Omron H8PS DATASHEET

Cam Positioner

H8PS

Please read and understand this catalog before purchasing the

products. Please consult your OMRON representative if you have any

questions or comments. Refer to Warranty and Application

Considerations (page 32), and Safety Precautions (pages 17 and 18).

This Compact Cam Positioner, Popular for

It’s Ease-of-use, Now Comes with Even

Better Functions.

• Compact 8-, 16-, and 32-output Models available that are 1/4DIN size at 96 x 96 mm.

• High-speed operation at 1,600 r/min and high-precision settings

to 0.5° ensure widespread application.

• Highly visible display with backlit negative transmissive LCD.

• Advance angle compensation function to compensate for output

delays.

• Bank function for multi-product production (8 banks).

(H8PS-16@/-32@ models.)

Features

Models with 8, 16, or 32 Outputs

The lineup includes Models with 32 outputs in a compact 1/4-DIN

size. Using the optional Parallel Input Adapter (Y92C-30) enables

expanding to up to 64 outputs for one encoder to support anything

from a simple positioning application to a large-scale system.

8-output Models 16-output Models 32-output Models

96 mm

96 mm

Simple Programming

The programming method is designed based on a one key-one

action concept for settings that could not be simpler. Both initial

settings and factory adjustments are effort-free.

Large, Backlit Negative LCDs

Large LCDs, red for the process value and green for set values, show

a wealth of operation information, making operating status visible at

a glance.

High Speed Up To 1,600 r/min

High Precision Up To 0.5

High-speed, high-precision applications can be easily handled and

productivity increased.

° (at 720 Resolution)

Bank Function for Multi-product Production

Up to eight different programs can be registered in advance to

enable fast and easy switching between products (16/32-output

Models only).

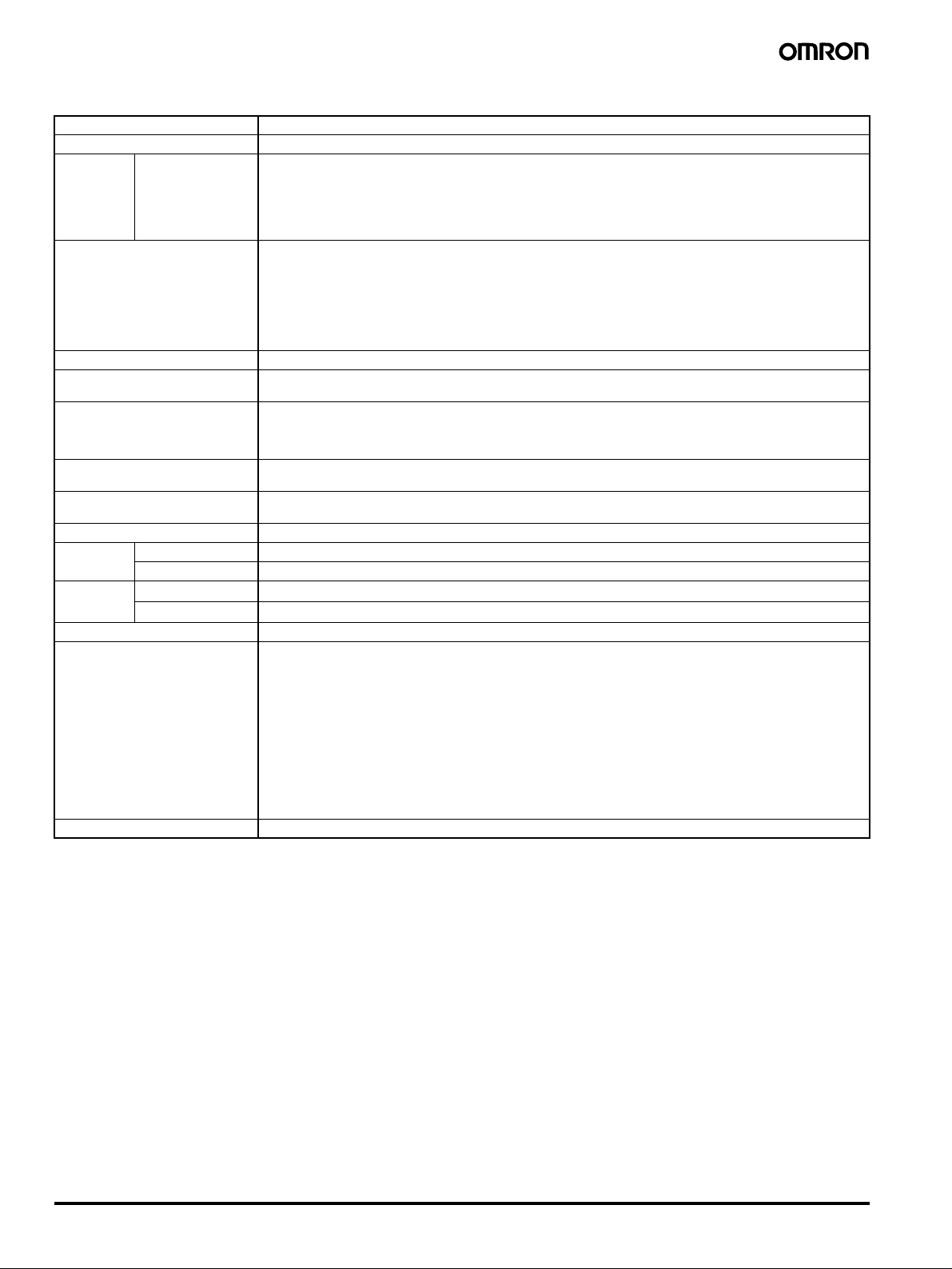

USB Communications for Easy Setting from

a Computer

Optional Support Software can be used to enable programming from

a personal computer via USB communications. Programs can be

easily copied, saved, printed, and much more.

