O Interface

Connecting to the I/O Interface

The HAWK MV-4000 has a digital I/O interface with 7 optically isolated signals. There are

three digital outputs and four digital inputs.

Outputs

Output Signals:

• Output 1

• Output 2

• Output 3 (External Strobe when Enabled)

• Output Common

The outputs support sinking (NPN) configurations only and operate at up to 24V nominal.

All three outputs are configurable for general-purpose use, but when External Strobe is

enabled in the software, Output 3 becomes dedicated to that purpose. When the HAWK

MV-4000 is used with the QX-1 interface device, or with any of the NERLITE Smart Series

lighting cables, the Strobe Output signal from the camera is automatically connected to

strobe trigger input on the Smart Series light.

Inputs

Input Signals:

• Trigger (Sensor)

• Input 1

• Input 2

• Input 3

• Input Common

The inputs support sinking (NPN) and sourcing (PNP) configurations and can receive

11-24V. Note that sinking (NPN) or sourcing (PNP) for inputs cannot be mixed in a

stem because the Input Common is shared by all Inputs.

sy

One input is dedicated as the camera trigger (sensor). The other three are configurable

general-purpose inputs. When the HAWK MV-4000 is used with the QX-1 interface device

and photo sensor, the trigger signal is automatically connected to the correct input channel.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-17

Page 32

Chapter 2 System Components

Sinking and Sourcing Note

Note that sinking and sourcing concepts refer to the conventional current flow, which

means current flows from the positive potential towards the negative potential. A sinking

device provides a path to sink current toward ground or to the return path. A sinking device

does not provide power. A sourcing device provides a path that sources current; it

provides a path from the power source. In the following diagram, the device on the right is

the sourcing device, and the device on the left is the sinking device.

(Equivalent circuit only.)

2-18 HAWK MV-4000 Smart Camera Guide

Page 33

Connectors and Pinouts

The pinout for the digital I/O and

power connector is as follows:

Pin Signal Name

1 Output Common

2 Analog Output

3 Output 3

4 Power

5 Trigger

6 Input Common

7 Input 2

8 Input 3

9 Input 1

10 Output 1

11 Ground

12 Output 2

To interface with this adapter cable connector, you can use either an Omron Microscan

accessory cable or you can build your own. To build your own digital I/O and power

cable, parts can be purchased from:

Cable Information

Manufacturer Phoenix Contact GmbH and Co. KG

Part Number SAC-12P- MS/3.0-PVC SC0 Order No: 1554788

Description

Sensor/Actuator Cable, 12-Pos., Black PVC, Straight M12 SPEEDCON Plug on Free Conductor End, 3.0 m

Connectors and Pinouts

The diagram below shows the pinout for the camera’s IO connector. This would typically be

used with the direct flying leads cable 61-9000151-01.

2

System Components

The diagram below shows the pinout for the Adapter Cable supplied with each unit. This

adapter changes the pinouts so that all of the standard MicroHAWK, Vision HAWK, and

QX Hawk accessories can be used. These include the power supply and interface cables

as shown earlier in this chapter.

HAWK MV-4000 Smart Camera Guide 2-19

Adapter Cable M12 12 Pin Plug – Power, I/O and Serial (61-9000132-01)

Page 34

Chapter 2 System Components

Outputs

Connecting Devices to Output Signals

HAWK MV-4000 output signals can be interfaced with input modules (with sourcing input

signals) found on most programmable logic controllers (PLCs) and other devices. The

output signals can also be interfaced with inductive load devices (such as a relay, light

stack, or a small motor).

The HAWK MV-4000’s output signals are sinking output signals, based on an NPN-type

transistor. Note that the HAWK MV-4000 outputs are not bi-directional outputs as they are

for the Vision HAWK or MicroHAWK. These are simple switches that allow current to flow

from the Output pin to the Output Common.

The outputs need to be connected to an external power source because they are not

capable of providing voltage to drive a device on their own. They are typically connected in

a sinking configuration because they only have one dedicated pin (Output1, Output 2,

Output 3 (External Strobe), respectively) and share their other pin (Output Common). So,

typically, a sourcing device is connected to their dedicated pin and the return path is

connected to the common pin. The exact connection between the output signal, the connected

device, and the power source depends on the type of device to which you connect.

(Equivalent circuit only.)

2-20 HAWK MV-4000 Smart Camera Guide

Page 35

Outputs

Connecting to a Digital Device That Requires Two Predictable Voltage Levels to Operate

The output signals can only present a low voltage level in a sinking configuration. Their

other output state is floating by default. So, if you need to connect to a digital device that

requires two predicable voltage levels to operate, pullup circuitry must be added.

(Equivalent circuit only.)

To add pull-up circuitry, attach an external pull-up resistor. A resistance value of 3 KOhms

is suggested to protect your HAWK MV-4000. Since your HAWK MV-4000 output signals

can sink up to 50 mA, use the documentation of your input to calculate the required

resistance for your external pull-up resistor (if necessary).

In the connections above, the pull-up circuitry causes an inversion if the input of the device

is connected to the Output pin. When the output signal is on, the circuit between its Output

pin and Output Common pin is closed, and current flows from the power source to the

Output Common pin. The observed voltage at the Output pin will be low. When the output

signal is off, the circuit between its Output pin and Output Common pin is open, and

current flows from the power source to the input of the device. In other words, the output is

active when it is turned off, so the output in the software must be set up as Active Low.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-21

Page 36

Chapter 2 System Components

are

Warning: The HAWK MV-4000 output signals

However, by default, the output signals offer low resistance. When they are on (their circuit

is closed), current flows directly through them. Ensure that the circuit created between the

power source, the output signal, the connected device, and return path does not cause

more than 50 mA to flow through the signal.

As a precaution, the output signals are individually fuse-protected up to 50 mA. HAWK

MV-4000 uses resettable fuses. The fuses protect HAWK MV-4000 if you accidentally

connect their corresponding output signal to a device that sources/sinks more current than

HAWK MV-4000 can safely transmit. If more than 50 mA of current goes through your

HAWK MV-4000, the fuse will eventually trip. After disconnecting your HAWK MV-4000,

the fuse will reset only after it has cooled sufficiently.

The diagram below depicts HAWK MV-4000’s onboard fuse.

compatible with voltages up to 24V.

2-22 HAWK MV-4000 Smart Camera Guide

Page 37

Outputs

About the Connections in the Following Subsections

The following subsections detail how to connect the most common third-party devices to

the HAWK MV-400

reference, in case you need to reference your return path to ground.

Power, as depicted in the following diagrams, represents a nominal voltage of up to 24V

(+/- 10%). For minimum and maximum voltage requirements, refer to the electrical

specification of the optoisolated output signals, in Appendix C: General Specifications.

0 output signals. Ground is only shown in the following subsections for

Connecting an Output Signal to a Sourcing Input

Connect a HAWK MV-4000 output signal to a sourcing input, as shown below.

2

System Components

(Equivalent circuit only.)

Note: When connecting a resistive load sourcing device instead of an input sensing

sourcing device, the same connection would be used as displayed above.

HAWK MV-4000 Smart Camera Guide 2-23

Page 38

Chapter 2 System Components

Connecting an Output Signal to a Sinking Input

In this configuration, you need to connect an external pull-up resistor. Since your HAWK

MV-4000 output signals can sink up to 50 mA, use the documentation of your sinking

device to calculate the required resistance for your external pull-up resistor (if necessary).

Using this method with a pull-up resistor will allow you to connect to up three sinking inputs.

(Equivalent circuit only.)

2-24 HAWK MV-4000 Smart Camera Guide

Page 39

Outputs

Connecting to a NPN PLC

NPN PLC inputs are normally pulled to high inside the PLC. Closing camera opto

connects the PLC input to Ground through the camera opto making the PLC signal go low.

The camera outputs should be set to Active Low so that when camera output is active

(opto open), the PLC is pulled up to +V through its internal pull-up resistors.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-25

Page 40

Chapter 2 System Components

Connecting to a PNP PLC

PNP PLC inputs are normally pulled to low inside the PLC. They need to be fed a voltage

to make the signal go high. This is done through the use of external pull-up resistors,

typically 3K Ohm.

When the camera opto is open, the PLC input signal is pulled up to high through the

external pull-up resistors. When the camera opto is closed, the current flows through

camera instead of to the PLC inputs, making the PLC input go low.

The camera outputs should be set to Active Low so that when camera output is active

(opto open), the PLC input is pulled high via the external pull up resistors.

2-26 HAWK MV-4000 Smart Camera Guide

Page 41

Outputs

Connecting HAWK to a Strobe Controller

To connect a HAWK MV-4000 output signal to an external strobe controller, follow the

diagram as shown below. Set the trigger to “falling edge”.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-27

Page 42

Chapter 2 System Components

Connecting an Output Signal to an Inductive Load Input

To connect a HAWK MV-4000 output signal to an inductive load input, follow the diagram

as shown below.

An inductive load device, such as a traditional relay, requires that you use a flyback diode

to protect HAWK MV-4000 from over and under-voltage, as shown below. This diode

should be connected as close as possible to the input and voltage source of your inductive

load device.

(Equivalent circuit only.)

2-28 HAWK MV-4000 Smart Camera Guide

Page 43

Inputs

Inputs

Connecting Devices to the Input Signals

HAWK MV-4000 input signals can be interfaced with a wide variety of devices (such as

proximity detectors). The HAWK MV-4000 input signals only detect when current flows

between their Input pin and Input Common pin. As such, an input signal must be

connected to a device that controls the flow of current. When current is detected, the

signal is reported as on; otherwise, it is reported as off. For information on the electrical

specifications of the on and off voltage levels, see the Electrical specifications section, in

Appendix C: General Specifications.

Each of the four available input signals has one dedicated pin (Trigger, Input 1, Input 2 and

Input 3) and shares its other pin (Input Common) with the other input signals.

You can connect the input signals in a sinking or sourcing configuration. Since the input

signals share a common pin, they must all be in a sinking configuration or all in a sourcing

configuration. The exact connection between the input signal, the connected device, and

the power source depends entirely on the type of device to which you connect. You should

essentially connect your device respecting the following:

2

System Components

(Equivalent circuit only.)

HAWK MV-4000 Smart Camera Guide 2-29

Page 44

Chapter 2 System Components

Pull-Up Circuitry

In some cases, you must add pull-up circuitry to connect an output device to an input

signal; specifically, you must attach an external pull-up resistor between the voltage

source and the Input pin.

This is required when you connect the Input Common pin to the electrical return path and

the third-party output device is in a sinking configuration. In this case, select a resistor

value that will not overcurrent the output device and instead provide just enough current

and voltage to your HAWK MV-4000 input signals, according to the electrical

specifications subsection in Appendix C: General Specifications. Note that you should use

a resistor with an appropriate power rating for your circuit.

(Equivalent circuit only.)

2-30 HAWK MV-4000 Smart Camera Guide

Page 45

Inputs

Bleeding Resistor

By default, if properly configured, the current should flow from the Input pin to the Input

Common pin (when connected to a sourcing device), or from the Input Common pin to the

Input pin (when connected to a sinking device). In some cases, the amount of current

going through the sensing circuit is insufficient for the connected output device to match its

minimum current requirement when the device is in an on or off-state, depending on the

configuration of the circuit. To boost the flowing current, connect a 2.2 kOhm external

bleeder resistor between the Input and Input Common pins. For example:

(Equivalent circuit only.)

About the Connections in the Following Subsections

The following subsections detail how to connect the most common third-party devices to

the HAWK MV-4000 input signals.