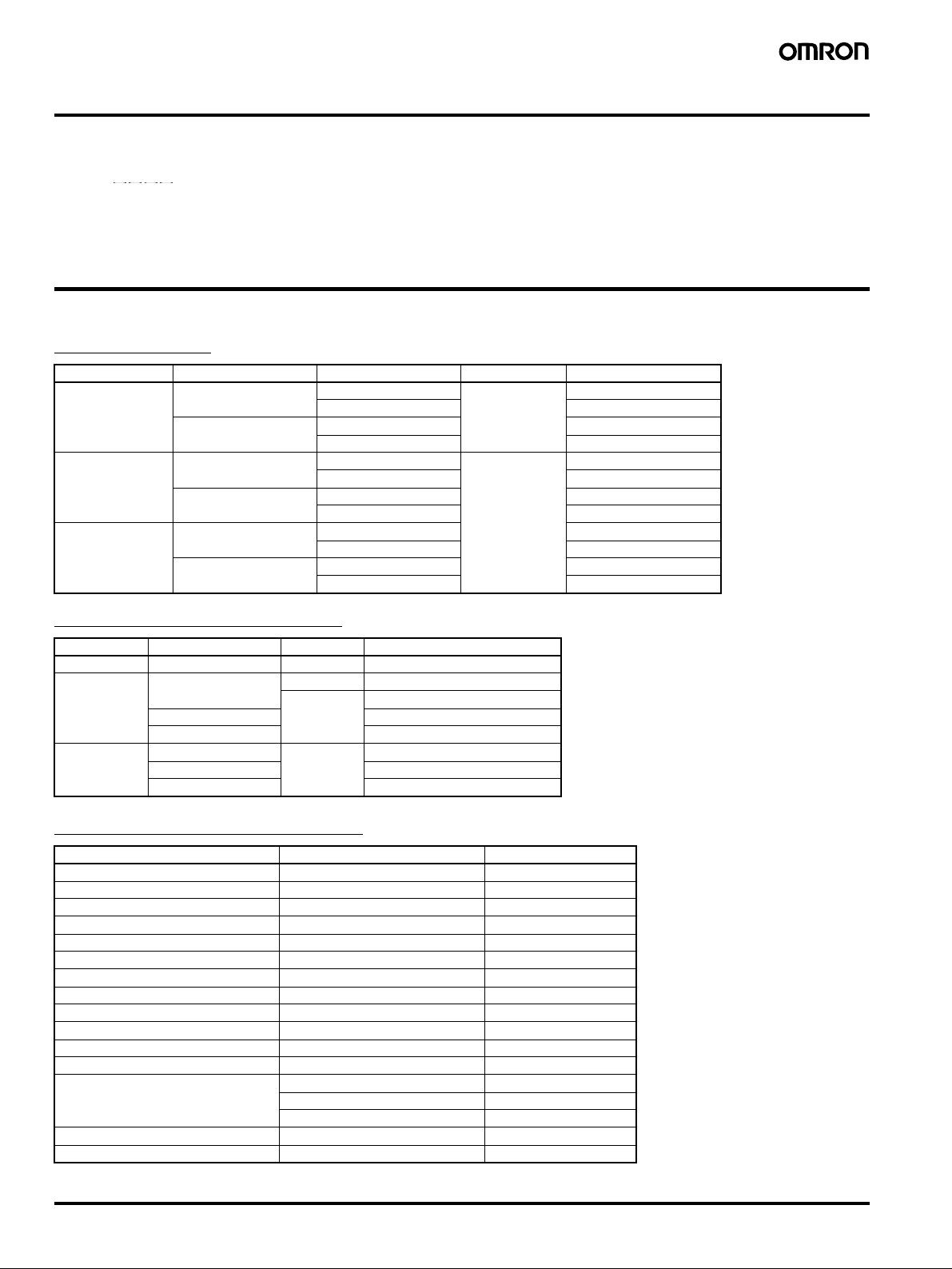

Speed Display and Speed Alarm Output

Both the speed (rotations/minutes) and present angular position can

be displayed at the same time. Alarm outputs can be produced for

both upper and lower speed limits.

12 7

CAM

12 7

CAM

STEP

STEP

RUN

Switchable

RUN

Present angular

position

Speed

Speed

Present angular

position

Upper limit

Lower limit

Upper limit

alarm output

Lower limit

alarm output

Speed

Errors

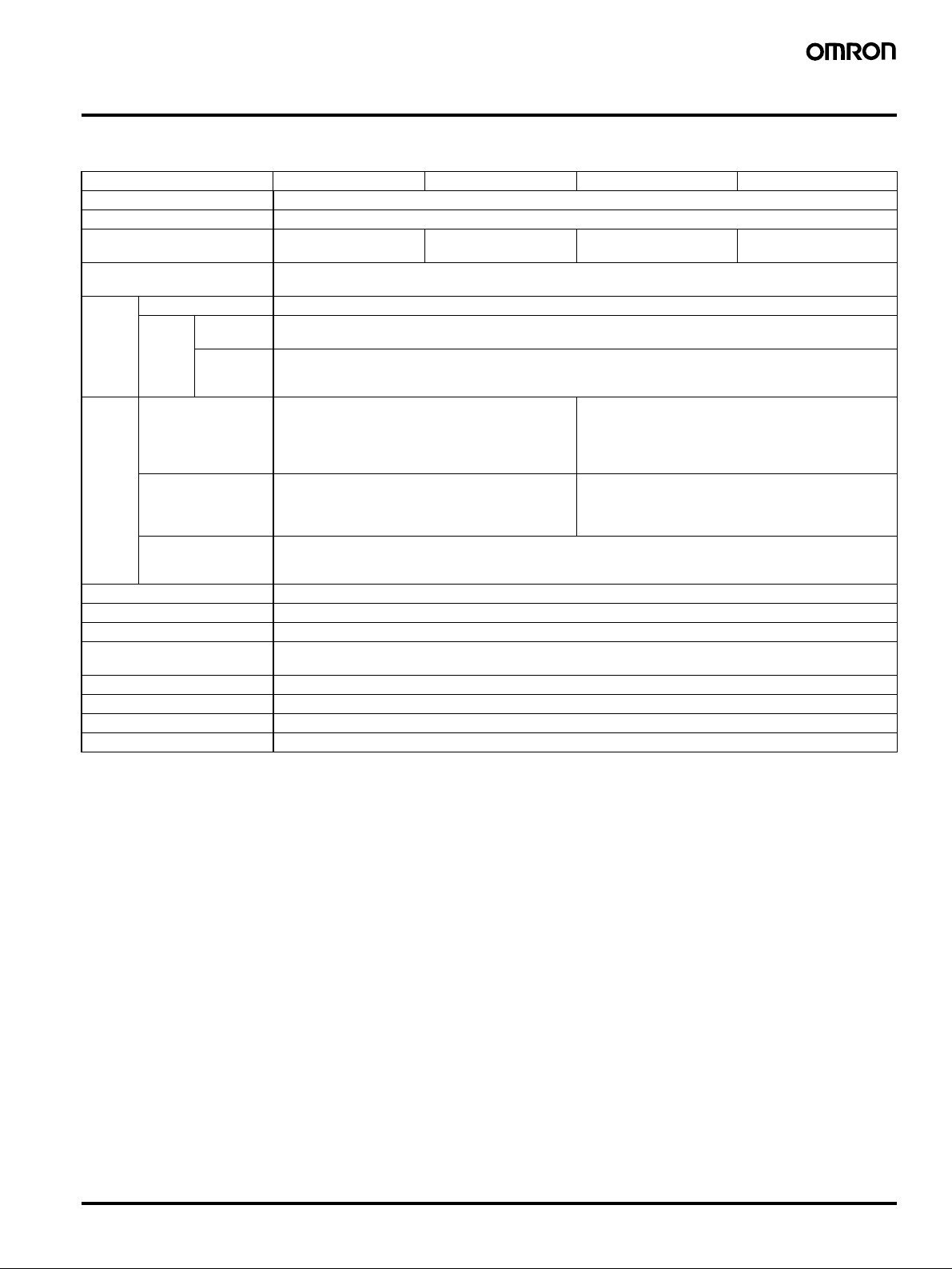

Advance Angle Compensation Function to

Compensate for Output Delays

The advance angle compensation (ADV) function automatically

advances the ON/OFF angle of outputs in proportion to machine

(encoder) speed to compensate for the delay in timing of ON/OFF

operation. ADV values can be set individually for 7 cam outputs.

Cam program settings

At high-speed (400 r/min)

100°

8° compensation

92° 172°

180°

Pulse Output for Timing Control

The number of pulses per rotation and the pulse output start angle

can be set to enable operations like adjusting timing with a PLC or

outputting to a rotation meter.