Note that HAWK MV-4000 input signals are optically isolated. Ground is only shown in the

following subsections for reference, in case you need to reference your return path to ground.

Power, as depicted in the following diagrams, represents a nominal voltage of 24 V (+/10%). For minimum and maximum voltage requirements, refer to the electrical

specification of the optoisolated input signals, in the Electrical specifications subsection in

Appendix C: General Specifications.

2

System Components

HAWK MV-4000 Smart Camera Guide 2-31

Page 46

Chapter 2 System Components

Connecting a Sourcing Output Device to an Input Signal

Connect a sourcing output device to HAWK MV-4000 input signal, as shown below.

(Equivalent circuit only.)

2-32 HAWK MV-4000 Smart Camera Guide

Page 47

Connecting a Sinking Output Device to an Input Signal

Connect a sinking output device to a HAWK MV-4000 input signal, as shown below.

Inputs

2

System Components

(Equivalent circuit only.)

HAWK MV-4000 Smart Camera Guide 2-33

Page 48

Chapter 2 System Components

Connecting a 3-Wire PNP Proximity Sensor to an Input Signal

Connect a 3-wire PNP proximity sensor to a HAWK MV-4000 input signal, as shown below.

(Equivalent circuit only.)

2-34 HAWK MV-4000 Smart Camera Guide

Page 49

Inputs

Connecting a 3-Wire NPN Proximity Sensor to an Input Signal

Connect a 3-Wire NPN proximity sensor to a HAWK MV-4000 input signal, as shown below.

2

System Components

(Equivalent circuit only.)

HAWK MV-4000 Smart Camera Guide 2-35

Page 50

Chapter 2 System Components

Connecting a 2-Wire Proximity Sensor to an Input Signal

You can connect a 2-wire proximity sensor to a HAWK MV-4000 input signal in either a

sourcing or sinking configuration (that is, on a positive or negative power wire). Note that in

both cases, you will need to install an external bleeder resistor, to ensure that a minimum

amount of current flows into the proximity sensor in its on-state and in its off- state.

For the input signal to source the current (that is, to connect an input signal on a positive

power wire), connect the 2-wire device to the input signal as shown below.

You must also install an external bleeder resistor between the Input Common pin and

brown wire of the proximity sensor.

(Equivalent circuit only.)

The bleeder resistor’s value should guarantee that the minimal required current is

provided to the connected sensor (the third-party device). For details regarding the

sensor’s minimum current requirements, refer to its documentation. Note that you should

use a bleeder resistor with an appropriate power rating for your circuit.

Note: You should use a resistor with an appropriate power rating for your circuit.

2-36 HAWK MV-4000 Smart Camera Guide

Page 51

Inputs

For the input signal to sink the current, connect the 2-wire device to input signal as shown

below. Install the external bleeder resistor between the blue wire of the proximity sensor

and the Input Common pin.

2

System Components

(Equivalent circuit only.)

HAWK MV-4000 Smart Camera Guide 2-37

Page 52

Chapter 2 System Components

M12 to Flying Leads Cable, 3 m – 61-9000151-01

Pin Signal Wire Color

1 Output Common Red/Blue

2 Analog Output Black

3 Output 3 Pink

4 Power Brown

5 Trigger White

6 Input Common Red

7 Input 2 Green

8 Input 3 Violet

9 Input 1 Yellow

10 Output 1 Gray

11 Ground Blue

12 Output 2 Gray / Pink

Input/Output Wiring Using Flying Lead Cable 61-9000151-01

Important: This cable is connected directly to the camera connector.

2-38 HAWK MV-4000 Smart Camera Guide

Page 53

Ground and Shield Considerations

An earth ground is provided through the cable shields and chassis of the camera.

HAWK

MV-4000

Ground and Shield Considerations

Proper grounding is necessary for operator safety, noise reduction, and the protection of

equipment from voltage transients. Buildings, including any steelwork, all circuits, and all

junction boxes must be grounded directly to an earth ground in compliance with local and

national electrical codes.

2

System Components

Ground Loops

Ground loops (signal degradation due to different ground potentials in communicating

devices) can be eliminated or minimized by ensuring that both the host, imager, and their

power supplies are connected to a common earth ground.

HAWK MV-4000 Smart Camera Guide 2-39

Page 54

Chapter 2 System Components

Expected Power and Ground Connections for Proper Operation

Grounding Notes

• Ensure that mounting bracket “Earth” is at the same potential as power source “Earth”.

• Supply “Return” and “Earth” ground must be stable, low-impedance reference points.

• “2-Terminal Power Supply” must still provide an “Earth” connection to the imager.

• “Signal Ground” can be used for communications and/or discrete signal ground

reference. It must not be used as Power Ground or Earth Ground.