Pulse output

PLC

Rotation meter

Cam Positioner H8PS 1

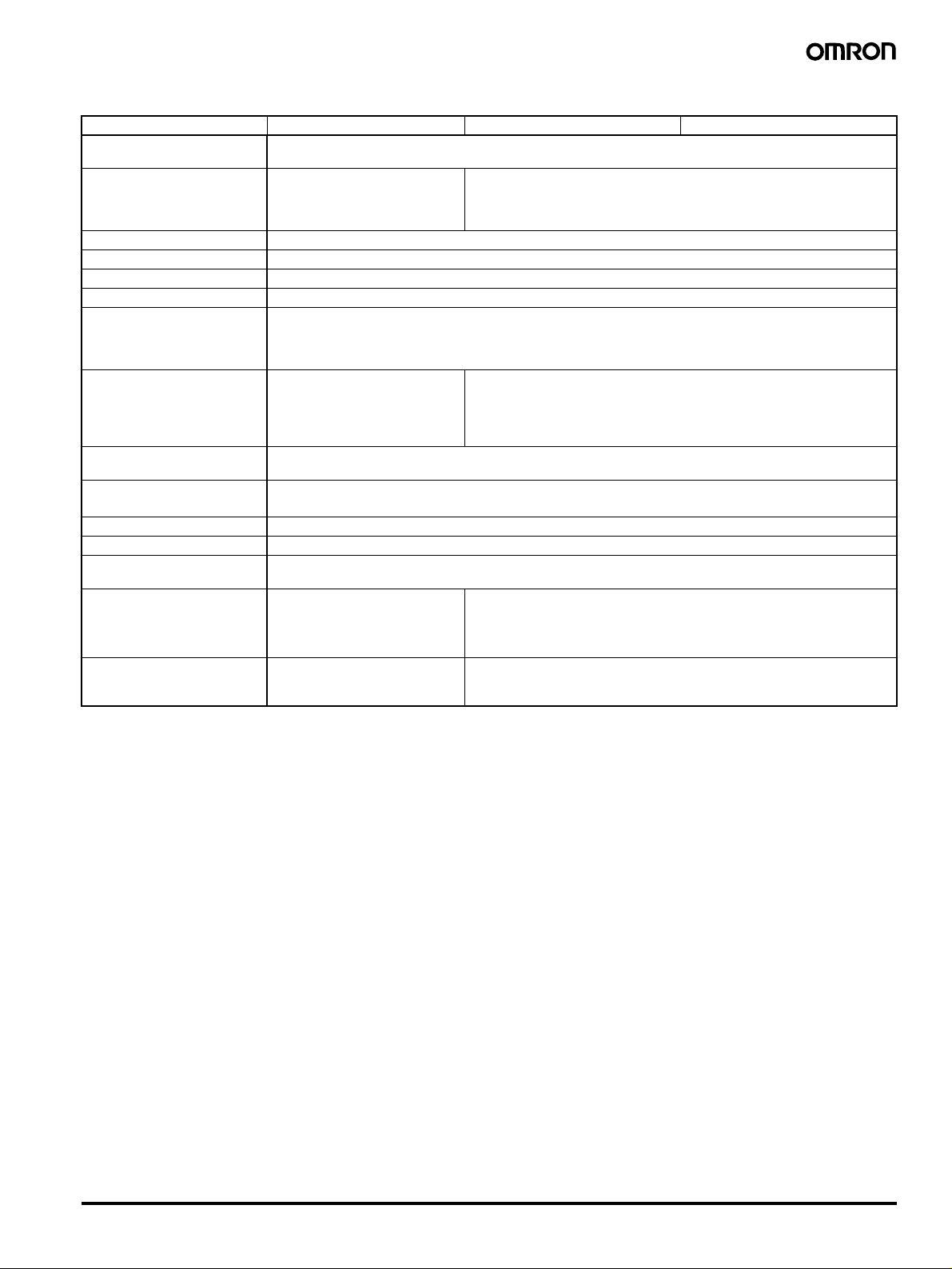

Model Number Structure

■ Model Number Legend

H8PS-@@@@

1. Number of outputs

1 2 3 4

8: 8 outputs

16: 16 outputs

32: 32 outputs

2. Panel language

B: English

3. Mounting method

None: Flush mounting

F: Surface mounting/

track mounting

Ordering Information

■ List of Models

Cam Positioner

Number of outputs Mounting method Output configuration Bank function Model

8 outputs Flush mounting NPN transistor output No H8PS-8B

PNP transistor output H8PS-8BP

Surface mounting/

track mounting

16 outputs Flush mounting NPN transistor output Yes H8PS-16B

Surface mounting/

track mounting

32 outputs Flush mounting NPN transistor output H8PS-32B

Surface mounting/

track mounting

Dedicated Absolute Encoder

NPN transistor output H8PS-8BF

PNP transistor output H8PS-8BFP

PNP transistor output H8PS-16BP

NPN transistor output H8PS-16BF

PNP transistor output H8PS-16BFP

PNP transistor output H8PS-32BP

NPN transistor output H8PS-32BF

PNP transistor output H8PS-32BFP

4. Output configuration

None: NPN transistor output

P: PNP transistor output

Type Resolution Cable length Model

Economy 256 2 m E6CP-AG5C-C 256 2M

Standard 256 1 m E6C3-AG5C-C 256 1M

2 m E6C3-AG5C-C 256 2M

360 E6C3-AG5C-C 360 2M

720 E6C3-AG5C-C 720 2M

Rigid 256 2 m E6F-AG5C-C 256 2M

360 E6F-AG5C-C 360 2M

720 E6F-AG5C-C 720 2M

Accessories (Order Separately)

Name Specification Model

Discrete Wire Output Cable 2 m Y92S-41-200

Connector-type Output Cable 2 m E5ZE-CBL200

Support Software CD-ROM H8PS-SOFT-V1

USB Cable A miniB, 2 m Y92S-40

Shaft Coupling for the E6CP Axis: 6 mm dia. E69-C06B

Shaft Coupling for the E6C3 Axis: 8 mm dia. E69-C08B

Shaft Coupling for the E6F Axis: 10 mm dia. E69-C10B

Extension Cable (See note.) 5 m (same for E6CP, E6C3, and E6F) E69-DF5

Parallel Input Adapter Two Units can operate in parallel. Y92C-30

Protective Cover --- Y92A-96B

Watertight Cover --- Y92A-96N

Track Mounting Base --- Y92F-91

Mounting Track 50 cm

End Plate --- PFP-M

Spacer --- PFP-S

Note: Ask your OMRON representative about the availability of non-standard lengths.

× 7.3 mm (l × t) PFP-50N

1 m

× 7.3 mm (l × t) PFP-100N

× 16 mm (l × t) PFP-100N2

1 m

2 Cam Positioner H8PS

Specifications

■ Ratings

Item H8PS-@BH8PS-@BF H8PS-@BP H8PS-@BFP

Rated supply voltage 24 VDC

Operating voltage range 85% to 110% of rated supply voltage

Mounting method Flush mounting Surface mounting,

Power consumption Approx. 4.5 W at 26.4 VDC for 8-output models

Inputs Encoder input Connections to a dedicated absolute encoder

External

inputs

Outputs Cam outputs

RUN output

Pulse output NPN open-collector transistor output

Number of outputs 8-output Models: 8 cam outputs, 1 RUN output, 1 pulse output

Number of banks 8 banks (for 16-/32-output Models only)

Display method 7-segment, negative transmissive LCD (Main Display: 11 mm (red), Sub-display: 5.5 mm (green))

Memory backup method EEPROM (overwrites: 100000 times min.) that can store data for 10 years min.

Ambient operating

temperature

Storage temperature

Ambient humidity 25% to 85%

Degree of protection Panel surface: IP40, Rear case: IP20

Case color Light gray (Munsell 5Y7/1)

Input

signals

Input type No voltage inputs: ON impedance:1 k

Approx. 6.0 W at 26.4 VDC for 16-/32-output models

8-output Models: None

16-/32-output Models: Bank inputs 1/2/4, origin input, start input

NPN open-collector transistor outputs

30 VDC max.,

100 mA max. (Do not exceed 1.6 A total for all cam

outputs and the RUN output.),

residual voltage: 2 VDC max.

30 VDC max.,

30 mA max.,

residual voltage: 0.5 VDC max.

16-output Models: 16 cam outputs, 1 RUN output, 1 pulse output

32-output Models: 32 cam outputs, 1 RUN output, 1 pulse output

−10 to 55°C (with no icing or condensation)

−25 to 65°C (with no icing or condensation)

track mounting

Ω max. (Leakage current: approx. 2 mA at 0 Ω)

ON residual voltage: 2 V max., OFF impedance: 100 k

Minimum input signal width: 20 ms

Flush mounting Surface mounting,

track mounting

Ω min., Applied voltage: 30 VDC max.

PNP open-collector transistor outputs

30 VDC max. (26.4 VDC for 16-/32-output Models),

100 mA max. (Do not exceed 1.6 A total for all cam

outputs and the RUN output.),

residual voltage: 2 VDC max.

PNP open-collector transistor output

30 VDC max. (26.4 VDC for 16-/32-output Models)

30 mA max.,

residual voltage: 2 VDC max.

Cam Positioner H8PS 3

■ Characteristics

Setting unit 0.5

Number of steps Up to 10 steps can be set for each cam to turn the output ON/OFF 10 times. (See note 2.)

Inputs Encoder input Connections to a dedicated absolute encoder

Encoder cable extension

distance

Output response time 0.3 ms max.

Insulation resistance 100 M

Dielectric strength 1000 VAC, 50/60 Hz for 1 min between current-carrying terminals and exposed non-current-carrying metal

Impulse withstand voltage 1 kV between power terminals

Noise immunity

Static immunity 8 kV (malfunction), 15 kV (destruction)

Vibration

resistance

Shock

resistance

Approved safety standards cULus (Listing): UL508/CSA C22.2 No. 14

EMC (EMI) EN61326

Weight Approx. 300 g (Cam Positioner main unit only)

Note: 1. Cam output precision, however, is 2° max. for Encoder with 256 resolution (P/R).

Destruction 10 to 55 Hz with 0.75-mm single amplitude each in 3 directions for 2 hours each

Malfunction 10 to 55 Hz with 0.5-mm single amplitude each in 3 directions for 10 minutes each

Destruction

Malfunction

2. Although 32-output Models can have 10 steps set for any one output, there must be no more than 160 steps total set for all cam outputs.

3. The maximum is 1000 r/min when an E6CP-AG5C-C Encoder is connected.

4. ADV stands for Advance Angle Compensation.

° increments at a resolution of 720, 1° increments at a resolution of 256 or 360 (See note 1.)

• Response rotation speed (in Run/Test Mode)

1600 r/min max. at a resolution of 256 or 360 (1200 r/min max. if ADV function is set for 4 or more cams)

(See notes 3 and 4.)

800 r/min max. at a resolution of 720 (600 r/min max. if ADV function is set for 4 or more cams)

• Includes error data detection

256/360 resolution

100 m max. at 330 r/min or less

52 m max. at 331 to 1200 r/min (331 to 900 r/min if ADV function is set for 4 or more cams)

12 m max. at 1201 to 1600 r/min (901 to 1200 r/min if ADV function is set for 4 or more cams)

720 resolution

100 m max. at 330 r/min or less

52 m max. at 331 to 600 r/min (331 to 450 r/min if ADV function is set for 4 or more cams)

12 m max. at 601 to 800 r/min (451 to 600 r/min if ADV function is set for 4 or more cams)

Ω min. (at 500 VDC) between current-carrying terminals and exposed non-current-carrying metal

parts, between all current-carrying parts and the USB connector

parts

500 VAC, 50/60 Hz for 1 min between current-carrying section and USB connector, and between currentcarrying terminals and non-current-carrying metal part of output connector

1.5 kV between current-carrying terminals and exposed non-current-carrying metal parts

±480 V between power terminals, ±600 V between input terminals

Square-wave noise by noise simulator (pulse width: 100 ns/1

2

300 m/s

200 m/s

Emission Enclosure: EN55011 Group1 Class A

(EMS) EN61326

Immunity ESD: EN61000-4-2: 4 kV contact discharge

Immunity RF-interference: EN61000-4-3: 10 V/m (Amplitude-modulated, 80 MHz to 1 GHz)

Immunity Conducted Disturbance EN61000-4-6: 10 V (0.15 to 80 MHz)

Immunity Burst: EN61000-4-4: 2 kV for power-line

Immunity Surge: EN61000-4-5: 1 kV line to line (power line)

3 times each in 6 directions

2

3 times each in 6 directions

8 kV air discharge

10 V/m (Pulse-modulated, 900 MHz

1 kV for I/O signal-line

2 kV line to ground (power line)

µs, 1-ns rise)

±5 MHz)

4 Cam Positioner H8PS

■ Functions

Item H8PS-8@ H8PS-16@ H8PS-32@

Encoder rotation direction

switching

Encoder origin designation The present display angular

Angle display switch Converts the Absolute Encoder value display from 256 divisions/revolution to 360

Rotation display monitor Graphically displays the Encoder rotational angular position.

Teaching function Sets the cam output ON/OFF angle based on actual machine (Encoder) operation.

Pulse output Outputs a preset number of pulses per Encoder rotation. It also sets the pulse output start angle.

Switching the angle and

speed displays

Bank function --- Enables the entire cam program to be changed at one time by switching

Advance angle compensation

(ADV) function

Speed alarm output A specified cam output can be used as an Encoder speed alarm output.

All protection function Disables all key and switch operations in Run Mode to prevent incorrect or unauthorized operation.

Cam protection function Prohibits program changes at the cam output level. Any cam numbers can be protected.

Step number limit Limits the number of steps that can be set per cam output. Prohibits incorrect operations by adding to the

Output prohibit --- The start input can be turned OFF in Run or Test Mode to prohibit cam

Support Software settings --- Programs can be uploaded or downloaded easily by connecting a personal

Encoder data can be set with a DIP switch to forward (CW) or reverse (CCW) direction.

position can be set to 0

pressing the ORIGIN Key on the

front panel.

Displays both the present angular position and the number of Encoder revolutions (speed) in Run Mode.

Switches back and forth between the main display showing the present angular position with the sub-display

showing the speed and the main display showing the speed with the sub-display showing the present angular

position.

Automatically advances the ON/OFF angle of cam outputs in proportion to machine (encoder) speed to

compensate for the delay in timing of ON/OFF operation. ADV values can be set individually for 7 cam outputs.

The function can output upper and lower limit speed alarms.

program.

° (origin) by

The present display angular position can be set to 0

origin input terminal or the ORIGIN Key on the front panel.