2-40 HAWK MV-4000 Smart Camera Guide

Page 55

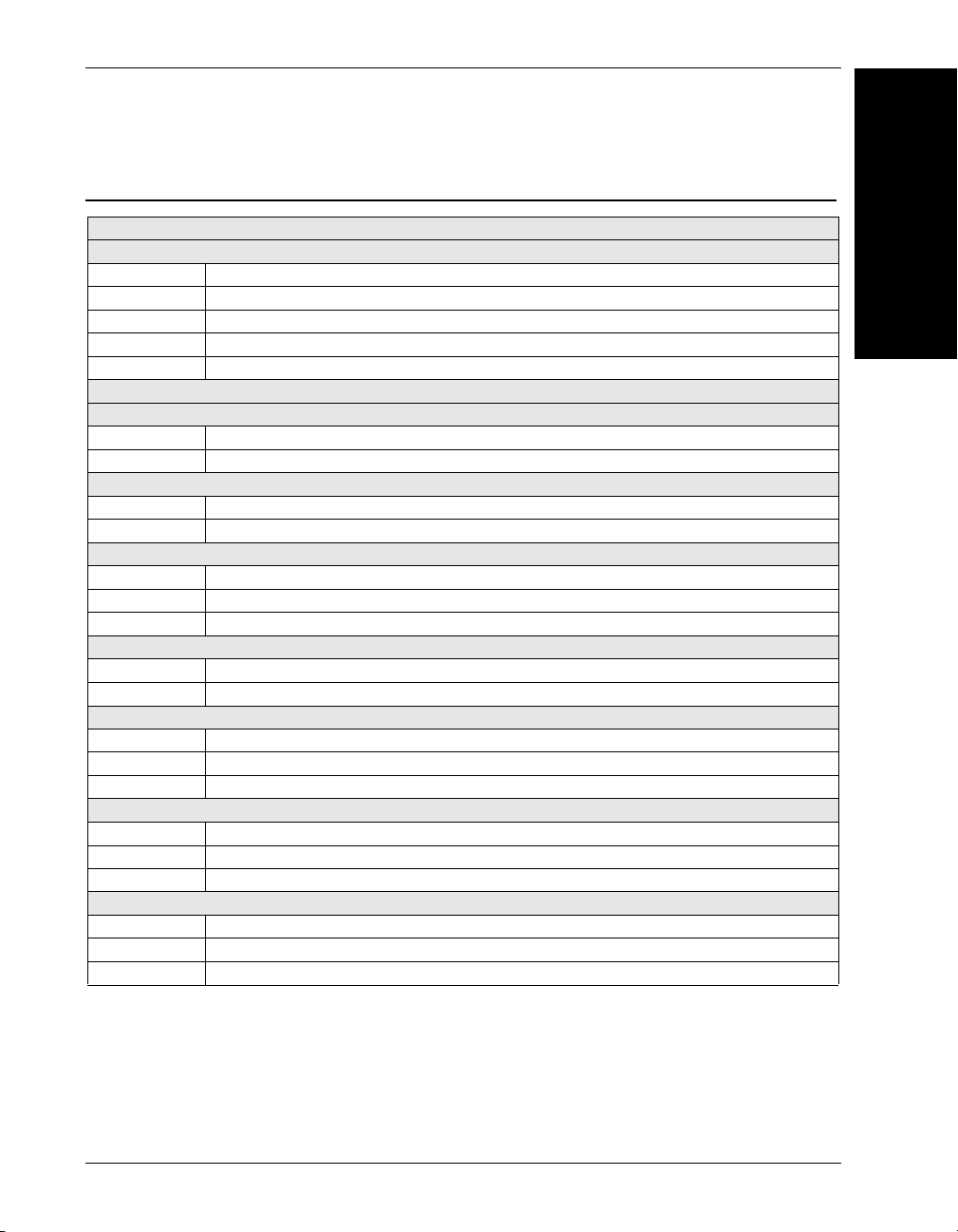

Electrical and I/O Specifications

Electrical and I/O Specifications

HAWK MV-4000-03, -03C, -13, -13C, -20, -20C, -50, -50C

Operating voltage for the HAWK MV-4000 under testing conditions 24 V

Rated current 600 mA

Operating voltage tolerance ± 10%

I/O Specifications

Operating Voltage 24 V (26 V abs. max.)

Sink Current 50 mA max.

Maximum Leakage Current

Optoisolated Output Signals

Optoisolated Input Signals

0-10 V Analog Control Output Signal

Varioptic Caspian C-39N0-160-I2C or C-39N0-250-I2C Liquid Lens

Typical

a. The PTC is an automatically resetting fuse.

b. This occurred under the following condition: output pulled to 24 V using 1 kW.

c. Regardless of whether the signal is sinking or sourcing, this measurement is the same.

d. Maximum input current at max. ON voltage. The connected device must not limit the

current to a value lower than this.

e. Minimum input current at min. ON voltage. Can be used to calculate bleeding resistor

needed for 2-wire proximity sensor.

f. Recommended > 12 V when using HAWK MV-4000 breakout board.

ON Voltage

a

Fuse Max. Time-to-Trip

PTC

OFF-to-ON Response 2 ms to reach 4 V

ON-to-OFF Response 50 ms to reach 11 V

Operating Voltage 24 V (26 V abs. max.)

Input Current (Sink or Source) 3.5 mA max.

ON Voltage Level > 11 V

OFF Voltage Level < 4 V

OFF-to-ON Response 6 ms

ON-to-OFF Response 80 ms

Non-isolated. Supports Advanced Illumination ICS3 (inline control

system) lighting devices. Note that the 0-10 V is intended for reference

voltage only (< 1 mA).

Supplied Voltage 5 V

Rated Current 50 mA

1 mA@ 24 V

1 mA@ 26 V

0.4 V @ 2 mA

1.1 V @ 25 mA

1.5V @ 50 mA

1 sec @ 0.5 A

f

b

c

d

, 1 mA min.

2

System Components

e

HAWK MV-4000 Smart Camera Guide 2-41

Page 56

Chapter 2 System Components

Environmental Specifications

• For indoor use only.

• Maximum altitude: 2,000 meters

• Operating temperature: 0° to 50° C (32° F to 122° F)