Note: All banks use the same origin.

banks (0 to 7).

The bank that is running can be switched using the bank input terminal or the

BANK Key on the front panel.

Also enables programs to be copied between banks.

output.

Note: Use this function carefully for the application because no cam outputs

are provided when the start input is turned OFF.

computer to the Cam Positioner using a USB Cable (Y92S-40, sold

separately) and the Support Software (H8PS-SOFT-V1, sold separately).

° (origin) by using the

°/revolution.

Cam Positioner H8PS 5

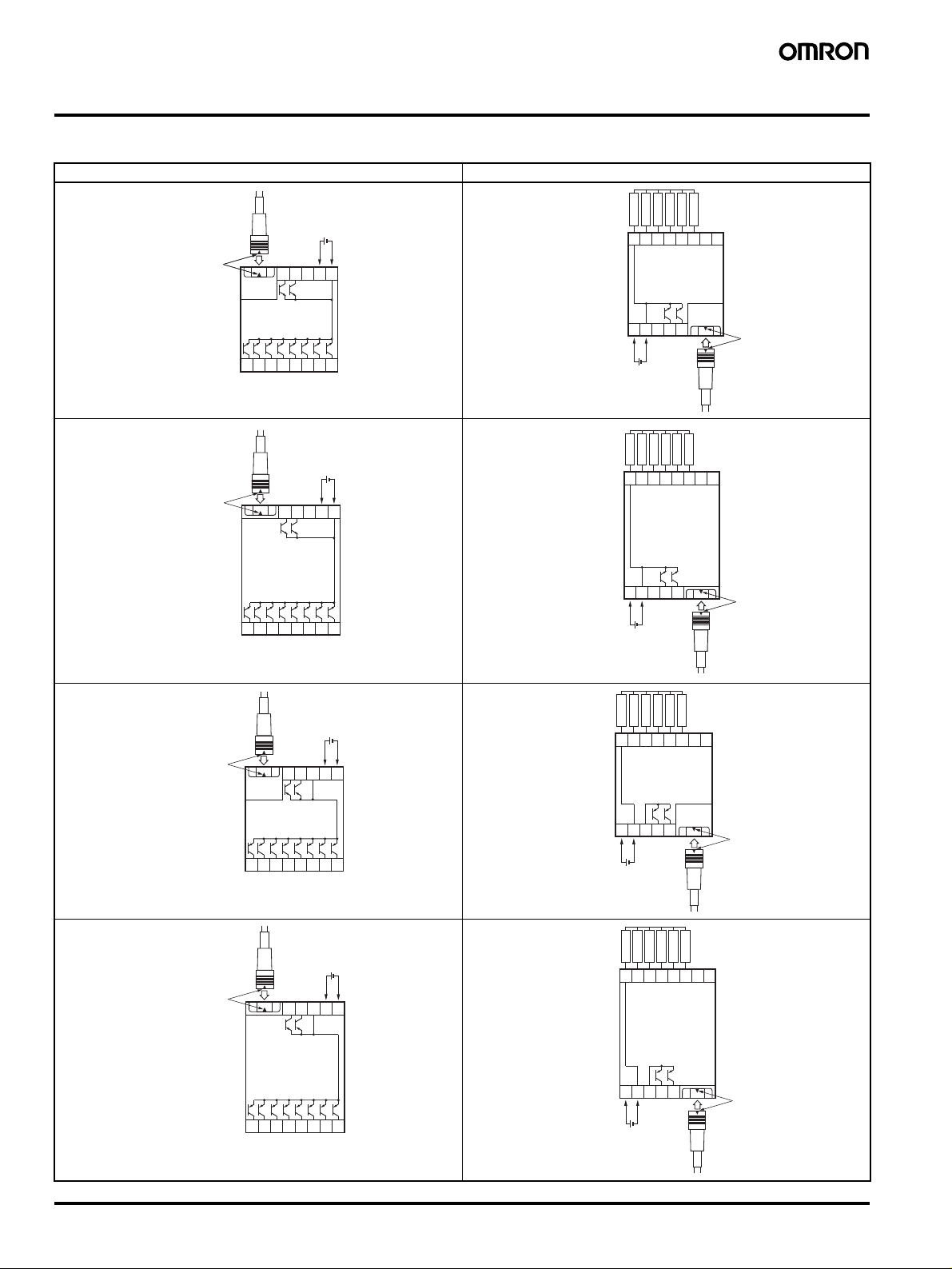

Connections

C

■ Terminal Arrangement

H8PS-8@ (8-output Models) H8PS-16@/-32@ (16-/32-output Models)

NPN Output,

Flush Mounting

H8PS-8@

Alignment markings

Encoder

RUN output

Pulse output

9 10111213

24 VD

+ −

Not used

NPN Output,

Flush Mounting

H8PS-16@/-32@

(Rear view)

Origin

Bank 4

COM

Bank 1

Bank 2

Start

Not used

678910111213

Not used

NPN Output,

Surface Mounting

H8PS-8@F

Alignment markings

PNP Output,

Flush Mounting

H8PS-8@P

Alignment markings

(Rear view)

(Front view)

12345678

am 1

am 2

am 3

am 4

am 5

am 6

am 7

am 8

Encoder

24 VDC

+ −

RUN output

Not used

Pulse output

910111213

12345678

am 1

am 2

am 3

am 4

am 5

am 6

am 7

Encoder

24 VDC

+ −

Vs (See note.)

RUN output

Pulse output

9 10111213

am 8

NPN Output,

Surface Mounting

H8PS-16@F/-32@F

(Front view)

PNP Output,

Flush Mounting

H8PS-16@P/-32@P

(Rear view)

12345

+ −

Not used

24 VDC

COM

678910111213

12345

+ −

24 VDC

COM

6 7 8 9 10111213

Bank 1

Bank 1

Bank 2

Pulse output

Encoder

Bank 4

Bank 2

Not used

Pulse output

Encoder

Origin

Bank 4

RUN output

Origin

Start

RUN output

Start

Not used

Not used

Not used

Not used

Alignment markings

Alignment markings

(Rear view)

Note: The VS terminal

is not internally

connected to the

12345678

positive (+) power

supply terminal.

PNP Output,

Cam 1

Cam 2

Cam 3

Encoder

Cam 4

Surface Mounting

H8PS-8@FP

Alignment markings

Note: The VS terminal

(Front view)

Pulse output

9 10111213

is not internally

connected to the

positive (+) power

supply terminal.

12345678

Cam 1

Cam 2

Cam 3

Cam 4

6 Cam Positioner H8PS

Cam 5

Cam 6

24 VDC

+ −

Vs (See note.)

RUN output

Cam 5

Cam 6

Cam 7

Cam 7

Cam 8

Cam 8

Note: The VS terminal

is not internally

connected to

the positive (+)

power supply

terminal.

PNP Output,

Surface Mounting

H8PS-16@FP/-32@FP

(Front view)

Note: The VS terminal

is not internally

connected to the

positive (+) power

supply terminal.

12345

+ −

24 VDC

24 VDC

RUN output

Pulse output

Vs (See note.)

Encoder

Origin

Bank 4

COM

Bank 1

Bank 2

6 7 8 9 10111213

12345

+ −

Pulse output

Vs (See note.)

Encoder

RUN output

Start

Not used

Alignment markings

Not used

Alignment markings

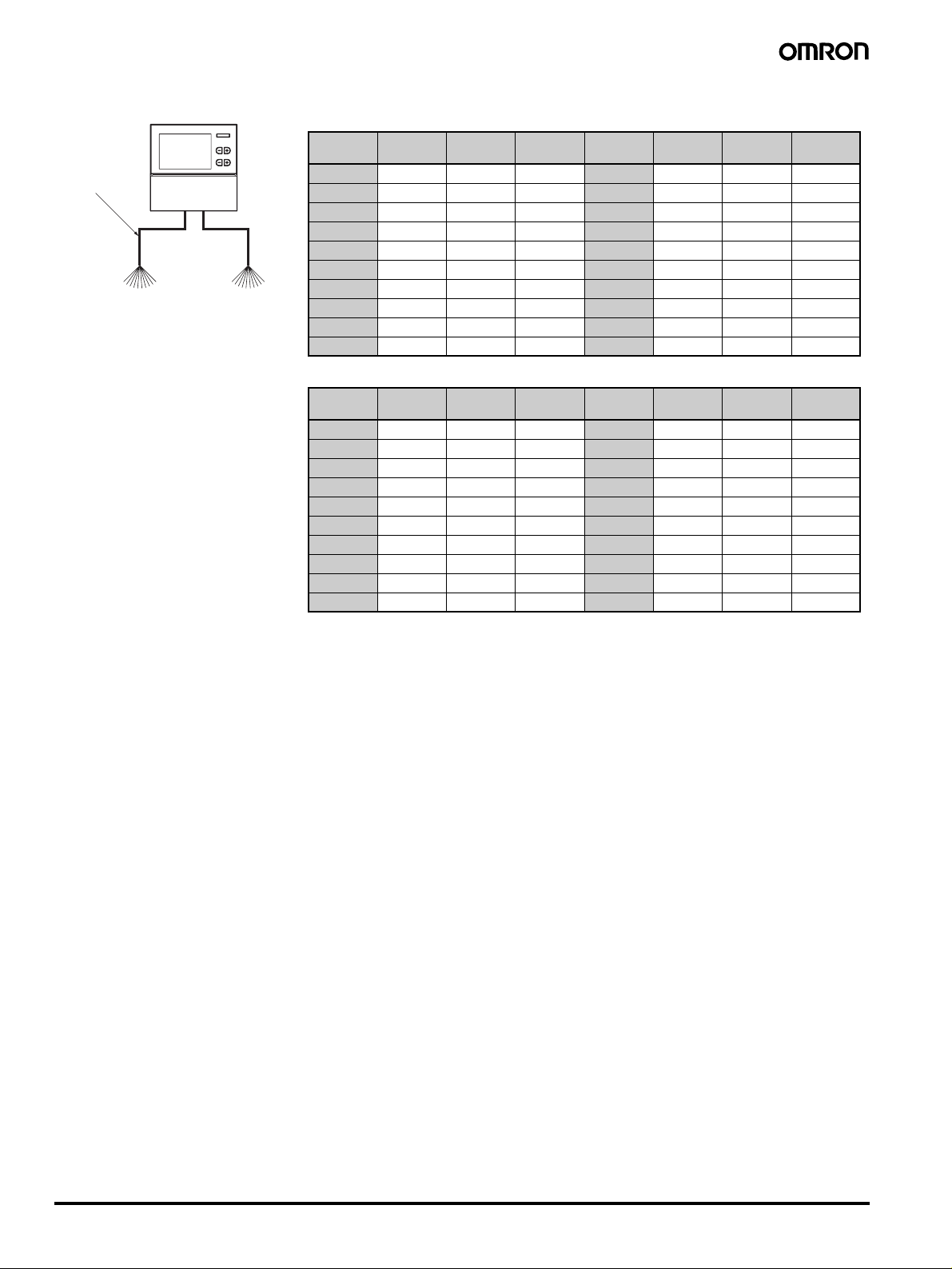

Output Cable Connections (16-/32-output Models Only)

Flush Mounting Models Surface Mounting Models

Output Connector 1 (CN1)

Output Connector 2 (CN2) (See note.)

(Bottom view) (Bottom view)

Output Connector Output signals

Output Connector 1 (CN1) Cam 1 to Cam 16, COM, Vs

Output Connector 2 (CN2) (See note.) Cam 17 to Cam 32, COM, Vs

Note: The 16-output Models do not have CN2 Connectors.

1. E5ZE-CBL200 Connector-type Output Cable (Order Separately) Connections

H8PS-16@/-32@

E5ZE-CBL200

Connector-type

Output Cable

(Order Separately)

Output

Cable 1

(CN1)

XG4M-2030

MIL Connector

(made by OMRON)

Output Cable 1 Wiring Table Output Cable 2 Wiring Table

Outputs Connector

pin No.

Cam 1 20 Cam 9 19

Cam 2 18 Cam 10 17

Cam 3 16 Cam 11 15

Cam 4 14 Cam 12 13

Cam 5 12 Cam 13 11

Cam 6 10 Cam 14 9

Cam 7 8 Cam 15 7

Cam 8 6 Cam 16 5

COM 4 COM 3

Vs 2 Vs 1

(CN2)

Output

Cable 2

Outputs Connector

pin No.

Output Connector 1 (CN1)

Output Connector 2 (CN2) (See note.)

Pin Arrangement of XG4M-2030 Connectors

1 3 5 7 9 1113151719

2 4 6 8 10 12 14 16 18 20

Outputs Connector

pin No.

Cam 17 20 Cam 25 19

Cam 18 18 Cam 26 17

Cam 19 16 Cam 27 15

Cam 20 14 Cam 28 13

Cam 21 12 Cam 29 11

Cam 22 10 Cam 30 9

Cam 23 8 Cam 31 7

Cam 24 6 Cam 32 5

COM 4 COM 3

Vs 2 Vs 1

Outputs Connector

pin No.

Using Connector-Terminal Block Conversion Units

H8PS-16@/-32@

E5ZE-CBL200

Connector-type

Output Cable

(Order Separately)

(CN1)

XW2D-20G6

Connector-Terminal Block

Conversion Unit (Order Separately)

(CN2)

Output Cable 2Output Cable 1

Terminal Arrangement of the XW2D-20G6 Connector-Terminal Block Conversion Unit

Output Cable 1

COM

Vs

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10

Vs

COM

Cam 16

Cam 8

Cam 15

Cam 7

Cam 14

Cam 6

Cam 13

Cam 5

Cam 12

Cam 4

Cam 11

Cam 3

Cam 10

Cam 2

Cam 9

Cam 1

Output Cable 2

Vs

COM

Cam 32

Cam 31

Cam 30

Cam 29

Cam 28

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10

Vs

COM

Cam 24

Cam 23

Cam 22

Cam 21

Cam 20

Cam 27

Cam 19

Cam 26

Cam 18

Cam 25

Cam 17

Cam Positioner H8PS 7

2. Y92S-41-200 Discrete Wire Output Cable (Order Separately) Connections

Y92S-41-200

Discrete Wire

Output Cable

(Order Separately)

H8PS-16@/-32@

(CN1)

(CN2)