• Ventilation requirements: Natural convection

• Pollution degree: 2 environment

• Over-voltage category: I

• Ingress protection rating: IP67

1

1. Under current testing conditions.

2-42 HAWK MV-4000 Smart Camera Guide

Page 57

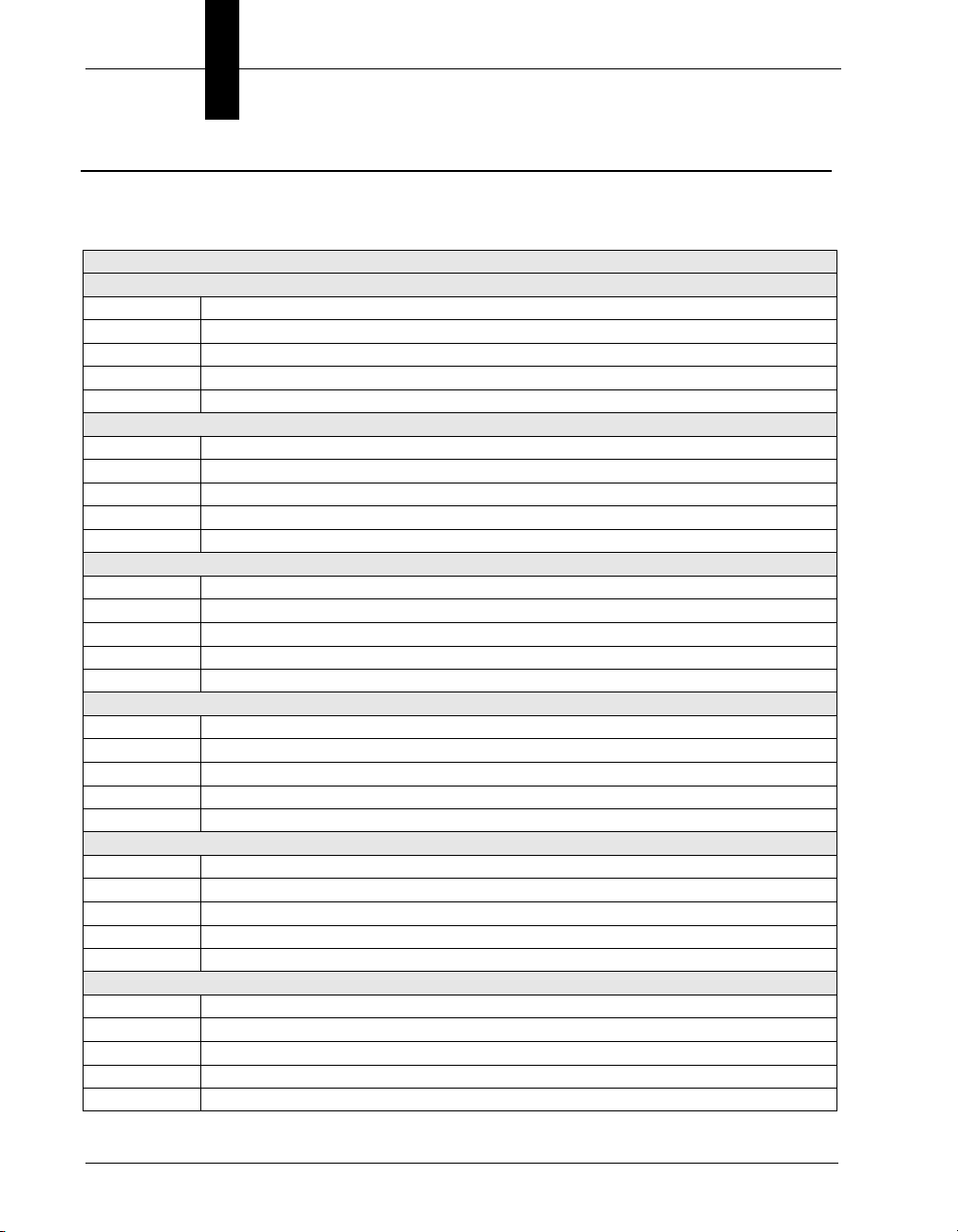

Status Indicators

Status Indicators

The base of the HAWK MV-4000 Smart Camera has multiple LEDs that indicate different

power, status, user, and communication states.

The HAWK MV-4000 LEDs are:

• POWER and USER. The colors of these two LEDs change as your HAWK MV-4000

boots up.

• Status. This LED shows the general activity of your HAWK MV-4000.

• 100/1G. This LED shows the connection status of your HAWK MV-4000.

2

System Components

The POWER and USER LEDs typically display one of the following sets of colors:

LED Color

Power User

Off Off HAWK MV-4000 has no power.

Red Red Power is available but the HAWK MV-4000 is not responding.

Red Orange Memory initialization error detected.

Orange Orange/Red Blinking Thermal trip detected.

Orange Orange BIOS execution in progress.

Orange Green BIOS execution completing.

Green Off AutoVISION is now in control of the camera.

Green Orange Operating system startup in progress.

Green Green Camera ready.

Green Orange/Off Blinking Overheat detected. Temperature is above throttle temperature limit.

HAWK MV-4000 Smart Camera Guide 2-43

Description

Page 58

Chapter 2 System Components

Adding a HAWK MV-4000 to a Network

Corporate-wide networks typically use DHCP servers to assign each connected device an IP

address. If your HAWK MV-4000 is still in its factory-configured state, and your network uses

a DHCP server, no configuration is required to use your HAWK MV-4000 on your network.

Default Device Name

By default, HAWK MV-4000 comes factory configured with a unique device name. The

device is preprogrammed with a Class C static IP address: 192.168.0.100. This name is

used when connecting to a network and is of the form:

HAWK329999

The last four hexadecimal digits of your HAWK MV-4000’s MAC address are used as the

numeric part of the device name. Both the network name of your HAWK MV-4000 and its

MAC address are written on a sticker on your HAWK MV-4000. Note that, when dealing

with the Windows version, the device name is also known as the computer name.

2-44 HAWK MV-4000 Smart Camera Guide

Page 59

Setting Up a Job in AutoVISION

Setting Up a Job in AutoVISION

AutoVISION is a critical component of the HAWK MV-4000’s functionality. Designed for use

with the HAWK MV-4000, AutoVISION provides an intuitive interface, step-by-step configuration,

and a library of presets that allow easy setup and deployment. For more complex vision

applications, the system can be upgraded from AutoVISION to Visionscape.

2

1. Mount and connect the HAWK MV-4000 hardware.

2. Plug in the power supply.

3. Select your HAWK MV-4000 in the AutoVISION Connect view, create a job, and adjust

camera settings.