Output Cable 2 Output Cable 1

Output Cable 1 Wiring Table

Outputs Cable

color

Marks Marking

color

Outputs Cable

color

Cam 1 Orange ■ Black Cam 9 Orange ■ Red

Cam 2 Gray ■ Black Cam 10 Gray ■ Red

Cam 3 White ■ Black Cam 11 White ■ Red

Cam 4 Yellow ■ Black Cam 12 Ye l l o w ■ Red

Cam 5 Pink ■ Black Cam 13 Pink ■ Red

Cam 6 Orange ■ ■ Black Cam 14 Orange ■ ■ Red

Cam 7 Gray ■ ■ Black Cam 15 Gray ■ ■ Red

Cam 8 White ■ ■ Black Cam 16 White ■ ■ Red

COM Yellow ■ ■ Black COM Ye l l o w ■ ■ Red

Vs Pink ■ ■ Black Vs Pink ■ ■ Red

Output Cable 2 Wiring Table

Outputs Cable

color

Marks Marking

color

Outputs Cable

color

Cam 17 Orange ■ Black Cam 25 Orange ■ Red

Cam 18 Gray ■ Black Cam 26 Gray ■ Red

Cam 19 White ■ Black Cam 27 White ■ Red

Cam 20 Yellow ■ Black Cam 28 Ye l l o w ■ Red

Cam 21 Pink ■ Black Cam 29 Pink ■ Red

Cam 22 Orange ■ ■ Black Cam 30 Orange ■ ■ Red

Cam 23 Gray ■ ■ Black Cam 31 Gray ■ ■ Red

Cam 24 White ■ ■ Black Cam 32 White ■ ■ Red

COM Yellow ■ ■ Black COM Ye l l o w ■ ■ Red

Vs Pink ■ ■ Black Vs Pink ■ ■ Red

Marks Marking

color

Marks Marking

color

8 Cam Positioner H8PS

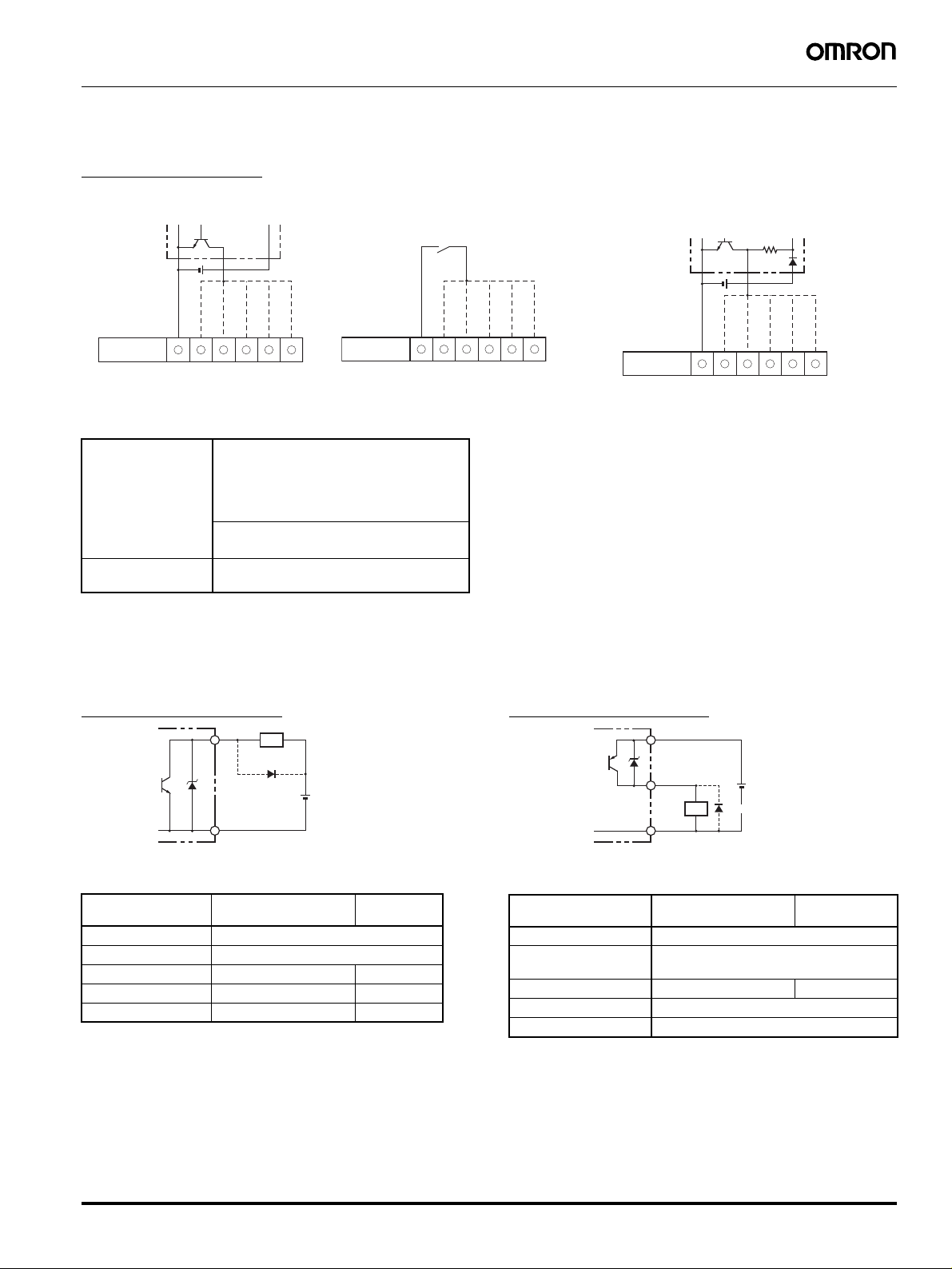

■ Input Connections

p

Only the Encoder inputs are connected with 8-output Models. The inputs are no-voltage (short-circuit or open) inputs.

No-voltage Inputs

Open Collector

PLC,

sensor,

etc.

Contact Input

Voltage-output sensors can also be connected.

Connection Examples

Sensor, etc.

COM

H8PS-16@

H8PS-32@

Note: O

6 7 8 9

erates when the transistor turns ON.

Bank 1

Bank 2

Bank 4

10 11

Origin

Start

H8PS-16@

H8PS-32@

Note: Operates when the contact turns ON.

COM

Bank 1

6 7 8 9

No-voltage Input Signal Levels

No-contact inputs Short-circuit level for transistor ON

• Residual voltage: 2 V max.

• Impedance when ON: 1 k

Ω max.

(The leakage current is approx. 2 mA

when the impedance is 0

Ω.)

Open level for transistor OFF

• Impedance when OFF: 100 k

Ω min.

Contact inputs Use a contact that can adequately switch

2 mA at 5 V.

Note: Use a maximum DC power supply of 30 V.

■ Output Connections

Note: Internal circuit damage may result from a short circuit in the load.

NPN Output Models

Outputs

Load

Bank 2

Bank 4

Origin

Start

10 11

H8PS-16@

H8PS-32@

Note: Operates when the transistor turns ON.

PNP Output Models

Vs

COM

Bank 1

Bank 2

6 7 8 9

Bank 4

10 11

Origin

Start

(See note.)

COM/(−)

Note: Always connect a diode to absorb

counter-electromotive force when

connecting an inductive load.

Item Cam outputs,

RUN output

Pulse output

Output method NPN open collector

Dielectric strength 30 VDC

Rated current 100 mA (See note.) 30 mA

Residual voltage 2 VDC max. 0.5 VDC max.

Leakage current 100

µA max. 5 µA max.