AutoVISION's Connect view allows you to select your device and configure its settings,

and to create a new job. The Select Device dropdown menu provides a list of available

devices. Hover the mouse over a device to see its details.

System Components

HAWK MV-4000 Smart Camera Guide 2-45

Page 60

Chapter 2 System Components

Note: The HAWK MV-4000’s default IP

address is: 192.168.AA.BB where

AA.BB are the last 2 octets in decimal of

the device MAC Address with subnet

Class B 255.255.0.0. Set your PC to the

same subnet (192.168.0.1, for example).

To access the camera’s “health status”,

enter the address http://[your camera

name]:8088 in a browser, where [your

camera name] is the name of the device

– HAWK3204E8, for example.

Modify camera settings in the

Details area at the left of the

Connect view. Create, Load, or

Upload a job using the buttons in

the center of the Connect view.

Important: When modifying camera settings,

you will need to enter a username and password

for the camera if a password has been defined.

Click the lock icon to take control of the camera. When you have control of the camera,

the Modify button will appear beneath the camera settings. Click the Modify button to

adjust camera settings.

2-46 HAWK MV-4000 Smart Camera Guide

Page 61

Setting Up a Job in AutoVISION

Once you have selected your camera, adjusted its settings, and created a new job, you will

move to the Image view. This view allows you to Auto Calibrate the camera, and to manually

adjust the camera's Exposure, Gain, and Focus, and also to set the Lighting Mode (On,

Off, or Strobe).

2

System Components

HAWK MV-4000 Smart Camera Guide 2-47

Page 62

Chapter 2 System Components

4. Edit the Job in AutoVISION.

After you have created a new job, loaded a job from your PC, or uploaded a job from

the camera, you will proceed to the Edit view to refine your machine vision job. The

Camera parameters below the captured image allow you to set Gain, Exposure, Focus,

Trigger, and Lighting. Inspection Outputs options allow you to connect your job to the

outside world. This is also the view where you can add multiple tools to the job. The

tool icons are located above the main view area.

2-48 HAWK MV-4000 Smart Camera Guide

Page 63

5. Run the Job in AutoVISION.

Going to the

Run

view will automatically download your job to the camera and start it running.

Setting Up a Job in AutoVISION

2

System Components

6. Save the Job.

Click the Save to Camera icon on the File menu bar to save the job to the camera.

HAWK MV-4000 Smart Camera Guide 2-49

Page 64

Chapter 2 System Components

Trigger Debounce

Trigger Debounce is the ability of the system to accommodate switching noise on a

trigger state change – a common issue with relays that have some intermittent contact

while engaging.

Trigger overruns (when the vision system is triggered faster than the device can process)

can sometimes be avoided by increasing the “debounce” time in the camera definition file

located in the C:\Microscan\Vscape\Drivers\CamDefs directory.

The IO Line Debounce High Time and IO Line Debounce Low Time can be added to the

file as in the example below. Debounce time is 100 μs.

The minimum value for "IO Line Debounce Time" is 0 µs, which disables software debounce

altogether. The maximum value is 268432 µs.

Standard debounce as described for the trigger:

IO Line Debounce High Time 100 //usecs (valid range: 0 to 268432 such that

debounce time * 1000 must be divisible by 16)

IO Line Debounce Low Time 100 //usecs (valid range: 0 to 268432 such that

debounce time * 1000 must be divisible by 16)

2-50 HAWK MV-4000 Smart Camera Guide

Page 65

Setting Up a Job in AutoVISION

Camera Definition File Example

// Camera Definition File

// Version: 1.10

Camera Name HAWK MV-4000 752x480 CMOS // Name

Displayed in Camdef Selection Dialog

Digitizer Type 4000 // Number

associated with HAWK MV-4000 CMOS Camera

Stride 752 // Image Width

Rows 480 // Image Height

X Offset 0 // Image X Offset

Y Offset 0 // Image Y Offset

Bits Per Pixel 8 // Bits that represent Pixel Value

Pixel Type 0 // Type of Pixel:

MONOCHROME=0, COLOR_RGB=1, COLOR_BGR=2, COLOR_BAYGR8=3,

COLOR_BAYRG8=4, COLOR_BAYGB8=5, COLOR_BAYBG8=6, COLOR_HSI=7

Image Structure1 // Pixel Organization: Packed=1,

TwoPlanes = 2, ThreePlanes = 3

Async Control 1 // Controllable shutter time.

Usually using a pulse width specified in usecs

Usecs Per Frame 16667 // Fastest time to acquire a

frame: 60 FPS for HAWK MV-4000 CMOS Camera // -1 Disables timeout

feature

// IO Configuration

GPIO Edit Mask 0x0000

GPIO Defaults 0x0001 // 1 General Purpose Input 3

General Purpose Outputs

GPIO Count 4

GPIO Inputs 1

GPIO Outputs 3

Sensors 1 // One input

dedicated to Trigger signal

Strobes 0

Virtual IO 2048

IO Line Debounce High Time 100 //usecs (valid range: 0 to 268432 such that

debounce time * 1000 must be divisible by 16)

IO Line Debounce Low Time 100 //usecs (valid range: 0 to 268432 such that

debounce time * 1000 must be divisible by 16)

Custom External Strobe Delay Time 0 //usecs

// Focus & Photometry Ranges

Gain Dflt 20

Gain Min 0

Gain Max 100 // 0 to 100%

Exp Dflt 400

Exp Min 25

Exp Max 100000// 1/10 to 1/40,000

Focus Dflt 400

Focus Min 100

Focus Max 4000 // 1 to 40 inches

// Lens Configuration

C-Mount 0 // 0 = false, 1 = true

2

System Components

HAWK MV-4000 Smart Camera Guide 2-51

Page 66

Chapter 2 System Components

Setting Up Partial Scan

Sensor WOI Limitations

The combination of X Offset and Y Offset determines the location of the top left corner

of the window of interest (WOI).

Stride determines the width of the WOI.

Rows determines the height of the WOI.

All the highlighted fields shown in the example above must be changed when creating a

partial scan camdef. The file name must also be changed, showing the WOI size in the name.

• X Offset: This value must be a multiple of 32.

• Y Offset: This value must be a multiple of 2.

• Stride: This value must be a multiple of 32.

• Rows: This value must be a multiple of 2.

Minimum size X of 32. Maximum value to whole sensor size.

Minimum size Y of 2. Maximum value to whole sensor size.

2-52 HAWK MV-4000 Smart Camera Guide

Page 67

3

CHAPTER 3 Lighting

This section describes HAWK MV-4000 Smart Camera illumination options.

3

Lighting

HAWK MV-4000 Smart Camera Guide 3-1

Page 68

Chapter 3 Lighting

Before correct lighting After correct lighting with a

NERLITE Illuminator

Illumination

The HAWK MV-4000 Smart Camera is a C-Mount camera and is used with external lighting.

Any lighting can be used, but the HAWK MV-4000 comes with accessories and cables that

allow it to connect directly with Omron Microscan's NERLITE Smart Series lights. Software

control allows the lights to be operated in multiple modes: Off, Continuous, and Strobe.

Machine Vision Lighting Principles

Proper lighting is critical to the success of a machine vision application. Depending on

the requirements of your application, you may need external lighting from Omron

Microscan's NERLITE family of machine vision lighting products.

Consider the following when setting up your application:

• Is the surface of the object flat, slightly bumpy, or very bumpy?

• Is the surface matte or shiny?

• Is the object curved or flat?

• What is the color of the object or area being inspected?

• Is the object moving or stationary?

Machine vision lighting should maximize contrast of the areas or features being inspected

while minimizing the contrast of everything else.

For more information about machine vision lighting, visit:

http://www.microscan.com/en-us/resources/know-your-tech/microscan-lighting-selector

3-2 HAWK MV-4000 Smart Camera Guide

.

Page 69

External Illumination Control and Wiring

Optics and Lighting

1

1

1

9

7

3

4

5

2

6

8

External Illumination Control and Wiring

The HAWK MV-4000 supports external lighting with Omron Microscan's NERLITE Smart

Series lights. The diagrams below demonstrate how the camera and light can be

configured with the QX-1 interface device and light kit Y-cables. The light is controlled

using the lighting control in AutoVISION

HAWK MV-4000 and Smart Series Light Configuration: QX-1

Item Description Part Number

1 Smart Series Light NER-011660XXXG

2 QX-1 Interface Device 98-000103-02

Cable, Adapter, HAWK MV-4000 to QX-1 61-9000132-01

3

4 Cordset, Common, M12 12-Pin Socket to M12 12-Pin Plug, 1 m 61-000162-02

Cordset, Common, M12 12-Pin Socket to M12 12-Pin Plug, 3 m 61-000148-02

or

5 Cable, Power, Smart Series to QX-1 61-000204-01

Power Supply, 100-240VAC, +24VDC, M12 12-Pin Socket 97-000012-01

6

7 Cordset, Host, Ethernet, M12 8-Pin Plug to RJ45, 1 m 61-9000134-0X

Photo Sensor, VIS, NPN, Light On/Dark On 99-9000016-01

8

9 HAWK MV-4000 Smart Camera

In Strobe mode, the external illuminator is strobed with the exposure of the camera to

maximize light for the short exposure times needed in dynamic applications.

ON/OFF mode allows the external illuminator to be enabled and disabled using the HAWK

MV-4000’s I/O.

Control is achieved using Output 3 on the camera.

Software’s camera configuration settings.