Note: Do not exceed 1.6 A total for all cam outputs and the RUN

output.

Note: Always connect a diode to absorb

counter-electromotive force when

connecting an inductive load.

Item Cam outputs,

Output method PNP open collector

Dielectric strength 8-output Models: 30 VDC

Rated current 100 mA (See note.) 30 mA

Residual voltage 2 VDC max.

Leakage current 100

Note: Do not exceed 1.6 A total for all cam outputs and the RUN

Outputs

(See note.)

Load

COM/(−)

RUN output

Pulse output

16-/32-output Models: 26.4 VDC

µA max.

output.

Cam Positioner H8PS 9

Operating Mode

■ Functions

The H8PS Cam Positioner receives angle signal inputs from the Dedicated Absolute Encoder and outputs the preset ON/OFF angles as cam outputs.

Program Examples

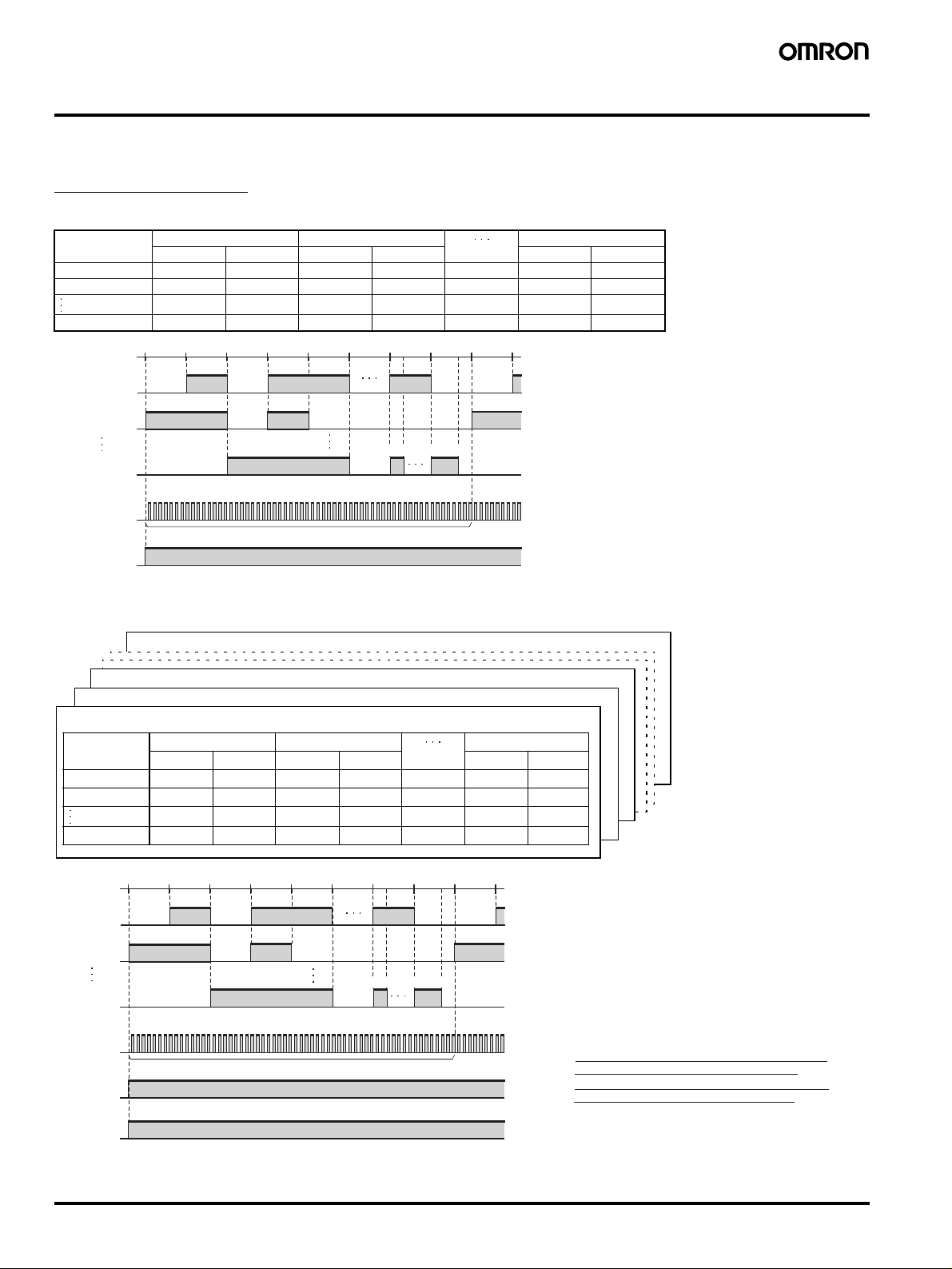

1. H8PS-8@ (8-output Models)

Cam output

(cam number)

145° 90° 135° 225° 270° 315°

20° 90° 135° 180° --- ---

890° 225° 270° 285° 315° 345°

0° 45° 90° 135° 180° 225° 270° 315° 0° 45°

Step 0 Step 1 Step 9

ON angle OFF angle ON angle OFF angle ON angle OFF angle

Cam output 1

Cam output 2

Cam output 8

Pulse output

(See note 1.)

RUN output

Step 0

Step 0

Outputs a preset number of pulses per Encoder rotation. (Default setting: 60 pulses/revolution)

ON during Run or Test Mode. OFF when an error occurs.

Step 1

Step 1

Step 0

(ON/OFF ratio 1:1)

Step 9

Step 1 Step 9

2. H8PS-16@ /-32@ (16-/32-output Models)

Cam Program (Bank No. 7)

Cam Program (Bank No. 2)

Cam Program (Bank No. 1)

Cam Program (Bank No. 0)

Cam output

(cam number)

145° 90° 135° 225° 270° 315°

20° 90° 135° 180° --- ---

32 90° 225° 270° 285° 315° 345°

Step 0 Step 1 Step 9

ON angle OFF angle ON angle OFF angle ON angle OFF angle

Note 1: The number of pulses per Encoder rotation

and the pulse output start angle can be set.

Note 2: With counterclockwise rotation (359°, 358°

...1°, 0°), step 0 for cam output 1 turns ON

at 89° and OFF at 44° at in the diagram.

0° 45° 90° 135° 180° 225° 270° 315° 0° 45°

Cam output 1

Cam output 2

Cam output 32

Pulse output

(See note 1.)

Step 0

Outputs a preset number of pulses per Encoder rotation. (Default setting: 60 pulses/revolution)

Step 1

Step 1

Step 0

(ON/OFF ratio 1:1)

Step 9Step 0

Step 1

Step 9

Note 1: The number of pulses per Encoder rotation

and the pulse output start angle can be set.

Note 2: Be sure to turn ON the start input in Run and

Test modes. Otherwise, there will be no

outputs (output prohibited), including the cam

RUN output

Start input

(See note 2.)

ON during Run or Test Mode. OFF when an error occurs.

Note 3: With counterclockwise rotation (359°, 358°

outputs, pulse output, and RUN output.

...1°, 0°), step 0 for cam output 1 turns ON at

89° and OFF at 44° in the diagram.

Note: The entire cam program can be changed at one time with 16- and 32-output Models with the bank function (banks 0 to 7).

For details on the procedure for switching banks, refer to page 28.

10 Cam Positioner H8PS

Loading...

Loading...