3

Lighting

HAWK MV-4000 Smart Camera Guide 3-3

Page 70

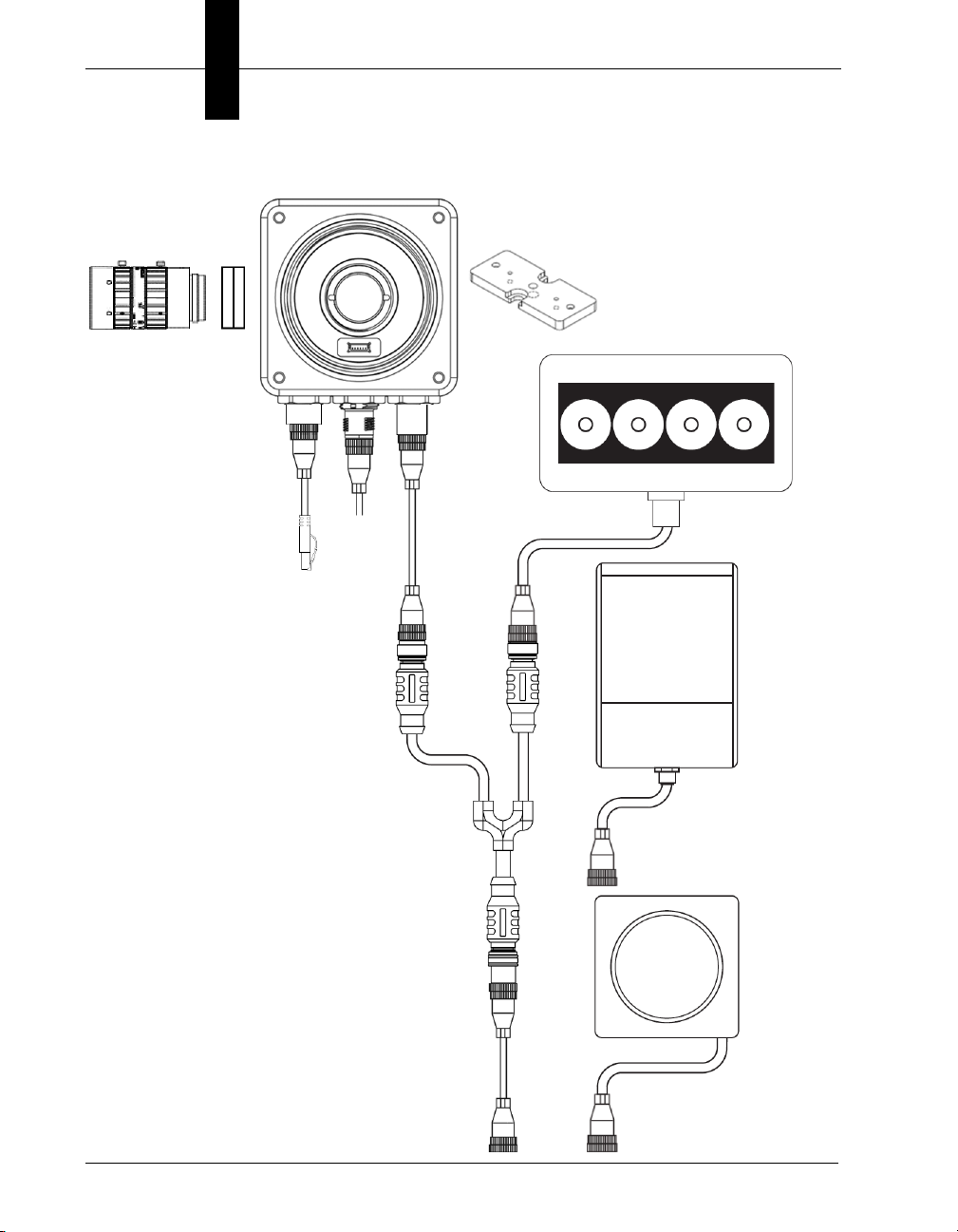

Chapter 3 Lighting

1

1

1

3

4

5

2

6

HAWK MV-4000 and Smart Series Light Configuration: Y-Cable

Item Description Part Number

1 Smart Series Light NER-011660XXXG

2 Assembly, Cable, QX-1 to Smart Series and Camera, Power 61-9000135-01

Assembly, Cable, QX-1 to Smart Series and Camera, On/Off 61-9000136-01

or

or Assembly, Cable, QX-1 to Smart Series and Camera, Strobe 61-9000137-01

Cordset, Common, M12 12-Pin Socket to M12 12-Pin Plug, 1 m 61-000162-02

3

or Cordset, Common, M12 12-Pin Socket to M12 12-Pin Plug, 3 m 61-000148-02

Cable, Adapter, HAWK MV-4000 to QX-1 61-9000132-01

4

5 Cordset, Host, Ethernet, M12 8-Pin Plug to RJ45, 1 m 61-000134-0X

6 HAWK MV-4000 Smart Camera

3-4 HAWK MV-4000 Smart Camera Guide

Page 71

A

APPENDIX A Selecting a Lens

This section contains information about choosing the best lens to suit

your application.

A

Selecting a Lens

HAWK MV-4000 Smart Camera Guide A-1

Page 72

Appendix A Selecting a Lens

Lens Selection

This section includes information on lens selection, an important consideration when

building your application. The HAWK MV-4000 comes accessorized with a variety of lens

types and sizes to aid you in solving your application challenges.

Choosing the Correct Lens Size for the Application

The primary consideration during lens selection is that the focal length of the selected

lens meets your application’s requirements. The choice of focal length, when combined

with the sensor size, determines the field of view the camera will see at a given distance

between the front of the camera lens and the object, which is called the object distance.

A simple formula can be used to compute any of the four parameters. The formula is:

Sensor Size / Focal Length = Field of View / Object Distance

Example: The application requirement is for a 75 mm wide field of view at an object

distance of 200 mm, using the 1.3 MP sensor. What is the required focal length of the

lens? Rearrange the equation as follows:

Focal Length = Sensor Size / Field of View x Object Distance

Focal Length = 6.144 mm / 75 mm x 200 mm = 16.38 mm

The closest lens to this in the price list is 16 mm.

The sensor sizes needed for the calculation above depend on the model of your HAWK

MV-4000 Smart Camera. The sensor sizes are listed below.

Model Horizontal Sensor Size Vertical Sensor Size

HAWK MV-4000-03, MV-4000-03C 3.072 mm 2.304 mm

HAWK MV-4000-13, MV-4000-13C 6.144 mm 4.915 mm

HAWK MV-4000-20, MV-4000-20C 9.216 mm 5.760 mm

HAWK MV-4000-50, MV-4000-50C 12.442 mm 9.830 mm

A-2 HAWK MV-4000 Smart Camera Guide

Page 73

Lens Selection

Crisp Image Created with a Higher-Quality, Higher-Cost Lens Matched to Pixel Size

Blurred Image Created with a Lower-Quality, Lower-Cost Lens Not Matched to Pixel Size

Choosing the Correct Lens Quality for the Application

The secondary consideration during lens selection is lens quality. Not all lenses are

created equal. Lenses are specified in combination with the sensor pixel size to which

they are able to resolve.

The diagrams below illustrate this concept. A lower-quality, lower-cost lens will create

some blur in the image, while a higher-quality, higher-cost lens will not. The choice of lens

will depend on the application requirements.

The first of the diagrams below shows an image blur created by a lens not matched with

the pixel size. The second of the two diagrams shows a crisp image created with a lens

matched with the pixel size.

A

Selecting a Lens

The HAWK MV-4000 sensors all have a pixel size of 4.8 microns.

The standard HAWK MV-4000 comes with 3 lens types:

• The first is a standard, low-cost lens for 5 to 7 micron pixels. This lens is adeq

st inspection and reading applications.

mo

• The second lens type is for 3.45 micron pixels. This lens is appropriate for mo

auging and code verification applications.

g

• The third lens type is also for 3.45 micron pixels, but is sized for the 1” sensor type